Patents

Literature

1075 results about "Thin glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

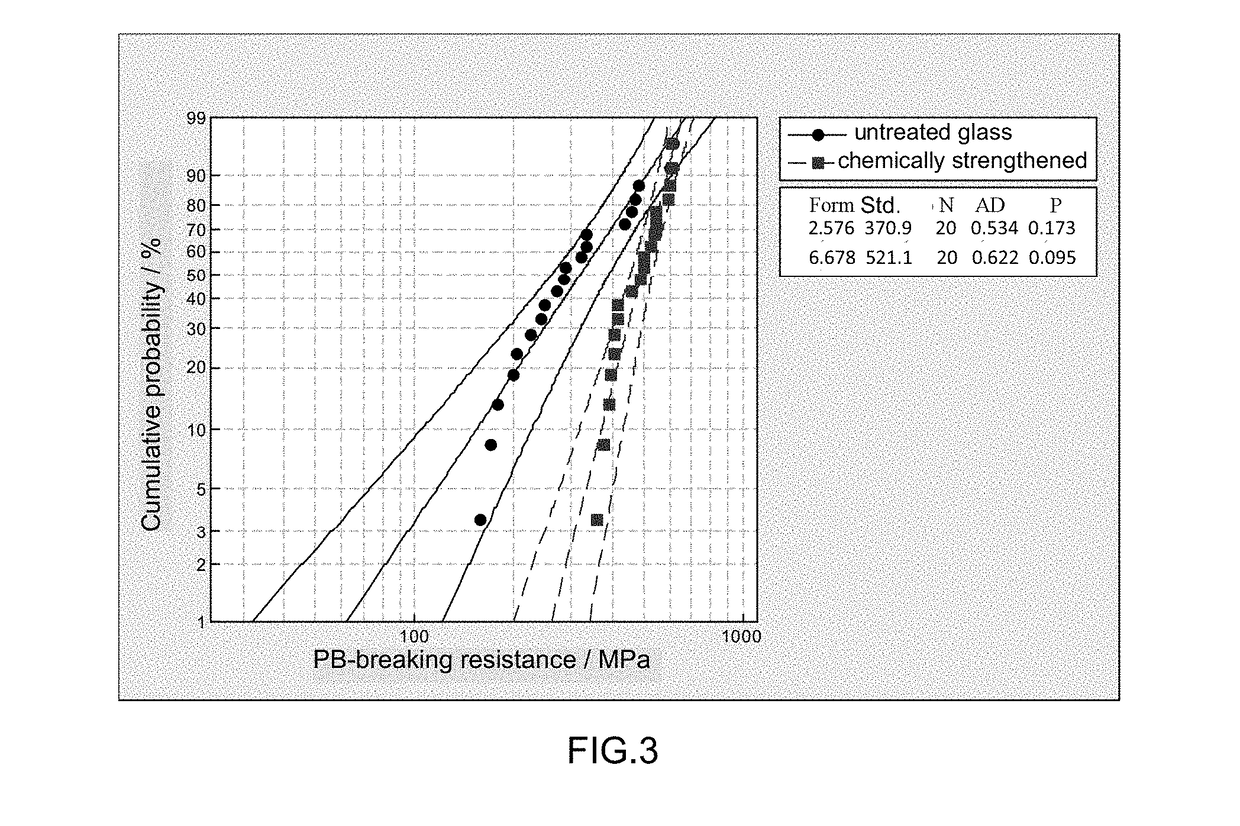

Impact-damage-resistant glass sheet

ActiveUS20110165393A1Increased and more consistent resistanceImprove flexural strengthSynthetic resin layered productsRecord information storageGlass coverDisplay device

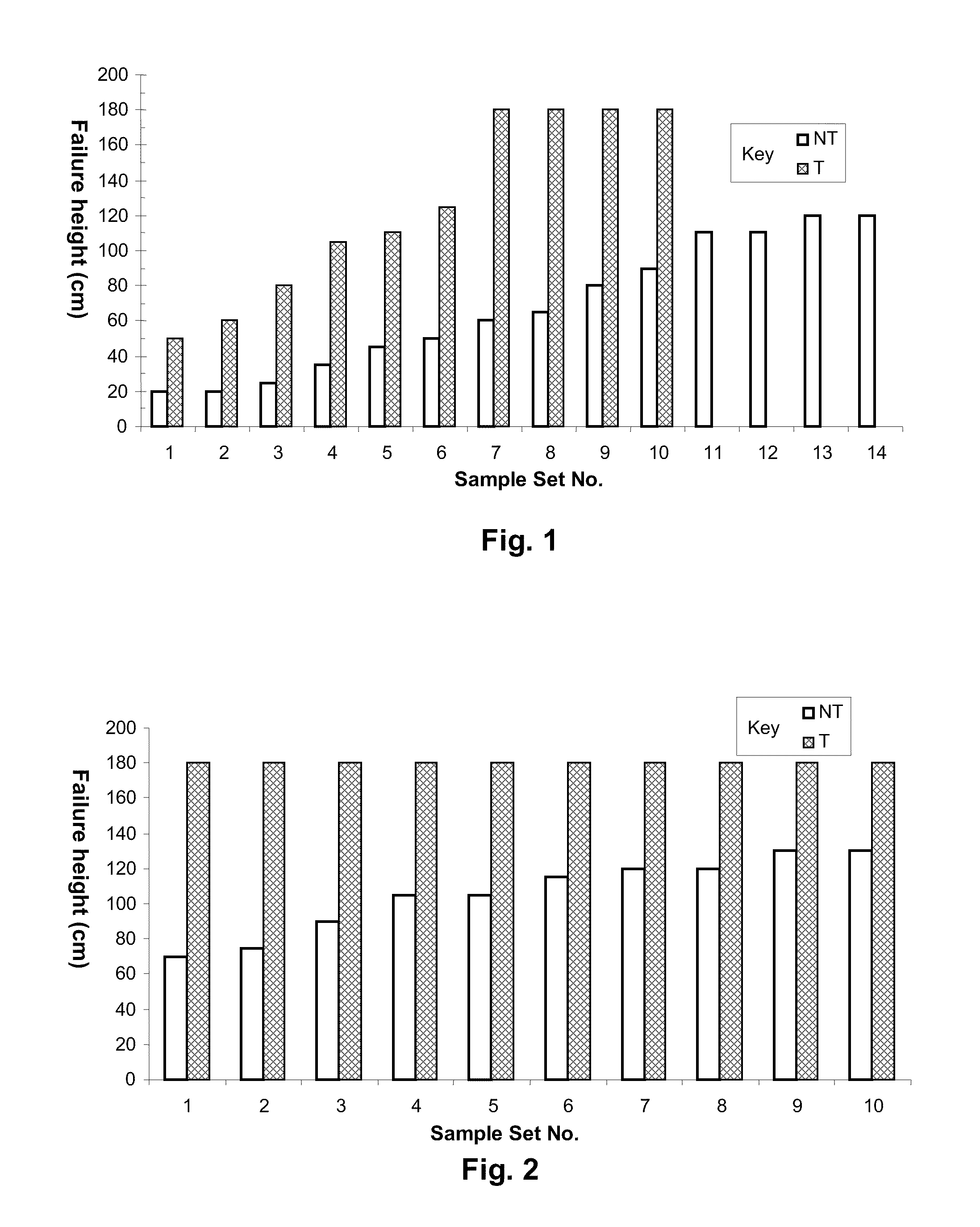

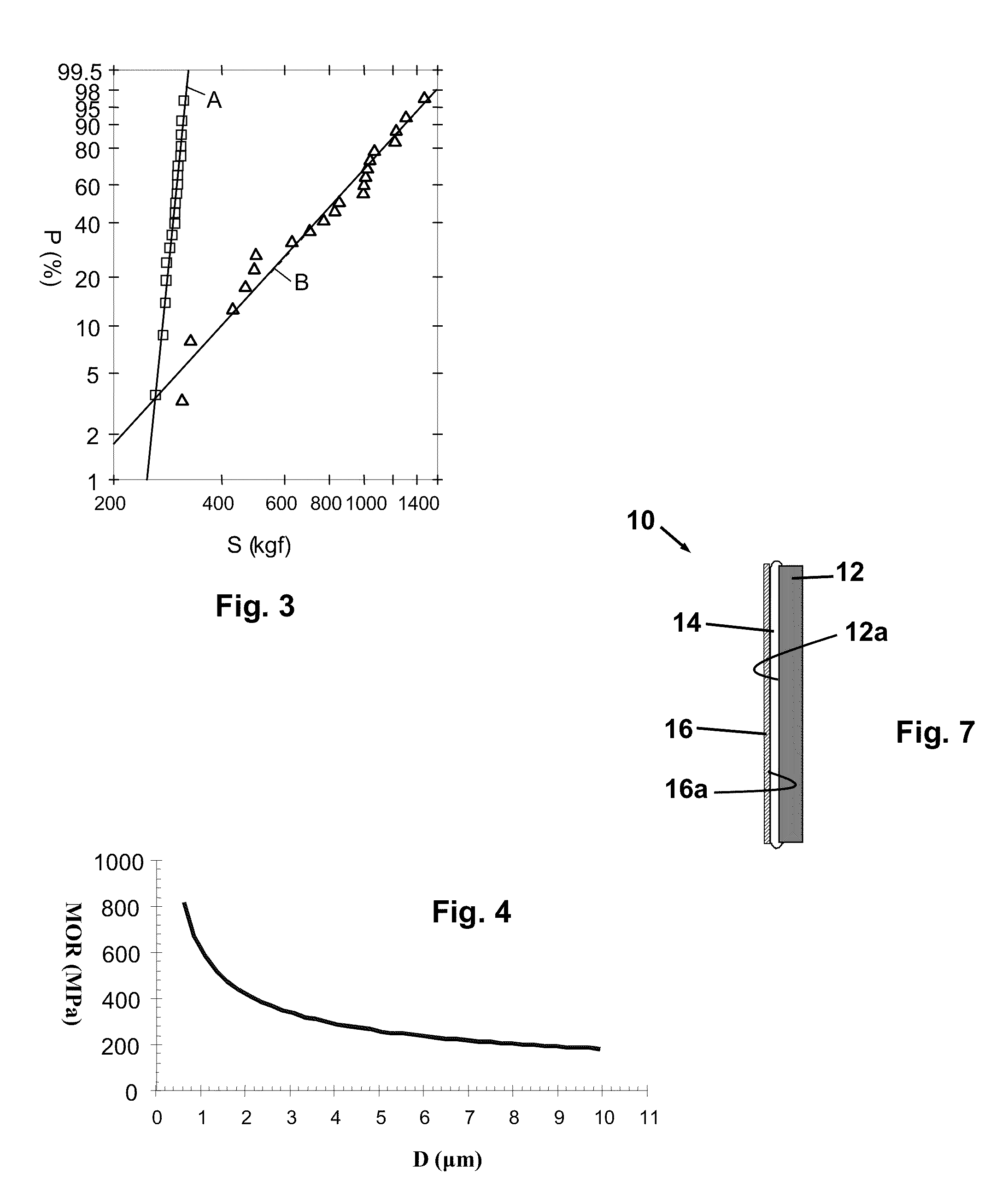

Impact-damage-resistant glass sheet comprising at least one chemically etched surface in combination with a tempering surface compression layer, the glass sheet exhibiting a high standardized ball drop failure height and a high flexural modulus of rupture strength, useful to provide damage-resistant glass cover sheets for consumer electronic video display devices, is provided by subjecting thin glass sheet to a combination of a surface tempering treatment and a surface etching treatment that improves strength while maintaining the optical glass sheet properties required for video display applications.

Owner:CORNING INC

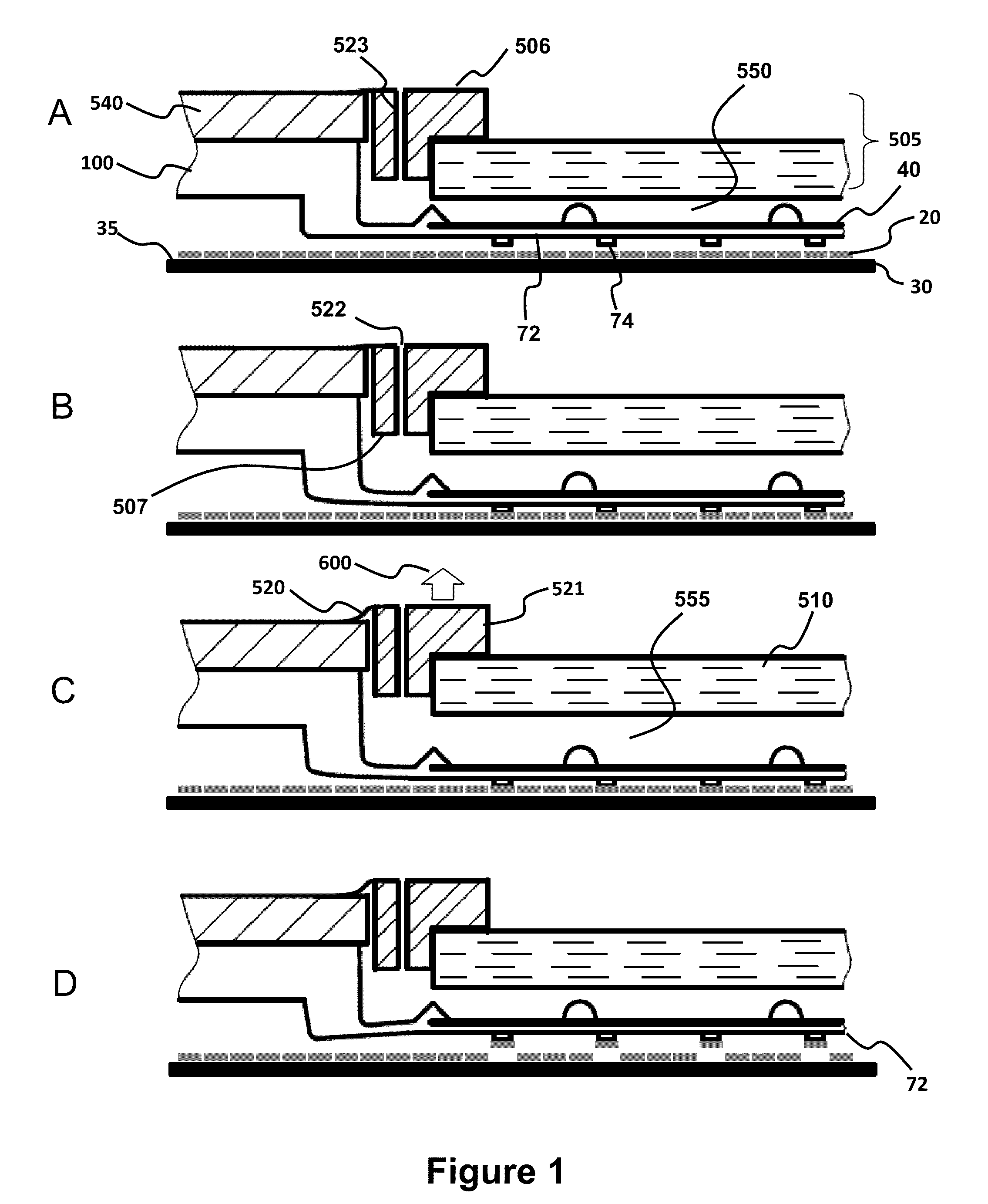

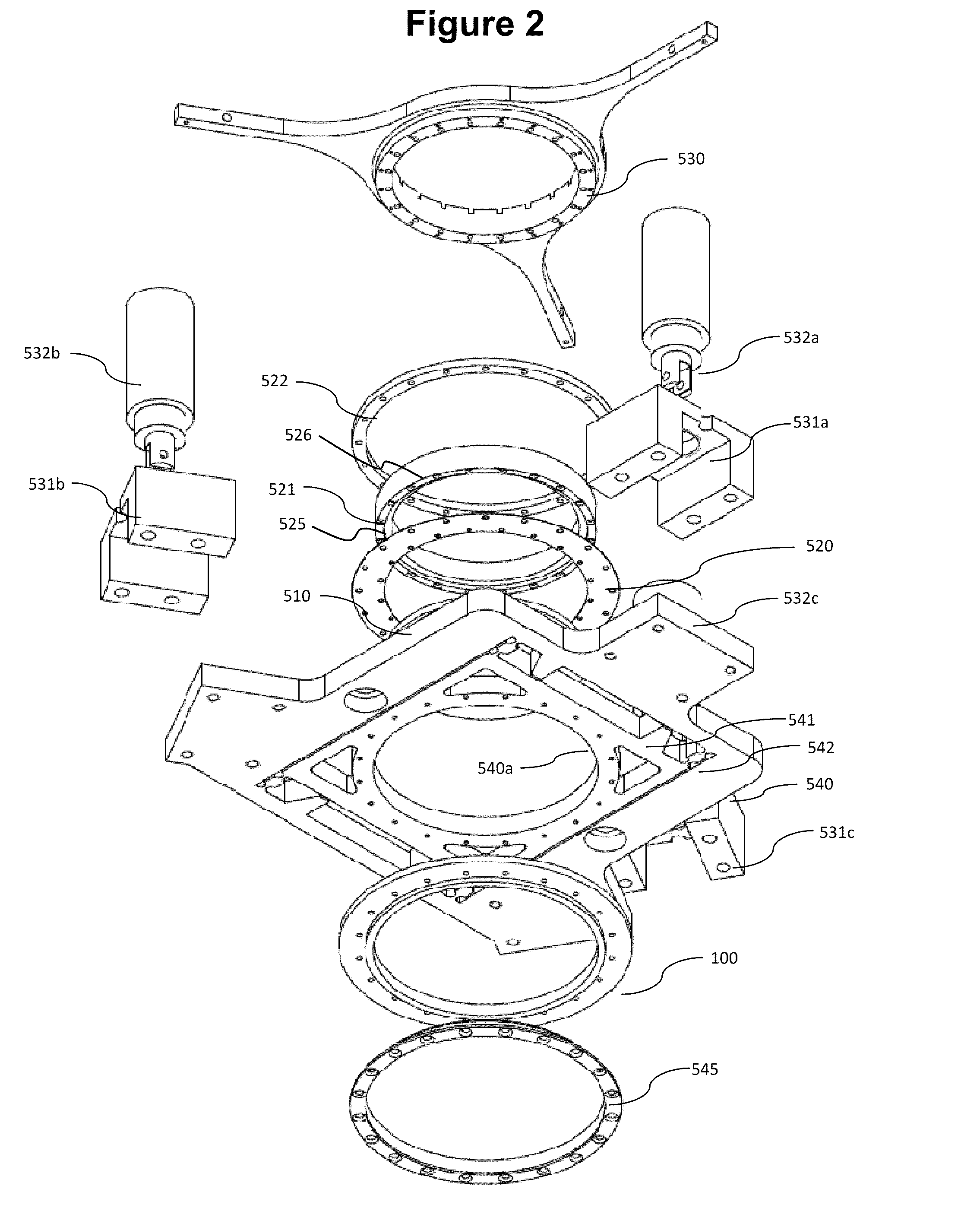

Vacuum coupled tool apparatus for dry transfer printing semiconductor elements

InactiveUS8261660B2Improvement in printing yield and placement accuracy and fidelityReduce pressureMechanical working/deformationDecorative surface effectsEngineeringThin glass

Owner:X DISPLAY CO TECH LTD

Thin glass chip for an electronic component and manufacturing method

ActiveUS20060057782A1Curb riskThe overall thickness is thinDecorative surface effectsSolid-state devicesElectronic componentThin glass

The manufacturing of electronic components on individual substrates made of an insulating material includes molding, in a silicon wafer, an insulating material with a thickness corresponding to the final thickness desired for the substrates, manufacturing the electronic components, and removing the silicon from the rear surface of the wafer after manufacturing of the components.

Owner:STMICROELECTRONICS SRL

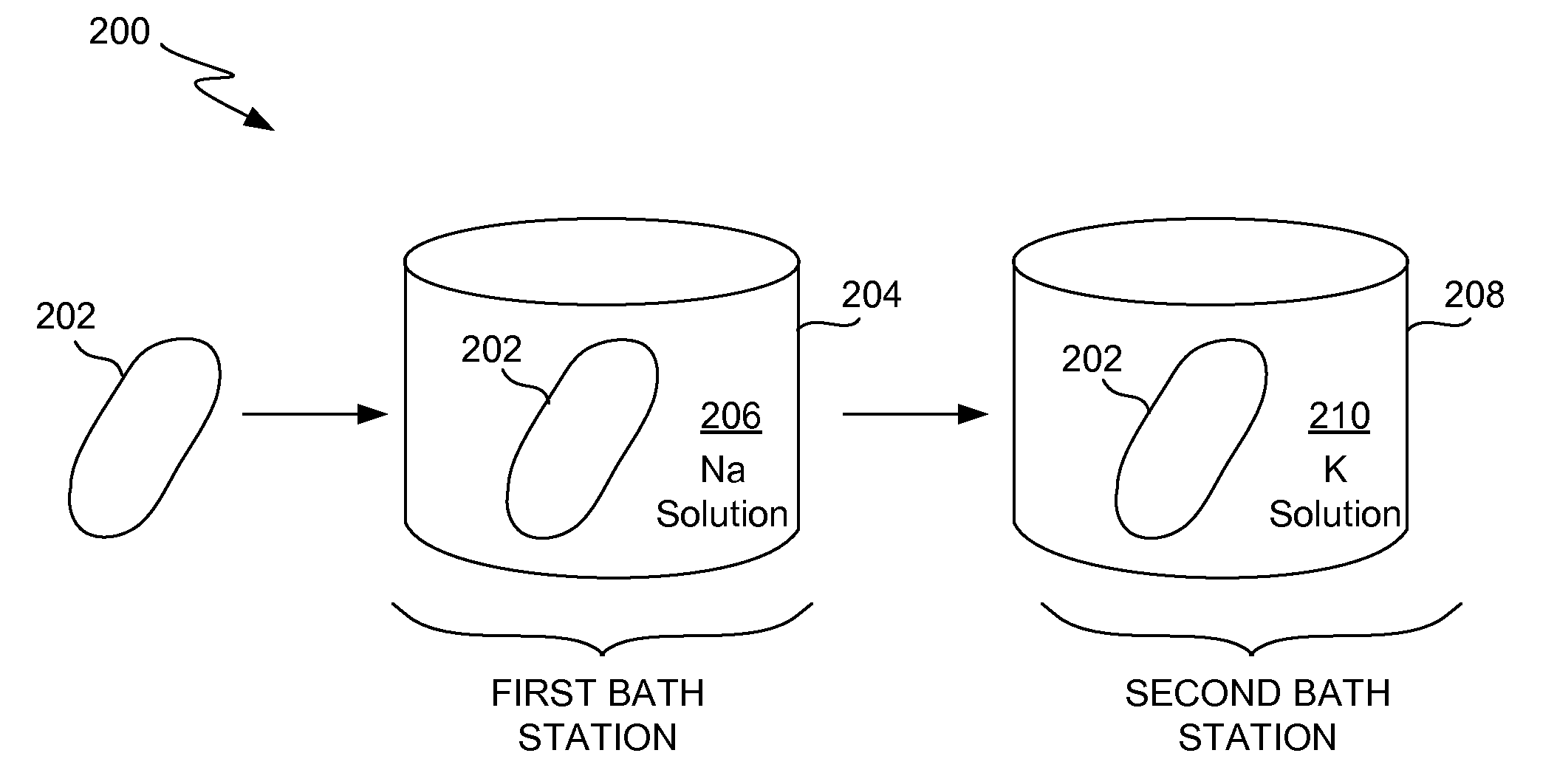

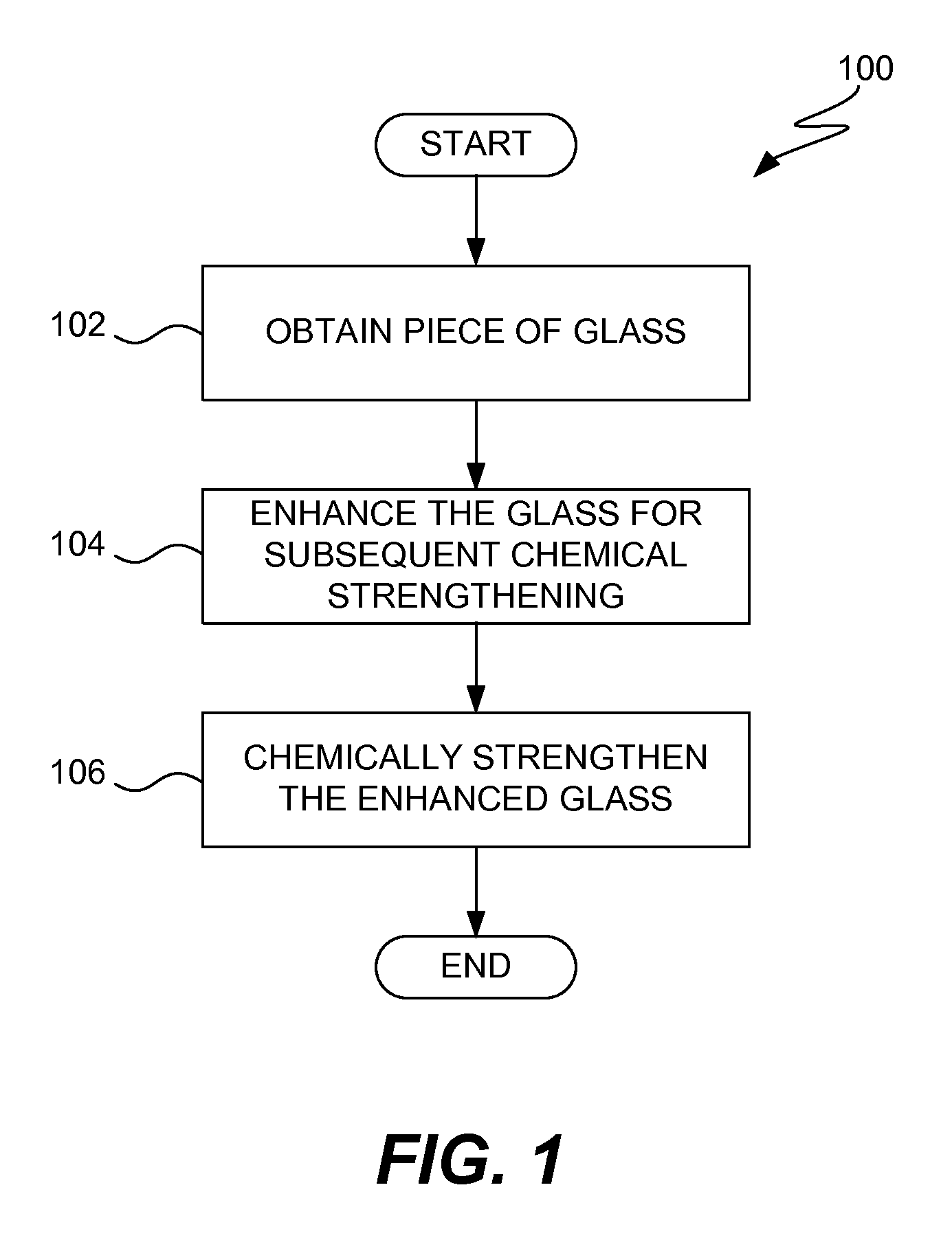

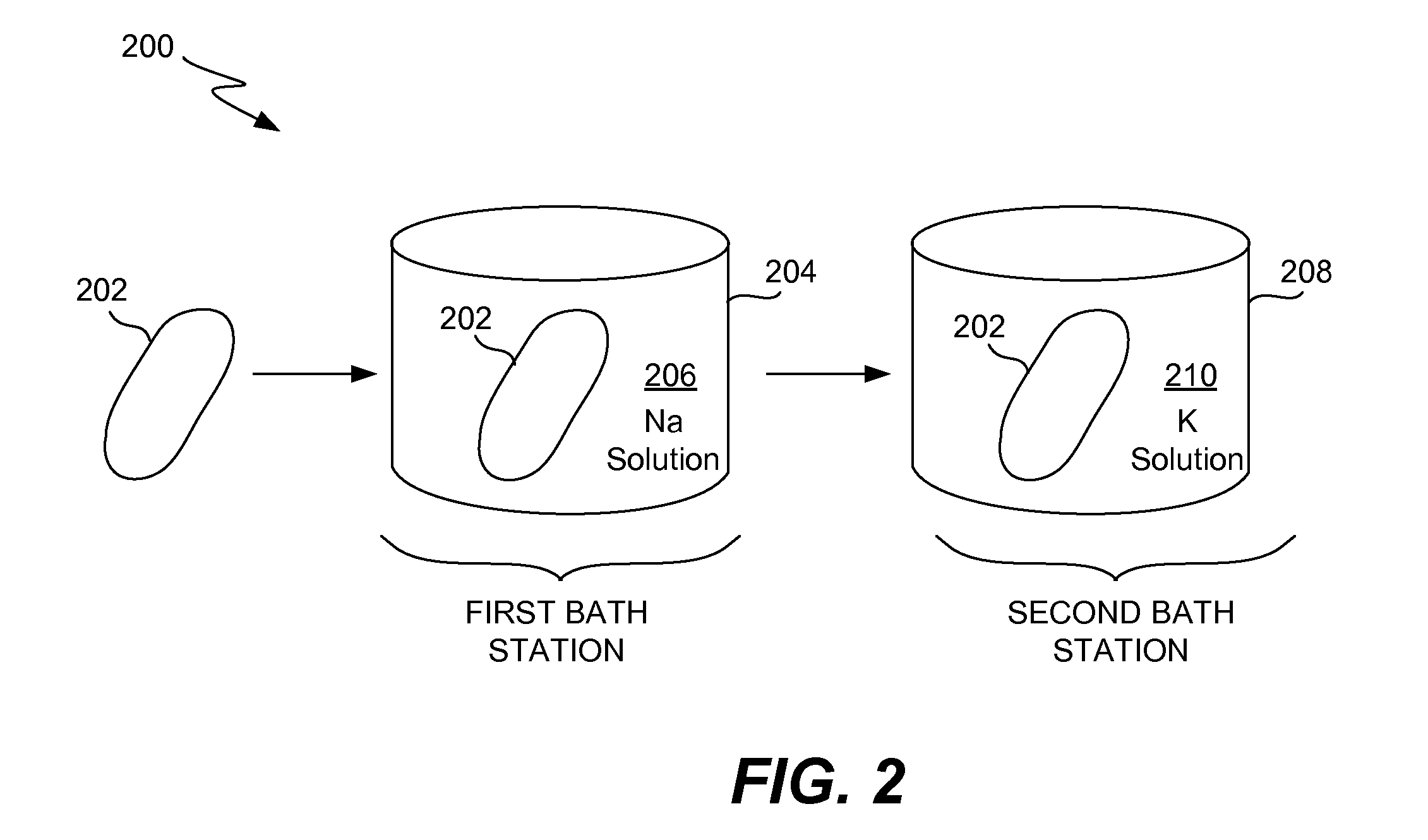

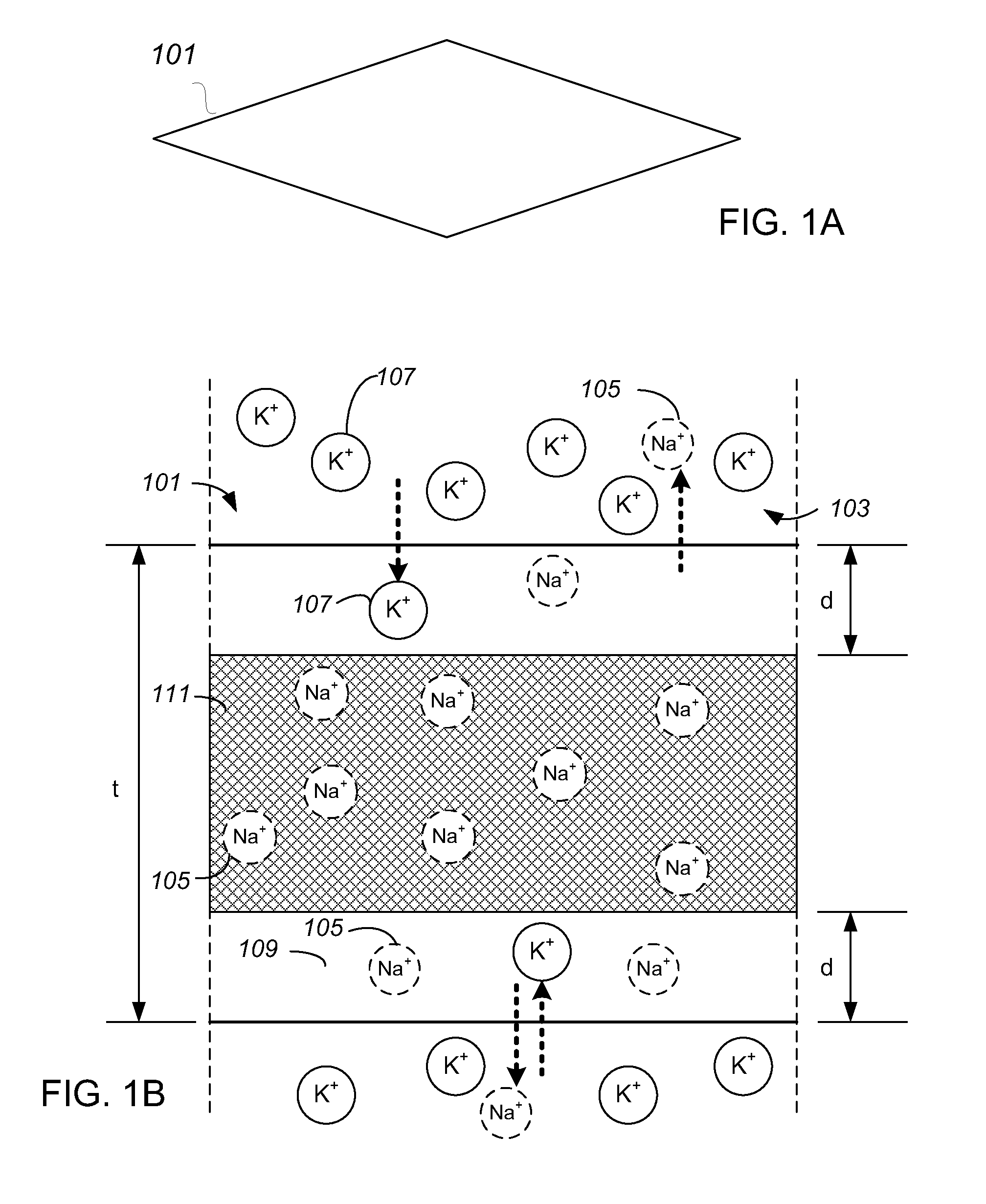

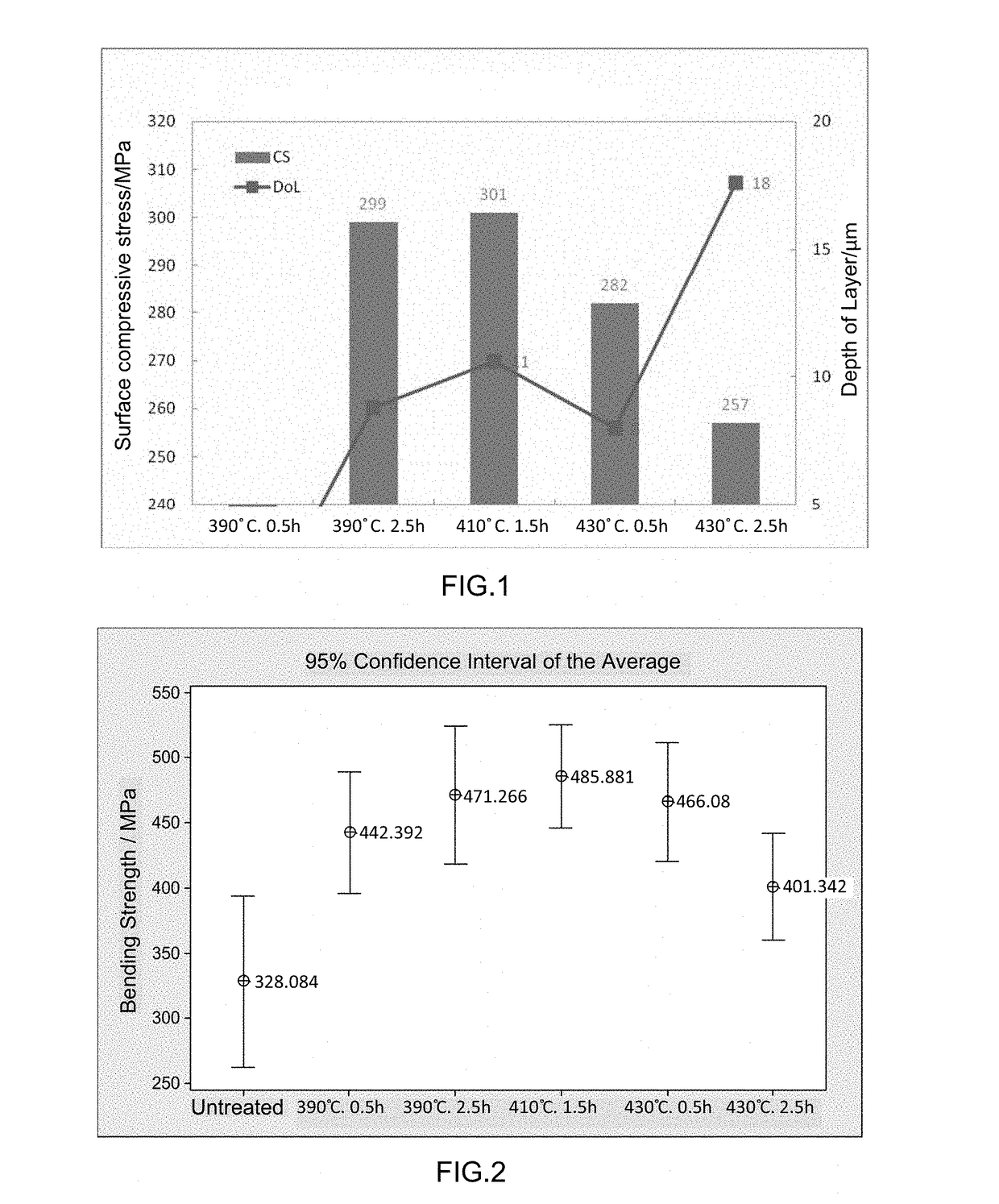

Enhanced Strengthening of Glass

ActiveUS20110067447A1Improve glass strengthImprove the level ofGlass drawing apparatusGlass transportation apparatusChemical treatmentGlass cover

Apparatus, systems and methods for improving strength of a thin glass member for an electronic device are disclosed. In one embodiment, the glass member can have improved strength by using multi-bath chemical processing. The multi-bath chemical processing allows greater levels of strengthening to be achieved for glass member. In one embodiment, the glass member can pertain to a glass cover for a housing of an electronic device.

Owner:APPLE INC

Thin Glass for Touch Panel Sensors and Methods Therefor

Improved techniques are disclosed for fabrication of touch panels using thin sheet glass, coupling external circuitry, and securely holding the touch panel within a portable electronic device. The thin sheet glass may be chemically strengthened and laser scribed.

Owner:APPLE INC

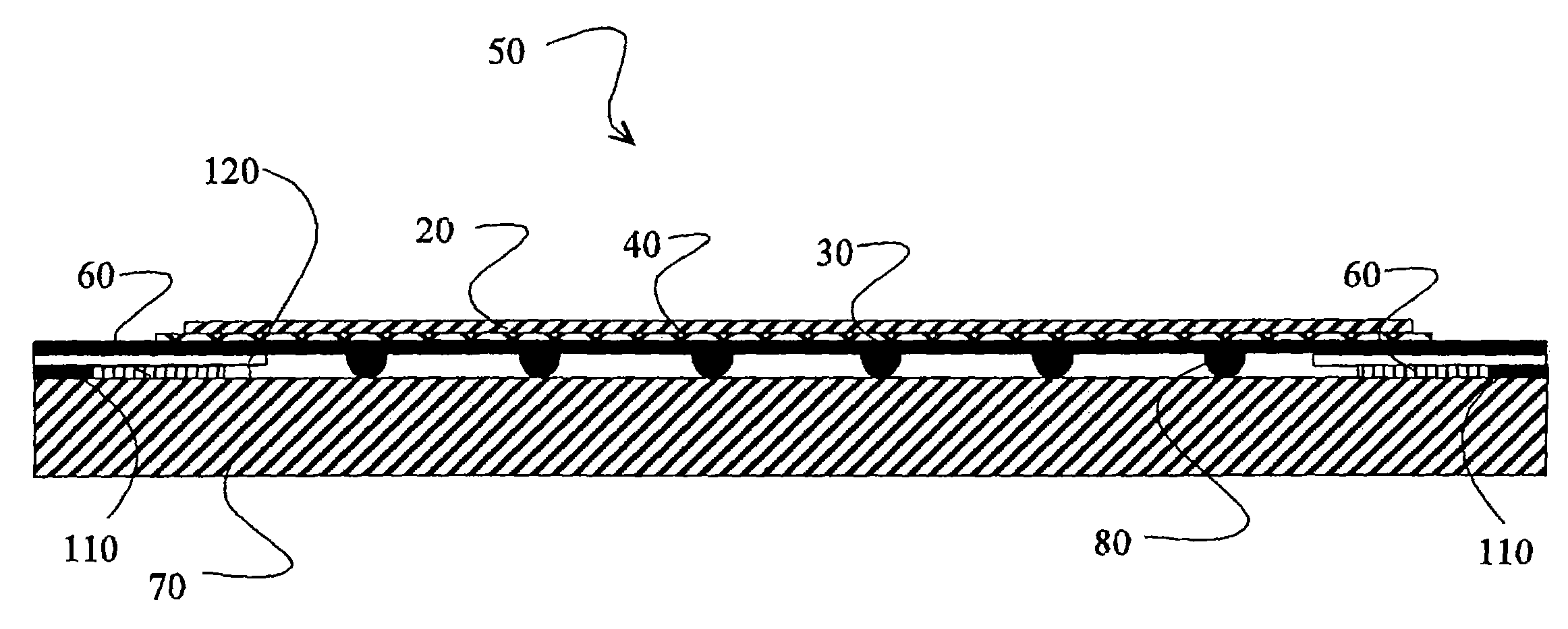

Laminated touch screen

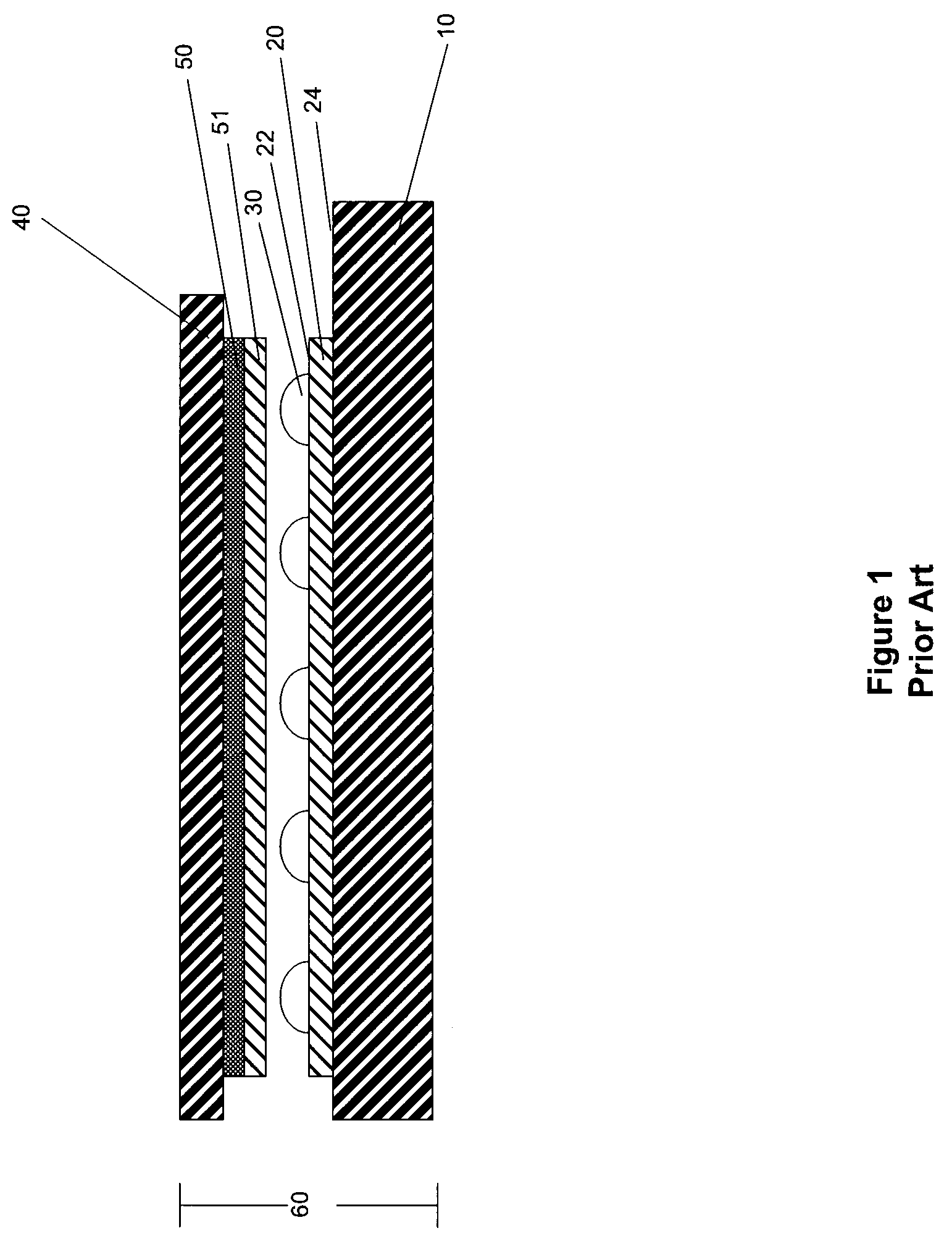

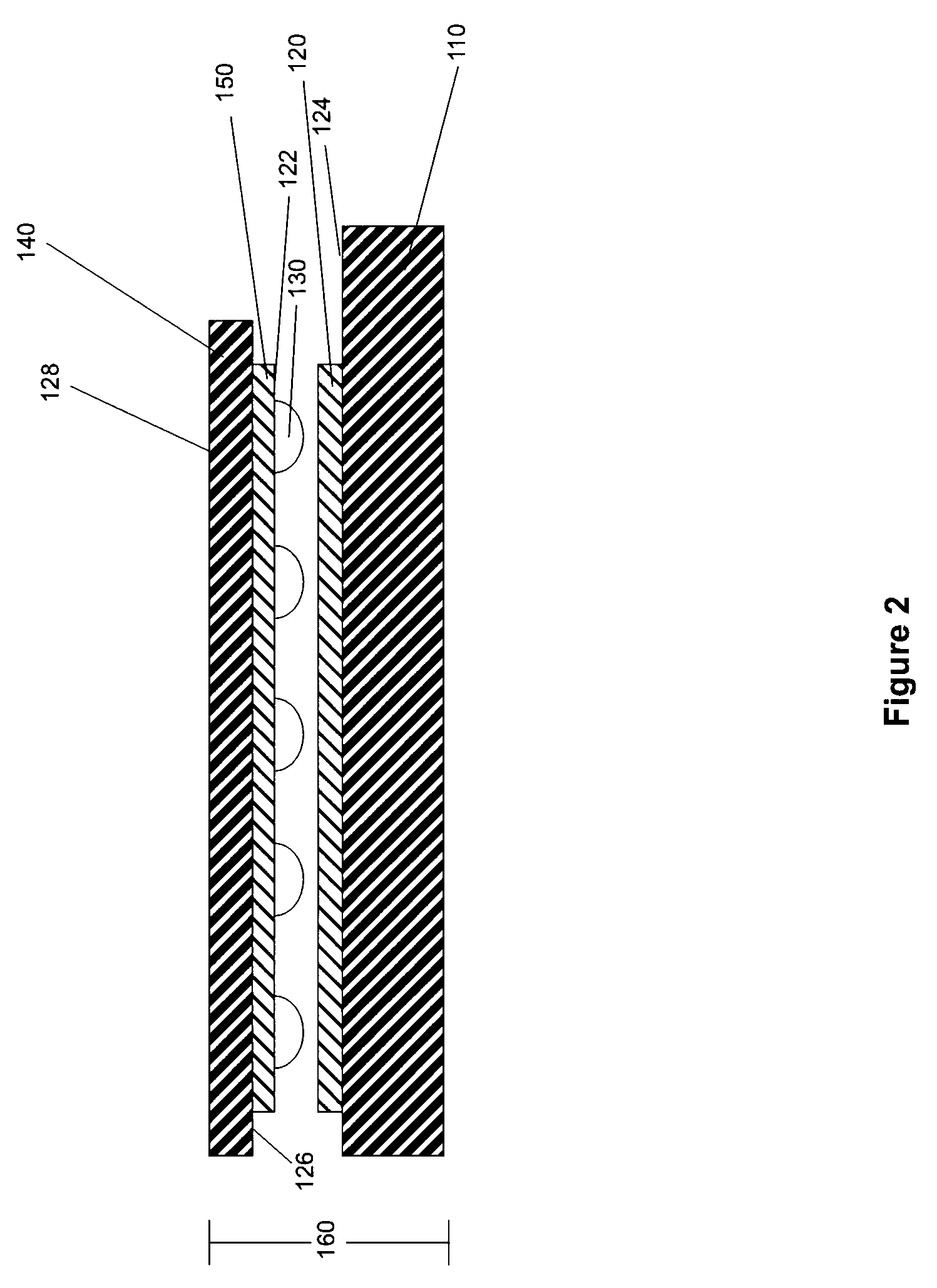

ActiveUS7345680B2Difficult to vandalizeOvercomes shortcomingTransmission systemsElectrical equipmentOptical bondingEngineering

In a touch screen having a flexible outer membrane with a first conducting surface, a backing surface with a second conductive surface, and sensors to detect contact between the first conducting surface and the second conducting surface, the improvement comprising the flexible outer membrane, wherein the flexible outer layer consists of an ultra-thin glass layer, a polymer layer; and an optical adhesive between the ultra-thin glass layer and the polymer layer, the optical adhesive holding the ultra-thin glass layer to the polymer layer.

Owner:DAVID ALBERT M

Glass product for use in ultra-thin glass display applications

InactiveUS20050001201A1Liquid crystal compositionsLayered product treatmentActive-matrix liquid-crystal displayAlkali free

The present invention is directed to a substrate product for use in the manufacture of active matrix liquid crystal display panels. The product includes a display substrate suitable for use as a display panel. The display substrate has a thickness less than or equal to 0.4 mm, a composition that is substantially alkali free, and a surface smoothness that allows the direct formation of thin-film transistors thereon without a prior processing step of polishing and / or grinding. The product also includes at least one support substrate removably attached to the display substrate.

Owner:CORNING INC

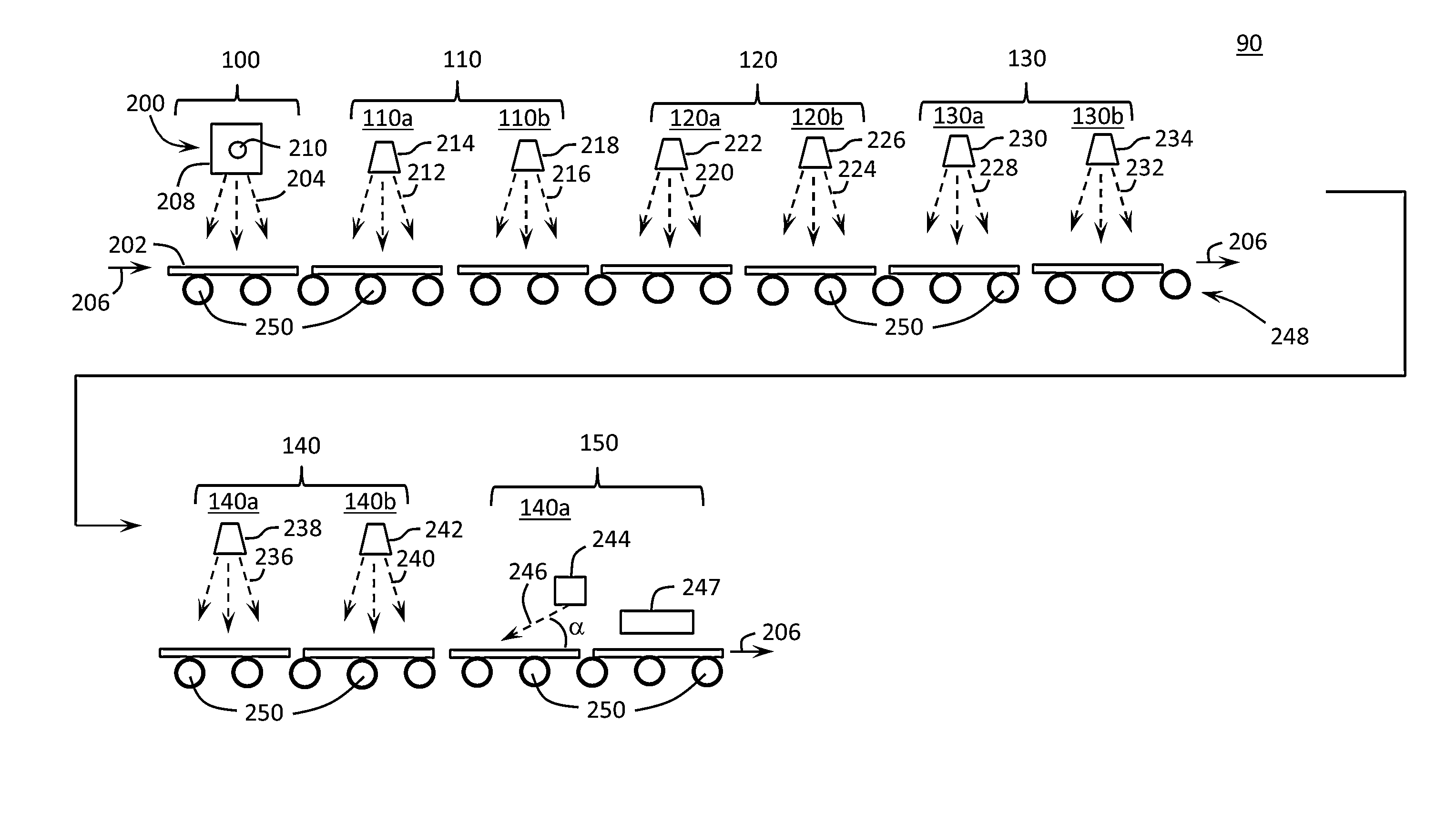

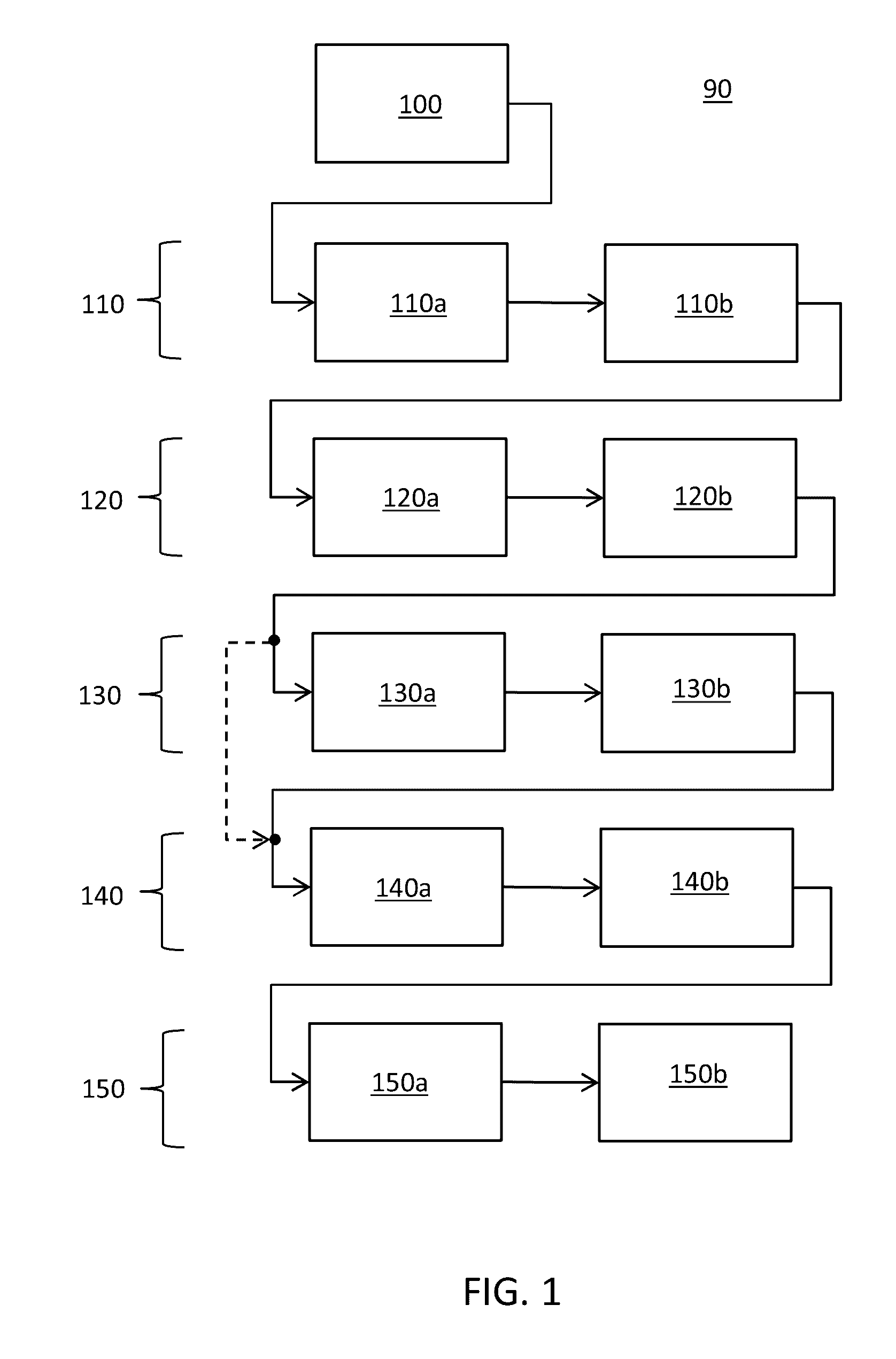

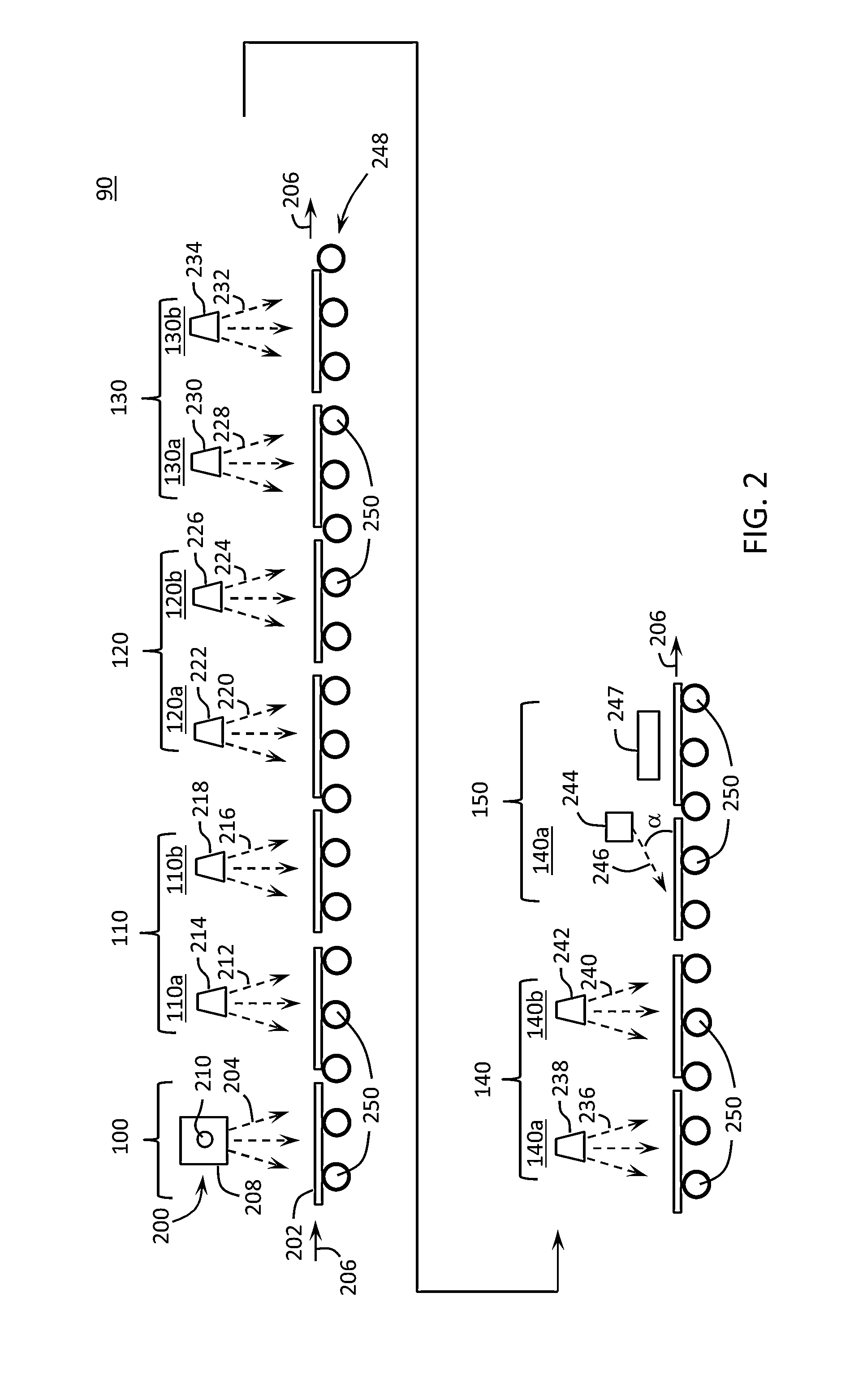

Method of cleaning glass substrates

InactiveUS9561982B2Low levelEnhance electrostatic interactionSemiconductor/solid-state device manufacturingFlexible article cleaningThin glassElectrostatic discharge

A method of cleaning thin glass substrates comprises applying a sequence of chemical washing steps as the thin glass substrate is being conveyed in a conveyance direction. In addition, surfaces of the glass substrate may be treated to enhance electrostatic discharge properties of the glass substrates.

Owner:CORNING INC

Techniques for Strengthening Glass Covers for Portable Electronic Devices

InactiveUS20110019354A1Improve glass strengthHigh strengthDigital data processing detailsElectrical apparatus contructional detailsLiquid-crystal displayGlass cover

Apparatus, systems and methods for improving strength of a thin glass cover for an electronic device are disclosed. In one embodiment, the glass member can have improved strength by chemical strengthening in a series of stages. The stages can, for example, have a first ion exchange stage where larger ions are exchanged into the glass cover, and a second ion exchange stage where some of the larger ions are exchanged out from the glass cover. Optionally, in one embodiment, the glass cover can improve its strength by forming its edges with a predetermined geometry. Advantageously, the glass cover can be not only thin but also adequately strong to limit susceptibility to damage. In one embodiment, the glass member can pertain to a glass cover for a housing for an electronic device. The glass cover can be provided over or integrated with a display, such as a Liquid Crystal Display (LCD) display.

Owner:APPLE INC

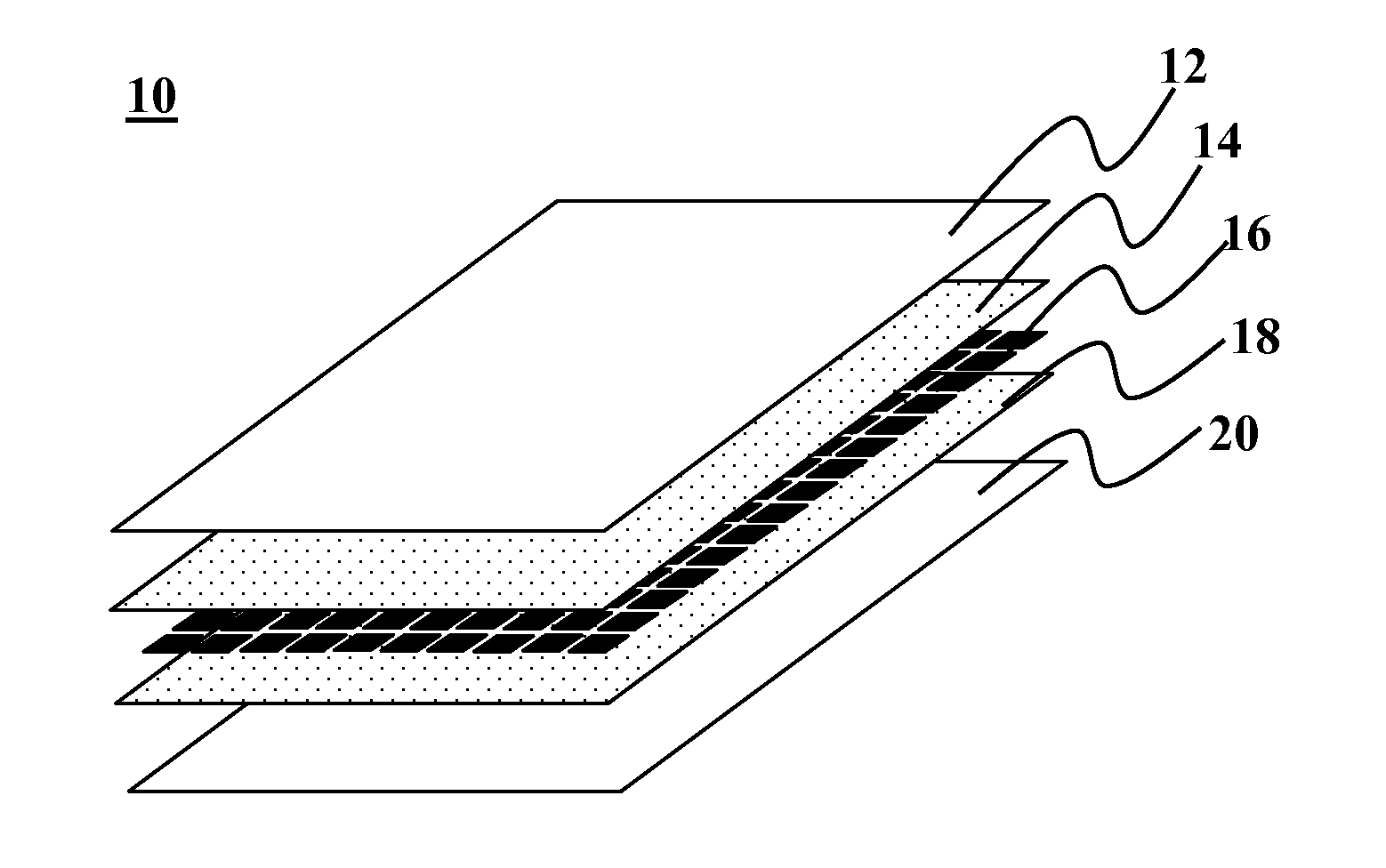

Impact Resistant Thin-Glass Solar Modules

InactiveUS20100065116A1Reduce manufacturing costReduce redundant partsSynthetic resin layered productsElectrical equipmentEngineeringThin glass

Methods and devices are provided for solar module designs. In one embodiment, a durable thin glass solar module is provided. The system comprises of a photovoltaic module with at least one layer comprised of a thin glass layer with protection which protects against microcracks (radial and concentric) which may form during hail impacts.

Owner:STANCEL ROBERT +3

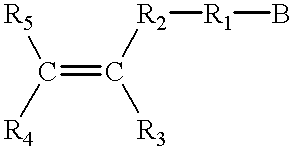

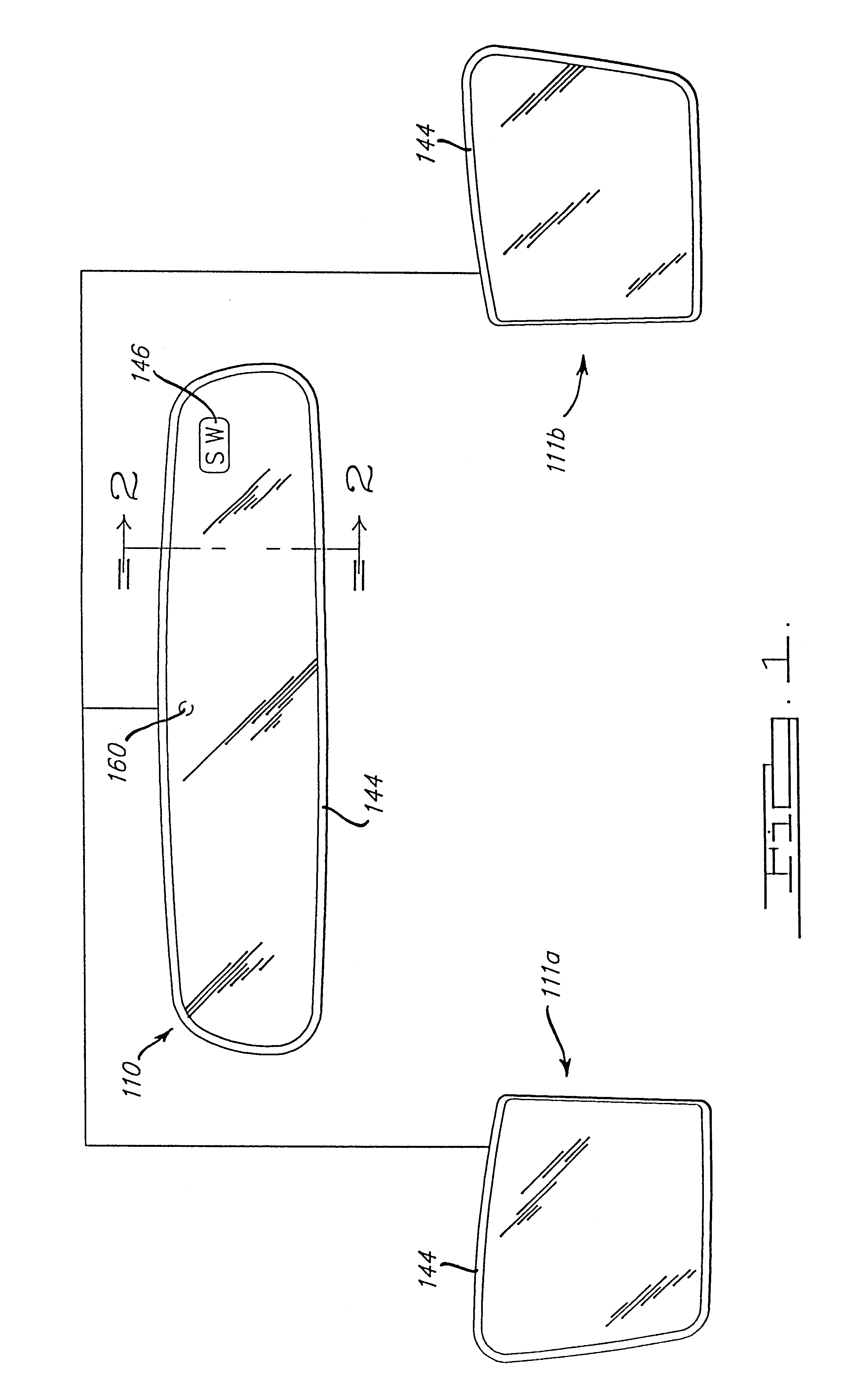

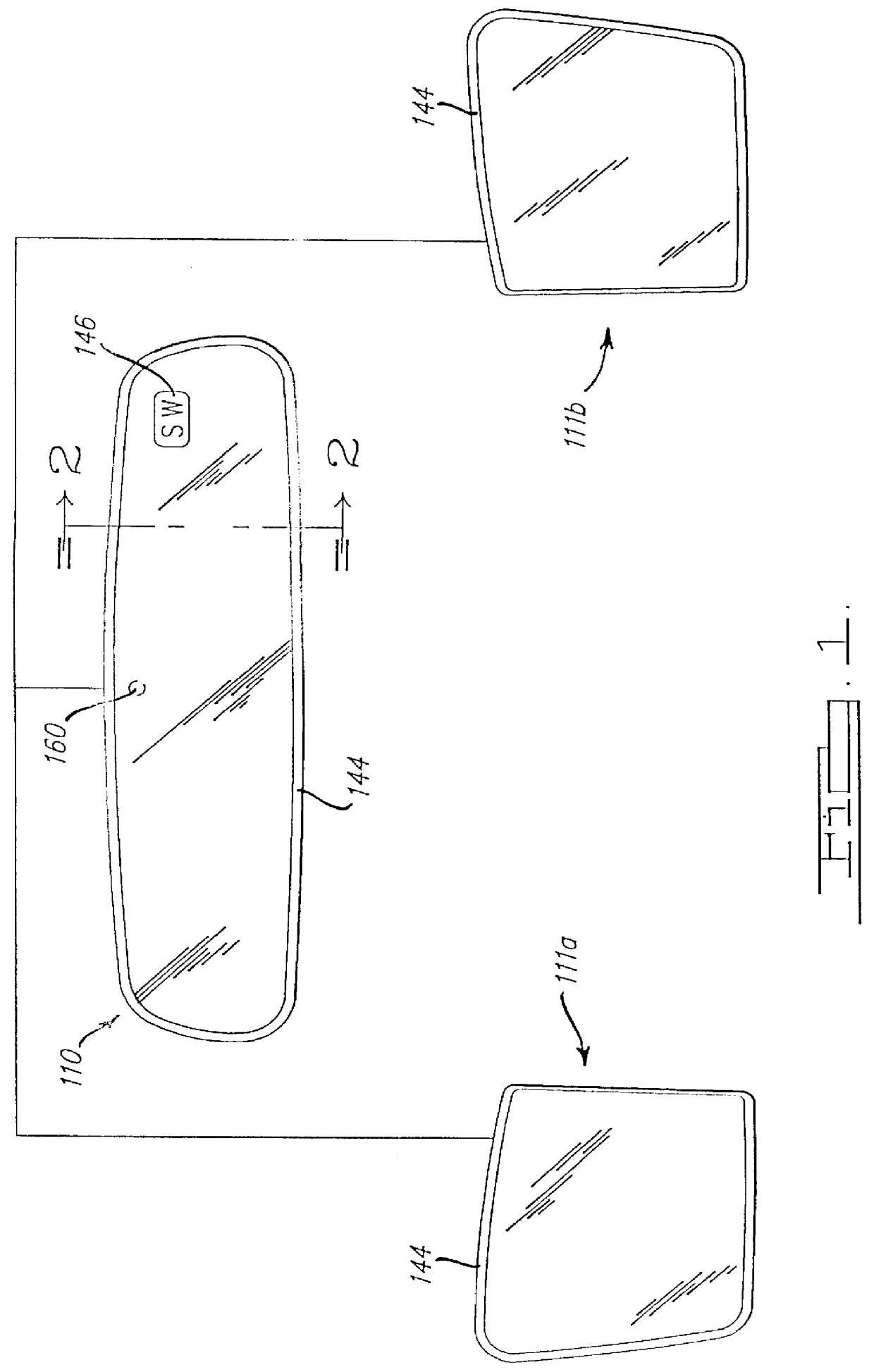

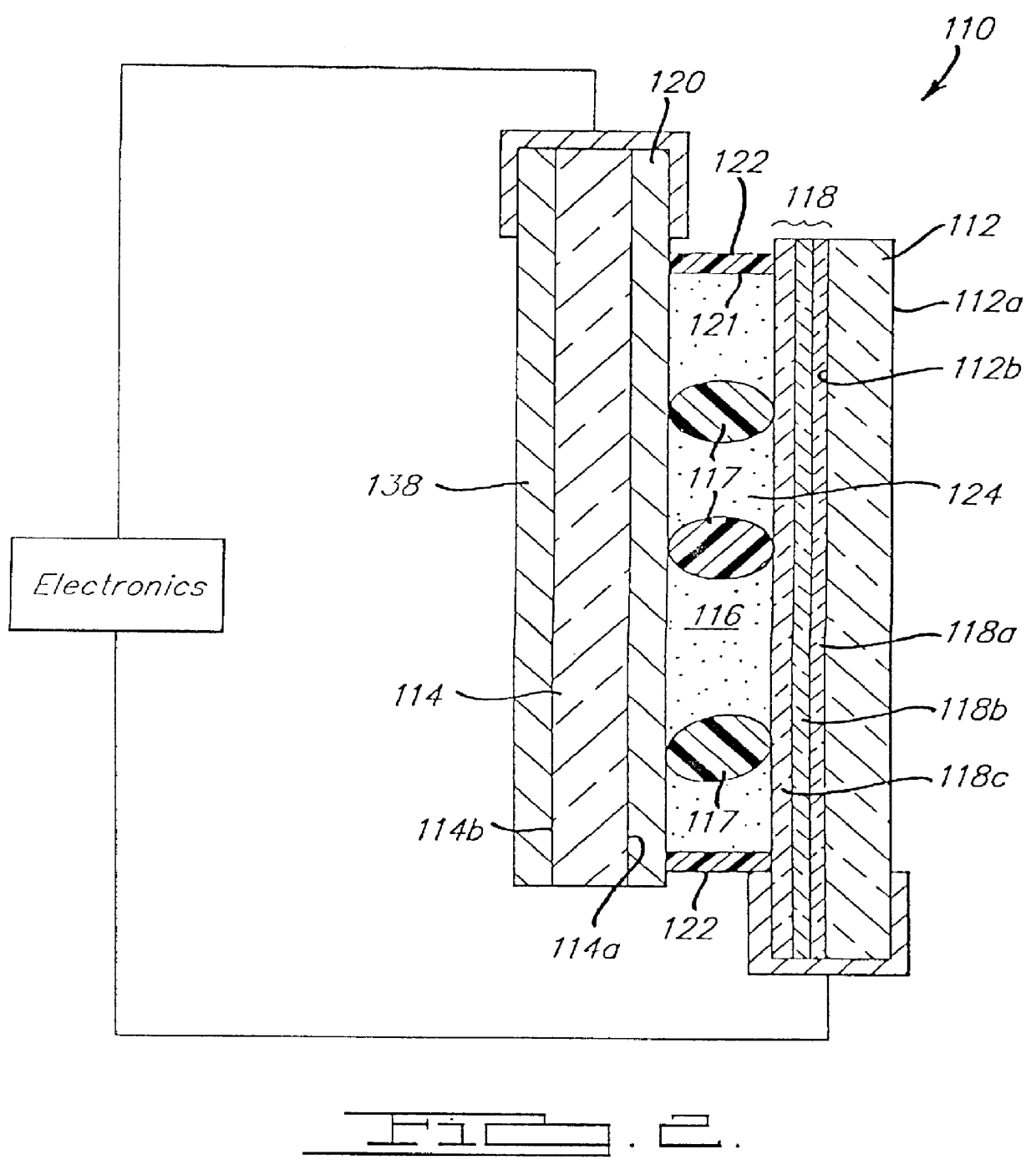

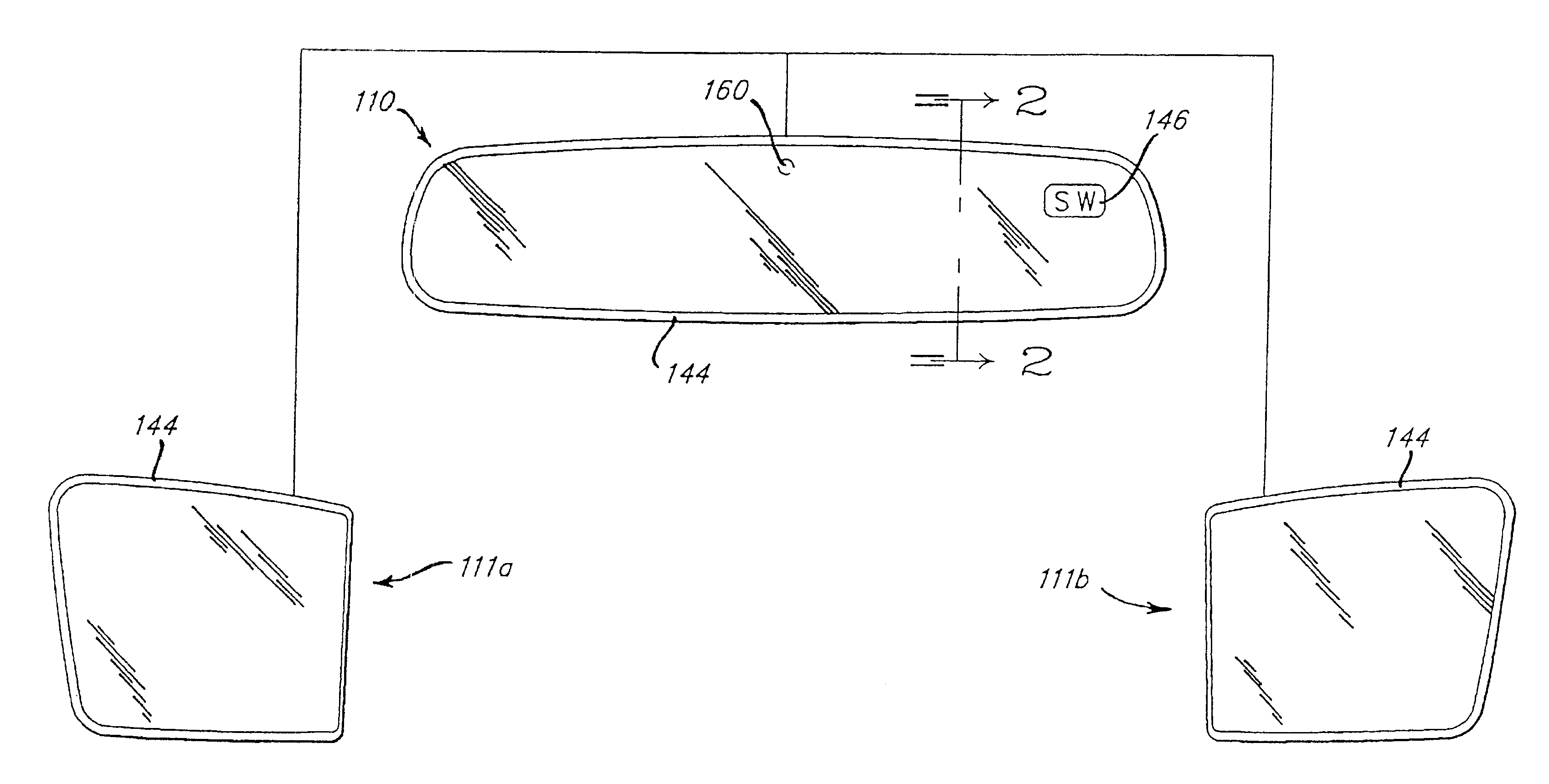

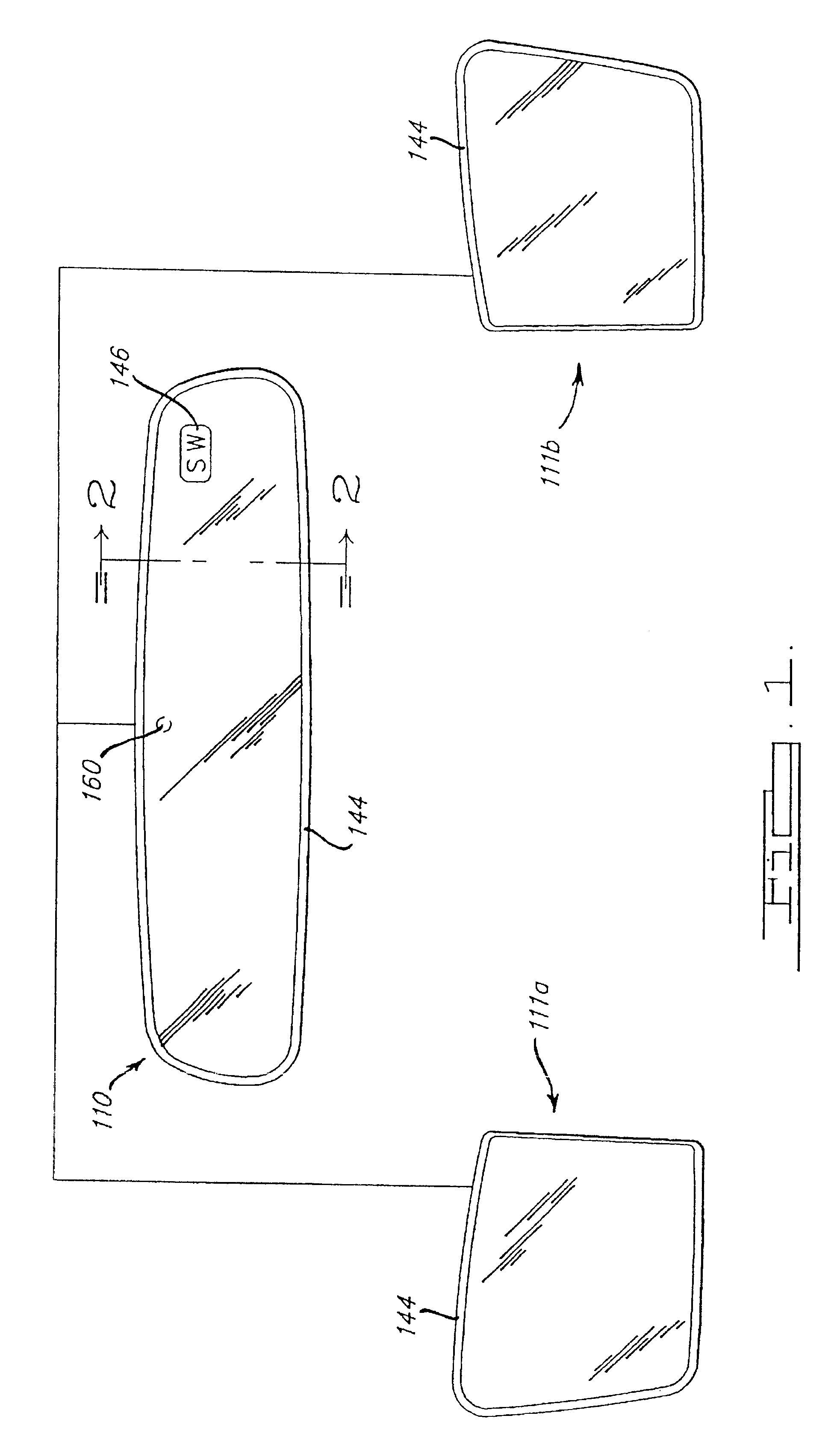

Electrochromic mirror with two thin glass elements and a gelled electrochromic medium

InactiveUS6268950B1Avoid distortionKeep the distanceTenebresent compositionsNon-linear opticsMobile vehicleConductive materials

An improved electrochromic rearview mirror for motor vehicles, the mirror incorporating thin front and rear spaced glass elements having a thickness ranging from about 0.5 to about 1.5. A layer of transparent conductive material is placed onto the mirror's second surface, and either another layer of transparent conductive material or a combined reflector / electrode is placed onto the mirror's third surface. A chamber, defined by the layers on the interior surfaces of the front and rear glass elements and a peripheral sealing member, contains a free-standing gel comprising a solvent and a crosslinked polymer matrix. The chamber further contains at least one electrochromic material in solution with the solvent and interspersed in the crosslinked polymer matrix. The gel cooperatively interacts with the thin glass elements to form a thick, strong unitary member which is resistant to flexing, warping, bowing and / or shattering and further allows the mirror to exhibit reduced vibrational distortion and double imaging.

Owner:GENTEX CORP

Process for producing thin glass on roll

InactiveUS6092392ALow probability of fractureImprove productivityRibbon machinesDuplicating/marking methodsFiberglass meshFiber

This invention relates to a continuous process for producing a web of thin, chemically hardened glass that can be wound on a roll. The process comprises the steps of (i) drawing glass, containing original alkali ions, to form a web of glass having a thickness equal to or lower than 1.2 mm and having a first and second major surface; (ii) directly after or during said drawing, treating both said surfaces of said web with chemical hardening means during less than two hours, replacing said original alkali ions by alkali ions having a larger radius; and (iii) after treating both said surfaces, winding said web on a core.

Owner:AGFA-GEVAERT NV

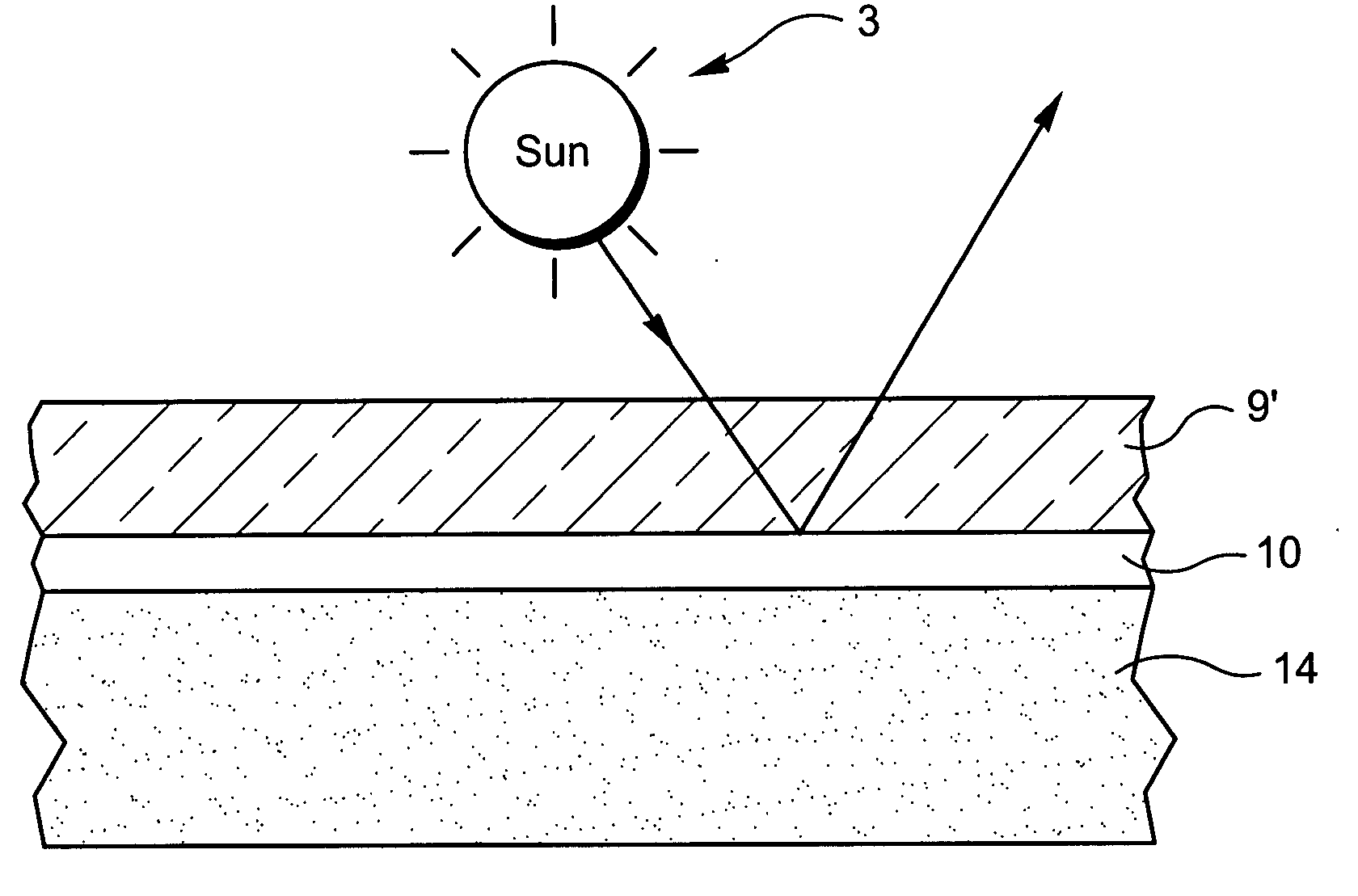

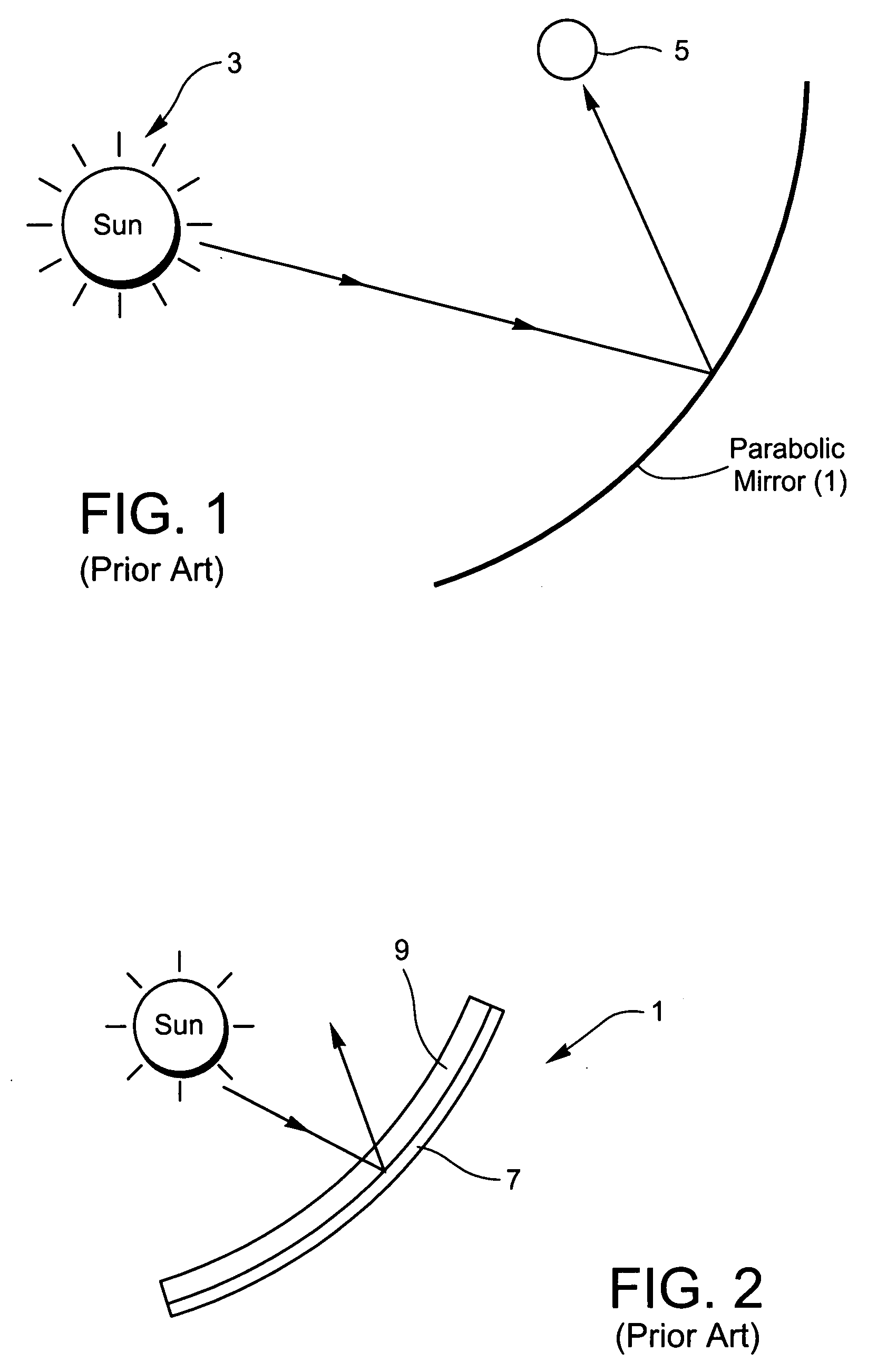

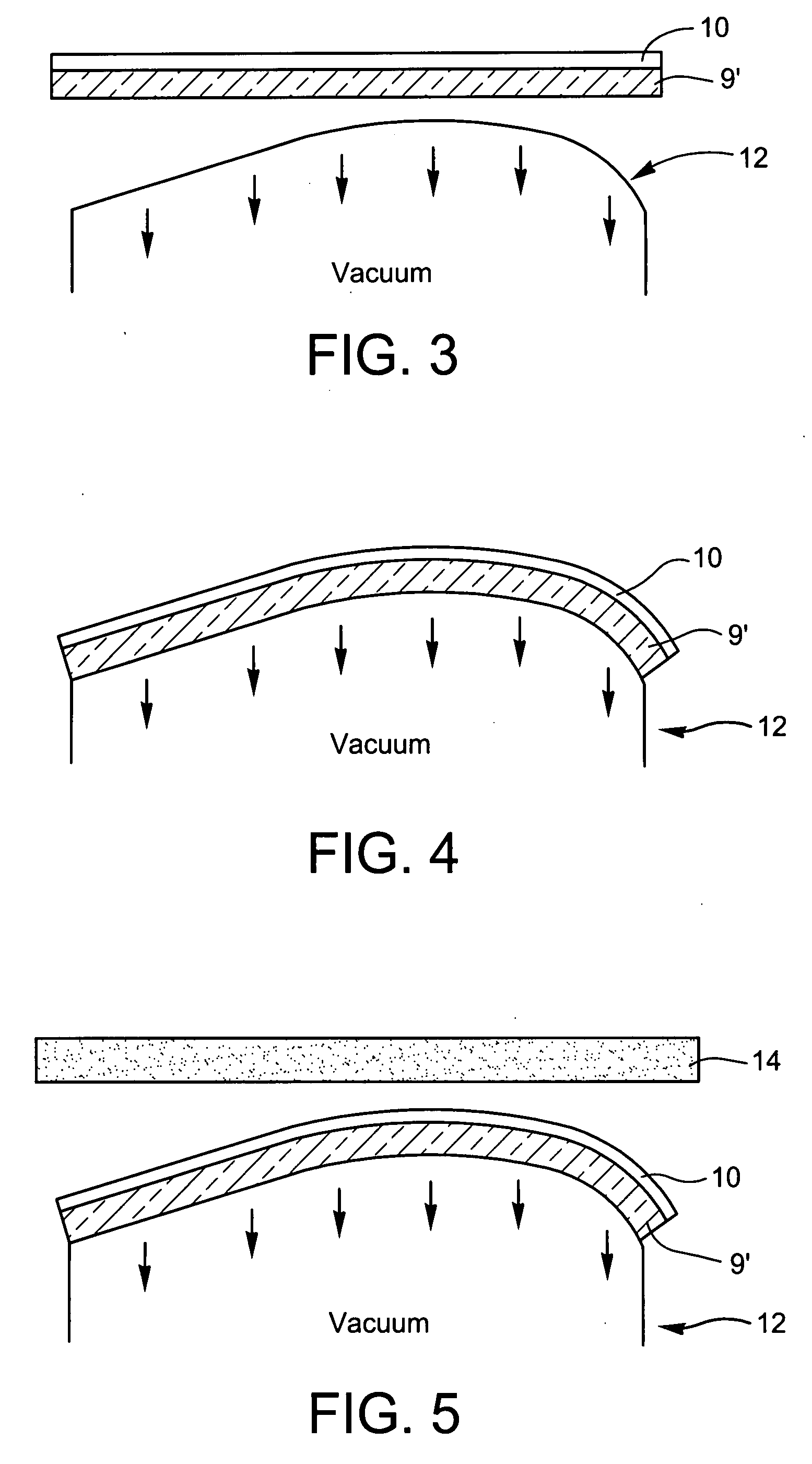

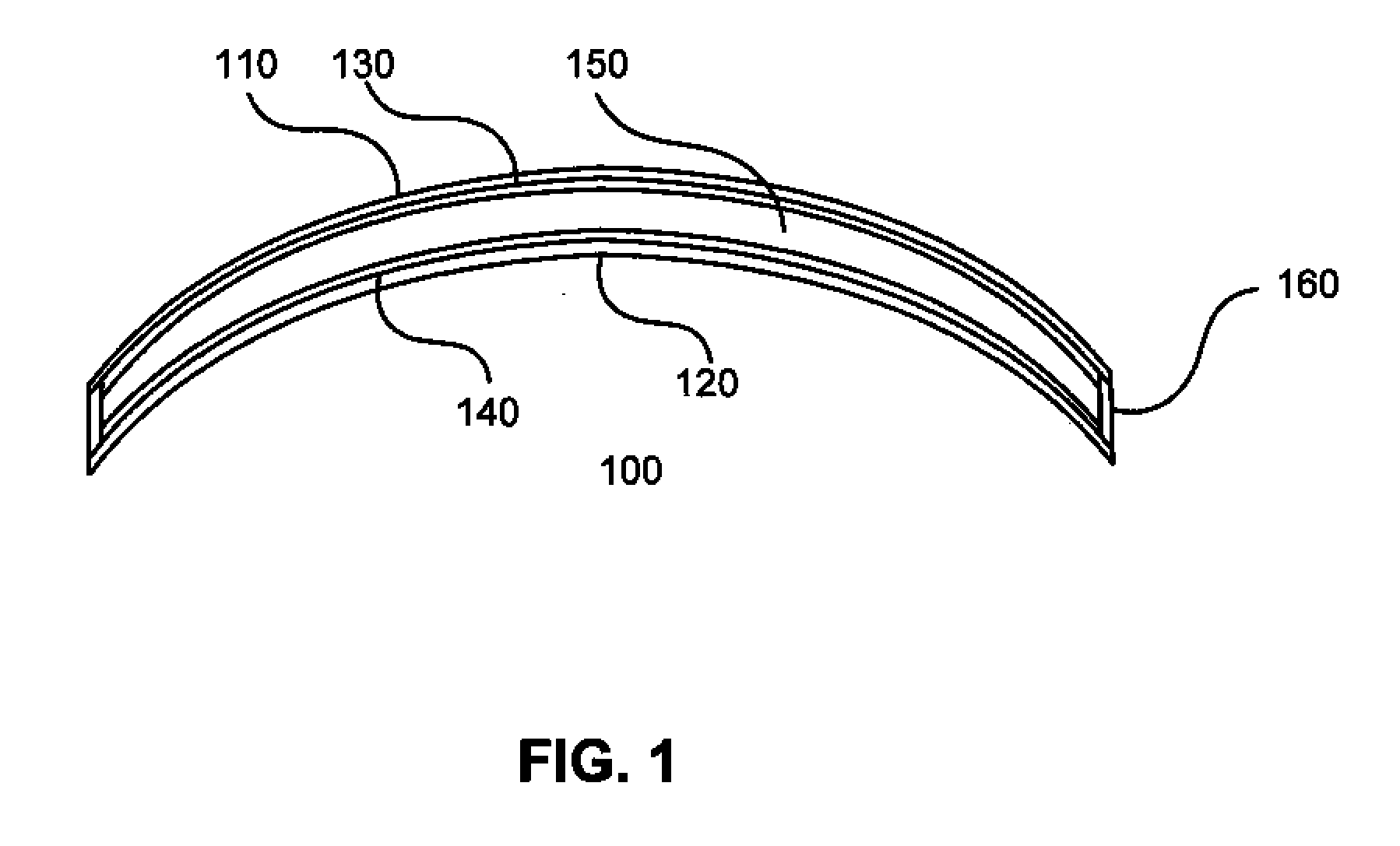

Parabolic trough or dish reflector for use in concentrating solar power apparatus and method of making same

A reflector (e.g., mirror) for use in a solar collector or the like is provided. In certain example embodiments of this invention, a reflector is made by (a) forming a reflective coating on a thin substantially flat glass substrate (the thin glass substrate may or may not be pre-bent prior to the coating being applied thereto), (b) optionally, if the glass substrate in (a) was not prebent, then cold-bending the glass substrate with the reflective coating thereon; and (c) applying a plate or frame member to the thin bent glass substrate with the coating thereon from (a) and / or (b), the plate or frame member (which may be another thicker pre-bent glass sheet, for example) for maintaining the thin glass substrate and coating thereon in a desired bent orientation in a final product which may be used as parabolic trough or dish type reflector in a concentrating solar power apparatus or the like.

Owner:GUARDIAN EURO S A R L +1

Glass product for use in ultra-thin glass display applications

InactiveUS20060250559A1Liquid crystal compositionsAfter-treatment detailsActive-matrix liquid-crystal displayAlkali free

The present invention is directed to a substrate product for use in the manufacture of active matrix liquid crystal display panels. The product includes a display substrate suitable for use as a display panel. The display substrate has a thickness less than or equal to 0.4 mm, a composition that is substantially alkali free, and a surface smoothness that allows the direct formation of thin-film transistors thereon without a prior processing step of polishing and / or grinding. The product also includes at least one support substrate removably attached to the display substrate.

Owner:CORNING INC

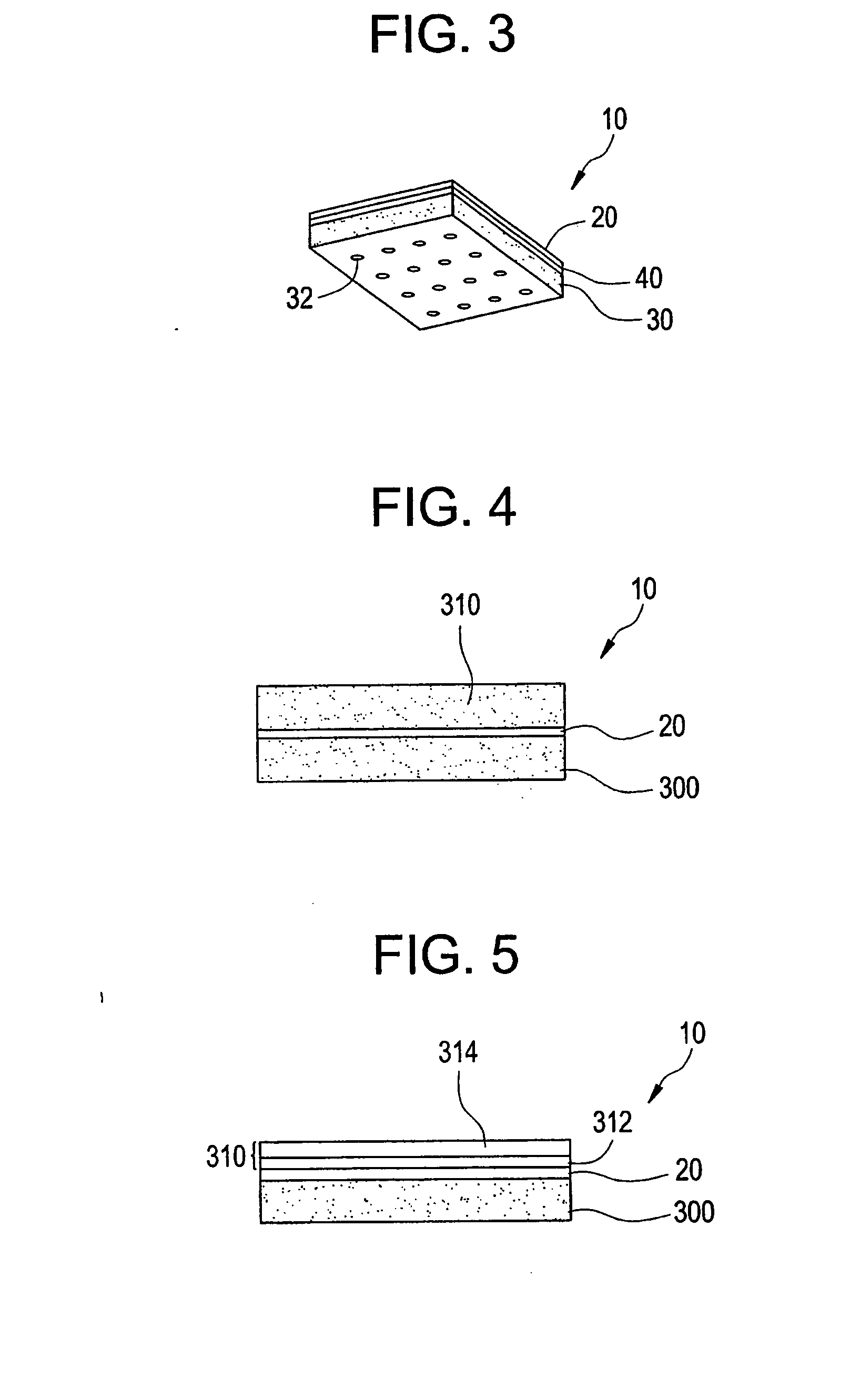

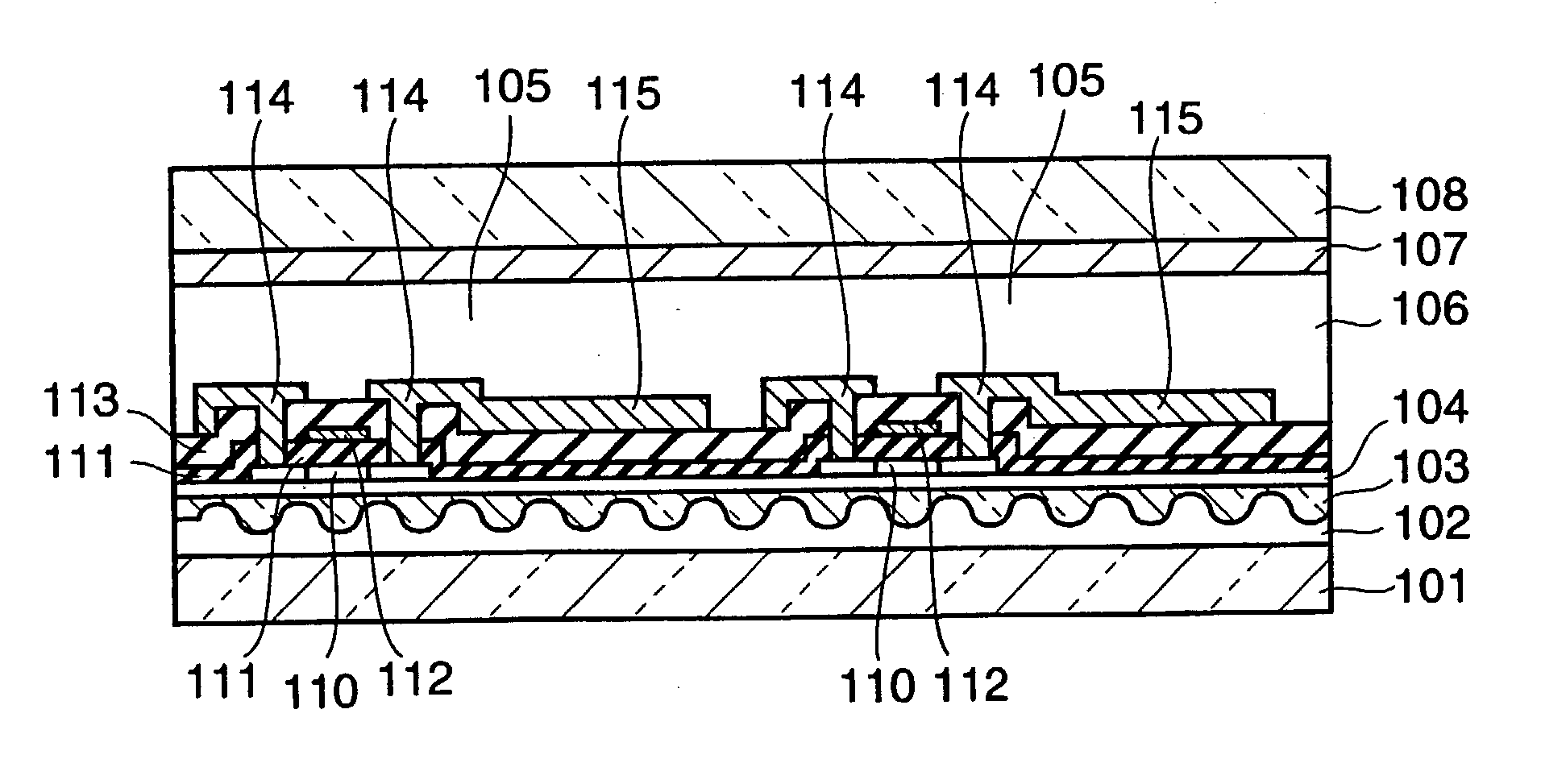

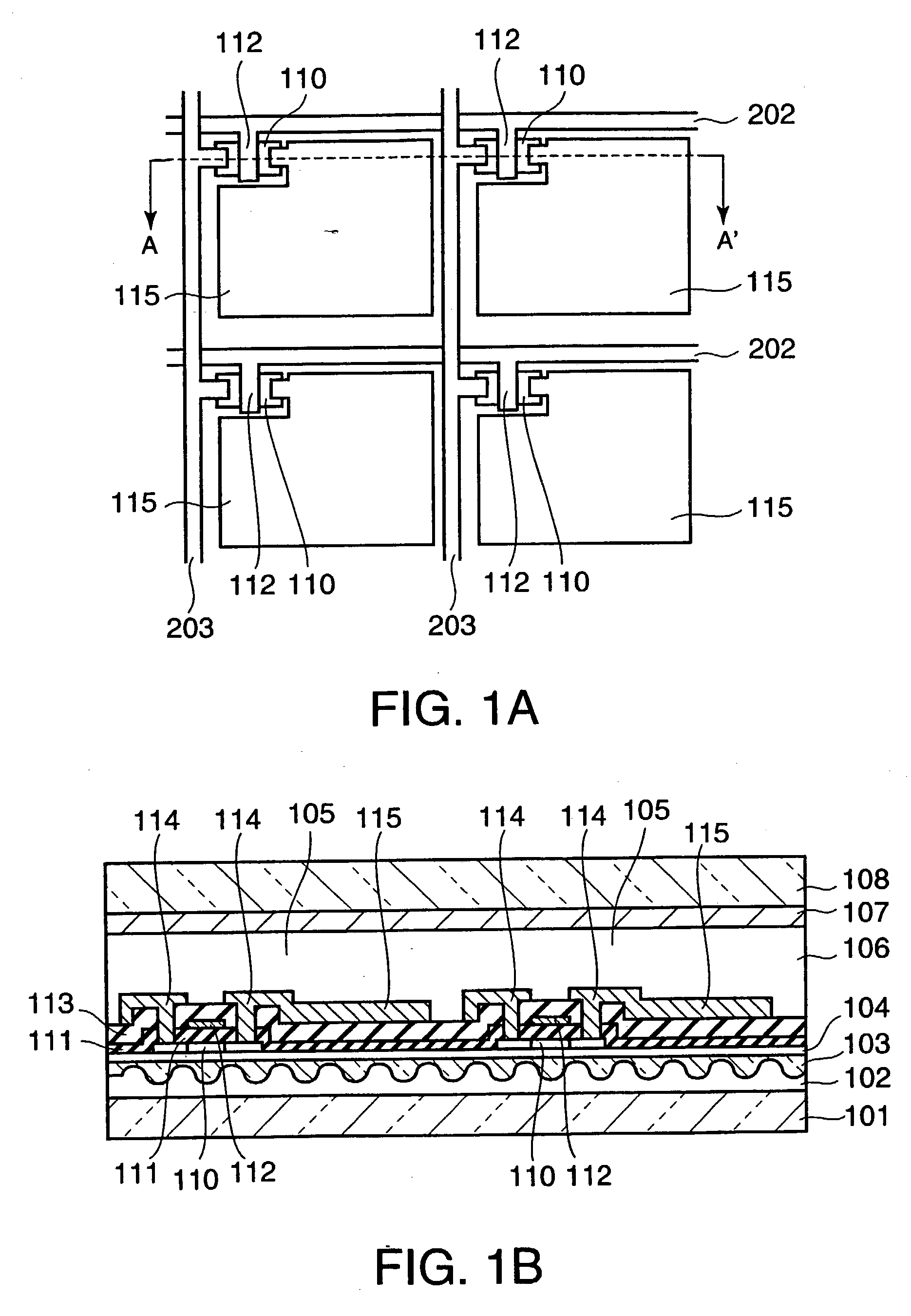

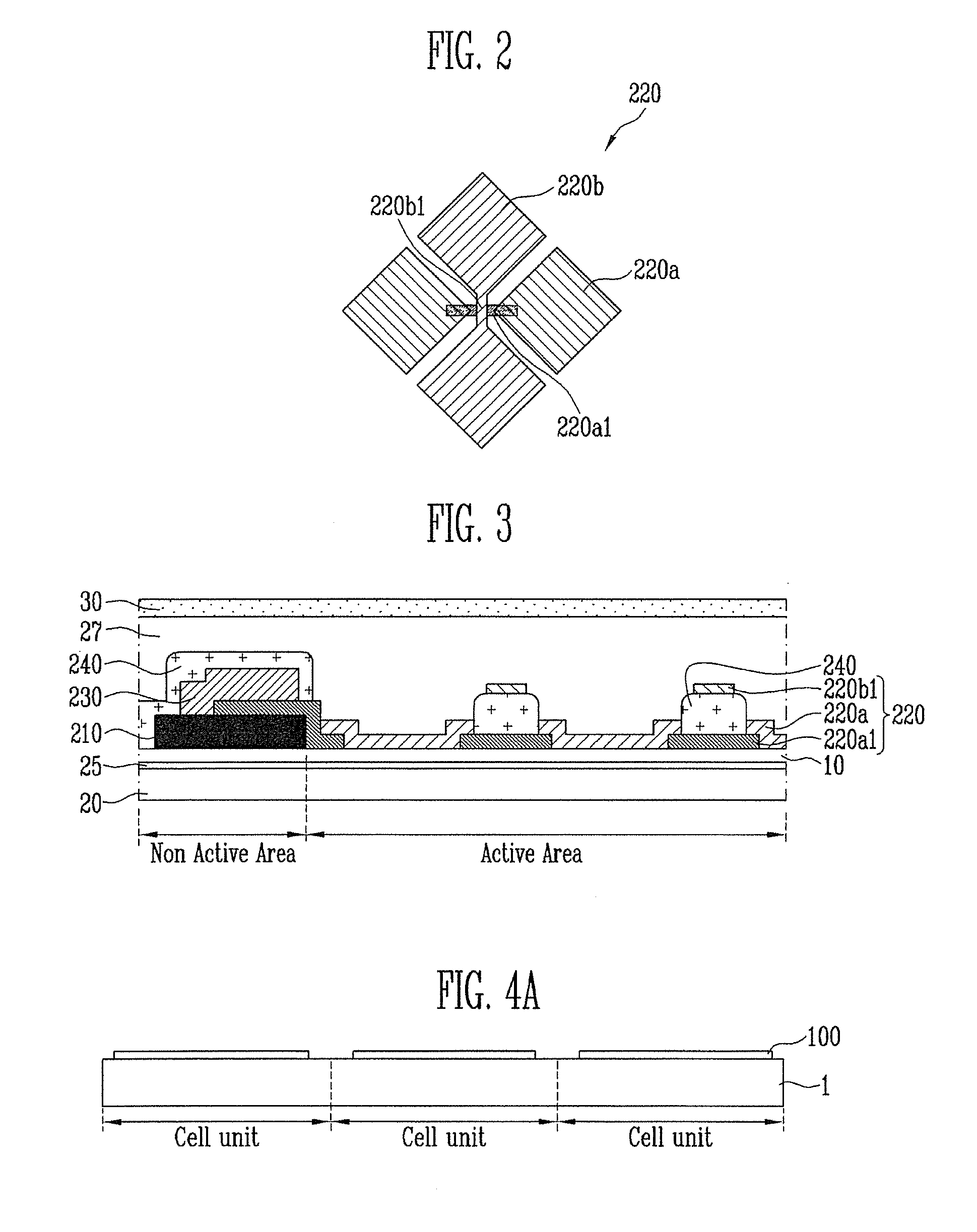

Active matrix type display device and method of manufacturing the same

A method of manufacturing an active matrix type display device, which is reliable and flexible, is provided. An active matrix type display device according to an aspect of the present invention includes: a first substrate, which is flexible; a thin glass layer provided on the first substrate via an adhesion layer, and having projections and depressions on a surface thereof opposing to the first substrate, the projections and depressions having rounded tips and bottoms; active elements provided on the thin glass layer, each active element corresponding to a pixel; a display provided above the thin glass layer, and driven by the active elements to display an image pixel by pixel; and a second substrate provided on the display, and having an opposing electrode formed thereon.

Owner:JAPAN DISPLAY CENTRAL CO LTD

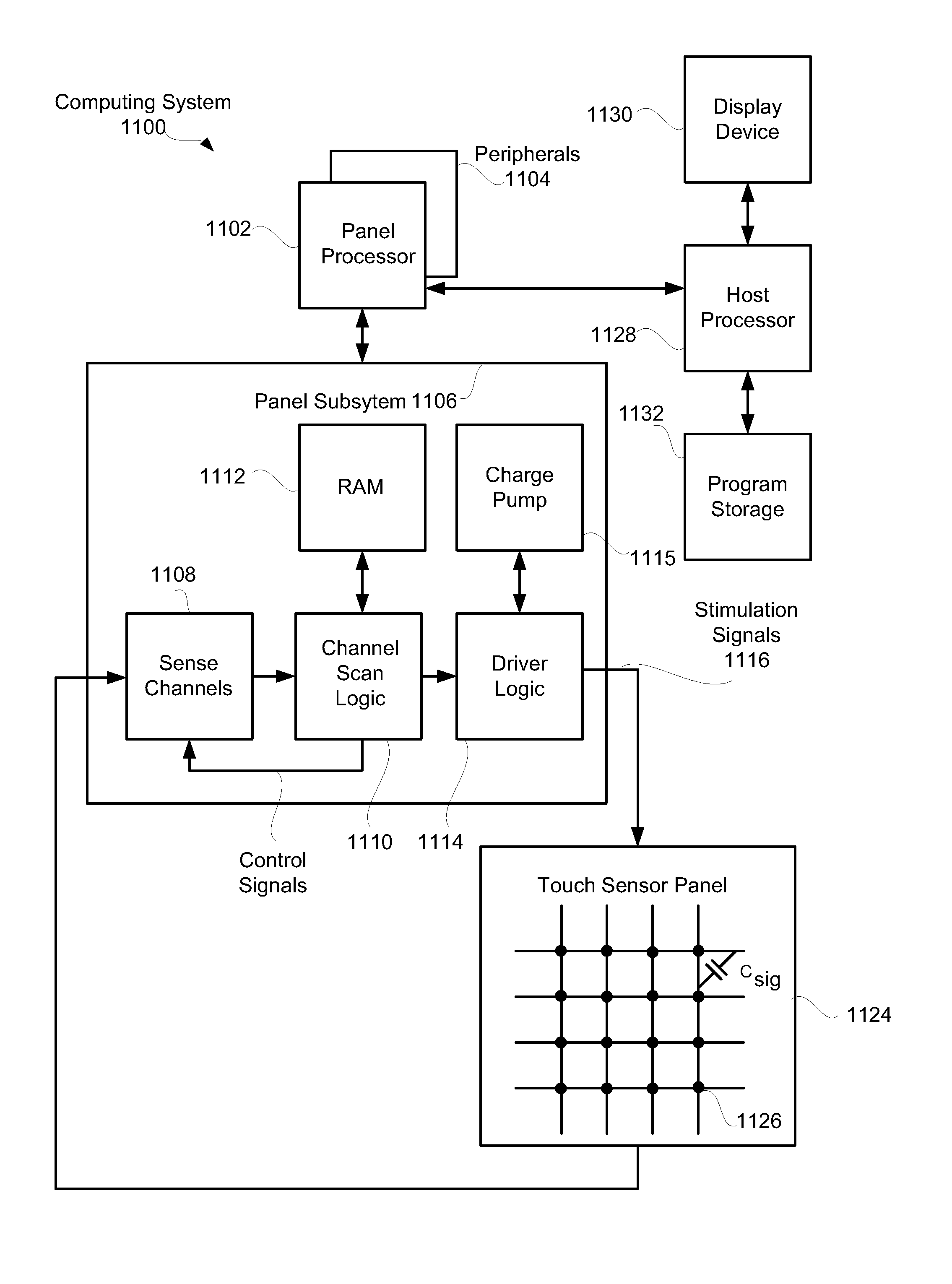

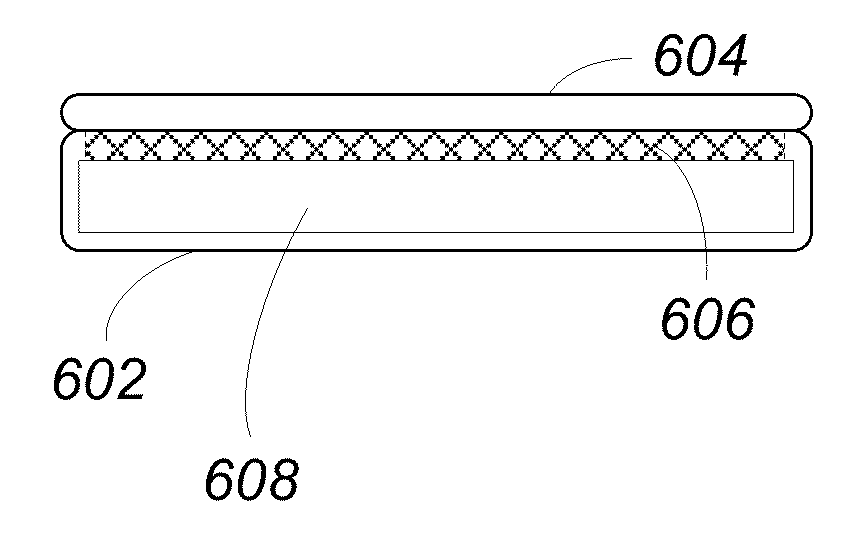

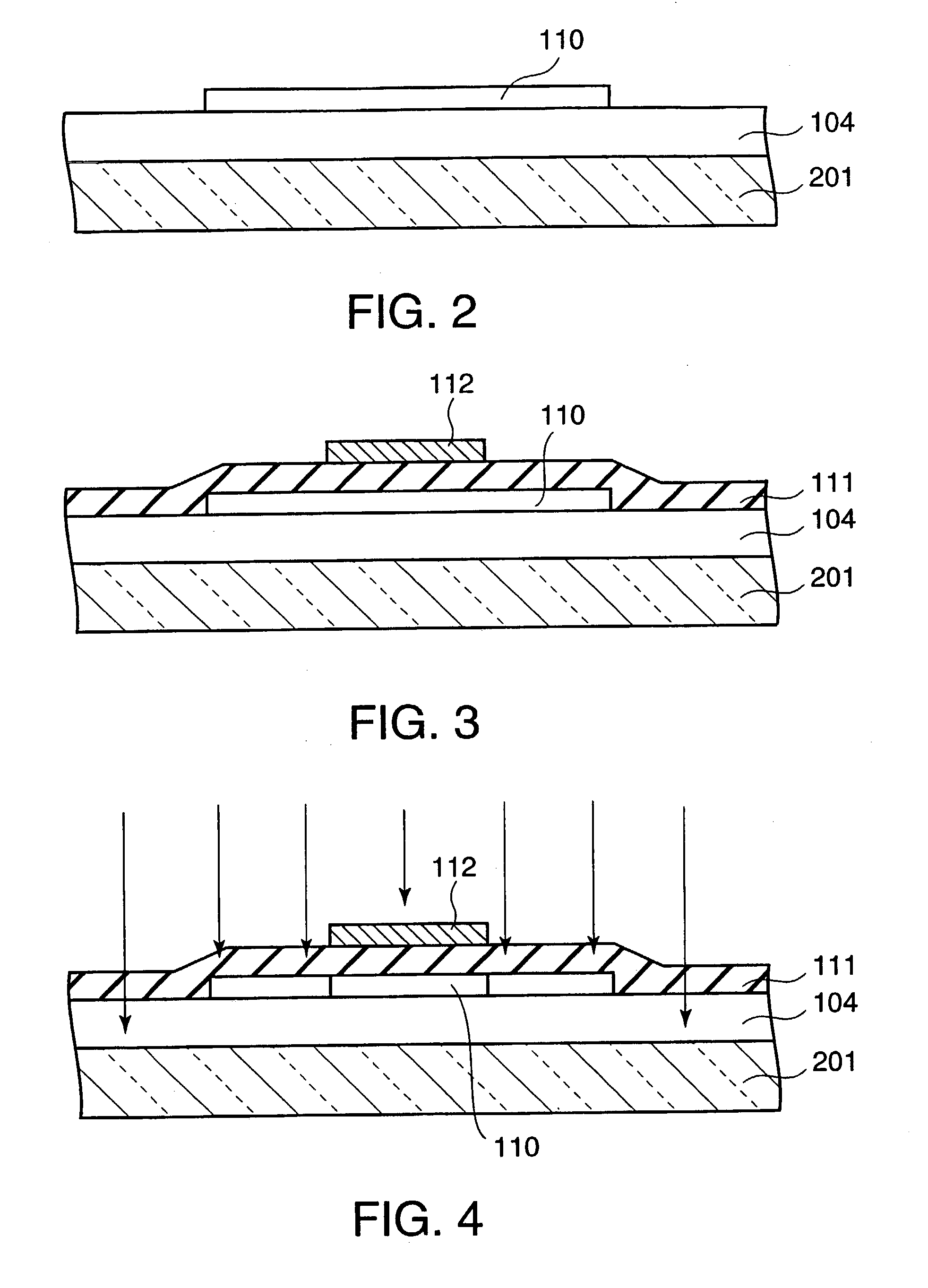

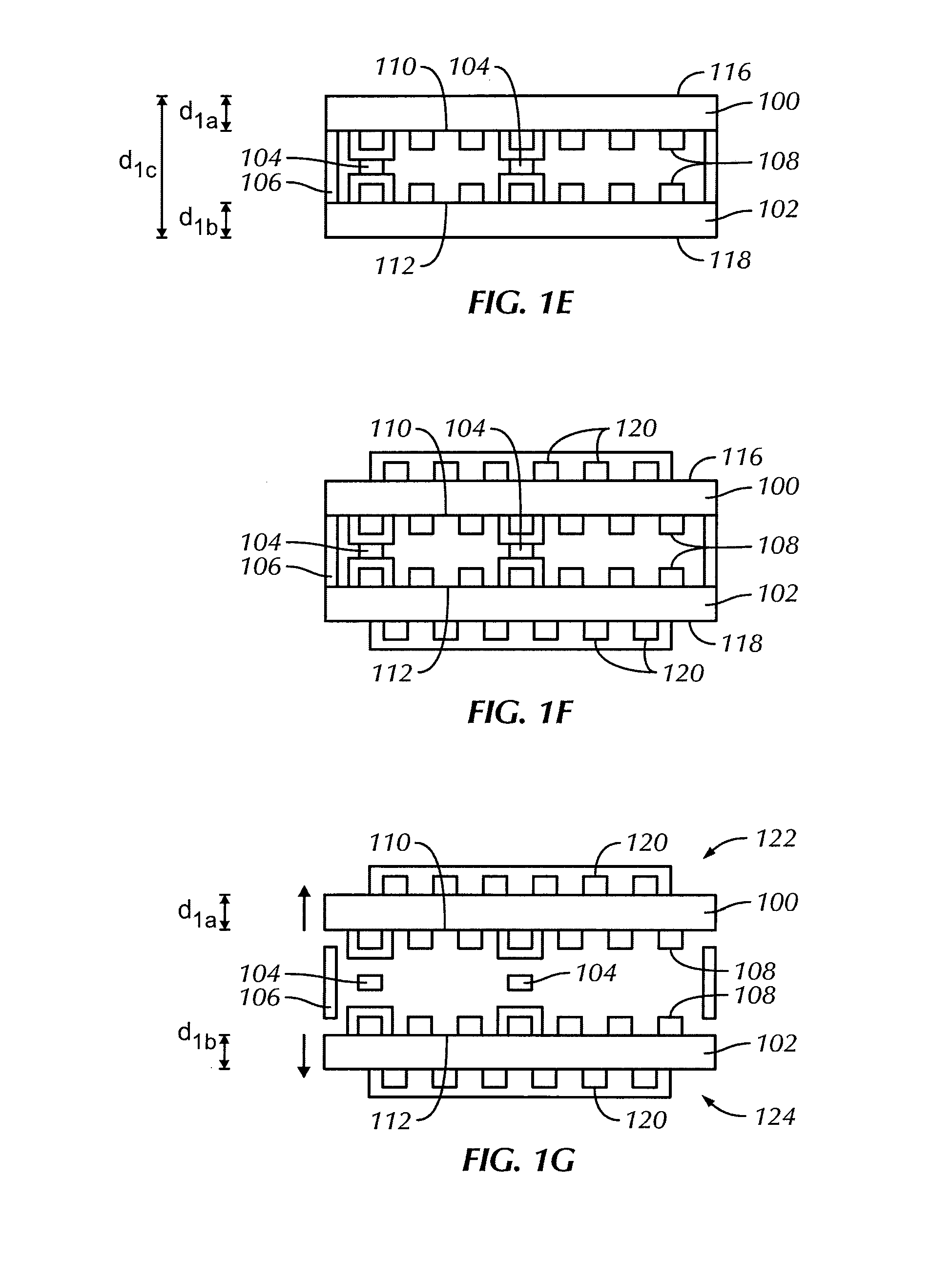

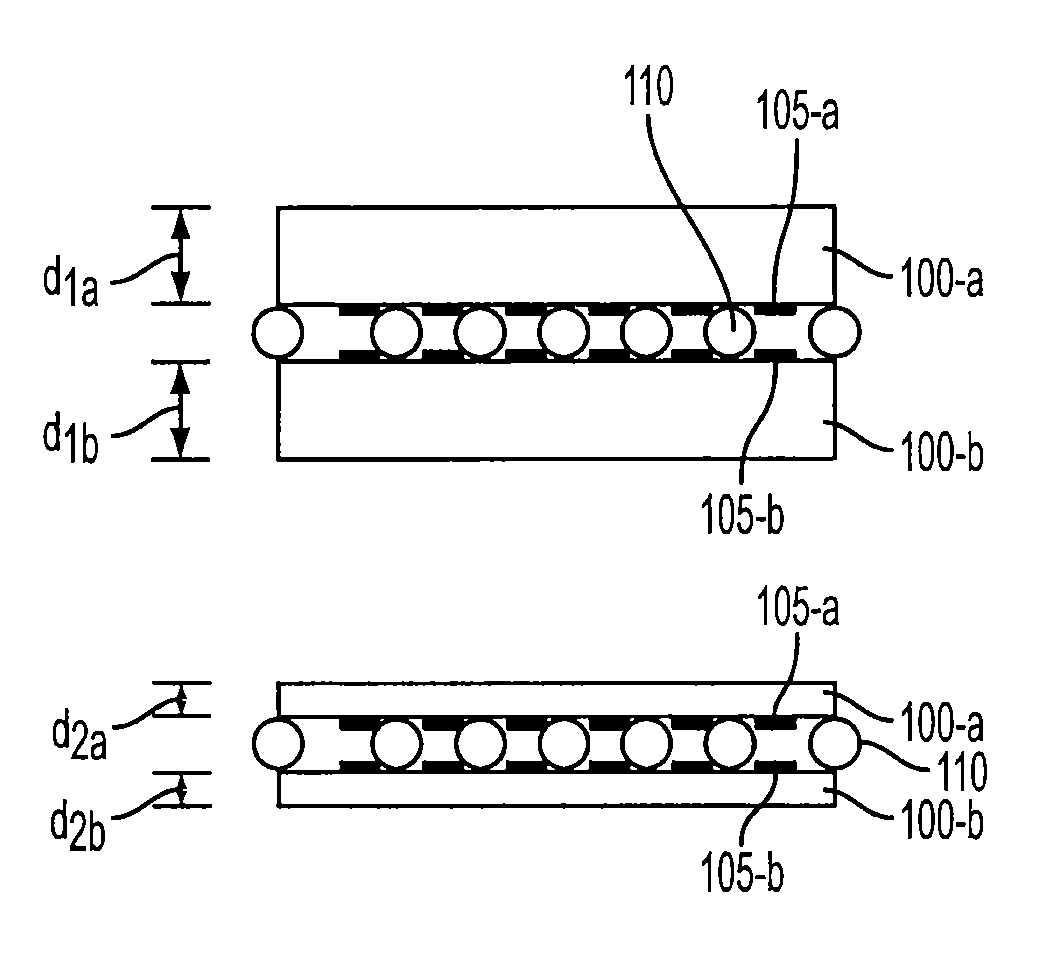

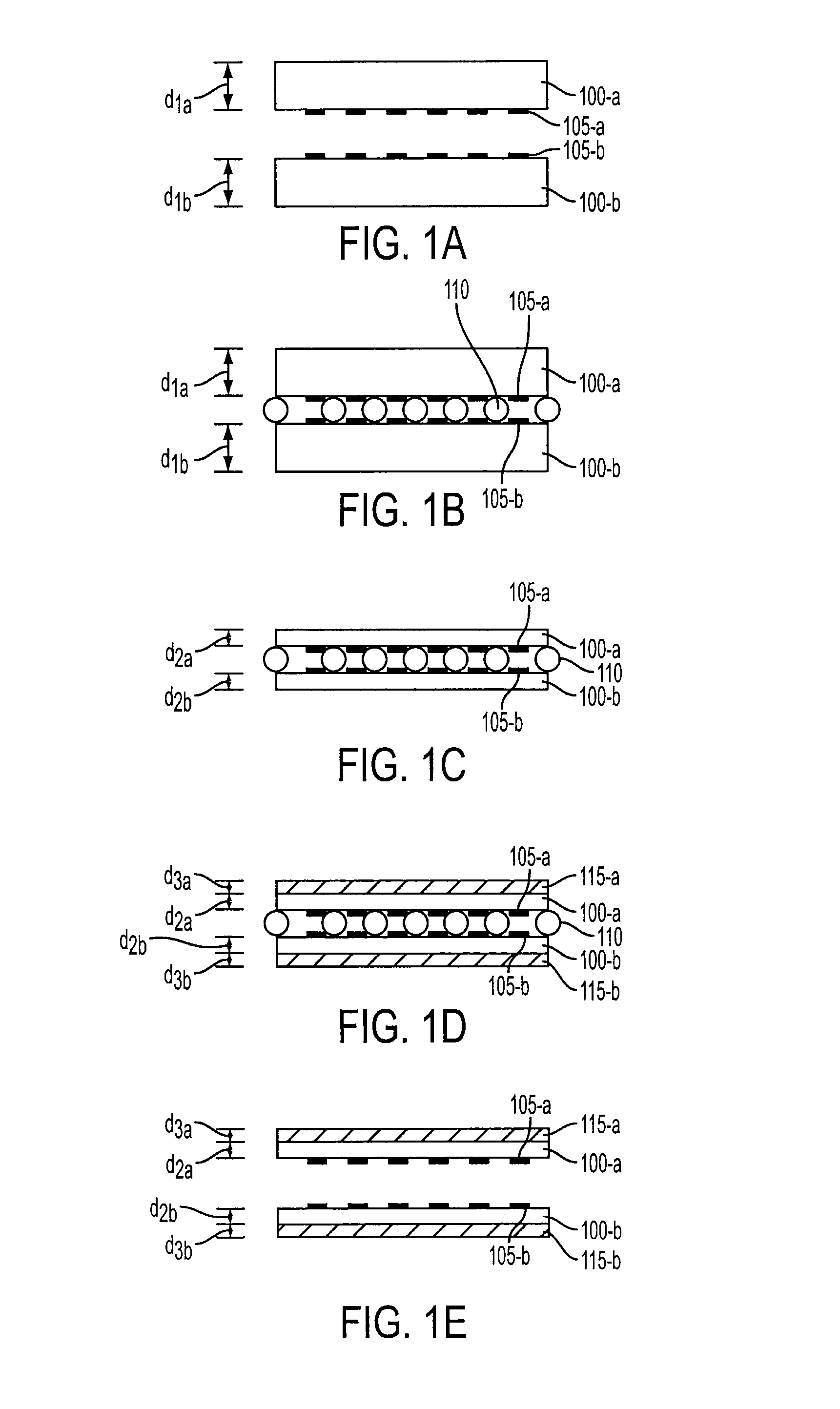

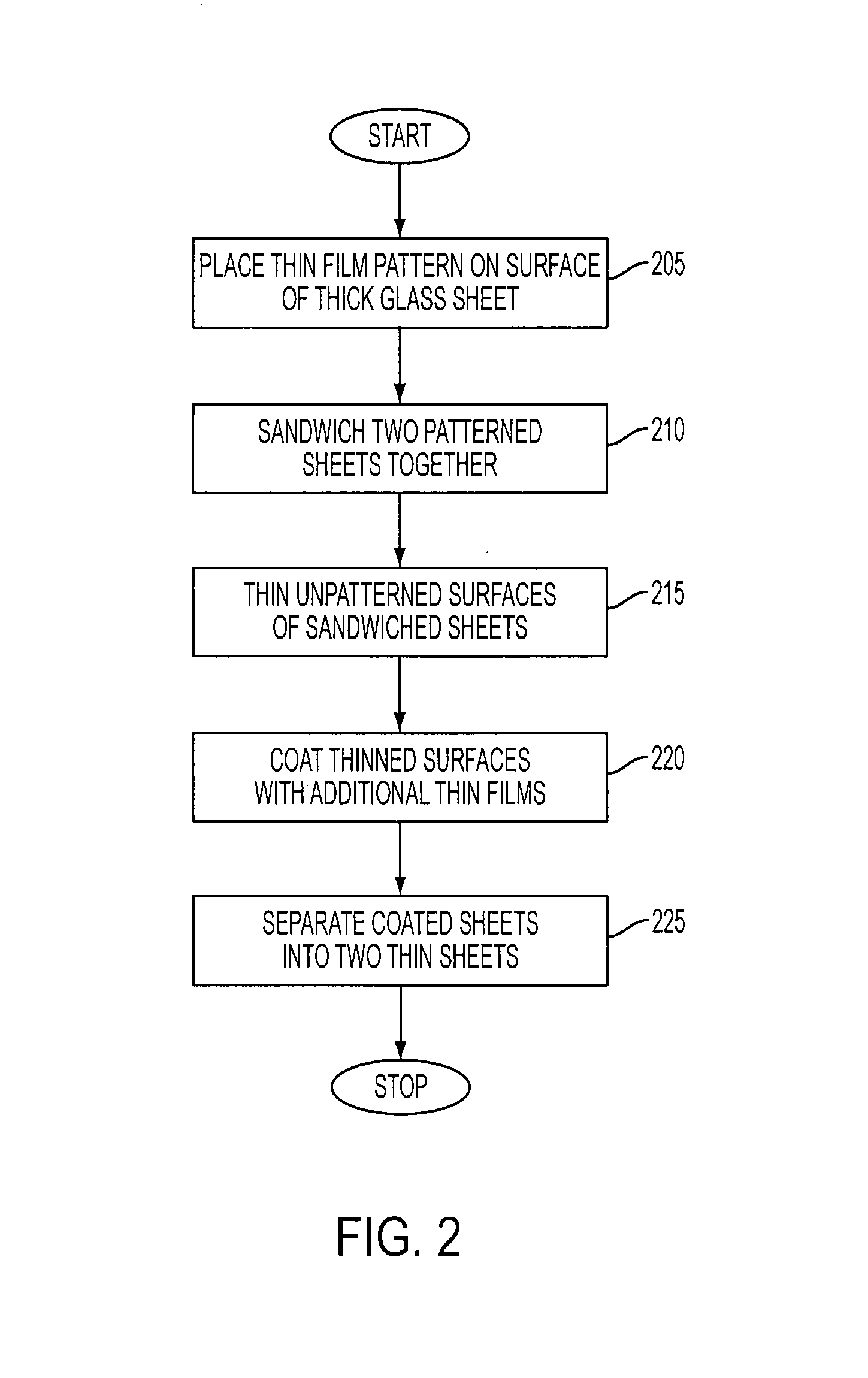

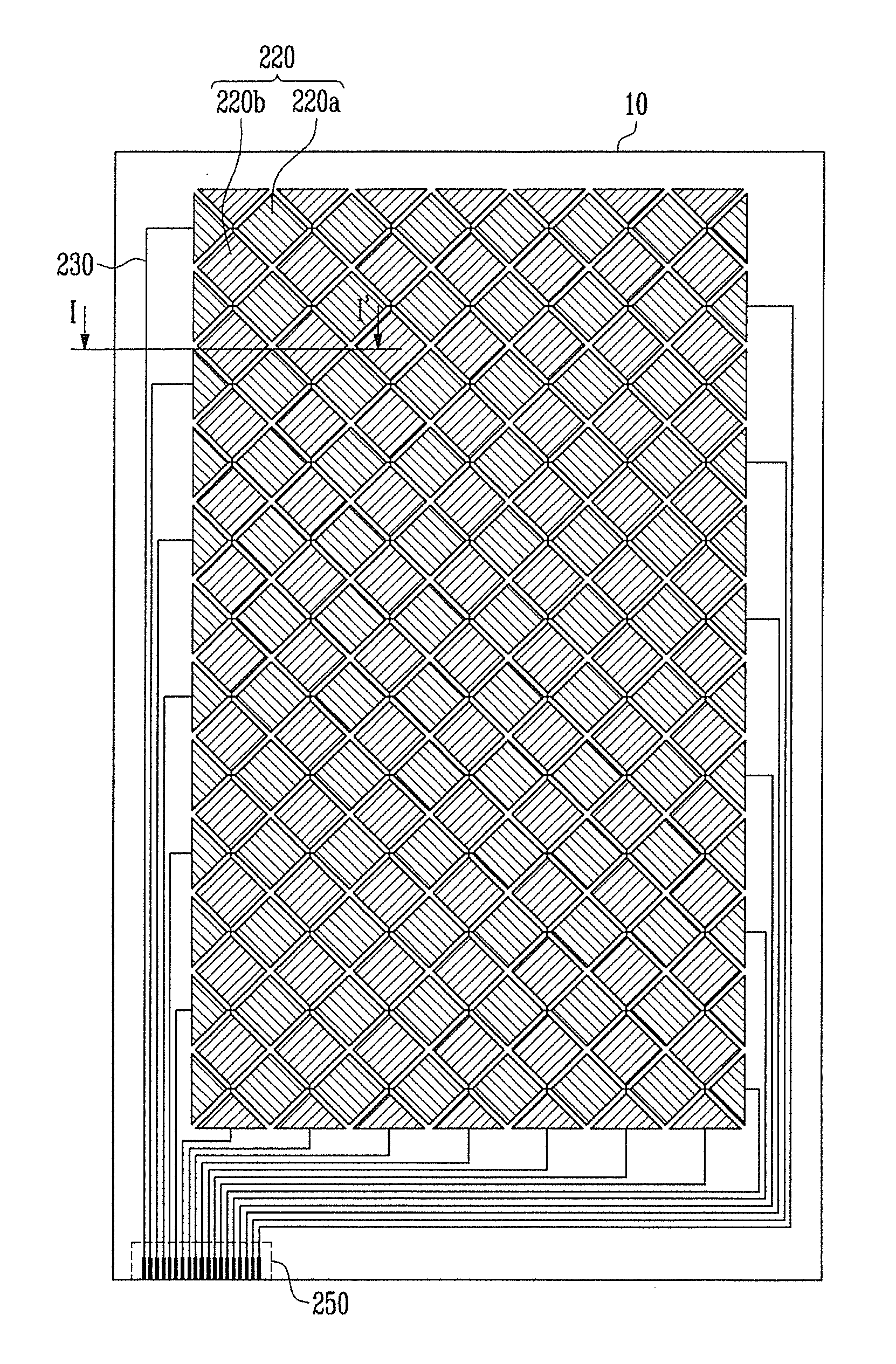

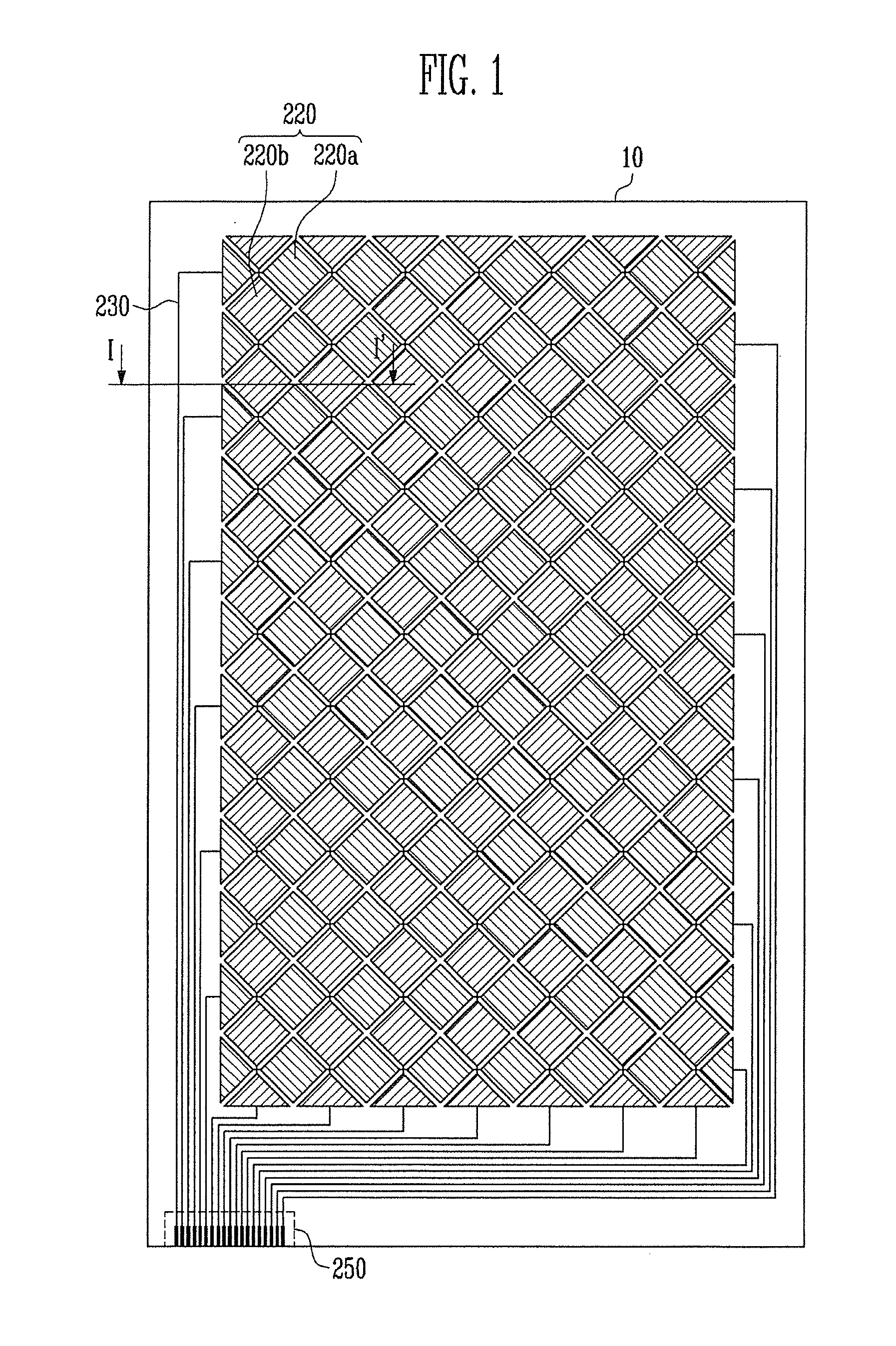

Method for fabricating thin touch sensor panels

A method for fabricating thin DITO or SITO touch sensor panels with a thickness less than a minimum thickness tolerance of existing manufacturing equipment. In one embodiment, a sandwich of two thin glass sheets is formed such that the combined thickness of the glass sheets does not drop below the minimum thickness tolerance of existing manufacturing equipment when thin film process is performed on the surfaces of the sandwich during fabrication. The sandwich may eventually be separated to form two thin SITO / DITO panels. In another embodiment, the fabrication process involves laminating two patterned thick substrates, each having at least the minimum thickness tolerance of existing manufacturing equipment. One or both of the sides of the laminated substrates are then thinned so that when the substrates are separated, each is a thin DITO / SITO panel having a thickness less than the minimum thickness tolerance of existing manufacturing equipment.

Owner:APPLE INC

Electrochromic mirror with two thin glass elements and a gelled electrochromic medium

InactiveUS6057956AAvoid distortionKeep the distanceTelescopesTenebresent compositionsMobile vehicleConductive materials

An improved electrochromic rearview mirror for motor vehicles, the mirror incorporating thin front and rear spaced glass elements having a thickness ranging from about 0.5 to about 1.5. A layer of transparent conductive material is placed onto the mirror's second surface, and either another layer of transparent conductive material or a combined reflector / electrode is placed onto the mirror's third surface. A chamber, defined by the layers on the interior surfaces of the front and rear glass elements and a peripheral sealing member, contains a free-standing gel comprising a solvent and a crosslinked polymer matrix. The chamber further contains at least one electrochromic material in solution with the solvent and interspersed in the crosslinked polymer matrix. The gel cooperatively interacts with the thin glass elements to form a thick, strong unitary member which is resistant to flexing, warping, bowing and / or shattering and further allows the mirror to exhibit reduced vibrational distortion and double imaging.

Owner:GENTEX CORP

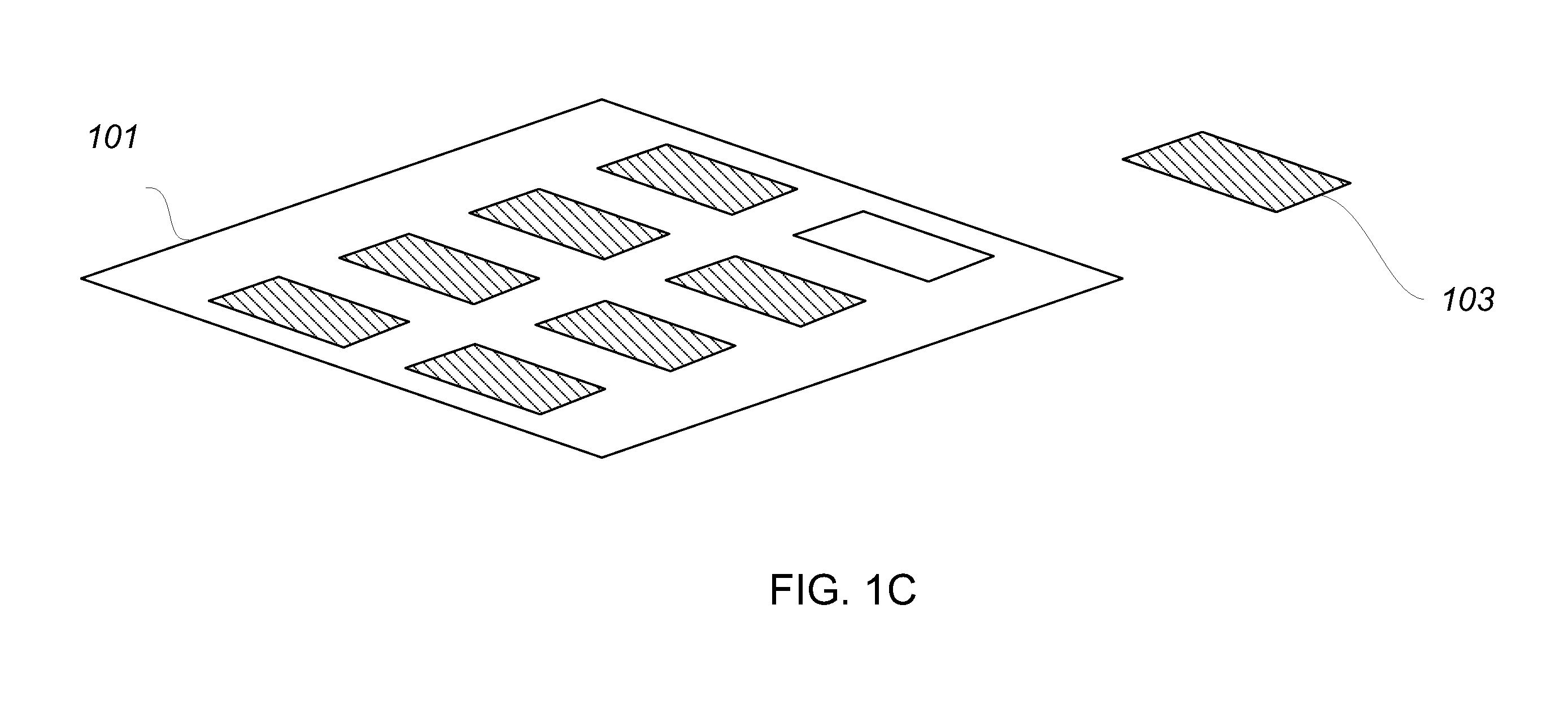

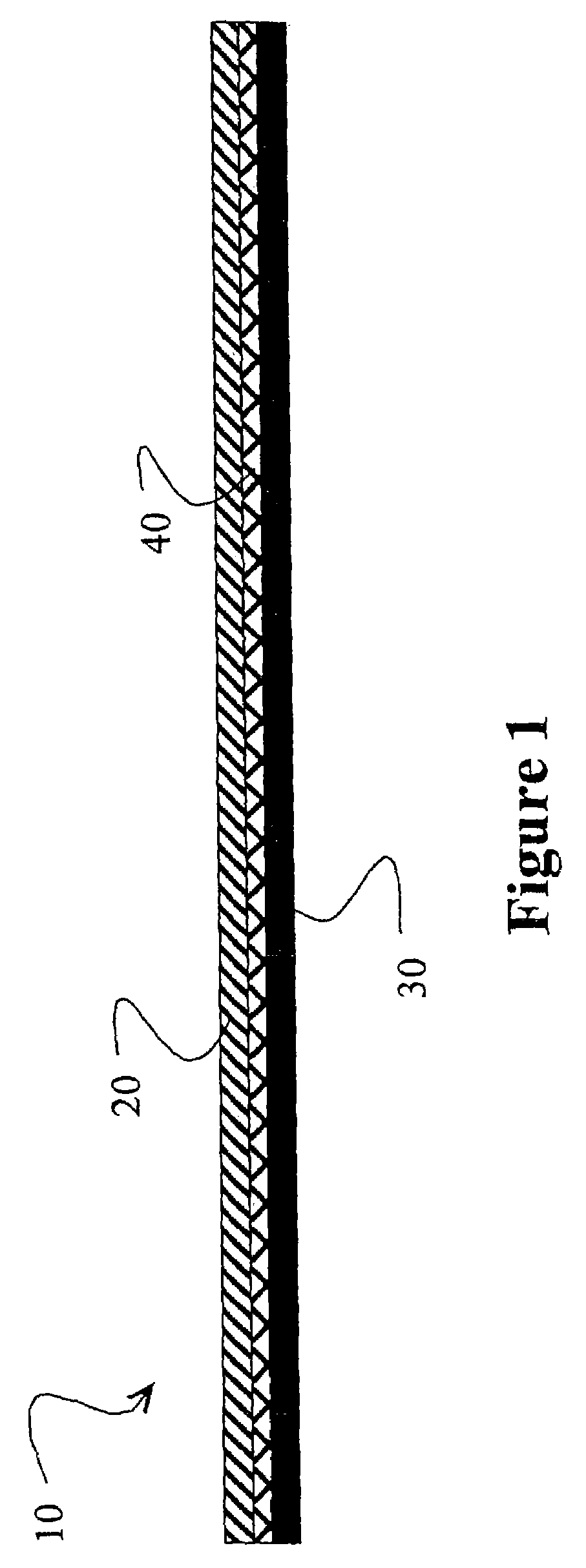

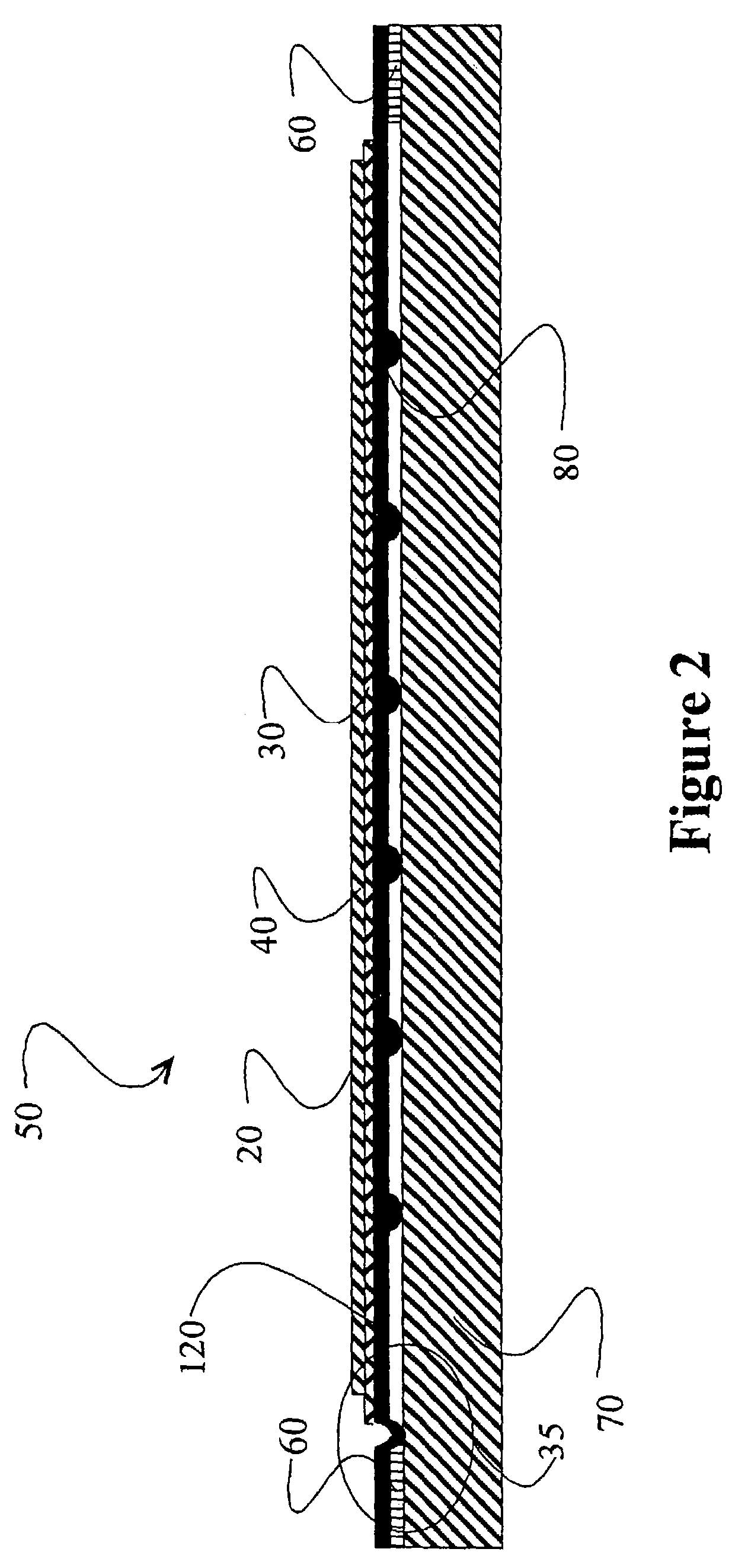

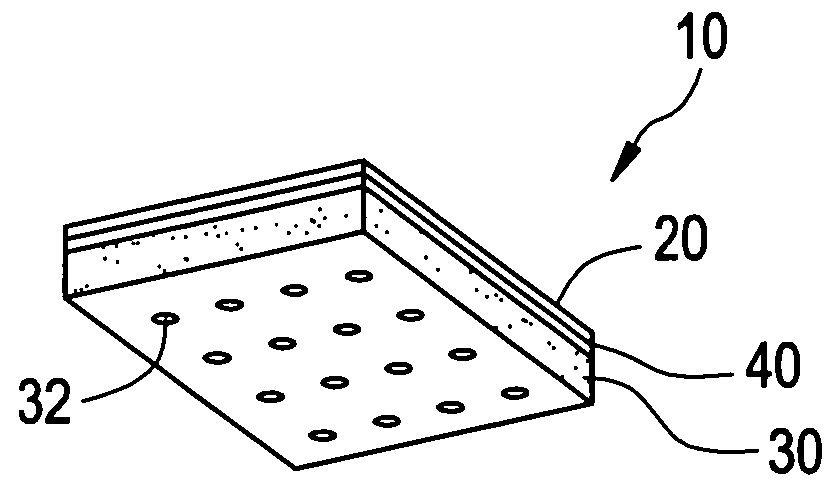

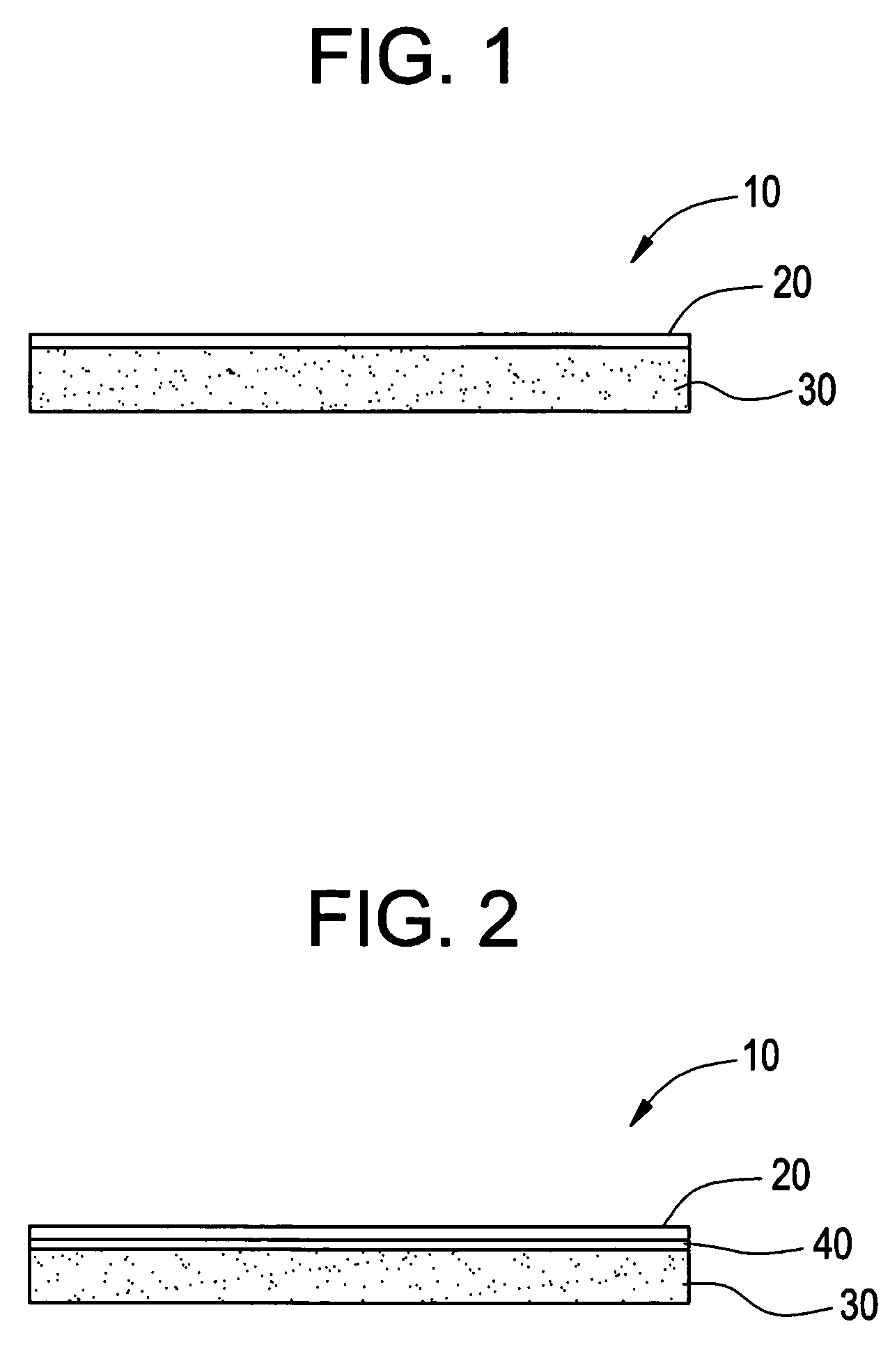

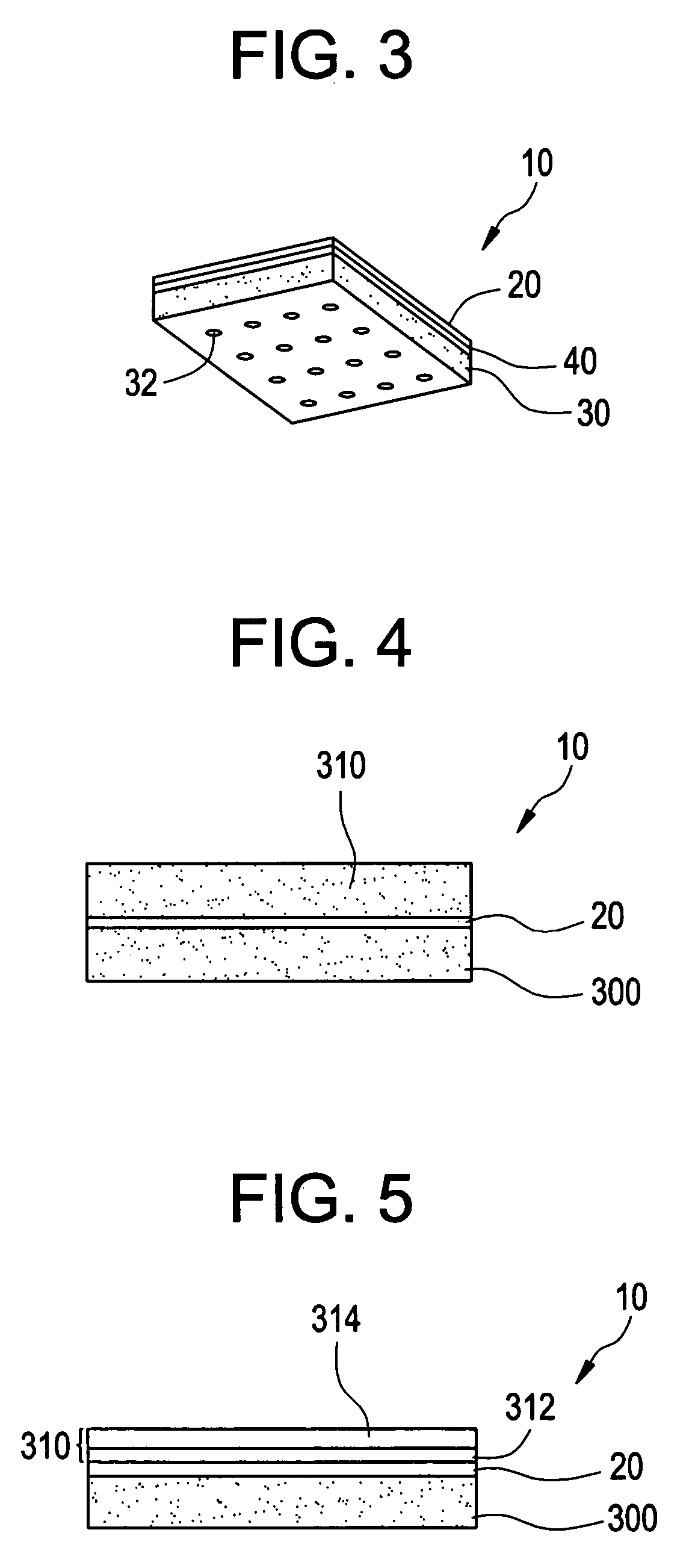

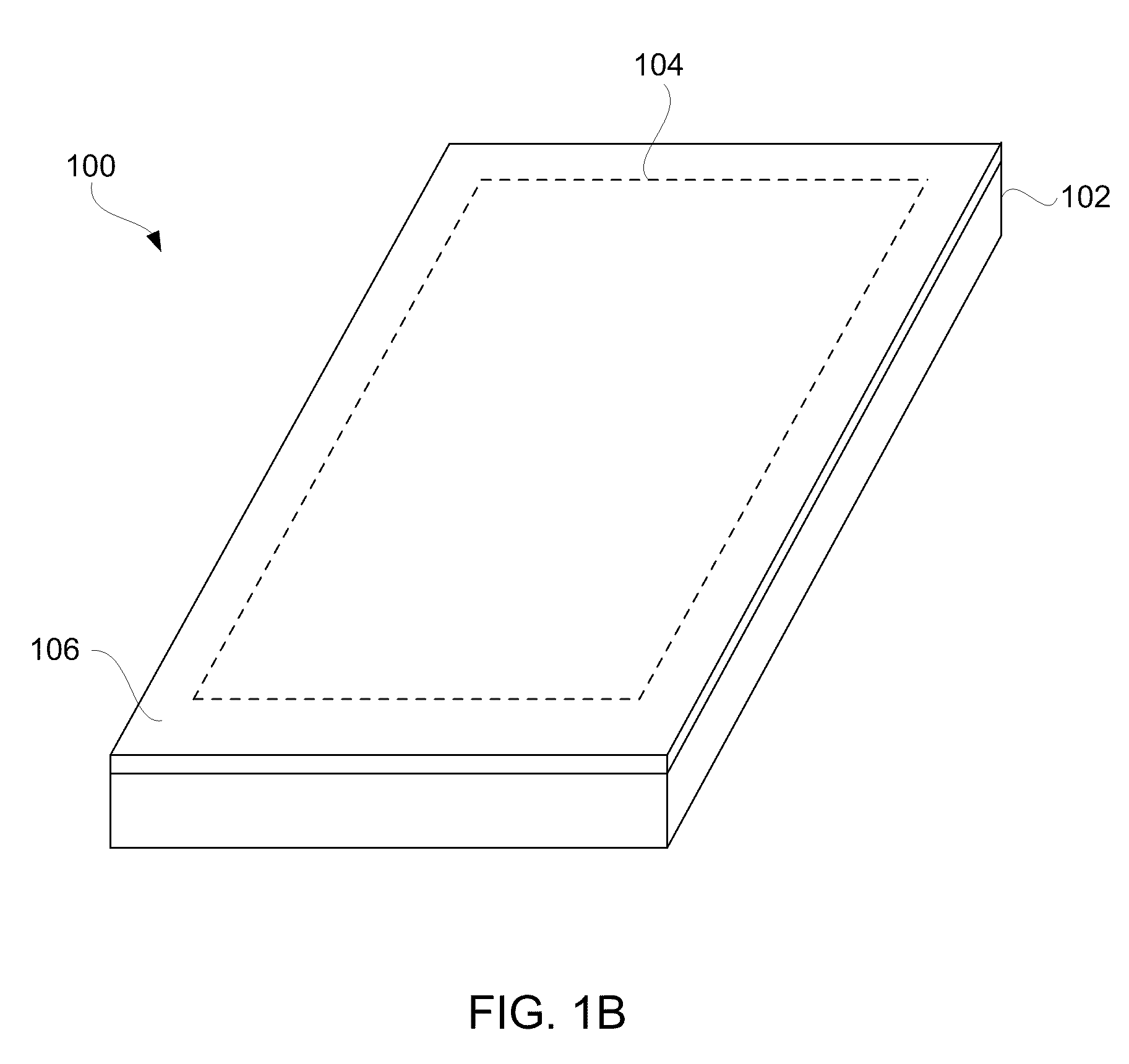

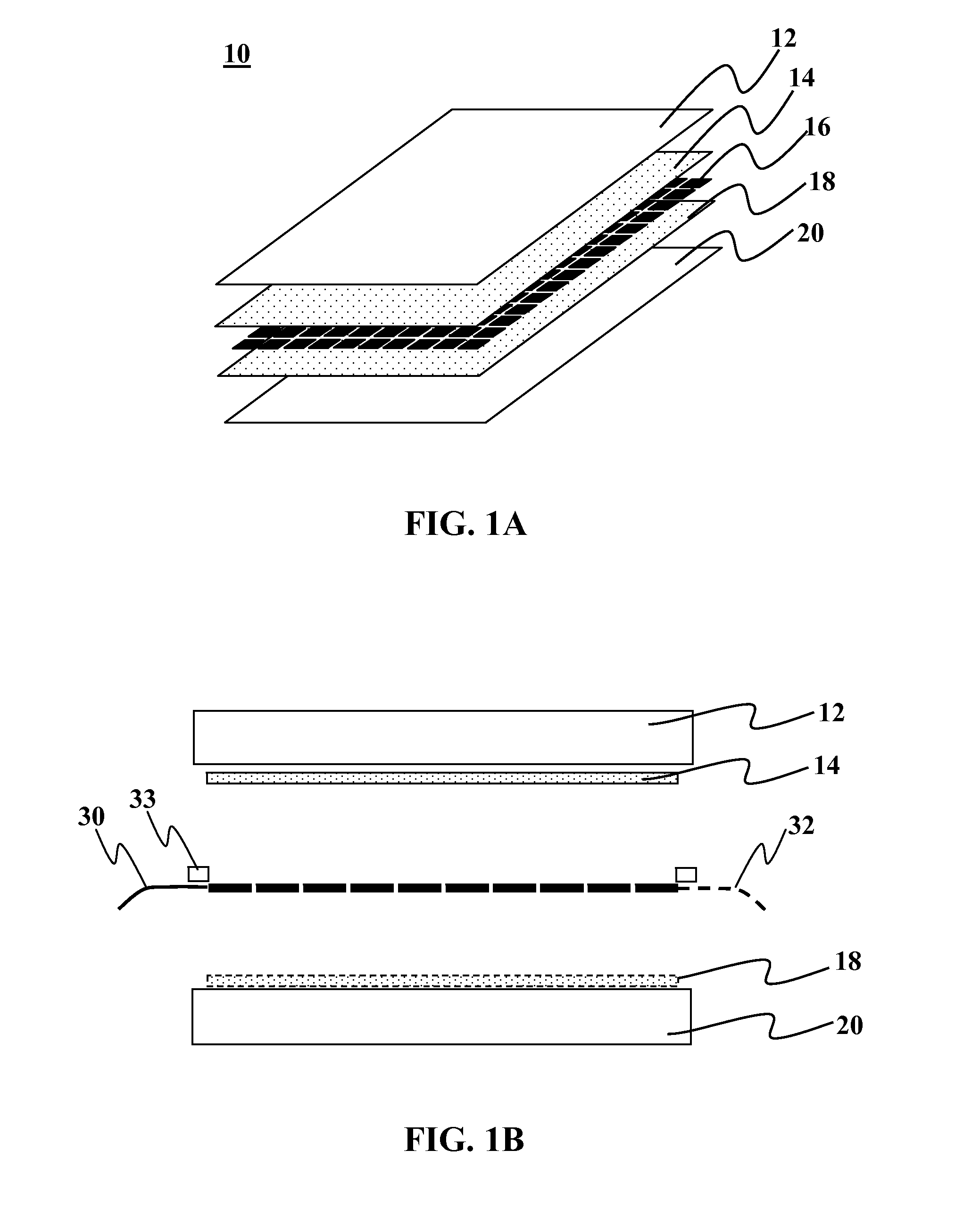

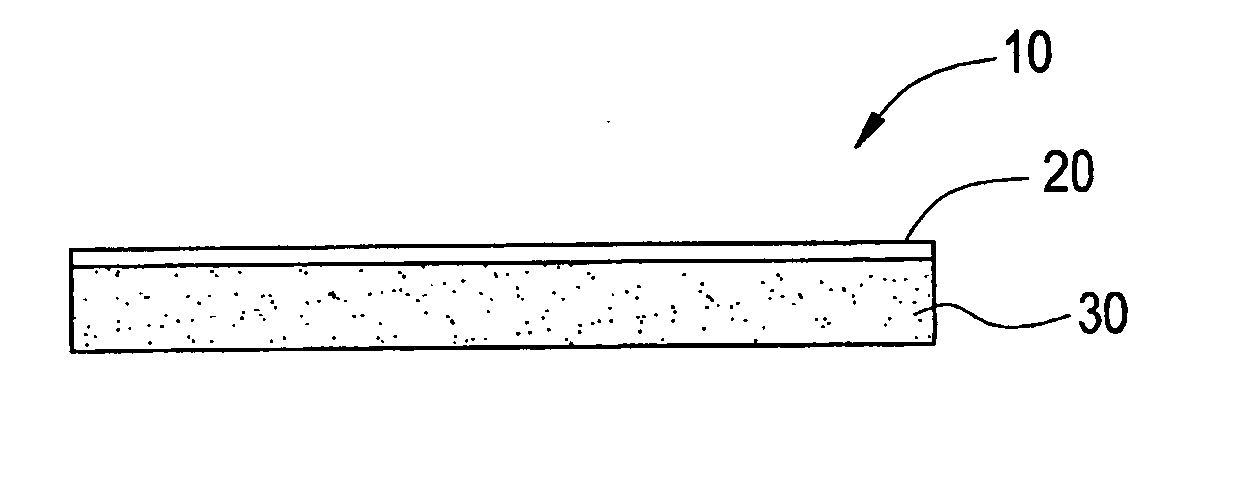

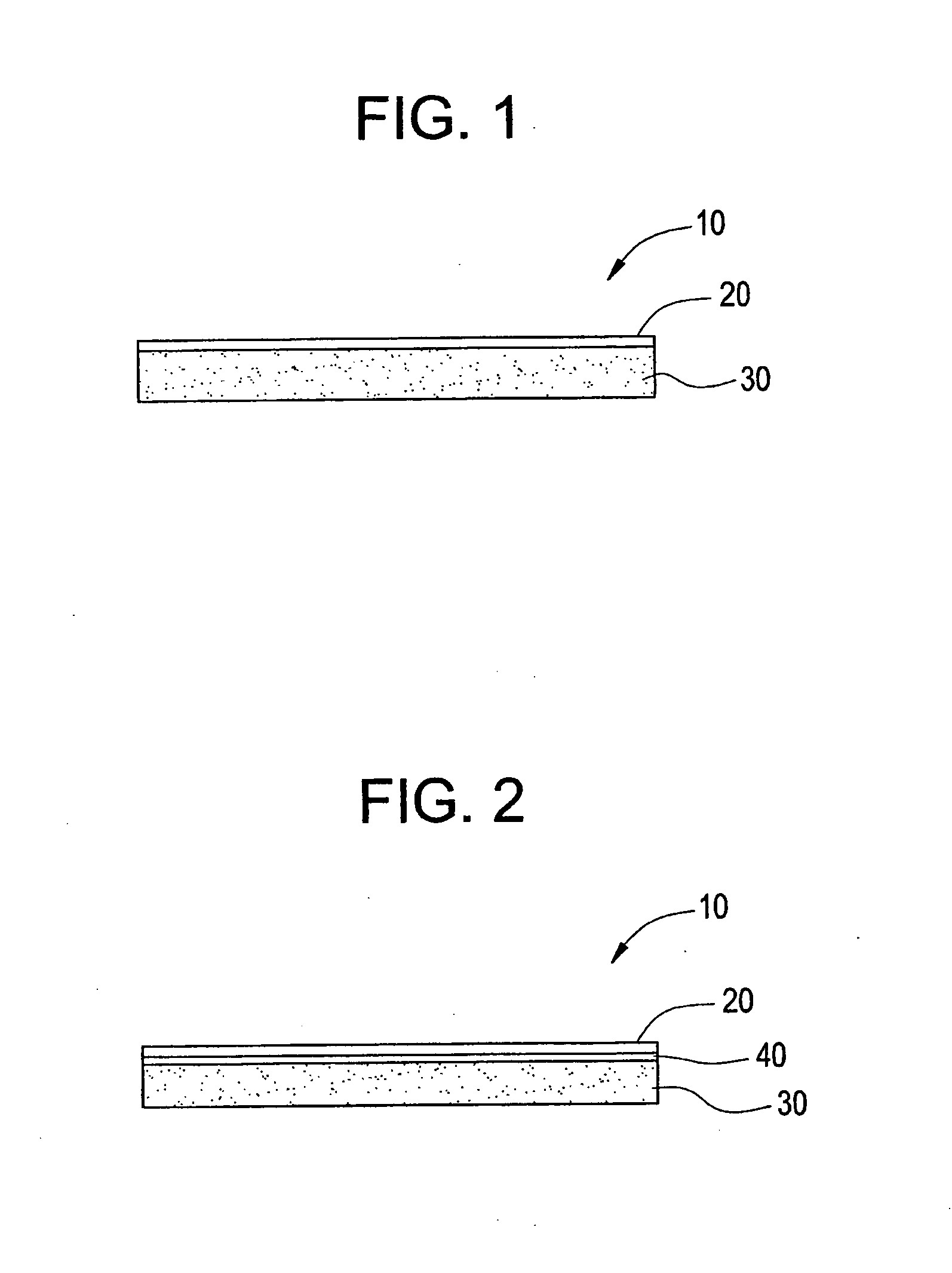

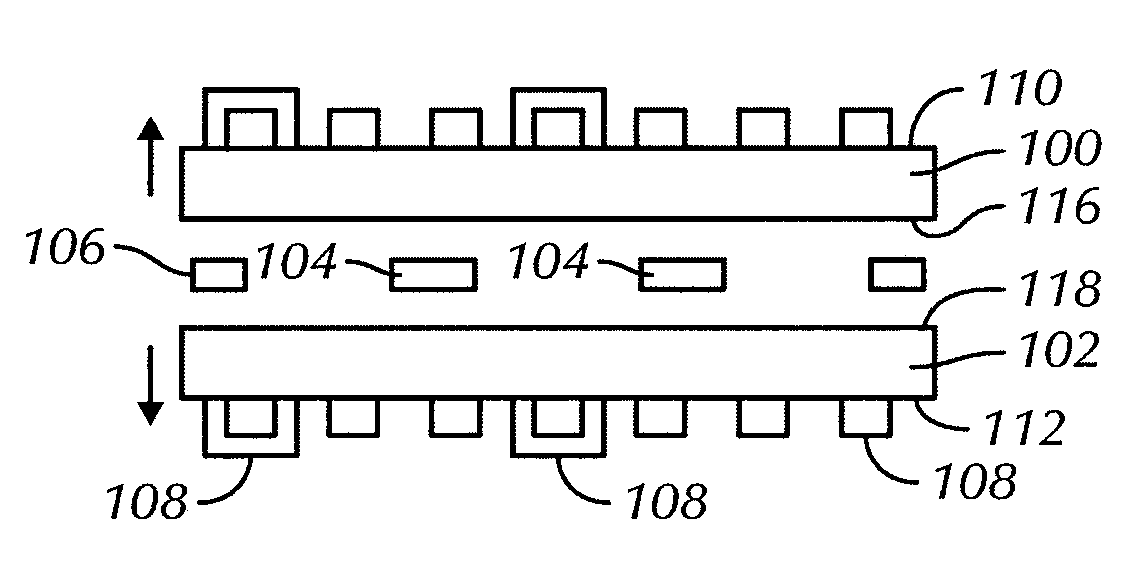

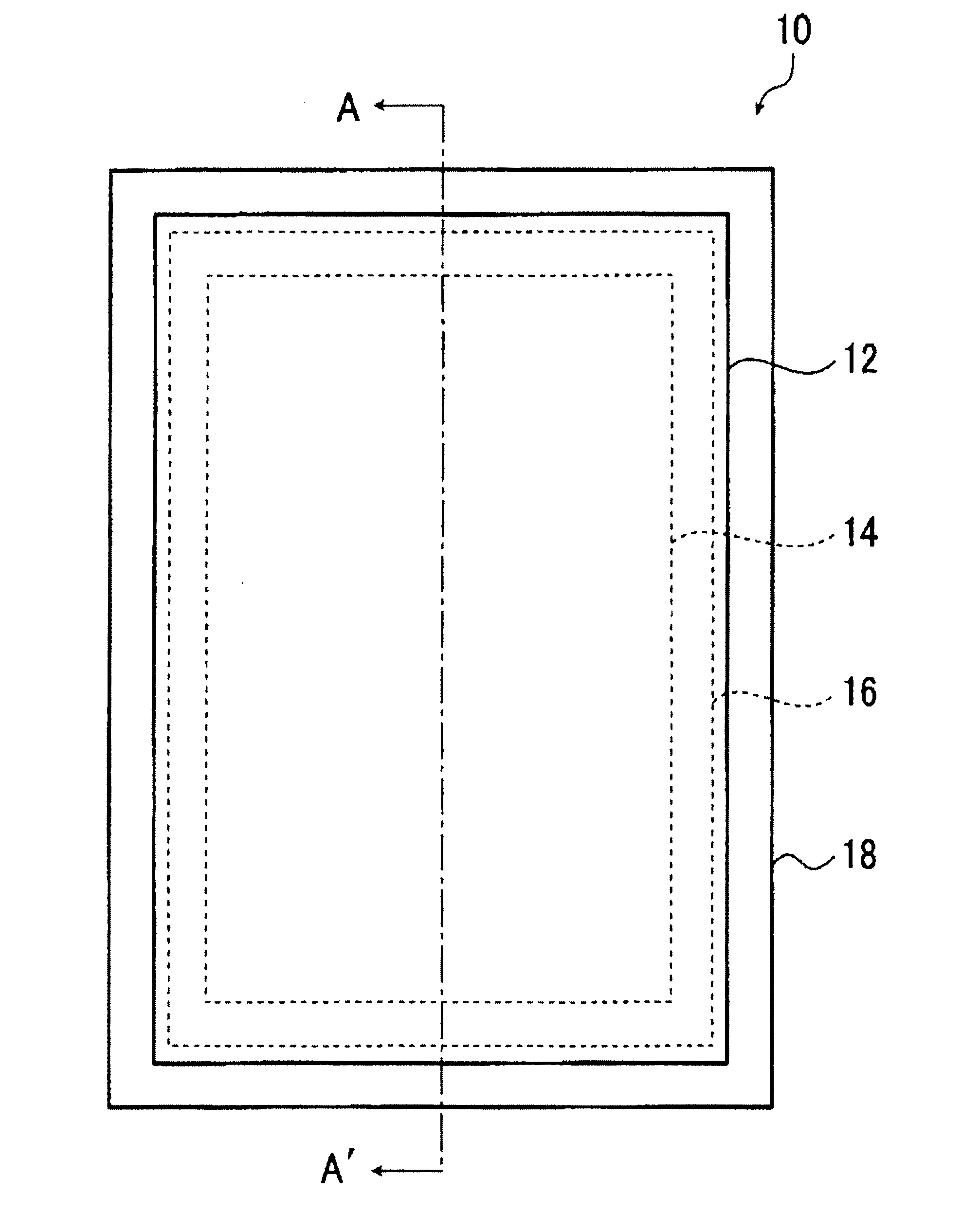

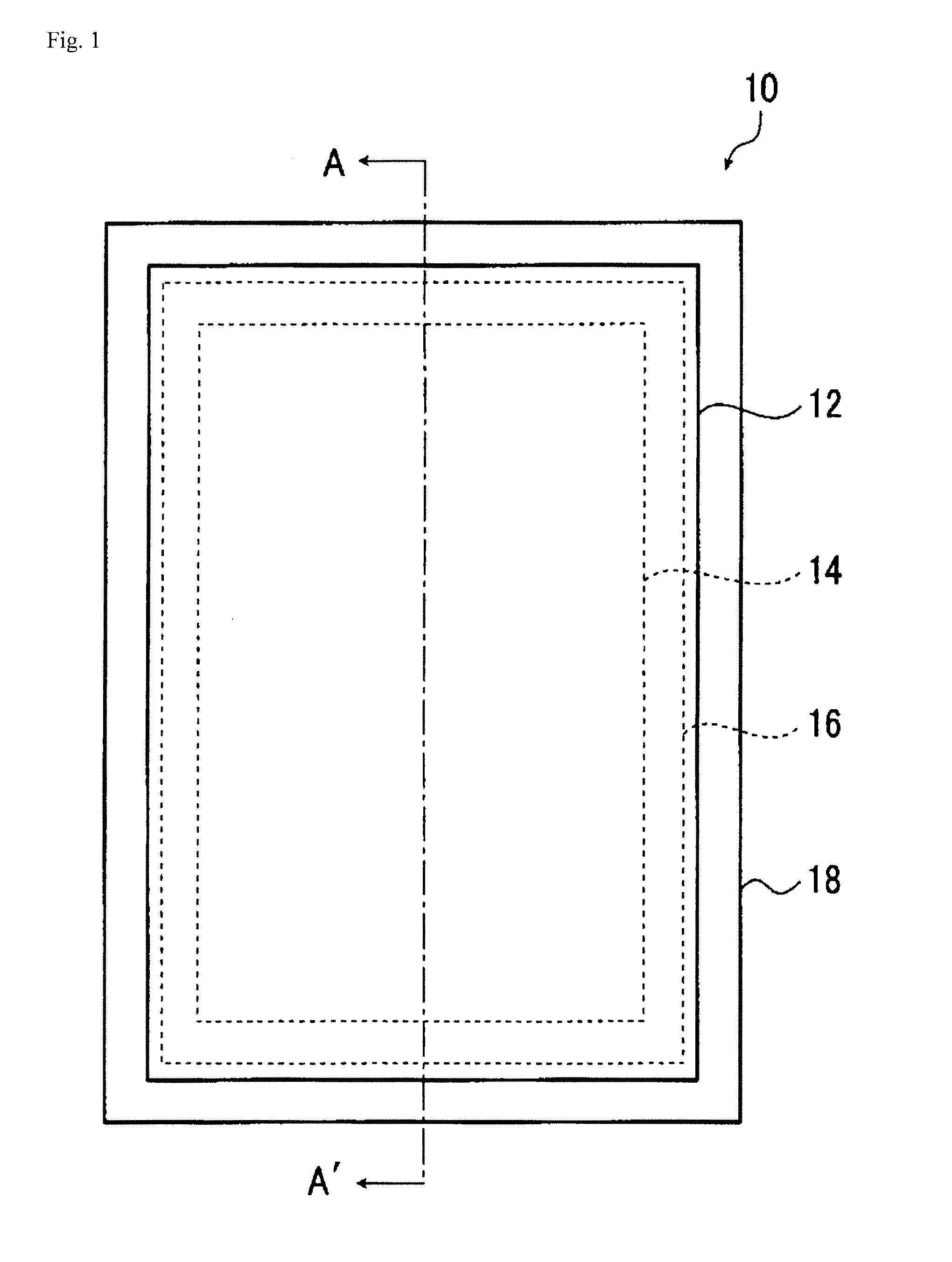

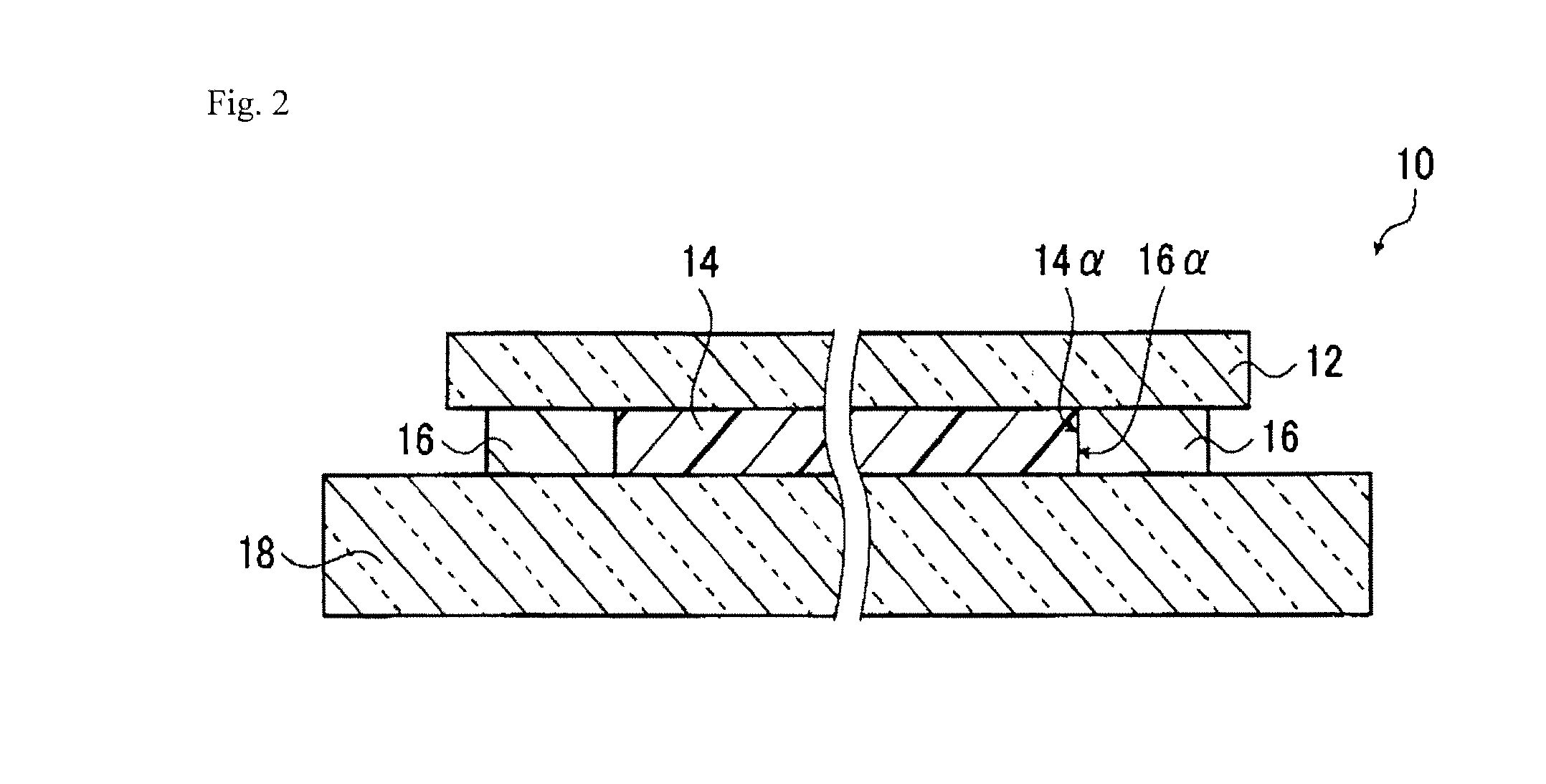

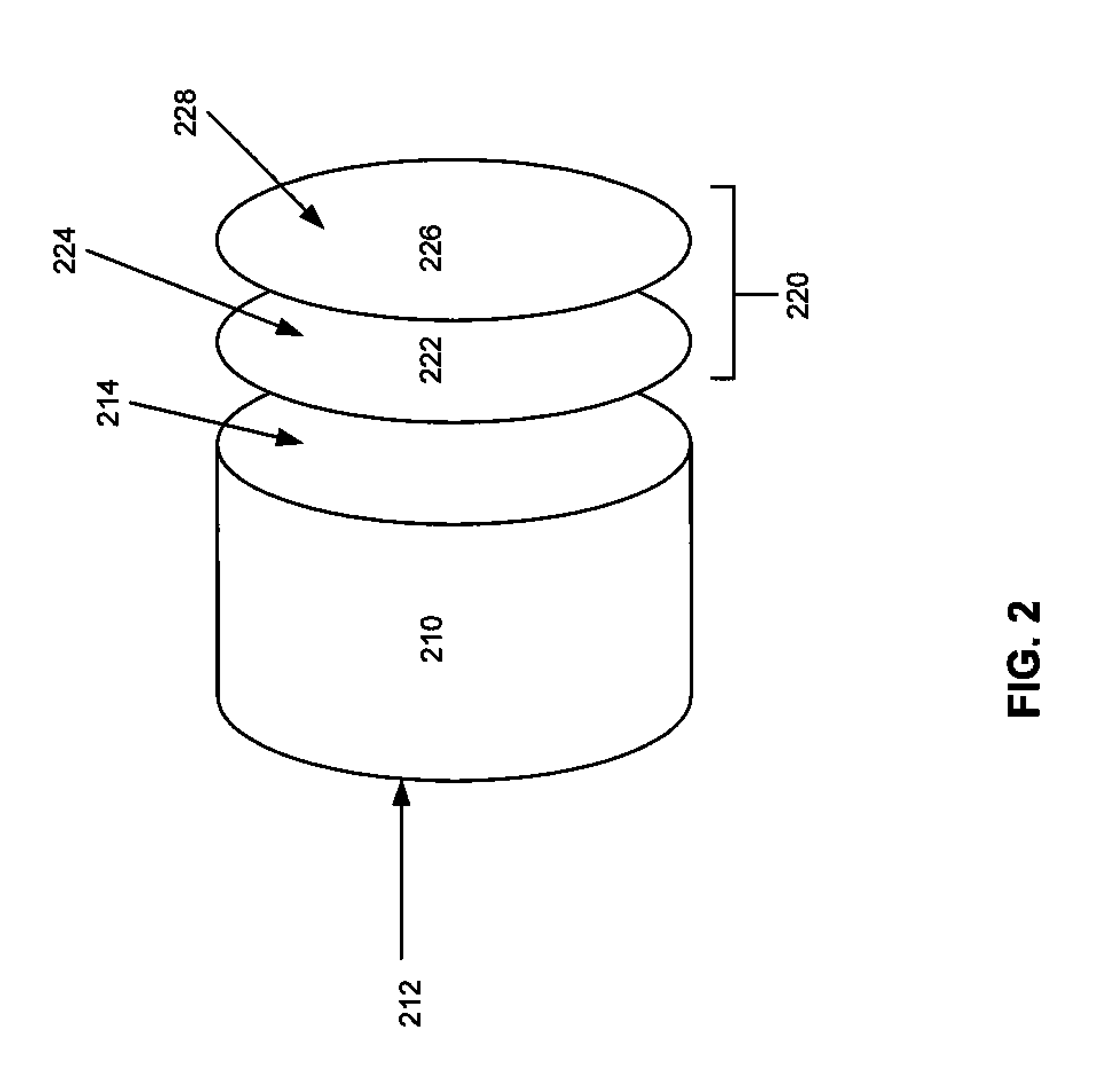

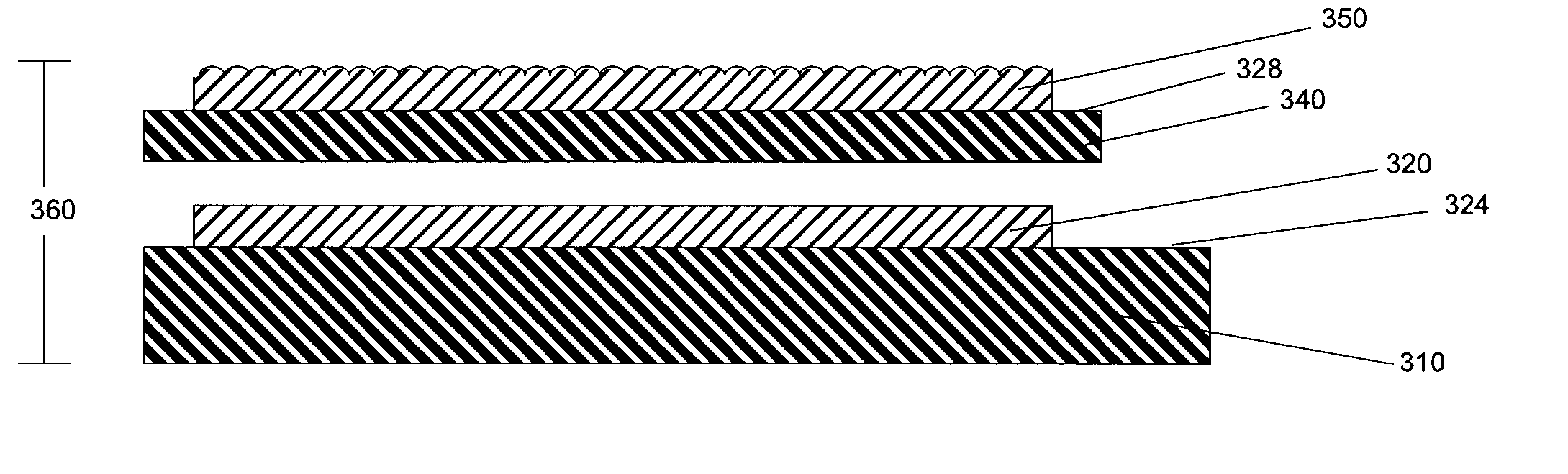

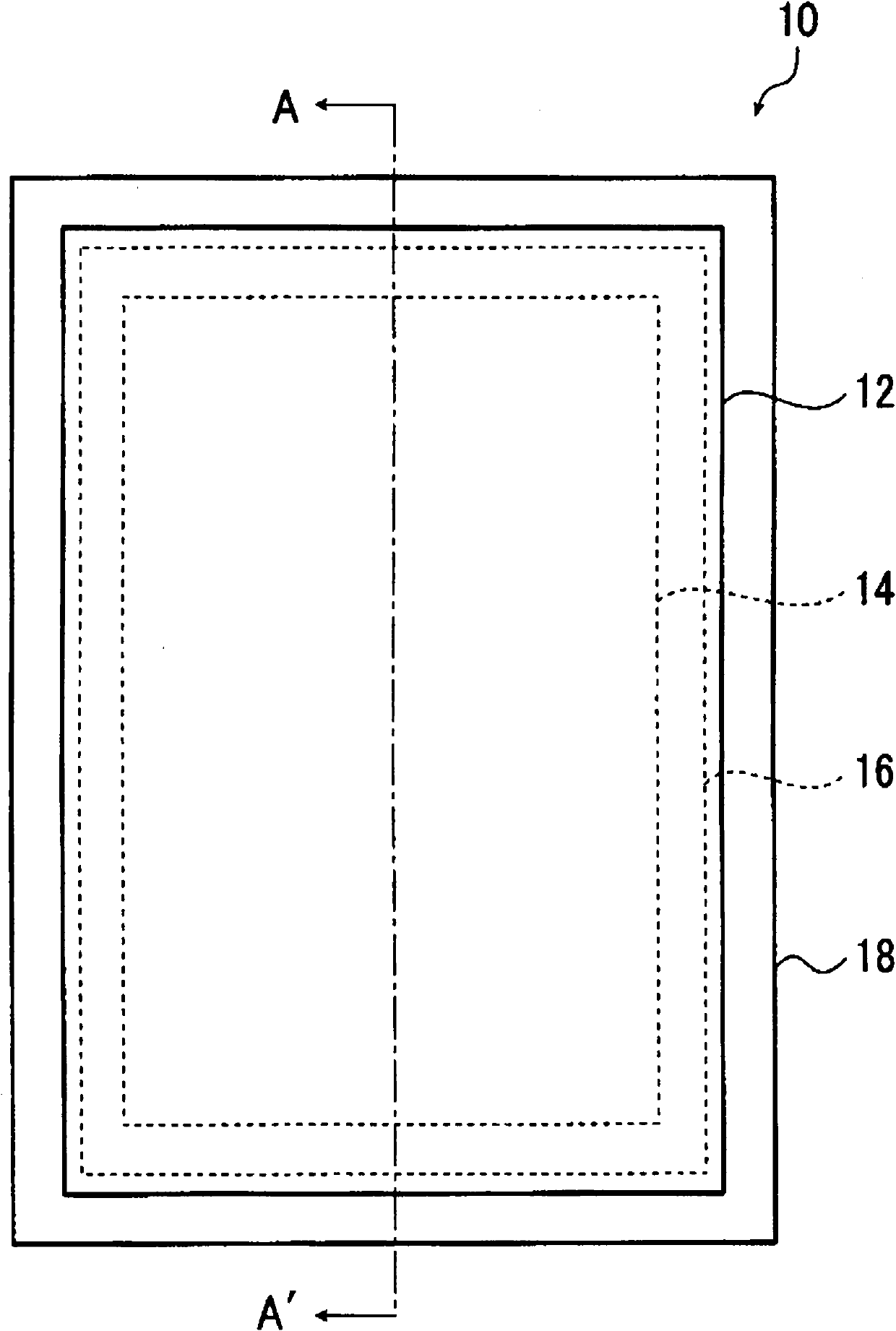

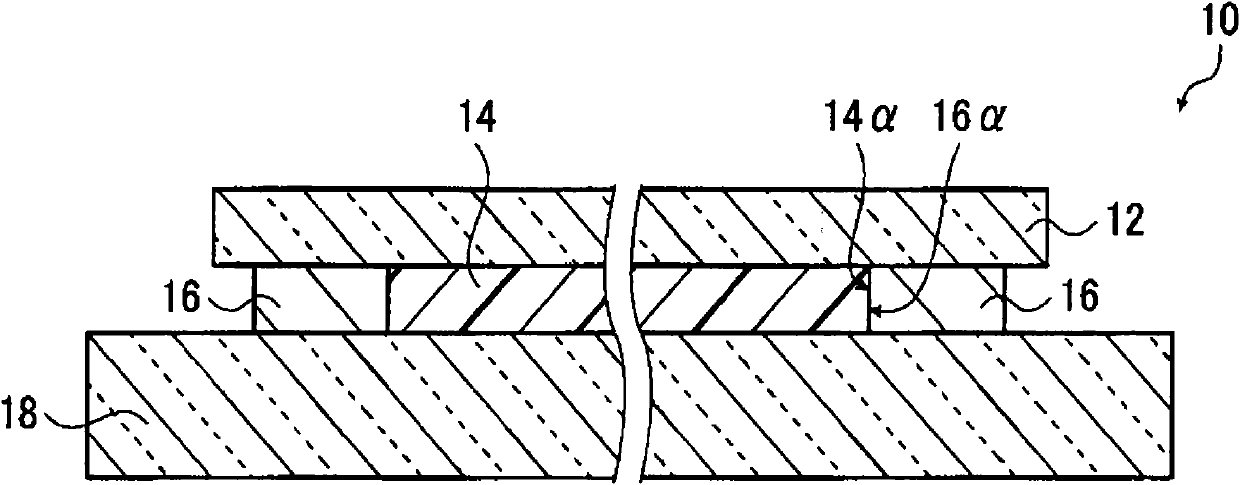

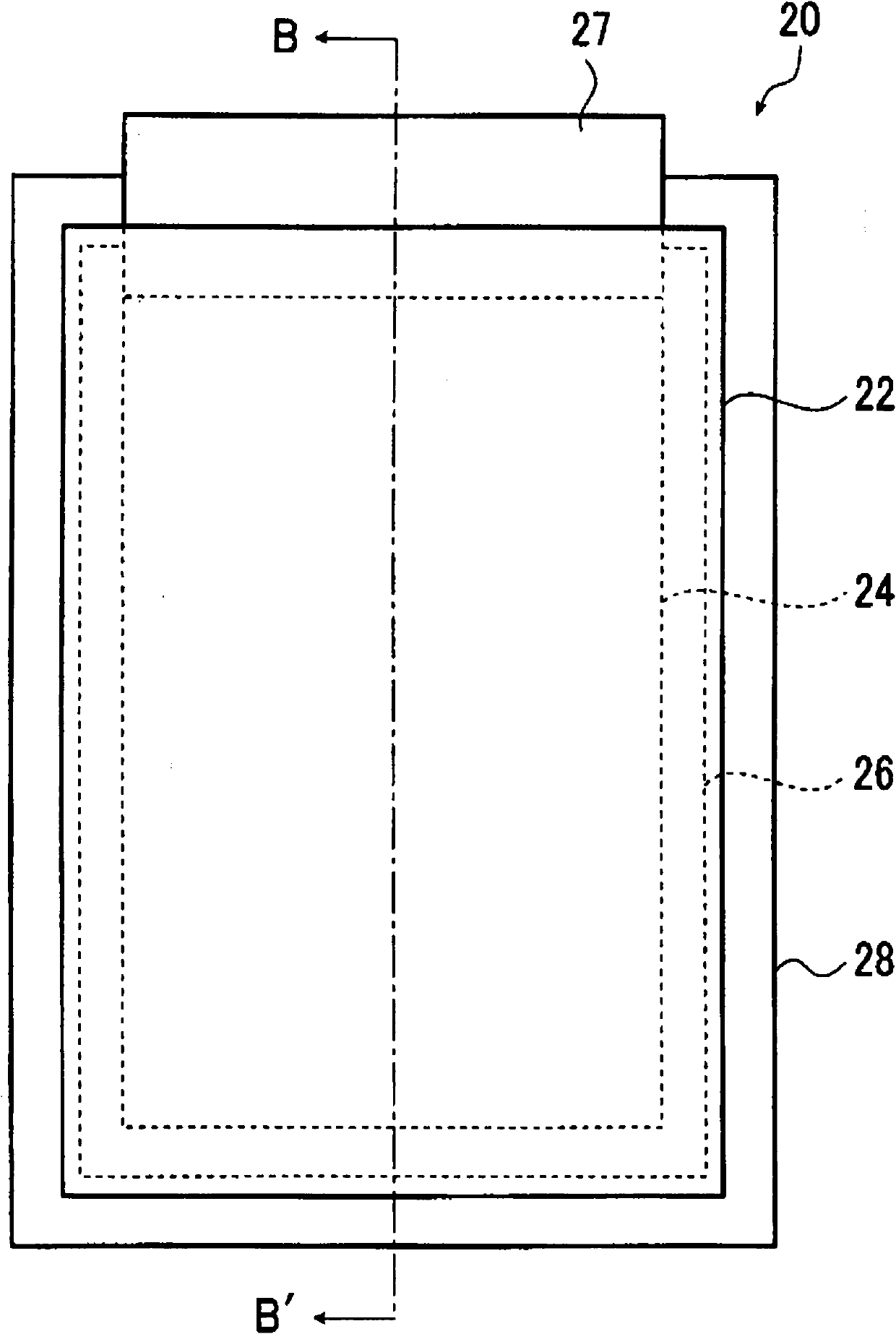

Glass laminate, display panel with support, method for producing glass laminate and method for manufacturing display panel with support

InactiveUS20110026236A1InhibitionEasy to separateLamination ancillary operationsSpecial ornamental structuresThin glassFace sheet

Disclosed is a glass laminate comprising a thin glass substrate having a first main surface and a second main surface, a supporting glass substrate having a first main surface and a second main surface, and a resin layer and an outer frame layer arranged between the thin glass substrate and the supporting glass substrate. The resin layer is fixed to the first main surface of the supporting glass substrate and is in close contact with the first main surface of the thin glass substrate, while having easy releasability from the first main surface of the thin glass substrate. The outer frame layer surrounds the resin layer on the first main surface of the supporting glass substrate so that the outside air does not come into contact with the resin layer.

Owner:ASAHI GLASS CO LTD

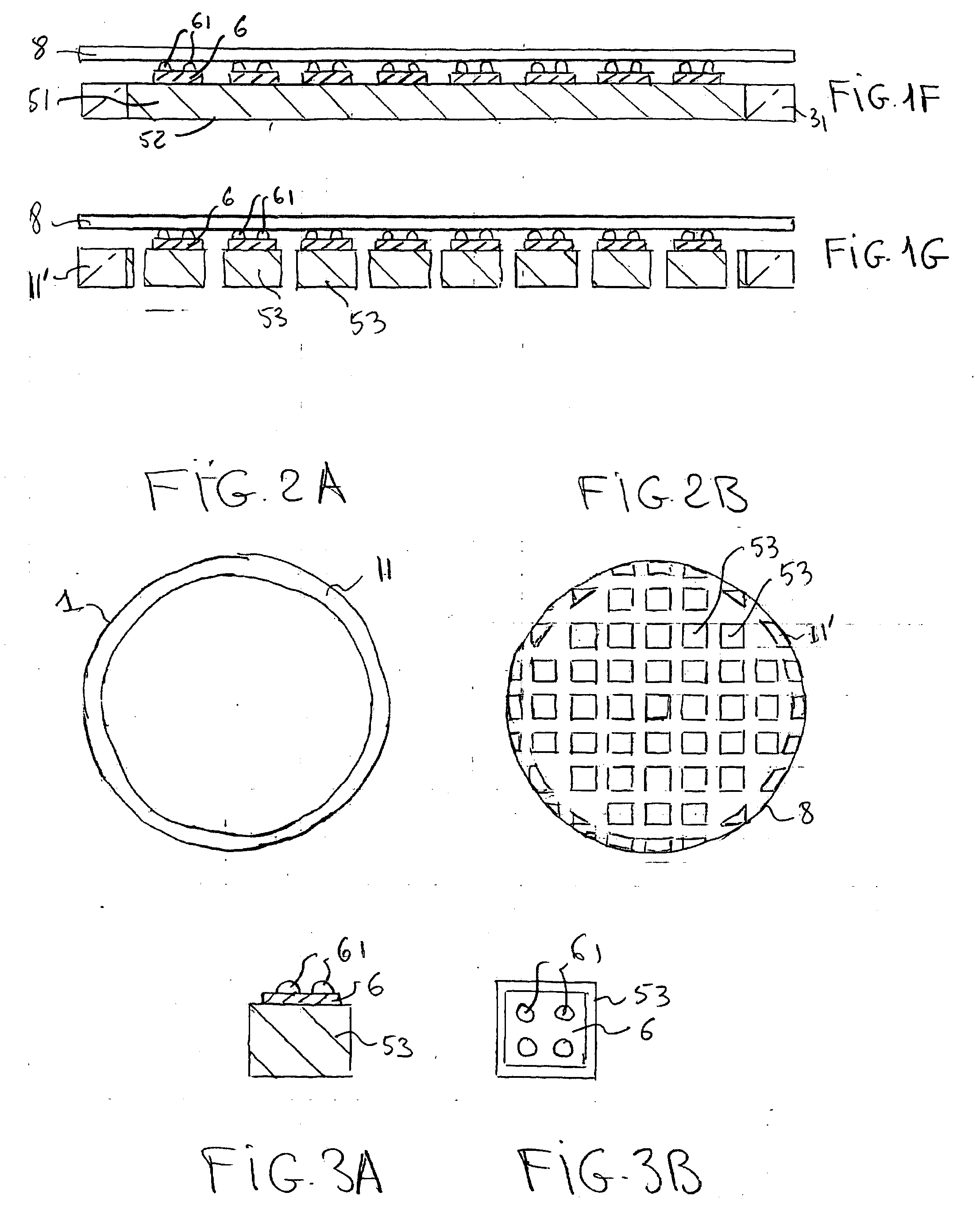

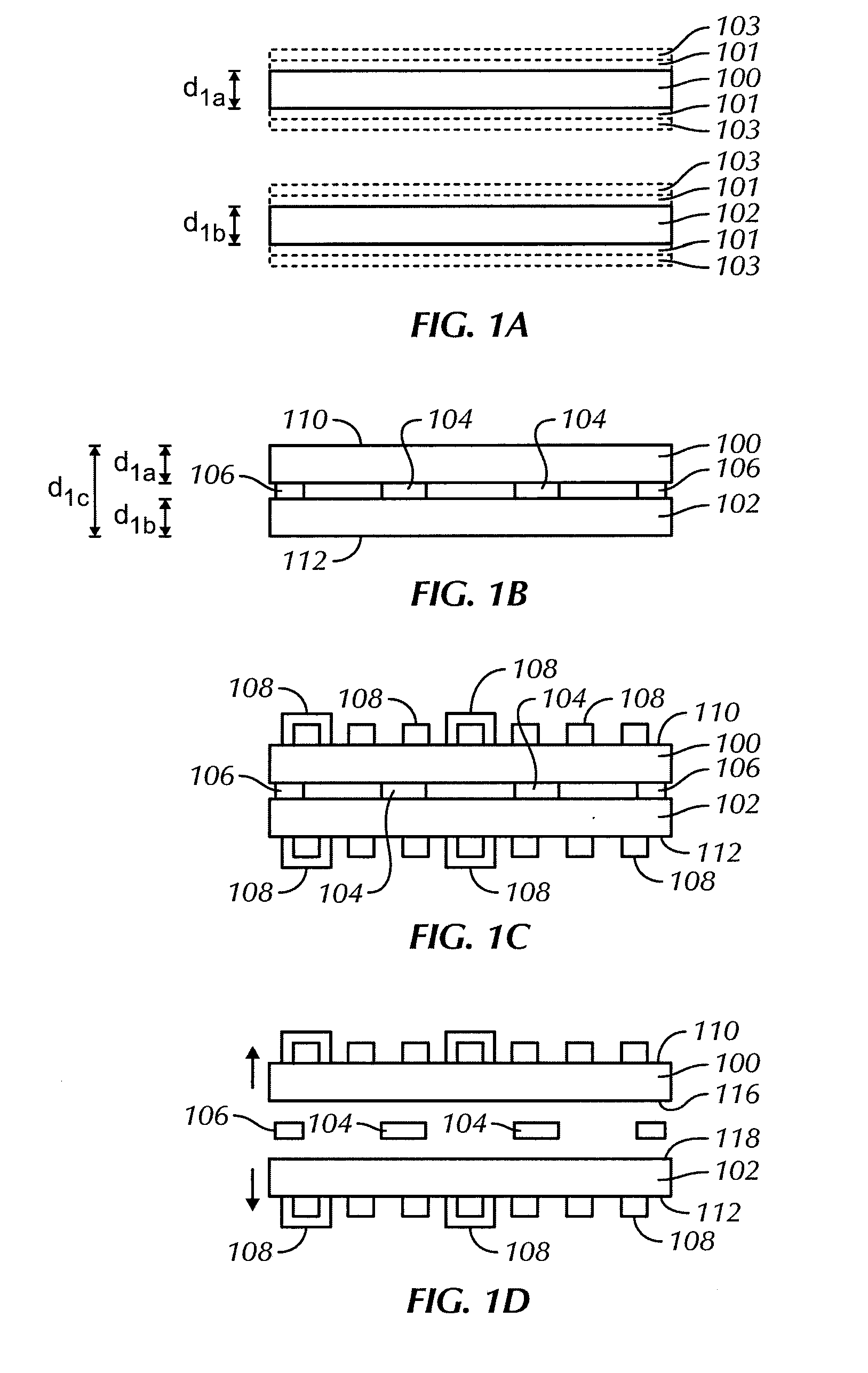

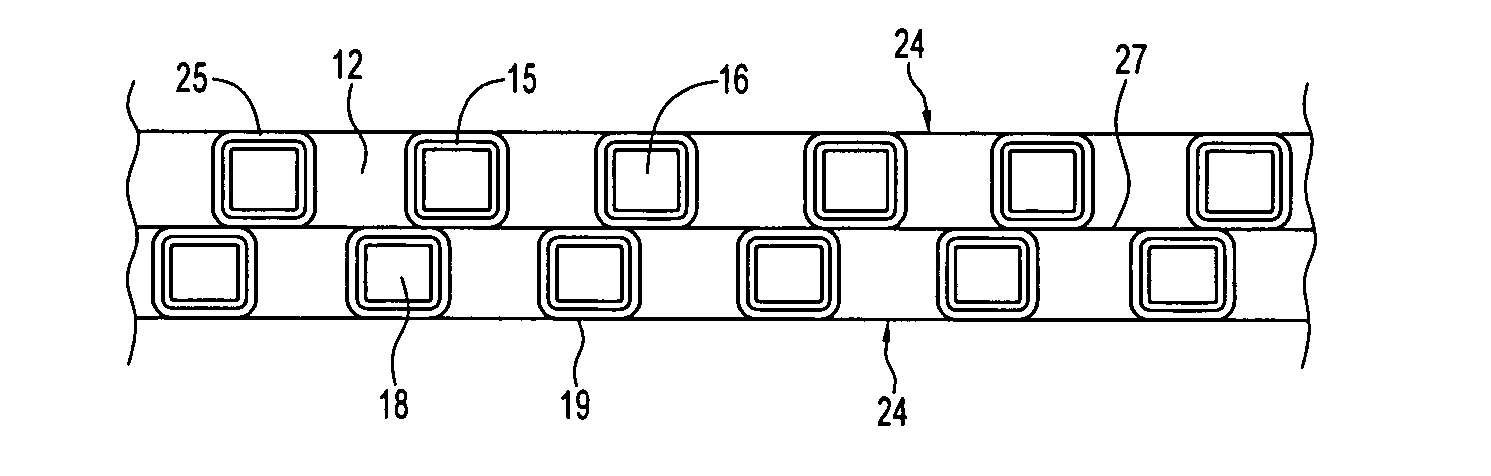

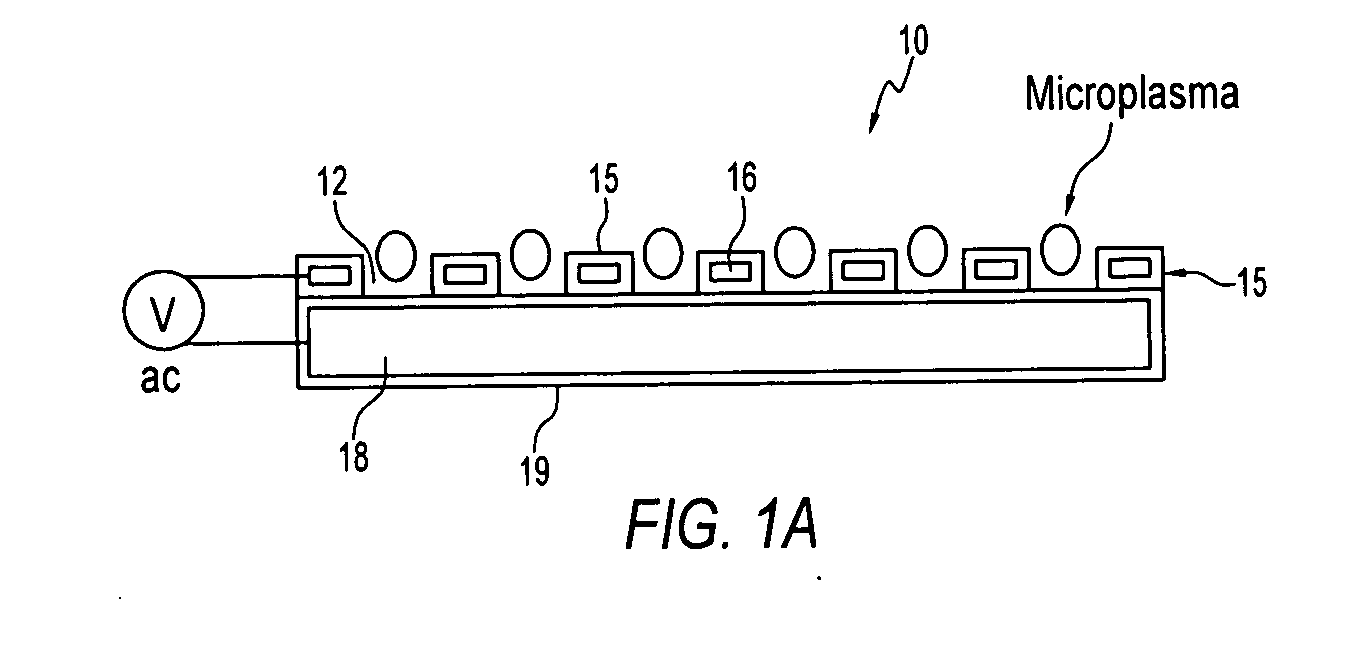

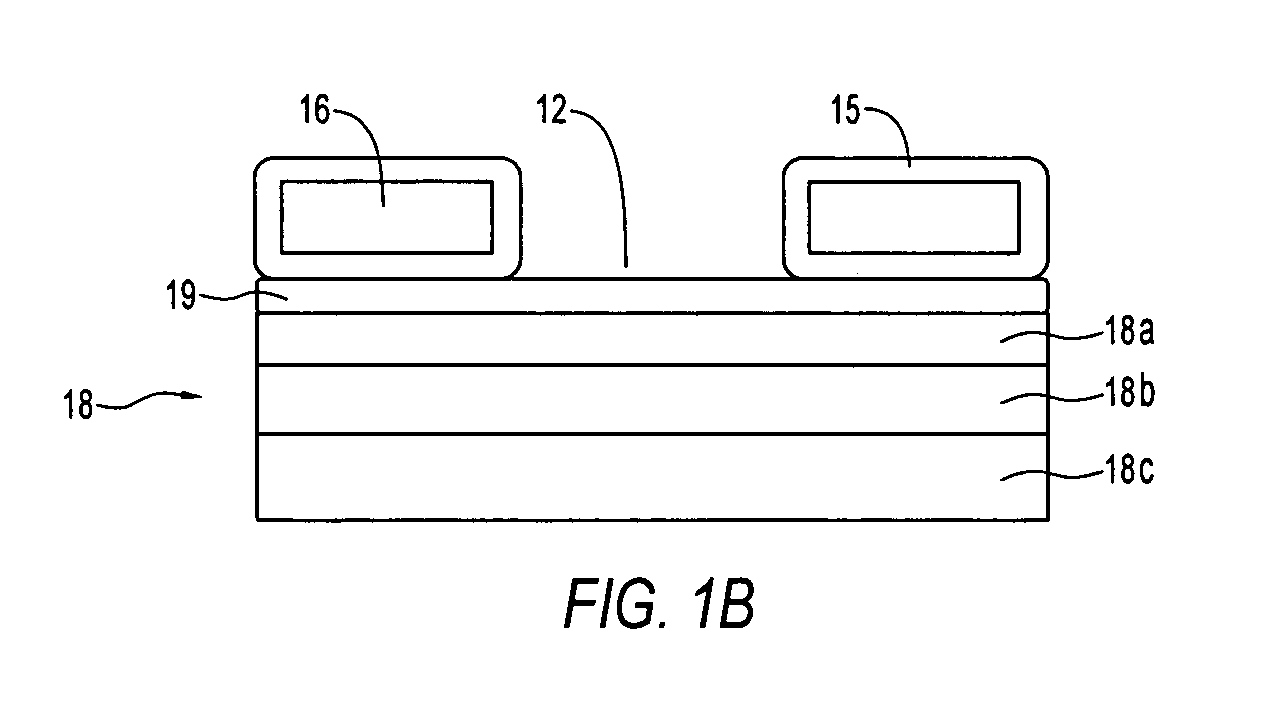

Arrays of microcavity plasma devices with dielectric encapsulated electrodes

ActiveUS20070170866A1Cheap to makeAlternating current plasma display panelsShieldingDielectricRoll-to-roll processing

The invention concerns microcavity plasma devices and arrays with thin foil metal electrodes protected by metal oxide dielectric. Devices of the invention are amenable to mass production techniques, and may, for example, be fabricated by roll to roll processing. Exemplary devices of the invention are flexible. Embodiments of the invention provide for large arrays of microcavity plasma devices that can be made inexpensively. The structure of preferred embodiment microcavity plasma devices of the invention is based upon thin foils of metal that are available or can be produced in arbitrary lengths, such as on rolls. In a device of the invention, a pattern of microcavities is produced in a metal foil. Oxide is subsequently grown on the foil and within the microcavities (where plasma is to be produced) to protect the microcavity and electrically isolate the foil. A second metal foil is also encapsulated with oxide and is bonded to the first encapsulated foil. For preferred embodiment microcavity plasma device arrays of the invention, no particular alignment is necessary during bonding of the two encapsulated foils. A thin glass layer or vacuum packaging, for example, is able to seal the discharge medium into the array.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

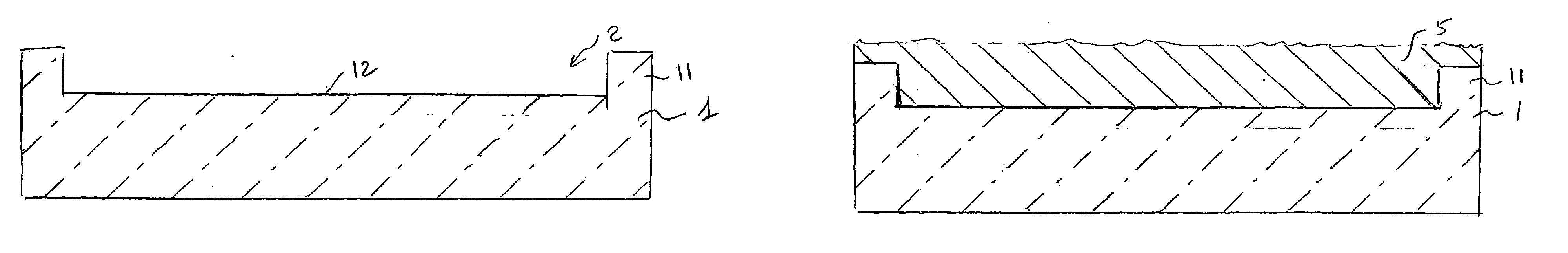

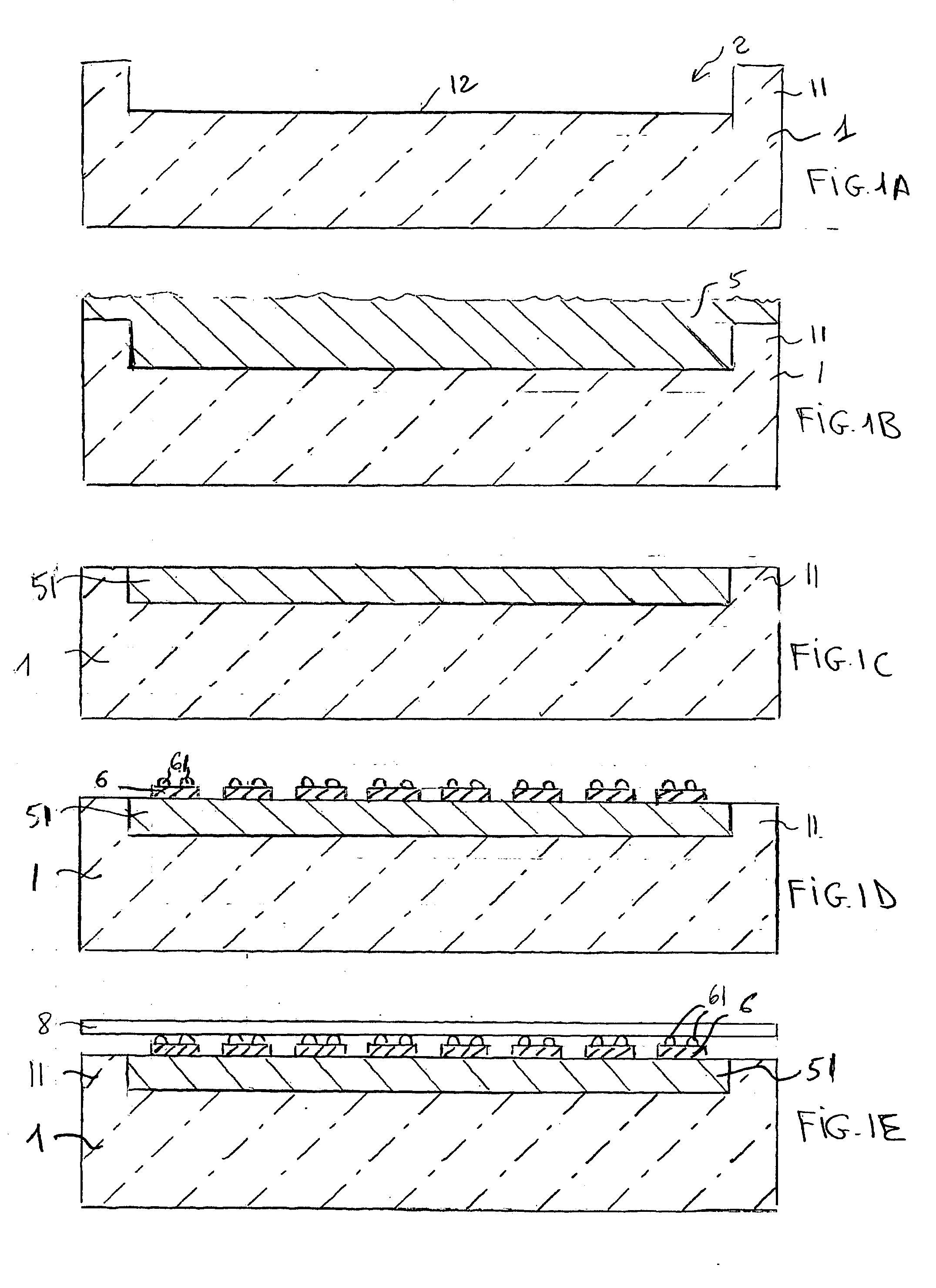

Method for fabricating thin sheets of glass

Fabrication of thin sheets of glass or other substrate material for use in devices such as touch sensor panels is disclosed. A pair of thick glass sheets, typically with thicknesses of 0.5 mm or greater each, may each be patterned with thin film on a surface, sealed together to form a sandwich with the patterned surfaces facing each other and spaced apart by removable spacers, either or both thinned on their outside surfaces to thicknesses of less than 0.5 mm each, and separated into two thin glass sheets. A single thick glass sheet, typically with a thickness of 0.5 mm or greater, may be patterned, covered with a protective layer over the pattern, thinned on its outside surface to a thickness of less than 0.5 mm, and the protective layer removed. This thinness of less than 0.5 mm may be accomplished using standard LCD equipment, despite the equipment having a sheet minimum thickness requirement of 0.5 mm.

Owner:APPLE INC

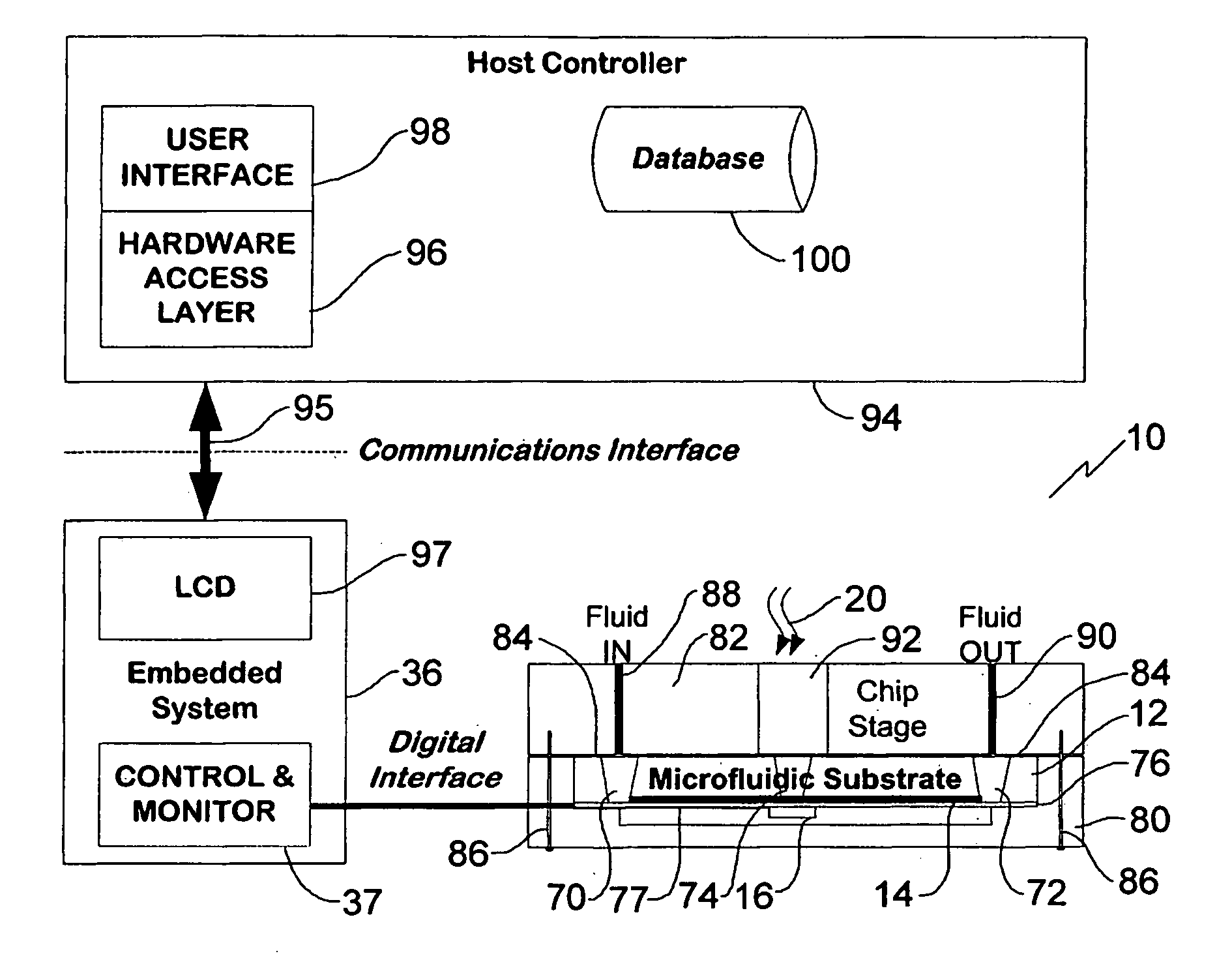

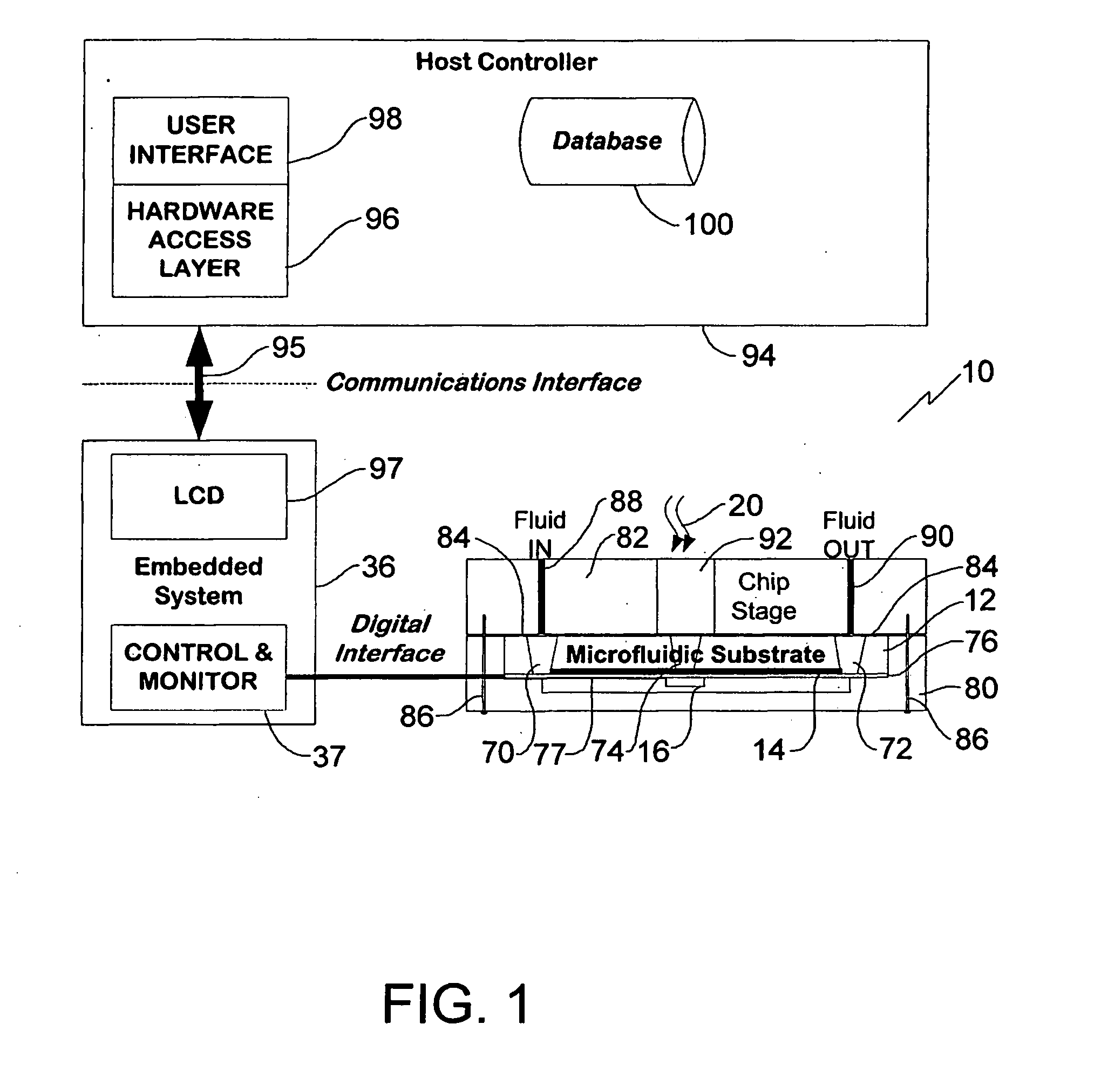

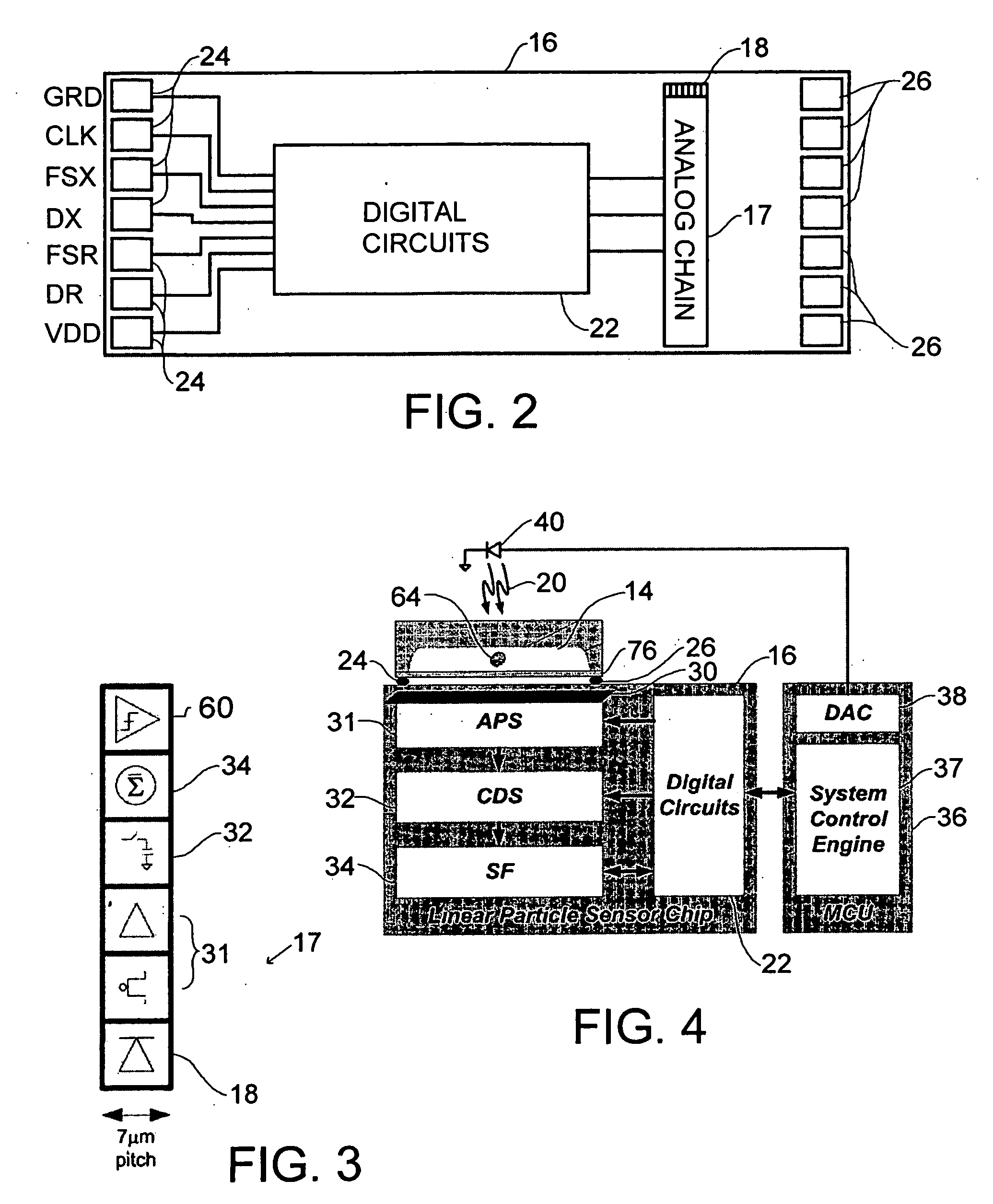

Cytometer

A real-time digital cytometer on a chip system utilizing a custom near field CMOS active pixel intelligent sensor that is flip-chip attached to a fluidic microchannel etched in a thin glass substrate. The CMOS active pixel sensor, fabricated using a 0.18 micron process, is a mixed signal chip comprising a sixteen pixel linear adaptive spatial filter coupled to a digital serial interface. This near field hybrid digital sensor topology obviates the need for both high resolution analog to digital conversion as well as conventional microscopy for the realization of real time optical cytometry. The custom sensor based design approach affords efficient scaling into a tiled multi-channel sensing configuration. The complete system, supported by a handheld graphical user interface and control module, demonstrates a viable micro total analysis sub-system for sample preparation and analysis which can support a wide range of applications ranging from cytometry to cell growth kinetics and analysis and various forms of fluid and droplet metering on an integrated and compact microfluidic platform.

Owner:UTI LLP

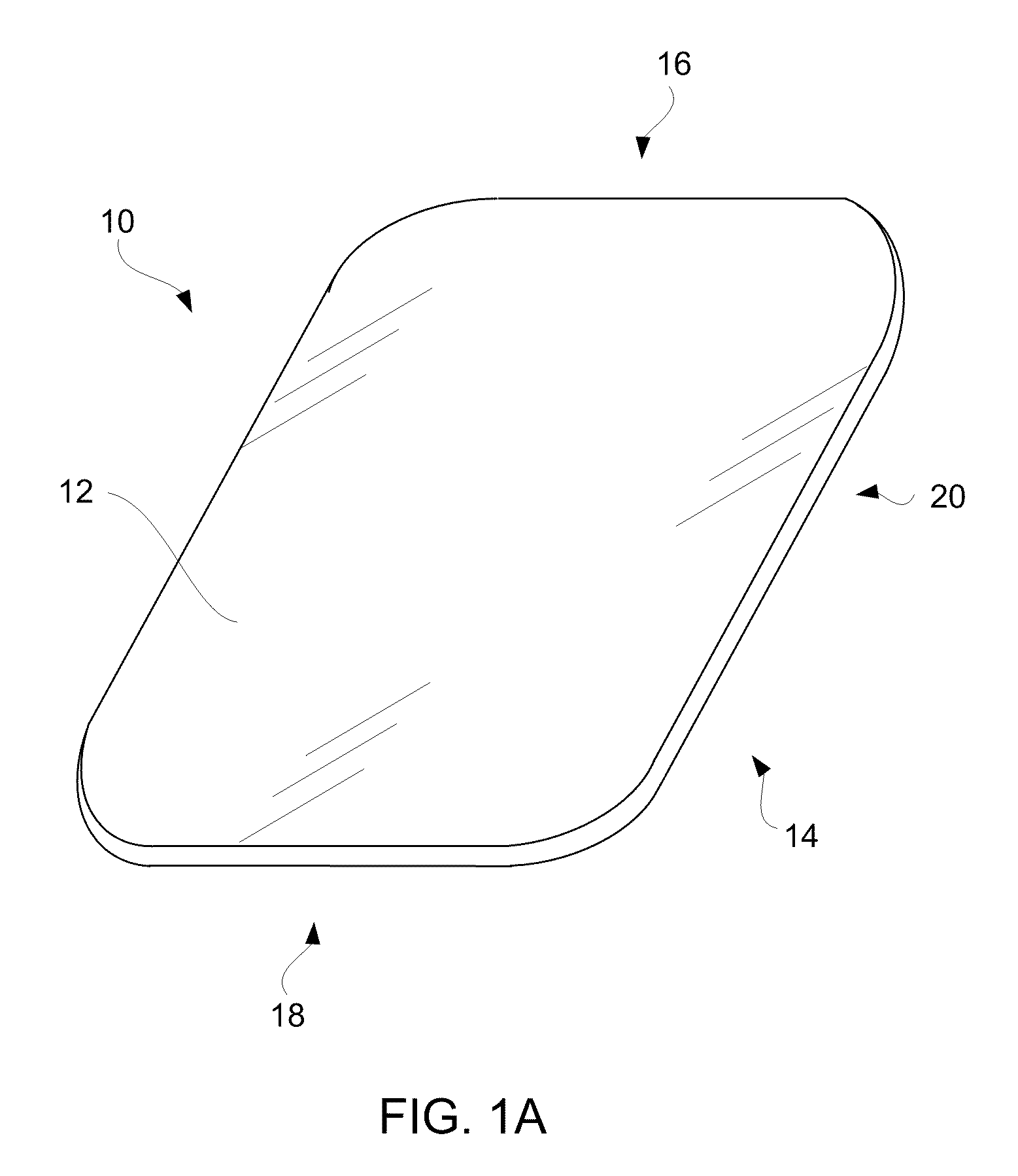

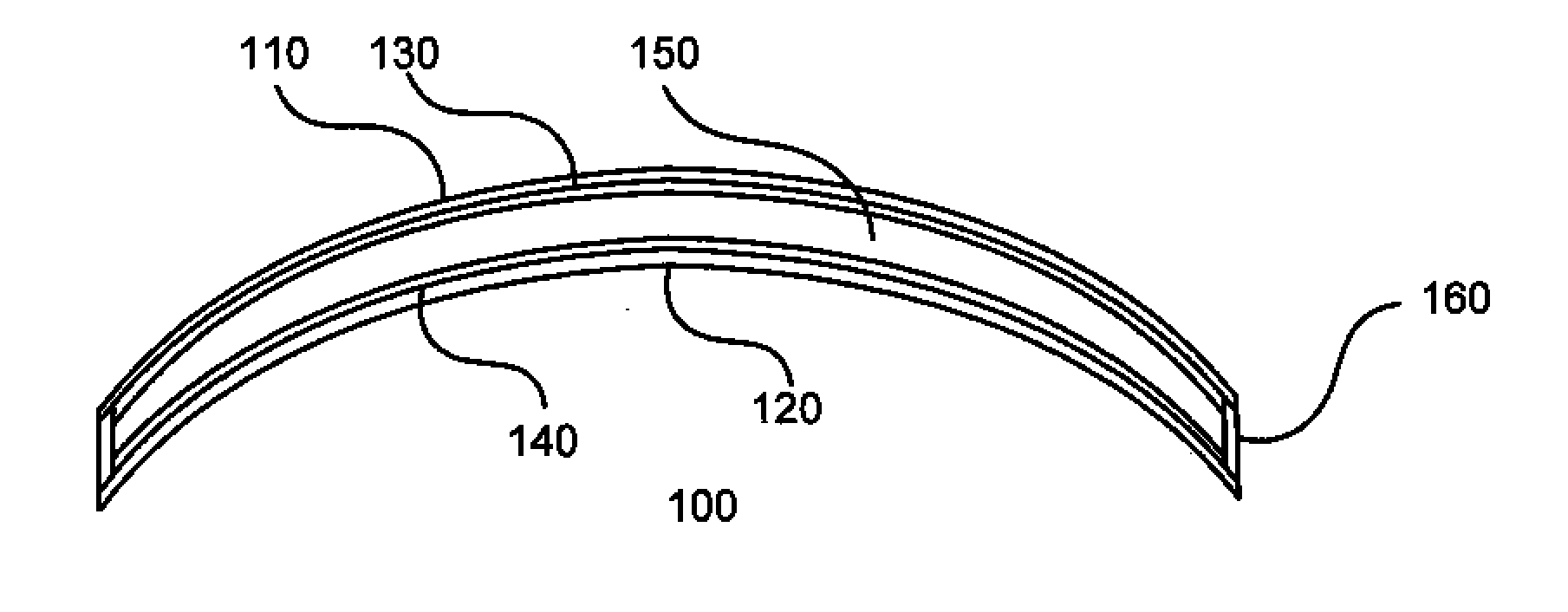

Electro-Active Lenses Including Thin Glass Substrates

ActiveUS20130027655A1Easy constructionSelf containedStatic indicating devicesNon-linear opticsOptical powerEngineering

An electro-active optical cell is described including a layer of electro-active material, a front glass substrate member, and a back glass substrate member. The optical cell is capable of independently providing changeable optical power with the application of an electrical potential. The cell is also configured to be affixed to an external surface of a plastic substrate and to provide the changeable optical power, with at least one of the front substrate or the back substrate of the optical cell being an outermost optical layer. The layer of electro-active material may have a thickness less than 10 μm, and the glass substrate members may each have a thickness approximately between 20 μm and 500 μm.

Touch screen panel and fabrication method thereof

InactiveUS20120146922A1Increasing the thicknessStay flexibleLine/current collector detailsInput/output processes for data processingEngineeringTouchscreen

A flexible and very thin touch screen panel is implemented by forming sensing patterns as touch sensors on a first surface of a flexible thin glass substrate and by forming a supporting film on a second surface of the glass surface. A method of fabricating a touch screen panel for securing the strength of a unit cell touch screen panel includes forming sensing patterns as touch sensors in every unit cell touch screen panel on a mother glass substrate, etching the glass substrate in the thickness direction, forming a supporting film under the glass substrate, and by cutting the glass substrate and the supporting film cell by cell using dual cutting.

Owner:SAMSUNG DISPLAY CO LTD

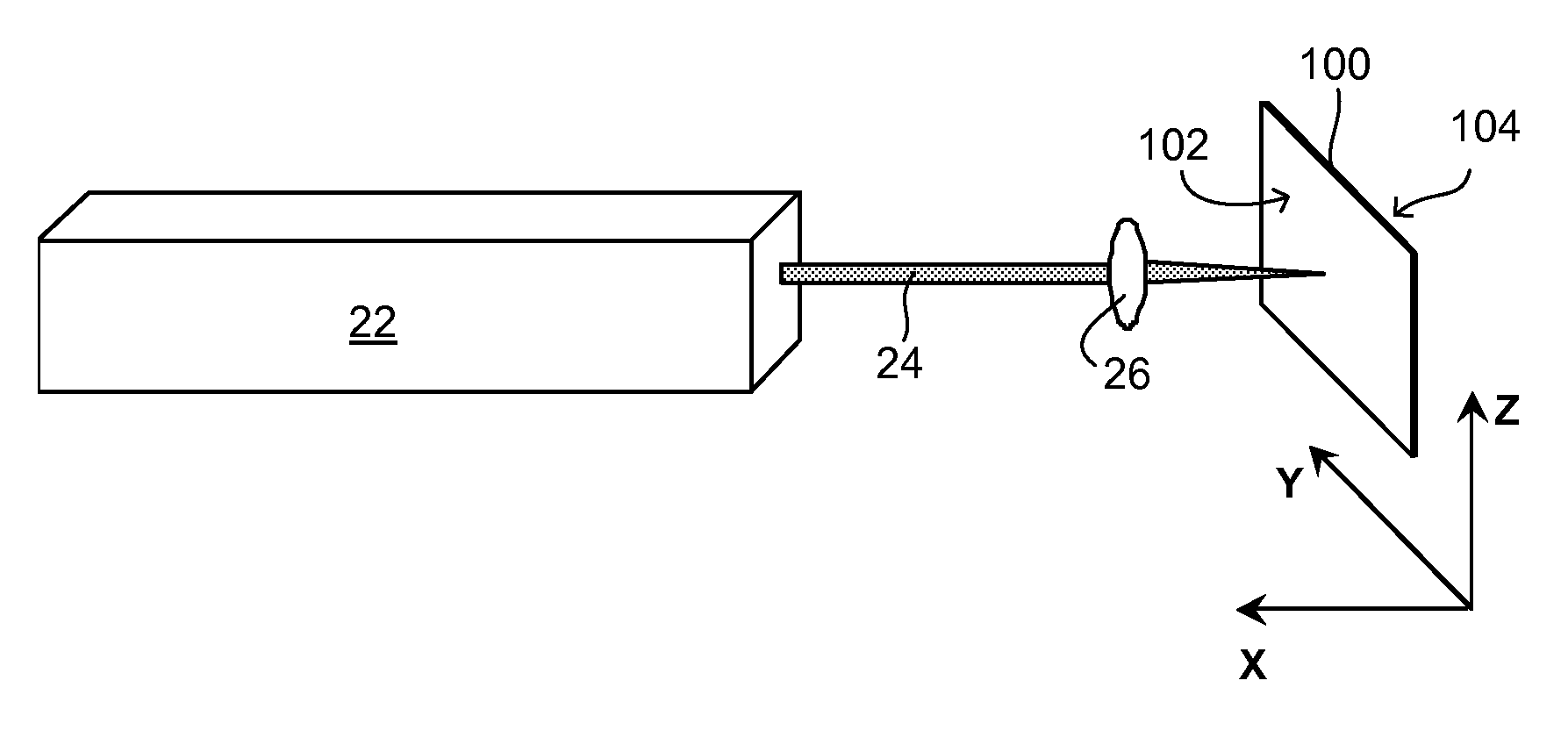

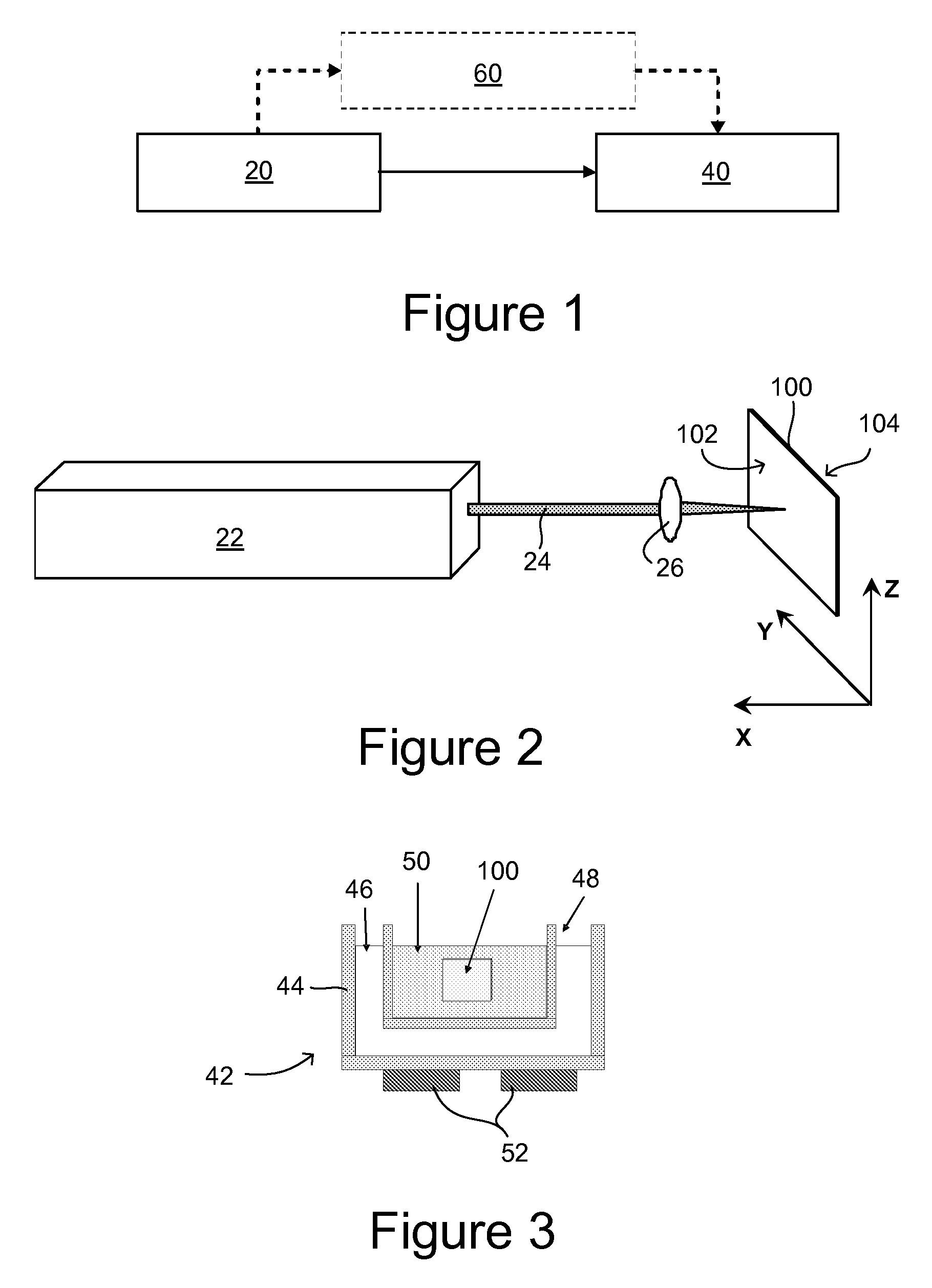

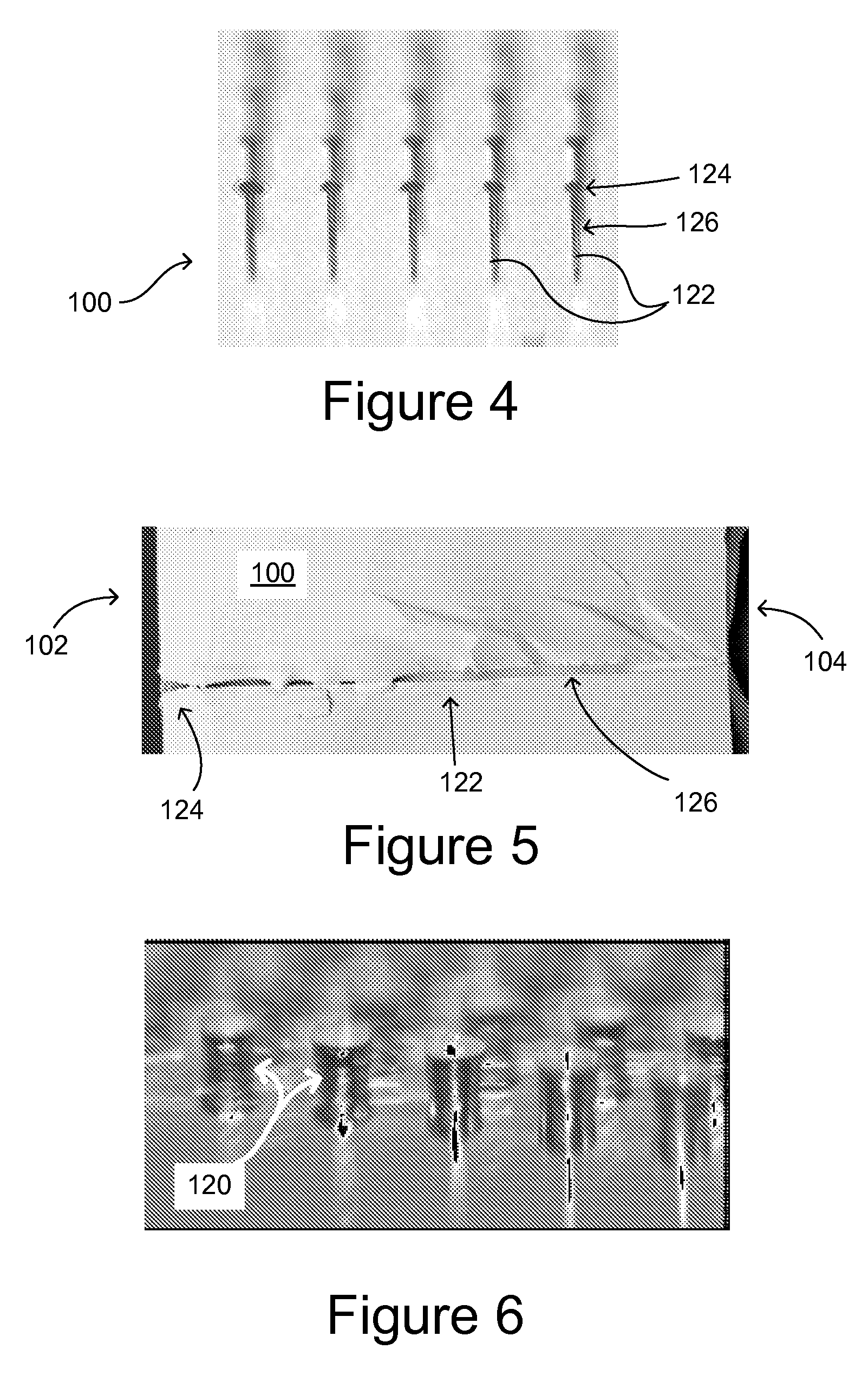

Methods of forming high-density arrays of holes in glass

ActiveUS9278886B2High positioning accuracyVariation in diameterGlass furnace apparatusSemiconductor/solid-state device detailsUv laserHigh density

A method of fabricating a high-density array of holes in glass is provided, comprising providing a glass piece having a front surface, then irradiating the front surface of the glass piece with a UV laser beam focused to a focal point within + / −100 μm of the front surface of the glass piece most desirably within + / −50 μm of the front surface. The lens focusing the laser has a numerical aperture desirably in the range of from 0.1 to 0.4, more desirably in the range of from 0.1 to 0.15 for glass thickness between 0.3 mm and 0.63 mm, even more desirably in the range of from 0.12 to 0.13, so as to produce open holes extending into the glass piece 100 from the front surface 102 of the glass piece, the holes having an diameter the in range of from 5 to 15 μm, and an aspect ratio of at least 20:1. For thinner glass, in the range of from 0.1-0.3 mm, the numerical aperture is desirably from 0.25 to 0.4, more desirably from 0.25 to 0.3, and the beam is preferably focused to within + / −30 μm of the front surface of the glass. The laser is desirable operated at a repetition rate of about 15 kHz or below. An array of holes thus produced may then be enlarged by etching. The front surface may be polished prior to etching, if desired.

Owner:CORNING INC

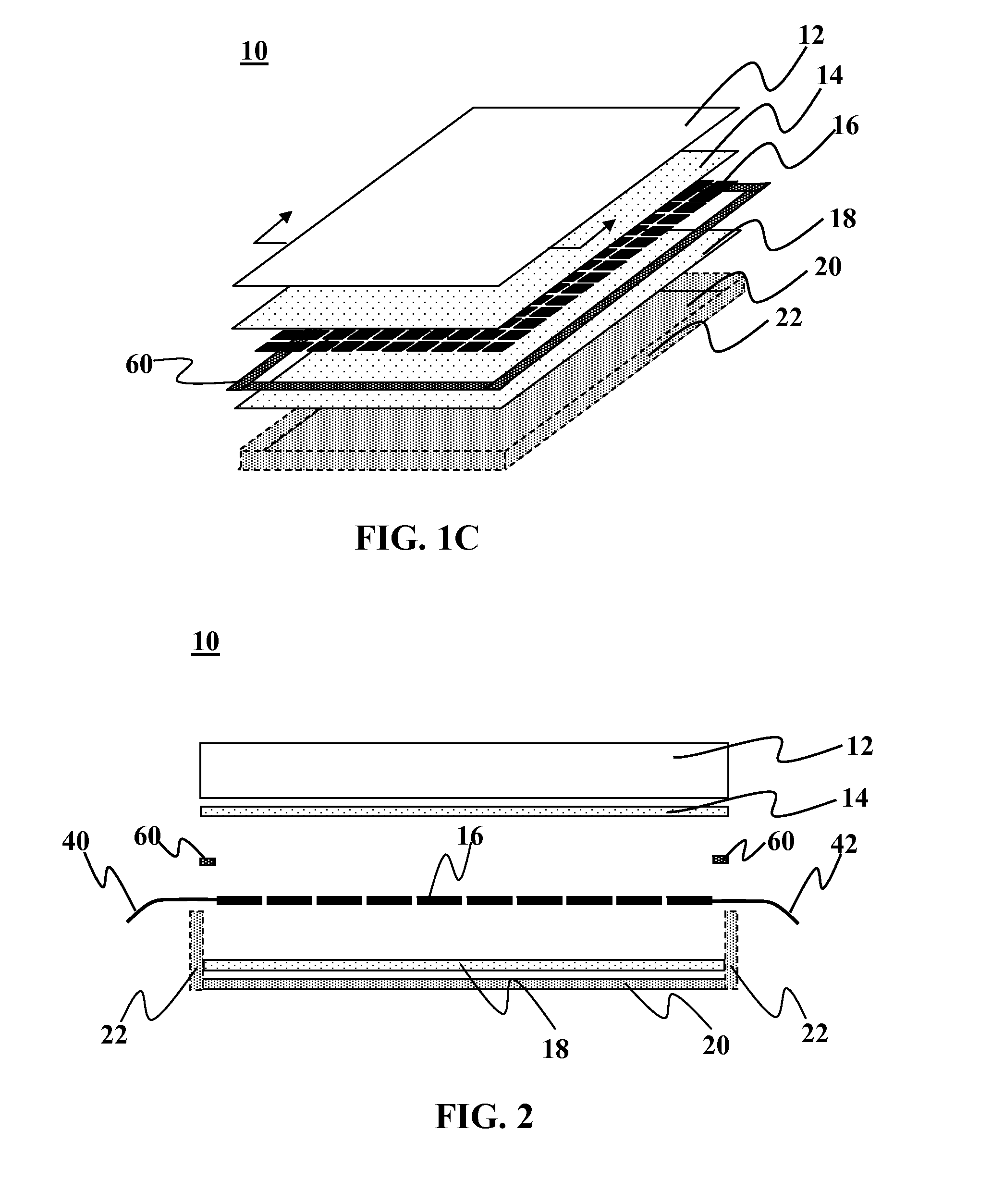

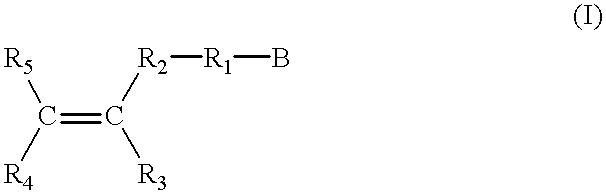

Electrochromic device with two thin glass elements and a gelled electrochromic medium

InactiveUS6545794B2Facilitates optical distortionTenebresent compositionsNon-linear opticsPolymer scienceConductive materials

An electrochromic device comprising: a first glass element having an electrically conductive material associated therewith, wherein said first element comprises a height (h1), a width (w1), a thickness (t1), an inner surface, and an outer surface; a second element having an electrically conductive material associated therewith, wherein said second element comprises a height (h2), a width (w2) , and a thickness (t2), an inner surface, and an outer surface; a cell spacing (c) which comprises a distance between said inner surface of said first element and said inner surface of said second element; a gelled electrochromic medium contained within a chamber positioned between said first and second elements; wherein (h1), (w1), (t1), (h2), (w2), (t2), and (c) are numerical values in millimeters; and wherein (h1), (w1), and (t1) of said first element, and (h2), (w2), and (t2) of said second element and (c) comprise numerical values such that the following inequality is satisfied:

Owner:GENTEX CORP

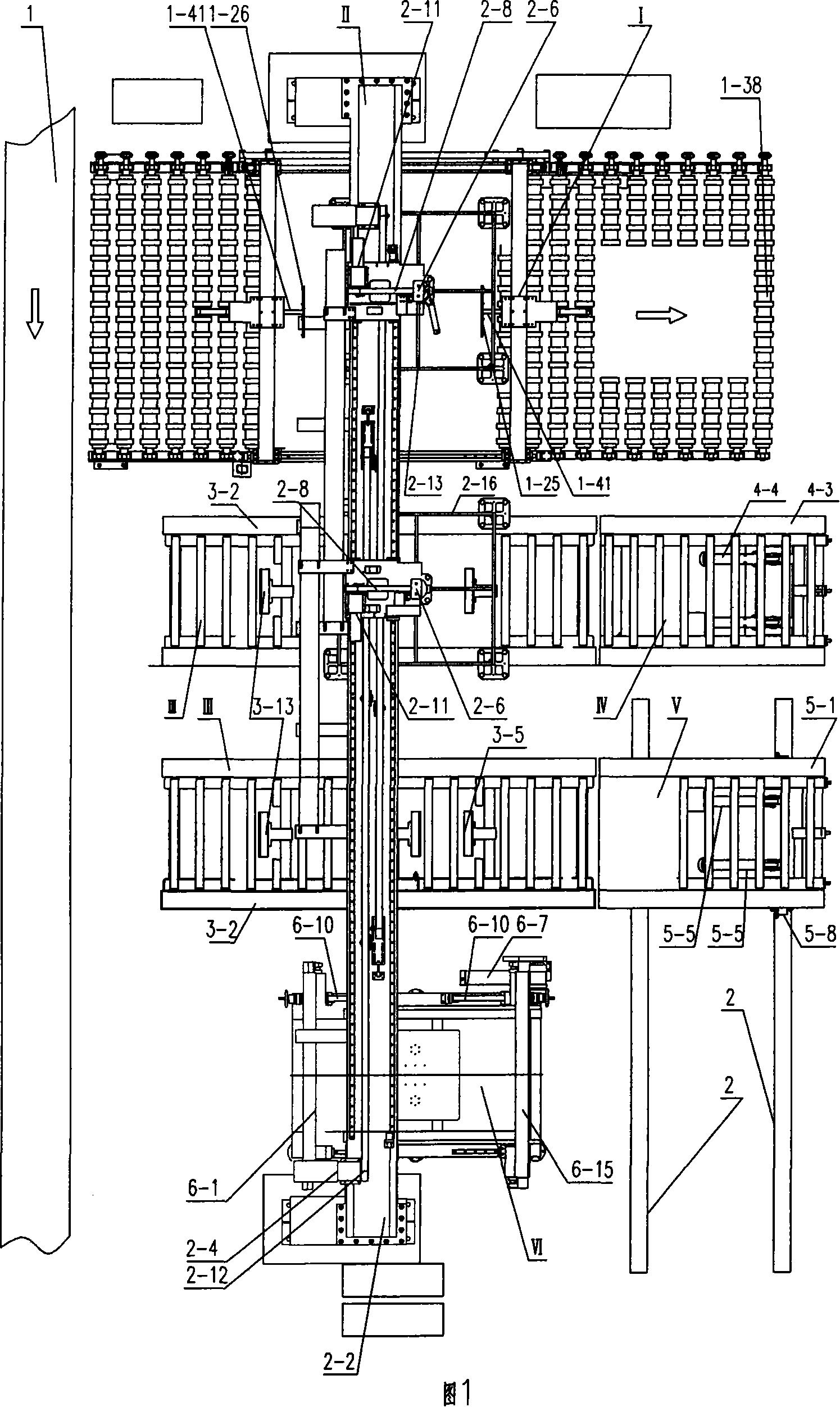

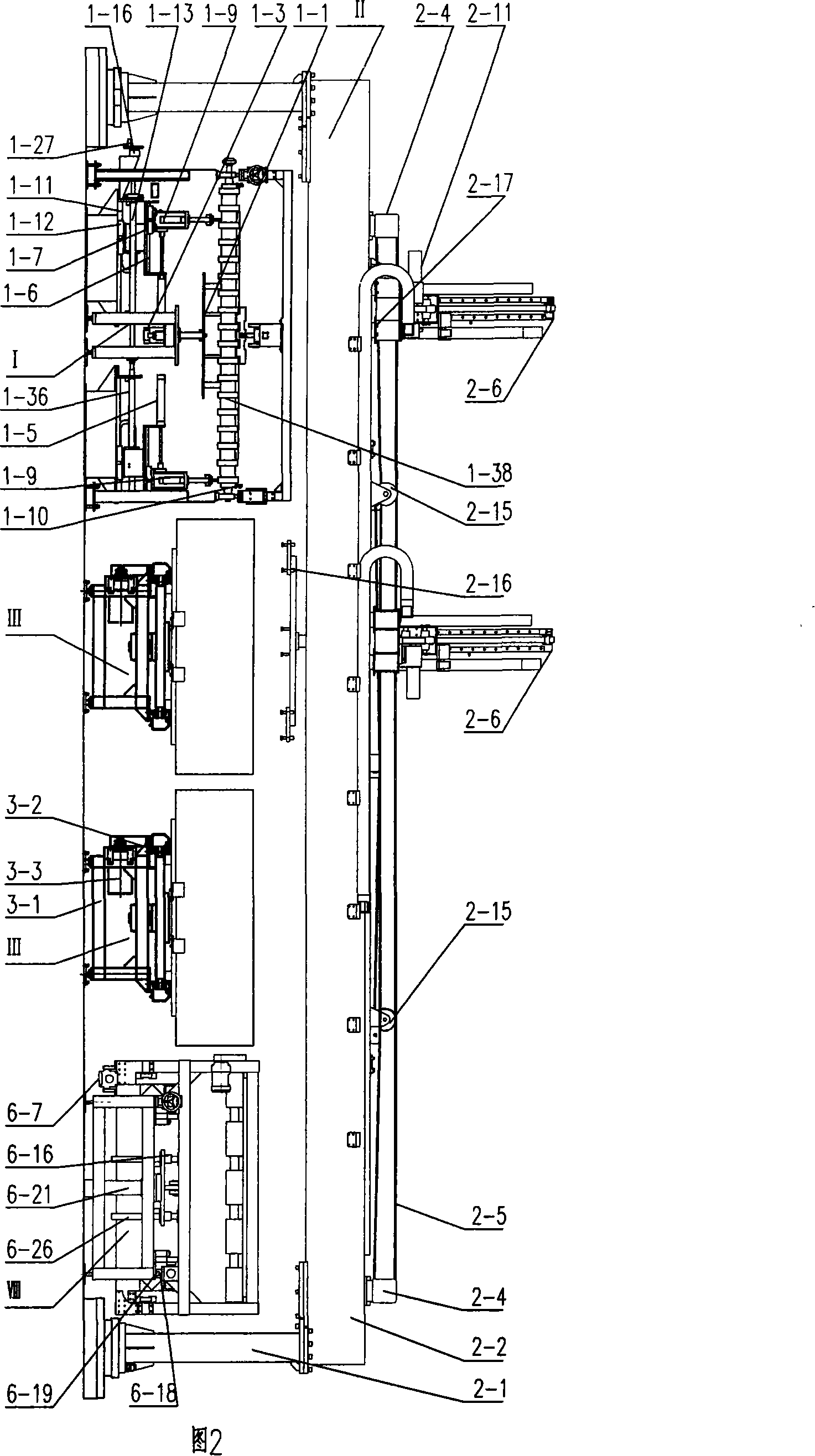

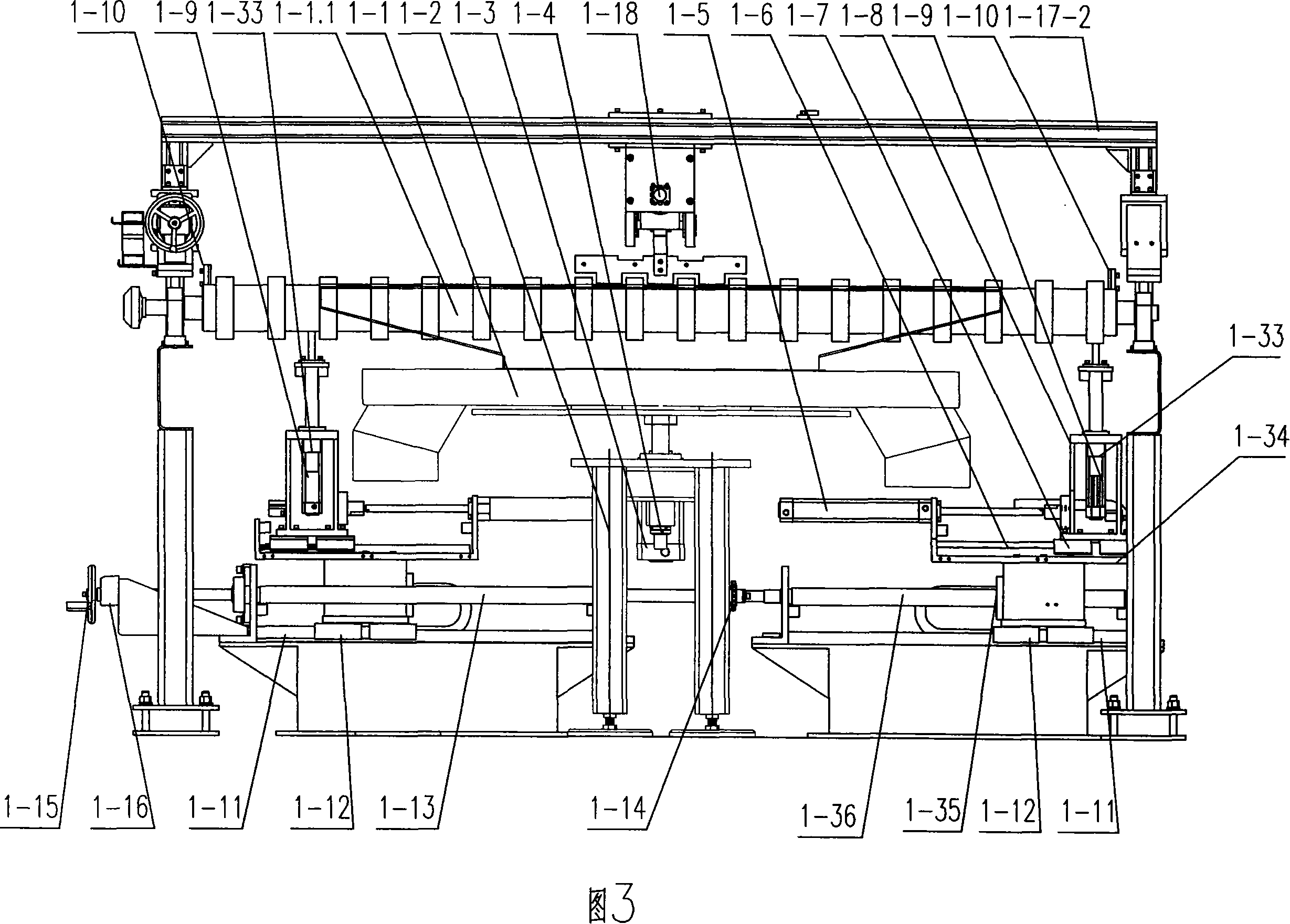

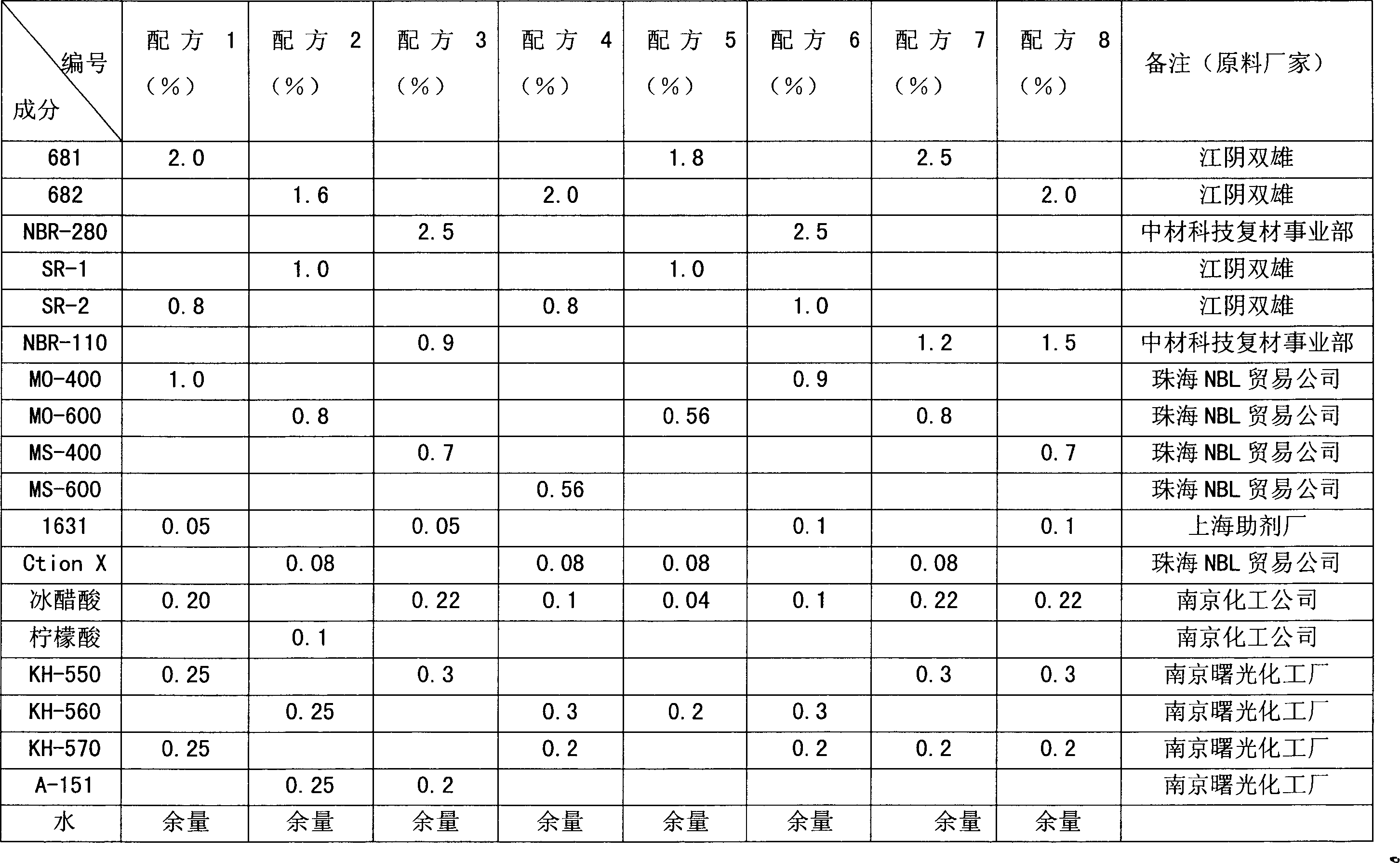

Automatic sheet-fetching system of ultra-thin glass

ActiveCN101139015ATimely crawlSolve the key technical problems of offlineRegistering devicesCharge manipulationEngineeringThin glass

The present invention discloses a ultra-thin glass automatic slicing system and comprises a glass transmission branch, a clean transportation robot and a packing box fixed turnover unit as well as a glass centering positioning unit, a packing box transmission positioning unit, a packing box moving turnover unit and a septum paper supplying unit. A glass transmission main line is vertical to the glass transmission branch and the glass centering positioning unit is arranged above and below the glass transmission branch; two packing box transmission positioning units are arranged in parallel with the glass transmission branch, wherein, the terminal of the packing box transmission positioning unit arranged close to the glass transmission branch is provided with the packing box fixed turnover unit; the terminal of the packing box transmission positioning unit far away from the glass transmission branch is provided with the packing box moving turnover unit; the septum paper supplying unit is arranged in parallel to the packing box transmission positioning unit; the present invention can meet the quality standard of glass in electronic industry and packing requirement of ultra-thin glass storage and transmission at the same time, and improve yield and packing quality of ultra-thin float glass.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

High durability touch screen and method for manufacturing

ActiveUS20050037184A1DurableDurable touch screenCeramic layered productsGlass/slag layered productsThin glassMaterials science

A method for manufacturing a touch screen that deposits a conductive layer or coating directly onto a surface of a sheet or ribbon or roll of thin glass material. The coated thin glass material may be cut to the desired shape or substrate for use as the outer, thin glass substrate of the touch screen device. Spacer elements and / or other functional coatings or layers or the like may also be applied to the conductive layer or opposite surface of the thin glass ribbon. Optionally, a functional coating or layer may be deposited or applied to a surface of a pre-cut thin glass substrate. The coated pre-cut thin glass substrate may be used as a top sheet for lamination as the protective top sheet of a touch screen device.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

Coated chemically strengthened flexible thin glass

InactiveUS20170183255A1Improve antifouling performanceEasy to cleanGlass forming apparatusPriming paintsNiobiumCerium

A coated chemically strengthened flexible thin glass includes a coating of an adhesive layer in the form of a silicon mixed oxide layer, which contains or consists of a silicon oxide layer in combination with at least one oxide of aluminum, tin, magnesium, phosphorus, cerium, zirconium, titanium, cesium, barium, strontium, niobium, zinc, or boron, and magnesium fluoride, such as at least aluminum oxide.

Owner:SCHOTT AG

Glass laminate, display panel with support, method for producing glass laminate and method for manufacturing display panel with support

InactiveCN102007524AEasy to separateSuppression of glass defectsGlass/slag layered productsNon-linear opticsThin slabOptoelectronics

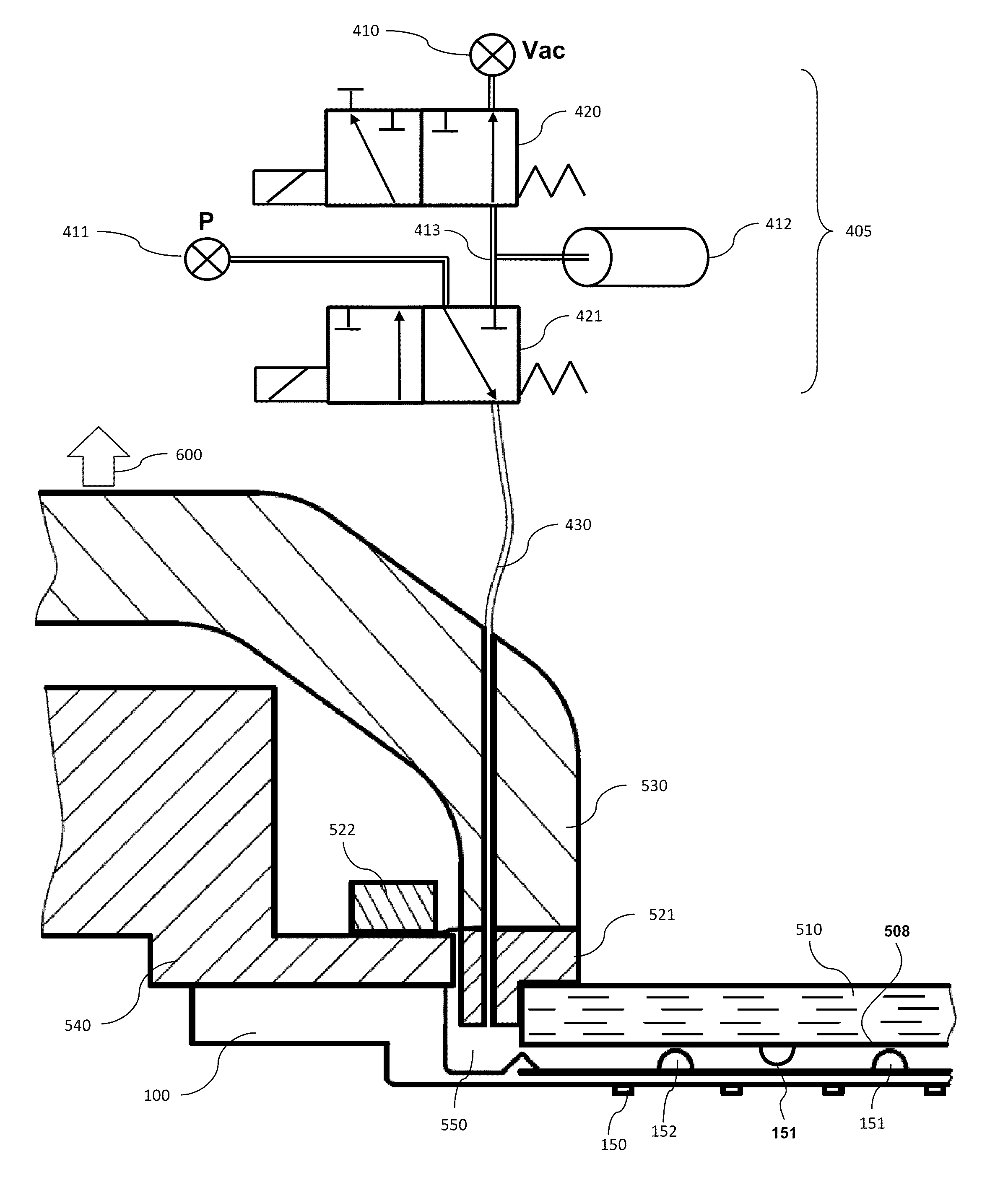

Disclosed is a glass laminate (10) comprising a thin glass substrate (12) having a first major surface and a second major surface, a supporting glass substrate (18) having a first major surface and a second major surface, and a resin layer (14) and an outer frame layer (16) arranged between the thin glass substrate (12) and the supporting glass substrate (18). The resin layer (14) is fixed to thefirst major surface of the supporting glass substrate (18) and is in close contact with the first major surface of the thin glass substrate (12), while having easy releasability from the first major surface of the thin glass substrate (12). The outer frame layer (16) surrounds the resin layer (14) on the first major surface of the supporting glass substrate (18) so that the outside air does not come into contact with the resin layer (14).

Owner:ASAHI GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com