Acceleration frequency response analysis-based body floor optimal design method

A frequency response, body floor technology, applied in the field of body floor optimization design based on acceleration frequency response analysis, can solve the problems of no error control, unable to optimize the design of body floor, etc., to achieve pleasant sound, shorten development time, and reduce development costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the drawings and specific embodiments.

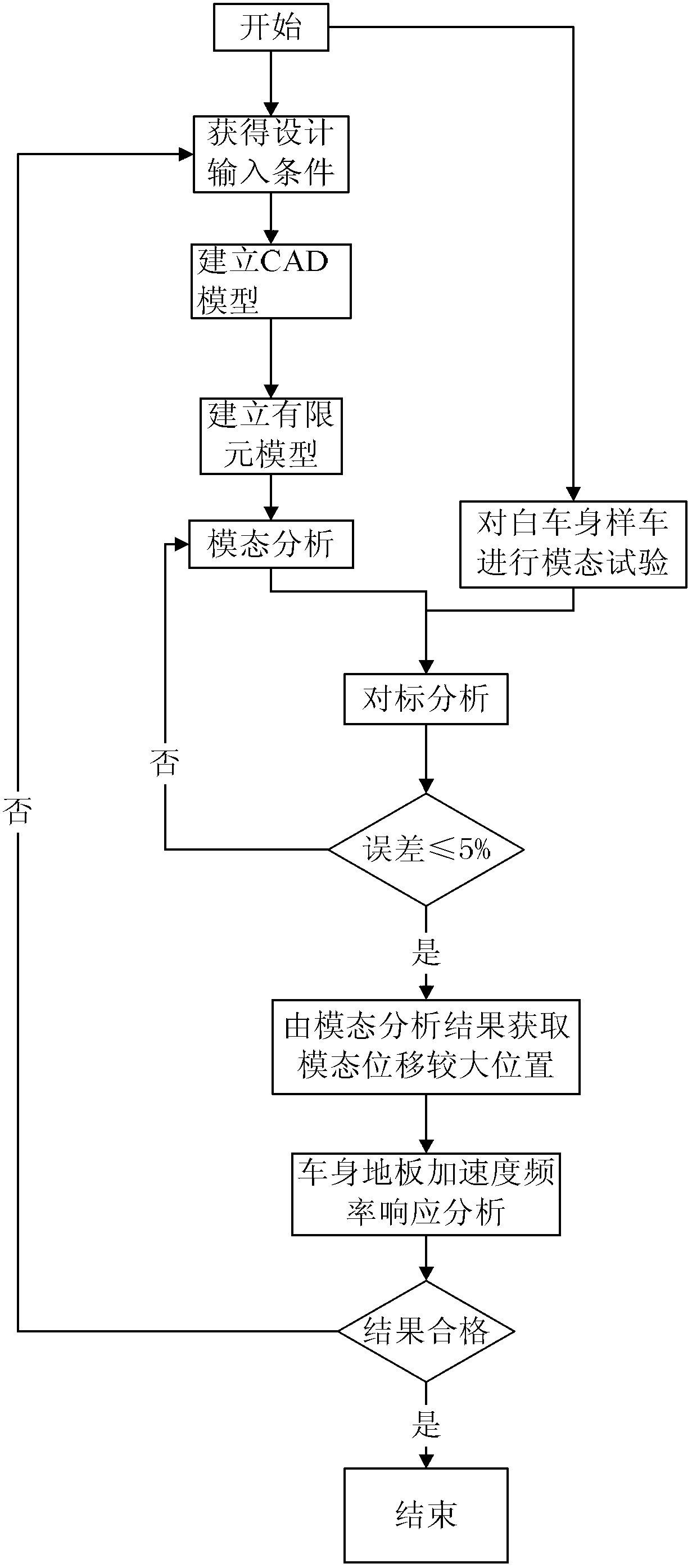

[0038] Such as figure 1 The illustrated embodiment is an optimization design method for vehicle body floor based on acceleration frequency response analysis, which includes the following steps:

[0039] (1) Obtain the design input conditions of the body floor according to the body shape and layout data;

[0040] (2) According to the design input conditions, carry out preliminary structural design of the car body floor, and establish a CAD model through CATIA software;

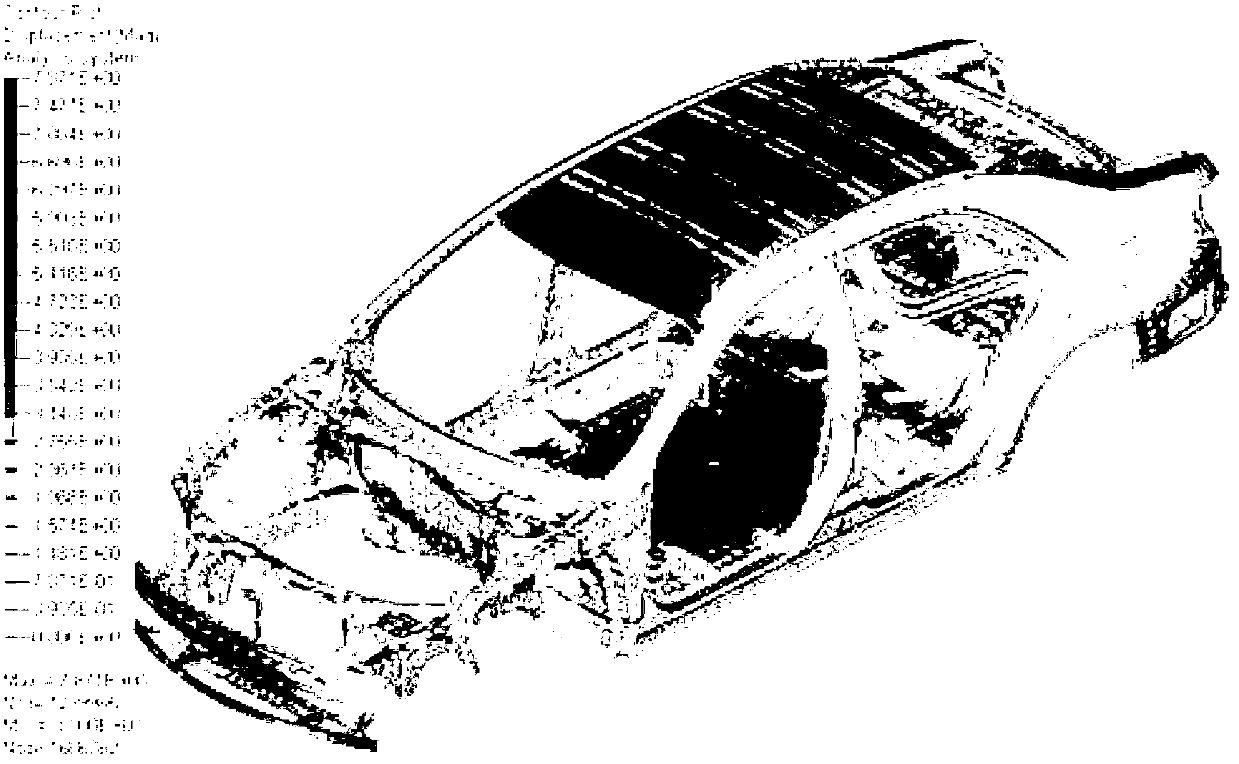

[0041] (3) Mesh the established CAD model and establish the finite element model of the white body; figure 2 The finite element model shown. The specific process is:

[0042] Import the CAD model into the finite element pre-processing software with CAD structure. The pre-processing software can use Hypermesh;

[0043] Mesh the data, and use shell elements as the element type;

[0044] Assign correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com