Patents

Literature

1569results about How to "Guaranteed concentricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

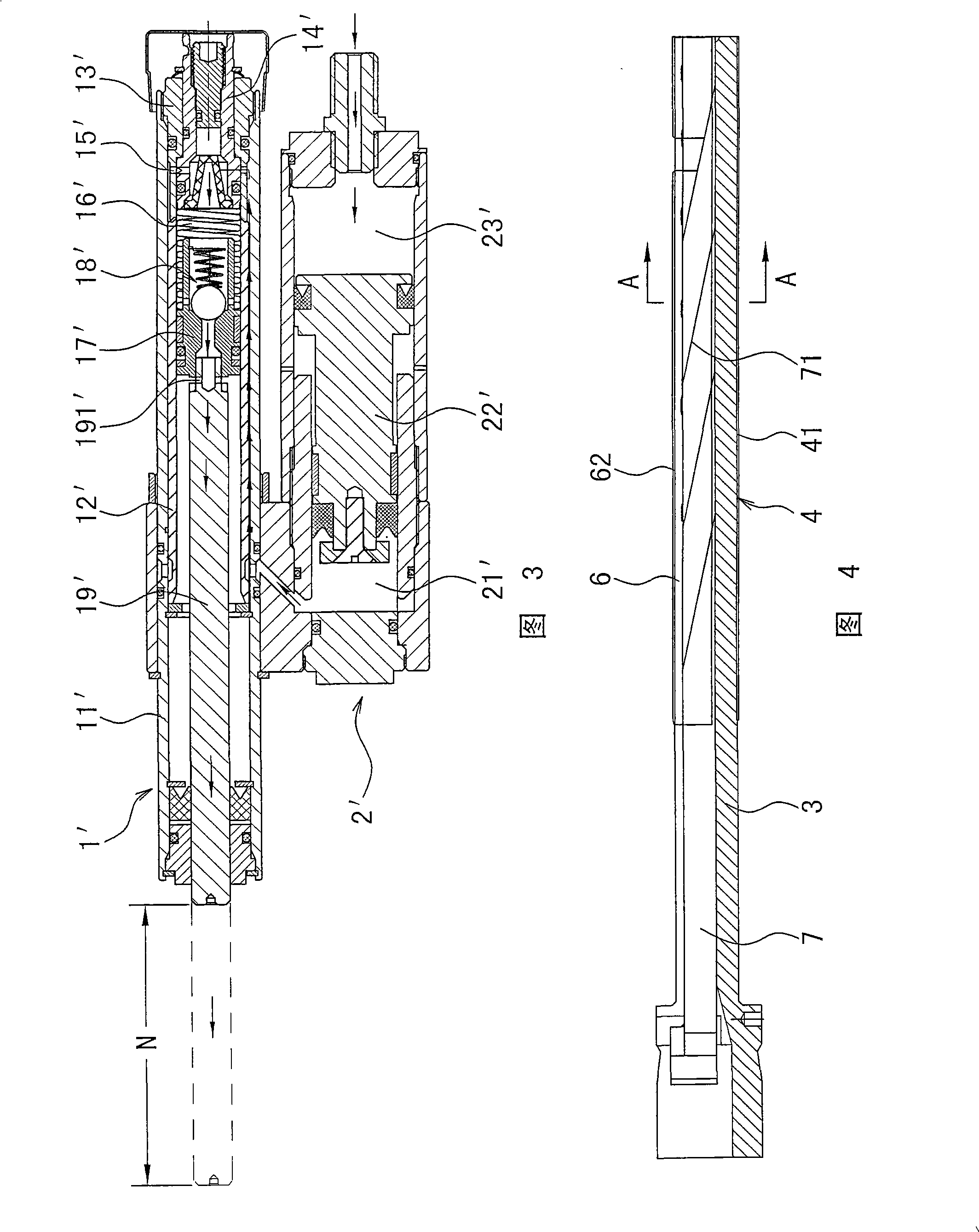

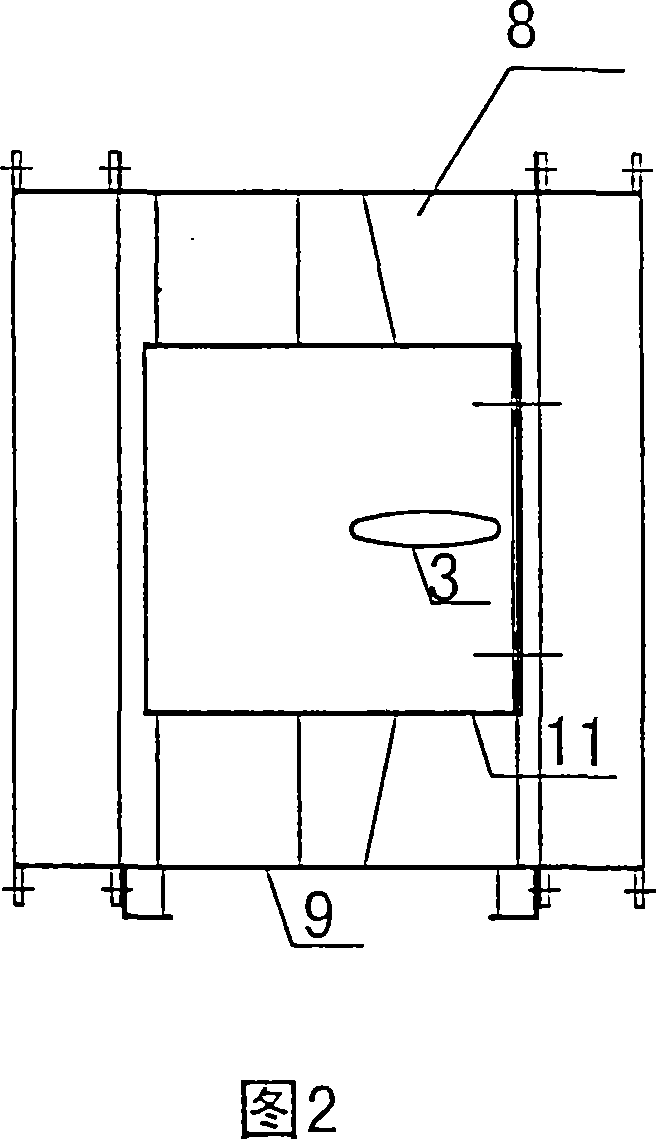

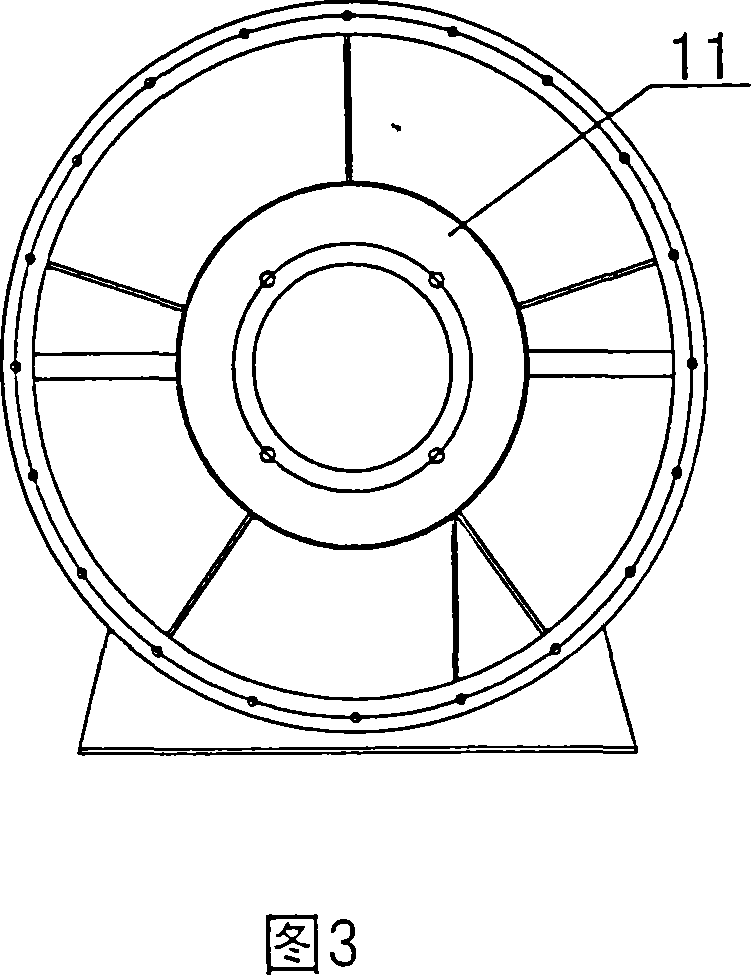

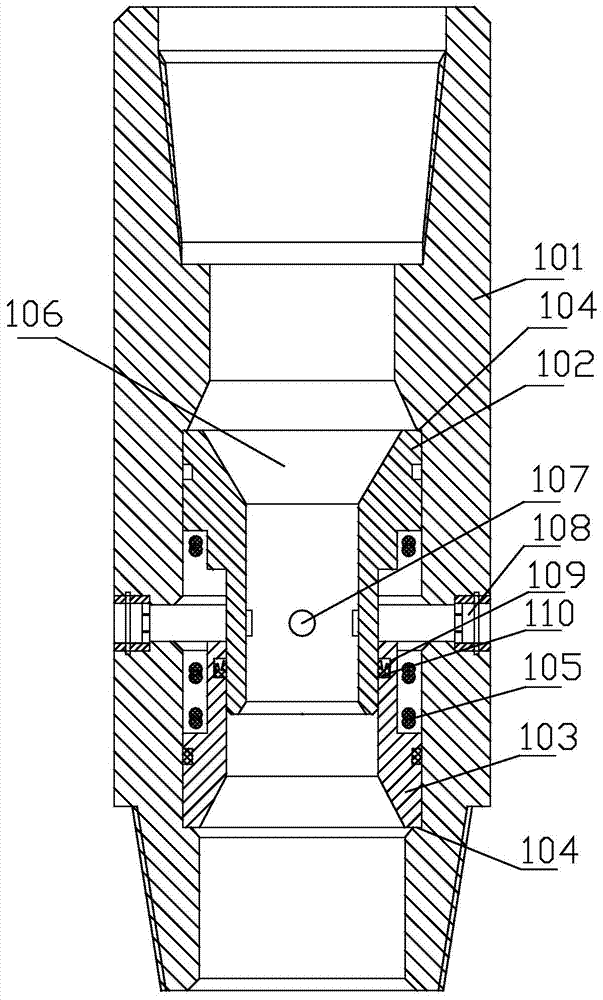

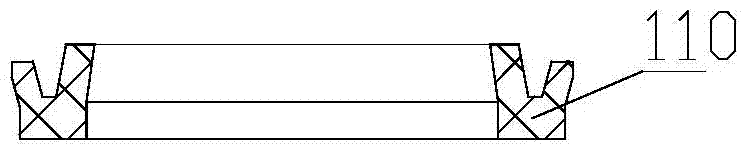

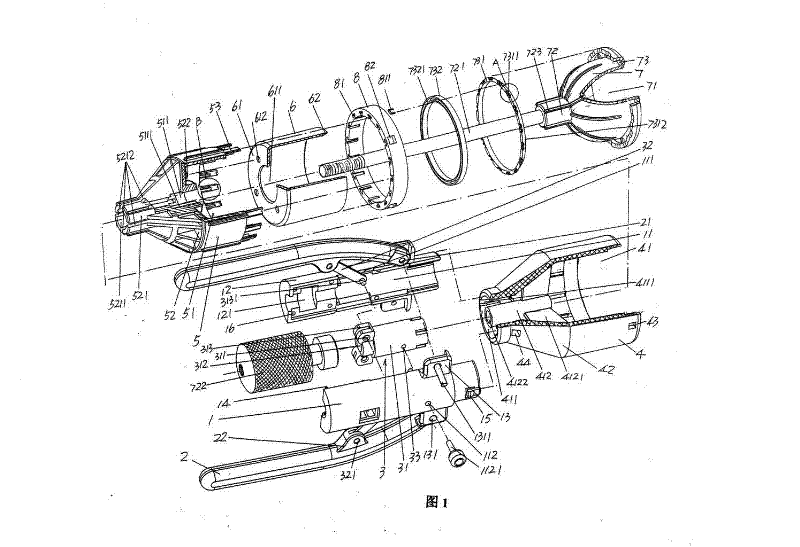

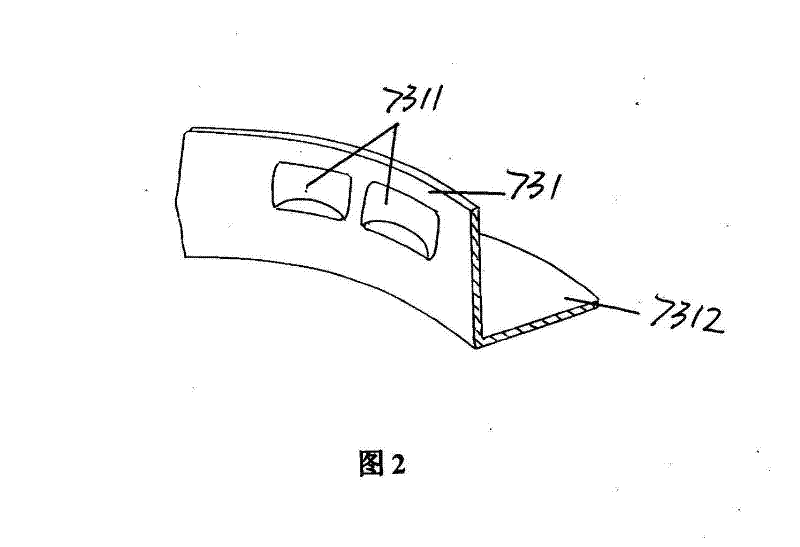

Foreskin cutting and sewing device

ActiveCN102217969AGuaranteed concentricityGuaranteed suture effectSurgical staplesForeskinEngineering

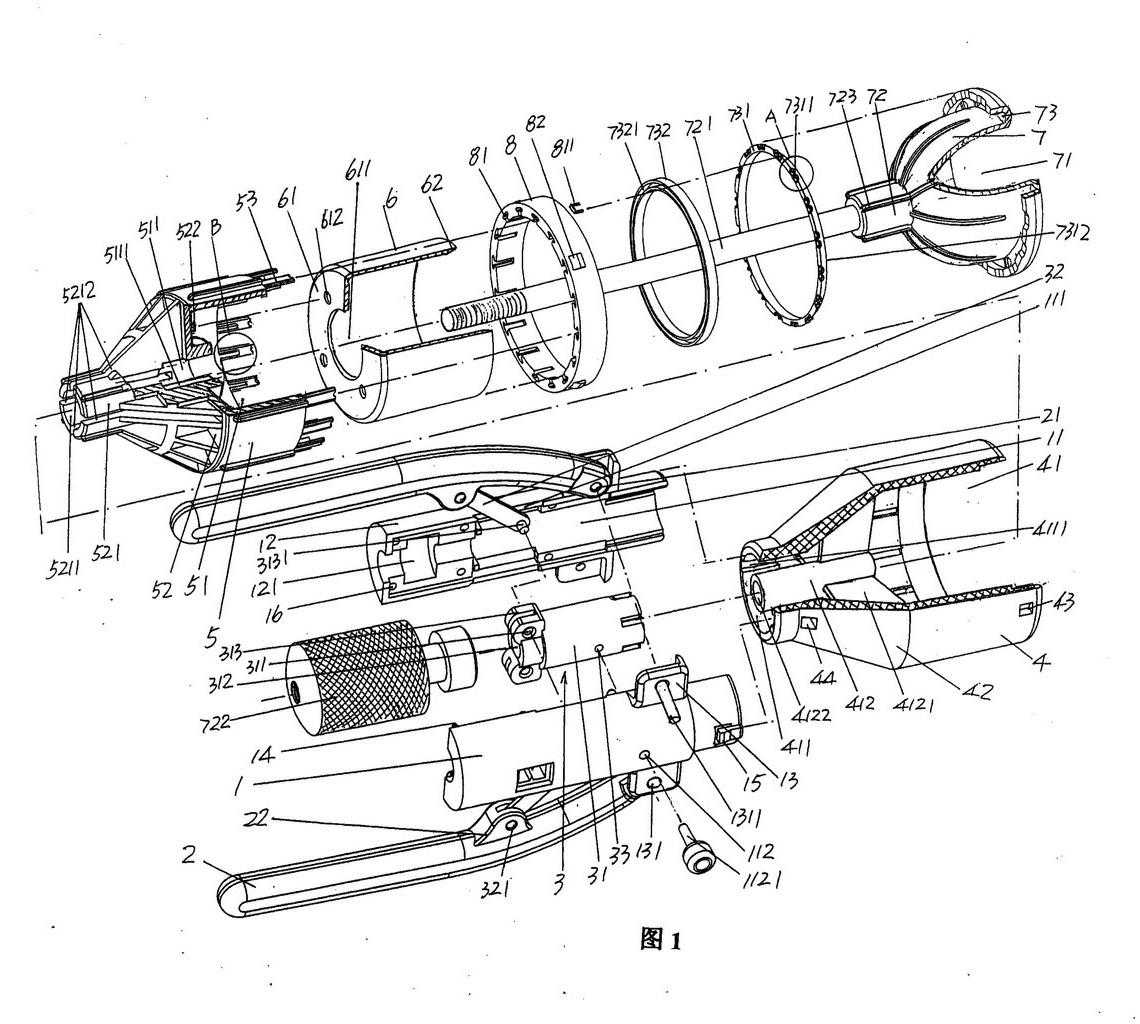

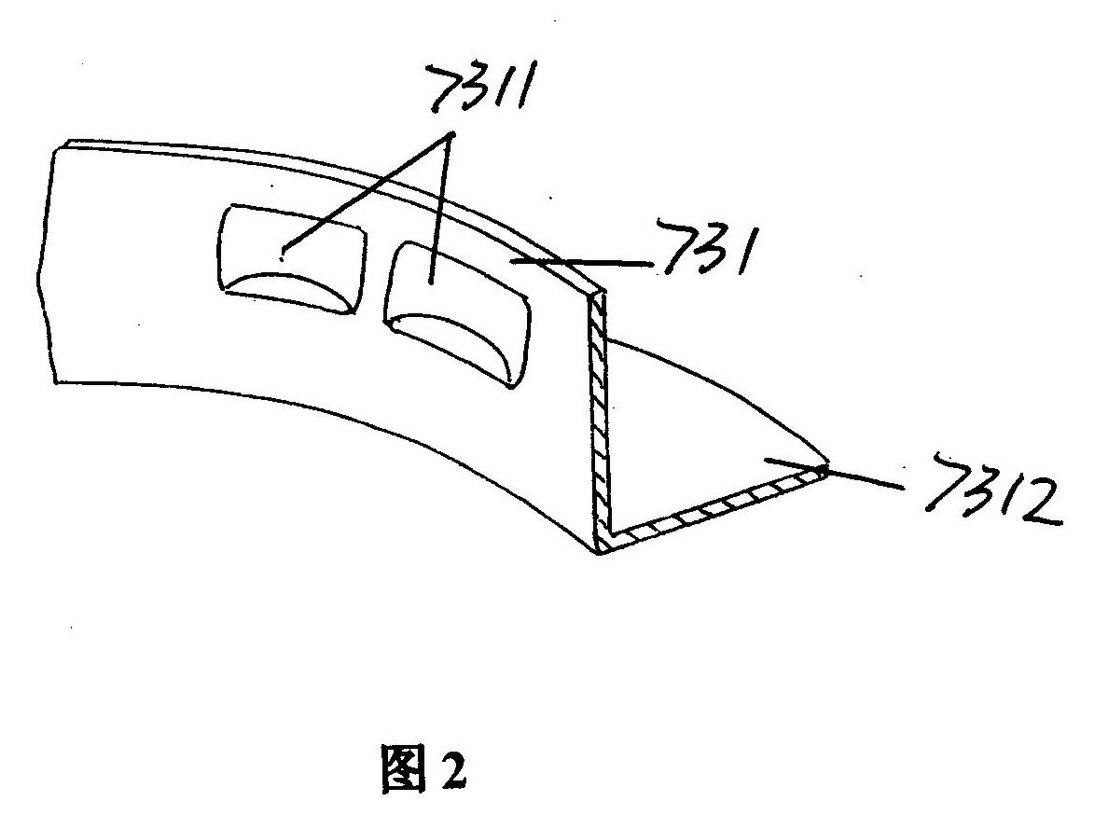

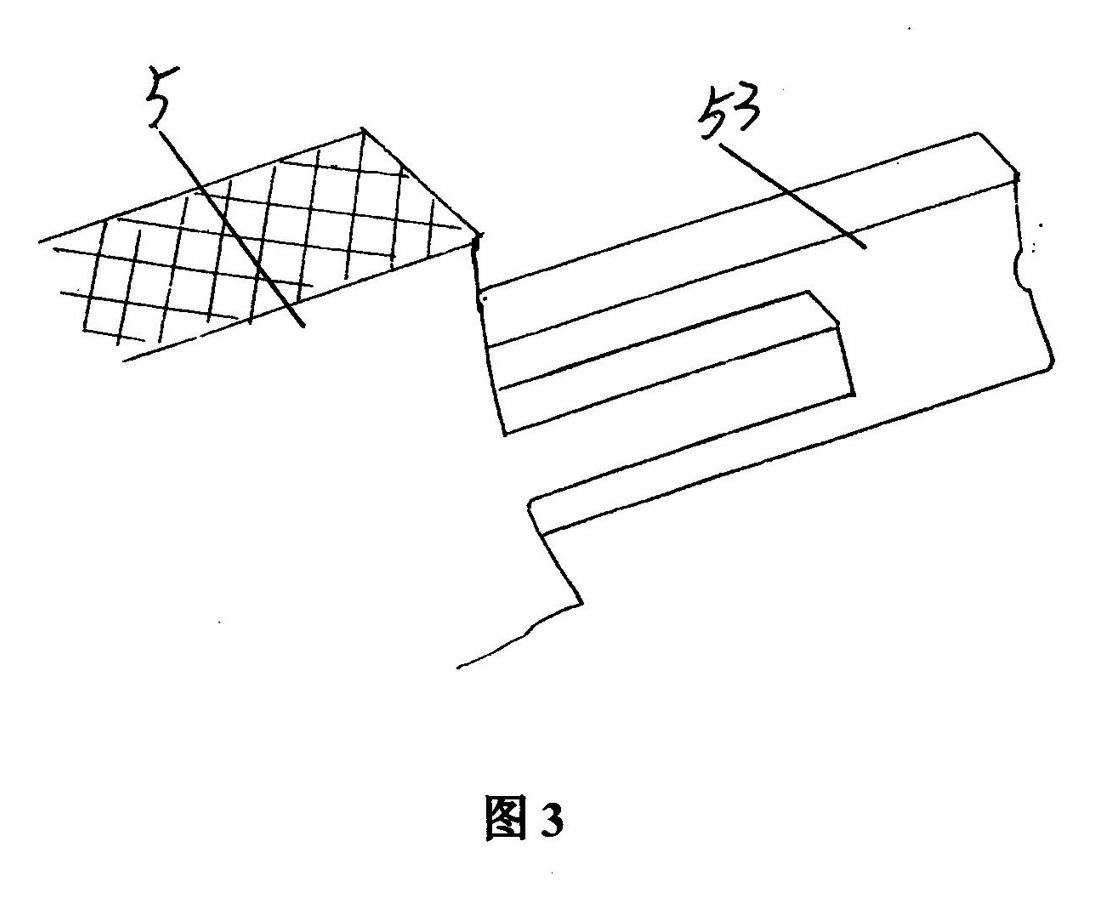

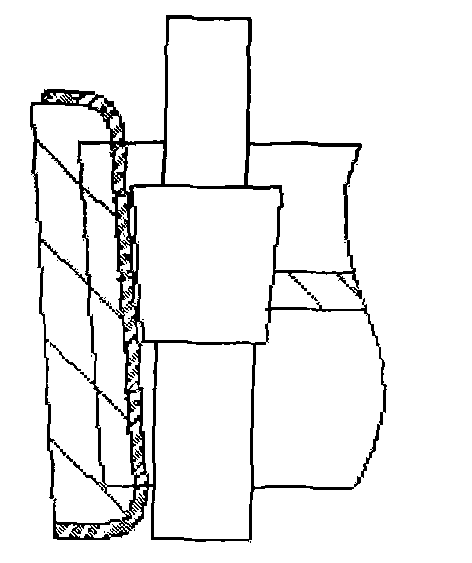

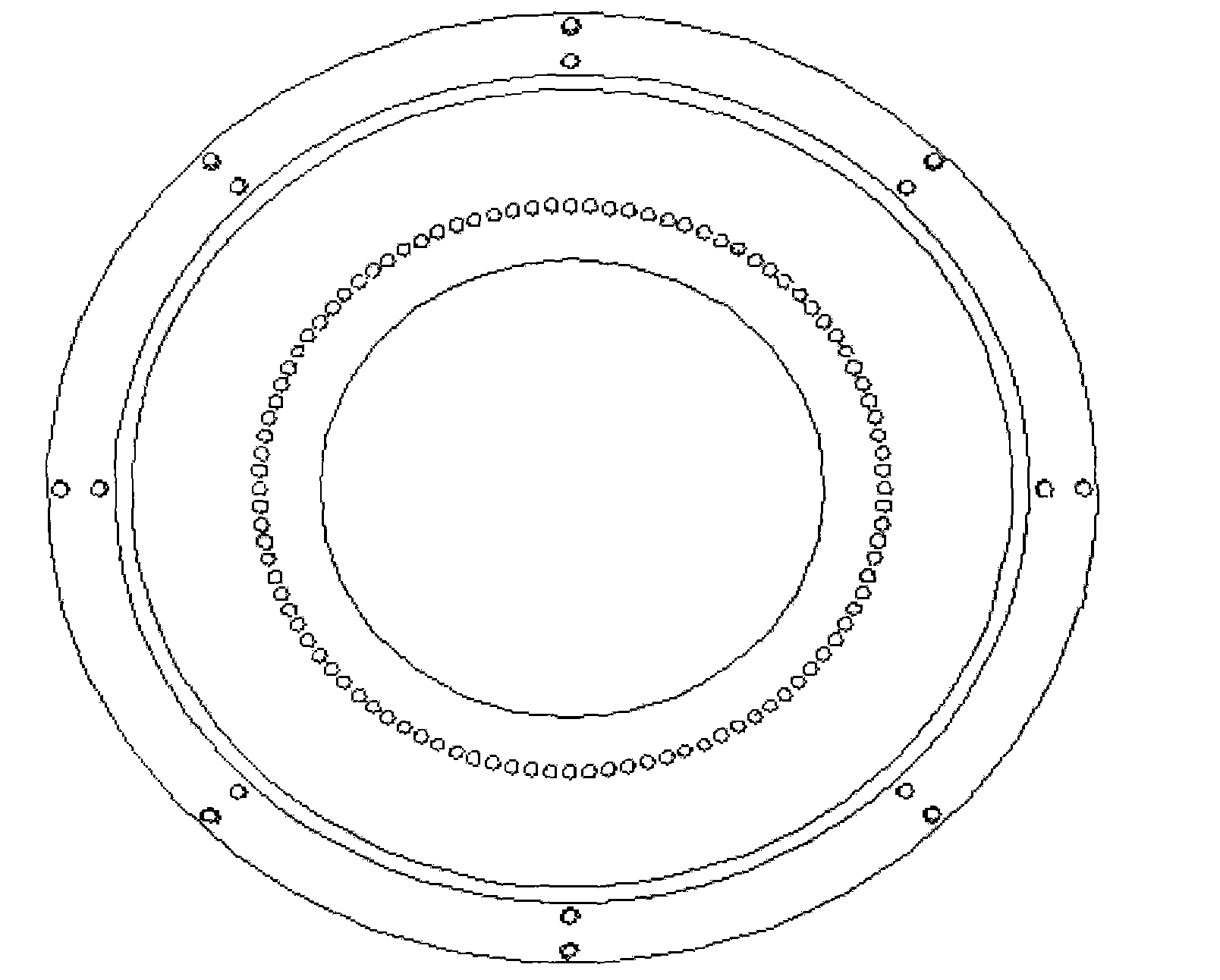

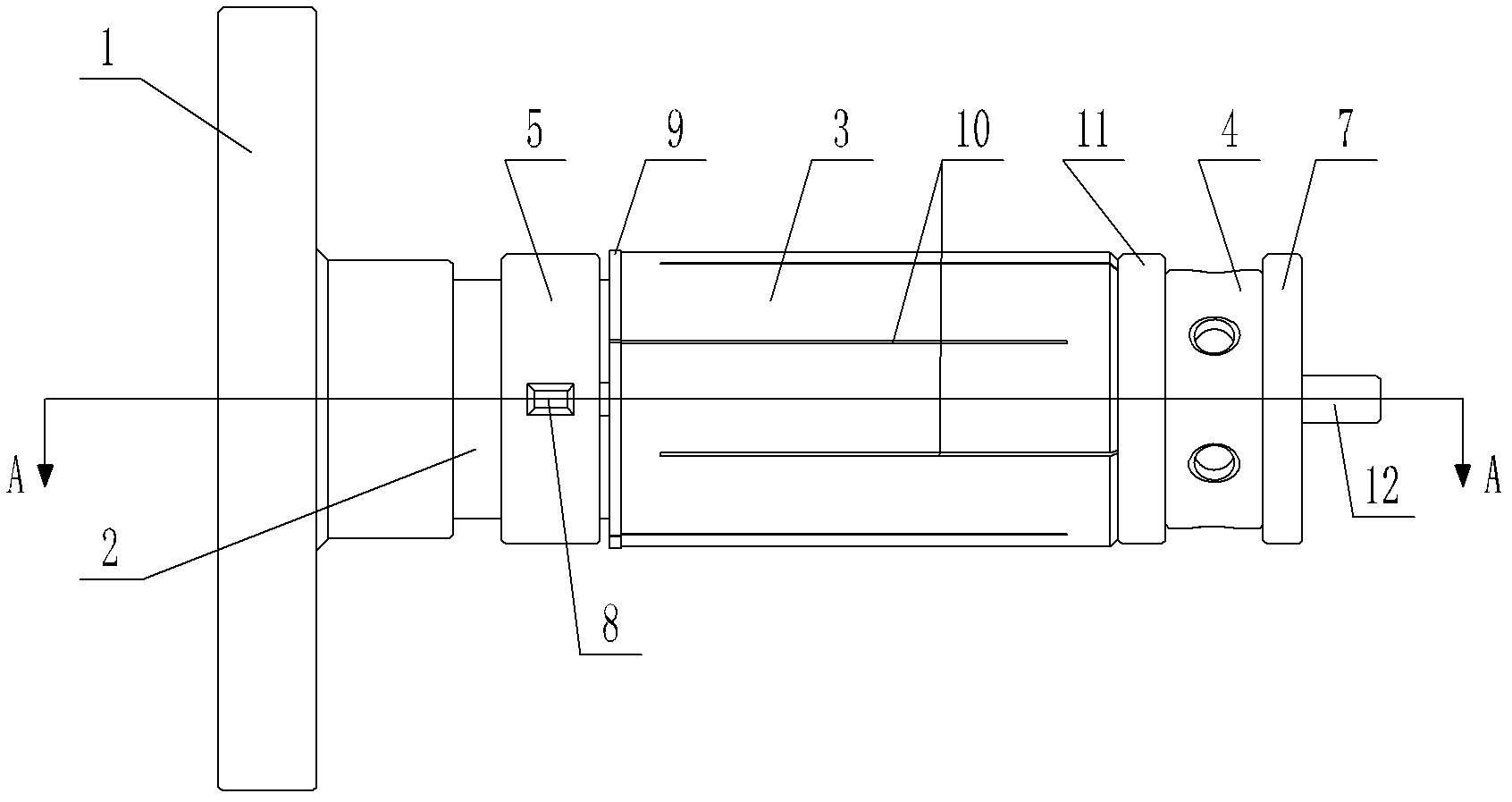

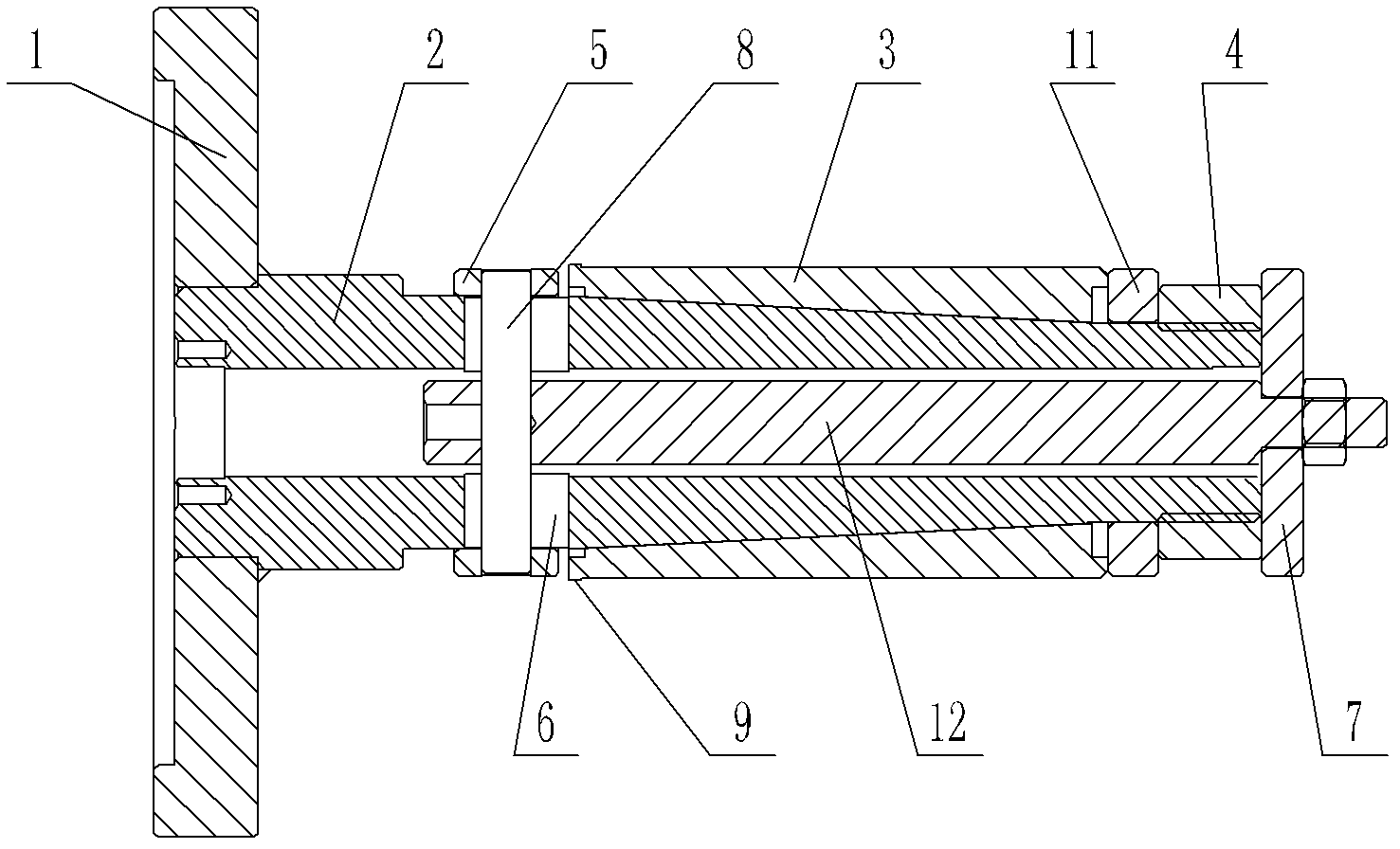

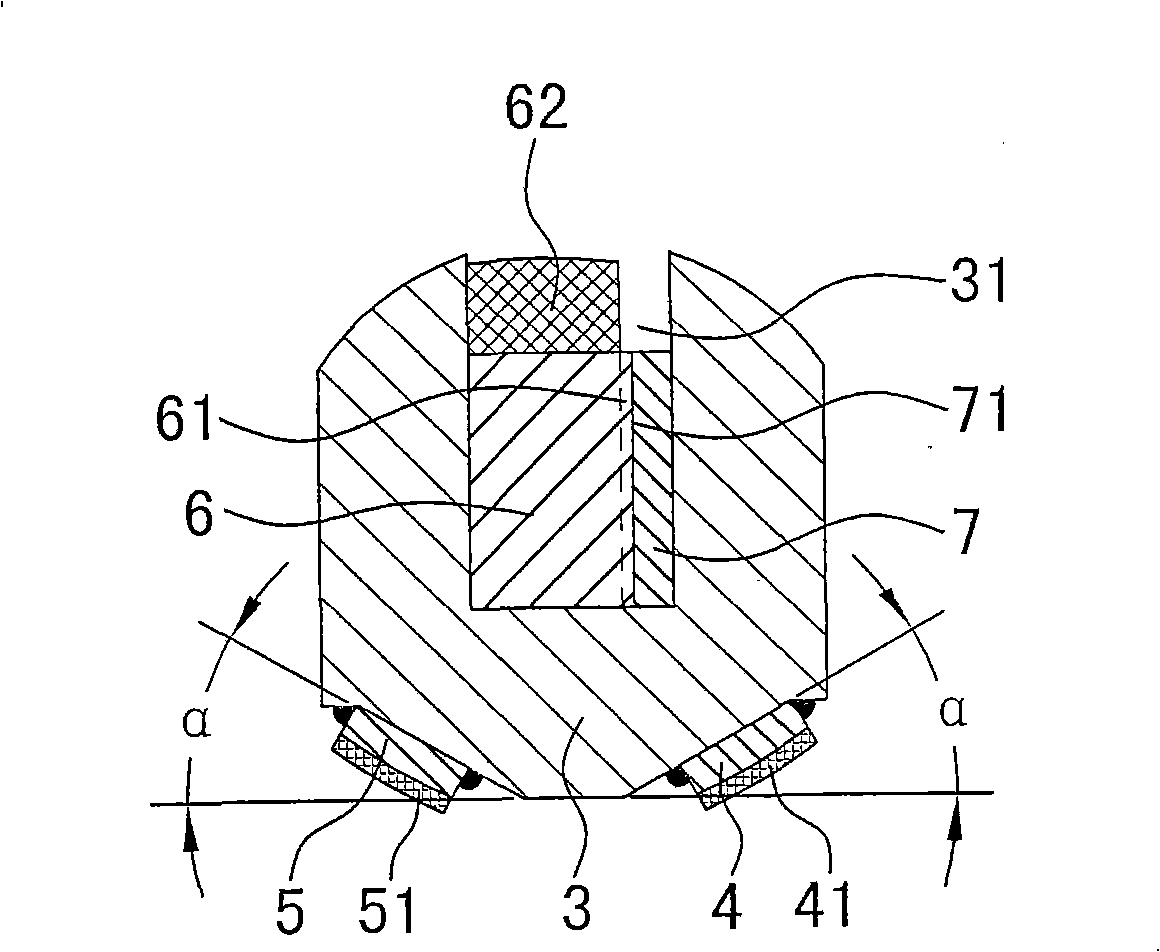

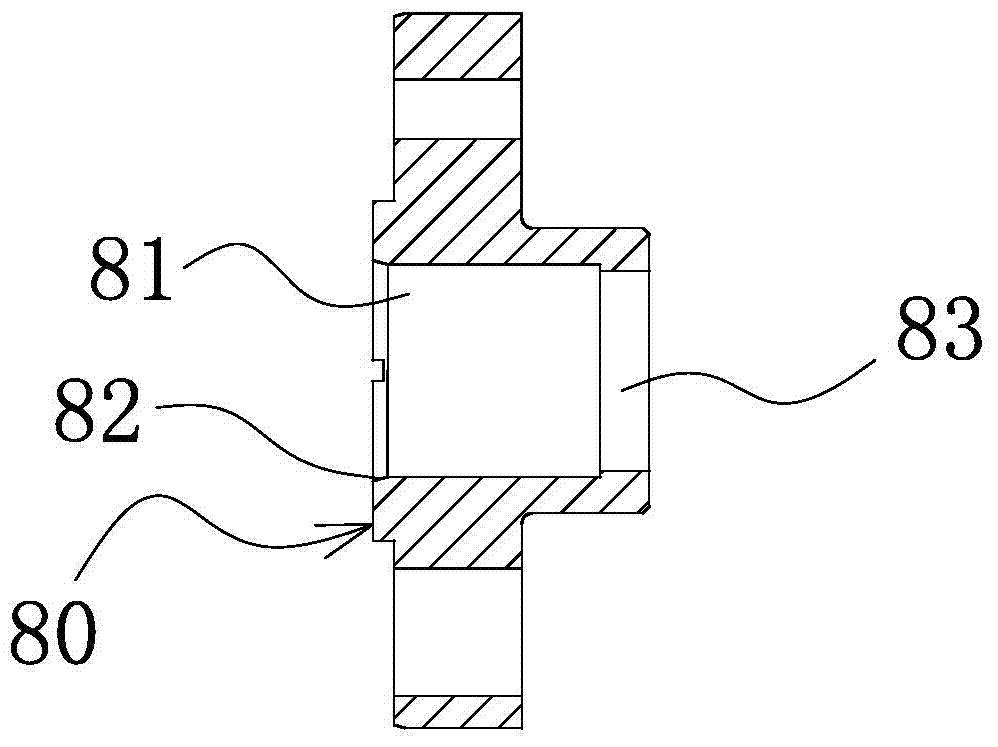

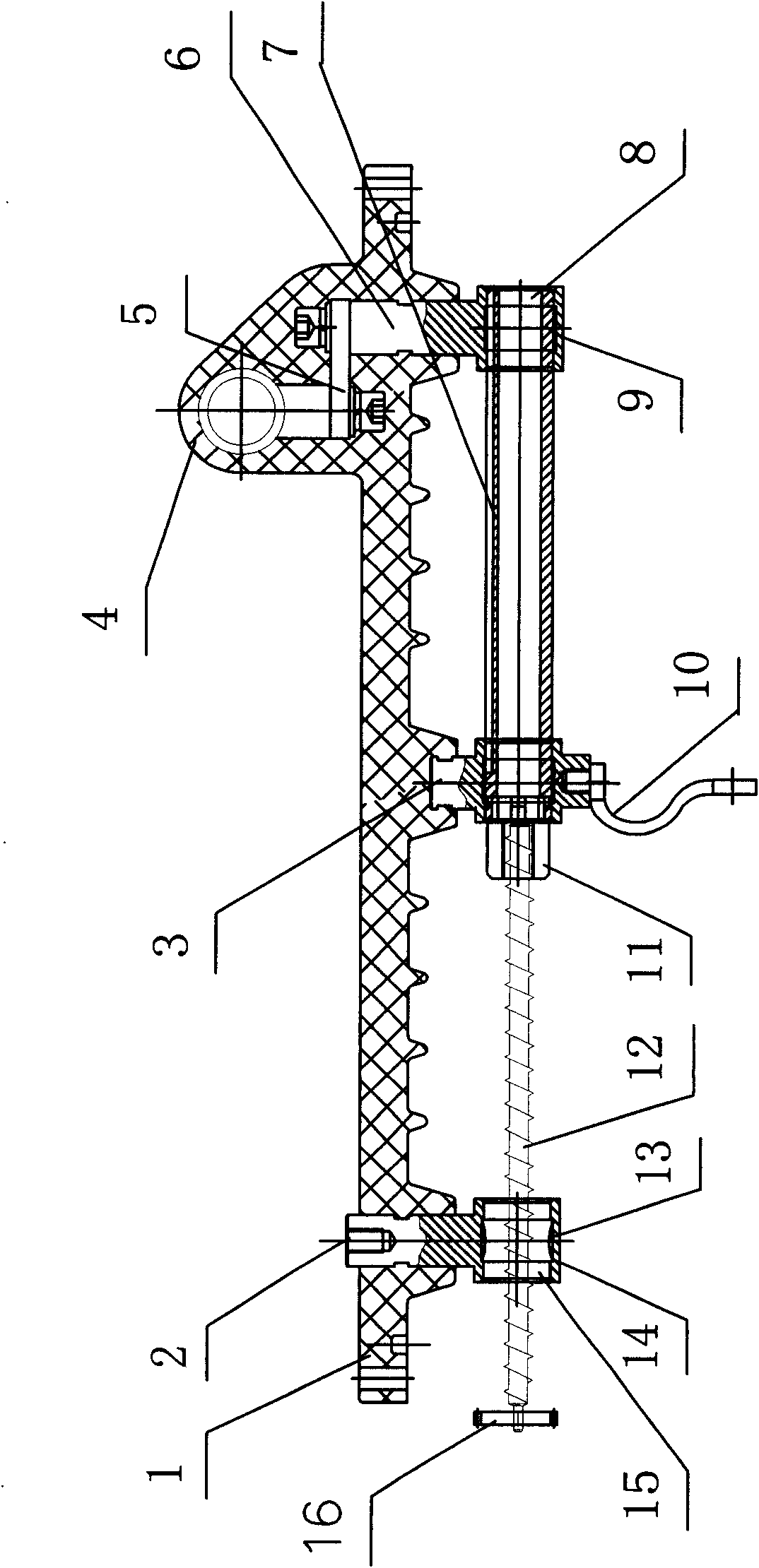

The invention relates to a foreskin cutting and sewing device, belonging to the technical field of medical and surgical instruments. The foreskin cutting and sewing device comprises a pair of handle valves, a balance shifter, a scalpel shell provided with a shell cavity, a scalpel push disk provided with a scalpel cavity, a cover-type cutting scalpel, a balanus cap provided with a balanus cavity, and a nail cabin. The foreskin cutting and sewing device is characterized in that one end of the inside of the shell cavity of the scalpel shell, which faces the balance shifter, is provided with a shifting bar sleeve; a plurality of guide vanes are formed between the outer wall of the shifting bar sleeve and the inner wall of the shell cavity; a scalpel push shaft of the scalpel push disk is circumferentially provided with a plurality of guide vane guide grooves; a shifting bar seat cavity is formed in the cutting scalpel cavity of the scalpel push disk; a plurality of guide rib guide grooves are formed on the wall of the shifting bar seat cavity; a plurality of guide ribs are formed on the outer wall of the shifting bar seat; a shifting bar penetrates through the shifting bar sleeve; and the balance shifter is matched with the shifting bar sleeve in the position corresponding to a shifter matching cavity. The foreskin cutting and sewing device can ensure the concentricity of the balanus cap, scalpel push disk and scalpel shell, thereby ensuring the sewing effect of the surgical wound.

Owner:常熟市亨利医疗器械有限公司

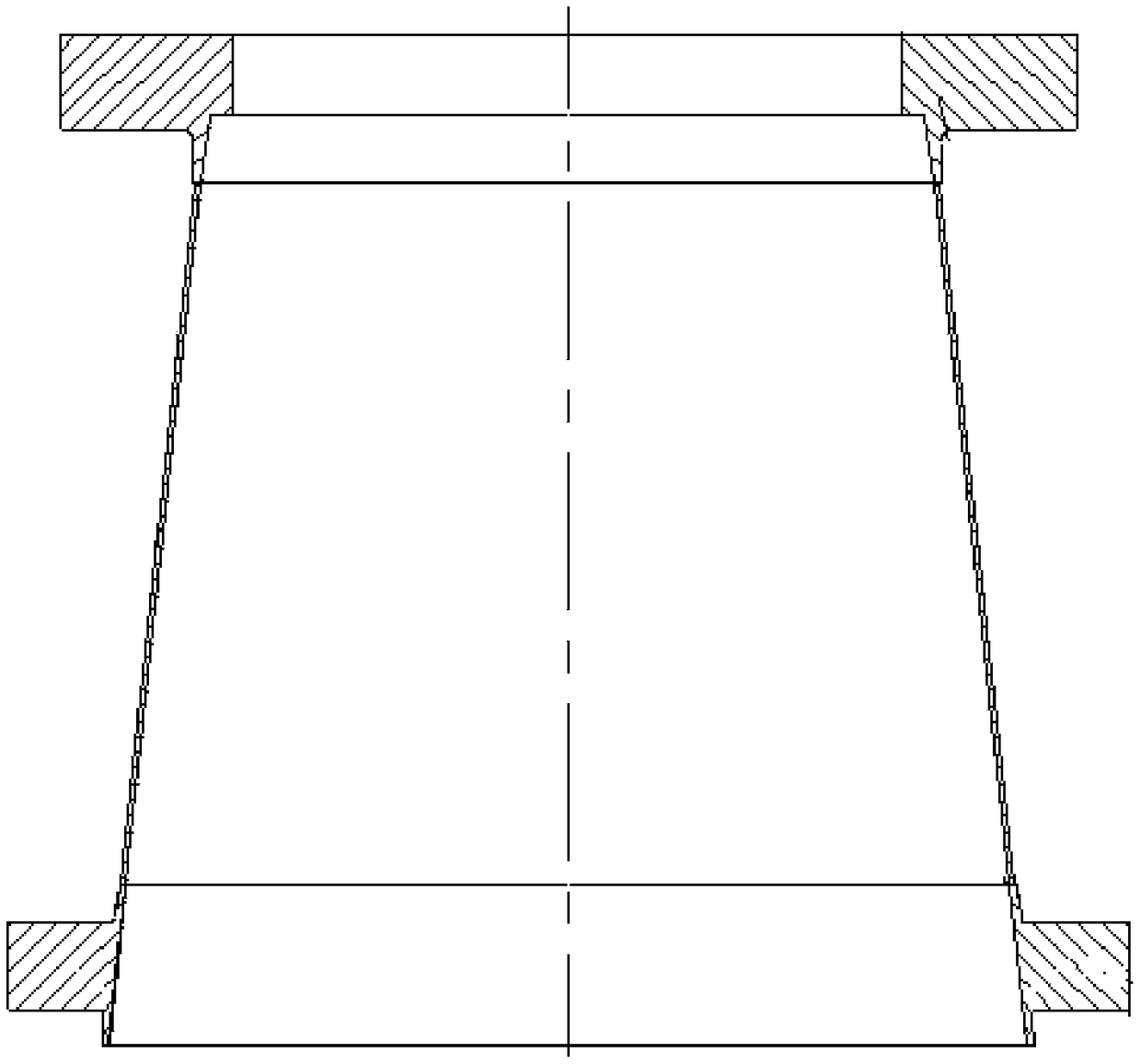

Correction device and correction method for inner ring of engine crankcase

The invention provides a correction device and a correction method for an inner ring of an engine crankcase. The correction device comprises a correction clamp base, positioning pins and a pressure plate; the tooling surface of the correction clamp base is provided with a circular seam allowance, and the inner side of the seam allowance is provided with a circle of uniform positioning pin holes; and the middle section of the positioning pin has a round table step-shaped columnar structure, the taper of the round table of the middle section is as same as that of the inner ring of the crankcase, and the maximum diameter of the positioning pin enables the positioning pin inserted into the positioning hole not to interfere with a blade of the crankcase. The correction method comprises the following steps of: jointing the seam allowance of the crankcase and the seam allowance on the correction clamp base; inserting the positioning pins into the positioning pin holes, positioning the positioning pins and the inner ring of the crankcase in a two-section contact mode, and then fixing the crankcase on the correction clamp base through the pressure plate; welding the inner ring and the blade of the crankcase; and finally, pouring a glue layer into the inner side of the inner ring of the crankcase, and gluing the inner ring and the blade of the crankcase. The device and the method ensurethe concentricity of the easily-deformed inner ring and the outer crankcase and the ellipticity of the inner ring.

Owner:AECC AVIATION POWER CO LTD

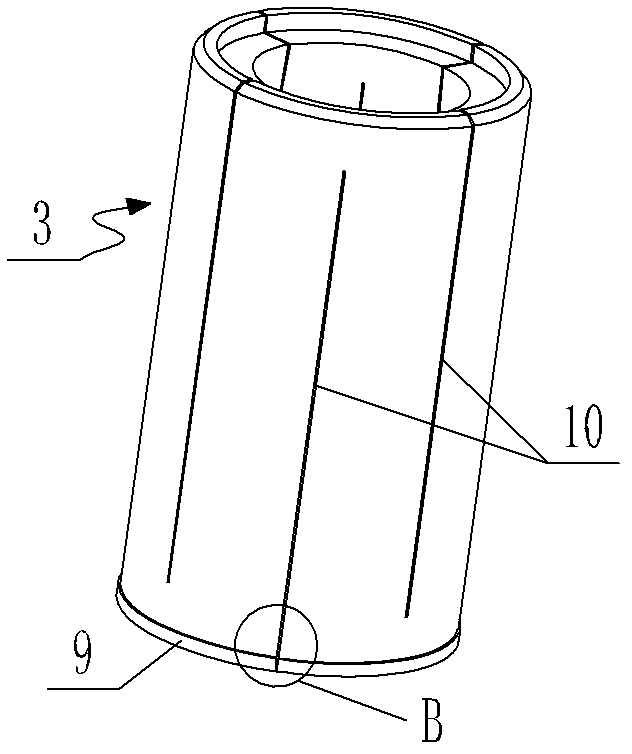

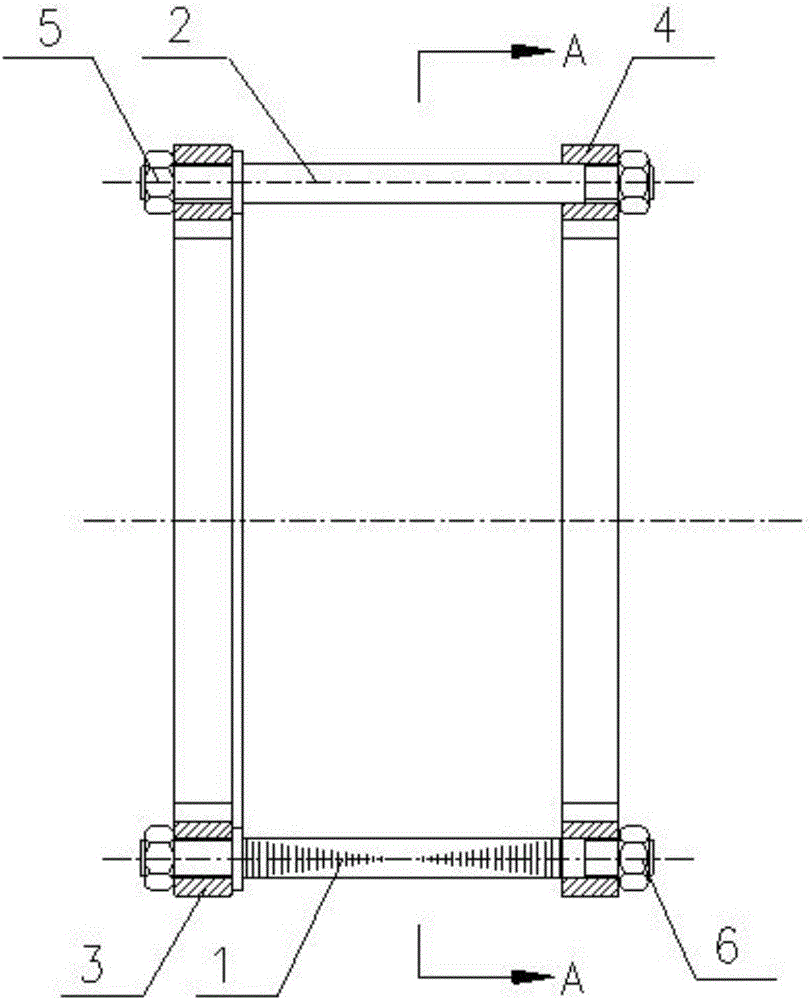

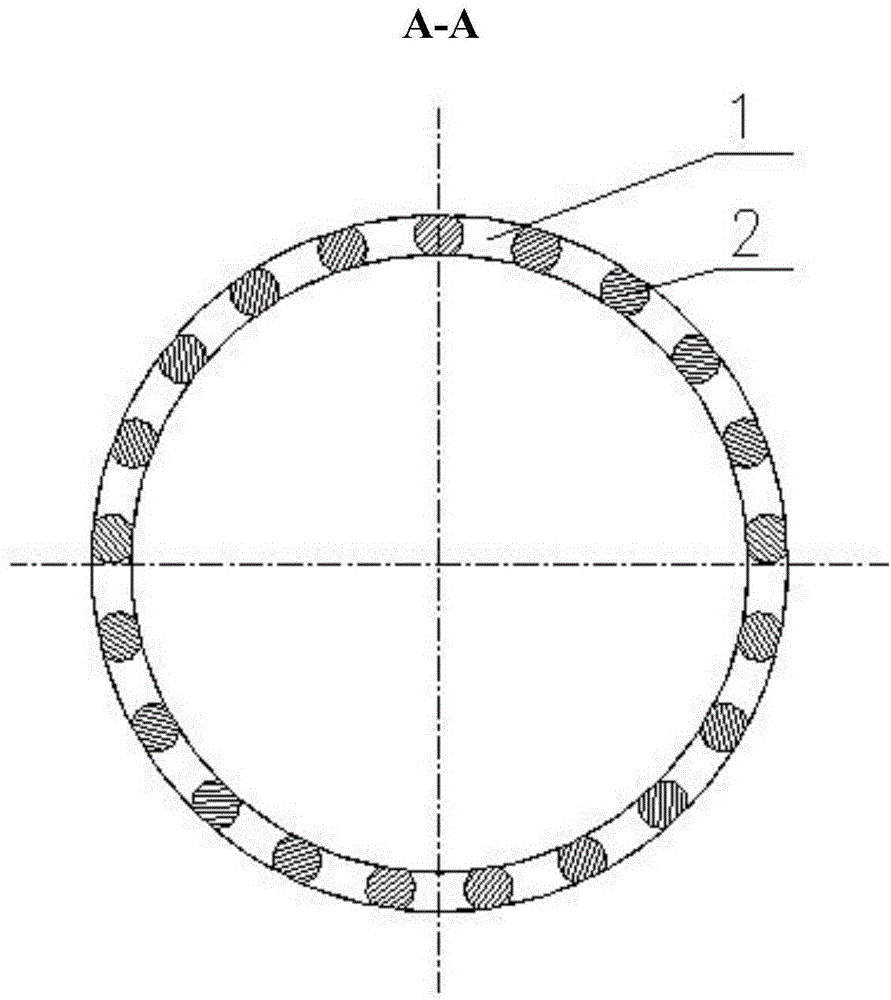

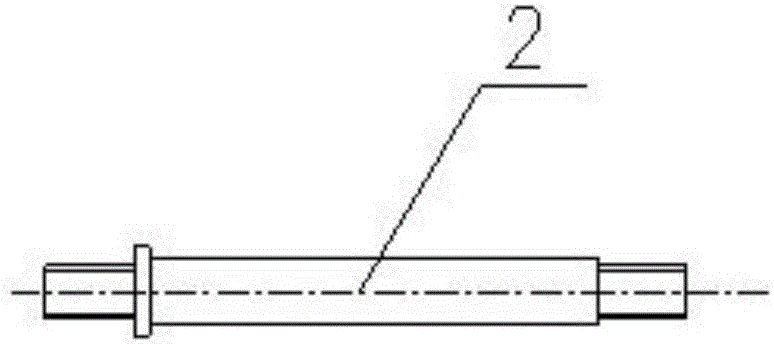

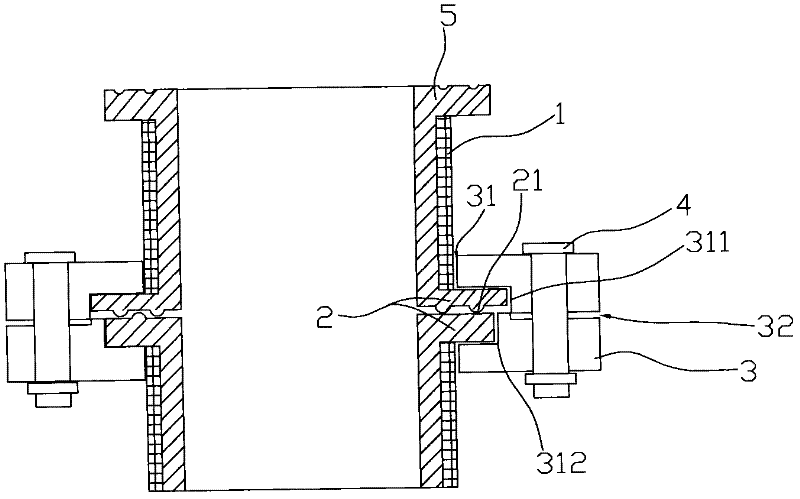

Self-centering fixture

InactiveCN102357826AEasy loading and unloadingGuaranteed concentricityPositioning apparatusMetal-working holdersExpansion jointCentring

The invention discloses a self-centering fixture which comprises a mandrel and an expansion sleeve, wherein the mandrel is mounted on a machine tool through a flange; the expansion sleeve is sleeved on the outer circumference of the mandrel and can move axially; multiple expansion joints are arranged on the outer wall of the expansion sleeve; the outer wall of the mandrel and the inner wall of the expansion sleeve are matched conical surfaces; the mandrel is provided with an adjusting nut for driving the expansion sleeve to move along the mandrel; a pull rod and a stop ring are arranged between the mandrel and the expansion sleeve to pull the expanded sleeve to a shrinkage end; and through the expansion and shrinkage of the expansion joints, the outer diameter is controlled to increase / reduce so as to position / dismantle a workpiece. The fixture has a simple structure, is convenient to use and can realize self centering; and moreover, the processing accuracy of the workpiece is improved, the concentricity and verticality between the processed surface and an inner hole of the workpiece can be ensured, and the fixture deserves popularization and application in the fields realizing positioning and clamping by use of the inner hole of the workpiece.

Owner:JIANGSU FULIHUA GENERAL EQUIP

Split type calibration target, calibration device with same and calibration method thereof

PendingCN108489401APrecise positioningHigh repeatability accuracyUsing optical meansLaser scanningLaser tracker

The invention provides a split type calibration target which cooperates with a target lens to be used as a measurement target when a laser tracker is utilized for calibrating a spatial distance indication error of a laser scanner. The split type calibration target comprises a target seat, a target lens bearing component and a sphere target component, wherein the target lens bearing component is provided with a taper shank, a connecting piece arranged on the taper shank and a target lens seat which is arranged on the connecting piece and used for being connected with the target lens through magnetic adsorption; and the sphere target component is provided with a sphere side taper shank, a three-dimensional regulating mechanism arranged on the sphere side taper shank and a sphere target arranged on the three-dimensional regulating mechanism, wherein the taper shank and the sphere side taper shank are morse taper shanks respectively, the morse taper shanks have the same size and tolerance,taper tips are arranged downward, a morse taper sleeve is arranged on the target seat, the taper tip of the morse taper sleeve is downward, an opening is upward, and the morse taper sleeve is matchedwith the taper shank and the sphere side taper shank. The invention also provides a calibration device provided with the split type calibration target and a method for calibrating the laser scanner by utilizing the calibration device.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

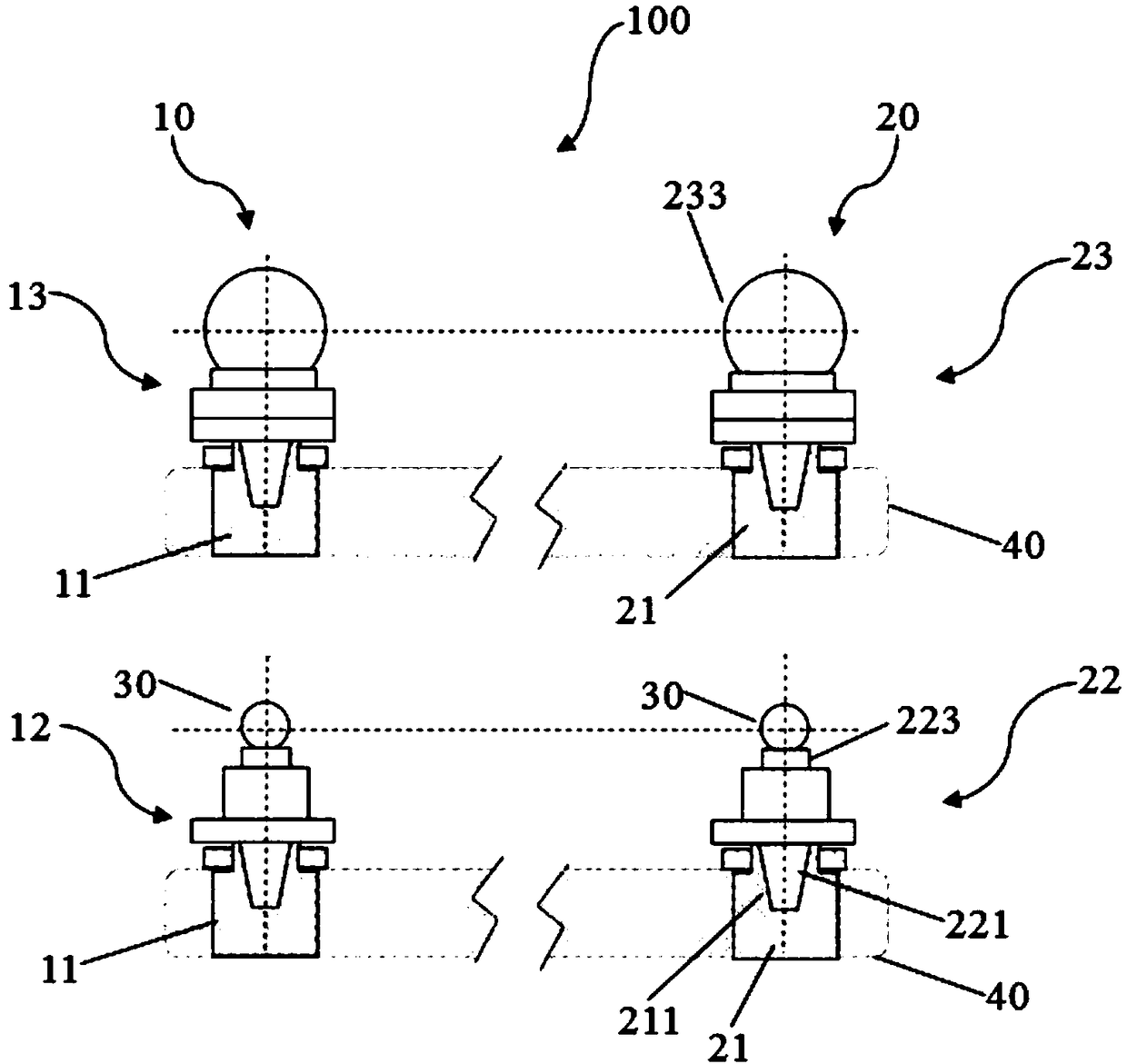

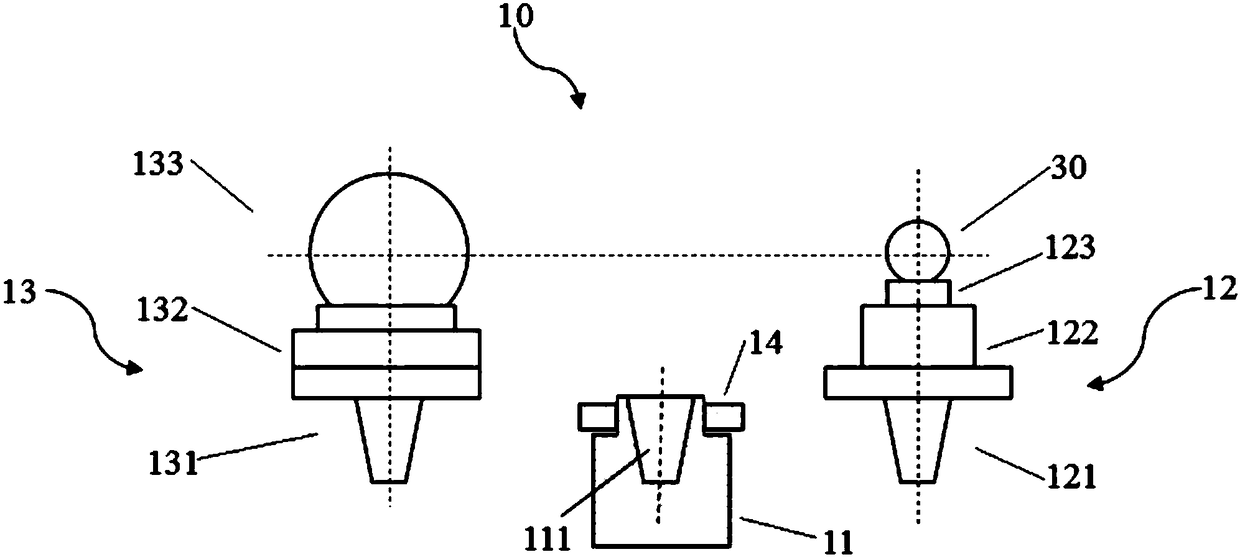

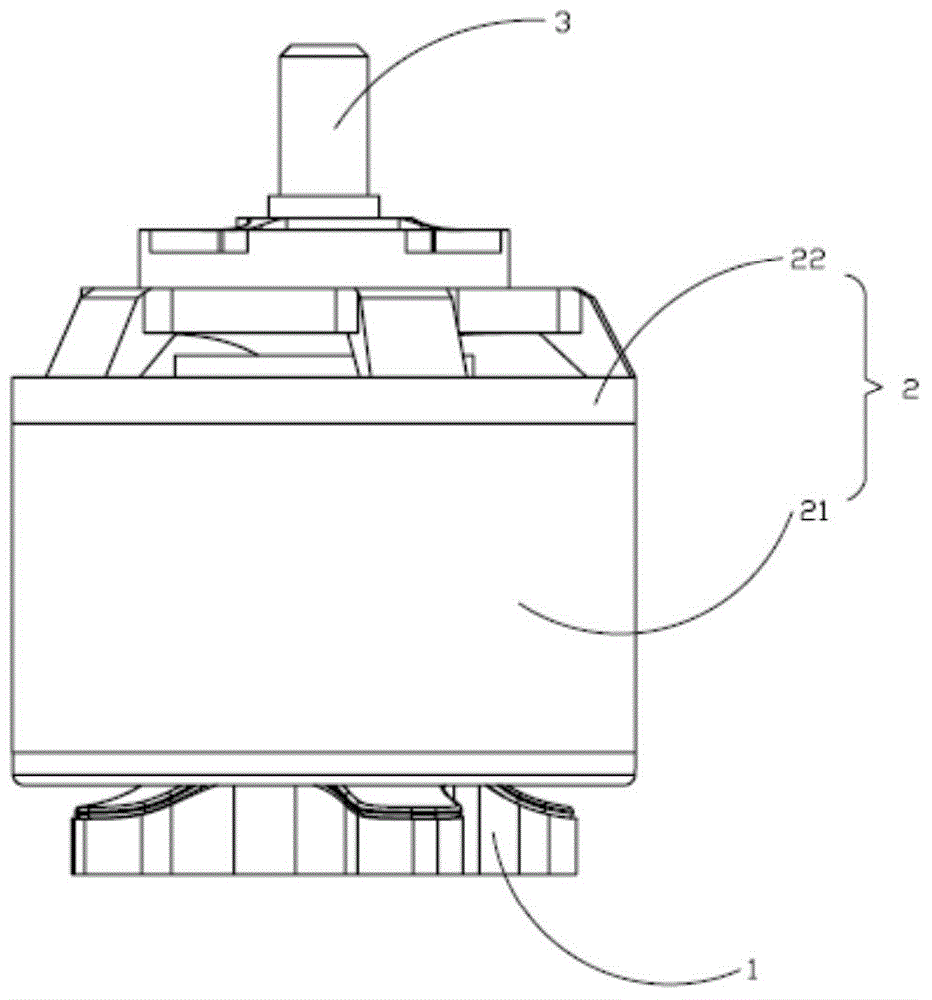

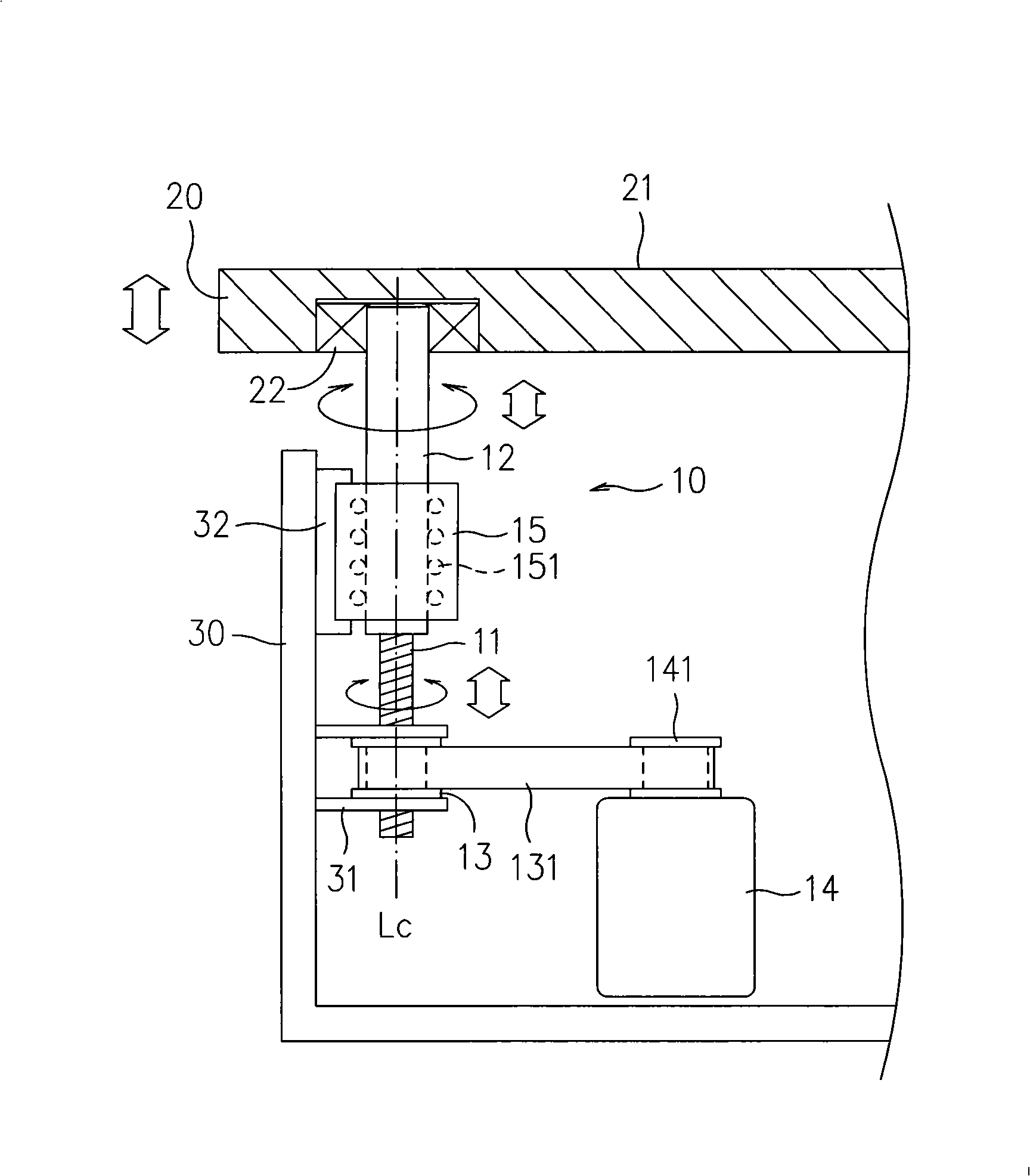

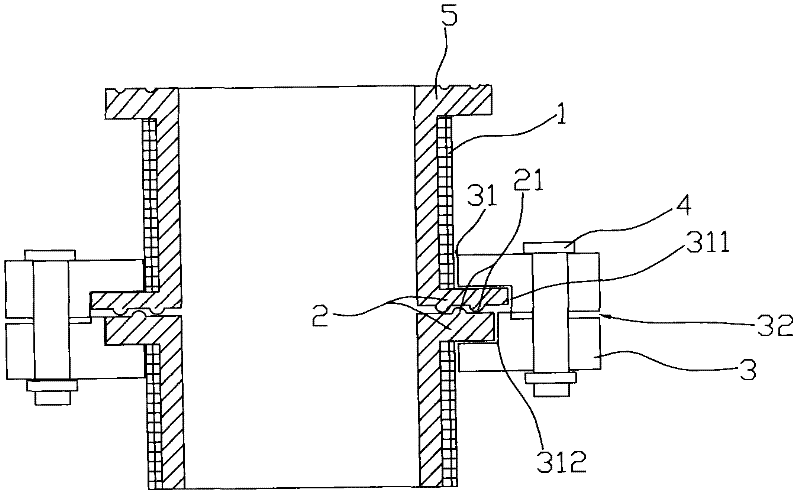

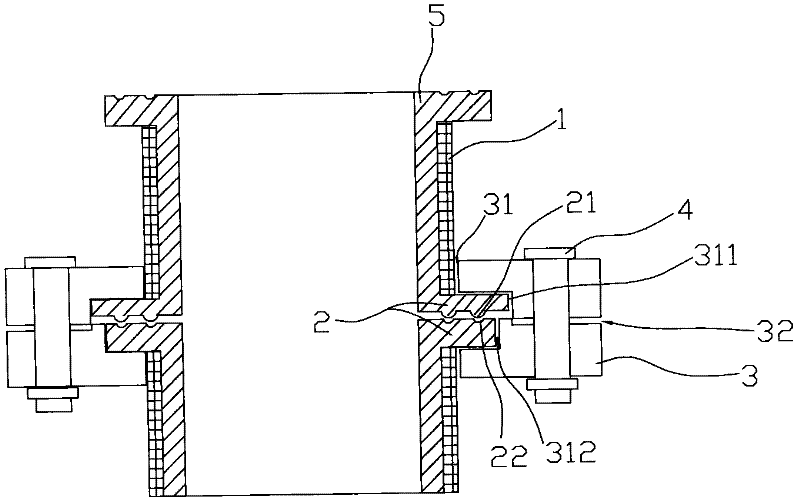

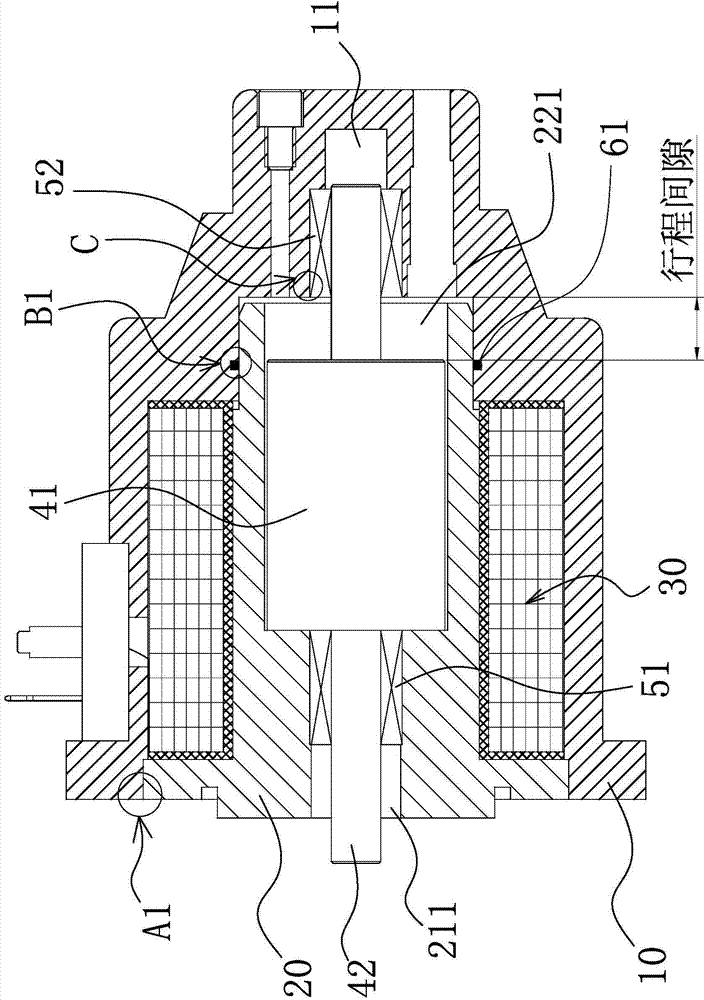

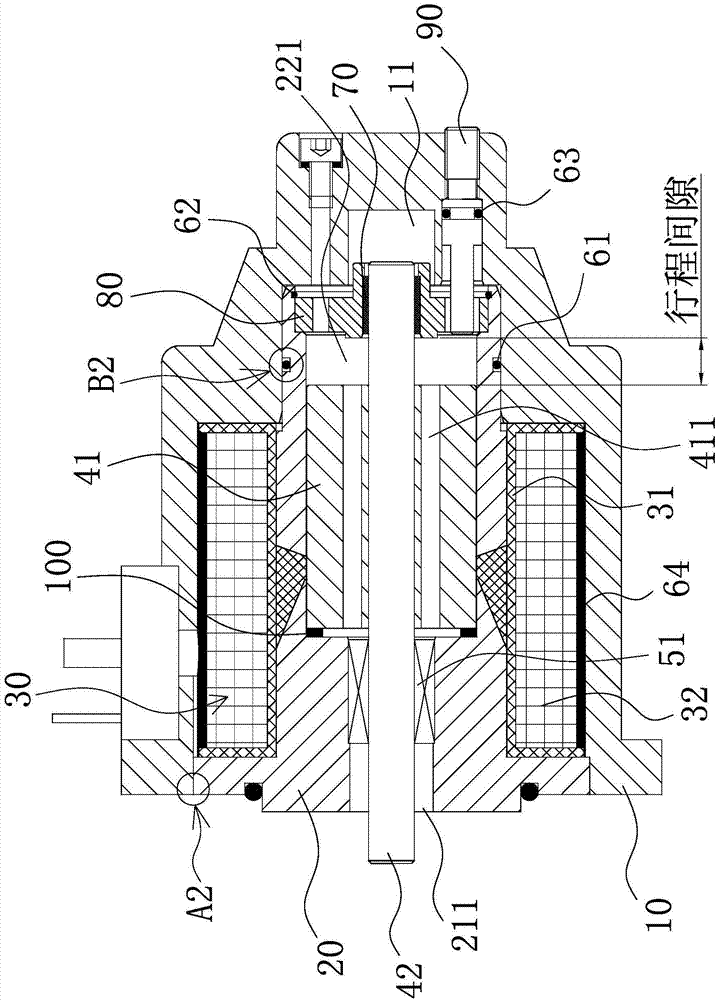

Power device and aircraft

ActiveCN104684805AEasy to assembleEasy to disassembleEfficient propulsion technologiesPower plant typePropellerPower apparatus

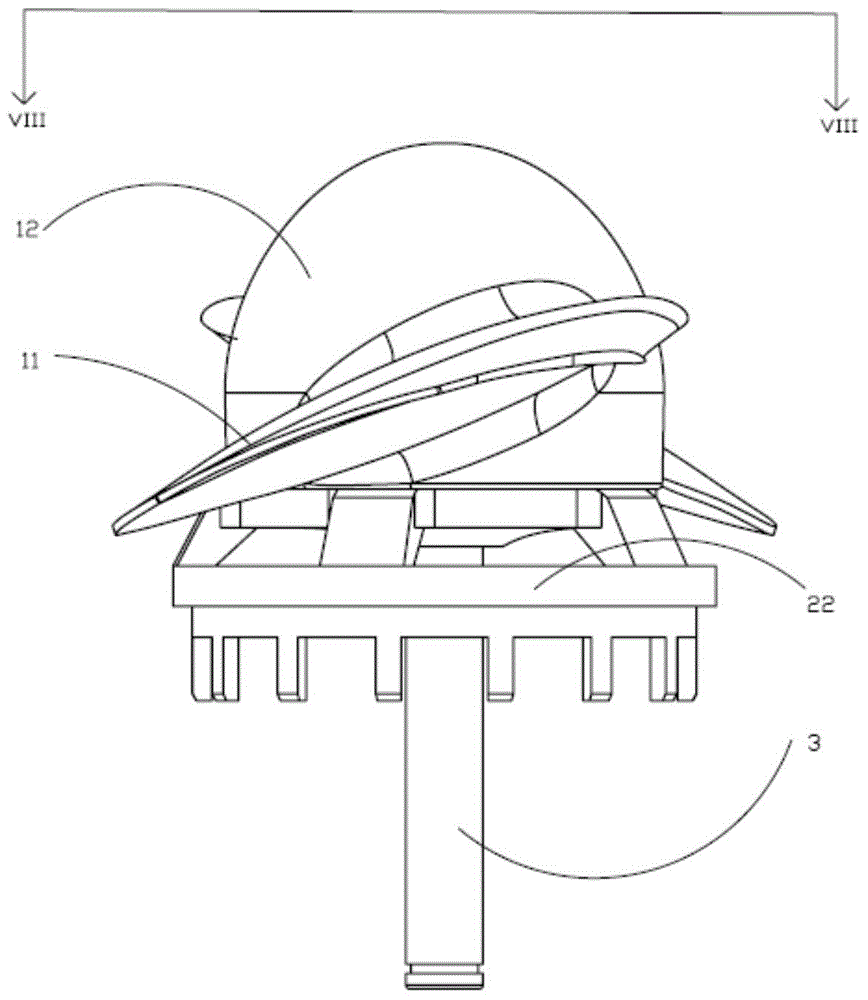

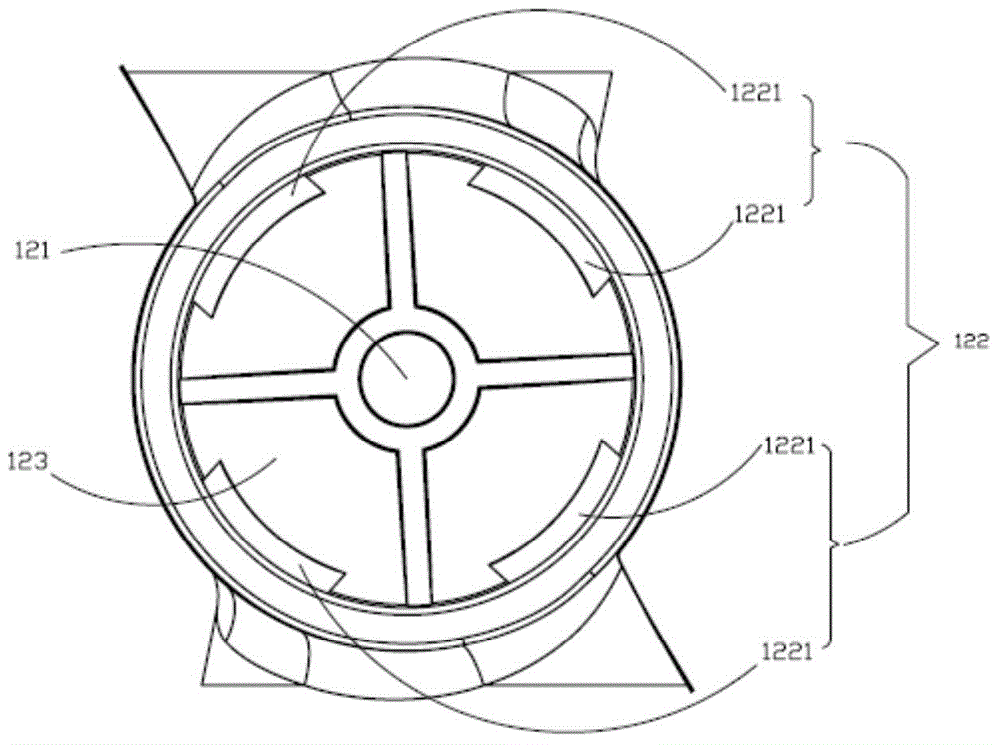

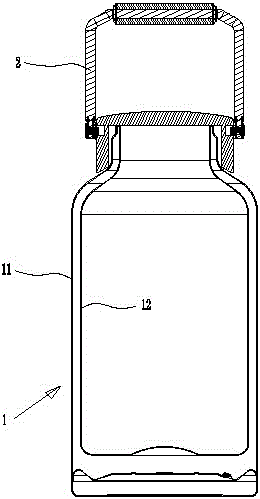

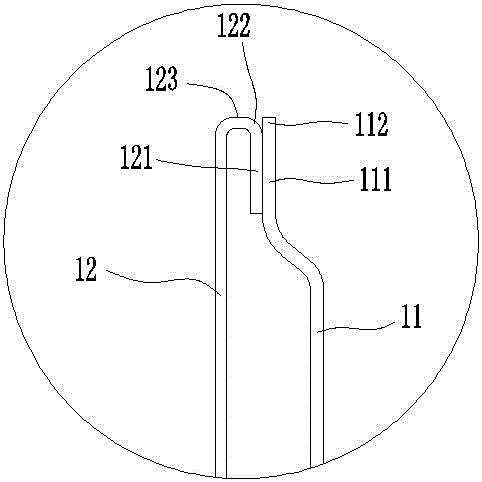

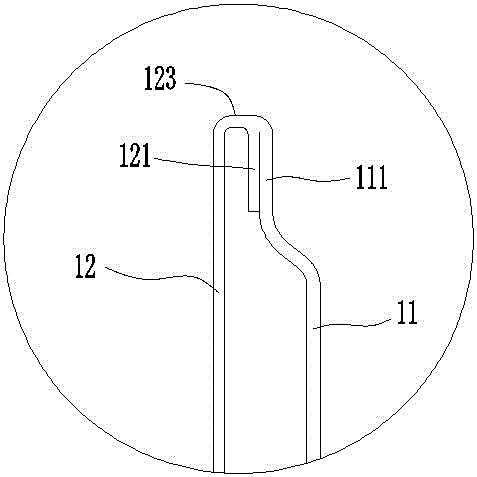

The invention provides a power device and an aircraft. The power device comprises a propeller and a motor, wherein the propeller comprises blades (11) and a propeller hub (12) and the motor comprises a stator component (1), a rotor component (2) and a rotating shaft (3). The rotor component (2) comprises a sleeve body (21) and a cover body (22). The propeller hub (12) is provided with a central hole (121) and a first clamping portion (122) and the cover body (22) is provided with a second clamping portion (221). The first clamping portion of the propeller hub and the second clamping portion of the cover body are in clamping fit and the rotating shaft cooperates with the central hole of the propeller hub, so that the propeller is fixed to the motor. According to the invention, the installation and detachment of the motor and the propeller in the power device of an aircraft can be completed conveniently and the concentricity and the perpendicularity of the motor and the propeller can be guaranteed to a certain extent.

Owner:SZ DJI TECH CO LTD

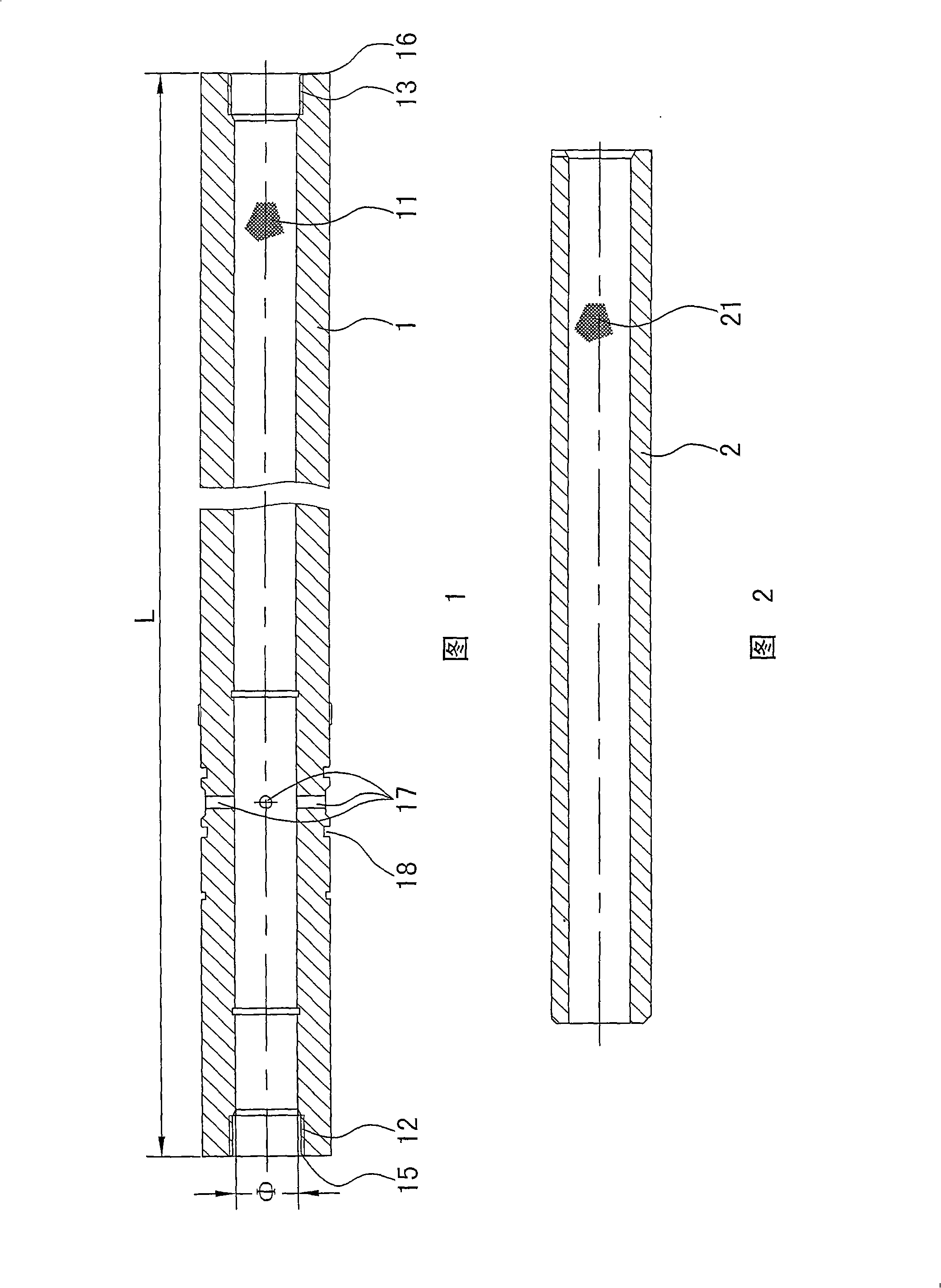

Long-stroke pneumatic hydraulic cylinder body and its processing method

InactiveCN101344169AHoning is easyGuaranteed processing effectCylindersHydraulic cylinderPulp and paper industry

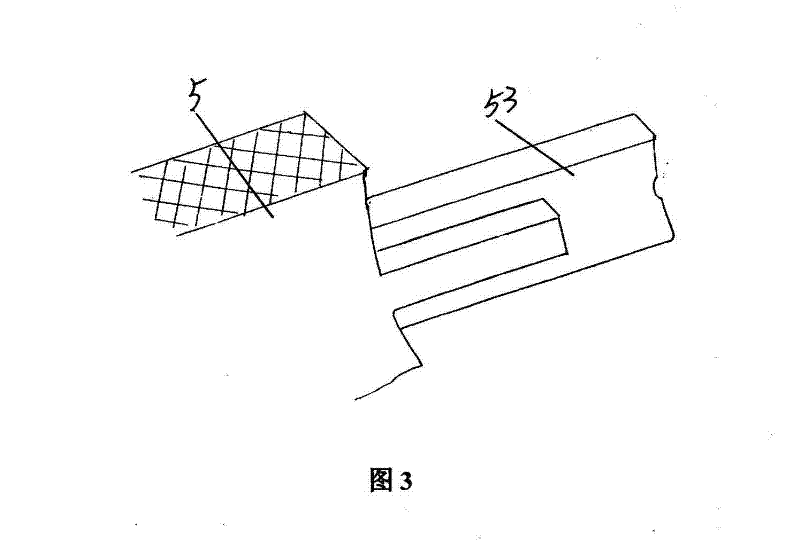

The invention discloses a long-stroke pneumatic hydraulic cylinder body which includes an outer cylinder body and an inner cylinder body which are made of circular steel pipes; the middle part of the outer cylinder body has an oil through which is communicated with the hydraulic cavity of the pneumatic cylinder body; the pneumatic hydraulic cylinder body is characterized in that the inner wall surfaces of the outer cylinder body and the inner cylinder body are respectively provided with grids which can store oil and lead the outer cylinder body and the inner cylinder body to keep long-time lubrication, reduce wear and prolong service life although the grids are tiny. The processing method of the outer cylinder body is as follows: a. fetching a seamless precision steel pipe with the specification of inner hole diameter of 15<-0.07><-0.10>mm, and length of 400 mm; b. using a lathe for turning both ends flat, and heat treatment quenching and tempering stereotype; c. using honing roughing, grinding the inner hole diameter up to be 15<-0.02><-0.03>mm; d. using a mandrel for sheathing the inner hole, using an excircle grinder for grinding the excircle, requesting concentricity; e. using a CNC lathe for cutting the oil through; f. carbonation treatment: enabling the depth up to be more than 0.05 mm; and g. adopting honing finishing so as to lead the finish to be about 0.05 mm and the straightness to be 400 / 0.01 mm, and the roundness to be controlled as 0.002 mm, and lead the inner wall surface of the steel pipe to form small grids.

Owner:浙江速成精密机械有限公司

Transmission shaft structure

The invention is a driving shaft structure, which comprises a screw bolt and a sliding piece which is coaxially arranged with the screw bolt, the sliding piece is penetrated in a sleeve piece, the screw bolt is rotated by driving of a motor, can perform linear displacement which is parallel to the axial direction of the screw bolt, and can synchronously drive the sliding piece to rotate and parallel to the linear displacement of the axial direction of the sliding piece in the sleeve piece, one end of the sliding piece is connected with a platform, the sliding piece drives the platform to move and replace the structure of a traditional sliding seat and a sliding rail, because the sliding piece is integrally and coaxially arranged with the screw bolt, the concentricity of the sliding piece and the screw bolt can be guaranteed, additionally, the driving shaft structure is high in accuracy, easy in assemble, maintenance, adjustment or changing parts, and can reduce the occupied space.

Owner:MPI CORP

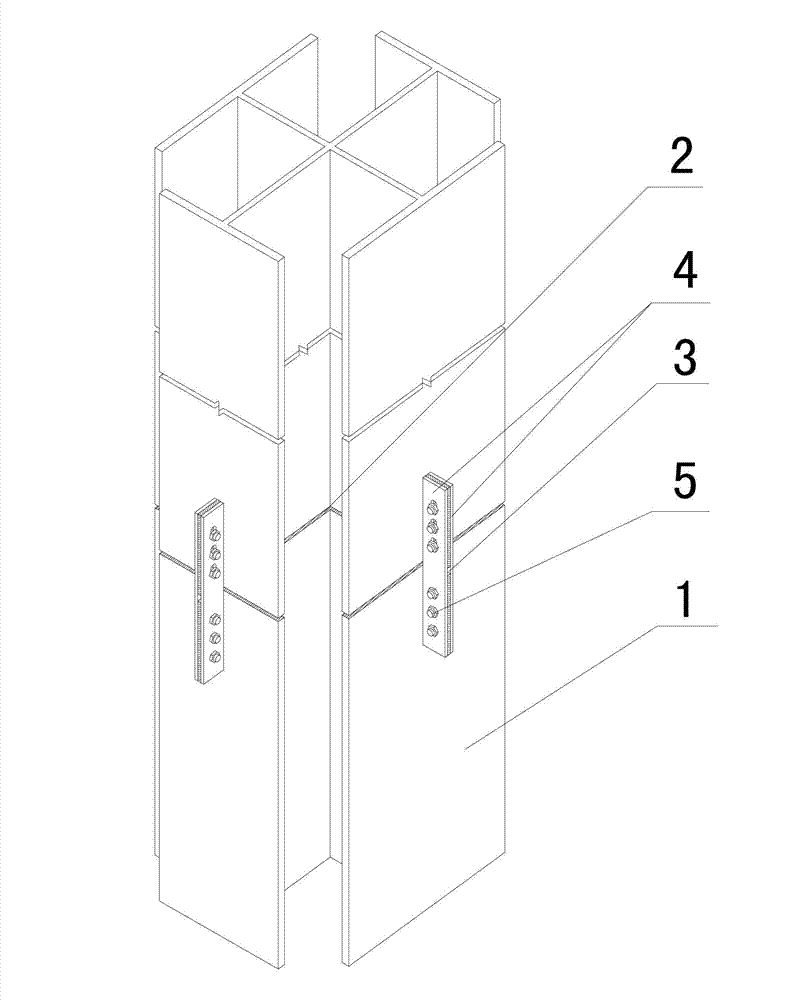

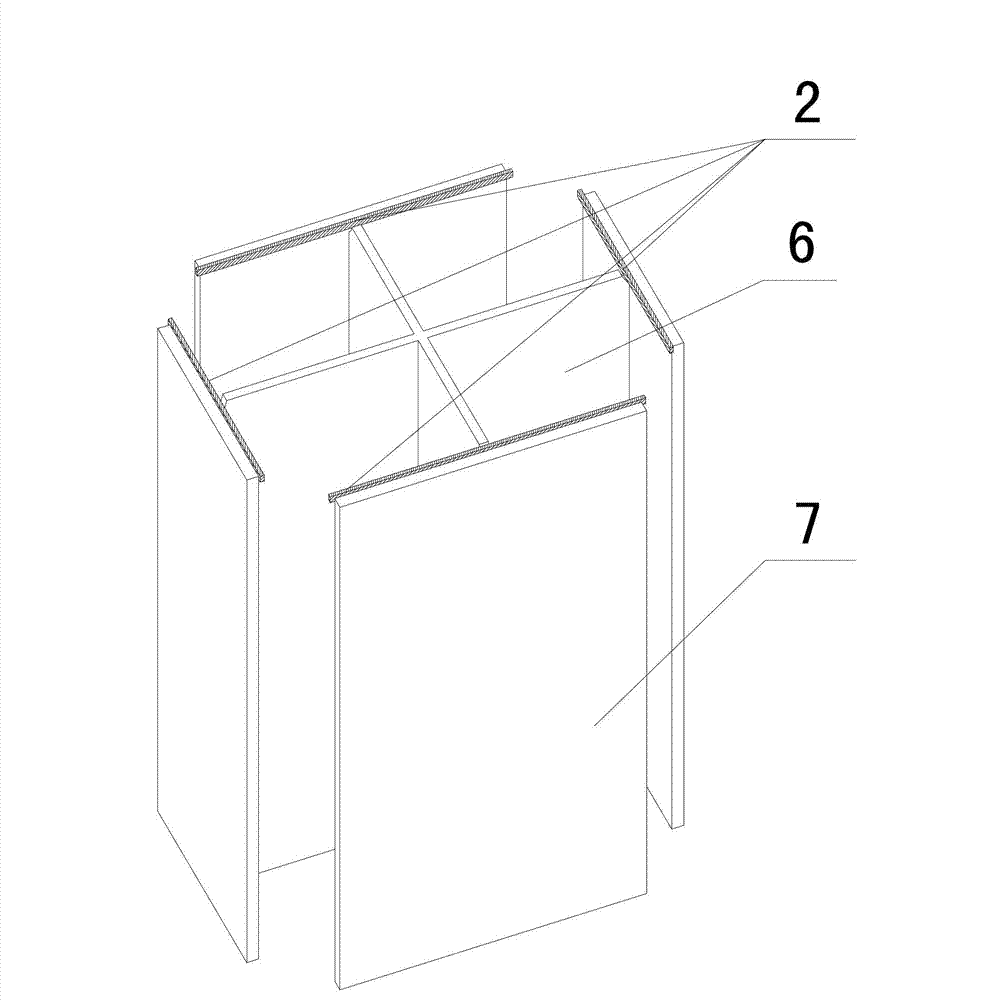

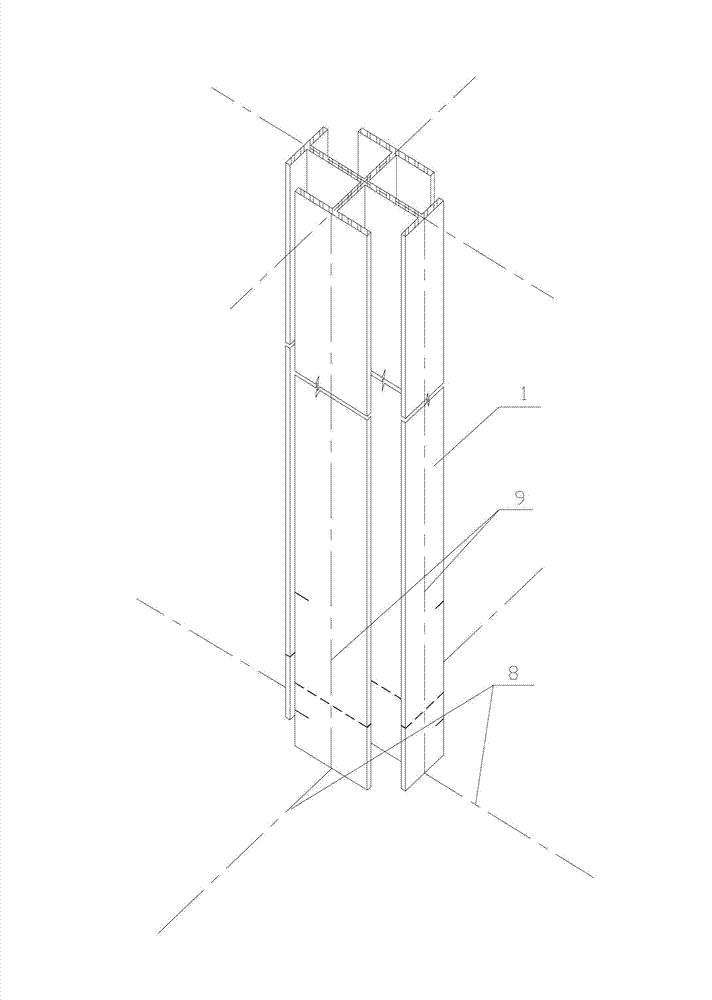

Section steel column for high-rise building section steel concrete combination structure, and construction method thereof

ActiveCN102733545AGuaranteed section sizeGuaranteed lengthStrutsBuilding material handlingConnection typeEngineering

The present invention discloses a section steel column for a high-rise building section steel concrete combination structure, and a construction method thereof. The section steel column comprises a plurality of column sections, wherein the column sections are sequentially connected from bottom to top, an interface position of two optionally adjacent column sections is provided with an inner sleeve interface, and an outer side wall of a connection position of the two adjacent column sections is provided with a buckle fixation type assembly. The construction method comprises that: the insert-connection type initial positioning of the two adjacent column sections is achieved through the inner sleeve interface; the cross extending line and the buckle fixation type assembly are combined to carry out positioning correction on the column; a scale measurement method is adopted to carry out column scale height adjustment; and the cross extending line and the buckle fixation type assembly are combined to carry out verticality correction on the full length of the column sections. With the section steel column of the present invention, the model of one construction interface in each floor of the traditional section steel column can be increased to the model of one construction interface in every two floors or three floors, such that more than half of the construction interfaces of the section steel column can be saved, the probability of deviation error due to construction interface operation can be greatly reduced, and the guarantee degree of installation quality can be improved.

Owner:广东中城建设集团有限公司 +1

Automatic clearing device for outer wall of pipeline

The invention relates to an automatic clearing device for the outer wall of a pipeline. Four arc-shaped partition blocks are connected together through connecting pins to form a main body structure ofa ring-shaped column cylinder shape, the main body structure surrounds the outer wall of the pipeline, then each arc-shaped main body is connected with the respective wheel type moving device througha telescopic support, the whole main body structure is supported, then a rack clamps the outer wall of the pipeline closely, then a motor drives a wheel type moving platform, and thus a rack main body can move in the axial direction of the pipe wall. The clearing device comprises a cutter frame and a blade type cutter brush. The assembled arc-shaped cutter frame is embedded into a corresponding groove of the rack, the motor rotates to drive the cutter frame to do rotation motion, when the cutter frame does rotation motion, the cutter brush is attached to the outer wall of the pipeline reversely under the effect of centrifugal force, thus the cutter brush does rotation motion constantly, thus the pipe wall is cleared, and by means of cooperation with the axial moving of the device body, clearing work over the outer wall of the whole pipeline is completed.

Owner:XIAN TECH UNIV

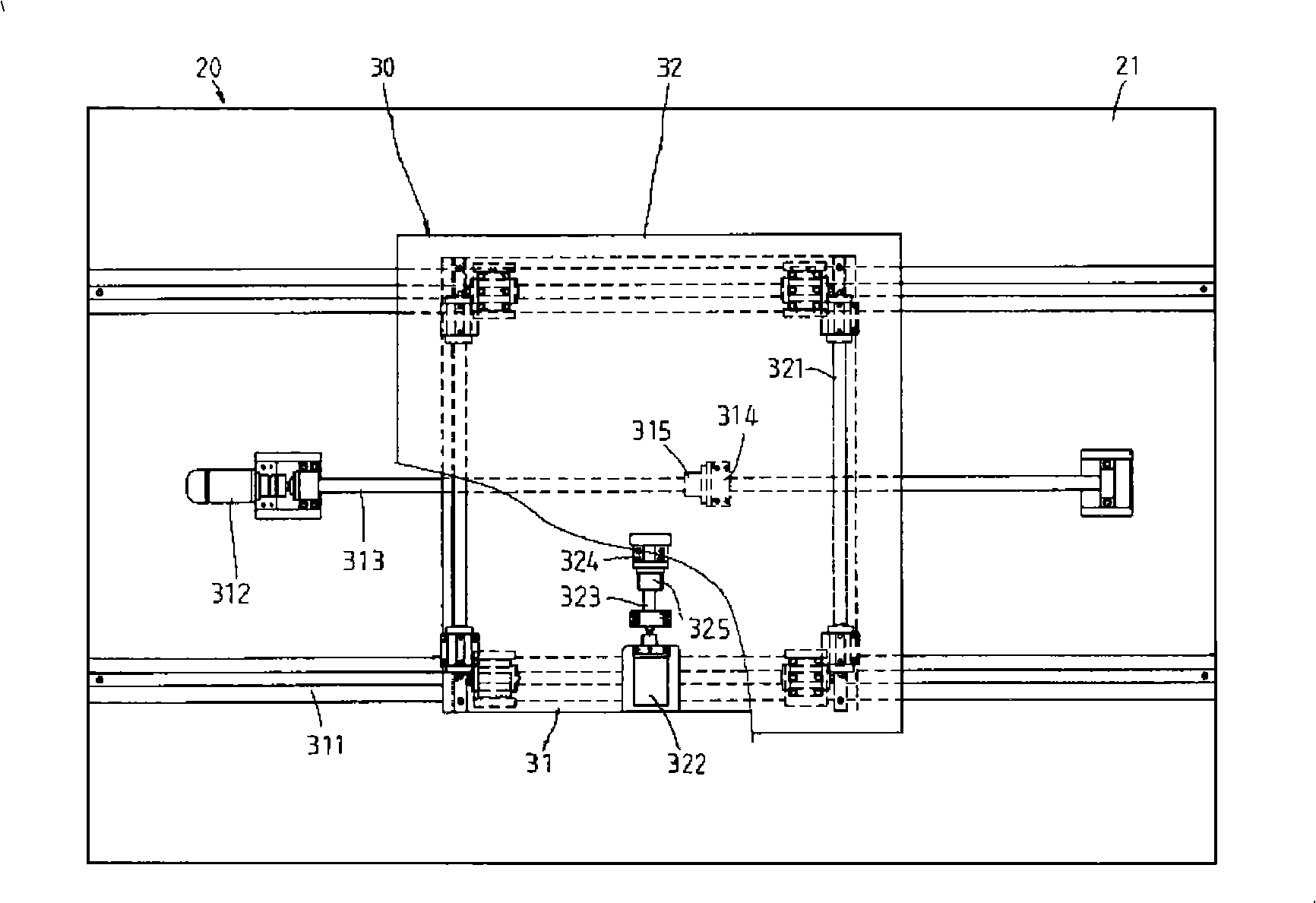

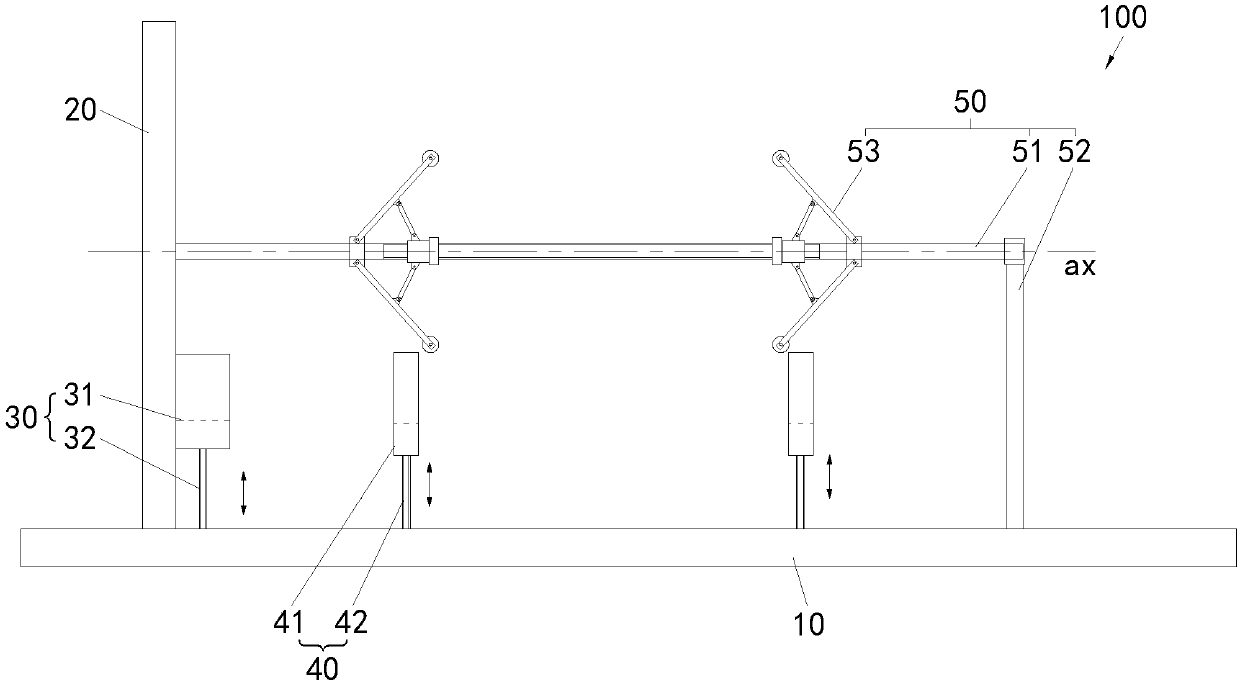

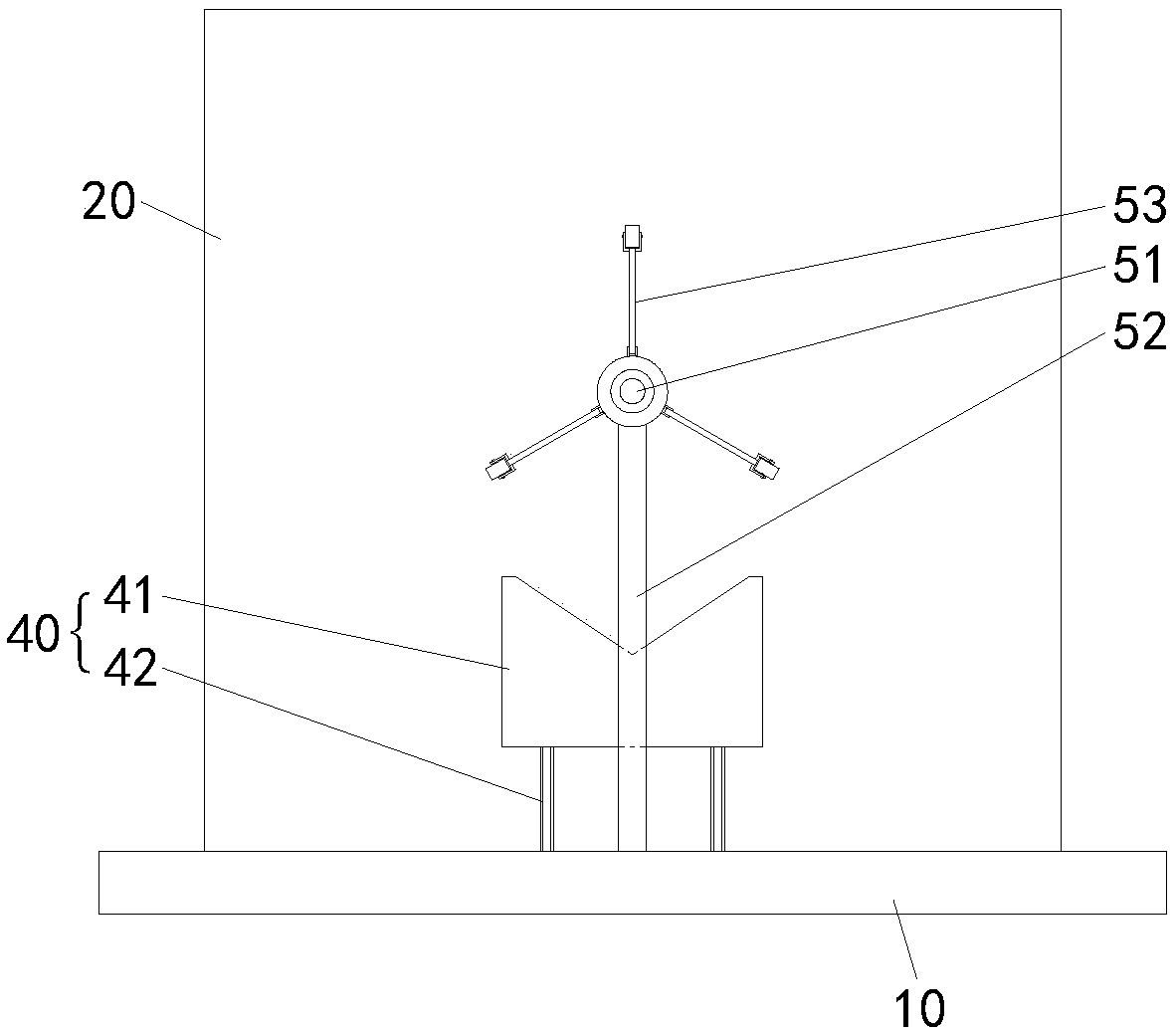

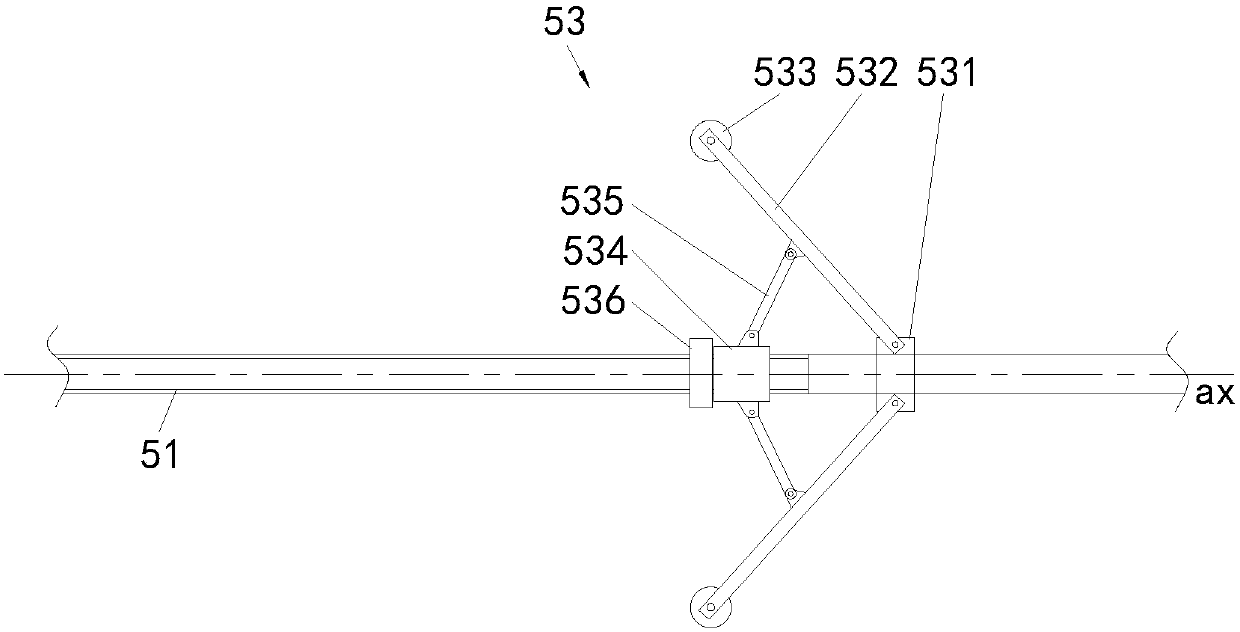

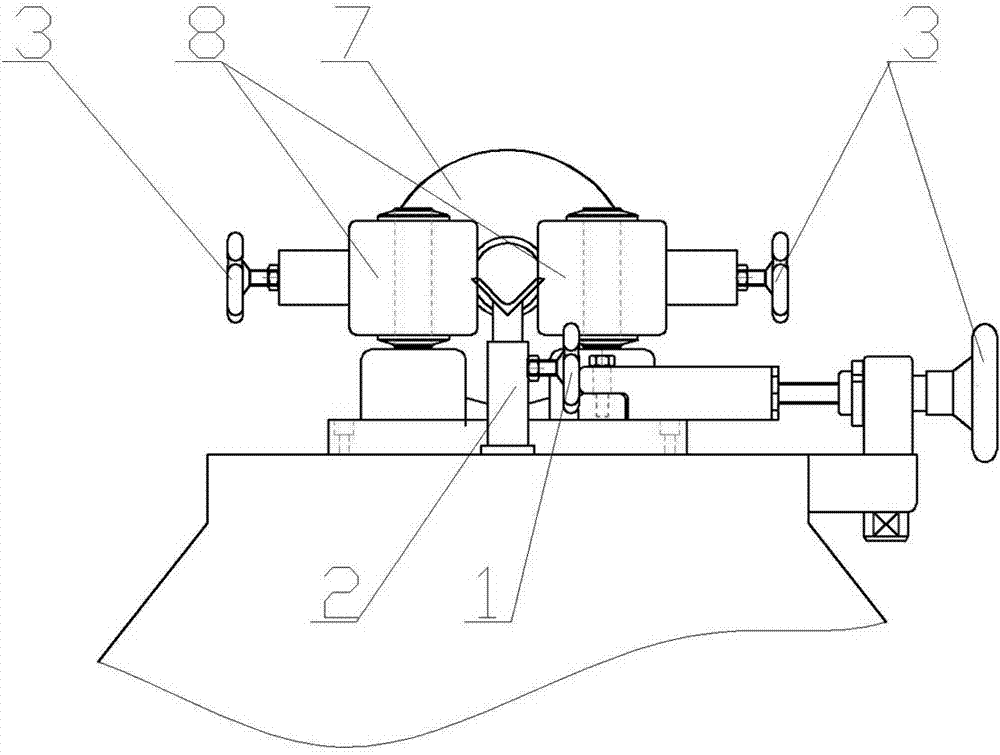

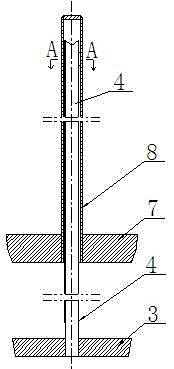

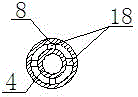

Prefabrication platform and prefabrication method for jacketed pipe

PendingCN107855721AEasy to penetrate and installGuaranteed verticalityWelding/cutting auxillary devicesAuxillary welding devicesFiberCompound (substance)

The invention discloses a prefabrication platform and a prefabrication method for a jacket pipe and relates to the technical field of petrochemical engineering and chemical fiber equipment installation. The prefabrication platform and the prefabrication method for the jacketed pipe are provided to solve the problems that according to existing prefabrication construction for a straight pipe sectionof a major-diameter jacketed pipe, operation is relatively complex, and the working efficiency is low. The prefabrication platform is composed of a flange plate positioning frame, an inner pipe positioning assembly and a plurality of outer pipe positioning assemblies. A first adjusting rod arranged on the bottom of a positioning base can adjust the height of a flange plate. The inner pipe positioning assembly is composed of a center rod perpendicularly fixed to a back plate, an extensible and retractable guide wheel supporting frame arranged on the center rod in a sleeving manner and a supporting frame connected to the other end of the center rod, wherein the extensible and retractable guide wheel supporting frame is composed of a fixing casing pipe arranged on the center rod in a sleeving manner, supporting rods which are evenly distributed in the radial direction of the axis of the center rod and hinged to the fixing casing pipe and extensible and retractable supports, one end of each extensible and retractable support is hinged to the corresponding supporting rod, the other end of each extensible and retractable support is hinged to the center rod, and the other end of each supporting rod is provided with a guide wheel. The outer pipe positioning assembly comprises an outer pipe support and a second adjusting rod which are detachably connected.

Owner:SHANGHAI INSTALLATION ENG GRP

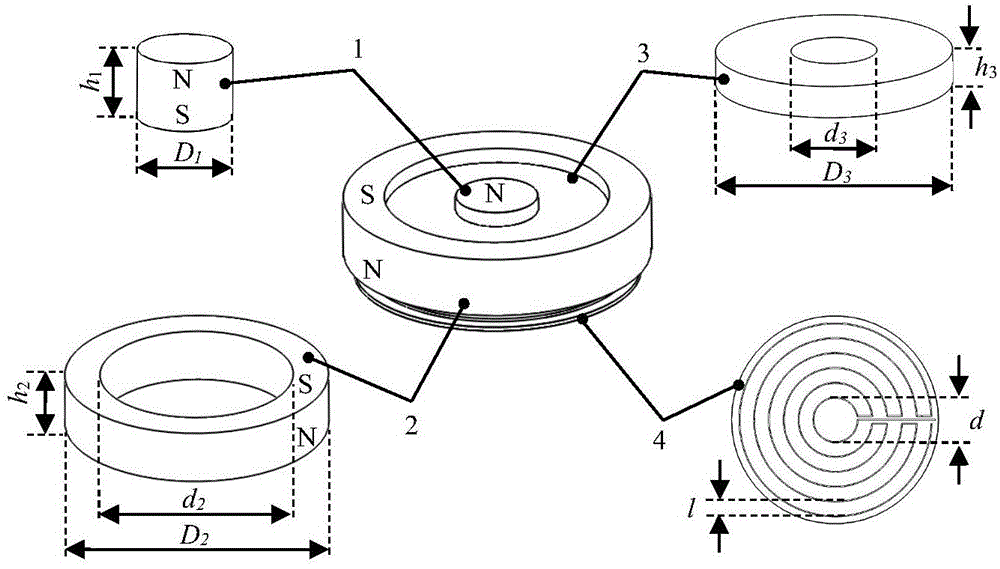

Concentric permanent magnetic gear magnetism regulation ring device and production method thereof

ActiveCN106452002AShorten the production cycleReduce manufacturing costPermanent-magnet clutches/brakesRing devicePole piece

Owner:DALIAN YULIN ELECTRIC MOTOR

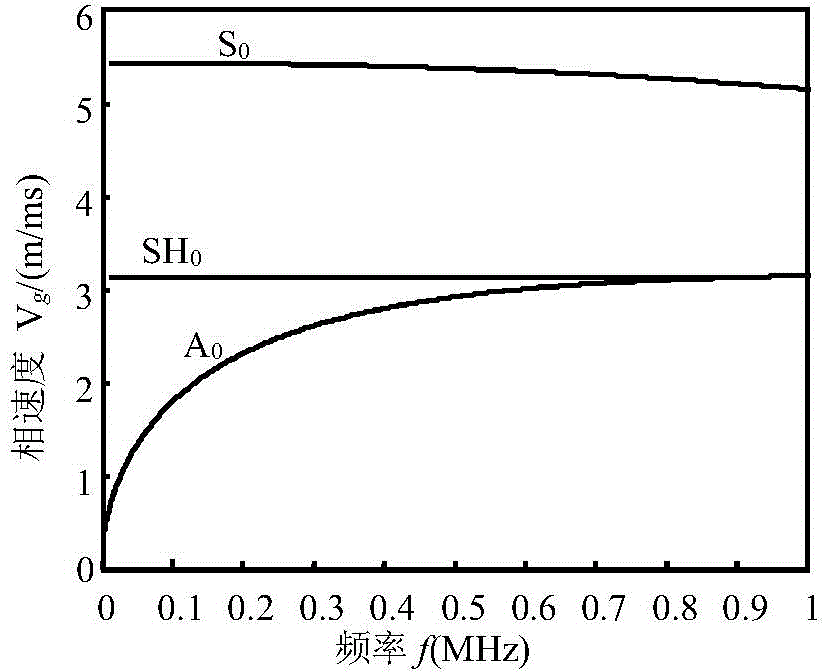

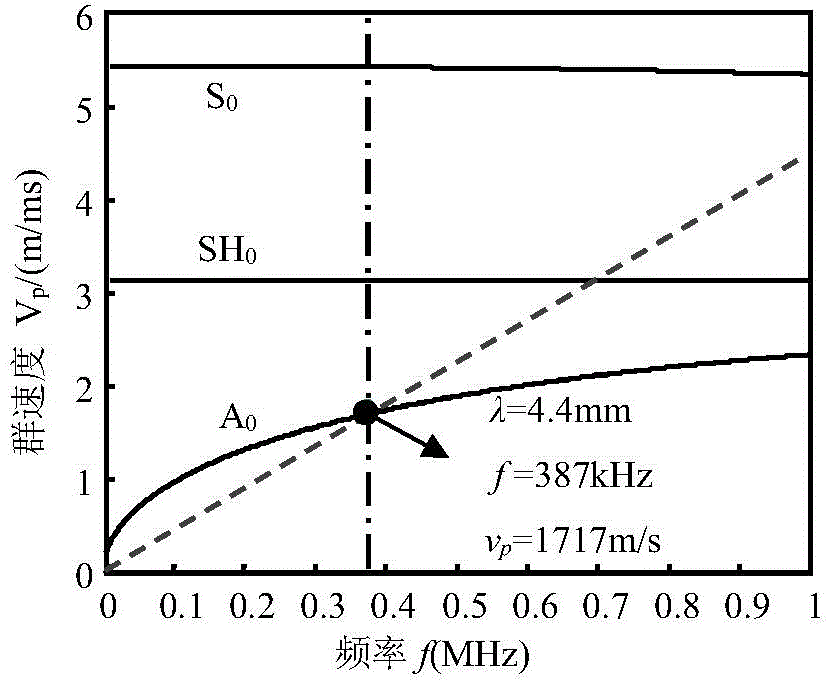

Omnidirectional A0 modal Lamb wave electromagnetic acoustic sensor

ActiveCN104820024AUniform magnetic field distributionGuaranteed Circular ConsistencyAnalysing solids using sonic/ultrasonic/infrasonic wavesCoil structureLamb waves

The invention discloses an omnidirectional A0 modal Lamb wave electromagnetic acoustic sensor, and belongs to the field of ultrasonic non-destructive testing. A double-layer spiral inflection coil structure is integrated in a flexible circuit board, and the omnidirectional A0 modal Lamb wave electromagnetic acoustic sensor is designed and developed to excite single A0 modal Lamb waves in an aluminum plate. The developed electromagnetic acoustic sensor is verified by experiments, the single A0 modal Lamb waves can be excited in the aluminum plate, defects in the aluminum plate are detected by the sensor, and positioning precision is high. The developed electromagnetic acoustic sensor has fine frequency response characteristics according to verification by scanning frequency experiments, and the developed electromagnetic acoustic sensor has fine omnidirectional characteristics according to verification by omnidirectional characteristic testing experiments. By the aid of the developed omnidirectional A0 modal Lamb wave electromagnetic acoustic sensor and an array combination imaging algorithm thereof, wide-range and high-efficiency defect imaging of a plate structure can be realized, and the sensor has great application values and potentials in the field of health monitoring and non-destructive evaluation for the plate structure.

Owner:BEIJING UNIV OF TECH

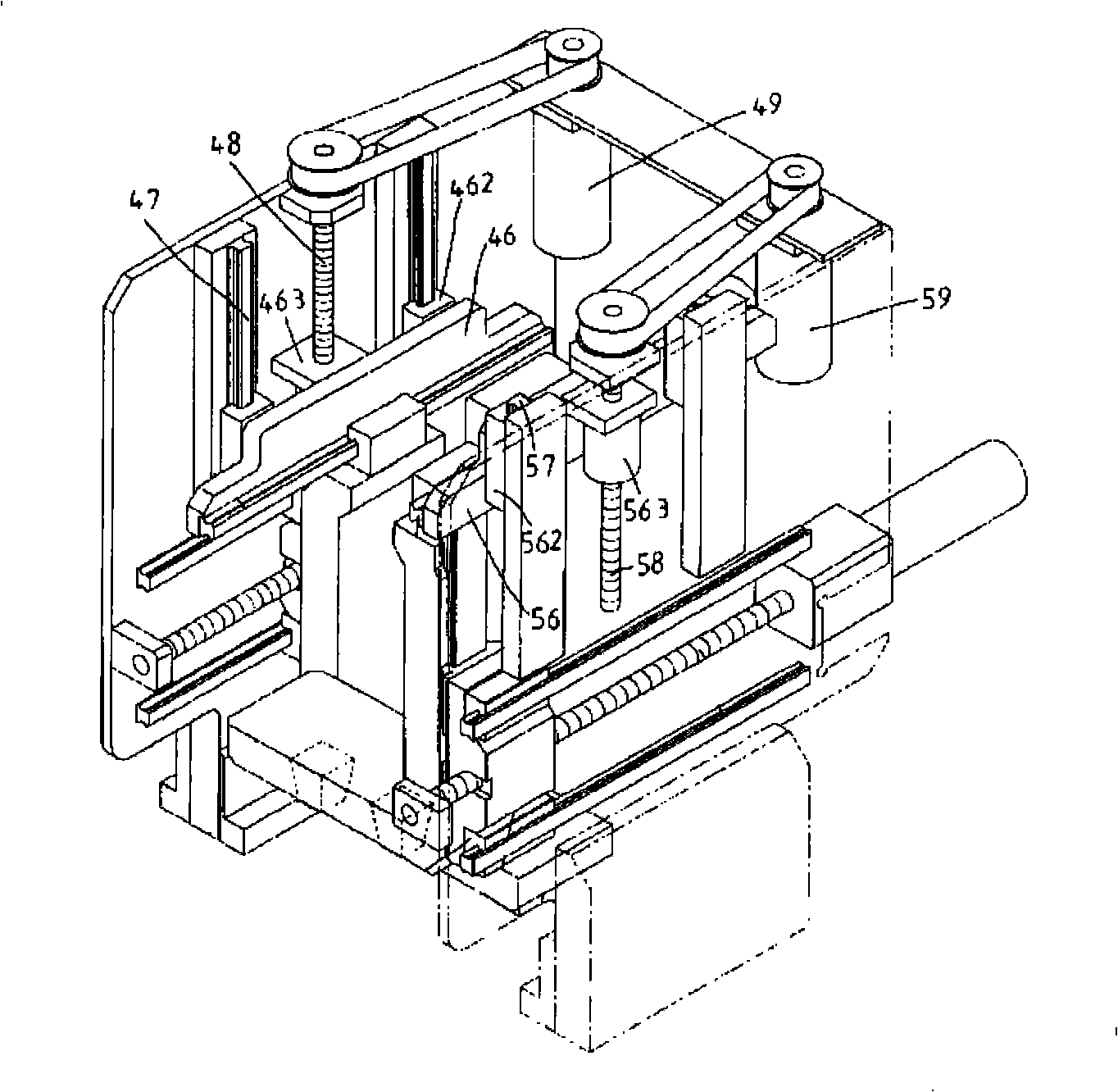

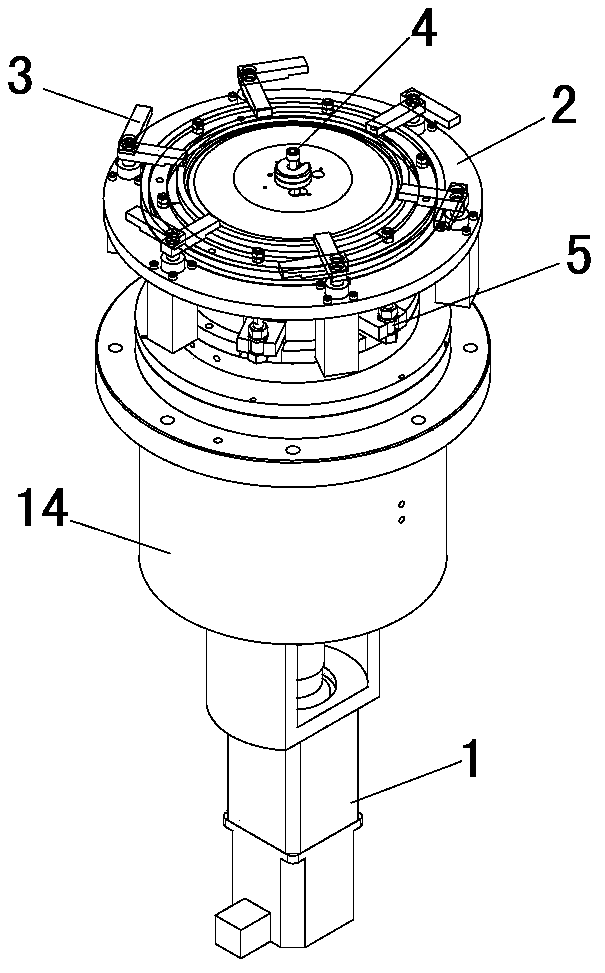

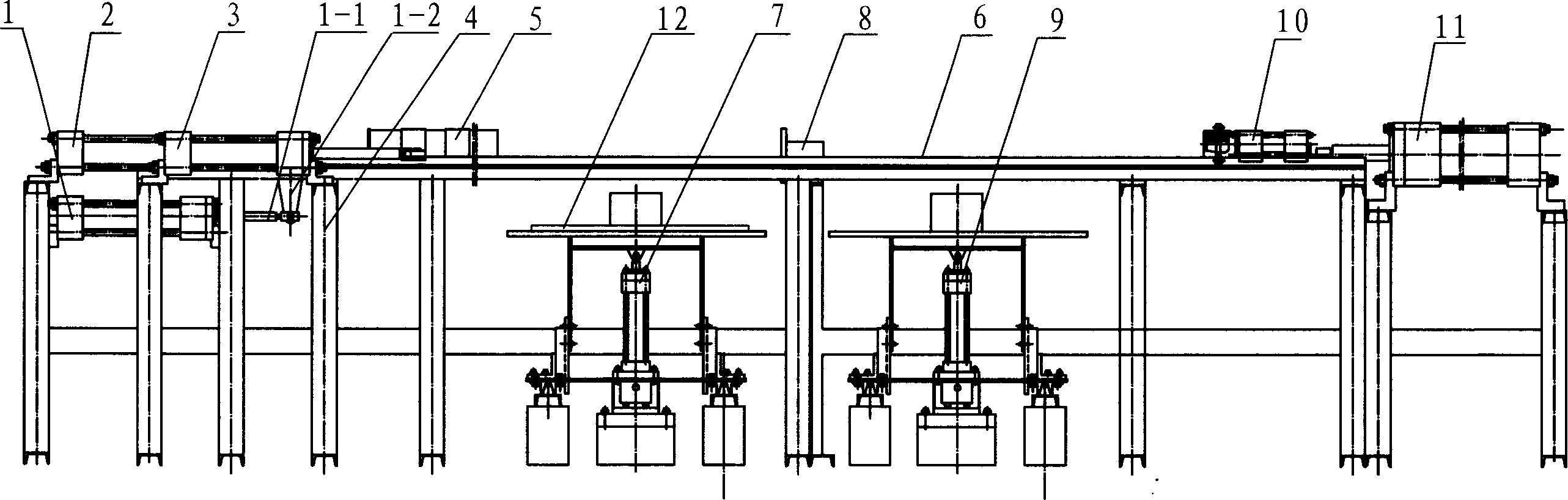

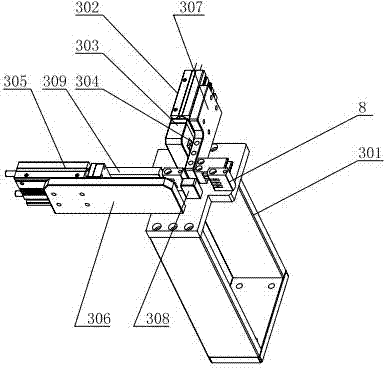

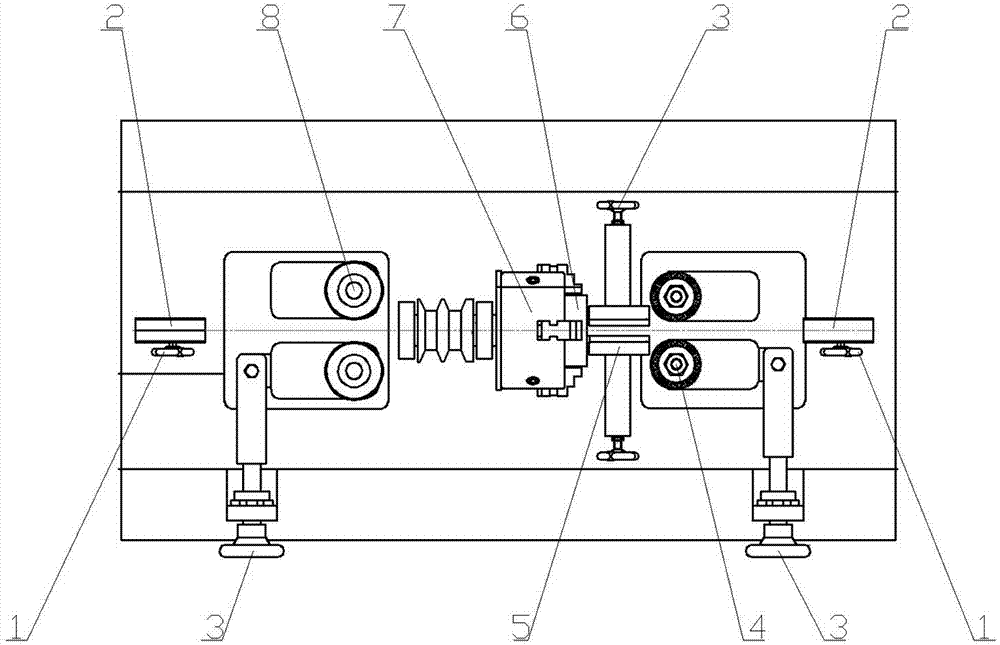

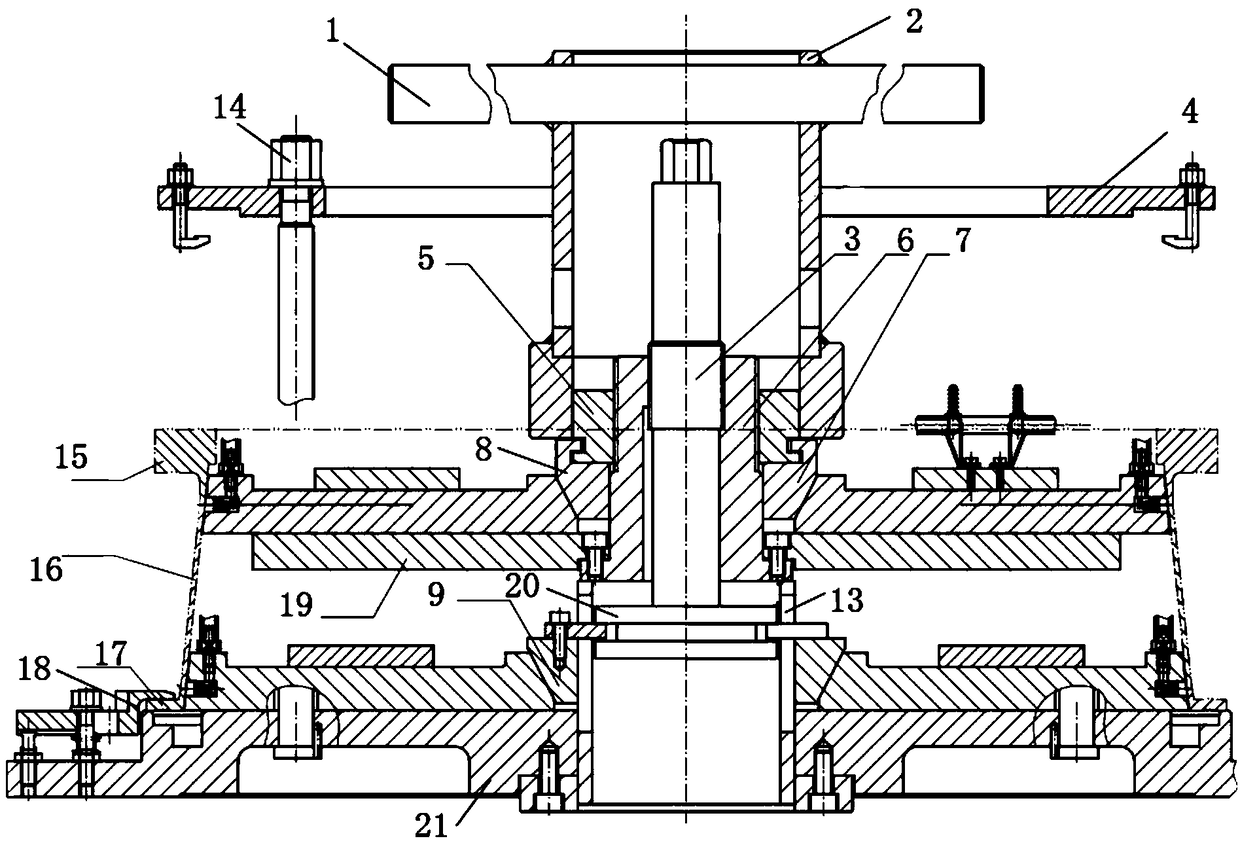

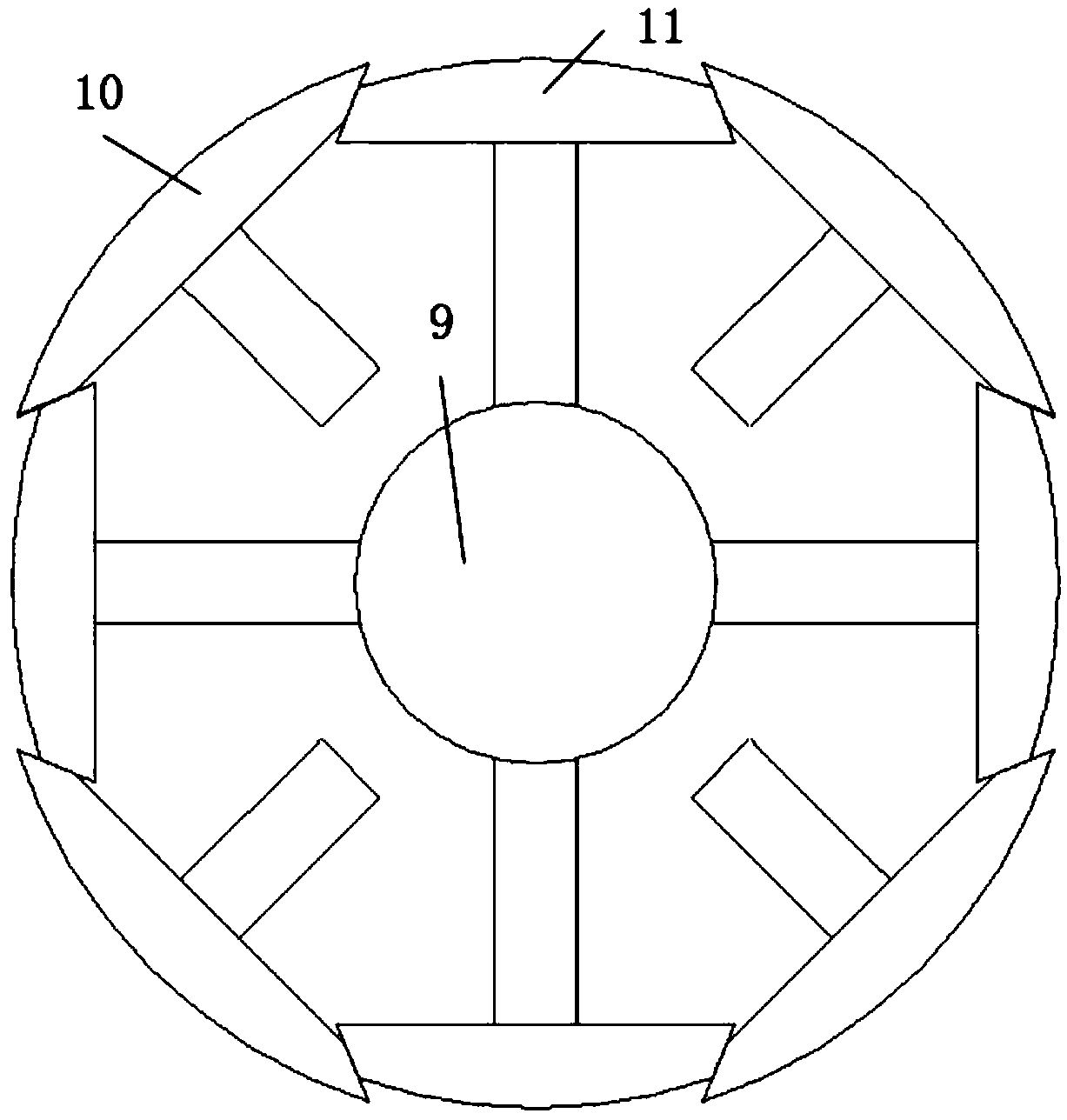

Laser welding fixture for gear

InactiveCN103506761AReduce complexityAvoid welding deformationWelding/cutting auxillary devicesAuxillary welding devicesGear wheelEngineering

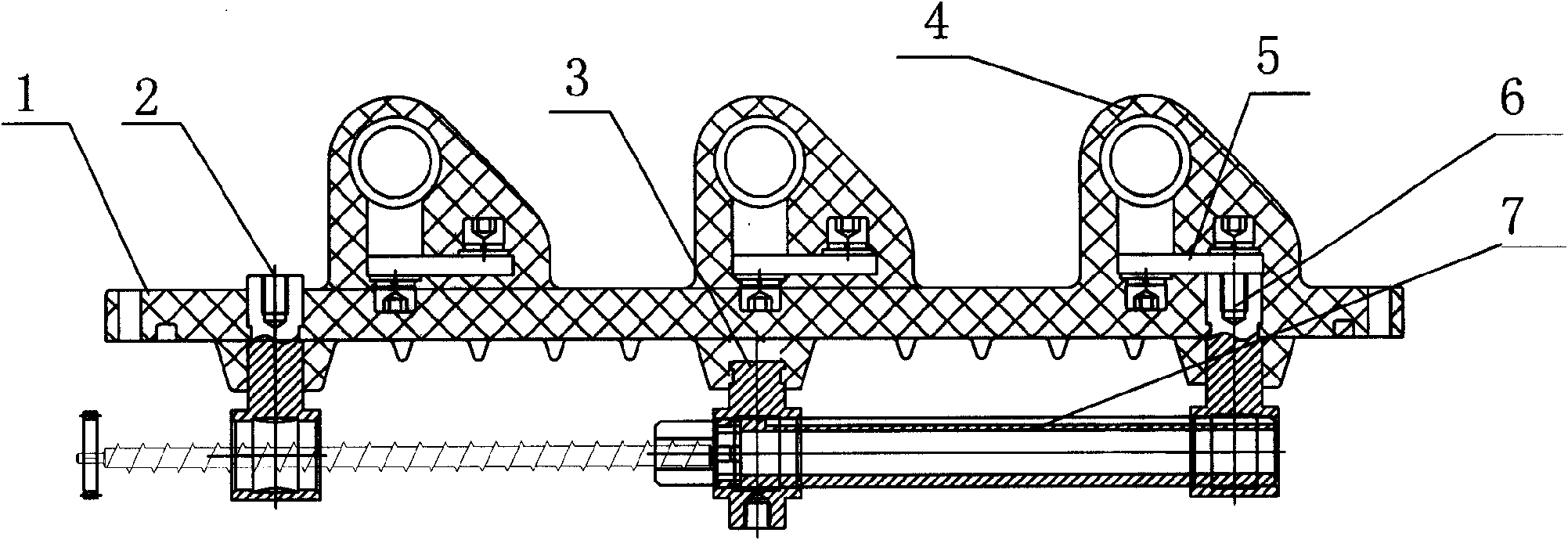

A laser welding fixture for a gear comprises a power rotating mechanism, a welding platform, a gear ring clamping mechanism, a wheel disc clamping mechanism and a gear ring tightening mechanism. The welding platform is in fixed transmission connection with the power rotating mechanism, the gear ring clamping mechanism is installed on the welding platform and used for clamping a gear ring axially, the wheel disc clamping mechanism is installed on the welding platform and used for clamping a wheel disc axially, and the gear ring tightening mechanism is arranged on the welding platform and used for clamping the gear ring radially. According to the laser welding fixture for the gear, the gear ring contracts and is clamped through the gear ring tightening mechanism in the radial direction, and therefore the concentricity of the gear ring can be guaranteed; the gear ring is clamped through the gear ring clamping mechanism in the axial direction, so that the end face accuracy of the gear ring is guaranteed, and the anti-splash protection effect is achieved at the same time; the wheel disc is clamped through the wheel disc clamping mechanism in the axial direction, so that welding deformation of the wheel disc is prevented, and welding accuracy is improved. The whole laser welding fixture for the gear can effectively prevent welding deformation, protect the gear, and improve welding accuracy and welding efficiency.

Owner:上海团结普瑞玛激光设备有限公司

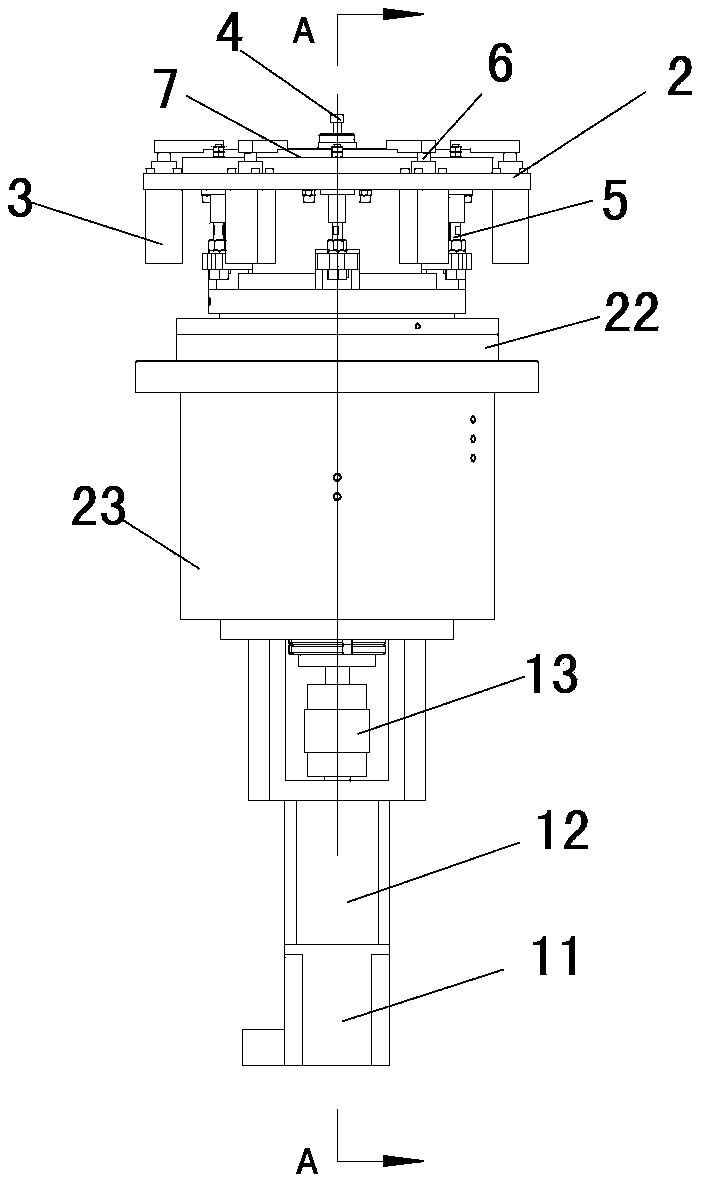

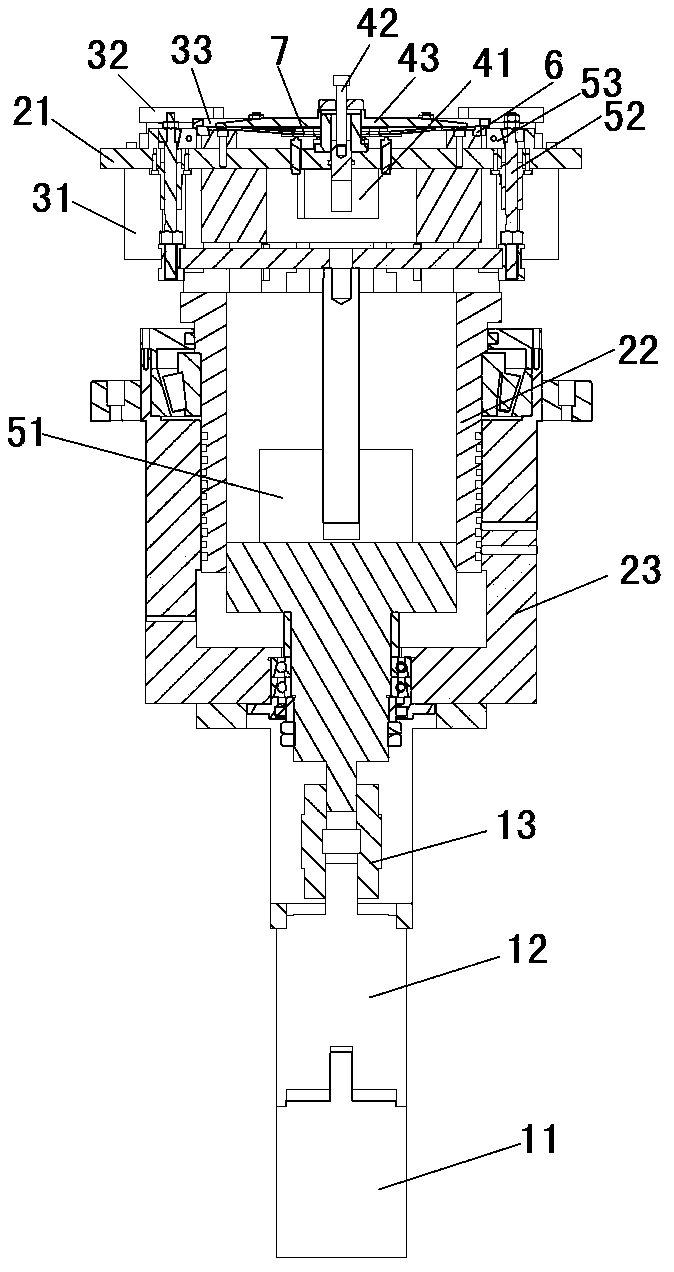

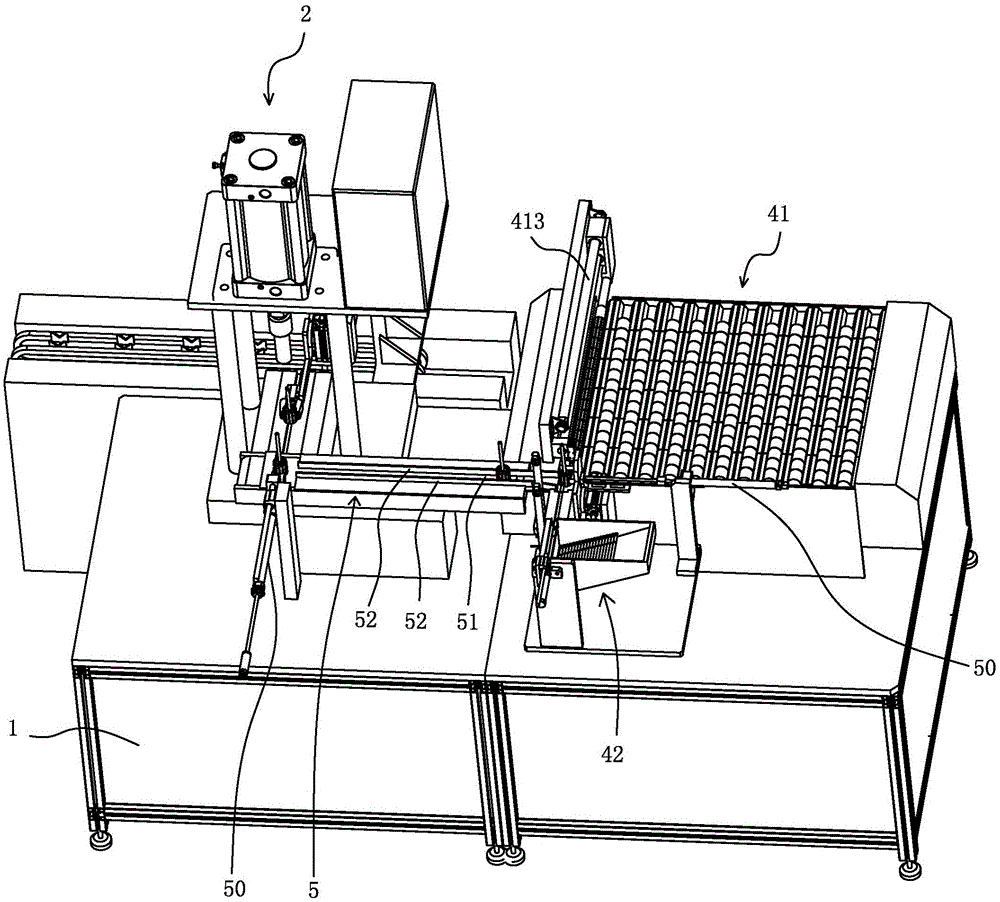

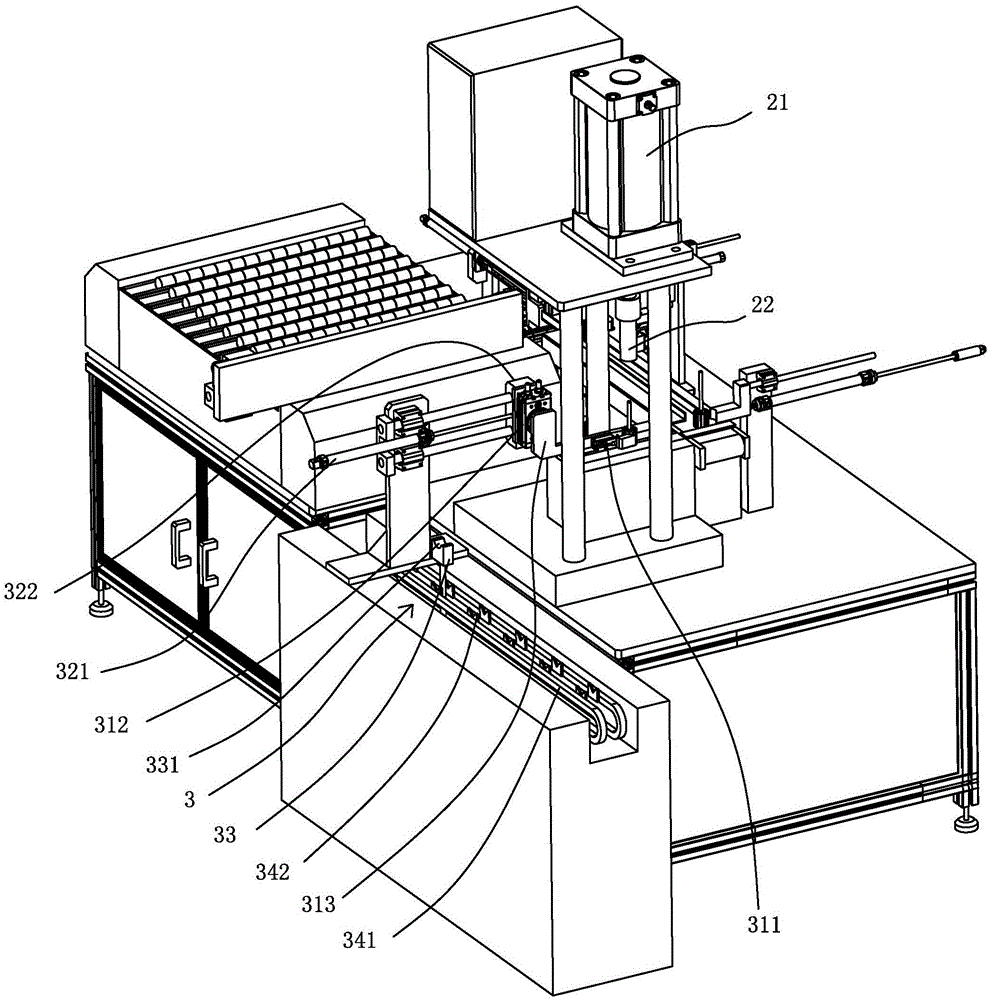

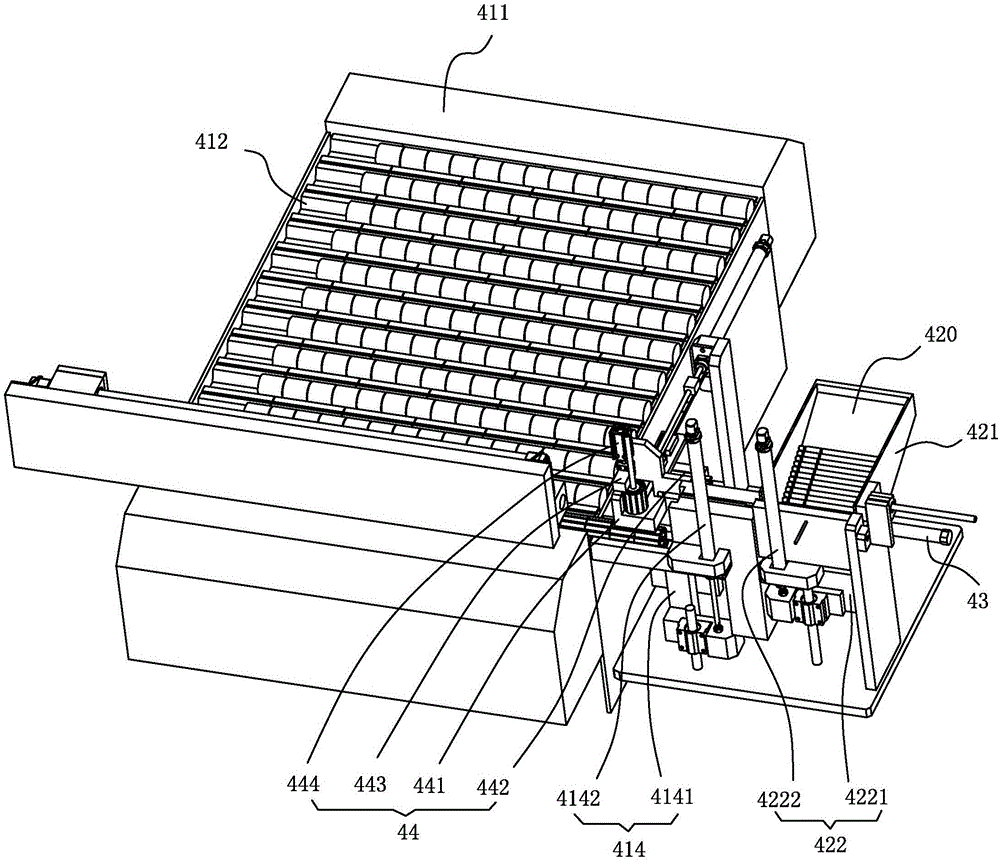

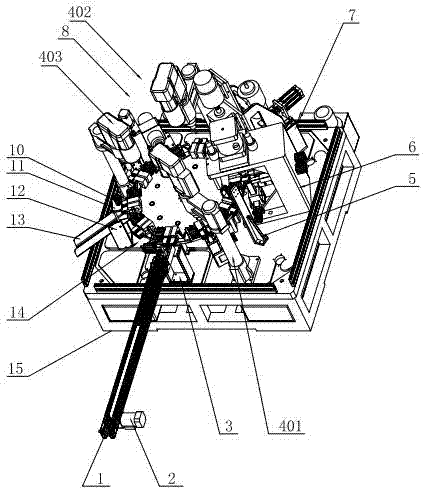

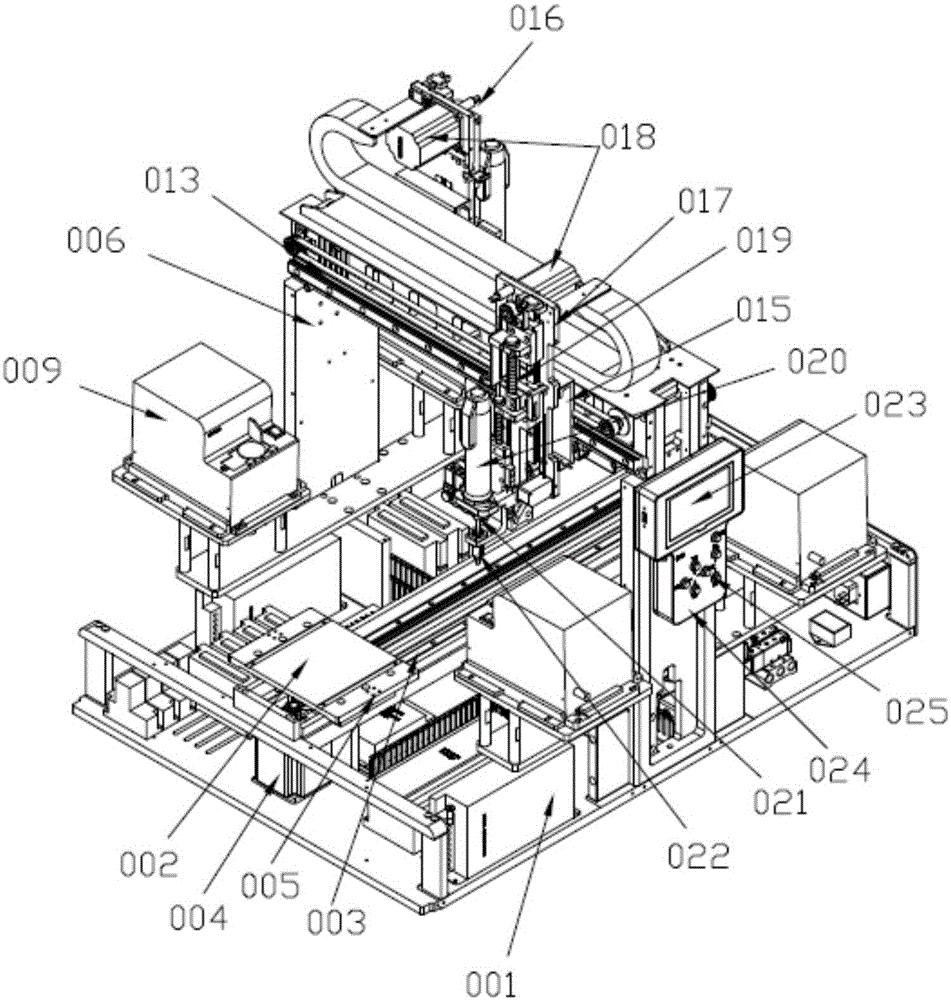

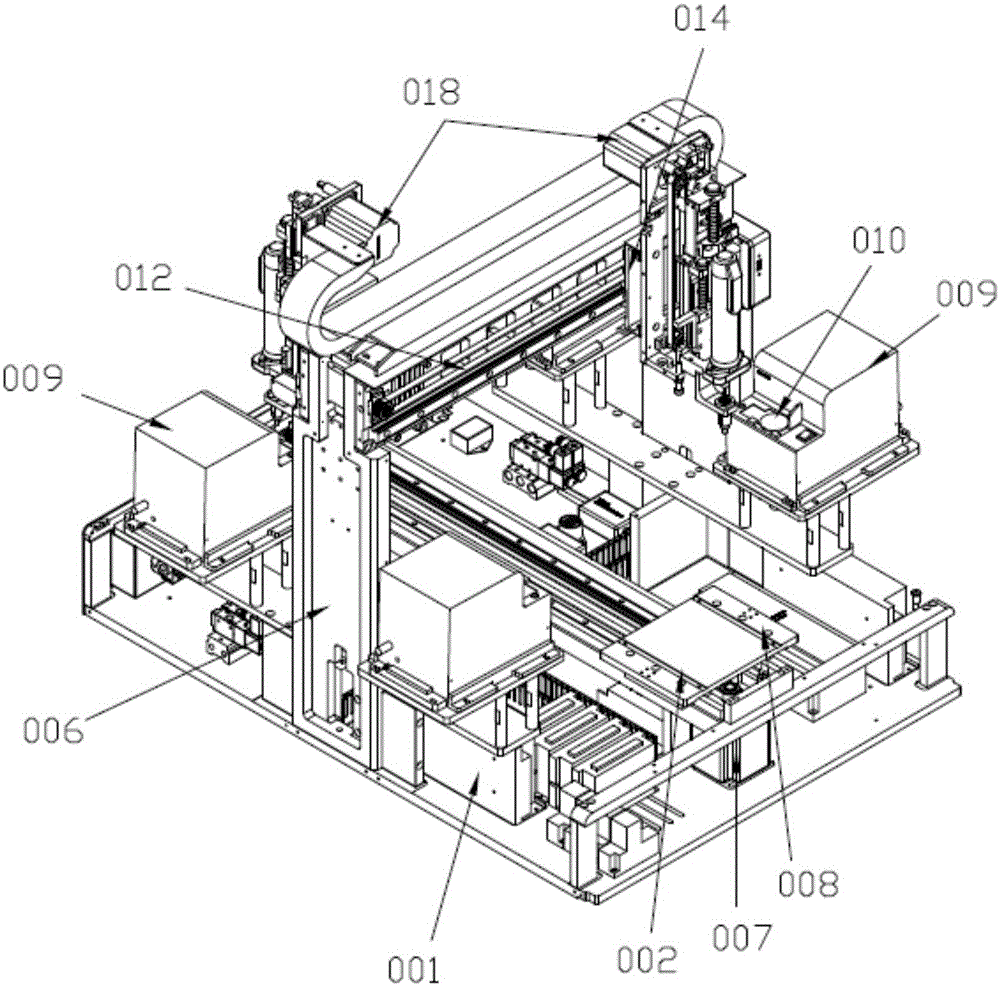

Motor rotor shaft automatic assembling machine

InactiveCN105071608AAvoid damageImplement automatic assemblyManufacturing stator/rotor bodiesOutput deviceEngineering

The invention discloses a motor rotor shaft automatic assembling machine, which comprises a machine frame and an output device, wherein the machine frame is provided with a press-fitting station; a press-fitting mechanism is arranged on the press-fitting station; the machine frame is provided with a pre-assembling station, an iron core automatic supply bin and a rotor shaft automatic supply bin on one side of the press-fitting station, the iron core automatic supply bin is used for conveying horizontally-placed iron cores to the pre-assembling station, and the rotor shaft automatic supply bin is used for conveying horizontally-placed rotor shafts to the pre-assembling station; the pre-assembling station is provided with an inserting and placing drive device and an overturning mechanism, the inserting and placing drive device is used for inserting the rotor shafts into the iron cores horizontally, and the overturning mechanism is used for overturning the iron cores inserted with the rotor shafts to be placed vertically; and an intermediate conveying mechanism which is used for conveying the iron cores inserted with the rotor shafts from the pre-assembling station to the press-fitting station is arranged on the machine frame. The motor rotor shaft automatic assembling machine can achieve the automatic assembly of the rotor shafts and the iron cores, greatly reduces labor intensity of workers, increases production efficiency, can effectively ensure the concentricity between the rotor shafts and the iron cores, prevents the iron cores from being damaged due to tilt rotor shafts because the rotor shafts are not inserted in place, and improves product quality.

Owner:江门市智能装备制造研究院有限公司

Hydraulic flexible method for producing cold-drawn pipe and apparatus

InactiveCN1803328ALow manufacturing costAvoid vibrationDrawing mandrelsDrawing diesPiston cylinderLubricant

The invention discloses a hydraulic flexible cold-drawing method and equipment in the metallurgical mechanic pipe moulding technique, which comprises the following parts: pushing piston cylinder, pushing core bar cylinder, pushing assembly cylinder, assembly, rail, feeding structure, mould, blanking structure, clamp structure and drawing cylinder. The mould doesn't touch the deformation metal to form the flexible deformation state of mould-hydraulic oil-hollow billet-hydraulic oil-core head, which improves the precision of cold-drawing pipe.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

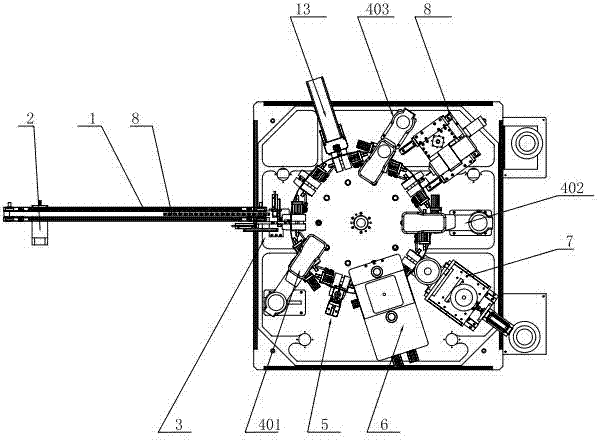

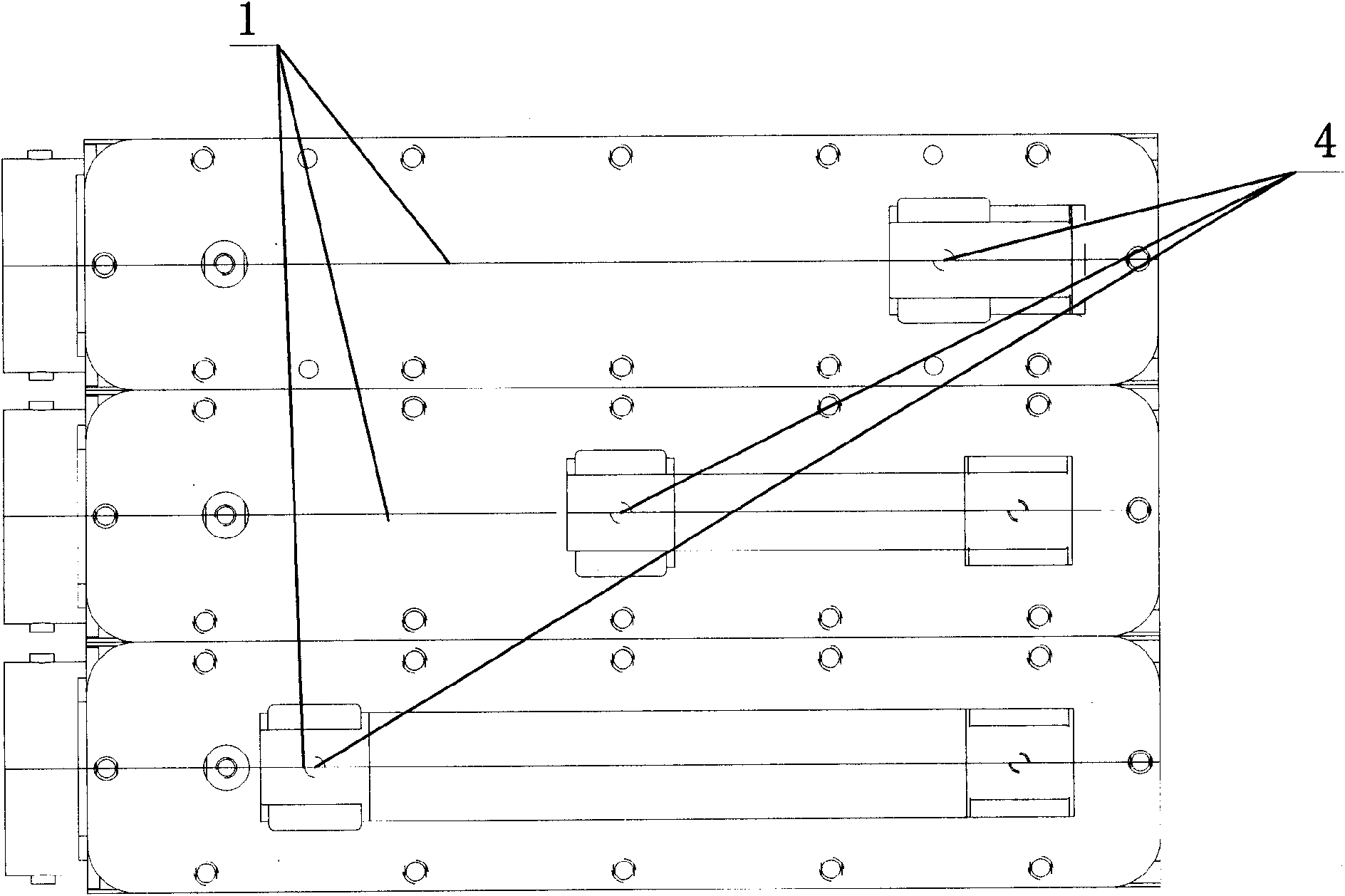

Lock body automatic machining device

ActiveCN103495867AGuaranteed accuracyGuaranteed concentricityMeasurement/indication equipmentsOther manufacturing equipments/toolsMachiningSmall hole

The invention relates to a lock body automatic machining device which comprises a machine frame and a rotation disc component arranged on the machine frame. A plurality of sets of locating and clamping units are arranged in the circumferential direction of the rotation disc component and located on the machine frame. The periphery of the rotation disc component is provided with a locating feeding unit, a first automatic drilling unit, a hole position automatic detection unit, an automatic notching unit, an automatic groove milling unit, a second automatic drilling unit, a small hole automatic machining unit, a third automatic drilling unit and a discharging unit in the anticlockwise direction. The lock body automatic machining device is simple in structure and convenient to operate, whole-journey automation of lock body machining is achieved, concentricity of central hole forming of the lock body is guaranteed, meanwhile groove machining is achieved at one time, groove accuracy is guaranteed, production efficiency is greatly improved, labor intensity is lowered, cost is saved for enterprise production, and enterprise production efficiency is improved.

Owner:余欣

Round stick processing machinery

InactiveCN103692500AExpand the scope of processingEliminate gap wobbleRounding machinesMechanical engineeringEngineering

The invention discloses round stick processing machinery, wherein a processing cutter is fixed on the axle center position of a three-jaw chuck, a material passing hole matched with the diameter of a round stick is formed in the center, cutter teeth are arranged on the front end, feeding and clamping rollers are a pair of rollers provided with 90-degree V-shaped grooves located in the front end of the processing cutter and are used for conveying a batten to be processed, a material shifting wheel is located on the rear end of the processing cutter and is used for outputting a processed round stick, and material brackets used for supporting the batten to be processed and the processed round stick are respectively arranged on the front end of each feeding and clamping roller and on the rear end of the material shifting wheel. According to the round stick processing machinery disclosed by the invention, the processing cutter does not need to be adjusted, and processing cutters with different specifications are directly changed to process round sticks with different specifications. The round stick processing machinery disclosed by the invention can be used for processing a round stick with a minimal diameter of only 1 mm.

Owner:山西晟龙木雕模型艺术有限公司

Hole guiding device

The invention discloses a hole guiding machine, comprising an upper plate, a lower plate, and at least two guiding elements arranged between the upper plate and the lower plate. The hole guiding machine is characterized in that the guiding elements comprise a guide column fixed on the lower plate and a guide bushing which is arranged at the corresponding position of the upper plate and used for connecting the upper plate and the lower plate so as to lead a cone-shaped positioning pin arranged on the upper plate to be concentric with a drilling guide sleeve arranged at the corresponding position of the lower plate. The hole guiding machine can better ensure the perpendicularity of the guided hole and the part surface and the concentricity of the guided hole and the guide hole by the guiding function of the guide bushing, and no slant holes can be guided out, thus improving the product quality. Ends of the upper plate and the lower plate are provided with a distance adjusting device arranged between the upper plate and the lower plate, thus leading the hole guiding machine to be applicable to guiding holes on various parts with different interlining thickness.

Owner:XIAN AIRCRAFT IND GROUP

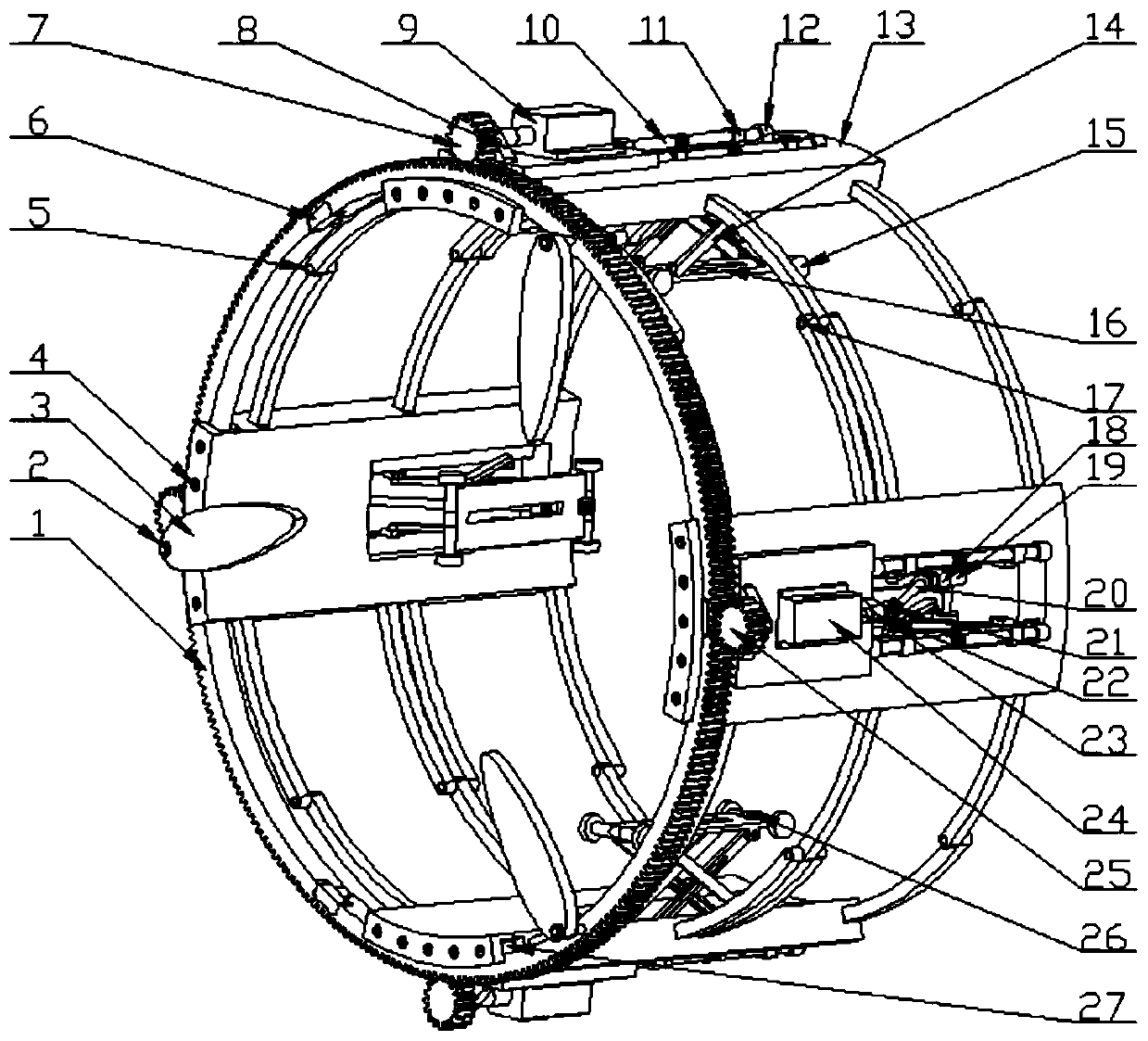

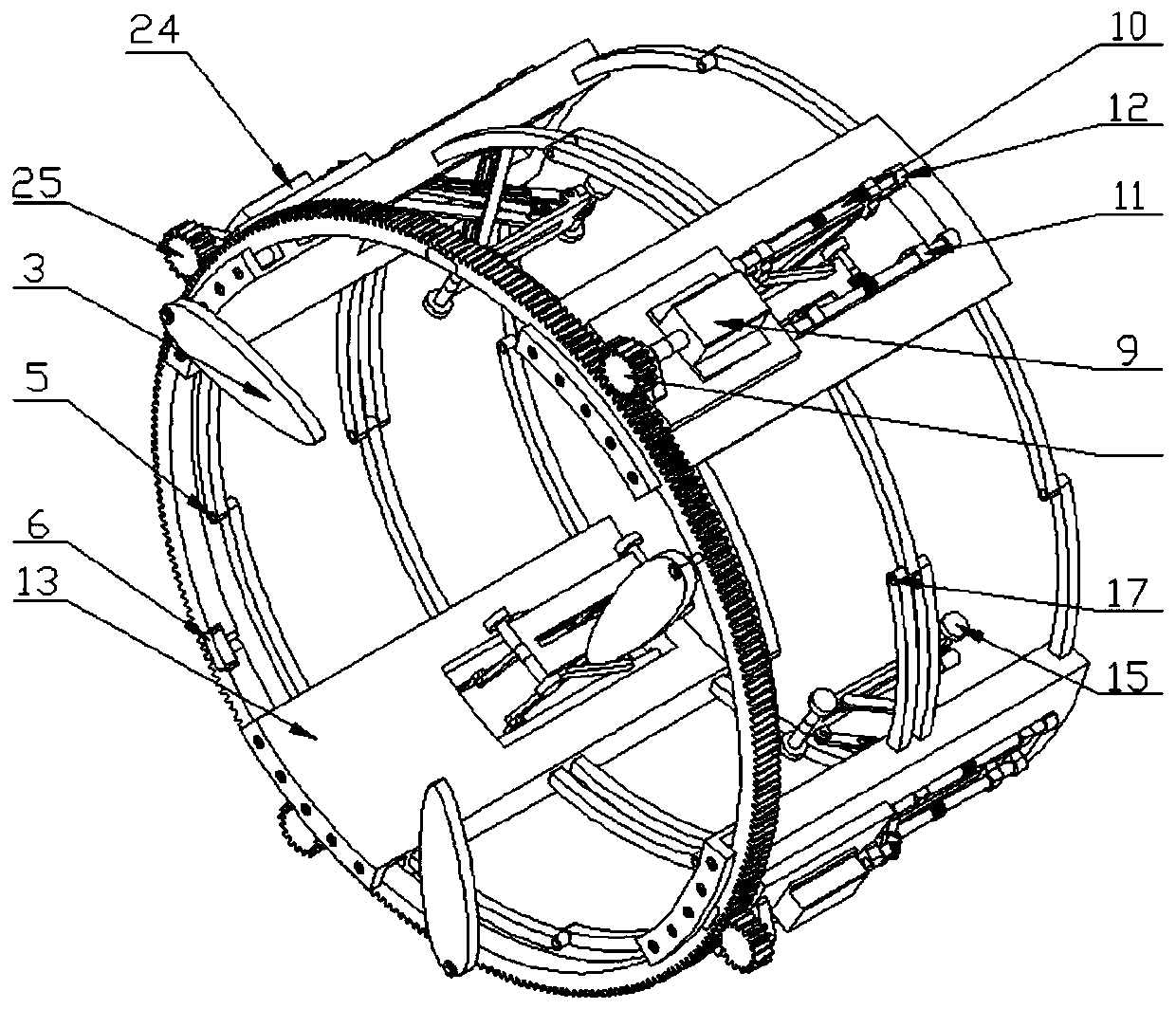

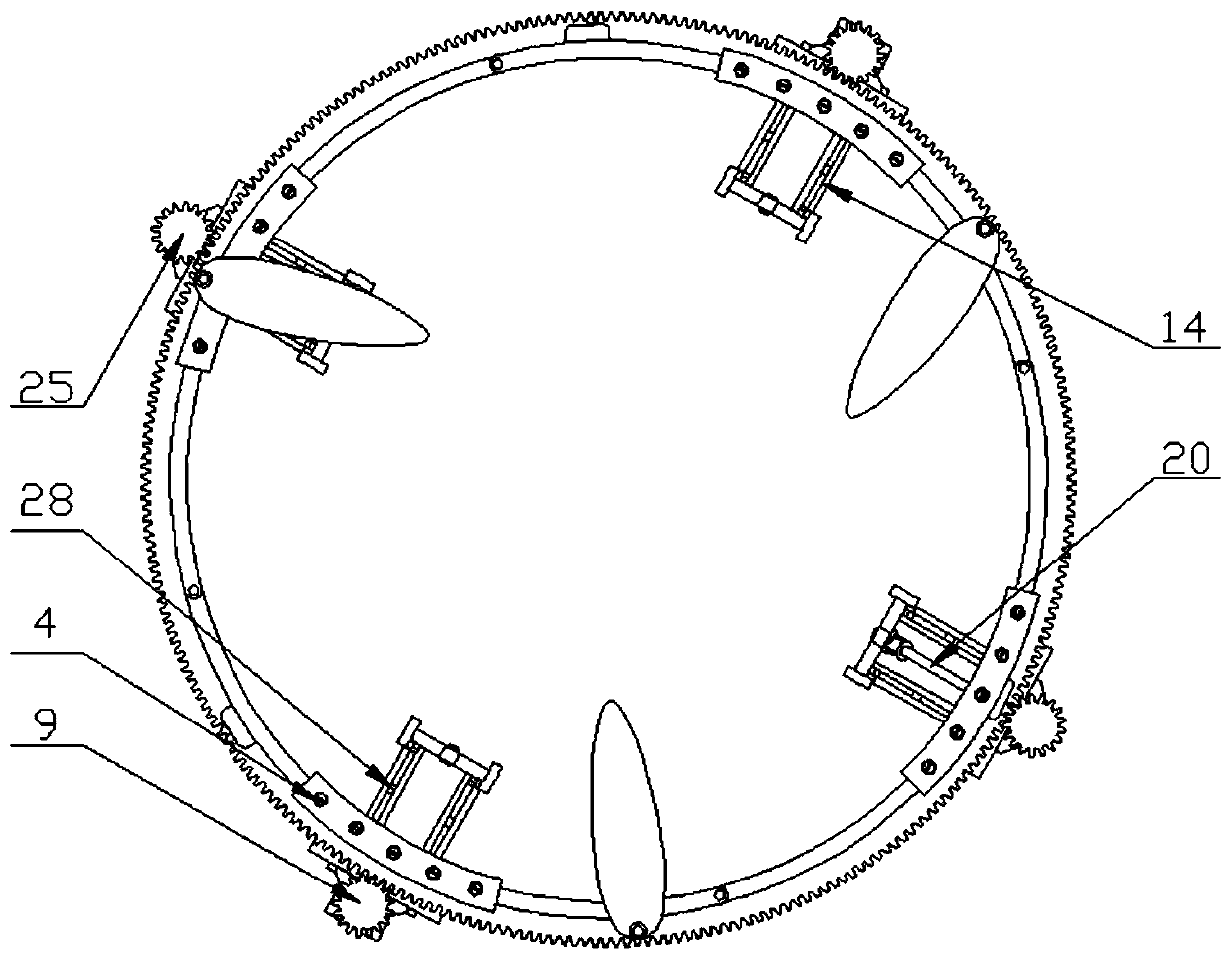

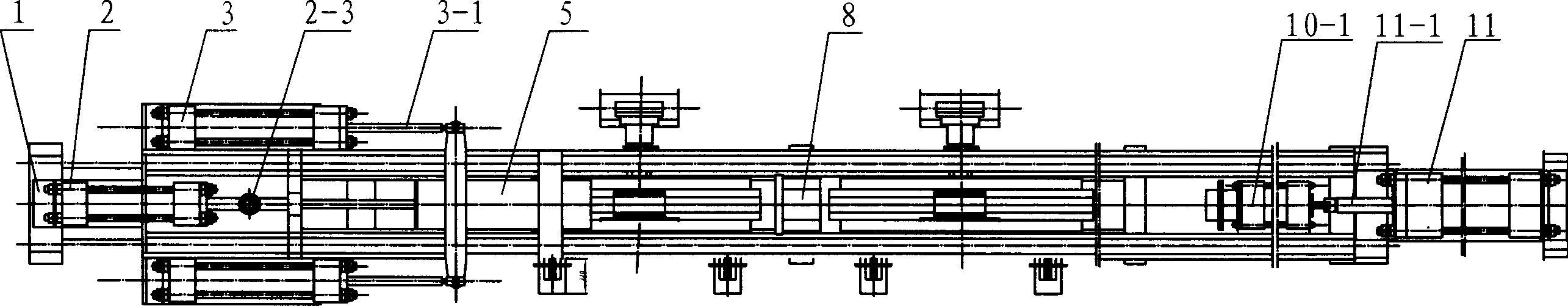

Engine outer duct casing welding device and method

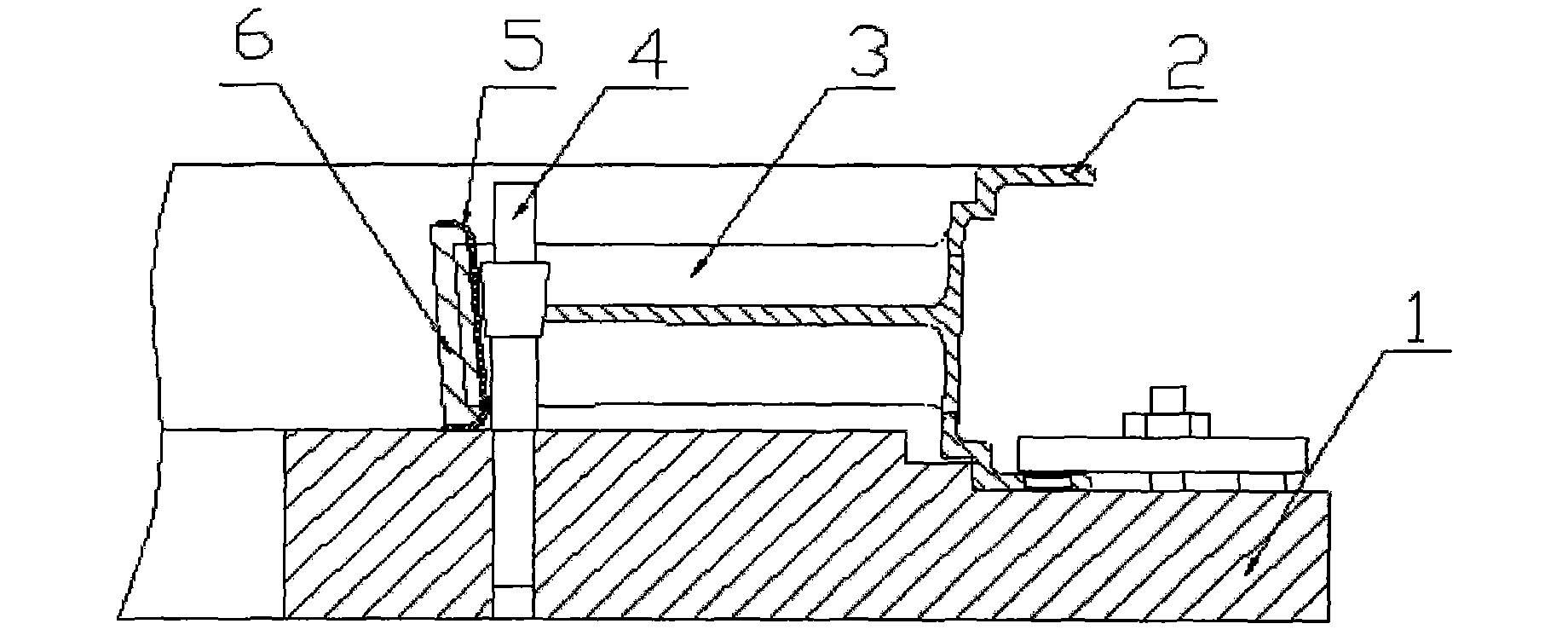

InactiveCN109128651AHigh concentricityGuaranteed concentricityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

The invention provides an engine outer duct casing welding device and method. The device comprises a base, an upper-layer pressing ring, a middle-layer expansion ring, a supporting plate, a lower-layer expansion ring and a movement device. Welding deformation is reduced by adopting the sectioning expansion structure, and the overall concentricity of a to-be-welded workpiece is ensured. The sectioning expansion structure is mainly composed of a wedge block, a supporting plate, a driving block, a driven block and the like. In the expansion process, the wedge block is moved downwards, therefore,the driving block is moved outwards, and the driven block is driven till being in tight fit with the part.

Owner:AECC AERO SCI & TECH CO LTD

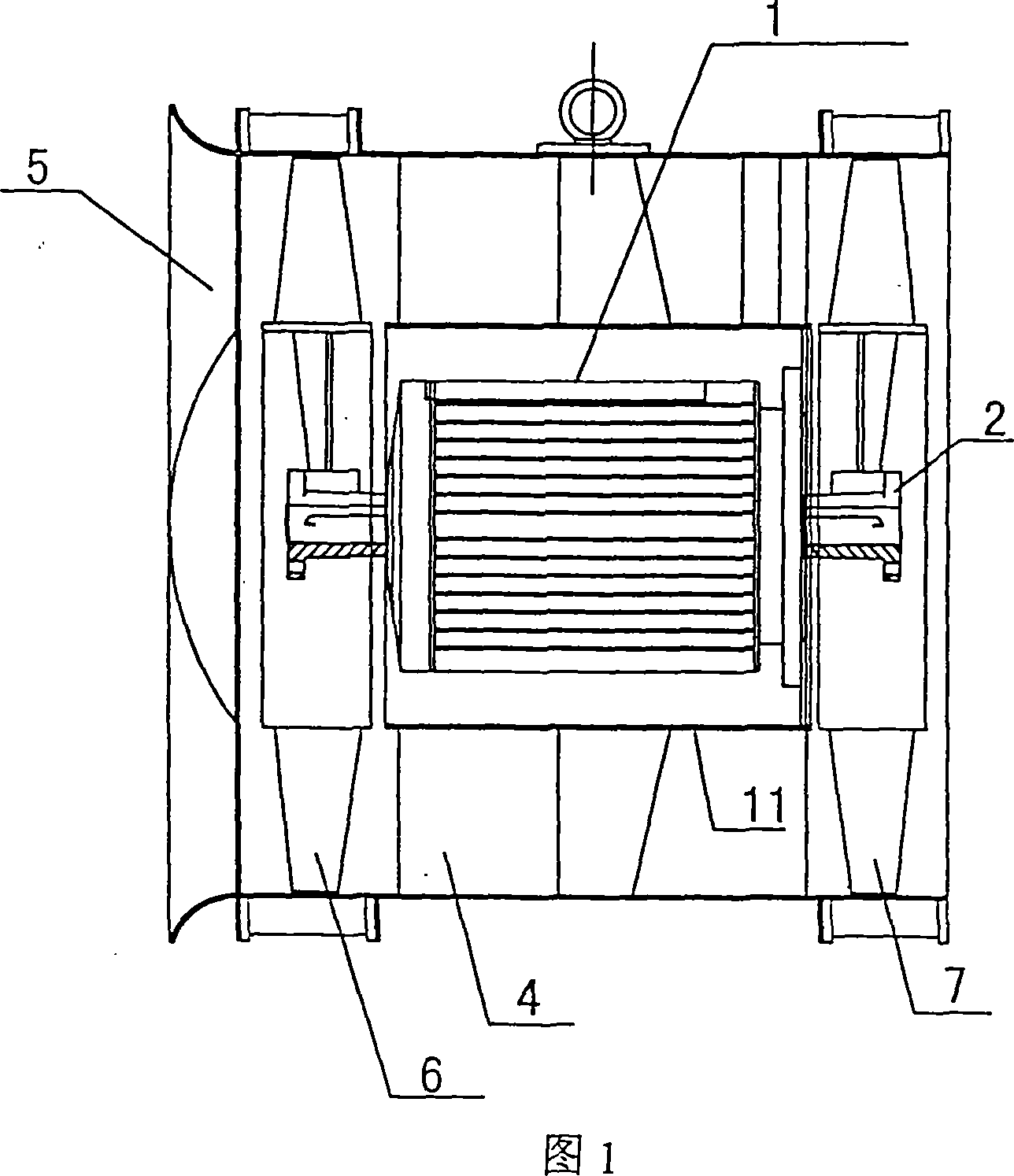

Couple-stage axial-flow fans

InactiveCN101033752AImprove assembly accuracyEliminate pollutionPump componentsPump installationsImpellerSelf locking

The invention is a twin-stage axial flow blower. It is characterized in that cone axile bush fixed on the two terminals of two-axle electric engine. Cooling pipe in cooling device installed between external and middle tube. One end of the pipe connects to exotic environment of electric engine in middle tube. Static guide blade fixed behind primary impeller. Current collector fixed in front of primary impeller which connects to one end of two-axle electric engine. Diode impeller connects to the other end of the engine. Stayed plate fixed between external and middle tube. Footing installed on the bottom of external tube. Because of the self-locking of cone axile bush, it can axial lock impeller and axle of electric engine effective. It can confirm concentricity of axial direction and make installment and disassembling convenience, increase assembled accuracy. Suction pressure gas flow created by revolution of diode impeller can achieve effectiveness. It has characteristics of simple structure, proper design, steady performance, low cost, denoise, and energy-saving etc.

Owner:陈泽民

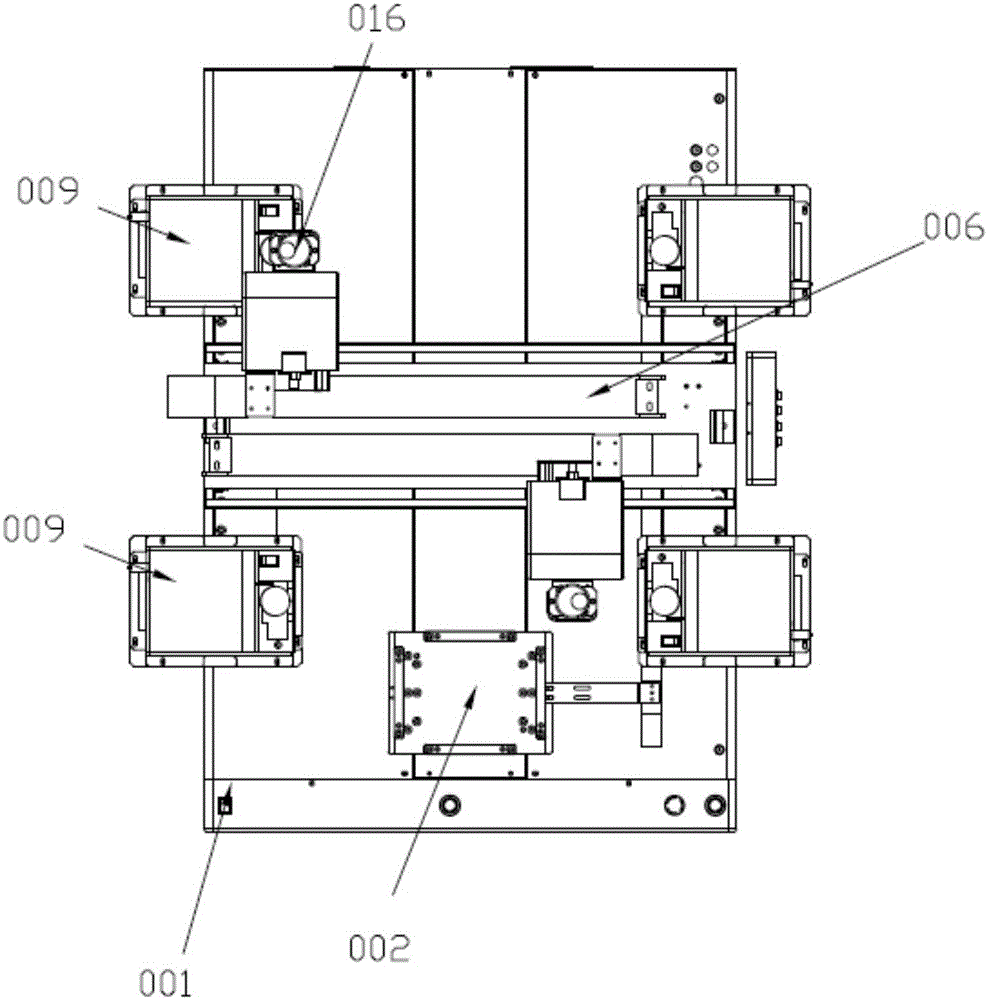

Automatic screw-driving machine with double electric screwdrivers and multiple feeders

InactiveCN105127730AImprove work efficiencyImprove assembly accuracyMetal working apparatusControl systemLocking mechanism

The invention discloses an automatic screw-driving machine with double electric screwdrivers and multiple feeders. The automatic screw-driving machine comprises a machine base; a Y-axis moving mechanism is arranged in the middle of the machine base and provided with two sets of clamps; a cross beam is arranged on the machine base and located above the middle of the Y-axis moving mechanism; at least two sets of symmetrical screw feeding mechanisms are arranged on the left and right sides of each of the head end and the tail end of the Y-axis moving mechanism; an X-axis moving mechanism is arranged on the cross beam, and two sets of locking mechanisms are arranged on the front and rear sides of the X-axis moving mechanism and are oppositely arranged; each set of locking mechanism comprises a locking fixing seat connected with the X-axis moving mechanism, and a Z-axis moving mechanism is arranged on each locking fixing seat and sequentially connected with a flexible device, one electric screwdriver, a screwdriver head and a suction nozzle component; a handheld type operation control system is arranged on one side of the cross beam. According to the automatic screw-driving machine, manual operation is replaced with an automatic mode, so that the work efficiency is improved, the production cost is lowered, operation is reliable, and the assembling precision is high.

Owner:NEW ROAD MARK AUTOMATION TECH

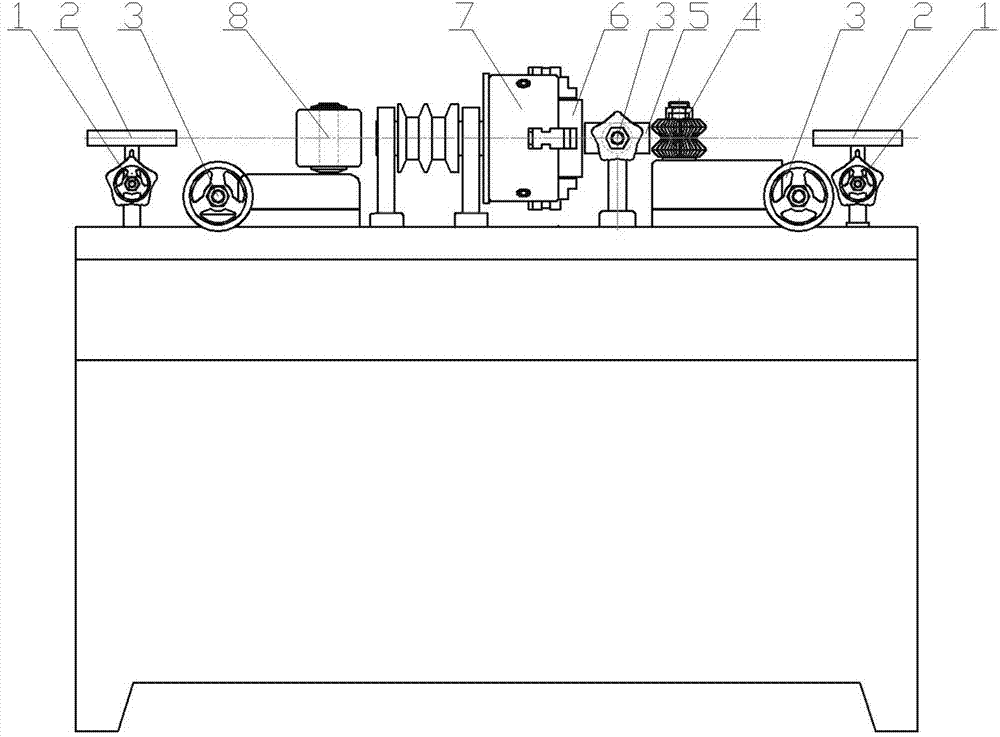

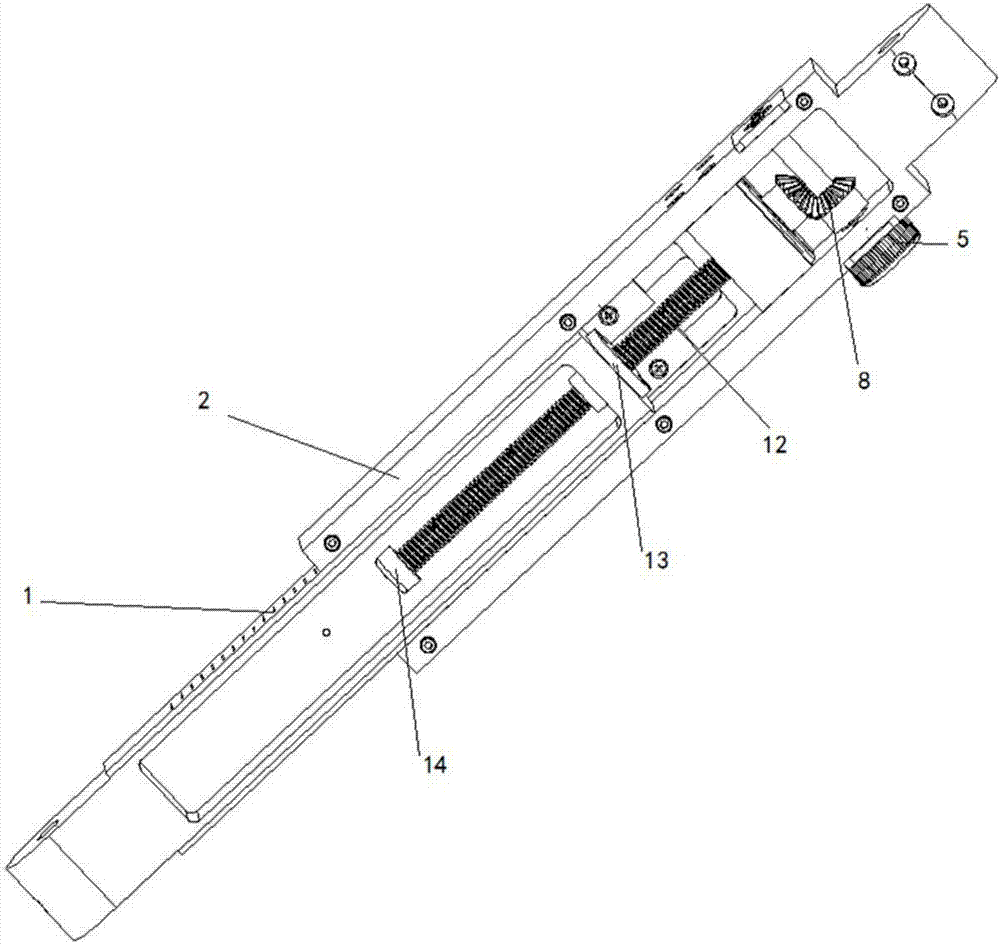

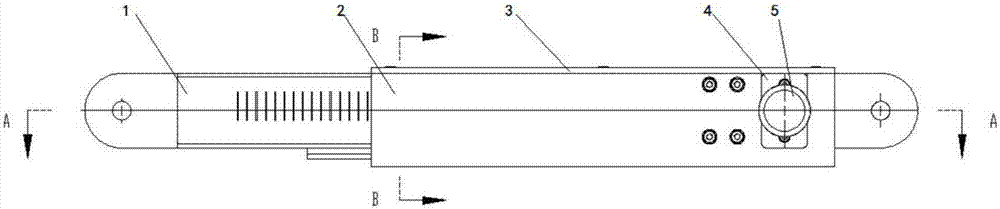

Stepless adjusting device applicable to lengths of four limbs of rehabilitation robot

PendingCN107361996AEfficient regulationMeet comfortGymnastic exercisingChiropractic devicesEngineeringBevel gear

The invention discloses a stepless adjusting device applicable to the lengths of four limbs of a rehabilitation robot. The stepless adjusting device comprises a fixed rod, a slide rod and a stepless adjusting mechanism. The stepless adjusting mechanism comprises a bevel gear shaft system and a lead screw pair transmission shaft system. The bevel gear shaft system comprises a bevel gear shaft and two meshing bevel gears. One end of each bevel gear is mounted in a groove, the other end of each bevel gear extends out of the fixed rod, and rotary operation portions are formed at the other ends of the bevel gears. One of the bevel gears is coaxially fixed to the bevel gear shaft and can be driven by the bevel gear shaft to rotate. The lead screw pair transmission shaft system comprises a lead screw shaft, a lead screw deep groove ball bearing and a nut. One end of the lead screw shaft is coaxially fixed to the other bevel gear, the other end of the lead screw shaft is screwed with the nut and extends into the slide rod via the nut. The lead screw deep groove ball bearing is matched with the lead screw shaft and is mounted between the inner side walls of the grooves and the lead screw shaft. Rotary force of the operation portions of the bevel gear shaft can be transmitted onto the lead screw shaft by the aid of meshing of the two bevel gears, and the nut can be ultimately driven to drive the slide rod to move relative to the fixed rod.

Owner:合肥哈工力训智能科技有限公司

Seamless vacuum cup and machining method thereof

InactiveCN106136769AUniform mouth thicknessImprove sealing performanceDrinking vesselsArc weldingMaterials science

The invention discloses a seamless vacuum cup and a machining method thereof. The machining method comprises the following steps: bending the upper end of an opening part of a stainless steel liner to the outer side to form a folding part; feeding the stainless steel liner into a stainless steel shell and sleeving the outer side of a drooping edge of the folding part on the upper end part of the opening part of the stainless steel shell; fusing and welding the end of the upper end part and a bent corner of the upper end of the drooping edge to form a whole body by argon-arc welding; and a polishing treatment step: carrying out polishing treatment on the outer surface of a welding part. The seamless vacuum cup machined by the method comprises a cup body and a cup cover, wherein the folding part which is bent toward the outer side is formed at the upper end part of the opening part of the stainless steel liner and the drooping edge of the folding part sleeves the upper end part of the opening part of the stainless steel shell; and the end of the upper end part and the bent corner of the upper end of the drooping edge are welded through the argon-arc welding to form an integrated structure. With the adoption of the seamless vacuum cup and the machining method thereof, the technical difficulty of seamless connection of the shell and the liner of the vacuum cup is solved, the sealing property and the whole intensity of the vacuum cup are improved, and the welding is more convenient and efficient.

Owner:ZHEJIANG HAERS VACUUM CONTAINERS CO LTD

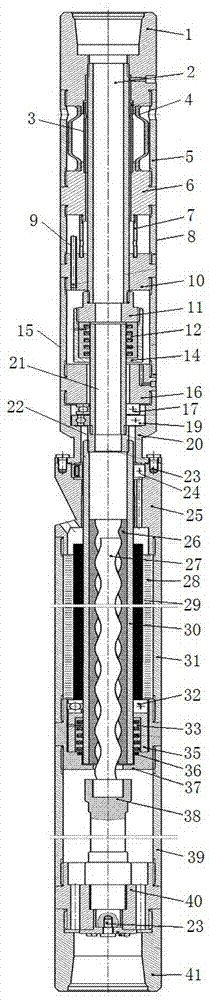

Efficient positive displacement motor drill under well

An efficient positive displacement motor under a well comprises a bypass valve assembly, a falling prevention joint, a motor joint, a universal joint assembly and a bearing joint assembly. The efficient positive displacement motor under the well is simple in structure, convenient to use, stable in operation under the well, safe, reliable, high in complete machine efficiency, capable of outputting larger torque, long in working time and service life, suitable for drilling needs of various complex wells at the present, free of piercing leakage and high in working reliability. A streamlined flow channel enables water conservancy losses of a main flow channel to be reduced, turn-off force is large, the defects of the interference effect and tooth form distortion of the conjugation curvature of a traditional single-screw machine type positive displacement motor are overcome, a universal shaft operates flexibly, energy efficiency is high, the universal shaft can work in the environments where no sand grain exists, and drilling fluid erosion exists, the service life is long, and mechanism strength is high.

Owner:QINGDAO JINJIANGYUAN IND EQUIP CO LTD

Foreskin cutting and sewing device

ActiveCN102217969BGuaranteed concentricityGuaranteed suture effectSurgical staplesForeskinEngineering

The invention relates to a foreskin cutting and sewing device, belonging to the technical field of medical and surgical instruments. The foreskin cutting and sewing device comprises a pair of handle valves, a balance shifter, a scalpel shell provided with a shell cavity, a scalpel push disk provided with a scalpel cavity, a cover-type cutting scalpel, a balanus cap provided with a balanus cavity,and a nail cabin. The foreskin cutting and sewing device is characterized in that one end of the inside of the shell cavity of the scalpel shell, which faces the balance shifter, is provided with a shifting bar sleeve; a plurality of guide vanes are formed between the outer wall of the shifting bar sleeve and the inner wall of the shell cavity; a scalpel push shaft of the scalpel push disk is circumferentially provided with a plurality of guide vane guide grooves; a shifting bar seat cavity is formed in the cutting scalpel cavity of the scalpel push disk; a plurality of guide rib guide grooves are formed on the wall of the shifting bar seat cavity; a plurality of guide ribs are formed on the outer wall of the shifting bar seat; a shifting bar penetrates through the shifting bar sleeve; and the balance shifter is matched with the shifting bar sleeve in the position corresponding to a shifter matching cavity. The foreskin cutting and sewing device can ensure the concentricity of the balanus cap, scalpel push disk and scalpel shell, thereby ensuring the sewing effect of the surgical wound.

Owner:常熟市亨利医疗器械有限公司

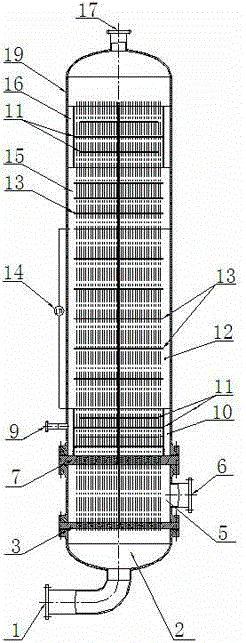

Straight-flow steam generator

InactiveCN102721031ARaise the outlet temperatureReasonable designSteam generation using hot heat carriersForced-flow steam boilerEngineeringHigh heat

The invention discloses a straight-flow steam generator which comprises a shell and a plurality of heat exchange tubes. The shell is sequentially divided into an oil inlet chamber, an oil outlet chamber, a preheating chamber, an evaporating chamber, a dehumidifying chamber and an overheating chamber from bottom to top, a heat transfer oil inlet is arranged on the oil inlet chamber, an inner tube plate is arranged between the oil inlet chamber and the oil outlet chamber, a heat transfer oil outlet is arranged on the oil outlet chamber, an outer tube plate is arranged between the oil outlet chamber and the preheating chamber, a feed-water inlet is arranged on the preheating chamber, a steam outlet is arranged on the overheating chamber, each heat exchange tube comprises an inner tube and an outer tube, the bottom end of each inner tube extends into the oil inlet chamber and is fixed onto the inner tube plate, the top end of each inner tube extends to the upper portion of the corresponding outer tube, the bottom end of each outer tube extends to the oil outlet chamber and is fixed onto the outer tube plate, the top end of each outer tube is provided with a closed structure and extends to the overheating chamber, and each inner tube and the corresponding outer tube form an interlayer structure. The straight-flow steam generator effectively solves the problem of poor heat expansion, and has the advantages of stability, reliability, safety, high heat exchange efficiency and the like.

Owner:DONGFANG TURBINE CO LTD

Concave-convex annular spacing sealing structure with flanges

The invention discloses a concave-convex annular sealing structure with flanges, which comprises two pipe ends, two flanges sleeved on the pipe ends, sealing pieces and fasteners, wherein each flange comprises an inner end surface and a through hole. The sealing structure is characterized in that an inner concave part is arranged on the inner end surface of each flange in a position near the periphery of the through hole; the sealing pieces are two composite linings arranged in the inner concave parts and embedded in the pipe ends, and can be in tight contact with each other after the flanges are fastened through the fasteners; and at least one convex sealing ring is arranged on one of the contact surfaces of the sealing pieces. The sealing structure has the benefit effects that the concentricity of connected pipelines can be guaranteed; the composite linings can not protrude radially due to over extrusion; and the sealing effect can be achieved on the condition that no shear stress is generated.

Owner:江苏吉星管业科技有限公司

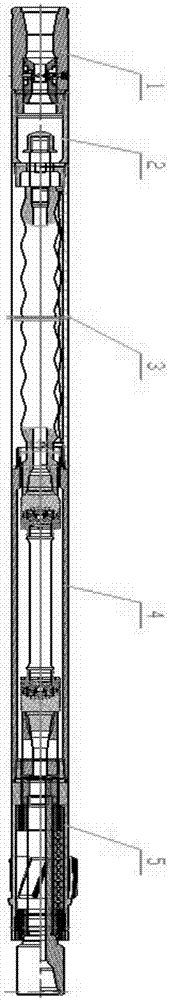

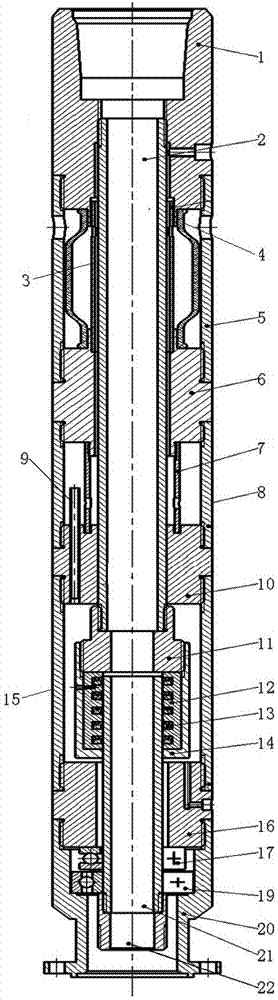

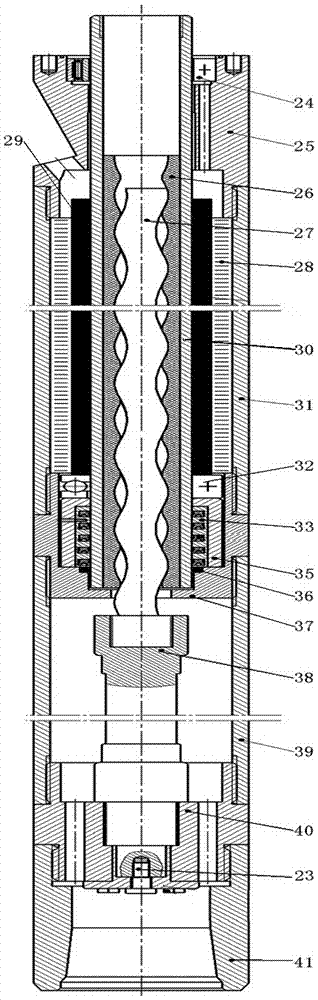

Integral submersible direct-driven screw pump

ActiveCN107461333AImprove adaptabilityShorten the lengthFluid removalRotary piston pumpsInterference fitBall bearing

The invention relates to an integral submersible direct-driven screw pump. The integral submersible direct-driven screw pump comprises a protector, a submersible motor and a screw pump; an oil transmission sleeve I and an oil transmission sleeve II are arranged in the protector; the upper end of the oil transmission sleeve I is connected with an oil pipe upper coupling; a base of the protector is fixedly connected with a motor upper joint of the submersible motor; the oil transmission sleeve II of the protector is connected with a motor rotor of the submersible motor; the motor rotor is a hollow pipe; a permanent magnet fixedly sleeves the motor rotor; a motor stator is arranged on the outer layer of the permanent magnet; a second thrust ball bearing is arranged between the permanent magnet and a second sealing base; a rubber bushing is arranged in the motor rotor; a screw rod and the rubber bushing are in interference fit; the motor rotor is a screw pump body; the screw rod is fixed on an oil inlet base through a flexible shaft; an oil inlet hole is formed in the oil inlet base; and the oil inlet base is connected with a pump body lower coupling. The submersible motor and the screw pump adopt the embedded design to realize motor-pump integration, so that the total length is greatly reduced, and the well type adaptability is improved.

Owner:NORTHEAST GASOLINEEUM UNIV

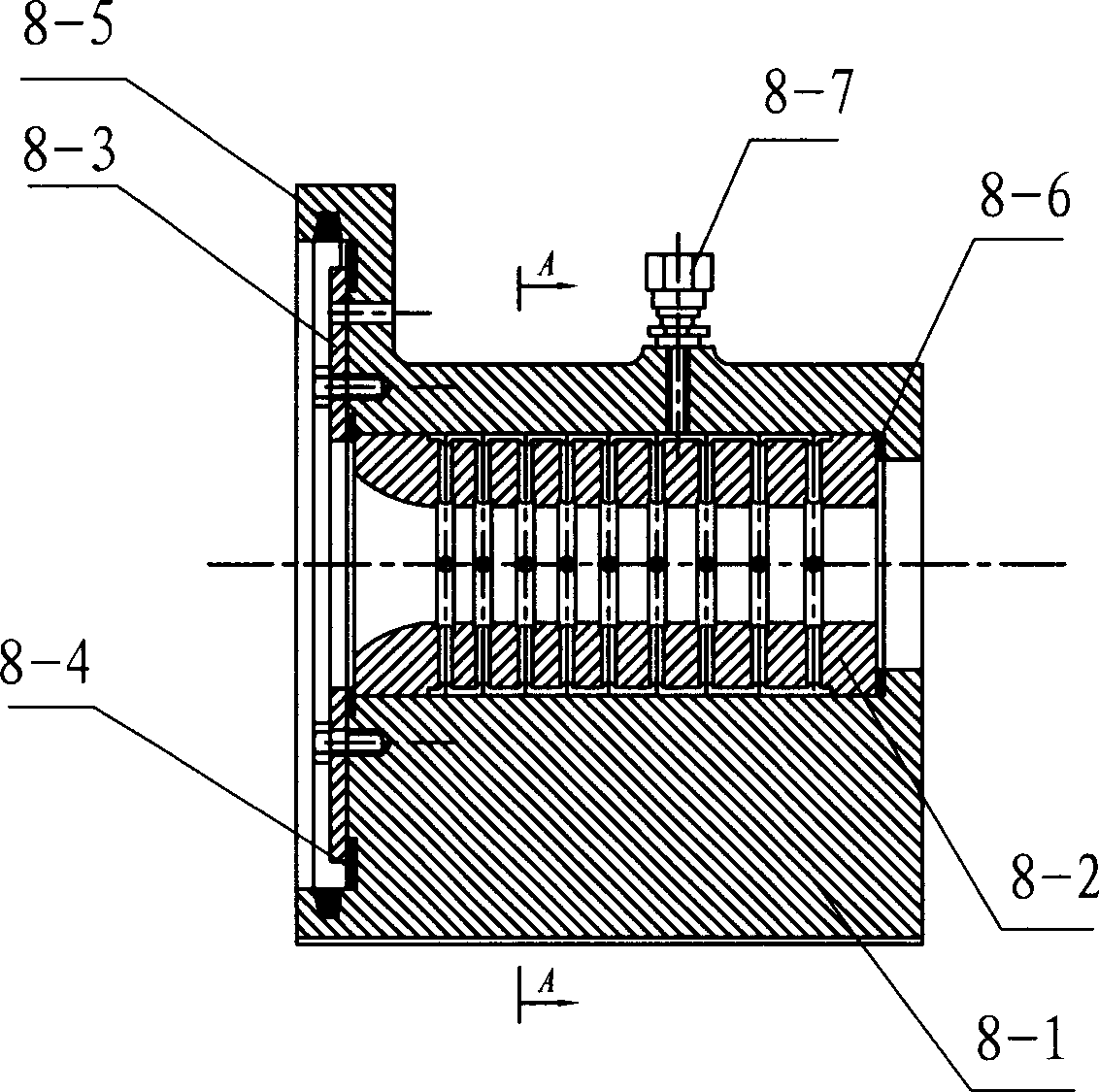

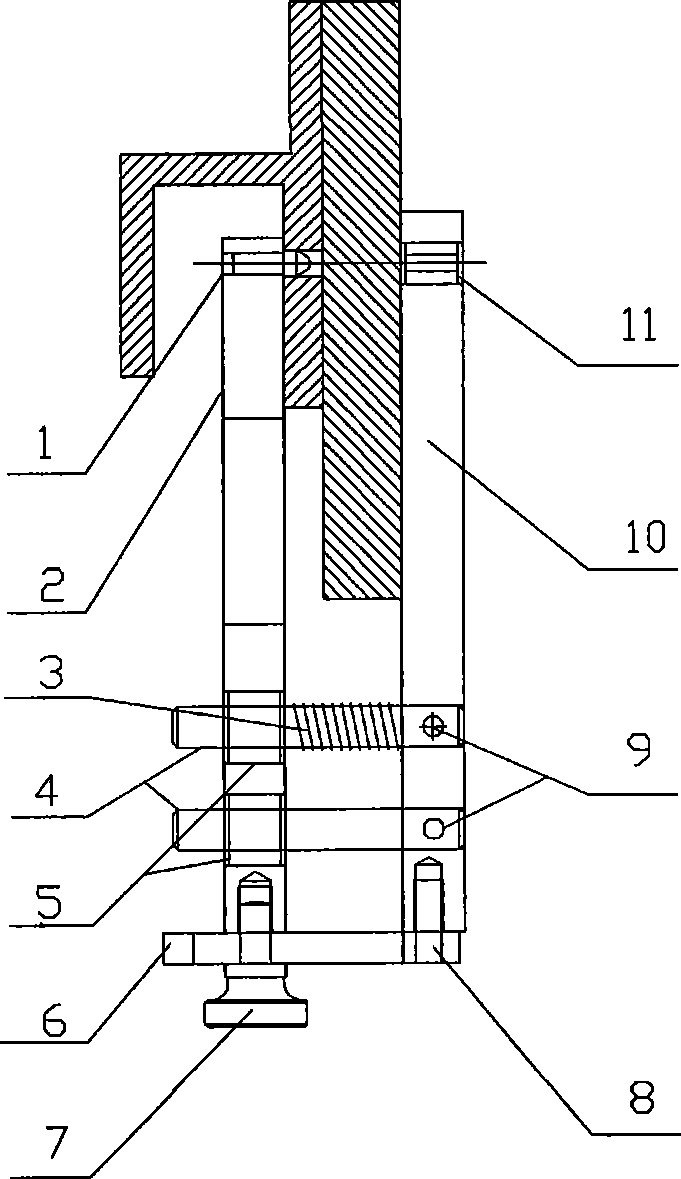

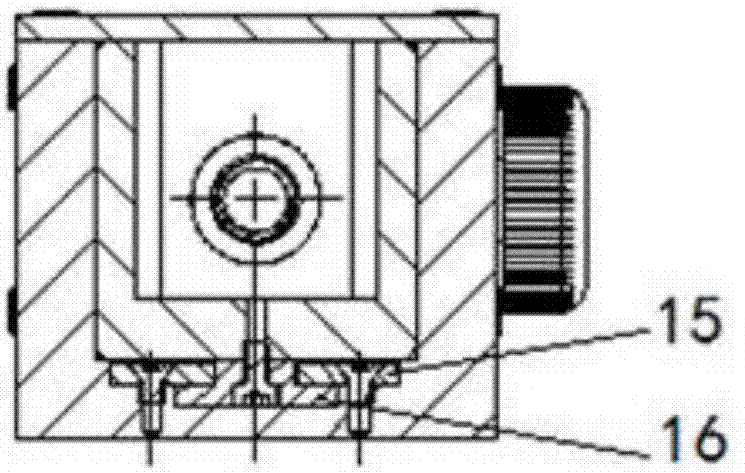

Novel proportion electromagnet

ActiveCN103700464AReduce scrap rateReduce fit sizeElectromagnets with armaturesEngineeringMechanical engineering

The invention provides a novel proportion electromagnet and belongs to the technical field of electromagnets. The electromagnet solves the problem that the existing proportion electromagnet is unreasonable in design and cannot ensure concentricity of two bearings arranged at two ends of a push rod. The novel proportion electromagnet comprises a casing with a first inner cavity and a second inner cavity. A magnetic core pipe, a coil assembly and a first sealing ring are arranged in the first inner cavity, an output through hole and a containing cavity are formed in the magnetic core pipe, an armature assembly formed by an armature and a push rod is installed in the containing cavity, a first bearing is sleeved at one end of the push rod, a self-lubricating bearing coaxial with the push rod is sleeved at the other end, a bearing seat for installing the self-lubricating bearing is connected onto one end of the containing cavity close to the second inner cavity in a sealing mode, and the push rod sequentially penetrates the first bearing, the armature and the self-lubricating bearing and partially stretches into the second inner cavity. The proportion electromagnet has the advantages of being reasonable in design, reducing matched size between parts and being capable of ensuring the concentricity of the two bearings arranged at two ends of the push rod.

Owner:NINGBO HOYEA MACHINERY MFG

Epoxy-pouring full-insulation solid isolating switch

ActiveCN101620947AUnaffected by the surrounding environmentImprove electricity safetySwitches with movable electrical contactsEpoxyGround contact

The invention relates to an epoxy-pouring full-insulation solid isolating switch, which comprises an isolation body, a grounded contact, an isolation contact, a middle contact, an isolation moving contact, a driving screw rod, a fixed nut and a driving gear part, wherein the grounded contact and the isolation contact are arranged at two ends of the isolation body respectively, the middle part of the isolation body is provided with the middle contact, the upper end of the isolation contact is connected with a bus contact through a bus-bar, the bus contact is arranged on the top of the isolation body, and the isolation moving contact is always contacted with the middle contact through a watch chain sensing finger. The isolation switch slides between two positions of the middle contact and the isolation contact or the middle contact and the grounded contact to form the conduction or the isolation grounding of the isolating switch. The entire isolating switch is poured into a fully-sealed integral structure with epoxy resin.

Owner:SHENYANG HAOCHENG ELECTRICAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com