Patents

Literature

771 results about "Surface deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

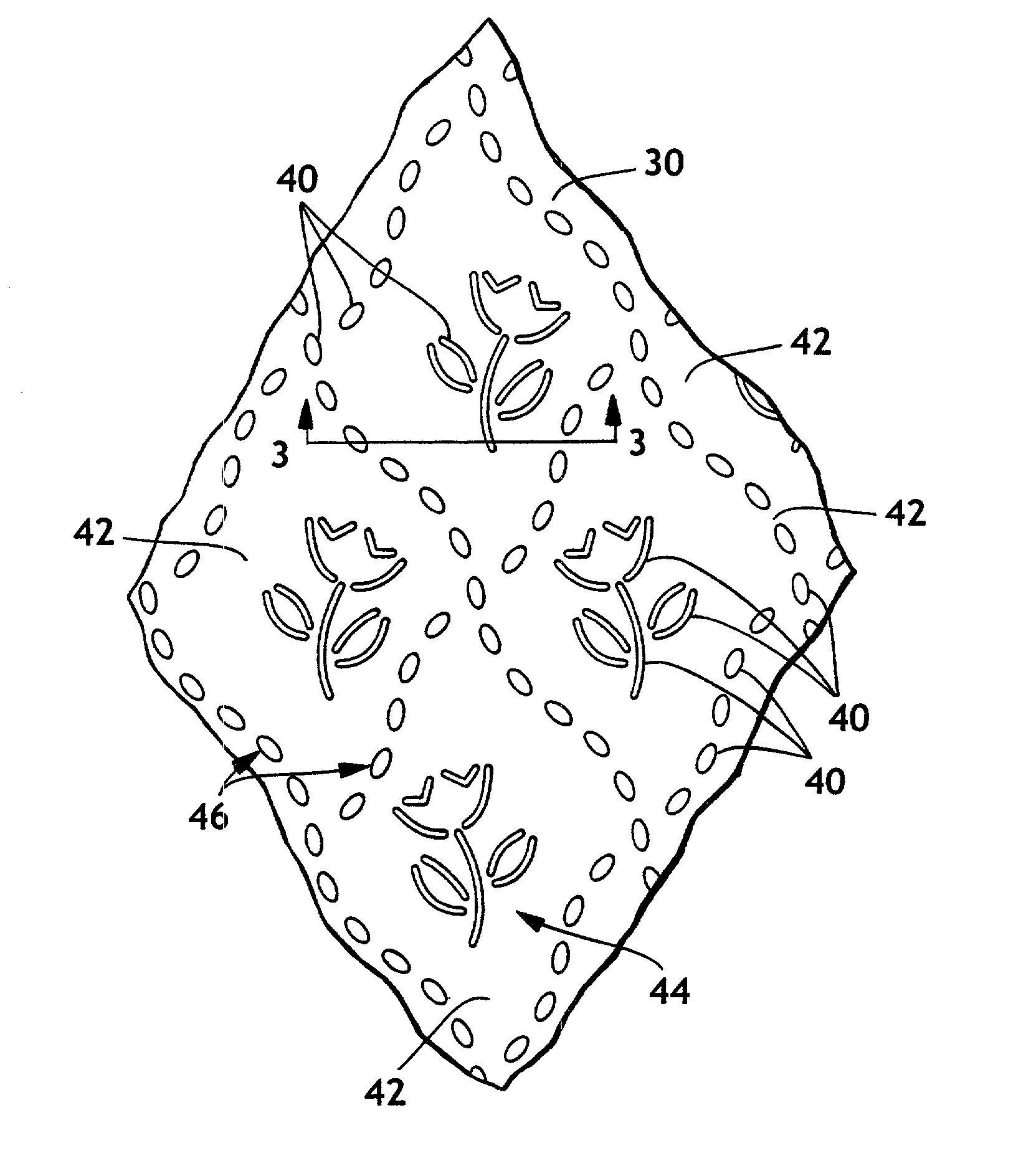

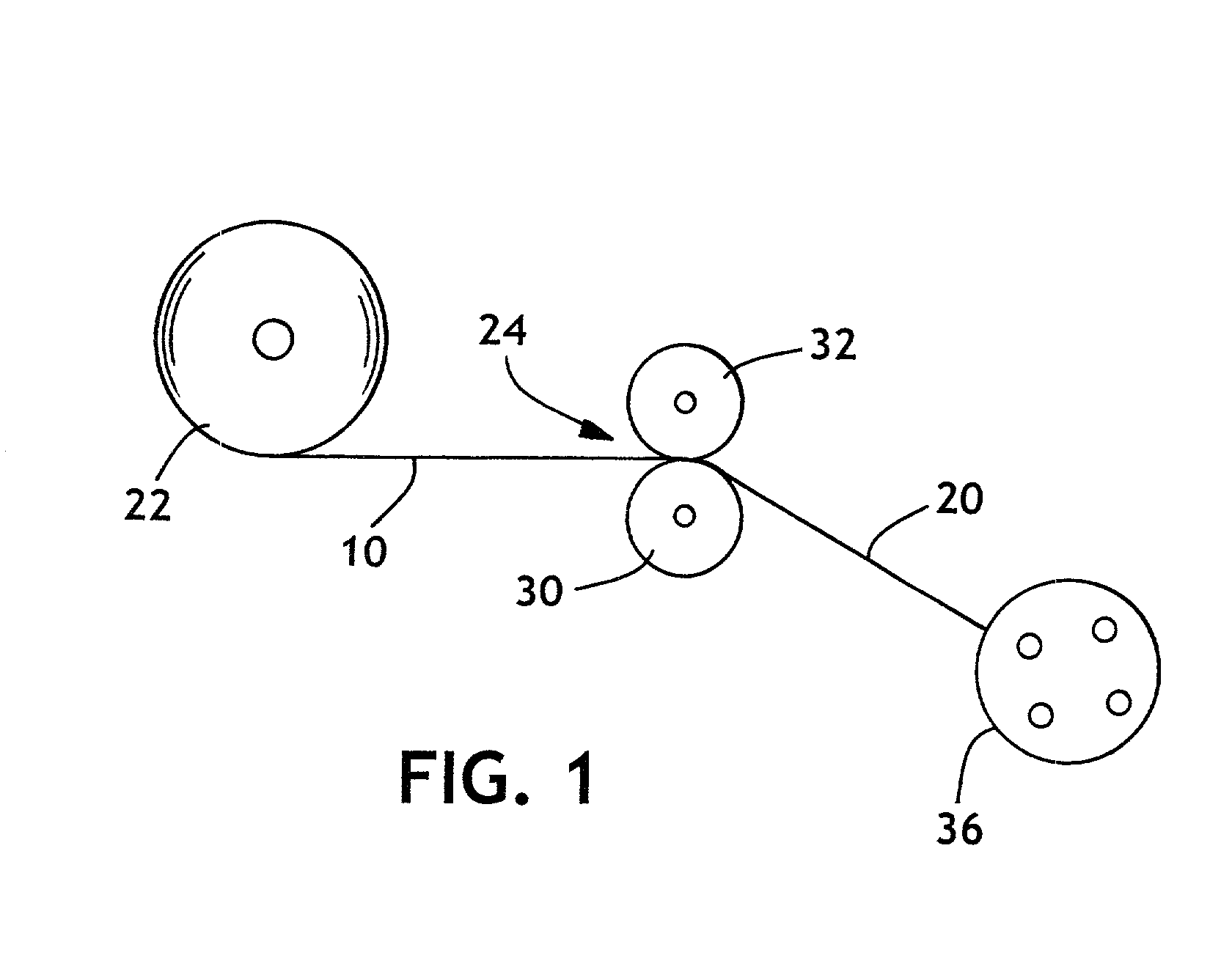

Paper tissue having enhanced softness

InactiveUS6344111B1Increase softnessMaintain tensile strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberUltimate tensile strength

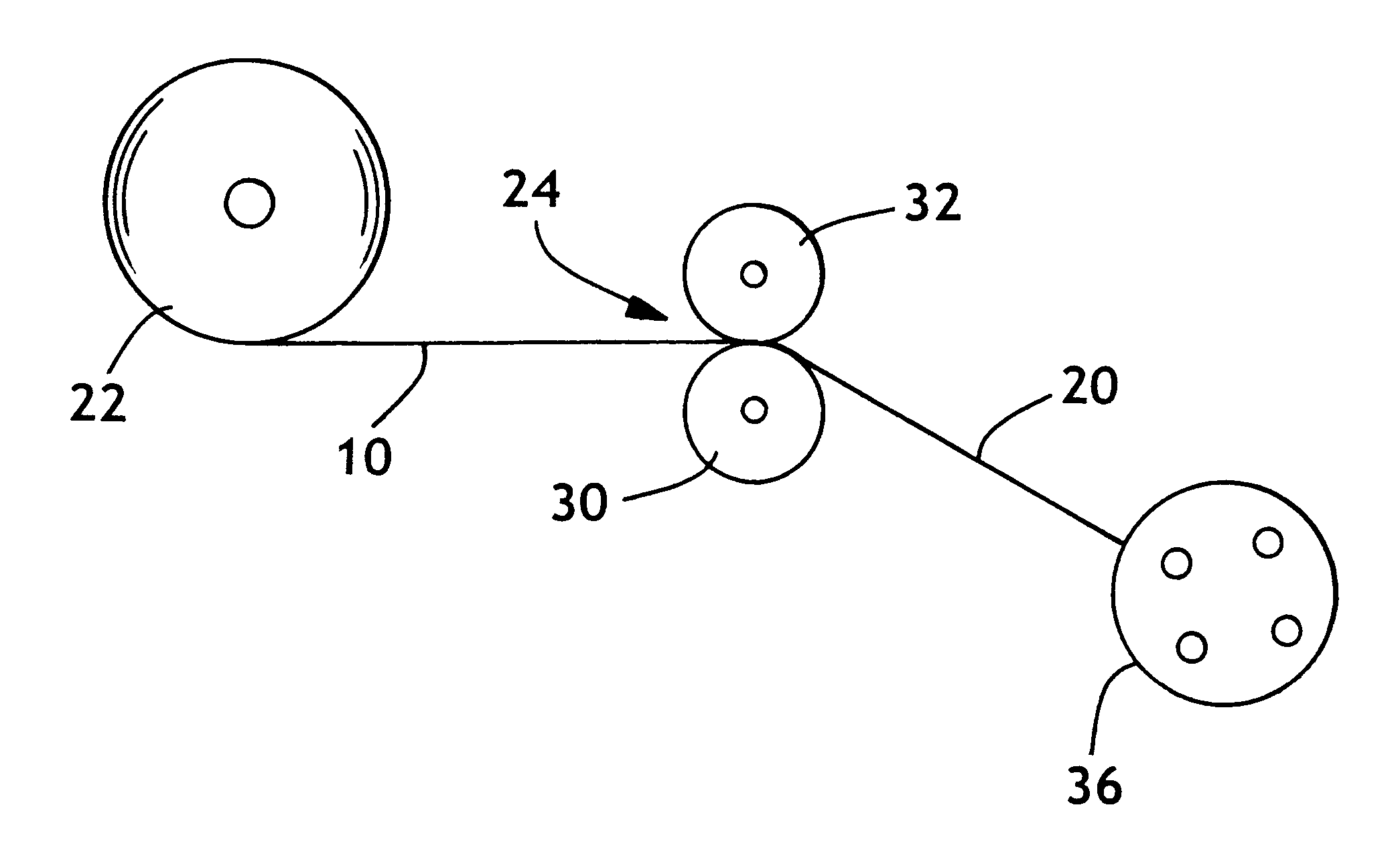

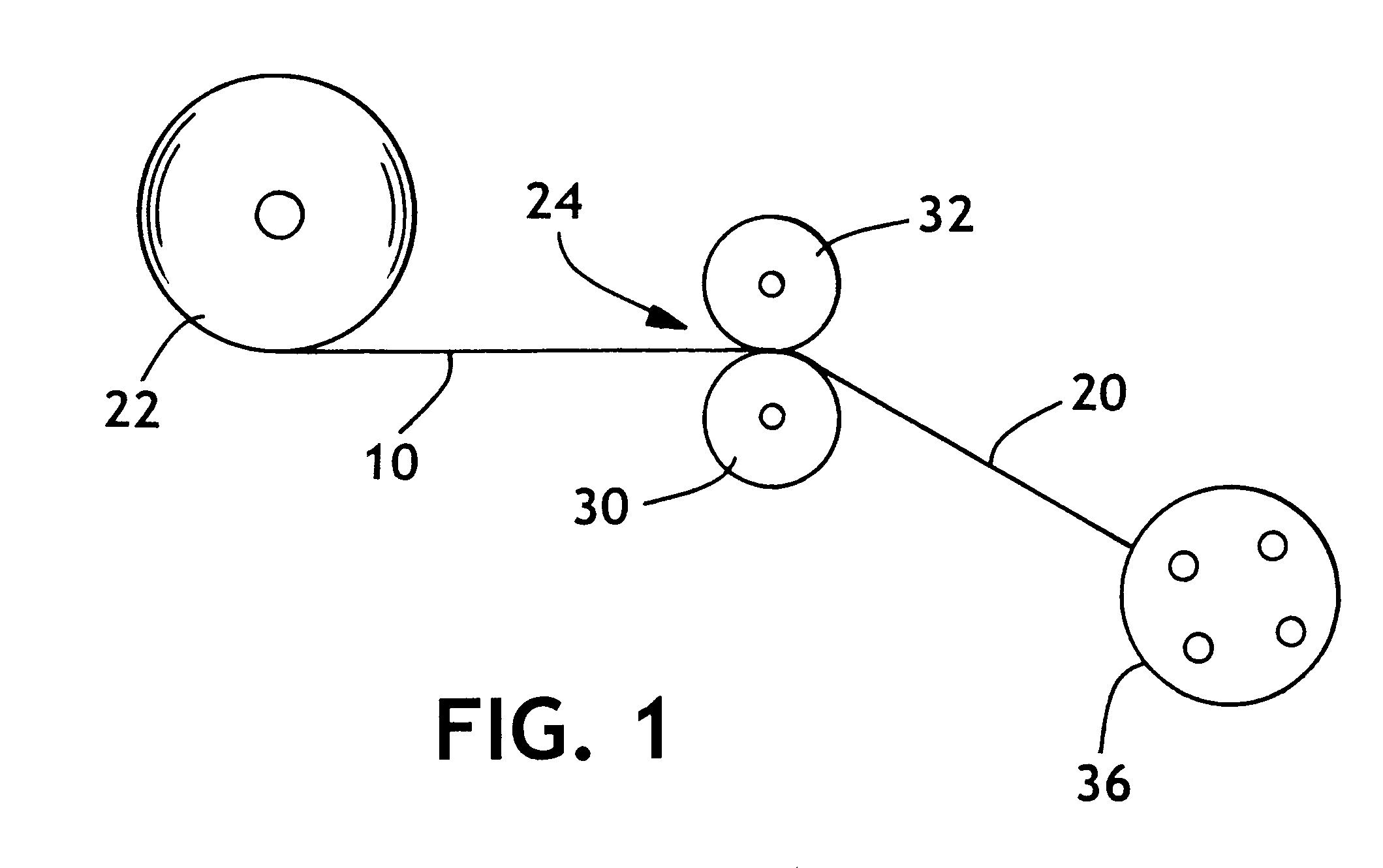

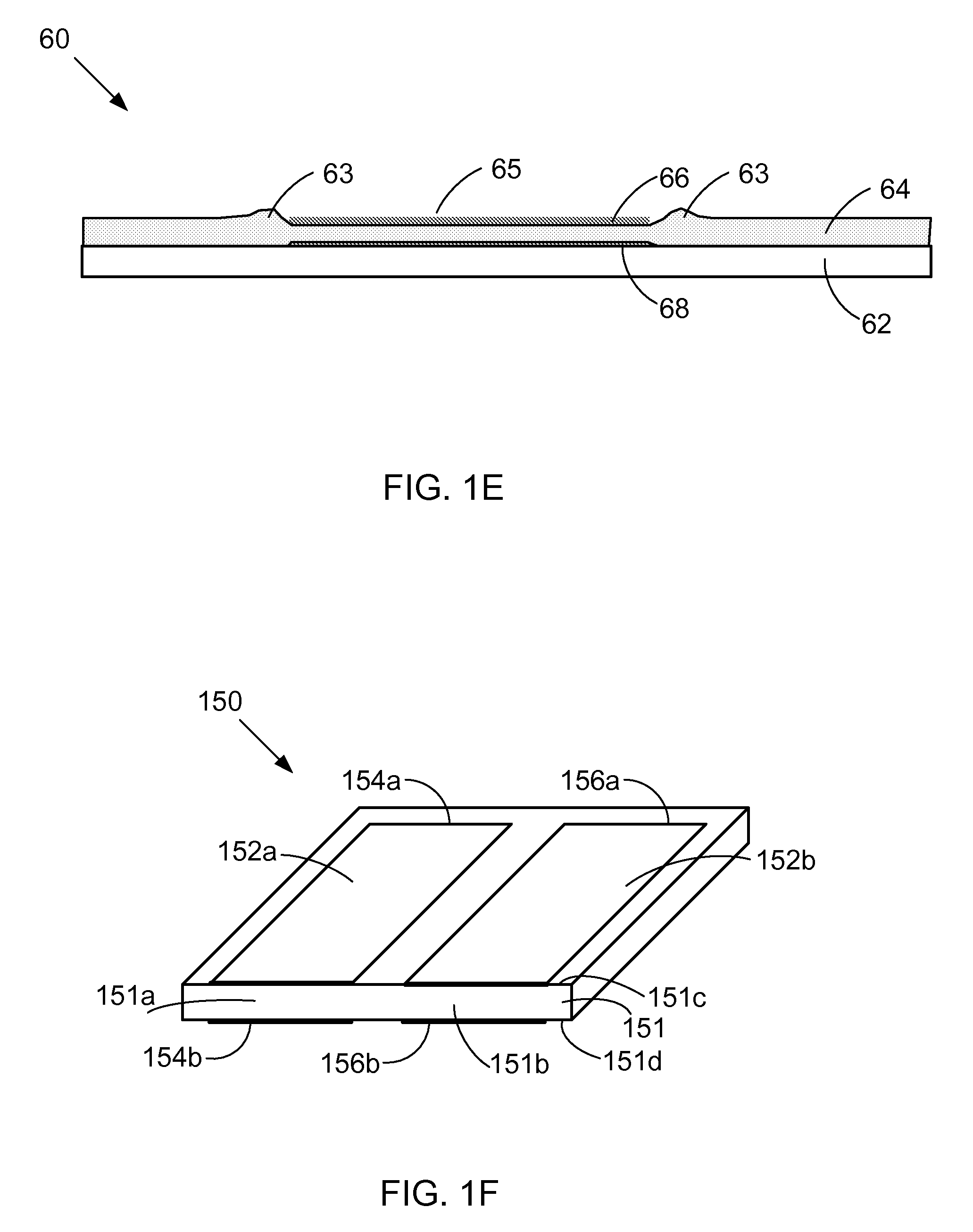

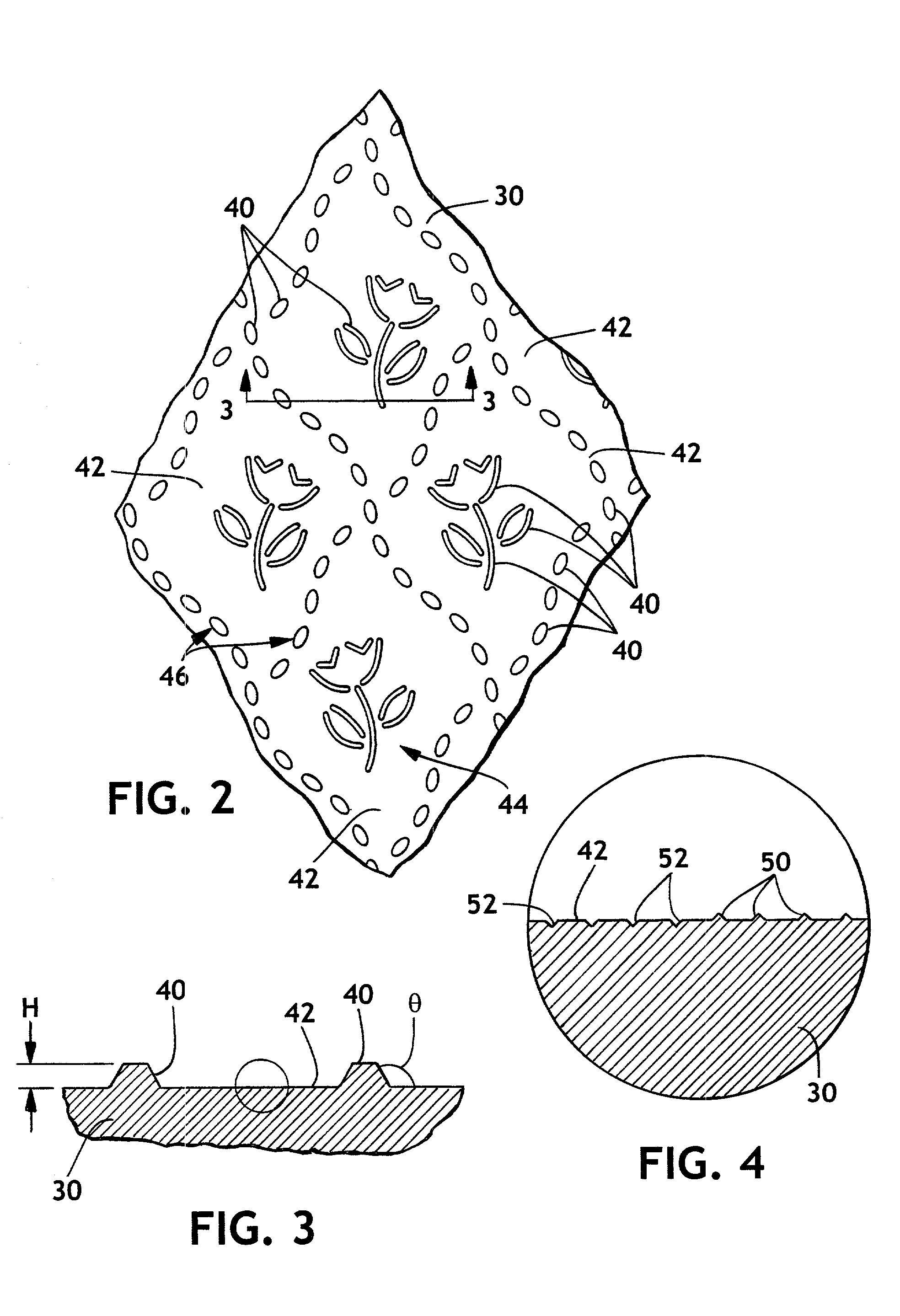

A novel paper article, a method of making a paper product, and an embossing roll are disclosed for providing a paper surface region having a minority of fiber to fiber bonds broken in the paper surface region to a depth less than about 0.02 mm from the paper surface. In one aspect, the roughened embossing roll includes protuberances or depressions sized at less than about 0.1 mm. In one aspect, the roughened embossing roll includes protuberances or depressions adapted to produce paper product surface deformations in the paper surface, wherein the paper product surface deformations are invisible to an unaided human eye. The present invention provides a paper product having higher perceived softness while maintaining tensile strength.

Owner:KIMBERLY-CLARK WORLDWIDE INC

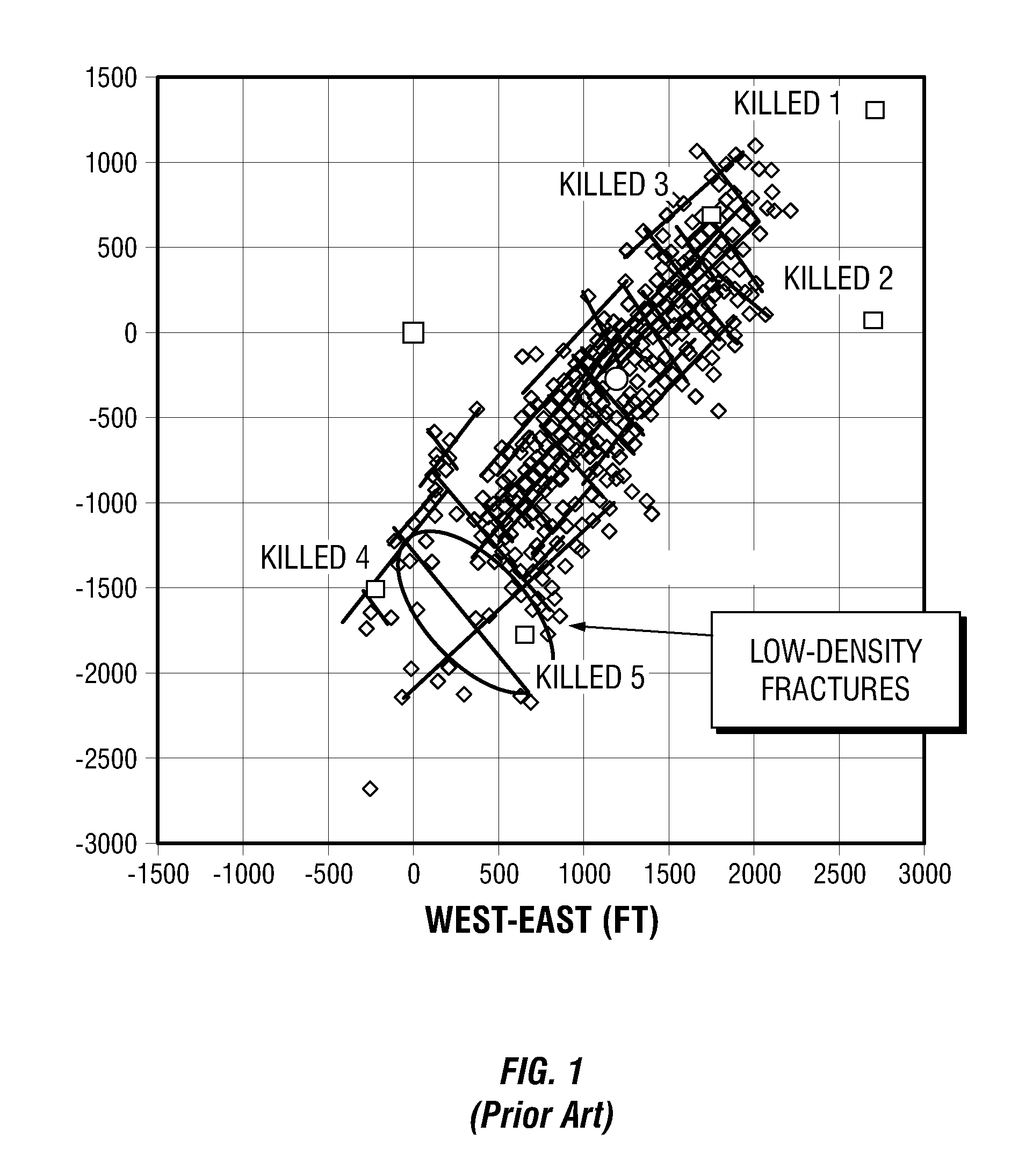

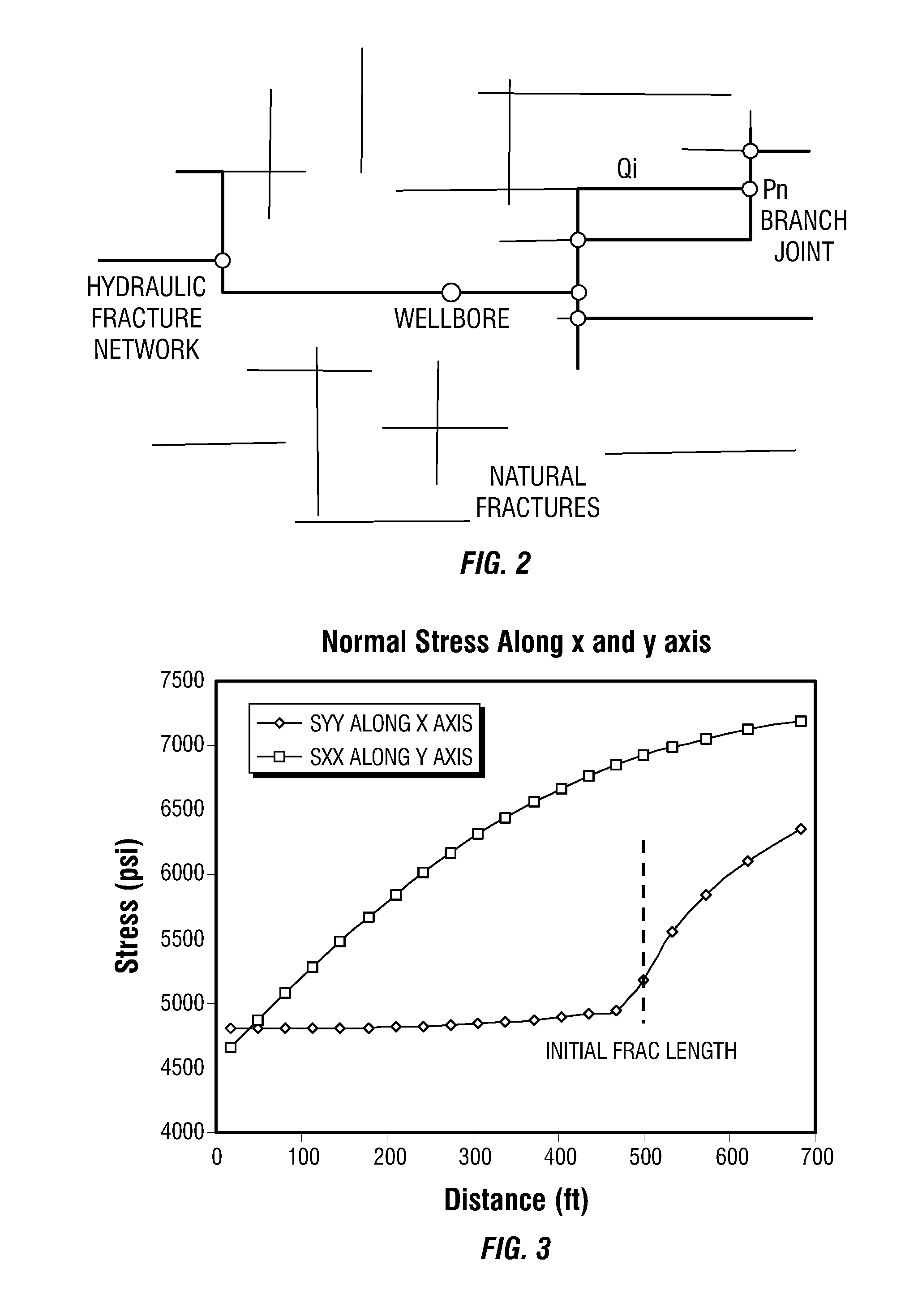

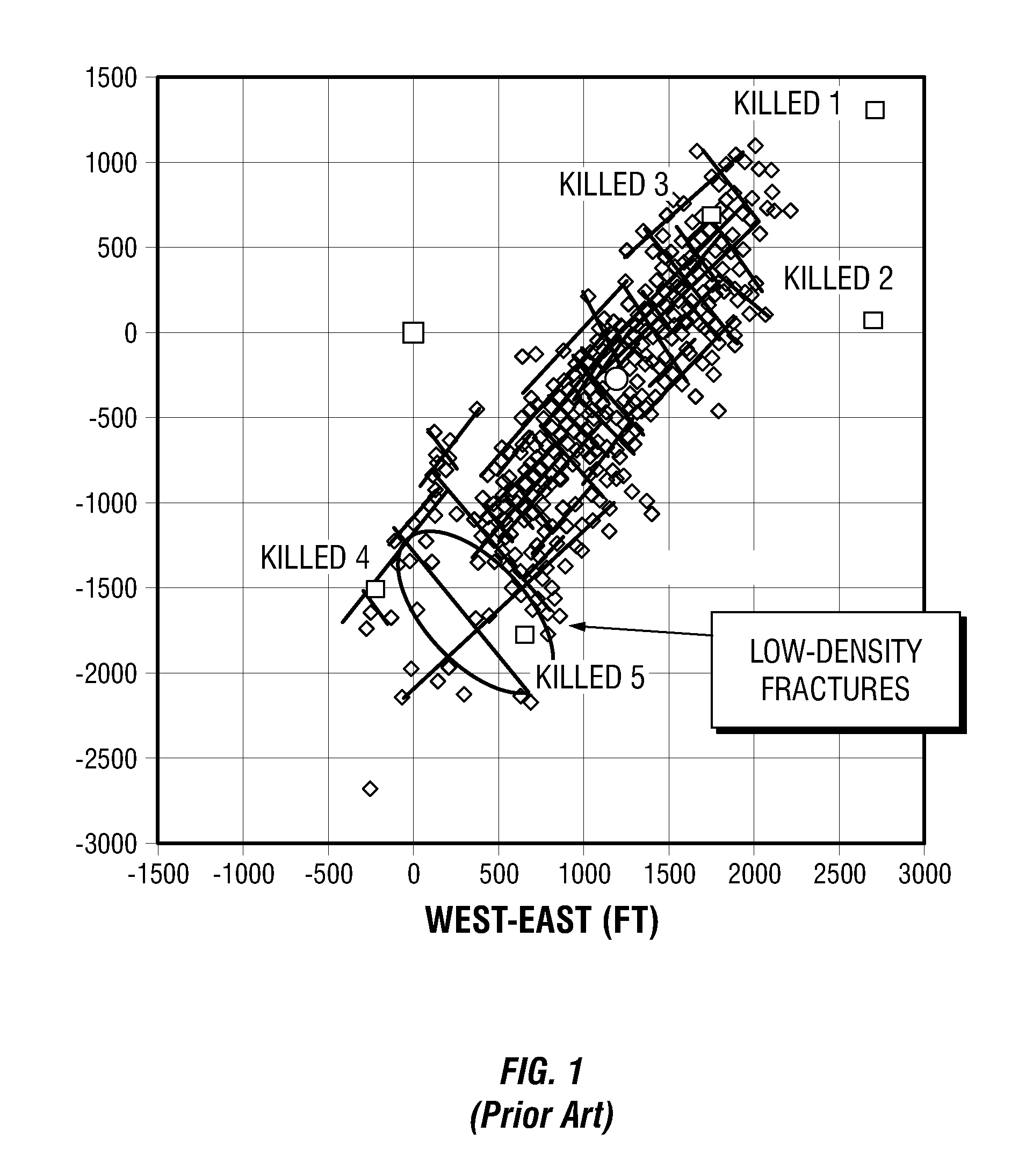

Simulations for Hydraulic Fracturing Treatments and Methods of Fracturing Naturally Fractured Formation

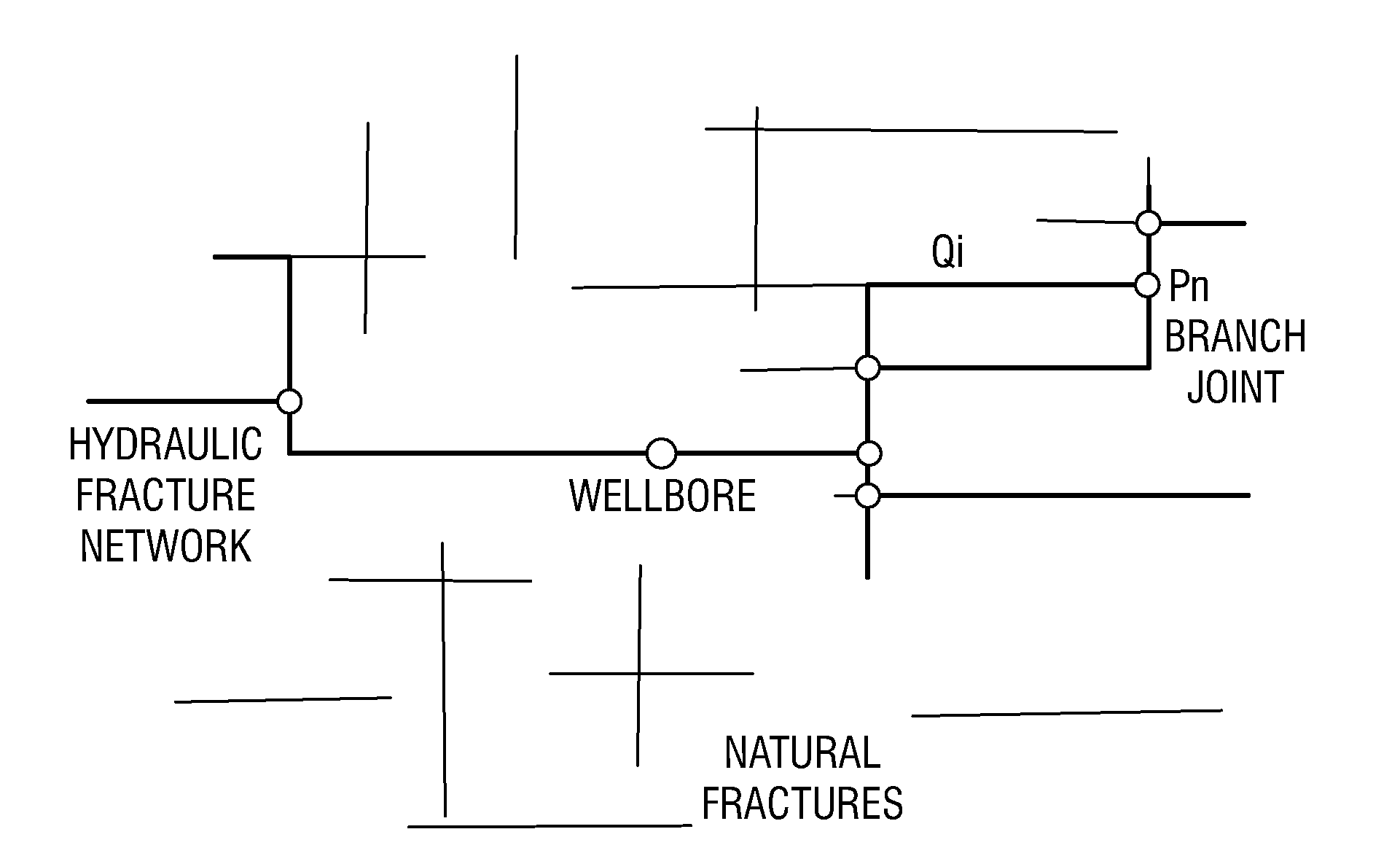

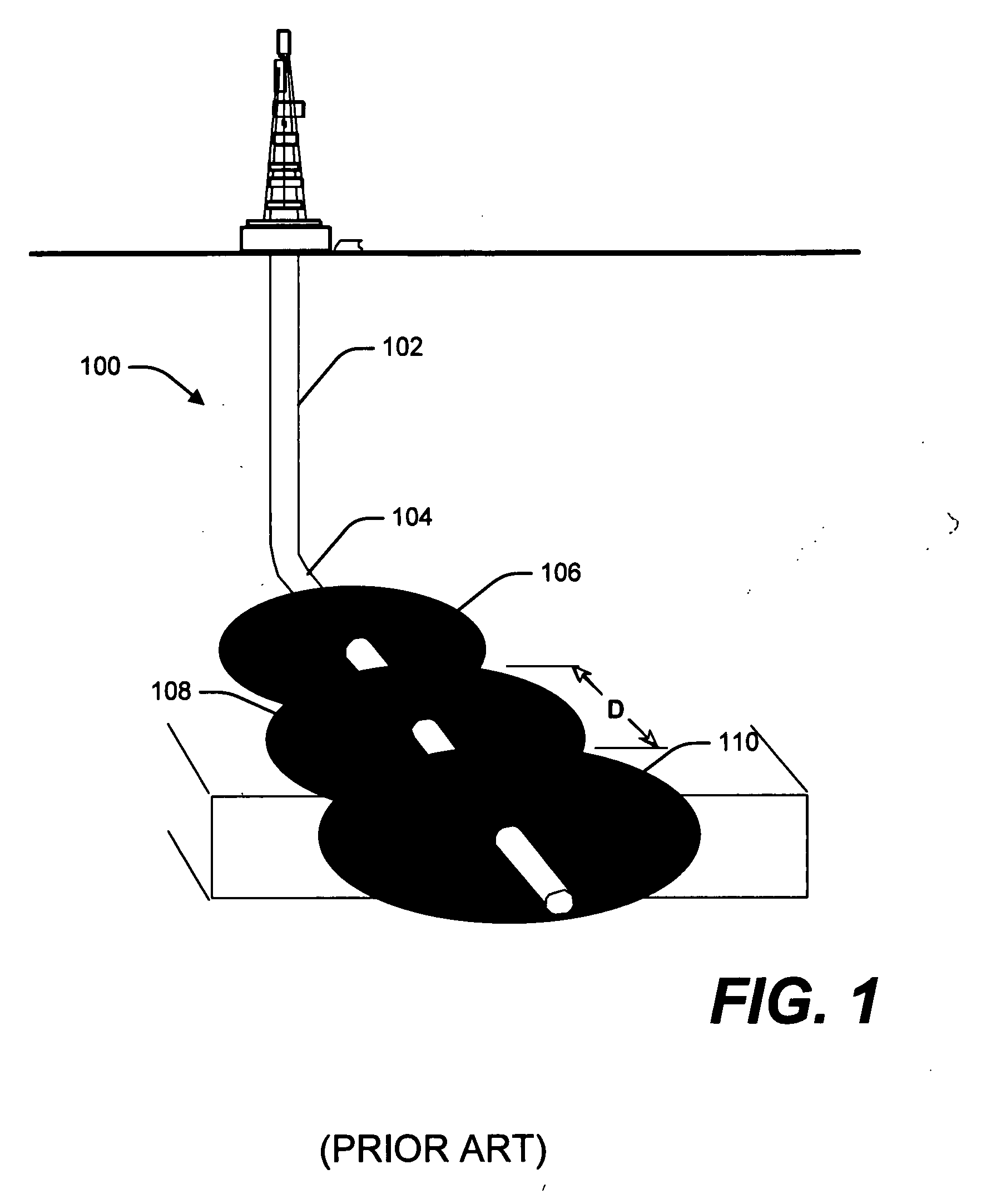

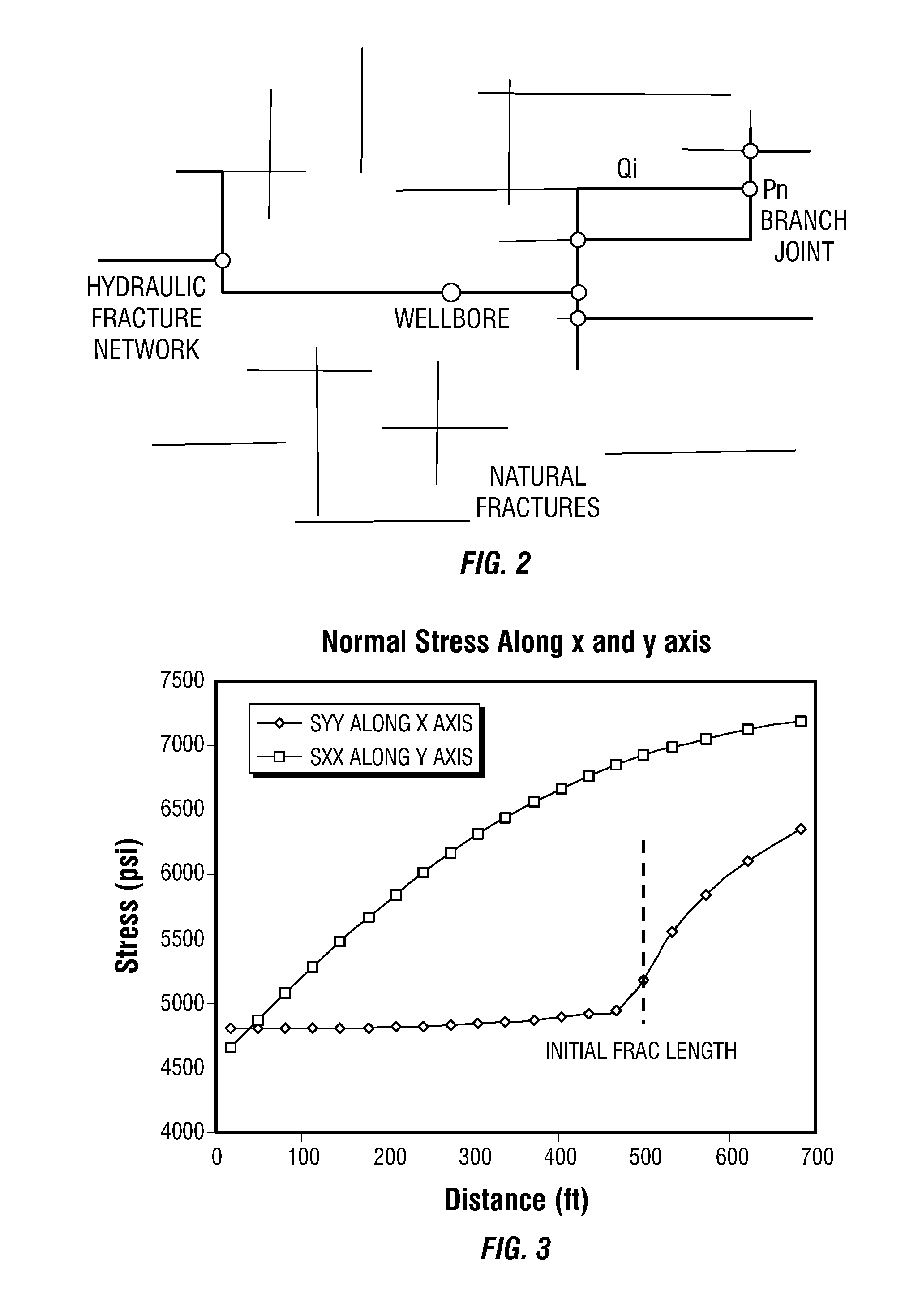

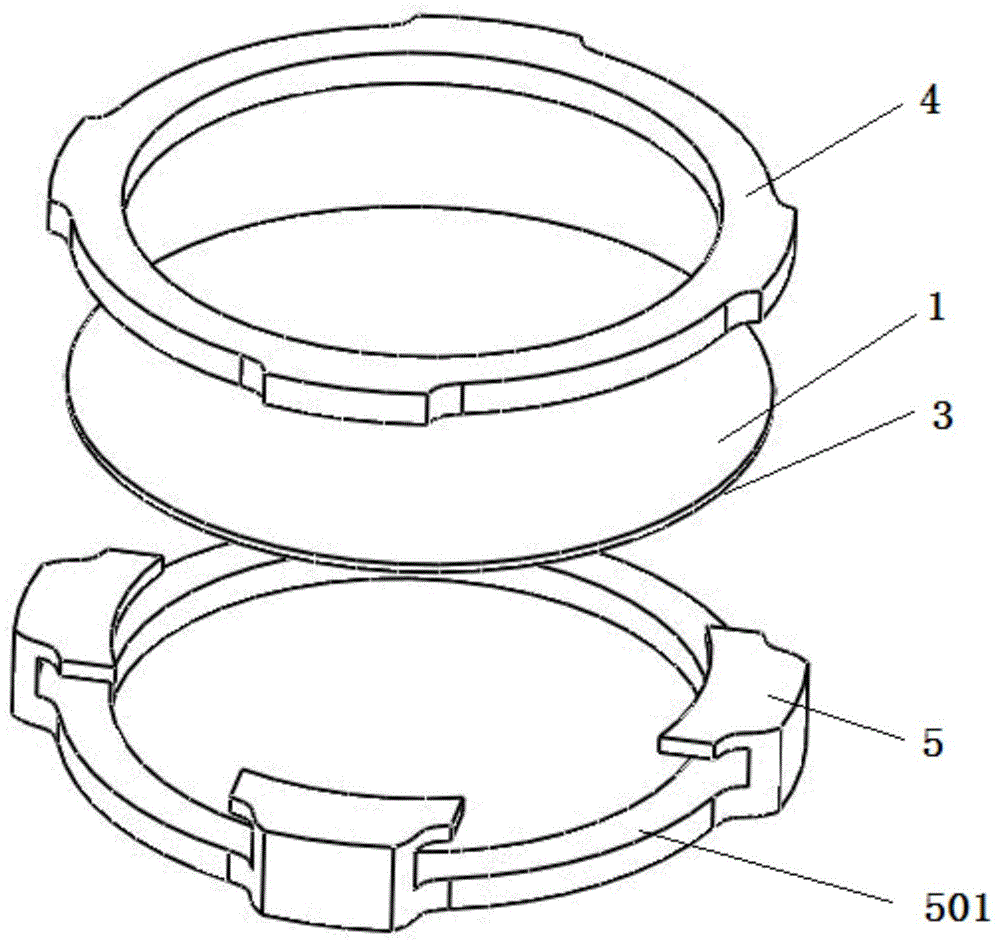

A hydraulic fracture design model that simulates the complex physical process of fracture propagation in the earth driven by the injected fluid through a wellbore. An objective in the model is to adhere with the laws of physics governing the surface deformation of the created fracture subjected to the fluid pressure, the fluid flow in the gap formed by the opposing fracture surfaces, the propagation of the fracture front, the transport of the proppant in the fracture carried by the fluid, and the leakoff of the fracturing fluid into the permeable rock. The models used in accordance with methods of the invention are typically based on the assumptions and the mathematical equations for the conventional 2D or P3D models, and further take into account the network of jointed fracture segments. For each fracture segment, the mathematical equations governing the fracture deformation and fluid flow apply. For each time step, the model predicts the incremental growth of the branch tips and the pressure and flow rate distribution in the system by solving the governing equations and satisfying the boundary conditions at the fracture tips, wellbore and connected branch joints. An iterative technique is used to obtain the solution of this highly nonlinear and complex problem.

Owner:SCHLUMBERGER TECH CORP

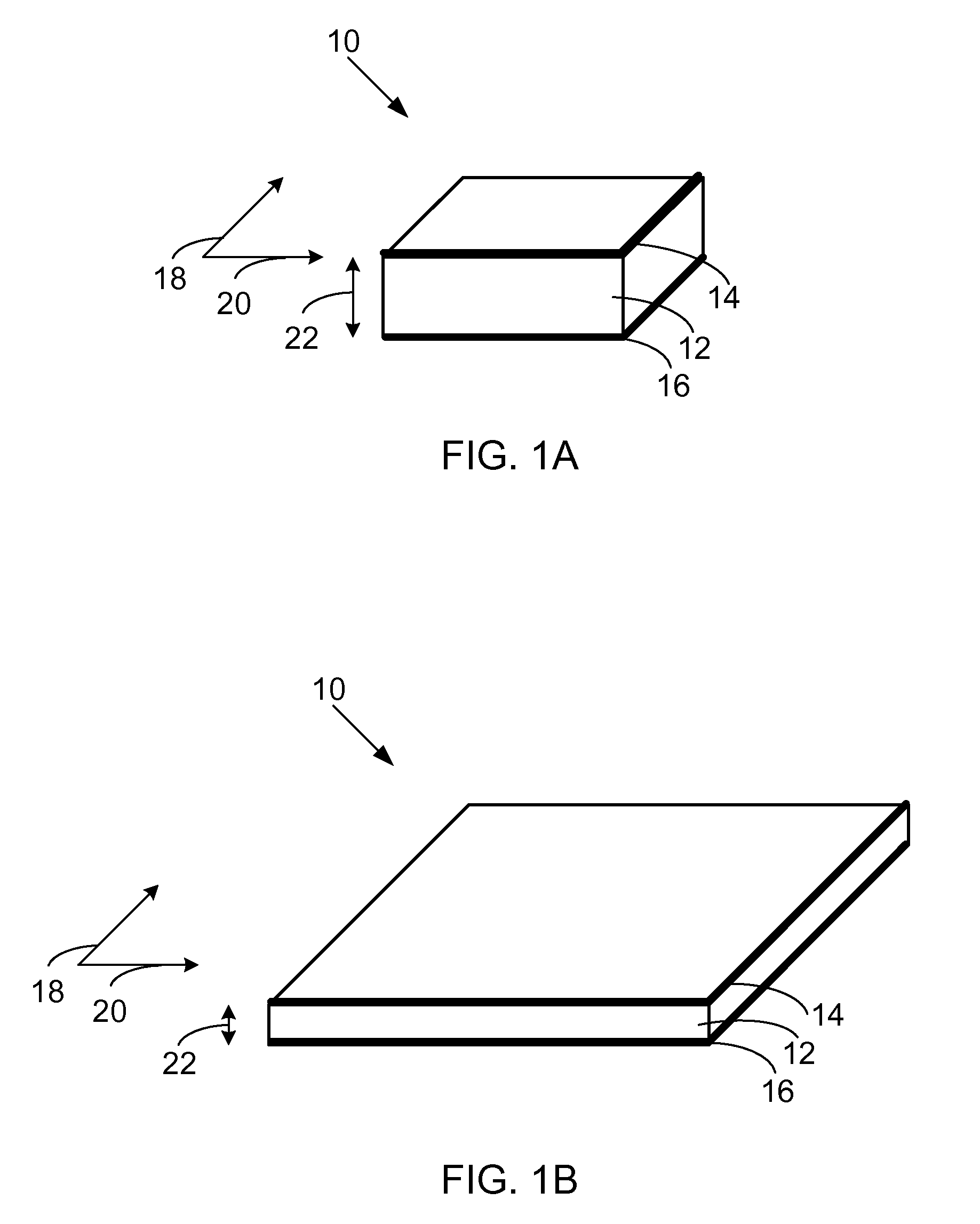

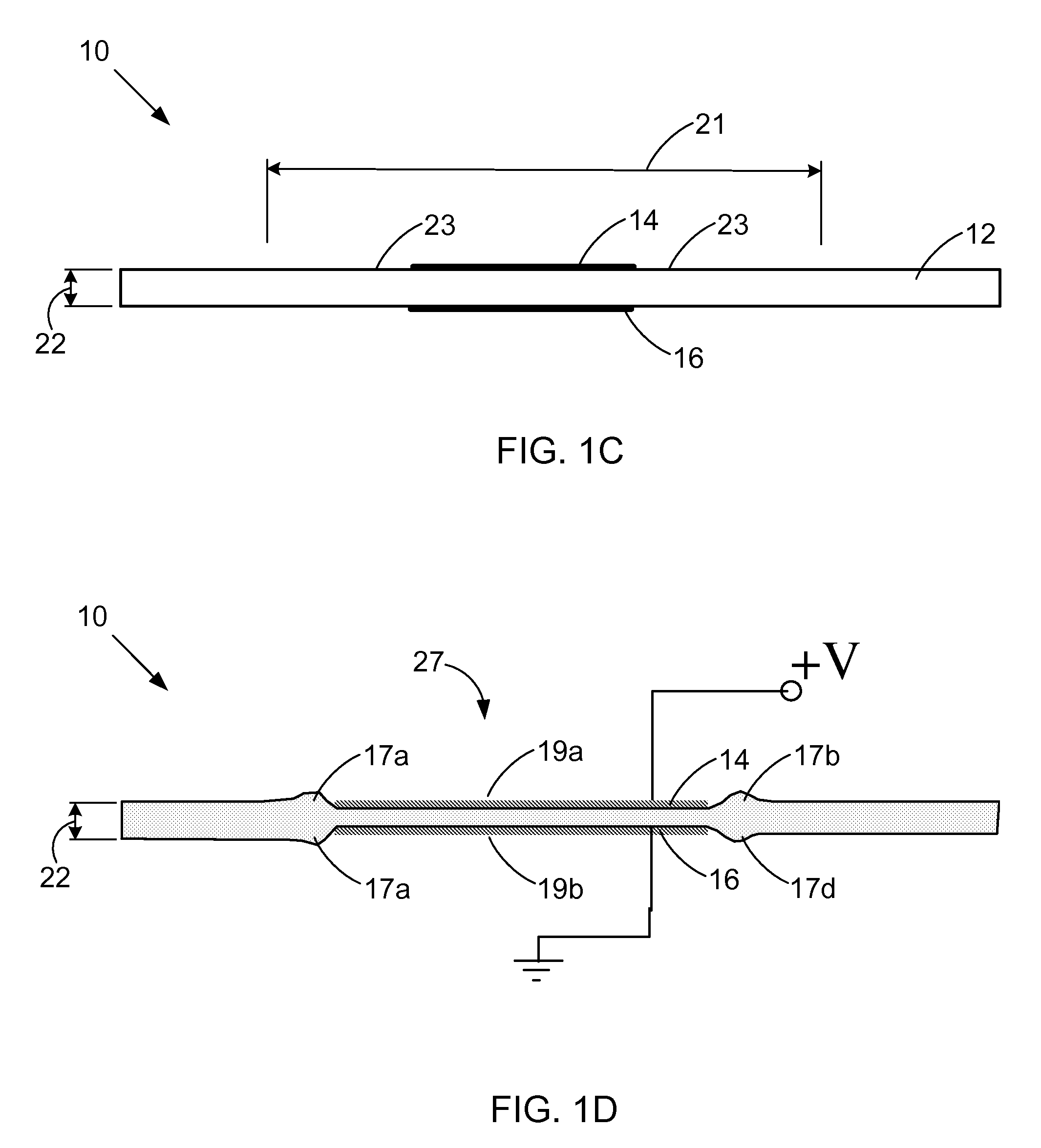

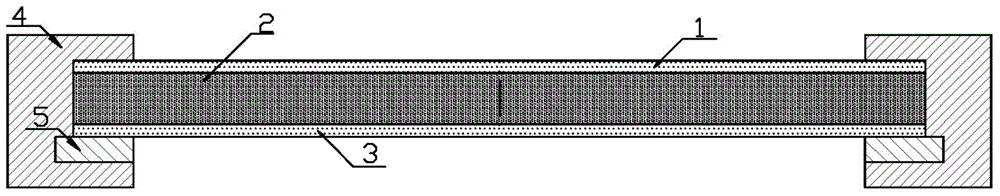

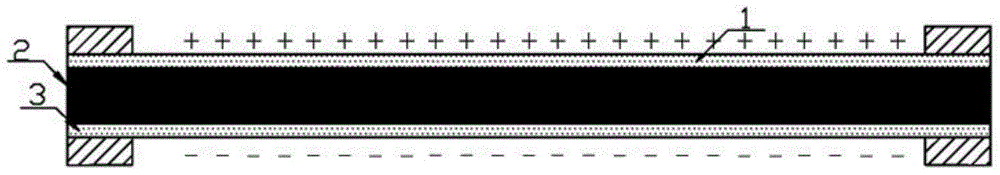

Surface deformation electroactive polymer transducers

InactiveUS20080289952A1Augments out-of-plane deflectionsIncrease awarenessPiezoelectric/electrostriction/magnetostriction machinesEfficient propulsion technologiesPolymeric surfaceVisibility

The present invention provides electroactive polymer transducers that produce out-of-plane deflections. The transducers form a set of surface features based on deflection of an electroactive polymer. The set of surface features may include elevated polymer surface features and / or depressed electrode surface features. Actuation of an active area may produce the polymer deflection that creates one or more surface features. A passive layer may operably connect to a polymer. The passive layer may comprise a thicker and softer material to amplify polymer thickness changes and increase surface feature visibility.

Owner:SRI INTERNATIONAL

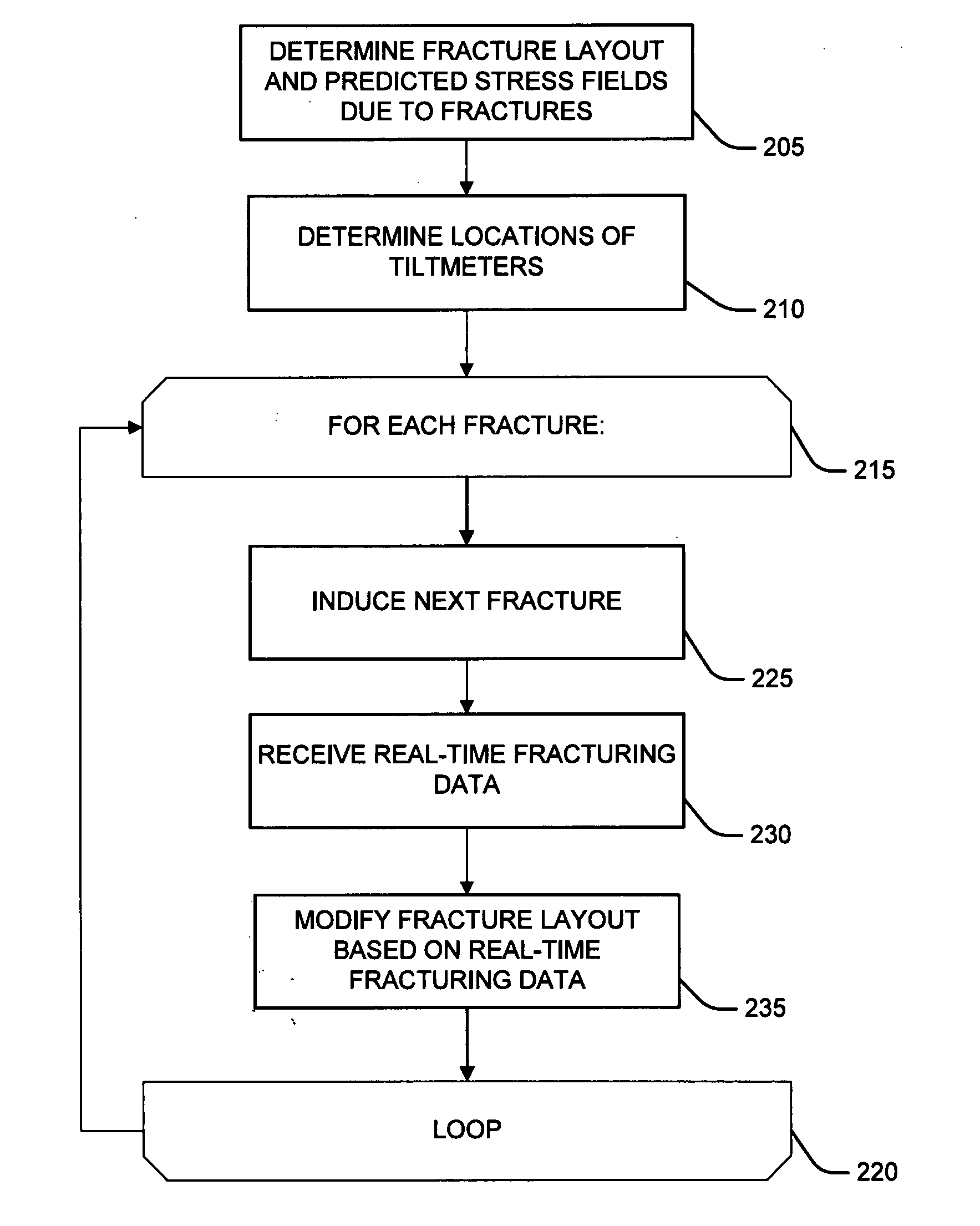

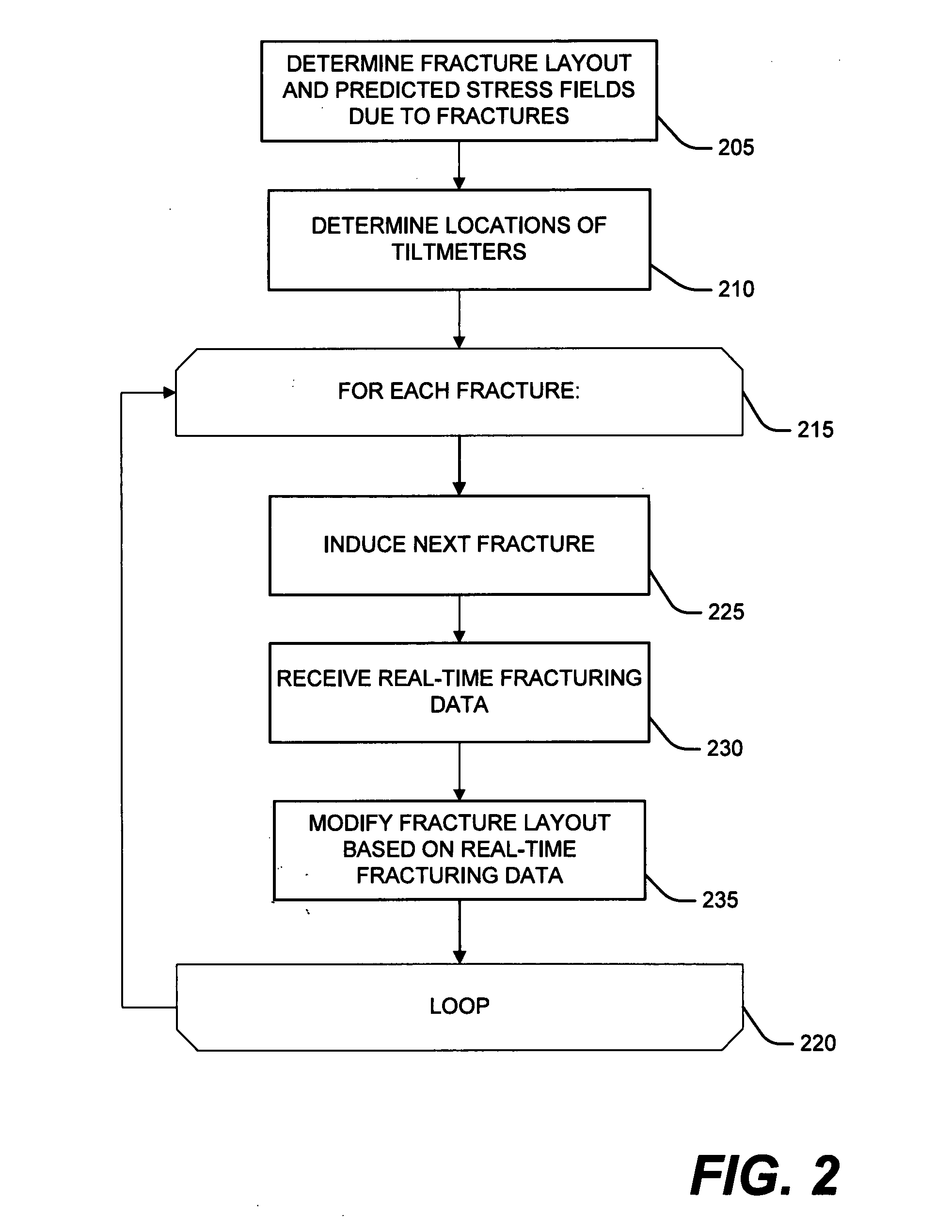

Methods for geomechanical fracture modeling

The present invention relates generally to methods for designing and optimizing the number, placement, and size of fractures in a subterranean formation and more particularly to methods that account for stress interference from other fractures when designing and optimizing the number, placement, and size of fractures in the subterranean formation. The present invention optimizes the number, placement and size of fractures in a subterranean formation. The present invention determines one or more geomechanical stresses induced by each fracture based on the dimensions and location of each fracture, including surface deformations caused by each fracture. The present invention determines a maximum number of fractures and a predicted stress field based on the geomechanical stresses induced by each of the fractures.

Owner:HALLIBURTON ENERGY SERVICES INC

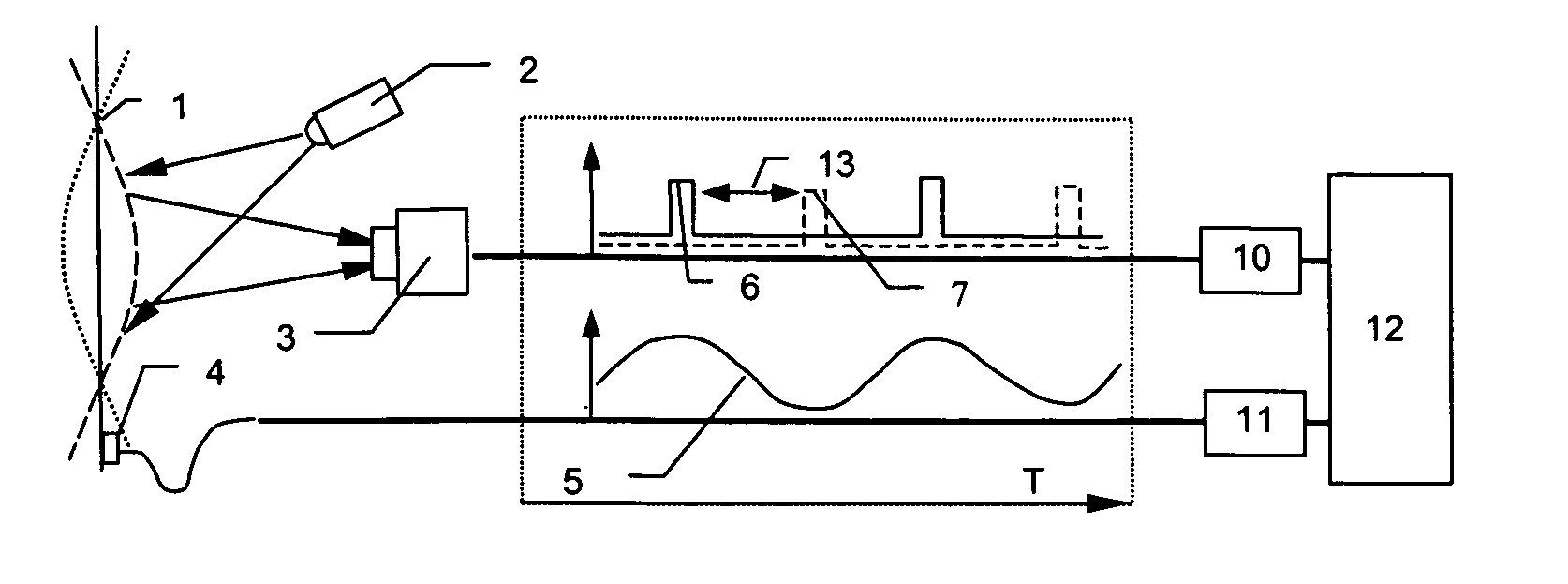

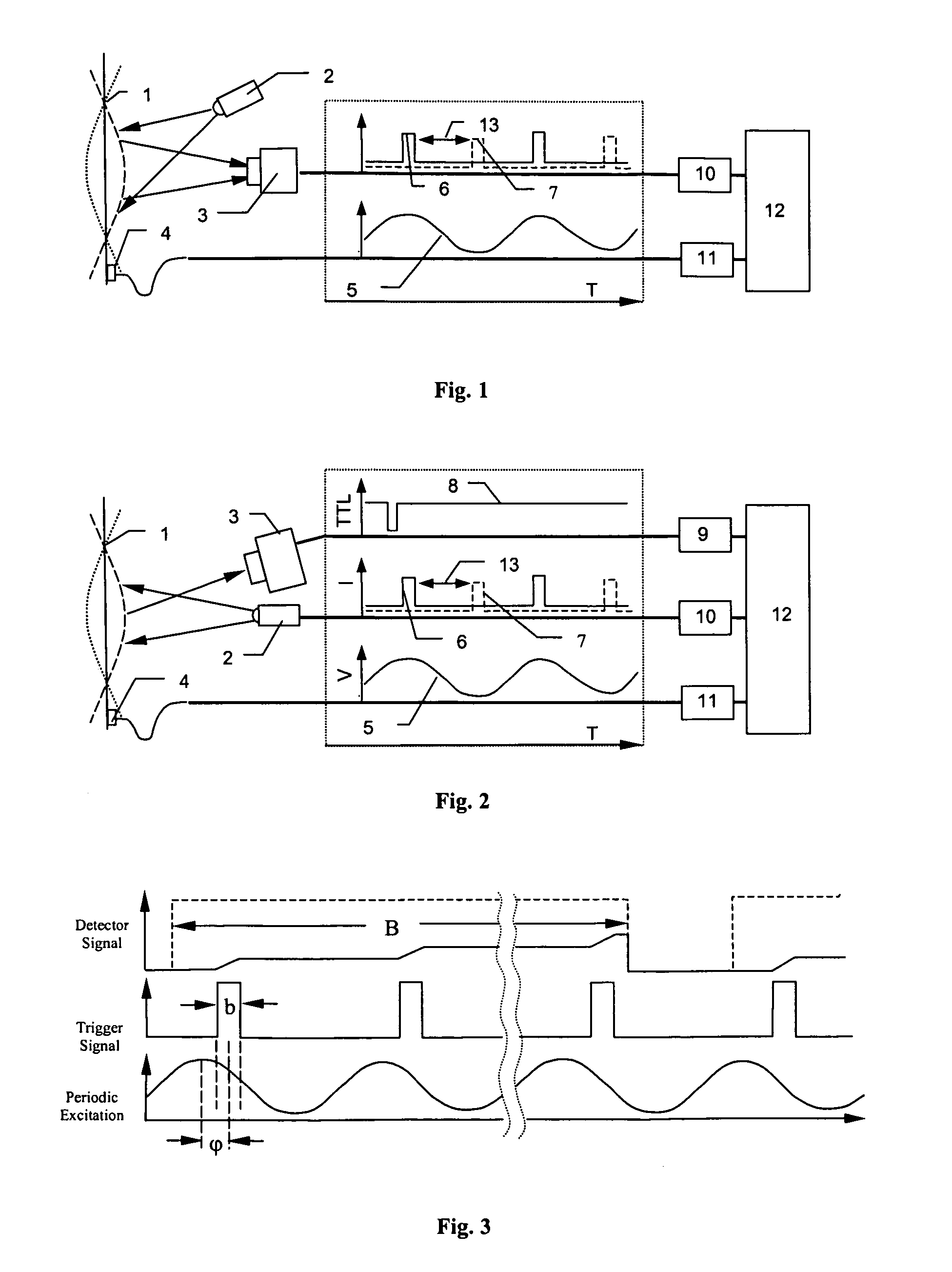

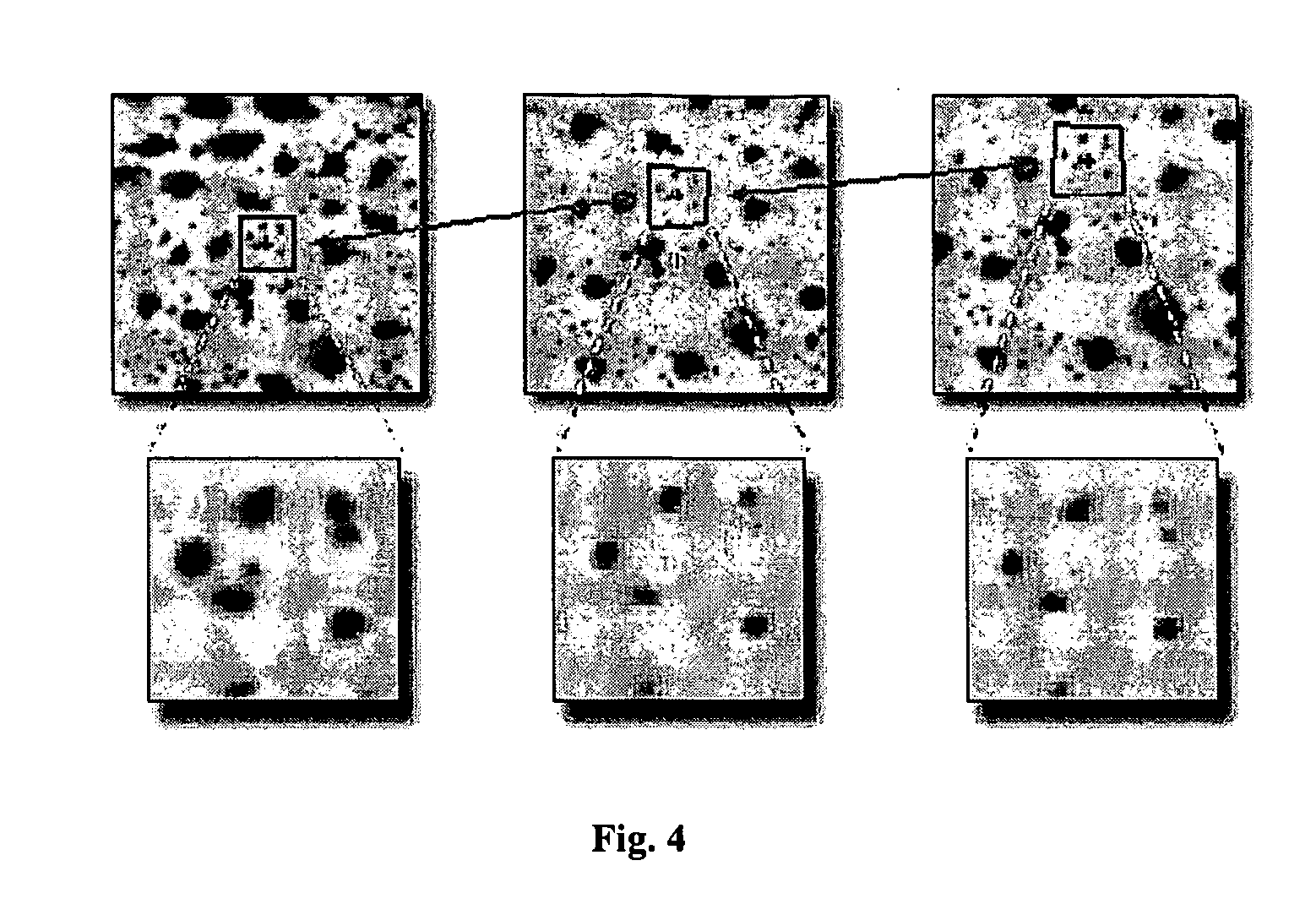

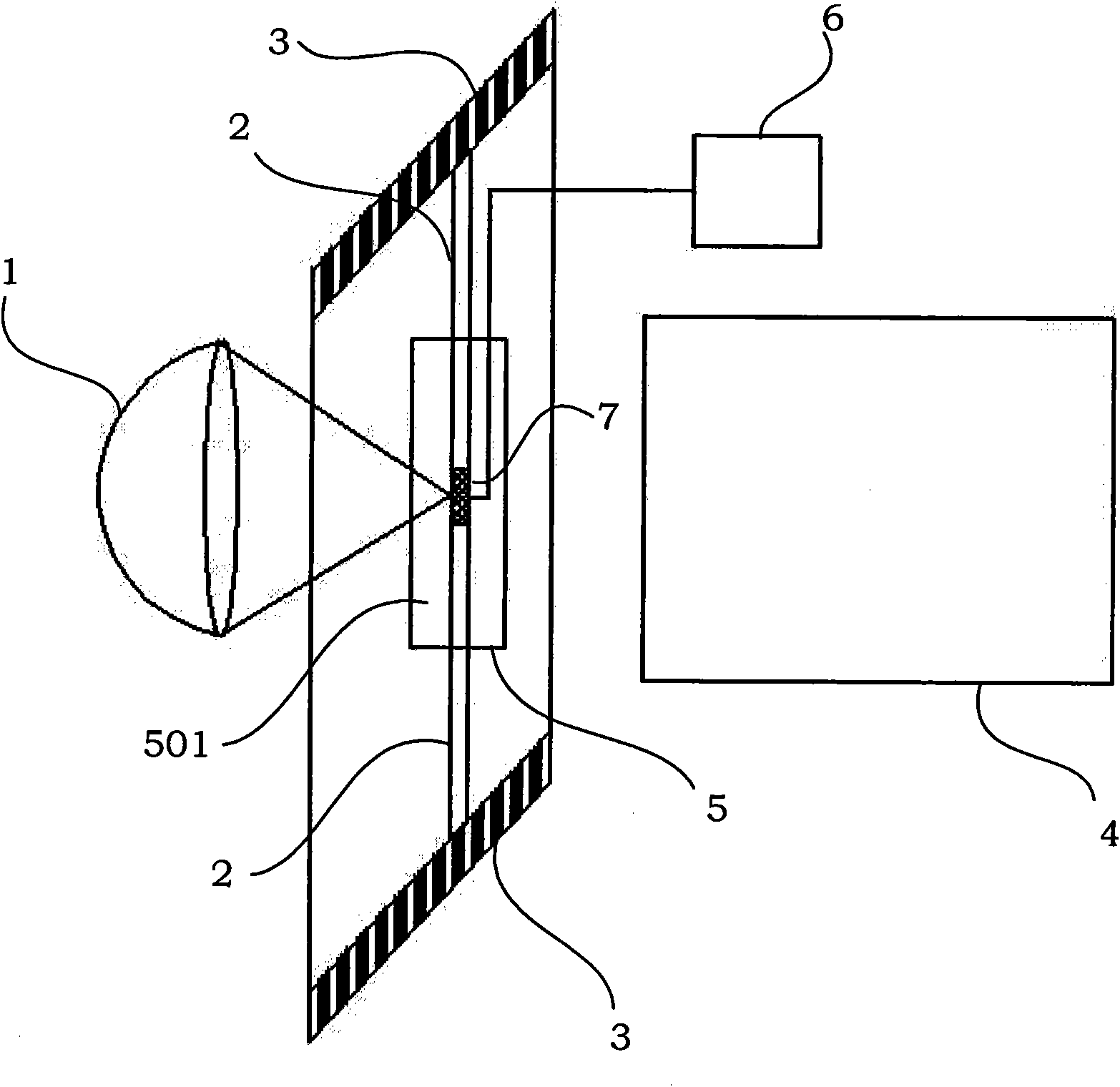

Visualization, measurement and analysis of vibrating objects

InactiveUS20050279172A1Low costReduce the numberVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesObject motionFull field

A simple, relatively inexpensive, non-contacting, full-field (total visible surface) measurement and visualization methodology is described to measure the object motions and the object stretches and object distortions (deformations) during oscillation of an object. The method is capable of full-field measurement of 1D, 2D and / or 3D object motions and the associated object surface deformations on vibrating objects. The methodology is based on a combination of stroboscopic image ascuisition and / or controlled image exposure time with a synchronization system to acquire the images at appropriate times during periodic oscillation of an object; the periodicity of the applied excitation is used to mitigate the requirement for high speed imaging. Then, image matching procedures, such as 3D digital image correlation, are used with software to extract full-field object motions and surface deformations at each time of interest.

Owner:CORRELATED SOLUTIONS

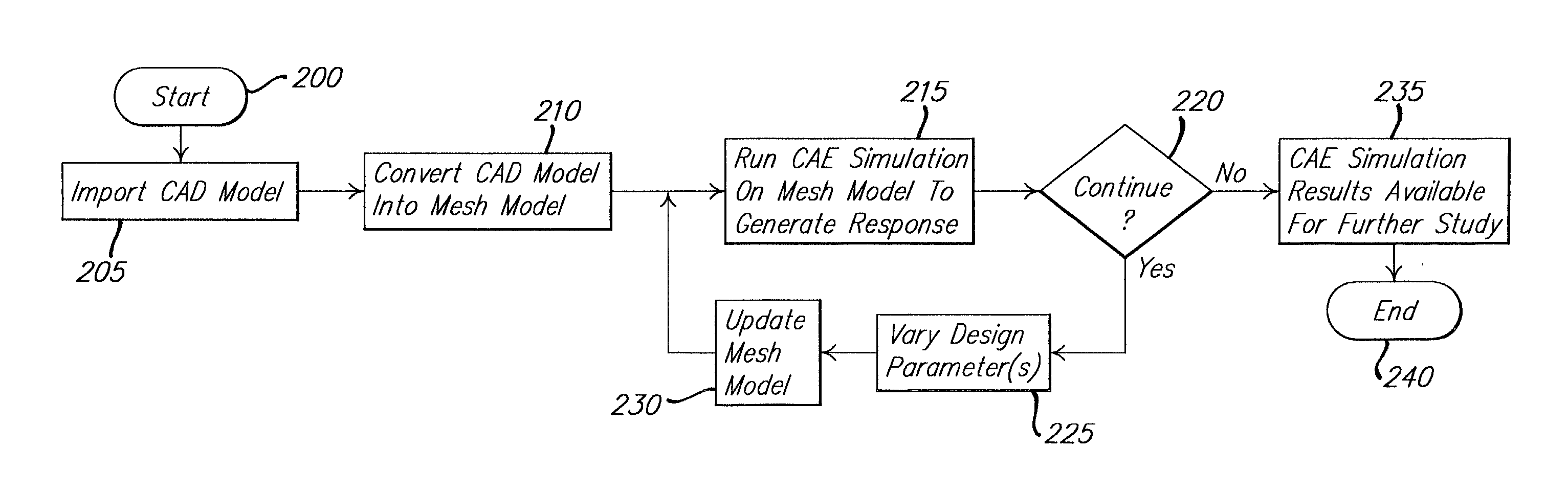

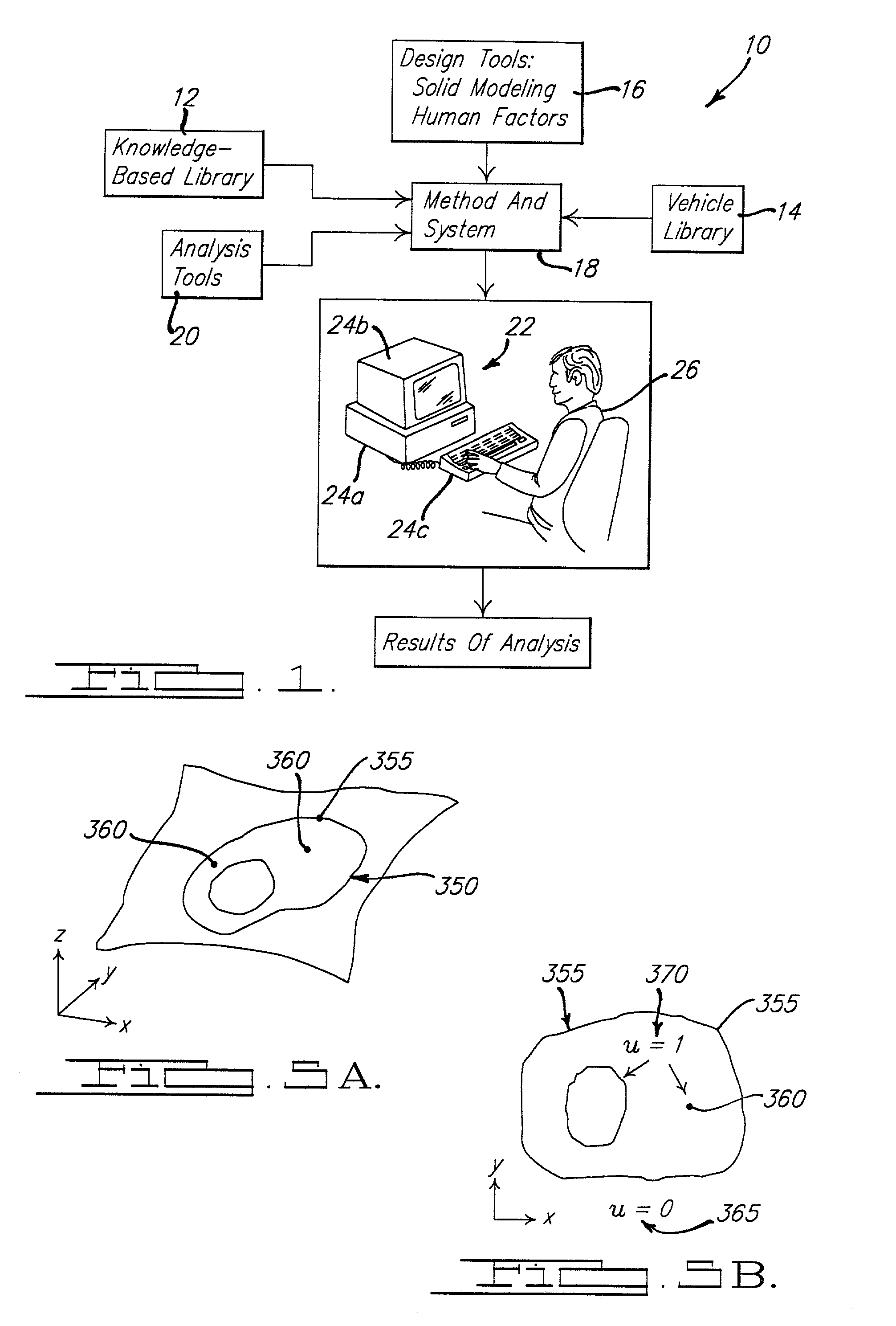

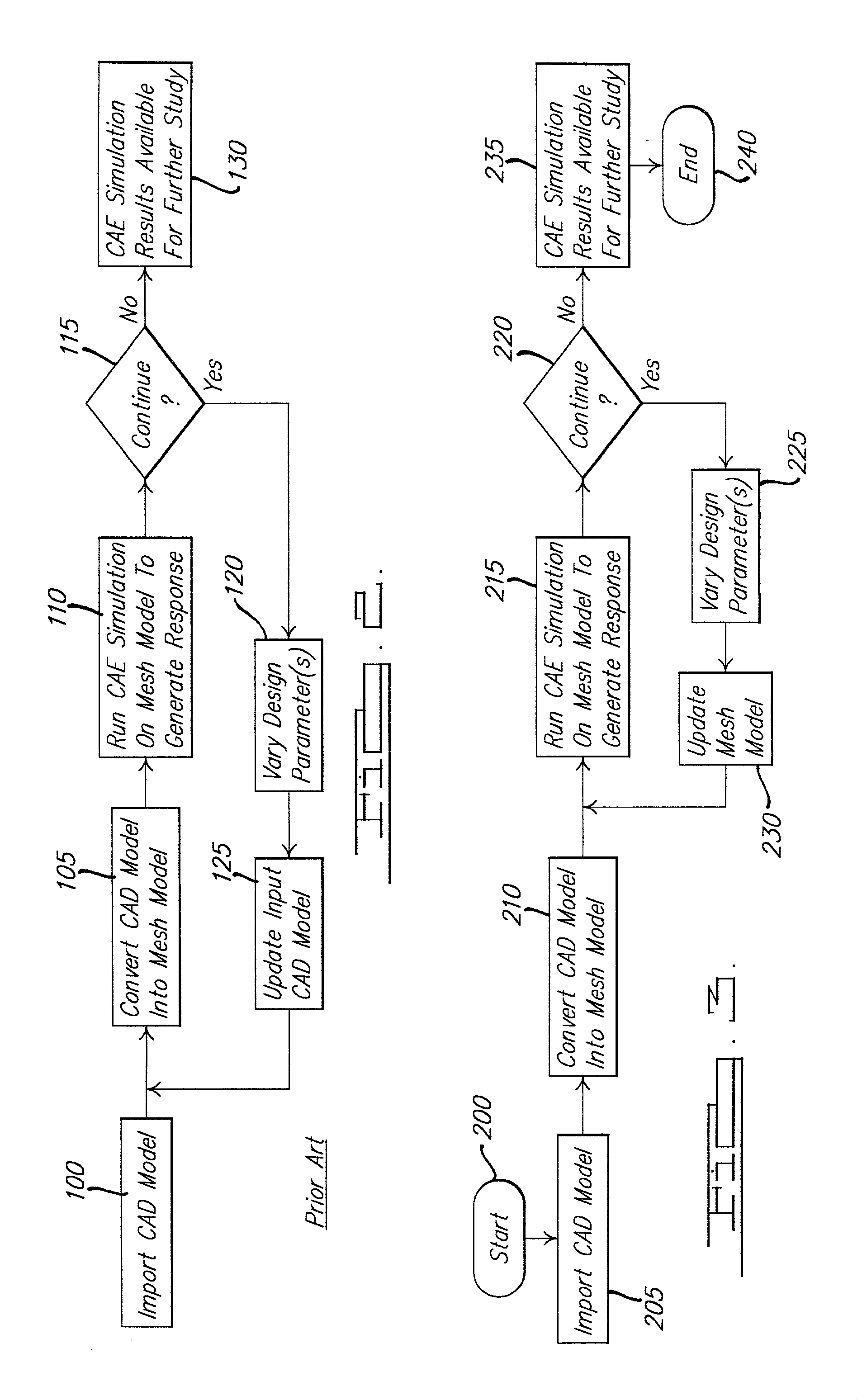

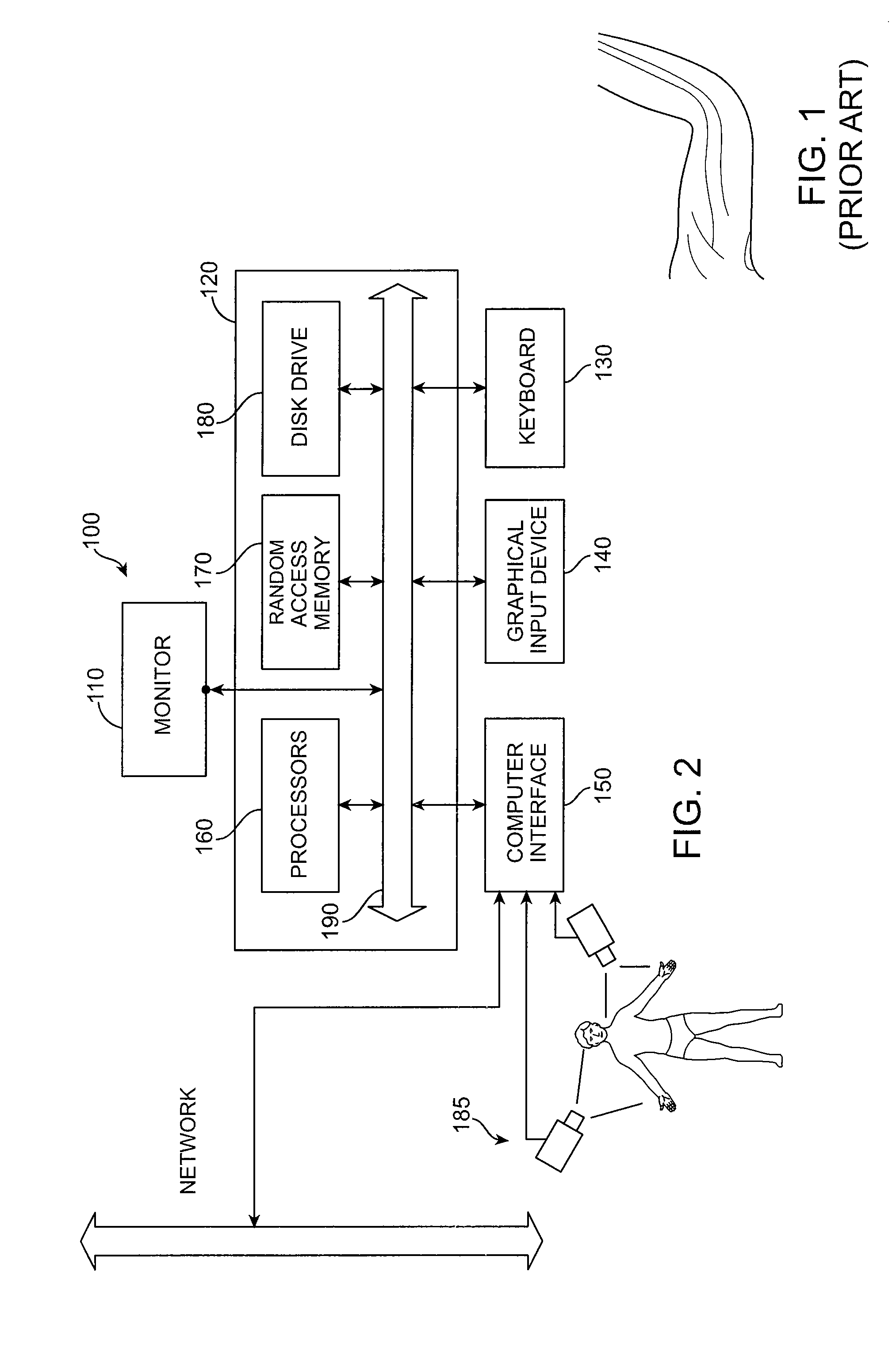

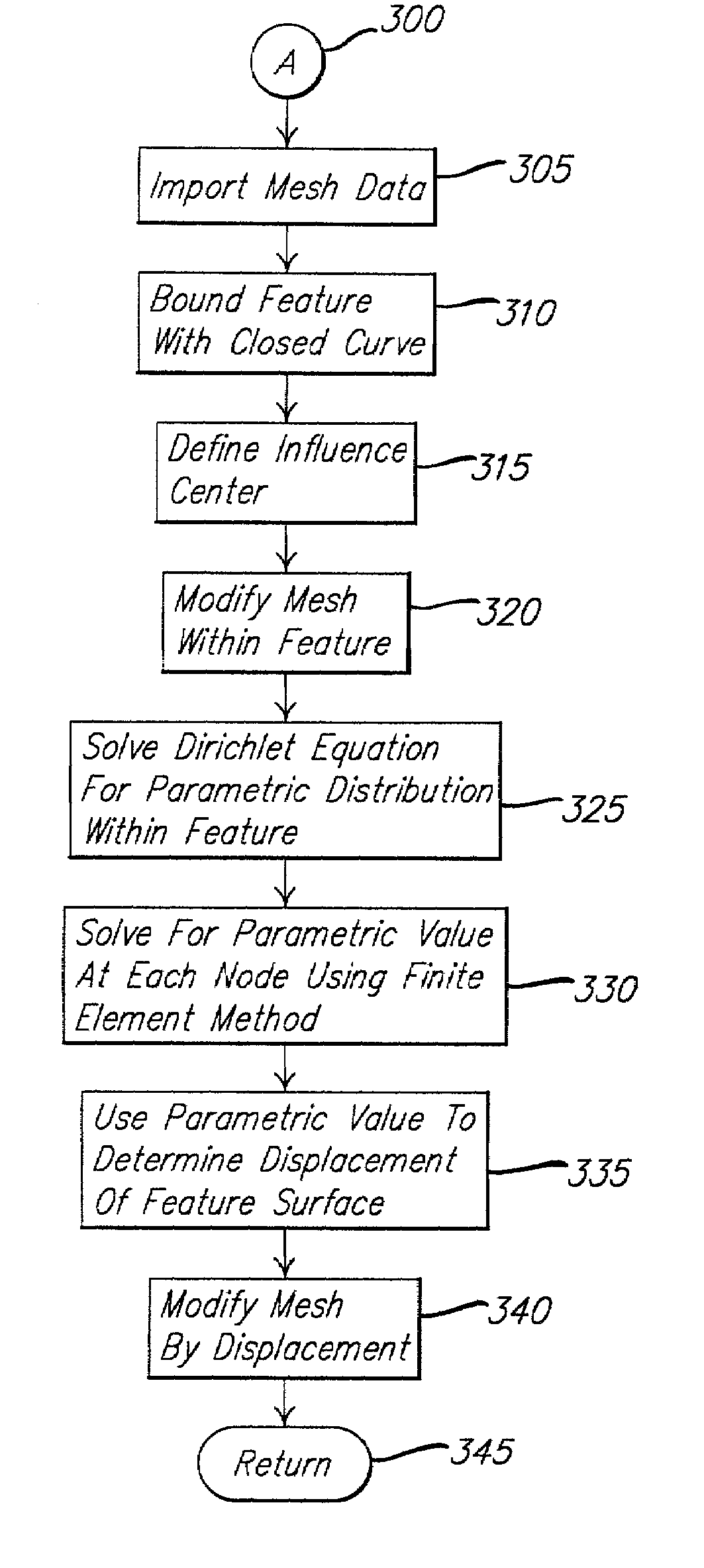

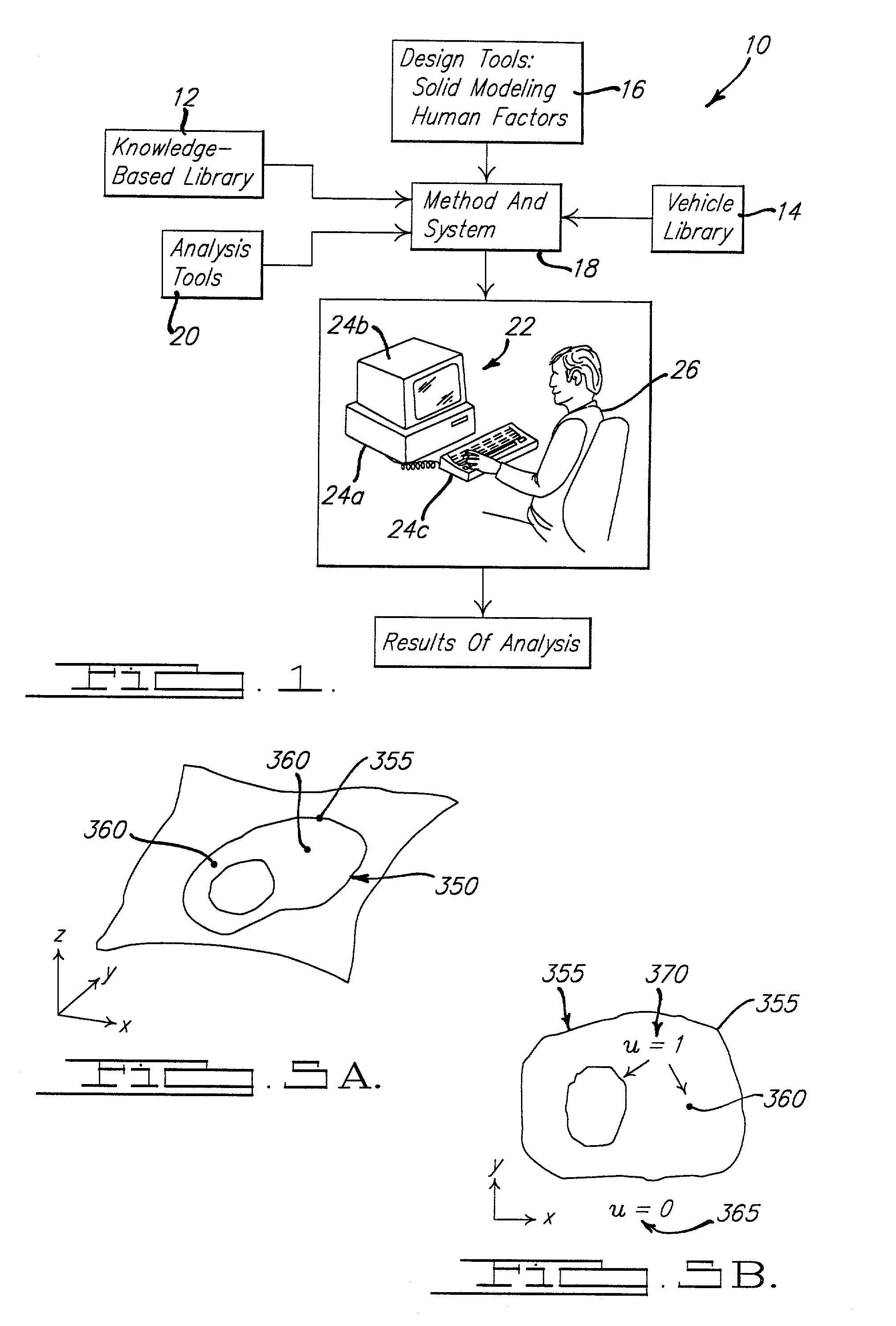

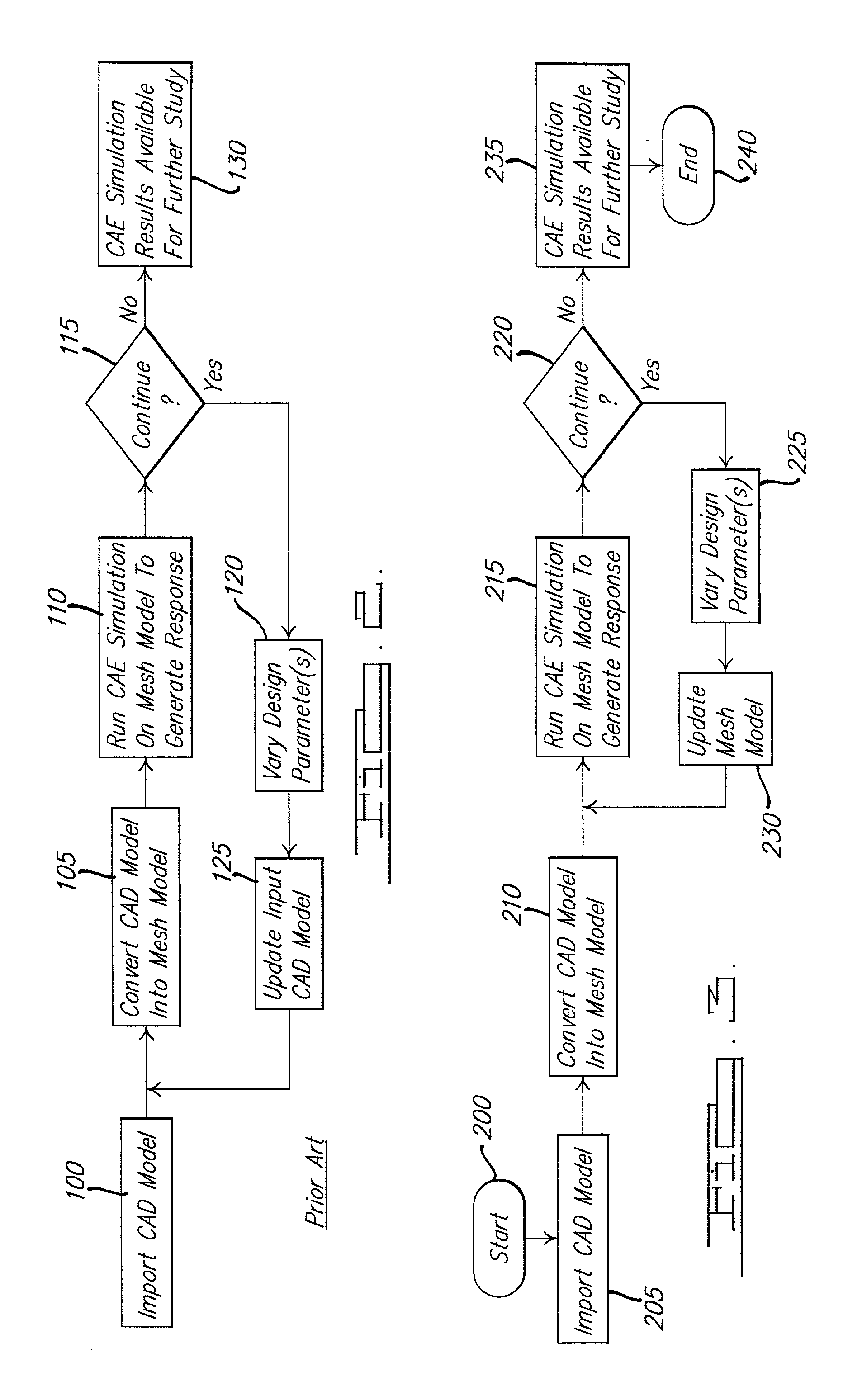

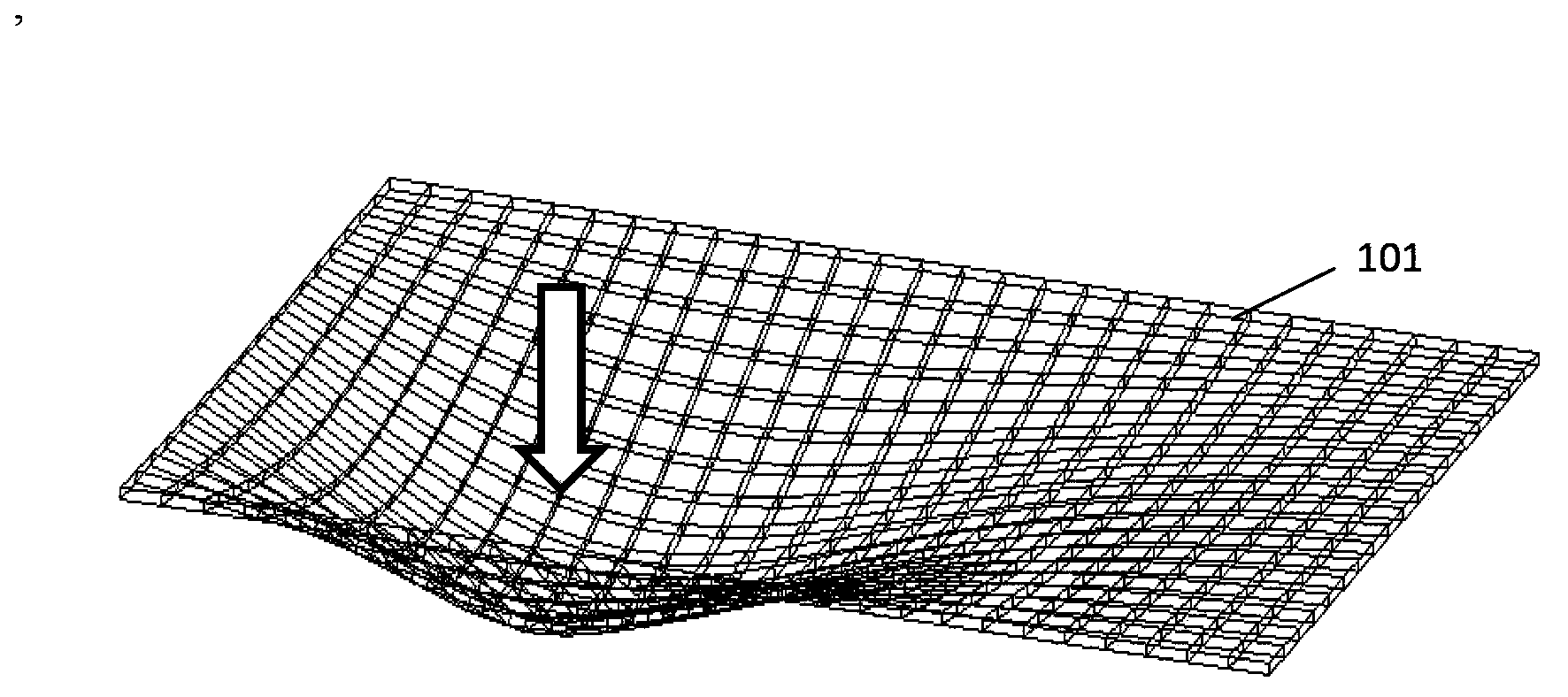

System and method of direct mesh manipulation

ActiveUS20030080957A1Geometric CADData processing applicationsComputer Aided DesignComputer graphics (images)

A system and method for computer-aided engineering analysis using direct mesh manipulation of a mesh model is provided. The system includes a computer system having a memory, a processor, a user input device and a display device. The method includes the steps of selecting a geometric model in a computer-aided design (CAD) format, converting the CAD model into a mesh model and evaluating the mesh model using a computer-aided engineering (CAE) analysis. The method also includes the steps of modifying a surface of the mesh model by varying a predetermined parameter using direct surface manipulation (DSM), updating the mesh model and using the updated mesh model in further CAE analysis. Three techniques are provided for modifying a surface feature, including using a Dirichlet parameter distribution to determine the displacement of the surface feature; modeling the surface feature as an elastic sheet to determine deformation; and enclosing the feature within a lattice structure and using lattice deformation to determine surface deformation.

Owner:FORD GLOBAL TECH LLC

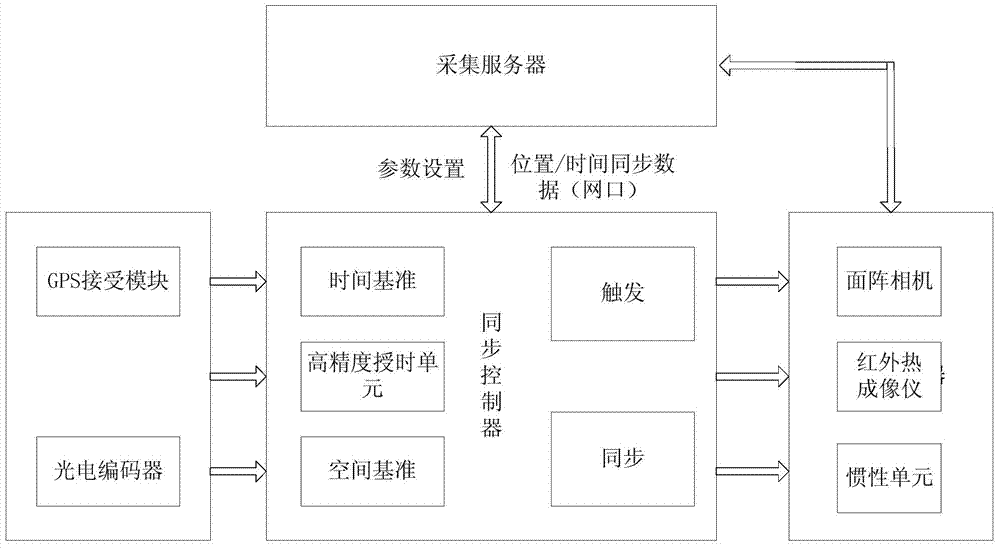

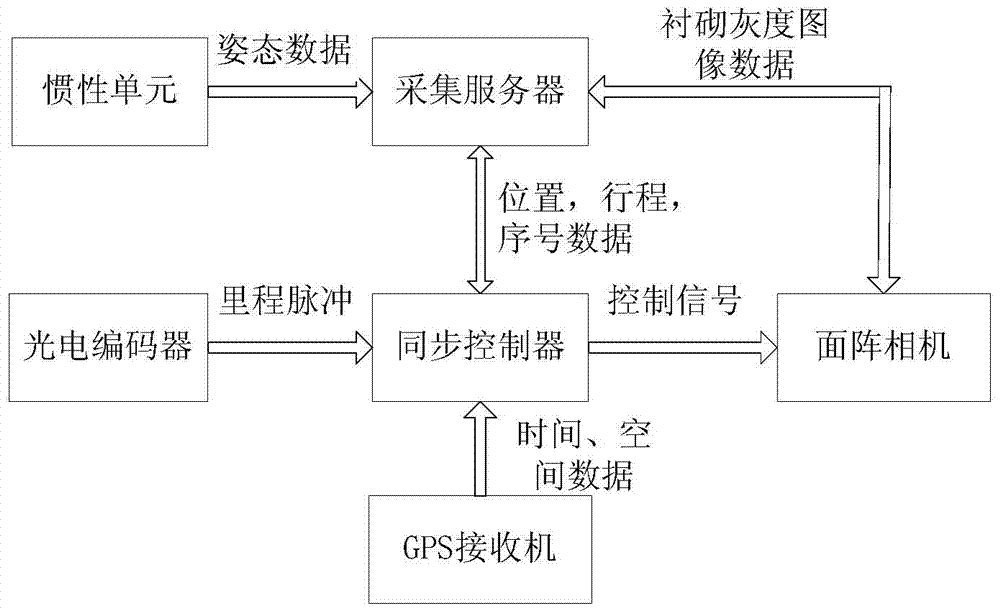

Tunnel lining disease detection device based on infrared temperature field and gray level image

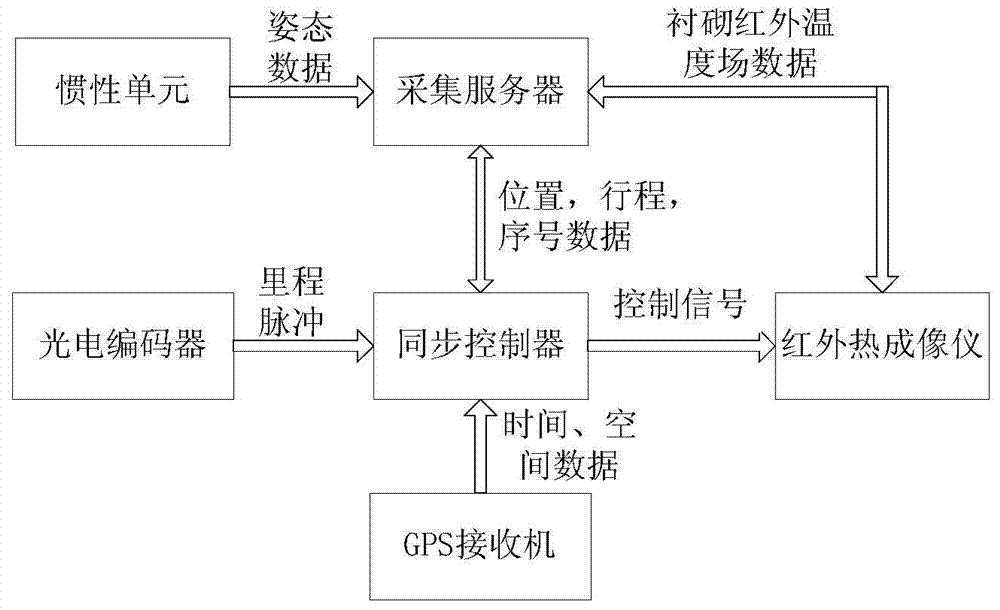

InactiveCN104749187AHigh synchronization accuracyReduce difficultyMaterial flaws investigationOptically investigating flaws/contaminationLight equipmentImaging data

The invention relates to a tunnel lining disease detection device based on an infrared temperature field and a gray level image. The tunnel lining disease detection device comprises a vehicle-mounted mobile platform, illumination equipment, a photoelectric encoder, a GPS (Global Position System) receiver, an inertia unit, a synchronous controller, an area-array camera, an infrared thermal imager, an acquisition server, a display control device and a power supply system; tunnel lining two-dimensional image data, infrared temperature field data and fracture surface deformation data are combined with positioning data of the GPS, the inertia unit and the photoelectric encoder to establish a tunnel model with gray level information, temperature information and fracture surface deformation; and tunnel lining cracks are analyzed, and the length, width and lining leakage water information of the cracks are automatically detected. For the tunnel lining disease detection device, the advantages of infrared temperature field detection and two-dimensional gray level image crack detection are combined so that the detection result is relatively reliable, the speed is rapid and the working efficiency is greatly improved.

Owner:WUHAN WUDA ZOYON SCI & TECH

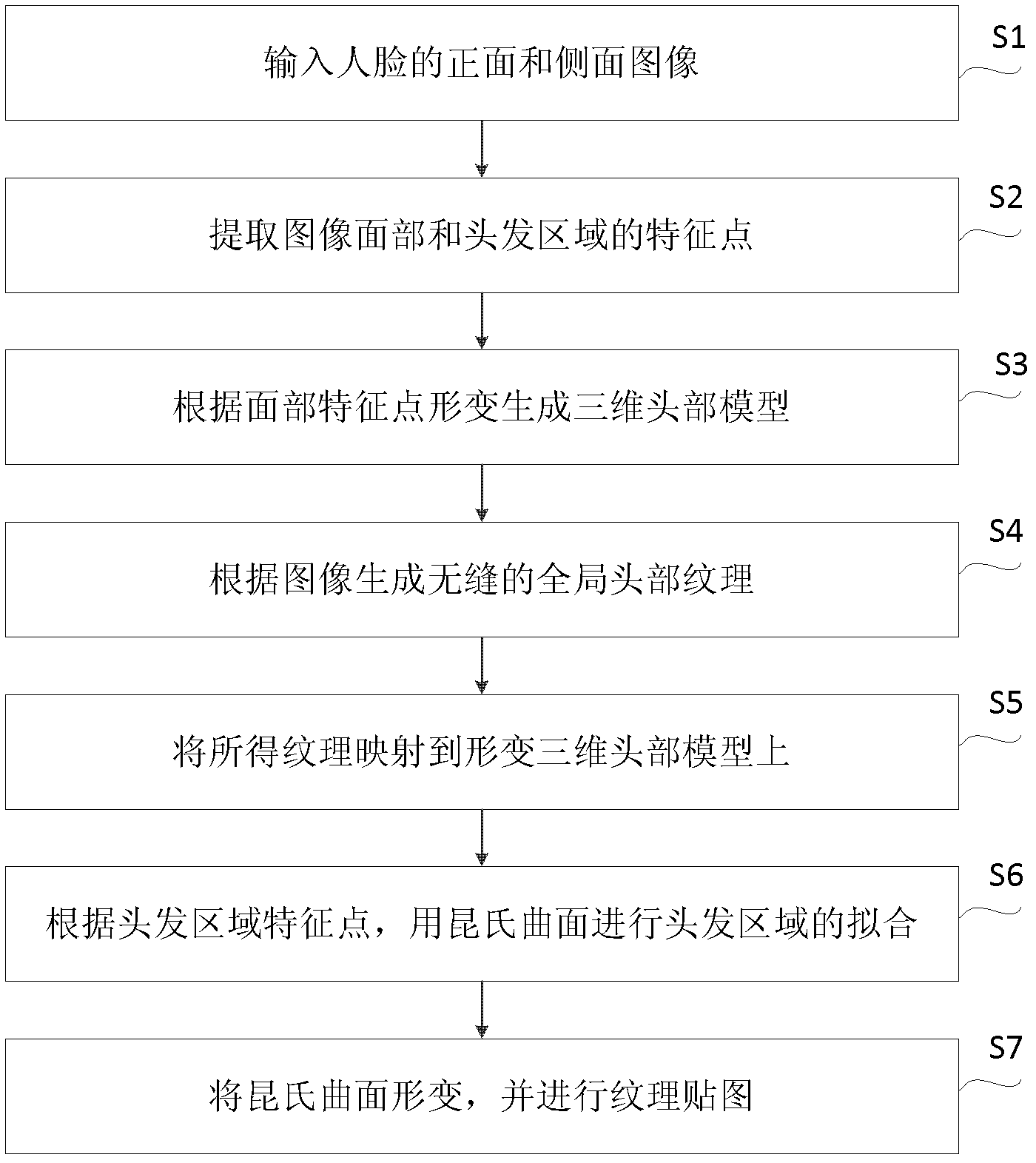

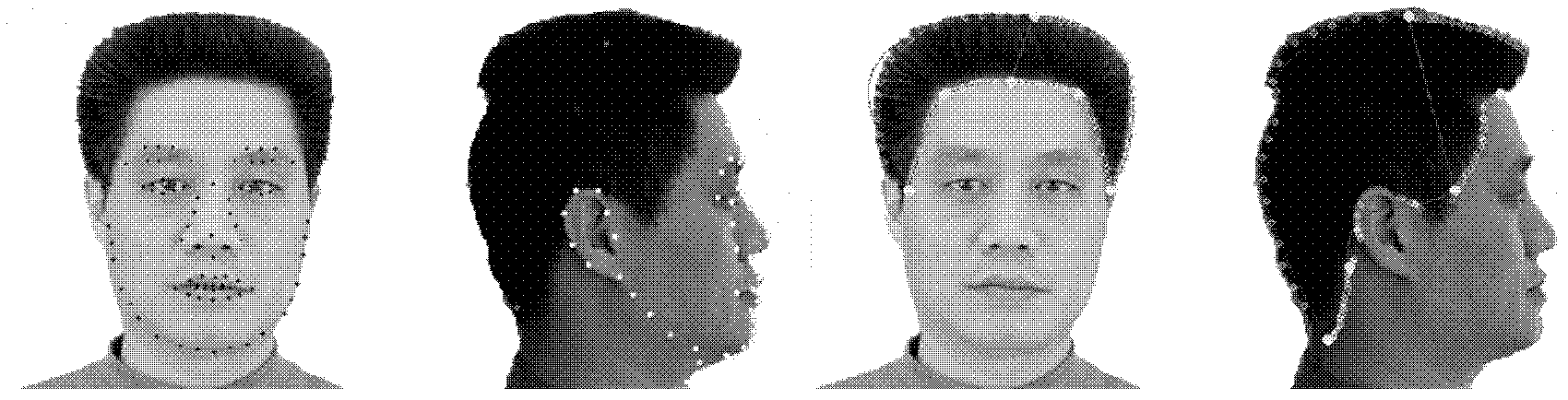

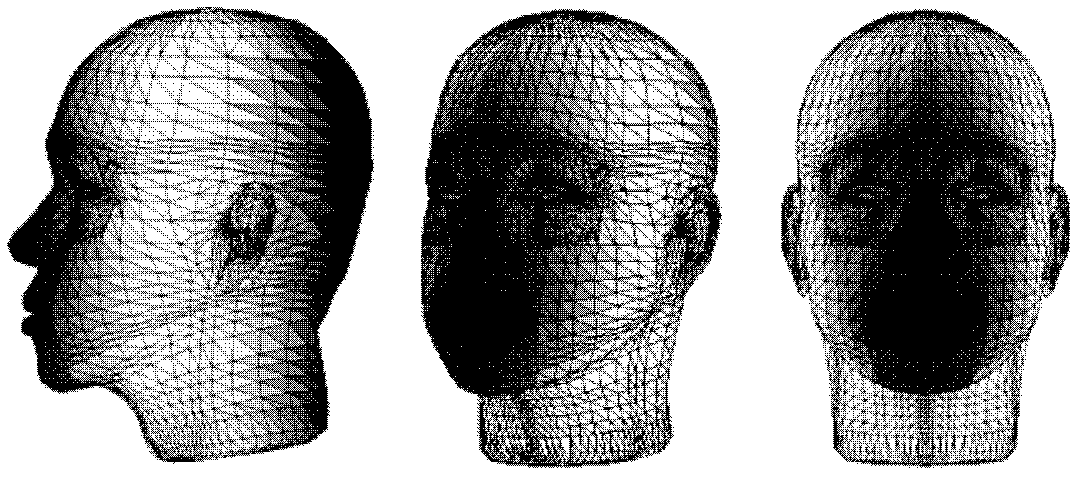

Three-dimensional head model reconstruction method

ActiveCN102663820ARebuild the realStrong sense of reality3D modellingComputation complexityReconstruction method

The invention discloses a three-dimensional head model reconstruction method. The method comprises the following steps of: S1: inputting a front image and a side image of a human face; S2: extracting feature points of face and hair regions in the image; S3: generating a three-dimensional head model according to the deformation of the facial feature points; S4: generating seamless overall head textures according to the image; S5: mapping all textures to the deformed three-dimensional head model; S6: fitting the hair region by using a coons surface according to the feature points of the hair region; and S7: performing coons surface deformation and texture mapping. The method is simple and practical, has low computation complexity and can actually reconstruct the three-dimensional head model on the premise of high precision.

Owner:TSINGHUA UNIV

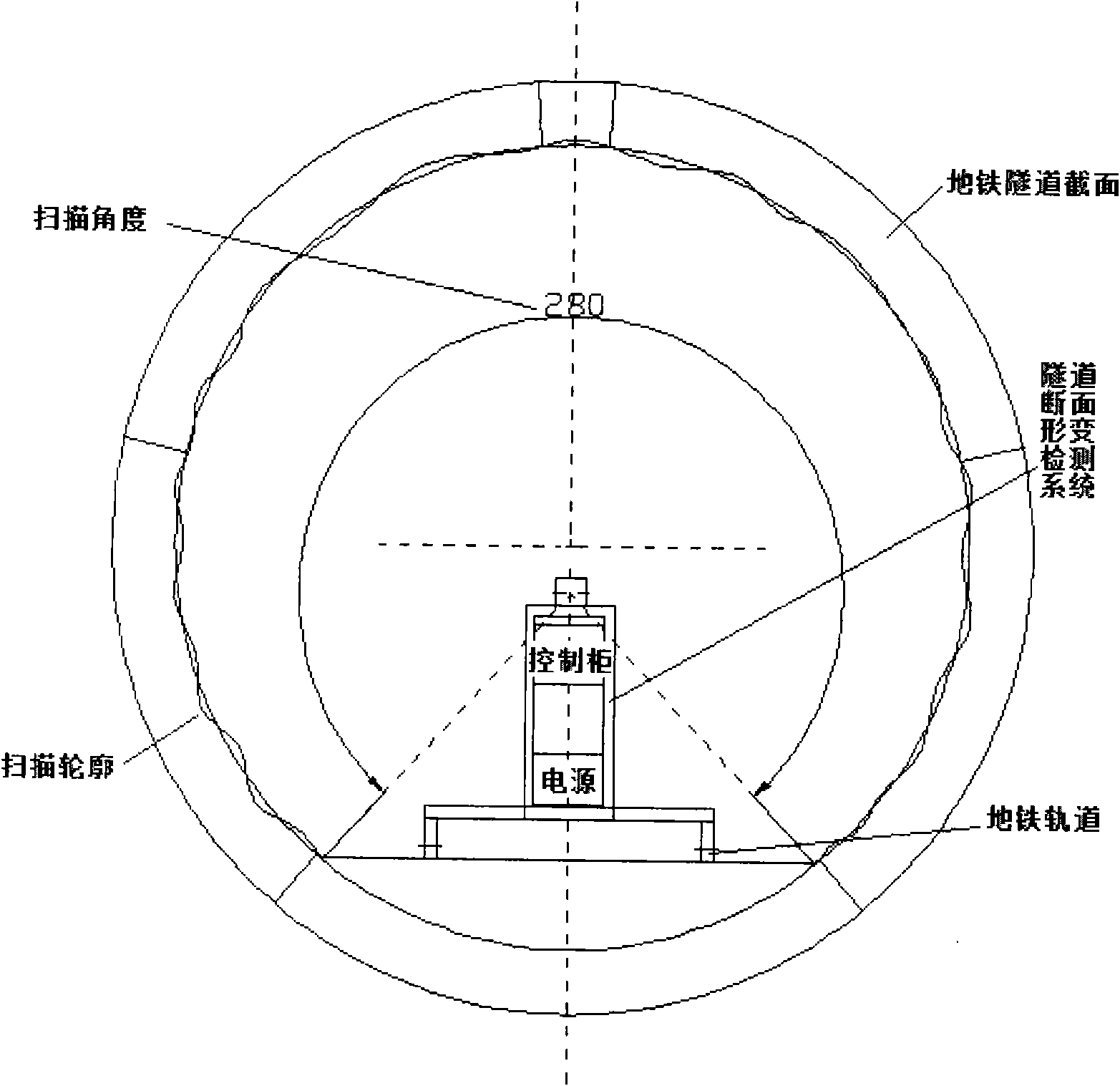

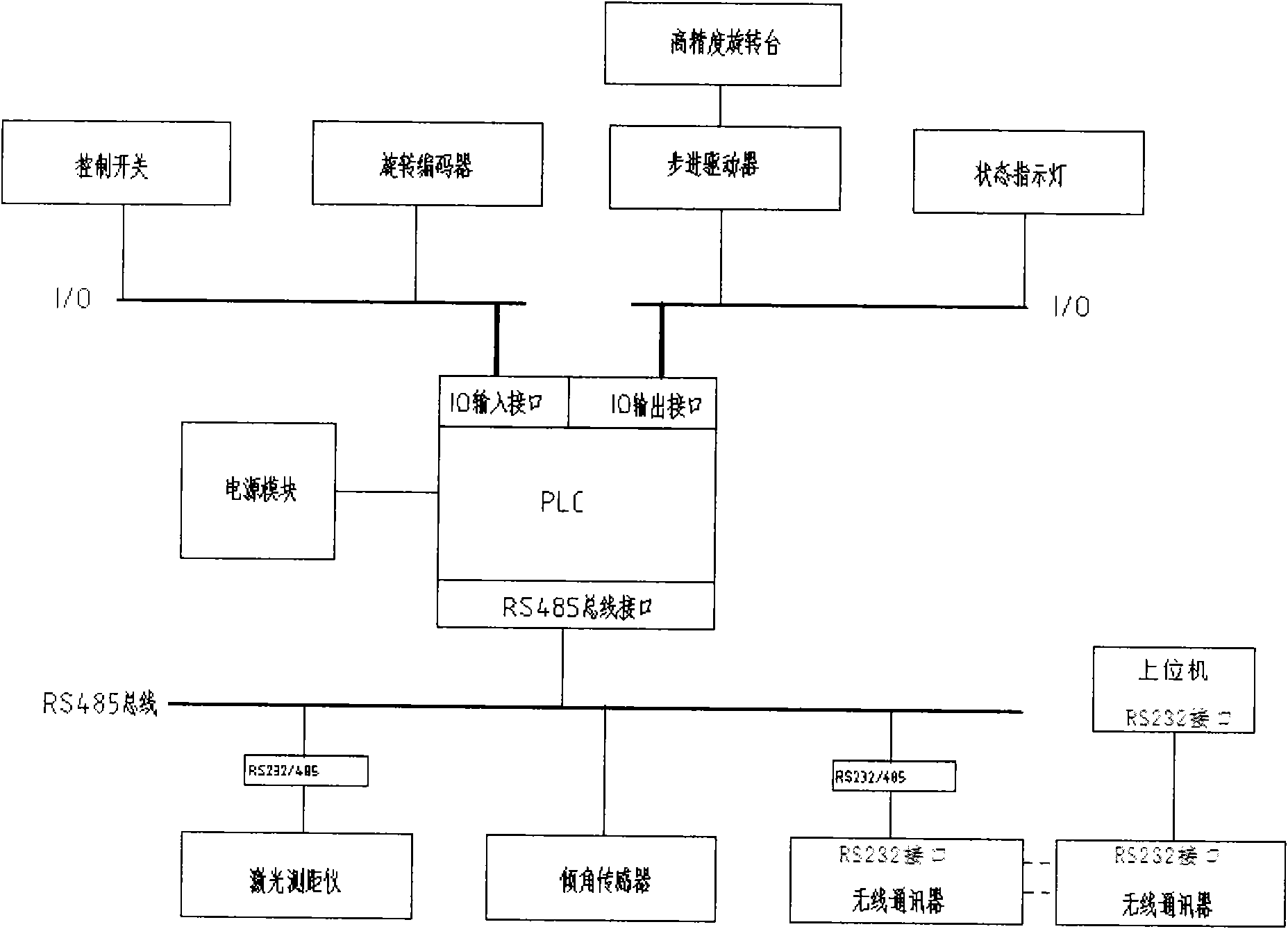

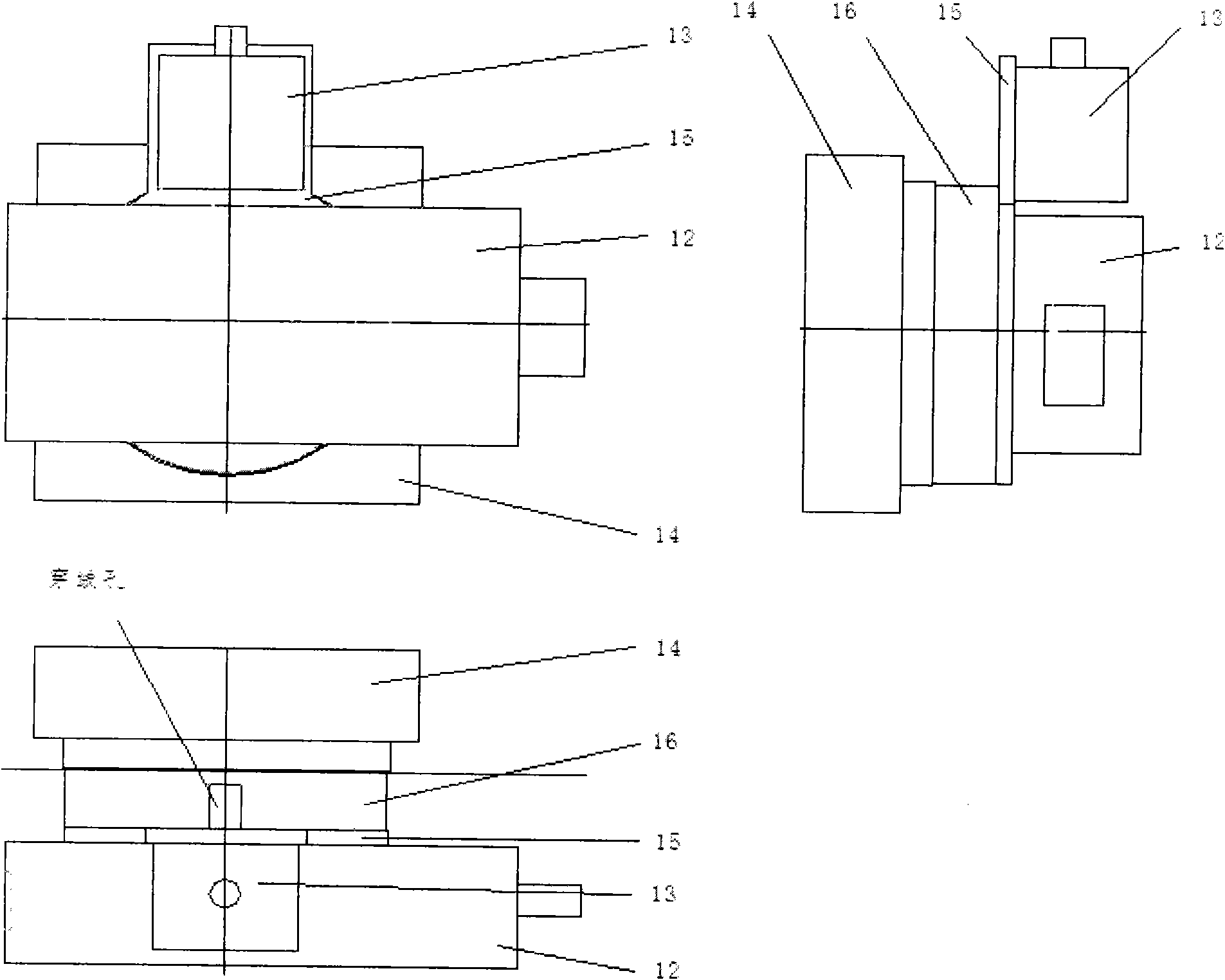

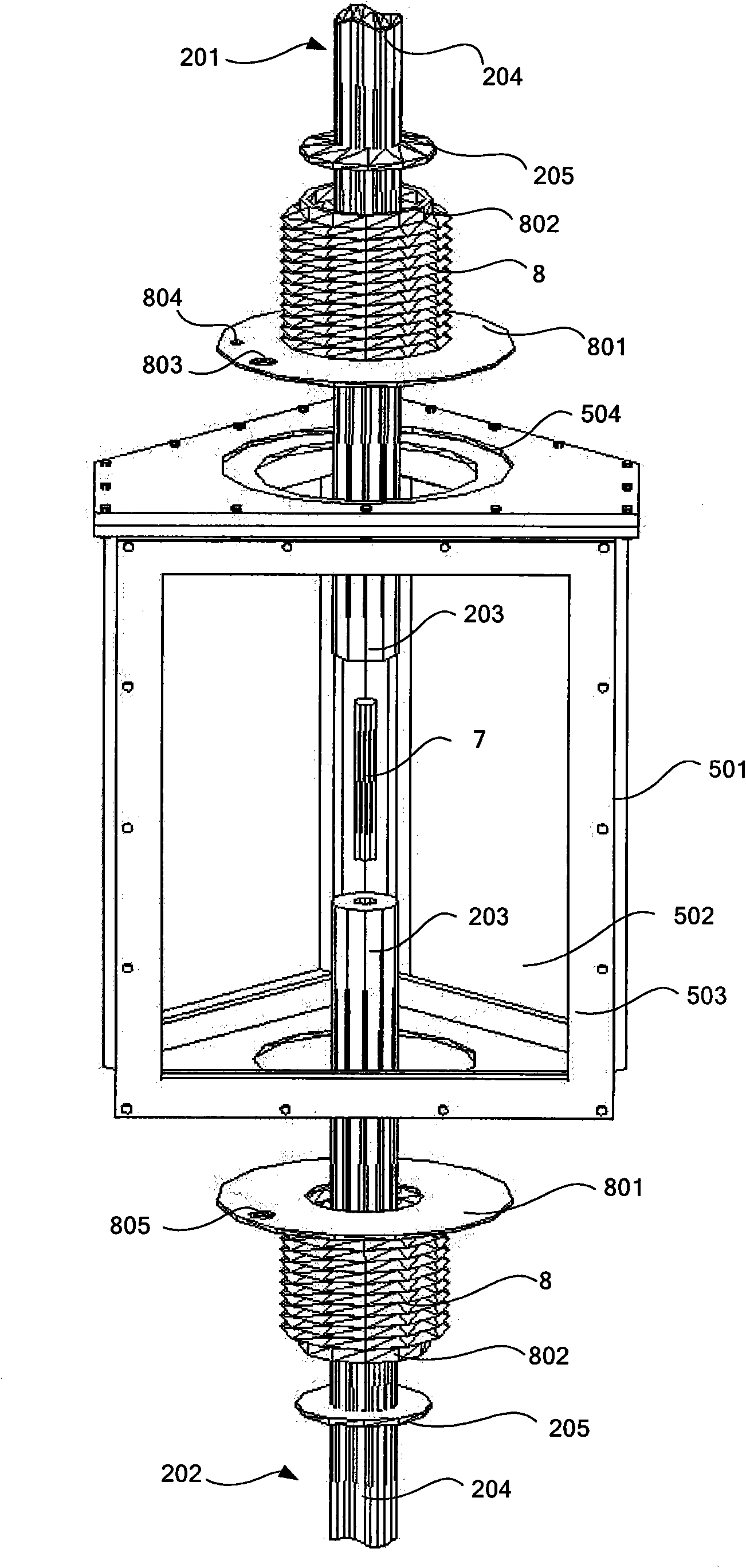

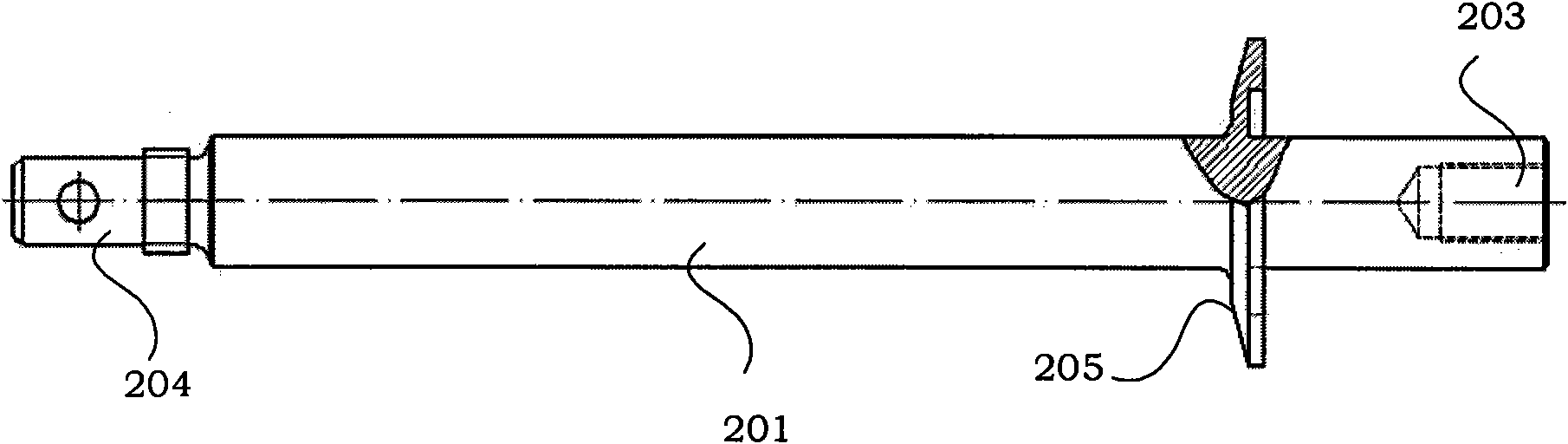

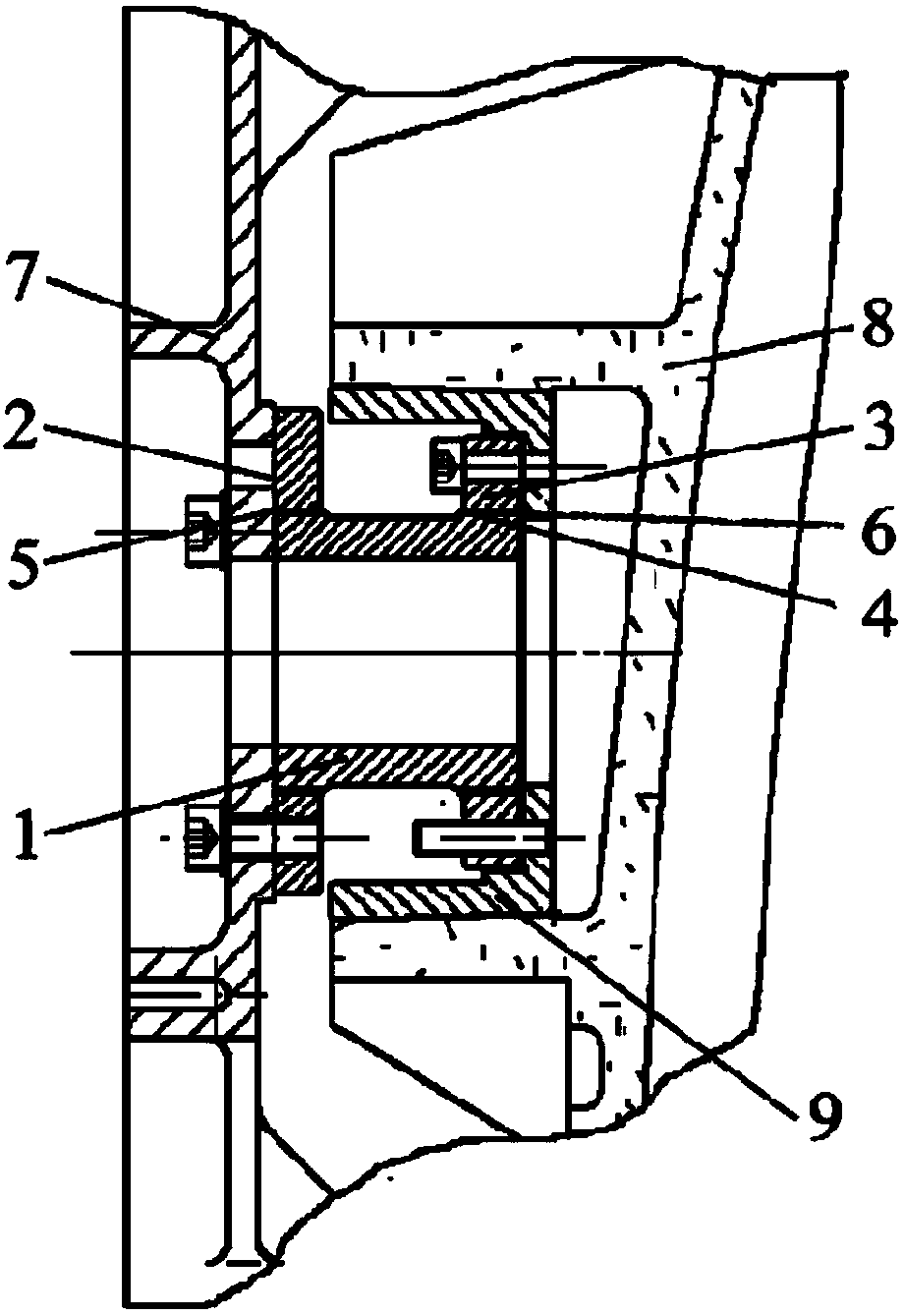

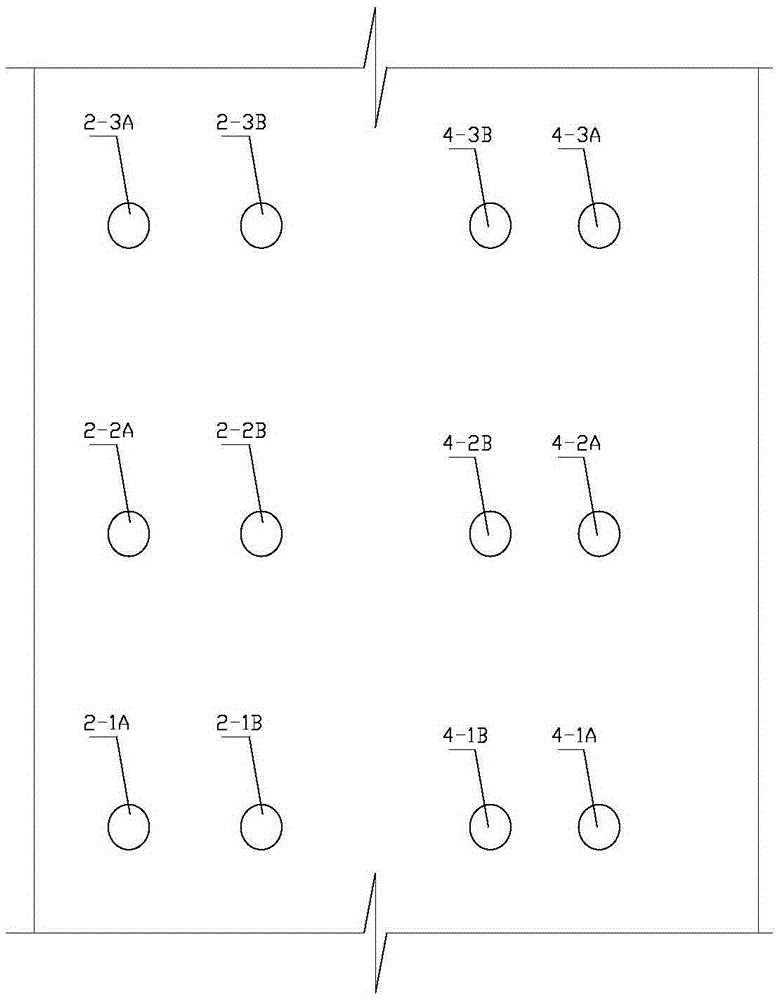

Metro tunnel fracture surface deformation detection system

ActiveCN101943577AWith long-term useWith automatic monitoringMeasurement devicesRailway auxillary equipmentData processing systemEngineering

The invention discloses a metro tunnel fracture surface deformation detection system, belonging to the tunnel engineering monitoring technical field. The system comprises a fracture surface scanning device, a mileage positioning device, an electrical equipment control device, a power source, a track detection vehicle and a station data processing system, wherein, the fracture surface scanning device, the mileage positioning device and the electrical equipment control device are arranged on the track detection vehicle; the power source is respectively connected with the fracture surface scanning device, the mileage positioning device and the electrical equipment control device through a power source convertor to supply power for the fracture surface scanning device, the mileage positioning device and the electrical equipment control device; a PLC controller is arranged in the electrical equipment control device; a rotary coder in the mileage positioning device, a sensor in the fracture surface scanning device and a rotary table stepped driver are respectively connected with the PLC controller; the PLC controller is connected with a wireless communicator through a wireless communicator in the station data processing system. The whole detection system of the invention has high portable integration degree, automatic operation process, convenient operation, low specialty technical requirements, rapid operation speed, extremely-time section surface measuring and high measuring precision, and the system precision is less than 3mm.

Owner:上海地铁盾构设备工程有限公司

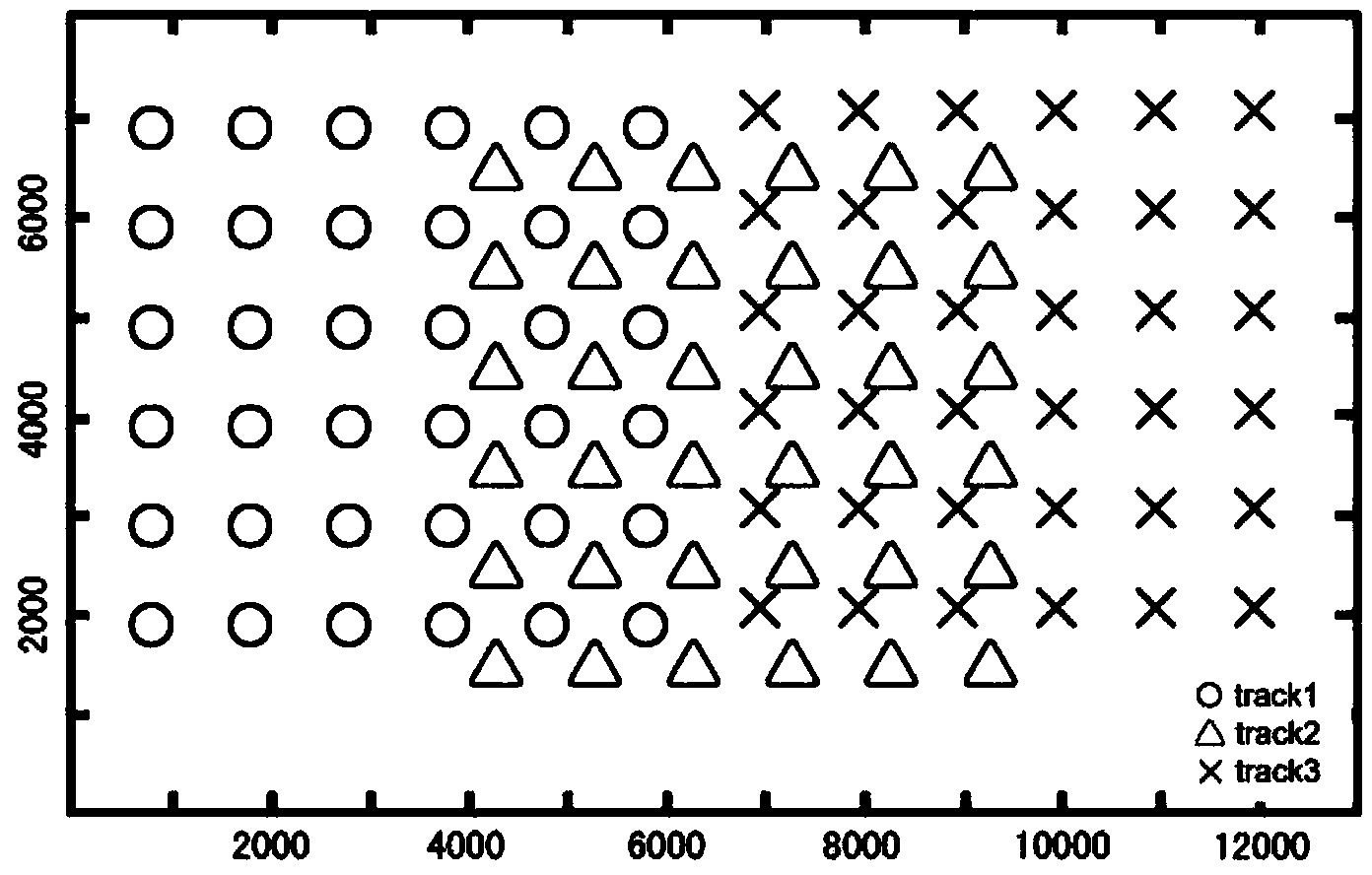

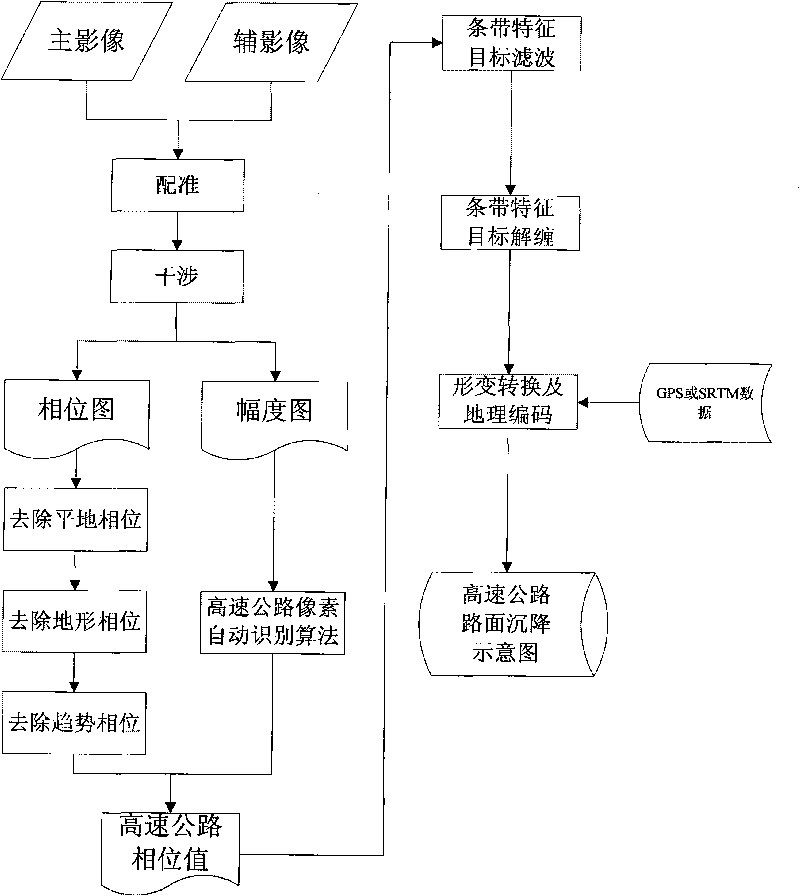

Ground surface deformation high-resolution interferometric synthetic aperture radar (InSAR) monitoring method along high speed railway

InactiveCN104111456AHigh precisionImprove the level of fine monitoringRadio wave reradiation/reflectionInterferometric synthetic aperture radarSubsidence

Disclosed is a ground surface deformation high-resolution interferometric synthetic aperture radar (InSAR) monitoring method along a high speed railway. The method includes four steps of (1) selection of high-resolution SAR data, (2) a high-resolution InSAR high speed railway area deformation information extraction method, (3) a multi-track deformation rate result integrating method and (4) a high speed railway target recognition and deformation extraction method. By means of the ground surface deformation high-resolution InSAR monitoring method along the high speed railway, the high speed railway can be completely covered and monitored by a high-resolution InSAR, recognition and separation of high speed railway subgrade settlement and area surface subsidence can be effectively achieved, and InSAR accurate monitoring level of high speed railway ground surface deformation in China can be greatly improved.

Owner:CHINA AERO GEOPHYSICAL SURVEY & REMOTE SENSING CENT FOR LAND & RESOURCES

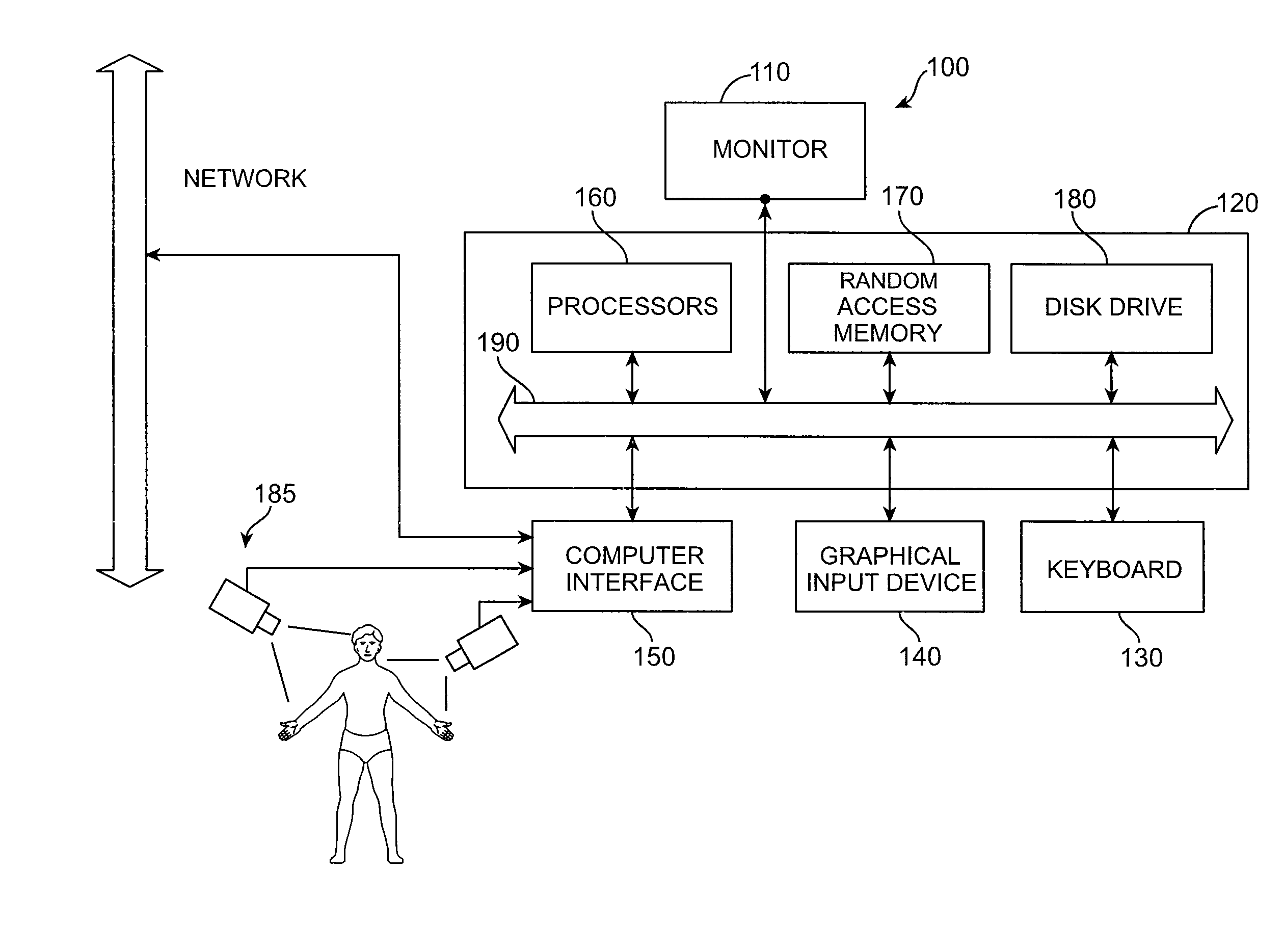

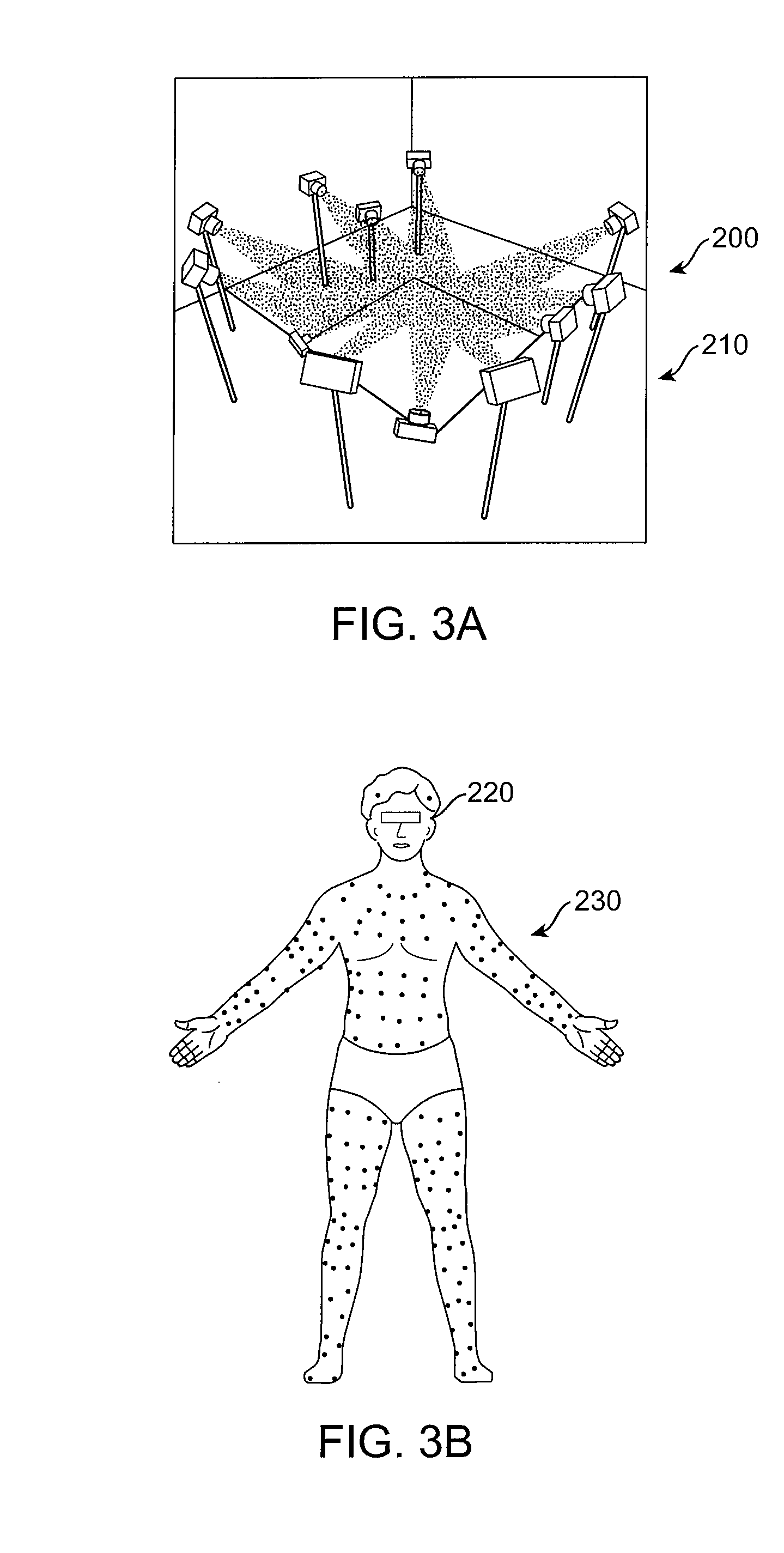

Methods and apparatus for capturing and rendering dynamic surface deformations in human motion

A method for a computer system includes receiving global positional data associated with a set of markers from a plurality of markers associated with a surface of an object at one or more time instances, wherein global positional data associated with a first marker from the plurality of markers is absent from a first time instance, using local statistical methods to determine global positional data associated with the first marker at the first time instance in response to the global positional data associated with the set of markers at the one or more time instances, and determining a model of the object in response to the global positional data associated with the set of markers and the global positional data associated with the first marker.

Owner:TWO PIC MC

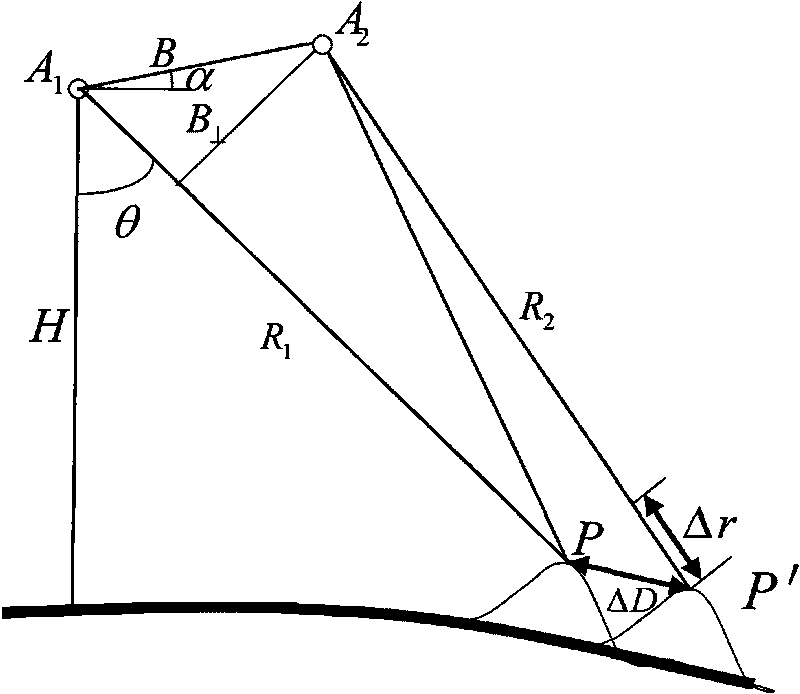

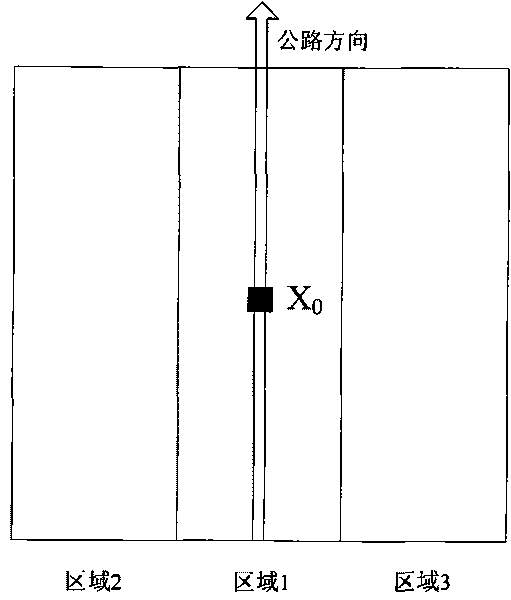

Method for monitoring roadbed subsidence of express way by InSAR

InactiveCN101706577AImprove monitoring accuracyHigh degree of automationRadio wave reradiation/reflectionRoad surfaceLandform

The invention relates to the field of geodetic survey based on remote sensing images, in particular to a method for monitoring roadbed subsidence of express way by an InSAR, which comprises the following steps of: firstly, preprocessing, rectifying and interfering SAR data to obtain an InSAR interfered phase and amplitude image; secondly, carrying out flat earth effect, orographic effect and track residual trend phase elimination on the InSAR interfered phase to obtain a phase value only including surface deformation information; thirdly, recognizing positions and coordinates of strips of the express way in the SAR image by strip characteristics of the express way in the InSAR amplitude image; fourthly, extracting the phase value of the corresponding position in the interfered phase image by using the coordinates, and restoring a real phase value by adopting a filtering and unwrapping algorithm of a strip characteristic target; and fifthly, carrying out geocoding and deformation value transformation on the real phase value to obtain a roadbed subsidence value of the express way. The method has the advantages of simple implementation, low expense, high monitoring precision, large monitoring range, high automation degree and the like.

Owner:CENT SOUTH UNIV

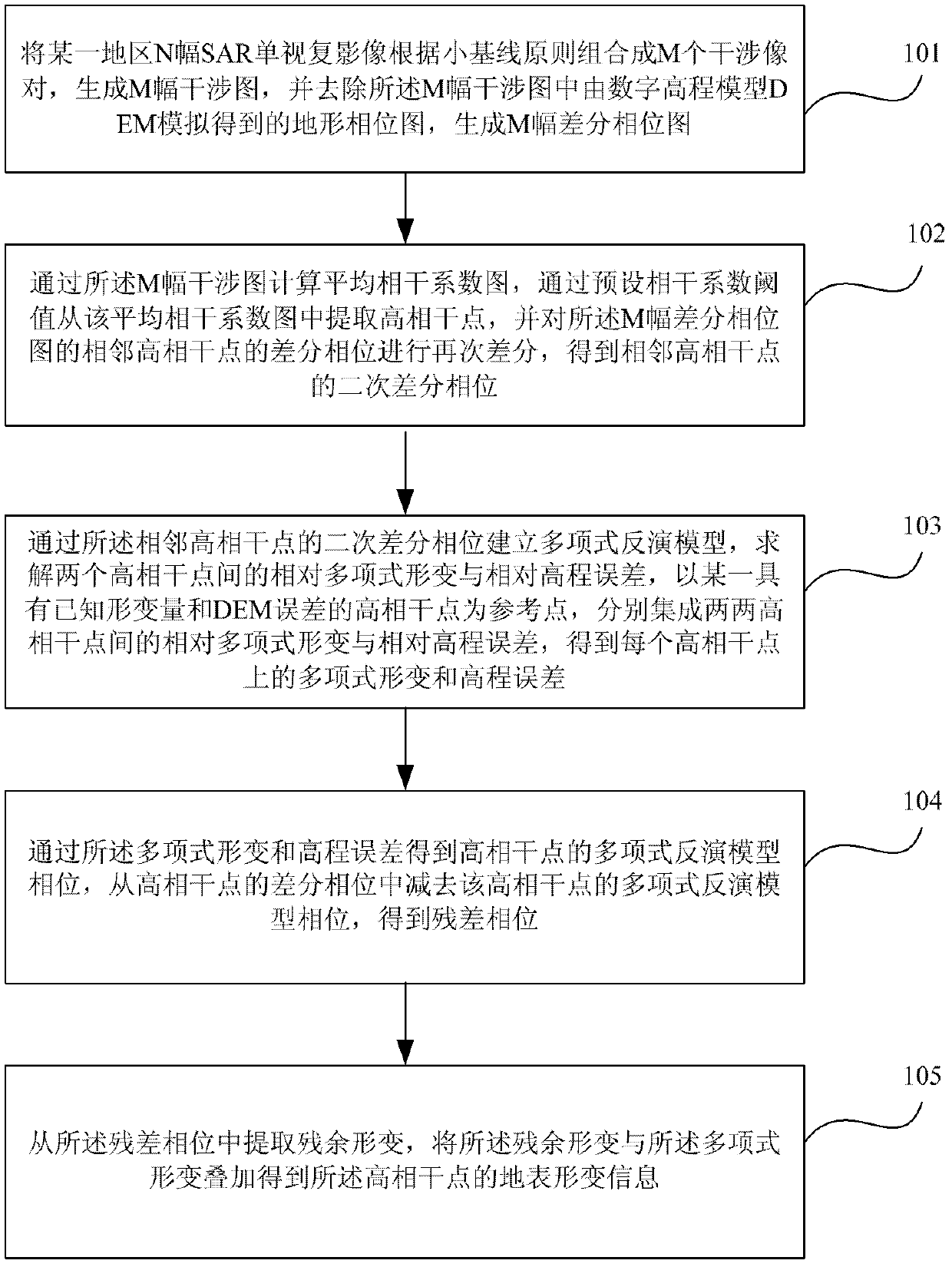

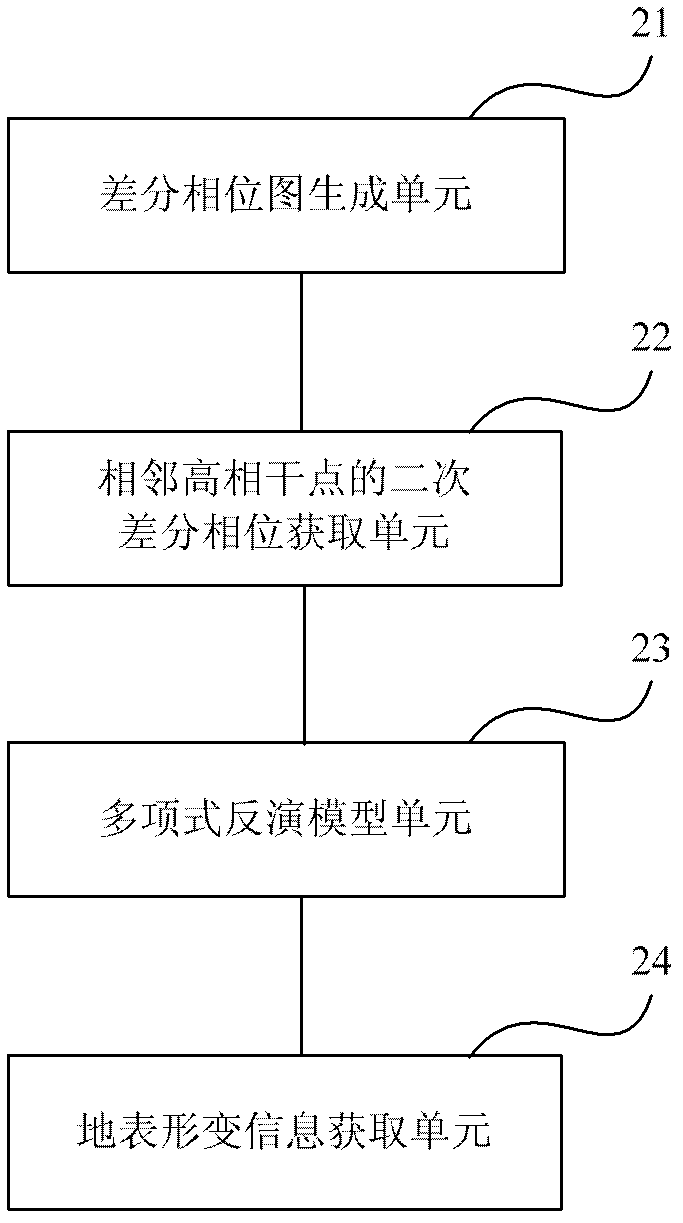

Time sequence InSAR (Interferometric Synthetic Aperture Radar) deformation monitoring method and device based on polynomial inversion model

InactiveCN102608584AFit closelyRadio wave reradiation/reflectionResidual deformationInterferometric synthetic aperture radar

The invention provides a time sequence InSAR (Interferometric Synthetic Aperture Radar) deformation monitoring method and a device based on a polynomial inversion model. The method comprises the following steps of: combining N SAR (Synthetic Aperture Radar) single look complexes of a certain region to generate M interference pictures and generate M differential phase pictures; calculating an average coherent coefficient picture and extracting high coherent points; establishing a polynomial inversion model by carrying out difference again on a differential phase of the two adjacent high coherent points; solving relative polynomial deformation and a relative elevation error of the adjacent points respectively integrating by taking a certain high coherent point provided with known deformation amount and a DEM (Dynamic Effect Model) error as a reference point to obtain the polynomial deformation and the elevation error of each high coherent point; after a phase of the polynomial inversion model is obtained, subtracting the phase of the polynomial inversion model from the differential phase of the high coherent points to obtain a residual phase; and extracting residual deformation from the differential phase to be overlapped with the polynomial deformation to obtain ground surface deformation information of the high coherent points. The method provides a solution for highly-precisely monitoring the ground surface deformation.

Owner:CHINESE ACAD OF SURVEYING & MAPPING

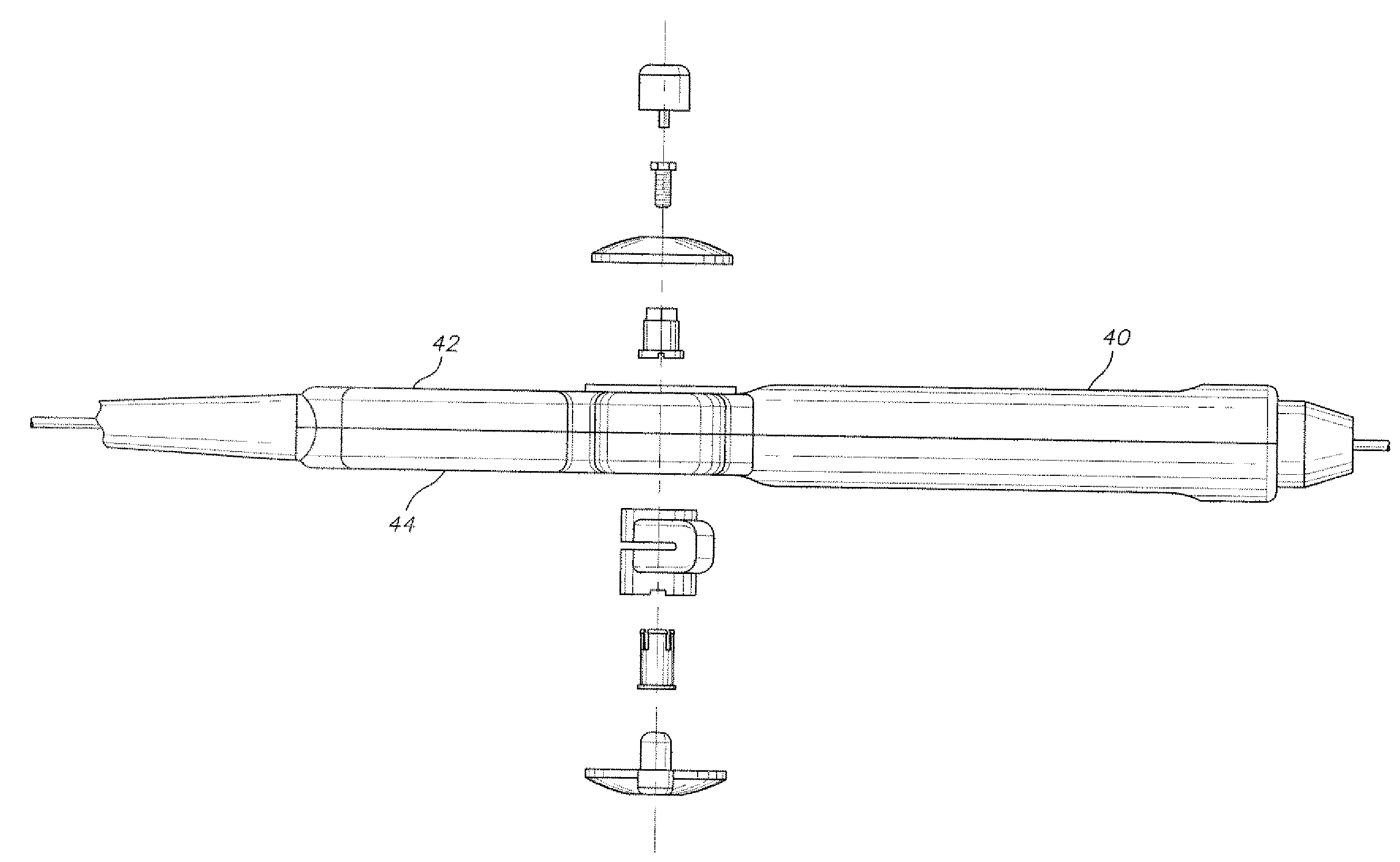

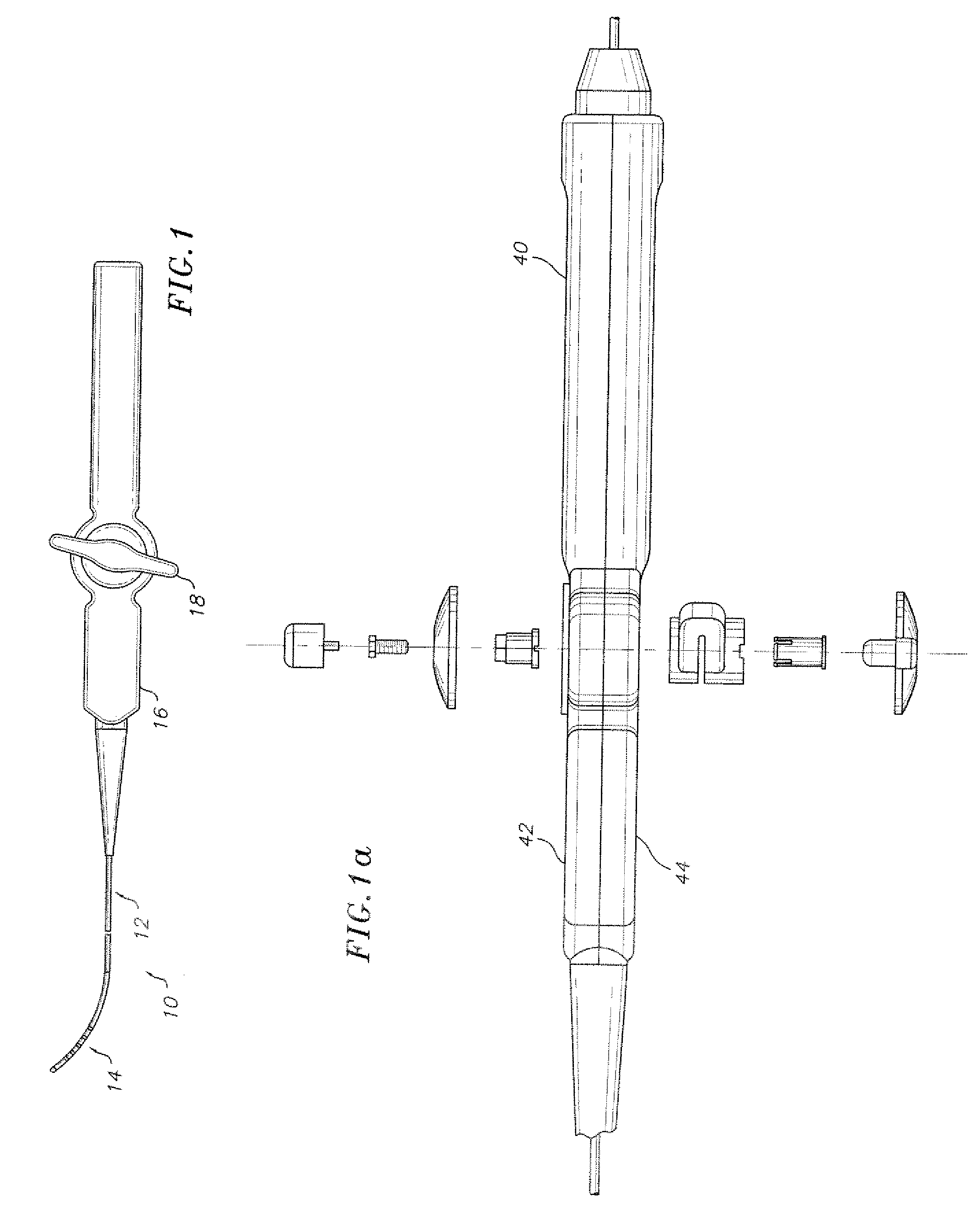

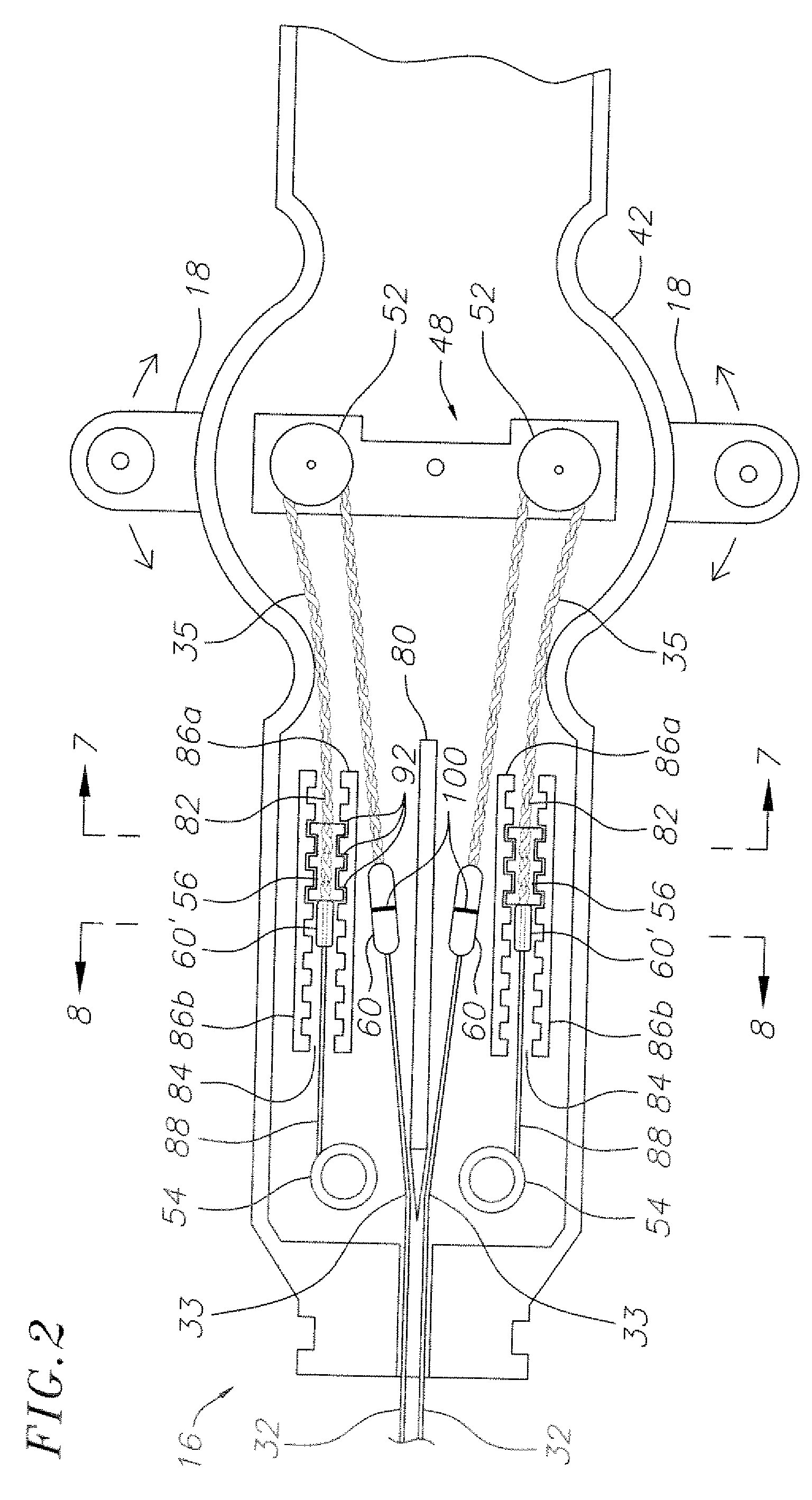

Insert molded catheter puller member connectors and method of making

ActiveUS20080103520A1Easy assessment processQuiet and smooth operationElectrotherapySurgeryFiberDistal portion

The present invention provides a deflectable catheter whose puller member connections are accomplished with minimal, if any, surface deformation which could otherwise accelerate breakage under tension. The catheter includes a molded member that encases an end of a puller member to enable connection of the end to a fixed or movable structure in the control handle without significant surface deformation in the puller member. The molded member is of a thermoplastic material that encases a preformed end of the puller member, which may be a puller wire or a high modulus fiber material.The molded member may be configured as desired, for example, as a screw that is fastened to a structure in the control handle. Alternatively, the preformed end of the puller member, for example, a puller wire, can be directly connected to and jointly encased in the molded member with another preformed end of a second puller member, for example, a high modulus fiber material. Such a connected puller member whose distal portion is the puller wire and whose proximal portion is the high modulus fiber material can be well suited for control handle that employs pulleys for increased throw capacity.

Owner:BIOSENSE WEBSTER INC

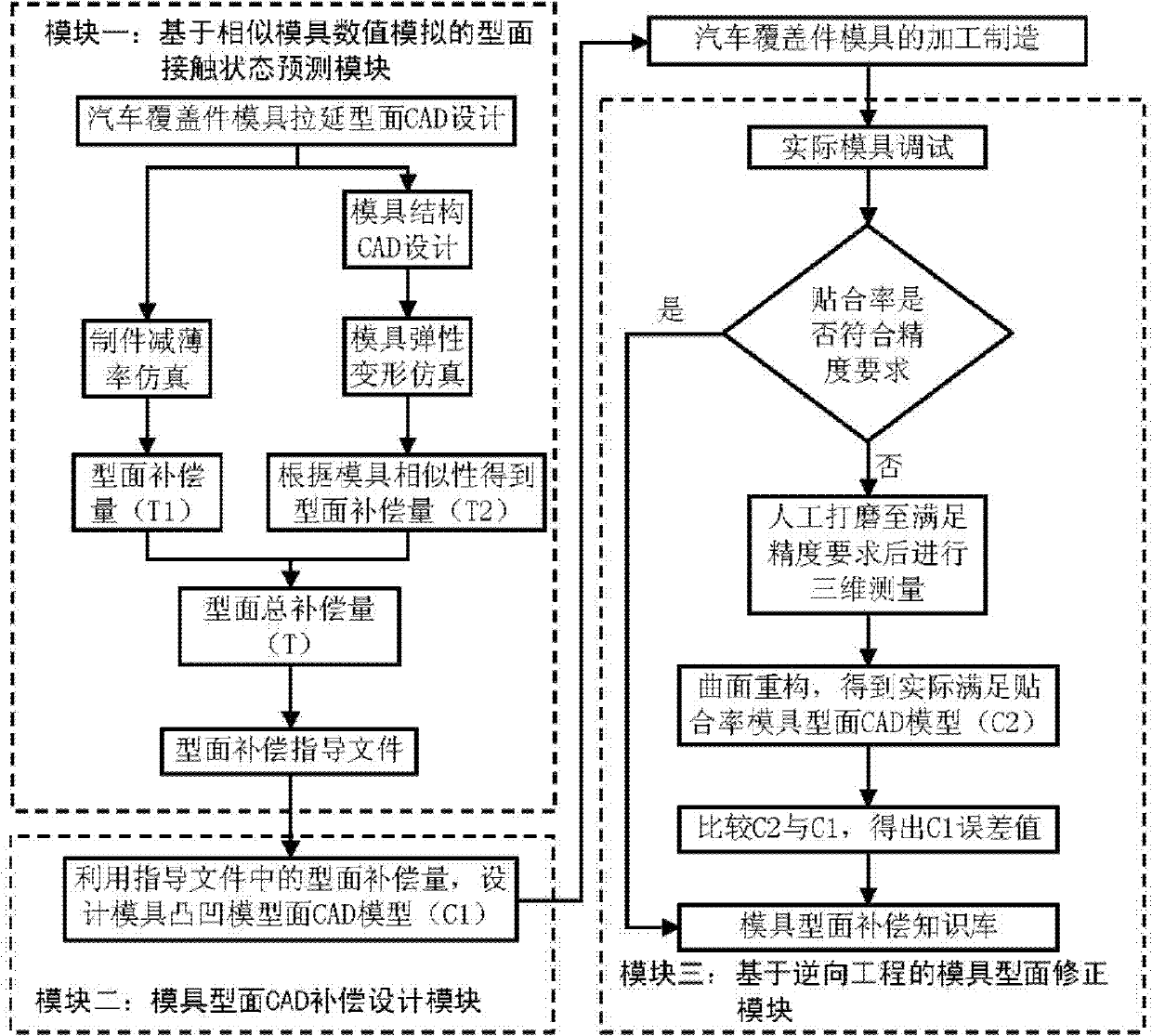

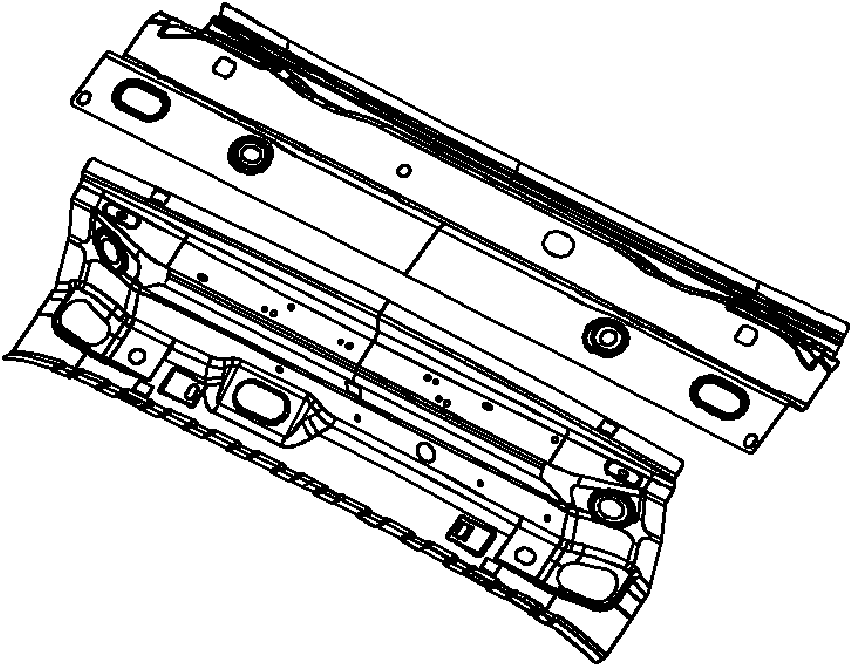

Design method for molded surface of automobile cover part die based on molded surface deformation compensation

InactiveCN102169521ASimple designQuality improvementSpecial data processing applicationsComputer Aided DesignCapability Maturity Model

The invention discloses a design method for a molded surface of an automobile cover part die based on molded surface deformation compensation, which comprises the steps of predicting the contact state of the molded surface based on similar die numerical value simulation, outputting a compensation guide document for the molded surface of the die based on the dethickness of a manufactured piece and the elastic deformation of the die, using CAD (computer aided design) software to design the compensation molded surface of the die based on the guide document and outputting the CAD compensation molded surface, and outputting the repaired actual molded surface of the die by using a method based on reverse engineering. Under the premises of reasonable technical conditions and die structures, a CAE-CAD-CMM (computer aided engineering-computer aided design-capability maturity model) integration system for the molded surface of the automobile cover part die based on the dethickness of the manufactured piece and the elastic deformation compensation of the die is formed. The method can be adopted for quickening the design process of the molded surface of the automobile cover part die, reducing the manual grinding time, guarantees the fit precision of the molded surface of the die and the forming precision of the automobile cover part, and provides a new method for the high-quality short-period debugging work of the automobile cover panel die.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE +1

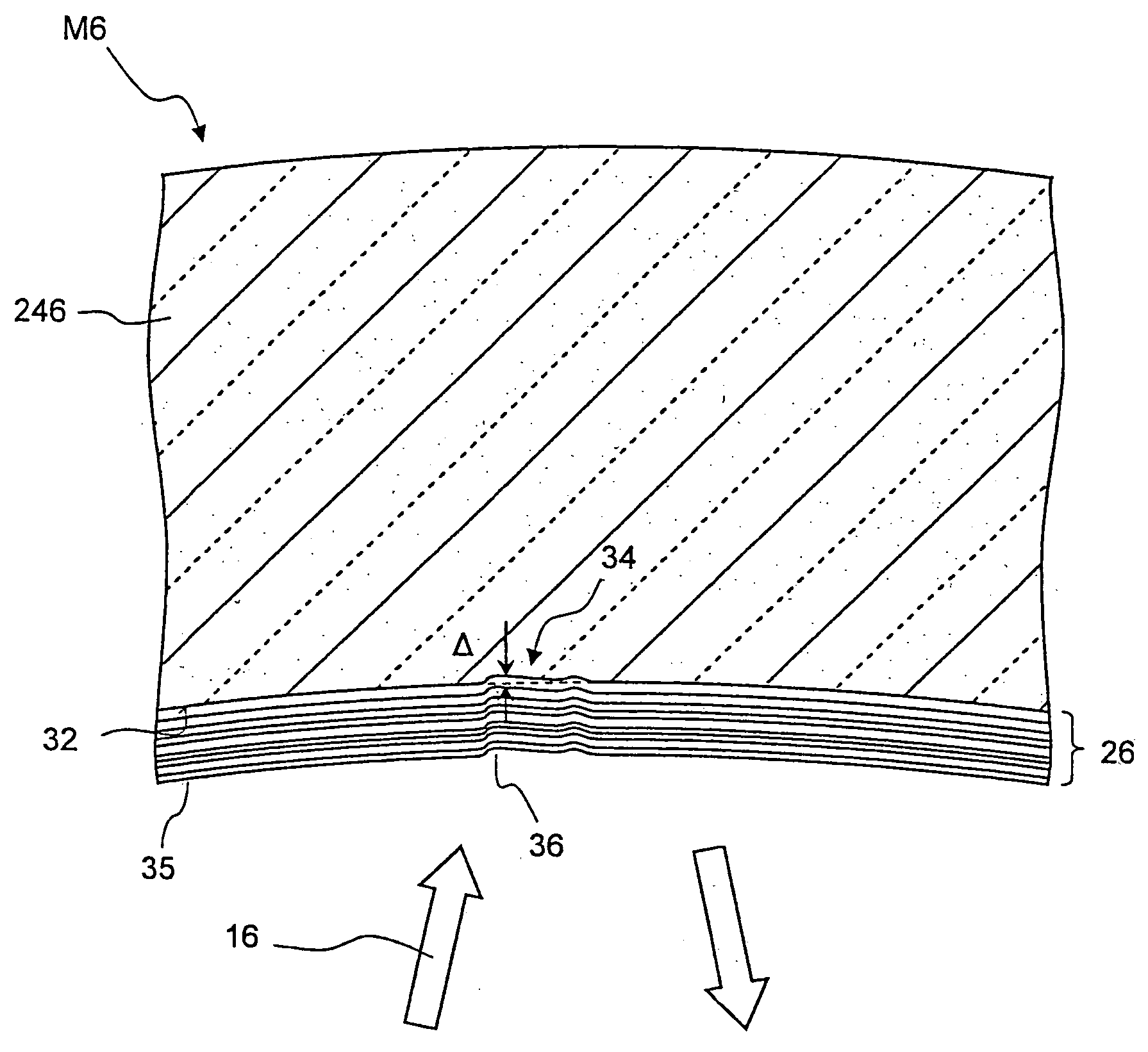

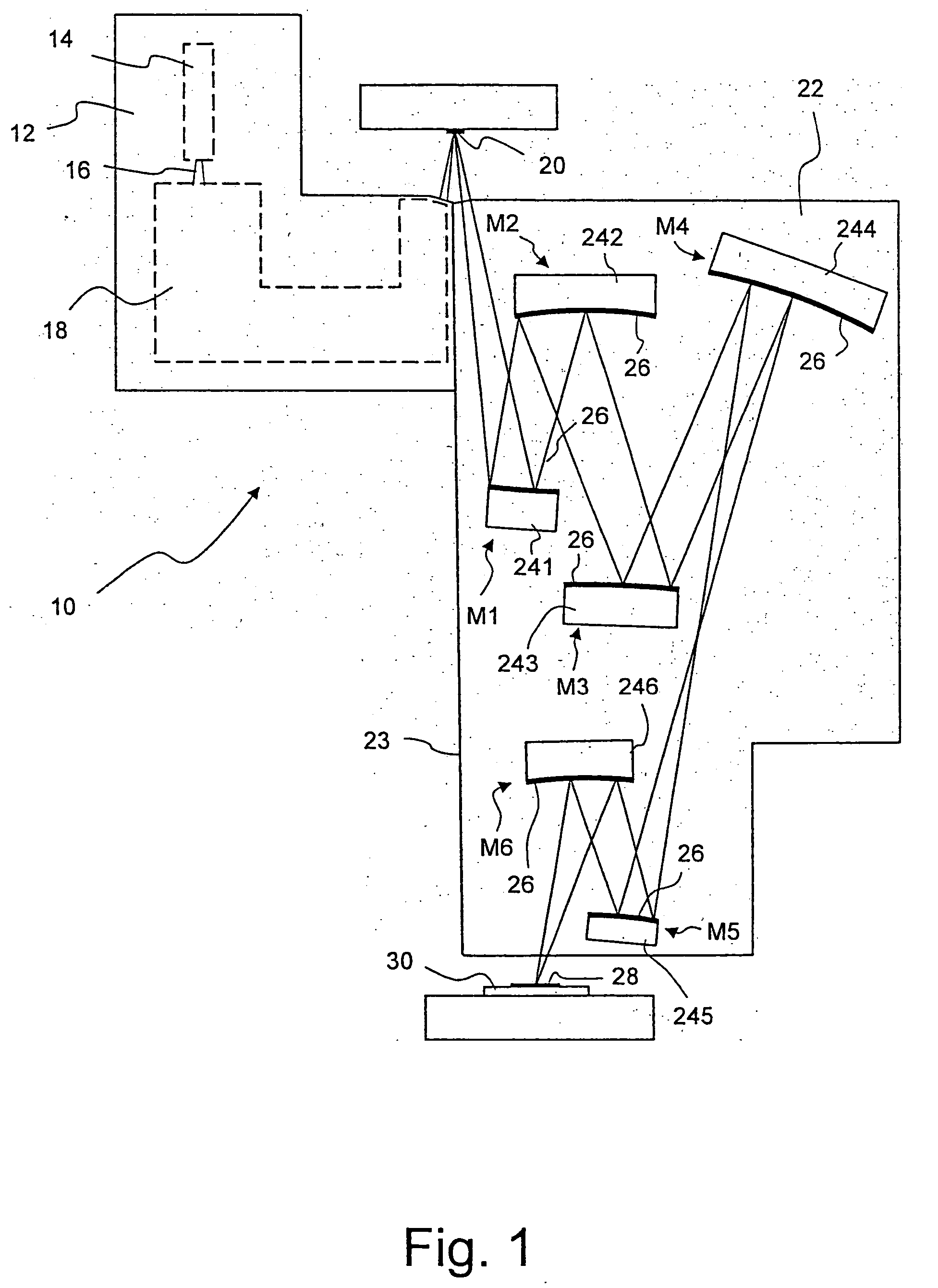

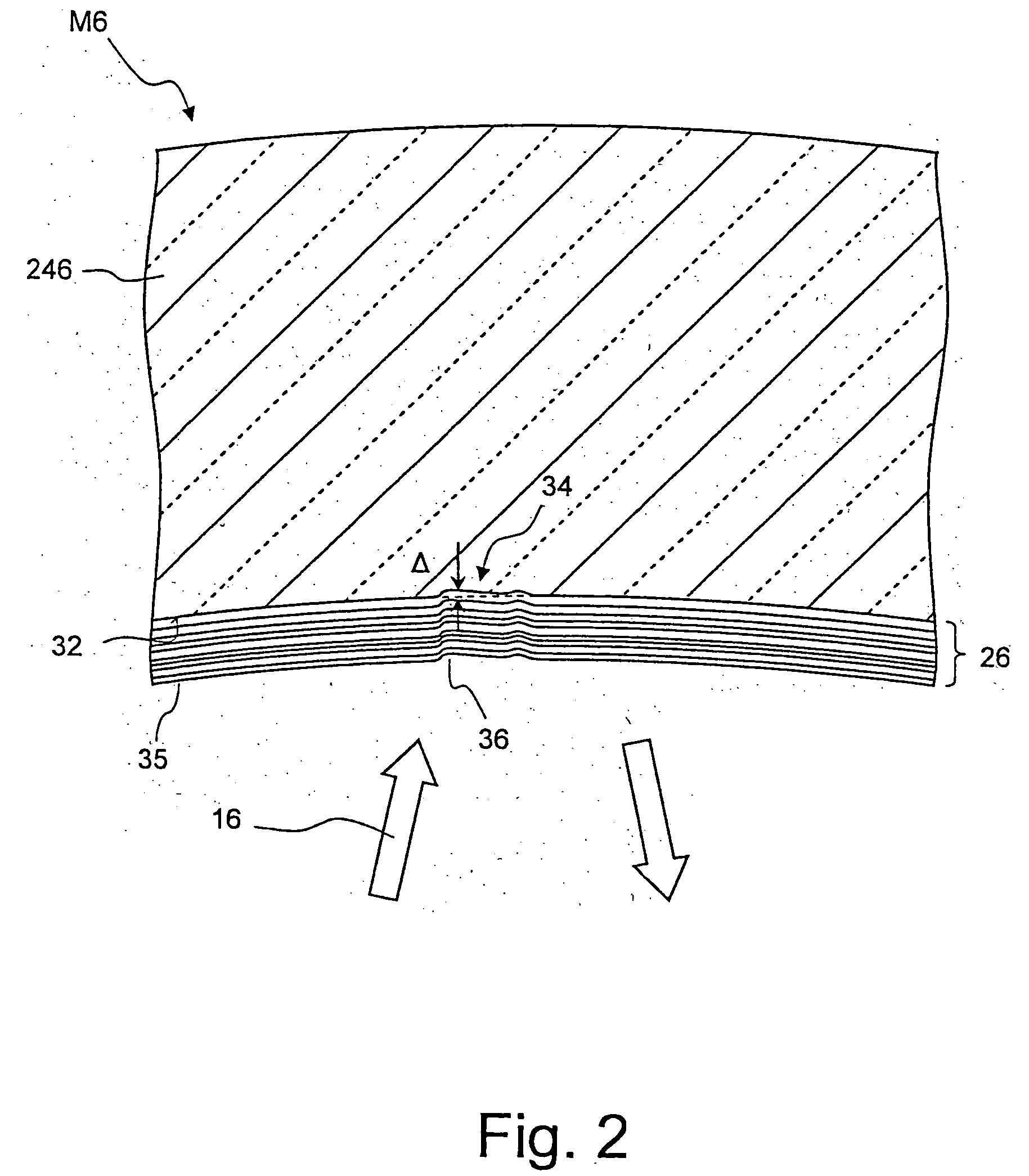

Projection objective and method for its manufacture

InactiveUS20050134980A1Reduce manufacturing-related aberrationReduce manufacturing-related aberrations without significantly changing the reflectivity of the mirrorsMirrorsRadiation/particle handlingLength waveOptical aberration

A method of manufacturing a projection objective (22) of a microlithographic projection exposure apparatus (10) is described. The projection objective (22) comprises at least one mirror (M1 to M6) that each have a mirror support (241 to 246) and a reflective coating (26) applied thereon. First imaging aberrations of a pre-assembled projection objective are measured. Before the coating (26) is applied, the mirror supports (241 to 246) are provided with a desired surface deformation (34). If the mirrors (M1 to M6) are not reflective for projection light without the coating (26), measuring light is used that has another wavelength. Alternatively, two identical mirror supports (246) may be provided. One support having a reflective coating is part of the pre-assembled projection objective whose imaging aberrations are measured. The other support is provided with surface deformations before coating and mounting the support into the objective.

Owner:CARL ZEISS SMT GMBH

Test device for surface deformation and material and test method thereof

InactiveCN101672749AHeating up fastFast mechanical loadingMaterial strength using tensile/compressive forcesUsing optical meansOptical testStrength of materials

The invention discloses a test device for surface deformation of a material and a test method thereof, wherein the device comprises a material mechanical property test machine, an infrared fast heating device, a surface deformation optical test system, a temperature collecting device, a vacuum system and a clamp. The clamp fixes a sample in a vacuum chamber of the vacuum system and is connected with the material mechanical property test machine, the infrared fast heating device supplies thermal load for the sample, and the surface deformation optical test system measures the surface deformation of the sample. The device and the test method can simultaneously heat, apply stress and synchronously test deformation field in the surface. The coupling simulation of an aero-engine under service environment with high temperature and loading level, and the surface deformation condition of the structural material with high temperature under the environment are tested.

Owner:BEIHANG UNIV

System and method of direct mesh manipulation

ActiveUS7324103B2Geometric CADData processing applicationsComputer Aided DesignComputer graphics (images)

A system and method for computer-aided engineering analysis using direct mesh manipulation of a mesh model is provided. The system includes a computer system having a memory, a processor, a user input device and a display device. The method includes the steps of selecting a geometric model in a computer-aided design (CAD) format, converting the CAD model into a mesh model and evaluating the mesh model using a computer-aided engineering (CAE) analysis. The method also includes the steps of modifying a surface of the mesh model by varying a predetermined parameter using direct surface manipulation (DSM), updating the mesh model and using the updated mesh model in further CAE analysis. Three techniques are provided for modifying a surface feature, including using a Dirichlet parameter distribution to determine the displacement of the surface feature; modeling the surface feature as an elastic sheet to determine deformation; and enclosing the feature within a lattice structure and using lattice deformation to determine surface deformation.

Owner:FORD GLOBAL TECH LLC

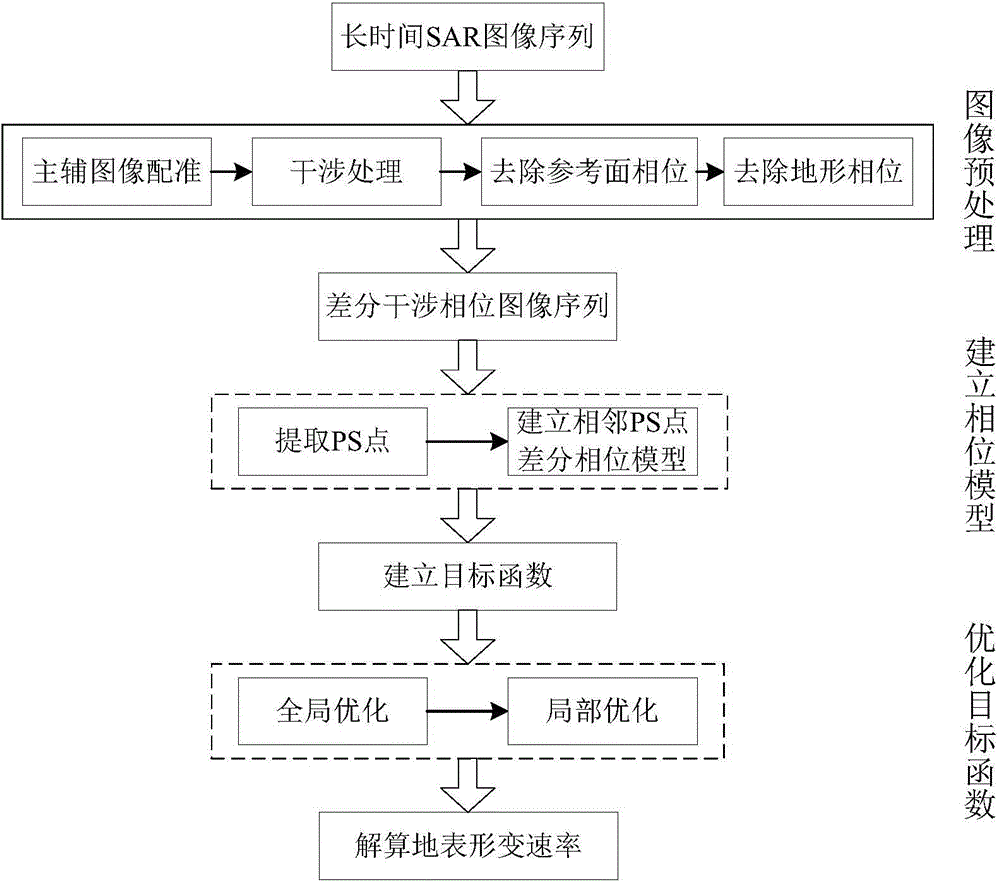

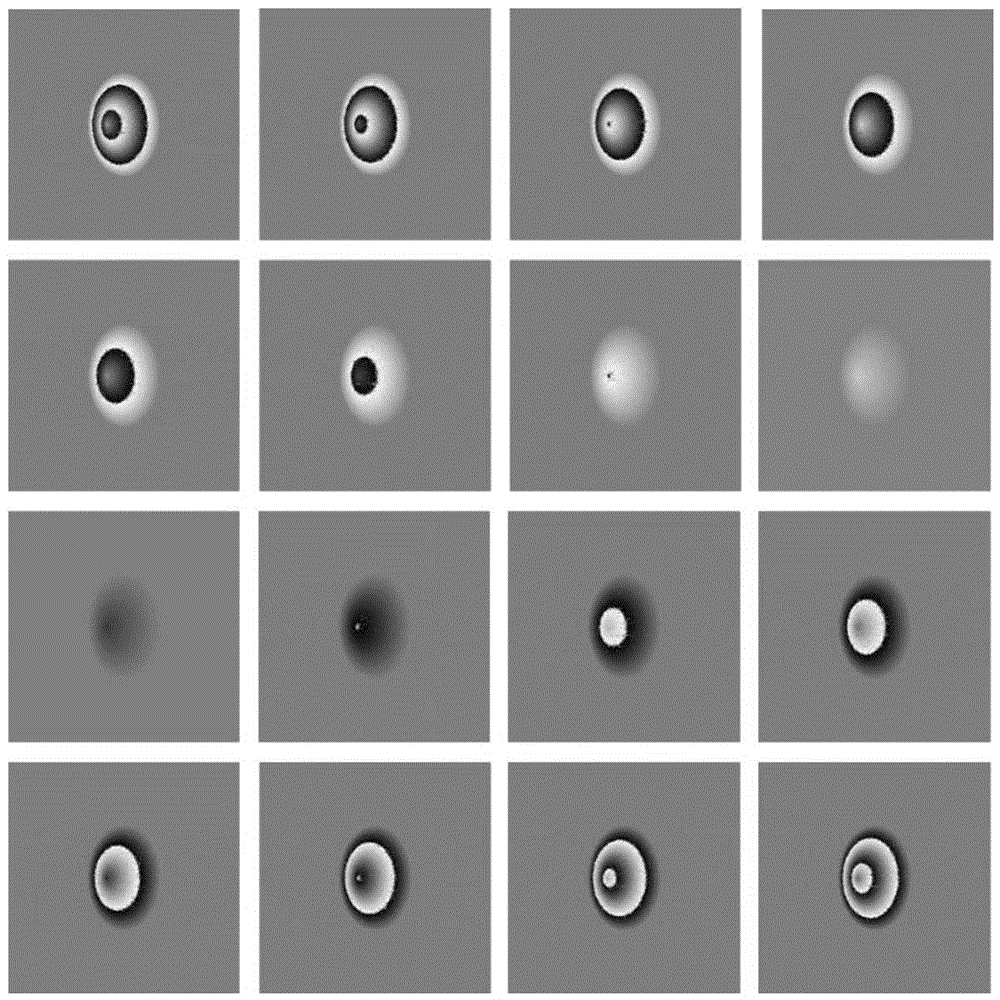

PS-DInSAR ground surface deformation measurement parameter estimation method based on optimal solution space search method

ActiveCN104091064ADoes not involve signal sampling issuesHigh precisionSpecial data processing applicationsRadio wave reradiation/reflectionLevenberg–Marquardt algorithmEstimation methods

The invention discloses a PS-DInSAR ground surface deformation measurement parameter estimation method based on an optimal solution space search method. The method comprises the first step of obtaining a difference interferometric phase image sequence, the second step of extracting permanent scatterer points from the difference interferometric phase image sequence and constructing a Delaunay triangular network, the third step of calculating the second-order difference phases of each pair of adjacent PS points in a kth difference interferometric phase image, the fourth step of establishing an objective function to be optimized, the fifth step of searching for the objective function in a two-dimensional solution space, the sixth step of conducting local optimization on the objective function through the Levenberg-Marquardt algorithm, and the seventh step of solving the ground surface deformation quantity and an elevation error. According to the PS-DInSAR ground surface deformation measurement parameter estimation method based on the optimal solution space search method, signal sampling is not involved, so that the influence of all interference images on nonuniformity of time and space base lines is avoided, a high-precision result can still be obtained without priori knowledge, and a new thought and path are provided for ground surface deformation measurement.

Owner:BEIHANG UNIV

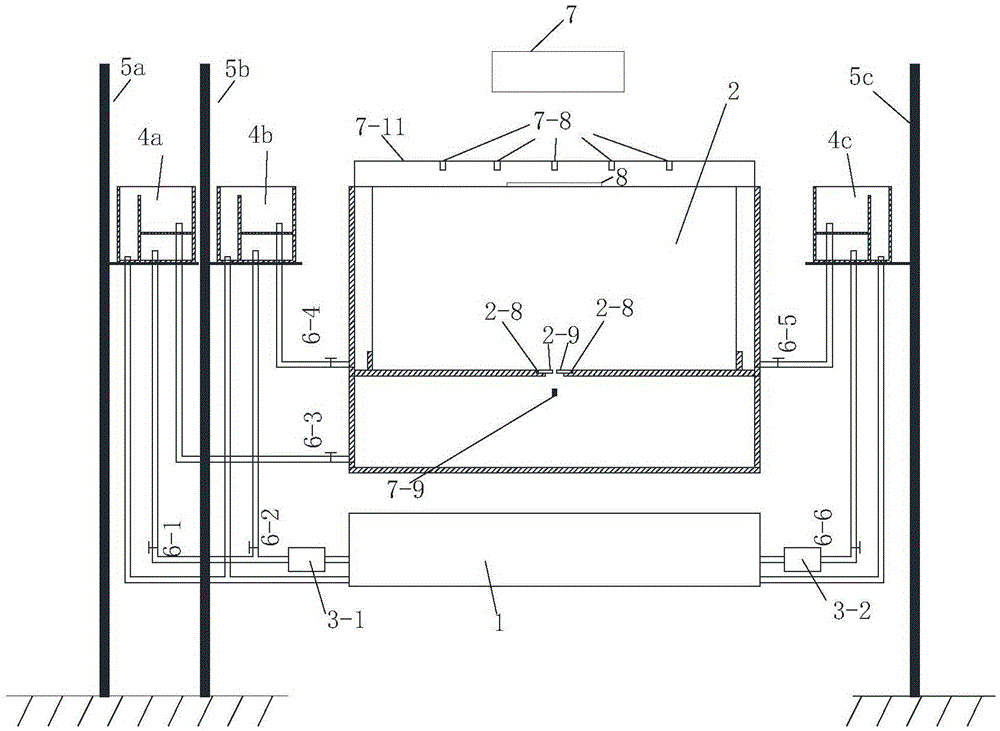

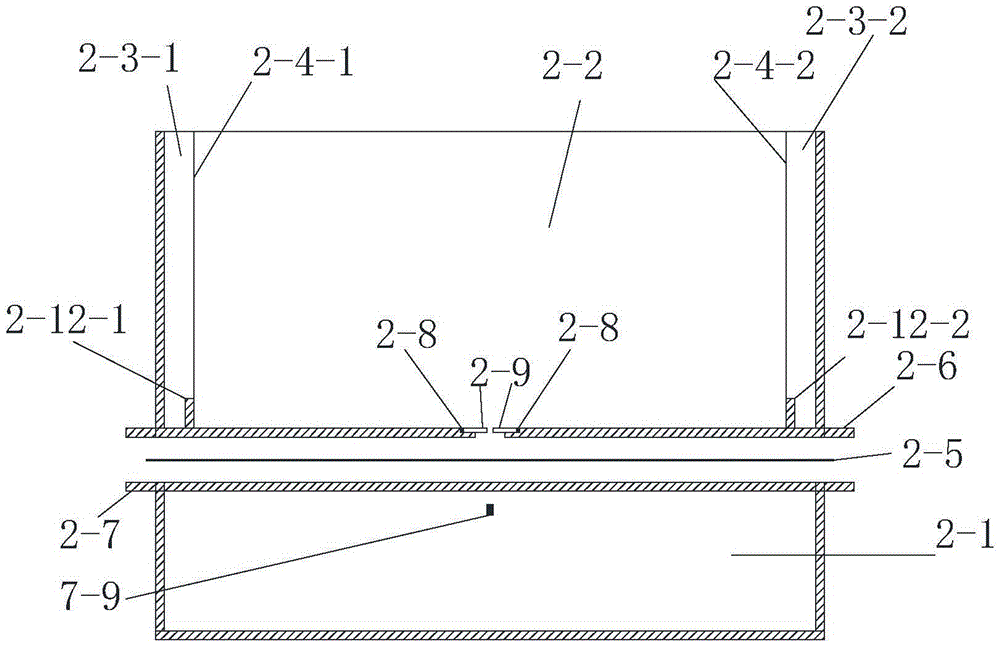

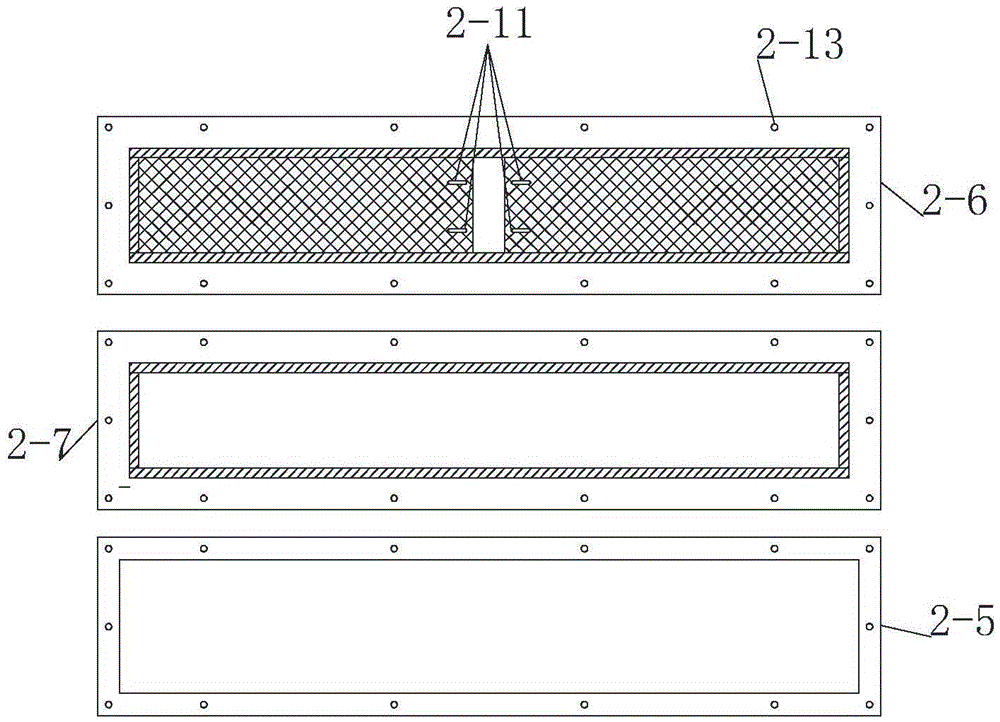

Hydraulic-induced covered karst collapse simulation testing device and using method

InactiveCN105572319AImprove stabilityReduce testing costsEarth material testingProcess mechanismPeristaltic pump

Owner:HOHAI UNIV

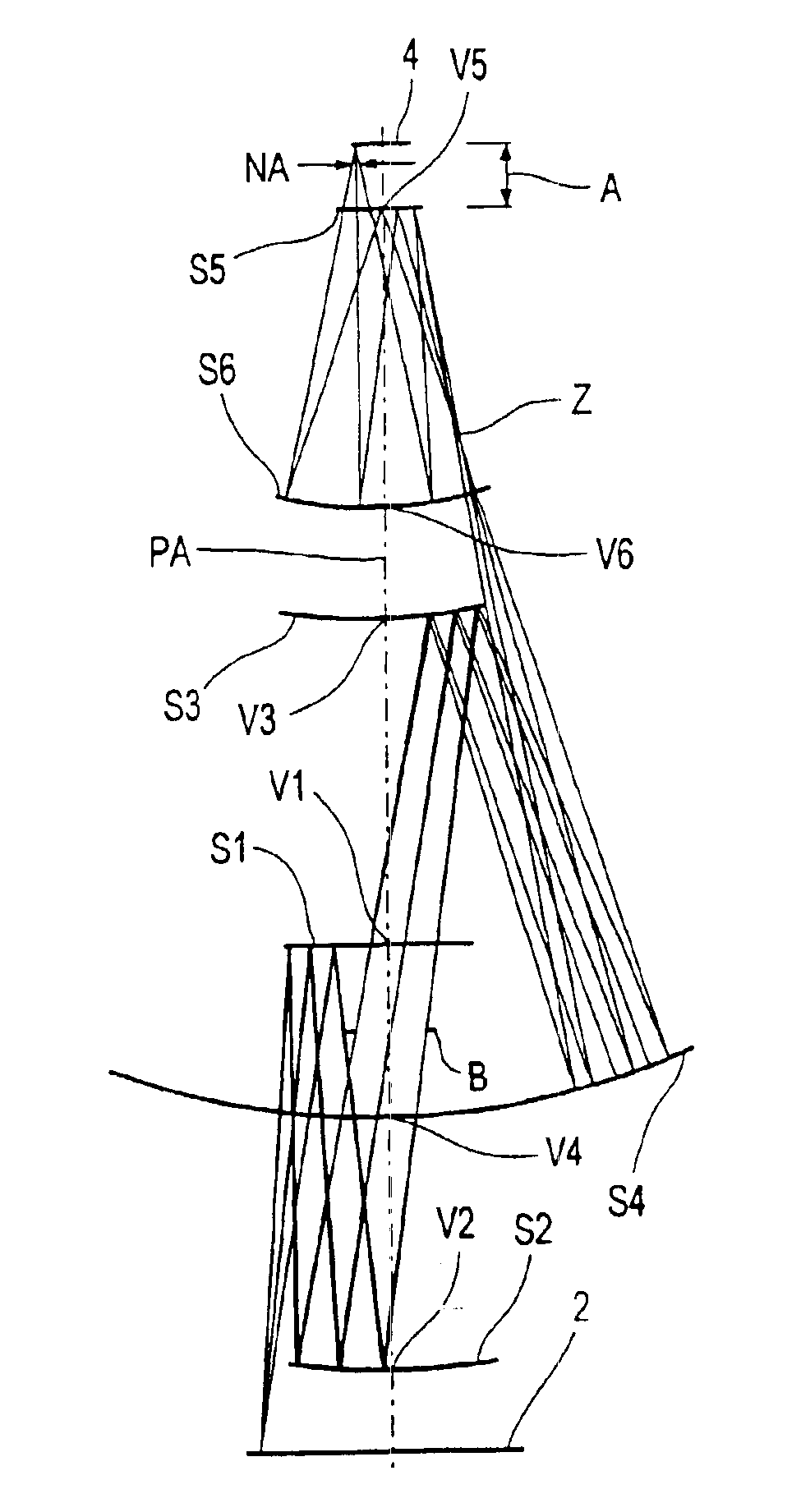

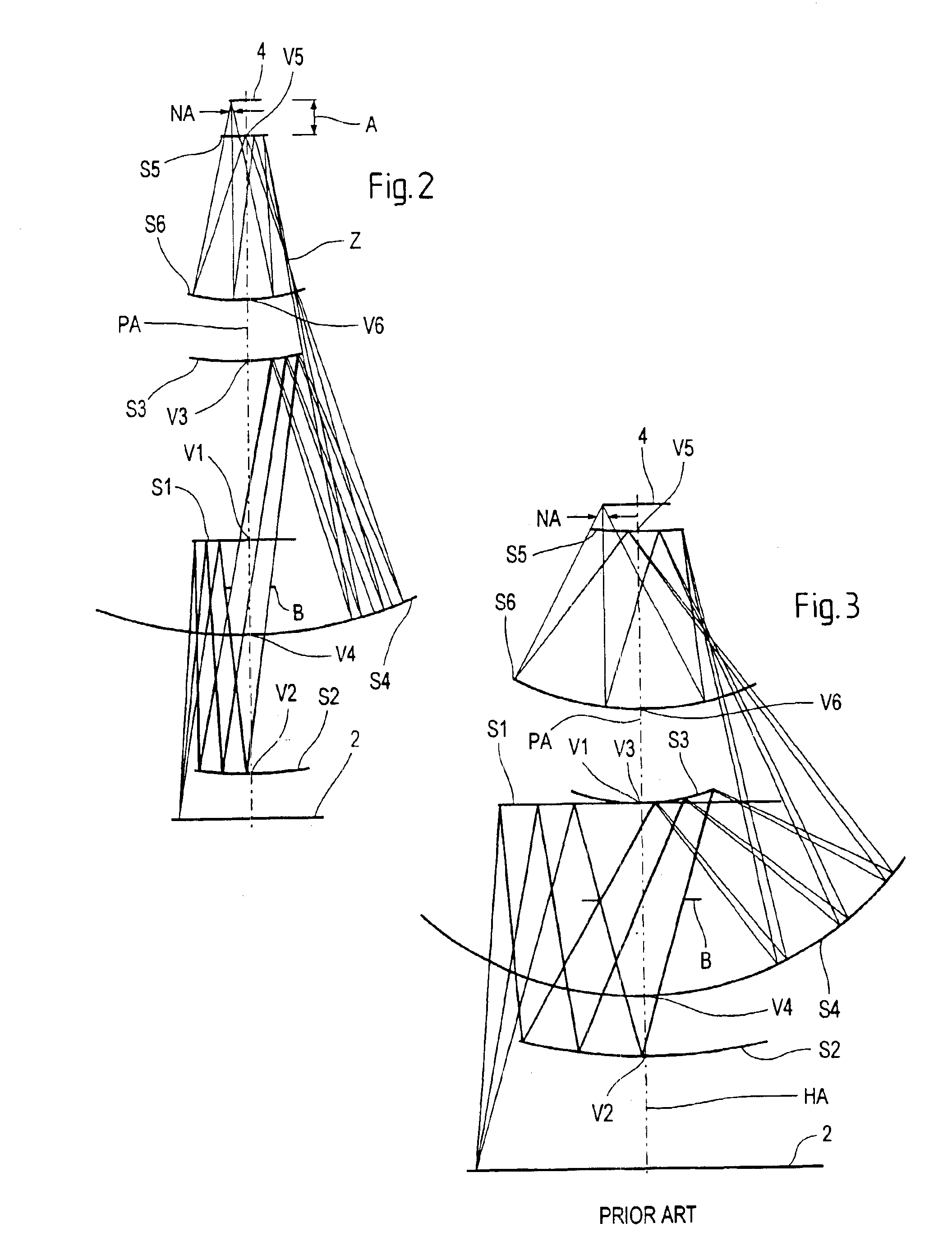

Microlithography reduction objective and projection exposure apparatus

InactiveUS6902283B2Efficiently maskedThe implementation process is simpleMirrorsPhotomechanical exposure apparatusImage planePhysics

A projection objective formed from six mirrors arranged in a light path between an object plane and an image plane is provided. The projection objective, in some examples, is characterized by having a physical distance between the vertexes of adjacent mirrors that is large enough to allow for the six mirrors to have sufficient thickness and stability properties to prevent surface deformations due to high layer tensions. In some embodiments, mirror thickness are such that surface deformations are prevented with mirrors having layer tensions lower than 350 MPa. Mirror surfaces may comprise multilayer systems of Mo / Be or Mo / Si layer pairs. In some examples, the physical distance between a vertex of the third mirror and a vertex of the sixth mirror (S3S6) satisfies the following relationship: 0.3×(a used diameter of the third mirror S3+a used diameter of the sixth mirror S6)<S3S6. In some examples, a ratio of a physical distance between a vertex of the first mirror and a vertex of the third mirror (S1S3) to a physical distance between the vertex of the first mirror and a vertex of the second mirror (S1S2) is within the range of: 0.5<S1S3 / S1S2<2. In some examples, the physical mirror surfaces of the mirrors have a rotational symmetry with respect to a principal axis (PA). In some examples, all physical mirror surfaces are aspherical. In some examples, at most five physical mirror surfaces are aspherical. Other examples are provided, along with microlithography projection exposure apparatuses and processes for producing a microelectronic device.

Owner:CARL ZEISS STIFTUNG

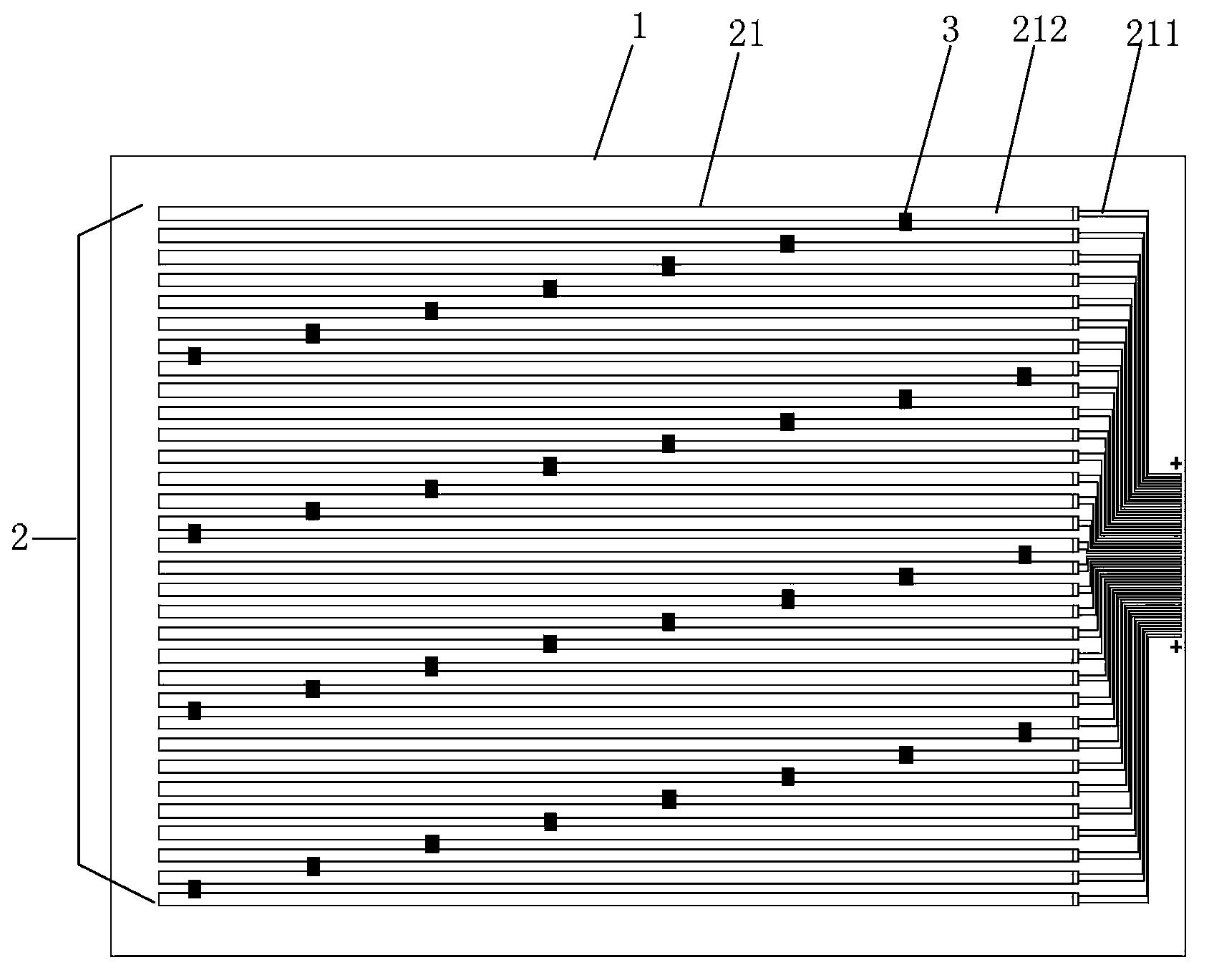

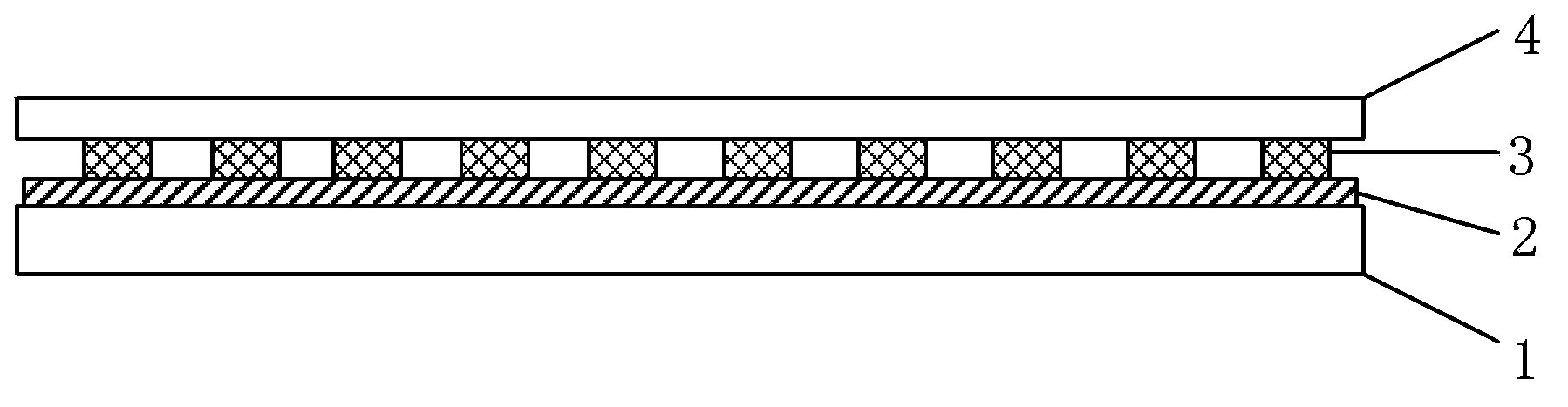

Touch screen pressure and position sensing method, touch screen pressure and position sensing element, and electronic touch device

InactiveCN103576960ASimple designSimple structureInput/output processes for data processingTouchscreenElectric signal

The invention is applied to the field of touch technology and provides a touch screen pressure and position sensing method. The method includes: providing a substrate, and setting an electrode layer, provided with a plurality of mutually independent electrodes, on the substrate; setting a plurality of strain sensors, used for measuring surface deformation produced when the substrate is under pressure, on the substrate, and connecting the strain sensors to two different electrodes; allowing the conductive electrodes to convert deformation information detected by the sensors into electrical signals transmitted to a touch screen controller; allowing the touch screen controller to receive sensing information and convert the sensing information into touch coordinates transmitted to a processing unit, and allowing the processing unit to analyze and process the data. The invention further provides a touch screen pressure and position sensing element and an electronic touch device. Compared with the existing touch screen, the sensing method, the sensing element and the electronic touch device have the advantages that only one substrate needs to be provided with the integrated electrodes, the circuit is simple in design, integration is convenient, the cost is low, omission of an insulating layer decreases light loss and increases transparency of a touch screen.

Owner:SHENZHEN NEW DEGREE TECH

Paper tissue having enhanced softness

A novel paper article, a method of making a paper product, and an embossing roll are disclosed for providing a paper surface region having a minority of fiber to fiber bonds broken in the paper surface region to a depth less than about 0.02 mm from the paper surface. In one aspect, the roughened embossing roll includes protuberances or depressions sized at less than about 0.1 mm. In one aspect, the roughened embossing roll includes protuberances or depressions adapted to produce paper product surface deformations in the paper surface, wherein the paper product surface deformations are invisible to an unaided human eye. The present invention provides a paper product having higher perceived softness while maintaining tensile strength.

Owner:KIMBERLY-CLARK WORLDWIDE INC

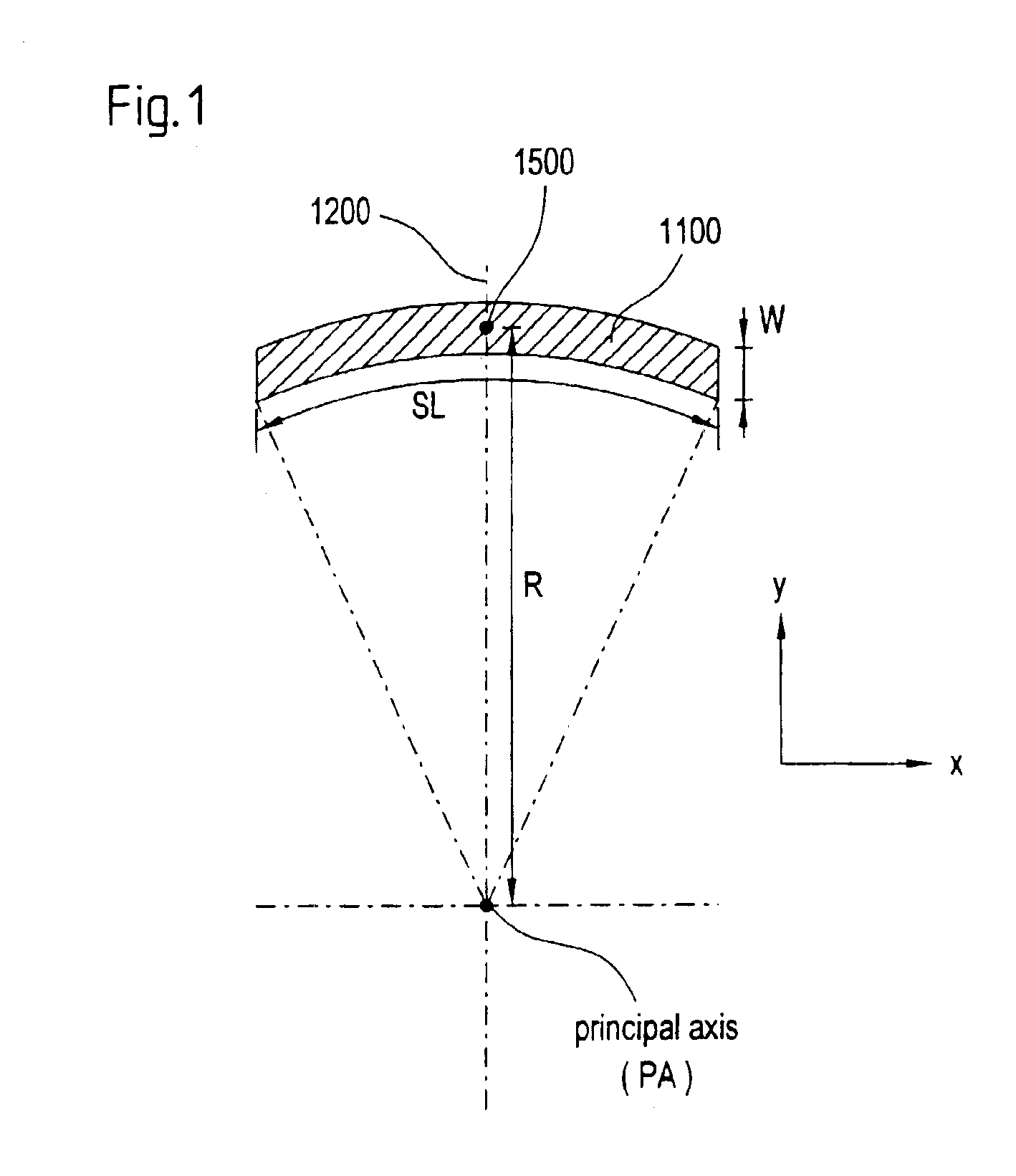

Projection objective of a microlithographic projection exposure apparatus

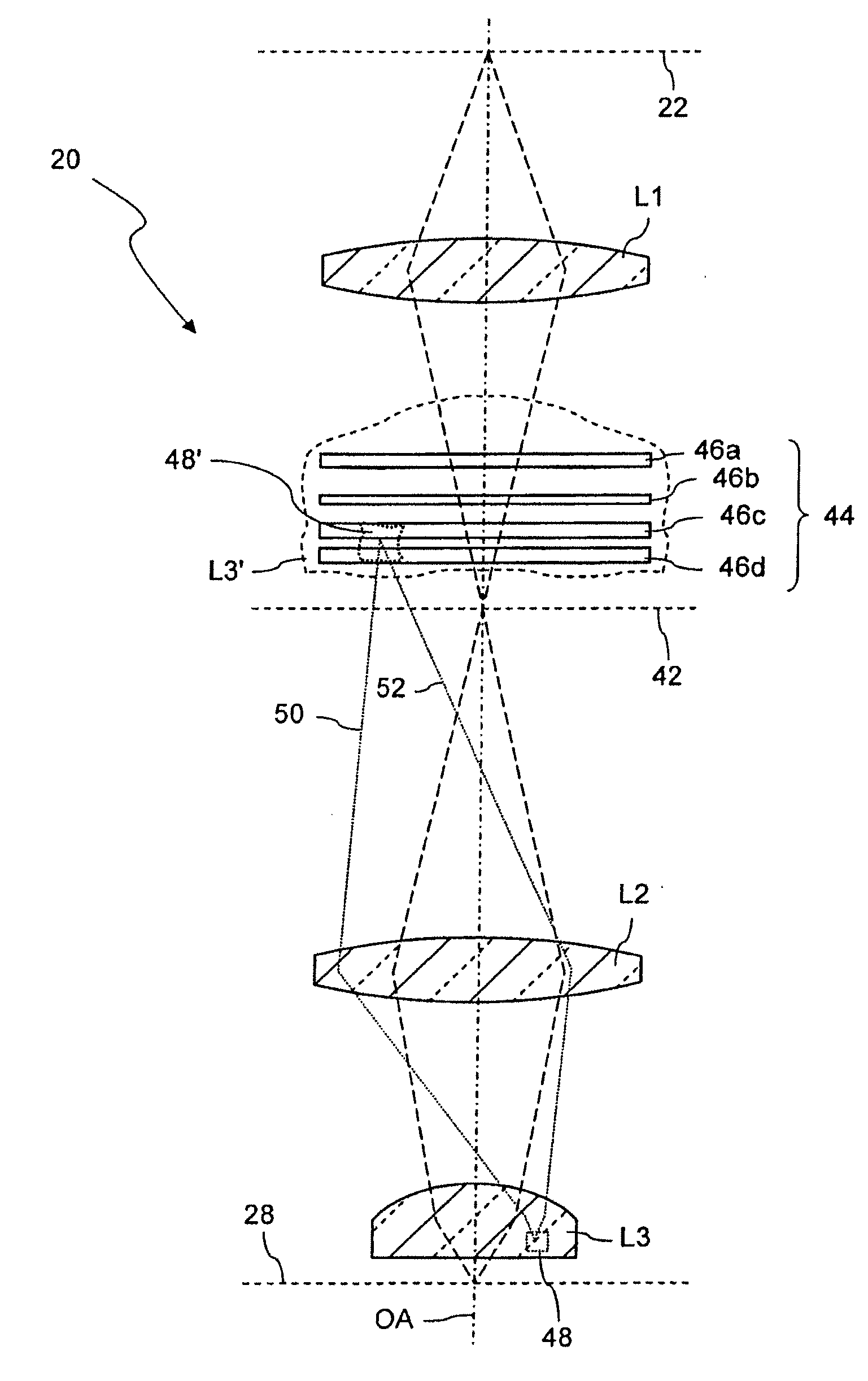

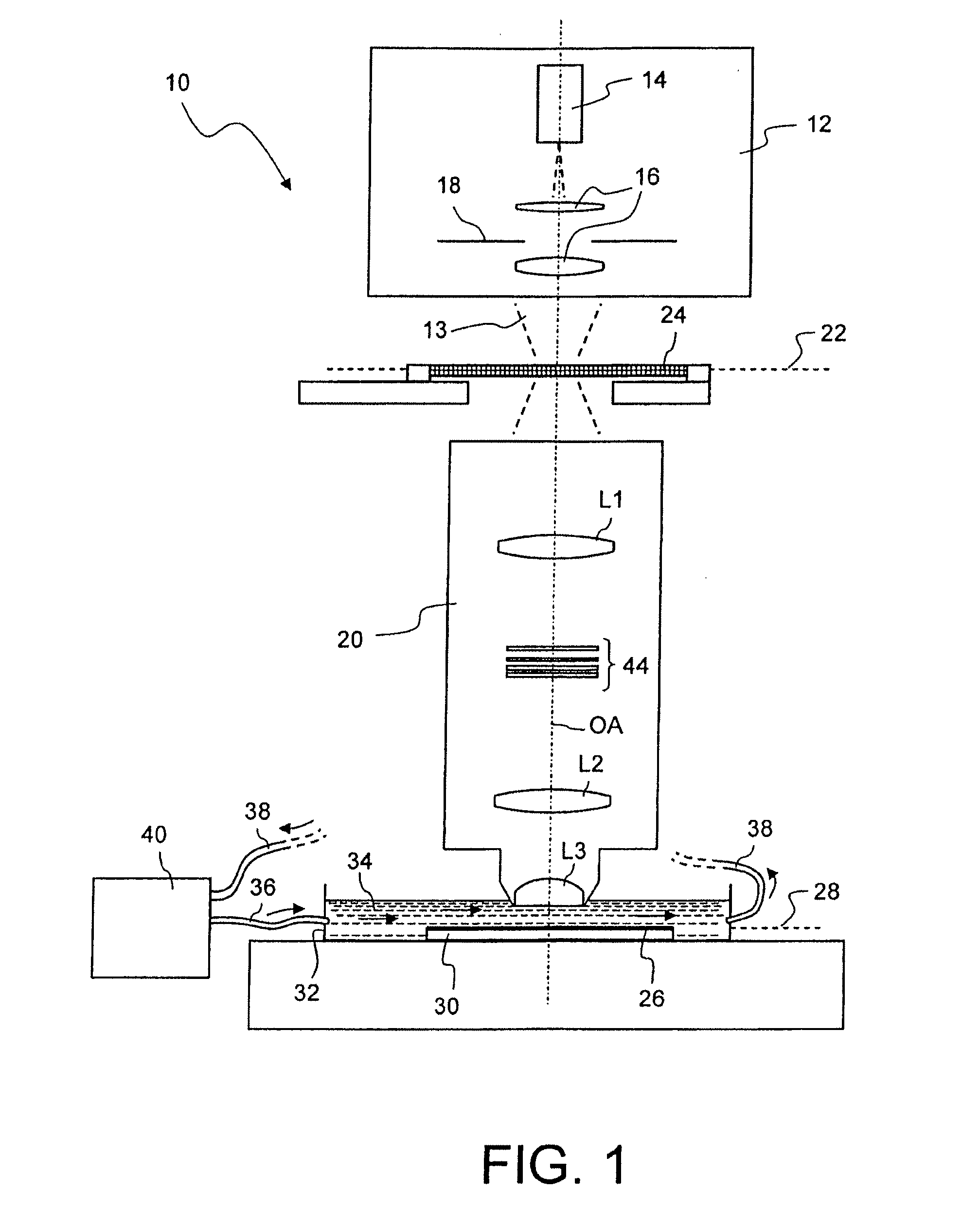

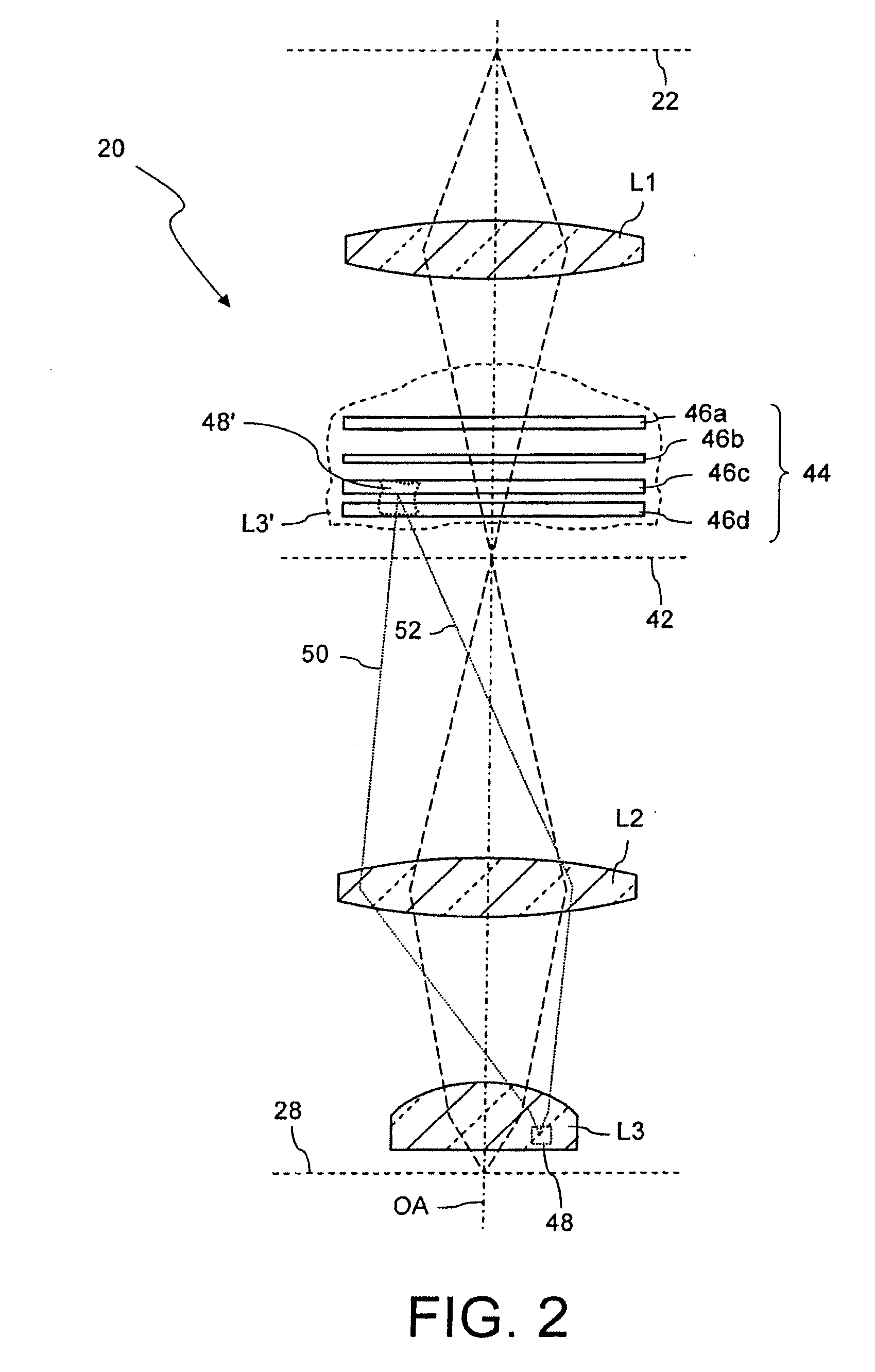

ActiveUS20090284831A1Reduce materialReduce aberrationPolarising elementsPhotomechanical exposure apparatusOptical propertyRefractive index

A projection objective of a microlithographic projection exposure apparatus has a high index refractive optical element (L3) with an index of refraction greater than 1.6. This element (L3) has a volume and a material related optical property which varies over the volume. Variations of this optical property cause an aberration of the objective. In one embodiment at least 4 optical surfaces are provided that are arranged in at least one volume (L3′) which is optically conjugate with the volume of the refractive optical element. Each optical surface comprises at least one correction means, for example a surface deformation or a birefringent layer with locally varying properties, which at least partially corrects the aberration caused by the variation of the optical property.

Owner:CARL ZEISS SMT GMBH

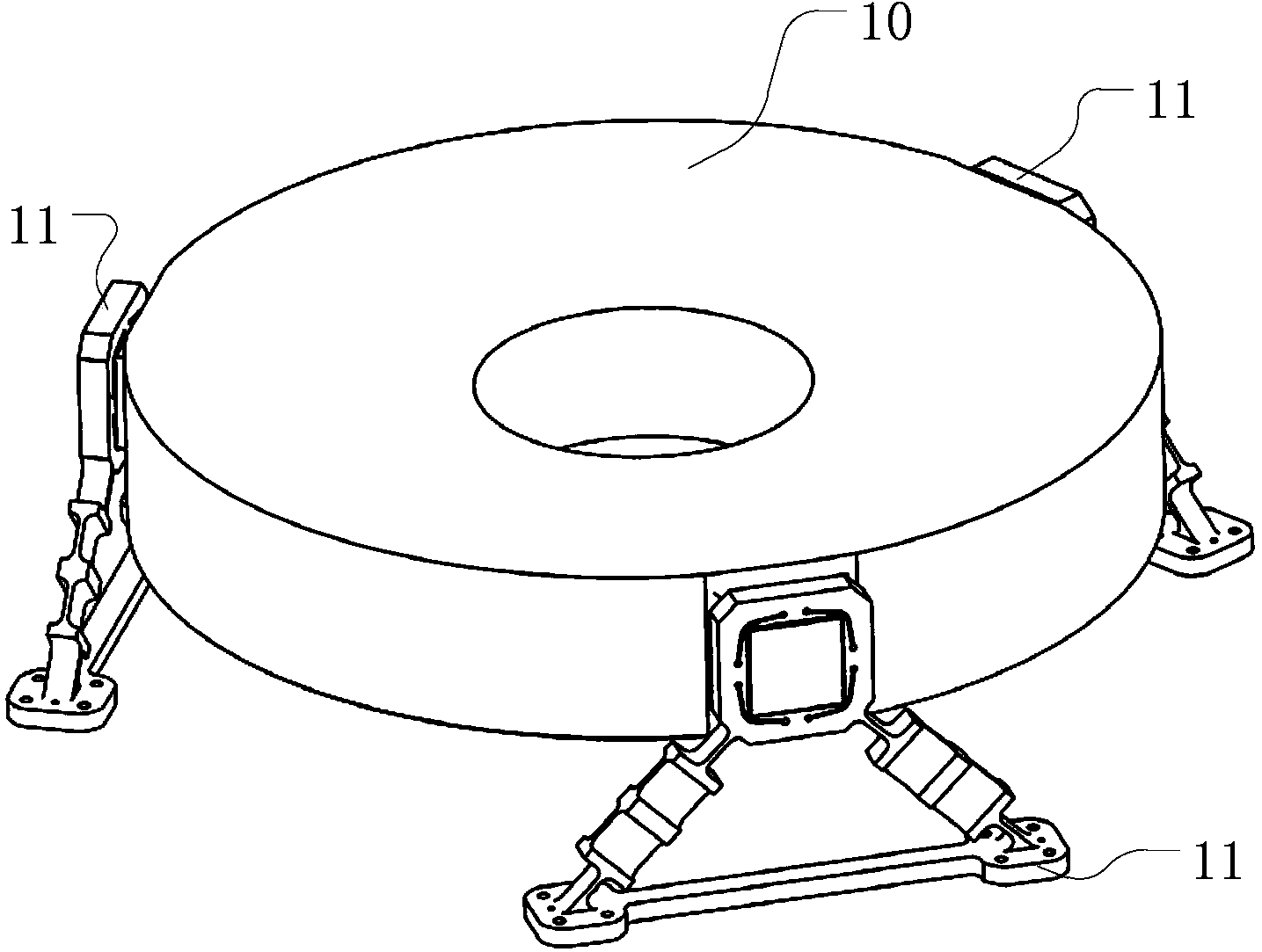

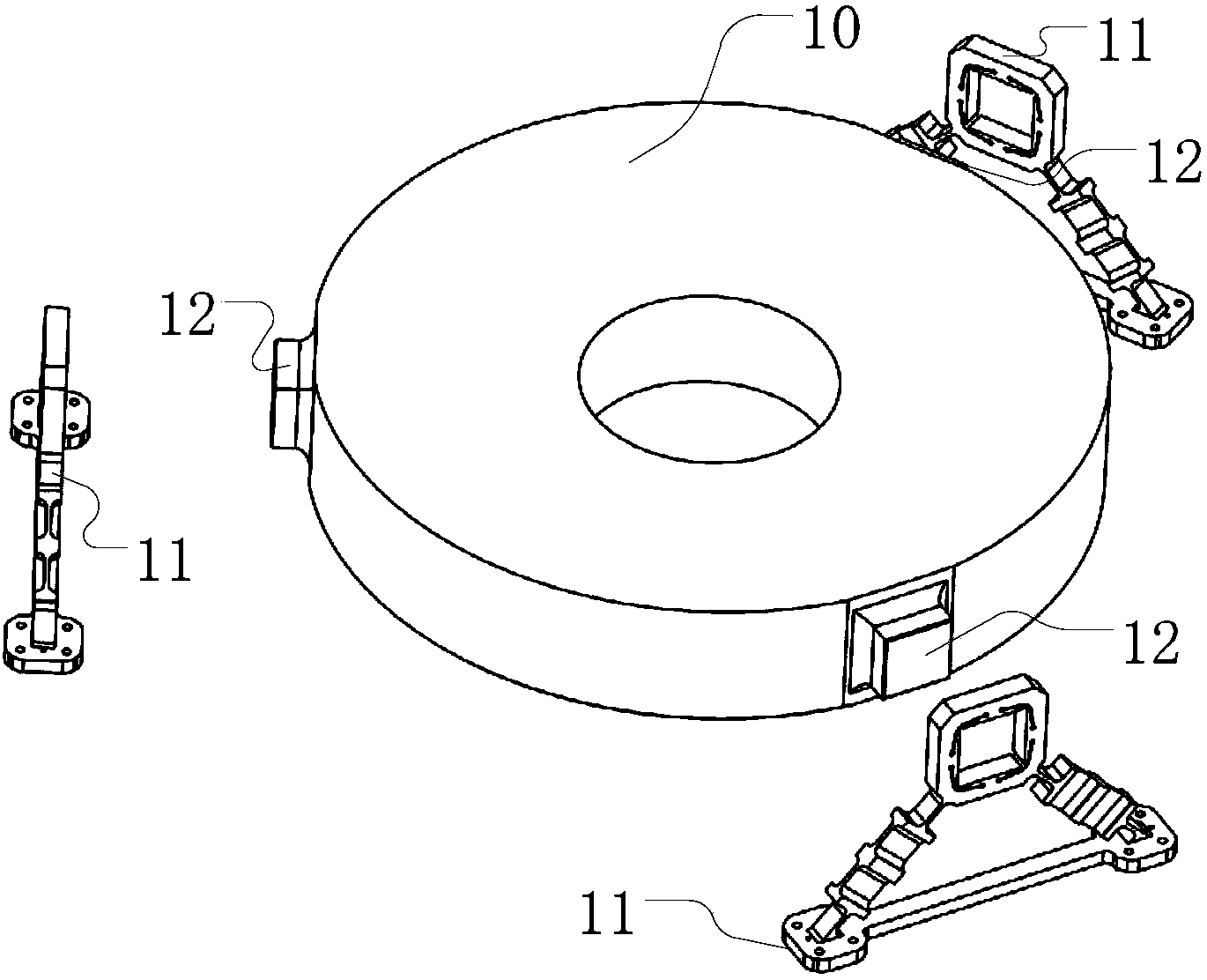

Lateral flexible supporting structure of space optical remote sensor circulator reflector

The invention belongs to the space optical remote sensing technical field and discloses a lateral flexible supporting structure of a space optical remote sensor circulator reflector to solve the problem that according to the prior art, mirror surface deformation and weight waste are severe. The structure comprises three reflector body bosses evenly machined on the lateral circumference of a reflector body, and three flexible supporting units connected with the three reflector body bosses respectively. Each flexible supporting unit comprises a bonding frame, supporting arms and a supporting base, wherein the two ends of the bonding frame are connected with the supporting base through the two supporting arms, flexible grooves are formed in the four interior corners of the bonding frame respectively, a notch is formed between every two adjacent flexible grooves, four bonding surfaces are formed in the end face of the bonding frame, the four bonding surfaces are flexible relative to the bonding frame around the notches, and the bonding frame is fixedly connected with the reflector body bosses through the four bonding surfaces. According to the structure, stress generated during bonding and assembly is reduced, and it is guaranteed that surface figure accuracy of the reflector does not exceed the allowance of optical design.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

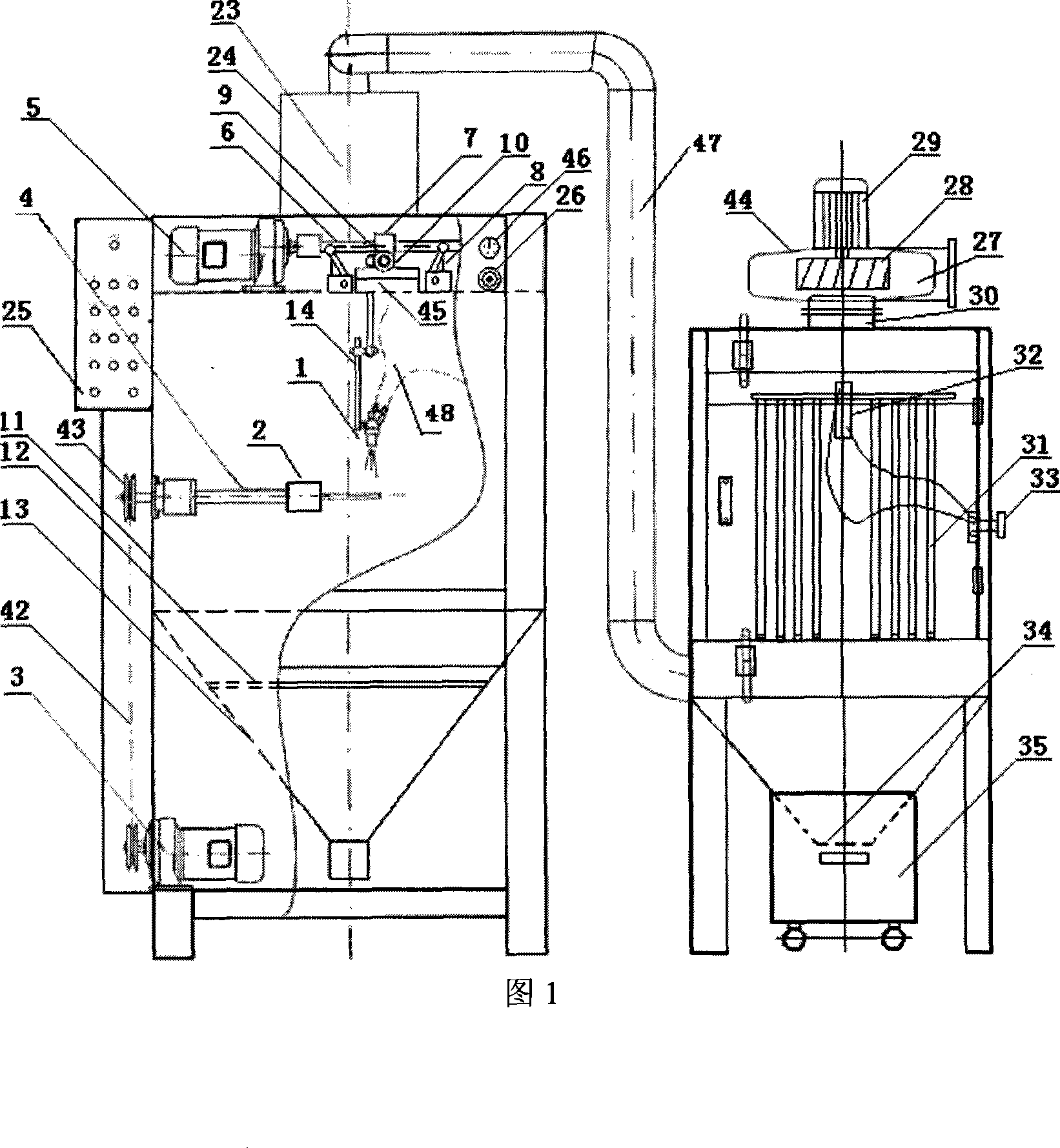

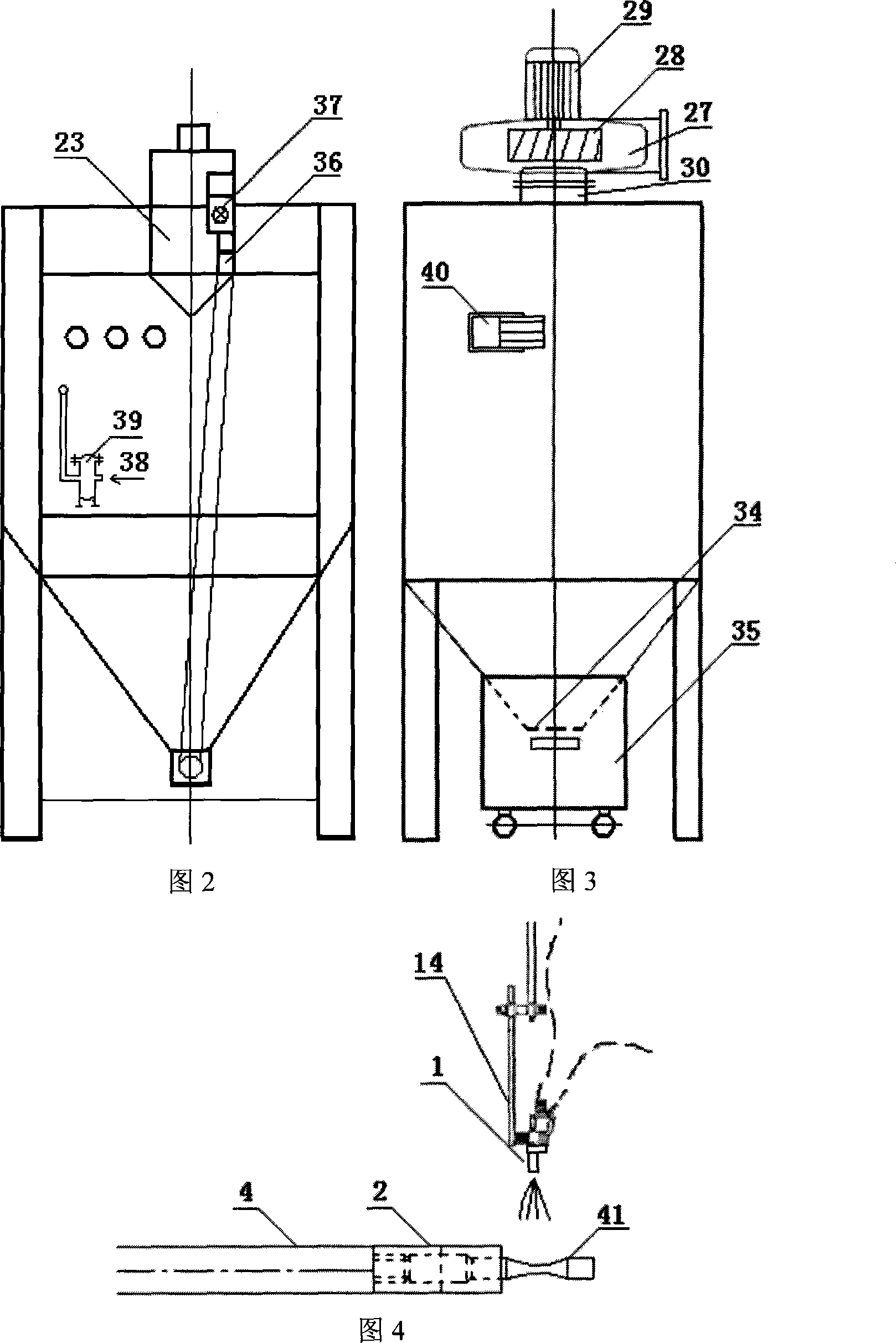

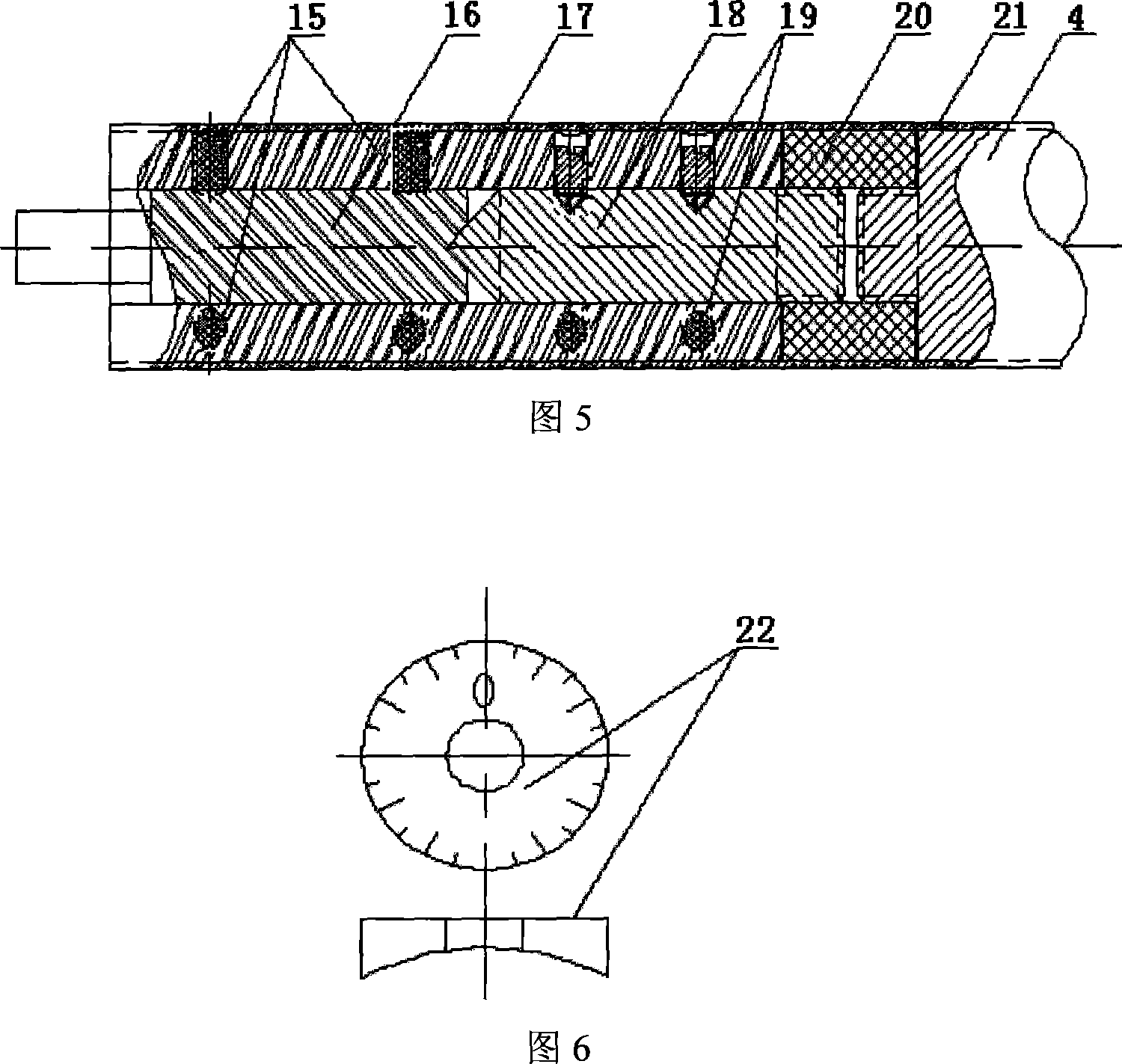

Shot peening machine for processing surface deformation strengthening treatment to magnesium alloy sample

InactiveCN101214633AGuaranteed concentricityGuaranteed parallelismImpeller wheelsBlast gunsAir compressionAbrasive blasting

The present invention relates to a device in the technical field of material processing, in particular to a peener which carries out the surface deformation strengthening process on magnesium alloy samples. The present invention comprises a main peening system, an upper whirlwind separation system, a dedusting system, an air compression system and an electric system, wherein, the upper whirlwind separation system is positioned on the upper end of the main peening system, the lower part of the upper whirlwind separation system is communicated with the main peening system, the upper part is connected with the dedusting system, which is positioned outside the main peening system, the air inlets of both the dedusting system and the main peening system are connected with the air compression system, and the electric system is connected with the main peening system, the upper whirlwind separation system, the dedusting system and the air compression system. The present invention can conveniently assemble and disassemble the samples of the shaft class, the range of the generated peening strenghth is wide, the effect and uniformity of peening is good, and moreover, pollution can be prevented.

Owner:SHANGHAI AIERSI LIGHT ALLOY

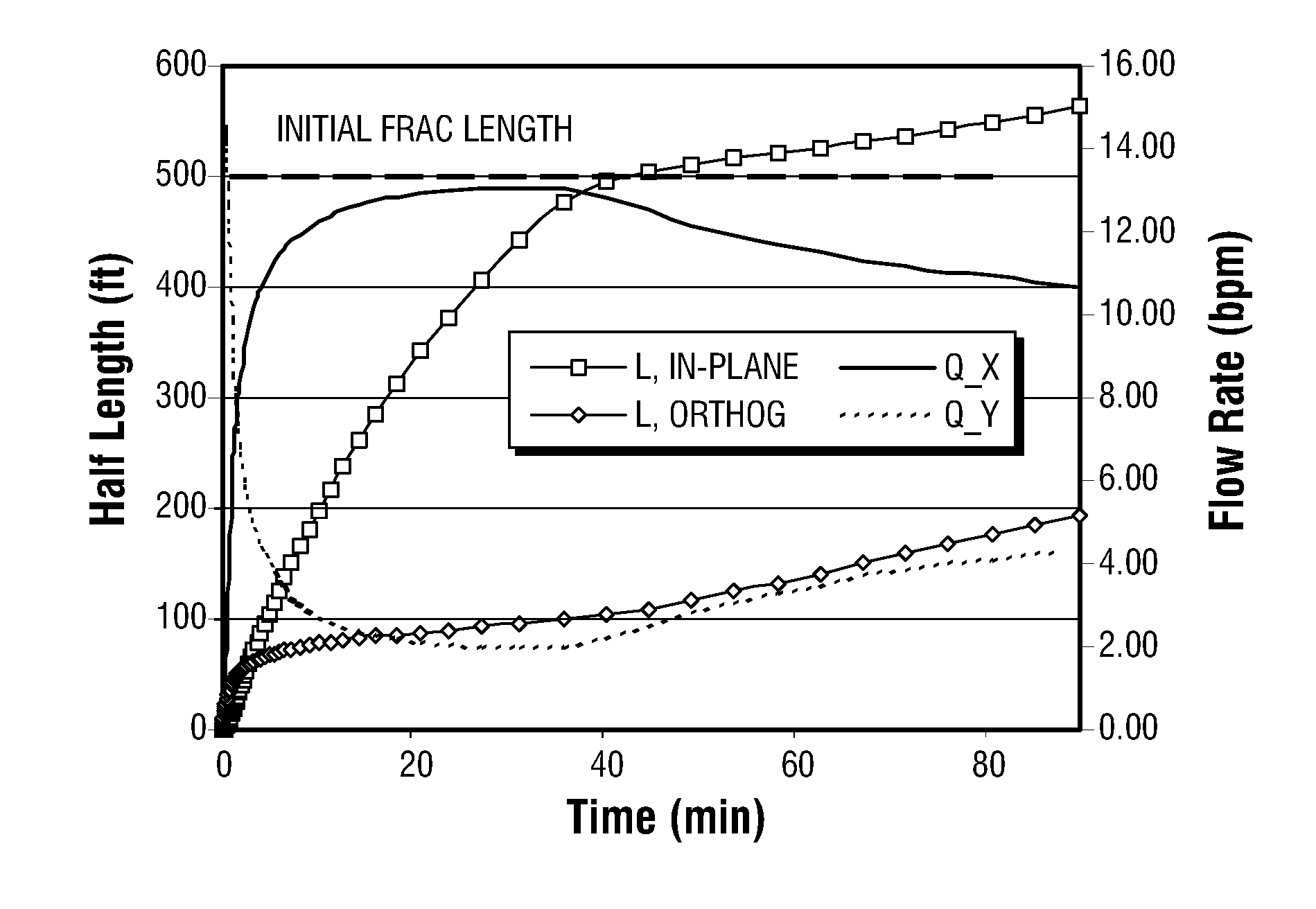

Simulations for hydraulic fracturing treatments and methods of fracturing naturally fractured formation

A hydraulic fracture design model that simulates the complex physical process of fracture propagation in the earth driven by the injected fluid through a wellbore. An objective in the model is to adhere with the laws of physics governing the surface deformation of the created fracture subjected to the fluid pressure, the fluid flow in the gap formed by the opposing fracture surfaces, the propagation of the fracture front, the transport of the proppant in the fracture carried by the fluid, and the leakoff of the fracturing fluid into the permeable rock. The models used in accordance with methods of the invention are typically based on the assumptions and the mathematical equations for the conventional 2D or P3D models, and further take into account the network of jointed fracture segments. For each fracture segment, the mathematical equations governing the fracture deformation and fluid flow apply. For each time step, the model predicts the incremental growth of the branch tips and the pressure and flow rate distribution in the system by solving the governing equations and satisfying the boundary conditions at the fracture tips, wellbore and connected branch joints. An iterative technique is used to obtain the solution of this highly nonlinear and complex problem.

Owner:SCHLUMBERGER TECH CORP

Flexible pressure sensor based on dielectric high-elastic polymer, and method for sensing pressure

InactiveCN103954394ASimple designImprove signal-to-noise ratioFluid pressure measurement using capacitance variationCapacitanceEngineering

The invention discloses a flexible pressure sensor based on a dielectric high-elastic polymer, and a method for sensing pressure. The sensor comprises a high-elastic polymer film interlayer, a flexible electret positive electrode and a flexible electret negative electrode which are respectively bonded to the upper surface and the lower surface of the high-elastic polymer film interlayer, and a conductive trace which is respectively clamped to the flexible electret positive electrode, the flexible electret negative electrode and the high-elastic polymer film interlayer and is led out through the edge of the side surface of the high-elastic polymer film interlayer. An upper insulation support ring and a lower insulation support ring fix a sandwich structure composed of multiple film layers in the middle. In the method for sensing the pressure, a polarized electric field is provided by using a flexible electret electrode respectively provided with a certain quantity of positive charge and negative charge, the dielectric elastic polymer film generates curved surface deformation under an external pressure effect, capacitance changes accordingly, and the size of external pressure can be obtained through measuring the voltages of the positive electrode and the negative electrode. By using the sensor and the method provided by the invention, the thickness direction dimension restrictions brought by a conventional capacitive sensor air dielectric layer are eliminated, the sensor can be adaptive to different working conditions by adjusting material combination of the electret electrodes and the dielectric elastic polymer film, the sensor can work in a severe environment with high temperature and high moisture, the energy loss is small, the integration is high, and the preparation cost is low.

Owner:XI AN JIAOTONG UNIV

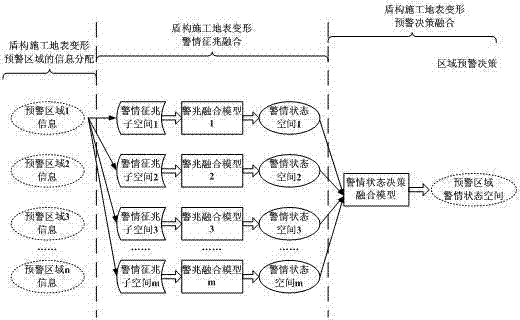

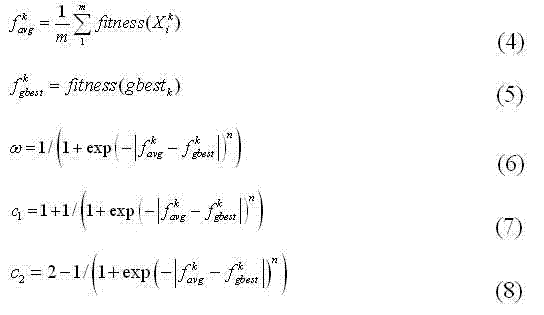

Subway shield construction surface deformation warning method based on temporal and spatial information fusion

InactiveCN104766129AAchieve integrationImprove safety risk management levelForecastingDeformation monitoringAlarm analysis

The invention discloses a subway shield construction surface deformation warning method based on temporal and spatial information fusion. According to the method, shield construction surface deformation warning sign fusion and regional warning decision fusion are realized by combining an information fusion theory and a hierarchical fusion thought with surface deformation monitoring information and through a feature fusion algorithm based on a RBF neural network and a decision fusion algorithm based on a D-S evidence theory. A warning means and informationization tool integrating the functions of alarm identification, alarm analysis, alarm prediction, alarm evaluation and alarm decision is provided for the construction site. The method is of important significance to the enhancement of shield construction surface deformation safety risk monitoring and the improvement of shield construction safety risk management level.

Owner:HUAZHONG UNIV OF SCI & TECH

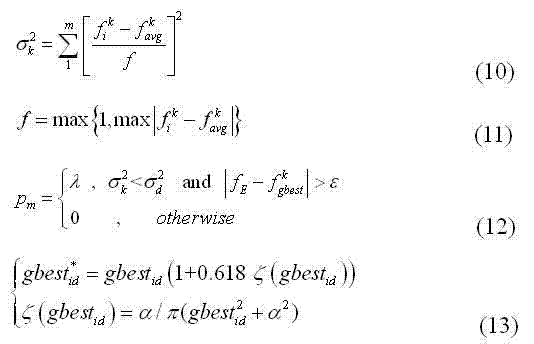

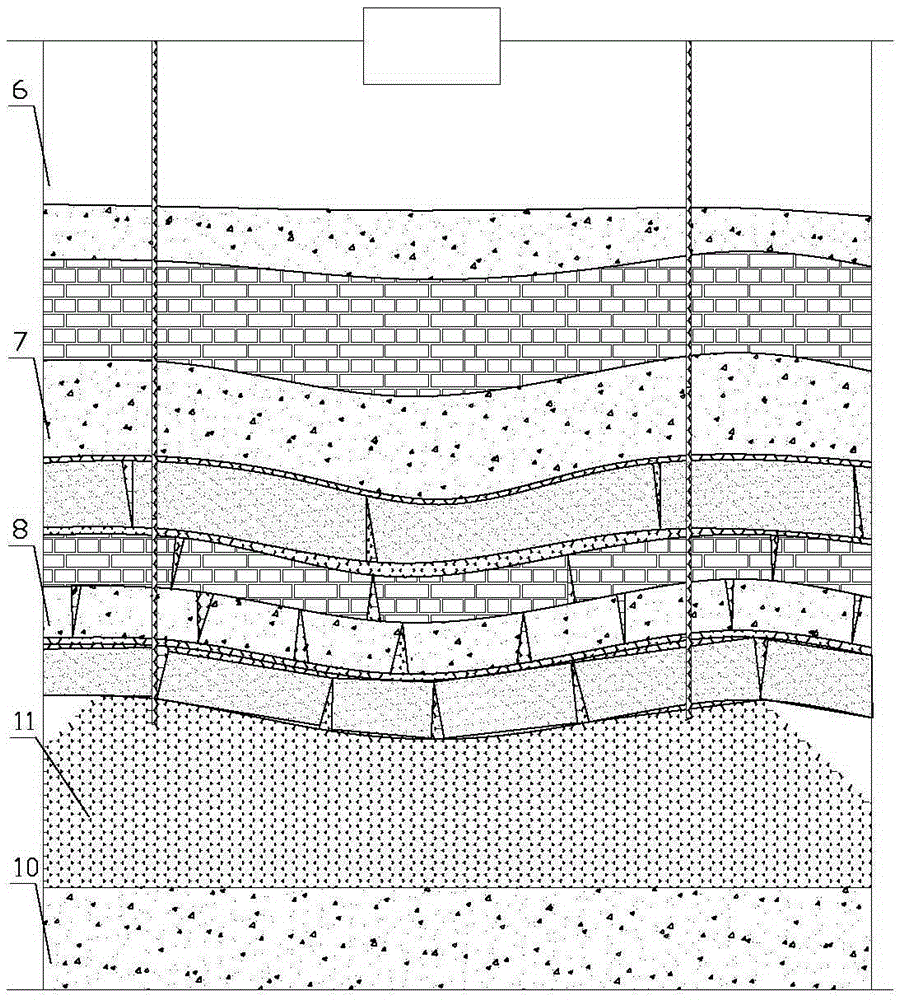

Grouting reinforcement treatment method for mid-depth goaf below building foundation

The invention provides a grouting reinforcement treatment method for a mid-depth goaf below a building foundation. The method mainly includes the steps that the grouting boundary range is determined through calculation, the grouting drilling depth is determined through a water injection test, grouting drilling, a grouting pump, a grouting rod and a hole packer are involved, the grouting boundary range is determined through theoretical calculation and the water injection test, grouting parameters and the grouting process are designed, and grouting reinforcement effect quality detection and settlement monitoring are conducted. The building foundation treatment method suitable for the coal mine goaf is provided. The method is characterized in that the grouting range is determined through theoretical calculation by looking up exploration and geographical data; the grouting drilling depth is determined through the water injection test; the corresponding grouting parameters are designed, grouting equipment is selected, and the grouting process is determined; drilling coring is conducted after one month after grouting construction, and grouting quality detection and surface deformation monitoring are conducted. The method has the beneficial effects that the damaged rock stratum and loosened rock of the coal mine goaf on the lower portion of a building are reinforced, residual displacement and deformation of overlaying rock on the upper portion of the goaf are effectively controlled, and normal use of the building is guaranteed.

Owner:徐州铭博矿山科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com