Patents

Literature

43results about How to "Achieve self-centeredness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

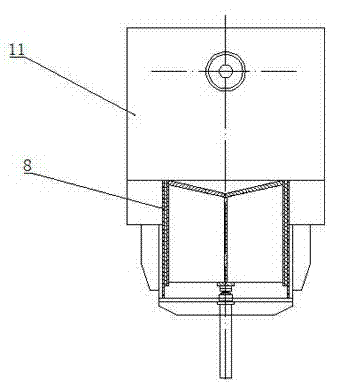

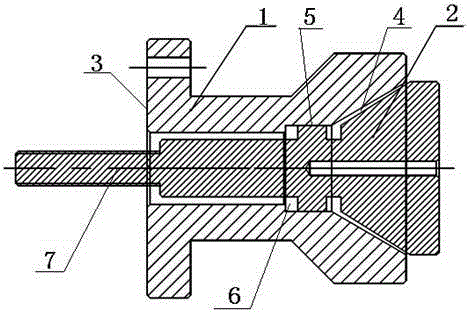

Self-centering fixture

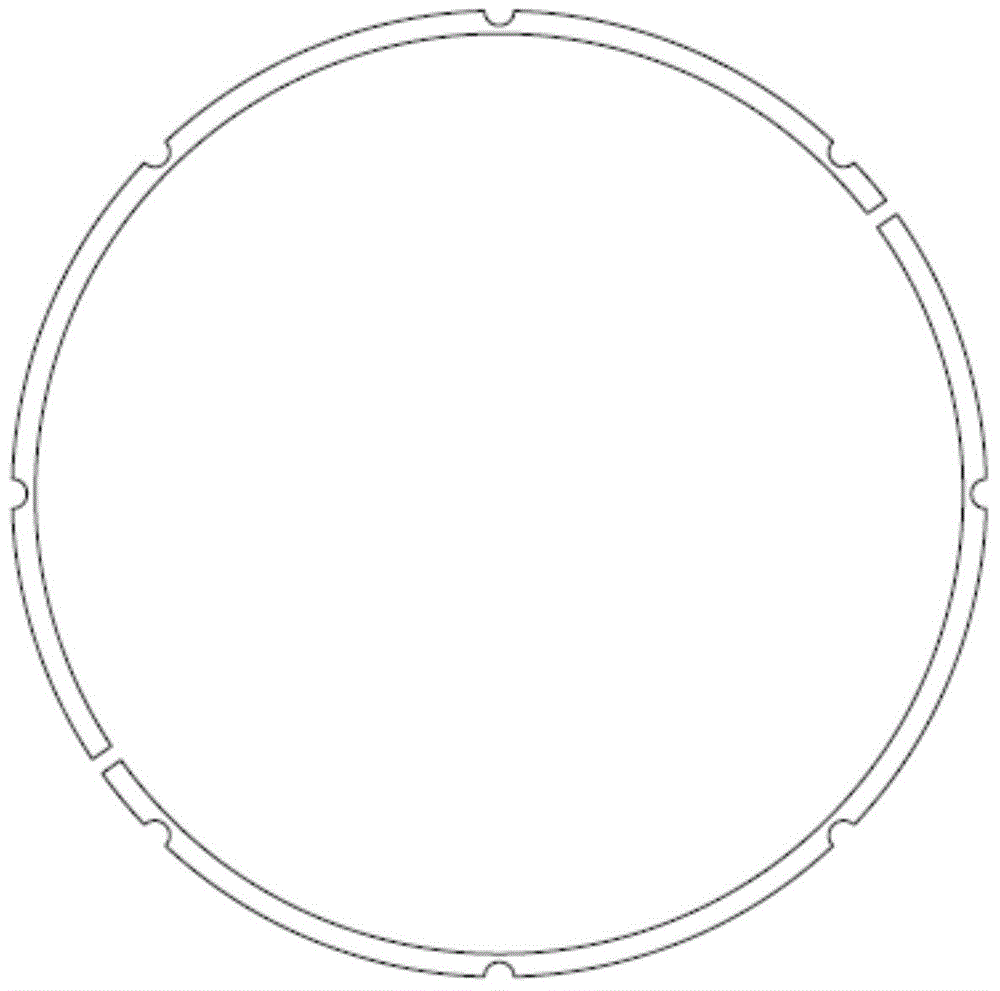

InactiveCN102357826AEasy loading and unloadingGuaranteed concentricityPositioning apparatusMetal-working holdersExpansion jointCentring

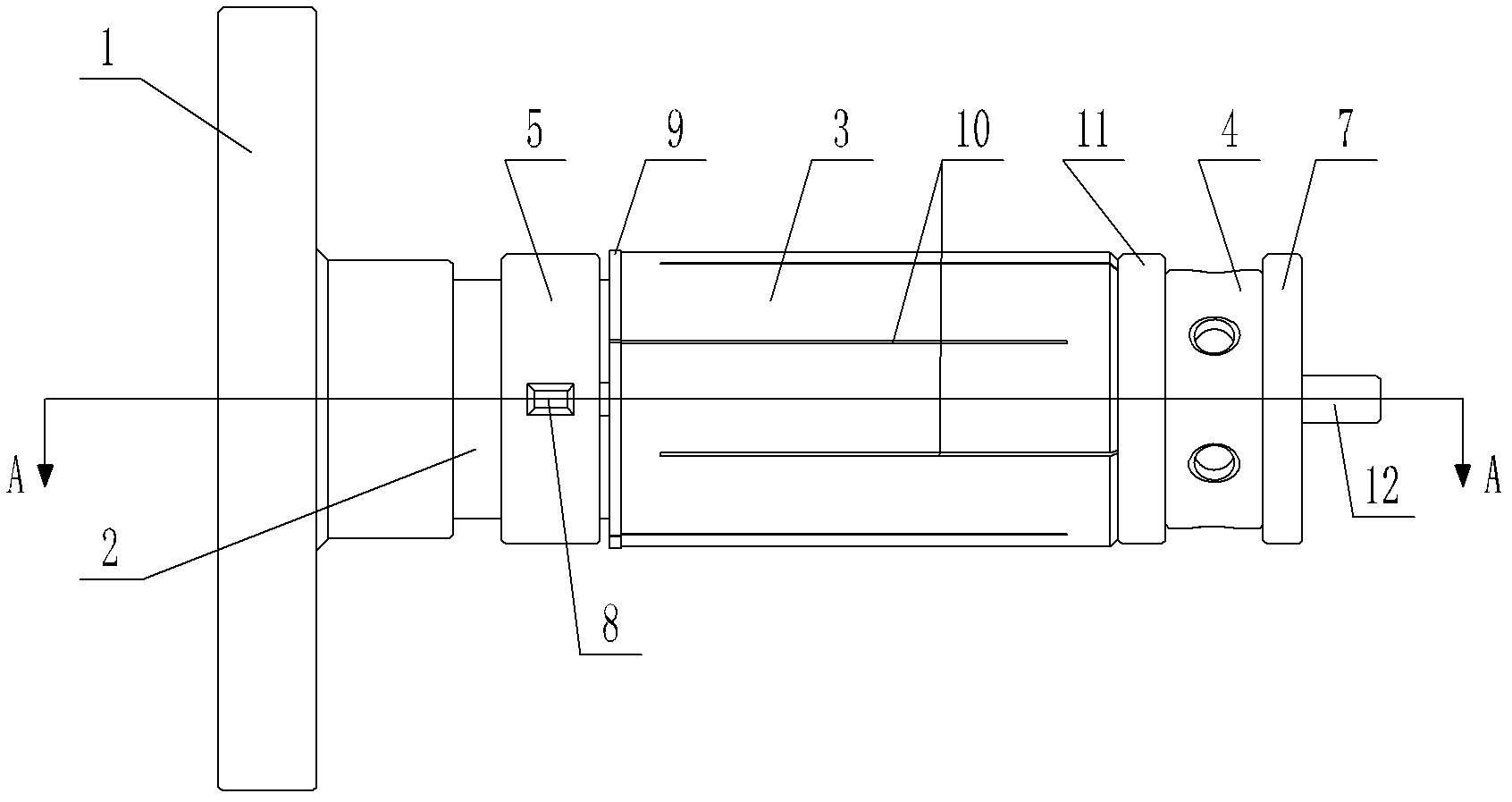

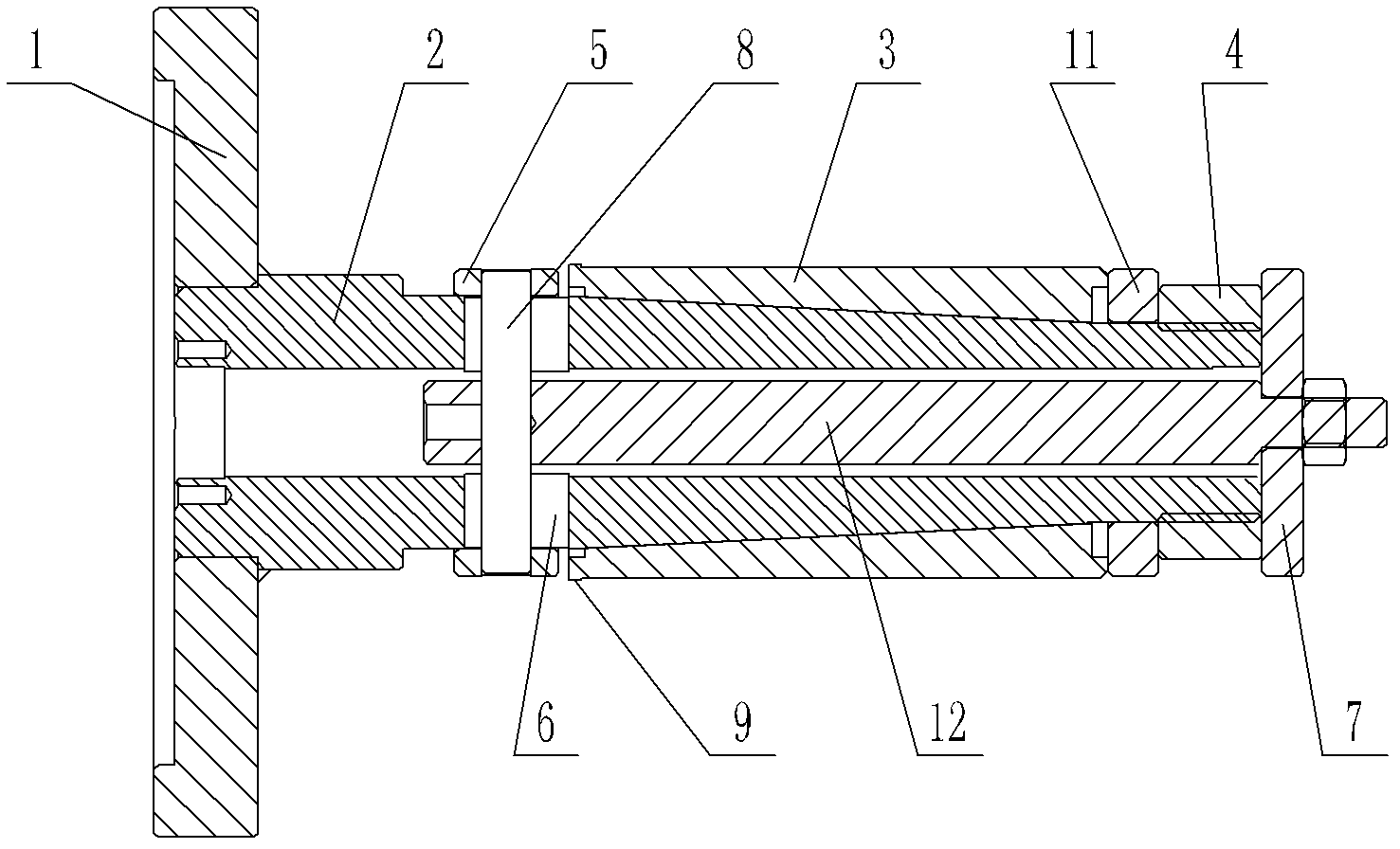

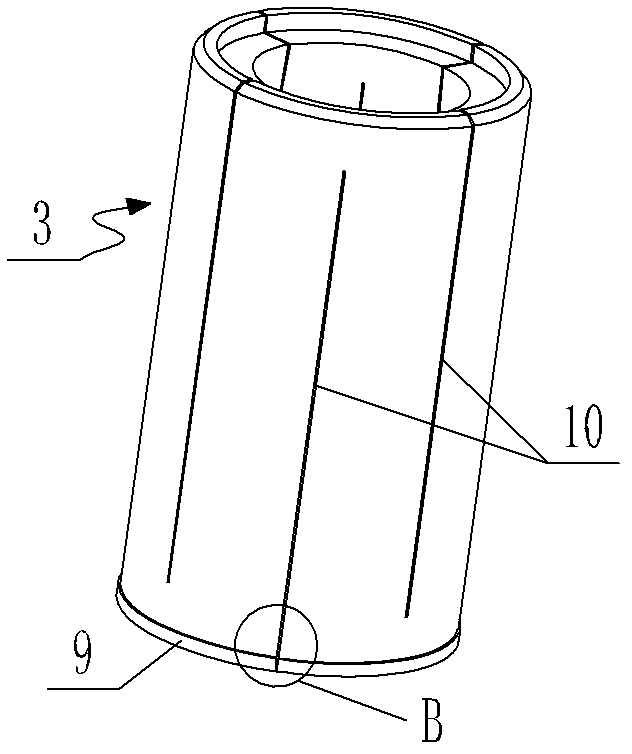

The invention discloses a self-centering fixture which comprises a mandrel and an expansion sleeve, wherein the mandrel is mounted on a machine tool through a flange; the expansion sleeve is sleeved on the outer circumference of the mandrel and can move axially; multiple expansion joints are arranged on the outer wall of the expansion sleeve; the outer wall of the mandrel and the inner wall of the expansion sleeve are matched conical surfaces; the mandrel is provided with an adjusting nut for driving the expansion sleeve to move along the mandrel; a pull rod and a stop ring are arranged between the mandrel and the expansion sleeve to pull the expanded sleeve to a shrinkage end; and through the expansion and shrinkage of the expansion joints, the outer diameter is controlled to increase / reduce so as to position / dismantle a workpiece. The fixture has a simple structure, is convenient to use and can realize self centering; and moreover, the processing accuracy of the workpiece is improved, the concentricity and verticality between the processed surface and an inner hole of the workpiece can be ensured, and the fixture deserves popularization and application in the fields realizing positioning and clamping by use of the inner hole of the workpiece.

Owner:JIANGSU FULIHUA GENERAL EQUIP

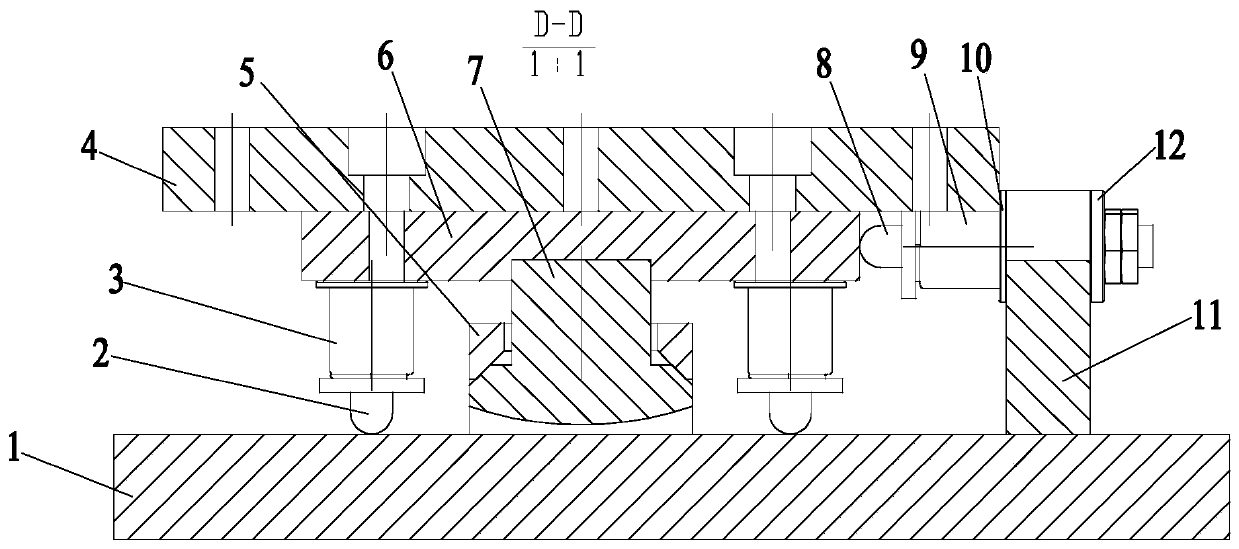

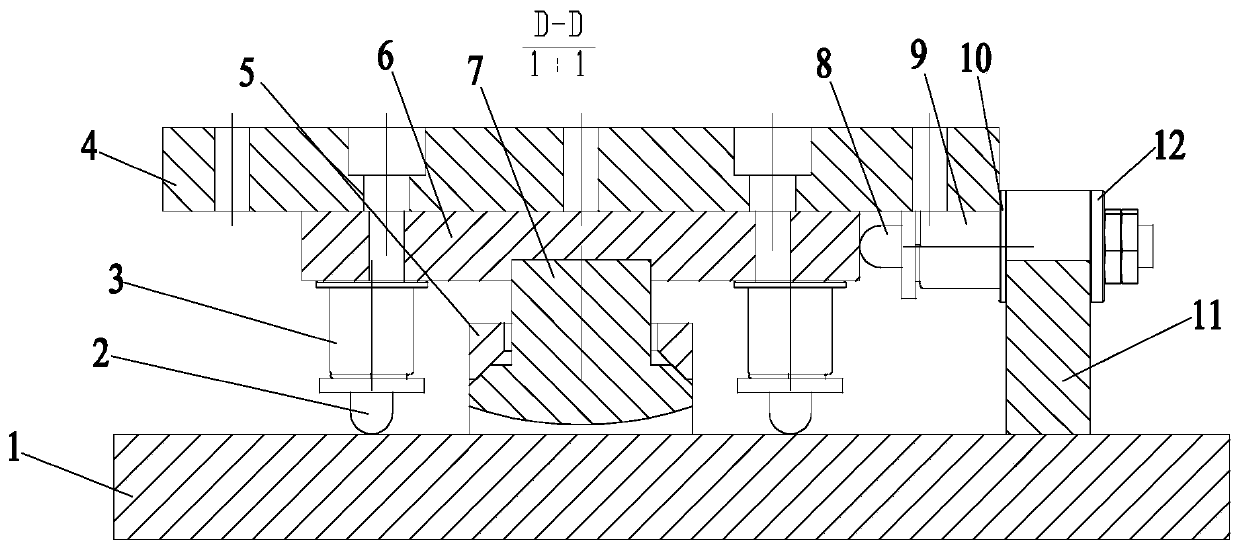

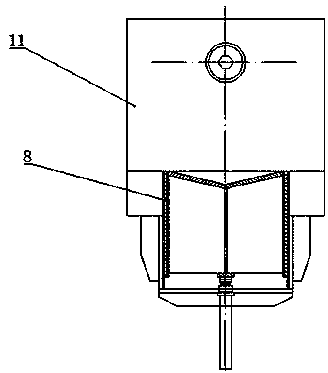

Self-centering clamp for thin-walled part

InactiveCN104858694AEasy loading and unloadingLoading and unloadingWorkpiecesBoring/drilling apparatusEngineeringMachining process

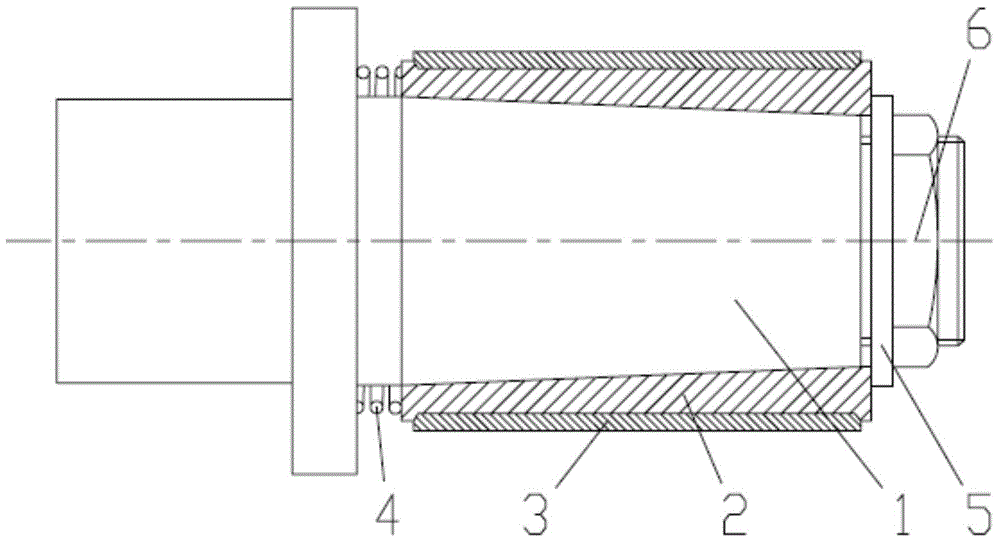

The invention relates to a self-centering clamp for a thin-walled part. The self-centering clamp comprises a mandrel, an expanding sleeve, an adjusting nut and a retaining ring, wherein the mandrel adopts a conical body; the inner wall of the expanding sleeve adopts a conical surface matched with the outer wall of the mandrel, and the outer wall of the expanding sleeve is a cylindrical surface; the expanding sleeve is matched and connected with the conical body of the mandrel through the conical surface of the inner wall; the front end of the expanding sleeve is connected with the step end surface at the rear end of the mandrel through a spring; the rear end of the expanding sleeve is contacted and connected with the adjusting nut through the retaining ring, and the adjusting nut is screwed at the threaded end of the mandrel; the expanding sleeve is sleeved with a flexible positioning sleeve. The self-centering clamp for the thin-walled part is simple in structure, workpieces are convenient to load and unload, self-centering can be realized, particularly, after the flexible positioning sleeve is used, the deformation of the thin-walled part is small in the machining process of clamping the thin-walled part, the machining precision is improved, and the coaxiality and the perpendicularity of the machined thin-walled part can be guaranteed; the expanding sleeve is loosened by the spring, so that the part is convenient to load, unload and machine.

Owner:张鸿来

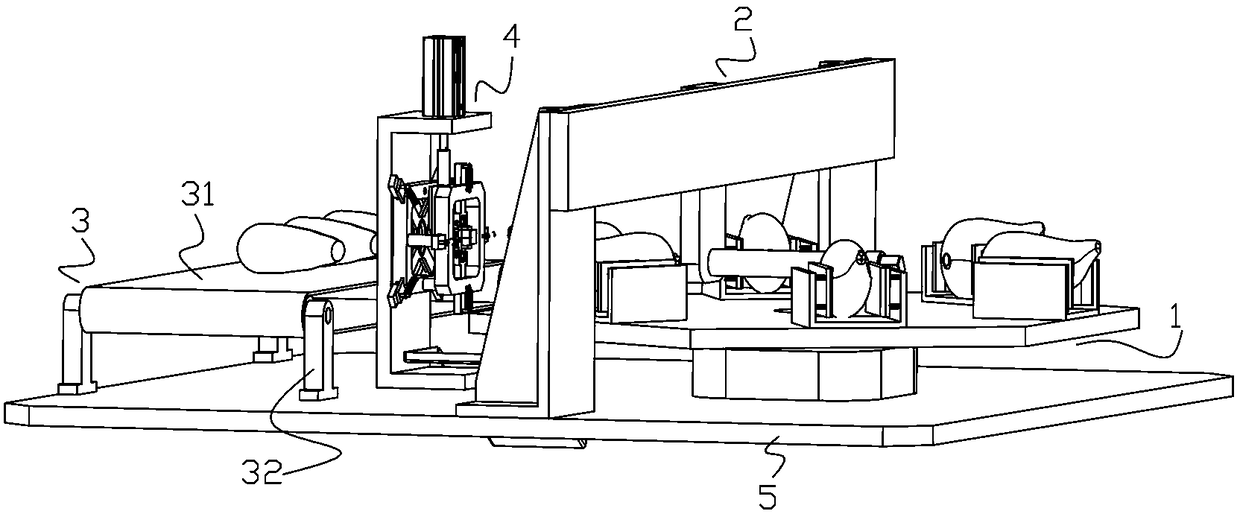

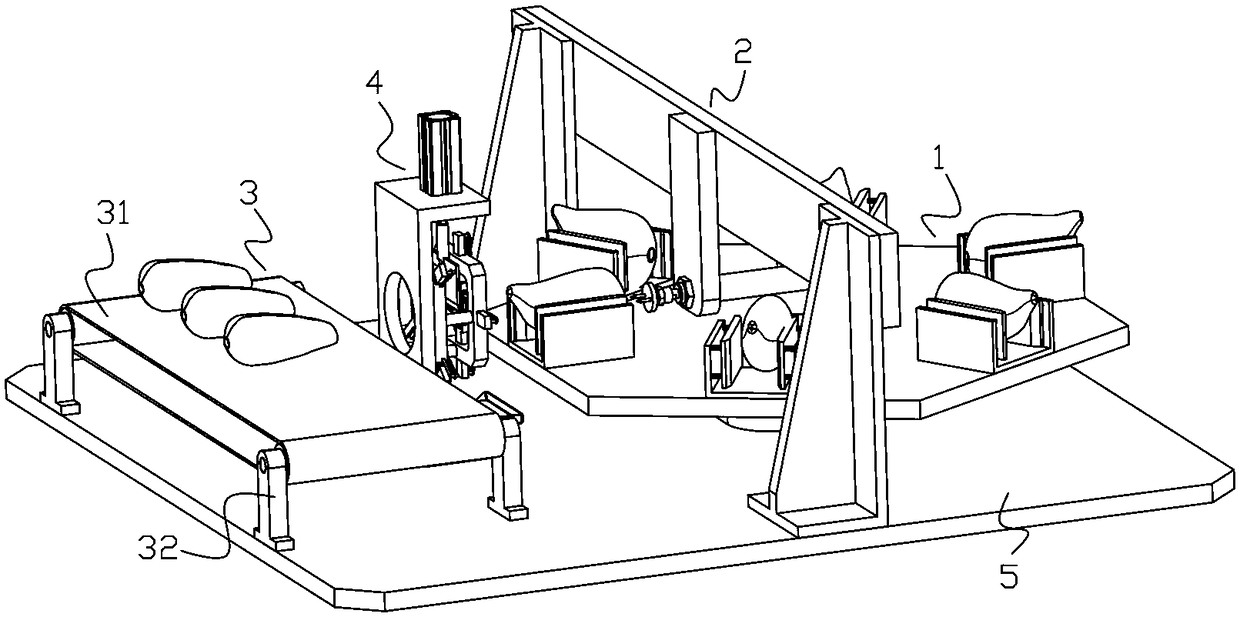

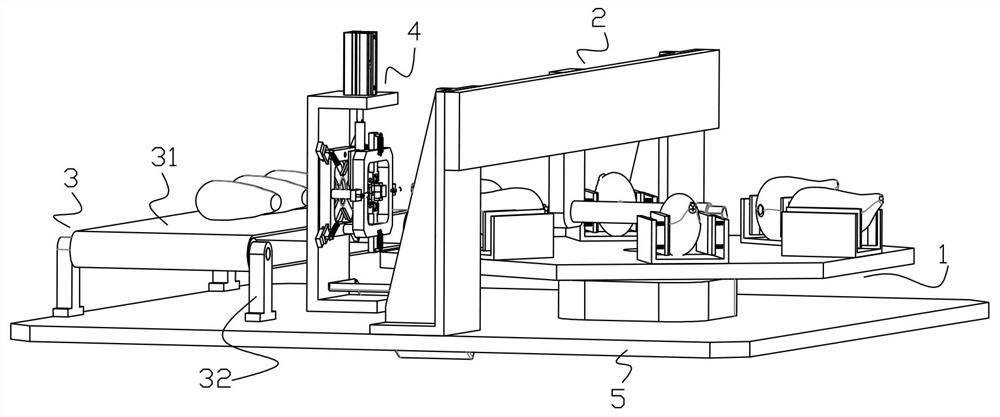

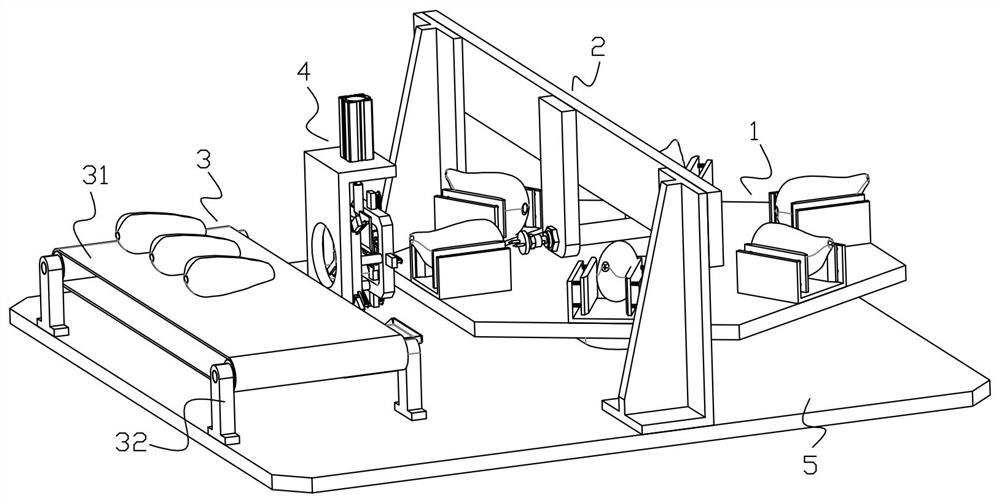

Self-centering wear-free barrel rotating device

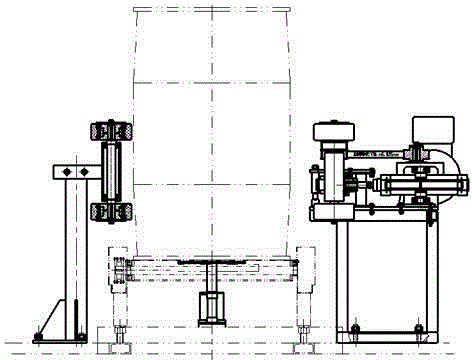

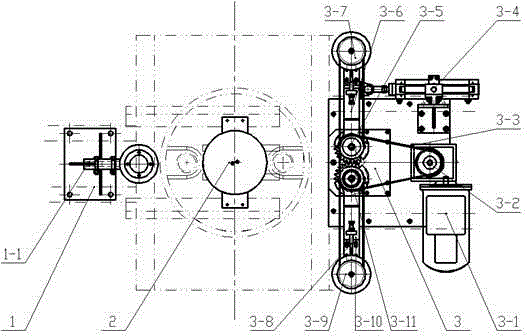

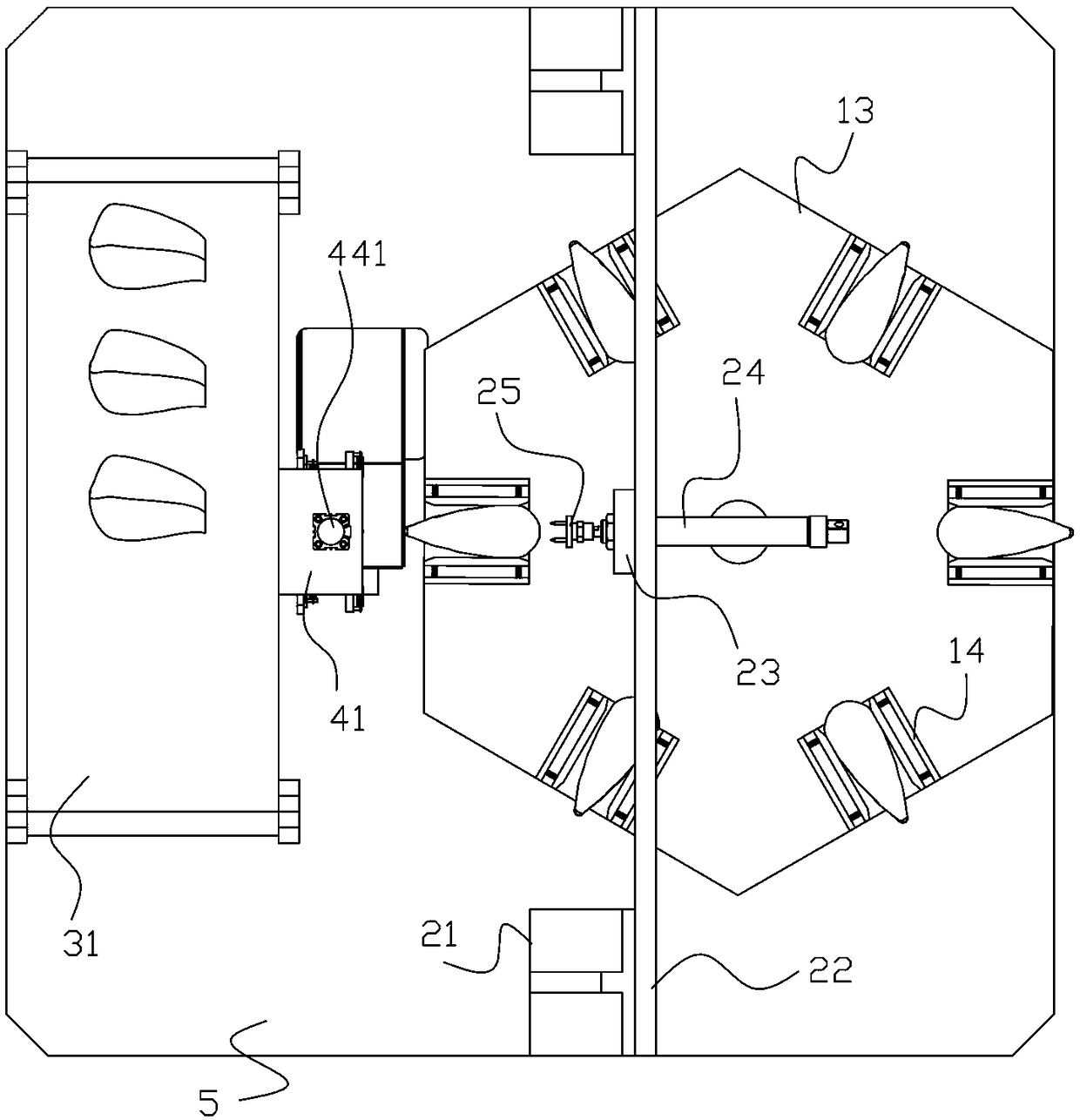

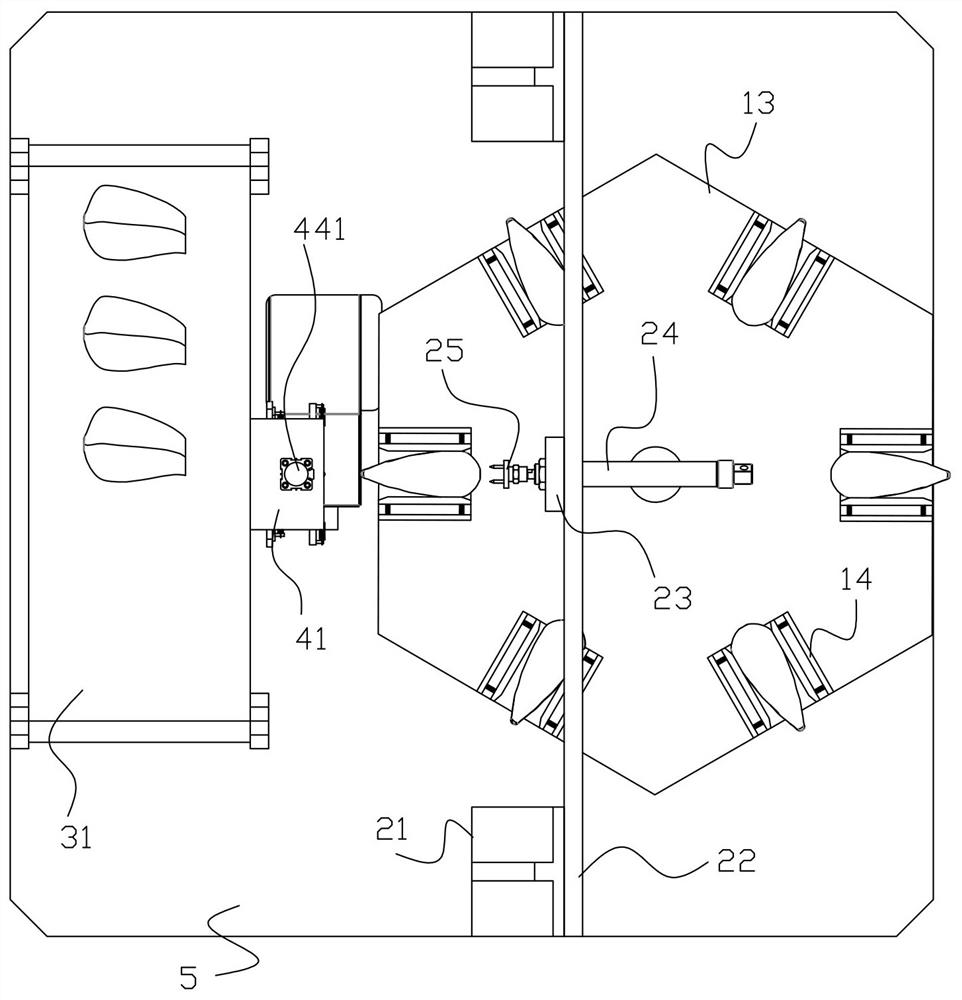

ActiveCN105800539AAchieve self-centerednessPrecise positioningBarrels/casks fillingTransport systemEngineering

The invention discloses a self-centering wear-free barrel rotating device and a barrel rotating method thereof. The device comprises a positioning mechanism, a barrel jacking mechanism and a driving mechanism, wherein the positioning mechanism comprises a positioning support and a free gear train; the barrel jacking mechanism is arranged below a conveying system and comprises a guiding seat and a rotating disc; and the barrel rotating mechanism comprises a power mechanism and a rotating seat. The method comprises the following steps: the barrel jacking mechanism 2 elevates through pushing the rotating disc by a cylinder when a material barrel arrives an assigned position in order to jack the material barrel; two rotating arms in the barrel rotating mechanism rotate with two gears as circular centers, and tightly hold the material barrel when a cylinder baffle stroke reaches a maximum value; and rollers in the barrel rotating mechanism rotate to drive the material barrel to rotate in order to align at the mouth of the barrel. The self-centering wear-free barrel rotating device has the advantages of high positioning precision, energy saving, and avoiding of the environment pollution problem caused by material barrel skin damages or deformation in the transportation process due to material barrel deformation caused by bumping of the barrel in the positioning and barrel rotating process.

Owner:CHANGCHUN BEIFANG INSTR EQUIP +1

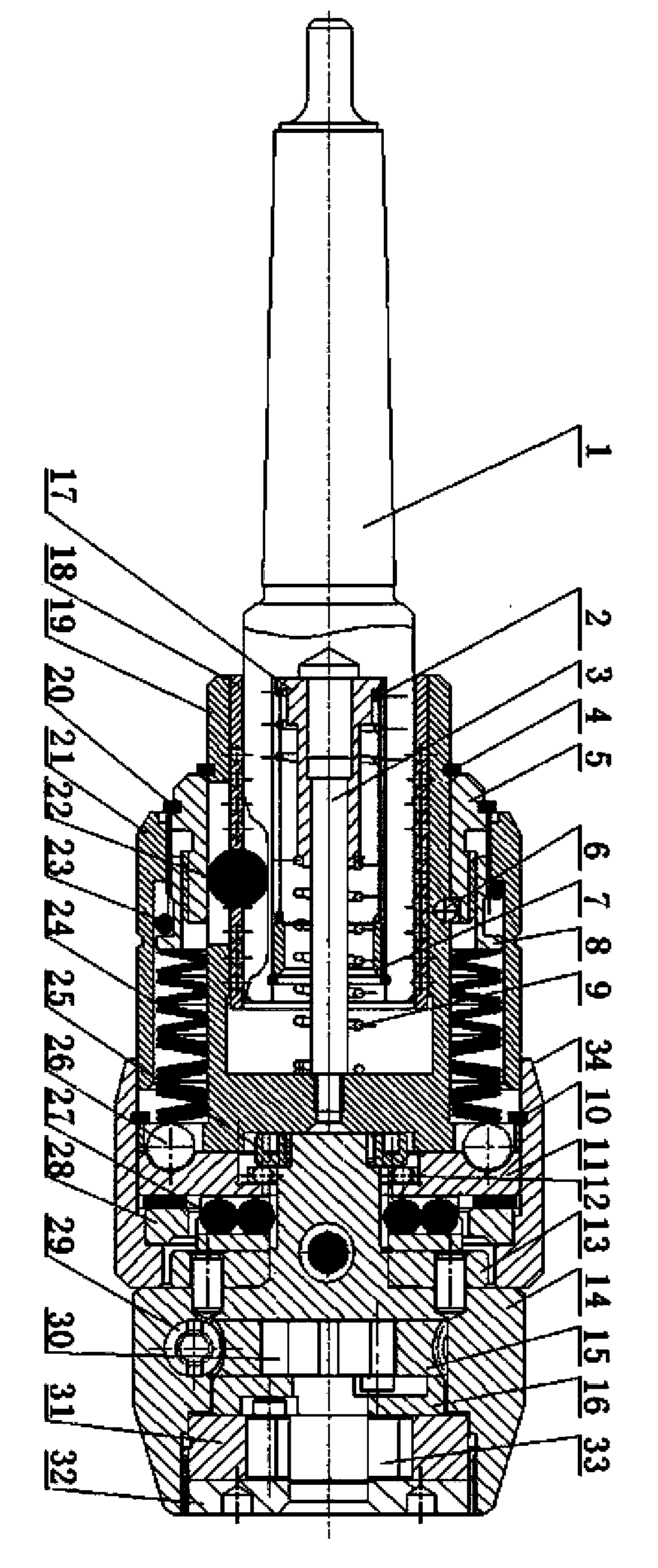

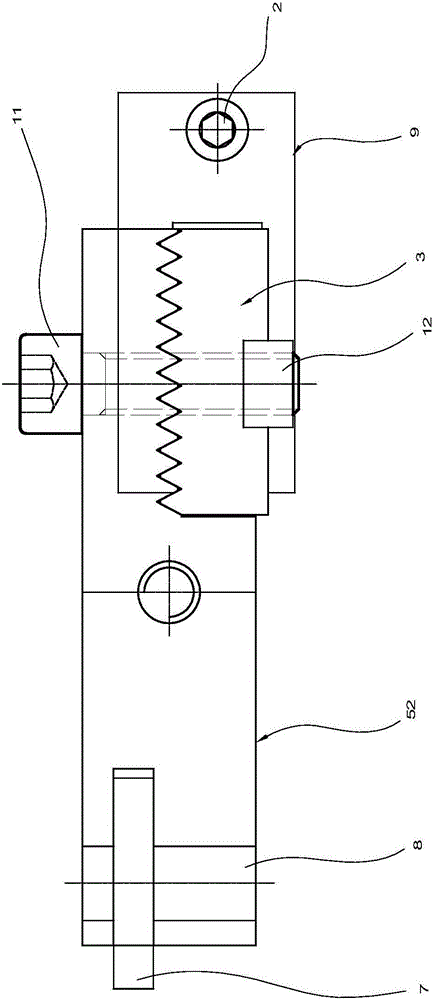

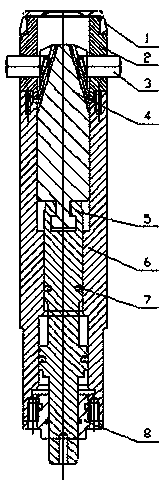

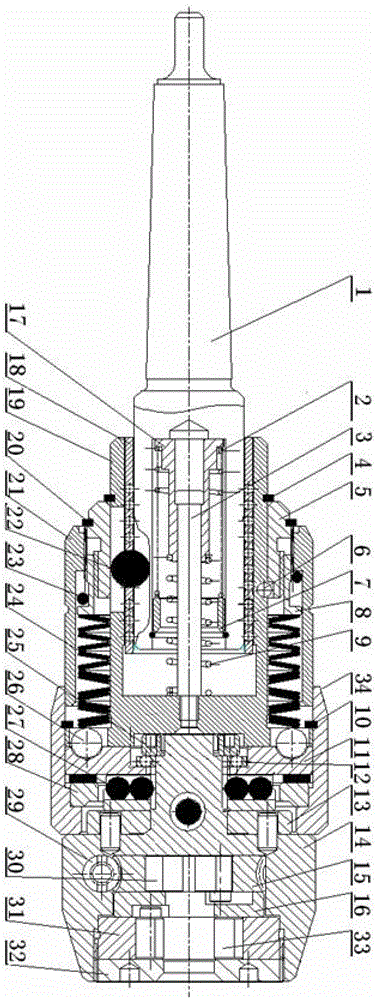

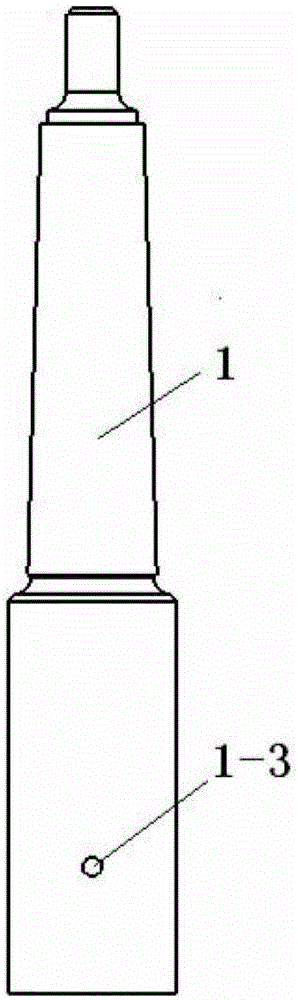

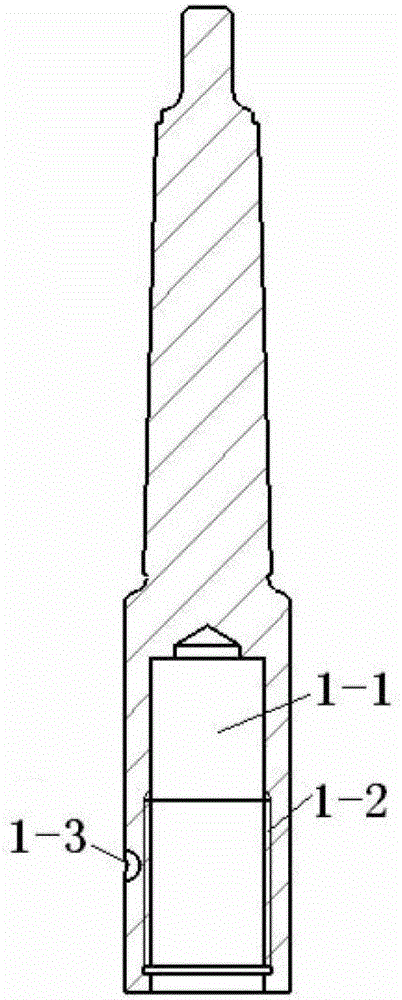

Elastic tap chuck

ActiveCN103433572AAchieve self-centerednessIncrease clamping stiffnessThread cutting machinesTorque regulationElectrical and Electronics engineering

The invention relates to a clamp for a machine tool, in particular to a tap chuck used for keeping a tap on a main shaft of a machine tool. The tap chuck comprises a chuck handle, a round sleeve and a clamping base, wherein the outer side of the round sleeve is provided with a torque regulating mechanism; a length compensation mechanism is arranged between the chuck handle and the round sleeve; a tap clamping mechanism is arranged in the clamping base. By virtue of adopting the structure, the elastic tap chuck can regulate the torque by virtue of the torque regulating mechanism so as to adapt to tap chucks with different torques. In addition, the length regulating mechanism is used for preventing the tap damage caused by the condition that one end of the tap is fixed, while the other end is fed unceasingly. The tap clamping mechanism can be used for realizing self centering of the tap and improving the tap clamping rigidity.

Owner:常州宇拓工业装备有限公司

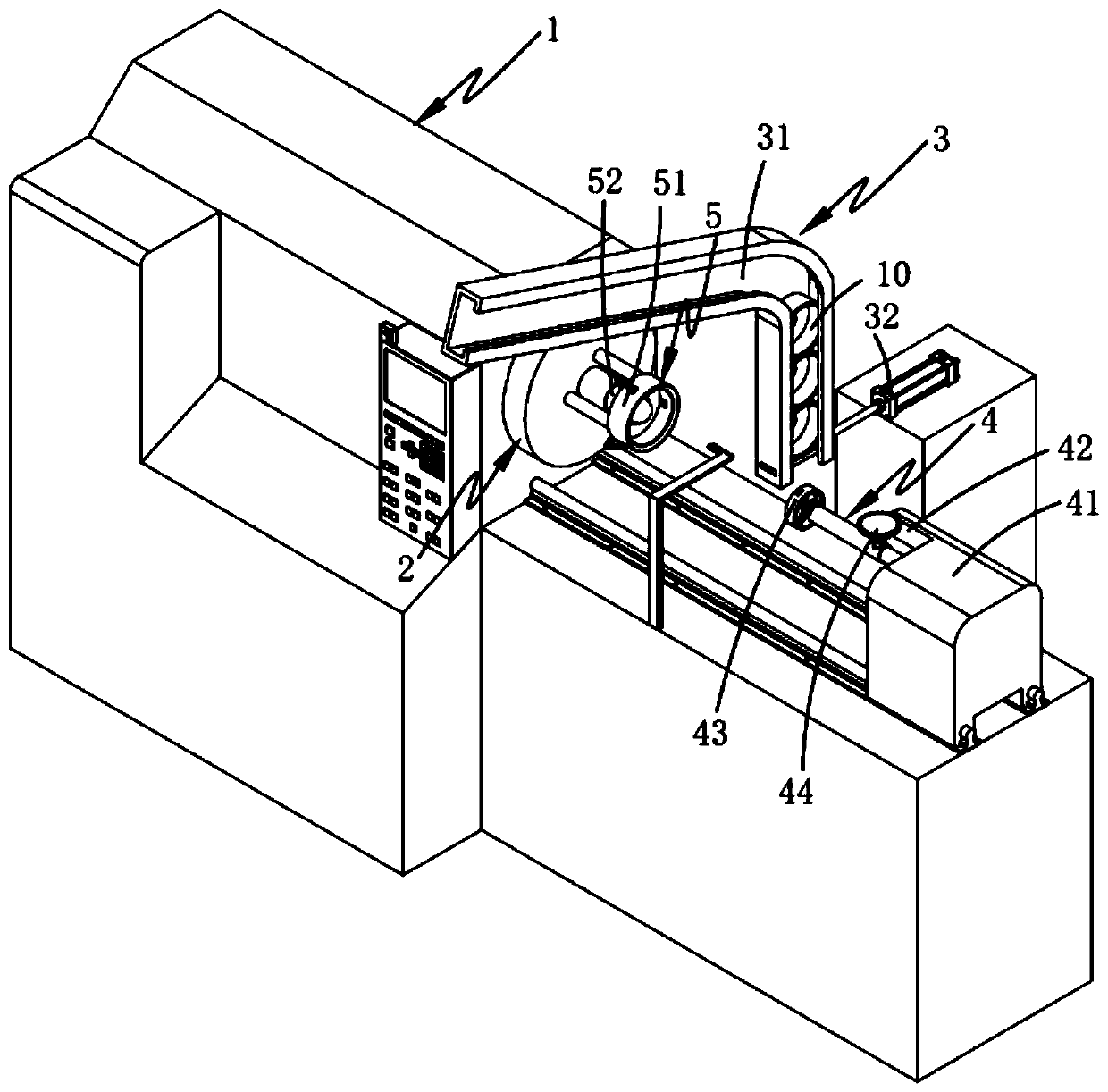

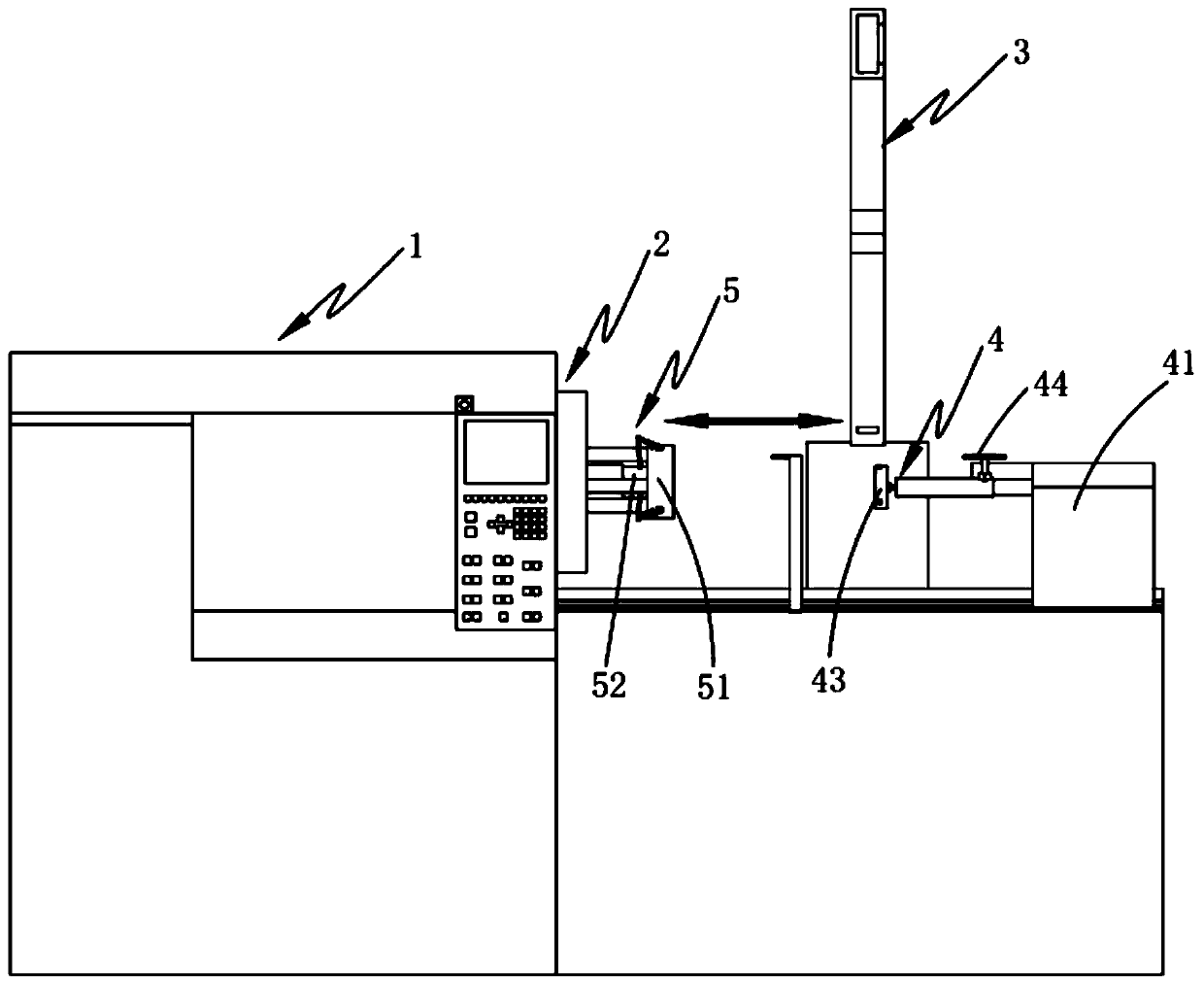

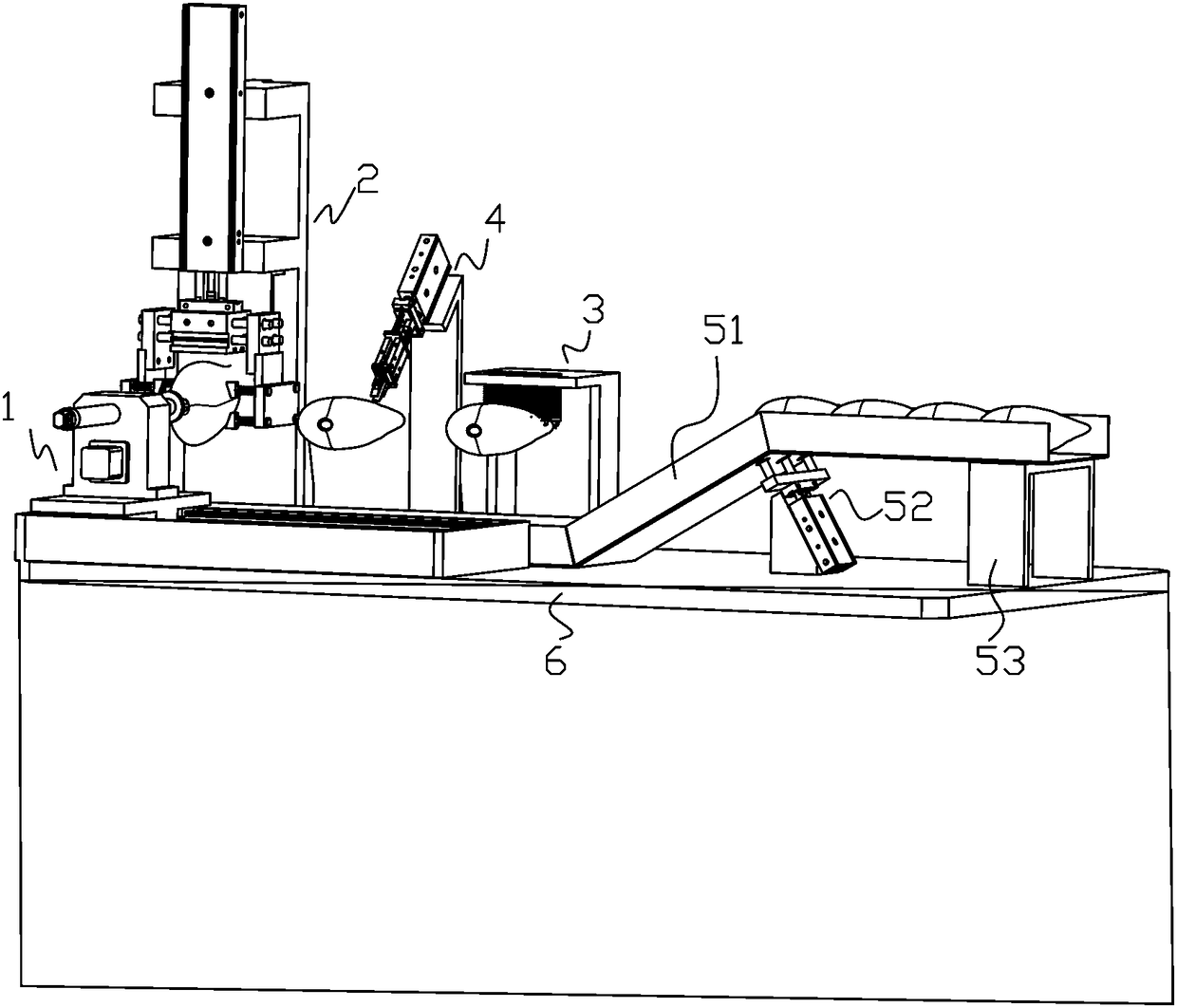

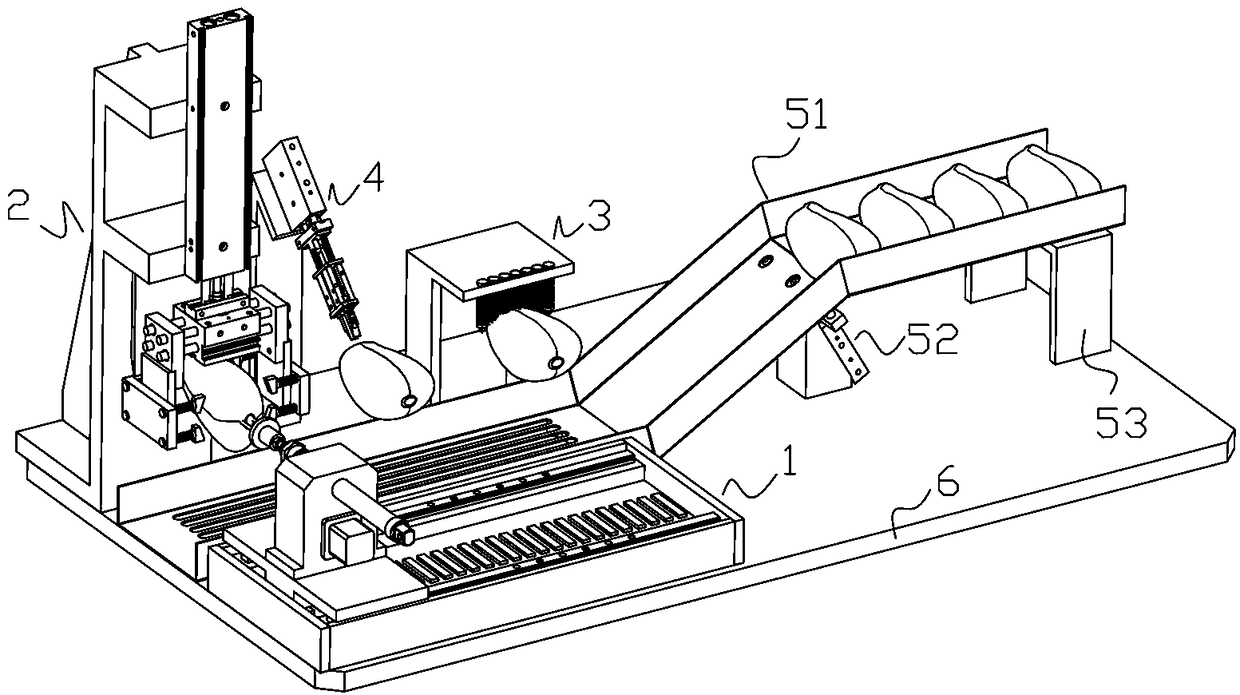

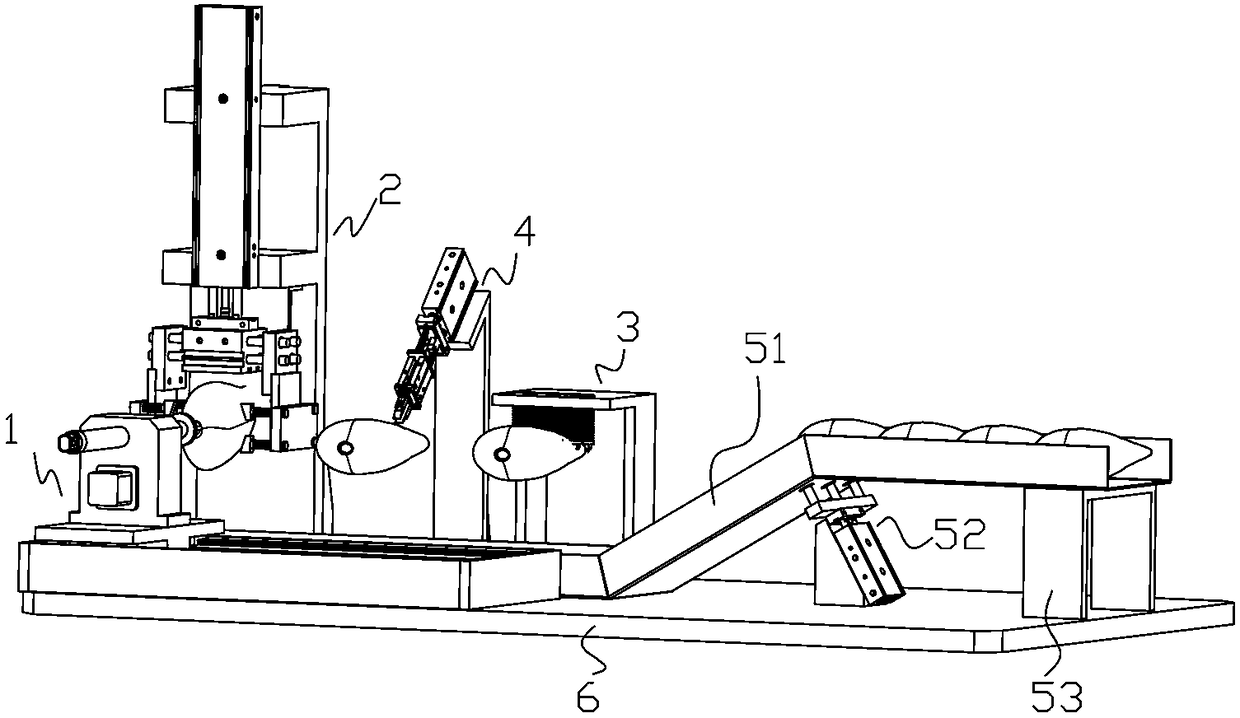

Self-positioning clamping lathe

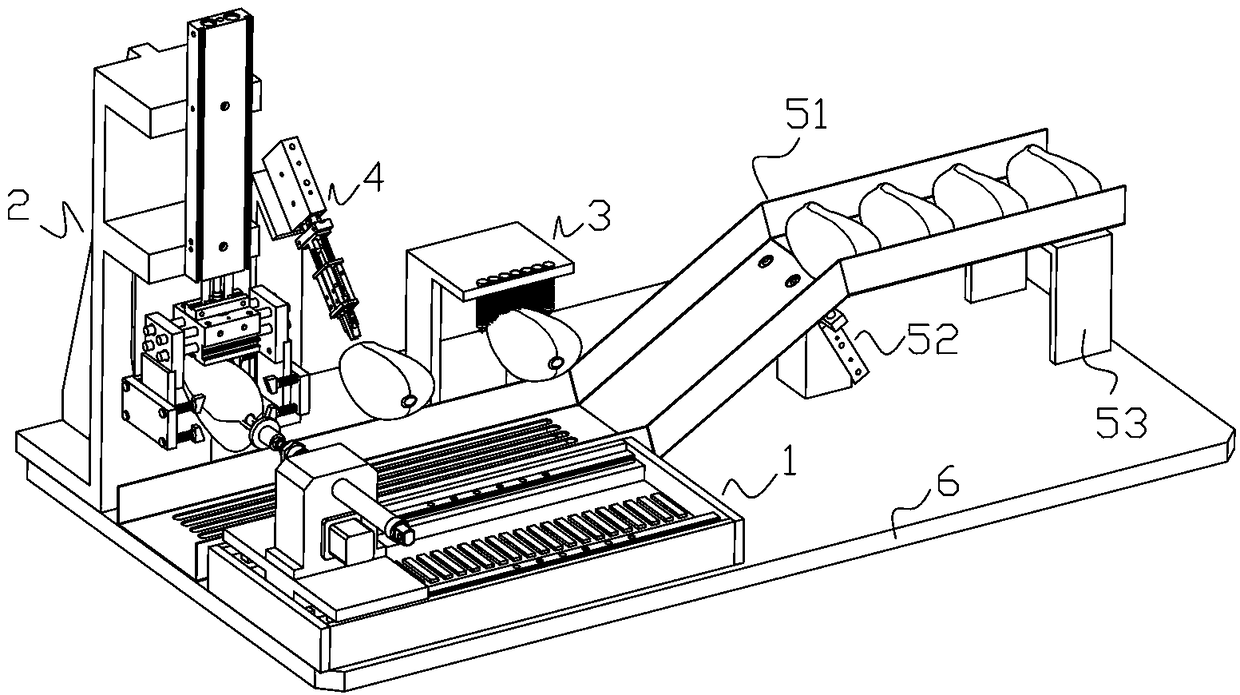

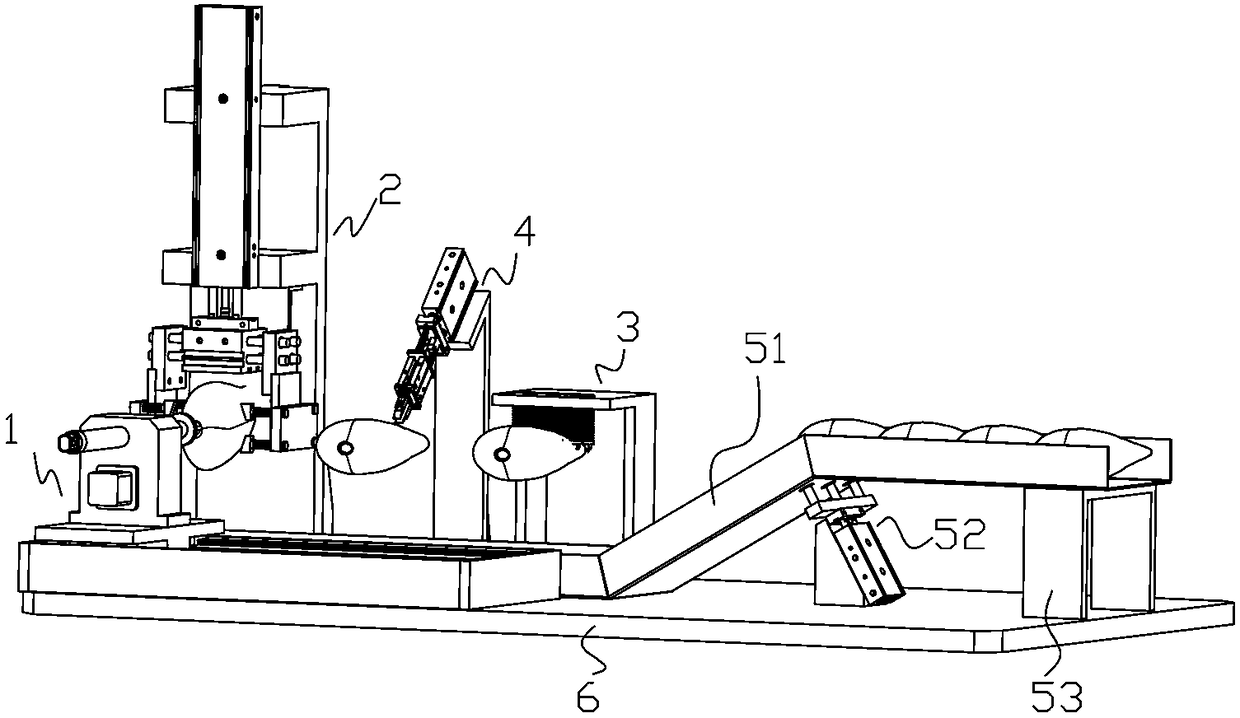

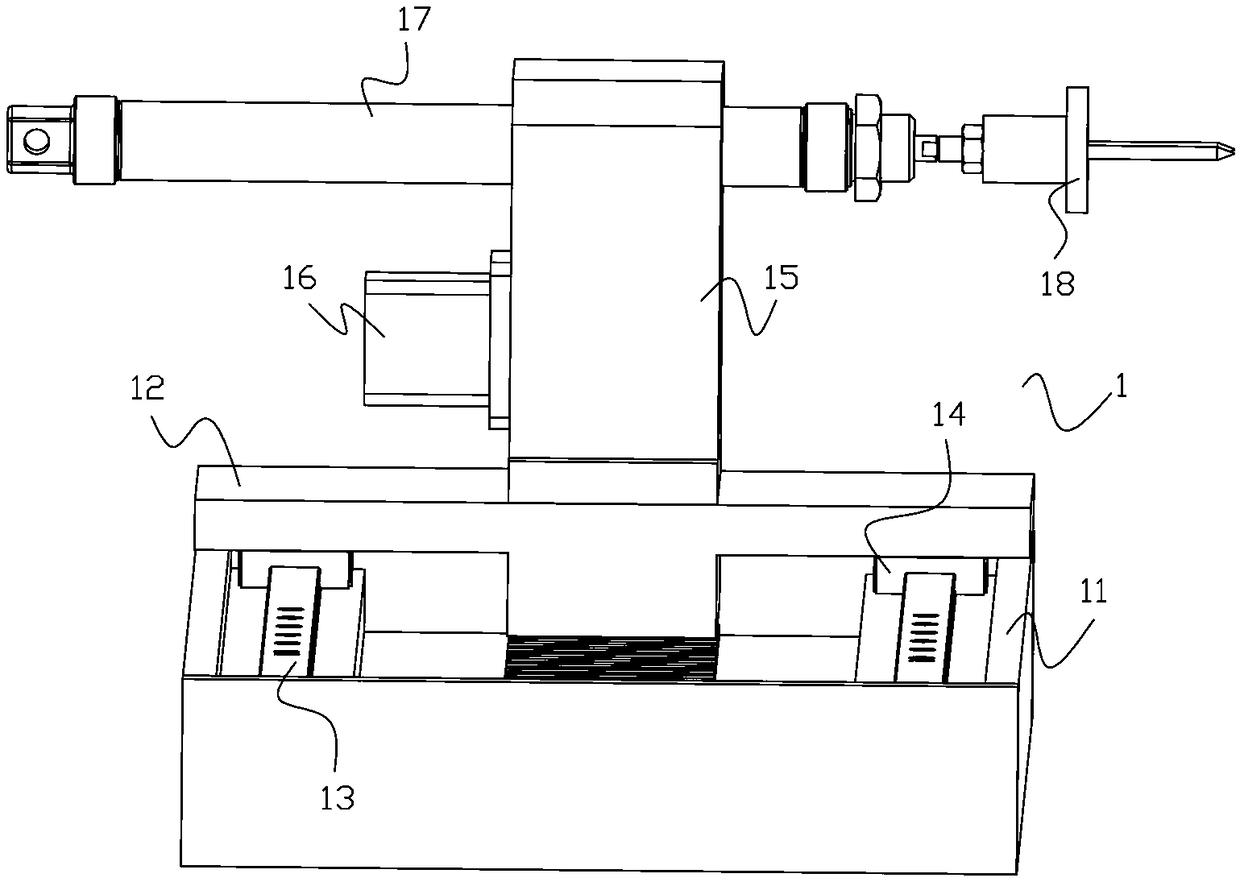

InactiveCN109794621AImprove production and processing efficiencyConvenient feeding and transportationPositioning apparatusMetal working apparatusFeed driveFeeding drive

The invention provides a self-positioning clamping lathe. The self-positioning clamping lathe comprises a lathe body, a rotating spindle, an automatic supplementing device, an automatic feeding deviceand a clamp rotating device; the automatic feeding device comprises a feeding driving assembly, a cutting assembly, a self-centering assembly and a cutting control assembly; the clamp rotating devicecomprises a clamping assembly and a clamping control assembly; when the automatic feeding device moves towards the rotating spindle, workpieces falling from the automatic supplementing device at intervals are transported into the clamp rotating device, make contact with the clamp rotating device and then are self-centered, in the process that the automatic feeding device continues moving forwards, the workpieces are automatically clamped through the clamping assembly, meanwhile, the distance between the cutting assembly and the workpieces is controlled through the cutting control assembly, thus automatic feeding, positioning, clamping and machining integration of workpieces are achieved, and the technical problems that in the prior art, the coaxiality between the workpieces and the rotating spindle is difficultly ensured during clamping, the machining error is large during machining, and the precision is low are solved.

Owner:ZHEJIANG FUSHI MACHINERY TECH

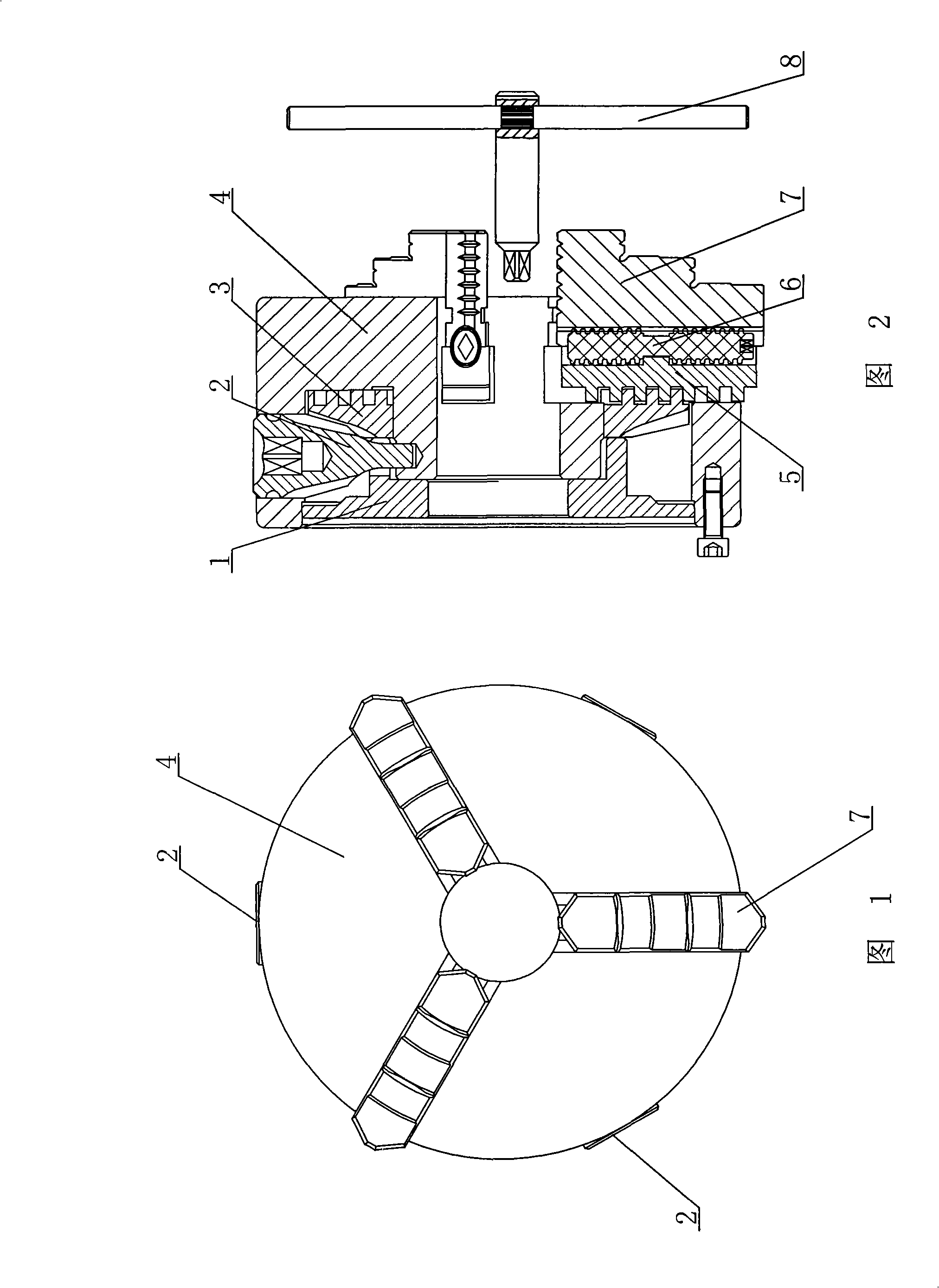

Improved three-jaw composite chuck

InactiveCN101491841AAchieve self-centerednessEffective clampingChucksEngineeringMechanical engineering

Owner:无锡大运服饰有限责任公司

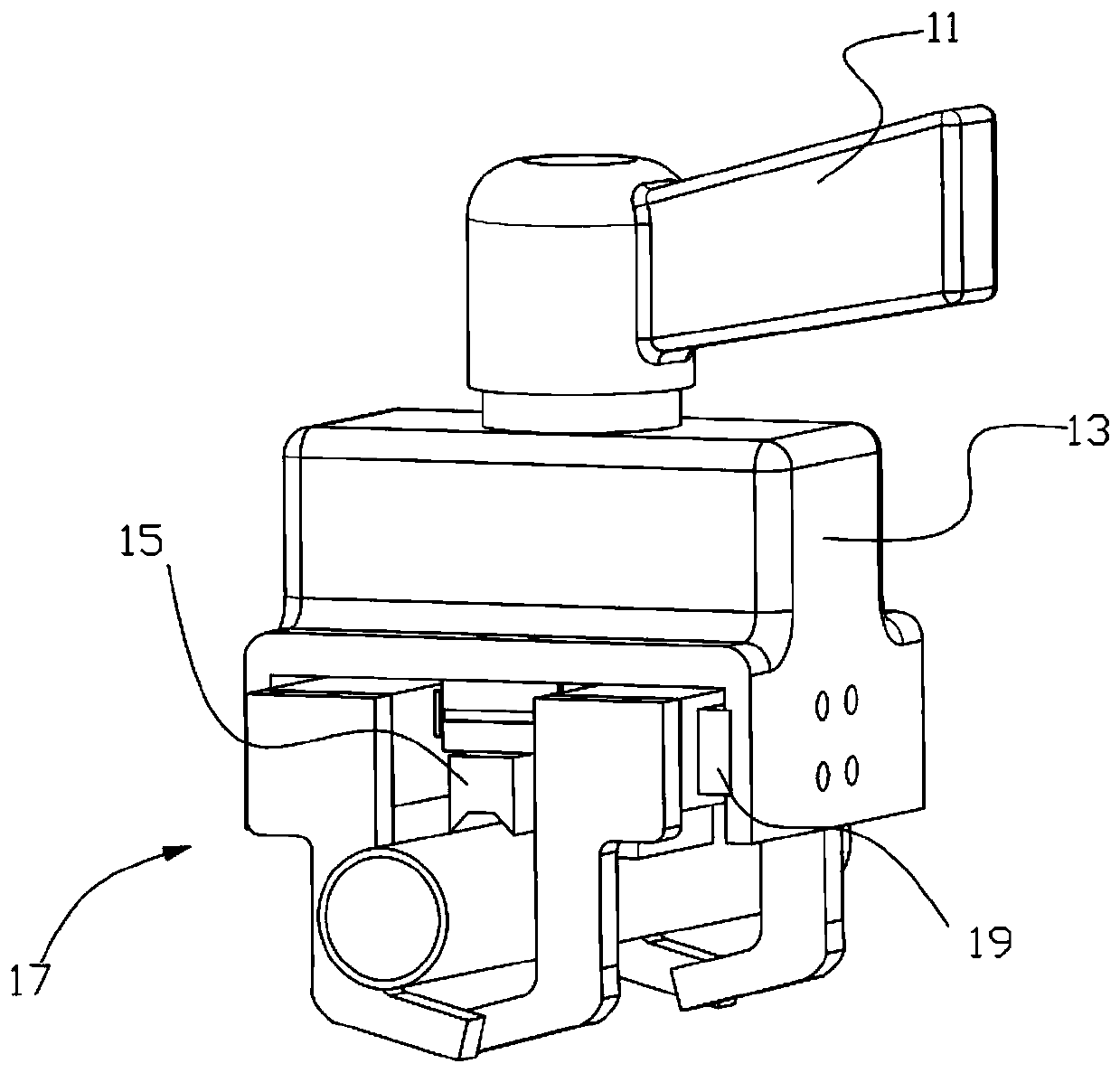

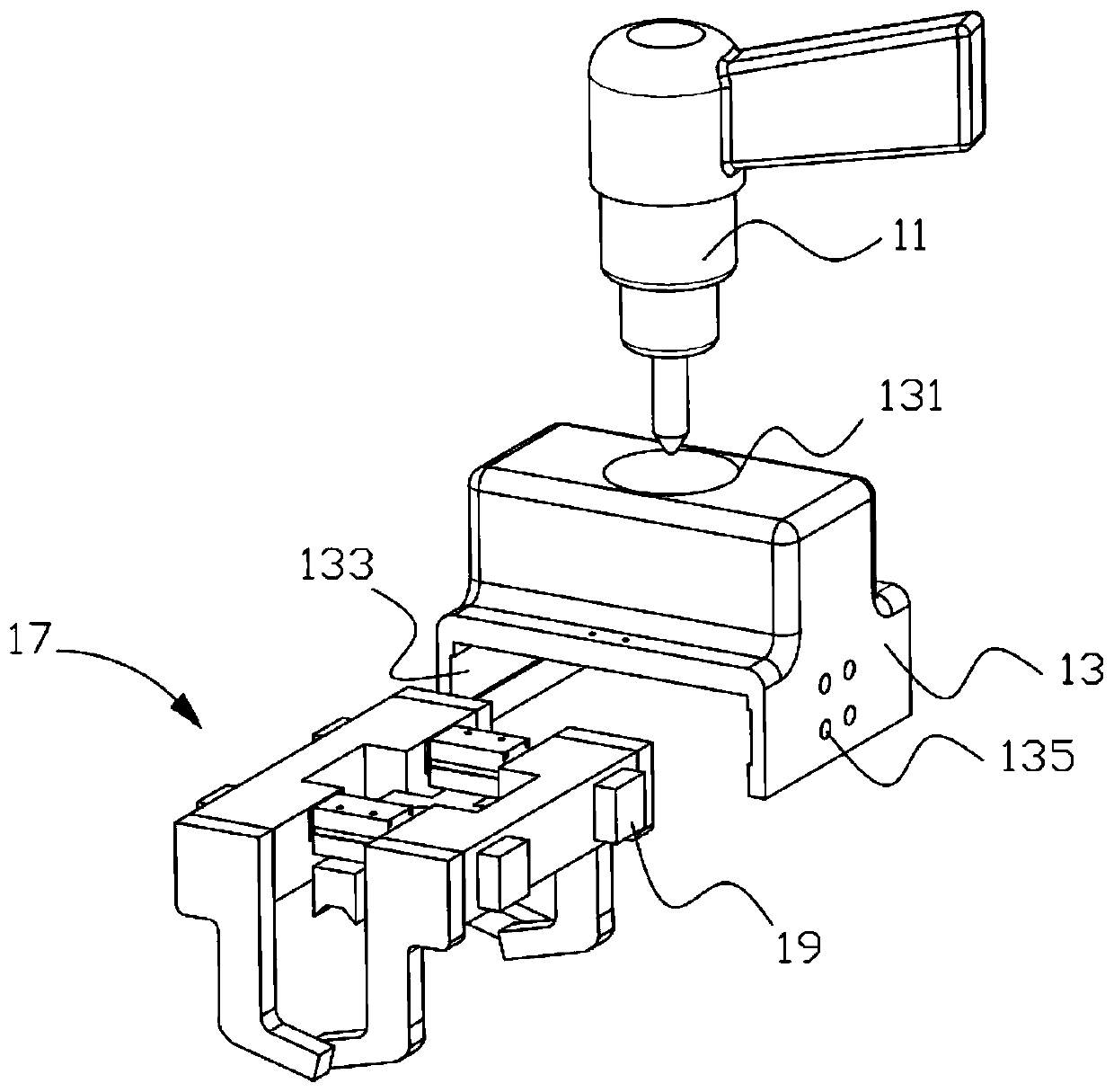

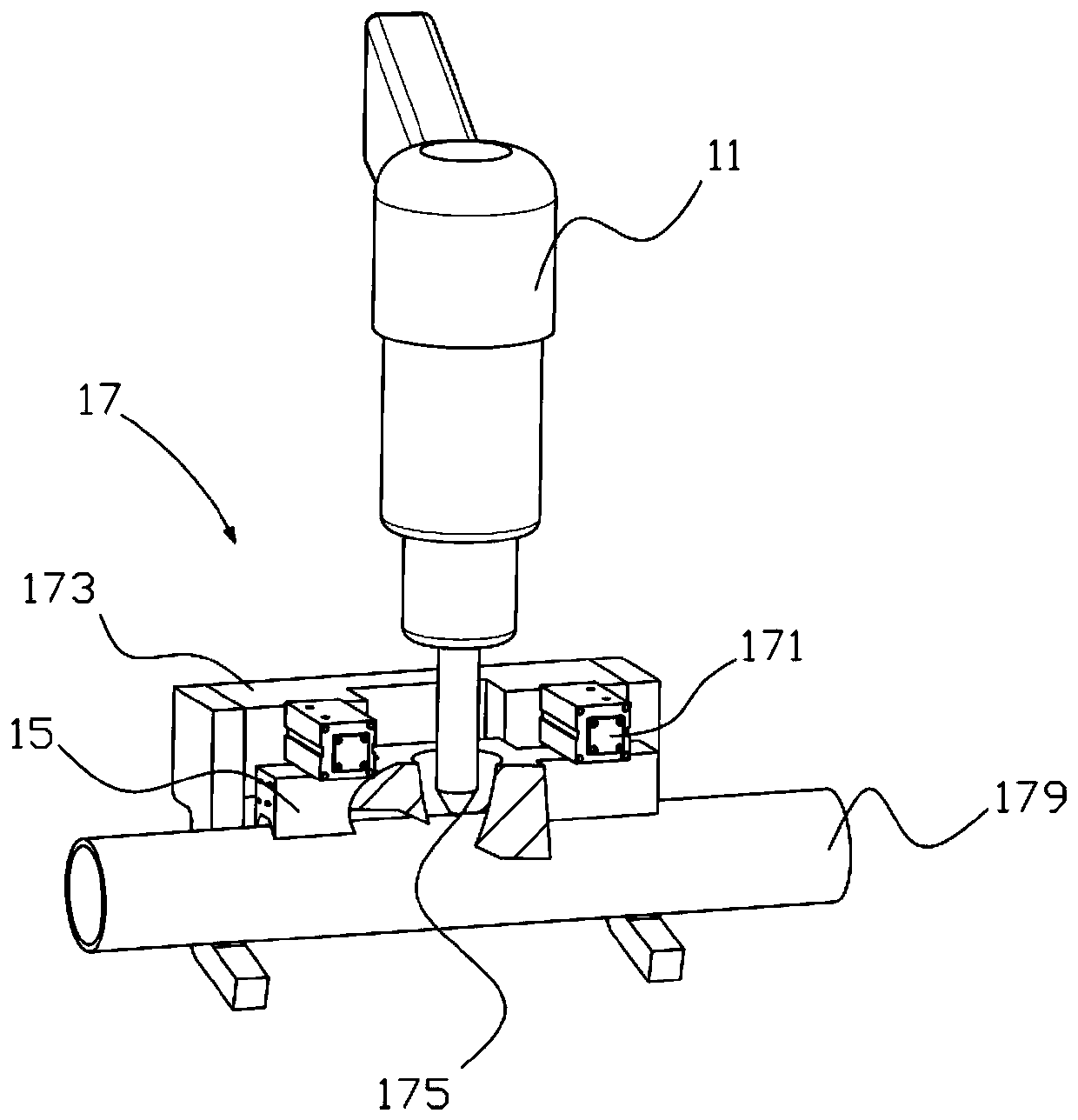

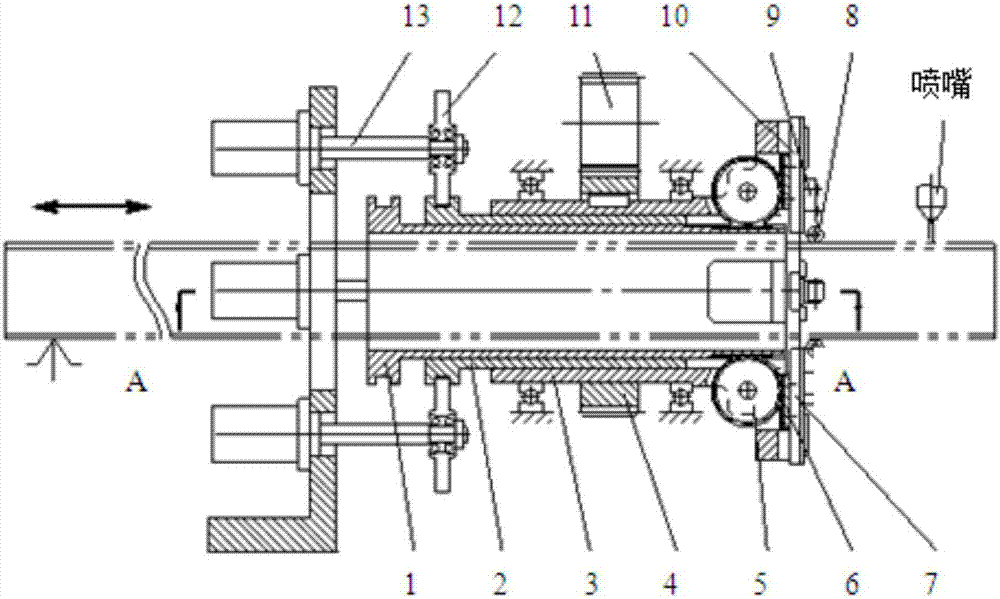

Mechanical arm end effector for leak stopping with pressure

ActiveCN109798415AHigh precisionMeet leak plugging requirementsGripping headsPipe elementsEngineeringActuator

The embodiment of the invention discloses a mechanical arm end effector for leak stopping with pressure. The mechanical arm end effector comprises an air impact hammer, a raised block, connecting blocks, a V-shaped self-centering module, and a clamping module. The clamping module is composed of air cylinders and two clamping jaws, the air cylinders are installed between the two clamping jaws, eachof the clamping jaws consists of a depressed block and two L-shaped plates, the connecting blocks are fixedly arranged on the outer sides of the two clamping jaws, the clamping module is installed atthe two ends of the raised block through the connecting blocks, the V-shaped self-centering module is fixedly arranged under the air cylinders, the air impact hammer is fixedly arranged on the raisedpart of the upper end of the raised block and penetrates through the V-shaped self-centering module, and leak points on leaked equipment are subjected to beating and striking and leak stopping. The mechanical arm end effector is novel in structural design and convenient to operate and can be applied to the beating and striking and leak stopping of various-sized leaked pipelines, self-centering can be realized by the V-shaped self-centering module, and leak stopping accuracy is high.

Owner:HUANENG SHANTOU HAIMEN POWER GENERATION CO LTD +1

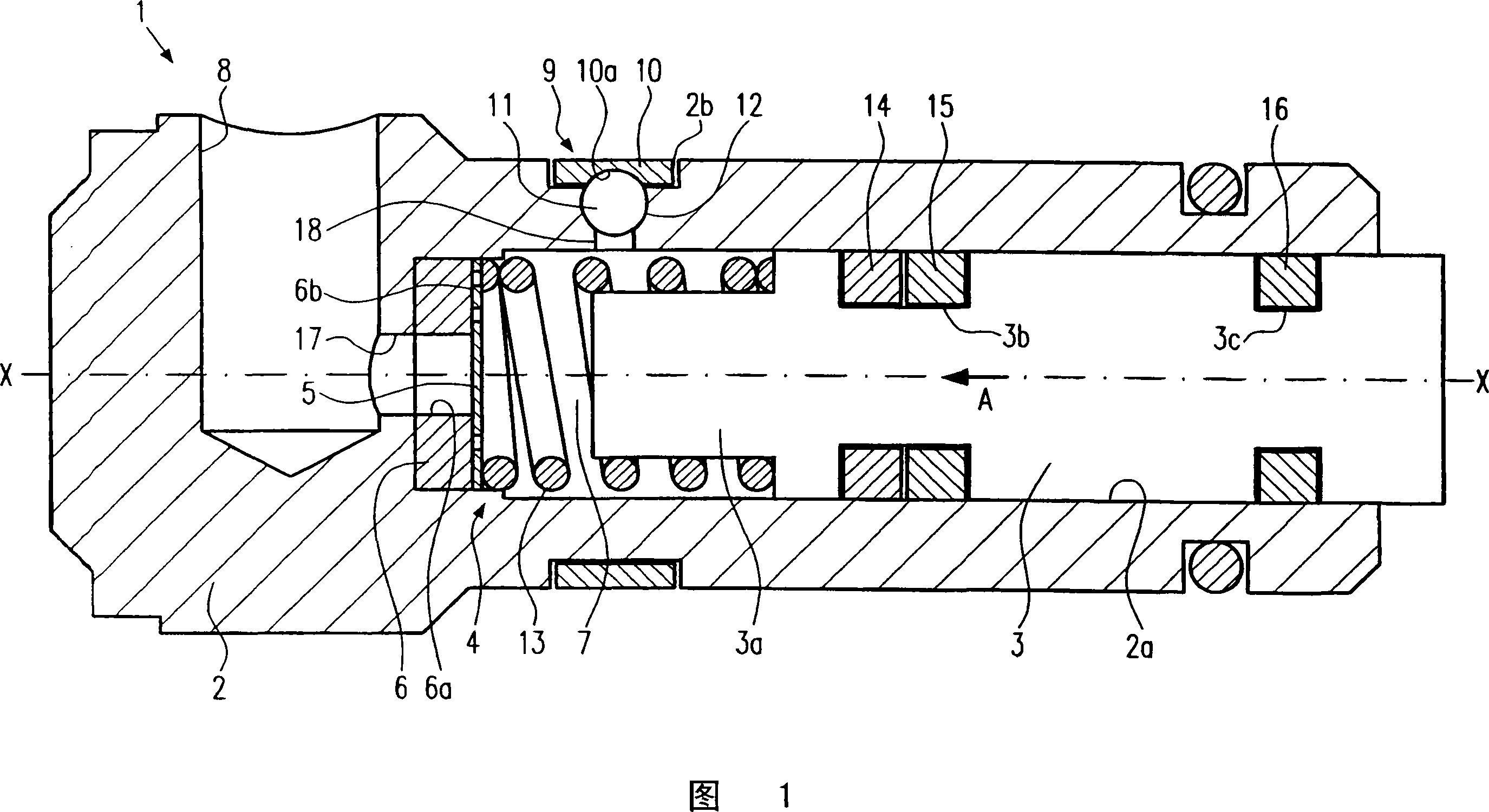

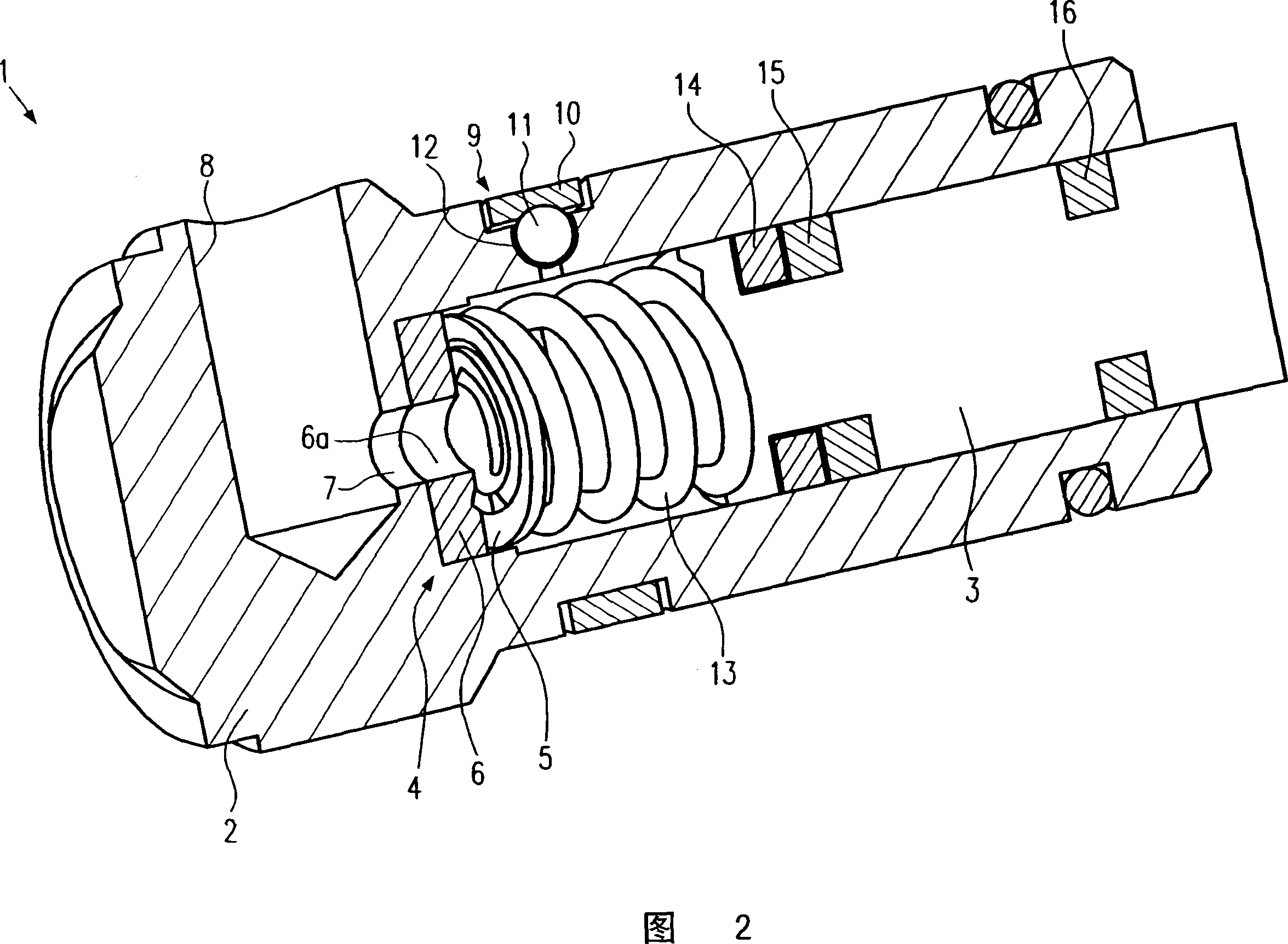

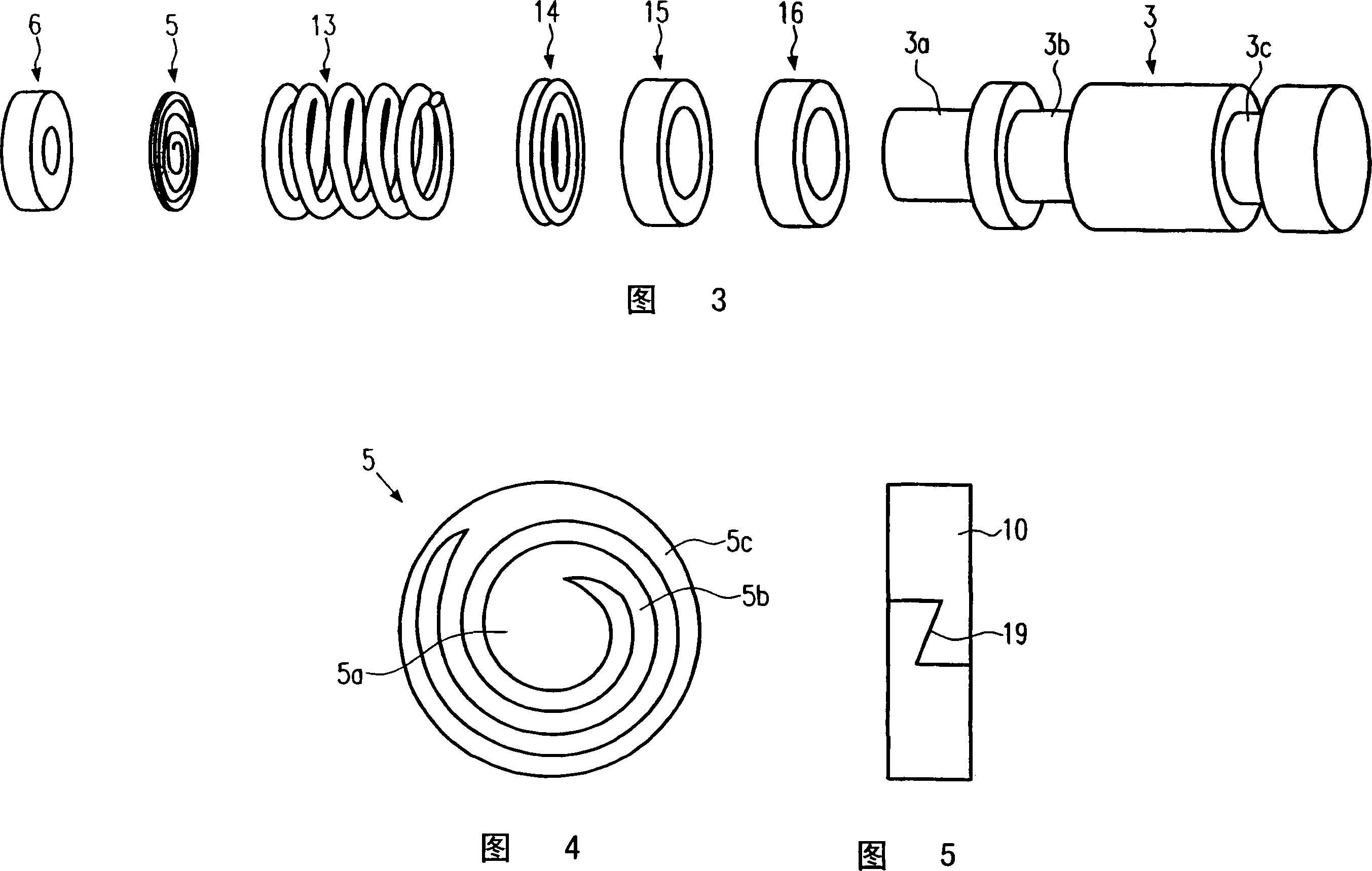

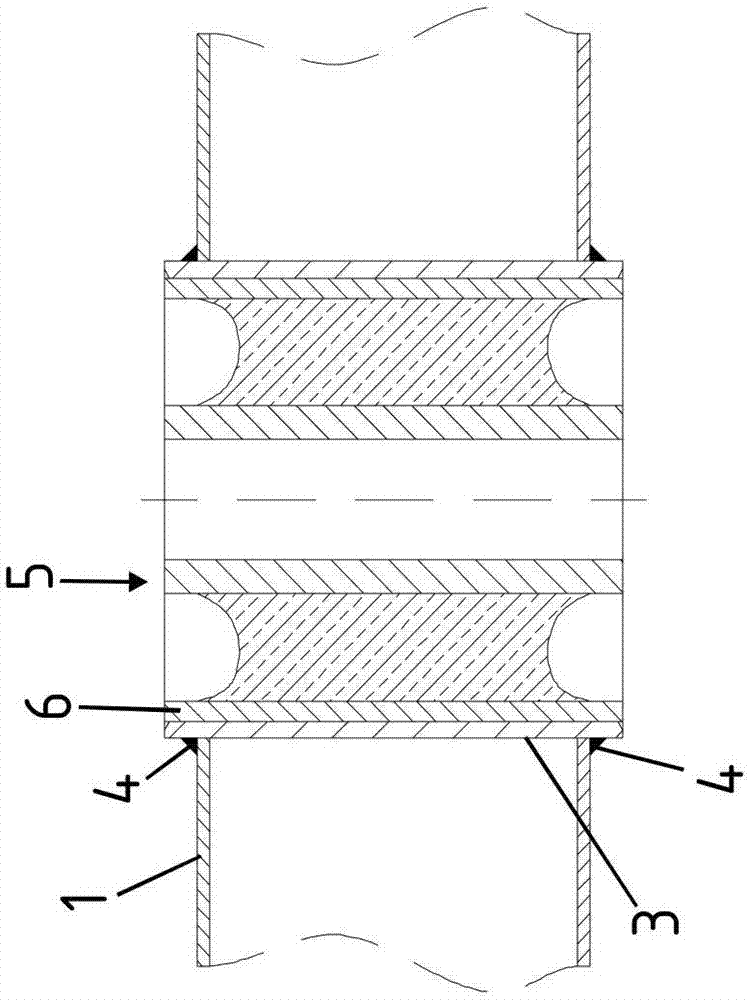

Piston pump with improved pressure build-up dynamics

InactiveCN1989344ACompact structureSmall structurePositive displacement pump componentsCheck valvesEngineeringHydraulic fluid

The invention relates to a piston of a pump for a hydraulic fluid flow comprising a reciprocating piston (3) for increasing pressure in a pressure chamber (7) and at least one valve provided with a spring sealing element (5), wherein said spring sealing element (5) comprises a sealing area (5a) and a spring area (5b) for releasing and closing an opening (6a).

Owner:ROBERT BOSCH GMBH

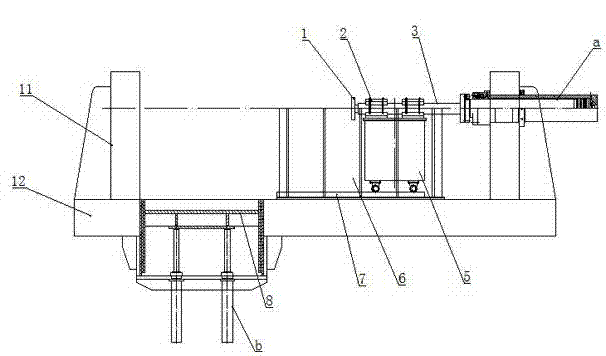

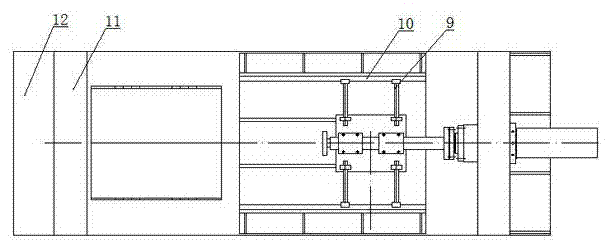

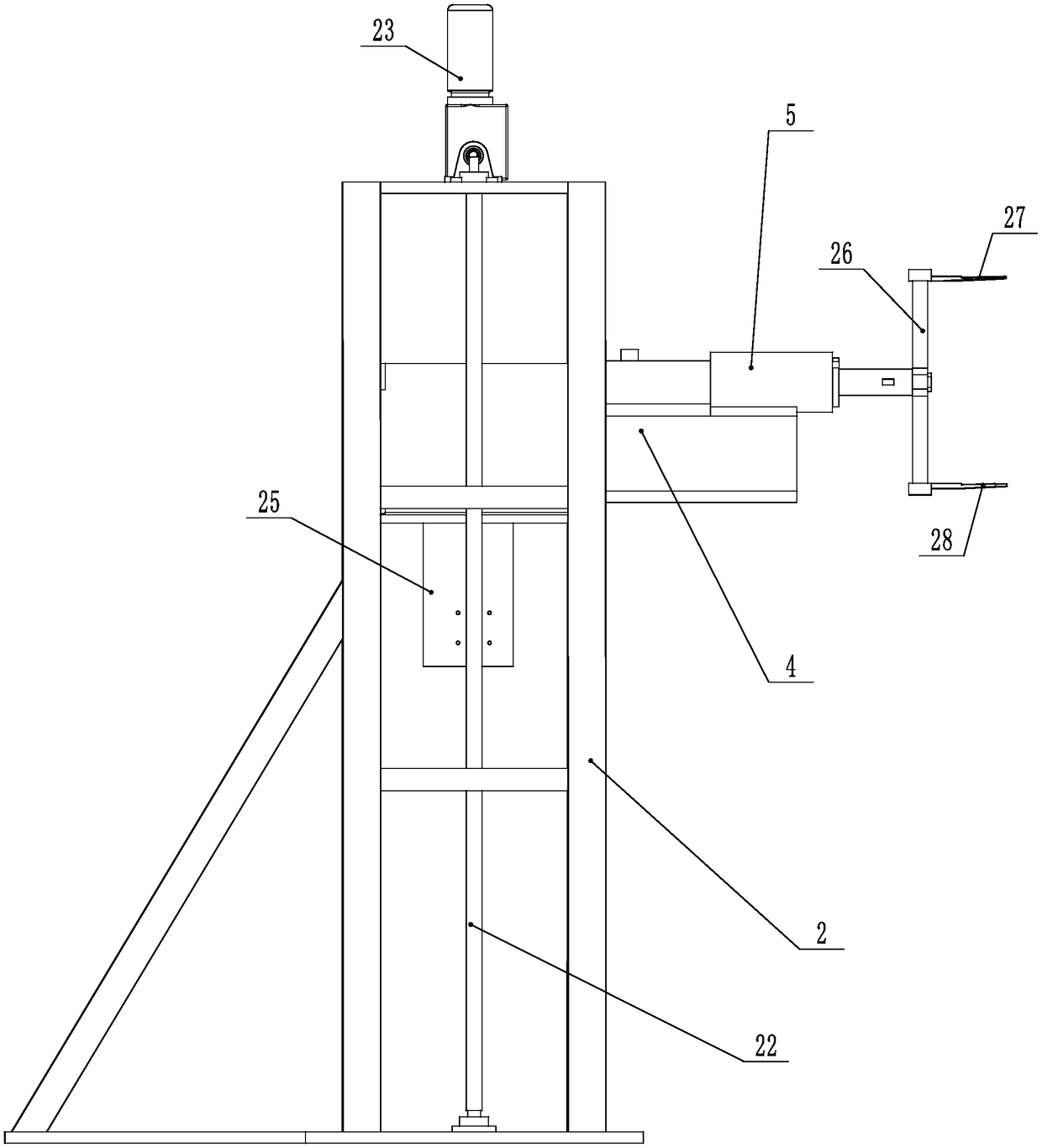

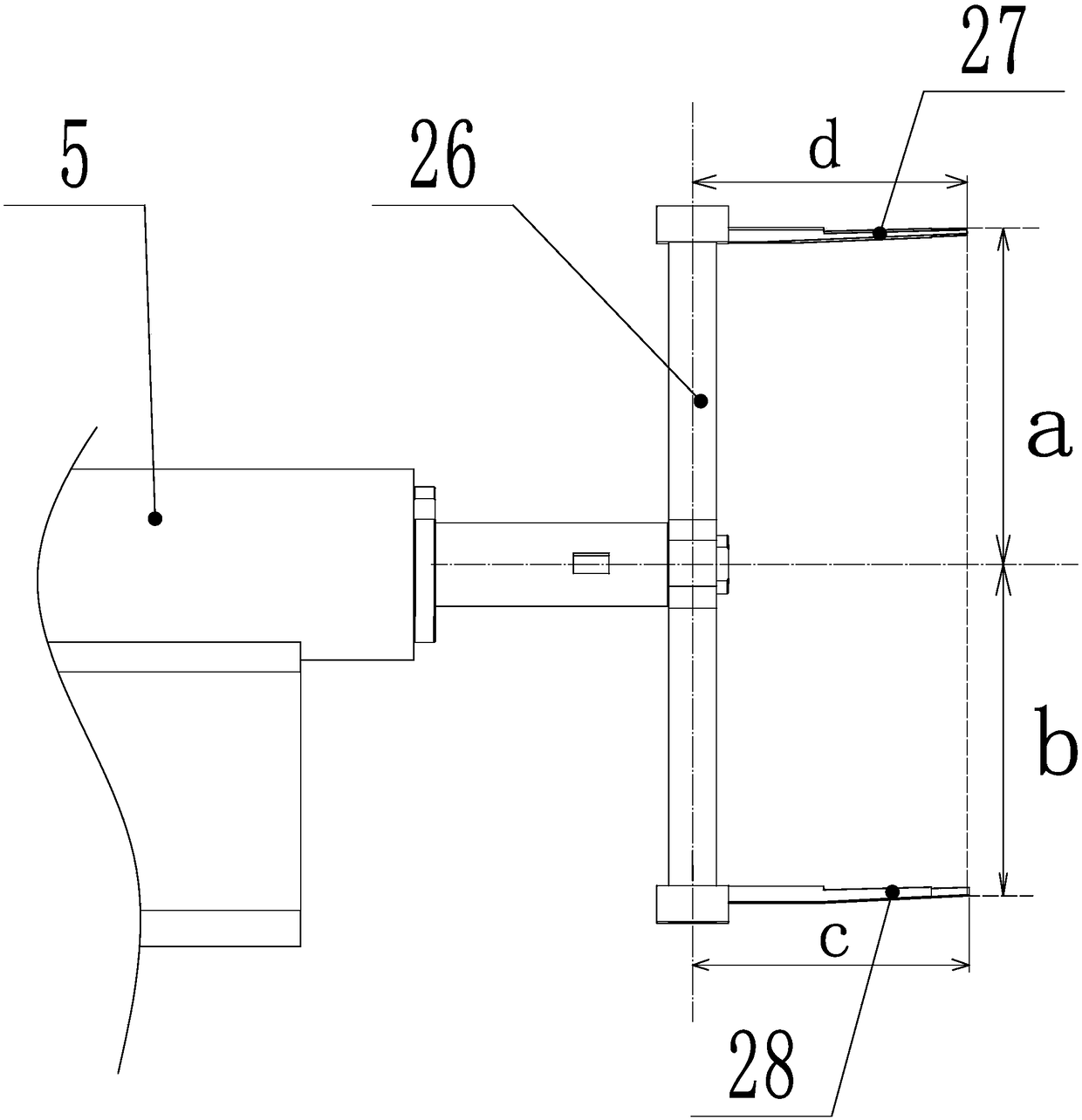

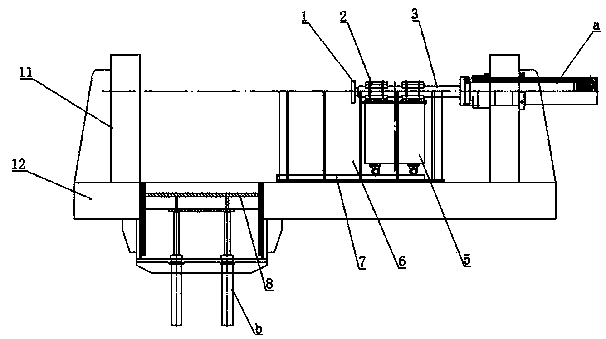

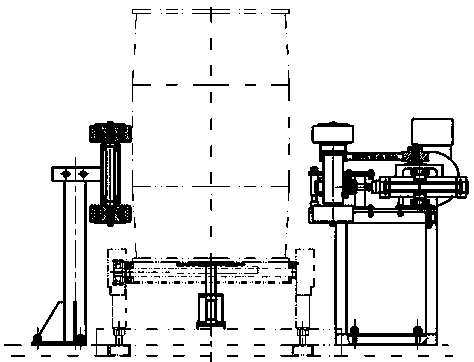

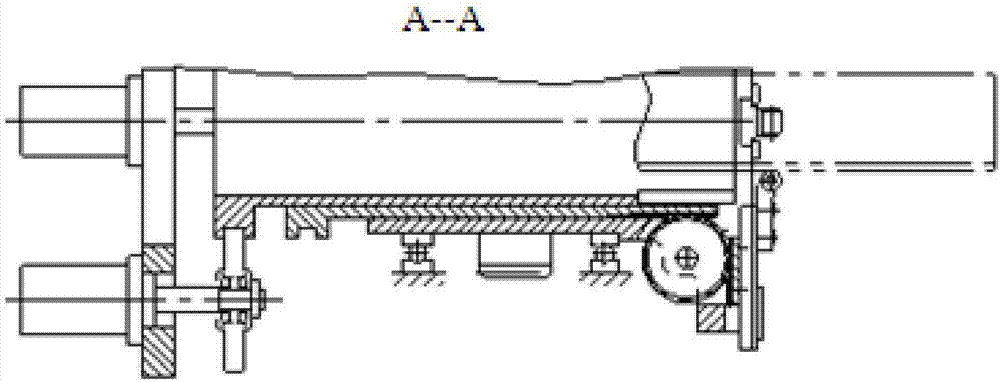

Special hydraulic machine for horizontal fan pressure shaft

InactiveCN102806457AAchieve self-centerednessAvoid suppressing influenceMetal working apparatusEngineeringMechanical engineering

The invention relates to a special hydraulic machine for a horizontal fan pressure shaft. The special hydraulic machine comprises a horizontal stand, wherein the stand consists of a base and brackets arranged on two sides of the base. The special hydraulic machine is characterized in that a press driving mechanism capable of moving along the horizontal direction is arranged on the bracket on one side of the base; the front end of the press driving mechanism is connected with a pressing plate; a fan bracket is arranged at the bottom of the stand; and an upper end surface of the fan bracket is of a V-shaped groove structure. When the special hydraulic machine is in use, a fan casing is arranged on the fan bracket and the pressing plate is pushed by the press driving mechanism to move forwards to press the fan shaft into the center of the casing. A horizontal length adjusting mechanism is arranged between the press driving mechanism and the pressing plate and can adapt to casings with different thicknesses and ensure a proper pressing force. A guiding support mechanism is arranged on the horizontal length adjusting mechanism, and thus the horizontal forward movement of the pressing plate is ensured, the stress direction is accurate and the bias press is avoided.

Owner:NANTONG GAOYE HEAVY IND CO LTD

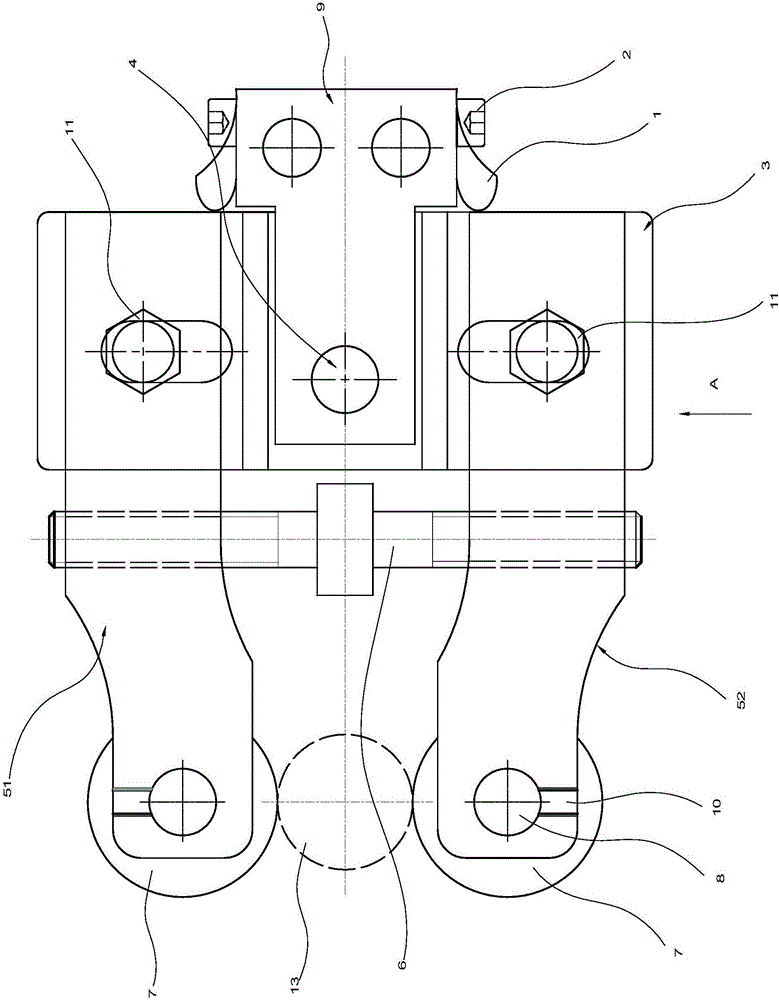

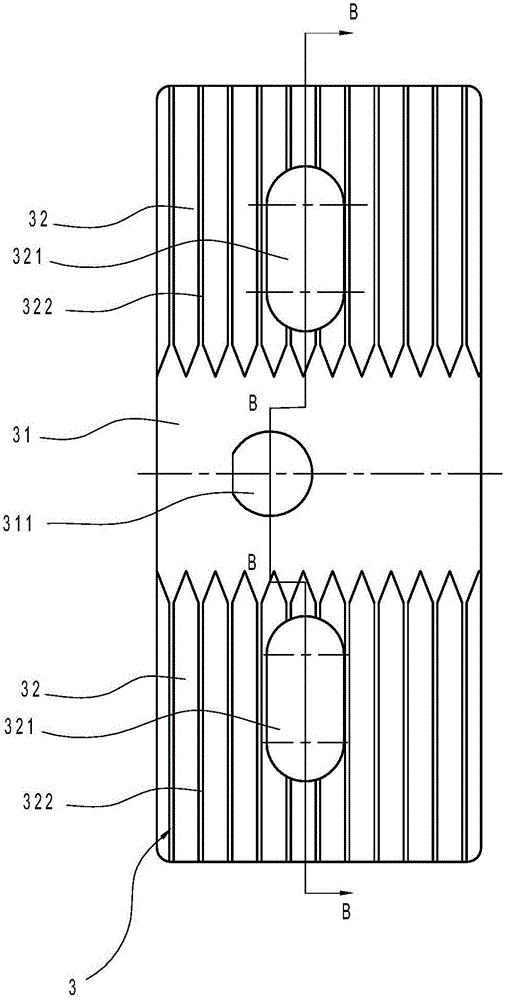

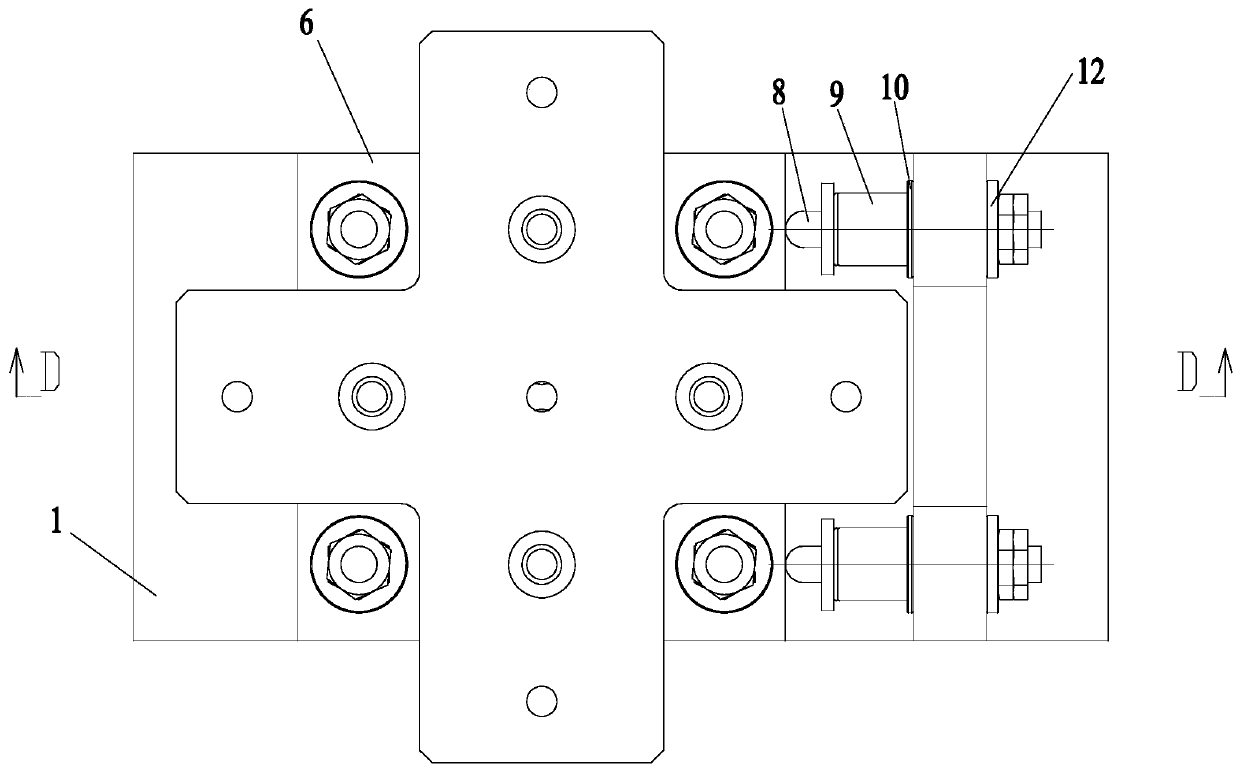

Knurl aligning device for shaft

The invention discloses a knurl aligning device for a shaft. The knurl aligning device for the shaft comprises a pair of positive tool arm and negative tool arm which are arranged opposite to each other and a tool arm supporting sliding plate used for connecting the positive tool arm and the negative tool arm, wherein knurl wheels are arranged at one ends of the positive tool arm and the negative tool arm respectively; and the other ends of the positive tool arm and the negative tool arm are arranged on the tool arm supporting sliding plate. The knurl aligning device for the shaft is characterized by also comprising a bracket used for connecting the tool arm supporting sliding plate and a processing machine, a positioning core shaft and spring leaves, wherein through holes are correspondingly formed in the tool arm supporting sliding plate and the bracket respectively; the positioning core shaft penetrates through the through holes of the supporting sliding plate and the bracket; the spring leaves are arranged on the two sides of the bracket respectively; one ends of the leaf springs are fixed to the bracket; the other ends of the leaf springs are abutted to the side part of the tool arm supporting sliding plate; and two spring leaves limit rotation of the tool arm supporting sliding plate with the positioning core shaft as the center. The invention provides the knurl aligning device for the shaft, which can realize self-centering and improve the processing efficiency and accuracy of a shaft spline.

Owner:WARNER SHENGLONG NINGBO CO LTD

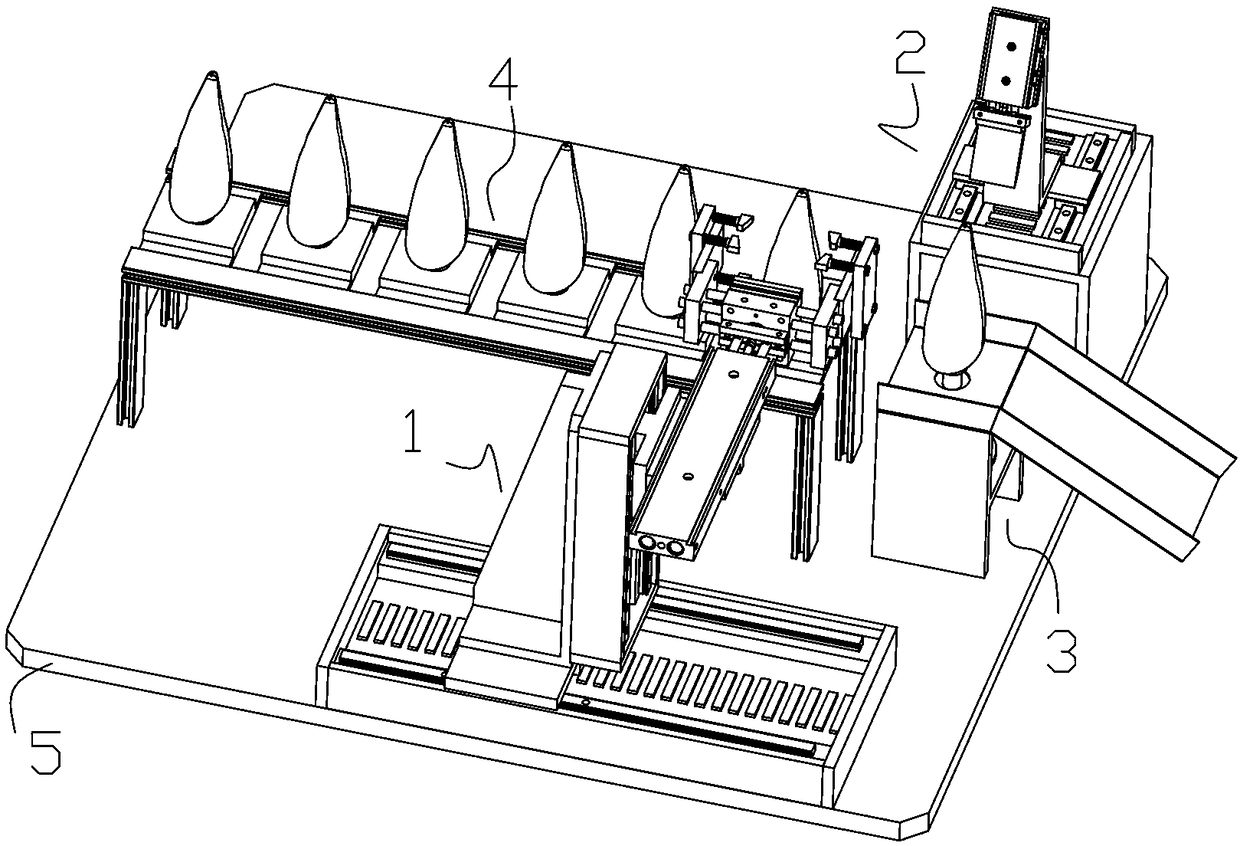

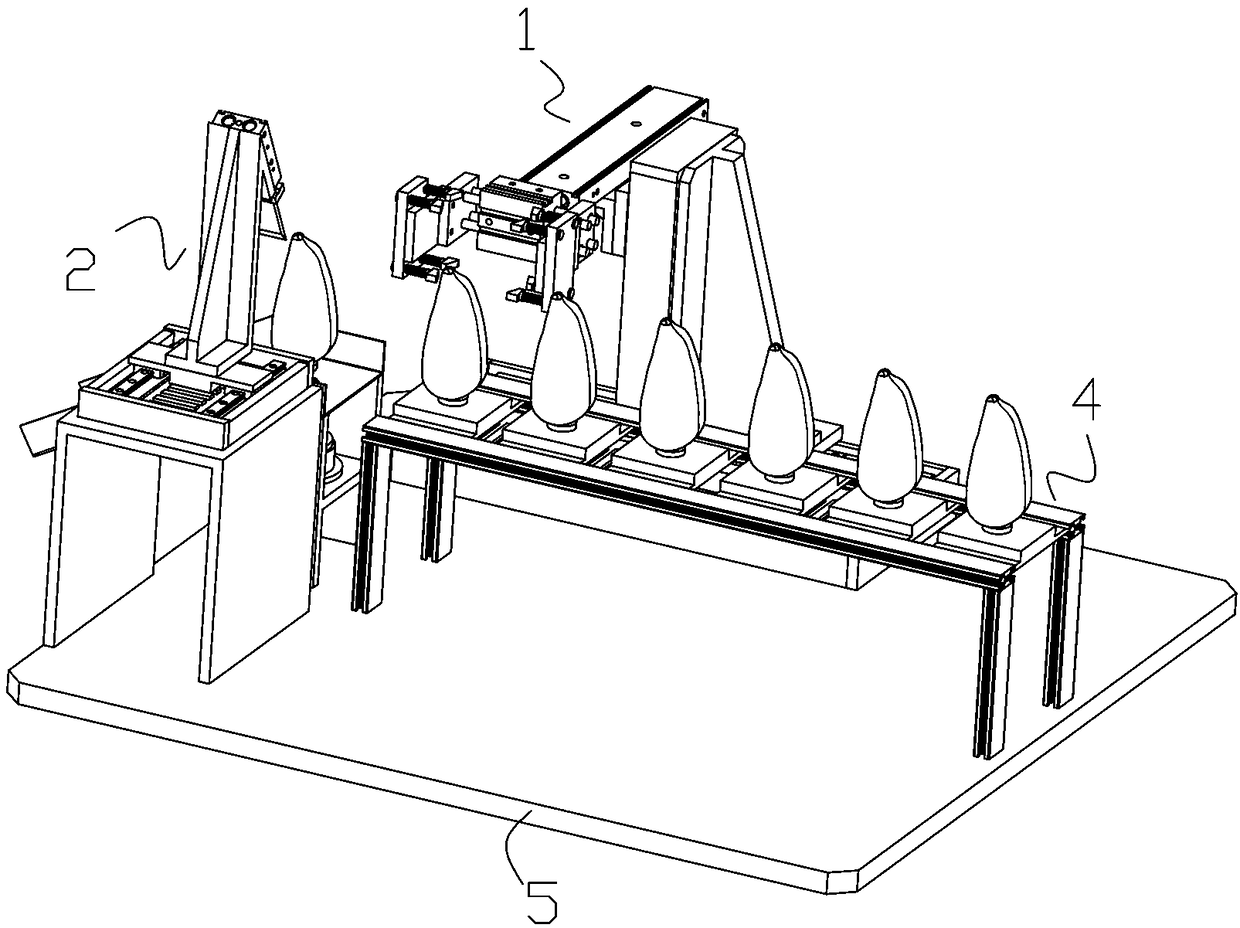

Mango peeling machine

ActiveCN108936717AAchieve self-centerednessAchieve separationVegetable peelingFood treatmentEngineeringKnife holder

The invention discloses a mango peeling machine. The machine comprises a pushing mechanism and a peeling mechanism, wherein the pushing mechanism comprises an ejection cylinder and a pushing head; theejection cylinder is used for driving the pushing head to push mangos; the peeling mechanism comprises a scaling device, a head cutting device and a breaking device, the scaling device comprises a square frame seat, inner jaws and outer jaws; the inner jaws are fixed on the square frame seat, and the outer jaws are fixed on the square frame seat; an arc tip is arranged at one end of each inner jaw, and an electromagnetic power block is fixed at the other end of each outer jaw; the electromagnetic power blocks are used for driving the outer jaws to mesh with the inner jaws; the breaking devicecomprises a square knife holder frame and a knife rest, the knife holder frame is fixed on the square frame seat, the knife rest is arranged on the knife holder frame, and a breaking knife is arranged on the knife rest; and the head cutting device is positioned between the scaling device and the breaking device. The mango peeling machine has the characteristics of simple structure, high production efficiency and convenience in operation.

Owner:JIANGSU SIDA HEAVY IND

Clamp

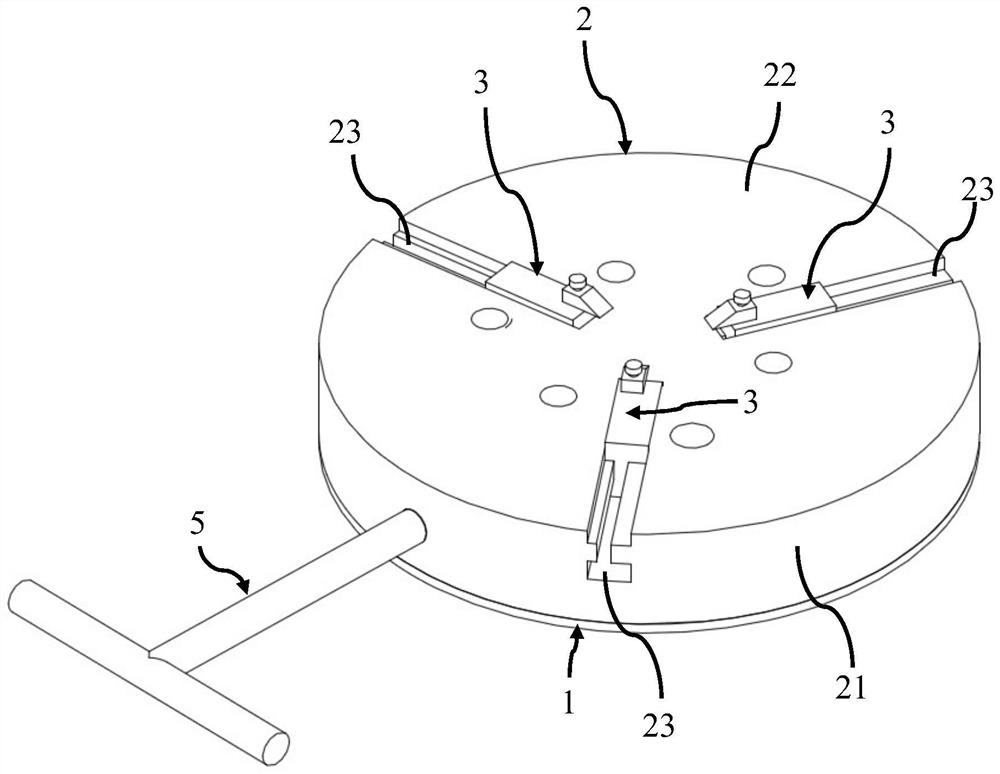

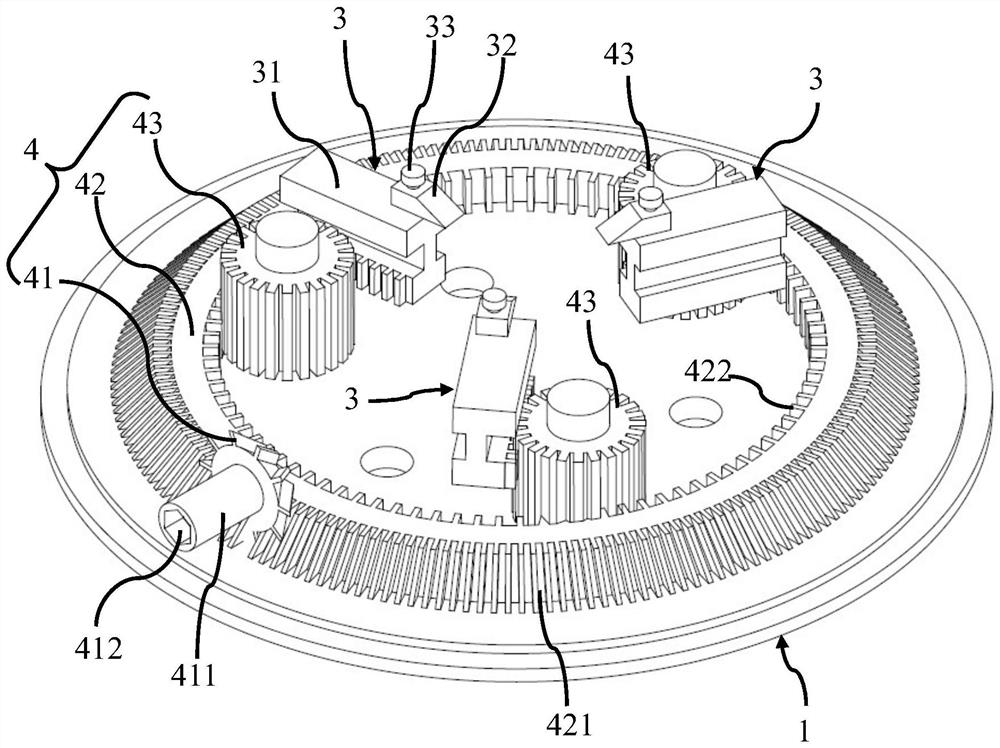

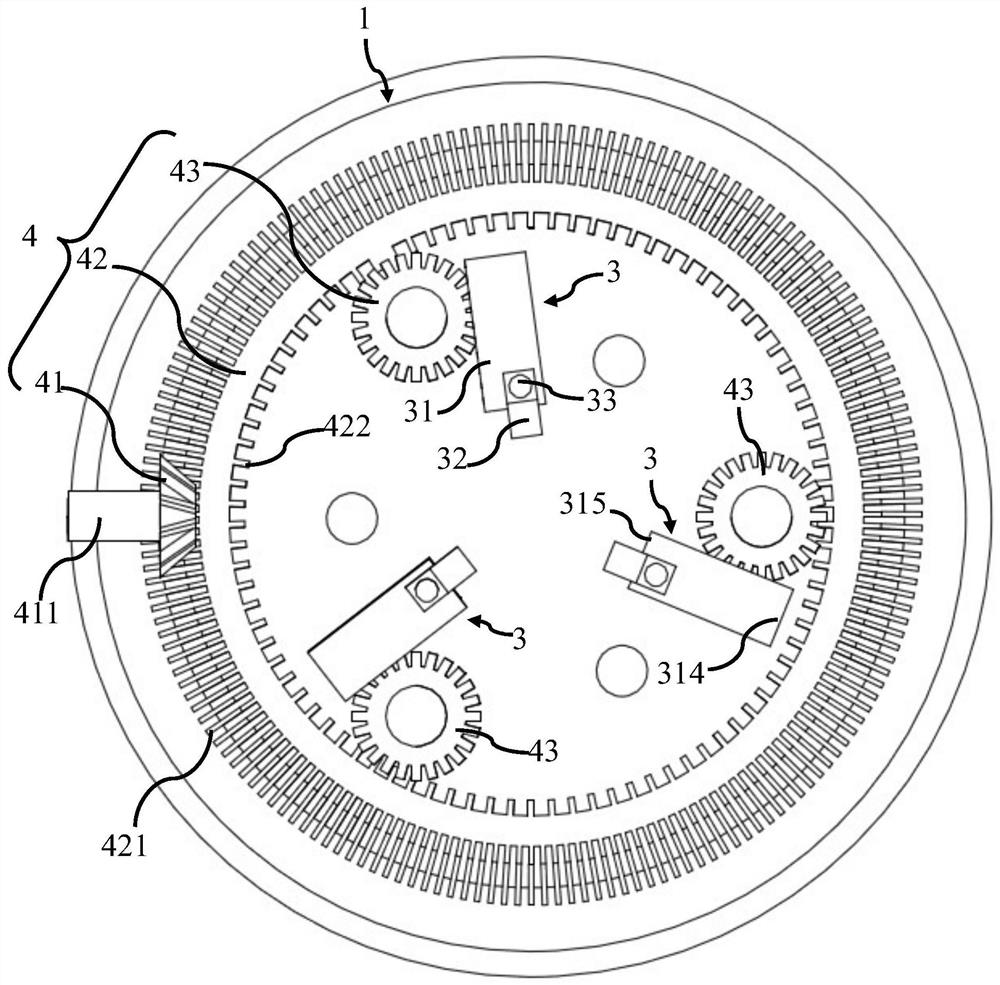

InactiveCN111993305AAchieving circumferential self-centeringAchieve axial fixationWork holdersCircular discPhysics

The invention discloses a clamp. The clamp comprises a base, a disc cover and multiple clamping claws. The disc cover comprises a circle of disc cover side plate and a disc cover top plate. Multiple top plate guide grooves are formed in the disc cover top plate. Each clamping claw comprises a clamping claw sliding rail and a clamping claw pressure head. The top faces of the clamping claw sliding rails are located above the disc cover top plate, and the clamping claw pressure heads are mounted on the top faces of the clamping claw sliding rails through locking bolts. At least part of each clamping claw pressure head can stretch out of the corresponding clamping claw sliding rail by facing the center of the disc cover top plate. A transmission device used for driving the multiple clamping claw sliding rails to move synchronously is mounted in the disc cover. According to the clamp, self centering of a sample disc can be achieved, it is ensured that the sample disc is located at the center position of the disc cover plate, meanwhile, peripheral and axial fixing of the sample disc is achieved, loosening and up-and-down motion are avoided in the experiment process of the sample disc, and testing precision is improved.

Owner:SHENHUA SHENDONG COAL GRP

Mango peeling device

InactiveCN108926011AImprove gripPrevent movementVegetable peelingFood treatmentEngineeringMechanical engineering

The present invention discloses a mango peeling device. The device comprises a rotary pushing mechanism, a material grabbing mechanism, a peel breaking mechanism and a peeling mechanism; the materialgrabbing mechanism comprises a first cylinder and a second cylinder; the second cylinder is arranged on the power output end of the first cylinder; the second cylinder is provided with two power output ends, each of which is connected to a fixing block; each fixing block is fixed with a connecting plate; each connecting plate is fixed with a clamping claw plate; each clamping claw plate is provided with four flexible clamping claws; each flexible clamping claw is sleeved by a first spring; the peel breaking mechanism comprises peel breaking knifes; each peel breaking knife is sleeved by a second spring; the peeling mechanism comprises a third cylinder; the third cylinder is connected to a swing upper connecting seat; the swing upper connecting seat is hinged to a swing lower connecting seat, and the two connecting seats are also connected by two third springs; the swing lower connecting seat is fixed with an air-operated clamping claw; and the power output end of the air-operated clamping claw is fixed with two peeling clamps. The device has the characteristics of high production efficiency and convenient operation.

Owner:DONGGUAN SONGYAN ZHIDA IND DESIGN CO LTD

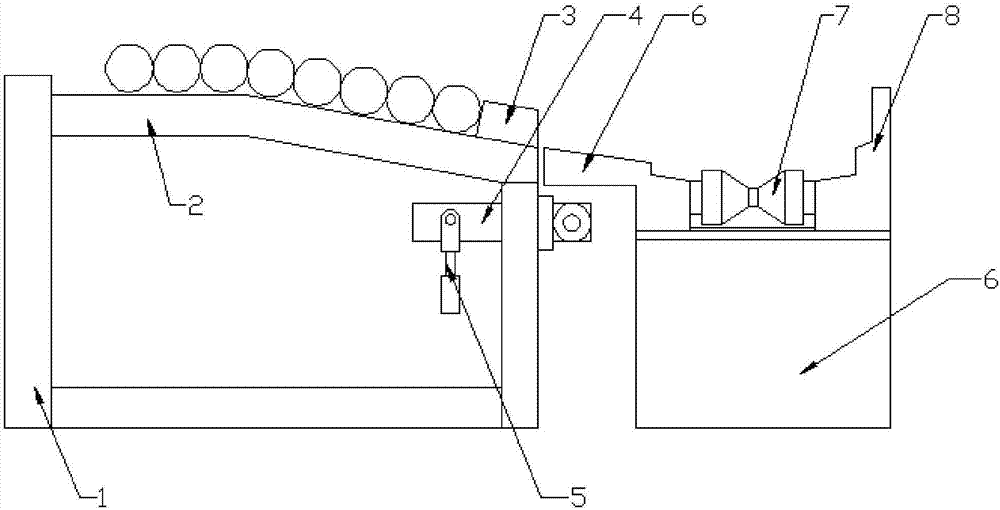

Feeding method for feeding mechanism of peeling equipment

The invention provides a feeding method for a feeding mechanism of peeling equipment, comprising the following steps: installing a feeding device, installing a jacking device, installing a conveying mechanism, installing a guiding mechanism, a debugging device and a using device, overcoming the problems in the prior art The technical problem of poor precision of the feeding mechanism of the peeling equipment, and the installation is simple and the operation is convenient, which ensures that there is only one anchor bolt for each feeding, and at the same time reduces the volume of the roller and improves the accuracy.

Owner:WUXI HOUFA AUTOMATIC EQUIP CO LTD

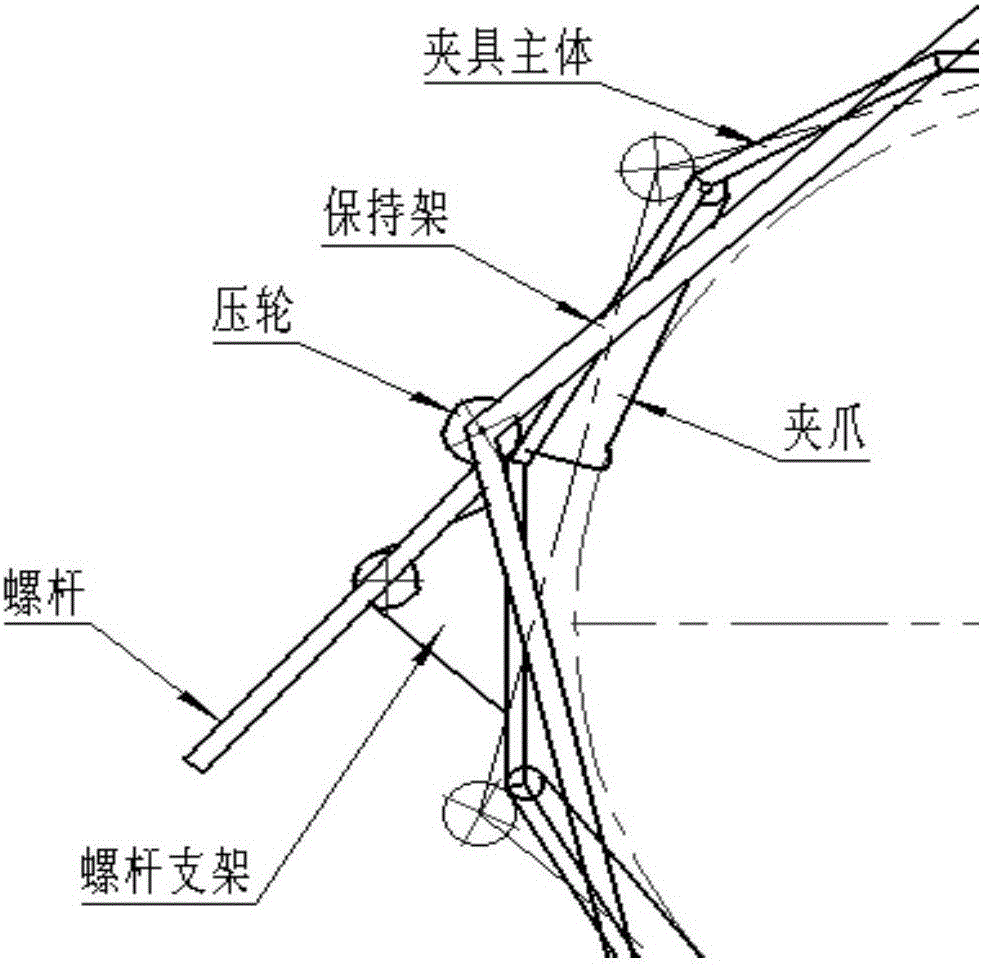

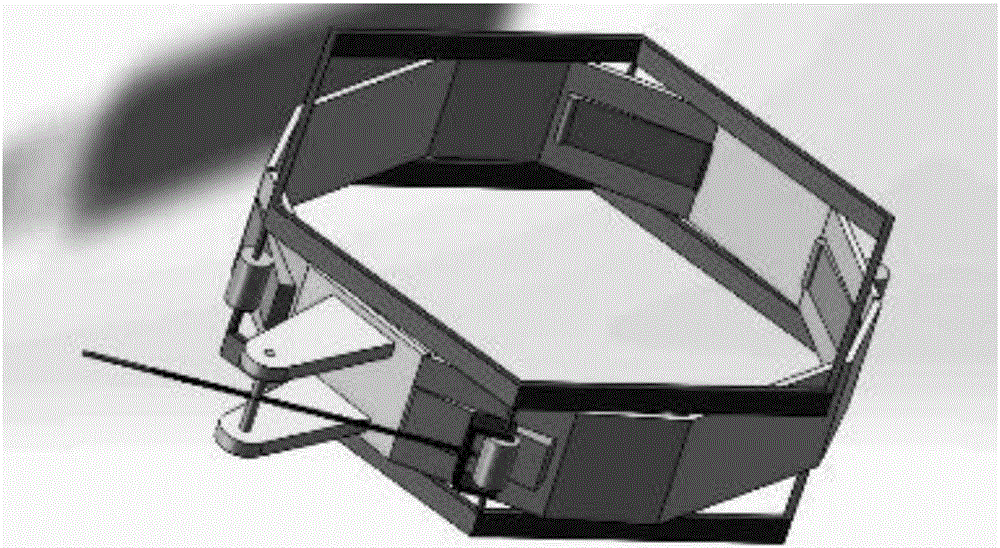

Self-centering clamping device adopting single-point driving mode

InactiveCN106002347AAchieve self-centerednessImprove stabilityPositioning apparatusMetal-working holdersEngineeringDriving mode

The invention belongs to a self-centering clamping structure and the object centering and positioning field, and particularly relates to a self-centering clamping device adopting a single-point driving mode. The self-centering clamping device consists of clamping jaws fixedly arranged on ac clamp main body and capable of swinging around a shaft, rotatable pressure wheels mounted between an upper holding frame and a lower holding frame, the holding frames and a screw for applying driving force, wherein the screw passes through a fixed nut on a screw bracket and then is fixed to a ring-shaped clamp main body; one end of the screw is pressed below the rotatable pressure wheels mounted between the upper holding frame and the lower holding frame; and wedge-shaped clamping jaws capable of swinging around the shaft are further mounted on the clamp main body below the pressure wheels. According to the self-centering clamping device adopting the single-point driving mode, the four pressure wheels are driven by the holding frames to act with the four clamping jaws, and move inwards, so that clamping action is completed and self-centering can be realized, and therefore, fixing stability can be further strengthened.

Owner:HARBIN ENG UNIV

Mango flower cutter

The invention discloses a mango flower cutter which comprises a material grabbing mechanism, a flower cutting mechanism and a flower cutting rotating mechanism. The material grabbing mechanism comprises a first linear motion device, a fixing base, a second linear motion device, a connecting plate and a material grabbing device; the fixing base is arranged on the first linear motion device, the second linear motion device is arranged on the fixing base, the connecting plate is arranged on the second linear motion device, the material grabbing device is arranged on the connecting plate, the flower cutting mechanism comprises a supporting base, a third linear motion device and a tool rest, the third linear motion device is arranged at the top face of the supporting base, the tool rest is arranged on the third linear motion device, a flower cutting cylinder is arranged on the tool rest, a cutter is connected to the flower cutting cylinder, the flower cutting rotating mechanism comprises adisc type motor and a stretchable cylinder, the disc type motor can driven mangos to rotate, and the stretchable cylinder can drive the mangos to ascend and descend; the mango flower cutter is convenient to operate and high in production efficiency.

Owner:DONGGUAN SONGYAN ZHIDA IND DESIGN CO LTD

Automatic hole opening device for large tank

ActiveCN108637310AOvercome the inconvenience of opening holes and low work efficiencyEasy hole operationPositioning apparatusMaintainance and safety accessoriesEngineeringChemical tank

The invention discloses an automatic hole opening device for a large tank. The defects that hole opening operation of a chemical tank is not convenient, and work efficiency is low are overcome. The device comprises a worktable and a hole opening rack; a support is arranged below the worktable, a rotation drive mechanism capable of driving the worktable to rotate to any angle is arranged between the worktable and the support, a clamping mechanism used for clamping the tank is arranged on the worktable, a mounting base is arranged on the hole opening rack in a lifting manner, a hole opening motor is arranged on the mounting base in a transverse moving manner, a hole opening tool bit is arranged on an output shaft of the hole opening motor, and the hole opening tool bit is arranged above theworktable. The automatic hole opening device for the large tank greatly facilitates hole opening operation of the chemical tank, and the hole opening work efficiency is improved.

Owner:杭州新安江工业泵有限公司

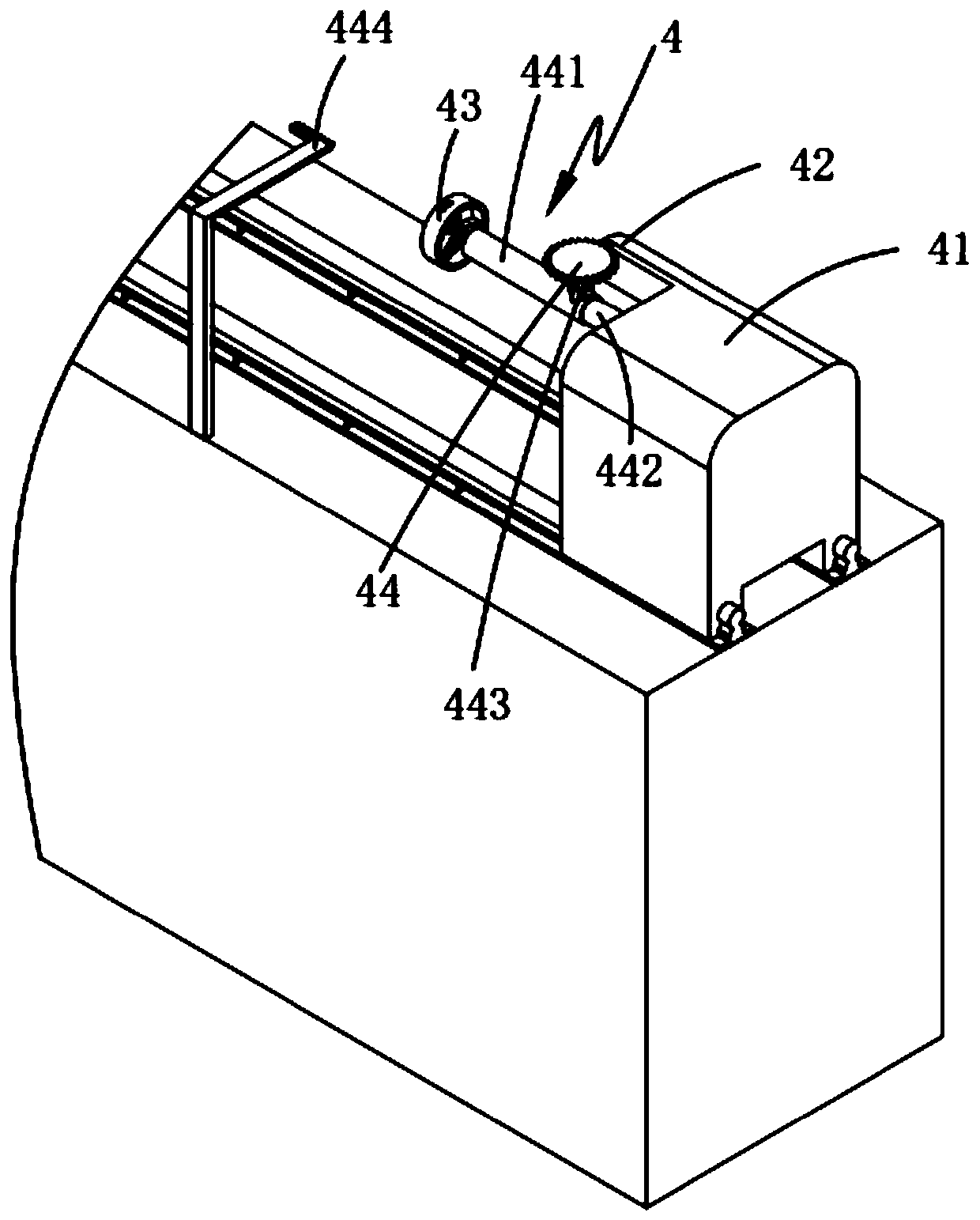

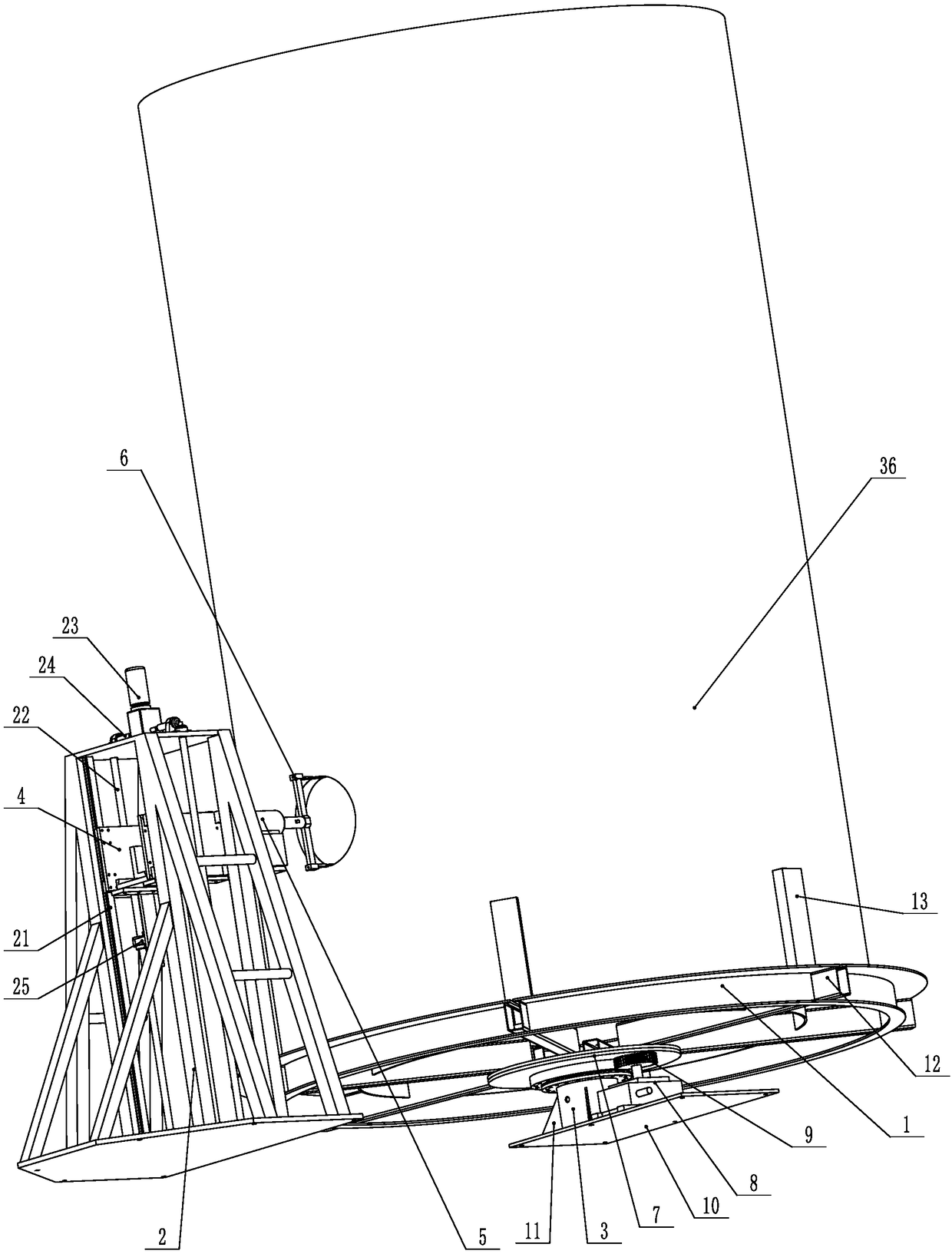

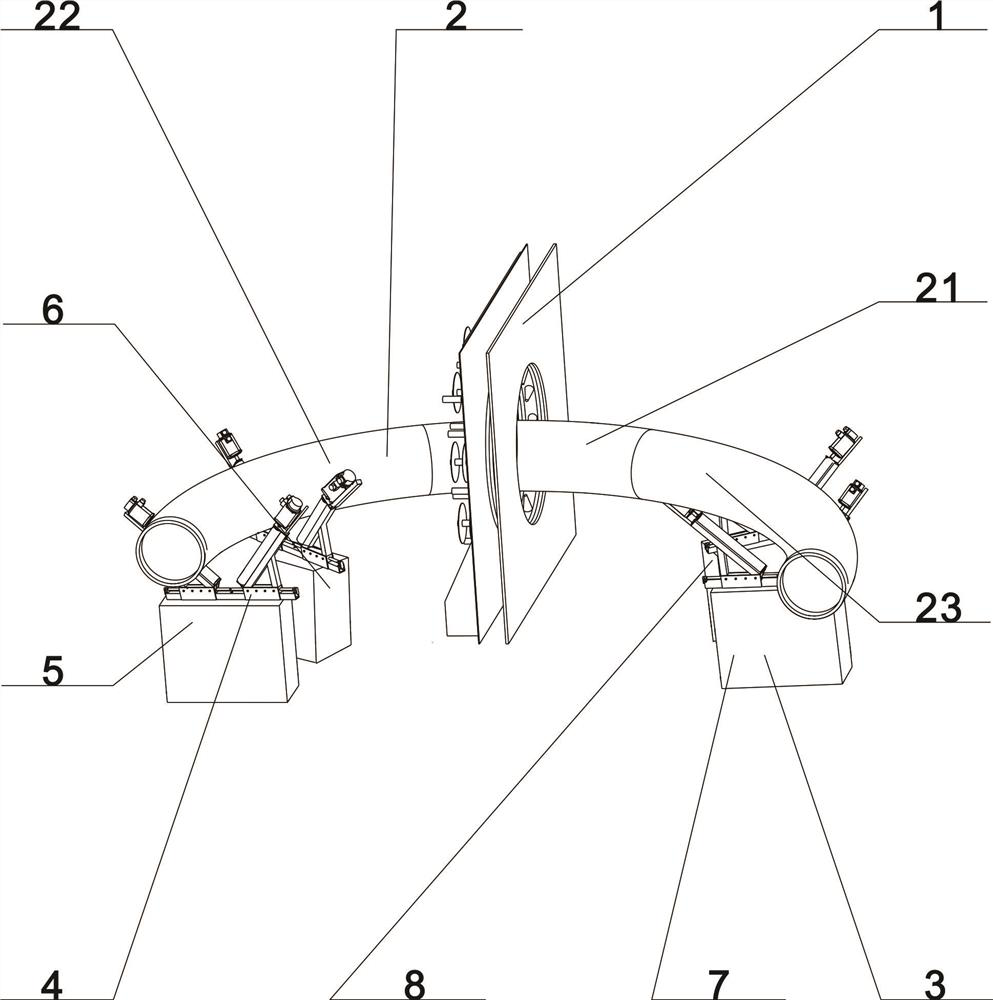

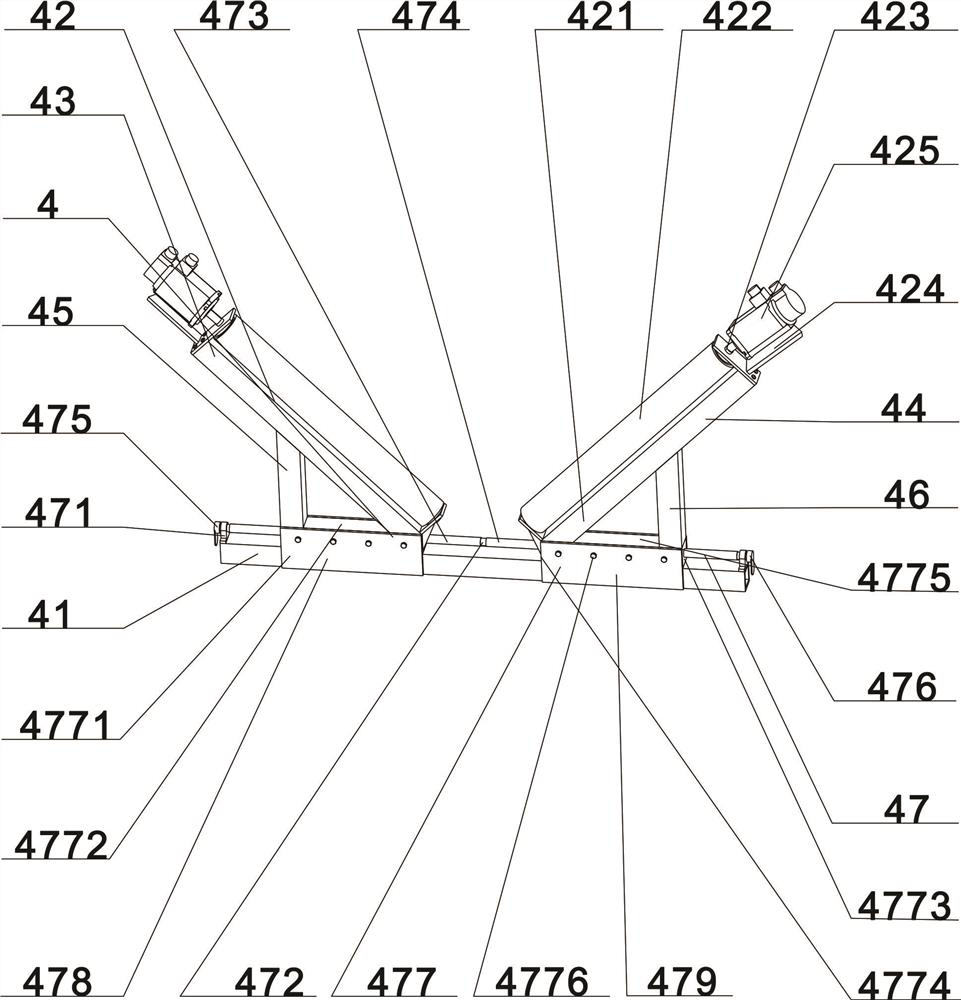

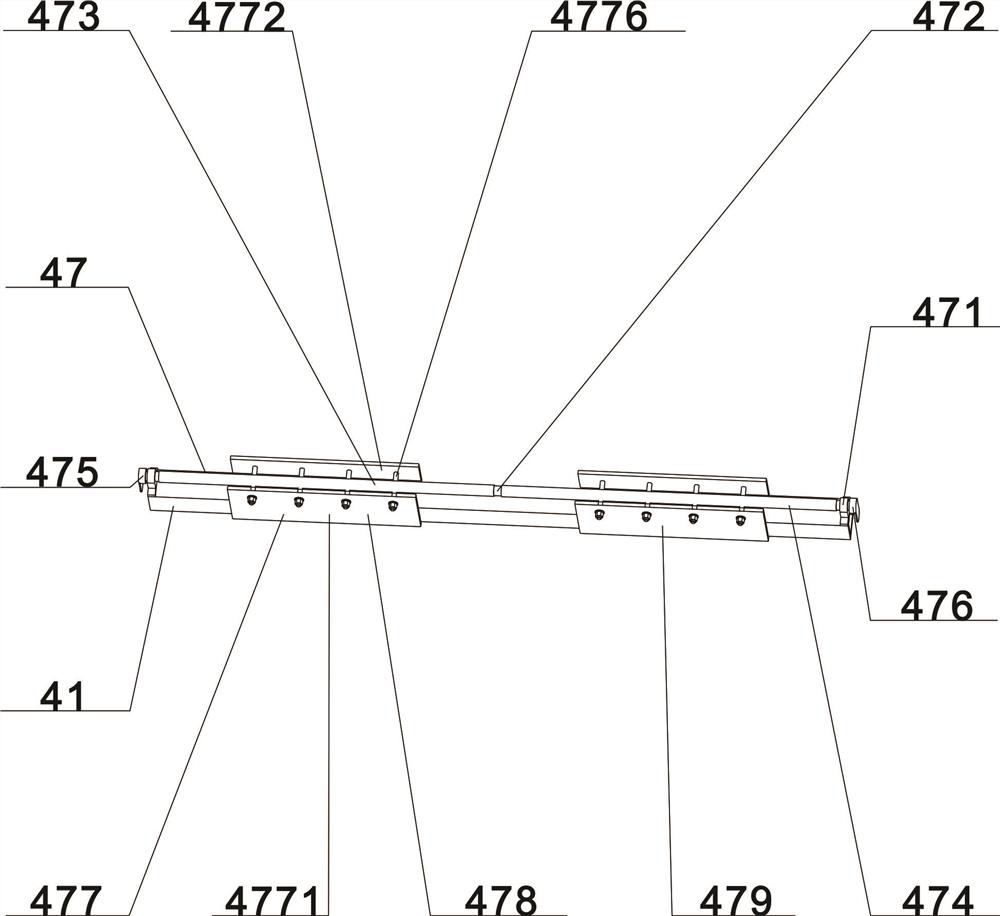

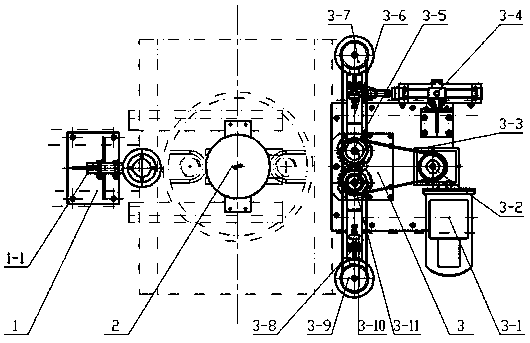

Elbow conveying device of elbow anti-corrosion adhesive tape winding machine

The invention belongs to the technical field of elbow conveying of elbow anti-corrosion adhesive tape winding machines, and relates to an elbow conveying device of an elbow anti-corrosion adhesive tape winding machine, a winding disc is fixedly arranged in the middle, an elbow penetrates through the center of the winding disc, a supporting table is fixedly arranged on the lower portion of the left end of the elbow and the lower portion of the right end of the elbow, and the supporting table is fixed to the ground; the driving centering support is transversely and fixedly arranged on the upper portion of the supporting table. The driving centering bracket is divided into a driving centering bracket I, a driving centering bracket II, a driving centering bracket and a driving centering bracket IV; the two supporting tables are arranged at the bottom of the left end of the bent pipe, and the two supporting tables are arranged at the bottom of the right side of the bent pipe. A driving centering support is arranged on the upper portion of each supporting table. According to the invention, the investment cost of equipment is reduced, the position adjustment between the support rollers of the support frame for supporting the bent pipe is realized, the adaptability to the bent pipes with different diameters is improved, and the self-driving and self-centering of the bent pipe on the driving and centering device are realized.

Owner:HENAN XINKAIYUAN PETROCHEM PIPELINE

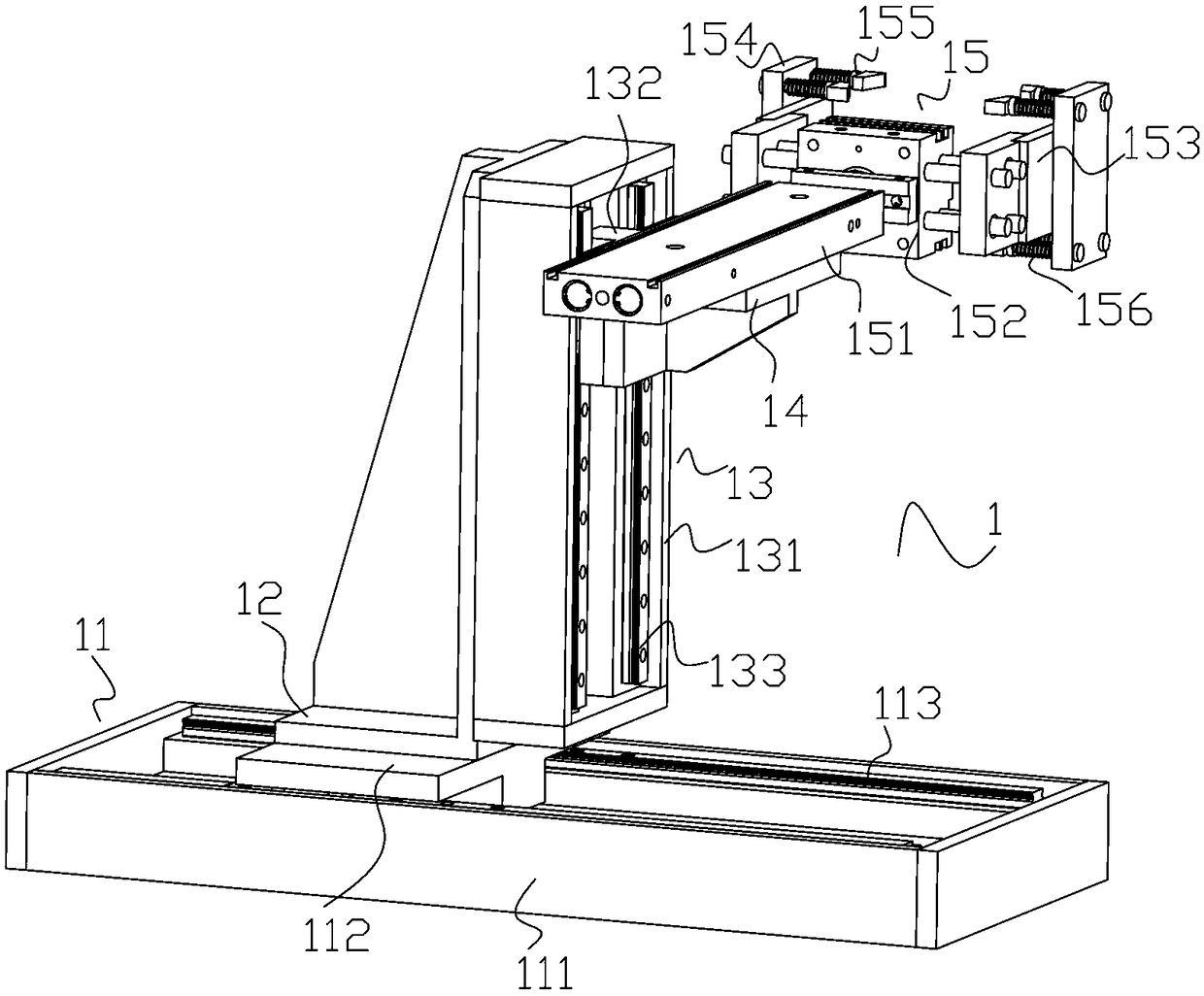

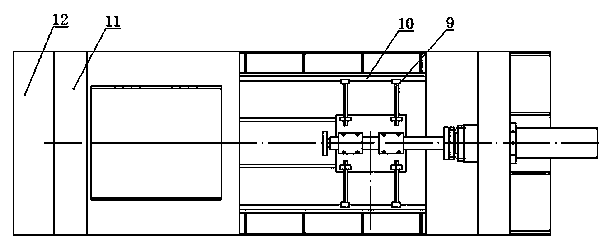

Variable cylinder hole reaming and honing floating tool

ActiveCN109702510AGuaranteed concentricityEasy to importPositioning apparatusMetal-working holdersProcessing accuracy

The invention belongs to the technical field of tool clamps, and relates to a variable cylinder hole reaming and honing floating tool. The variable cylinder hole reaming and honing floating tool comprises a mounting plate, a supporting pin mounting plate is vertically arranged on the upper surface of the mounting plate, a first support pin capable of elastically stretching out and drawing back isarranged on the supporting pin mounting plate in a through manner, and the upper surface of the mounting plate is also fixedly provided with a centering plate; a workpiece clamp mounting bottom plateis arranged above the mounting plate in parallel, the bottom surface of the workpiece clamp mounting bottom plate is fixedly provided with a connecting plate, and the working end of the first supportpin elastically abuts against the side face of the connecting plate; and a ball head floating shaft is fixed to the middle part of the bottom surface of the connecting plate, the ball head floating shaft is provided with a centering plate in a matched manner, and the centering plate and the ball head floating shaft are connected in a movable fit manner. The variable cylinder hole reaming and honing floating tool is simple in structure, durable and low in maintenance cost; a workpiece can be moved and rotated on the x-axis, can be moved and rotated on the y-axis and can be rotated and floated on the z-axis; the concentricity of a cutter and a hole can be ensured, and the machining precision is improved; and the floating tool can achieve self-centering, and the knife is conveniently guided into the workpiece hole.

Owner:WUXI WEIFU PRECISION MACHINERY MFG

A mango peeling machine

ActiveCN108936717BAchieve self-centerednessAchieve separationVegetable peelingFood treatmentEngineeringKnife holder

The invention discloses a mango peeling machine, which includes a material pushing mechanism and a peeling mechanism, the material pushing mechanism includes a material ejecting cylinder and a material pushing head, and the material ejecting cylinder is used to drive the material pushing head to push For mango, the peeling mechanism includes a peeling device, a head cutting device and a peeling device, the peeling device includes a square frame seat, inner claws and outer claws, the inner claws are fixed on the square frame seat, and the outer claws are fixed on the square frame seat. The claw is fixed on the frame seat, one end of the inner claw is provided with an arc-shaped tip, and the other end of the outer claw is fixed with an electromagnetic power block, and the electromagnetic power block is used to drive the outer claw and the The inner claws are engaged, the skin-breaking device includes a square knife seat frame and a knife frame, the knife seat frame is fixed on the square frame seat, the knife frame is installed on the knife seat frame, and the knife A skin-breaking knife is installed on the frame, and the head cutting device is located between the peeling device and the skin-breaking device; the present invention has the characteristics of simple structure, high production efficiency and convenient operation.

Owner:JIANGSU SIDA HEAVY IND

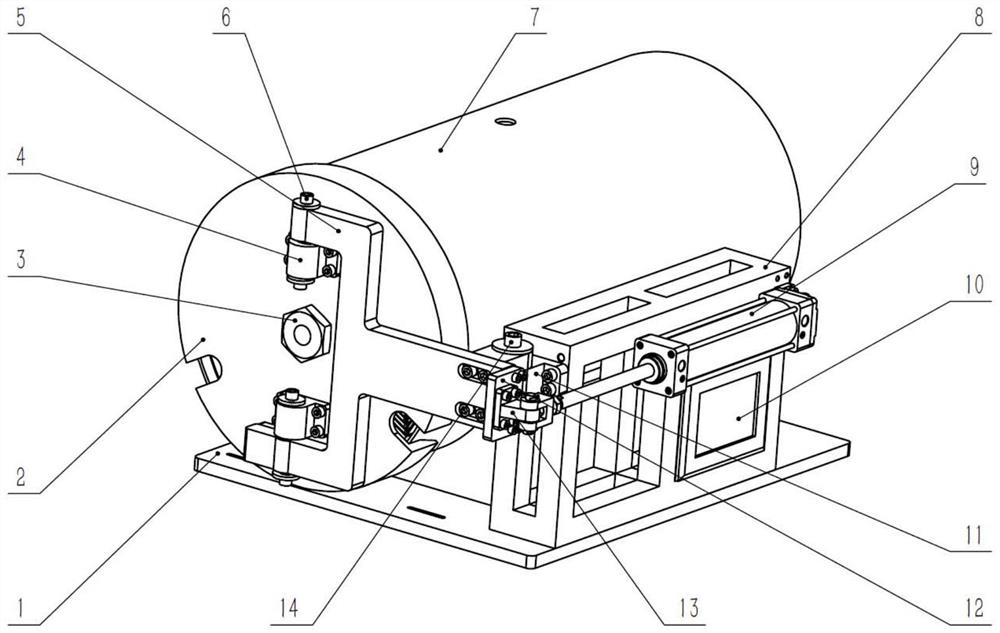

A self-centering magnetic shielding device with automatic opening and closing

ActiveCN111044955BReduce electromagnetic influencePrevent rotationMagnetic sensor packagingRotational freedomStructural engineering

The invention discloses an automatic opening and closing self-centering magnetic shielding device, which specifically includes a pneumatic drive unit, a self-centering cover unit, and a magnetic shielding cavity. The pneumatic drive unit is connected with the self-centering cover unit to drive the self-centering The center cover unit rotates to realize the automatic opening or closing of the magnetic shielding device; the self-centering cover unit includes a cover body, a driving force arm, a horizontal and vertical adjustment mechanism arranged on the cover body, one end of the driving force arm and a pneumatic drive The unit is connected, and the other end is rotatably connected with the cover body to realize the rotation of the cover body around the driving force arm; the vertical and horizontal degrees of freedom of the cover body are realized through the horizontal and vertical adjustment mechanism; the cover body is closed with the magnetic shielding cavity An inward guide bevel is set at the position, and the self-centering of the self-centering cover unit and the magnetic shielding cavity is realized through the guide bevel, rotational degree of freedom, horizontal and vertical degrees of freedom. The invention has the advantages of compact structure, convenient control and good magnetic shielding effect.

Owner:HANGZHOU INNOVATION RES INST OF BEIJING UNIV OF AERONAUTICS & ASTRONAUTICS

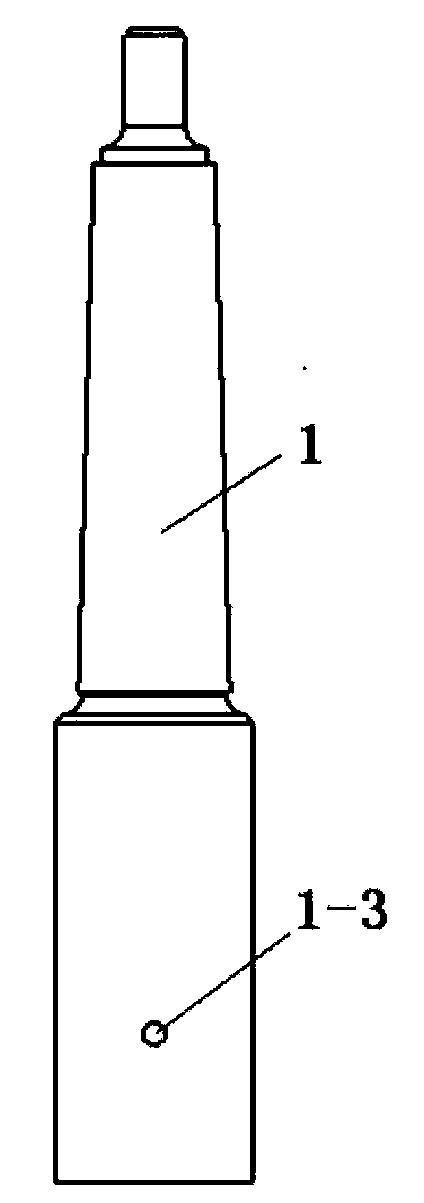

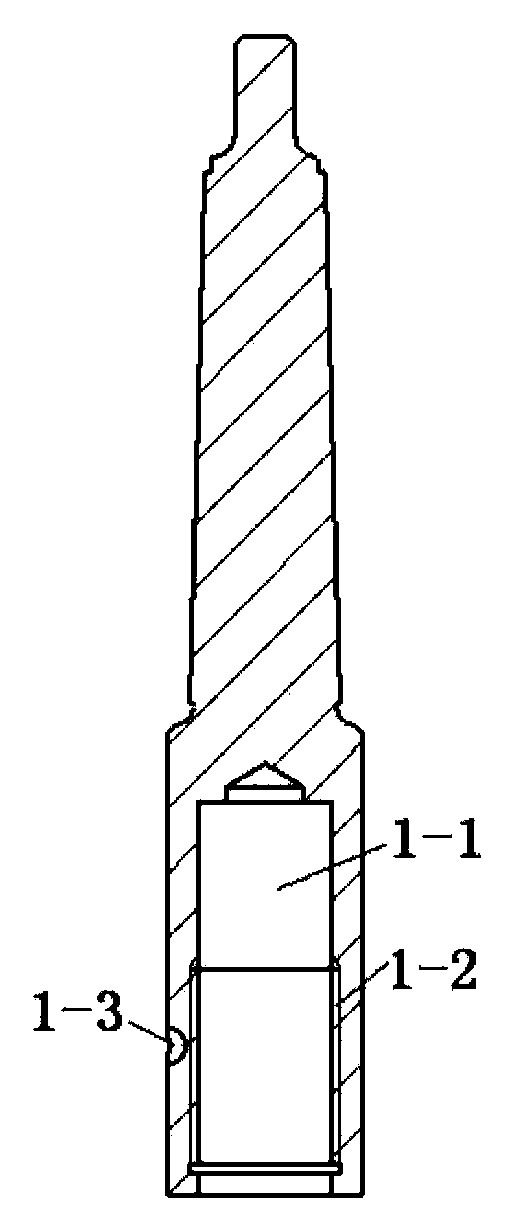

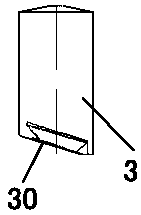

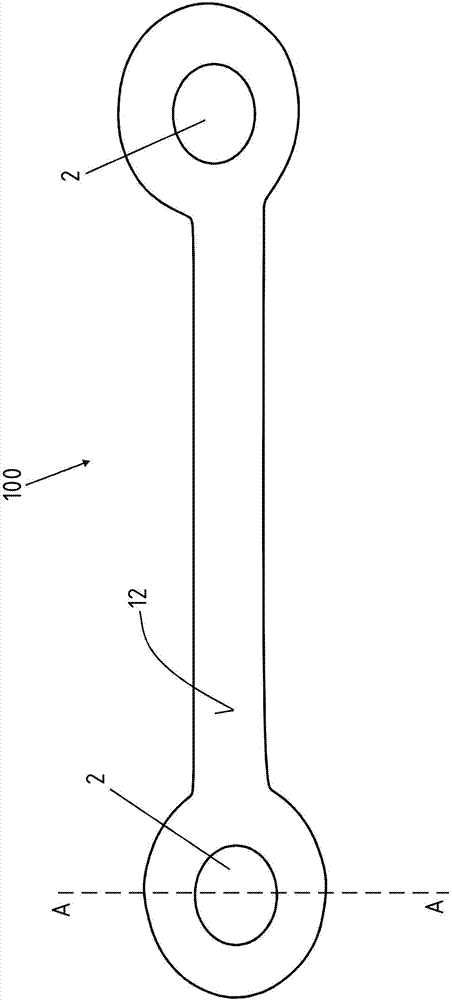

Self-centering outer-diameter clamp

InactiveCN106584177AEasy loading and unloadingGuaranteed concentricityPositioning apparatusMetal-working holdersEngineeringMechanical engineering

A self-centering outer-diameter clamp is composed of a clamp base and a clamp pull rod. The clamp base is composed of a contracting face, a guiding face and a mounting face. The clamp pull rod is composed of a spindle connecting thread, a connecting rod, a guiding step, a contracting receding groove and a contracting body. The self-centering outer-diameter clamp is characterized in that the clamp pull rod is inserted into the clamp base, and the clamp is positioned through the guiding step and the guiding face. The self-centering outer-diameter clamp is simple and reliable in structure, a workpiece is convenient to assemble and disassemble, self-centering can be achieved, machining precision is improved, and the concentricity and perpendicularity of a machined face and a workpiece inner hole can be guaranteed; and the self-centering outer-diameter clamp is suitable for being applied and popularized in the fields where positioning and clamping need to be achieved relying on workpiece inner holes.

Owner:徐四儿

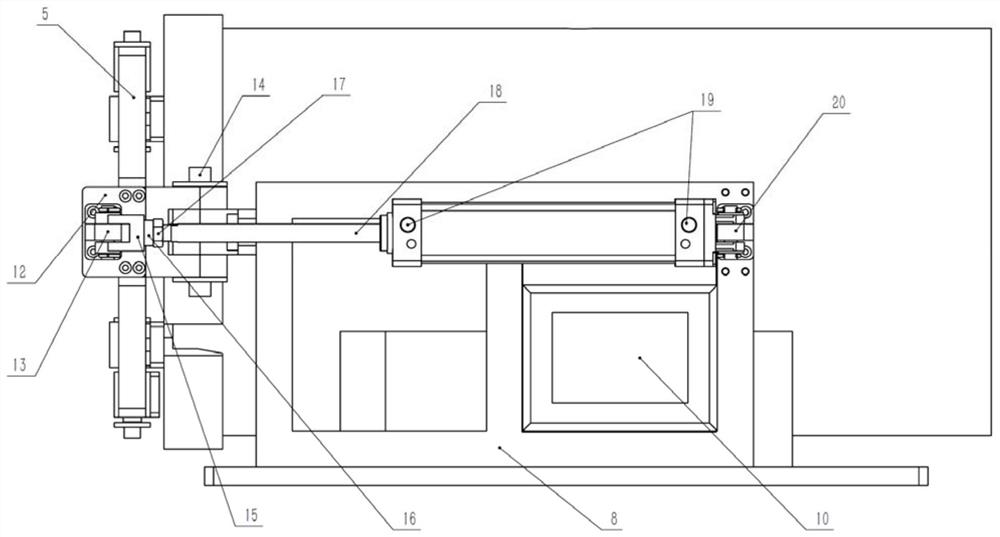

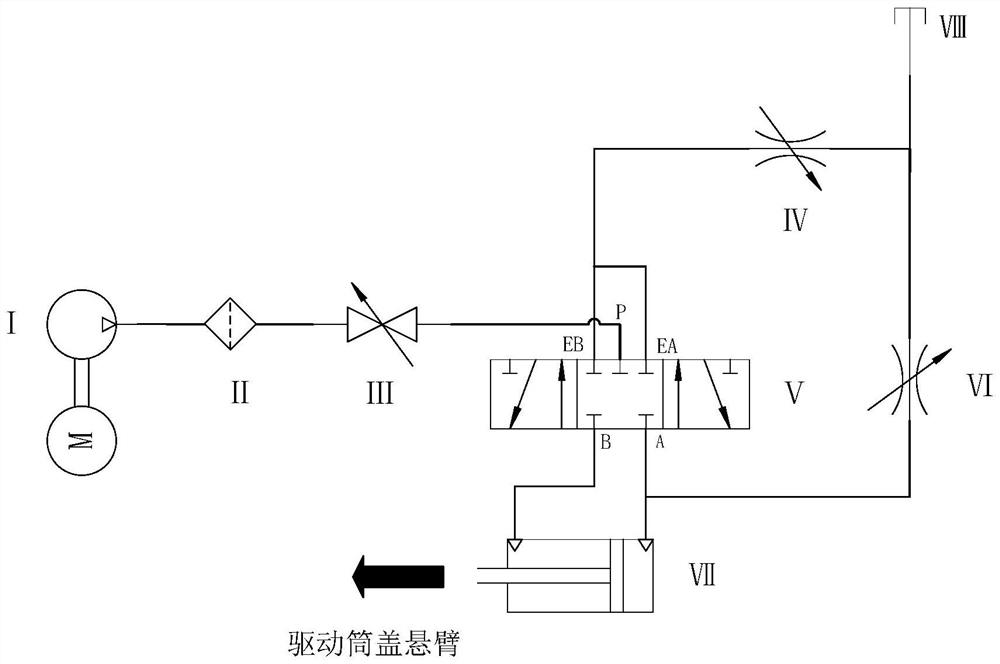

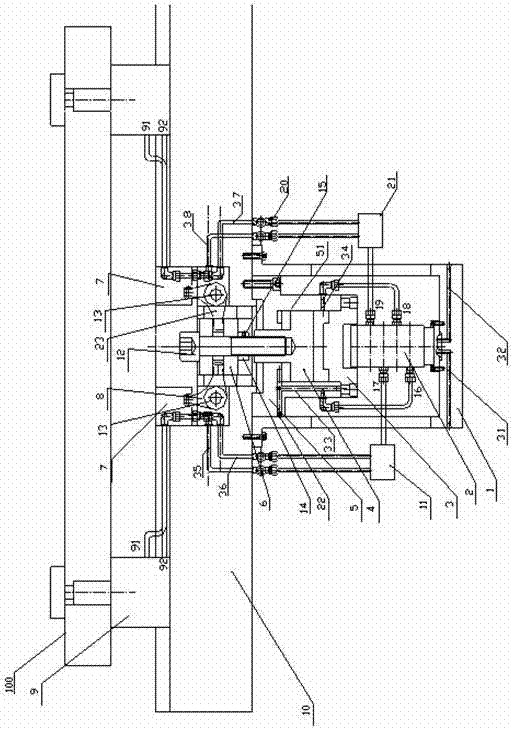

Self-centering of Worktable and Control Method of Workpiece Clamping Device

InactiveCN102554662BAchieve self-centerednessAvoid deformationAutomatic control devicesFeeding apparatusSolenoid valveCompression method

The invention discloses a self-centering and work piece clamping device for a working table and a control method of the self-centering and work piece clamping device. The device comprises hydraulic claws which are pushed by a piston to close or open. The work piece is clamped by compression method instead of clamping method in the prior art, so as to prevent deformation of thin-wall parts during the clamping process. The closed or opened state of each oil outlet is controlled by an integrated solenoid valve, so that the work piece has the self-centering effect. The invention has the advantages that the device changes the conventional manual centering and inner / outer-side clamping structure in the prior art, increases the work piece clamping efficiency, prevents deformation of the work piece during the clamping process, improves the reliability of work piece machining, and reduces the production cost.

Owner:SANY GRP

Special hydraulic machine for horizontal fan pressure shaft

InactiveCN102806457BAchieve self-centerednessAvoid suppressing influenceMetal working apparatusEngineeringMechanical engineering

The invention relates to a special hydraulic machine for a horizontal fan pressure shaft. The special hydraulic machine comprises a horizontal stand, wherein the stand consists of a base and brackets arranged on two sides of the base. The special hydraulic machine is characterized in that a press driving mechanism capable of moving along the horizontal direction is arranged on the bracket on one side of the base; the front end of the press driving mechanism is connected with a pressing plate; a fan bracket is arranged at the bottom of the stand; and an upper end surface of the fan bracket is of a V-shaped groove structure. When the special hydraulic machine is in use, a fan casing is arranged on the fan bracket and the pressing plate is pushed by the press driving mechanism to move forwards to press the fan shaft into the center of the casing. A horizontal length adjusting mechanism is arranged between the press driving mechanism and the pressing plate and can adapt to casings with different thicknesses and ensure a proper pressing force. A guiding support mechanism is arranged on the horizontal length adjusting mechanism, and thus the horizontal forward movement of the pressing plate is ensured, the stress direction is accurate and the bias press is avoided.

Owner:NANTONG GAOYE HEAVY IND CO LTD

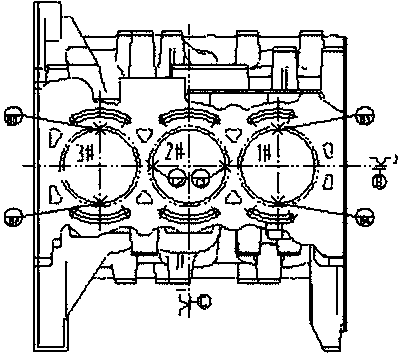

Engine cylinder wedge-shaped centering clamp

PendingCN108145493AEliminate errorsUniform finishing allowancePositioning apparatusMetal-working holdersEngineeringWedge shape

The invention relates to an engine cylinder wedge-shaped centering clamp. The engine cylinder wedge-shaped centering clamp comprises a guiding sliding sleeve with a main guiding hole, and a positioning mechanism which is connected with the guiding sliding sleeve in a matched manner. The positioning mechanism comprises three or more positioning sliding clamping heads and sliding pieces which are intransmission connection with the positioning sliding clamping heads. The positioning sliding clamping heads are arranged in positioning guiding holes in the side portion of the guiding sliding sleevein the radial direction, the sliding pieces are arranged in the main guiding hole of the guiding sliding sleeve, and the axial directions of the positioning guiding holes are located in the same plane perpendicular to the axial direction of the main guiding hole. The tails of the positioning sliding clamping heads are connected with a plurality of dovetail grooves in the sliding pieces in a one-to-one corresponding fit manner. The dovetail grooves are obliquely arranged relative to the axial direction of the main guiding hole, and the inclination angles of the dovetail grooves are consistent.The guiding sliding sleeve is provided with a standard end face perpendicular to the axial direction of the main guiding hole. According to the scheme, air cylinder sleeve self-centering can be achieved, errors are eliminated to the maximum degree, it is guaranteed that the later air cylinder sleeve finish machining allowance is uniform, and single sides are avoided.

Owner:RUIQING AUTOMOBILE ENGINE TECH

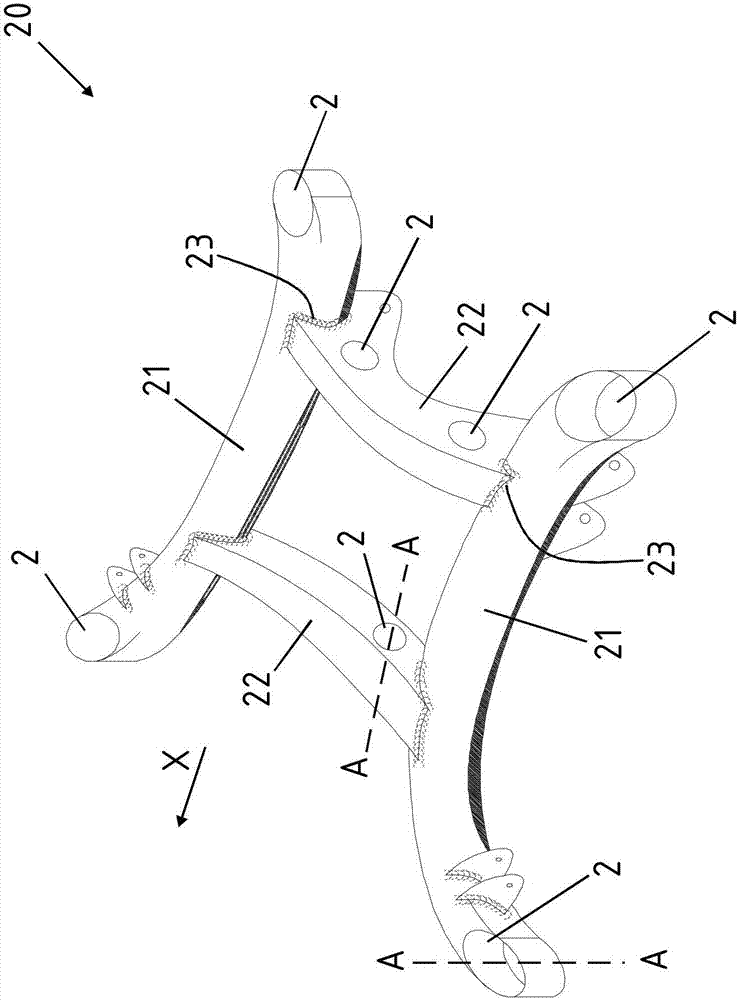

Axle component for a motor vehicle axle

InactiveCN107303790ANo increase in construction spaceAvoid skewUnderstructuresPivoted suspension armsInterior space

An axle component for a motor vehicle axle is disclosed having rim holes for the insertion of a rubber-metal bearing. The upper and lower collars of the two rim holes are oriented in the same direction. An outwardly oriented collar is set back into the interior space in relation to an outer wall of the axle component. Thus the precision of a press-in process is improved and necessary structural space is not increased at the same time.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

A self-centering wear-free rotating barrel device

ActiveCN105800539BAchieve self-centerednessPrecise positioningBarrels/casks fillingEngineeringSkin damage

The invention discloses a self-centering non-abrasive drum rotating device and a drum rotating method thereof, which include a positioning mechanism, a bucket jacking mechanism and a driving mechanism, and are characterized in that the positioning mechanism includes a positioning bracket and a free wheel train; The mechanism is arranged under the transmission system and includes a guide seat and a turntable; the rotating bucket mechanism includes a power mechanism and a turn seat. It includes the following working steps. When the material bucket reaches the designated position, the top bucket mechanism 2 pushes the turntable to lift through the cylinder to withstand the material bucket; the two rotating arms in the bucket rotation mechanism rotate with the two gears as the center of the circle, and the gear cylinder Hold the material barrel tightly when the stroke is maximum; the rollers in the rotating barrel mechanism rotate to drive the material barrel to rotate and align with the mouth of the barrel. The invention has the advantages of high positioning accuracy and energy saving, and can avoid bumping into the barrel during positioning and rotating the barrel, avoiding deformation of the material barrel, and further environmental pollution caused by skin damage or deformation of the material barrel during transportation. .

Owner:CHANGCHUN BEIFANG INSTR EQUIP +1

A self-centering chuck and cutting device for cutting square tubes

InactiveCN106238929BAchieve self-centerednessSimple structureLaser beam welding apparatusSlide plateEngineering

The invention discloses a self-centering chuck for square pipe cutting and a cutting device. The self-centering chuck comprises an inner sleeve, an outer sleeve and a hollow spindle, wherein the inner sleeve, the outer sleeve and the hollow spindle are coaxially mounted in sequence from inside to outside. The inner sleeve is in clearance fit with the outer sleeve, and the outer sleeve is in clearance fit with the hollow spindle. The hollow spindle is driven by a driving device to rotate along the axis of the hollow spindle. One end of the outer cylindrical surface of the inner sleeve is connected with driving air cylinders driving the inner sleeve to move in the axis direction of the hollow spindle, and the other end of the outer cylindrical surface of the inner sleeve is engaged with transition gears; one end of the outer cylindrical surface of the outer sleeve is connected with driving air cylinders driving the outer sleeve to rotate in the axis direction of the hollow spindle, and the other end of the outer cylindrical surface of the outer sleeve is engaged with transition gears; and the transition gears are fixed to the hollow spindle and synchronously rotate along with the hollow spindle. Meanwhile, the transition gears are engaged with racks, the racks are mounted in the radial direction of the hollow spindle and are perpendicular to the axis direction of the hollow spindle; and the racks drive sliding plates connected with the racks to move in the radial direction of the hollow spindle, and clamping devices used for clamping workpieces are mounted on the sliding plates.

Owner:UNIV OF JINAN

Mango peeling machine

ActiveCN108926009AImprove gripPrevent movementVegetable peelingFood treatmentEngineeringPower output

The invention discloses a mango peeling machine. The machine comprises a rotary ejection mechanism, a gripping mechanism, a crushing mechanism and a peeling mechanism, wherein the gripping mechanism comprises a first cylinder and a second cylinder, and the second cylinder is arranged at the power output end of the first cylinder; two power output ends are arranged on the second cylinder, and are respectively connected with a fixed block which is fixedly provided with a connecting plate; a clamping plate is fixed on each connecting plate, and is provided with four flexible clamping jaws; the flexible clamping jaws are provided with first springs in a sleeving manner; the crushing mechanism comprises a crushing knife which is provided with a second spring in a sleeving manner; the peeling mechanism comprises a third cylinder; the third cylinder is connected with an oscillating upper connecting seat; the oscillating upper connecting seat is hinged with an oscillating lower connecting seat, and two third springs are connected between the oscillating upper connecting seat and the oscillating lower connecting seat; pneumatic clamping jaws are fixed on the oscillating lower connecting seats; and two peeling clips are fixed at the power output ends of the pneumatic clamping jaws. The mango peeling machine has the characteristics of high production efficiency and convenience in operation.

Owner:黎钗

A kind of elastic tap chuck

ActiveCN103433572BAchieve self-centerednessIncrease clamping stiffnessThread cutting machinesEngineeringMachine tool

Owner:常州宇拓工业装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com