Patents

Literature

835 results about "Feed drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drive To Feed is an initiative made possible by Nutra Blend, LLC, its customers and suppliers whom are working together to provide food for hungry children.

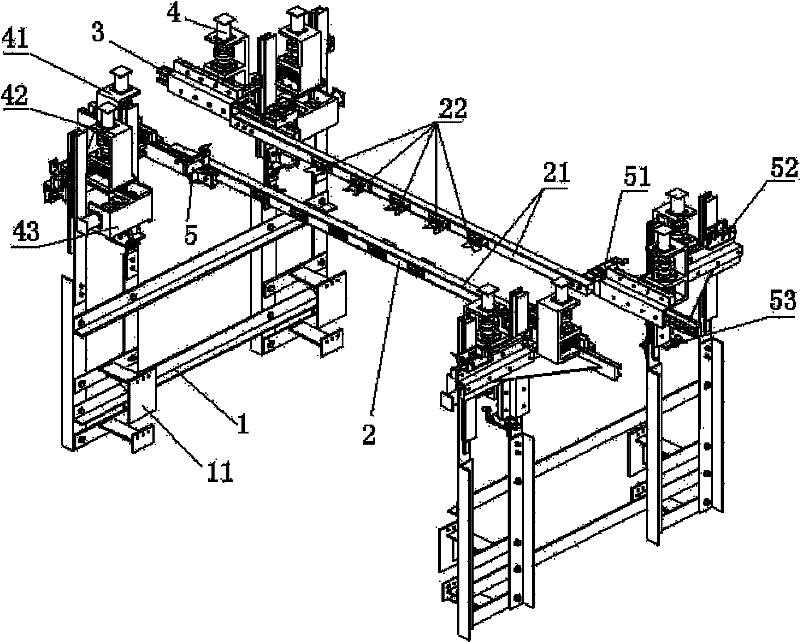

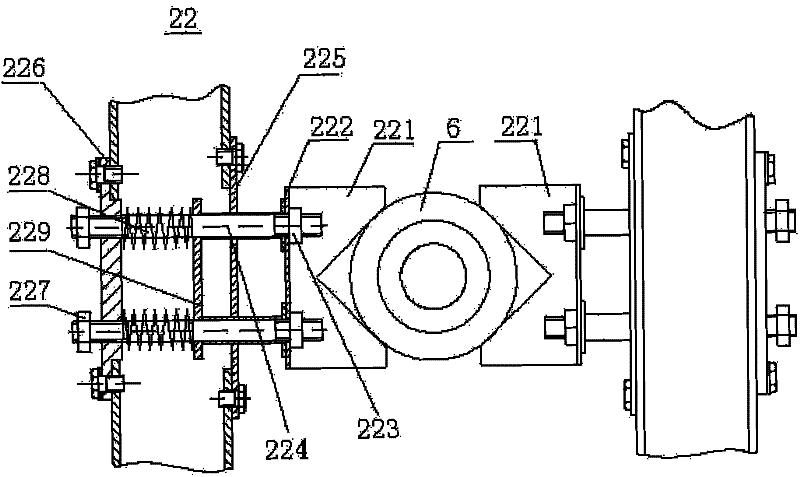

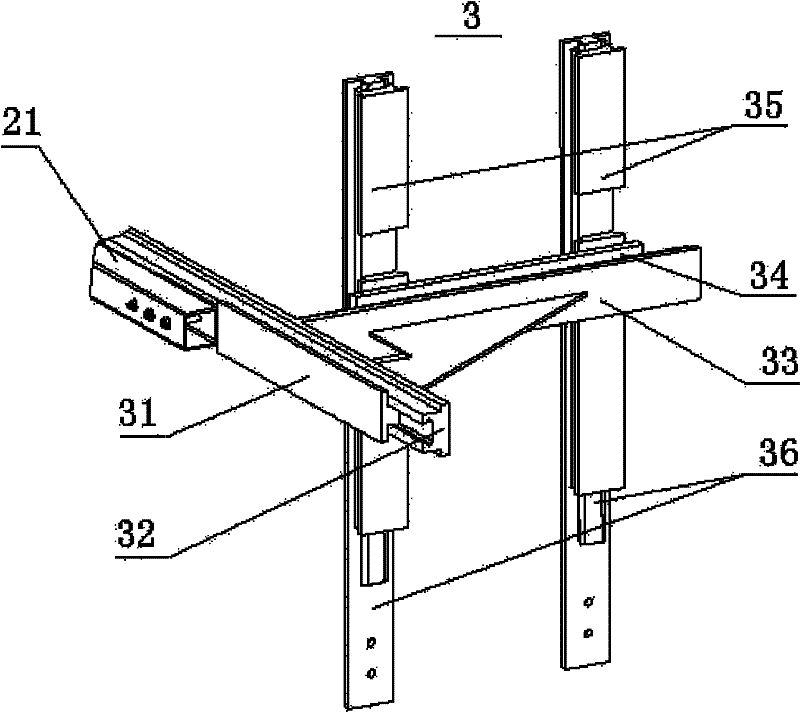

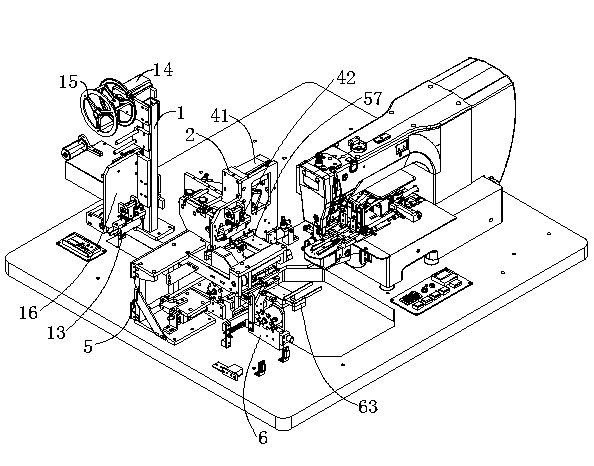

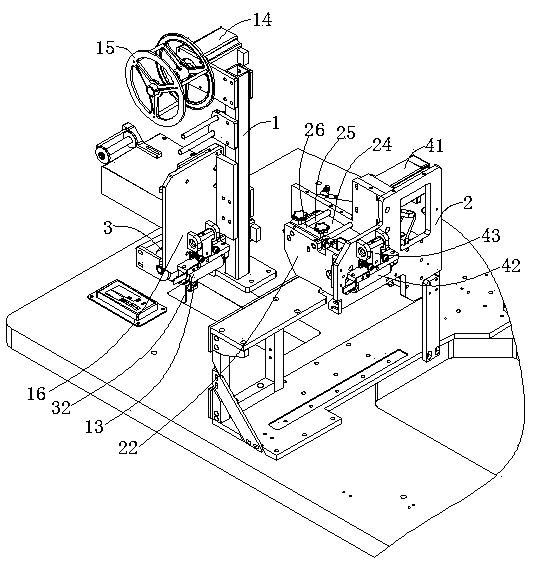

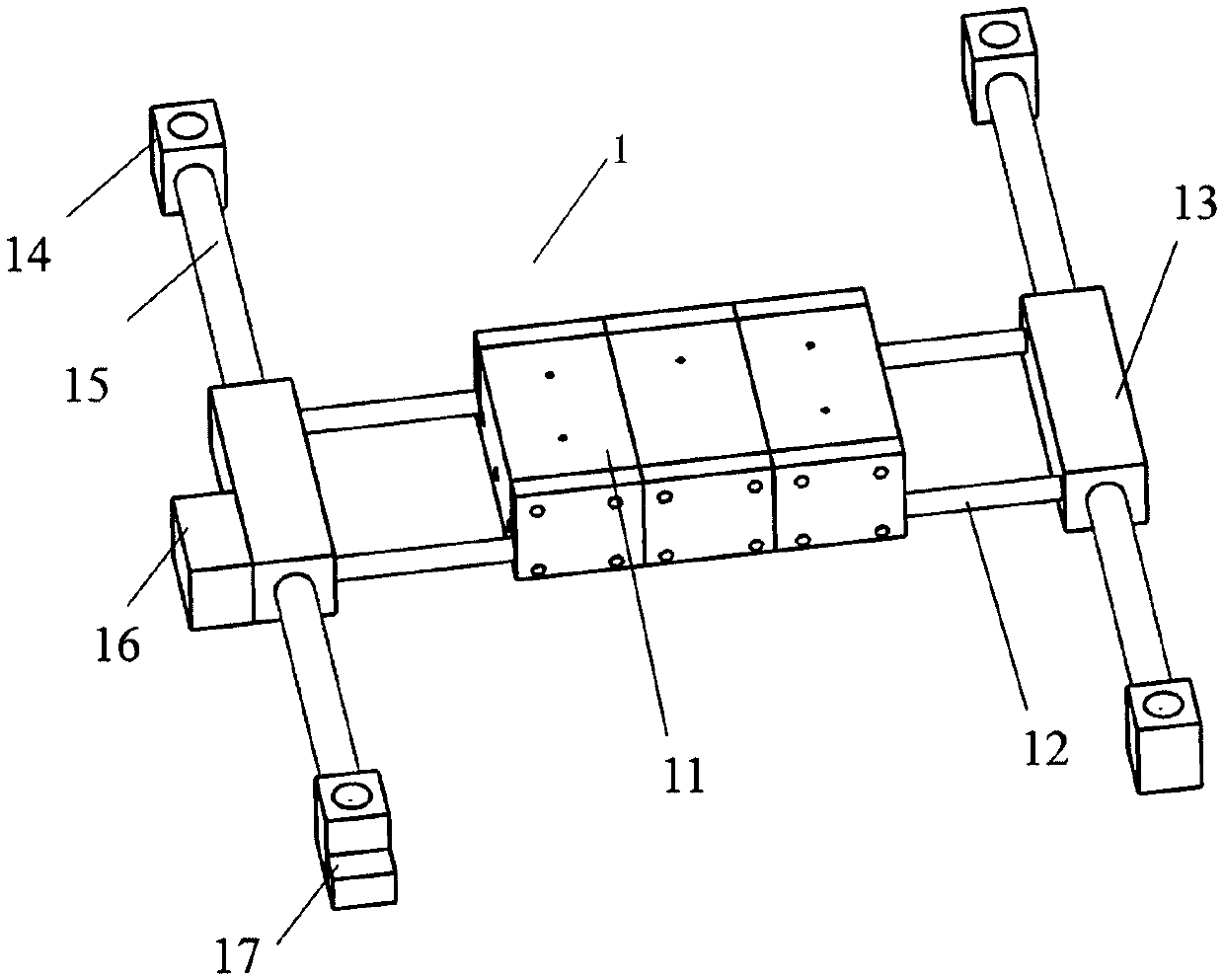

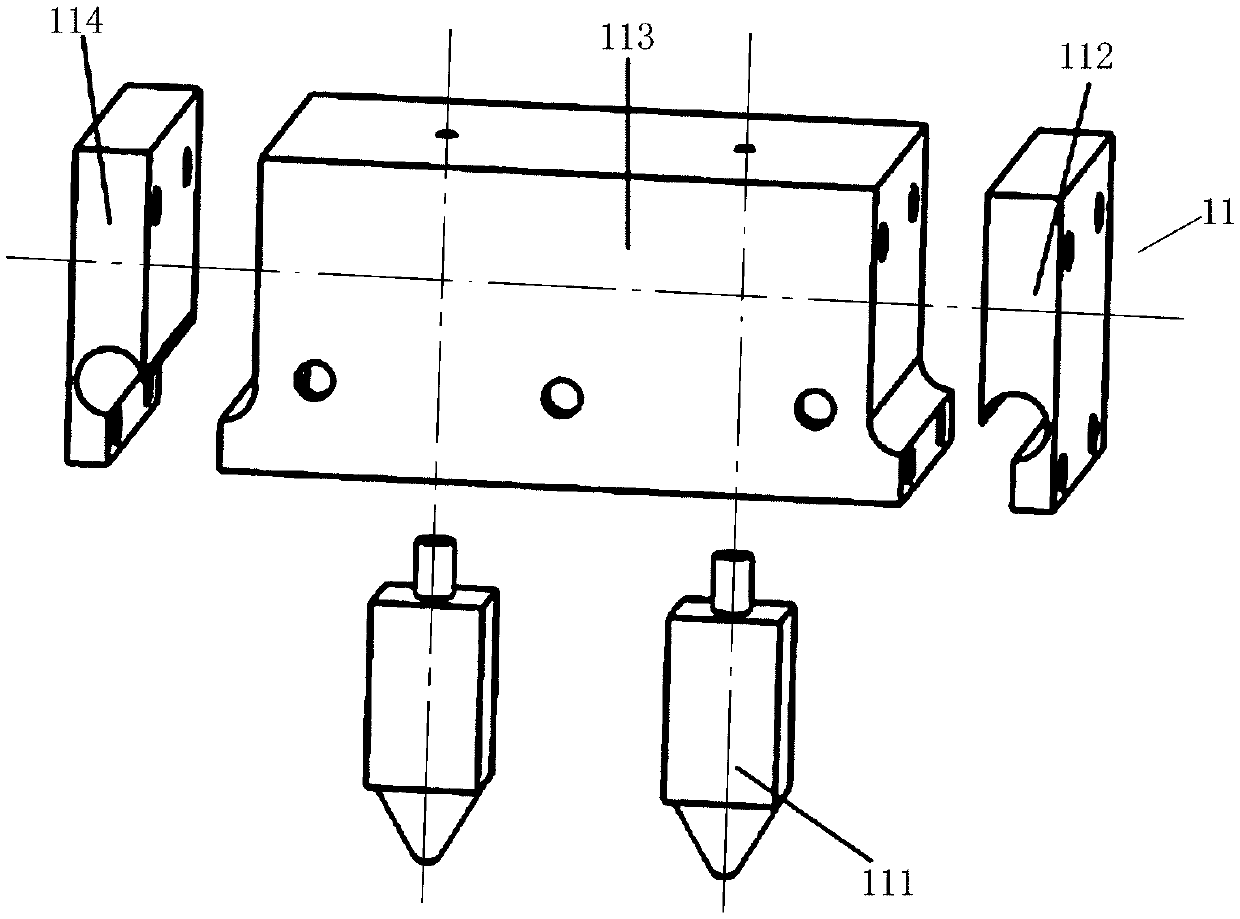

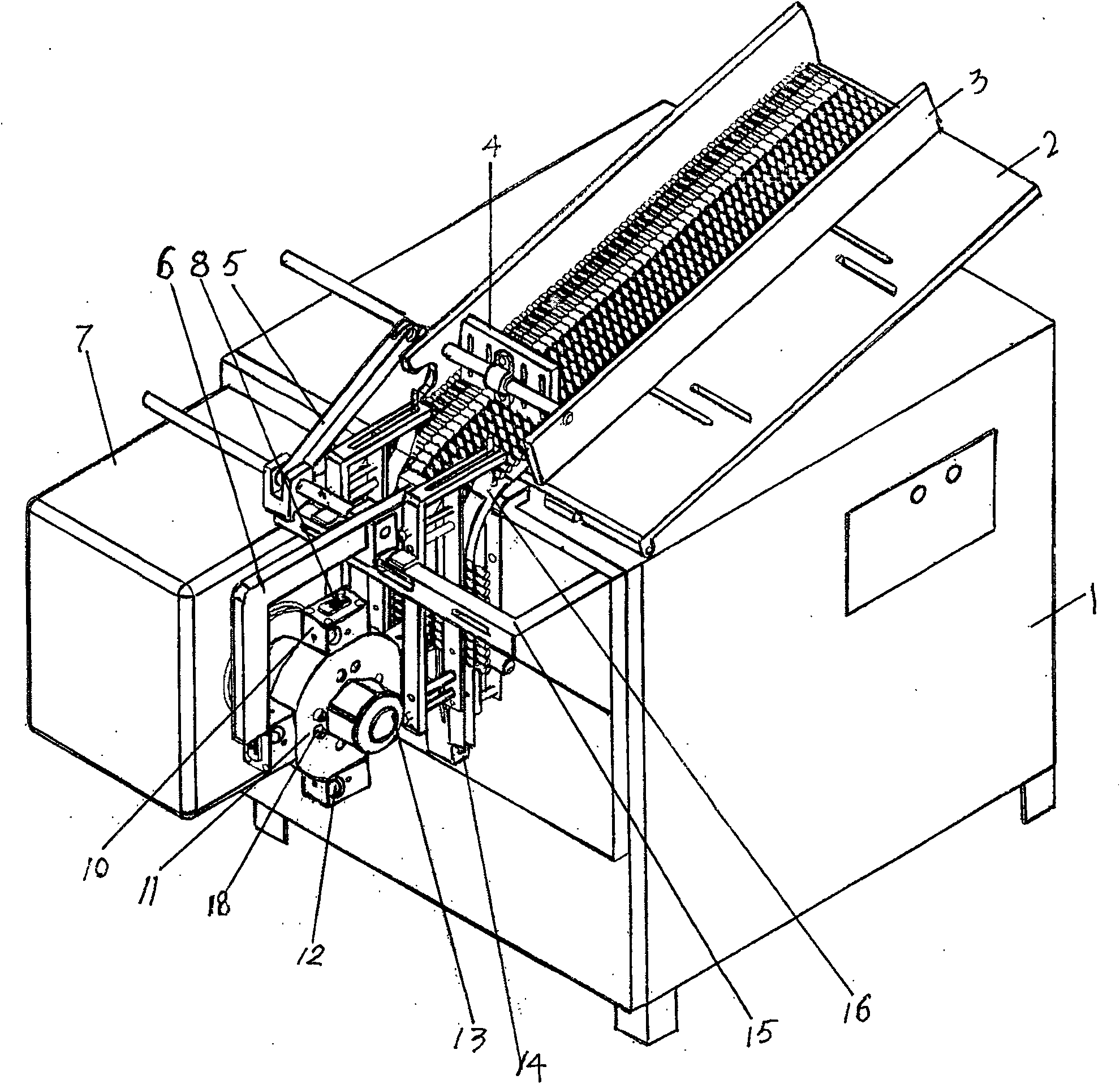

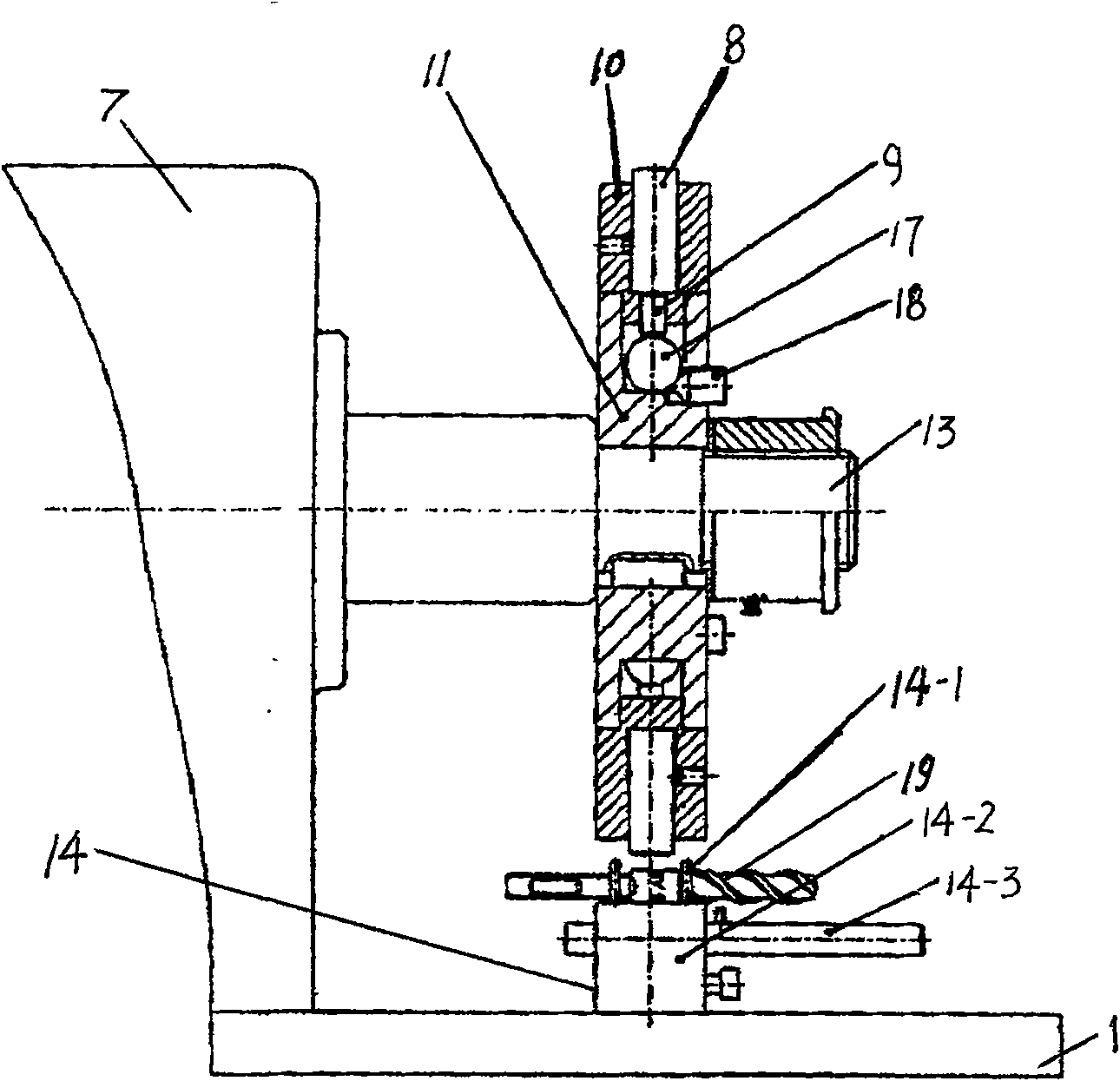

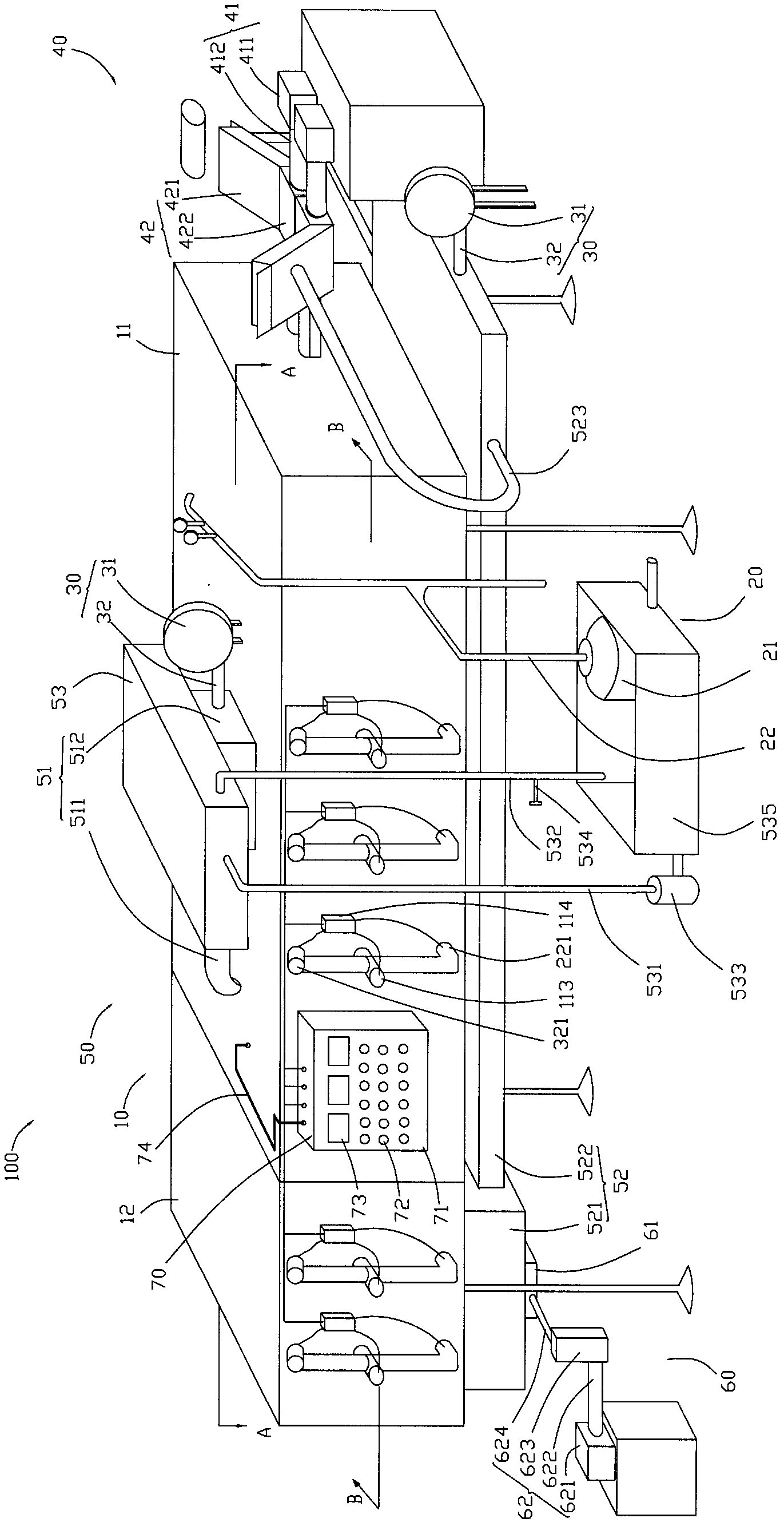

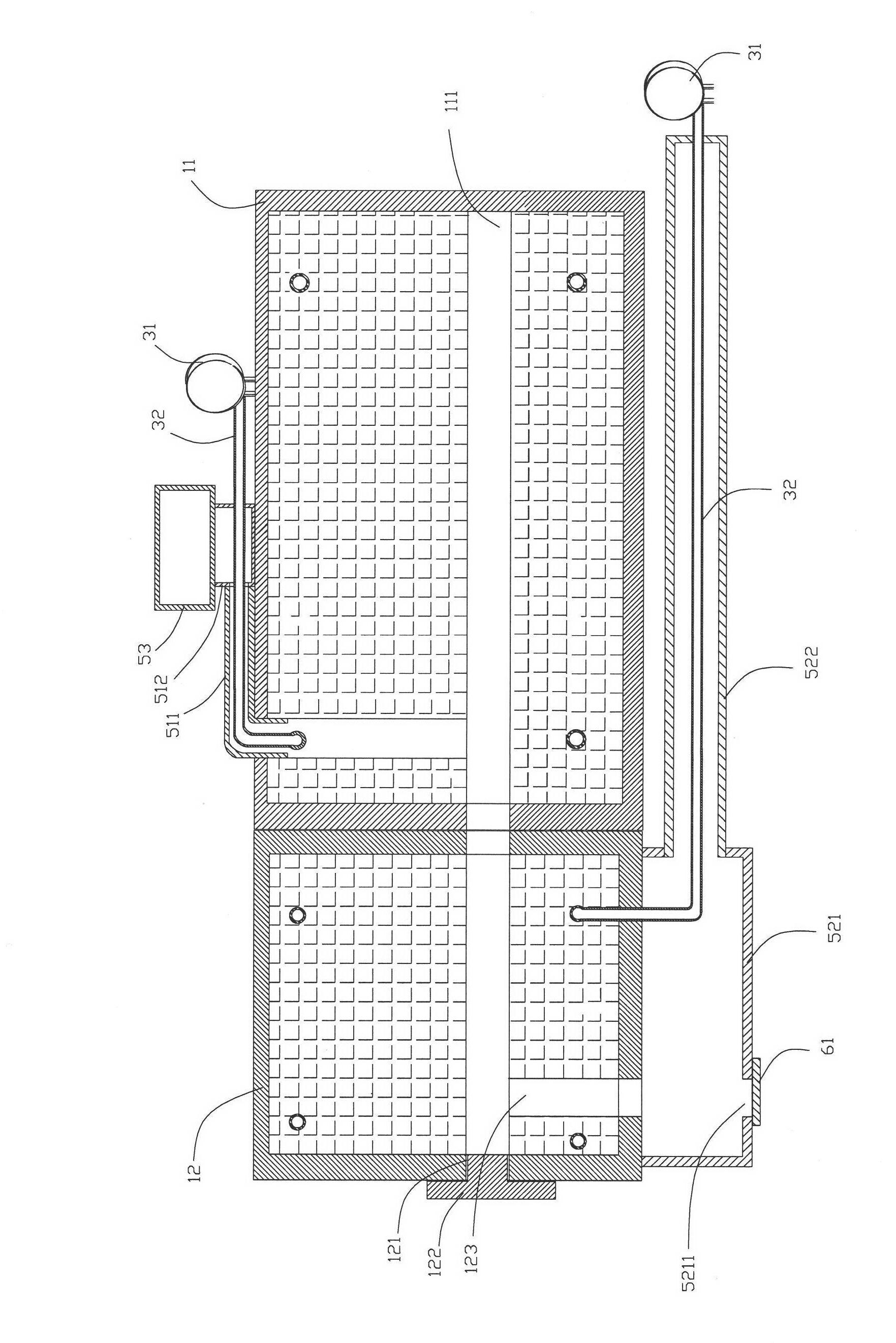

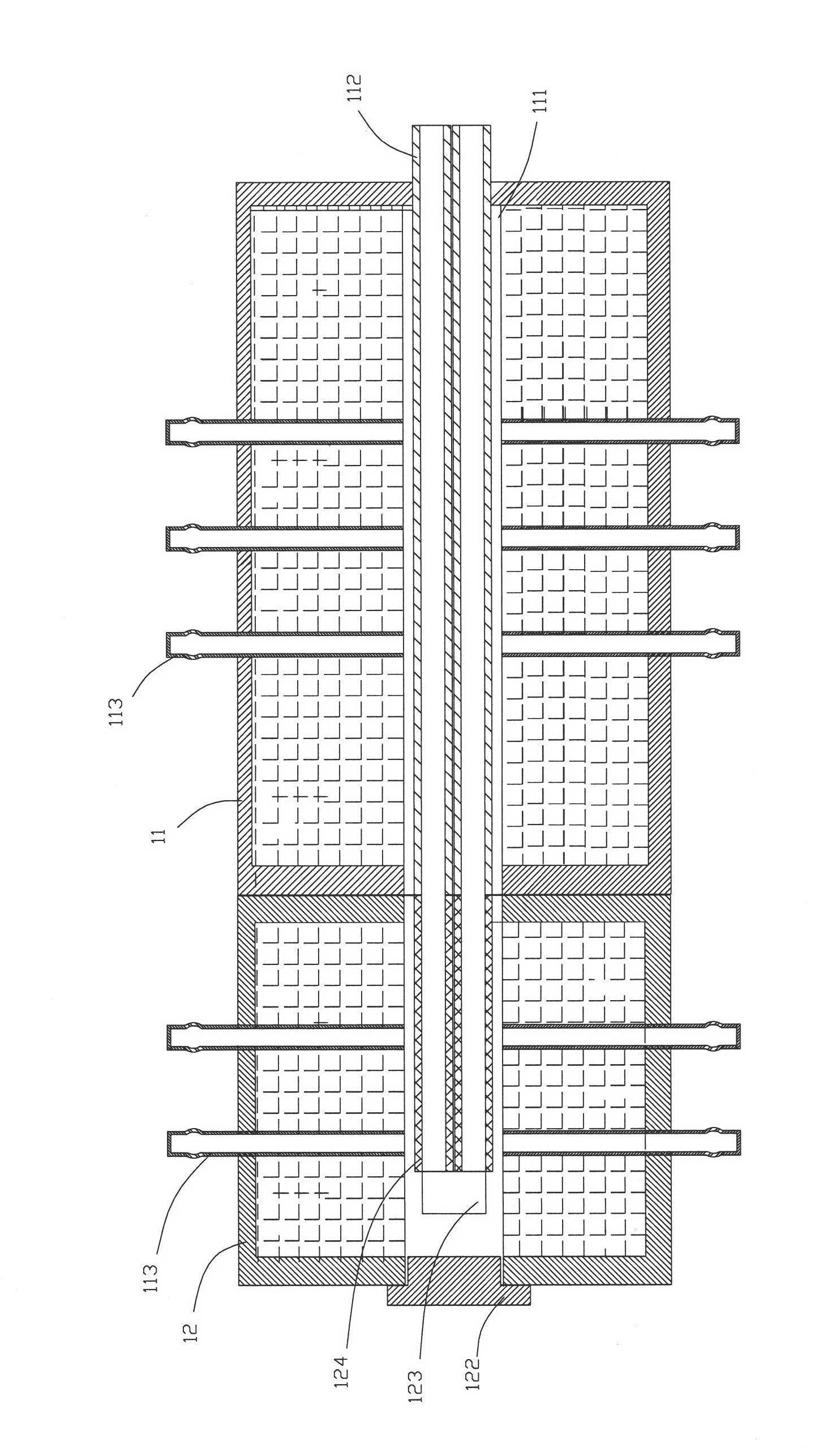

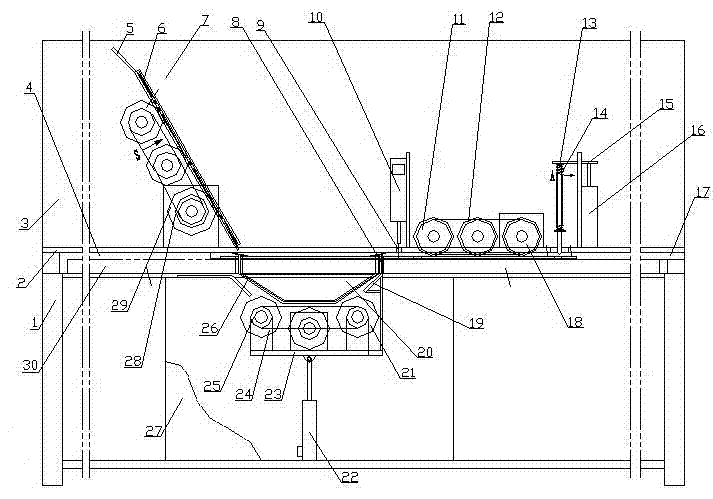

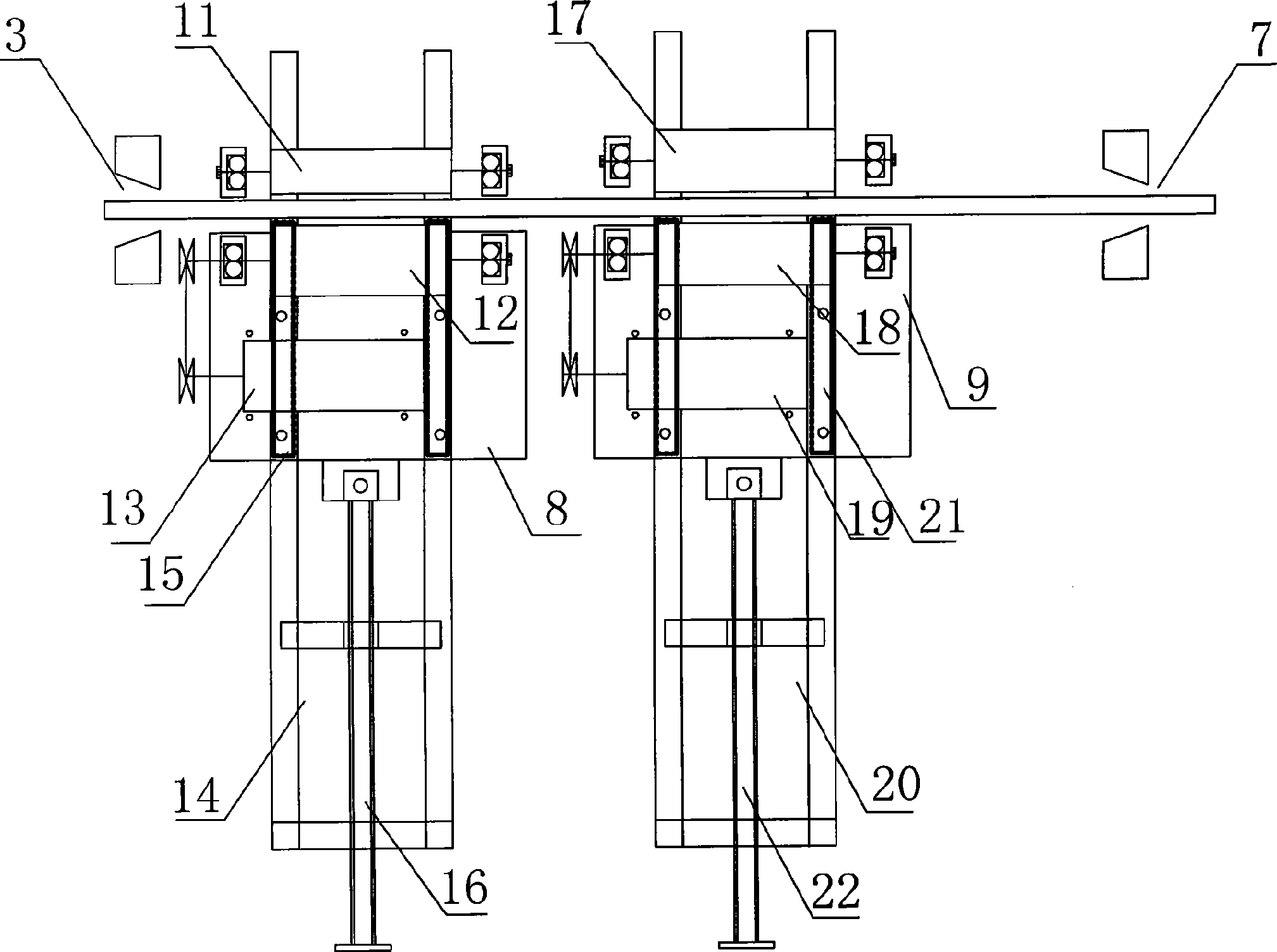

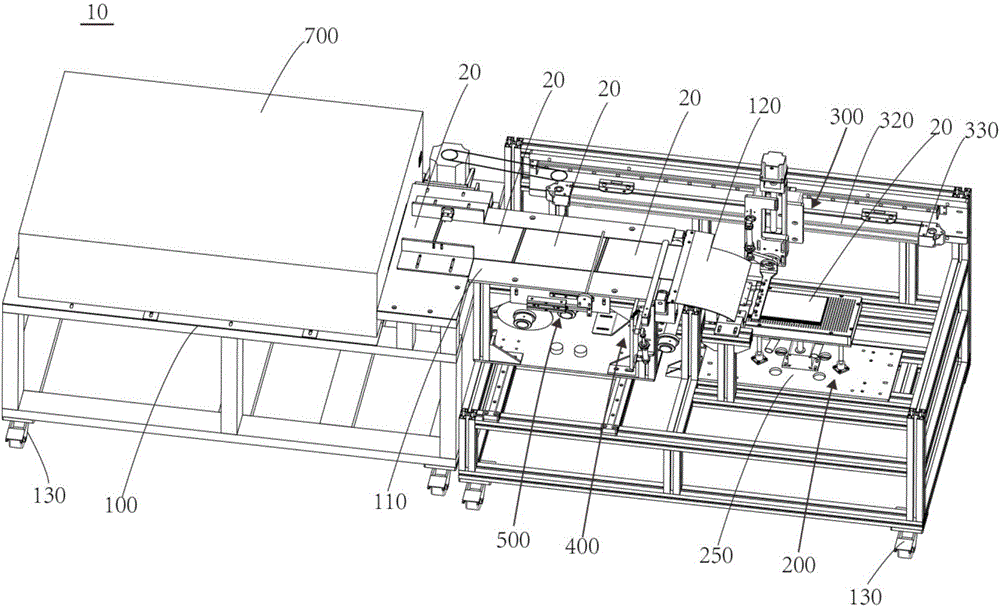

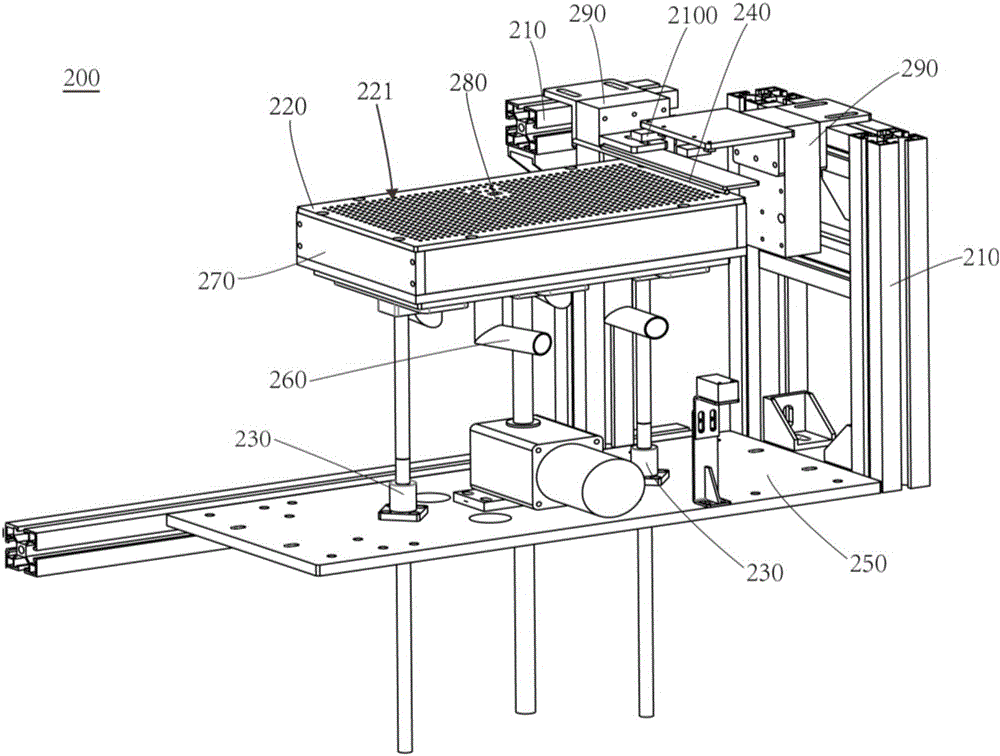

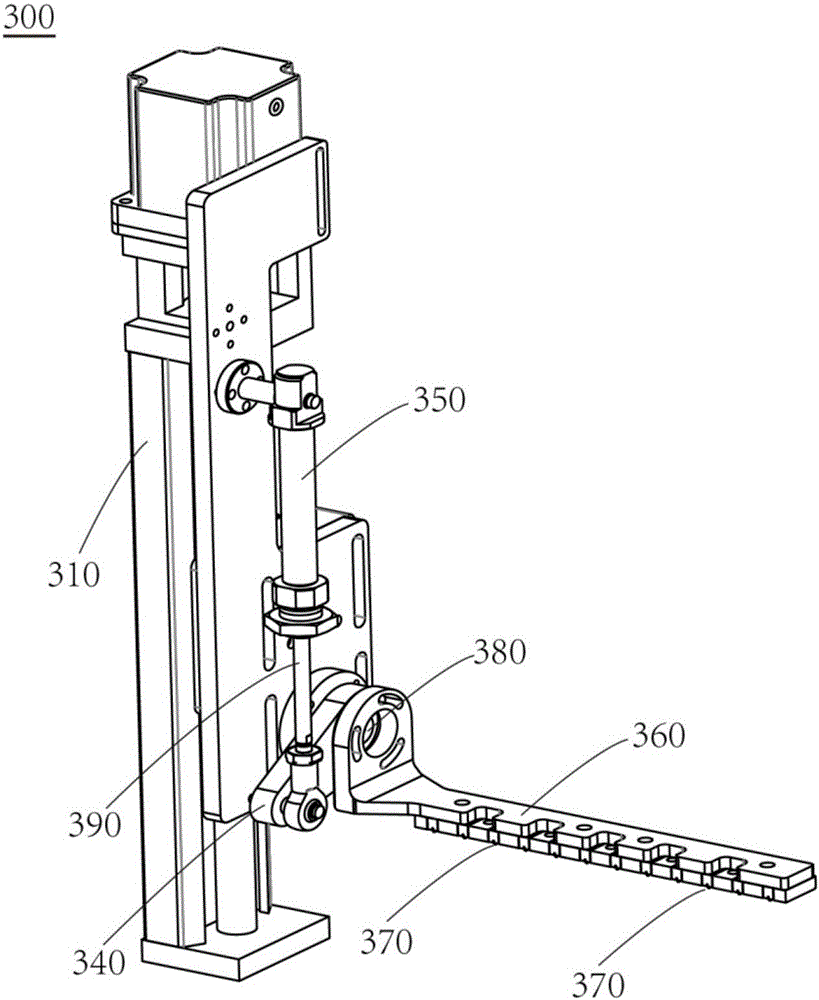

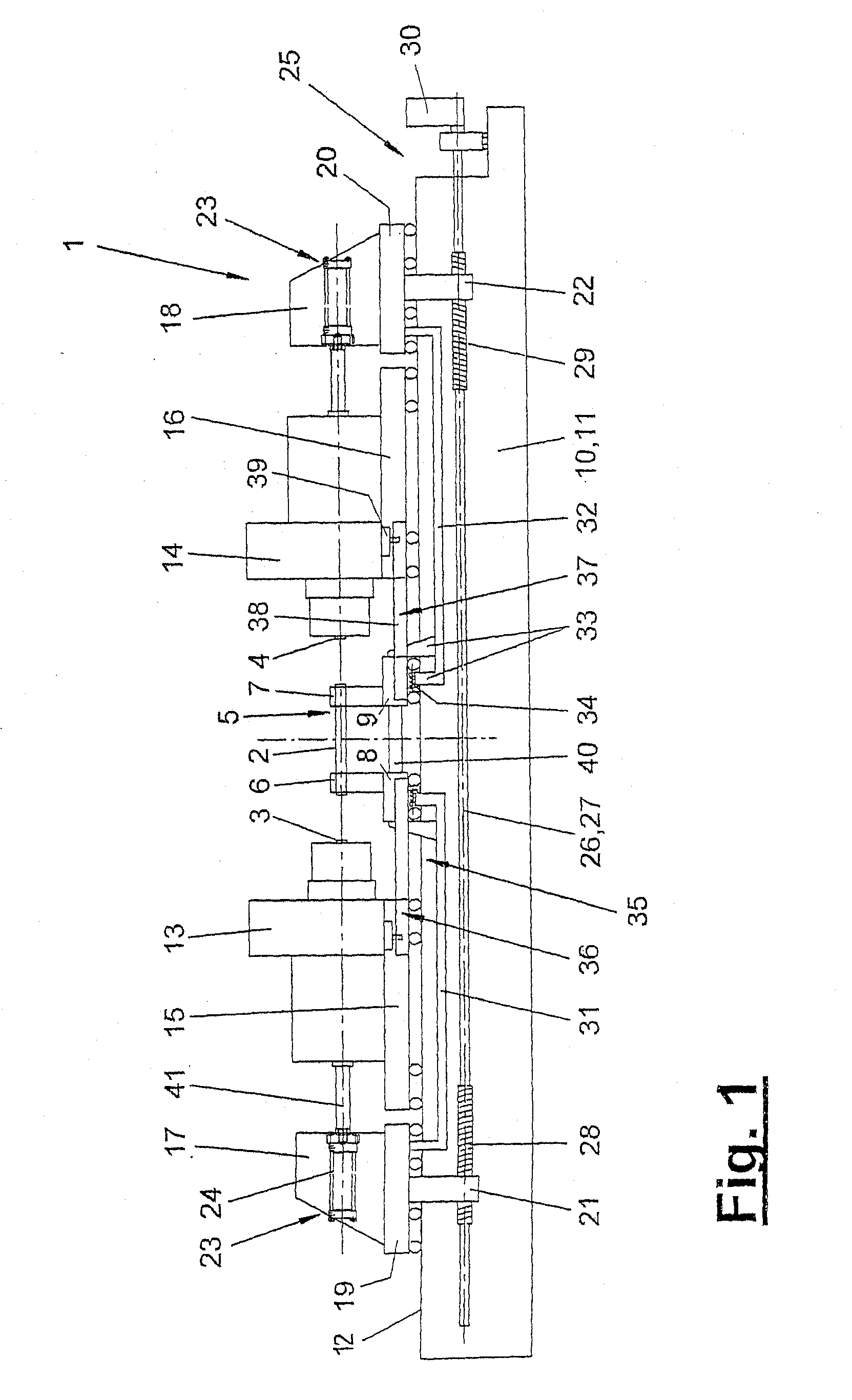

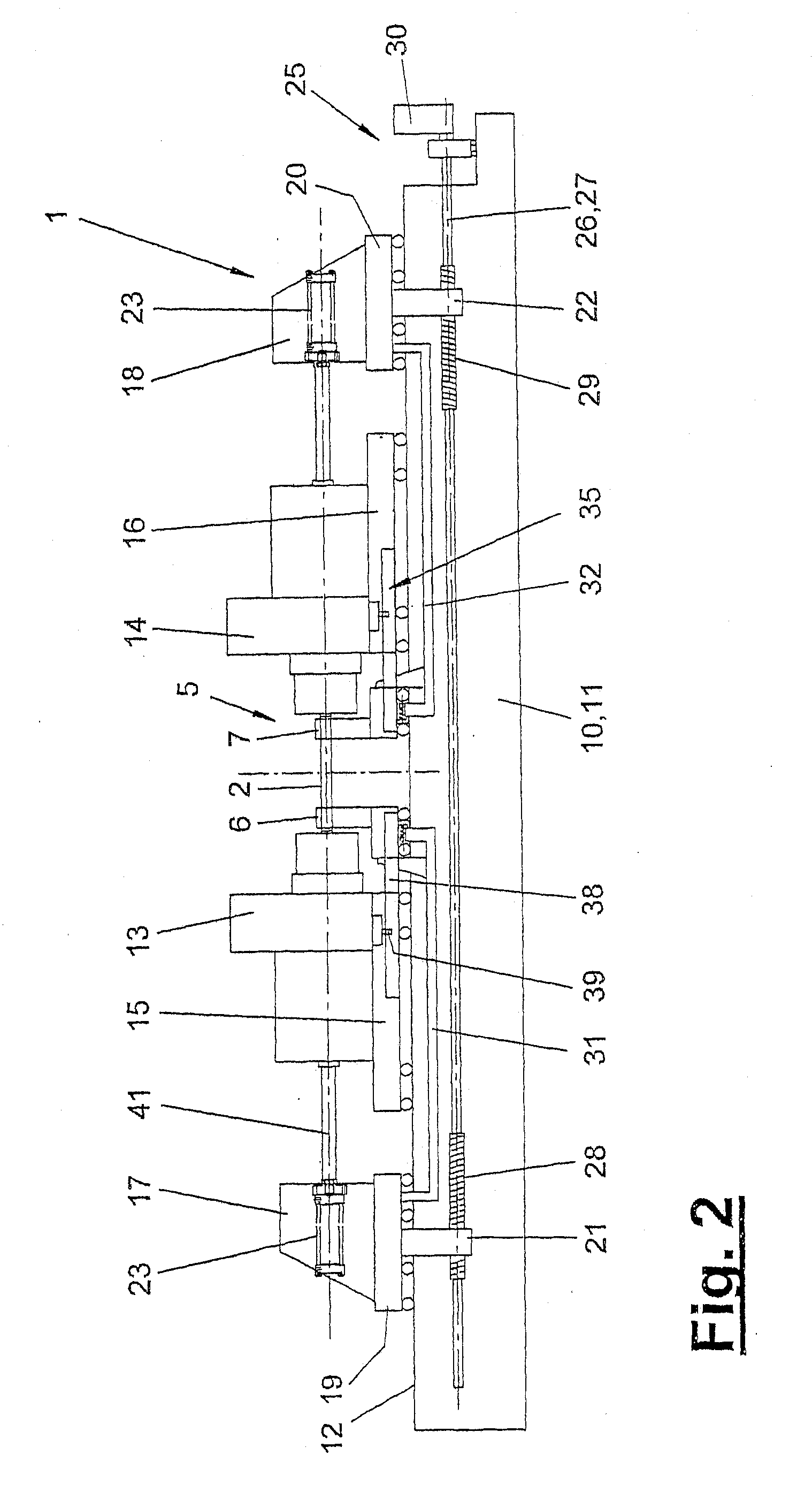

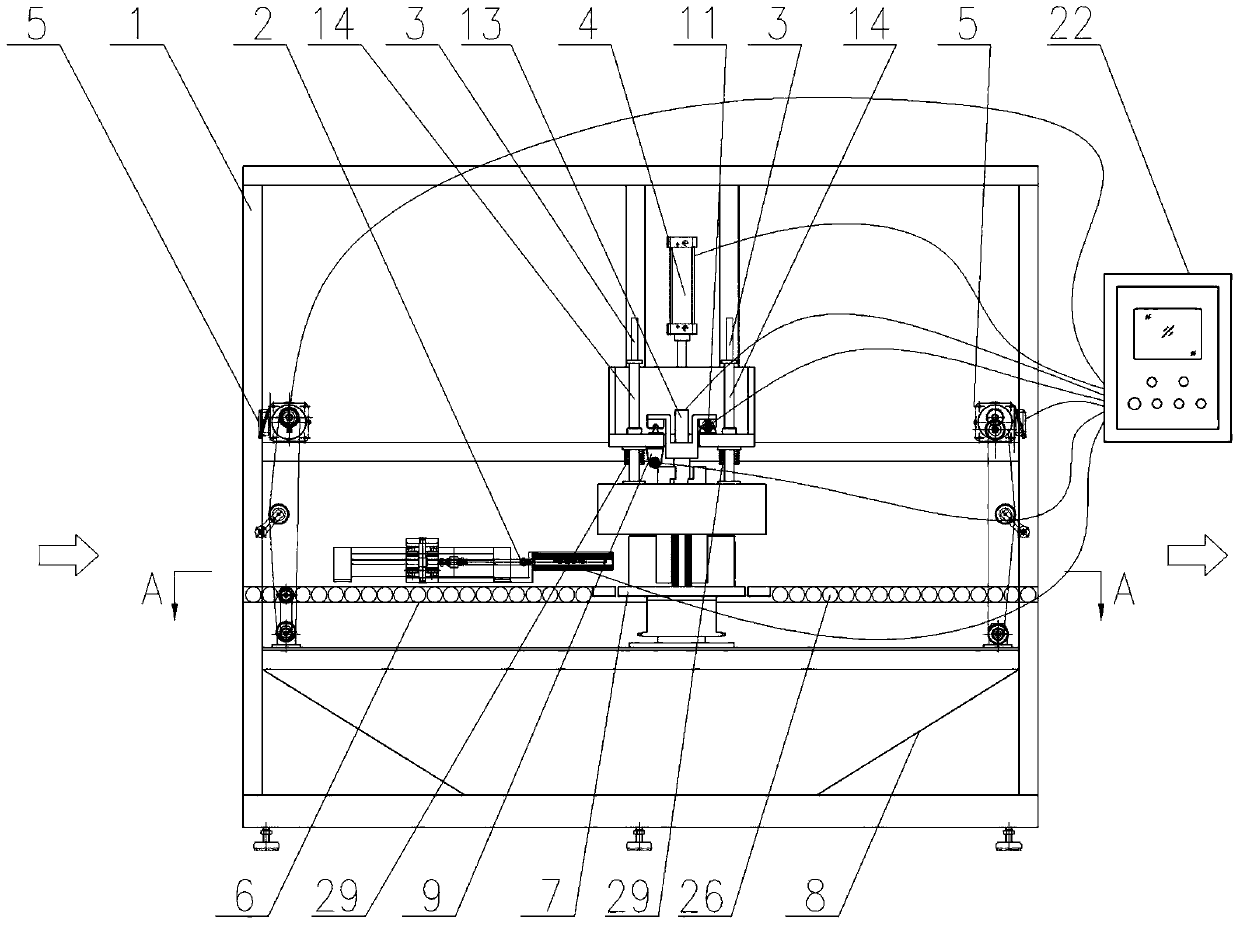

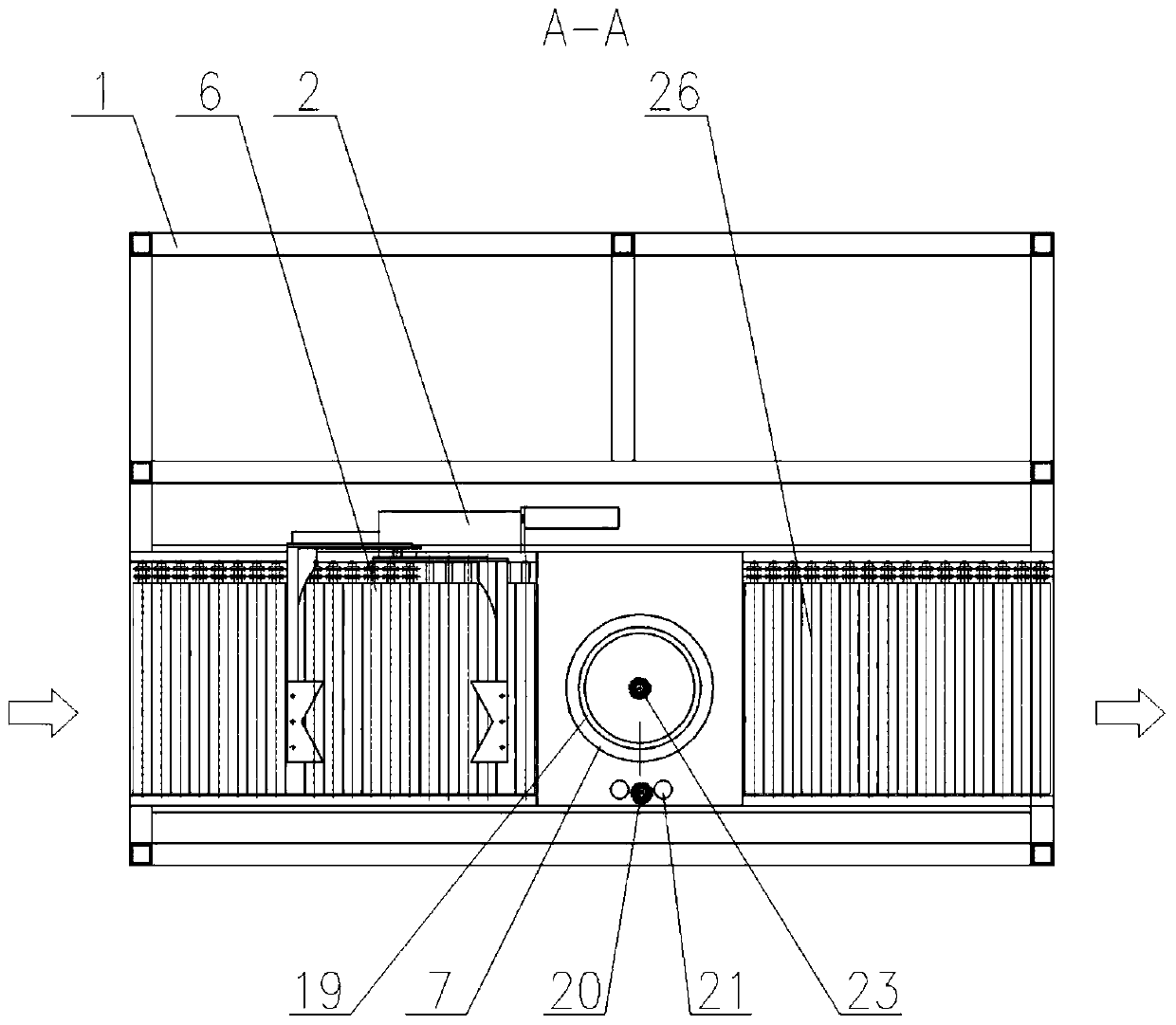

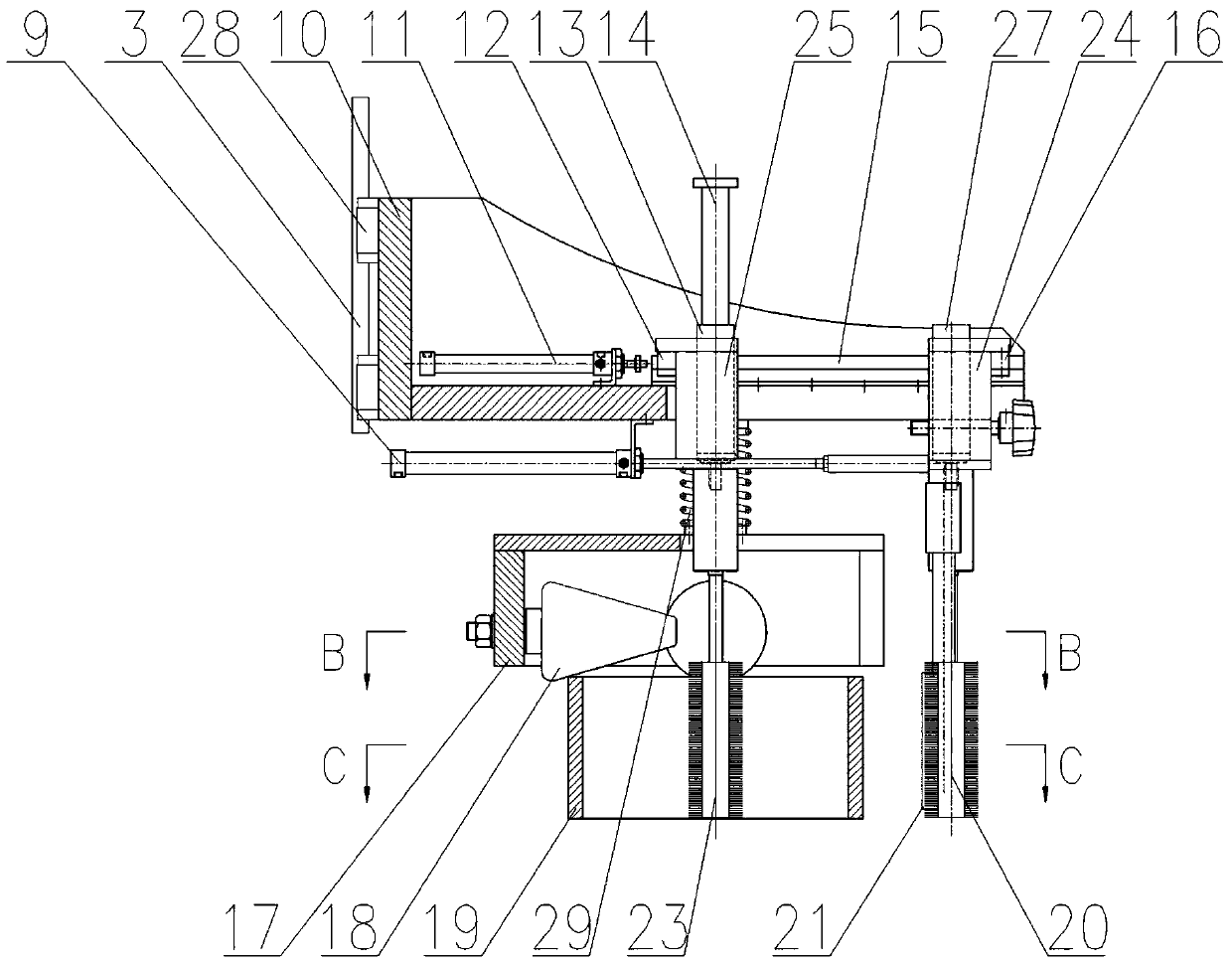

Multi-station automatic feeding method and device

InactiveCN102173097ARealize continuous automatic feedingAccurate clamping forceMetal-working feeding devicesForging/hammering/pressing machinesControl systemFeed drive

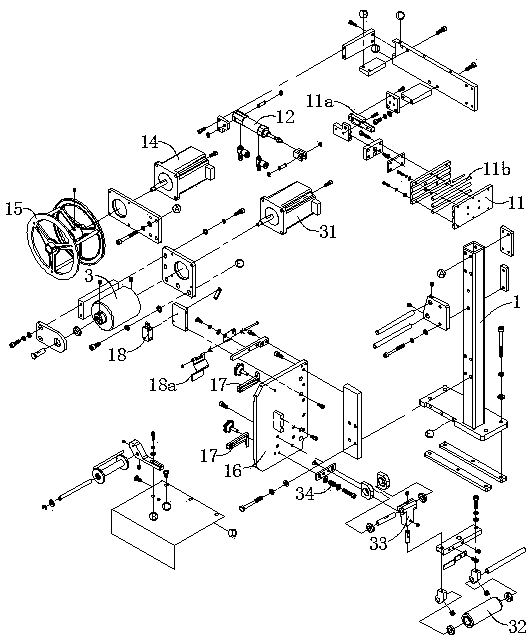

The invention relates to a multi-station automatic feeding method and device. The feeding device is characterized by comprising an execution mechanism, a guiding mechanism, a driving device, a sensing limiting device and a control system, wherein the execution mechanism, the guiding mechanism, the driving device and the sensing limiting device are arranged on a frame; the execution mechanism comprises two walking beams which are arranged in parallel; a plurality of pairs of clamping devices are alternately arranged on the two walking beams; the guiding mechanism comprises feeding guide rails and feeding guide grooves, which are respectively arranged at two ends of the walking beams; a clamping guide groove which slides along one clamping guiderail is vertically fixedly arranged in the middle of each feeding guide groove; two ends of the clamping guide rails are respectively fixedly arranged on lifting guide grooves which slide along lifting guide rails; the bottom ends of the two lifting guide rails are respectively fixedly arranged on the frame; the driving device comprises a feeding driving device, a clamping driving device and a lifting driving device; the sensing limiting device comprises a feeding sensing limiting device, a clamping sensing limiting device and a lifting sensing limiting device; and the output end of the control system is connected with the sensing limiting device while the output end is connected with the driving device.

Owner:CHINA AGRI UNIV

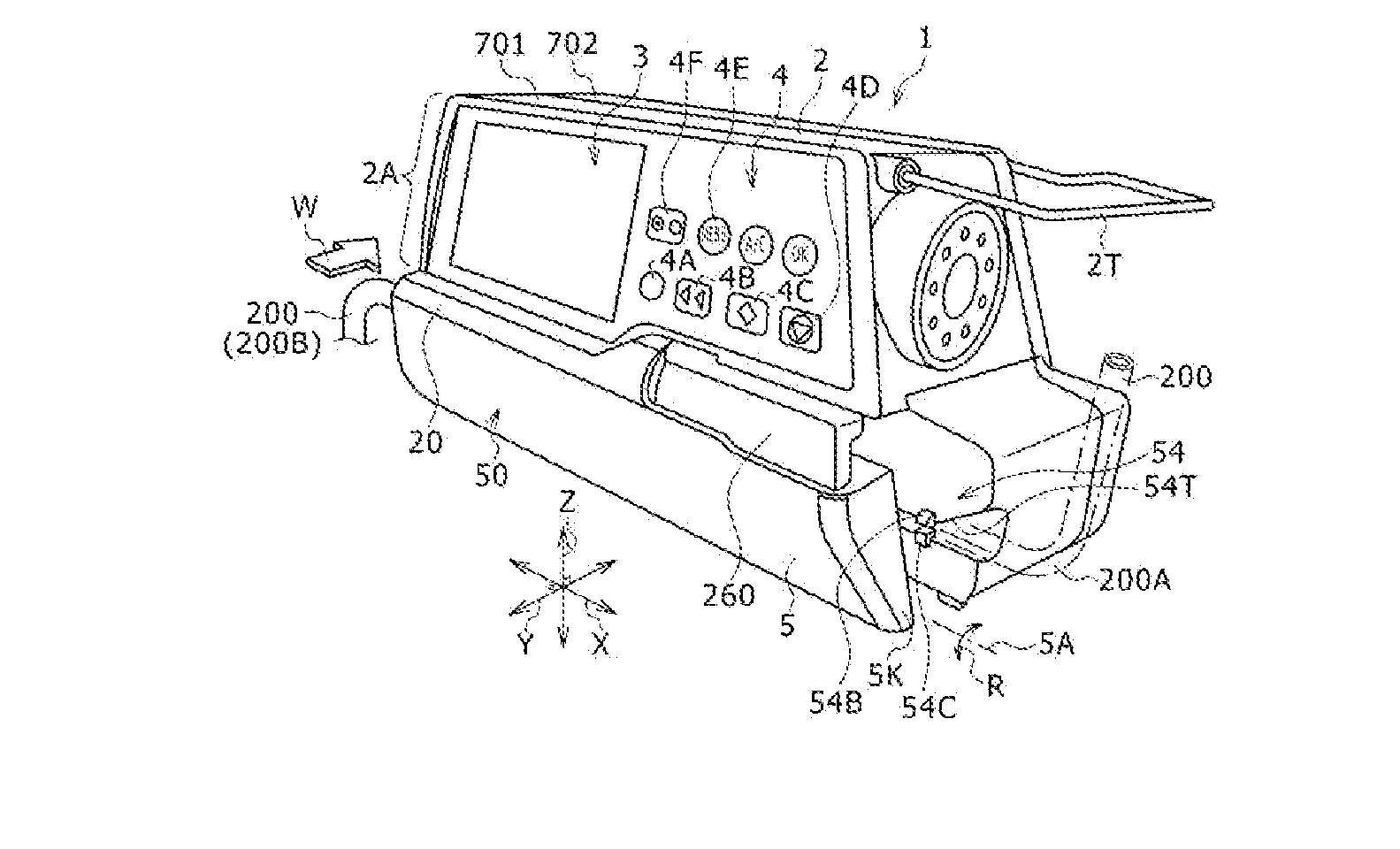

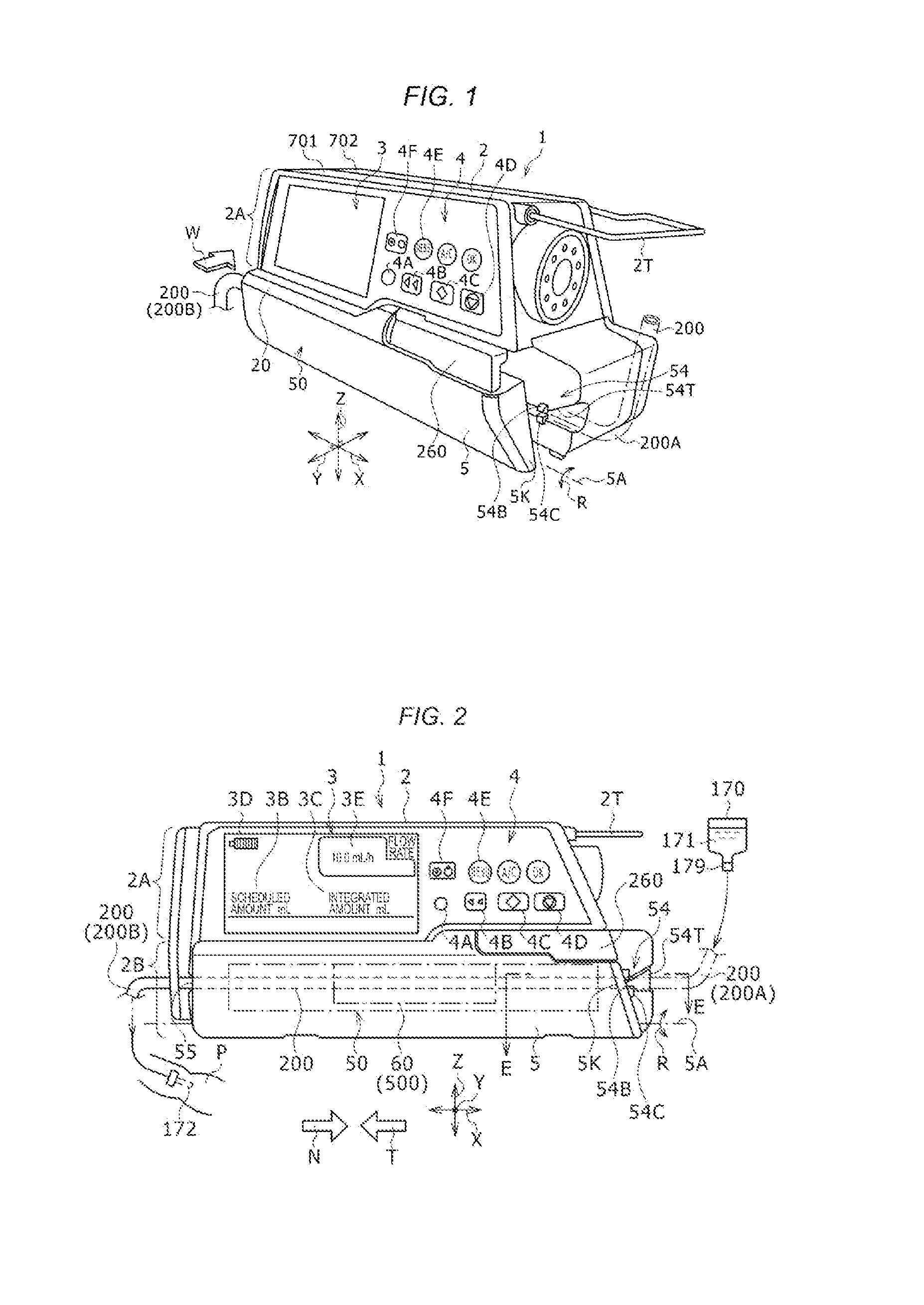

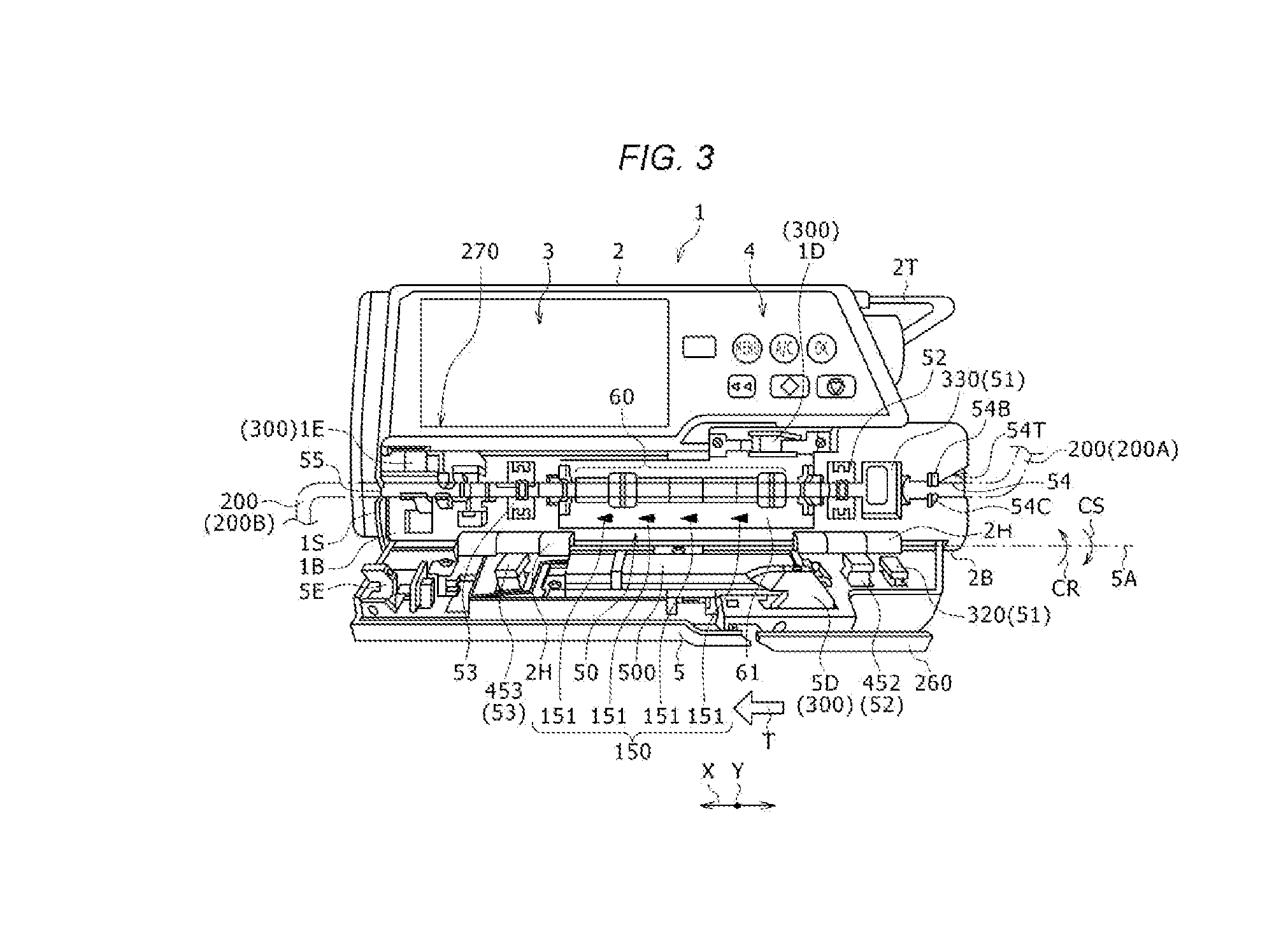

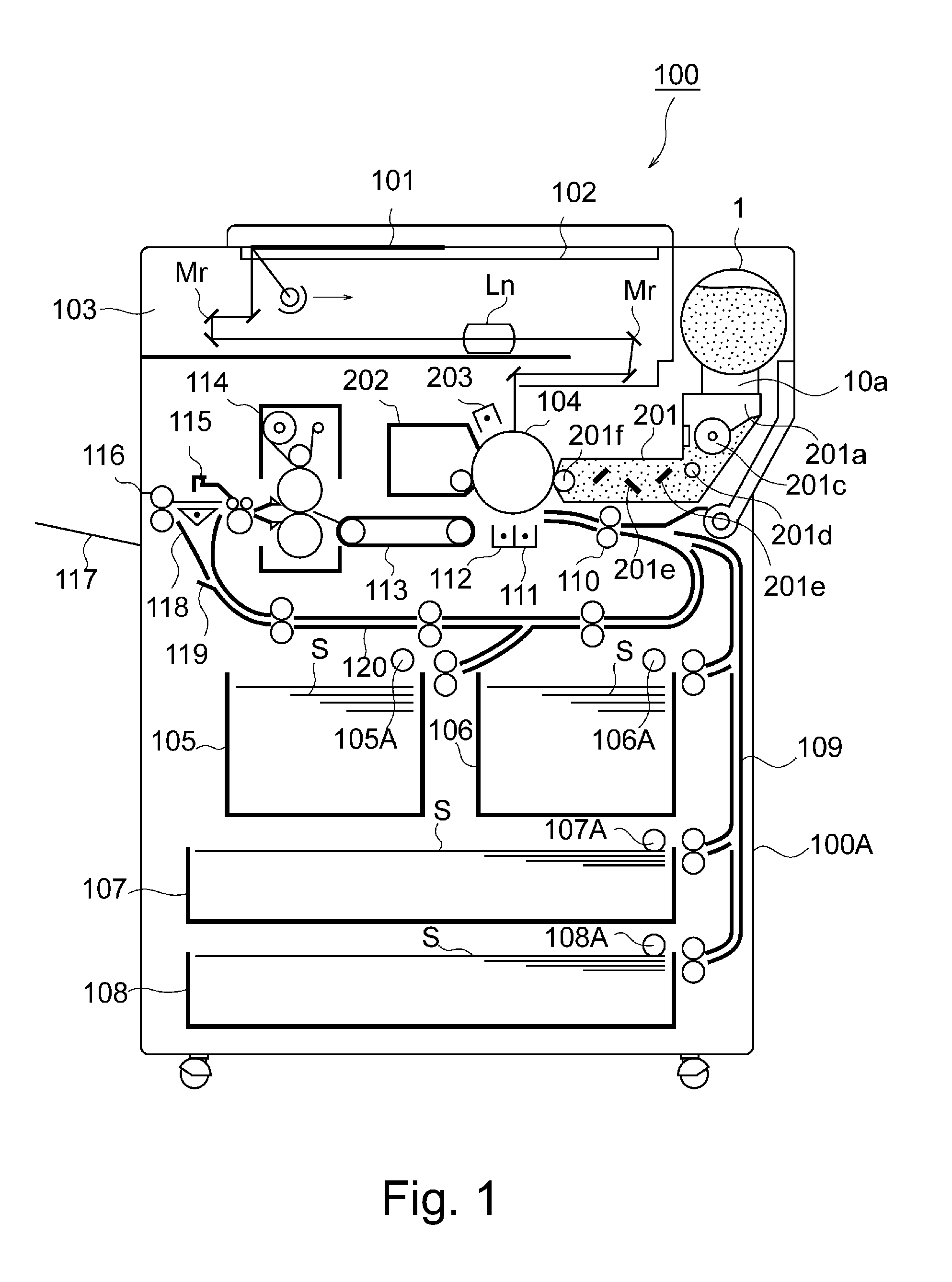

Infusion pump

ActiveUS20150151057A1Prevent false detectionReduce in quantityPressure infusionSuction devicesFeed driveInfusion pump

An infusion pump includes a main body; a tube attachment section, in which an infusion tube is attachable; a liquid feed driving unit disposed inside the main body; an access cover mounted on the main body and configured to cover the infusion tube when the infusion tube is attached to the tube attachment section when closed; and a bubble detection unit. The bubble detection unit includes a first member disposed at the access cover and a second member disposed at the main body. The infusion pump is configured such that, when the infusion tube is attached to the tube attachment section, a first space of the infusion tube is located between the first member and the second member of the bubble detection unit a second space of the infusion tube is located downstream of the first space, and the second space is smaller than the first space.

Owner:TERUMO KK

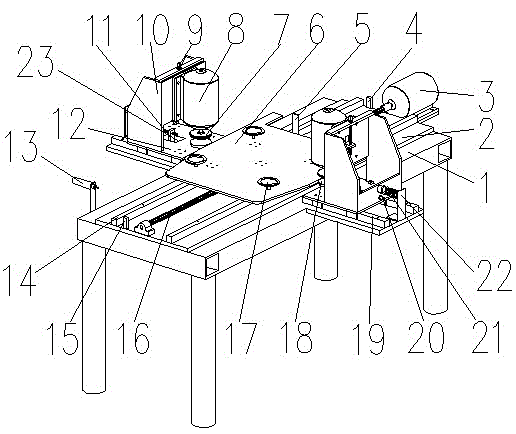

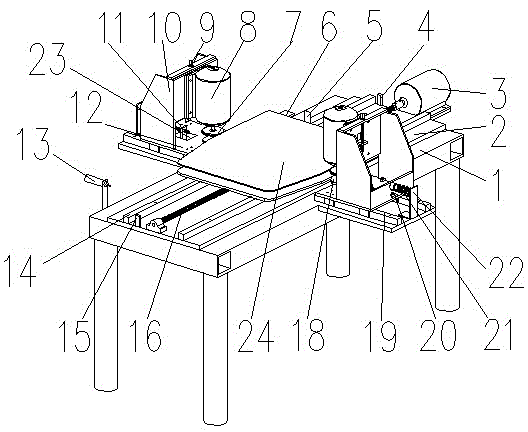

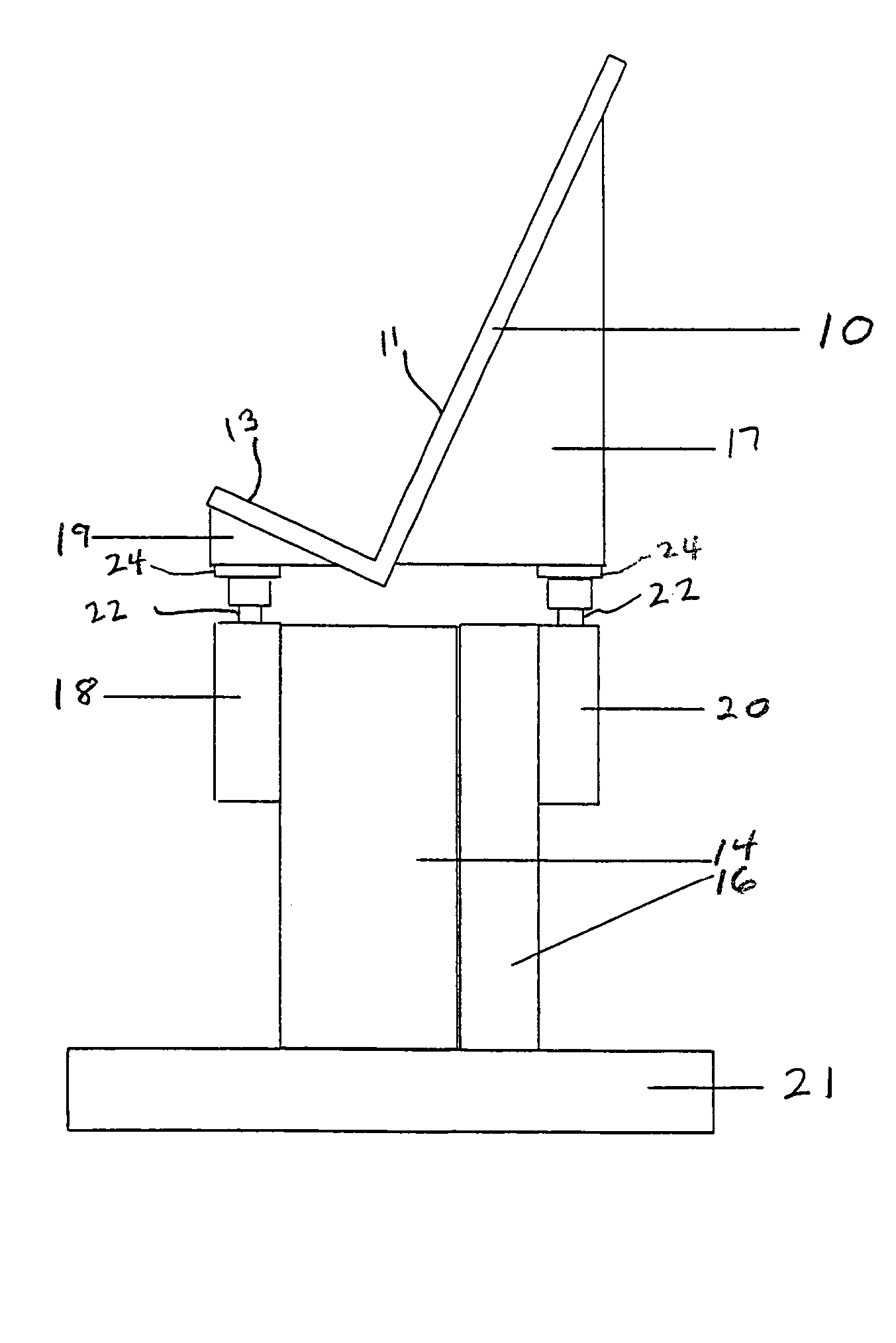

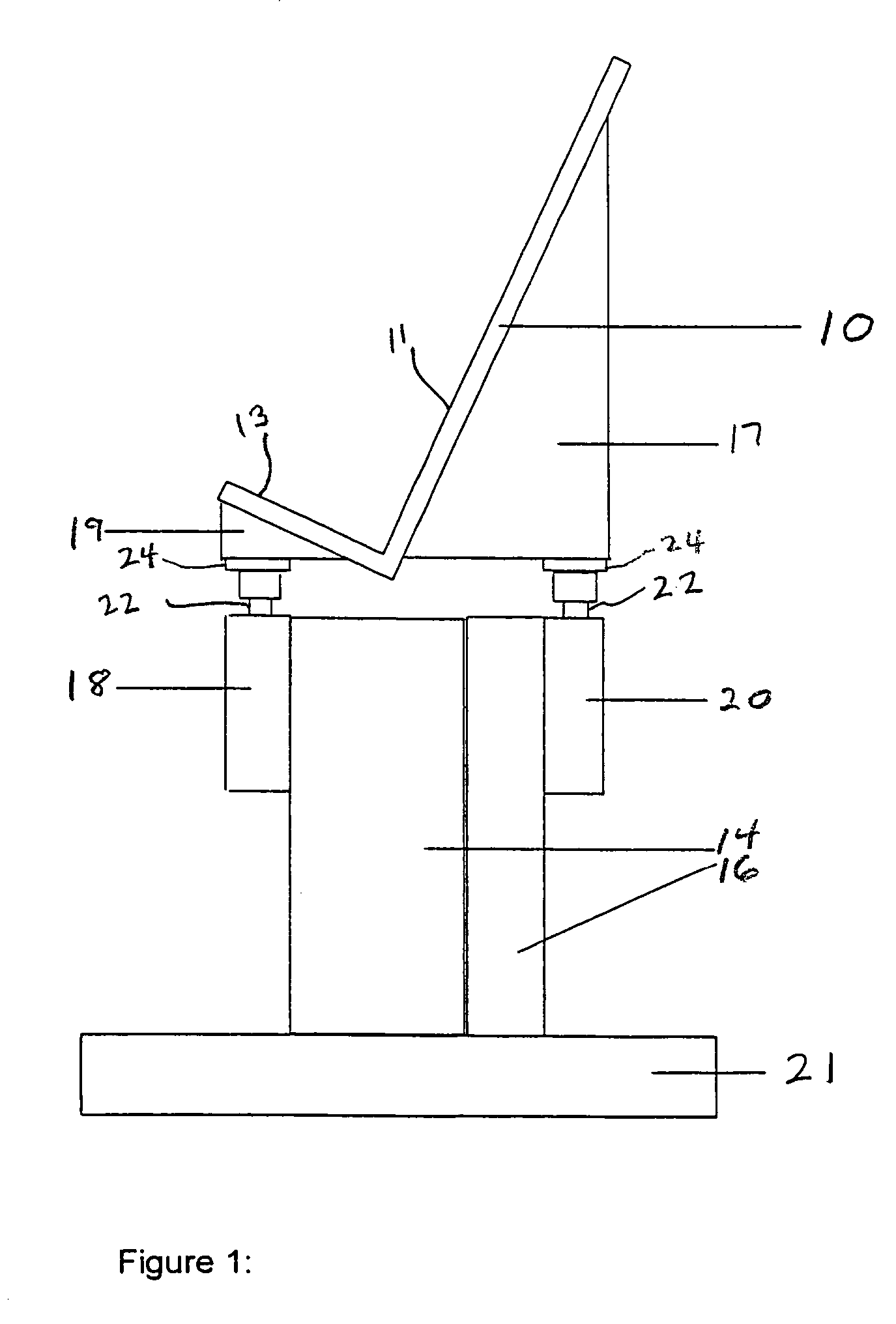

Elastic ribbon machine

ActiveCN103352330ASimple structureEasy to fix with sewingWorkpiece carriersWork-feeding meansAutomatic controlFeed drive

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

Safe type timber cutting machine with multiple cutting saw blades

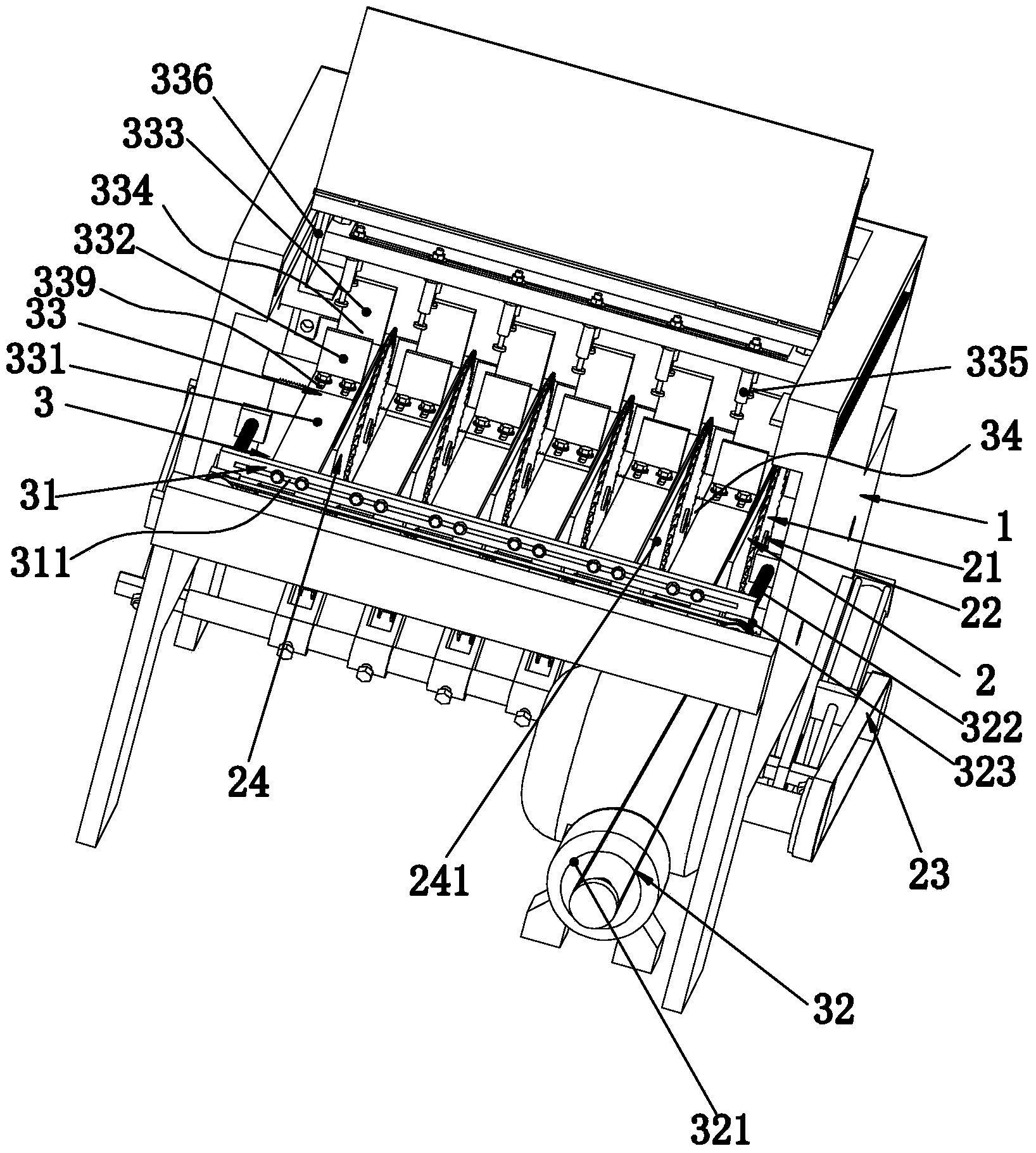

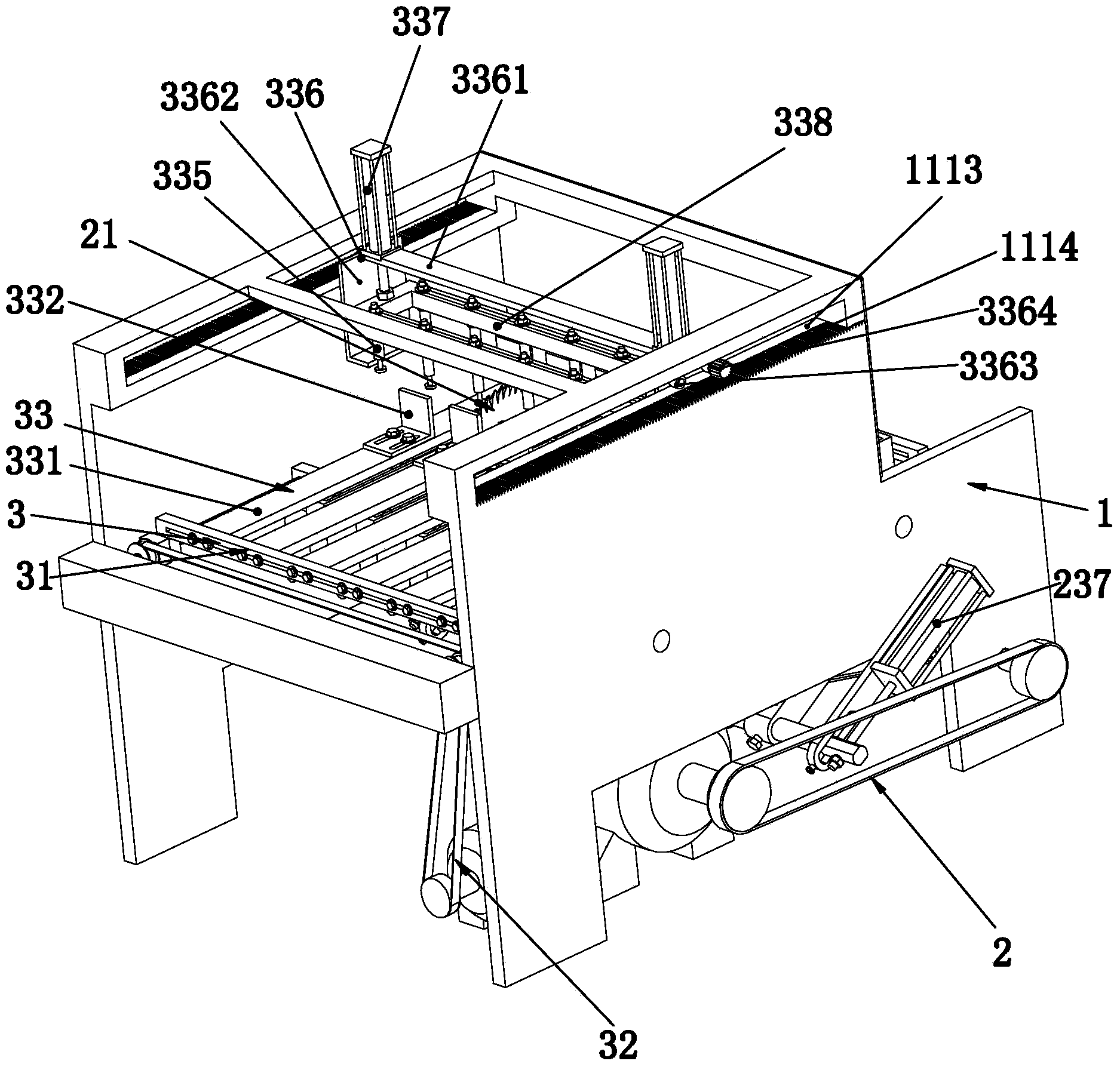

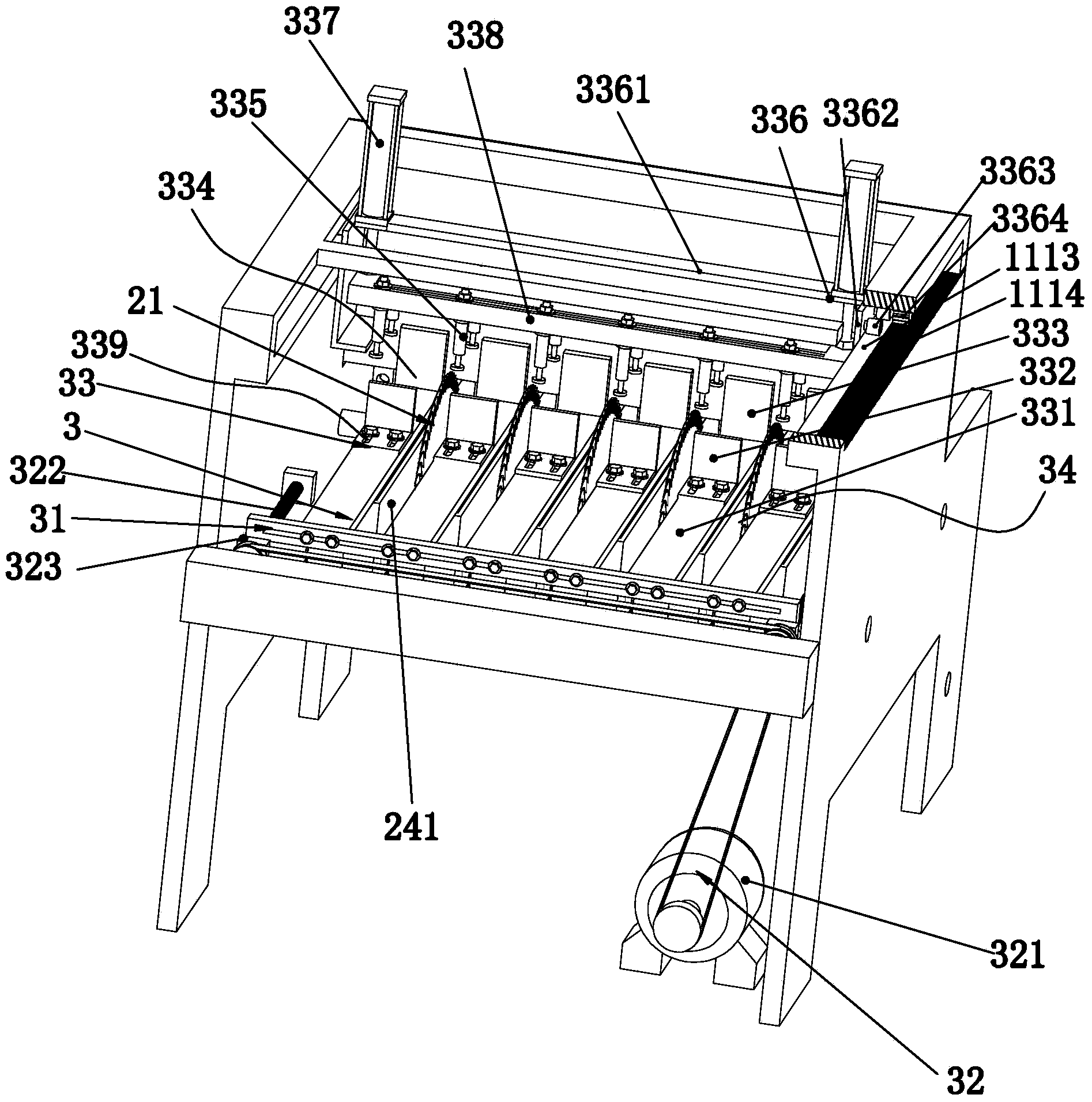

The invention relates to a safe type timber cutting machine with multiple cutting saw blades. The safe type timber cutting machine comprises a machine base and a cutting device arranged on the machine base. The cutting device comprises a plurality of cutting saw blades, a saw blade mounting rotary shaft and saw blade driving mechanisms, wherein the cutting saw blades are coaxially assembled, and the spacing between the cutting saw blades can be adjusted, the saw blade mounting rotary shaft is used for allowing the cutting saw blades to be installed on, and the saw blade driving mechanisms drive the cutting saw blades to rotate and are in drive connection with the saw blade mounting rotary shaft. The machine base is further provided with an automatic feeding device. The automatic feeding device comprises a feeding rack and a feeding driving mechanism, wherein the feeding rack is arranged in a moving and sliding mode in the rotating and cutting direction of the cutting saw blades, and the feeding driving mechanism drives the feeding rack. A plurality of timber fixing platforms are arranged on the feeding rack, the number and the positions of the timber fixing platforms correspond to those of the cutting saw blades. The timber fixing platforms are coaxially arranged. Timber cutting passages for allowing the cutting saw blades to enter and cut timbers are formed between the adjacent timber fixing platforms in a spaced mode. The spacing between the adjacent timber fixing platforms can be adjusted. Compared with the prior art, the safe type timber cutting machine with the multiple cutting saw blades can automatically feed the timbers and is more convenient and safer to operate.

Owner:邹建静

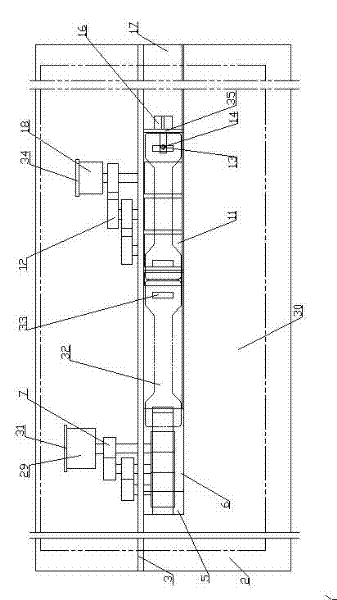

Copying double-sided glass edging machine

ActiveCN103144003ADifficulty improvingGood precisionEdge grinding machinesProcessing accuracyFeed drive

The invention discloses a copying double-sided glass edging machine, which comprises a rack (1), a longitudinal feed drive motor (3) arranged on the rack (1), a longitudinal guide rail (14) arranged on the rack (1), a longitudinal slide block slidably connected onto the longitudinal guide rail (14), and a master plate (6) arranged on the longitudinal slide block, wherein a power output end of the longitudinal feed drive motor (3) is in transmission connection with a feed screw rod (16) parallel to the longitudinal guide rail (14); the feed screw rod (16) penetrates through the longitudinal slide block and is in thread connection with the longitudinal slide block; two groups of edging devices are respectively arranged on a left side and a right side of the master plate (6); and a vacuum chuck (17) is arranged on the master plate (6). The copying double-sided glass edging machine has a simple structure, is provided with a control system, can realize double-sided grinding of curved glass, has high use efficiency, is convenient and quick to operate, can be used for edging the double sides when glass is run, is easy to operate, and is high in processing accuracy and low in cost.

Owner:CONPROFE TECH GRP CO LTD +1

System for high-speed automatic weighing of items in a mail stream

InactiveUS7271352B2Reduced settling timeWeighing apparatus detailsFranking apparatusLeading edgeControl system

Owner:RABINDRAN K GEORGE

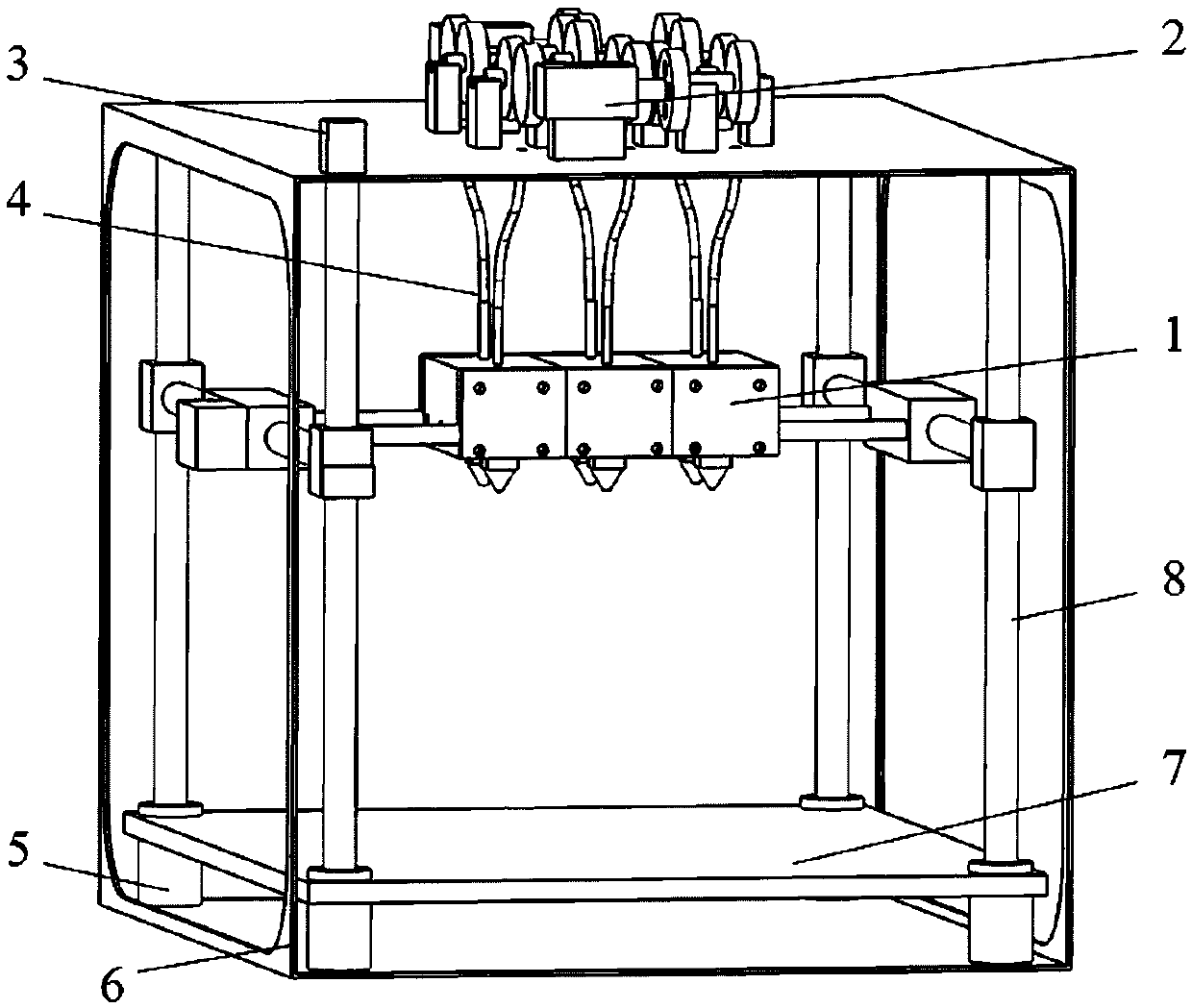

Array-type forming 3D printing system

ActiveCN105500714AImprove printing efficiencyAchieve multi-color printingAdditive manufacturing apparatusFeed driveGear wheel

Owner:WUXI VOCATIONAL & TECHN COLLEGE

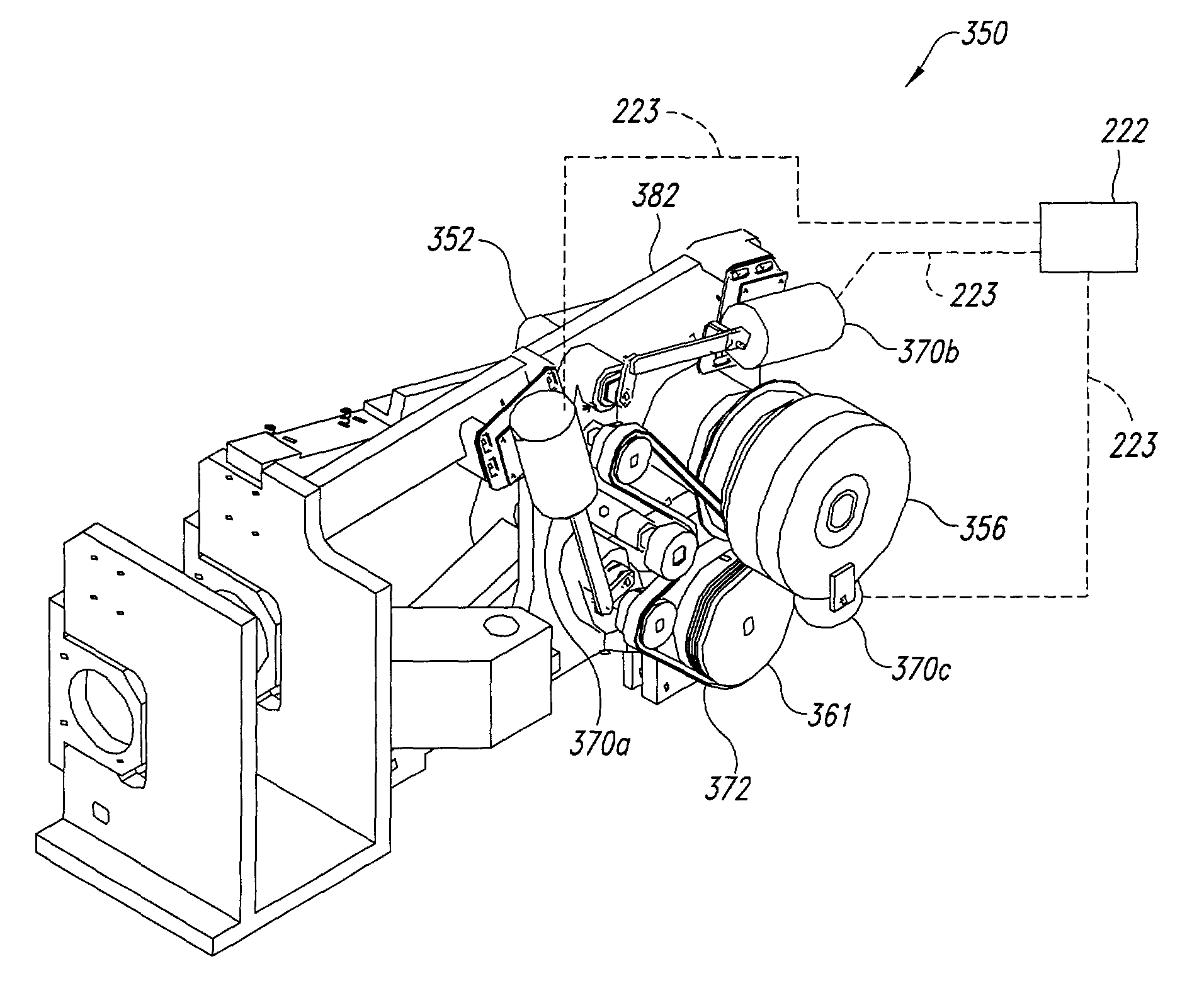

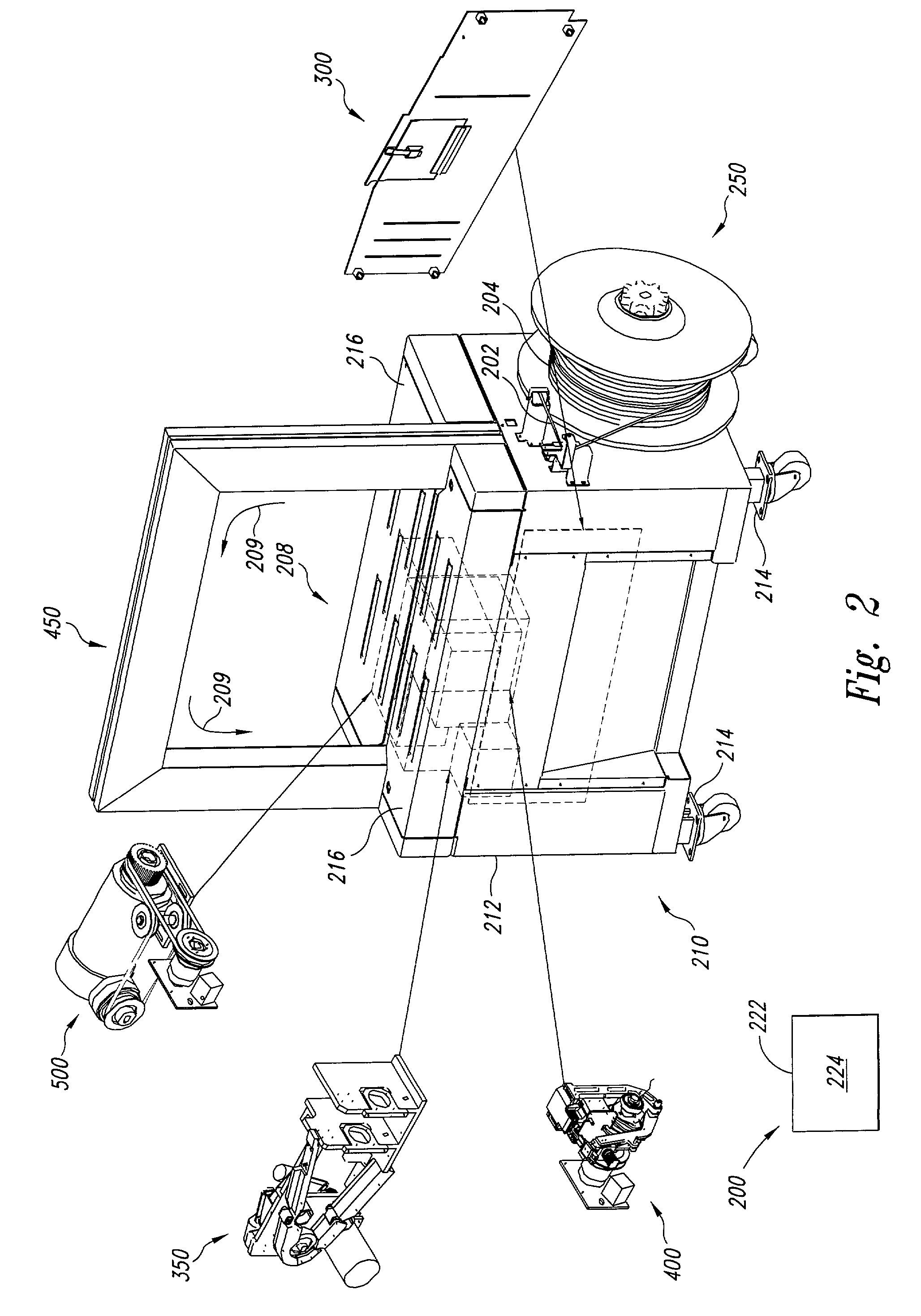

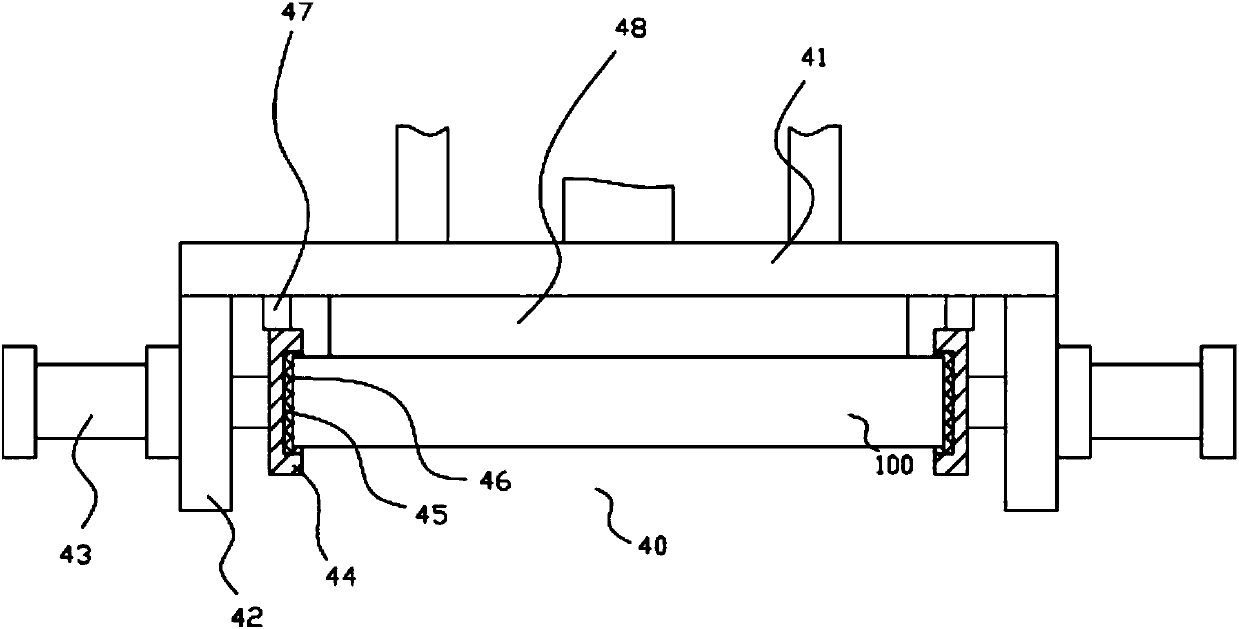

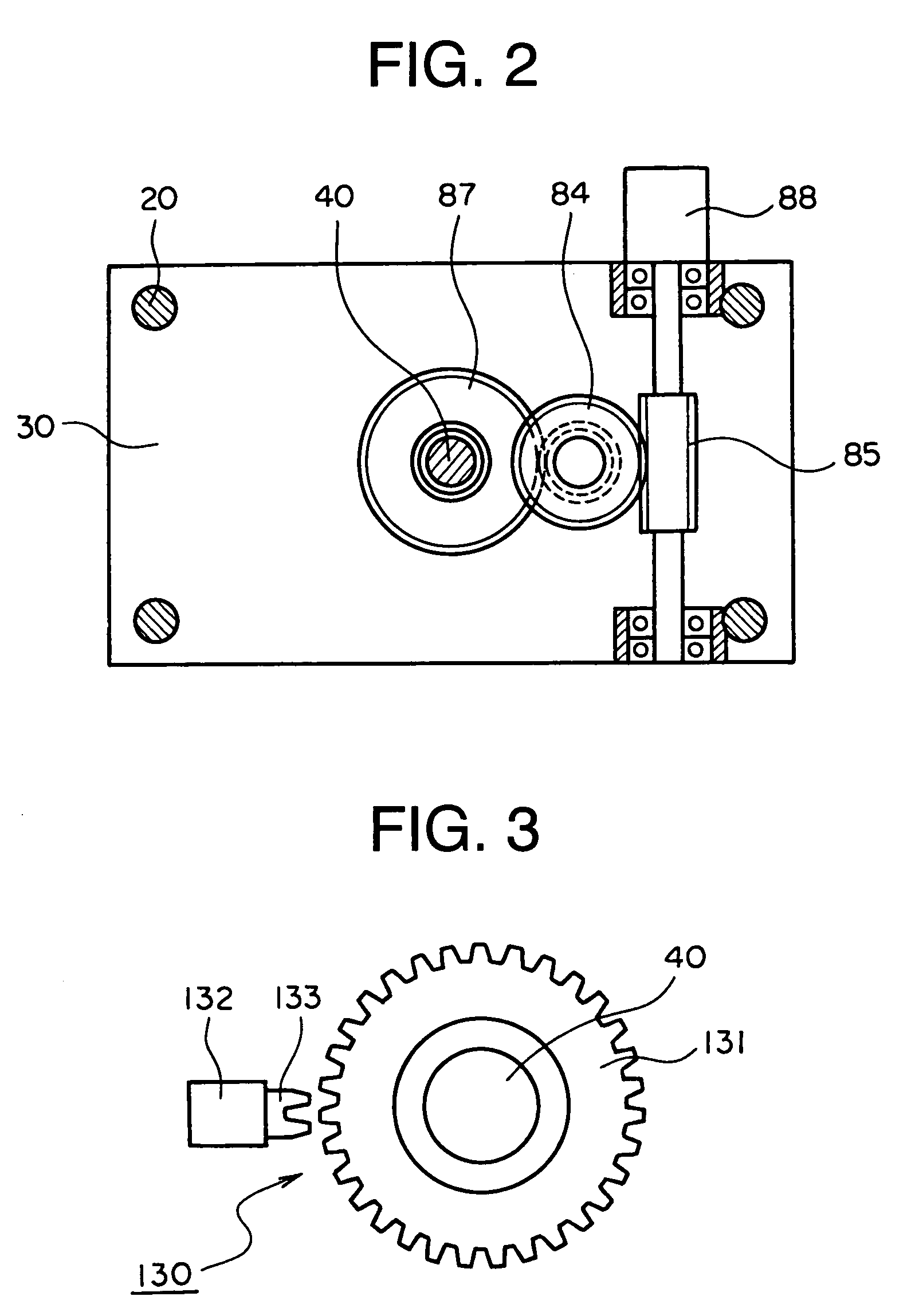

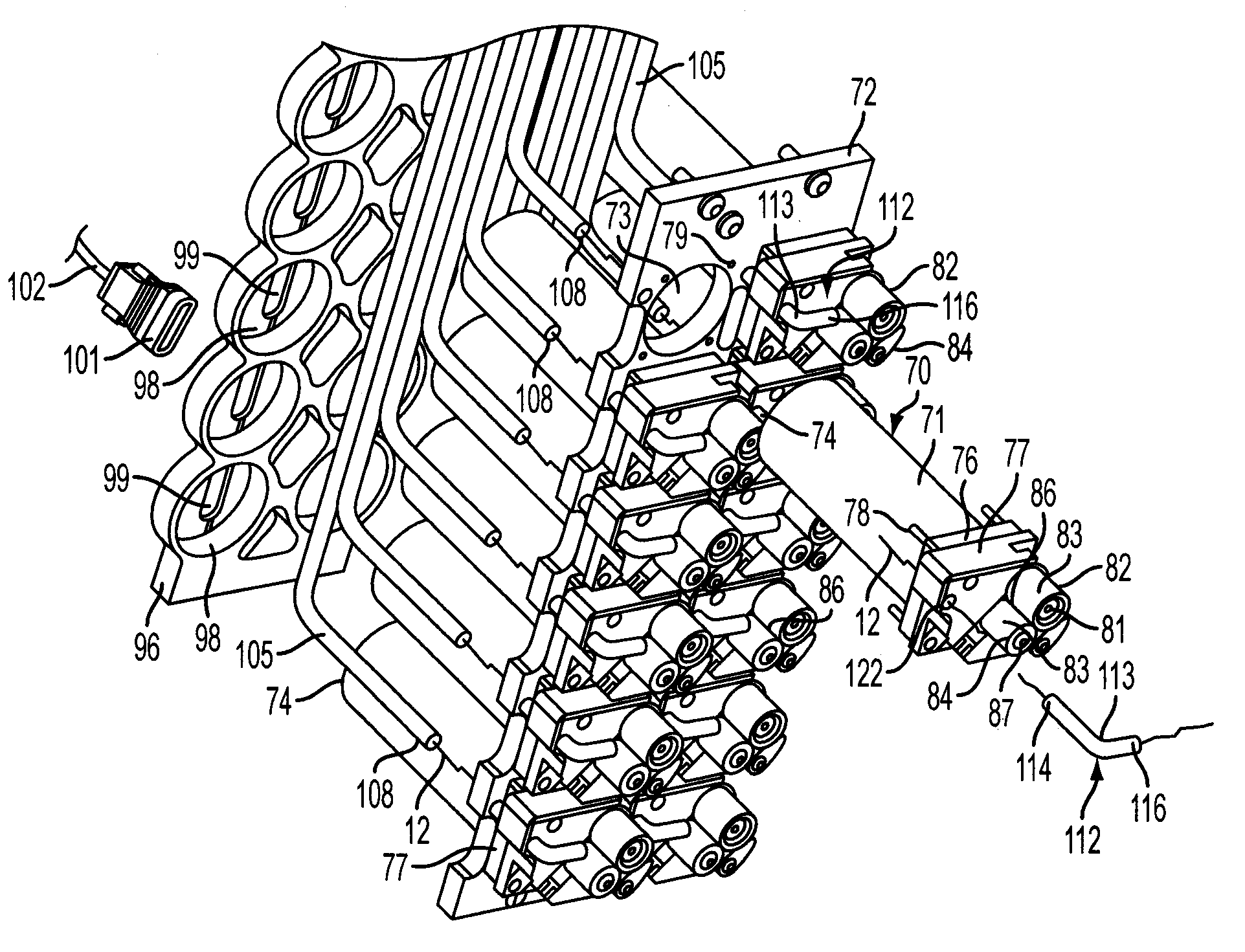

Control mechanism for a feed and tension unit in a strapping apparatus

InactiveUS20020129717A1Easy to changeVariability in apparatusBinding material applicationBundling machine detailsDrive wheelFeed drive

Apparatus and methods for applying flexible straps around objects include a feed and tension unit a feed drive wheel and a feed pinch wheel, a primary tension drive wheel and a primary tension pinch wheel, and a secondary tension drive wheel and a secondary tension pinch wheel, wherein at least one of the pinch wheels is controllably biased against the respective drive wheel by a solenoid that is controlled in two stages: a first stage that provides a full feed or tensioning force and a second stage that provides a reduced feed or tensioning force by altering the pulse width modulation of the solenoid. In another embodiment, the three sets of wheels of the feed and tension unit are configured to provide a simplified "V-shaped" strap path that reduces bending of the strap, thereby reducing friction and consequent feeding difficulties. In another embodiment, the feed and tension unit includes inner and outer guides that form a strap channel through the feed and tension unit to provide easy access to the strap path for clearing the strap path in the event of a jam. In another embodiment, a track assembly includes a plurality of sections providing modularity of construction. Each section includes a backplate attached to at least one support member, and a slotted cover pivotably attached to the at least one support member proximate the backplate and moveable between an open position spaced apart from the backplate and a closed position proximate the backplate. In another embodiment, a cutting assembly for severing strap material includes a press platen and a cutter having a first cutting blade along a first edge thereof and a second cutting blade along a second edge thereof, the cutter being removably and variably engaged to the press platen.

Owner:SAMUEL MANU TECH

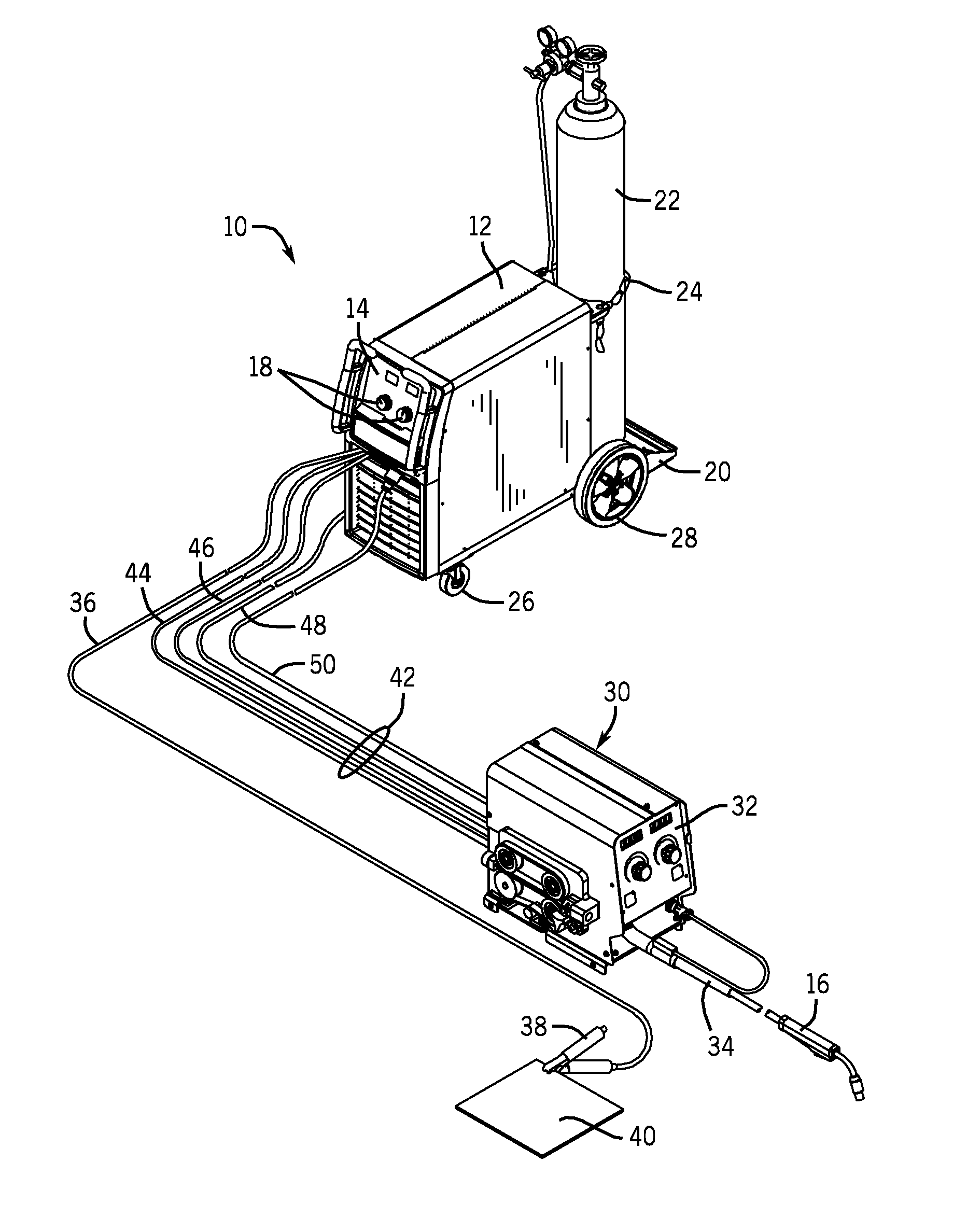

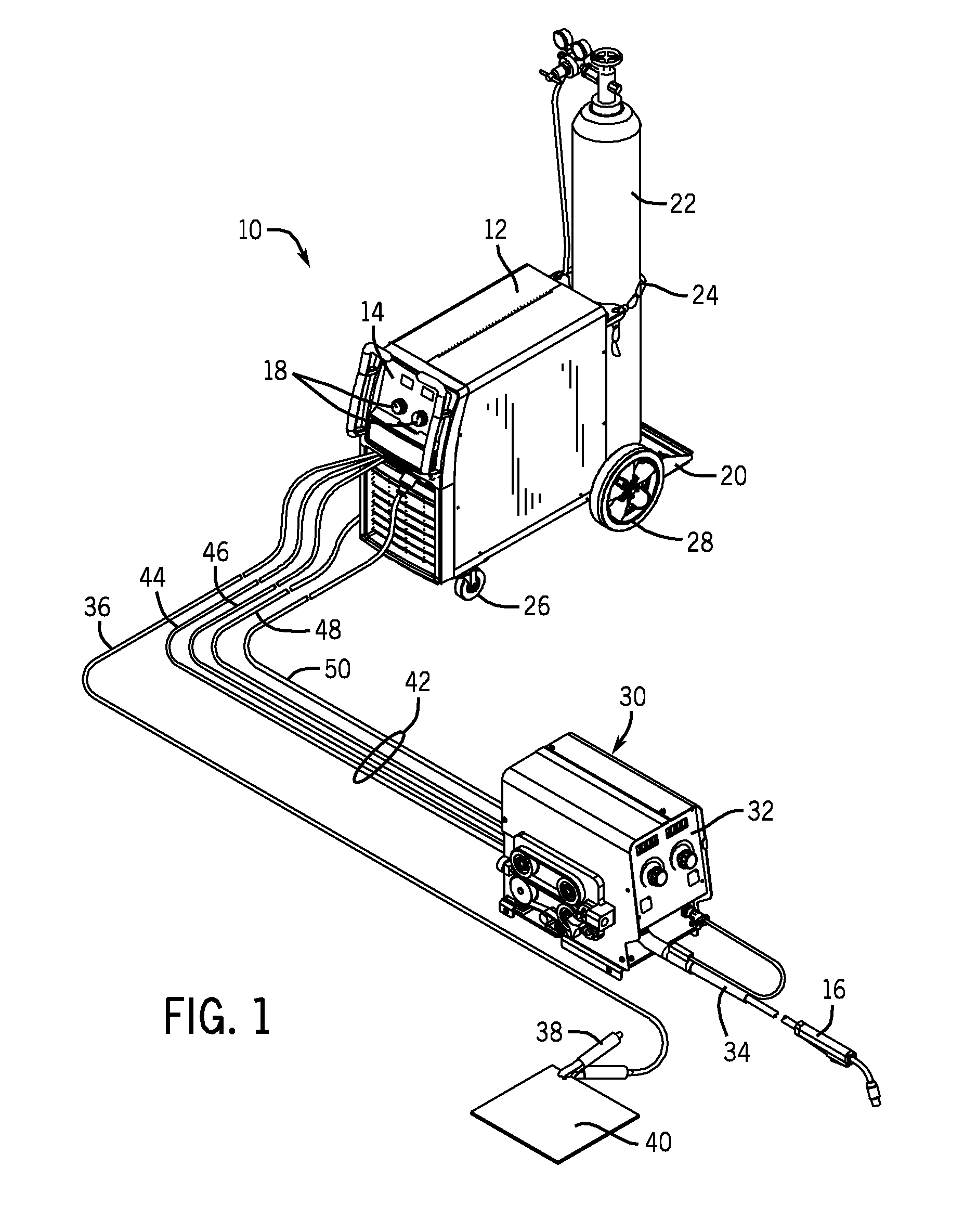

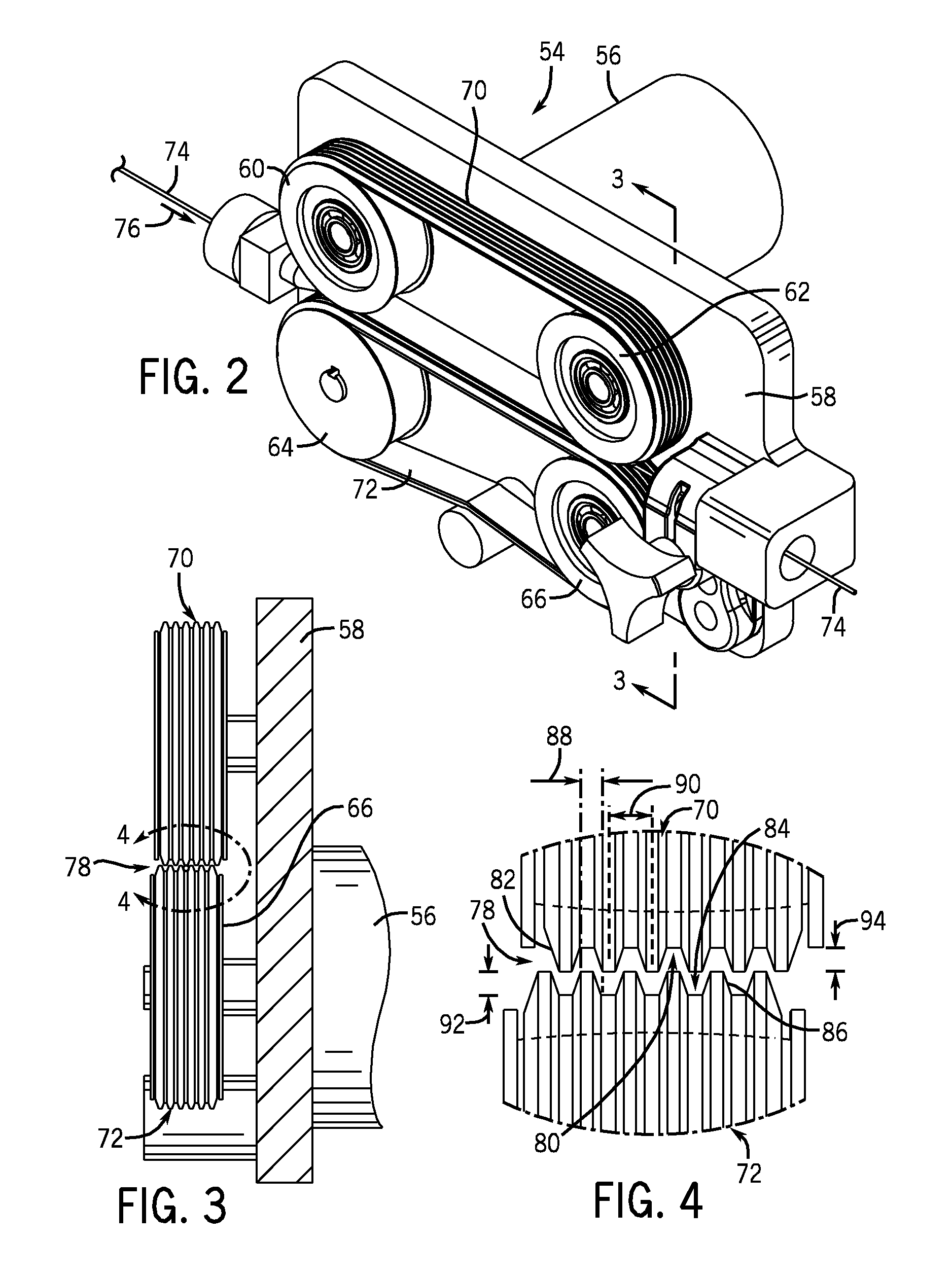

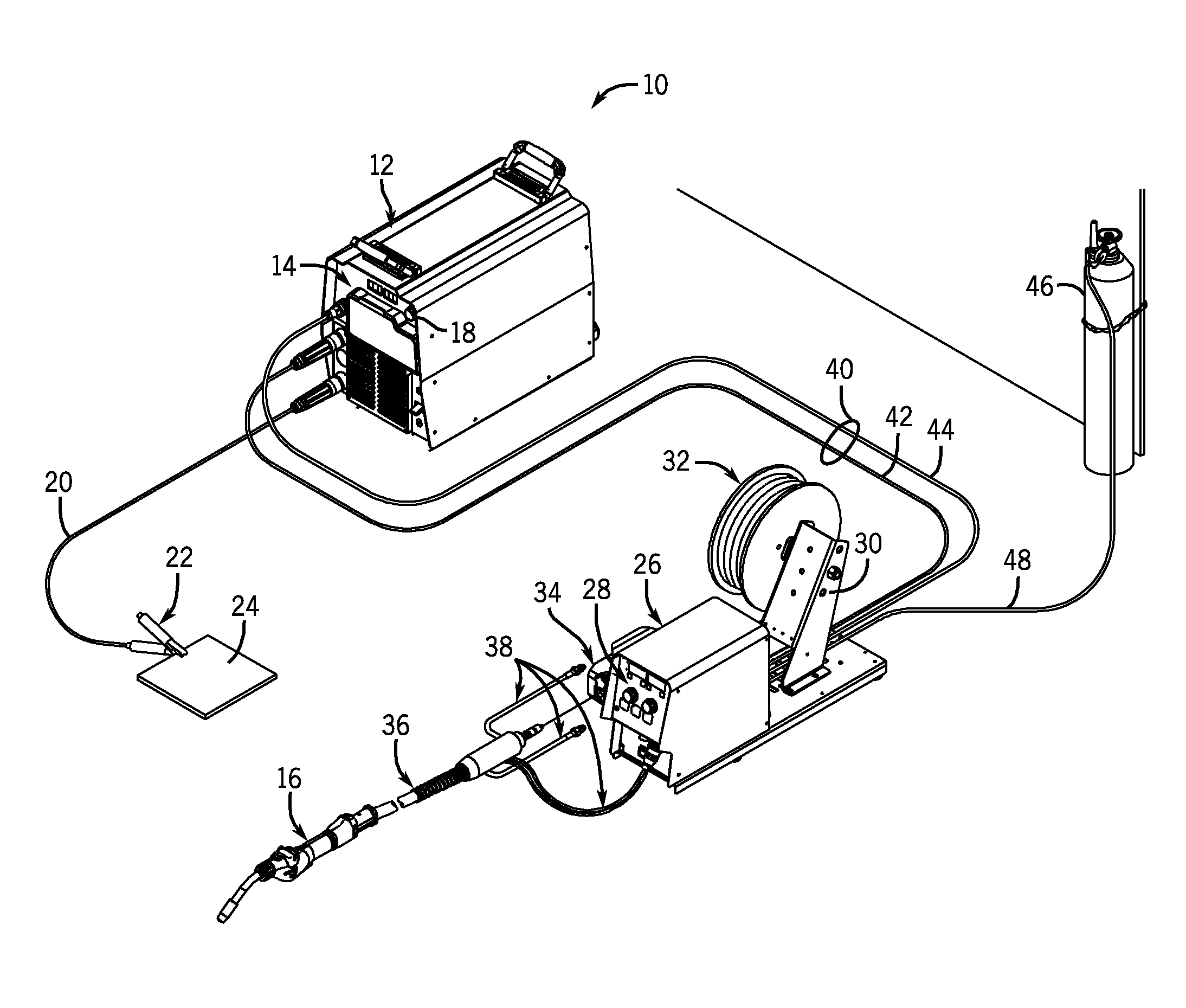

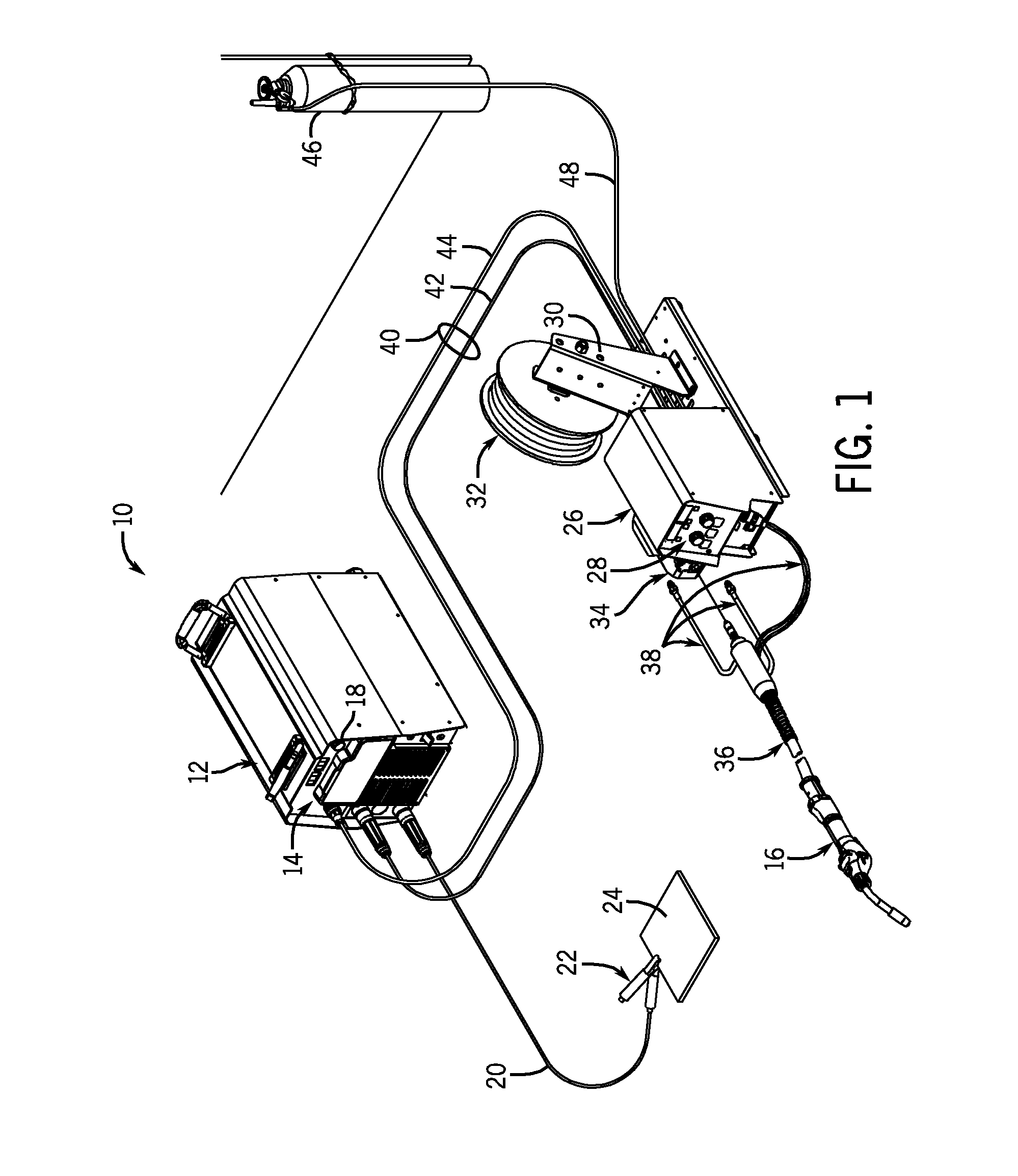

Belt drive for feeding welding wire

A welding wire feed drive system is provided including belts mounted on wire drive rollers. One or both belts may be poly-V belts mounted on the rollers and positioned such that grooves of the belts are outward facing. Opposing grooves and projections of the belts may form an interfacing or interlocking arrangement suitable for the securement of a welding wire therein. The grooves and projections of the belts may be utilized to facilitate the movement of the welding wire towards a welding application.

Owner:ILLINOIS TOOL WORKS INC

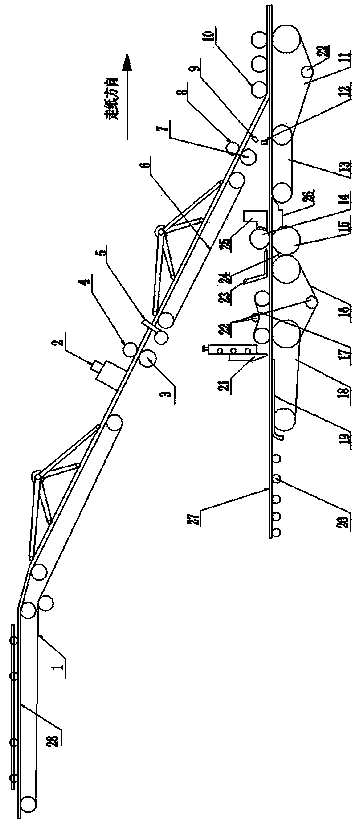

Synchronous body paper and face paper feeding device and control method

ActiveCN104340703ARealize synchronous high-speed paper feedingRealize functionArticle feedersWebs handlingMotor driveLow speed

The invention provides a synchronous body paper and face paper feeding device and a control method. The device is characterized in that a face paper front lay gauge, a face paper pressing wheel, a face paper side lay gauge, a body paper front lay gauge and a body paper lifting plate assembly are configured with cam mechanisms respectively and are driven by the respective cam mechanisms; a face paper motor drives a low-speed face paper feeding belt assembly, a body paper induced draft air distribution valve, a face paper side pull gauge and cam mechanisms thereof through a synchronous toothed belt or a roller chain; a paper injection driving roller, an upper pressing driving roller, a paper feeding driving roller, a high-speed face paper injection wheel and a high-speed face paper conveying belt assembly are driven by a body paper motor at the same speed. The distance between the face paper front lay gauge and a laminating roller is equal to the distance between the body paper front lay gauge and the laminating roller, so that body paper and face paper reach a converging point at the same time, and surface lamination is completed. The functions of synchronously feeding the body paper and the face paper at a high speed and automatically aligning the body paper with the face paper can be realized, the use of the motors is reduced, and the phenomenon that the motors are frequently started is avoided. The working efficiency is improved, and the manufacturing cost is reduced.

Owner:QINGDAO MEIDA INTELLIGENT TECH CO LTD

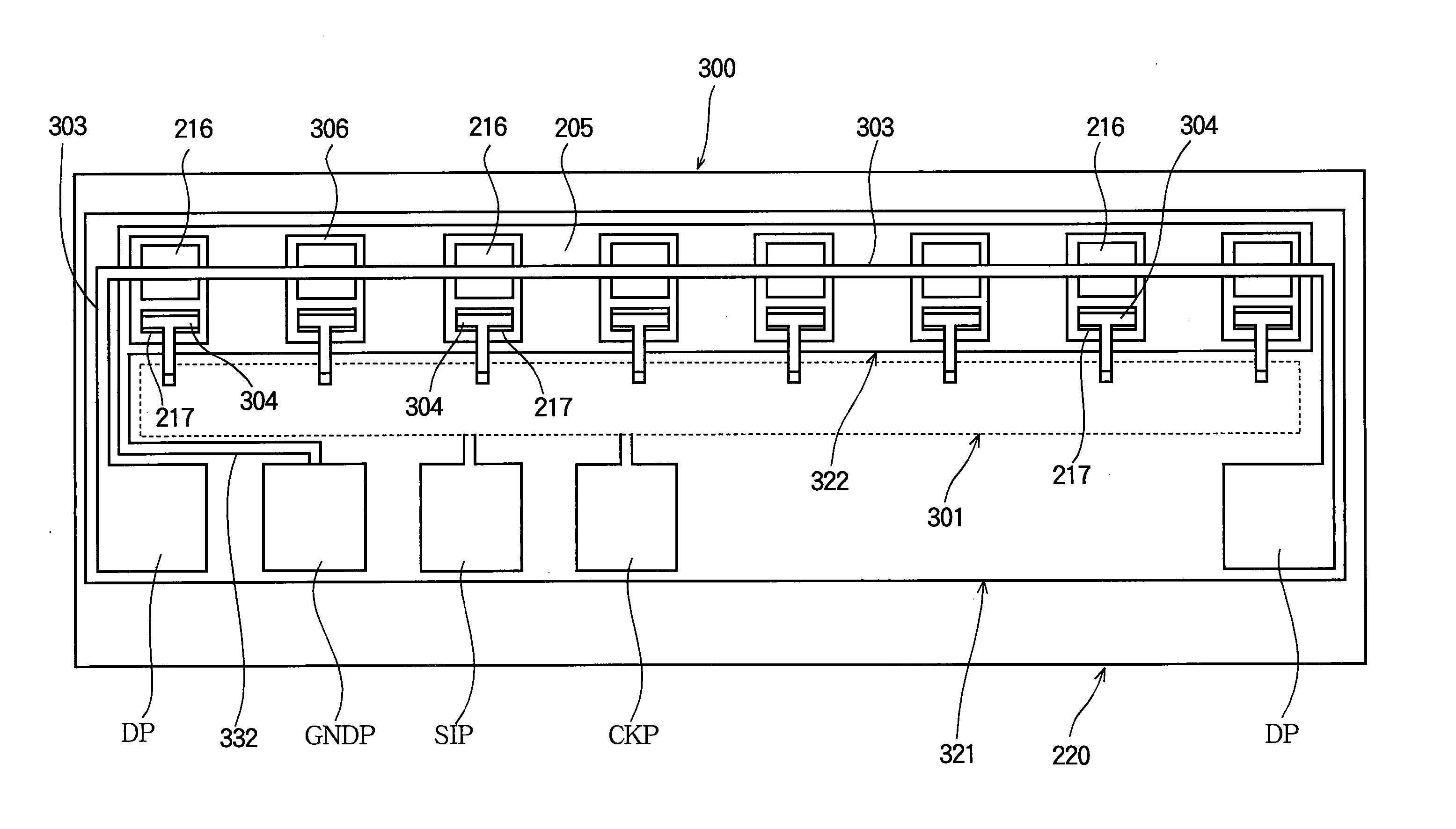

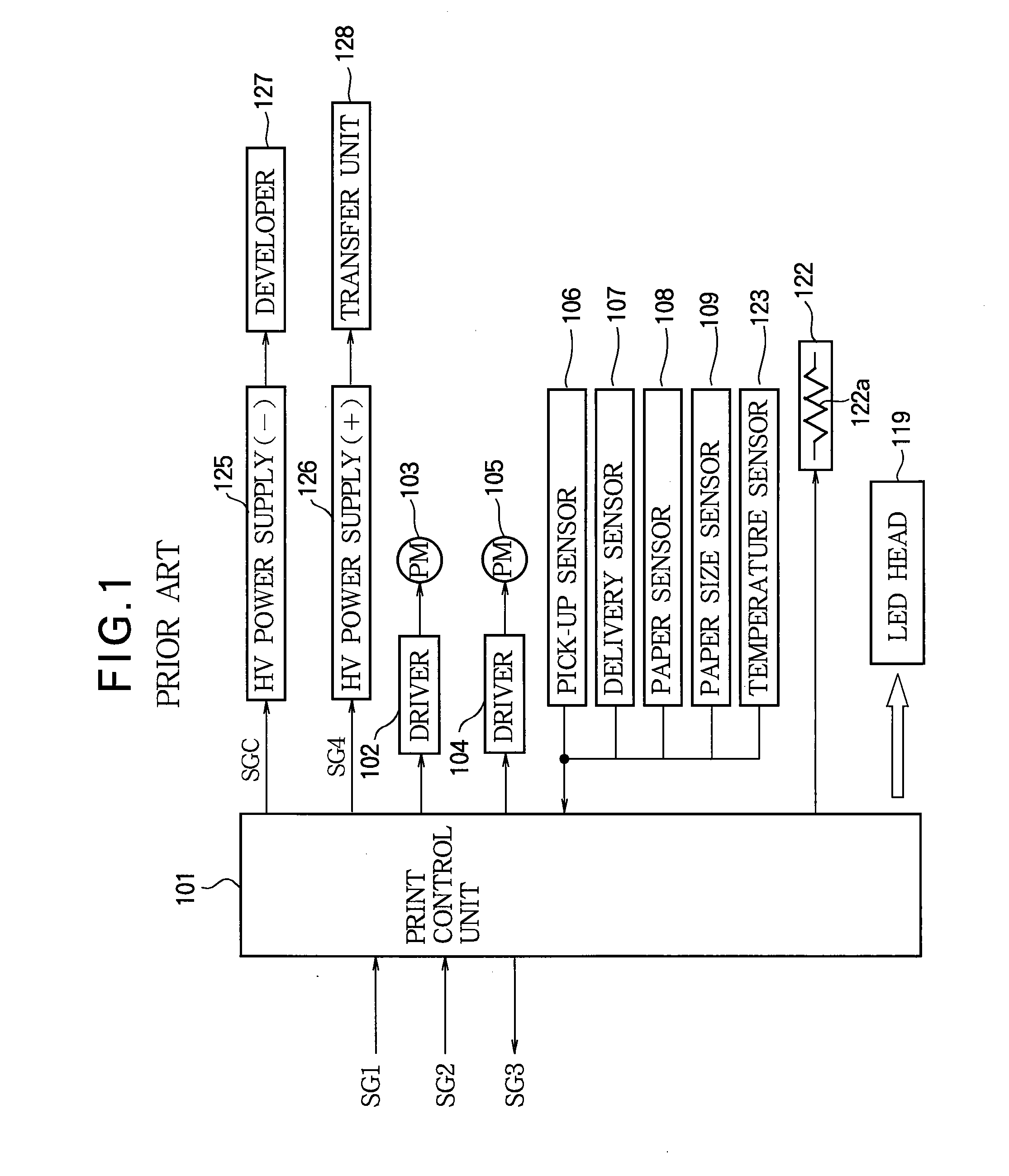

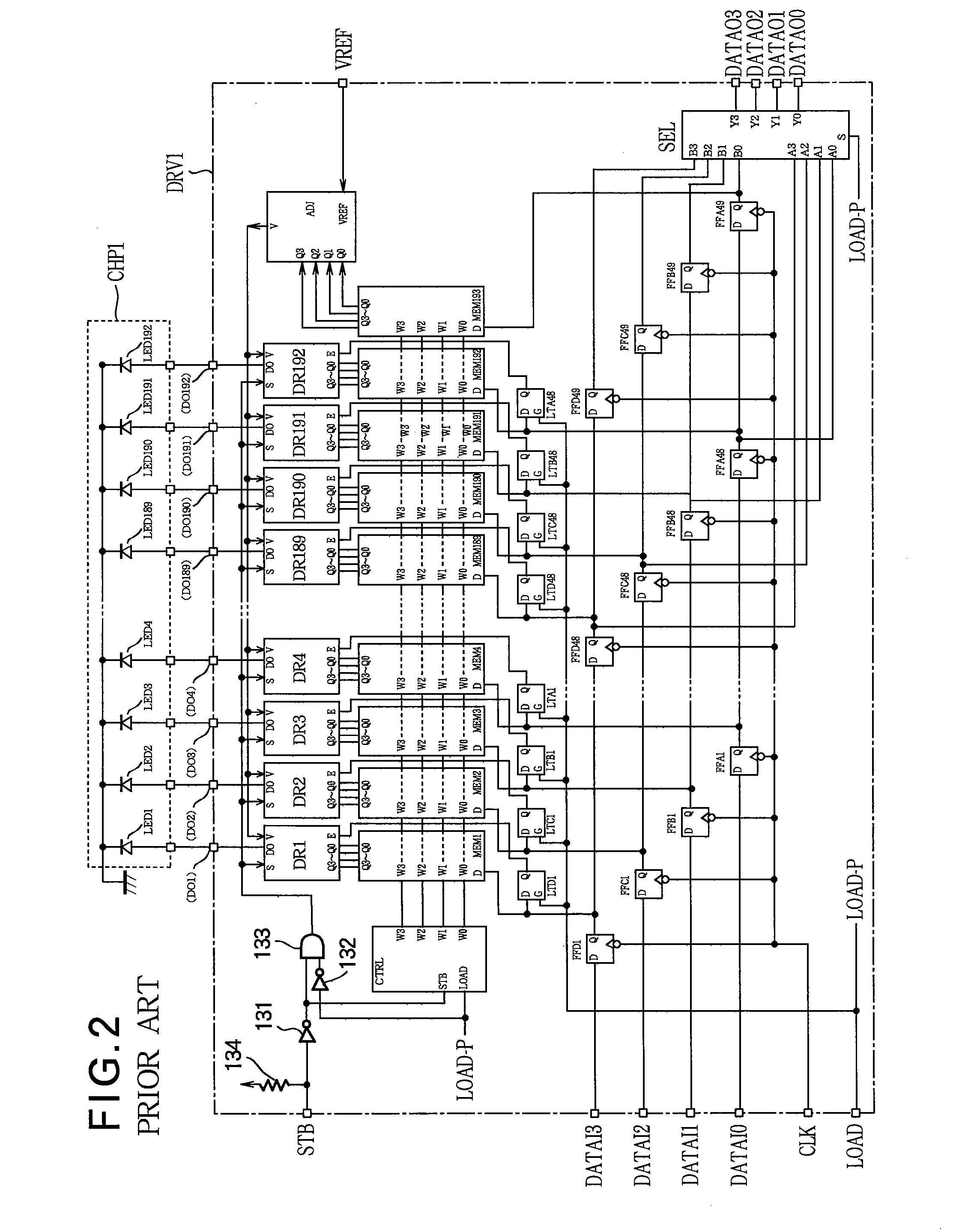

Three-terminal switch array, three-terminal switch array device, combined semiconductor device, and image form appartus

InactiveUS20070057259A1Small sizeLow costSolid-state devicesSemiconductor/solid-state device manufacturingShift registerTransistor array

An array of three-terminal switching elements such as light-emitting thyristors is formed from a thin semiconductor film. A combined semiconductor device may be formed by bonding the thin-film three-terminal switching elements to a major surface or edge surface of an integrated circuit chip including a shift register that shifts data supplied to the control electrodes of the three-terminal switching elements, or by bonding both the thin-film three-terminal switching elements and another thin semiconductor film including the shift register to a substrate. In either case, thin-film wiring may be used to interconnect the shift register and the switching elements, and the need for an array of large transistors to feed driving current to the switching elements is eliminated, reducing the size and cost of the combined semiconductor device, which can be advantageously used in the optical head of an electrophotographic printer.

Owner:OKI DATA CORP

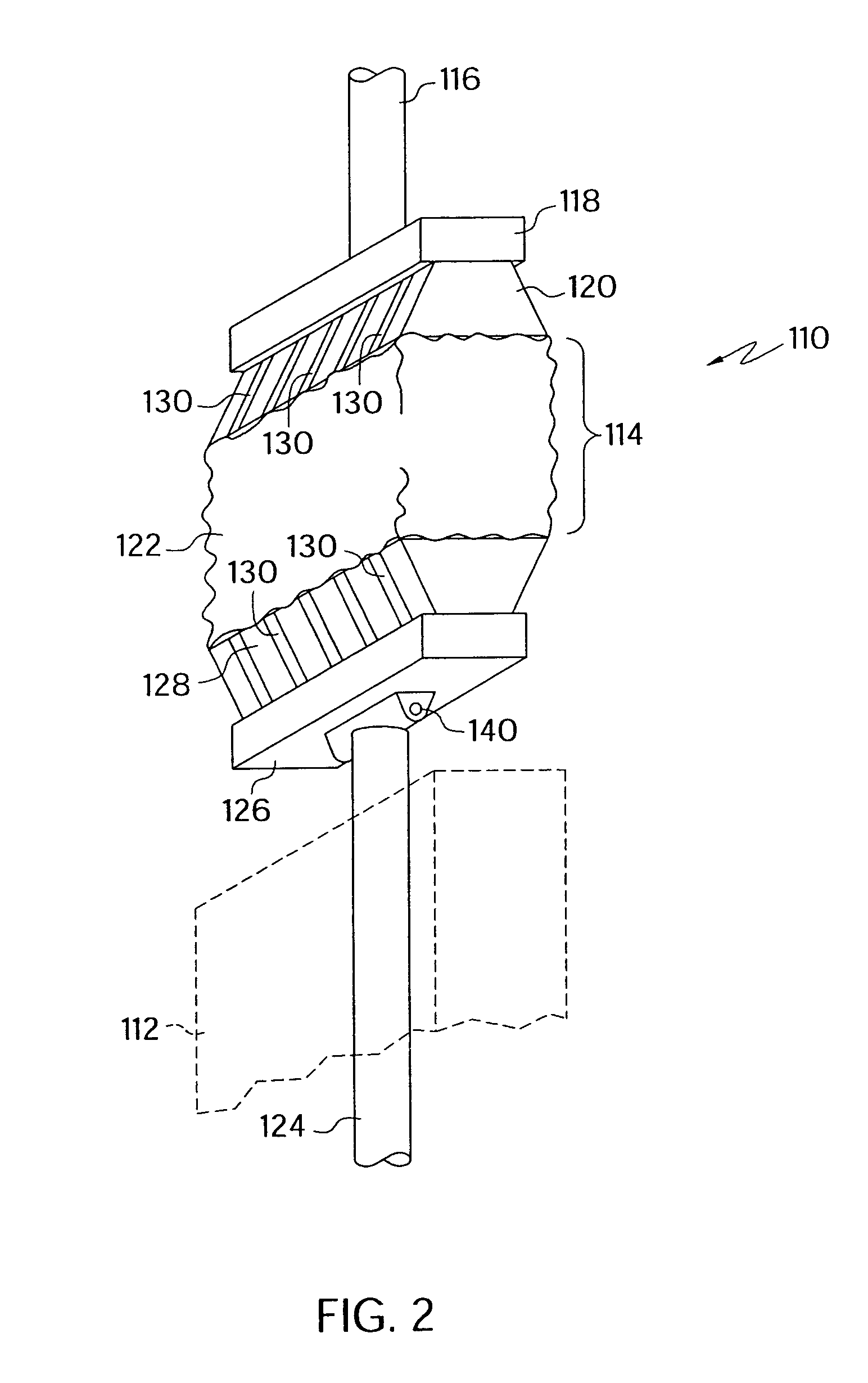

Loaf seam synchronization device for continuous loaf feed slicing machine

A mechanism and method is provided for controllably loading multiple food loaves into the slicing station of a continuous slicing machine. The parallel loaves that are engaged by a common loaf feed drive or side-by-side, independent loaf feed drives are engaged by the loaf feed drive or drives simultaneously such that the interface or seam between a preceding loaf and a trailing loaf in different loaf feed paths are located substantially at the same location during slicing of two side-by-side loaf streams. A clamp device is provided that clamps multiple food loaves when loaded to move along the parallel food loaf paths together, wherein the clamp device can be released once the multiple food loaves are simultaneously engaged by the loaf feed drive.

Owner:PROVISUR TECHNOLOGIES INC

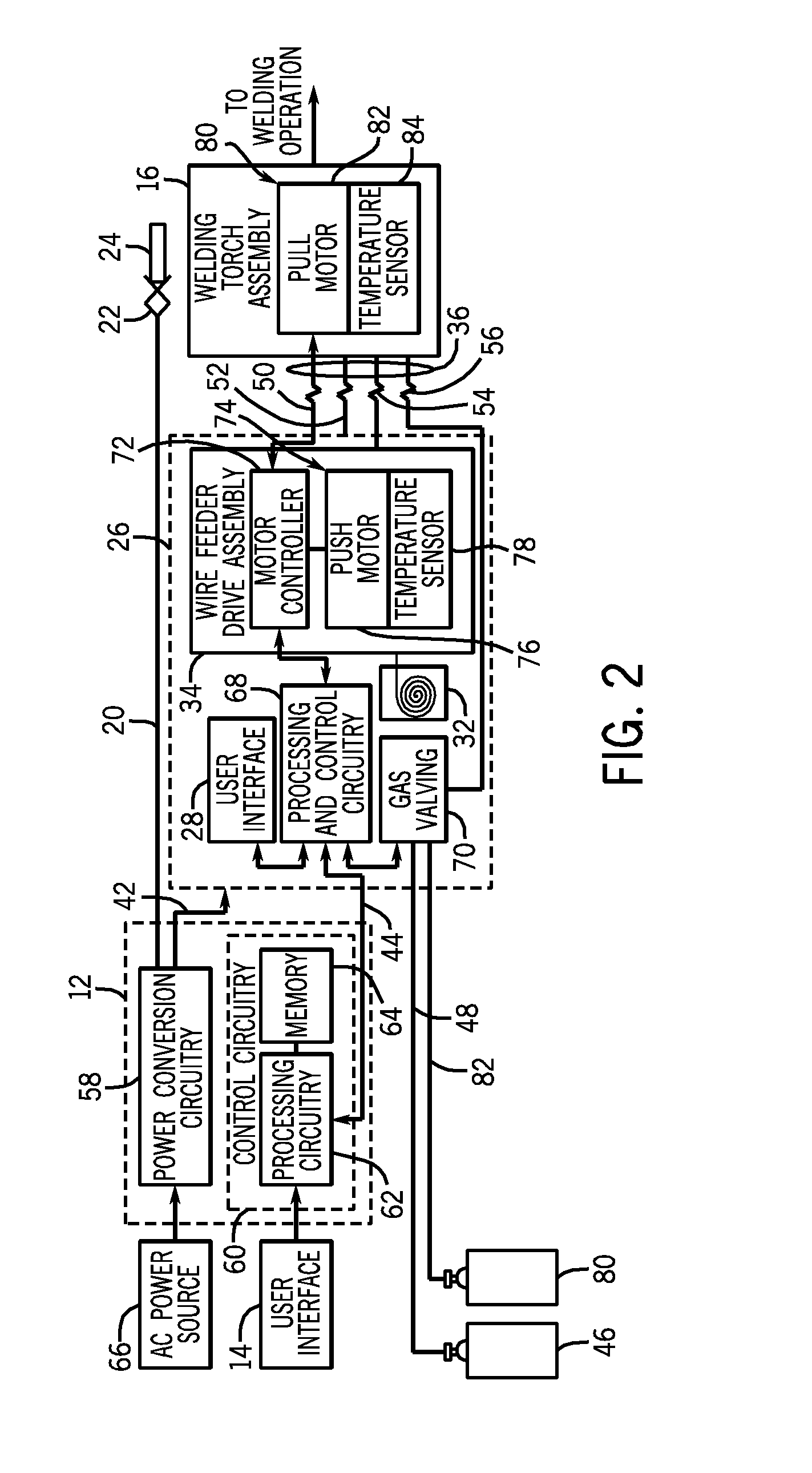

Wire feed motor control systems and methods

Wire feed drive assemblies having welding wire mounted thereon and a motor that rotates a wire feed roller to drive the weld wire toward a welding torch are provided. The wire feed drive assemblies also include a temperature sensor coupled to the motor and adapted to measure a temperature of the motor. The wire feed drive assemblies further include a motor controller coupled to the temperature sensor and the motor and adapted to receive temperature feedback from the temperature sensor and to utilize the temperature feedback to regulate a speed of the motor.

Owner:ILLINOIS TOOL WORKS INC

Cylinder type workpiece code word machine

A cylindrical workpiece coding machine, the body is built with a motor and its gearbox, the body is obliquely installed with an adjustable bracket, the width adjustable hopper is installed on the adjustable bracket, the width adjustable hopper is connected to a curved material channel, the width The front end of the adjustable hopper is equipped with a puller mechanism, the front side of the fuselage is fixed with the headstock, the headstock supports the main shaft, the gearbox drives the main shaft, the front end of the main shaft is fixed with rollers, and at least one font box is fixed around the rollers, and the characters and patterns are embedded in the font box Among them, a cam is installed on one side of the font box, and a special-shaped backing plate mechanism is fixed on the other side of the front side of the fuselage. The frame is installed on the adjustment bracket, and when the main shaft rotates, the cam drives the feeding frame, the material pulling drive frame contacts and moves with the feeding frame, and the material pulling drive frame contacts and pulls the material pulling mechanism. The handwriting it engraves is neat and clear, and the production efficiency is high.

Owner:李钢放

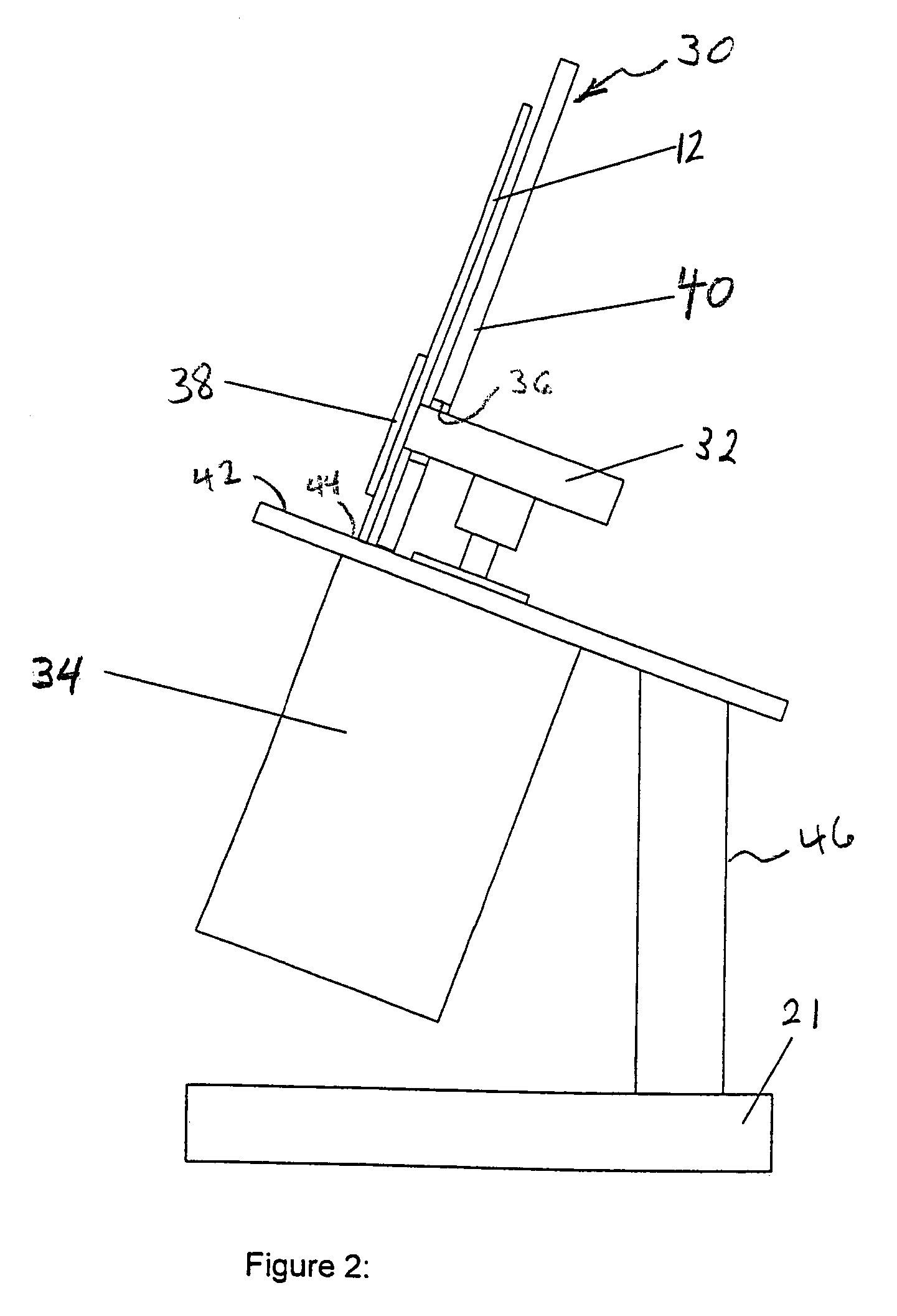

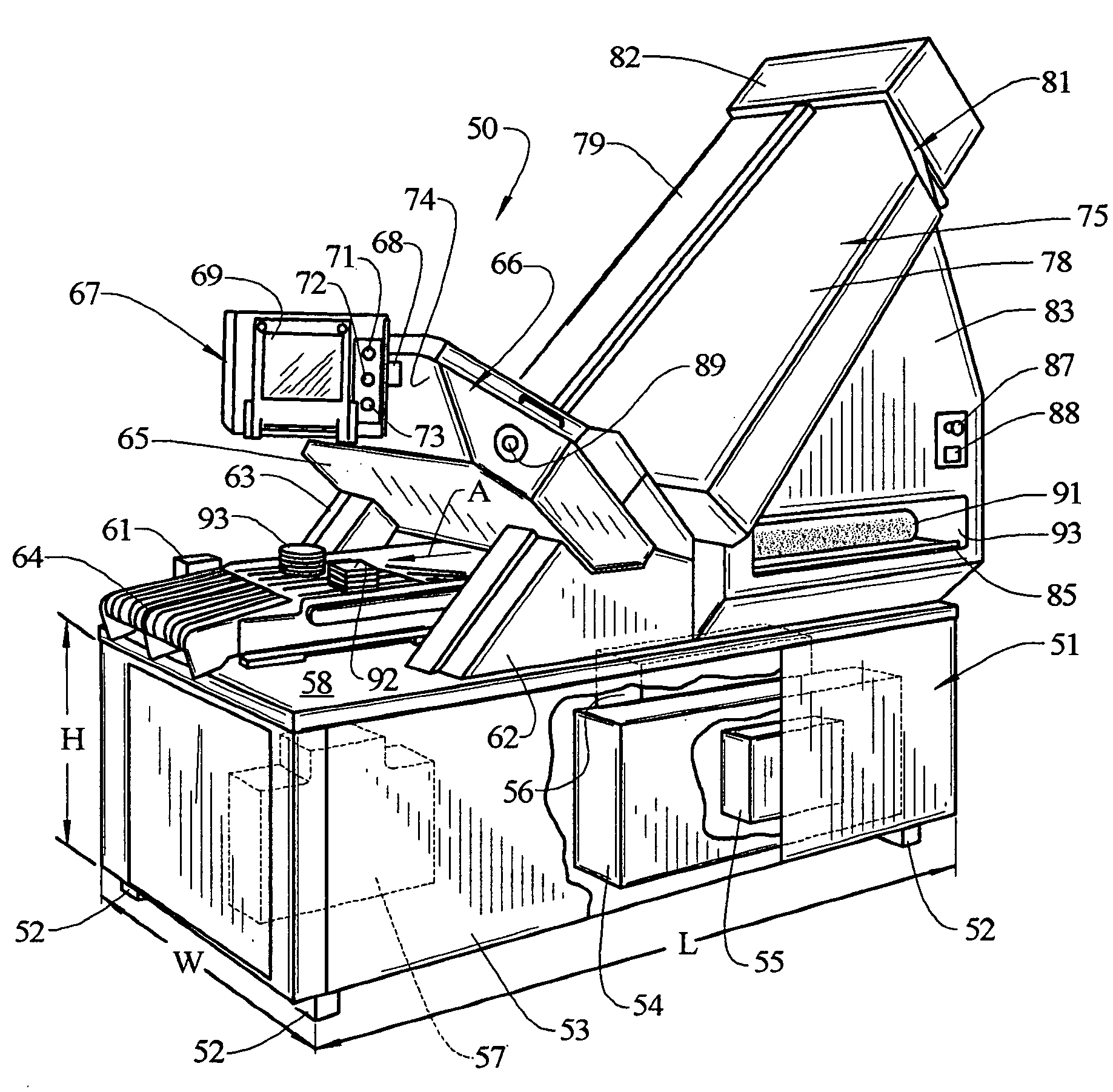

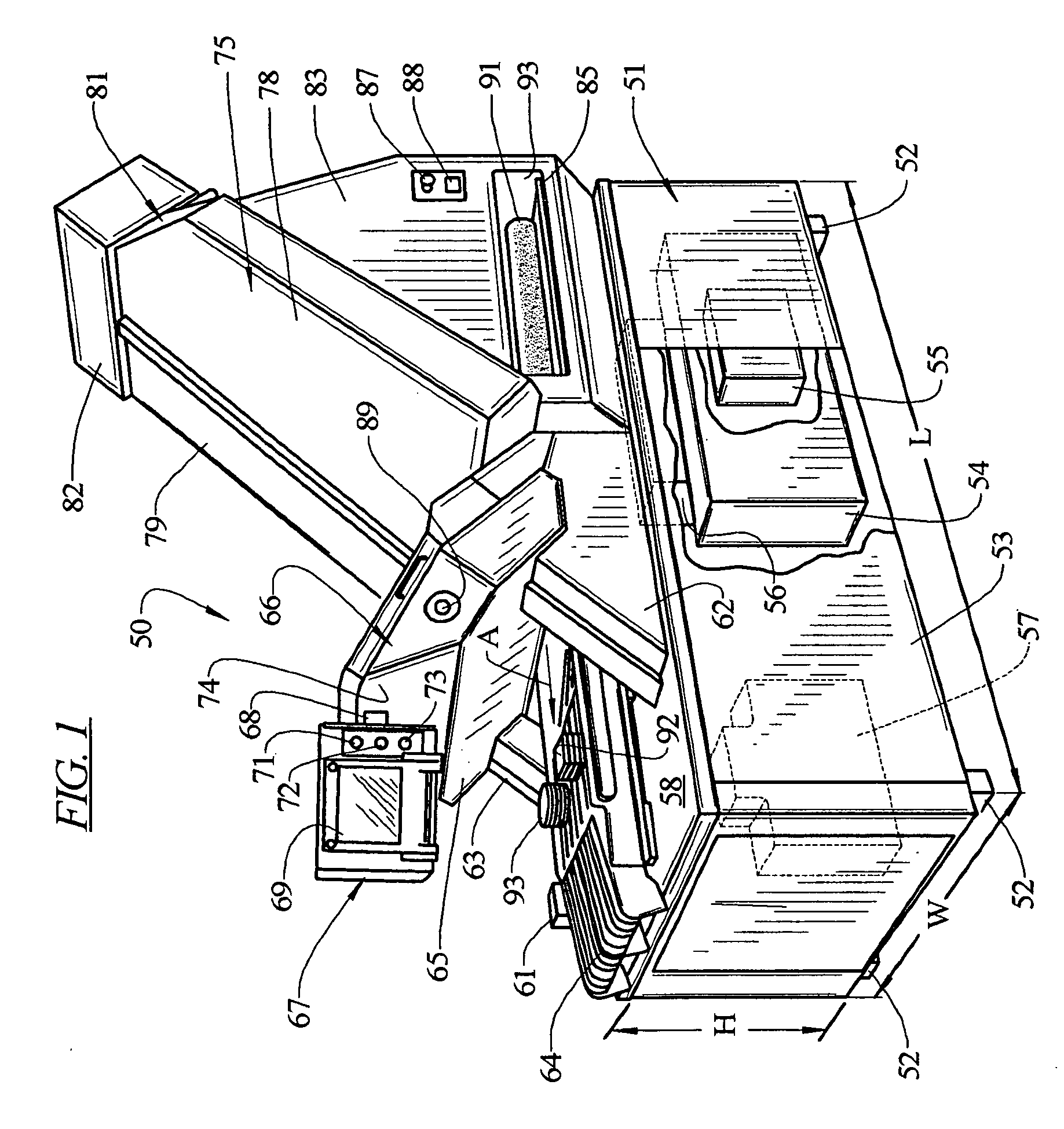

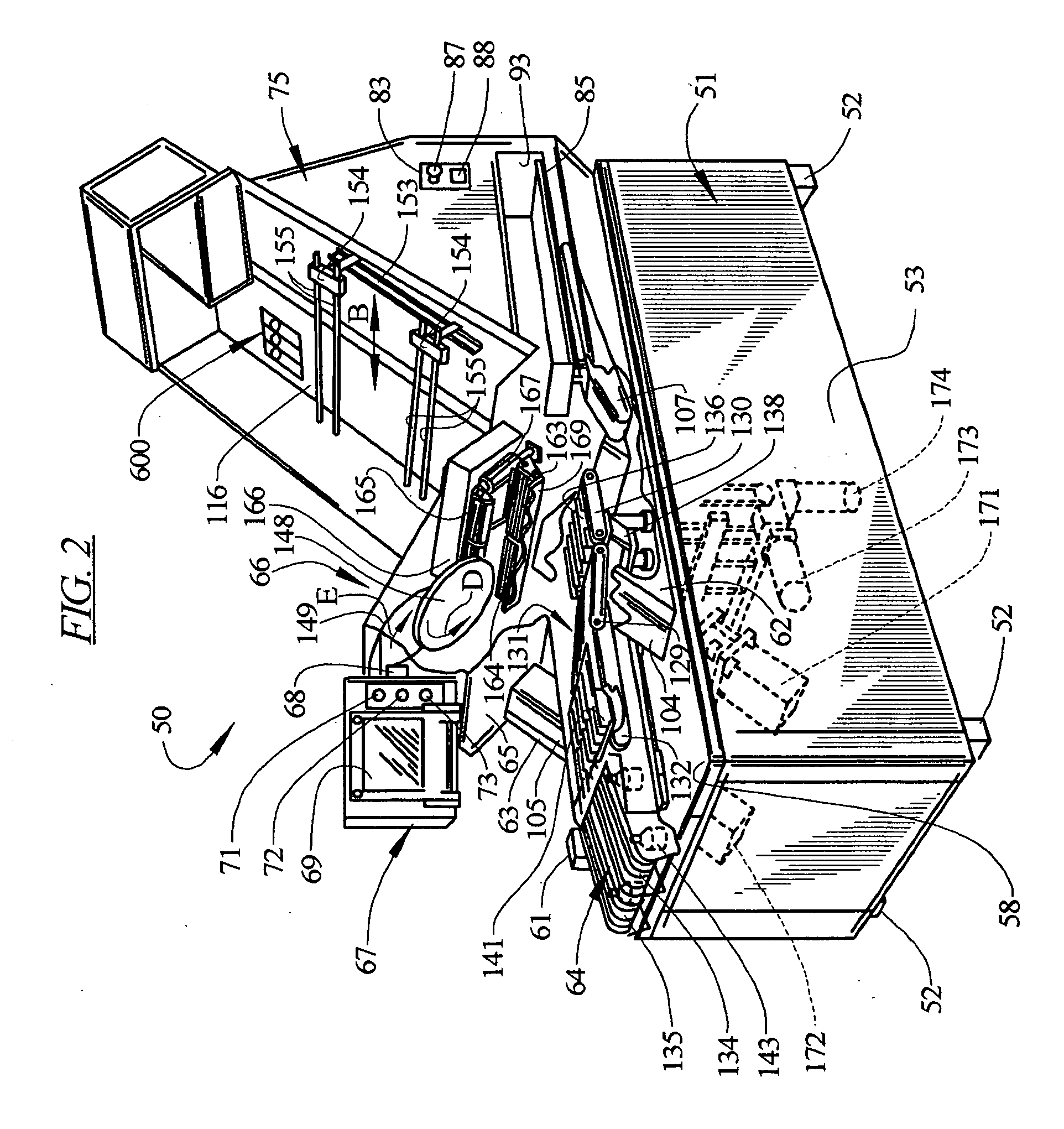

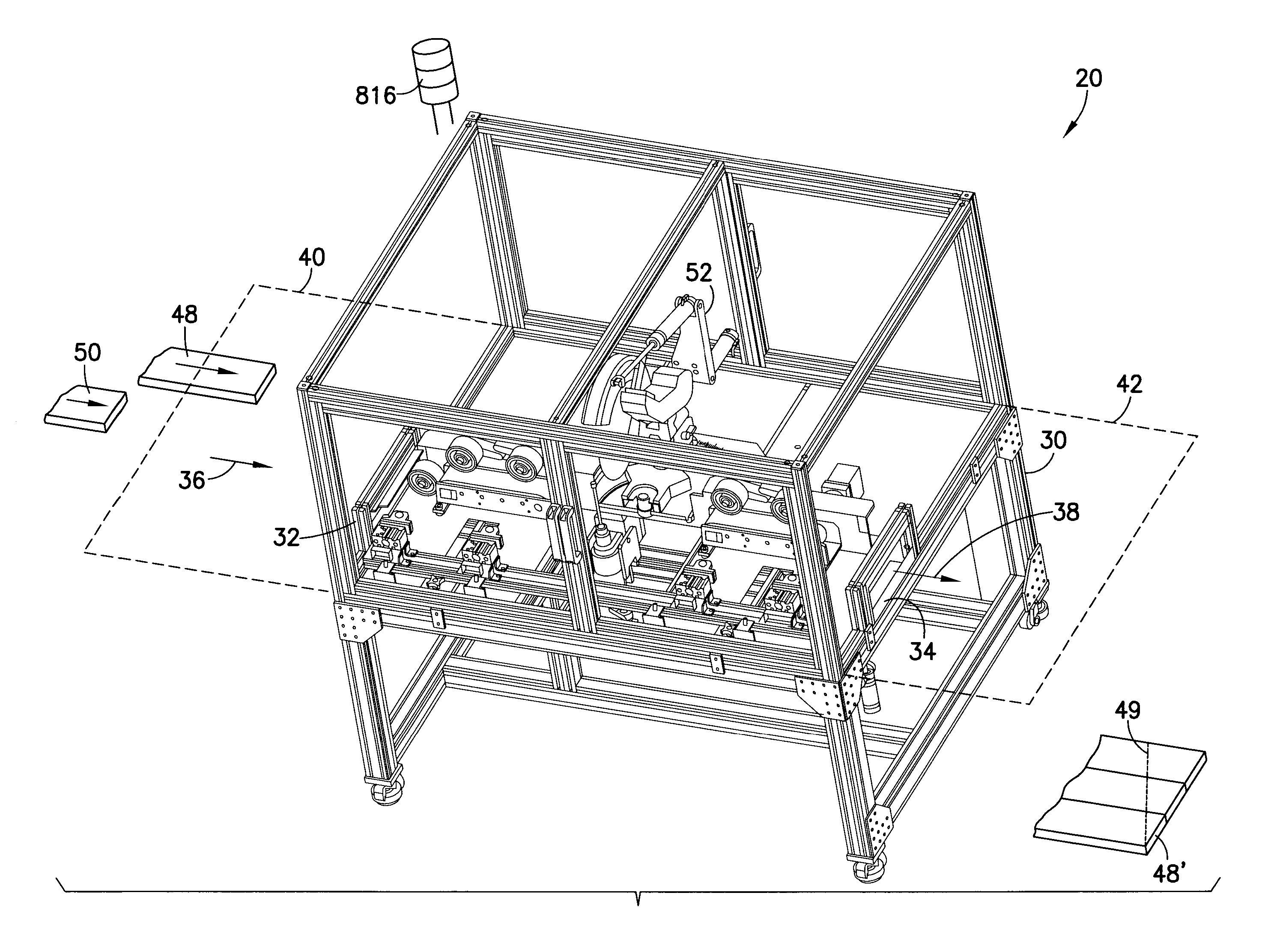

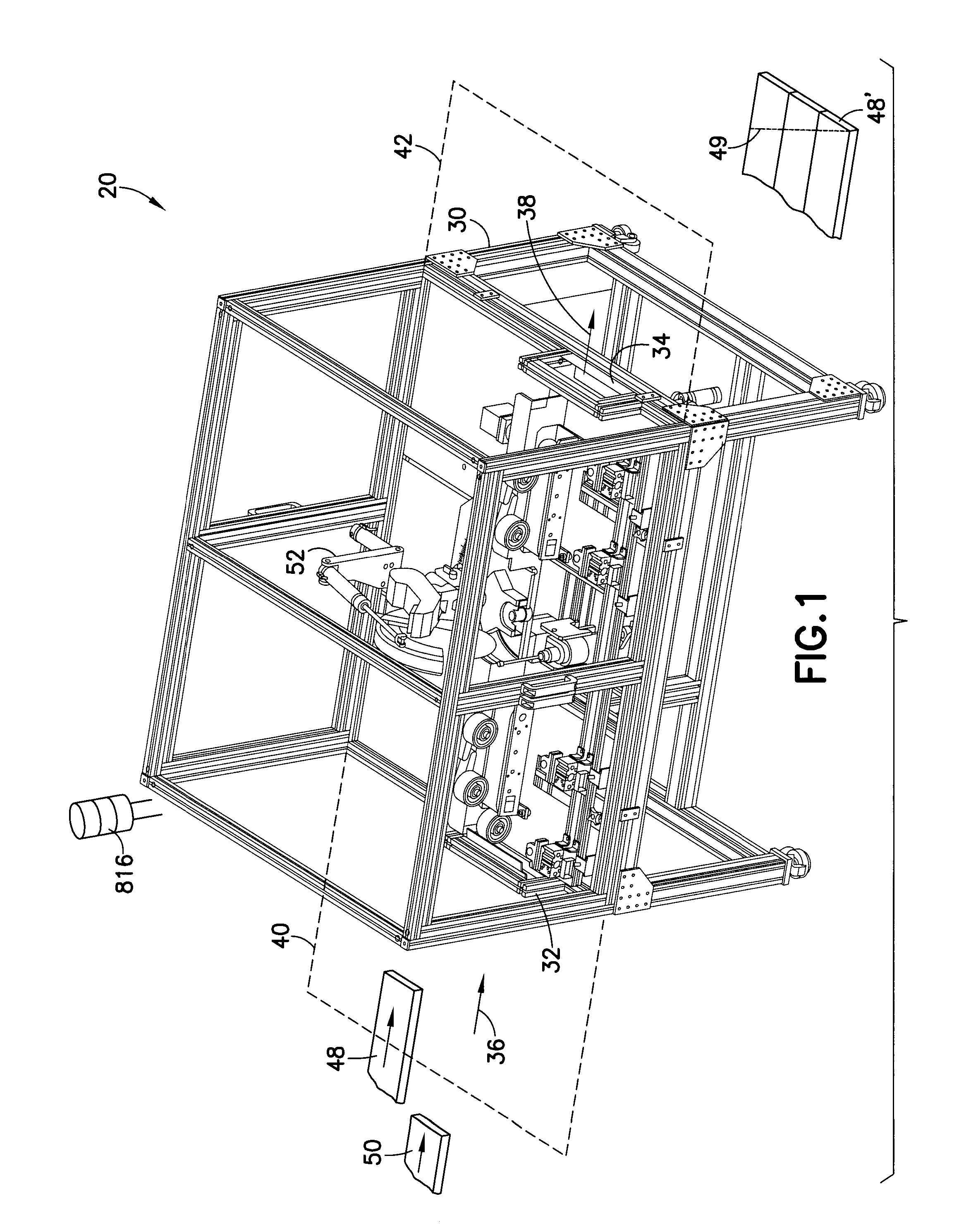

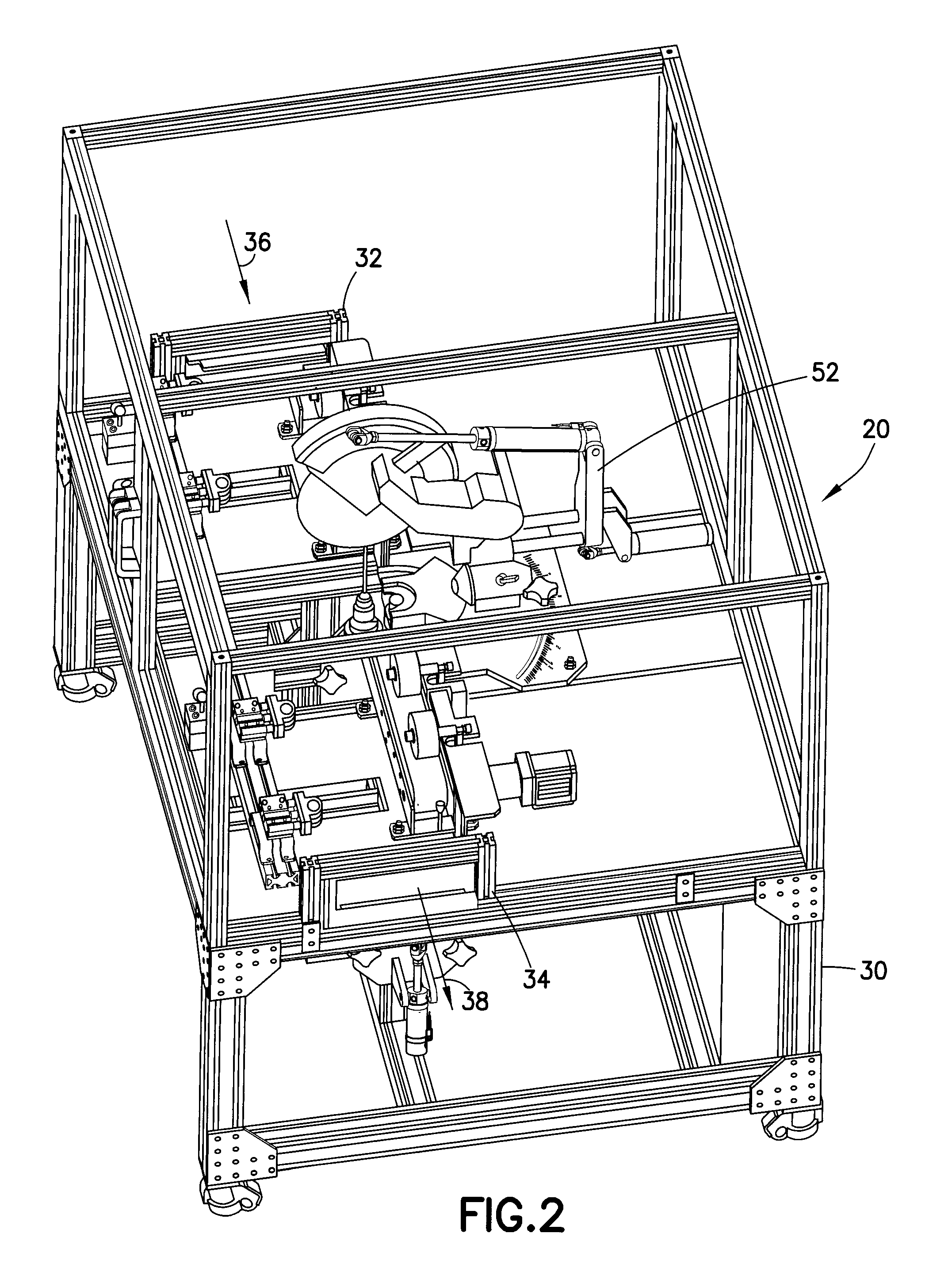

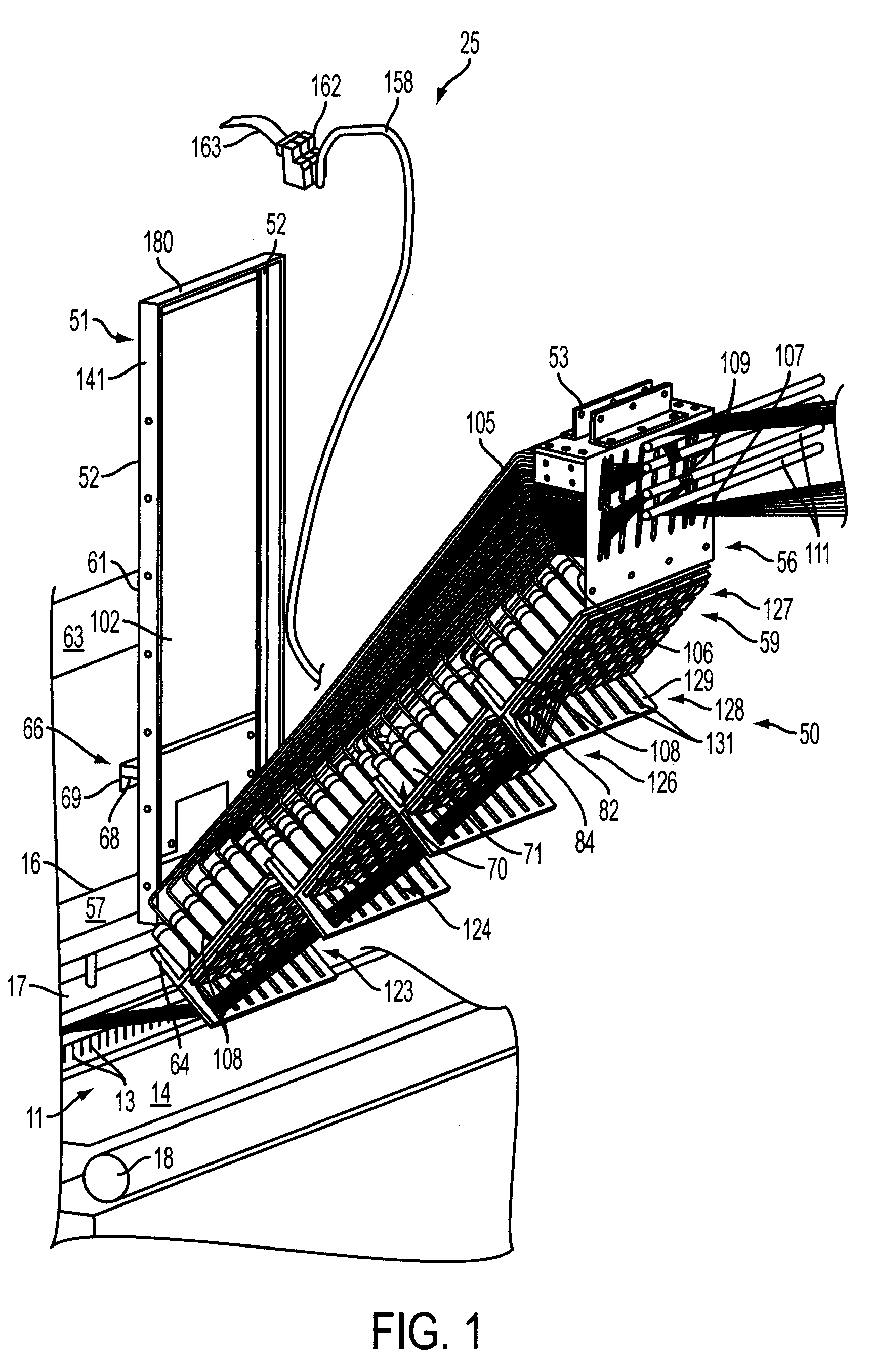

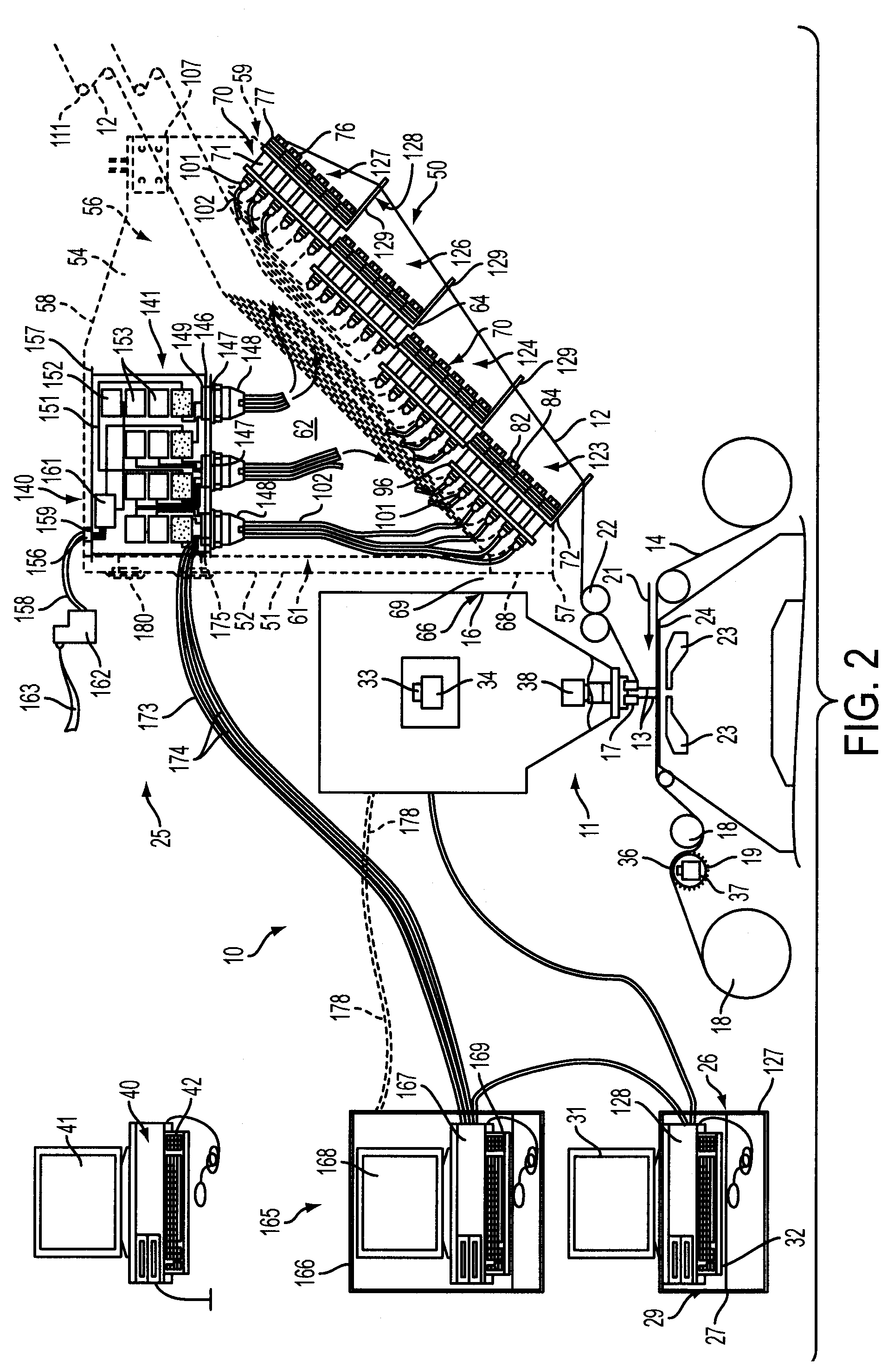

Automated stick-frame system

A automated stick cutting system is provided adapted to produce stick-frame construction components from material for building construction. The automated stick cutting system has a frame having an in-feed portion and an out-feed portion. A saw is adapted to cut the material, the saw coupled to the frame. An in-feed drive is coupled to the frame, the in-feed drive adapted to accept the material from the in-feed portion and feed the material to the saw. A position detector is coupled to the frame, the position detector adapted to track a position of the material relative to the in-feed drive. An out-feed drive is adapted to accept the material uncut from the in-feed drive, the out-feed drive adapted to accept the material cut from the saw and feed cut material to the out-feed portion. An edge detector is adapted to detect a leading edge of the material when being fed to the saw by the in-feed drive. The position detector and the edge detector cooperate with operation of the saw to meter lengths of the material through the in-feed drive and to cut a predetermined length of the material with the saw.

Owner:DUNMOW SYST CORP

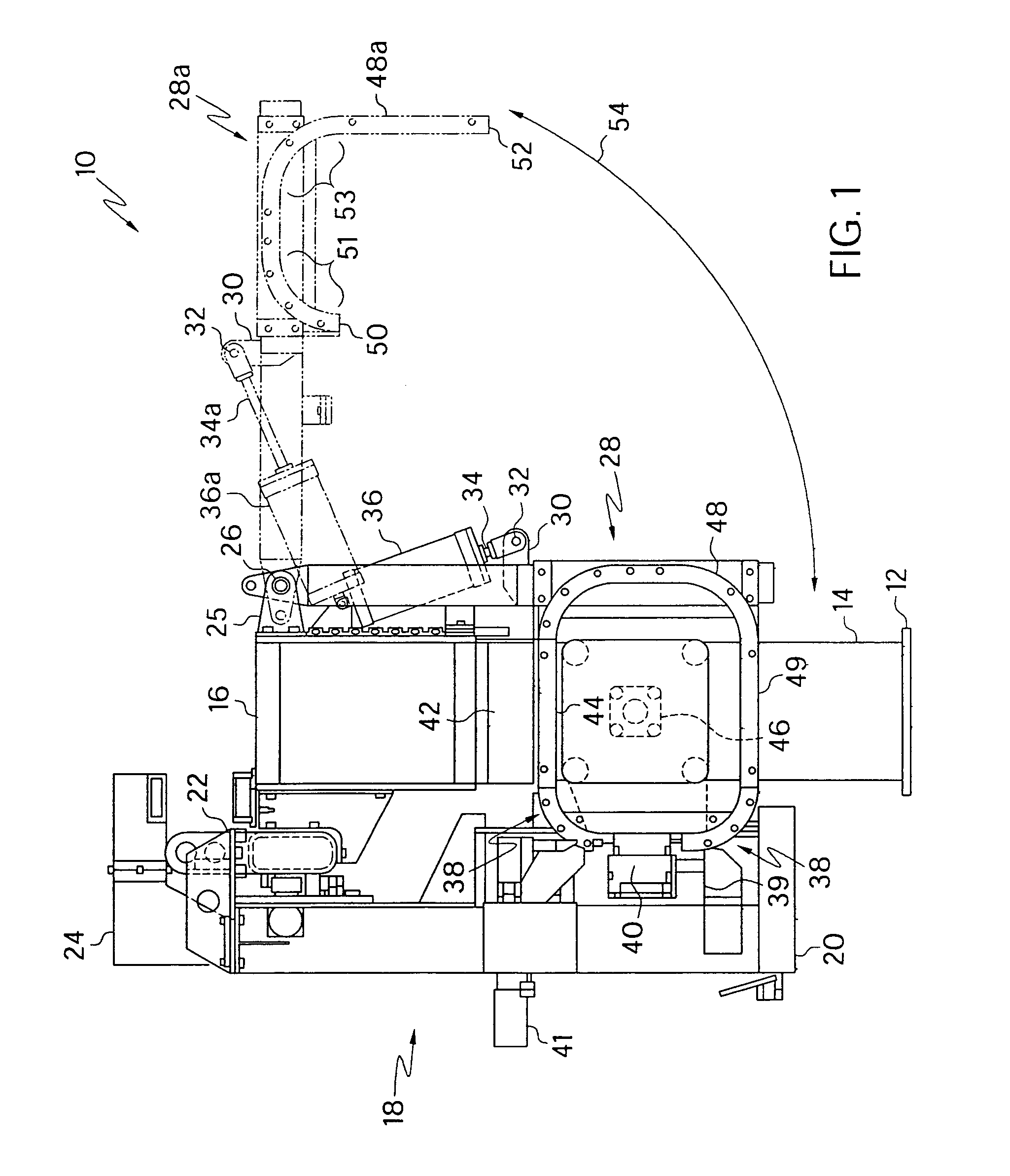

Continuous forging furnace

The invention relates to a continuous forging furnace. The continuous forging furnace comprises a furnace body, a gas mechanism and a combustion-supporting mechanism, wherein the furnace body comprises a hearth; the gas mechanism comprises a gas tube; the combustion-supporting mechanism comprises a combustion-supporting gas tube, and the gas provided by the gas mechanism passes through the gas tube to be mixed with the combustion-supporting gas which is provided by the combustion-supporting mechanism and passes through the combustion-supporting gas tube, so that the gas and the combustion-supporting gas are matched for burning so as to heat the hearth; the forging furnace also comprises a feeding mechanism and a waste heat utilizing mechanism, wherein the feeding mechanism comprises a plurality of feed driving pieces; the hearth is internally provided with a plurality of material guiding cylinders and is communicated with a material discharging hole, the plurality of feed driving pieces push heating pieces to the corresponding material guiding cylinders by turns; and the waste heat utilizing mechanism comprises a plurality of heat conduction pipe sleeves which are connected with the material discharging hole and the material feeding end of the furnace body and is sleeved with the combustion-supporting gas tube. The continuous forging furnace realizes the continuous heating as the plurality of feed driving pieces can push the heating pieces, and the waste heat utilizing mechanism can fully utilize the waste heat, so that the utilization ratio of the energy resources can be improved.

Owner:彭亦楚

Tape threading machine for paper box handle

InactiveCN102328458AImprove efficiencyFast loadingPaper-makingBox making operationsFeed driveEngineering

The invention relates to a machine used for small package paper boxes, in particular to a tape threading machine for a paper box handle. The tape threading machine for the paper box handle comprises a handle feeding mechanism, a guide mechanism, a cutting mechanism, a gasket feeding mechanism and a positioning mechanism, wherein an upper supporting plate cover is arranged above a feeding supporting plate in the handle feeding mechanism; the outer edge of a feeding driving roller is formed in a through hole on the feeding supporting plate; guide plates are arranged on the two sides of a positioning plate in the guide mechanism; a guide driving roller is arranged below the positioning plate; a supporting device is arranged below the guide driving roller; a cutter in the cutting mechanism isconnected with a cutter driving device; a gasket driving roller in the gasket feeding device is connected with a gasket driving device; a returning spring is sleeved out of a positioning pin of the positioning mechanism; the other end of the positioning pin is placed on a transverse connecting plate; and the other end of the transverse connecting plate is provided with a lifting device. The tape threading machine has high efficiency; the feeding driving roller can realize rapid feeding; the handle is inserted into a gasket hole smoothly by the guide mechanism; and the positioning mechanism facilitates the transportation of a gasket in a continuous feeding process.

Owner:于颢明

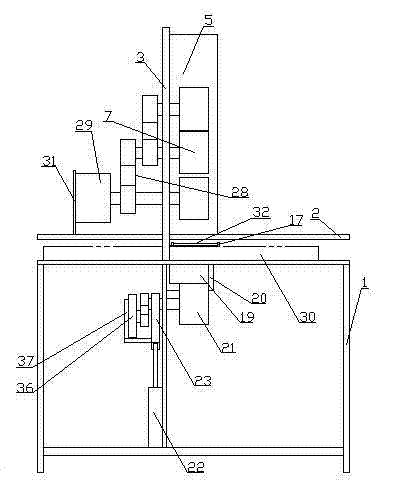

Core-rod grinding device

InactiveCN101417404AReasonable structureHigh degree of automationRevolution surface grinding machinesDrive wheelFeed drive

The invention discloses a core rod grinder, comprising a rod feeding platform and a rod grinding platform; wherein, the rod feeding platform is provided with two rod feeding driven wheels and driving wheels which are levelly arranged up and down, and the rod feeding driving wheels are connected with a rod feeding motor belt and provided with rotational screw threads on the surfaces and a rod feeding cross section consisting of the rod feeding driven wheels and driving wheels is an inverted isosceles triangle; the rod grinding platform is provided with two rod grinding driven wheels and driving wheels which are levelly arranged up and down, and the rod grinding driving wheels are connected with the rod feeding motor belt, and the rod grinding driven wheels and driving wheels are roller-typed grinding wheels and a rod grinding cross section consisting of the rod grinding driven wheels and driving wheels is an inverted isosceles triangle; and the rod feeding cross section is parallel with the rod grinding cross section and the center of the cross sections are on the same line. The invention is high in automation degree and stable in product quality, greatly reduces the labor intensity and eliminates most potential safety hazards; and after an outer cover is added, the working conditions are closed, and much of the dust is collected, thus ensuring the good health of workers and environmental sanitation.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ZHENGZHOU POWER SUPPLY +2

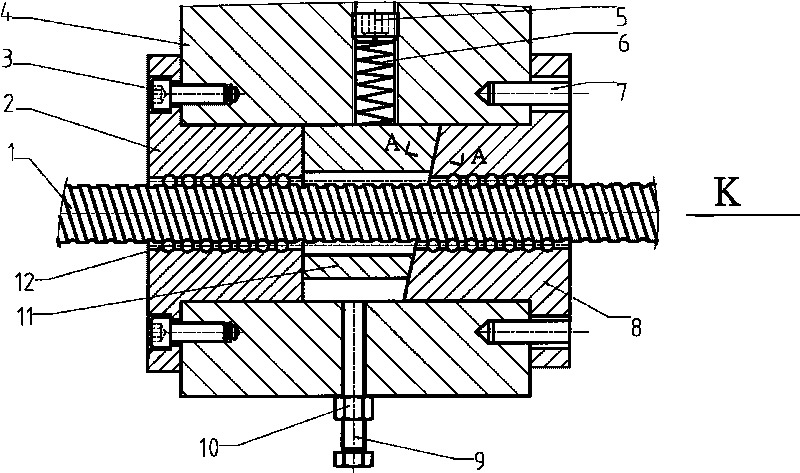

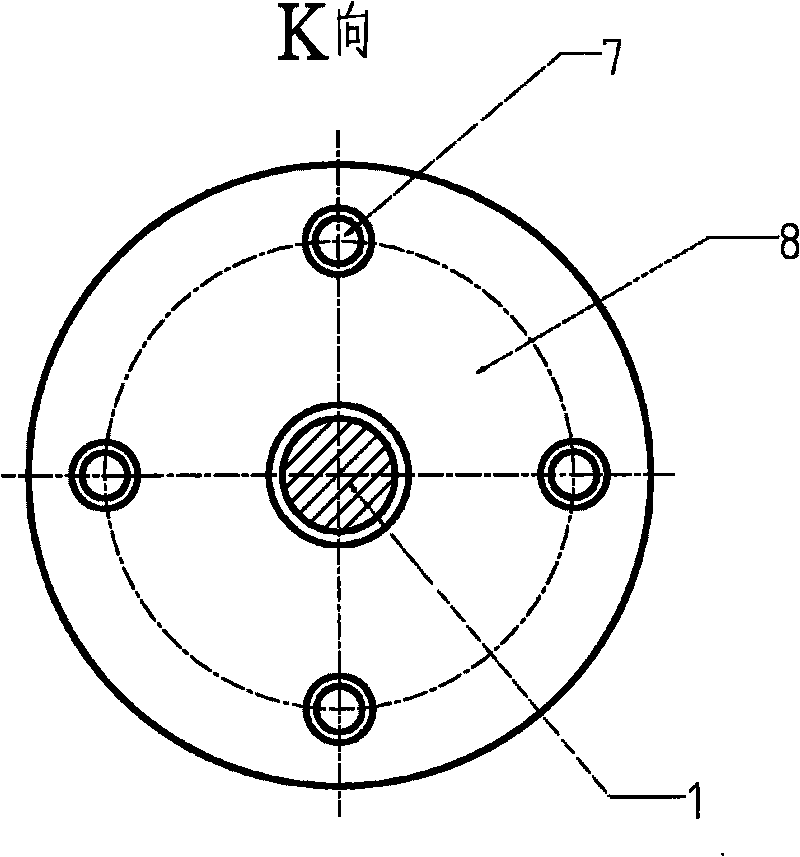

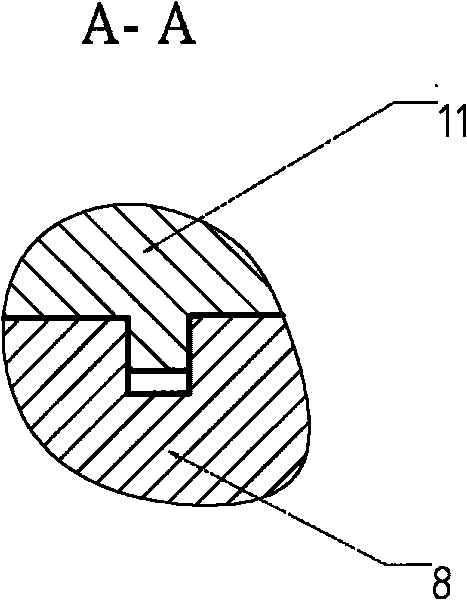

Device for automatically eliminating clearances of screw drive pair

InactiveCN101698284AAxial clearance automatically eliminatedNo reverse idle travelMetal working apparatusNumerical controlFeed drive

The invention relates to a device for automatically eliminating clearances of a screw drive pair, which comprises a leading screw, a main nut, a bolt, a machine tool sliding plate, an adjusting bolt, a spring, a guide post, a nut with an inclined plane, a bolt, a locking nut, a wedge block and a ball. The device is characterized in that the main nut and the nut with the inclined plane are connected with the leading screw respectively, the main nut is connected with the machine tool sliding plate through the bolt, and the flange of the nut with the inclined plane is provided with a through hole so that the nut with the inclined plane can move axially along the guide post. The wedge block with a self-locking function is supported between the main nut and the nut with the inclined plane; andone end of the spring is pressed on the wedge block with the self-locking function, while the other end is tightly pressed by the adjusting bolt. The incline plane of the nut with the inclined plane is provided with a guide groove. The device automatically eliminates axial clearances, has no reverse idle stroke, has adjustable pretightening force, good axial rigidity, smooth transmission, low cost, compact structure and high space utilization rate, is applied to feed drive systems of a metal cutting machine tool and a numerical control machine tool, and can greatly improve the processing accuracy.

Owner:李慎旺

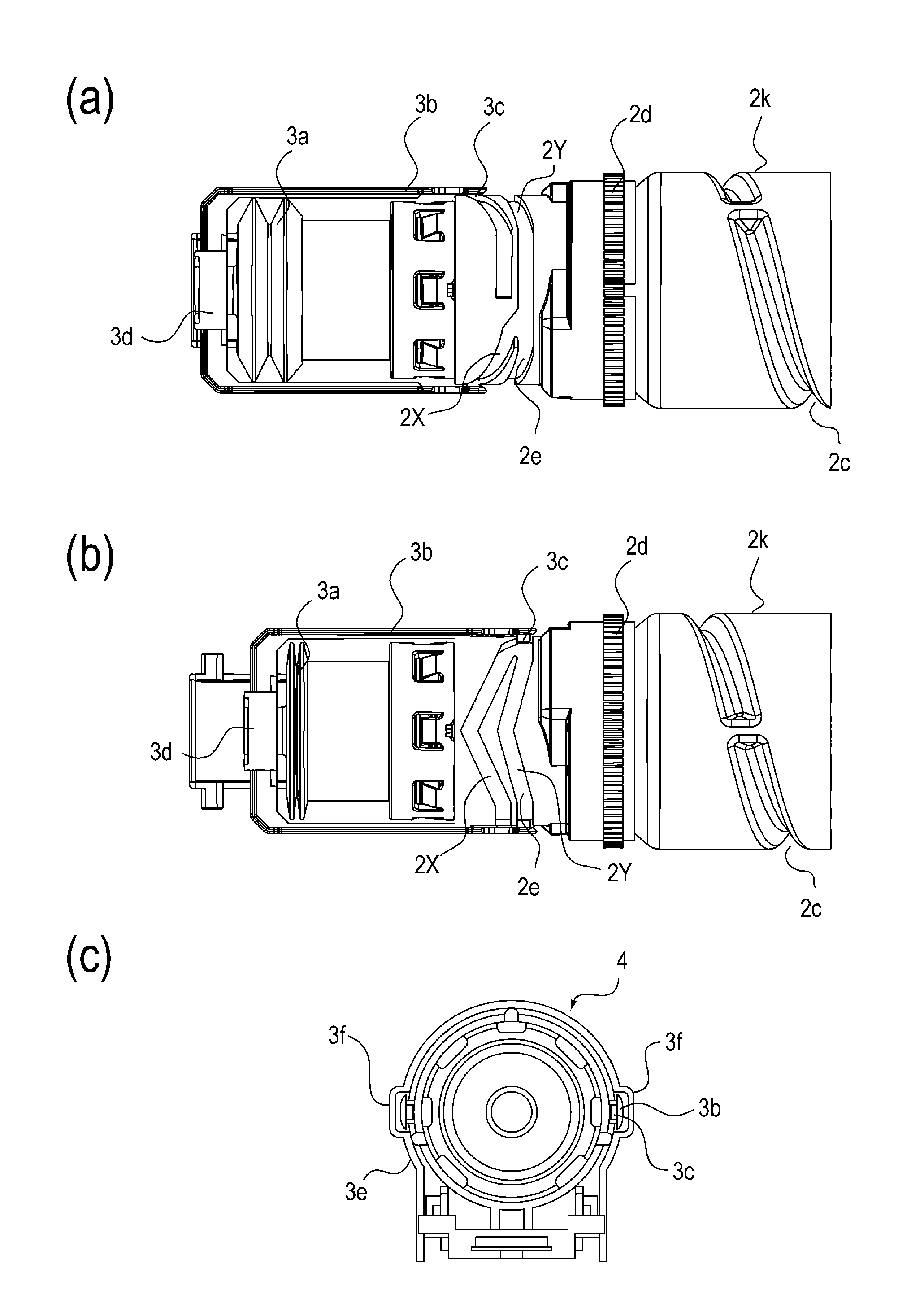

Developer supply container, developer supplying apparatus and image forming apparatus

A developer supply container, the developer supply container includes a developer accommodating chamber; a rotatable feeding portion; a developer discharging chamber including a discharge opening; a driving force receiving portion for receiving a rotational force for rotating the feeding portion; an pump capable of changing an inside volume of the accommodating chamber in a longitudinal direction of the container to apply a pressure to the discharge opening; a driving force converter for converting the rotational force into a feeding driving force for feeding the developer by an operation of the pump in a longitudinal direction of the container; and wherein an expansion and contraction stroke of the pump provided by the converter in a initial predetermined number of rotations in a initial stage is different from that in a subsequent stage after the initial stage.

Owner:CANON KK

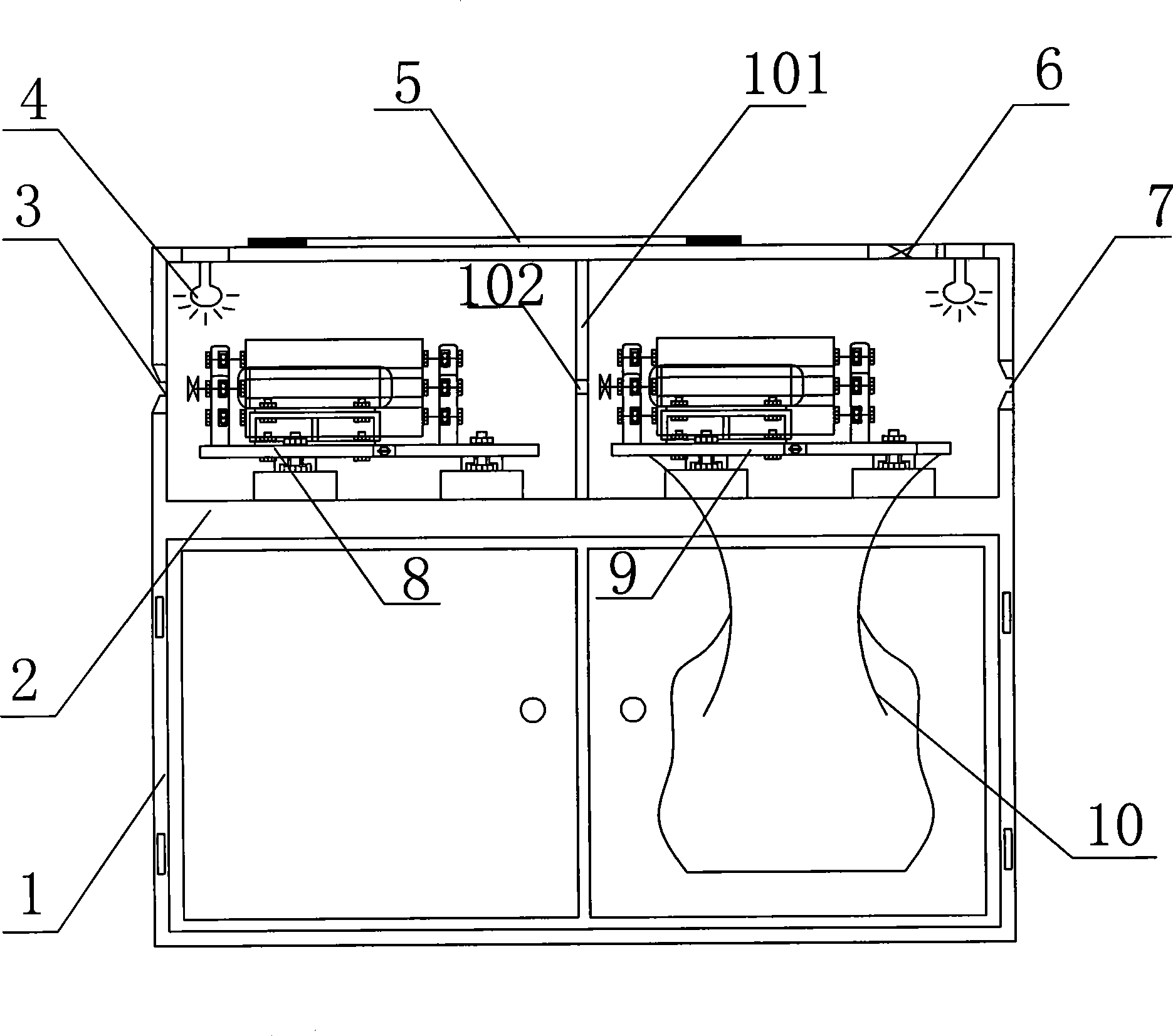

Ironing and interlining system

ActiveCN106087277ARealize automatic reclaimingRealize automatic feedingSewing-machine elementsClothes making applicancesInterliningFeed drive

The invention discloses an ironing and interlining system which comprises a machine, a feeding device, a taking device and an ironing and interlining device. A conveying surface is arranged on the machine, and can be used for holding interlining ribbons. The feeding device is provided with a support, a feeding plate, feeding drive components and a positioning blowpipe, the support is connected to the machine, the feeding drive component is arranged on the machine and connected to the feeding plate to drive the feeding plate to move, the feeding plate is used for overlap placement of multiple cut-parts, the feeding plate is provided with fixing air suction holes, and the positioning blowpipe is arranged on the support and located above the feeding plate. The taking device is arranged on the machine and used for getting the cut-parts from the feeding plate and moving the cut-parts to the interlining ribbons located on the conveying surface. The ironing and interlining device is arranged on the machine and used for ironing and interlining the interlining ribbons and the cut-parts. The ironing and interlining system is timesaving, laborsaving and high in ironing and interlining efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

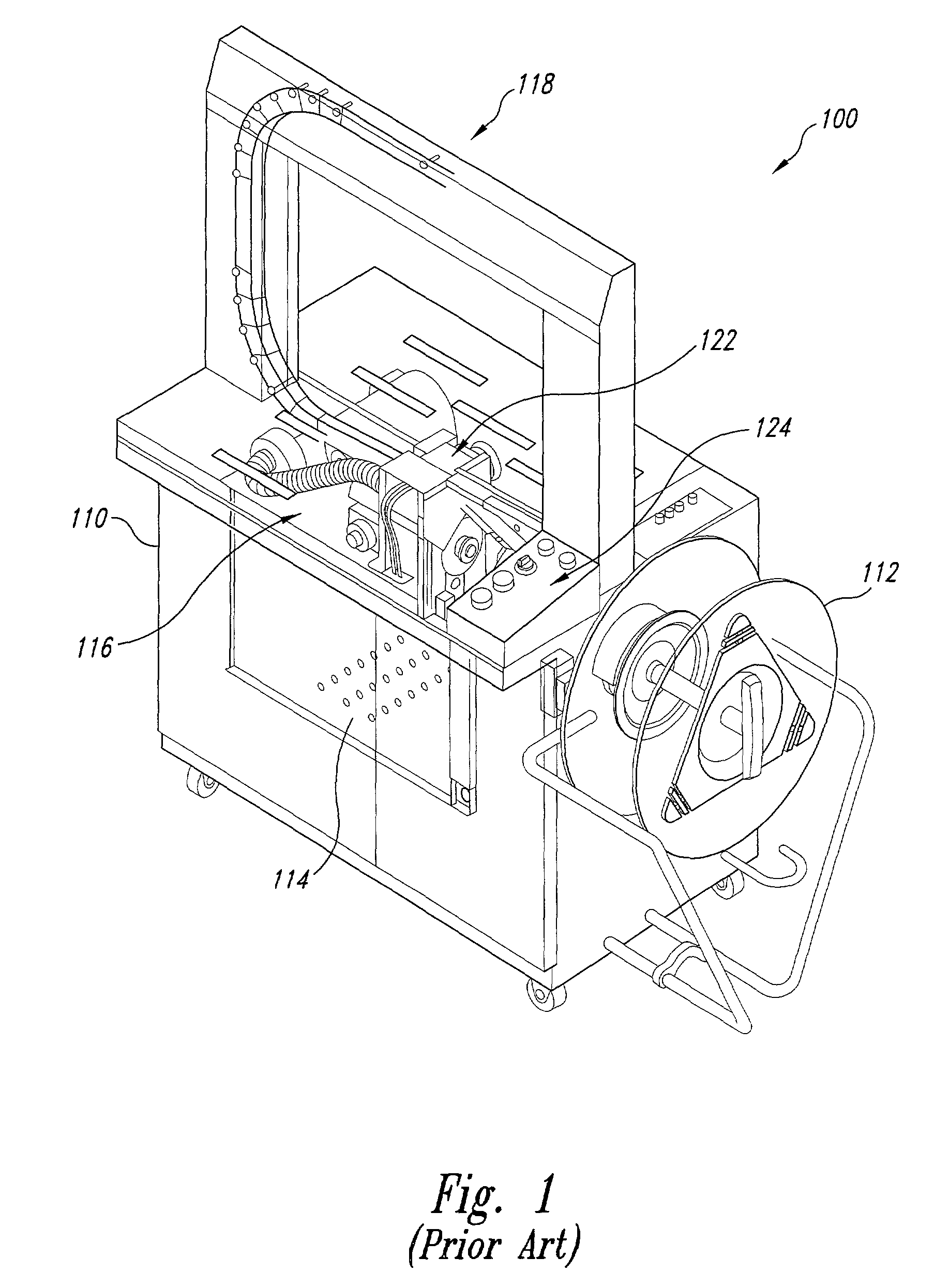

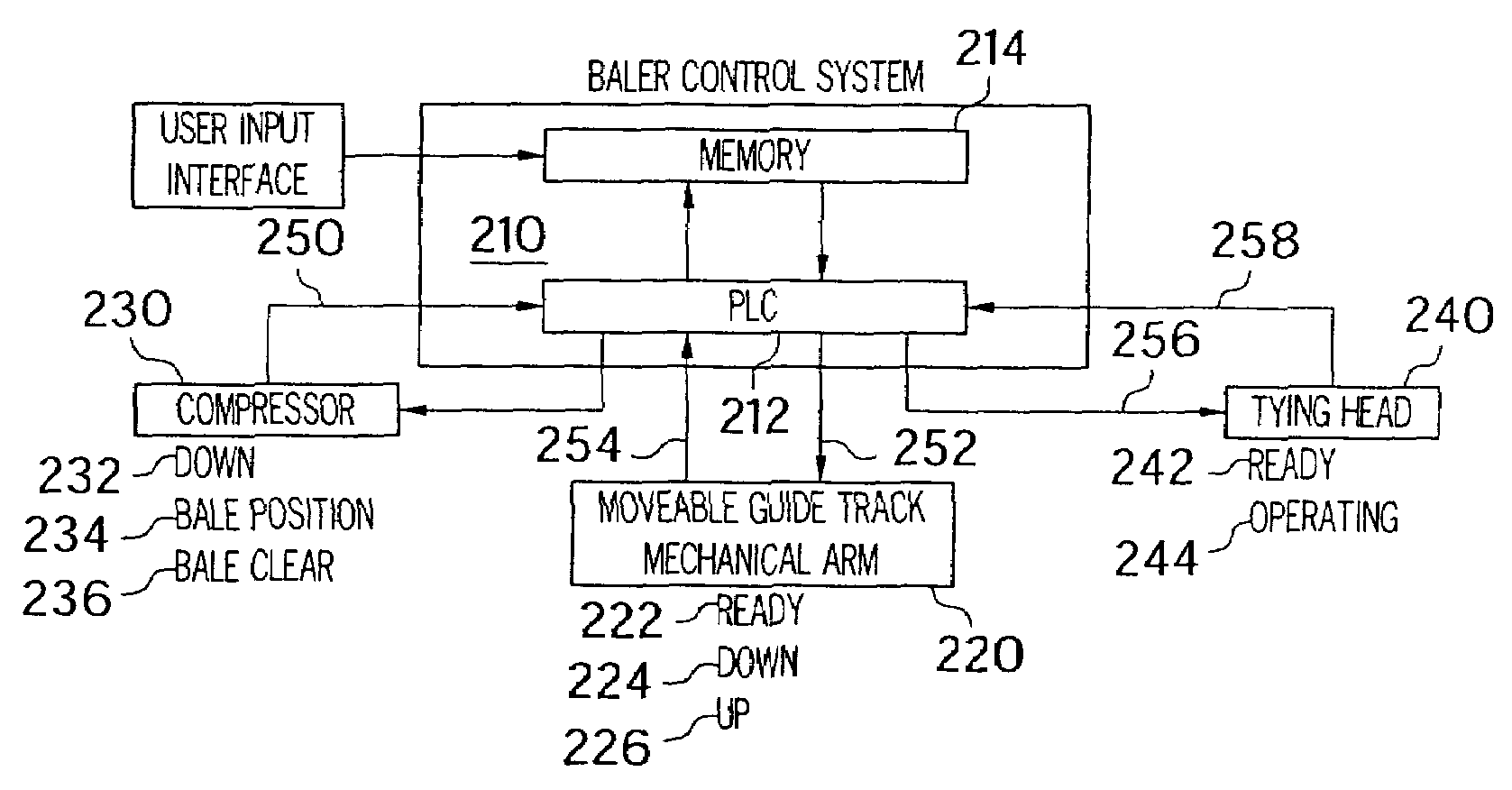

Control system for baling machine

InactiveUS7085625B2Precise torque controlAccurate measurementAnalogue computers for trafficTemperatue controlControl systemFeed drive

A control system for a bulk material baler embodied in a machine readable data structure and including an instruction to a moveable guide track to move from a removed position to a closed position to create a guide track loop around a volume of bulk material to be baled while that bulk material is under compression and also including in instruction to a bale strap feed drive to feed a pre-determined length of strapping around the guide track loop, and including an instruction to a cutter to cut the end of the bale strap and including an instruction to a strap fastener to fasten together the ends of the bale strap and including an instruction to remove the moveable guide track section from around the bale and an instruction to release compression and an instruction to eject a bound bale.

Owner:L P BROWN COMPANY INC DELAWARE

Hardware plate oil immersion device with automatic moving and feeding structure

InactiveCN107716210ANo need for manual applicationHigh degree of automationLiquid surface applicatorsCoatingsRotational axisElectric machine

The invention discloses a hardware plate oil immersion device with an automatic moving and feeding structure. The device comprises a rack. A vertical supporting plate is fixedly arranged on the top face of one side of a top plate of the rack, a main supporting column is fixedly arranged on the other side of the top plate of the rack, an upper main plate is fixedly arranged at the top end of the main supporting column, a feeding rotating motor is fixedly arranged on the bottom face of the right side of the upper main plate, an output shaft of the feeding rotating motor penetrates through the upper main plate and is fixedly provided with a feeding driving gear, a rotating shaft is hinged to the left side of the upper main plate, a feeding transmission gear is fixedly arranged in the middle of the rotating shaft, the feeding transmission gear is meshed with the feeding driving gear, a feeding plate is fixedly arranged at the top end of the rotating shaft, and a stretchable cylinder is fixedly arranged on the top face of the left end of the feeding plate. A plate to be machined can be automatically moved to a permanent magnet and attached to the permanent magnet, the grabbed plate to be machined can be automatically rotated, an oil drum can be lifted, and the plate to be machined is immersed into the oil drum, so that no artificial smearing is needed, and the device is high in automatic degree, good in effect and high in efficiency.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

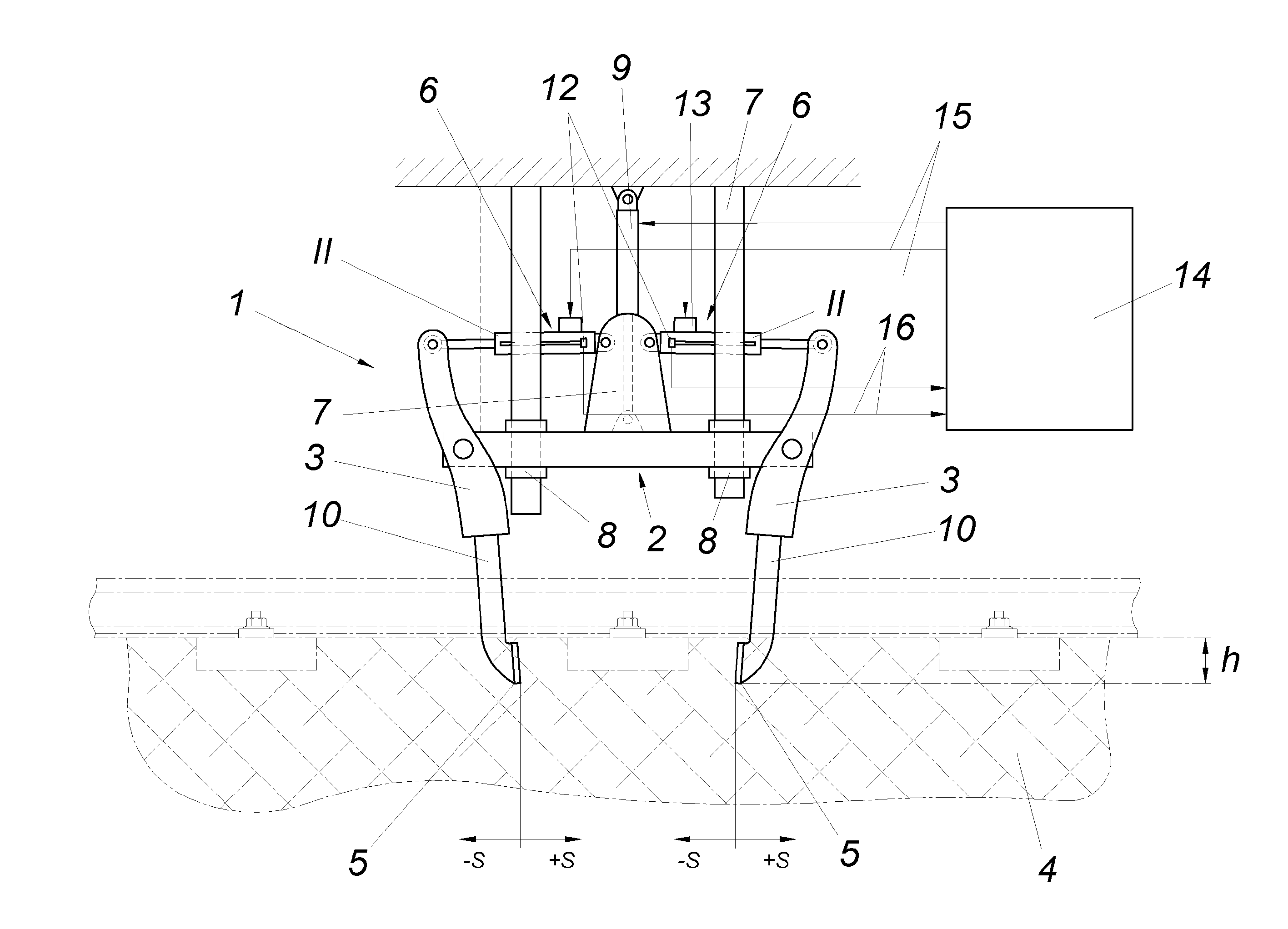

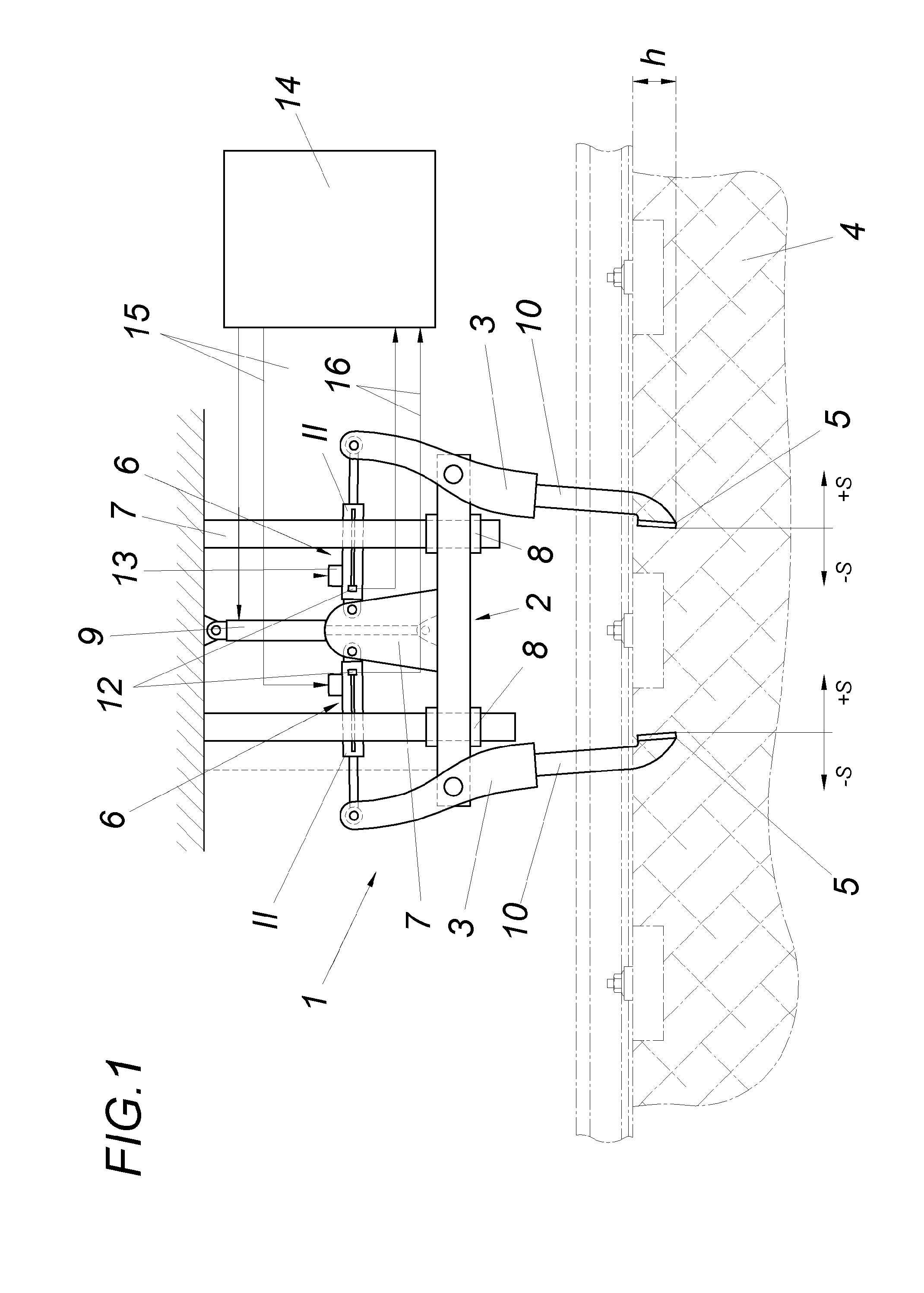

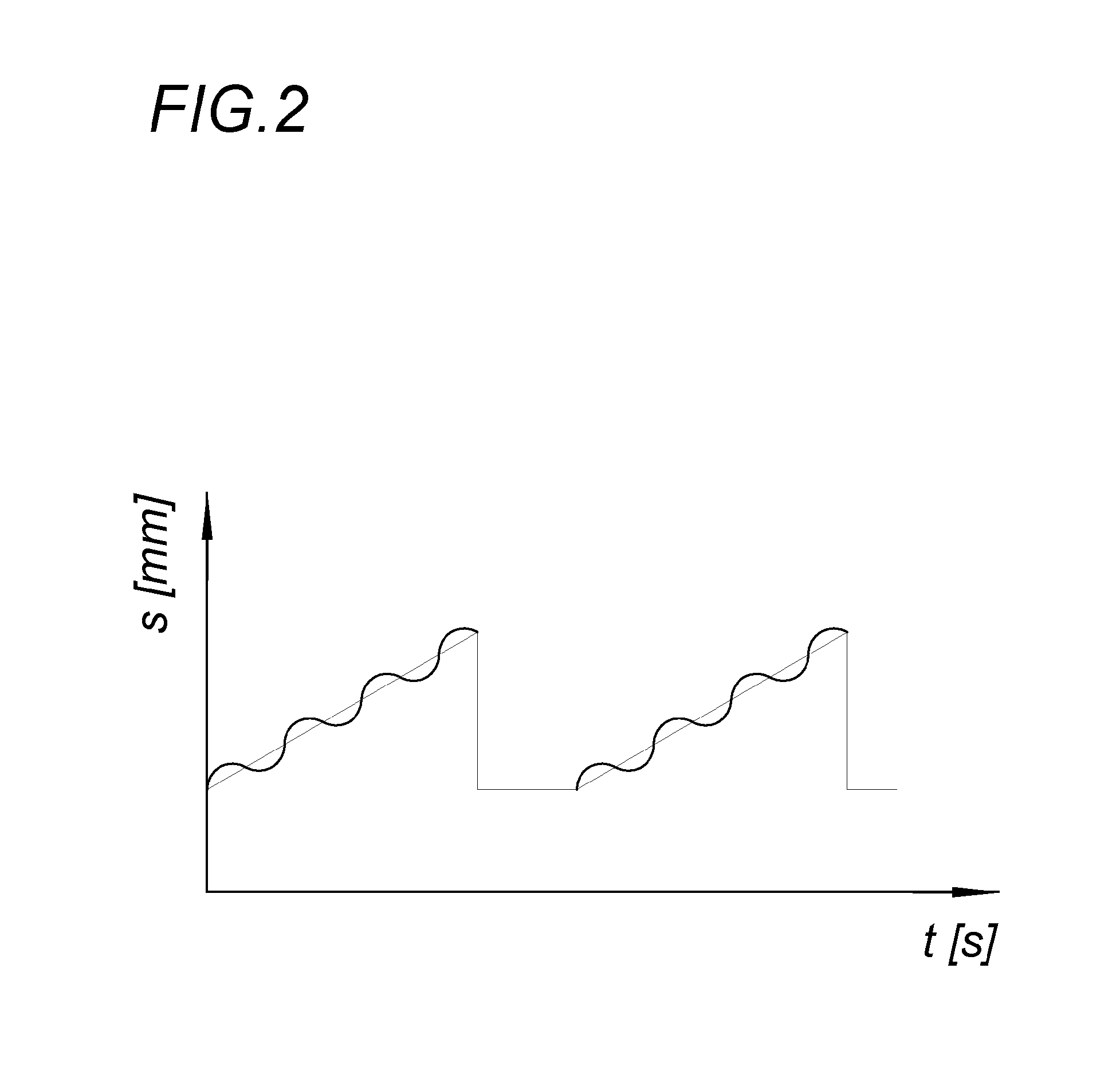

Tamping unit for a track tamping machine

Owner:HP3 REAL GMBH

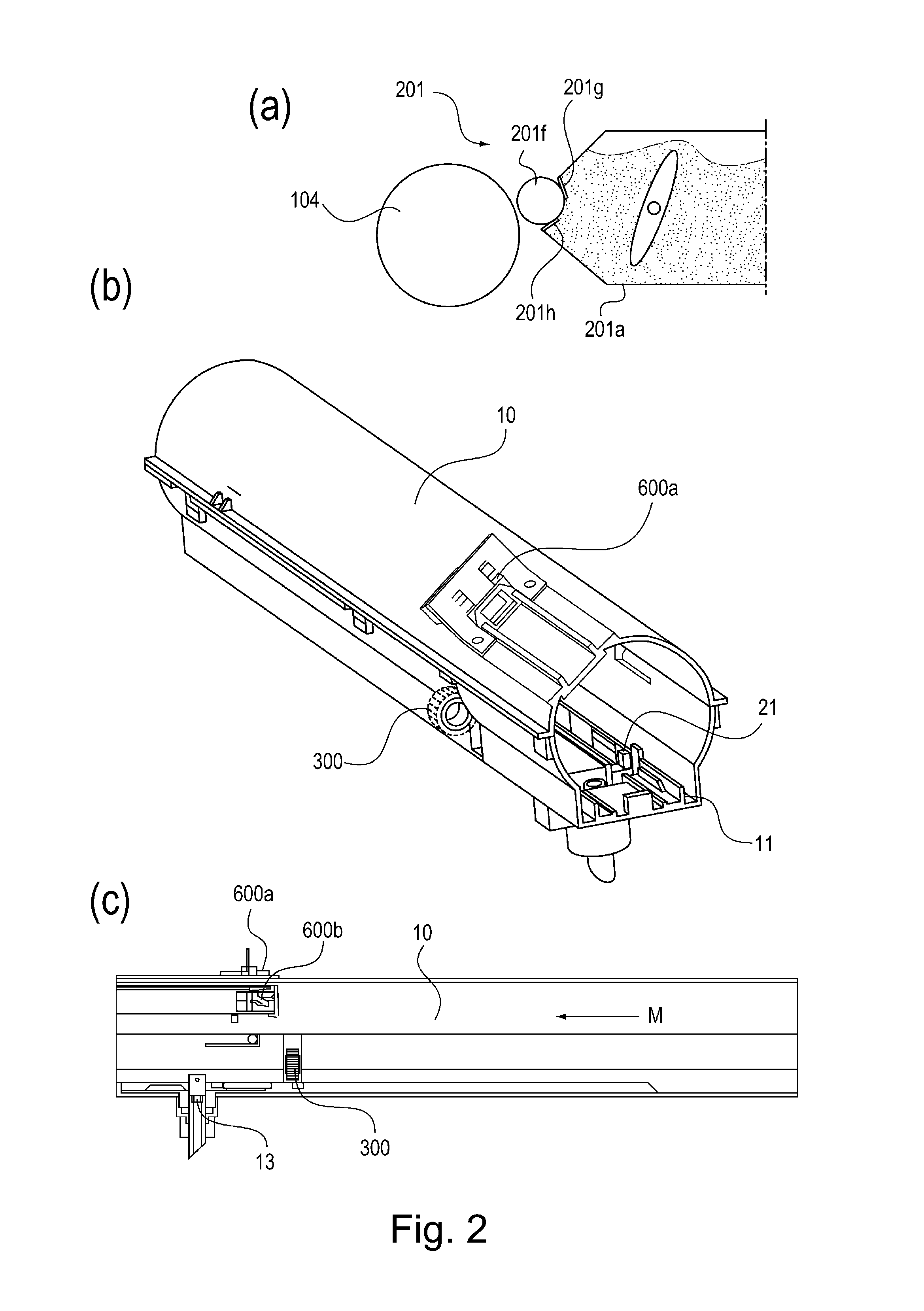

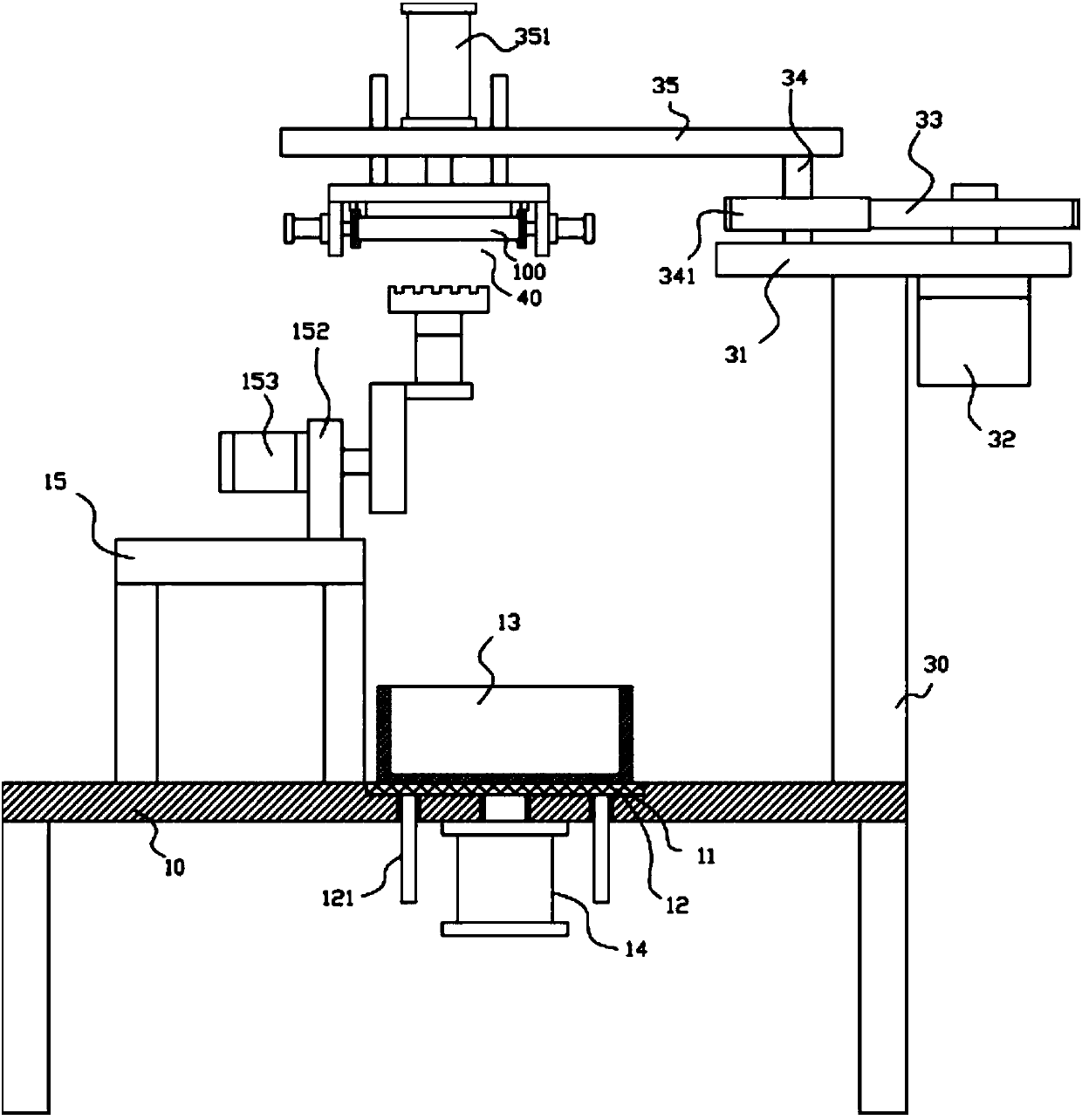

Pressure welding machine and pressure welding method

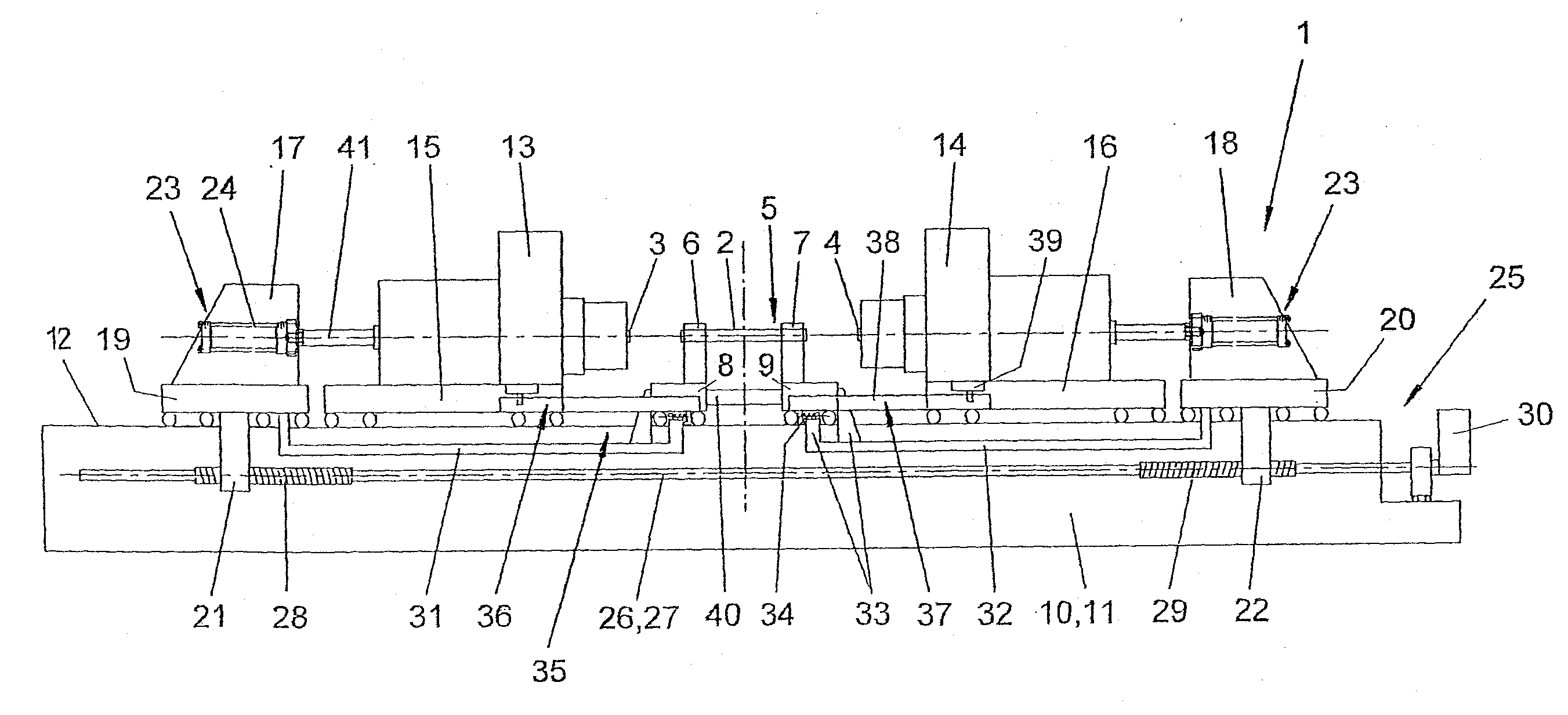

ActiveUS20100206861A1Improve accessibilityReduce loadWelding/cutting auxillary devicesArc welding apparatusFeed driveEngineering

A pressure welding method is provided and a pressure welding machine (1) is provided with a frame (10), two welding heads (13, 14), mobile along a feed axis (41), and two adjusting units (17, 18). The adjusting units (17, 18) include feed drives (23) for the welding heads (13, 14). The two adjusting units (17, 18) are mounted so as to be axially movable (41) on the frame (10) and are interlinked with an adjusting drive (25) by means of a common adjusting element (26) and supported in a closed system of forces while receiving the pressure welding forces, thereby relieving the frame (10). The common adjusting element (26) is configured as a continuous spindle (27) having two self-locking threads (28, 29) that run in opposite directions.

Owner:KUKA SYSTEMS

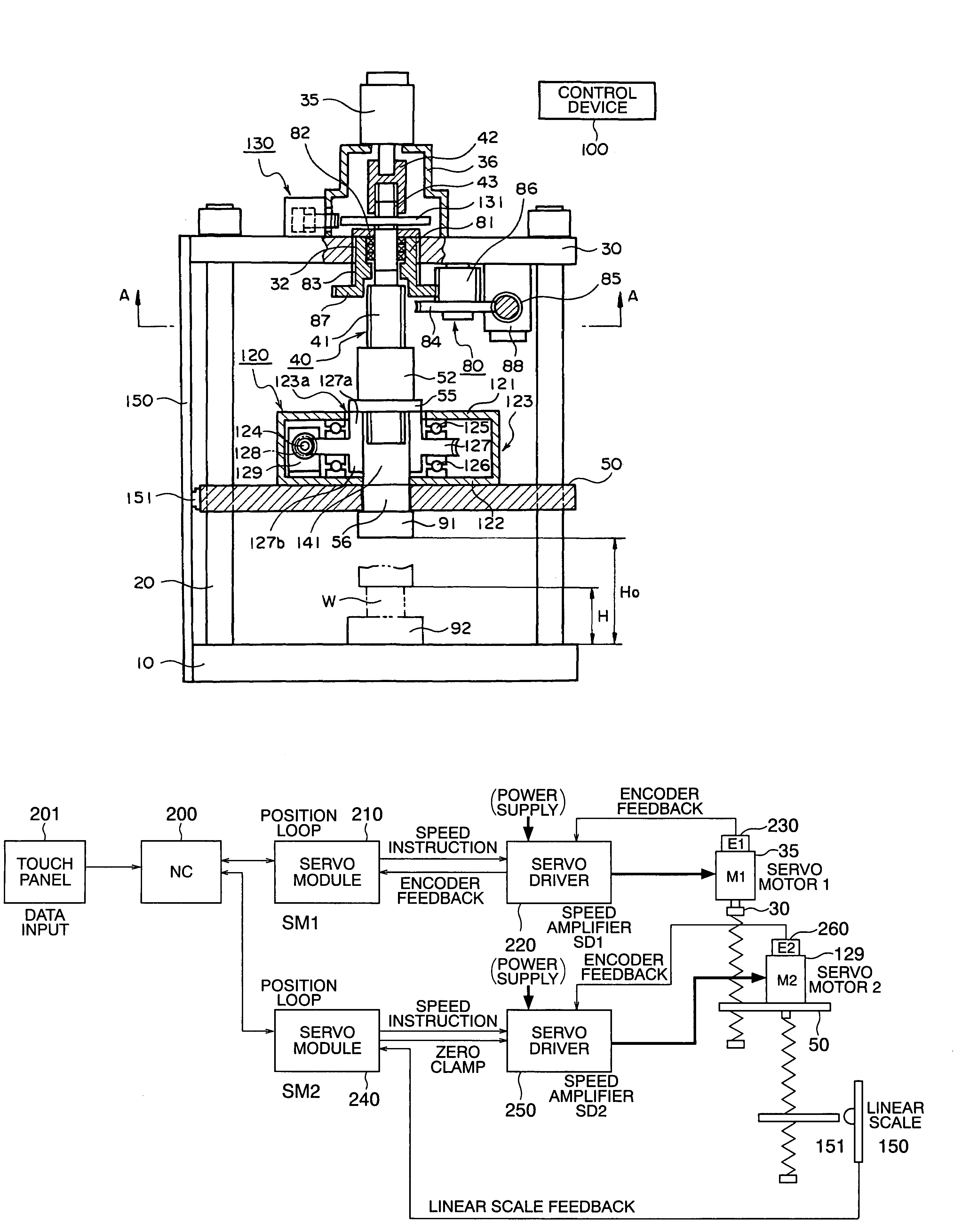

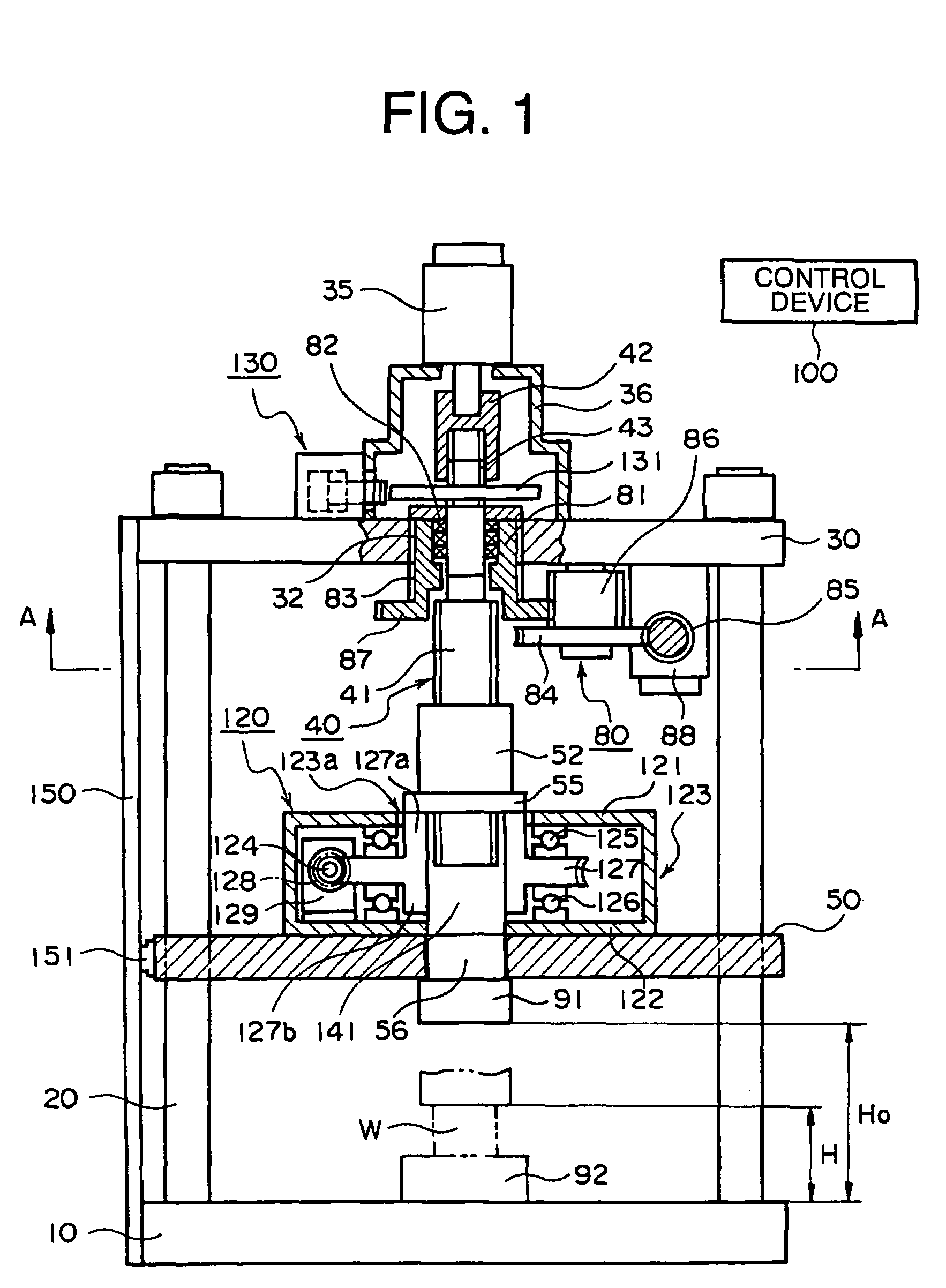

Press

Owner:HODEN SEIMITSU KAKO KENKYUSHO CO LTD

Rotary scrubbing control device capable of cleaning bearings with different sizes

InactiveCN103624017AEasy to useOvercome the problems of low conversion efficiency and complicated adjustment for each conversionCleaning using toolsFeed driveEngineering

Owner:DALIAN UNIV OF TECH

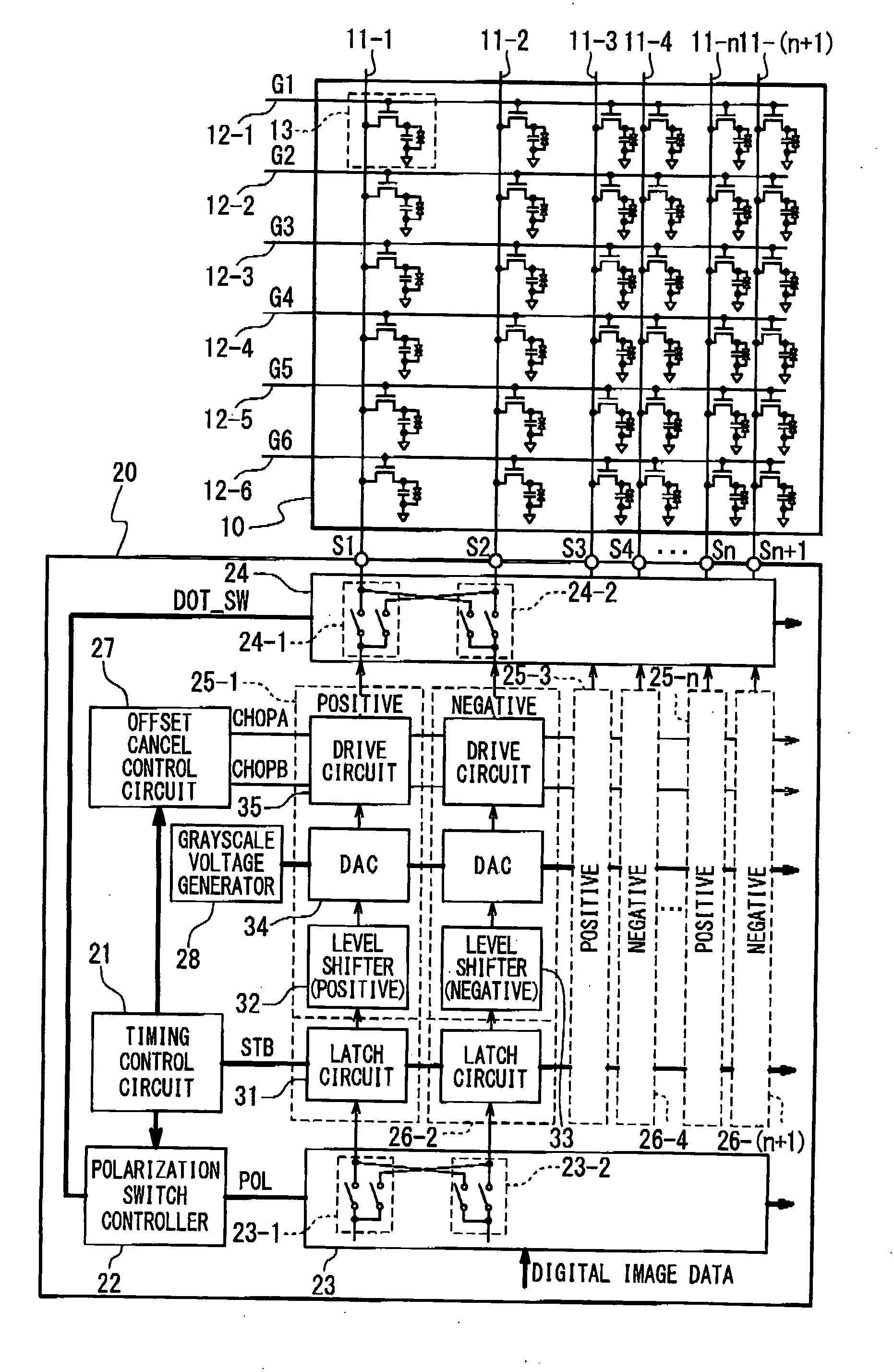

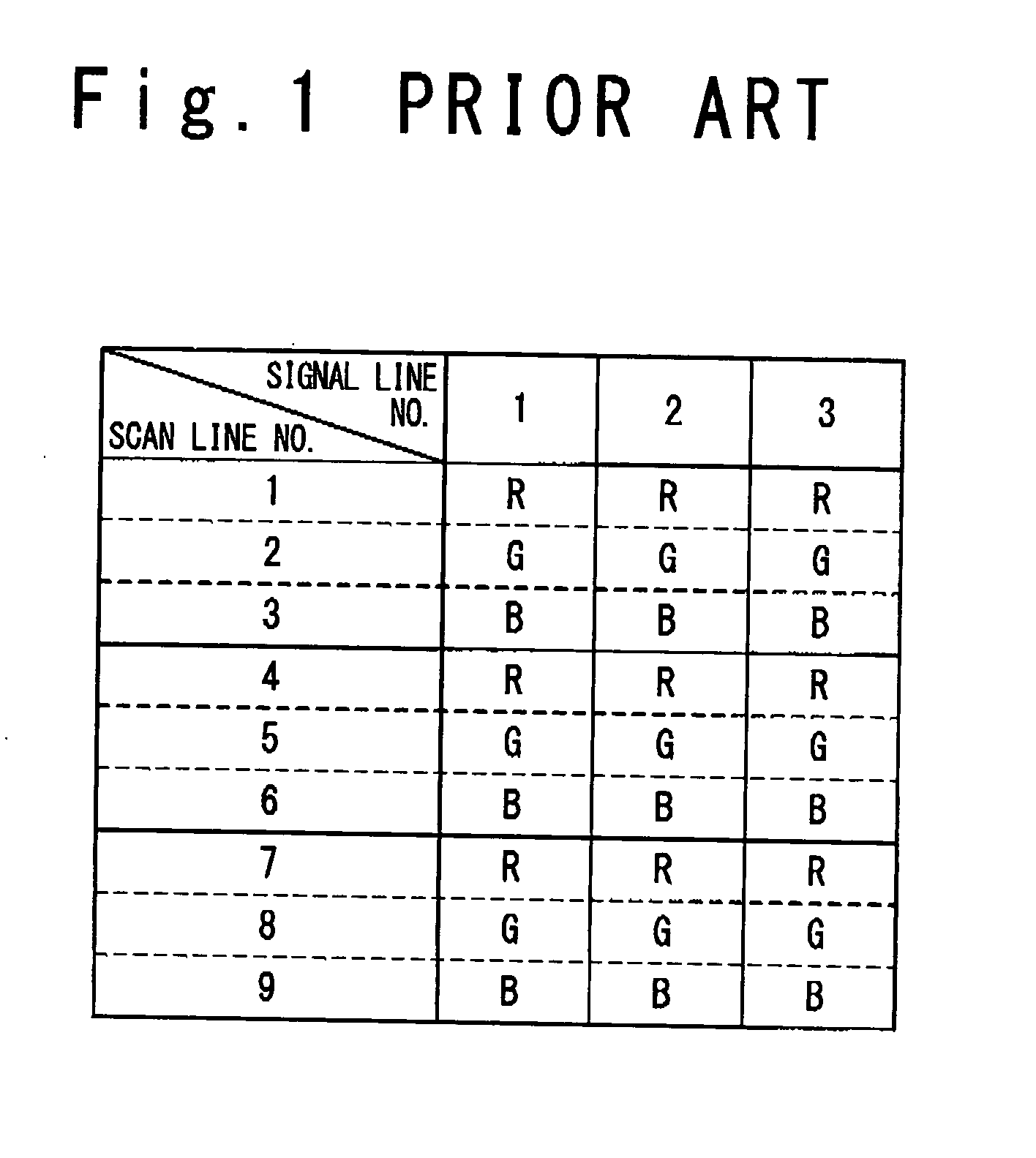

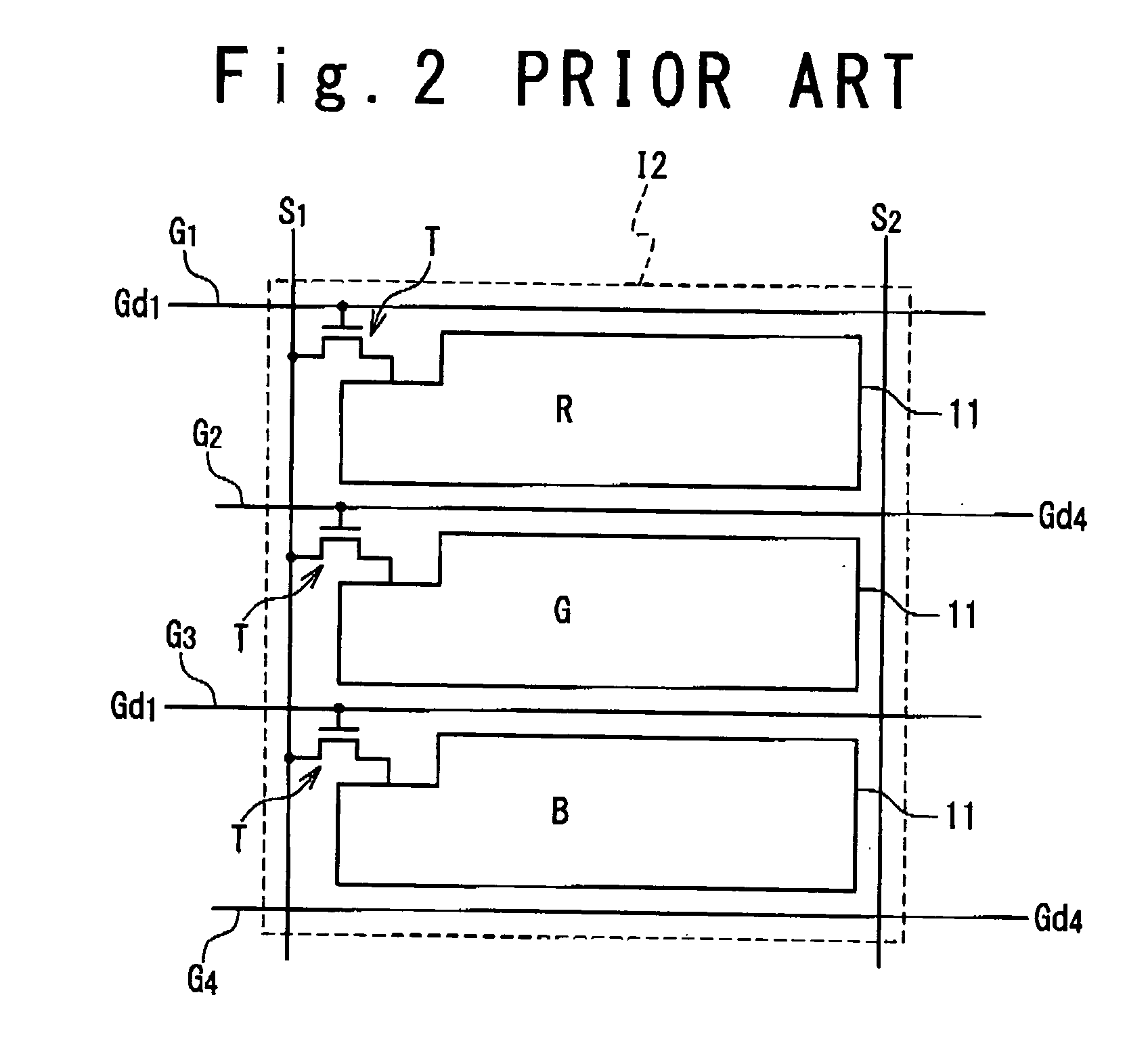

Method for driving liquid crystal display panel with triple gate arrangement

InactiveUS20090102777A1Static indicating devicesNon-linear opticsAudio power amplifierLiquid-crystal display

A method is provided for driving a liquid crystal display panel in which each pixel includes a plurality of sub-pixels arranged in a specific direction, the method including feeding drive voltages to sub-pixels within the liquid crystal display panel by using operational amplifiers. The polarities of the drive voltages fed to each of the sub-pixels are inverted between two adjacent frame periods. The offset polarities of the operational amplifiers are inverted for every a predetermined number of successive sub-pixels. The number of the sub-pixels within each pixel is coprime to the predetermined number of successive sub-pixels.

Owner:RENESAS ELECTRONICS CORP

Integrated motor drive system for motor driven yarn feed attachments

A yarn feed system, enabling the control of individual yarns to the needles of a tufting machine, and which system can be manufactured as a substantially standardized unit or attachment that can be removably mounted to a tufting machine. The yarn feed unit includes a series of yarn feed devices each including a drive motor for feeding one or more selected yarns to the needles of the tufting machine, and a series of yarn feed controllers integrated with each yarn feed drive motor for monitoring and controlling the operation of the yarn feed devices to control the feeding of the yarns to the needles according to programmed pattern instructions.

Owner:CARD MONROE

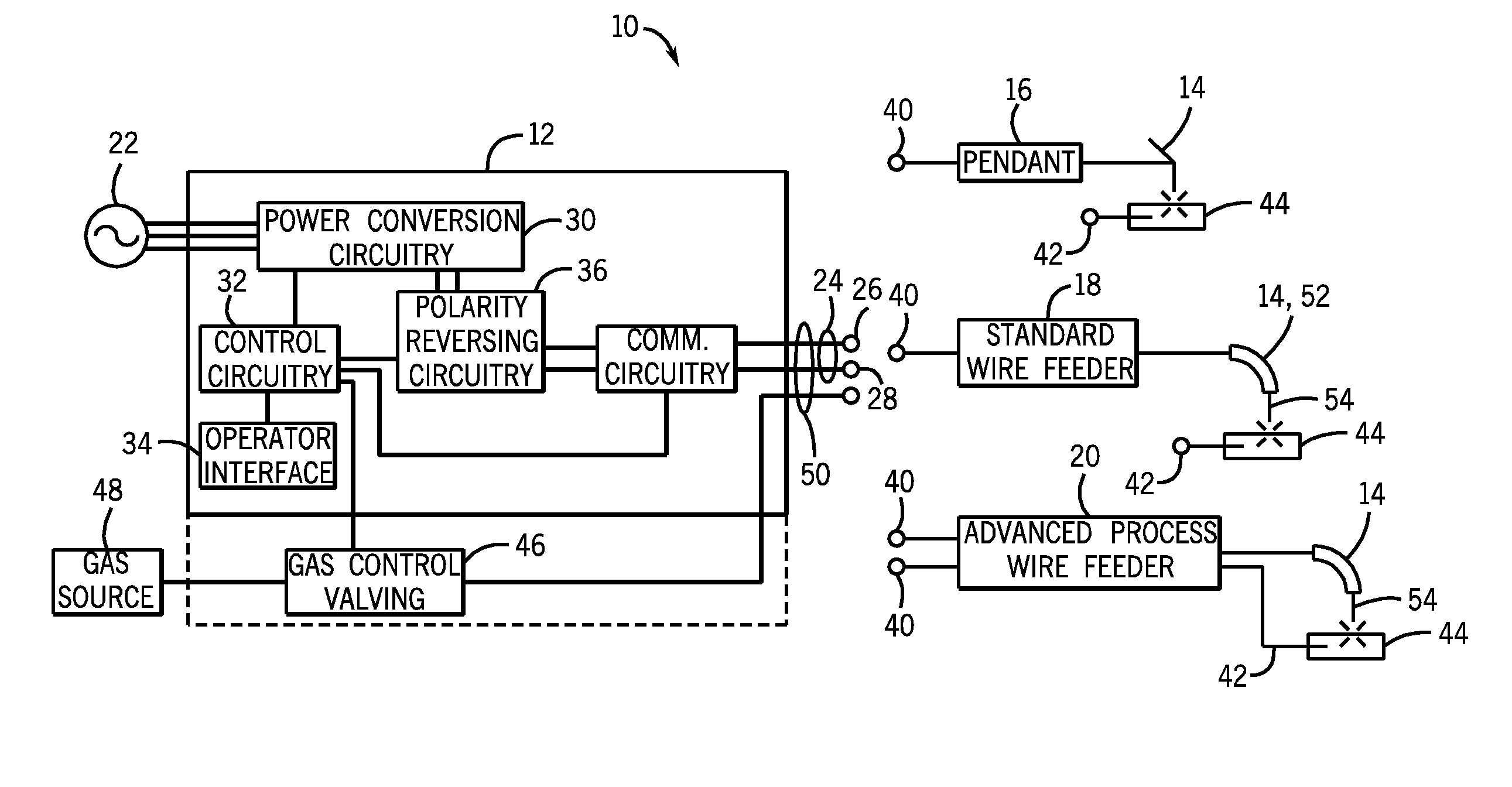

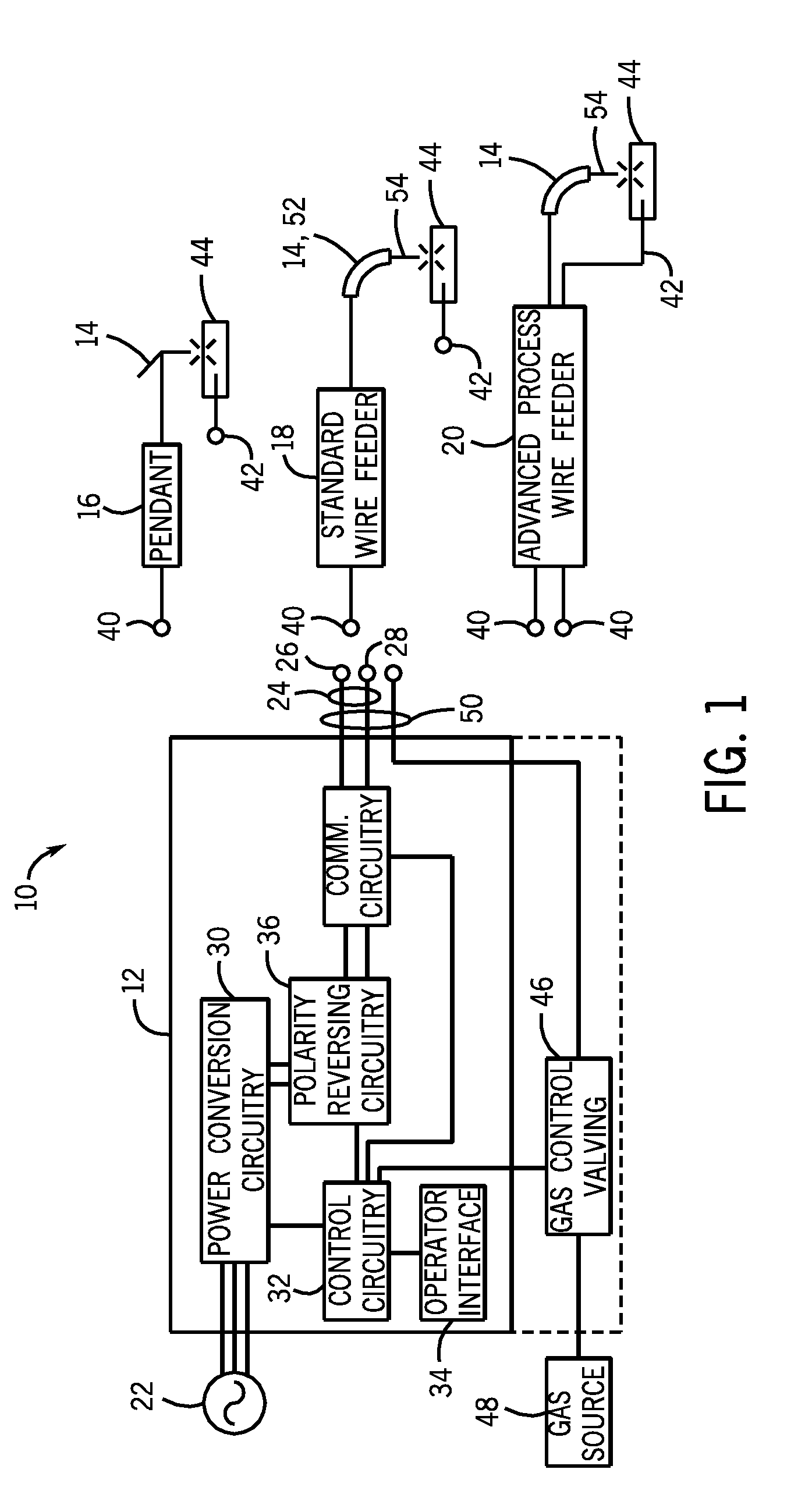

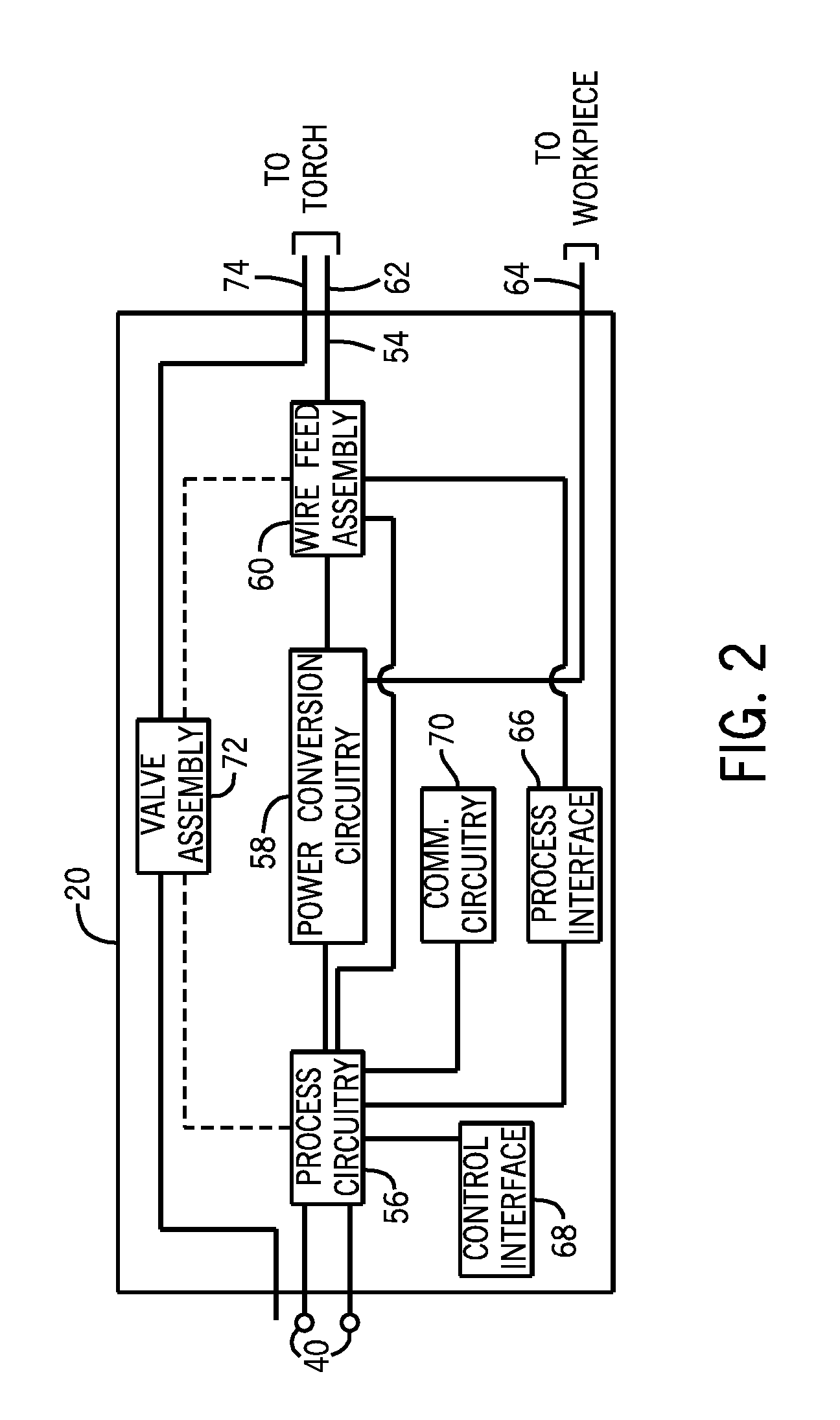

Controlled waveform welding wire feeder system and method

A welding wire feeder includes a welding wire feed drive configured to drive welding wire towards a welding application and wire feed control circuitry coupled to the welding wire feed drive. The wire feed control circuitry is also configured to control the drive of welding wire towards the welding application. The welding wire feeder also includes power conversion circuitry and welding process control circuitry coupled to the power conversion circuitry. The power conversion circuitry is configured to receive input power from a welding power source and to convert the input power to controlled waveform welding output. The welding process control circuitry is configured to provide control signals for conversion of the input power to the controlled waveform welding output. The welding wire feeder also includes a process operator interface coupled to the welding process control circuitry and configured to permit operator selection of a controlled waveform welding process.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com