Patents

Literature

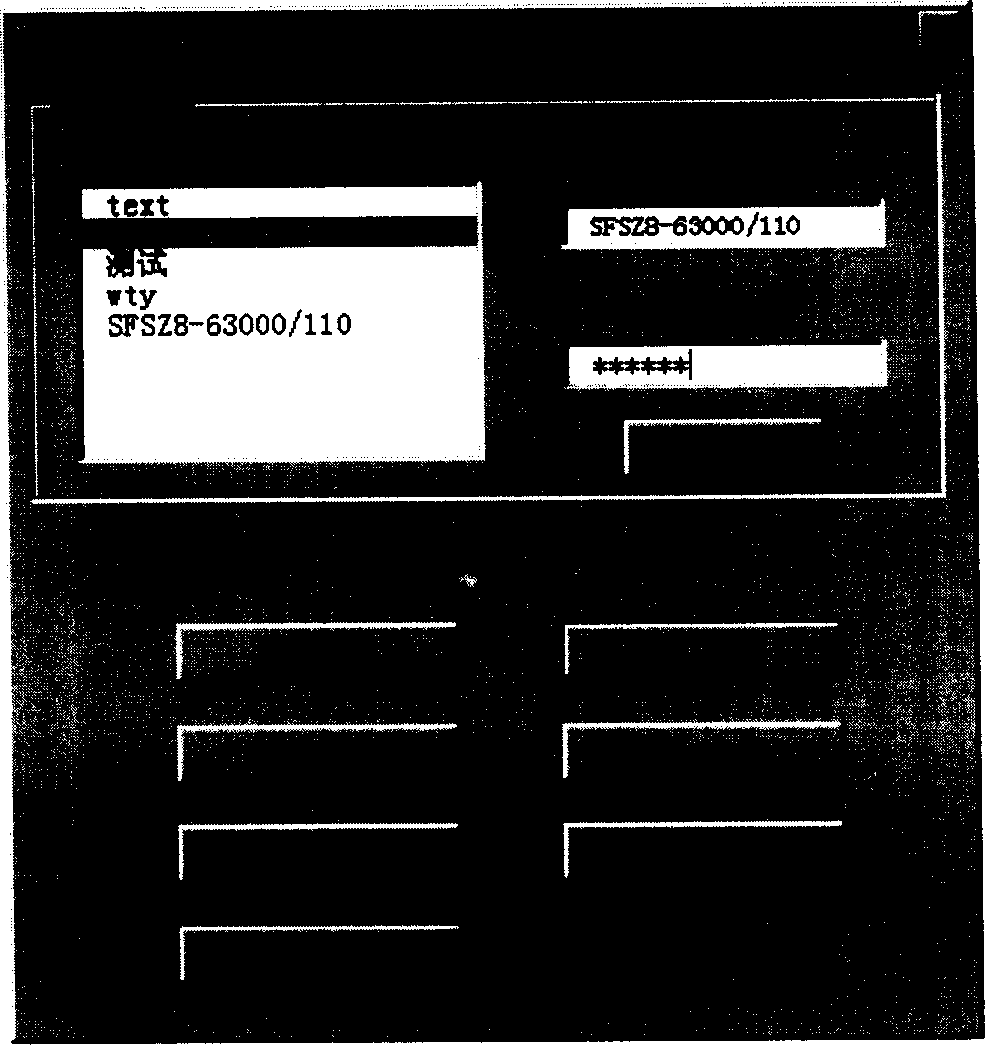

367 results about "Quality by Design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quality by Design (QbD) is a concept first outlined by quality expert Joseph M. Juran in publications, most notably Juran on Quality by Design. Designing for quality and innovation is one of the three universal processes of the Juran Trilogy, in which Juran describes what is required to achieve breakthroughs in new products, services, and processes. Juran believed that quality could be planned, and that most quality crises and problems relate to the way in which quality was planned.

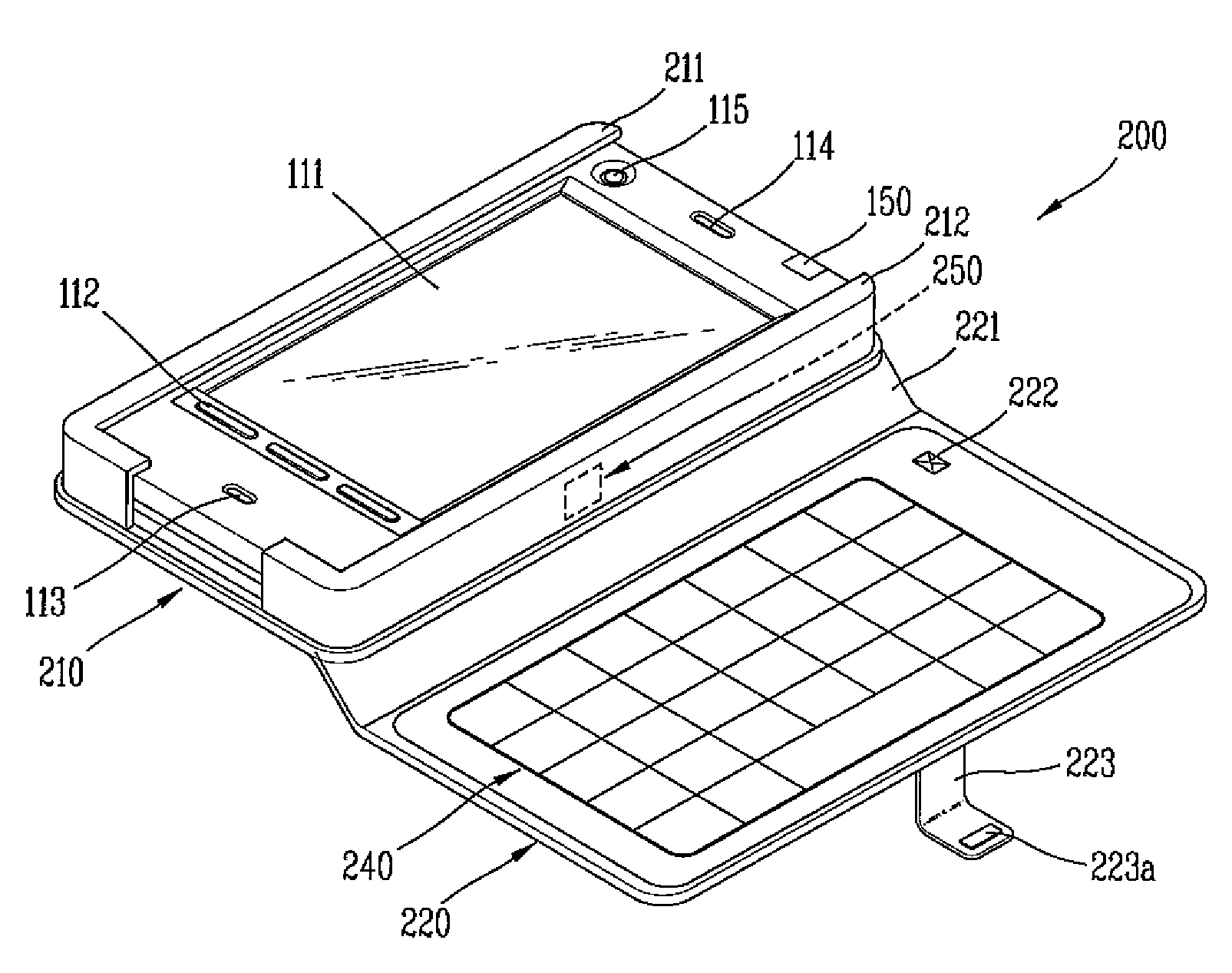

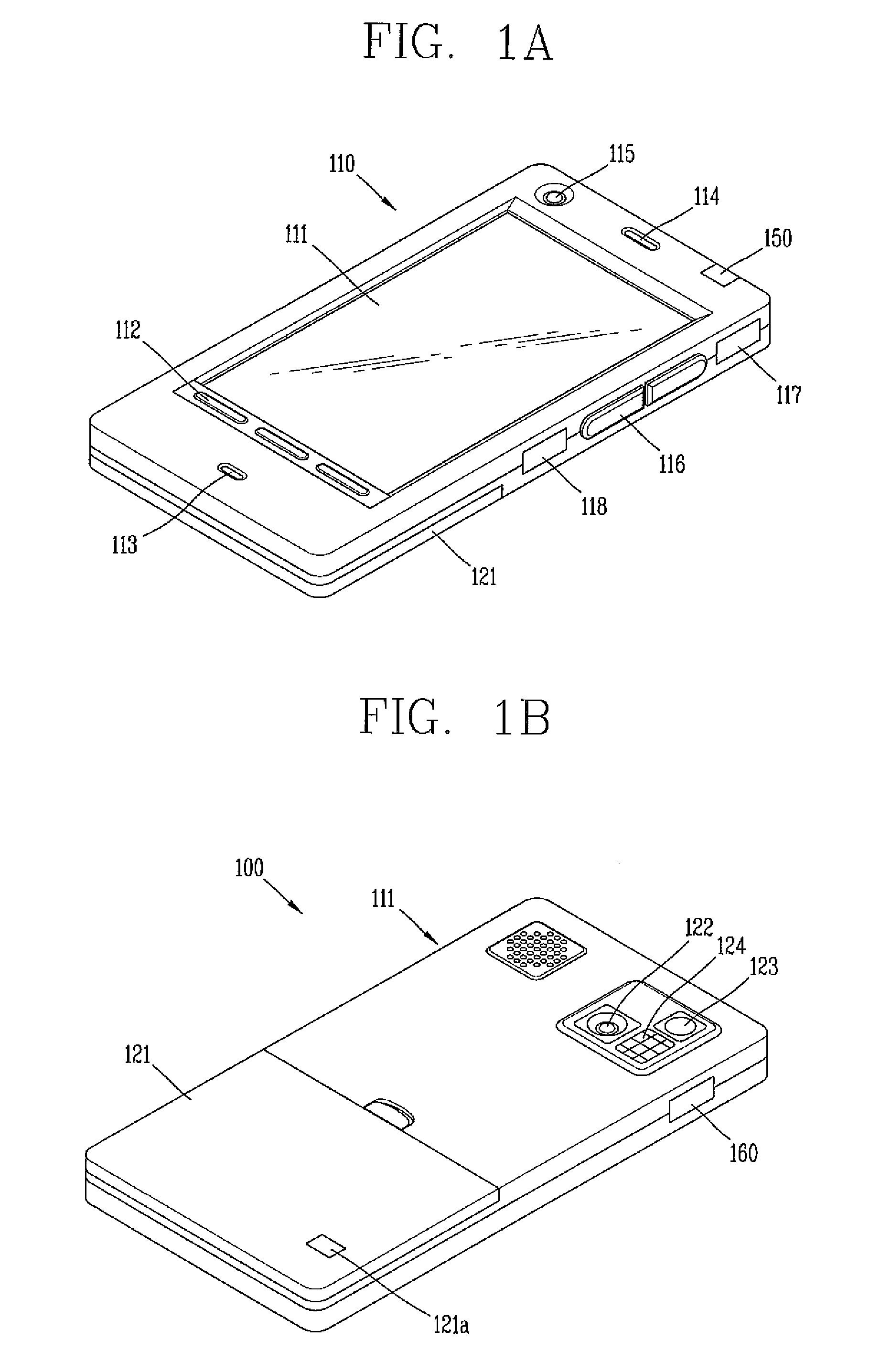

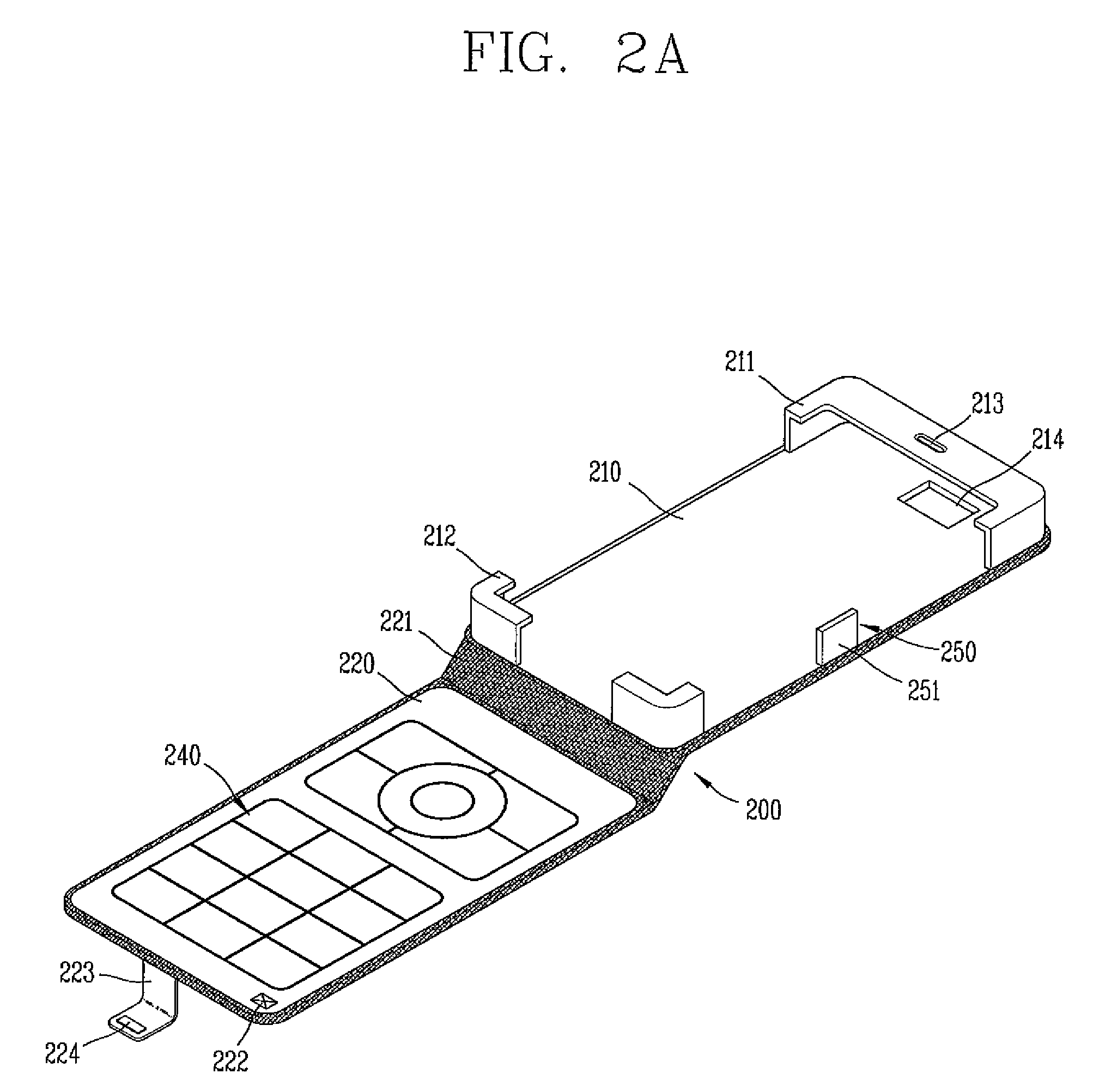

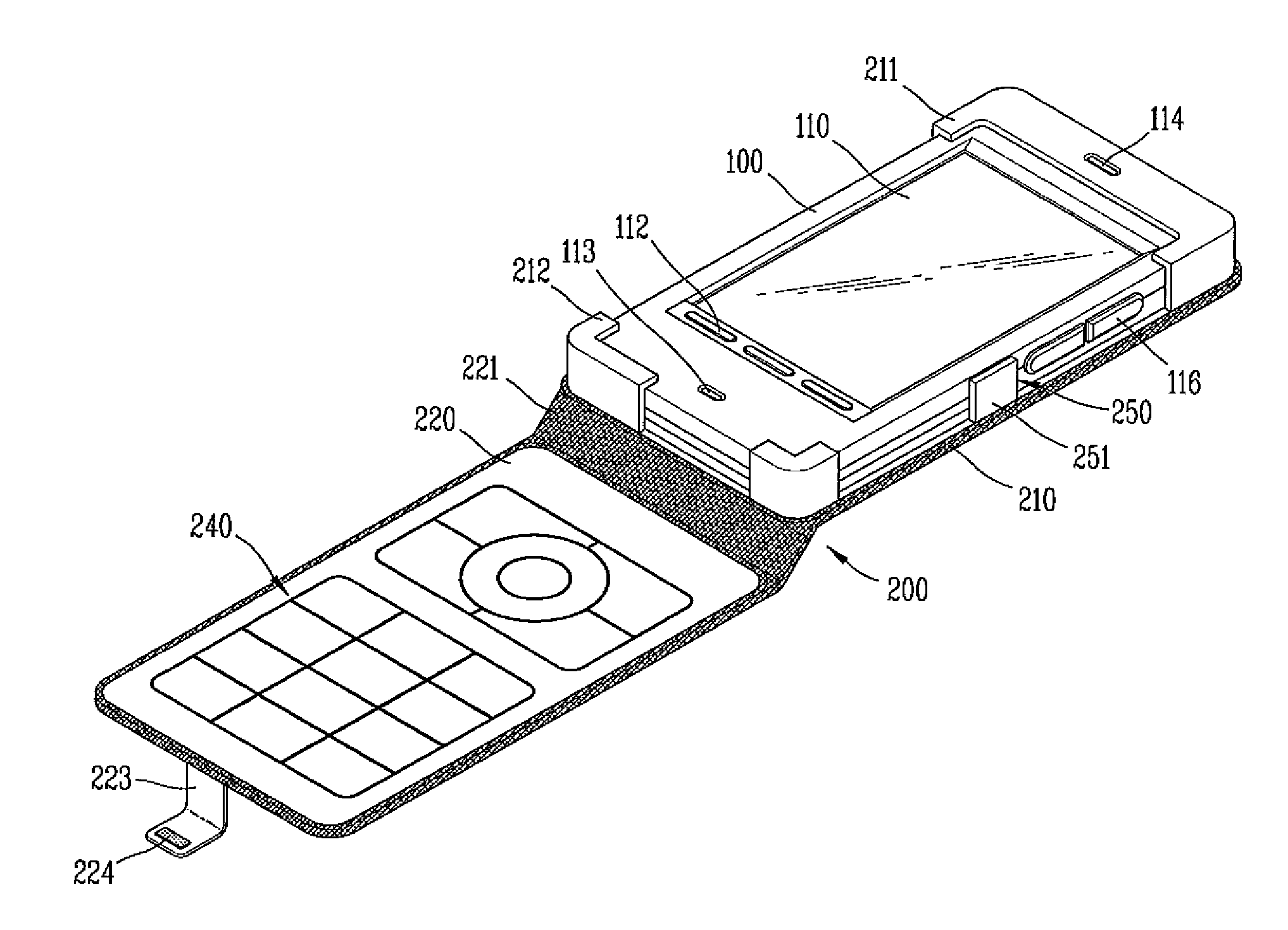

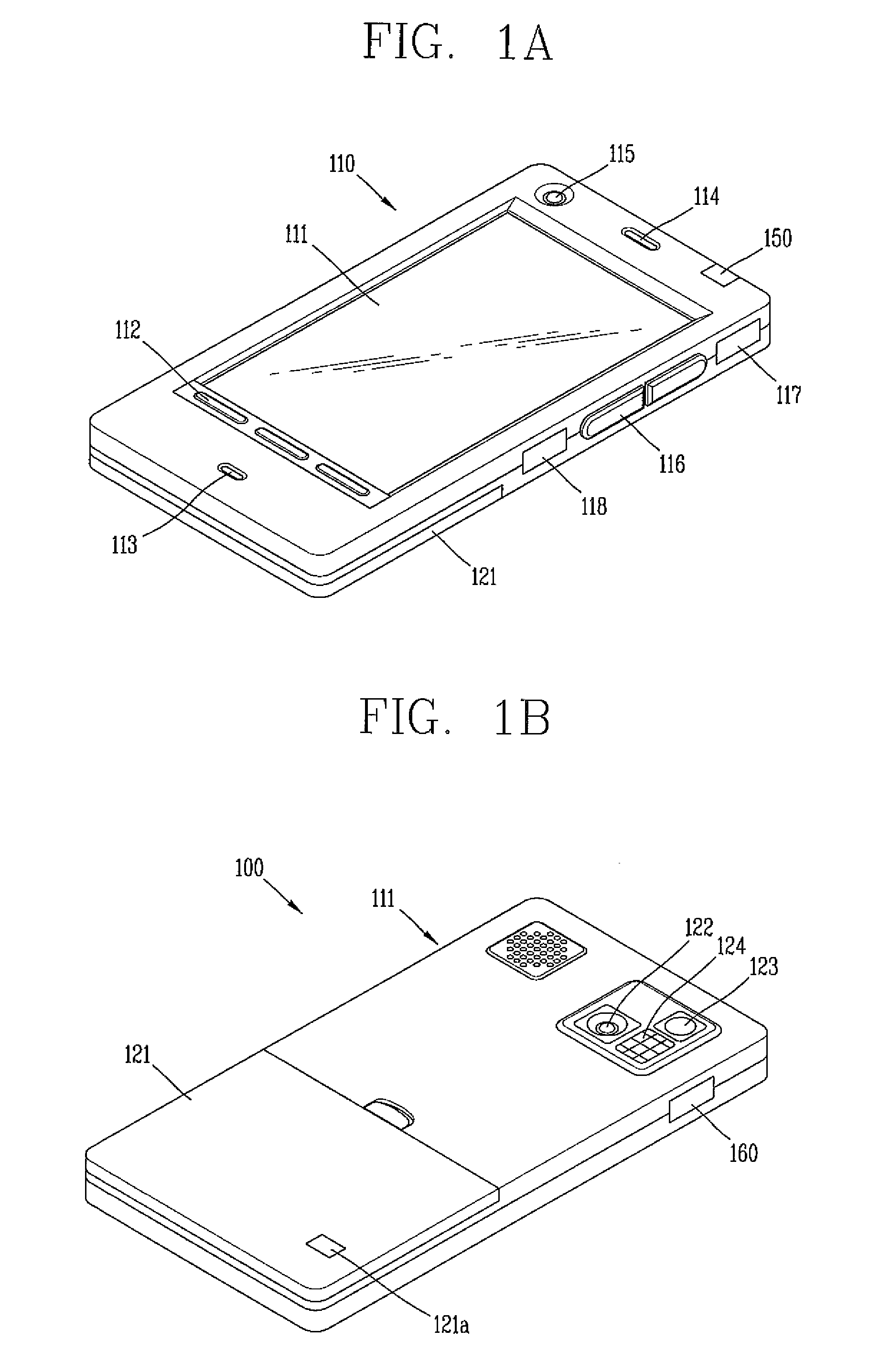

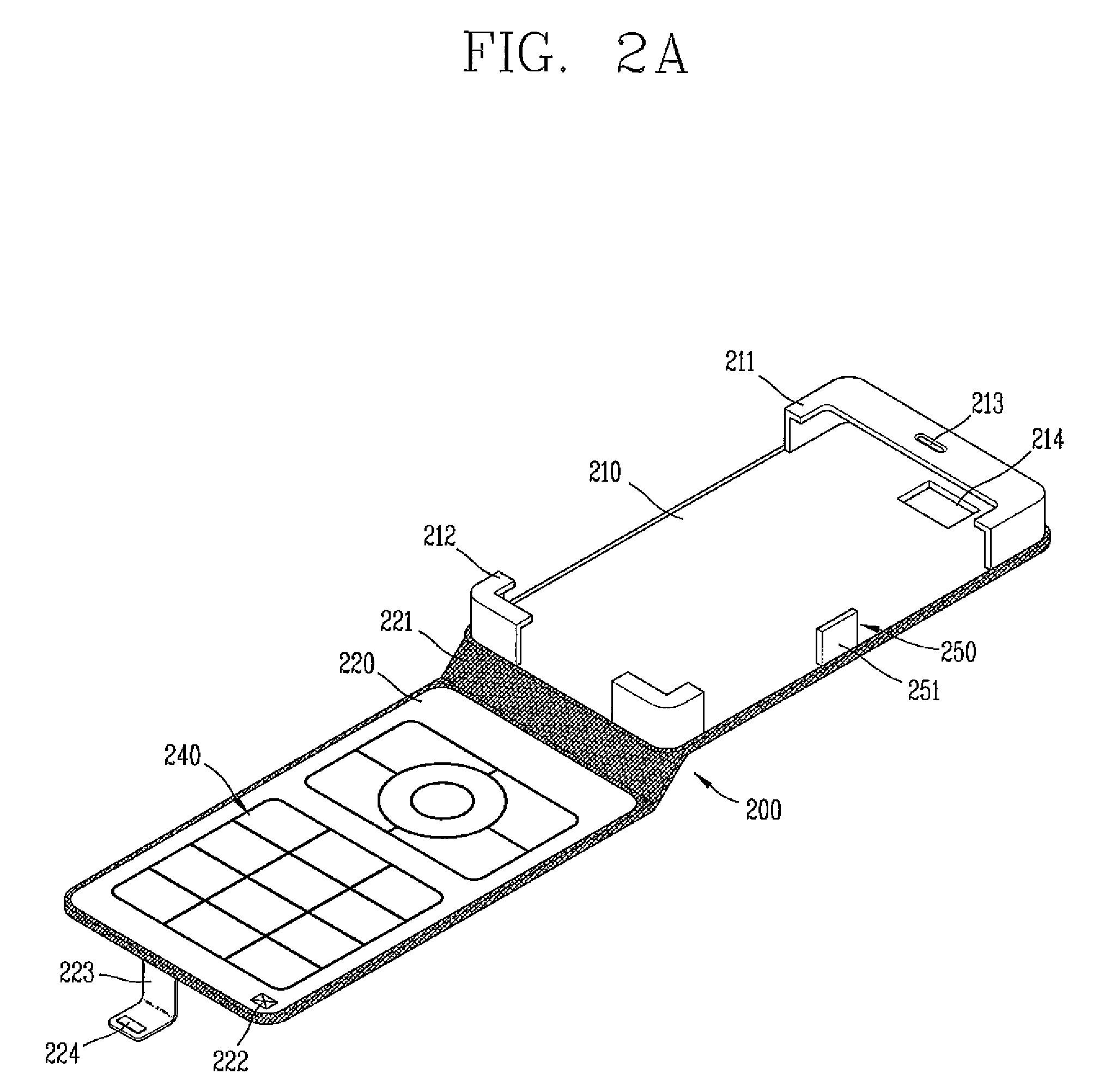

Mobile terminal and case for mobile terminal

ActiveUS20080096620A1Protect appearanceEasy inputDigital data processing detailsTransmissionTelecommunicationsUser input

A case of a mobile terminal includes a user input unit, a controller for manipulating an input signal, an interface for transmitting the manipulated input signal and protects a mobile terminal. As the case of the mobile terminal provides an additional user input, this allows a user to control each function of the mobile terminal with user friendly manner, or to input data efficiently, and to improve a design quality of the mobile terminal

Owner:LG ELECTRONICS INC

Mobile terminal and case for mobile terminal

ActiveUS8046039B2Protect appearanceEasy inputDigital data processing detailsTransmissionComputer hardwareUser input

Owner:LG ELECTRONICS INC

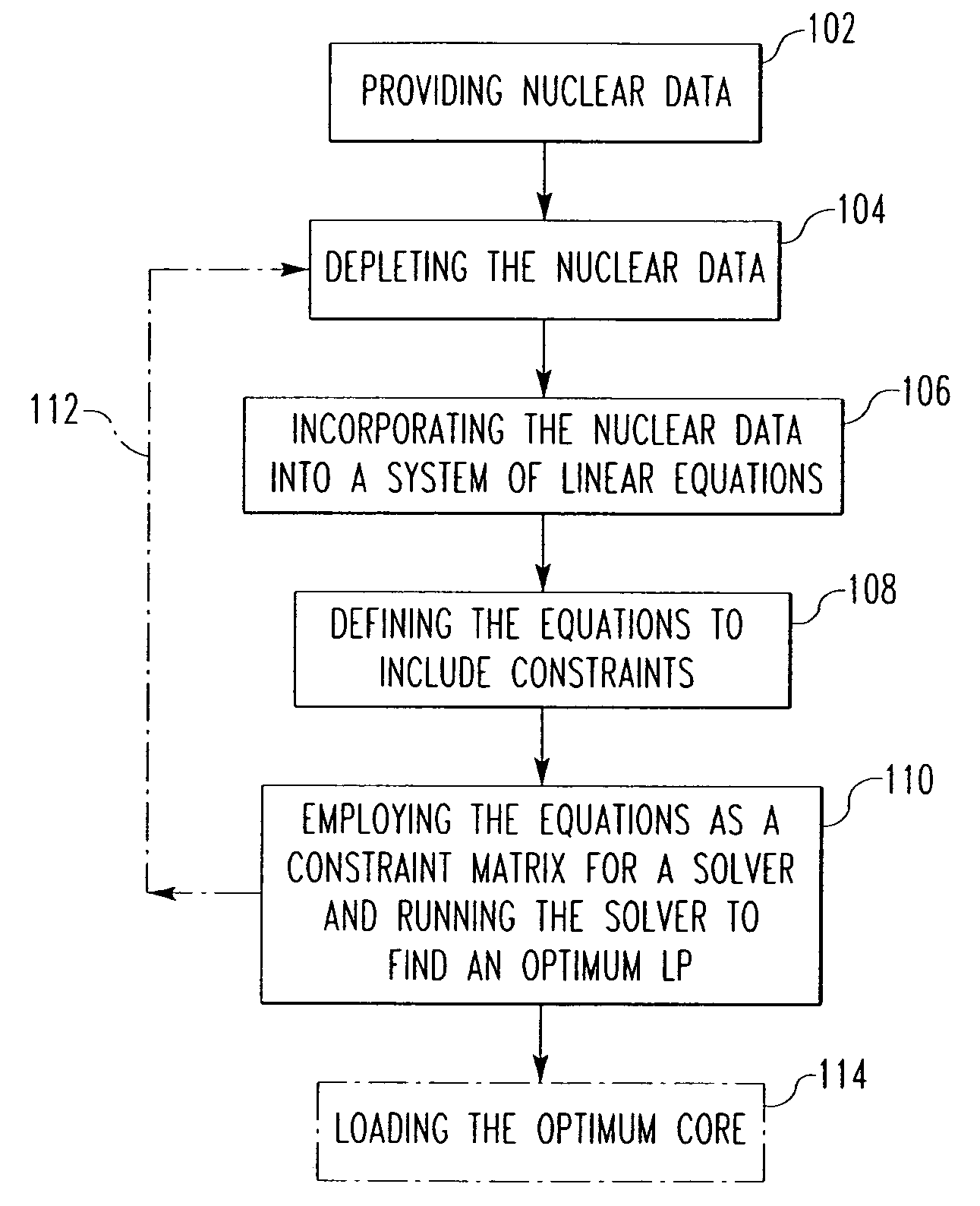

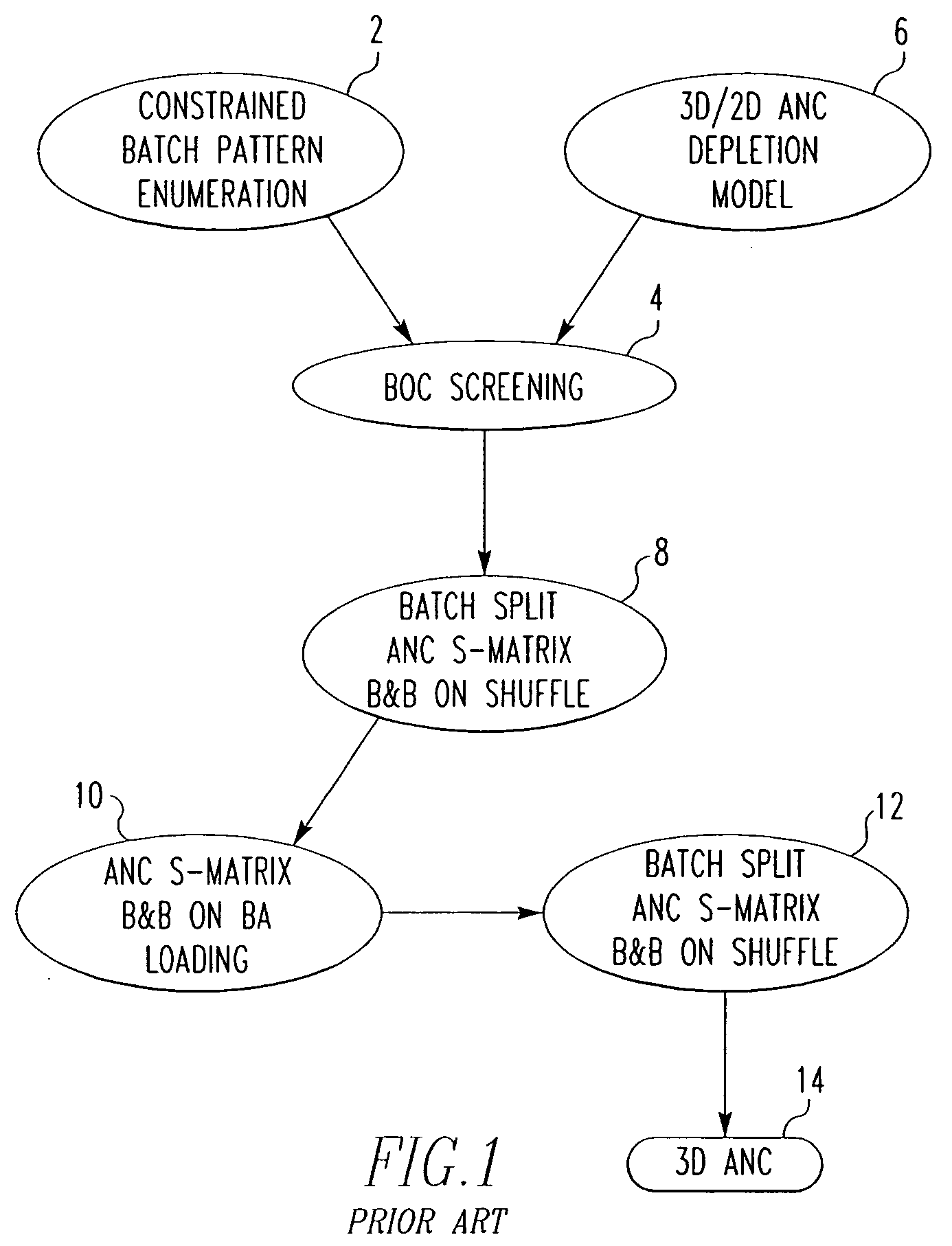

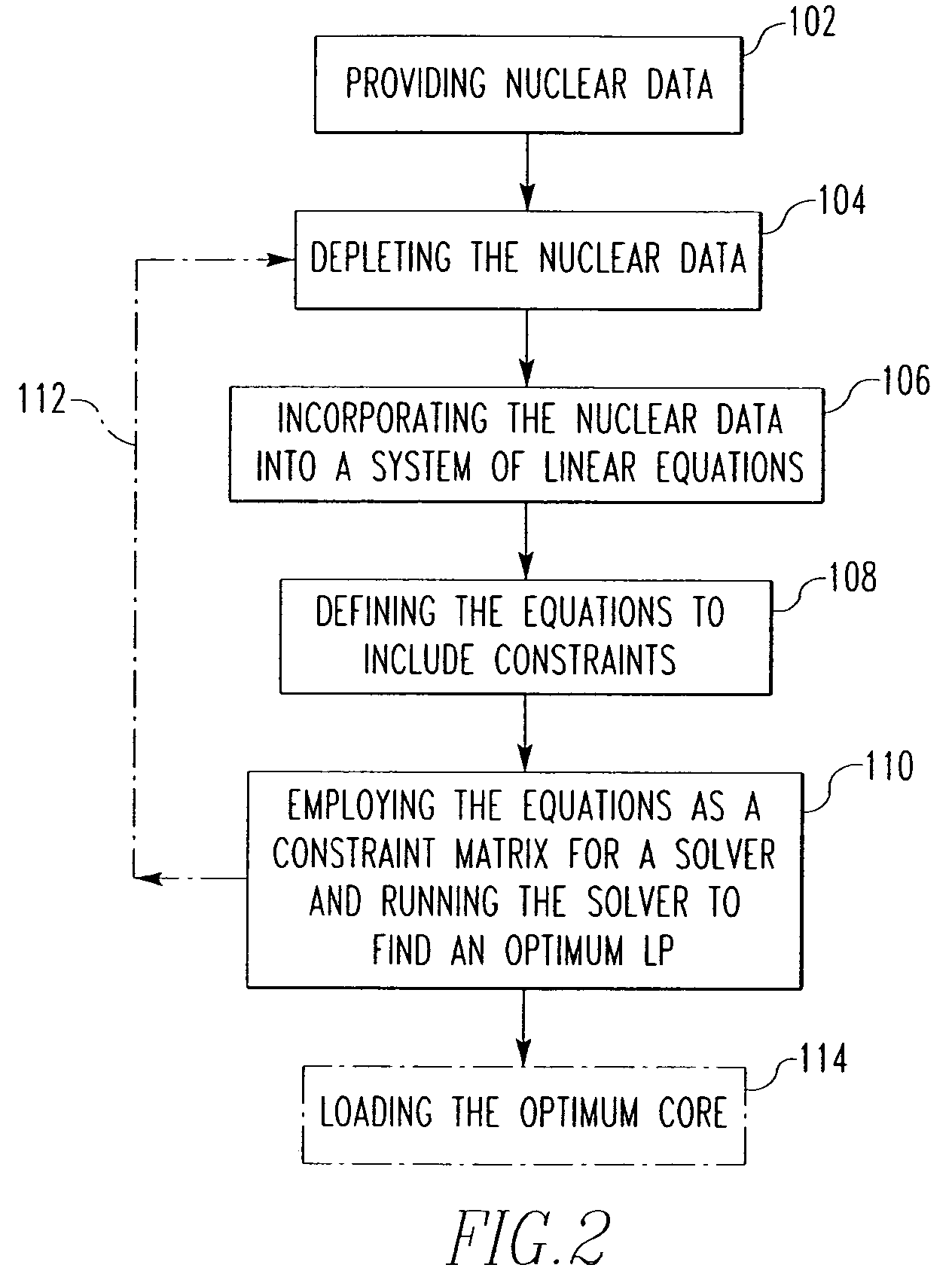

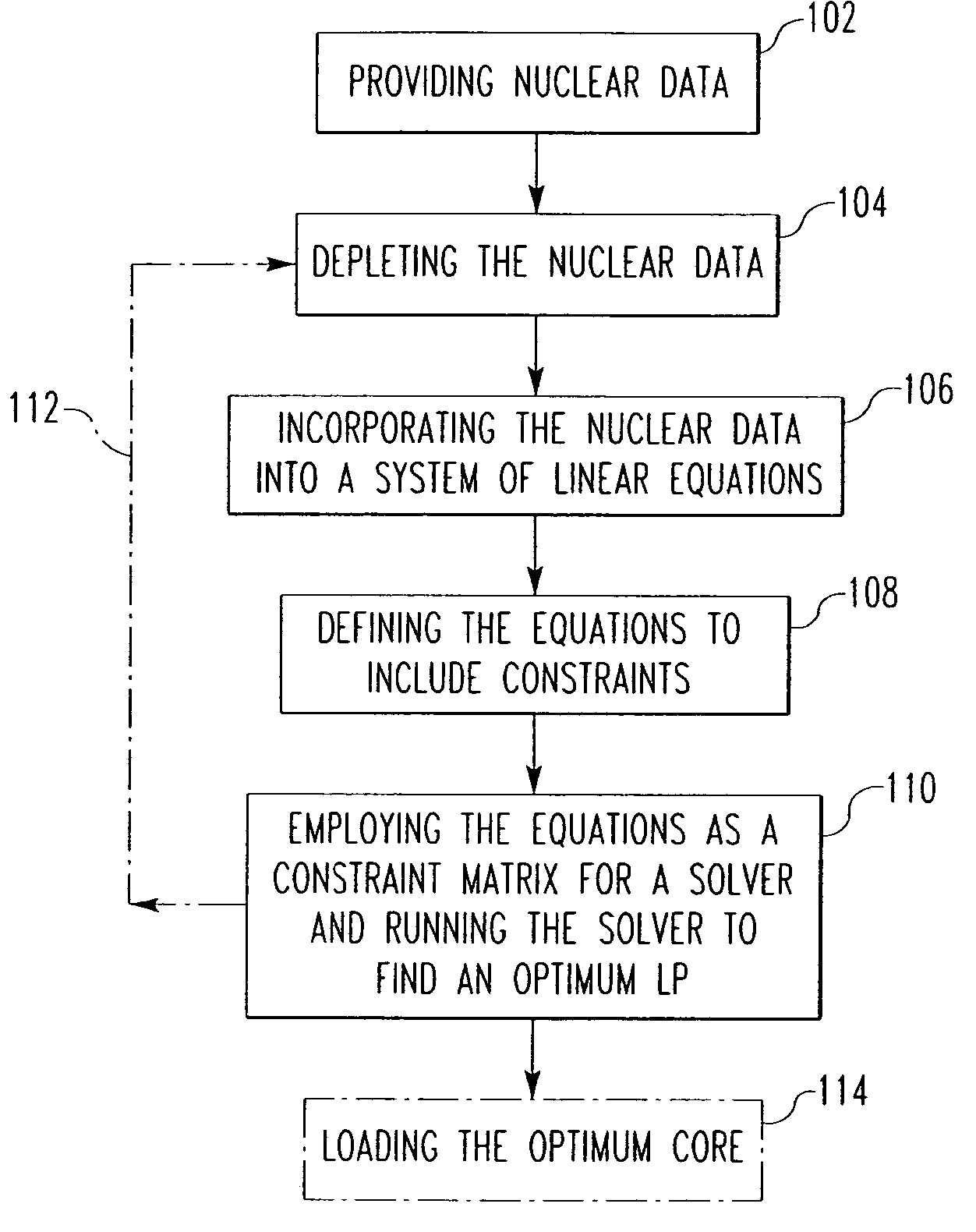

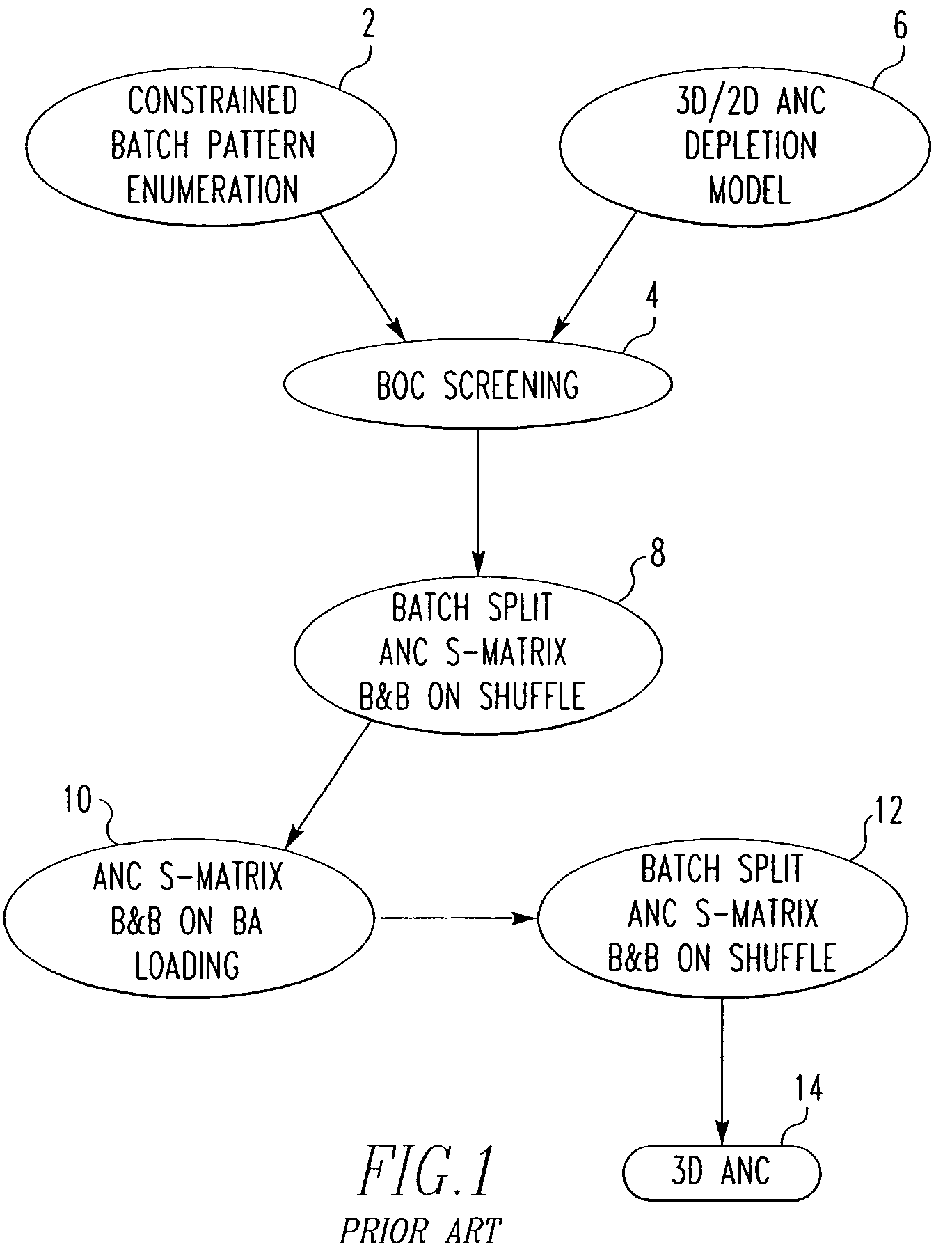

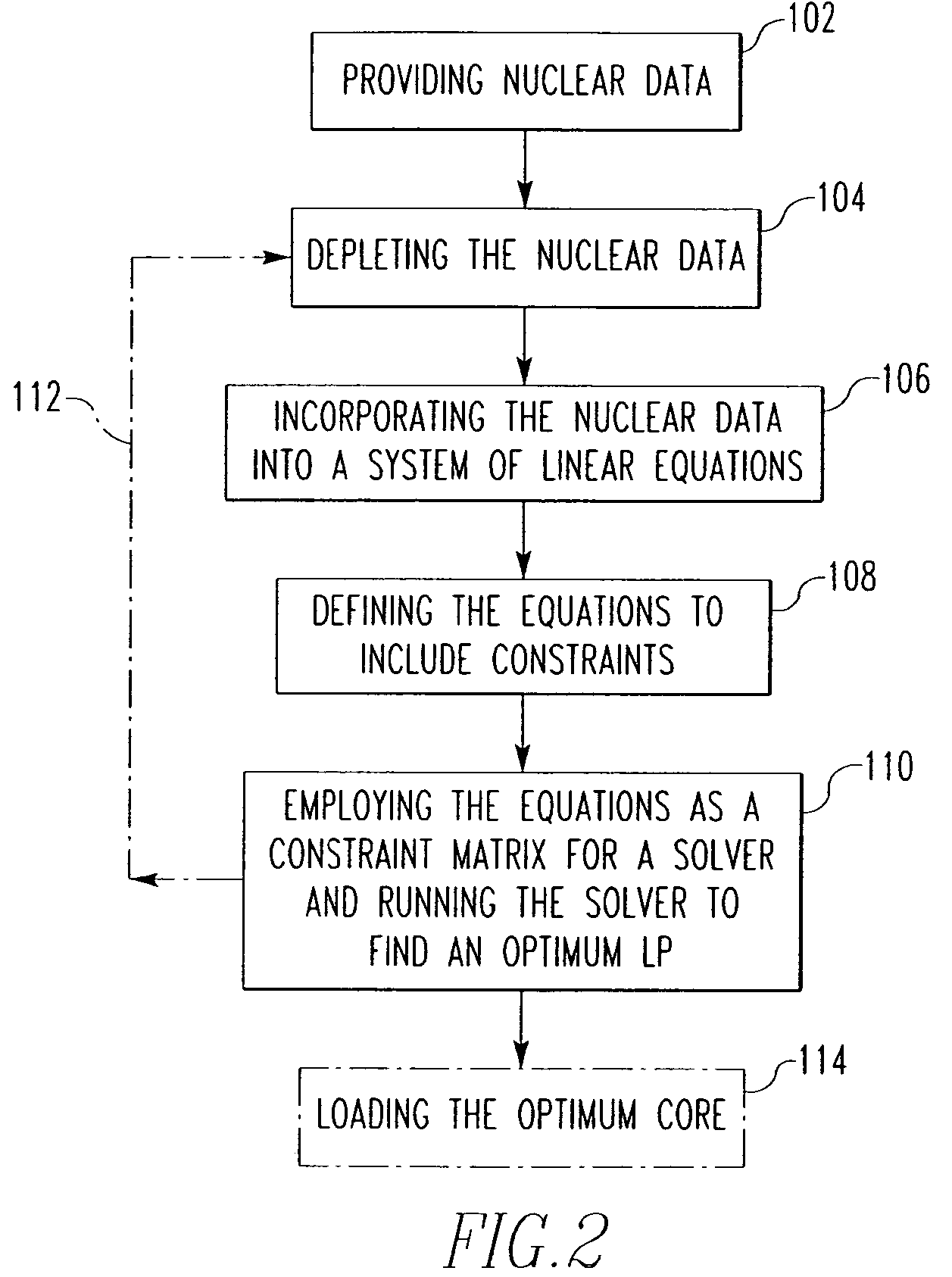

Method and algorithm for searching and optimizing nuclear reactor core loading patterns

ActiveUS20060109944A1Accurate representationSatisfies requirementCosmonautic condition simulationsNuclear energy generationNuclear reactor coreNuclear reactor

A method is for establishing a nuclear reactor core loading pattern (LP) for fuel assemblies and burnable absorbers (BAs). The method establishes an optimum LP through the steps of: a) providing nuclear data representing fuel assemblies and BAs in a nuclear reactor core; b) depleting the nuclear data to form a reference core depletion; c) incorporating the nuclear data into a system of linear equations of a nuclear design quality flux solution method; d) defining the system of linear equations to include constraints which accurately represent the neutron physics of the reactor; employing the equations as a constraint matrix for a MIP solver to find an optimum core pattern solution; f) repeating steps b) through e) updating the constraints and objective functions to satisfy specified engineering requirements and establish an optimum core loading pattern. An algorithm for deriving the system of equations is also disclosed.

Owner:WESTINGHOUSE ELECTRIC CORP

Method and algorithm for searching and optimizing nuclear reactor core loading patterns

ActiveUS7224761B2Accurate representationCosmonautic condition simulationsNuclear energy generationNuclear reactor coreNuclear reactor

A method is for establishing a nuclear reactor core loading pattern (LP) for fuel assemblies and burnable absorbers (BAs). The method establishes an optimum LP through the steps of: a) providing nuclear data representing fuel assemblies and BAs in a nuclear reactor core; b) depleting the nuclear data to form a reference core depletion; c) incorporating the nuclear data into a system of linear equations of a nuclear design quality flux solution method; d) defining the system of linear equations to include constraints which accurately represent the neutron physics of the reactor; employing the equations as a constraint matrix for a MIP solver to find an optimum core pattern solution; f) repeating steps b) through e) updating the constraints and objective functions to satisfy specified engineering requirements and establish an optimum core loading pattern. An algorithm for deriving the system of equations is also disclosed.

Owner:WESTINGHOUSE ELECTRIC CORP

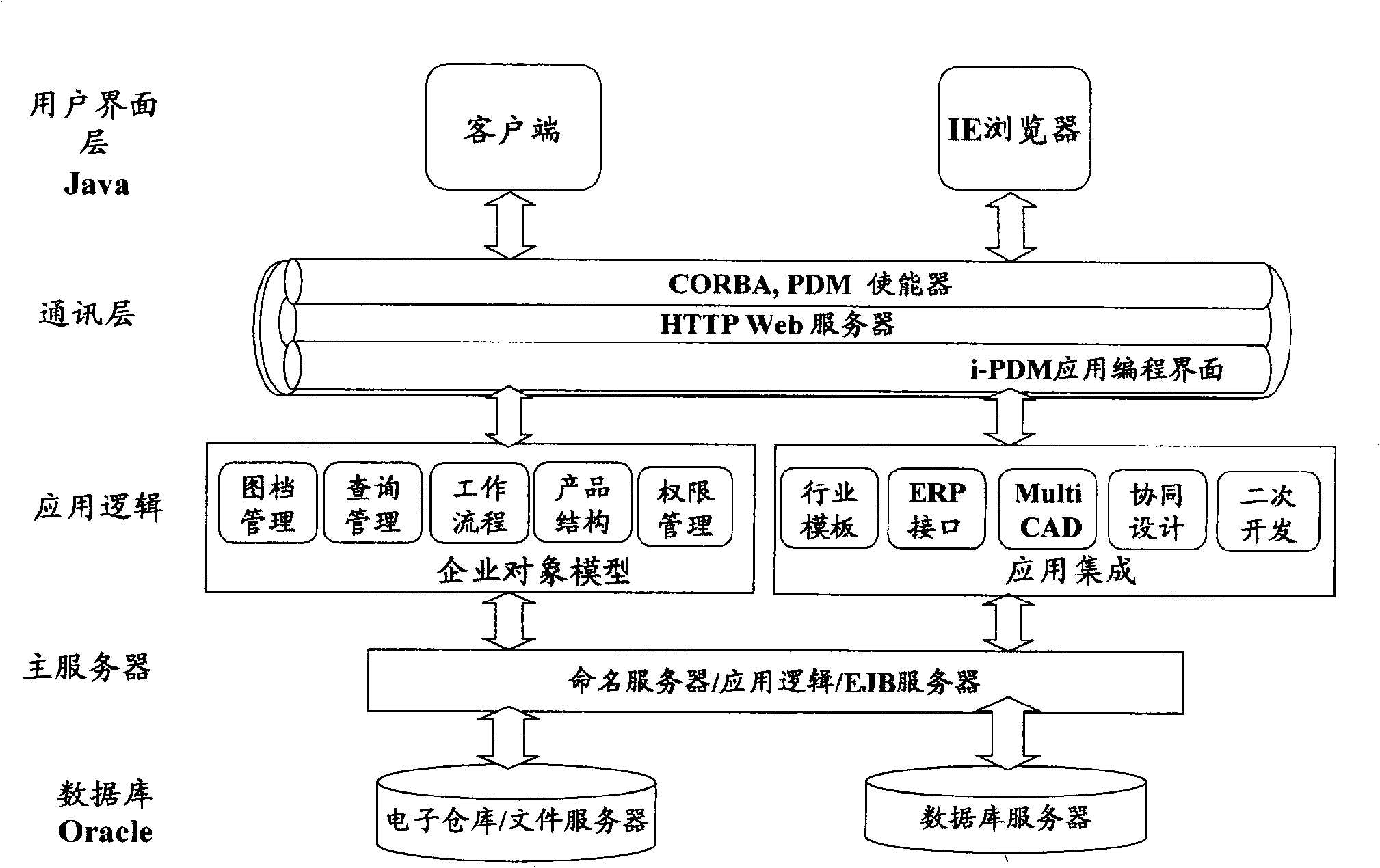

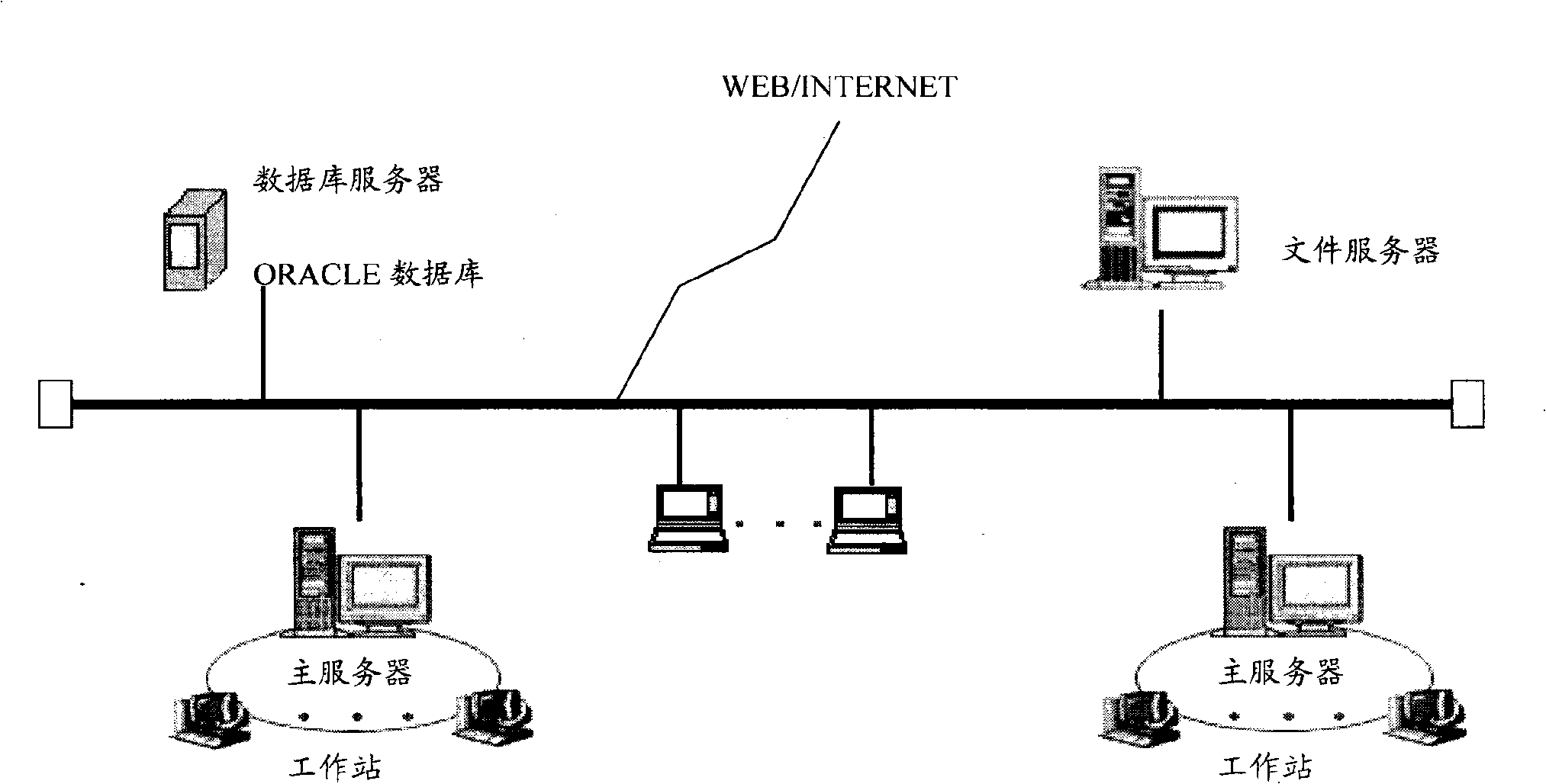

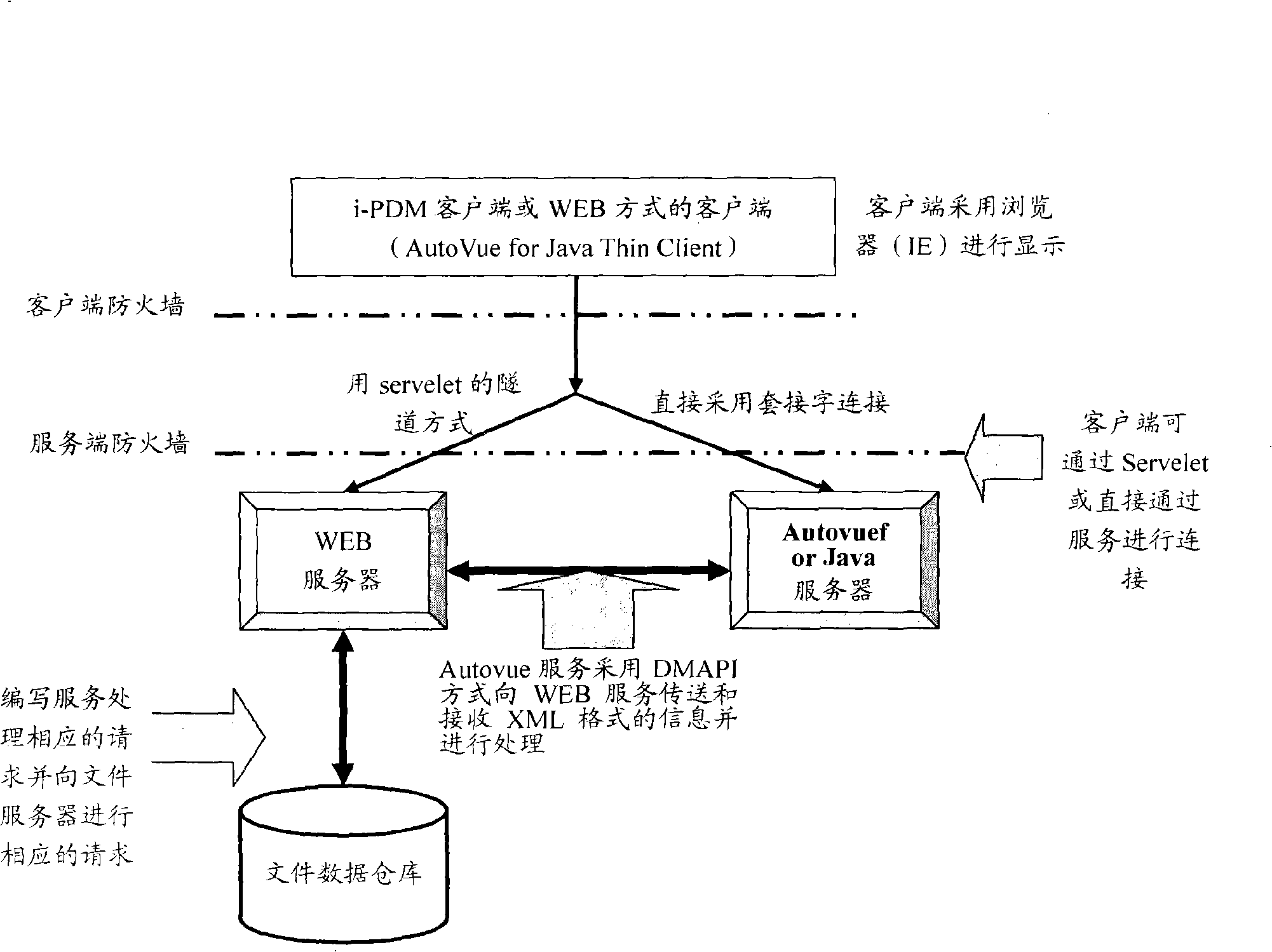

Data management system for vehicle products and collaborative design method thereof

InactiveCN101515308AShorten the development cycleImprove design qualityAerodynamics improvementSpecial data processing applicationsData synchronizationData query

The invention relates to a data management system for vehicle products and a method thereof, wherein the system comprises a user interface layer, a communication layer, an application logic layer, a main sever layer and a database layer, the use interface layer is connected with the database layer through the communication layer, the application layer and the main sever layer in sequence. The method comprises a graph document management and processing operation, a vehicle production structure management operation, a right management operation and a data query processing operation. By using the data management system for vehicle products and the collaborative design method thereof, the collaborative design of the vehicle development process is jointly achieved, and the real-time collaboration in the CAD environment and data sync update of associated parts are creatively achieved to effectively reduce the development period of the vehicle styles, and increase design quality, therefore the development period of the vehicle styles is reduced by about 20%, and the design alteration is reduced by over 30%, then, the system has simple and practical structure, fast and convenient usage process, high-efficient development design, stable and reliable working performance, and wider applicable range.

Owner:TJI INNOVA ENG & TECH

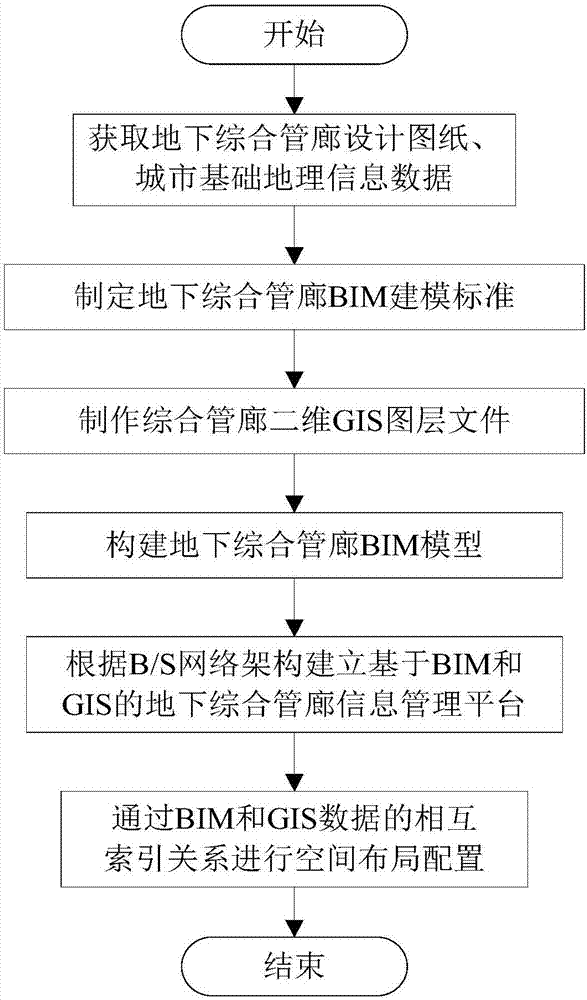

Underground comprehensive pipe gallery information management method based on BIM and GIS technologies

InactiveCN106960410ASustainable development impactImprove methodGeometric CADData processing applicationsRelevant informationQuality by Design

The invention discloses an underground comprehensive pipe gallery information management method based on BIM and GIS technologies. The method comprises the following steps of S1, acquiring an underground comprehensive pipe gallery design drawing and urban basic geographic information data; S2, making an underground comprehensive pipe gallery BIM modeling standard; S3, making a comprehensive pipe-gallery two-dimensional GIS layer file; S4, constructing an underground comprehensive pipe gallery BIM model; S5, according to a B / S network configuration, establishing an underground comprehensive pipe gallery information management platform based on the BIM and the GIS; and S6, through a mutual index relation of BIM and GIS data, carrying out space layout configuration, and simultaneously displaying an underground comprehensive pipe-gallery two-dimensional GIS model and a three-dimensional BIM model. In the invention, a GIS technology and a BIM technology are combined and are applied to comprehensive pipe gallery engineering so that design and operation management persons can carry out multiple-dimension analysis, multi-view space verification and visualization management on underground comprehensive pipe gallery correlation information in a three-dimensional on-site environment. Management efficiency, design quality and operation quality can be increased.

Owner:CHINA CONSTR UNDERGROUND SPACE

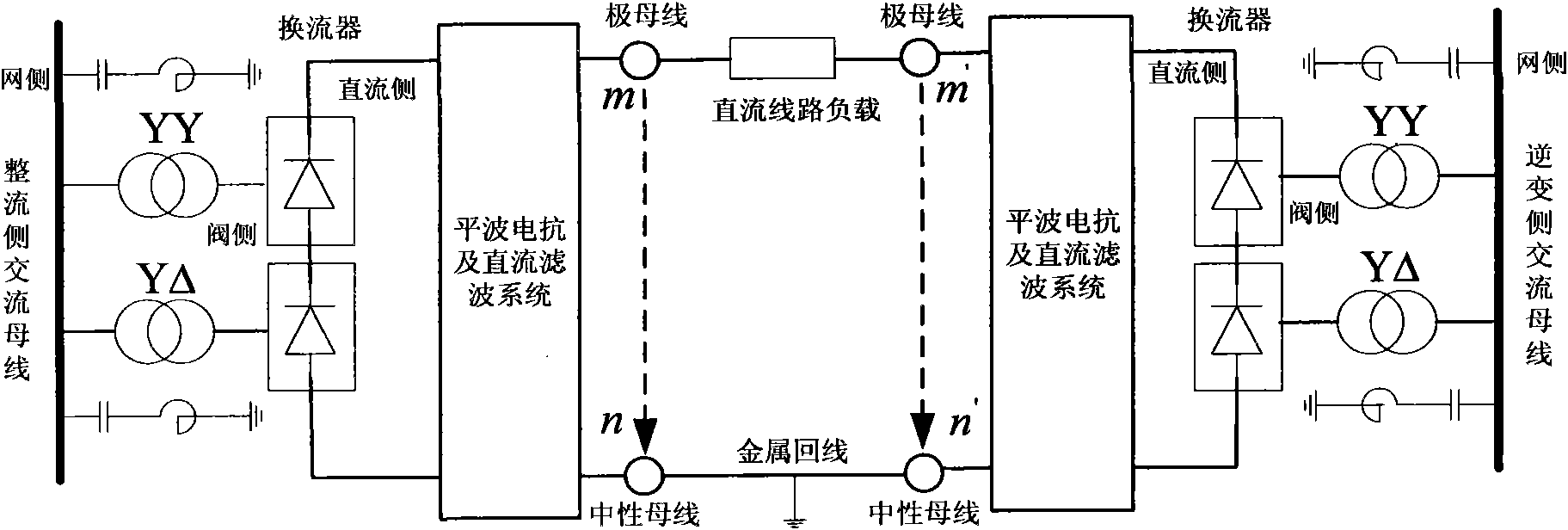

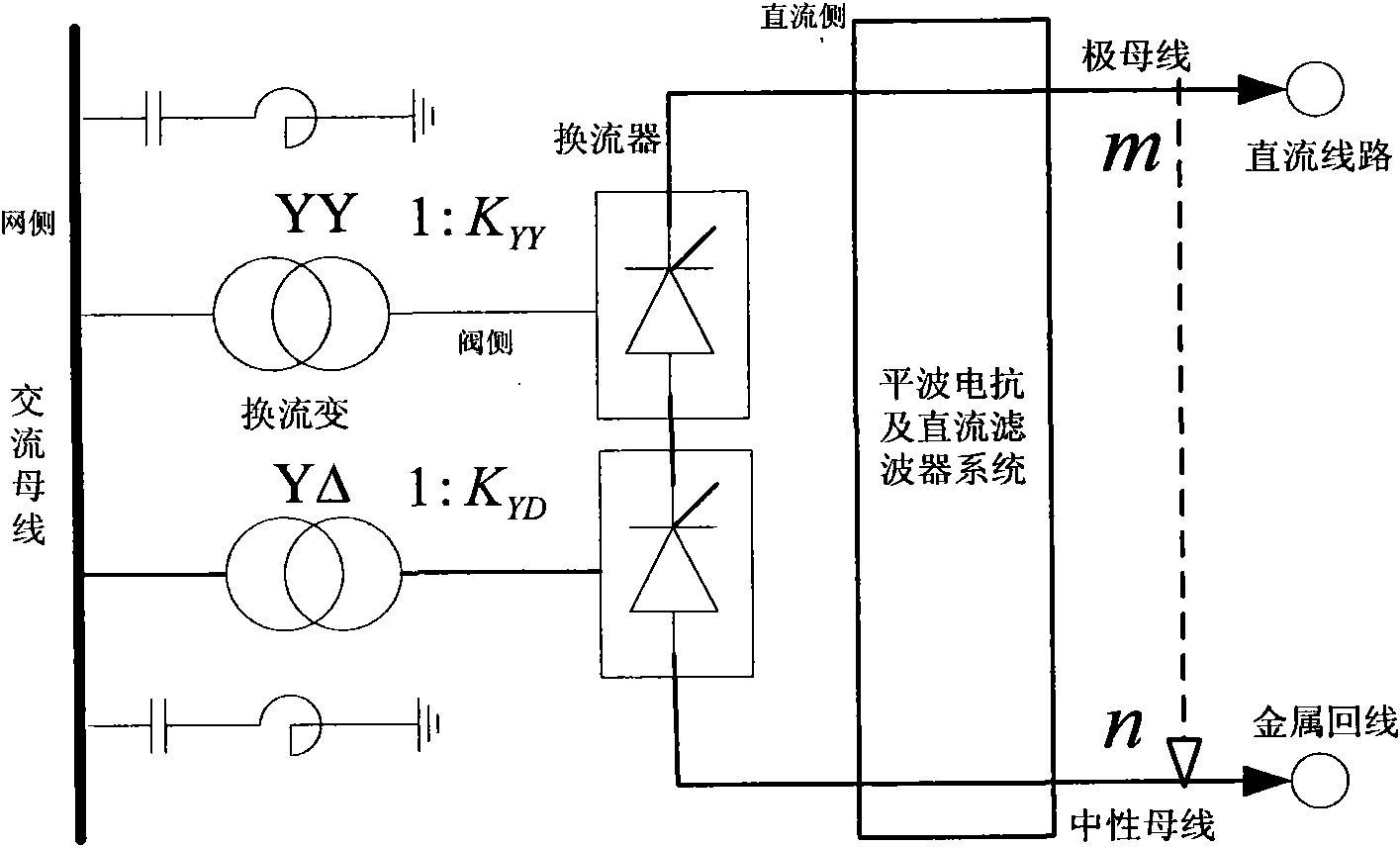

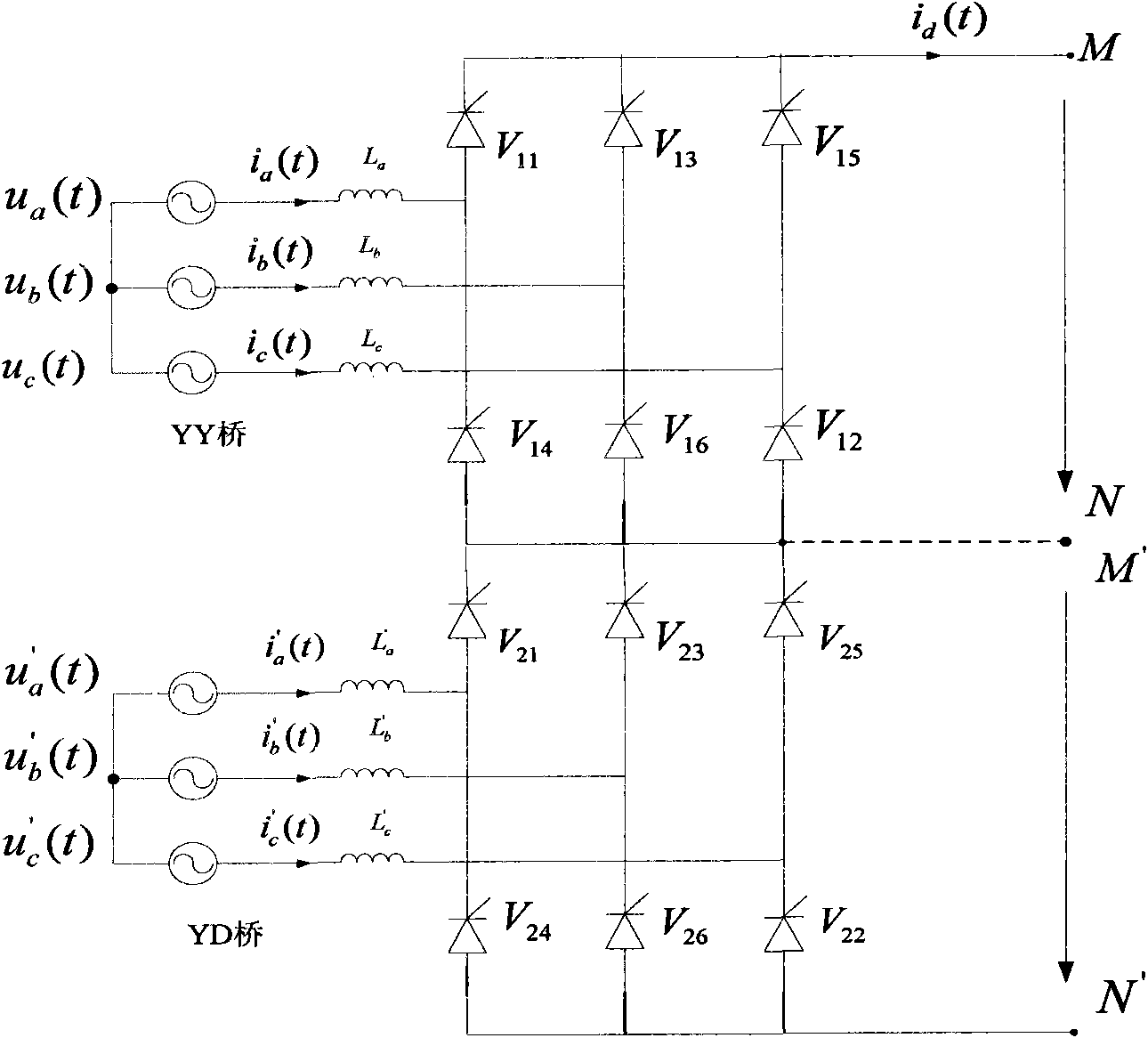

Determination method of network side harmonic current of high-voltage direct current power transmission system

InactiveCN101860037AAccelerate Design CycleImprove design qualityElectric power transfer ac networkHarmonic reduction arrangementTransformerInternal resistance

The invention discloses a determination method of network side harmonic current of a high-voltage direct current power transmission system. The determination method comprises the following steps: if the harmonic current voltage at a direct current power transmission line inlet is zero, decoupling and equalizing a rectifying side and an inverting side into a plurality of independent six-pulse moving bridge units; dividing a work period of the six-pulse moving bridge units into six phase converting sections and six non-phase converting sections; calculating a phase converting overlapping angle of each phase converting section; equalizing a current converter into a harmonic current voltage source containing internal resistance; calculating the direct current side harmonic current according to the concrete forms of a smoothing reactor and a direct current filter; obtaining valve side harmonic current according to an equivalent circuit of the current converter; and converting the valve side harmonic current to a network side according to a connecting structure of a transformer to obtain the network side harmonic current. The invention considers background harmonic current and other nonideal factors, and can quickly and accurately obtain the harmonic current at the network side of a converter transformer, accelerate the period for designing an alternating current filter in the high-voltage direct current power transmission engineering and improve the design quality and the design efficiency.

Owner:ZHEJIANG UNIV

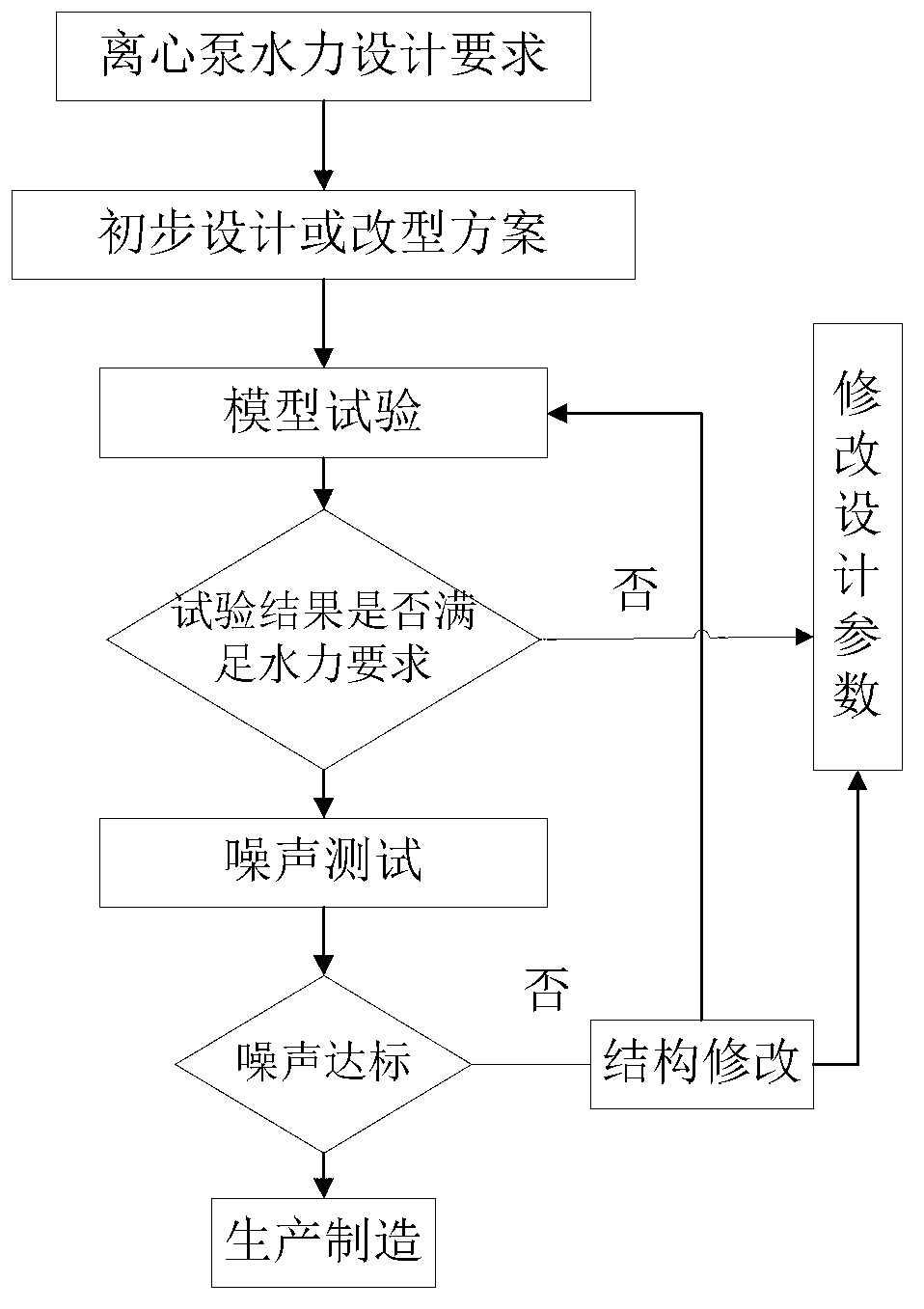

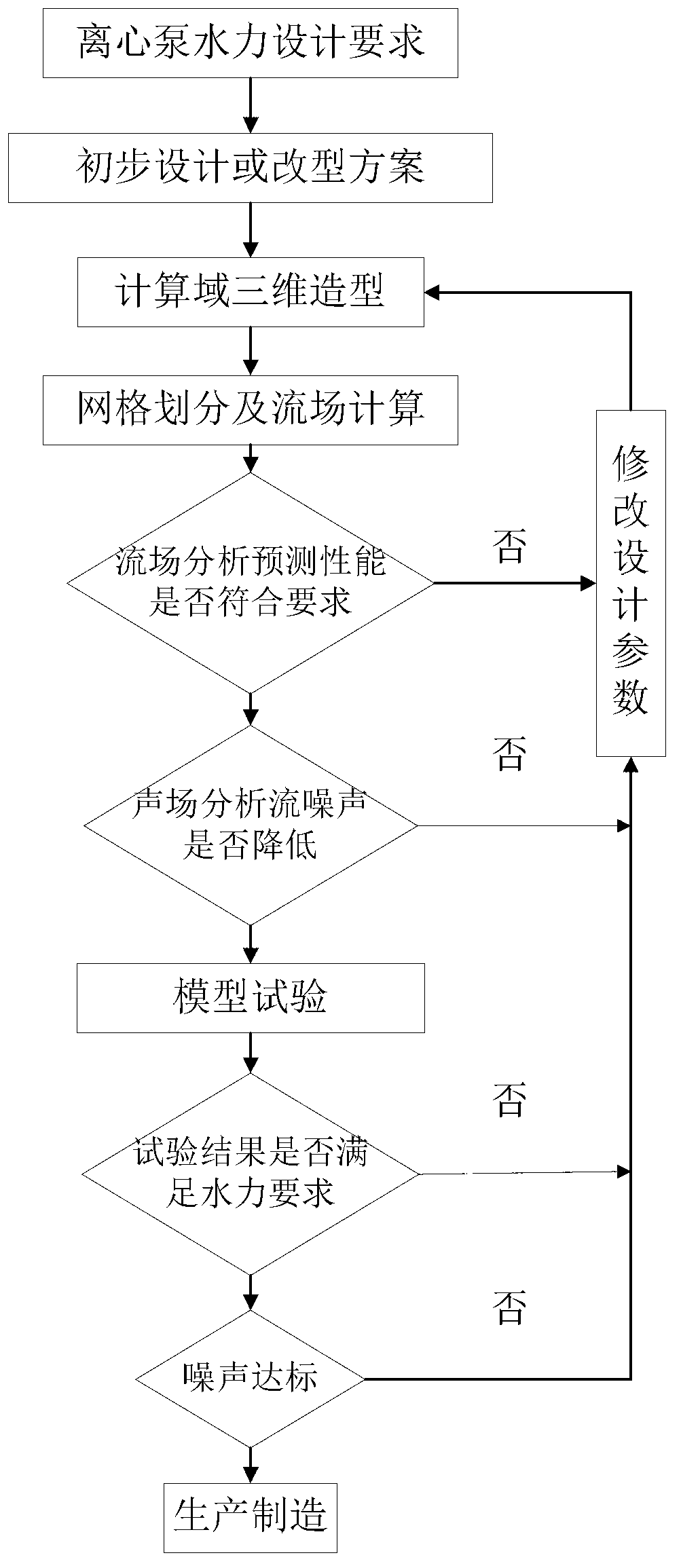

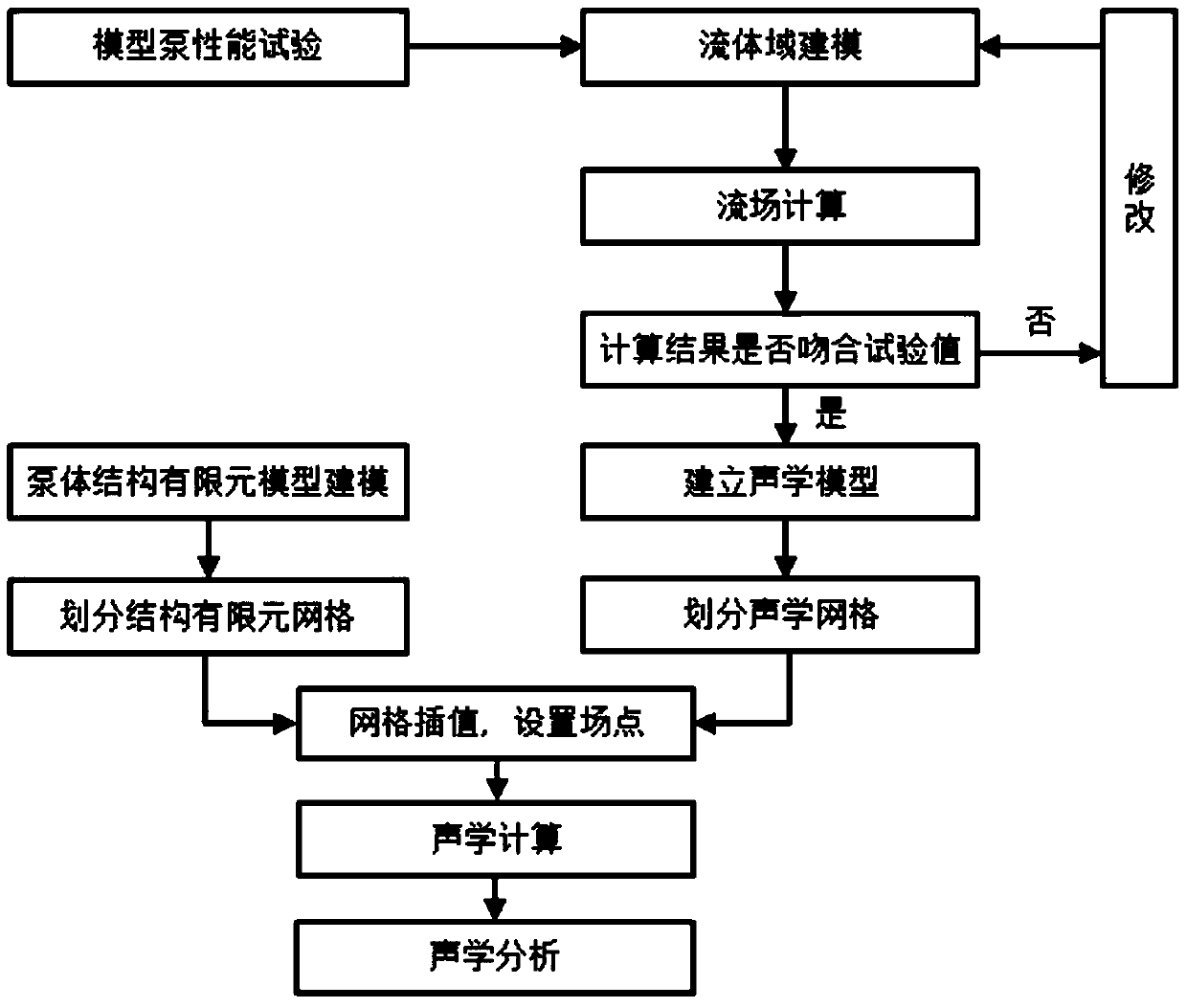

Low-noise hydraulic design method of centrifugal pump with low specific speed

ActiveCN103306985AImprove design qualityImprove machine performancePump componentsSpecial data processing applicationsLow noiseComputational acoustics

The invention discloses a low-noise design method of a centrifugal pump with low specific speed, and relates to an active control method of flow noise of turbomachinery. The design method comprises the steps that firstly, main structural dimensions of a centrifugal pump impeller and a helical pumping chamber (volute) are obtained by the traditional low-specific-speed pump design method; secondly, an internal flow field of the pump is computed by a computational fluid mechanics method; the performance of the pump is predicted whether to meet a design requirement; an optimum design improvement is performed by analyzing a stationary flow field; thirdly, flow induction noise of the pump with low specific speed is predicted by a computational acoustics method; if a flow noise index is qualified, the design is accomplished; if the flow noise index is disqualified, subsequent steps are performed; fourthly, the diameter of the impeller basically meeting a performance requirement in the design is adjusted to allow a gap between the impeller and a volute tongue to be increased continuously to 20%; splitter blades are added in the middles of blades to increase the lift, control the flow situation, and ensure the efficiency; and finally, the pump subjected to the impeller improvement design is subjected to noise prediction; if the flow noise index is qualified, the design is accomplished; and if the flow noise index is disqualified, the beginning step is repeated. The design method shortens the research and development period, saves the development cost, effectively improves the design quality of the centrifugal pump, can simultaneously meet low-noise requirements of the lift and the efficiency, and realizes optimization of the performance of the complete centrifugal pump with low specific speed.

Owner:JIANGSU UNIV

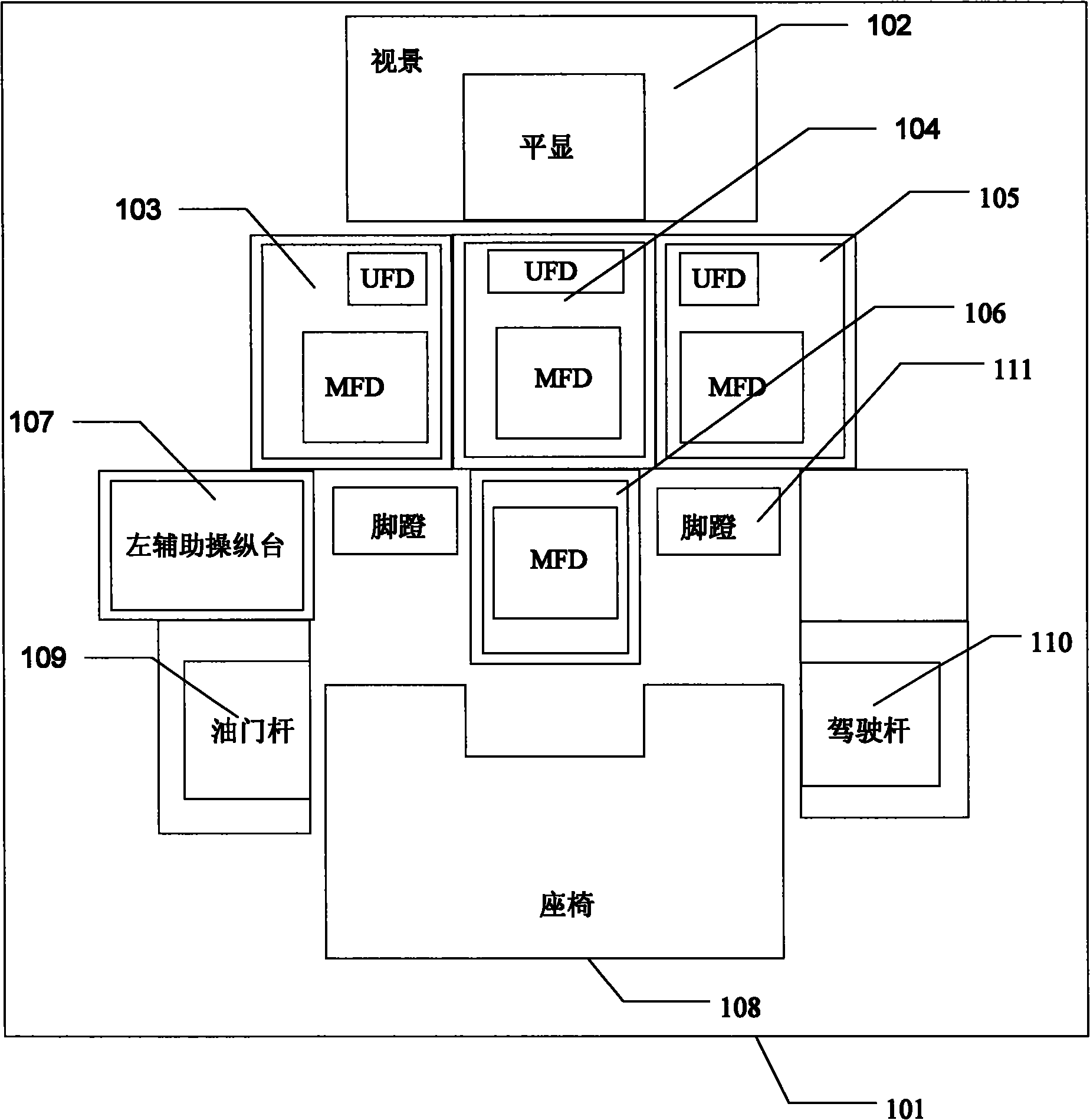

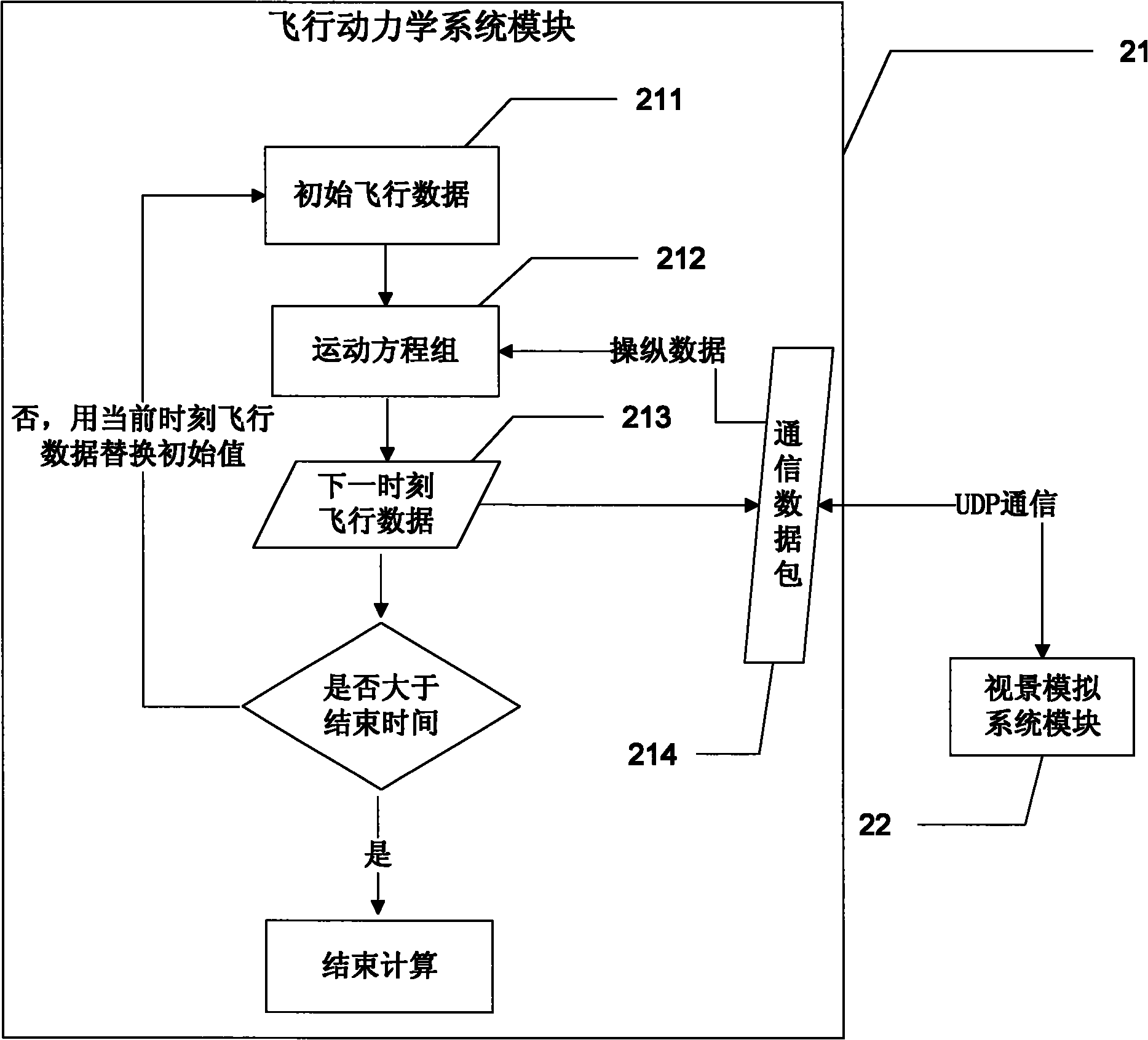

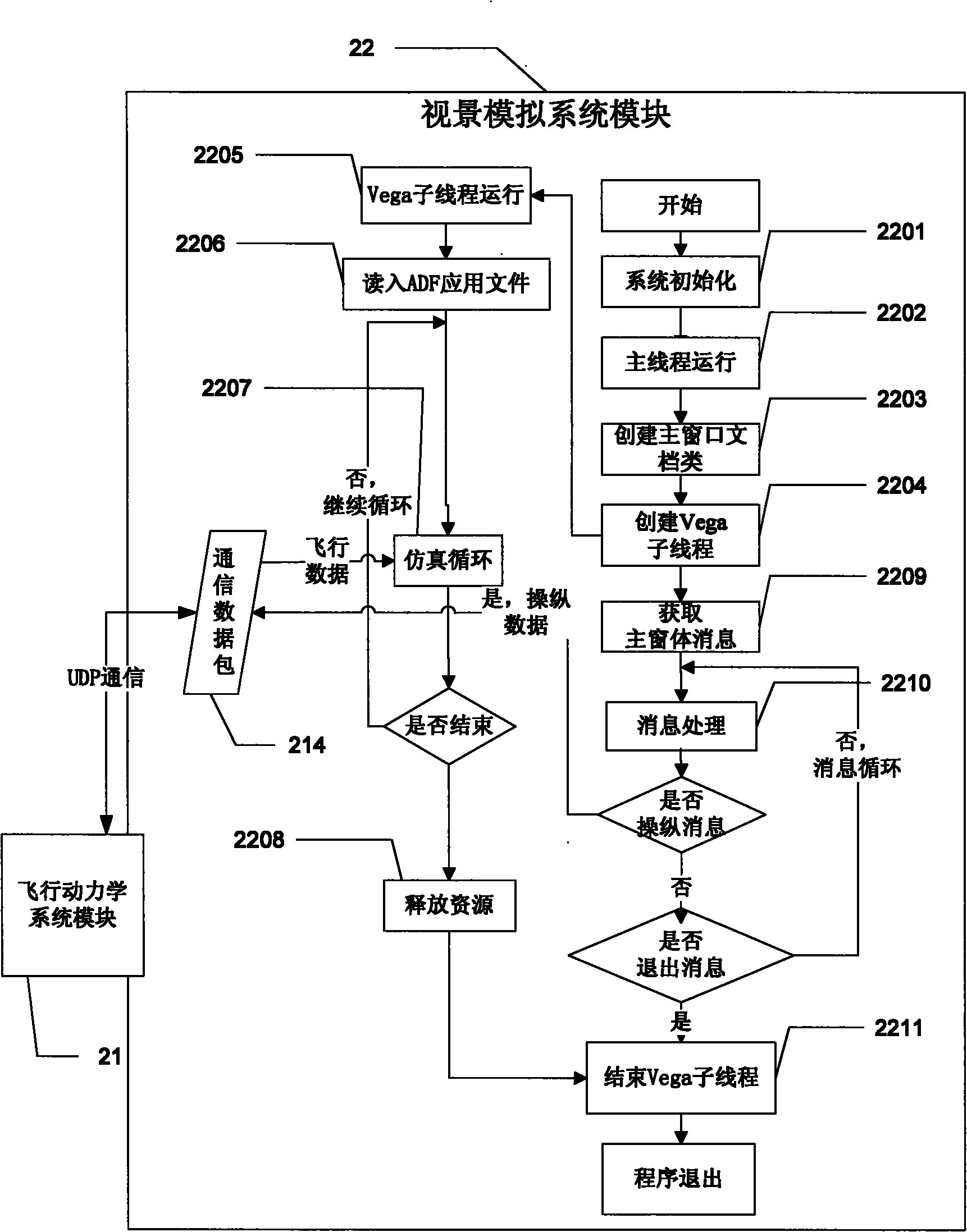

Flight simulation system with design and test functions of information display interface

The invention discloses a fight simulation system. An experiment table of the fight simulation system comprises a navigation bridge hardware system, a fight task simulation system and a human-machine work efficiency assessment system. The human-machine work efficiency assessment experiment table integrates the work efficiency assessment of the information display interface with the traditional fight task simulation. By loading the design scheme of the information display interface of the aviation cockpit into the fight simulation system, the design scheme of the information display interface is assessed by using the human-machine work efficiency assessment system after a tester simulates the fight, thereby assessing the human suitability of the information display interface of the aviation cockpit. By using the human-machine work efficiency assessment experiment table, the design quality of the information display interface of the aviation cockpit can be improved, the development period can be shortened and the development cost can be reduced.

Owner:BEIHANG UNIV

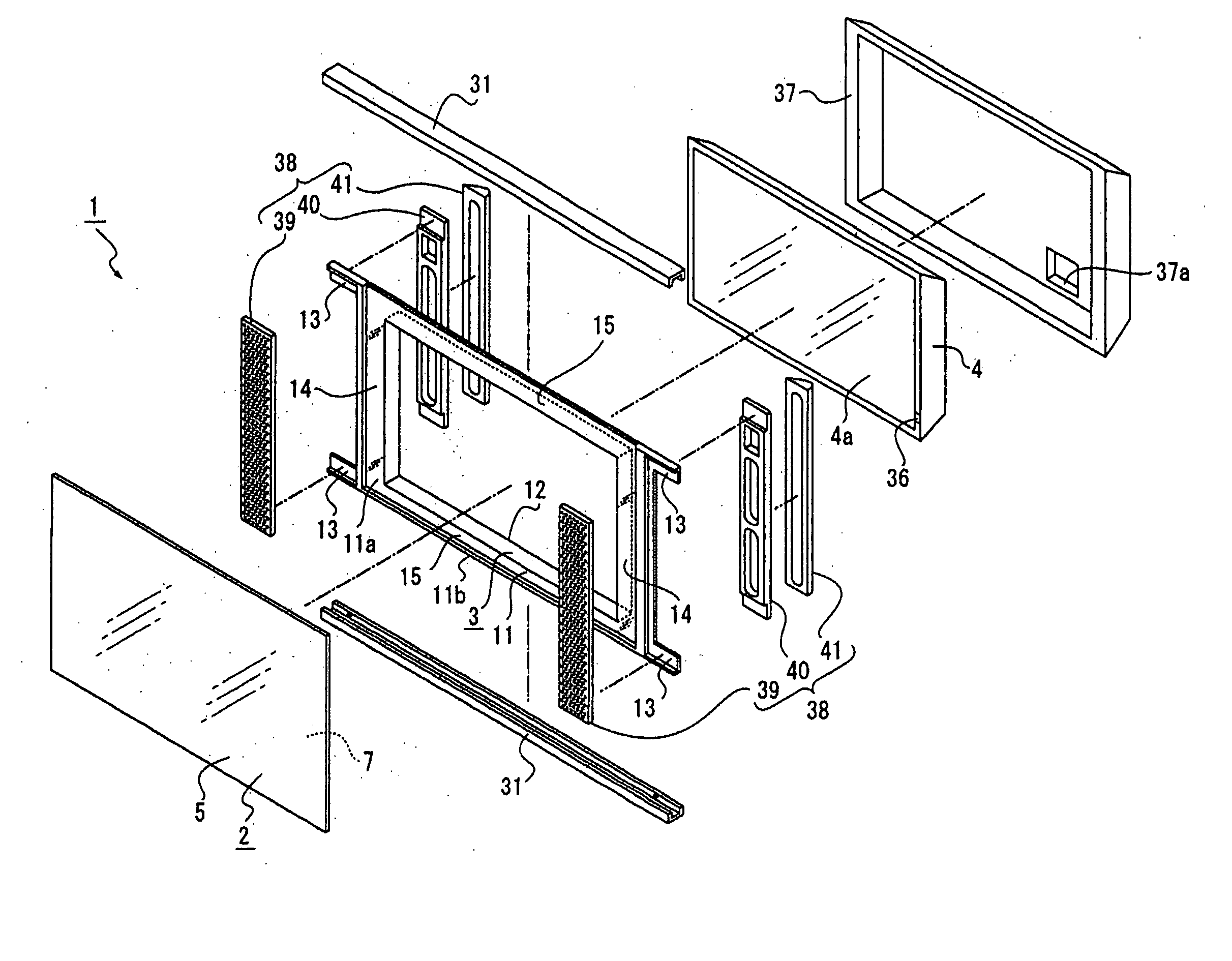

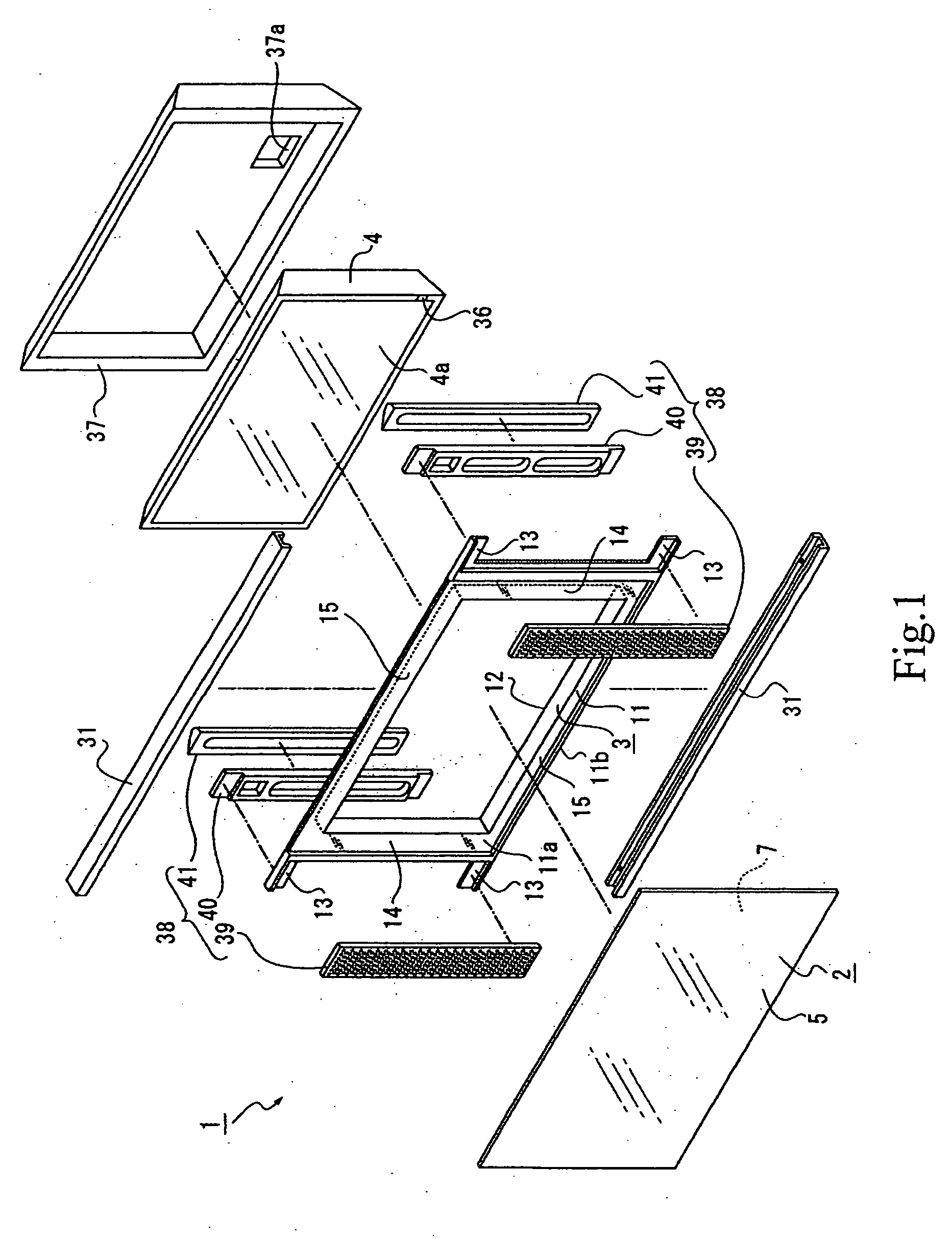

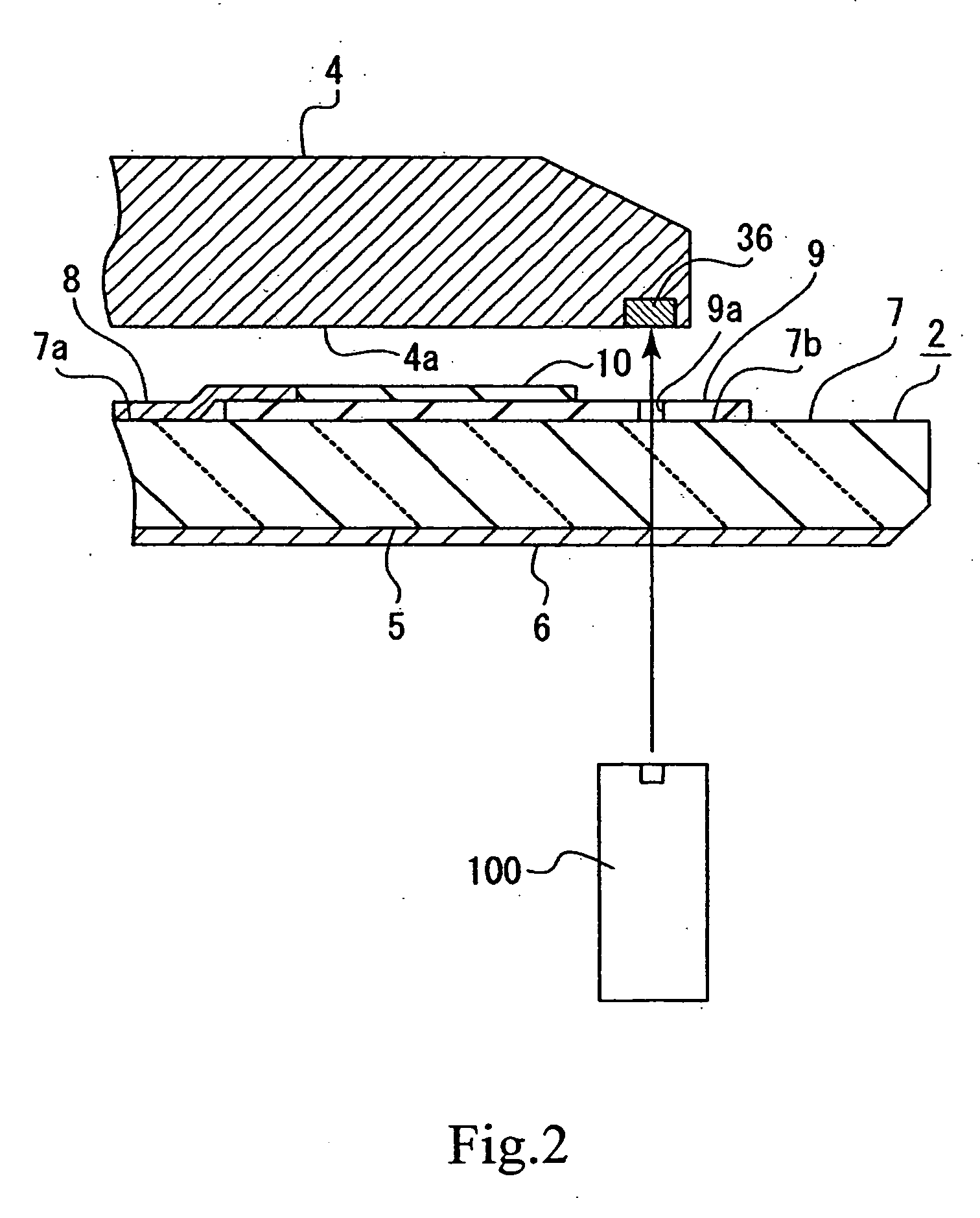

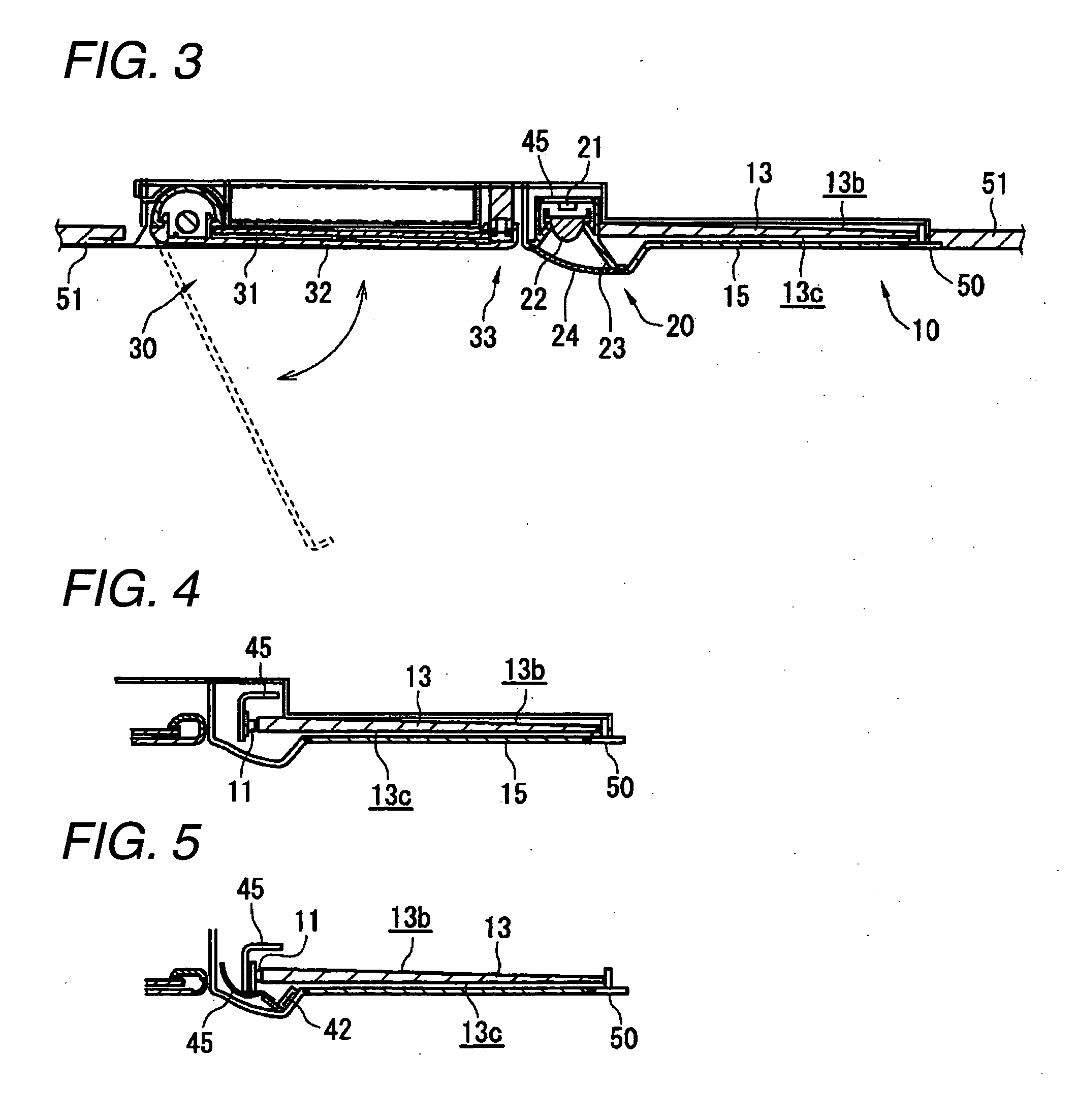

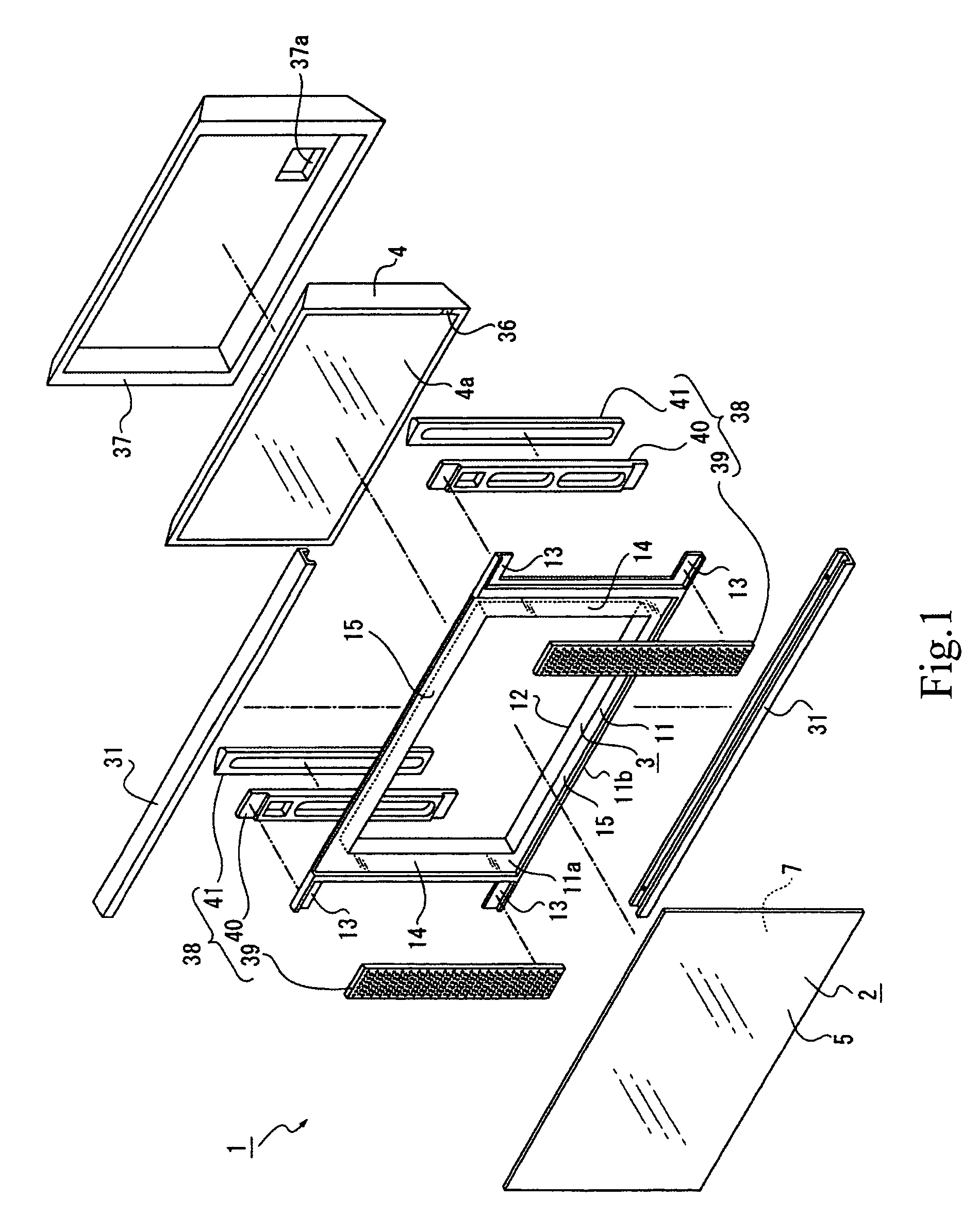

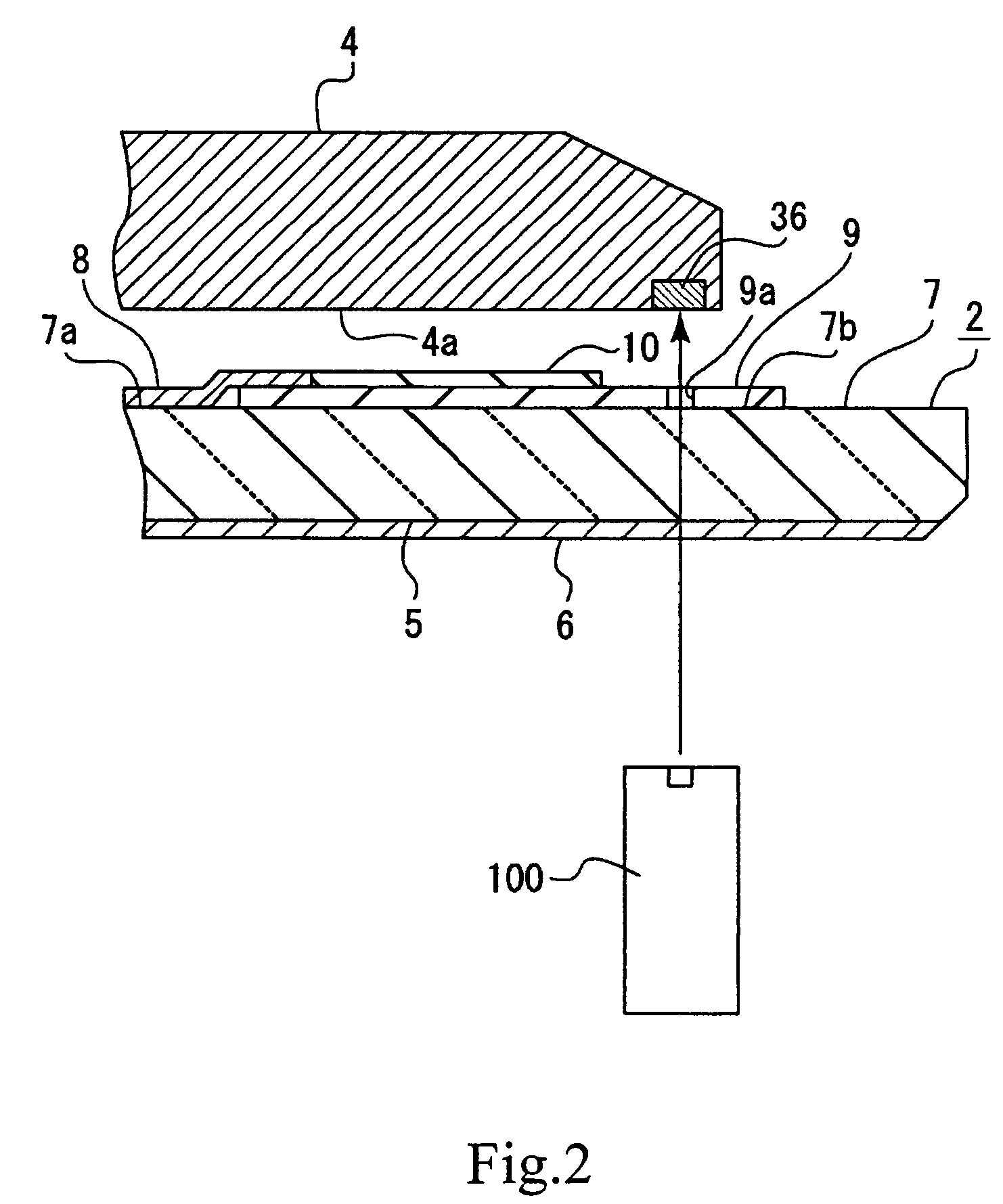

Flat type image display apparatus

InactiveUS20060238446A1Television system detailsDigital data processing detailsQuality by DesignEngineering

There are provided a bracket 3 that has a frame section 11 integrally formed by a transparent material, an apparatus mounting section 12 disposed in an inner peripheral edge of the frame section, and parts fixing sections 13, 13, . . . disposed on the outside of the frame section; a front panel 2 that is formed by a transparent material and disposed on the front surface side of the bracket; an apparatus body section 4 that has a screen surface 4a and is mounted at the apparatus mounting section of the bracket; holding members 31, 31 that hold the front panel and the bracket in the state that they are connected together at the front and rear; and functional sections that are fixed to the parts fixing sections of the bracket so as to be disposed on the outside of the front panel, and that sends and receives electric signals to exhibit a predetermined function. Signal paths 35, 35 to perform sending and receiving of electric signals between the apparatus body section and the functional sections are formed in the inside of the bracket or in a boundary portion between the front panel and the bracket. This enables sending and receiving of electric signals between the apparatus body section and the functional sections that send and receive electric signals to exhibit a predetermined function, while maintaining good design quality.

Owner:SONY CORP

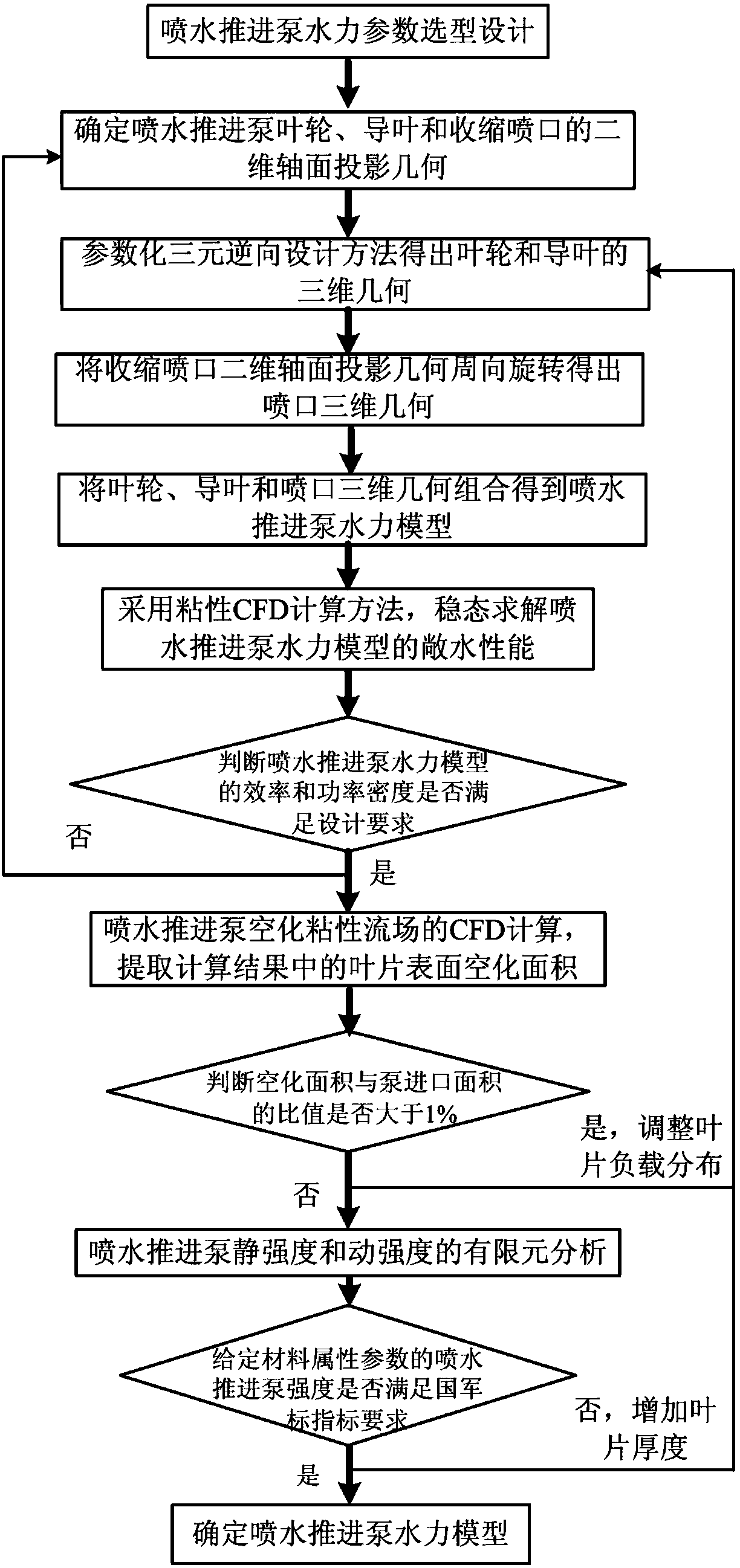

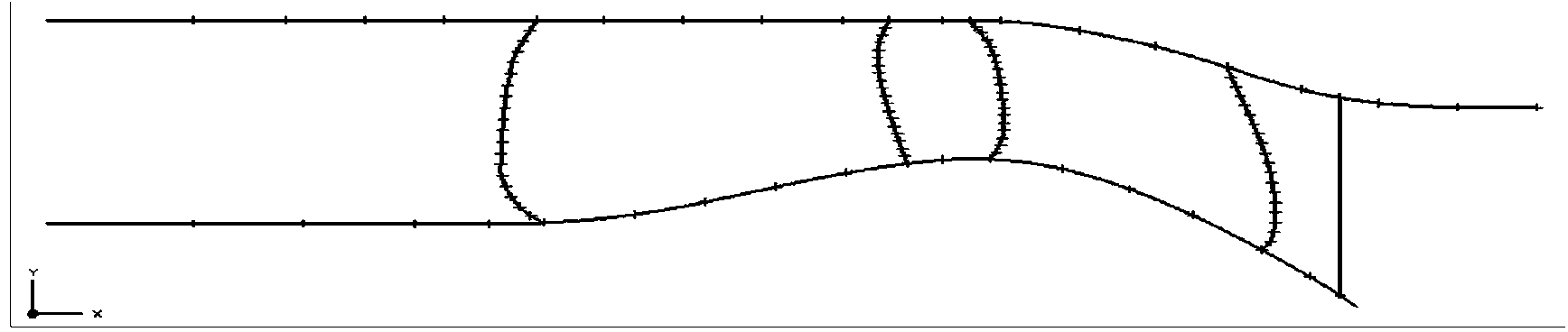

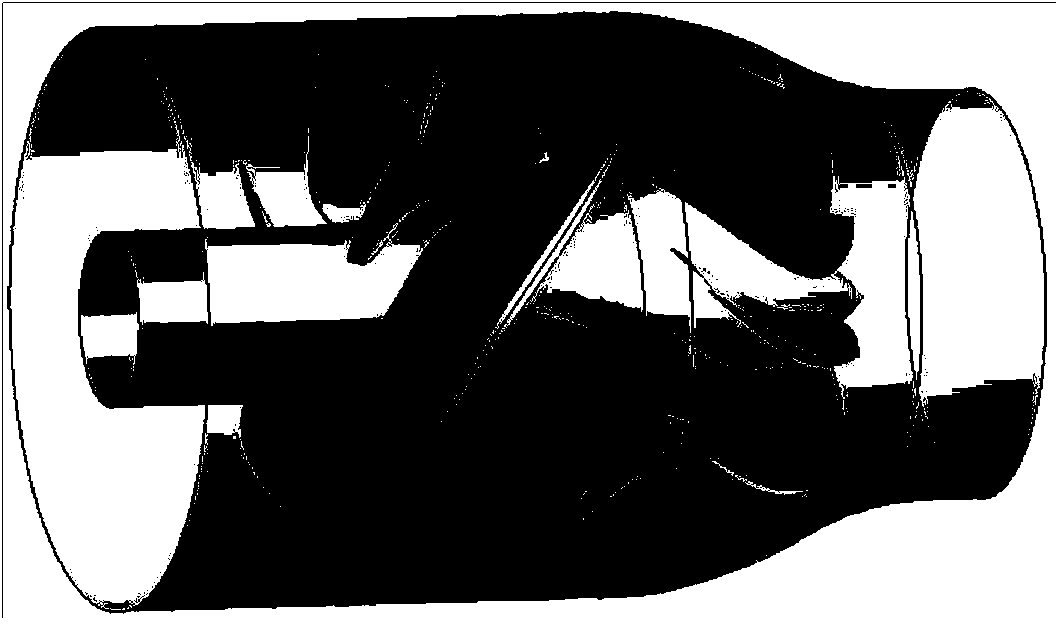

Method for designing water-spraying boost pump hydraulic model for efficient and large-power-density ship

ActiveCN104112040ABreak the monopoly high speedBreaking the Game for High-Performance Marine Waterjet Propulsion ApplicationsSustainable transportationSpecial data processing applicationsImpellerCavitation

The invention discloses a method for designing a water-spraying boost pump hydraulic model for an efficient and large-power-density ship. The method comprises the following steps that type selection design of water-spraying boost pump hydraulic parameters is conducted, two-dimensional axial face projective geometry is determined, three-dimensional geometrical shapes of an impeller and guide blades are obtained according to a parameterized ternary reversal design method, a three-dimensional geometrical shape of a shrinkage nozzle is obtained through circumferential rotation, the three-dimensional geometrical shapes of the impeller, the guide blades and the shrinkage nozzle are combined to obtain the water-spraying boost pump hydraulic model. The method has the outstanding advantages that the design period is short, the design quality is high, and the water-spraying boost pump hydraulic model which has the advantages of being high in efficiency, compact and large in power density can be rapidly and reliably designed. The geometrical shapes of the impeller and the blades are obtained according to the parameterized ternary reversal design method, so that on the condition that the water-spraying boost pump hydraulic model is kept compact, the efficiency is improved, cavitation is restrained, and the power density is increased in the researching and developing process of a high-speed ship water-spraying boost pump.

Owner:NAVAL UNIV OF ENG PLA

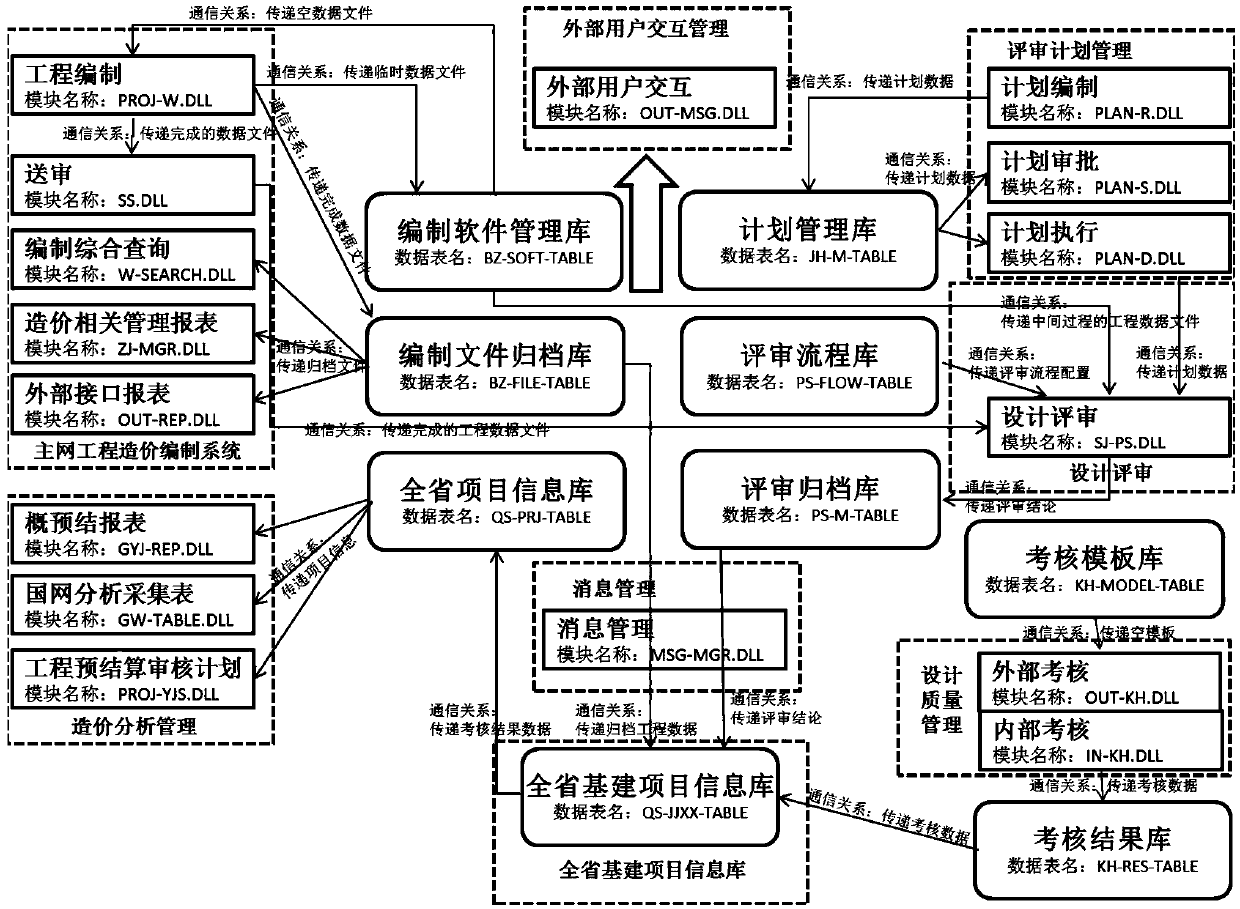

Electric power engineering design review and technical economic evaluation information system

InactiveCN105373885AImprove the level of intensive managementImprove Design ReviewsResourcesInformation repositoryEconomic management

The invention discloses an electric power engineering design review and technical economic evaluation information system. The electric power engineering design review and technical economic evaluation information system comprises a project review plan management module, a project review module, a province infrastructure project information database construction module, a design quality management module, an external user interaction management module, a main network engineering cost compilation system module, a cost analysis management module and a message management module. The system integrates demands of actual engineering project design review and technical economic management works, makes engineering project design review and technical economic management works have great improvement in standardization, unification, normalization and refinement, greatly improves an intensive management level, effectively and practically improves efficiency of engineering project design review and technical economic management works and brings about substantial economic and social benefits.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

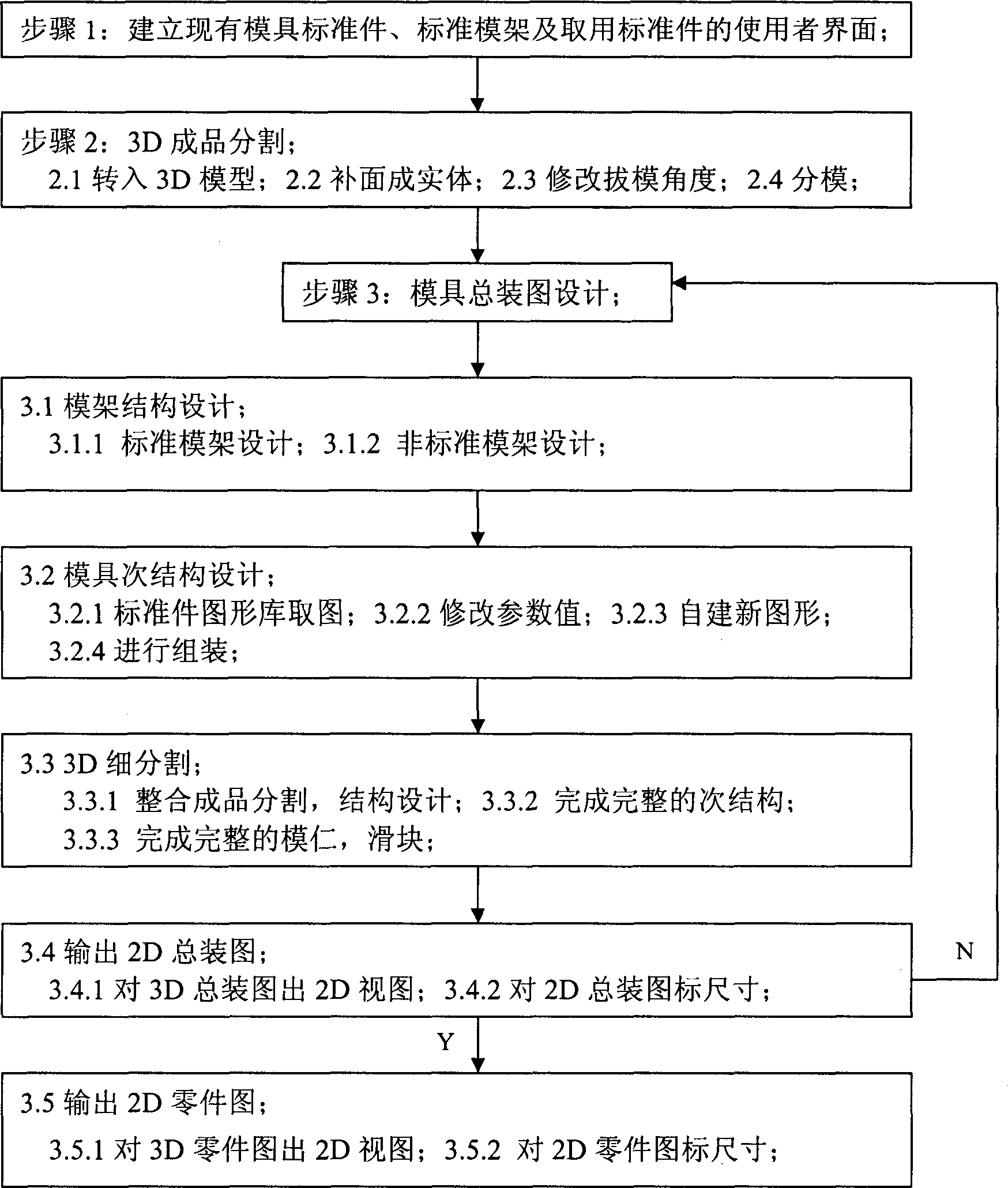

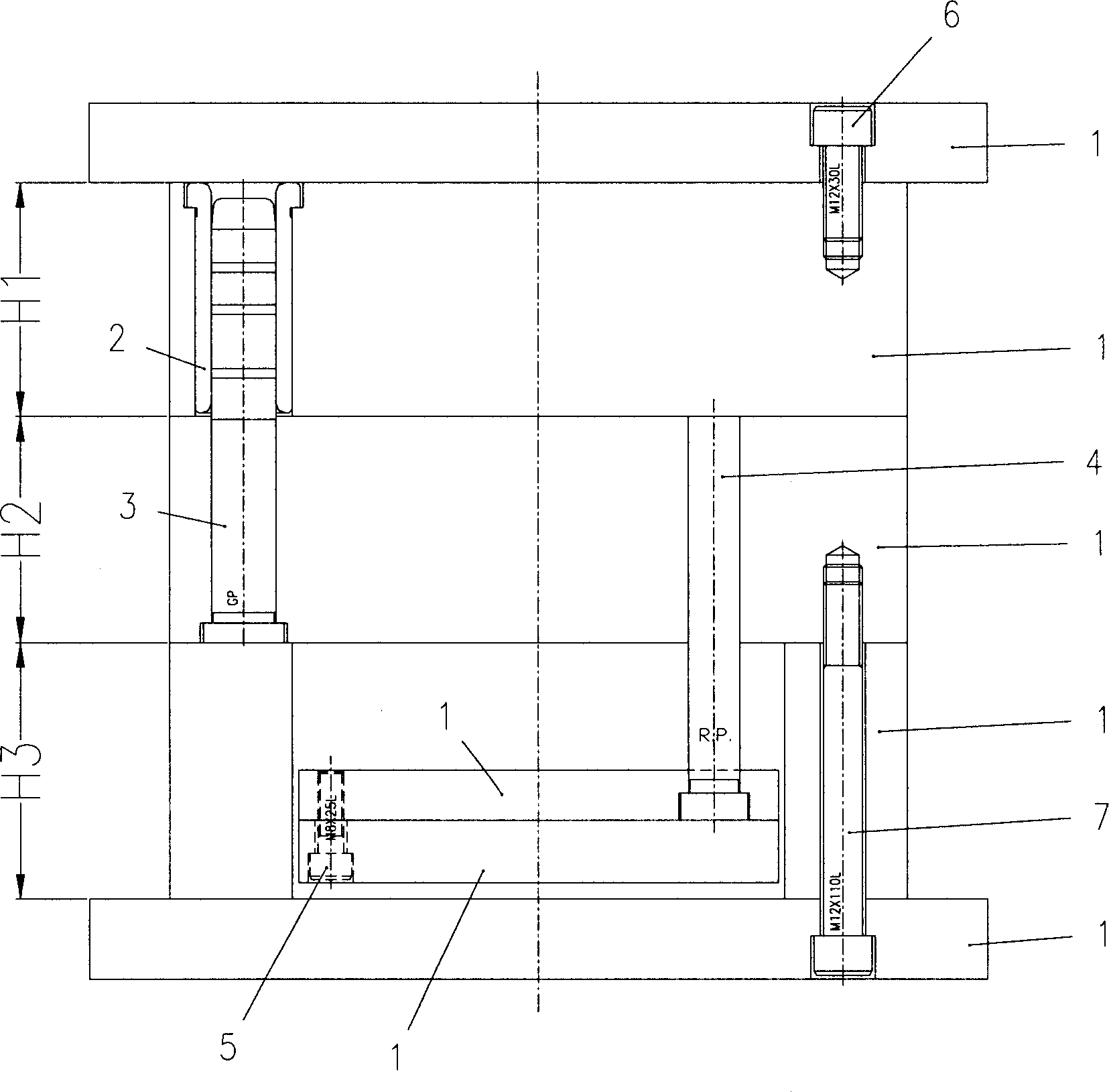

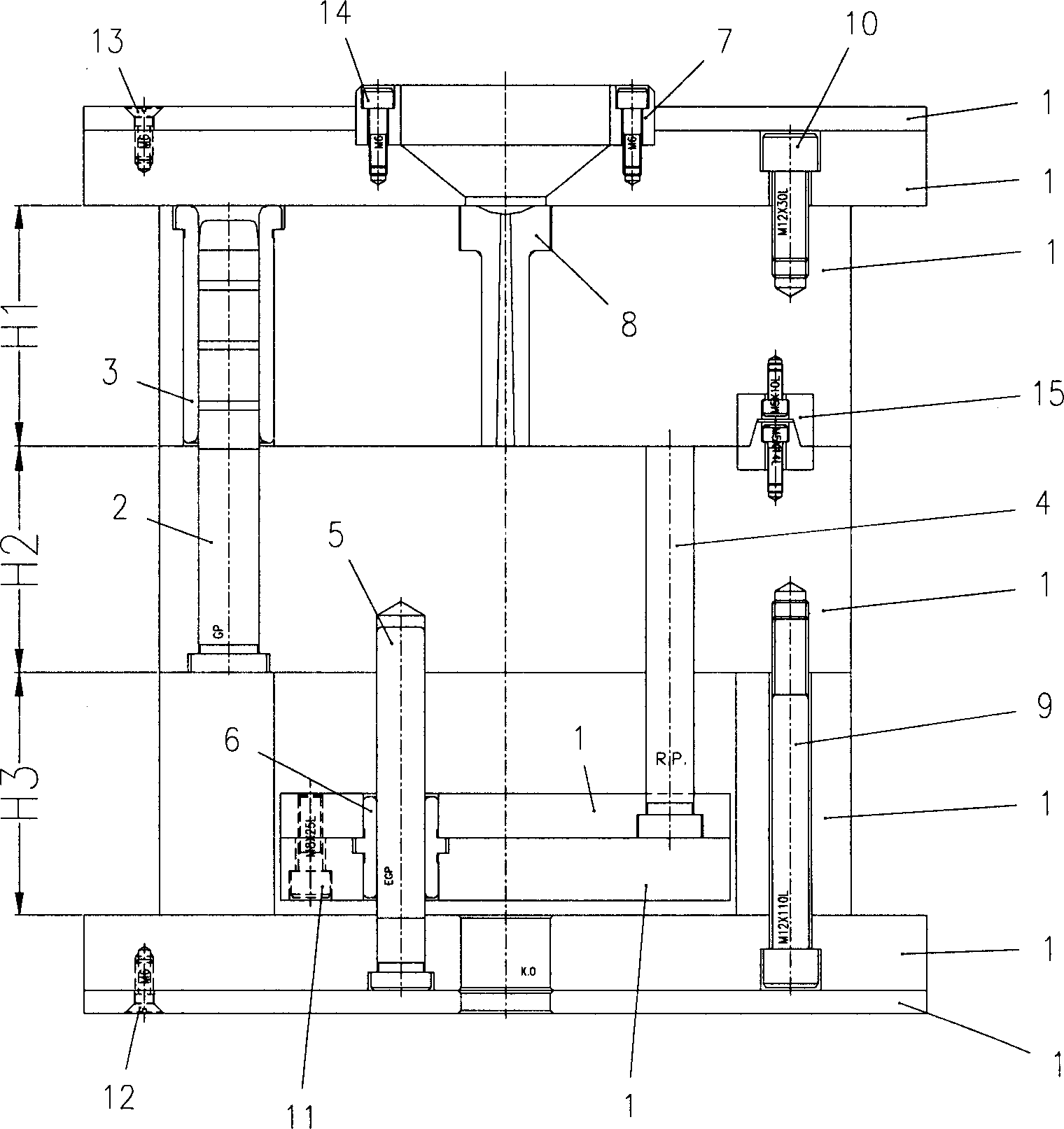

Parametered assembly and design of three-dimensional mould structure and automatic dimension labeling method for two-dimensional figure

InactiveCN1841386AReasonable structural designImprove design qualitySpecial data processing applicationsQuality by DesignEngineering

The related auto size marking method for 3D / 2D mold parameters assembly design comprises: 1. designing mold frame, determining all of the member size, mold nest and core quantity, distance among product, nest and template; 2. designing secondary structure by receiving computer command and calculating to generate slide block, slope pin, cooling loop, and other assembly; 3. executing whole assembly diagram command to generate 2D diagram; 4. alternating request, repeating step 2-3; 5. outputting the formal 2D diagram; 6. outputting the 2D member processing diagram. This invention has more reasonable process, improves design quality, and reduces manual error.

Owner:陈金德

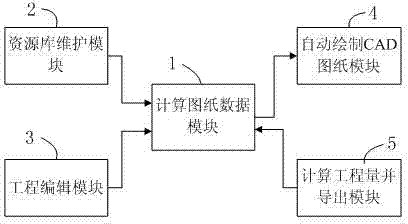

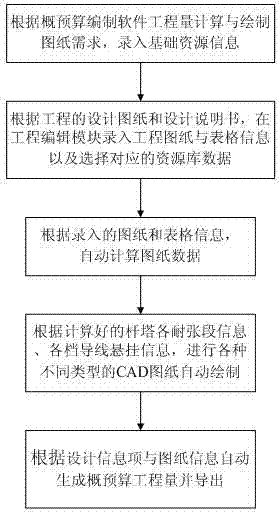

System and method for automatically generating project amount and drawing CAD chart

InactiveCN103617243AImprove efficiencyQuality improvementSpecial data processing applicationsCost comparisonTerrain

The invention discloses a system and method for automatically generating the project amount and drawing a CAD chart and belongs to the field of electric power engineering design. The system comprises a resource library maintaining module, a project editing module, a drawing paper data calculating module, a CAD drawing paper automatic drawing module and a project amount calculating and exporting module. A data information bridge is established between a CAD drawing tool and budget establishment software, the project amount of data is calculated directly through the software instead of being calculated manually as done in the prior art, and therefore efficiency and quality of budget establishment are improved. During CAD, comprehensive analysis can be achieved by the software according to project amount information such as terrains, geological conditions, tower land occupation, the cubic meter of earth and stone and foundation works, cost information corresponding to a designing scheme can be obtained more quickly, overall cost of the scheme can be obtained to participate in cost comparison, and then an optimal path designing scheme is selected, and design quality is effectively improved.

Owner:STATE GRID CORP OF CHINA +4

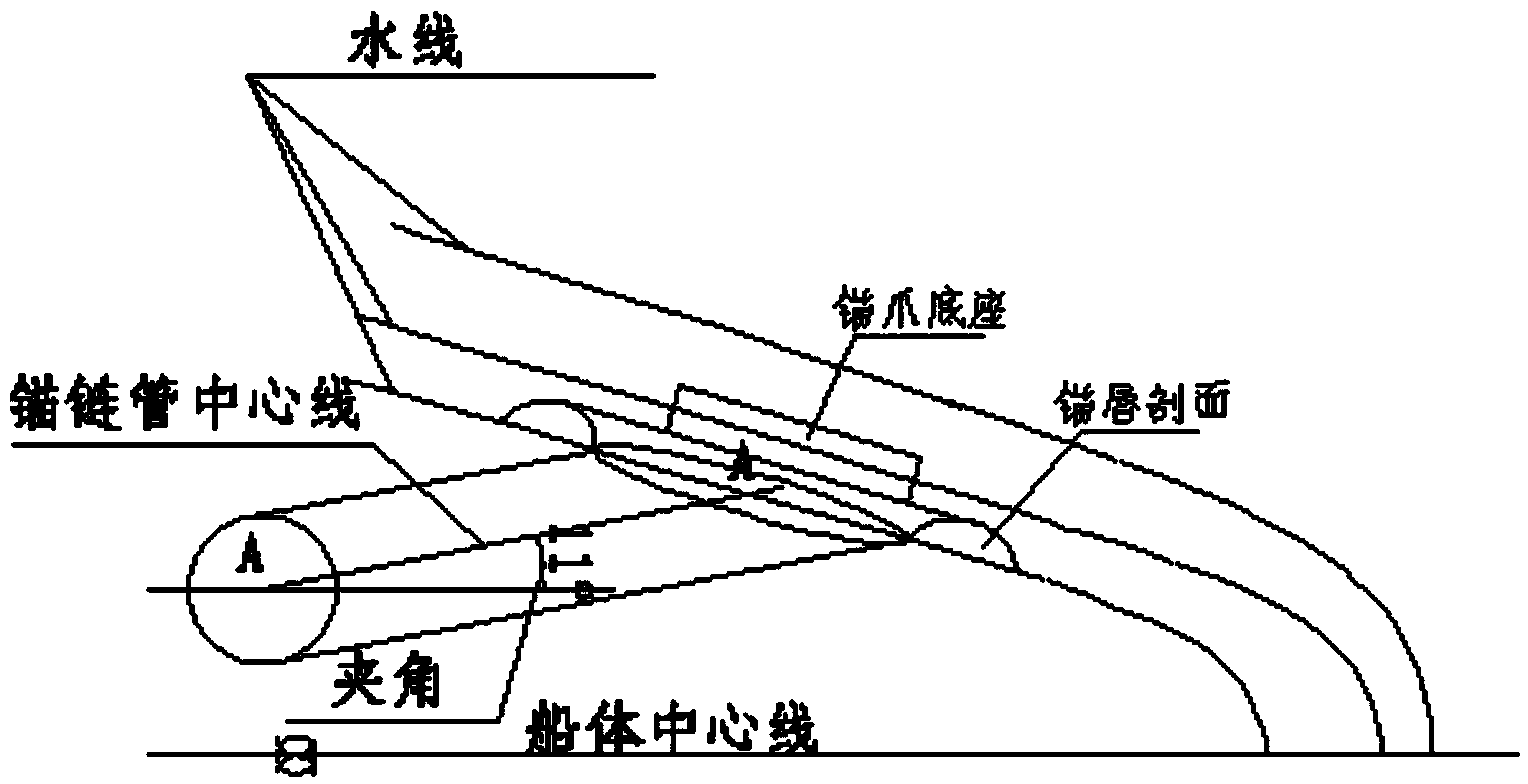

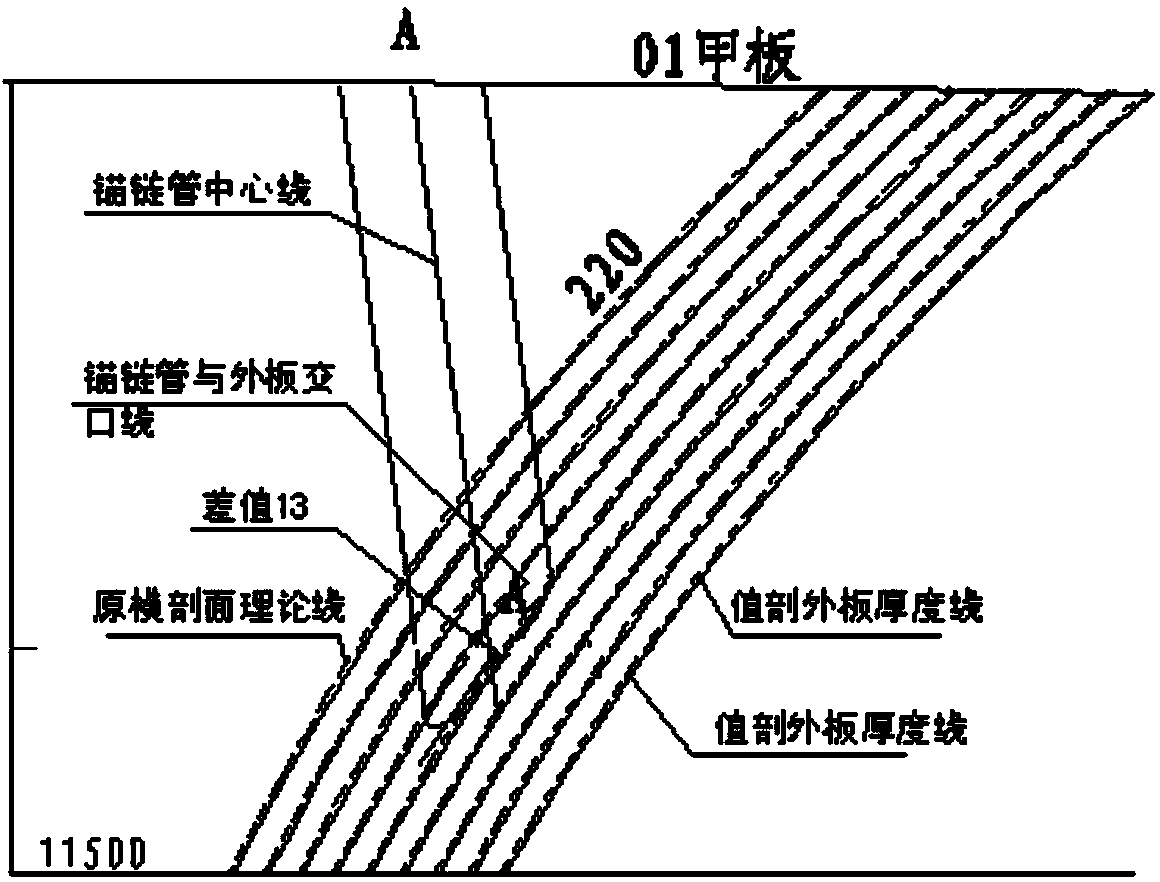

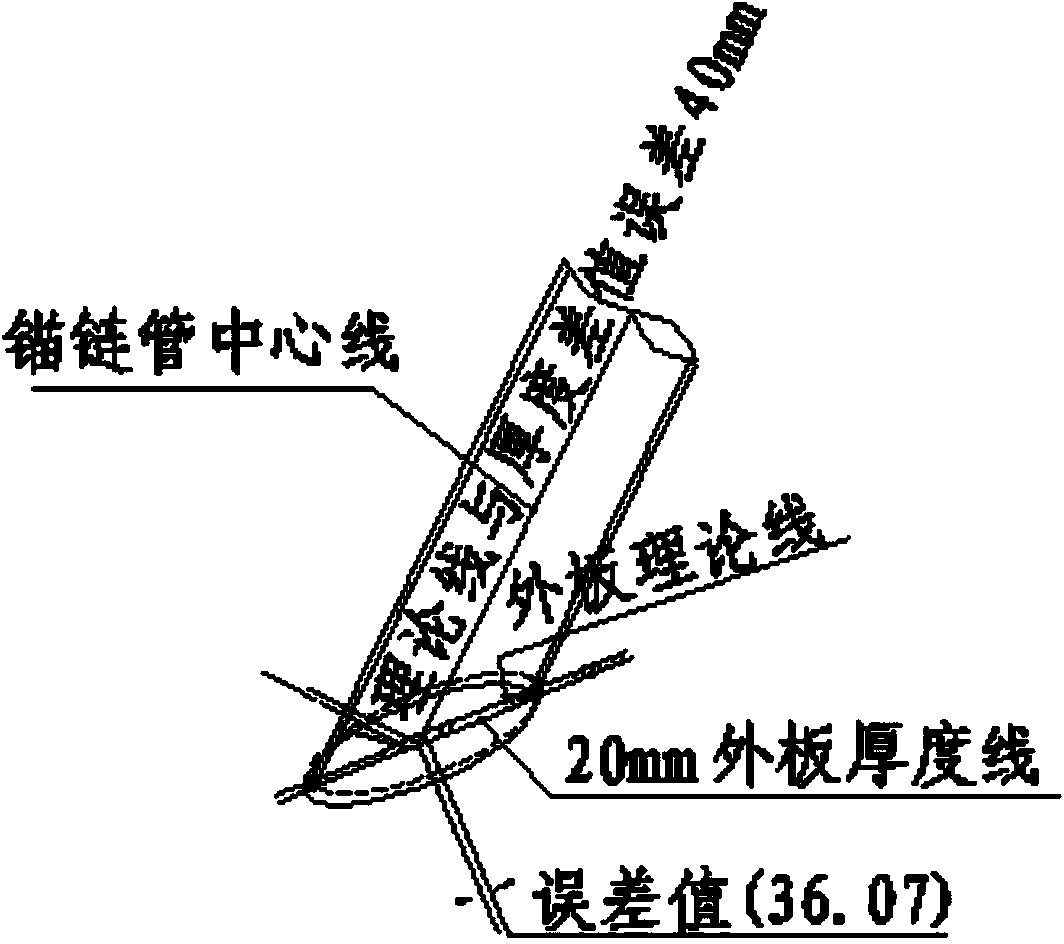

Lofting production method of anchor recess of planking thickness line of hull

ActiveCN103625603AImprove accuracyIncrease success rateVessel partsQuality by DesignStructural engineering

The invention discloses a lofting production method of an anchor recess of a planking thickness line of a hull. The lofting production method comprises the following steps: (1) line type lofting of an anchor recess region adopts a method of deducting the planking thickness line of the hull; (2) the line type of the anchor recess takes an A-A section of a center line of a hawse pipe as a reference, and projection is carried out on a three-directional line type deducting the planking thickness; (3) the protection of a section of an anchor mouth takes a 7# section and a 3# section of the center line of an anchor pipe as reference, and an origin of the outlet of the anchor pipe is a constant value; (4) the center line of the anchor pipe and a rib position of a water line are marked on a tapping sample; (5) the anchor mouth is located on the outlet point of the anchor pipe of the planking of the hull; (6) values are reasonably corrected by a cat anchor test; (7) the anchor recess is installed. According to the lofting production method, the validity and the success rate of the cat anchor test are improved, the design quality is improved, the production cost is reduced, the production cycle is shortened, the production design is matched with a production method of a production department, so that anchor release, anchor raise and mooring of a ship can be successfully carried out after the anchor recess is installed.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Management system and management method for enterprise information

InactiveCN102831505AEasy retrievalRealize paperless officeResourcesChange managementQuality by Design

The invention relates to a management system and a management method for enterprise information, and aims to solve problems that work states are non-transparent and delayed, design quality is uncontrollable and the like which are exposed gradually due to facts that large quantities of information are generated in different business links in a process from development and initiation of a new product to final mass production of the product of some enterprises at present, and the decentralized management of the information, agreement, approval and issue of technical data and project management are all completed manually. The management system comprises a drawing and document and table management module, a material category and attribute management module, a research and development project management module, an approval process management module and a design change management module. By project management and electronic workflow management methods, the management system can control progress of a product development project and monitor the workflow, and assist in dynamically learning actual work conditions of a product by project monitoring so as to realize effective and reasonable work arrangement and allocation according to the actual work conditions, and accordingly, paper-less office work is realized.

Owner:南京徐工汽车制造有限公司

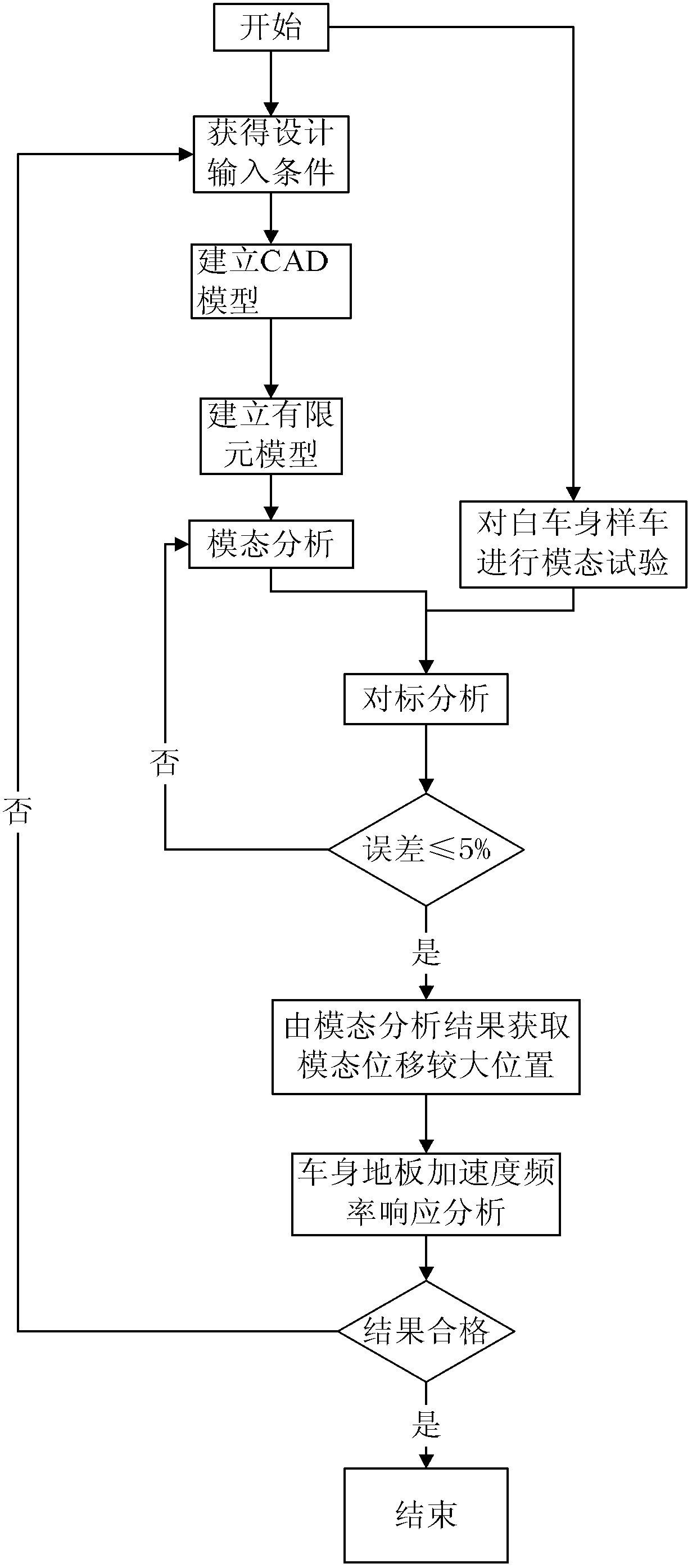

Acceleration frequency response analysis-based body floor optimal design method

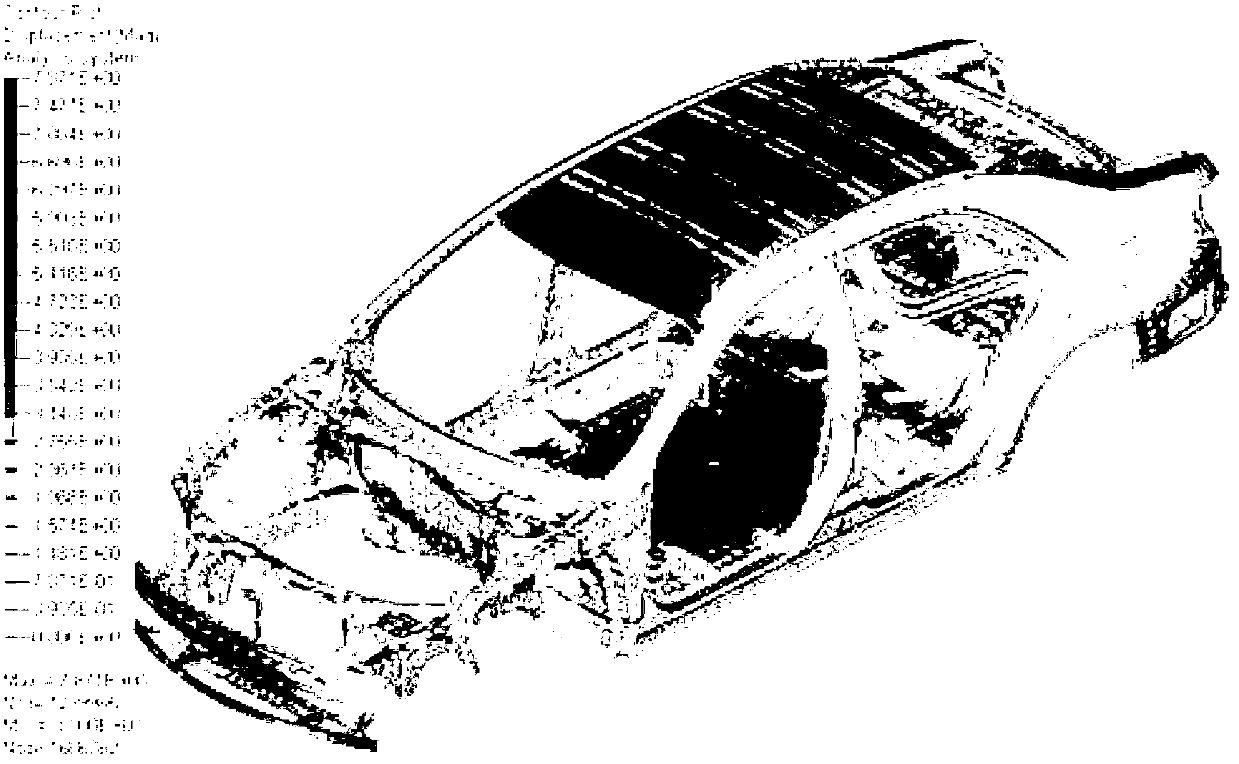

ActiveCN102867075AReduce mistakesImprove noiseSustainable transportationSpecial data processing applicationsComputer Aided DesignElement model

The invention discloses an acceleration frequency response analysis-based body floor optimal design method, which comprises the following steps of: acquiring a body floor design input condition; establishing a CAD (Computer Aided Design) model; establishing a finite element model; performing mode CAE (Computer Aided Engineering) analysis on the finite element model to perform mode test on a white body sample; performing benchmarking; checking and verifying the finite element model according to a benchmarking result; searching a region of a large vibration displacement of the white body floor in the finite element model according to a mode CAE analysis result, extracting an inspection point from the region, and performing acceleration frequency response analysis on the inspection point; and modifying the floor design input condition according to the acceleration frequency response analysis result until the vibration response requirement is met. The method has the characteristics of shortening the development time, reducing the development cost, improving the entire noise, the vibration and the comfort, reducing the error between the finite element model and the floor sample and keeping high design quality.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

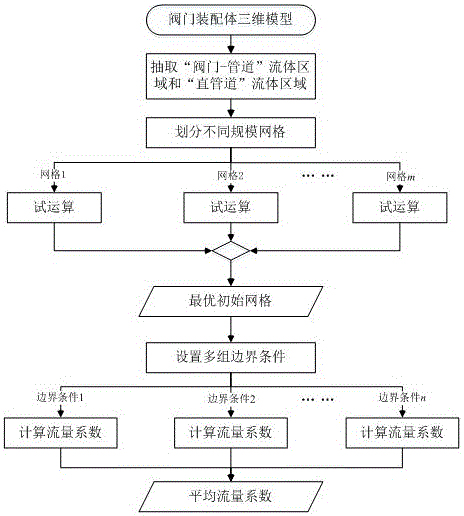

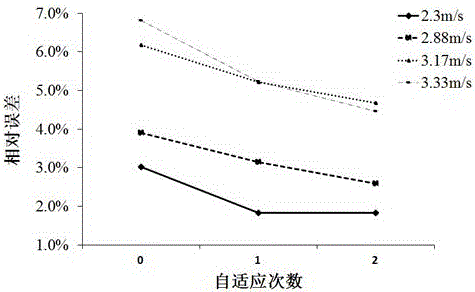

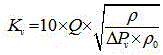

CFD simulation and grid self-adaption based valve flow coefficient calculating method

ActiveCN105677964AAccurately predict circulation capacityEnrich flow field detailsSpecial data processing applicationsComputing MethodologiesQuality by Design

The invention discloses a CFD simulation and grid self-adaption based valve flow coefficient calculating method. The CFD simulation and grid self-adaption based valve flow coefficient calculating method comprises the main steps that a 'valve-pipe' flow field model and a 'straight pipeline' flow field model are extracted based on a valve assembly body three-dimensional model; initial grids are divided for the flow field models, wherein multiple groups of initial grids different in scale are divided for the 'valve-pipe' flow field model; trial operation is performed by applying the groups of initial grids respectively, the change tends with grid scales of the obtained pressure differences are compared to select optimal initial grids; the optimal initial grids are applied to set different boundary conditions, and simulating calculation of corresponding flow coefficients is performed by combining a grid self-adaption technology; finally, the arithmetic average of the obtained flow coefficients is obtained to serve as a valve flow coefficient prediction result. The CFD simulation and grid self-adaption based valve flow coefficient calculating method can more rapidly and flexibly predict the flow capacity of a valve under various conditions, shorten a development period and improve the design quality and can effectively improve the calculation accuracy and reduce the dependence on specialization level of operators.

Owner:JIANGSU SHENTONG VALVE +1

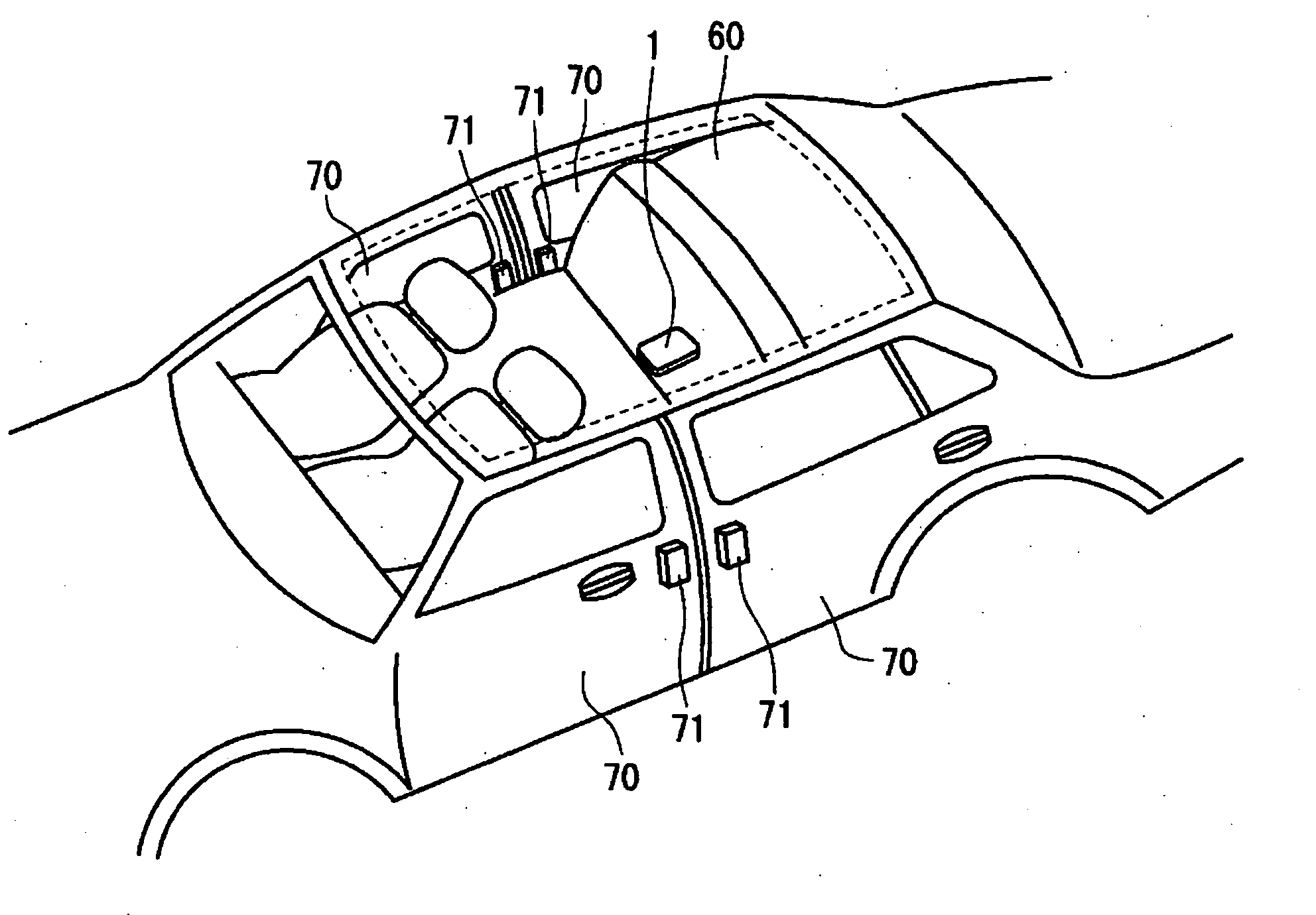

In-vehicle illuminination device

In an in-vehicle illumination device including: a room lamp section provided with a first light source section and a light guide plate, a map lamp section provided with a second light source section and a lens, a first switch for use by the room lamp section, and a second switch for use by the map lamp section, a light source configuring the first light source section and a light source configuring the second light source section are mounted on any same heat sink member. In the resulting in-vehicle illumination device, measures are taken against heat generation, and the reduction of size and weight is achieved. The design quality of the illumination device can be also improved.

Owner:TOYODA GOSEI CO LTD

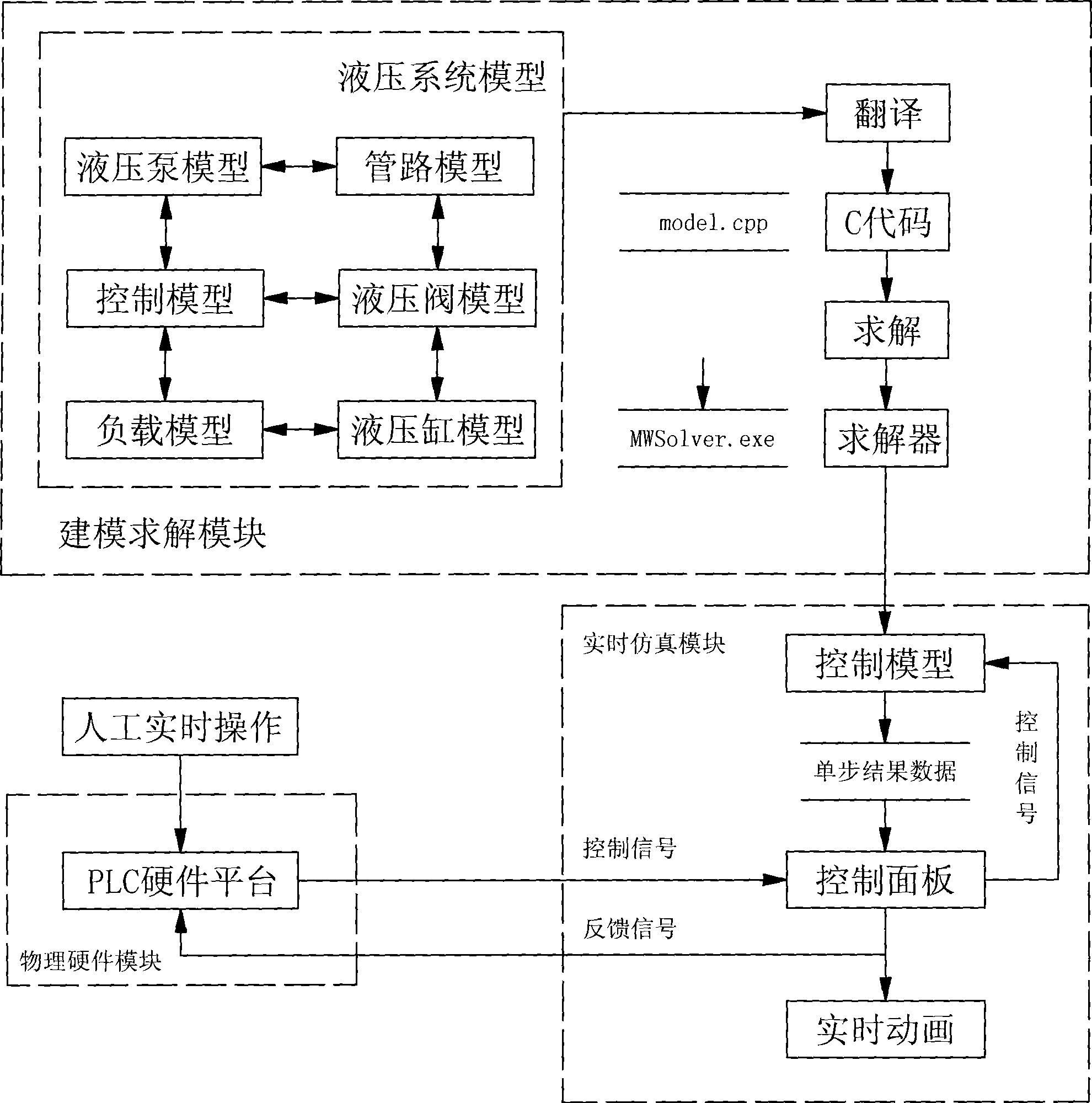

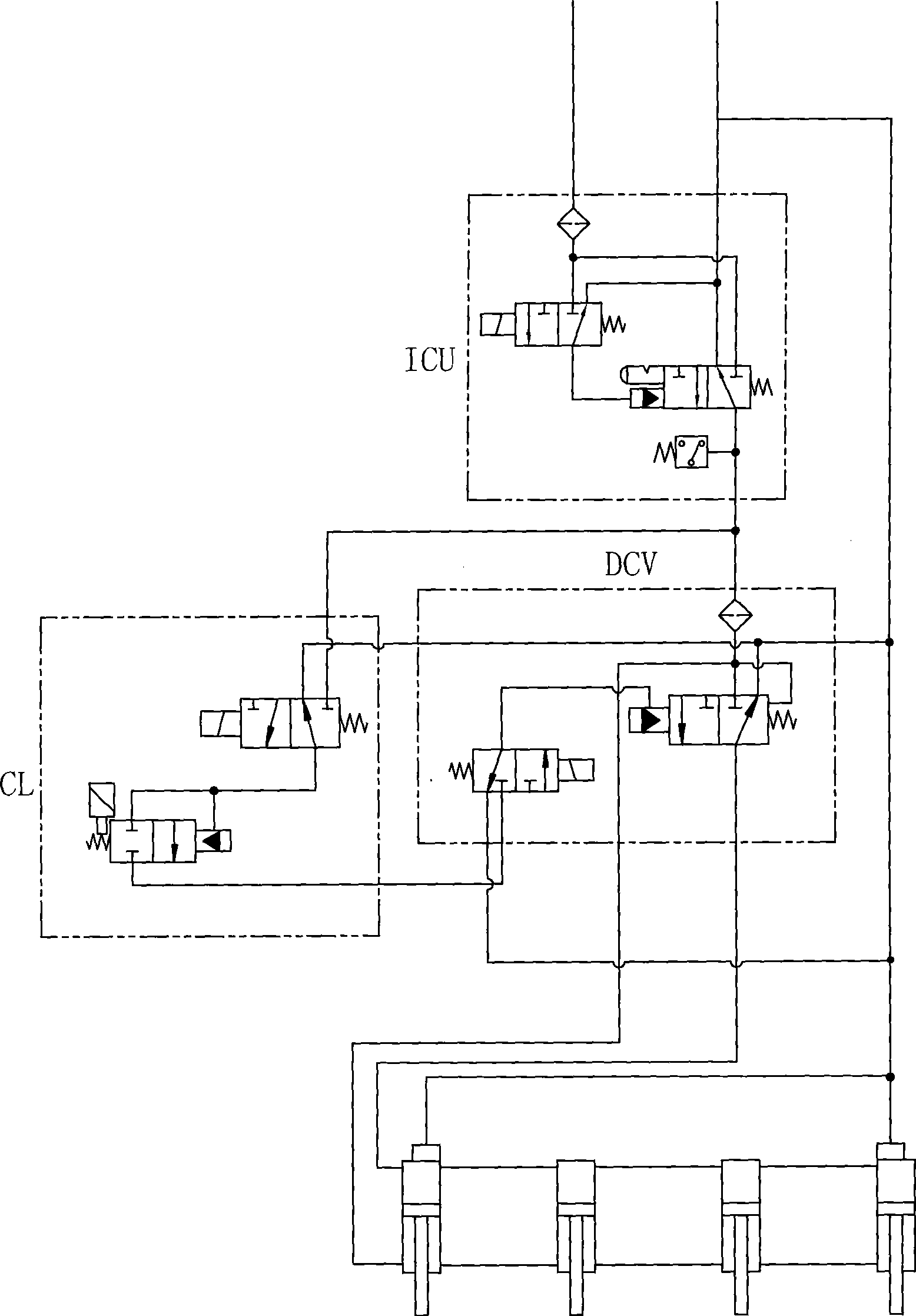

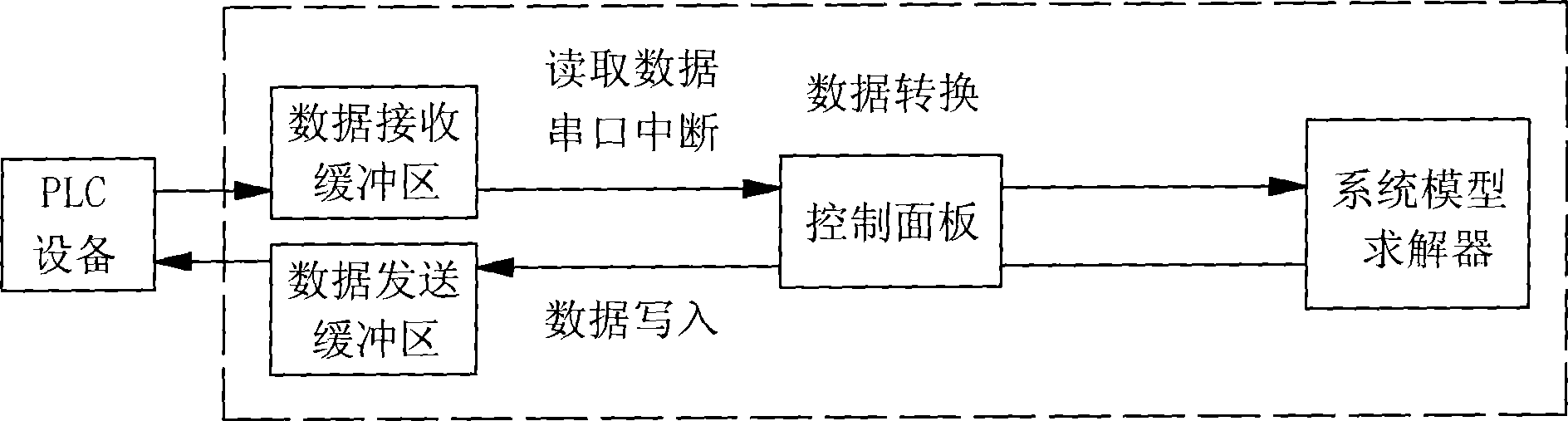

Semi-physical real-time simulation system of airplane reverse thrust hydraulic unit

ActiveCN101544281AShorten the development and analysis cycleImprove design qualityCosmonautic condition simulationsElectric testing/monitoringJet aeroplaneSoftware emulation

The invention discloses a semi-physical real-time simulation system of an airplane reverse thrust hydraulic unit. A closed loop testing system mainly comprises a computer, a programmable logic controller (PLC) hardware platform, an input device, and a software simulation device arranged in the computer; submodels of a hydraulic system are built by utilizing a hydrokinetics and electronic control theory, and then each simulation submodel forms the software simulation device; the PLC hardware platform performs parameter control and logic control to the software simulation device according to a state signal of the input device, and the output quantity of the software simulation device is shown in the computer by a digital and cartoon mode and also used as a feedback signal to be fed back to the PLC hardware platform through a communication interface. The invention can test and analyze various parameters of the airplane reverse thrust hydraulic unit without preparing the hydraulic unit, thereby greatly shortening the developing and analyzing periods of the reverse thrust hydraulic unit, improving the design quality and reducing the test expense.

Owner:苏州同元软控信息技术有限公司

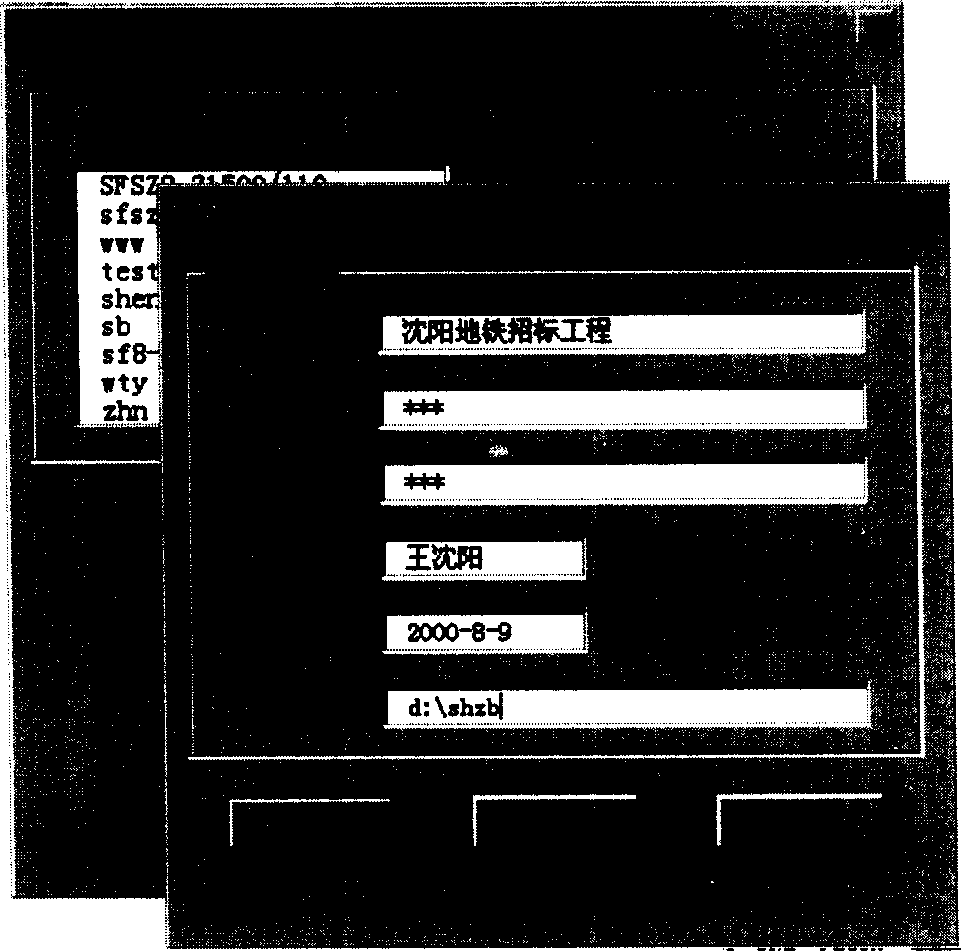

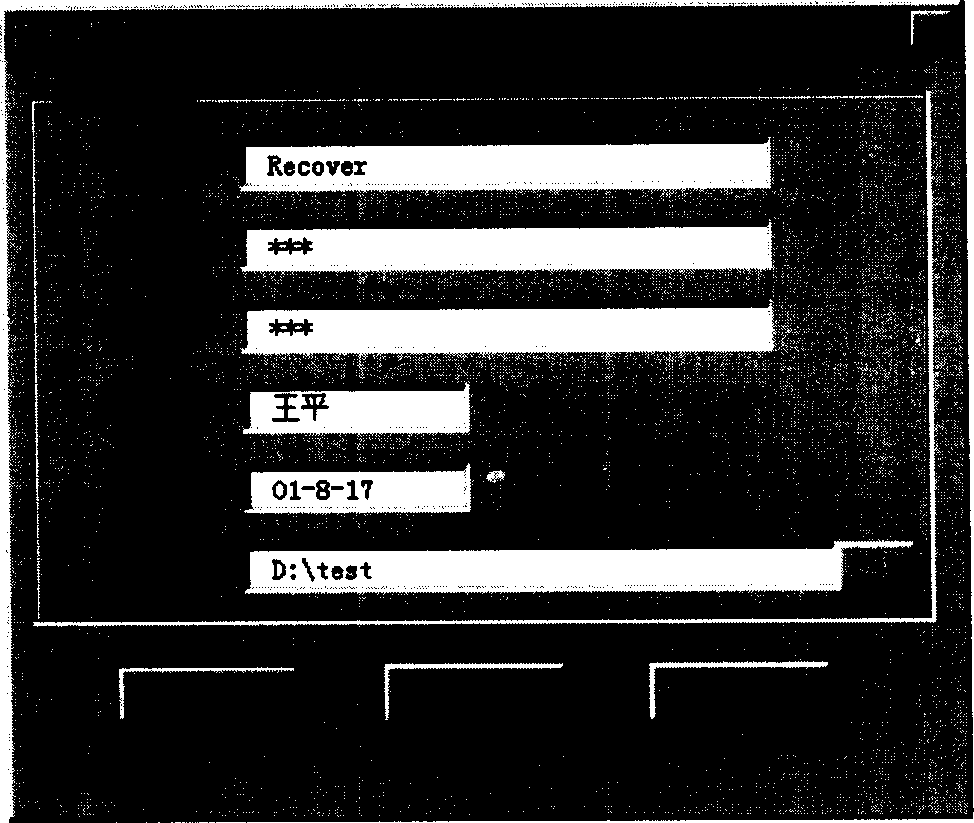

3D design system for transformer

InactiveCN1670874AProtection of rights and interestsInductances/transformers/magnets manufactureSpecial data processing applicationsOff design3d design

This invention provides three-D shaping software, which can simulate the complete assembling process of transformer in screen, produce the three-D products model same with the real products in shape, reflect the fitting information of parts and make the designer modifying the design before production, which is operated in MDT three-D software platform and adapted to the power transformer equal to or lower than 110 kv type.

Owner:沈阳变压器研究院有限公司

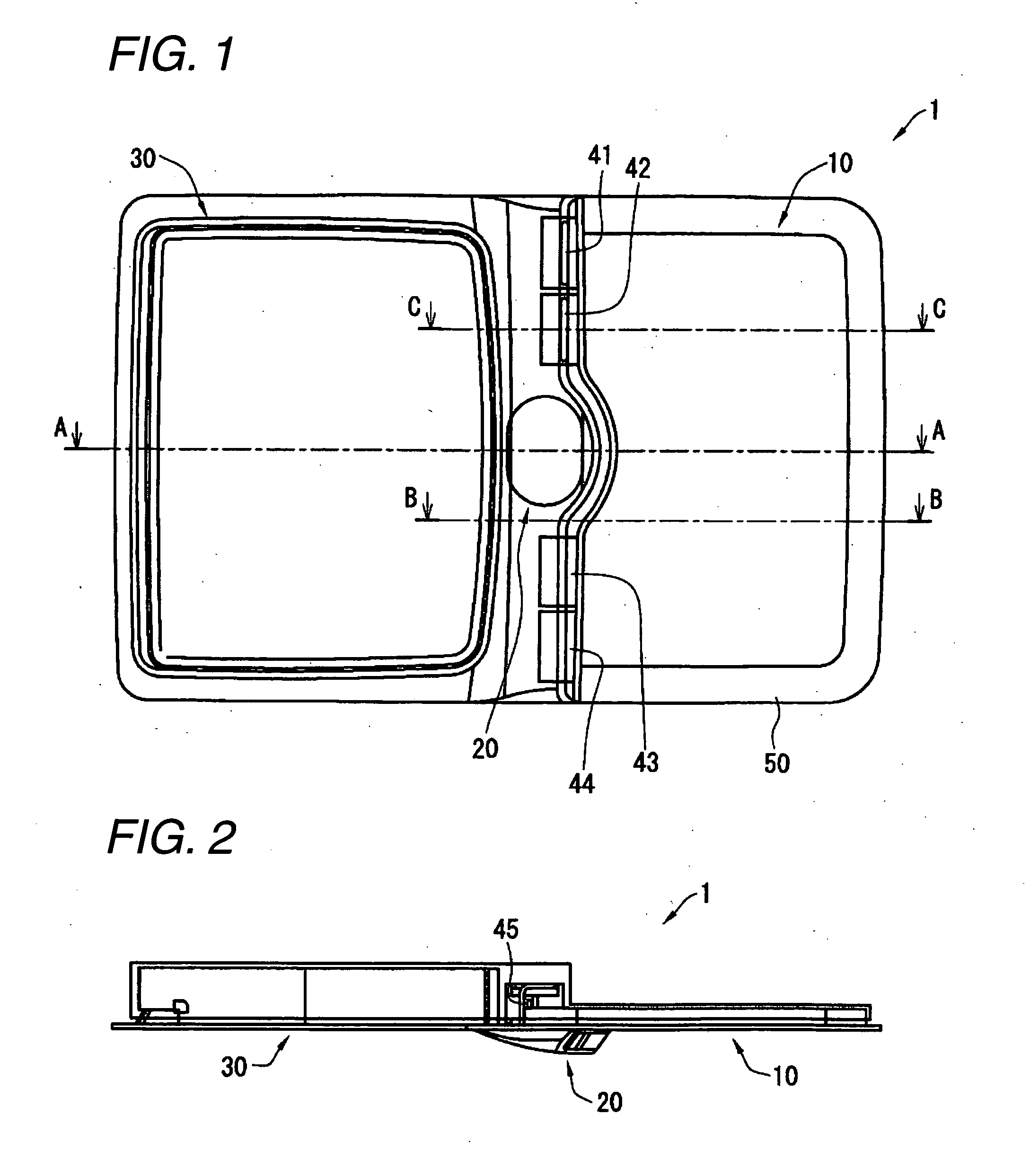

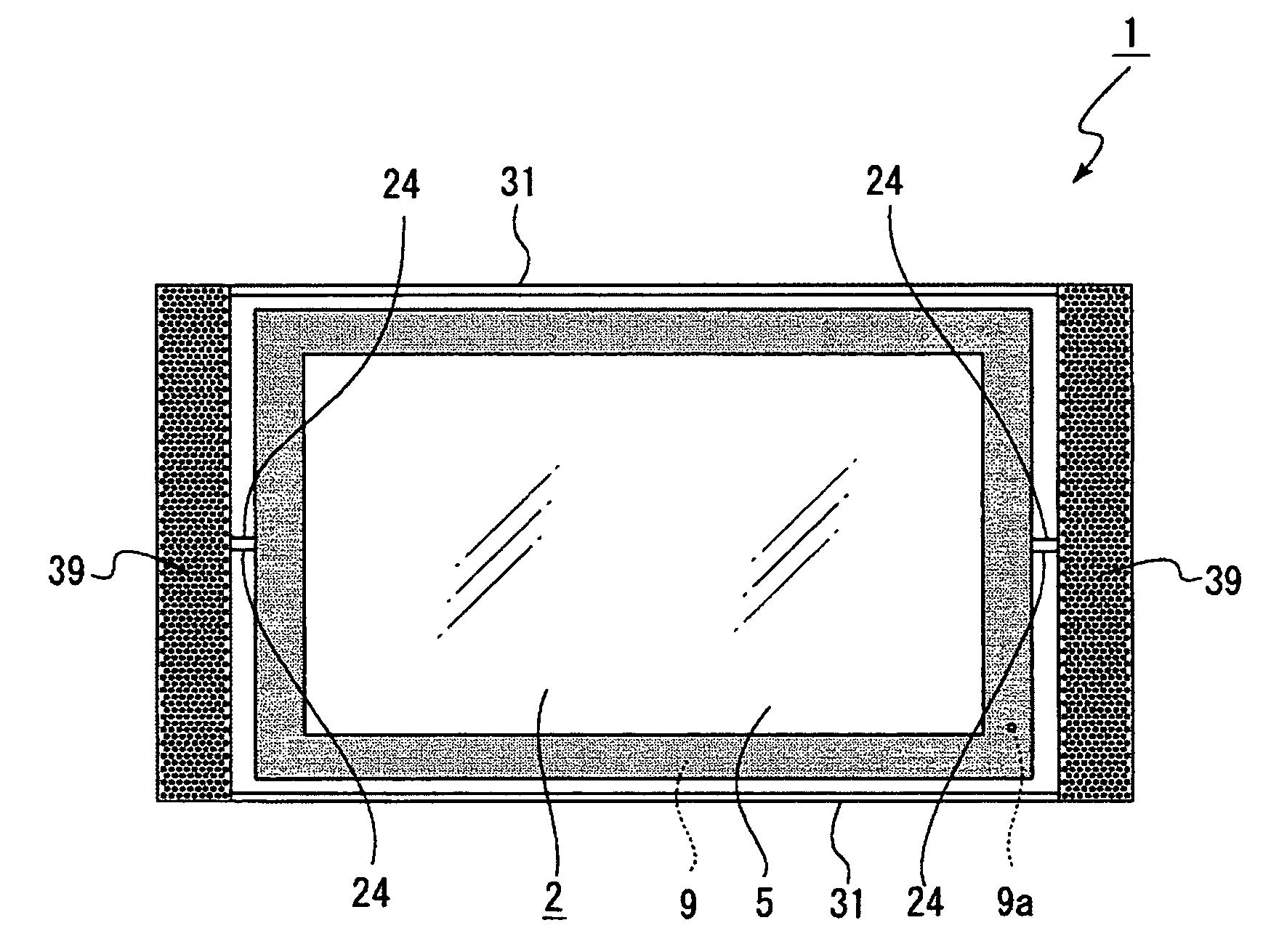

Flat type image display device

InactiveUS7120011B2Television system detailsDigital data processing detailsQuality by DesignElectric signal

There are provided a bracket 3 that has a frame section 11 integrally formed by a transparent material, an apparatus mounting section 12 disposed in an inner peripheral edge of the frame section, and parts fixing sections 13, 13, . . . disposed on the outside of the frame section; a front panel 2 that is formed by a transparent material and disposed on the front surface side of the bracket; an apparatus body section 4 that has a screen surface 4a and is mounted at the apparatus mounting section of the bracket; holding members 31, 31 that hold the front panel and the bracket in the state that they are connected together at the front and rear; and functional sections that are fixed to the parts fixing sections of the bracket so as to be disposed on the outside of the front panel, and that sends and receives electric signals to exhibit a predetermined function. Signal paths 35, 35 to perform sending and receiving of electric signals between the apparatus body section and the functional sections are formed in the inside of the bracket or in a boundary portion between the front panel and the bracket. This enables sending and receiving of electric signals between the apparatus body section and the functional sections that send and receive electric signals to exhibit a predetermined function, while maintaining good design quality.

Owner:SONY CORP

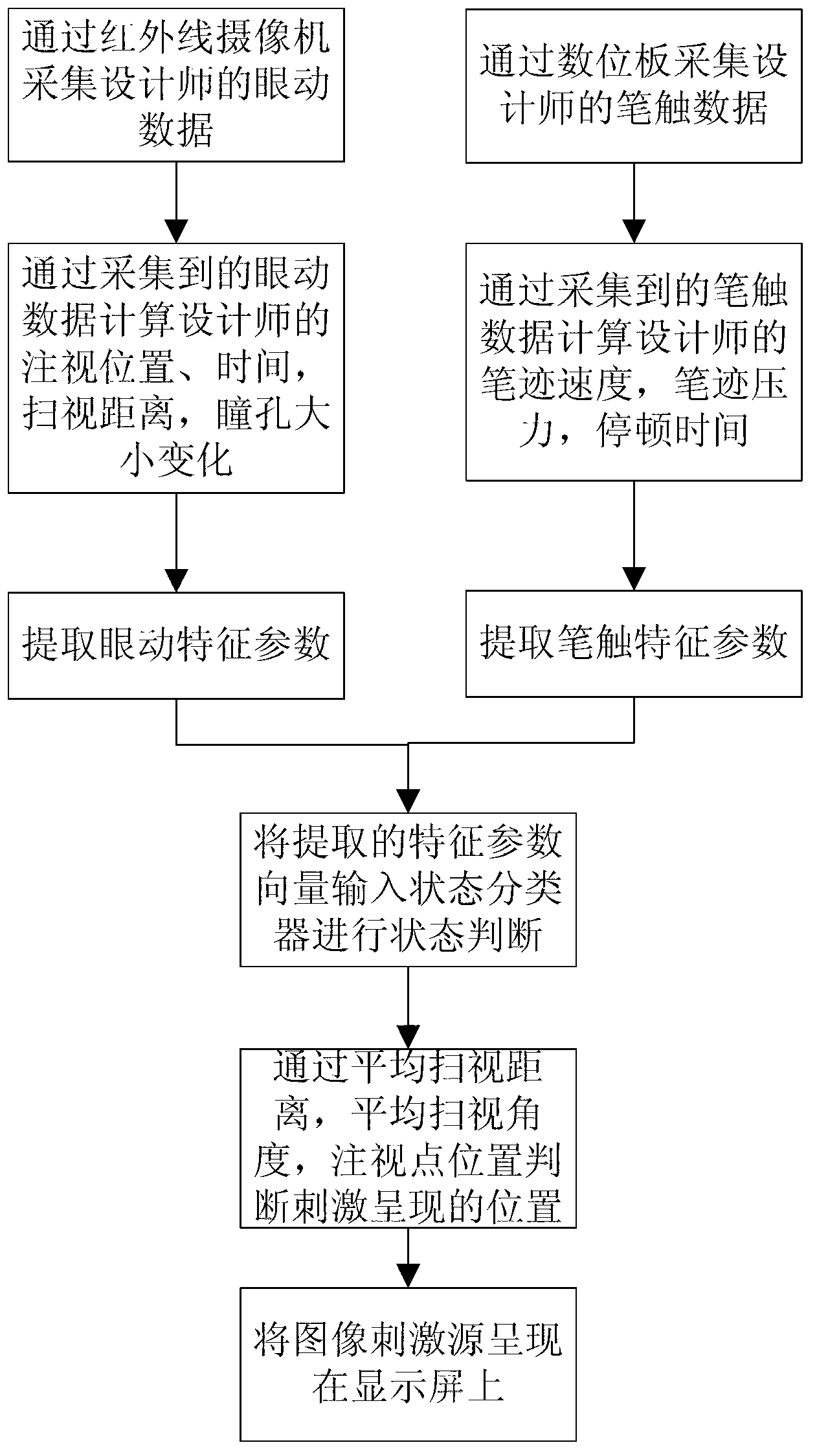

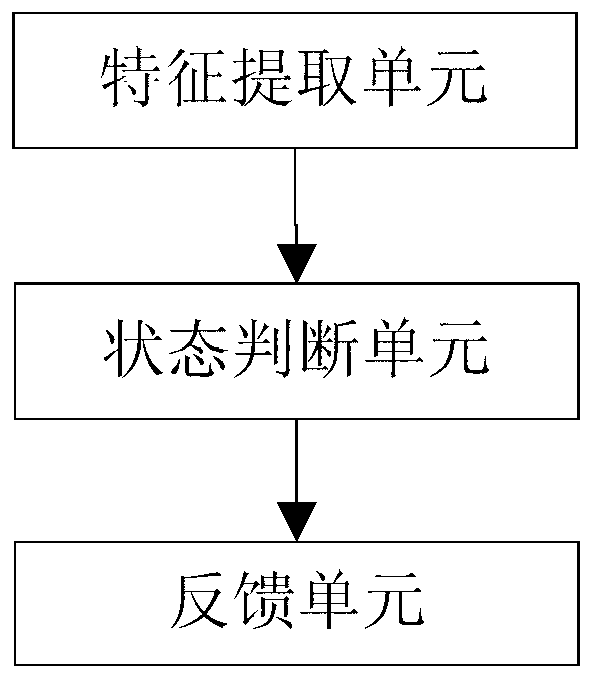

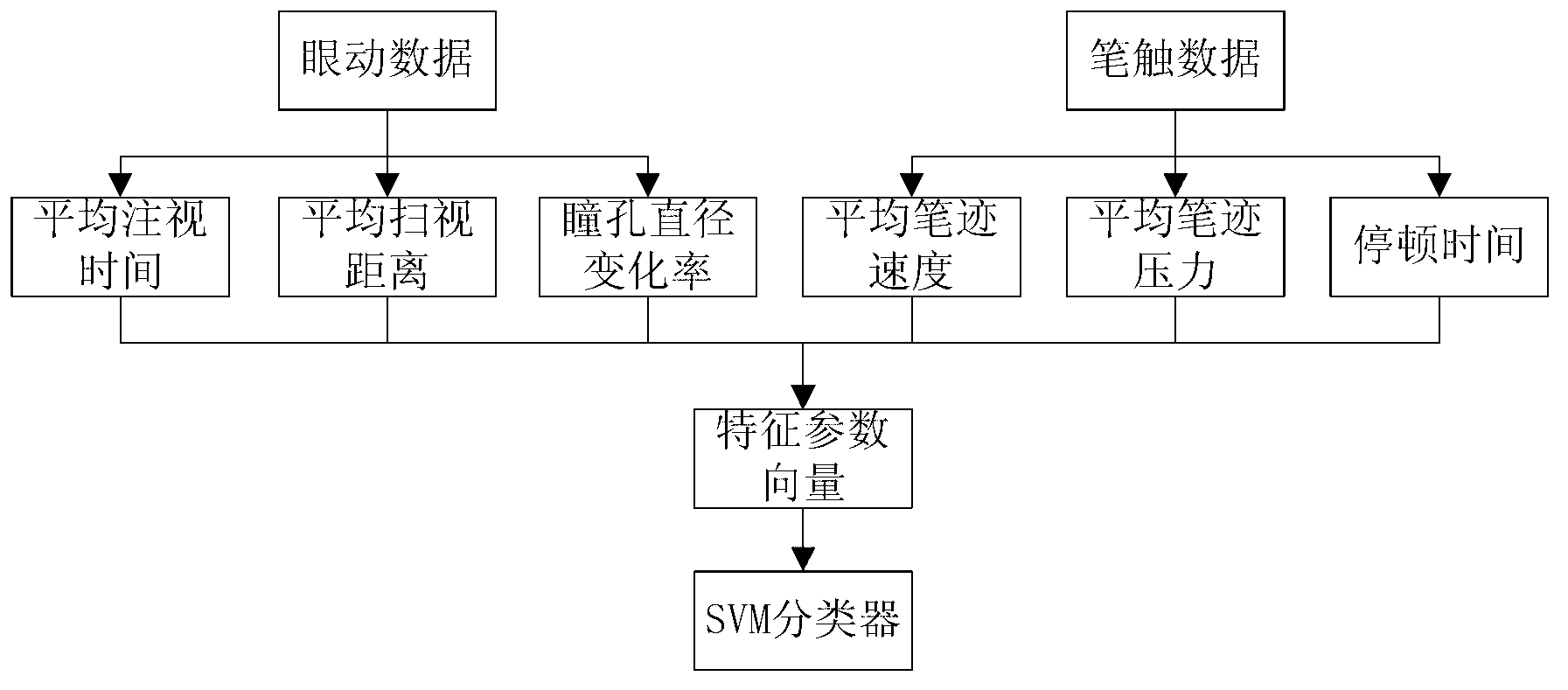

Computer-assisted sketch drawing method and system based on eye movement and brush stroke data

ActiveCN103324287AImprove design qualityStimulation effect optimizationInput/output for user-computer interactionGraph readingFeature extractionStaring

The invention discloses a computer-assisted sketch drawing method and system based on eye movement and brush stroke data. The method includes the following steps that feature extraction is conducted on eye movement data and brush stroke data of a designer, and eye movement feature parameters and brush stroke feature parameters are obtained; the eye movement data and the brush stroke data are collected and obtained in a sketch drawing process by using a computer; whether the current state of the designer is a creative thinking state is judged according to the eye movement feature parameters and the brush stroke feature parameters; when the designer is in the creative thinking state, the next staring point position of the designer is judged according to the eye movement data, and an image stimulus source is shown at the position and assists the designer to conduct sketch drawing. According the eye movement and brush stroke information of the designer, the creative thinking state of the designer is identified and stimulated. By predicting staring point position changes of the designer, the image stimulus source position is optimized, and designing quality of the designer is improved.

Owner:ZHEJIANG UNIV

BIM (Building Information Modeling)-based metro comprehensive pipeline adjustment method

ActiveCN102867077AAvoid collisionAvoid Abandoned ProjectsSpecial data processing applications3D modellingQuality by DesignIndustrial engineering

The invention discloses a BIM (Building Information Modeling)-based metro comprehensive pipeline adjustment method, which is characterized in that a pipeline is adjusted by using a manual or automatic method on the basis of constructing a BIM model. According to the method, the manual or automatic pipeline adjustment mode is adopted on the basis of the constructing the BIM model, so that avoidance adjustment can be freely and flexibly realized, pipeline collision can be avoided, the design efficiency and the design quality can be improved, an abandoned project caused by pipeline collision can be avoided, and the construction cost is reduced. The method is suitable for various BIM technology-based three-dimensional aided design platforms.

Owner:XIAN UNIV OF TECH

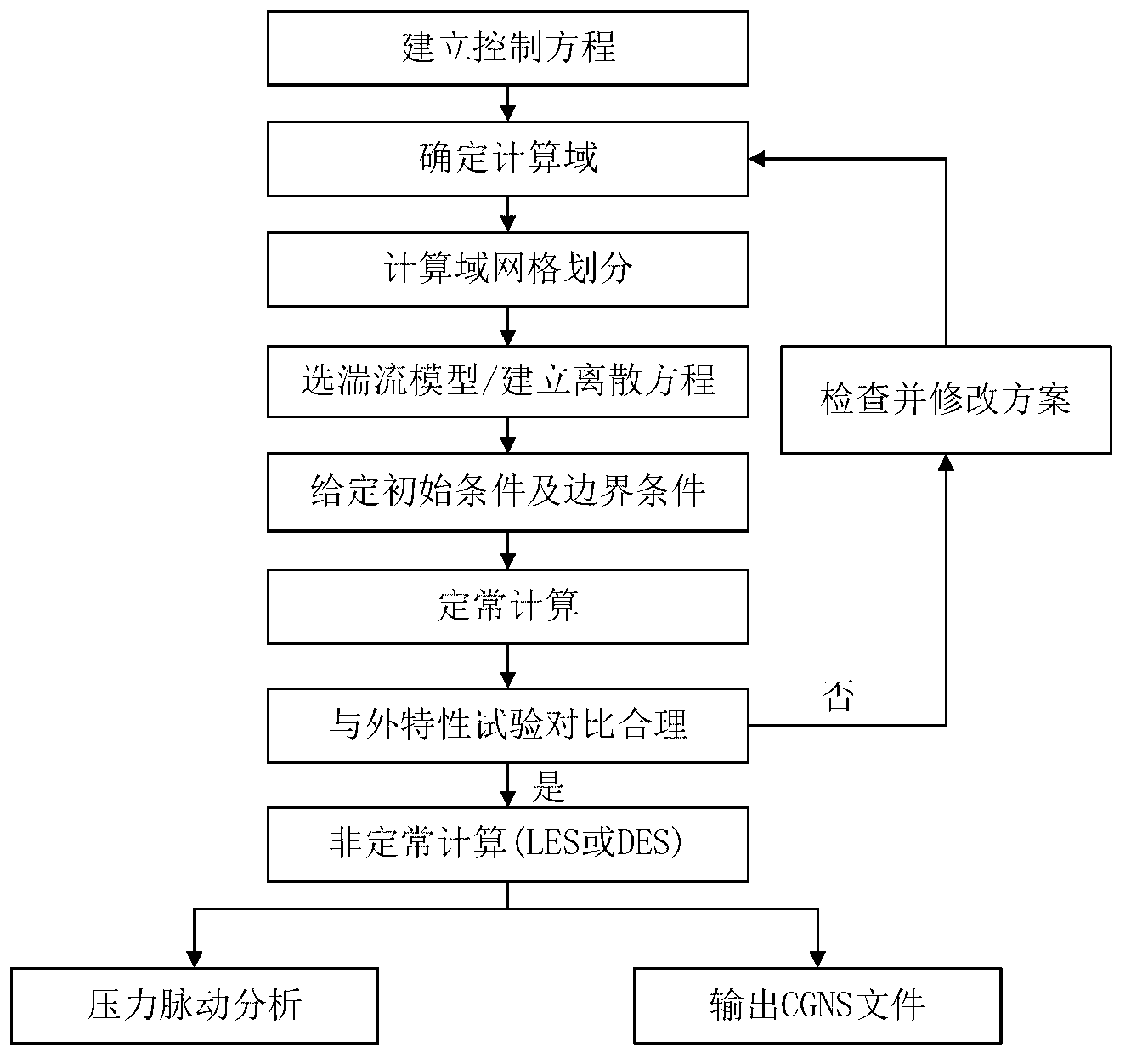

Centrifugal pump flow induction noise numerical prediction method

ActiveCN103631989AImprove design qualityOptimize early designSpecial data processing applicationsLow noiseBroadband noise

The invention discloses a centrifugal pump flow induction noise numerical prediction method which is used for computing the sound source feature of flow noise on the basis of the test results of a centrifugal pump performance test. The method can well overcome the shortcomings that in a traditional computing method, the influence from a pump body structure on acoustic propagation is not considered, and eddy broadband noise is ignored. Centrifugal pump inner flow analysis and far-field noise value computing results are used in centrifugal pump low-noise waterpower design, test frequency can be reduced, the development cycle can be shortened, development cost can be saved, the design quality of a centrifugal pump can be effectively improved, an interpolation method is used between a fluid mesh and an acoustics mesh, sound source information of flow field calculation can be reserved to the maximum degree, GREEN analysis is used, the contribution degree on noise from different parts of a shell body can be obtained, such study is carried out, and early design or later modifying of the shell body can be optimized.

Owner:JIANGSU UNIV

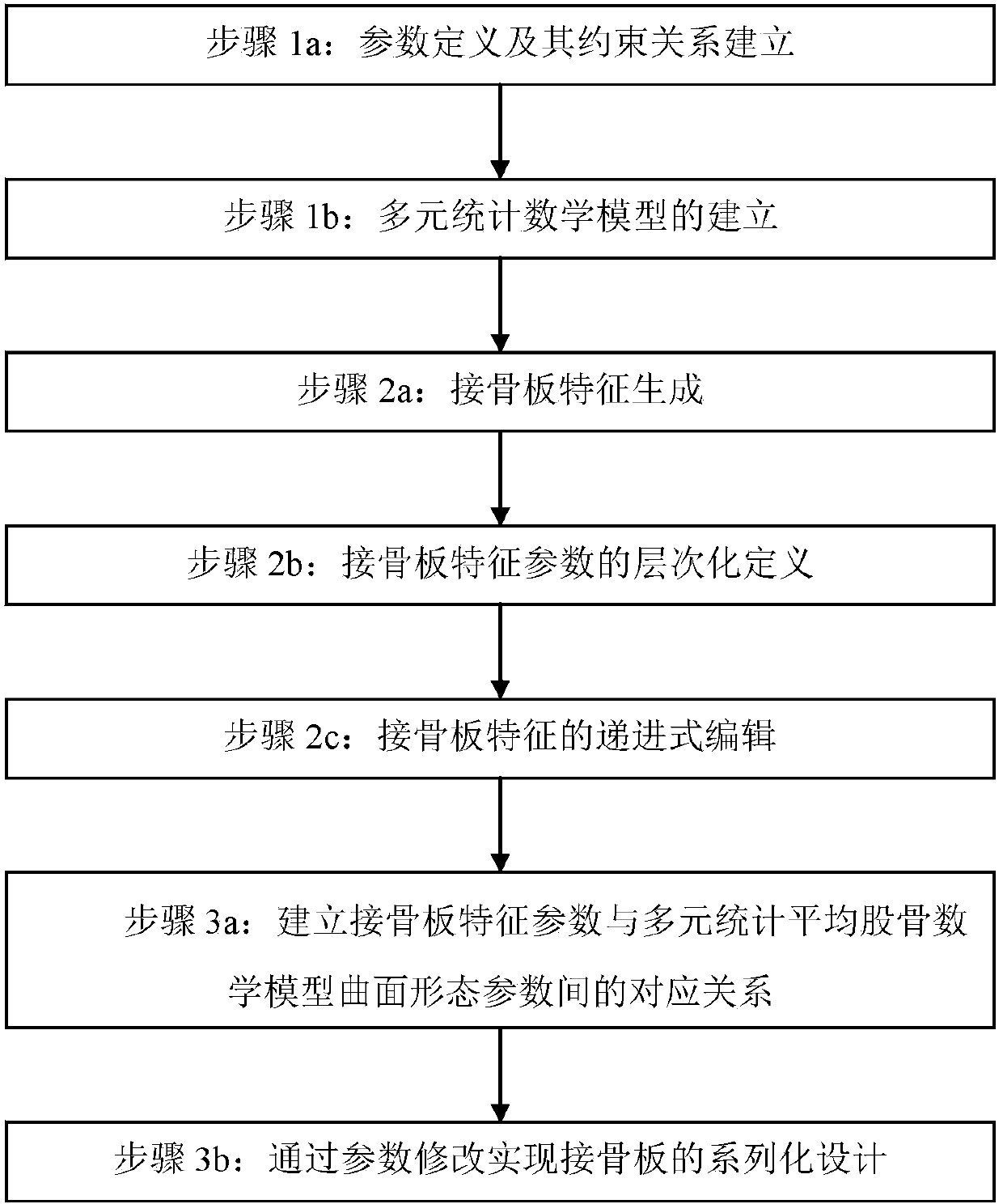

Serial bone plate design method based on average thighbone model

ActiveCN104933263AImprove design efficiencyImprove the quality of surgerySpecial data processing applicationsMultivariate statisticsMedicine

The invention discloses a serial bone plate design method based on an average thighbone model. The design method includes the steps of 1 building the average thighbone model, wherein parameters are defined, a constraint relation of the parameters is set up, and a multivariate statistics mathematic model is set up; 2 parameterizing characteristics of a bone plate, wherein the characteristics of the bone plate are generated, the characteristic parameters of the bone plate are defined in a layered mode, and the characteristics of the bone plate are compiled progressively; 3 designing the bone plate serially, wherein a mapping relation between the characteristic parameters of the bone plate and curved surface morphological parameters of the average thighbone model is set up, and serial bone plate design is achieved by modifying the parameters. A scientific basis is provided for reasonable and serial bone plate design in the field of computer-assisted orthopedic operations, and the serial bone plate design method is of great significance in improving the bone plate design quality and shortening design time.

Owner:HOHAI UNIV CHANGZHOU

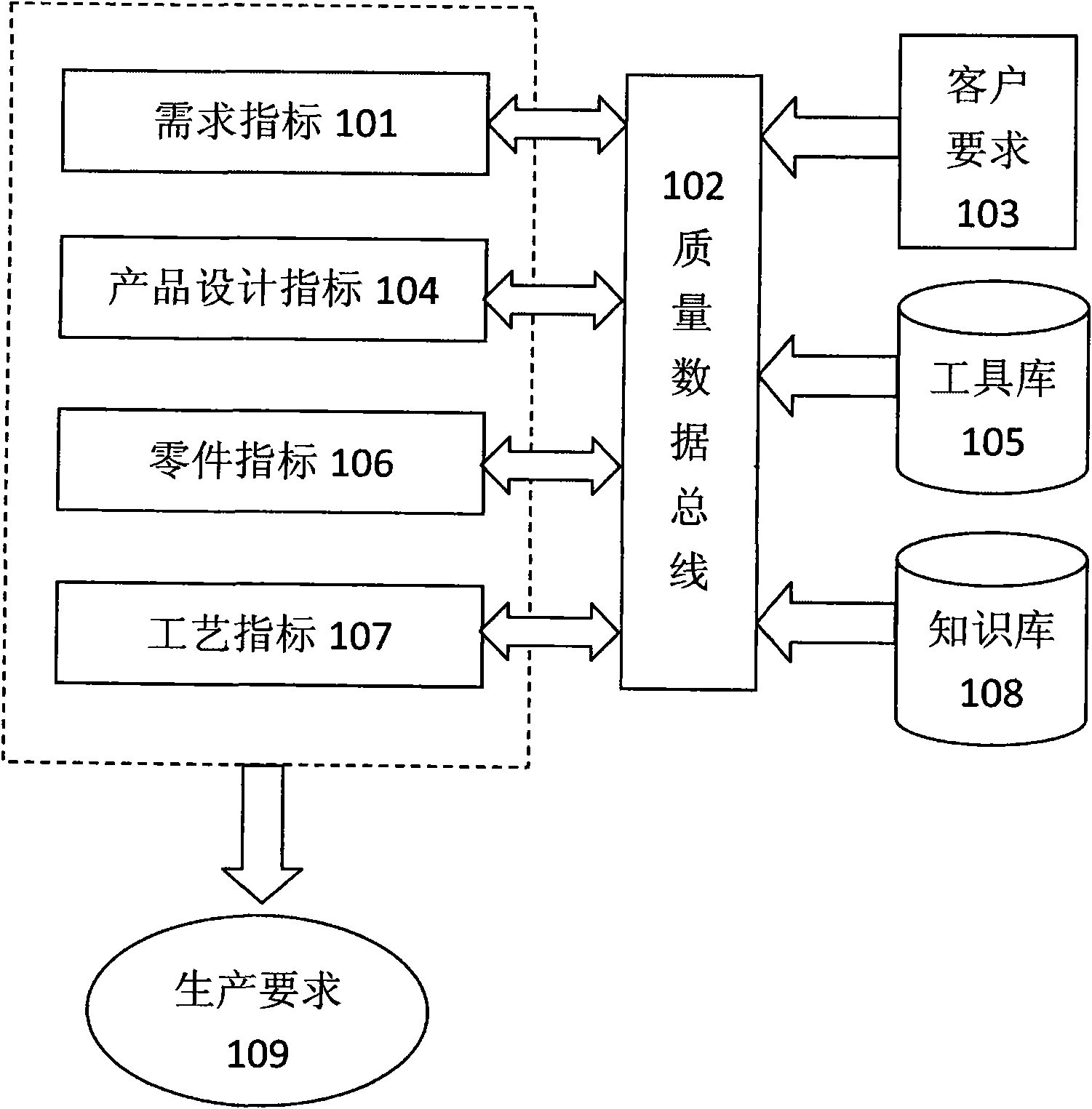

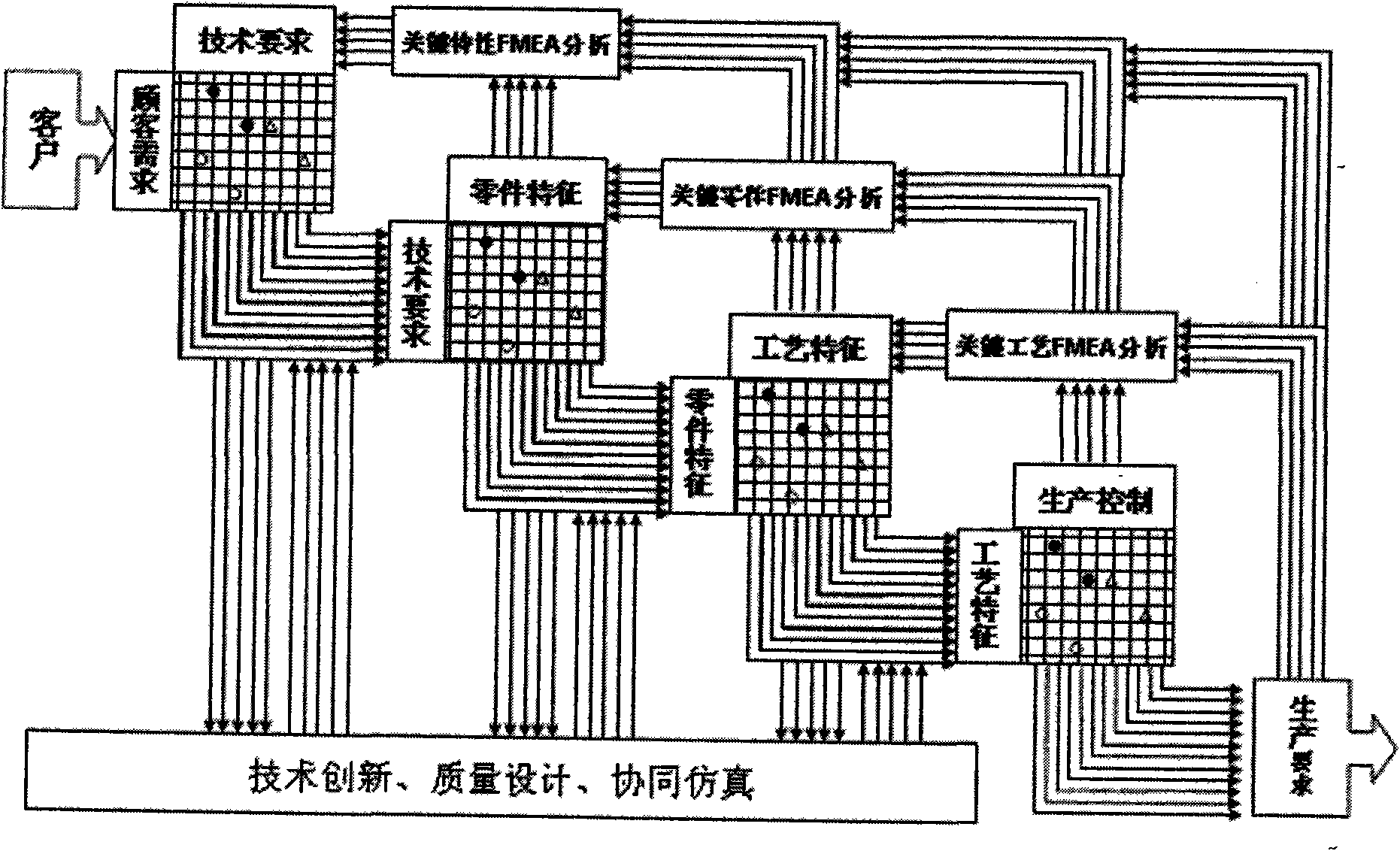

System and method for controlling researching and developing quality of product

InactiveCN101540012ARealize Lean R&DPrecise control of design qualitySpecial data processing applicationsQuality dataQuality by Design

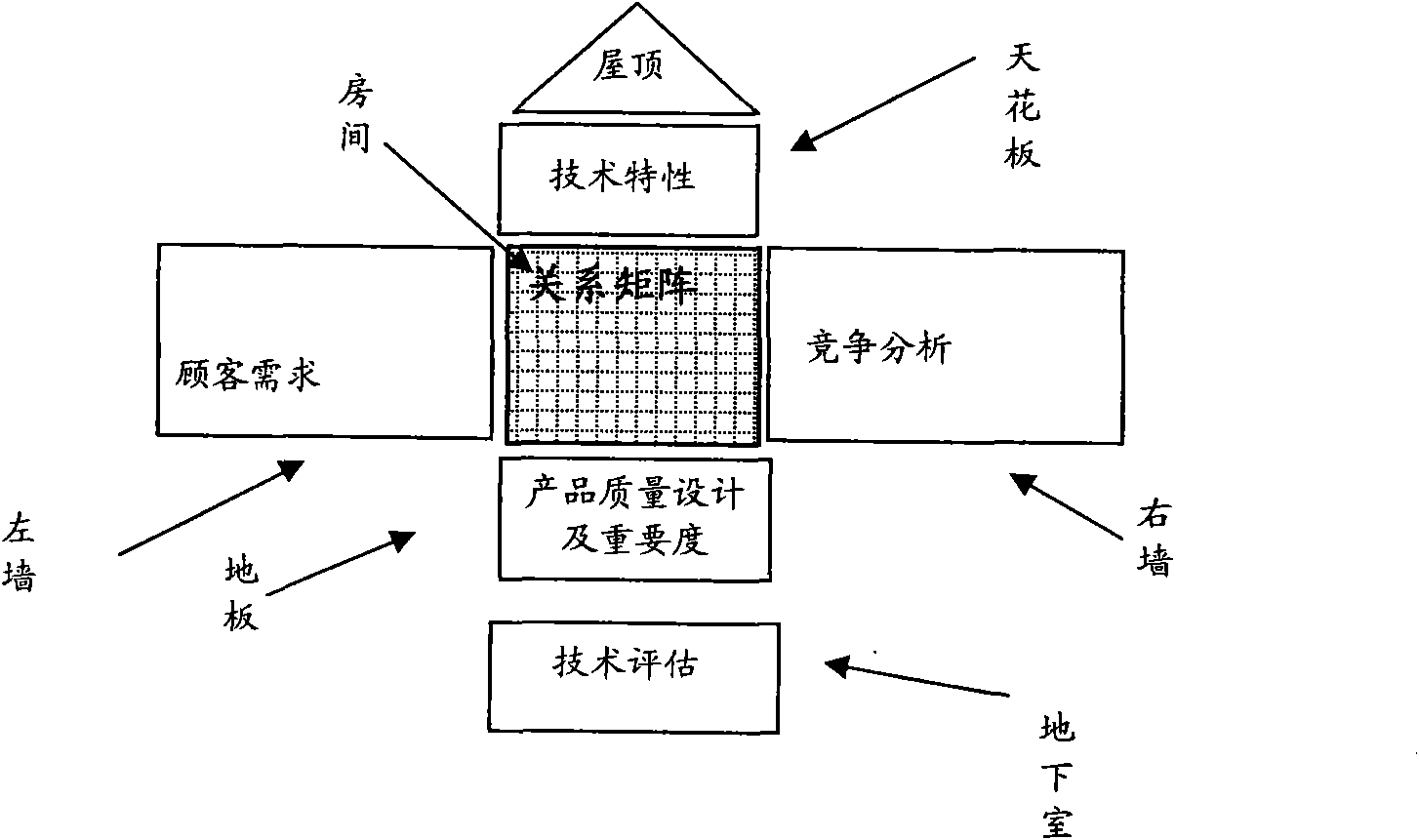

The invention provides a system and a method for controlling the researching and developing quality of a product. The system comprises a data bus, a quality function deployment QFD module, an index management module and a memory, wherein the quality function deployment QFD module is used for carrying out staged conversion on a product index, converting a client requirement index into a first stage product researching and developing index in a multi-stage product researching and developing index in the first stage, and converting the previous stage product researching and developing index into the next stage product researching and developing index in a subsequent stage; the index management module is used for correlating data of the client requirement index and data of the product researching and developing index in each stage through the data bus, and forming a mapping path; and the memory is used for storing the data of the product quality requirement indexes and the data of the product researching and developing index in each stage. Product researching and developing quality information (such as all technical indexes) can be integrated by the quality data bus, so that quality of design can be controlled accurately.

Owner:亿维讯软件(北京)有限公司

Three-dimensional mechanical in-process model sequential modeling method based on removal feature recognition

InactiveCN103020381ADifficulty of SimplificationEnsure rapid creation of requirementsSpecial data processing applicationsQuality by DesignModel order

The invention relates to a three-dimensional mechanical in-process model sequential modeling method based on removal feature recognition, which mainly aims to solve the technical problems of repetitive work and big application limitation in the prior art. In the method, first of all, the removal features are classified into boundary feature, inset feature, communication feature, thread feature and loop feature. On the basis of the classification, the method includes the steps of: 1) producing a workblank; 2) judging whether a next process is necessary, and if yes, entering the third step; 3) recognizing the removal features in the process, which includes selecting a feature type and recognizing the feature; and 4) modeling the in-process models. All the in-process models are assembled to form a whole process model and are organized by a standard structure of a process all-information model. The method makes full use of the geometrical characteristics of the original components, solves the problem of high quality requirement to the original component model design in three dimensional process design, speedily creates the in-process models according to the practical mechanical processing sequence and improves the overall efficiency of the process design system.

Owner:SHENYANG AEROSPACE UNIVERSITY

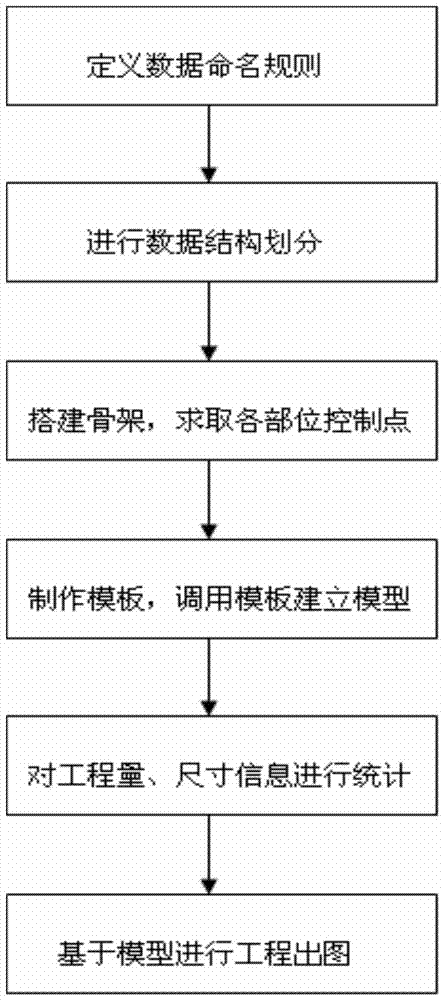

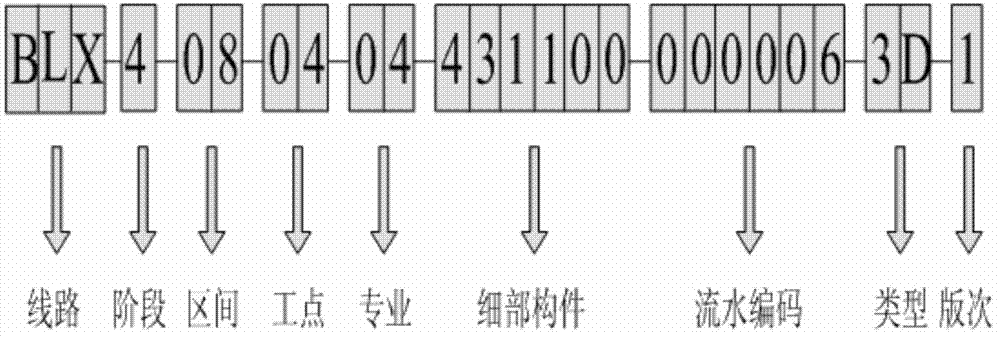

CATIA (Computer-graphics Aided Three-dimensional Interactive Application) three-dimensional model establishing method for railway simple-support bridge

ActiveCN104778334AFacilitate management inquiriesAvoid duplication of numbersBridgesSpecial data processing applicationsQuality by DesignComputer module

The invention relates to a three-dimensional modeling technology and discloses a CATIA (Computer-graphics Aided Three-dimensional Interactive Application) three-dimensional model establishing method for a railway simple-support bridge, for a purpose of improving the design quality and the design efficiency. The CATIA-based three-dimensional model establishing method comprises the following steps: firstly, formulating a data naming rule for completely eradicating number repetition of parts, and carrying out distinct data structure division for a purpose of better design after the strict data naming rule is formulated; then, erecting a framework to provide accurate reference information for subsequence design; then, establishing corresponding parameters and functions and making templates of various parts and various types by using the established framework information, then calling the templates to finish establishment of the model, measuring work amounts and sizes of various parts and hanging information of the work amounts and sizes of various parts under the corresponding templates, and finally finishing two-dimensional drawing output under a CATIA engineering drawing module. The CATIA-based three-dimensional model establishing method is applicable to rapid and accurate establishment of the three-dimensional model of the railway simple-support bridge, and provides a technical guidance for actual construction.

Owner:CHENGDU XIMENG TEKE TECH DEV CO LTD

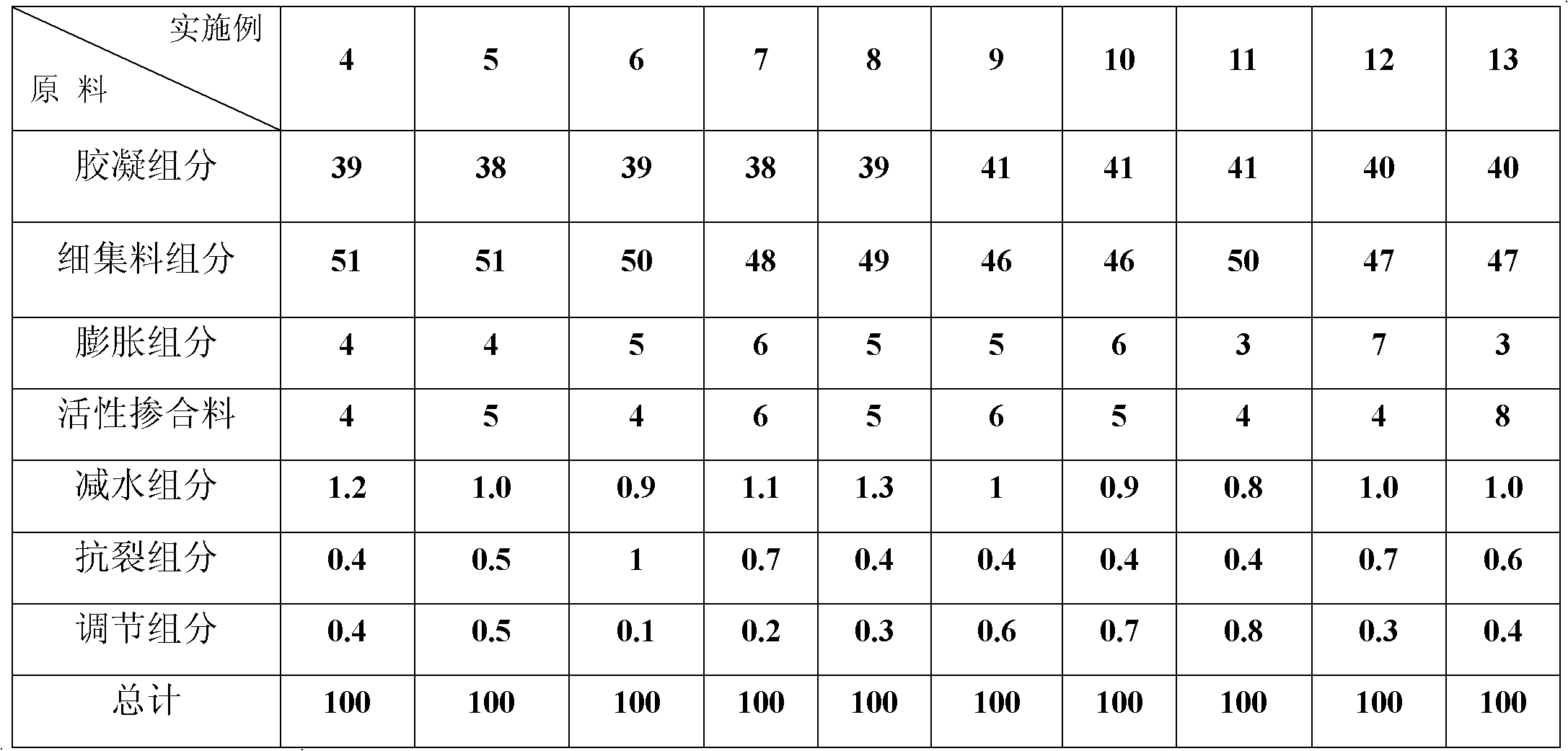

High-strength micro-expansion prestress anchoring grouting material and preparation method thereof

InactiveCN102180628AImprove rheologyGuaranteed StrengthSolid waste managementMass ratioQuality by Design

The invention discloses a high-strength micro-expansion prestress anchoring grouting material and a preparation method thereof. The material is prepared from a gelatinization component, a fine aggregate component, an expansion component, an active doped material, a water reducing component, a crack resistant component and a regulation component in a certain weight proportion. The preparation method specifically comprises the following steps: A, adding the gelatinization component, the expansion component, the active doped material, the crack resistant component and the water reducing component in a ball-mill in a designed mass ratio for commonly mixing and grinding, so as to obtain a even powder material; B, at room temperature and normal pressure, grinding until the Blaine specific surface of the material is not less than 350m<2> / kg; and C, evenly mixing and stirring the obtained in the step B with quartz sand prepared in a proportion at the room temperature and the normal pressure so as to obtain the grouting material. The method is practicable and is convenient for operation; the grouting material has high early strength and micro-expansion, thereby effectively compensating the hydration shrinkage of a cement-based material, obviously improving the adhesive strength of an anchor rod and a periphery base, effectively protecting the anchor rod from being corroded and prolonging the service of the anchor rod.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com