Lofting production method of anchor recess of planking thickness line of hull

A hull plate and manufacturing method technology, which is applied in shipbuilding, ship parts, ships, etc., can solve the problems of actual sample deviation, inconsistent anchor fluke and anchor lip, difficulty in increasing or decreasing the thickness of anchor lip, etc. Achieve the effect of improving accuracy and success rate, reducing production cost and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation, but the protection scope of the present invention cannot be limited by this.

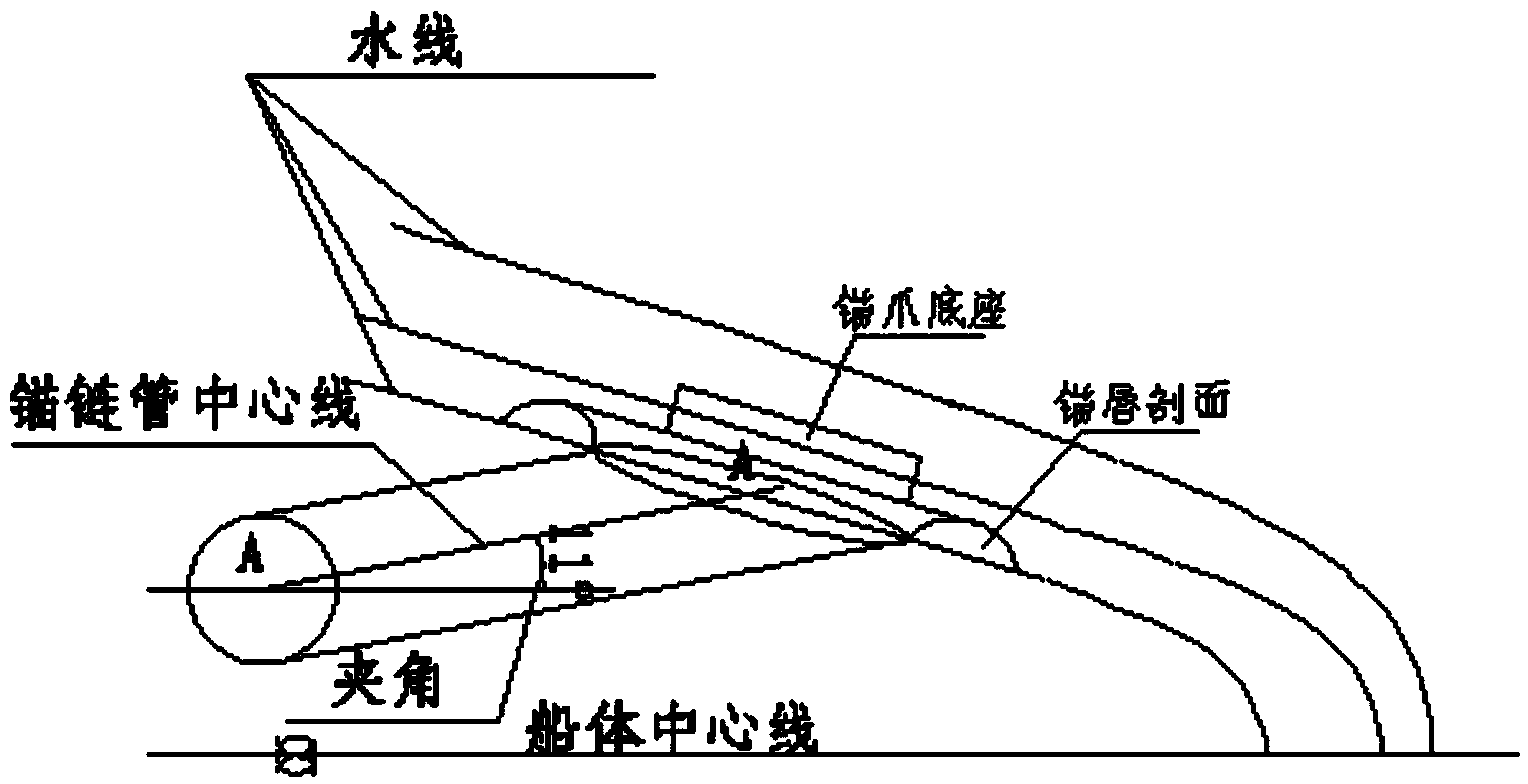

[0026] 1. First establish the three-way line pattern of the bow anchor hole area, that is, waterline, rib line, and straight section line. The linetype of the line.

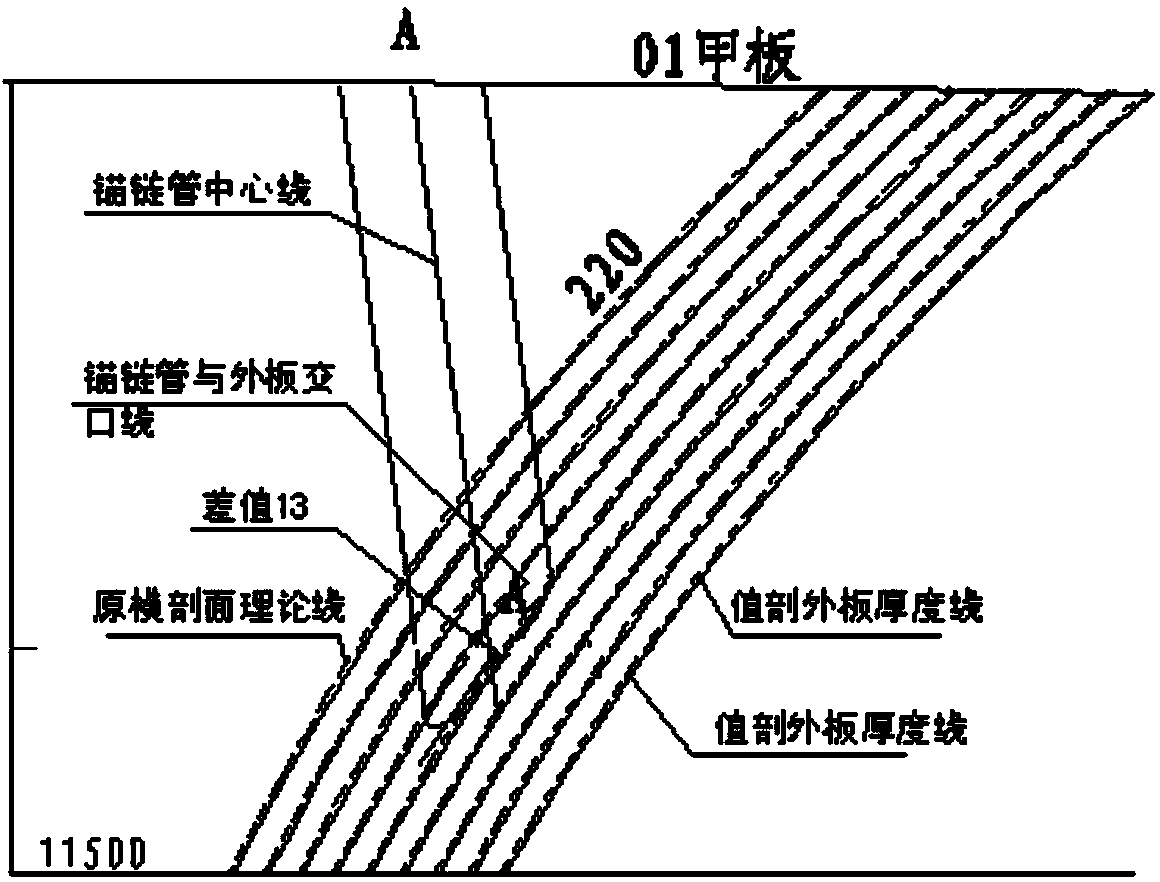

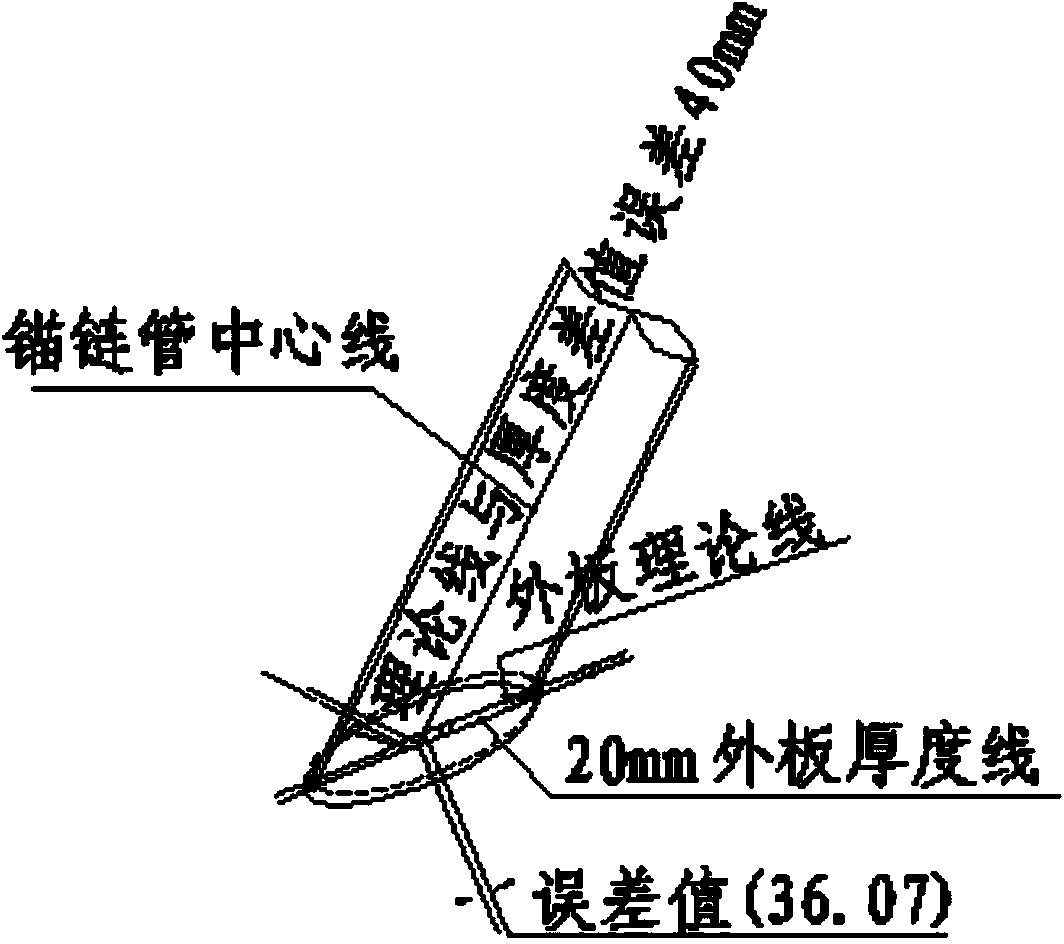

[0027] According to the intersection angle between the main deck of the center line of the anchor chain pipe and the opening of the outer plate of the hull determined by the design drawings, the theoretical line projection of the horizontal plane and the side is obtained to obtain the exit point of the outer plate, and then projected to the linear position of the side with the thickness line of the outer plate deducted, to obtain The intersection angle between the center line of the main deck anchor pipe and the exit point of the shell plate from which the thickness line is actually deducted....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com