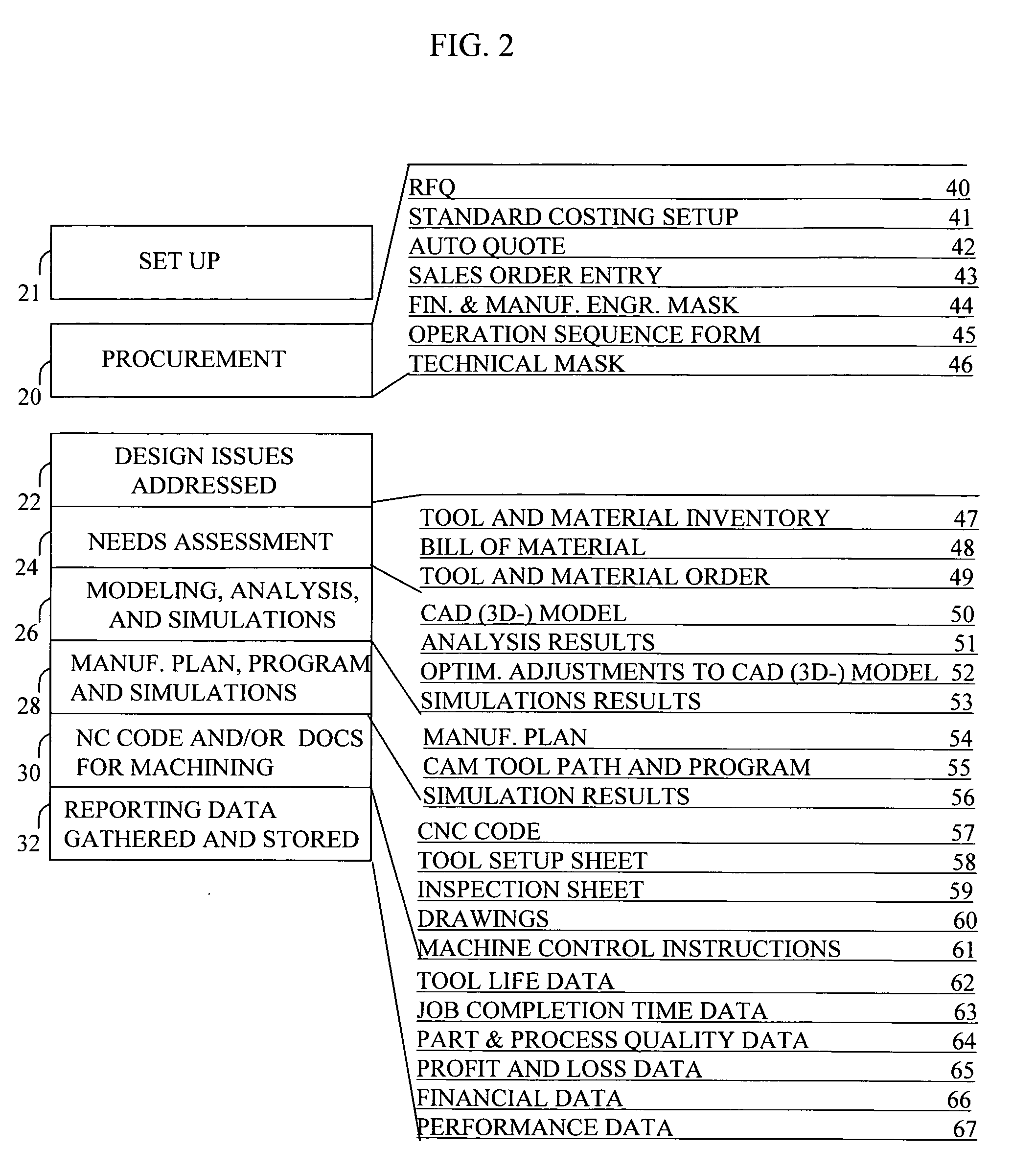

Patents

Literature

286 results about "Computer-aided engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

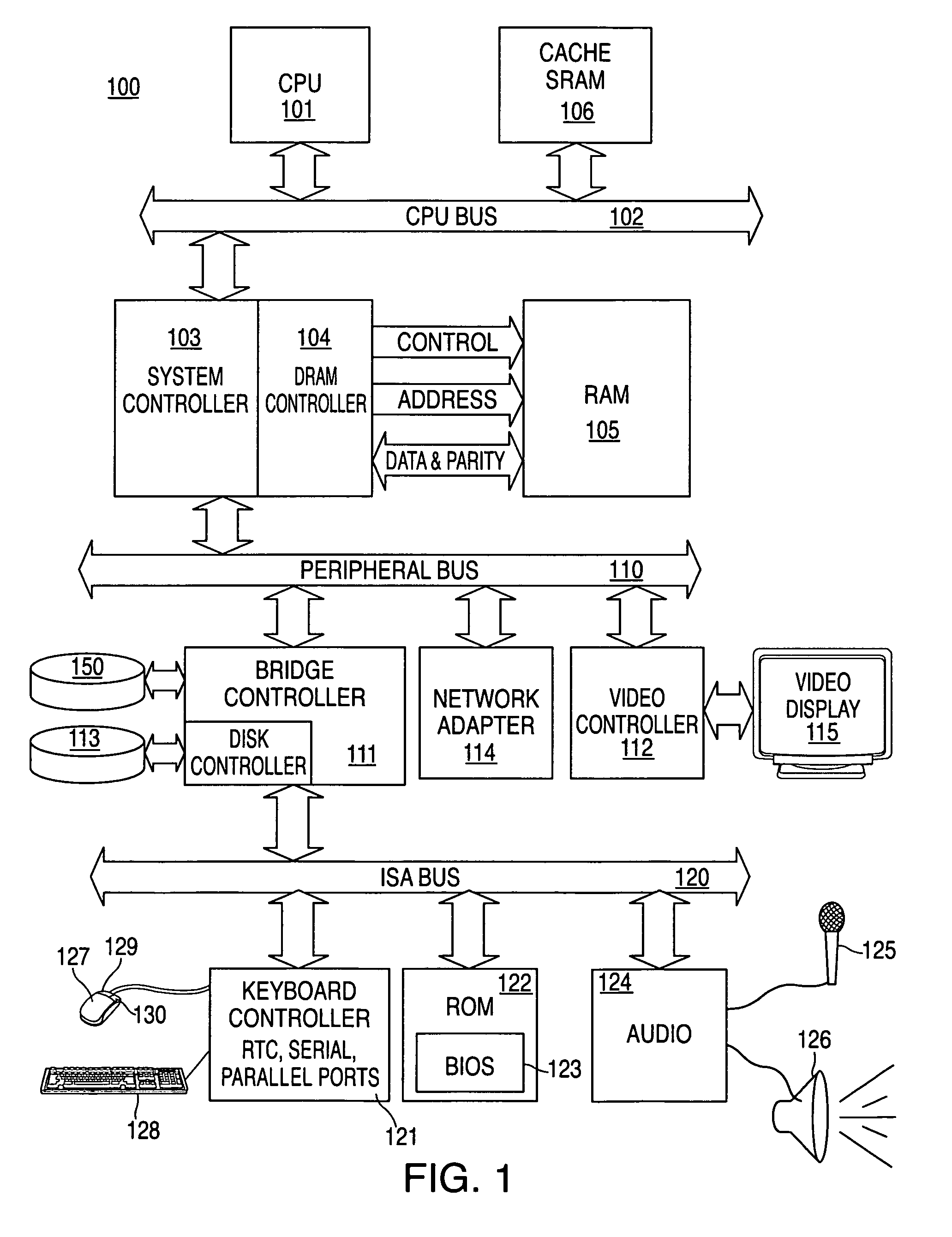

Computer-aided engineering (CAE) is the broad usage of computer software to aid in engineering analysis tasks. It includes finite element analysis (FEA), computational fluid dynamics (CFD), multibody dynamics (MBD), durability and optimization.

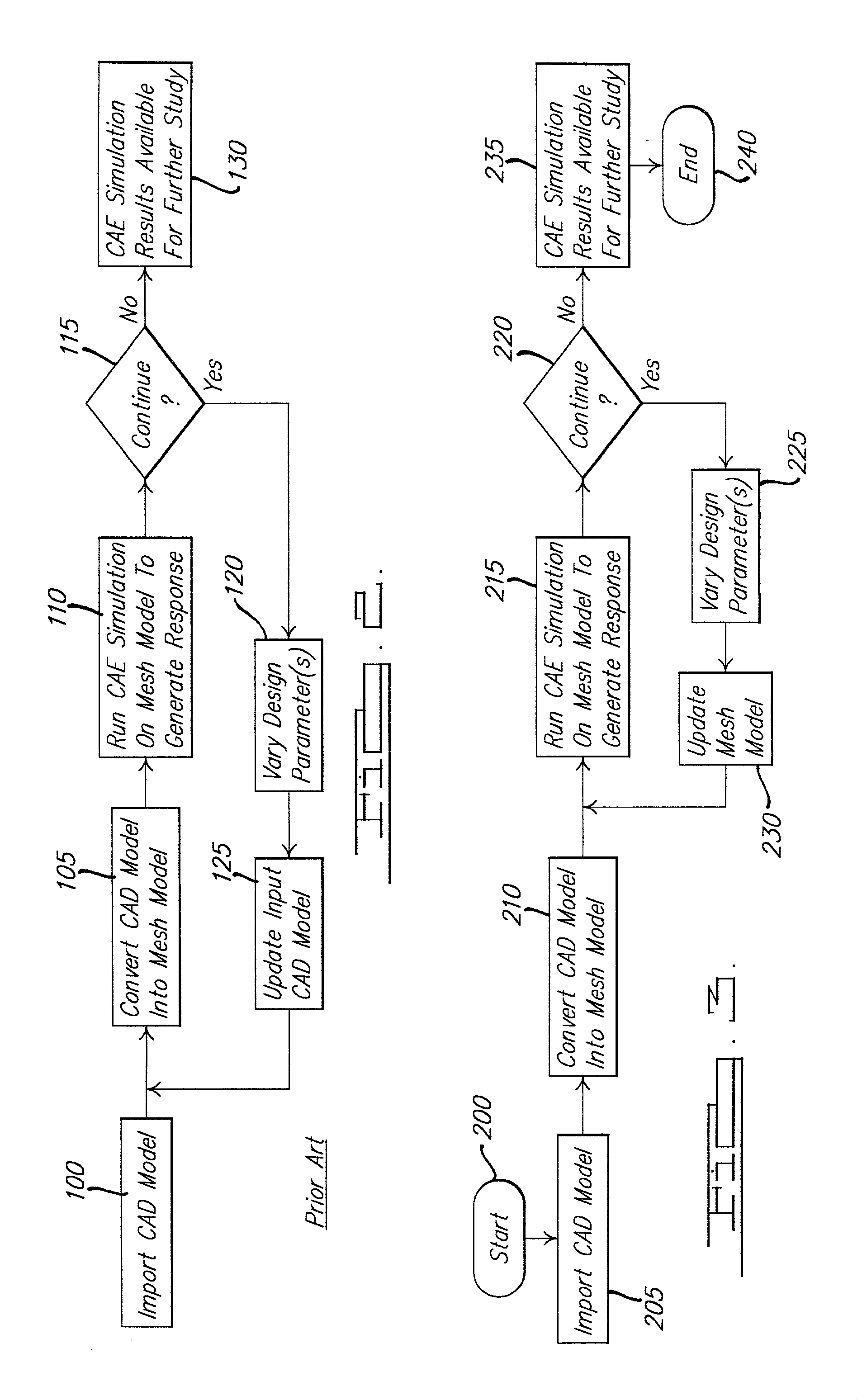

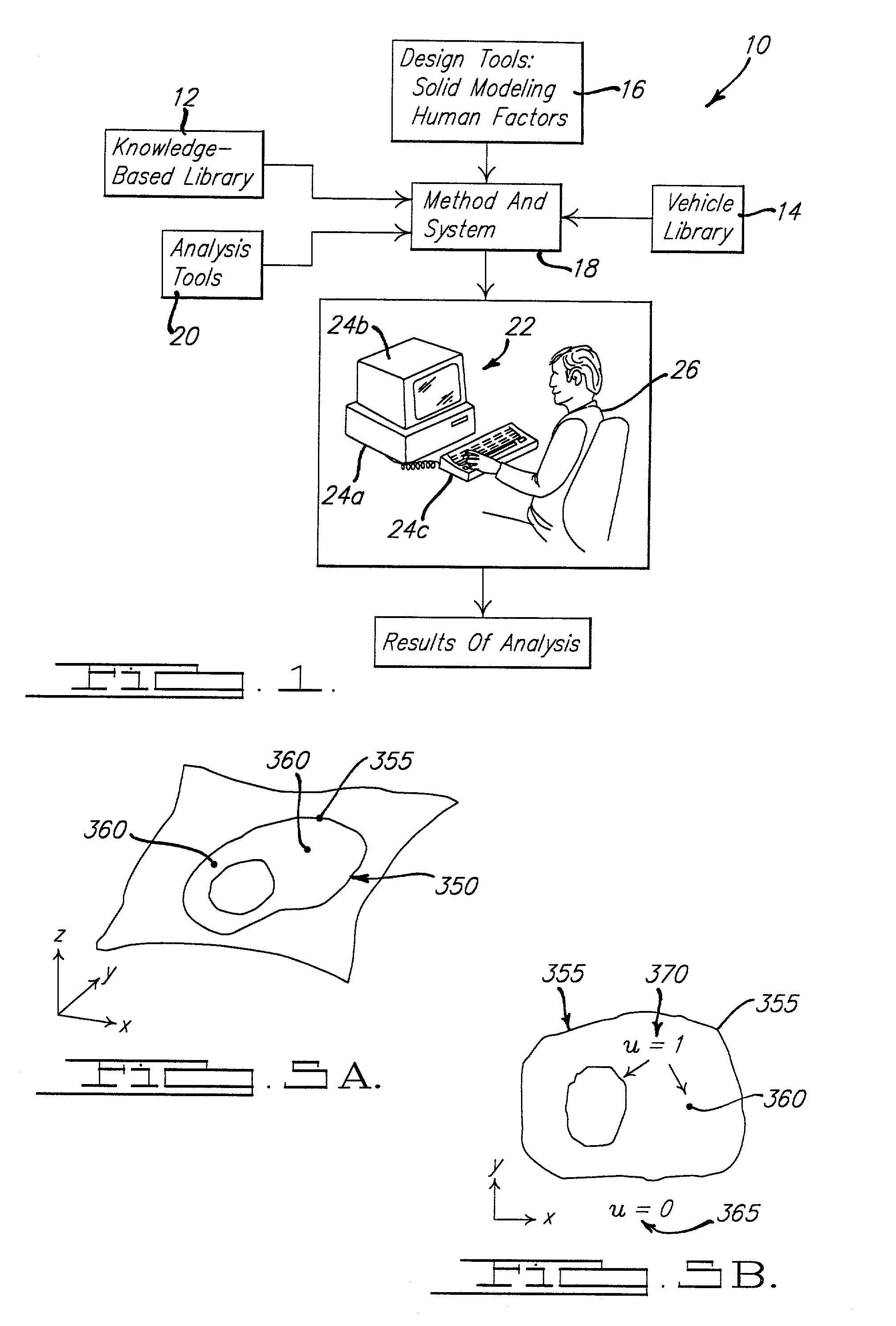

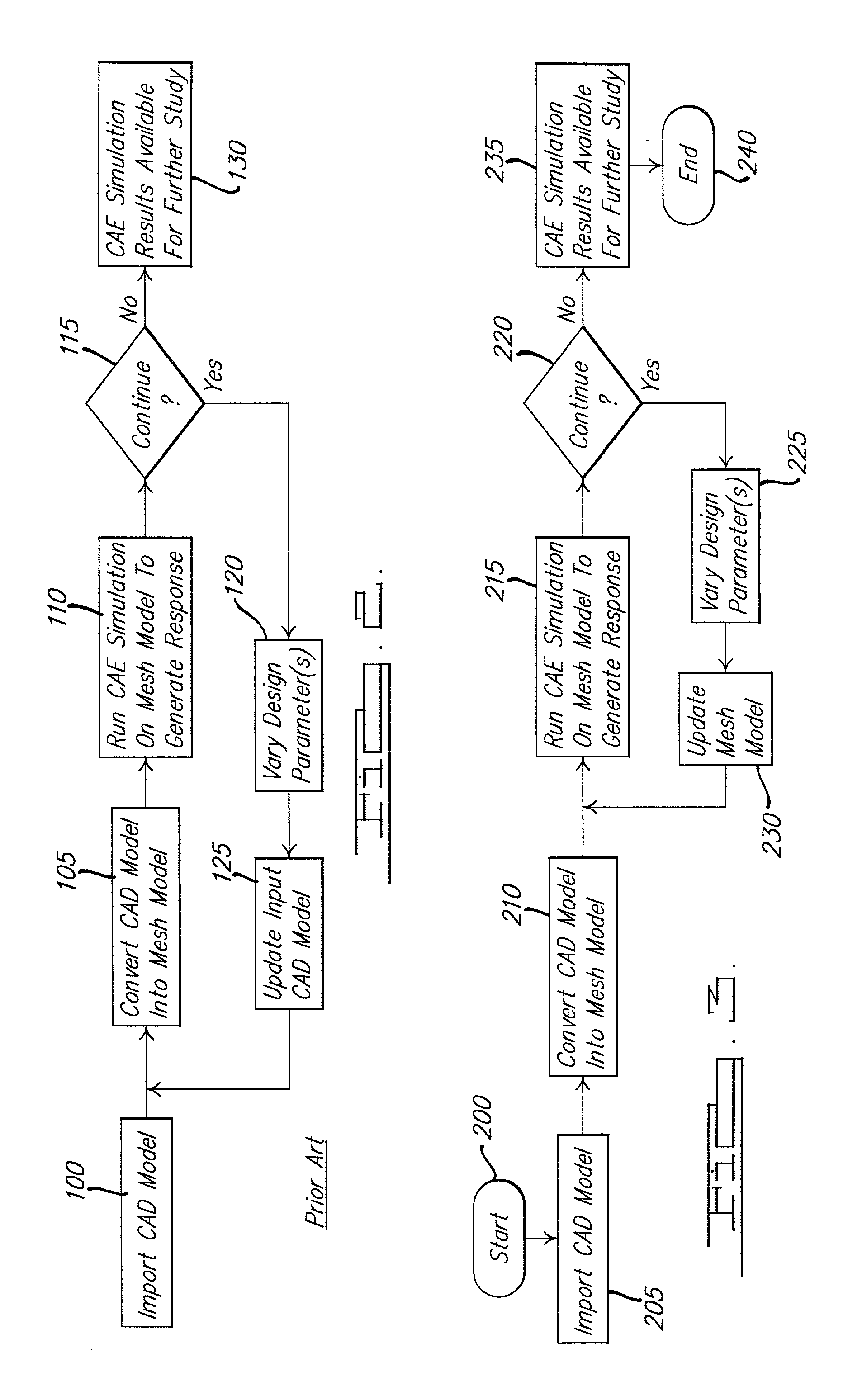

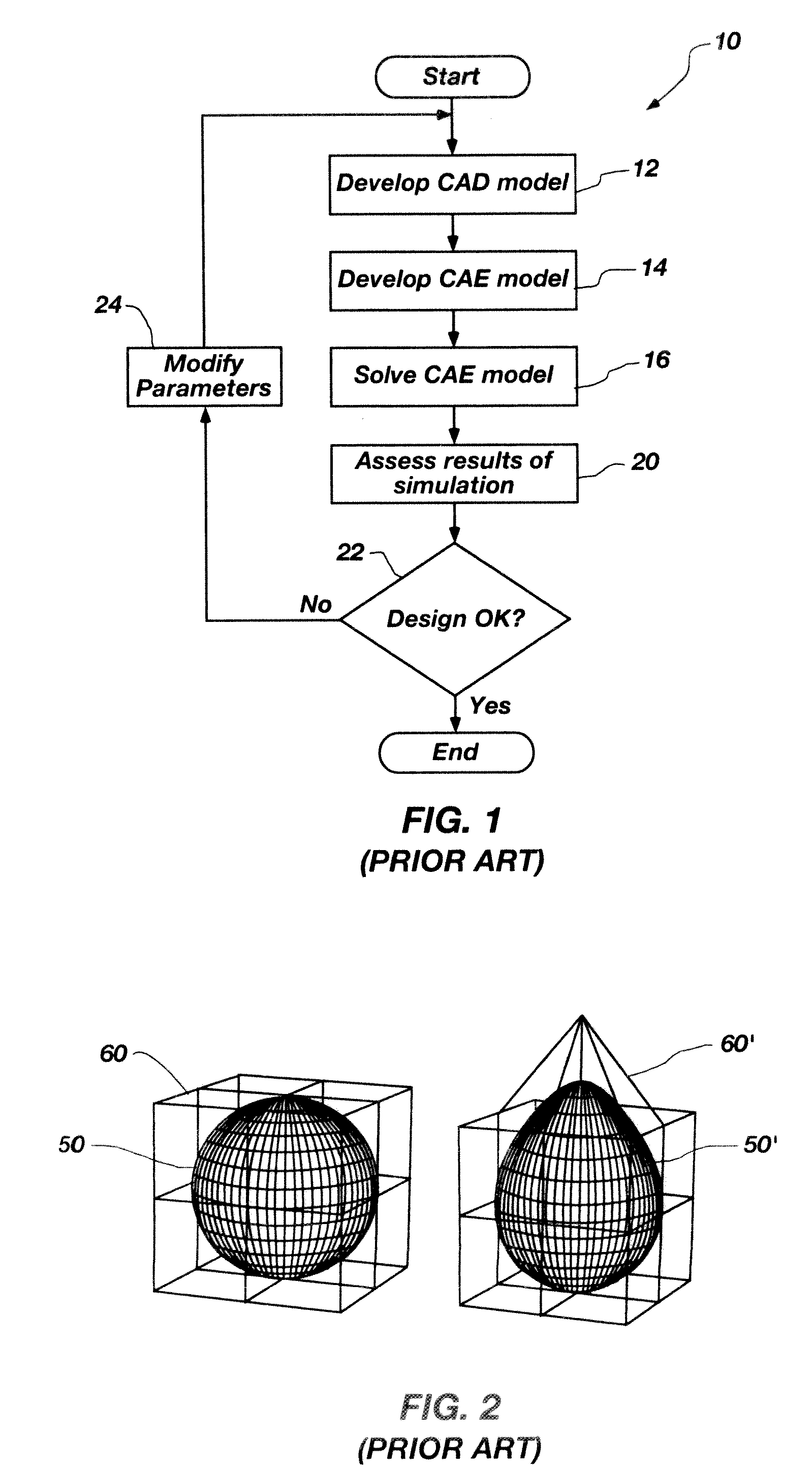

System and method for design of experiments using direct surface manipulation of a mesh model

InactiveUS7079996B2Easy to appreciateGeometric CADCathode-ray tube indicatorsComputer Aided DesignGeometric modeling

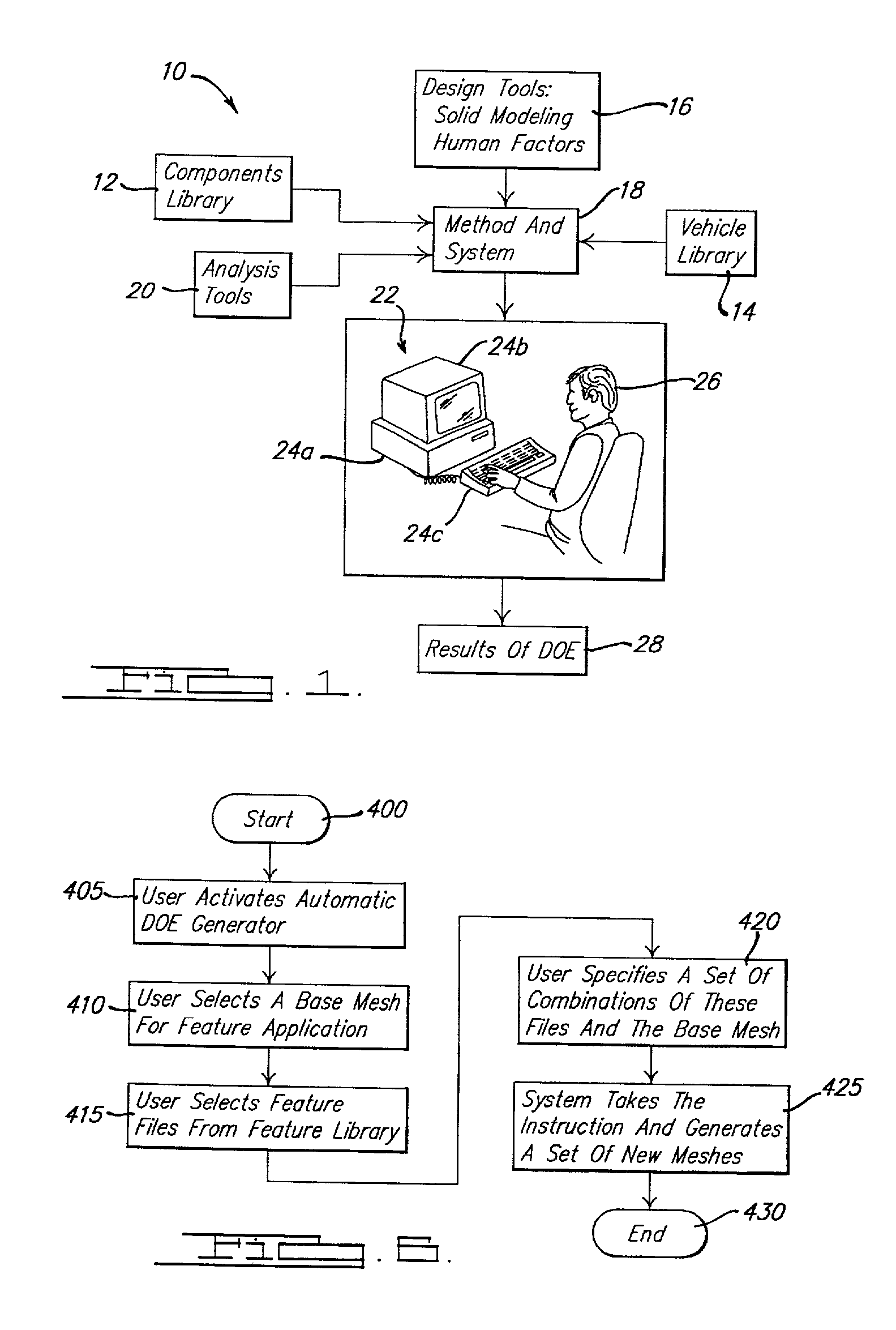

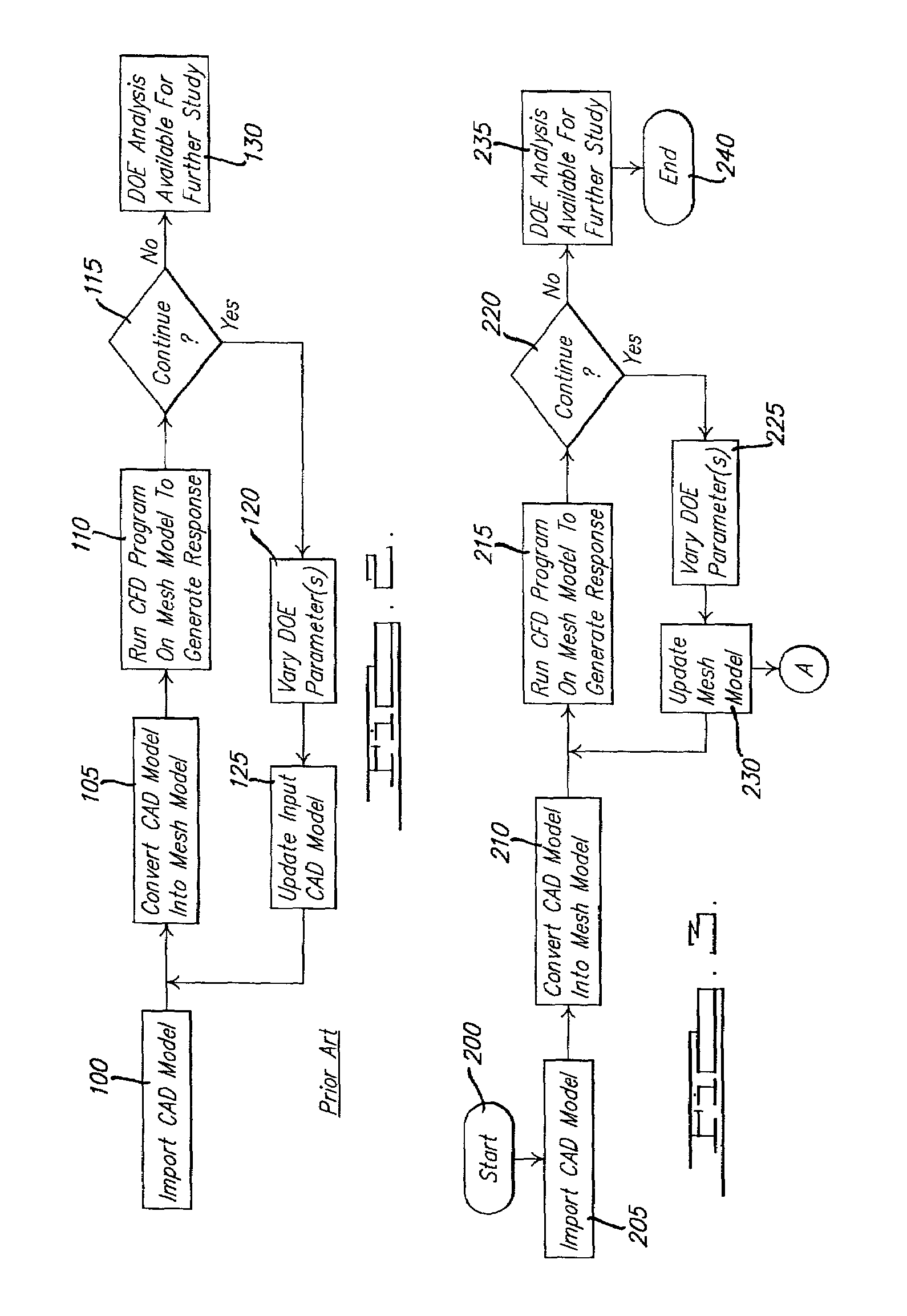

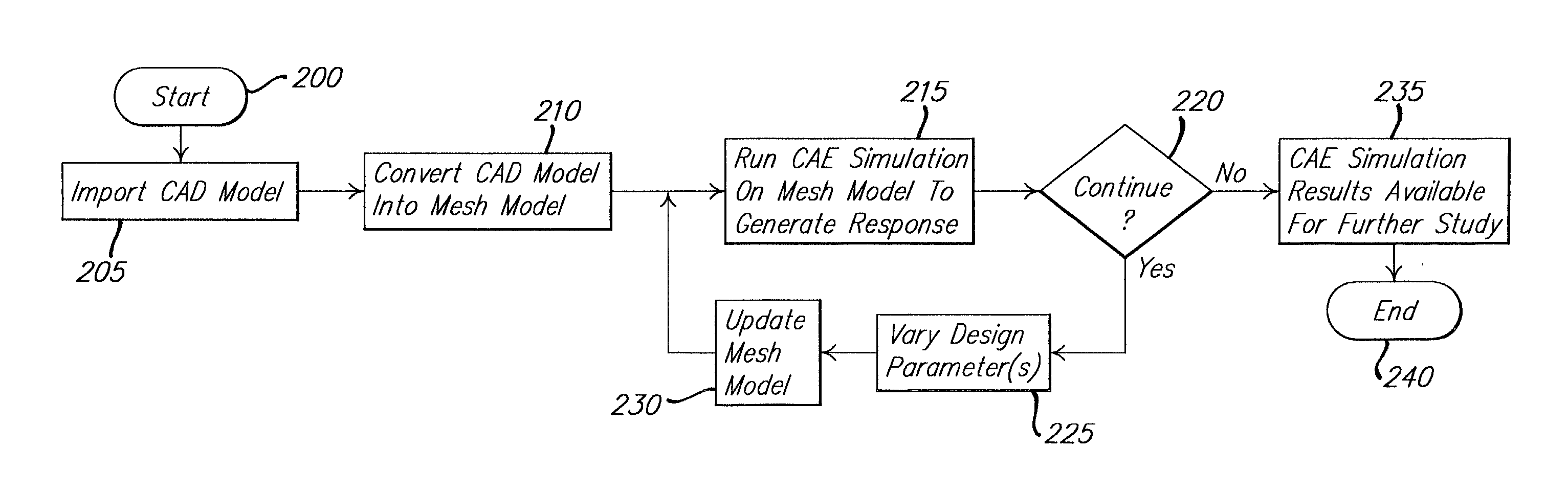

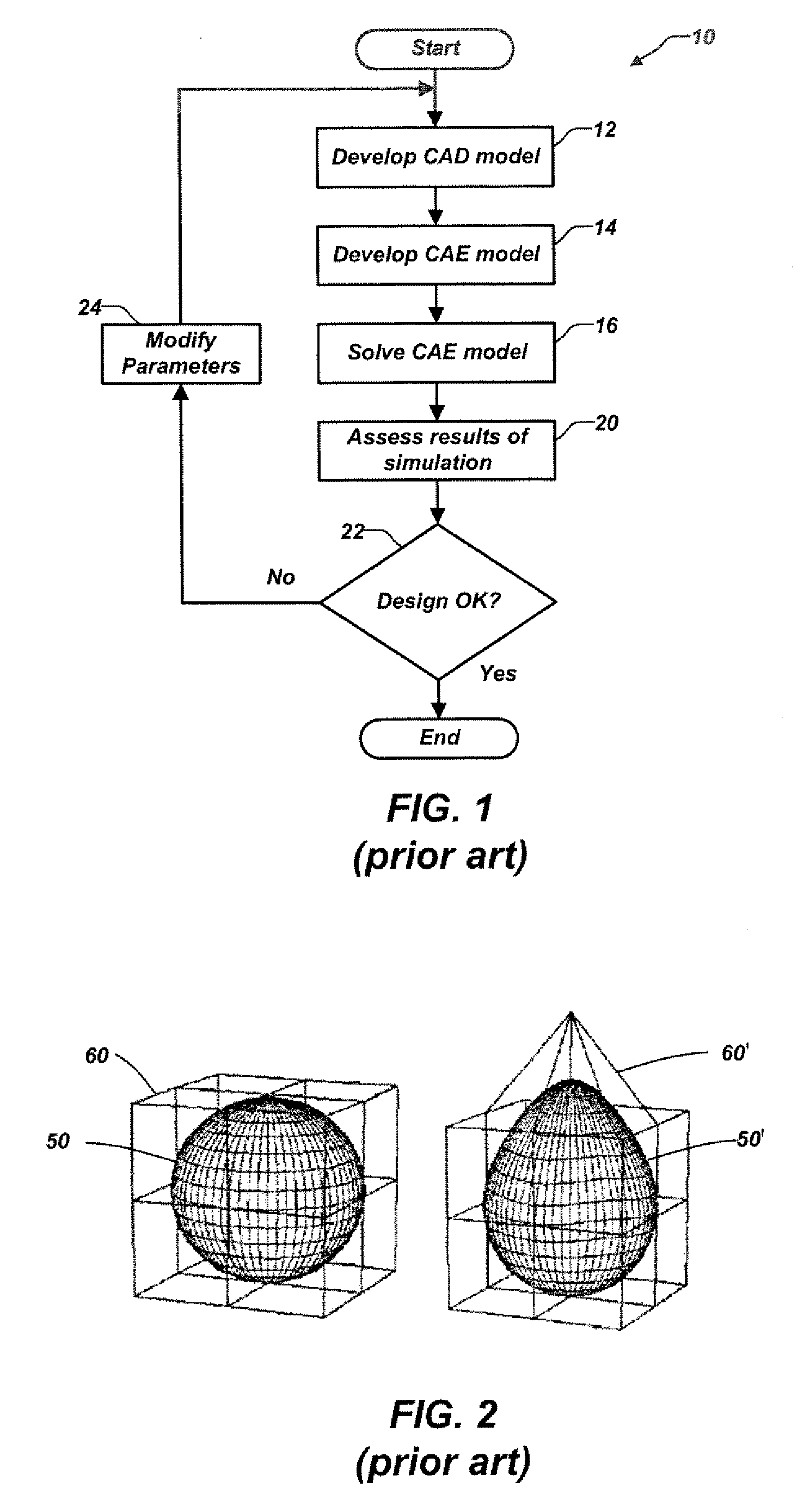

A system and method for design of experiments (DOE) using direct surface manipulation of a mesh model. The method includes the steps of selecting a geometric model in a computer-aided design (CAD) format, converting the geometric model into a mesh model and evaluating the mesh model using a computer-aided engineering (CAE) analysis. The method also includes the steps of determining whether to continue generating the design of experiments response, and modifying a surface of the mesh model by varying a predetermined parameter, wherein the surface is modified using direct surface manipulation (DSM), the mesh model is updated and the updated mesh model is used in continuing generating the design of experiments response, if determined to continue the design of experiments. The method further includes the steps of using the results of the CAE analysis for the design of experiments.

Owner:FORD GLOBAL TECH LLC

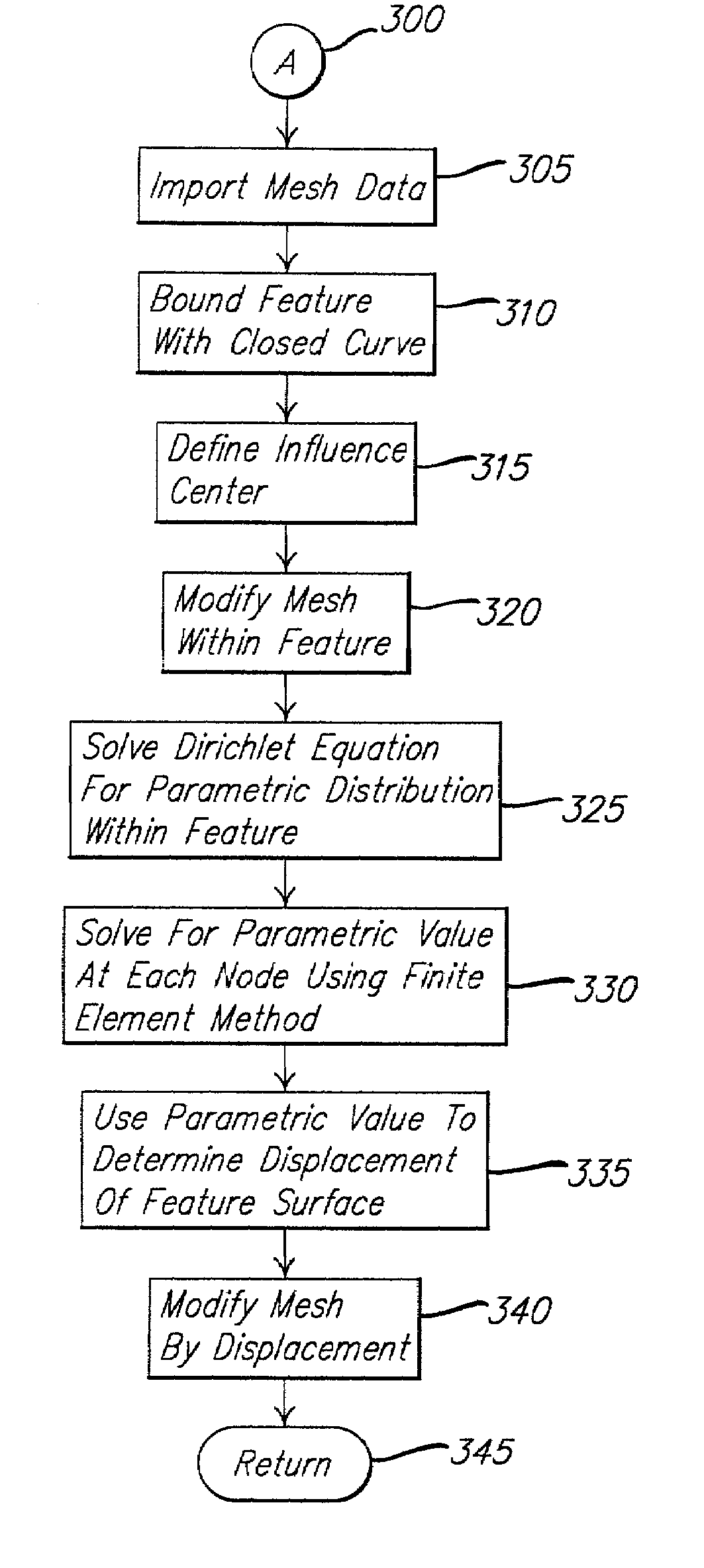

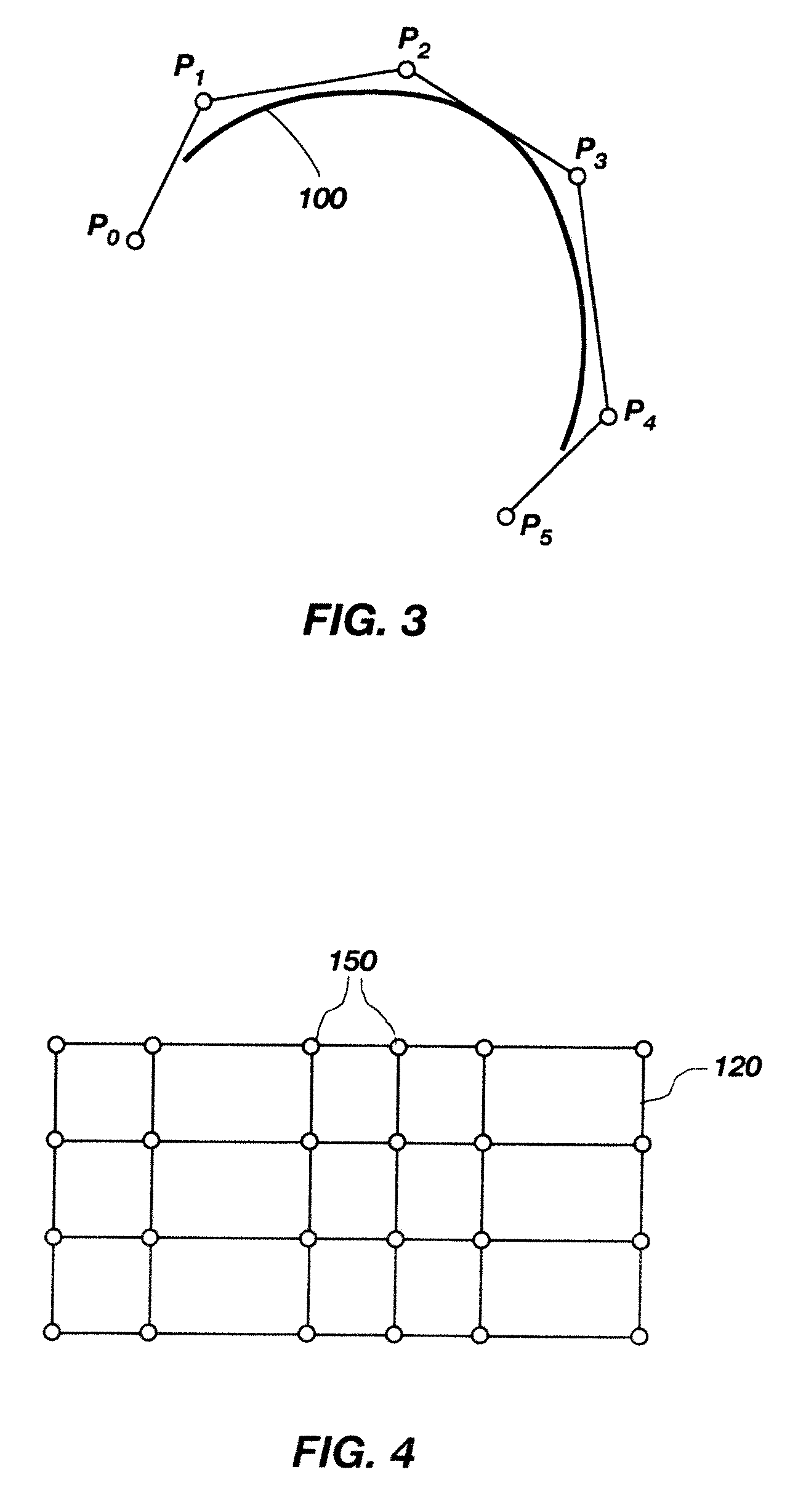

System and method of direct mesh manipulation

ActiveUS20030080957A1Geometric CADData processing applicationsComputer Aided DesignComputer graphics (images)

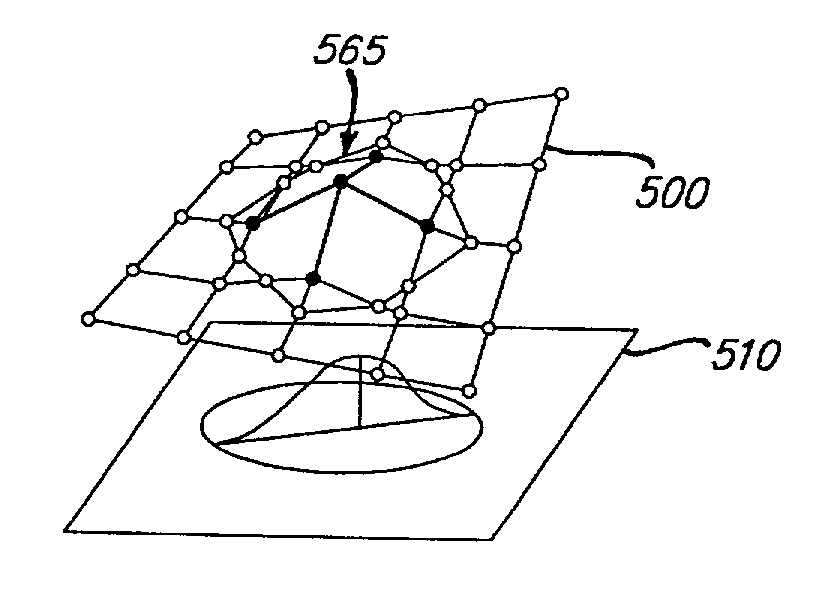

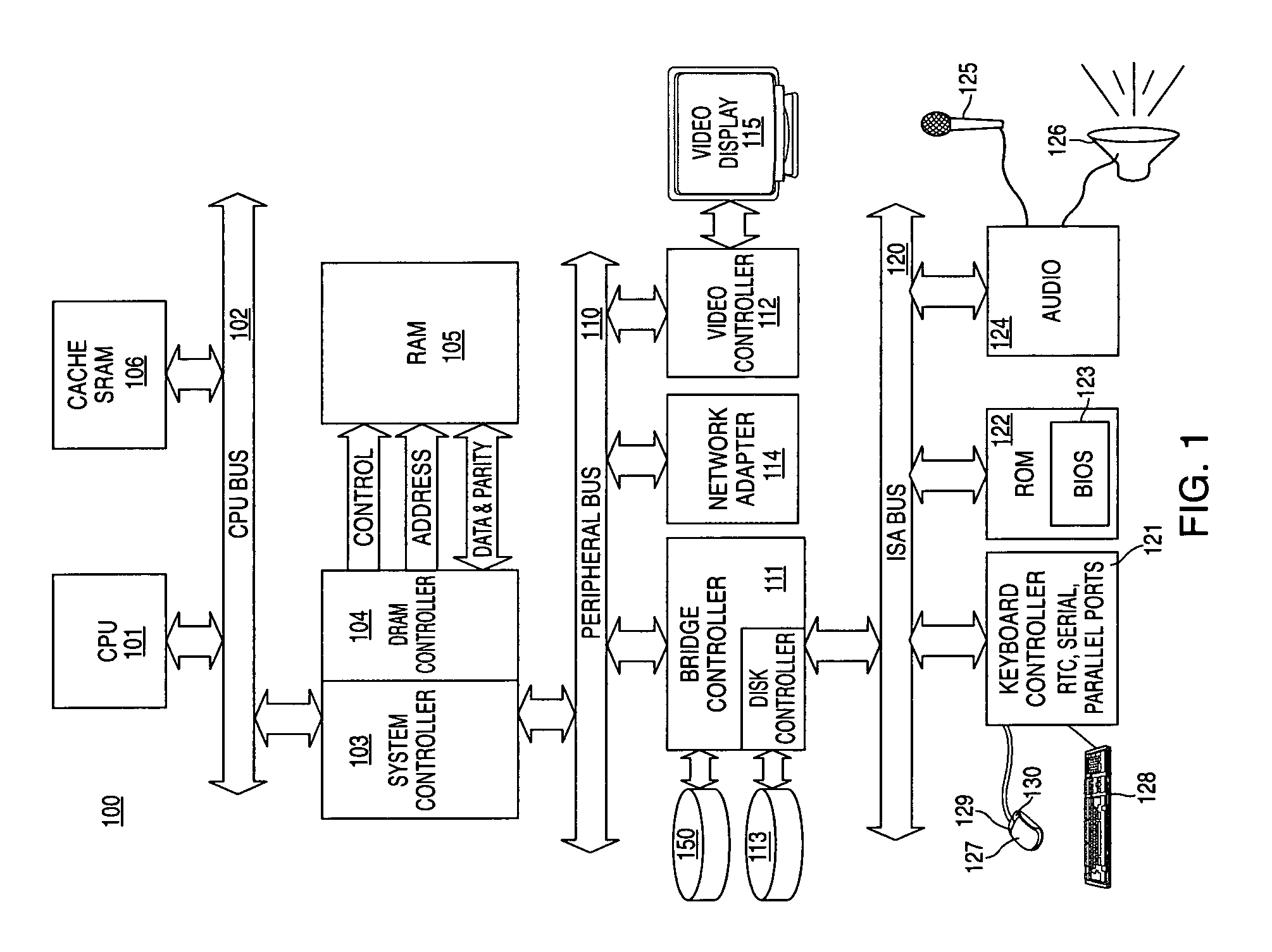

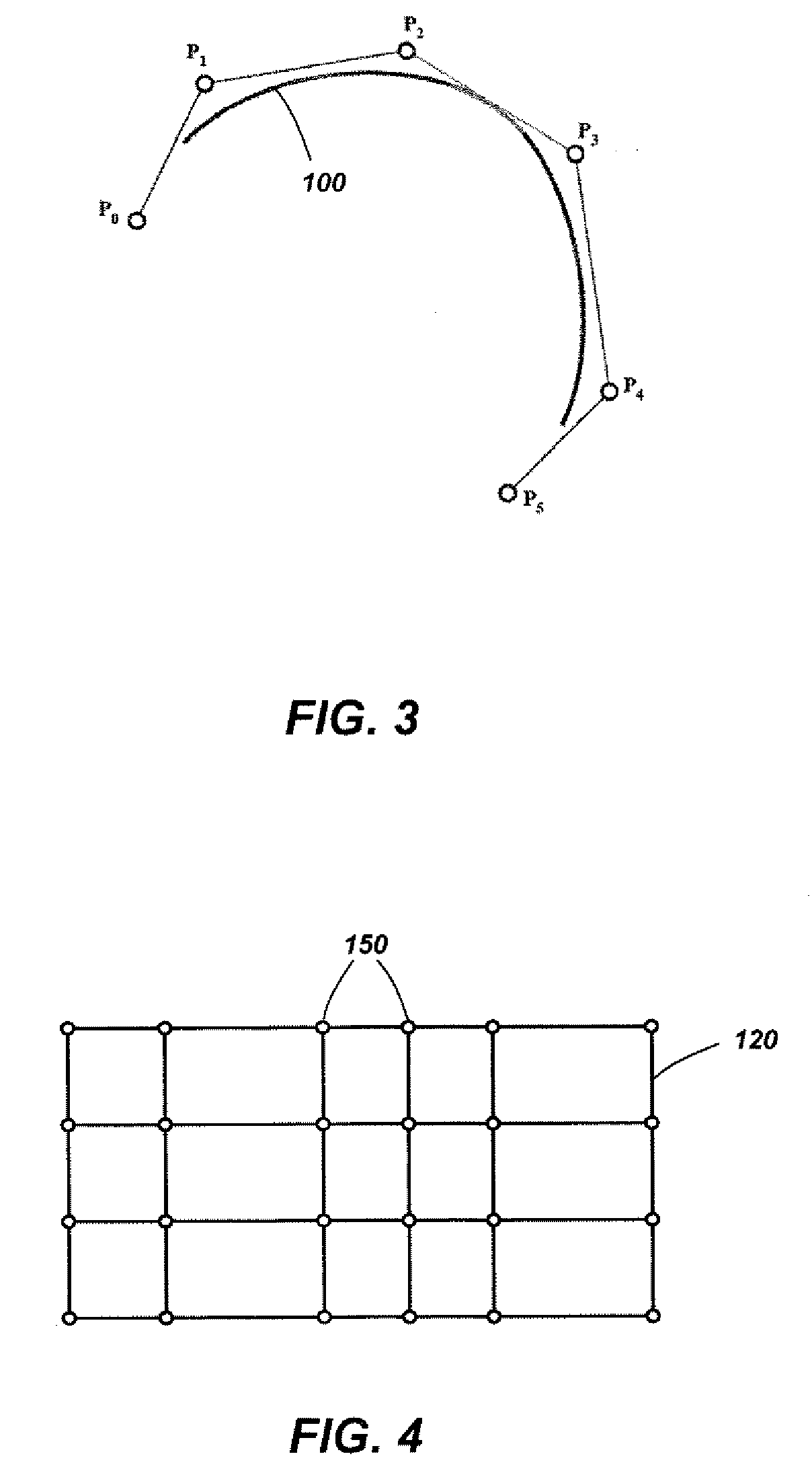

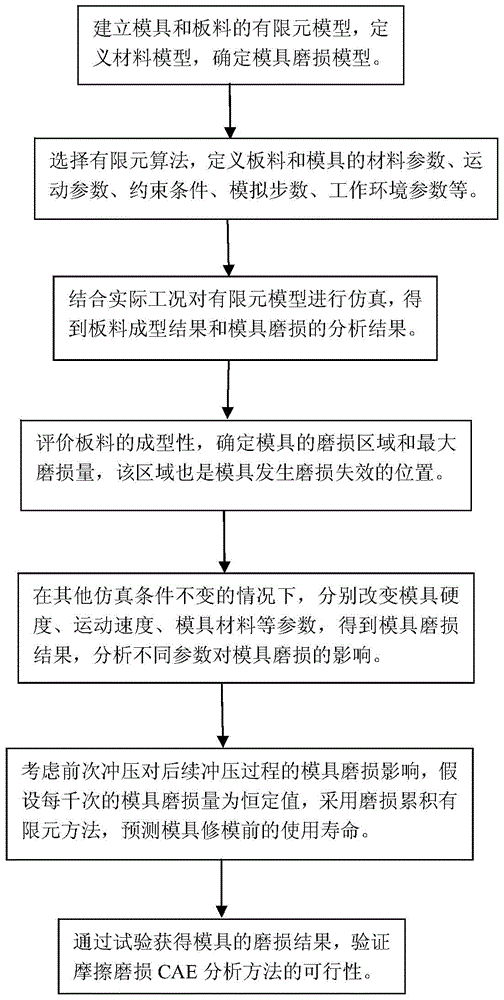

A system and method for computer-aided engineering analysis using direct mesh manipulation of a mesh model is provided. The system includes a computer system having a memory, a processor, a user input device and a display device. The method includes the steps of selecting a geometric model in a computer-aided design (CAD) format, converting the CAD model into a mesh model and evaluating the mesh model using a computer-aided engineering (CAE) analysis. The method also includes the steps of modifying a surface of the mesh model by varying a predetermined parameter using direct surface manipulation (DSM), updating the mesh model and using the updated mesh model in further CAE analysis. Three techniques are provided for modifying a surface feature, including using a Dirichlet parameter distribution to determine the displacement of the surface feature; modeling the surface feature as an elastic sheet to determine deformation; and enclosing the feature within a lattice structure and using lattice deformation to determine surface deformation.

Owner:FORD GLOBAL TECH LLC

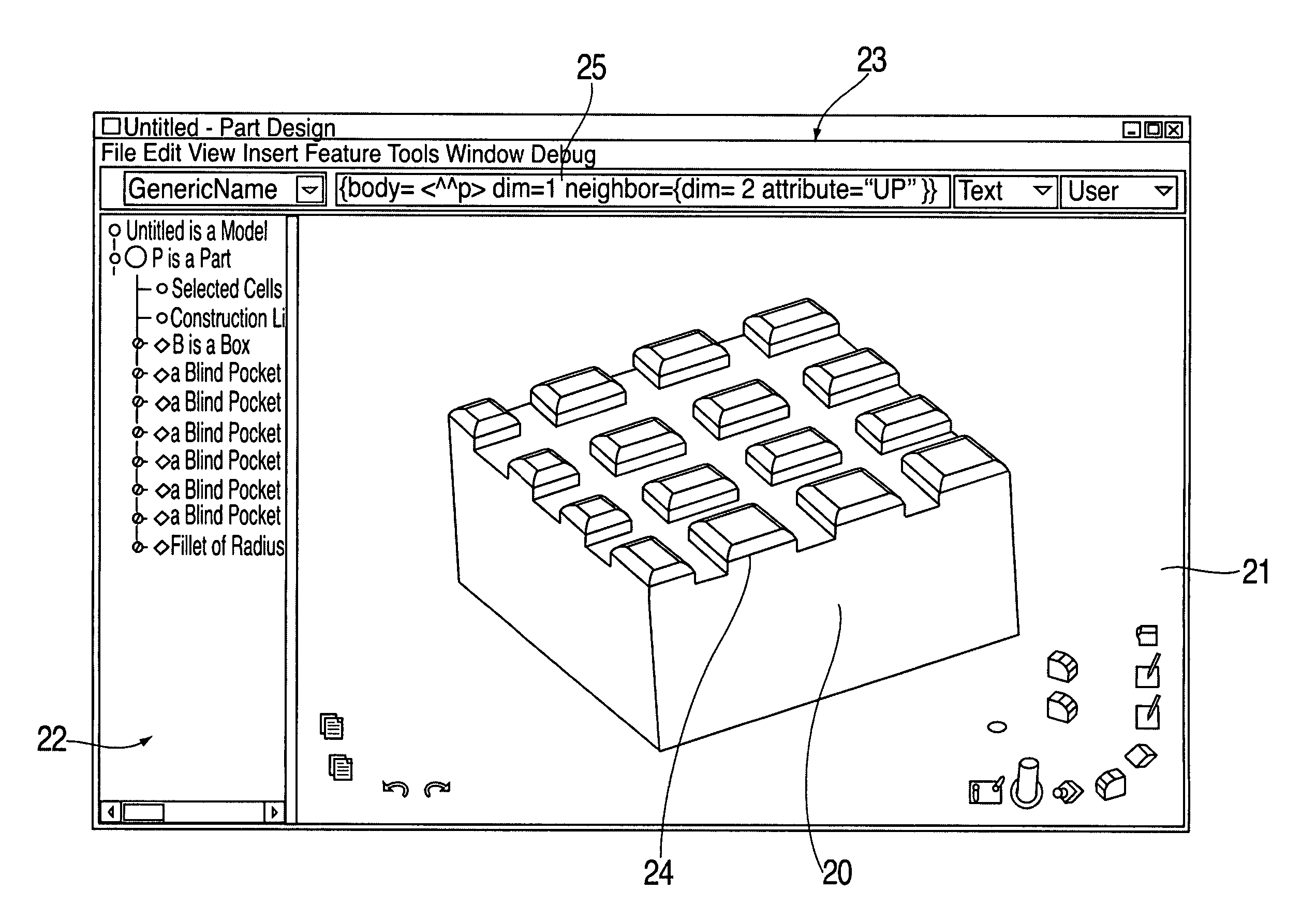

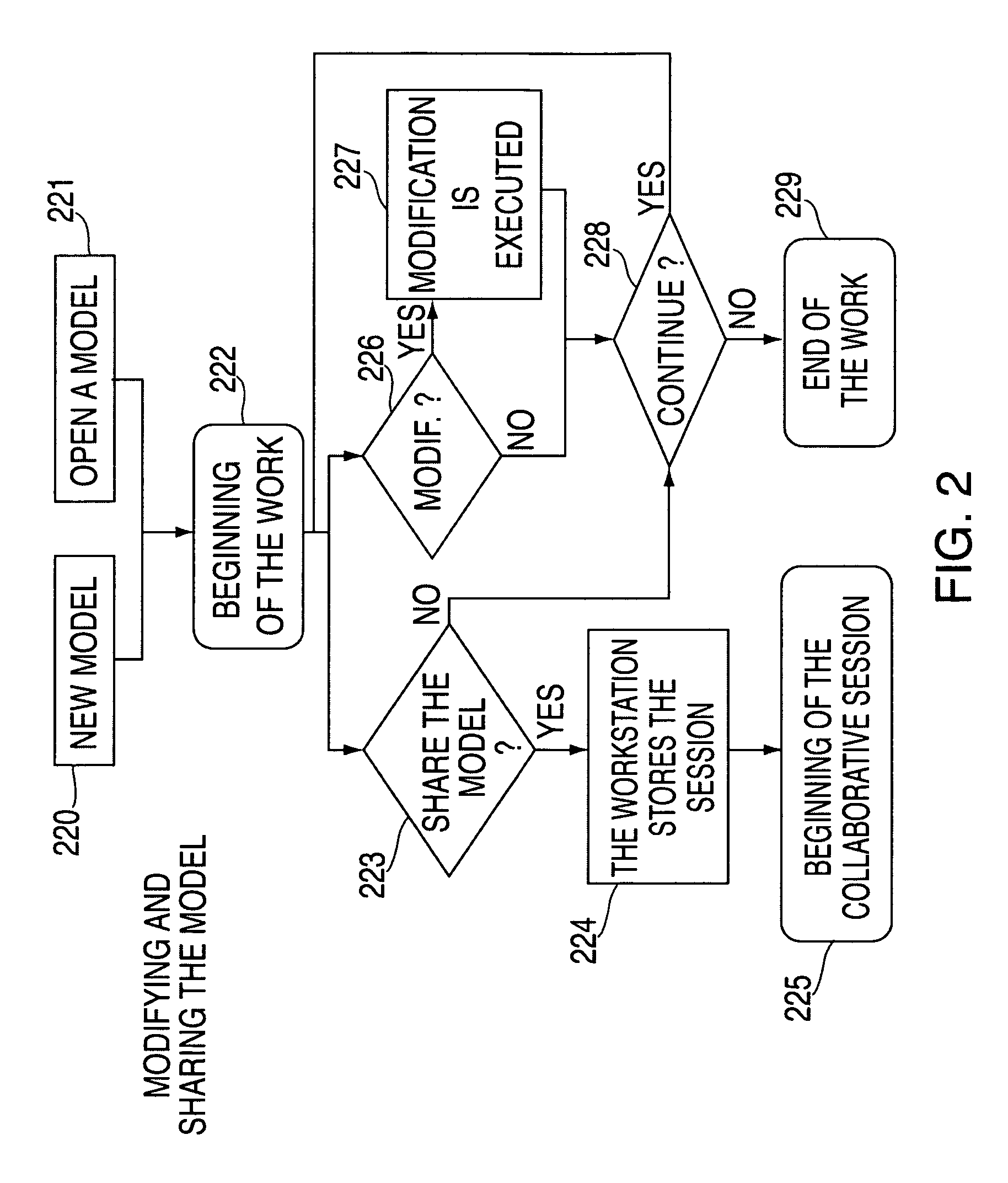

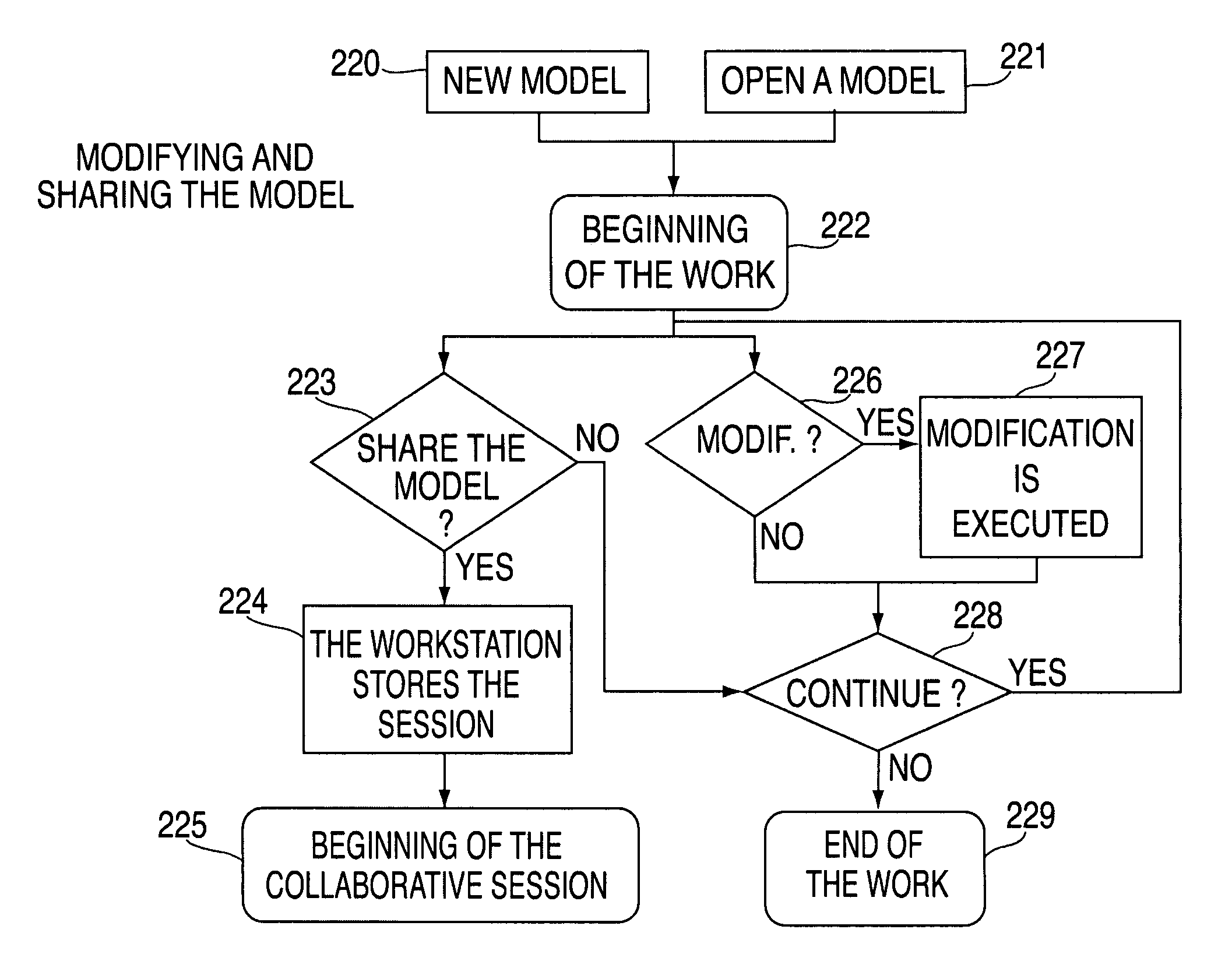

Collaborative design

InactiveUS20060250418A1Improve productivityLess timeData processing applicationsDrawing from basic elementsSoftware engineeringWorkstation

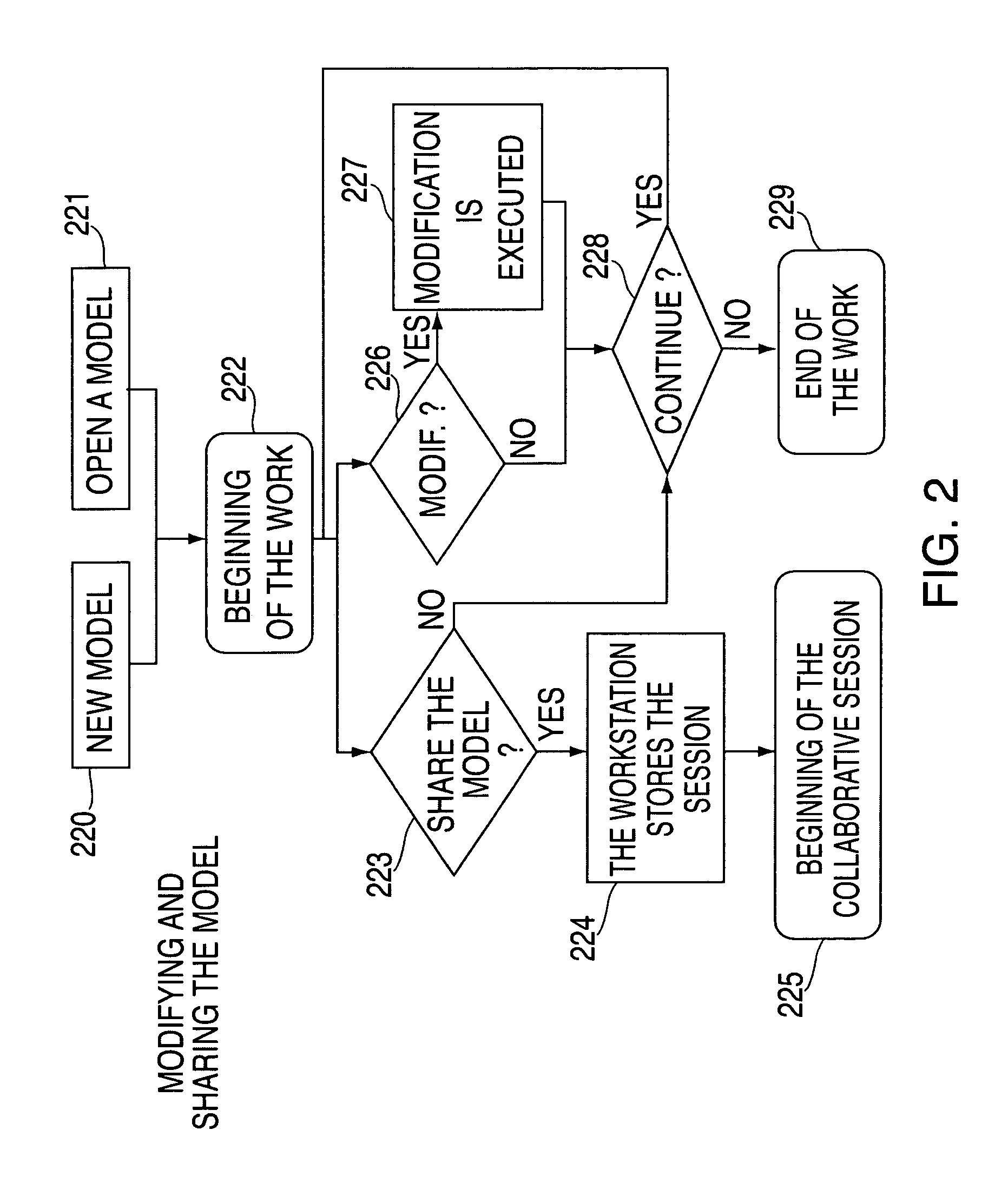

A method, system and apparatus for use in computer-aided design, computer-aided manufacturing, computer-aided engineering and product lifecycle management. An efficient, non-centralized communications framework makes “synchronous” collaborative design possible. Users are resident at workstations that are connected in a peer-to-peer arrangement. In a collaborative design session, the model is resident in memory at each workstation. Modifications are made at any workstation, and commands, which are interpreted at each workstation to effect the modifications, are transmitted over the network. In addition, cell descriptors may be used to identify one or more geometric cells of a model. The cell descriptors are in the form of scripts specifying constraints or filters for identifying cells. The constraints are based on characteristics of items in the model, or associations between items in a model, that are readily discernable to the user, and are therefore easily written and susceptible to easy distribution to other systems.

Owner:DASSAULT SYSTEMES

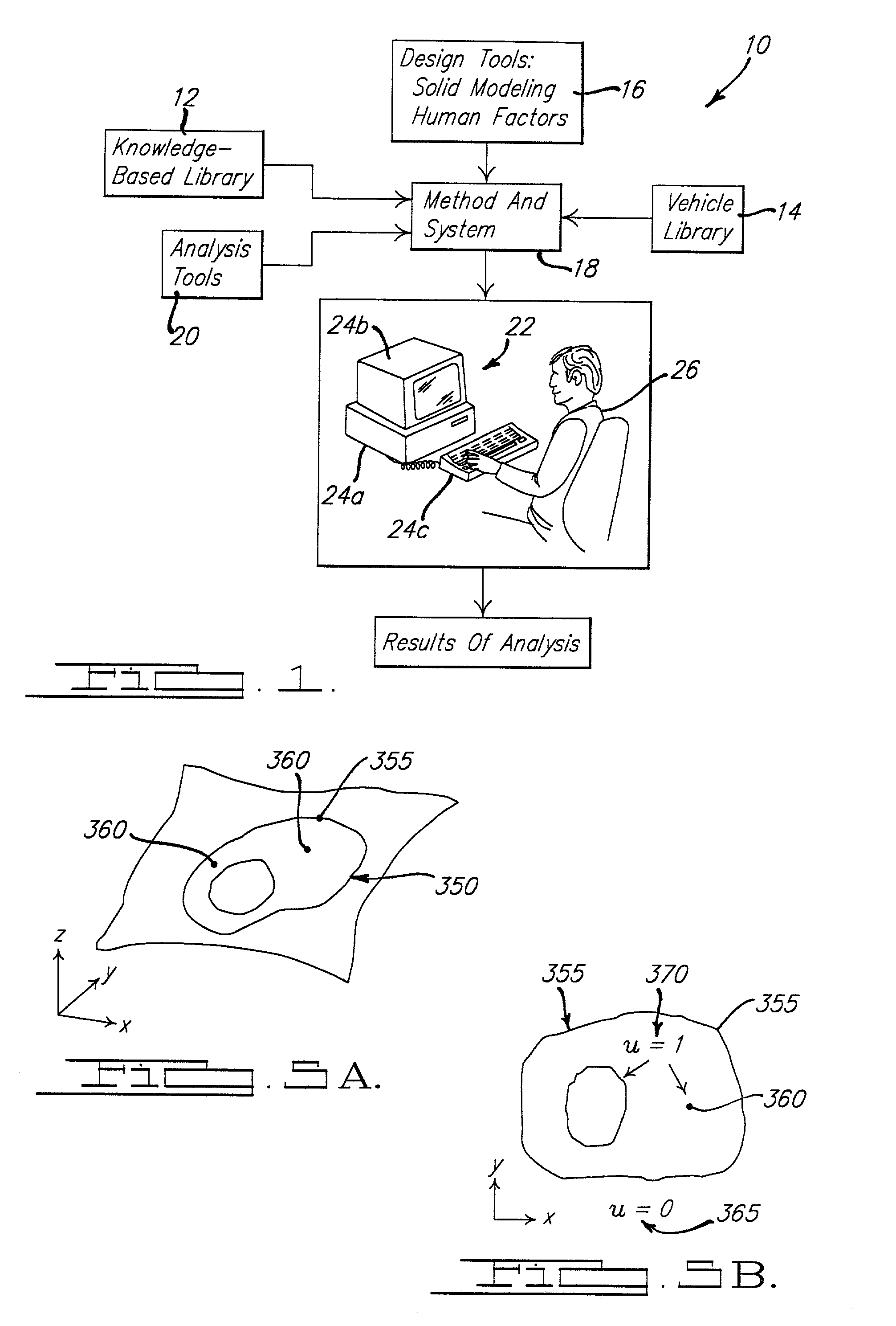

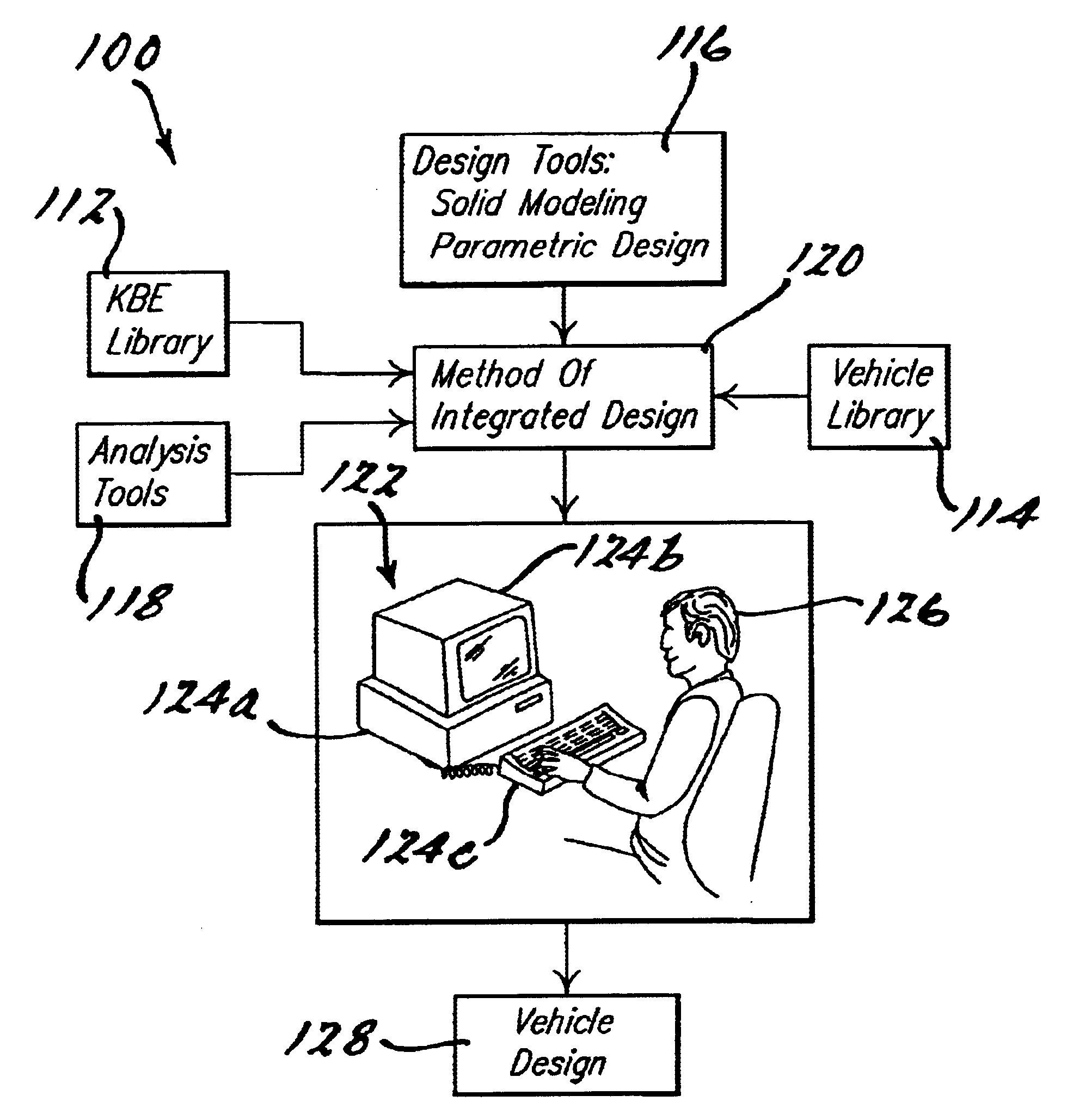

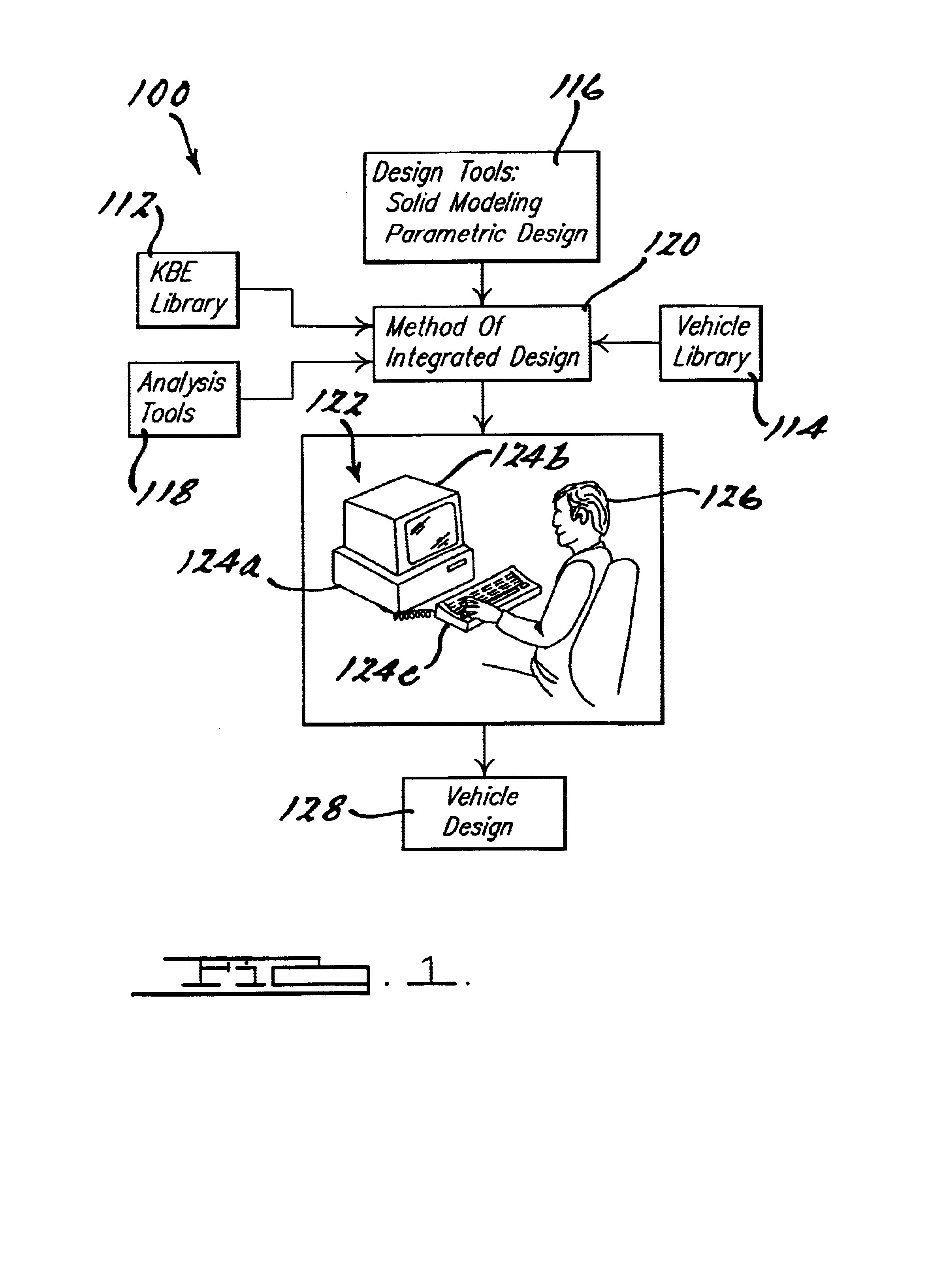

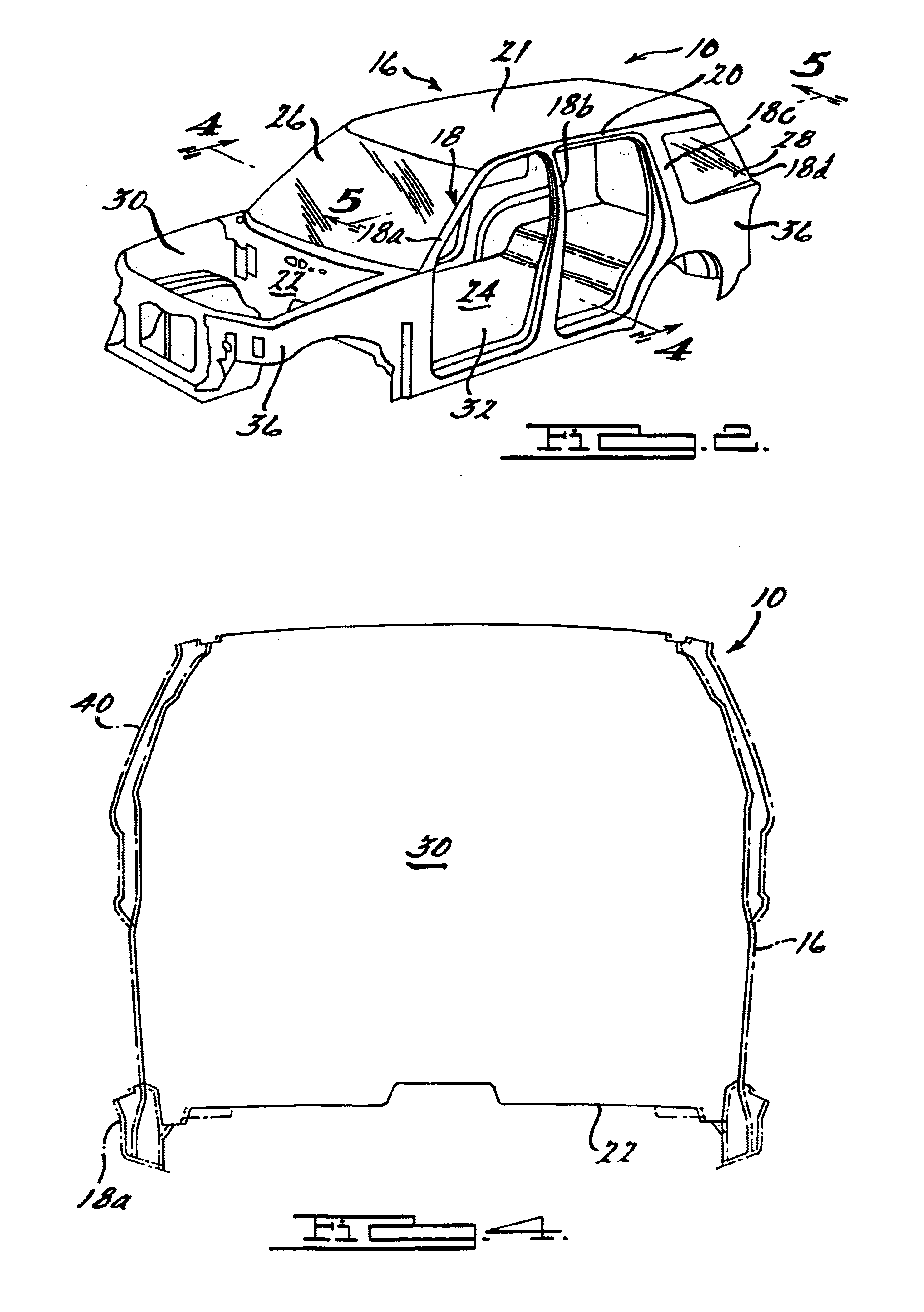

Method of integrating computer visualization for the design of a vehicle

InactiveUS6760693B1Geometric CADSpecial data processing applicationsComputer-aided engineeringAutomotive engineering

A method of integrating computer visualization for the design of a vehicle includes the steps of determining a low-level geometric model of the vehicle and determining a modifiable parameter to modify the model of the vehicle. The method also includes the steps of morphing the model of the vehicle into a morphed model of the vehicle including the modifiable parameter using a computer visualization, and analyzing the morphed model of the vehicle using a computer aided engineering (CAE) analysis. The method further includes the steps of determining if the CAE analysis of the morphed model of the vehicle meets a predetermined criteria and using the morphed vehicle model in the design of the vehicle.

Owner:FORD GLOBAL TECH LLC

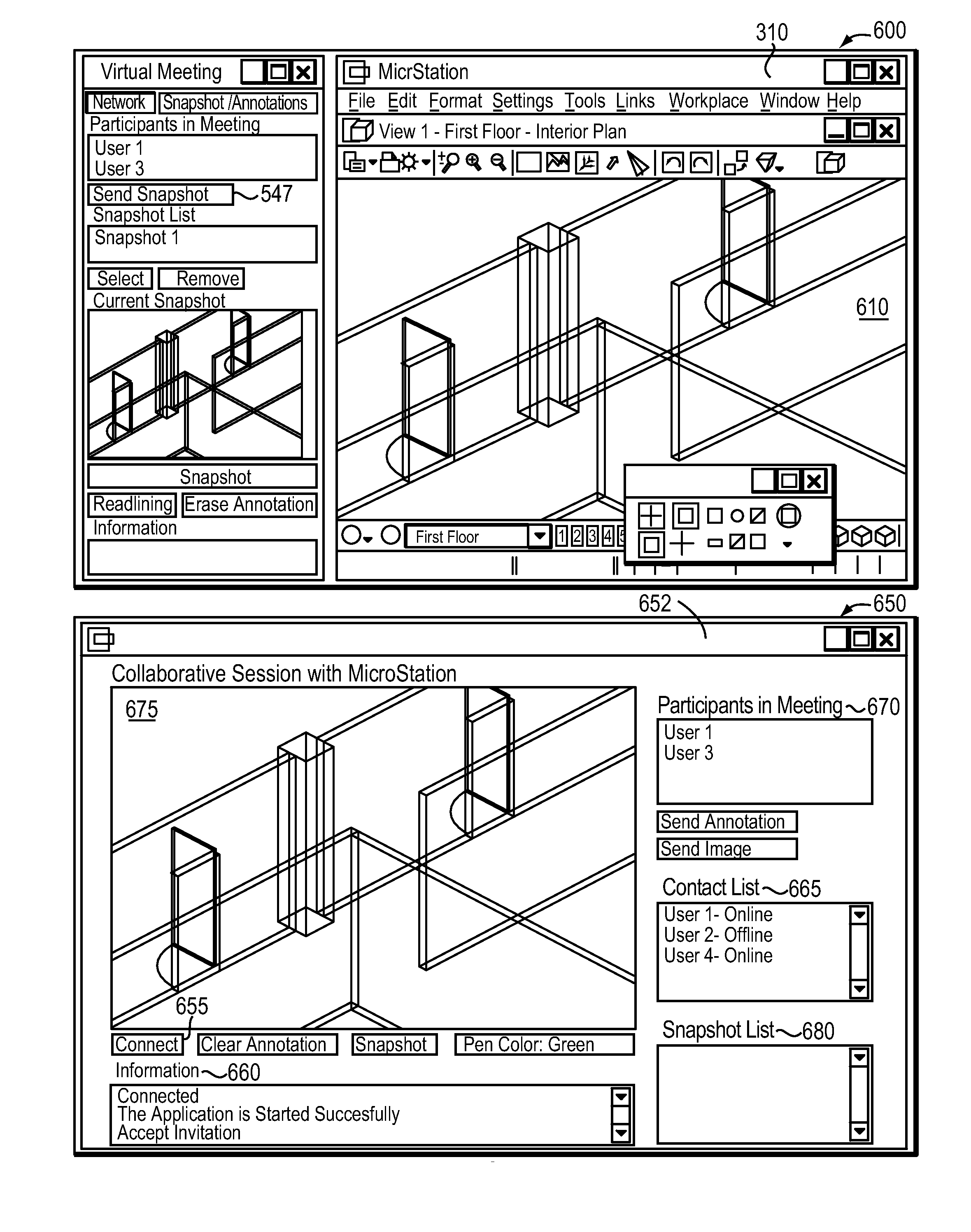

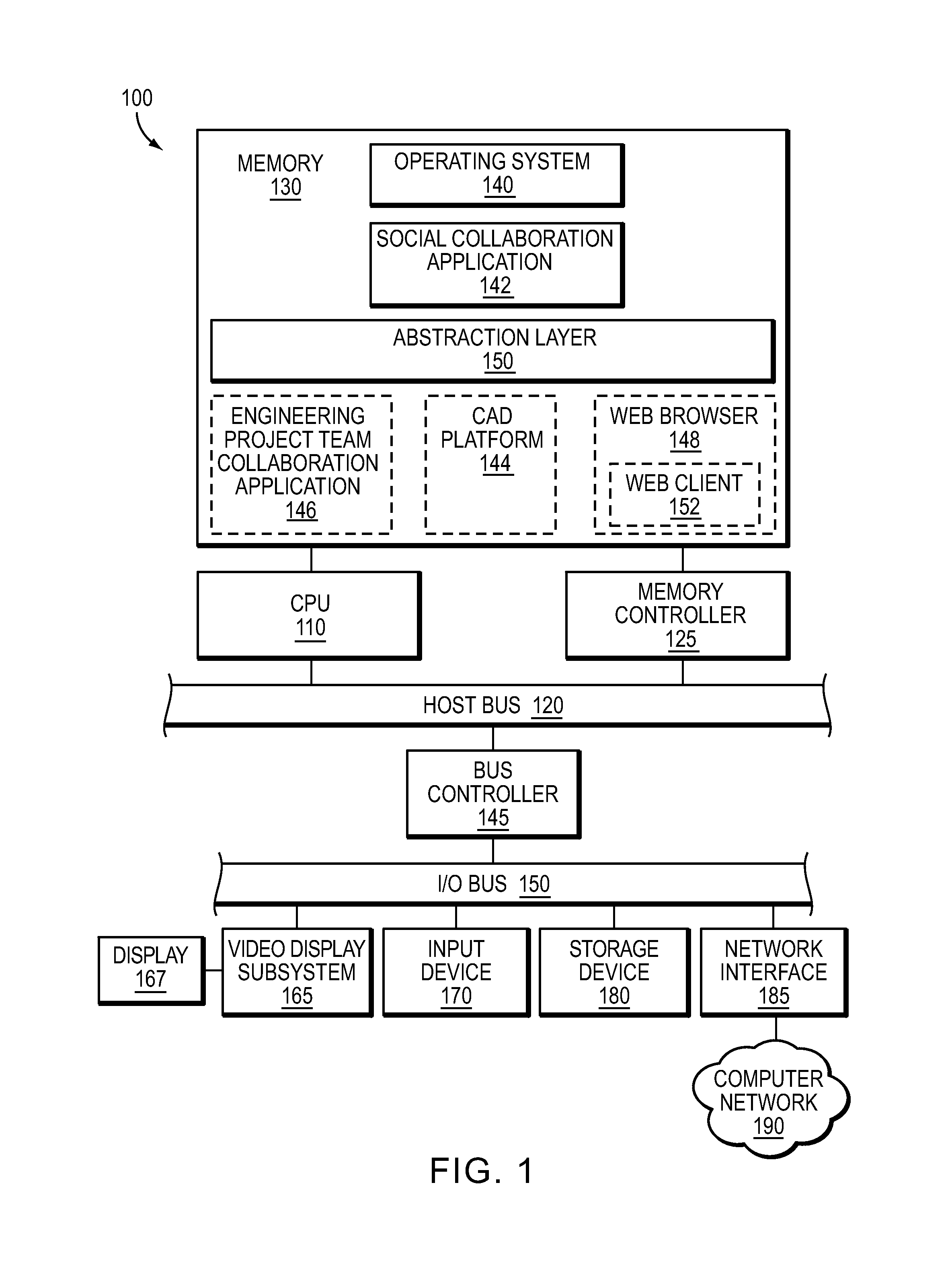

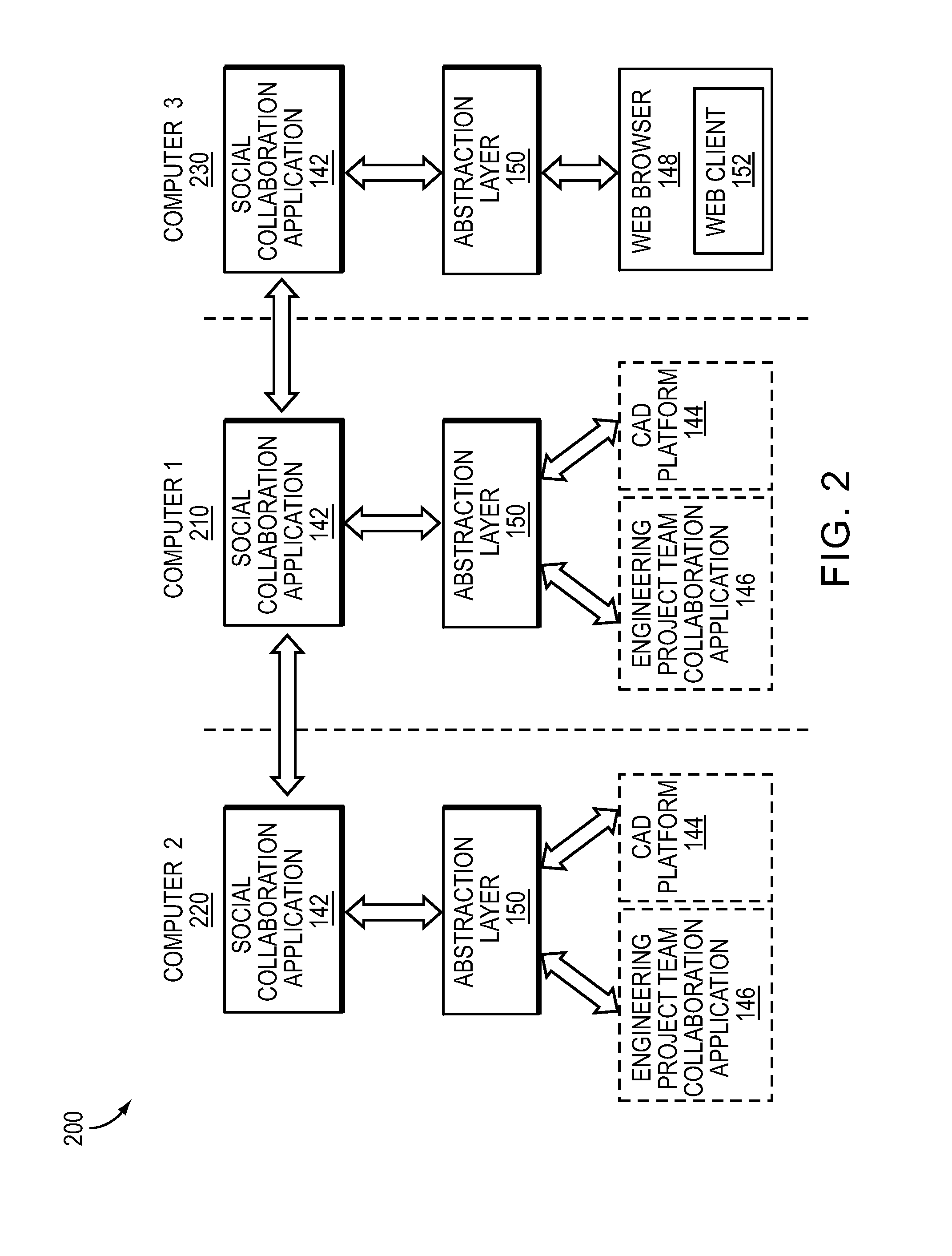

Social computer-aided engineering design projects

ActiveUS9454623B1Geometric CADCAD network environmentComputer Aided DesignEngineering design process

In one embodiment of the present disclosure, the capabilities of a social collaboration application are leveraged to permit synchronized viewing of computer aided design (CAD) models and exchange of annotations (e.g., redlines) related thereto, in a social review session involving differing applications executing on different computers. By utilizing the capabilities of the social collaboration application as a transport mechanism, users operating differing applications on different computers may participate in the social review session for the CAD model, thereby allowing users who do not, for example, have access to the application in which the CAD model was developed to be part of the review process.

Owner:BENTLEY SYST INC

Collaborative design

InactiveUS7176942B2Improve productivityLess timeData processing applicationsDigital computer detailsApplication lifecycle managementWorkstation

A method, system and apparatus for use in computer-aided design, computer-aided manufacturing, computer-aided engineering and product lifecycle management. An efficient, non-centralized communications framework makes “synchronous” collaborative design possible. Users are resident at workstations that are connected in a peer-to-peer arrangement. In a collaborative design session, the model is resident in memory at each workstation. Modifications are made at any workstation, and commands, which are interpreted at each workstation to effect the modifications, are transmitted over the network. In addition, cell descriptors may be used to identify one or more geometric cells of a model. The cell descriptors are in the form of scripts specifying constraints or filters for identifying cells. The constraints are based on characteristics of items in the model, or associations between items in a model, that are readily discernable to the user, and are therefore easily written and susceptible to easy distribution to other systems.

Owner:DASSAULT SYSTEMES

Design method for molded surface of automobile cover part die based on molded surface deformation compensation

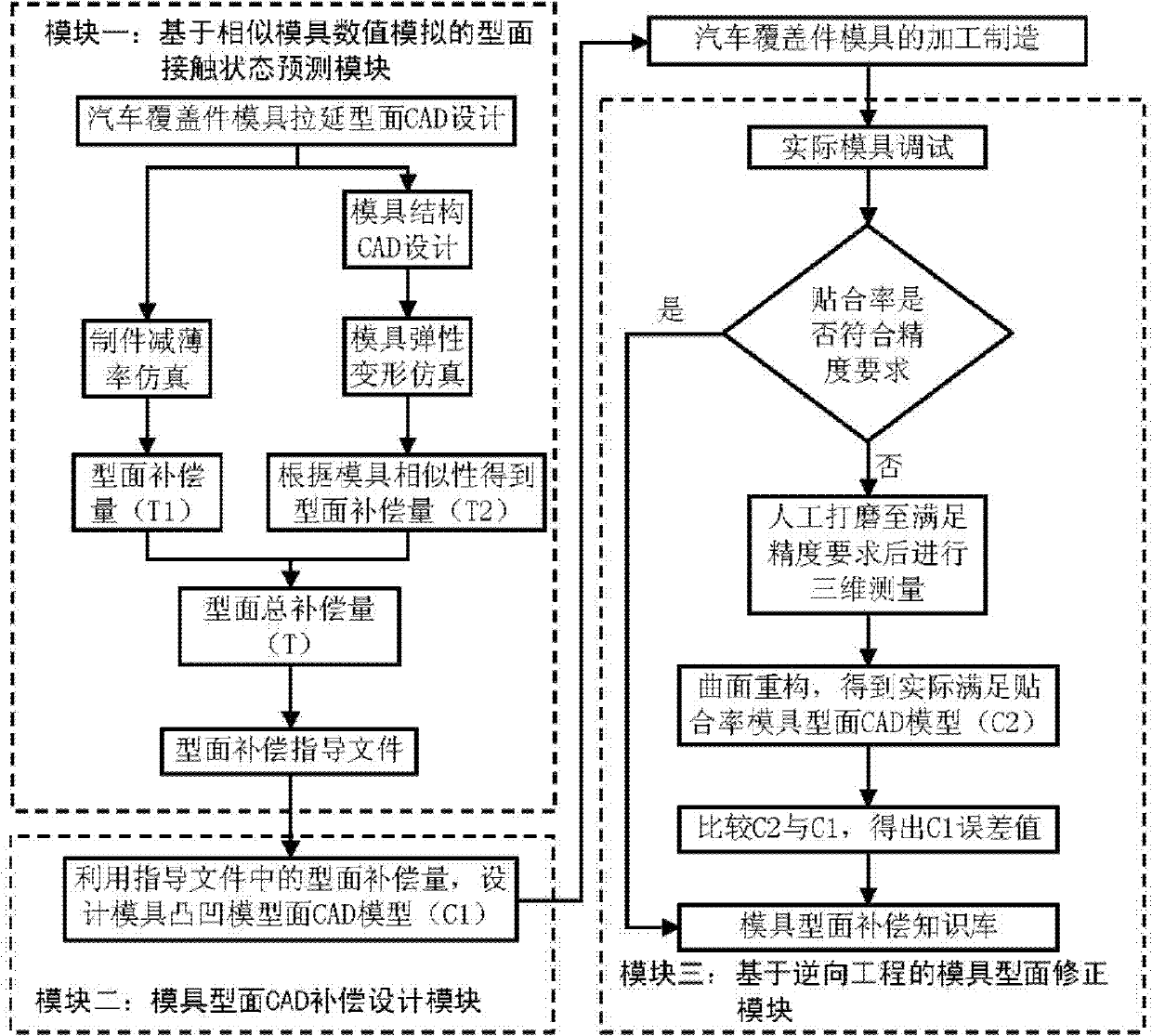

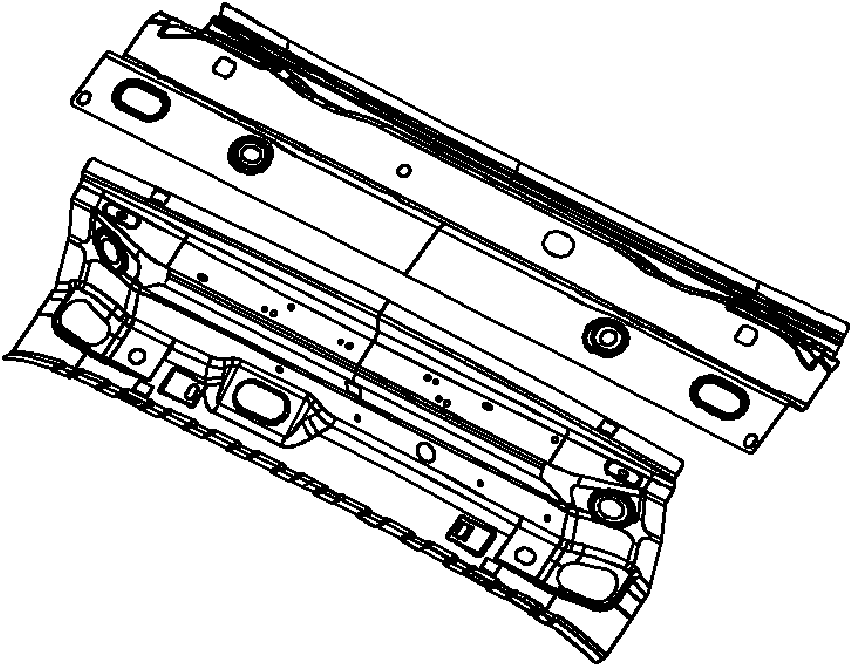

InactiveCN102169521ASimple designQuality improvementSpecial data processing applicationsComputer Aided DesignCapability Maturity Model

The invention discloses a design method for a molded surface of an automobile cover part die based on molded surface deformation compensation, which comprises the steps of predicting the contact state of the molded surface based on similar die numerical value simulation, outputting a compensation guide document for the molded surface of the die based on the dethickness of a manufactured piece and the elastic deformation of the die, using CAD (computer aided design) software to design the compensation molded surface of the die based on the guide document and outputting the CAD compensation molded surface, and outputting the repaired actual molded surface of the die by using a method based on reverse engineering. Under the premises of reasonable technical conditions and die structures, a CAE-CAD-CMM (computer aided engineering-computer aided design-capability maturity model) integration system for the molded surface of the automobile cover part die based on the dethickness of the manufactured piece and the elastic deformation compensation of the die is formed. The method can be adopted for quickening the design process of the molded surface of the automobile cover part die, reducing the manual grinding time, guarantees the fit precision of the molded surface of the die and the forming precision of the automobile cover part, and provides a new method for the high-quality short-period debugging work of the automobile cover panel die.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE +1

System and method of direct mesh manipulation

ActiveUS7324103B2Geometric CADData processing applicationsComputer Aided DesignComputer graphics (images)

A system and method for computer-aided engineering analysis using direct mesh manipulation of a mesh model is provided. The system includes a computer system having a memory, a processor, a user input device and a display device. The method includes the steps of selecting a geometric model in a computer-aided design (CAD) format, converting the CAD model into a mesh model and evaluating the mesh model using a computer-aided engineering (CAE) analysis. The method also includes the steps of modifying a surface of the mesh model by varying a predetermined parameter using direct surface manipulation (DSM), updating the mesh model and using the updated mesh model in further CAE analysis. Three techniques are provided for modifying a surface feature, including using a Dirichlet parameter distribution to determine the displacement of the surface feature; modeling the surface feature as an elastic sheet to determine deformation; and enclosing the feature within a lattice structure and using lattice deformation to determine surface deformation.

Owner:FORD GLOBAL TECH LLC

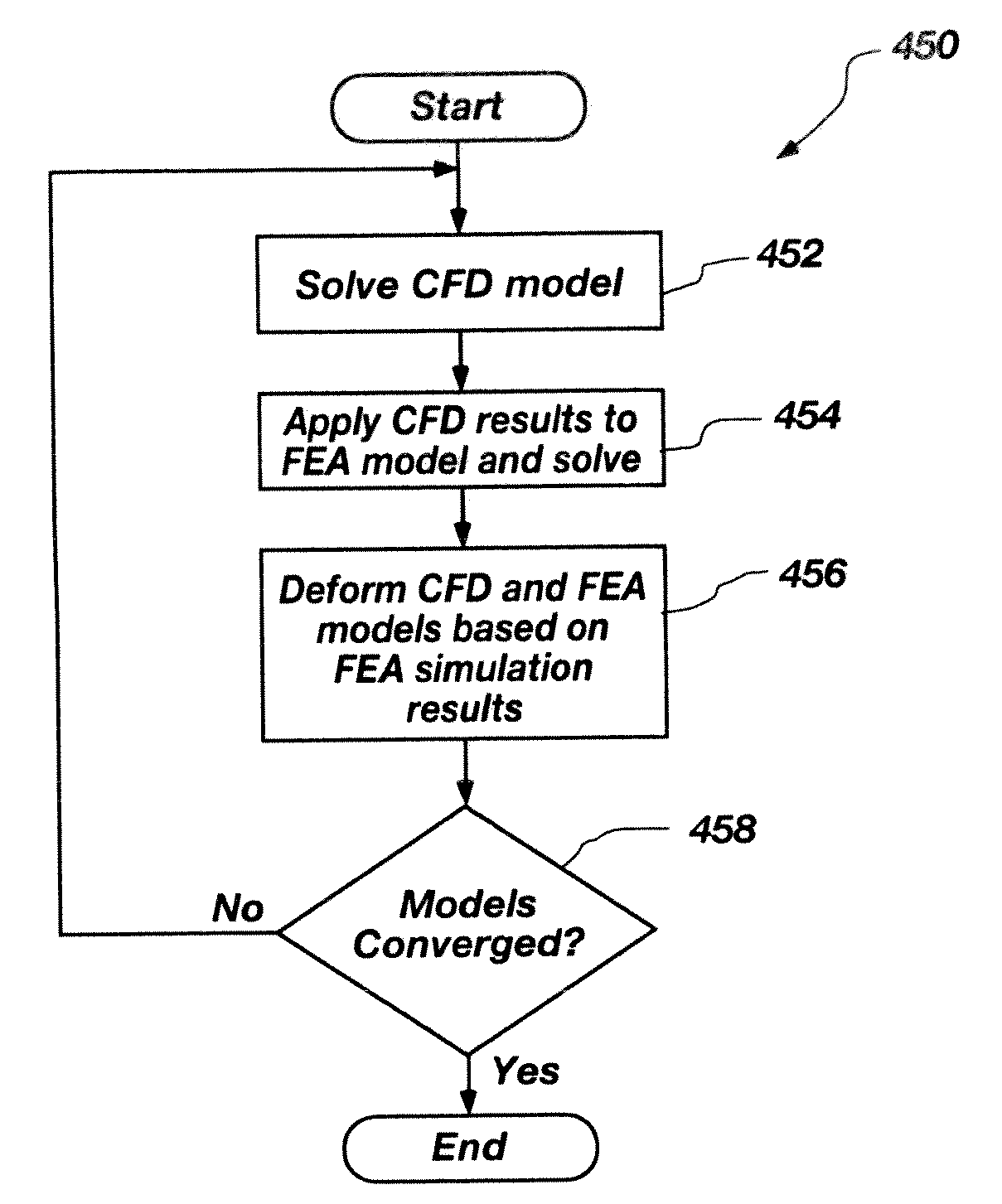

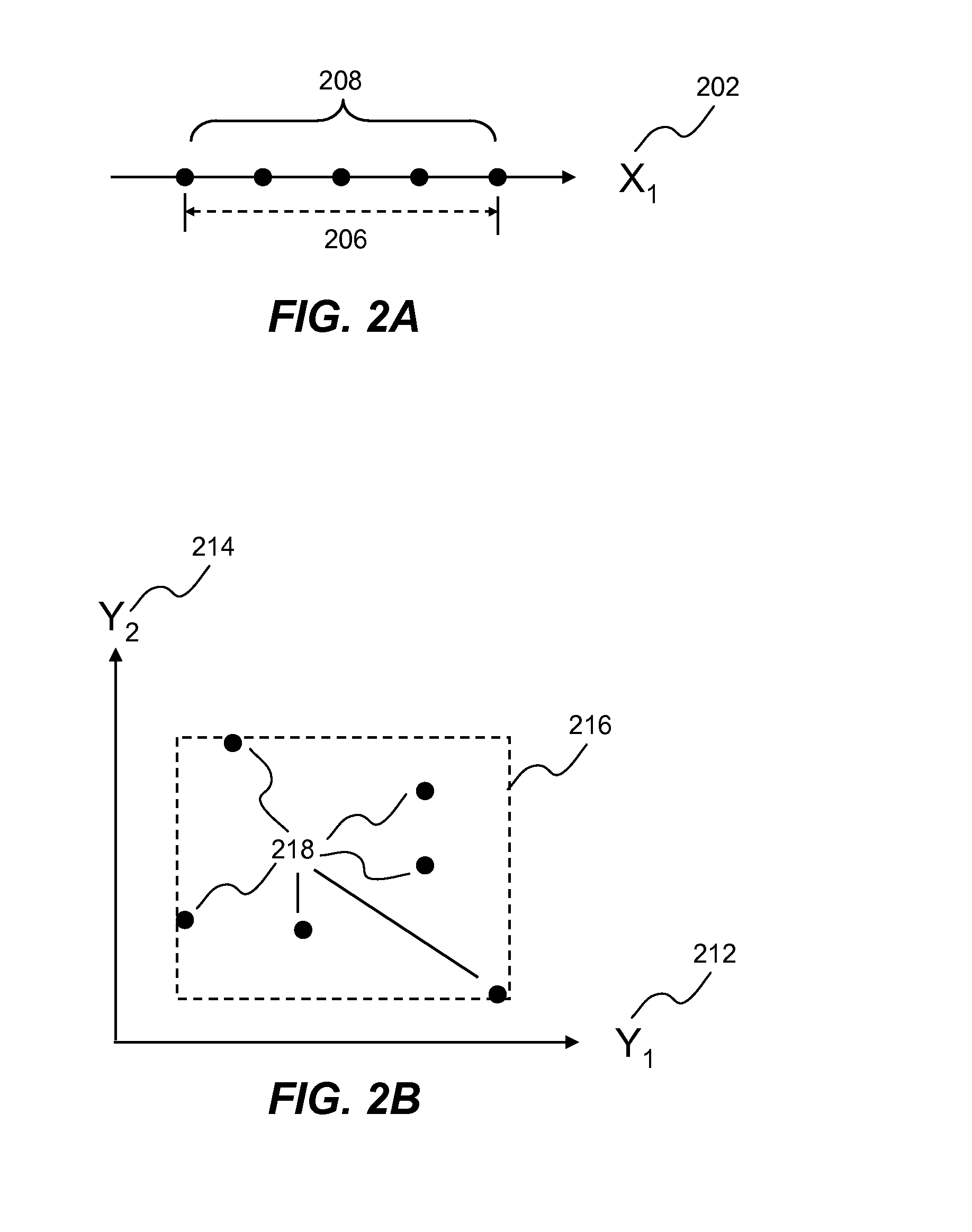

System, methods, and computer readable media, for product design using coupled computer aided engineering models

InactiveUS20080275677A1Reduce database requirementImprove design flexibilityComputation using non-denominational number representationDesign optimisation/simulationComputational scienceModel method

Methods, systems, and computer readable media are used for analyzing a design. A finite element analysis (FEA) model and a correlated computational flow dynamics (CFD) model are defined. A parametric volume is defined with control points forming a mesh bounding a common design object of the models. Control points on the parametric volume are adjusted to develop a design deformation of the FEA model and the CFD model. An analysis loop is performed until a convergence is achieved. The analysis loop includes simulating the CFD model to develop resultant forces and simulating the FEA model with the resultant forces applied to develop resultant displacements. The analysis loop also includes deforming the CFD model and the FEA model to match the resultant displacements by adjusting control points on the parametric volume to generate a corresponding analysis deformation of the FEA model and the CFD model.

Owner:OPTIMAL SOLUTIONS SOFTWARE

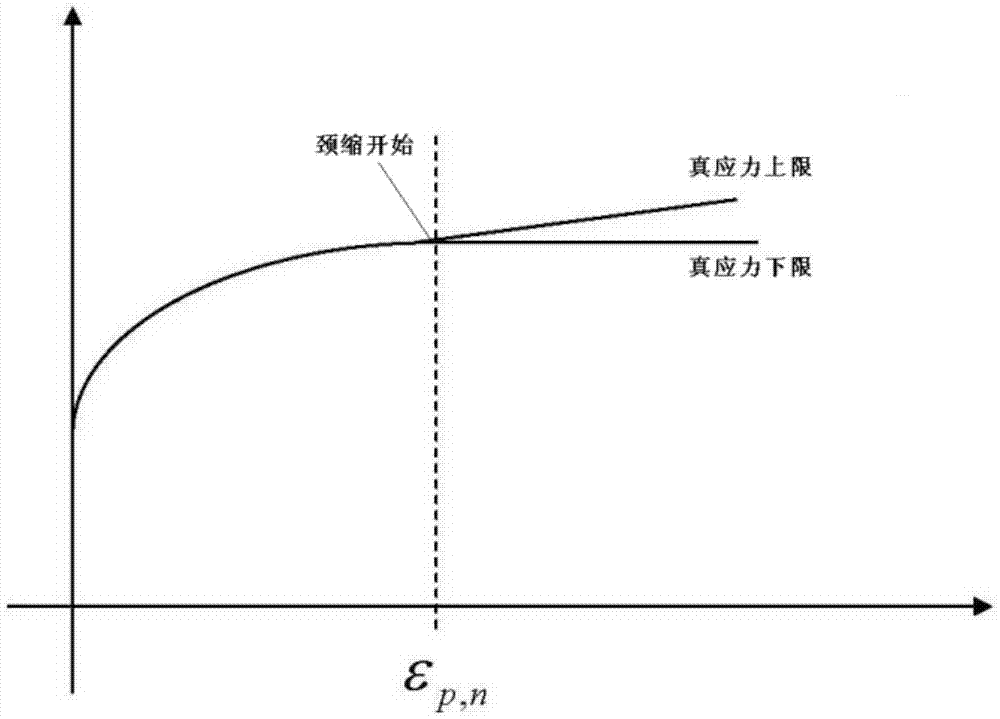

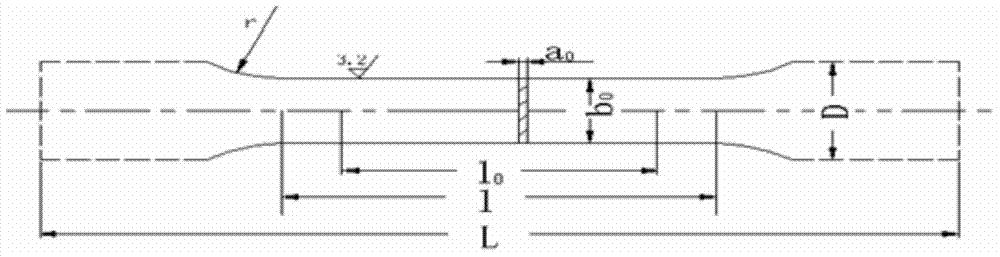

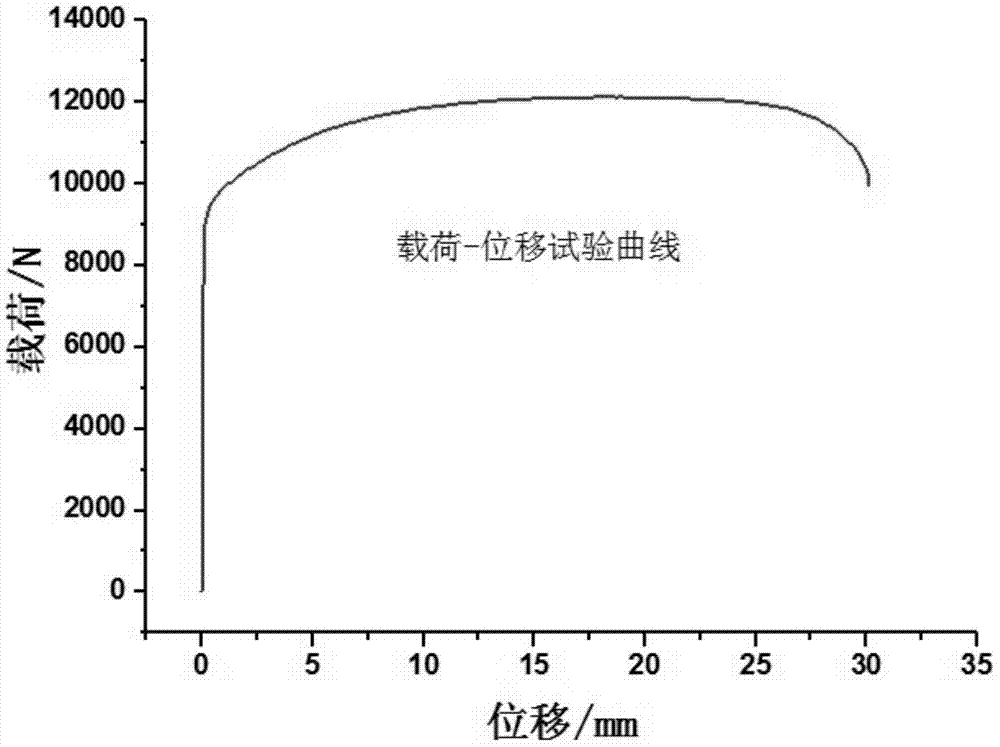

Quick acquisition method of true stress strain curve in whole process of uniaxial drawing

ActiveCN103792143AEffects that impair analytical accuracySimple and fast operationMaterial strength using tensile/compressive forcesStress–strain curveComputer science

The invention relates to a quick acquisition method of a true stress strain curve in whole process of uniaxial drawing. The method comprises the steps of verifying the accuracy of a CAE (computer aided engineering) simulation model by a true stress-true strain curve at an even plastic deformation stage based on the static uniaxial drawing data, and indirectly predicting the true stress-true strain curve at a necking section through the CAE model to obtain the equivalent true stress-true strain curve in whole process of uniaxial drawing. The simple acquisition method of the true stress strain curve of the material in whole process of uniaxial drawing is easy and simple to operate, thus meeting the need of the CAE simulation in the engineering design. Furthermore, the quick acquisition method is in combination with a CAE technology, the influence of the grid effect to the CAE analysis accuracy can be weakened as much as possible.

Owner:CHERY AUTOMOBILE CO LTD

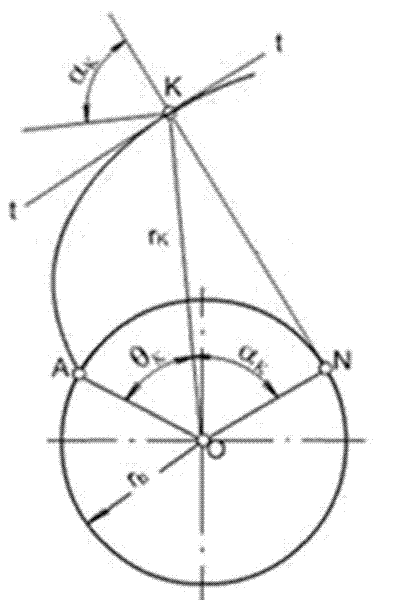

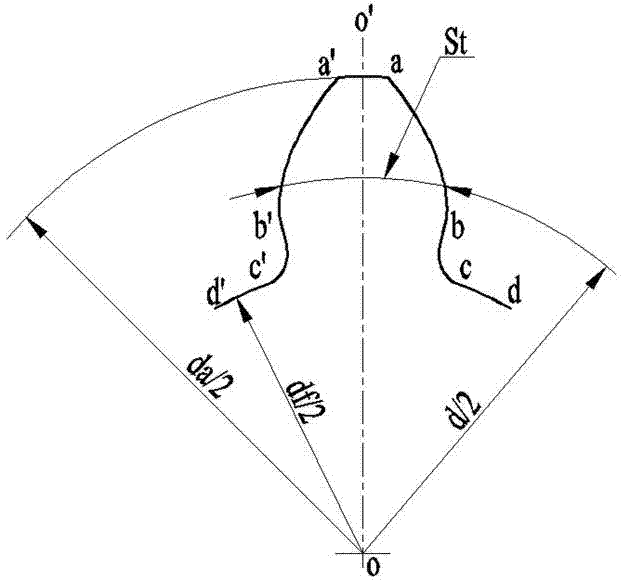

Gear load wireless monitoring system and interactive multi-stage gear physical simulation method finished based on same

ActiveCN102542105AMaster the law of forceImprove practicalityMachine gearing/transmission testingSpecial data processing applicationsWireless transmissionElement analysis

The invention belongs to the technical field of gear detection and measurement, in particular relates to a gear load wireless monitoring system and an interactive multi-stage gear physical simulation method finished based on the same. The invention overcomes the defects and limitations of the existing gear monitoring and simulation method. The gear load wireless monitoring system comprises an upper computer and a lower computer, wherein the lower computer is internally arranged on a measured gear structure, and the lower computer with a wireless transmission function is in wireless transmission with the upper computer. The interactive multi-stage gear physical simulation method comprises the following steps of: detecting an external field; carrying out gear solid modeling, and carrying out grid partition on the gear solid model by adopting swept mapping; setting boundary conditions; carrying out finite element analysis; and verifying the data subjected to finite element analysis and actual measurement. According to the invention, wireless data transmission and load identification testing schemes are used for correcting the error of CAE (Computer Aided Engineering) analysis so as to master the stress rule of the gear, thereby providing a basis for fatigue life prediction. The system and method provided by the invention have higher practical and economic values.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

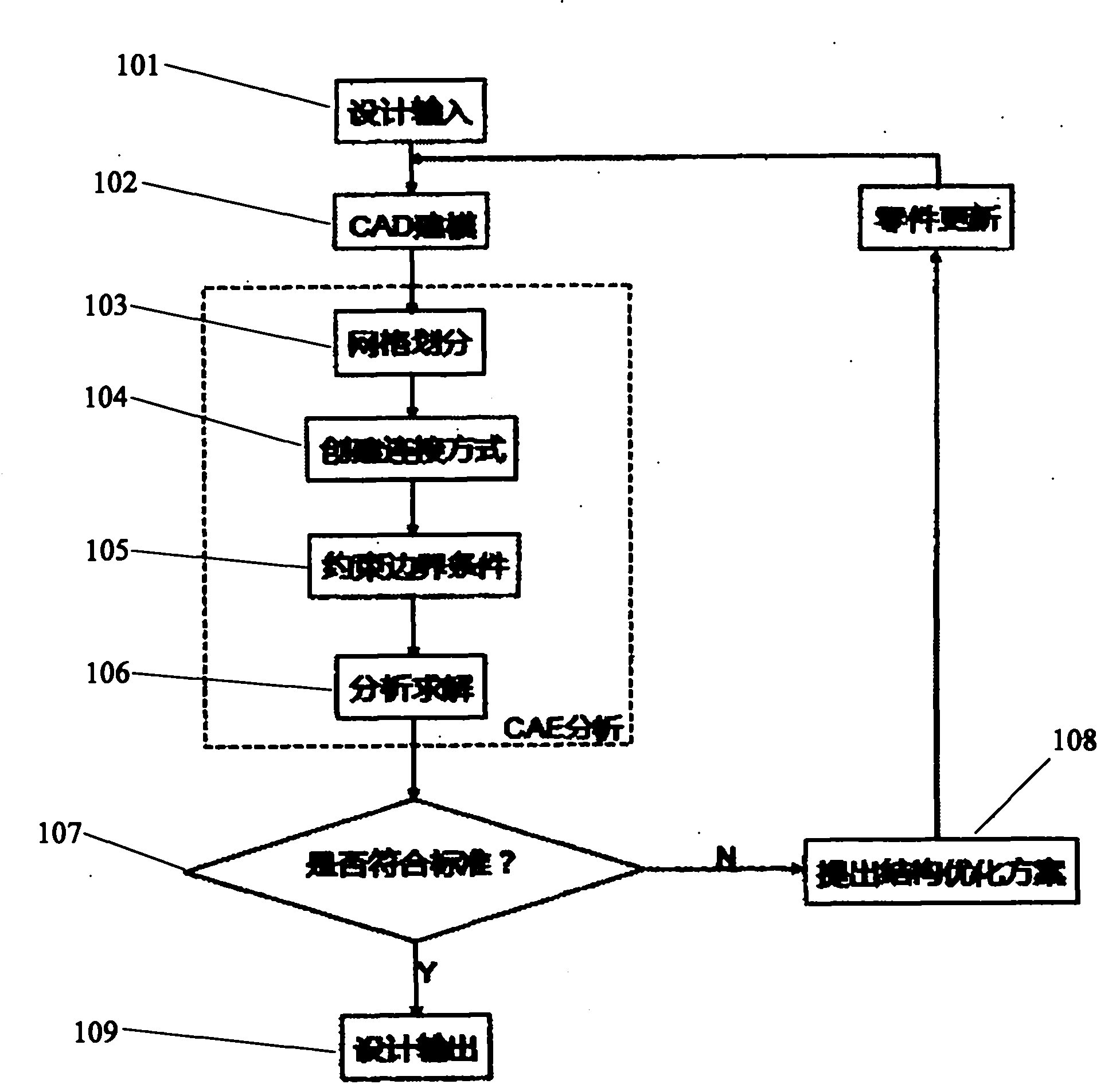

Optimization design method for sagging problem of car door based on CAE (Computer Aided Engineering) structural analysis

InactiveCN101916322AShort cycleShorten the timeSpecial data processing applicationsComputer Aided DesignElement model

The invention discloses an optimization design method for the sagging problem of a car door based on CAE structural analysis, which comprises the steps of: obtaining a design input condition from total arrangement and configuration of a car body; creating a CAD (Computer Aided Design) model by modeling software; dividing grids of the CAD model; simulating actual conditions to create a connection relationship; simulating a boundary constraint condition during an actual test of a car door assembly; carrying out solution analysis on a finite element model generated finally; comparing a result obtained by finite element simulation operation with an industry standard; if an obtained conclusion is lower than the industry standard, providing a structural optimization design; and if the obtained conclusion is higher than the industry standard, completing final design output. The method not only enhances the inspection accuracy, but also greatly reduces the period of a whole repair part so as to shorten the time of developing the whole car. Structural errors can be corrected in time by CAE analysis in early design, thereby reducing the cost of developing the whole car.

Owner:上海奕代汽车技术有限公司

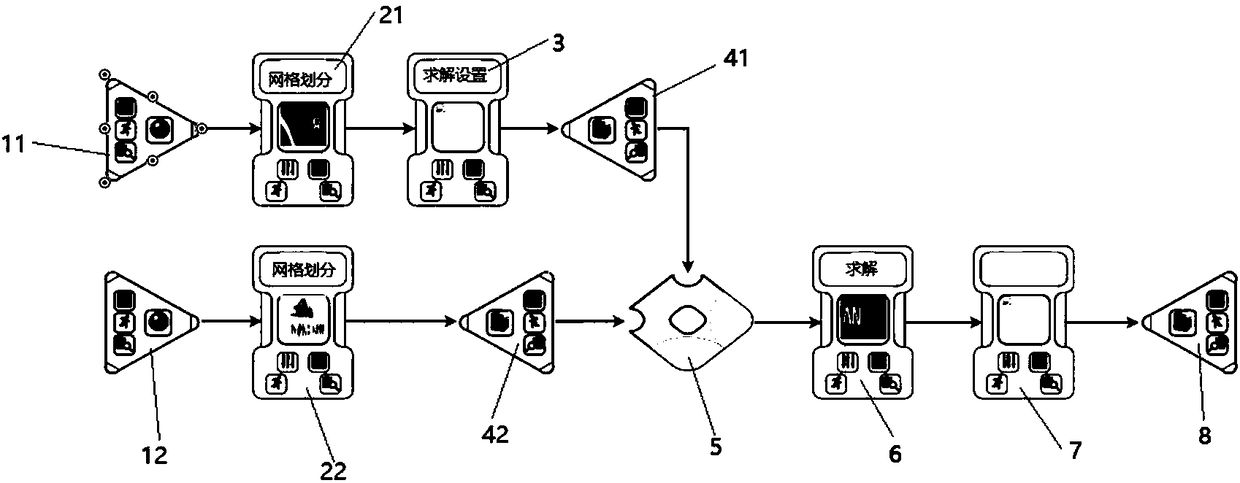

Computer analogue simulation analysis system and method

PendingCN108229085AImprove design efficiencyImprove the design levelDesign optimisation/simulationSpecial data processing applicationsComputer Aided DesignSystems design

The invention relates to a computer analogue simulation analysis system and method. The method includes the steps: extracting predetermined parameterization information of an uploaded geometric model;updating the size of the geometric model according to the extracted parameterization information; selecting a portion needing grid division in the geometric model or the whole geometric model, dividing the grids and displaying a grid dividing result; performing simulation solution calculation, and outputting a simulation solution calculation result into a visible result. According to the method,the steps in CAE (computer aided engineering) analysis such as rapid modeling of CAD (computer aided design), automatic grid generation in pre-processing of CAE and setting of boundary conditions arefixed, multidisciplinary tools are integrated into the same environment, so that system designers can independently, rapidly and conveniently analyze structural modes, strength and the like, a plurality of schemes are compared, and an optimal scheme is selected, so that overall design efficiency and design level are improved.

Owner:上海索辰信息科技股份有限公司

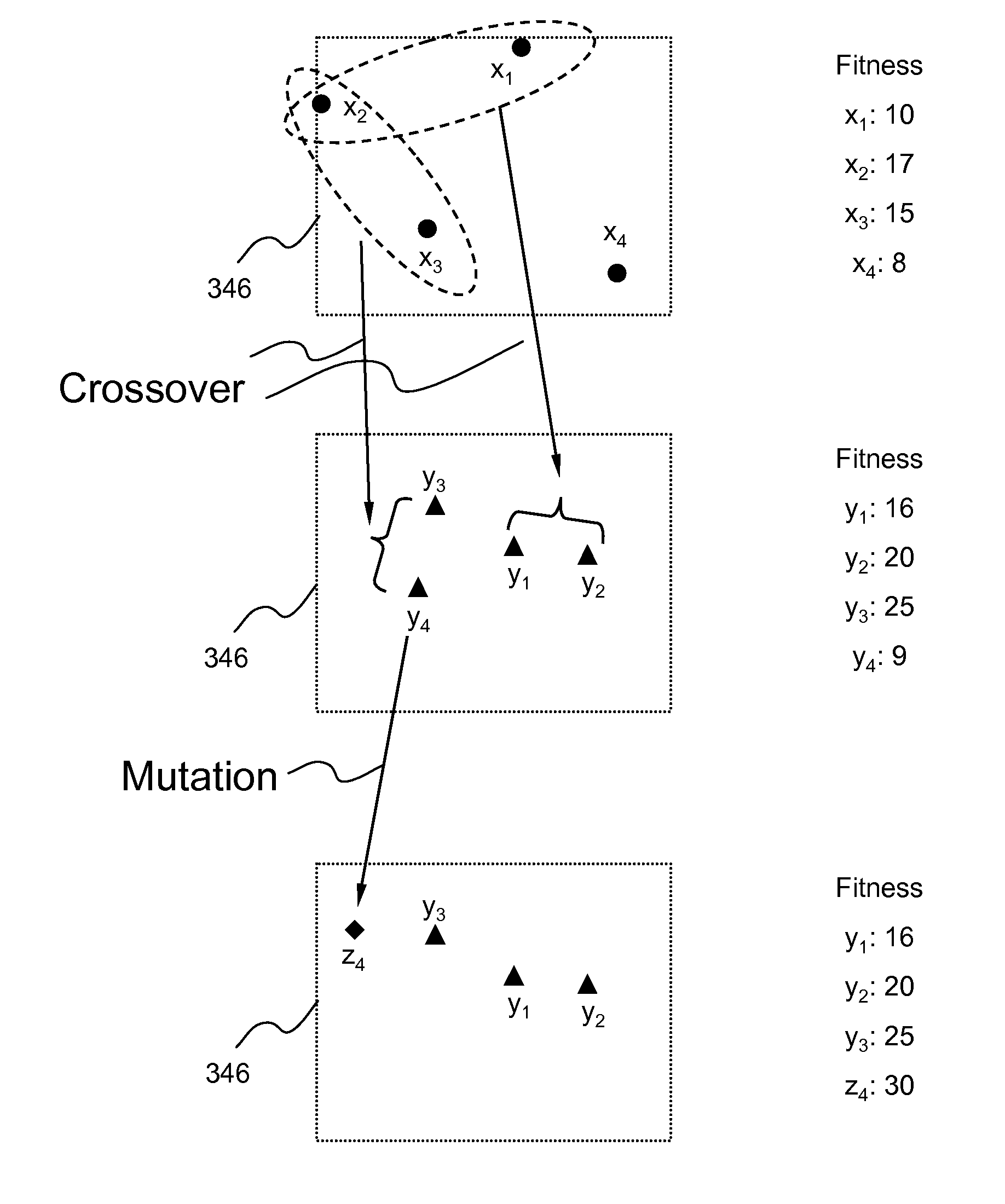

Sampling Strategy Using Genetic Algorithms in Engineering Design Optimization

InactiveUS20090319453A1Digital computer detailsDesign optimisation/simulationAlgorithmElement analysis

A sampling strategy using genetic algorithms (GA) in engineering design optimization is disclosed. A product is to design and optimize with a set of design variables, objectives and constraints. A suitable number of design of experiments (DOE) samples is then identified such that each point represents a particular or unique combination of design variables. The sample selection strategy is based on genetic algorithms. Computer-aided engineering (CAE) analysis or analyses (e.g., finite element analysis, finite difference analysis, mesh-free analysis, etc.) is / are performed for each of the samples during the GA based sample selection procedure. A meta-model is created to approximate the CAE analysis results at all of the DOE samples. Once the meta-model is satisfactory (e.g., accuracy within a tolerance), an optimized “best” design can be found by using the meta-model as function evaluator for the optimization method. Finally, a CAE analysis is performed to verify the optimized “best” design.

Owner:LIVERMORE SOFTWARE TECH

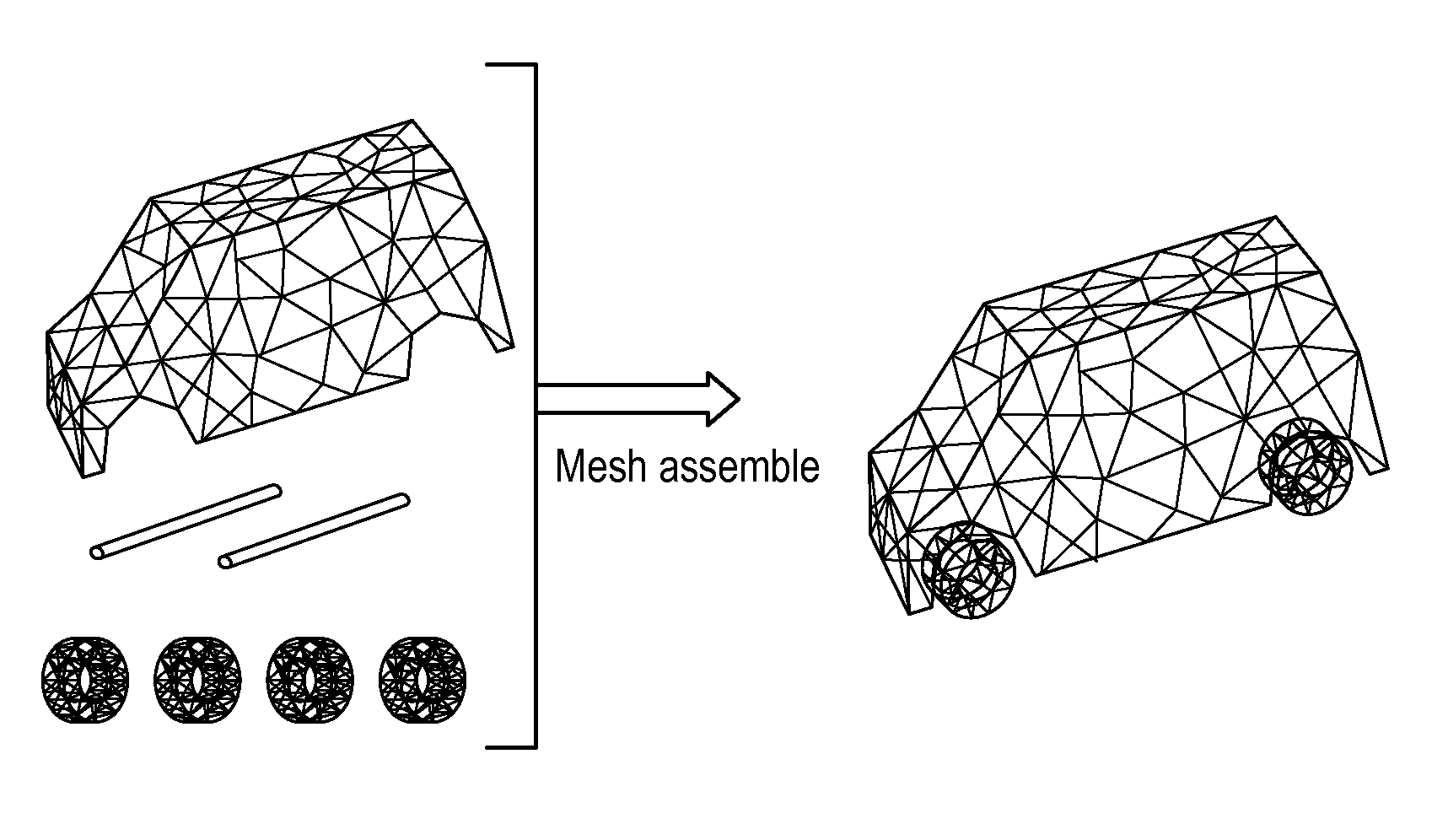

Decoupled parallel meshing in computer aided design

InactiveUS20140039847A1Easy to assembleImprove good performanceGeometric CADProgram initiation/switchingComputer Aided DesignComputer science

In a meshing method for use in a computer-aided design (CAD) or computer-aided engineering (CAE) system, in which one or more serial meshing units are used to carry out a decoupled parallel meshing process in respect of all parts of a CAD assembly model, input parameters for the meshing process automatically, for each part to be processed, are set using live runtime information about the meshing process for the part concerned, such as information about the outcome of previous attempts to carry out the meshing process of the part.

Owner:FUJITSU LTD

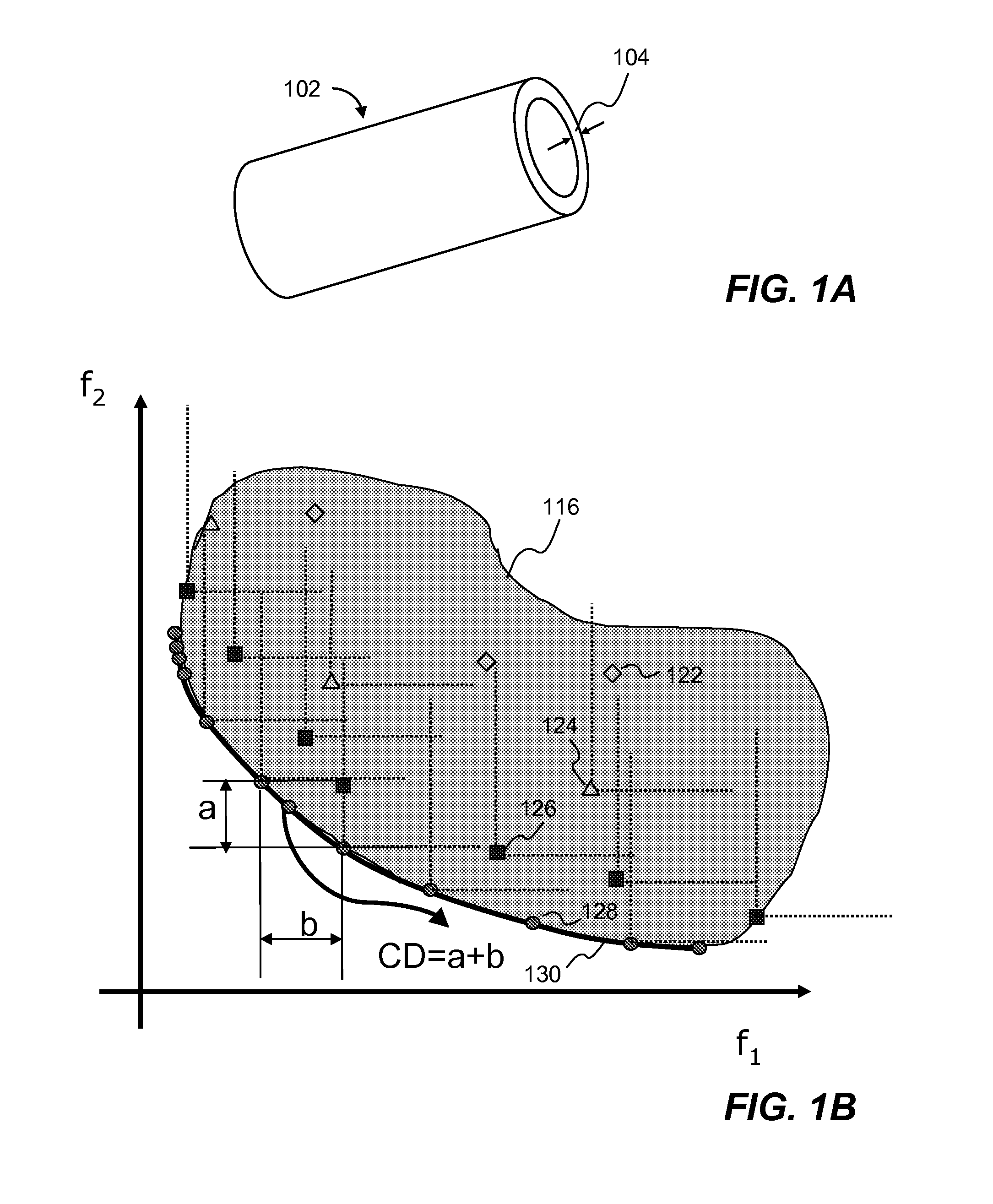

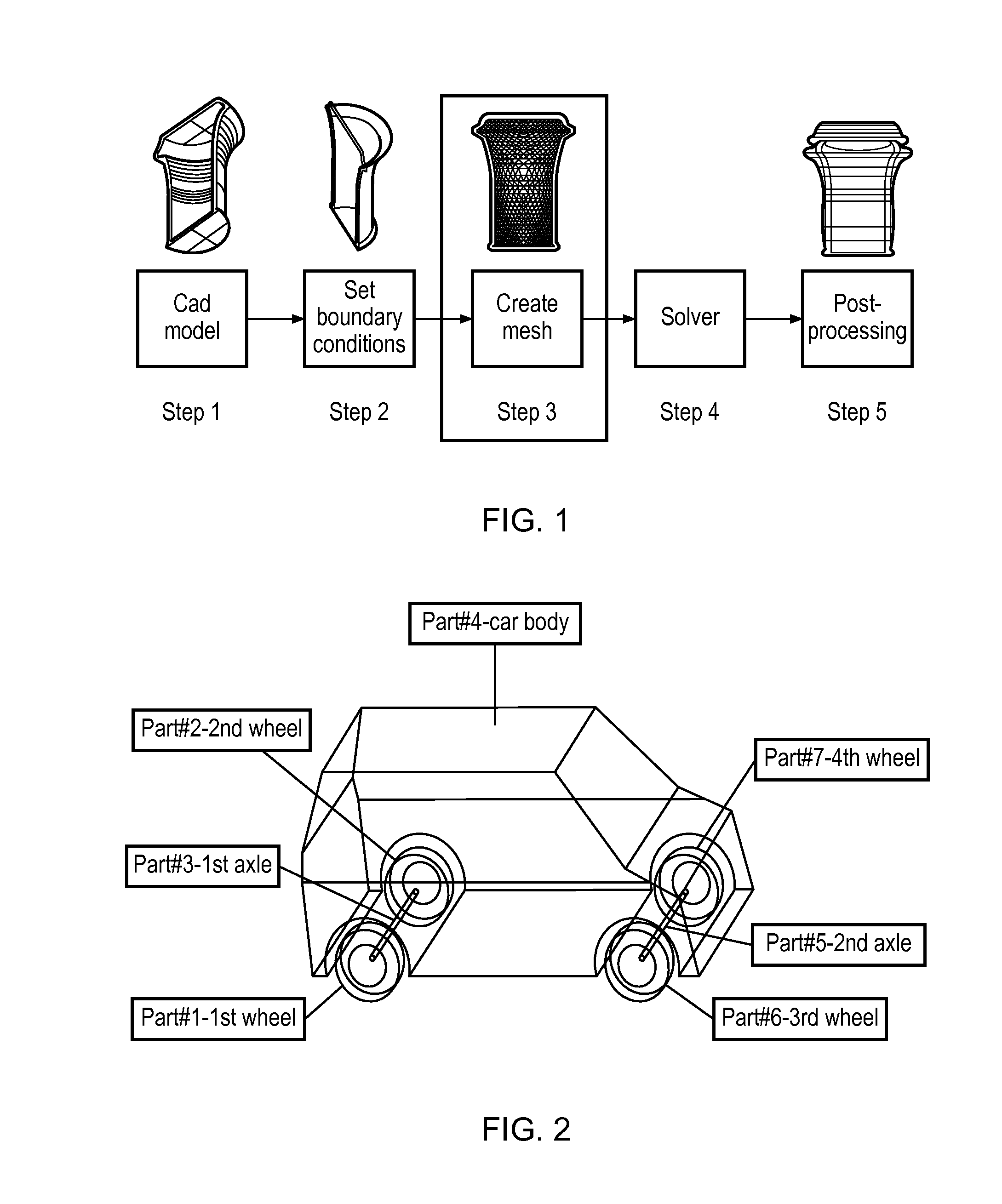

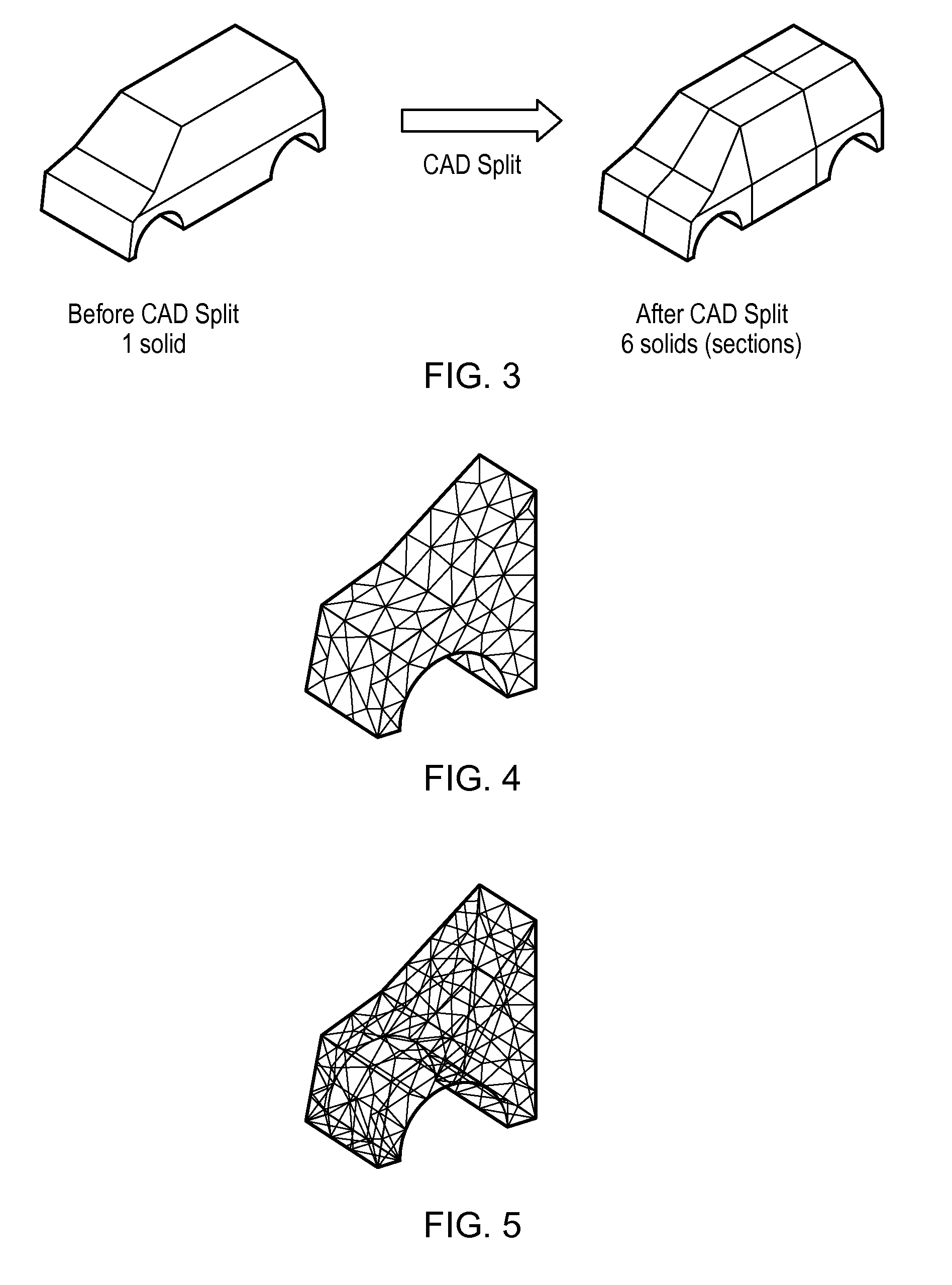

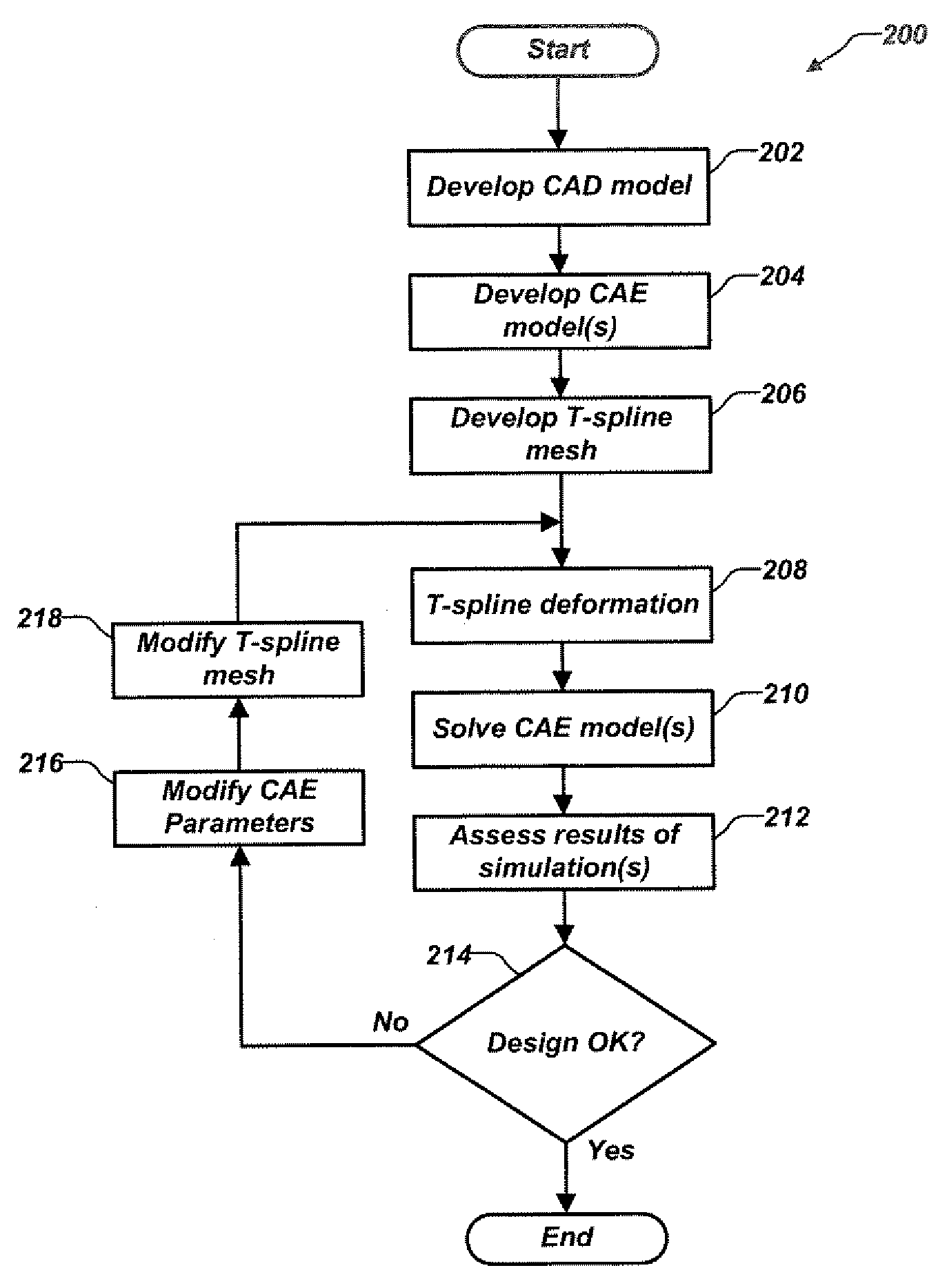

System, methods, and computer readable media, for product design using t-spline deformation

InactiveUS20080162090A1Reduce database requirementImprove design flexibilityComputation using non-denominational number representationDesign optimisation/simulationSimulationDesign objects

Methods, systems, and computer readable media are disclosed for analyzing a simulation model. The method includes defining the simulation model utilizing a Computer-Aided Engineering (CAE) tool. A parametric volume including mesh elements at least partially bounding a design object of the simulation model is formed. The parametric volume includes at least one T-spline control point. The method also includes adjusting at least one control point on the parametric volume to deform a portion of the simulation model correlated to the control point. The deformed simulation model is simulated to develop a simulation result. The control point adjusting and the simulating may be repeated.

Owner:PERRY ERNEST CLAY +2

Frictional wear CAE (Computer Aided Engineering) analysis-based mold optimization method

ActiveCN104573237AQuick detection of actual wearVerify feasibilityInternal combustion piston enginesSpecial data processing applicationsMotion parameterWorking environment

The invention relates to a frictional wear CAE (Computer Aided Engineering) analysis-based mold optimization method, and belongs to the technical field of stamping dies of automotive structural parts. The method comprises the following steps: (1) establishing a mesh model and determining a material model of a plate and a mold and an Archard wear model; (2) defining conditions such as a material parameter, a motion parameter, a constraint condition, simulation steps and working environment parameters by combining actual working conditions; (3) performing simulation calculation under the conditions defined in the step (2) to obtain a plate forming result and a model wear result; (4) changing a mold hardness parameter, a mold material parameter and the motion parameter respectively under the condition that other simulation conditions are not changed to perform calculation so as to obtain wearing capacity of the mold and analyze the influence of different parameters on mold wear; (5) supposing the mold wear every thousand times as a constant value, predicting service life before mold repair; (6) obtaining actual wear after the mold wear in production through a test method and verifying the feasibility of the CAE analysis method.

Owner:HUNAN UNIV +1

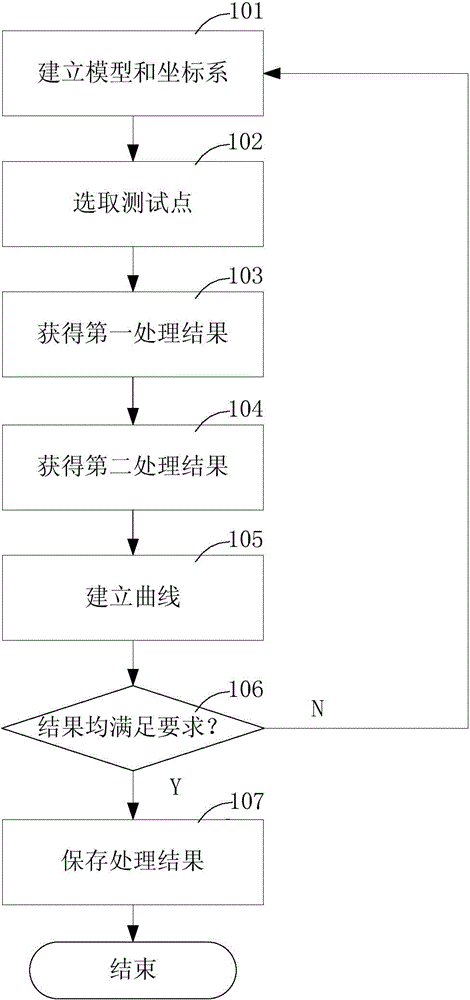

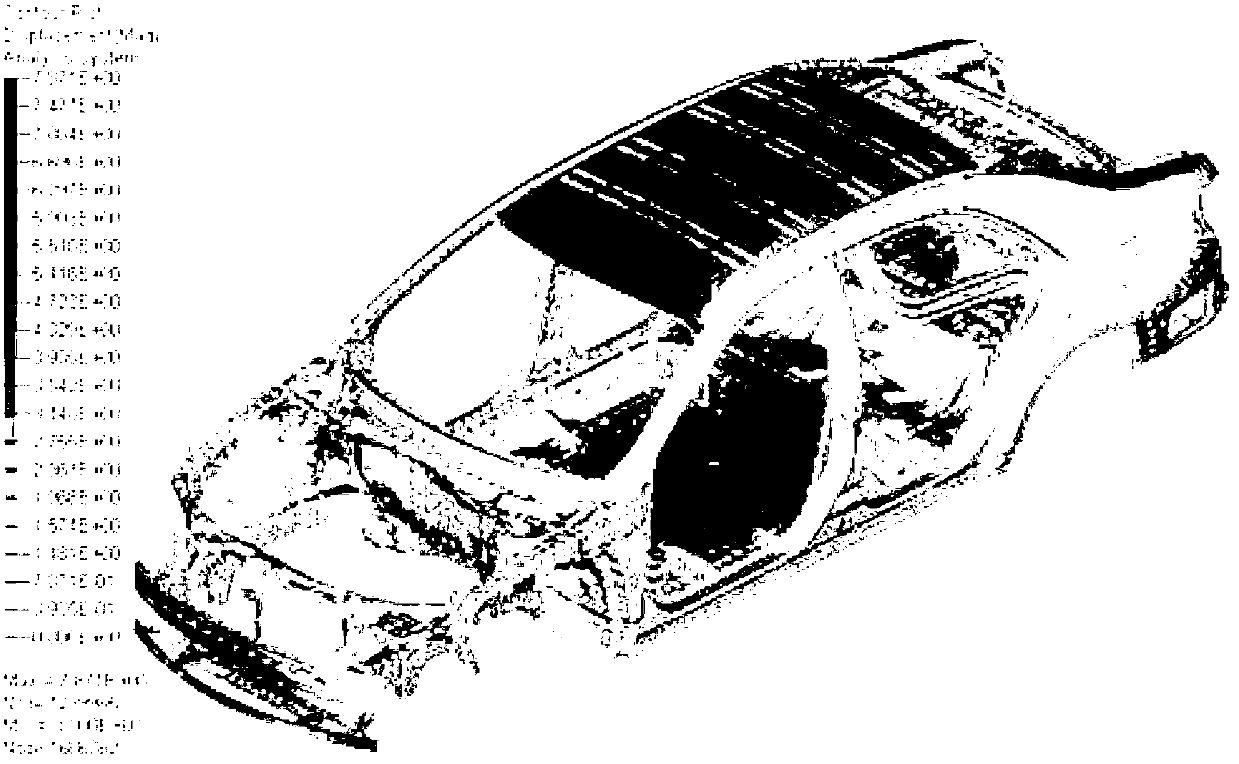

CAE (computer aided engineering)-based car body rigidity analysis method

InactiveCN104573174AReduce workloadThe result is accurateSpecial data processing applicationsReturn-to-zeroWorkload

The invention relates to the technical field of computer aided engineering (CAE), in particular to a CAE (computer aided engineering)-based car body rigidity analysis method used for analyzing the bending rigidity and the torsional rigidity of a front longitudinal beam, a threshold and a rear longitudinal beam of the car body. The CAE-based car body rigidity analysis method comprises the following steps: establishing a finite element mesh model of the car body and a coordinate system; carrying out a simulation test by applying load and constraints; obtaining a processing result, and generating a curve; then, judging whether the processing result meets requirements; if the processing result meets the requirements, storing the processing result, and otherwise, establishing a finite element mesh model of the car body again to conveniently carry out a simulation test. In the method, the displacement and the torsion angle of a node are analyzed by the finite element mesh model of the car body to carry out rigidity analysis instead of calculating by selecting the node by experience, and therefore the result is more accurate; an analysis result is automatically obtained, the workload of engineers is lightened, and project development time is saved; the result can be returned to zero to make the result to be normalized, the result has high compatibility, and comparison and analysis can be conveniently carried out.

Owner:BRILLIANCE AUTO

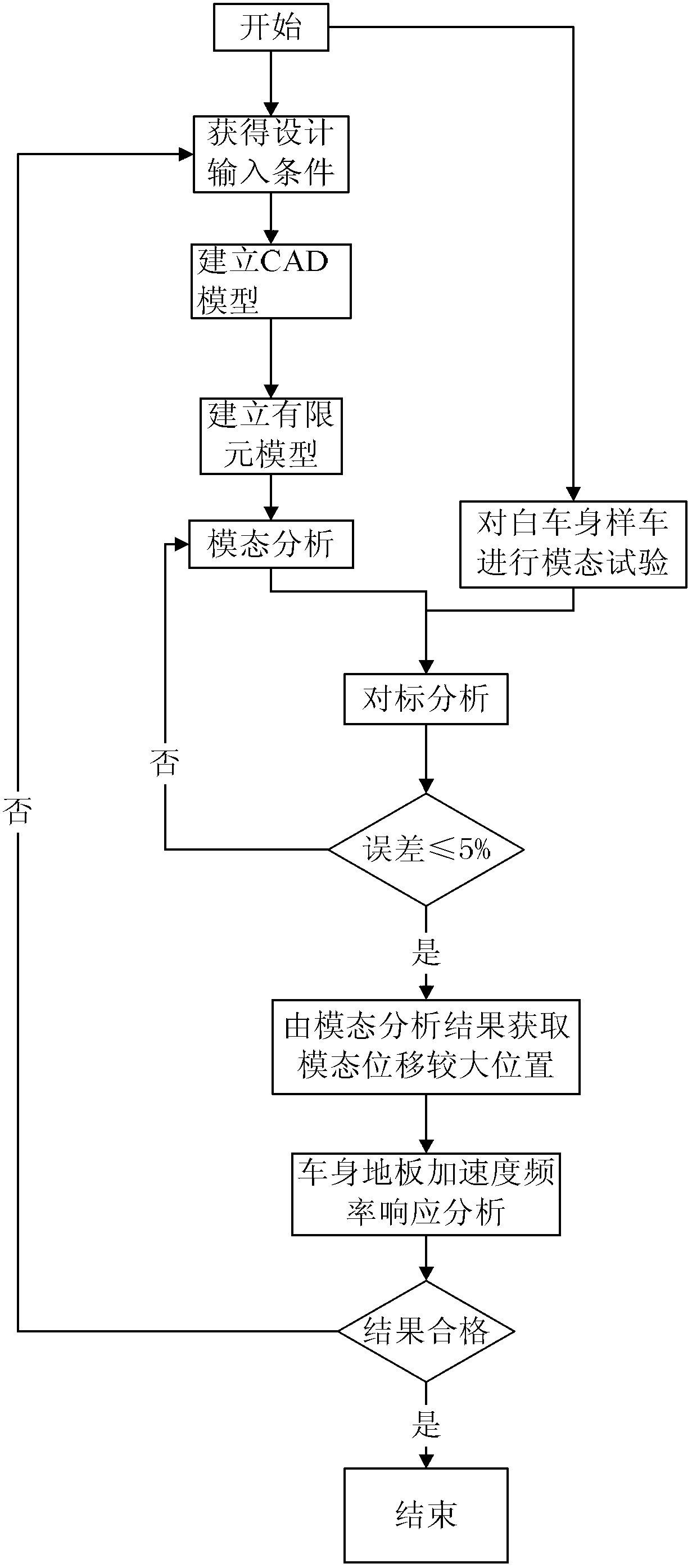

Acceleration frequency response analysis-based body floor optimal design method

ActiveCN102867075AReduce mistakesImprove noiseSustainable transportationSpecial data processing applicationsComputer Aided DesignElement model

The invention discloses an acceleration frequency response analysis-based body floor optimal design method, which comprises the following steps of: acquiring a body floor design input condition; establishing a CAD (Computer Aided Design) model; establishing a finite element model; performing mode CAE (Computer Aided Engineering) analysis on the finite element model to perform mode test on a white body sample; performing benchmarking; checking and verifying the finite element model according to a benchmarking result; searching a region of a large vibration displacement of the white body floor in the finite element model according to a mode CAE analysis result, extracting an inspection point from the region, and performing acceleration frequency response analysis on the inspection point; and modifying the floor design input condition according to the acceleration frequency response analysis result until the vibration response requirement is met. The method has the characteristics of shortening the development time, reducing the development cost, improving the entire noise, the vibration and the comfort, reducing the error between the finite element model and the floor sample and keeping high design quality.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

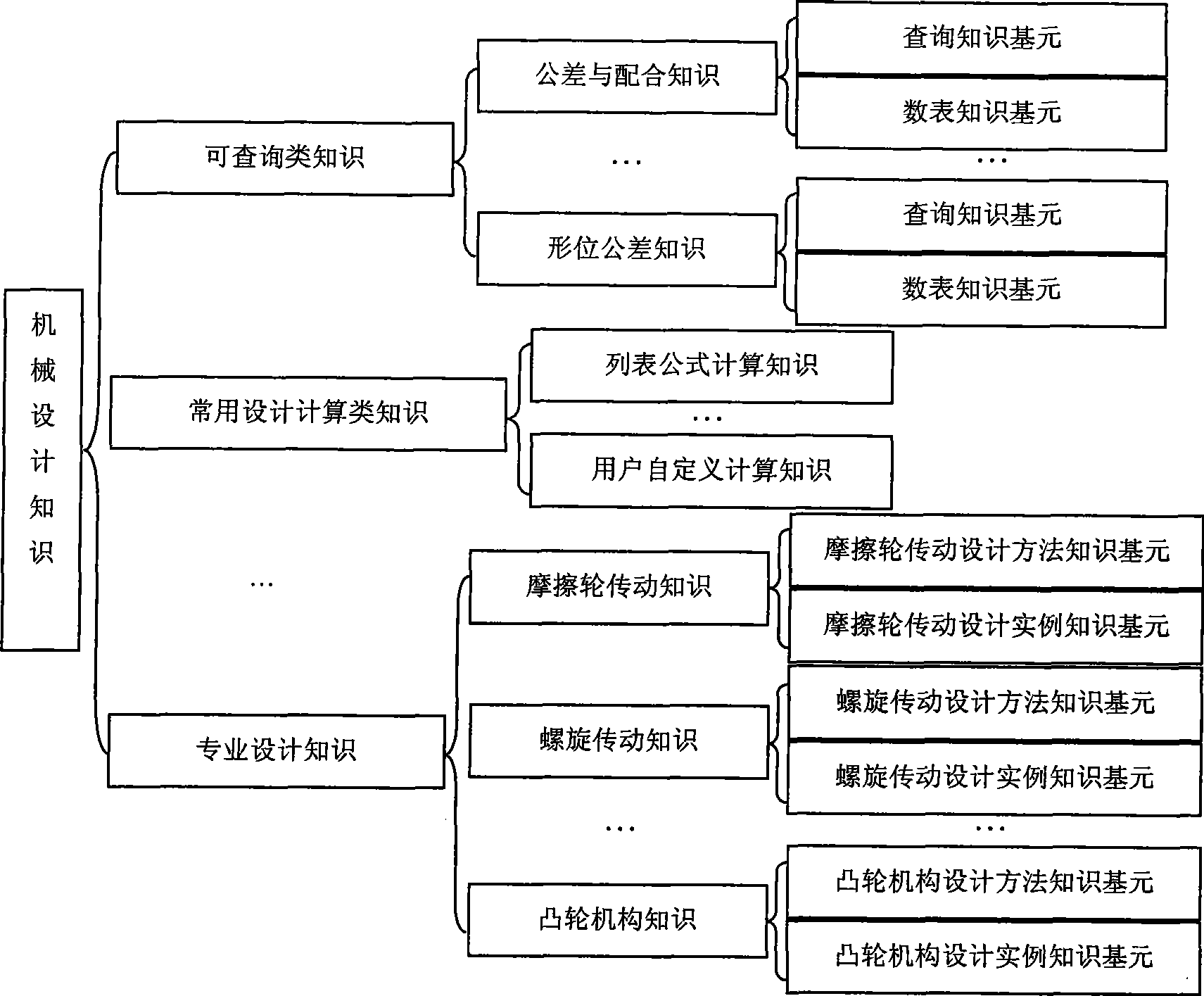

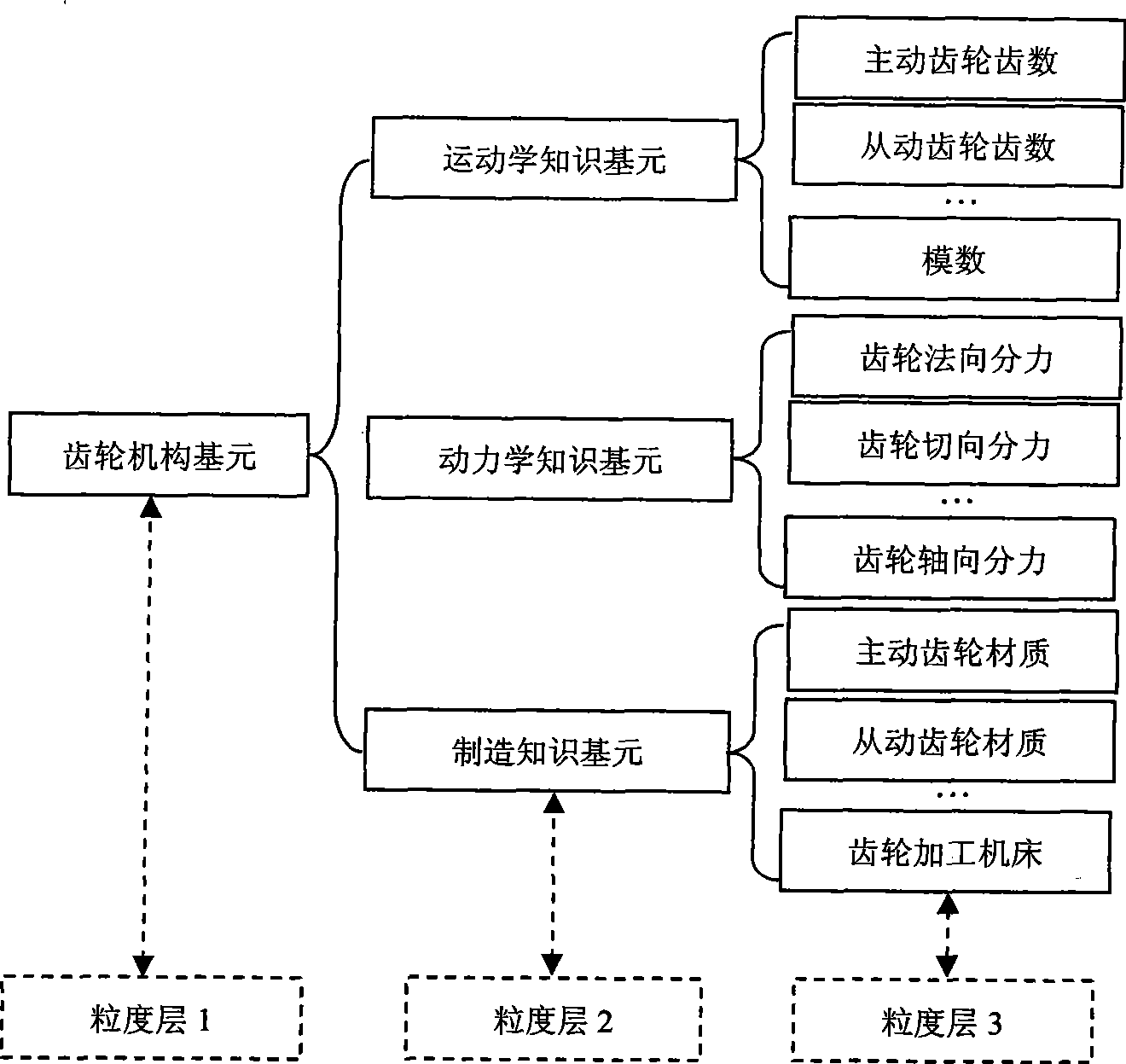

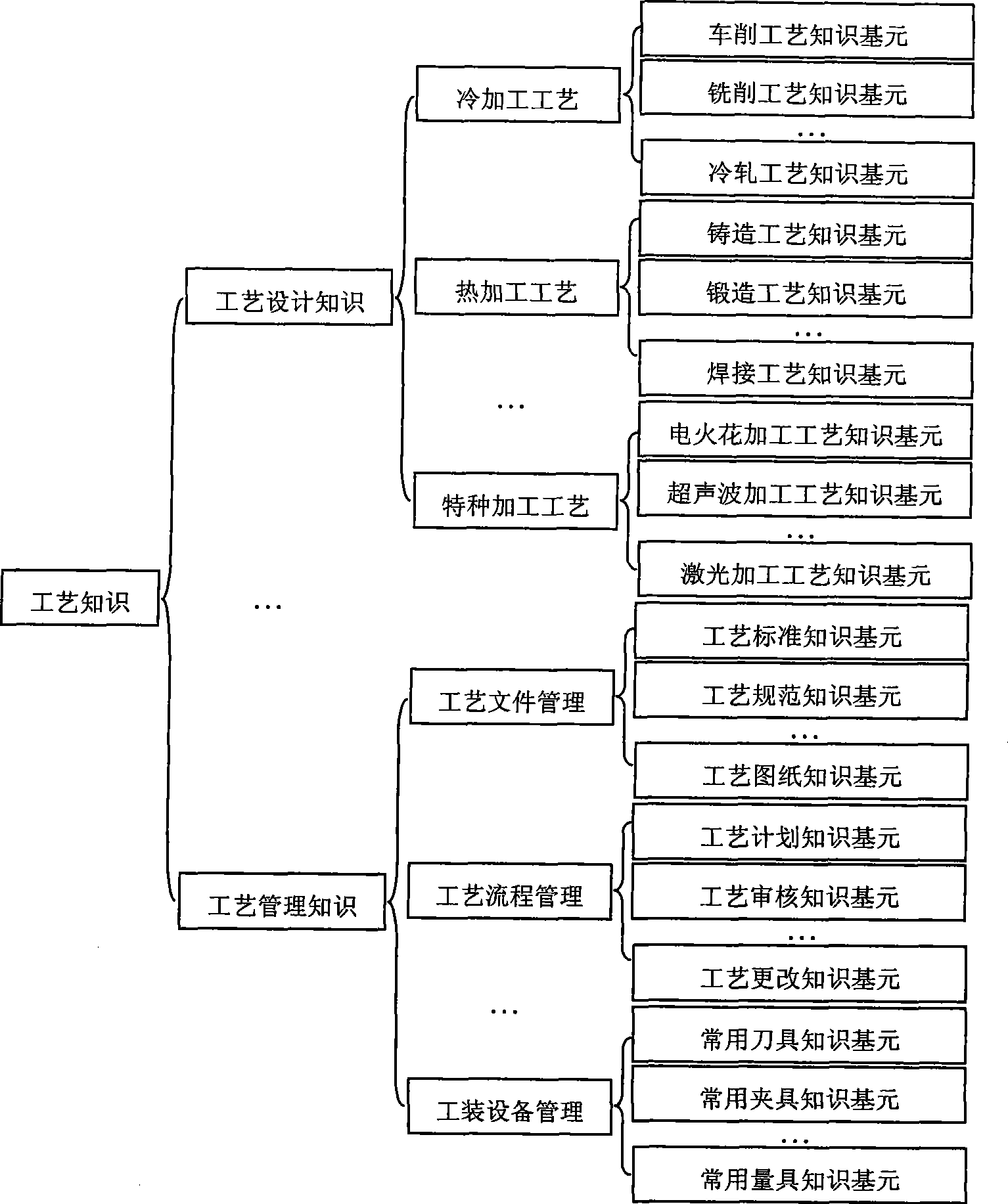

Non-standard knowledge acquisition method used for constructing mechanical product design knowledge base

InactiveCN101477521AEliminate transmissionEliminate DiffusionSpecial data processing applicationsInformation processingInformatization

The invention discloses a method for obtaining irregular knowledge used for constructing a mechanical product design knowledge base. Aiming at the requirements for knowledge processing and knowledge base system development in the mechanical product design field, the invention defines the irregular knowledge, discloses a computation module for dividing irregular knowledge granularity by adopting granularity calculation principle, studies mechanical product design irregular knowledge base structure system and basic format, discloses an irregular knowledge base display method based on metadata, and invents a method for obtaining semantic matching, irregular knowledge base in serial data source, and multi-mode irregular knowledge based on irregular example knowledge obtaining of cluster analysis; and on the basis, designs a system frame and a prototype software system for mechanical product design knowledge base system construction and application. The invention can be used to solve the technical problem of treating irregular knowledge in an information processing system such as CAD (computer-aided design), CAM (computer-aided manufacturing), CAE (computer-aided engineering) or PDM (products data management) in manufacturing industry, so as to satisfy the requirements for the deepening development of the manufacturing industry information project technology.

Owner:SICHUAN UNIV

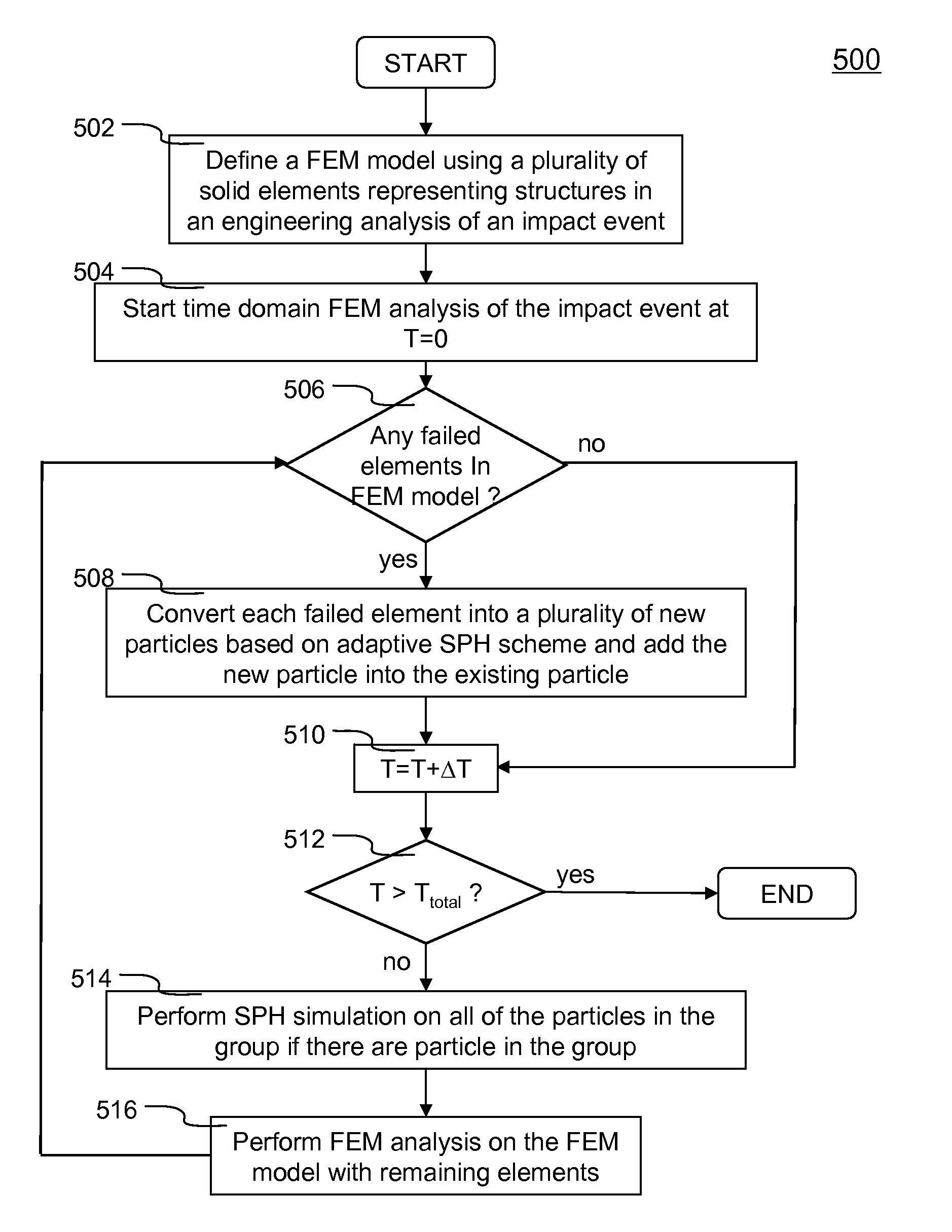

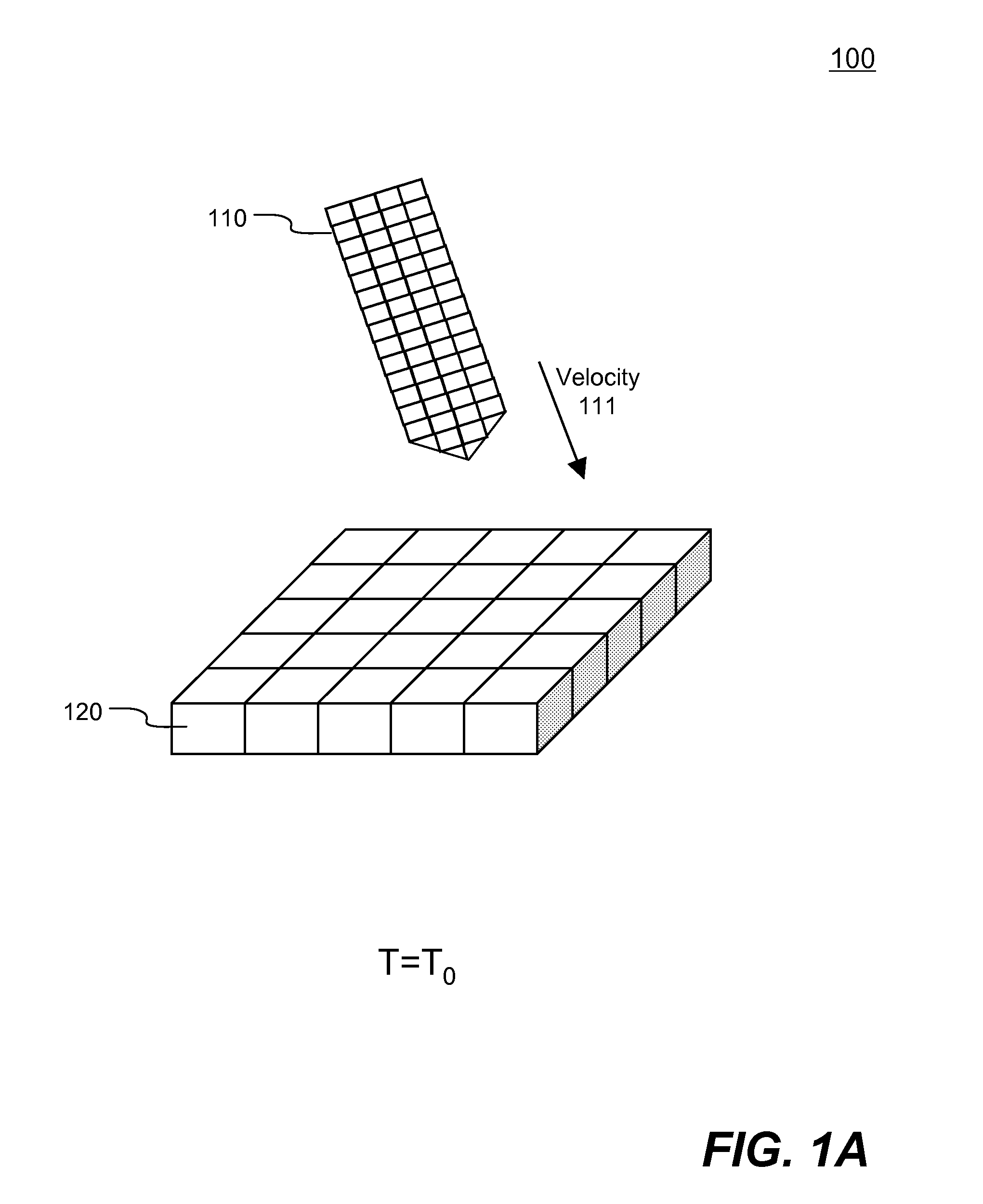

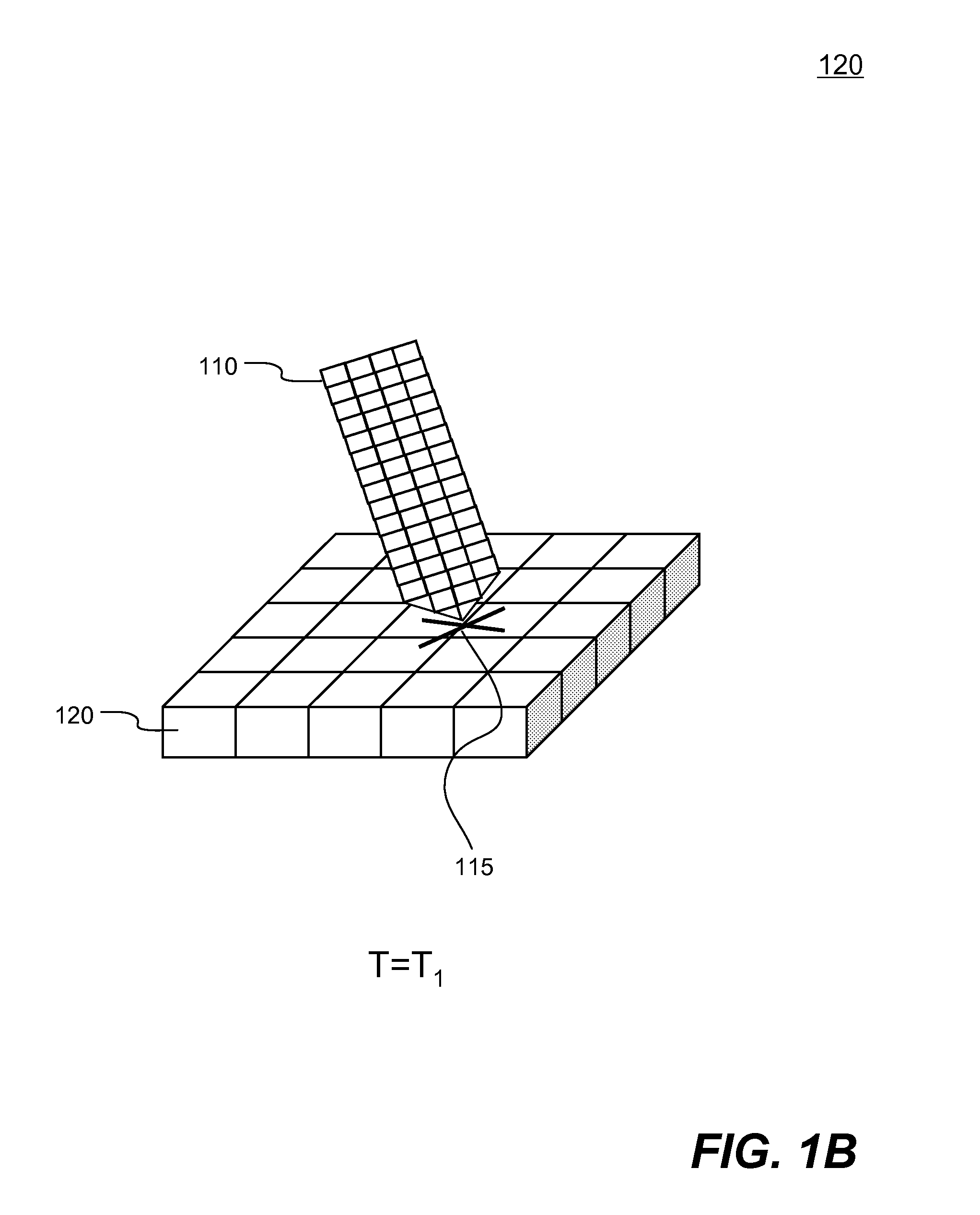

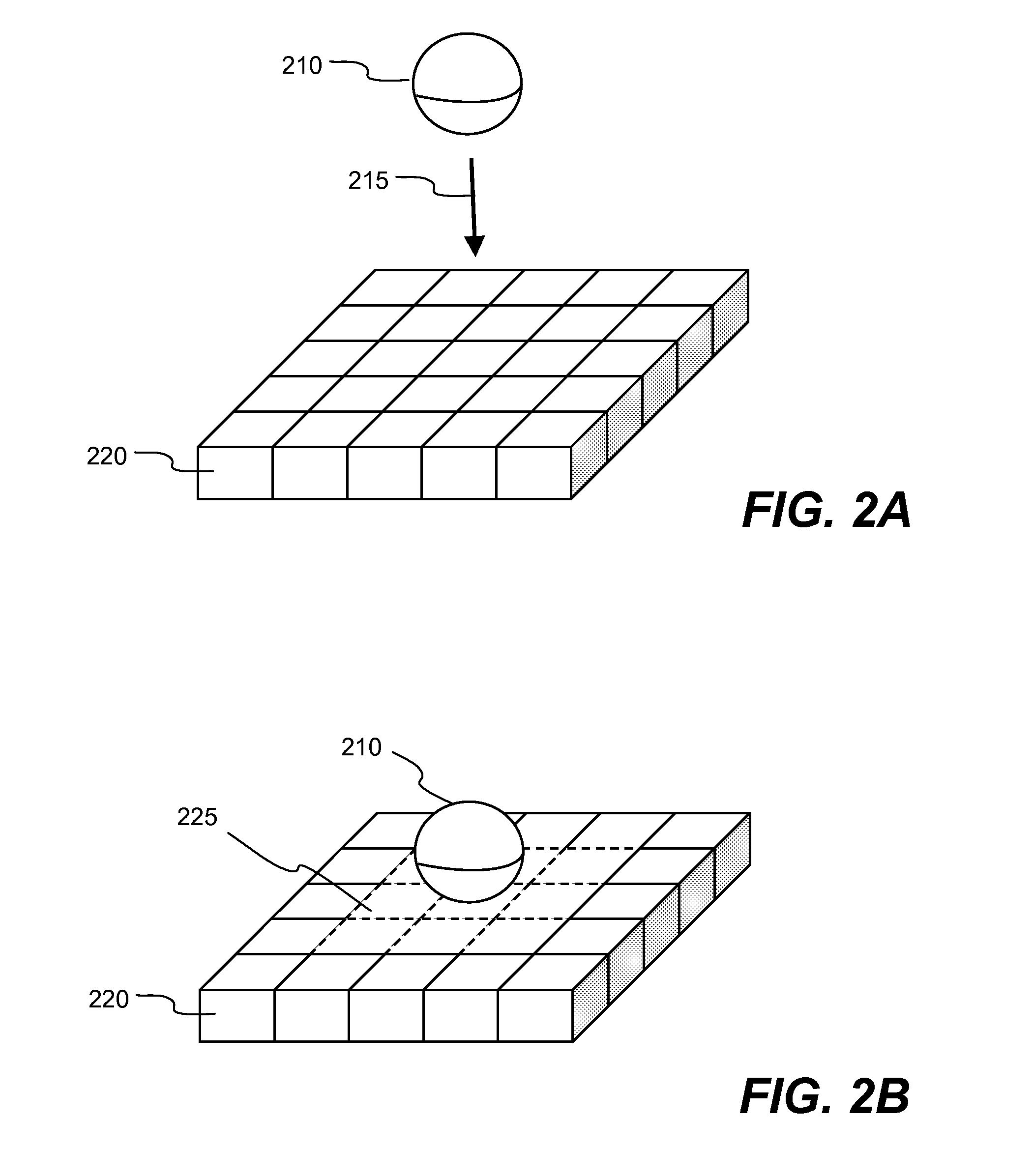

Methods and systems of engineering analysis using a hybrid approach with FEM and adaptive SPH

ActiveUS20090228246A1Real timeComputation using non-denominational number representationInvestigating material hardnessSmoothed-particle hydrodynamicsMomentum

Systems and methods of computer aided engineering analysis using hybrid approach of finite element method (FEM) and adaptive smoothed particle hydrodynamics (SPH) are described. According to one aspect, a computer-aided engineering analysis is performed to simulate an impact event between structures. A FEM grid model is created to represent the structures using a plurality of solid elements which represents geometry and material properties. Once a contact between two structures resulted into a material or structural failure according to predefined material constitutive equation, solid elements representing the failed portion of the structure are removed. Each failed solid element is then replaced by a plurality of particles to be analyzed using the SPH analysis. The particles replacing the failed element inherit all of the states and properties of the failed element, such as location, mass, velocity, acceleration, etc. The replacement is conducted according to the principles of mass, momentum and energy conservation.

Owner:ANSYS

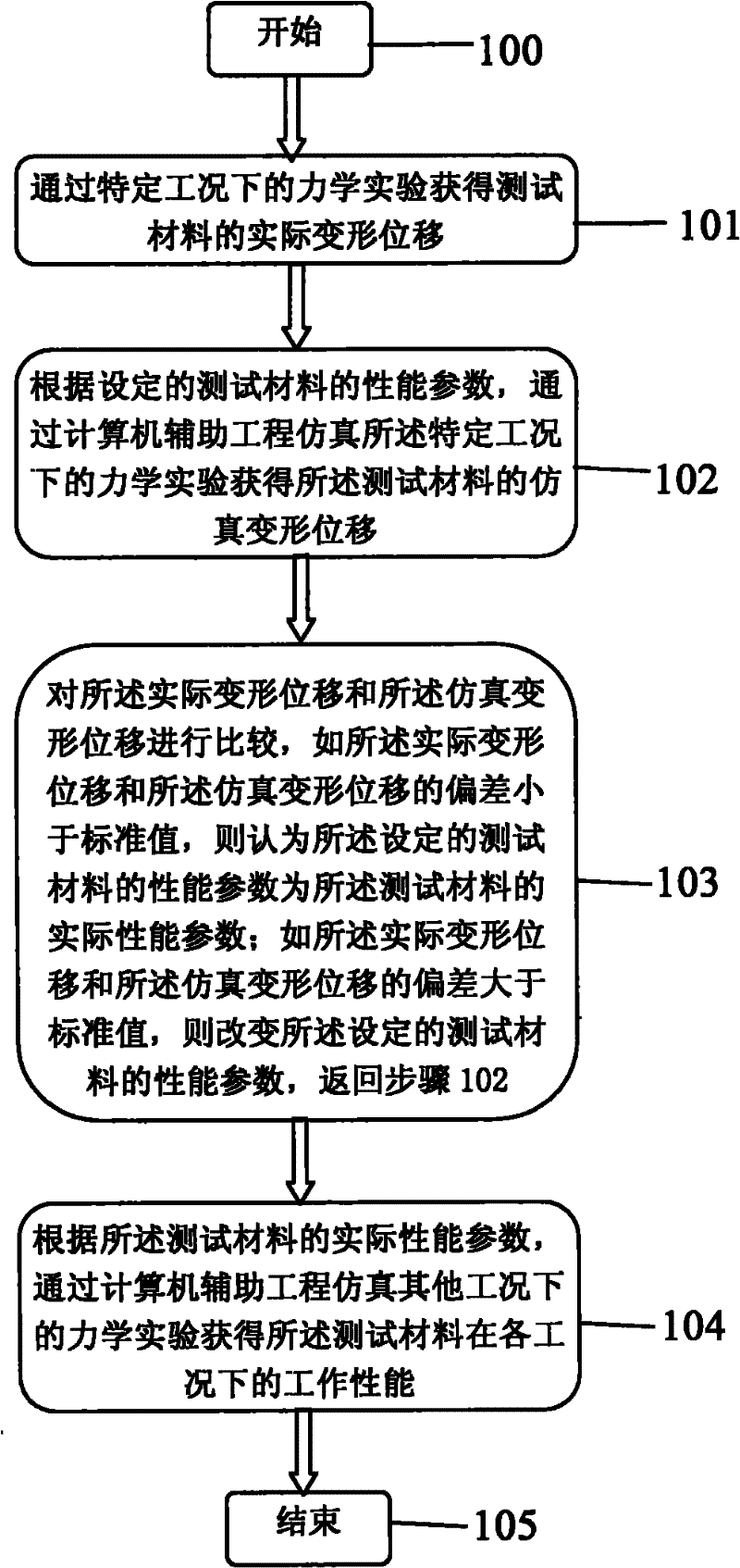

Method and system for estimating material property

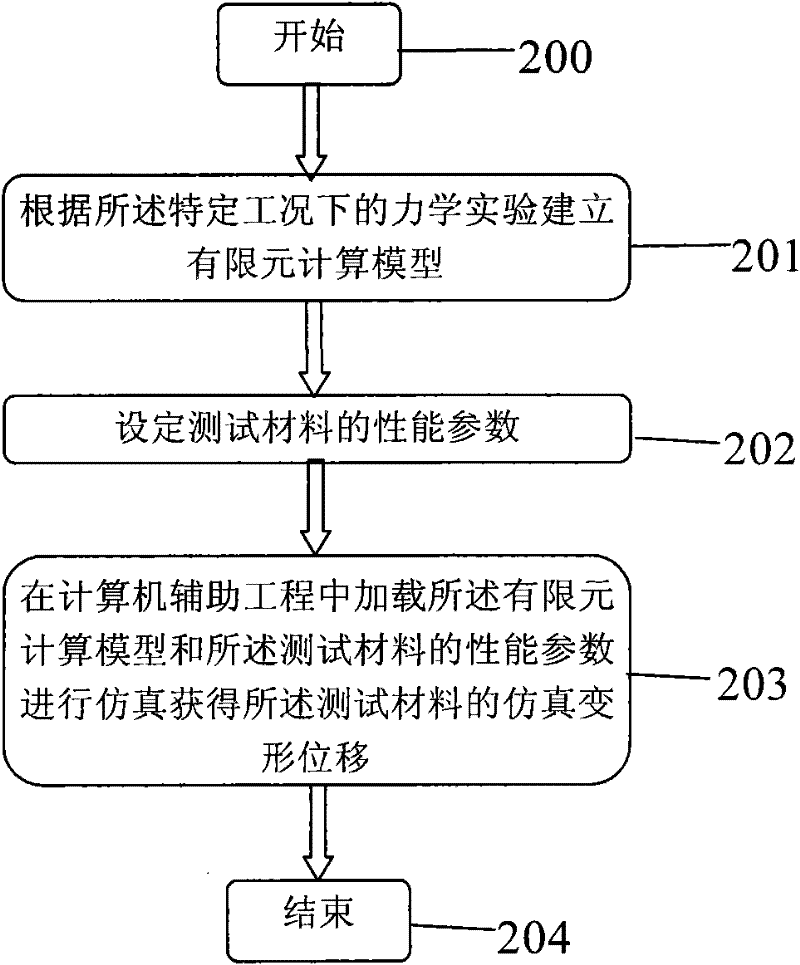

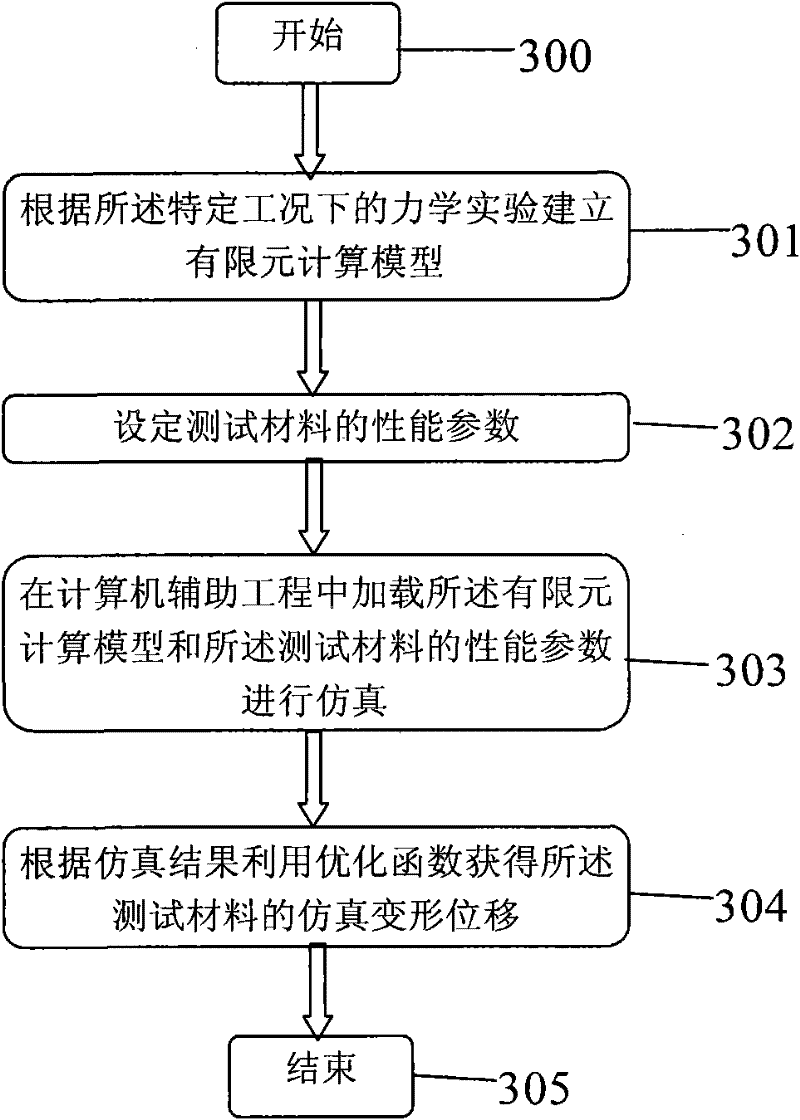

ActiveCN102175511AAccurately obtain material performance parametersAvoid defects where the testing workload is hugeSpecial data processing applicationsStrength propertiesTest materialMaterials science

The invention relates to a method for estimating material property, and the method comprises the following steps: acquiring the actual transformation displacement of a tested material through a mechanical experiment under a specific working condition; according to a preset property parameter of the tested material, acquiring the simulated transformation displacement of the tested material by utilizing the computer aided engineering to simulate the mechanical experiment under the specific working condition; comparing the simulated transformation displacement with the actual transformation displacement, thereby acquiring the actual property parameter of the tested material; and according to the actual property parameter of the tested material, acquiring the working property of the tested material under various working conditions by utilizing the computer aided engineering to simulate the mechanical experiment under other working conditions. The invention relates to the method for estimating the material property. The system and method for estimating the material property provided by the invention can be used for accurately acquiring the property parameter of the material through experiment and computer aided engineering simulation and performing the simulation test for various working conditions according to the property parameter of the material, thereby avoiding the defect of huge test work load caused by retesting the material property under the condition of the change of the tested working condition.

Owner:HANS CNC SCI & TECH

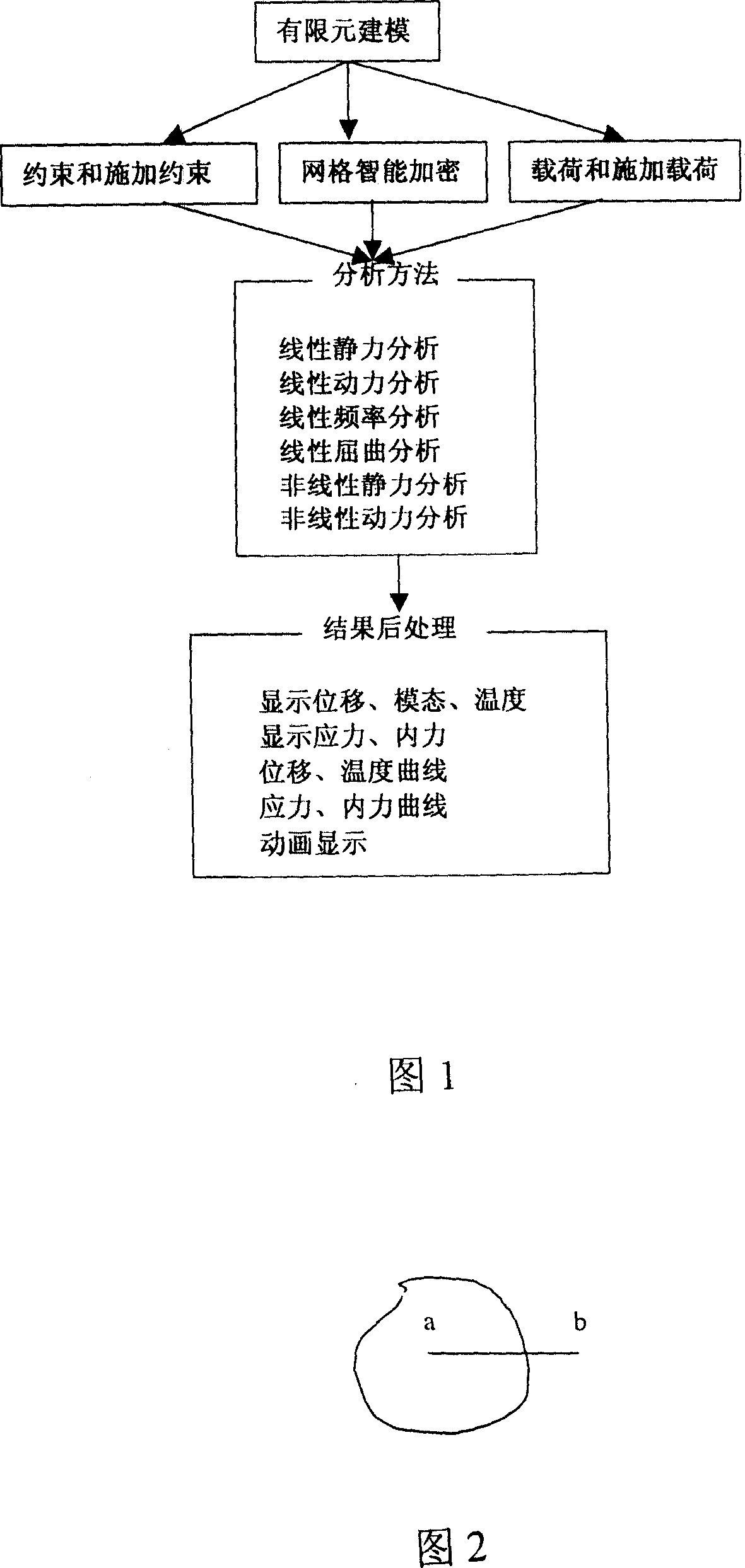

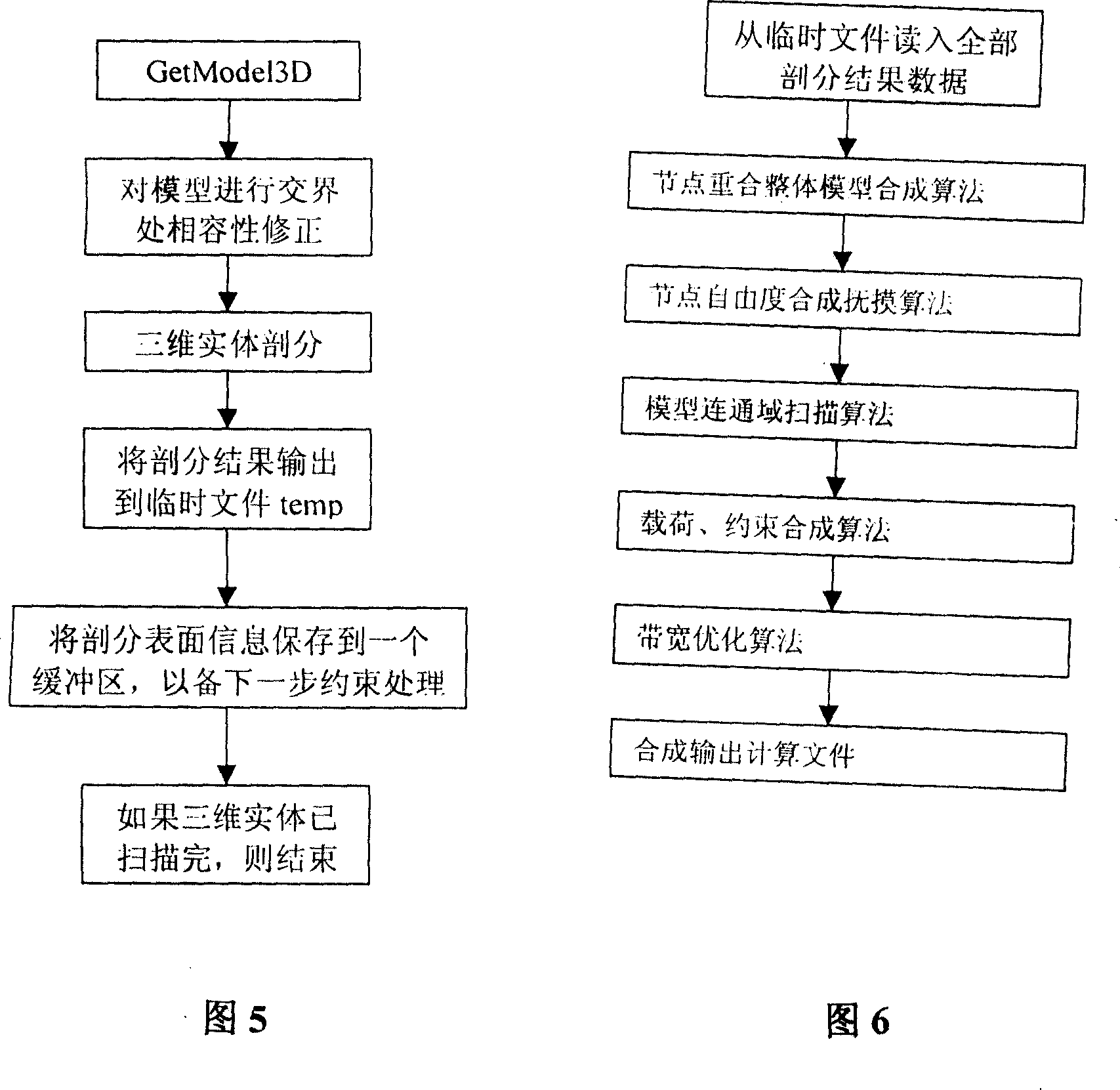

Intelligentized method for mesh generation of CAE software system

The invention is an intelligent computer-aided engineering software system, which is an intelligent method that can be applied to machinery, automotive, construction, water conservancy, transportation, energy, aviation, aerospace, shipbuilding and other areas for structural design and analysis of CAE software system mesh generation. The first step is finite element modeling; the second step: mesh generation and intelligent encryption; imposing constraints; imposing load; reducing the burden of users to study, as well as boosting the request of the success rate of procedures automatically partition because there is no second algorithm as substitute. The automatic mesh, the ideal that it pursuit is 'one-button', namely only a mouse click on partition menu is needed, there is no need for any of the other operating.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

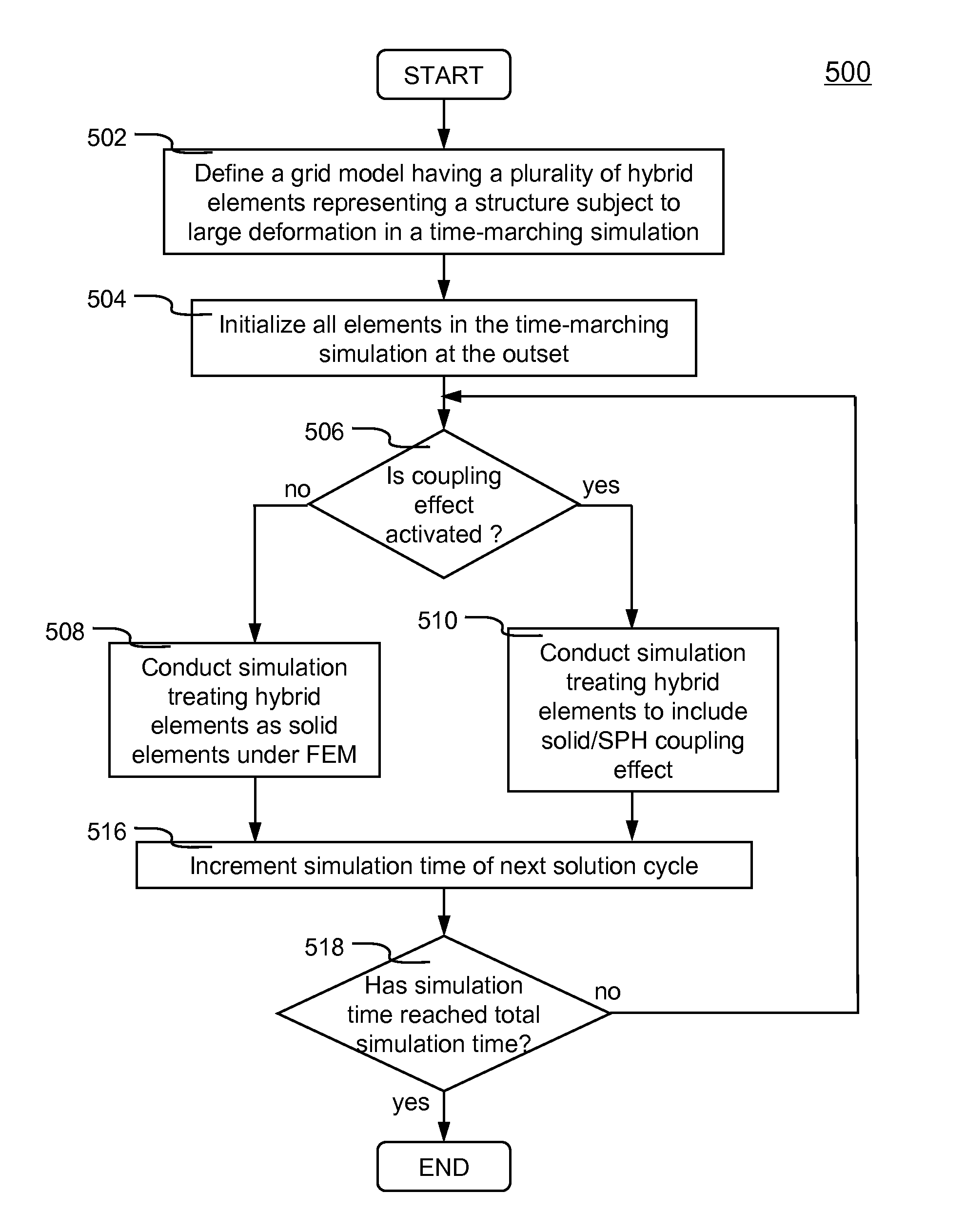

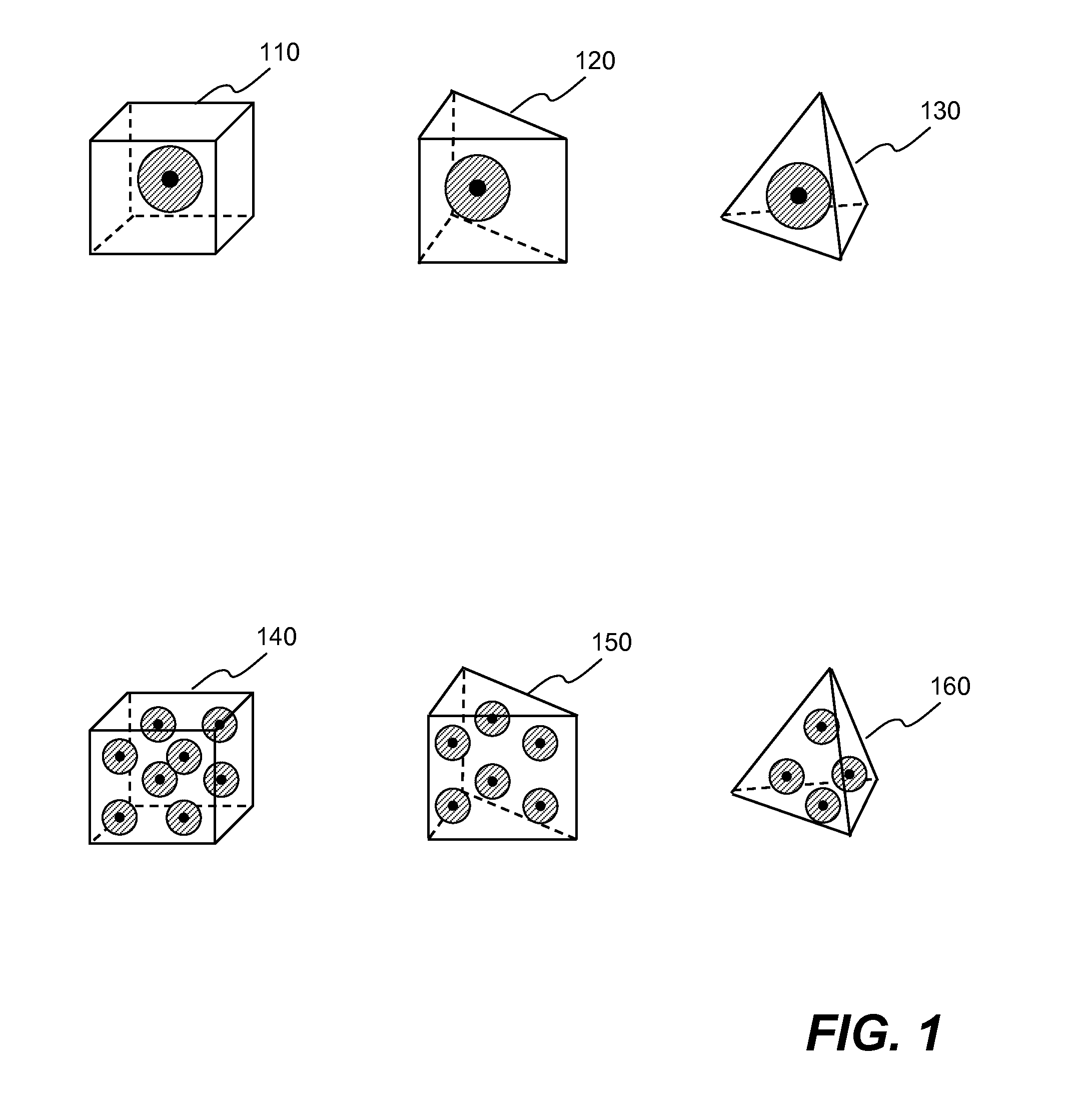

Hybrid Element Enabling Solid/SPH Coupling Effect

ActiveUS20110077912A1Geometric CADComputation using non-denominational number representationSmoothed-particle hydrodynamicsEngineering

Hybrid elements that enable coupling effects between SPH particles and FEM solid are disclosed. According to one aspect of the present invention, hybrid elements are configured to facilitate coupling effect of solid element based on finite element method (FEM) and one or more corresponding particles based on smoothed particle hydrodynamics (SPH). Hybrid elements are defined in a computer aided engineering (CAE) grid model as a buffer or interface between the SPH particles and FEM solids. For example, a portion of the grid model comprises SPH particles because the likelihood of enduring large deformation, while the rest of the model comprises FEM solid elements. Hybrid elements are placed between the solids and the particles. Each hybrid element comprises two layers: solid layer and particle layer.

Owner:ANSYS

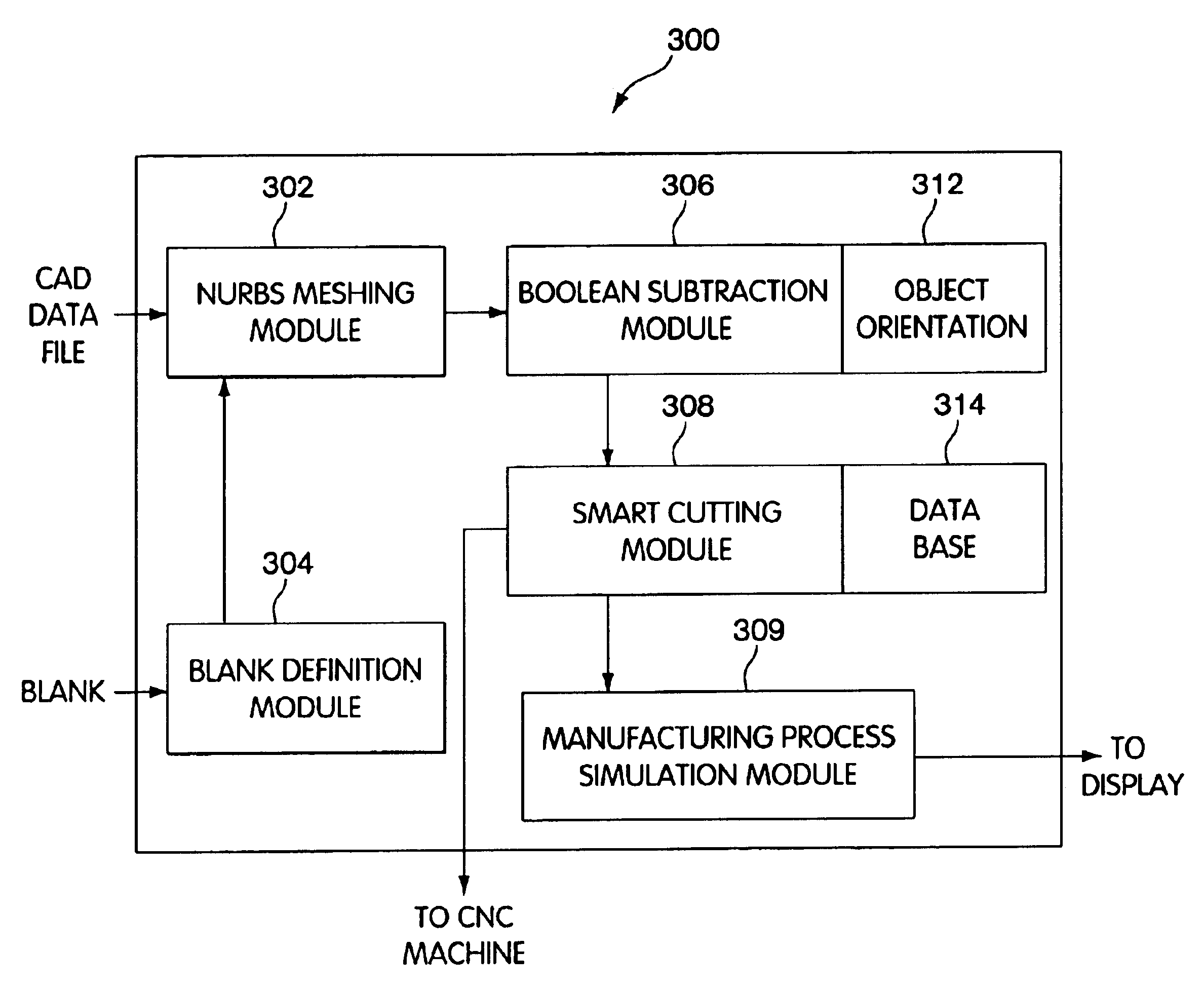

Nurbs based CNC machine process using boolean substraction

InactiveUS6904394B2Precise positioningProgramme controlComputer controlNumerical controlHuman–machine interface

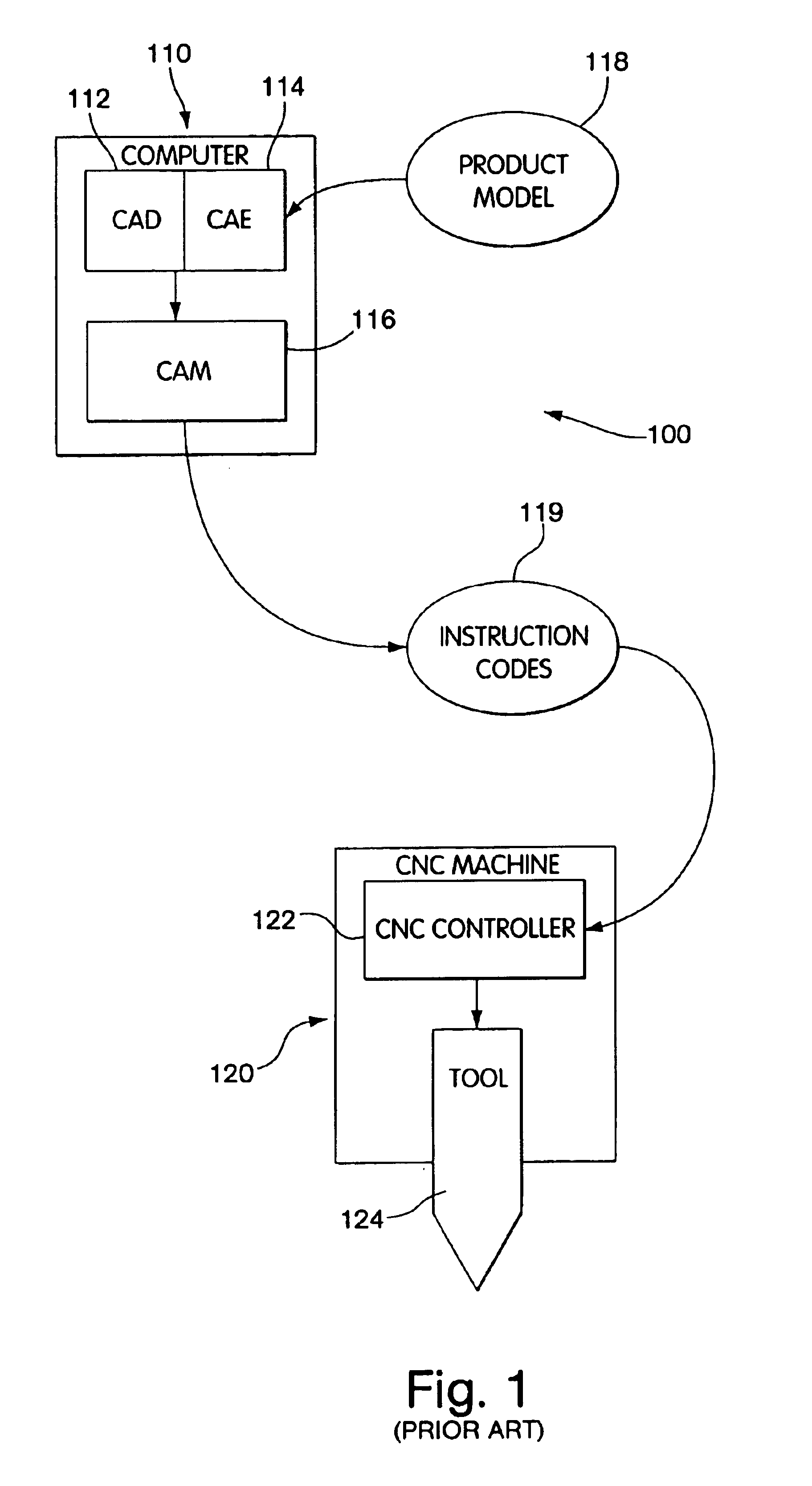

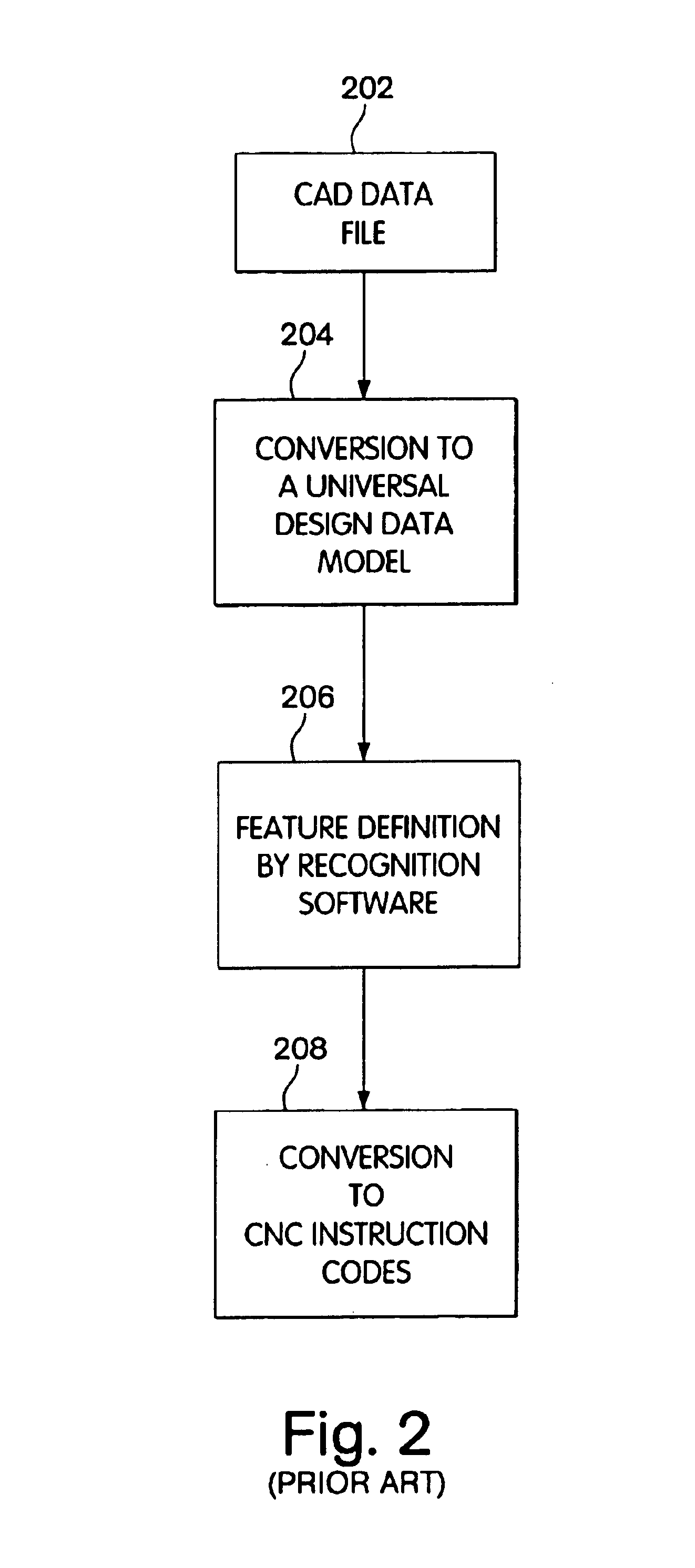

A method and apparatus is directed to an integration of a computer modeling process in which a Computer Numerically Controlled (CNC) machine is used for manufacture or rapid prototyping. As a result, conventional processes that require a level of human interface during the intermediate stages are minimized or otherwise removed. Intermediate stages include Computer Aided Design(CAD) stage, Computer Aided Engineering (CAE) stage, Computer Aided Manufacturing (CAM) stage and Computer Numerical Controlled (CNC) machine stage. By using Non-Uniform Rational B-Splines (NURBS), a CAD data file is converted for direct input to the CNC machine that is able to read NURBS instruction codes. In particular, the method and apparatus is a paradigm shift (from conventional approaches to minimizing human interfaces in which the product features are defined) to NURBS which describes geometrically the difference between the material blank from which the product (or prototype) is made and the product itself using boolean substraction.

Owner:DELTA SEARCH LABS

Processes and systems for creation of machine control for specialty machines requiring manual input

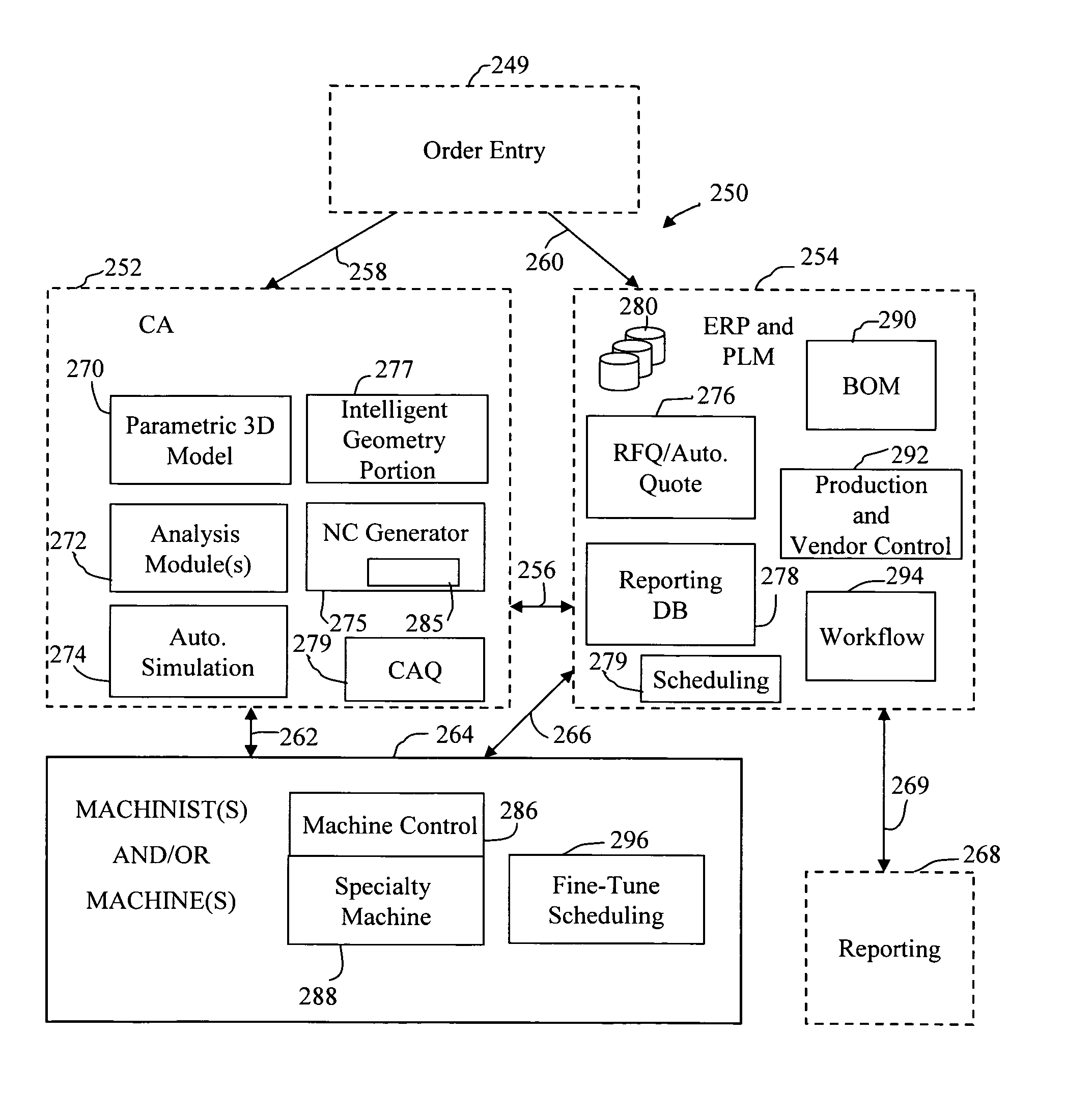

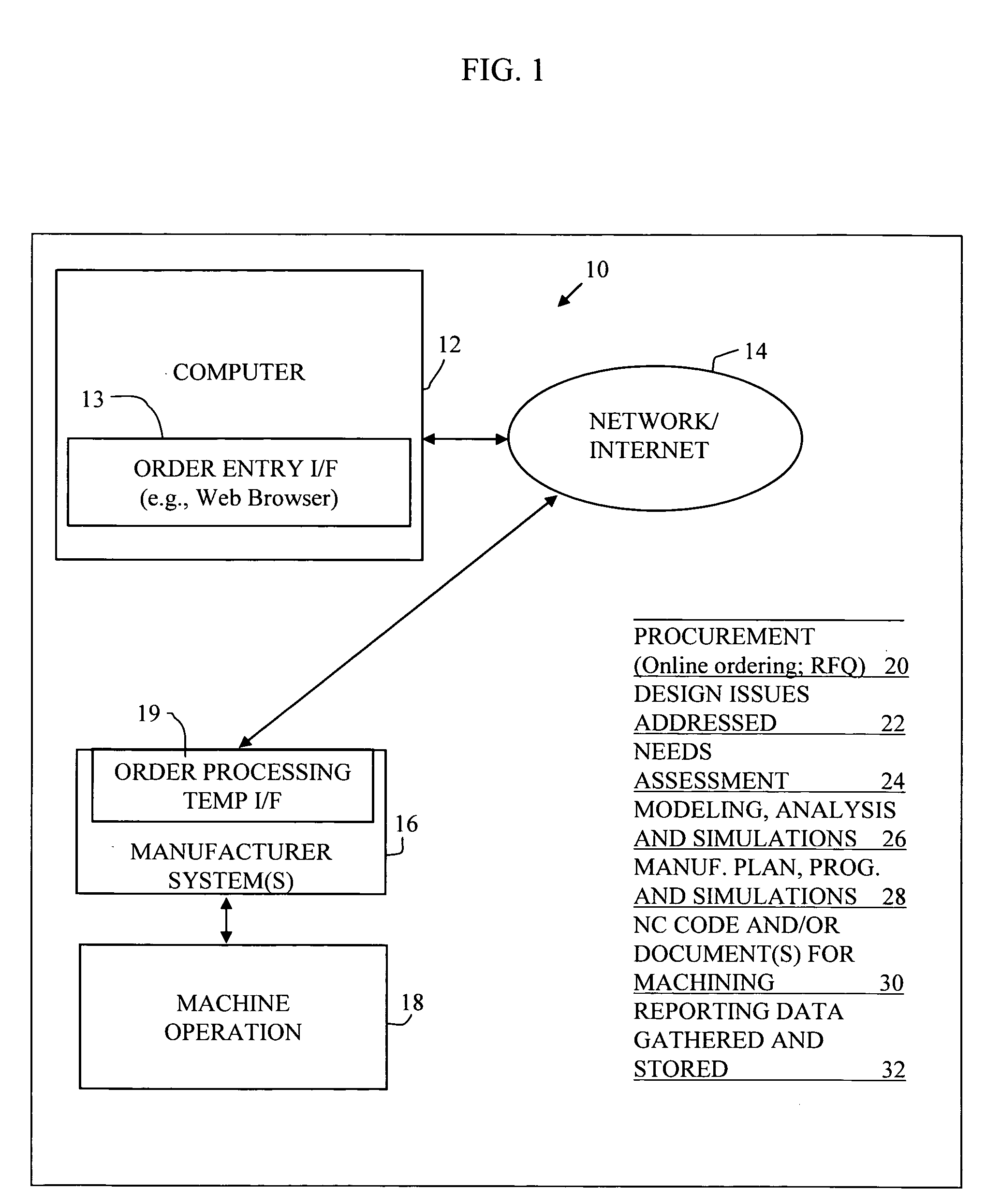

InactiveUS20060129270A1Increased riskImprove product qualityComputer controlSimulator controlComputer architectureMachine control

A system is provided for creating specialty machine control programs for manufacturing a part. A CA (computer aided) computer system is provided. The CA system may comprise a computer aided design and computer aided manufacture (CAD / CAM) computer system. The CA computer system may further comprise a computer aided engineering (CAE) computer system. The CA computer system may further comprise a computer aided quality (CAQ) computer system. The CA computer system comprises a parametric design mechanism to specify geometries of the part with parameters. In addition, an intelligent geometry portion is provided to determine machining cycles to manufacture the part. A 3D solid modeling function is provided, and one or more simulation components are provided. A human-readable control program generator is provided to generate from the CA computer system a human-readable control program including instructions for a human to carry out.

Owner:PANKL GEROLD +1

Manufacturing method of neodymium iron boron based on three-dimensional (3D) printing technology

The invention discloses a manufacturing method of neodymium iron boron based on a three-dimensional (3D) printing technology. Three-dimensional model modeling is conducted on a product through a computer, three-dimensional model modeling data are transmitted to a 3D printer, a plurality of continuous layered planar graphs are generated by utilizing the computer aided engineering (CAE) technology, a nozzle of the 3D printer is controlled to fill powder according to the planar graphs, and the powder is accumulated layer by layer and is magnetized until the product is formed. A large amount of mold development cost is saved, production phase is shortened, and production efficiency is improved greatly. The size of the manufactured product can be changed arbitrarily, the method is suitable for heterotypic products which are large in machining difficulty, the thickness of the product can be smaller than 1mm, the product can be assembled and used conveniently by a client, and the requirements that a micro motor develops towards the directions of being small in size, ultrathin, high in speed, high in precision and low in noise are satisfied.

Owner:宁波金科磁业有限公司

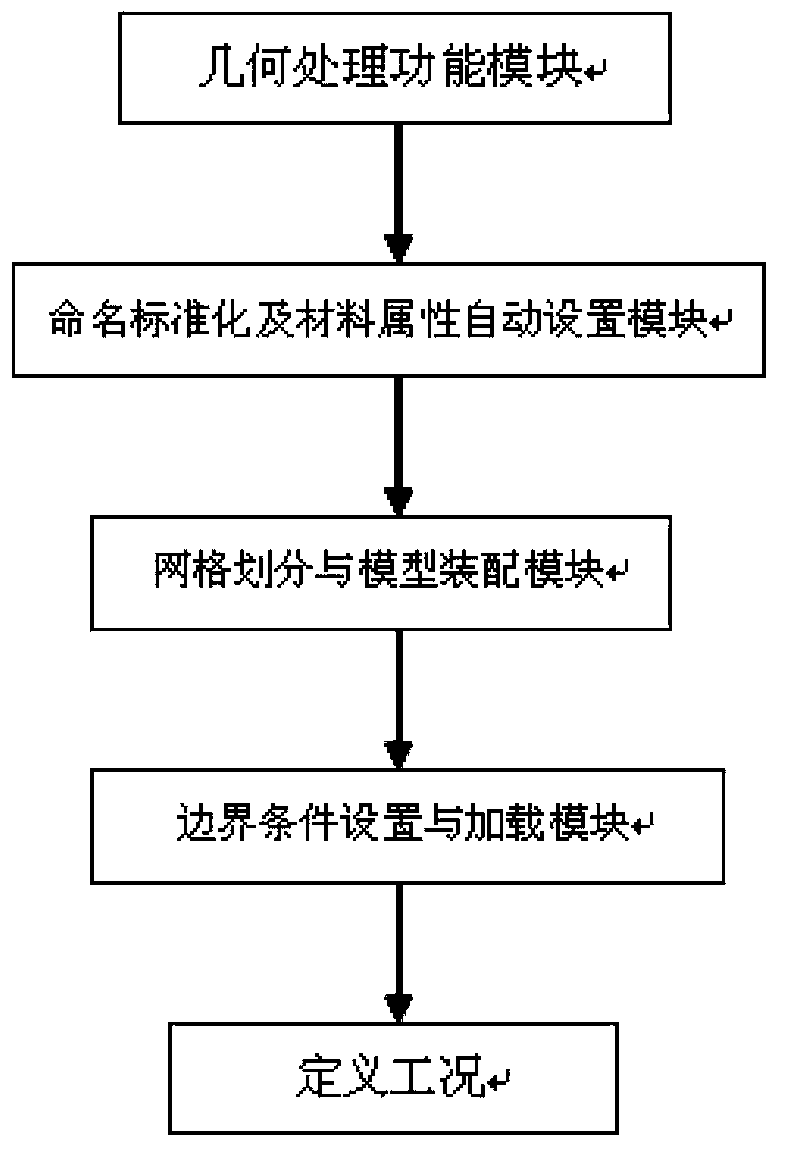

Preprocessing template for vehicle model

ActiveCN103870623AImprove work efficiencyReduce human errorSpecial data processing applicationsTruckGrid partition

The invention relates to a preprocessing template for a vehicle model. The preprocessing template for the vehicle model consists of a geometric parameterized module, a naming standardization and material property automatic setting module, a grid partitioning module and a boundary condition module which are connected in sequence. Vehicles under research and development involve different vehicles such as railway locomotives, passenger cars, trucks, motor train units, urban rails and railways, the establishment of a general preprocessing template for a railway vehicle CAE (Computer Aided Engineering) model is particularly important. By developing the general preprocessing template for the general CAE model, complex preprocessing work in simulated analysis can be standardized and normalized. By means of a flow automation tool, the working efficiency can be increased while standard processing is realized, human errors are reduced, the CAE simulation preprocessing knowledge and experience of enterprises are accumulated and solidified, and the CAE simulation technology organization process capitals of enterprises are well accumulated and extended.

Owner:CRRC QINGDAO SIFANG CO LTD +1

Finite element analysis method for formula racing car frames

InactiveCN108170972ASolve problems that cannot be solved by manual calculation in experimentsImprove accuracyGeometric CADDesign optimisation/simulationElement modelVehicle frame

The invention provides a finite element analysis method for formula racing car frames, belongs to the technical field of computer aided engineering, and aims at solving the problem that existing racing car frame optimization and analysis are bad in correctness and long in design period. The finite element analysis method comprises the following steps of: A, constructing a three-dimensional model and carrying out meshing to convert the three-dimensional model into a finite element model; B, applying boundary conditions according to each working condition, carrying out finite element analysis and calculation on frame bending rigidity under each working condition, and comparing the analysis result with material bending strength to carry out structure optimization; C, respectively applying forced displacement in opposite directions on two sides of the car frame, carrying out finite element analysis and calculation to obtain torsional rigidity of the car frame, and carrying out structure optimization according to the analysis result; and D, analyzing and comparing whether a fixed frequency of each order modal of the car frame is different from an external main excitation frequency or not, and carrying out structure optimization according to the result. According to the method, the correctness of optimization and analysis is improved, the expenditure is decreased and the design period is shortened.

Owner:ZHEJIANG JIRUN AUTOMOBILE +2

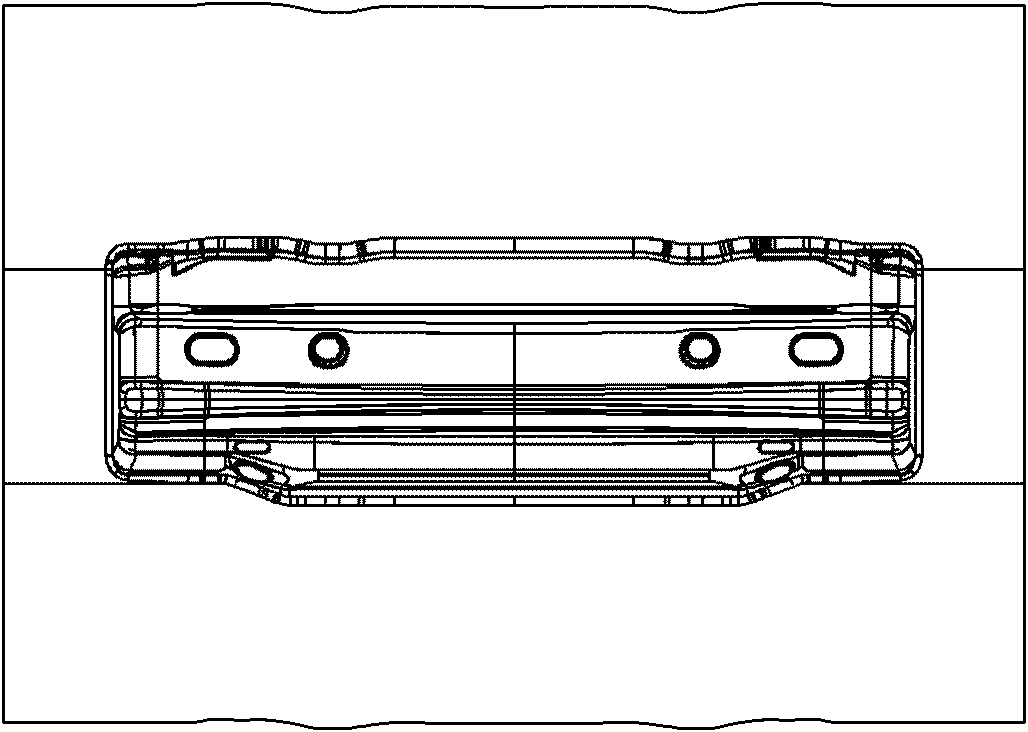

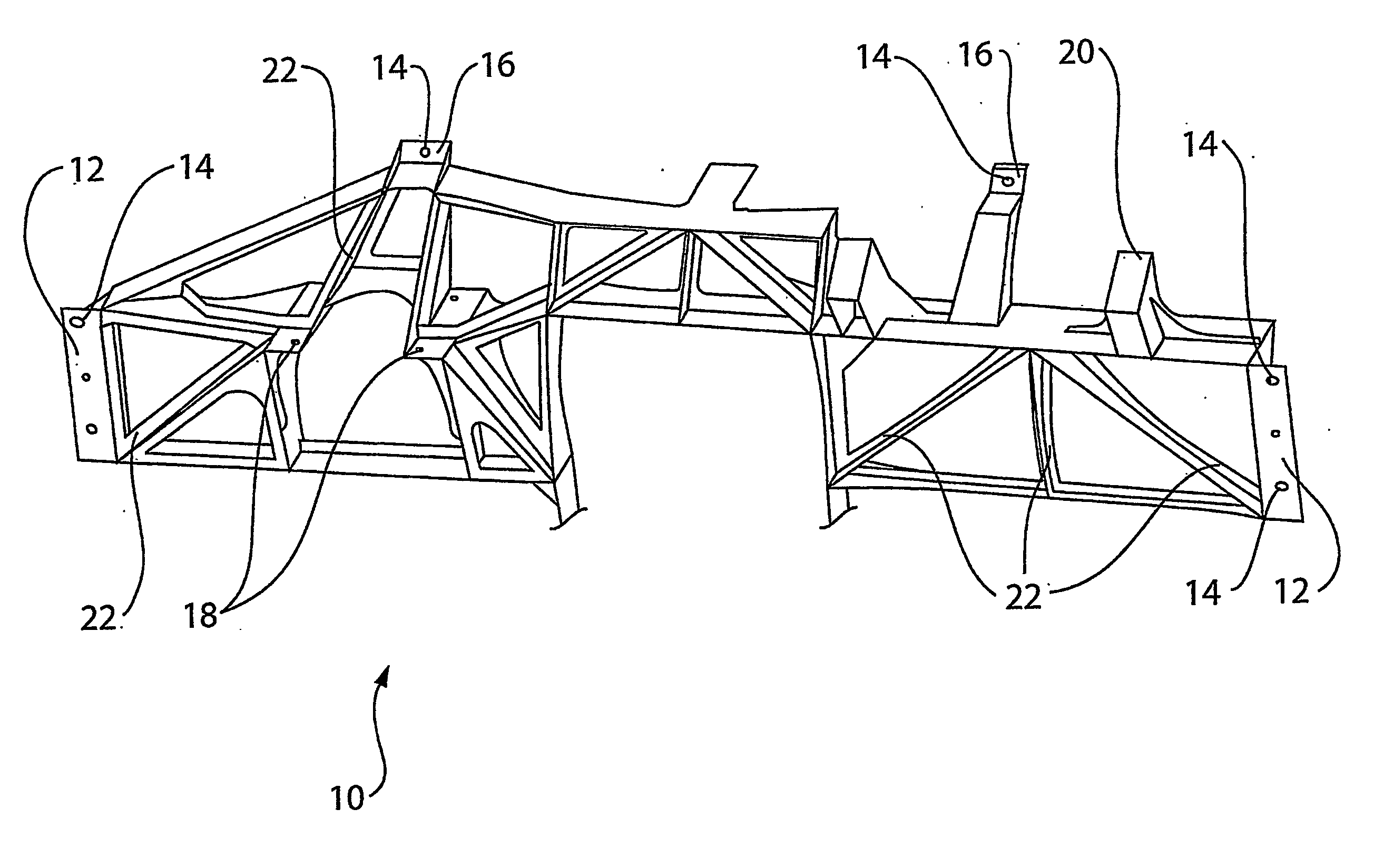

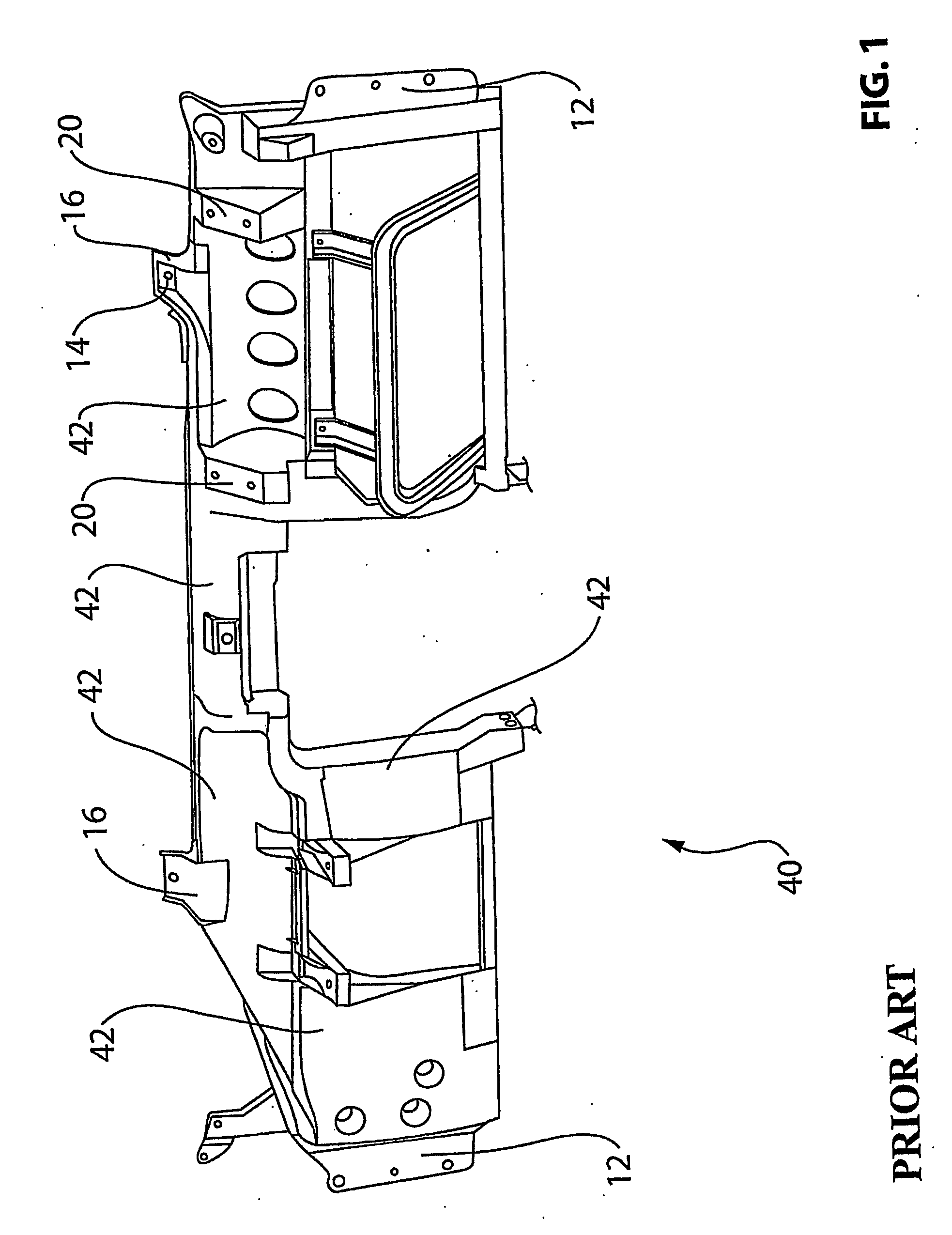

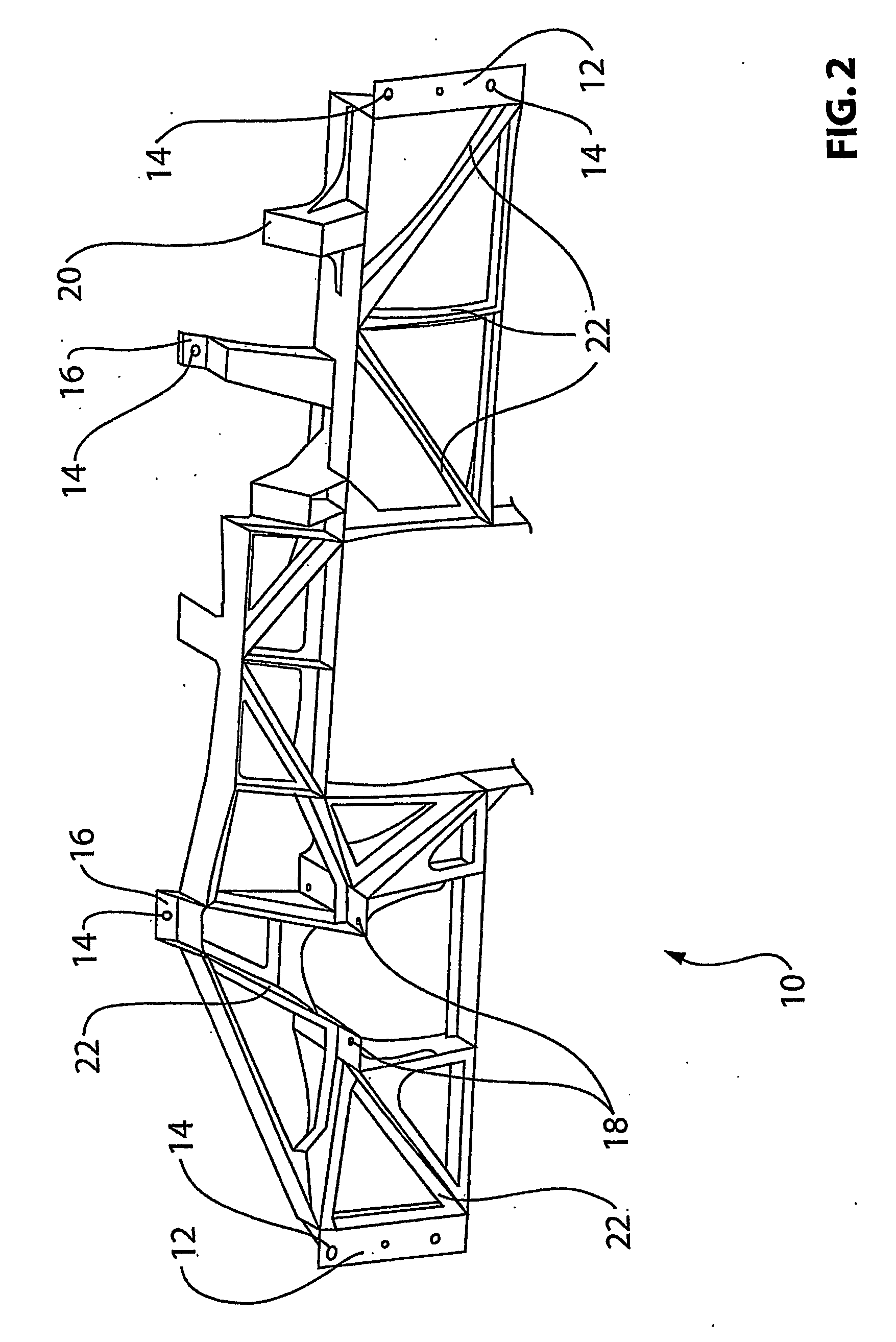

Instrument panel rib structure

A vehicle instrument panel support structure is provided having fixing and mounting surfaces linked together by ribs in an open space frame structure. The ribs are sized, shaped and positioned to create critical load paths and eliminate the outer skin of the instrument panel support structure. Magnesium alloy material is only placed where it is needed for structure and function. The functionality of the vehicle instrument panel support structure is maintained as are the stiffness and crashworthiness when compared to the traditional design, but the weight of the instrument panel structure and the projected area are reduced. A method of designing an instrument panel support structure using a computer aided engineering platform is also provided.

Owner:SIMONDS GLEN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com