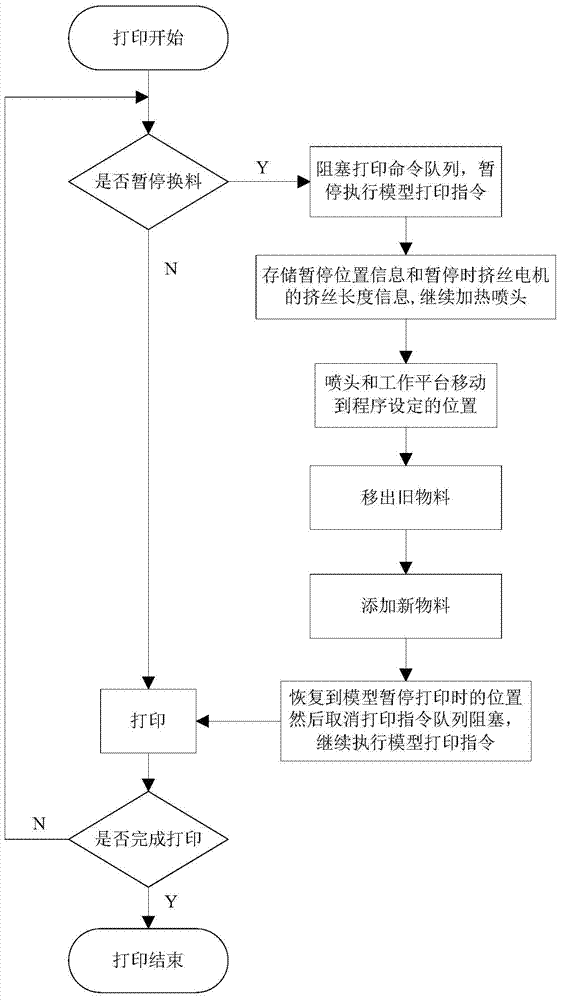

A method for pausing refueling for 3D printers

A technology for 3D printers and printing instructions, applied in 3D object support structures, additive manufacturing, processing data acquisition/processing, etc., can solve the problems of time and material waste, increase the difficulty of model making, etc., and achieve the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in more detail below in conjunction with specific embodiments and accompanying drawings.

[0023] The 3D printer includes a human-computer interaction screen, fan, X-axis motor, Y-axis motor, Z-axis motor, extrusion motor, heater, photoelectric sensor and control system. The working platform is connected to the Z-axis motor and can move up and down along the Z-axis direction. The nozzle is connected with the X-axis motor and the Y-axis motor and can move freely in the direction of the X-axis and Y-axis. The material is sent to the nozzle through the wire extrusion motor, and the material is melted by the heater. The inlet of the wire extrusion motor is equipped with a useful A photoelectric sensor for detecting materials, and a fan for real-time cooling of the printed model;

[0024] The human-computer interaction screen, fan, X-axis motor, Y-axis motor, Z-axis motor, wire extrusion motor, heater, and photoelectric sensor are all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com