Enhancement soakage agent for thin glass fiber bulked yarn

A glass fiber and sizing technology, applied in the field of glass fiber sizing, can solve problems such as energy waste, affecting product performance, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with embodiment.

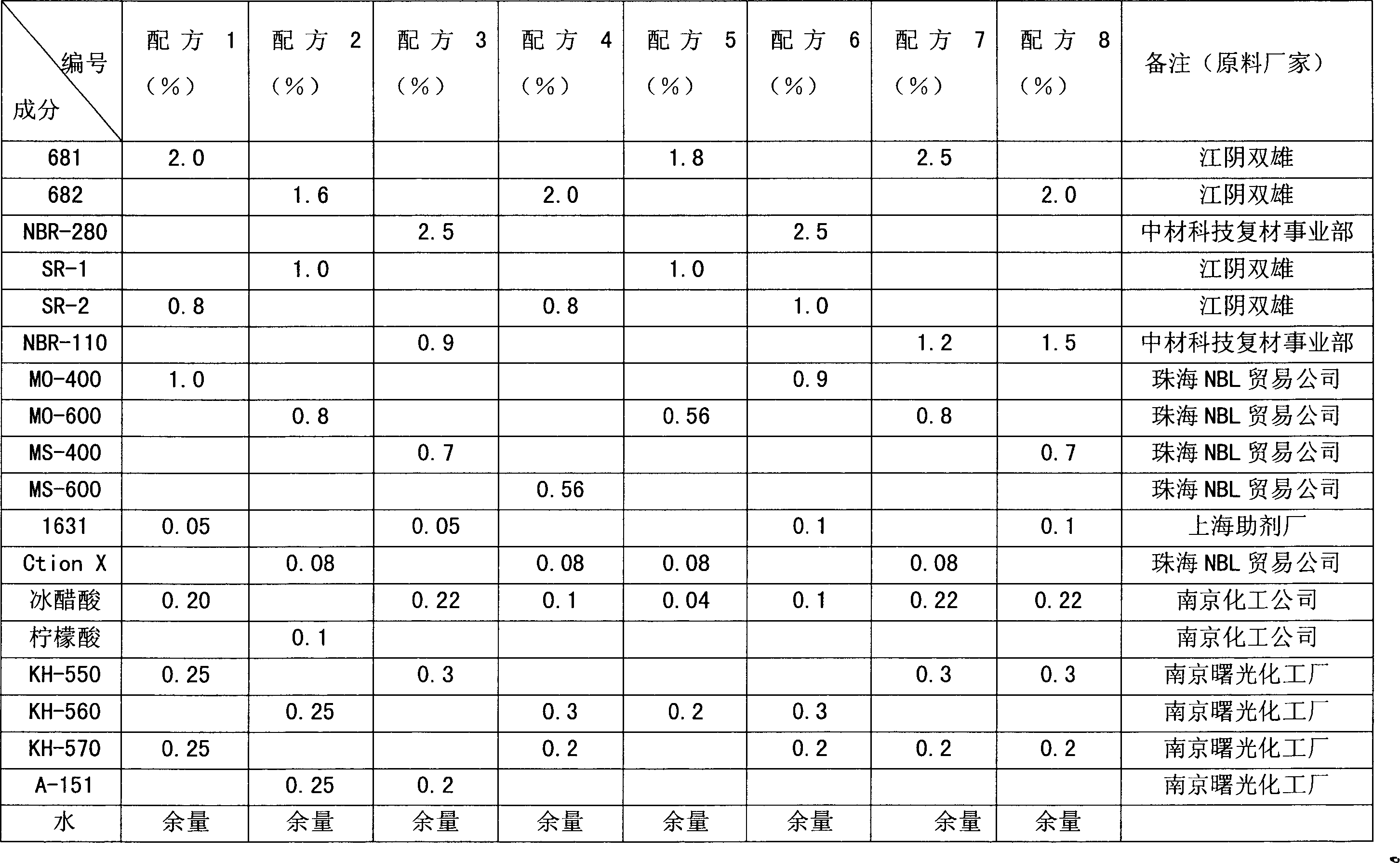

[0024] Examples The specific formulations are shown in Table 1, and each formulation is calculated based on the configuration of 100 kg of infiltrating agent. The amount of each component involved therein is the content of dry basis (non-volatile matter) unless otherwise specified. The "stirring condition" means that the stirring speed is preferably such that no air bubbles are generated. Its preparation process is briefly described by taking formula 1, formula 2 and formula 4 as examples. For the preparation process of the remaining examples, refer to the preparation process of formula 1 or formula 2 or formula 4 according to the components in the formula composition. For example:

[0025] 1) The addition ratio of the PH regulator of the coupling agent KH-560, KH-570, A-151 is 20% of the amount of the coupling agent, the dispersion concentration of the coupling agent is 2%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com