Patents

Literature

843 results about "Flexography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexography (often abbreviated to flexo) is a form of printing process which utilizes a flexible relief plate. It is essentially a modern version of letterpress which can be used for printing on almost any type of substrate, including plastic, metallic films, cellophane, and paper. It is widely used for printing on the non-porous substrates required for various types of food packaging (it is also well suited for printing large areas of solid colour).

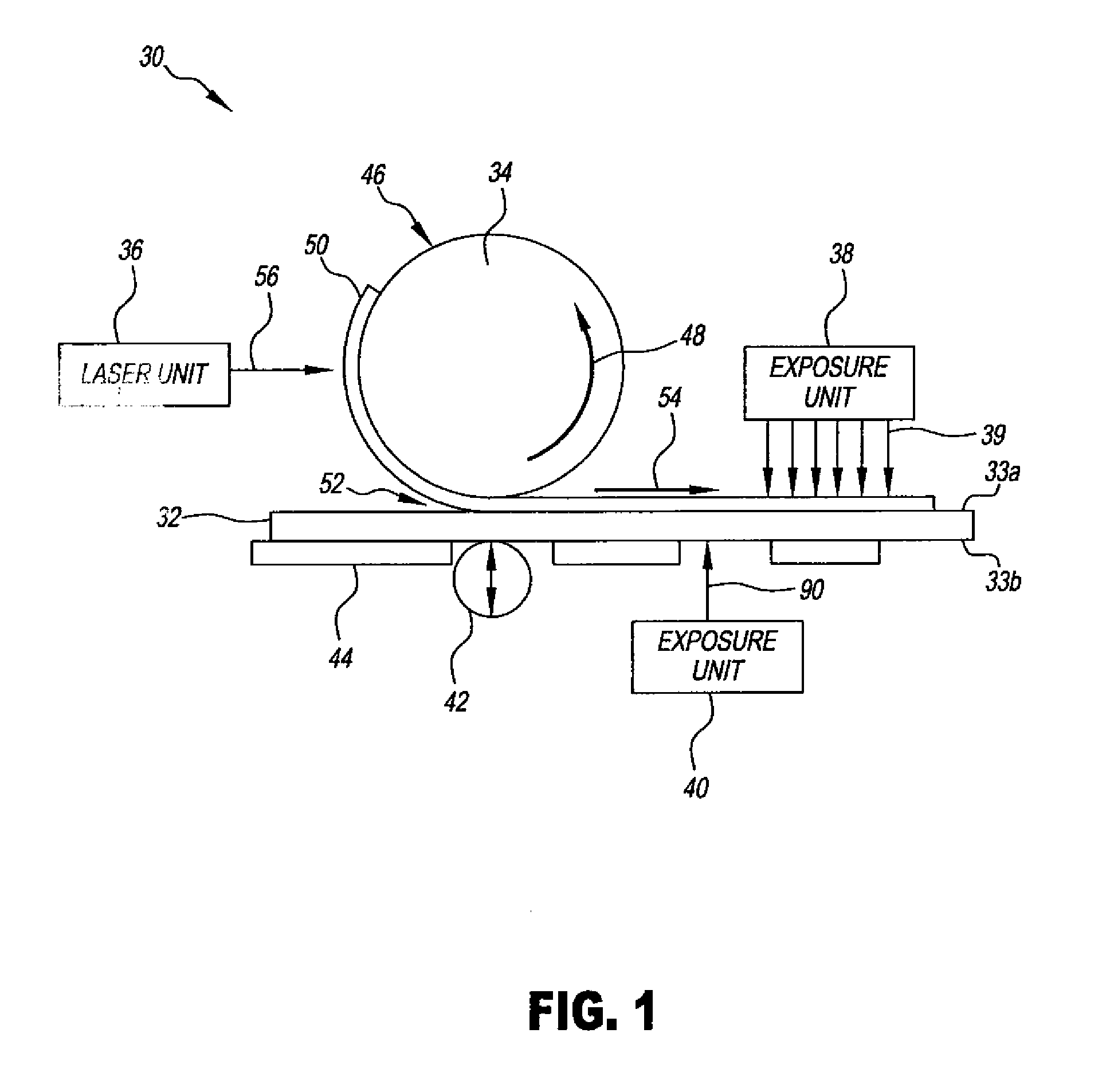

Method of improving print performance in flexographic printing plates

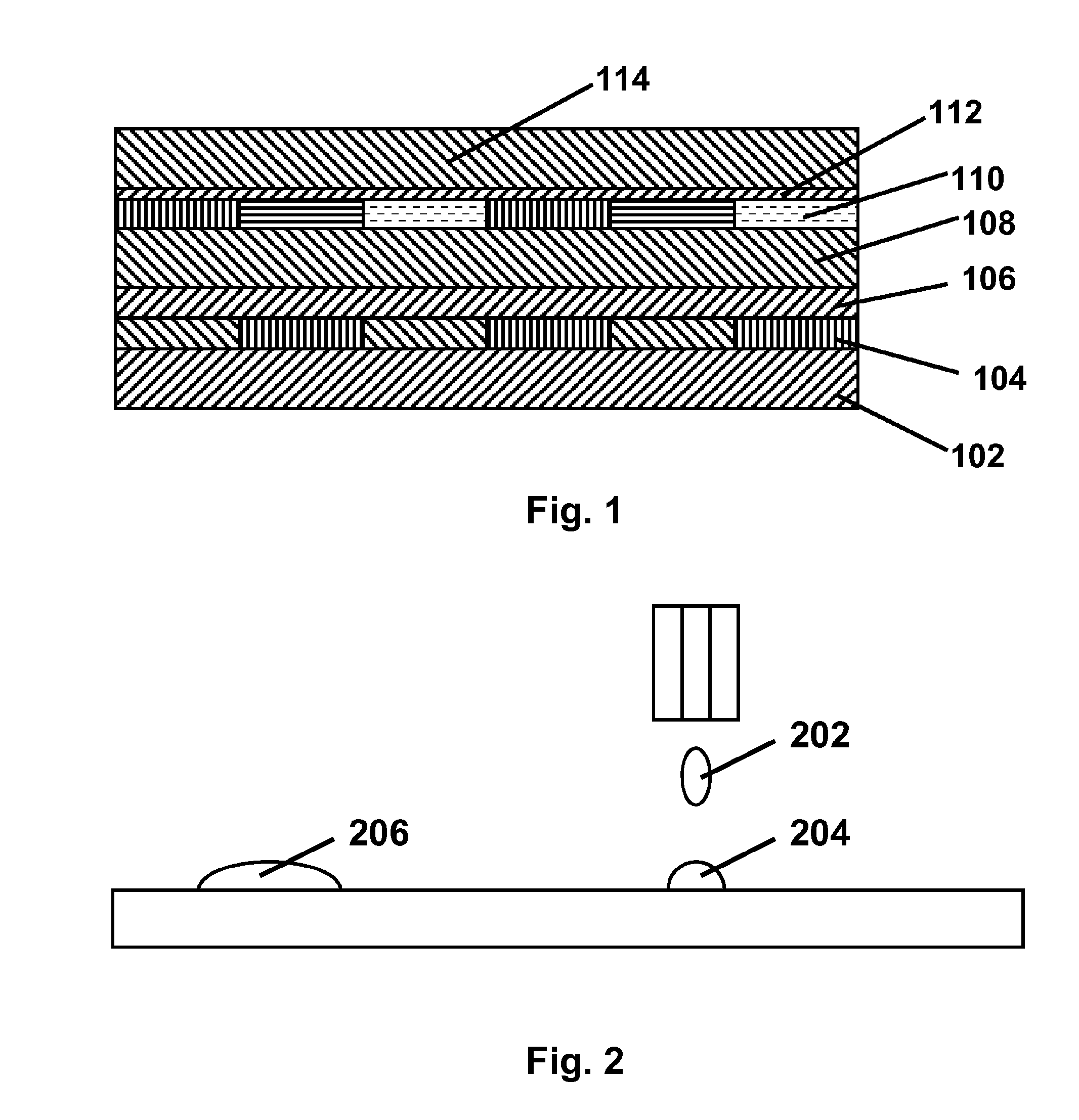

ActiveUS20110079158A1Promote resultsReduces print flutingLayered productsPlate printingCross-linkEngineering

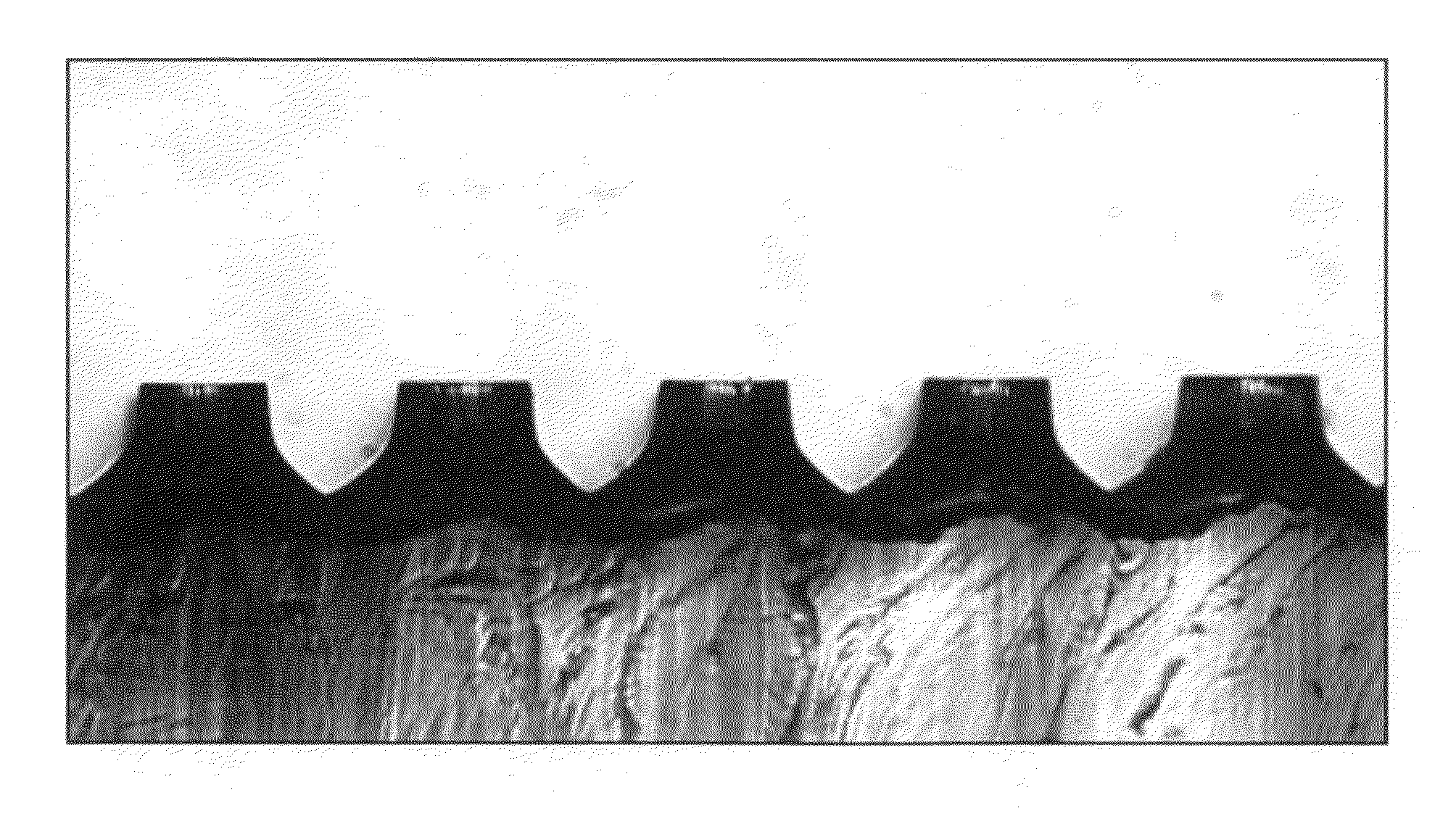

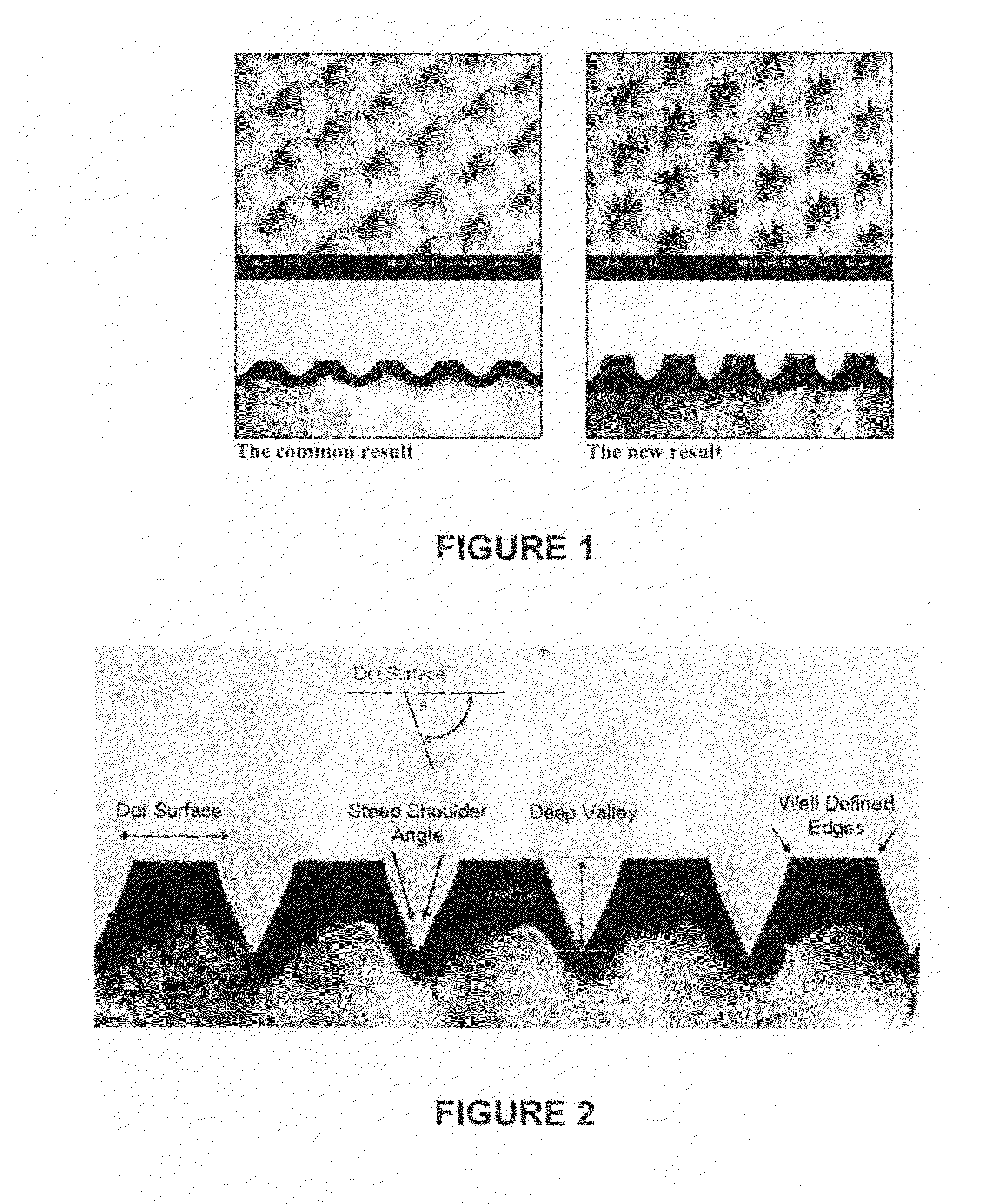

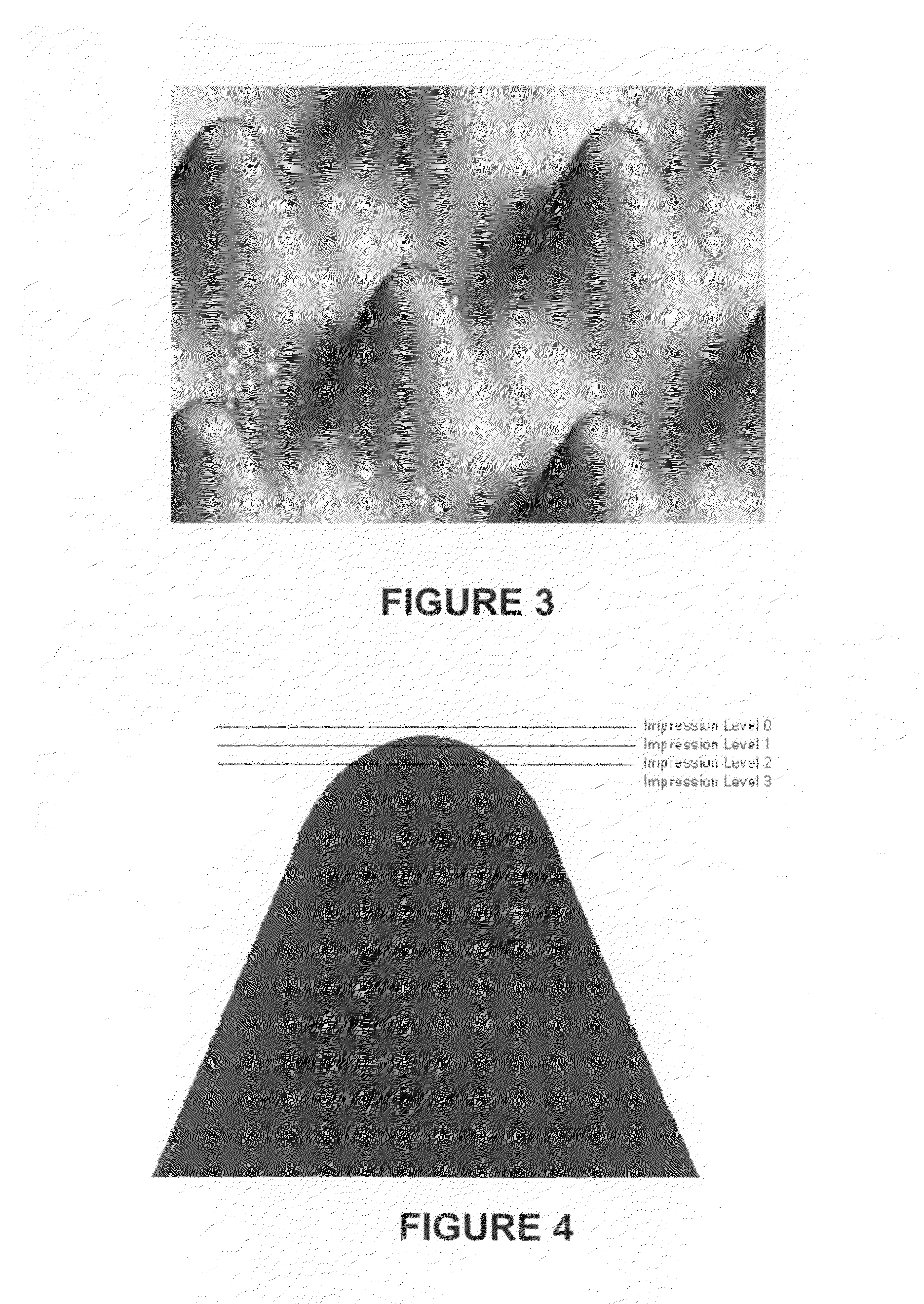

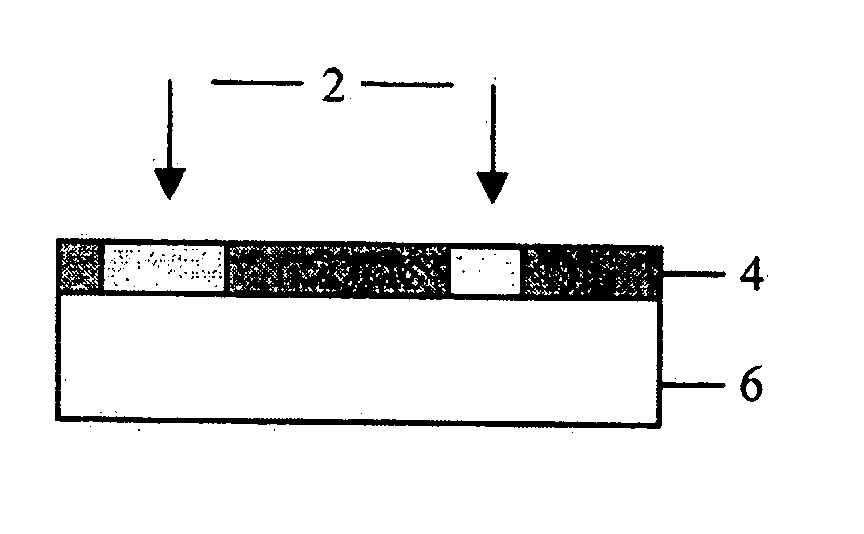

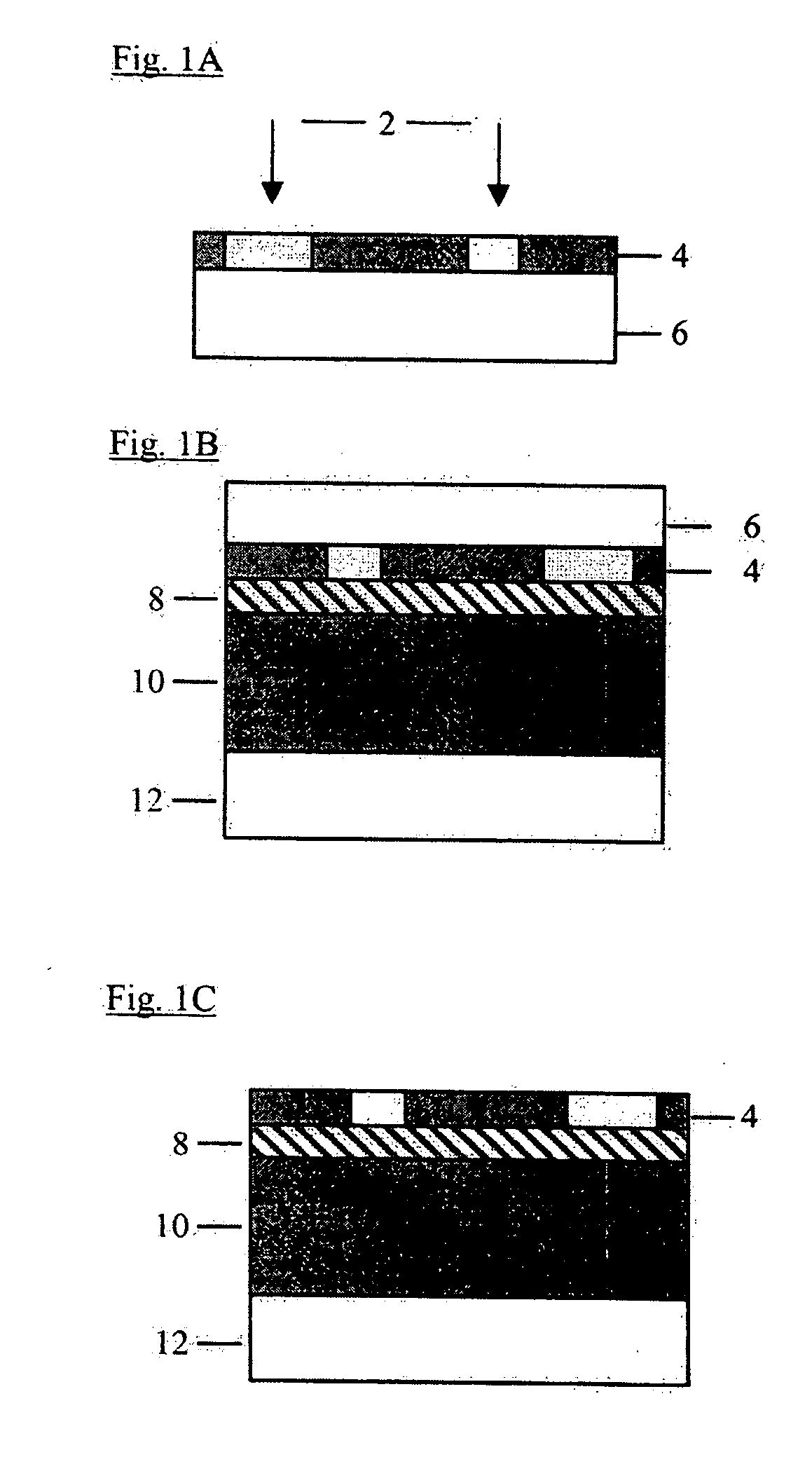

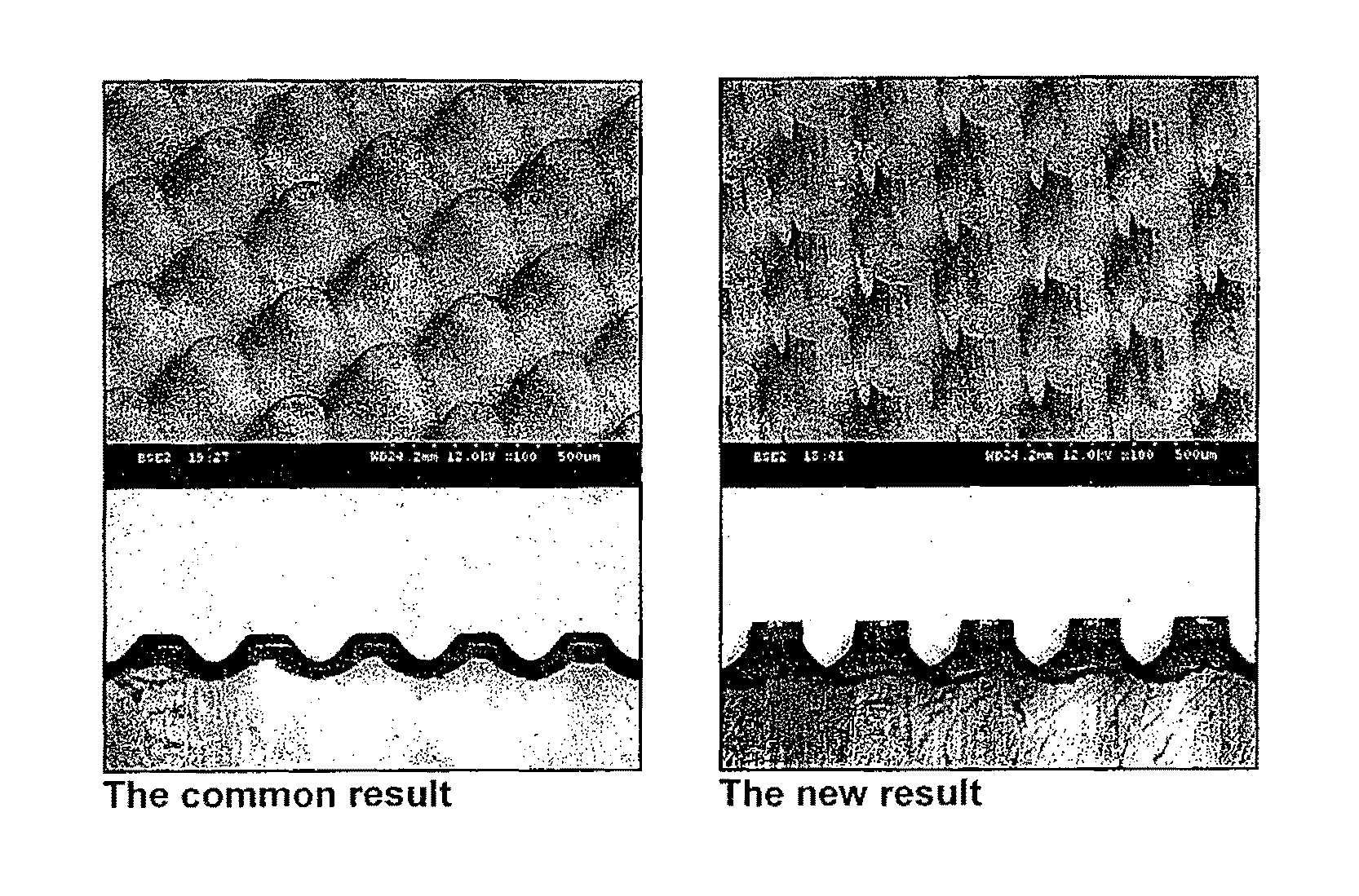

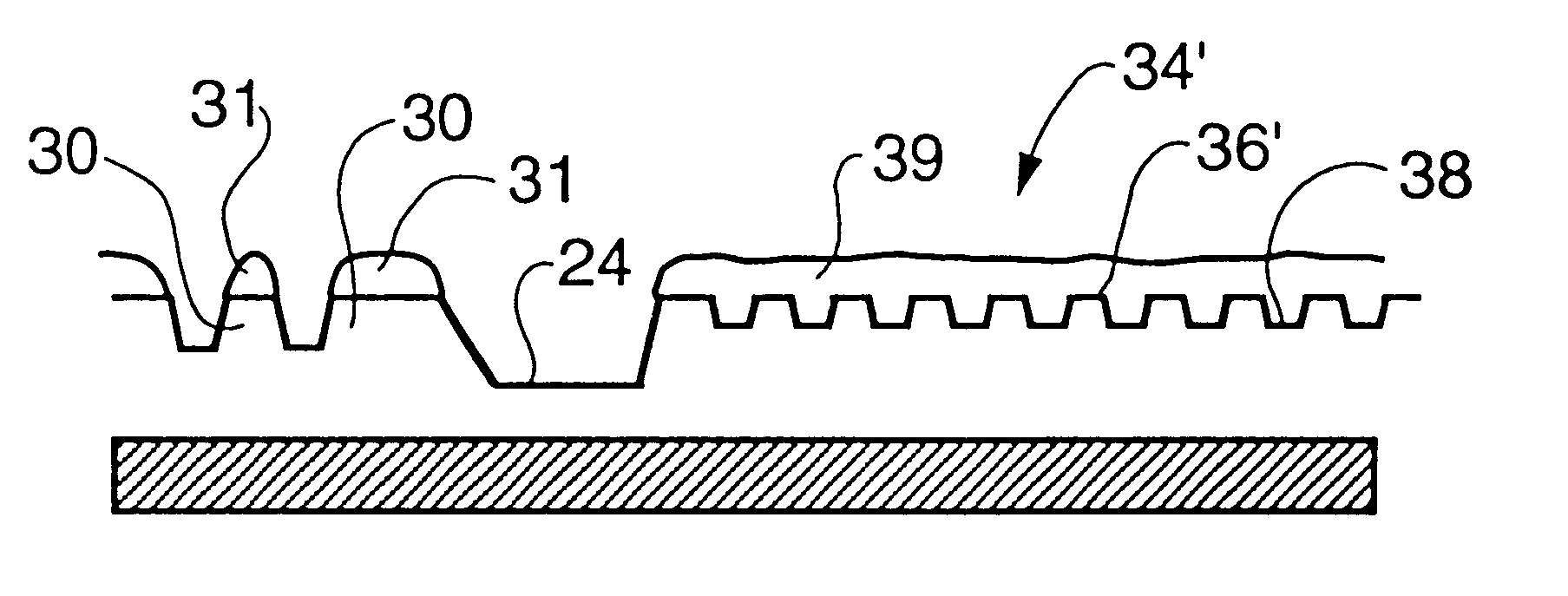

A method of making a relief image printing element from a photosensitive printing blank is provided. A photosensitive printing blank with a laser ablatable layer disposed on at least one photocurable layer is ablated with a laser to create an in situ mask. The printing blank is then exposed to at least one source of actinic radiation through the in situ mask to selectively cross link and cure portions of the photocurable layer. Diffusion of air into the at least one photocurable layer is limited during the exposing step and preferably at least one of the type, power and incident angle of illumination of the at least one source of actinic radiation is altered during the exposure step. The resulting relief image comprises a plurality of dots and a dot shape of the plurality of dots that provide optimal print performance on various substrates, including corrugated board.

Owner:MACDERMID PRINTING SOLUTIONS

Processes for the production of electro-optic displays, and color filters for use therein

ActiveUS20090004442A1Decorative surface effectsPhotomechanical apparatusRadiative transferEngineering

Processes are provided for depositing multiple color filter materials on a substrate to form color filters. In a first process, the surface characteristic of a substrate is modified by radiation so that a flowable form of a first color filter material will be deposited on a first area, and converted to a non-flowable form. A second color filter material can then be deposited on a second area of the substrate. In a second process, first and second color filter materials are deposited on separate donor sheets and transferred by radiation to separate areas of the substrate. A third process uses flexographic printing to transfer the first and second color filter materials to the substrate.

Owner:E INK CORPORATION

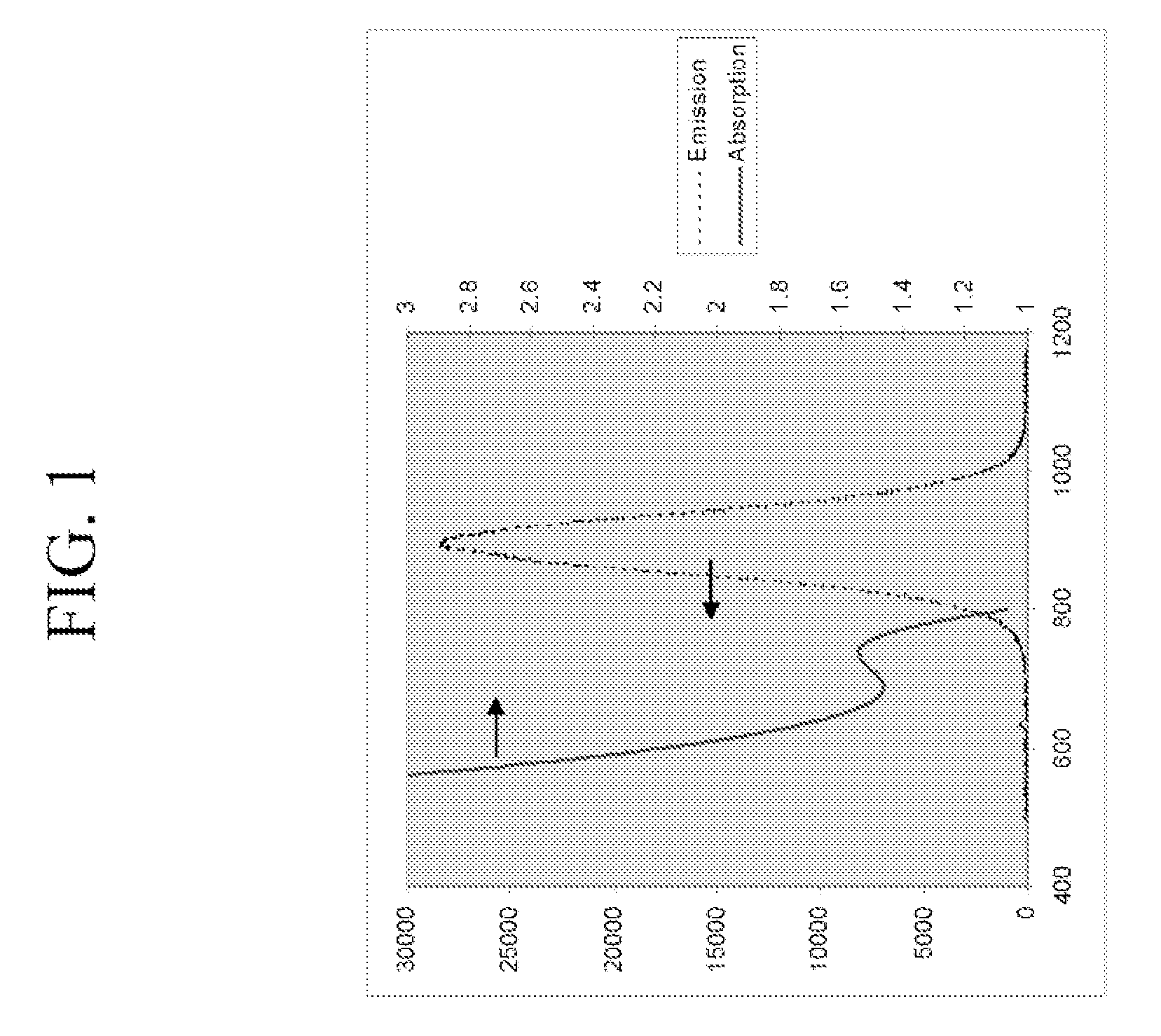

Quantum dot fluorescent inks

The present invention relates to inks and more particularly, to fluorescent ink formulations including quantum dots for various printing processes such as inkjet, flexographic, screen printing, thermal transfer, and pens. The inks include one or more populations of fluorescent quantum dots dispersed in polymeric material, having fluorescence emissions between about 450 nm and about 2500 nm; and a liquid or solid vehicle. The vehicle is present in a ratio to achieve an ink viscosity, surface tension effective, drying time and other printing parameters used for printing processes.

Owner:EVIDENT TECH

Processes for the production of electro-optic displays, and color filters for use therein

ActiveUS9199441B2Lamination ancillary operationsLayered product treatmentRadiative transferEngineering

Processes are provided for depositing multiple color filter materials on a substrate to form color filters. In a first process, the surface characteristic of a substrate is modified by radiation so that a flowable form of a first color filter material will be deposited on a first area, and converted to a non-flowable form. A second color filter material can then be deposited on a second area of the substrate. In a second process, first and second color filter materials are deposited on separate donor sheets and transferred by radiation to separate areas of the substrate. A third process uses flexographic printing to transfer the first and second color filter materials to the substrate.

Owner:E INK CORPORATION

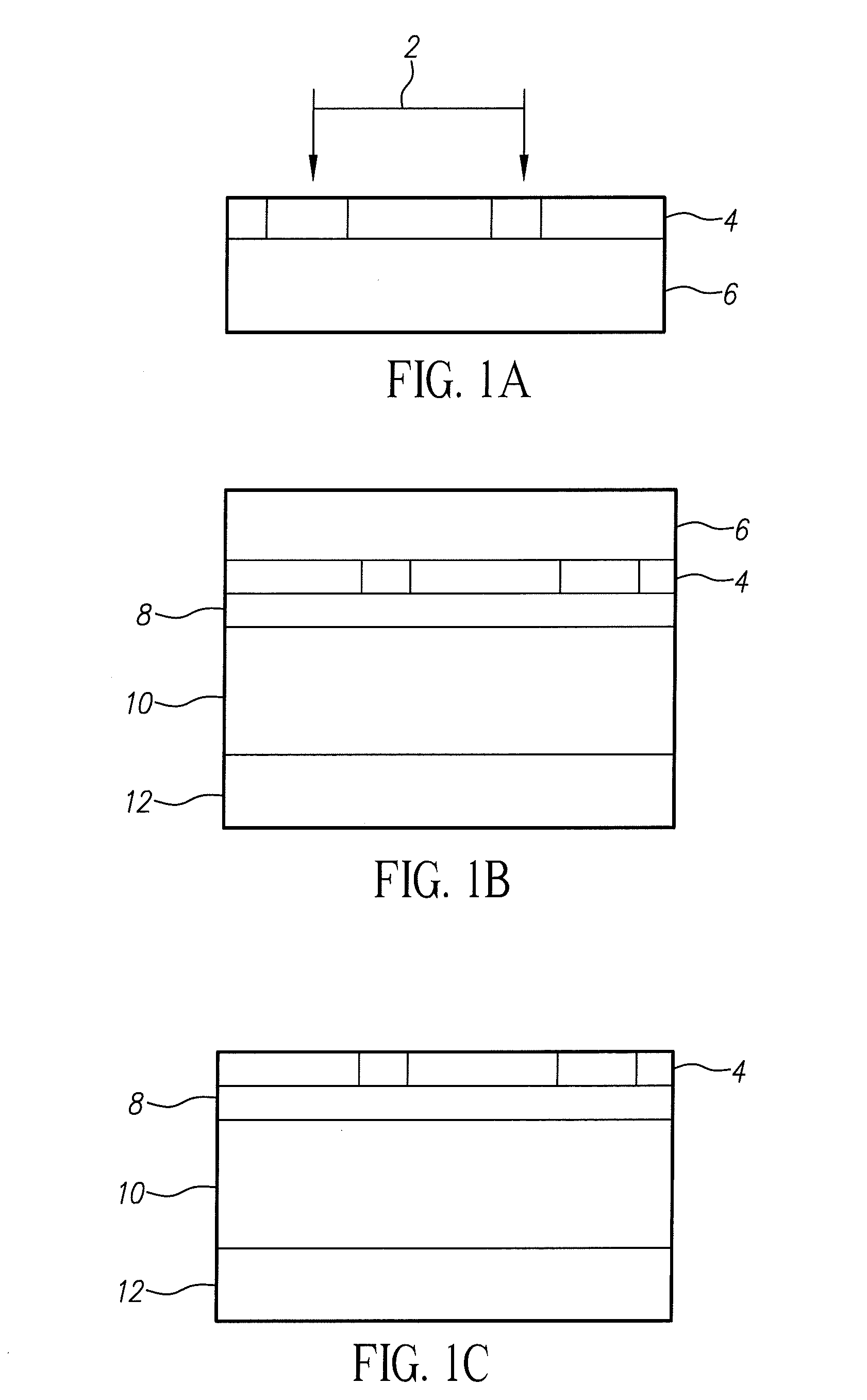

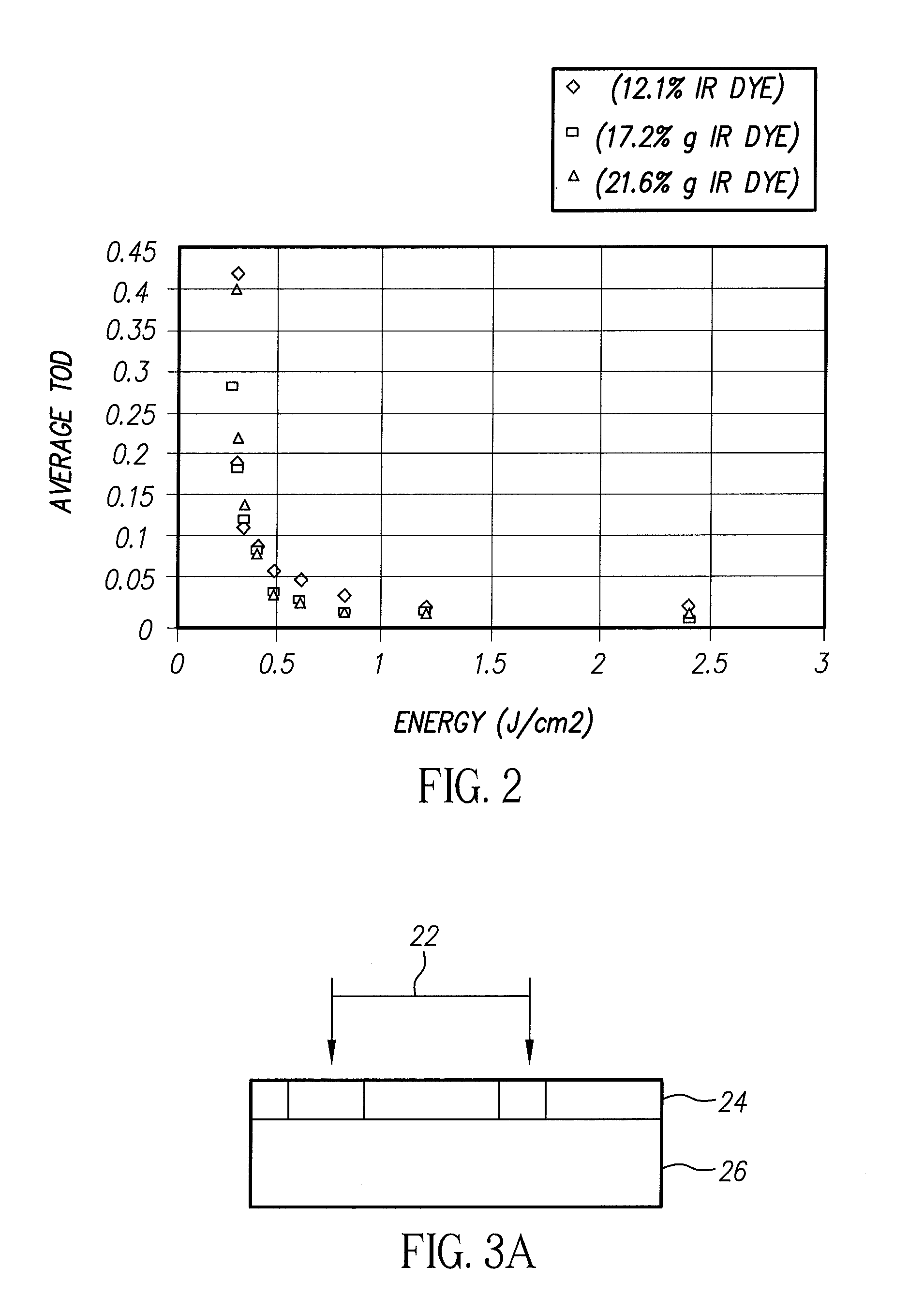

Method of producing a relief image for printing

ActiveUS20050227182A1Low costHigh imaging sensitivityRadiation applicationsSemiconductor/solid-state device manufacturingEngineeringRadiation

The present invention involves a method for making a relief image. A film that includes a carrier sheet and an imageable material is used to form a mask image that is opaque to a curing radiation. In one embodiment, the mask image is formed on the carrier sheet while in another embodiment, the mask image is formed on a receptor sheet. The mask image is then transferred to a photosensitive material, such as a flexographic printing plate precursor. The resulting assembly is exposed to the curing radiation resulting in exposed and unexposed areas of the photosensitive material. The carrier sheet or the receptor sheet may be removed from the mask image either before or after exposure to the curing radiation. Finally, the photosensitive material and mask image assembly is developed with a suitable developer to form a relief image.

Owner:KODAK POLYCHROME GRAPHICS +1

Method of improving print performance in flexographic printing plates

ActiveUS8158331B2Promote resultsReduces print flutingPhotosensitive materialsDuplicating/marking methodsCross-linkEngineering

Owner:MACDERMID PRINTING SOLUTIONS

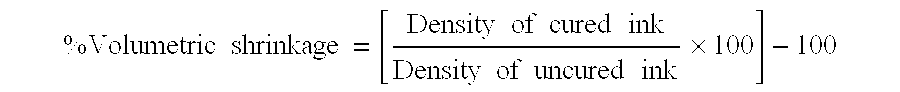

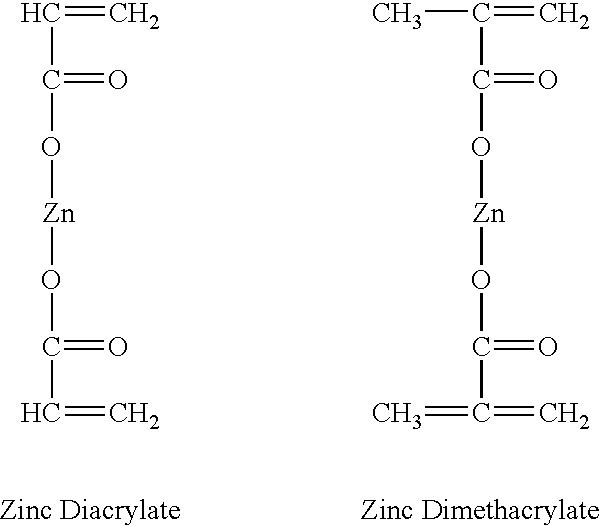

Method for manufacturing a flexographic printing master

InactiveUS20060055761A1Fast and simple and environmentalImprove image qualityPlate printingHand compositionOligomerPolymer science

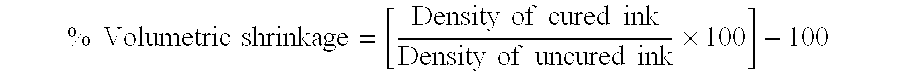

A method for manufacturing a flexographic printing master comprising the steps of: (a) providing an ink-receiver surface; (b) jetting a curable jettable fluid on the ink-receiver surface characterized in that the curable jettable fluid comprises at least one photo-initiator, at least one monofunctional monomer, at least 5 wt % of a polyfunctional monomer or oligomer and at least 5 wt % of a plasticizer both based on the total weight of the curable jettable liquid capable of realizing a layer after curing having an elongation at break of at least 5%, a storage modulus E′ smaller than 200 MPa at 30 Hz and a volumetric shrinkage smaller than 10%.

Owner:AGFA NV

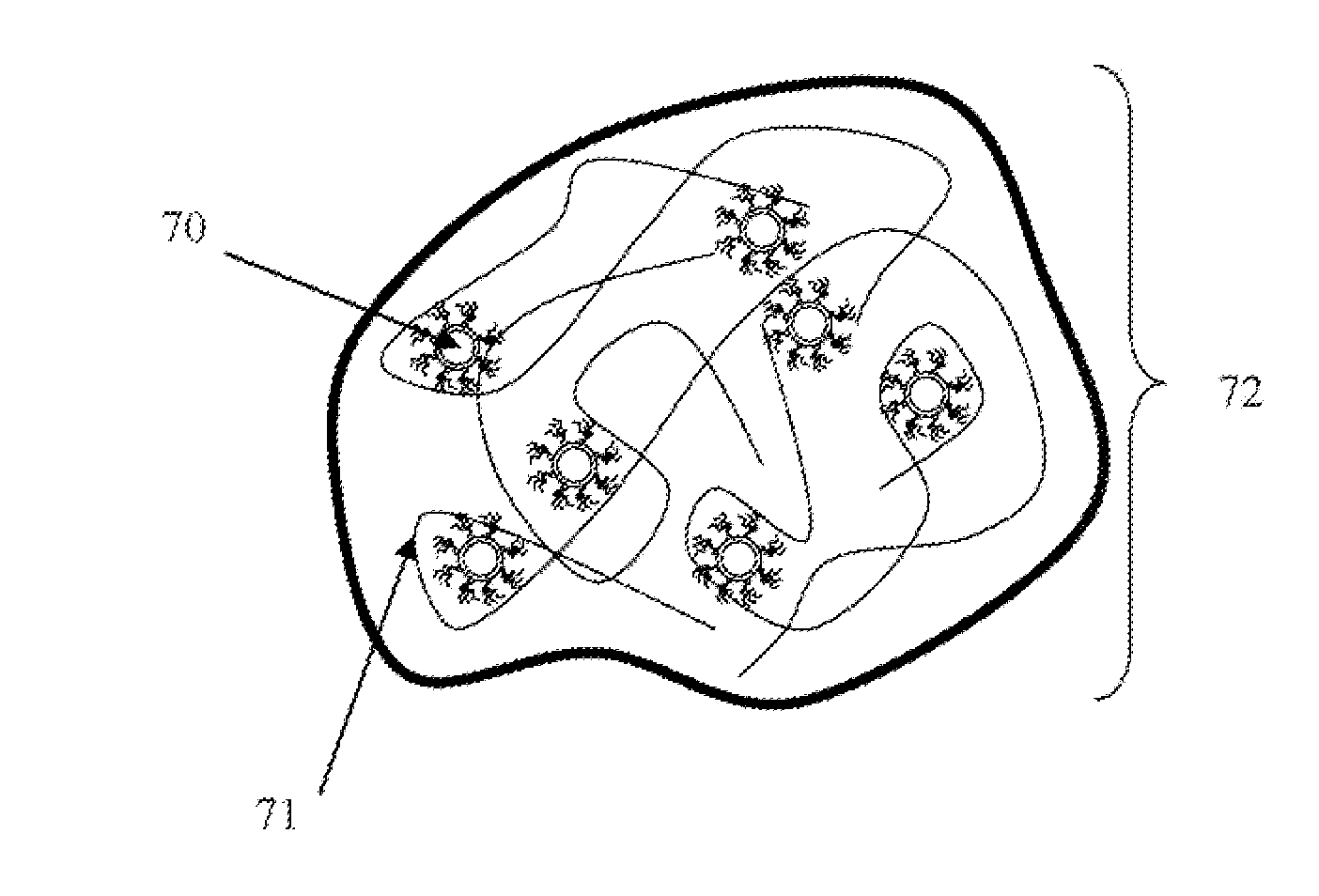

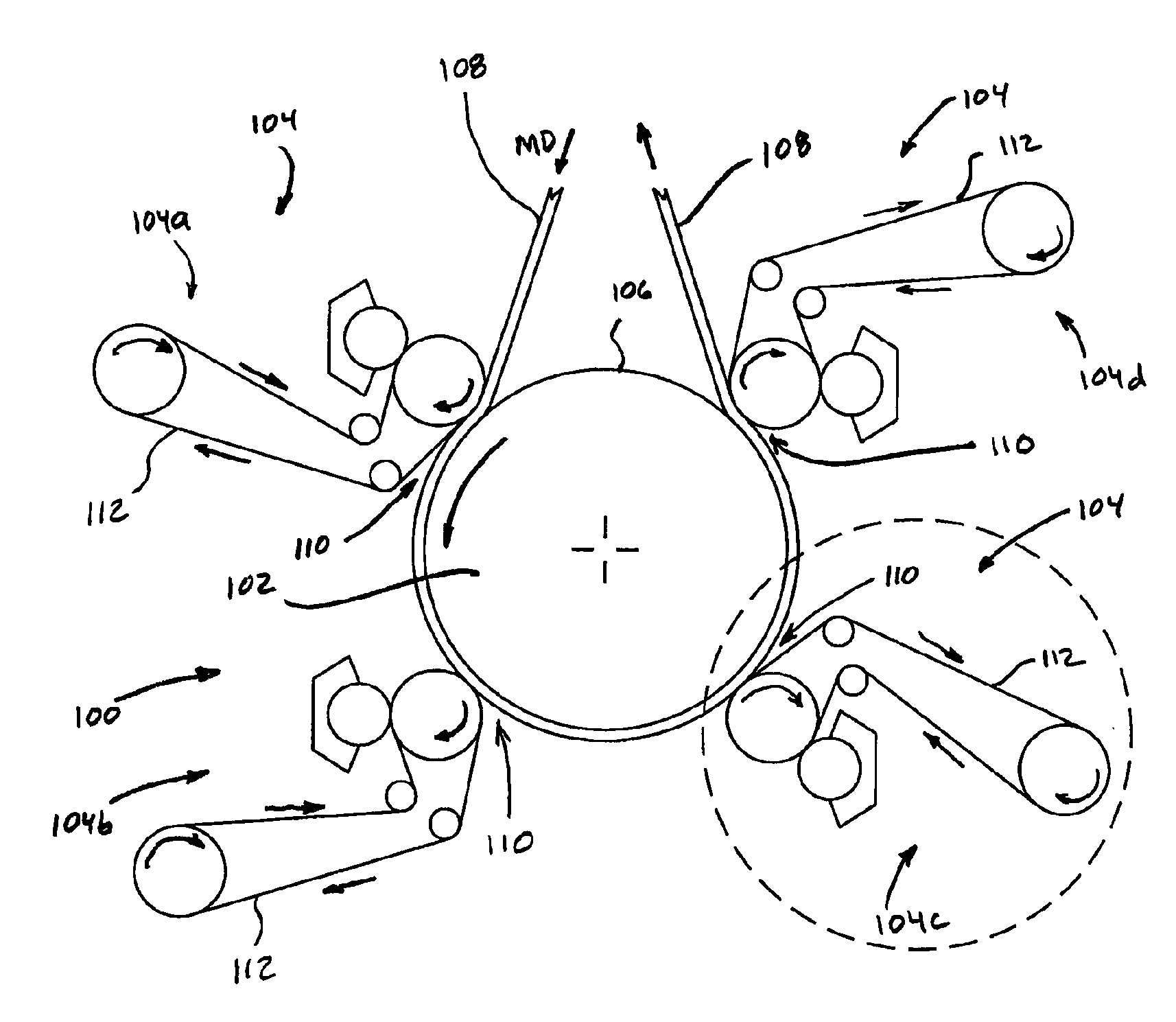

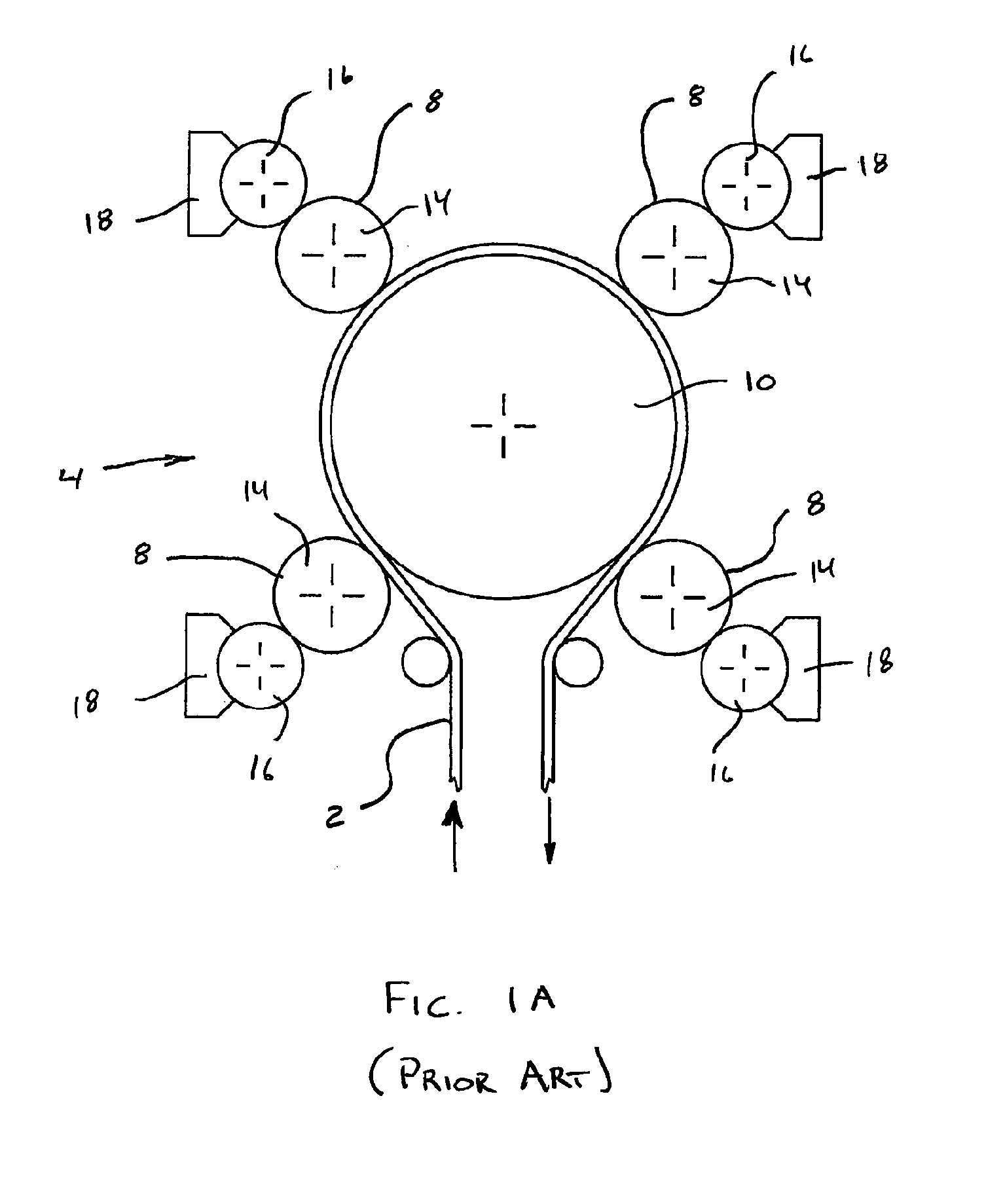

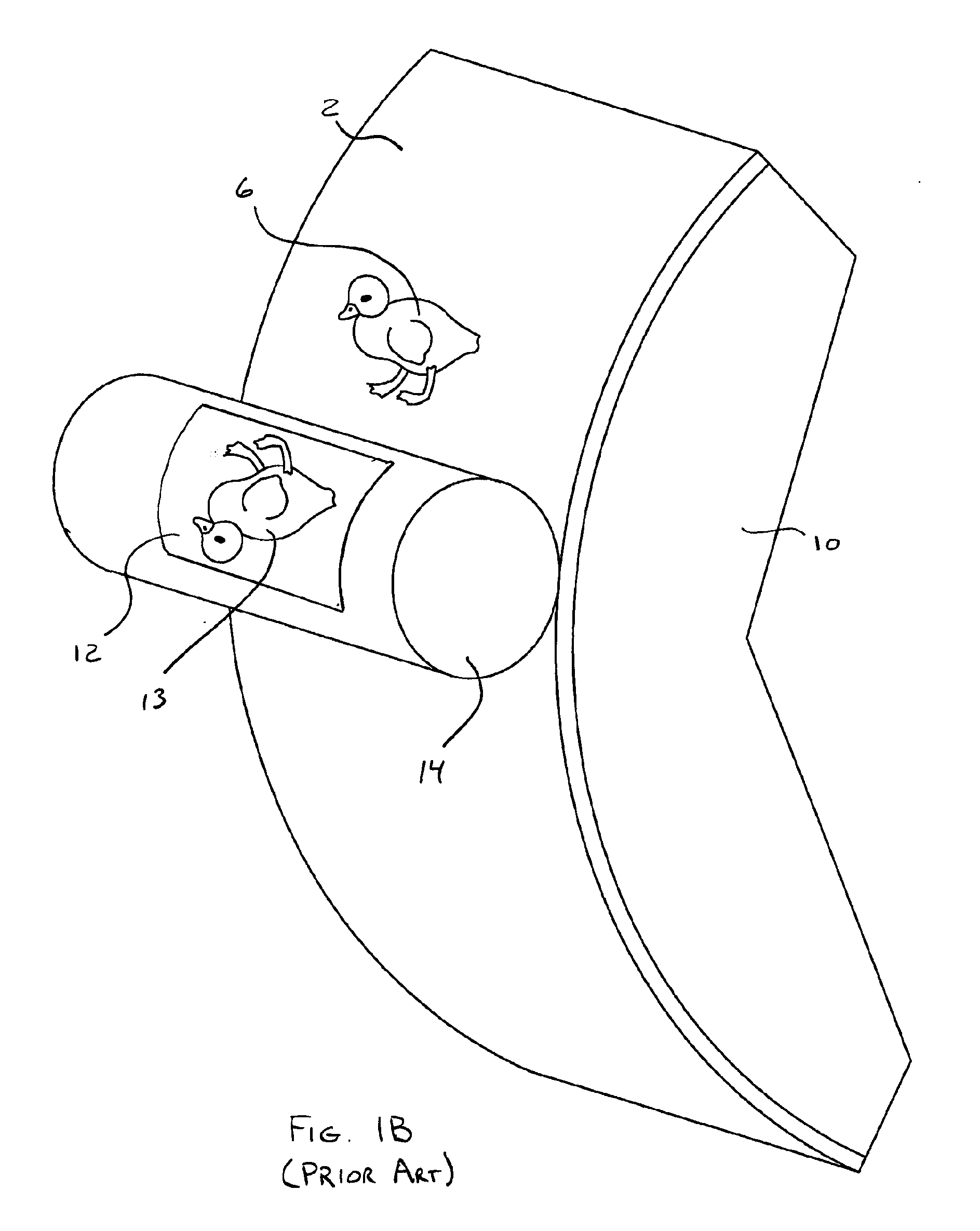

Absorbent Articles Having Distinct Graphics And Apparatus And Method For Printing Such Absorbent Articles

The present disclosure provides embodiments of processes and apparatuses for printing series of different graphics on substrates used in the manufacture of absorbent articles. Such printed substrates can be used, for example, in the manufacture of printed diaper components, such as backsheets, topsheets, landing zones, fasteners, ears, absorbent cores, and acquisition layers. Embodiments of the apparatuses and methods disclosed herein utilize flexographic printing to provide for a sequential manufacture of a series of n absorbent articles having different graphics printed thereon, wherein n can be a number of 2 or greater. In addition, an absorbent product may be produced by placing one or more, or a portion, of the series of n absorbent articles in a package.

Owner:FUSEPROJECT +1

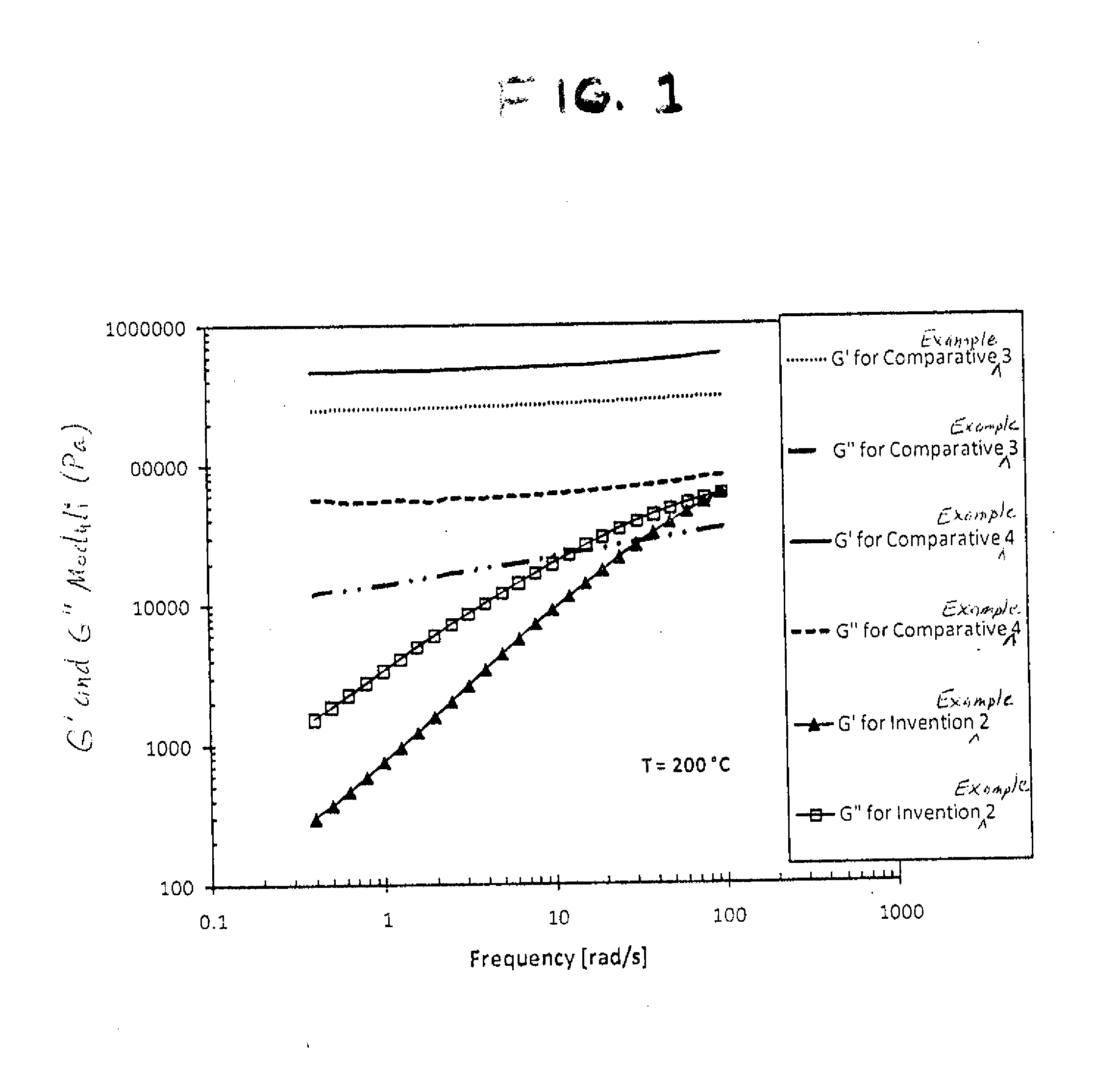

Aqueous coating compositions, methods for making same and uses thereof

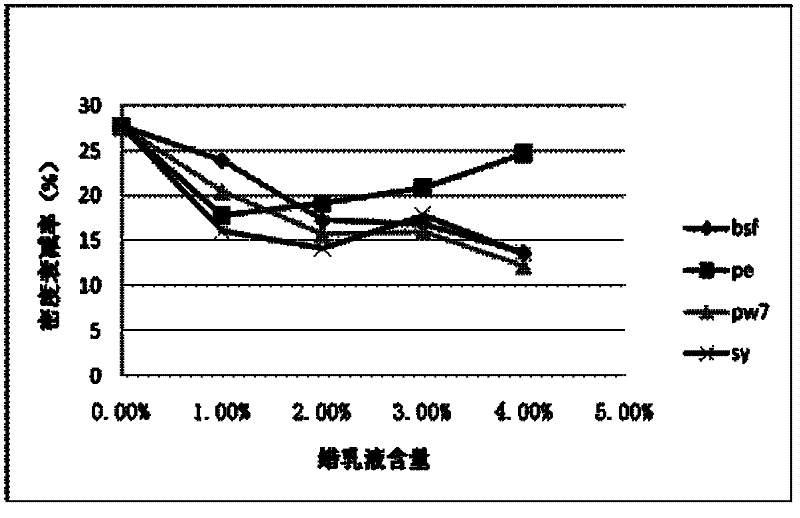

InactiveUS6140386AImprove stabilityMinimum tendencyFilm/foil adhesivesOptical articlesOligomerEmulsion

An aqueous unpigmented coating and printing composition useful for gravure and flexographic printing on plastic and metal substrates is provided by preparing an aqueous emulsion of a hydrophobic UV curable oligomer and a photoinitiator and adding about 1 to 10% by weight of the composition of a water soluble or reducible polymeric thickener in an amount effective to provide a viscosity of about 10 to 50 poises and specified rheology properties whereby the composition is capable of yielding clear cured films as low as about 2 microns in thickness.

Owner:LEHIGH UNIVERSITY

Curable jettable liquid for flexography

InactiveUS20060054040A1Fast and simple and environmentalThe way is simple and fastDuplicating/marking methodsInksOligomerPlasticizer

A curable jettable liquid for manufacturing a flexographic printing plate comprising at least one photo-initiator, at least one monofunctional monomer, at least 5 wt % of a polyfunctional monomer or oligomer and at least 5 wt % of a plasticizer both based on the total weight of the curable jettable liquid capable of realizing a layer after curing having an elongation at break of at least 5%, a storage modulus E′ smaller than 200 MPa at 30 Hz and a volumetric shrinkage smaller than 10%.

Owner:AGFA NV

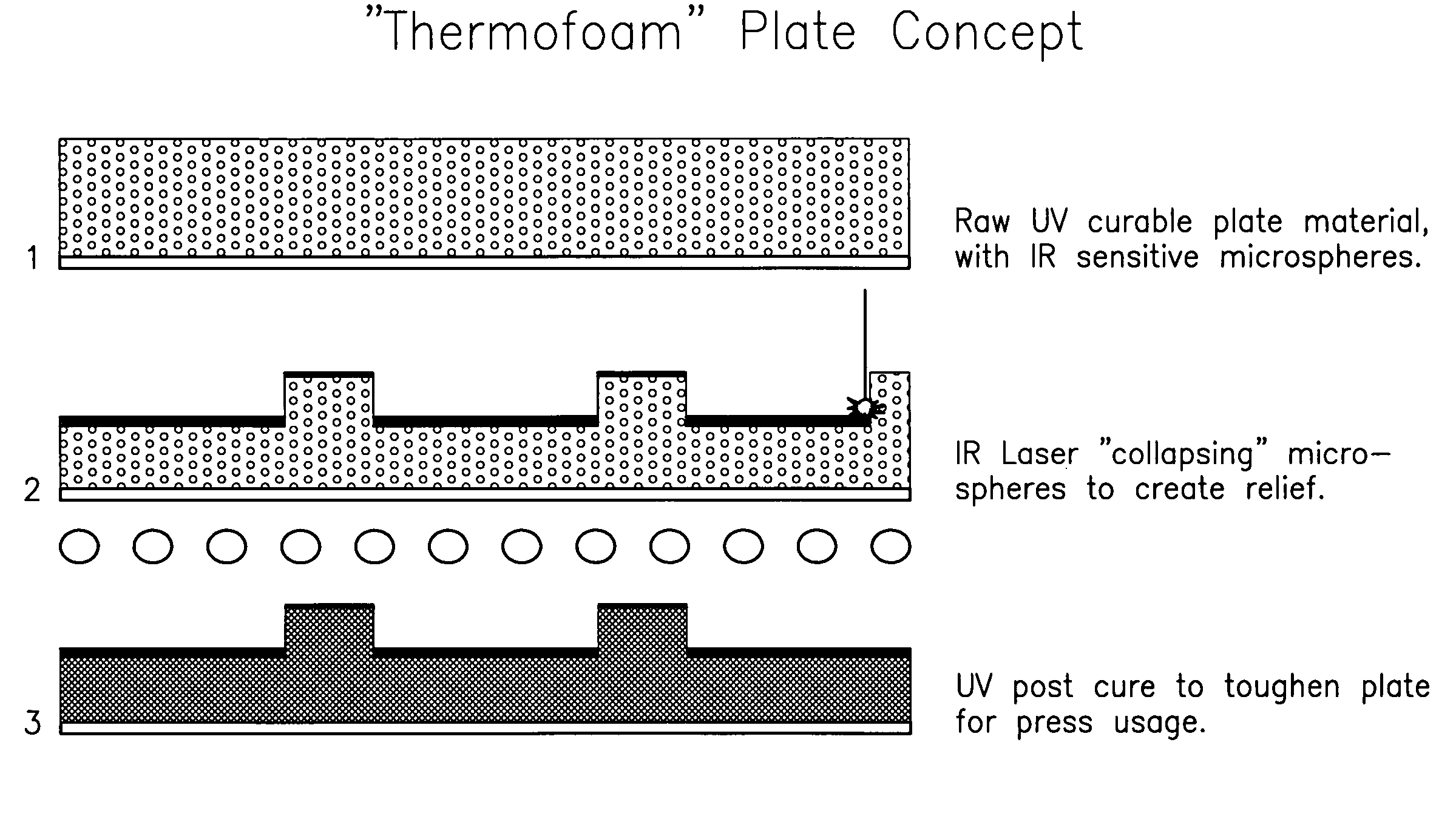

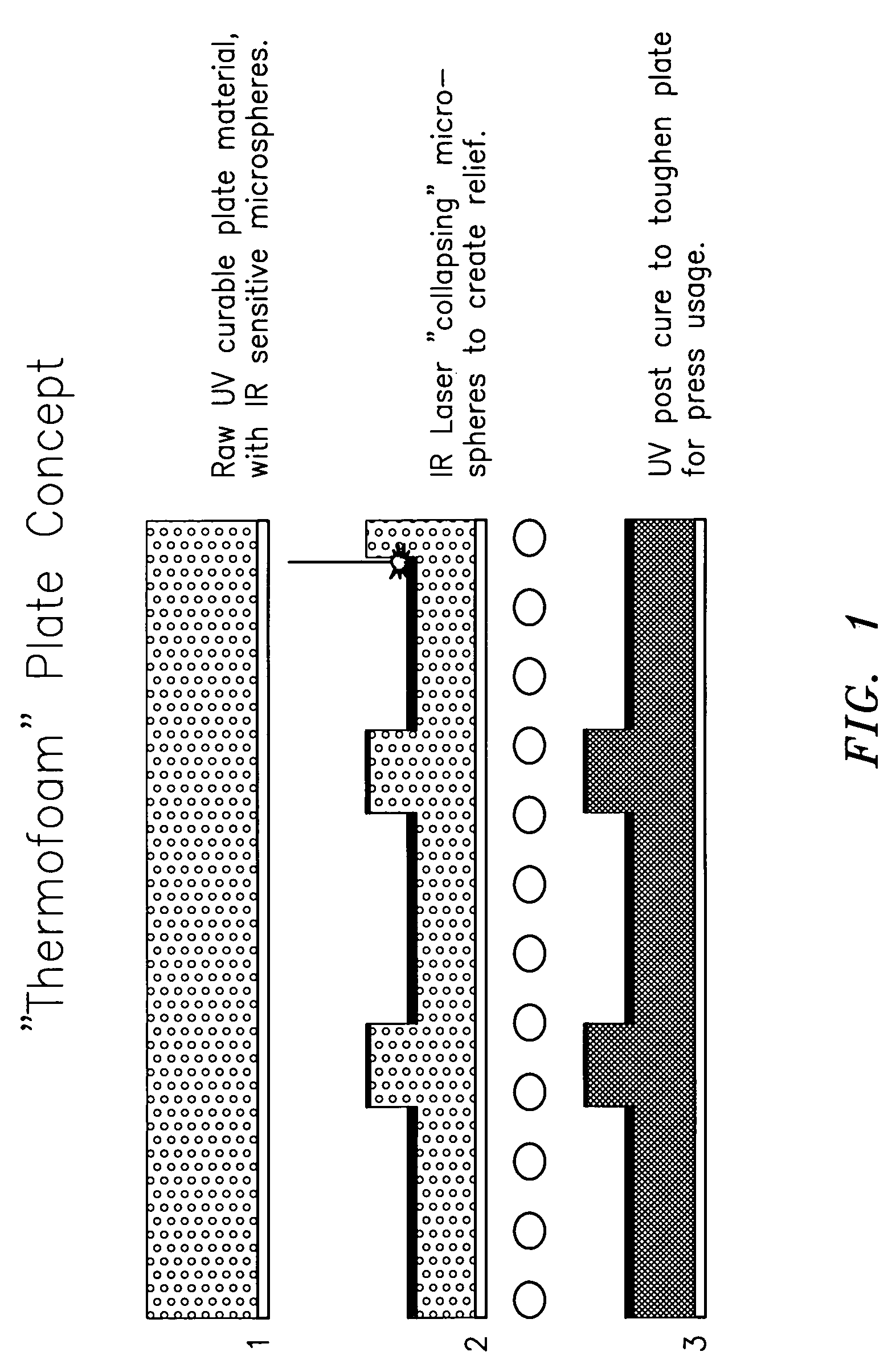

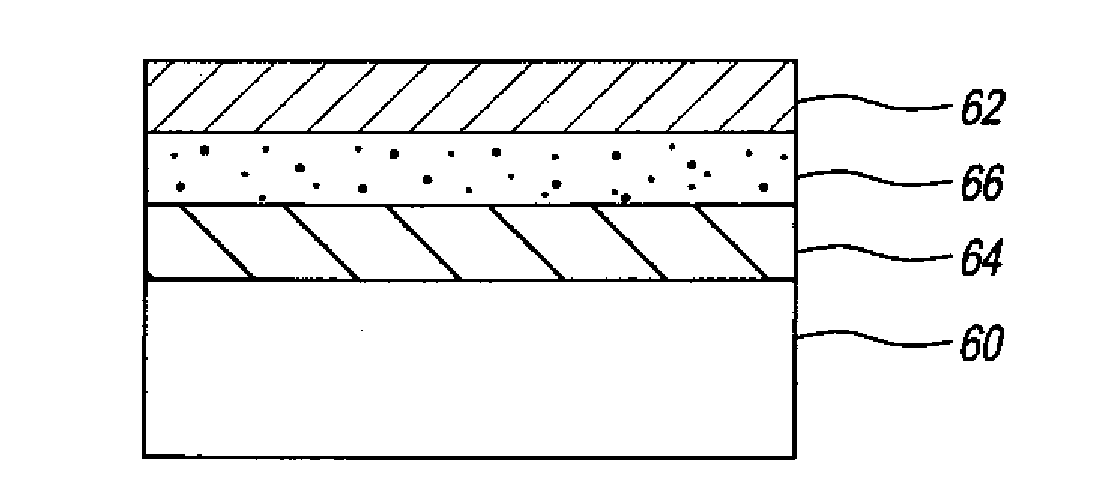

Processless digitally imaged photopolymer elements using microspheres

InactiveUS6989220B2Decrease final densityLow densityPhotosensitive materialsRadiation applicationsChemical treatmentMicrosphere

Laser imageable flexographic printing elements, including printing plates and printing sleeves and methods of making the laser imageable flexographic printing elements using a collapsible cross-linkable material comprising a curable elastomer, a material that absorbs laser radiation at a selected wavelength, and microspheres are disclosed. A laser is used to collapse and melt the collapsible cross-linkable material to form a relief image on the printing element. The printing element is thereafter cured by face exposure to crosslink and cure the formed relief image. The invention addresses a market need for eliminating chemical processing of printing elements, thus going from printing element to press much more quickly and using an environmentally friendly process.

Owner:MACDERMID PRINTING SOLUTIONS

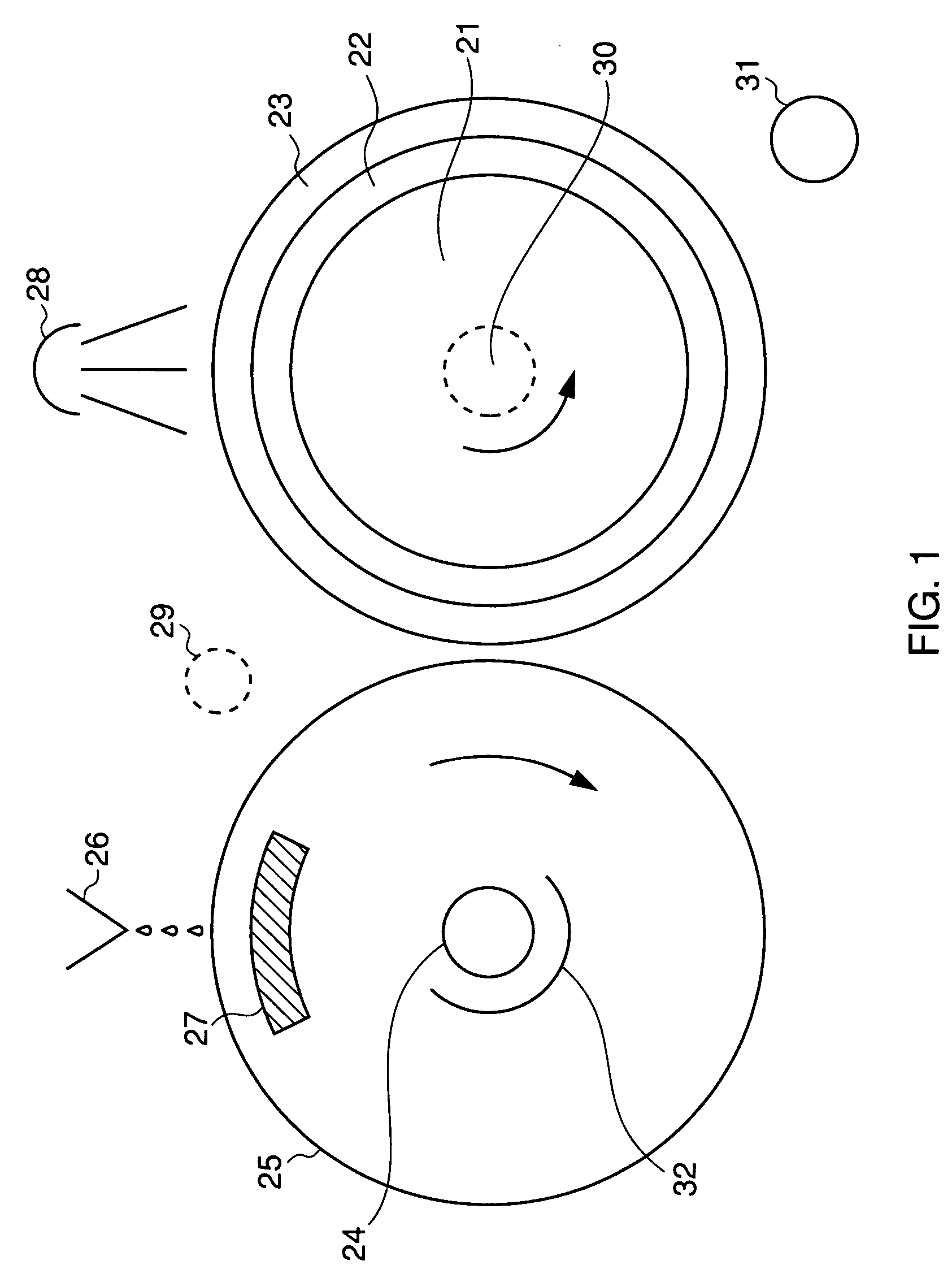

Method for producing a flexographic printing plate formed by inkjetted fluid

InactiveUS20040129158A1Rapid and inexpensive mannerDuplicating/marking methodsMounting boardsEngineeringElectrical and Electronics engineering

Owner:KODAK IL

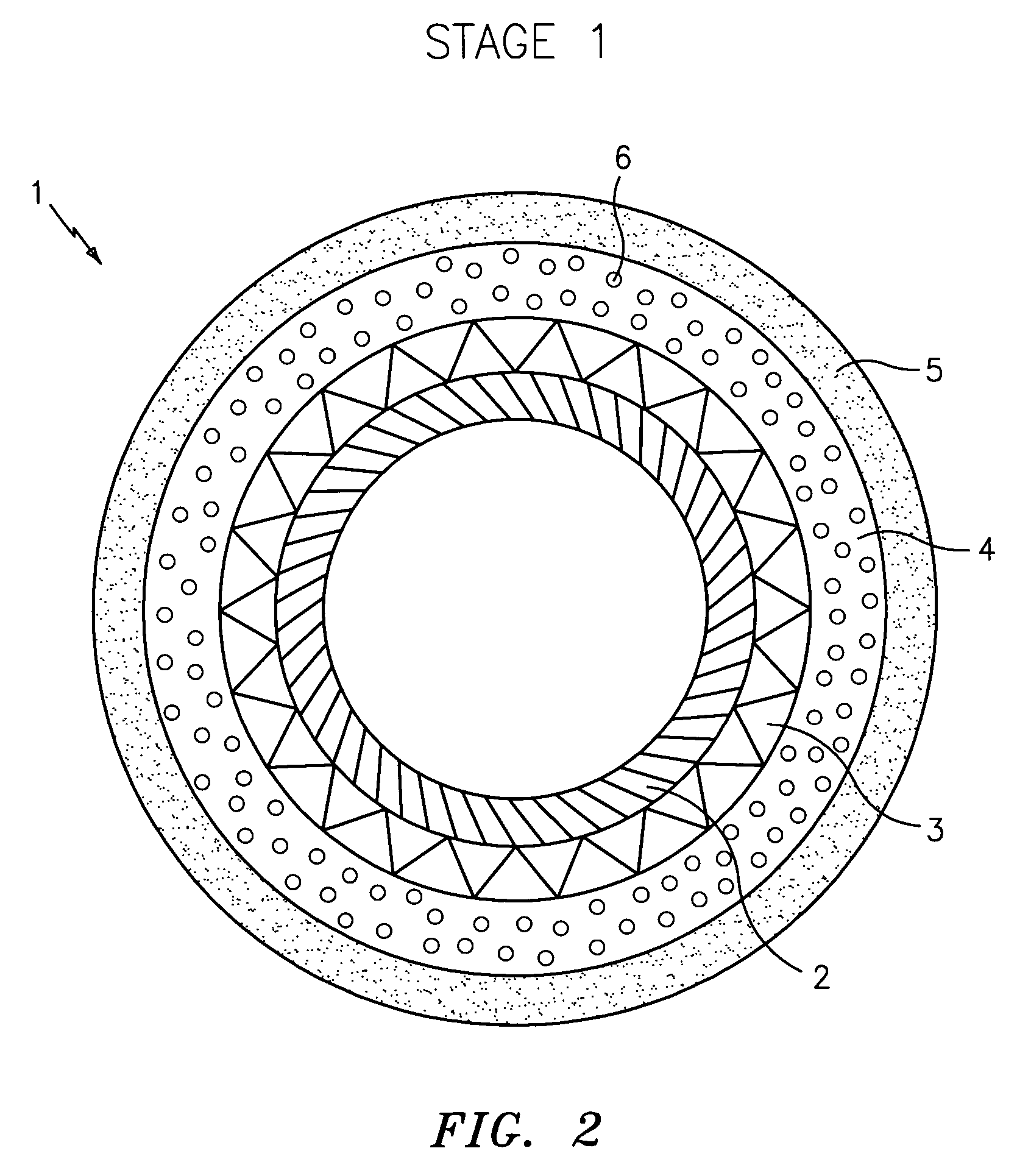

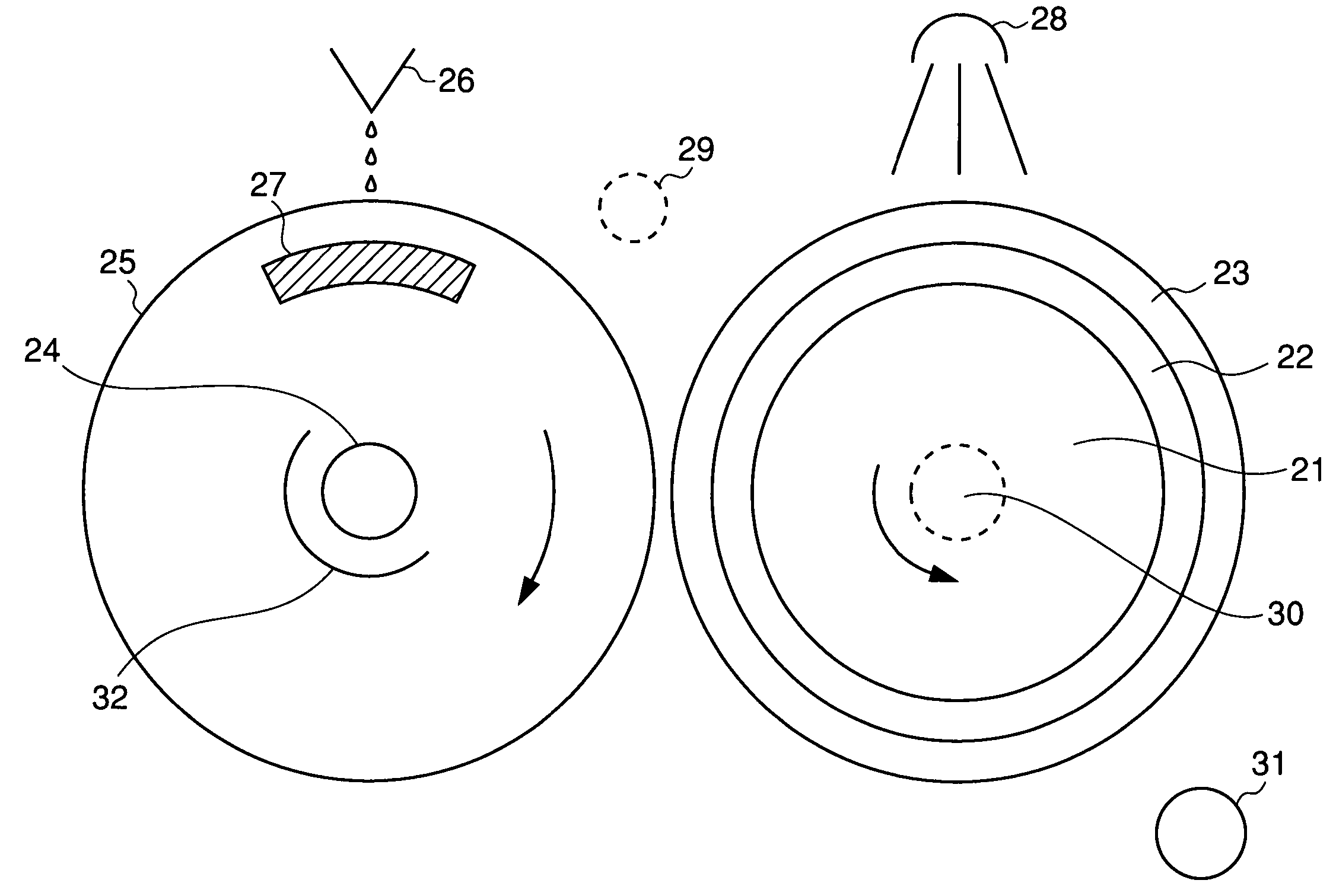

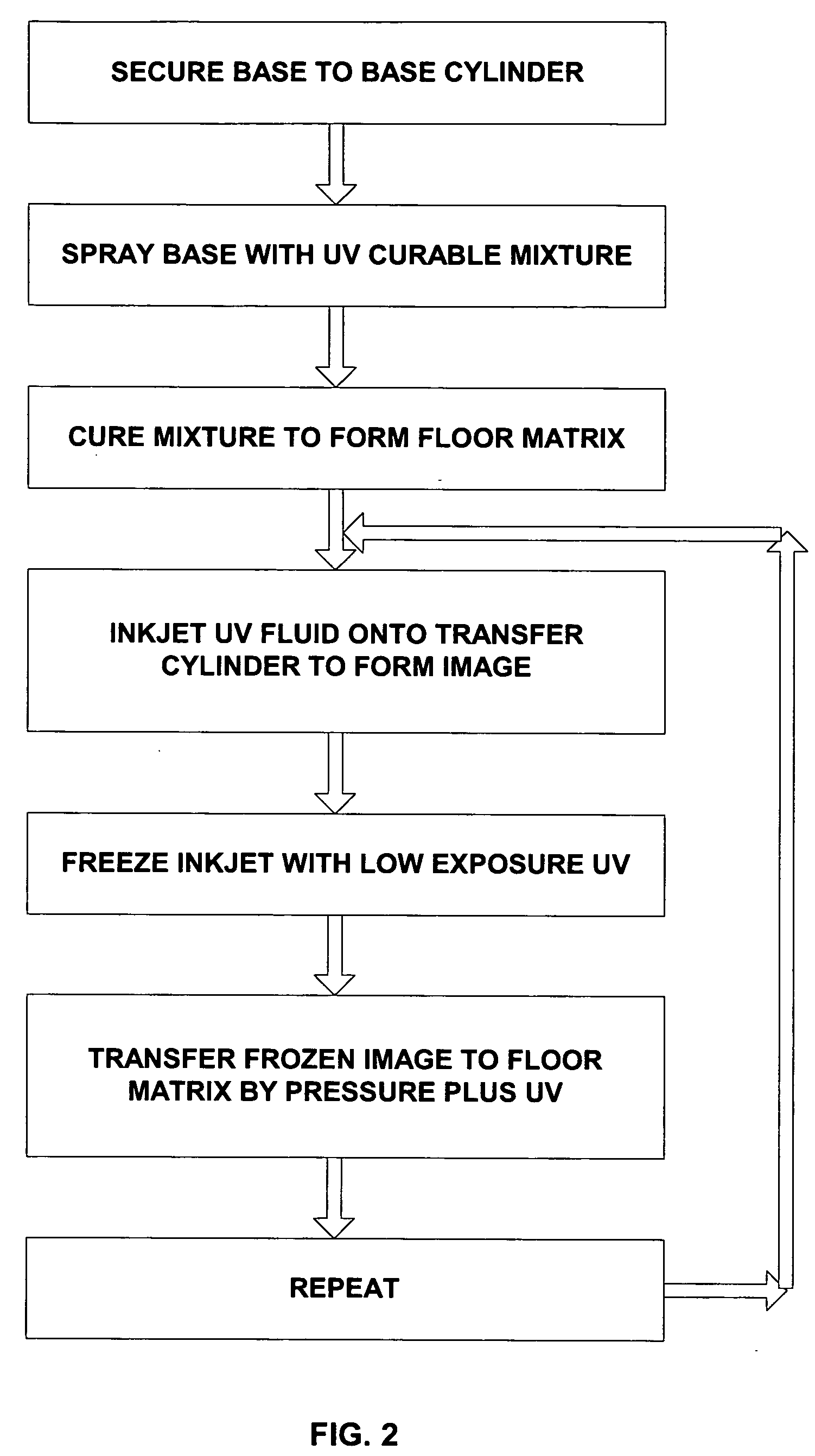

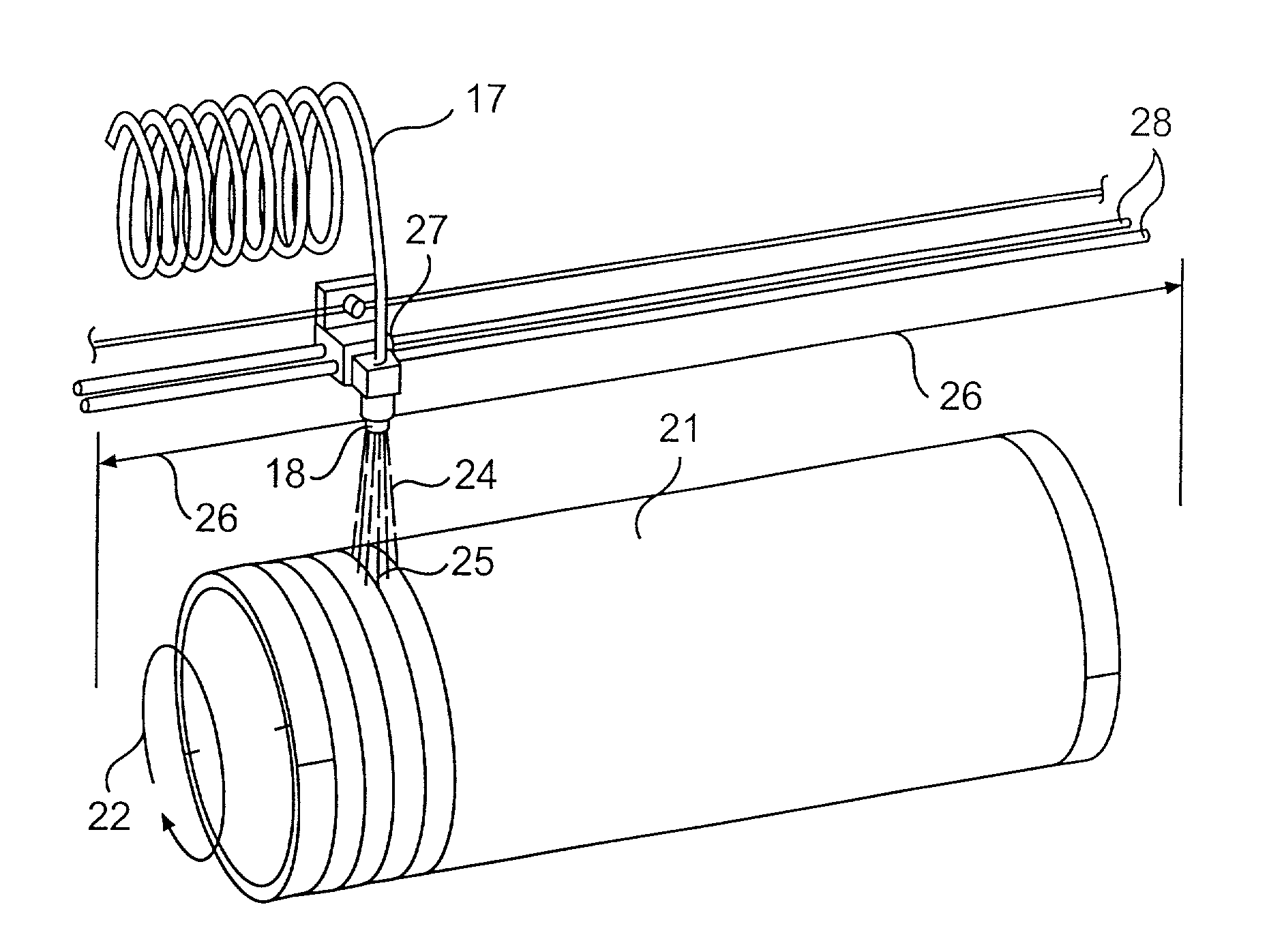

Printing sleeves and cylinders applied with a photopolymer composition

A method of forming a photopolymer layer on a printing substrate (e.g., flexographic printing sleeves and cylinders) is provided. The method includes providing a photopolymer composition that contains a photopolymer and at least one monomer bonded to the photopolymer. The monomer can help reduce the hardness of the resulting photopolymer composition. In addition, the method also includes spraying the photopolymer composition onto a rotating generally cylindrical surface of the printing substrate. In one embodiment, the sprayed photopolymer composition is then cured. The resulting photopolymer layer is seamless and continuous and, in some embodiments, has a hardness of between about 50 to about 70 Shore A.

Owner:ROSSINI SPA

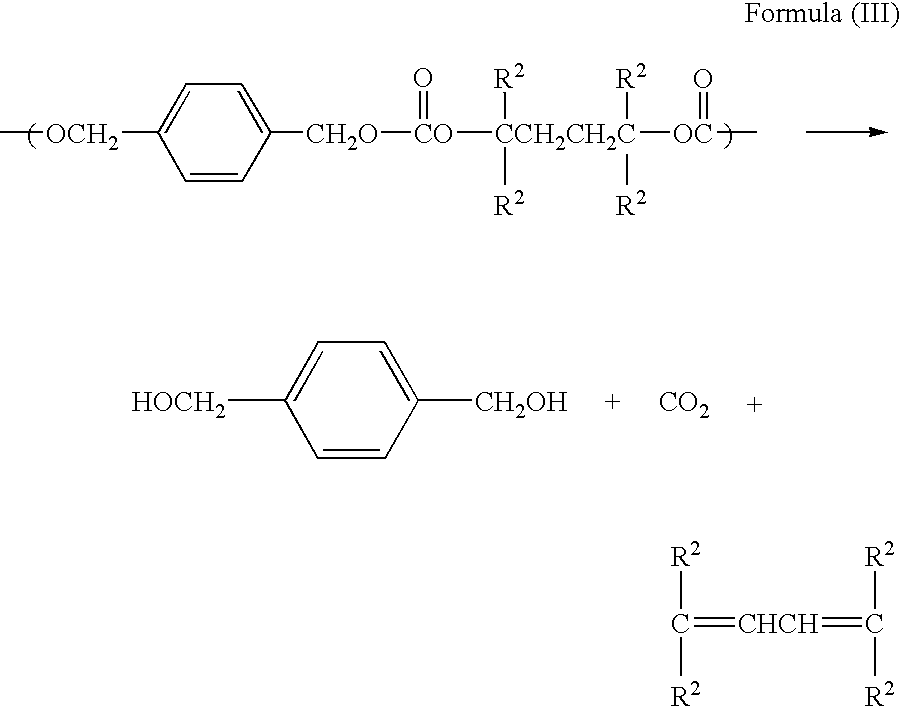

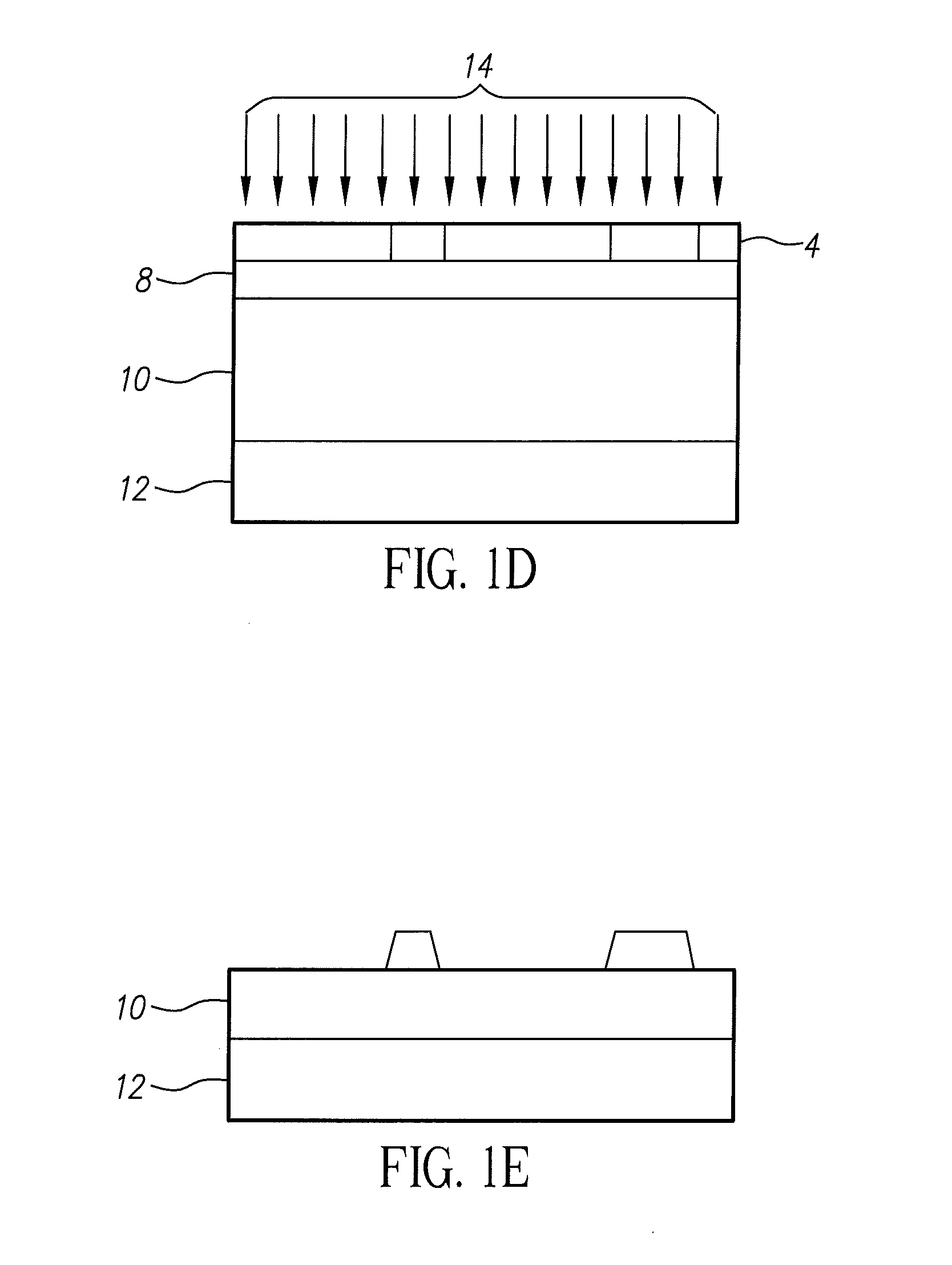

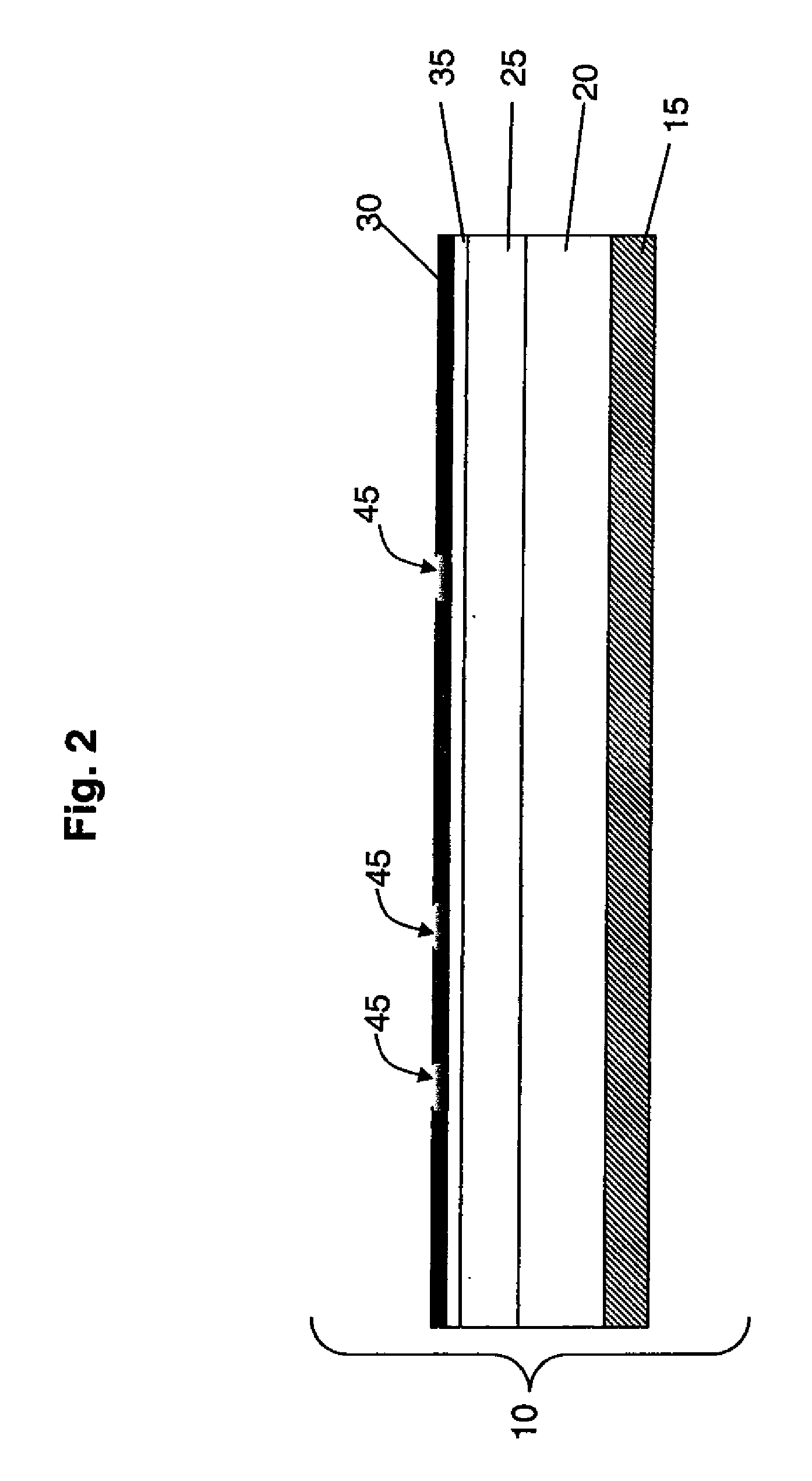

Ablatable elements for making flexographic printing plates

InactiveUS20080258344A1Reduce the environmentReduce health hazardsRadiation applicationsSynthetic resin layered productsPolymerLaser ablation

Flexographic printing plates and other relief images can be formed from a laser-ablatable element having a laser-ablatable layer that is at least 20 μm in thickness. The laser-ablatable layer includes a film-forming material that is a laser-laser-ablatable material or the film-forming material has dispersed therein a laser-ablatable material. The laser-ablatable material is a polymeric material that when heated to 300° C. at a rate of 10° C. / minute, loses at least 60% of its mass to form at least one predominant low molecular weight product. The element can be imaged by ablation at an energy of at least 1 J / cm2 to provide a relief image.

Owner:EASTMAN KODAK CO

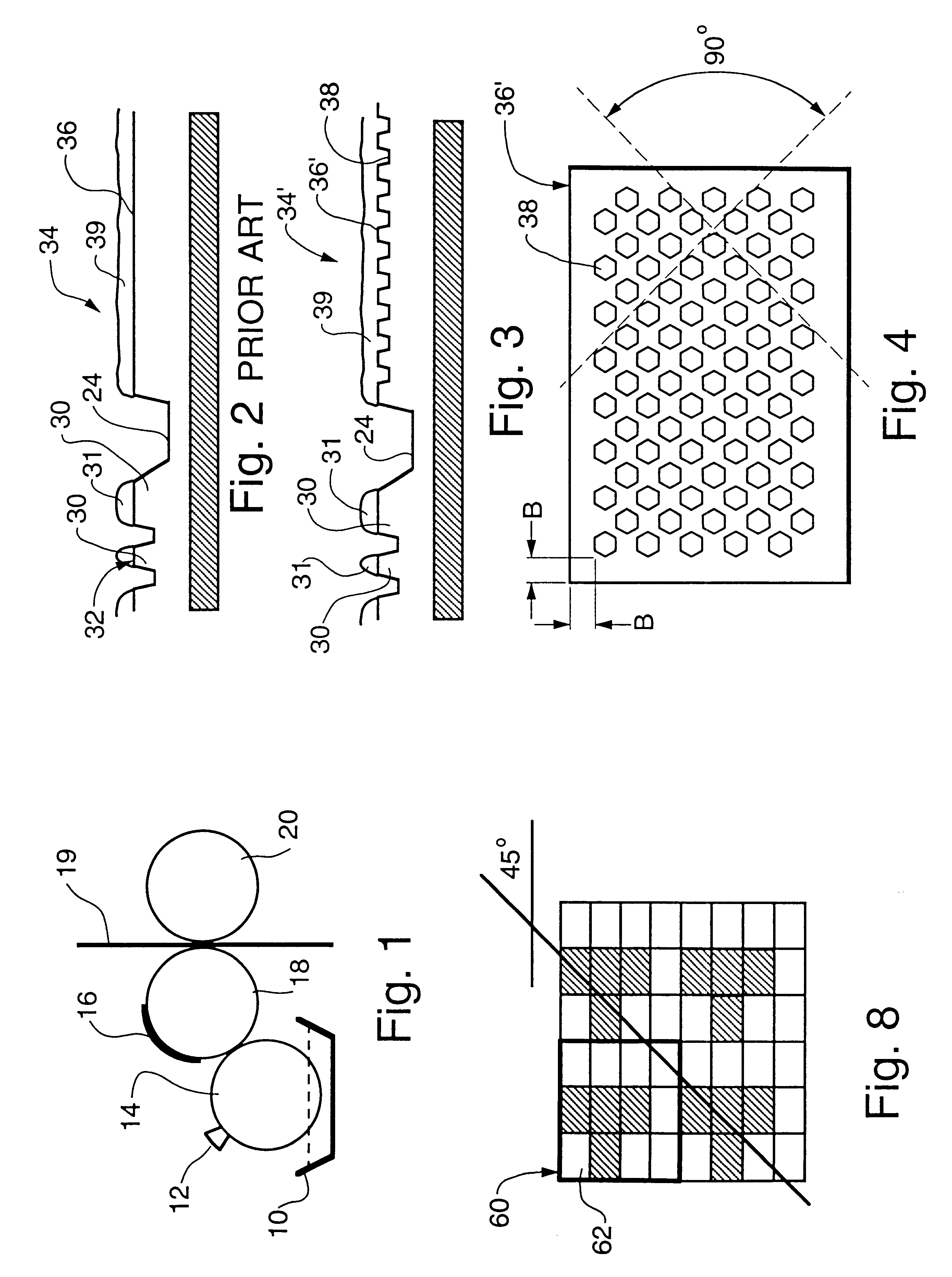

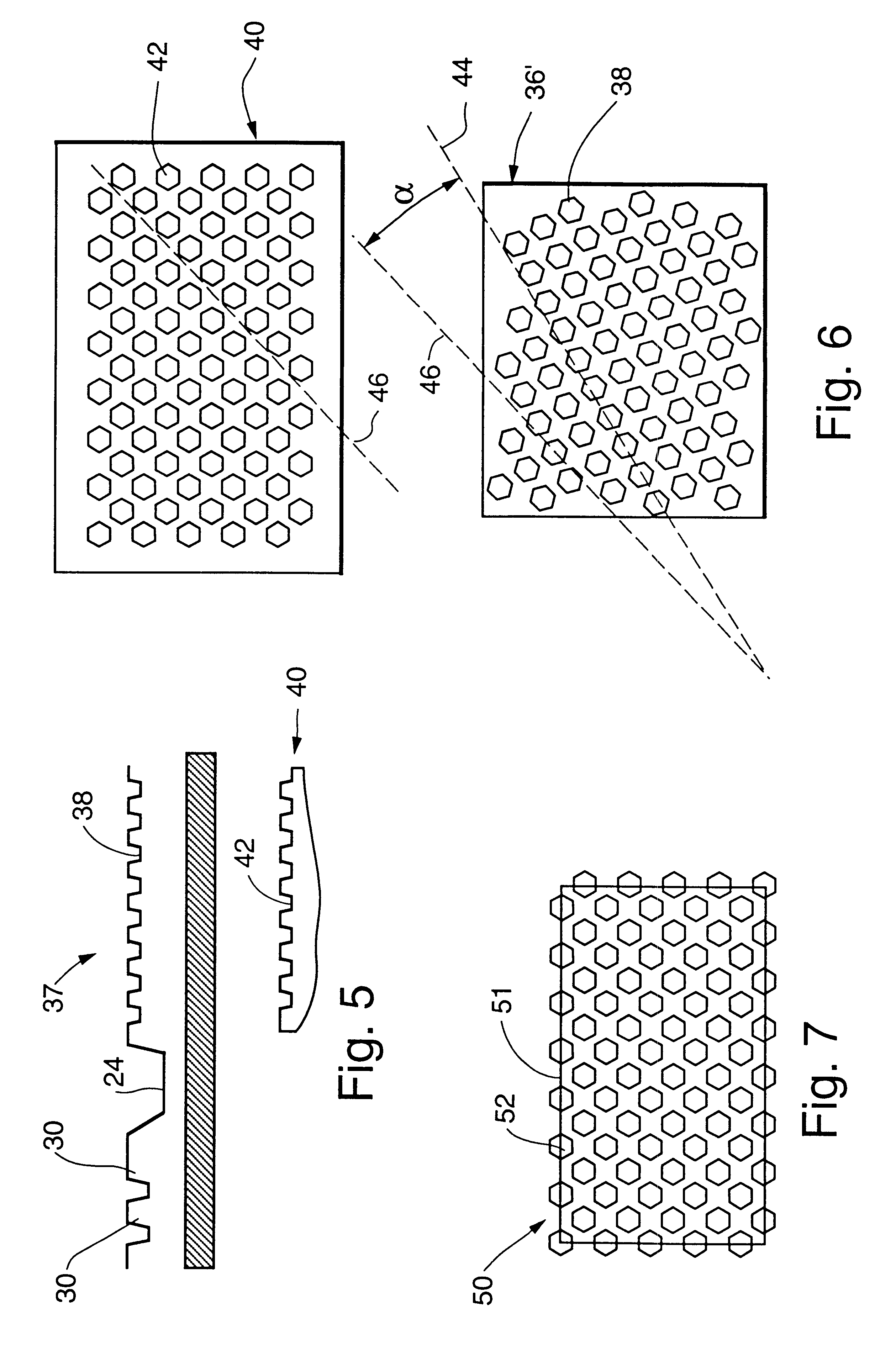

Screened film intermediate for use with flexographic printing plate having improved solids rendition

InactiveUS6492095B2Digitally marking record carriersInking apparatusColor saturationMechanical engineering

flexographic printing plate having solid image areas which are covered by a plurality of very small and shallow cells similar to the ink carrying cells found in anilox ink metering rolls. These cells fill with ink during the plate inking step and reproduce solid image areas with better color saturation while at the same time reducing the halo typical of flexographic printing of solids. Associated with this plate is a method for producing the cells, including the use of an intermediate screened film and of a computer program for generating the film intermediate.

Owner:ESKO SOFTWARE

Optically variable water-based inks

Optically variable water-based inks, methods of providing security information, and documents are provided. The optically variable water-based inks are suitable for flexographic printing processes, and the optically variable water-based inks display a viewing angle dependent color shift between at least a first color and at least a second color. The optically variable water-based inks may be used to provide security information and to flexographically print documents.

Owner:TAYLOR COMM INC

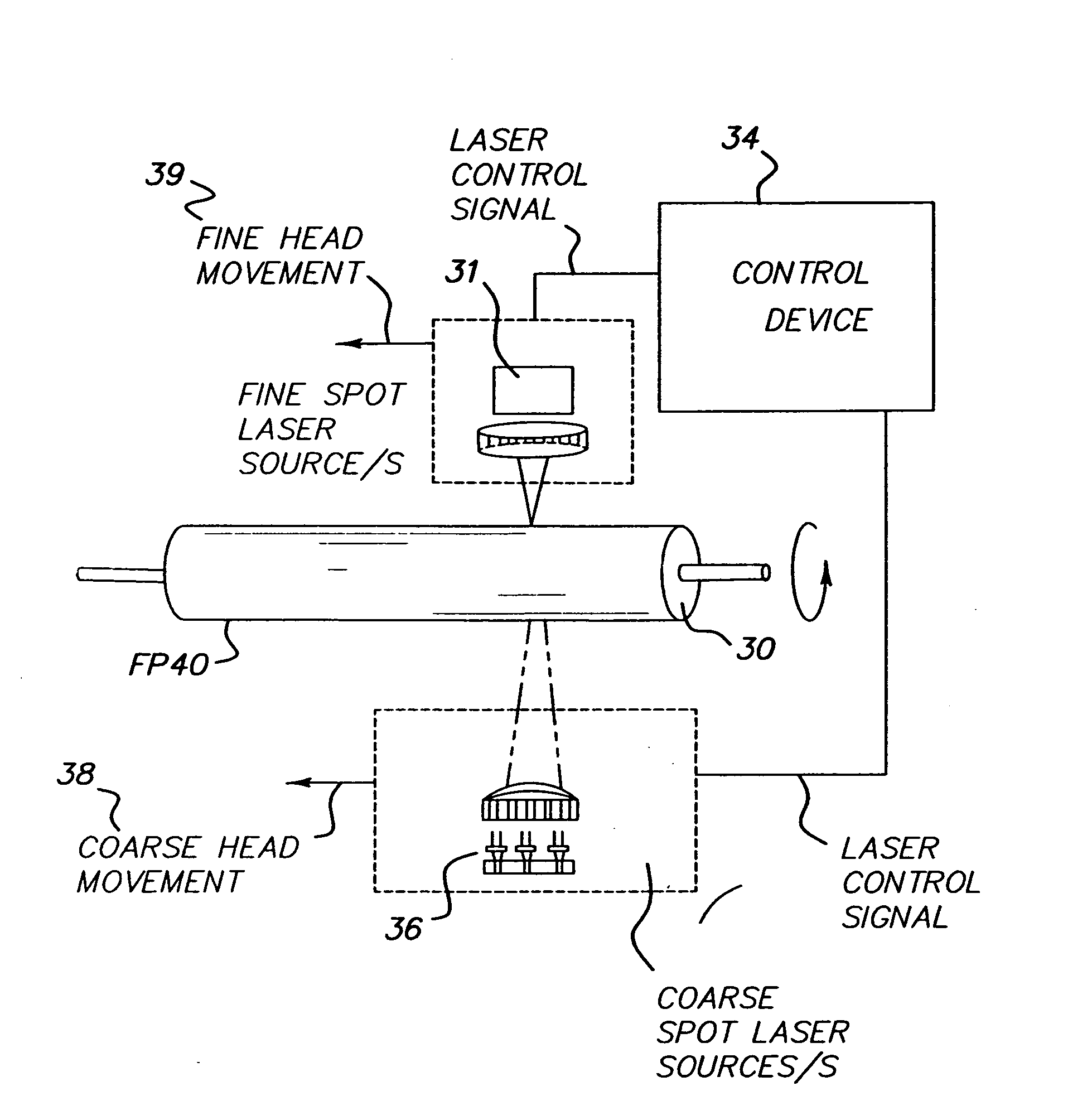

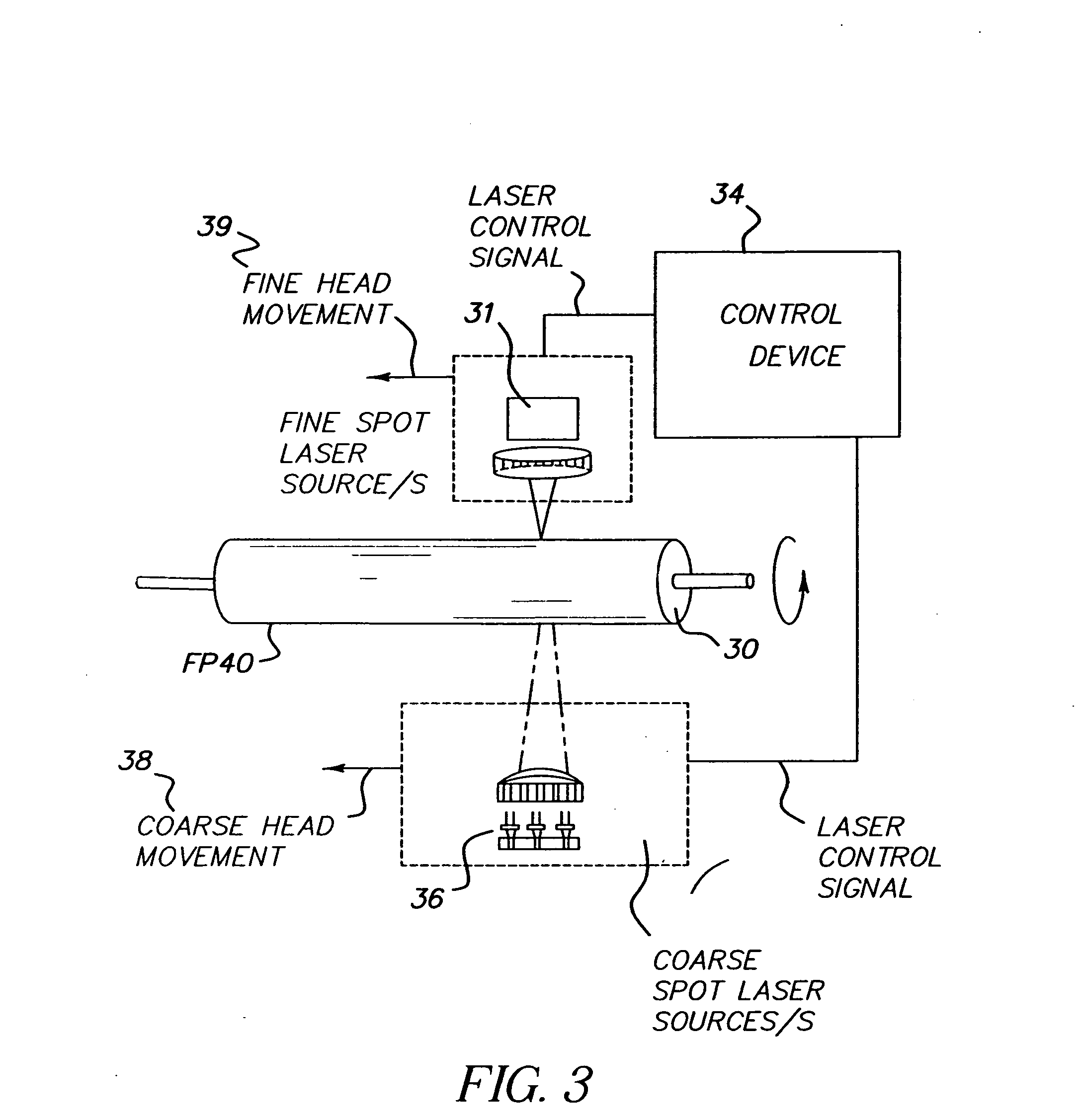

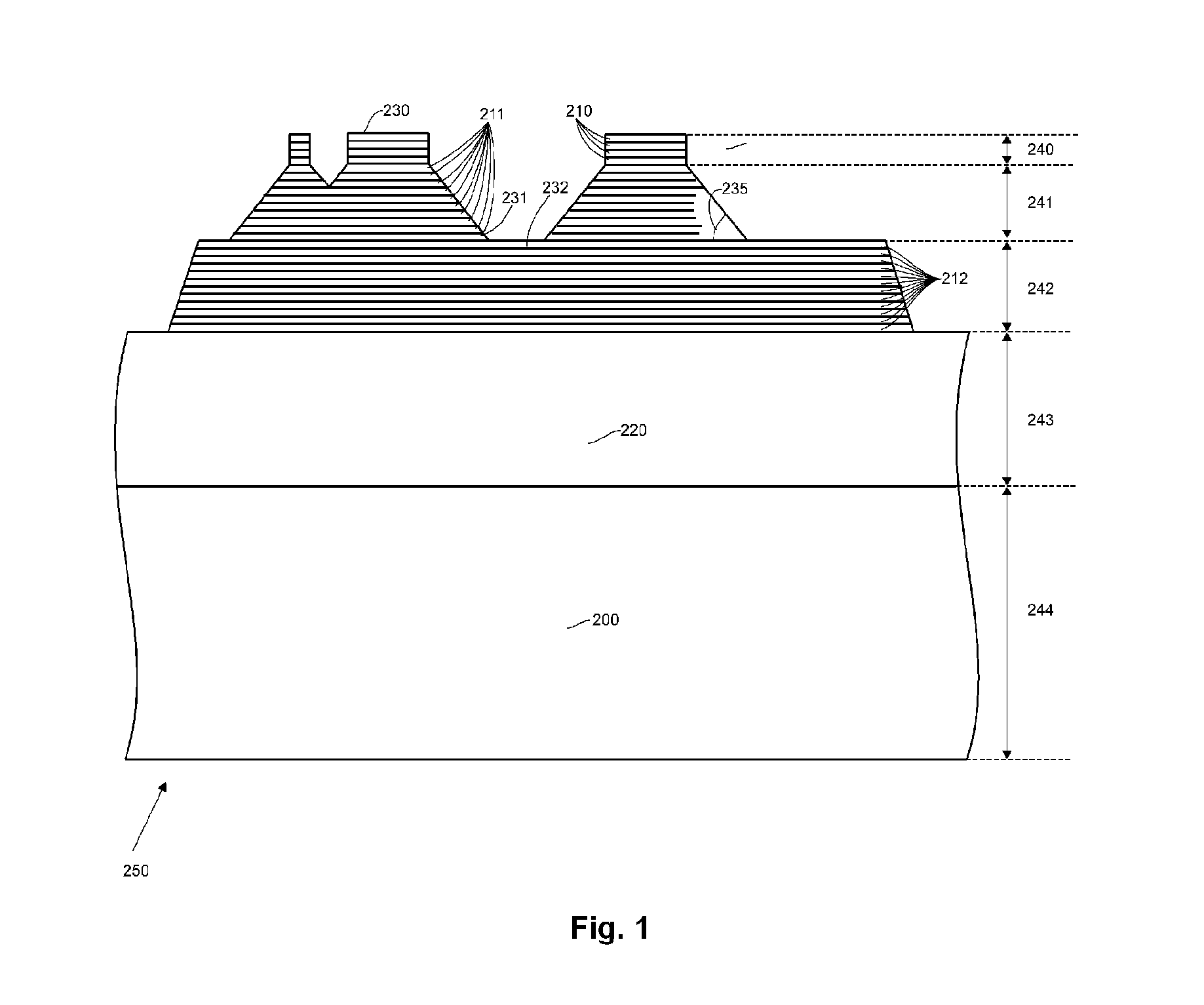

Hybrid optical head for direct engraving of flexographic printing plates

An optical imaging head for direct engraving of flexographic printing plates, comprising: at least two groups of radiation sources, each group comprising at least one radiation source, wherein the radiation sources within each group emit radiation having the same intensity and spot size, different from the intensity and spot size of radiation sources in the other groups, said groups of radiation sources operating simultaneously.

Owner:MIRACLON CORP

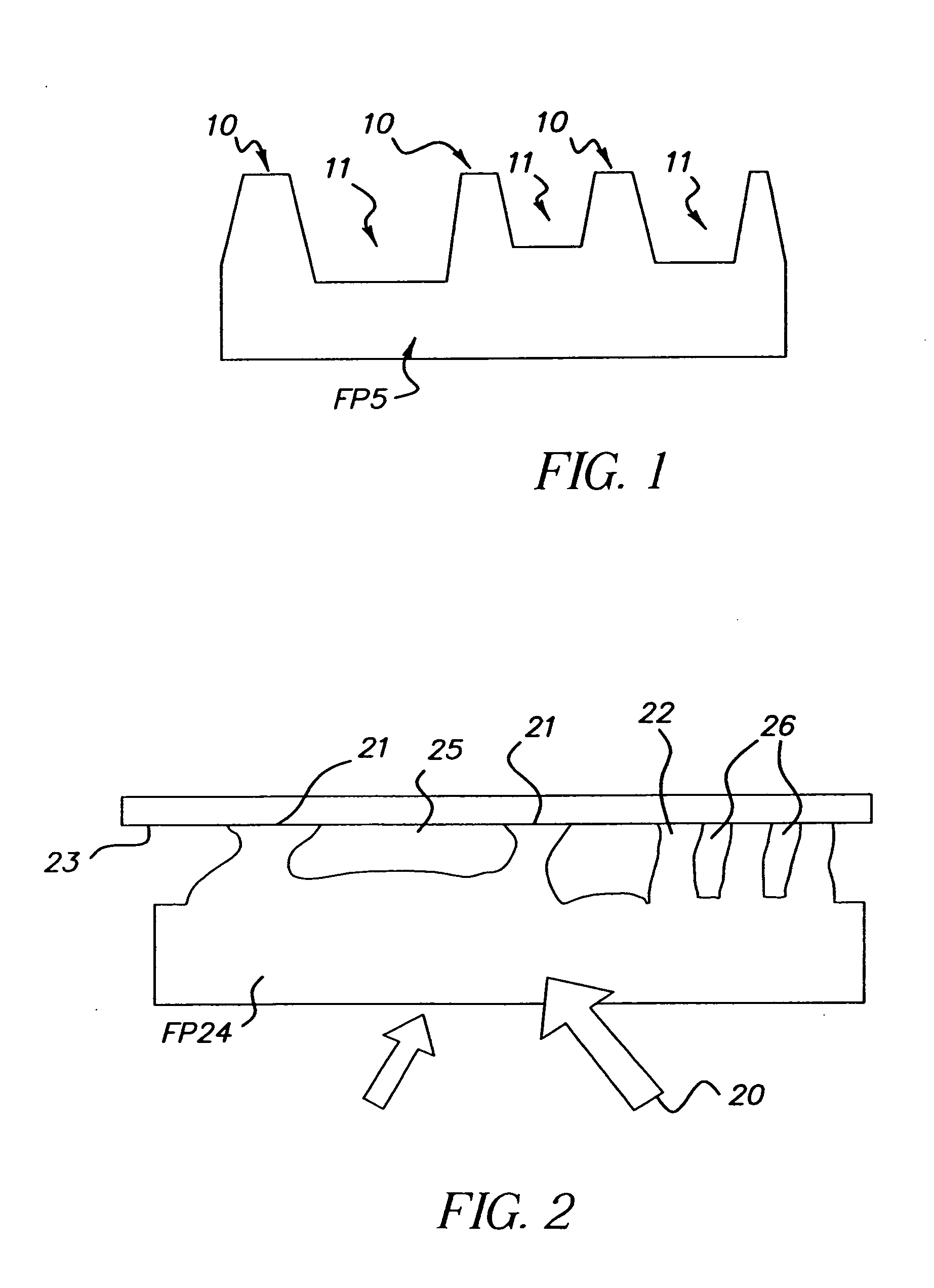

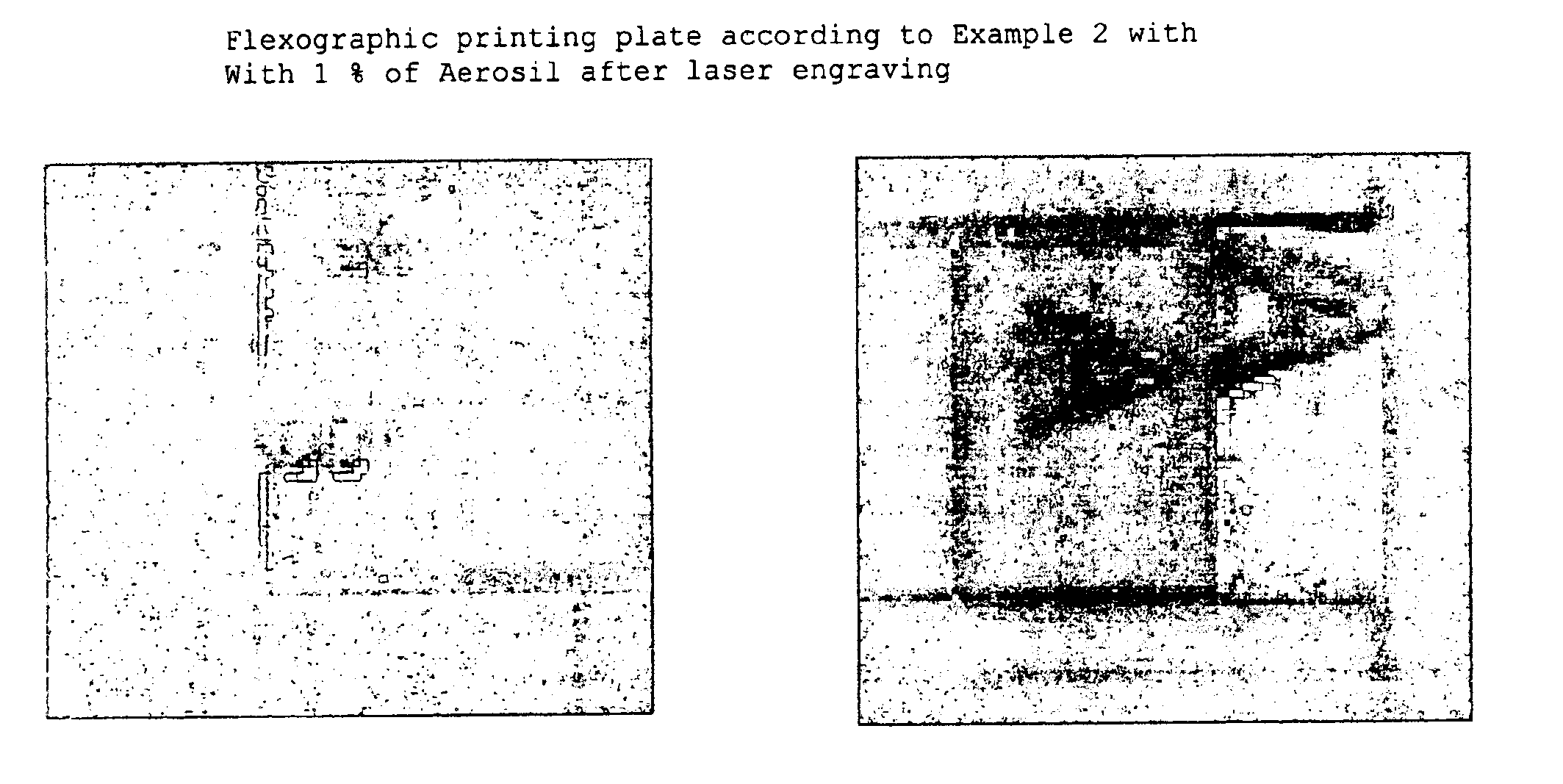

Method for producing flexographic printing plates by means of laser engraving

InactiveUS6935236B2High resolutionAvoid it happening againDuplicating/marking methodsSemiconductor/solid-state device manufacturingCross-linkLaser engraving

The invention relates to a method for producing flexographic printing forms by engraving a printing relief on a flexographic printing element that can be laser engraved, said element having a photochemically cross-linked relief layer. The relief layer is transparent and comprises oxidic, siliceous or zeolitic solid matter with a particle size between 1 and 400 nm in a quantity of between 0.1 and 8 wt. % in relation to the quantity of all components in the relief layer.

Owner:XSYS PRINT SOLUTIONS DEUT GMBH

Developer solvent for photopolymer printing plates and method

InactiveUS6248502B1Improved relief depthImproved sidewall structurePhotosensitive material processingOriginals for photomechanical treatmentNon solventOrganic solvent

Flexographic printing plates crosslinkable by photopolymerization are produced by exposing the plates to a light source and washing out (developing) with a solvent the non-crosslinked areas that are masked out during the exposure process. The invention provides terpene ester-based solvents suitable for use in the development of photopolymer printing plates. The solvents, which include terpene esters alone or terpene esters mixed with organic solvents and / or non-solvents, are effective in developing a a large number of different photopolymer printing plates and can produce images superior to those obtained with commercially available solvents currently used in such applications.

Owner:EASTMAN KODAK CO

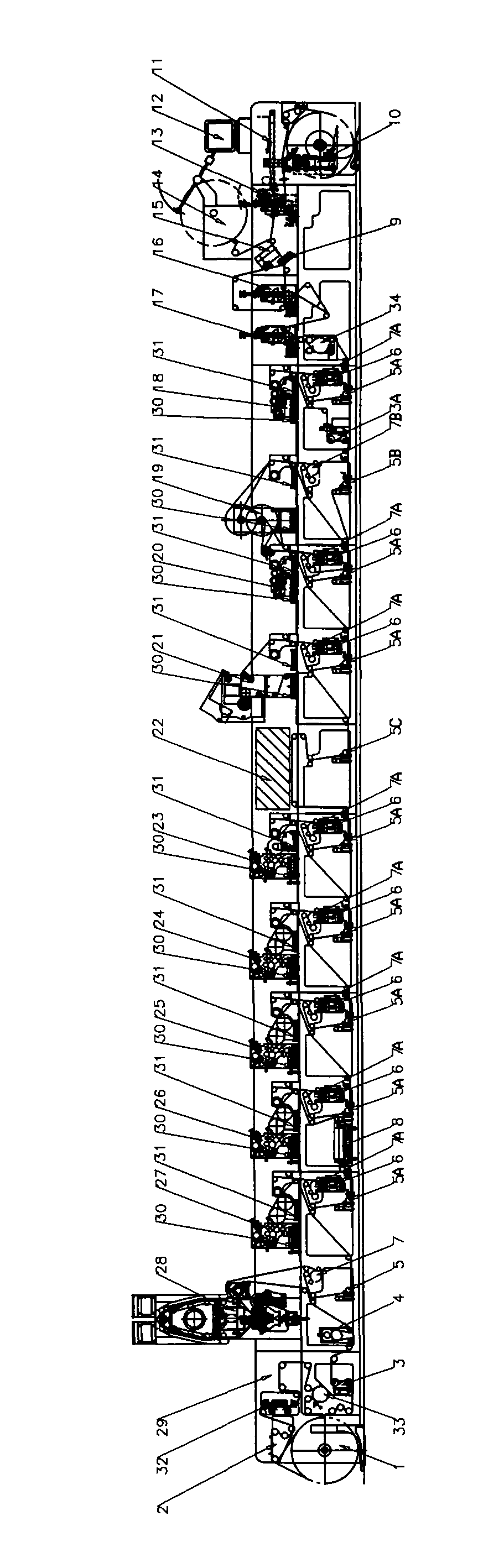

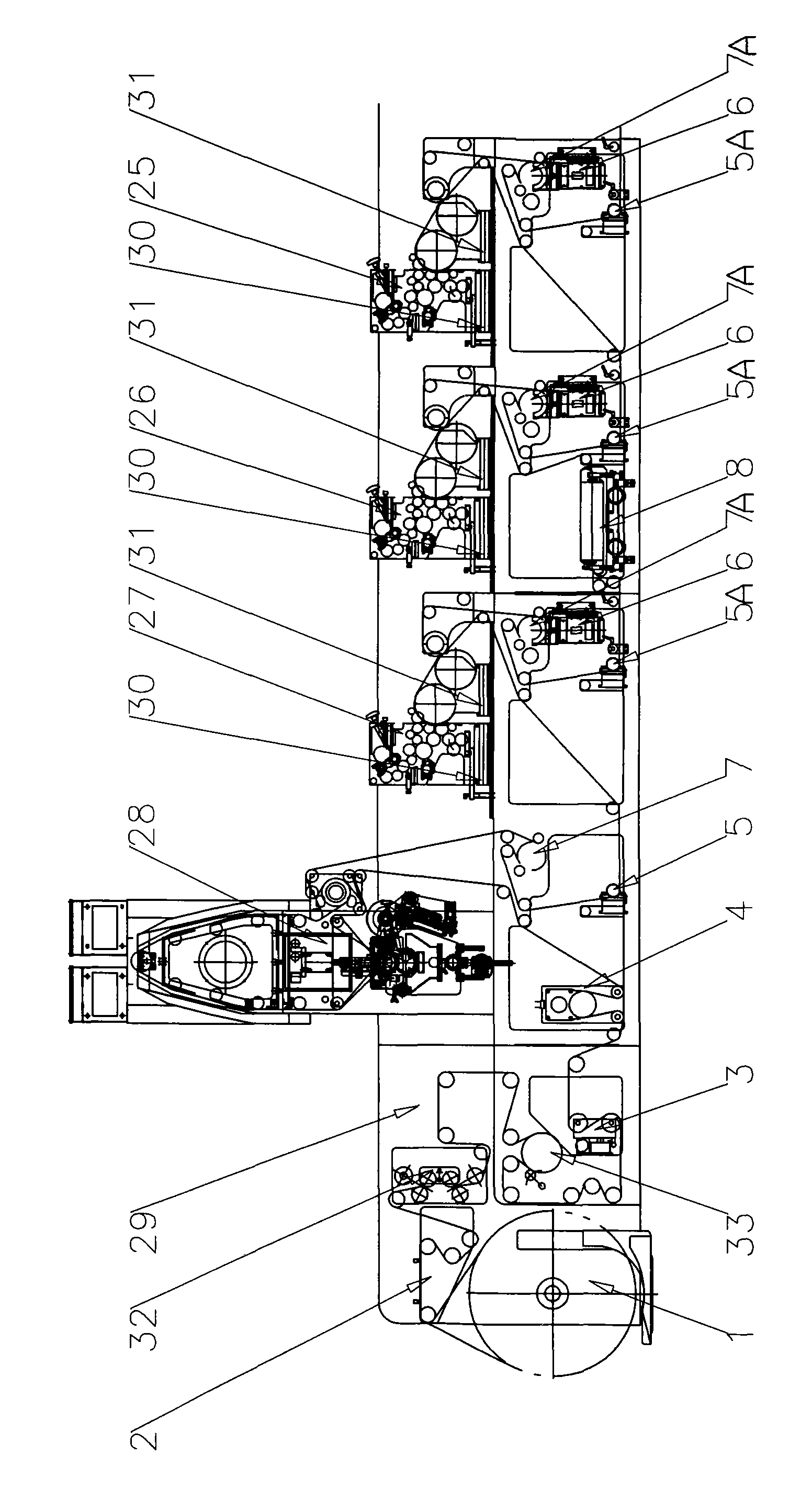

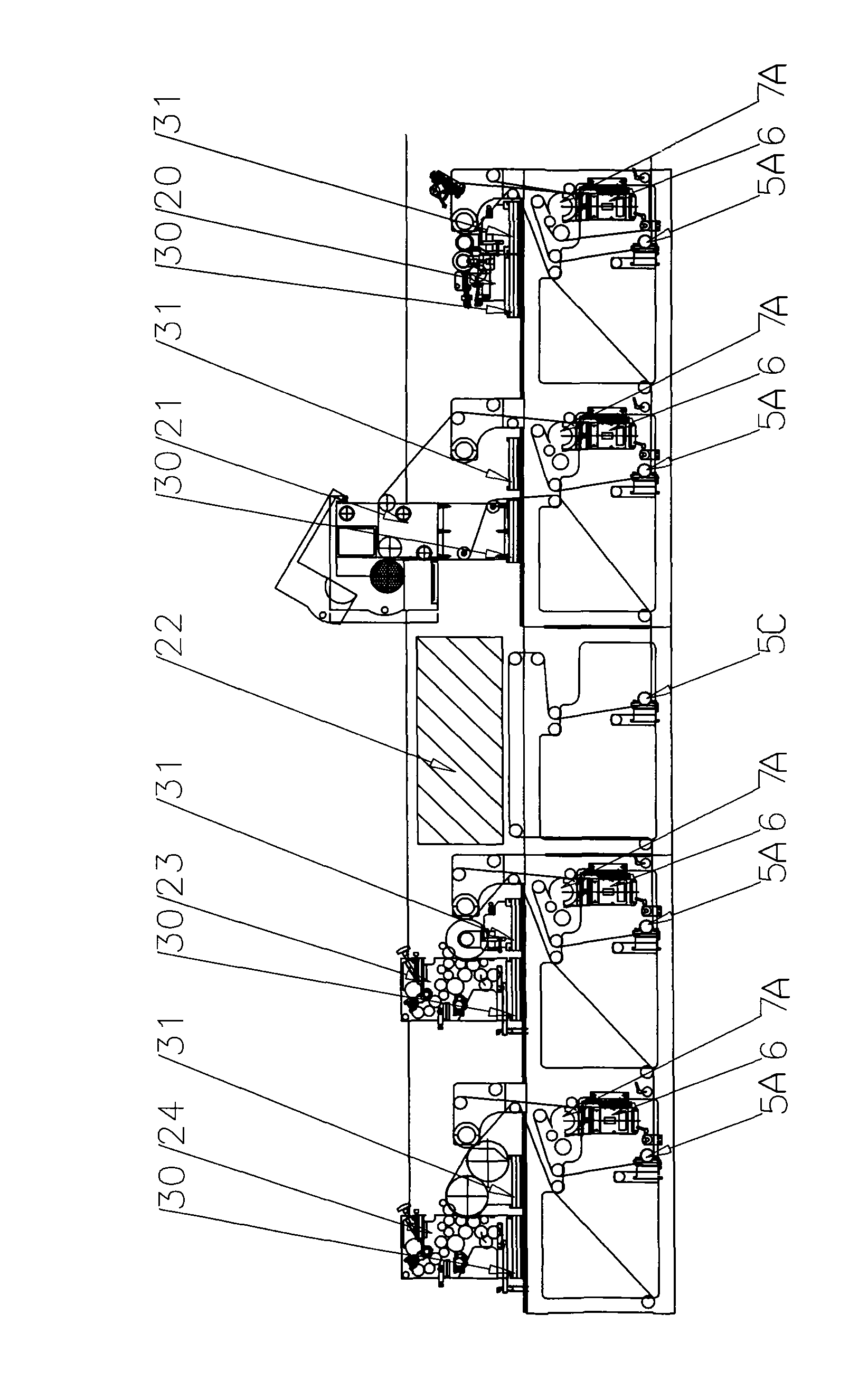

Multifunctional complex printer

InactiveCN101524912AControllable tensionHigh sensitivityTypewritersRotary pressesScreen printingLetterpress printing

The invention relates to a multifunctional complex printer. The multifunctional complex printer comprises a lifting device of a paper feed part. The multifunctional complex printer is characterized in that a corona device, a first AC servo tension detection device and a first cooling pull roll device are sequentially arranged at right side of a first deviation correction device, an intaglio printing unit is arranged above the corona device, the first AC servo tension detection device and the first cooling pull roll device, a first interchangeable hectograph unit, a second interchangeable hectograph unit, a third interchangeable hectograph unit, a fourth interchangeable hectograph unit, an interchangeable letterpress printing unit, an interchangeable screen printing unit and a first interchangeable flexography printing unit are sequentially arranged at the right side of the intaglio printing unit, a fourth AC servo tension detection device is arranged below a reserved platform of an inkjet device, and a second two-cylinder die cutting device, a back cutting device and a television monitoring camera are sequentially arranged at the right side of a first two-cylinder die cutting device. The multifunctional complex printer has the advantages of flexibly combining various printing modes according to pluralism of products and optionally exchanging printing modes of various color classes.

Owner:SHANGHAI XINMIN TAIYO KIKAI

Method of producing a relief image for printing

ActiveUS8142987B2Low costLess timePhotosensitive materialsRadiation applicationsImage formationEngineering

The present invention involves a method for making a relief image. A film that includes a carrier sheet and an imageable material is used to form a mask image that is opaque to a curing radiation. In one embodiment, the mask image is formed on the carrier sheet while in another embodiment, the mask image is formed on a receptor sheet. The mask image is then transferred to a photosensitive material, such as a flexographic printing plate precursor. The resulting assembly is exposed to the curing radiation resulting in exposed and unexposed areas of the photosensitive material. The carrier sheet or the receptor sheet may be removed from the mask image either before or after exposure to the curing radiation. Finally, the photosensitive material and mask image assembly is developed with a suitable developer to form a relief image.

Owner:KODAK POLYCHROME GRAPHICS +1

Laser-engravable flexographic printing element containing a conductive carbon black and method for production of flexographic printing forms

ActiveUS7223524B2Improve accuracySuitable for usePhotosensitive materialsRadiation applicationsLaser engravingEngineering

In a laser-engravable flexographic printing element, the relief-forming layer comprises a conductivity carbon black having a specific surface area of at least 150 m2 / g and a DBP number of at least 150 ml / 100 g. Flexographic printing plates are produced by a process in which a printing relief is engraved into said flexographic printing element by means of a laser system.

Owner:XSYS PRINT SOLUTIONS DEUT GMBH

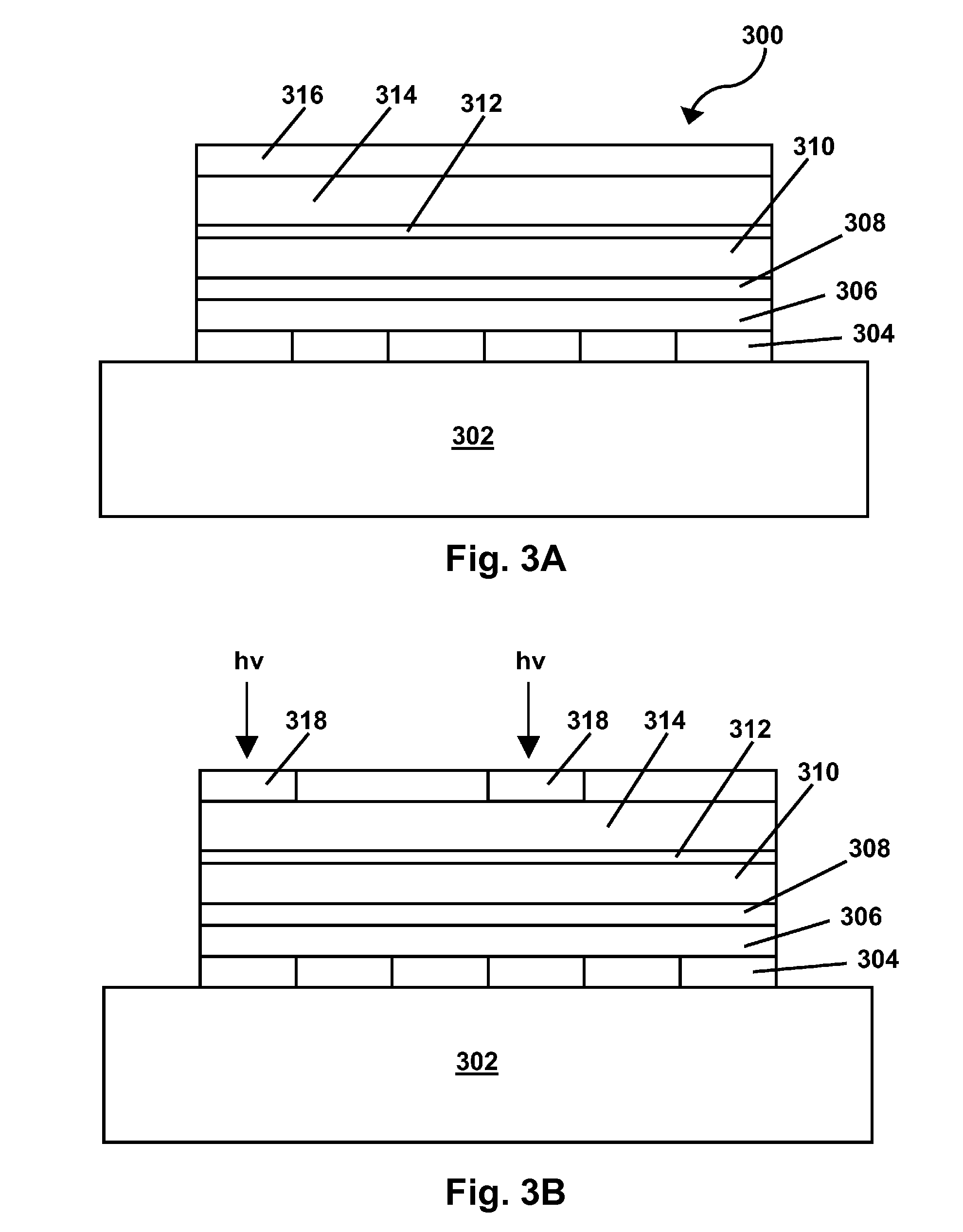

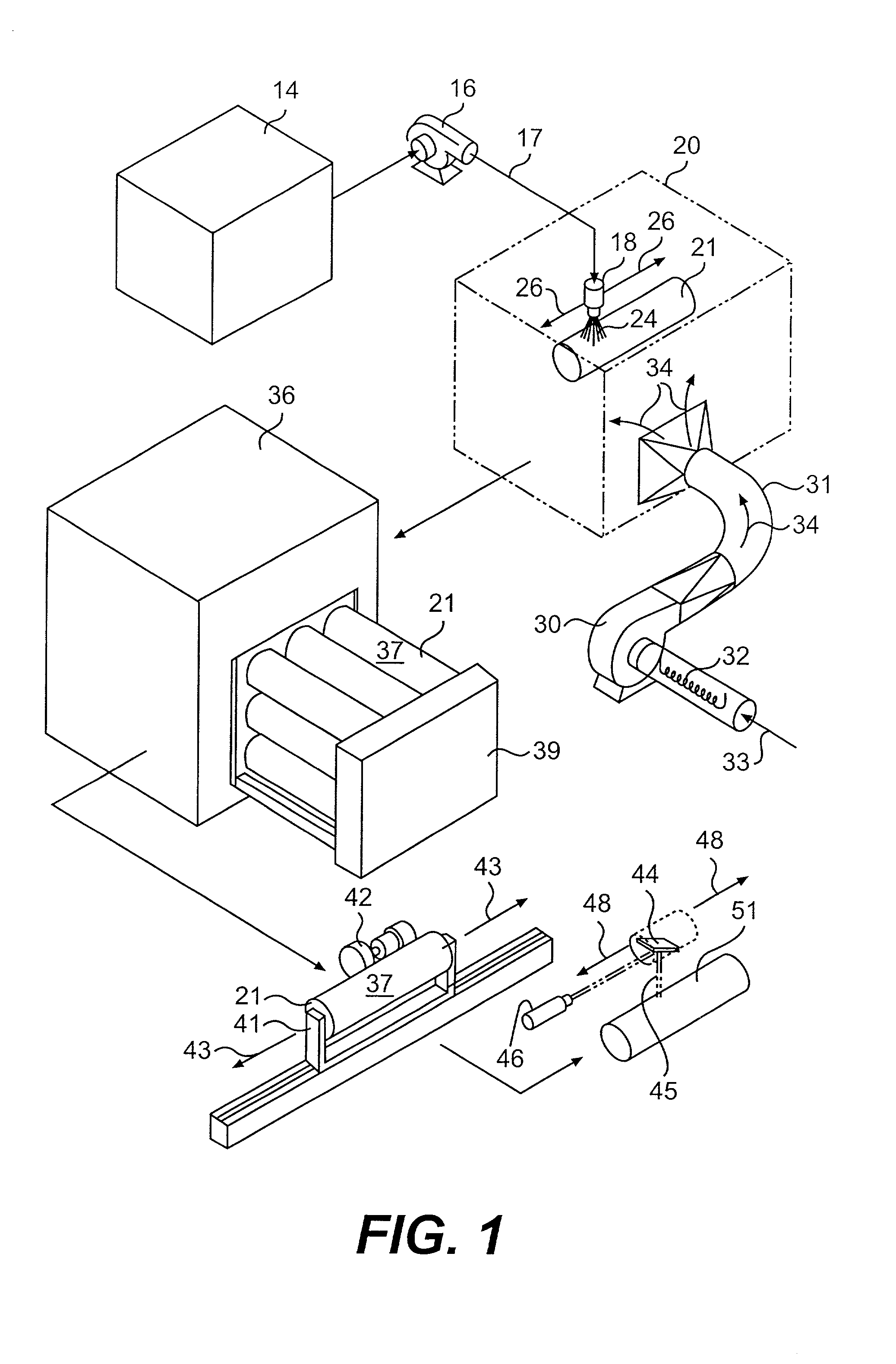

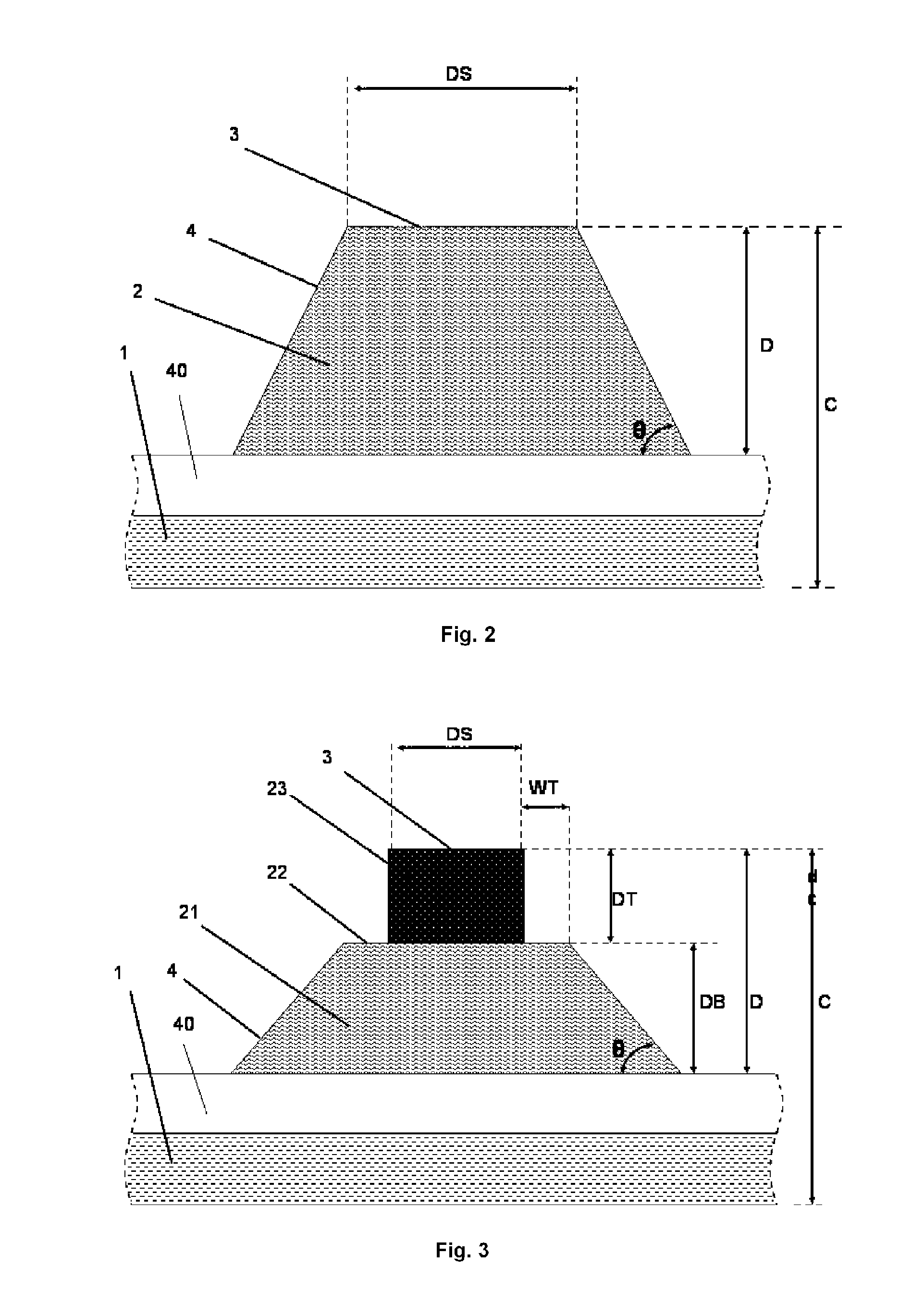

Imaging apparatus and method for making flexographic printing masters

InactiveUS20110219973A1Short manufacturing timeMounting boardsPlate printingEngineeringInkjet printing

A method for making a flexographic printing master includes the steps of providing a flexographic printing support; providing an inkjet printing device; applying a mesa relief on the flexographic printing support with the inkjet printing device; and applying an image relief with the inkjet printing device on the mesa relief. A method for making a flexographic printing master includes the imaging apparatus.

Owner:AGFA NV

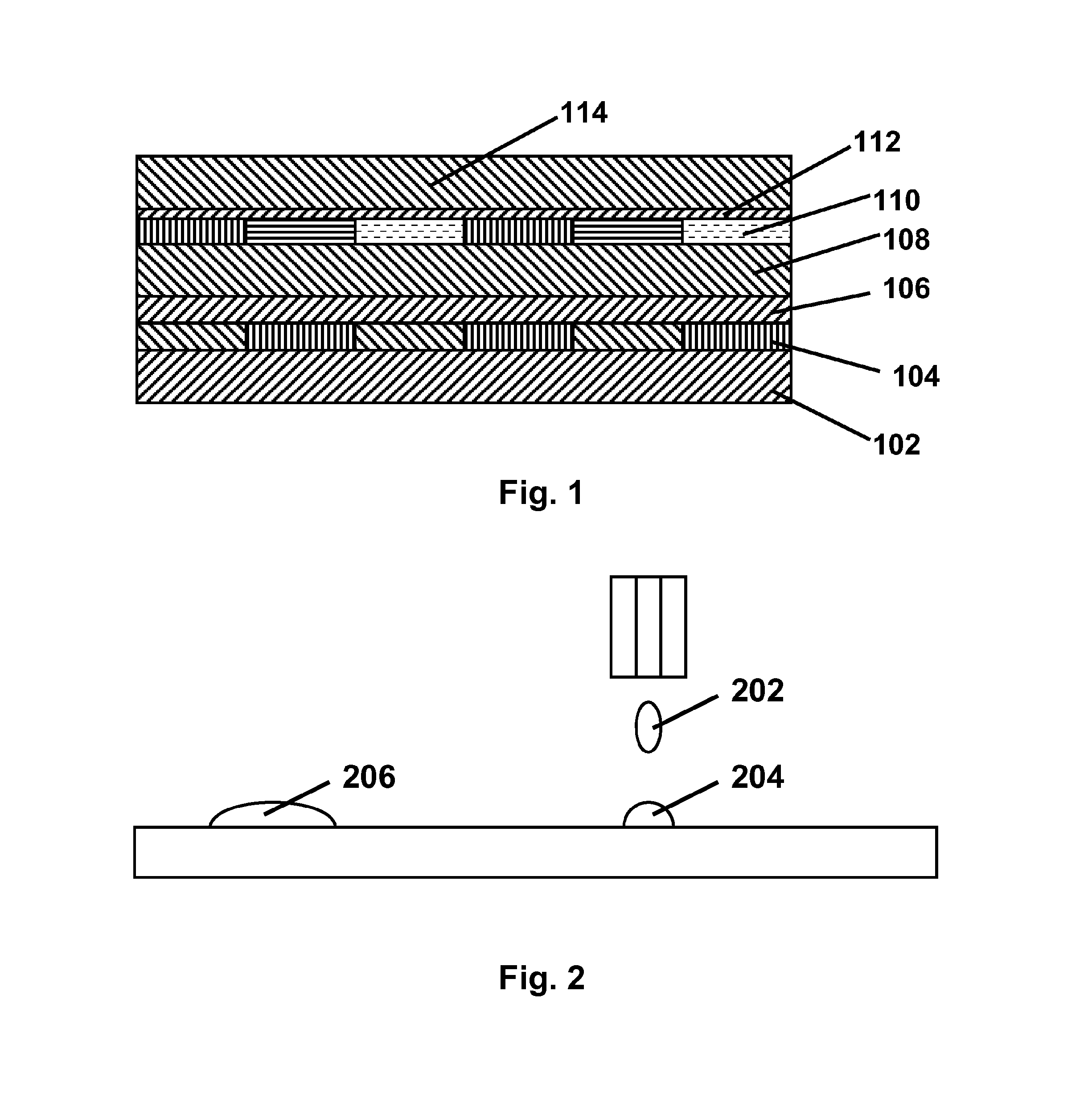

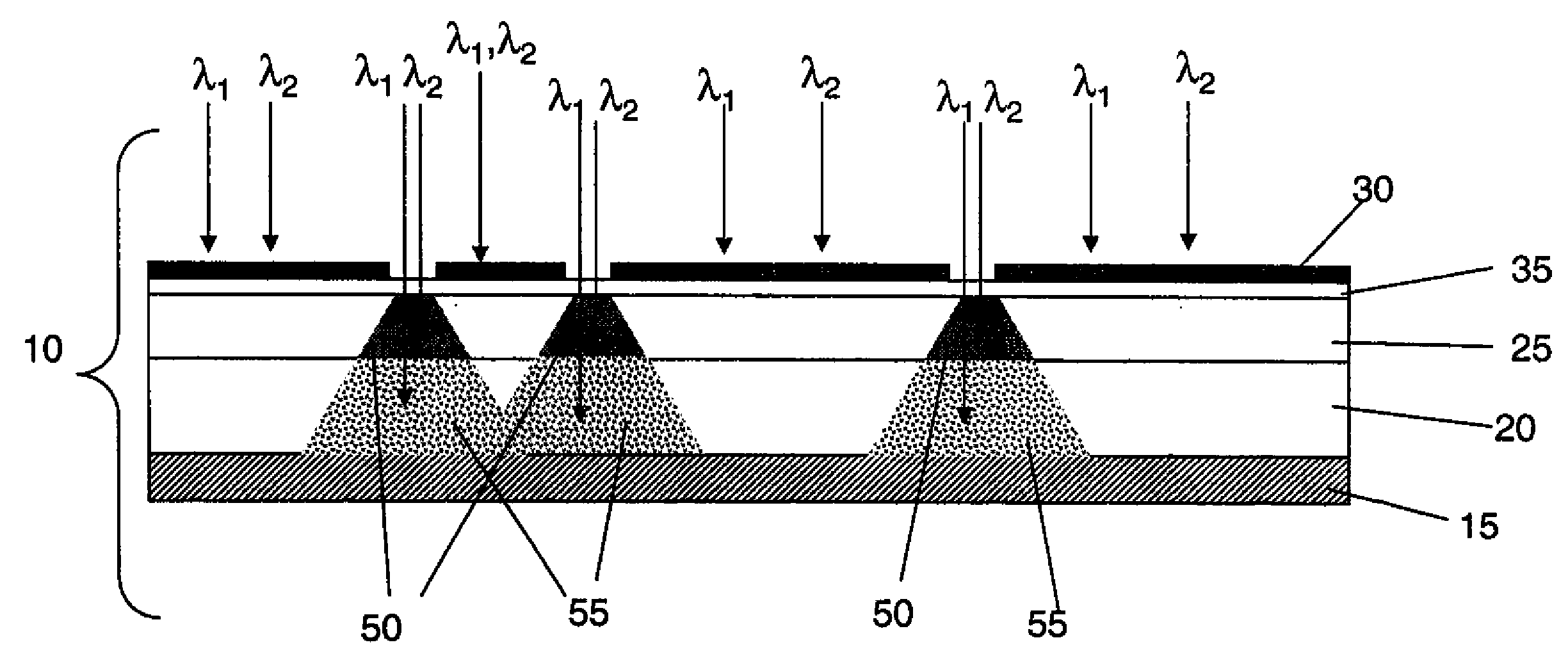

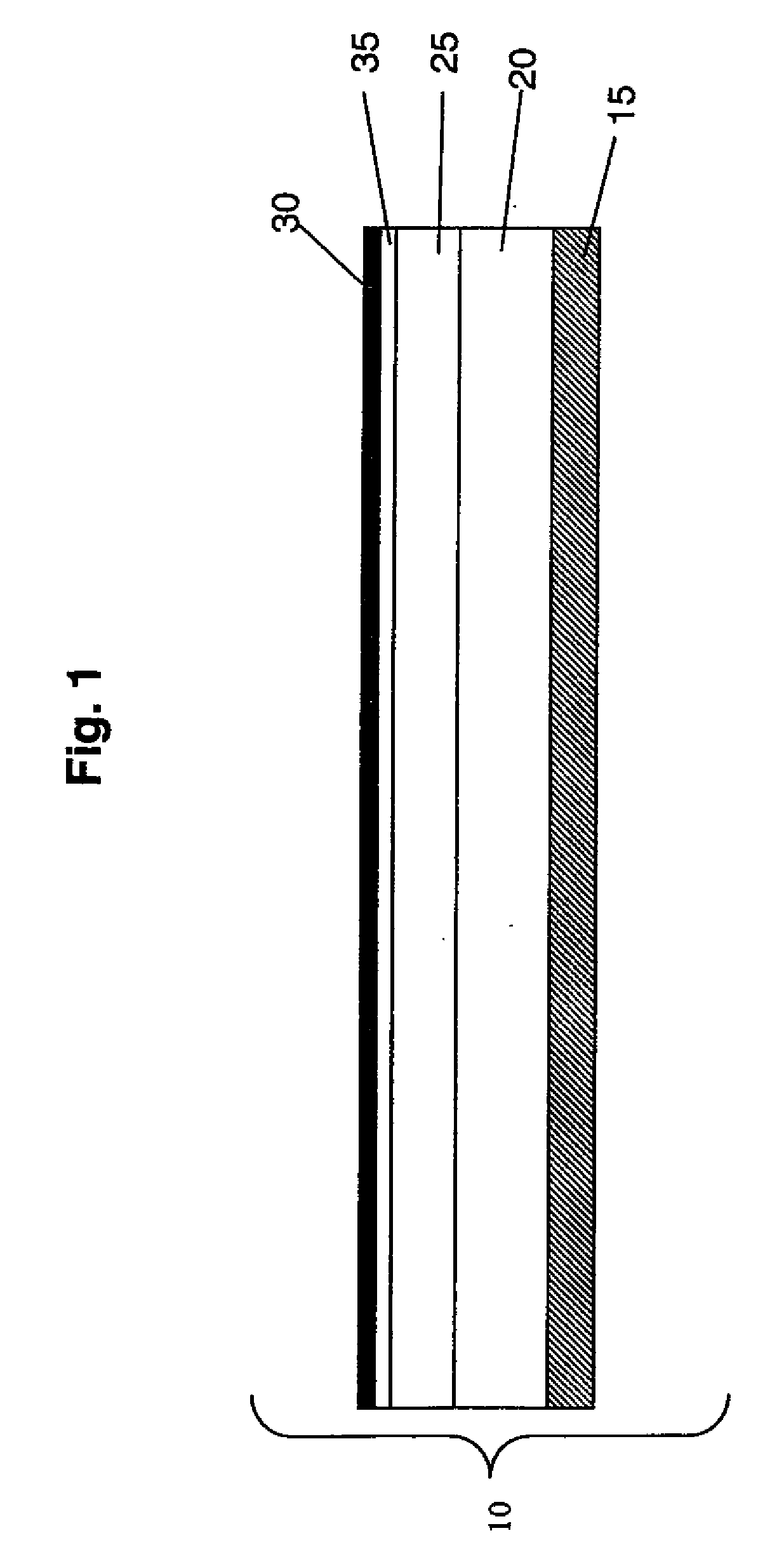

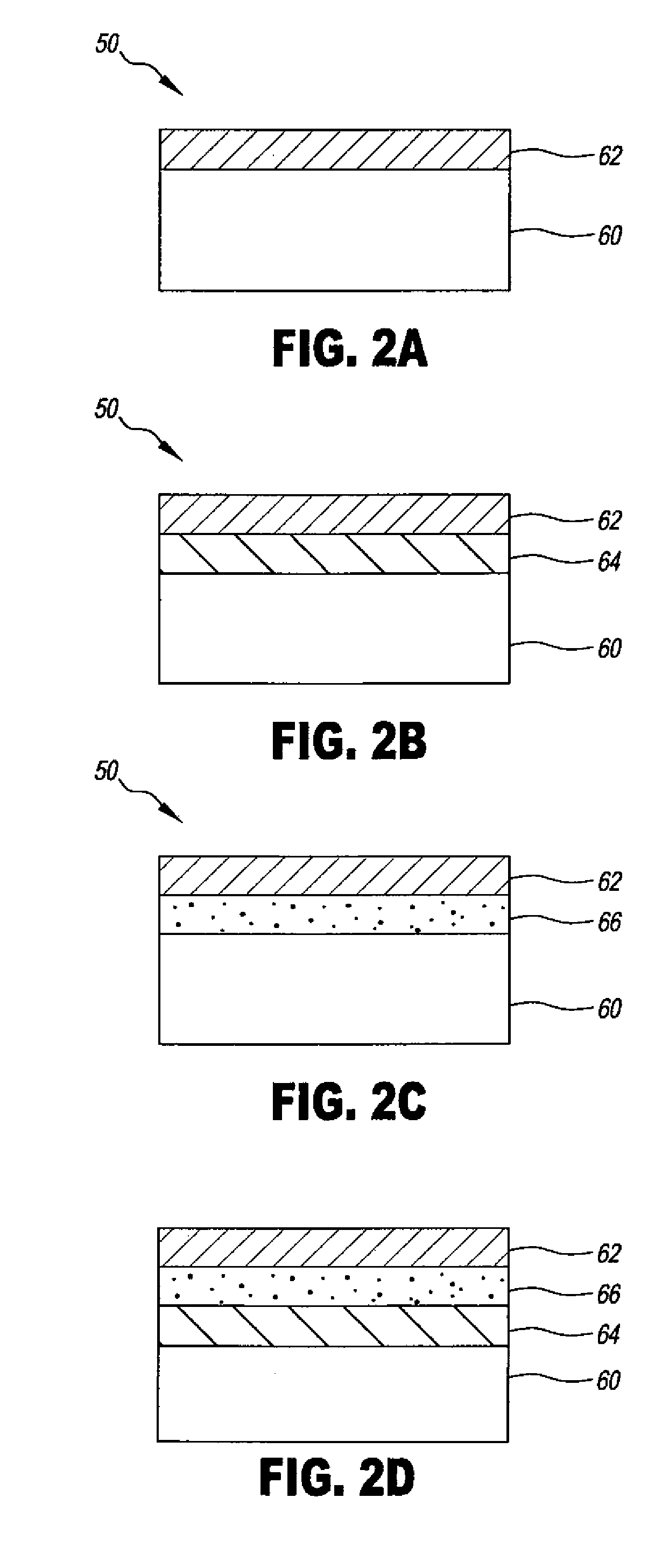

Flexographic element and method of imaging

InactiveUS20100143840A1Without any loss in strengthEnhance the imagePhotosensitive materialsSemiconductor/solid-state device manufacturingRelief printingPhysics

A relief (or flexographic) printing precursor has first and second radiation-sensitive layers, or a plurality of radiation-sensitive layers. The first radiation-sensitive layer is sensitive to a first imaging radiation having a first λmax. The second radiation-sensitive layer is disposed on the first radiation-sensitive layer and is sensitive to a second imaging radiation having a second λmax that differs from the first λmax by at least 25 nm. An infrared radiation ablatable layer can be present and is opaque or insensitive to the first and second imaging radiations and contains an infrared radiation absorbing compound. These relief printing precursors can be used to prepare flexographic printing plates, cylinders, or sleeves where the ablatable layer is used to form an integral mask on the element. Use of the invention provides a relief image without any loss in the strength of the small dots and can be carried out using multiple irradiation steps using the same apparatus.

Owner:EASTMAN KODAK CO

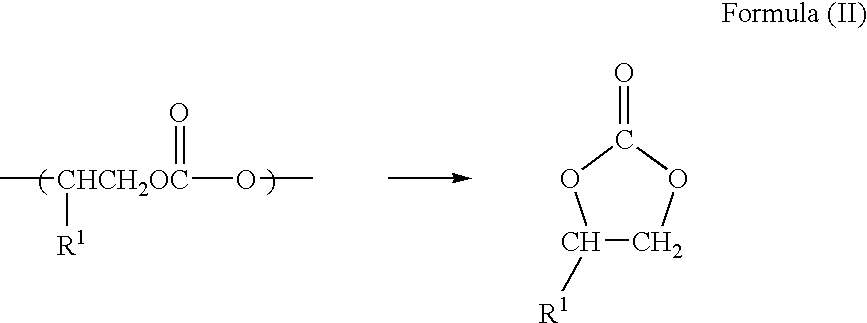

Process for preparing a flexographic printing plate

InactiveUS7122295B2Easy to disassembleQuality improvementPhotosensitive materialsPhoto-taking processesPolymer sciencePolymer chemistry

Owner:DUPONT ELECTRONICS INC +1

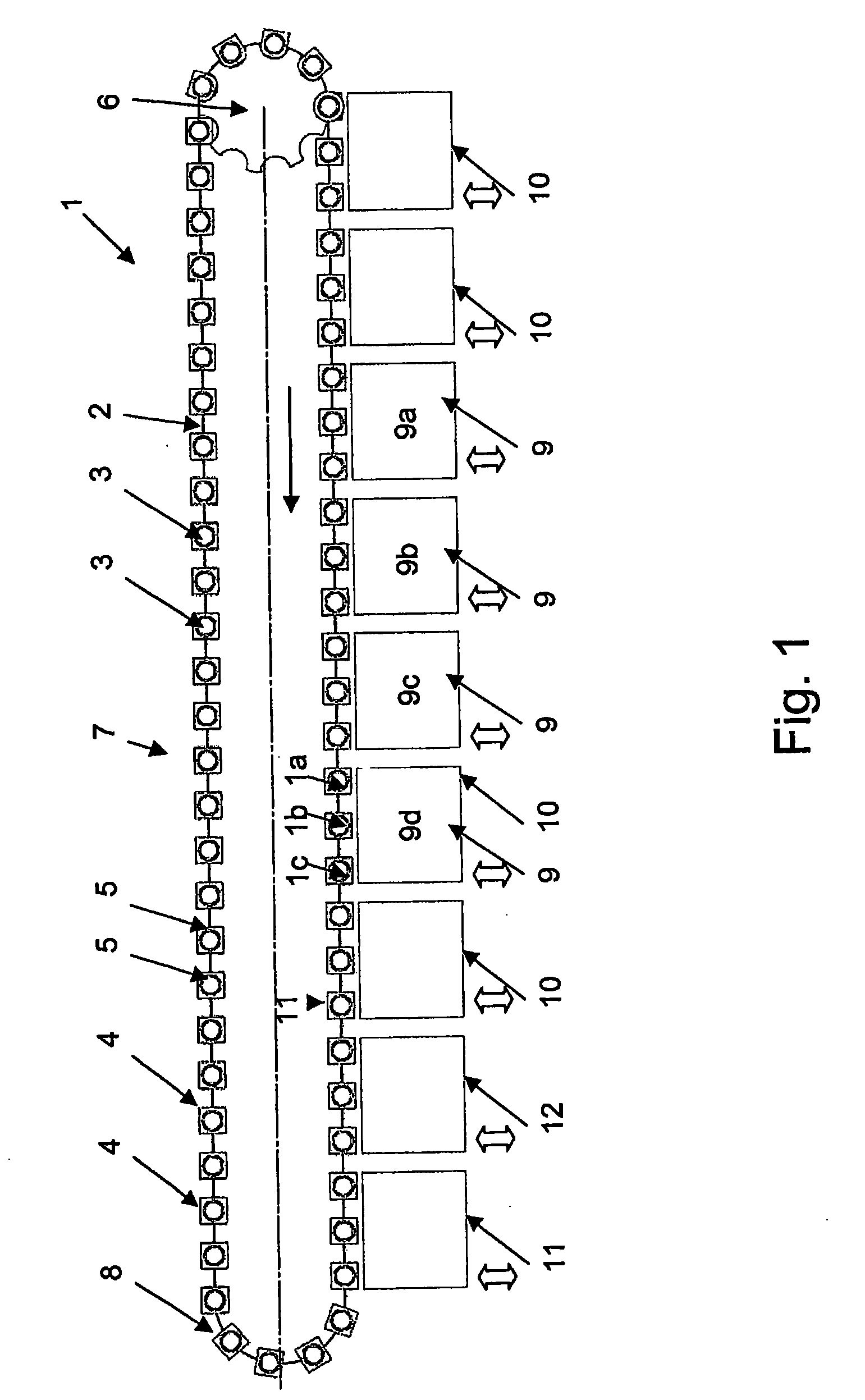

Modular linear printing press for printing hollow articles by means of different printing processes

InactiveUS20110067584A1Increase productionMethod is differentScreen printersTypewritersScreen printingTransport system

A linear printing machine with exchangeable printing modules for printing on hollow bodies. The machine includes a transport system including a drive, using which the hollow bodies to be printed on are transported through the linear printing machine and at least a first printing station and a second printing station which is arranged downstream of the first printing station in the conveying direction of the hollow bodies. At least one drying station dries the ink on the hollow bodies which have been printed on. A machine controller controls at least the transport of the hollow bodies through the linear printing machine, wherein each of the printing stations is prepared to accommodate a printing module comprising a drive of its own, and wherein the printing module can be connected to the machine controller via an interface, wherein the printing modules print on the hollow bodies using a printing method selected from screen printing and / or flexographic printing and / or offset printing and / or cold embossing and / or hot embossing and / or laser colour transfer and / or inkjet.

Owner:POLYTYPEAG

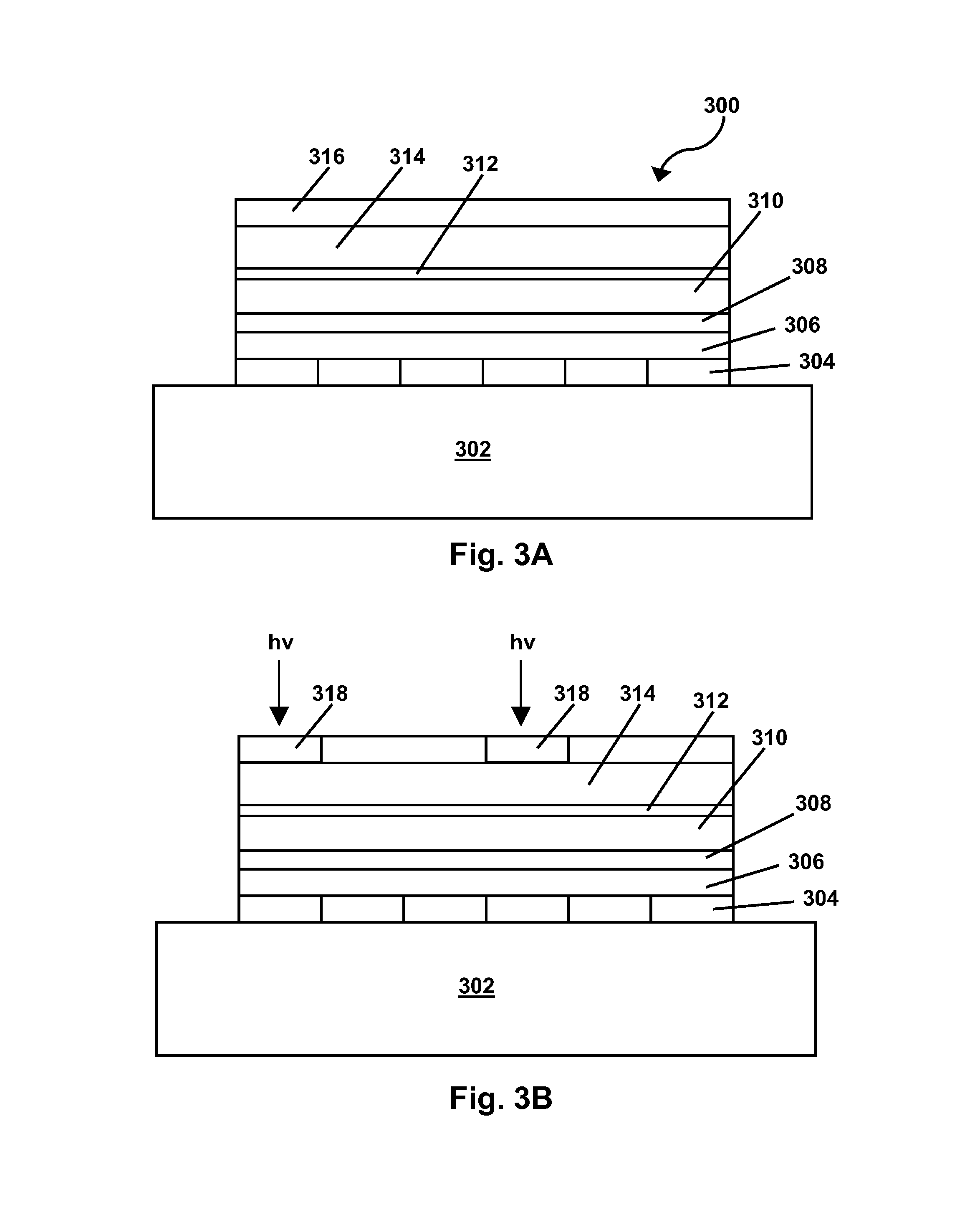

System and method employing secondary back exposure of flexographic plate

ActiveUS20100028815A1Photography auxillary processesDuplicating/marking methodsEngineeringImage area

A method of making a relief image on a flexographic print plate including imagewise exposing a mask including an imageable material disposed on a mask substrate to form an imaged mask having a mask image in the imageable material disposed on the mask substrate, the mask image including mask image areas each having a highlight value. The method further includes laminating the imaged mask to a front surface of a flexographic printing plate precursor, and exposing selected areas of the flexographic printing plate precursor to an imagewise addressable curing radiation via a back surface of the flexographic printing plate precursor based on the highlight values of corresponding mask image areas of the mask image.

Owner:MIRACLON CORP

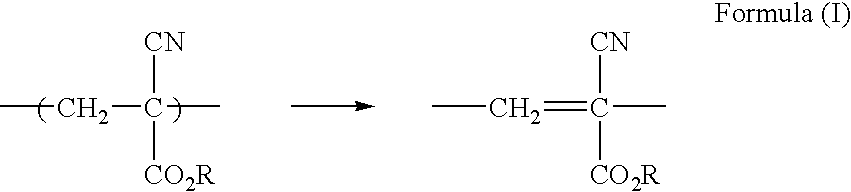

Laser-engraveable flexographic printing precursors

InactiveUS20120240802A1Enhance the imageIncrease elasticityMaterial nanotechnologyLayered productsElastomerPolyolefin

A laser-engravable flexographic printing precursor or other patternable material can be laser-engraved to provide a relief image. The relief image is formed in an elastomeric, relief-forming, laser-engravable layer comprising a thermoplastic elastomeric nanocrystalline polyolefin that is melt processable. The laser-engraveable composition can be readily recycled and reformed into another flexographic printing plate precursor.

Owner:EASTMAN KODAK CO

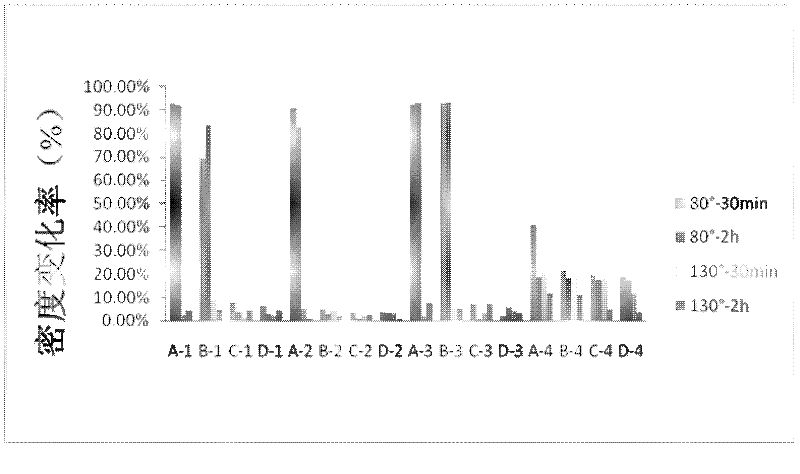

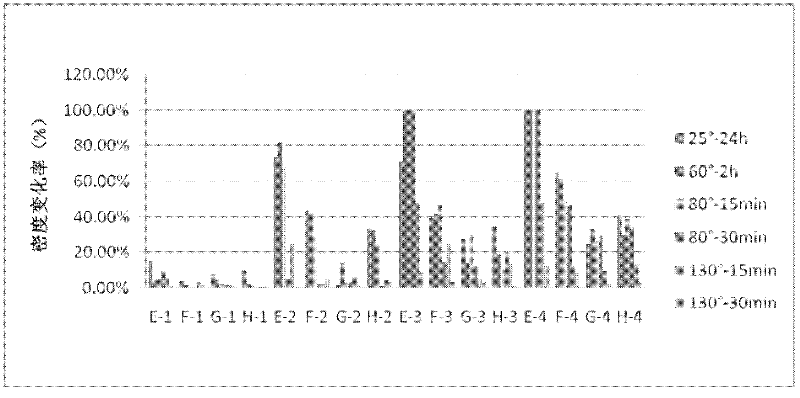

Flexographic printing water-based ink for food packaging

The invention relates to a flexographic printing water-based ink for food packaging, which comprises an acrylic resin binder, an addition agent, a colorant and deionized water. The flexographic printing water-based ink is good in moving resistance after solidified crosslinking is adopted and is prepared by premixing, sanding and dispersing water-based polyacrylic acid resin having no toxic effect on the human body, food-grade colorants, addition agents and the like according to a fixed proportion. The obtained ink utilizes flexographic printing to form pictures, and after high-temperature drying treatment is performed to a sample, the ink is high in adhesion, resists hot water of 80 DEG C and has a certain acidproof and alkaliproof performance. The water-based ink can replace traditional solvent ink, is applied to various plastics and paper printing, and is particularly used for the printing surface (such as the surface of a paper plate) directly contacted with food or the printing surface of a toy possibly closely contacted with sense organs of infants, thereby greatly improving safety performance.

Owner:银川市富邦印刷包装有限公司

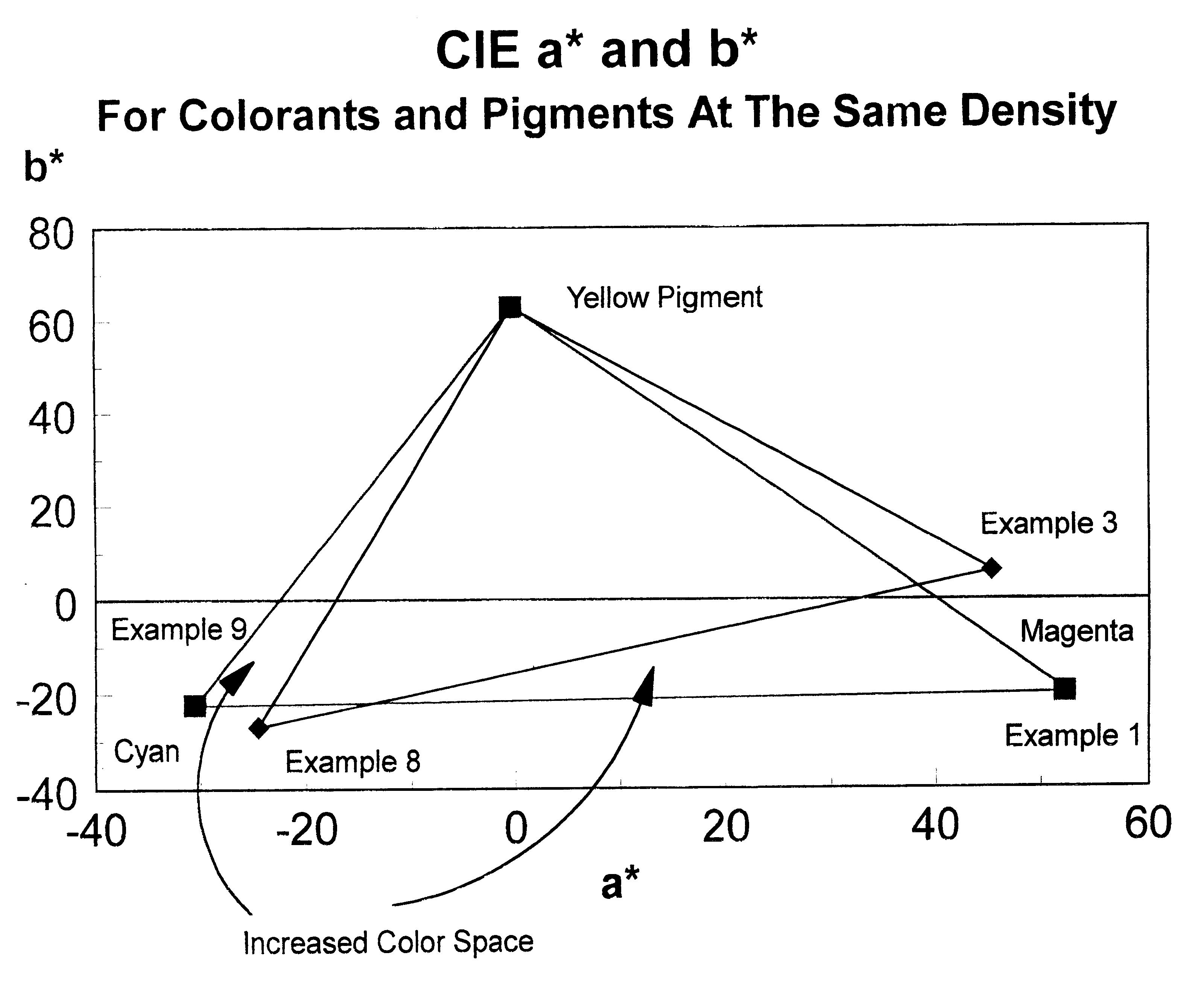

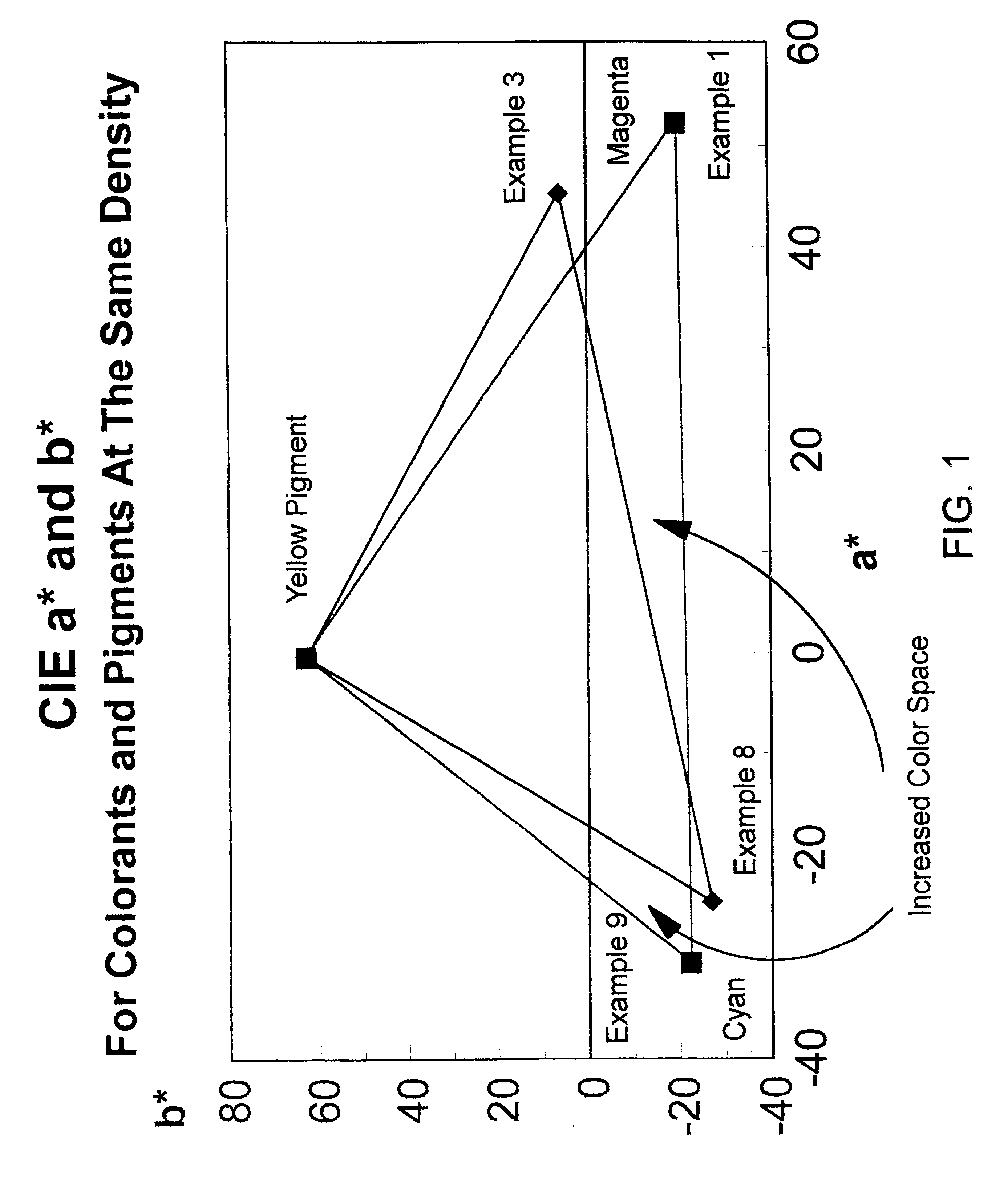

Inks exhibiting expanded color-space characteristics for water-based printing

Novel magenta and cyan colorants for utilization within water-based inks are provided which exhibit improved chromatic properties. In particular, such colorants provide magenta or cyan colorations that exhibit increased color space characteristics, high water solubility, excellent compatability with impurities, and correspondingly cost-effectiveness for flexographic printing procedures. The methods of utilizing such colorants within flexographic printing processes are also encompassed within the invention.

Owner:MILLIKEN & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com