Patents

Literature

218results about How to "High quality printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

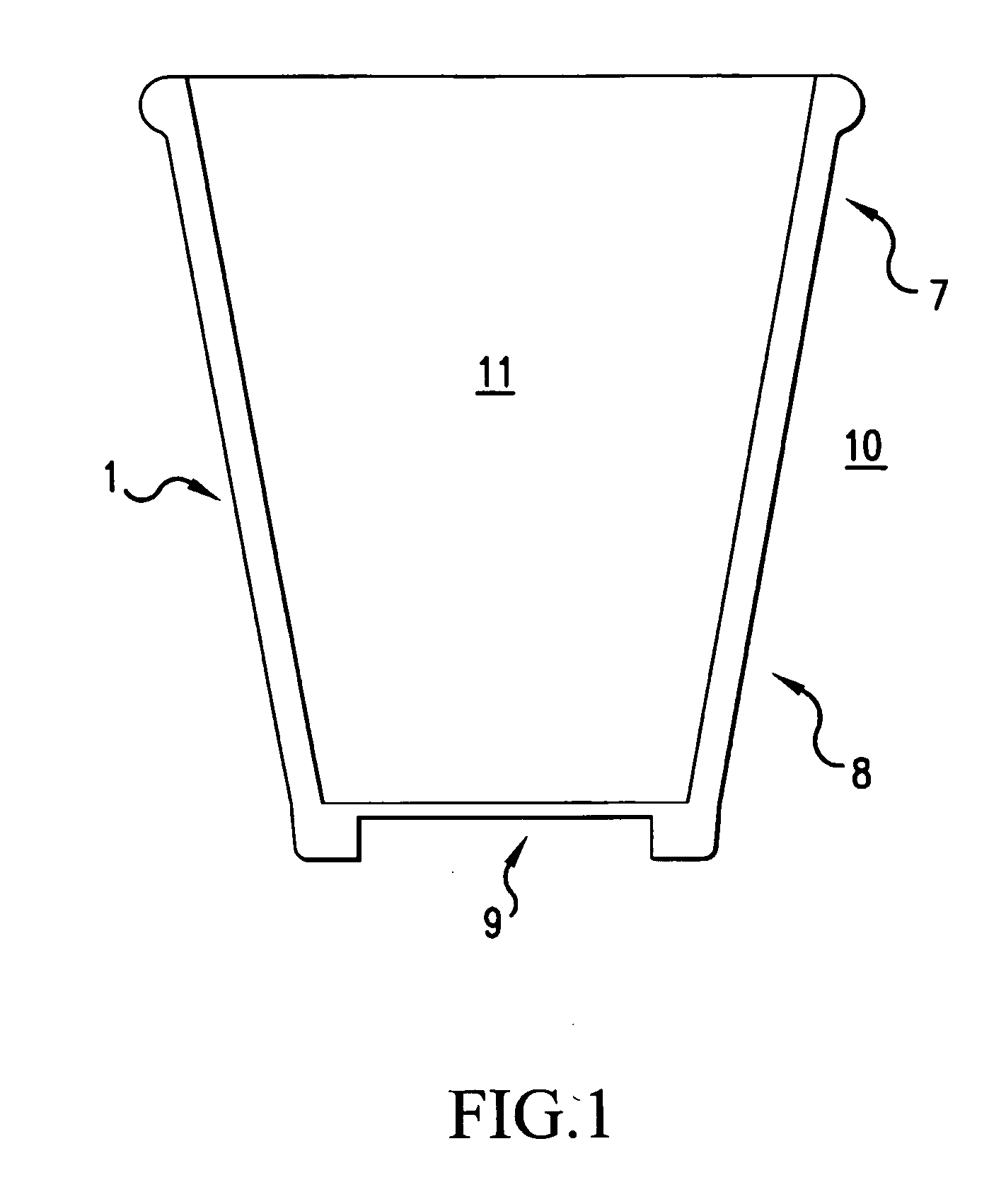

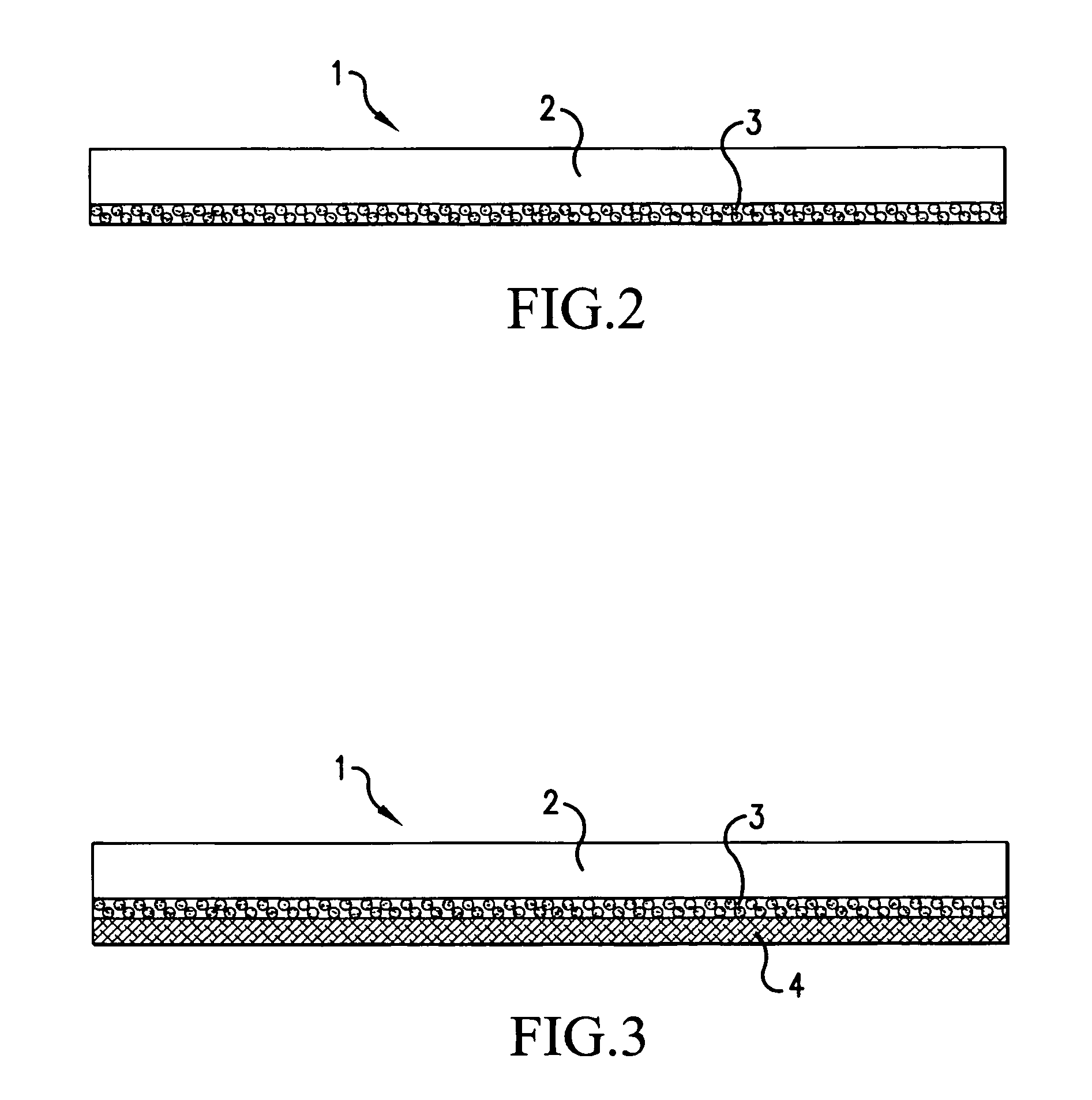

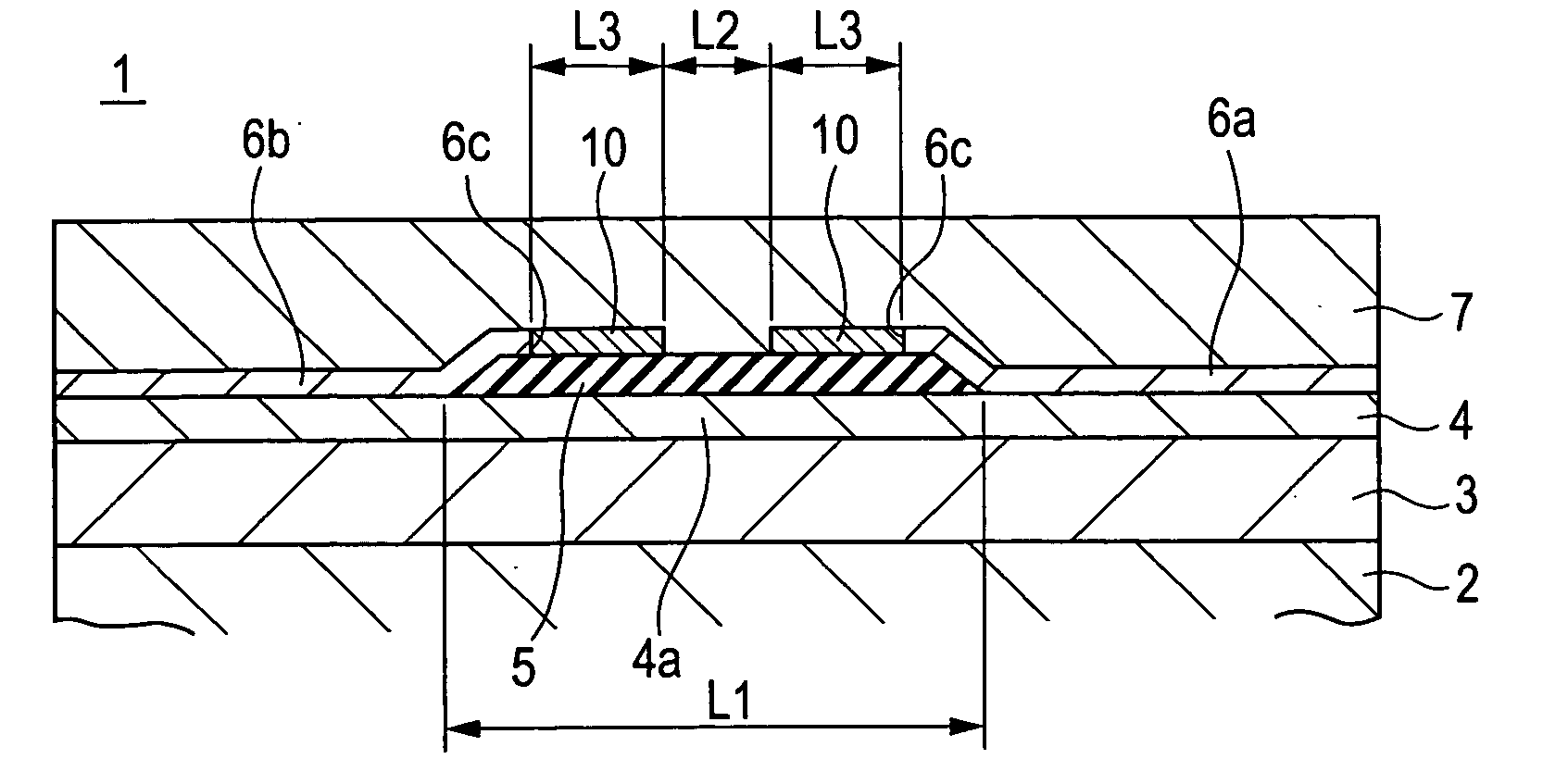

Insulated beverage or food container

InactiveUS6852381B2Reduce energy transferImprove functionalityWrappers shrinkageRefuse receptaclesEnergy transferEngineering

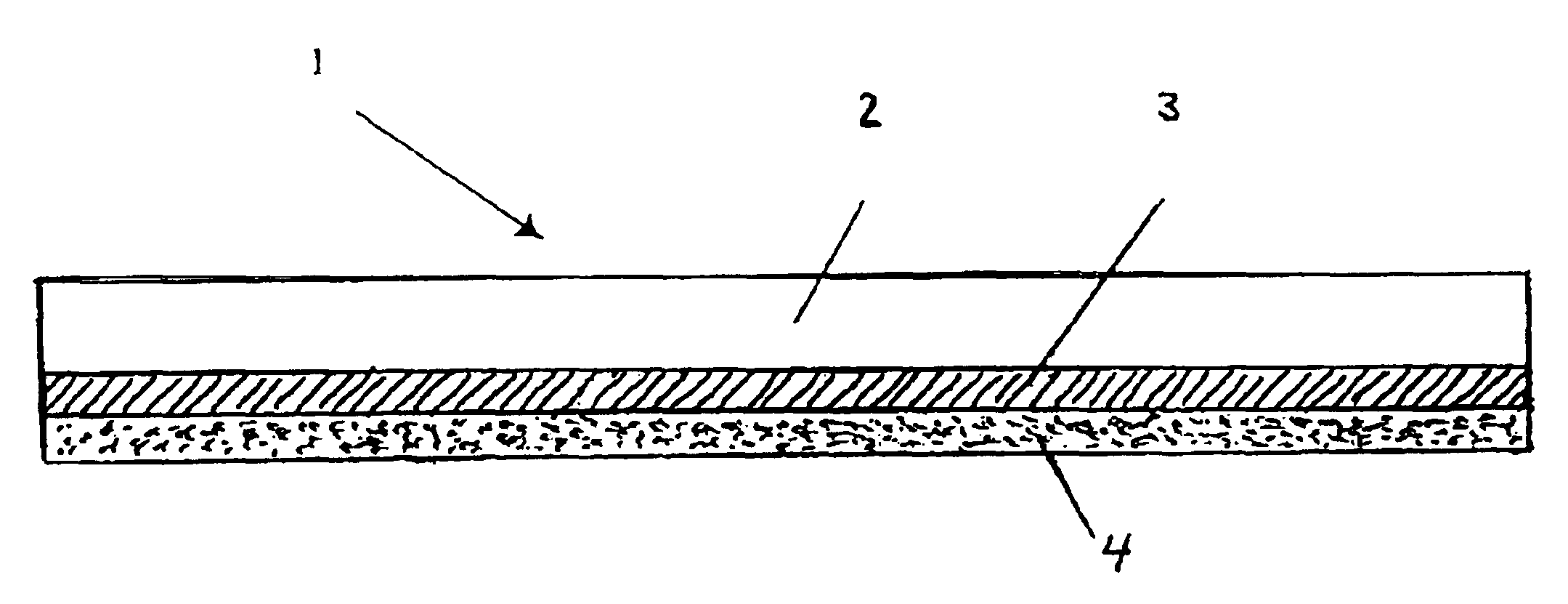

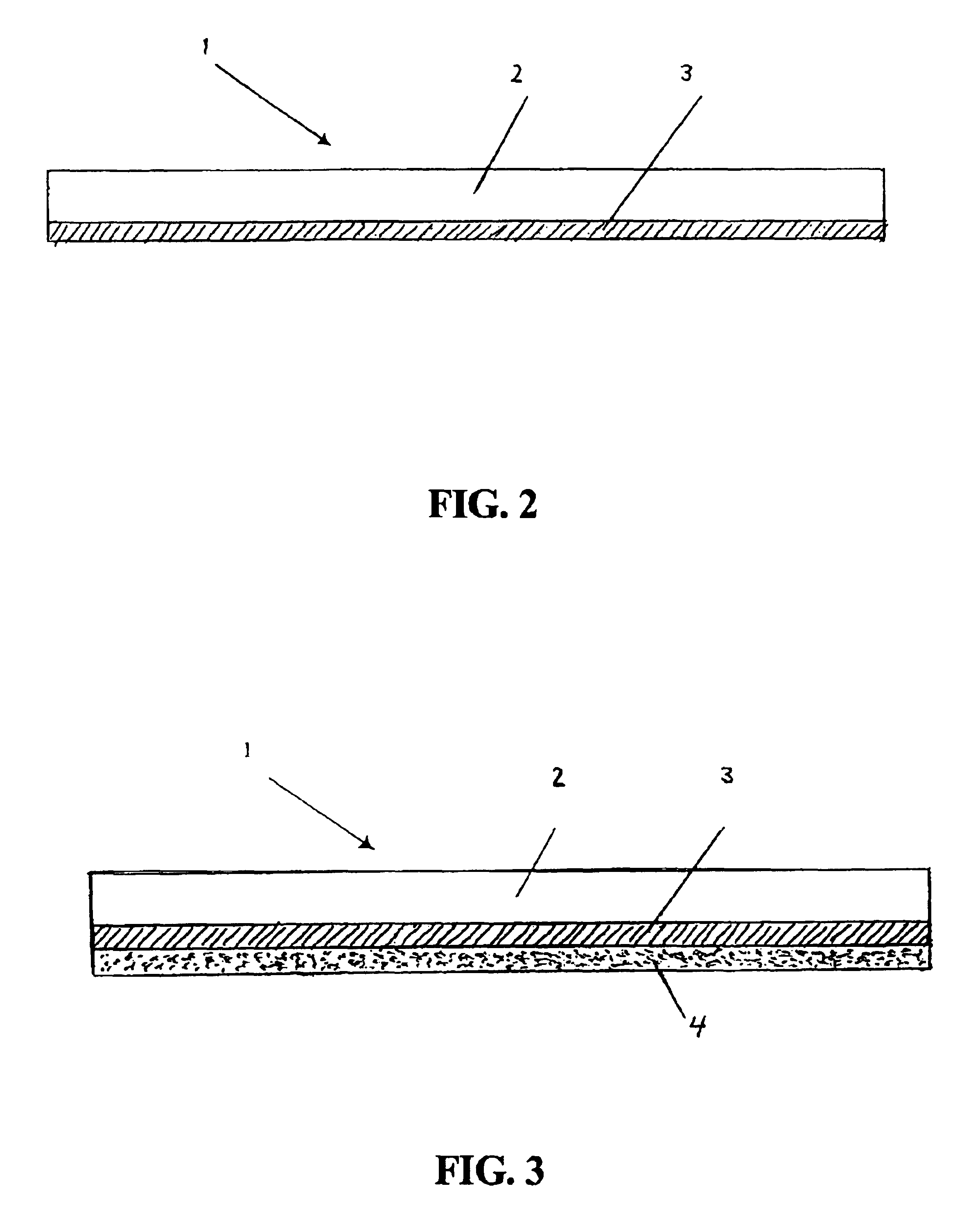

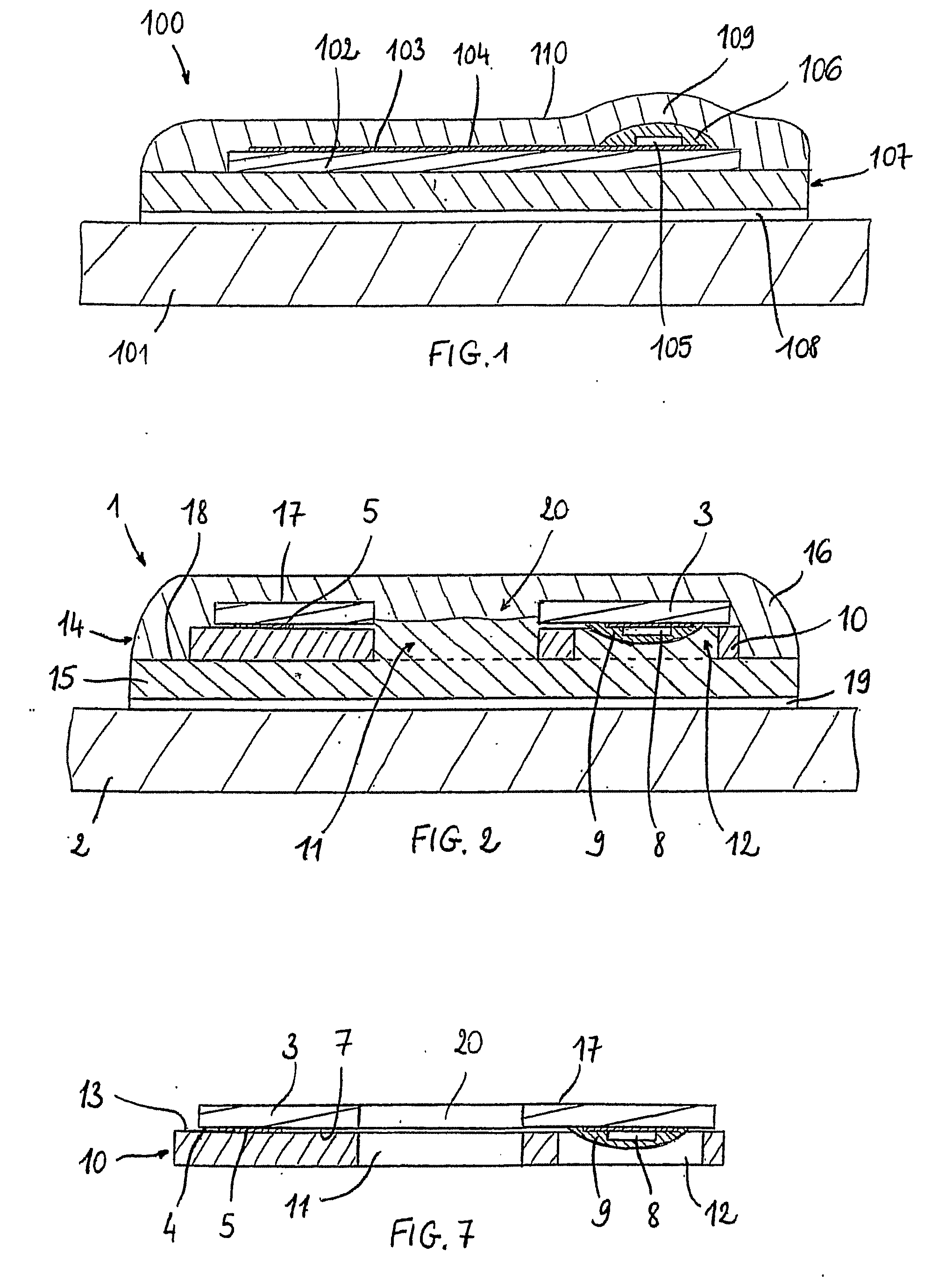

An insulating beverage or food container or sleeve is produced with a foam layer disposed on an inner surface of a paper stock. A polymer shrink film layer is arranged in a position along an inside surface of the beverage container. The foam layer is sandwiched between the polymer shrink film layer and the paper stock and decreases the energy transfer between the beverage and the user's hands allowing the user to hold onto the container for an extended period of time without causing user discomfort or pain. The polymer shrink film layer is produced from a shrink film polymer having a percent shrink in the range of 30% or less, and more particularly a percent shrink range of 5 to 10%.

Owner:APPVION LLC

Insulated beverage or food container

InactiveUS20050003122A1Reduce energy transferImprove functionalityFibreboardWrappersEnergy transferEngineering

An insulating beverage cup or sleeve is produced with a foam layer disposed on an inner surface of a food or beverage paper stock. A polyethylene film layer is arranged in a position between a paper stock layer and an inside surface of the beverage container. The foam layer decreases the energy transfer between the beverage and the user's hands allowing the user to hold onto the cup for an extended period of time without causing user discomfort or pain, e.g. greatly extends the hold time of the paper cup. The exterior surface of the beverage cup remains highly printable and predisposed to high quality graphics both before and after cup manufacture.

Owner:APPLETON PAPERS INC

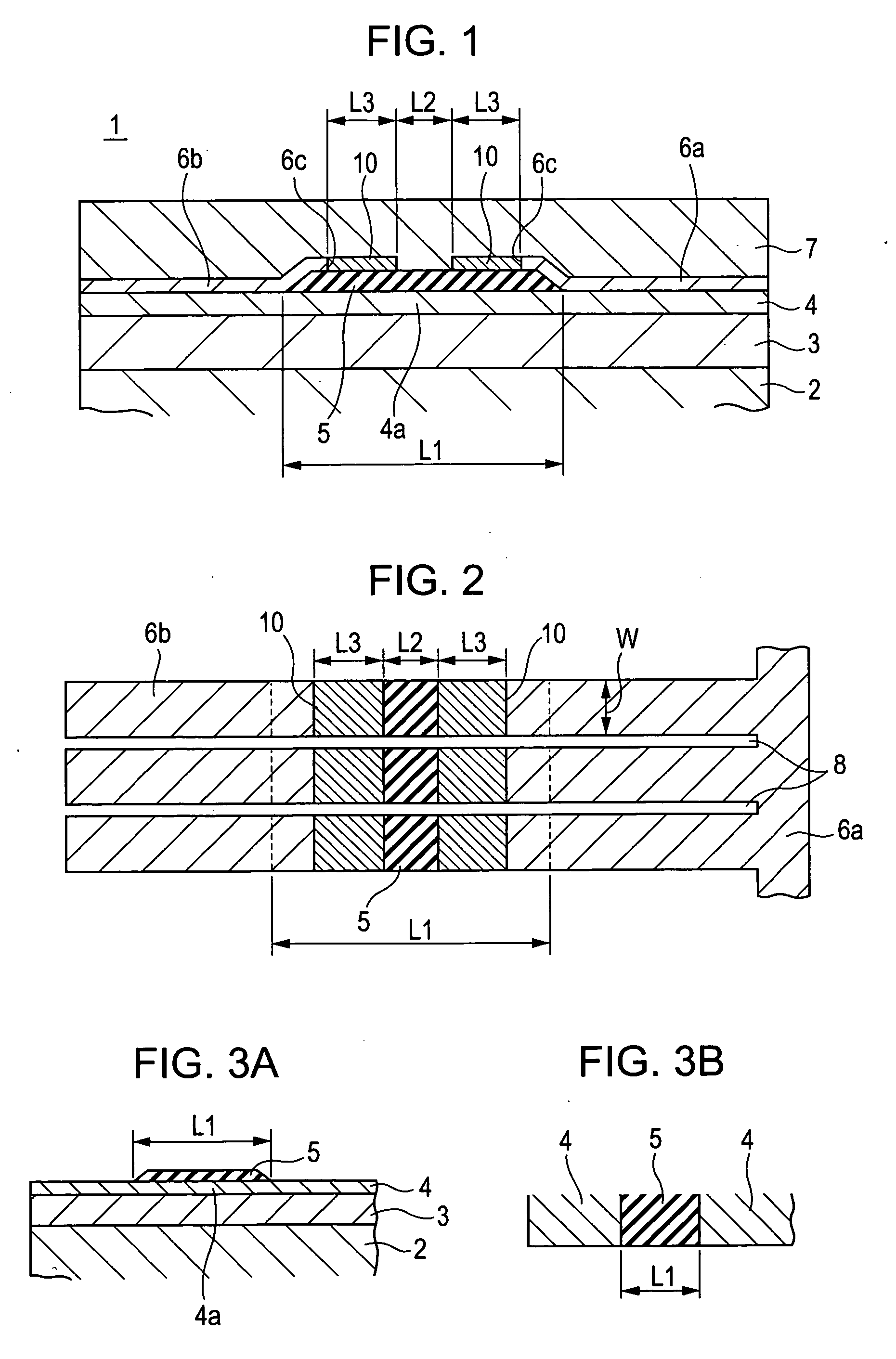

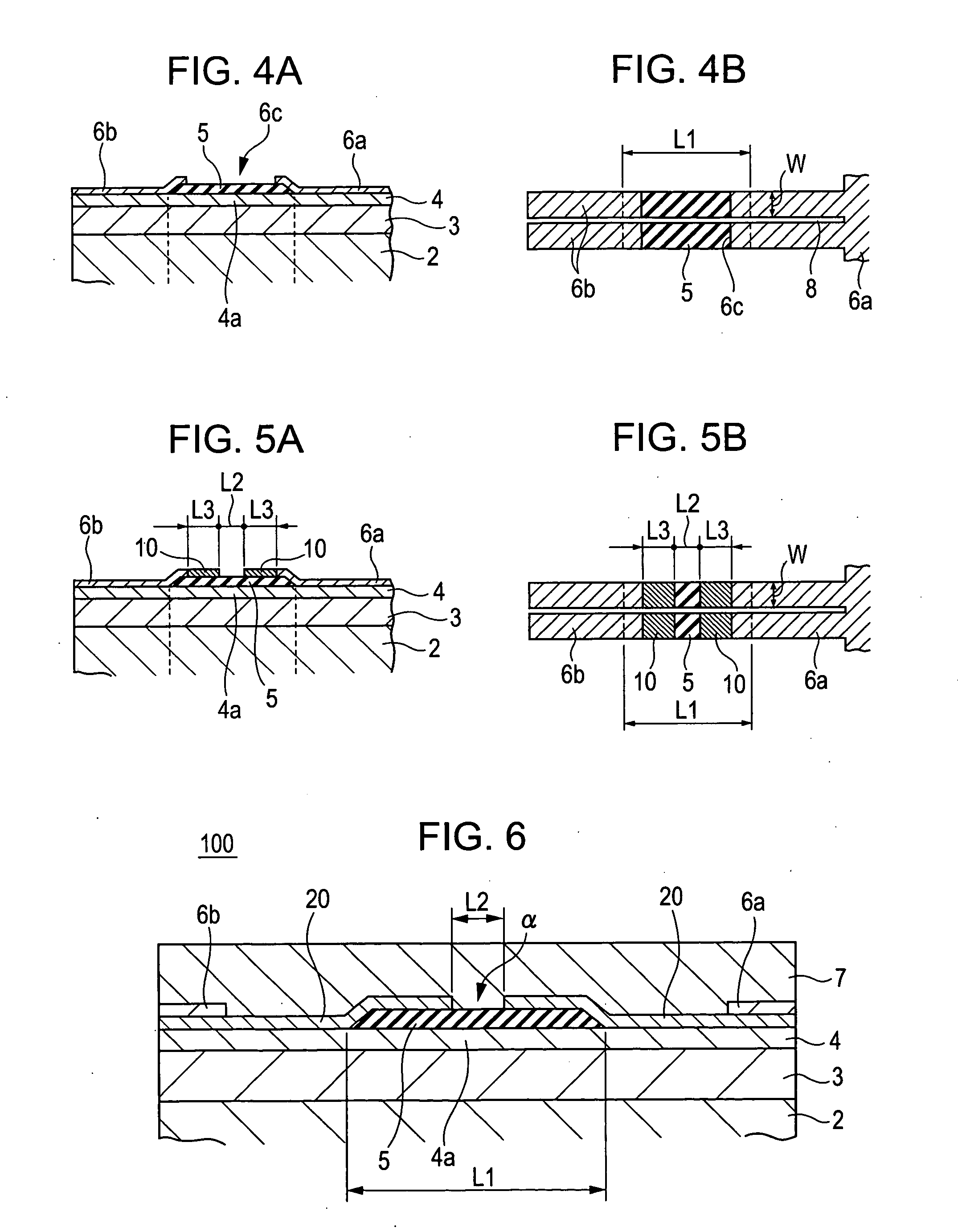

Thermal head, method for manufacturing the same, and method for adjusting dot aspect ratio of thermal head

In a thermal head provided with a resistance layer having a plurality of heating element portions which generate heat by energization, an insulating barrier layer which determines the two-dimensional size of each heating element portion by covering each heating element portion, and electrode layers electrically connected to two end portions of each of the plural heating element portions, in the length direction of the resistance, a heat transfer layer is disposed on at least the insulating barrier layer to determine the two-dimensional surface exposure area of the insulating barrier layer by covering part of the insulating barrier layer and to dissipate the heat generated from the plural heating element portions, and surface exposure regions of the insulating barrier layer are specified as effective heating regions of the plural heating element portions by adjusting the two-dimensional size of the heat transfer layer.

Owner:ALPS ALPINE CO LTD

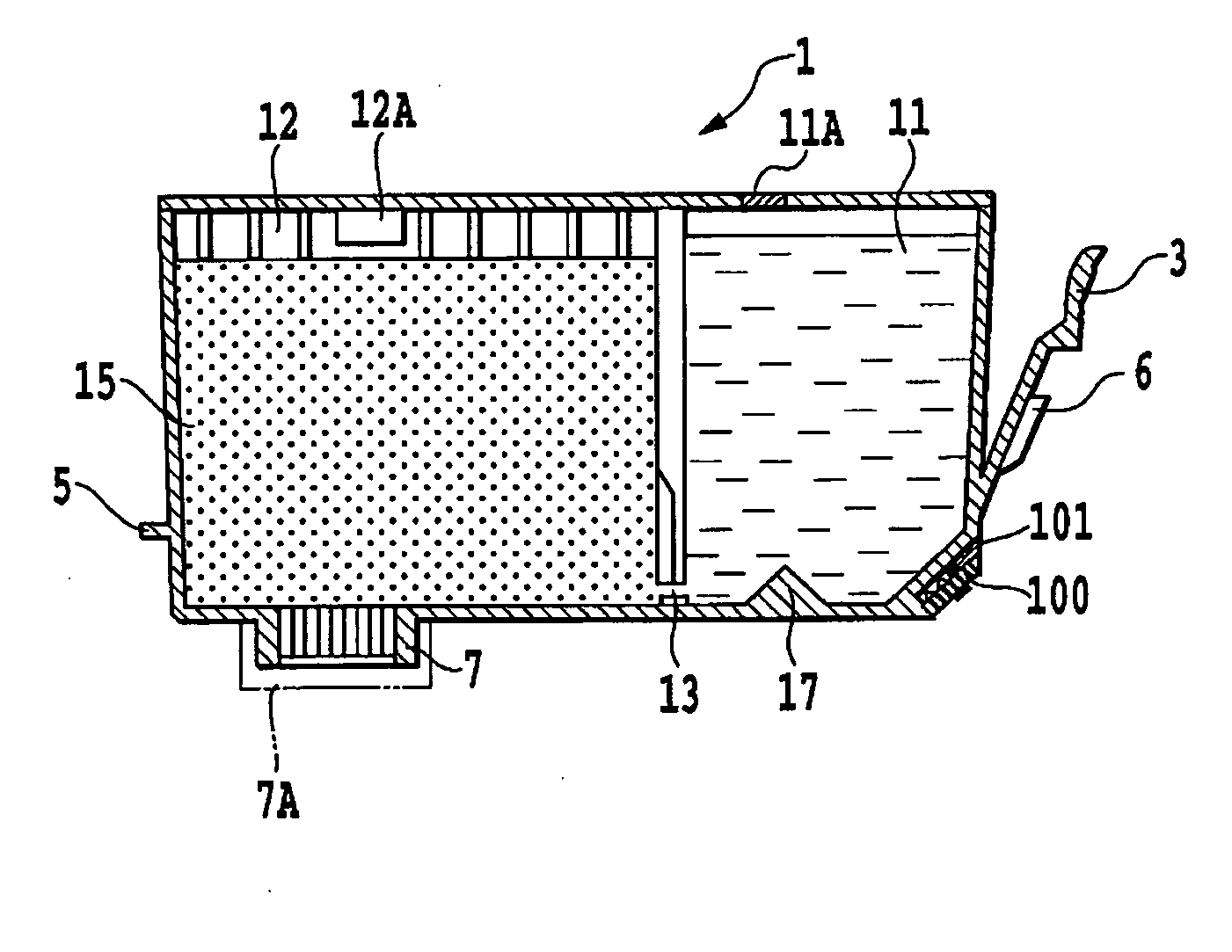

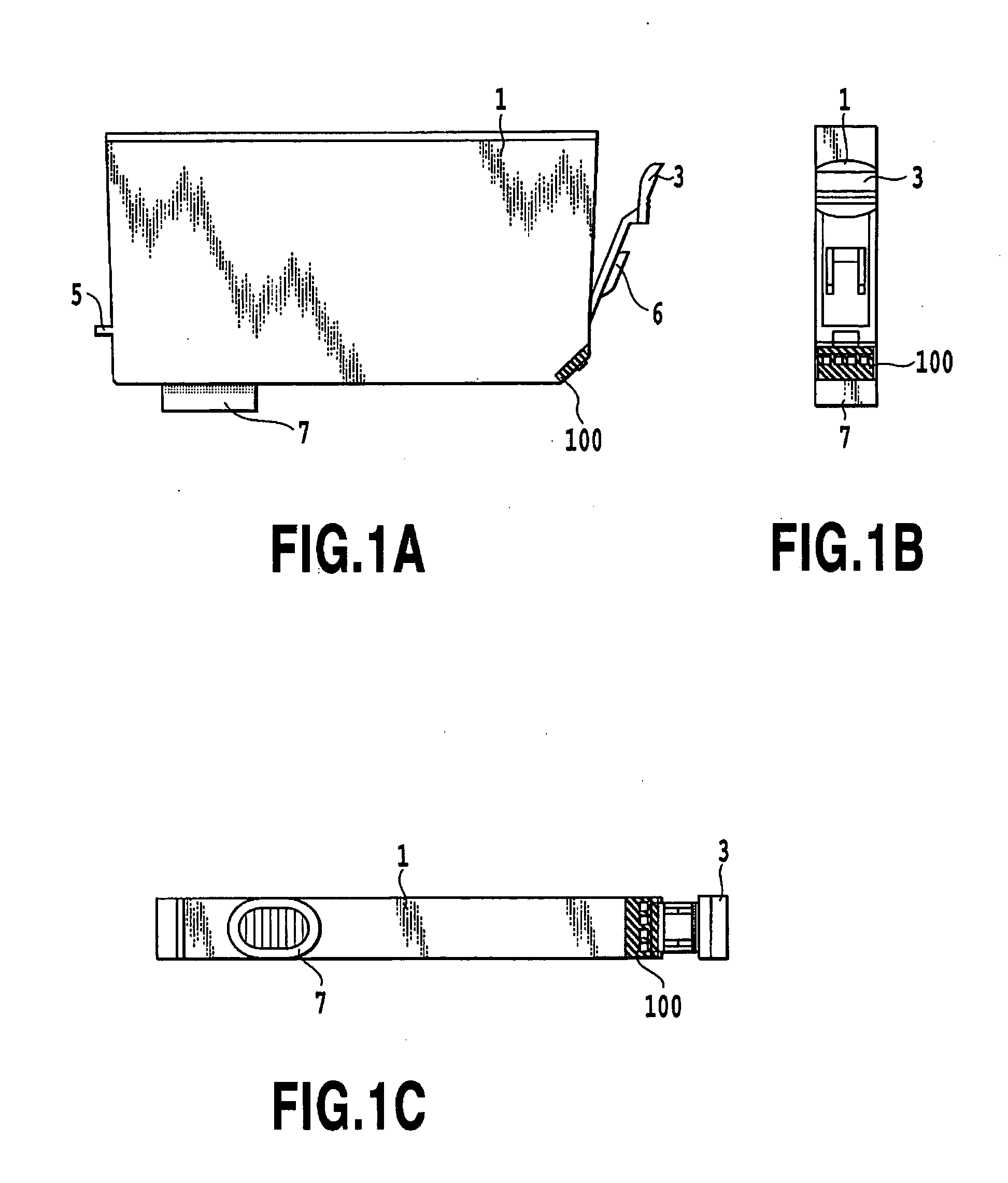

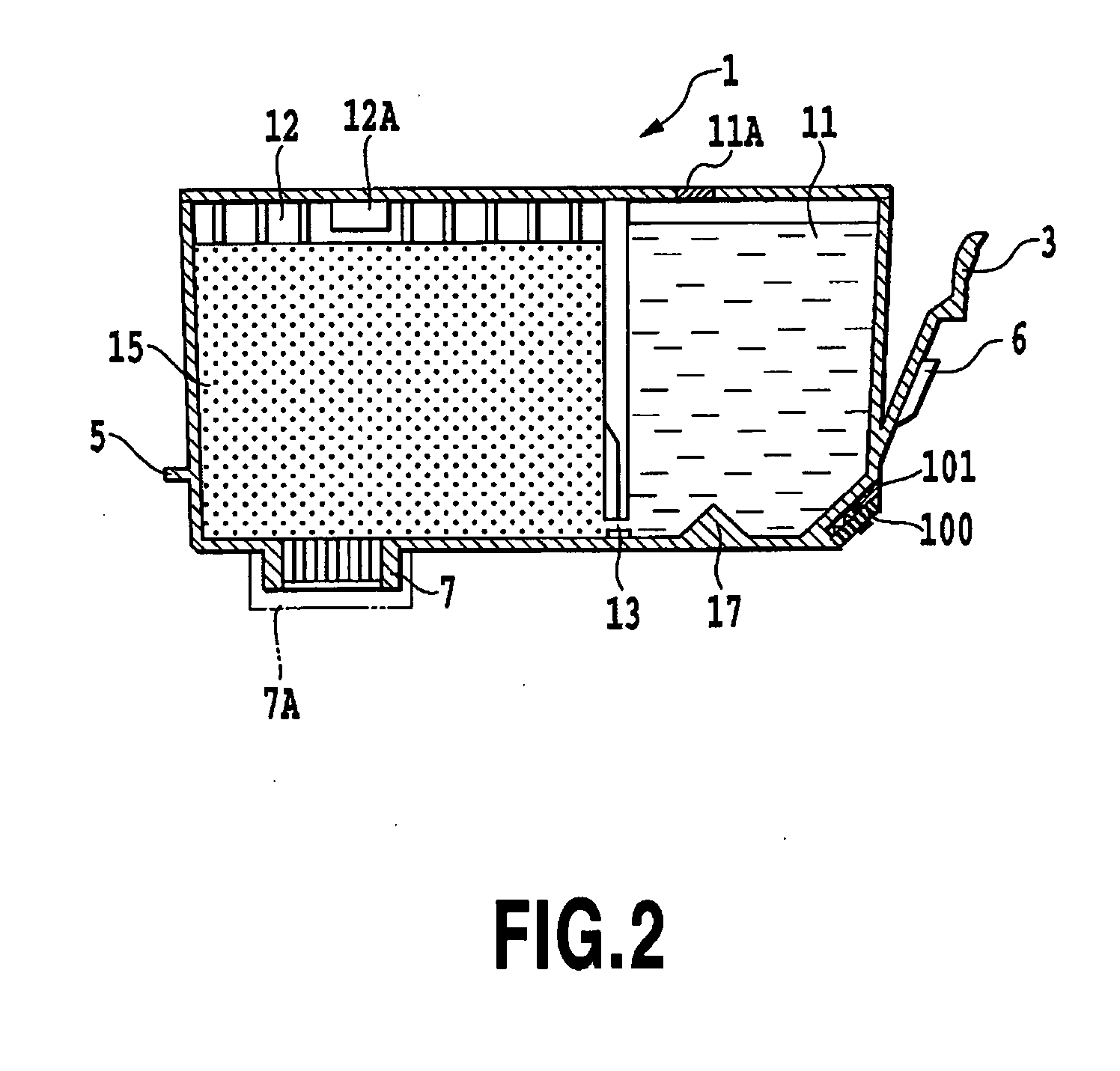

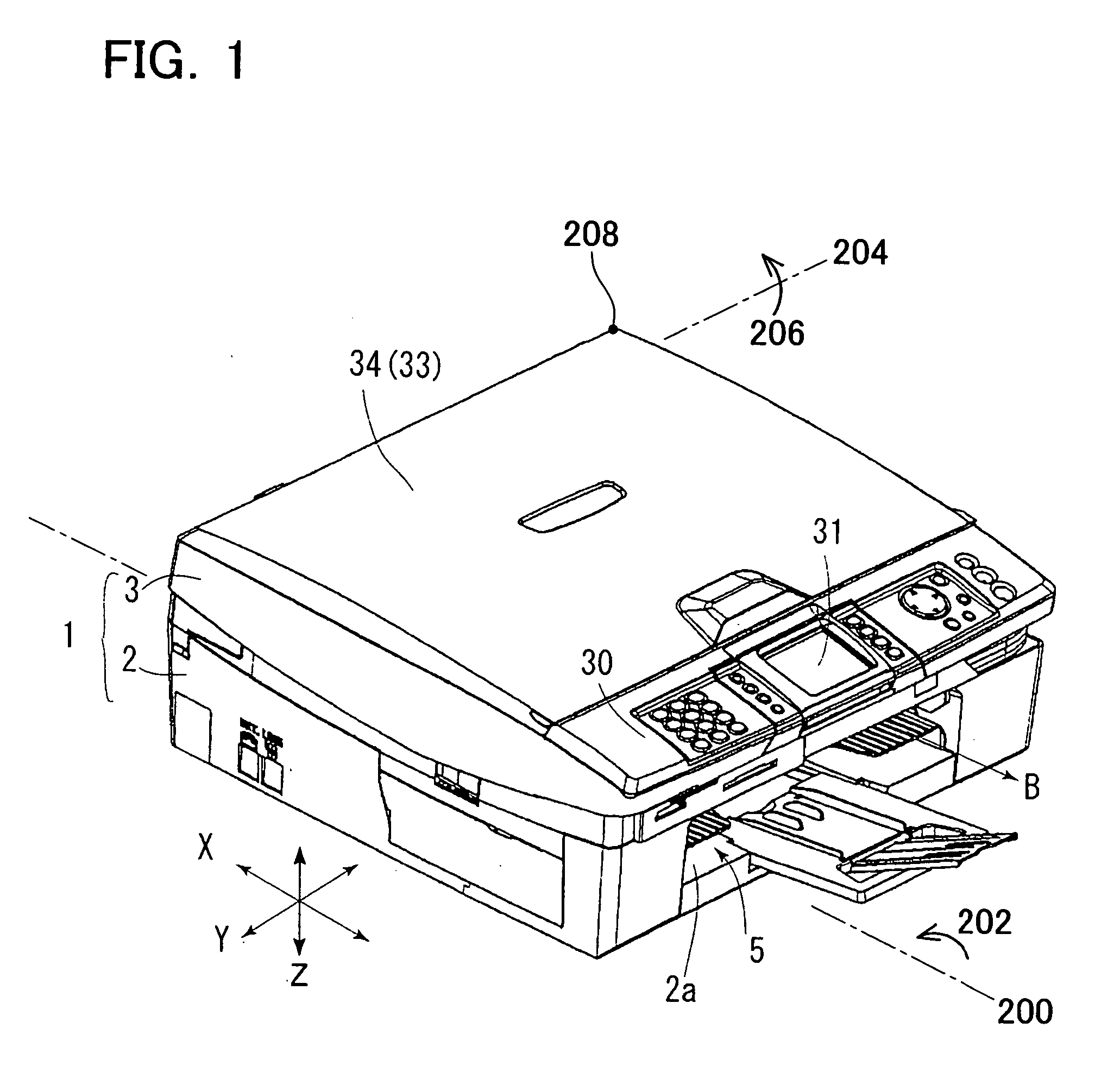

Liquid container, liquid supply system and printing device using liquid container, and circuit board for liquid container

ActiveUS20060244795A1Easy to operateHigh quality printingOther printing apparatusFuel tankLight emission

An ink tank detachably mounted on a printer includes a non-volatile memory and a LED for executing a process in response to a condition of the tank such as ink residual quantity by transmitting information stored in the memory to a printer, and informing the condition of the ink by use of the LED. Further, the content stored in the memory is prevented from being destroyed, and the LED can perform light emission until immediately before detachment and thus contribute to improvement in workability of a user. A volatile memory element is provided in addition to the non-volatile memory. When a user can detach the tank, condition information on the ink tank retained by the non-volatile memory is transferred to the volatile memory in advance. When it is possible to detach the tank, control for turning the LED on and off is achieved by accessing only to the volatile memory.

Owner:CANON KK

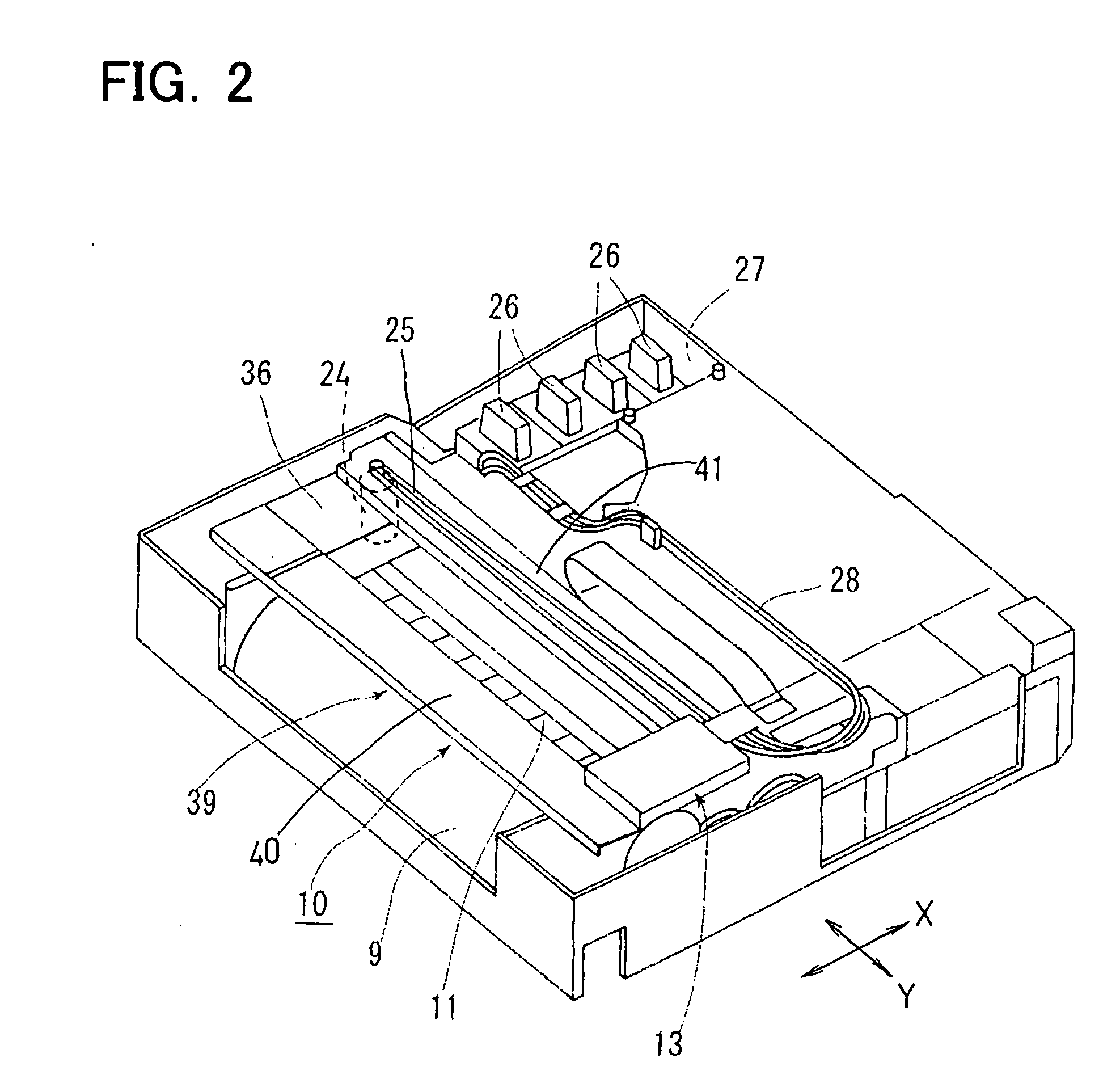

Inkjet recording apparatus and inkjet recording method

InactiveUS20080055356A1High quality printingImprove absorption rateInking apparatusMeasurement apparatus componentsSolventBiomedical engineering

The inkjet recording apparatus has: an ink droplet ejection device which ejects a droplet of an ink containing a coloring material; a treatment liquid deposition device which deposits a treatment liquid that causes the coloring material contained in the ink to aggregate so as to create a coloring material aggregate; and an absorbing body which absorbs a solvent of a mixed liquid including the ink ejected as the droplet by the ink droplet ejection device and the treatment liquid deposited by the treatment liquid deposition device, wherein solvent absorption holes having an opening diameter larger than a spreading width of the coloring material aggregate in the mixed liquid on a surface of a recording body are formed in a surface of the absorbing body.

Owner:FUJIFILM CORP

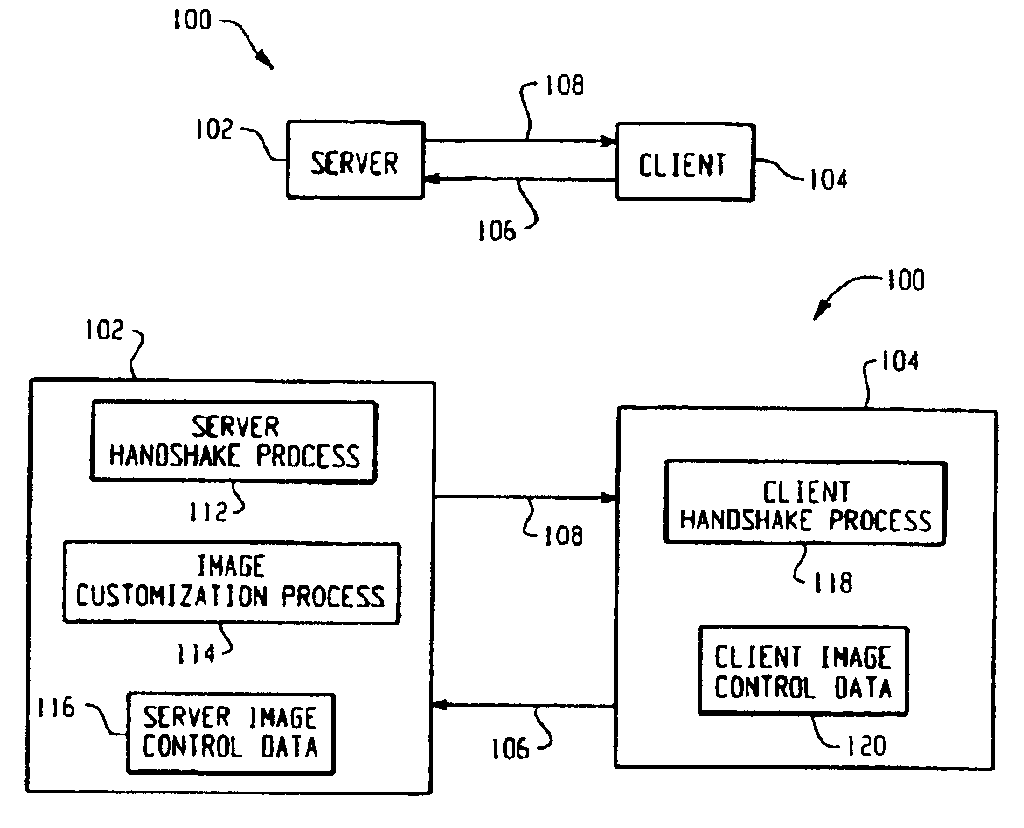

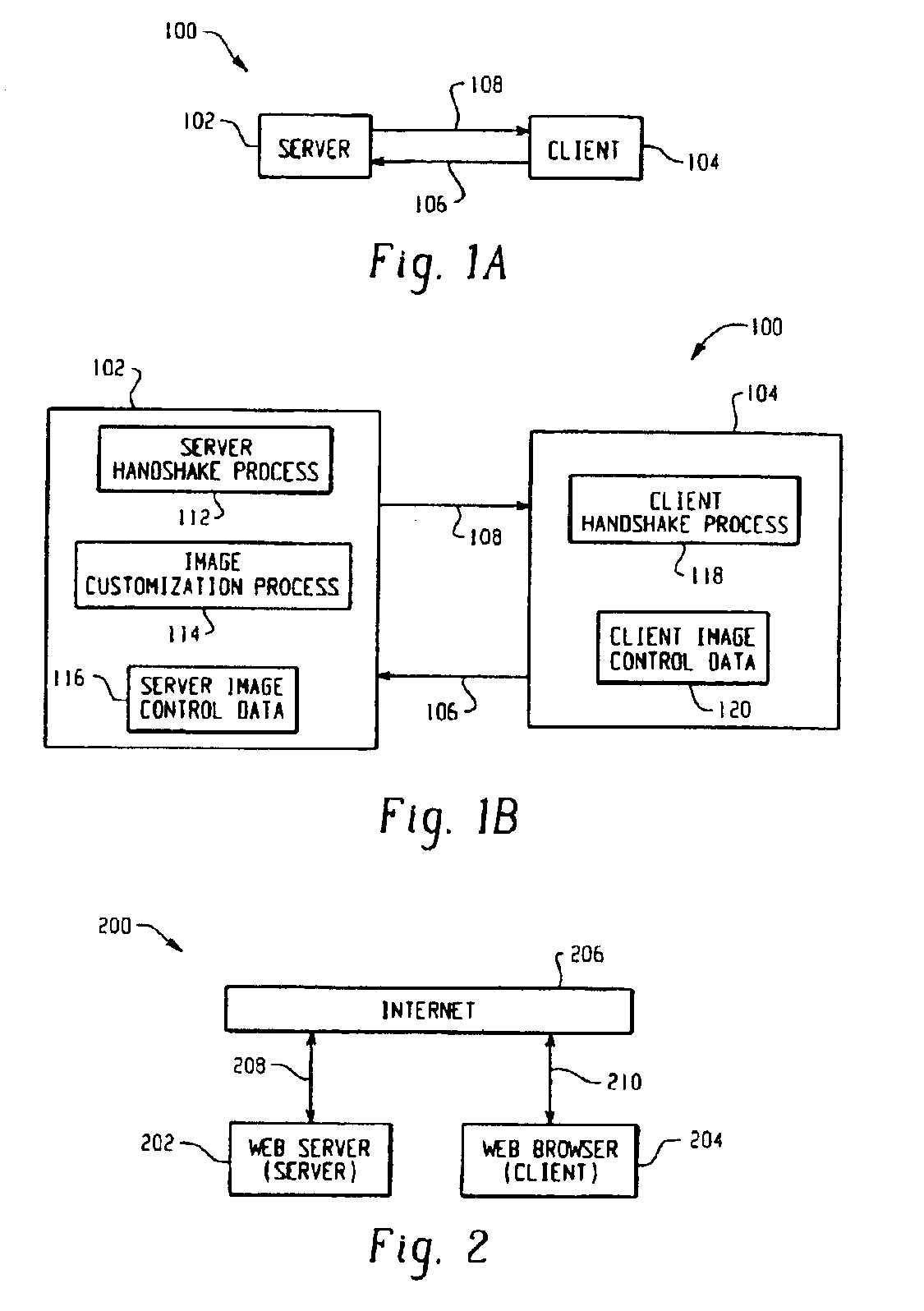

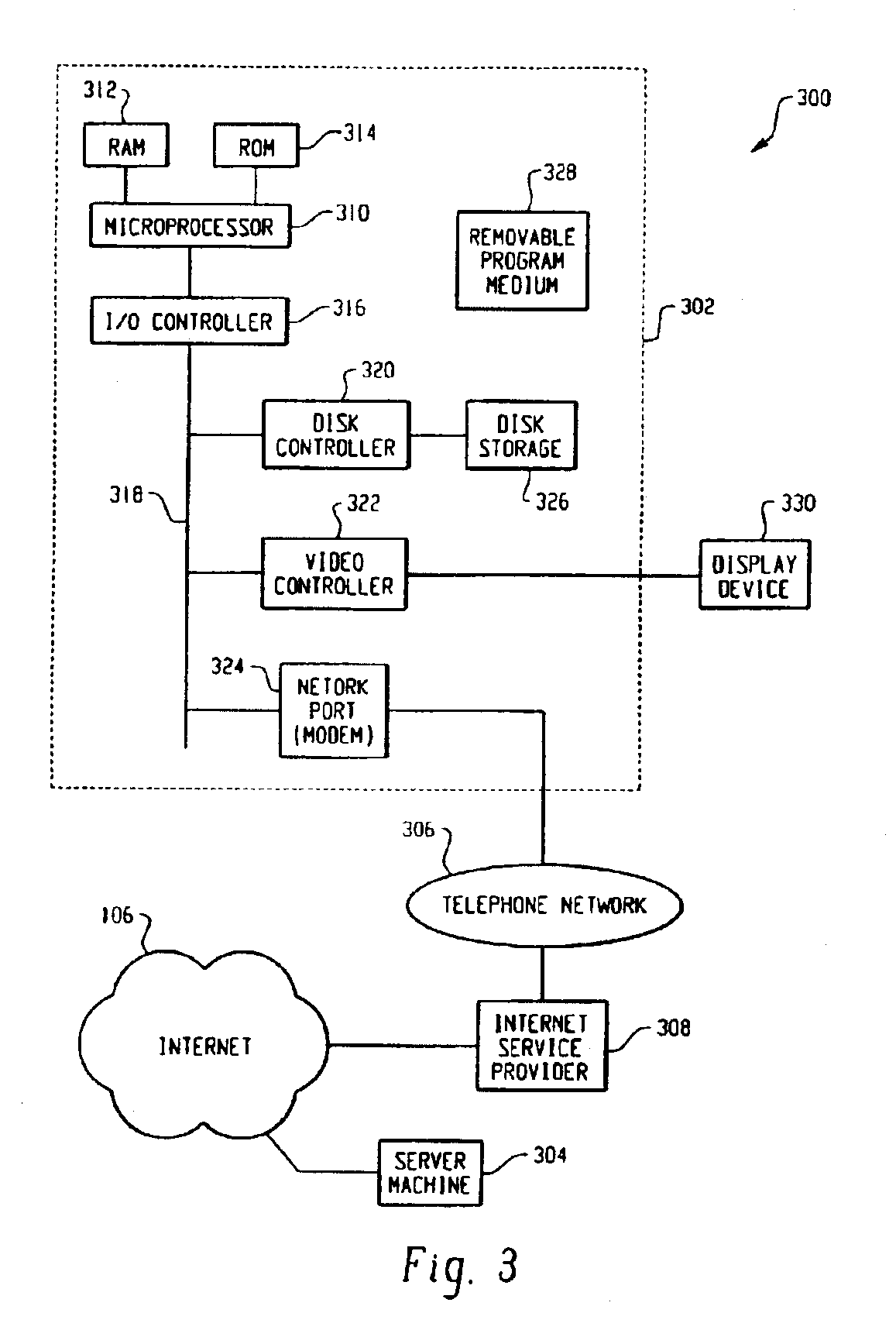

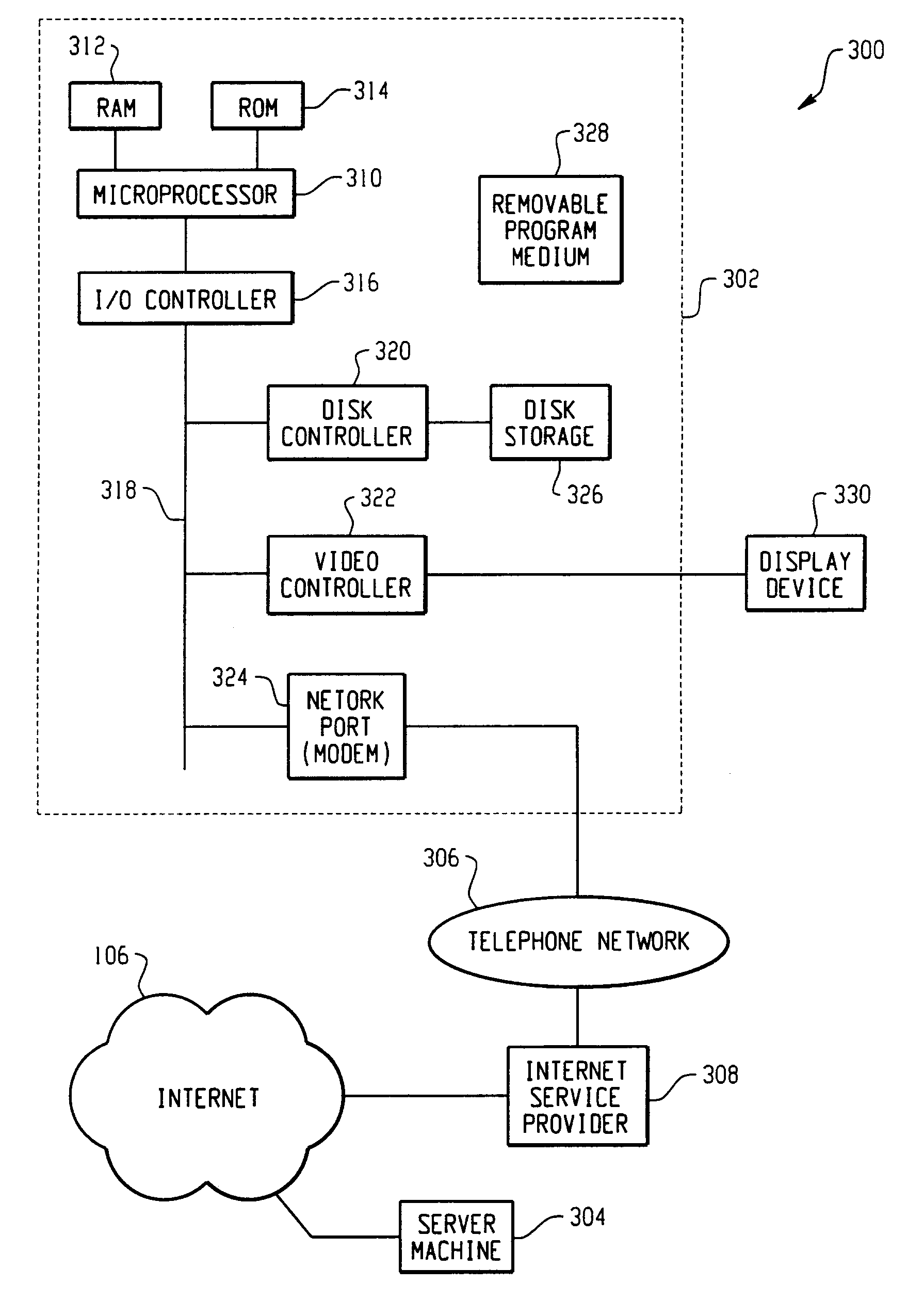

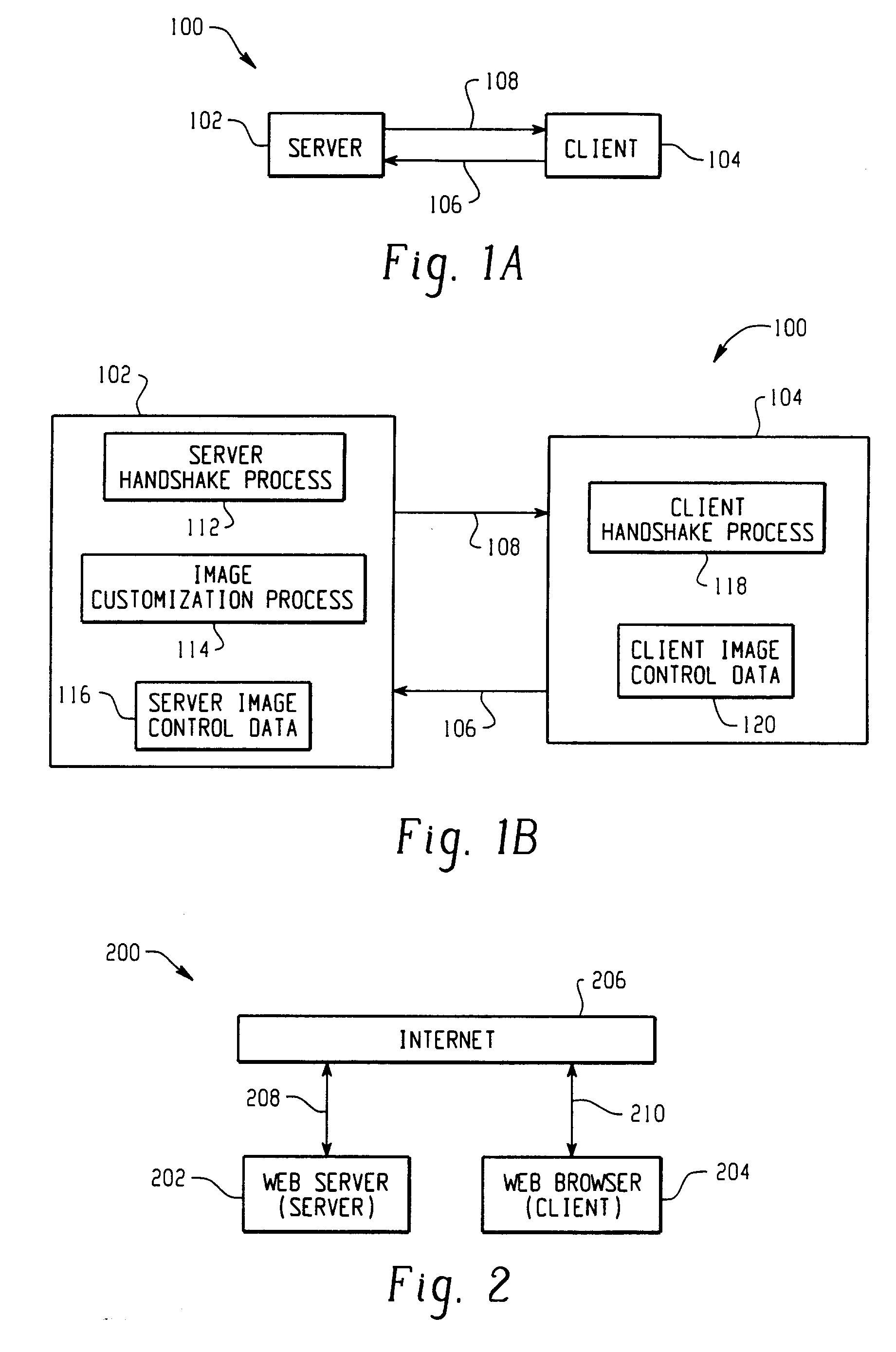

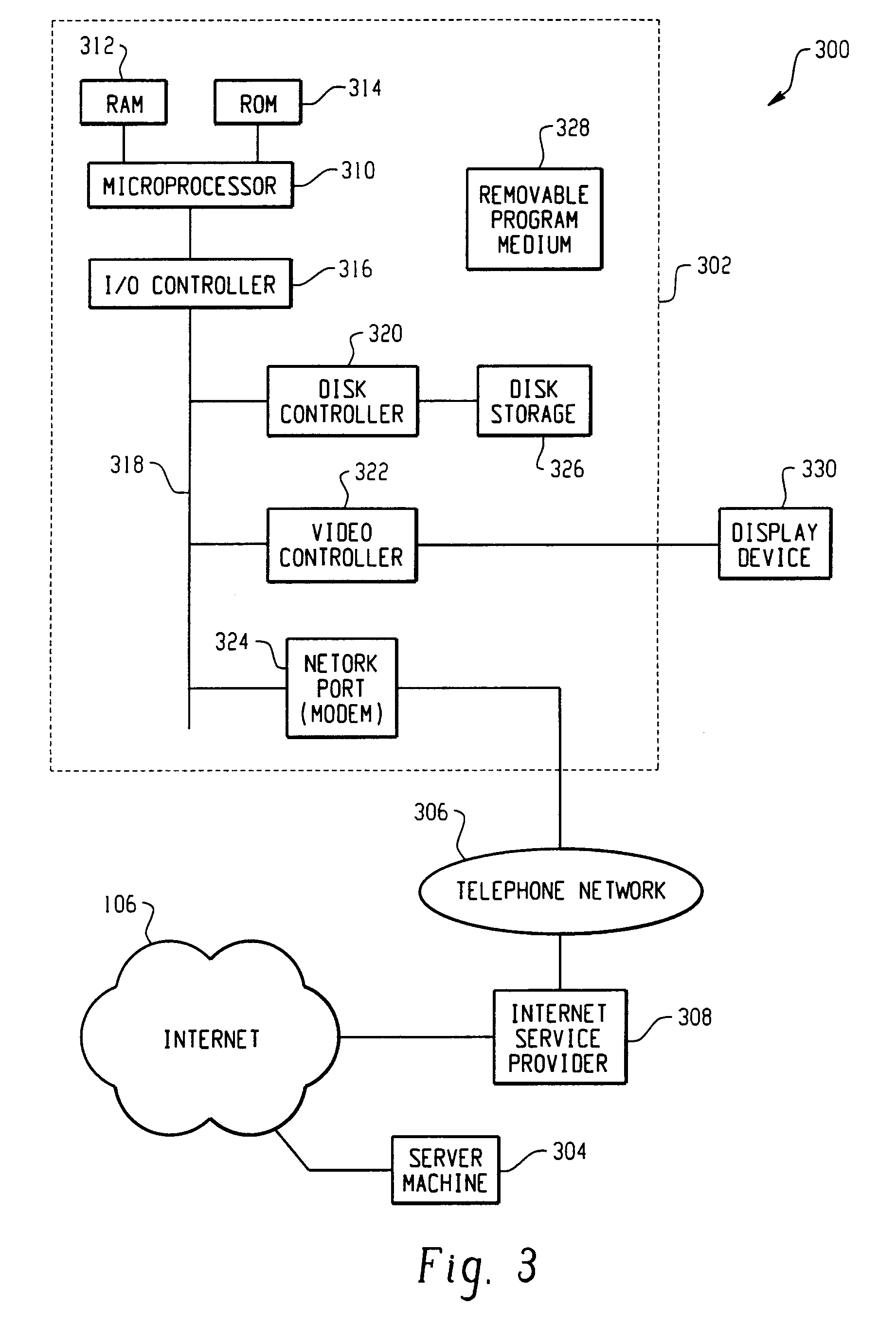

Computer implemented method and system for transmitting graphical images from server to client at user selectable resolution

InactiveUS6950101B2Reduce the amount requiredSave network bandwidthDigital data information retrievalNatural language data processingGraphicsImage resolution

Techniques for transmitting graphical images in a network environment are described. According to the techniques, the amount of data of the graphical images that is transmited is customized in accordance with client and / or server supplied information. The techniques enable graphical images to be transmitted more efficiently than previously possible, thus saving precious network bandwidth and reducing transmision time. The invention is particularly suitable for network (Internet or Internet) implementations wherein graphical images often need transferred.

Owner:RAKUTEN INC

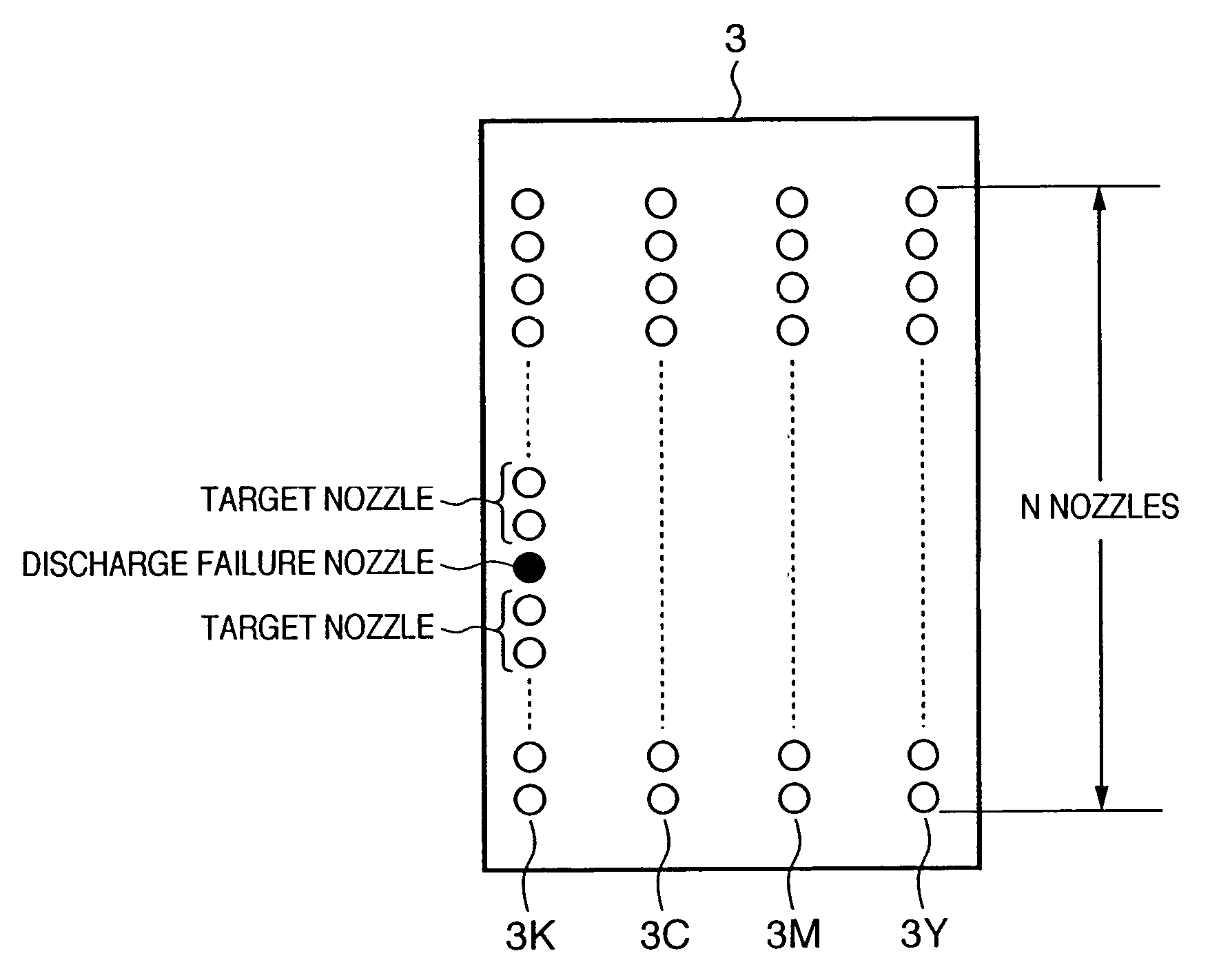

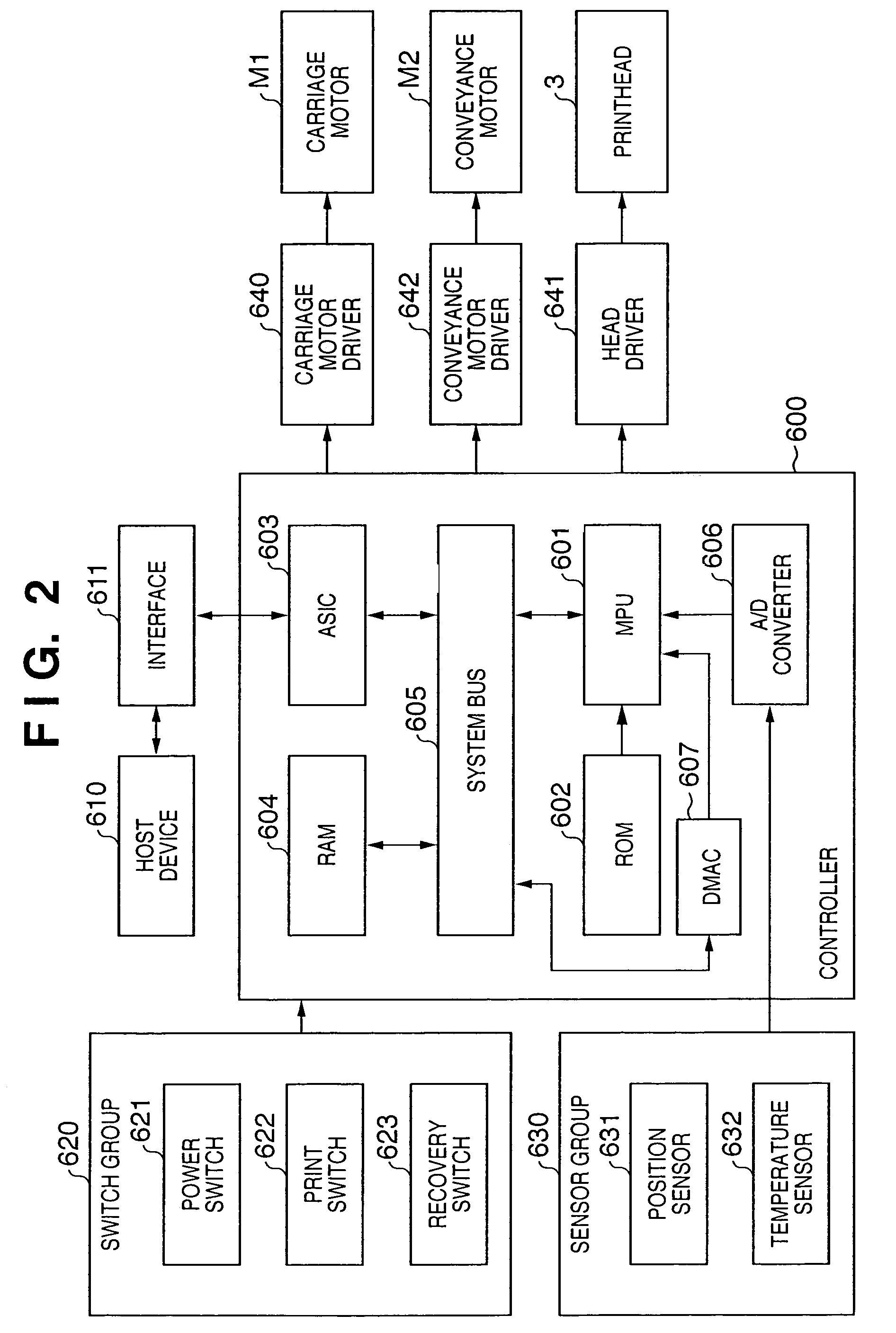

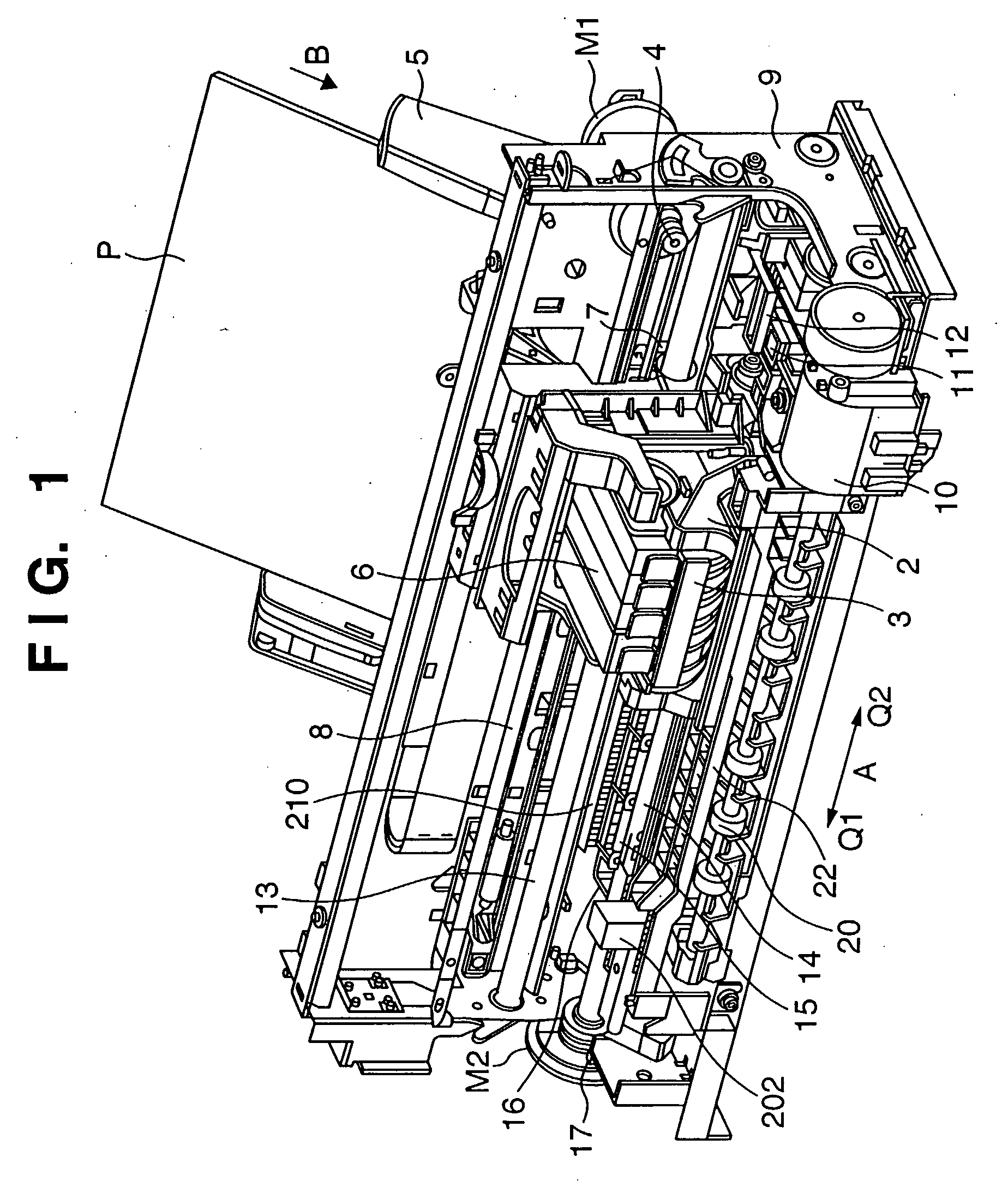

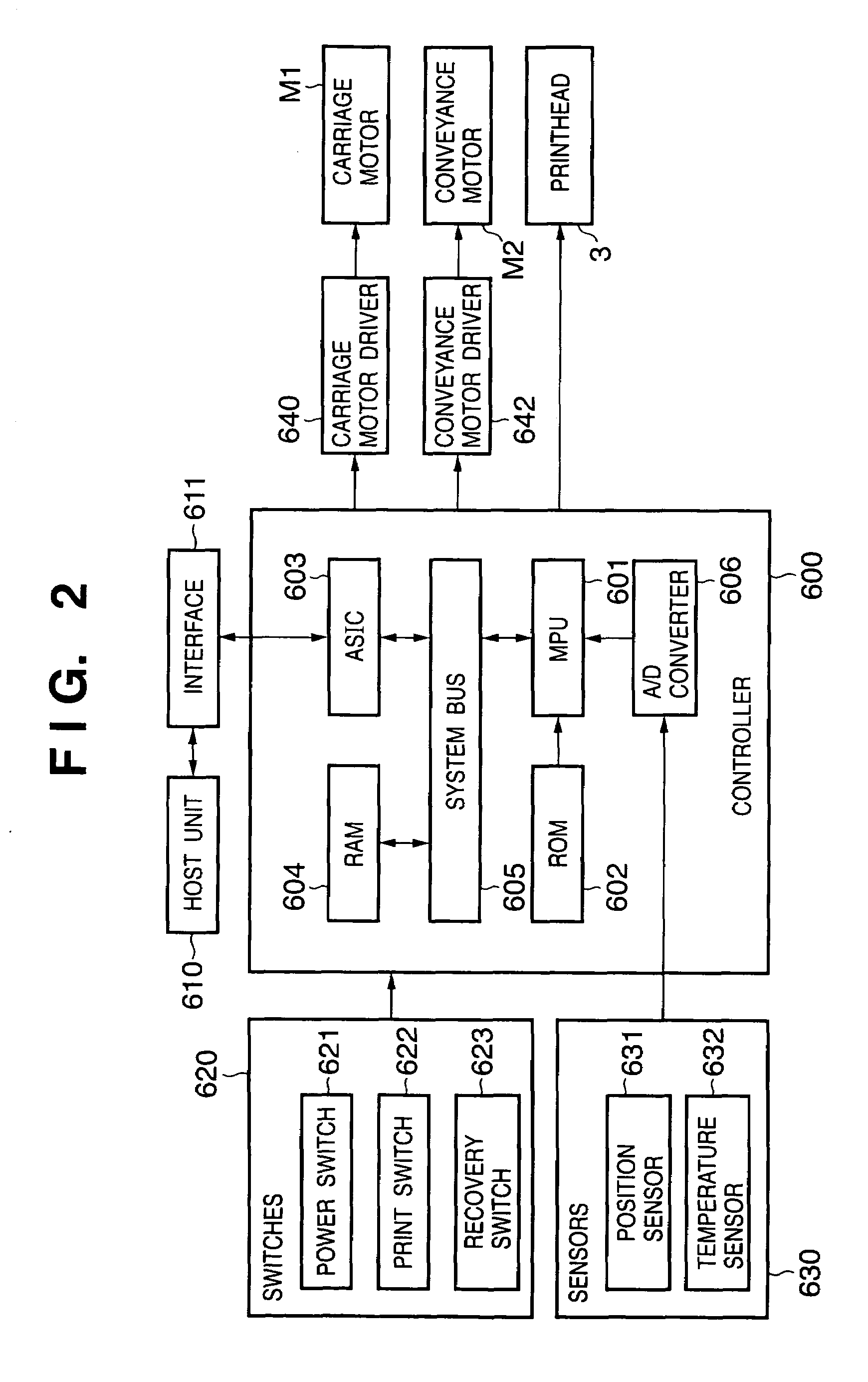

Printing apparatus and printing method

A printing apparatus and printing method can realize high-quality printing without degrading the quality of a printed image even when a nozzle restriction function is adopted in addition to a discharge failure complement function. In a printing apparatus using an inkjet printhead having a plurality of nozzles, whether the position of an ink discharge failure nozzle exists at or near the end of a nozzle area which is still usable regardless of the use restriction on the nozzles is detected. The use of a nozzle for complementary printing executed with a nozzle positioned near the ink discharge failure nozzle is controlled in accordance with the detection result.

Owner:CANON KK

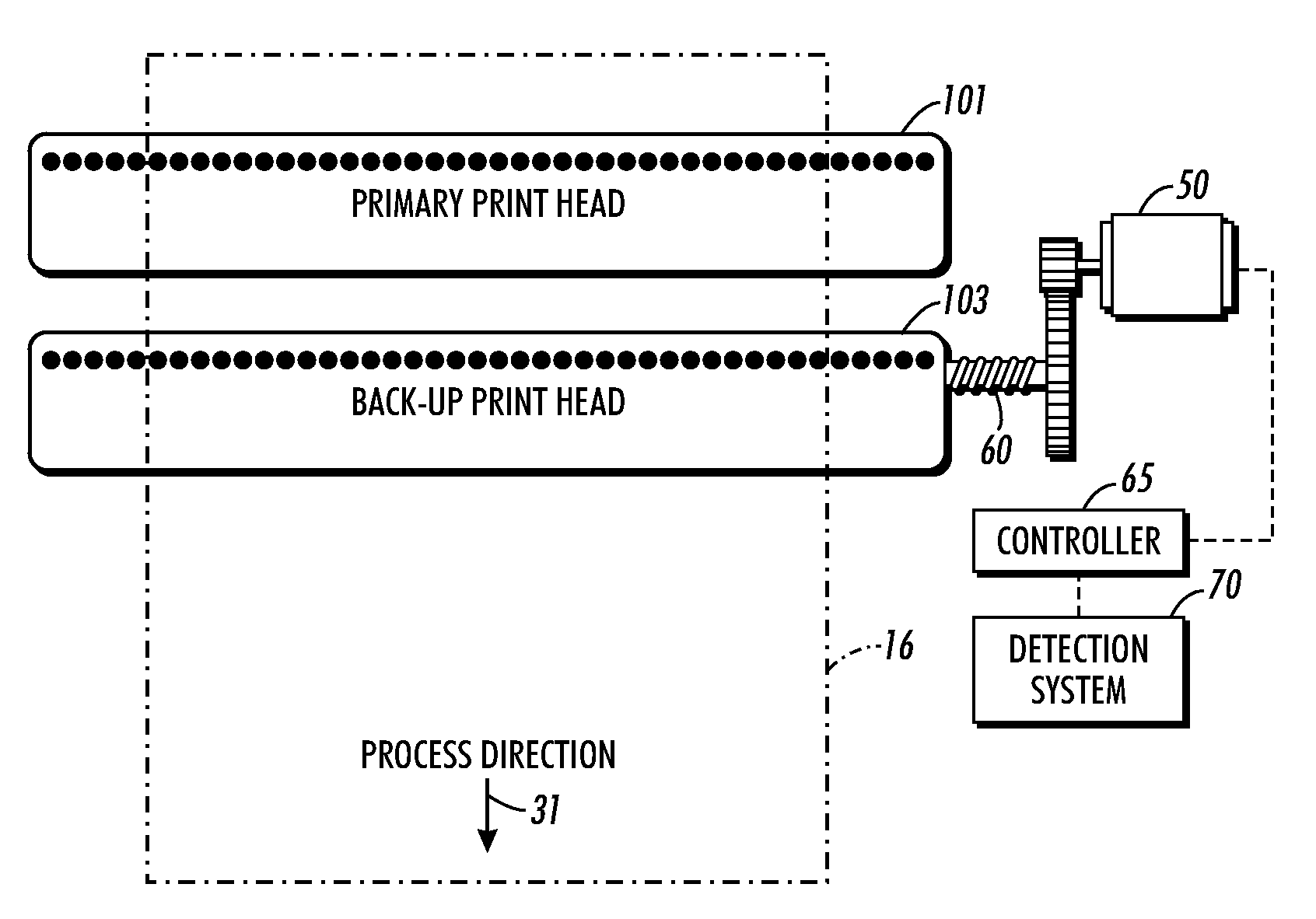

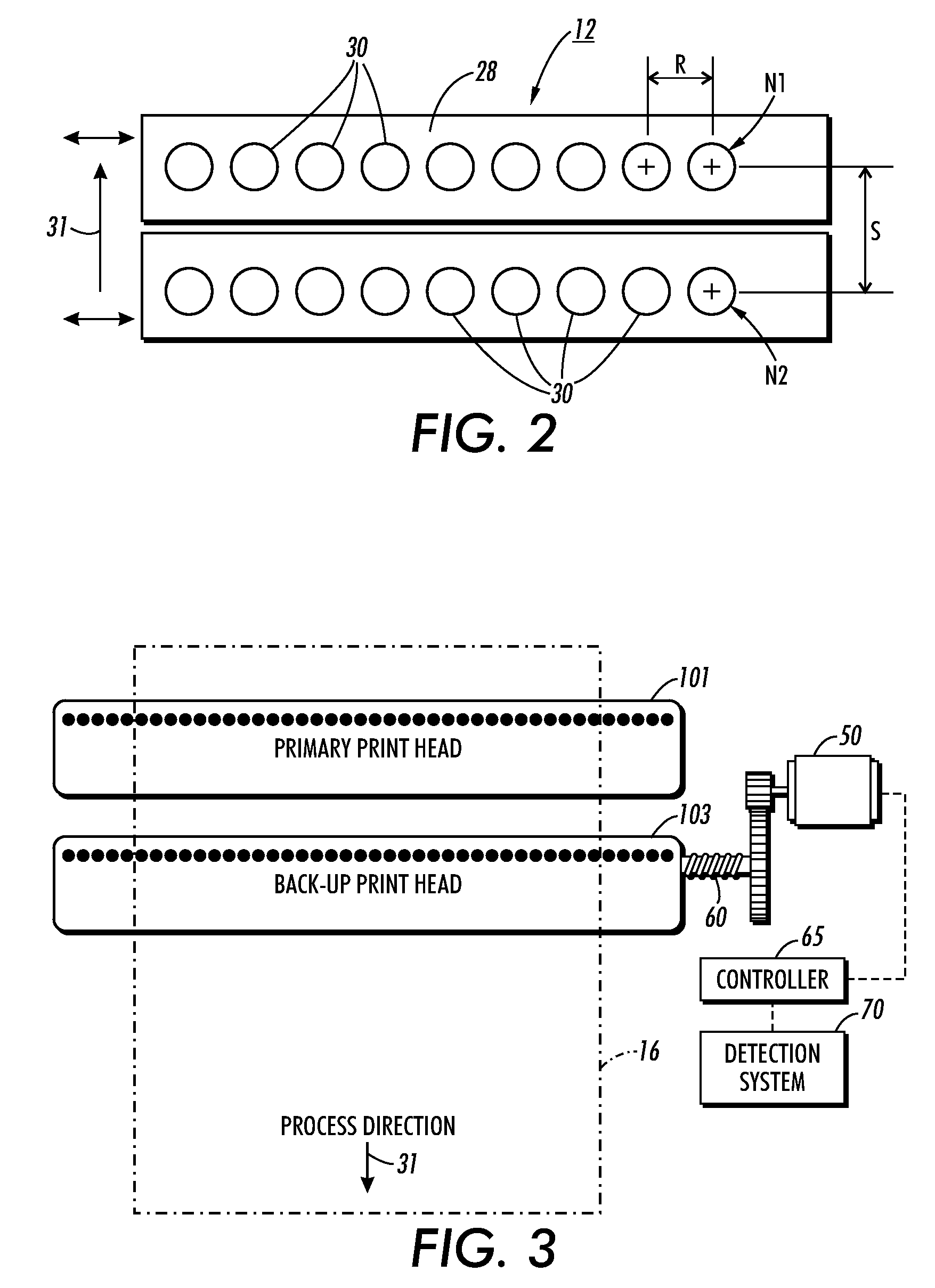

Ink jet printhead having a movable redundant array of nozzles

There is provided a printhead for an ink jet printer, including a primary and a secondary array of nozzles in the printhead, the nozzles in the primary array of nozzles being in alignment with the nozzles in the secondary array of nozzles in a printing process direction; detection system for detecting defective nozzles in both the primary array of nozzles and in the secondary array of nozzles; a first mode operation having means for selectively activating nozzles in the secondary array of nozzles that are in alignment with defective nozzles in the primary array of nozzles; and a second mode of operation having means, responsive to the detecting means, for translating the secondary array of nozzles in relation to the primary array of nozzles along a path to a first position to realigned the nozzles in the primary array of nozzles to nozzles in the secondary array of nozzles if defective nozzles are aligned in both the primary and the secondary array of nozzles.

Owner:XEROX CORP

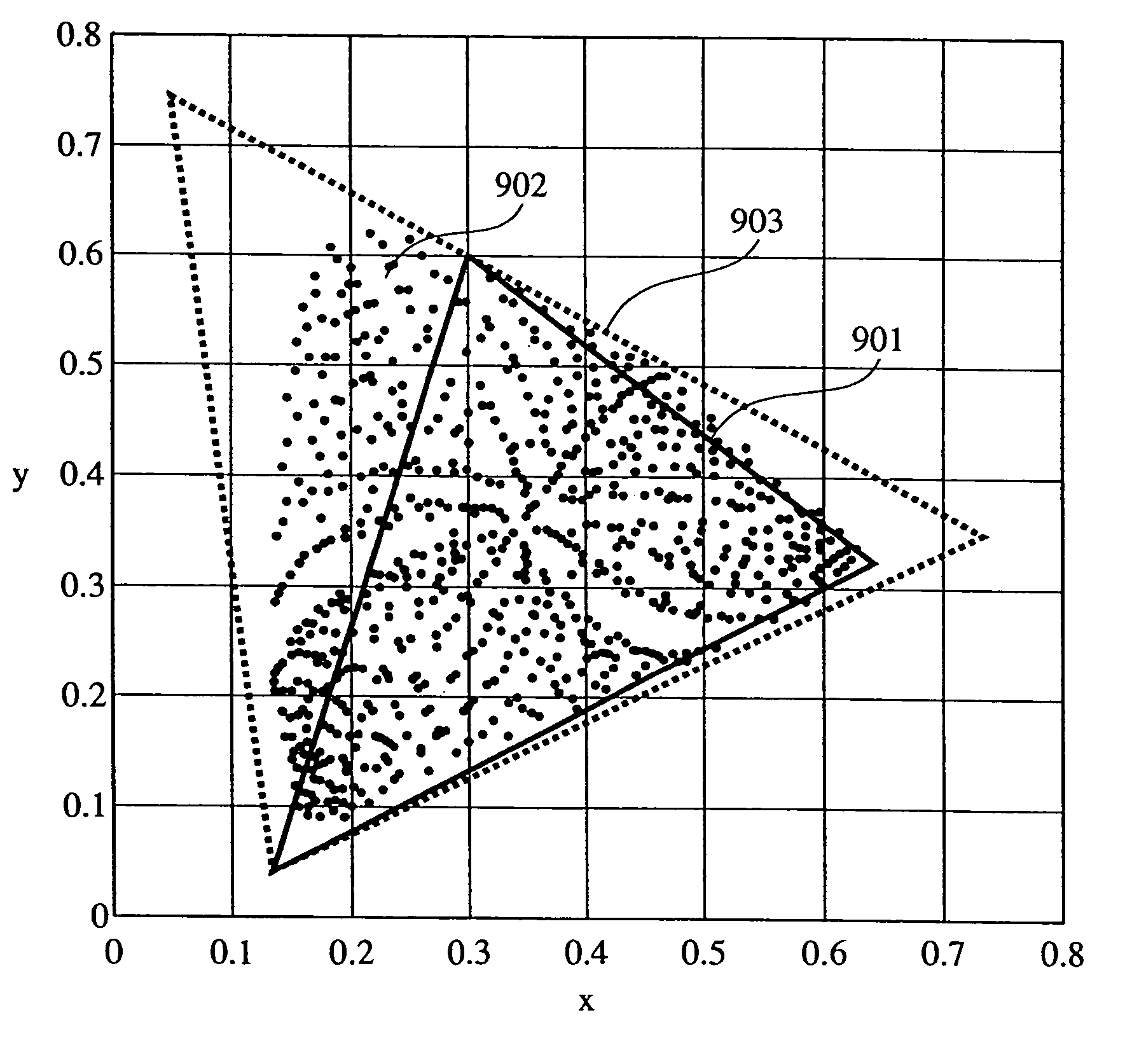

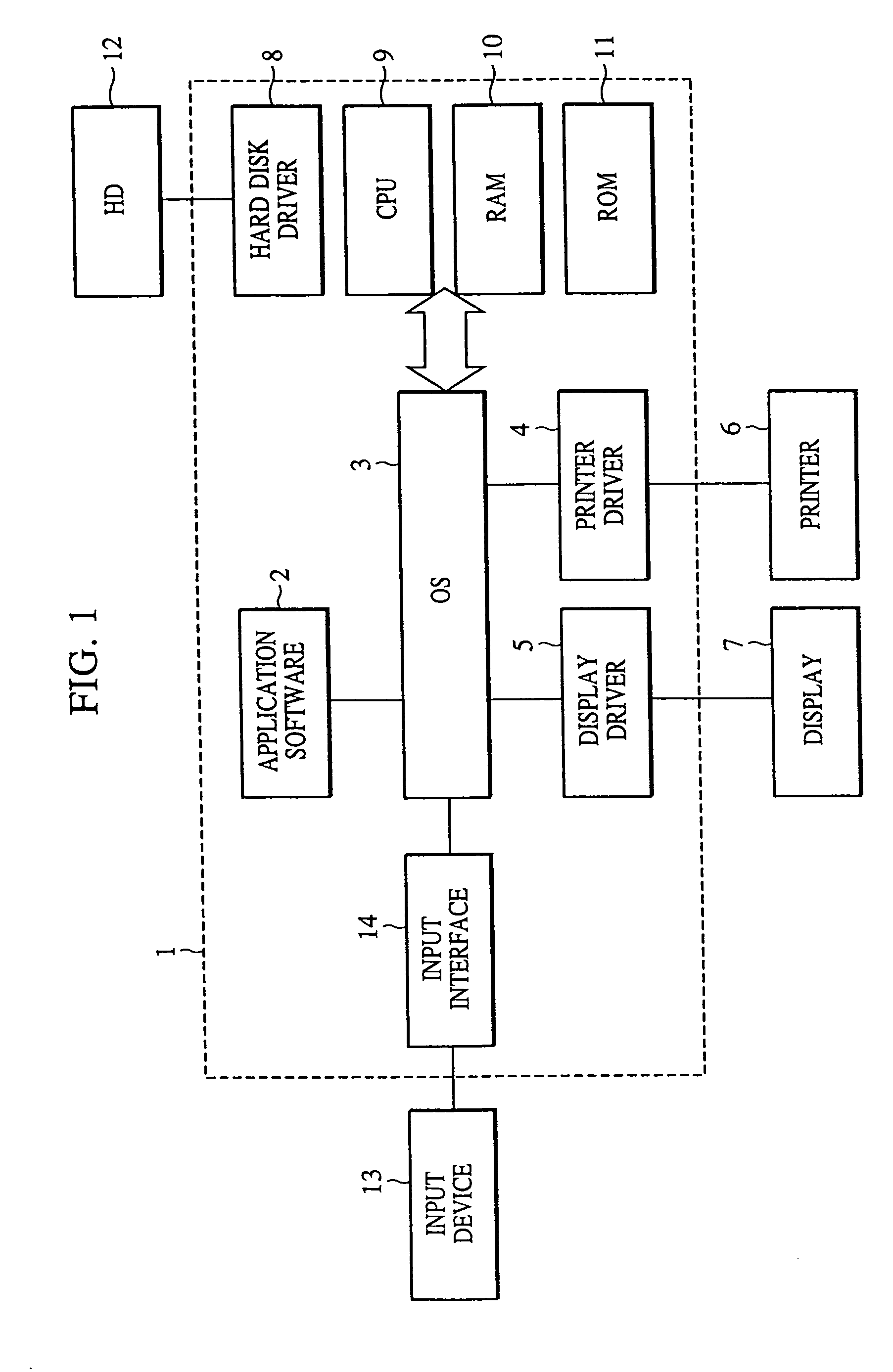

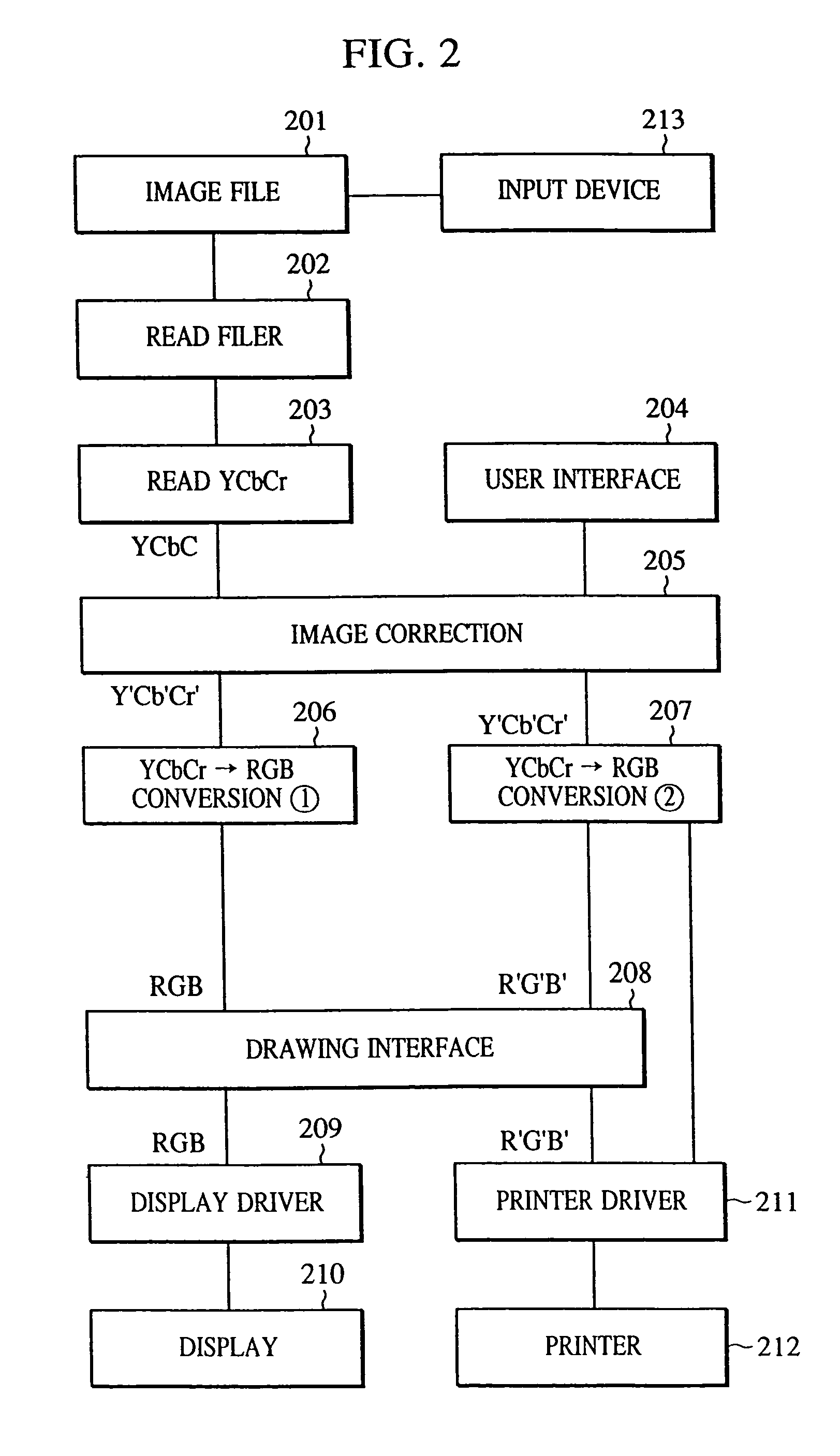

Image data processing method and apparatus, storage medium product, and program product

InactiveUS7034844B2Efficient use ofQuality improvementCathode-ray tube indicatorsImage data processing detailsScale downComputer science

Owner:CANON KK

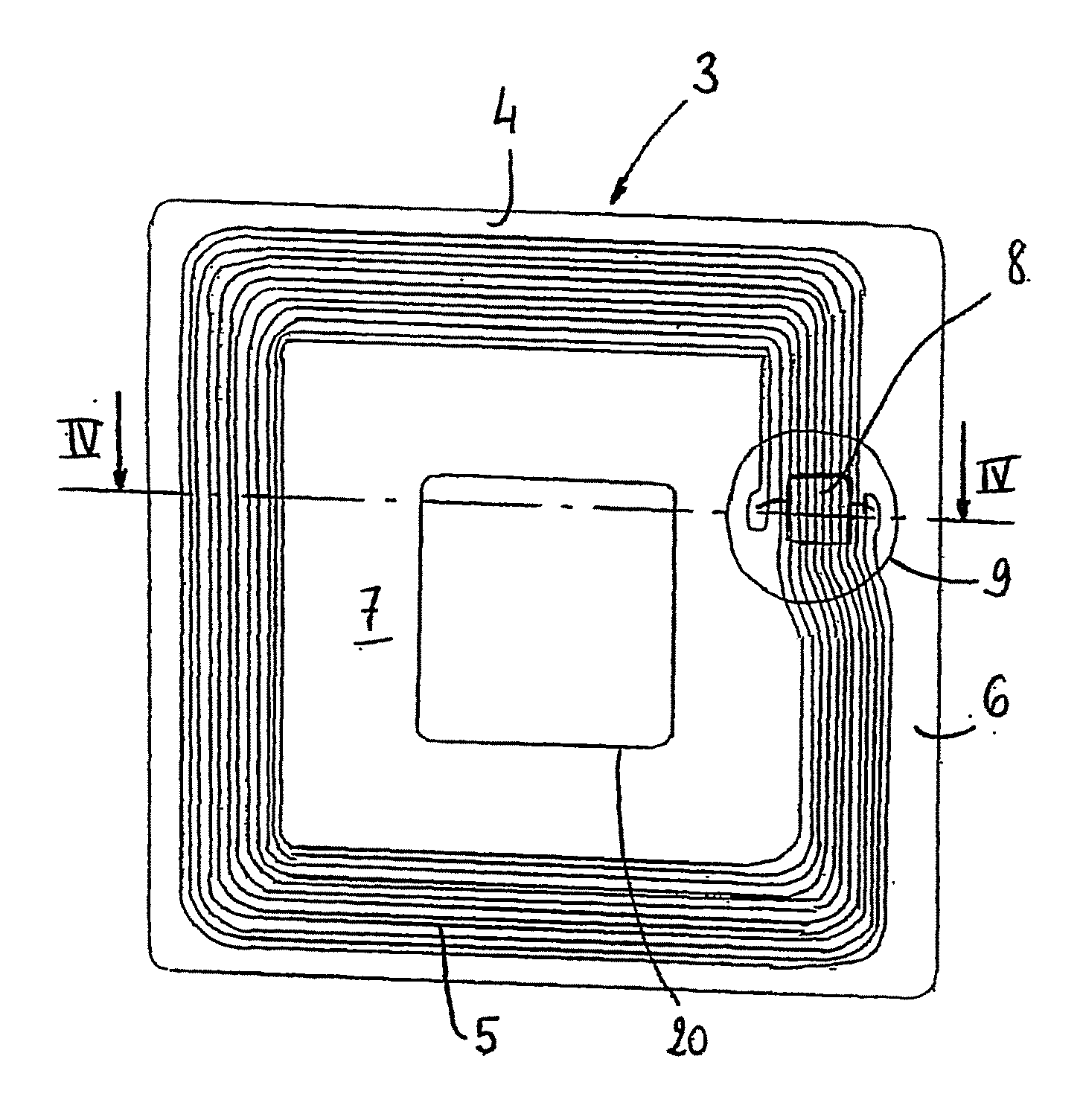

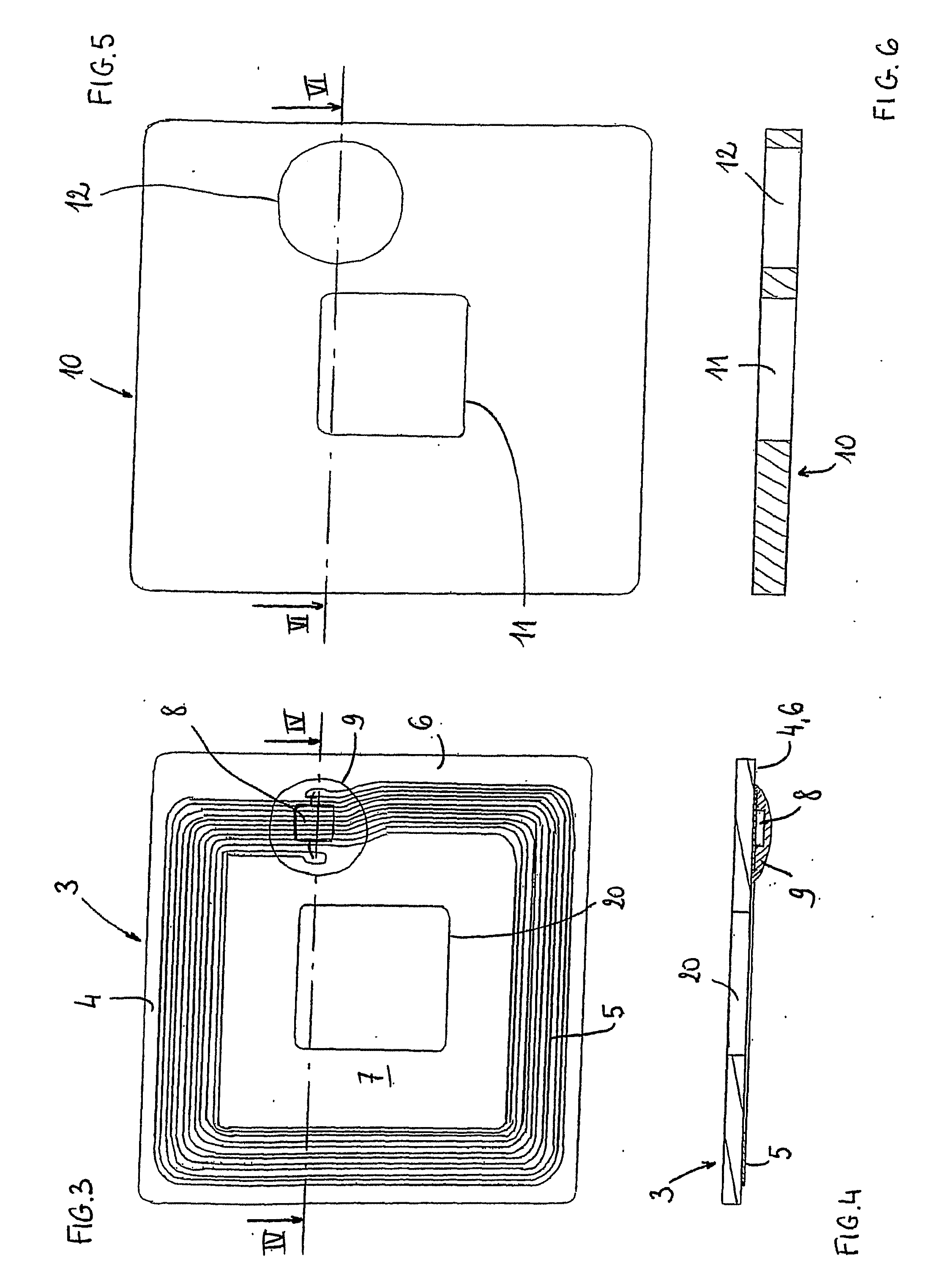

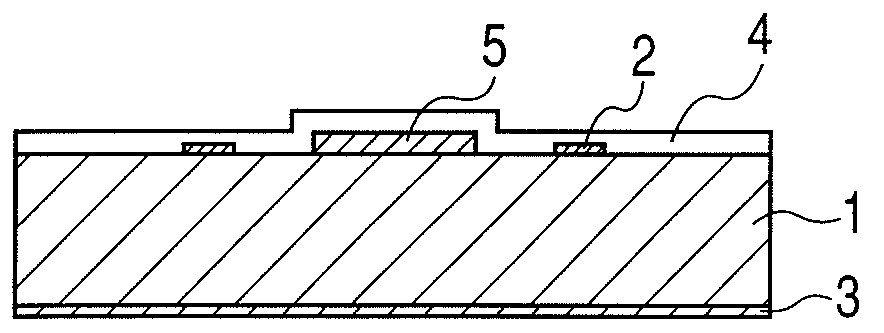

Radiofrequency identification device and method for producing said device

InactiveUS20090314842A1Increasing the thicknessReduce rigiditySemiconductor/solid-state device detailsSolid-state devicesIdentification deviceRadio frequency

“The radio-frequency identification device includes embedded in an envelope a substrate on one face of which an antenna is produced and a chip connected to the antenna is positioned, a potting locally covering the substrate face level with the chip, an intermediate layer made of a magnetic superconductor material placed against the substrate on the antenna side, the intermediate layer having dimensions greater than those of the antenna so as to be able to cover the antenna and having a cavity arranged so that the potting and the chip can be approximately completely housed therein.”

Owner:ID3S IDENTIFICATION SOLUTIONS SYST & SERVICES

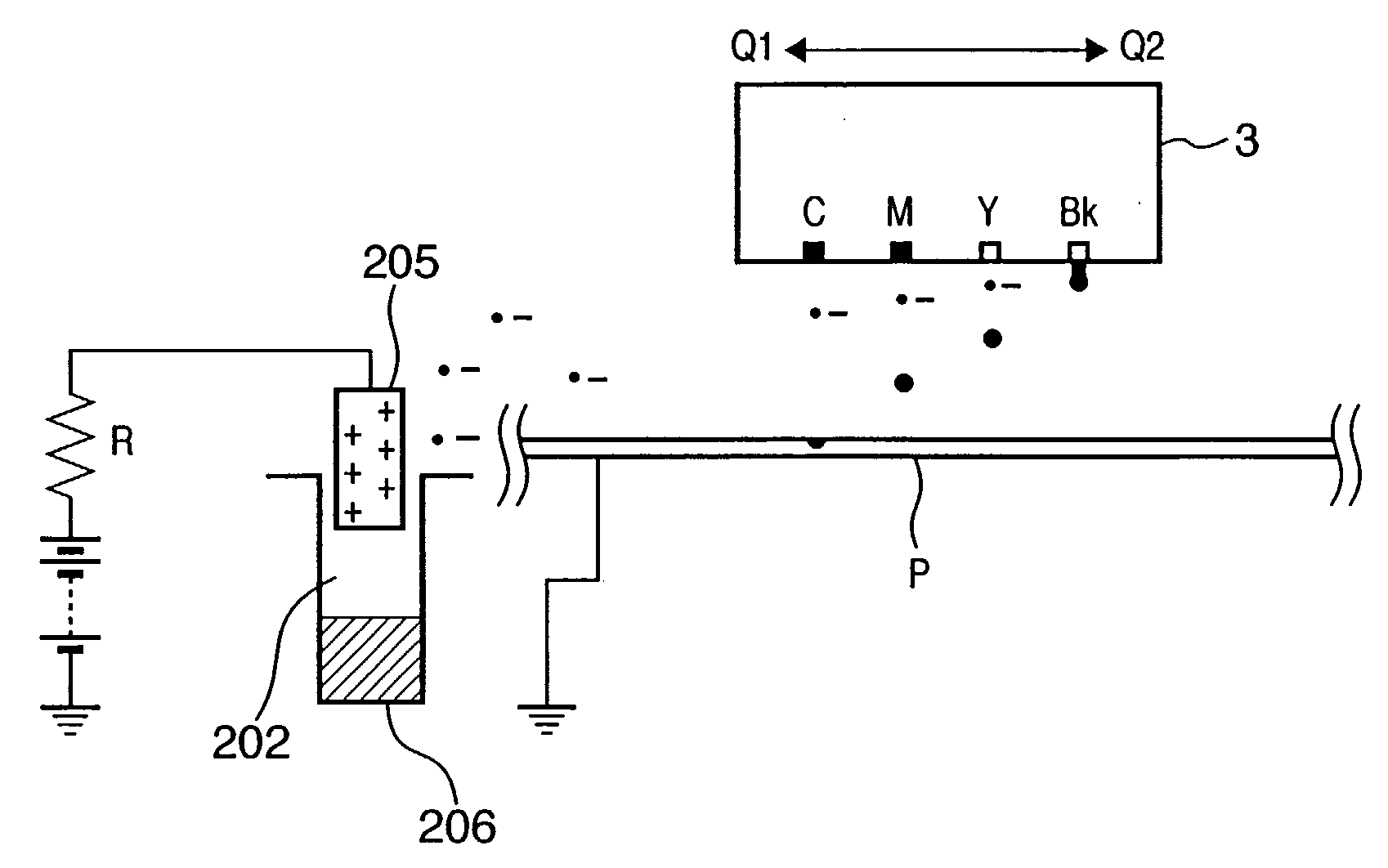

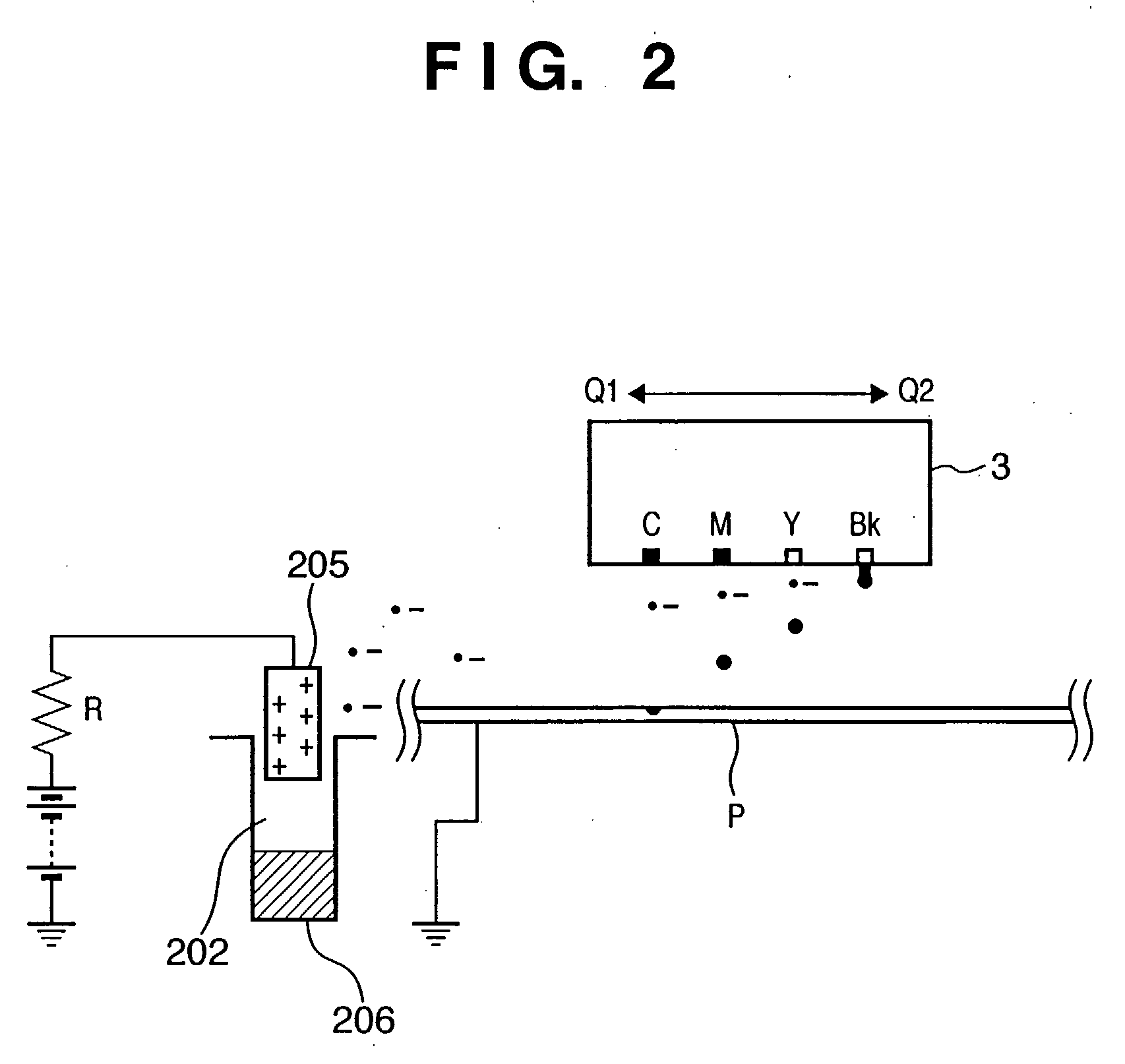

Printing Apparatus, Ink Mist Collecting Method, and Printing Method

InactiveUS20080018707A1High quality printingEfficient attractionOther printing apparatusEngineeringElectrical and Electronics engineering

There are provided a printing apparatus and printing method capable of collecting unwanted ink mist and achieving high-quality printing by fine ink droplets. According to the method, the charges of a printing medium are removed prior to printing, and an ink mist collecting unit having an electrode of a positive polarity is employed. Floating ink mist is collected such that ink mist generated from discharged ink droplets and negatively charged is moved toward the ink mist collecting unit by the electrostatic force.

Owner:CANON KK

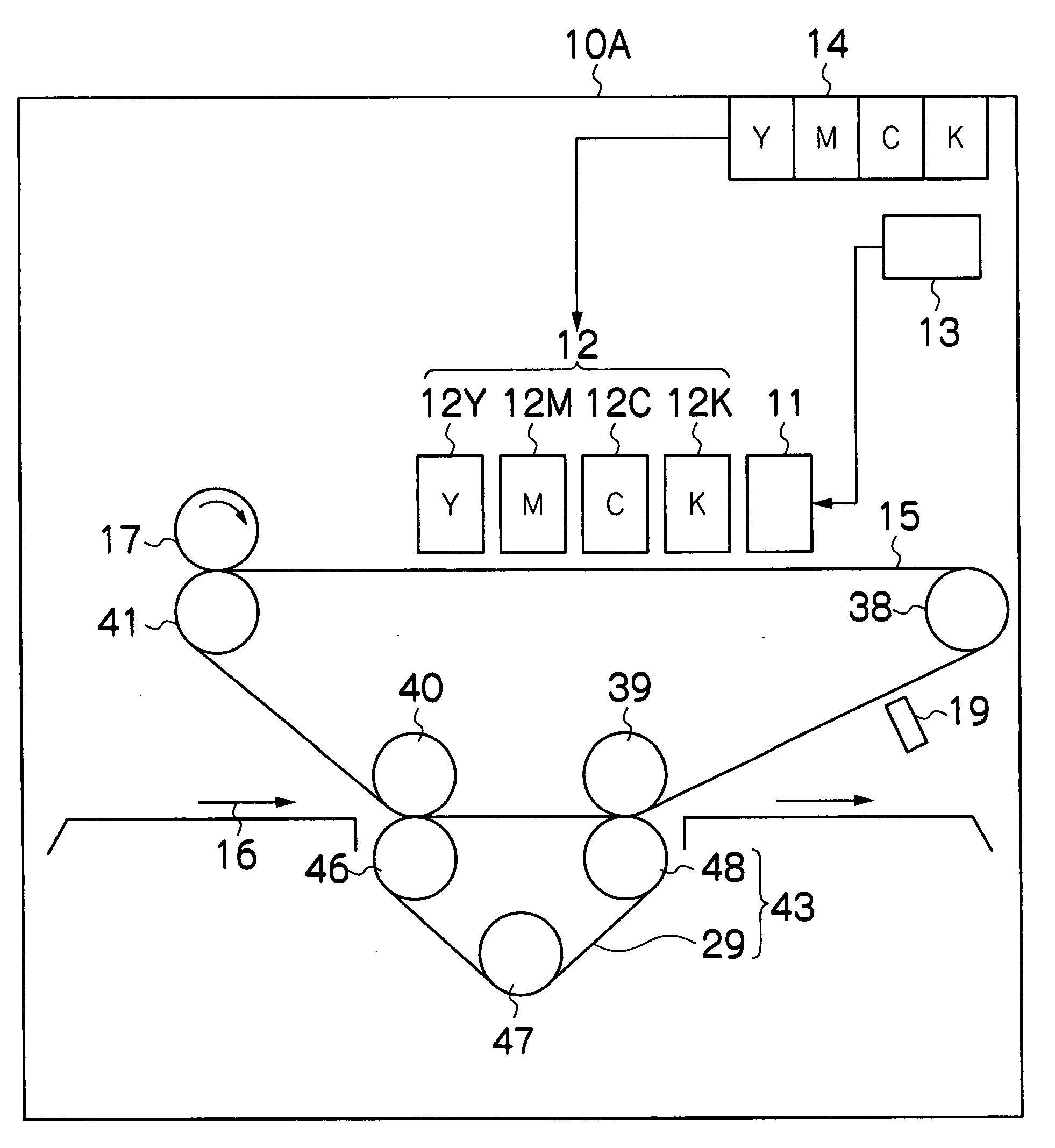

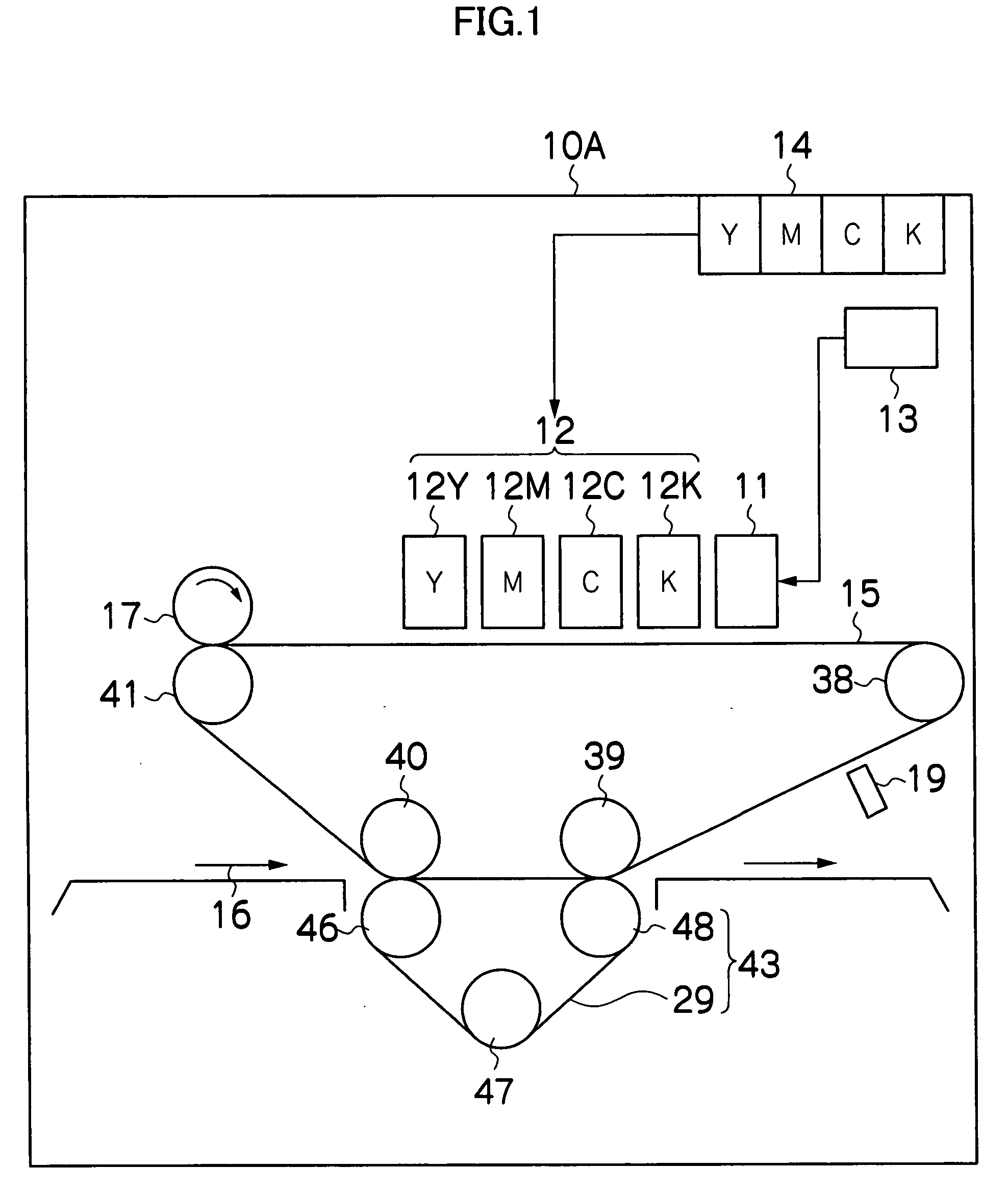

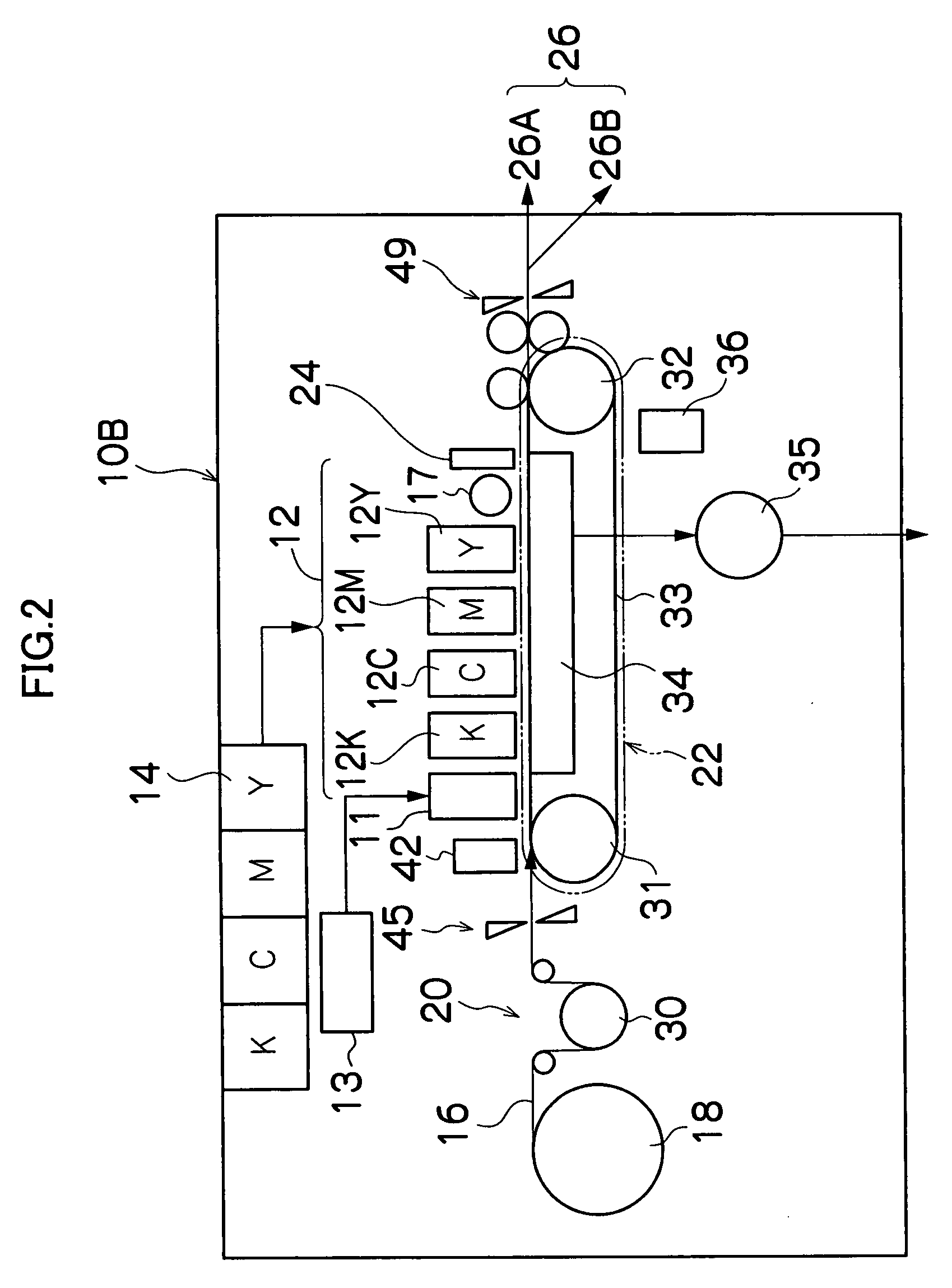

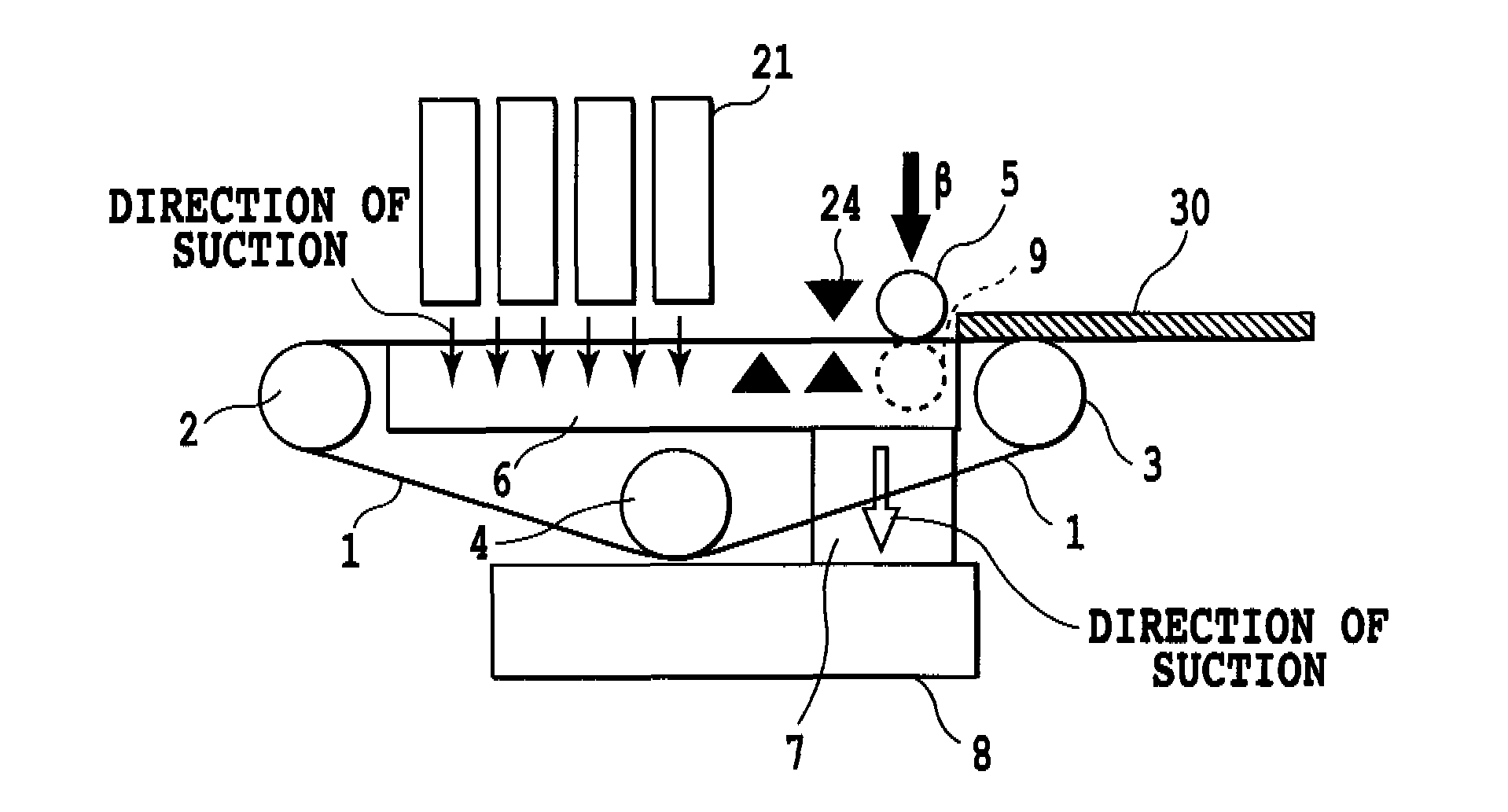

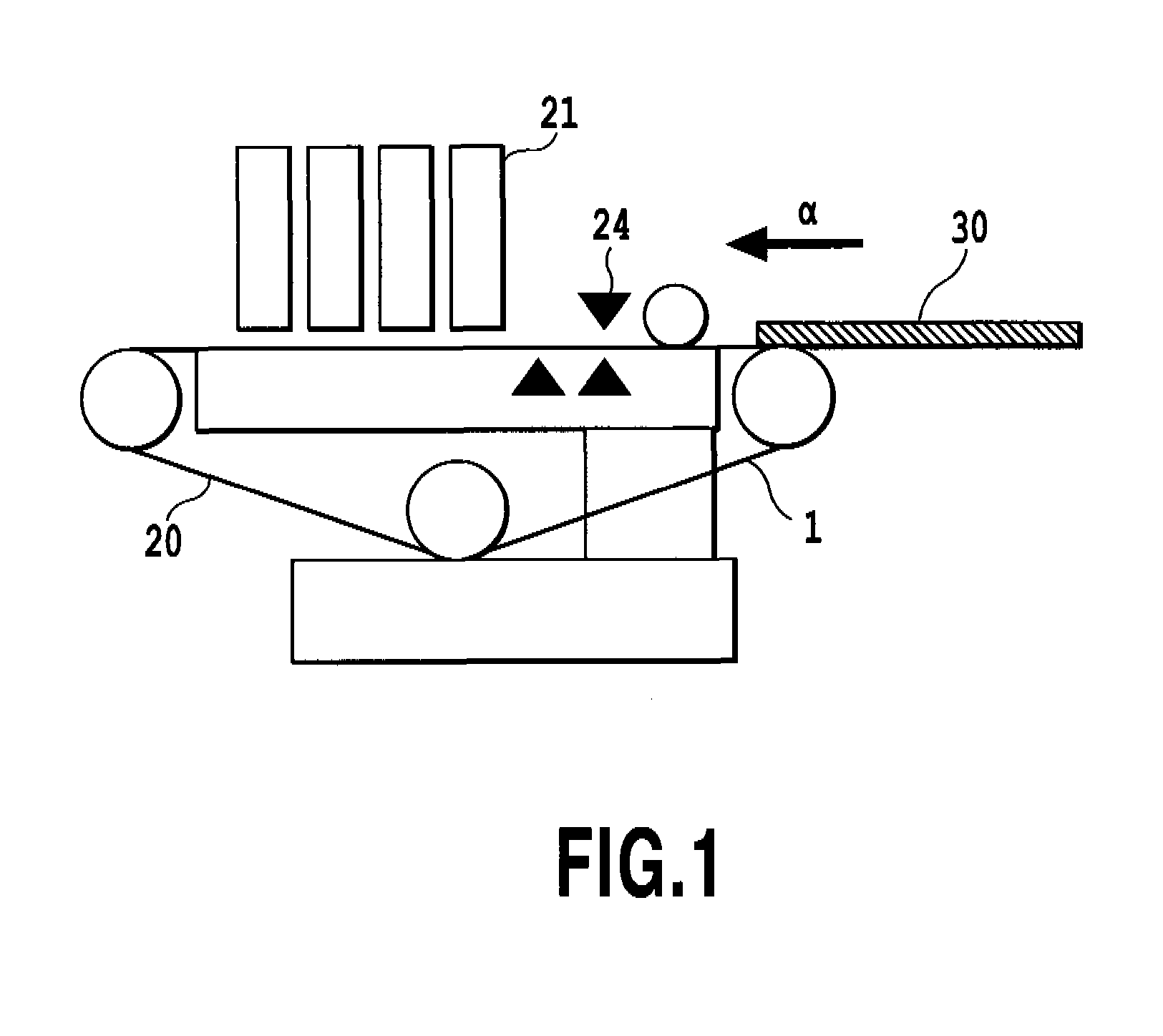

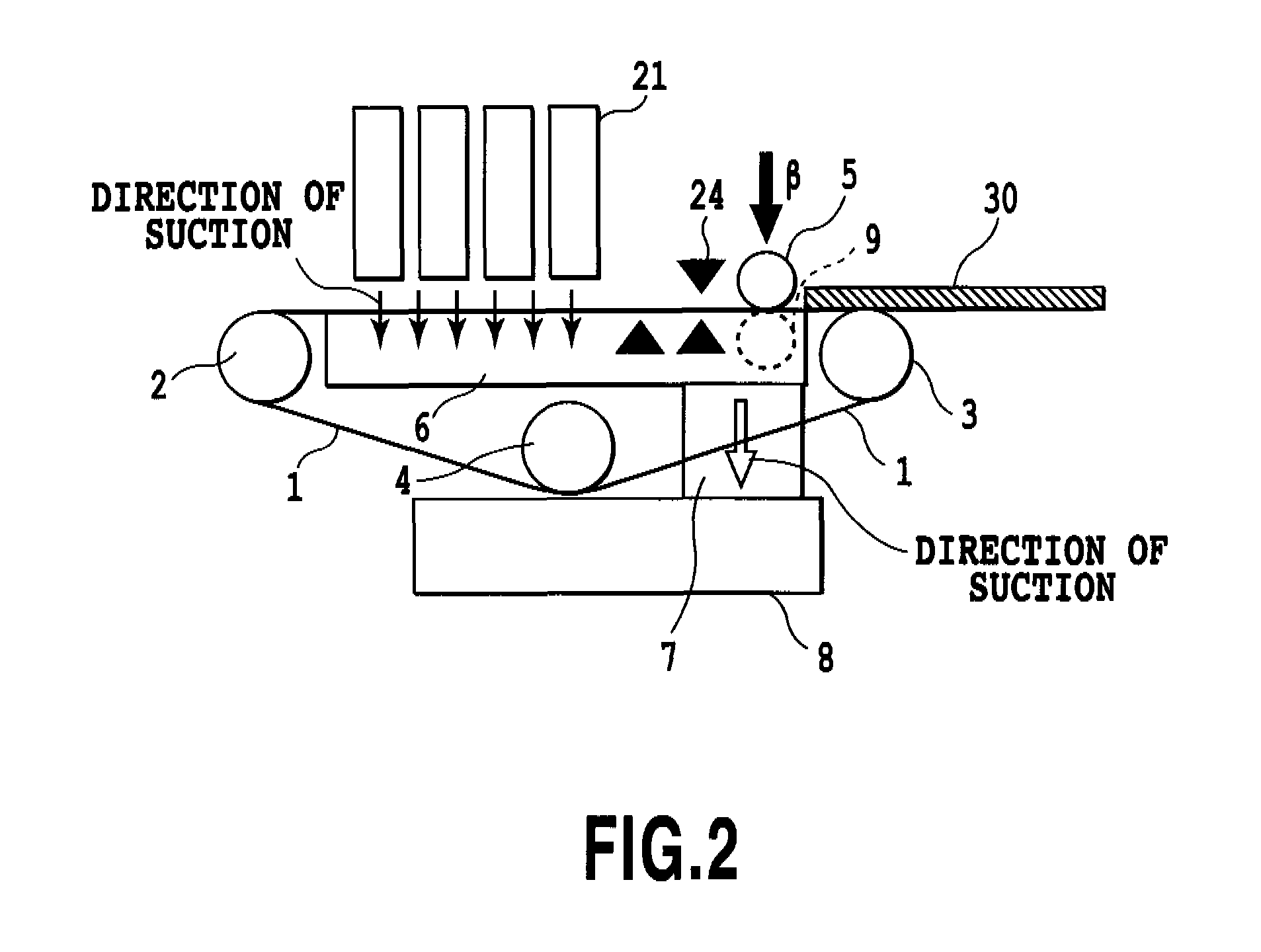

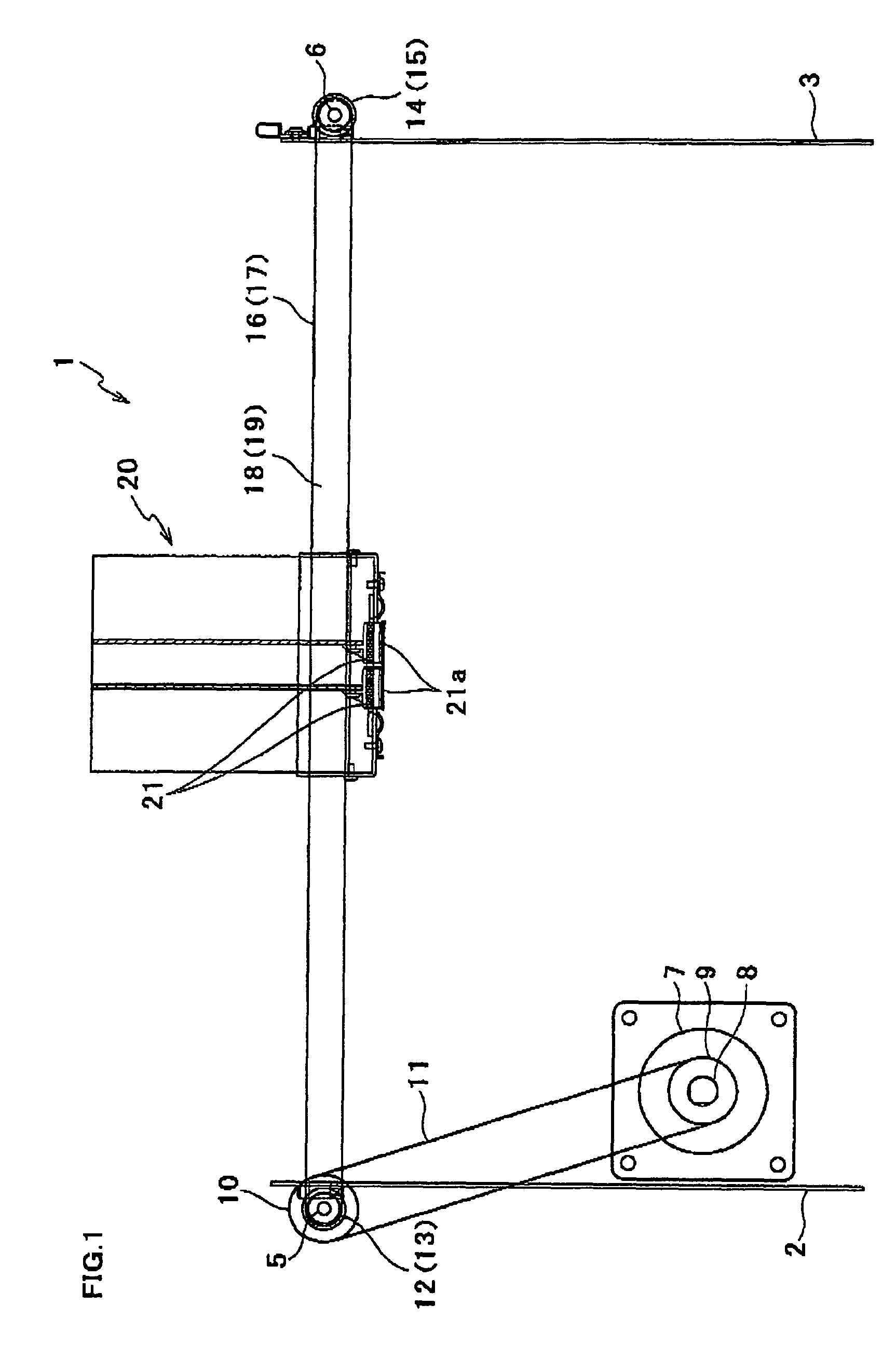

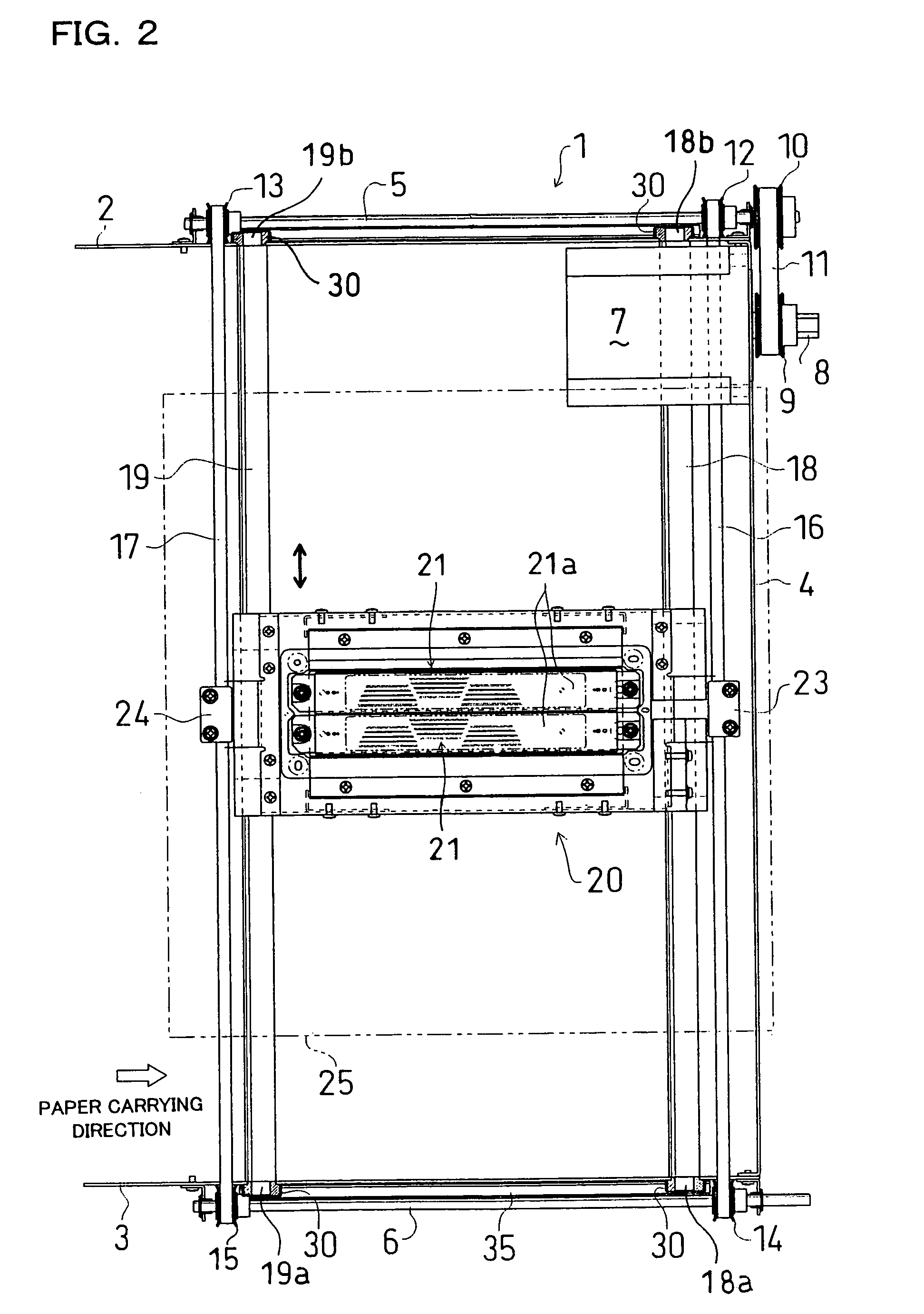

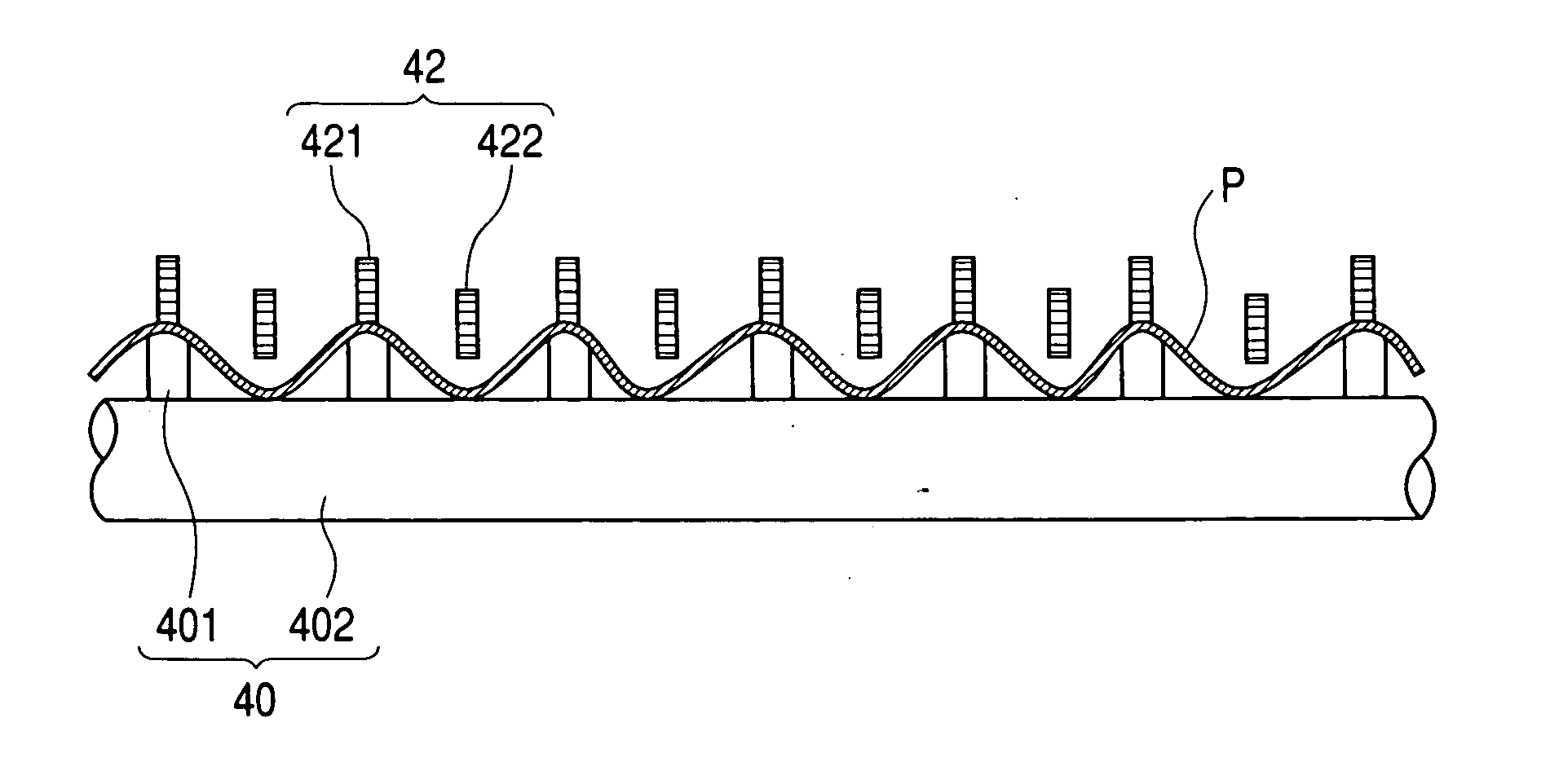

Conveying device and printing apparatus using same

ActiveUS20110293346A1High quality printingQuality improvementOther printing apparatusArticle feedersEngineeringMechanical engineering

Owner:COPYER

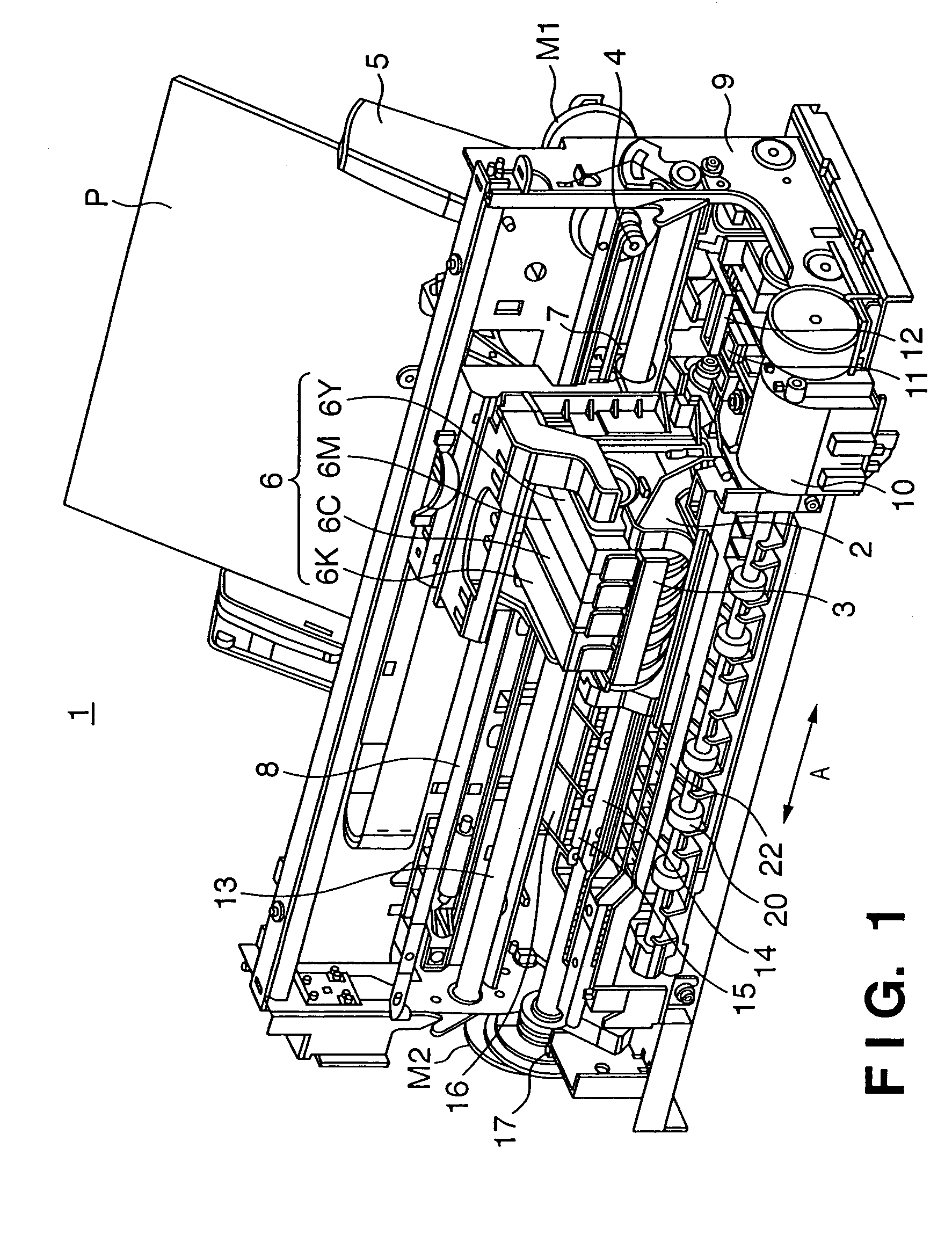

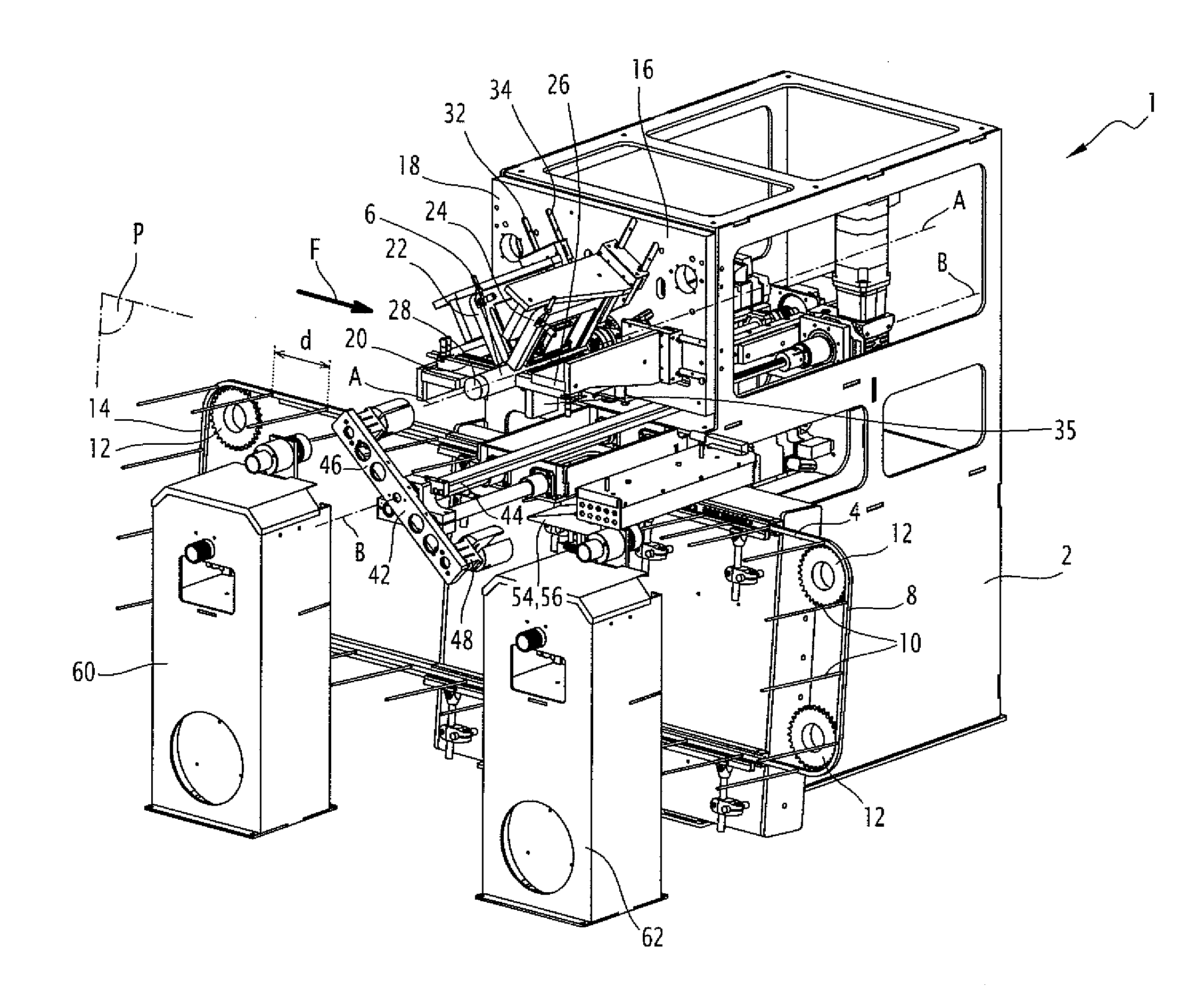

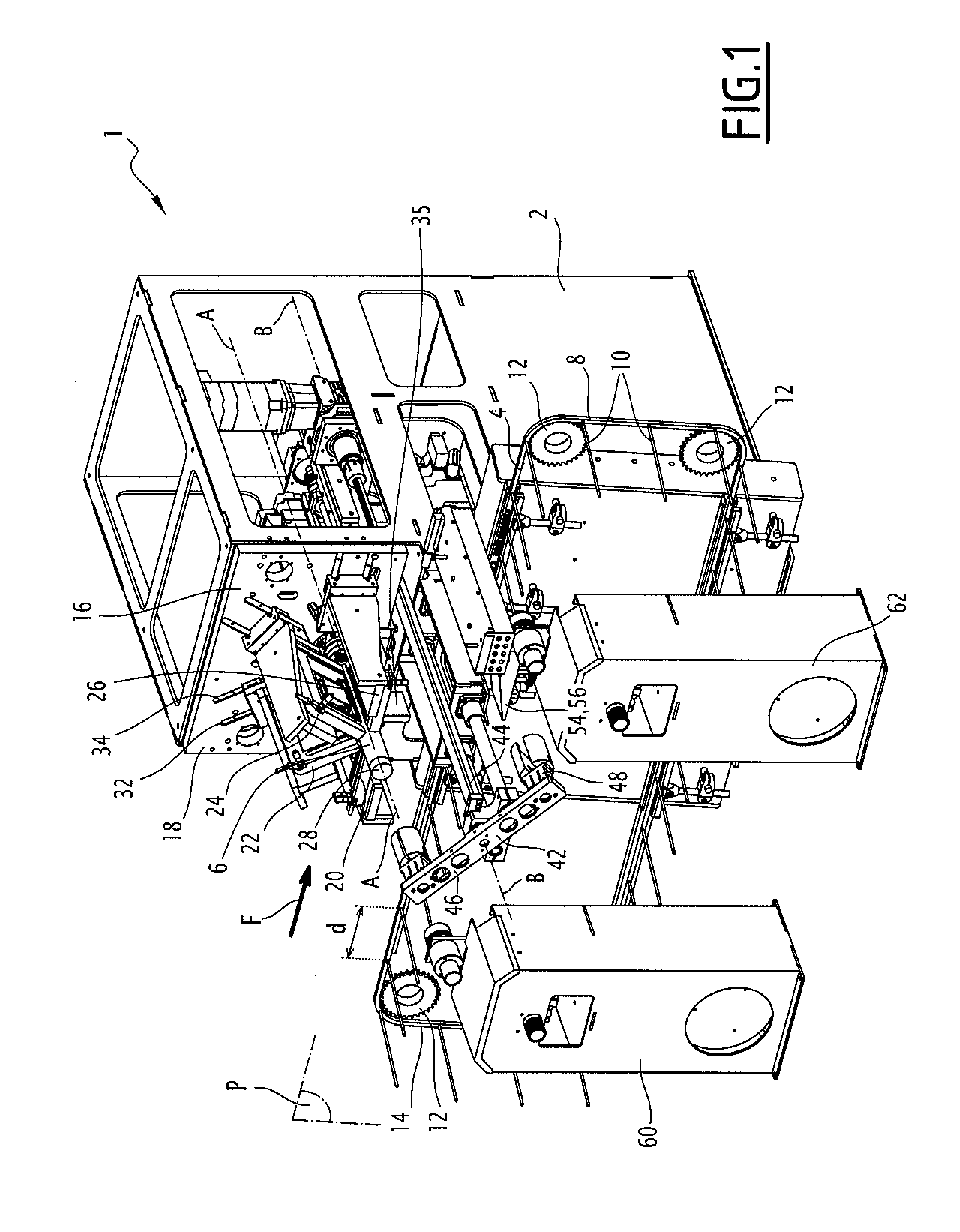

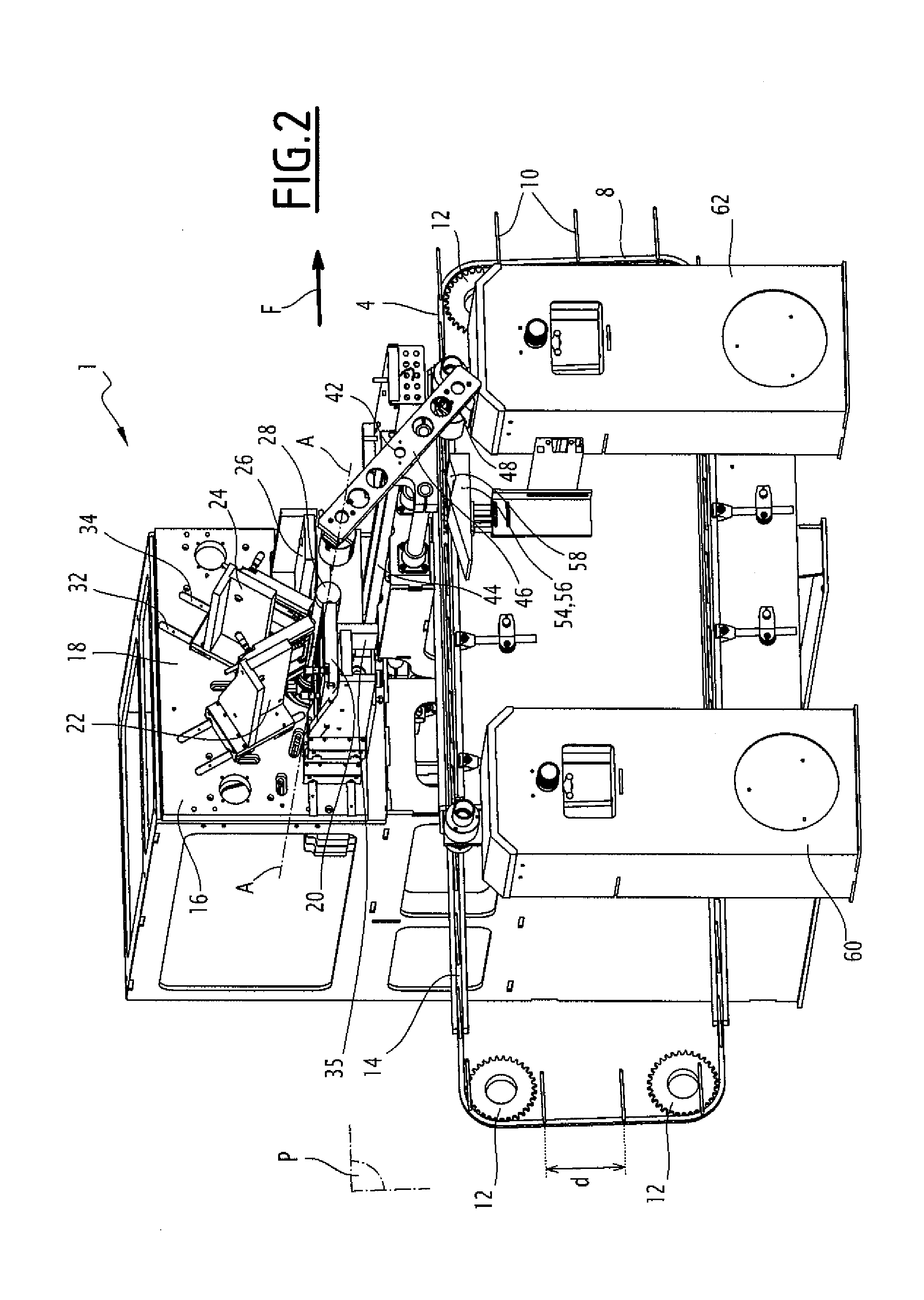

Inkjet printing machine

The printing machine (1) according to the invention includes:a transporter (4) for transporting objects (6) to be printed,a printing station (16) including at least four printing units (20, 22, 24, 26) arranged to project ink on the objects (6) to be printed,a transfer device (42) for transferring an object (6) to be printed from the transporter (4) to the printing station (16) and from the printing station (16) to the transporter (4).The printing station (16) includes a single mandrel (28) corresponding to the maintenance of an object (6) to be printed, the corresponding mandrel (28) being rotatably movable around its axis (A-A) so that the printing units (20, 22, 24, 26) project ink onto the object (6) maintained by the corresponding mandrel (28), the printing station (16) being arranged to print only the objects (6) maintained by the corresponding mandrel (28).

Owner:MACHINES DUBUIT

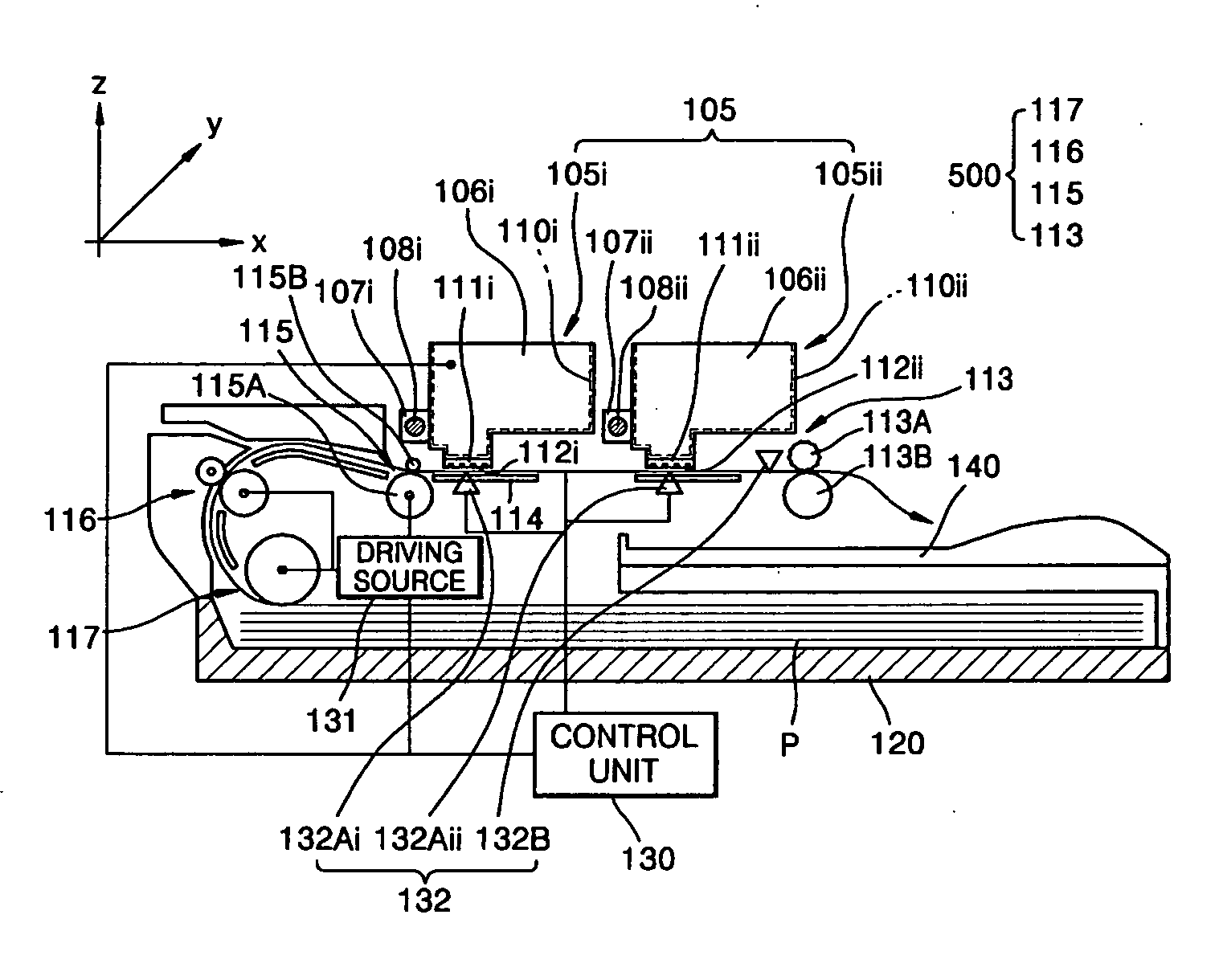

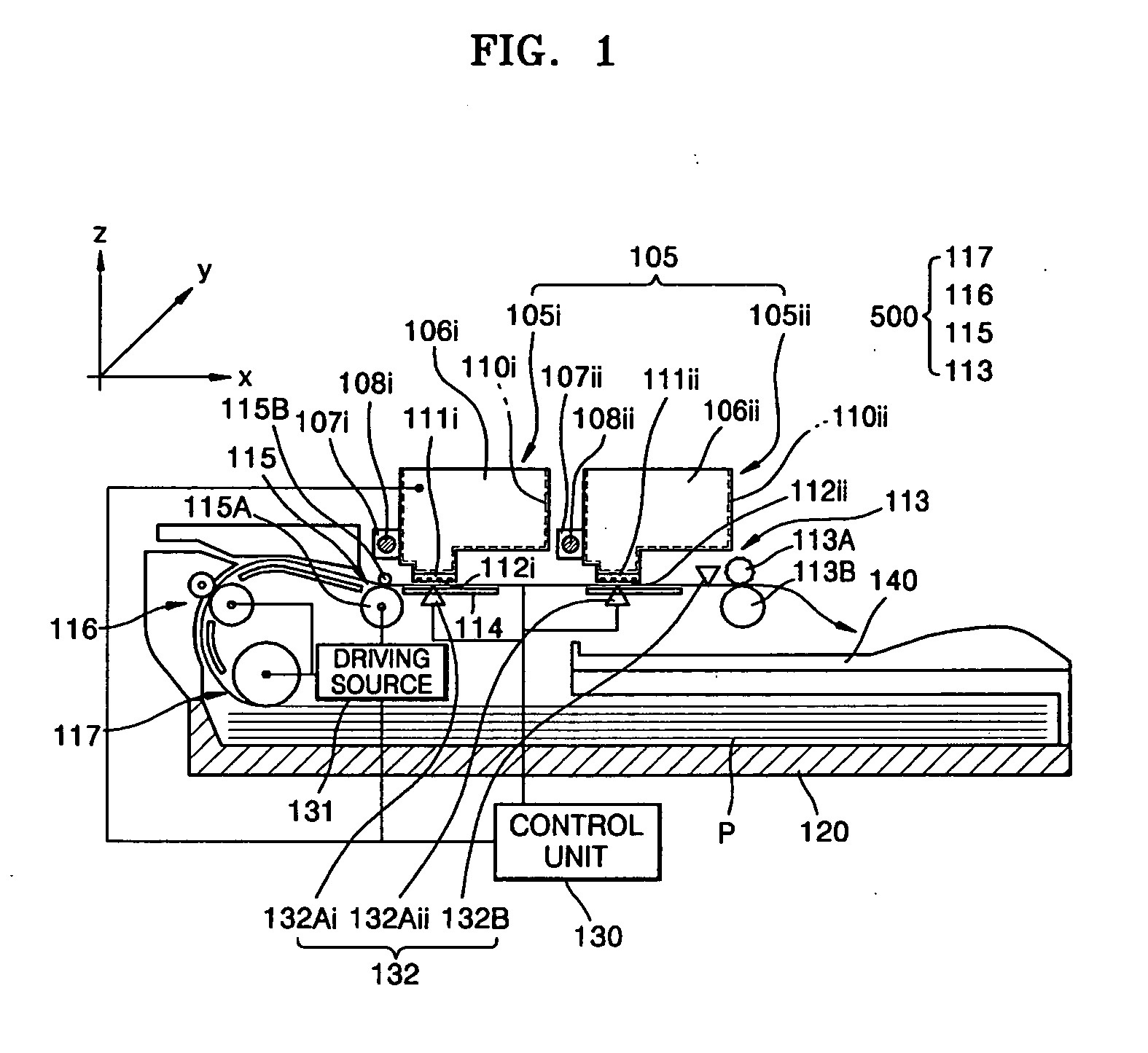

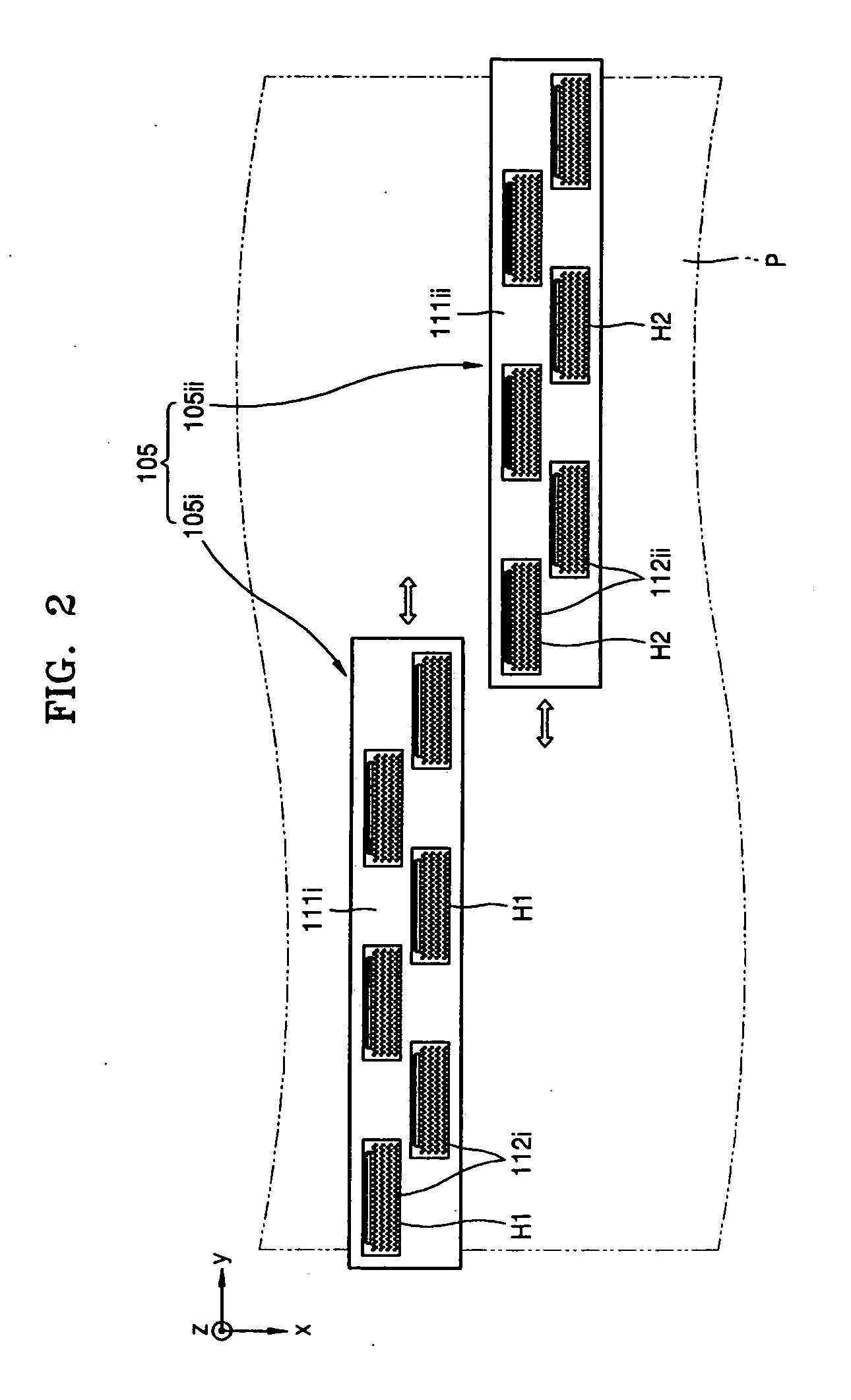

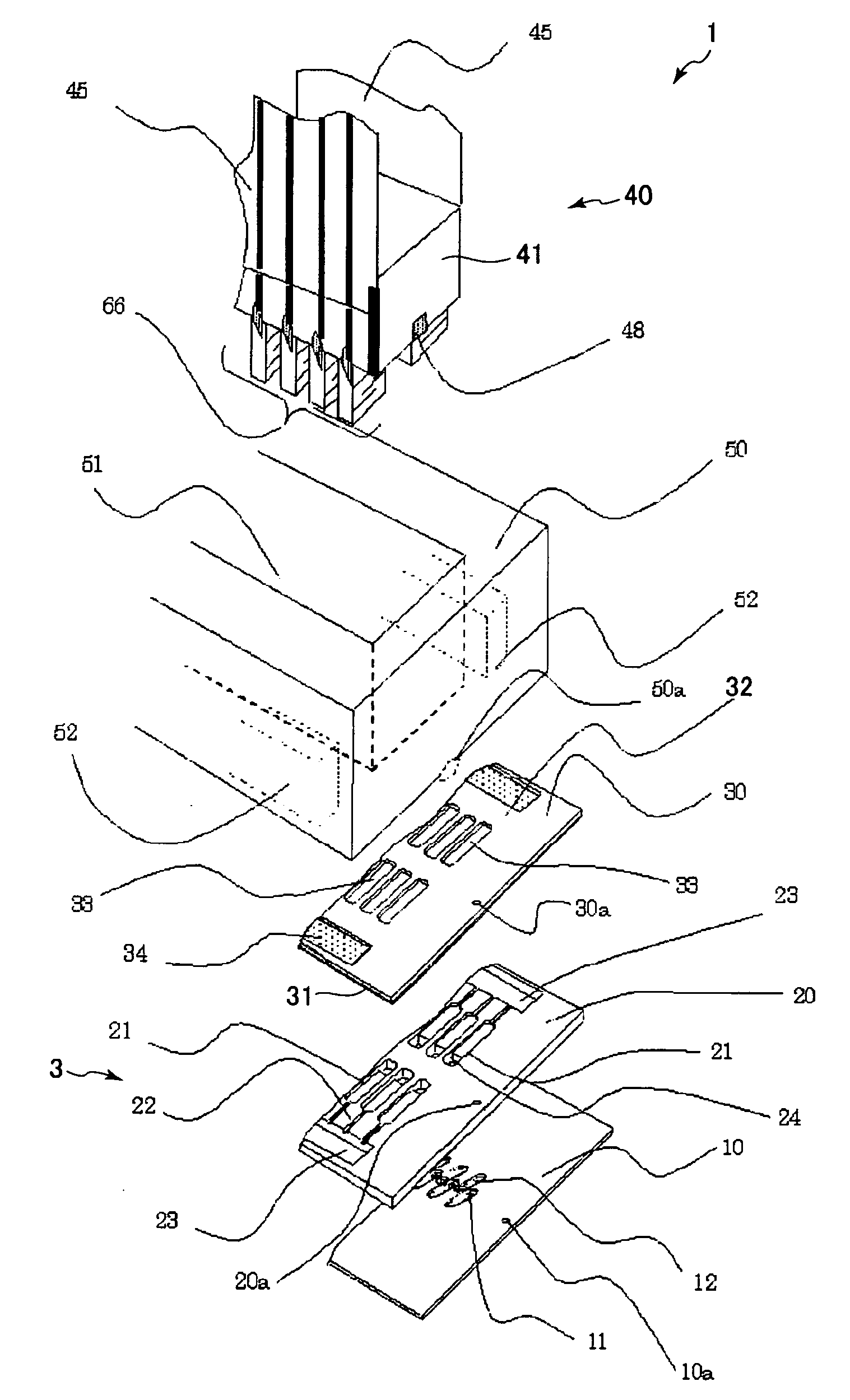

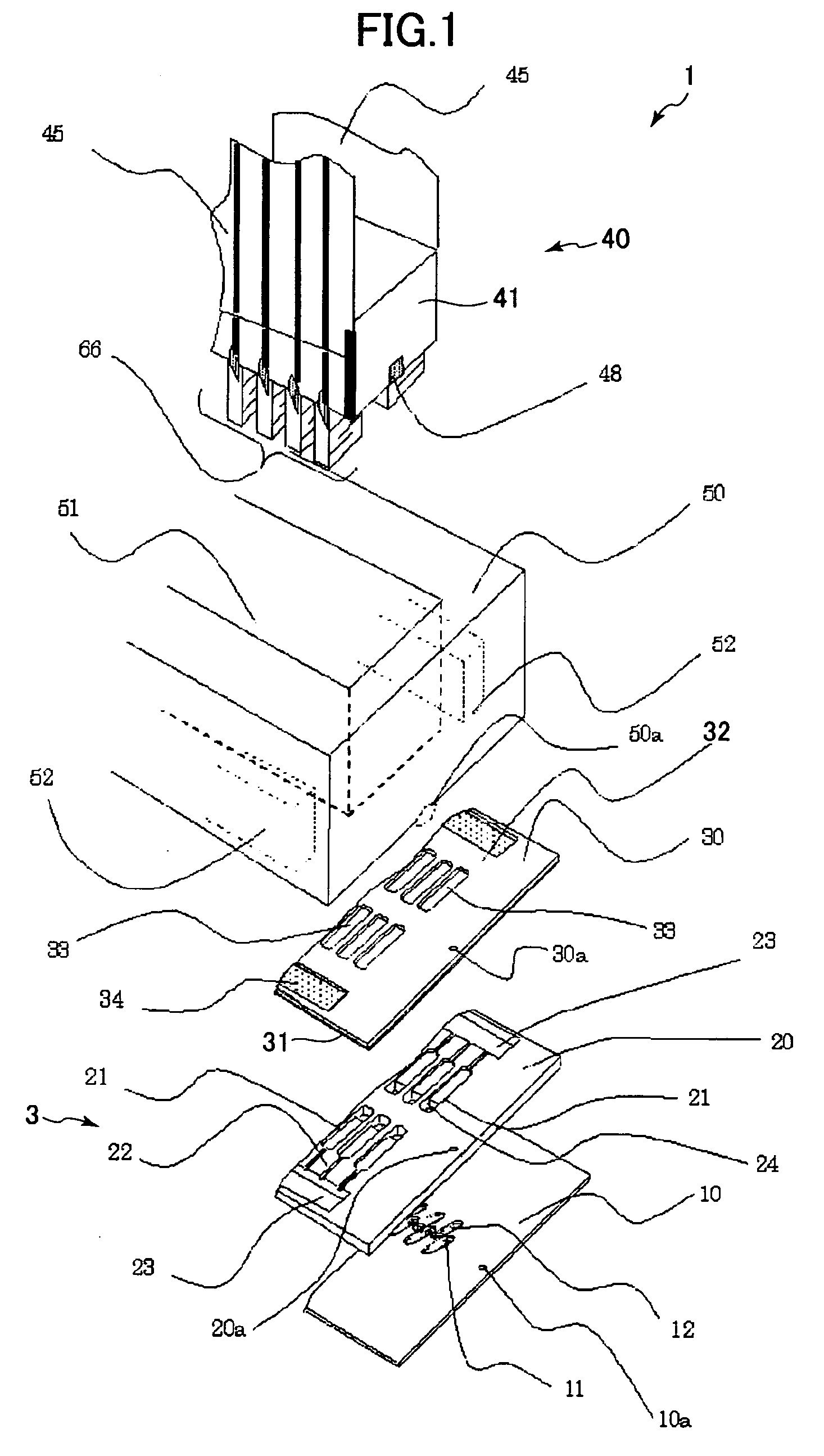

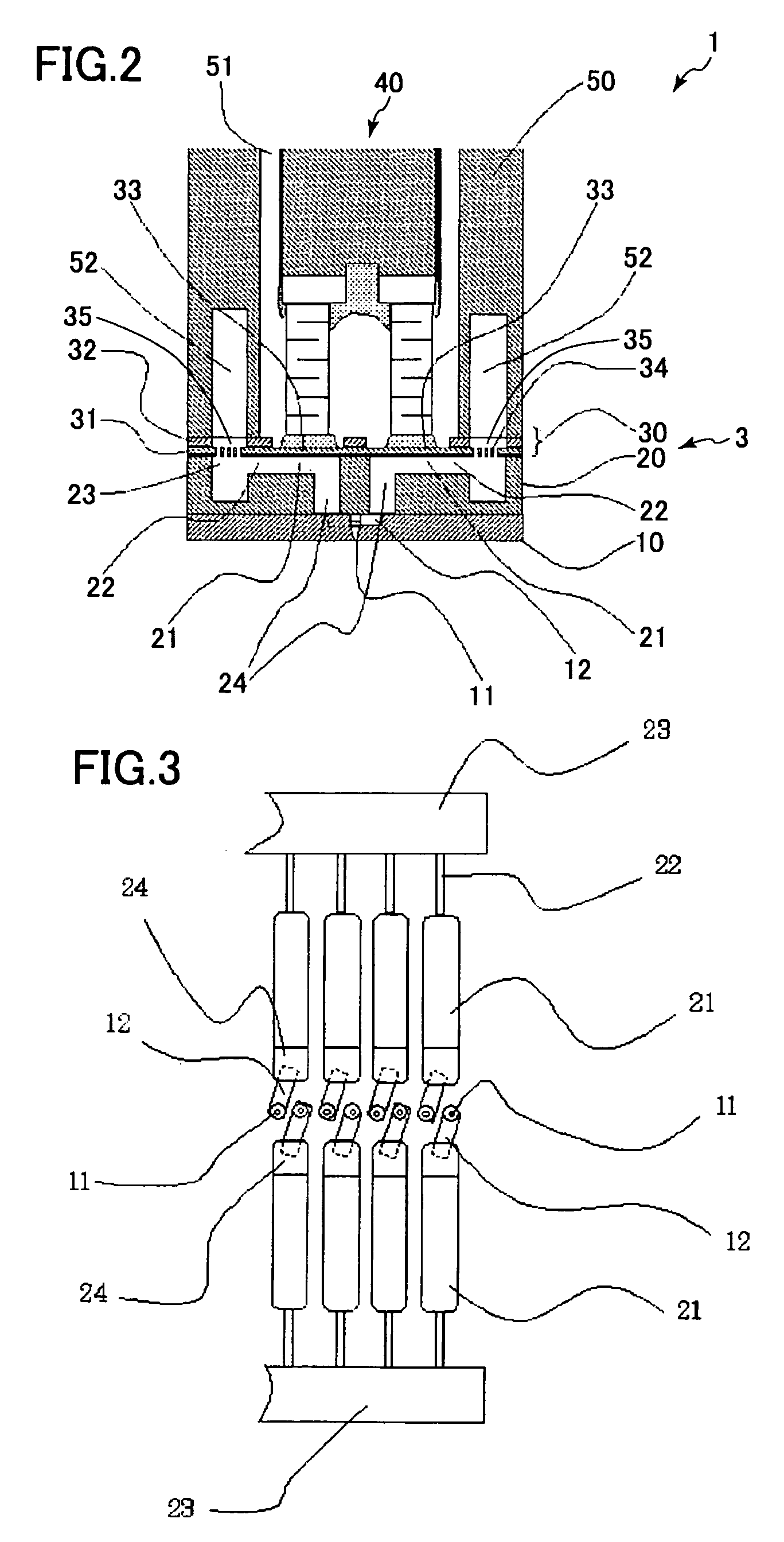

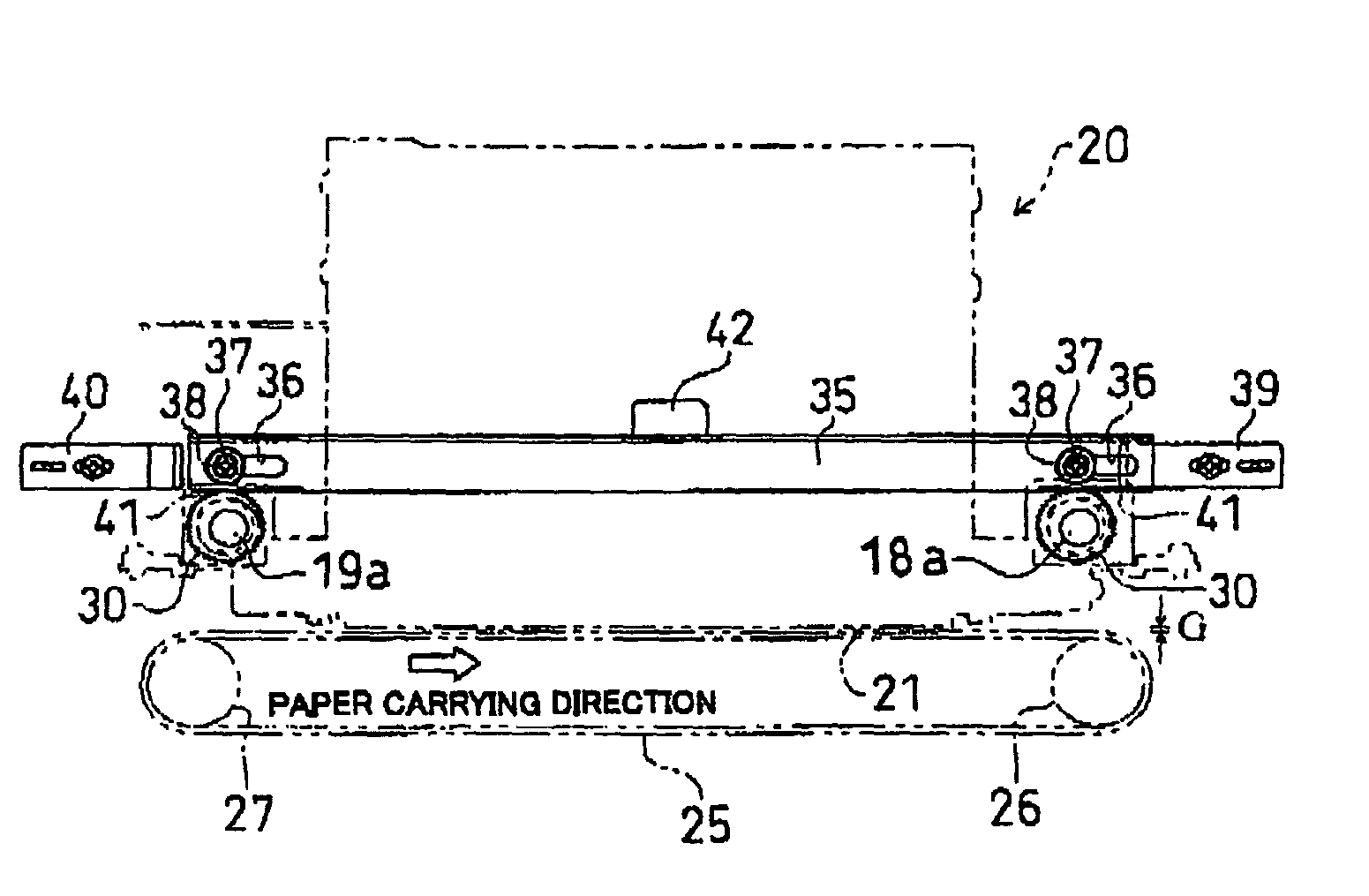

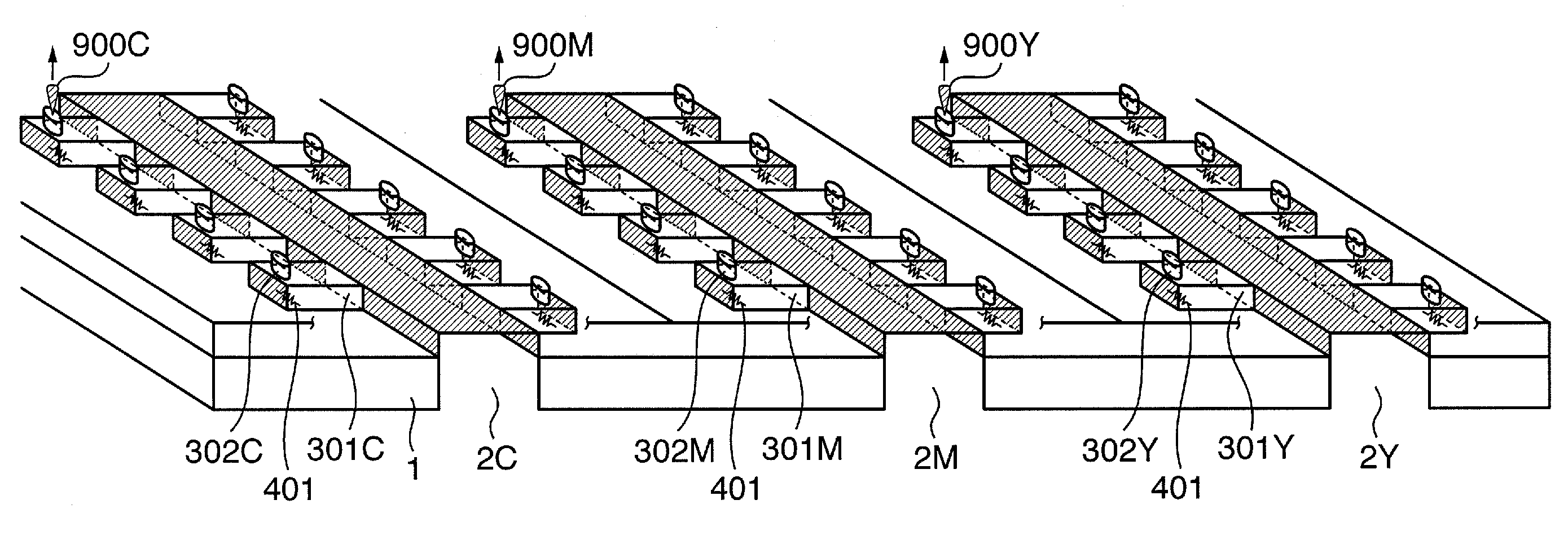

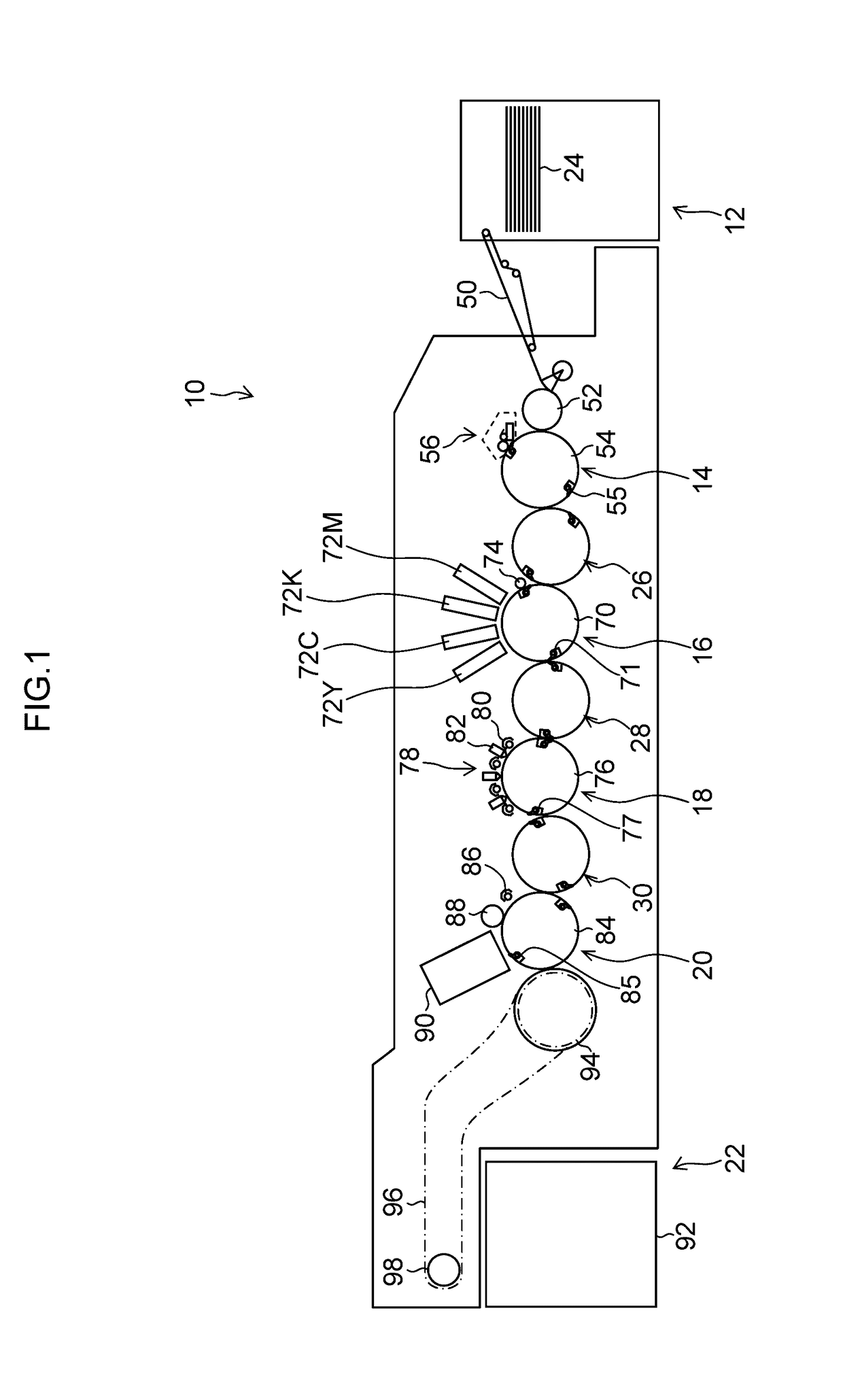

Inkjet image forming apparatus and high-quality printing method of the same

An inkjet image forming apparatus and a high-quality printing method. The inkjet image forming apparatus for high-quality printing includes a plurality of printheads with lengths equal to a half-width of a print medium are arranged in a single line along a transferring direction of the print medium transferred in a subsidiary scanning direction, and are moveable along a main scanning direction to eject ink onto the print medium to print an image, a plurality of carriages where the plurality of printheads are mounted, a plurality of carriage moving units to reciprocally move the carriages in the main scanning direction, and a control unit to generate control signals to synchronize ejecting operations of the printheads and operations of the carriage moving units so that the ink ejected from the printheads is deposited on a desired area of the print medium.

Owner:S PRINTING SOLUTION CO LTD

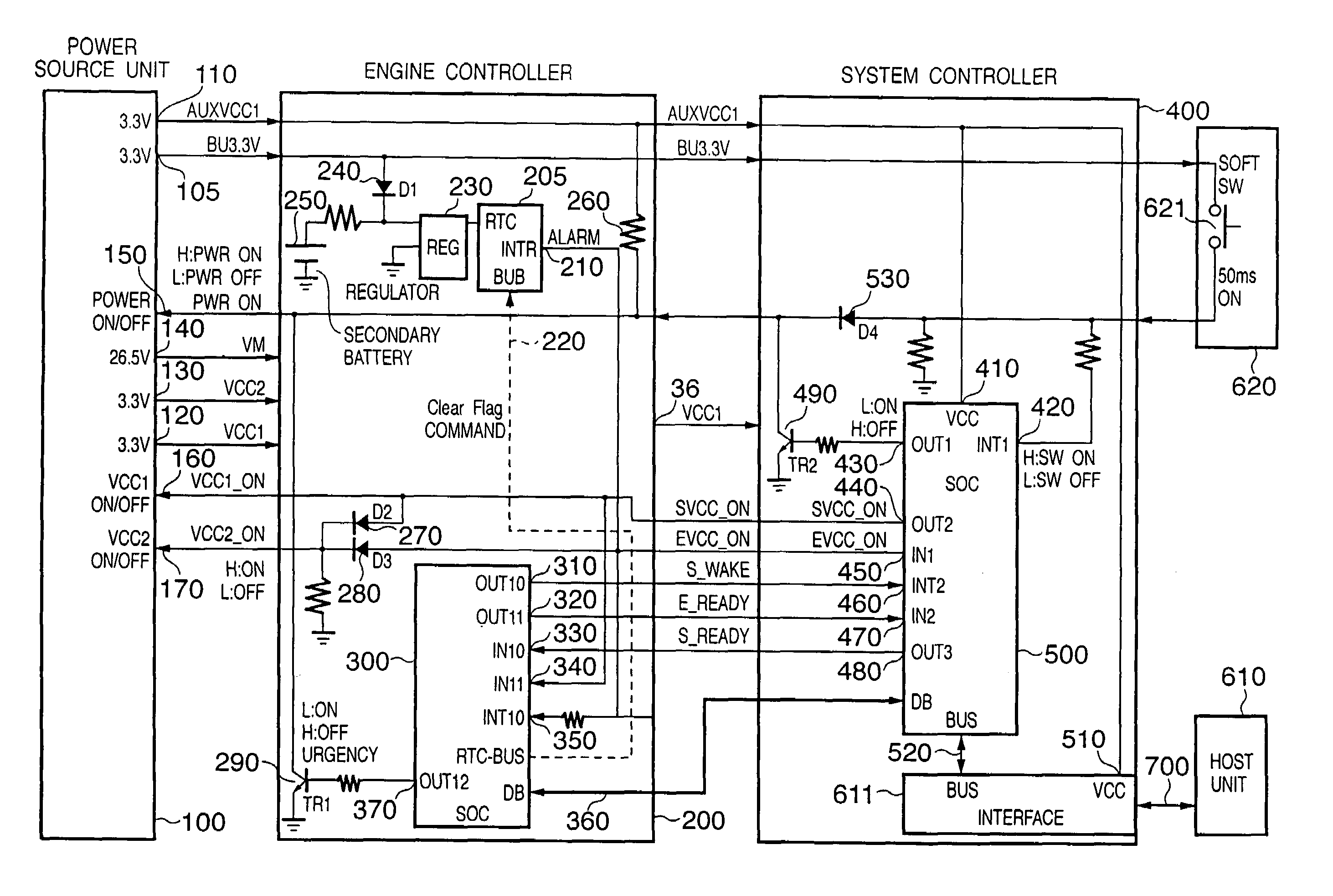

Power management control method and printing apparatus

InactiveUS7278705B2Reduce power consumptionExcellent stateVolume/mass flow measurementVisual representation by matrix printersNormal modeEngineering

A power management control method of a printing apparatus, which can reduce power consumption of the printing apparatus during a sleep mode and maintain an excellent state of the printing apparatus in a sleep mode, and enables high-quality printing when the printing apparatus returns from the sleep mode to a normal mode. In the printing apparatus employing the present invention which operates in a sleep mode of low power consumption or a normal mode of high power consumption, an event that causes the printing apparatus to shift from the sleep mode to the normal mode is detected, the printing apparatus is shifted from the sleep mode to the normal mode based on the detection result, then it is determined whether or not the detected event is a maintenance operation executed periodically by the printing apparatus to maintain an excellent printing state, execution of the maintenance operation is controlled based on the determination result, and the printing apparatus is returned from the normal mode to the sleep mode.

Owner:CANON KK

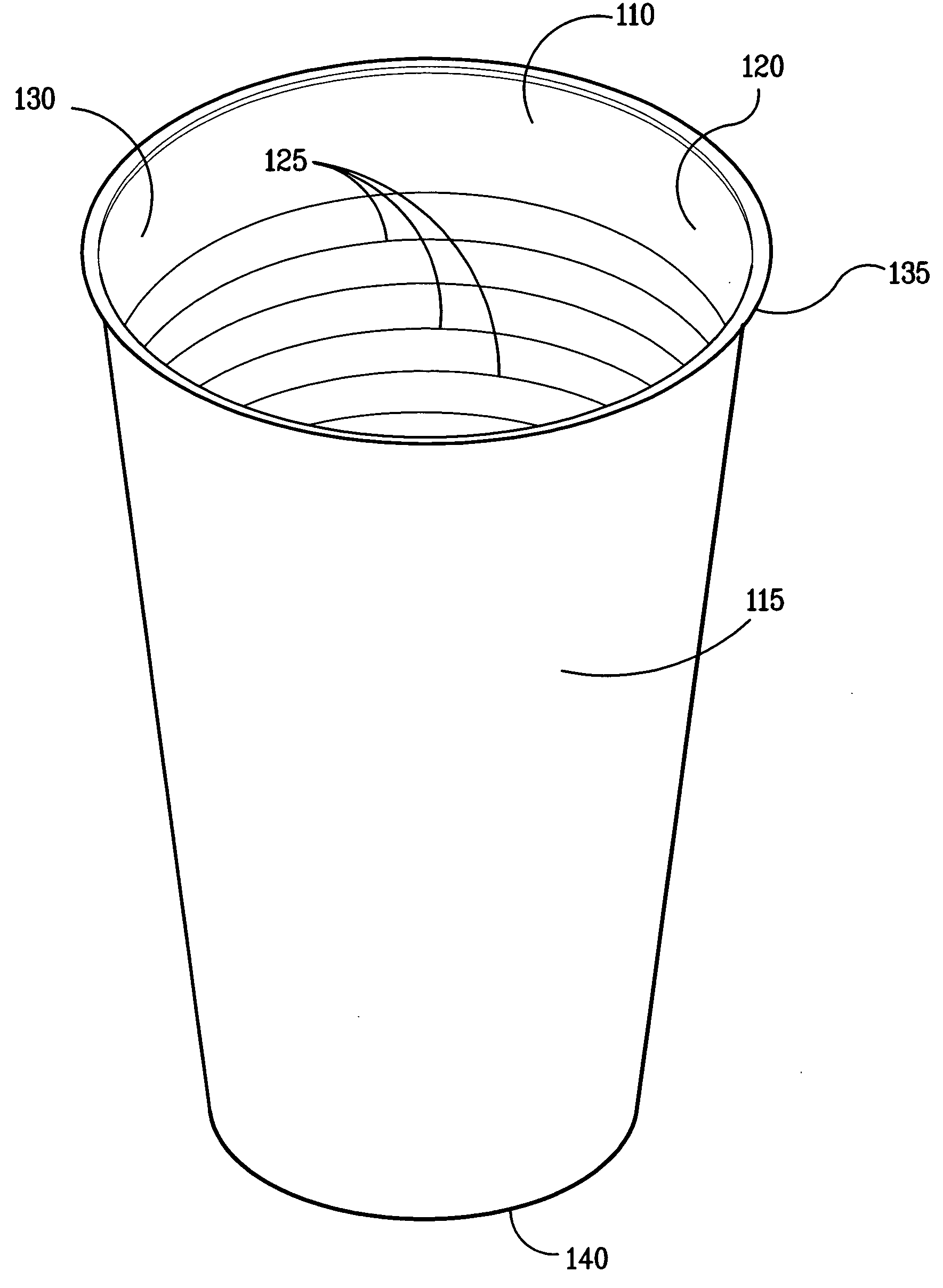

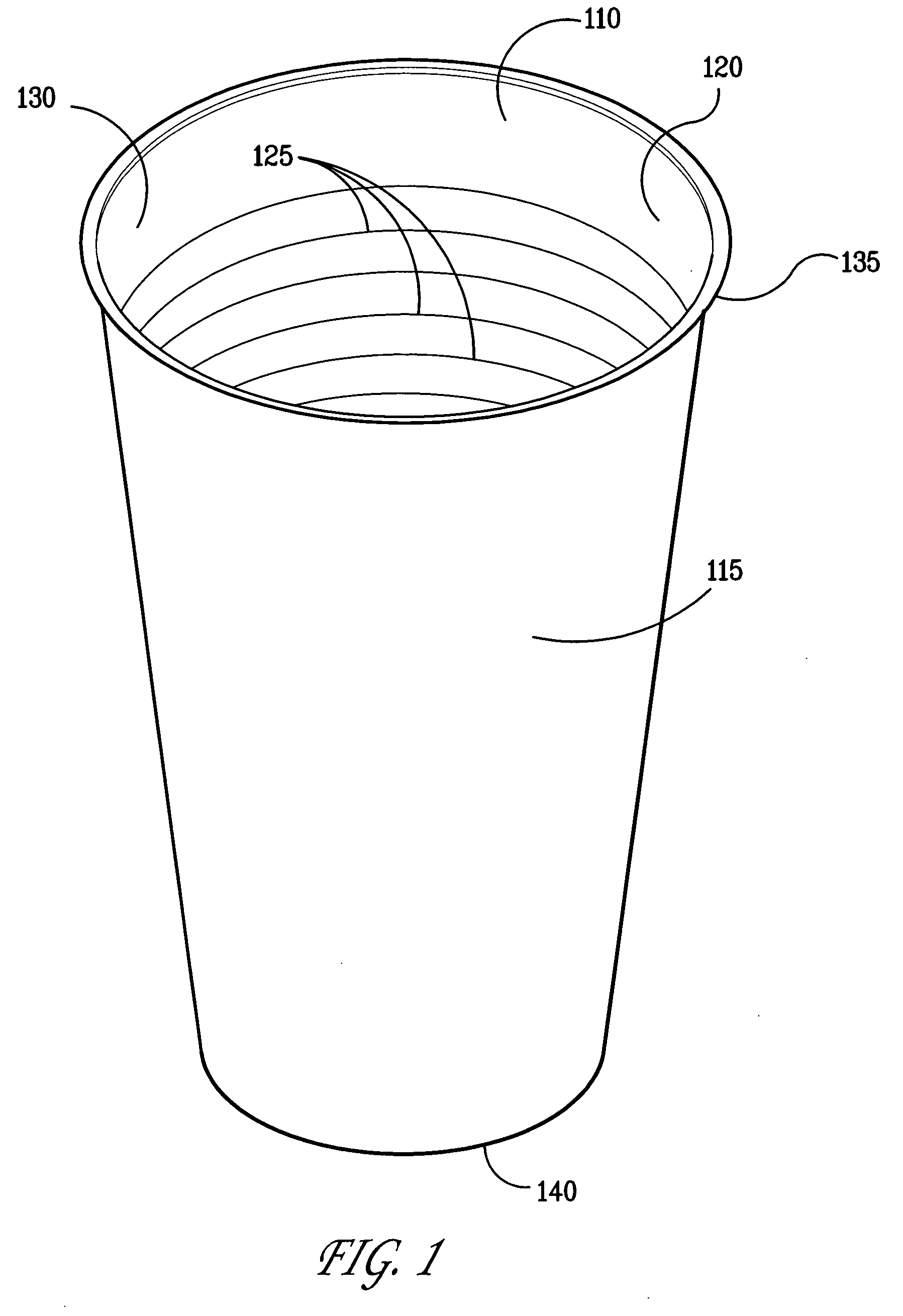

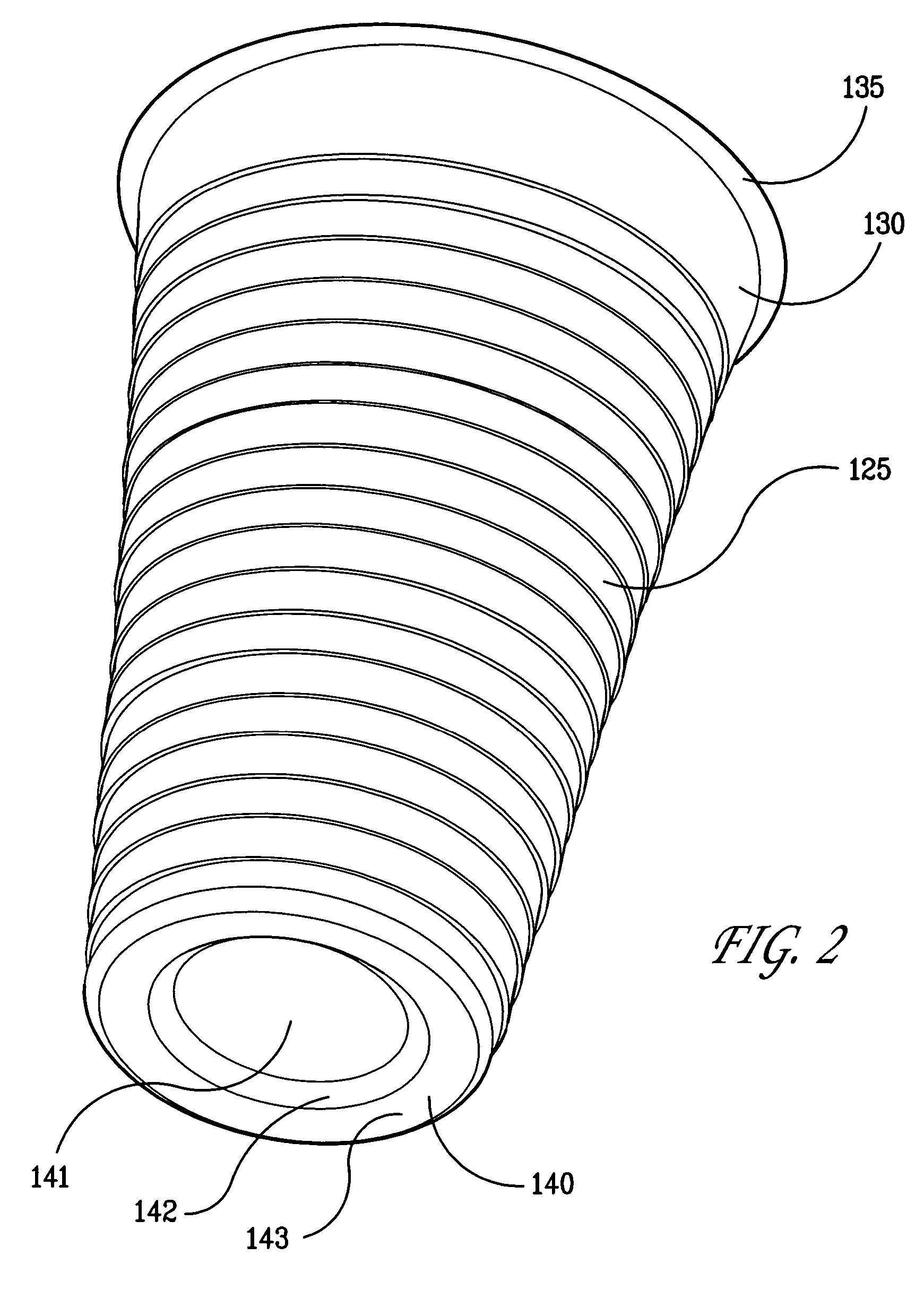

Paper-wrapped polymer beverage container

InactiveUS20060131317A1Quality improvementHigh quality printingContainer/bottle contructionRigid containersThermal insulationEngineering

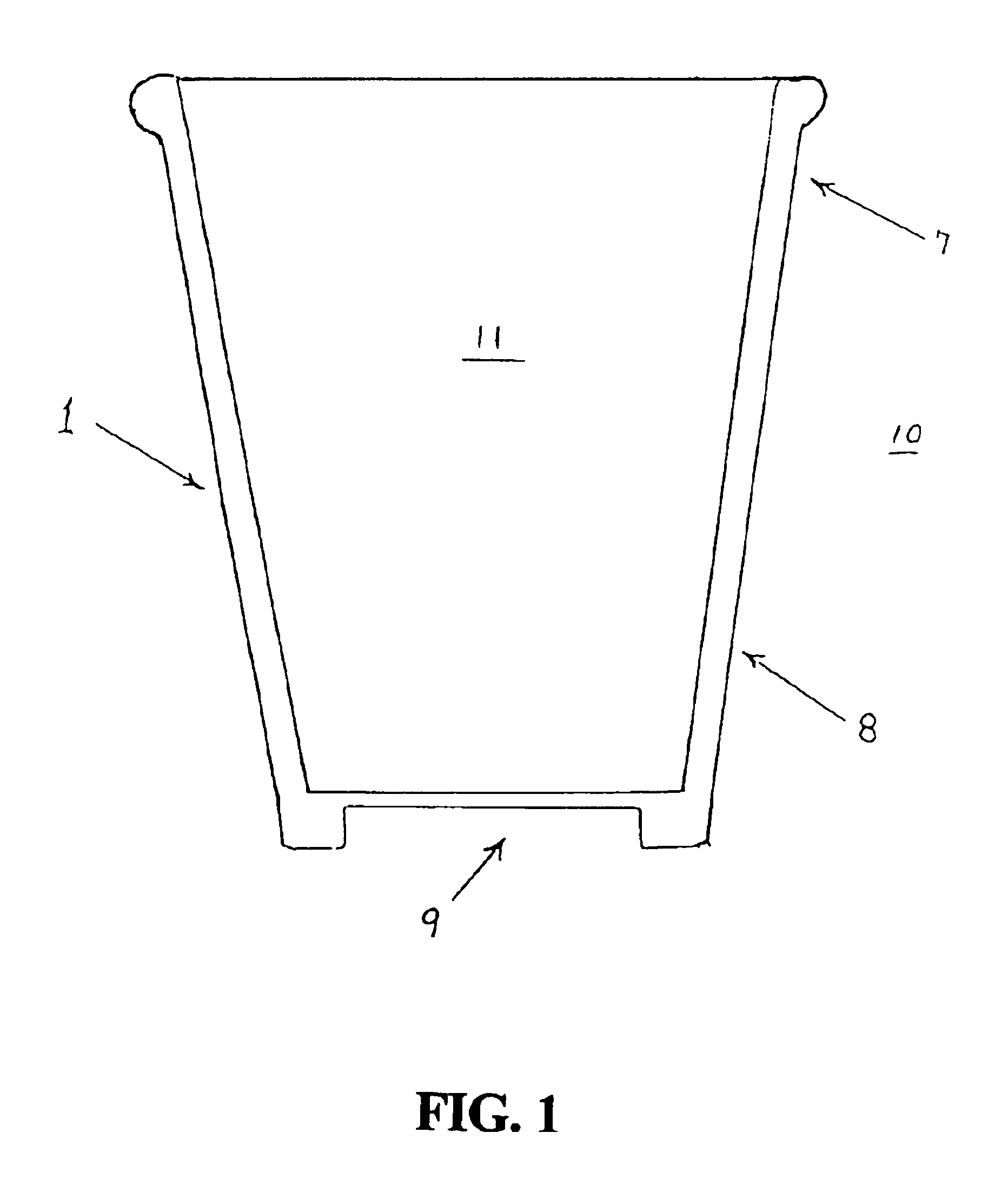

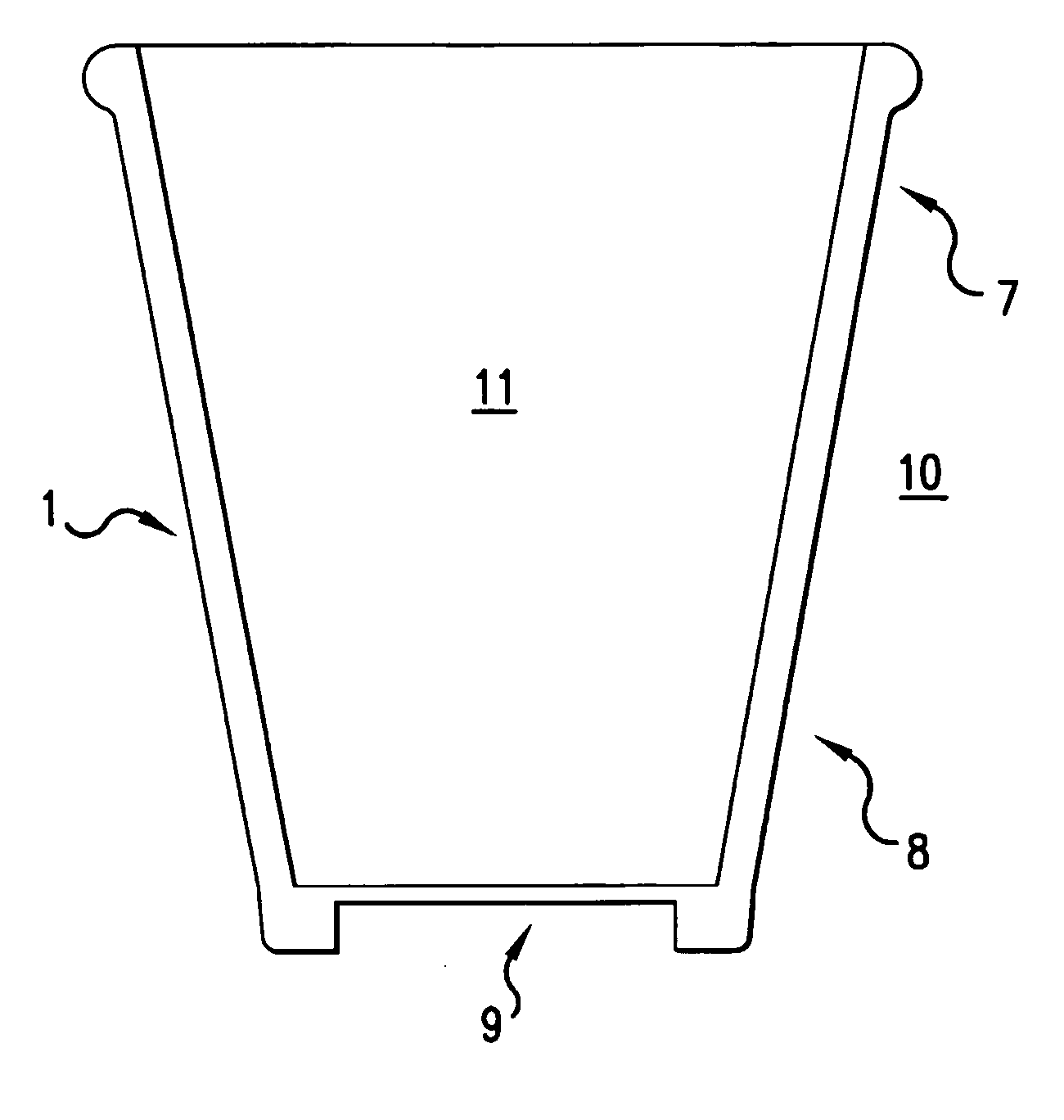

A beverage container having a polymer cup body wrapped in a paper covering is disclosed. The paper-wrapped polymer beverage container may provide thermal insulation while simultaneously providing a means to display high quality printed matter to the user. Such a container may include a polymer cup body having a bottom and a side wall extending from the bottom. The cup body may have a plurality of annular ribs disposed adjacent to one another circumferentially around the side wall parallel to a plane defined by the bottom of the cup body. A paper wrap may be disposed circumferentially around an exterior of the cup body. A promotional item may be attached to the paper wrap.

Owner:WINCUP HLDG

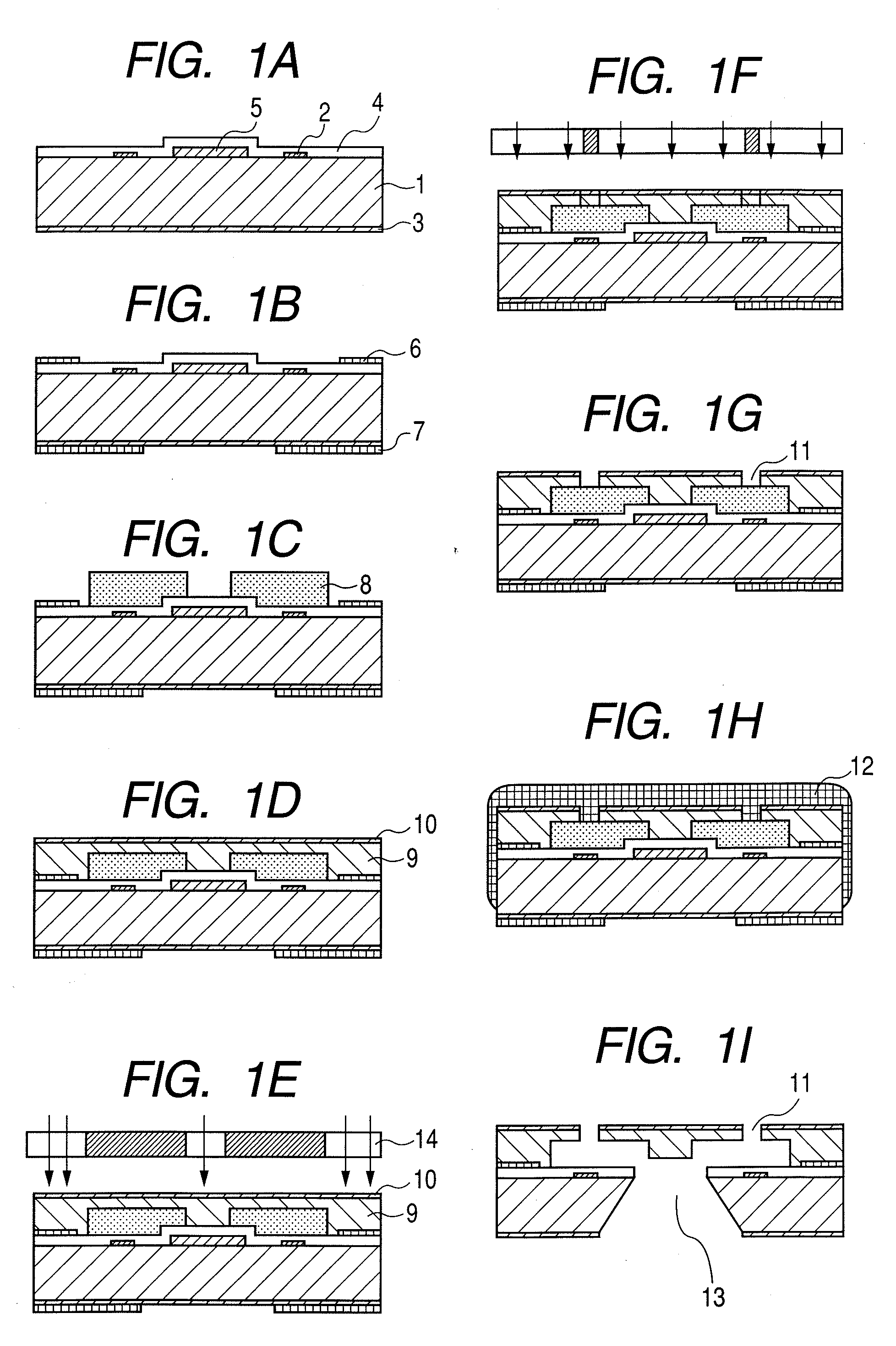

Ink jet recording head and manufacturing method of the same

InactiveUS20070207414A1High quality printingSolve the lack of adhesionPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringCoating

A manufacturing method of an ink jet recording head has: forming a liquid flow path mold material of a soluble resin on a substrate on which an energy generating elements is formed, the energy generating element being configured to generate energy for use in discharging ink; forming a coating resin layer of a negative photosensitive resin on the substrate on which the mold material is formed; exposing and developing the coating resin layer to form an ink discharge port in the coating resin layer; and dissolving and removing the mold material to form a liquid flow path, wherein during the exposing of the coating resin layer, a total amount of exposure energy per unit area, applied to an exposure region other than a region of the coating resin layer positioned above the mold material, is larger than that of exposure energy per unit area, applied to the region of the coating resin layer positioned above the mold material.

Owner:CANON KK

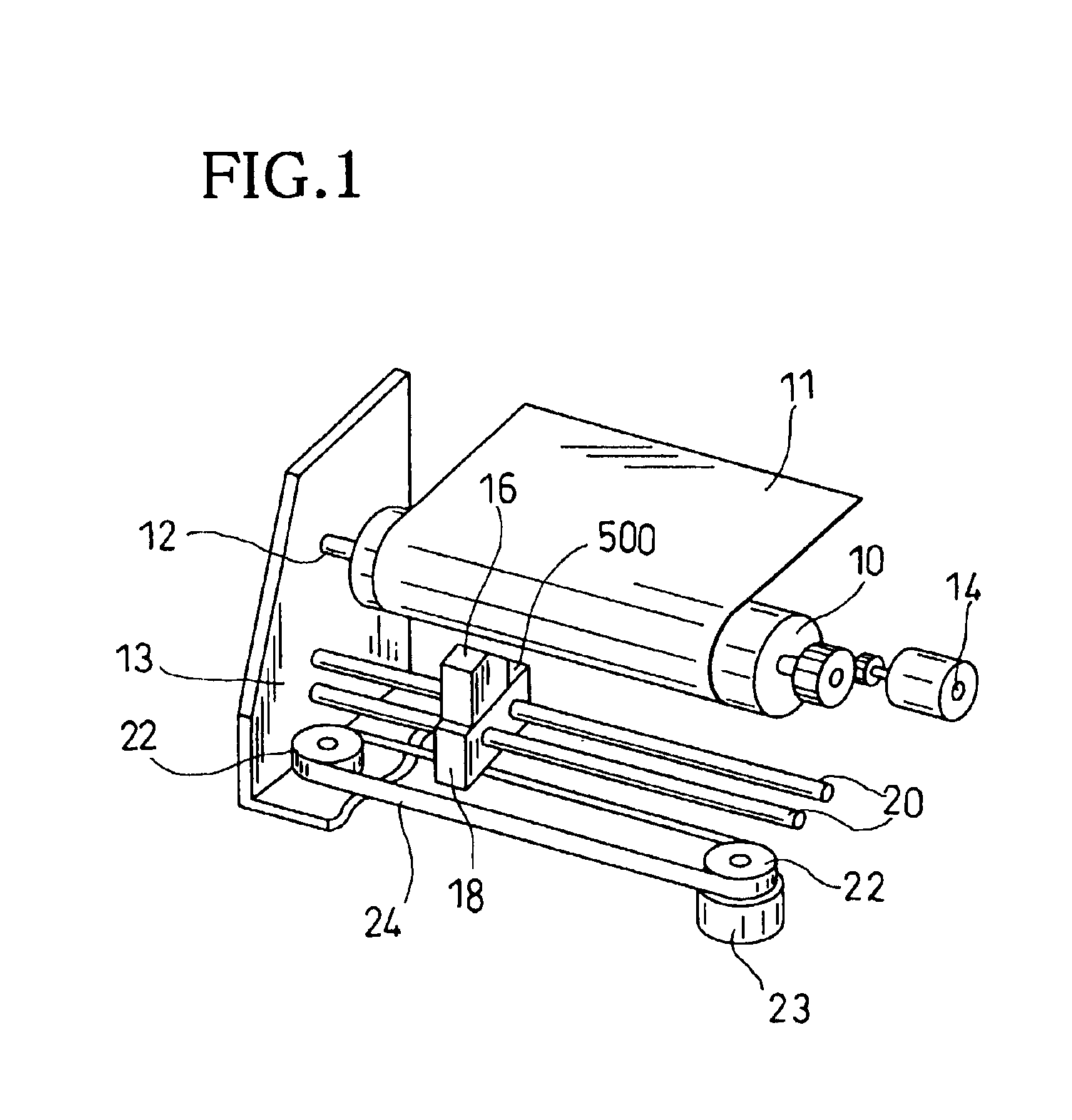

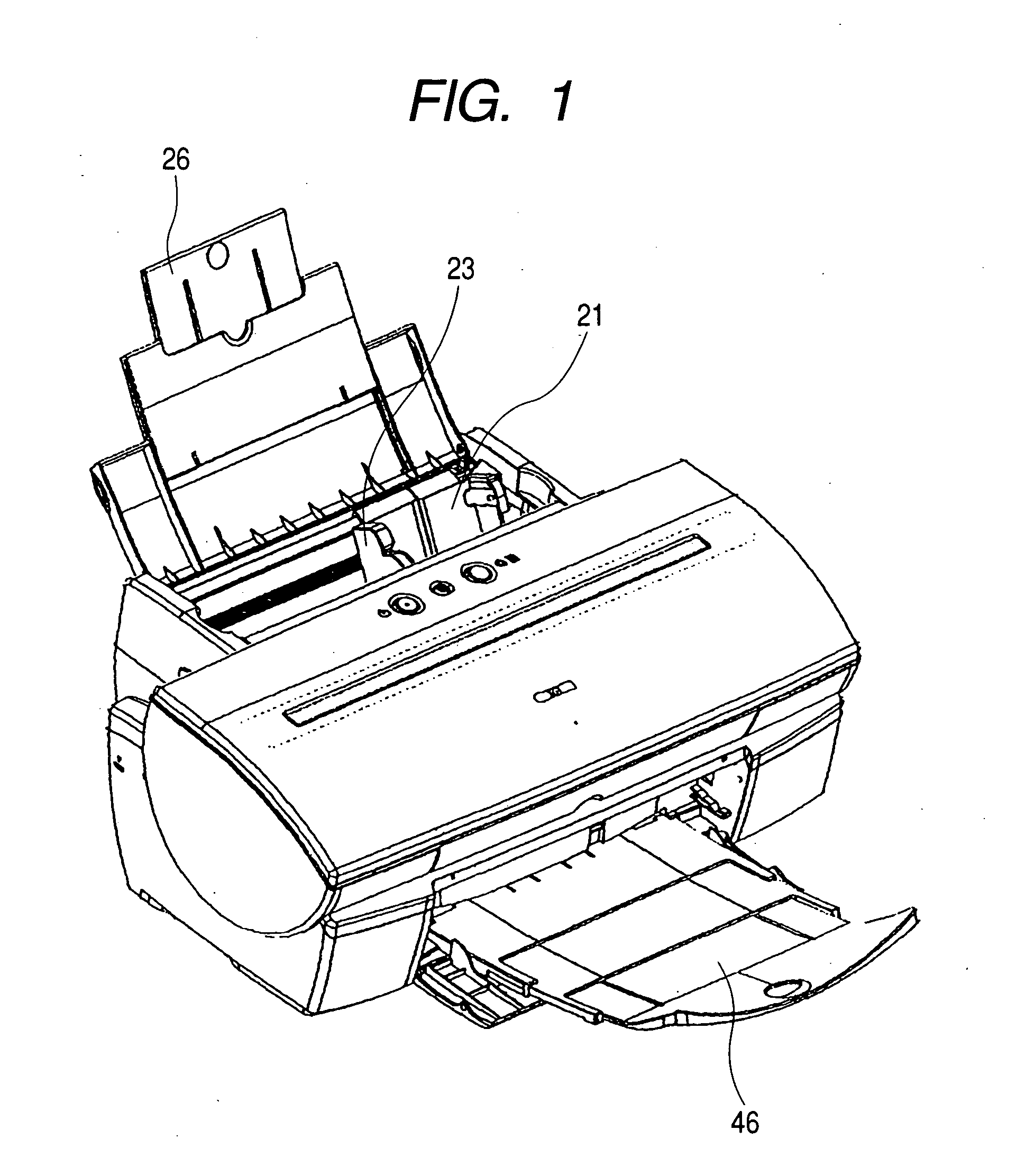

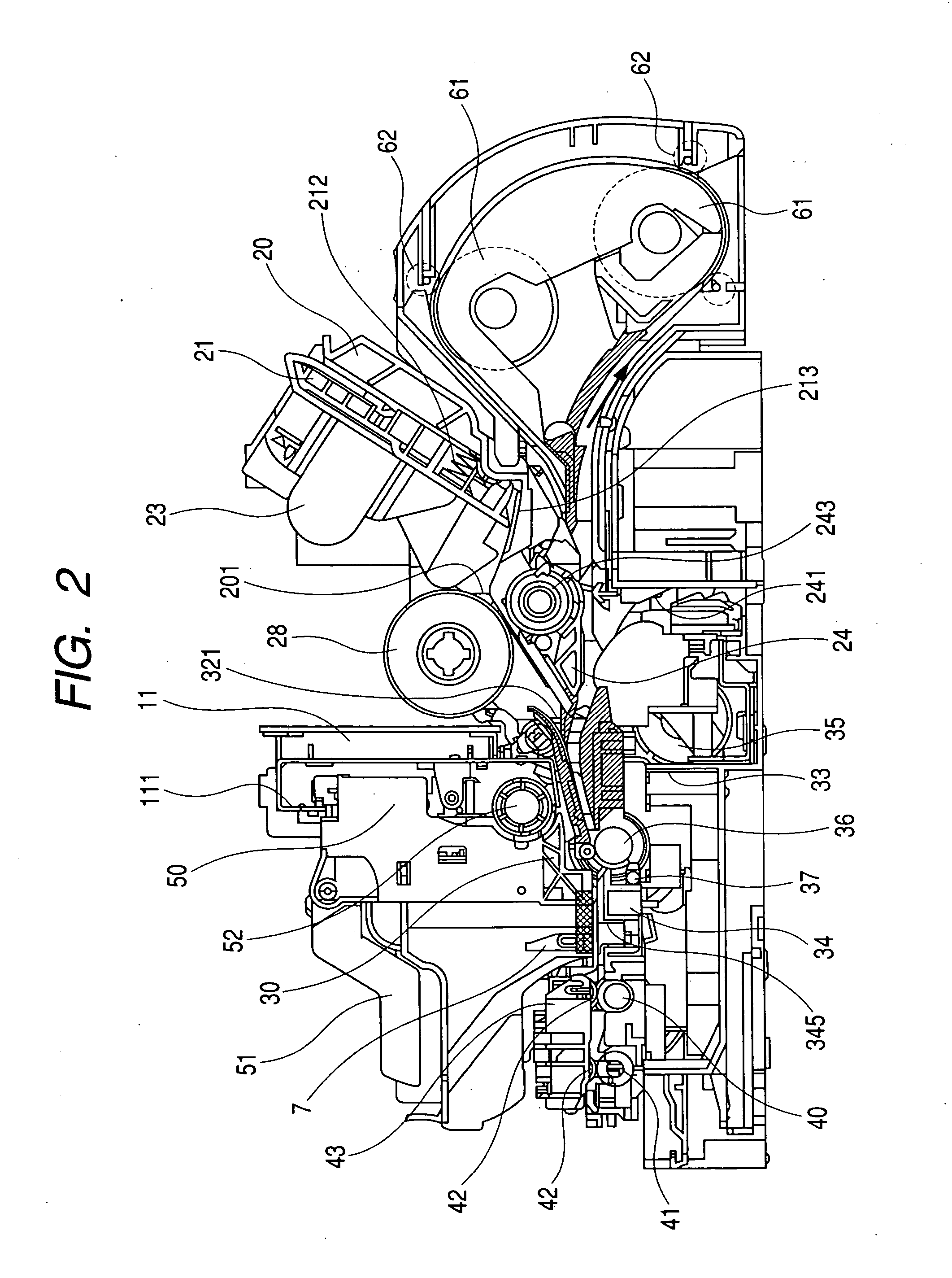

Printer with sheet sending mechanism

InactiveUS20070048059A1High quality printingIncrease speedSpacing mechanismsPower drive mechanismsEngineeringSheet material

Owner:BROTHER KOGYO KK

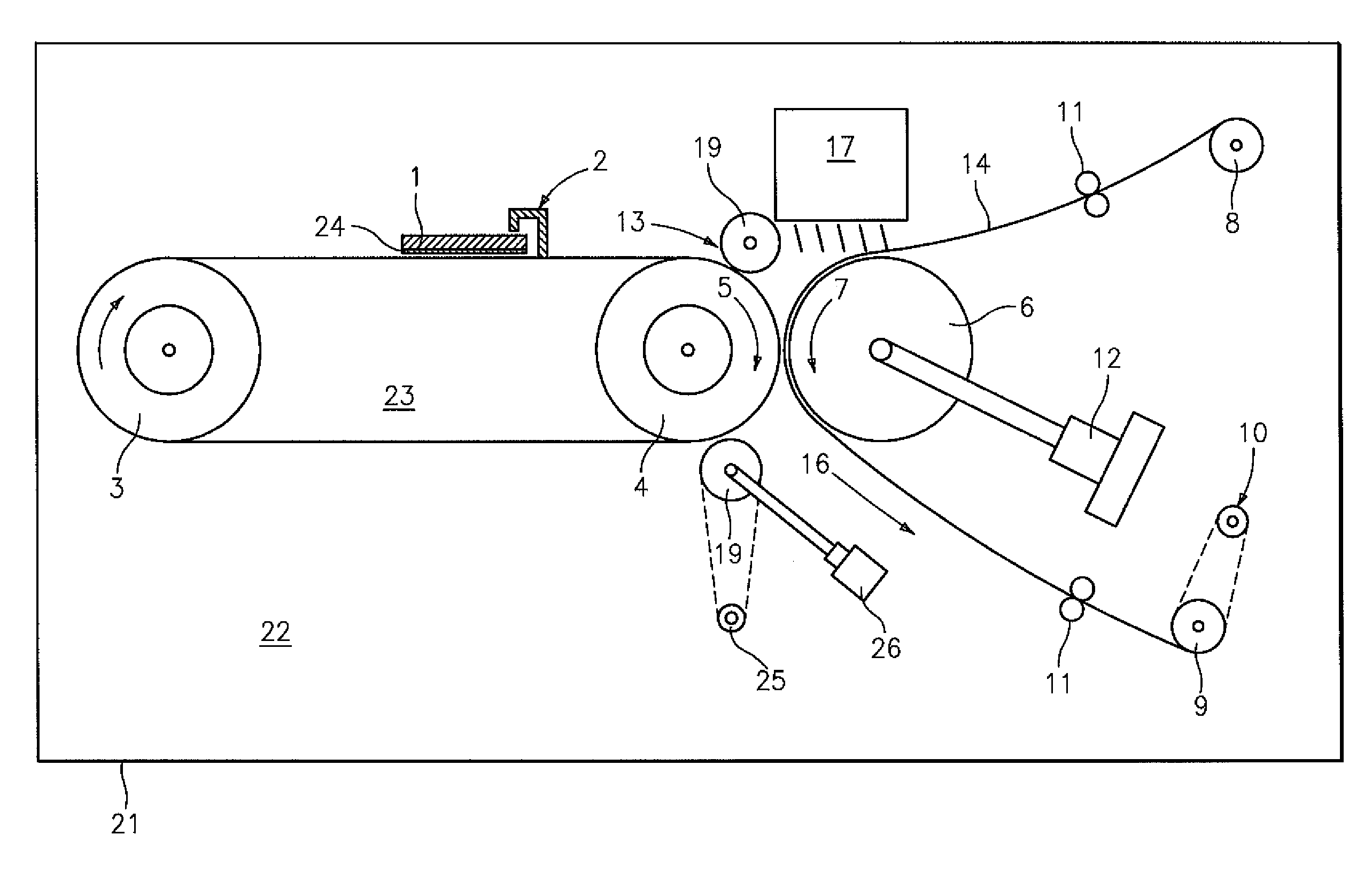

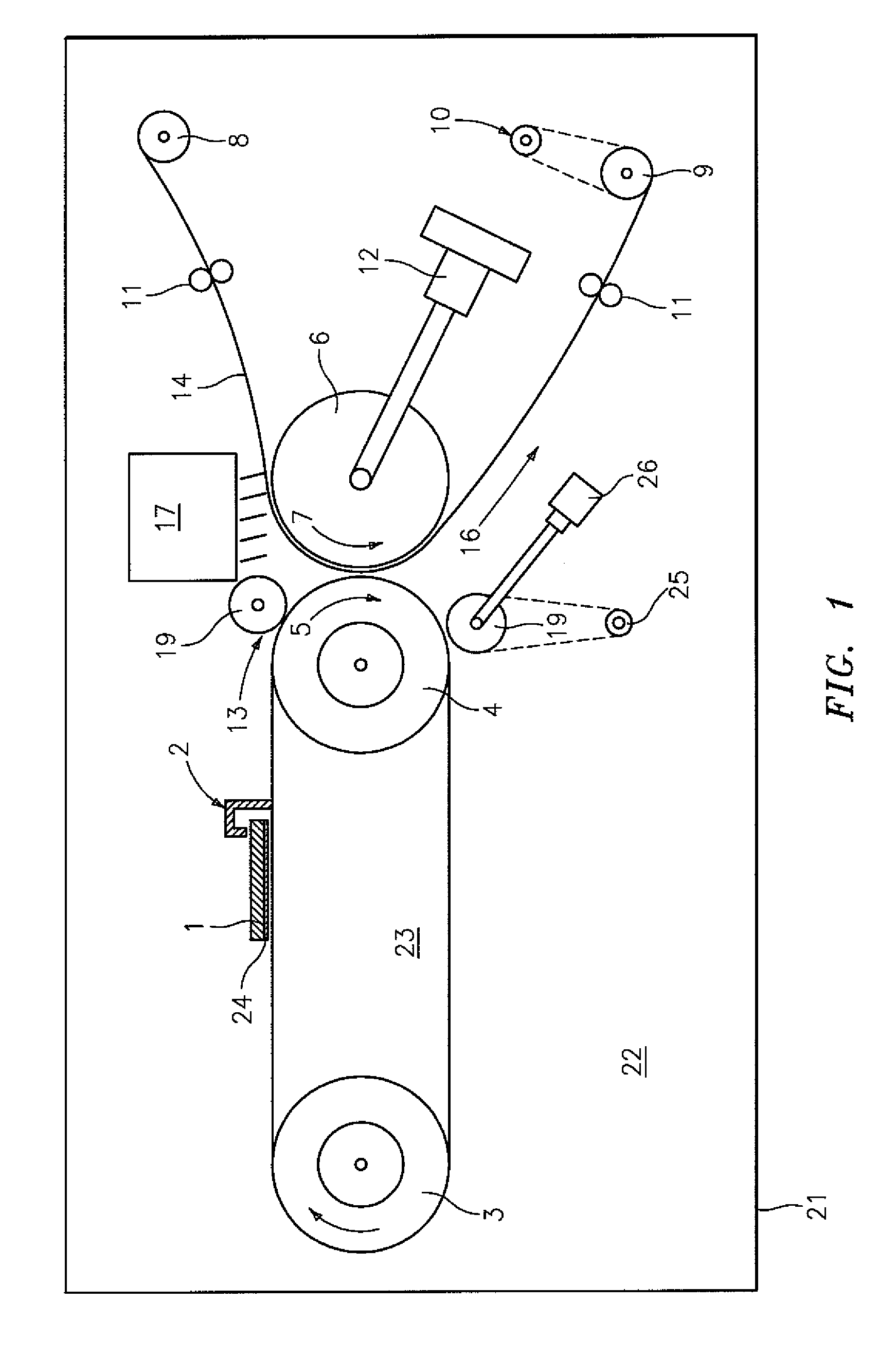

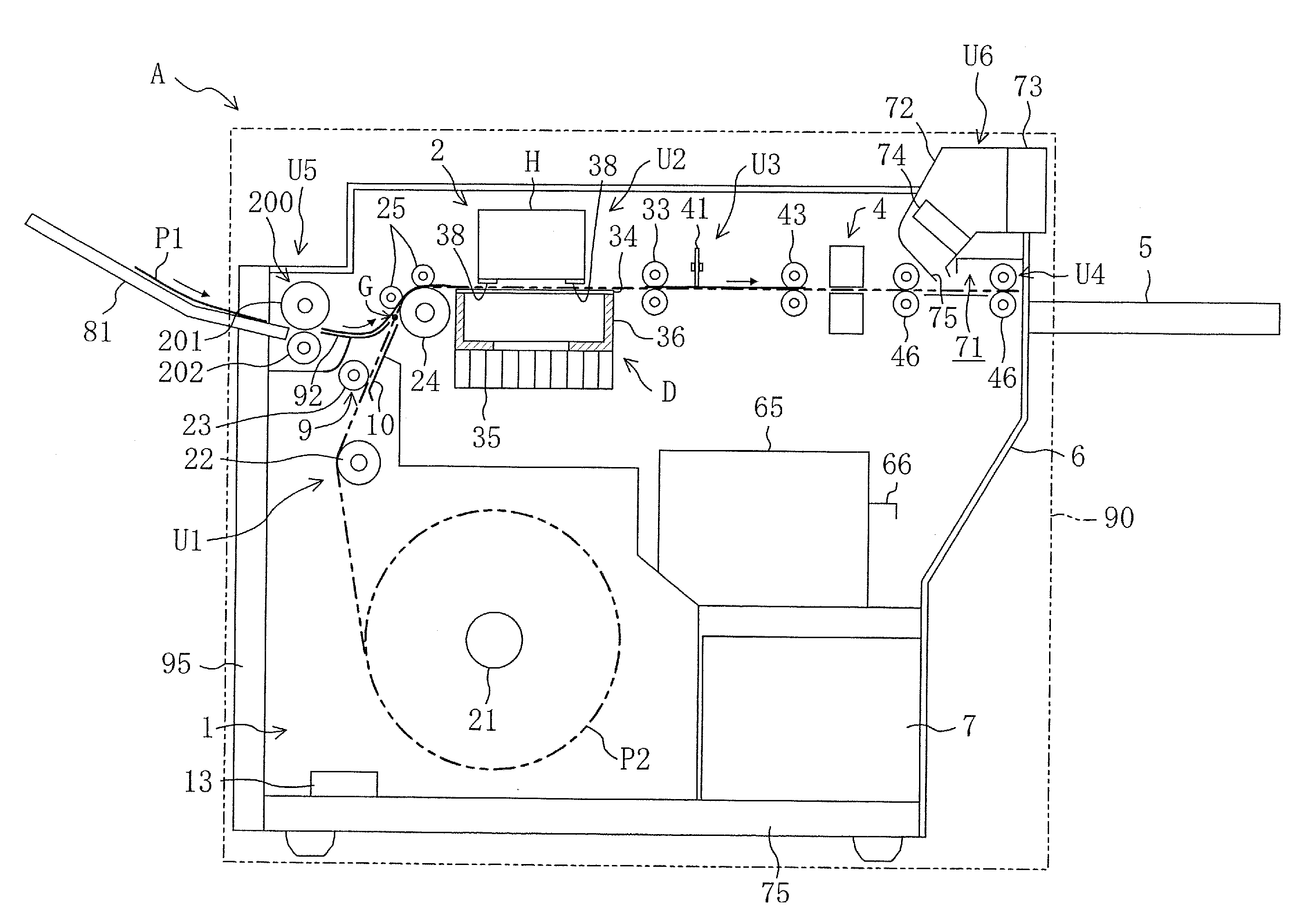

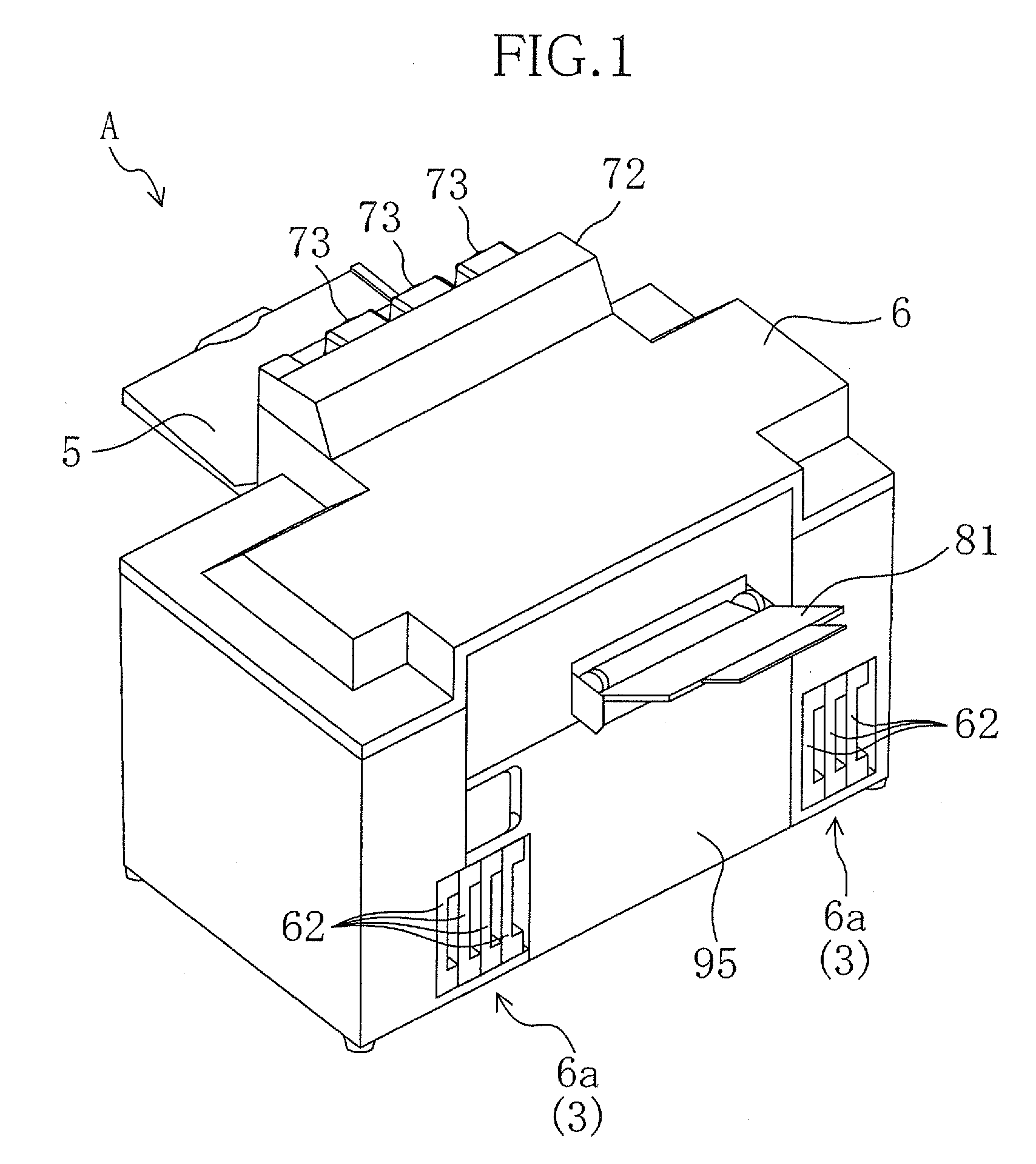

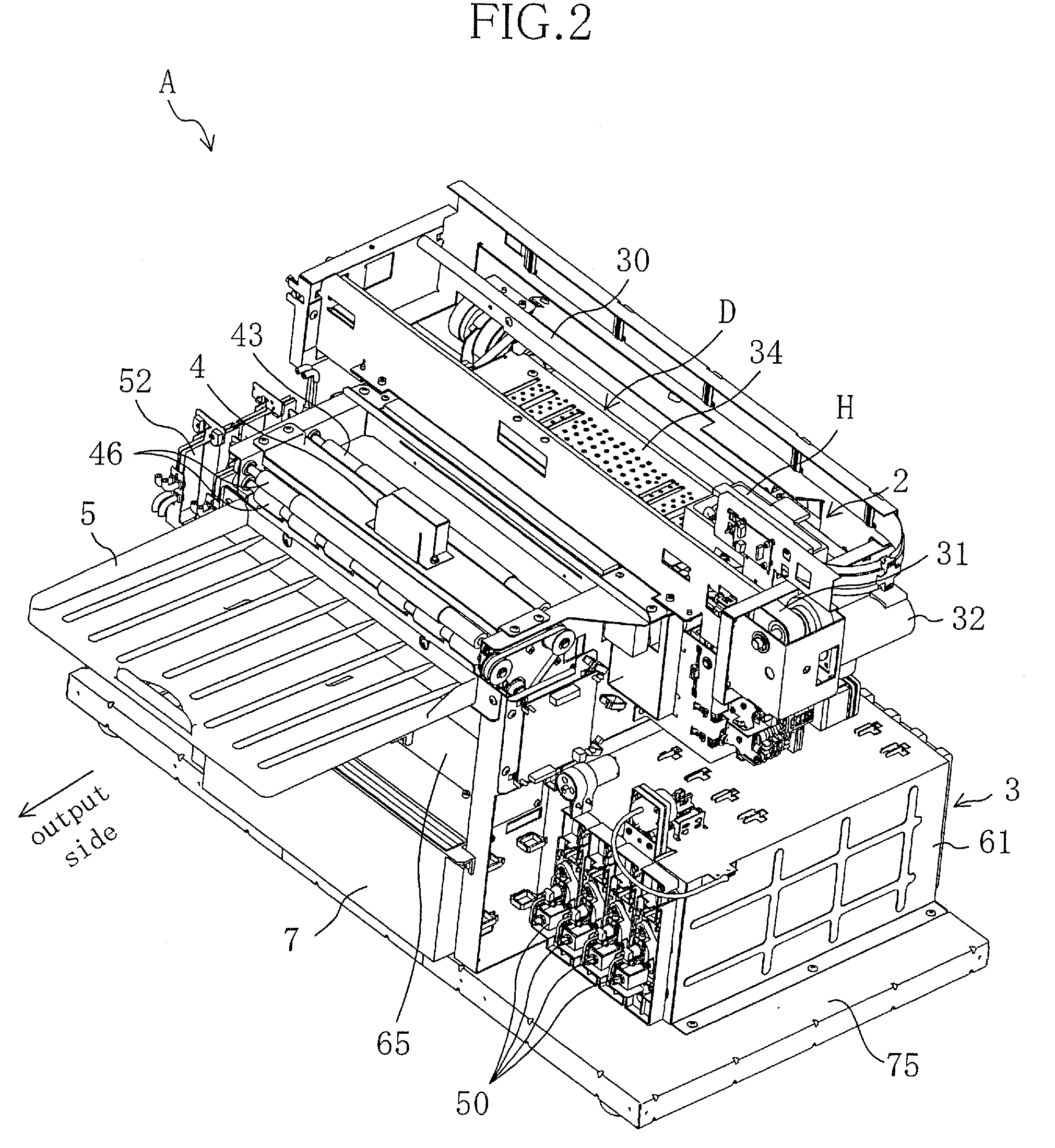

Method and Apparatus for Thermal Processing of Photosensitive Printing Elements

ActiveUS20100024672A1High quality printingSmooth structureDuplicating/marking methodsSemiconductor/solid-state device manufacturingFlexographyEngineering

The present invention pertains to a process and an apparatus for treating a photosensitive element to form a relief structure suitable for flexographic printing plate. The apparatus comprises an enclosure, a conveyor, a heatable roller with absorbent material conducted over it, and a roller that can significantly smooth or uniformly roughen the relief structure of the flexographic printing plate. Previously selectively cured photosensitive elements are developed by means of the heatable roller by blotting with the absorbent material, and the resulting relief structure is made uniform by way of a smoothing or roughening roller. The flexographic plates produced by the method and apparatus are especially suited to processes that require substantially smoothed or uniformly roughened printing plate surfaces, which are capable of producing better quality printing.

Owner:MACDERMID PRINTING SOLUTIONS

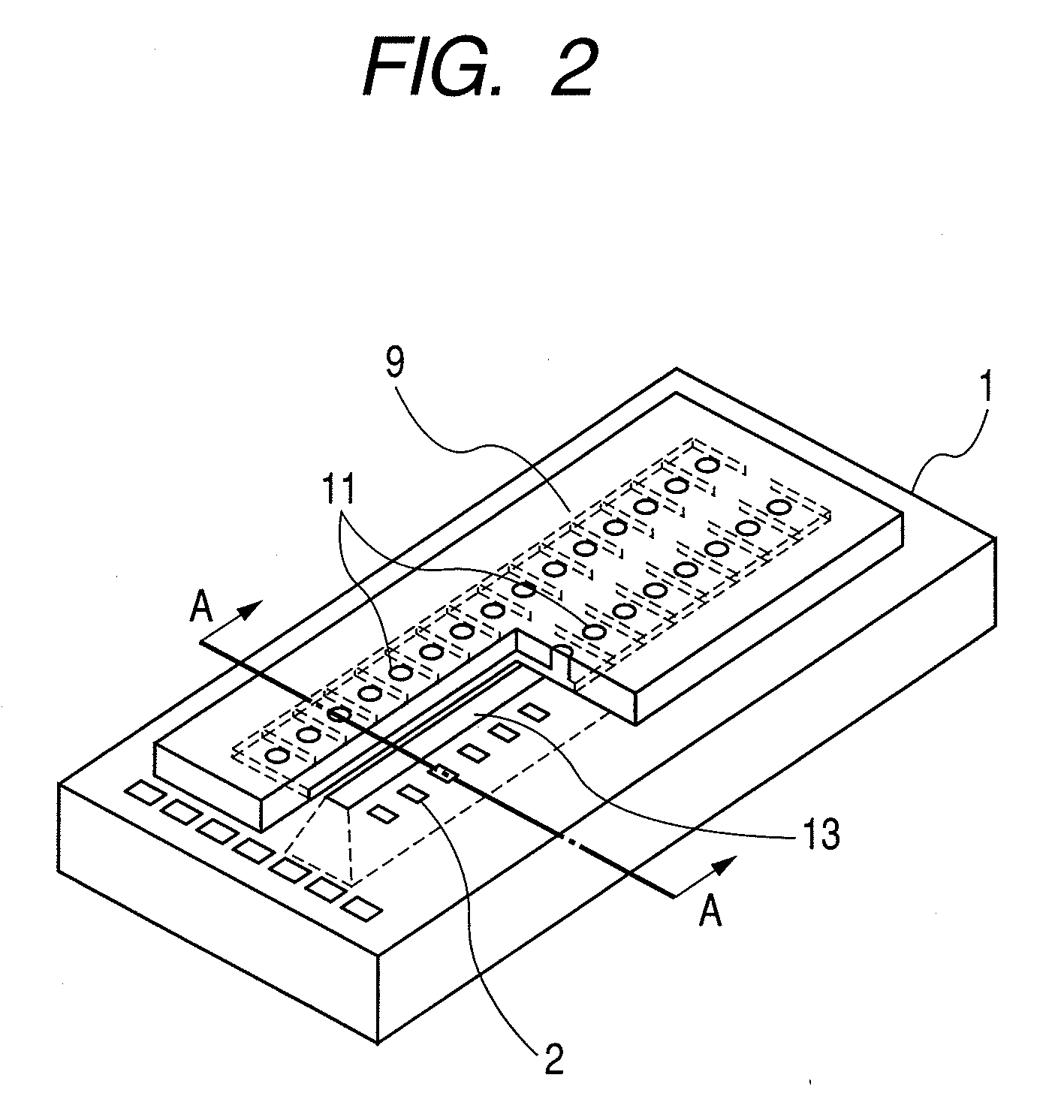

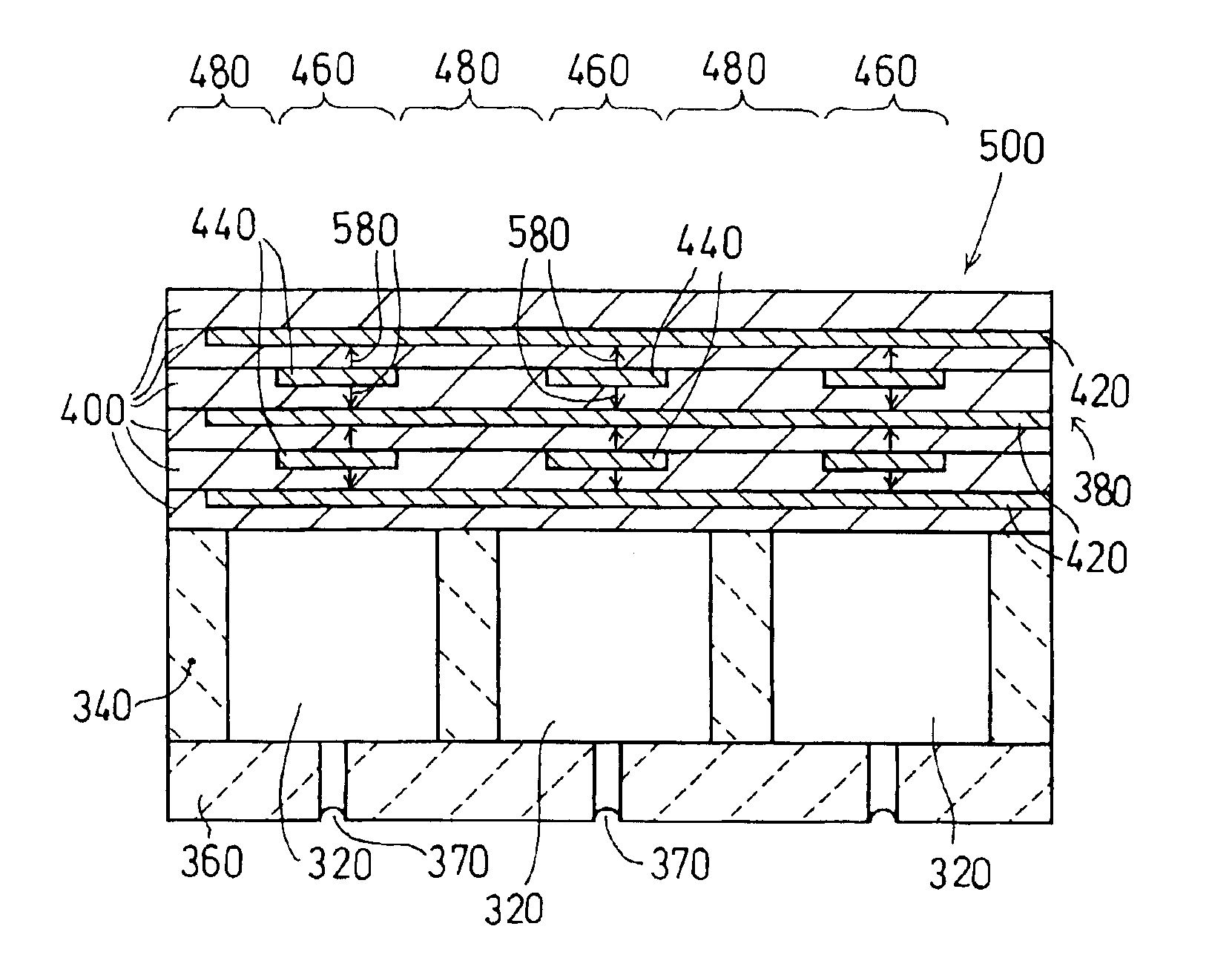

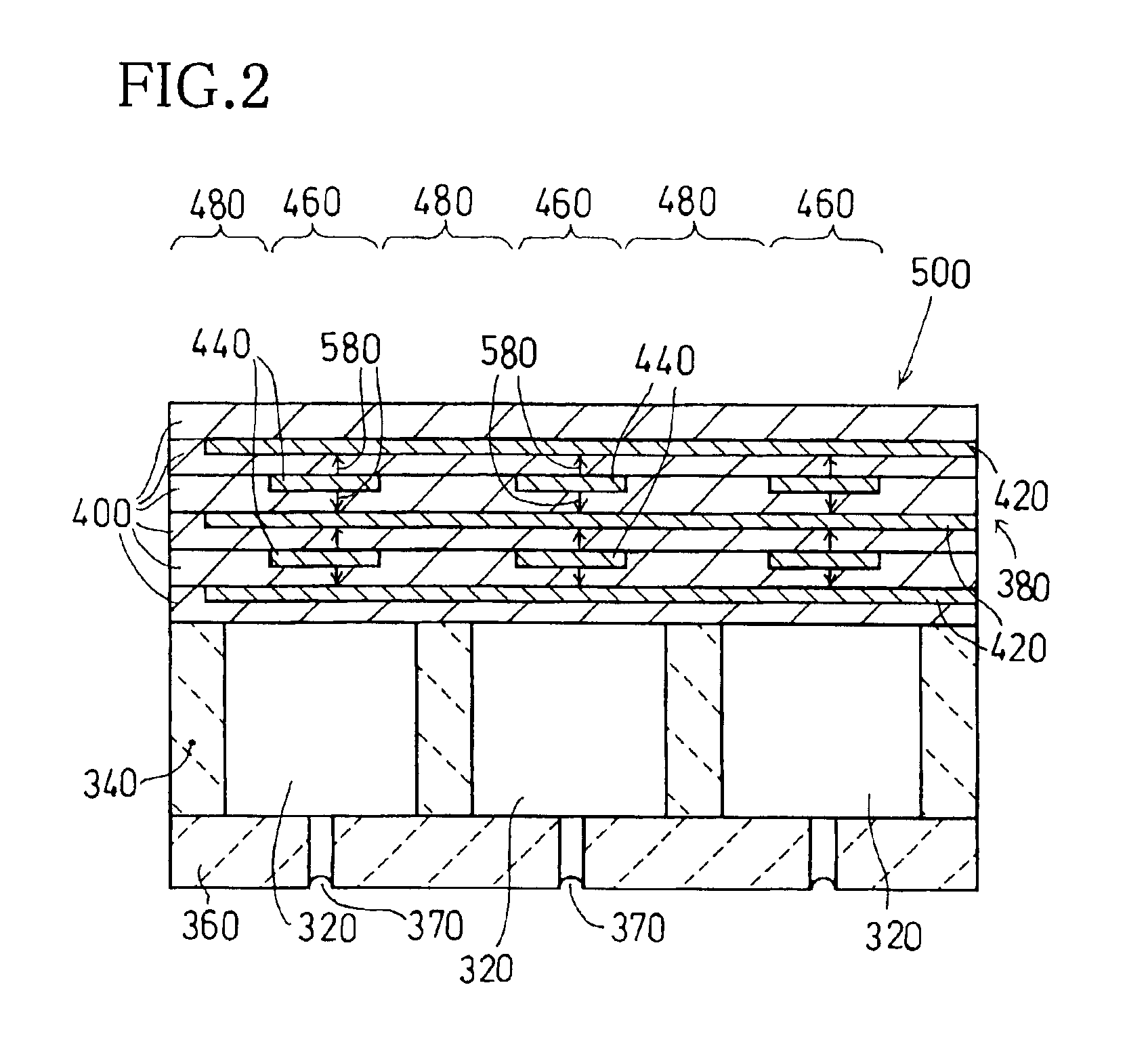

Inkjet recording head

An inkjet recording head includes a nozzle plate, chamber plate, and a diaphragm plate. The nozzle plate includes a plurality of nozzles for ejecting ink droplets, a plurality of connecting channels in communication with the nozzles and pressure chambers. The nozzles are formed in a row at a uniform pitch. The connecting channels extend from the nozzles alternately in opposite directions in a staggered formation and are offset a prescribed angle to a direction orthogonal to the row of nozzles. The chamber plate includes the pressure chambers, restrictors, and common ink chambers formed therein. Each pressure chamber has an elongated shape extending in a direction orthogonal to the row of nozzles. The pressure chambers are formed in rows, one on either side of the row of nozzles, so that the pressure chambers in one row oppose the corresponding pressure chambers in the other row. The diaphragm plate has a vibration plate that seals the pressure chambers.

Owner:RICOH KK

Method and system for transmitting graphical images

InactiveUS20030072299A1Reduce the amount requiredSave network bandwidthDigital data information retrievalNatural language data processingGraphicsThe Internet

Abstract of Disclosure Techniques for transmitting graphical images in a network environment are described. According to the techniques, the amount of data of the graphical images that is transmitted is customized in accordance with client and / or server supplied information. The techniques enable graphical images to be transmitted more efficiently than previously possible, thus saving precious network bandwidth and reducing transmission time. The invention is particularly suitable for network (Internet or Internet) implementations wherein graphical images often need transferred.

Owner:RAKUTEN INC

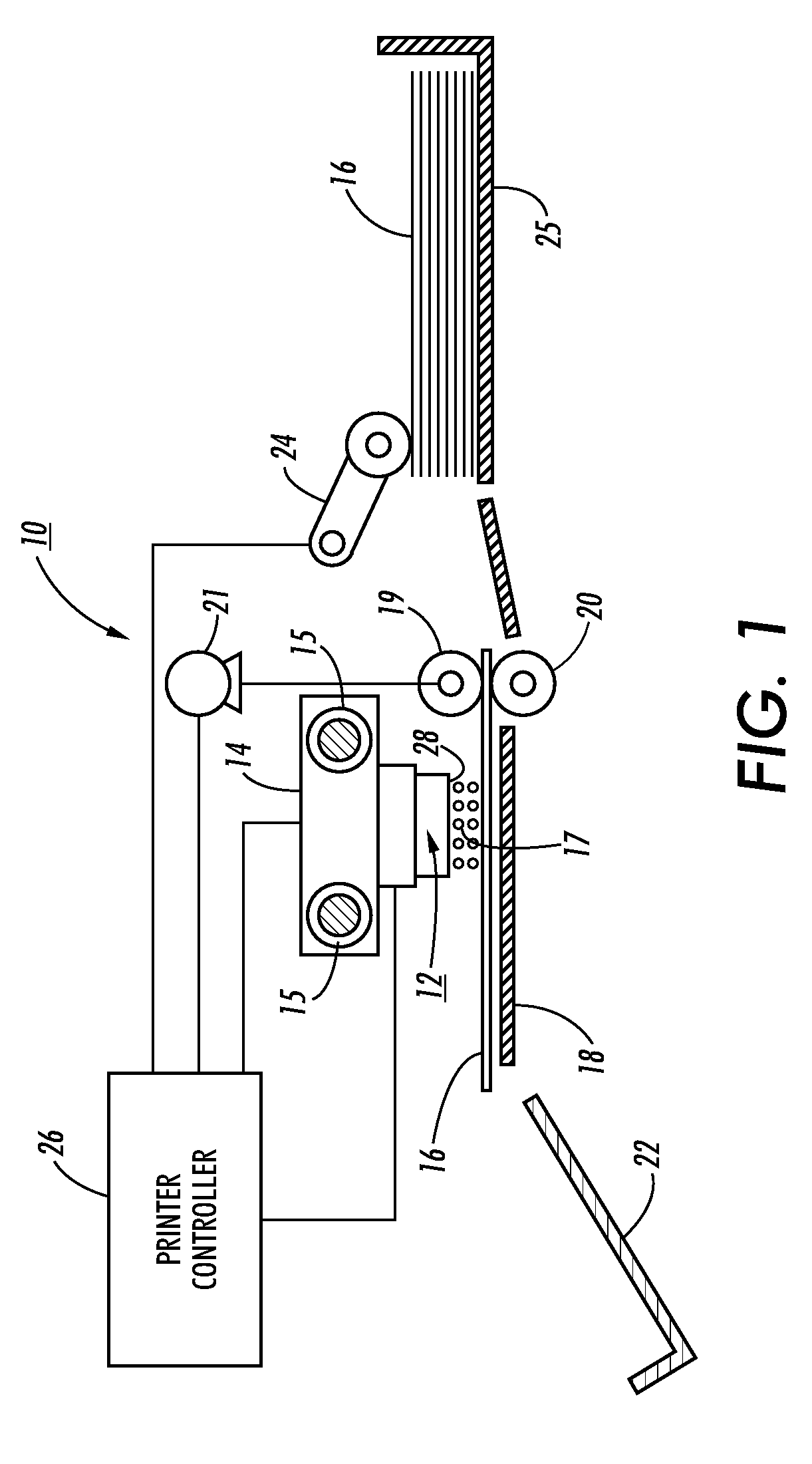

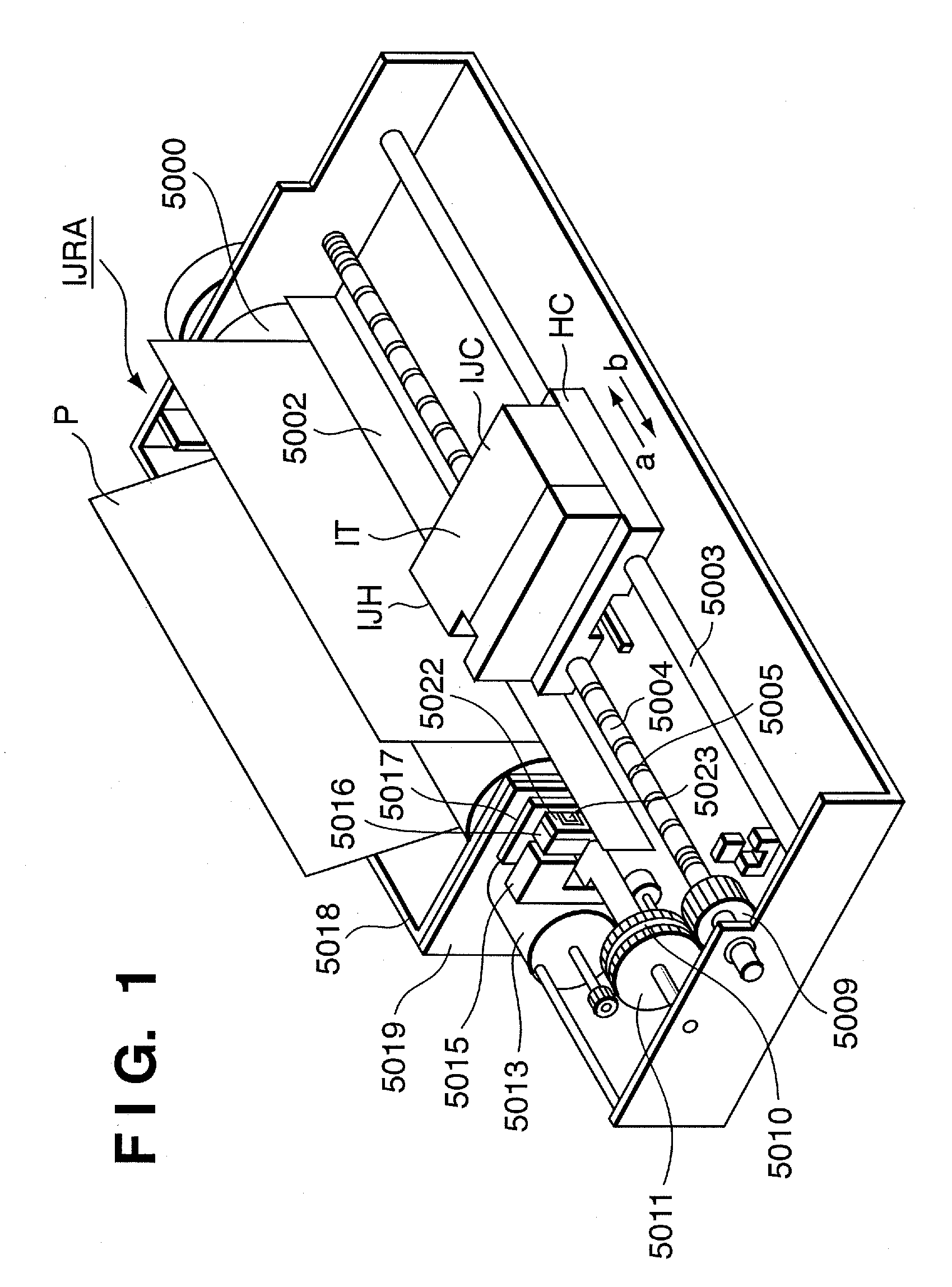

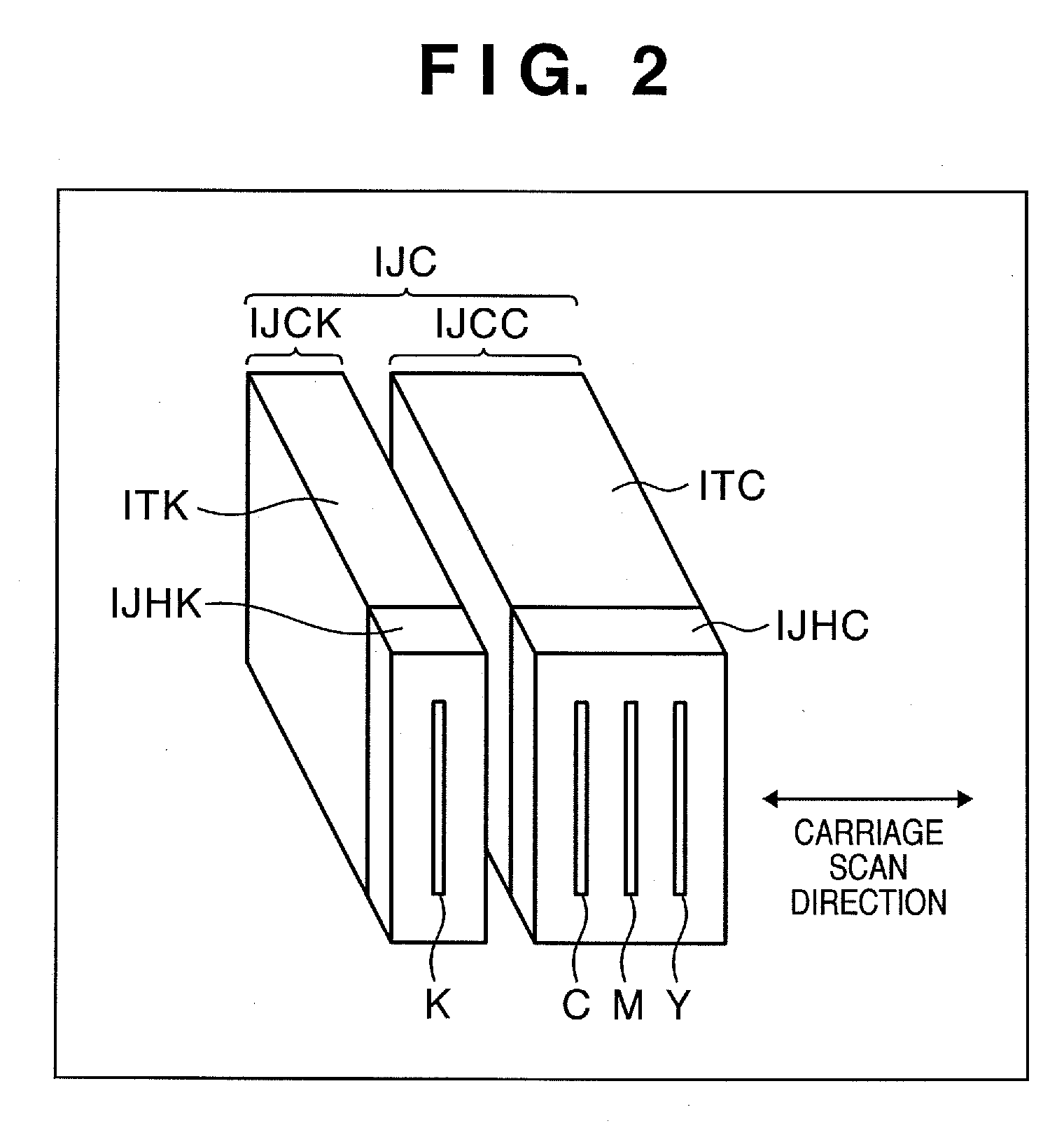

Ink-jet recording apparatus

ActiveUS6964476B2High qualityQuality improvementPower drive mechanismsOther printing apparatusEngineeringReciprocating motion

An ink-jet recording apparatus comprises an ink-jet head having an ink ejection surface on which a plurality of nozzles are arrayed; a medium carrier forming a carrying surface on which a record medium is carried; a carriage mounted with the ink-jet head such that the ink ejection surface confronts the carrying surface; a carriage drive mechanism including a plurality of parallel guide rods supporting the carriage and extending across the direction where the record medium is carried by the medium carrier, the carriage drive mechanism reciprocating the carriage along the guide rods; and a guide shift mechanism for shifting the plurality of guide rods in a direction where the gap between the ink ejection surface and the carrying surface varies.

Owner:BROTHER KOGYO KK

Head substrate, printhead, head cartridge, and printing apparatus

InactiveUS20090091594A1Suppress power consumptionStable ink droplet dischargeOther printing apparatusReference currentVoltage reference

This invention is directed to: a printhead substrate which employs a constant current driving method and can suppress power consumption in a standby state, prevent an increase in printhead temperature, and stably discharge ink; a printhead using the printhead substrate; a head cartridge incorporating the printhead; and a printing apparatus using the printhead. The head substrate includes a plurality of printing elements; a plurality of driving elements which are provided in correspondence with the plurality of printing elements and drive the plurality of printing elements; a reference voltage generation circuit which generates a reference voltage; a reference current generation circuit which generates a first reference current on the basis of the generated reference voltage; a plurality of constant current sources, each of which generates a constant current to drive the plurality of printing elements on the basis of the generated first reference current; and a switch which controls supply of the first reference current in accordance with a printing operation.

Owner:CANON KK

Inkjet printer

A paper web not in use for printing is put on standby at a standby position in which the leading edge of the paper web is located upstream of a meeting point of paper conveyance paths and a closing roller bears against a margin of the paper web.

Owner:NORITZ CORP

Method of manufacturing the piezoelectric transducer

InactiveUS6993812B2High quality printingPiezoelectric/electrostrictive device manufacture/assemblyLine/current collector detailsCapacitanceTransducer

Inner individual electrodes are formed at intervals on a piezoelectric ceramic layer so as to correspond in a one-to-one relationship with ink channels, and an inner common electrode are formed on another piezoelectric ceramic layer. The required number of piezoelectric ceramic layers with inner individual electrodes and with an inner common electrode are laminated alternately. An outer common electrode is connected to the inner common electrodes, and outer individual electrodes are connected to the respective inner individual electrodes. The capacitance between the outer common electrode and each of the outer individual electrodes is measured. A polarization electric field adjusted based on the measured value is applied between the common electrode and each of the outer individual electrodes to perform polarization. As a result, each area defined over an ink channel by the stacked inner individual and common electrodes is polarized so as to be deformed by a uniform amount when a constant drive voltage is used.

Owner:BROTHER KOGYO KK

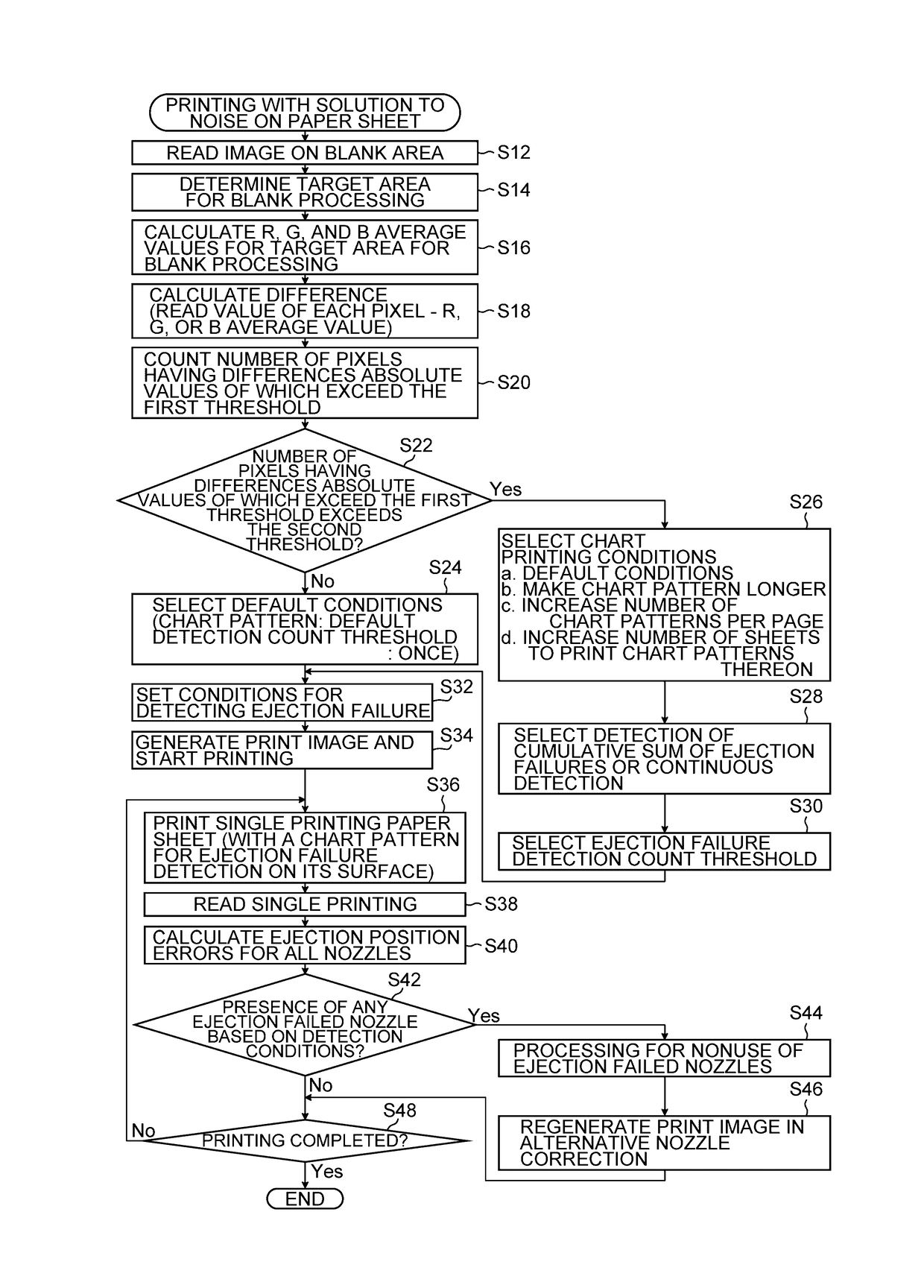

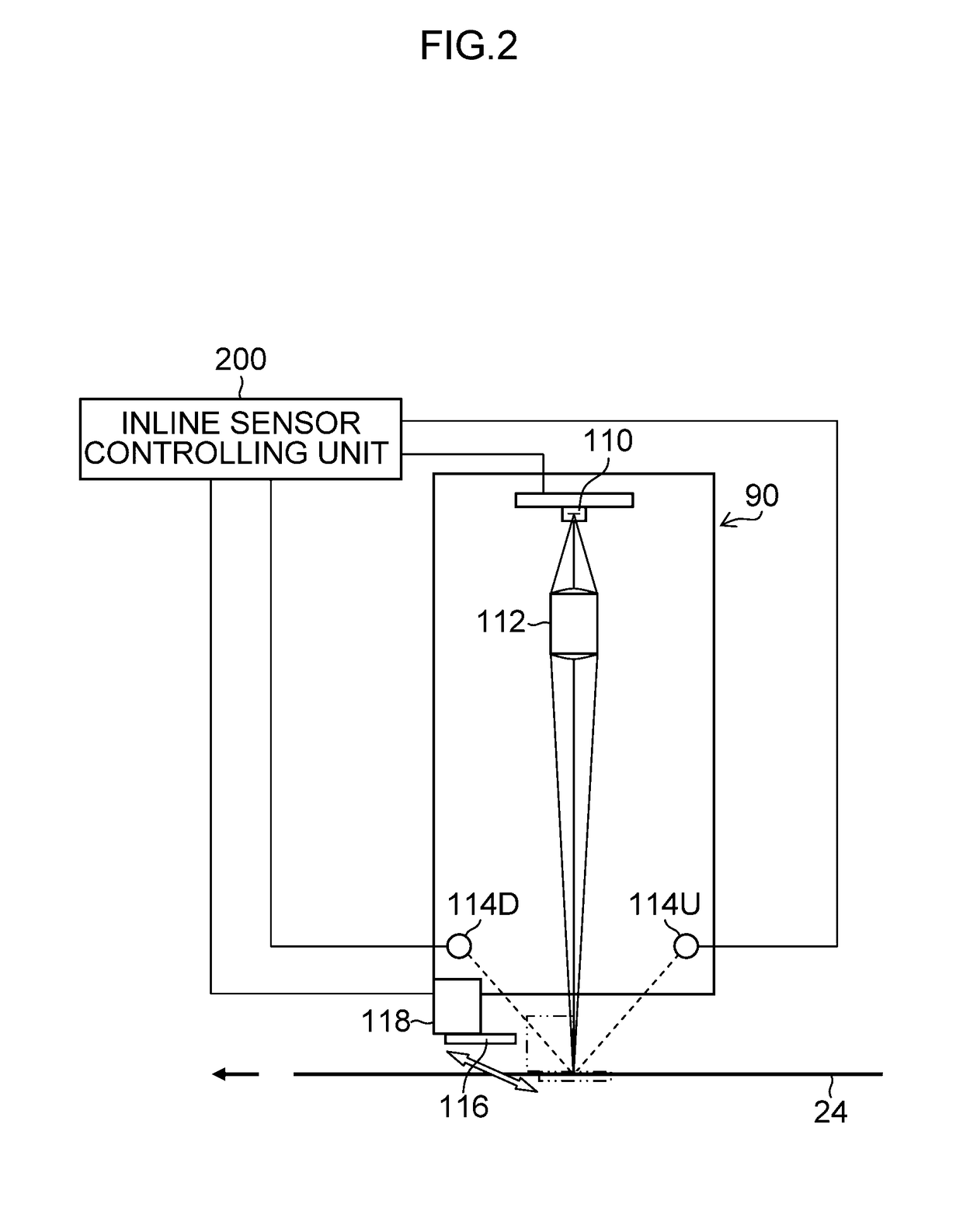

Inkjet printer and method of controlling inkjet printing

ActiveUS20170087910A1High qualityHigher-quality printingPower drive mechanismsOther printing apparatusPaper sheetEngineering

An inkjet printer includes: an optical reading device that optically reads at least one of an unprinted area on a printing paper sheet, a test chart printed area on a first printing in which a test chart is printed, and an image printed area on a second printing in which an image other than a test chart is printed, and acquires image data on the read area; an abnormal noise detecting device that analyzes the acquired image data and detects abnormal noise on a surface of a printing paper sheet; and a control device that changes at least a setting related to detection of an ejection state of an inkjet head or a printing state, or a setting related to printing correction, based on a state of the detected abnormal noise.

Owner:FUJIFILM CORP

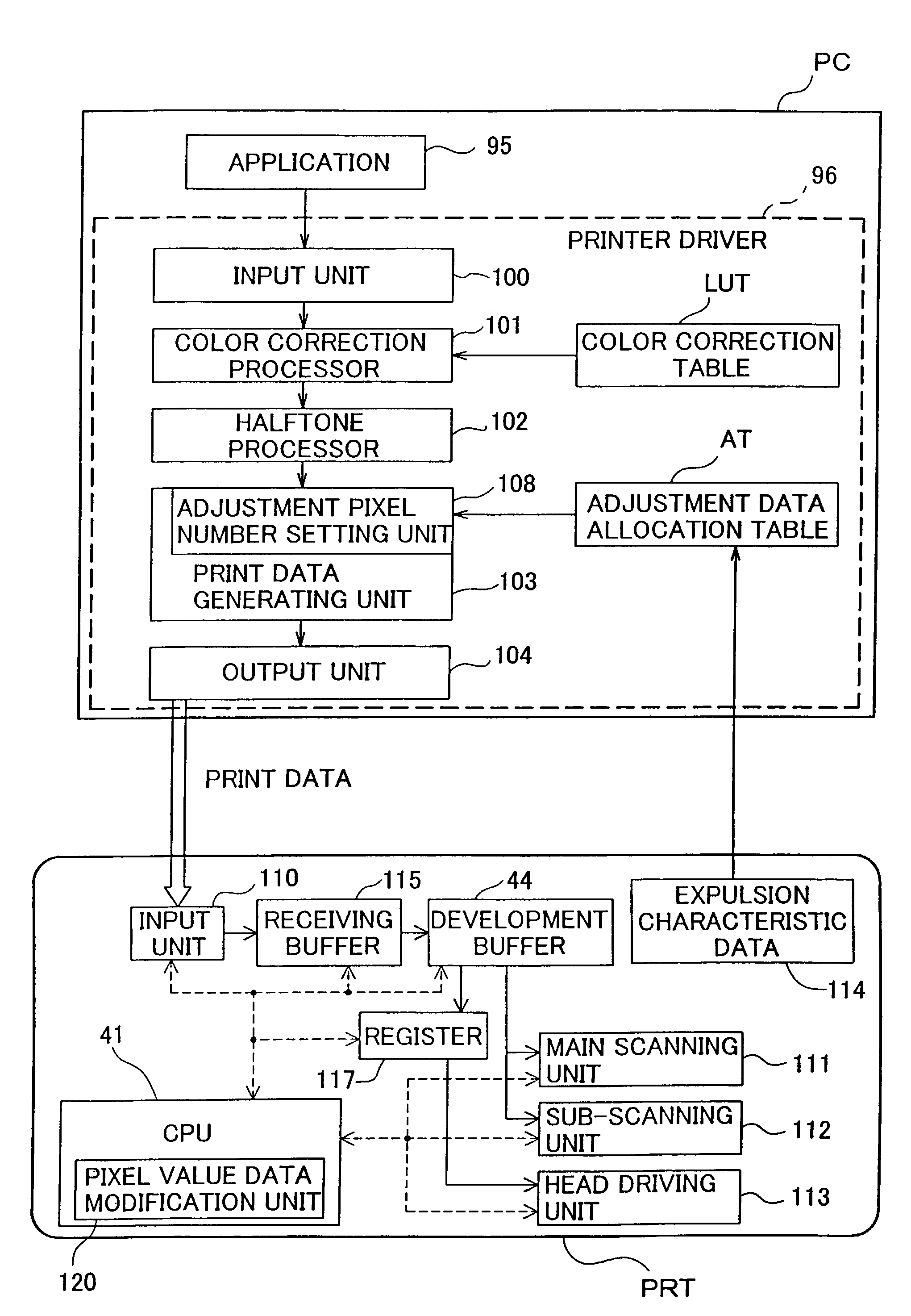

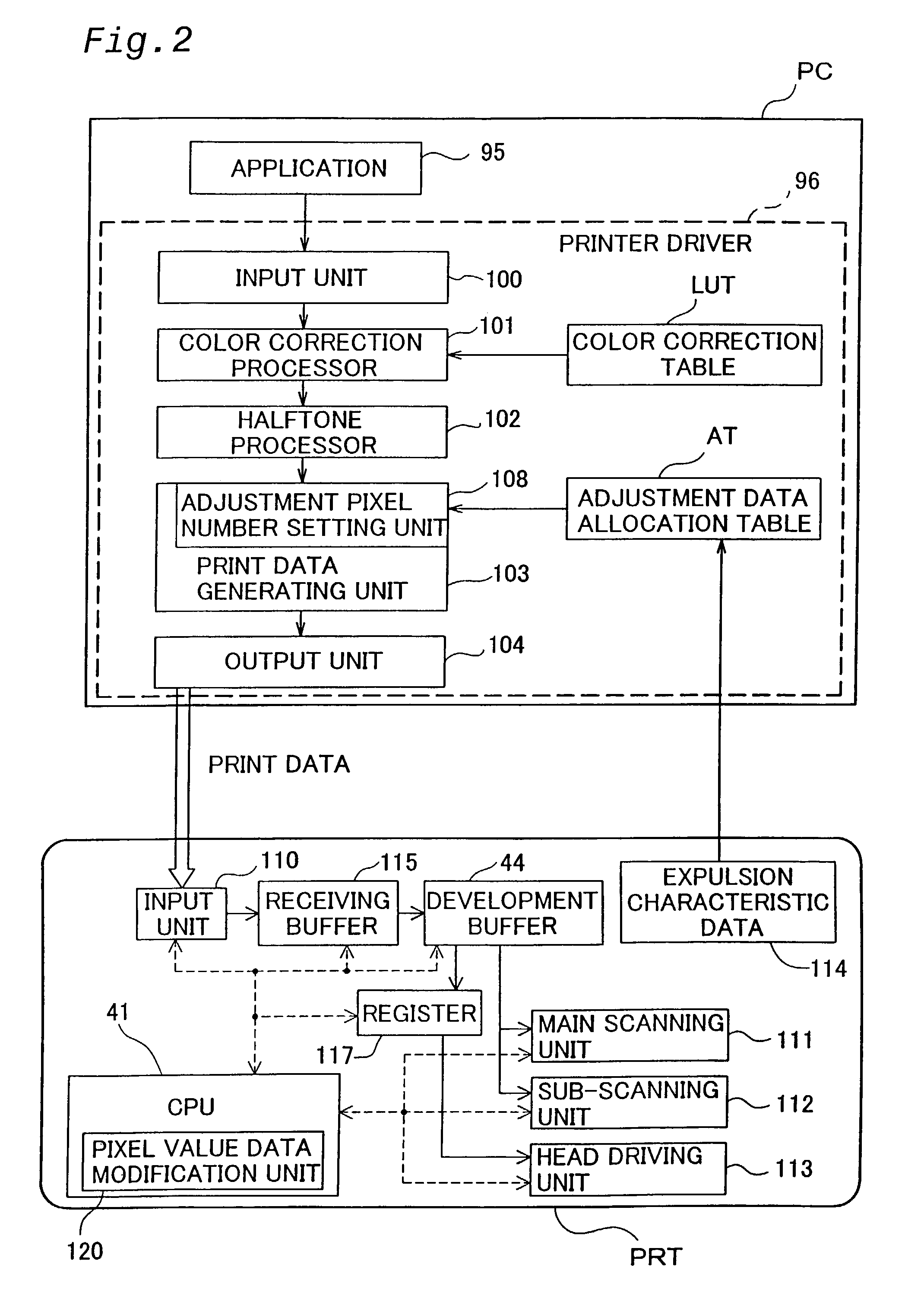

Dot formation position misalignment adjustment performed using pixel-level information indicating dot non-formation

InactiveUS6984011B2Shorten the timeHigh quality printingSpacing mechanismsOther printing apparatusComputer graphics (images)Nozzle

While performing main scanning in which a head having a plurality of nozzles that eject ink is moved in prescribed forward and reverse main scanning directions relative to a print medium, print images are printed on the print medium by forming dots in each pixel aligned in the main scanning direction in accordance with print data. The dot formation position misalignment amount for each nozzle is corrected using image pixel value data indicating the existence of image pixels comprising images and adjustment pixel value data indicating the existence of adjustment pixels in which dots are not formed.

Owner:SEIKO EPSON CORP

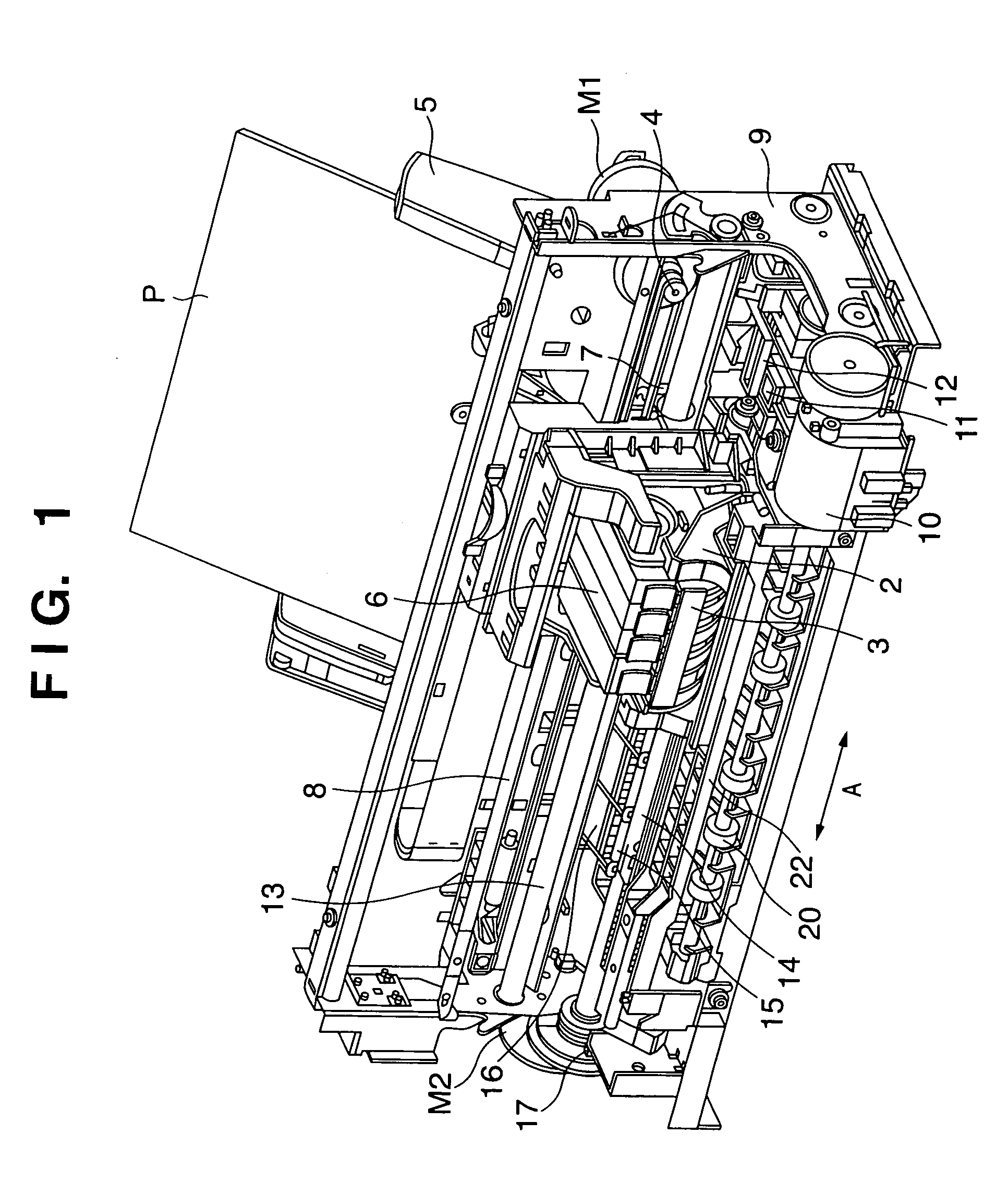

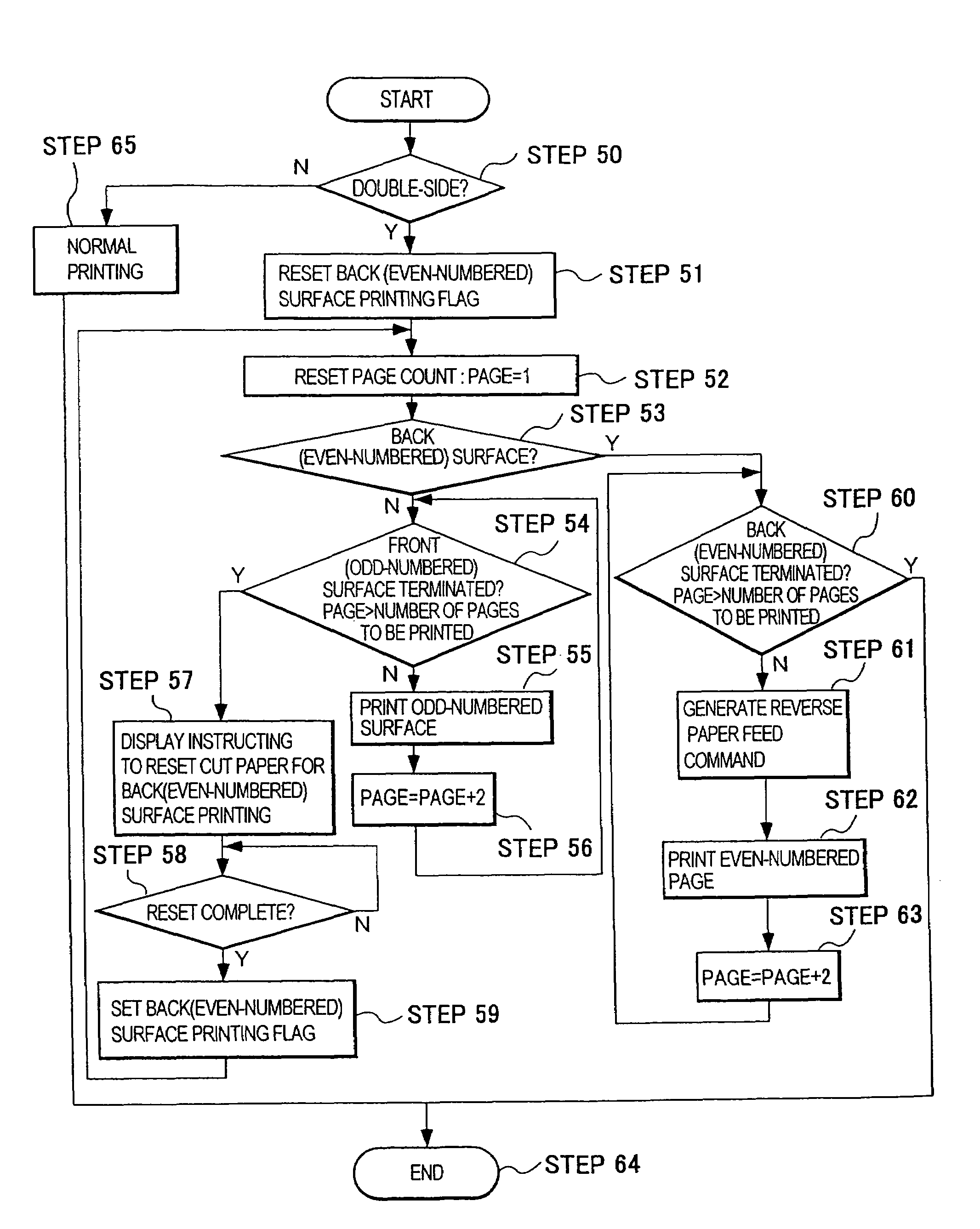

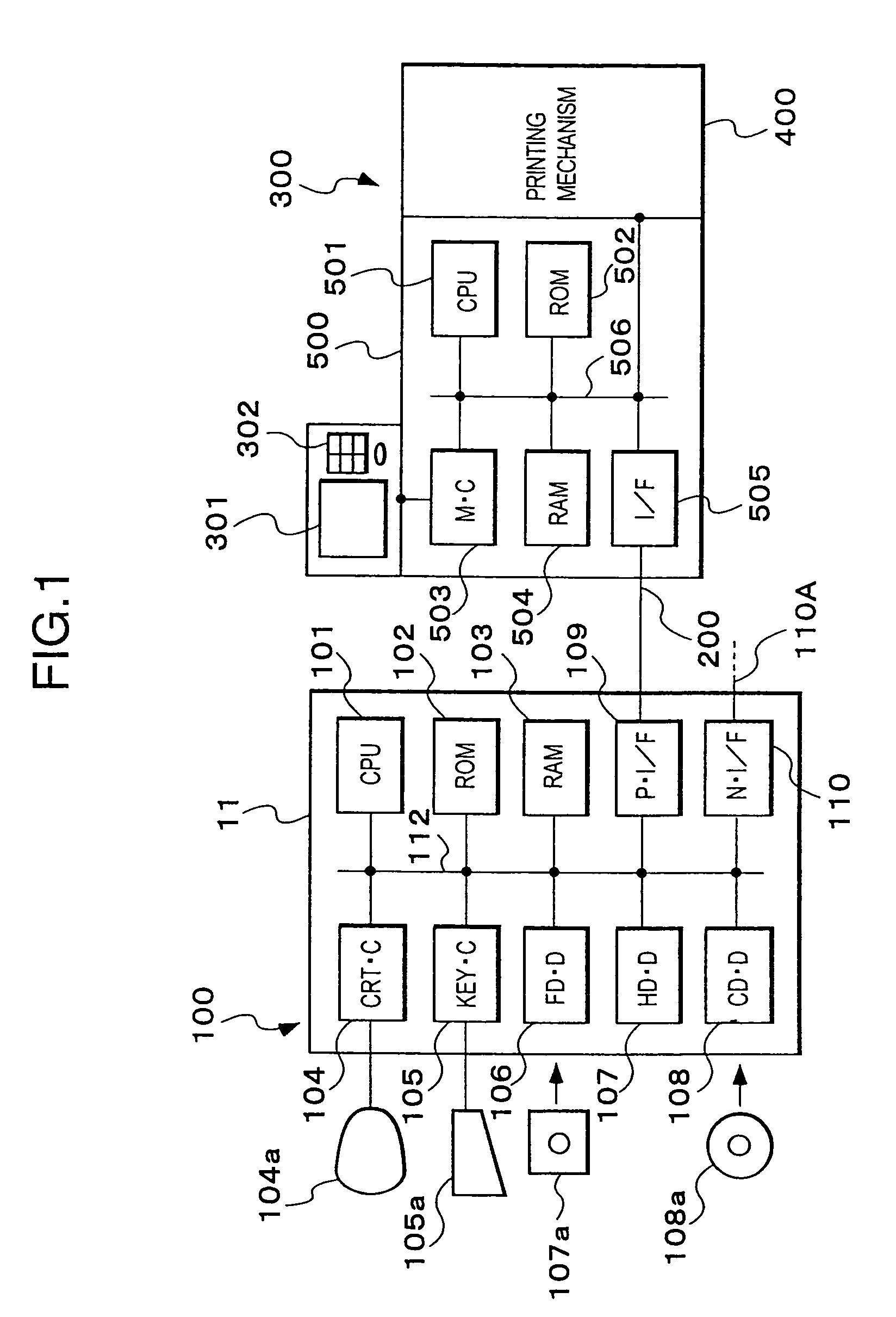

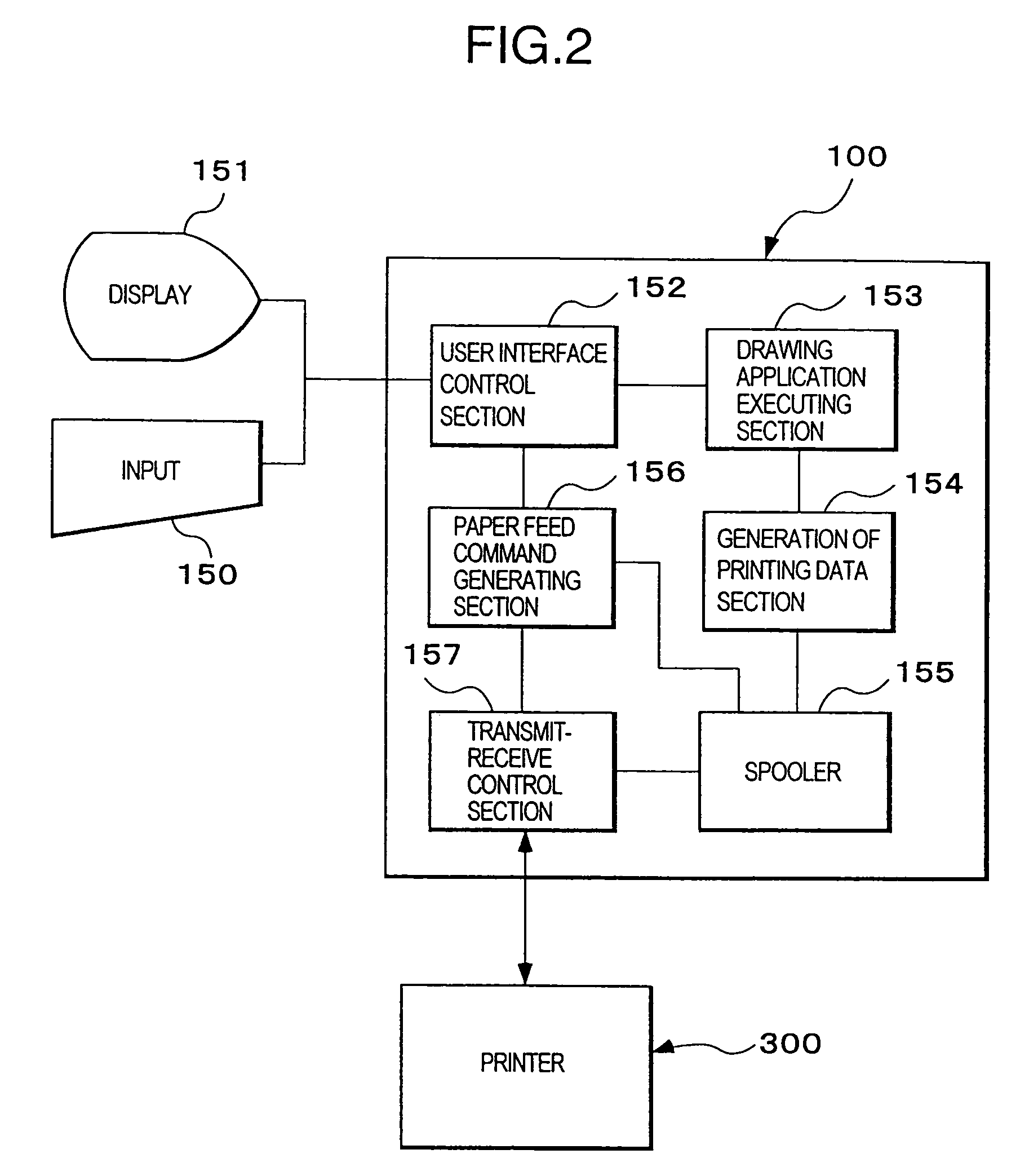

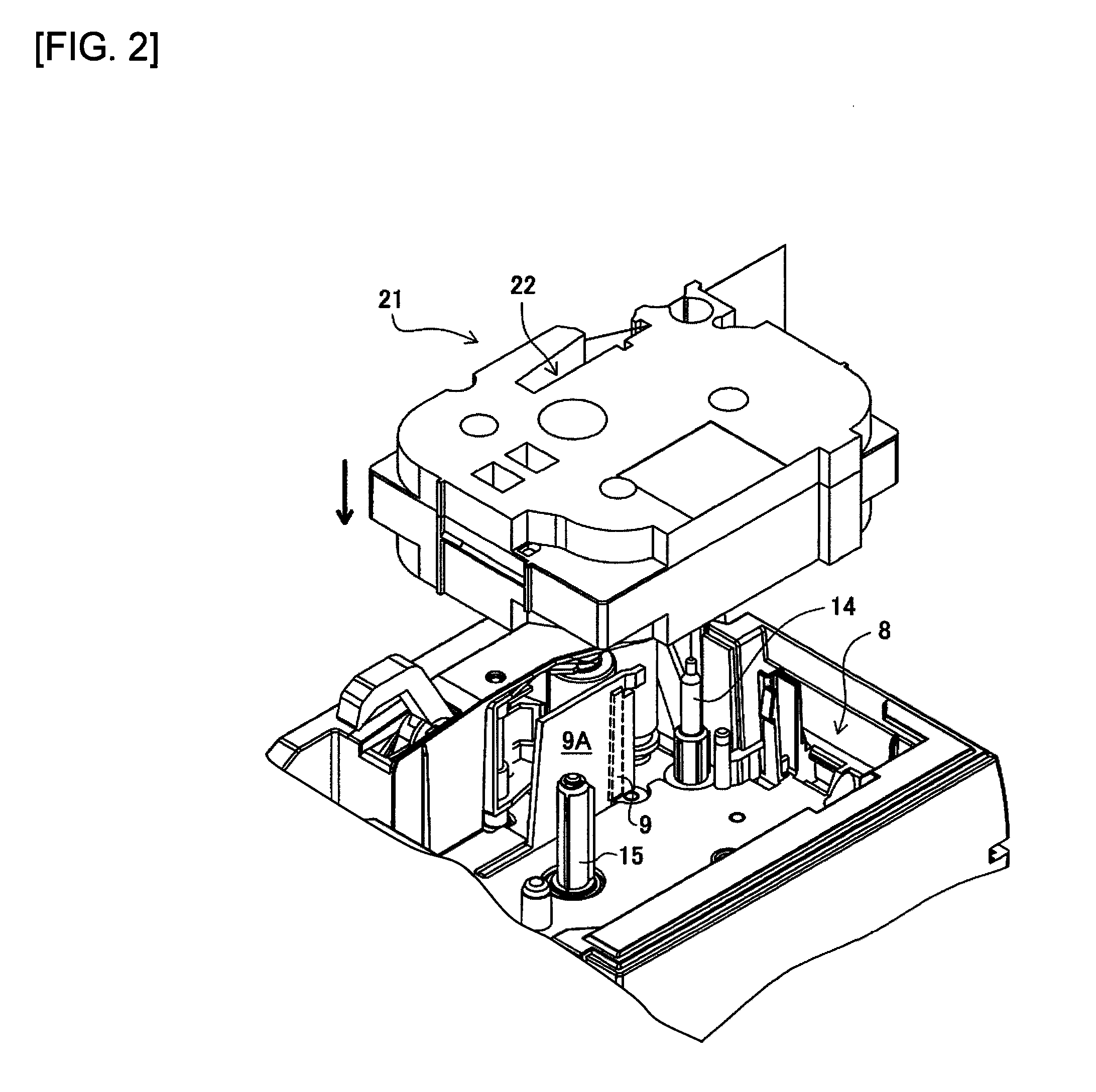

Ink jet printer, printer control unit, printer system including the same, and storage medium with the operation program of the printer control unit stored for controlling double-side printing

InactiveUS7576875B2Reduce the hassle of operationQuality improvementDigitally marking record carriersRegistering devicesEngineeringControl unit

An ink jet printer with a double-side printing function enables to print page images at a proper position on both surfaces of a cut paper, is provided. When feeding the cut paper A having an image printed on the front surface, the feeding roller 407 is rotated in the direction C1 to feed the cut paper A and simultaneously the registering rollers 410a, 410b are rotated in the direction D1 to push back the cut paper. In addition, the double-side printing is easily realized in both of the cases where the ink jet printer with the double-side printing function is connected to the host, and where the ink jet printer without double-side printing function is connected to the host by having the host make an inquiry of the printer whether or not double-side printing is available (step 6). Based on the results of the inquiry, printing commands are generated and sent to the printer.

Owner:SEIKO EPSON CORP

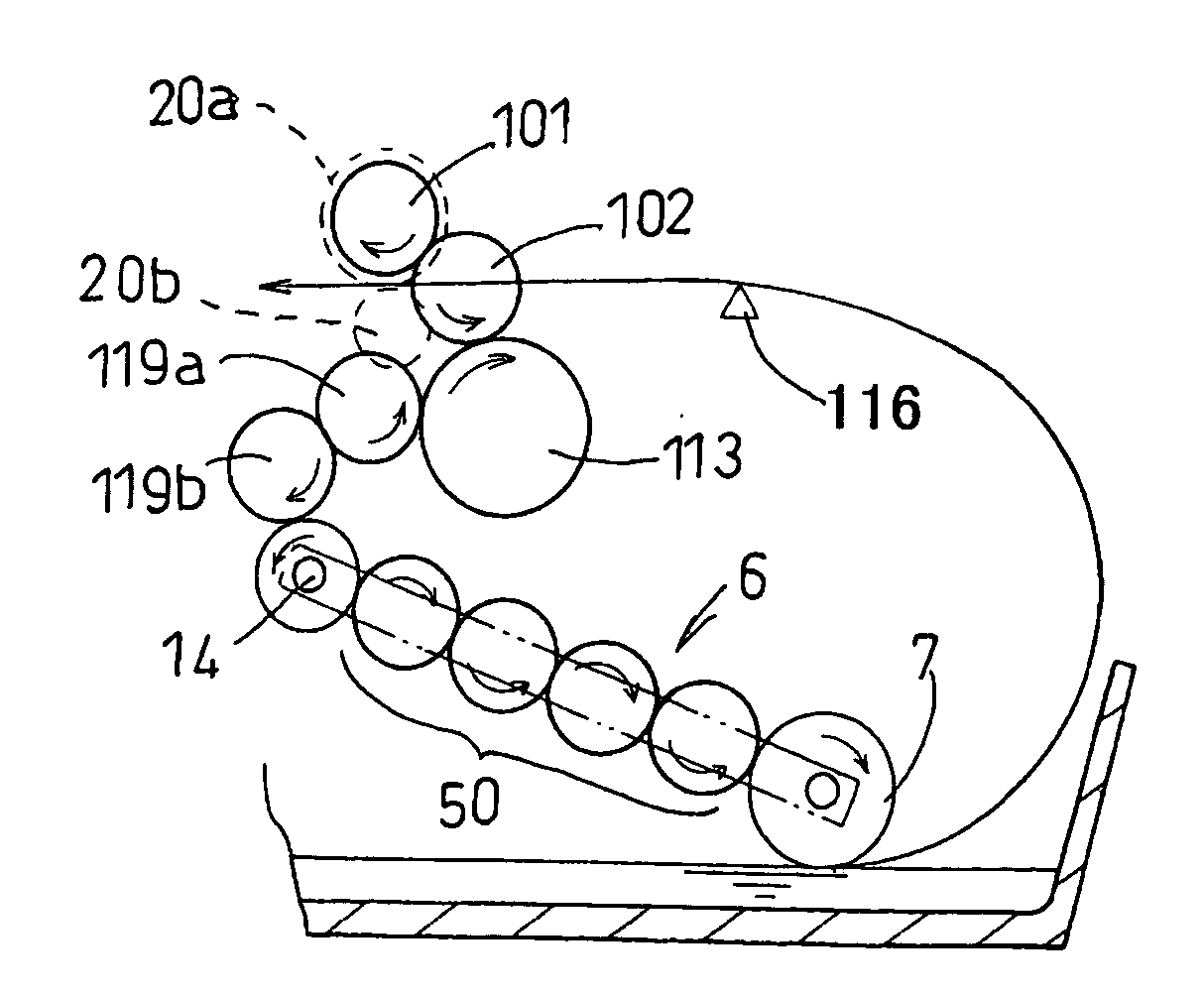

Both-side recording apparatus

InactiveUS20050024463A1High quality printingPrevent floatingTypewritersOther printing apparatusEngineeringMechanical engineering

A clear-cut high-quality printing result is obtained in a both-side recording apparatus. The both-side recording apparatus has first unevenness imparting means for imparting an uneven shape to a recording medium in a plane orthogonal to the conveying direction of the recording medium. The first unevenness imparting means comprises sheet expelling rollers, having a plurality of roller portions in a direction orthogonal to the conveying direction of the recording medium in the plane of the recording medium, conveying spurs for nipping the recording medium between them and each roller portion, and a plurality of push-in spurs disposed between the conveying spurs.

Owner:CANON KK

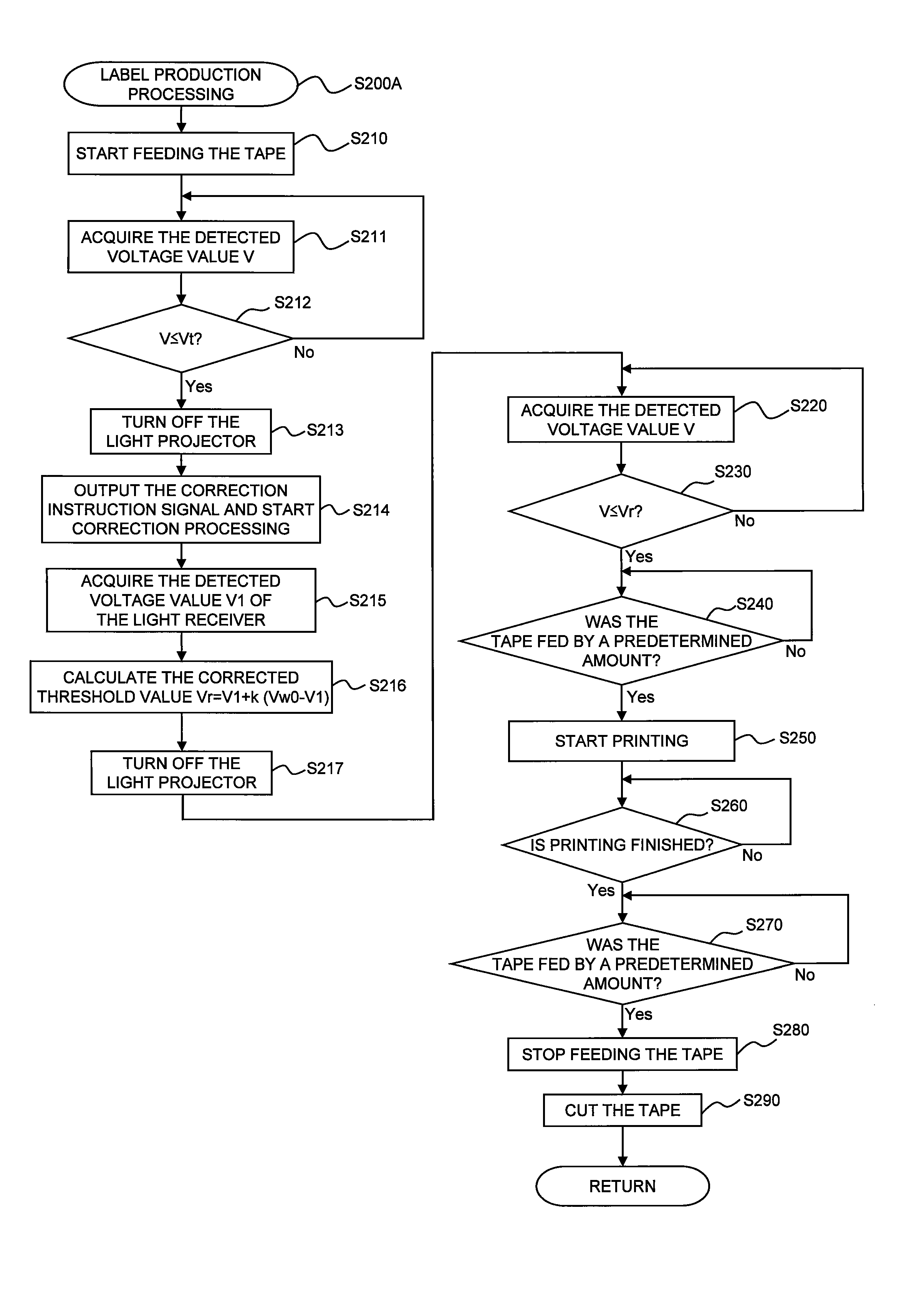

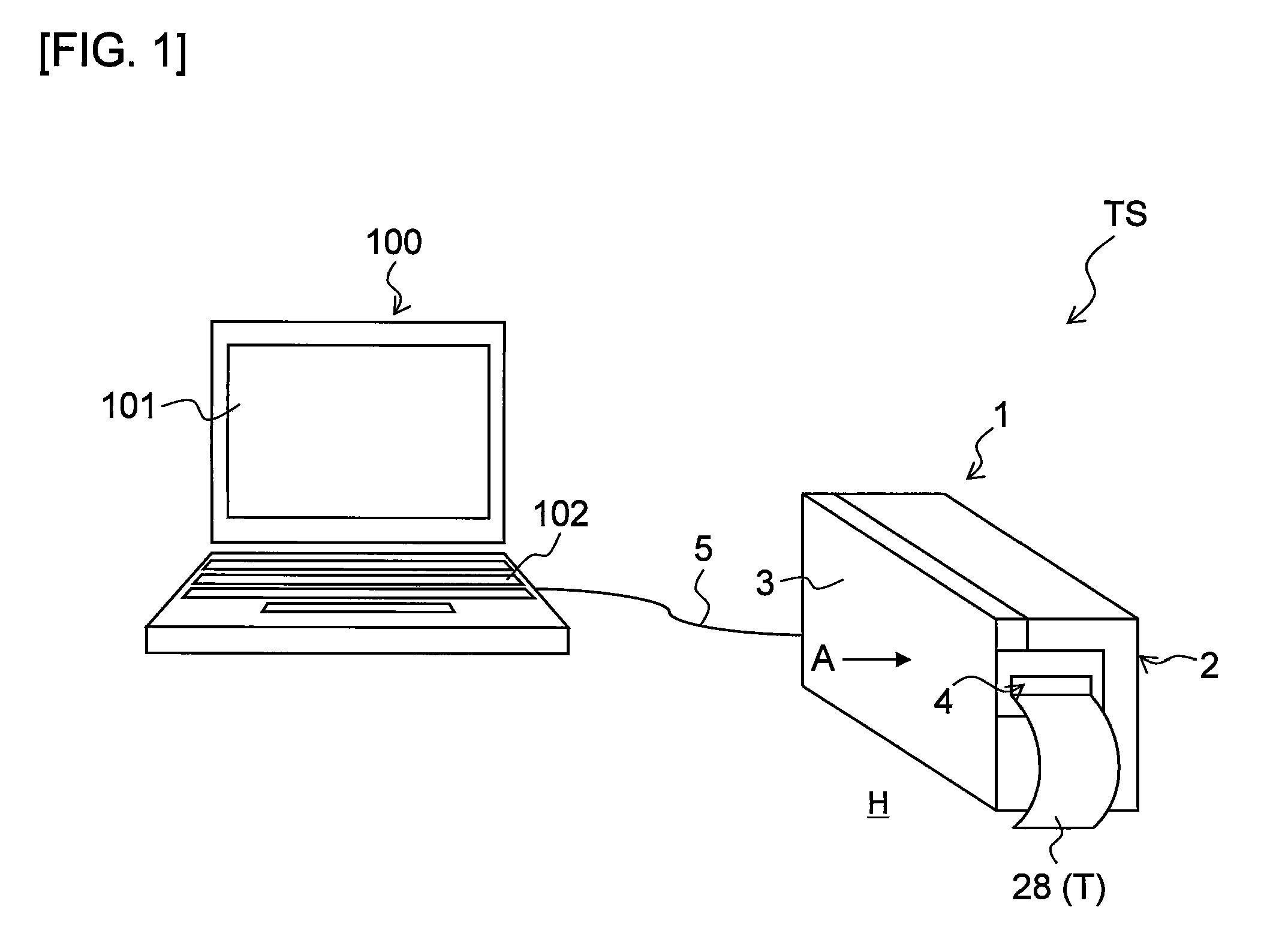

Label producing apparatus and label producing method

ActiveUS20110217108A1Decreases fluctuation widthSlow changeTypewritersOther printing apparatusEngineeringVoltage

This disclosure discloses a label producing apparatus comprising: a housing; a feeding device that feeds a label tape; a printing device that prints desired print; an optical sensor comprising a light projecting device and a light receiving device capable of outputting a detected voltage value; a light-on control portion that controls said optical sensor so that said light projecting device is turned on; an initial value storage device that stores a predetermined initial threshold value; a threshold value correction portion that calculates a corrected threshold value using said initial threshold value; a mark detecting portion that detects a positioning mark by an arrival of said detected voltage value at said corrected threshold value after calculation of said corrected threshold value; a feeding control portion that controls said feeding device; and a print control portion that controls a print operation of said printing device.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com