Patents

Literature

230results about How to "Efficient printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water based inks for printing on confectionery

Non-pigmented, water-based inks are disclosed which are compatible with industrial piezojet printheads and which can be used to form high resolution images on edible substrates, including sugar shell confectionery polished with a hydrophobic wax polish. The ink comprises a hydrolyzable polysaccharide adhesive agent, such as tapioca dextrin or gum arabic, which enhances the compatibility of the ink for hydrophobic surfaces.

Owner:MARS INC

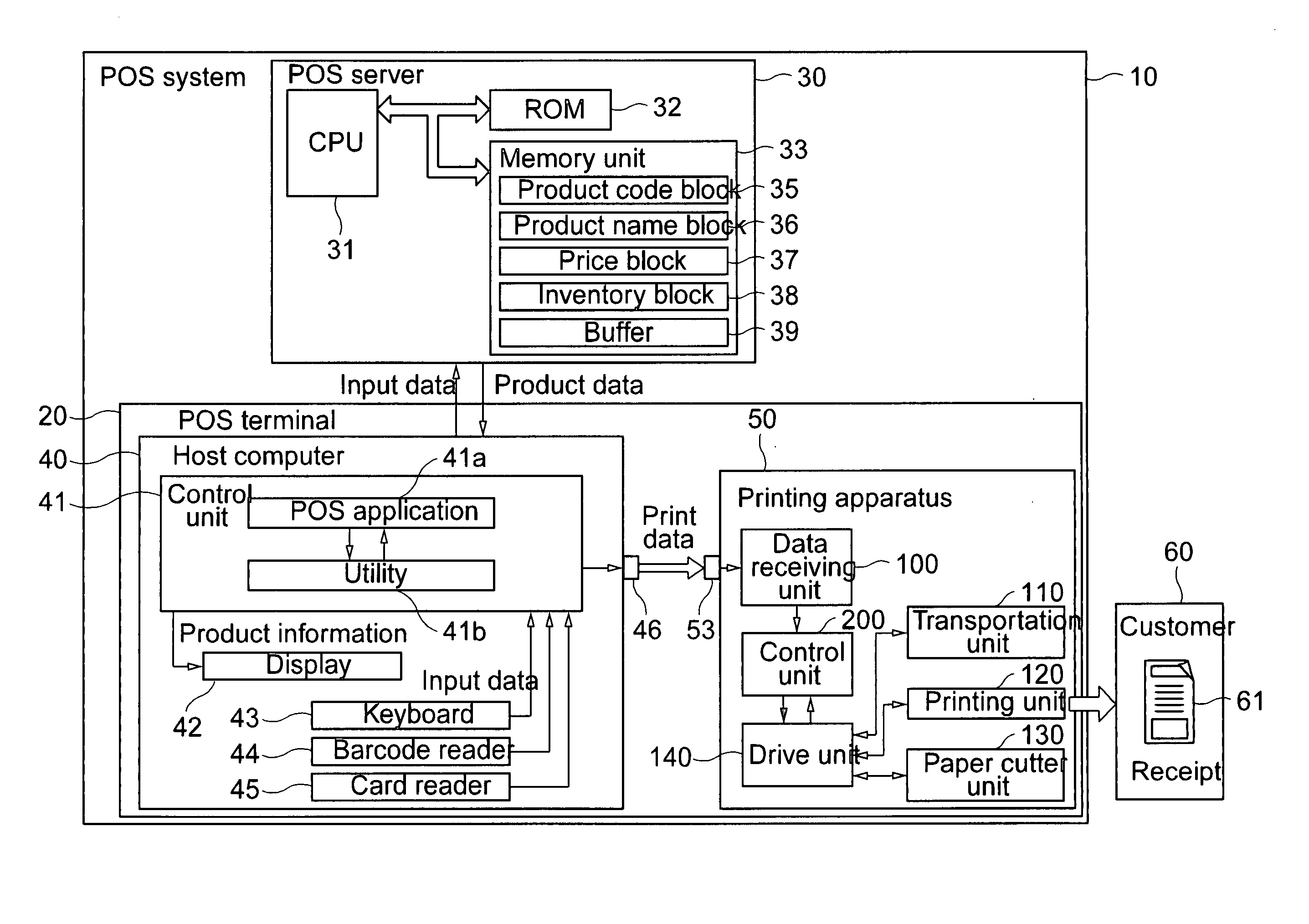

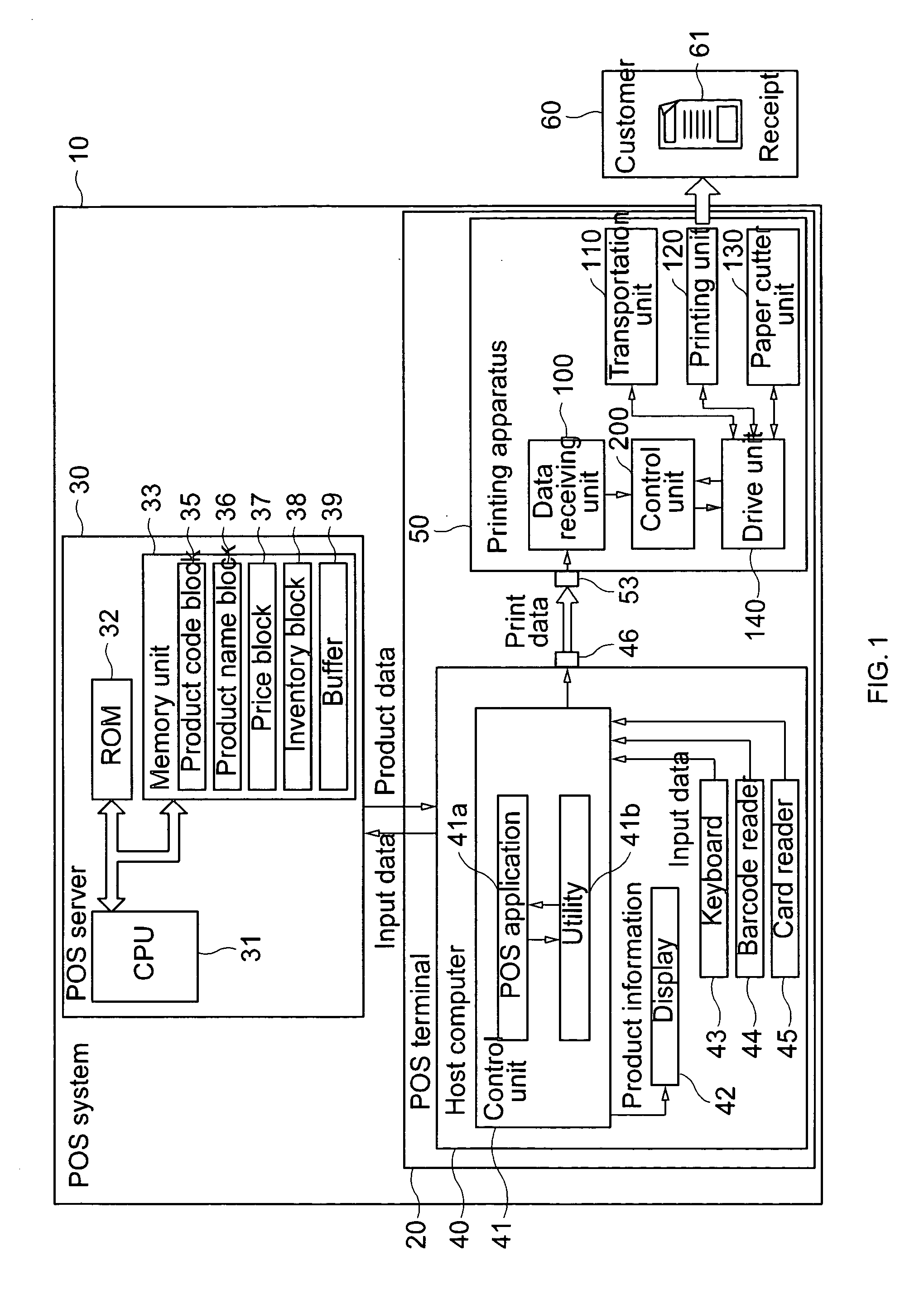

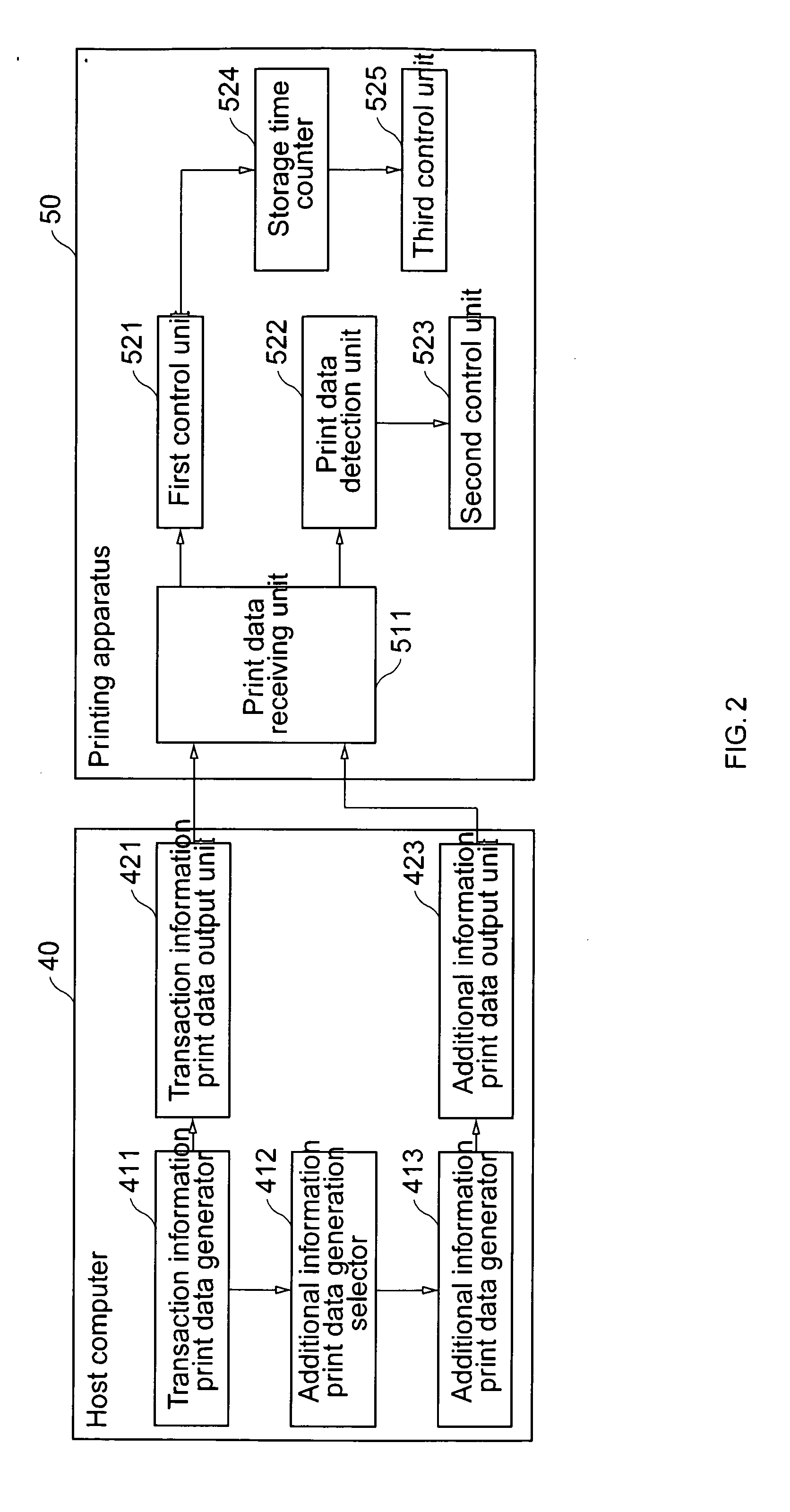

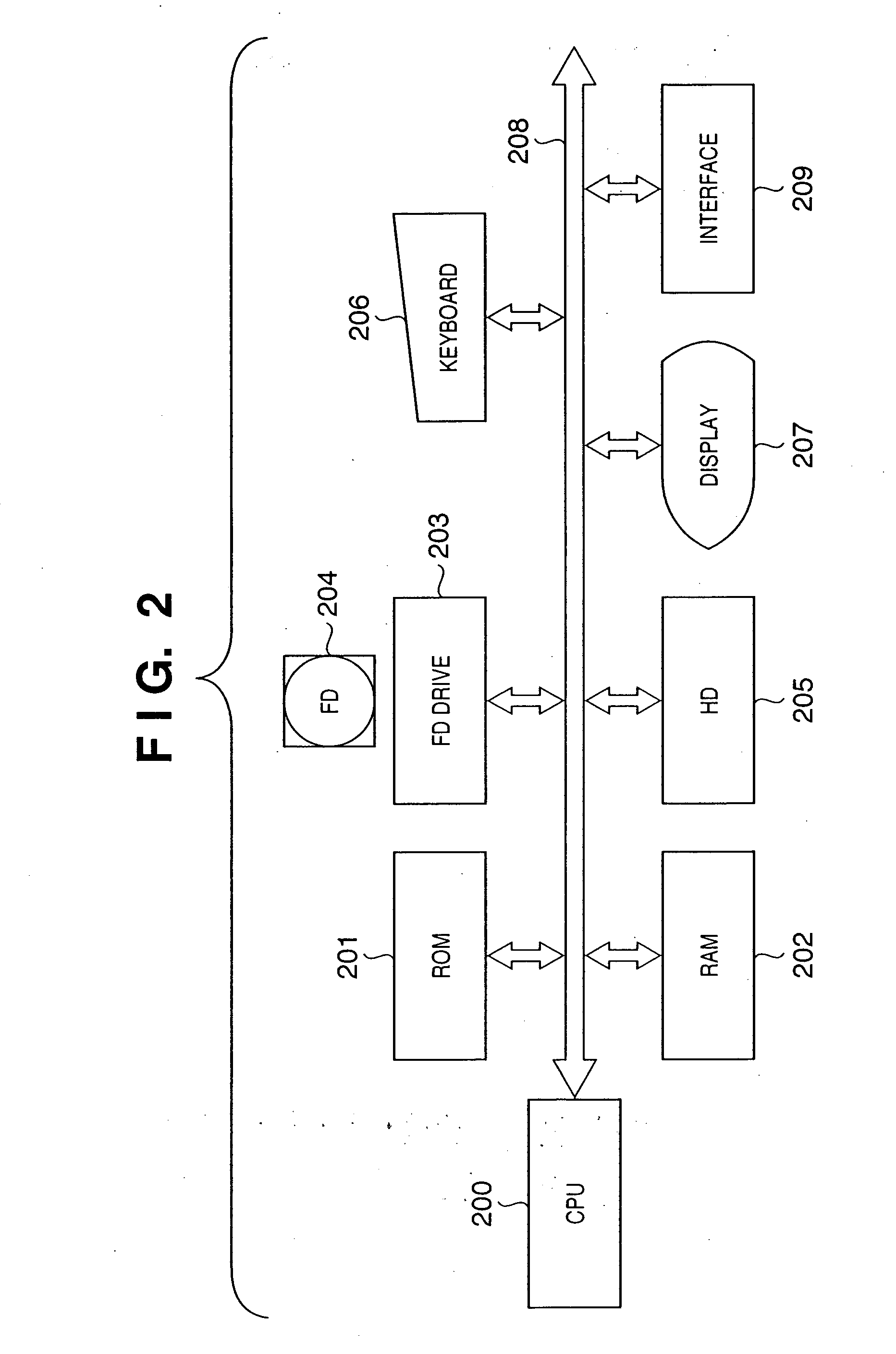

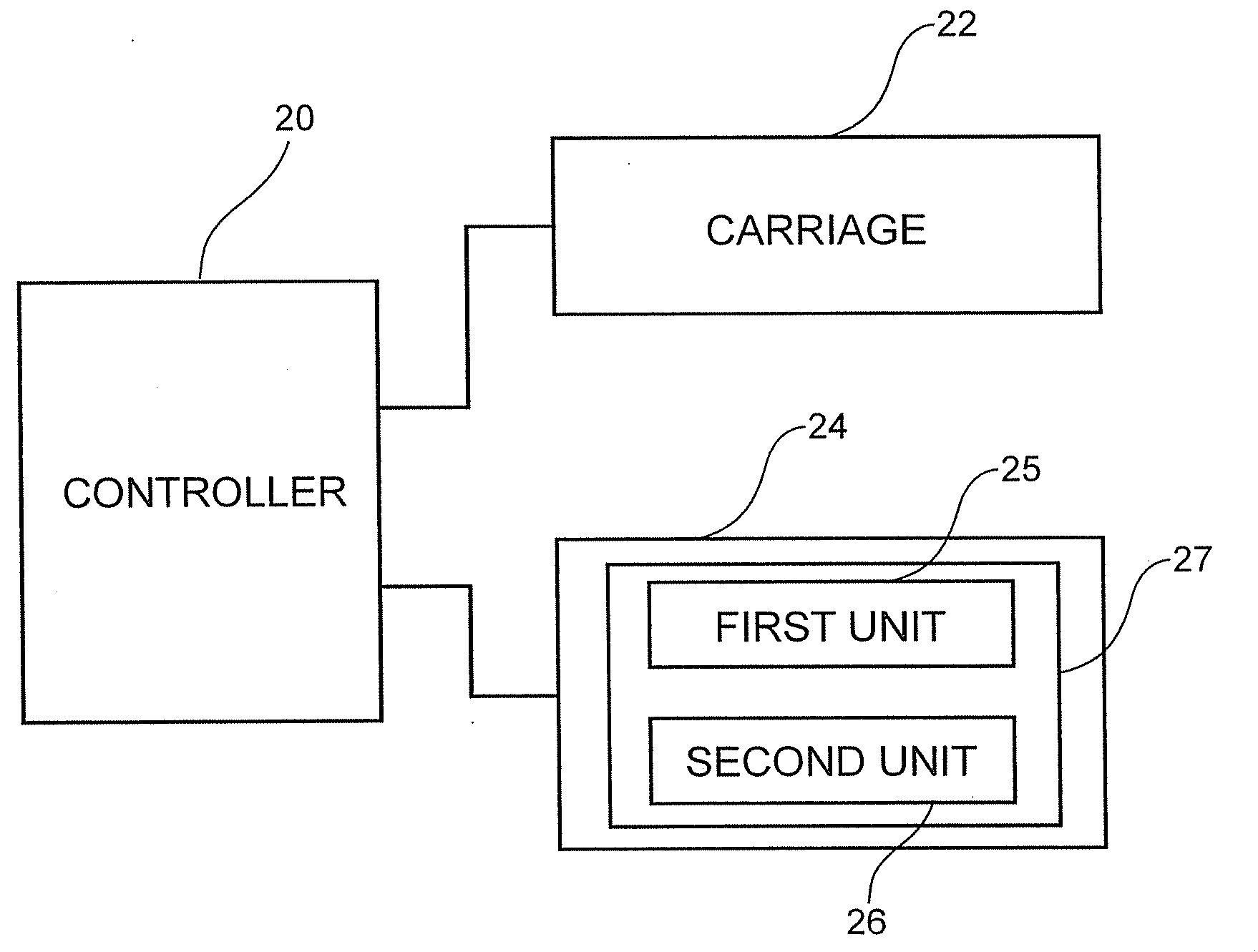

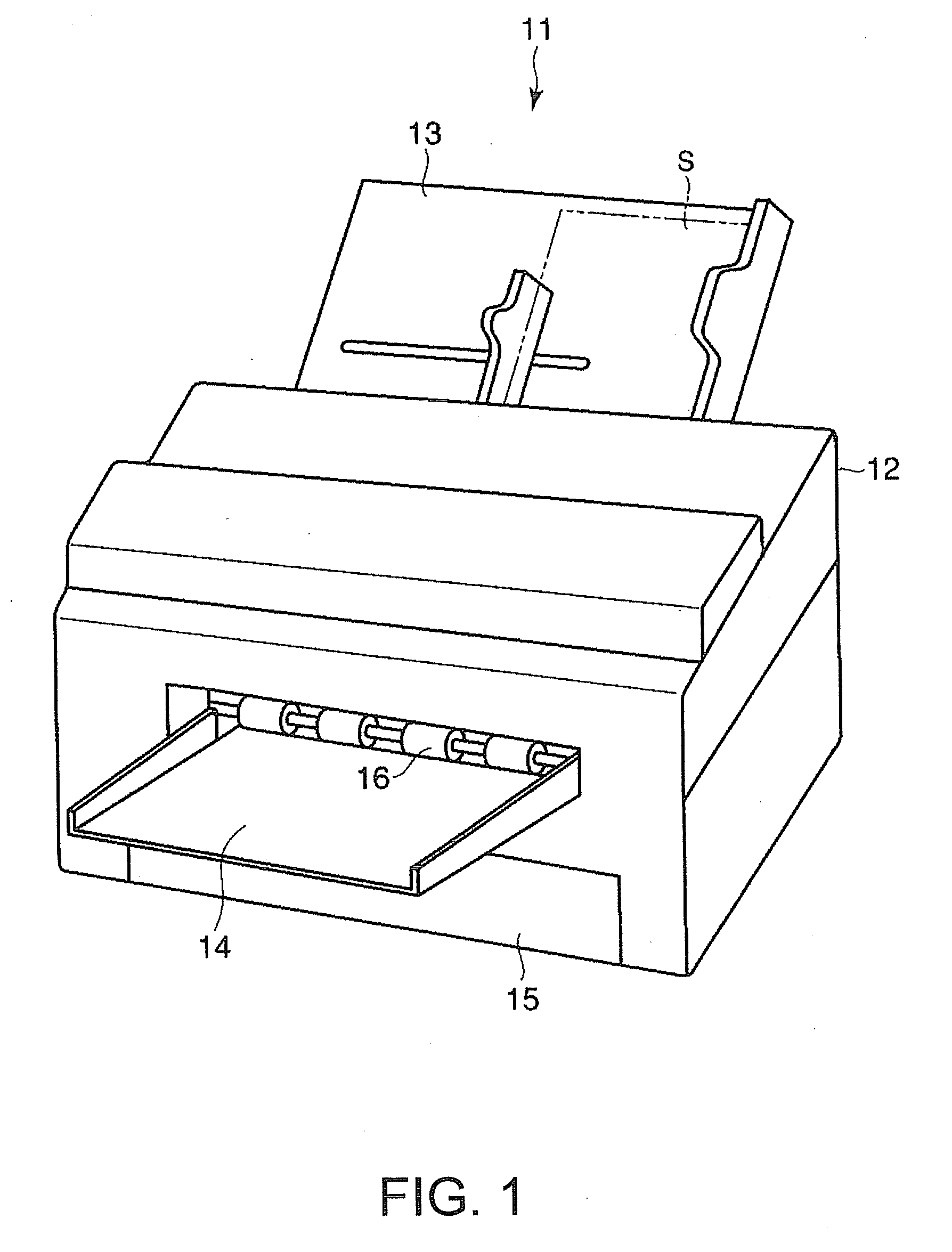

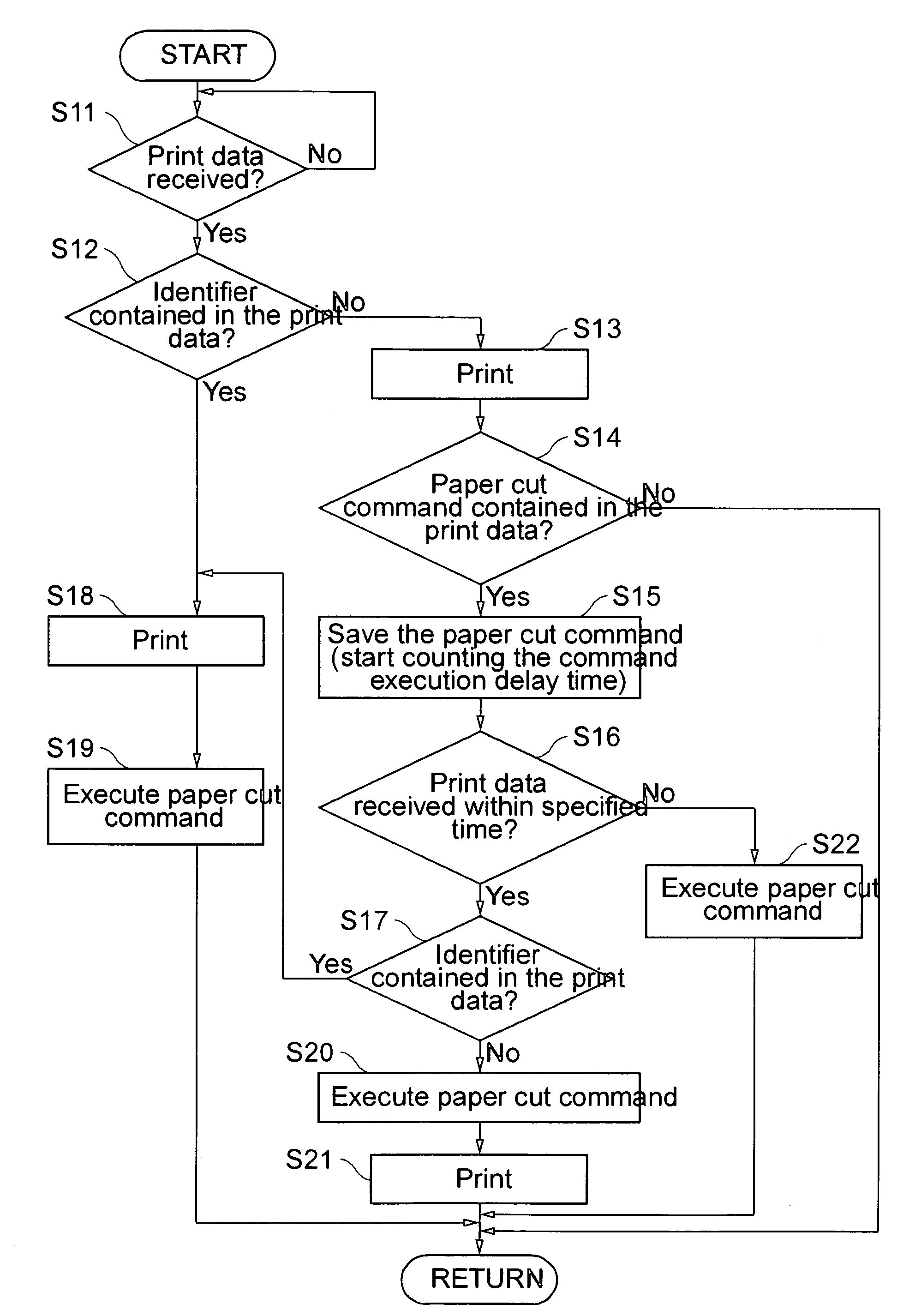

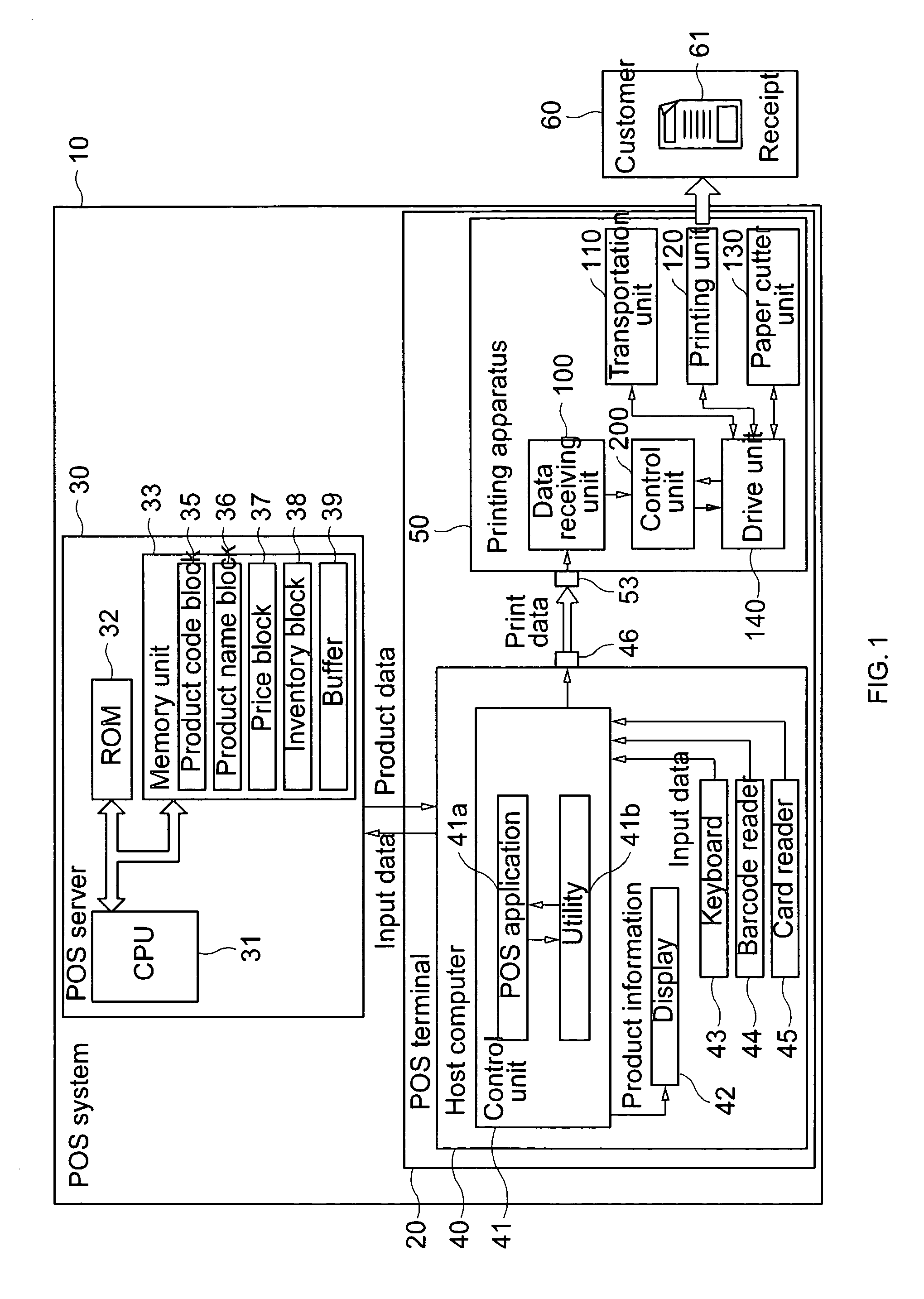

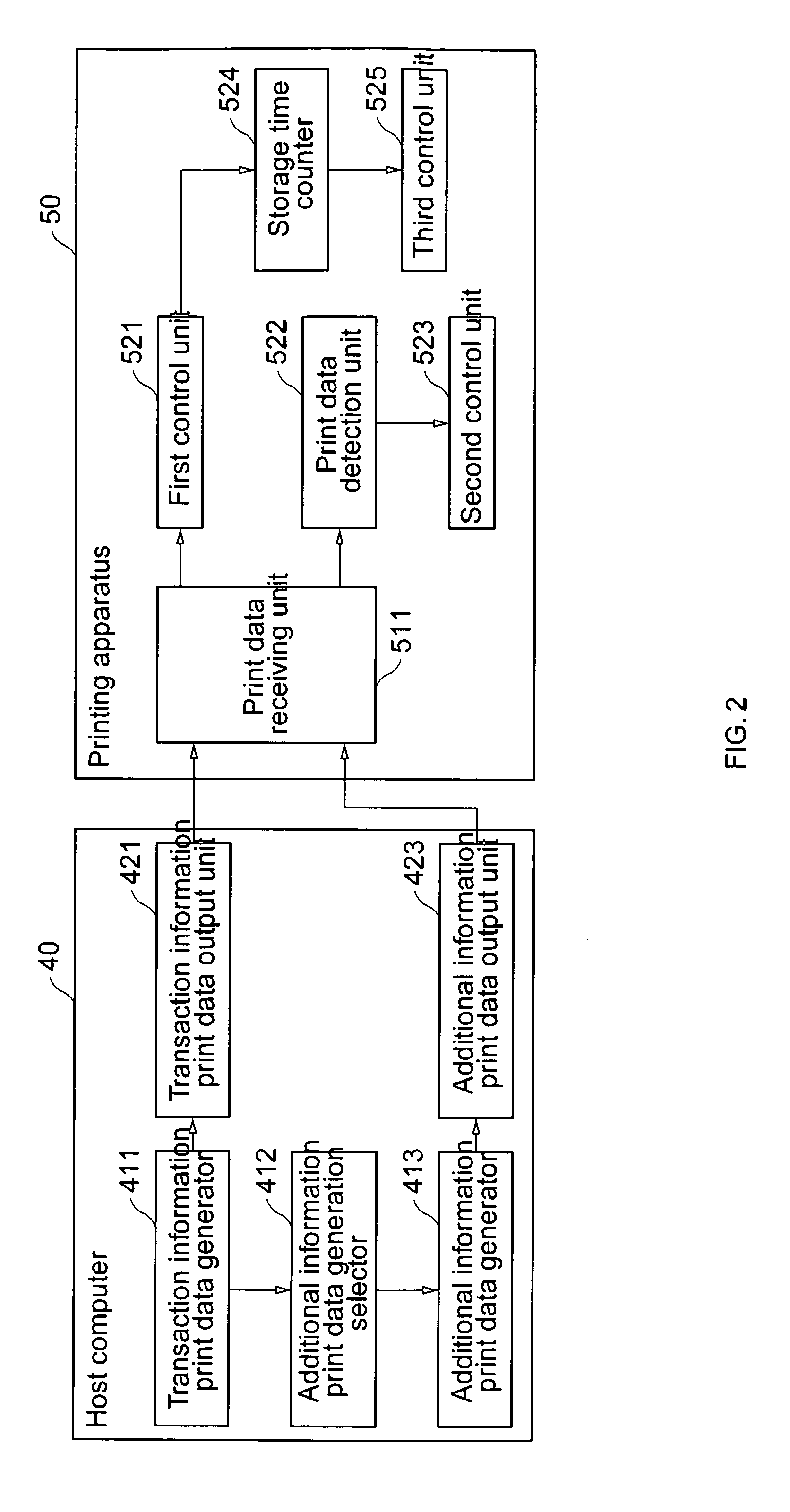

Printing apparatus, POS system and printing apparatus control method

InactiveUS20050271446A1Efficient printingReduce processing stepsCash registersMultiple digital computer combinationsEngineeringData detection

A printing apparatus and method for printing receipts and for controlling the cutting of each receipt in succession from a recording medium such as print paper at an appropriate position determined from the print data received from a host computer. The printing apparatus 50 prints first print data representing transaction information with a paper cut command appended thereto and second print data representing additional information from print data received from a host computer 40. A first control unit 521 prints the first print data and delays executing the paper cut command added to the first print data when first print data is received from the host computer. When print data is received while execution of the paper cut command is delayed, a print data detection unit 522 determines the type of print data received based on the presence or absence of an identifier in the received print data. If the received print data is recognized as second print data, a second control unit 523 prints the received second print data and then executes the paper cut command. If the received print data is determined not to be second print data, the second control unit 523 executes the paper cut command before printing the received print data.

Owner:SEIKO EPSON CORP

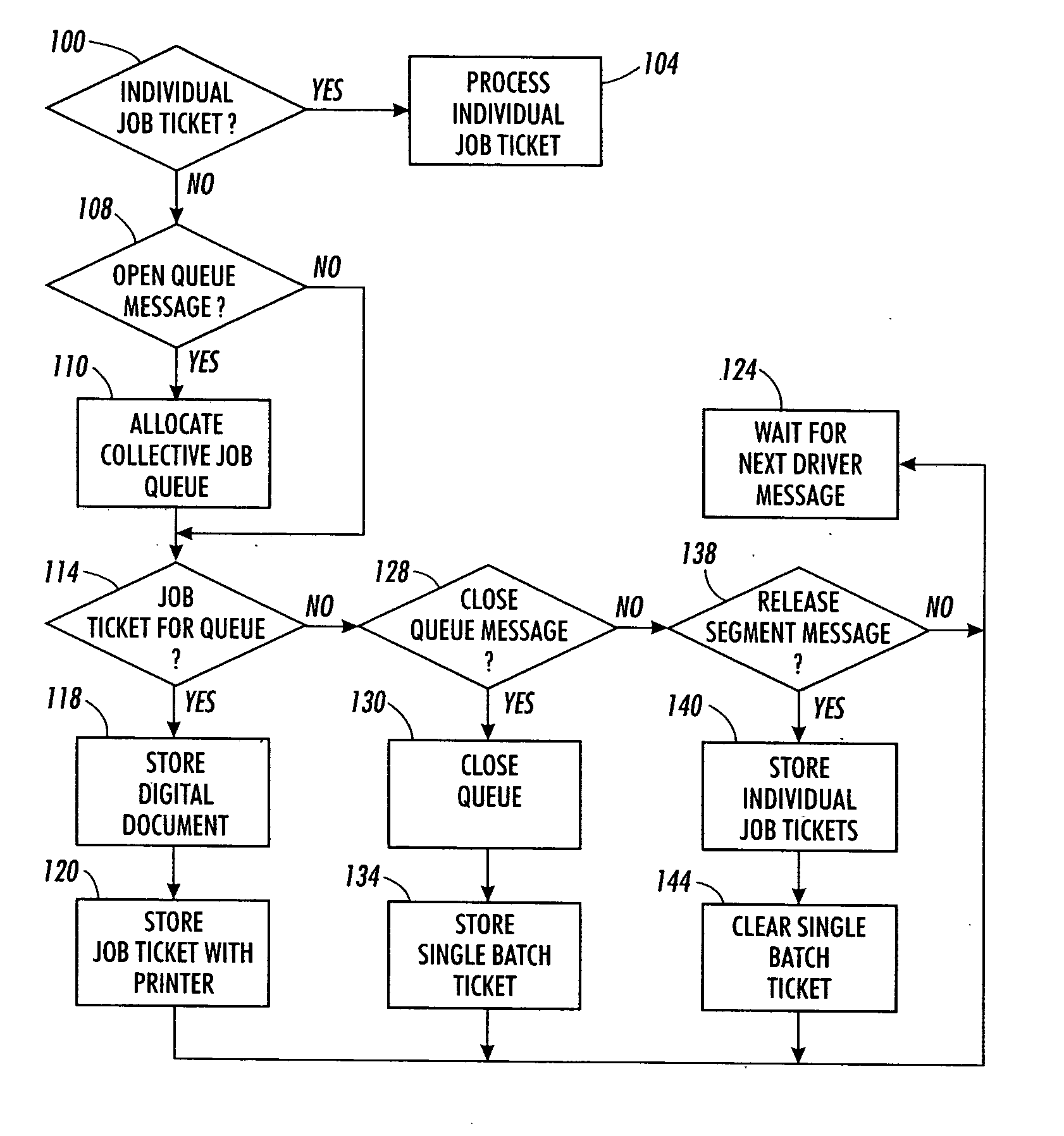

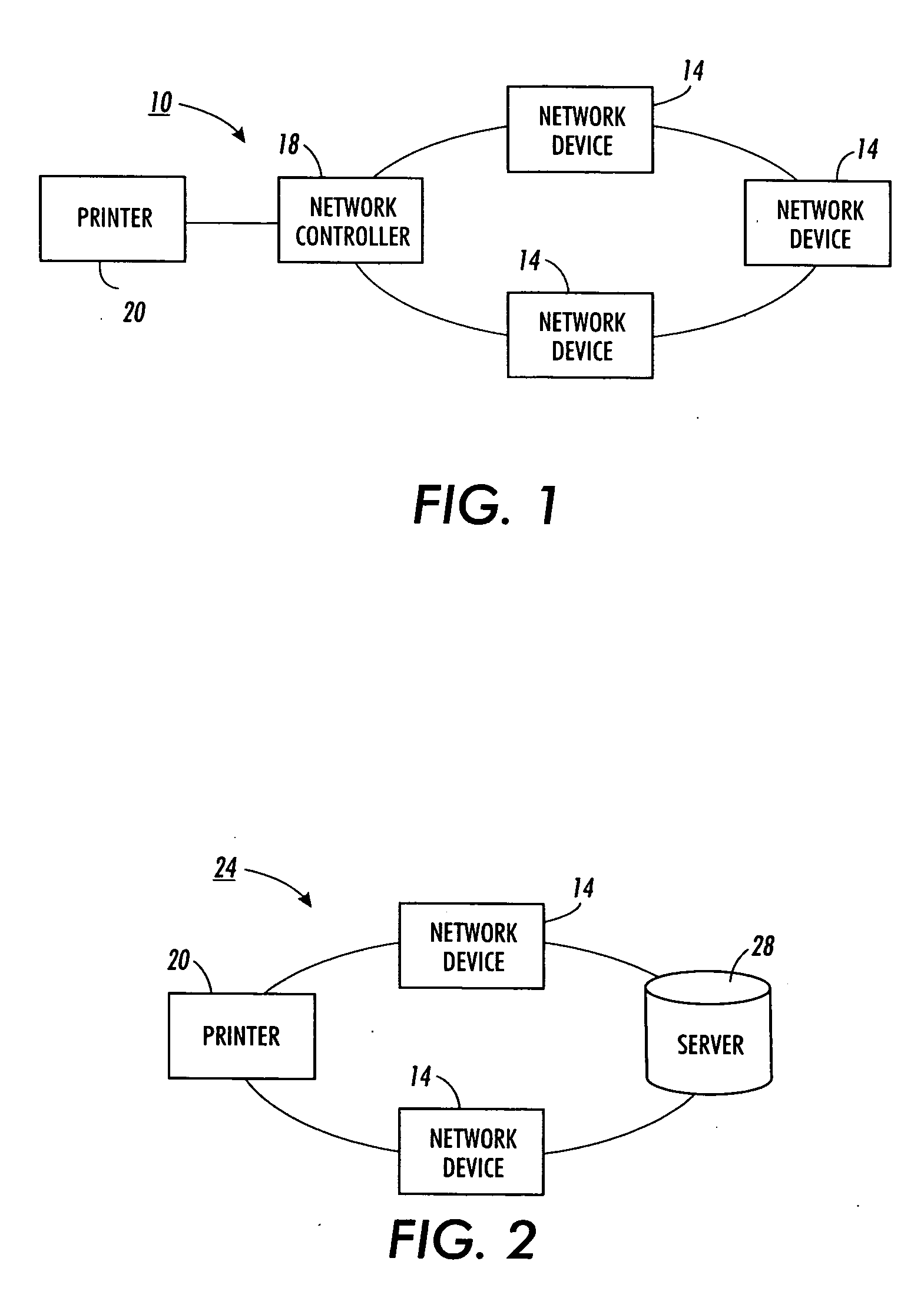

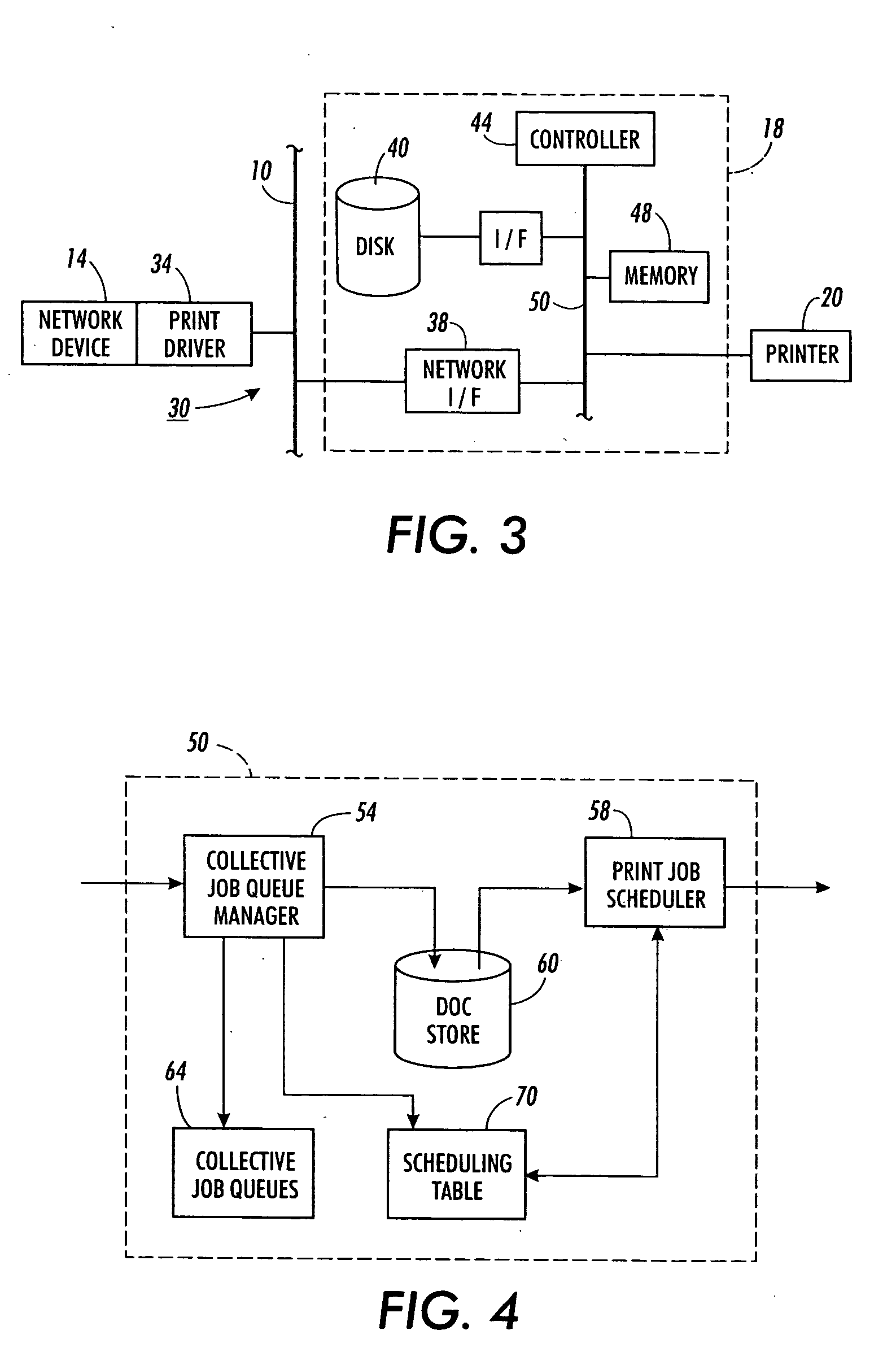

Method and system for managing print job files for a shared printer

InactiveUS20060033958A1Promote recoveryEfficient printingDigitally marking record carriersVisual presentation using printersComputer scienceQueue manager

A system and method enable a user to generate a single batch job ticket for a plurality of print job tickets. The system includes a print driver, a print job manager, and a print engine. The print driver enables a user to request generation of a collective job queue and to provide a plurality of job tickets for the job queue. The print job manager includes a collective job queue manager and a print job scheduler. The collective job queue manager collects job tickets for a job queue and generates a single batch job ticket for the print job scheduling table when the job queue is closed. The print job scheduler selects single batch job tickets in accordance with various criteria and releases the job segments to a print engine for contiguous printing of the job segments.

Owner:XEROX CORP

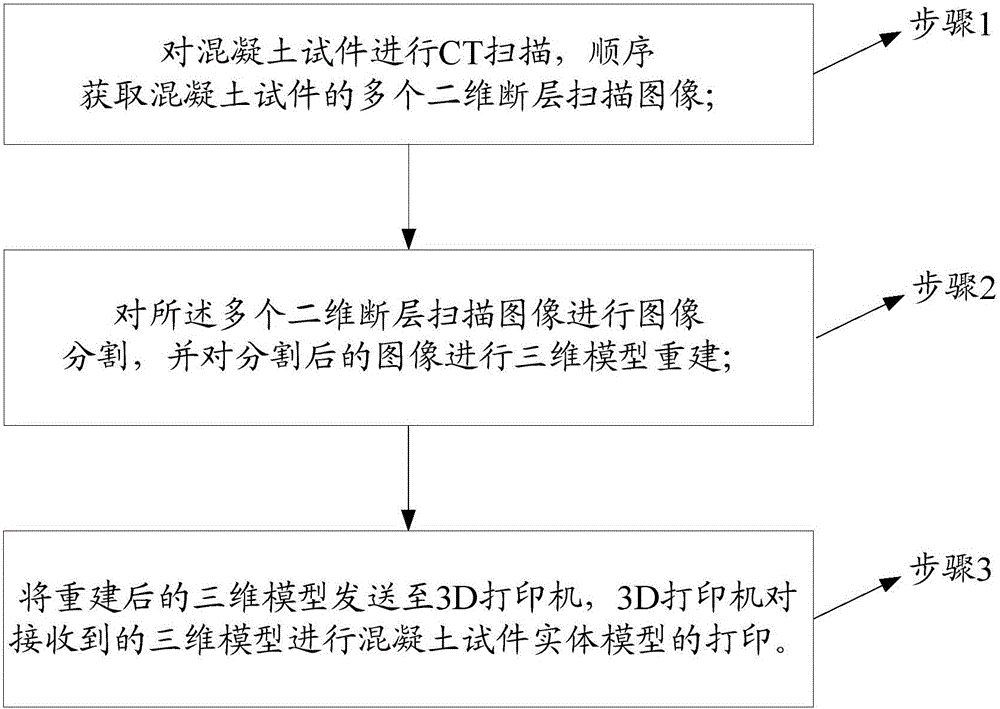

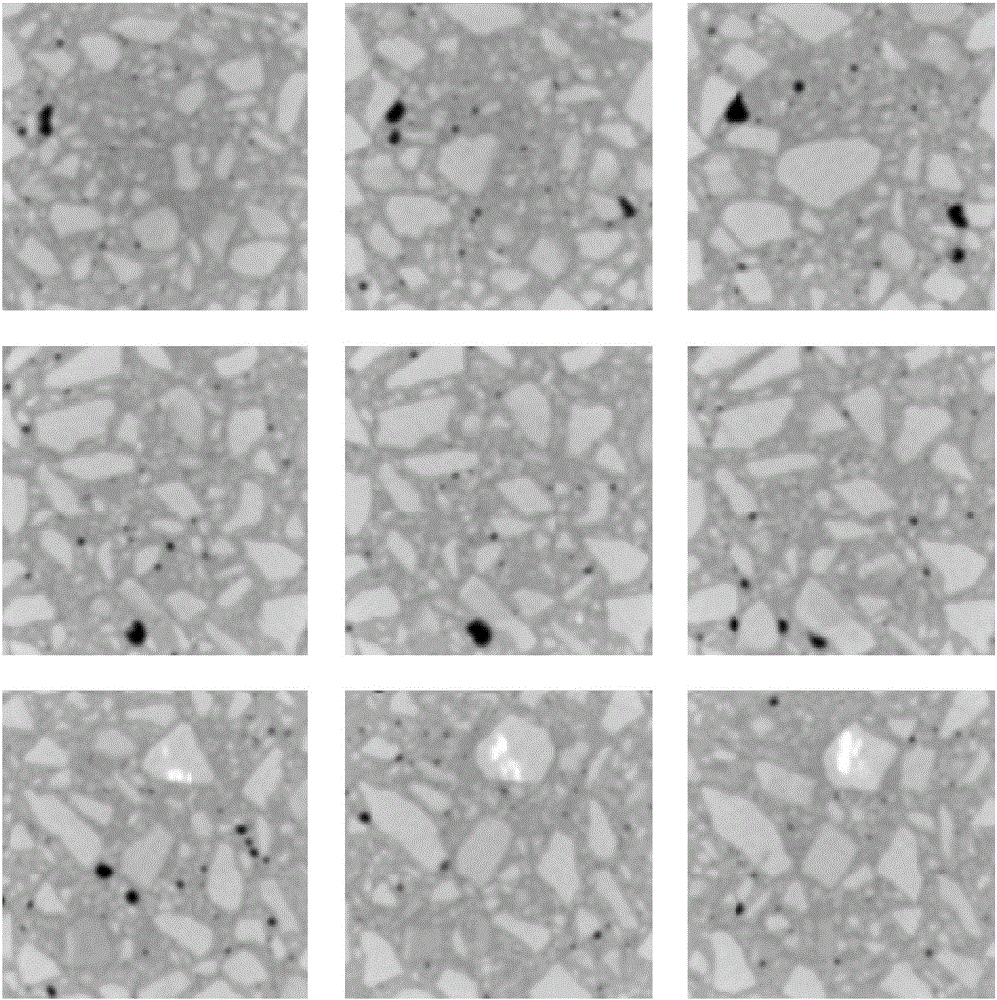

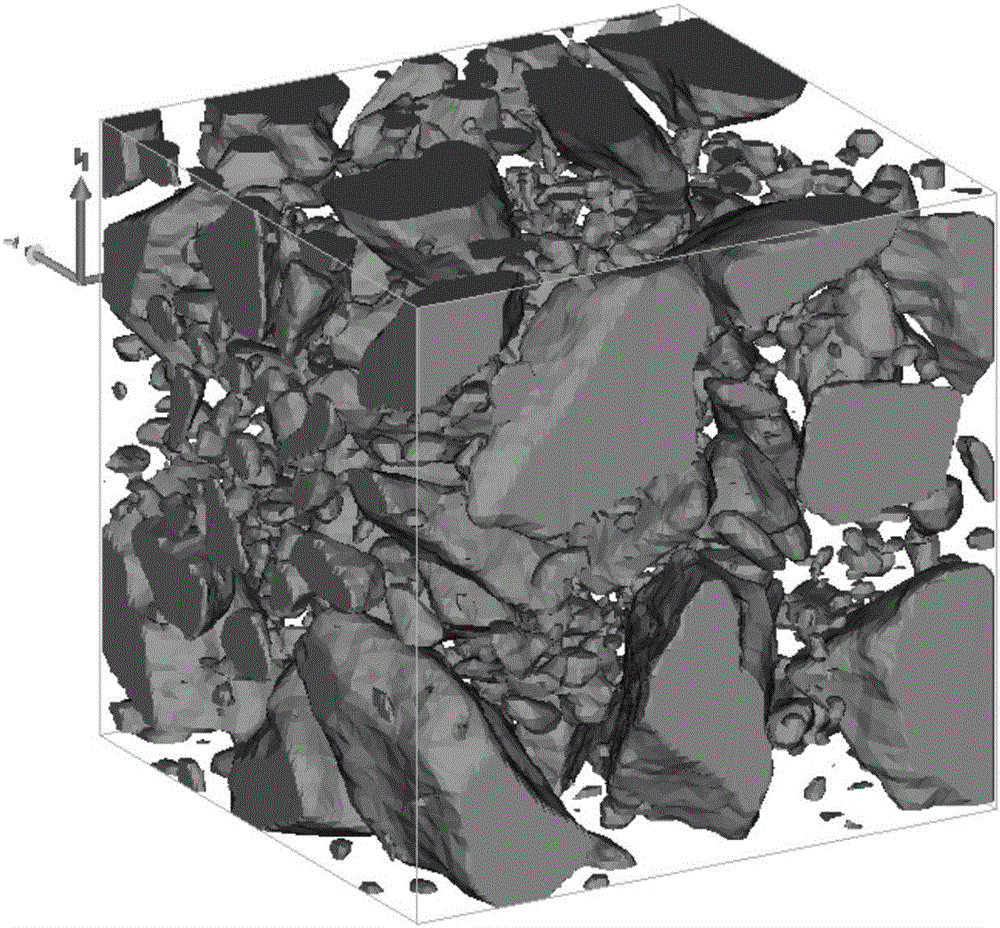

Concrete microscopic three-phase structure visualization method based on 3D printing technology

InactiveCN106053168AAchieve preparationEfficient printingPreparing sample for investigationNon destructiveComputed tomography

The invention belongs to the technical field of concrete structure non-destructive microscopic detection, and specifically discloses a concrete microscopic three-phase structure visualization method based on a 3D printing technology. The method comprises the following steps: step one, subjecting a concrete test piece to CT scanning to obtain a plurality of two-dimensional tomography images of the concrete test piece in sequence; step two, cutting the obtained two-dimensional tomography images, and subjecting the cut images to three-dimensional model reconstruction; step three, sending the reconstructed three-dimensional model to a 3D printing machine, and printing a solid model by the 3D printing machine according to the received three-dimensional model. The provided method is based on a three-dimensional digital model, and is combined with a 3D printing technology. Aiming at three phases: mortar in concrete, aggregate, and pores, different composite materials are adopted to carry out 3D printing, a concrete three-phase structure interior visualization model, which cannot be produced by a conventional manufacturing technology, can be produced, and the printing is high efficient and repeatable.

Owner:CHANGAN UNIV

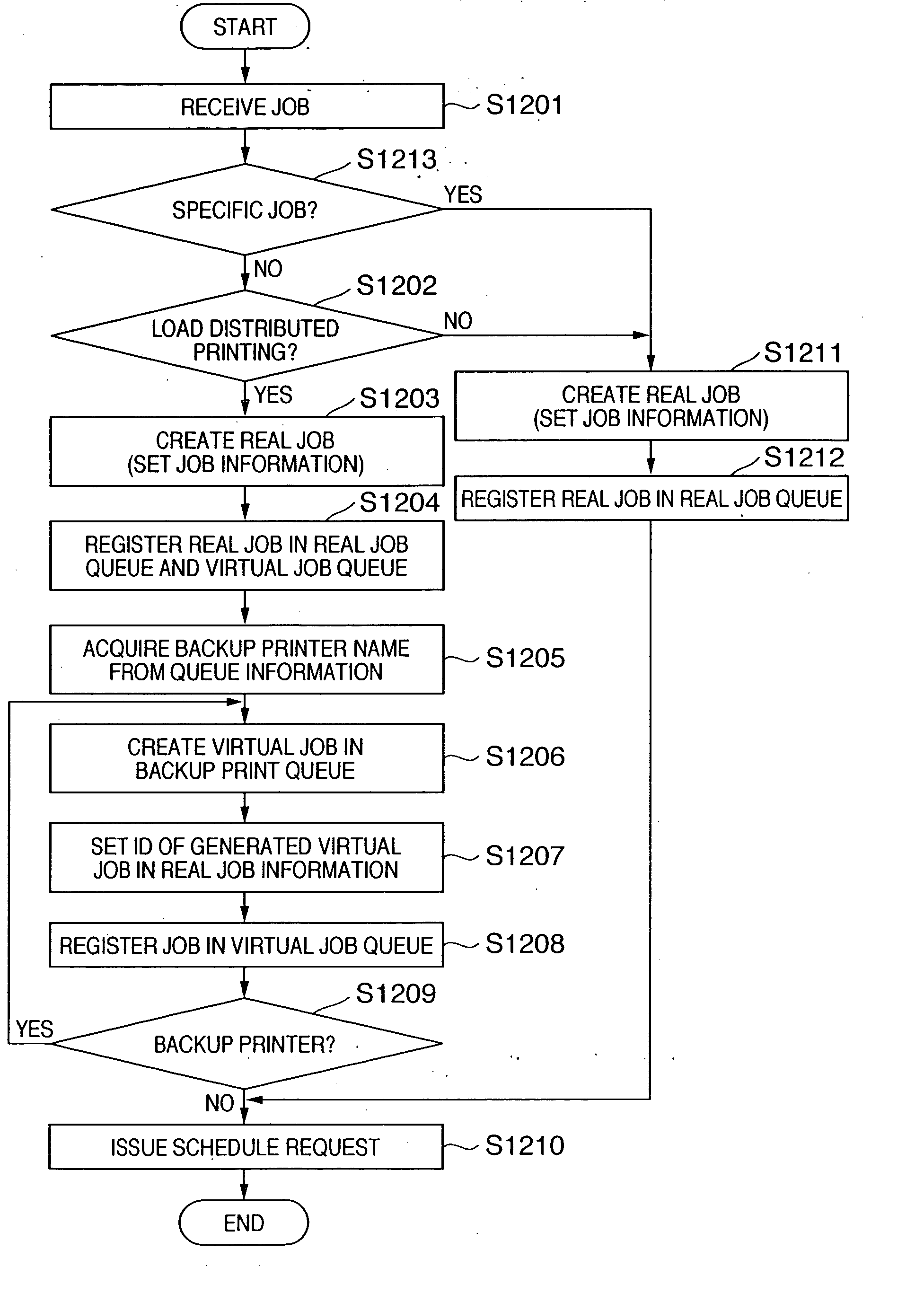

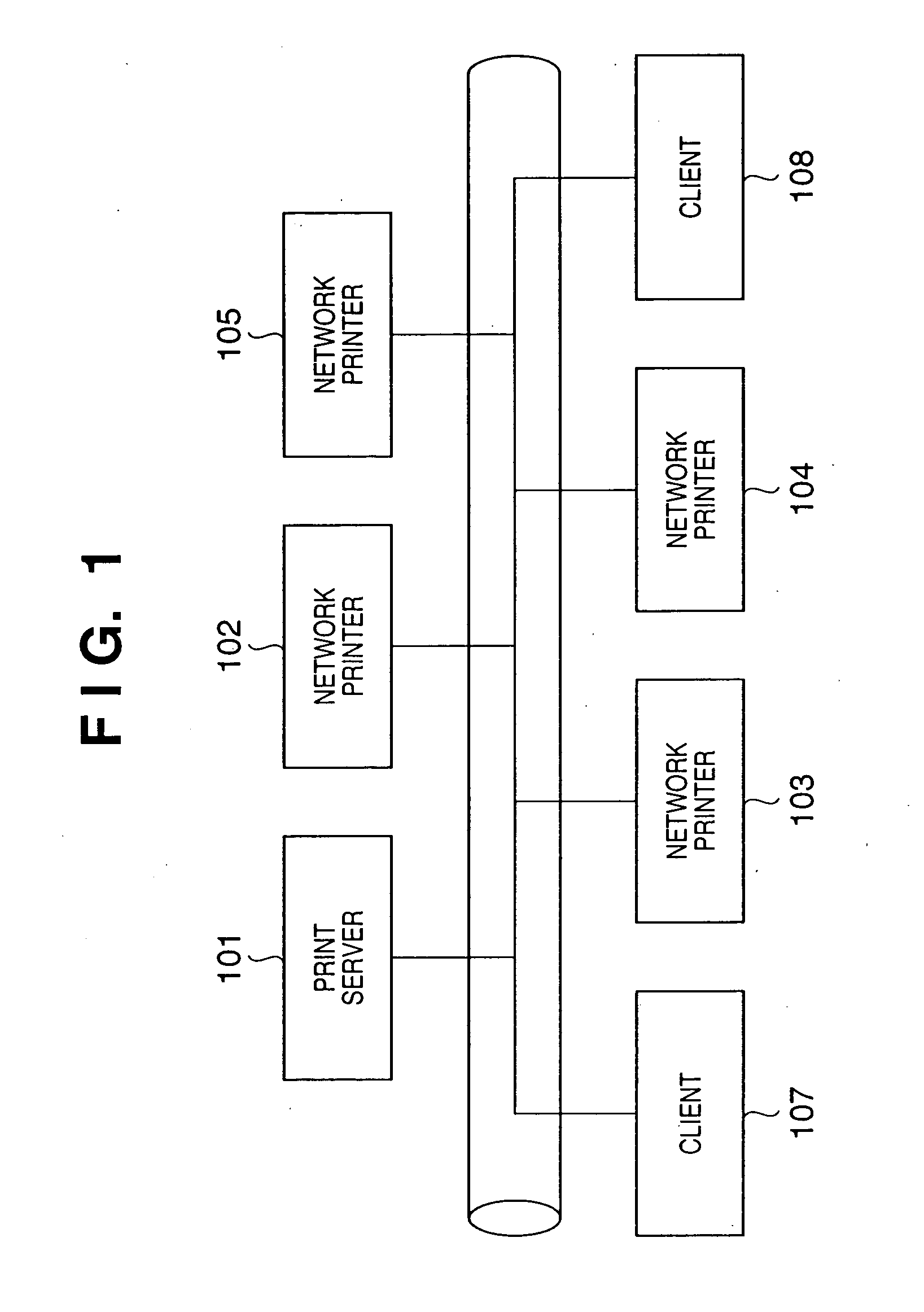

Method and apparatus for executing load distributed printing

InactiveUS20050128512A1Efficient and effective printingEfficient printingDigitally marking record carriersDigital computer detailsInformation processingComputer science

There is disclosed a system which efficiently and effectively executes printing even when an error occurs in a printing apparatus. An apparatus according to the present invention is an information processing apparatus which includes a plurality of print queues corresponding to a plurality of printing apparatuses, comprising registration means for registering, in the plurality of print queues, job information including information which can link to print data, and means for excluding, from schedule up targets, job information except job information scheduled up first in accordance with a vacant state of the print queues, and when interruption of printing has occurred in a printing apparatus which has output a print job based on the job information scheduled up, setting the job information excluded from the schedule up targets as a schedule up target.

Owner:CANON KK

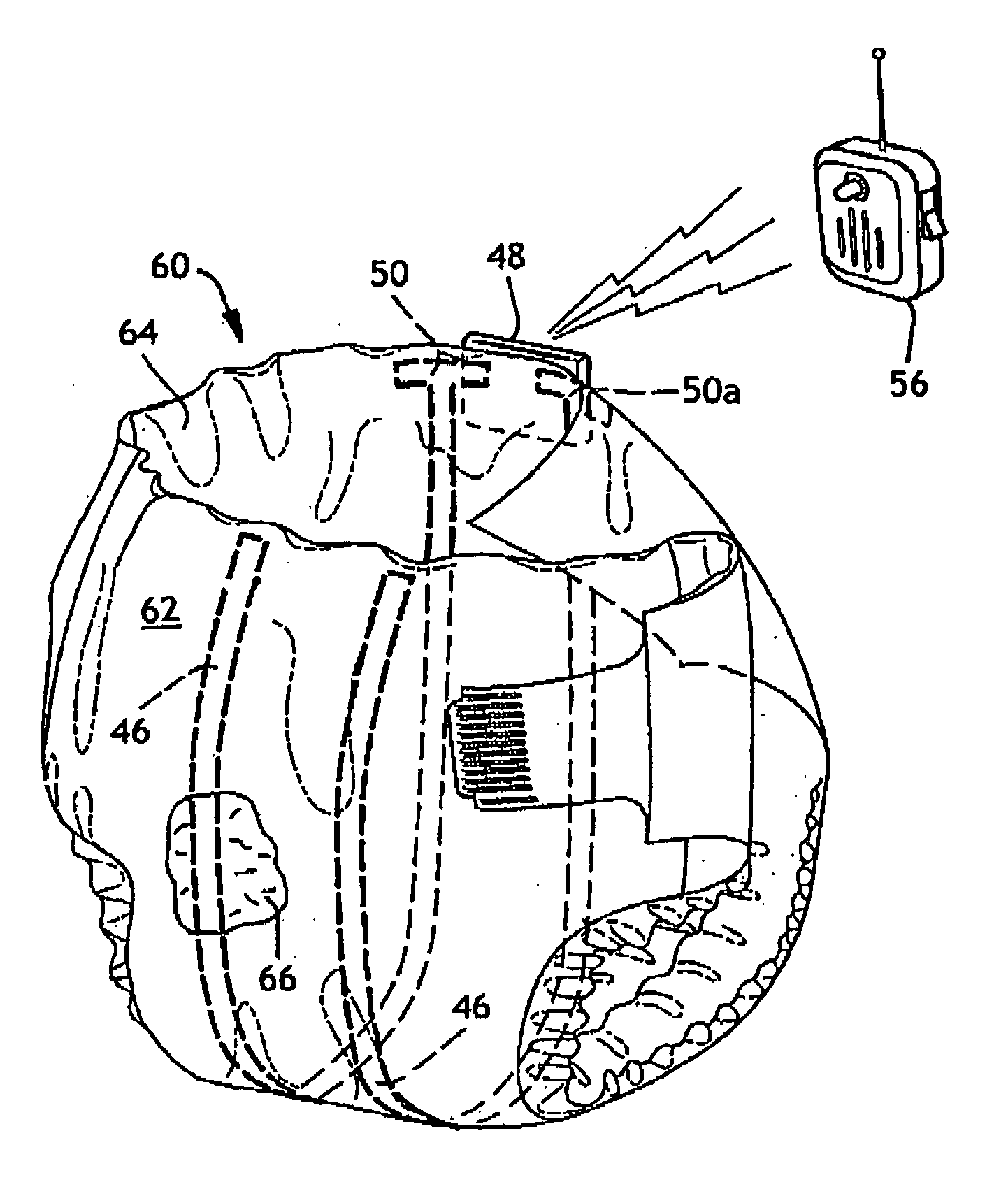

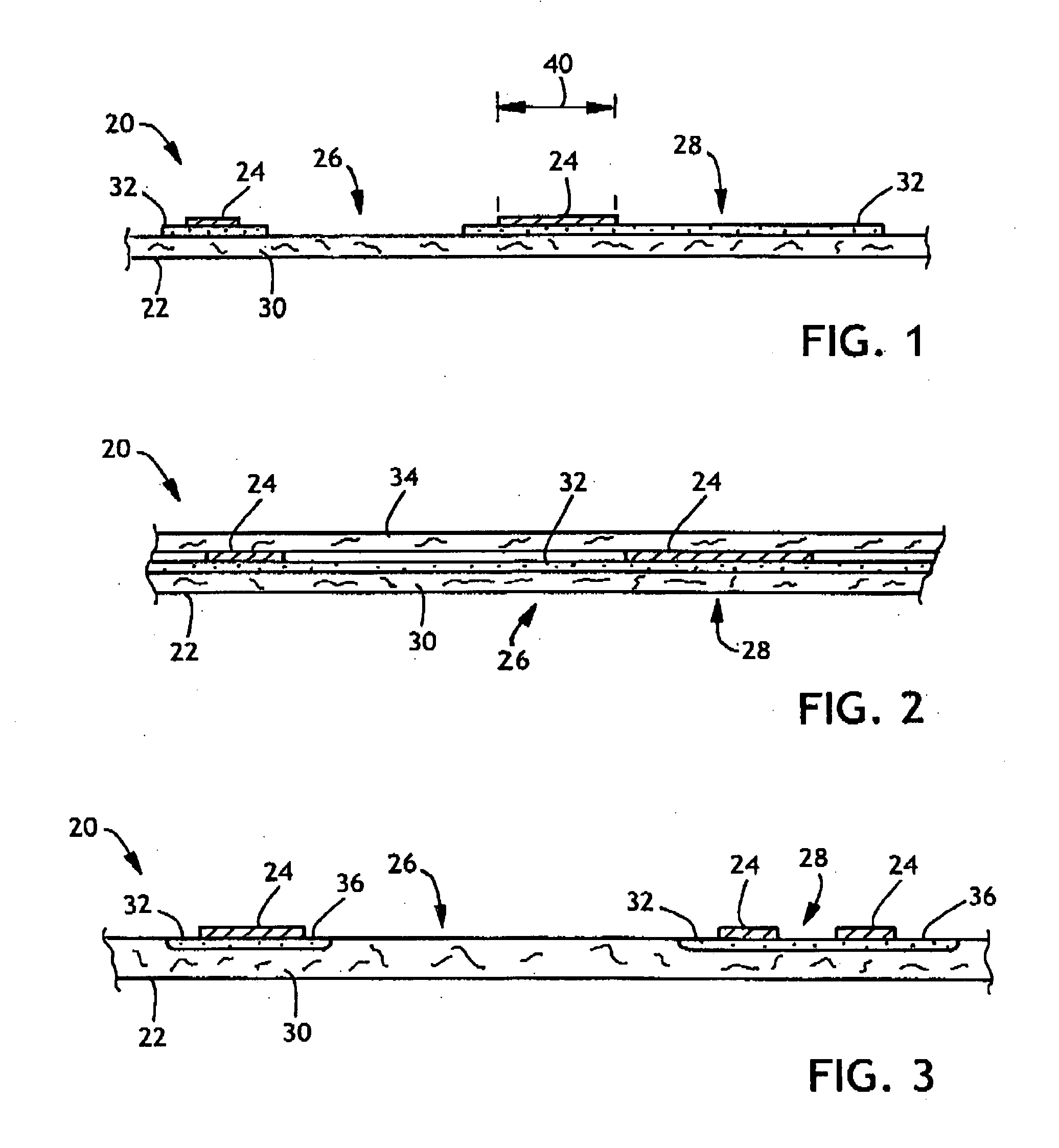

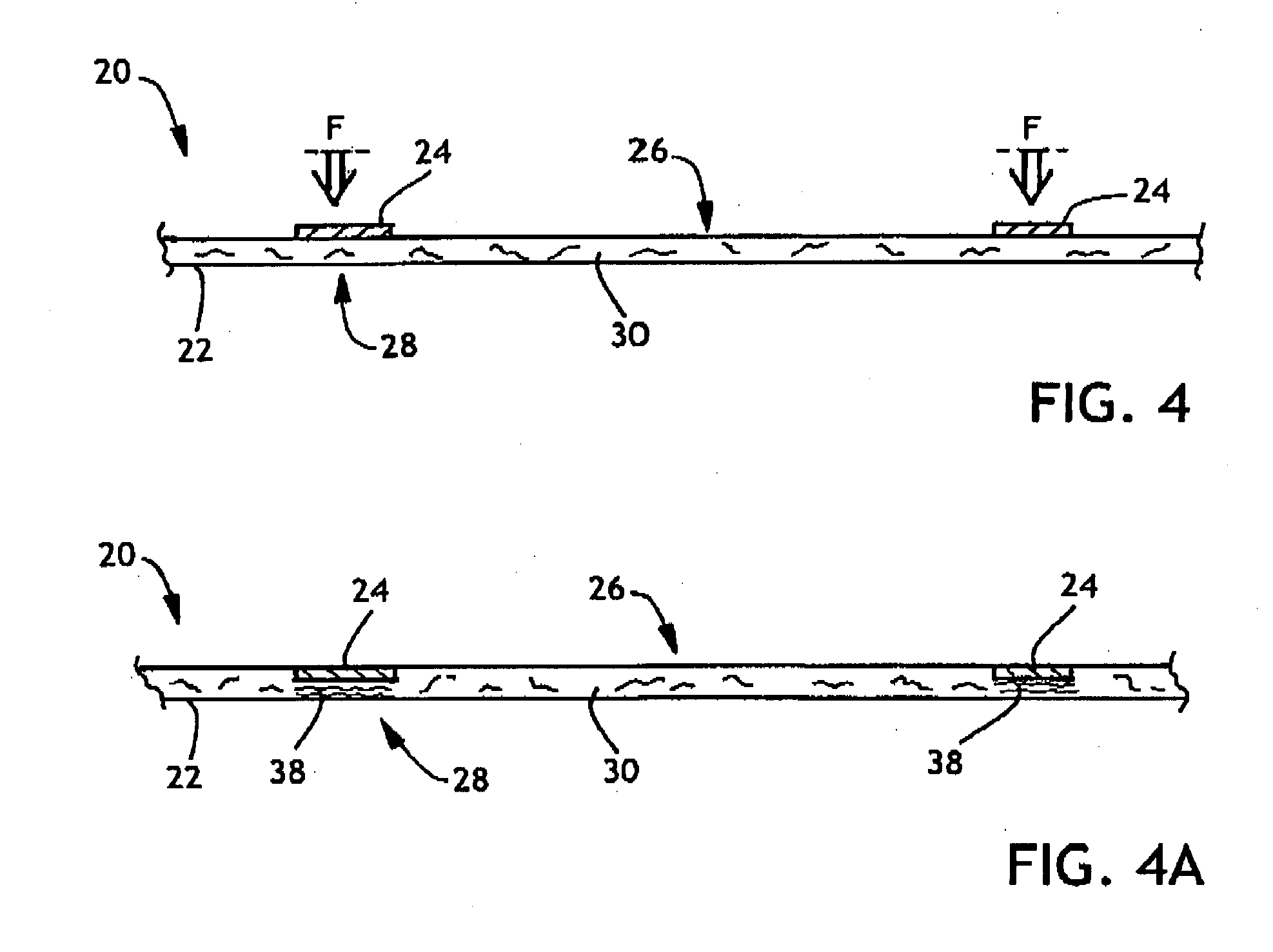

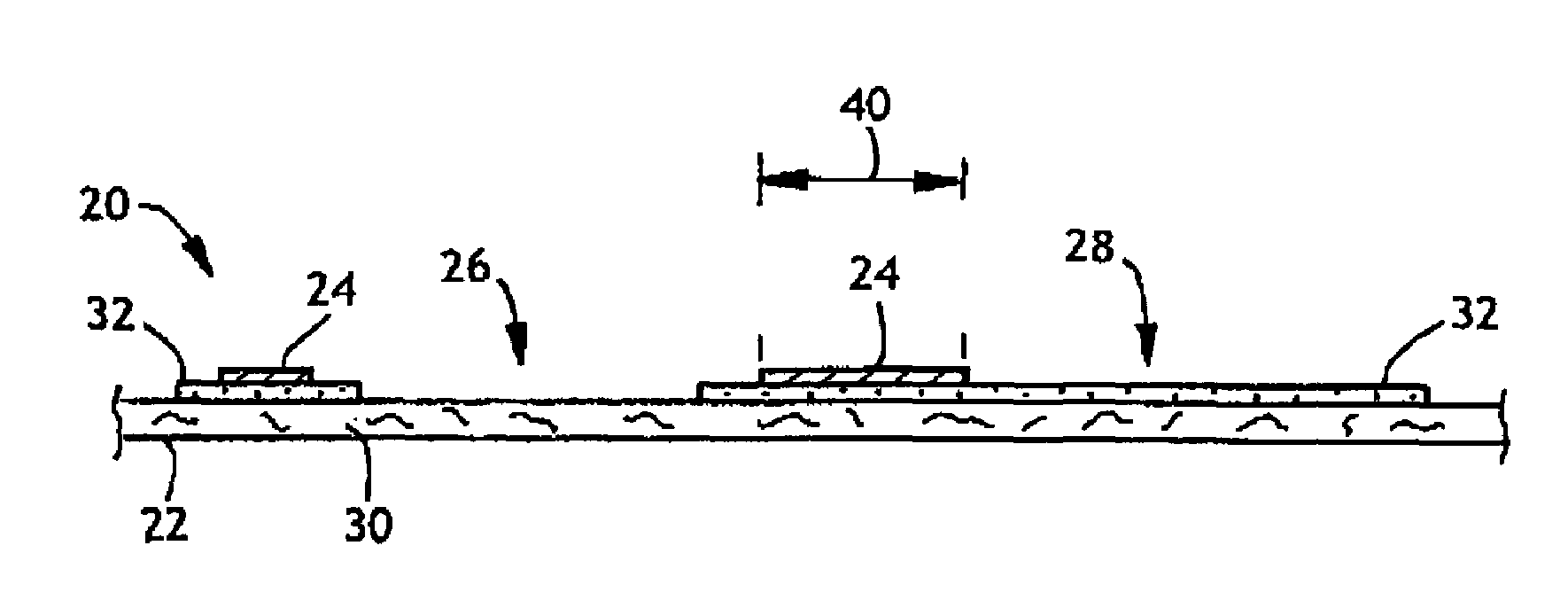

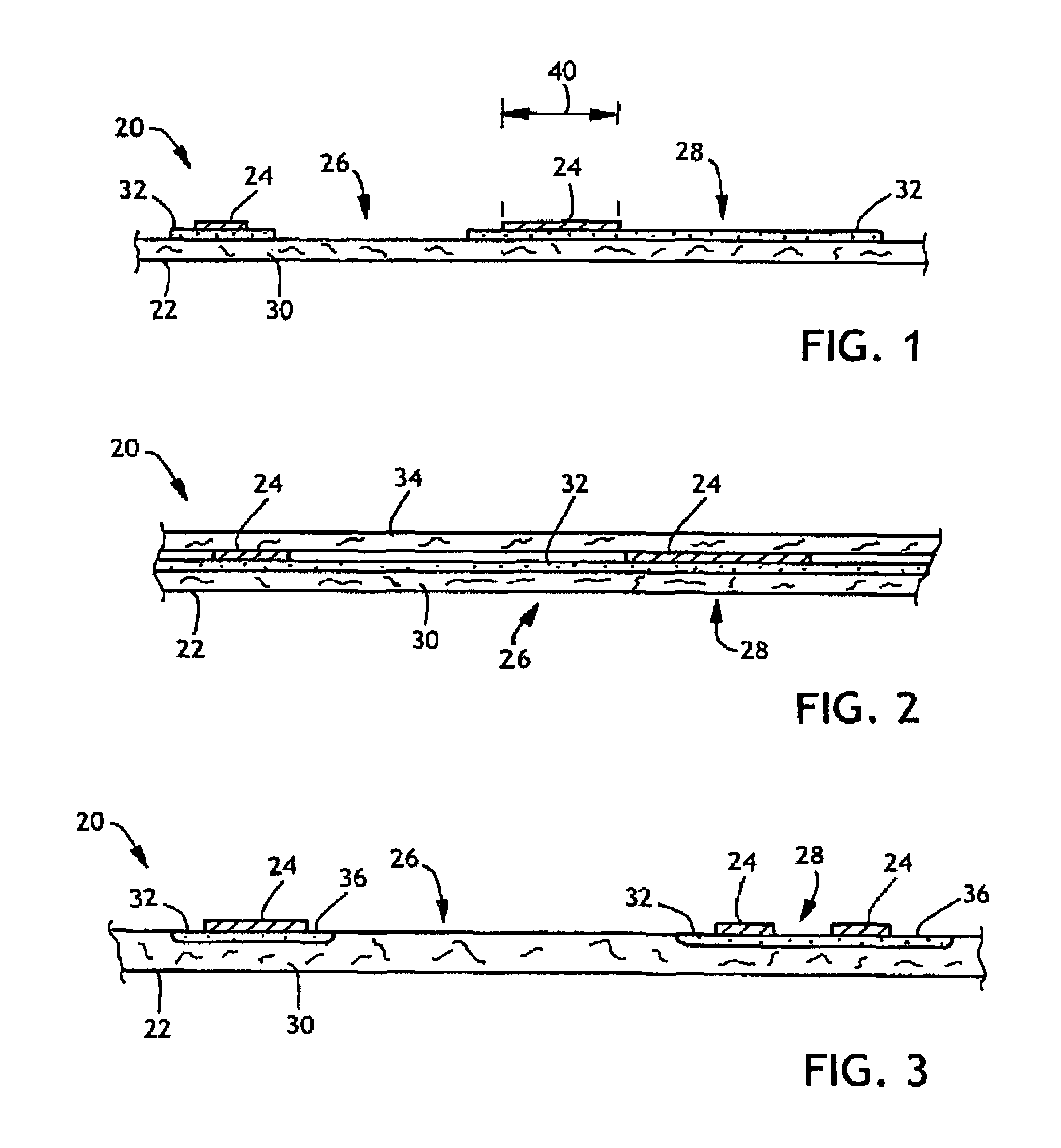

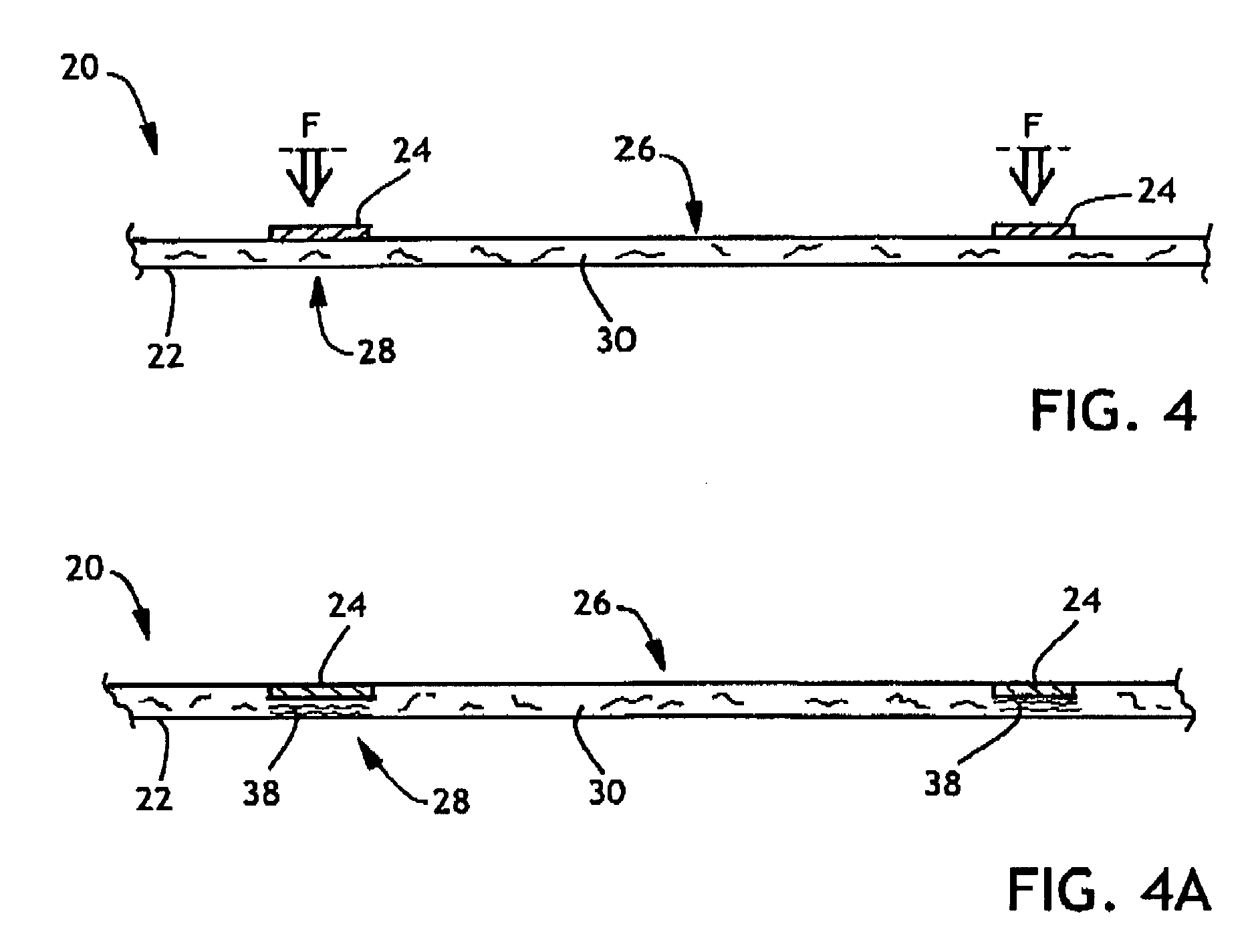

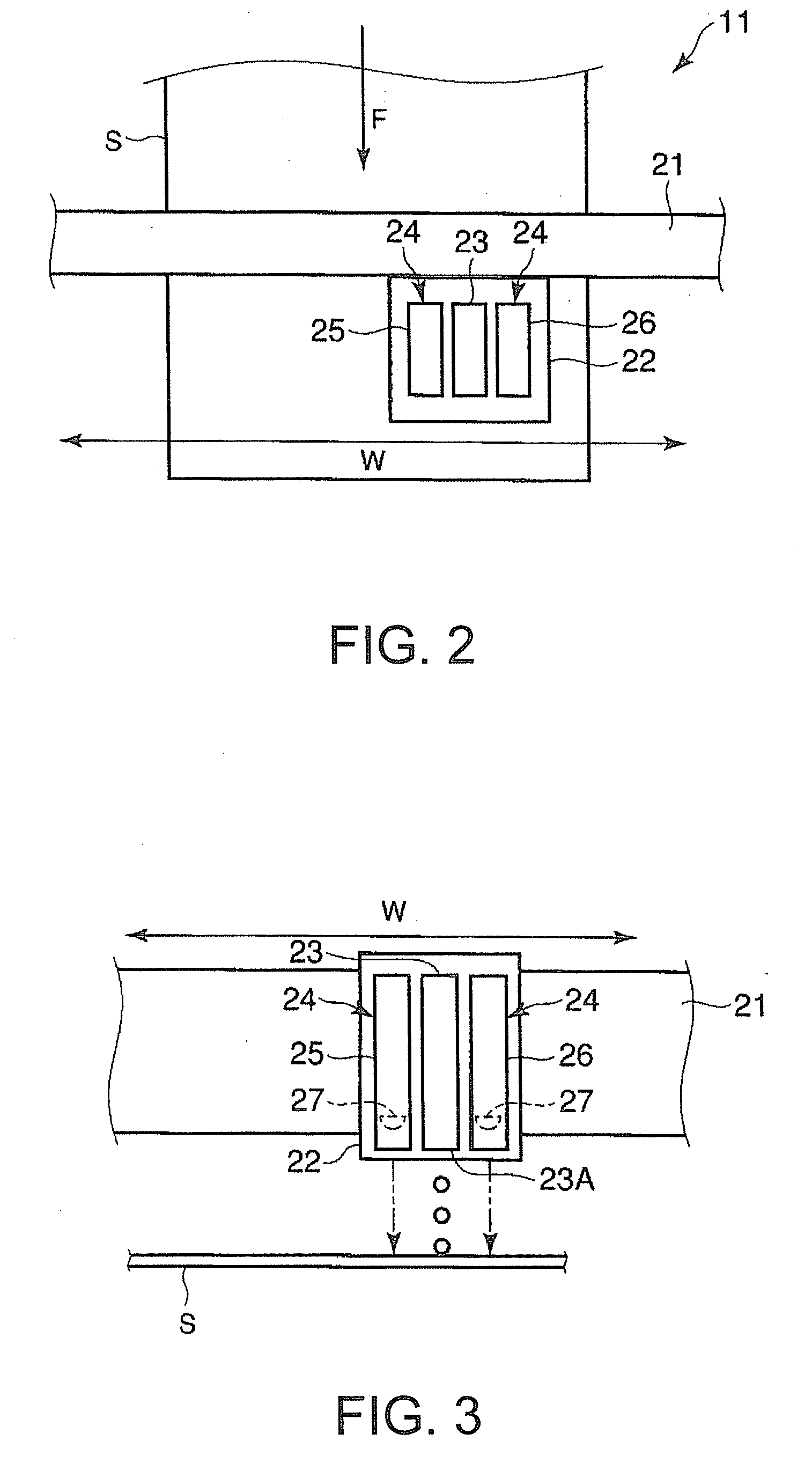

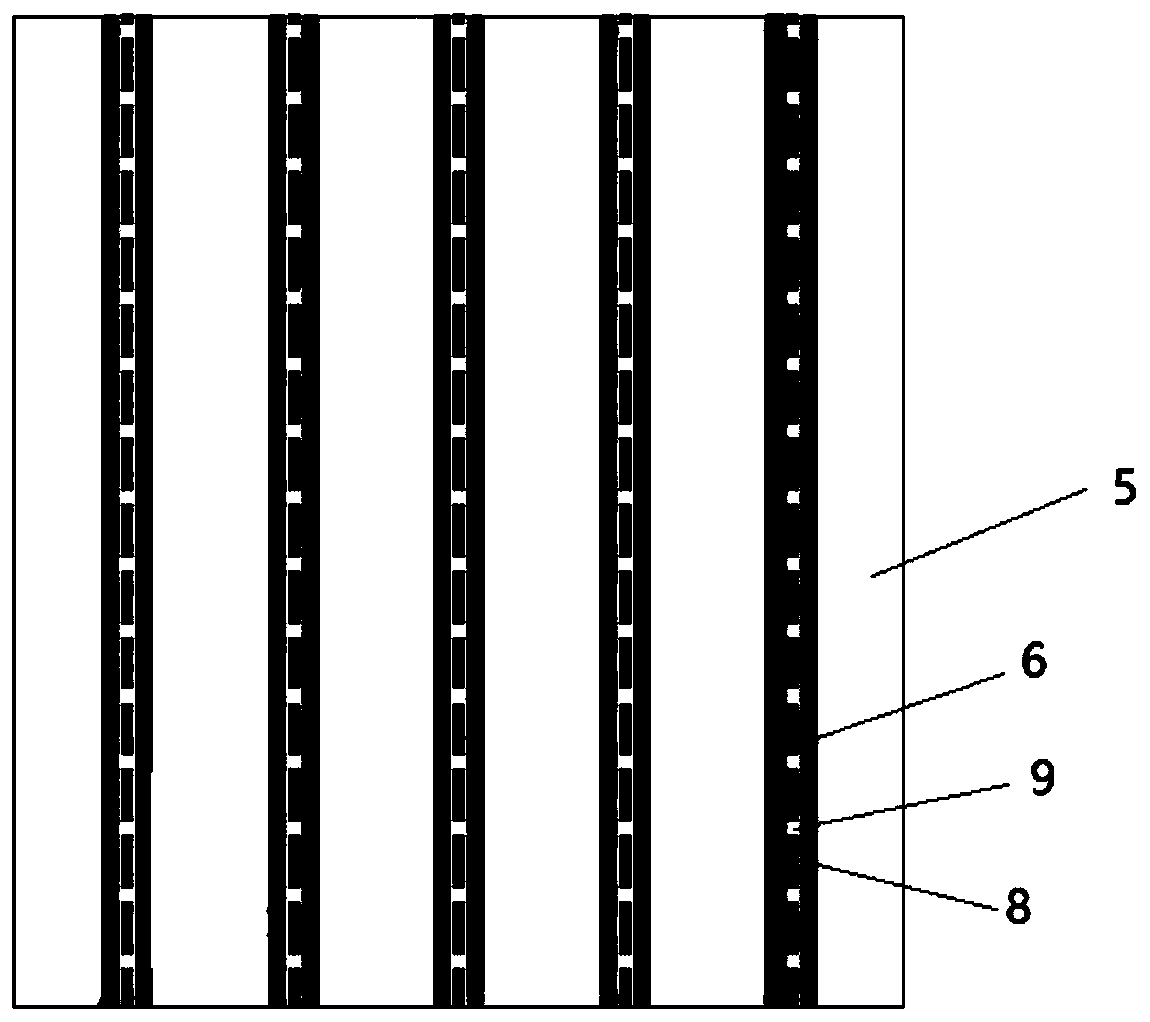

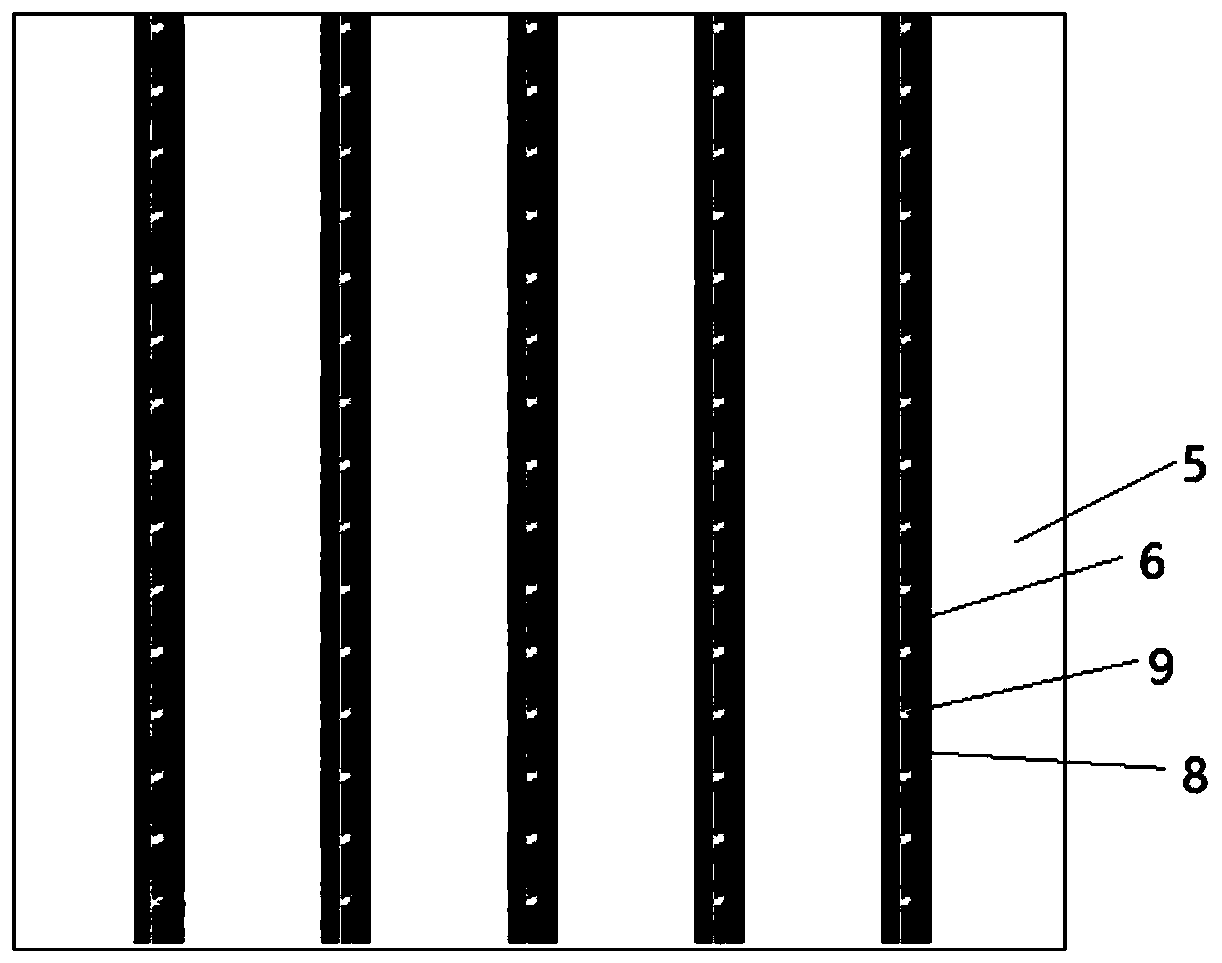

Conductive porous materials

InactiveUS20080058744A1Reduce conductivityEfficient printingBaby linensWoven fabricsHigh resistivityConductive materials

A limited use, disposable article (20), comprises a matrix-substrate (22), and an electrically-conductive region (24) of a separately provided, electrically-conductive material that has been operatively applied to the matrix-substrate from a viscous configuration of the electrically-conductive material. The matrix-substrate includes a first matrix-region (26), and at least a second matrix-region (28). At least the second matrix-region (28) can include a treatment that provides for an operative formation of a selected resistivity in the electrically-conductive region. The first matrix-region (26) has a high resistivity, and the electrically-conductive region (24) is positioned operatively adjacent the second matrix-region (28). The electrically-conductive region (24) has a low resistivity, as determined when the electrically-conductive region is positioned operatively adjacent the second matrix-region and configured for its intended use.

Owner:KIMBERLY-CLARK WORLDWIDE INC

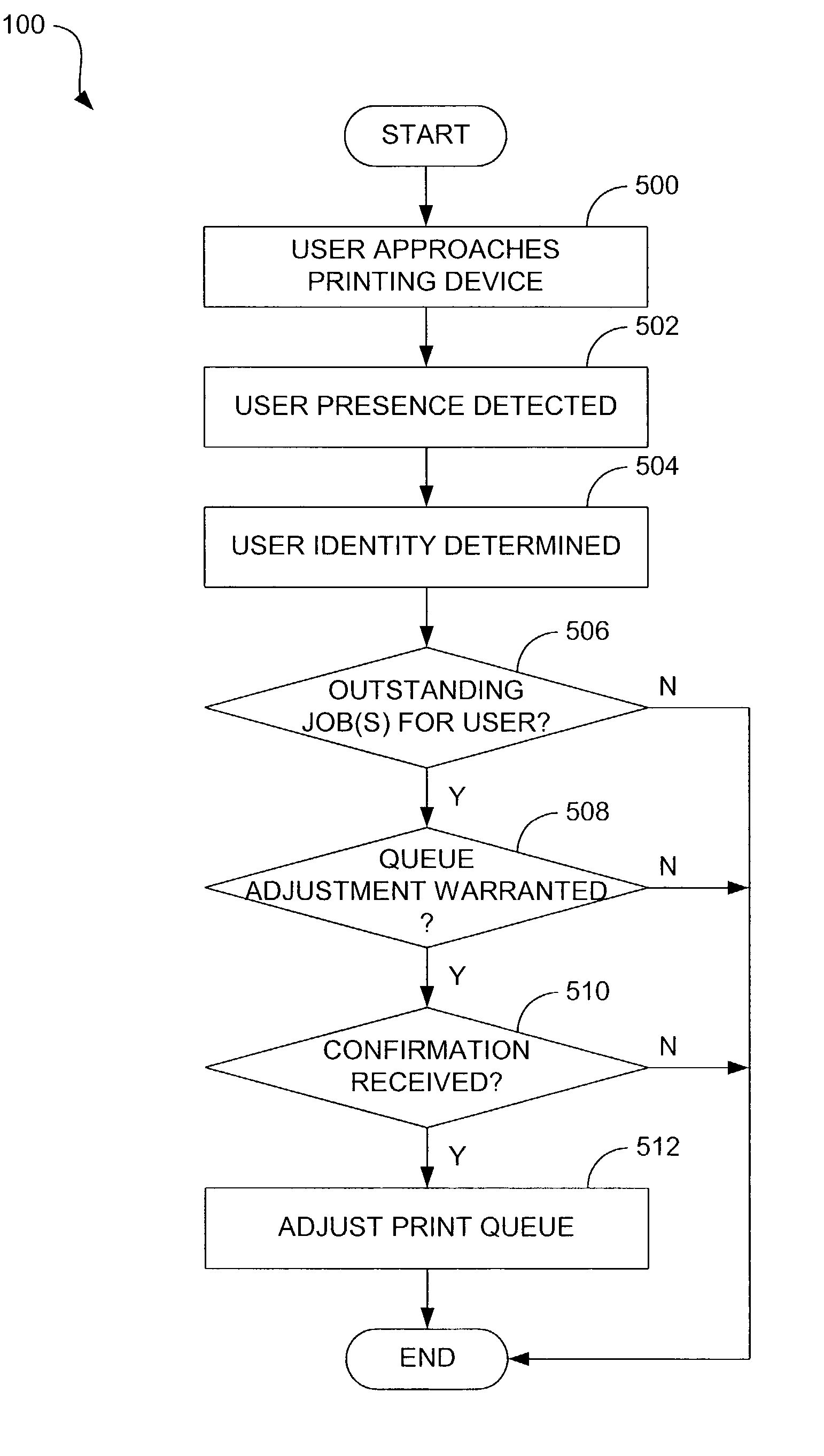

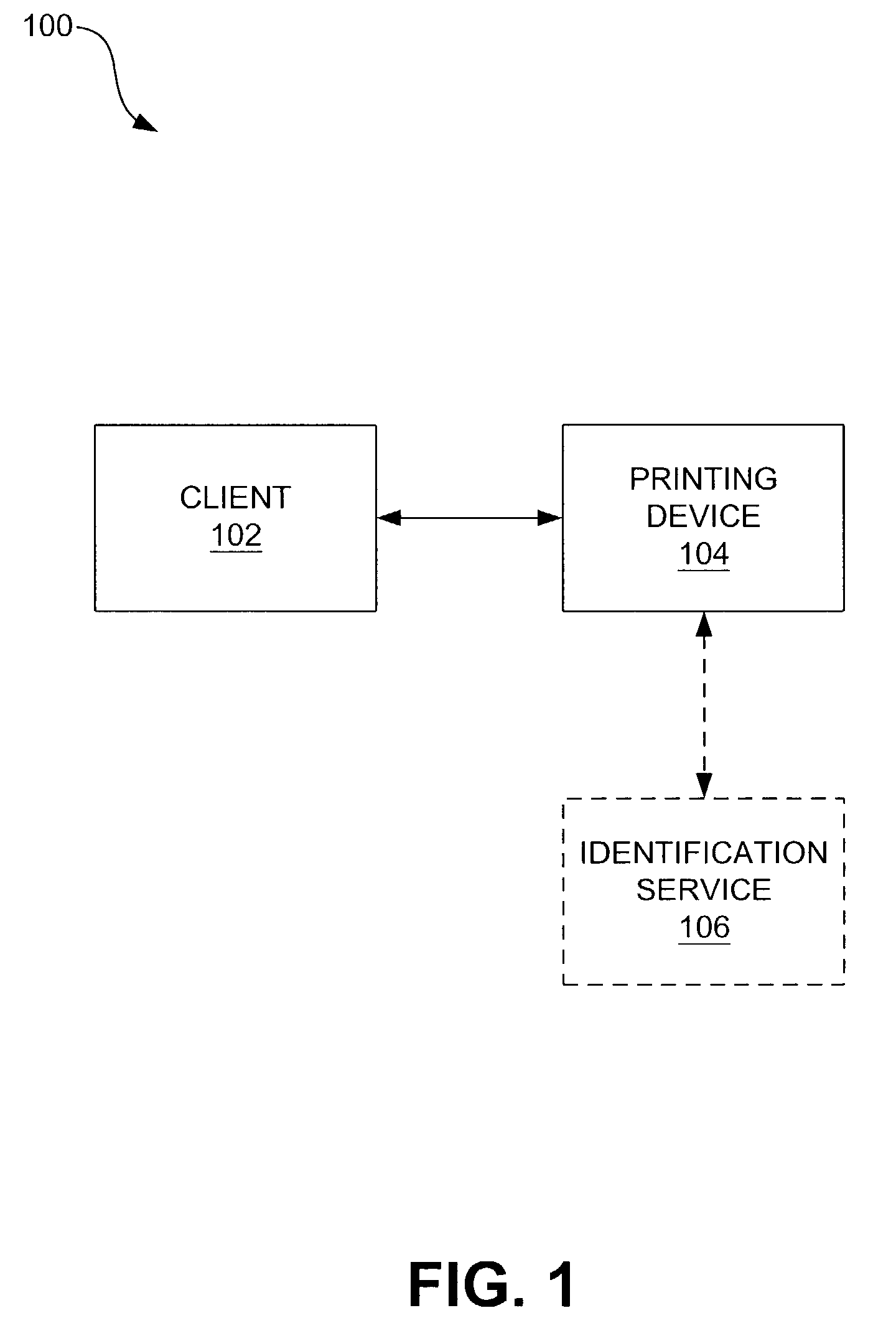

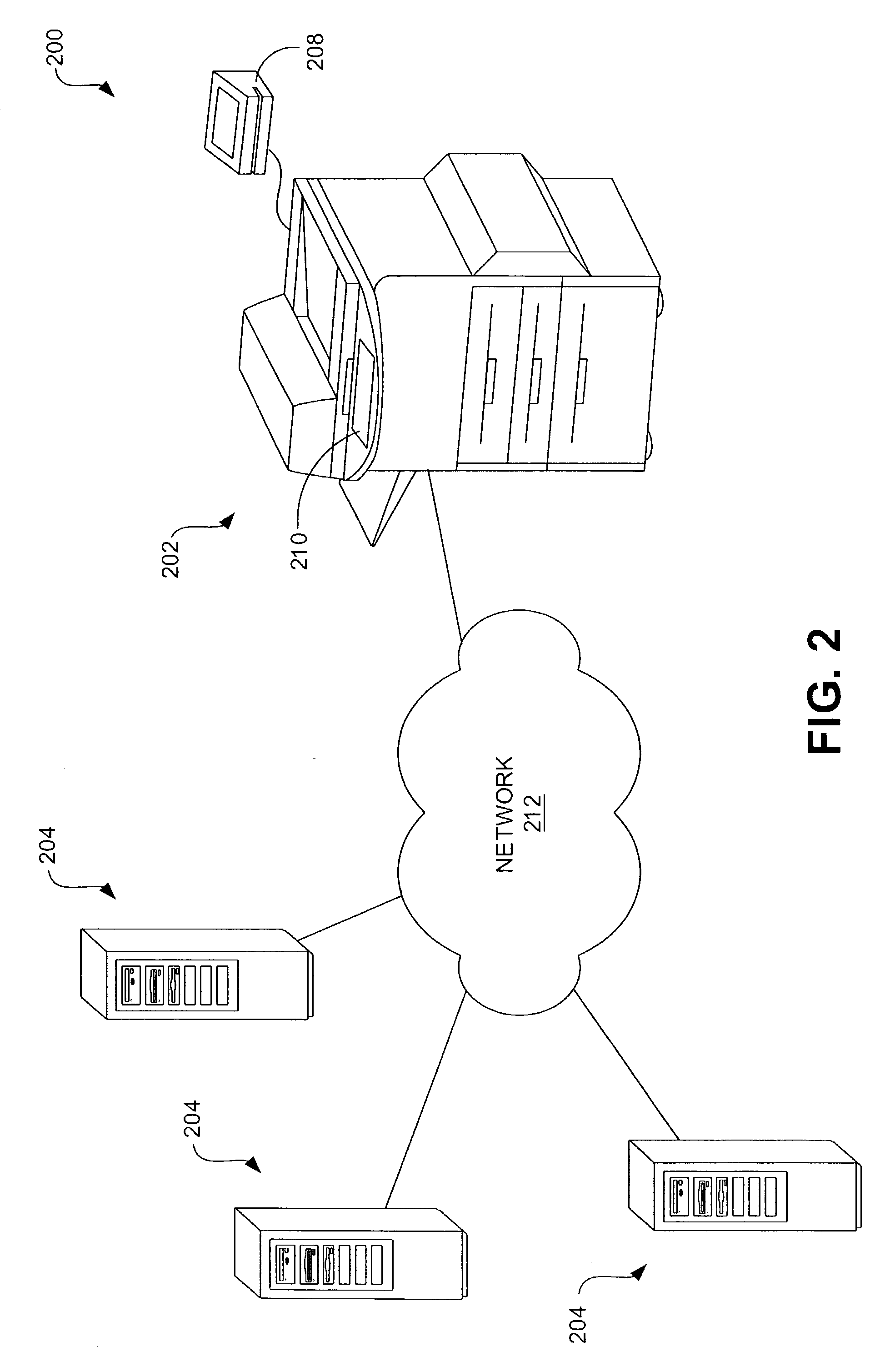

Proximity-based print queue adjustment

ActiveUS7187462B2Efficient printingDigital data processing detailsUnauthorized memory use protectionDatabase

Systems and methods for adjusting print queues to obtain more efficient printing are disclosed. In one embodiment, a system and method for adjusting a print queue pertain to detecting proximity of a user to the printing device, determining if the user has any outstanding print jobs, and adjusting a print queue for the printing device if it is determined that the user does have an outstanding print job. By way of example, adjusting the queue can include one or more of interrupting a current print job so that the user's print job can be printed, elevating the user's print job in the order of the queue, and adding the user's print job from another queue to the queue for the printing device.

Owner:HEWLETT PACKARD DEV CO LP

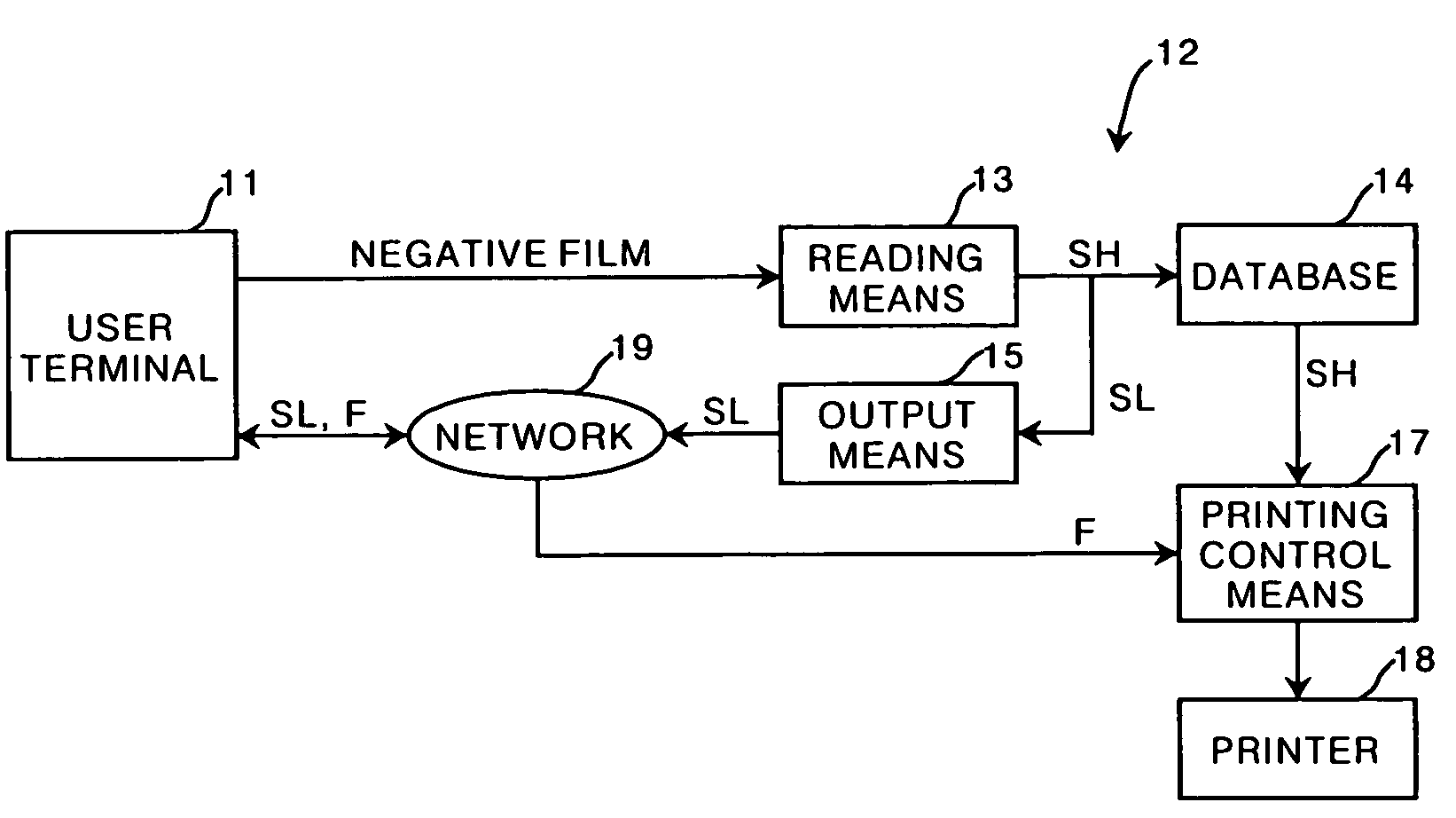

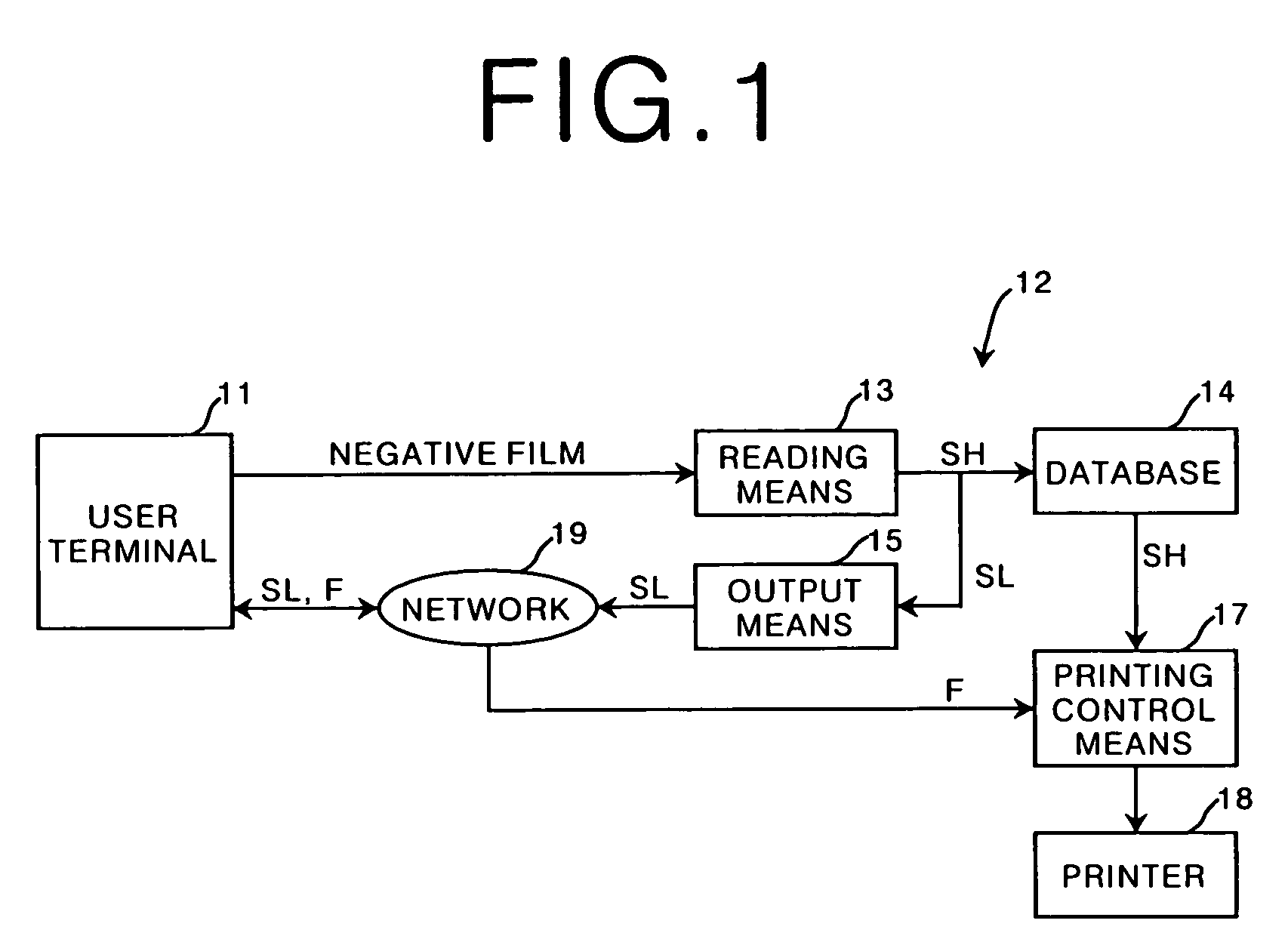

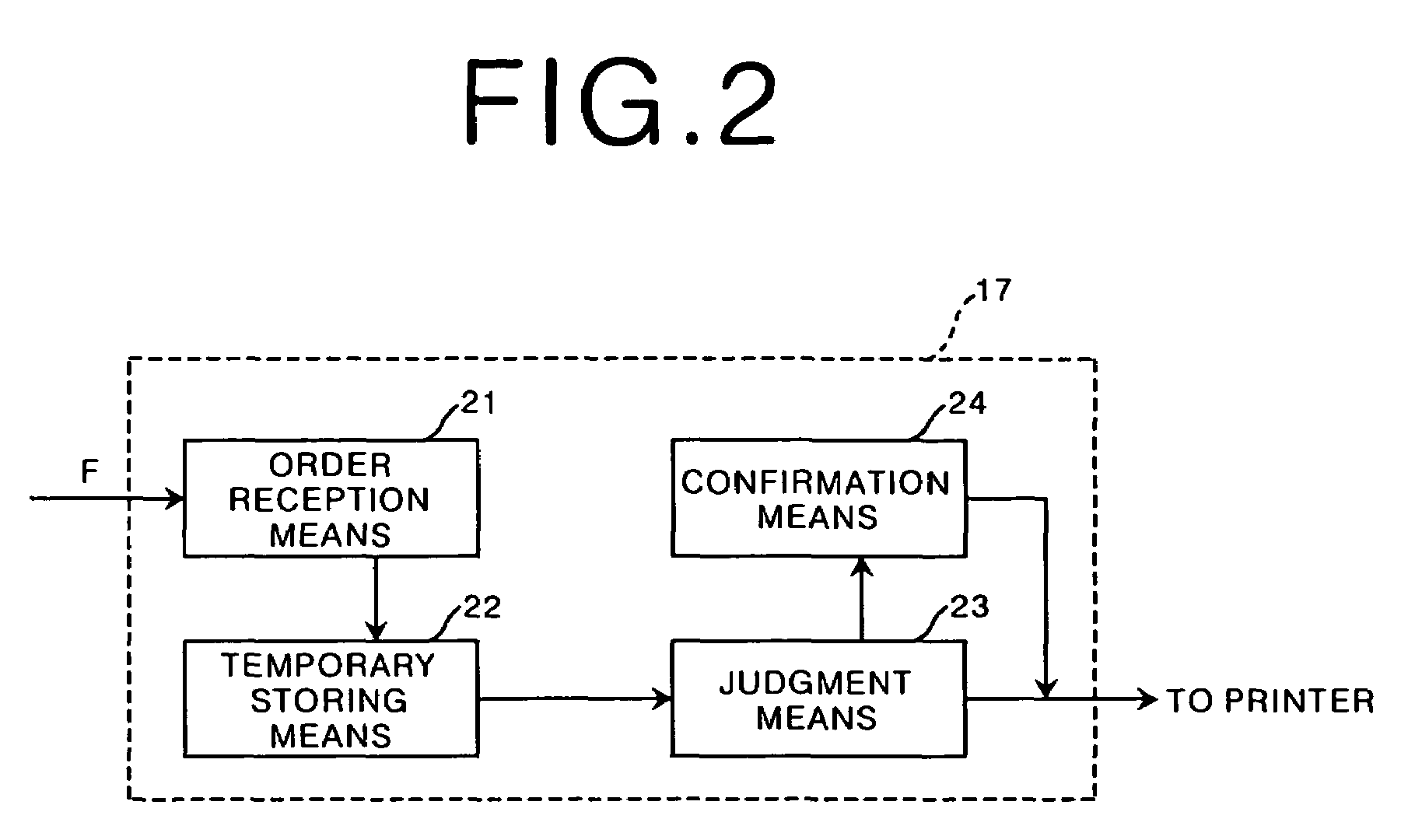

Method, apparatus and recording medium for printing control

InactiveUS7034958B1Reduction in the operator's workloadEfficient printingDigitally marking record carriersDigital computer detailsOrder formWorkload

Upon carrying out printing based on order information, a workload of an operator can be reduced. An order file transferred to a laboratory via a network is input to a printing controller and accepted by an order reception device. The order file is temporarily stored in temporary storage and input to a judgment device. The judgment device judges whether a print is a target of automatic printing or manual printing based on the order information described in the order file F. In the former case, the order information and image data to be printed are input to a printer and printing is a carried out. In the latter case, a confirmation device temporarily stores the order file F. An operator regularly confirms the order file of manual printing target and the content of printing by using the confirmation device, and inputs the image data to be printed and the order file to the printer to carry out printing.

Owner:FUJIFILM CORP

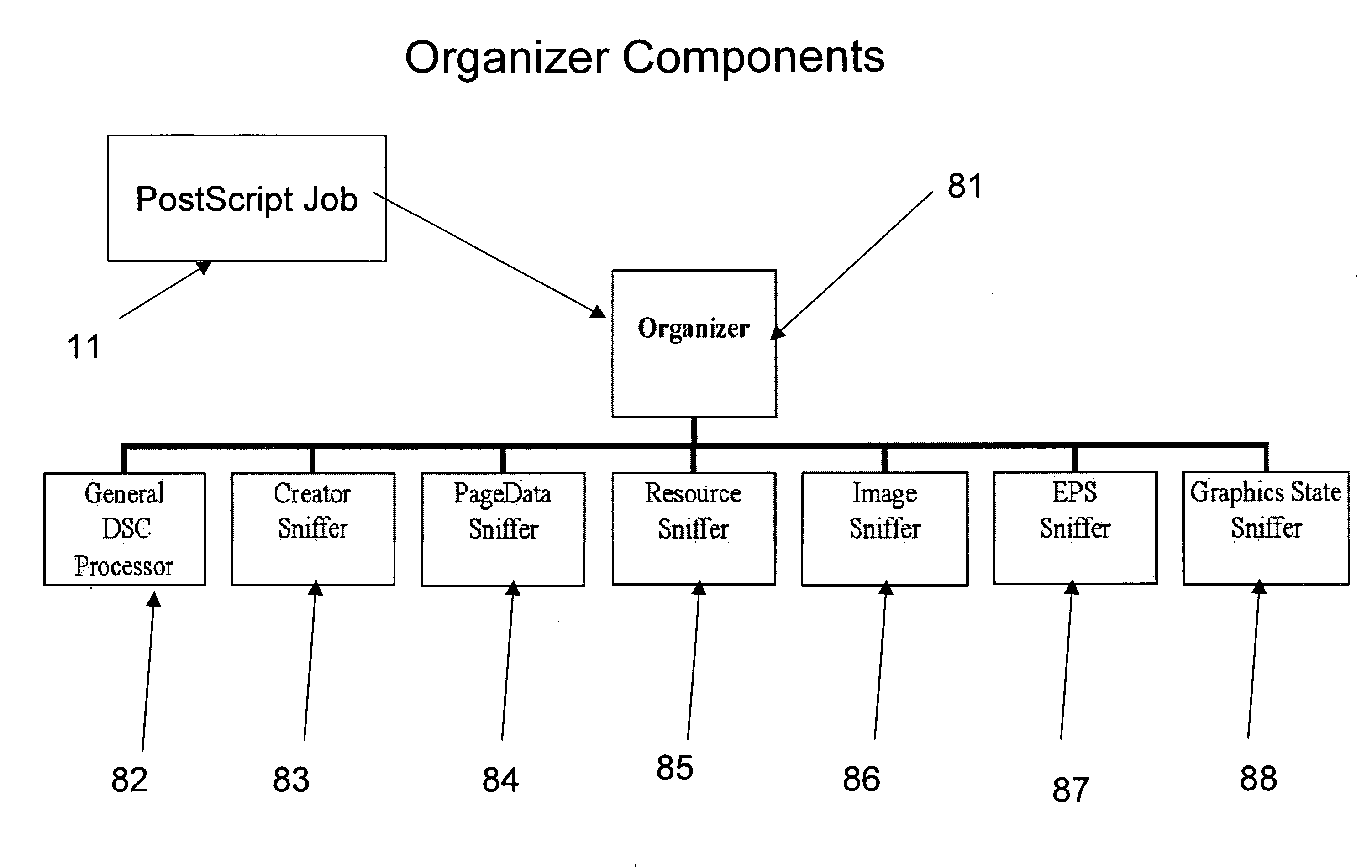

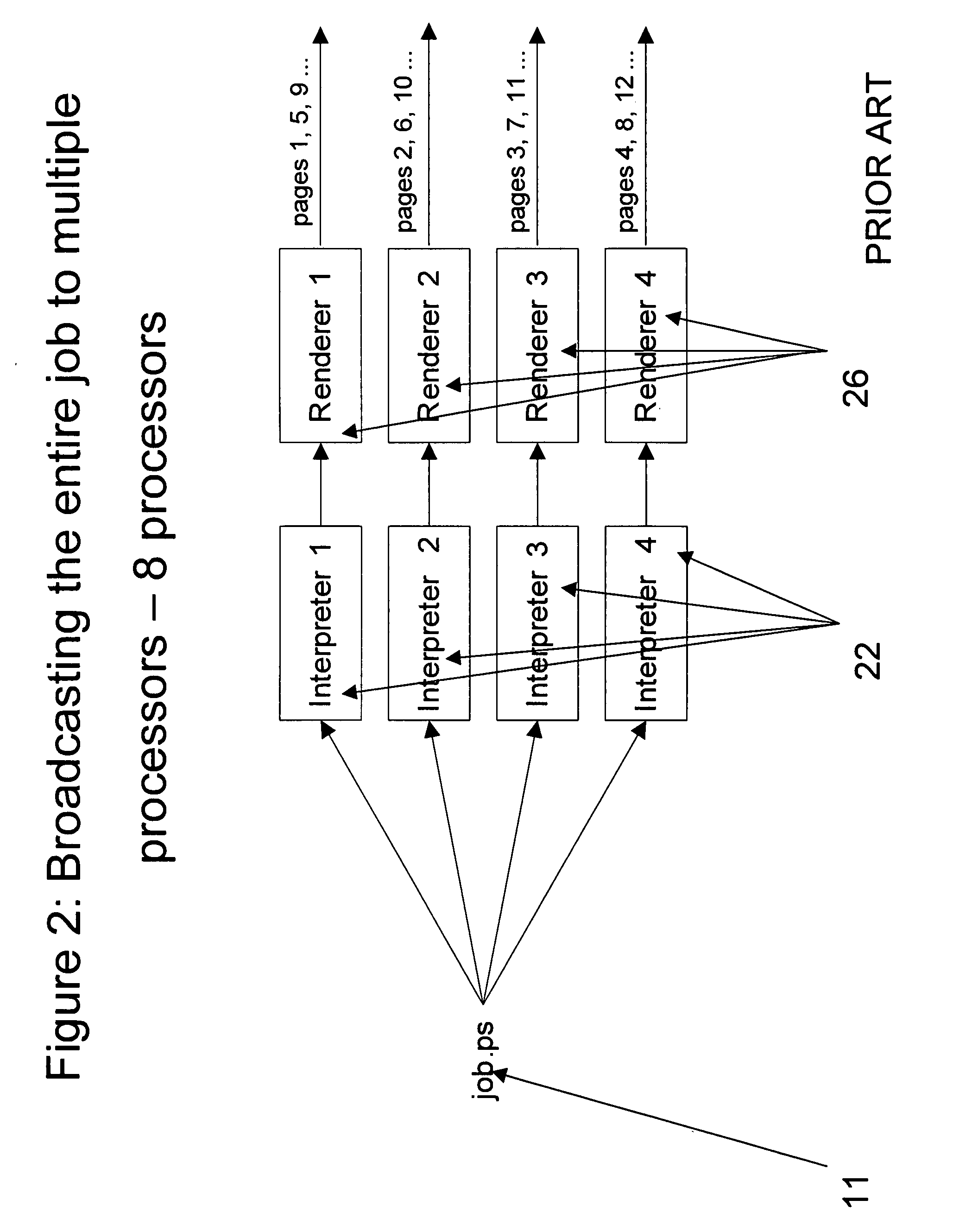

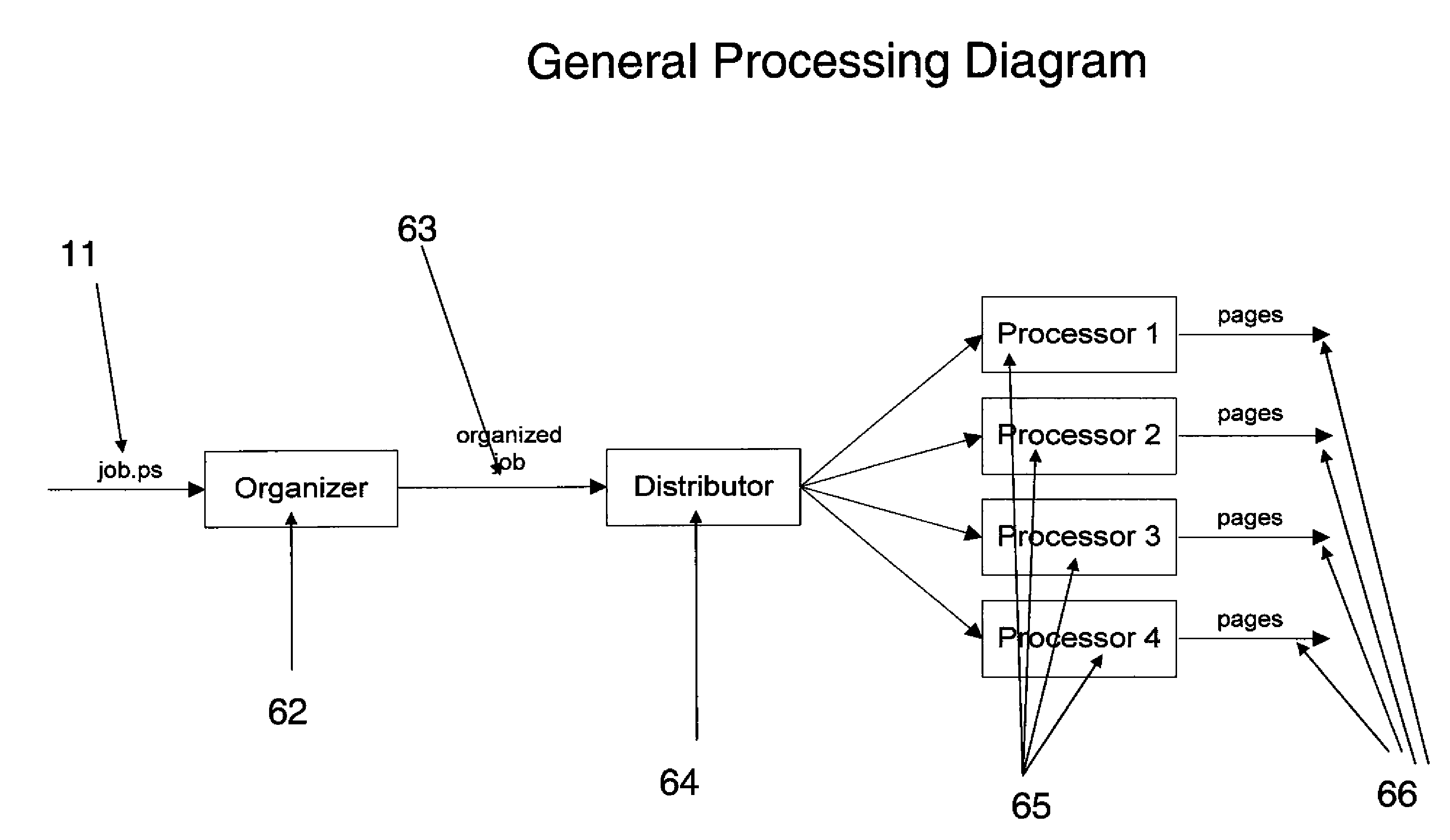

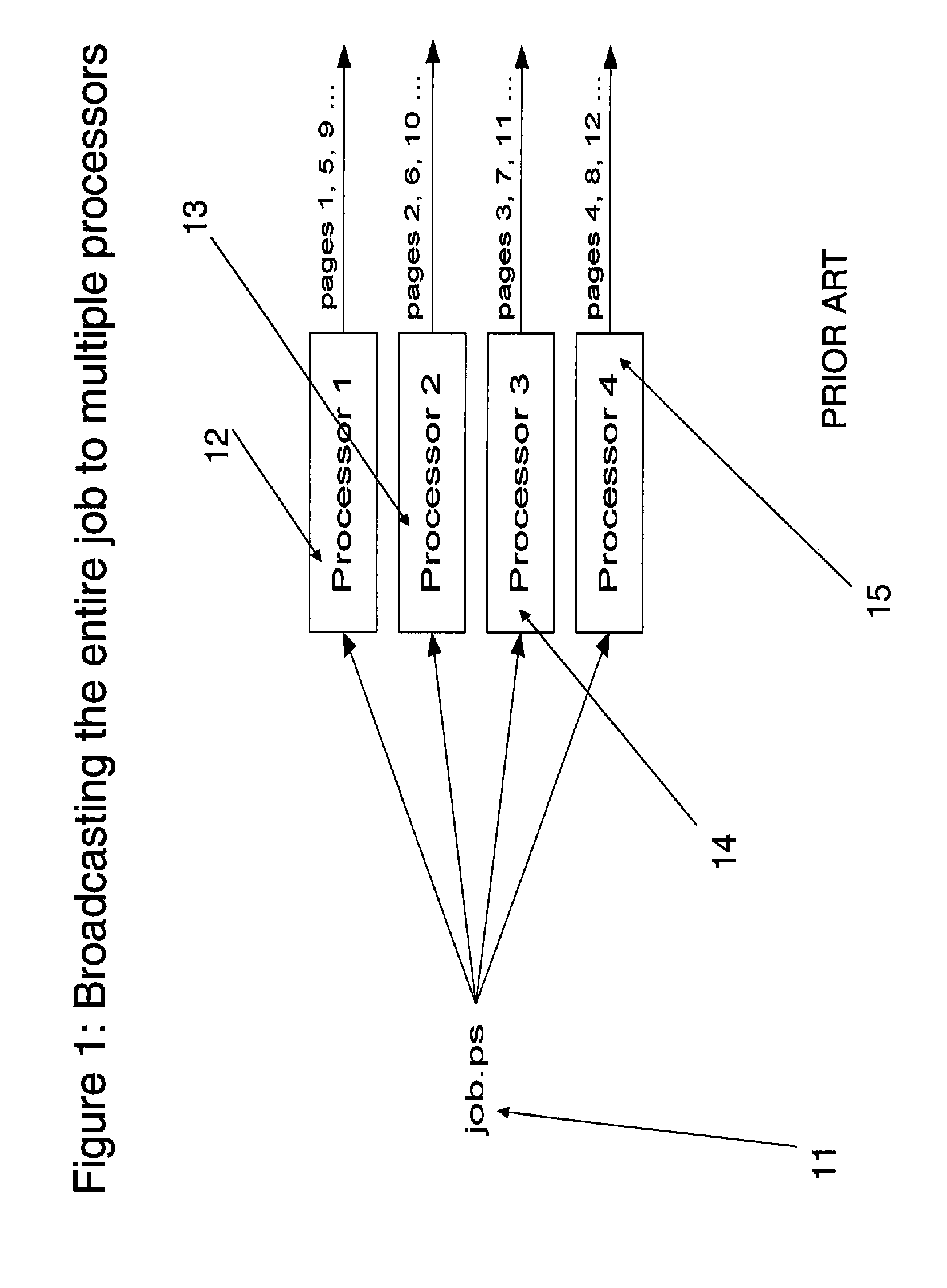

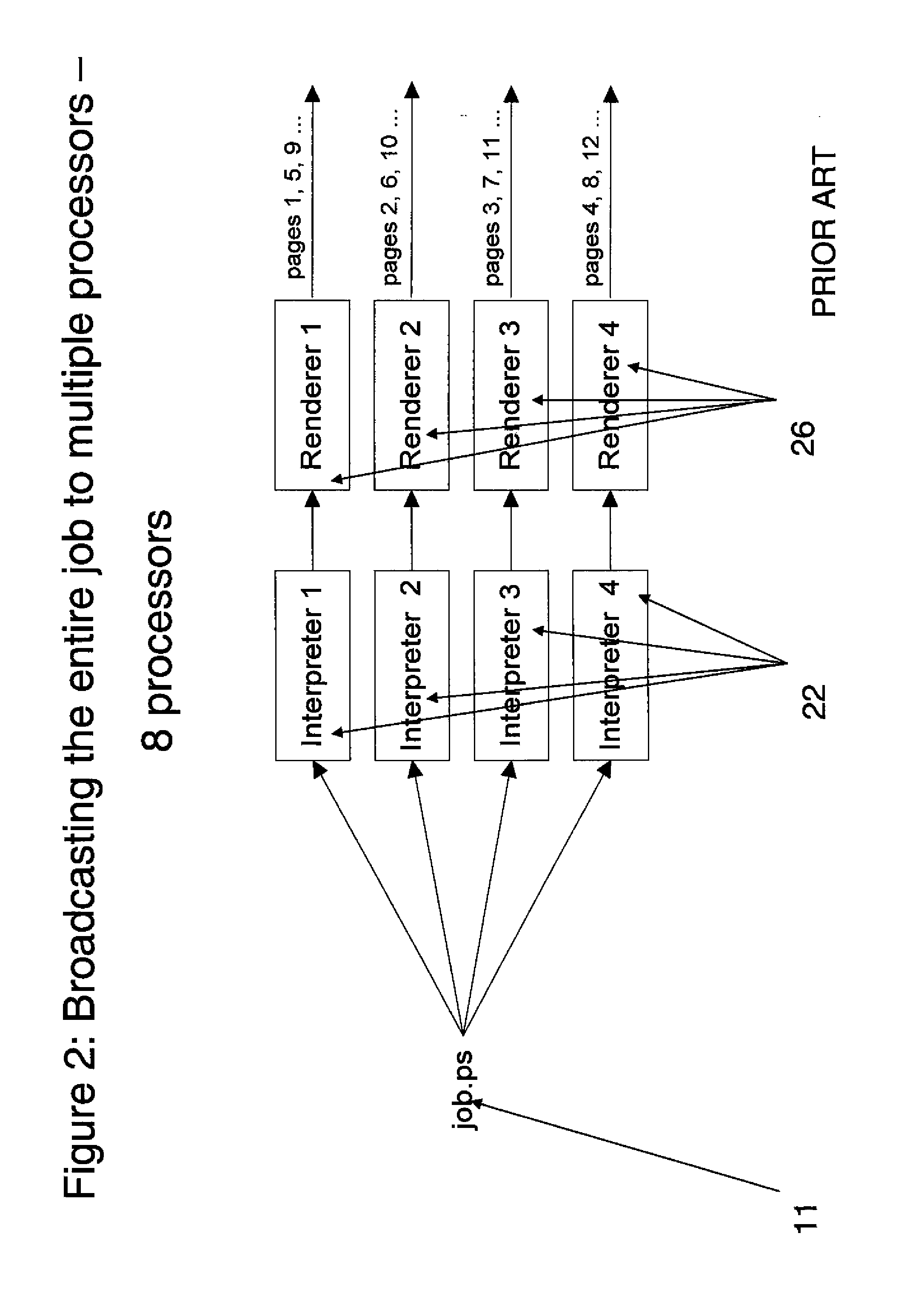

Parallel processing of page description language

InactiveUS20090080025A1Efficiently rearrangedEfficient processingVisual presentationDigital output to print unitsData streamPage description language

A method and apparatus for efficient processing a page description language (“PDL”) data stream lacking page independence is described. The method and apparatus includes applying a single parsing pass for a PDL job and detecting PDL job producers by creator sniffer (83). Shared resources in the PDL job are detected by resource sniffer (85). Page boundaries in the PDL job are detected by page data sniffer (84) and an organized representation (63) is produced without rearranging data and resources in the PDL job. The system efficiently organizes PDL stream into pages, data and resources without rearranging the stream. The organized data can be efficiently submitted to plurality of PDL processors (65).

Owner:EASTMAN KODAK CO

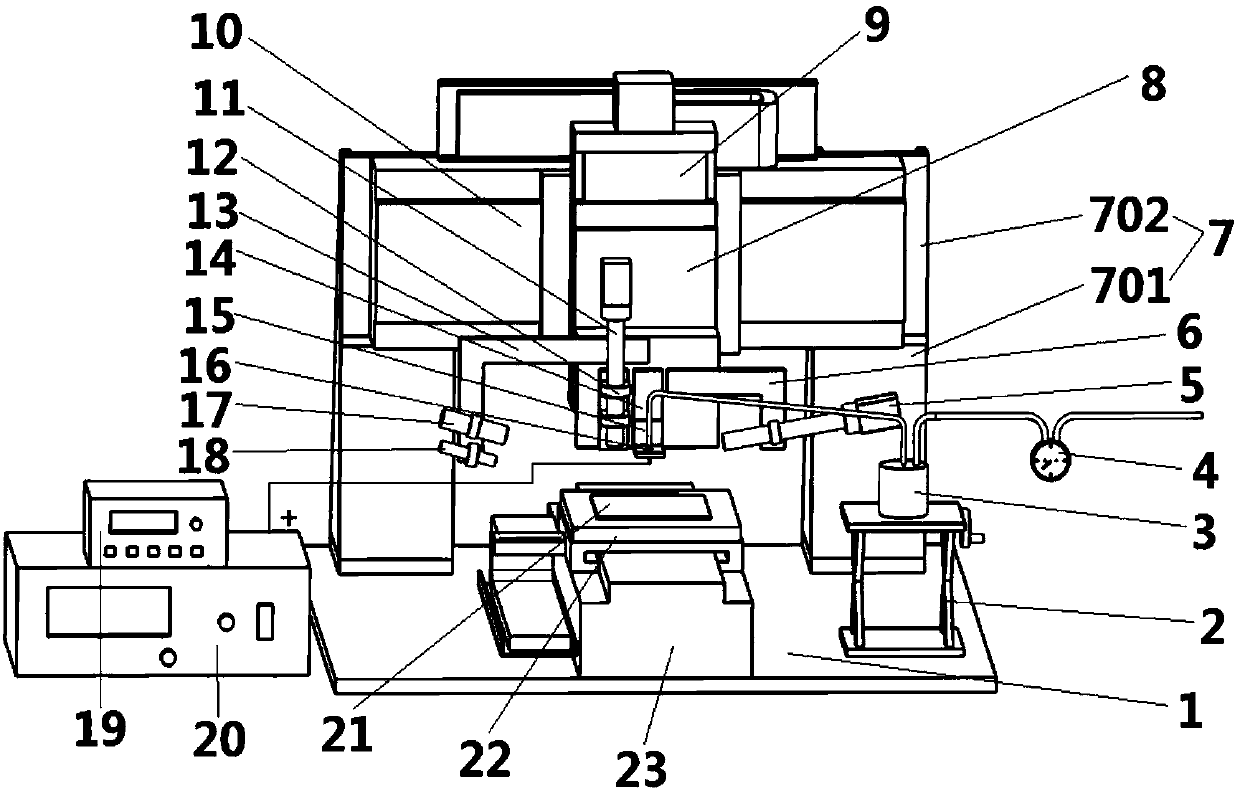

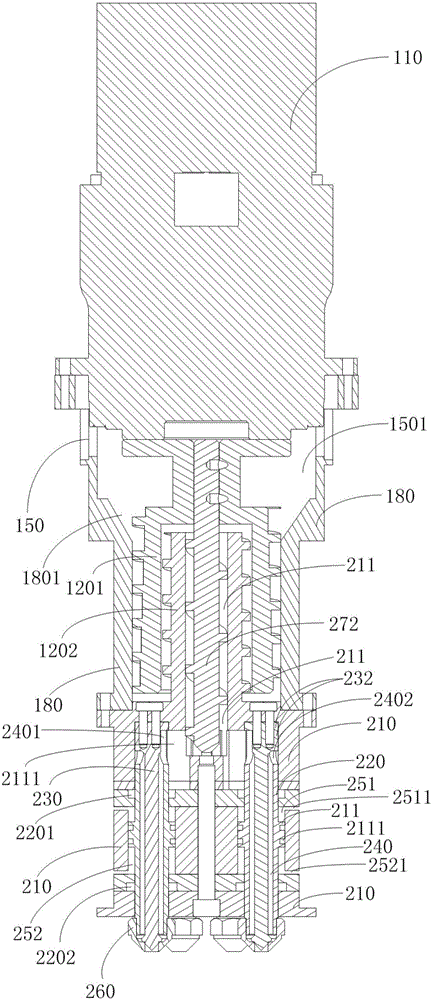

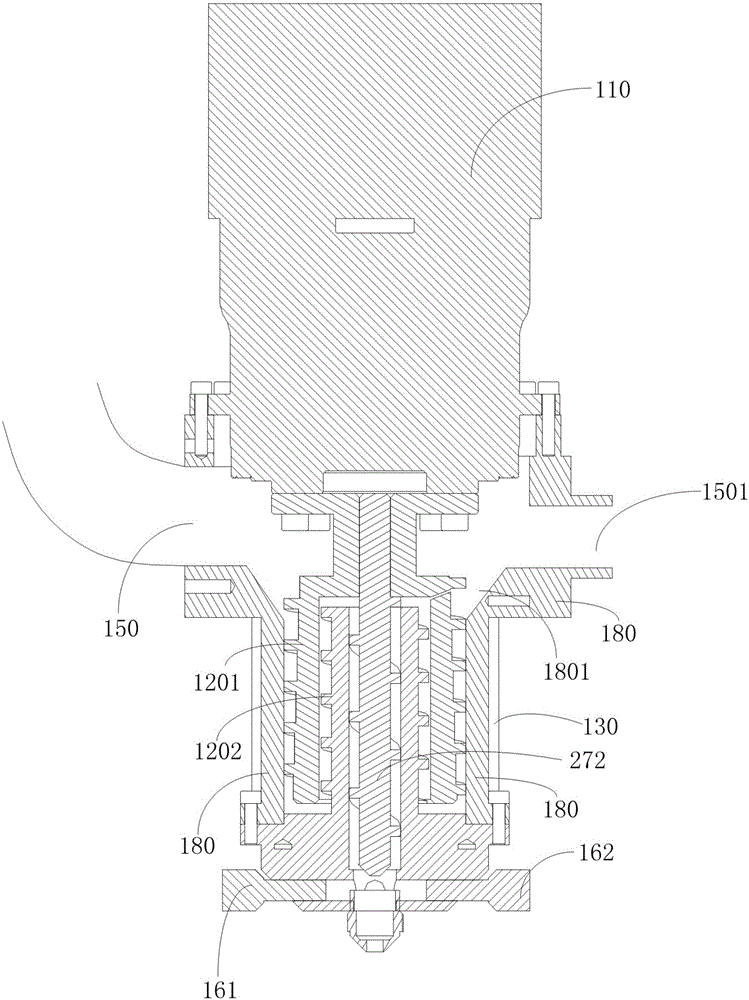

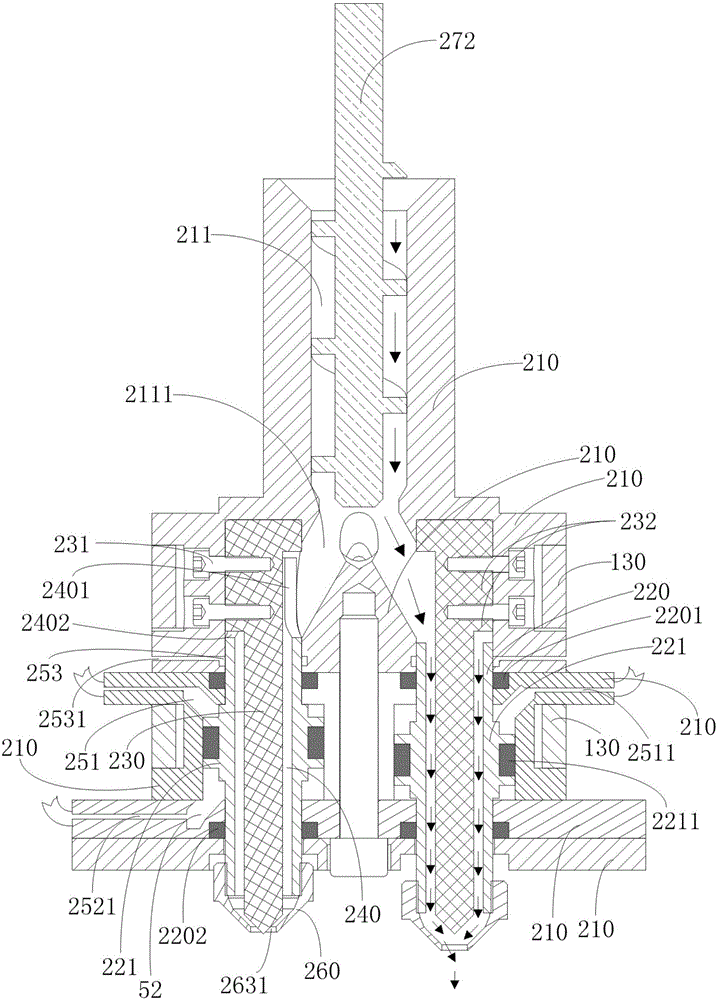

High-precision electric field driven spray deposition 3D printer and working method thereof

PendingCN107932894AHigh frequencyContinuous and stable feedingAdditive manufacturing apparatus3D object support structuresComputer printingImage resolution

The invention discloses a high-precision electric field driven spray deposition 3D printer and a working method thereof, and solves the problems of a traditional 3D printer on multiple aspects of resolution, stability and controllability; high-precision printing of multilayer structures can be realized; the printing process is observed and monitored in real time; and high-precision pattern printing is performed on insulation substrates through electric conducting materials. The high-precision electric field driven spray deposition 3D printer comprises a mounting baseplate; a Y-axle worktable is arranged on the mounting baseplate; a vacuum absorption platform is fixed on the Y-axle worktable; a printing substrate is absorbed on the vacuum absorption platform; a printing nozzle and a vertical observation camera are correspondingly arranged above the printing substrate, and are connected to a Z-axle worktable; the Z-axle worktable is fixed on an X-axle worktable; a squint observation camera is correspondingly arranged on one side of the printing nozzle; an LED light source and a far infrared curing light source are correspondingly arranged on the other side of the printing nozzle; theprinting nozzle communicates with a storage bottle; and the storage bottle is arranged on a lifting table.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Conductive porous materials

InactiveUS7504550B2Reduce conductivityEfficient printingBaby linensWoven fabricsHigh resistivityConductive materials

A limited use, disposable article (20), comprises a matrix-substrate (22), and an electrically-conductive region (24) of a separately provided, electrically-conductive material that has been operatively applied to the matrix-substrate from a viscous configuration of the electrically-conductive material. The matrix-substrate includes a first matrix-region (26), and at least a second matrix-region (28). At least the second matrix-region (28) can include a treatment that provides for an operative formation of a selected resistivity in the electrically-conductive region. The first matrix-region (26) has a high resistivity, and the electrically-conductive region (24) is positioned operatively adjacent the second matrix-region (28). The electrically-conductive region (24) has a low resistivity, as determined when the electrically-conductive region is positioned operatively adjacent the second matrix-region and configured for its intended use.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method of dry transfer printing of synthetic fibrous material with disperse dye and transfer paper

InactiveCN101688358AImprove qualityFeel goodNon-fibrous pulp additionSpecial paperDisperse dyeOrganic solvent

A transfer paper which comprises a transfer paper base and a disperse dye ink printed thereon or imparted thereto. The transfer paper is used in a dry transfer printing method in which the transfer paper is pressed against a synthetic fibrous material with heating to thereby transfer the dye (pattern) from the transfer paper to the fibrous material. The transfer paper is characterized in that thetransfer paper base has a releasant layer comprising a synthetic resin soluble in organic solvents and an ink-receiving layer made from a mixture comprising a hydrophilic synthetic resin which softensor melts upon heating, a hydrophilic binder, and various aids, the ink-receiving layer being superposed on the releasant layer. With this transfer paper for dry transfer printing, a highly fine pattern can be printed with excellent reproducibility. Furthermore, the transfer paper enables quick delivery by so-called printing without platemaking. The method of dry transfer plating employs this transfer paper.

Owner:NORITZ CORP

Printing head for 3D printing, control system, 3D printer and printing method

The invention discloses a printing head for 3D printing. The printing head comprises a machine shell, a screw extruding system, an installation seat, barrels, valve needles and spray nozzles. A drive system is arranged at one end of the machine shell. The screw extruding system is arranged in the machine shell and is composed of at least two screws which are embedded internally and externally, and at least one screw is driven by the drive system. The installation seat is mounted below the screw extruding system. One or more inner holes are distributed in the installation seat in the axial direction, and a discharge outlet is formed in the top or the side face of each inner hole. The barrels are mounted in all the inner holes of the installation seat correspondingly, the barrels extend out from one end of the installation seat, and barrel feeding openings are formed in the top ends of the barrels. Valve cavities are formed in the barrels. The valve needles penetrate through all the valve cavities of the barrels to be mounted on the installation seat, and the gaps between the valve needles and the valve cavities form discharging channels communicating with the feeding openings of the barrels. The spray nozzles are arranged at the tail ends of all the barrels. The printing head for 3D printing is light in weight, small in size, capable of achieving high printing precision and printing speed, novel in design, high in practicability and high in economic value.

Owner:浙江光镀智造科技有限公司

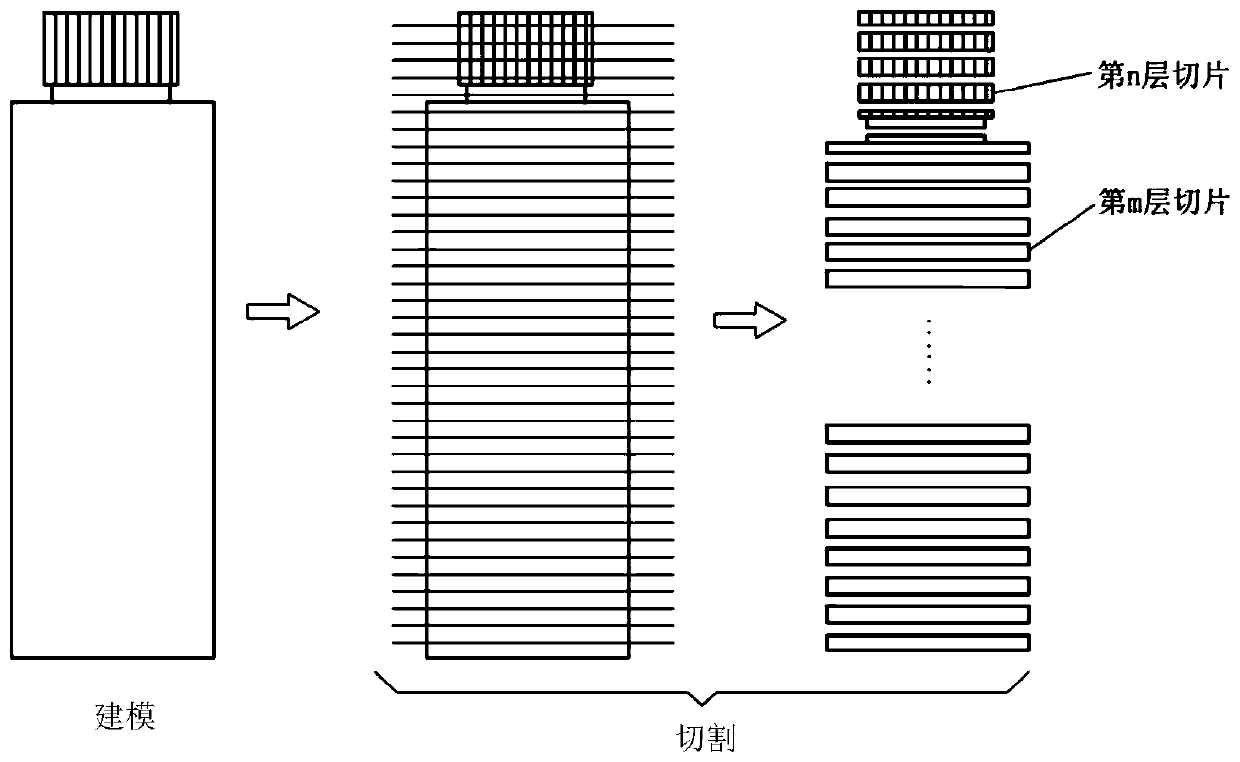

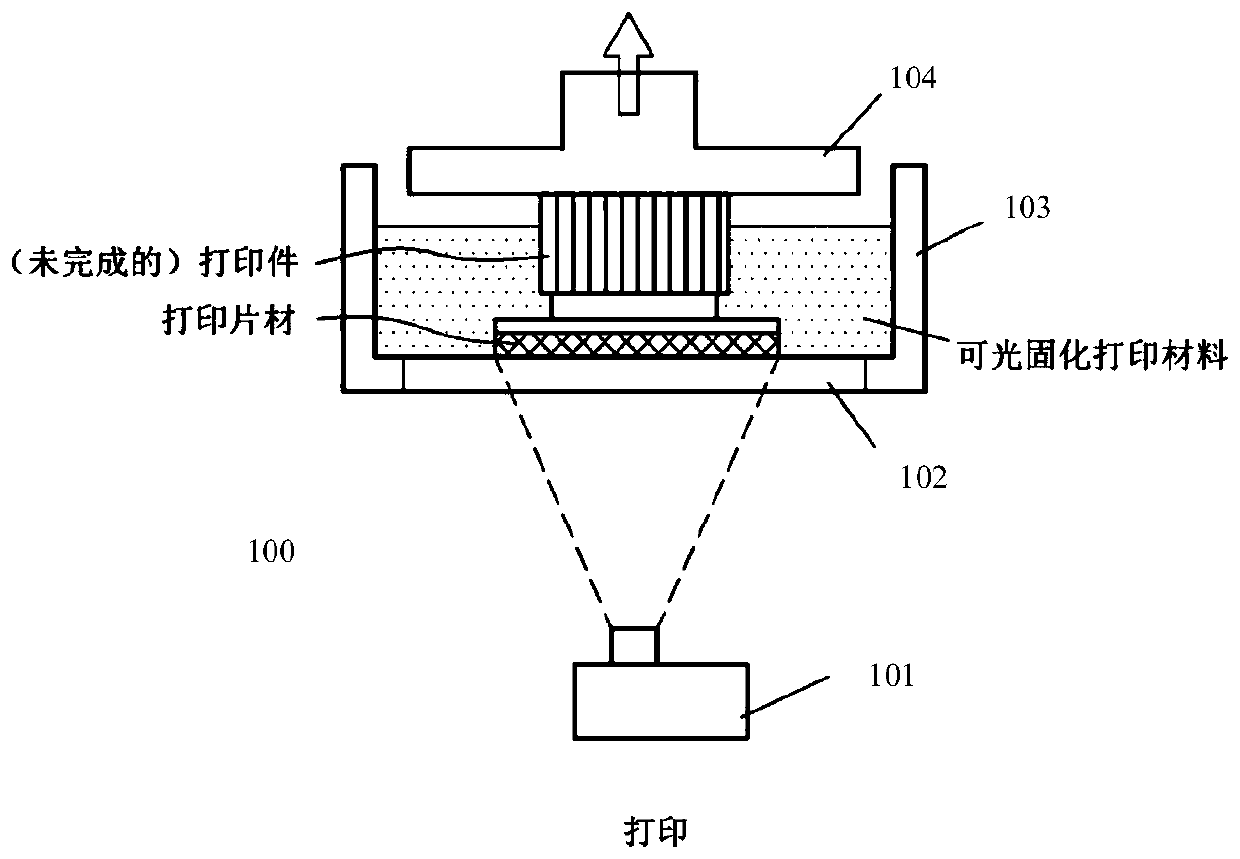

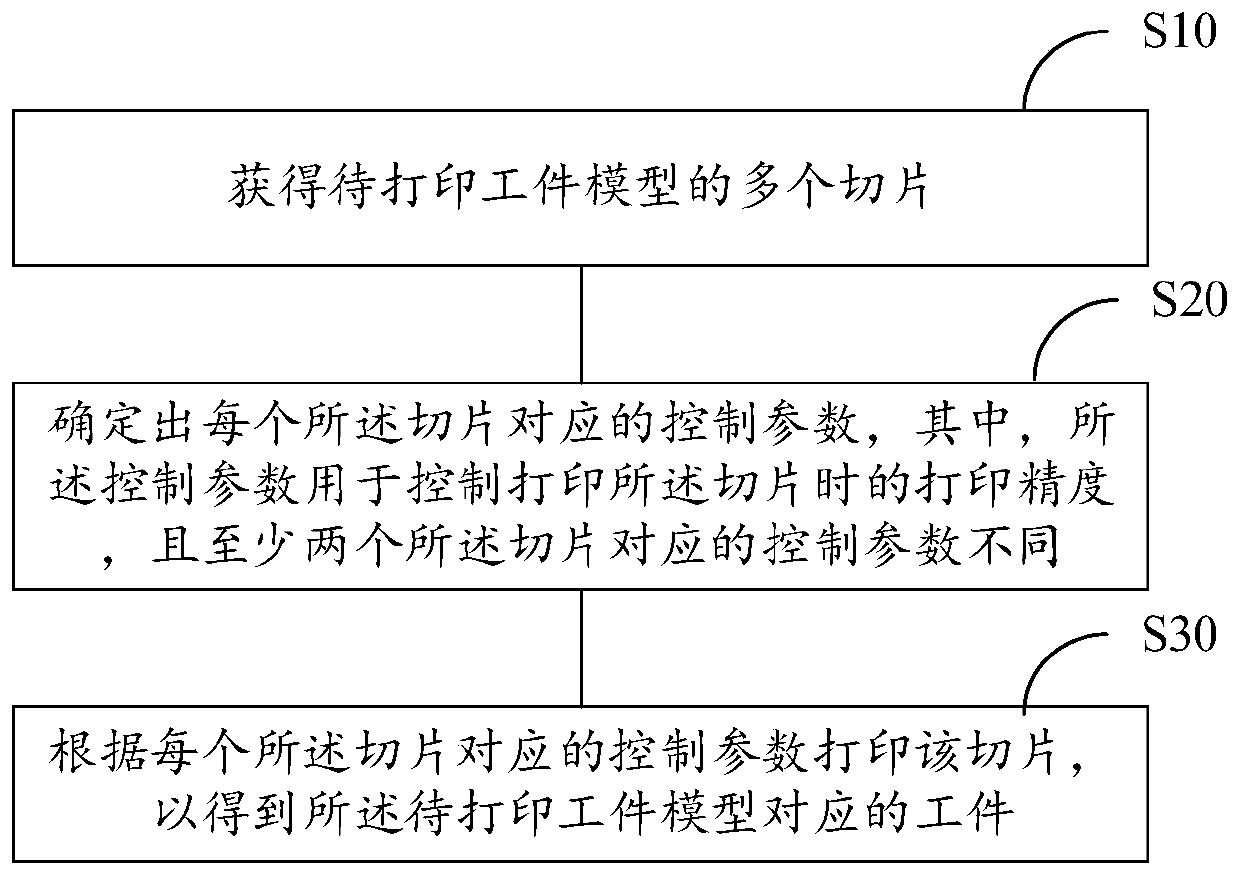

3D printing method and device, storage medium and 3D printing system

ActiveCN111497231AImprove printing efficiencyGuaranteed printing qualityAdditive manufacturing apparatus3D object support structuresProcess engineeringIndustrial engineering

The application provides a 3D printing method and device, a storage medium and a 3D printing system. The 3D printing method comprises the following steps: obtaining a plurality of slices of a workpiece model to be printed; determining control parameters corresponding to each slice, wherein the control parameters are used for controlling the printing accuracy when printing the slice, and the control parameters corresponding to at least two slices are different; and printing the slices according to the control parameters corresponding to each slice, so as to obtain the workpiece corresponding tothe workpiece model to be printed. The printing accuracy when printing the slice is controlled by determining the control parameters corresponding to each slice of the workpiece model to be printed,therefore, different parts of the workpiece can be printed with different accuracy; relatively high-accuracy printing can better reflect details; and relatively low-accuracy printing can maintain theprinting efficiency. Therefore, different parts of the workpiece can be printed with different accuracy, and therefore, the print quality can be ensured.

Owner:GUANGZHOU HEIGE ZHIZAO INFORMATION TECH CO LTD

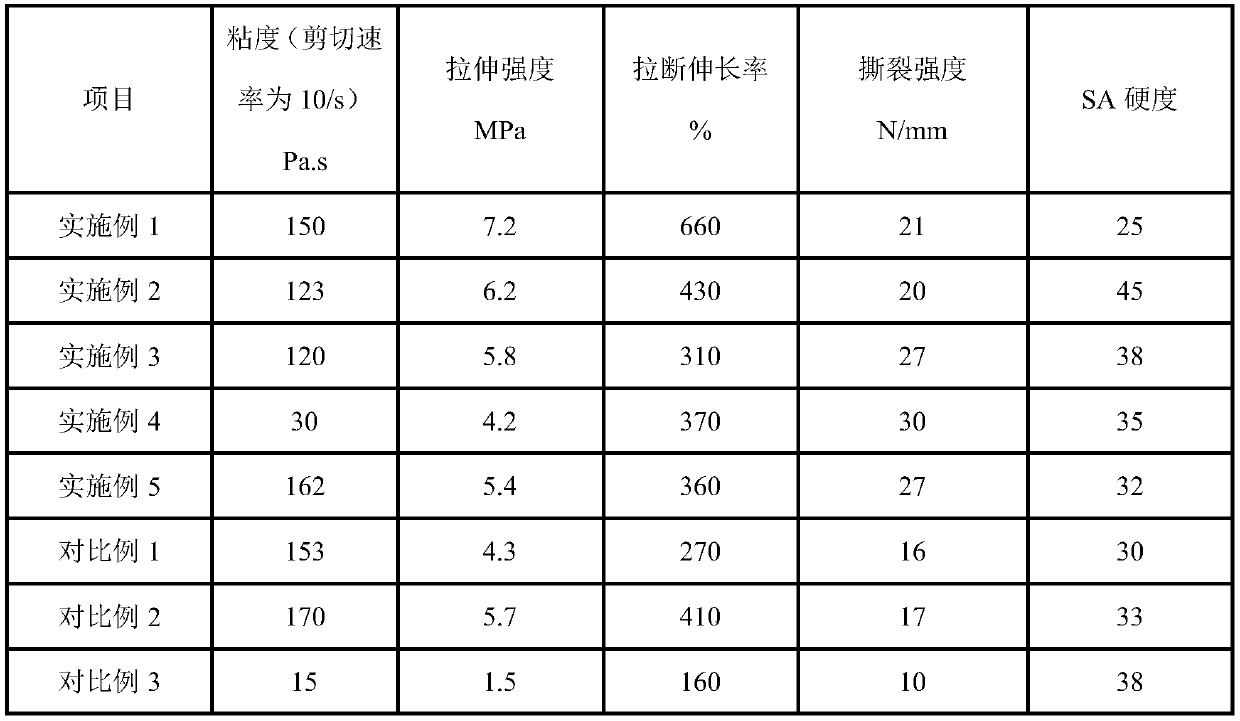

Ultraviolet-cured silicone rubber for DIW (direct ink writing) 3D (three-dimensional) printing and preparation method thereof

InactiveCN109810516AFast curingImprove processing efficiencyAdditive manufacturing apparatusPhotoinitiatorToxicity

The invention relates to ultraviolet-cured silicone rubber for DIW (direct ink writing) 3D (three-dimensional) printing and a preparation method thereof. The ultraviolet-cured silicone rubber is prepared from the following raw materials in percentage by weight: 50-80% of polysiloxane containing unsaturated groups, 1-10% of a sulfydryl-containing cross-linking agent, 0.1-10% of a photoinitiator, 1-10% of rheological modifier, 6-40% of a filler and 5-20% of reinforcing resin. According to the ultraviolet-cured silicone rubber and the preparation method thereof, the polysiloxane containing the unsaturated groups, the sulfydryl-containing cross-linking agent and the rheological modifier are subjected to quick reaction and curing under ultraviolet irradiation, proper rheological property enables DIW (direct ink writing) 3D (three-dimensional) printing to be carried out more efficiently, a printed product has the characteristics of high elasticity and high strength, especially shows outstanding advantages in the aspect of the strength, meanwhile, has appropriate hardness, and has no unpleasant smell after being cured, the toxicity is low, the pollution is small, and the size precision controllability of a printing material is realized.

Owner:SHANDONG UNIV

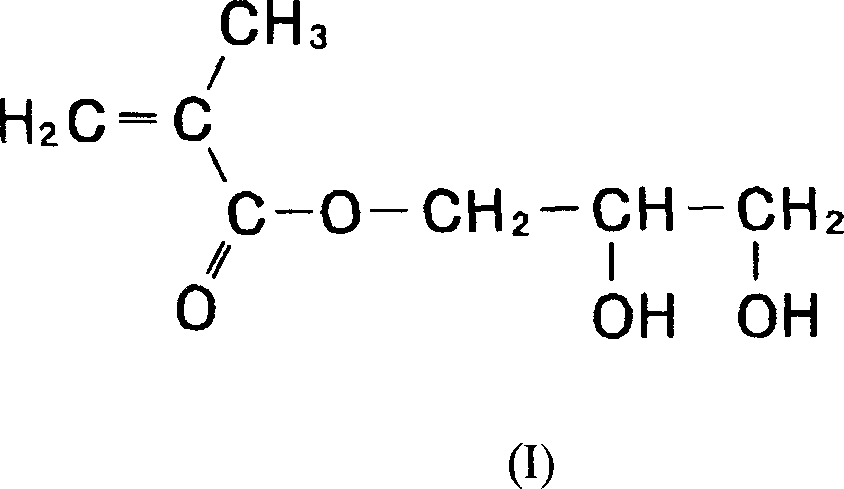

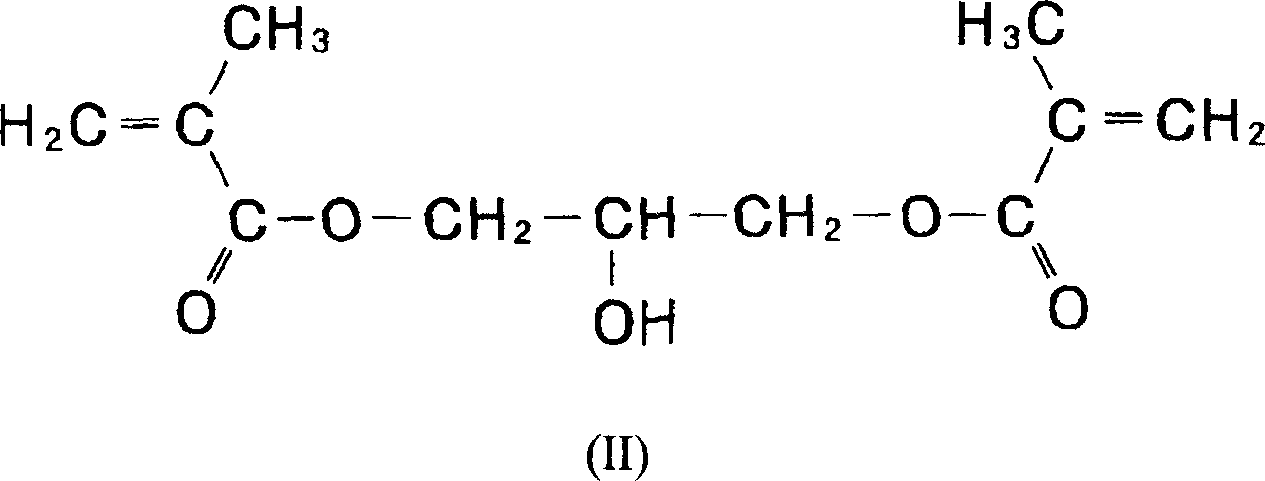

Printing ink using ultraviolet cured resin composition as active ingradient

The present invention relates to one kind of printing ink, and the printing ink has ultraviolet cured resin composition as the effective component. The ultraviolet cured resin composition contains glyceryl monomethacrylate and / or glyceryl dimethacrylate as light reactive diluent, and may be used in printing, spraying or adhering polypropylene, polyethylene and other polyolefin, ethylene-vinyl alcohol copolymer and other un-adhesive plastic material. In addition, it may be used in printing, spraying or adhering polycarbonate, polyester, paper, metal and other adhesive material.

Owner:SEIKO ADVANCE

Ink jet recording apparatus and ink jet recording method

InactiveUS20090207203A1Simple and inexpensive constitutionEfficient printingOther printing apparatusUltravioletWavelength

The ink jet recording apparatus includes an ink jet head configured to discharge UV ink onto a printed article fed in a feeding direction, an ultraviolet irradiation device having a single light source capable of irradiating light including a first wave length zone to reform a surface of the printed article and a second wave length zone for hardening the UV ink, and a controller configured to control the light source so as to emit light in the first wave length zone and light in the second wave length zone.

Owner:TOSHIBA TEC KK

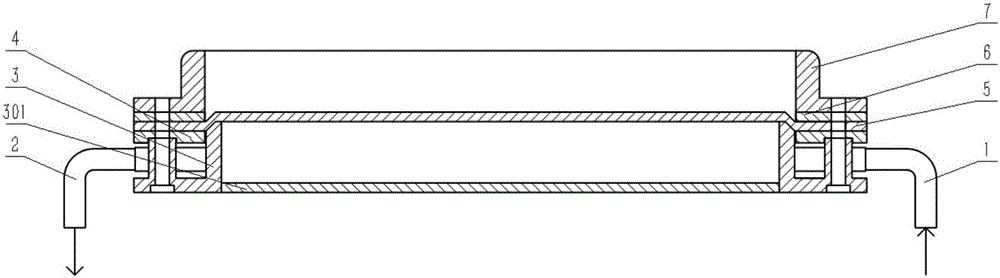

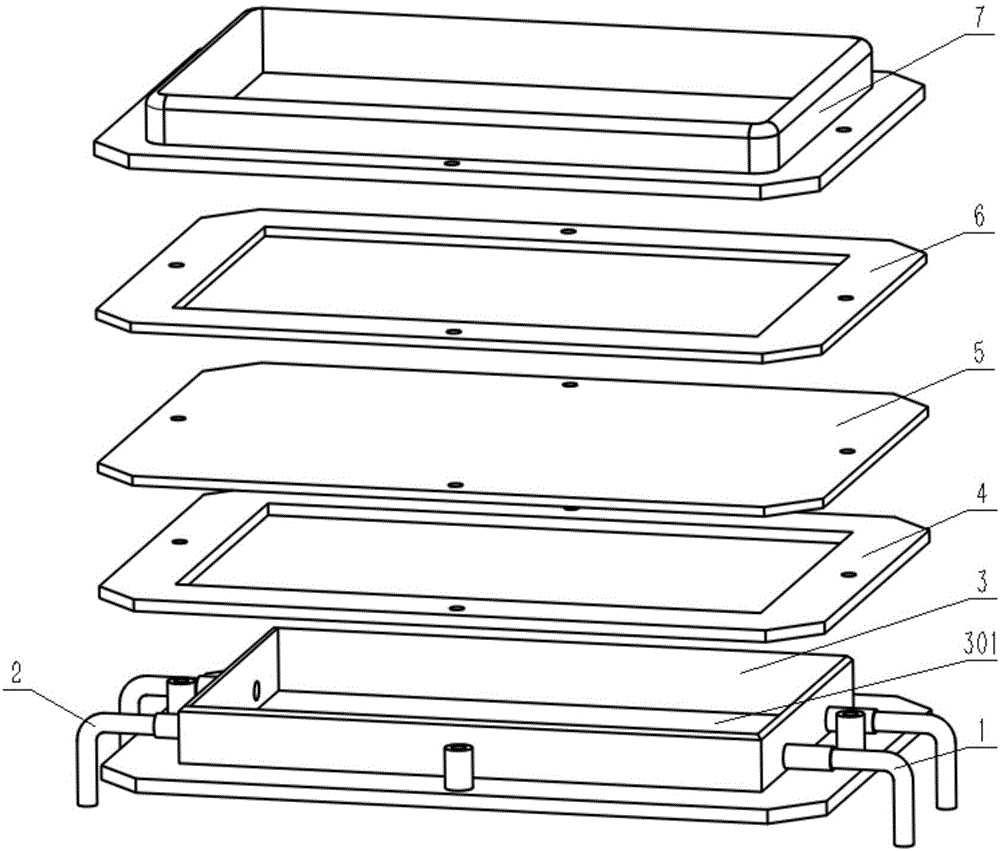

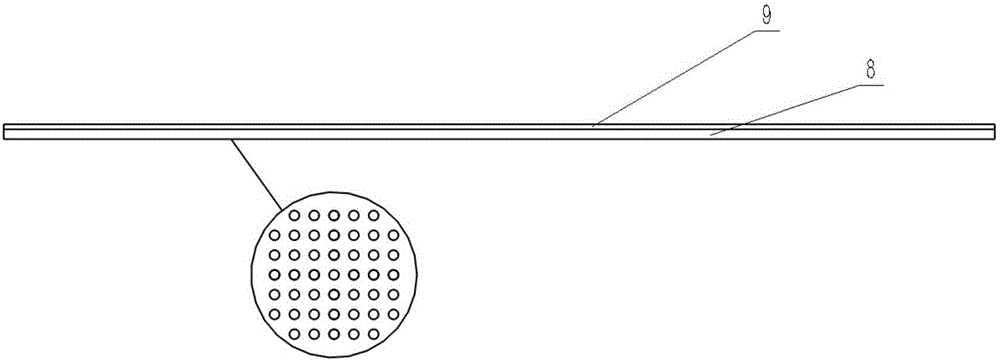

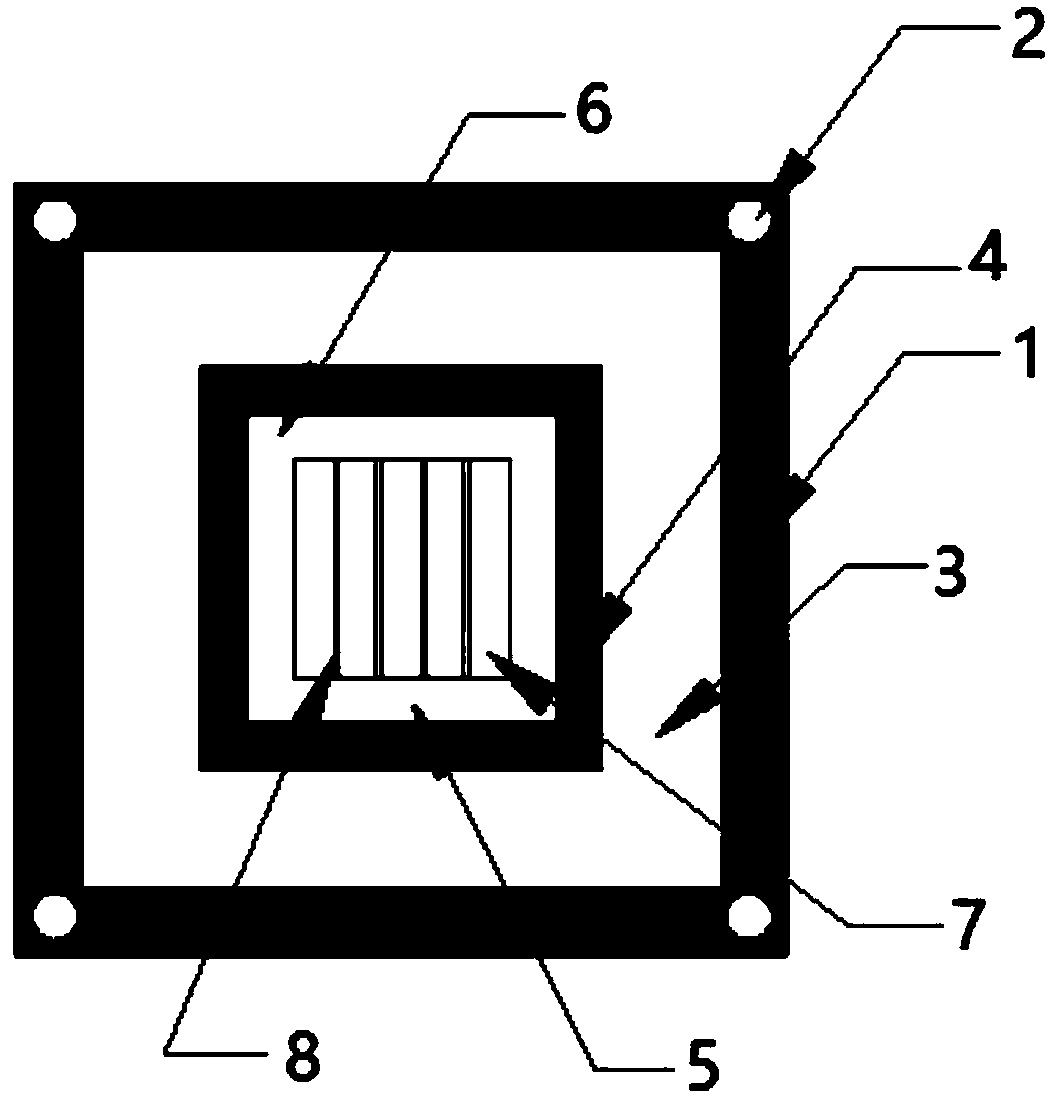

Forming window for high-speed continuous photocuring 3D printing

ActiveCN106273516AEfficient printingTroubleshoot quick fixesAdditive manufacturing apparatusCooling chamberEngineering

The invention discloses a forming window for high-speed continuous photocuring 3D printing. The forming window applied to a photocuring 3D printer comprises a window box and an oxygen supply cooling module. The photocuring 3D printer is divided into an upper cavity and a lower cavity through a middle partition. The window box and the oxygen supply cooling module are arranged in the upper cavity of the case of the photocuring 3D printer. The window box and the oxygen supply cooling module are fixedly mounted on the middle partition in a combined manner. Two ends of an oxygen supply cooling chamber are respectively connected with a cooling gas inlet pipeline and a cooling gas outlet pipeline, and the oxygen supply cooling chamber, the o cooling gas inlet pipeline and the cooling gas outlet pipeline form the oxygen supply cooling module. The forming window has the advantages that low-cost and efficient continuous printing of large-size optional-shape parts can be achieved, the forming window is wide in applicable materials, the precision and quality of the printed parts are high, the printed parts are good in consistency, and process stability and reliability are achieved. In addition, the forming window is high in industrial application value and applicable to a desktop-level 3D printer and industrial 3D printing.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

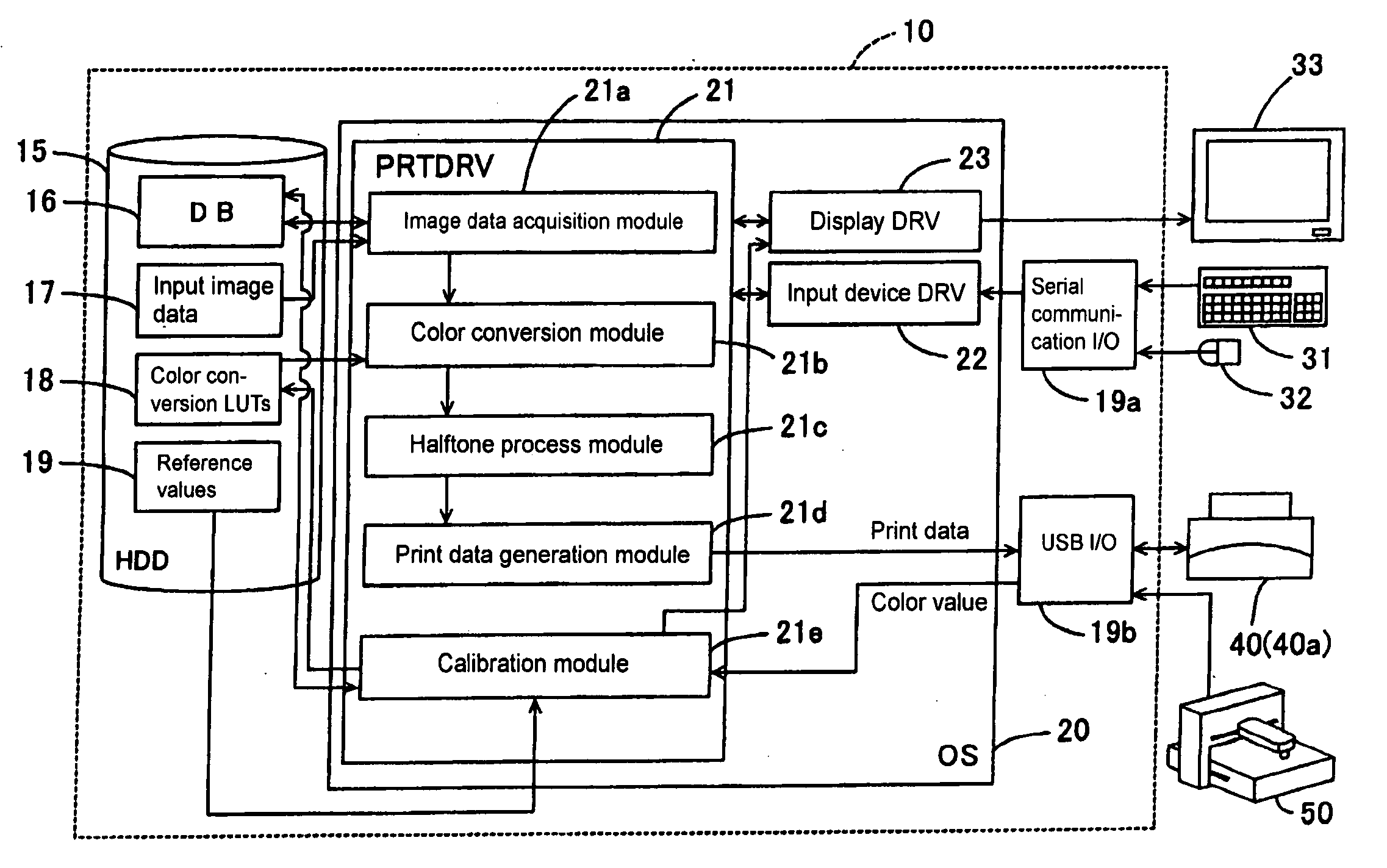

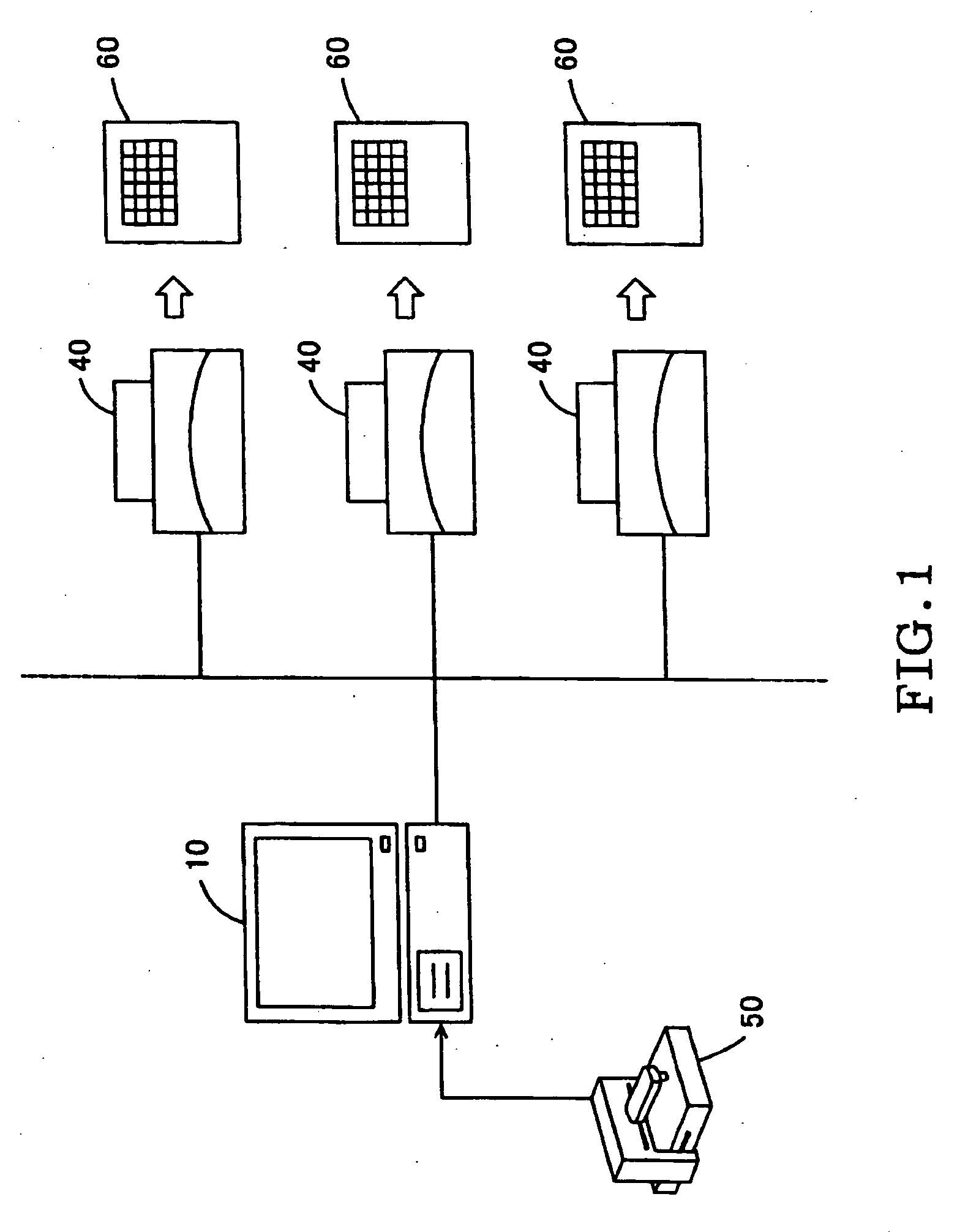

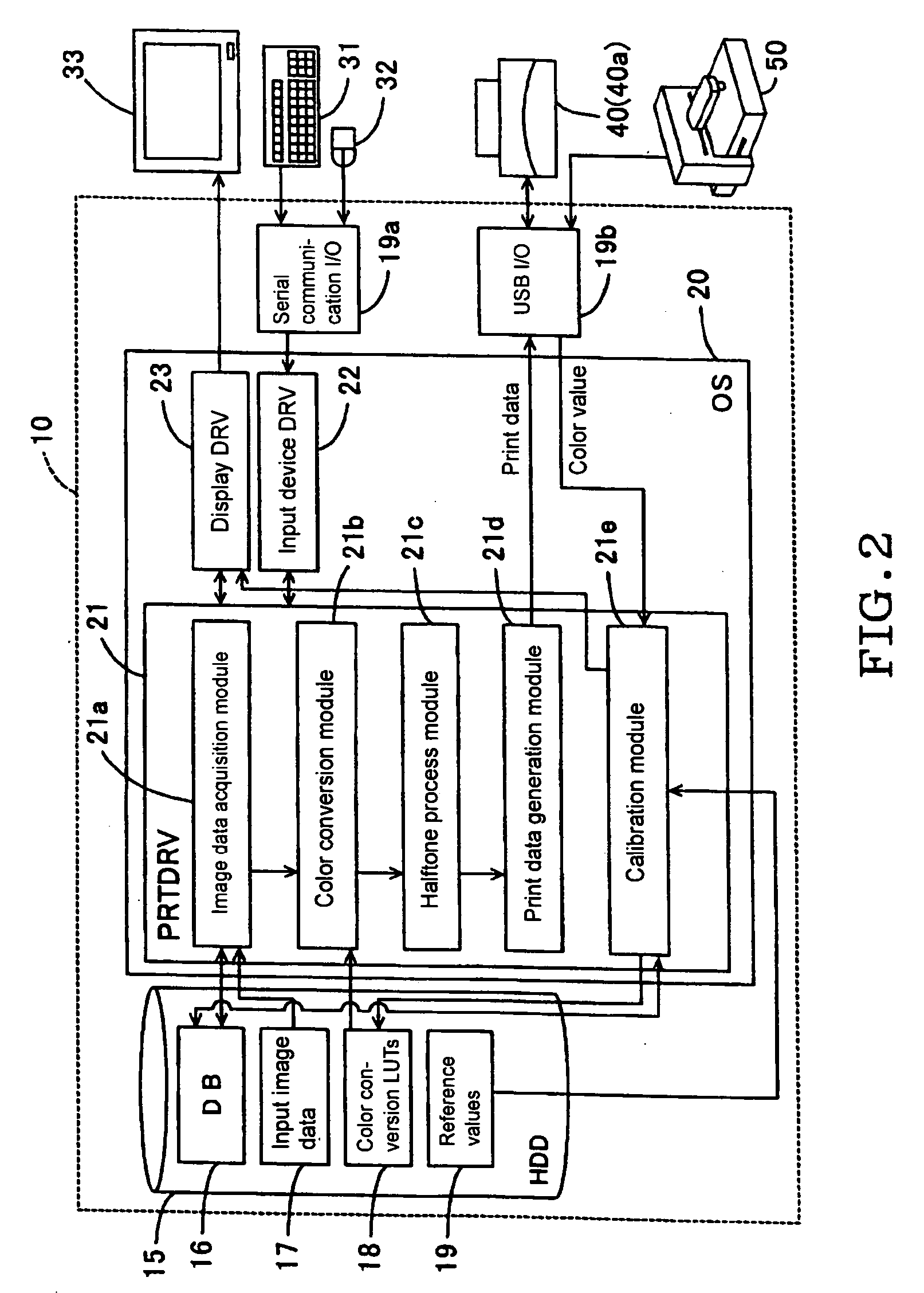

Program product, device, and method for color chart discrimination and program product, device, and method for color correction

InactiveUS20050270321A1Accurate identificationEfficient measurementImage data processing detailsOther printing apparatusColor correctionEngineering

Conventionally, wasteful processes are required for identifying the printing conditions for a color chart. According to the present invention, the printing conditions are identified as follows: a printing condition acquisition unit acquires predetermined printing conditions under which a color chart is outputted from a printing device. A color chart output unit outputs a color chart in which the disposition of predetermined patches is specified in correspondence with the acquired printing conditions under the printing conditions. A printing condition identification unit acquires the disposed positions of the predetermined patches when the color chart is subjected to color measurement to acquire the color value of each patch, and identifies the printing conditions based on the disposed positions.

Owner:SEIKO EPSON CORP

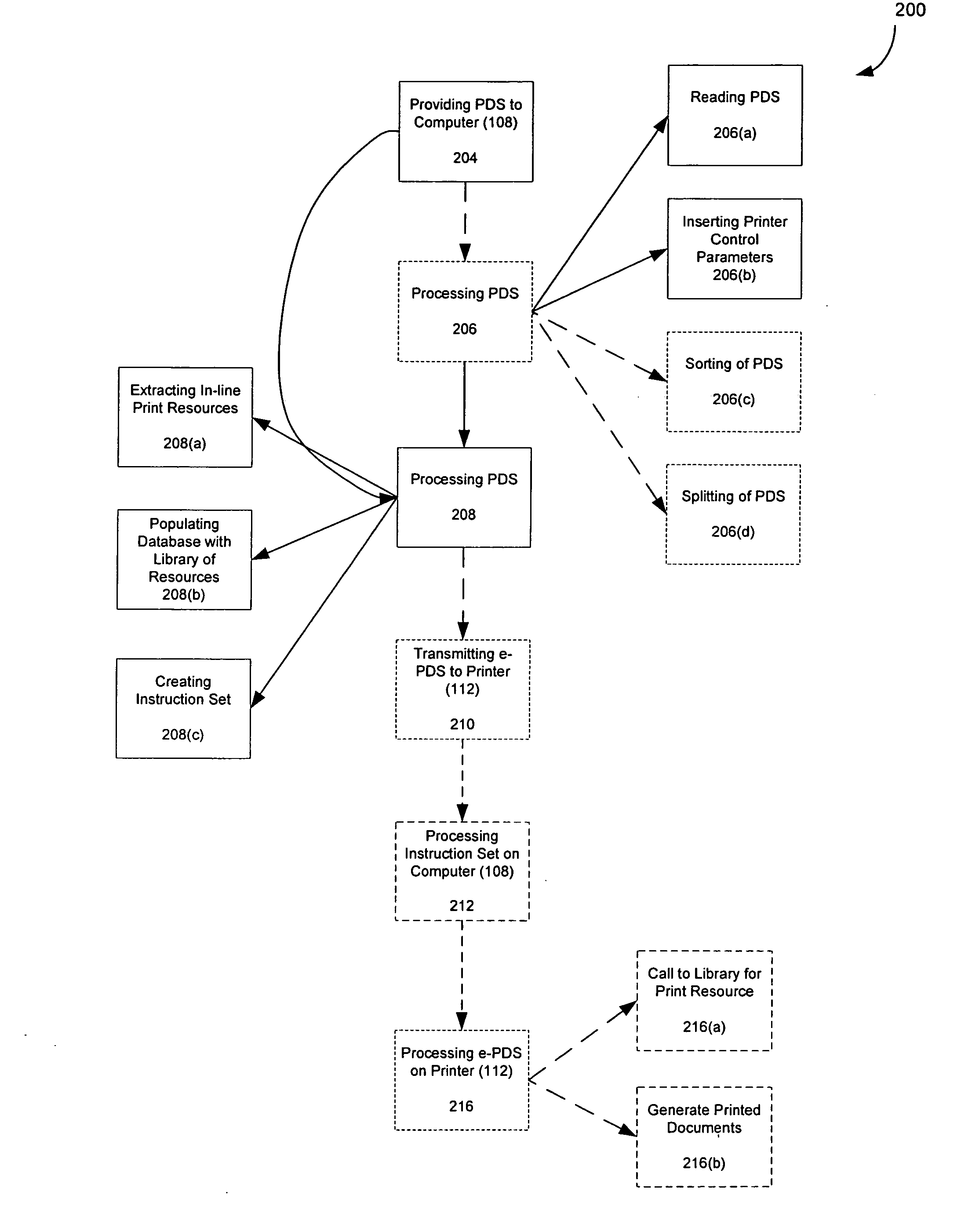

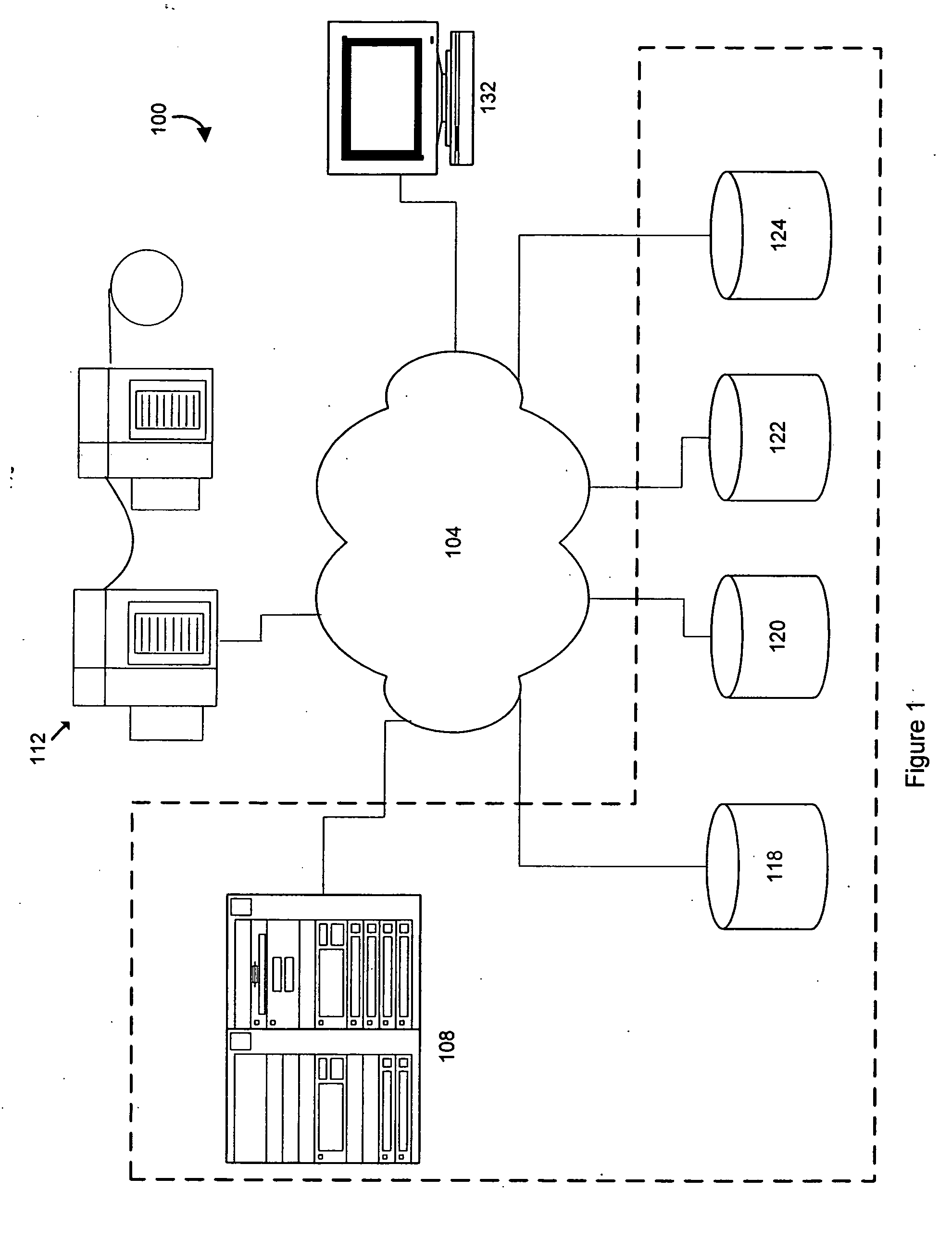

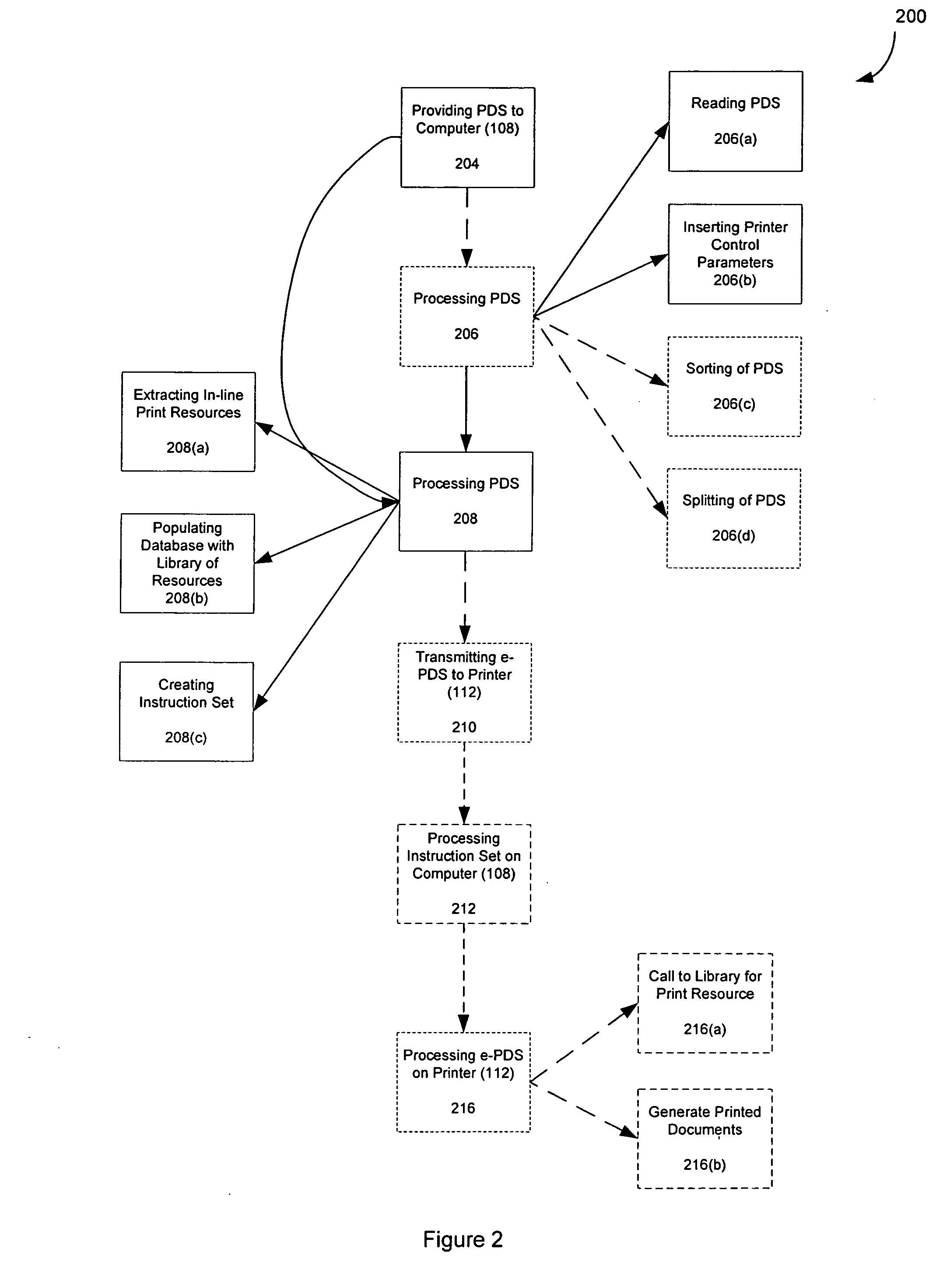

System and method for improved printing efficiency

InactiveUS20060256357A1Improve efficiencyHigh operating requirementsDigital computer detailsVisual presentationData streamLine printer

In accordance with the present invention, the efficiency of printing systems are improved by manipulating the print data stream (PDS), e.g., an AFP data stream (AFPDS) prior to communication to the printer. The methods generally involve manipulating a PDS prior to communication to a printer to provide a modified PDS which is more efficiently process by a printer. The PDS may be manipulated in a variety of ways, including combinations of in-line printer resource extraction, data parsing, insertion of printer control parameters, etc. In various embodiments, in-line printer resources may be extracted from the data stream and placed in a database for later access, or alternatively may be processed by software or algorithms to generate a modified resource which is reintroduced to the data stream.

Owner:FIRST DATA

Comprehensive print job skeleton creation

InactiveUS20100202008A1Preserving original jobAvoid overheadVisual presentation using printersDigital output to print unitsData streamPage description language

A method and apparatus for efficient processing a page description language (“PDL”) data stream lacking page independence is described. The method and apparatus includes applying a single parsing pass for a PDL job and detecting PDL job producers by creator sniffer (83). Shared resources in the PDL job are detected by resource sniffer (85). Page boundaries in the PDL job are detected by page data sniffer (84) and an organized representation (63) is produced without rearranging data and resources in the PDL job. The system efficiently organizes PDL stream into pages, data and resources without rearranging the stream. The organized data can be efficiently submitted to plurality of PDL processors (65).

Owner:EASTMAN KODAK CO

Method for producing environment-friendly false proof cover paper

ActiveCN101319475AImprove tear resistanceHigh folding resistanceNon-fibrous pulp additionNatural cellulose pulp/paperFiberTear resistance

The invention relates to a method for producing environment-friendly anti-counterfeiting cover paper. In the method, raw fibers with the purity of 100 percent are used to produce base paper; the raw fibers selected comprise the following components in weight portion: 50 to 65 percent of needle oil pulp,10 to 20 percent of silking pulp, and 20 to 30 percent of cotton pulp; the raw fibers are subjected to disintegration by a pulp plate, pulping treatment, blending, pulp conveying, forming by a head box, drying and dehydration and bundling reeling to produce the base paper, and the base paper is orderly subjected to dip dyeing, dip latex, base coating, anti-counterfeiting printing and top coating to produce the anti-counterfeiting cover paper. The cover paper has excellent tearing resistance and folding resistance and good anti-counterfeiting function. The method of the invention has the advantages of simple processing and manufacturing, low production cost and environmental protection, and has the tearing resistance and anti-counterfeiting function. The environment-friendly anti-counterfeiting cover paper is suitable for being manufactured into covers of all certificates, particularly a cover of an environment-friendly anti-counterfeiting passport.

Owner:SHANDONG KAILI SPECIAL PAPER

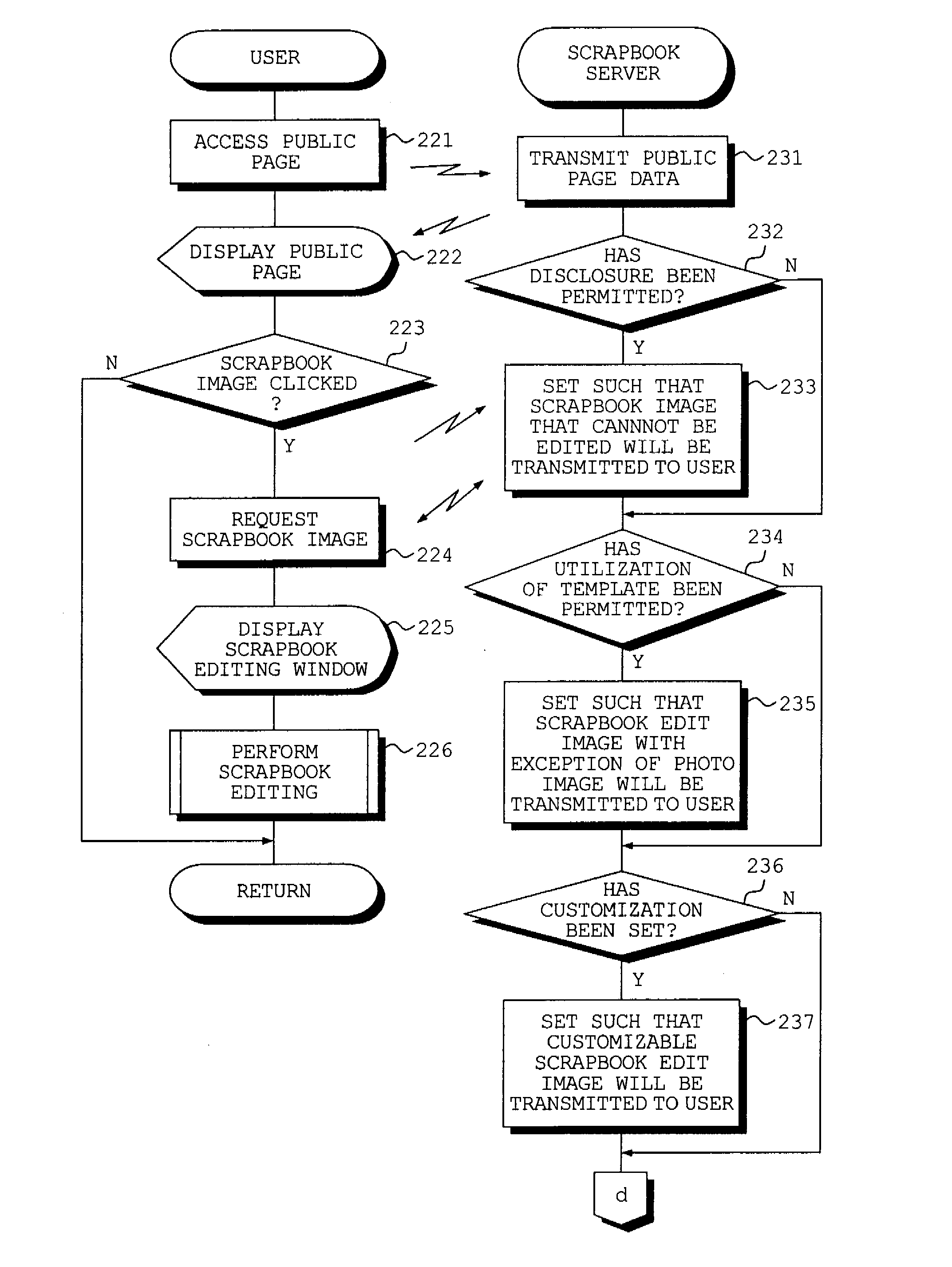

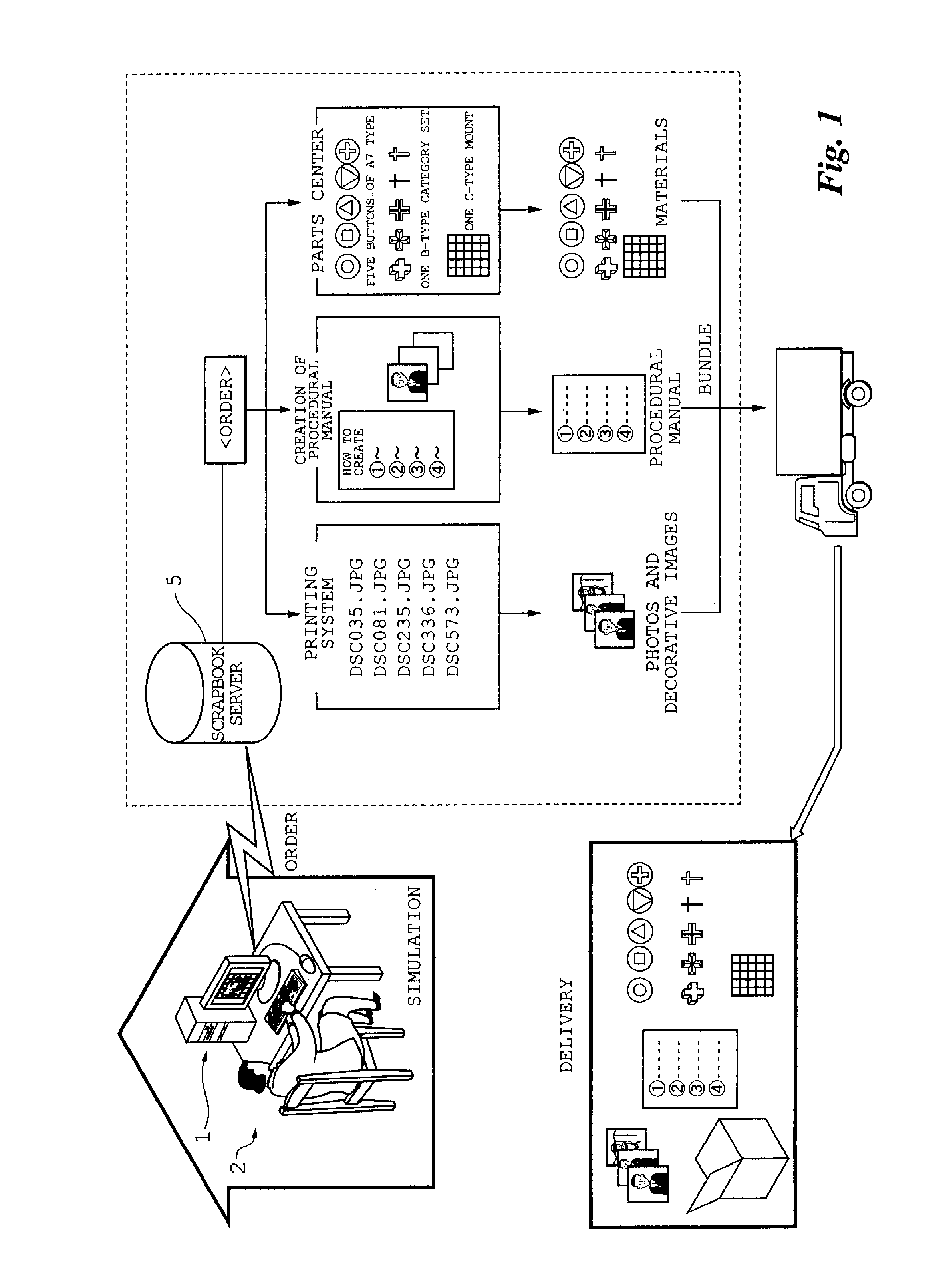

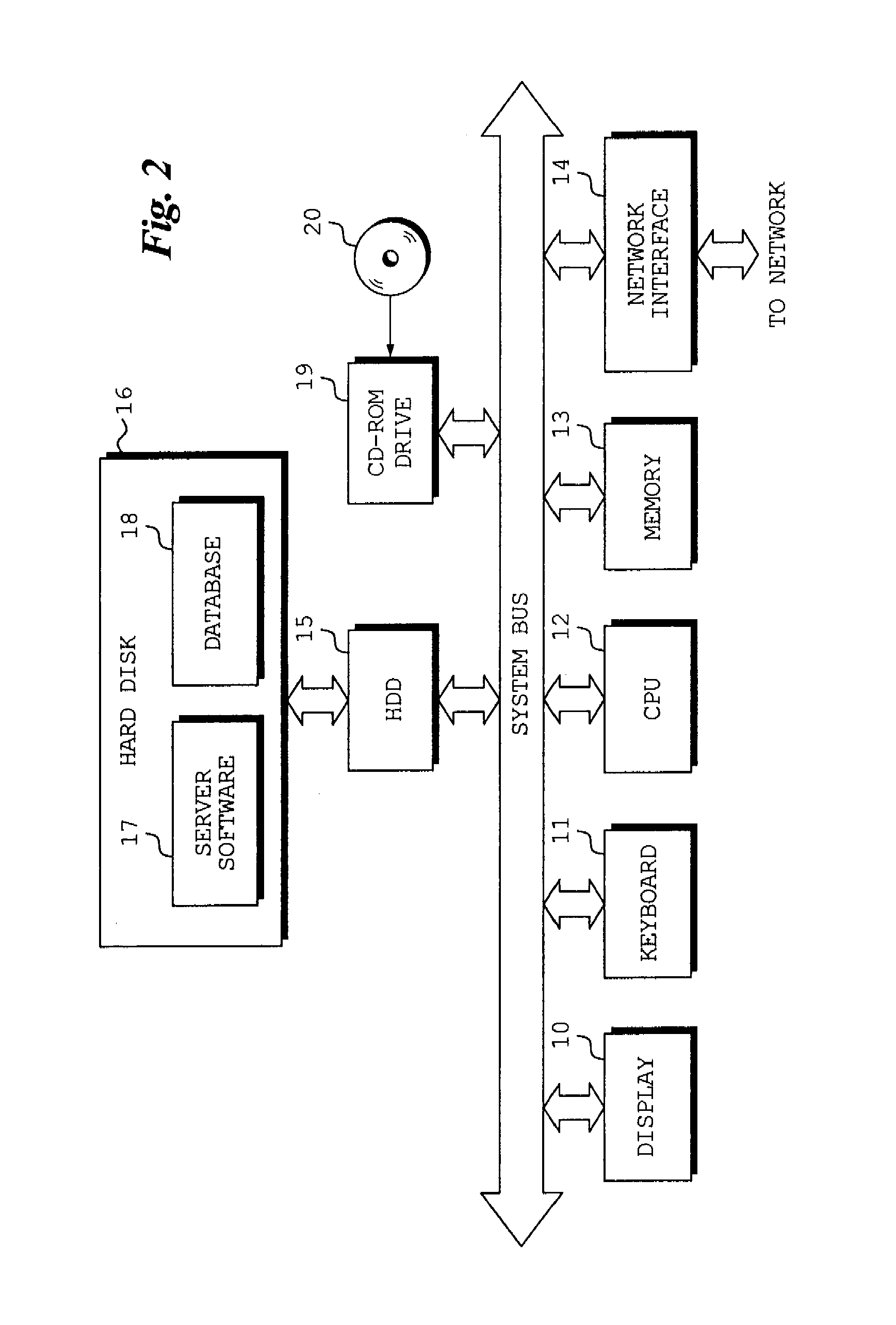

Apparatus for controlling printing of part images of scrapbook, method of controlling same, and control program therefor

InactiveUS20080117455A1Efficient printingNot to wasteDigitally marking record carriersOffice automationComputer graphics (images)Computer access

Decorative images for creating a scrapbook are printed efficiently. To achieve this, a creator accesses a scrapbook server using a computer and executes a simulation for creating a scrapbook by affixing part images such as photographic images and decorative images to an image of a paper mount on the display screen of the computer. When a paper mount, photographs and decorative images, etc., for actually creating the scrapbook are printed on paper or the like by the creator him / herself, the decorative images are printed upon being arranged in order of decreasing area of rectangles that enclose the decorative images. The decorative images are placed and printed automatically in an efficient manner.

Owner:FUJIFILM CORP

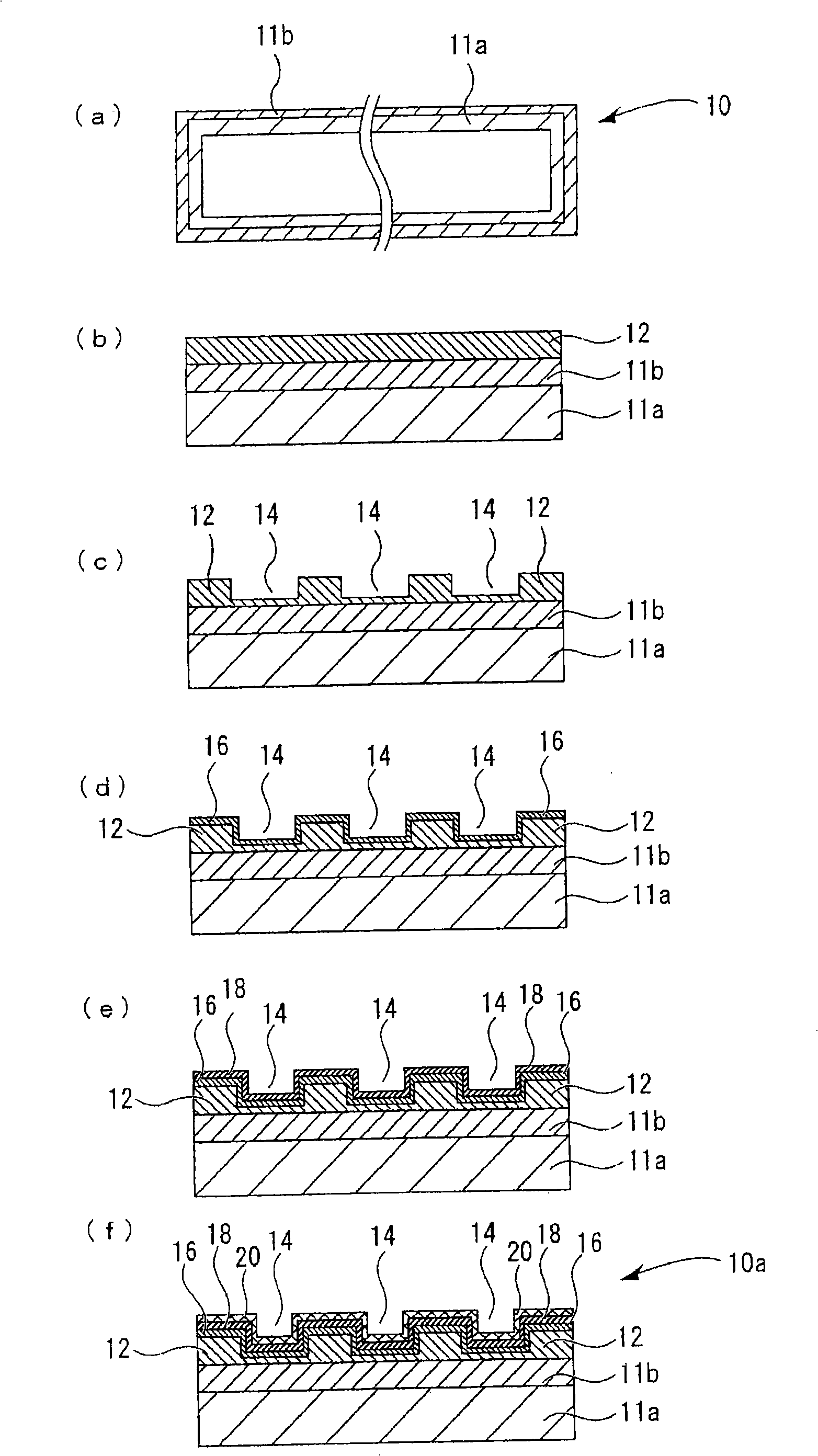

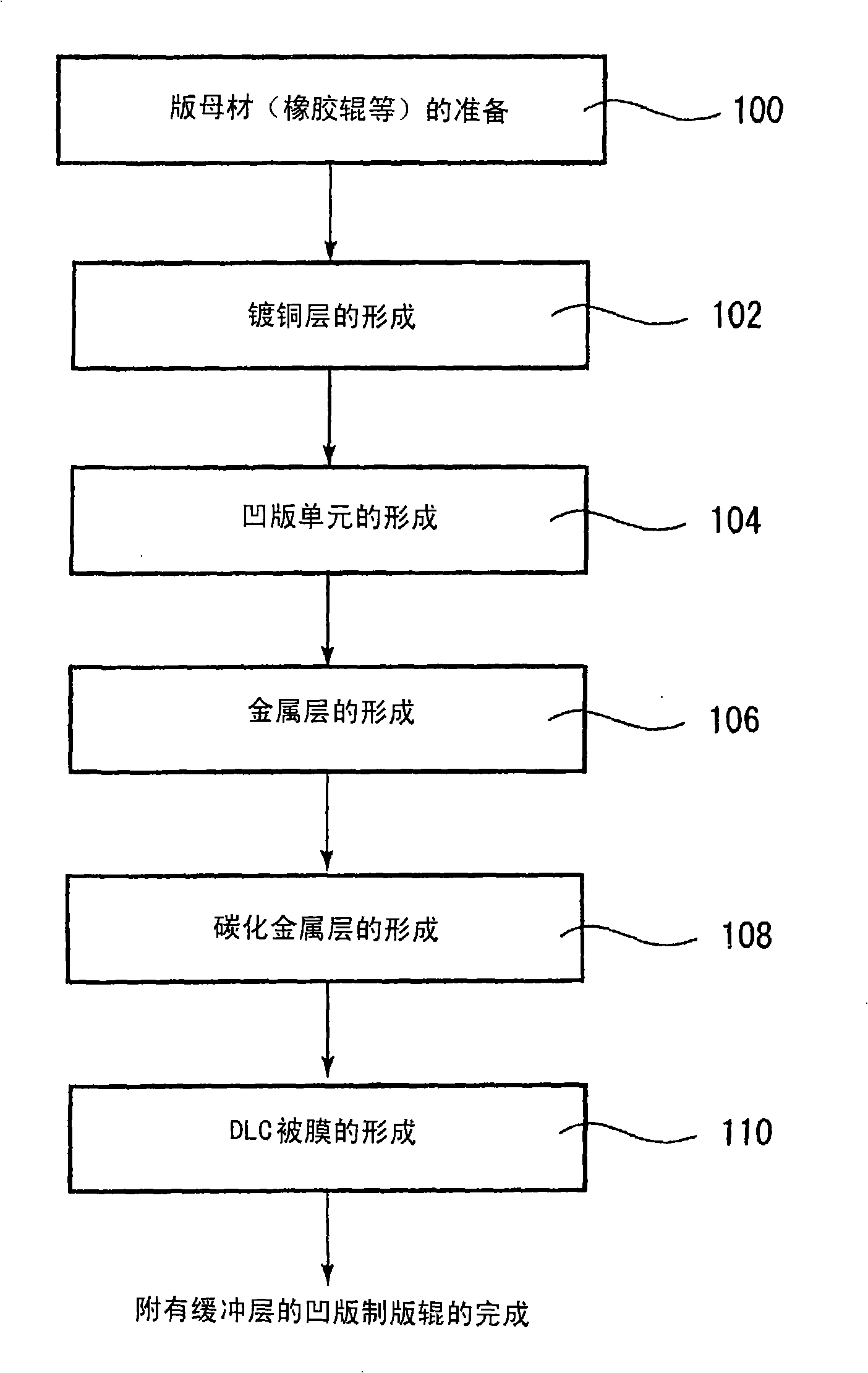

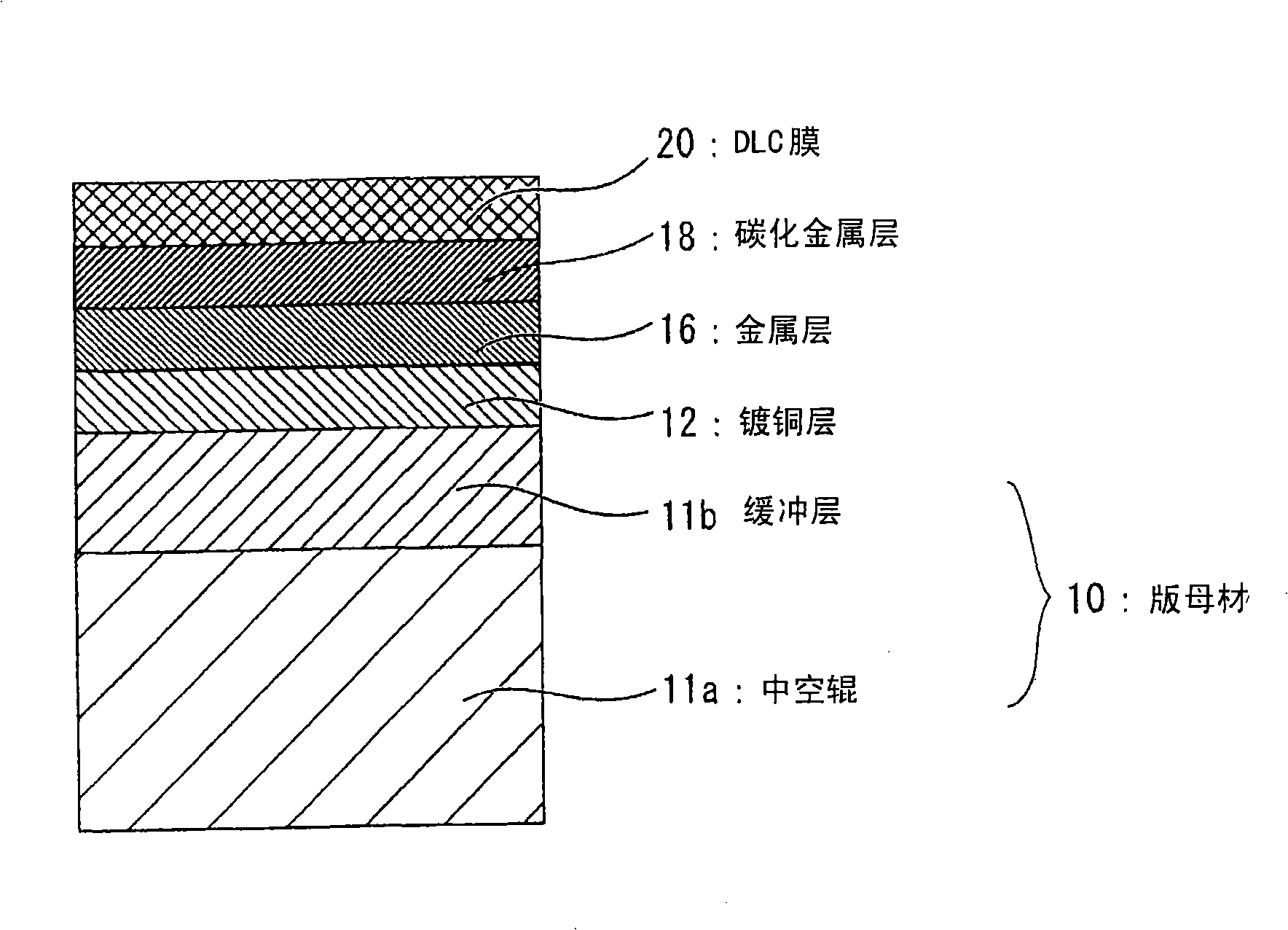

Photogravure reproduction roll with cushion layer and its manufacturing method

InactiveCN101272918AEfficient printingExcellent brush resistanceOptical filtersPlate printingCardboardDiamond-like carbon

A production method for a printing plate, especially a gravure plate with a cushioning property, which enables direct gravure printing on a hard printing matter without using a blanket roll by being provided with a cushioning property, effects a satisfactory gravure printing on a rough surface such as cardboard printing, and is suitable for color-printing a matrix image for forming a color filter on a liquid crystal panel-use glass sheet or an image on a compact disk or the like. The gravure plate comprises a hollow roll provided on the surface thereof with a cushioning layer consisting of rubber or cushioning resin, a copper plated layer provided on the surface of the cushioning layer and formed on the surface thereof with many gravure cells, a metal layer provided on the surface of the copper plated layer, a metal carbide layer provided on the surface of the metal layer, and a diamond-like carbon coating for coating the surface of the metal carbide layer.

Owner:THINK LABORATORY CO LTD

Manufacturing method of metal alloy composite screen plate

InactiveCN110039883ALow elongationGood dimensional stabilityPlate printingFoil printingDouble supportPuncture resistance

The invention discloses a manufacturing method of a metal alloy composite screen plate. The manufacturing method comprises the following specific steps of 1) carrying out net pulling compounding; 2) manufacturing an alloy sheet pattern outer contour; 3) preparing a film layer; 4) coating an adhesive layer; 5) coating a film; 6) drying; 7) laser; 8) cleaning; and 9) detecting and packaging. In thisway, according to the manufacturing method of the metal alloy composite screen plate, a metal alloy sheet is adopted to replace traditional mesh cloth, and the manufacturing method has low elongationrate, better dimensional stability, printing resistance, puncture resistance, double supports of the metal alloy sheet and the film layer are adopted, the service life of the bonding strength far beyond a silk-screen and the film layer can be improved by 30% or above, and under the action of a high-molecular adhesive, the adhesion force of the high-molecular composite layer is extremely high, theplate making yield is greatly improved, the production cost is saved, the printing is good, the line type is good, and the efficiency of a battery piece is obviously improved.

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

Printing apparatus, POS system and printing apparatus control method

InactiveUS7689461B2Efficient printingReduce processing stepsCash registersMultiple digital computer combinationsEngineeringData detection

A printing apparatus and method for printing receipts and for controlling the cutting of each receipt in succession from a recording medium such as print paper at an appropriate position determined from the print data received from a host computer. The printing apparatus 50 prints first print data representing transaction information with a paper cut command appended thereto and second print data representing additional information from print data received from a host computer 40. A first control unit 521 prints the first print data and delays executing the paper cut command added to the first print data when first print data is received from the host computer. When print data is received while execution of the paper cut command is delayed, a print data detection unit 522 determines the type of print data received based on the presence or absence of an identifier in the received print data. If the received print data is recognized as second print data, a second control unit 523 prints the received second print data and then executes the paper cut command. If the received print data is determined not to be second print data, the second control unit 523 executes the paper cut command before printing the received print data.

Owner:SEIKO EPSON CORP

Multilayer graphic systems

ActiveUS7361403B1Efficient removalHigh quality printingSynthetic resin layered productsWoven fabricsGraphicsGraphic system

A multilayer graphic article comprising (a) a fabric matrix or support having an upper and lower surface, (b) at least one image layer disposed on the upper surface of the fabric matrix or support, (c) a protective layer disposed over the at least one image layer, and, (d) an adhesive layer adhered to the lower surface of the fabric matrix or support.

Owner:INSITE SOLUTIONS

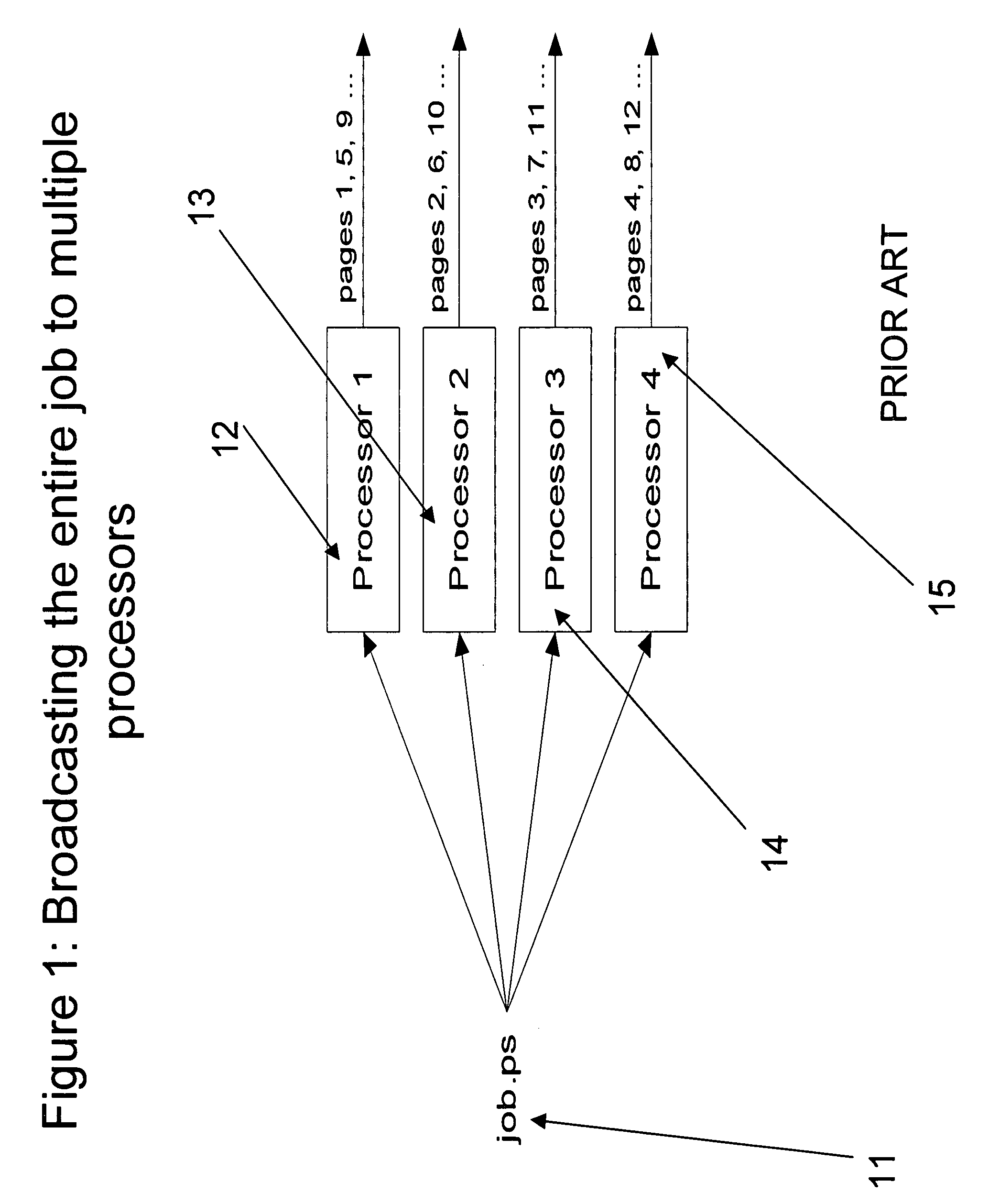

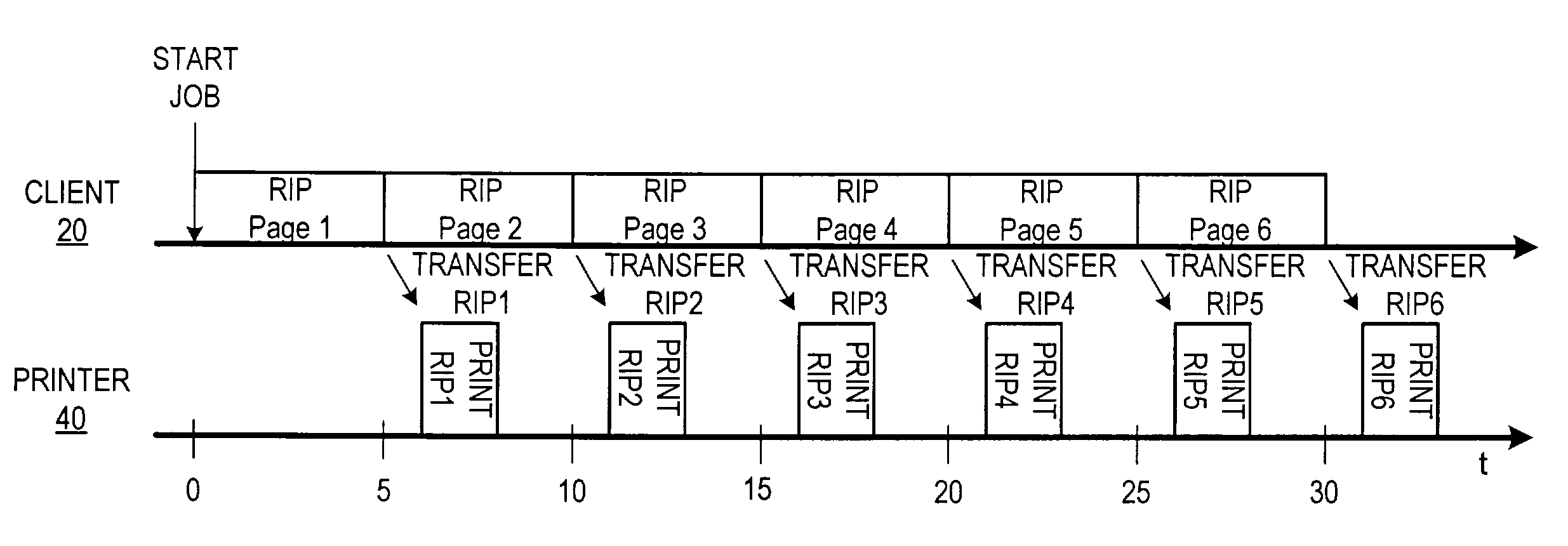

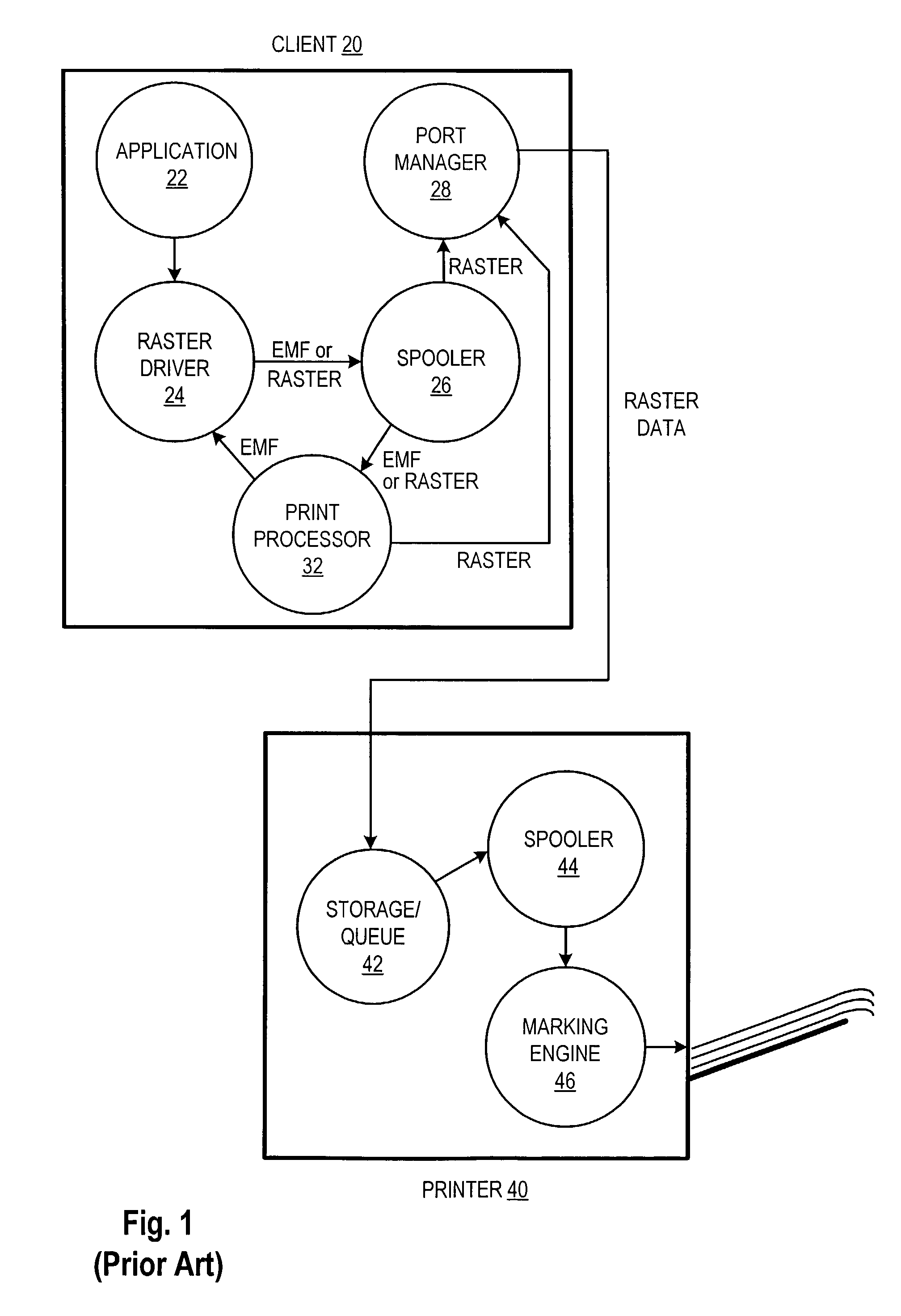

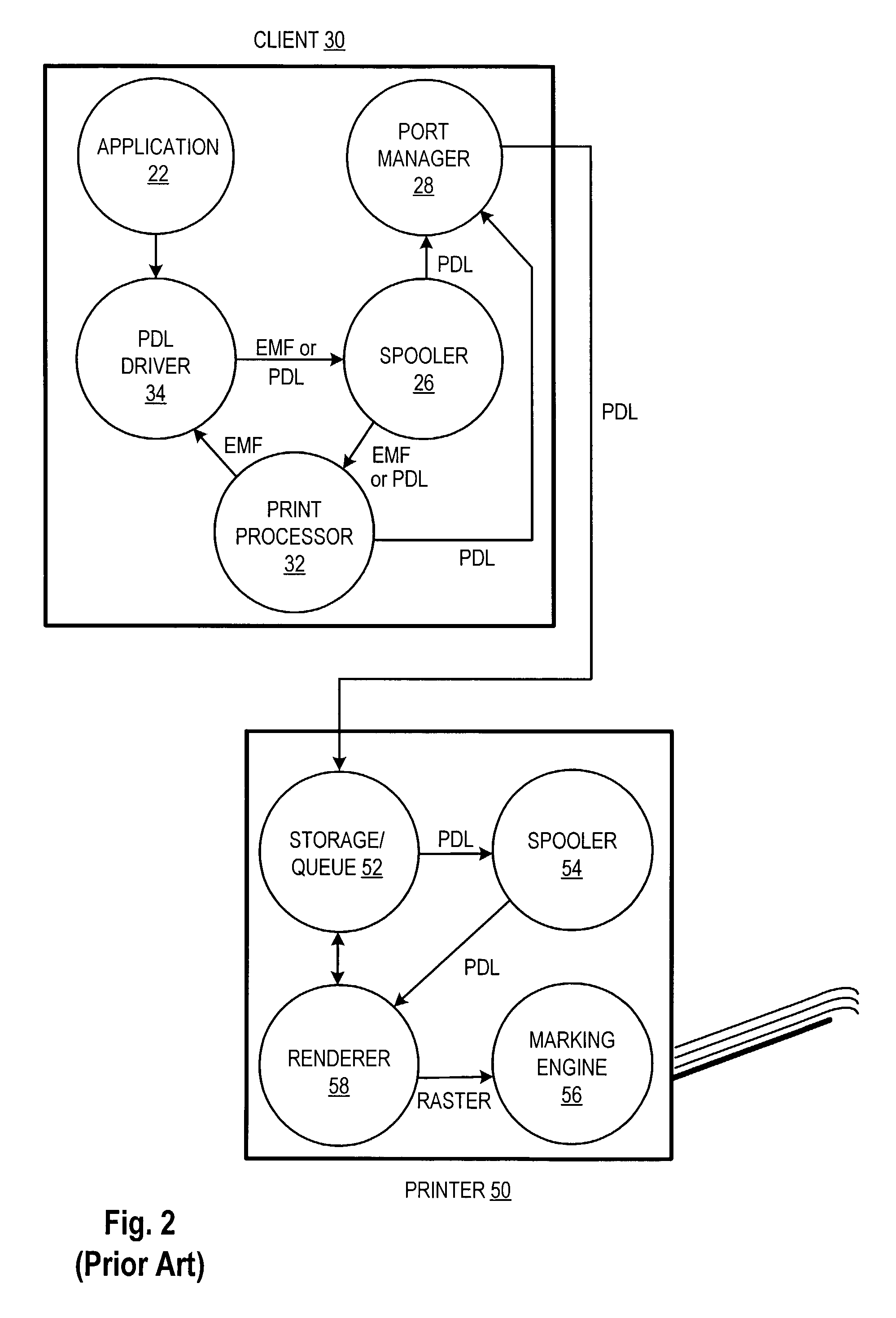

Load-balancing distributed raster image processing

ActiveUS7339687B2Efficient printingRasterization load can be balancedDigitally marking record carriersDigital computer detailsRaster image processingDirect printing

A method and apparatus for raster processing print data wherein multiple print-processing nodes process a print stream serially as it passes through those nodes. For instance, a client generates a print job with some pages in raster format and some pages in a Page Description Language (PDL) format, e.g., every other page. The pages are encapsulated with Printer Job Language commands that allow a printer to detect which pages in the mixed-format stream are in which format. The printer prints raster-format pages directly, and sends PDL-format pages to an internal renderer before submitting them to its marking engine. This arrangement allows printing, e.g., at full-marking-engine speed, on a printer with a low-speed renderer and from a client that can only render pages at low speed.

Owner:SHARP KK

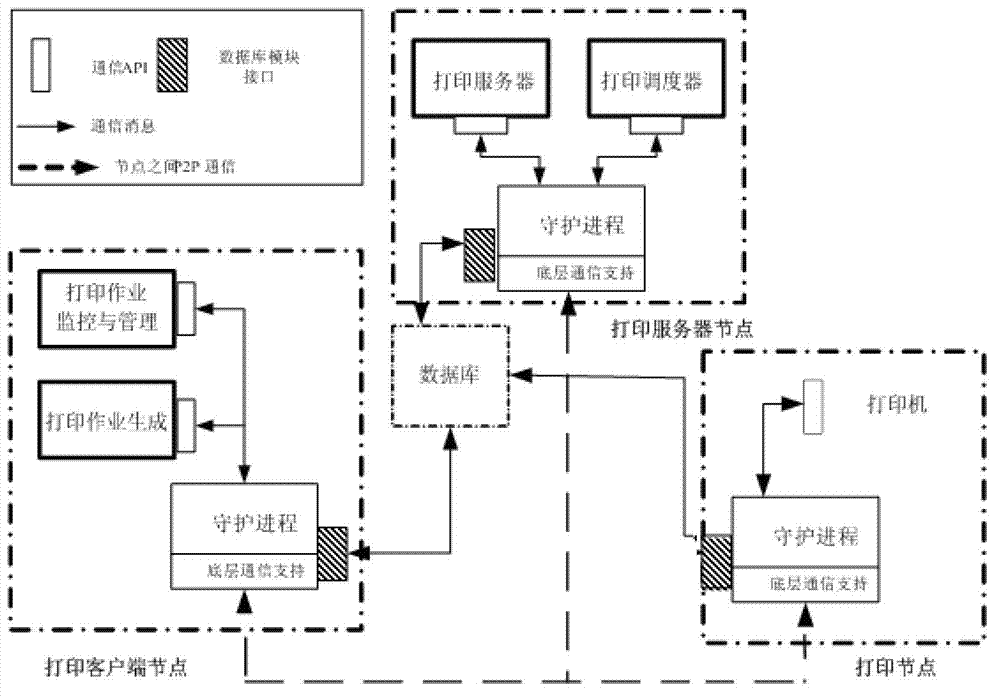

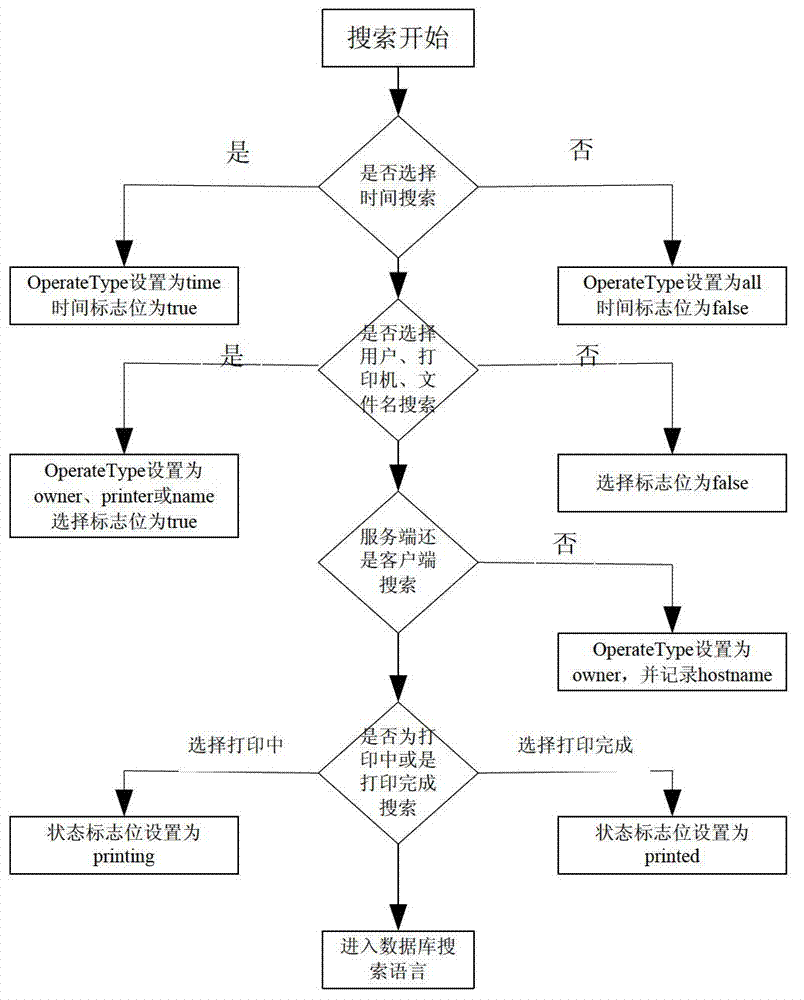

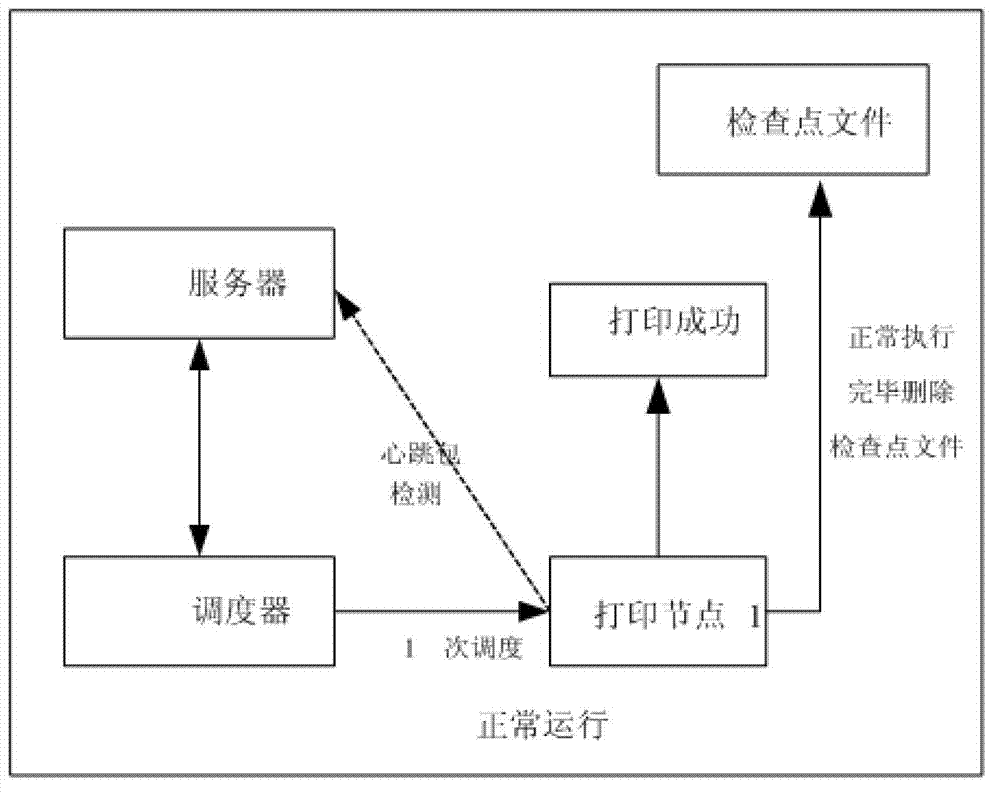

Network printing system under private cloud environment for massive seismic data processing

InactiveCN102830946AFast printEfficient printingTransmissionDigital output to print unitsClient-sideData treatment

The invention discloses a network printing system under a private cloud environment for massive seismic data processing. The network printing system comprises a database, a printing client node, a printing server node and a printing node, wherein the printing client node, the printing server node and the printing node are respectively communicated with the database. The database is used for storing information related to printing. The printing client node is used for generating printing operation and managing and monitoring the printing operation. The printing server node is used for analyzing and scheduling the printing operation. The printing node executes printing. A daemon runs in each of the printing client node, the printing server node and the printing node and is used for underlying communication support, message creation and analysis and printing operation starting. The printing client node, the printing server node, the printing node and the database are communicated with one another through an underlayer. The network printing system has the advantages that the private cloud environment is fully utilized, and network printing is faster, efficient and easy to manage.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

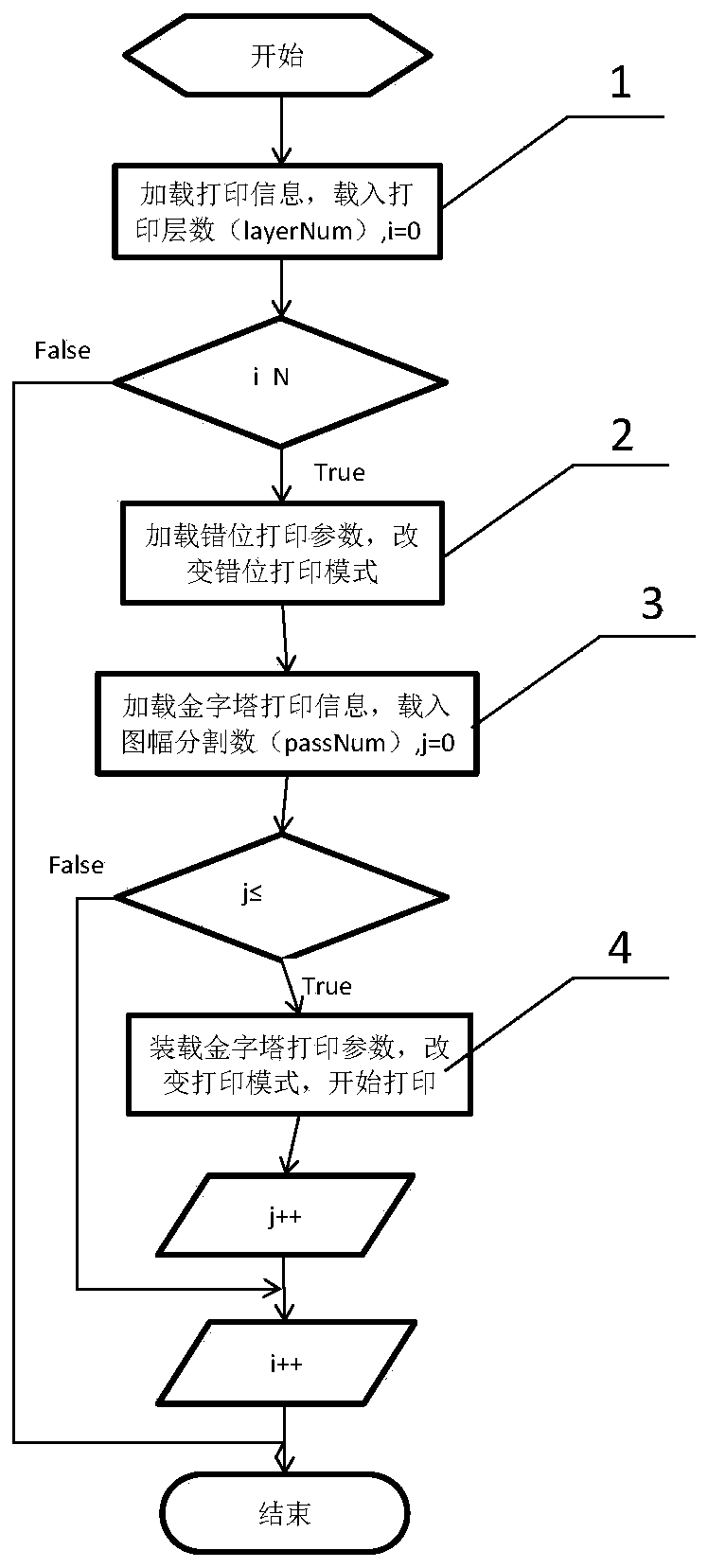

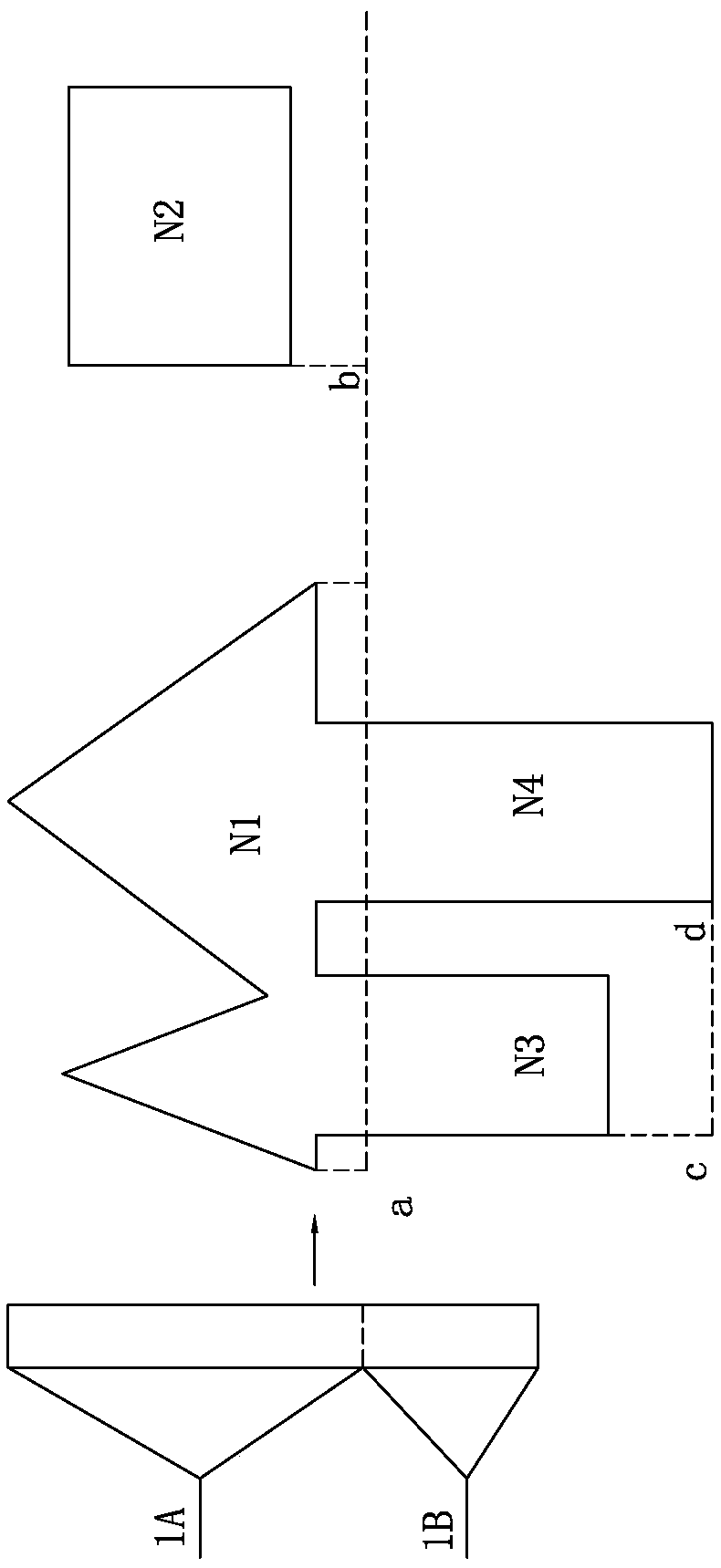

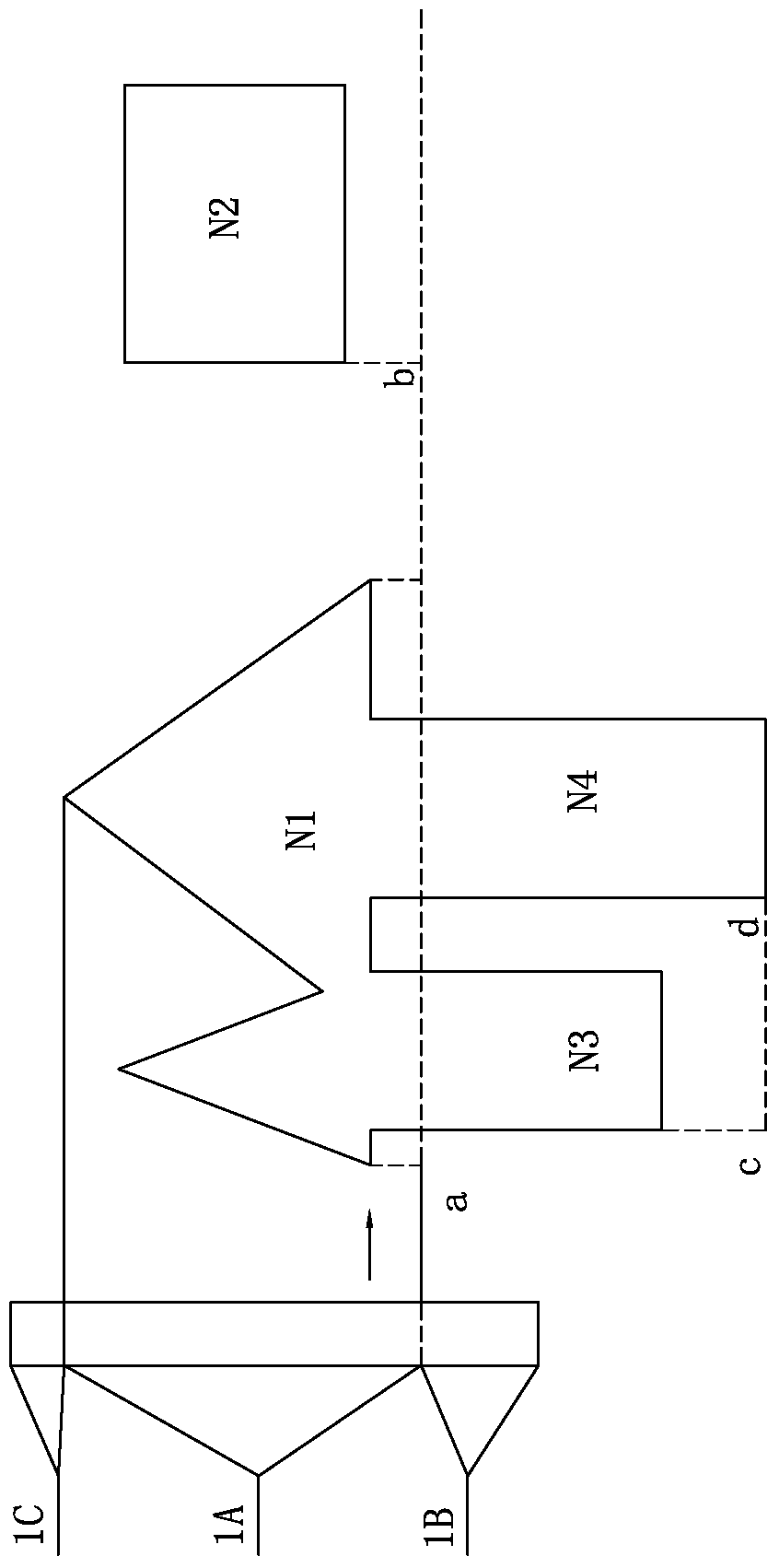

3DP printing method combining hierarchical shifting printing and layered mappable unit partition method

ActiveCN107639824AReduce maintenance costsExtended service lifeAdditive manufacturing apparatus3D object support structuresElectrical and Electronics engineering3D printing

The invention relates to a 3DP printing method combining hierarchical shifting printing and layered sheet partition method in the technical field of 3D printing. In the 3DP printing method provided bythe invention, in each layer of printing, a printing head adopts a way of shifting printing layer by layer, so as to enable the same orifices are staggered in the corresponding position in every adjacent layers, thereby avoiding defects of printing module section breaking caused by blockage of multiple orifices or belated repairing; when performing printing in each layer, cutting the whole sheetinto multiple respectively printed sheet according to the width of the printing, and re-planning the treading trace of the printing head, realizing fast blocking on each layer of printing sheet blankarea, so as to improve the printing efficiency. Therefore, according to the invention, printing by using the printing head for hierarchical shifting printing and cutting each layer of printing sheet and re-planning the treading trace, high efficient and fast printing can be realized, the defect of printing section breaking caused by blockage of multiple orifices is avoided, the maintenance cost ofthe printing head is reduced, the service life of the printing head is prolonged.

Owner:NINGXIA KOCEL MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com