Patents

Literature

9621results about "Rotary presses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions and methods for use in three dimensional model printing

InactiveUS7300619B2Similar elasticitySimilar strengthButtonsLiquid surface applicatorsOrganic compoundPolymer chemistry

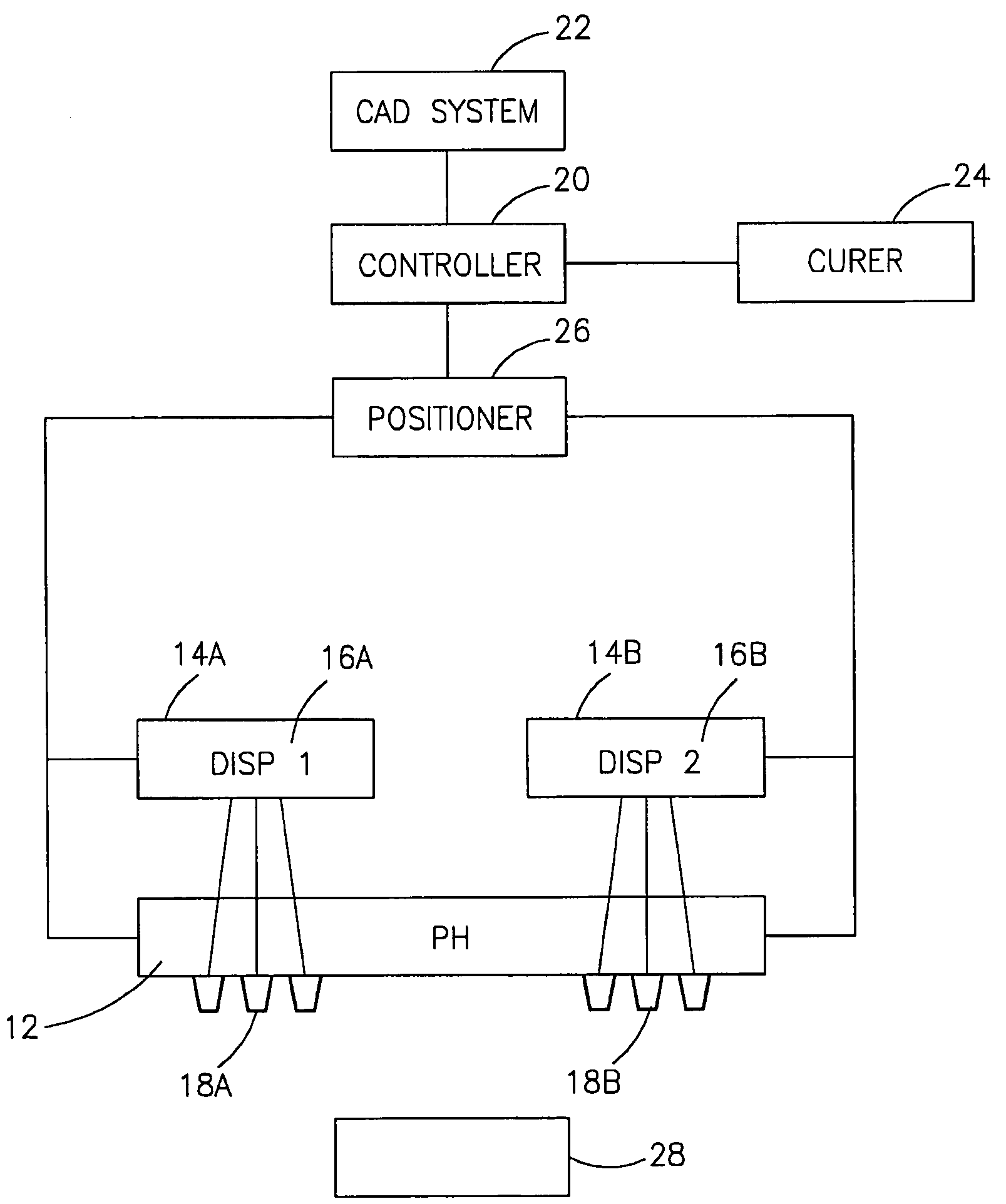

A pseudo composite material, may include, inter alia, a first phase and a second phase, wherein each phase may include, inter alia, an organic compound, wherein each phase comprising a multiplicity of construction layers, wherein the layers were deposited by ink-jet printing, wherein the pseudo composite material exhibits non-homogeneous three-dimensional structure. A method is disclosed for the preparation of a pseudo composite material. An apparatus is disclosed for printing a pseudo composite material. Furthermore, there is disclosed a method for printing a three-dimensional object using various suitable materials.

Owner:STRATASYS LTD

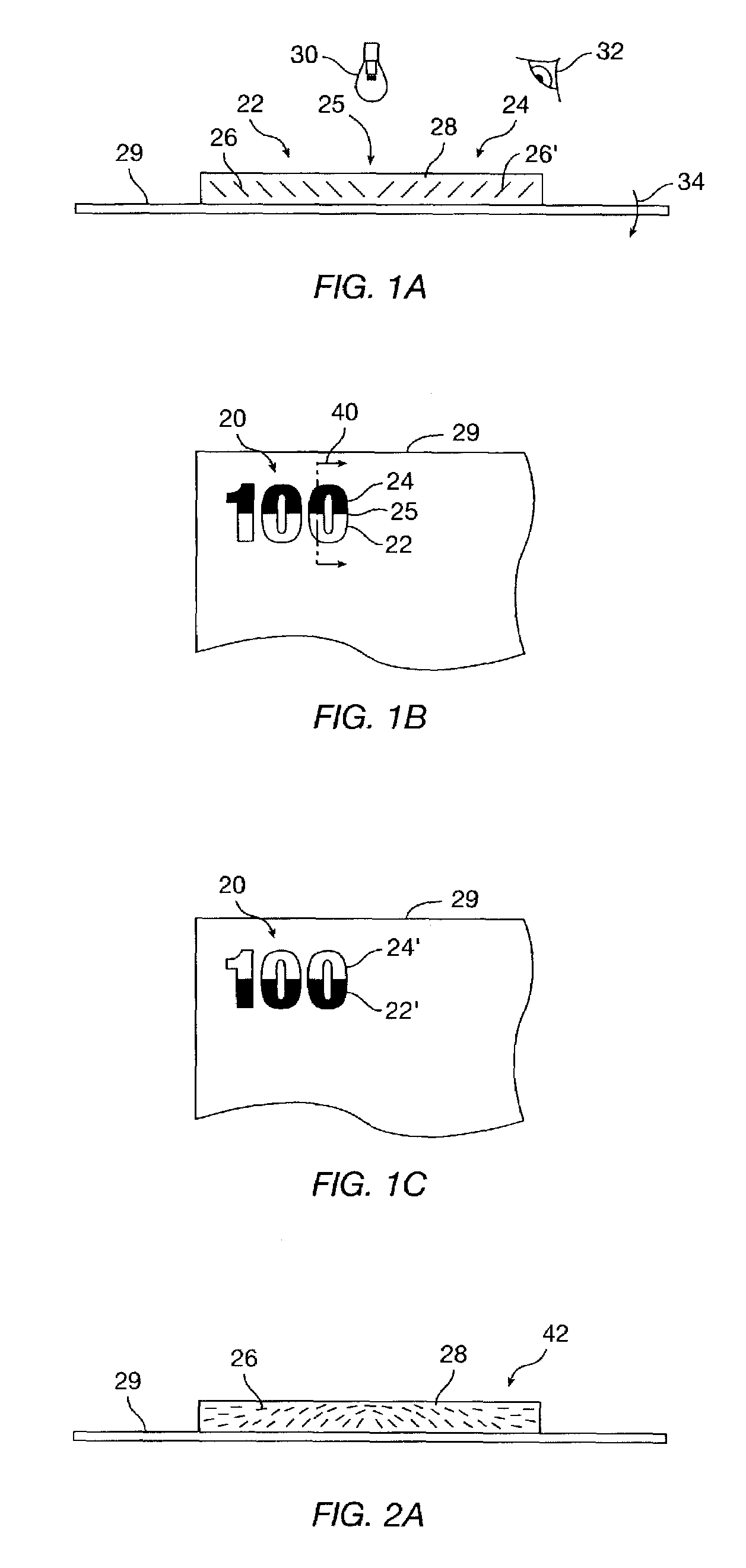

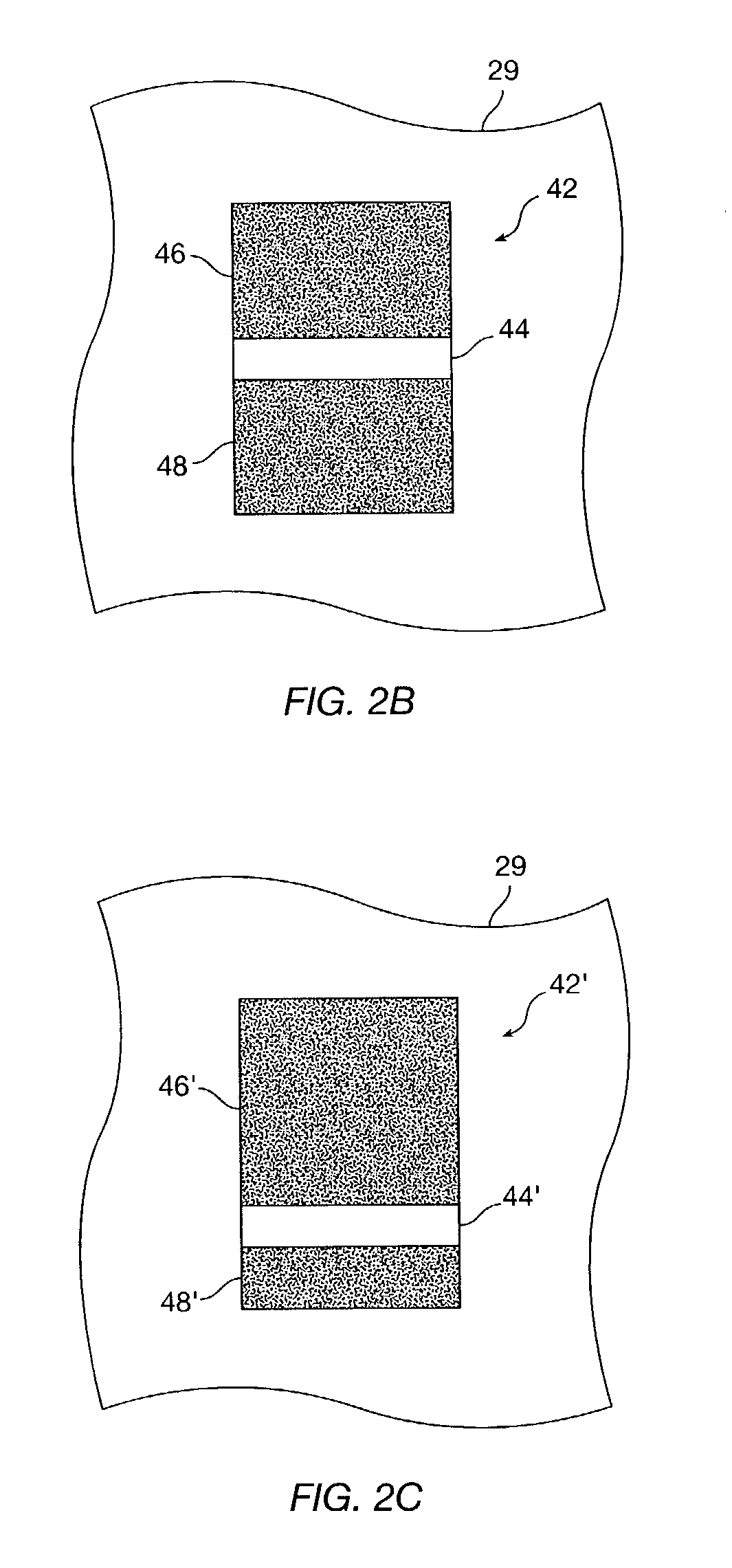

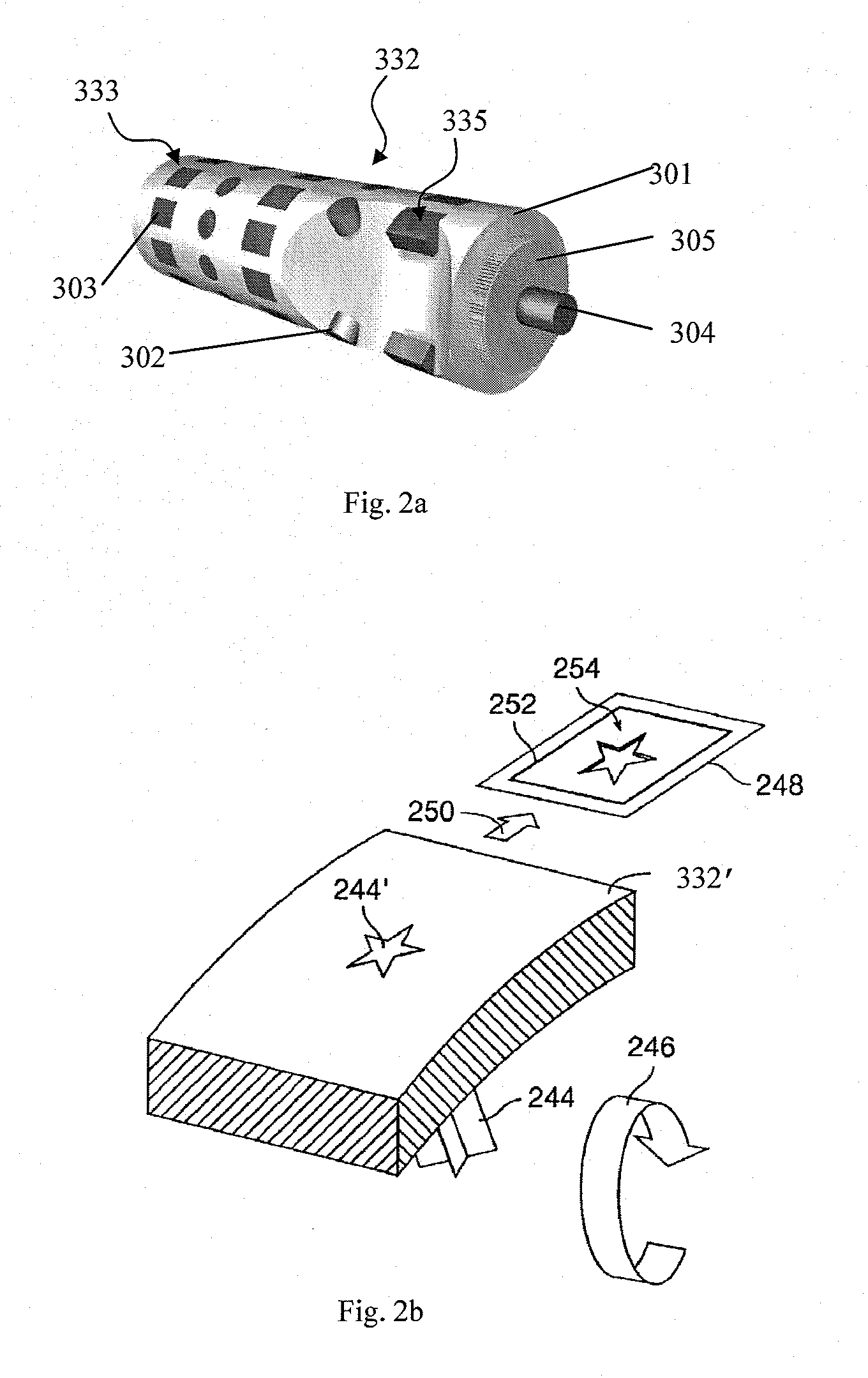

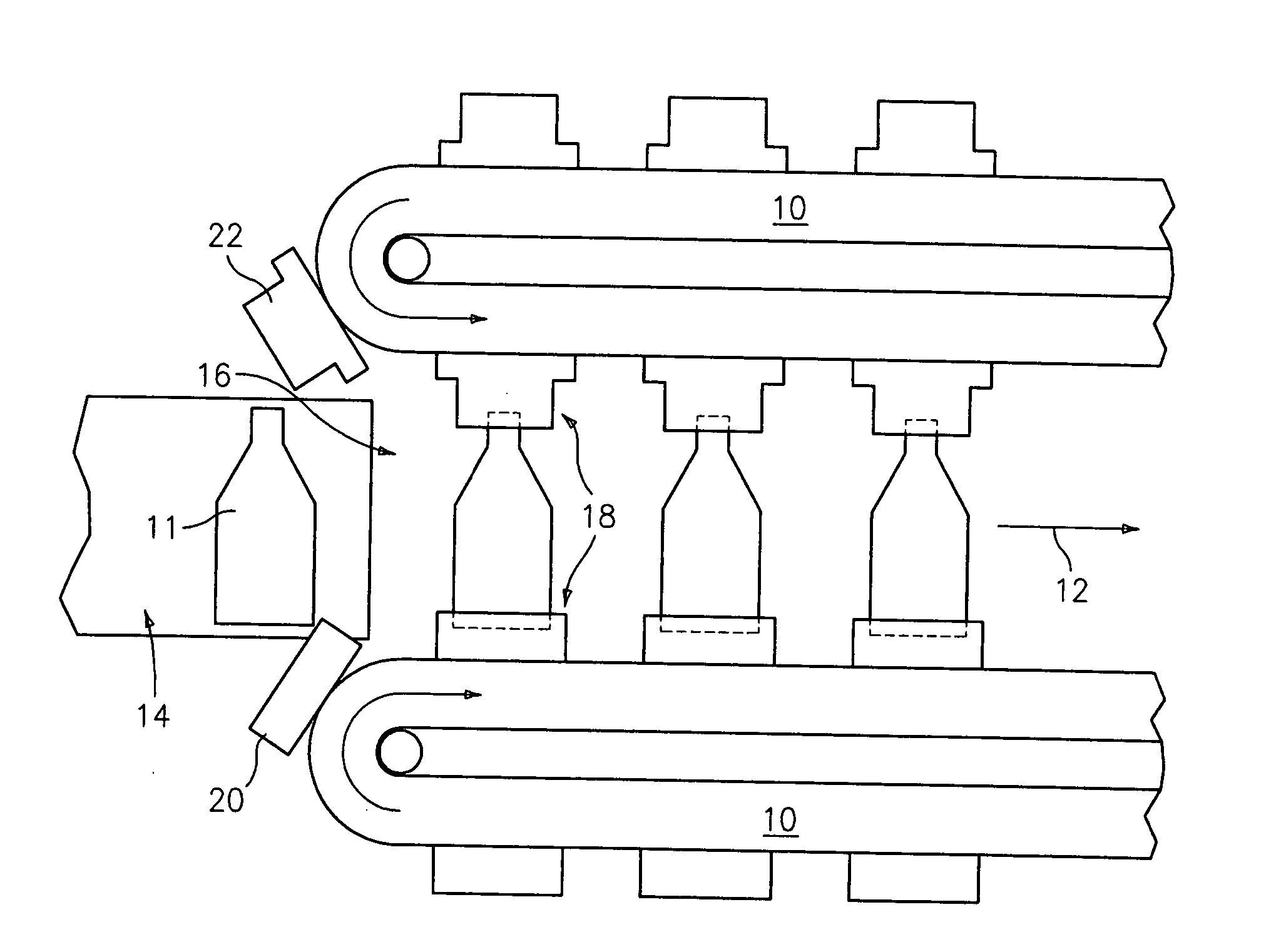

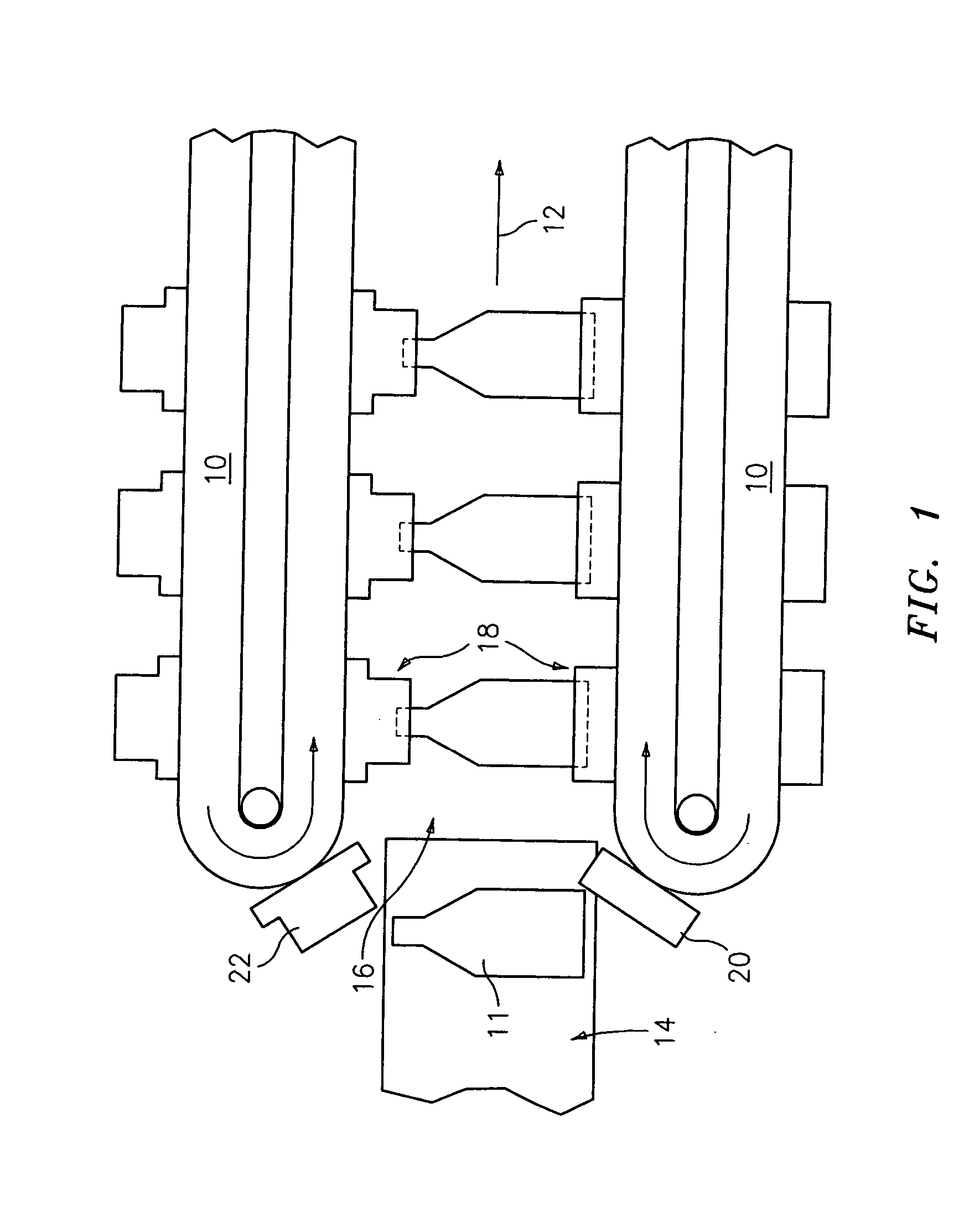

Method and apparatus for orienting magnetic flakes

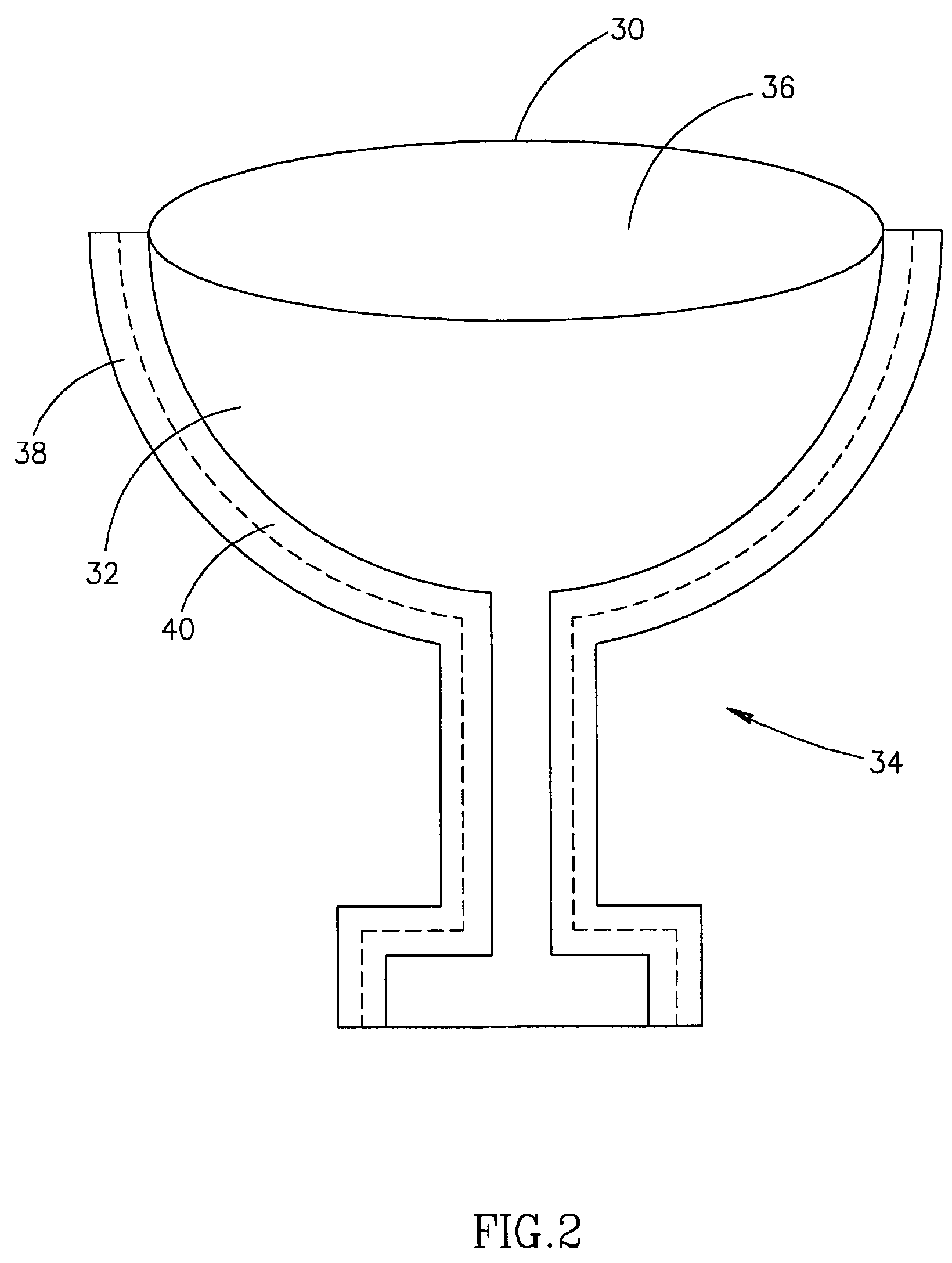

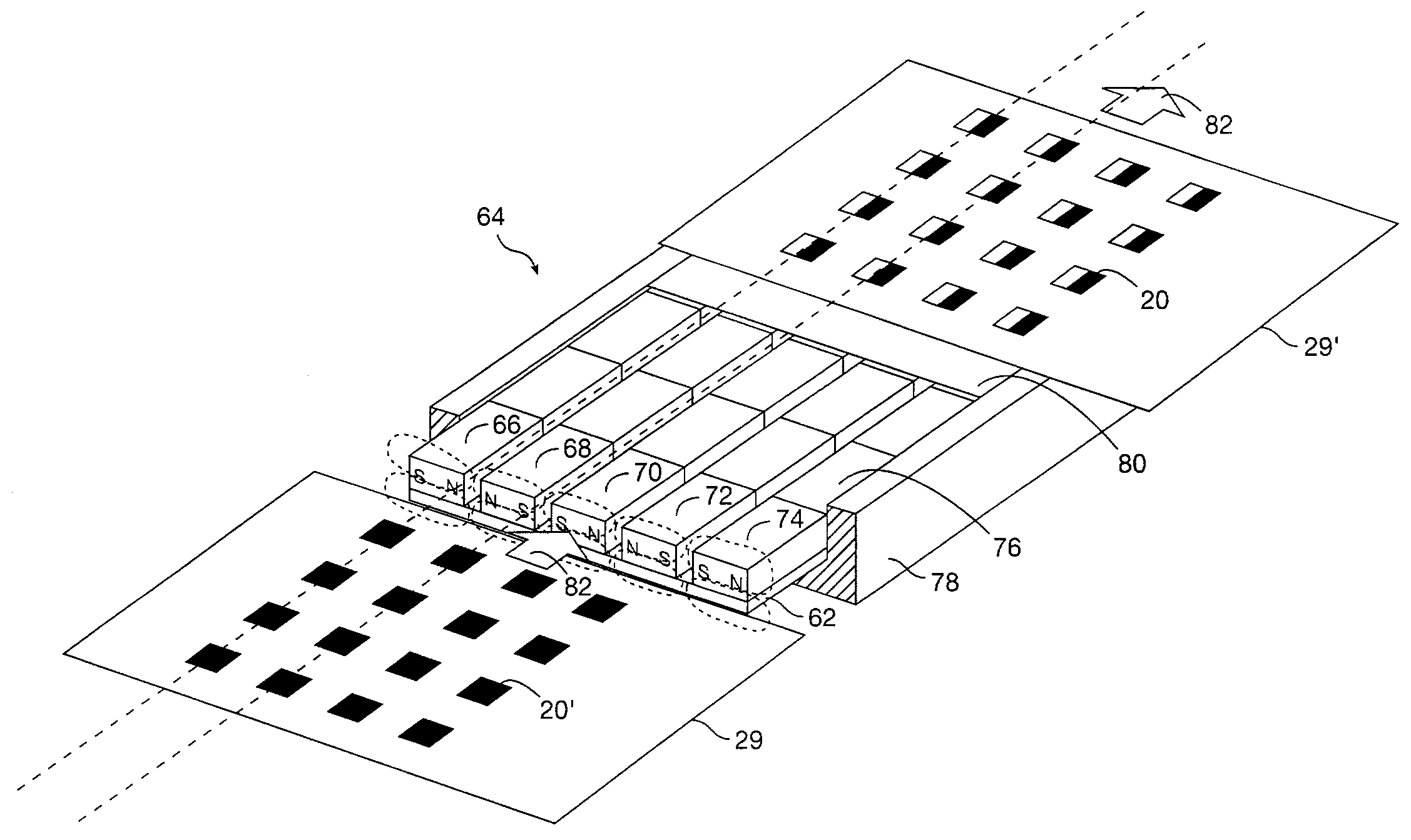

Apparatus and related methods align magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnets in a linear printing operation. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

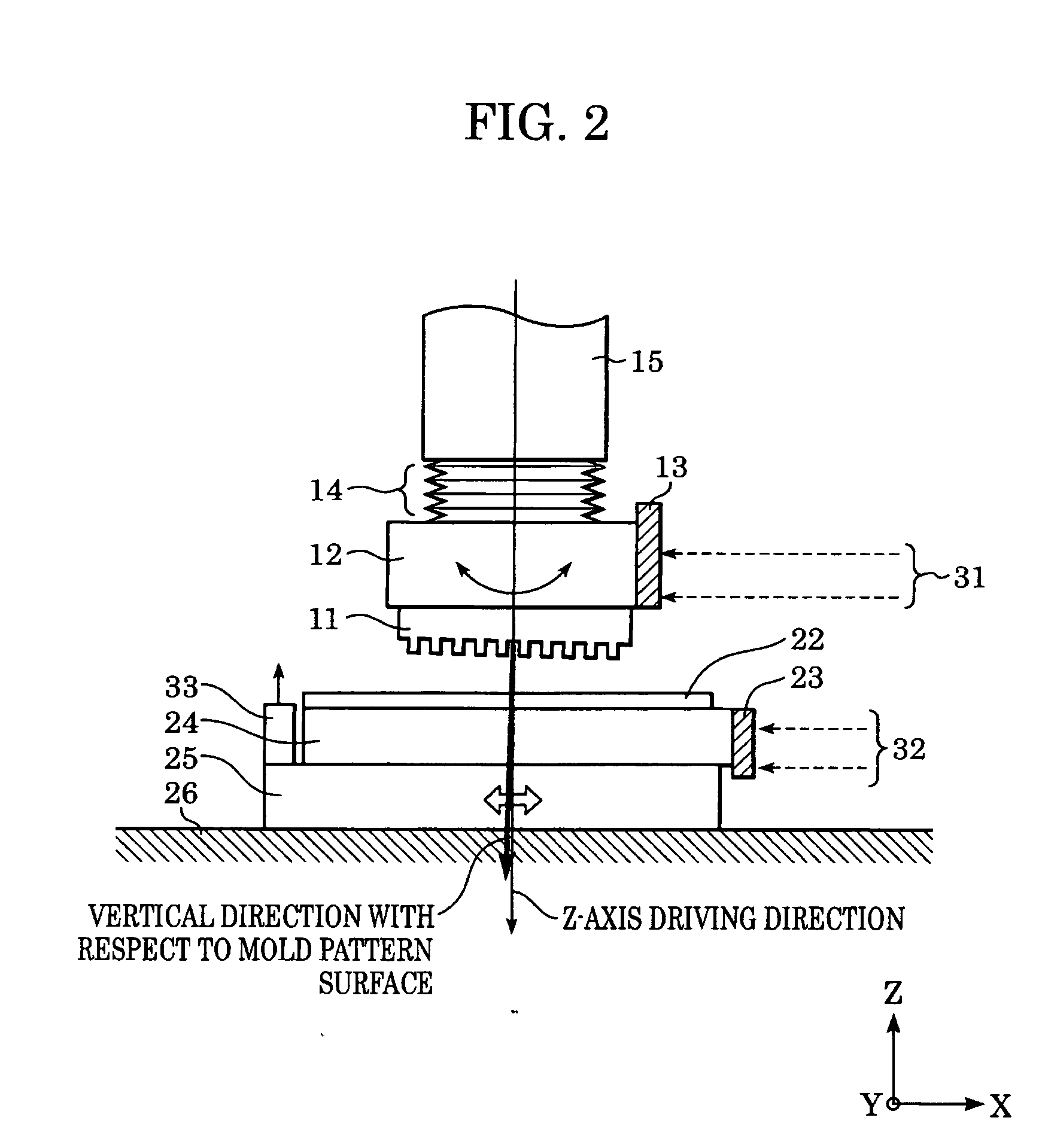

Pattern forming apparatus

InactiveUS20050064054A1High precision alignmentMechanical working/deformationTurning machine accessoriesMaterials scienceMachine press

Owner:CANON KK

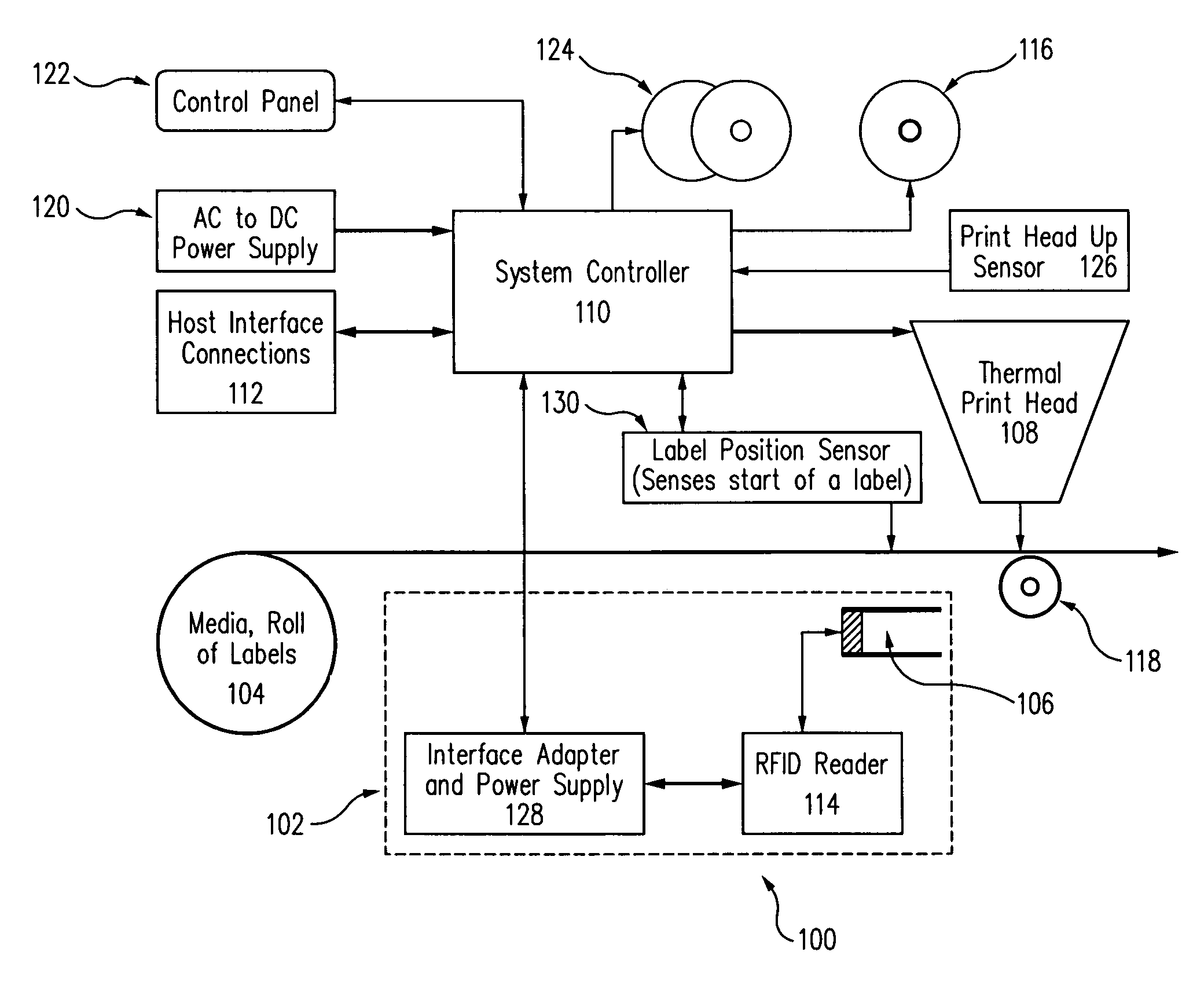

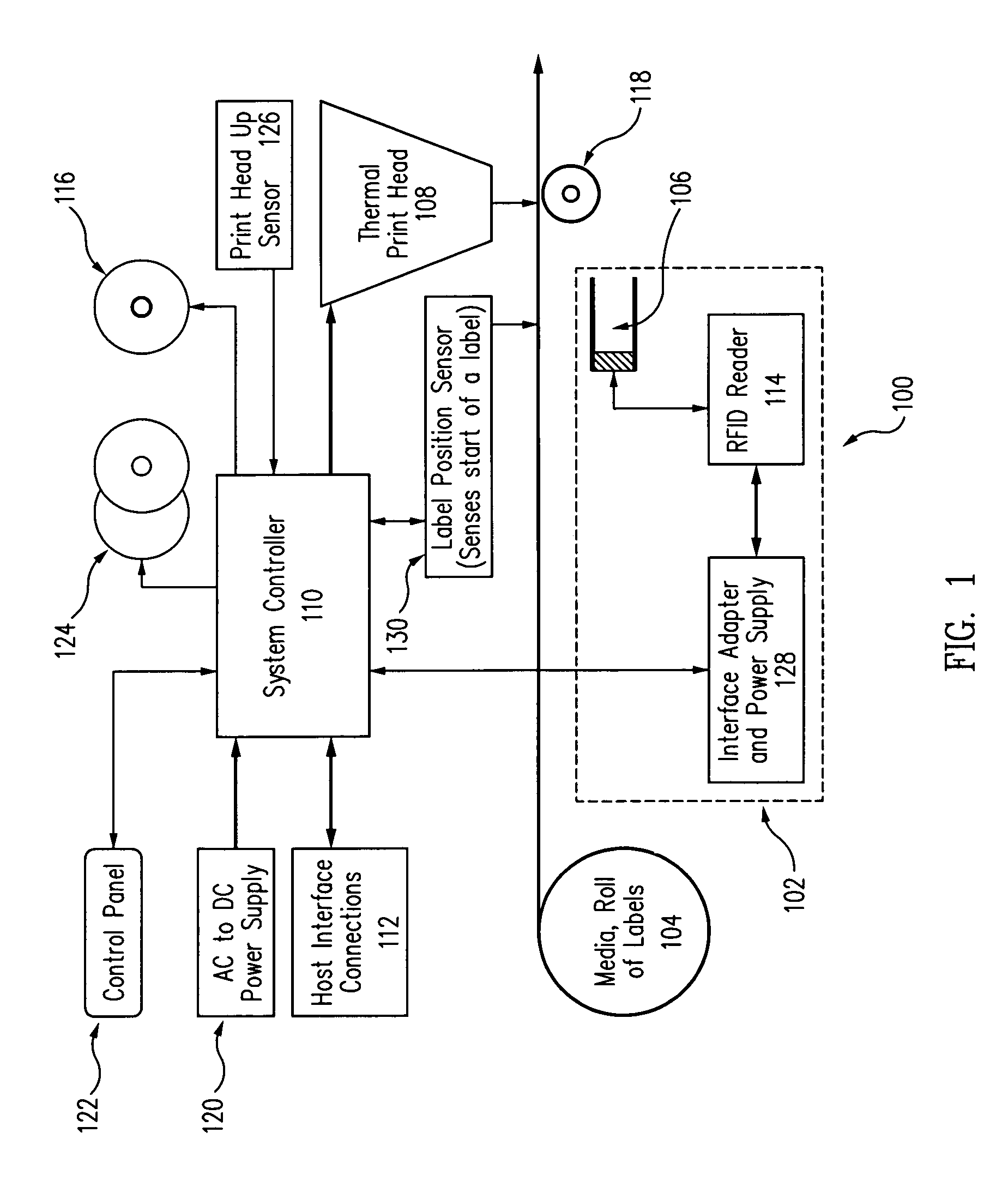

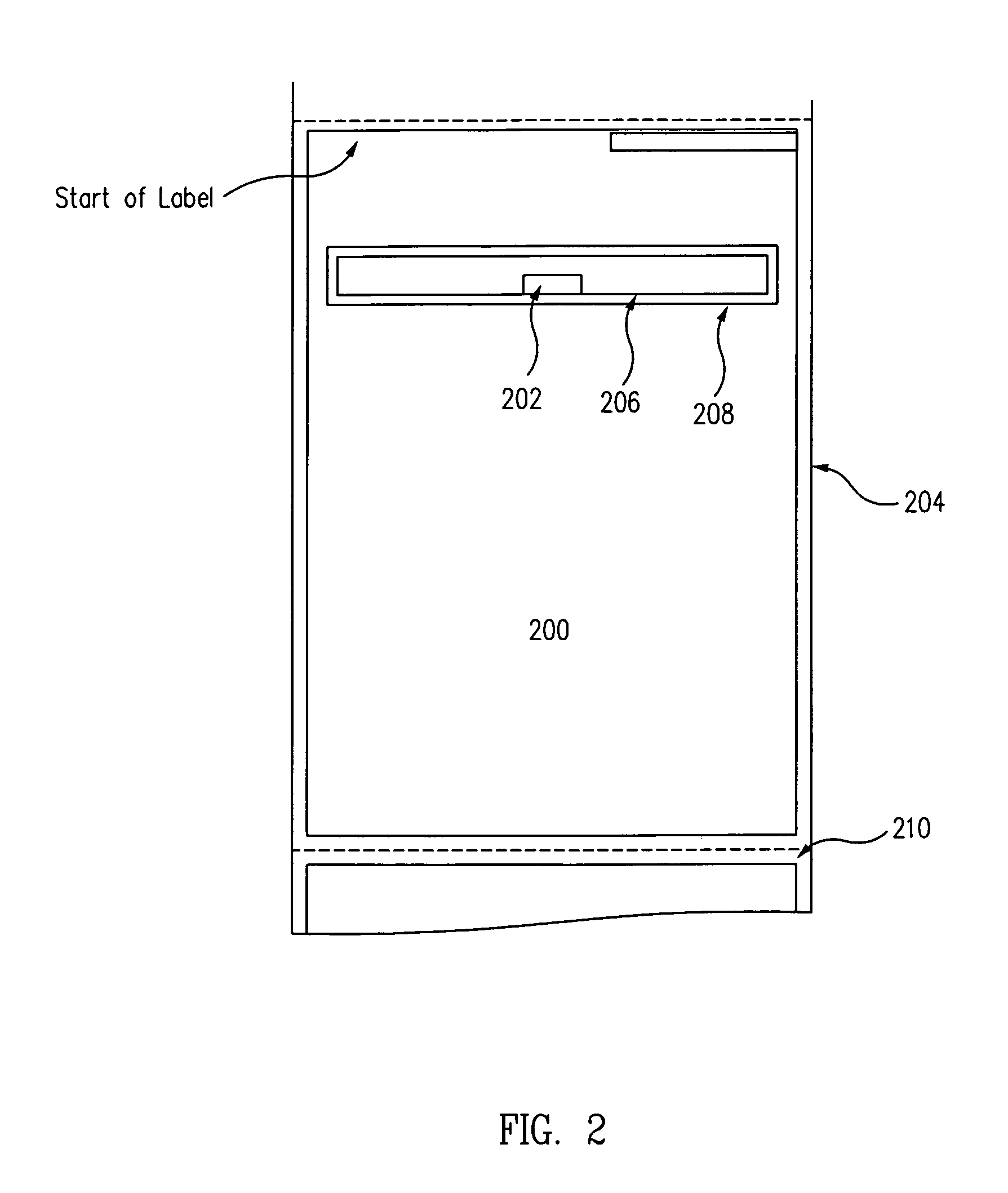

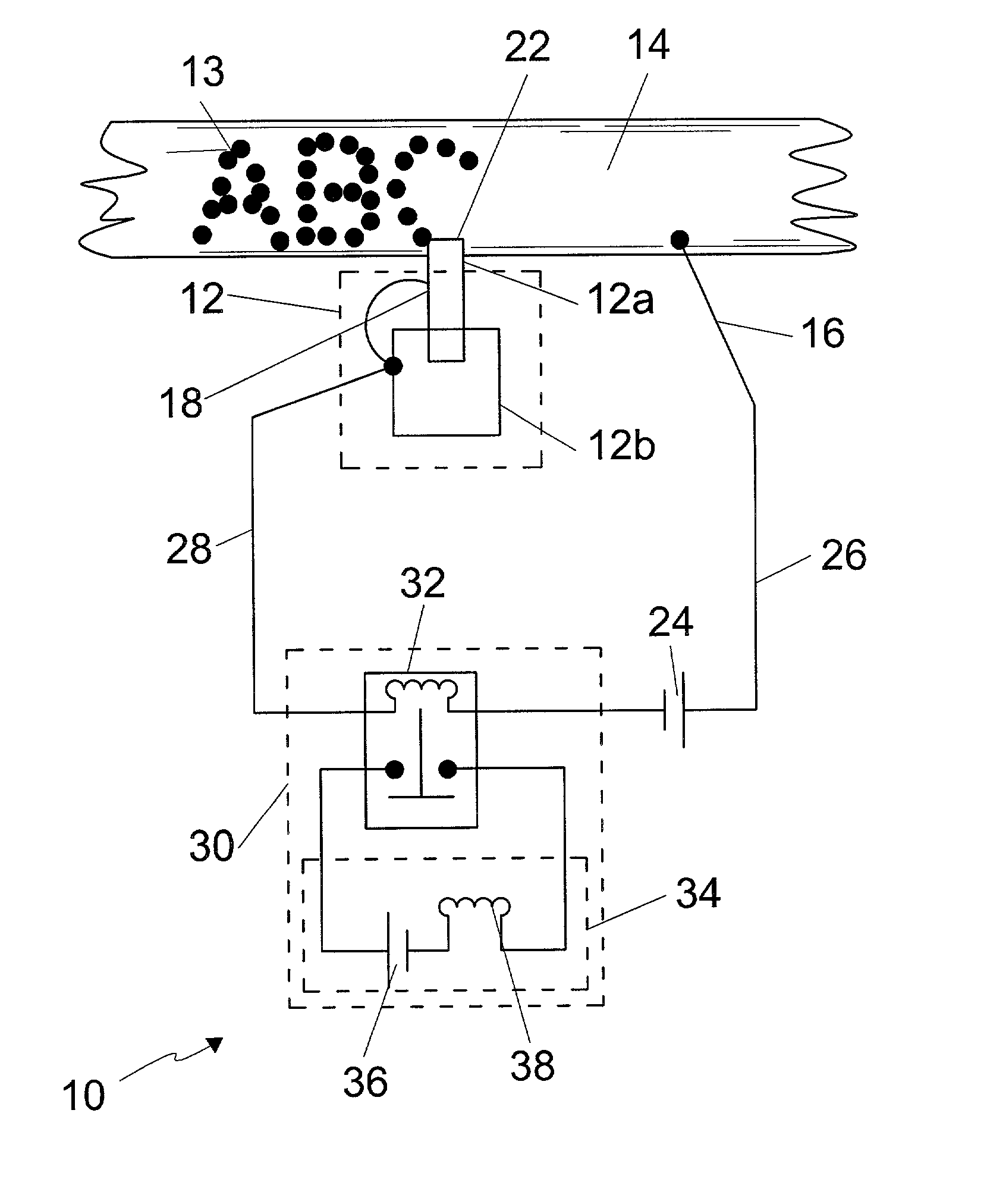

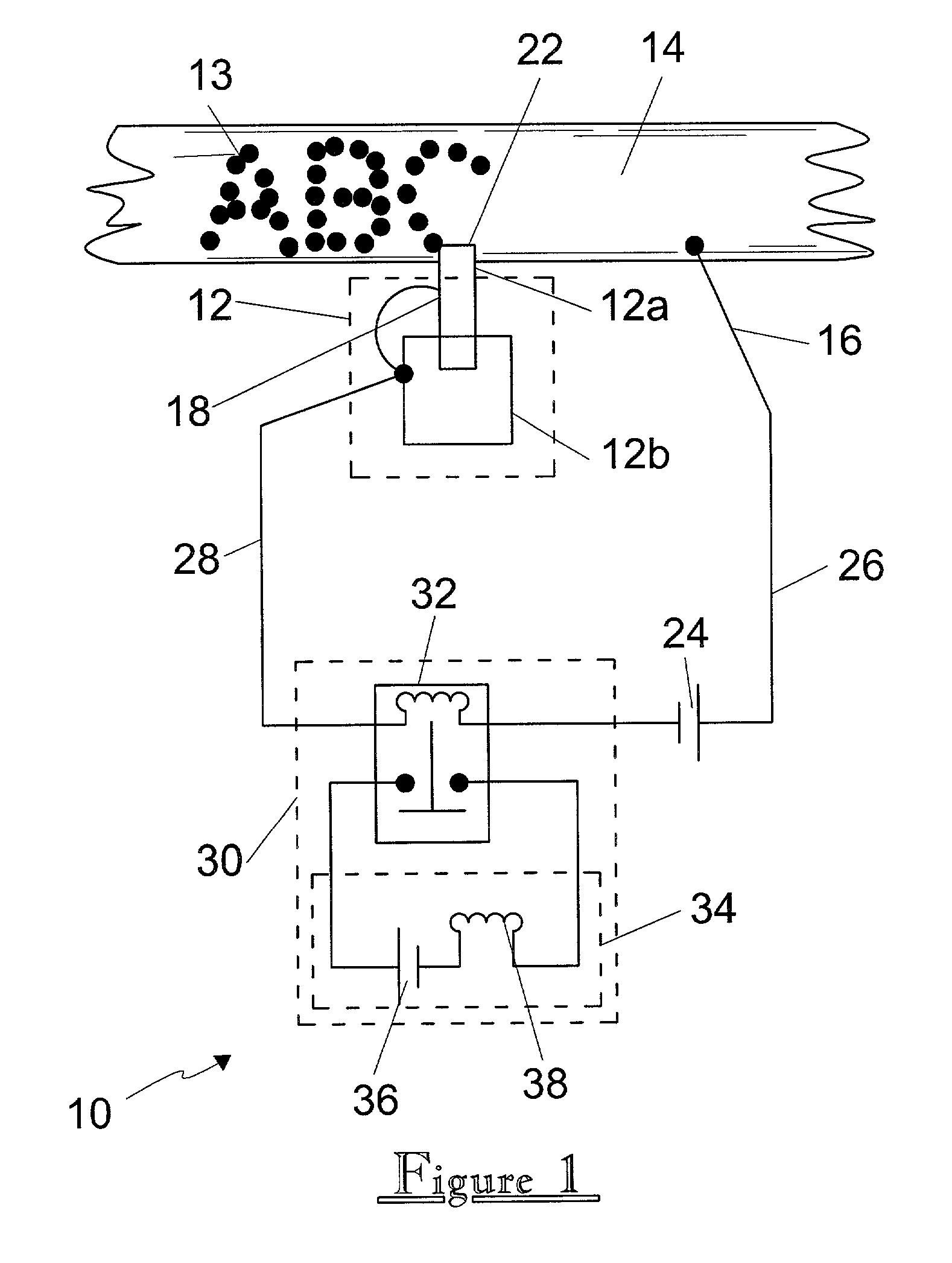

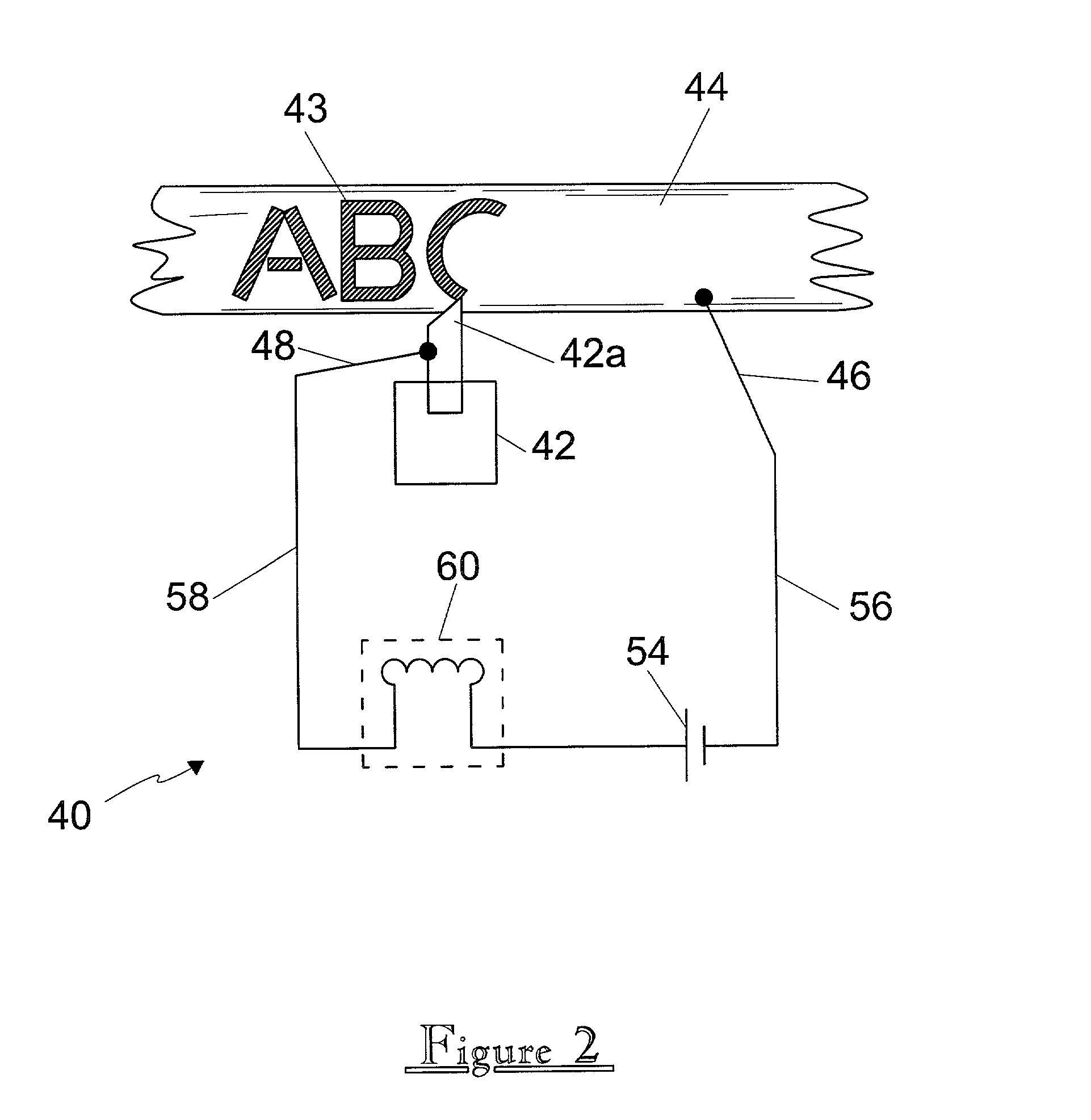

RFID tag, antenna, and printer system

InactiveUS6899476B1Ensure complianceEasy to migrateCharacter printing data arrangement from carrierError detection/correctionPhase splitterTransmission line

An RFID label with embedded tag is passed through an RFID antenna in a printer system, where the RFID antenna allows a roll of such labels to pass in close proximity to the antenna and still allow each individual RFID tag to be read and / or programmed. The RFID antenna module is formed with a transmission line coupled to an RF phase splitter, where in one embodiment, the transmission line is formed from two parallel conductive strips.

Owner:TSC AUTO TECH

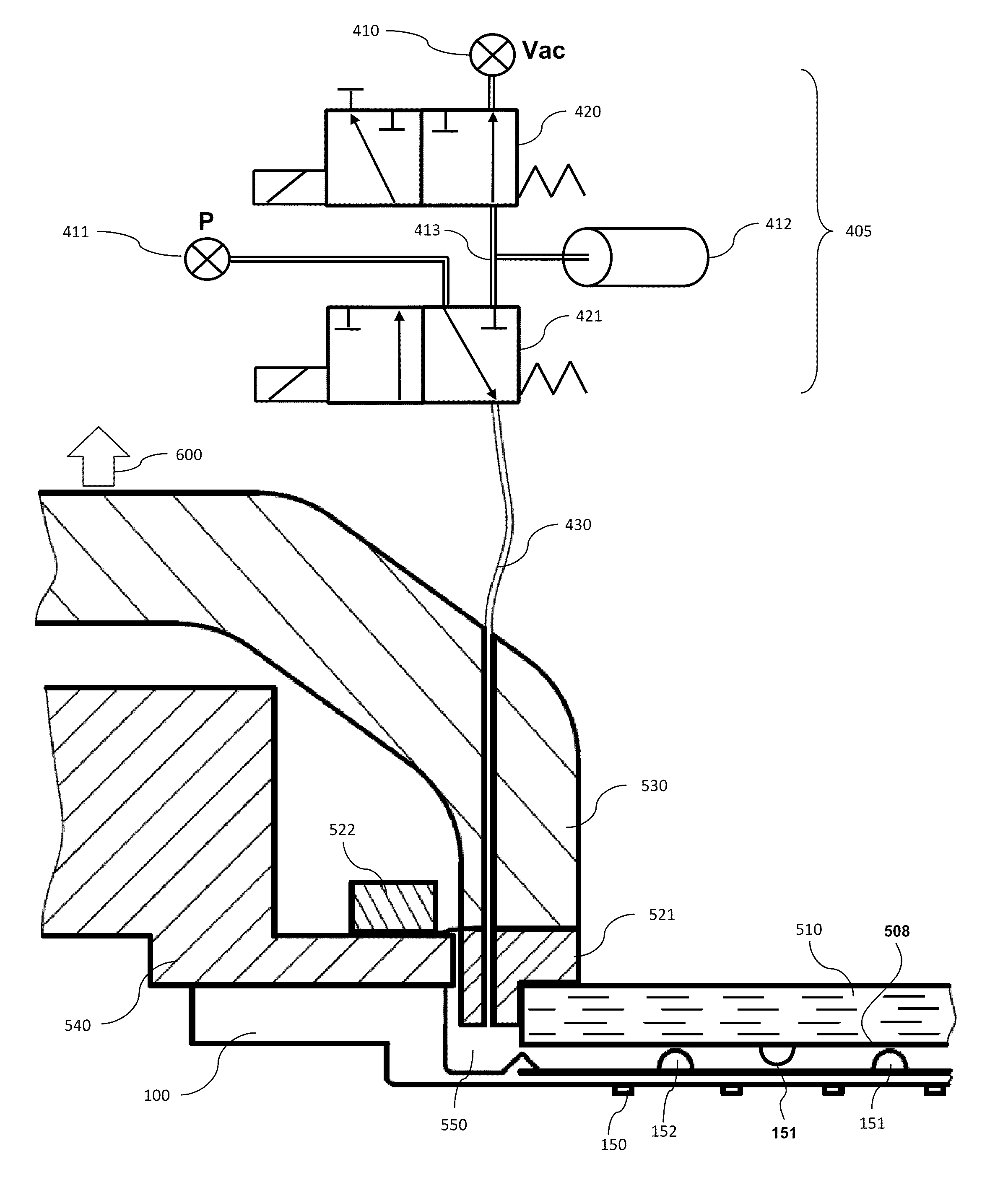

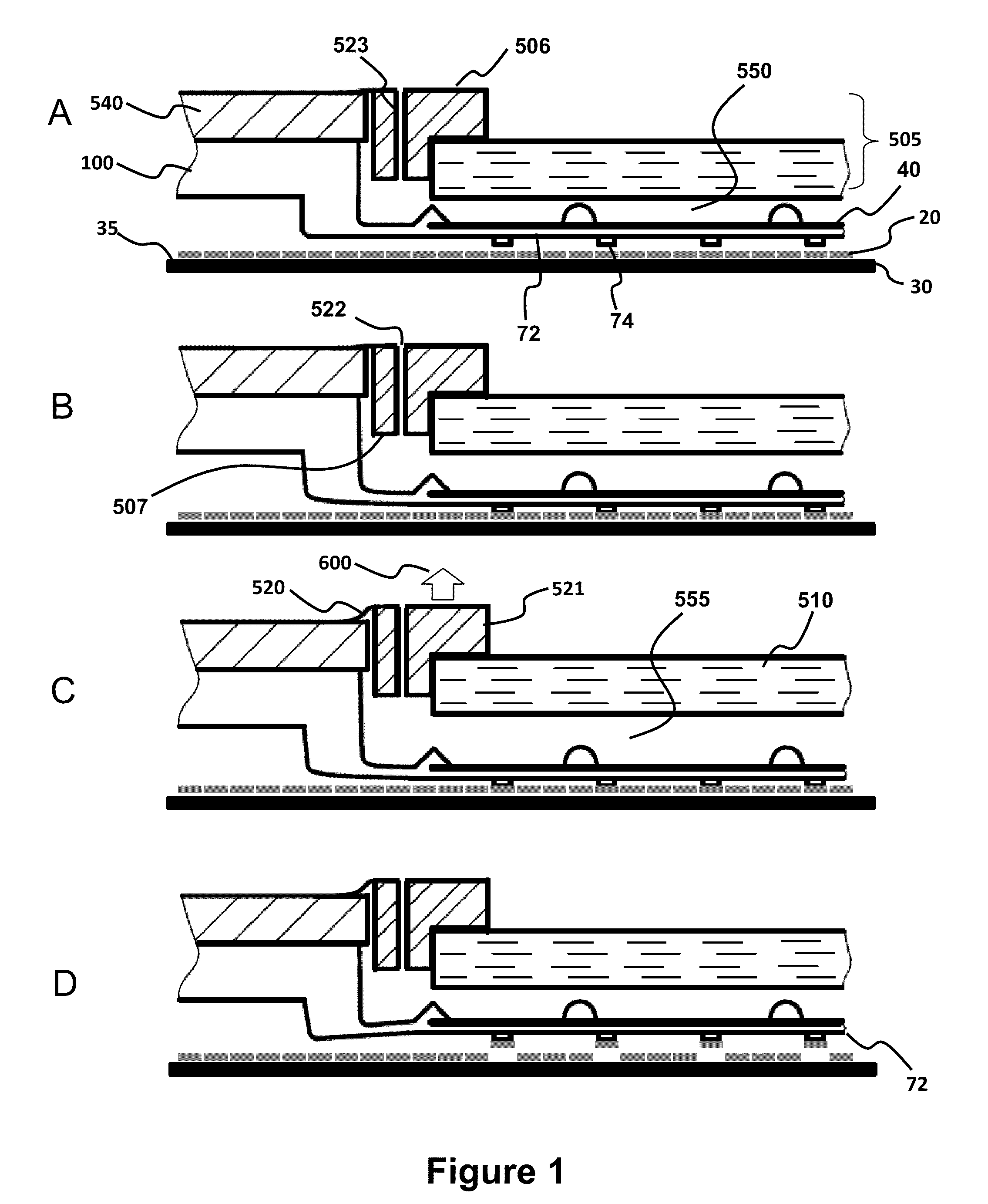

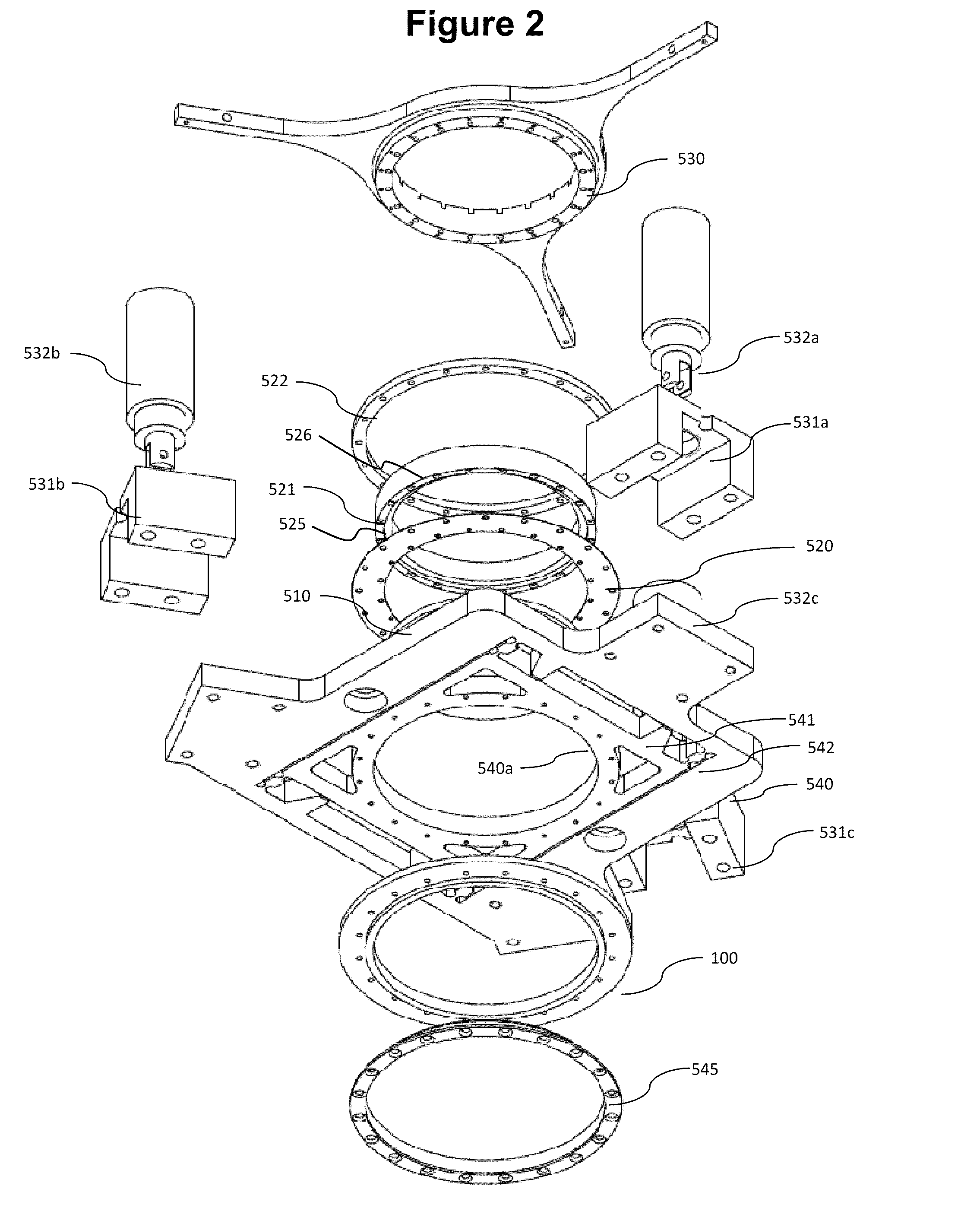

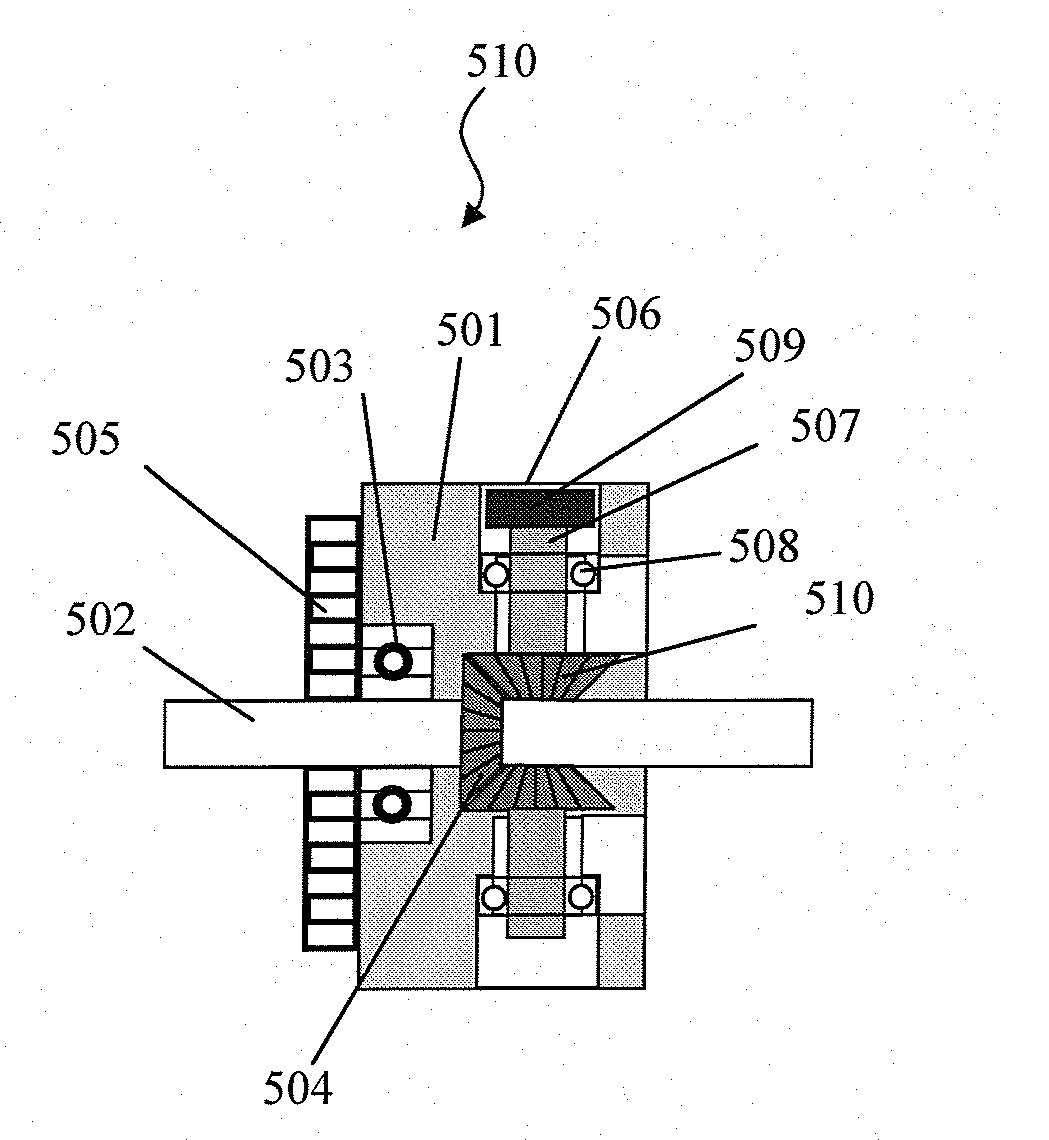

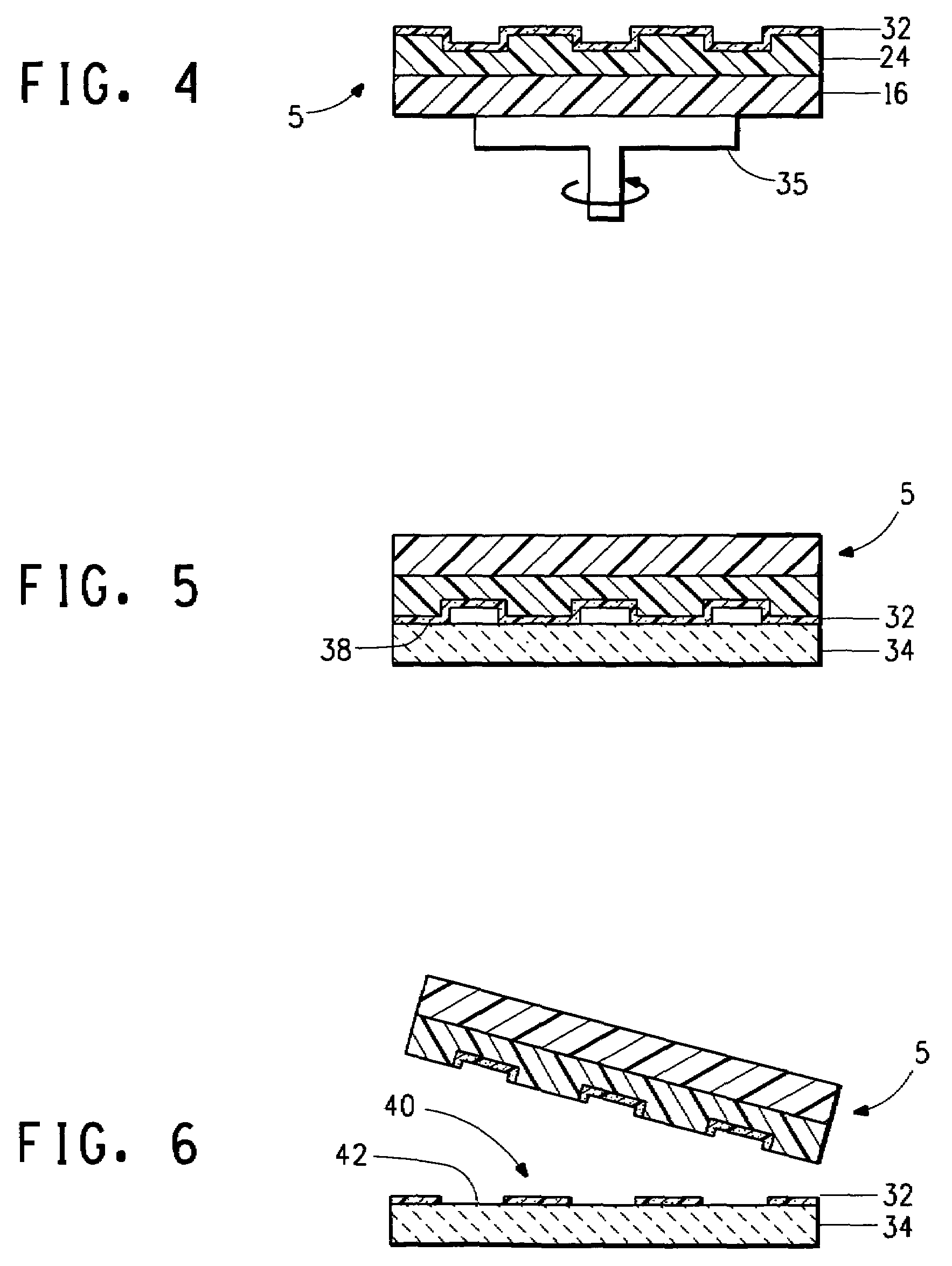

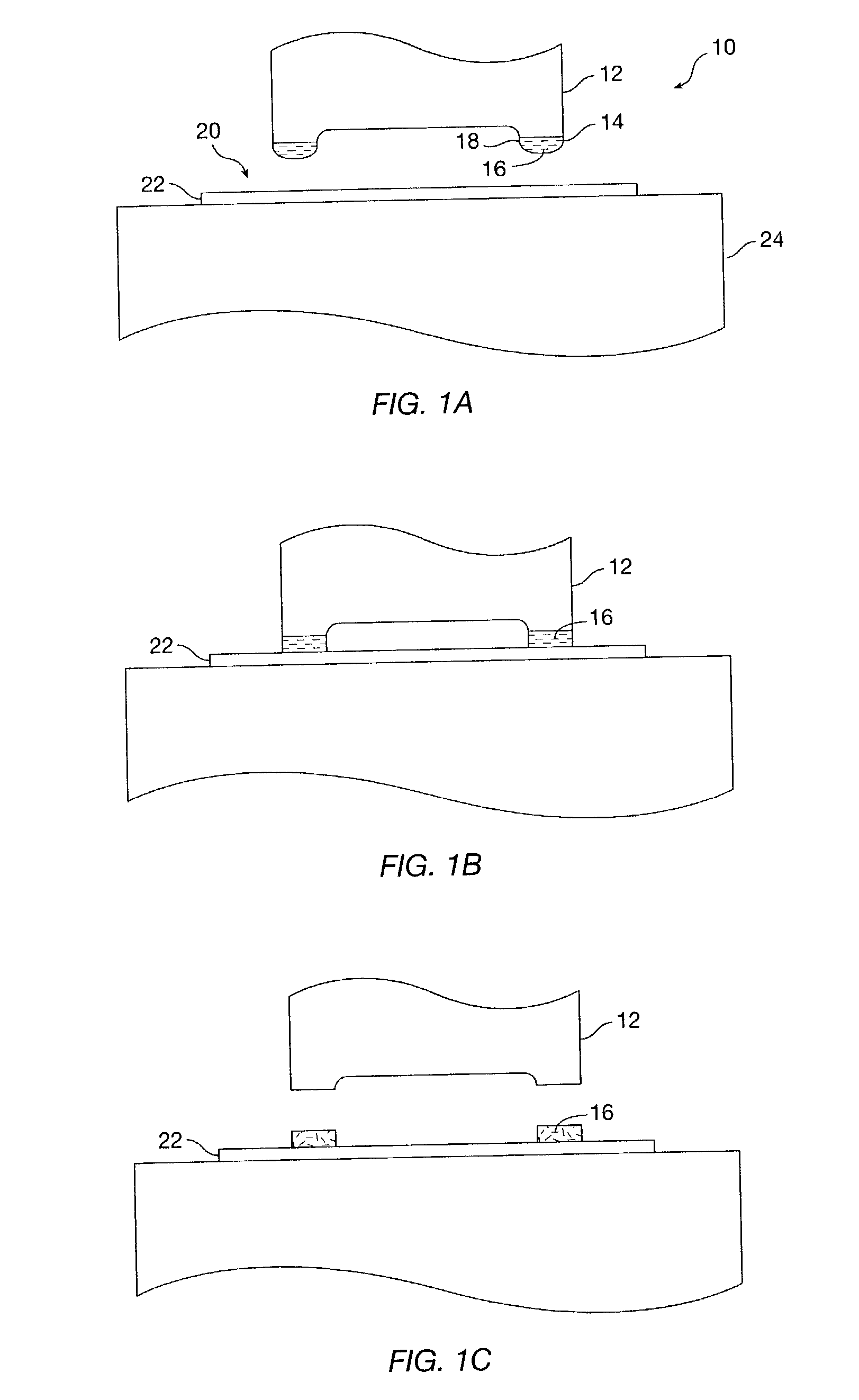

Vacuum coupled tool apparatus for dry transfer printing semiconductor elements

InactiveUS8261660B2Improvement in printing yield and placement accuracy and fidelityReduce pressureMechanical working/deformationDecorative surface effectsEngineeringThin glass

Owner:X DISPLAY CO TECH LTD

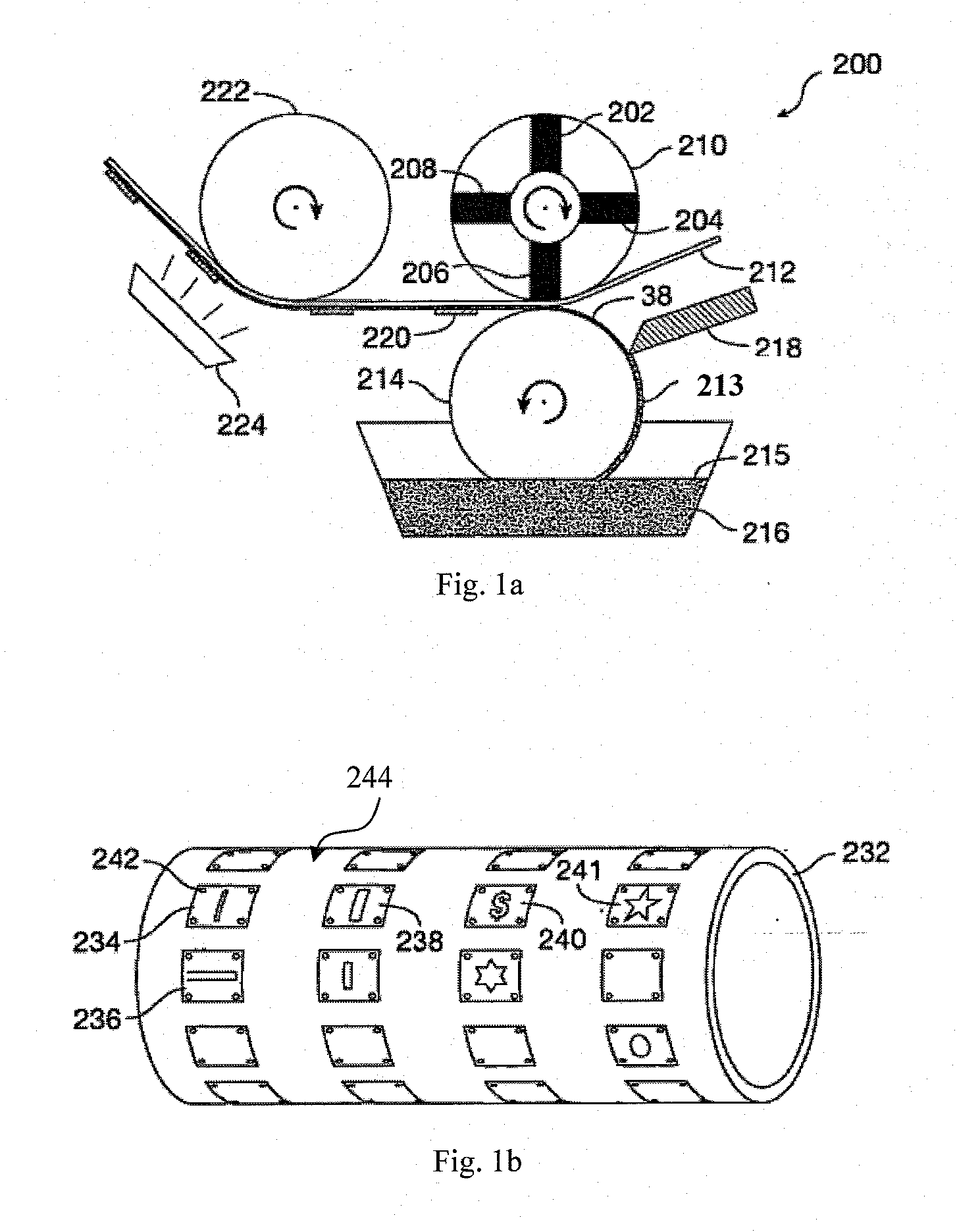

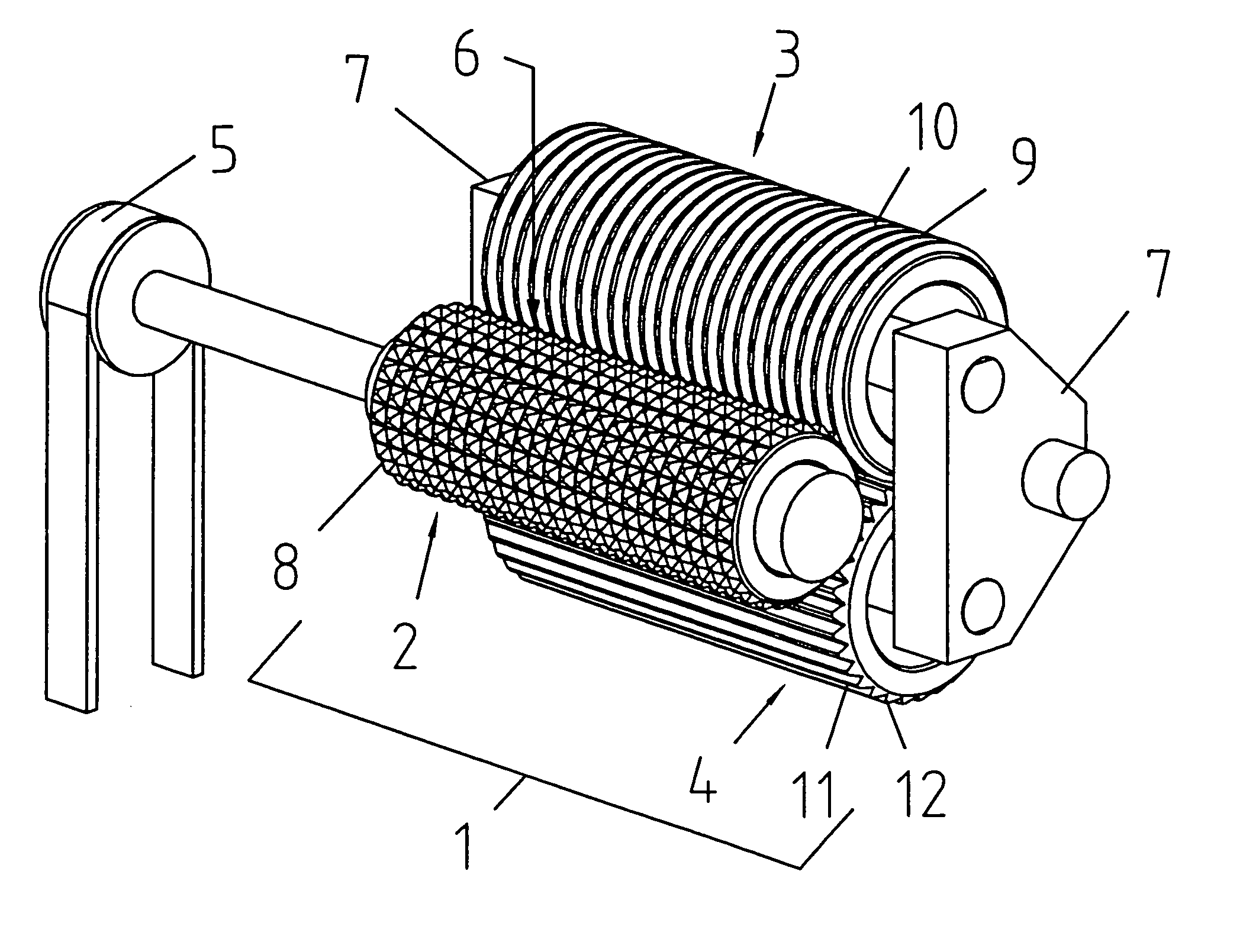

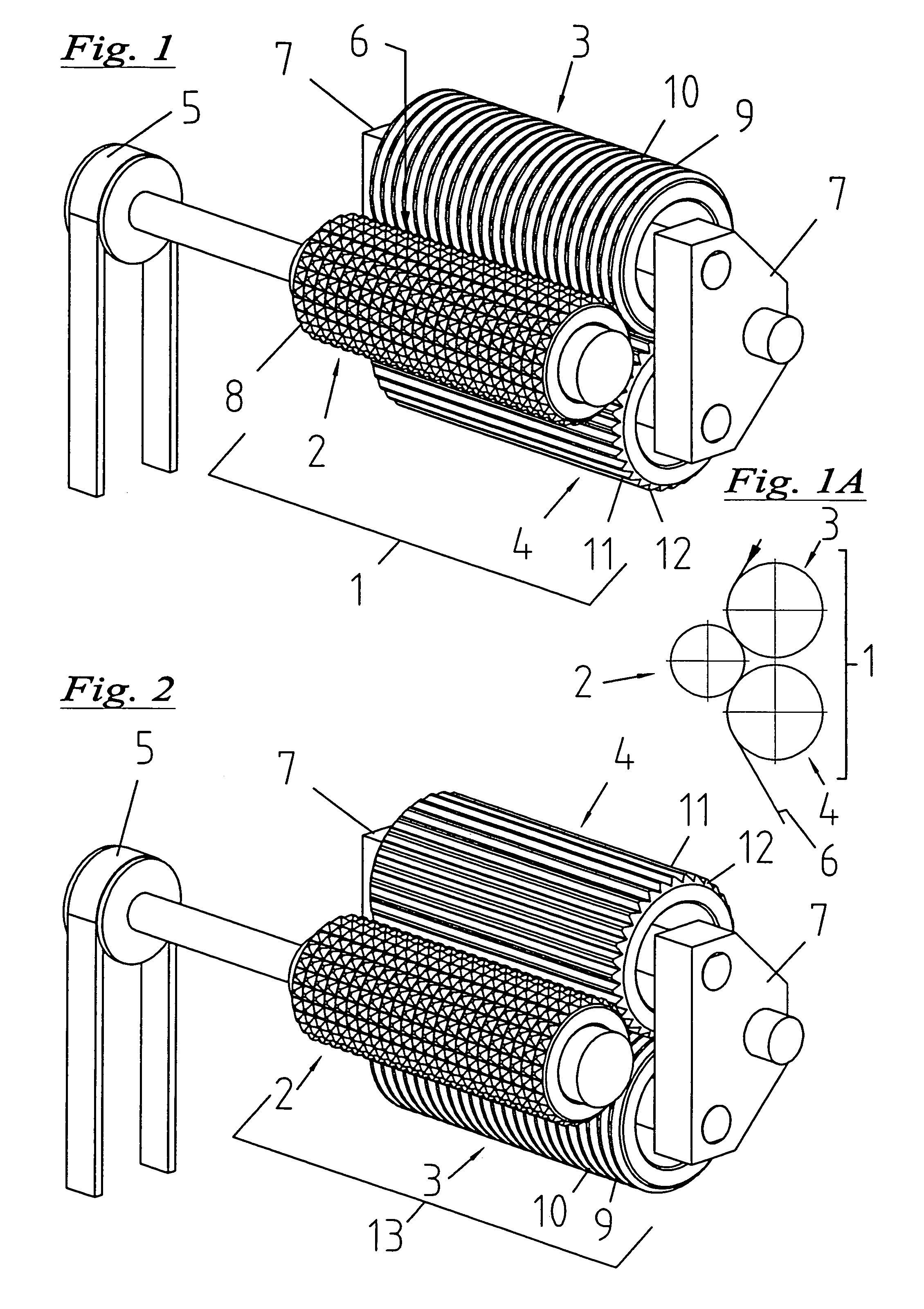

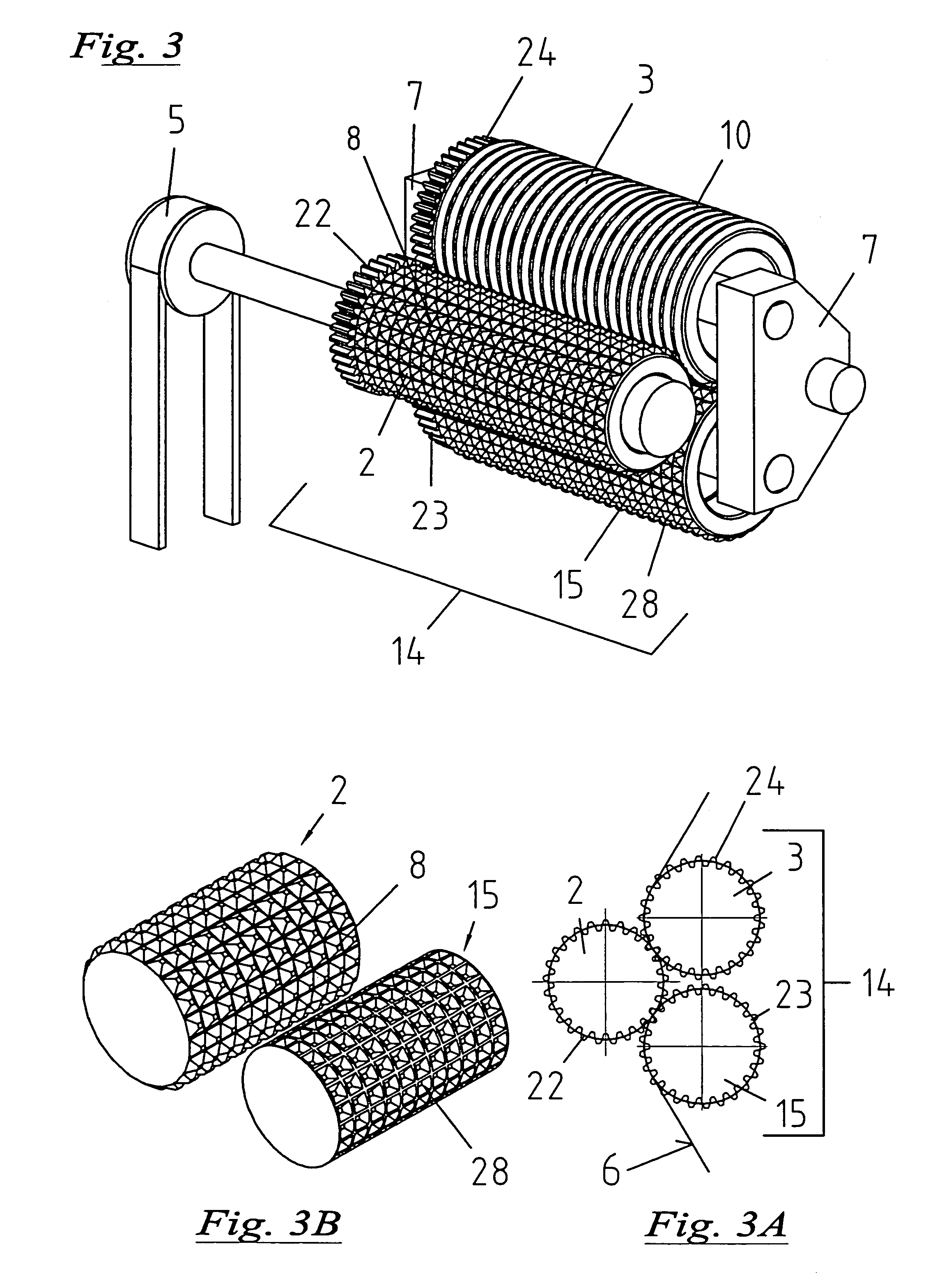

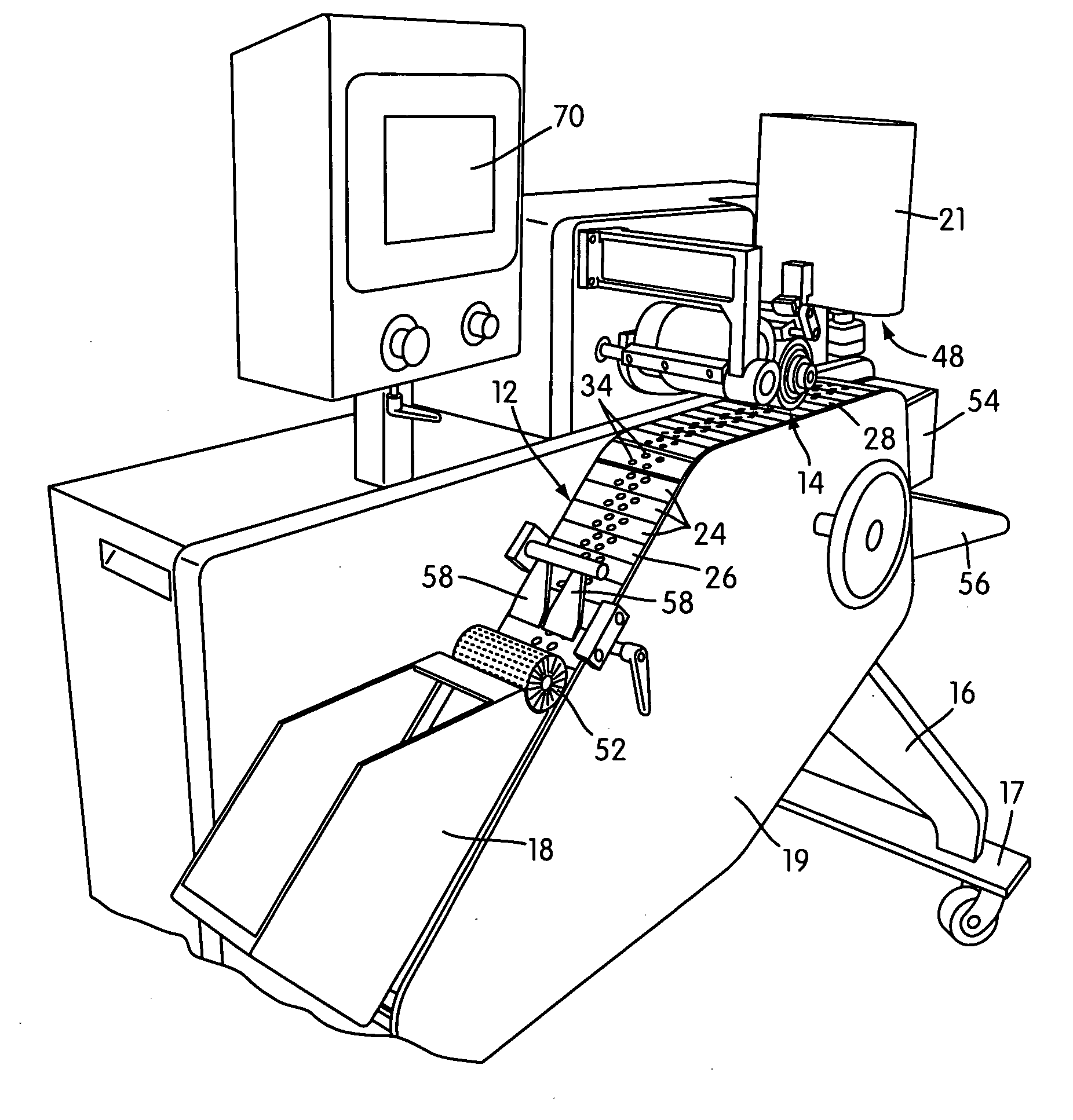

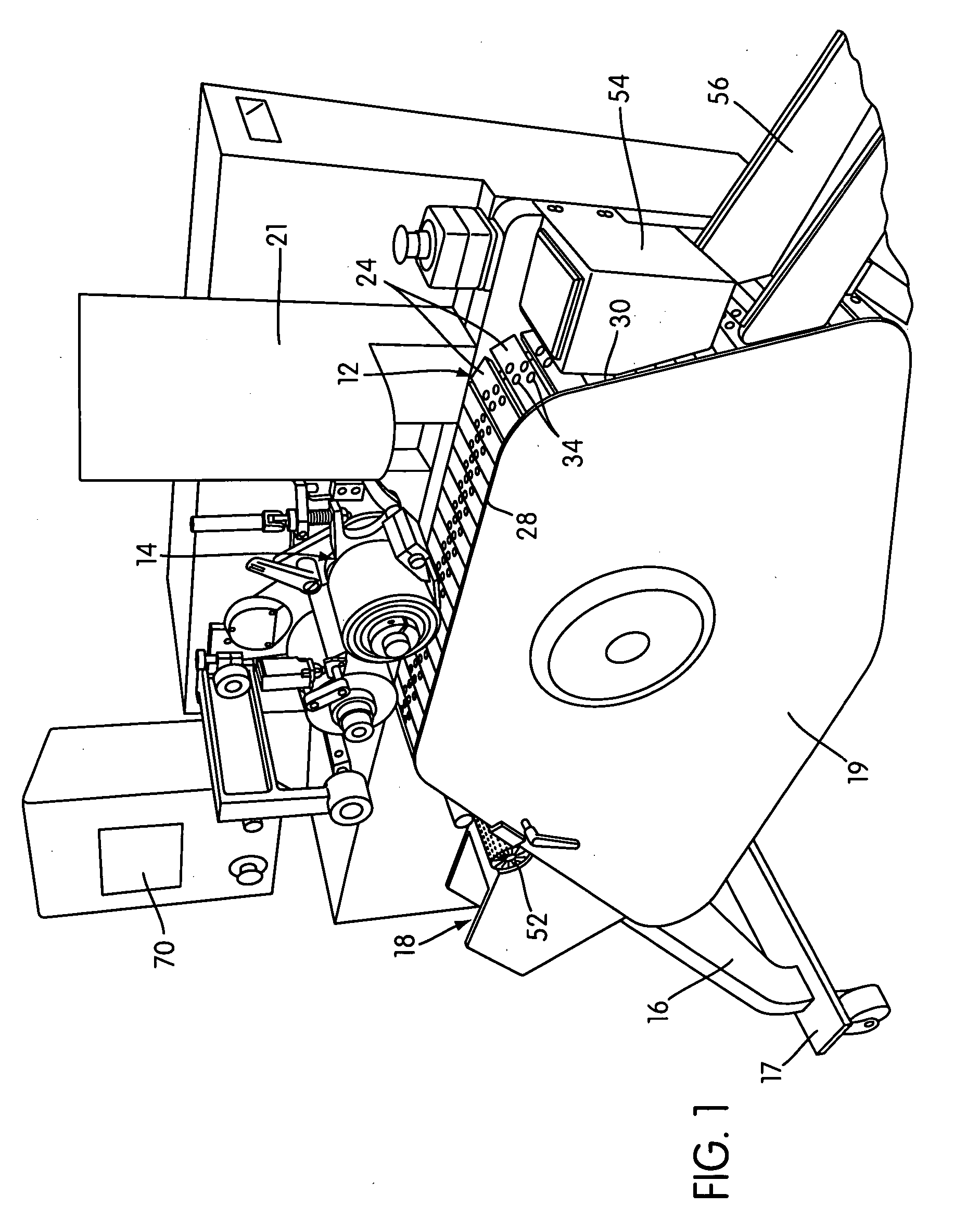

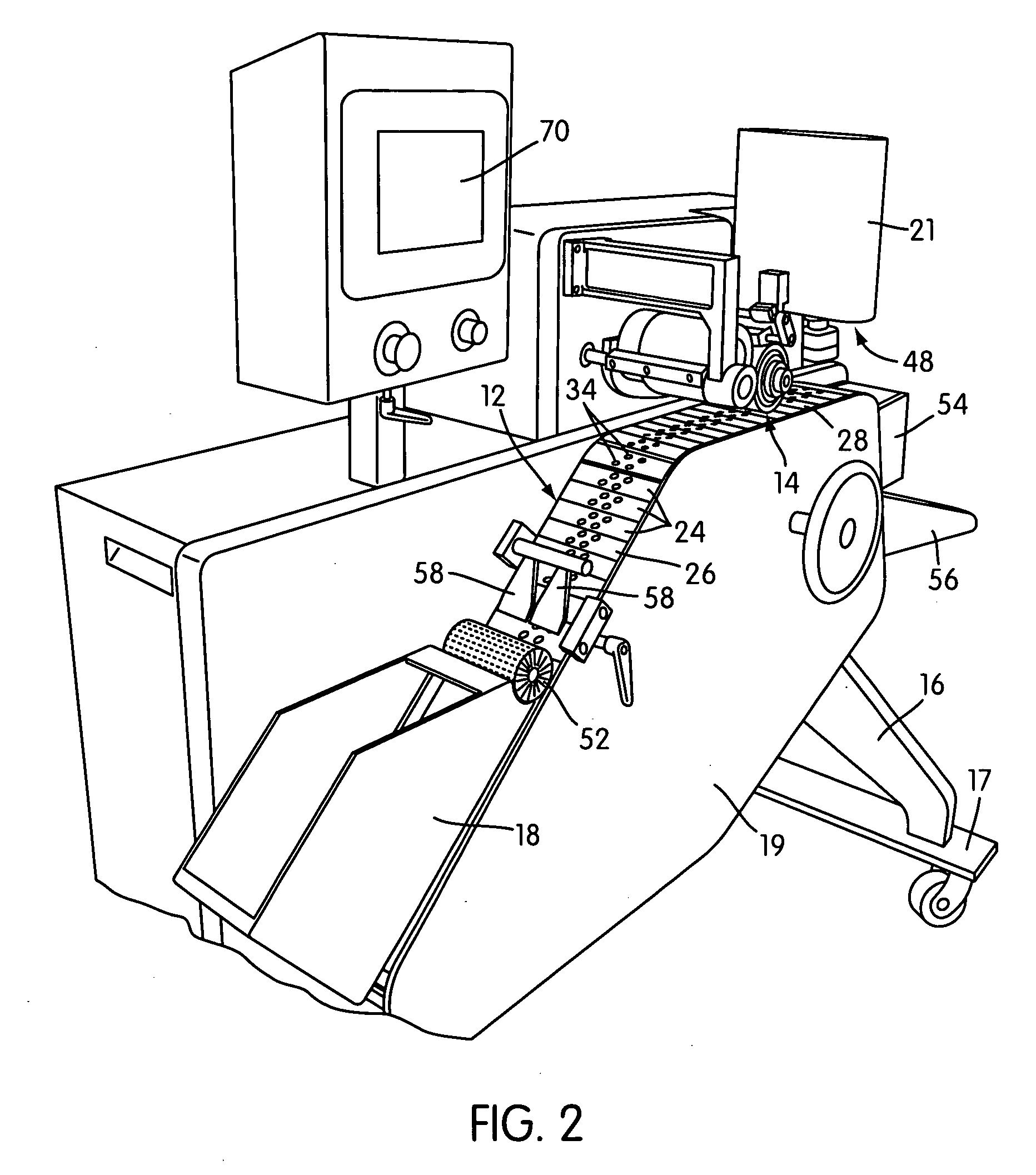

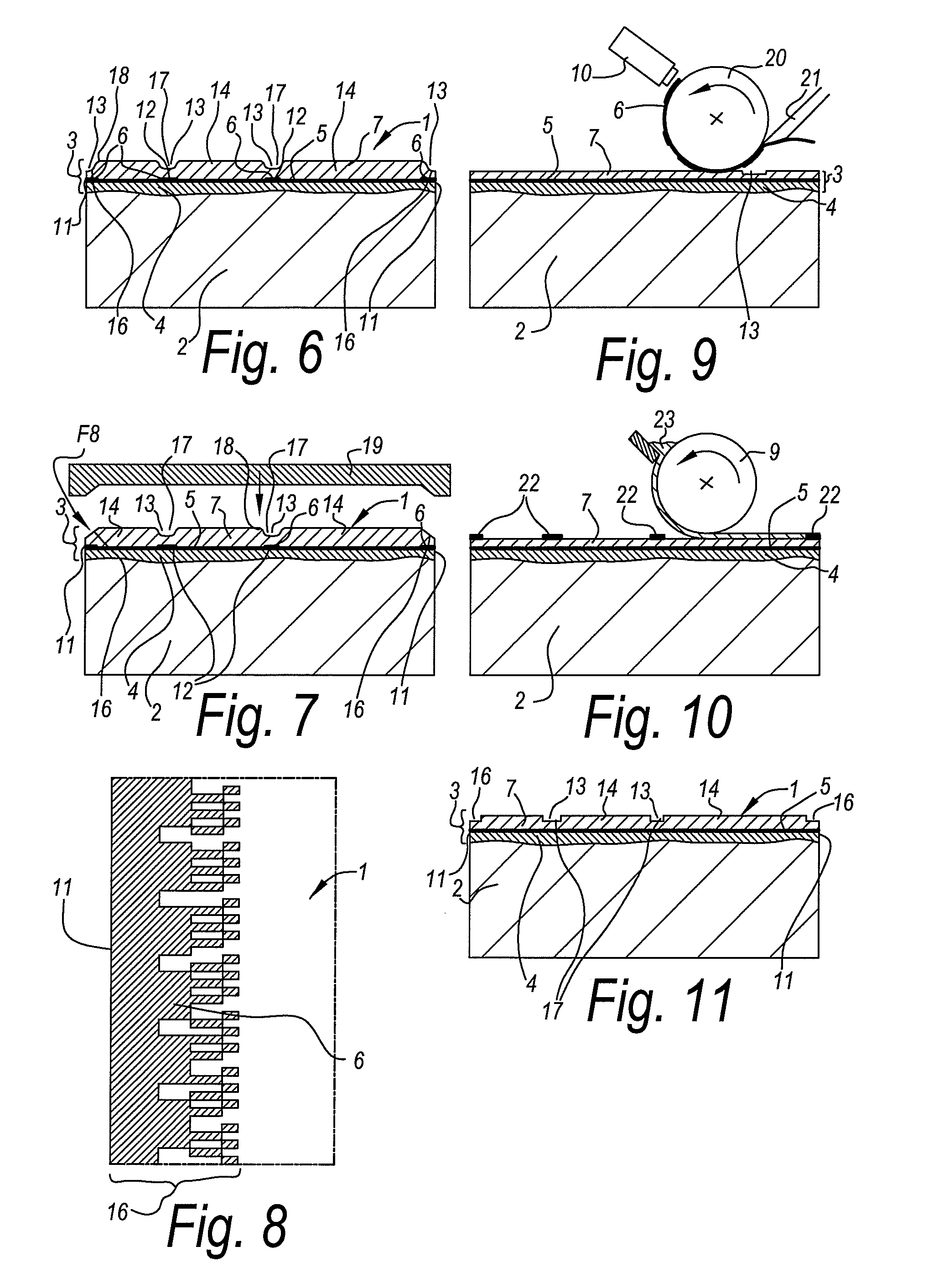

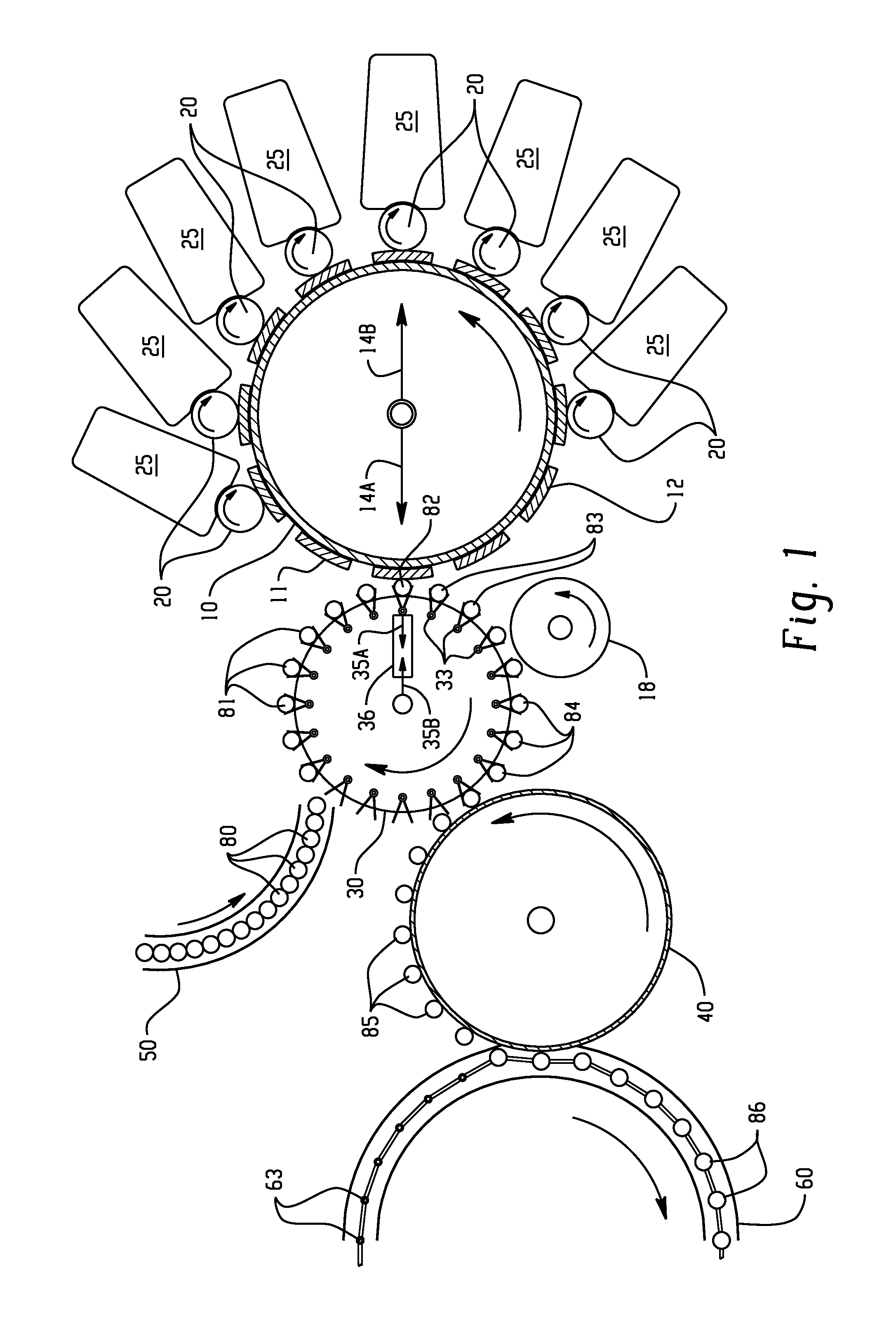

Apparatus For Orienting Magnetic Flakes

A printing apparatus includes a magnetic rotatable roller with a smooth even outer surface for aligning magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnetic portions of the roller, that can be formed by permanent magnets embedded in a non-magnetic roller body, or selectively magnetized portions of a flexible magnetic cover of the roller. In some embodiments, the roller is assembled for a plurality of interchangeable sections, which can include spinning magnets. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

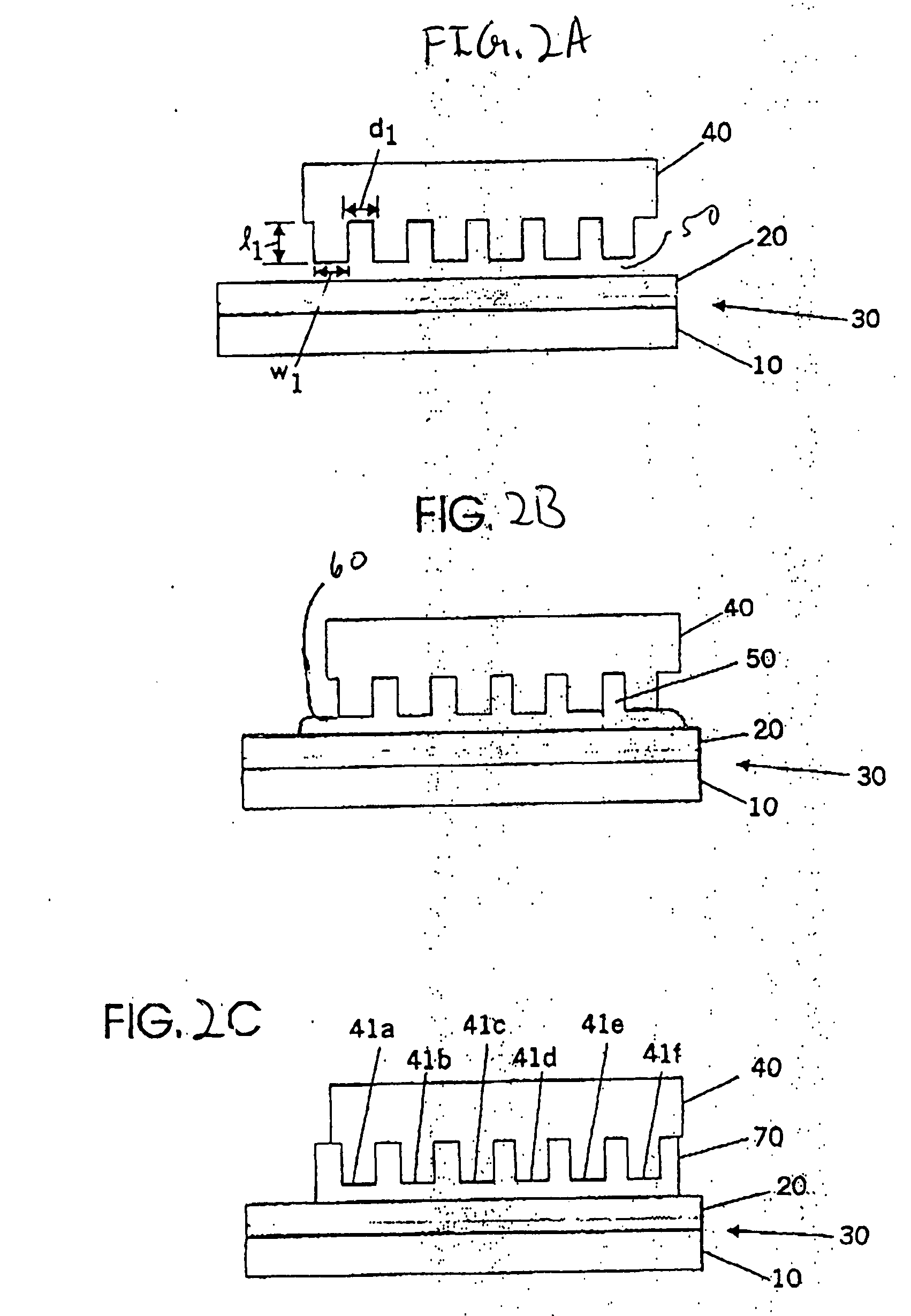

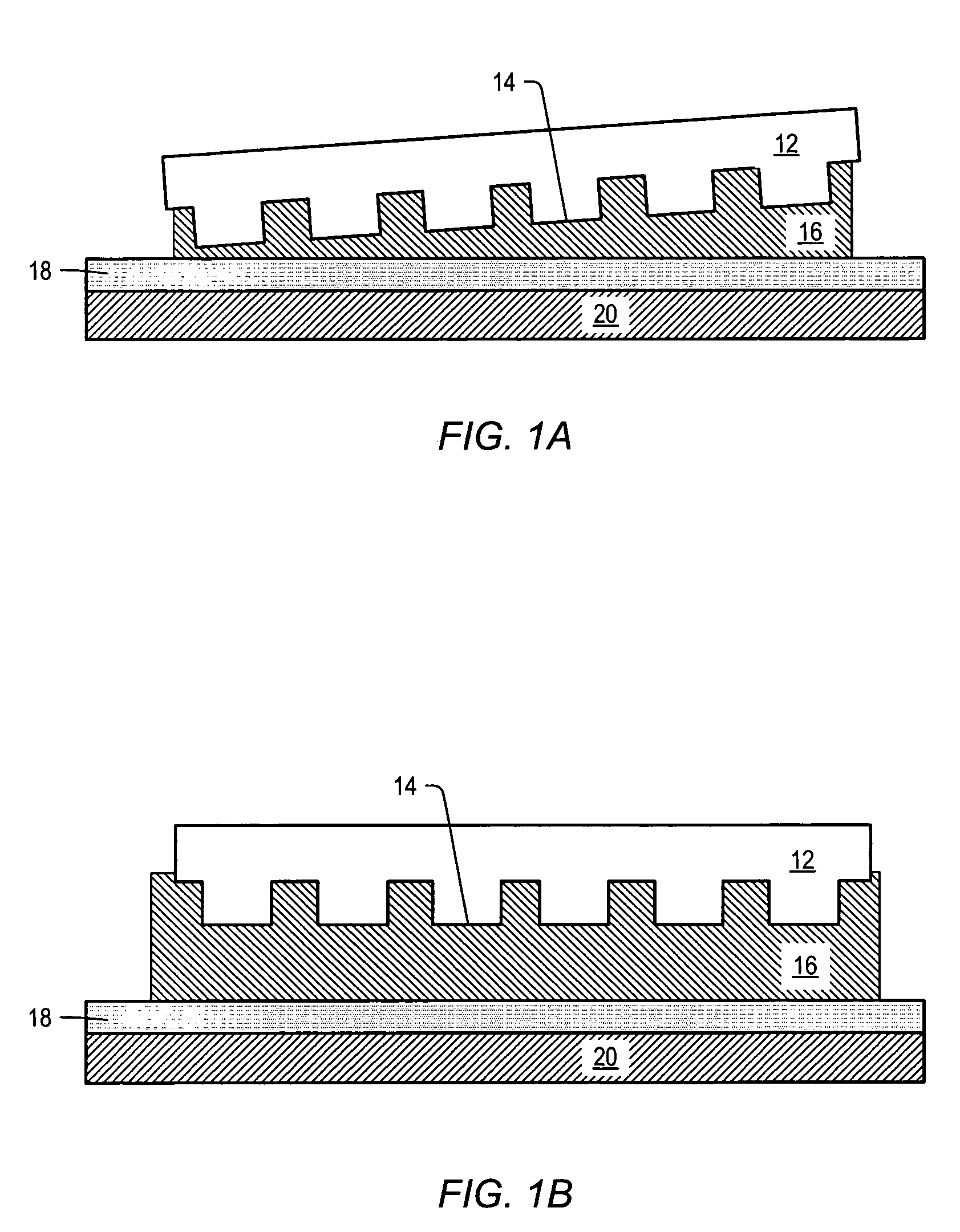

Imprint lithography templates having alignment marks

One embodiment of the present invention is an imprint template for imprint lithography that comprises alignment marks embedded in bulk material of the imprint template.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

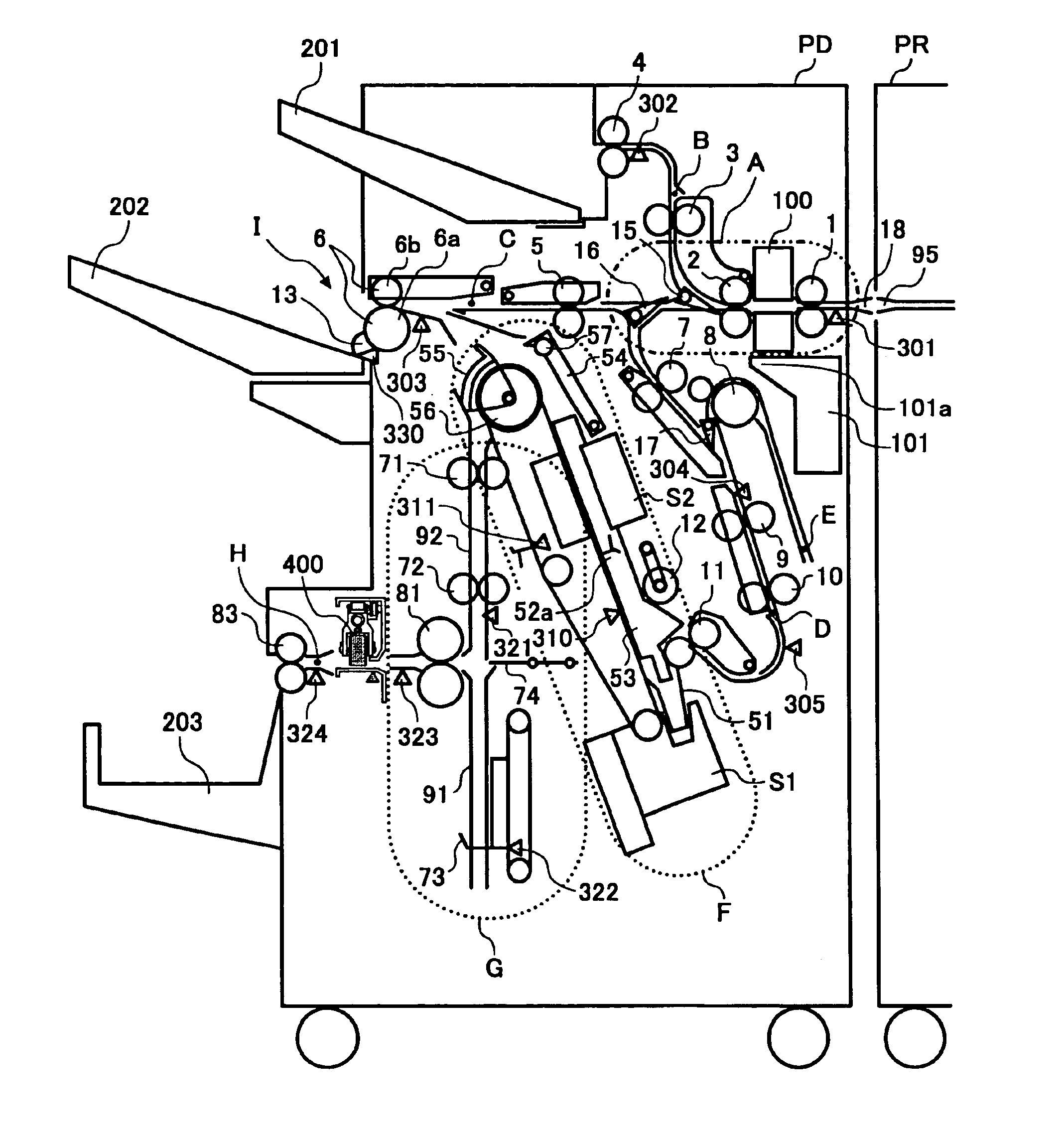

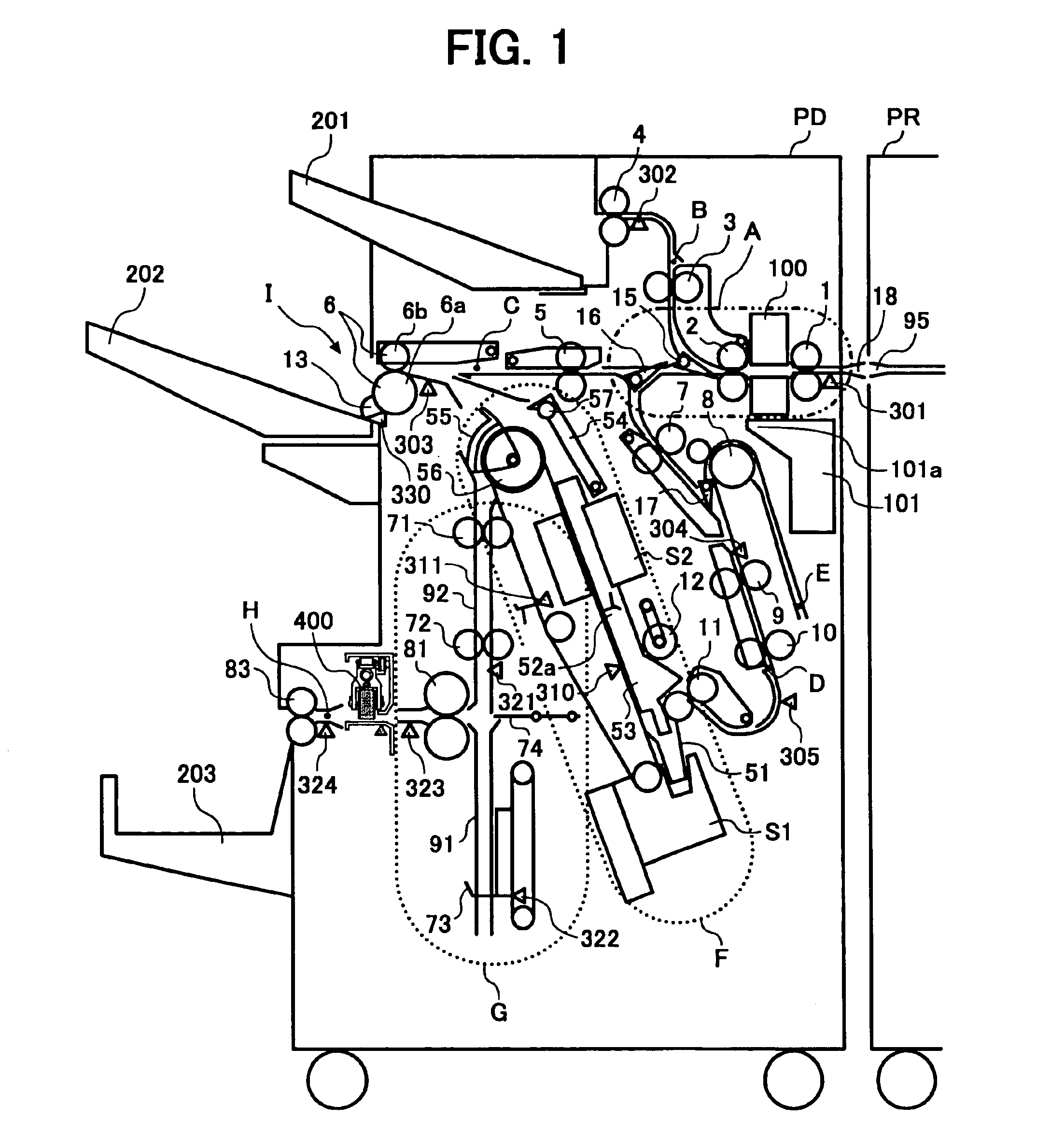

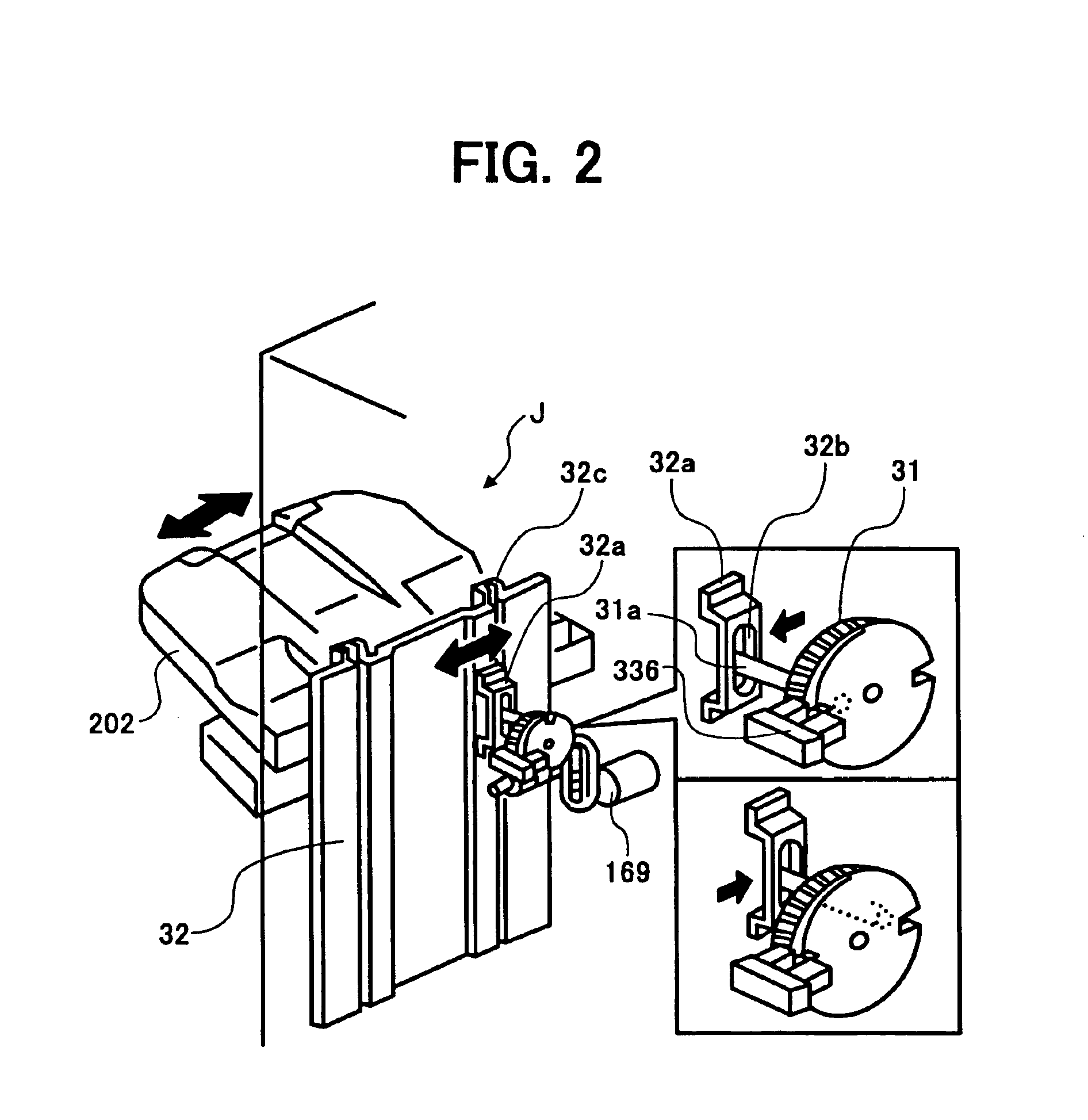

Sheet finisher and image forming system using the same

InactiveUS6905118B2Neatly foldedReduce frictionMechanical working/deformationFolding thin materialsImage formationEngineering

A sheet finisher of the present invention is included in an image forming system and folds a stack of sheets sequentially transferred from an image forming apparatus thereto. The sheet finisher includes a fold roller pair for holding the stack of sheets being conveyed via a nip thereof. A reinforce roller reinforces the fold of the folded sheet stack in cooperation with a guide plate. A drive mechanism causes the reinforce roller to move in a direction perpendicular to a direction of sheet conveyance. A shock absorbing member is located at a position where the reinforce roller and guide plate contact each other.

Owner:RICOH KK

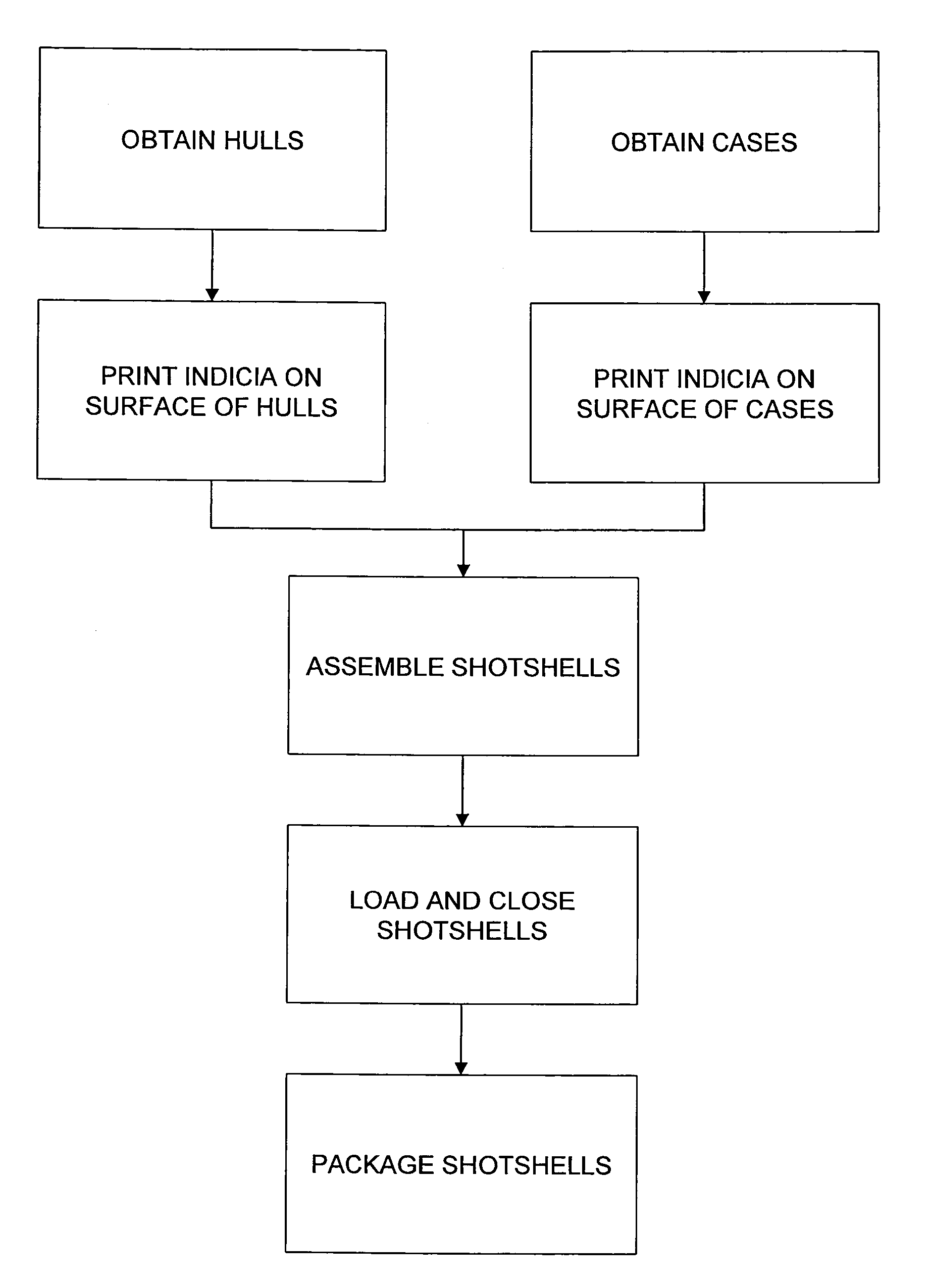

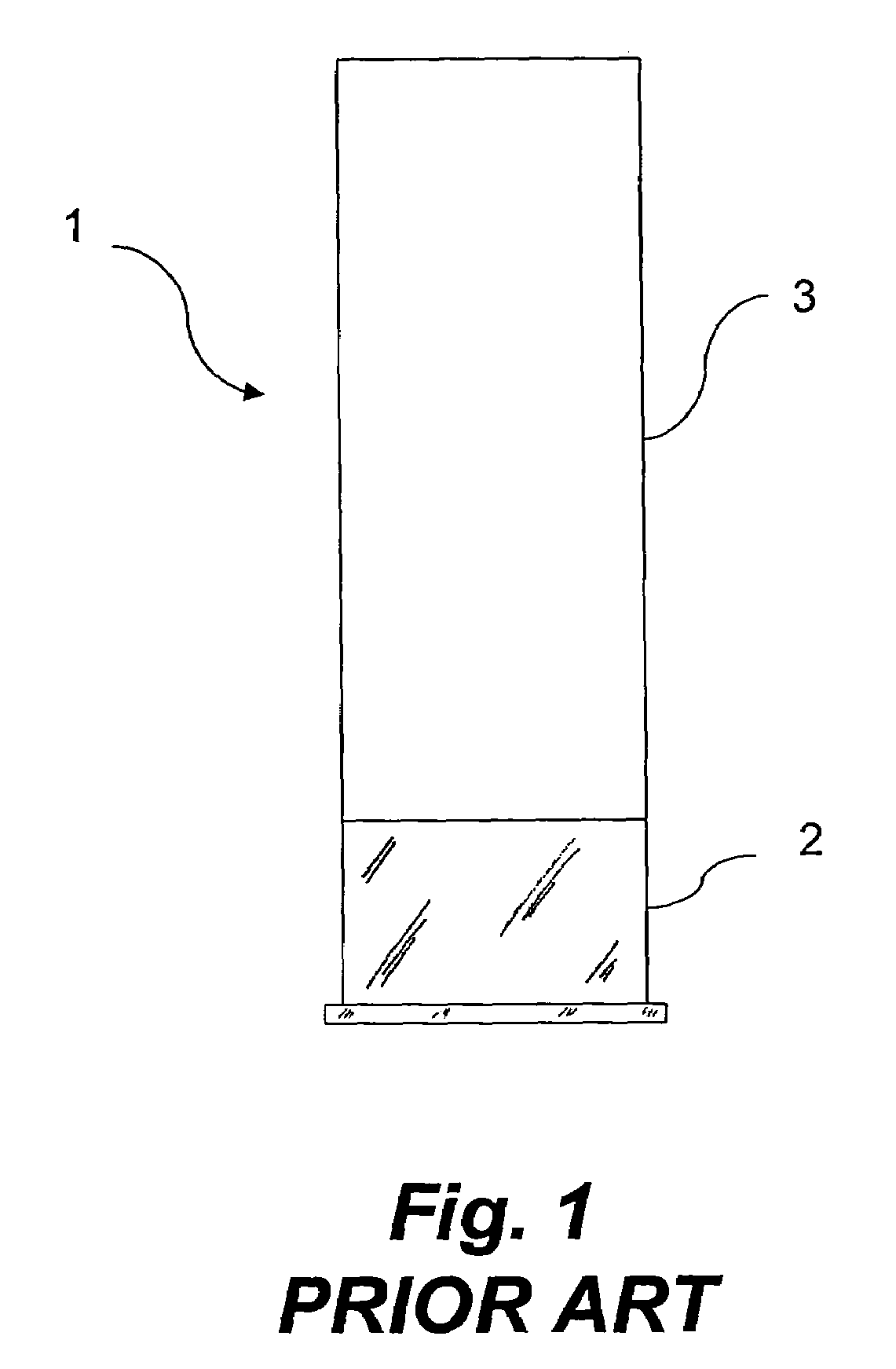

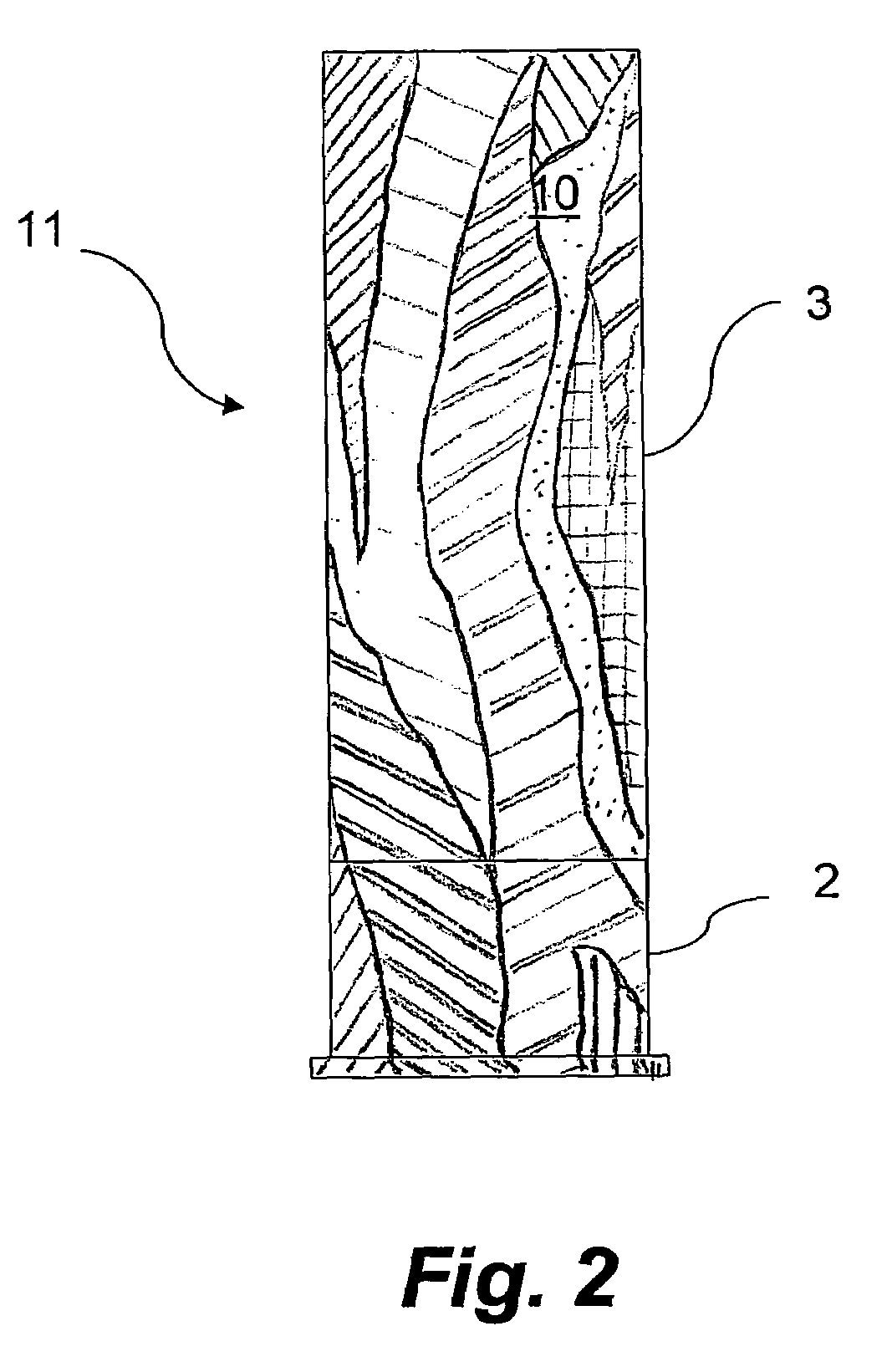

Ammunition having surface indicia and method of manufacture

InactiveUS7014284B2Improved adhesion to surfaceReduce glareShotgun ammunitionTypewritersBiomedical engineeringHeat transfer

Ammunition, such as shotshells used in waterfowl hunting, have indicia applied to substantially all of the external surface to reduce glare normally a problem in conventional ammunition. The indicia, such as a camouflage pattern, is applied either through the use of inkjet printing directly on the shotshell surface or through the application of a heat transfer sleeve to which the indicia has been previously applied. The process of applying the camouflage pattern may be incorporated into the manufacture of the ammunition or may be operable as a standalone process used for pre-manufactured ammunition.

Owner:MORTON WILLIAM BILL +2

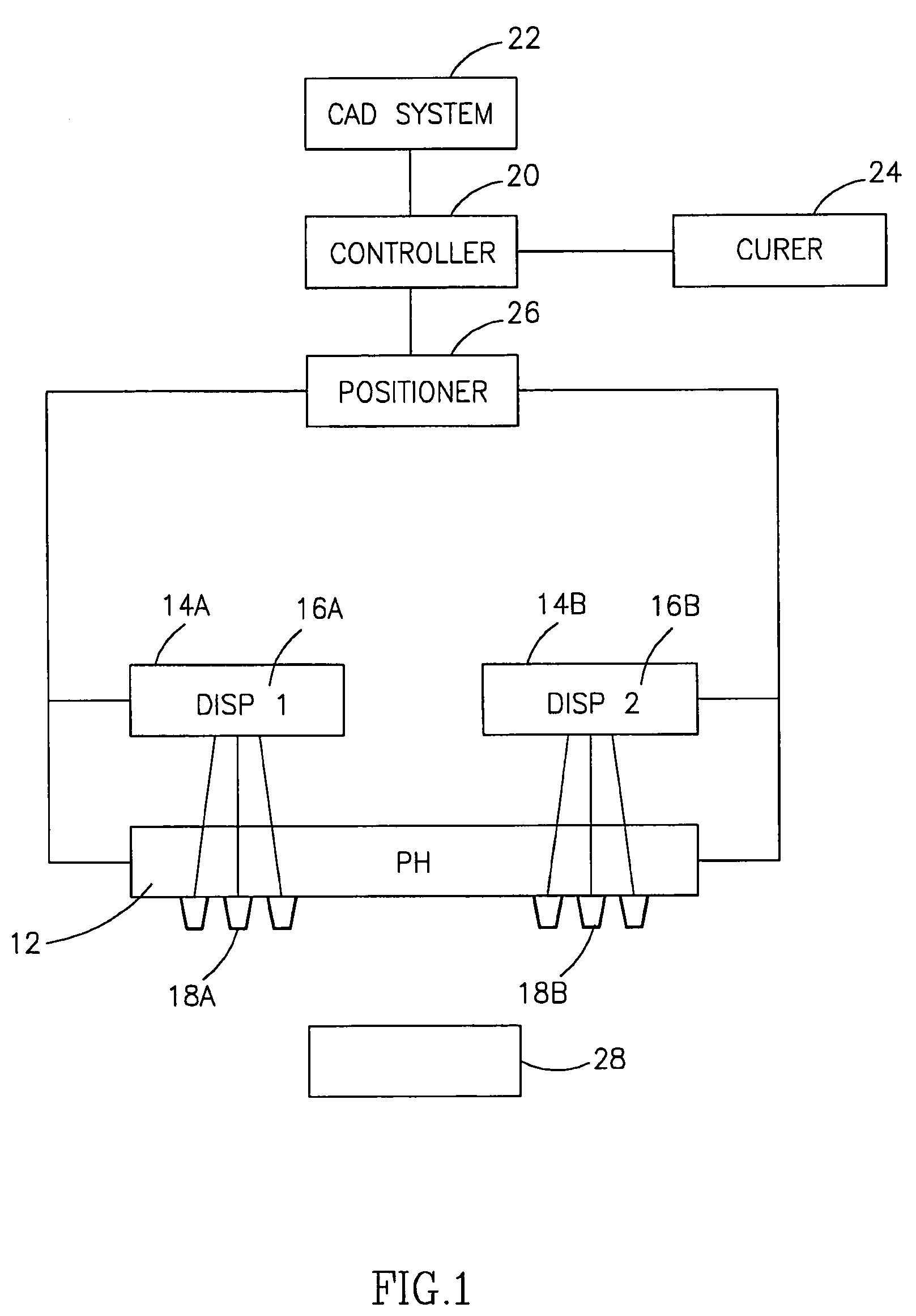

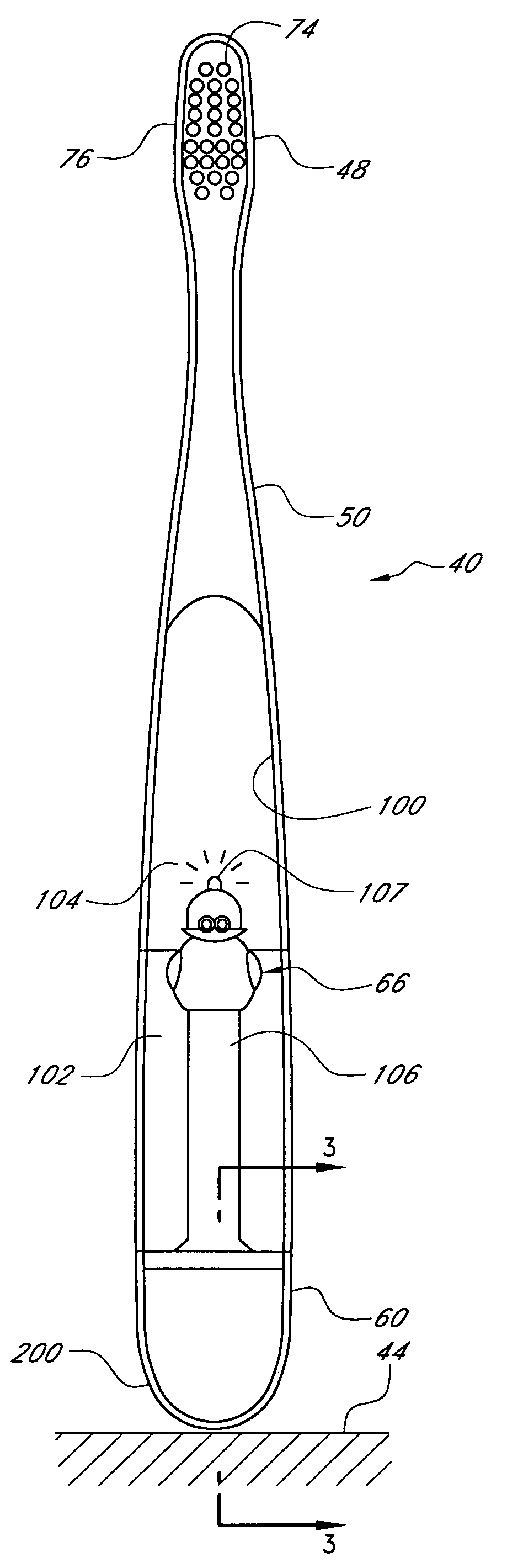

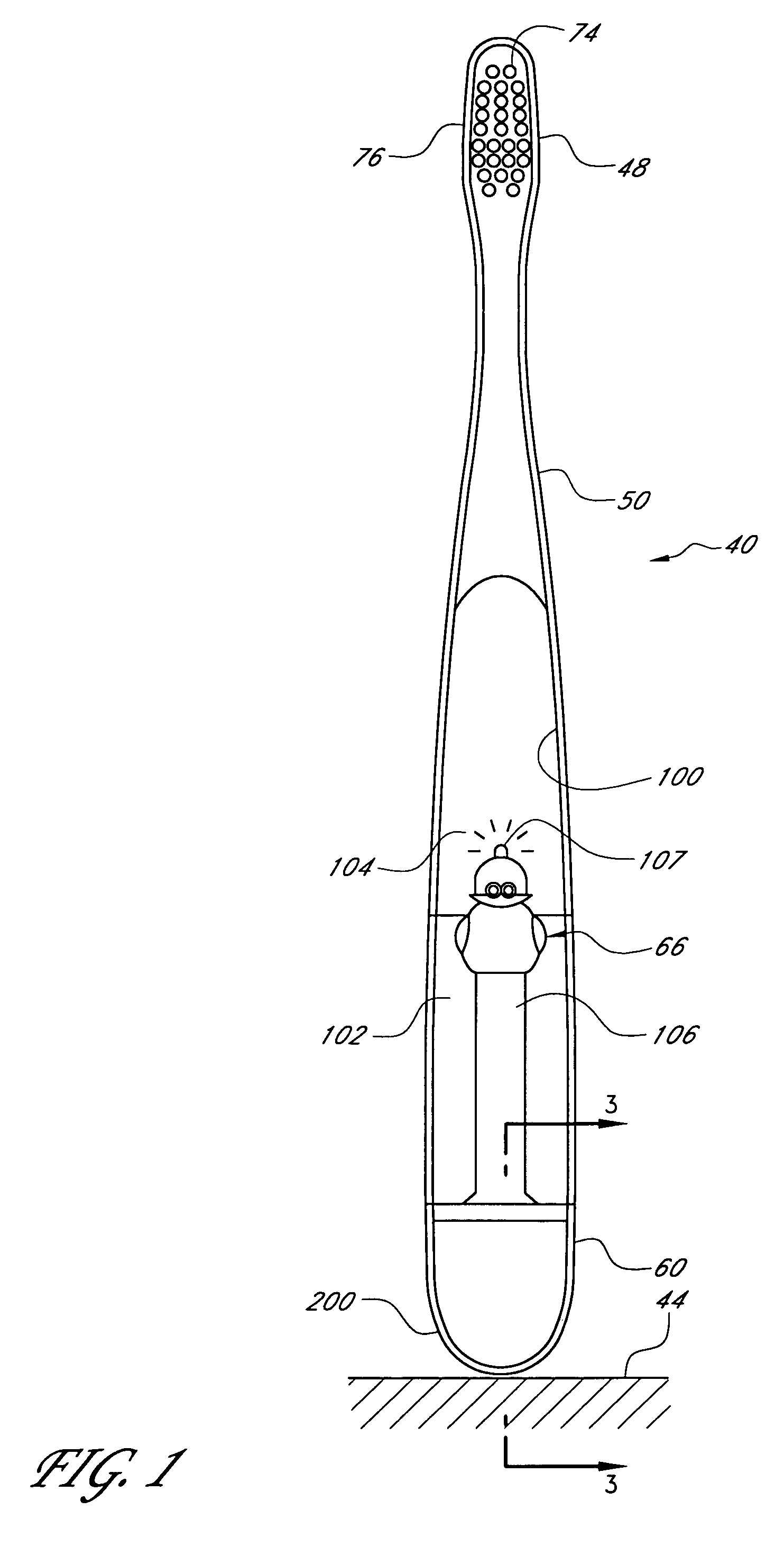

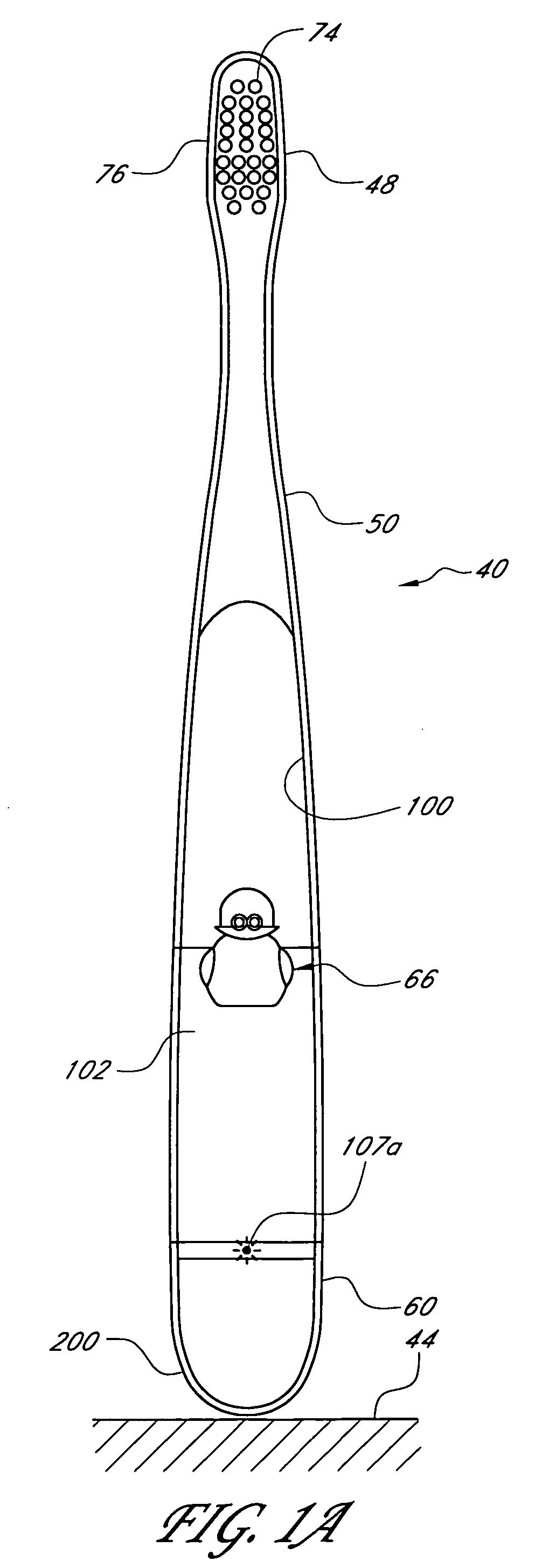

Toothbrush

Disclosed herein are toothbrushes. The toothbrushes are self-standing and are oriented in an upright position when resting on a support surface. In some arrangements, the toothbrush can have a stamp. A closure of the toothbrush can be removed to expose the stamp. The toothbrush has an ink source that deposits ink on the stamp. A receiving stand configured to receive the lower portion of the toothbrush can maintain the toothbrush in a generally vertical orientation.

Owner:NANDA PUNEET

Booklet maker

A low cost, high speed, high resolution laser printer method and apparatus for re-writable media is presented. A method for finishing of printed sheets into booklets is described. Novel mechanical operations permit the manufacture of a very low-cost, off-line booklet maker for use with desktop laser and ink jet printers. The technology can scale to medium-speed, in-line booklet manufacture. The method is novel because most of the finishing operations are performed on a sheet-by-sheet basis using precision paper positioning and a transverse tool carrier that cuts, scores, folds, punches, and staples the sheets. To form a finished saddle-stitched booklet, each sheet is cut to length determined by its sequence in the booklet and paper thickness, scored, punched (if required), folded, accumulated in a stack, and stapled. The sheet-wise method allows finishing operations to be done with low-cost tools and low actuation forces.

Owner:HEWLETT PACKARD DEV CO LP

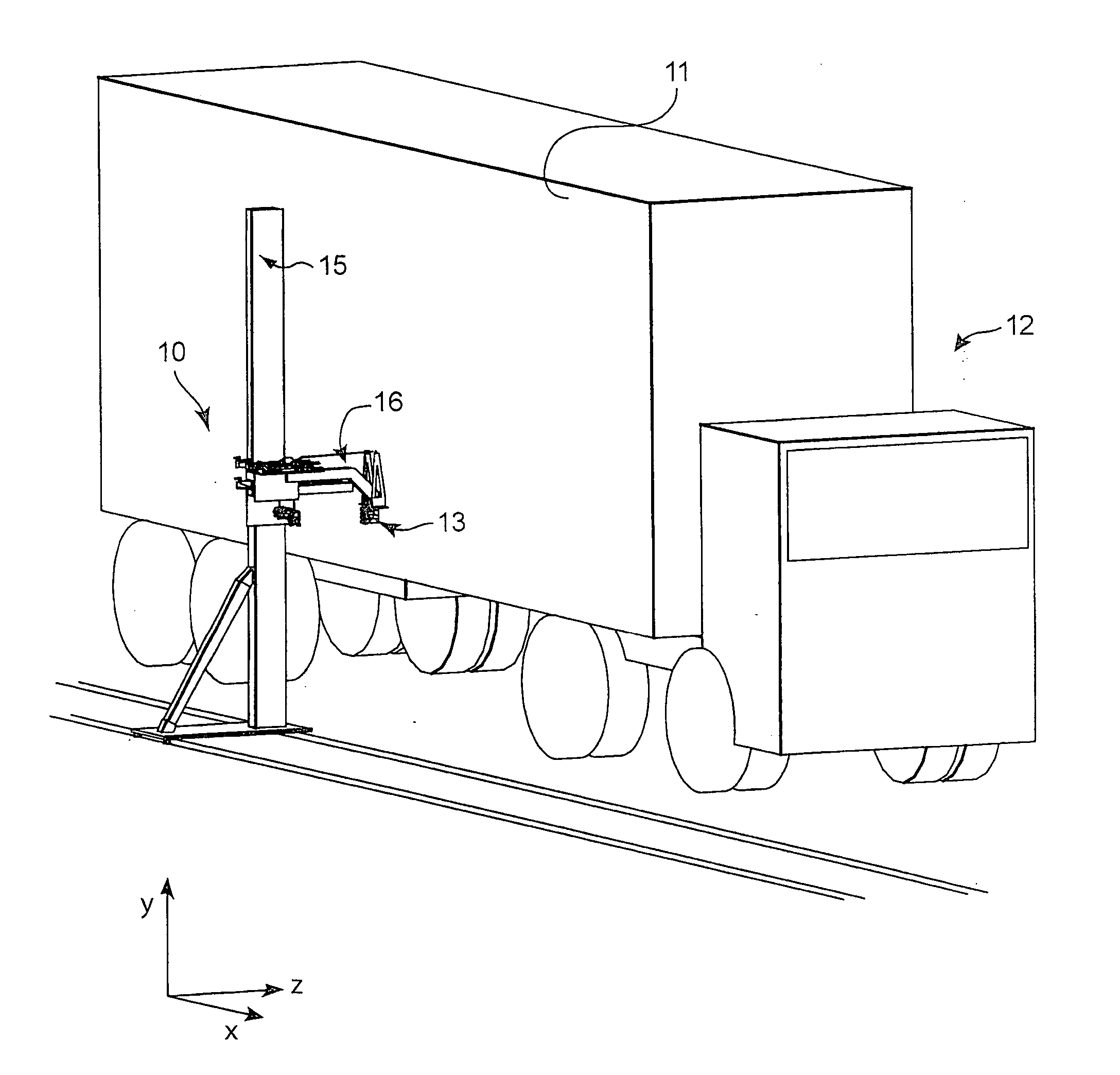

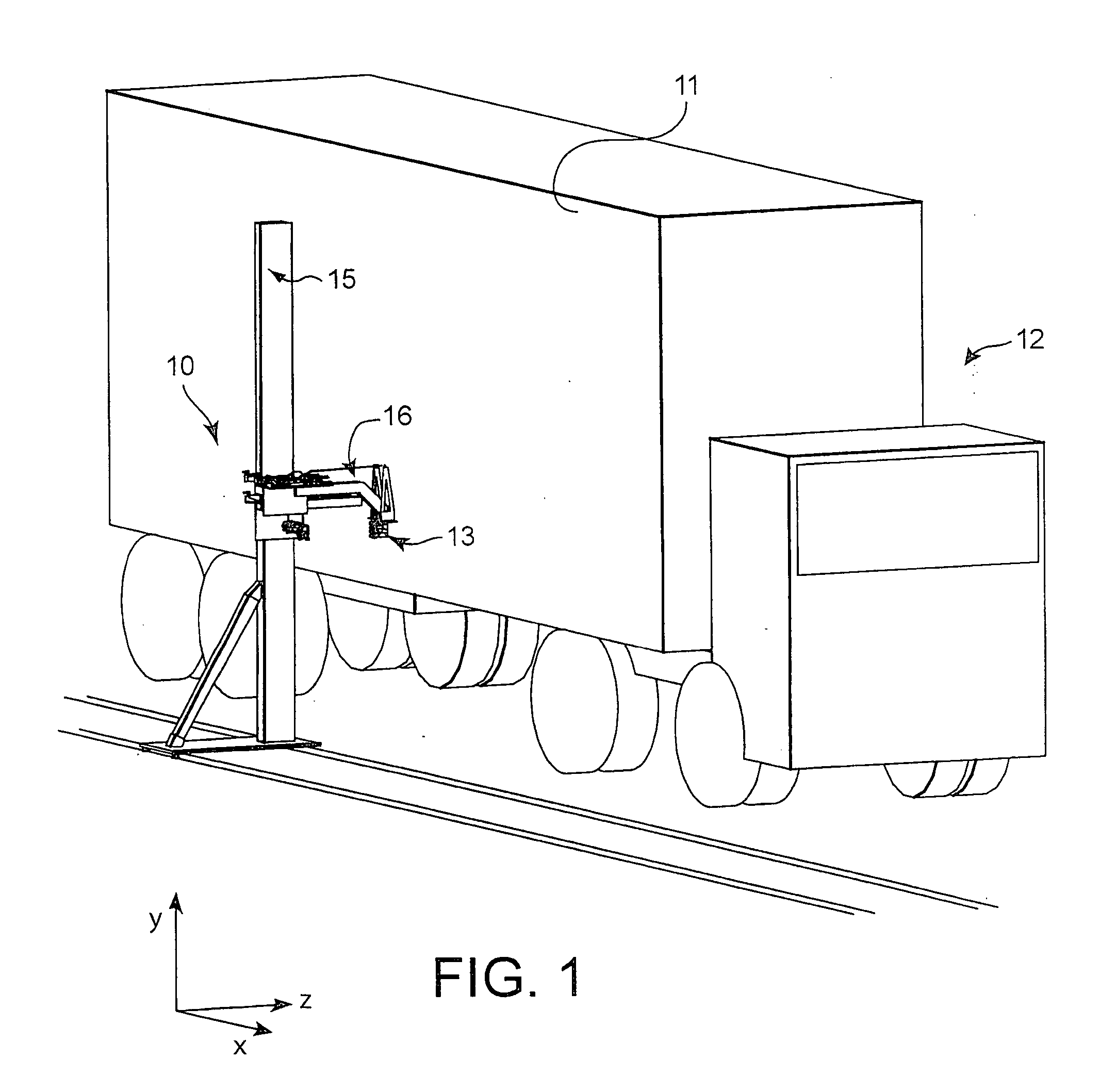

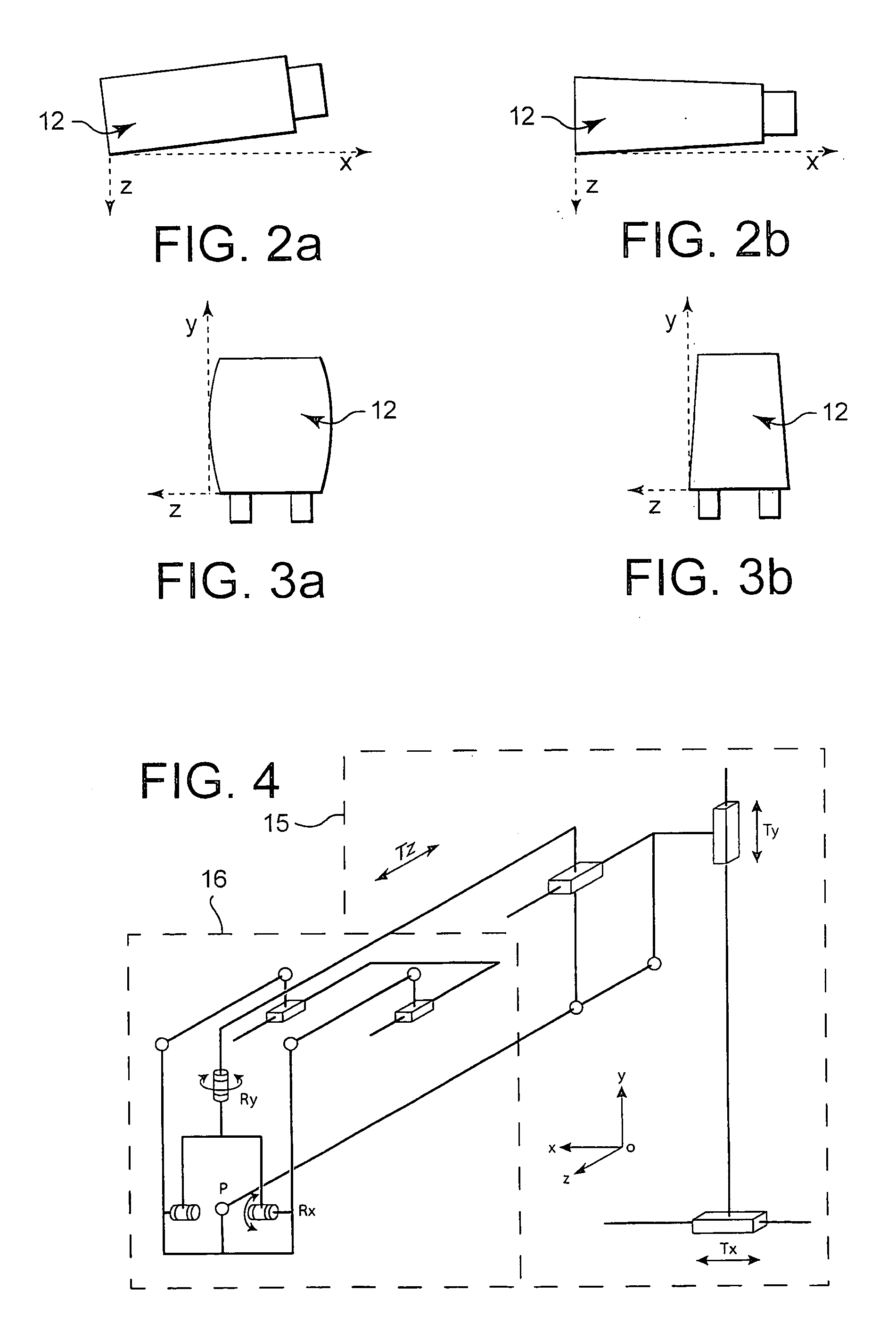

Robot for large-format, three dimensional digital printing on a fixed surface and printing method involving at least one such robot

InactiveUS20070062383A1Avoid couplingAdditive manufacturing apparatusDuplicating/marking methodsThree degrees of freedomEngineering

The invention concerns a print robot for large format three-dimensional printing on a fixed surface ( 11 ) having five motorized axes, comprising an inkjet printing block ( 13 ), means for displacing and orientating this printing assembly along several axes, at least one control unit controlling these means and a drying device to dry the ink sprayed onto said surface ( 11 ), wherein these means comprise: a carrier ( 15 ) with three degrees of freedom in translation, ensuring the positioning of the printing assembly allowing its horizontal, vertical and depth translation, a wrist ( 16 ) with two degrees of freedom which supports and orientates the printing assembly ( 13 ) allowing its rotations along two perpendicular axes. The invention also concerns a process implementing this robot.

Owner:CENT NAT DE LA RECHERCHE SCI +1

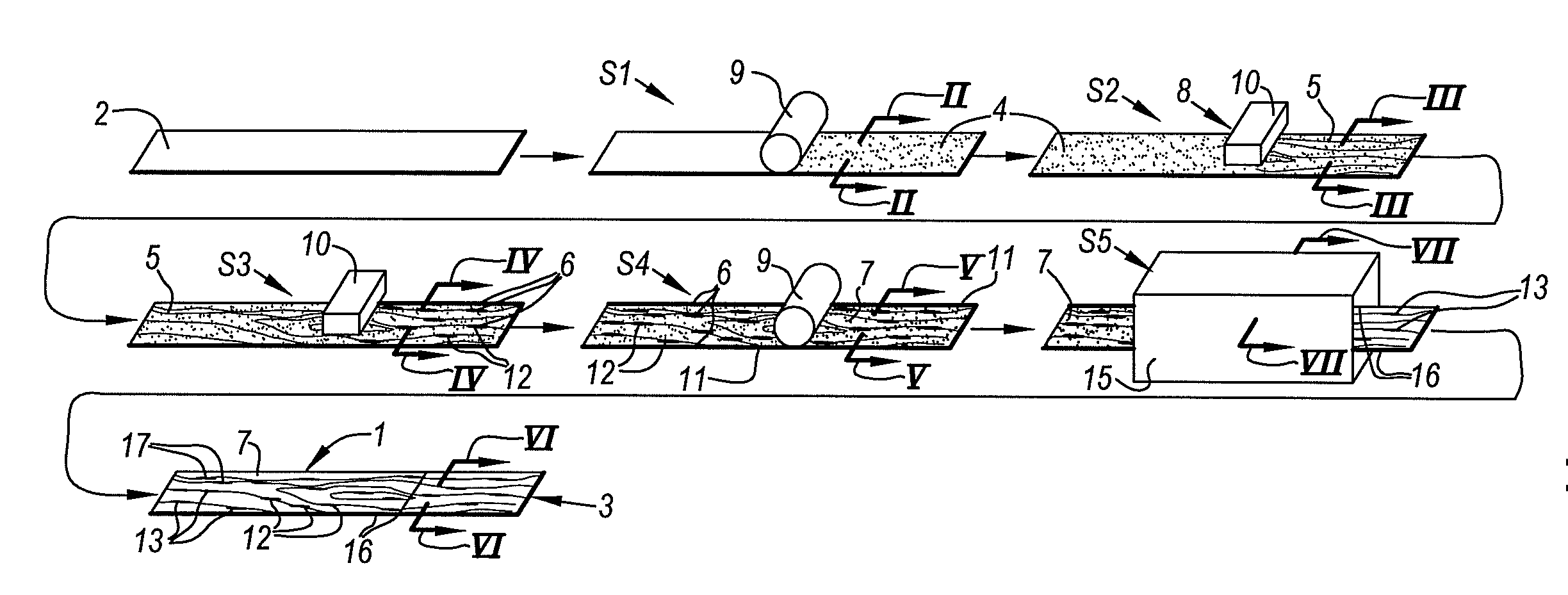

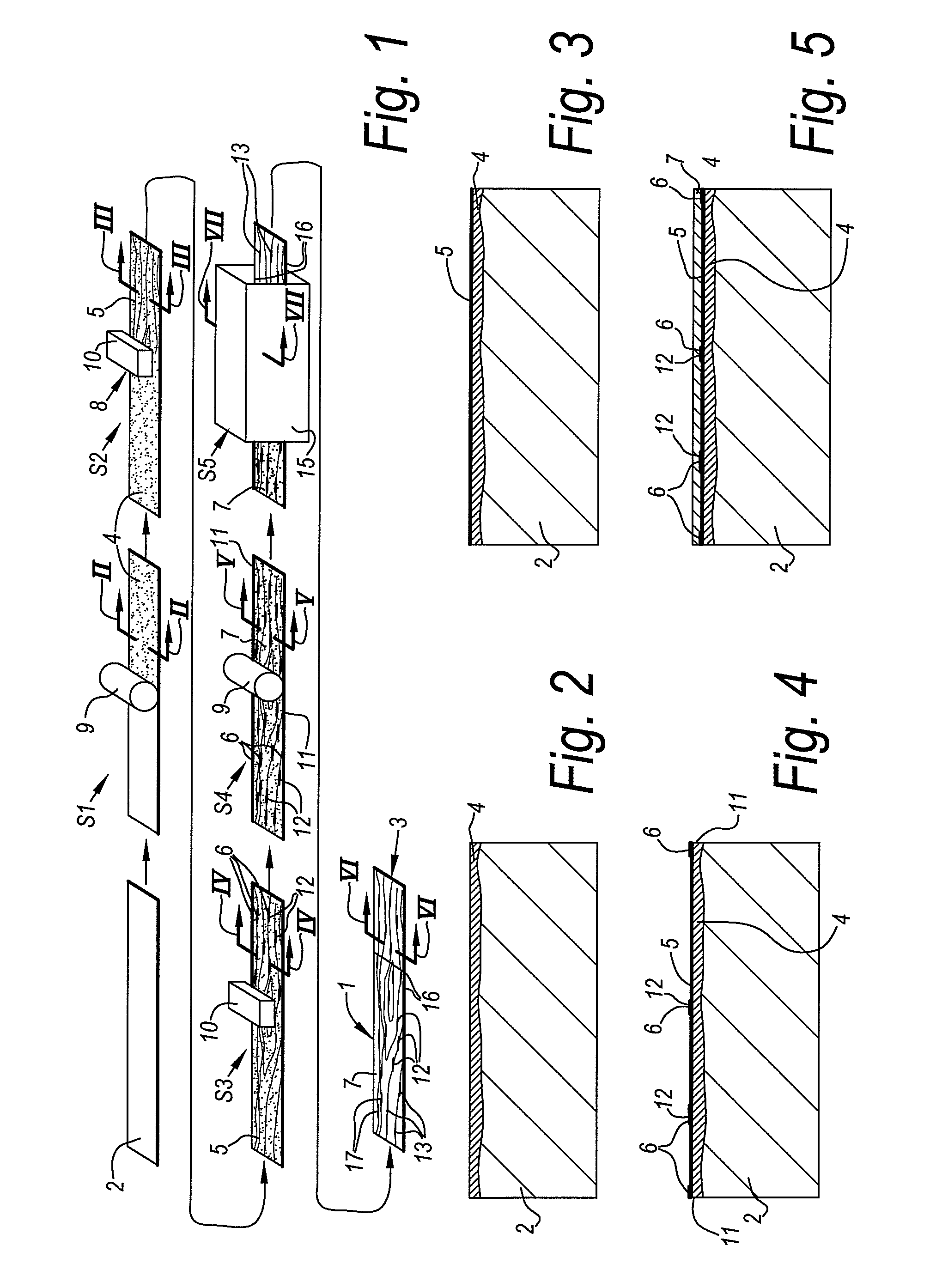

Coated panel and method for manufacturing such panel

ActiveUS20110268937A1Smoother economicalAvoid uneven performanceCovering/liningsNatural patternsEngineeringSemi transparent

Owner:FLOORING IND LTD

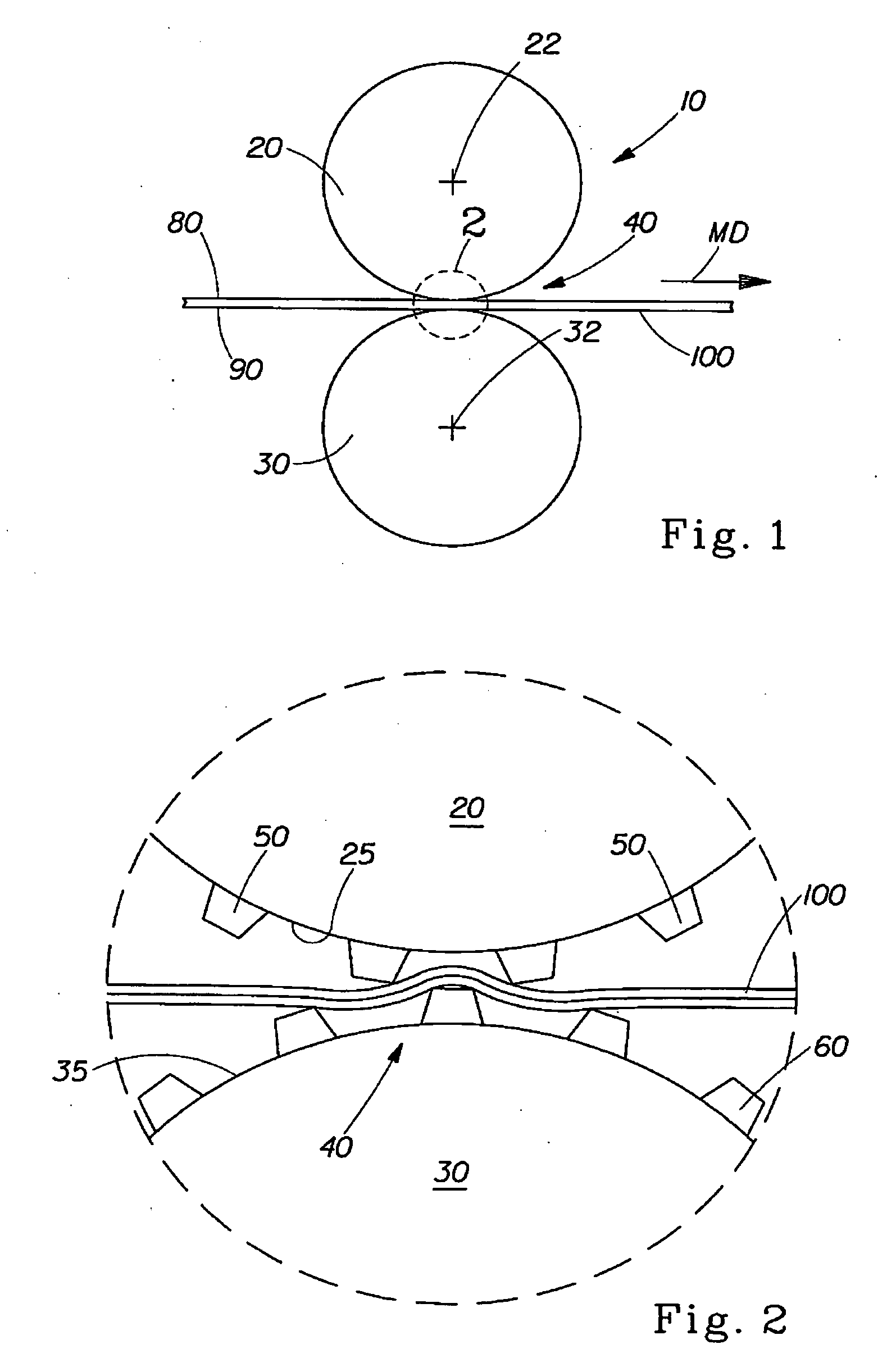

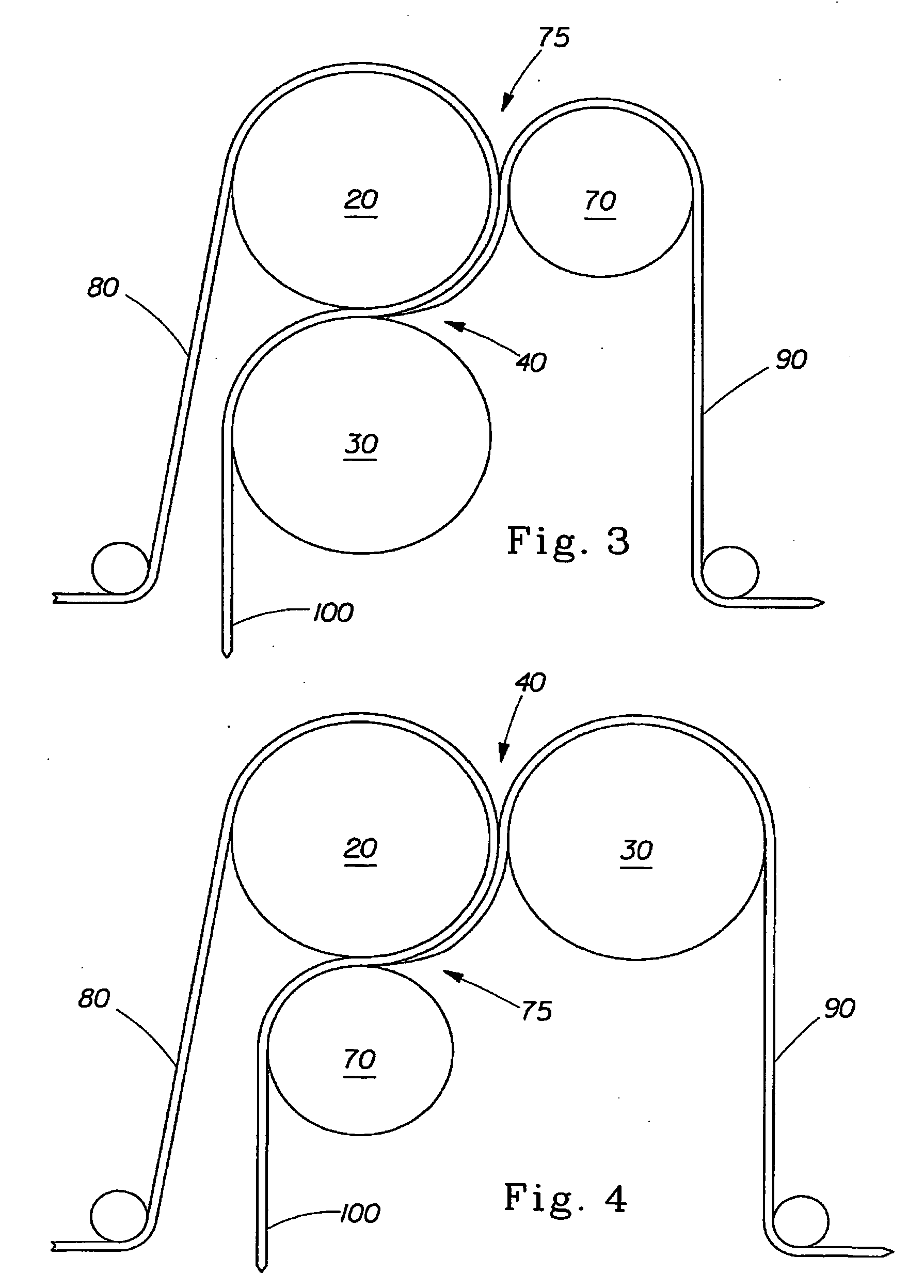

Device for treating flat material

InactiveUS7147453B2Not easy to copyImprove accuracyMechanical working/deformationDough-sheeters/rolling-machines/rolling-pinsEngineeringMechanical engineering

The invention relates to a device for embossing and / or glazing films. The device for embossing includes a first and second embossing roll, through which flat material can be fed under pressure, in order to create a pattern. An additional embossing roll is connected downstream of the second embossing roll, this additional embossing roll interacting with the first or preceding embossing roll. The patterned flat material may be fed between these embossing rolls, in order to be embossed again with essentially the same pattern. In a simplified embodiment, only a total of two rolls are used. In order to achieve as precise an embossing as possible, with special effects, the first driven embossing roll is provided with teeth, while at least one other embossing roll comprises rings or longitudinal ribs, or is smooth.

Owner:BOEGLL GRAVURES SA

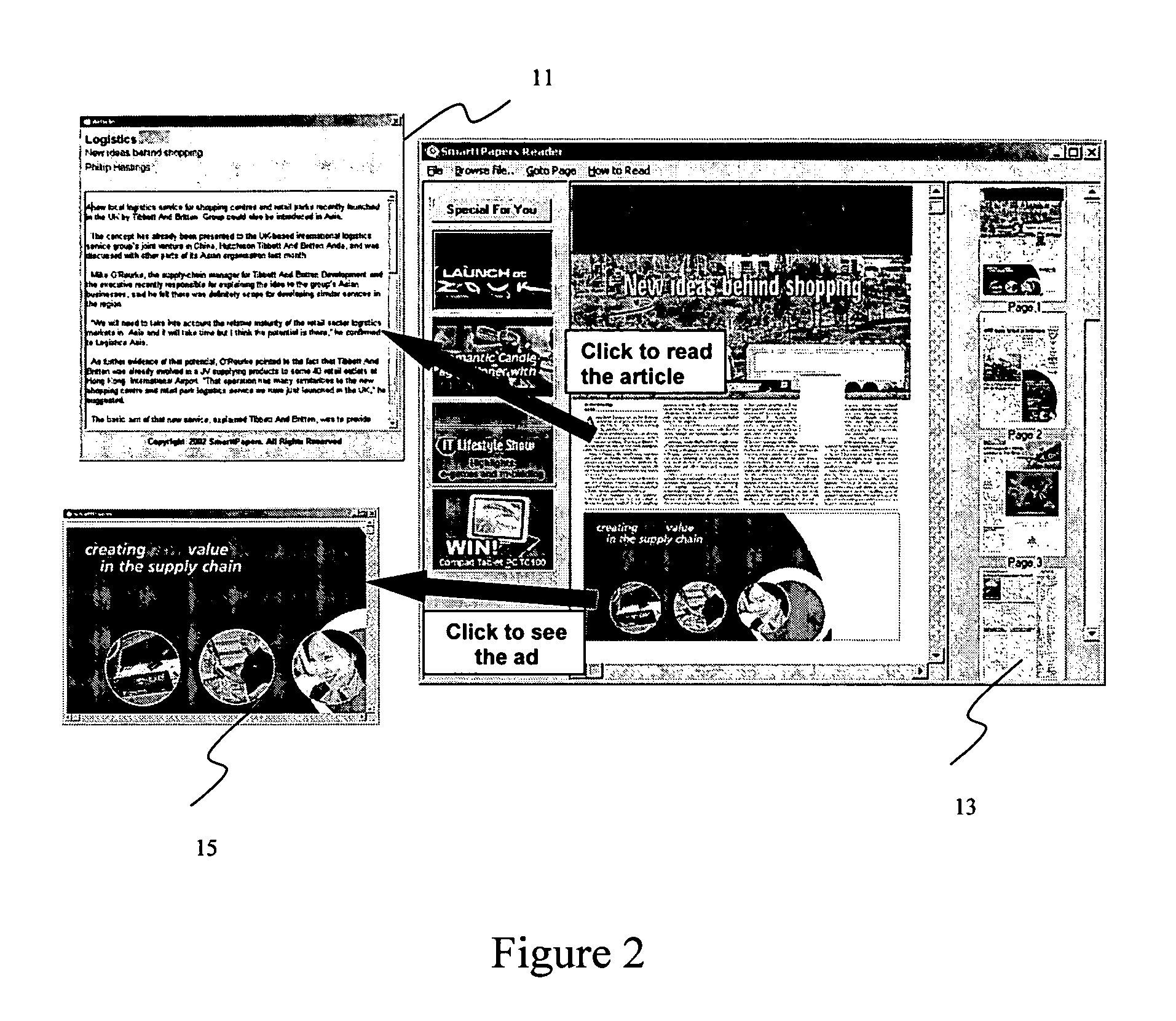

Apparatus and method for creating an electronic version of printed matter

InactiveUS20050288943A1Change effectEasily identifiableNatural language translationMechanical working/deformationThe InternetSpeech sound

The present invention relates to an apparatus and method for creating an electronic version of printed matter. Advantageously, the electronic version of the printed matter is such that is has the same appearance and layout as the printed matter. The electronic version of the printed matter is also such that that a viewer's interaction with the electronic version can trigger the sending of information to the viewer. The information can be in various forms including an e-mail or e-coupon. It comes with an intelligence and interactive module where viewers can read other languages' printed matter instantaneously with multi-lingual translation both in text and voice. The apparatus and method is also capable of compressing the electronic version so that it can be quickly and efficiently distributed to viewers over numerous networks. These networks can include LAN, WAN, internet, or mobile and wireless communication networks.

Owner:PROPERTY PUBLICATIONS PTE

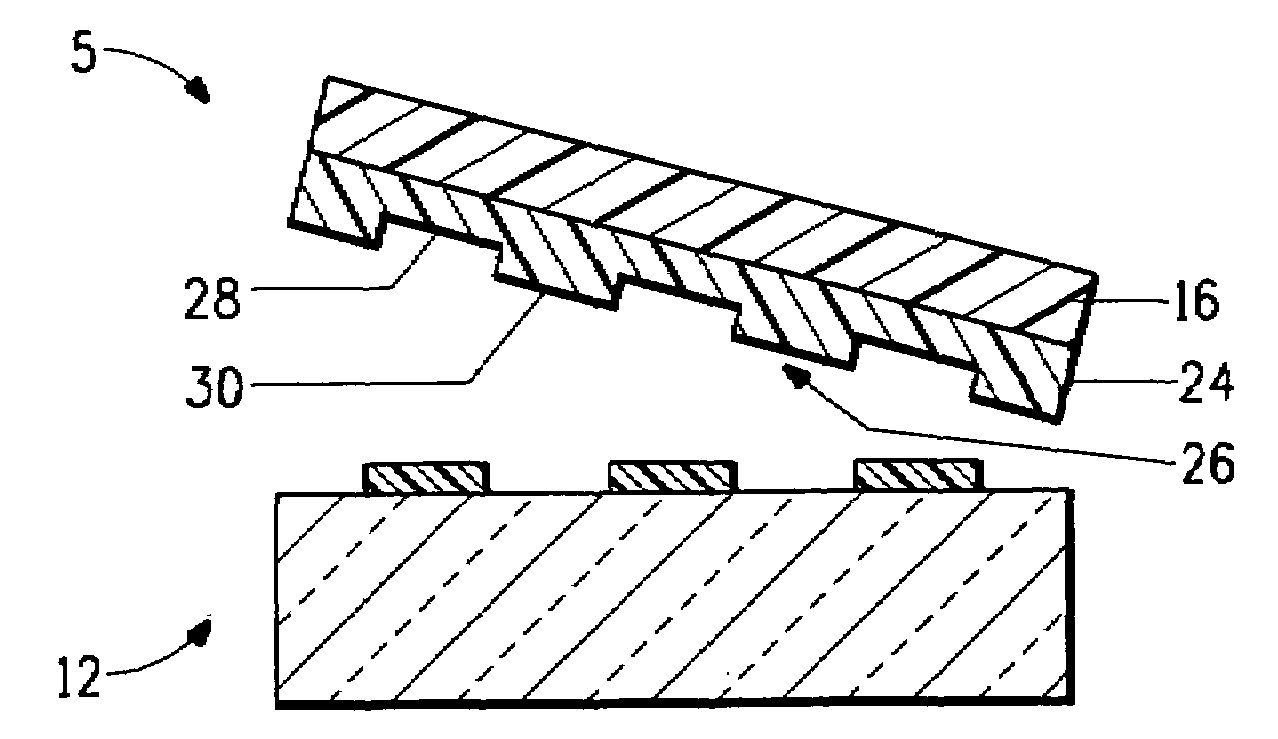

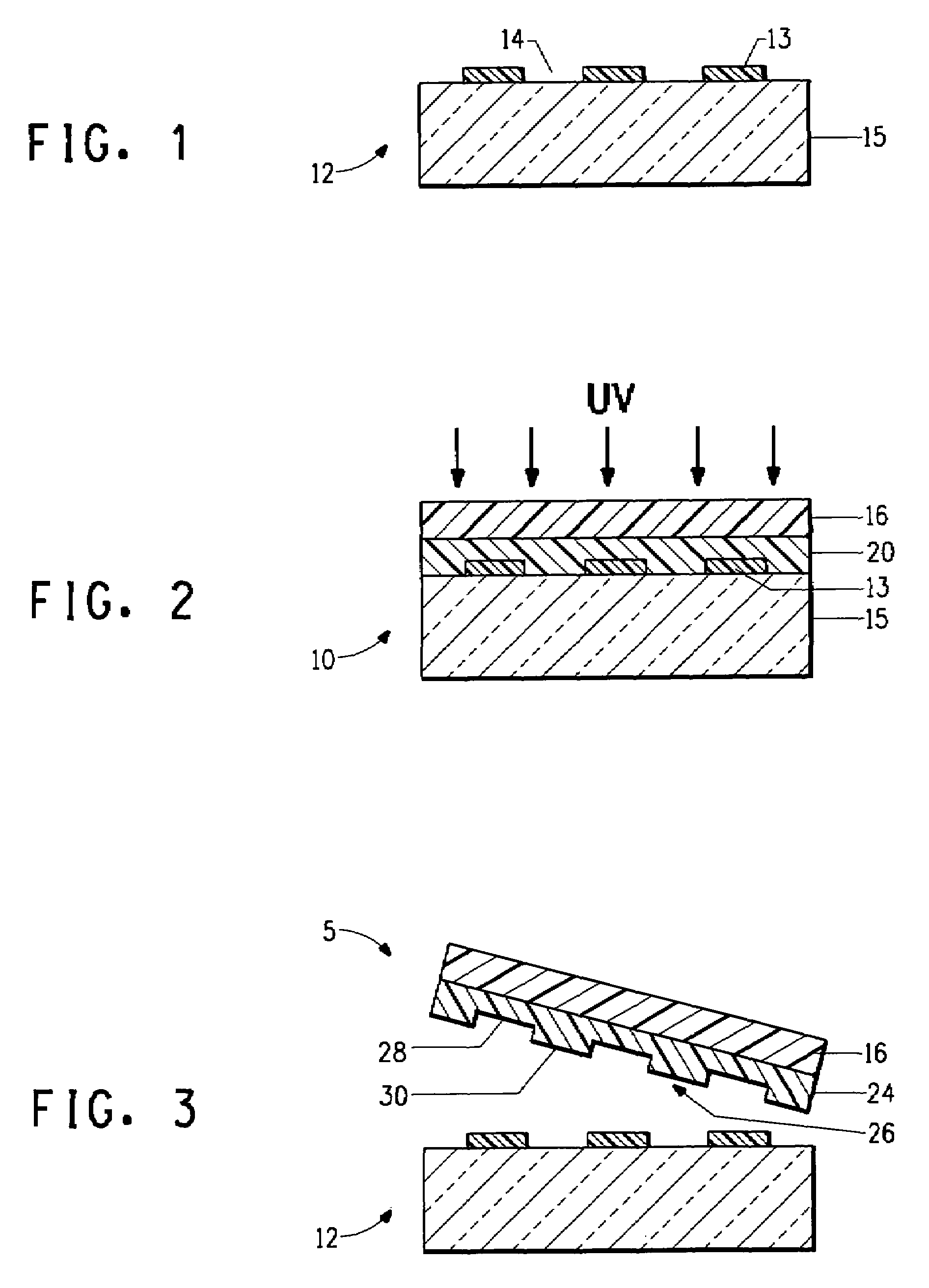

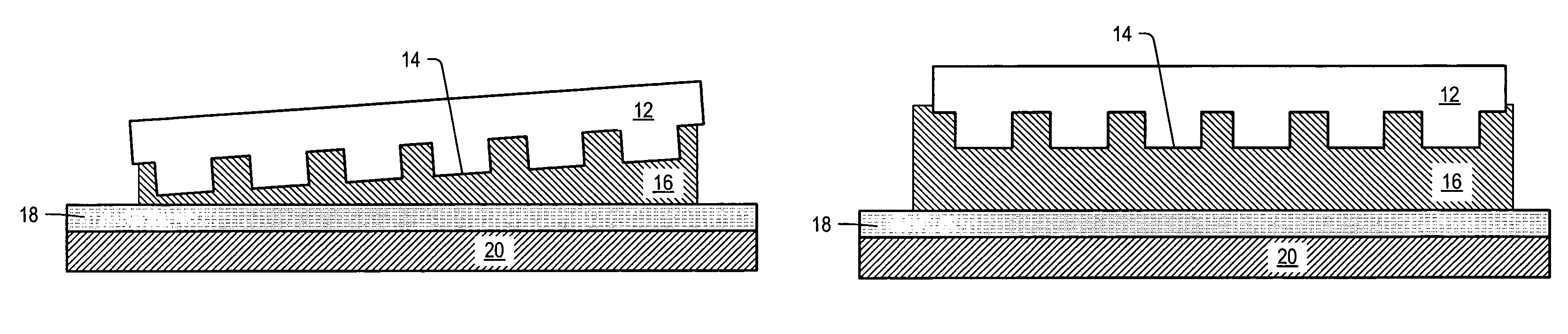

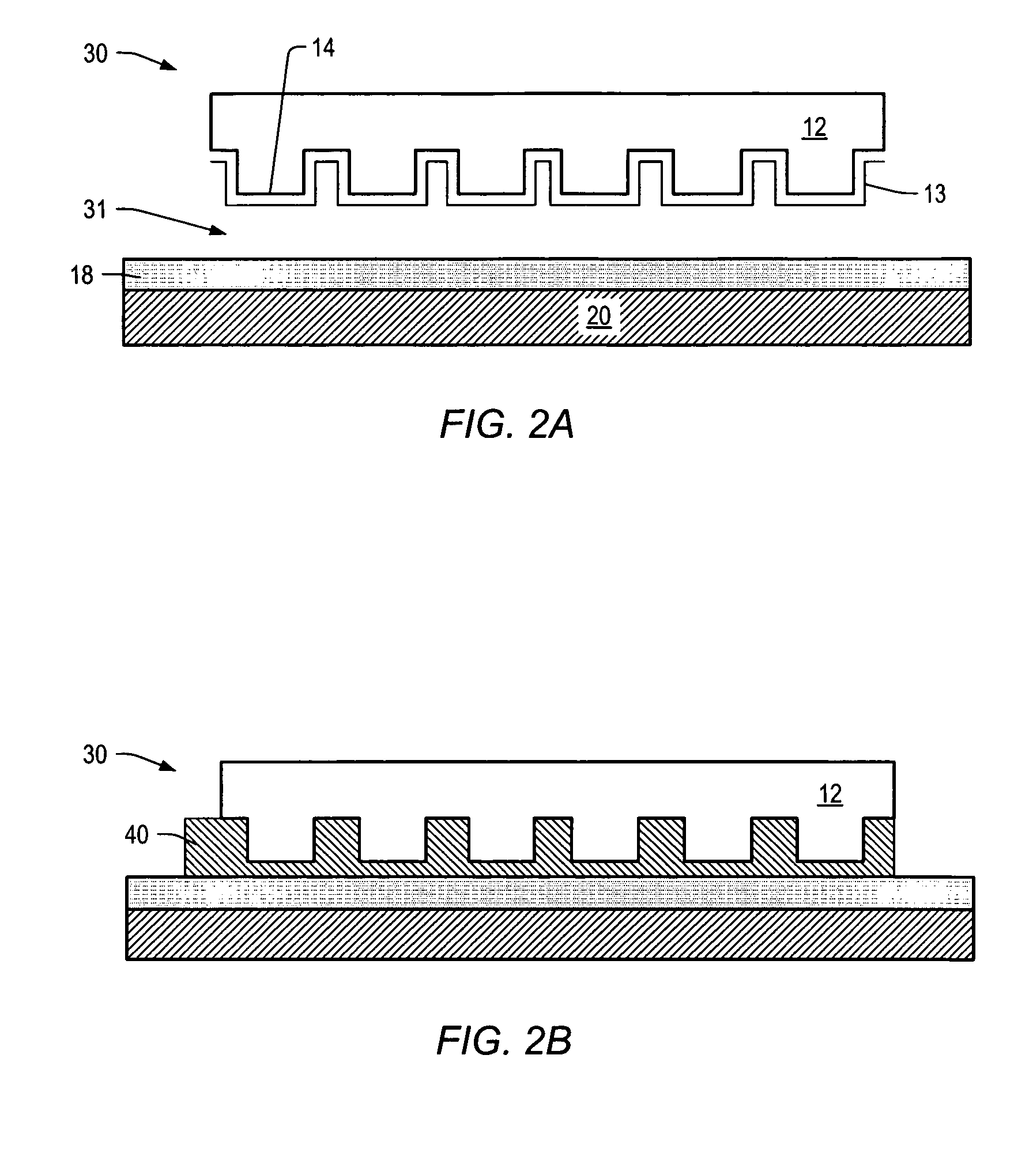

Method to form a pattern of functional material on a substrate

InactiveUS20080047930A1Excellent conductive silver pattern formationEliminates possibility of shortingDecorative surface effectsNanoinformaticsOptoelectronicsMaterial transfer

The invention provides a method to form a pattern of a functional material on a substrate for use in electronic devices and components. The method uses a stamp having a relief structure to transfer a mask material to a substrate and form a pattern of open area on the substrate. The functional material is applied to the substrate in at least the open area. The mask material is removed from the substrate, forming the pattern of functional material on the substrate. The method is suitable for the fabrication of microcircuitry for electronic devices and components.

Owner:EI DU PONT DE NEMOURS & CO

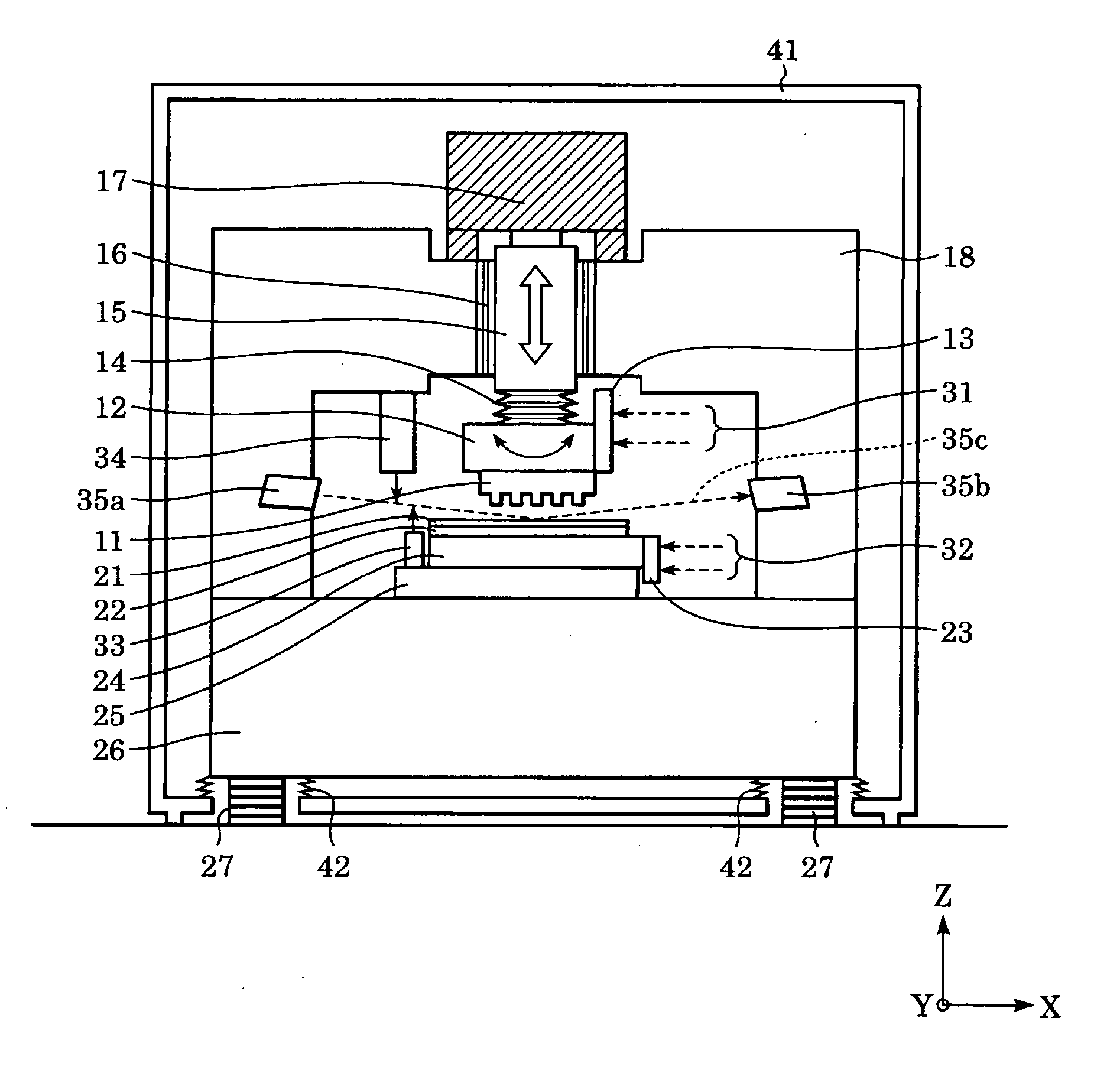

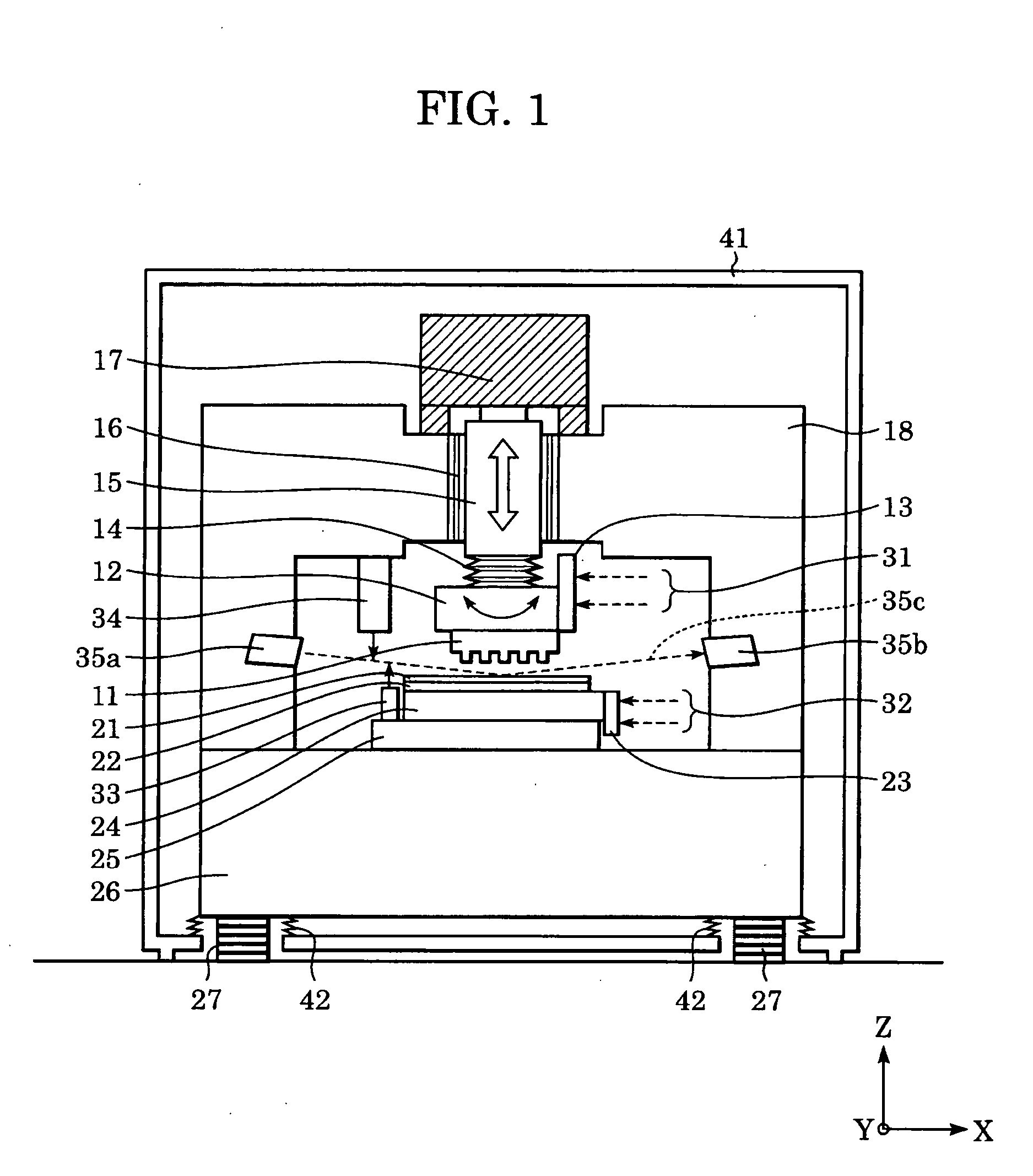

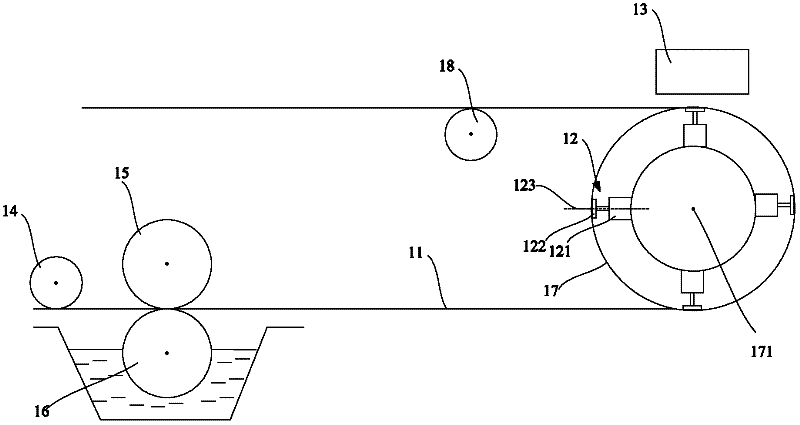

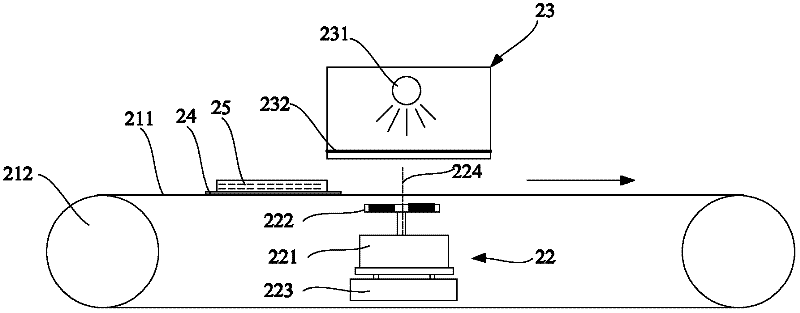

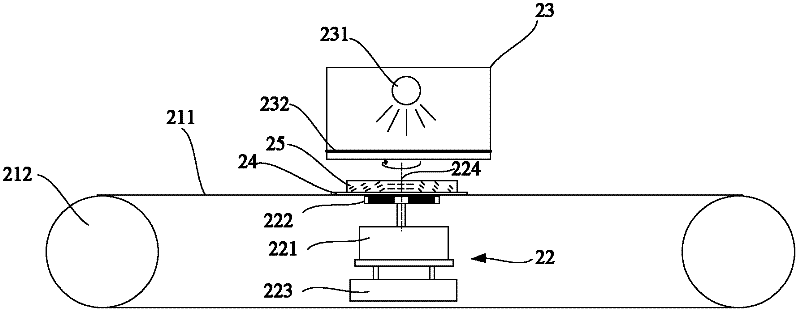

Magnetic orientation device, manufacture device and manufacture method of magnetic pigment printed product

ActiveCN102529326AImprove the three-dimensional effectPattern printingPretreated surfacesEngineeringSubstrate surface

The invention provides a magnetic orientation device, a manufacture device and a manufacture method of a magnetic pigment printed product. The magnetic orientation device comprises a drive device and a magnet, wherein the drive device is used for driving the magnet to rotate around a rotation shaft; and the rotating magnet produces a magnetic field to realize magnetic orientation of magnetic pigment flakes in magnetic ink printed on the substrate surface of the printed product, thereby forming a magnetically oriented pattern with three-dimensional effect in the magnetic ink. According to the invention, the magnetic orientation device, the manufacture device and the manufacture method of the magnetic pigment printed product provided by the invention can improve the three-dimensional effect of the magnetically orientated pattern by using the magnetic field produced by the rotating magnet to realize magnetic orientation of the magnetic pigment flakes in the magnetic ink.

Owner:HUIZHOU FORYOU OPTICAL TECH

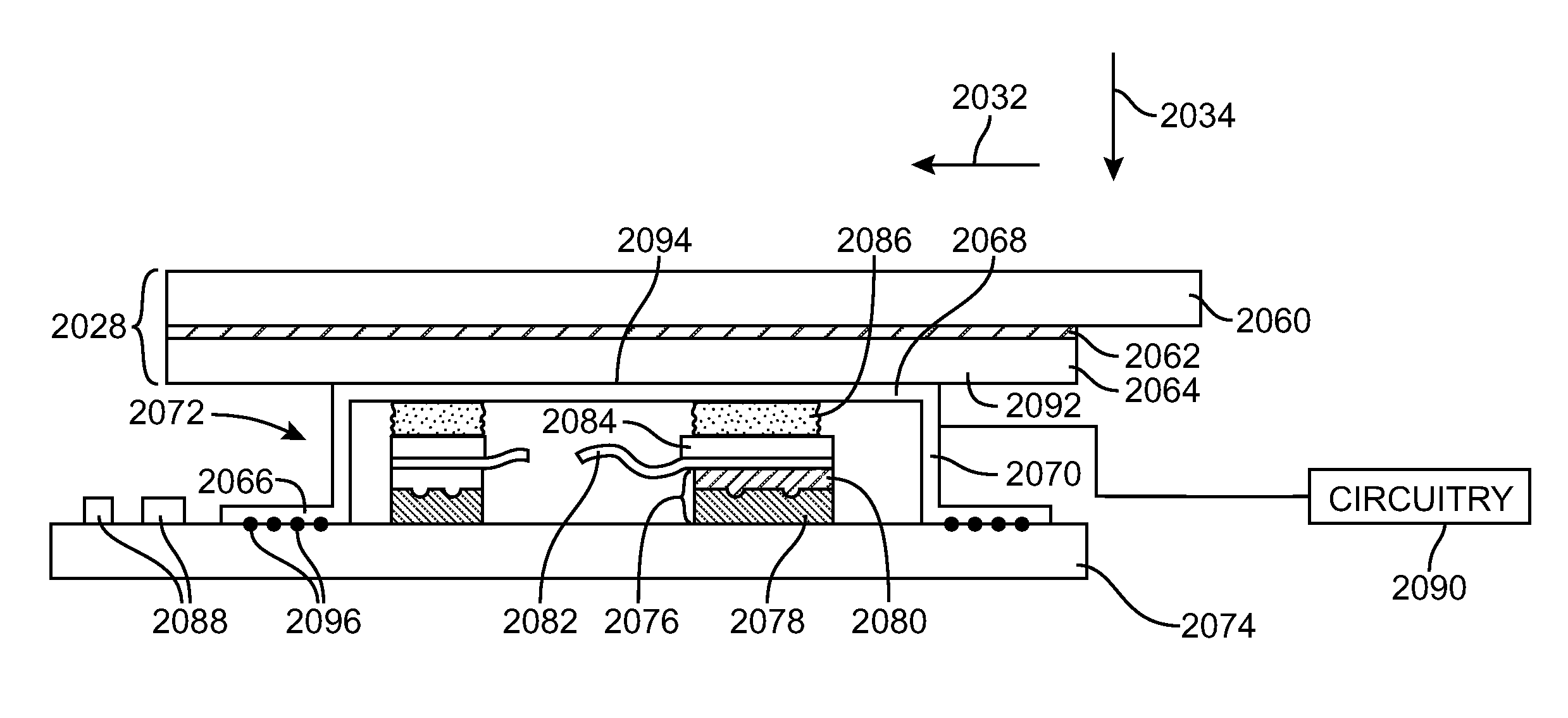

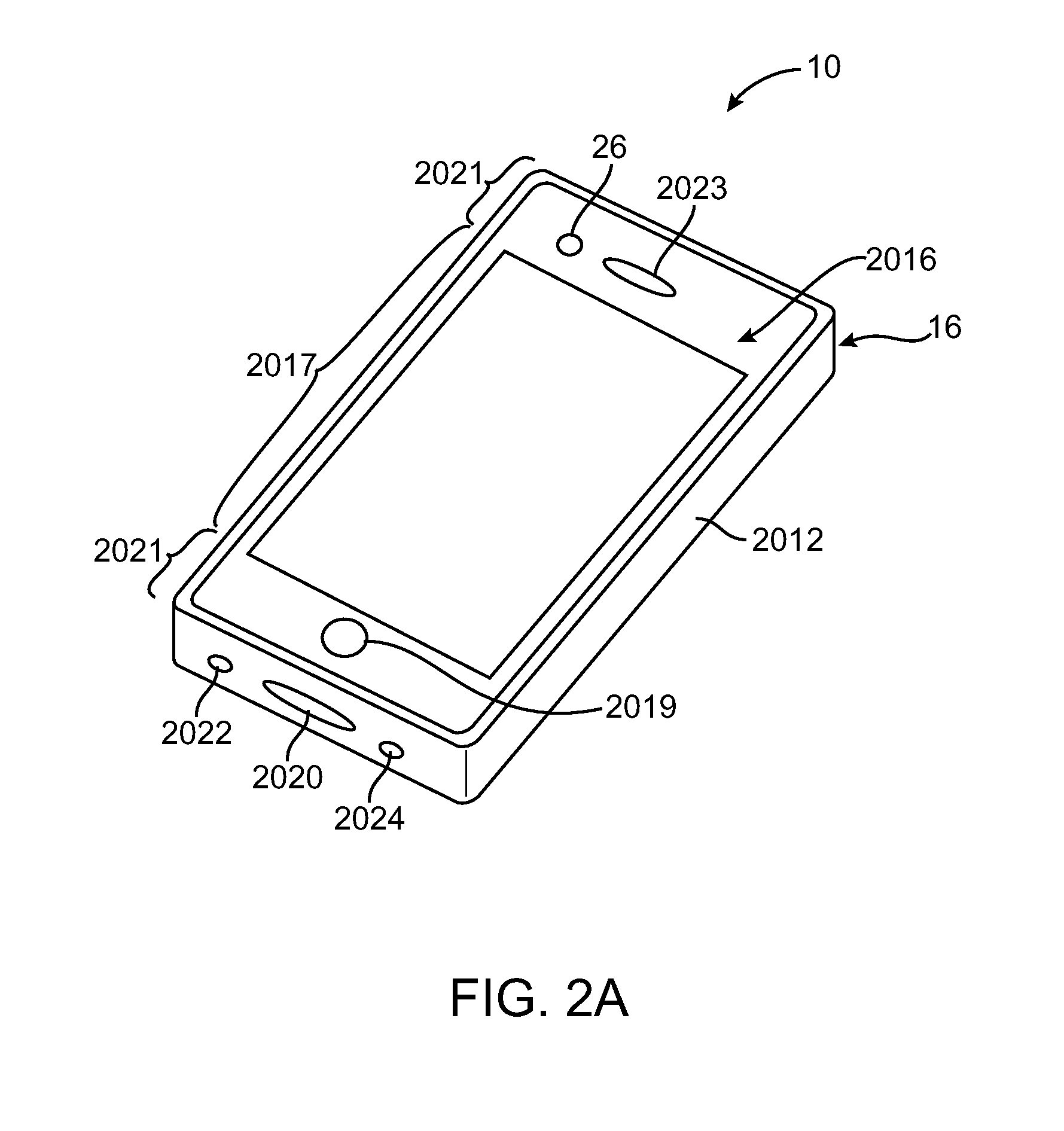

Electronic subassemblies for electronic devices

InactiveUS20110255850A1Improve device aestheticImprove device aestheticsCoupling device connectionsFinal product manufactureEngineeringHeat sink

Electronic devices may be provided that include mechanical and electronic components. Connectors may be used to interconnect printed circuits and devices mounted to printed circuits. Printed circuits may include rigid printed circuit boards and flexible printed circuit boards. Heat sinks and other thermally conductive structures may be used to remove excess component heat. Structures may also be provided in an electronic device to detect moisture. Integrated circuits and other circuitry may be mounted on a printed circuit board under a radio-frequency shielding can.

Owner:APPLE INC

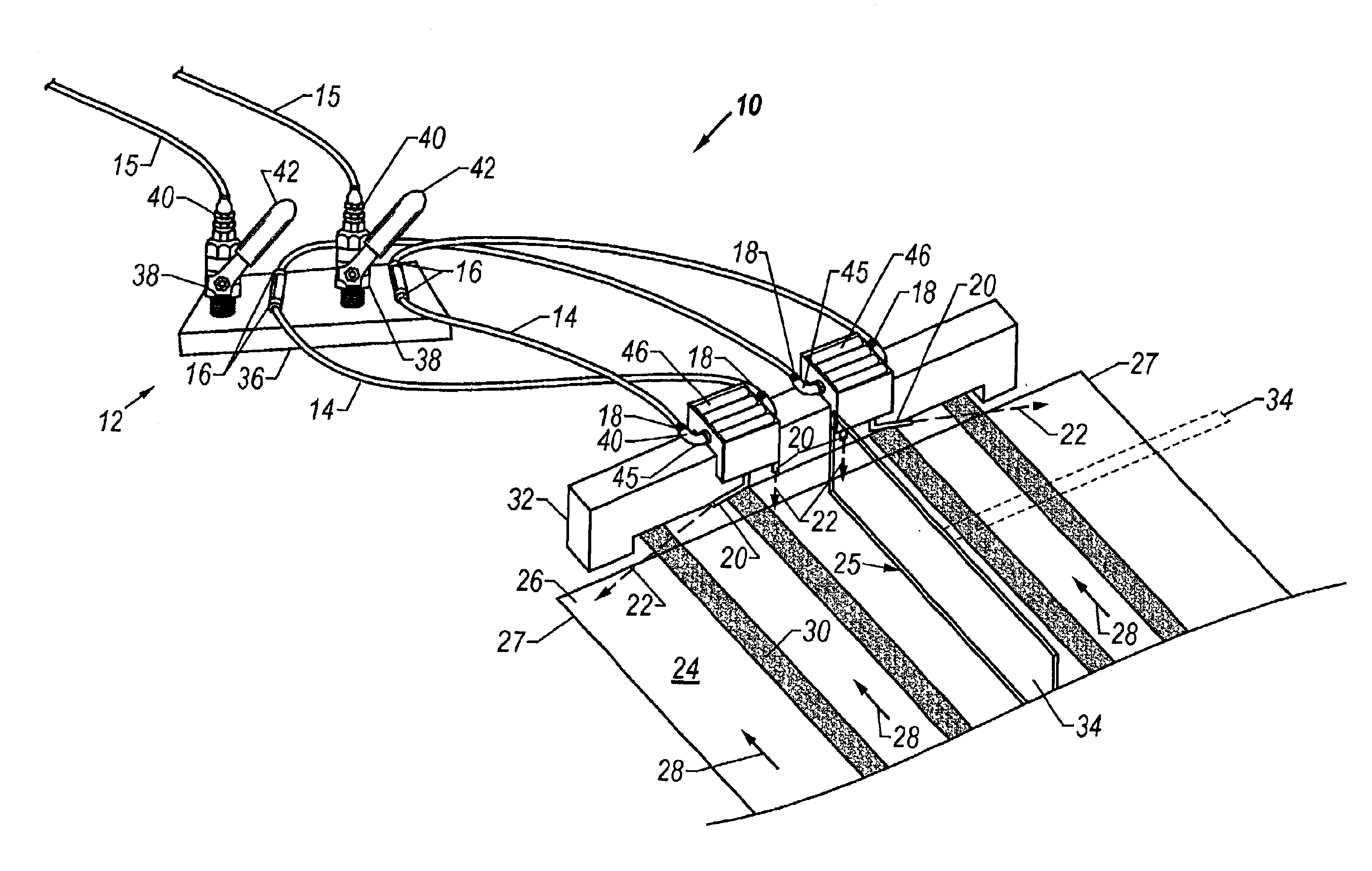

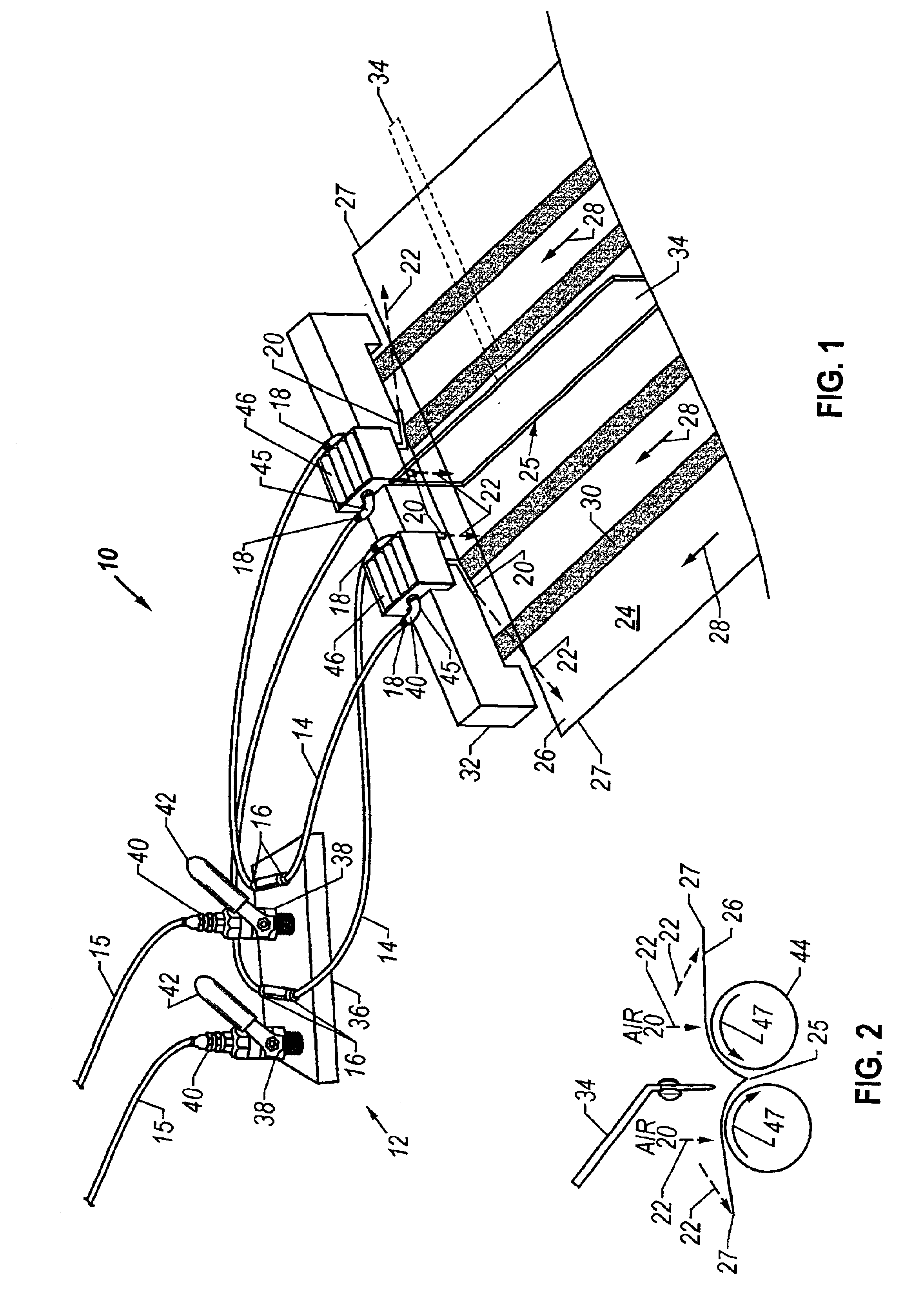

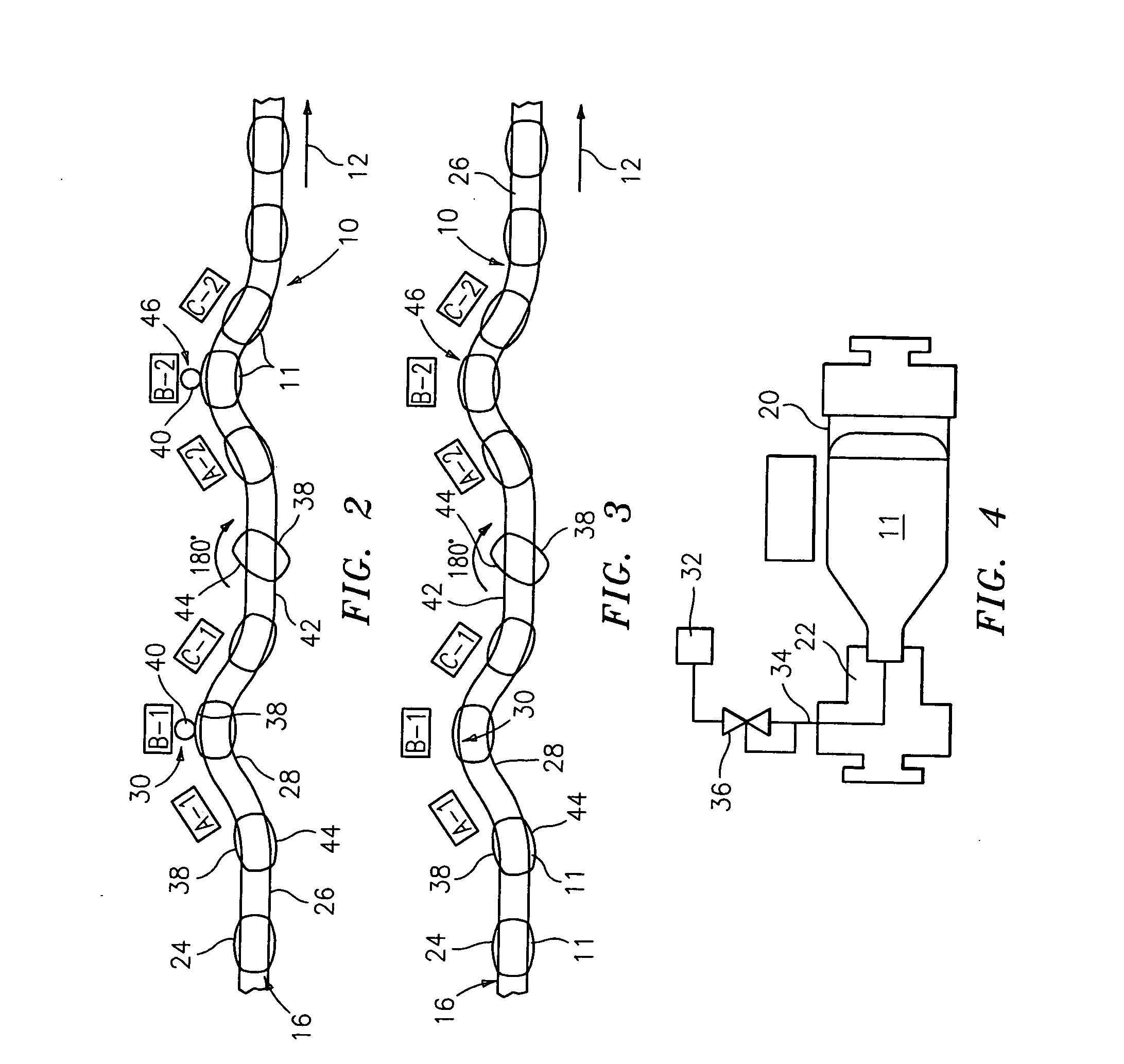

Air folder adjuster apparatus and method

InactiveUS6840616B2Mechanical working/deformationFolding thin materialsPaper documentDocument preparation

An air folder adjuster (10) includes an air supply (12) and air supply tubing (14) connected to air supply (12) at end (16). The opposite end (18) of air supply tubing (14) is connected to one or more air nozzles (20). In a printing press utilized for folding documents such as books, air folder adjuster (10) is positioned so that air nozzles (20) direct compressed air from air supply (12) downward onto the head (26) of document (24) on either side of chopper arm (34) during the folding process thus ensuring that the document (24) lies flat, square, and untouched during the folding process and thereby allowing the elimination of chopper brushes altogether.

Owner:SUMMERS SCOTT

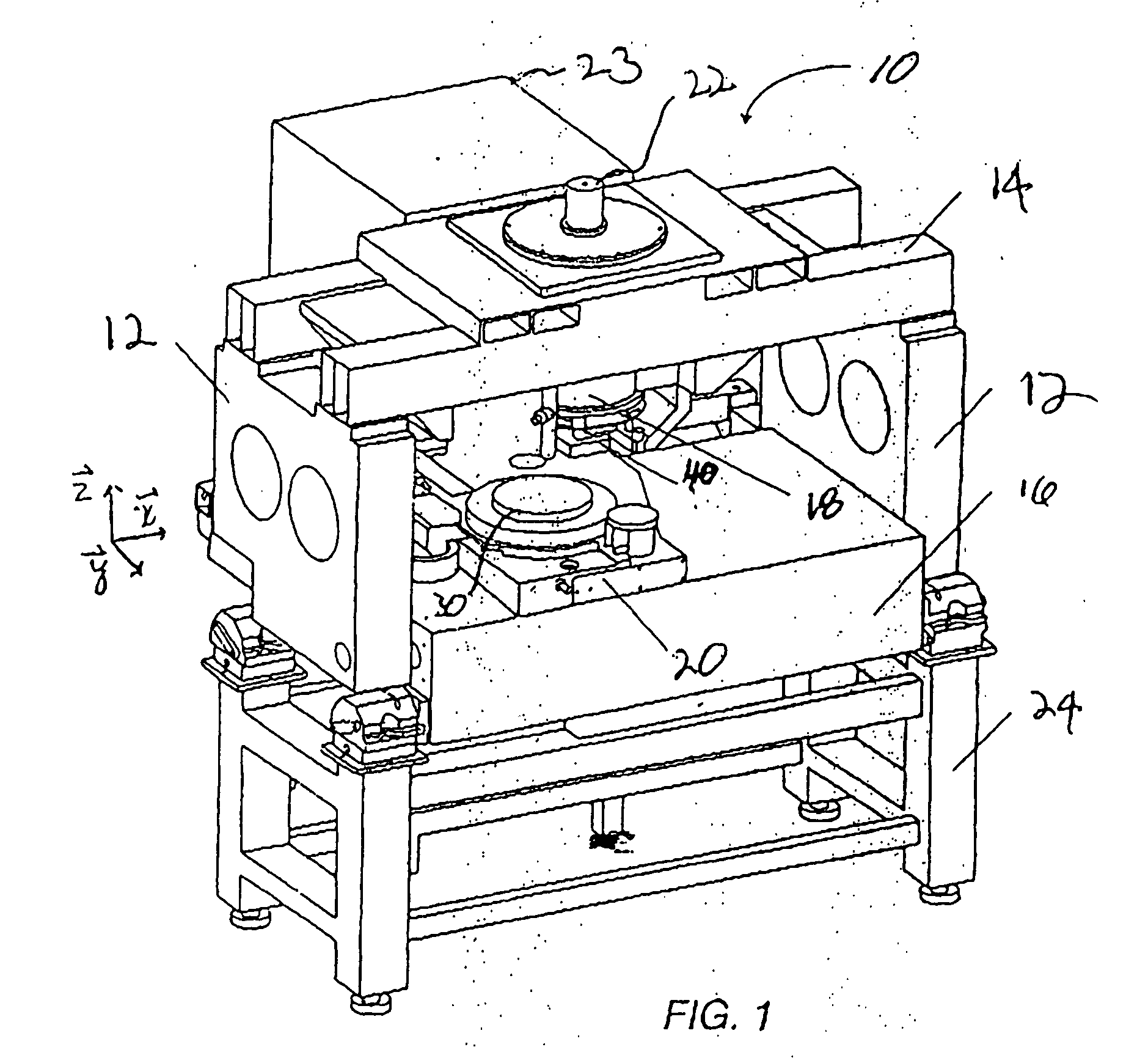

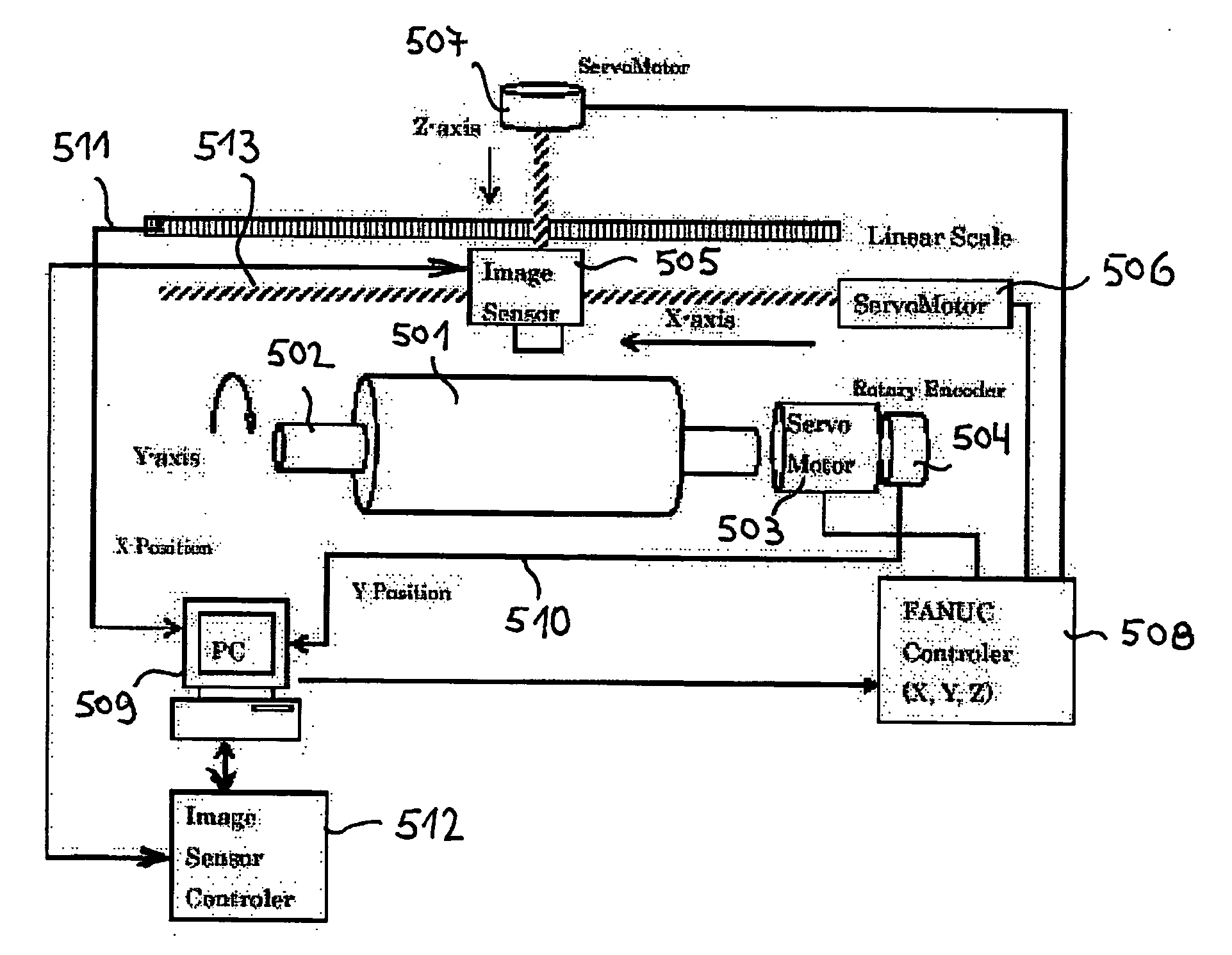

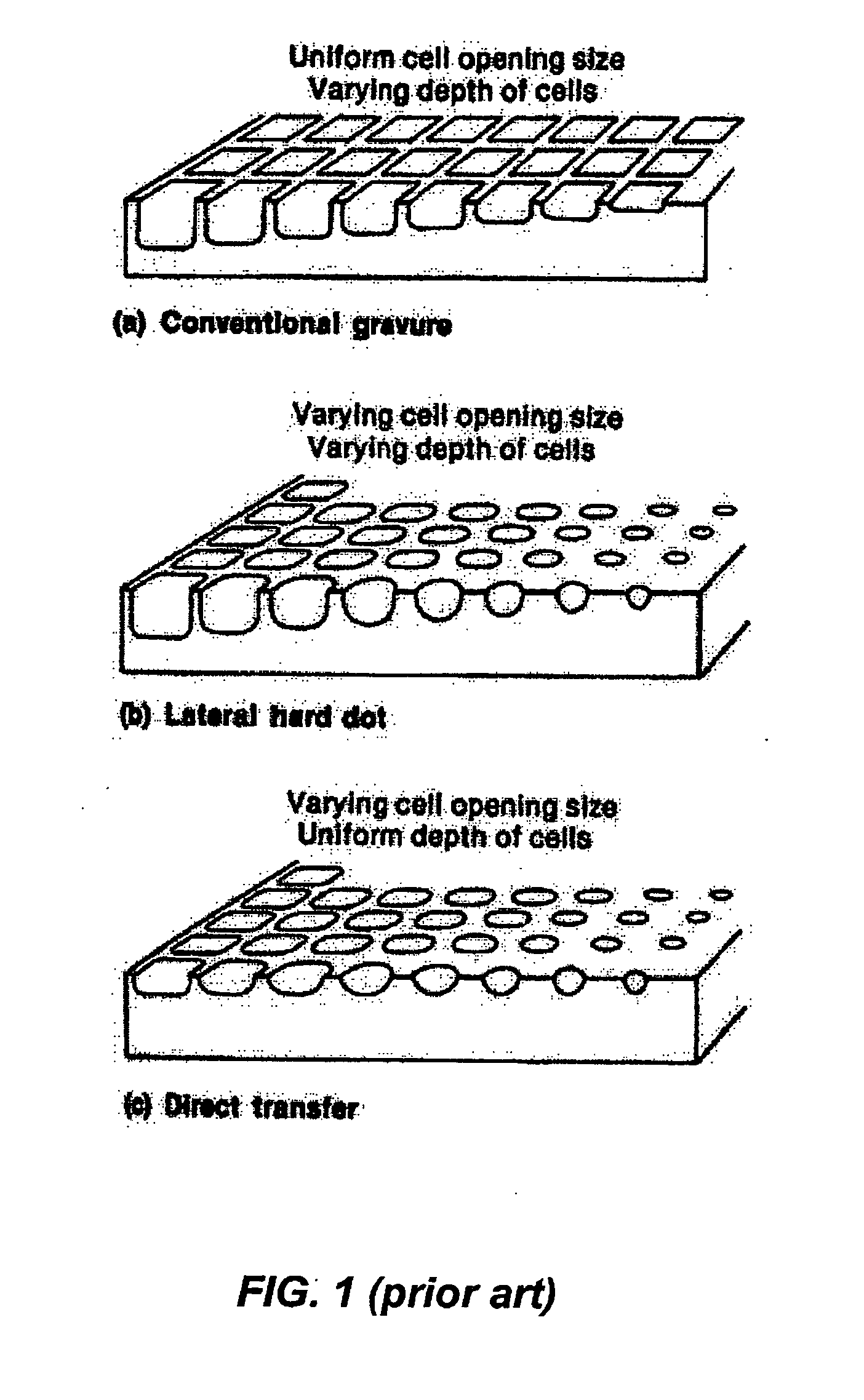

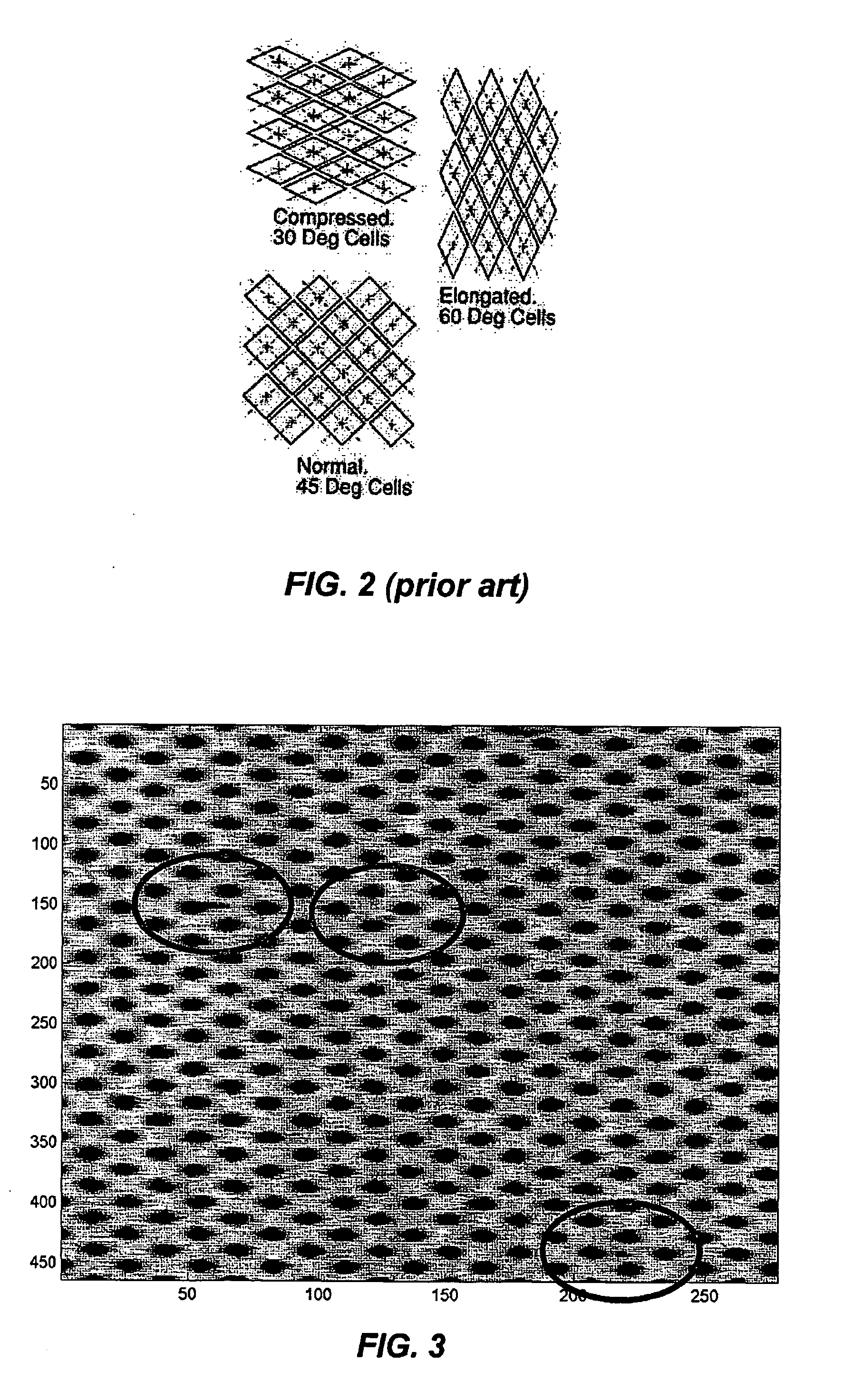

Method and system for detecting defects during the fabrication of a printing cylinder

The invention relates generally to the field of printing. More specifically, the invention relates to a method and system for automatically detecting defects in a printing cylinder during its fabrication process. The invention further relates to a process for fabricating a printing cylinder.

Owner:ELBIT VISION SYST

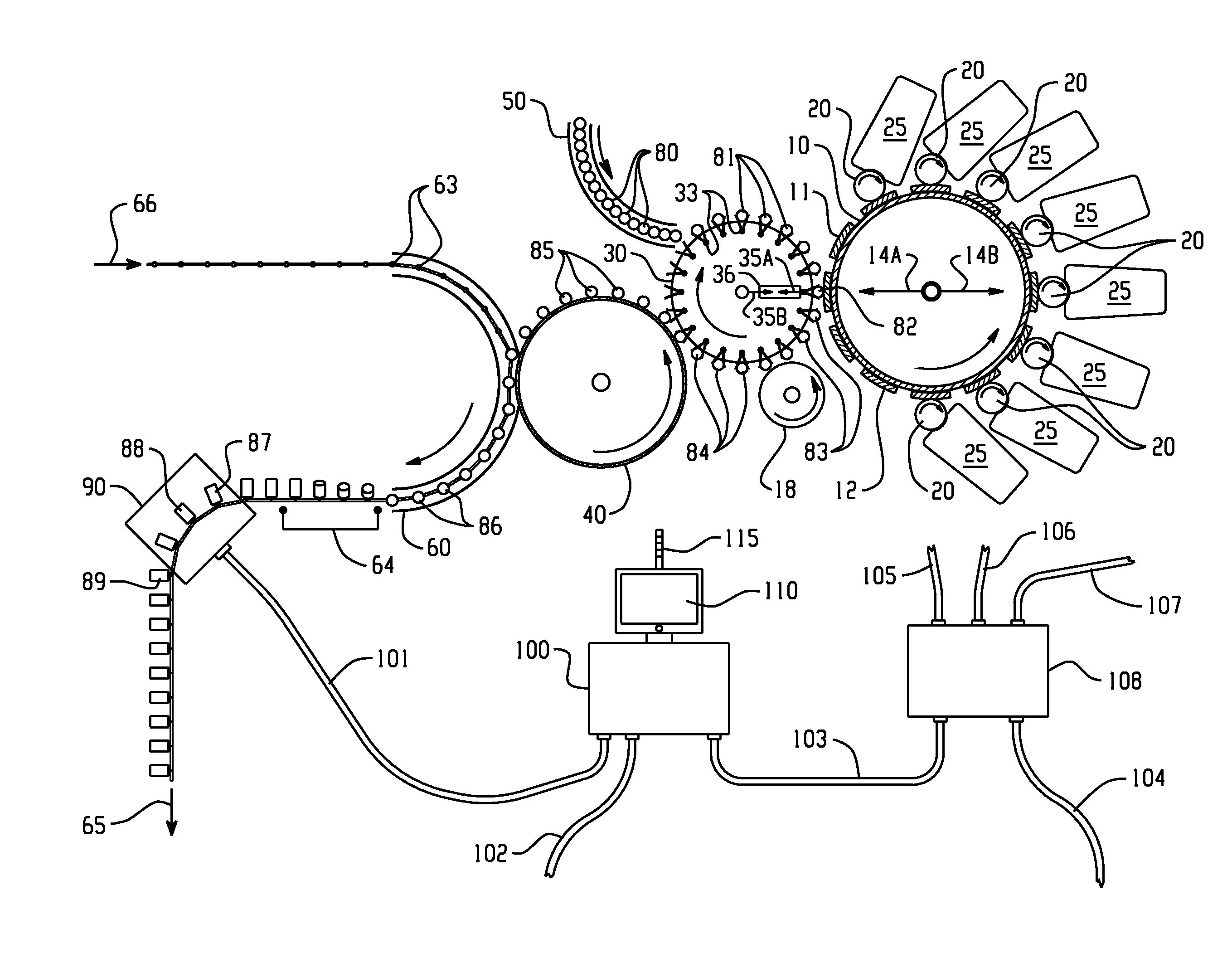

Laser unit, inspection unit, method for inspecting and accepting/removing specified pellet-shaped articles from a conveyer mechanism, and pharmaceutical article

ActiveUS20040094050A1Optically investigating flaws/contaminationRotary pressesMechanical engineeringSpherical form

A pellet-shaped article inspection unit is structured for use with a conveyer mechanism having a plurality of carrier bars, each carrier bar being structured to convey a plurality of pellet-shaped articles along a predetermined path. The article inspection unit includes a first camera unit positioned adjacent a first side of the conveyer mechanism. The first camera unit is configured to sense a first predetermined characteristic, e.g., laser holes, of the plurality of pellet-shaped articles. A removal mechanism, downstream from the first camera unit, is structured to remove or maintain at least a selected one of the plurality of pellet-shaped articles from at least a selected one of the plurality of carrier bars depending on whether the first predetermined characteristic is sensed by the first camera unit. A laser unit may be provided to create unique holes in the pellet-shaped articles, e.g., those by a larger exposed surface to improve time-release characteristics of the pellet-shaped articles.

Owner:ACKLEY MACHINE

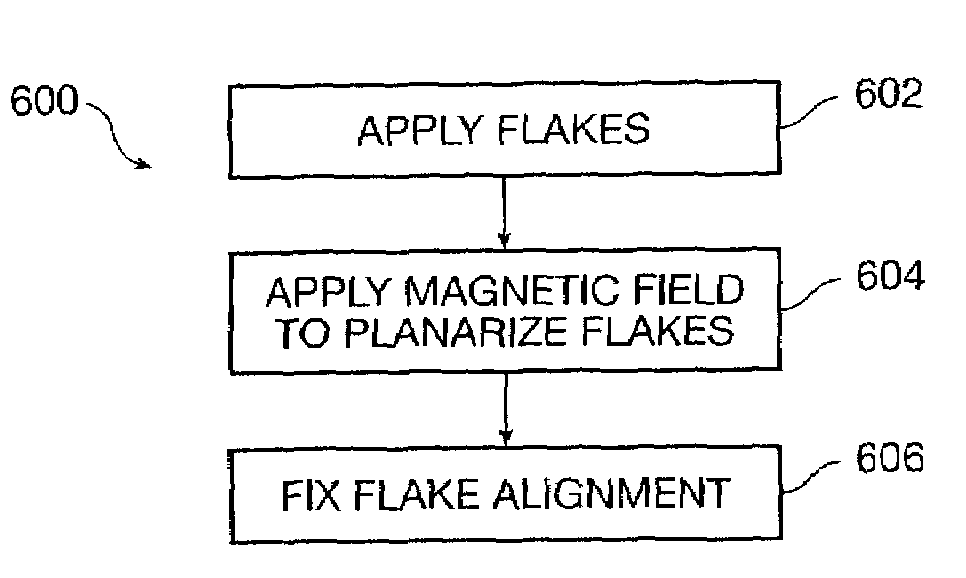

Magnetic planarization of pigment flakes

InactiveUS7258900B2Improve visual appearanceGood lookingPretreated surfacesPattern printingOut of planePigment

A magnetic field is applied to planarize magnetic pigment flakes relative to a surface. Pigment flakes, such as optically variable pigment flakes, are used in a variety of paints, inks, extrusions, powder coatings, and other forms for decorative and security applications. In many applications pigment flakes tend to align parallel to each other and to the surface to which they are applied. If the pigment flakes include a suitable magnetic structure, a magnetic field can be applied to subsequently align the flakes or enhance the alignment of the flakes in the plane of the substrate if the carrier that the flakes are dispersed in is still fluid. In some printing operations, pigment flakes that are applied parallel to the substrate are pulled out of plane when the print screen or printing die is lifted off the substrate. Application of a magnetic field can re-align pigment flakes to the plane of the substrate, enhancing the visual quality of the printed image, especially with optically variable pigments.

Owner:VIAVI SOLUTIONS INC

Printing plastic containers with digital images

A method for printing digital images on plastic containers having curved surfaces, including providing a series of hollow plastic containers, moving the containers along a track past first and second digital printing locations, and printing first and second digital images on the curved container surfaces while maintaining the container being printed under internal pressure and while firmly holding the container being printed at spaced locations thereon.

Owner:PLASTIPAK PACKAGING

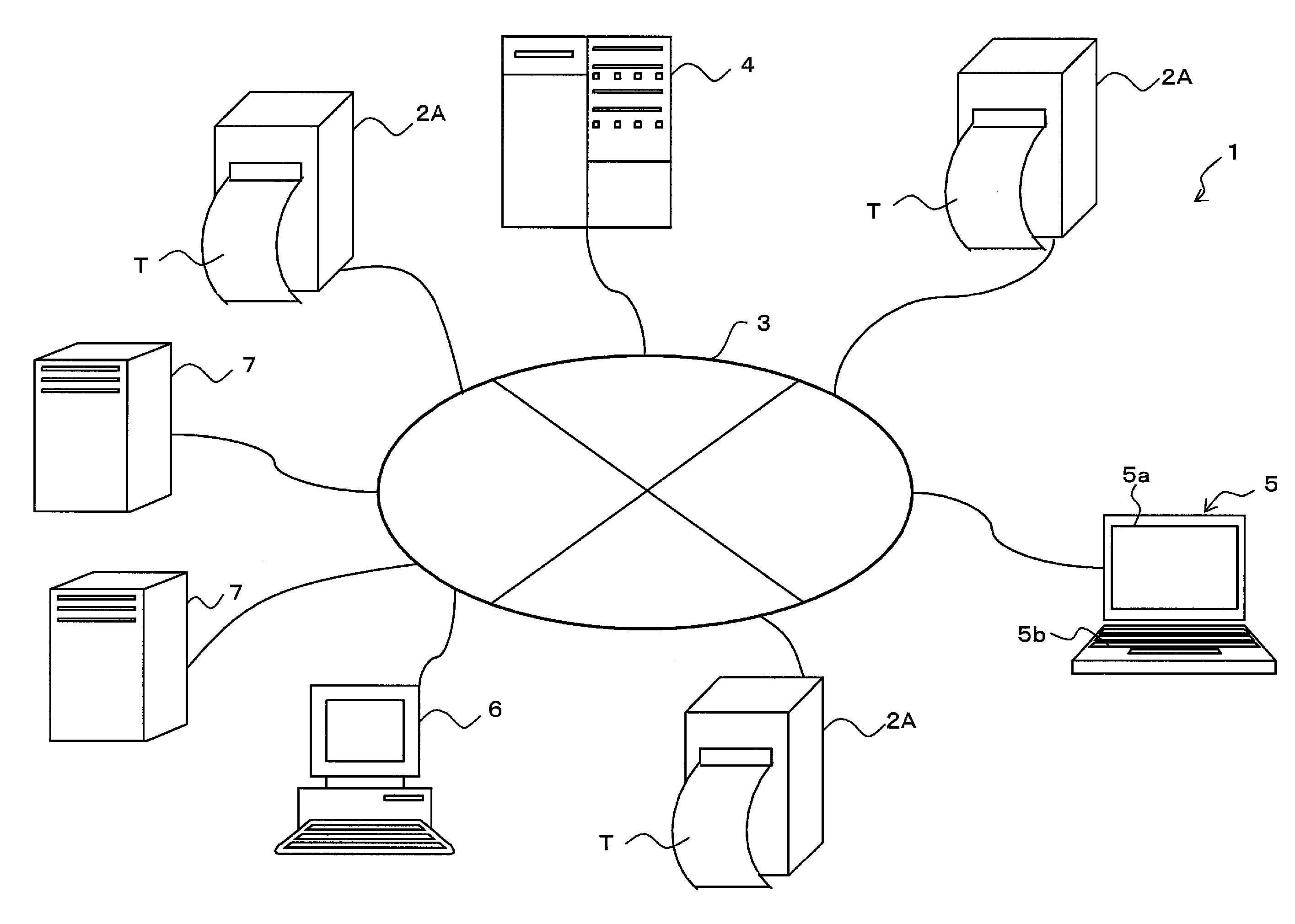

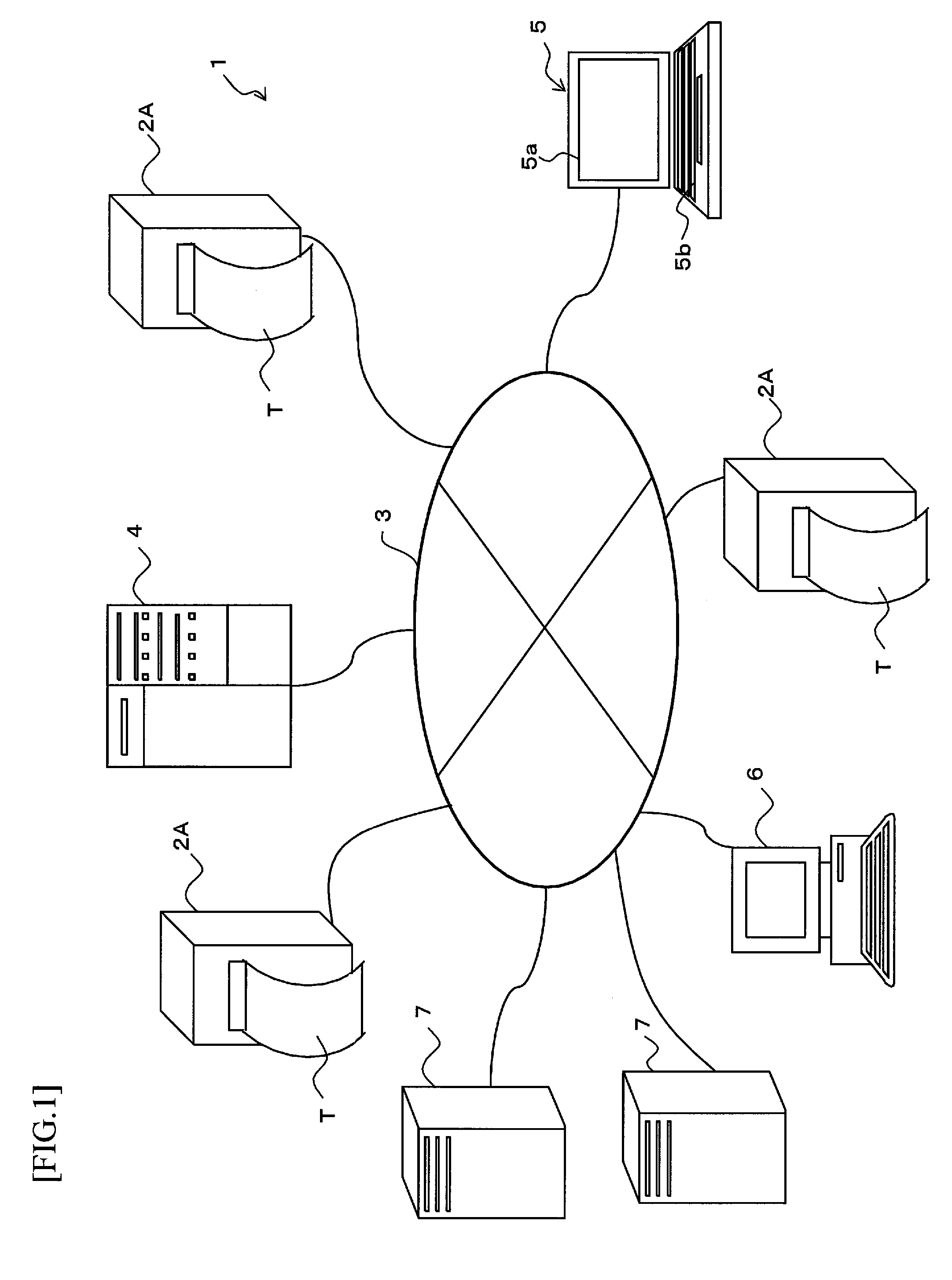

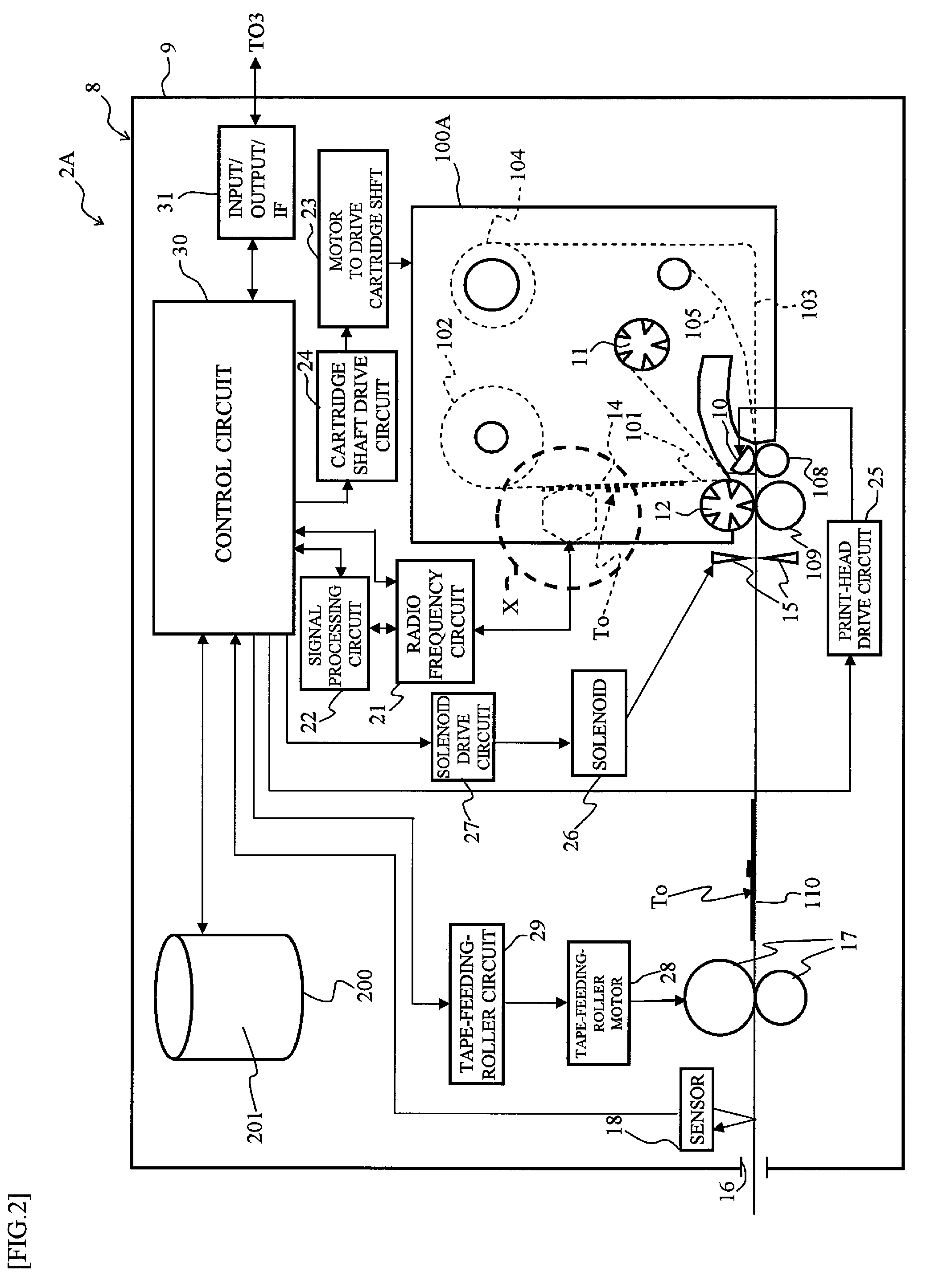

System For Managing Information Of A RFID Tag, Appratus For Communicating With A RFID Tag, Reader For Communicating With A RFID Tag, Cartridge For Including At Least A RFID Tag, And RFID Tag

ActiveUS20070273519A1Smoothly and rapidly issuingEnsuring for accessCo-operative working arrangementsTypewritersSignal processing circuitsDrive shaft

An apparatus for communicating with a RFID tag comprises an antenna for communicating with a RFID circuit element by wireless communication, a signal processing circuit and a radio frequency circuit for accessing an IC circuit part of the RFID circuit element through the antenna based on an access instruction to information in a RFID tag, a storage device for storing at least correlation information of identification information of an object which is to bear a RFID tag containing the RFID circuit element to identification of the RFID circuit element corresponding thereto in a database, a control circuit for accessing the database based on an access instruction to a storage device, a tape feeding roller drive shaft for feeding out a cover film associated with the RFID circuit element, and a print head for printing a print based on a printing instruction.

Owner:BROTHER KOGYO KK

Imprint lithography template having a feature size under 250 nm

InactiveUS7229273B2Nanostructure manufactureMechanical working/deformationEngineeringPhotolithography

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

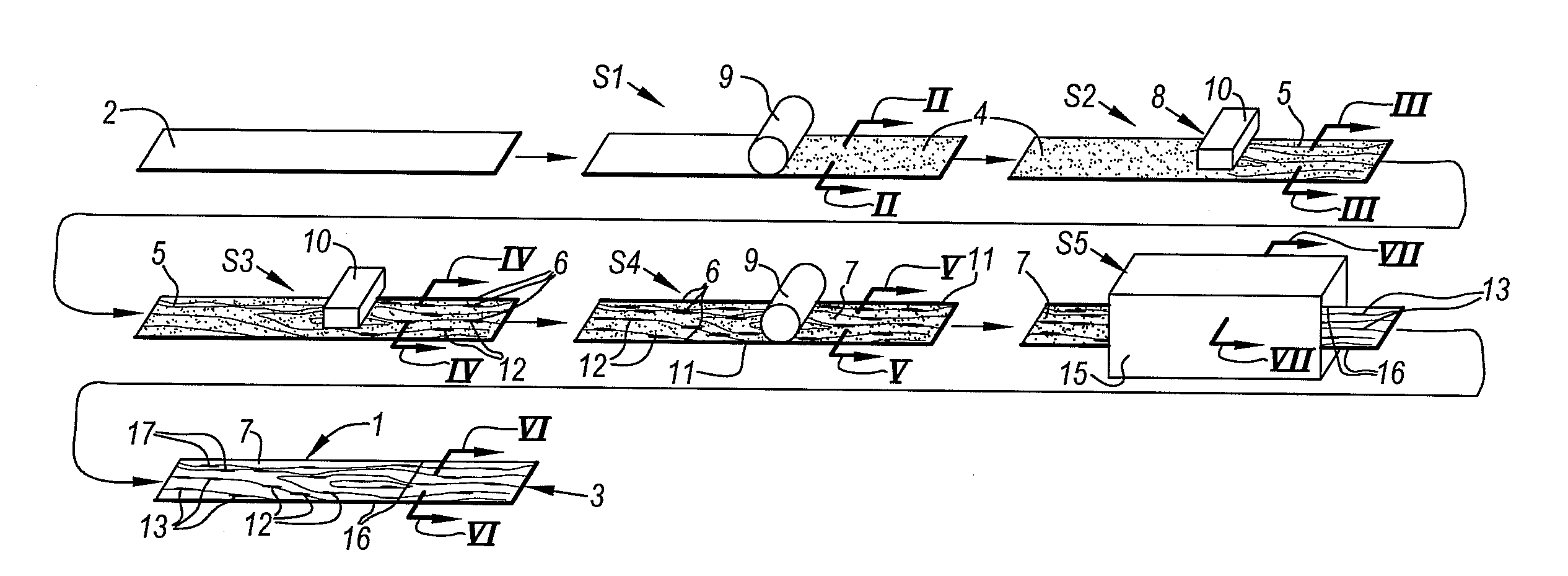

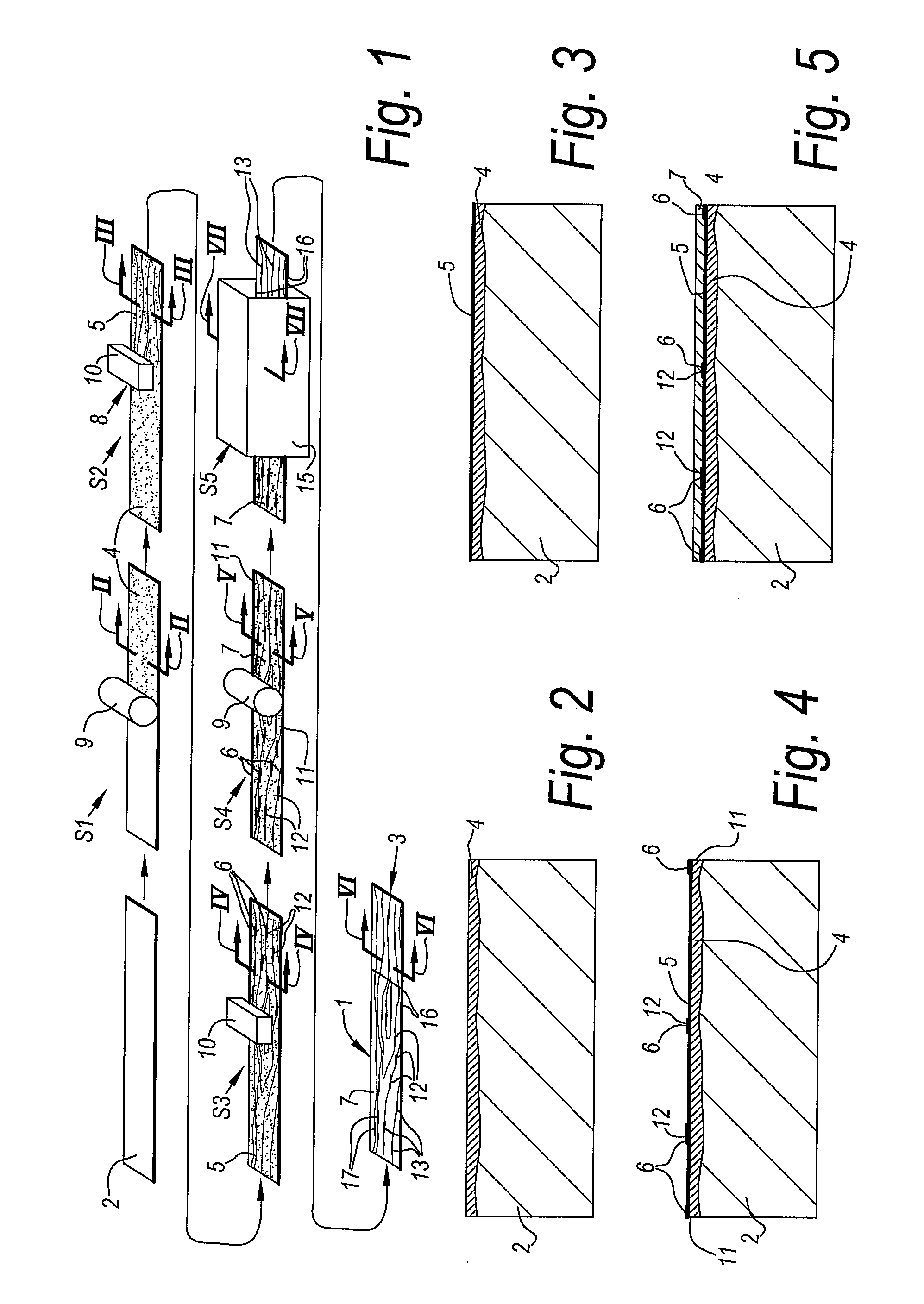

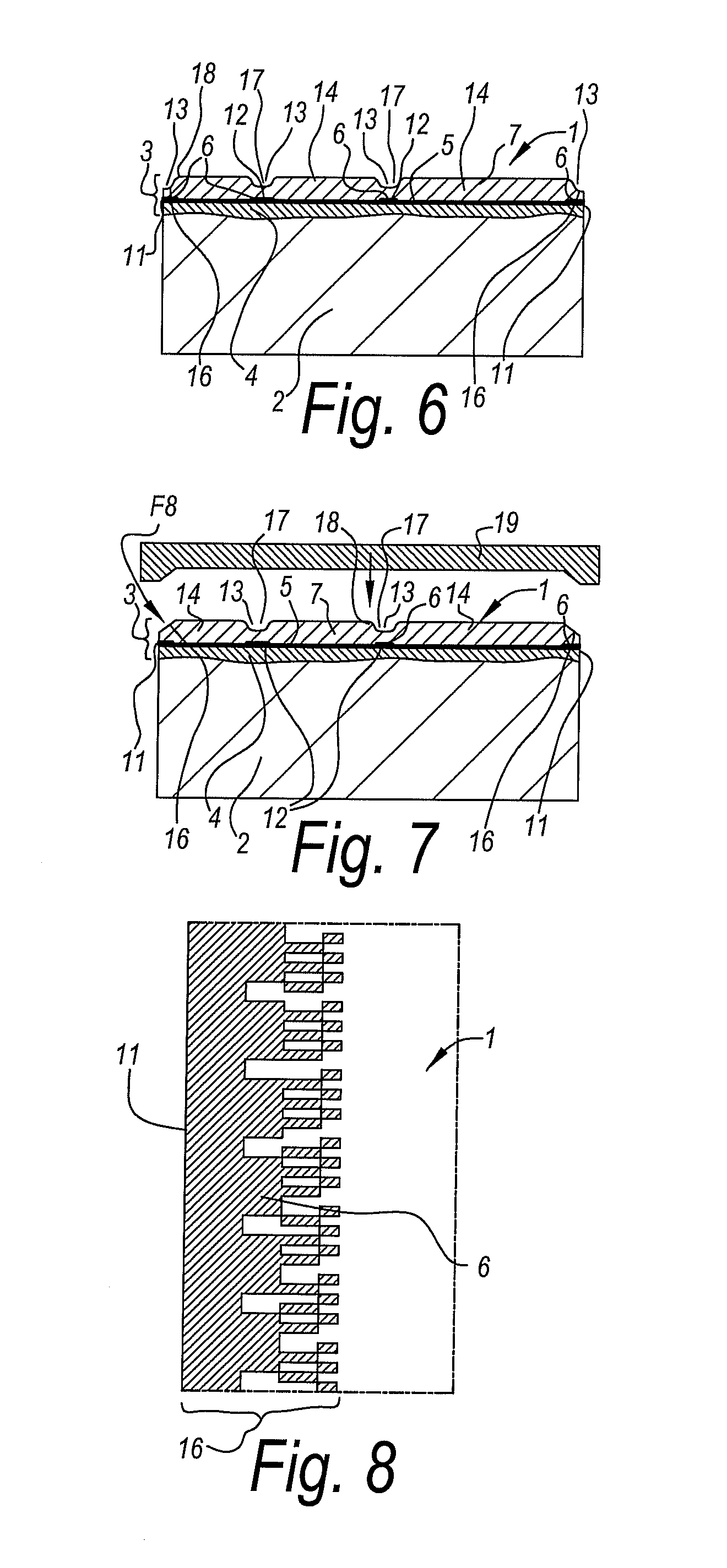

Methods for manufacturing panels and panel obtained thereby

ActiveUS20120015107A1Smoother economicalAvoid uneven performanceCovering/liningsNatural patternsSynthetic materialsEngineering

Owner:FLOORING IND LTD

Positive piece engagement indicator for marking tool

InactiveUS20020114653A1Automatic control devicesMechanical working/deformationMechanical engineeringVoltage

A positive piece engagement indicator for marking tool is provided in which a metal workpiece is contacted with a workpiece contact probe for providing physical contact with, as well as electrical communication with the metal surface of a workpiece. A test voltage and indicator means are placed in series between the workpiece and marking tool. Upon physical contact of the marking tool engagement surface with the surface of the metal workpiece, a circuit is completed by the electrical communication there between, thereby engaging the indicator means. This allows positive verification of actual engagement of worktool to workpiece.

Owner:GATTA RAYMOND P

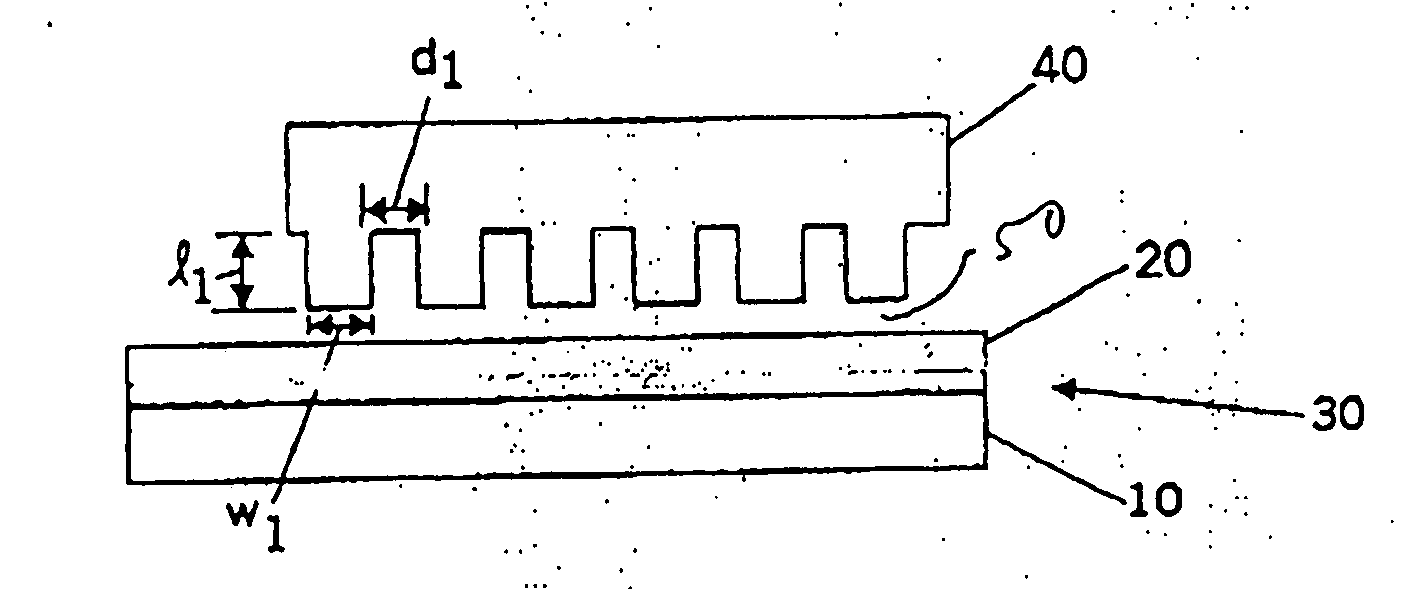

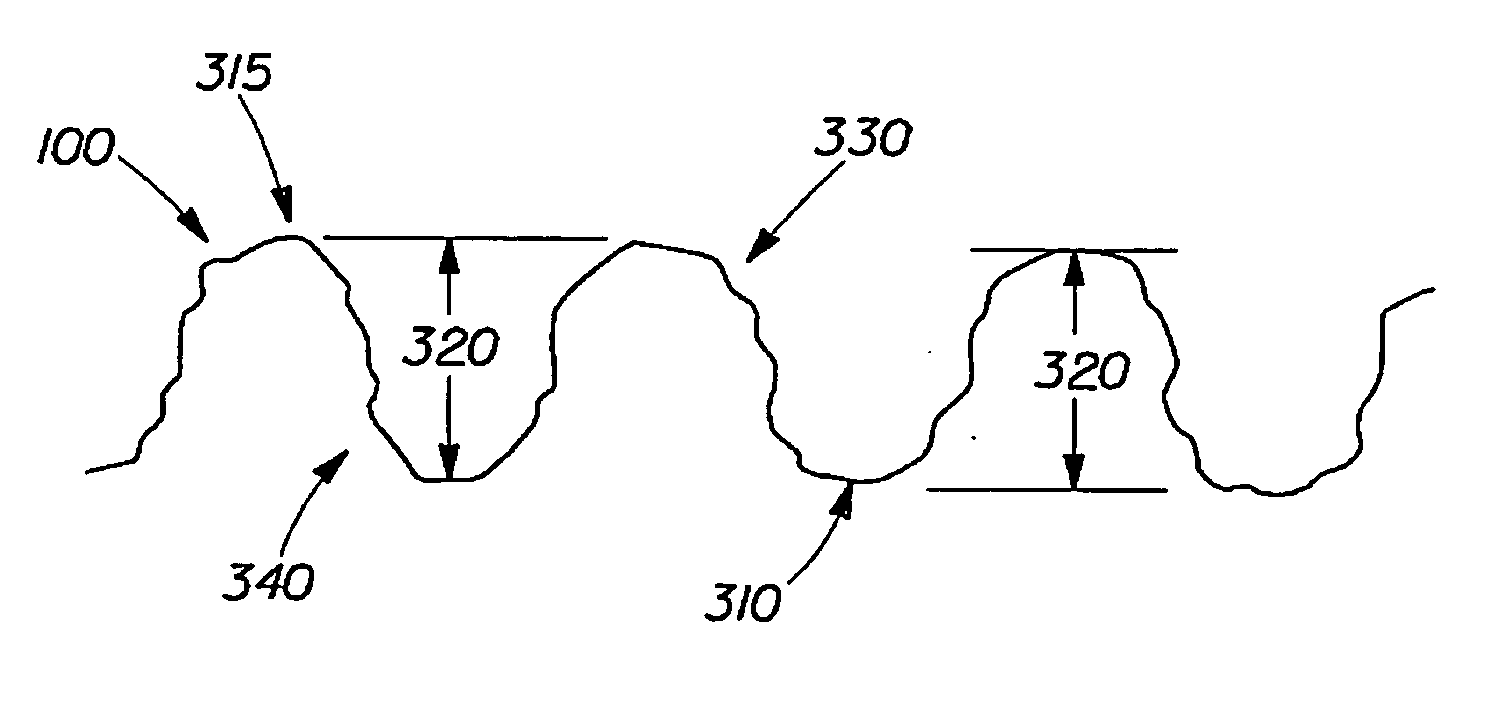

Embossing process including discrete and linear embossing elements

InactiveUS20060278355A1Non-fibrous pulp additionNatural cellulose pulp/paperEngineeringRandom pattern

An apparatus for producing an embossed product including a first embossing member having a plurality of discrete embossing elements disposed in a first non-random pattern having at least one first single pattern unit. The total area of the distal ends of the discrete embossing elements in the first single pattern unit is less than about 5.0 cm2. The apparatus also includes a second embossing member having a plurality of linear embossing elements disposed in a second non-random pattern having at least one second single pattern unit. The total area of the second distal ends in the second single pattern unit is less than about 10 cm2. The second non-random pattern is coordinated with the first non-random pattern such that when engaged with each other the first single pattern unit and the second single pattern unit make up an embossing pattern single pattern unit.

Owner:THE PROCTER & GAMBLE COMPANY

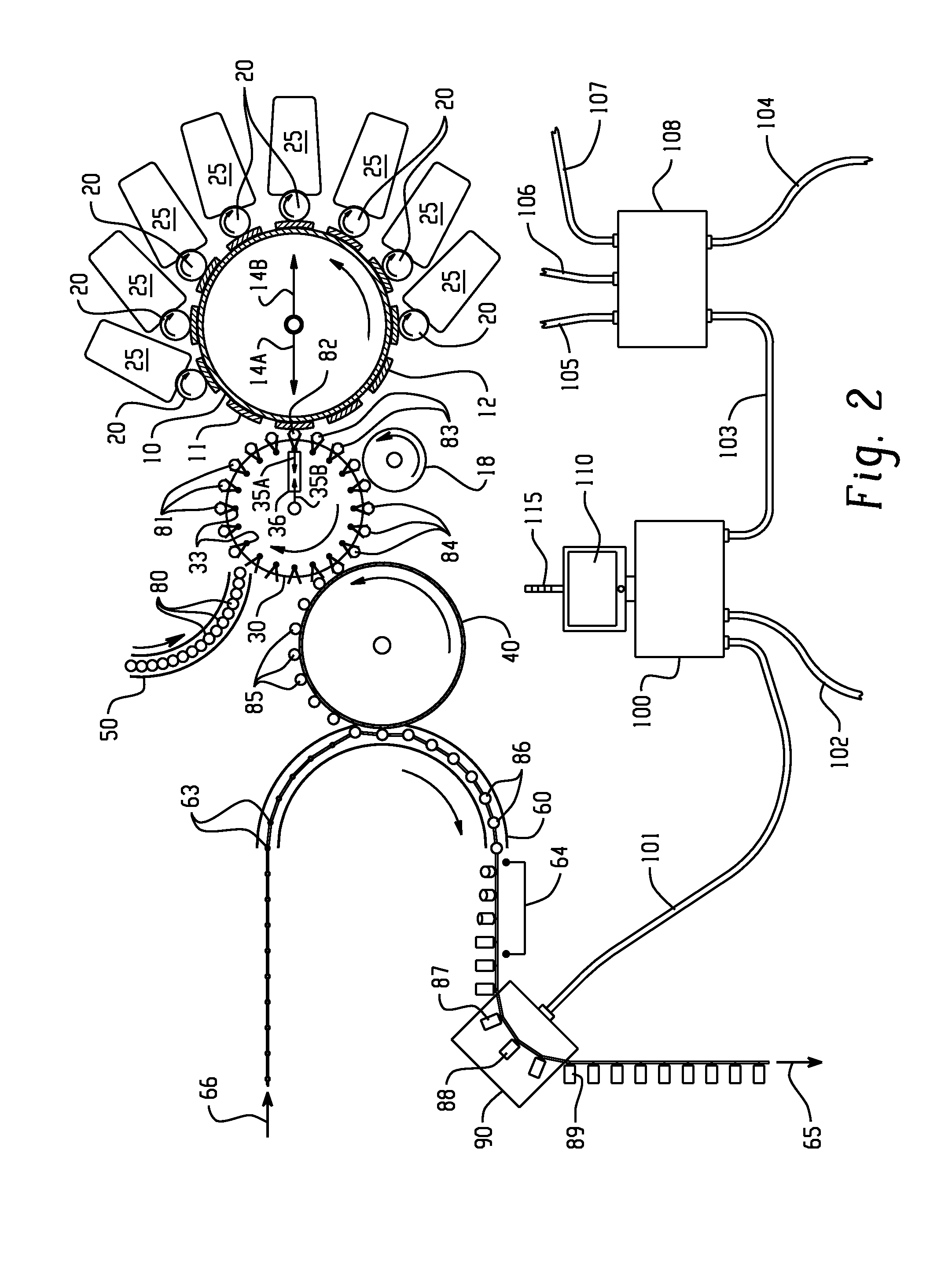

Method and system for decorator component identification and selected adjustment thereof

Automated inspection technology is integrated with a cylindrical container print decorator machine to optimize the decoration process by making critical process and machine information properly and immediately available for corrective adjustments to the process. With this information, a high speed decoration machine operator will be made directly aware of the portions or subsystems of the decorator machine not functioning properly. The information directly facilitates, and can even recommend, corrective adjustments that are necessary to the decorator to better optimize printing functions. It is possible to use this information to optimize the operation of the decorator. It is possible to use this information by way of a properly configured control system, after specific augmentation capabilities are added to the decorator machine, to automatically close the loops with specific decorator printing machine parts or subsystems to dramatically improve the decorating process even while the machine is printing.

Owner:PRESSCO TECH INC

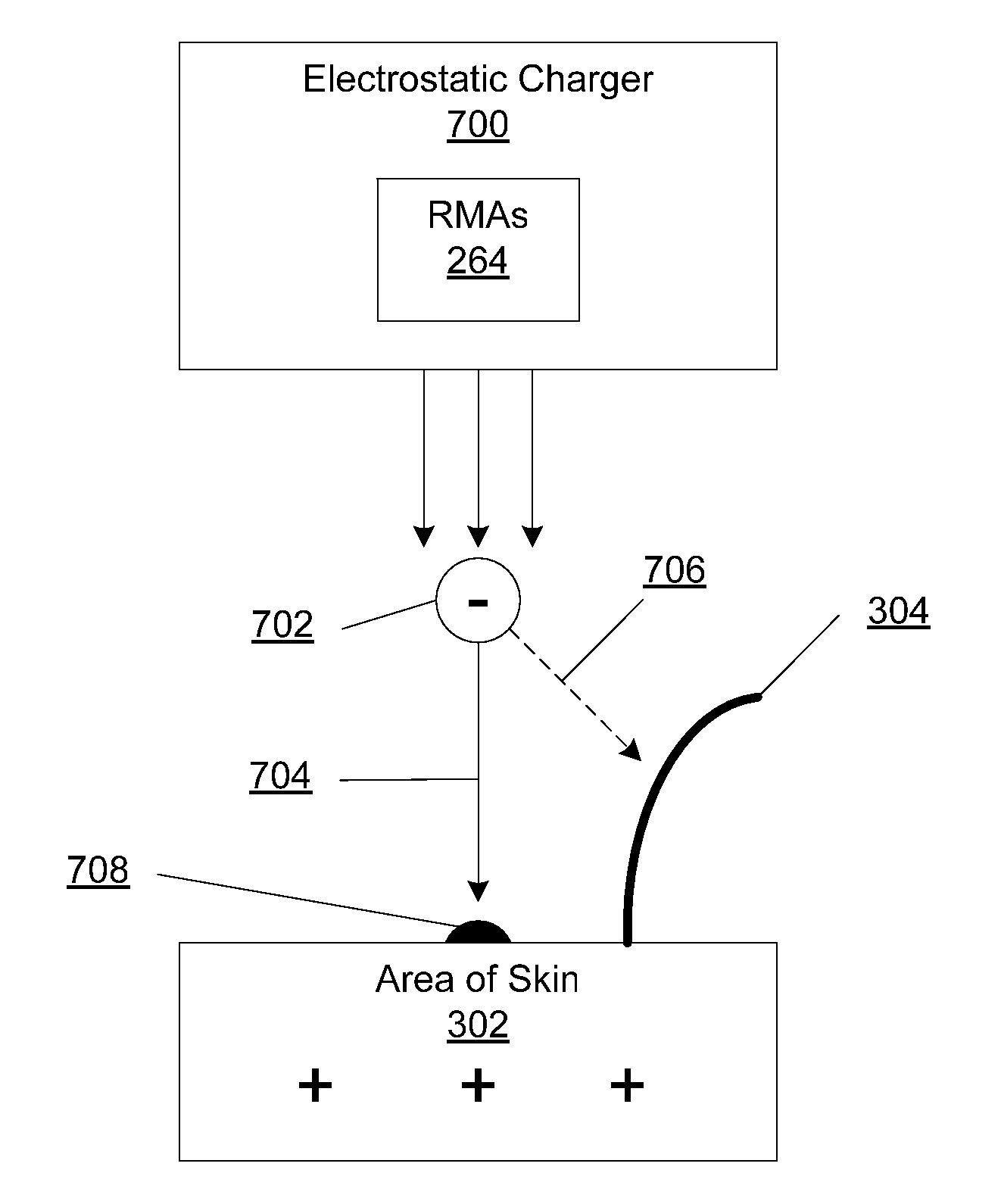

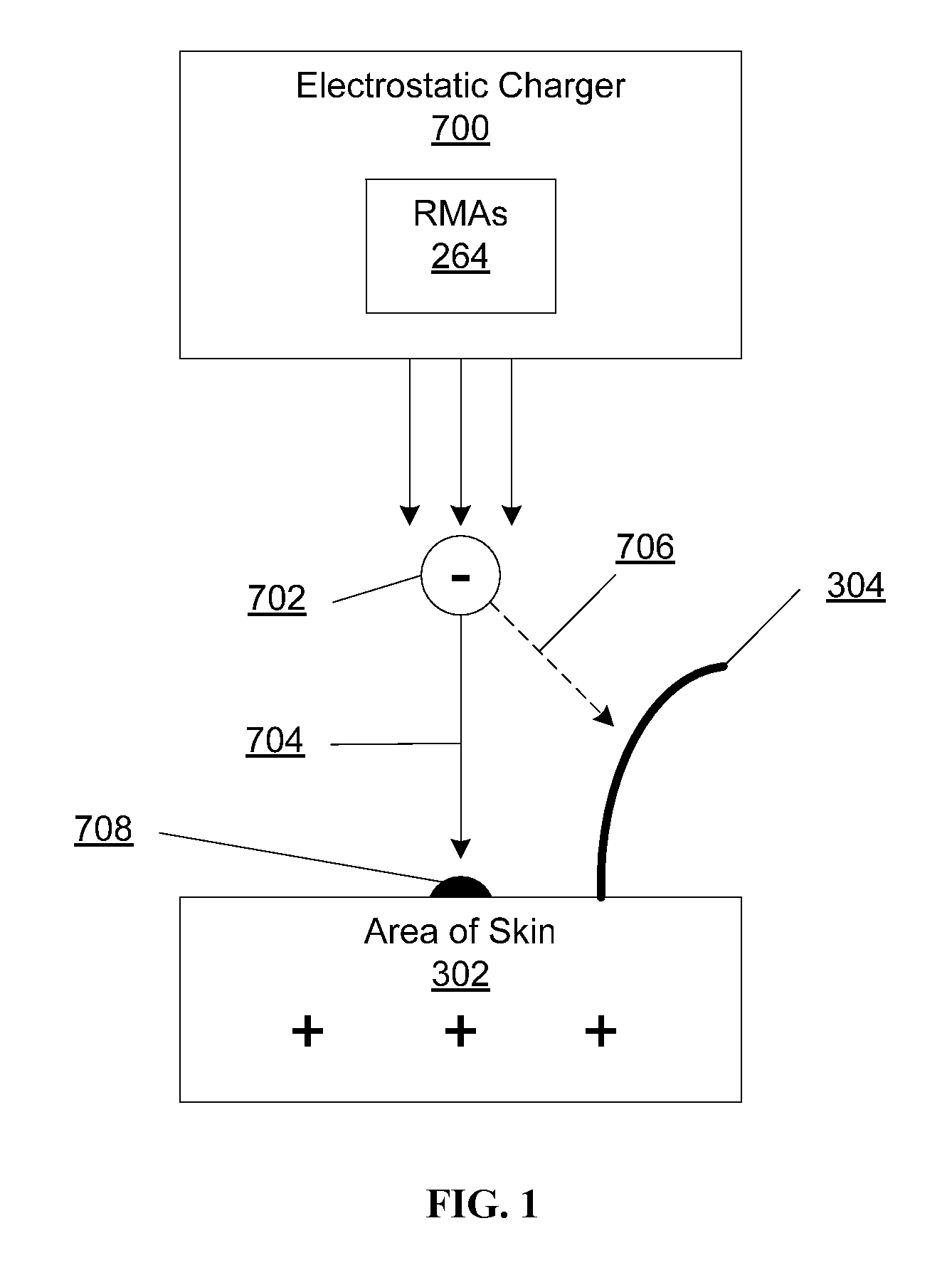

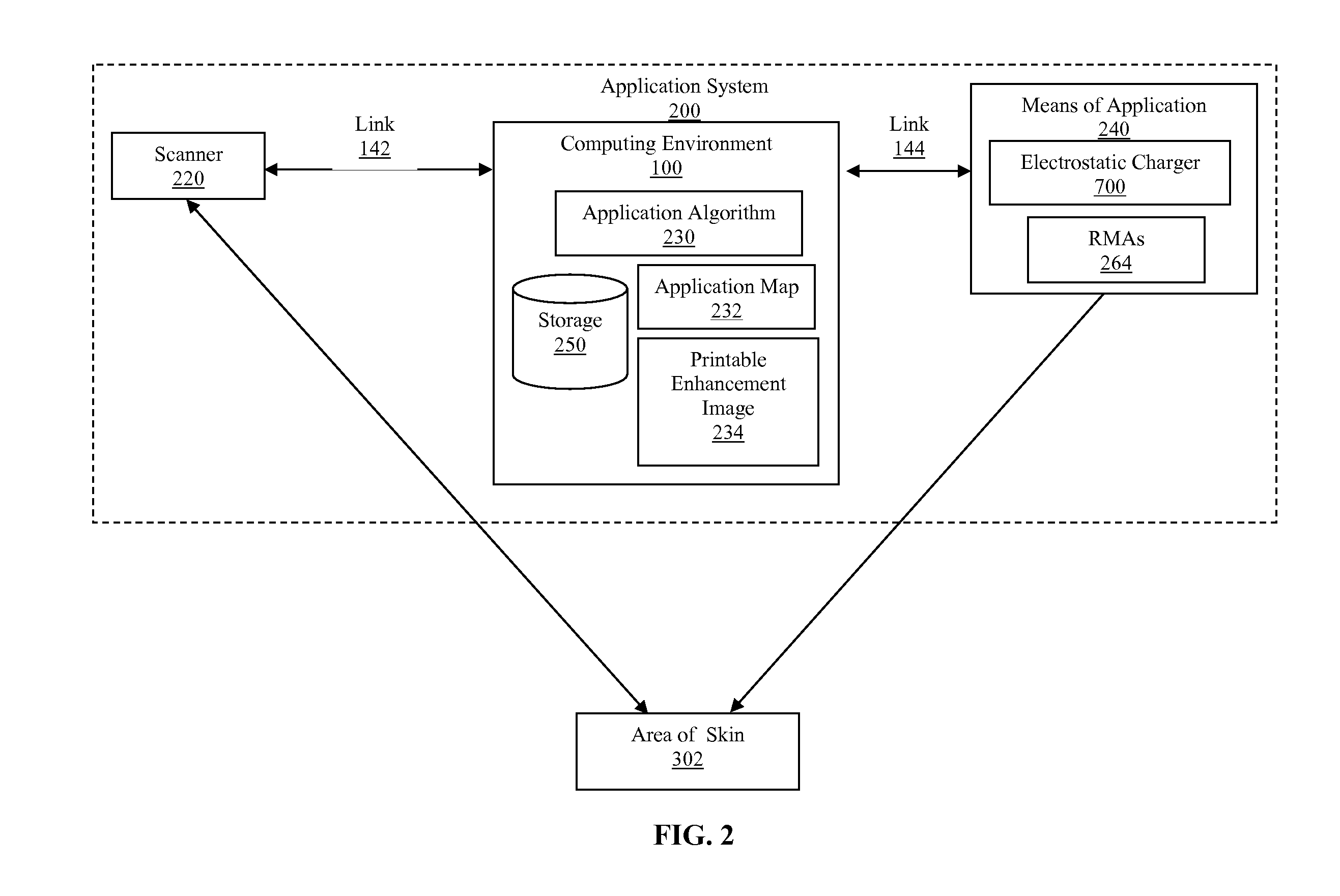

System and method for applying a reflectance modifying agent electrostatically to improve the visual attractiveness of human skin

ActiveUS20080194971A1Enhanced surface irregularityTypewritersMedical applicatorsComputer control systemHuman skin

Owner:TCMS TRANSPARENT BEAUTY LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com