Frictional wear CAE (Computer Aided Engineering) analysis-based mold optimization method

A technology of friction and wear, optimization methods, used in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

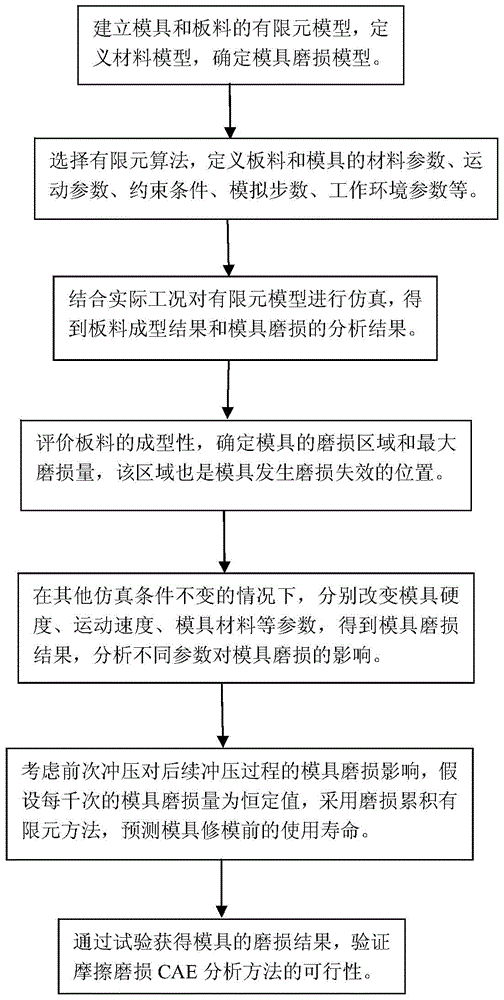

Method used

Image

Examples

Embodiment 1

[0083] Taking the molding process mold of Chevrolet Malibu front longitudinal beam middle reinforcement as an example, the CAE analysis and mold optimization of mold wear are carried out. The sheet material is DP780 steel, and the mold material is commonly used Cr12MoV.

[0084] step one

[0085] In the finite element software, the finite element grid model of the mold is set up, the sheet material is thick 1mm, and the tetrahedron unit size is set to 1mm when meshing, and the grid unit number obtained is 38038; the mesh of the sheet The grid unit used in the lattice model is a solid unit; the material model of the plate is an elastic-plastic model; The number of grid units of the mold model is respectively: 341391 dies, 381928 punches, and 310173 upper blank holders; the grid units used in the grid model of the mold are solid units; the material model of the mold is an ideal rigid model. The wear model of the mold used is the Archard theoretical wear model;

[0086] step t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com