Patents

Literature

31results about How to "Achieve multi-color printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

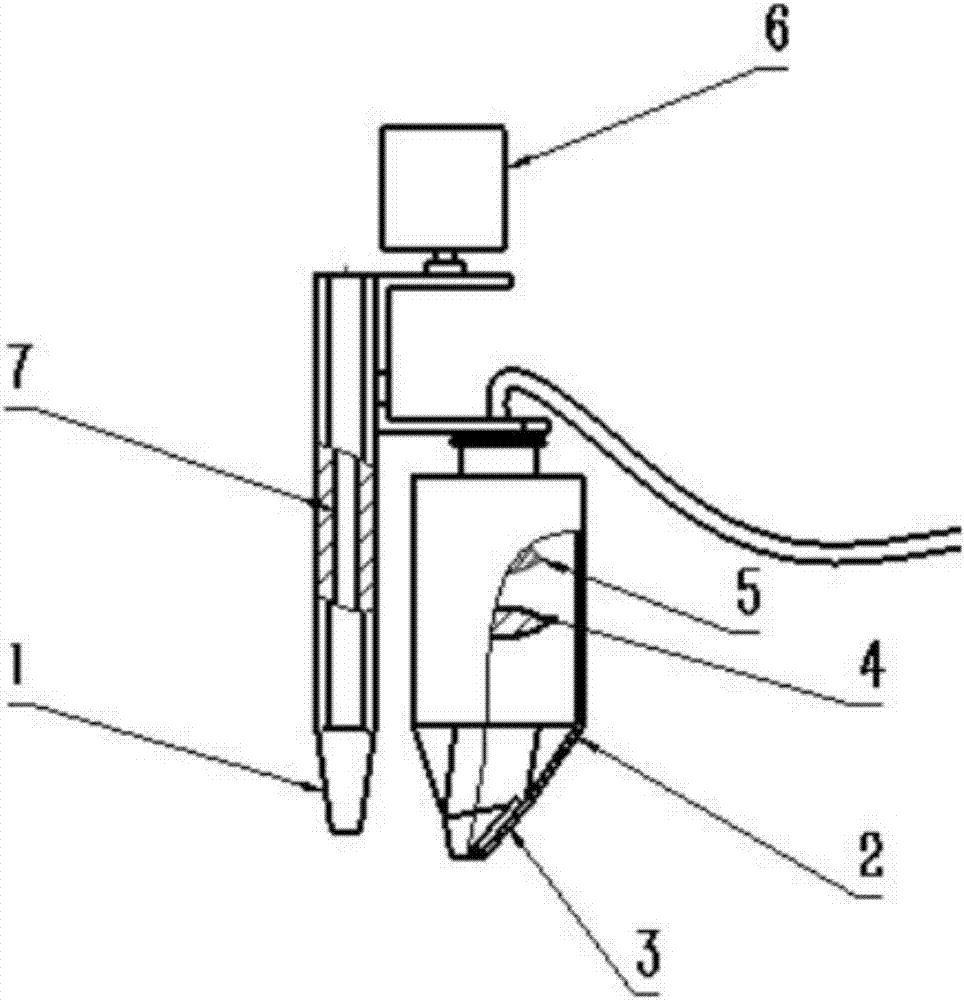

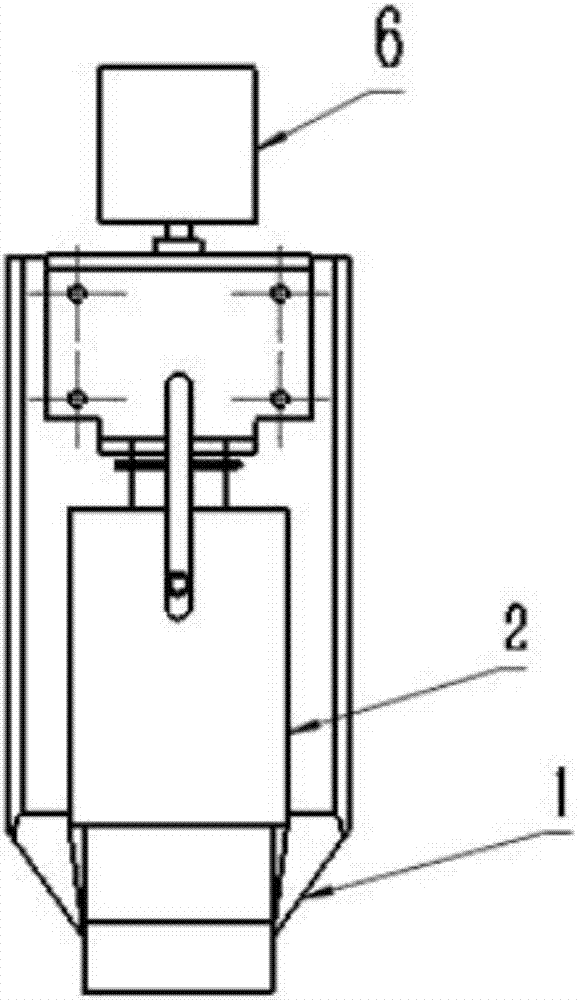

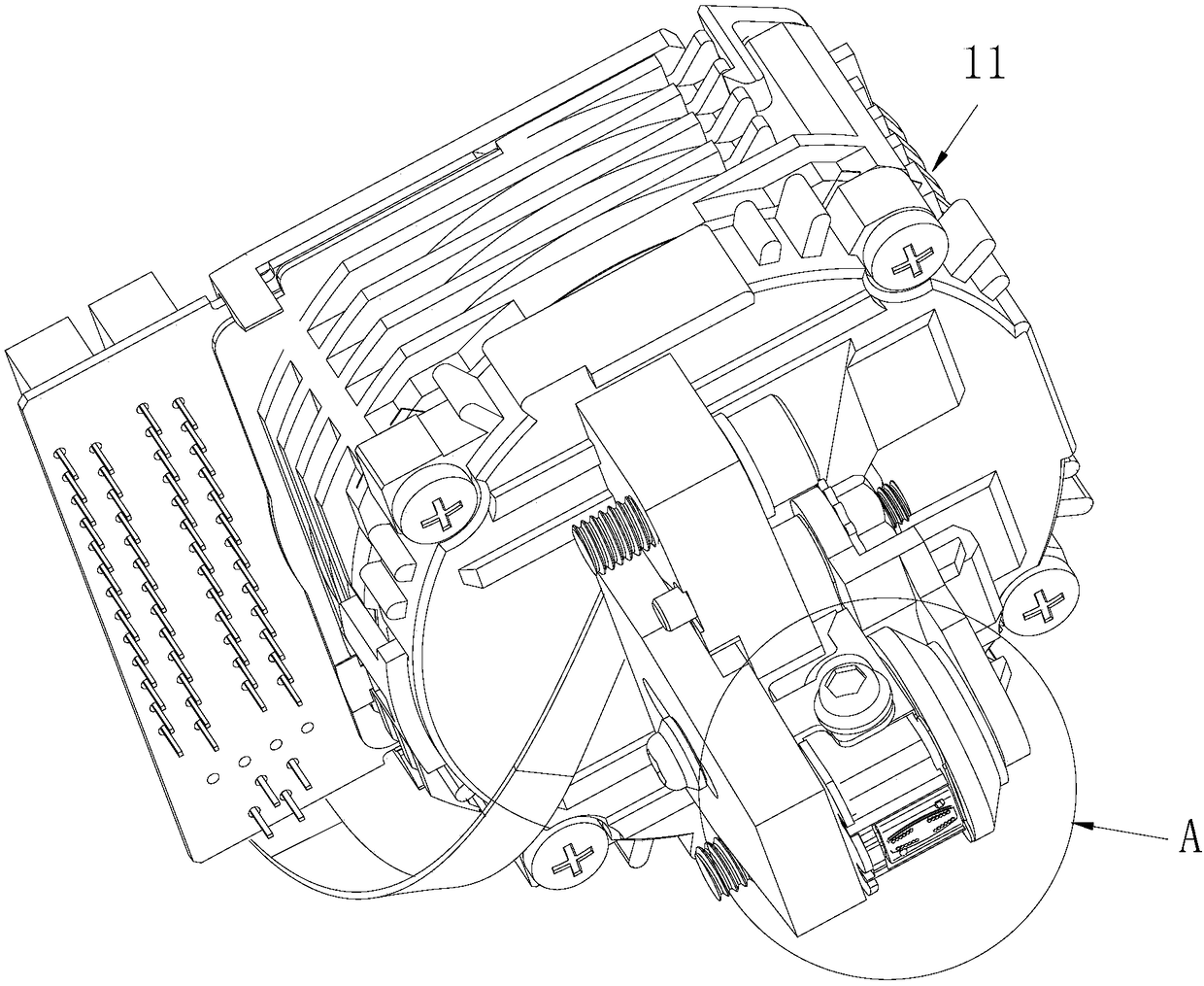

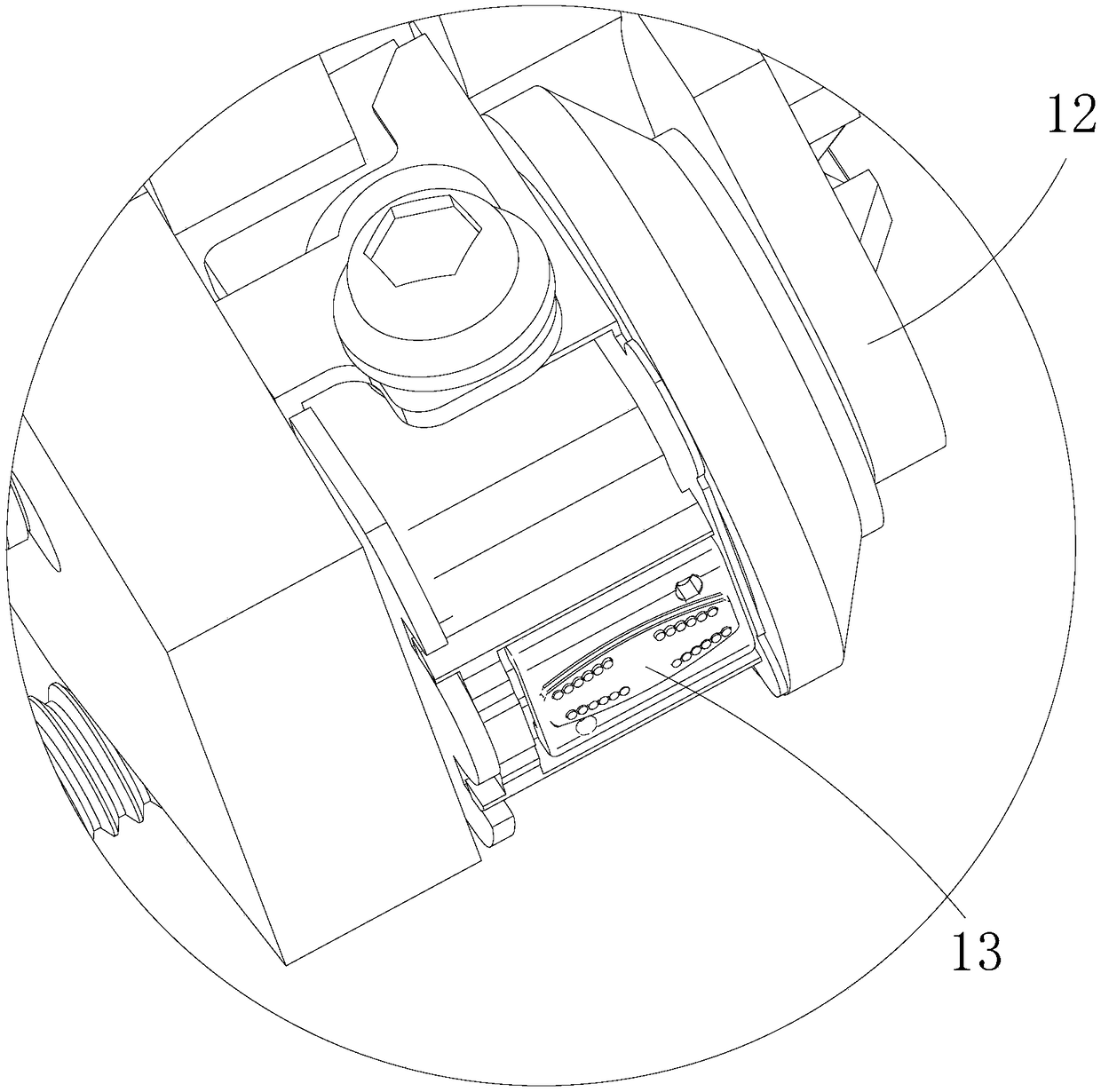

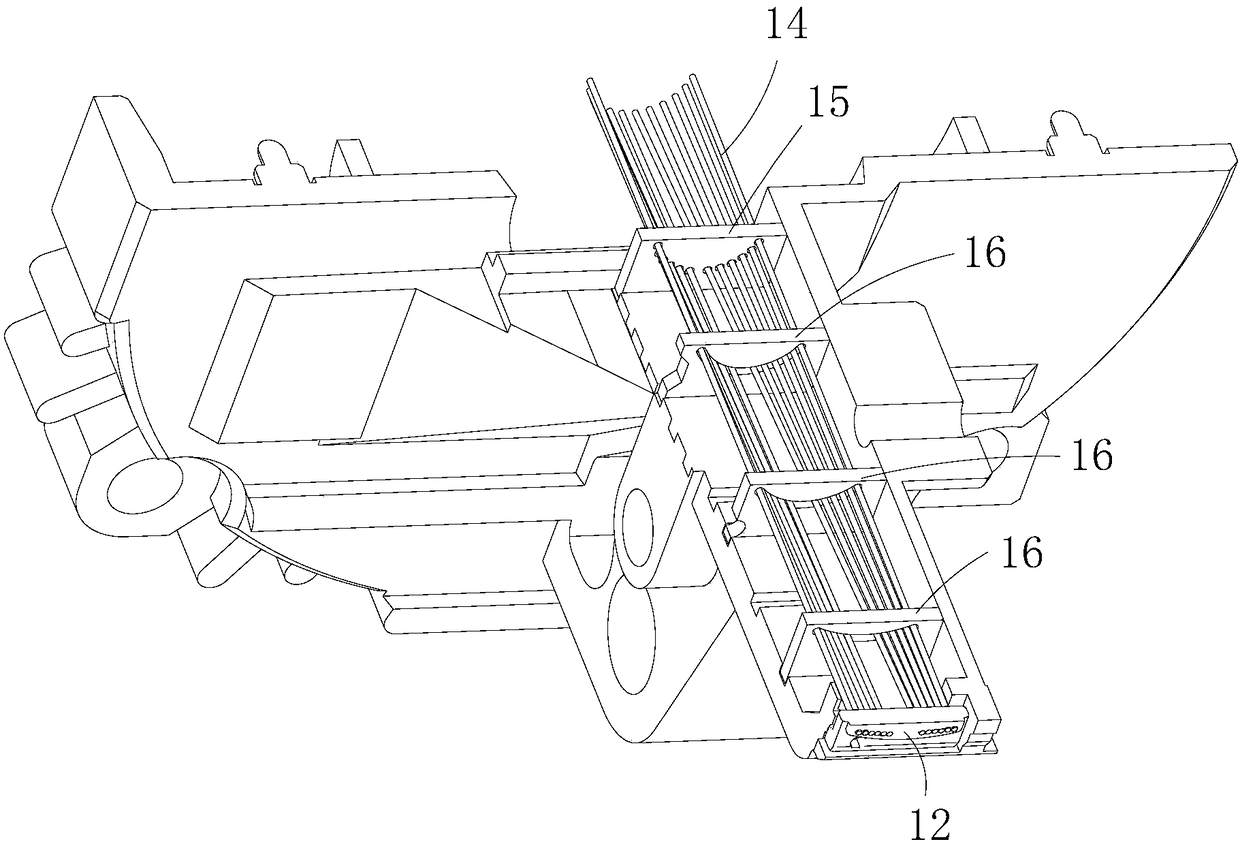

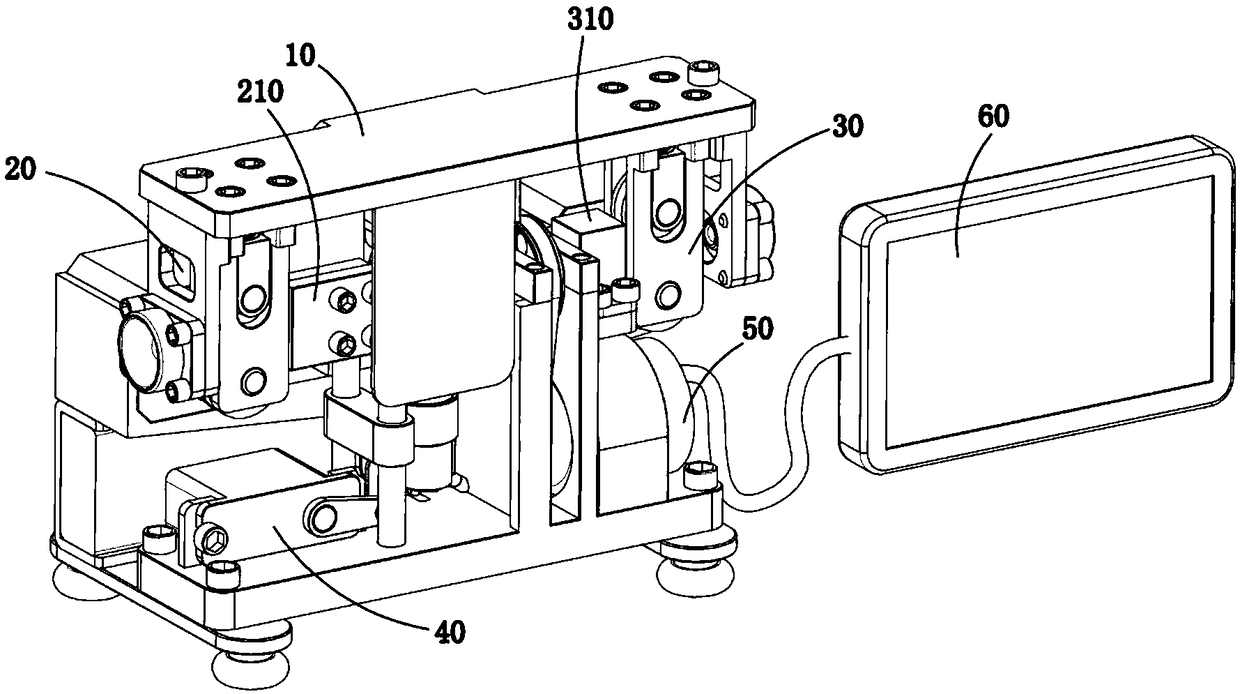

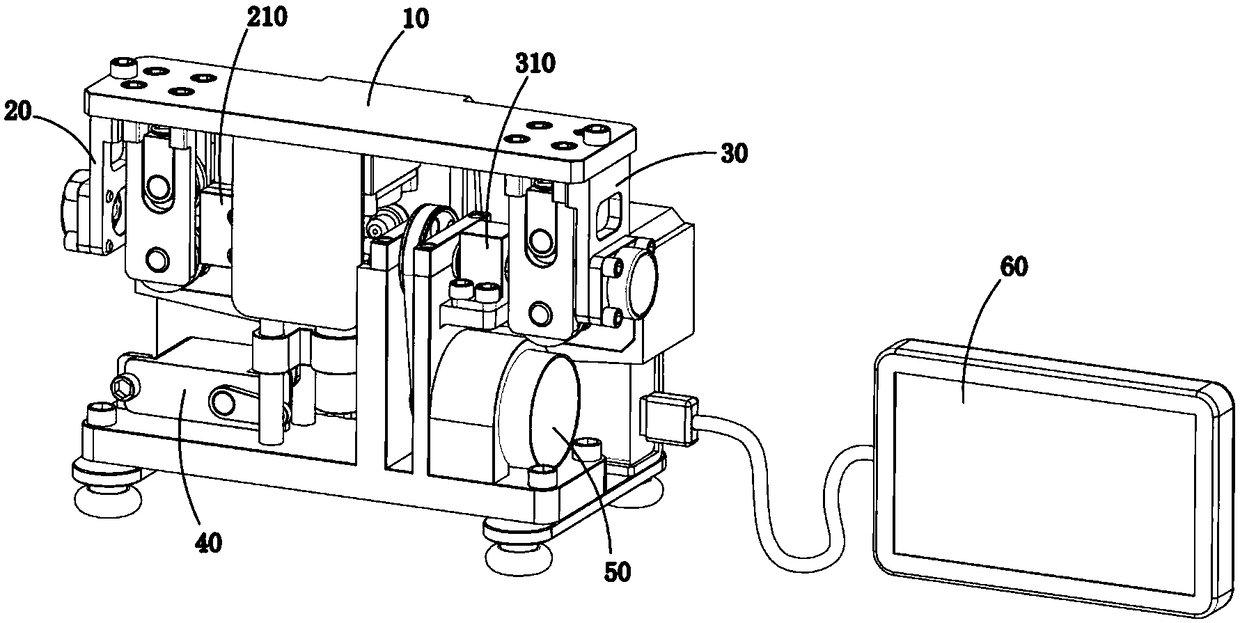

Desktop-level 3D printer

InactiveCN105252776AReasonable structural designHigh precisionAdditive manufacturing apparatusElectricityColor printing

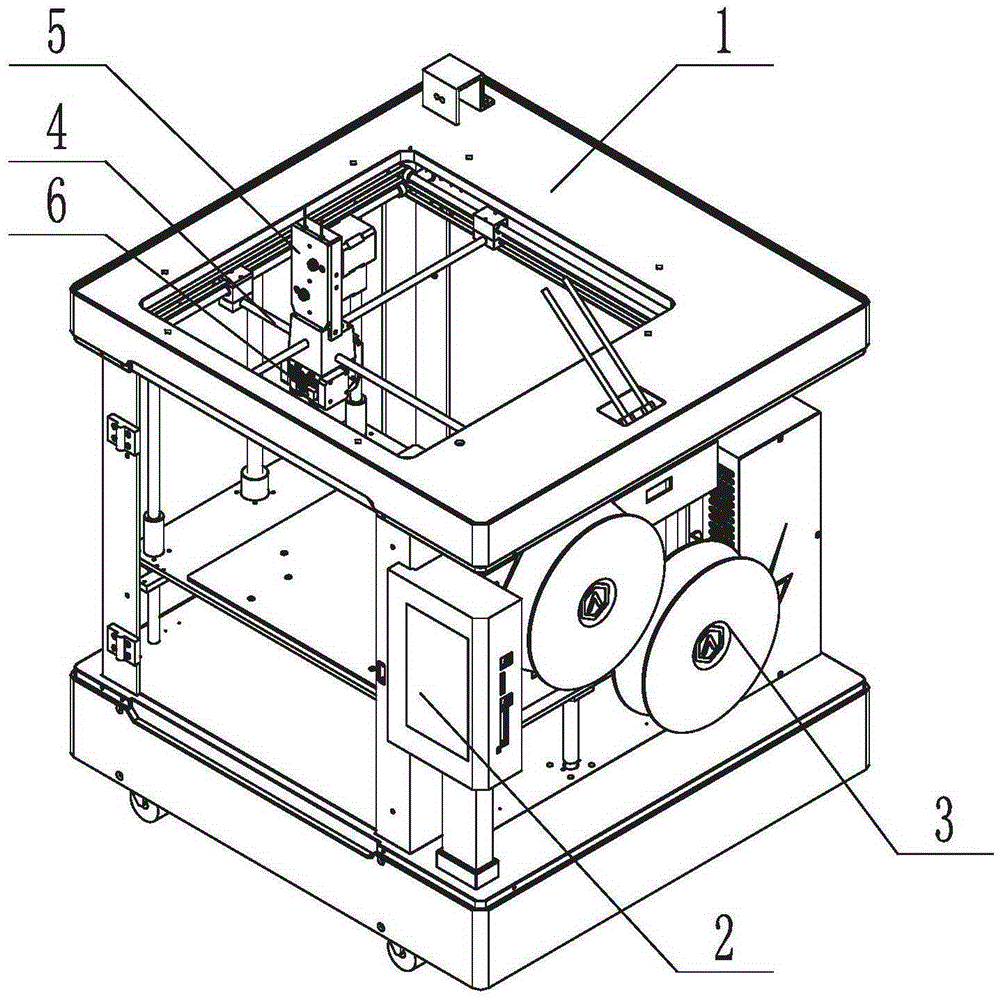

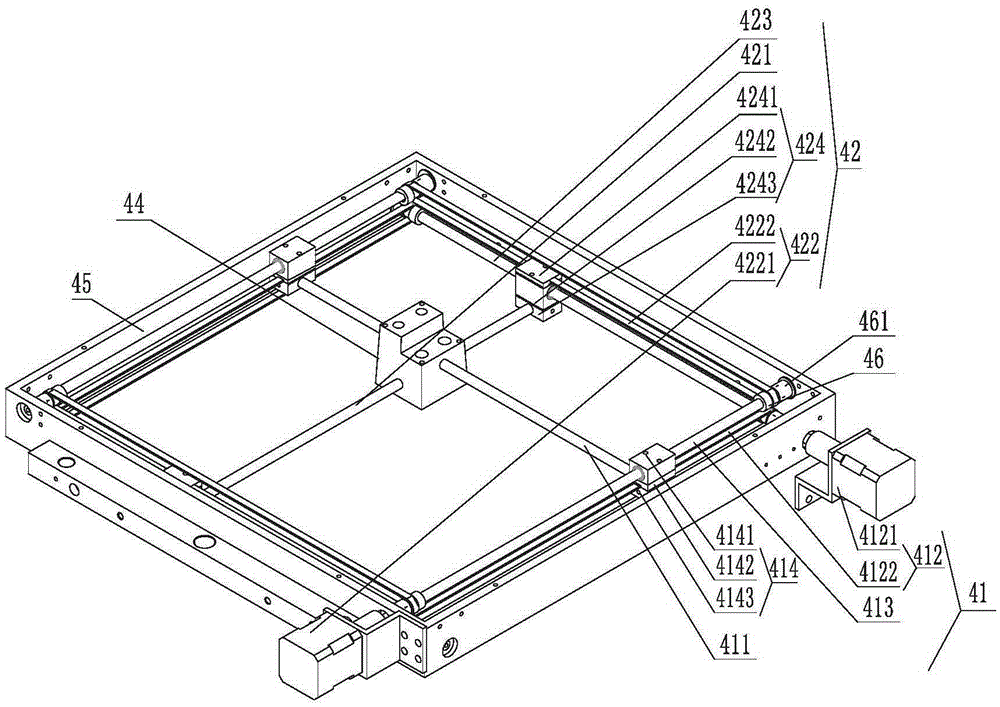

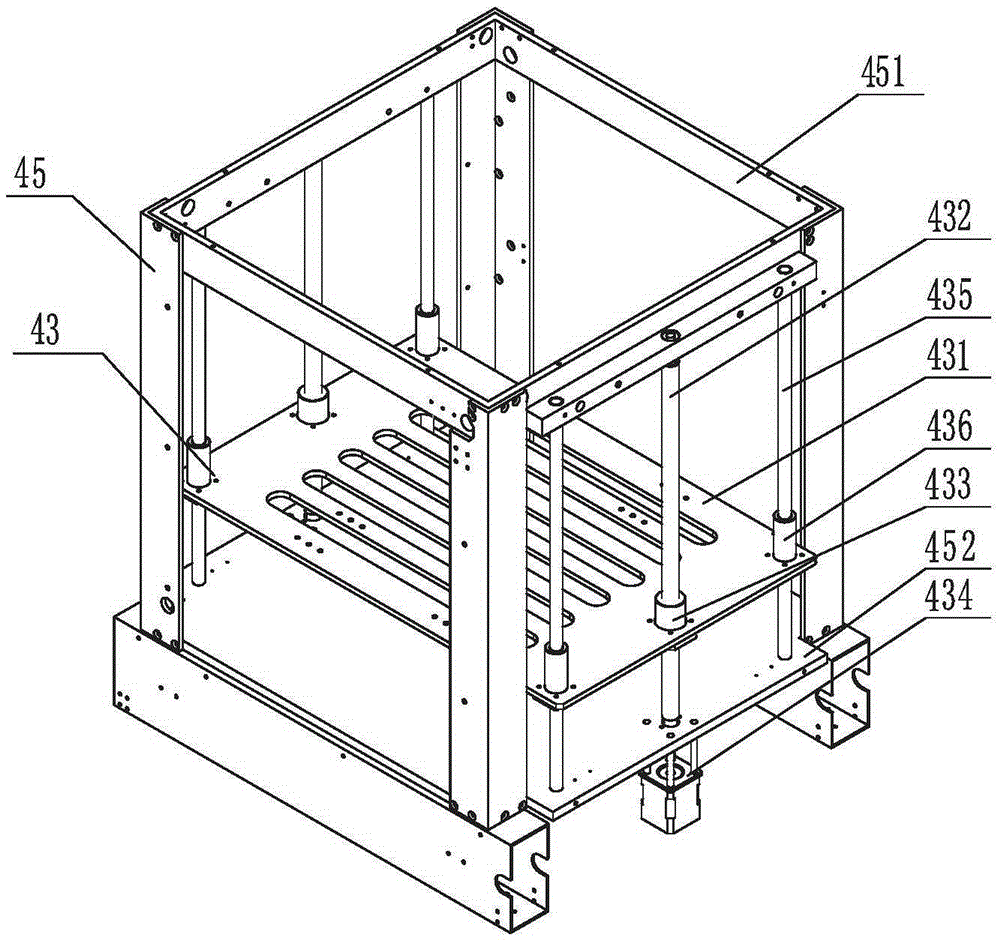

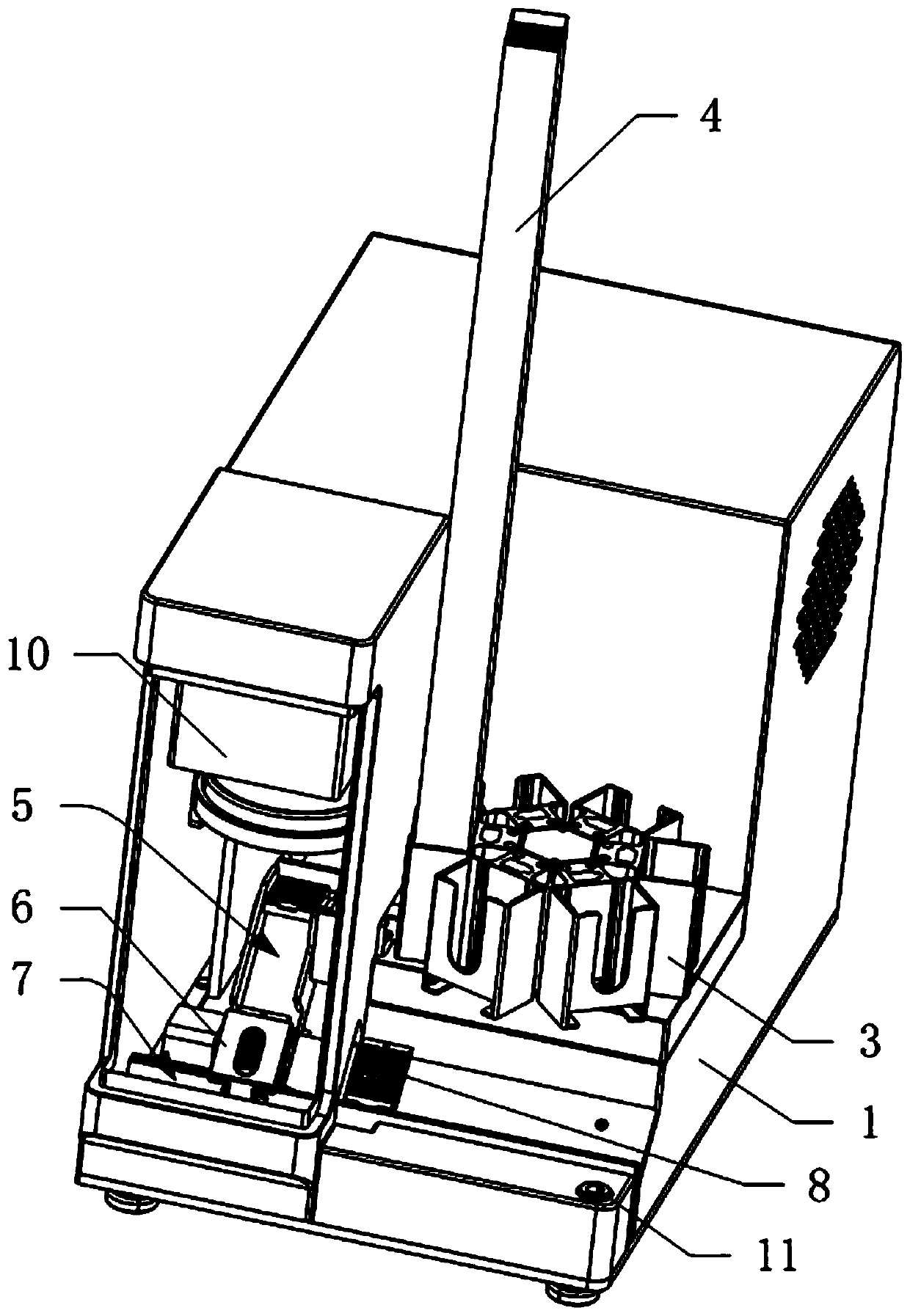

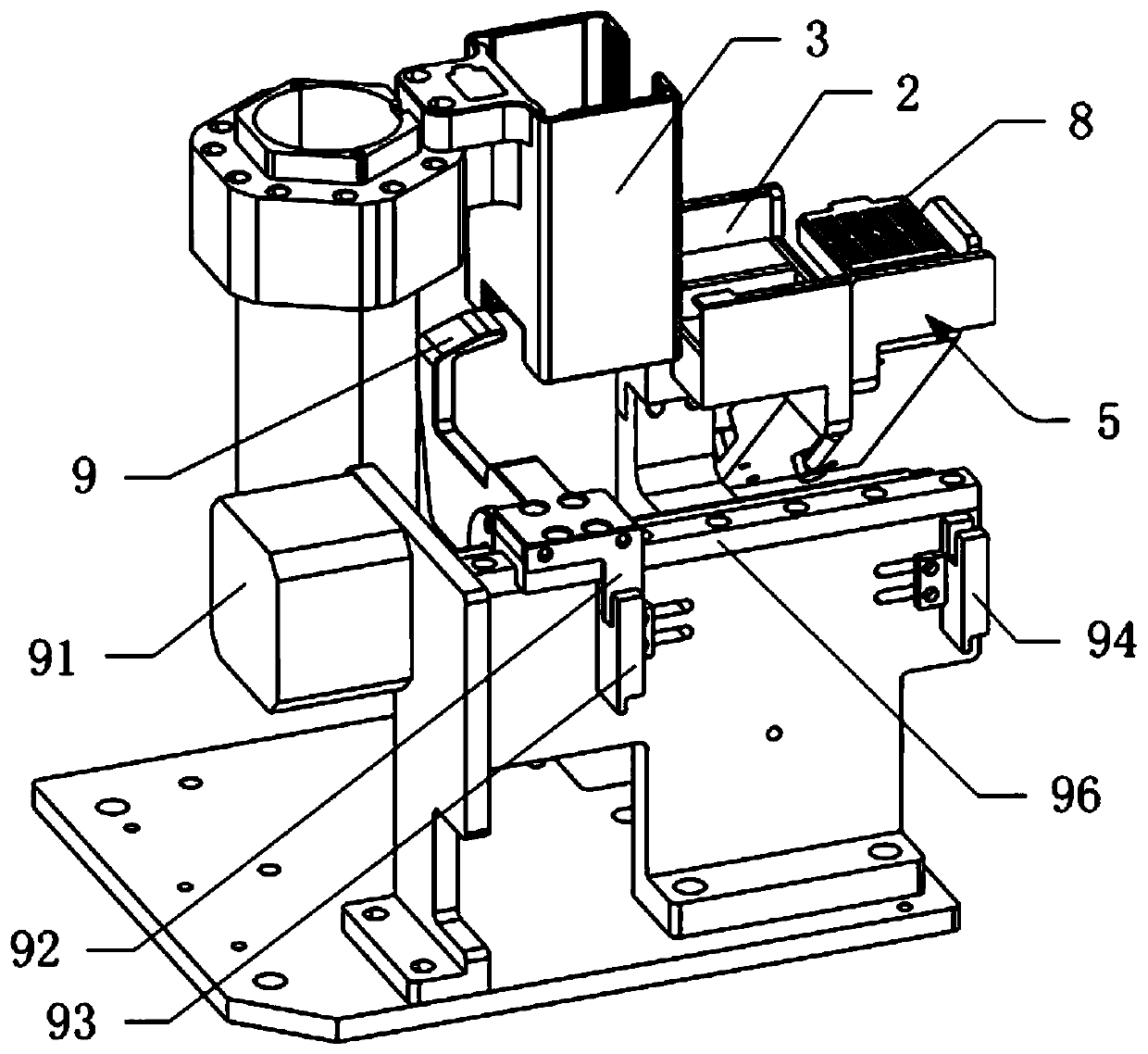

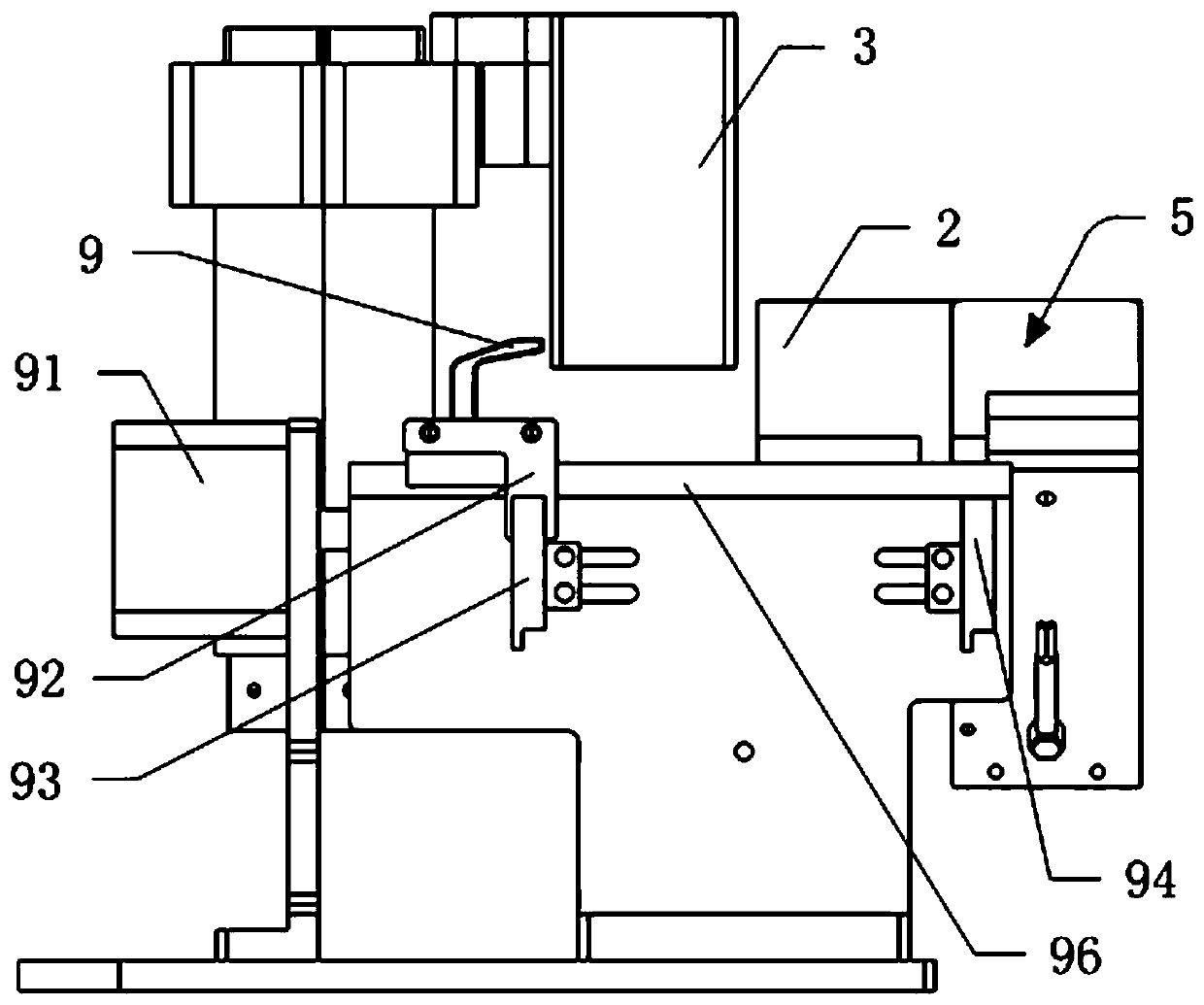

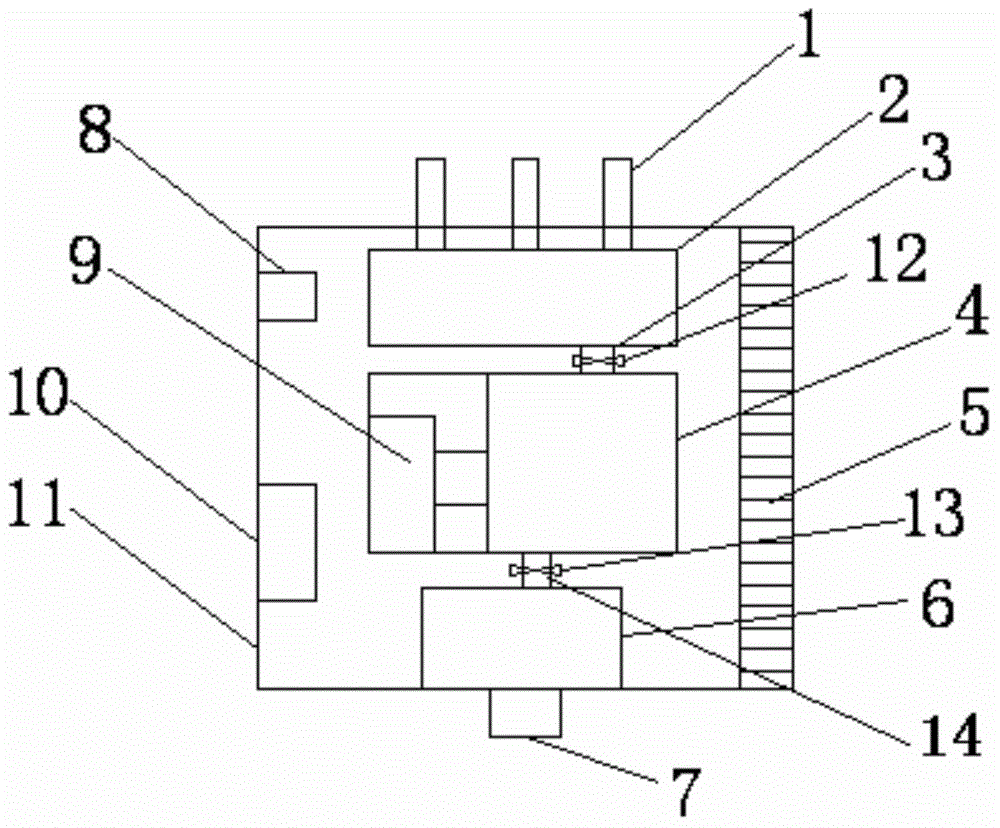

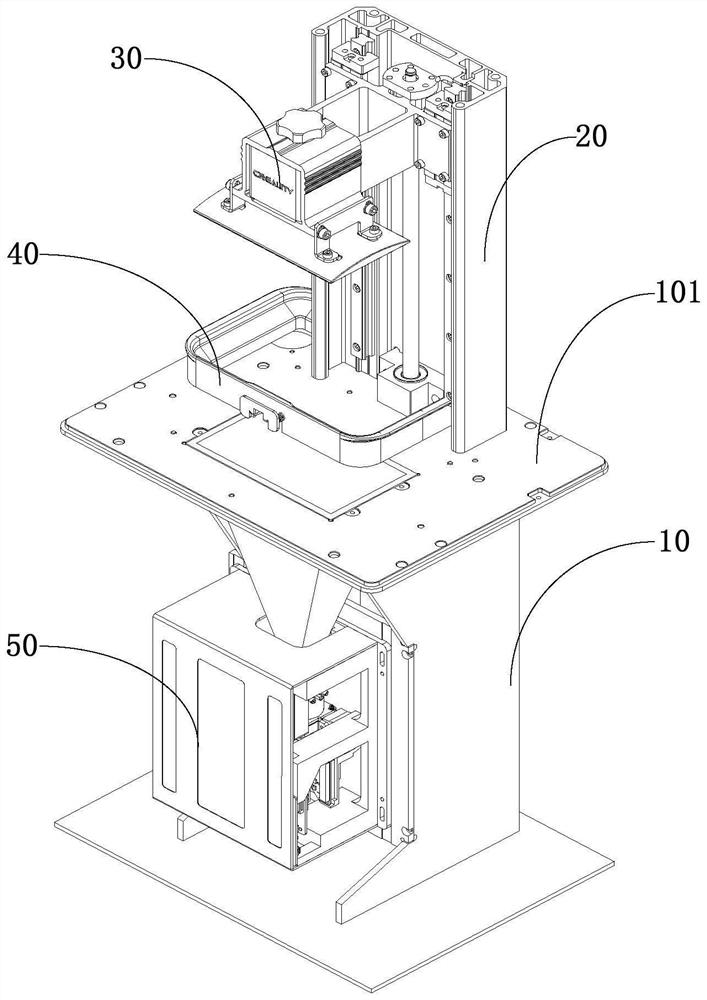

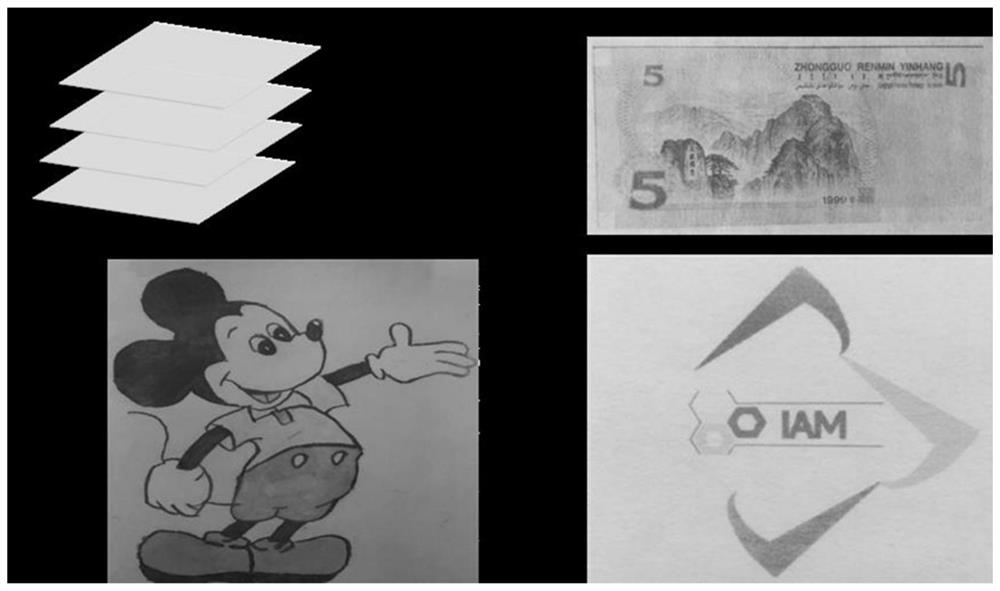

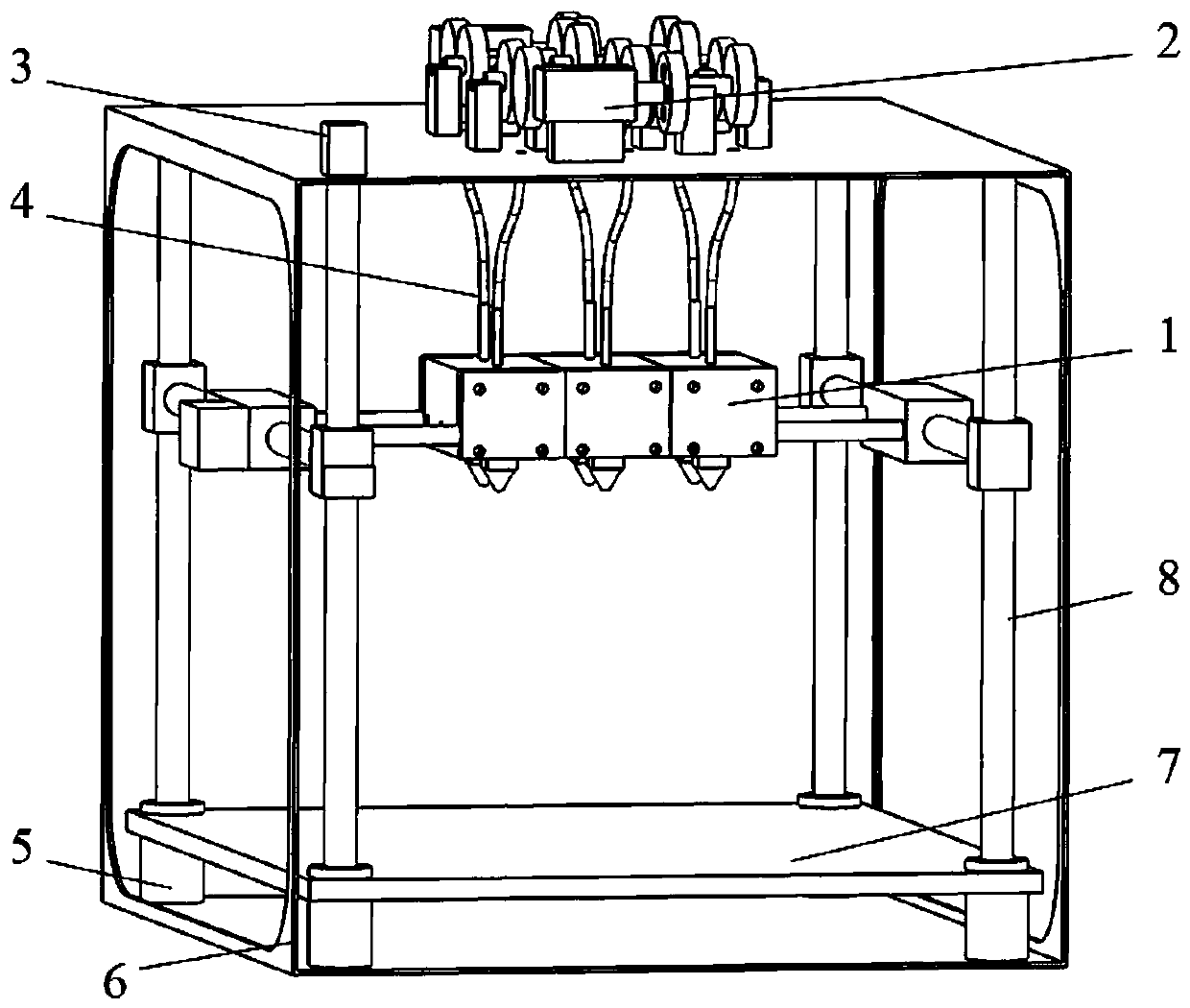

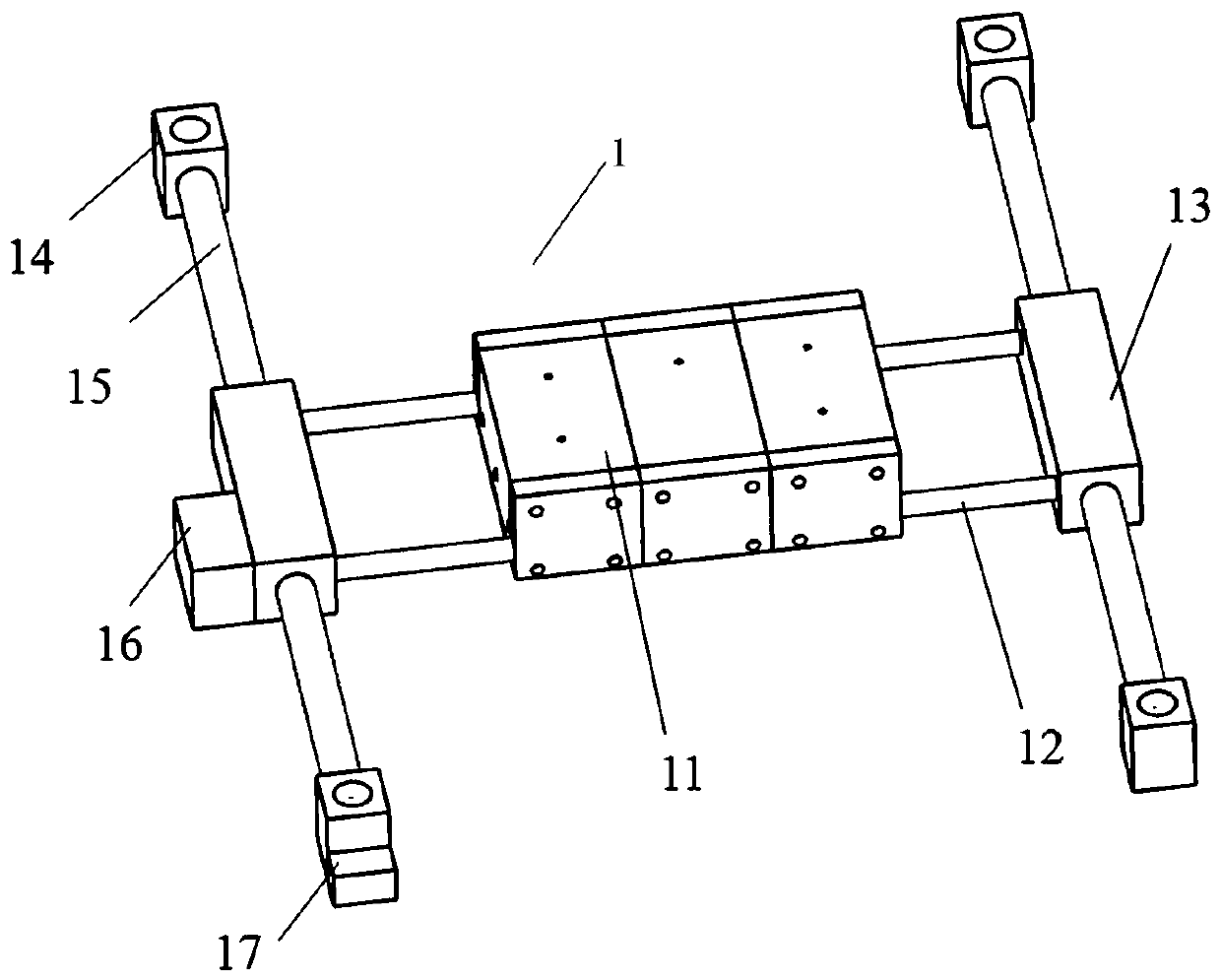

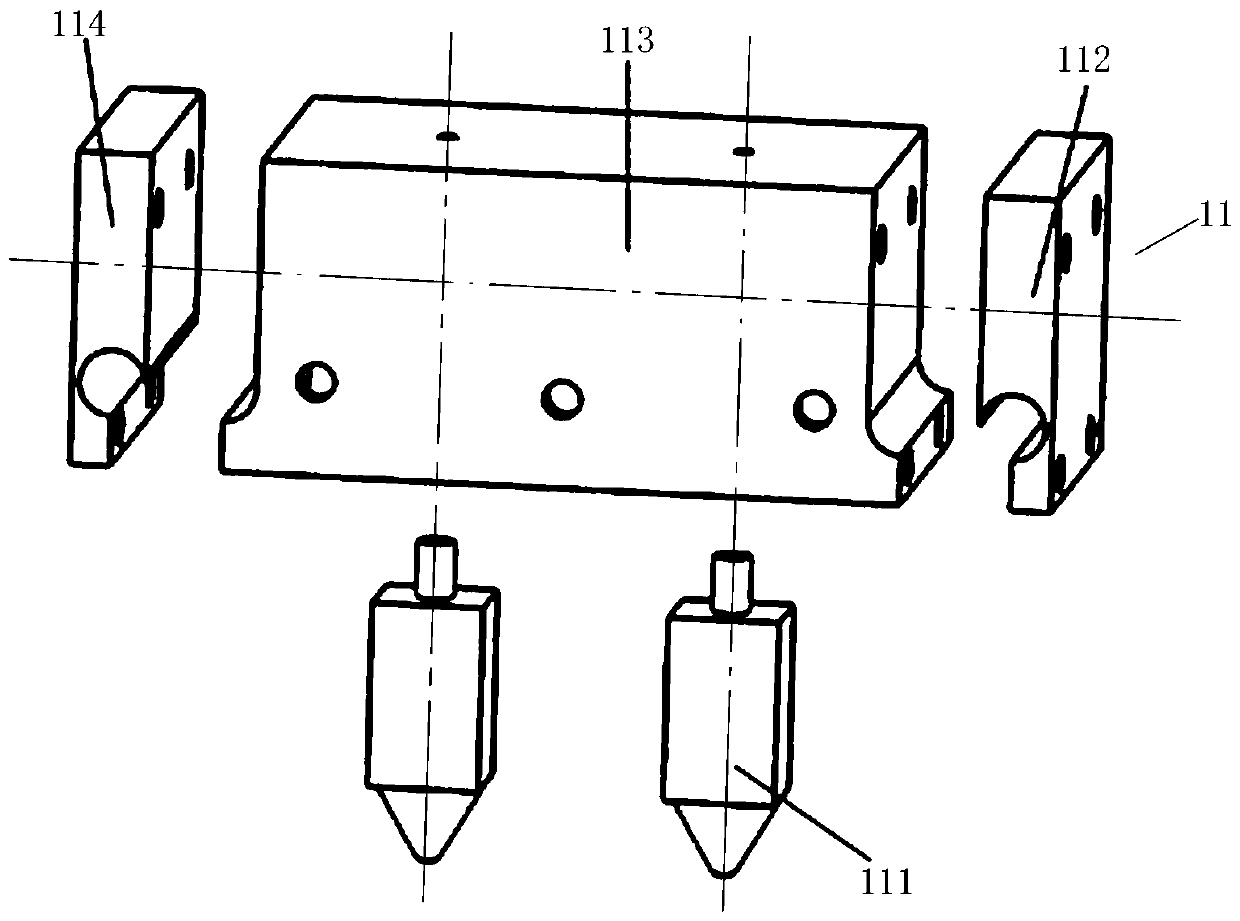

The invention discloses a desktop-level 3D printer. The desktop-level 3D printer comprises a machine frame, a controller, a material conveying device, an X,Y and Z axis movement device, a feeding device and a spraying nozzle device, wherein the material conveying device and the X,Y and Z axis movement device are installed on the machine frame; the feeding device and the spraying nozzle device are installed on the X,Y and Z axis movement device; the material conveying device is connected with the feeding device; the feeding device is connected with the spraying nozzle device; the controller is electrically connected with the material conveying device, the X,Y and Z axis movement device, the feeding device and the spraying nozzle device. The desktop-level 3D printer can realize effective multi-color printing, a printed model is high in accuracy, the printing effect is good, and color switching nearly without errors can be achieved. Meanwhile, the environmental characteristic that materials like acrylonitrile butadiene styrene (ABS) need to be printed at a constant temperature can be realized, so that technical support is provided for clients needing to print the ABS. The products with the biggest effective printing area are included, and requirements of various clients can be met.

Owner:SHANGHAI FUSION TECH CO LTD

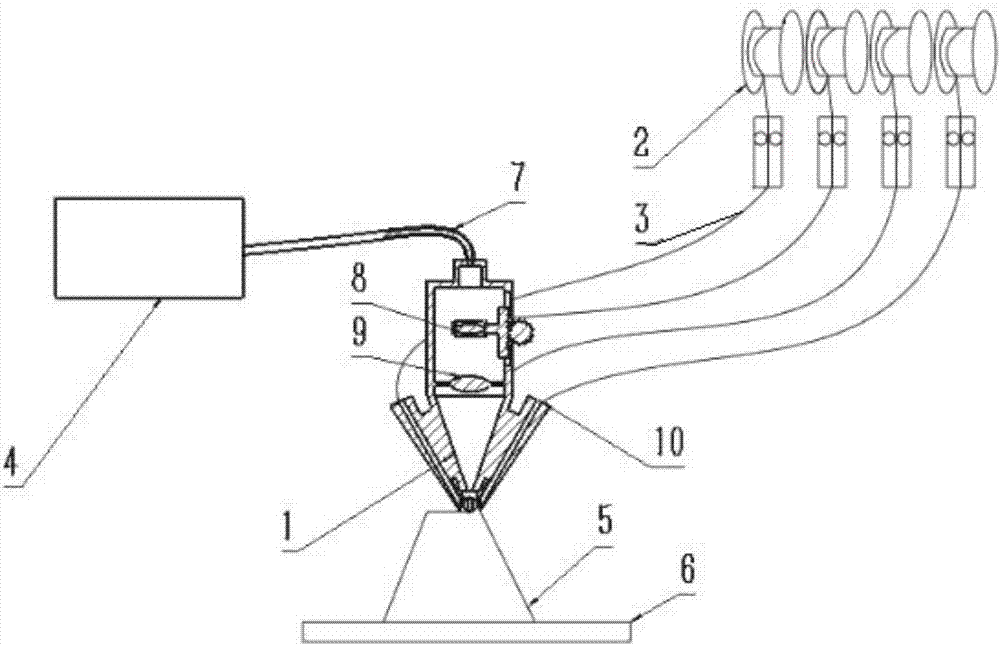

Multipath wire feed laser fused deposition modeling (LFDM) device and method

InactiveCN106926447AEfficient printingImprove molding efficiency3D object support structuresApplying layer meansEngineeringFused deposition modeling

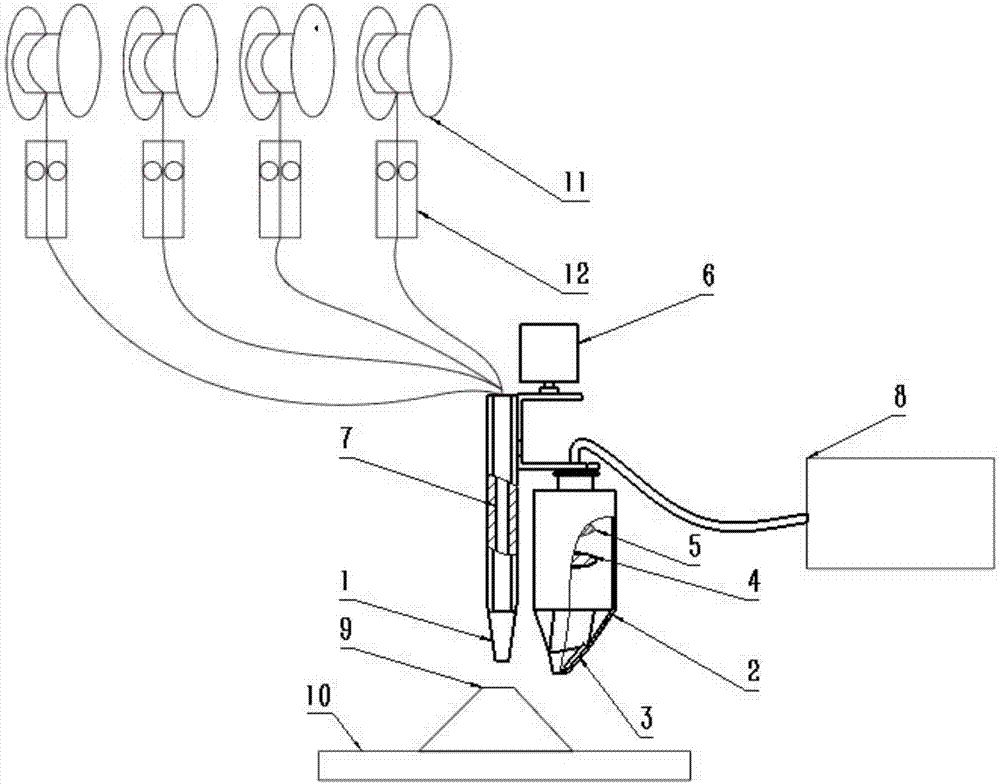

The invention discloses a multipath wire feed laser fused deposition modeling (LFDM) device and method. The device comprises a wire feed nozzle composed of multiple wire conveying pipelines, a laser head and a carbon dioxide laser. The wire feed nozzle and the laser head are fixedly connected together through a connecting part to form a composite printing head. A steering engine is mounted on the connecting part so as to increase the freedom degree of the composite printing head. The laser head can transmit a rectangular laser beam, and the rectangular laser beam ejects out from the lateral direction of the laser head and irradiates and covers the ends of corresponding wires stretching out of the outer portion of the wire feed nozzle to carry out fusing on the ends. According to the device, on the basis of a traditional fused deposition technology, a laser fused deposition technology is developed, some problems existing in traditional equipment are solved, meanwhile, more functions are given to the novel device, and more possibilities and methods and thoughts for solving the problems are provided for the fused deposition modeling technology. Meanwhile, by means of linear multipath wire feed, an effective multi-conveying-pipeline arrangement manner is provided.

Owner:SOUTH CHINA UNIV OF TECH

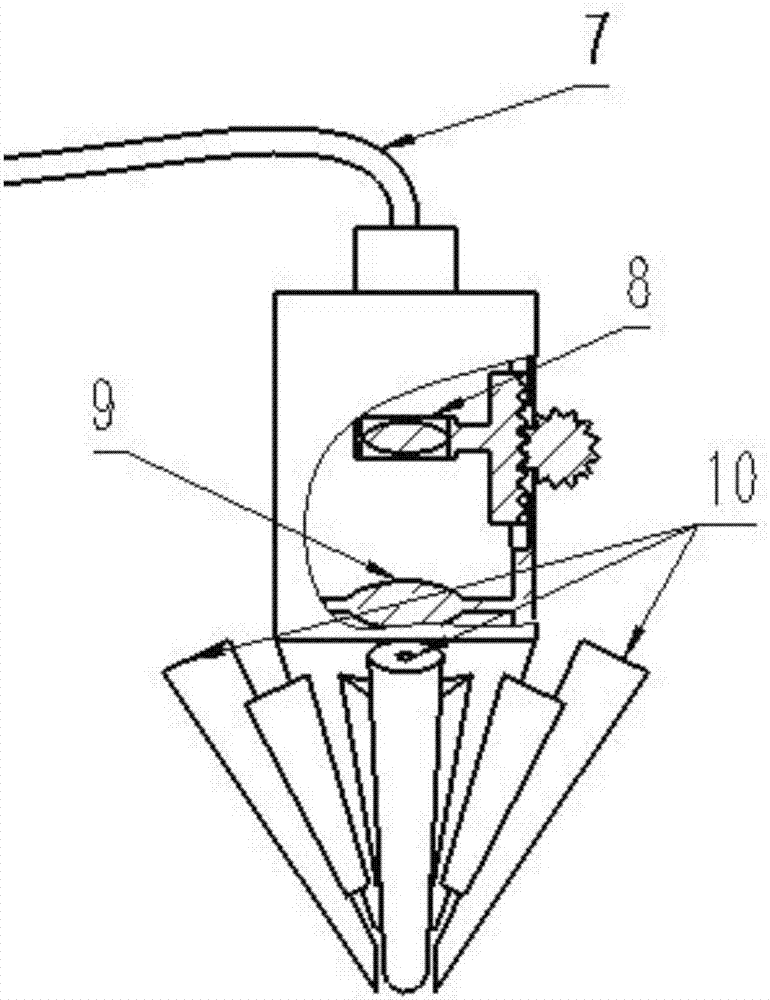

Laser fused deposition modeling device and running method thereof

InactiveCN106975750AReduce deliveryImprove molding efficiencyAdditive manufacturing apparatusFused deposition modelingCarbon dioxide

The invention discloses a laser fused deposition modeling device and a running method thereof. The device comprises a carbon dioxide laser generator, a composite printing head and a multi-way wire feeding mechanism, wherein the carbon dioxide laser generator is connected with the composite printing head through an optical fiber and is connected with a moving lens set and a focusing lens in the composite printing head by means of optical paths; the lower end of the composite printing head is of a tapered structure, and a plurality of wire guide channels are distributed along the outer circumferential wall of the tapered structure; a wire supplied by the multi-way wire feeding mechanism passes through the corresponding wire guide channel; the carbon dioxide laser generator is used as a heat source for fusing the wires, and laser focus points focus the end parts of the wires so as to fuse the wires; an X- and Y-directional moving mechanism is used for carrying the composite printing head, and the fused wires are fused and deposited on a hot bed according a planned path. According to the device, the carbon dioxide laser generator and the composite printing head are organically integrated; the wires are fused at the outside of the composite printing head, so that the problem that a spray head of an existing printing head is easily blocked during printing can be solved.

Owner:SOUTH CHINA UNIV OF TECH

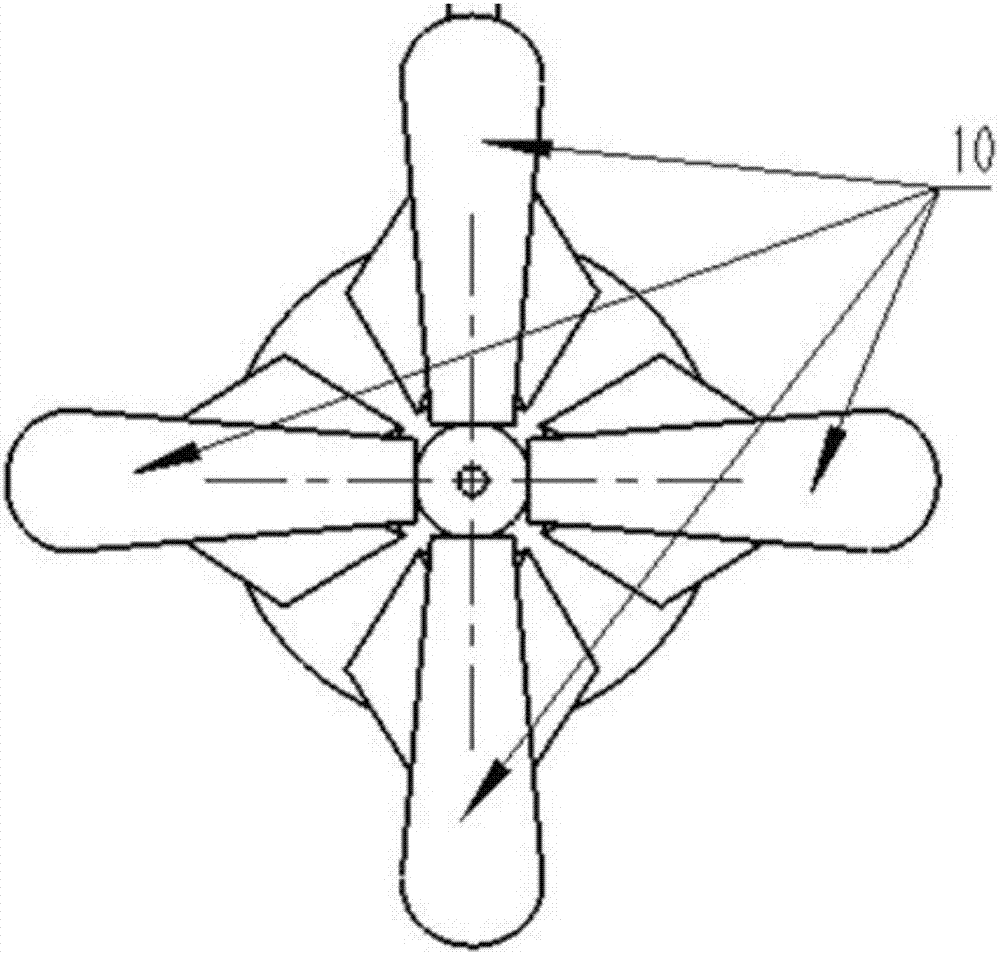

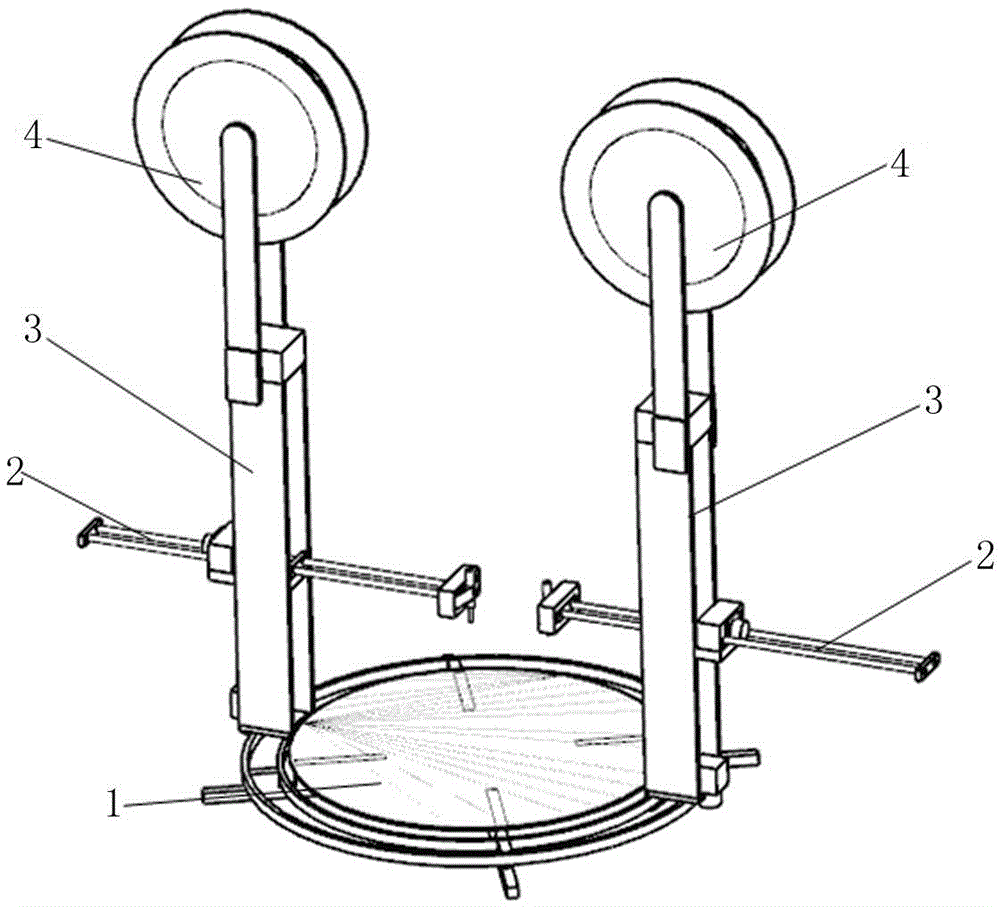

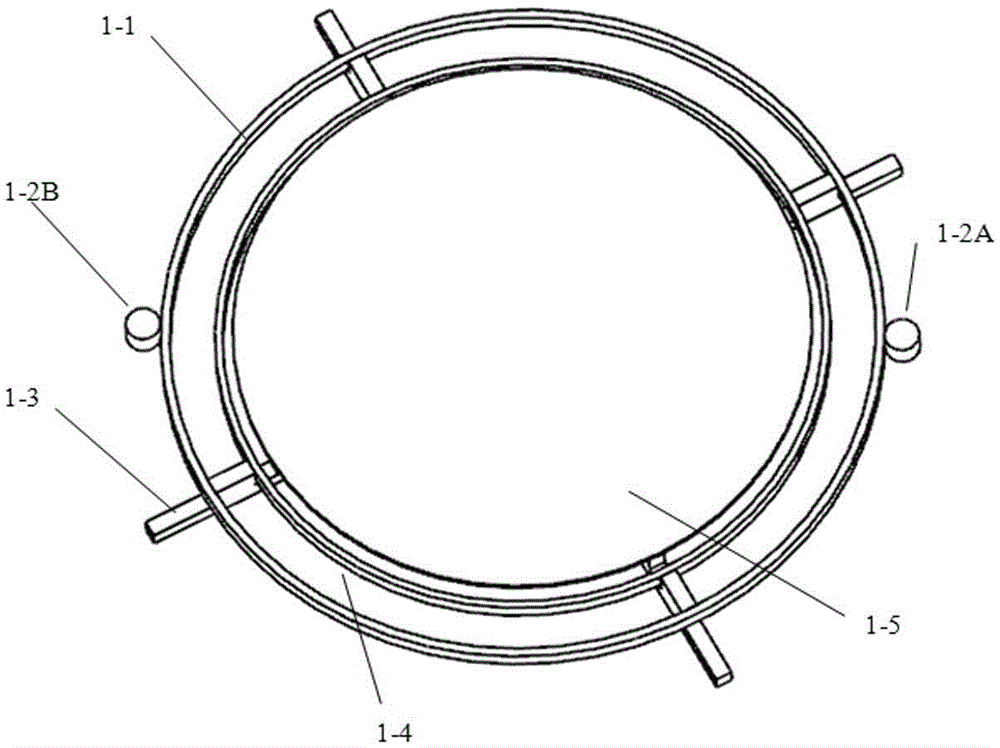

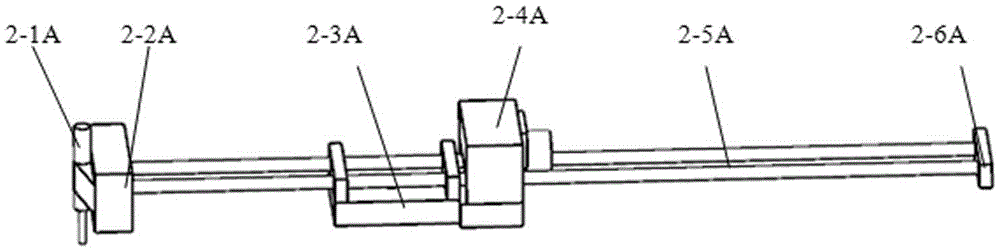

Cylindrical coordinate type 3D printer capable of achieving simultaneous multi-spray-head printing

ActiveCN105415691AAchieve multi-color printingImprove printing efficiencyAdditive manufacturing apparatusCantilevered beamGear wheel

The invention relates to a cylindrical coordinate type 3D printer capable of achieving simultaneous multi-spray-head printing. The printer comprises an external gearing precision planetary gear mechanism, a telescopic cantilever beam mechanism, a Z-axis movement mechanism and a feeding mechanism. The external gearing precision planetary gear mechanism is composed of a sun gear, a planetary gear, a supporting block, a reinforcing circular ring and a disc-shaped workbench. The telescopic cantilever beam mechanism comprises a spray head, a feeding motor, a Z-axis movement block, a polar axis driving motor, a polar axis ball screw and a limiting block. The Z-axis movement mechanism comprises a Z-direction driving motor, a Z-direction movement mechanism supporting frame, a Z-direction ball screw, a planetary gear driving motor and a motor base. The feeding mechanism comprises a feeding wheel and a feeding wheel supporting frame. Polar coordinate plane printing is achieved through the external gearing precision planetary gear mechanism and the telescopic cantilever beam mechanism, and Z-direction movement is achieved through a Z-axis control mechanism, so that three-dimensional printing movement of spray heads is achieved; by means of multi-layer multi-telescopic-arm cooperation, simultaneous multi-spray-head machining is achieved.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

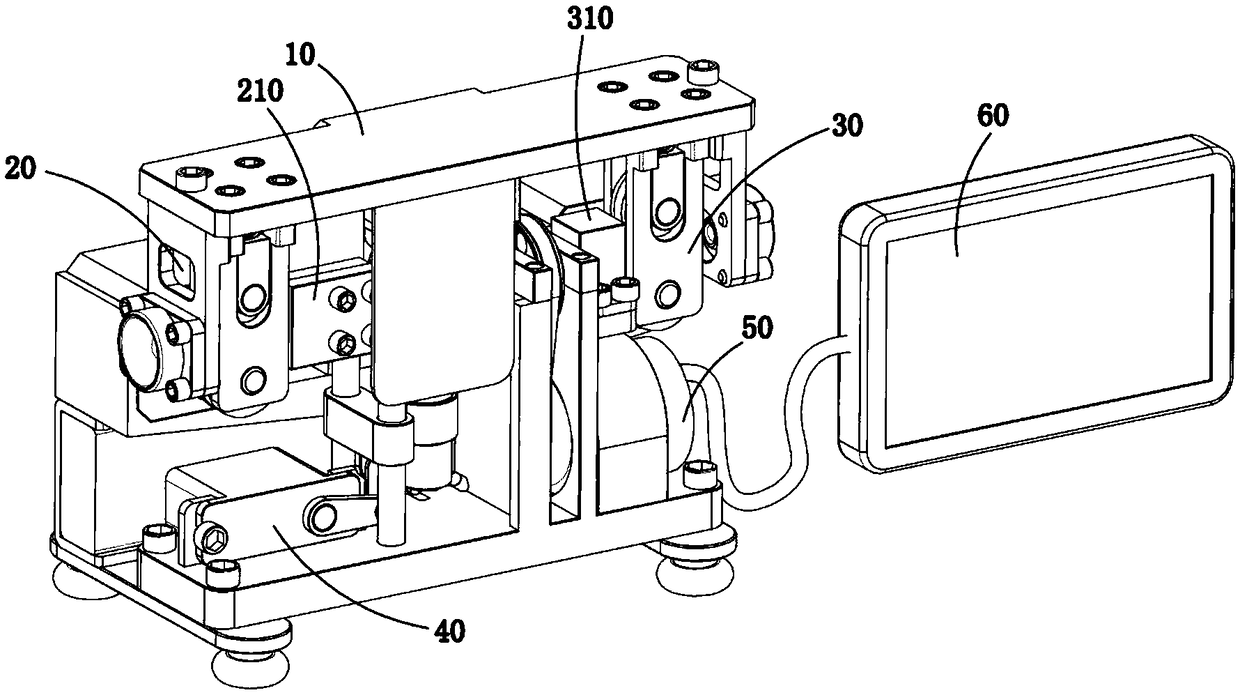

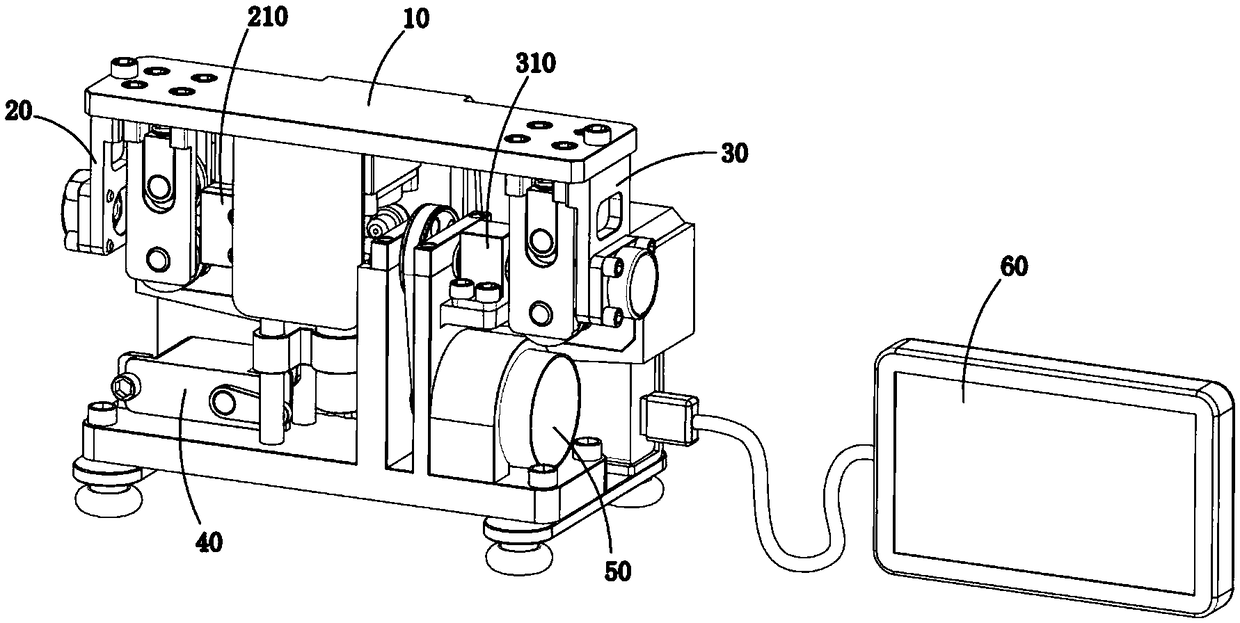

Medical embedding box laser coding machine capable of realizing multi-color printing

PendingCN110303251AAchieve multi-color printingMulticolor printing withLaser beam welding apparatusTypewritersColor printingEngineering

The invention discloses a medical embedding box laser coding machine capable of realizing multi-color printing. The machine is fast in coding, and stable in operating, and can adapt to coding work ofdifferent embedding boxes. The machine comprises a laser device arranged at a base, a discharging barrel frame, a charging barrel clamped in an inner cavity of the discharging barrel frame, a feedingpush rod with an inclined top surface and a slope rail, wherein the charging barrel is provided with an inner cavity which is vertically provided with embedding boxes horizontally arranged, a discharging passage with a side plate is arranged on one side of the slope rail, a protecting plate connected with the side plate is arranged on the slope rail, the discharging barrel frame is arranged on oneside of the discharging passage, a first opening for the embedding boxes to pass through is formed in the front surface of the discharging barrel frame, the back surface and the bottom surface of thedischarging barrel frame and the bottom surface of the discharging passage are provided with second openings for the feeding push rod to pass through, the bottom end of the slope rail is provided with a discharging rail which enables the embedding boxes to be placed side by side and a positioning pushing sleeve, the slope rail is provided with a first detector capable of detecting the embedding boxes to move into the positioning pushing sleeve so as to control the laser device to work, and the positioning pushing sleeve can horizontally move so as to push the embedding boxes to move from theslope rail to the discharging rail.

Owner:广东金泉医疗科技有限公司

Novel three-color stirring device of 3D printer head

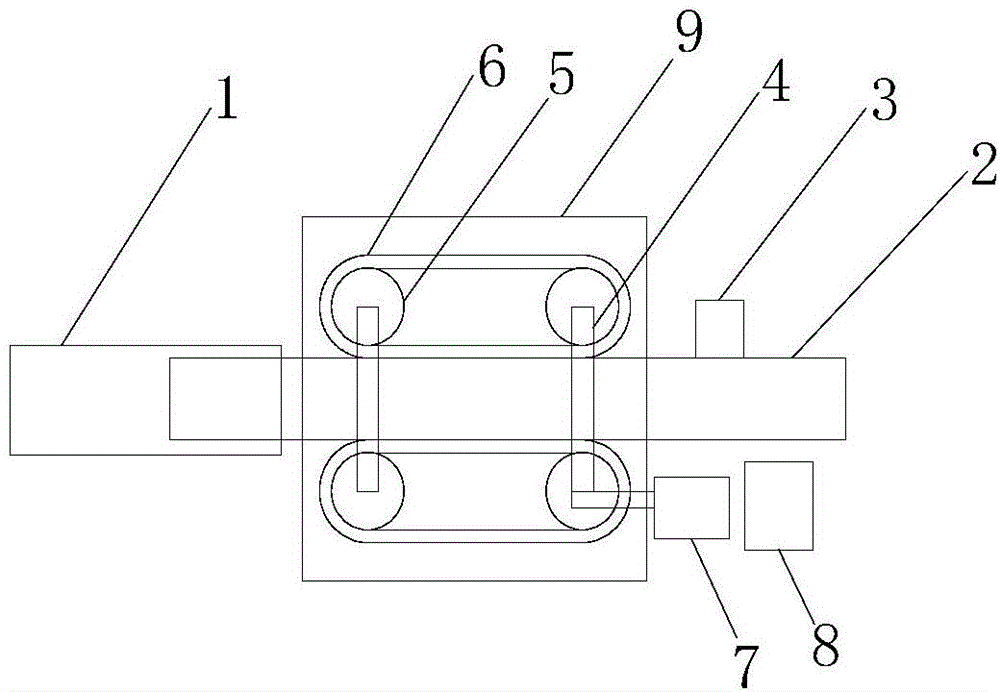

InactiveCN104626563AAchieve multi-color printingSolve the solid color problemColor printingEngineering

The invention provides a novel three-color stirring device of a 3D printer head. The stirring device comprises material inlet pipe ports, a material storing container, a flow guiding pipe, a stirring chamber, a heater, a material container to be used, a material discharging port, a temperature tester, a stirring execution mechanism, a stirring controller, a housing and a solenoid valve. Three primary color materials are blended according to a ratio to compound various colors, and multi-color printing of a 3D product can be realized. The novel three-color stirring device of the 3D printer head is easy to operate, is easy to realize, and can effectively solve the pure color problem of a 3D product.

Owner:XIAN SHANGSHANG ELECTROMECHANICAL

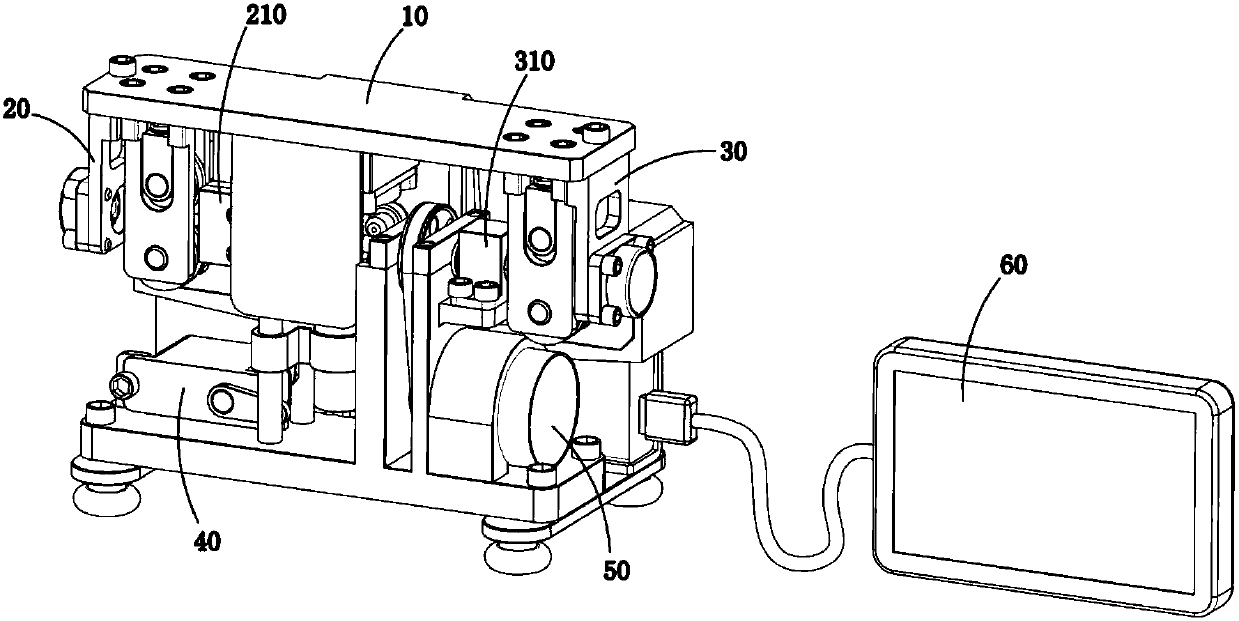

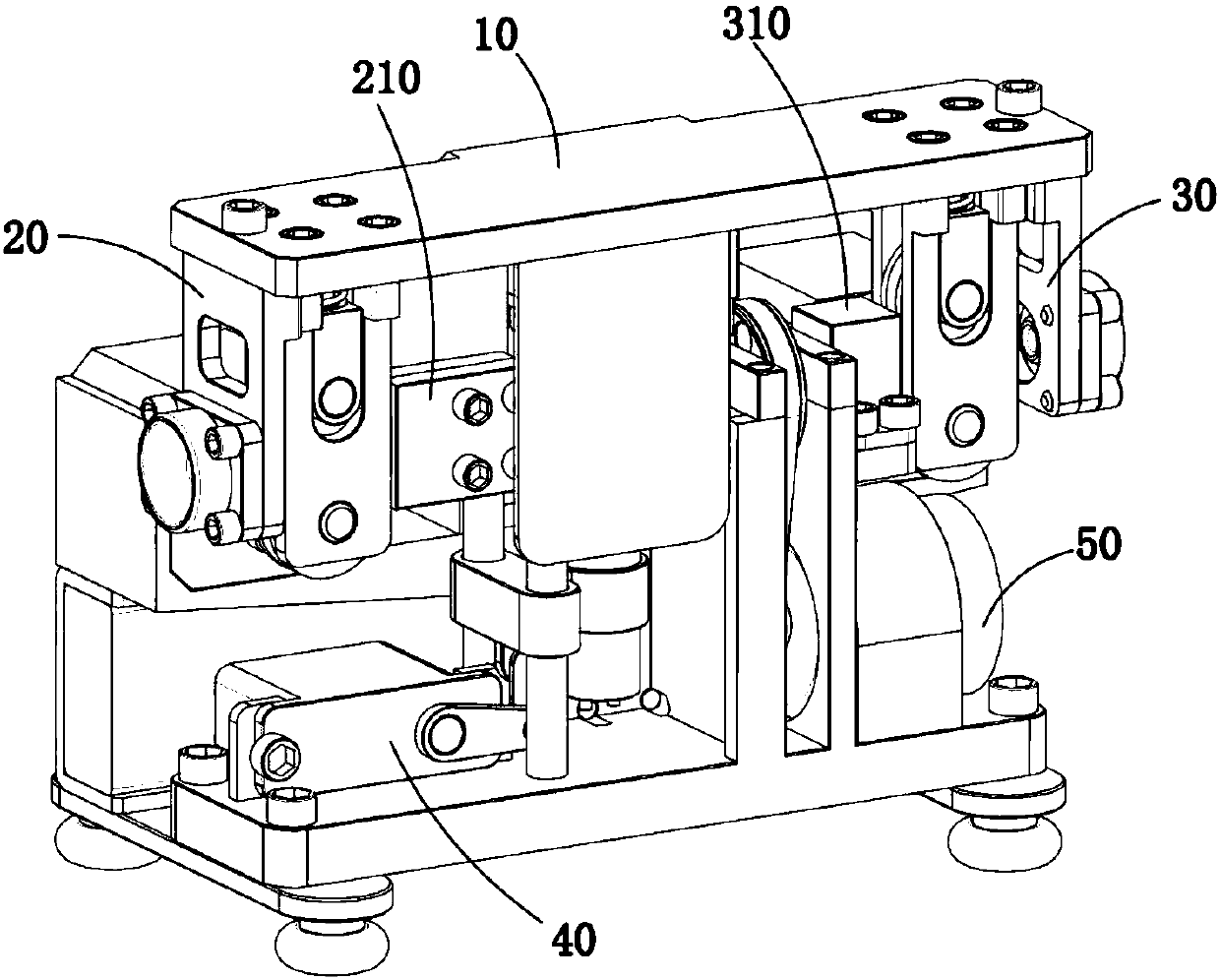

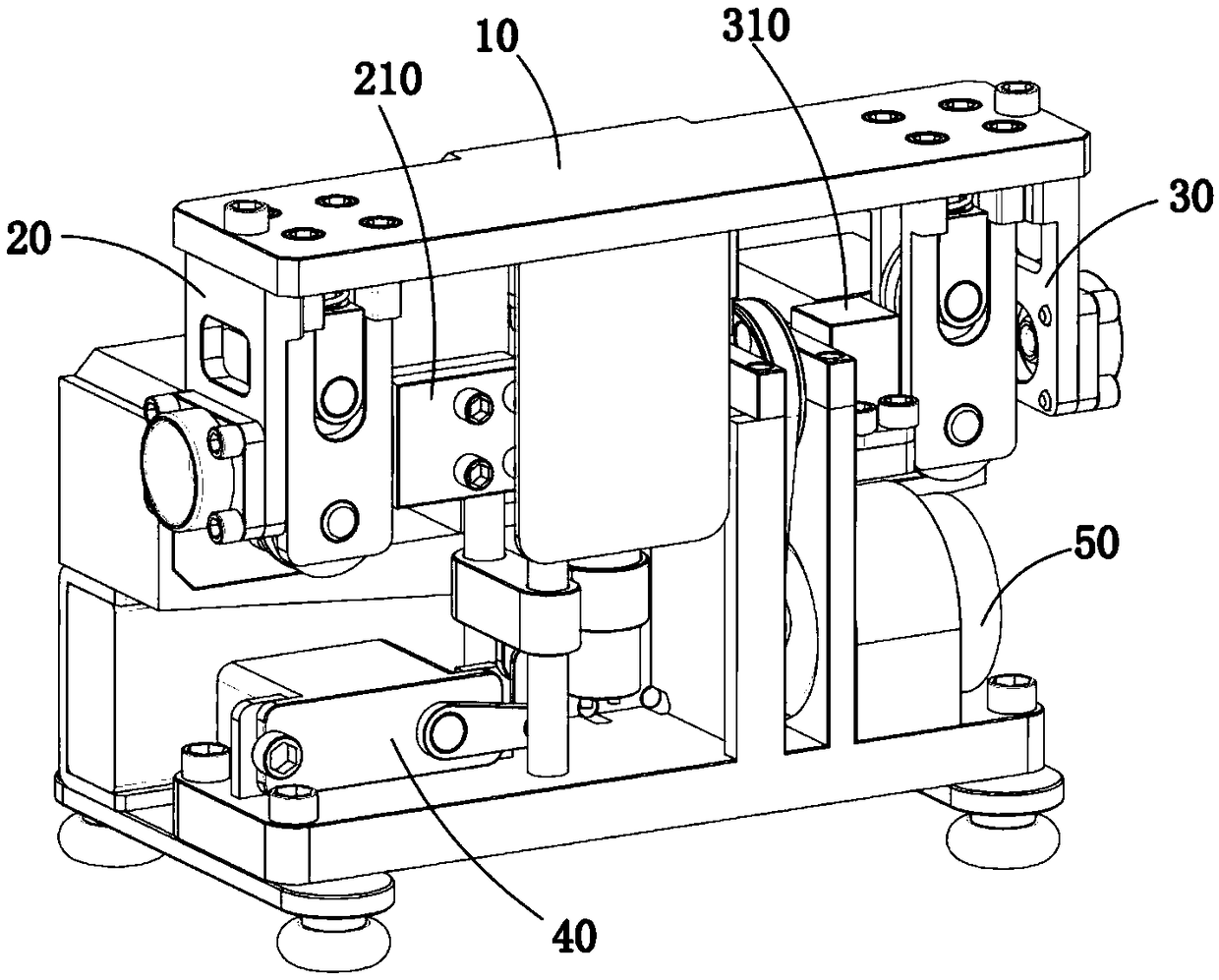

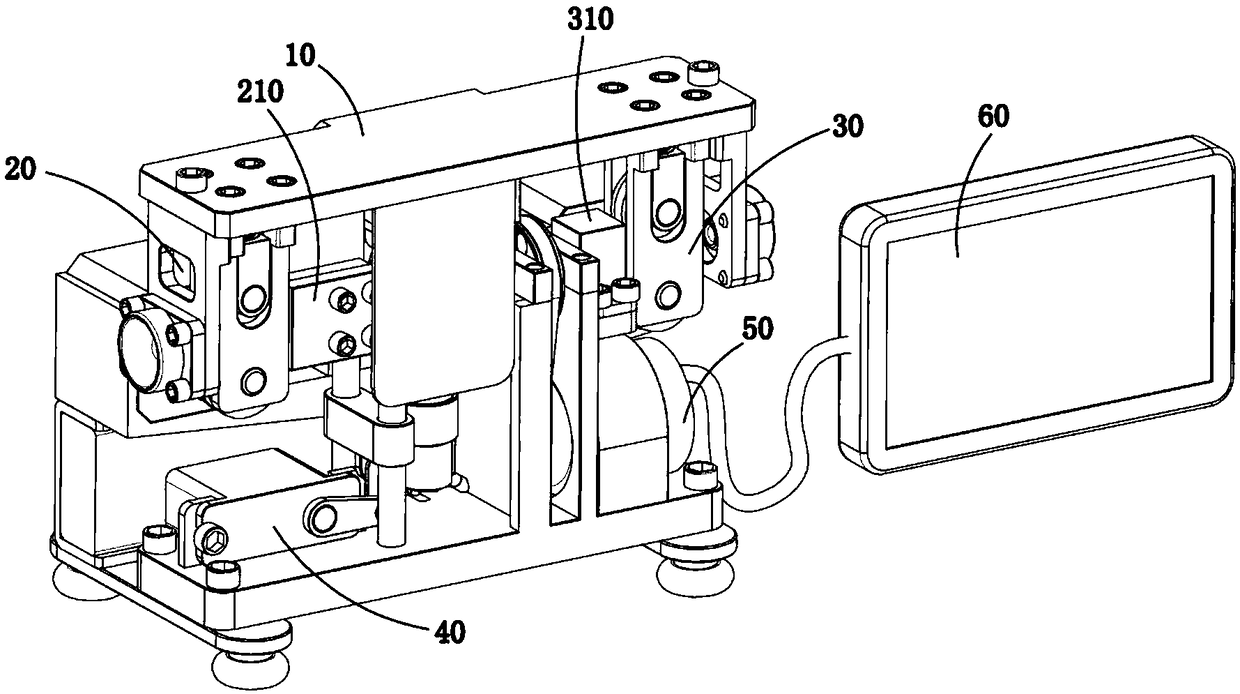

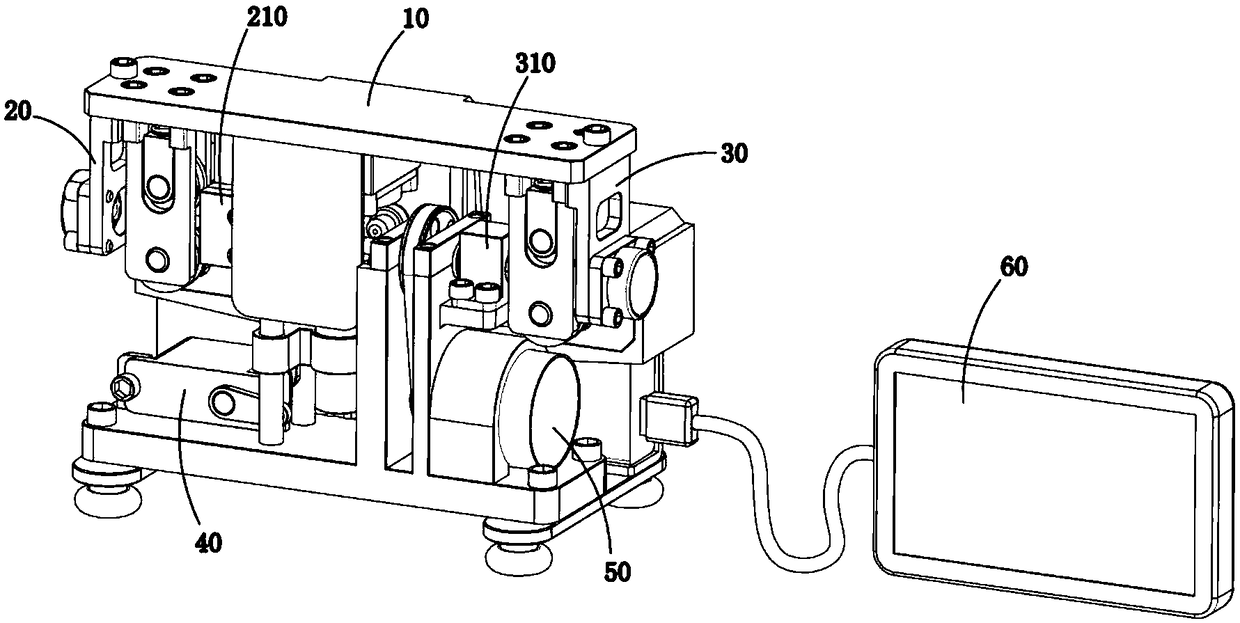

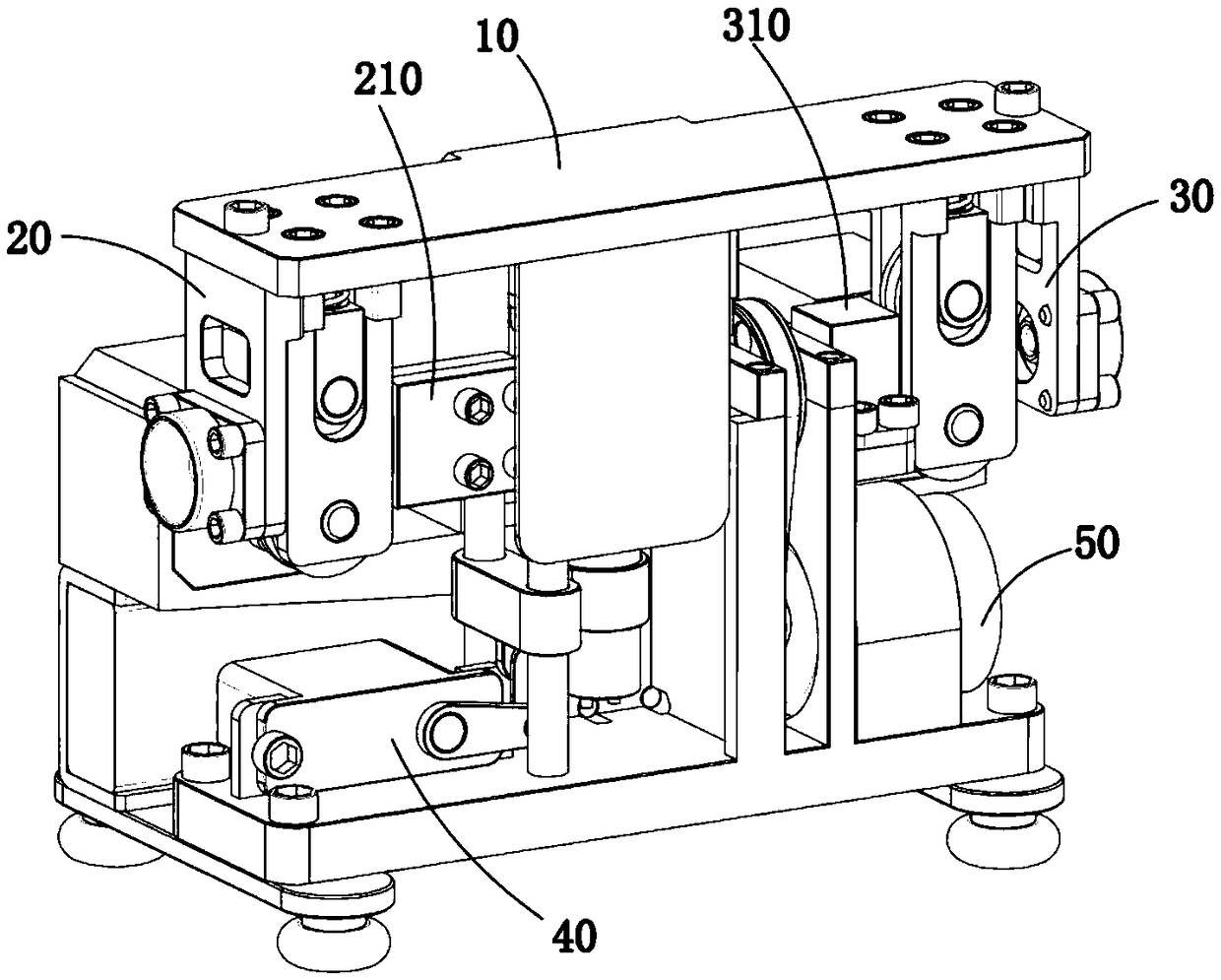

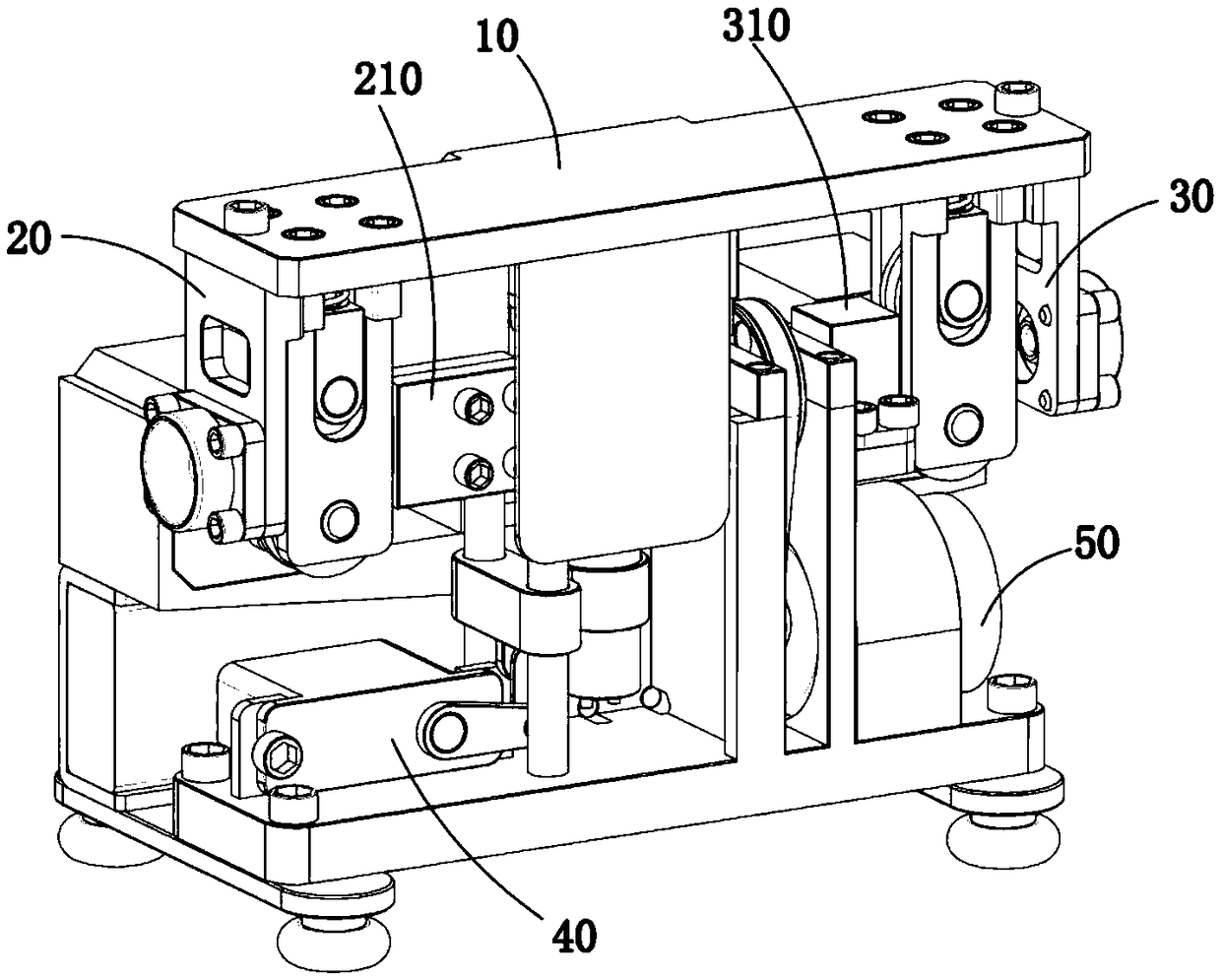

Tandem connection equipment of 3D printer consumables

ActiveCN107856308AAchieve recyclingAchieve multi-color printingManufacturing driving meansManufacturing heating elementsColor printingEngineering

The invention discloses tandem connection equipment of 3D printer consumables. The tandem connection equipment comprises a supporting frame, wherein a first threading mechanism and a second threadingmechanism are mounted on the supporting frame; the first threading mechanism and the second threading mechanism respectively lead a strand of wire consumables to be subjected to tandem connection; a spacer region between the first threading mechanism and the second threading mechanism is a hot connection region; the first threading mechanism and the second threading mechanism can convey the wire consumables to the hot connection region, and complete tandem connection in the hot connection region; and the first threading mechanism and the second threading mechanism can convey the wire consumables subjected to the hot connection towards the outside along a direction from the first threading mechanism to the second threading mechanism. The tandem connection equipment realizes recycling of residual or redundant 3D printer consumables; furthermore, by the adoption of the technical scheme provided by the invention, multi-color printing of a common 3D printer can be also realized; and the problem of single color of a pattern printed by the existing common 3D printer is solved.

Owner:LUAN YONGZHEN GRIZZLY ELECTRICAL & MECHANICAL TECH CO LTD

Consumable serial connecting method capable of realizing color printing of 3D printer

ActiveCN107672176AAchieve recyclingAchieve multi-color printingAdditive manufacturing apparatus3D object support structures3d printColor printing

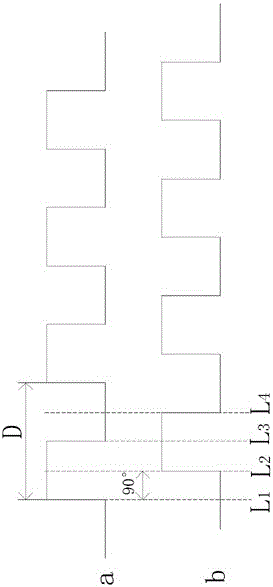

The invention discloses a consumable serial connecting method capable of realizing color printing of a 3D printer. The method comprises the following steps: (A) a wire consumable a with a color as delta and a length as L1 is selected; a wire consumable b with a color as gamma and a length as L2 is selected; and the lengths of the wire consumable a and the wire consumable b are calculated accordingto a size of a printed image; (B) the wire consumable a and the wire consumable b are determined to enter the 3D printer in sequence; (C) the wire consumable a is leaded into a second wire stringingmechanism; and the wire consumable b is leaded into a first wire stringing mechanism; (D) a power supply part of a heating mechanism drives a heat source body to move to a heat connecting area; (E) the wire consumables a and b are conveyed to move to the heat connecting area by the first wire stringing mechanism and the second wire stringing mechanism; (F) the power supply part of the heating mechanism drives the heat source body to the heat connecting area; (G) free ends of the wire consumable a and the wire consumable b are thermally connected; and (H) after thermal connection in the step (G) is finished, the wire consumables a and b are stood for a period of time.

Owner:泰州市津专知识产权服务有限公司

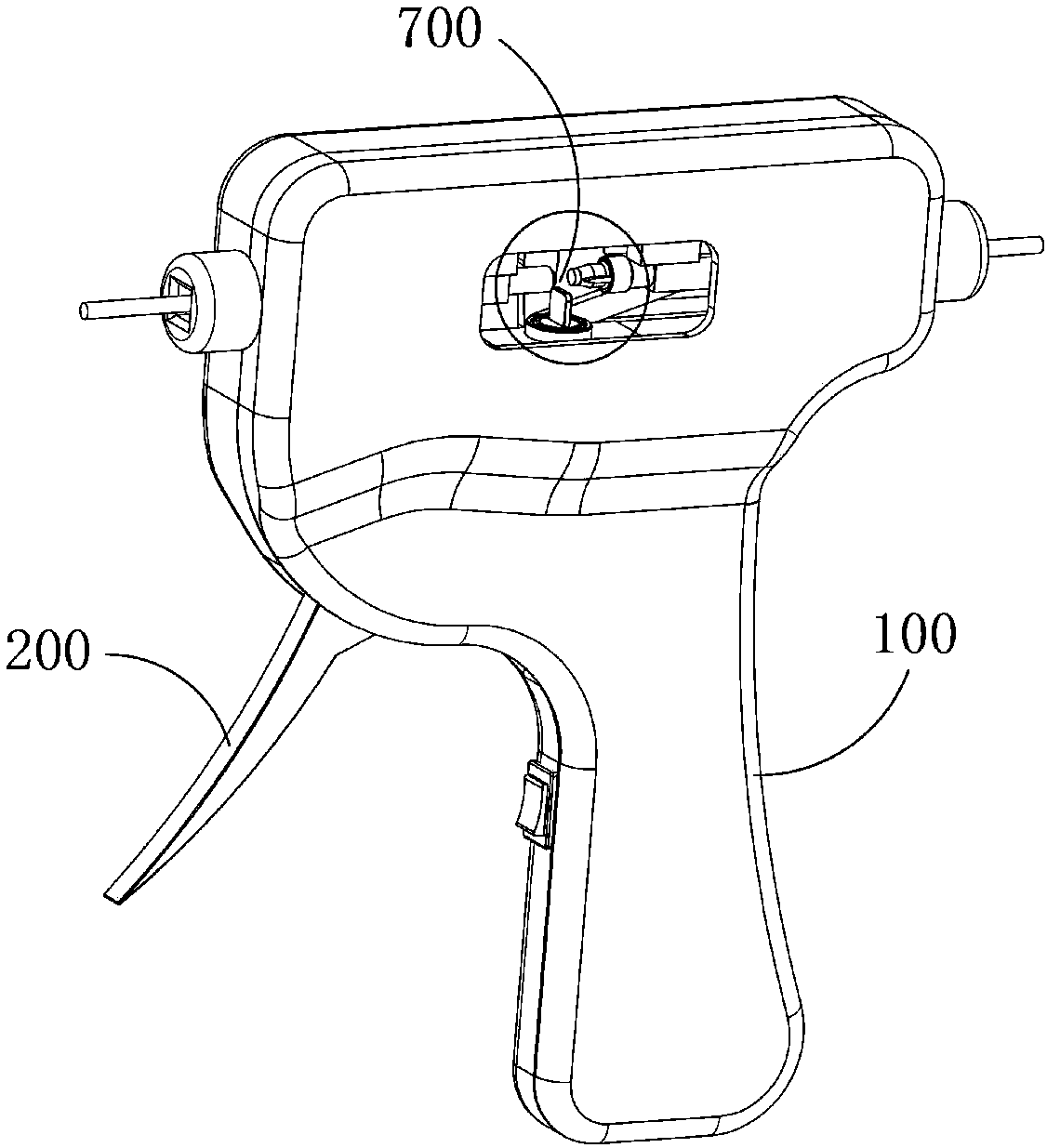

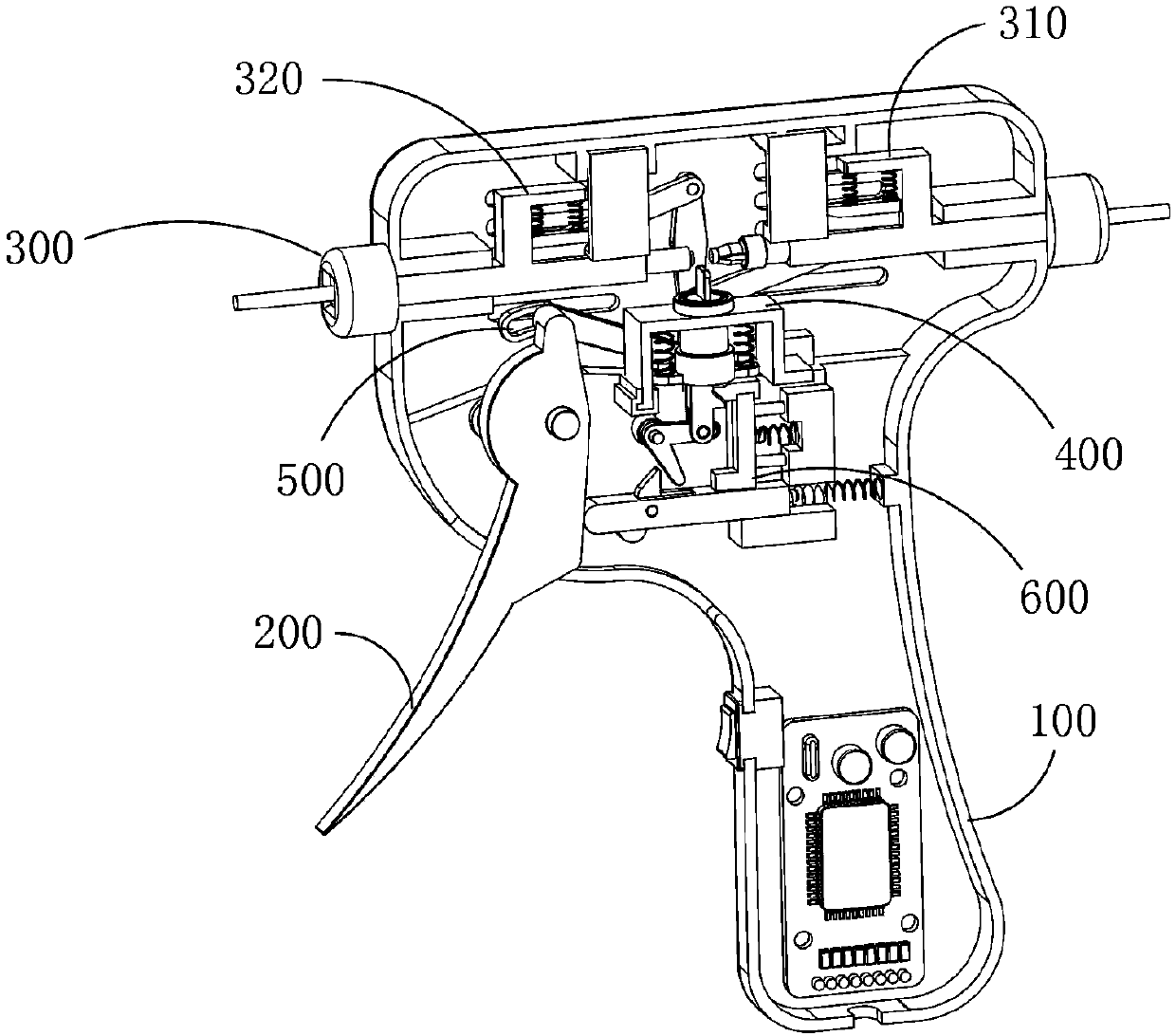

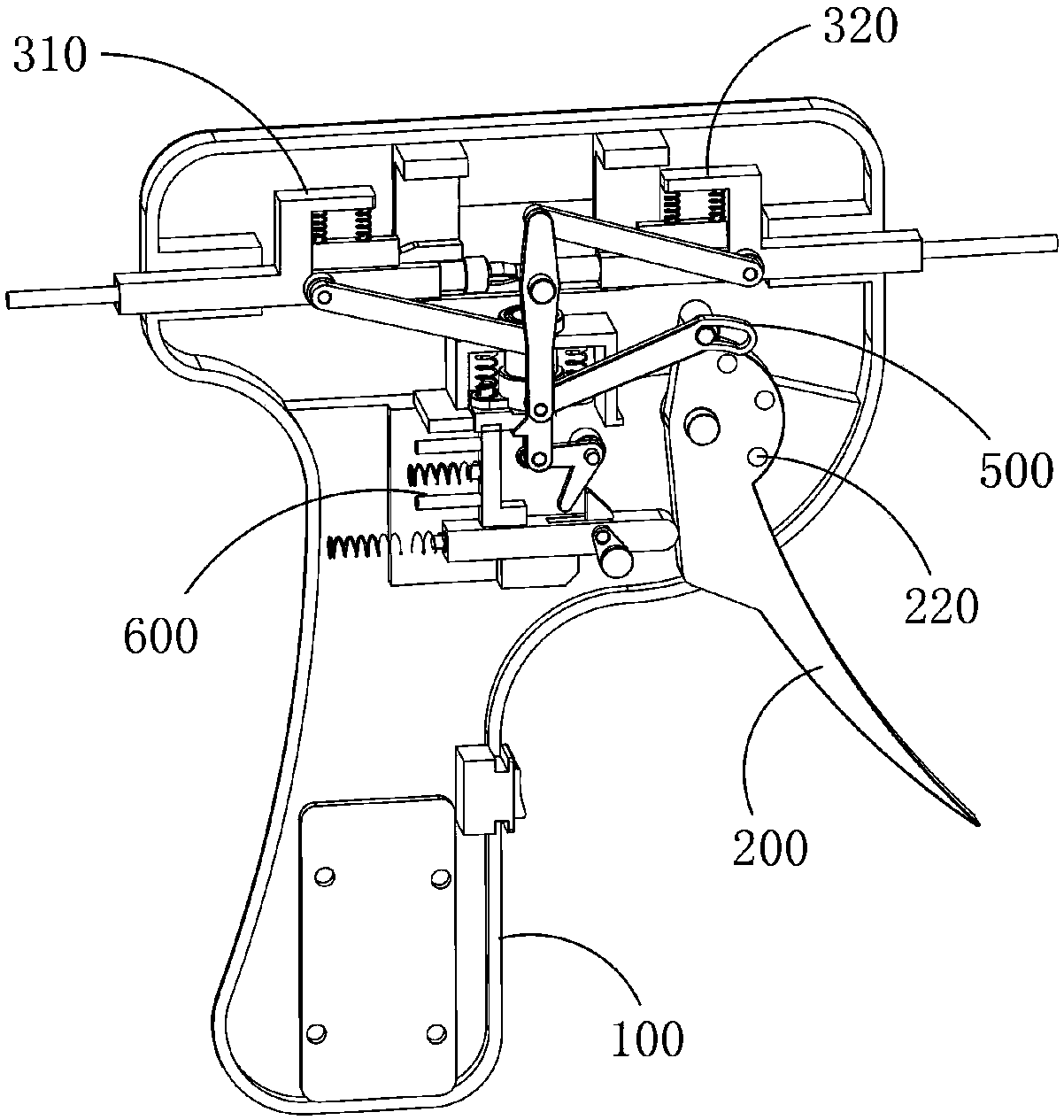

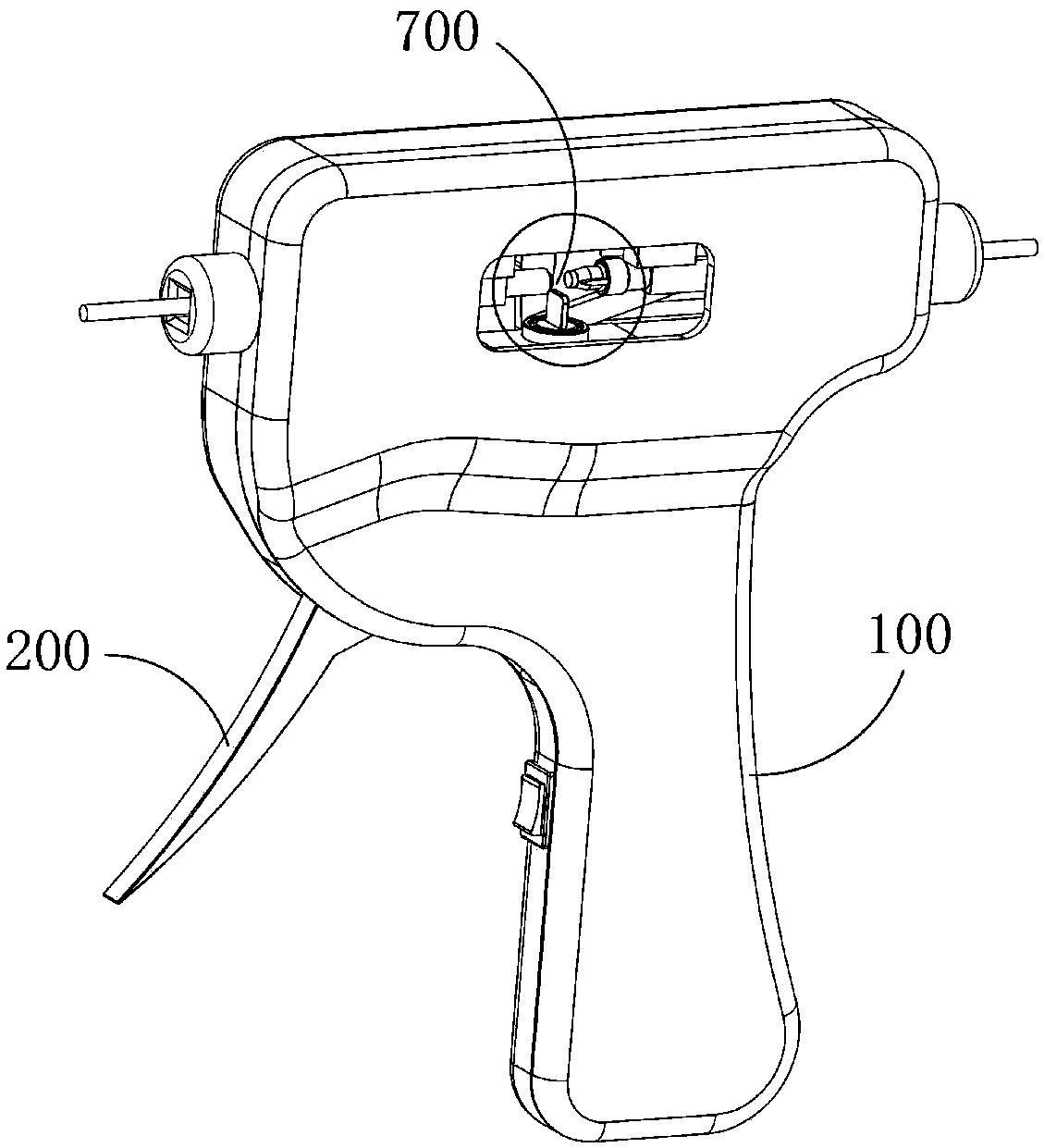

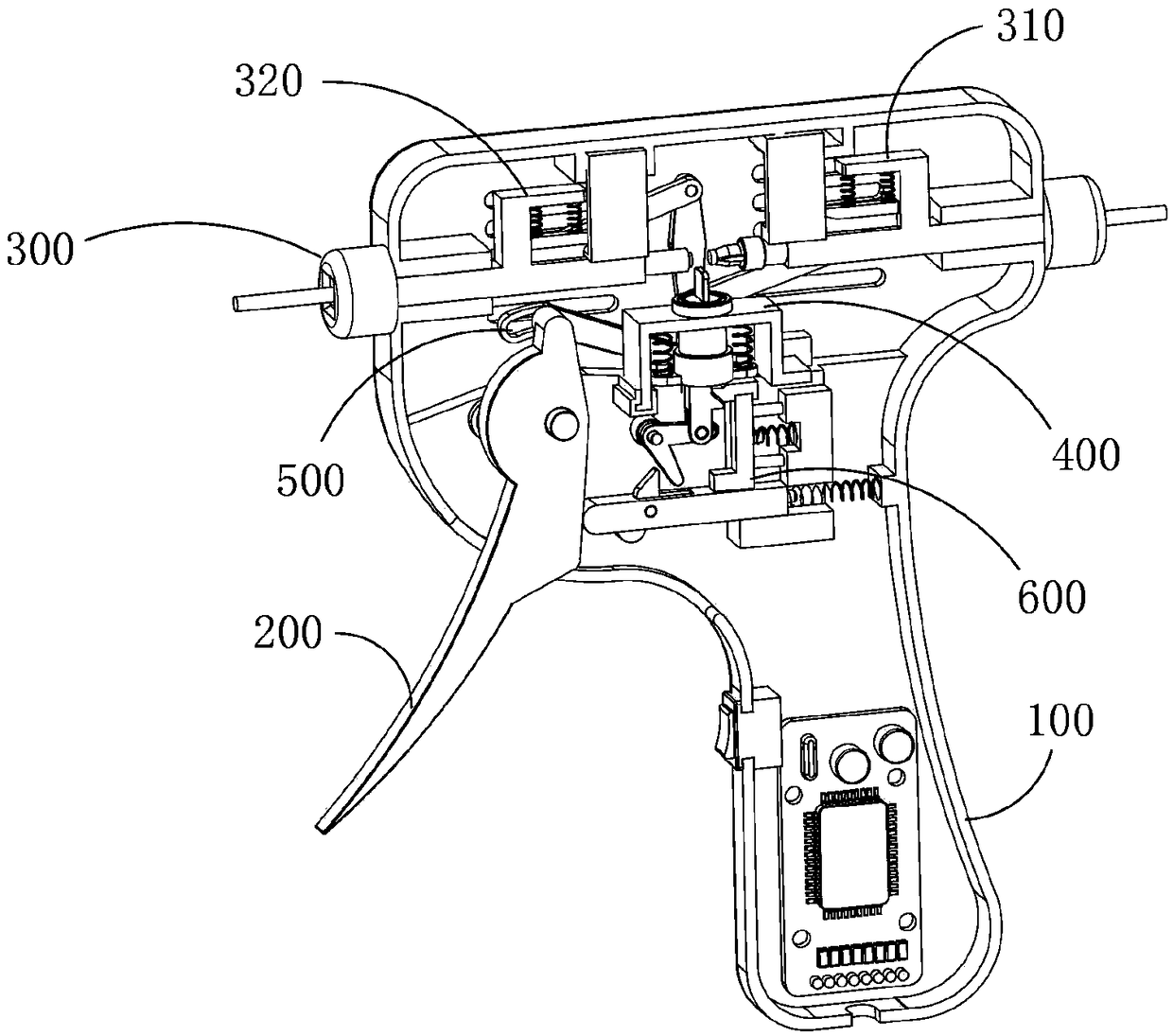

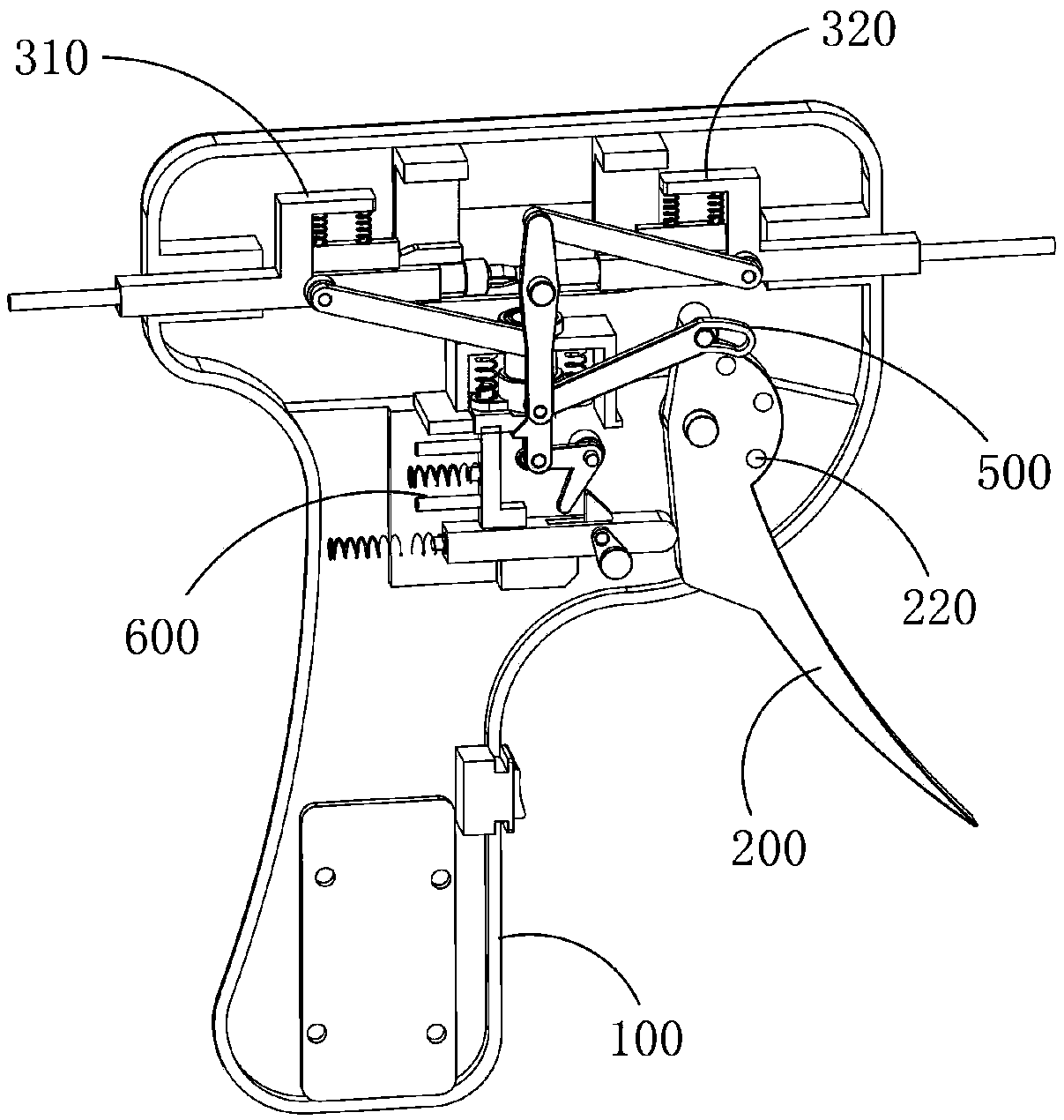

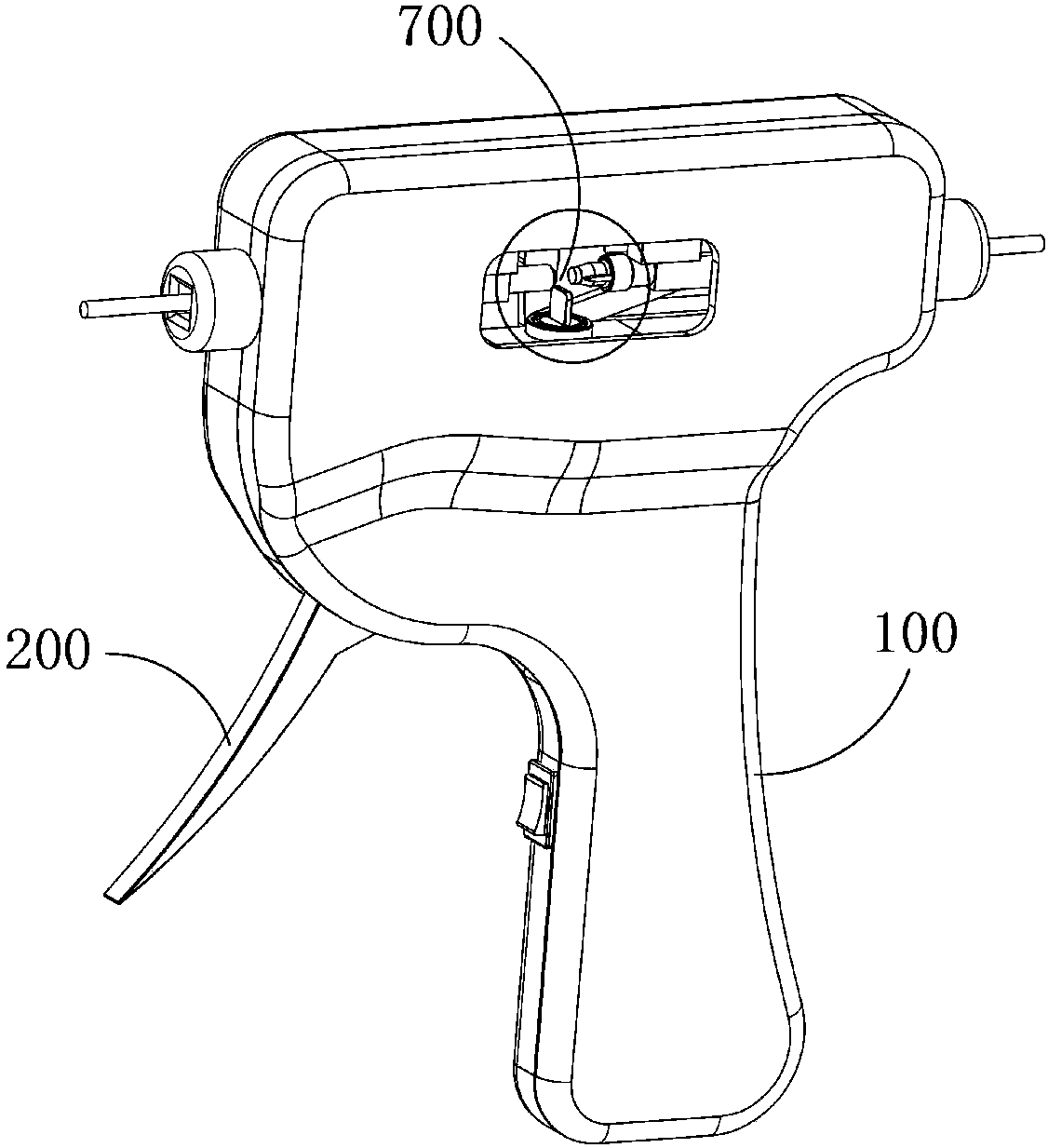

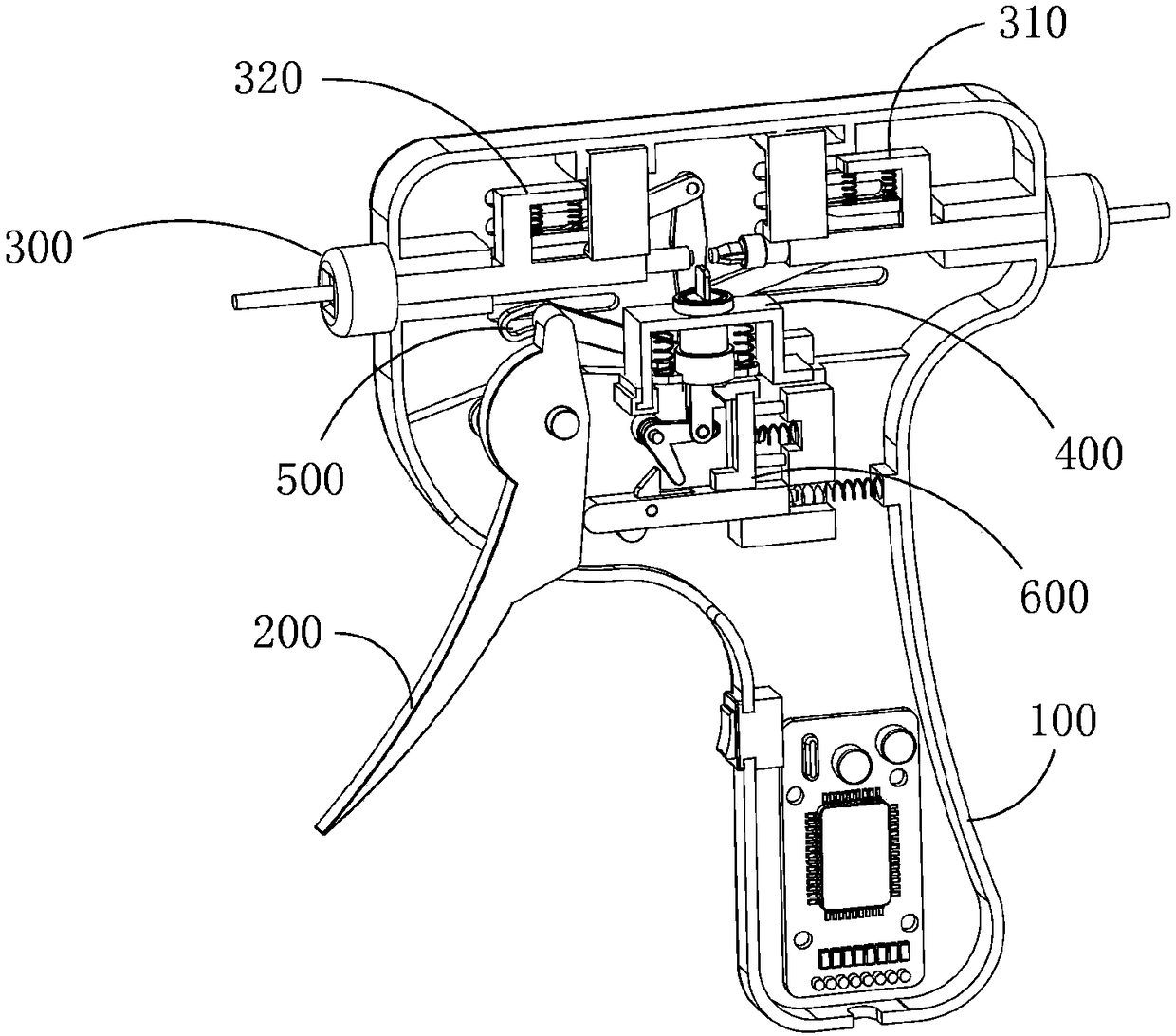

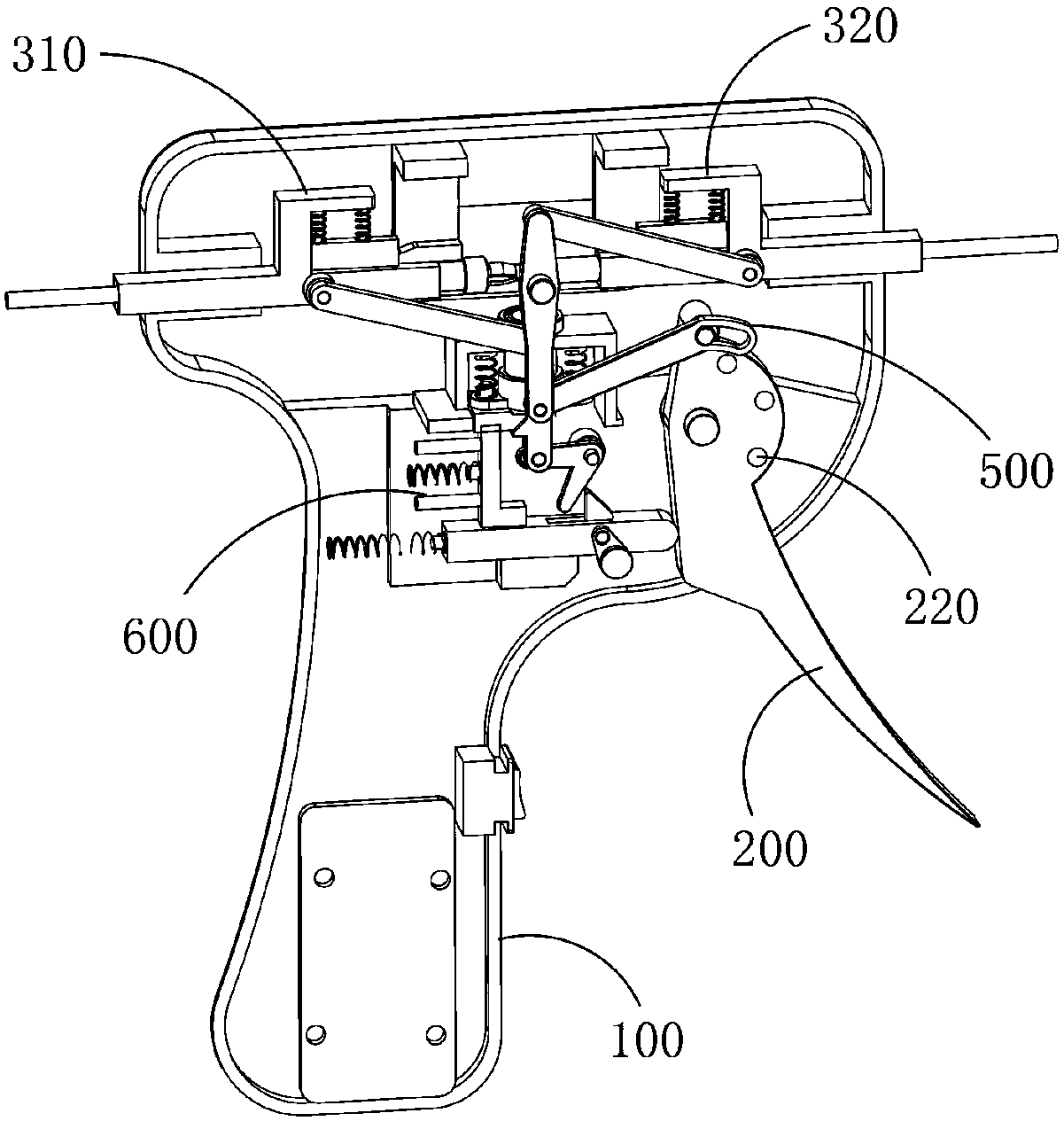

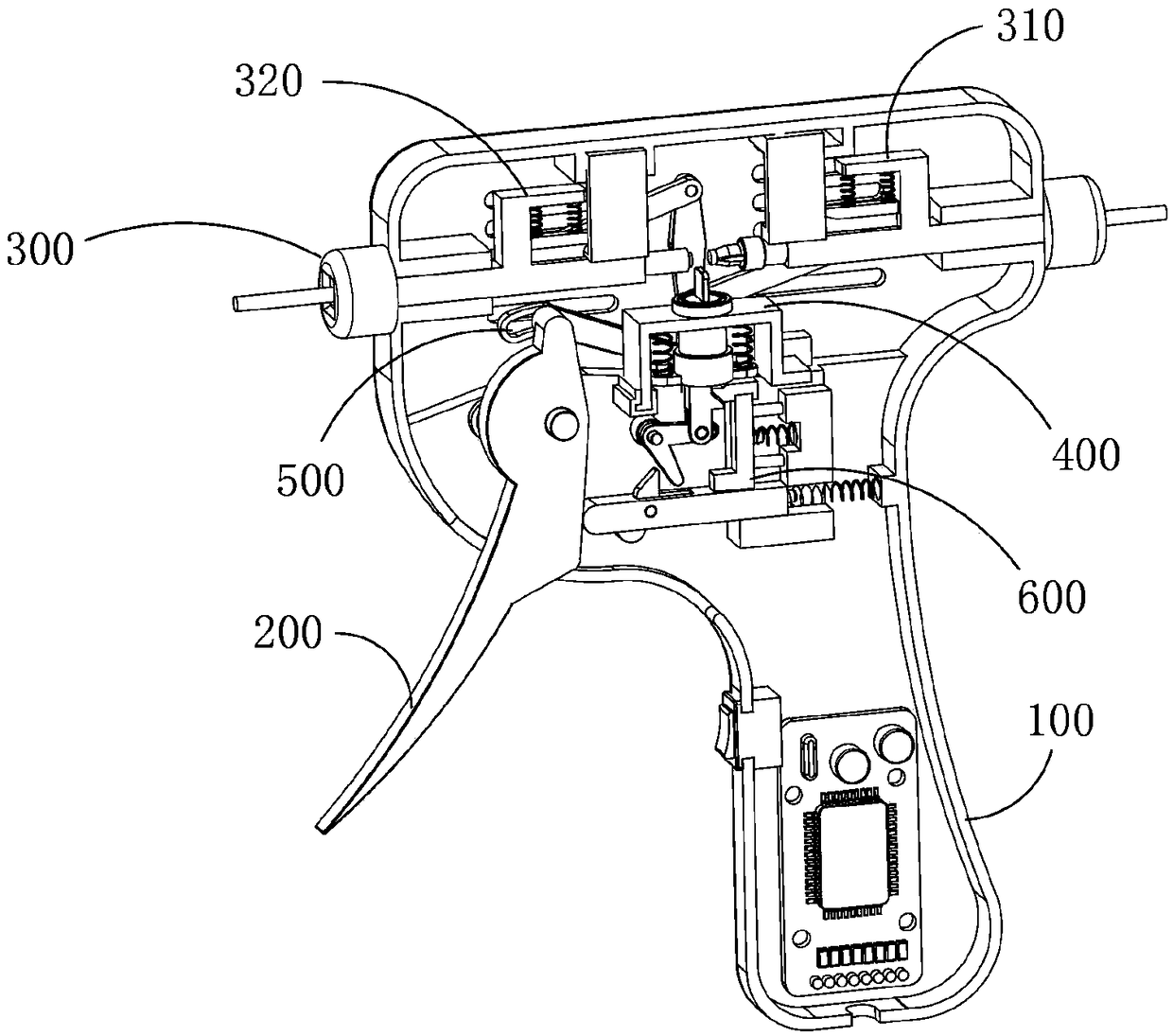

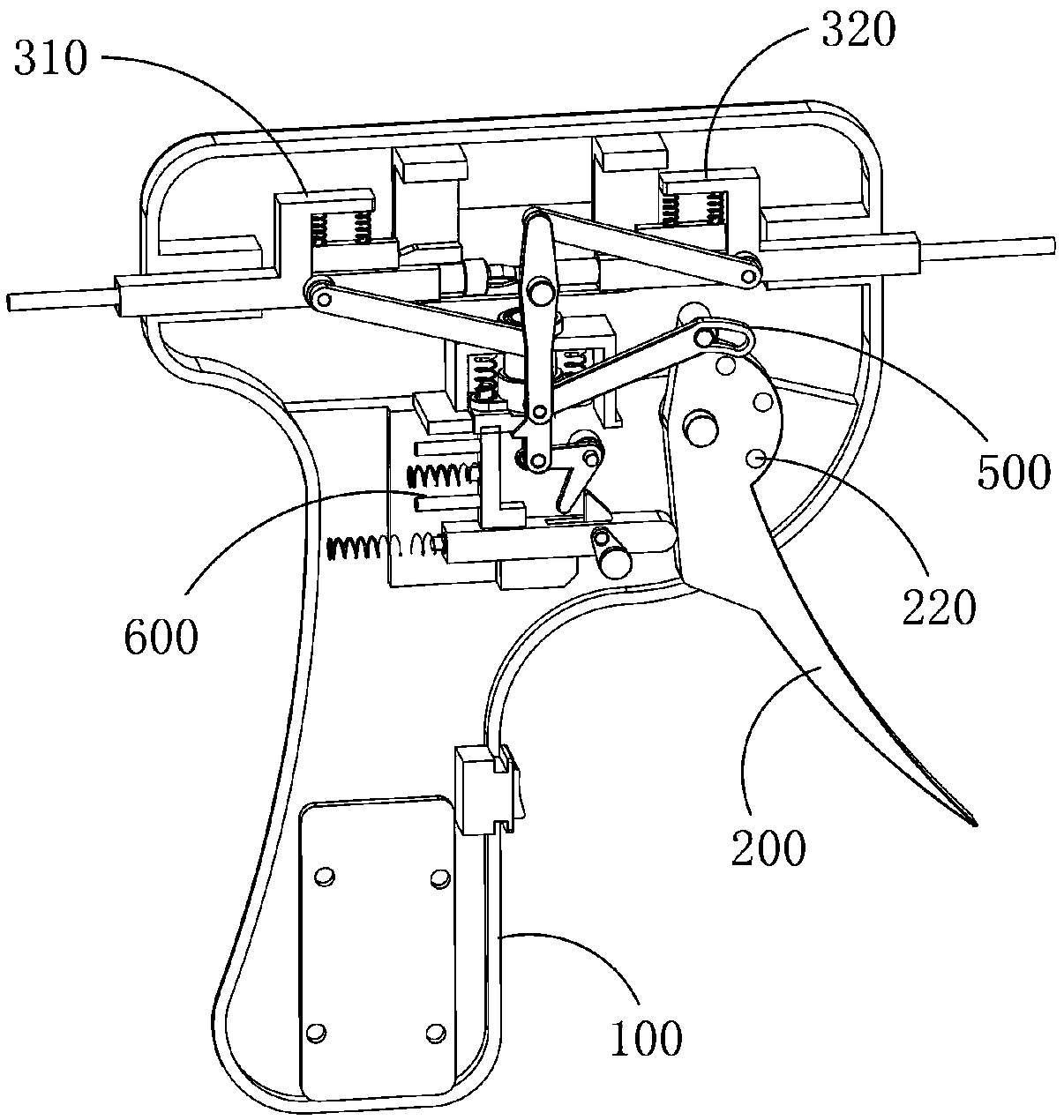

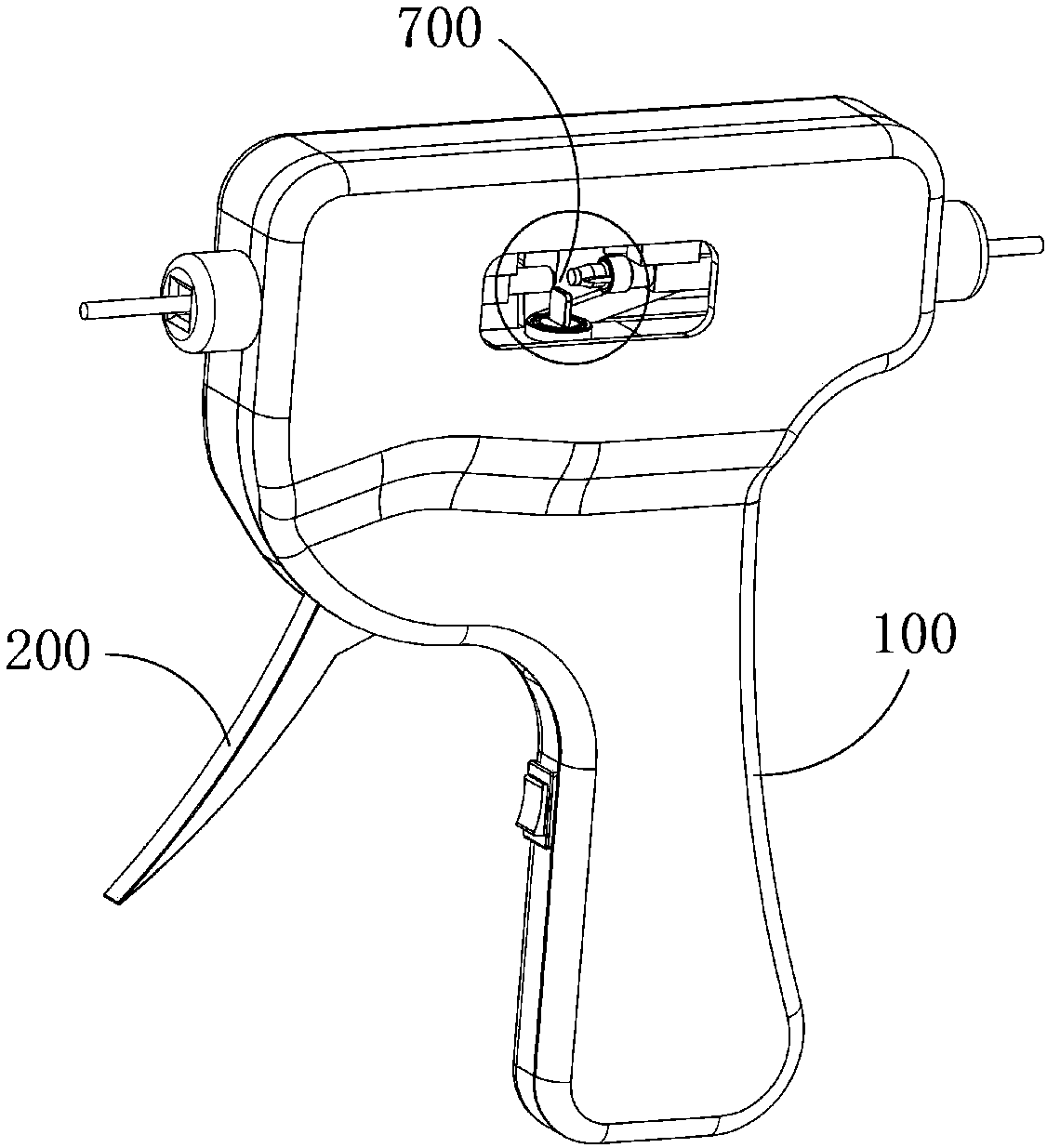

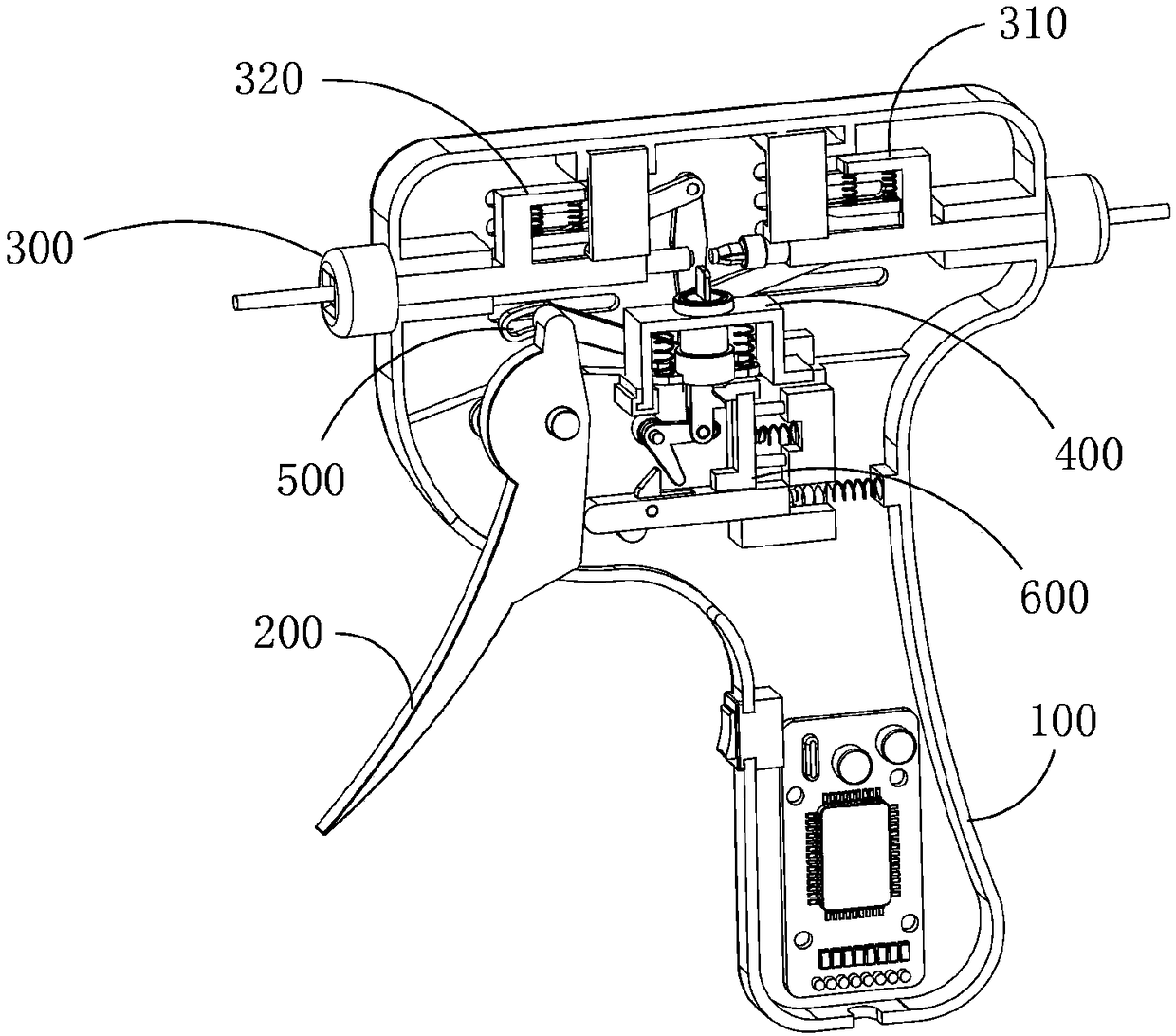

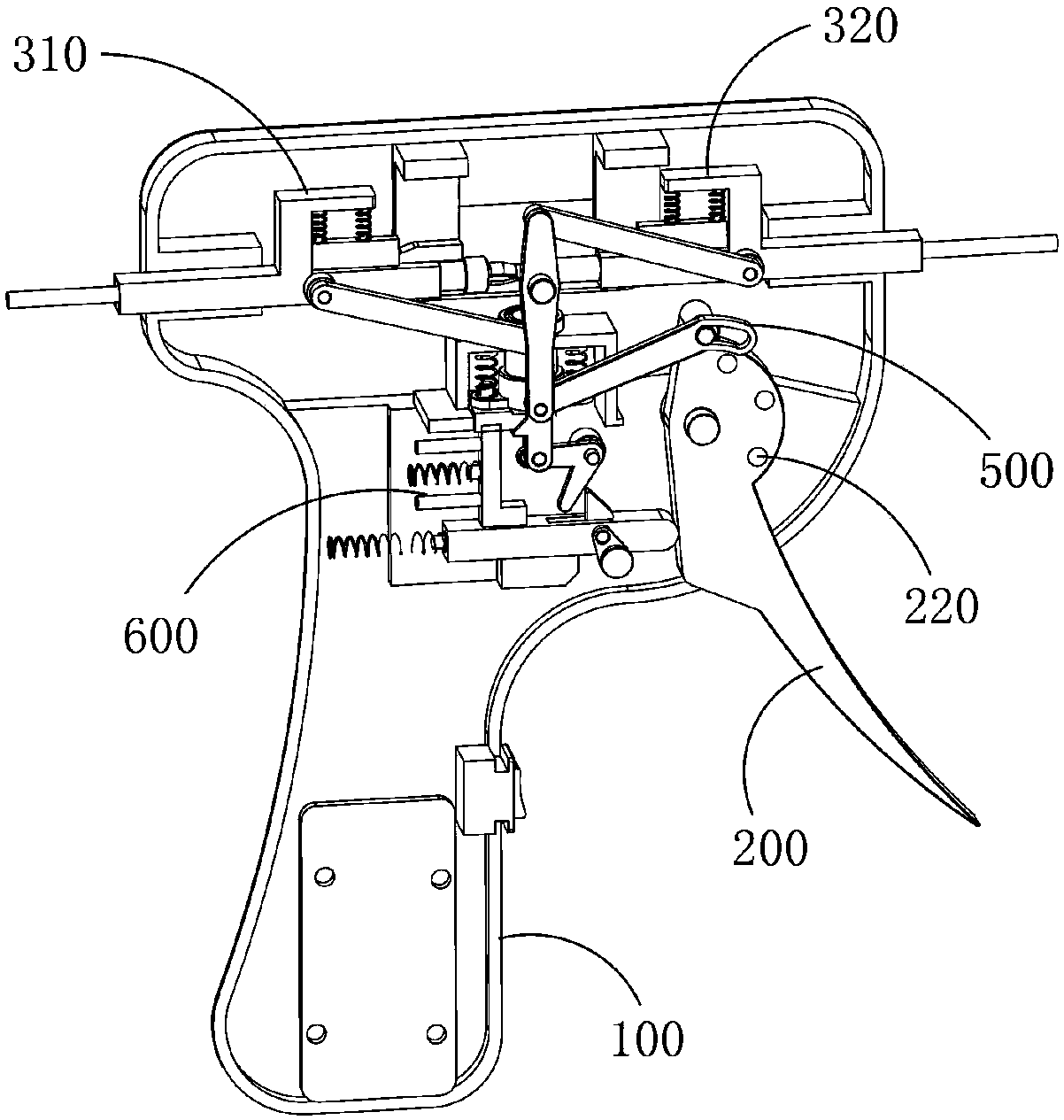

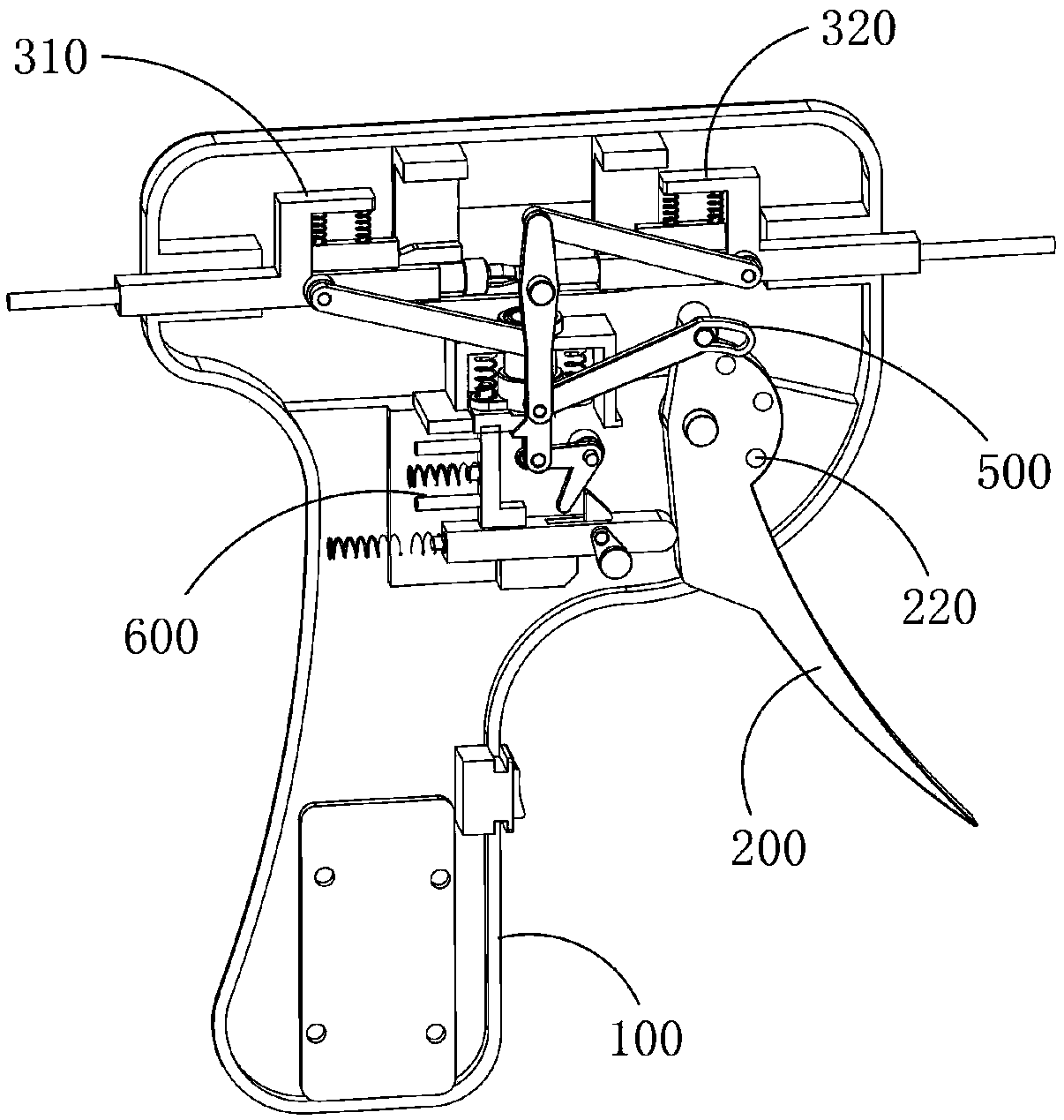

Heat source lifting mechanism for 3D printer line body consumable butt joint

ActiveCN108032513AAchieve recyclingAchieve multi-color printingAdditive manufacturing apparatusAdditive manufacturing with liquidsButt jointEngineering

The invention provides a heat source lifting mechanism for 3D printer line body consumable butt joint. The heat source lifting mechanism comprises a shell. A handle, a heating mechanism and an elevator mechanism are installed inside the shell. The handle can generate pushing force in the moving process. The elevator mechanism receives the pushing force generated in the moving process of the handleand further drives the heating mechanism to ascend or descend under the effect of the pushing force. The heating mechanism is used for providing heat energy required by hot jointing for a hot jointing area. The handle is divided into three parts which include a handle part, a linkage part and a pushing part located between the handle part and the linkage part. The handle is hinged to the shell, and the hinged position of the handle and the shell is located between the linkage part and the pushing part. The core axis of a hinged shaft is perpendicular to conveying trails of consumables conveyed to the hot jointing area. The handle part is located outside the shell. The linkage part and the pushing part are located inside the shell and the pushing part makes contact with the elevator mechanism.

Owner:上海术字信息科技有限公司

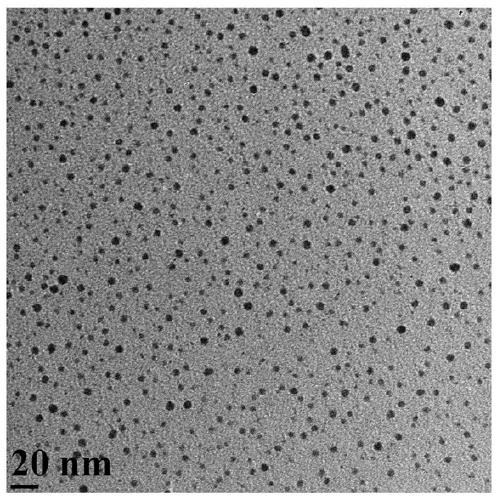

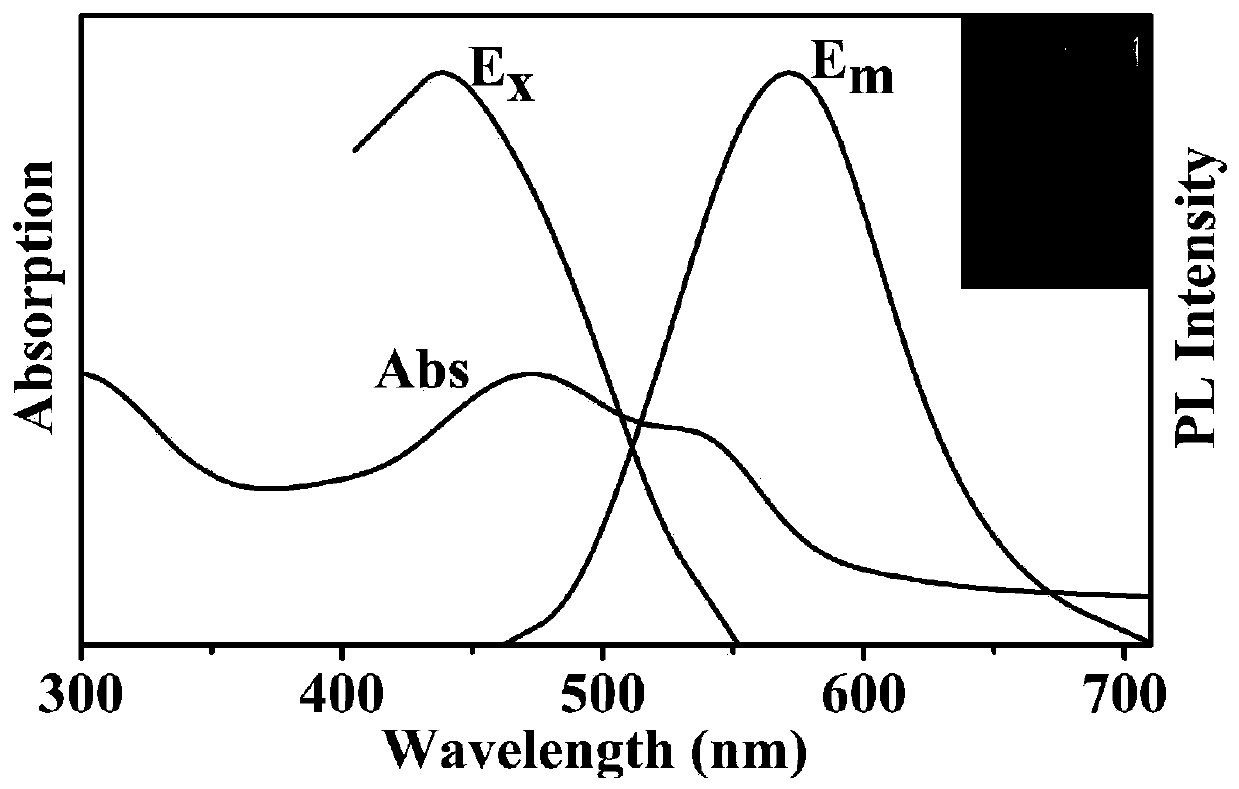

A preparation method of full-color carbon dots for multi-color fluorescent printing and products thereof

ActiveCN108587615BSmall particle sizeImprove stabilityInksNanoopticsColor printingSolvothermal reaction

The invention provides a preparation method and a product of full-color carbon dots for multi-color fluorescent printing. Citric acid is used as a single carbon resource, a nitrogen-containing compound is added, and a solvothermal reaction is carried out for 6-8 hours for obtaining a full-color carbon dot mixture. The fine separation of blue, green, yellow and orange fluorescence carbon dots can be realized through the regulation and control of the volume ratio of methanol to dichloromethane by using a column chromatography method. The obtained carbon dots have excellent water solubility, light stability and luminosity, so that the obtained carbon dots can be used to prepare multi-color fluorescent ink, and multi-color printing is realized. The preparation process provided by the inventionis simple, the repeatability is strong, the reaction condition is mild, and the product has excellent stability and practicability.

Owner:JIANGNAN UNIV

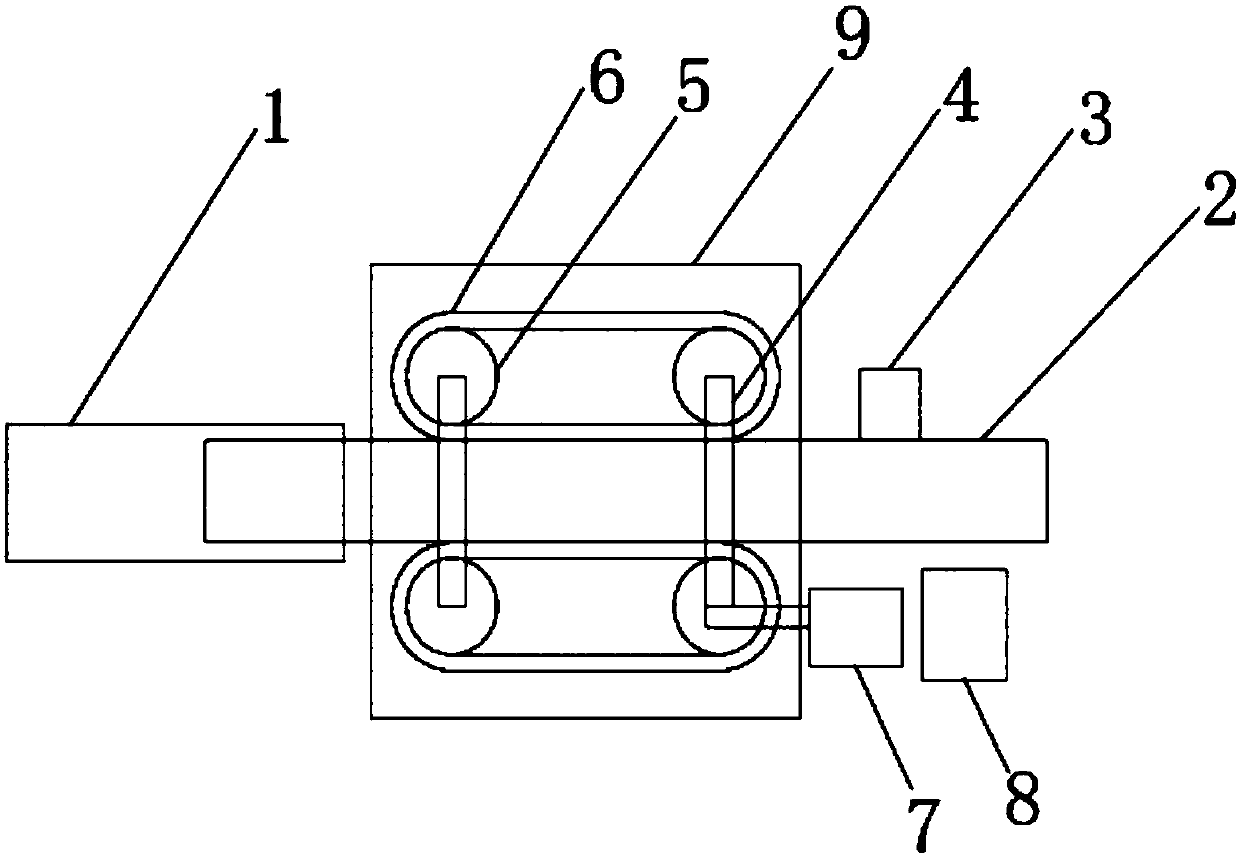

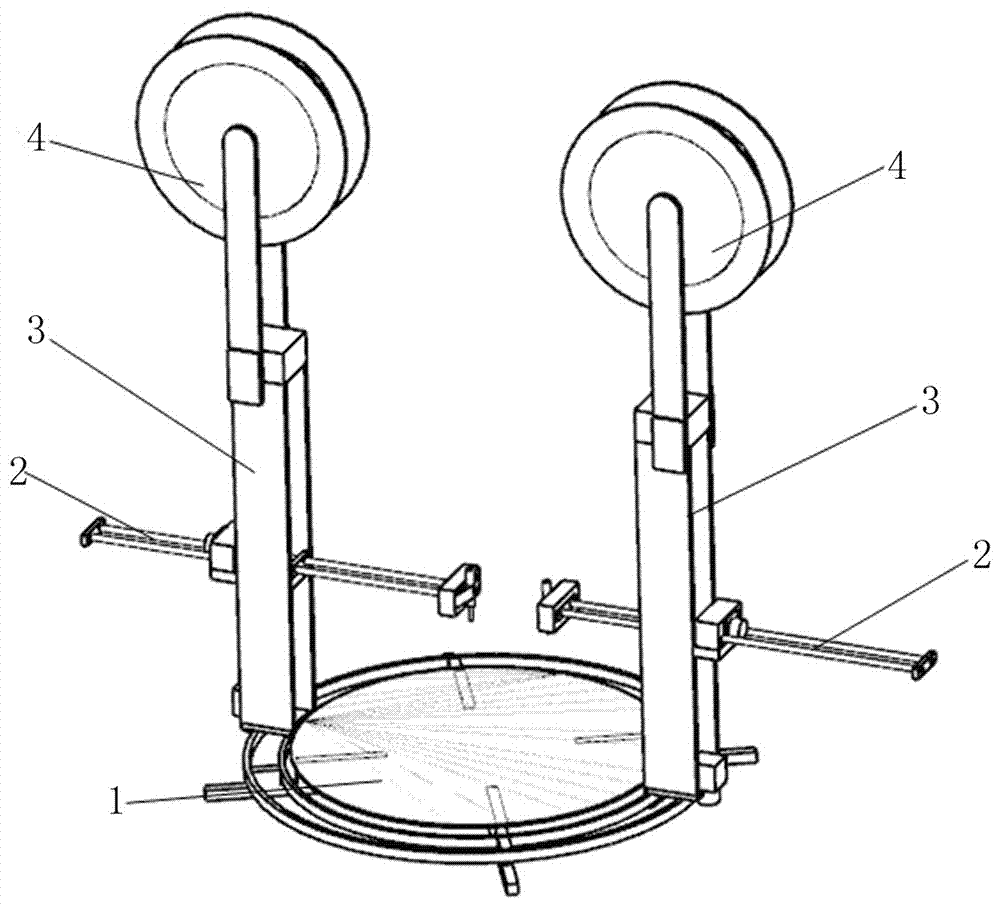

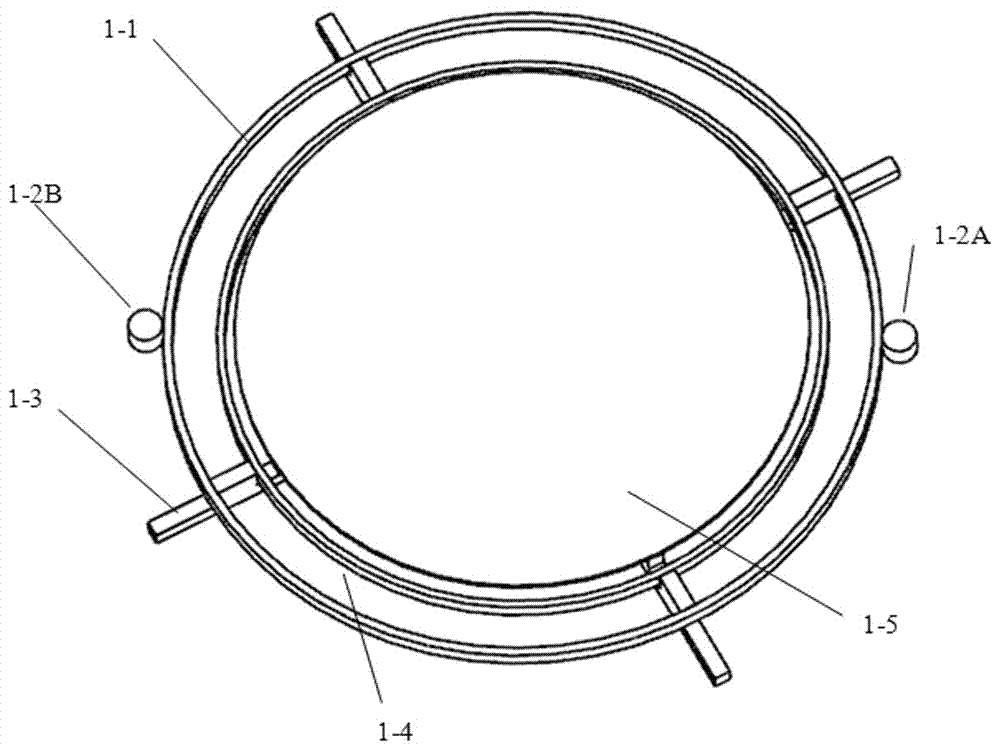

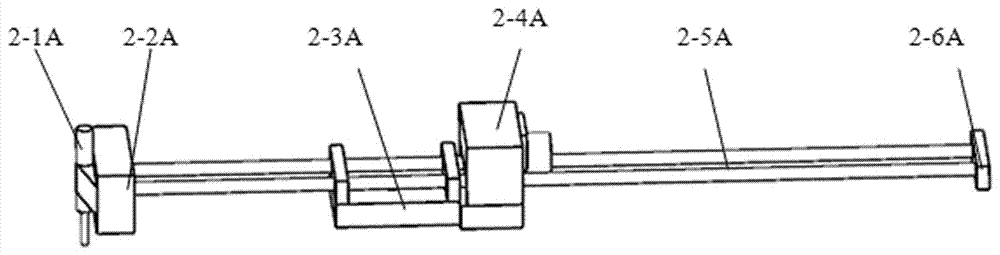

Synchronous wire transport mechanism for docking of 3D printer wire body consumables

ActiveCN108215199BAchieve recyclingAchieve multi-color printingAdditive manufacturing apparatusManufacturing material handlingButt joint3d printer

The invention provides a synchronous wire conveying mechanism for butt joint of wire consumables of a 3D printer. The mechanism comprises a casing, wherein a handle, a wire serial connecting device and a transmission mechanism are mounted in the casing; the wire serial connecting device comprises a first wire serial connecting mechanism and a second wire serial connecting mechanism; a wire consumable to be serially connected is led out of each of the first wire serial connecting mechanism and the second wire serial connecting mechanism, a spacer region between the first wire serial connectingmechanism and the second wire serial connecting mechanism is a thermal joining region; the transmission mechanism receives pushing force generated by handle movement and transmits the pushing force tothe first wire serial connecting mechanism and the second wire serial connecting mechanism; the first wire serial connecting mechanism and the second wire serial connecting mechanism convey the wireconsumables to the thermal joining region under the action of pushing force and complete serial connection in the thermal joining region; the moving state of the wire serial connecting device can be divided into a conveying state of conveying the consumables to the thermal joining region, a melting state when the free ends of the consumables absorb heat a re-conveying state of continuing conveyingthe consumables to the thermal joining region, a serial connecting state of contacting and joining free ends of the consumables, and a flat state of deburring at thermal junctions of the consumables.

Owner:安徽奇点智能科技有限公司

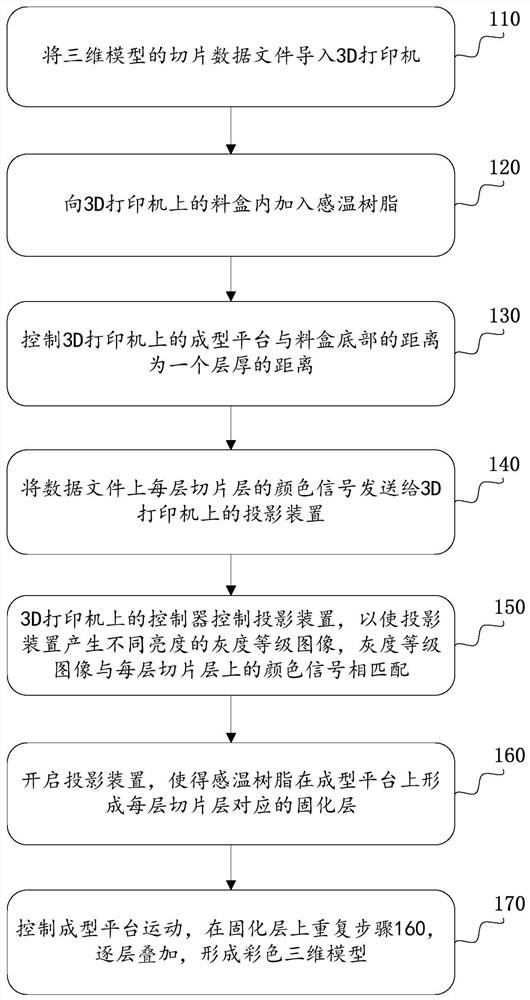

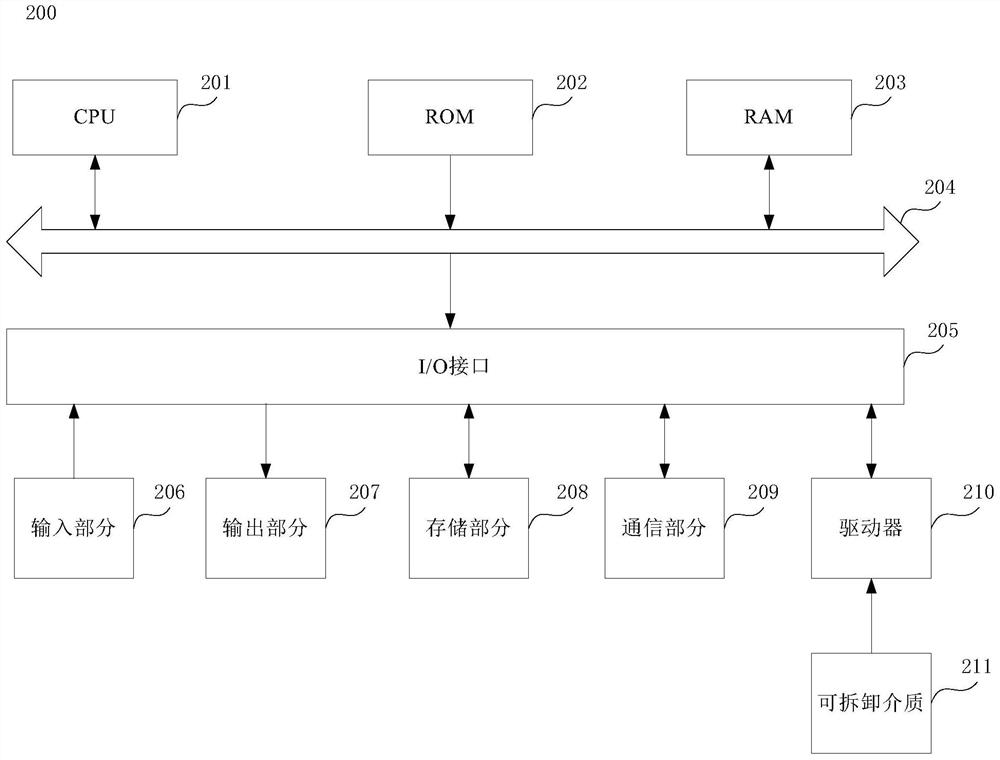

Color-variable photocuring 3D printer and printing method, equipment and storage medium

ActiveCN113400641APrecise color changeAchieve multi-color printingManufacturing platforms/substratesManufacturing enclosuresComputer hardwareComputer printing

The invention relates to a color-variable photocuring 3D printer and printing method, equipment and a storage medium. The printing method comprises the steps that a slice data file of a three-dimensional model is imported into the 3D printer, color signals of slice layers on the data file are sent to a projection device on the 3D printer, a controller on the 3D printer controls the projection device, the projection device is started, therefore temperature sensing resin forms a curing layer corresponding to each slice layer on a forming platform, the forming platform is controlled to move, layer-by-layer superposition is carried out, and a colorful three-dimensional model is formed. According to the scheme, the working temperature during printing is adjusted to be the reference temperature, so that consumable does not change color at the reference temperature; and the resin shows different colors when bearing different temperatures, so that the gray scale of pixel points only needs to be controlled through a DLP projector, each pixel point can be irradiated with different energy, the preset color during slicing can be obtained through precise color changing of different pixel points, and multi-color printing is achieved.

Owner:SHENZHEN CREALITY 3D TECH CO LTD

Three-color feeding device of 3D printing machine head

The invention provides a three-color feeding device of a 3D printing machine head. The three-color feeding device comprises a feeding detector, a feeding controller and a transmission mechanism, wherein the feeding device is arranged at an inlet of a feeding pipeline port and comprises transferring belts, rotating shafts and a coupling mechanism; the detector is arranged at the front part of the transferring belt for entering of materials; the two rotating shafts are coupled by the coupling mechanism; the rotating shaft of one transferring belt is coupled with the output end of the motor; and the feeding controller controls the motor to rotate and drive the rotating shafts to rotate, so that the belts are driven to feed the materials into a feeding pipeline. The three-color feeding device provided by the invention has the advantages that the operation is simple, the implementation is easy and the problem of feeding in the printing process can be effectively solved.

Owner:XIAN SHANGSHANG ELECTROMECHANICAL

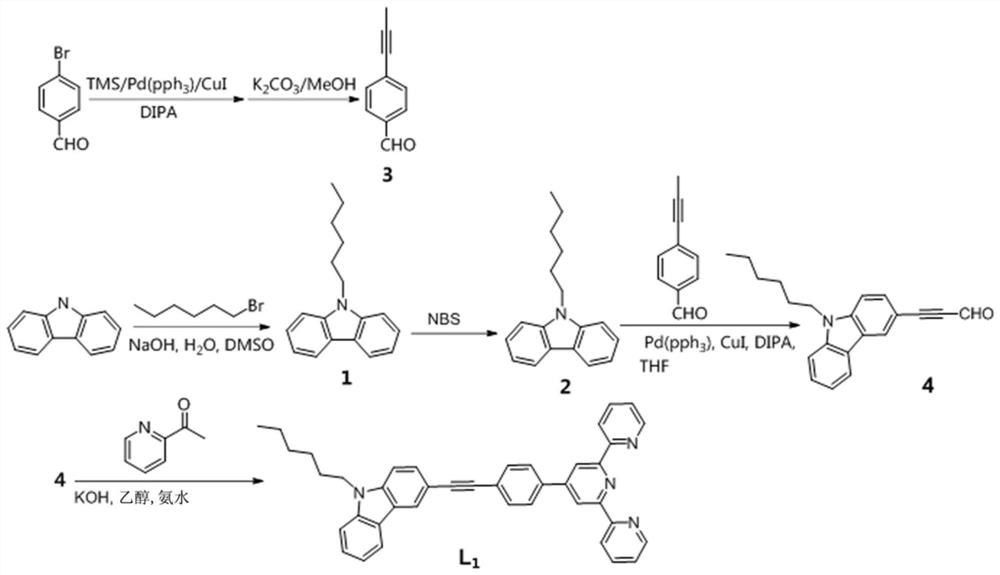

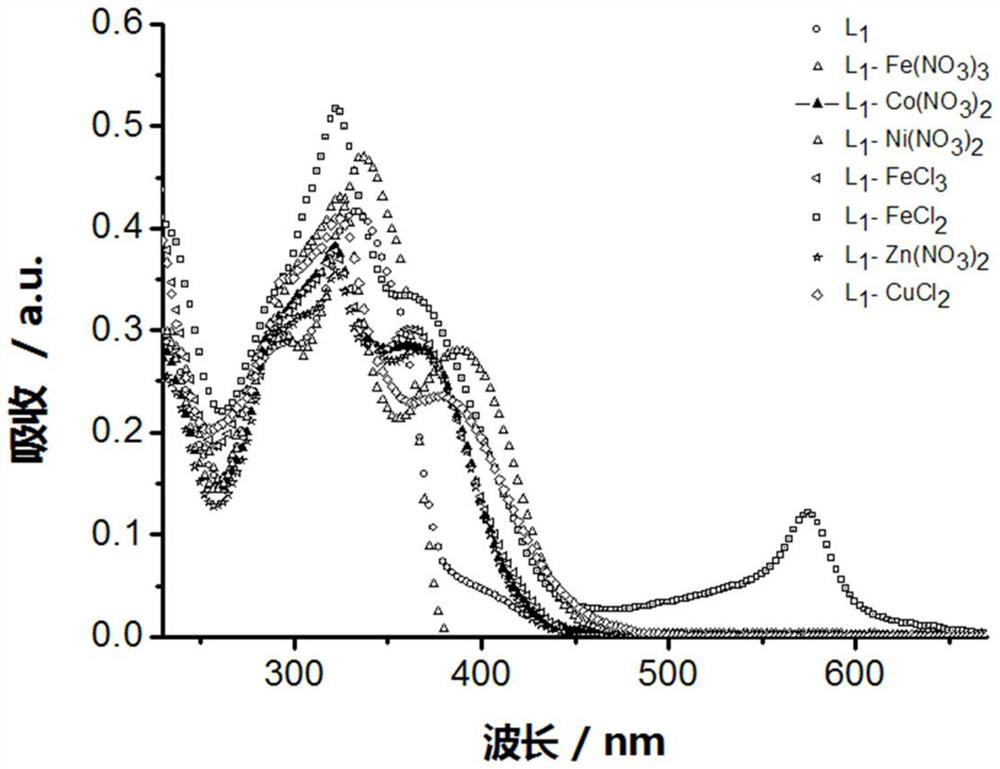

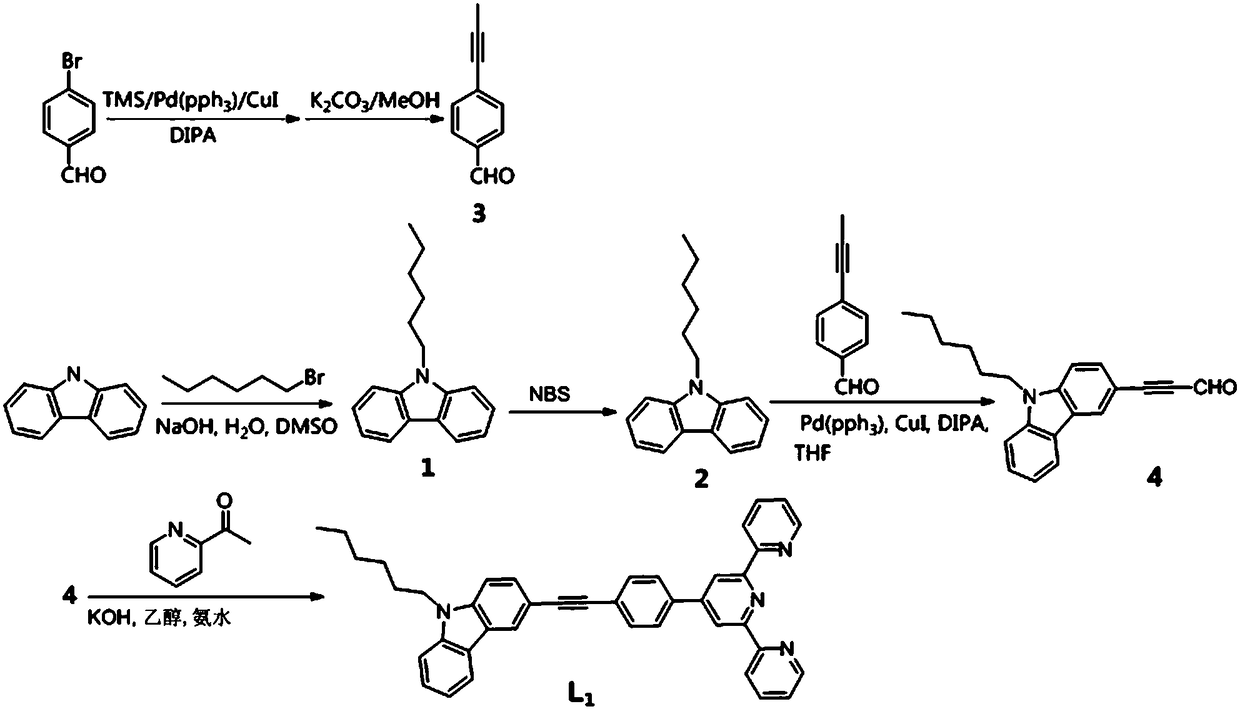

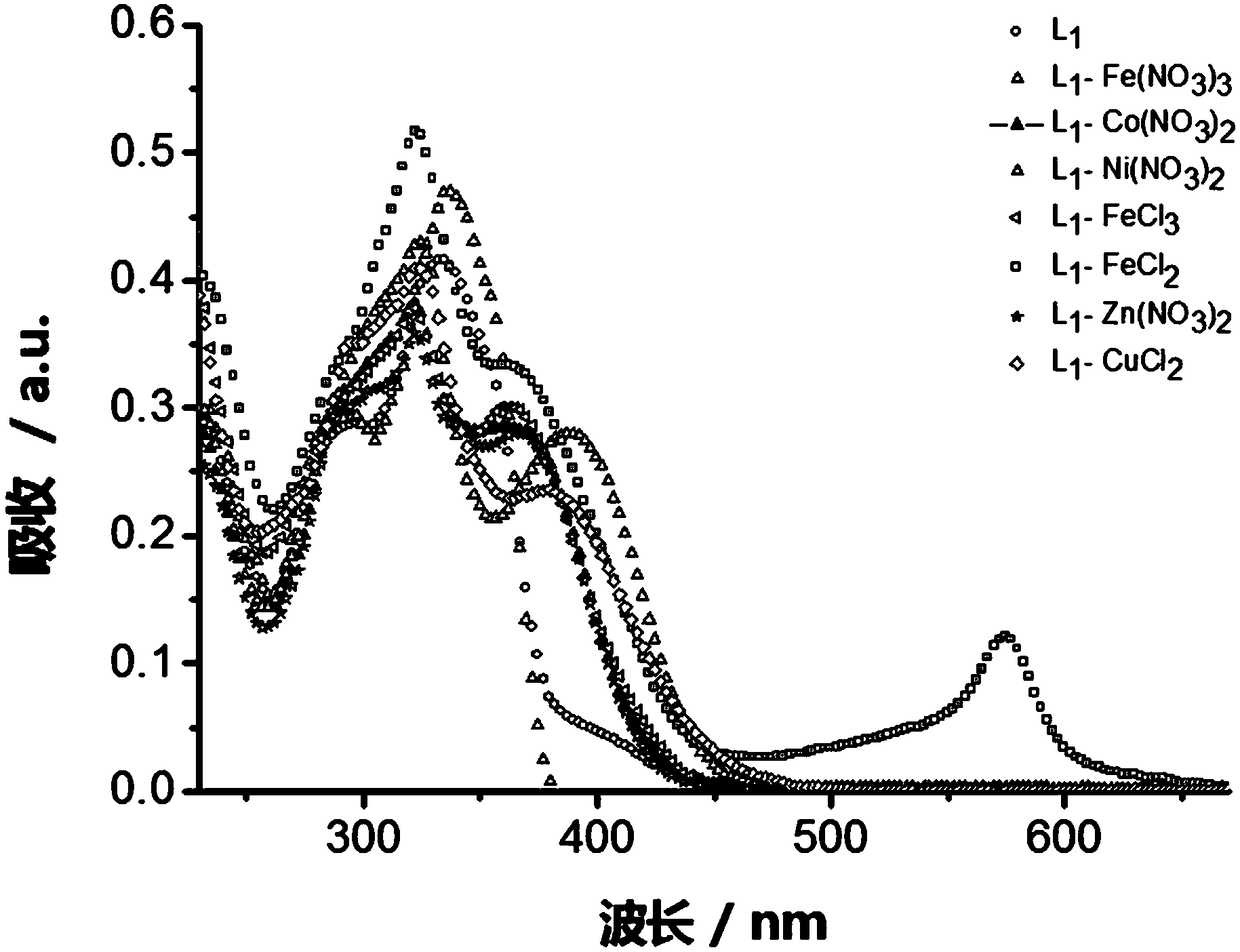

Preparation method and application of a kind of terpyridine compound and metal complex thereof

The invention discloses preparation methods and applications for a terpyridine compound and a terpyridine metal complex. The preparation method for the terpyridine compound comprises the following steps: subjecting carbazole, bromohexane and a sodium hydroxide aqueous solution with the concentration of 50% to a substitution reaction in a DMSO solvent system at 50 DEG C; subjecting a compound 1 andNBS to a regioselective bromination reaction in a dichloromethane solvent system at 25 DEG C; subjecting bromobenzaldehyde, trimethylsilylacetylene, cuprous iodide and (beta-4)-platinum to a Sonogashira coupling reaction in a nitrogen gas environment and a dry diisopropylamine solution system at 80 DEG C; subjecting a compound 2, a compound 3, cuprous iodide and (beta-4)-platinum to a Sonogashiracoupling reaction in a nitrogen gas environment and a dry diisopropylamine and tetrahydrofuran solution system; and subjecting an alkyne-containing compound 4, diacylpyridine and potassium hydroxideto a Krohnke intermediate cyclization process reaction in an ethanol solvent system at 25 DEG C. The preparation method for the terpyridine compound provided by the invention has simple synthetic steps and mild conditions, and realizes multi-color printing and encrypted printing under visible sunlight.

Owner:NANJING UNIV OF POSTS & TELECOMM

Multi-purpose seal type print head

ActiveCN108556488AReduce use costAchieve multi-color printingInking apparatusOther printing apparatusLarge sizeMonochrome

The invention relates to the technical field of a print head, and discloses a multi-purpose seal needle type print head. The multi-purpose seal needle type print head comprises a machine body and a plurality of print head parts, wherein the print head parts are arranged at the lower end part of the machine body side by side, and a needle ejecting plate is arranged at the lower end part of each print head part. A plurality of print needles are arranged in each print head part, and the upper end of each print needle extends into the machine body. A driving structure used for driving the print needles to move up and down is arranged in the machine body, the upper end of each print needle is connected with the driving structure, and the lower end of each print needle movably penetrates in eachneedle ejecting plate. A gap is formed between the print needles of the adjacent print head parts. A plurality of print head bodies are arranged at the lower end part of the machine body side by side, and a gap is formed between the adjacent print head bodies. The same one print head body realizes multicolor printing on a color zone, and monochrome printing can be realized through multiple printhead parts. The multi-purpose seal needle type print head realizes a one-body multi-purpose effect, does not need to add an inner structure, solves the problems of complex structure and large size, and meanwhile is compatible with most needle printers on the market today.

Owner:SHENZHEN PU YING INNOVATION TECH CORP LTD

Preparation methods and applications for terpyridine compound and terpyridine metal complex

The invention discloses preparation methods and applications for a terpyridine compound and a terpyridine metal complex. The preparation method for the terpyridine compound comprises the following steps: subjecting carbazole, bromohexane and a sodium hydroxide aqueous solution with the concentration of 50% to a substitution reaction in a DMSO solvent system at 50 DEG C; subjecting a compound 1 andNBS to a regioselective bromination reaction in a dichloromethane solvent system at 25 DEG C; subjecting bromobenzaldehyde, trimethylsilylacetylene, cuprous iodide and (beta-4)-platinum to a Sonogashira coupling reaction in a nitrogen gas environment and a dry diisopropylamine solution system at 80 DEG C; subjecting a compound 2, a compound 3, cuprous iodide and (beta-4)-platinum to a Sonogashiracoupling reaction in a nitrogen gas environment and a dry diisopropylamine and tetrahydrofuran solution system; and subjecting an alkyne-containing compound 4, diacylpyridine and potassium hydroxideto a Krohnke intermediate cyclization process reaction in an ethanol solvent system at 25 DEG C. The preparation method for the terpyridine compound provided by the invention has simple synthetic steps and mild conditions, and realizes multi-color printing and encrypted printing under visible sunlight.

Owner:NANJING UNIV OF POSTS & TELECOMM

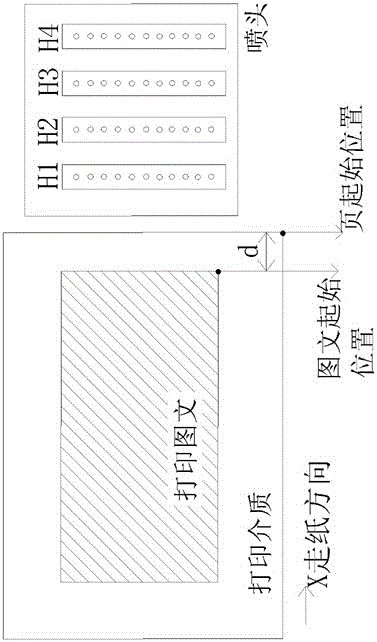

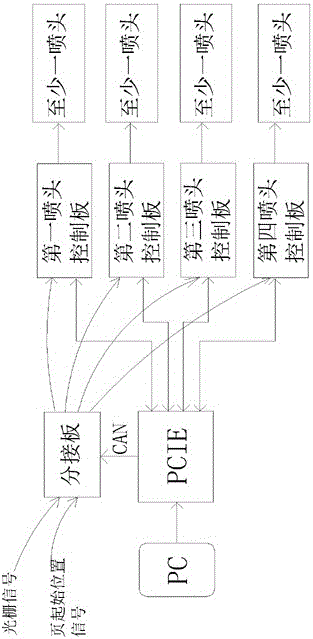

An inkjet printer signal synchronous breakout board and signal transmission method

ActiveCN104057731BIncrease print widthIncrease printing speedOther printing apparatusImage resolutionColor printing

The invention discloses an inkjet printer signal synchronous splitter board and a signal transmission method, which are characterized in that one end is provided with a receiving port to receive a detection signal, and the other end is provided with an output port connected to a nozzle control board to output a detection signal, and the signal synchronous splitter board An FPGA is set inside, and the FPGA splits the received detection signal into at least two channels of identical detection signals at the same time, and the output port transmits the split at least two channel detection signals to at least two nozzle control boards synchronously and in parallel for Control nozzle printing. The signal synchronization breakout board divides the detection signal into multi-channel signals, and can connect multiple printhead control boards at the same time, thereby controlling more printheads for inkjet printing. Arranging multiple printheads in different ways can increase the printing width and printing speed , Enhance the printing resolution or achieve multi-color printing, and at the same time make the control boards of each nozzle receive signals synchronously, avoiding the printing lag of a certain nozzle caused by signal asynchrony, and avoid affecting the quality of inkjet printing.

Owner:BEIJING MEIKEYI

Seamless heat-bonding method for 3D printer consumables

ActiveCN107901402BAchieve recyclingAchieve multi-color printingAdditive manufacturing apparatus3D object support structuresEngineering3d printer

The invention discloses a 3D printer consumable seamless hot joining method. The method comprises the steps that S1, a heating mechanism arranged on a supporting frame moves towards a hot joining zone; S2, wire consumables are conveyed correspondingly to move towards the hot joining zone through a first threading mechanism and a second threading mechanism of the supporting frame; S3, a power supply part of the heating mechanism drives a heat source body to move downwards in the vertical direction and moves away from the hot joining zone; S4, the first threading mechanism and the second threading mechanism continue conveying the wire consumables to the center of the hot joining zone, and the free ends of the two wire consumables are connected; S5, after hot joining of the S4 is completed, still standing is conducted for certain time; and S6, after still standing is completed, a wire consumable of a series structure is conveyed out by the first threading mechanism and the second threading mechanism in the direction from the first threading mechanism to the second threading mechanism.

Owner:天长市金凤电子有限公司

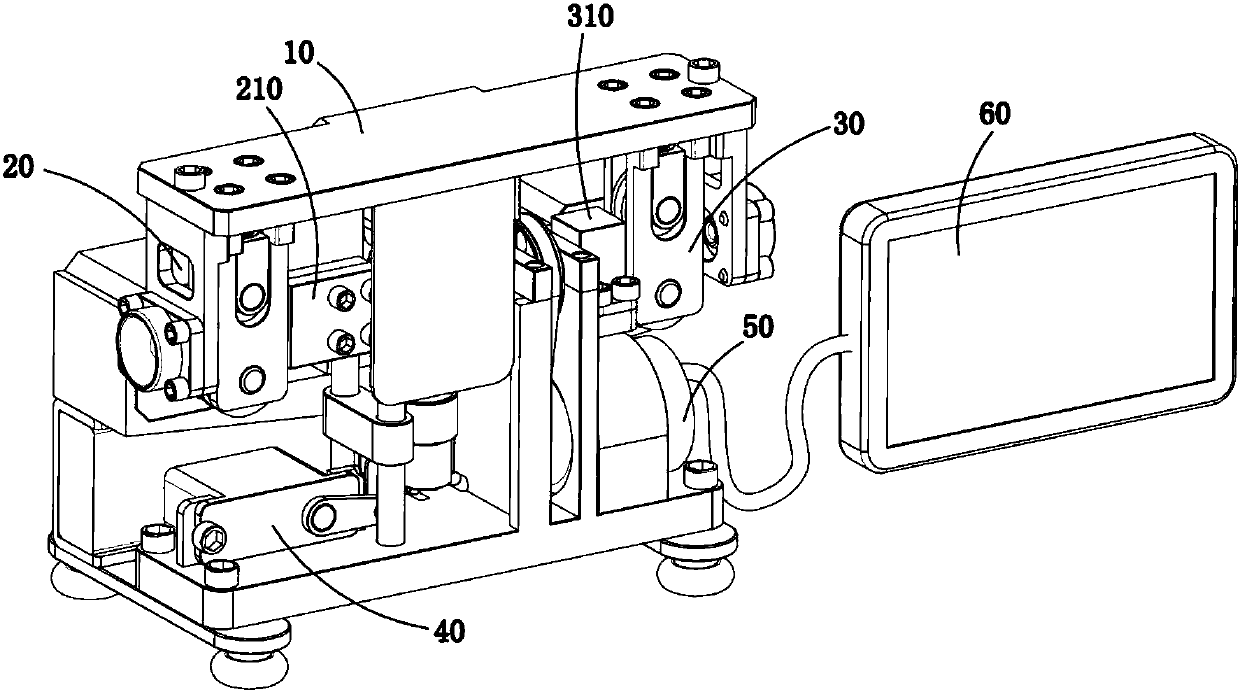

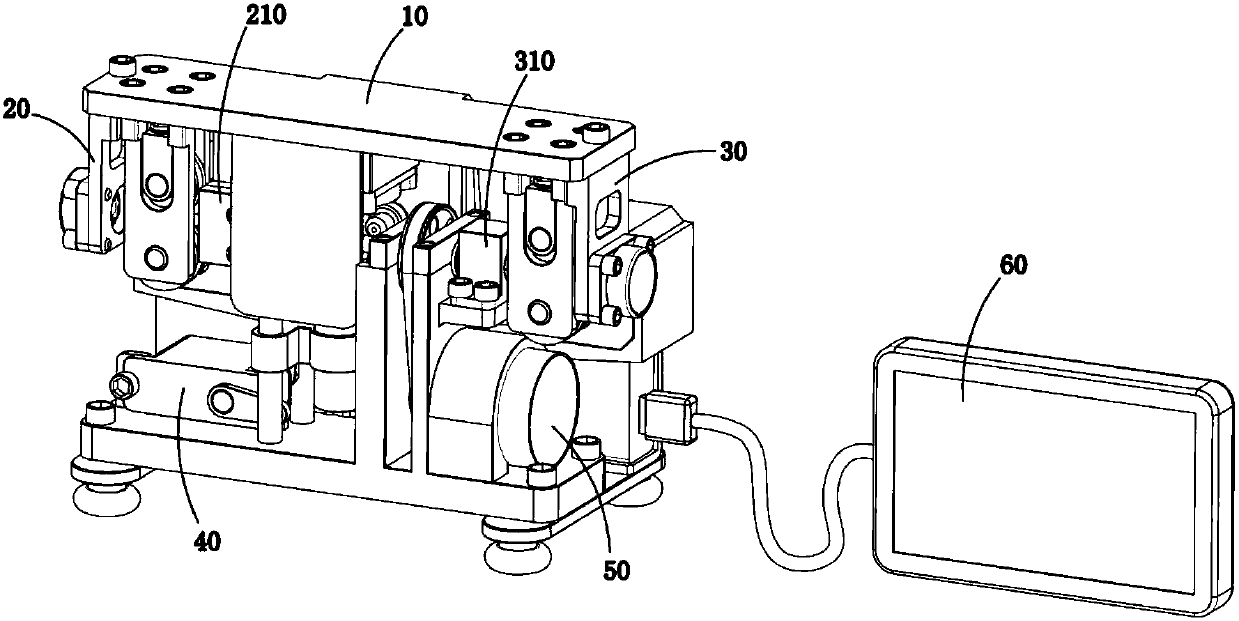

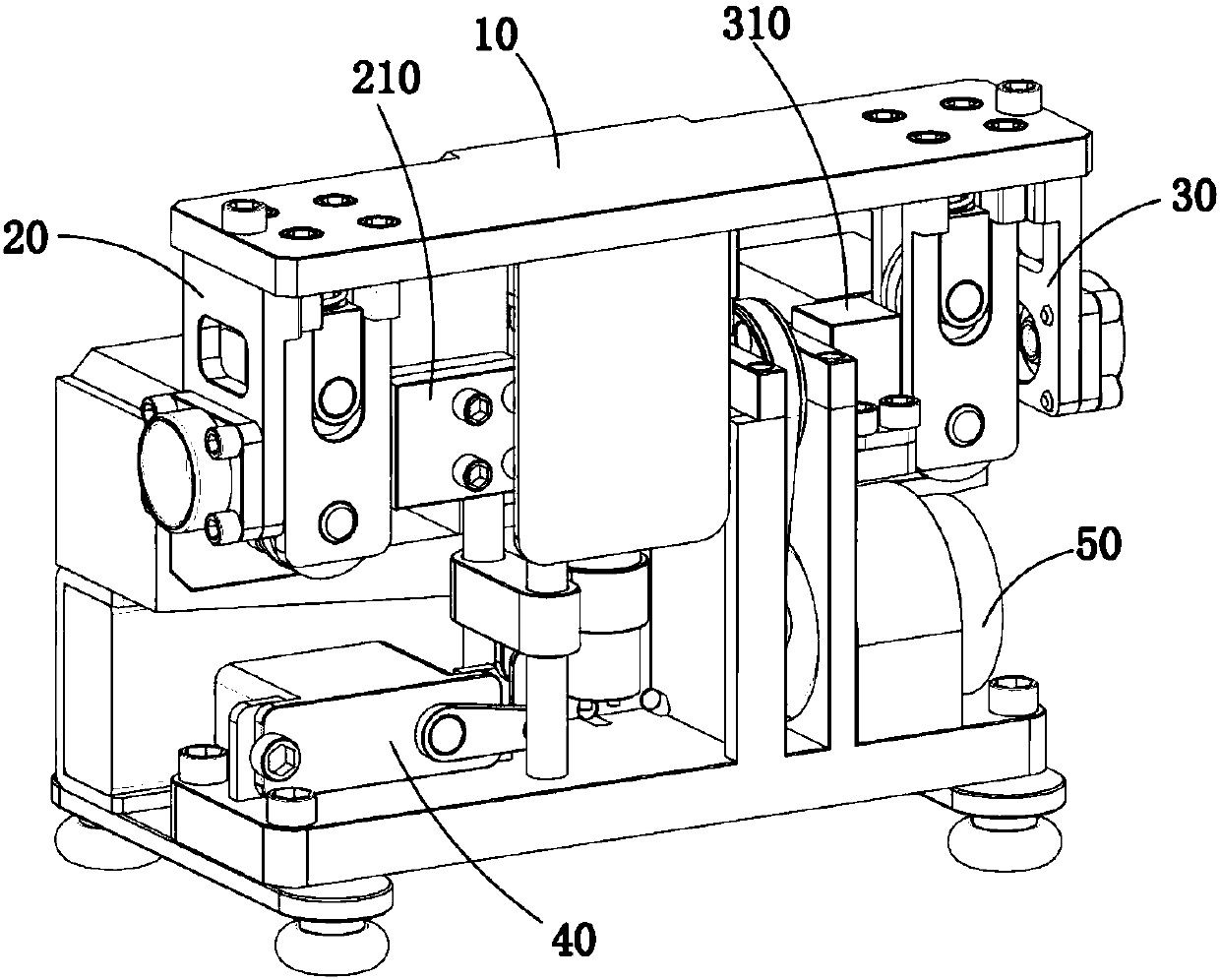

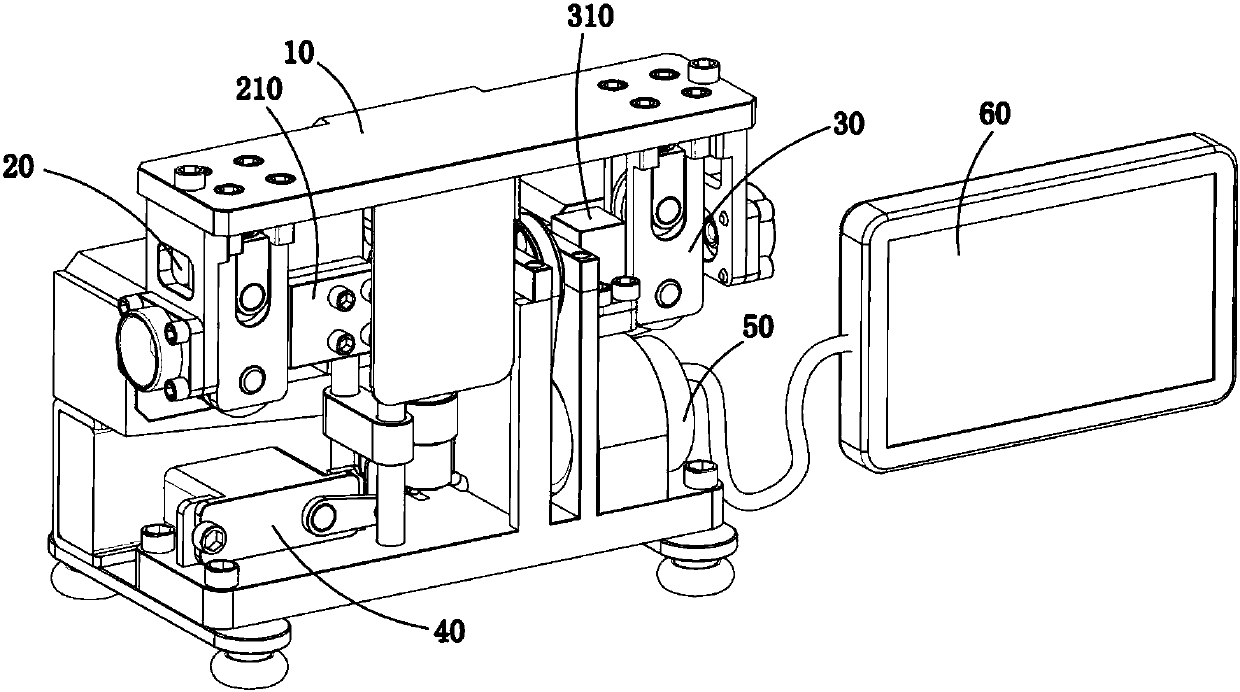

Serial connection equipment for 3d printer consumables

ActiveCN107856308BAchieve recyclingAchieve multi-color printingManufacturing driving meansManufacturing heating elementsColor printingEngineering

The invention discloses tandem connection equipment of 3D printer consumables. The tandem connection equipment comprises a supporting frame, wherein a first threading mechanism and a second threadingmechanism are mounted on the supporting frame; the first threading mechanism and the second threading mechanism respectively lead a strand of wire consumables to be subjected to tandem connection; a spacer region between the first threading mechanism and the second threading mechanism is a hot connection region; the first threading mechanism and the second threading mechanism can convey the wire consumables to the hot connection region, and complete tandem connection in the hot connection region; and the first threading mechanism and the second threading mechanism can convey the wire consumables subjected to the hot connection towards the outside along a direction from the first threading mechanism to the second threading mechanism. The tandem connection equipment realizes recycling of residual or redundant 3D printer consumables; furthermore, by the adoption of the technical scheme provided by the invention, multi-color printing of a common 3D printer can be also realized; and the problem of single color of a pattern printed by the existing common 3D printer is solved.

Owner:LUAN YONGZHEN GRIZZLY ELECTRICAL & MECHANICAL TECH CO LTD

A 3D printing system for array forming

ActiveCN105500714BImprove printing efficiencyAchieve multi-color printing3D object support structuresApplying layer meansGear wheelDrive motor

Owner:WUXI VOCATIONAL & TECHN COLLEGE

Seamless cascading method for 3D printer filament consumables

The invention discloses a seamless cascading method for 3D printer filament consumables. The method comprises steps as follows: a handle is moved, a push part of the handle pushes a pushing componentto move, the pushing component moves and enables a moving component to move, and the moving component moves and pulls a heating mechanism to move towards a heat joining region; when the heating mechanism is located in the heat joining region, a fixing component locks and fixes the heating mechanism, besides, a linkage part of the handle drives the driving mechanism to move and drives a filament cascading device to move to convey two strands of to-be-cascaded consumables to the heat joining region, and free ends of the consumables are contacted with the heating mechanism and absorb heat to be molten; the push part of the handle pushes the pushing component to move continuously, the pushing component moves and pushes the fixing component to move, so that the fixing component removes fixing restriction to the heating mechanism, the heating mechanism is away from the heat joining region, and the linkage part of the handle continues to move and enables the free ends of the two strands of consumables to be cascaded; force is continuously applied to the handle, a flattening mechanism perform deburring treatment on a heat joint point of the consumables; the consumables with burrs removed are taken out manually.

Owner:绍兴柯桥茂良化纤有限公司

Novel three-color material supply device for 3D (Three-Dimensional) printing head

InactiveCN107756800AAchieve multi-color printingEasy to operateAdditive manufacturing apparatus3D object support structuresEngineering3d printer

The invention provides a novel three-color material supply device for a 3D (Three-Dimensional) printing head. The material supply device consists of a material inlet detector, a material supply controller and a drive mechanism, wherein the material supply device is mounted at an inlet of an orifice of a material inlet pipeline, and comprises delivery belts, rotating shafts and linkage mechanisms;the detector is mounted in a front where a material enters the delivery belts; all the rotating shafts are linked through the linkage mechanisms; the rotating shaft of one delivery belt is linked withan output end of a motor; the motor is controlled through the material supply controller to rotate to drive the rotating shafts to rotate; the belts are driven to rotate to send the material into thematerial inlet pipeline. The technique is simple to operate and easy to realize, and can be used for effectively solving the material supply problem in a printing process.

Owner:CHANGSHA YUANDAHUA INFORMATION TECH CO LTD

The seamless connection method of 3D printer line body consumables

The invention discloses a seamless cascading method for 3D printer filament consumables. The method comprises steps as follows: a handle is moved, a push part of the handle pushes a pushing componentto move, the pushing component moves and enables a moving component to move, and the moving component moves and pulls a heating mechanism to move towards a heat joining region; when the heating mechanism is located in the heat joining region, a fixing component locks and fixes the heating mechanism, besides, a linkage part of the handle drives the driving mechanism to move and drives a filament cascading device to move to convey two strands of to-be-cascaded consumables to the heat joining region, and free ends of the consumables are contacted with the heating mechanism and absorb heat to be molten; the push part of the handle pushes the pushing component to move continuously, the pushing component moves and pushes the fixing component to move, so that the fixing component removes fixing restriction to the heating mechanism, the heating mechanism is away from the heat joining region, and the linkage part of the handle continues to move and enables the free ends of the two strands of consumables to be cascaded; force is continuously applied to the handle, a flattening mechanism perform deburring treatment on a heat joint point of the consumables; the consumables with burrs removed are taken out manually.

Owner:绍兴柯桥茂良化纤有限公司

A cylindrical coordinate 3D printer capable of simultaneous printing with multiple nozzles

ActiveCN105415691BAchieve multi-color printingImprove printing efficiency3D object support structuresManufacturing data aquisition/processingCircular discComputer printing

The invention relates to a cylindrical coordinate 3D printer capable of simultaneously printing with multiple nozzles. It includes an external meshing precision planetary gear mechanism, a telescopic cantilever beam mechanism, a Z-axis motion mechanism, and a feeding mechanism; the external meshing precision planetary gear mechanism is composed of a sun gear, a planetary gear, a support block, a reinforced ring and a disc-shaped working platform; the telescopic cantilever beam mechanism includes a nozzle, a feeding motor, a Z motion block, a polar axial drive motor, a polar axial ball screw and a limit block; the Z axis motion mechanism includes a Z drive motor, a Z The supporting frame of the moving mechanism, the Z-directing ball screw, the planetary gear drive motor and the motor seat; the feeding mechanism includes a feeding wheel and a feeding wheel supporting frame. The printing of the polar coordinate plane is realized through the external meshing precision planetary gear mechanism and the telescopic arm beam mechanism, and the Z-axis control mechanism realizes the Z-direction movement, thereby realizing the 3D printing movement of the nozzle. Multi-nozzle processing at the same time.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

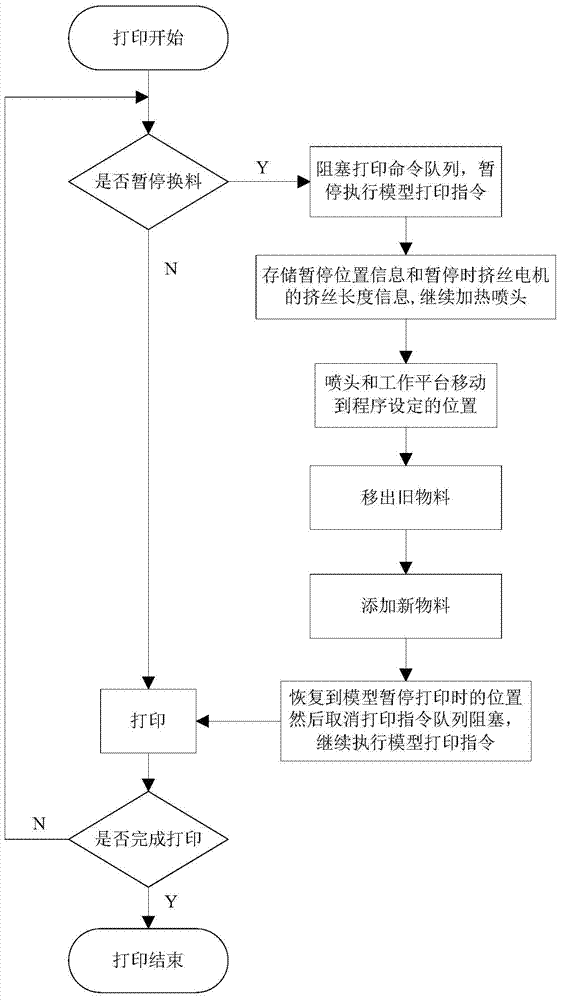

A method for pausing refueling for 3D printers

ActiveCN105109046BImprove yieldAchieve multi-color printingAdditive manufacturing apparatus3D object support structuresProgram instructionControl system

The invention discloses a method for suspending refueling of a 3D printer. The method is that the control system of the 3D printer continuously inquires whether a suspending refueling instruction is received during the model printing process. If the suspending refueling instruction is received, the control system The system suspends the model printing command and executes the subsequent suspending refueling work. If the suspending refueling command is not received, the control system executes the model printing command. In the process of model printing, when the material is insufficient, the material can be replenished to improve the utilization rate of the material and the finished product rate of the model; at the same time, by adding the pause material change command at the position where the color needs to be changed in advance in the printing model program command, you can During the printing process, different color materials can be replaced at the specified precise position of the model according to the color change of the model, so as to realize multi-color printing with a single nozzle.

Owner:MICOLOR DIGITAL TECH CO LTD

Consumable concatenation method capable of realizing color printing of 3D printer

ActiveCN107672176BAchieve recyclingAchieve multi-color printingAdditive manufacturing apparatus3D object support structures3d printColor printing

The invention discloses a consumable serial connecting method capable of realizing color printing of a 3D printer. The method comprises the following steps: (A) a wire consumable a with a color as delta and a length as L1 is selected; a wire consumable b with a color as gamma and a length as L2 is selected; and the lengths of the wire consumable a and the wire consumable b are calculated accordingto a size of a printed image; (B) the wire consumable a and the wire consumable b are determined to enter the 3D printer in sequence; (C) the wire consumable a is leaded into a second wire stringingmechanism; and the wire consumable b is leaded into a first wire stringing mechanism; (D) a power supply part of a heating mechanism drives a heat source body to move to a heat connecting area; (E) the wire consumables a and b are conveyed to move to the heat connecting area by the first wire stringing mechanism and the second wire stringing mechanism; (F) the power supply part of the heating mechanism drives the heat source body to the heat connecting area; (G) free ends of the wire consumable a and the wire consumable b are thermally connected; and (H) after thermal connection in the step (G) is finished, the wire consumables a and b are stood for a period of time.

Owner:泰州市津专知识产权服务有限公司

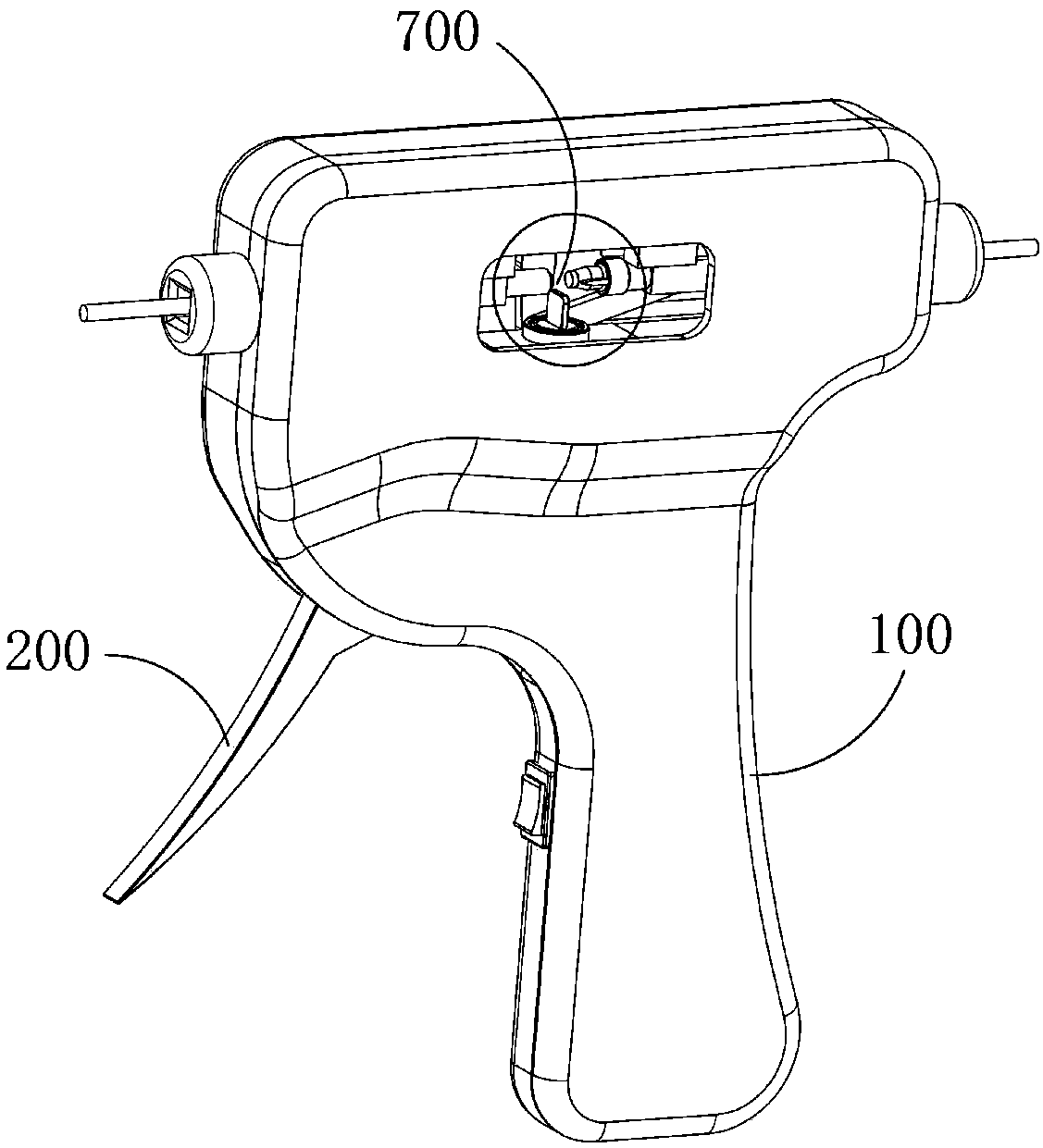

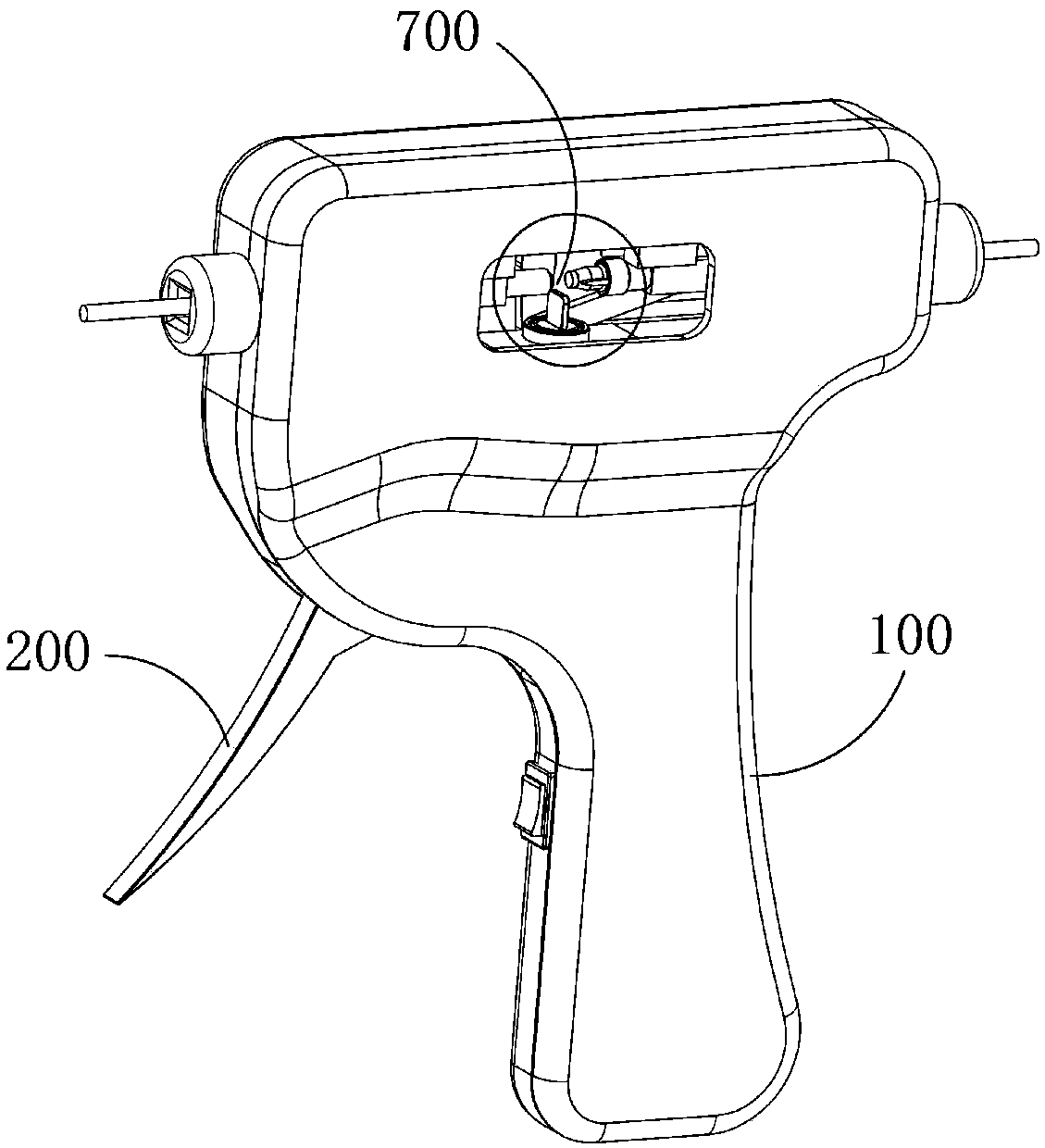

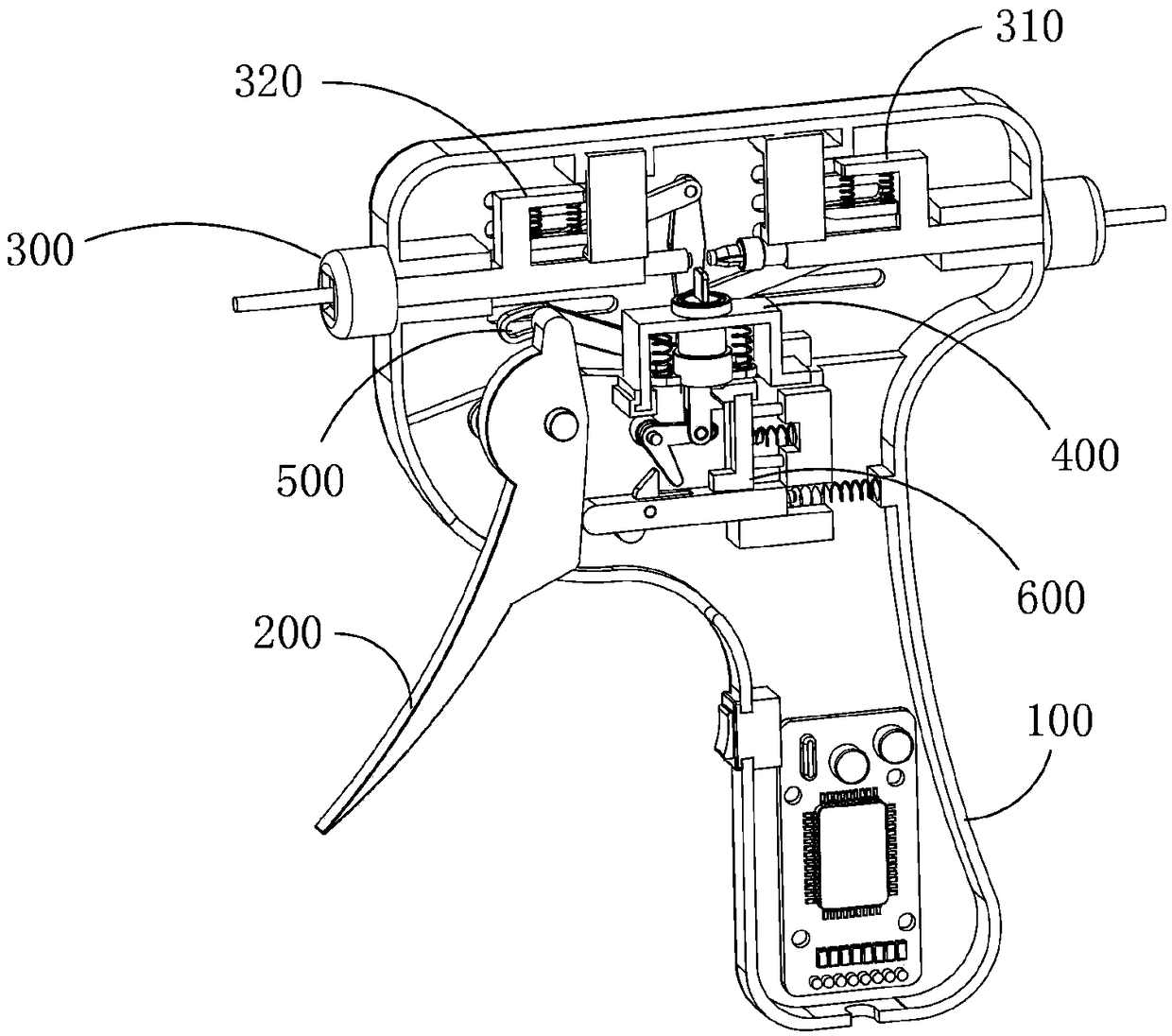

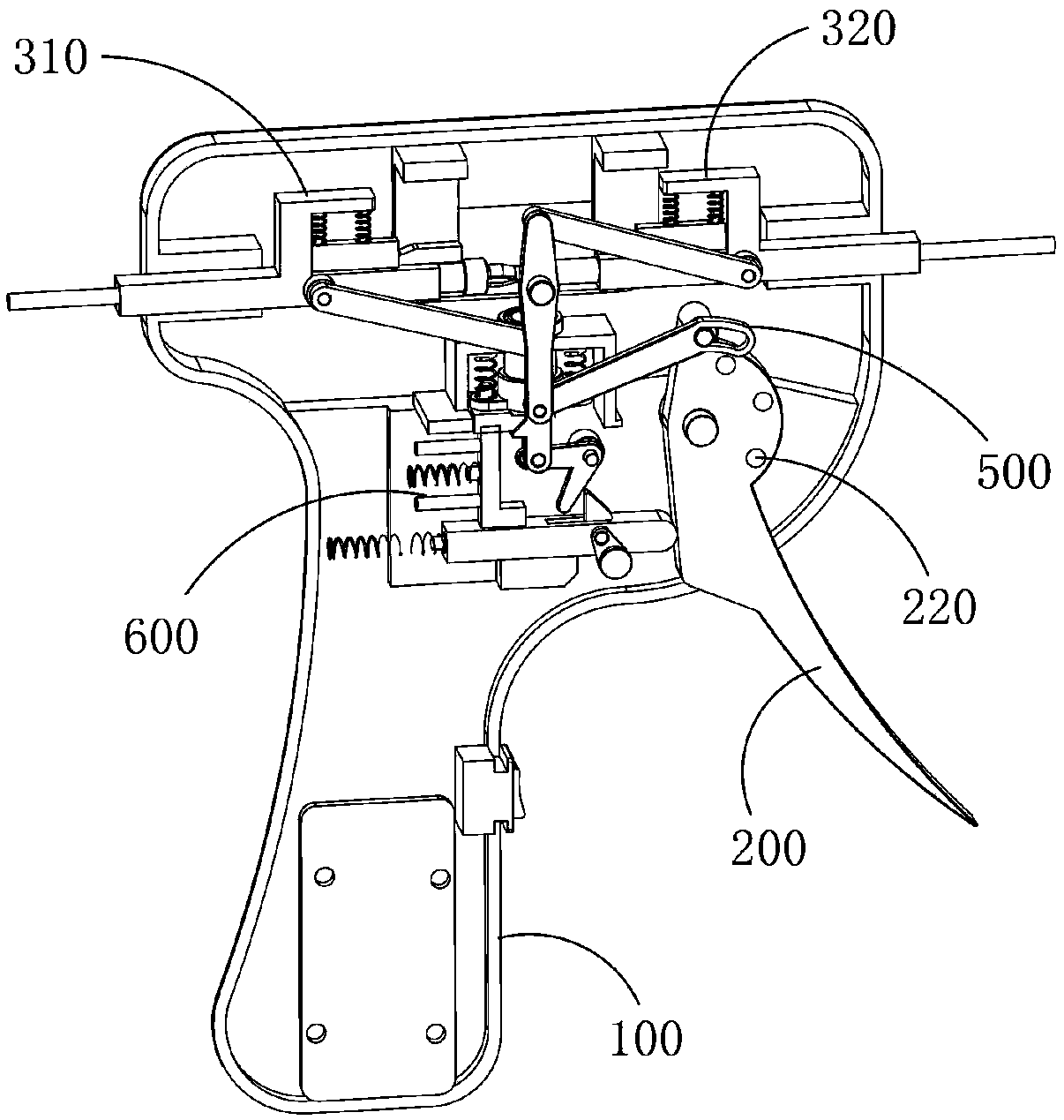

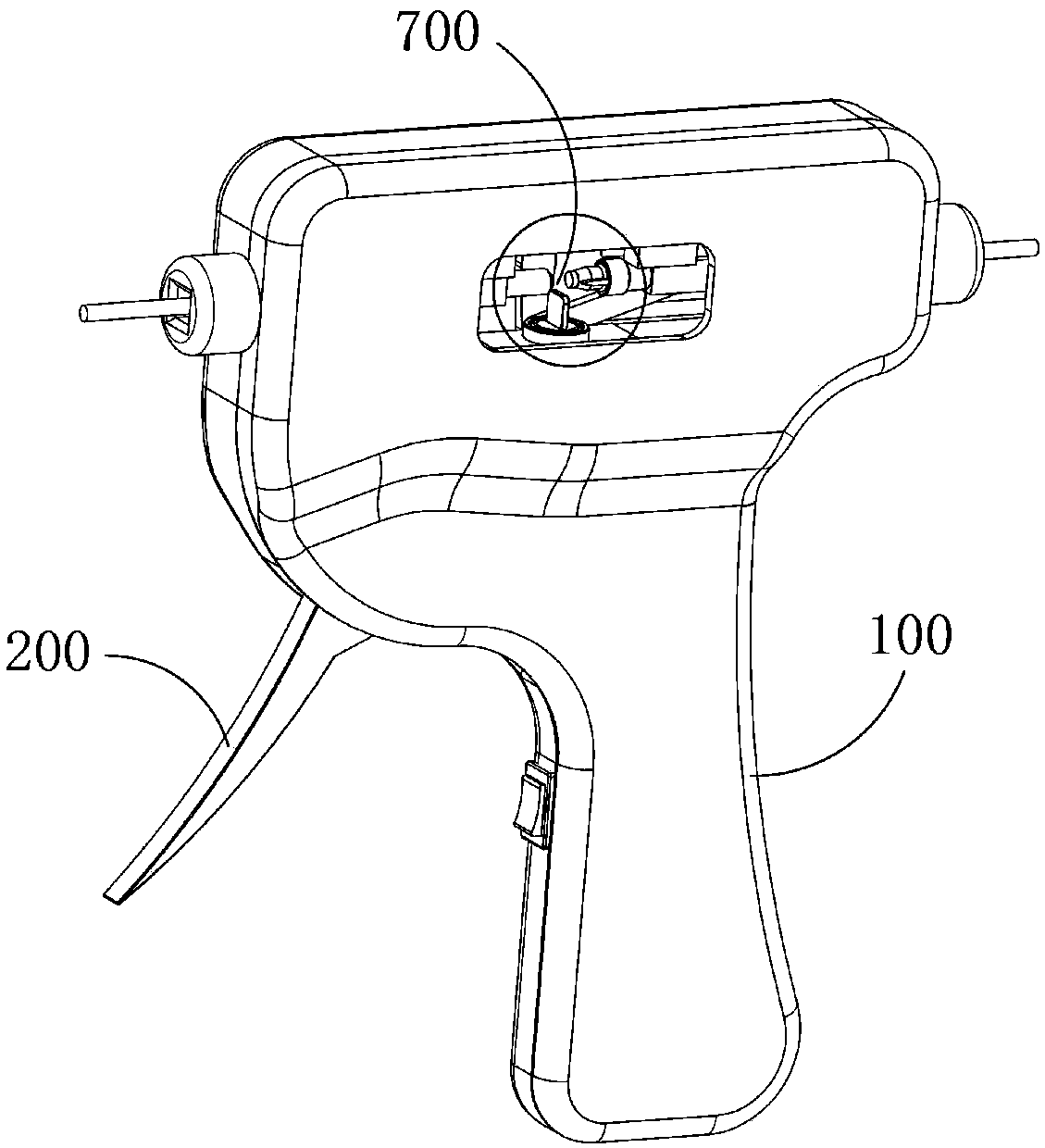

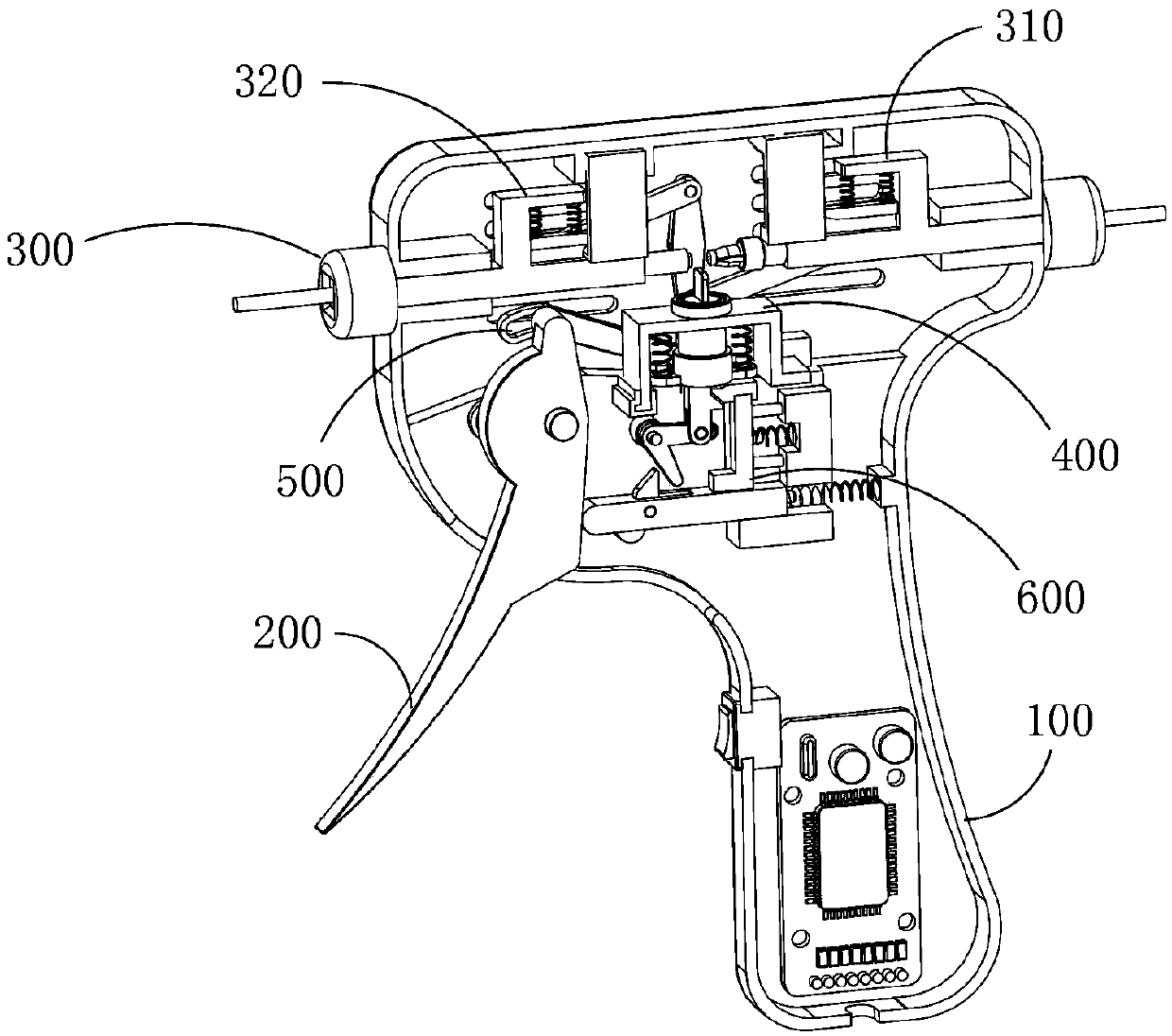

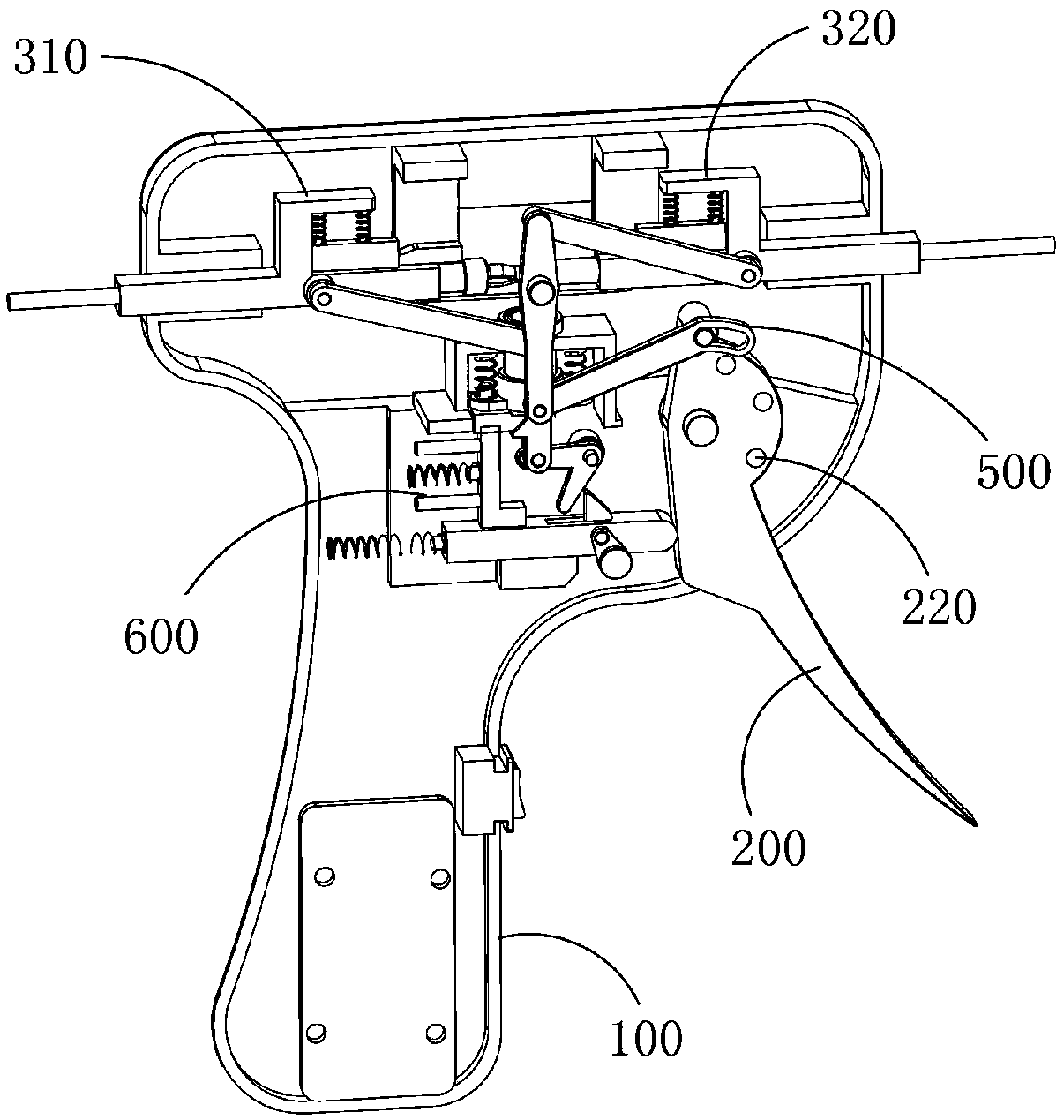

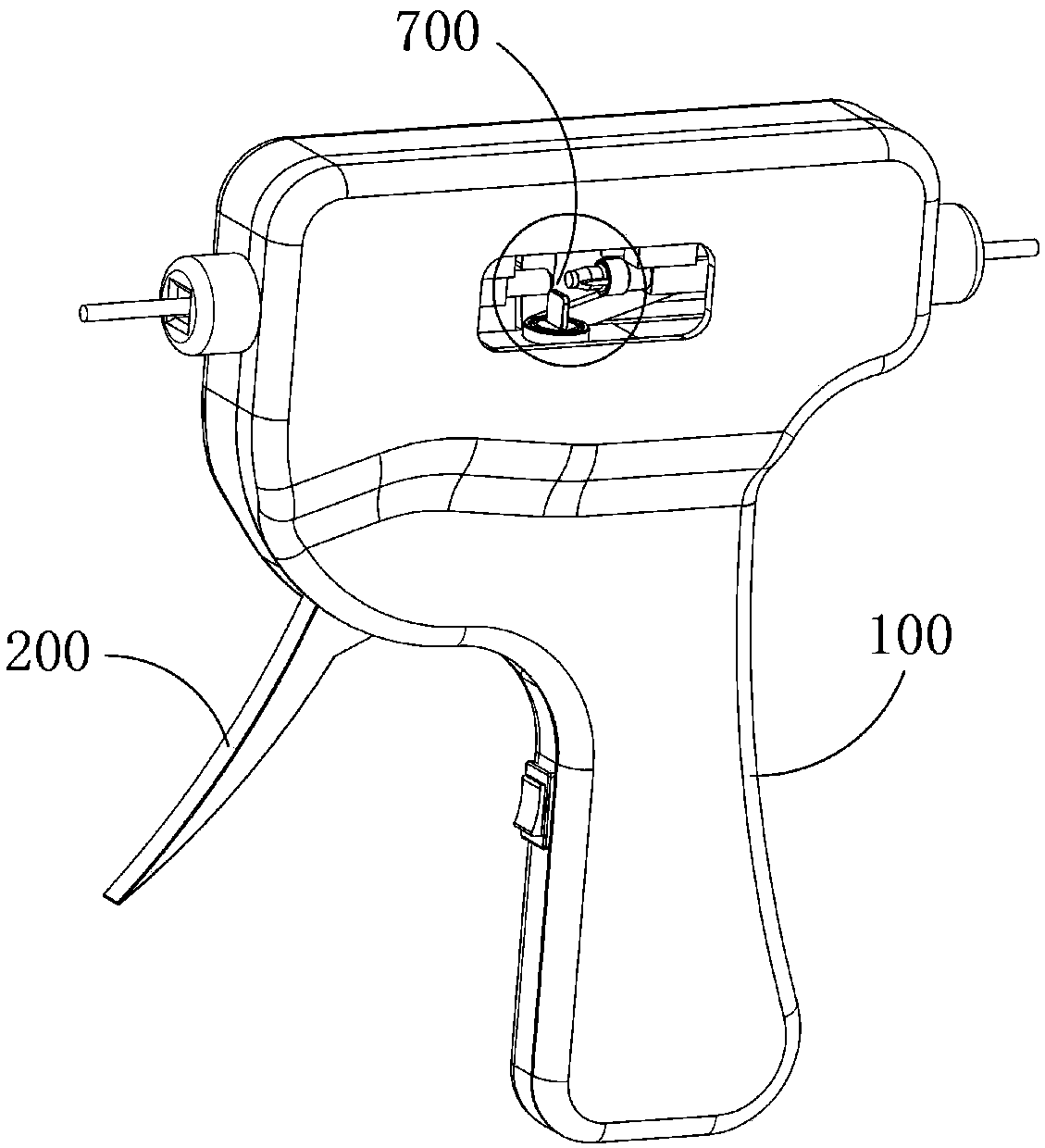

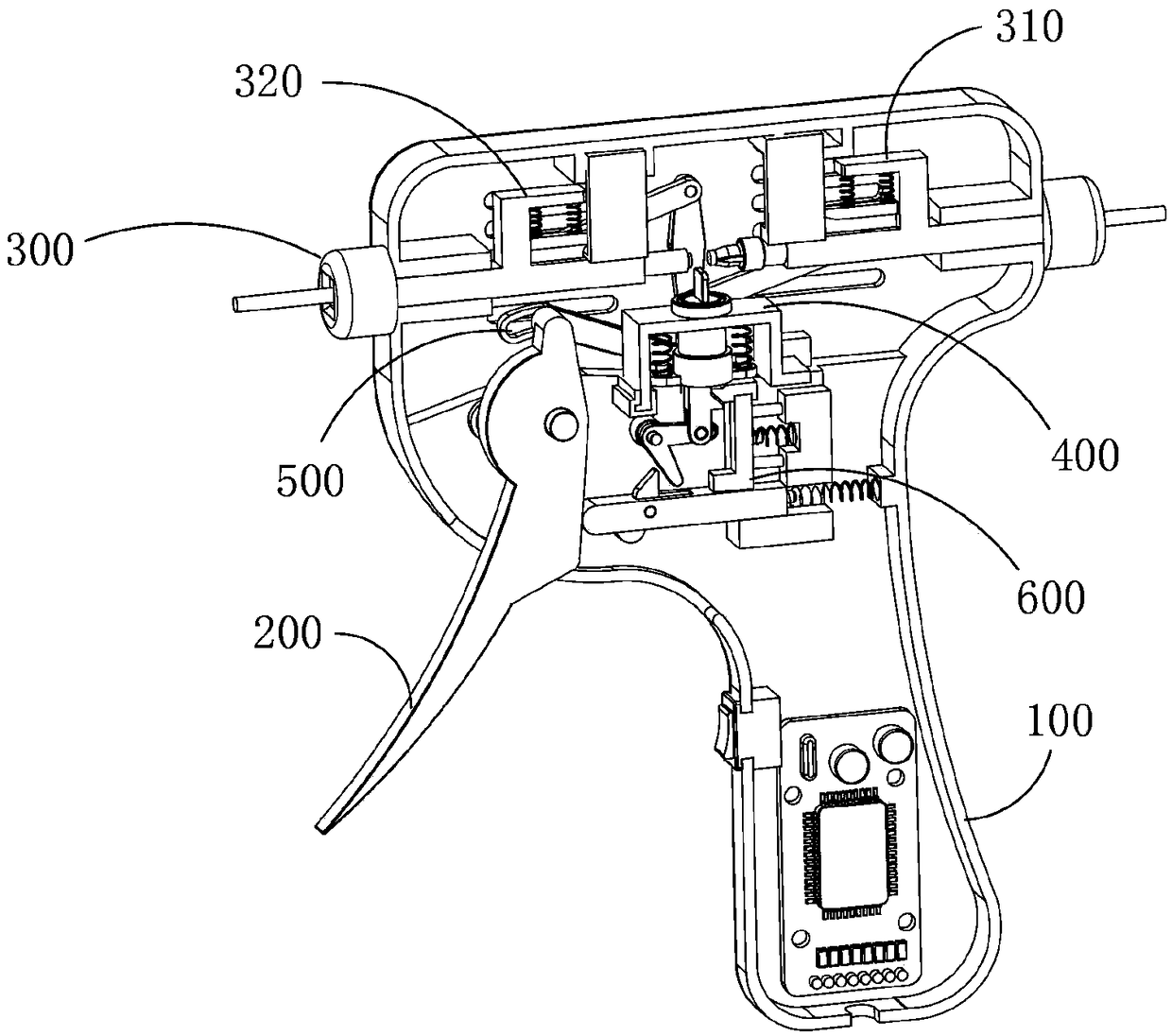

Manual cascading equipment for 3D printer filament consumables

ActiveCN108215155AAchieve recyclingAchieve multi-color printingAdditive manufacturing apparatusAdditive manufacturing with liquidsEngineering3d printer

The invention provides manual tandem connection equipment for 3D printer filament consumables. The equipment comprises a casing, wherein a handle, a filament cascading device, a heating mechanism, a drive mechanism and a lifting mechanism are mounted in the casing; the filament cascading device comprises a first filament cascading mechanism and a second filament cascading mechanism, the first filament cascading mechanism and the second filament cascading mechanism are concentrically arranged and distributed at an interval, a to-be-cascaded filament consumable is guided into each of the first filament cascading mechanism and the second filament cascading mechanism, the spacer region between the first filament cascading mechanism and the second filament cascading mechanism is a heat joiningregion, push force is produced when the handle is moved, the drive mechanism receives the push force produced during movement of the handle and transmits the push force to the first filament cascadingmechanism and the second filament cascading mechanism, the first filament cascading mechanism and the second filament cascading mechanism convey the filament consumables to the heat joining region under the action of the push force, cascading is completed in the heat joining region, the lifting mechanism receive push force produced during movement of the handle and drives the heating device to move up or down under the action of the push force, and the heating device is used for providing heat energy required by heat joining in the heat joining region.

Owner:润琛液压机械南通有限公司

Manual serial connection equipment for 3d printer wire body consumables

ActiveCN108215155BAchieve recyclingAchieve multi-color printingAdditive manufacturing apparatusAdditive manufacturing with liquids3d printerConsumables

The invention provides manual tandem connection equipment for 3D printer filament consumables. The equipment comprises a casing, wherein a handle, a filament cascading device, a heating mechanism, a drive mechanism and a lifting mechanism are mounted in the casing; the filament cascading device comprises a first filament cascading mechanism and a second filament cascading mechanism, the first filament cascading mechanism and the second filament cascading mechanism are concentrically arranged and distributed at an interval, a to-be-cascaded filament consumable is guided into each of the first filament cascading mechanism and the second filament cascading mechanism, the spacer region between the first filament cascading mechanism and the second filament cascading mechanism is a heat joiningregion, push force is produced when the handle is moved, the drive mechanism receives the push force produced during movement of the handle and transmits the push force to the first filament cascadingmechanism and the second filament cascading mechanism, the first filament cascading mechanism and the second filament cascading mechanism convey the filament consumables to the heat joining region under the action of the push force, cascading is completed in the heat joining region, the lifting mechanism receive push force produced during movement of the handle and drives the heating device to move up or down under the action of the push force, and the heating device is used for providing heat energy required by heat joining in the heat joining region.

Owner:润琛液压机械南通有限公司

Heat source lifting mechanism for docking of 3D printer wire body consumables

ActiveCN108032513BAchieve recyclingAchieve multi-color printingAdditive manufacturing apparatusAdditive manufacturing with liquidsThermal energyButt joint

The invention provides a heat source lifting mechanism for 3D printer line body consumable butt joint. The heat source lifting mechanism comprises a shell. A handle, a heating mechanism and an elevator mechanism are installed inside the shell. The handle can generate pushing force in the moving process. The elevator mechanism receives the pushing force generated in the moving process of the handleand further drives the heating mechanism to ascend or descend under the effect of the pushing force. The heating mechanism is used for providing heat energy required by hot jointing for a hot jointing area. The handle is divided into three parts which include a handle part, a linkage part and a pushing part located between the handle part and the linkage part. The handle is hinged to the shell, and the hinged position of the handle and the shell is located between the linkage part and the pushing part. The core axis of a hinged shaft is perpendicular to conveying trails of consumables conveyed to the hot jointing area. The handle part is located outside the shell. The linkage part and the pushing part are located inside the shell and the pushing part makes contact with the elevator mechanism.

Owner:上海术字信息科技有限公司

A method for seamless connection of linear consumables capable of color printing by 3D printers

InactiveCN108215195BAchieve recyclingAchieve multi-color printingAdditive manufacturing apparatus3D object support structuresColor printing3d printer

The invention discloses a seamless cascading method for filament consumables capable of realizing color printing by a 3D printer. The method comprises steps as follows: A, a filament consumable a withthe color of delta and the length of L1 and a filament consumable b with the color of gamma and the length of L2 are selected, and the lengths of the filament consumable a and the filament consumableb are calculated according to the volume of a print image; B, the filament consumable a and the filament consumable b enter the 3D printer sequentially; C, the filament consumable a is led to a firstfilament cascading mechanism, and the filament consumable b is led to a second filament cascading mechanism; D, a handle is moved, a push part of the handle pushes a pushing component to move, the pushing component moves and enables a moving component to move, and the moving component moves and pulls a heating mechanism to move towards a heat joining region; when the heating mechanism is locatedin the heat joining region, a fixing component locks and fixes the heating mechanism, and besides, a linkage part of the handle drives a driving mechanism to move and drives a filament cascading device to move to convey two strands of to-be-cascaded consumables to the heat joining region.

Owner:绍兴柯桥恒松针纺有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com