Patents

Literature

6793 results about "Fatty acid ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

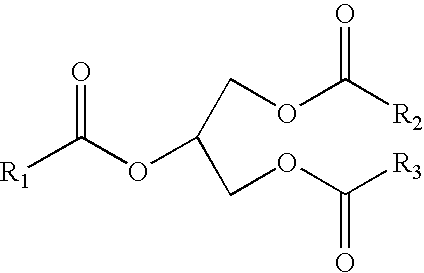

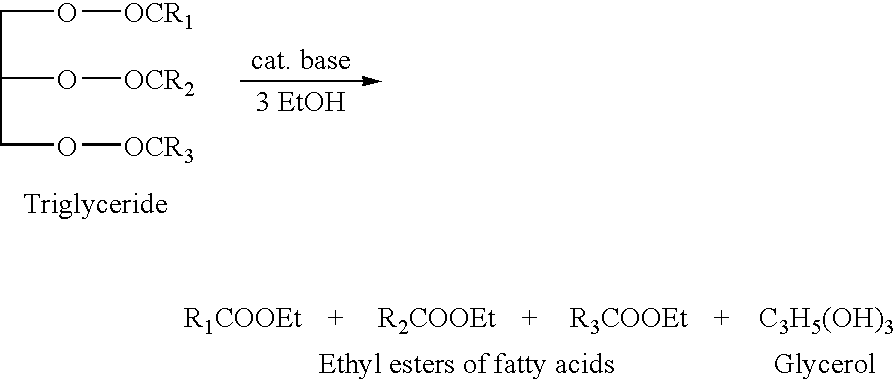

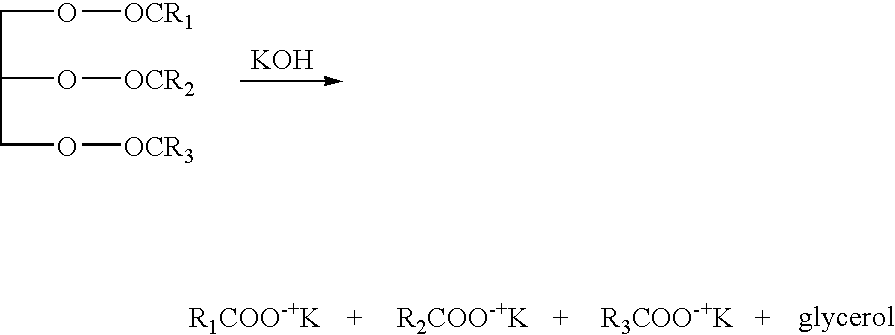

Fatty acid esters (FAEs) are a type of ester that result from the combination of a fatty acid with an alcohol. When the alcohol component is glycerol, the fatty acid esters produced can be monoglycerides, diglycerides, or triglycerides. Dietary fats are chemically triglycerides.

Process for producing a hydrocarbon component of biological origin

ActiveUS20040230085A1Improve performanceLow densityLiquid hydrocarbon mixture productionHydrocarbonsIsomerizationHydrocarbon

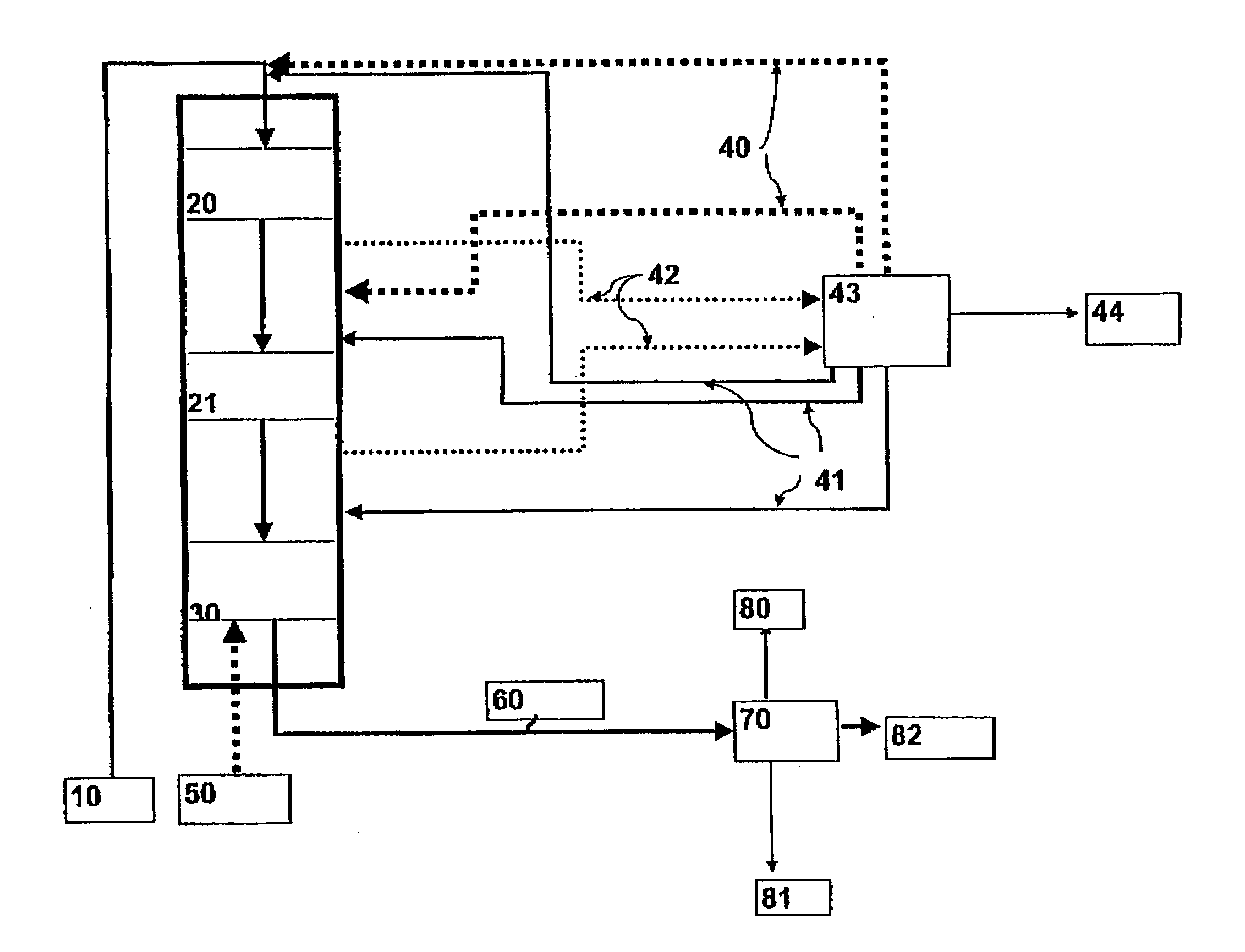

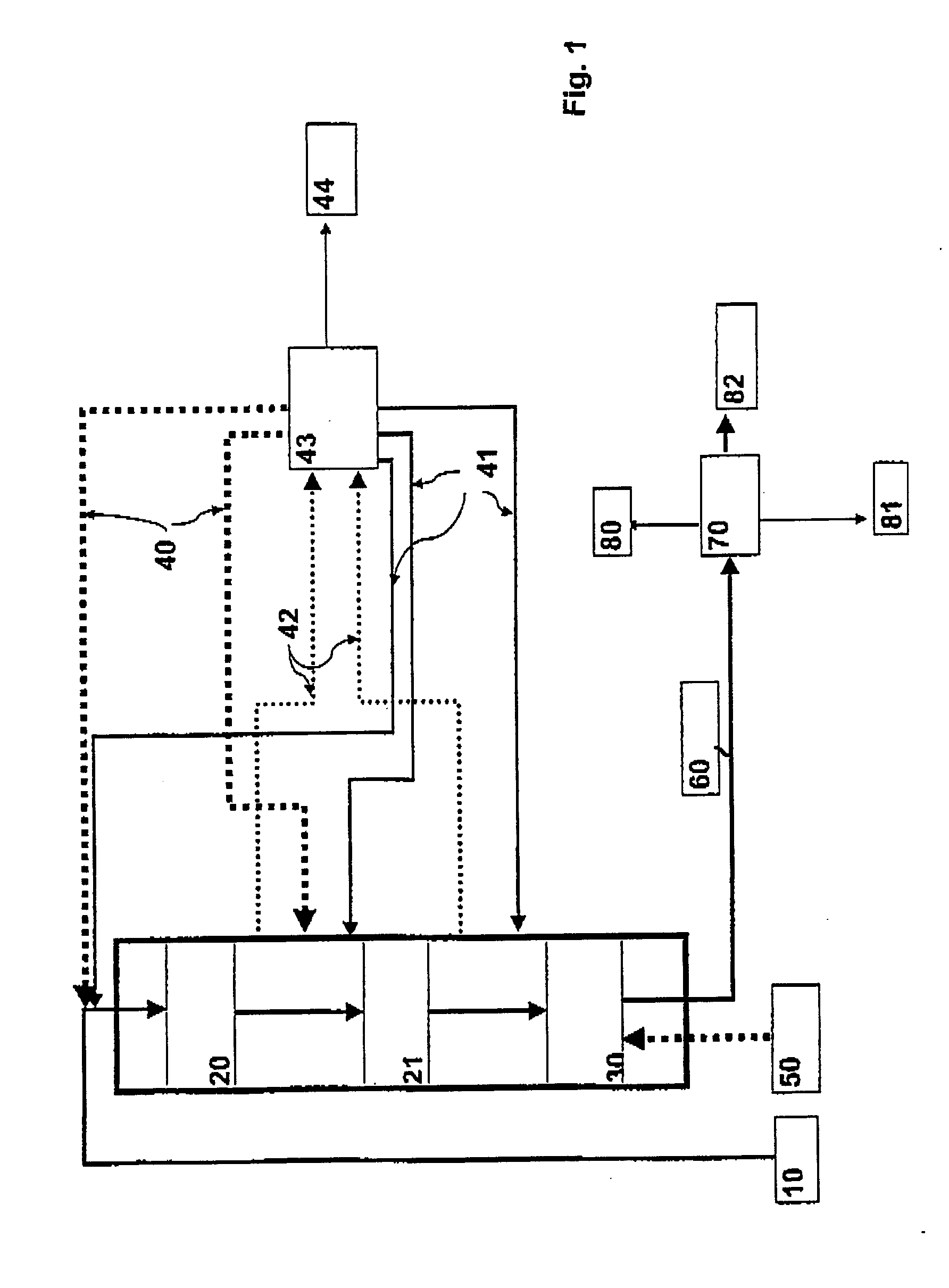

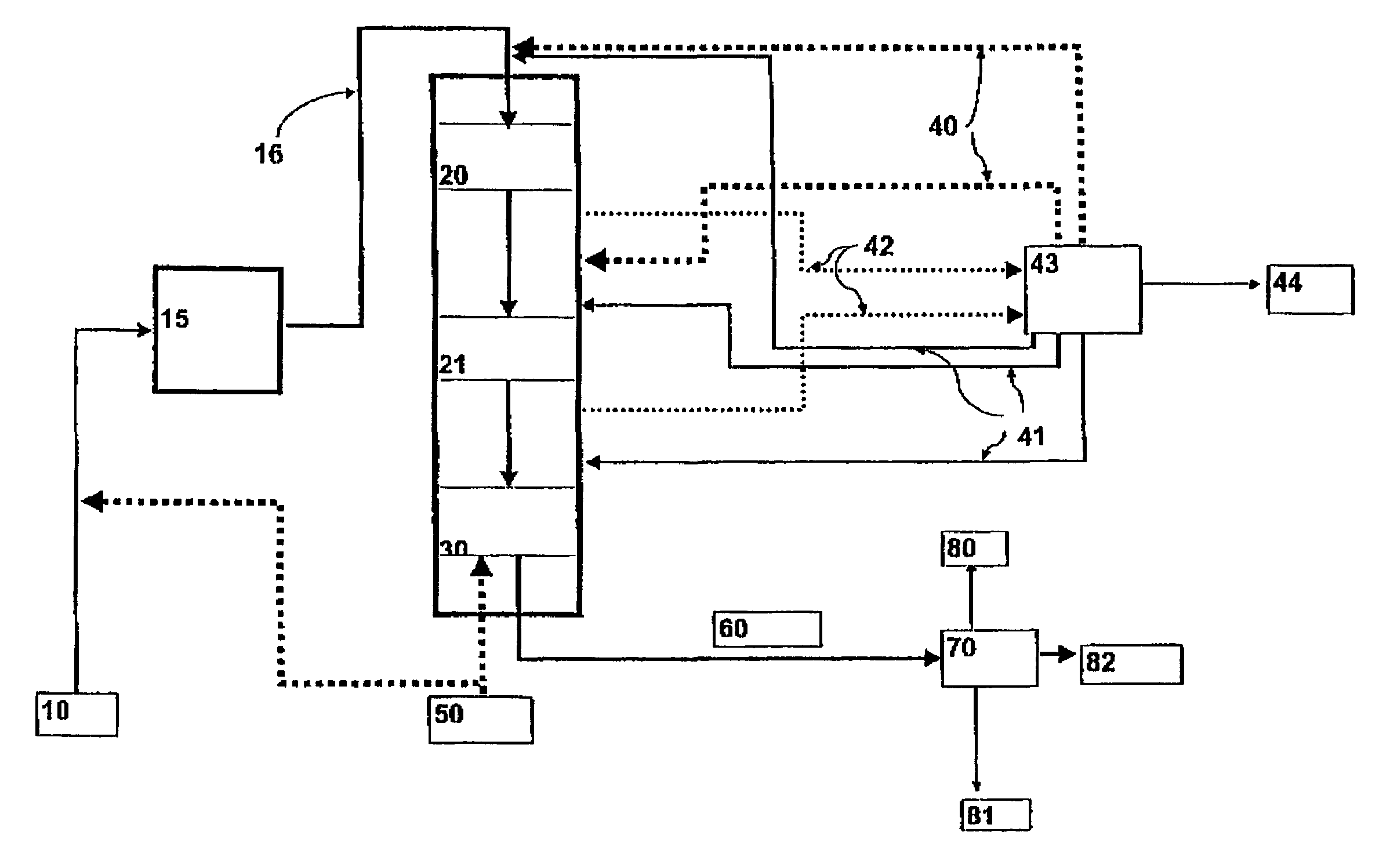

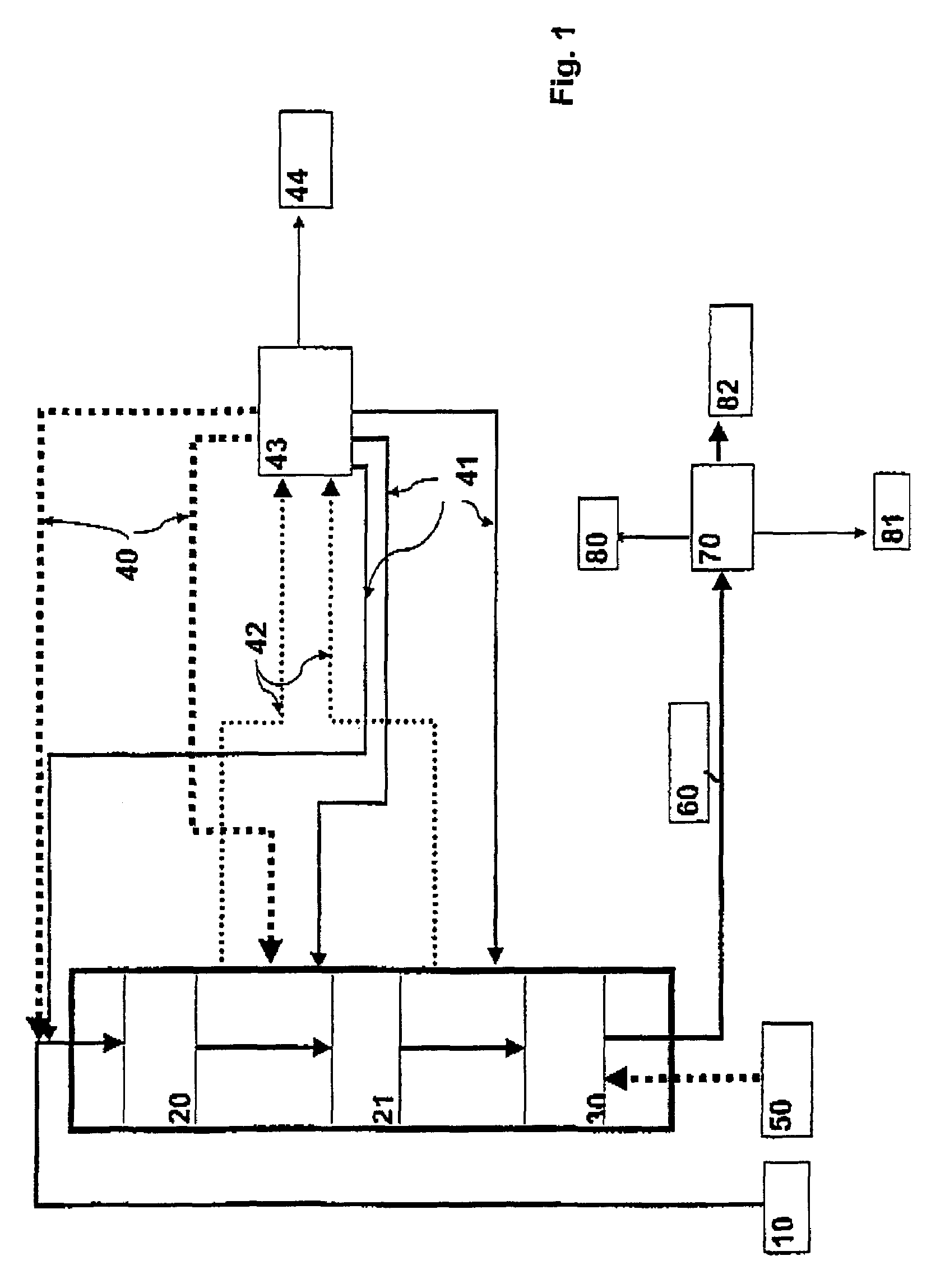

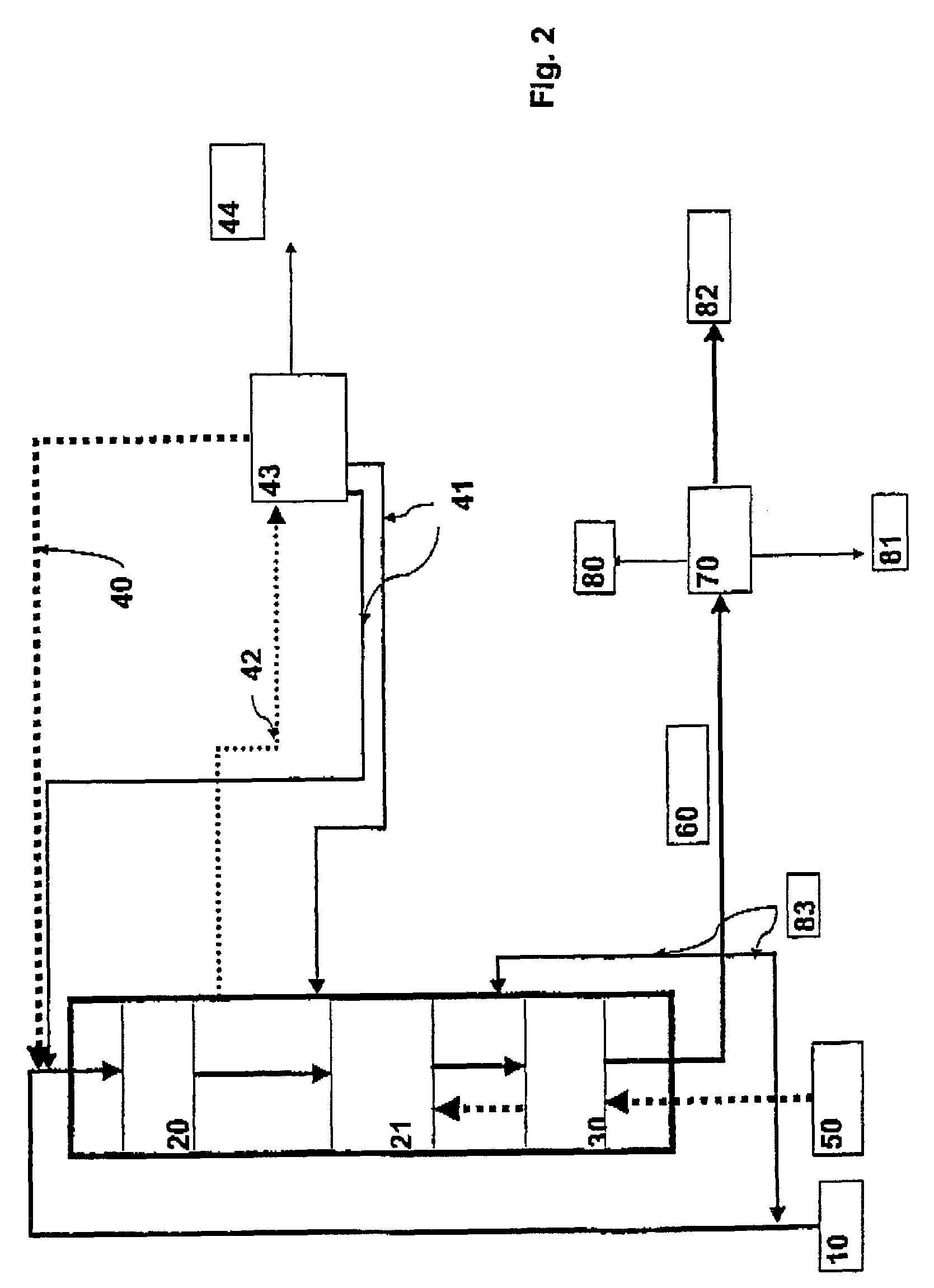

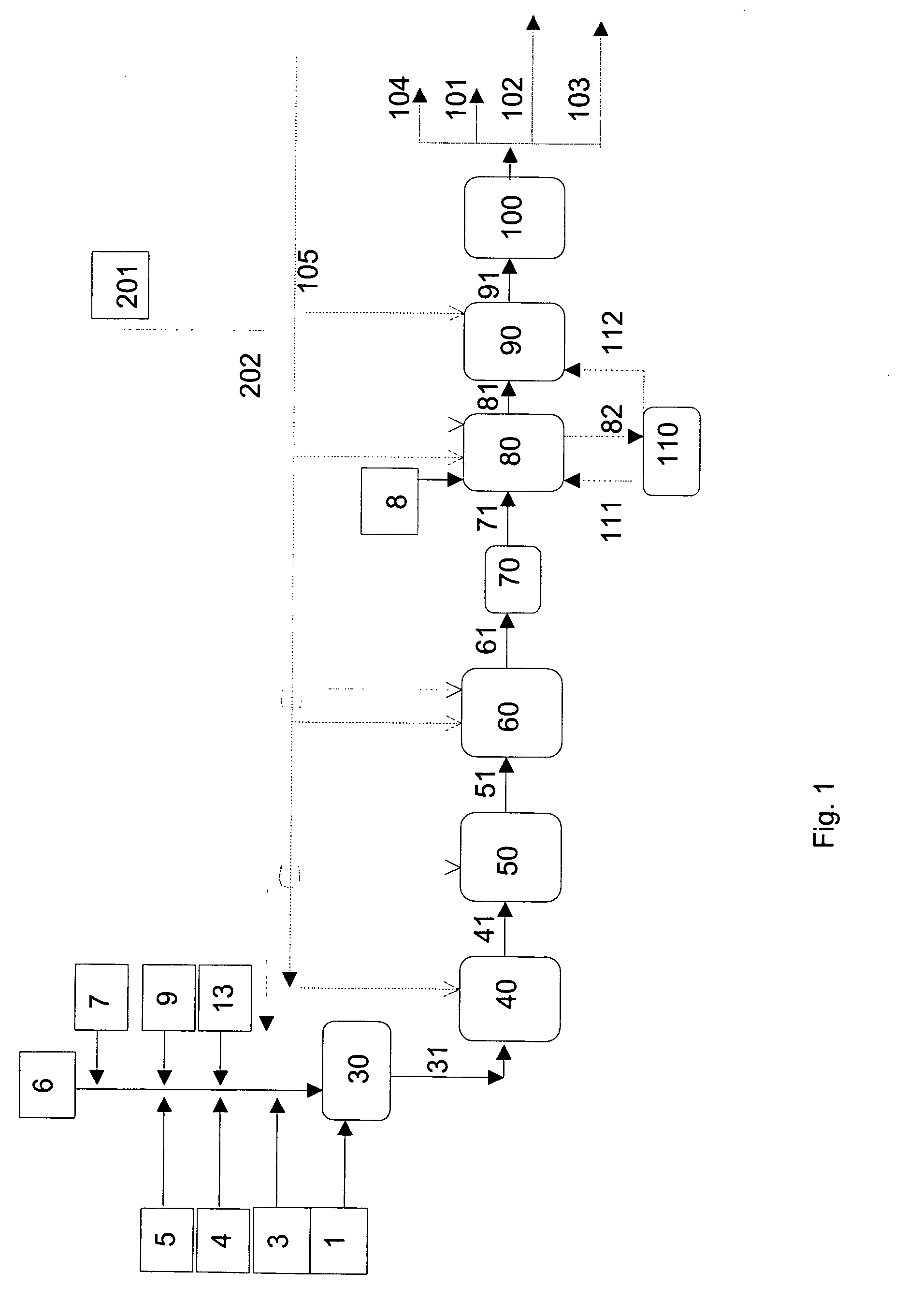

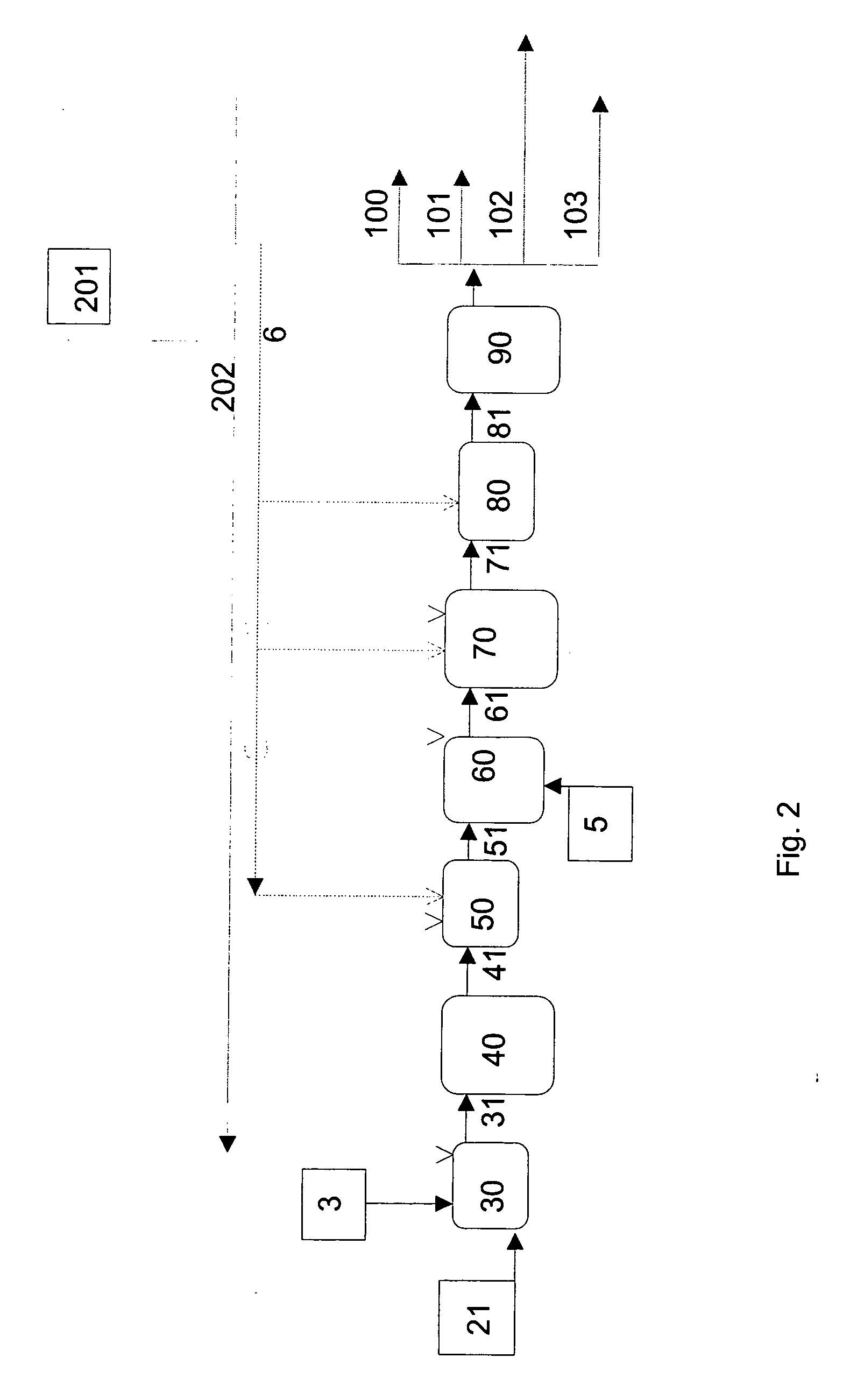

The invention relates to a process for producing a hydrocarbon component of biological origin. The process comprises at least two steps, the first one of which is a HDO step and the second one is an isomerization step operated using the counter-current flow principle. A biological raw material containing fatty acids and / or fatty acid esters serves as the feed stock.

Owner:OYJ NESTE OIL +1

Process for producing a hydrocarbon component of biological origin

ActiveUS7232935B2Improve performanceLow densityHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionIsomerizationHydrocarbon

The invention relates to a process for producing a hydrocarbon component of biological origin. The process comprises at least two steps, the first one of which is a HDO step and the second one is an isomerization step operated using the counter-current flow principle. A biological raw material containing fatty acids and / or fatty acid esters serves as the feed stock.

Owner:OYJ NESTE OIL +1

Hydroprocessing Microalgal Oils

InactiveUS20100170144A1Improve efficiencyLow costHydrocarbon by isomerisationHydrocarbon purification/separationChemical treatmentAlkaline hydrolysis

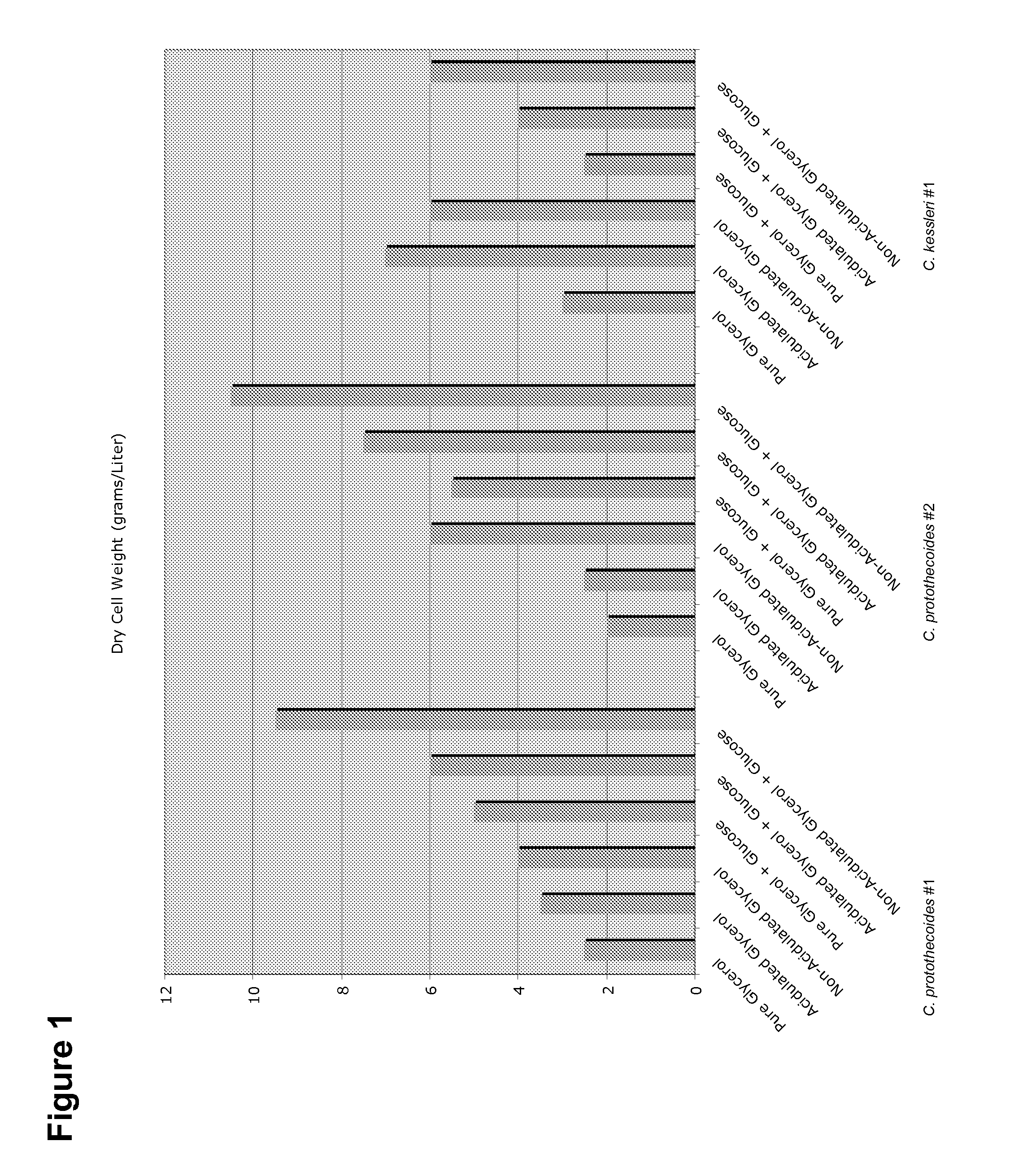

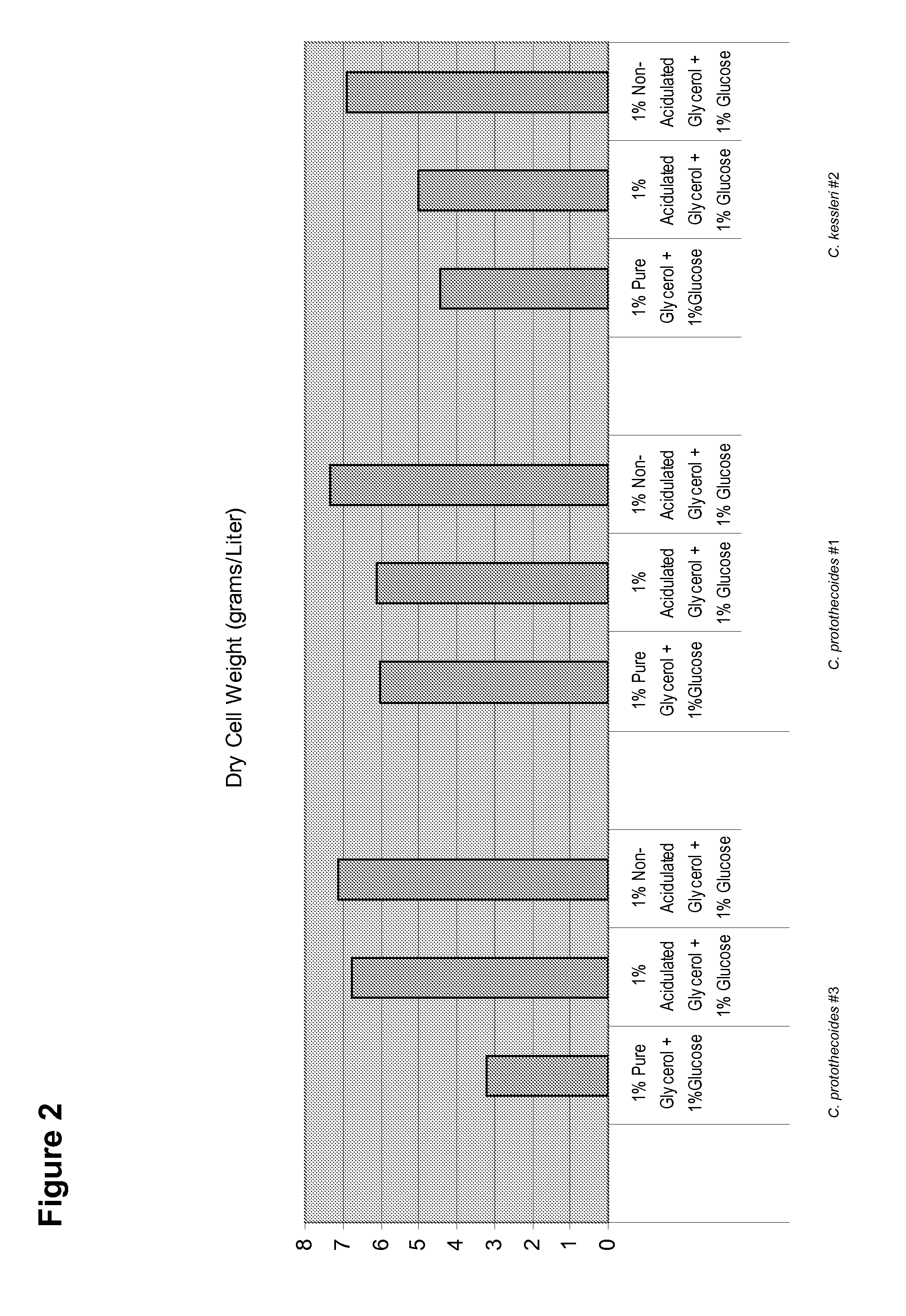

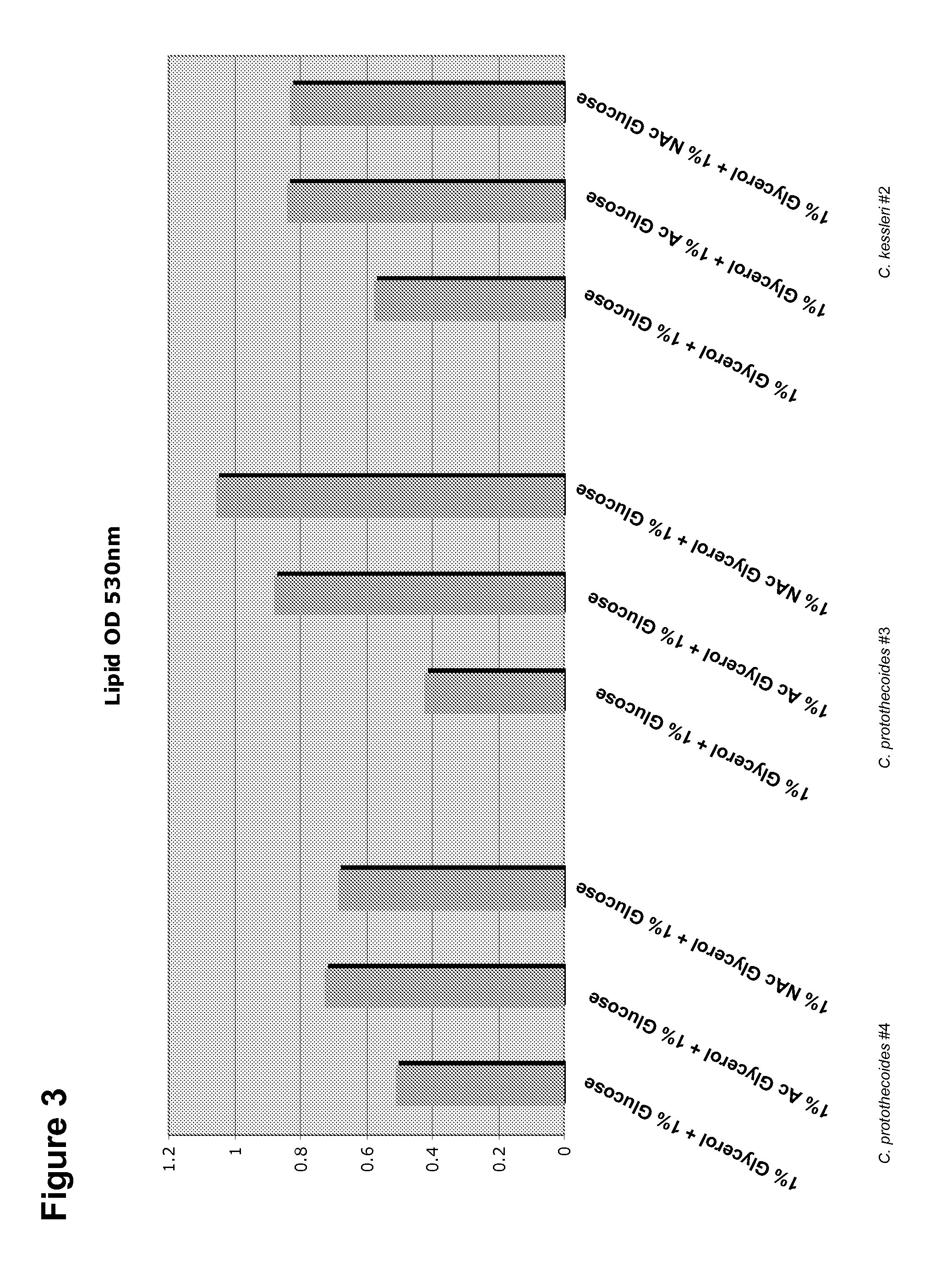

Fuels and other valuable compositions and compounds can be made from oil extracted from microbial biomass and from oil-bearing microbial biomass via hydroprocessing and / or other chemical treatments, including the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts.

Owner:TERRAVIA HLDG INC

Process for producing a hydrocarbon component

ActiveUS20070161832A1Reduce carbon dioxide emissionsImprove low temperature performanceFatty oils/acids recovery from wasteFatty acid hydrogenationIsomerizationHydrodeoxygenation

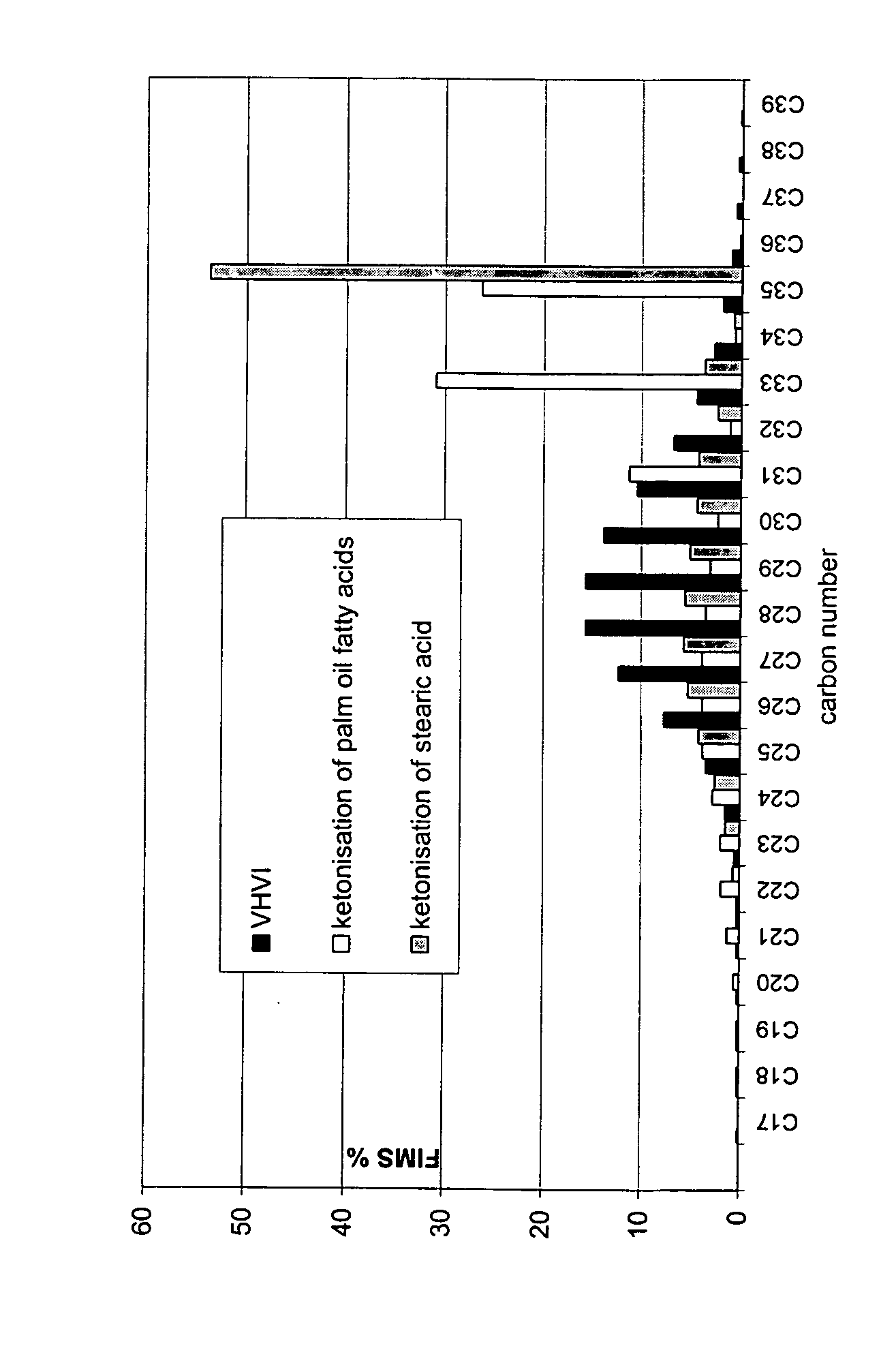

The invention relates to a process for producing a new type of high-quality hydrocarbon base oil of biological origin. The process of the invention comprises ketonisation, hydrodeoxygenation, and isomerization steps. Fatty acids and / or fatty acid esters based on a biological raw material are preferably used as the feedstock.

Owner:NESTE OIL OY

Antimicrobial compositions and methods

Antimicrobial compositions, especially those useful when applied topically, particularly to mucosal tissues (i.e., mucous membranes), including, in particular, an antimicrobial lipid component, such as a fatty acid ester, fatty ether, or alkoxide derivative thereof. The compositions can also include an enhancer component, a surfactant, a hydrophobic component, and / or a hydrophilic component. Such compositions provide effective topical antimicrobial activity and are accordingly useful in the treatment and / or prevention of conditions that are caused, or aggravated by, microorganisms (including viruses).

Owner:3M INNOVATIVE PROPERTIES CO

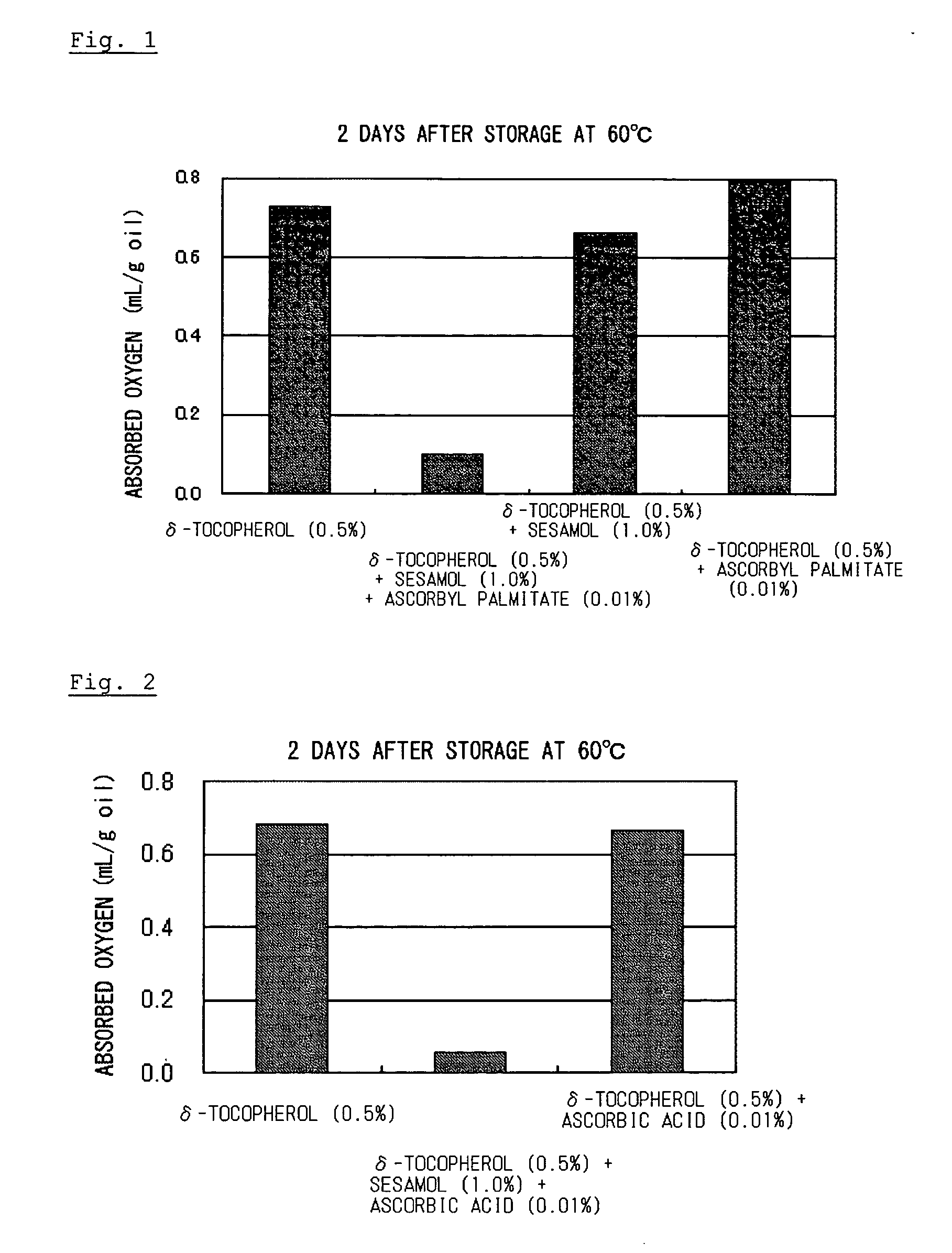

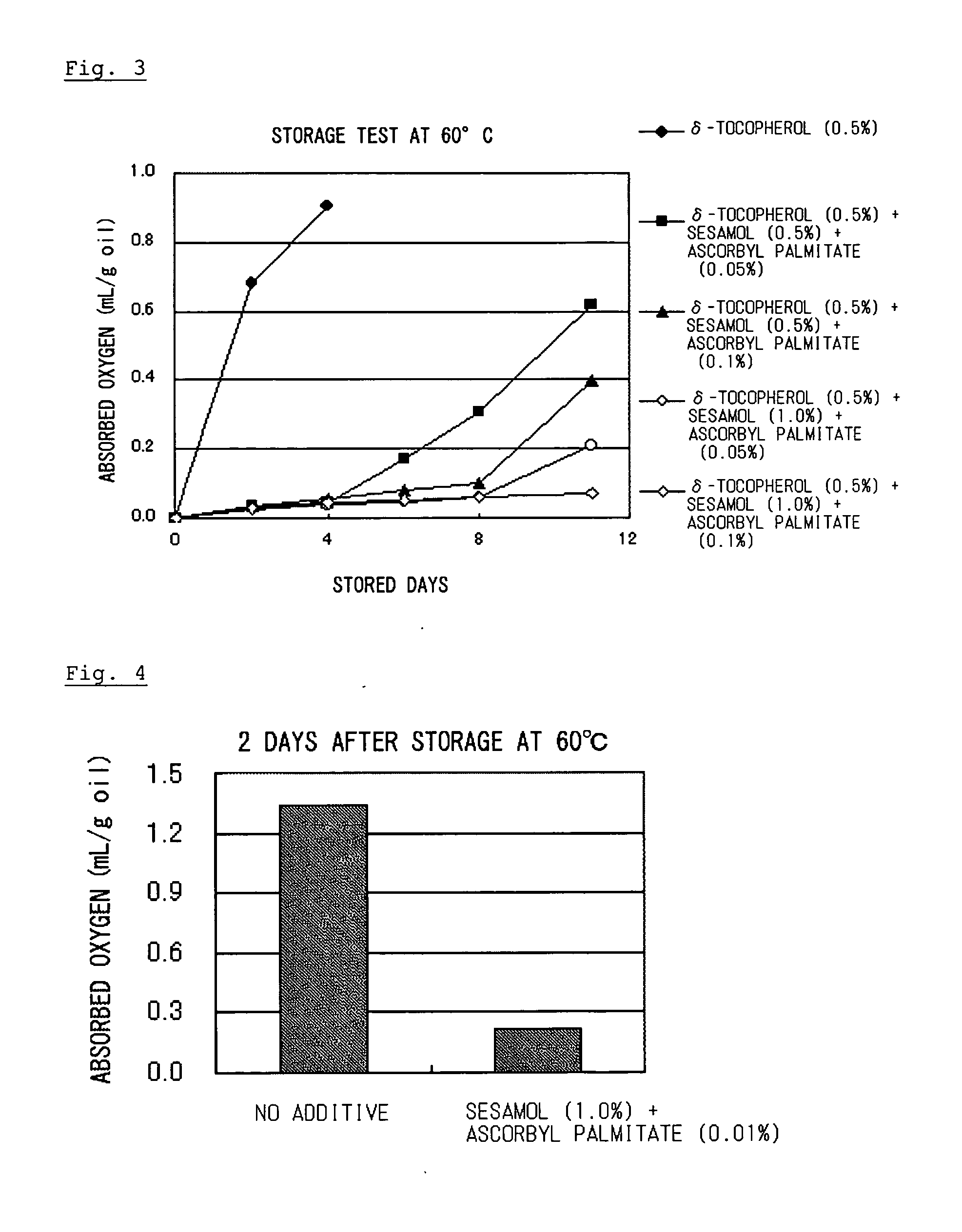

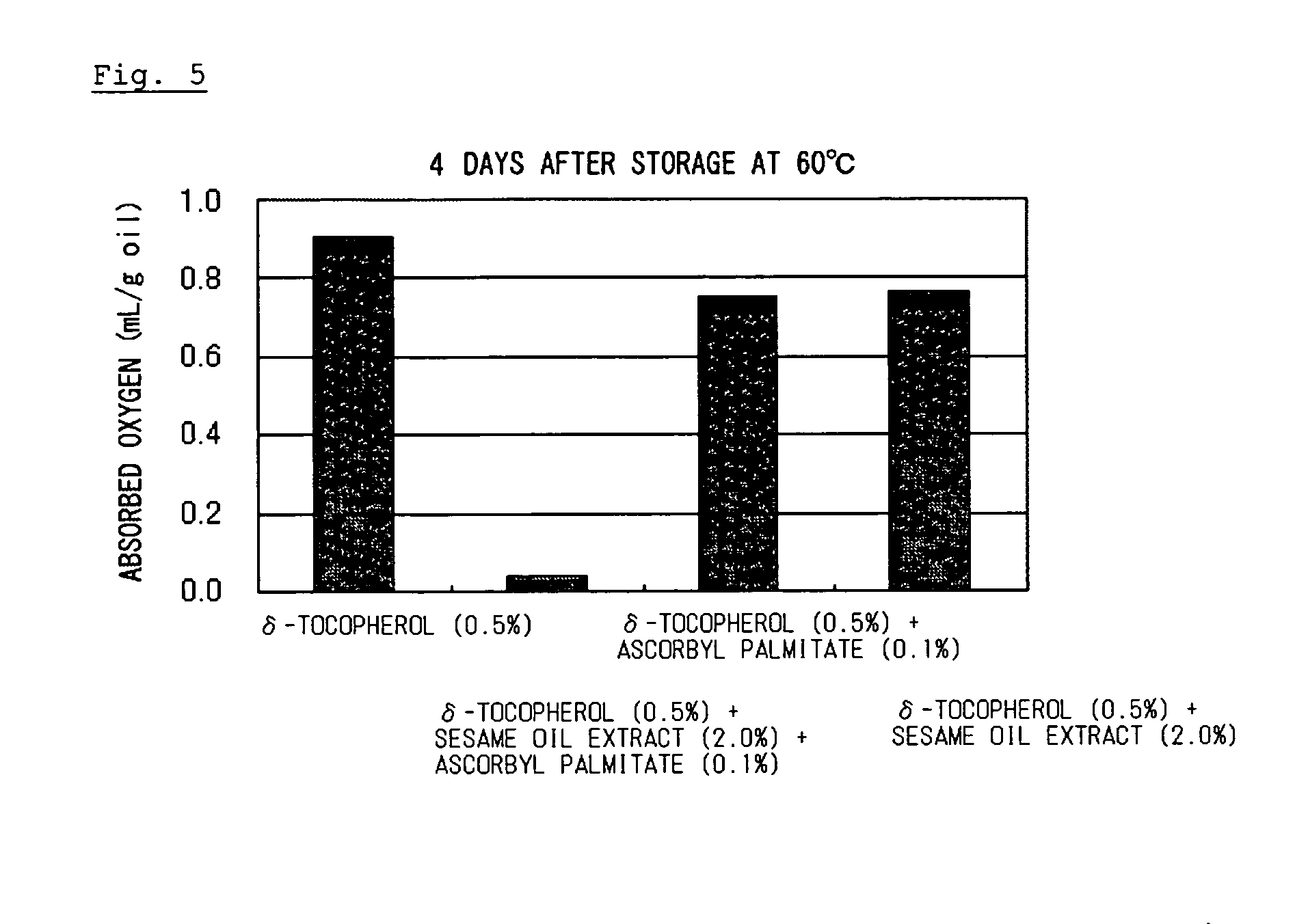

Composition containing organic substance having double bond with improved oxidative stability

ActiveUS20060134178A1Improve stabilitySafe antioxidantOrganic active ingredientsCosmetic preparationsSesamum orientaleGeneral purpose

To an organic substance having a double bond such as a polyunsaturated fatty acid was added an antioxidative component containing an antioxidative sesame component and ascorbic acid or an ascorbyl fatty acid ester. The above method provides a composition containing an organic substance having a double bond exhibiting enhanced oxidative stability. Particularly, it extremely improves oxidative stability of fat and oil which contains polyunsaturated fatty acid. General-purpose refined fish oil which is easy to handle can be provided for food, medicine or feed uses.

Owner:NIPPON SUISAN KAISHA LTD

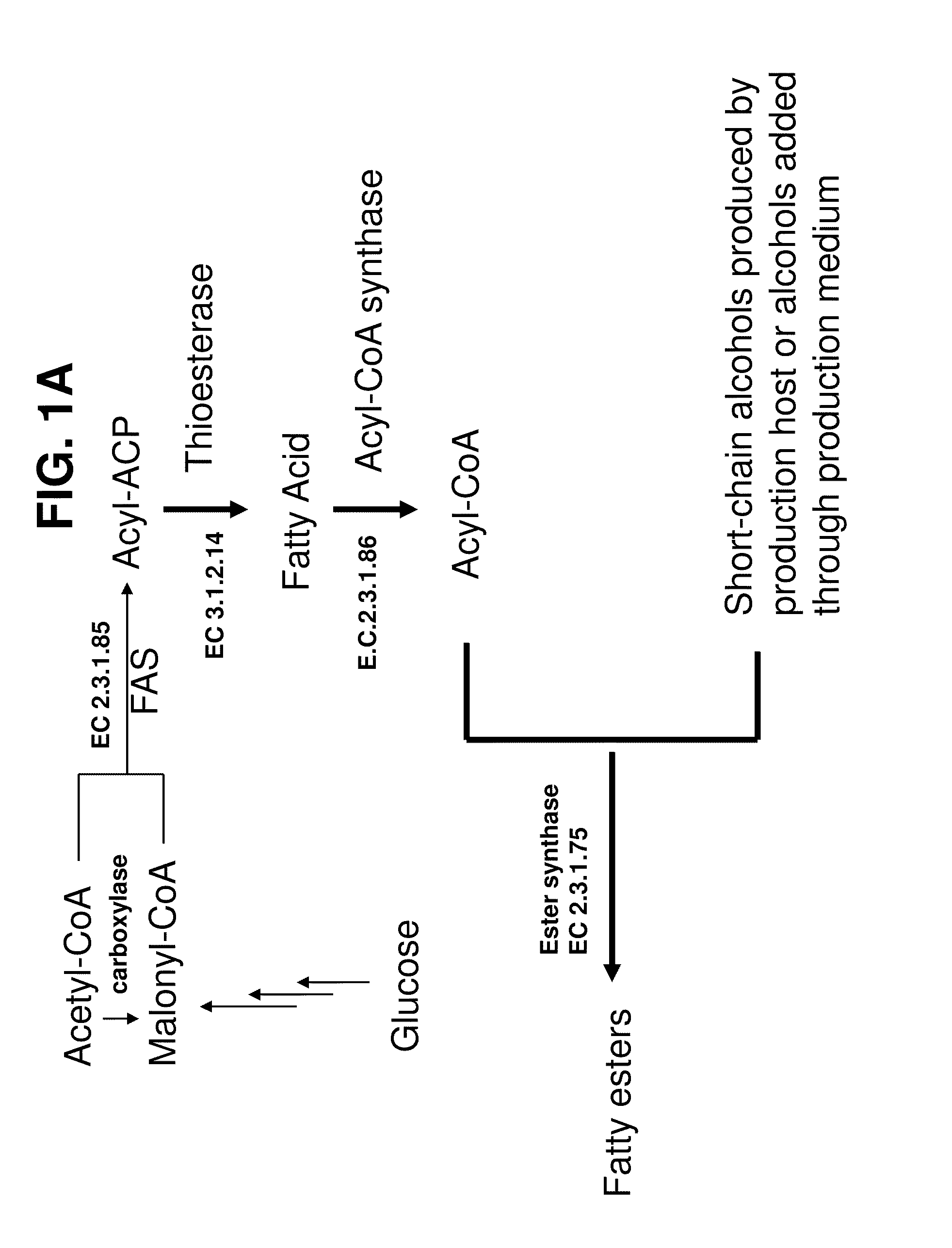

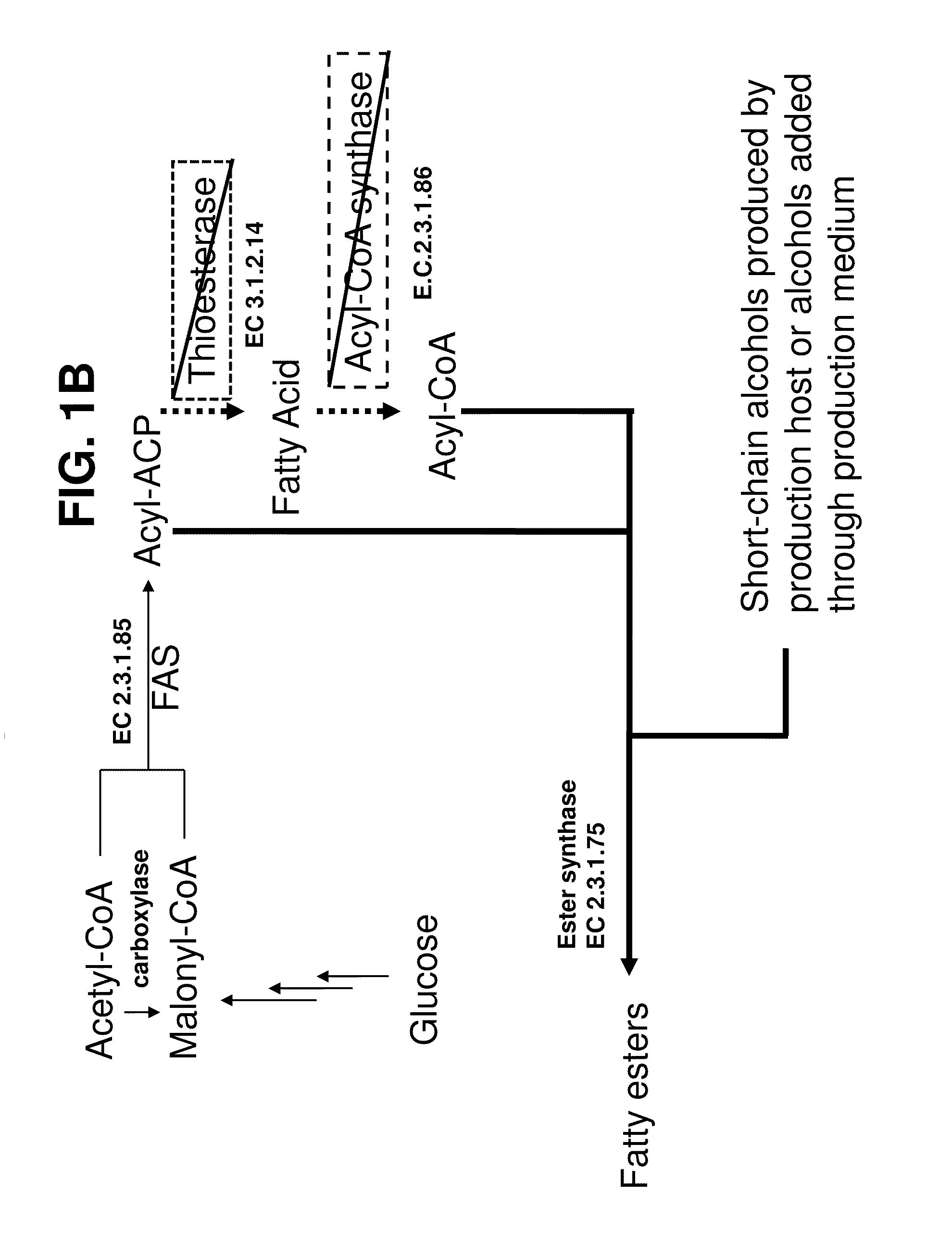

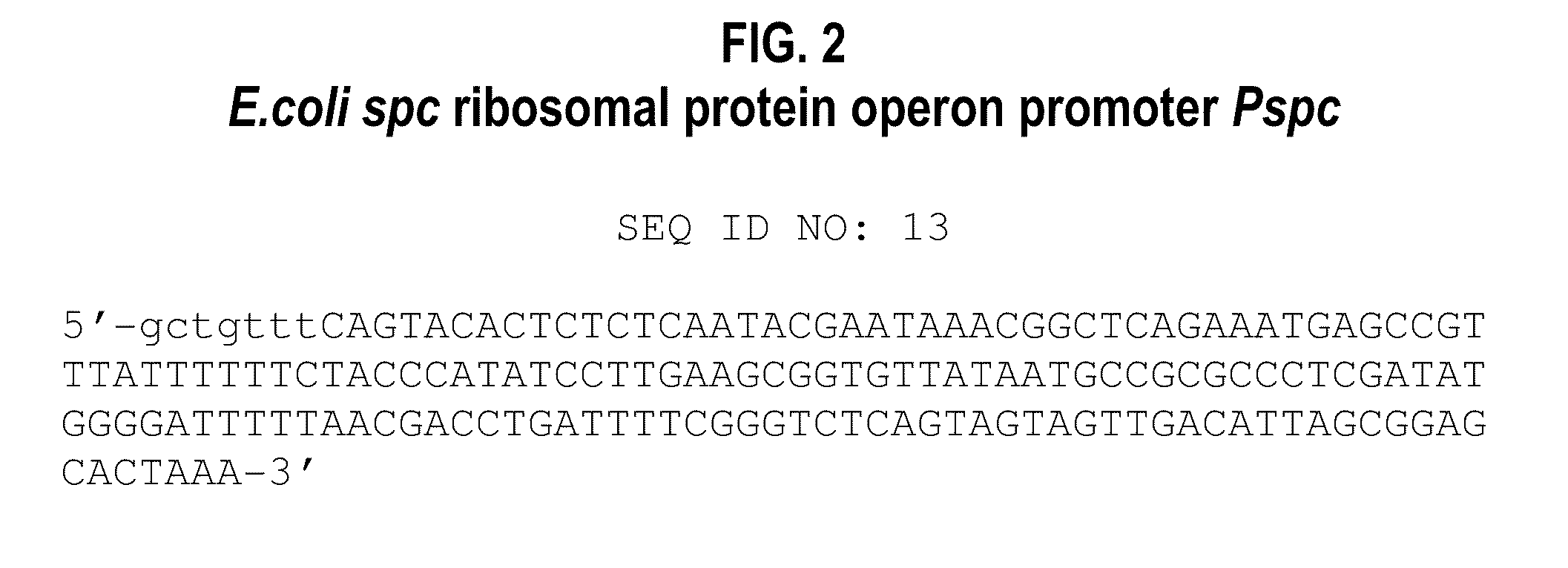

Production of fatty acid derivatives

ActiveUS20110072714A1High expressionHigh activityOrganic chemistryBacteriaAcid derivativeFatty acid derivatives

Methods and compositions for producing fatty acid derivatives, for example, fatty esters, and commercial fuel compositions comprising fatty acid derivatives are described.

Owner:GENOMATICA INC +1

Orally administrable composition capable of providing enhanced bioavailability when ingested

InactiveUS6054136AImprove solubilityImprove bioavailabilityCosmetic preparationsToilet preparationsFatty acid esterIngestion

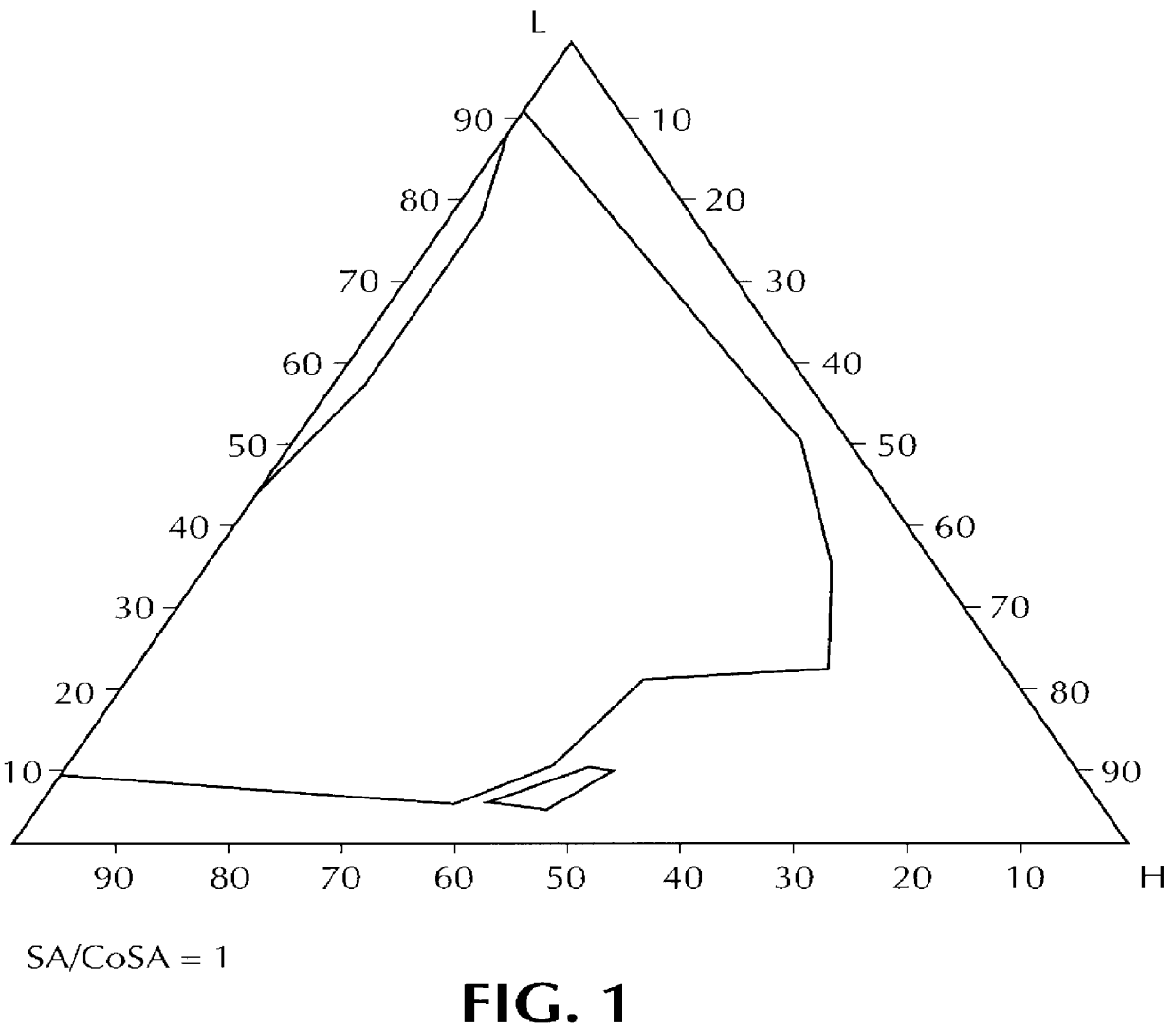

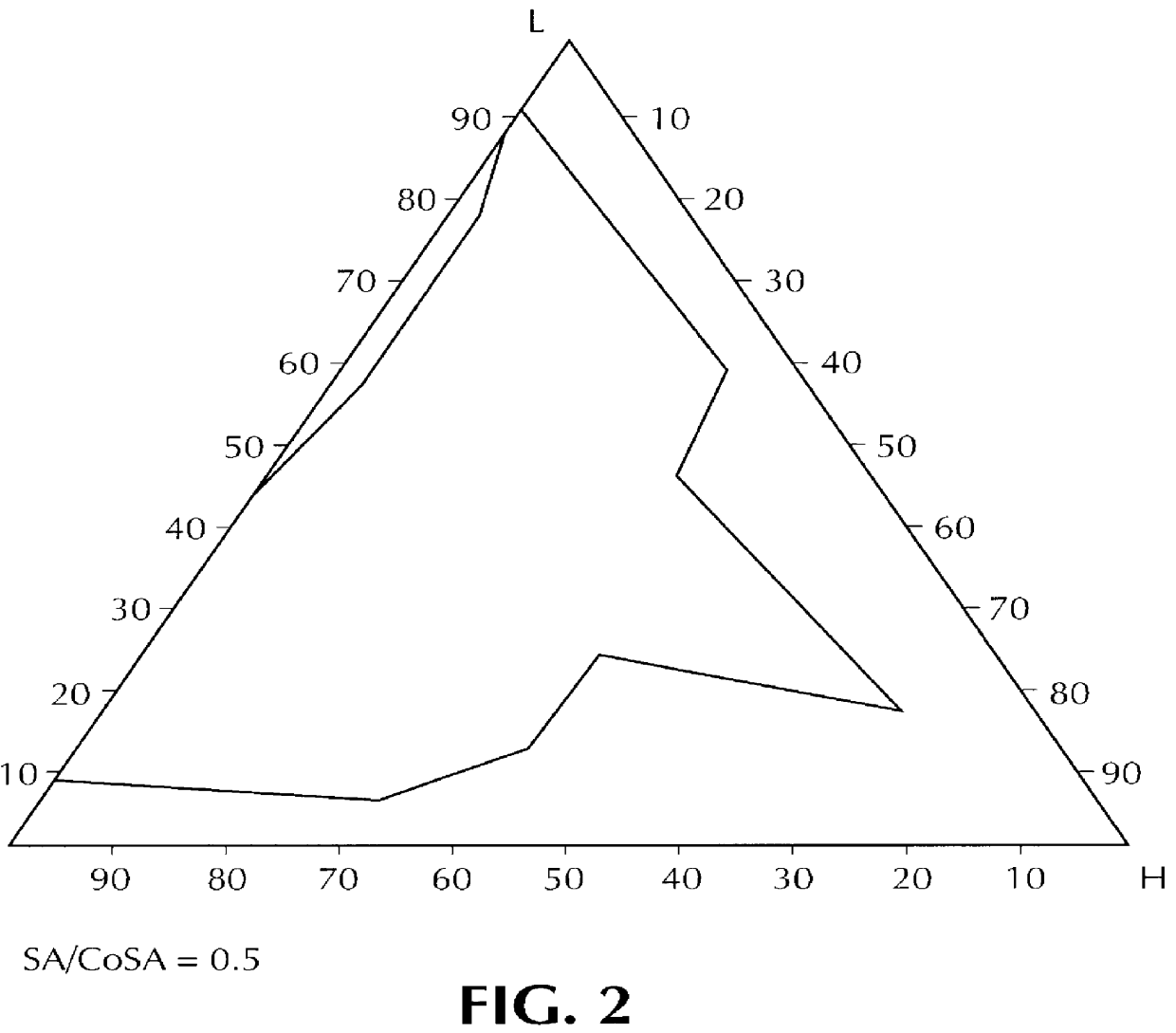

Composition for pharmaceutical or cosmetic use, capable of forming a microemulsion, comprising at least: an active principle, a lipophilic phase consisting of a mixture of fatty acid esters and glycerides, a surfactant (SA), a cosurfactant (CoSA), a hydrophilic phase, characterized: in that the lipophilic phase consists of a mixture of C8 to C18 polyglycolized glycerides having a hydrophilic-lipophilic balance (HLB) of less than 16, this lipophilic phase representing from 30 to 75% of the total weight of the composition; in that the surfactant (SA) is chosen from the group comprising saturated C8-C10 olyglycolized glycerides and oleic esters of polyglycerol, this surfactant having an HLB of less than 16; in that the cosurfactant (CoSA) is chosen from the group comprising lauric esters of propylene glycol, oleic esters of polyglycerol and ethyl diglycol; in that the SA / CoSA ratio is between 0.5 and 6; and in that the hydrophilic phase of the final microemulsion is supplied after ingestion by the physiological fluid of the digestive milieu.

Owner:GATTEFOSSE HLDG

Reactive oil compositions and uses thereof

InactiveUS20020103091A1Low viscosityImprove abilitiesEsterified saccharide compoundsSugar derivativesPolyolOxygen

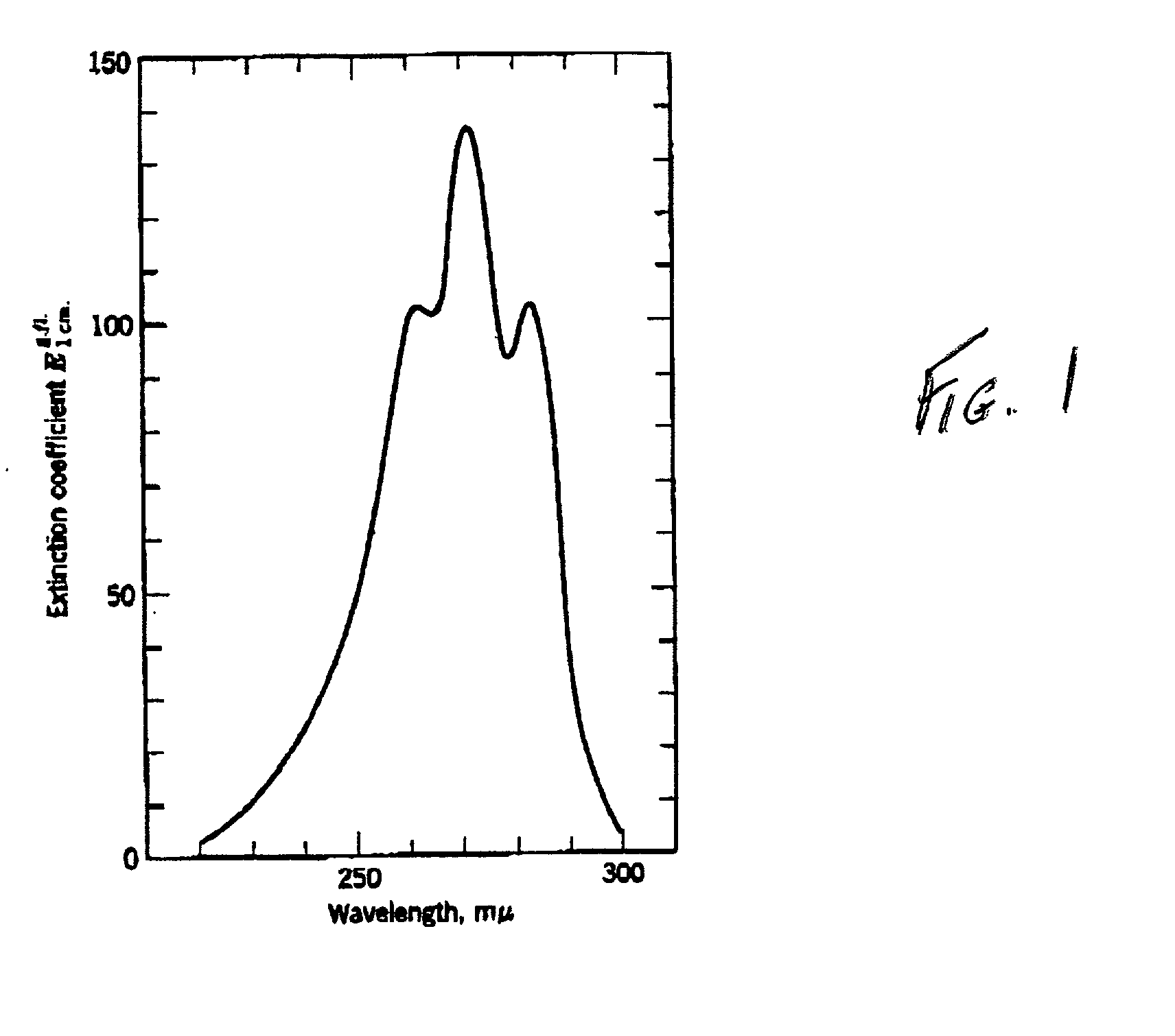

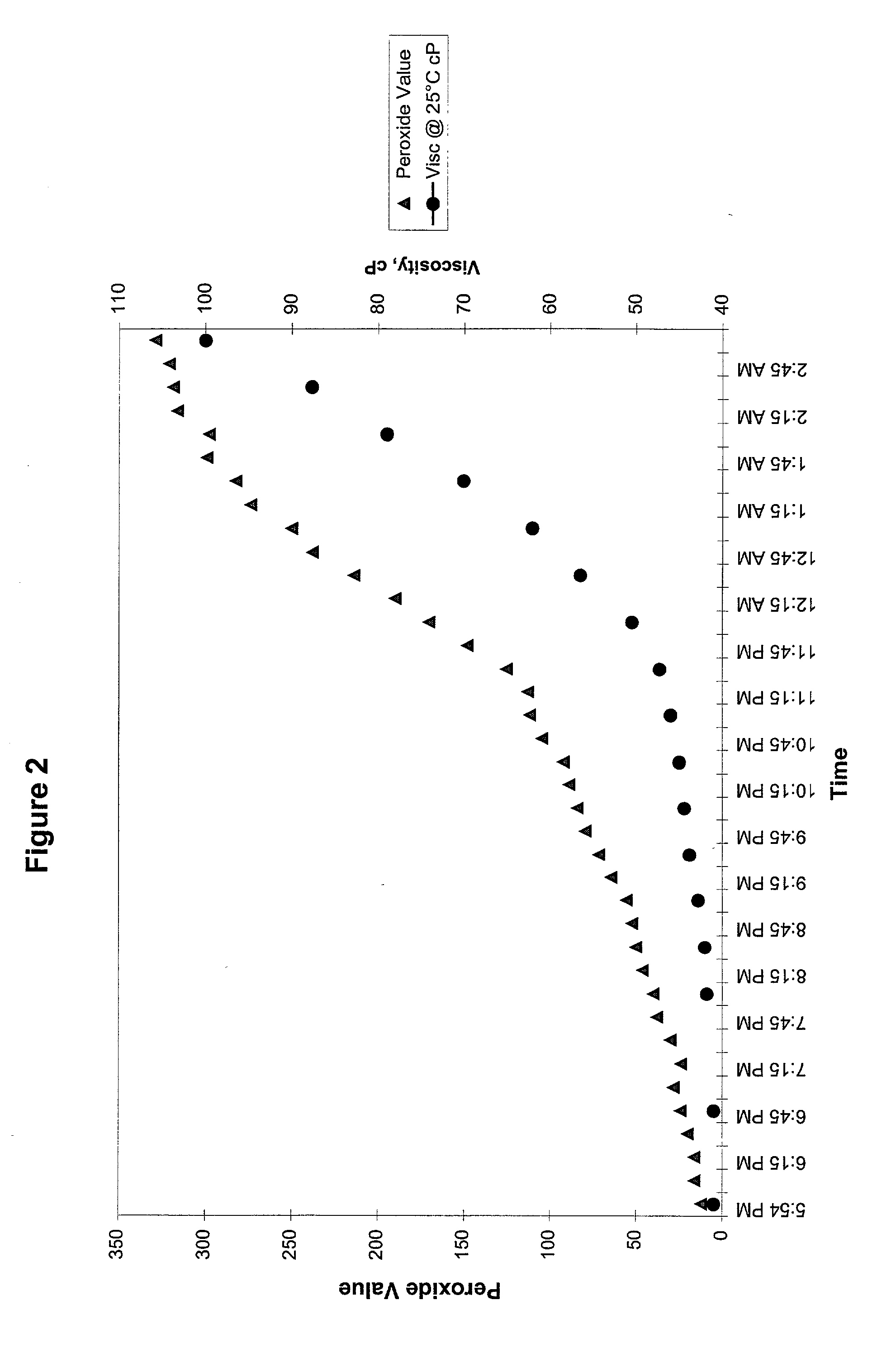

A process for modifying an unsaturated polyol fatty acid ester stock, such as an unsaturated triacylglycerol oil, to enhance its reactivity provided. The method includes reacting the unsaturated polyol fatty acid ester stock with an oxygenating agent, such as an oxygen-containing gas. Tempering oils containing reactive polyol fatty acid esters and methods for their production and use are also provided.

Owner:CARGILL INC

Antimicrobial compositions and methods

InactiveUS20050058673A1Effective topical antimicrobial activityReduce usageAntibacterial agentsCosmetic preparationsEtherFatty acid ester

Antimicrobial compositions, especially those useful when applied topically, particularly to mucosal tissues (i.e., mucous membranes), including a fatty acid ester, fatty ether, or alkoxide derivative thereof. The compositions can also include an enhancer component, a surfactant, a hydrophobic component, and / or a hydrophilic component. Such compositions provide effective topical antimicrobial activity and are accordingly useful in the treatment and / or prevention of conditions that are caused, or aggravated by, microorganisms (including viruses).

Owner:3M INNOVATIVE PROPERTIES CO

Purification of glycerin

InactiveUS7126032B1Low costEfficient recyclingOrganic compound preparationOxygen compounds purification/separationAlcoholWash water

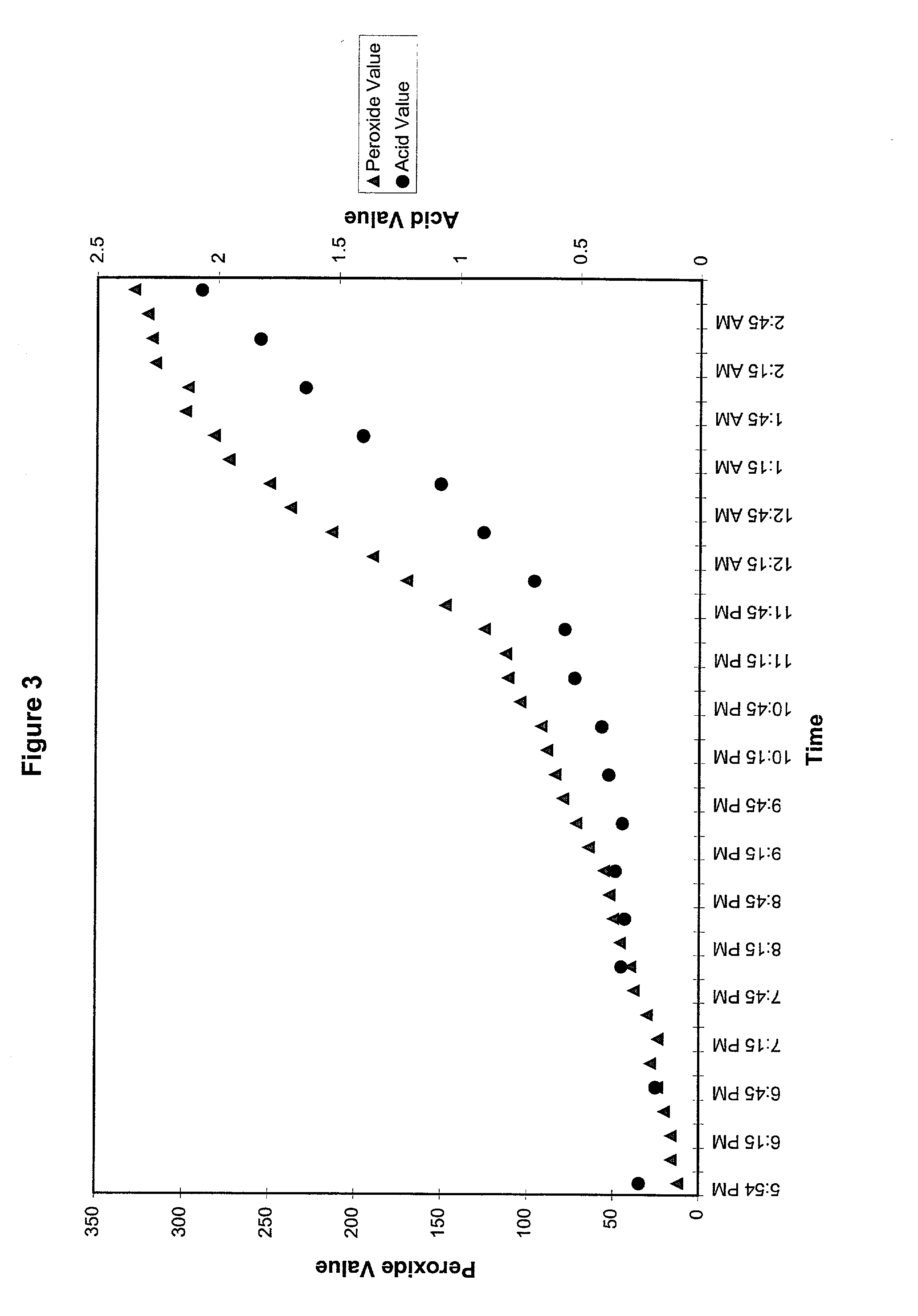

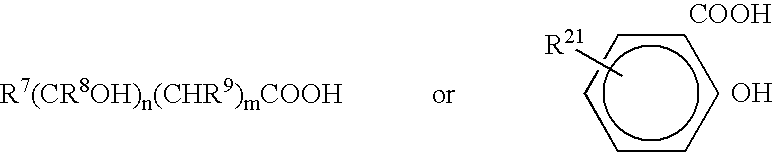

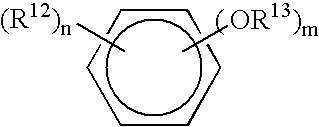

A process for purifying glycerin recovered as a byproduct of biodiesel production comprises heating a glycerin effluent stream containing a low molecular weight alcohol, water and fatty acid esters of the low molecular weight alcohol to cause transesterification of the fatty acid esters to glycerides and additional low molecular weight alcohol. The reaction mixture is sparged with nitrogen to help remove water and low molecular weight alcohol, which drives the transesterification reaction towards glyceride formation. A wash water stream may also be added to the recovered glycerin stream from biodiesel production. Either before or following the transesterification reaction, an oil layer can be separated from the recovered glycerin stream by reducing the pH of the stream to below 7. Following separation of the oil layer and transesterification the glycerin stream is flash distilled to separate glycerin from water, salts, and glycerides.

Owner:SUNOCO INC (R&M)

Topical Composition for Treating Pain

ActiveUS20080311167A1Ameliorate and eliminate painFree from painBiocideHydrocarbon active ingredientsSequelaPreventing pain

Topical compositions having as the active ingredient a lipid, fatty acid ester, natural wax, sterol, or combinations thereof referred to herein as “lipophilic vehicle” or “LV” and methods of use, have been developed for the amelioration or prevention of pain or the sequelae of pain. The composition may be in the form of an ointment, cream, gel, lotion, spray, foam, paste, patch, suspension or dispersion. In the preferred embodiment, the formulation is a gel. The LV may contain a penetration enhancer, most preferably one with membrane disruptive properties. The formulation may be applied to or impregnated into a gauze, wrap, bandage, cotton-tipped stick, adhesive bandage strip, or other support wrap or medical bandage or wound cover. For example, the compositions may be are incorporated onto or into disposables such as hemorrhoid wipes, sponge, mouth guards, dental trays; needles or catheters; adult diapers; gloves, socks or wrist bands, for ease of application. The composition is applied topically to a site at or adjacent to a painful region. The composition is reapplied as necessary. Pain relief is typically obtained within minutes and lasts for periods of variable duration ranging from minutes to several hours and even, in some cases, days. The composition is variably effective to treat visceral, somatic and neuropathic pain both acute and chronic as well as muscle pain and stiffness and joint pain and stiffness.

Owner:EPICENTRX

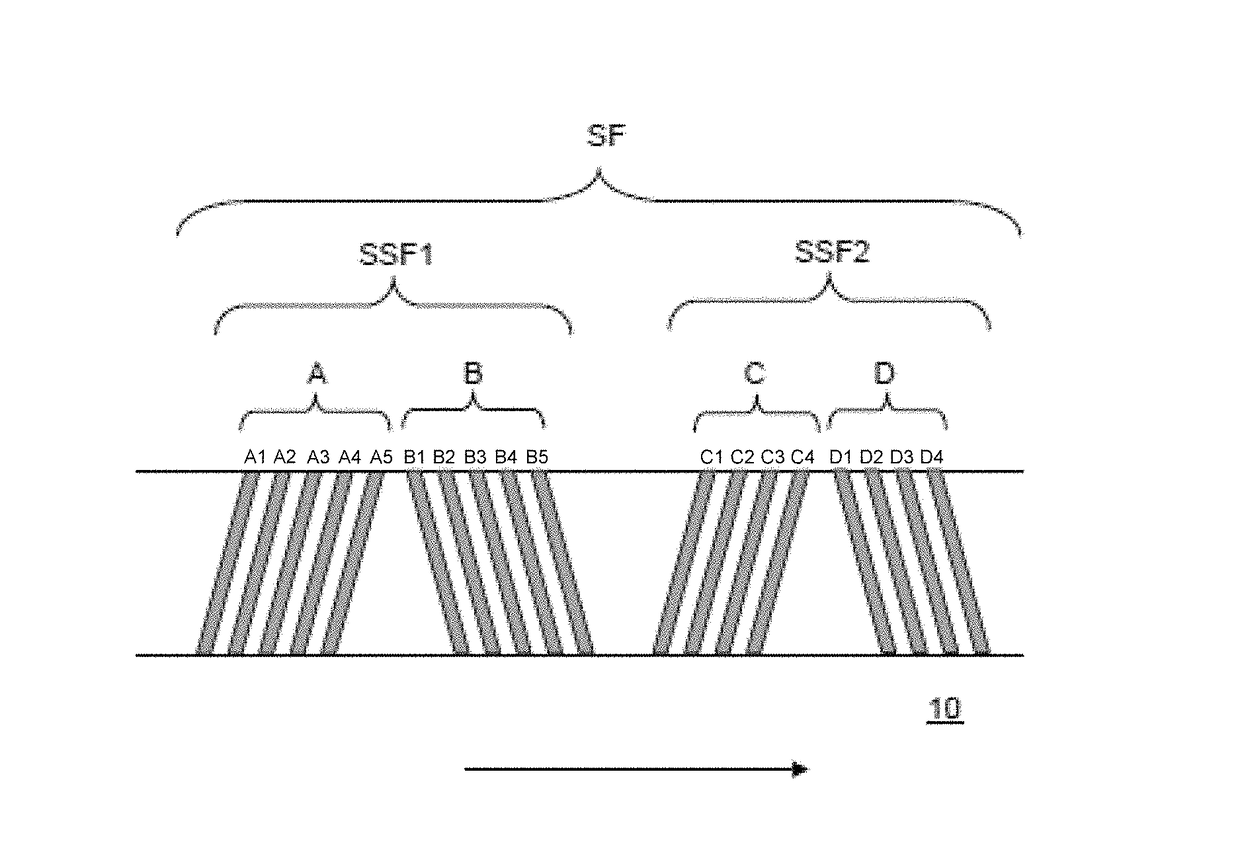

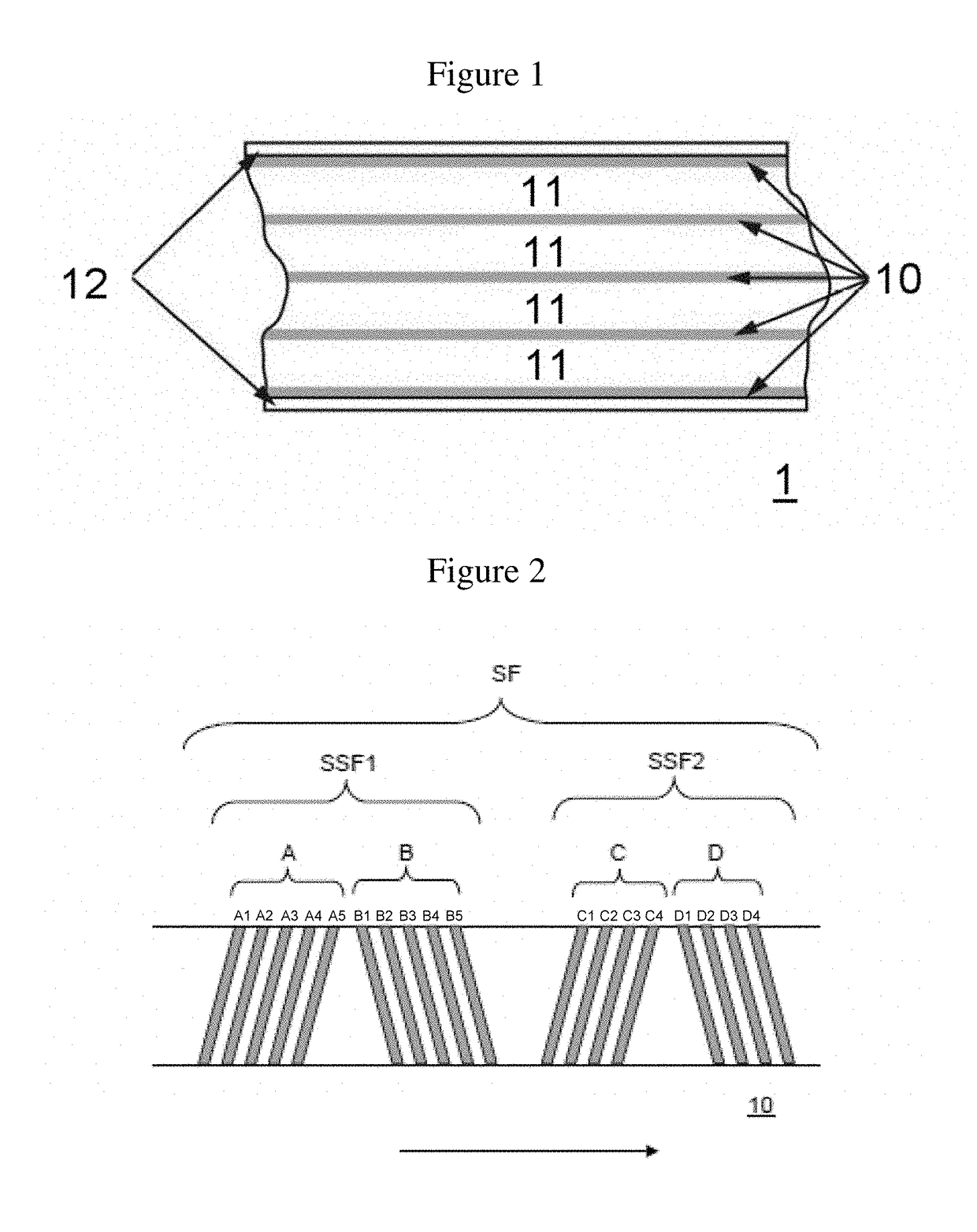

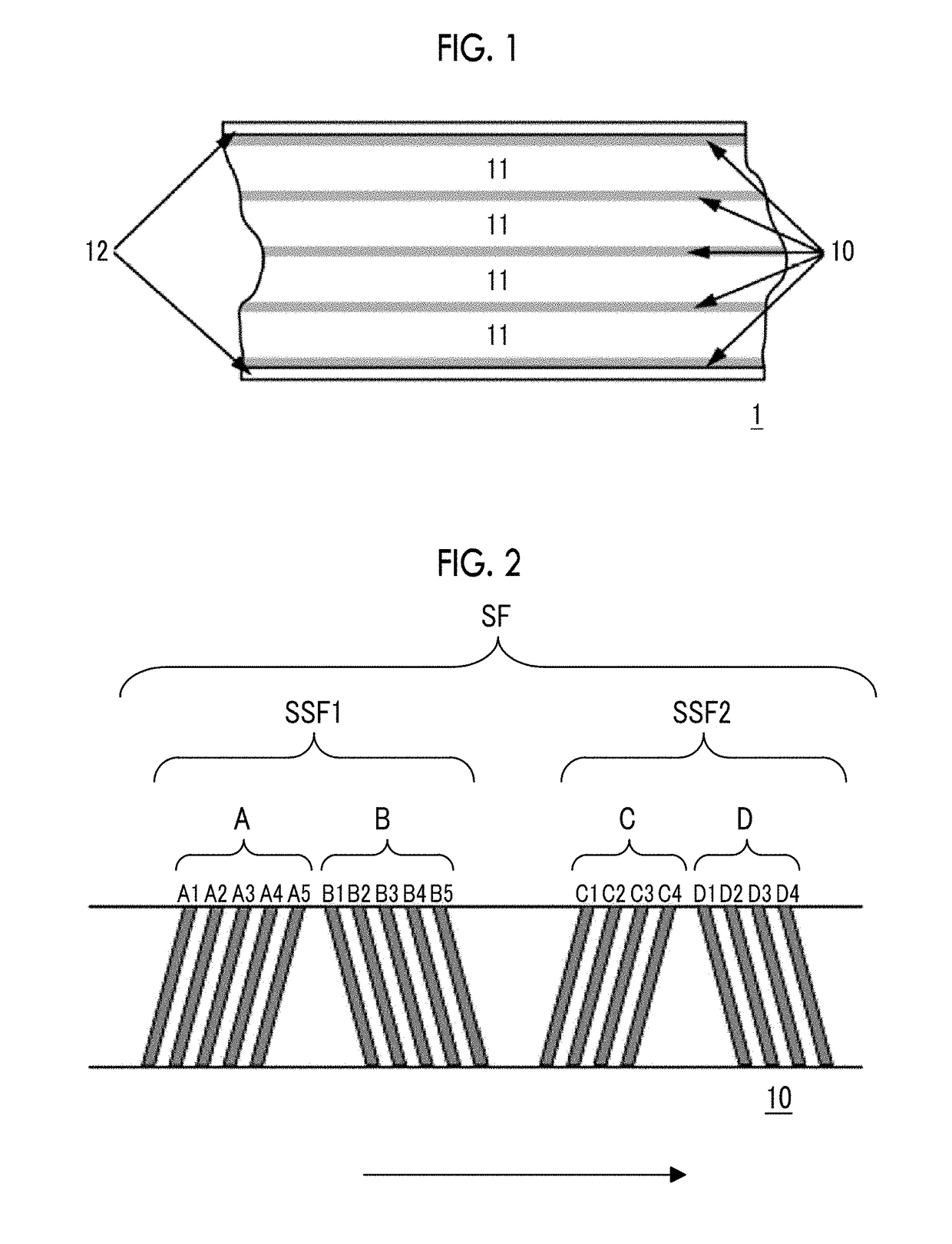

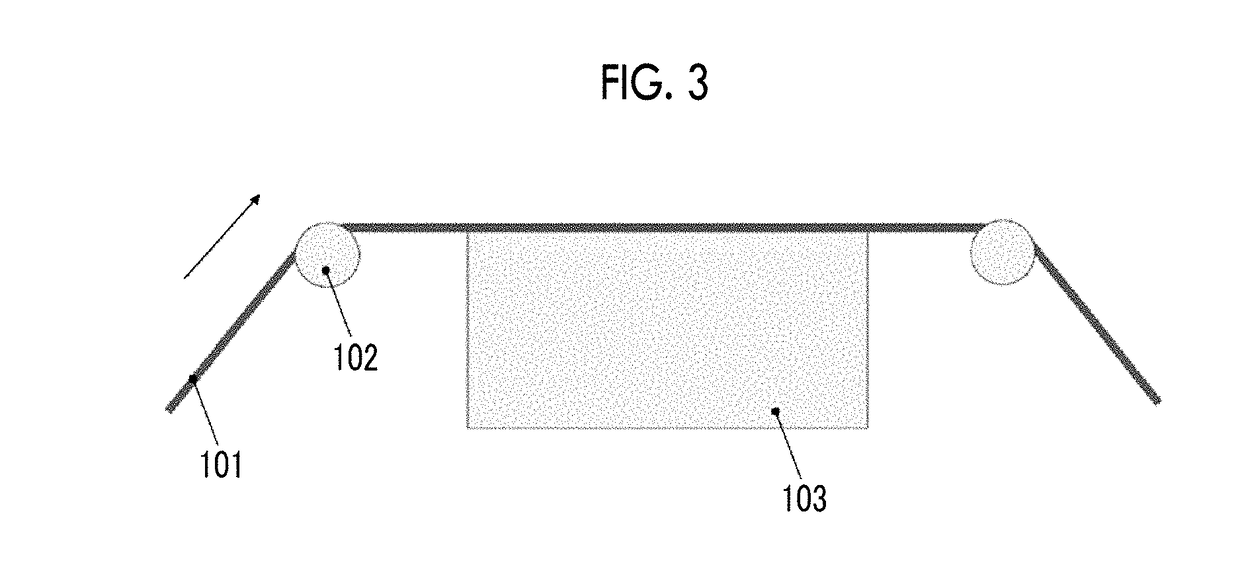

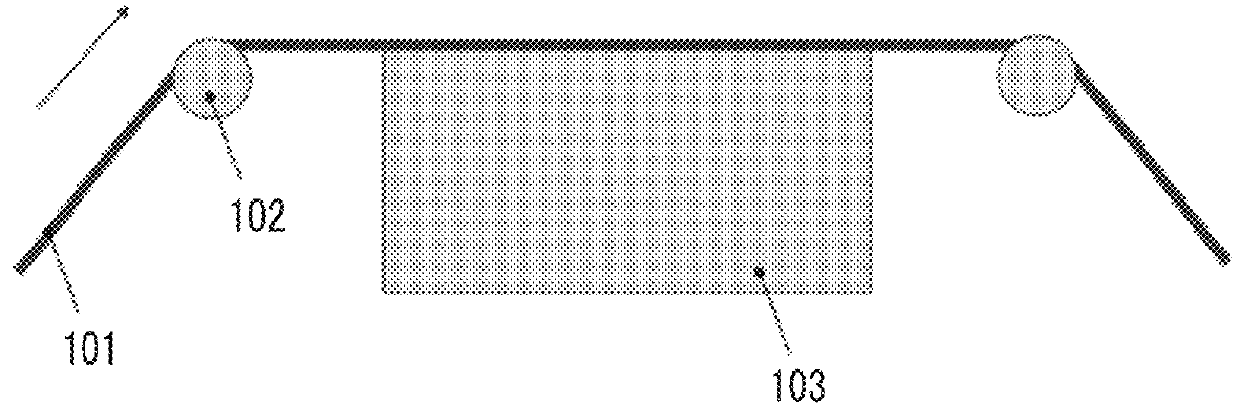

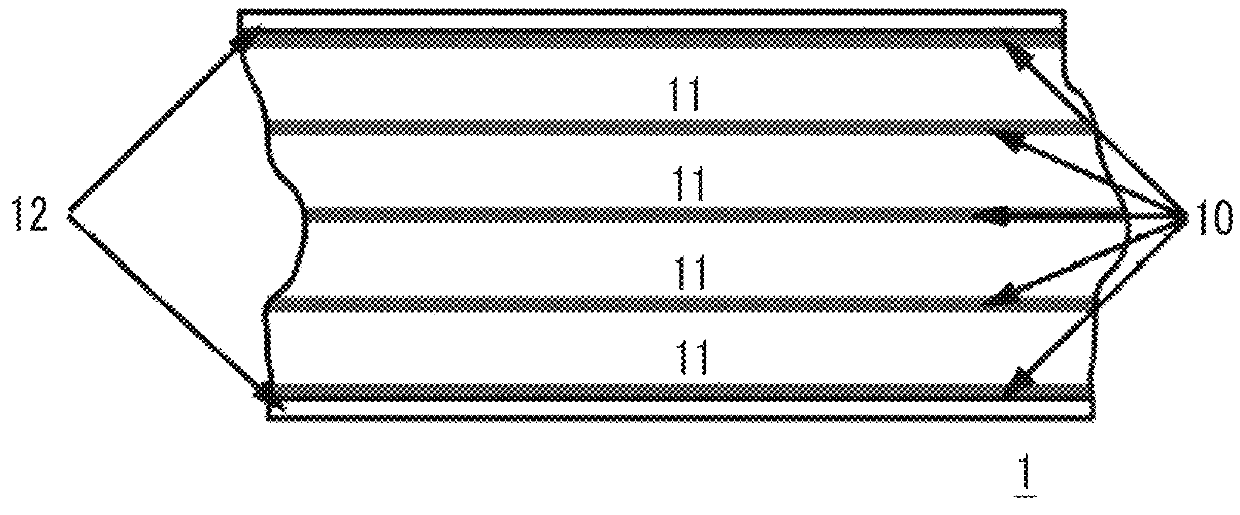

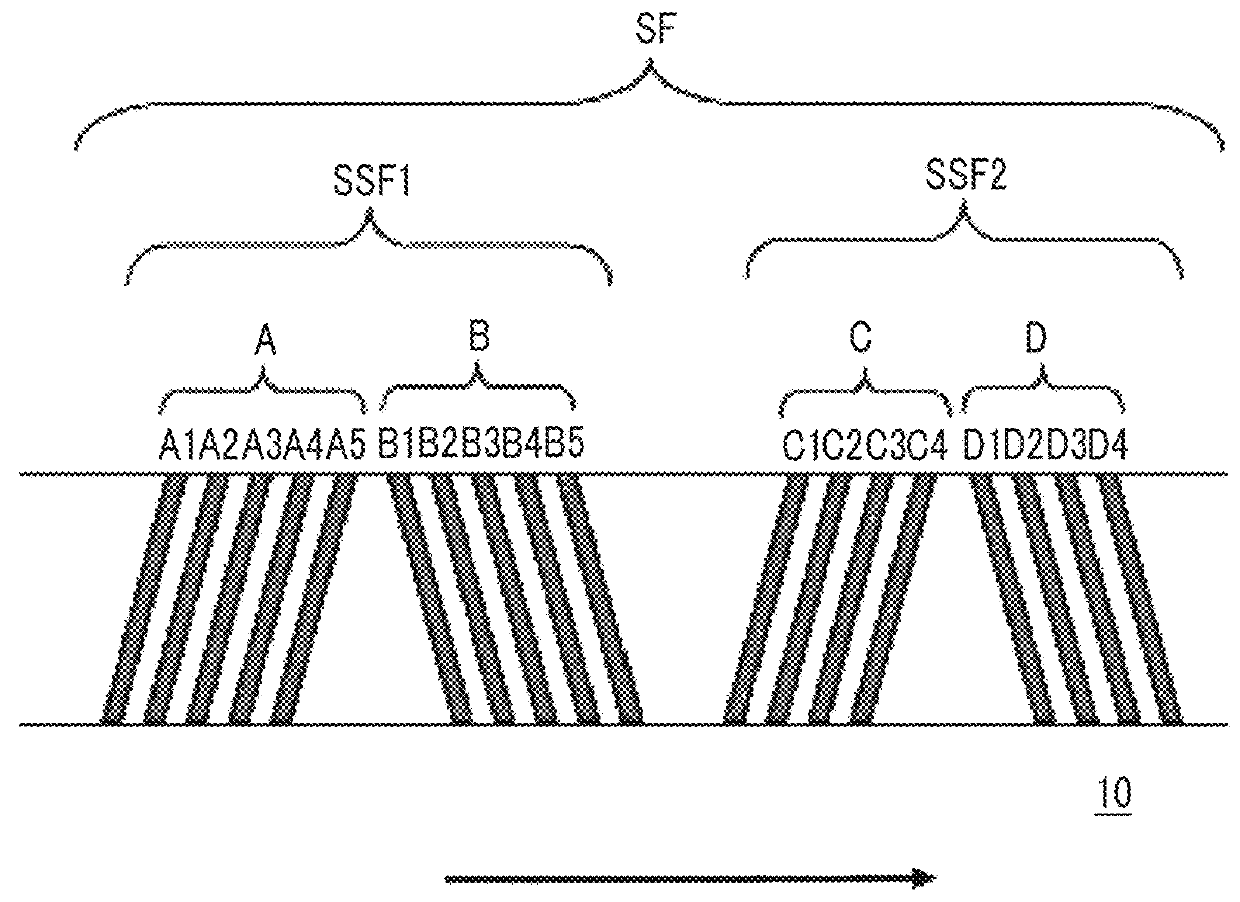

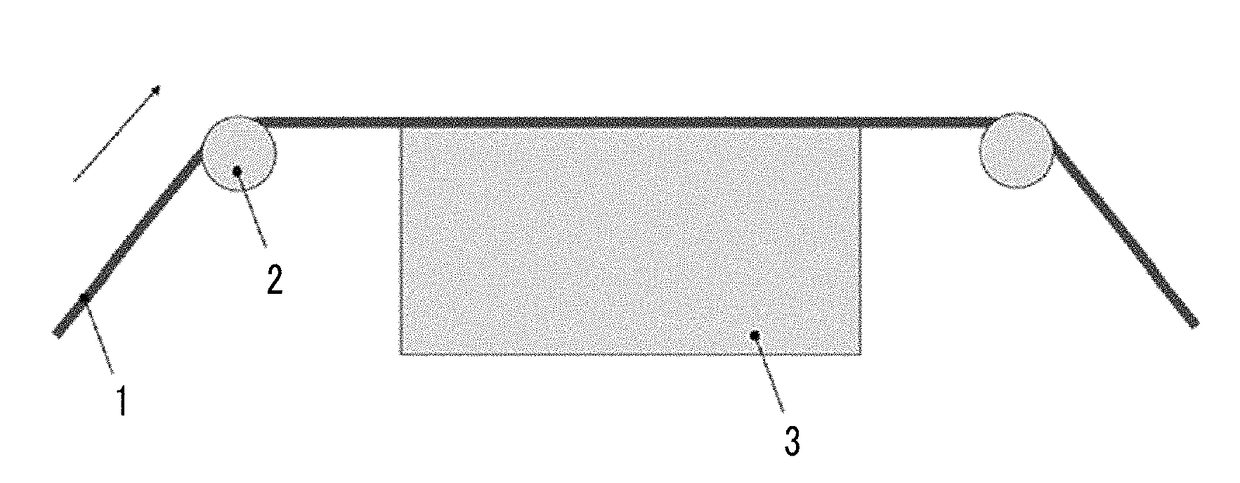

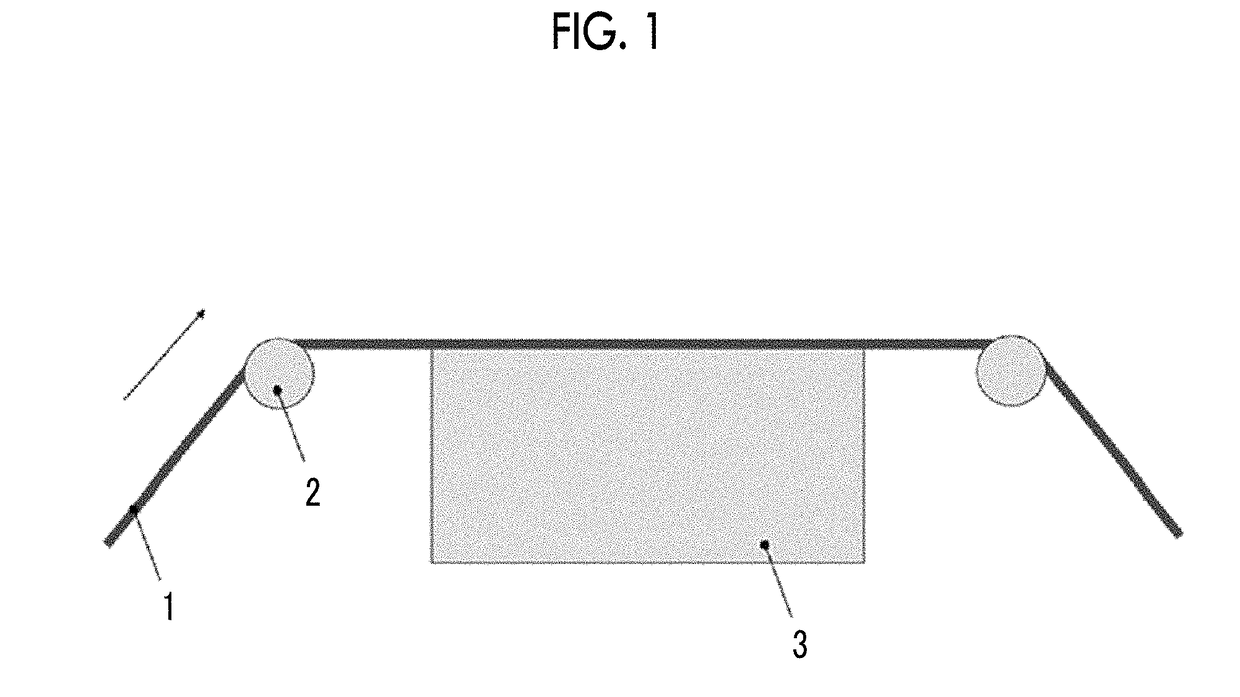

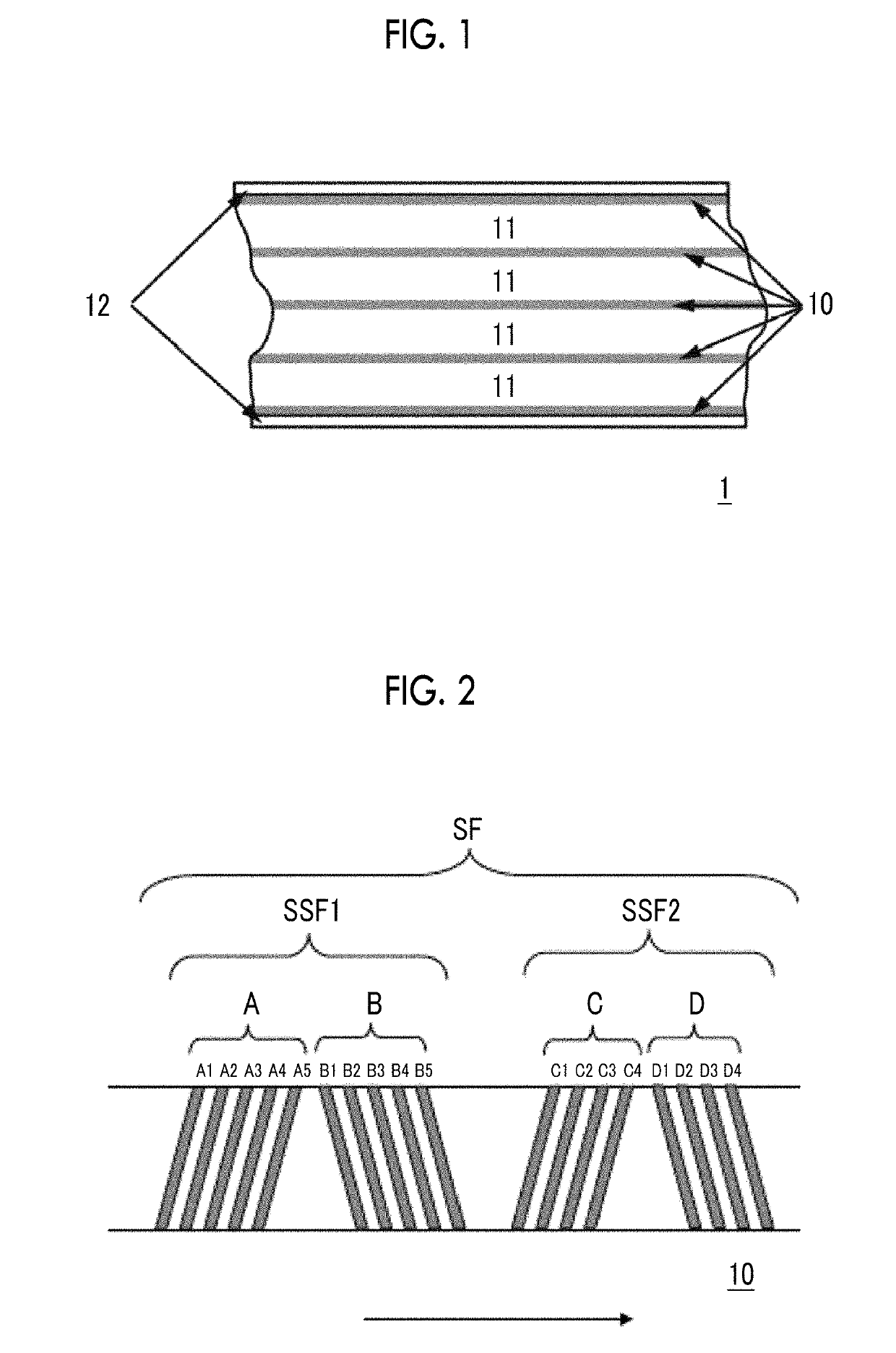

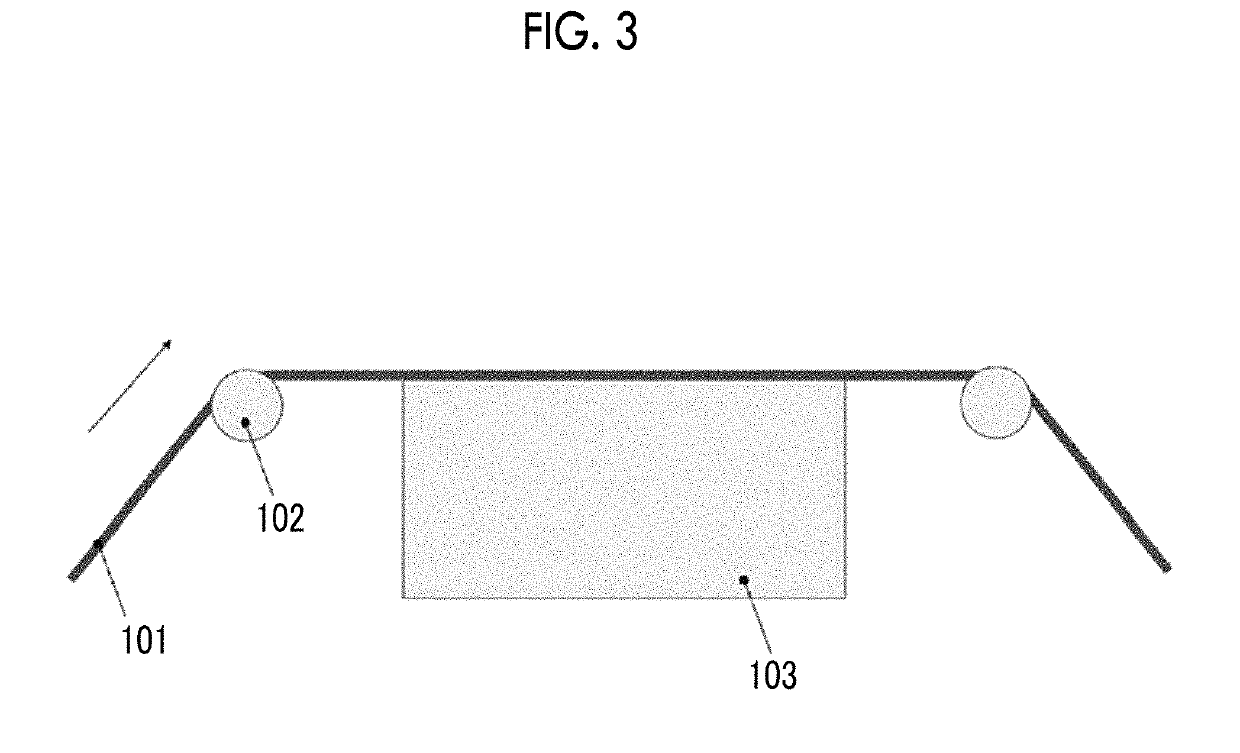

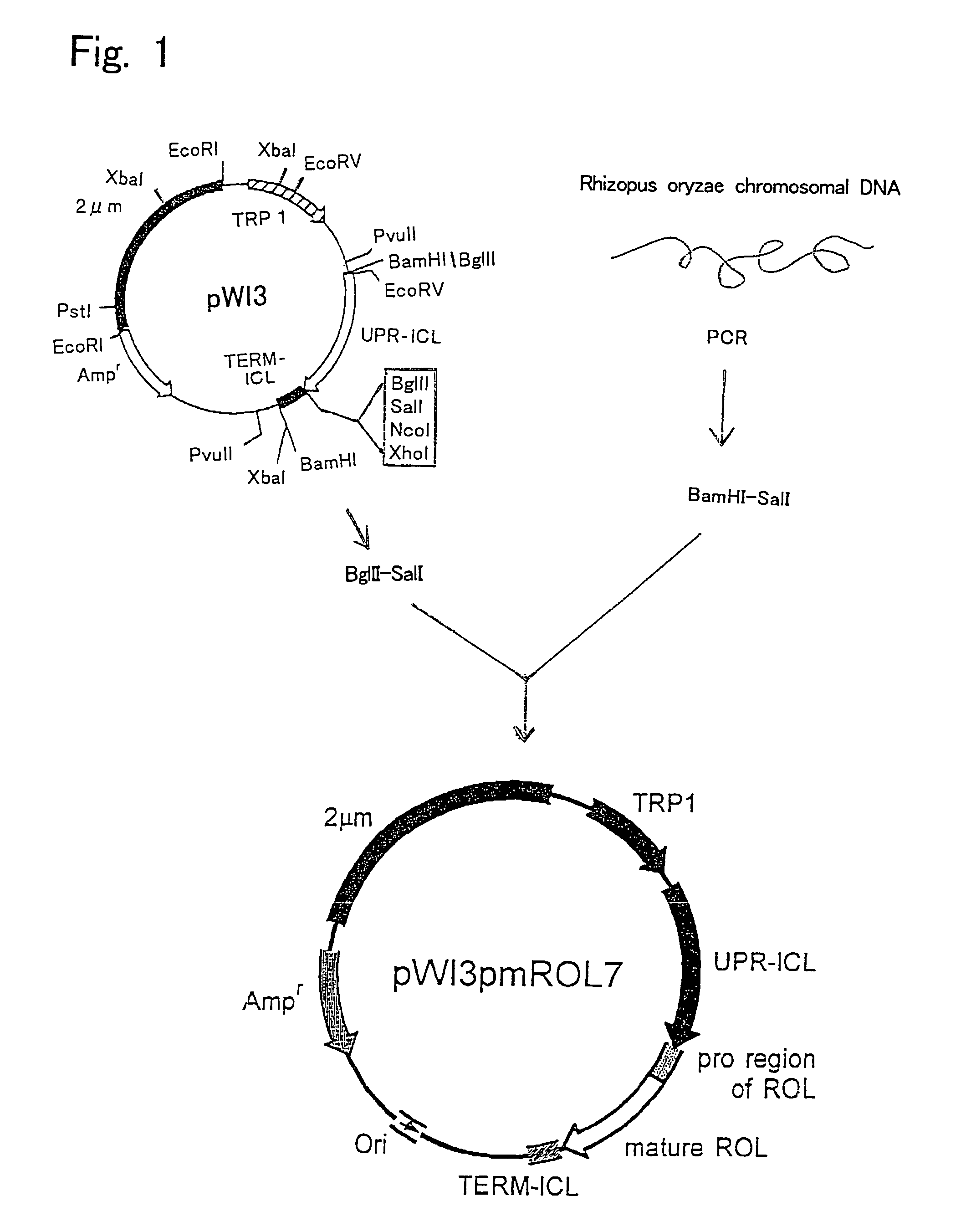

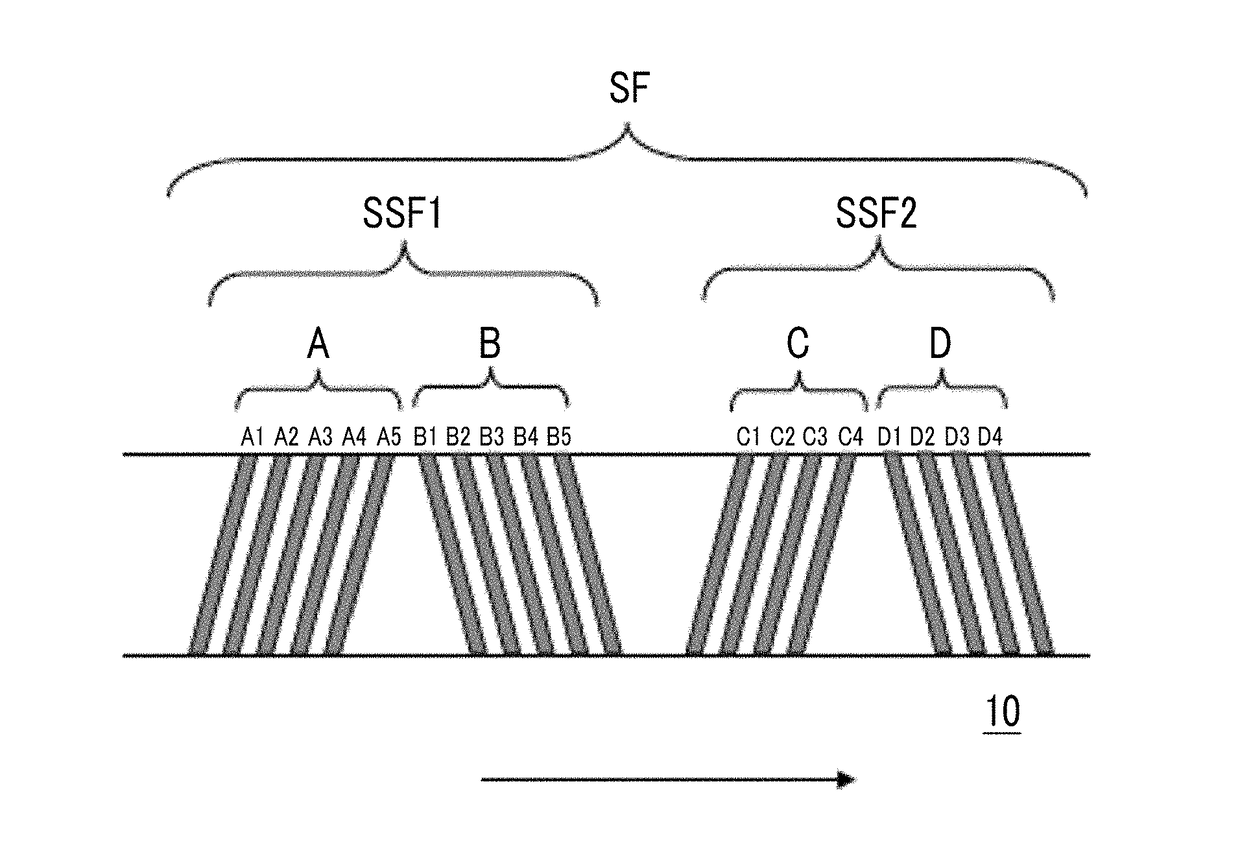

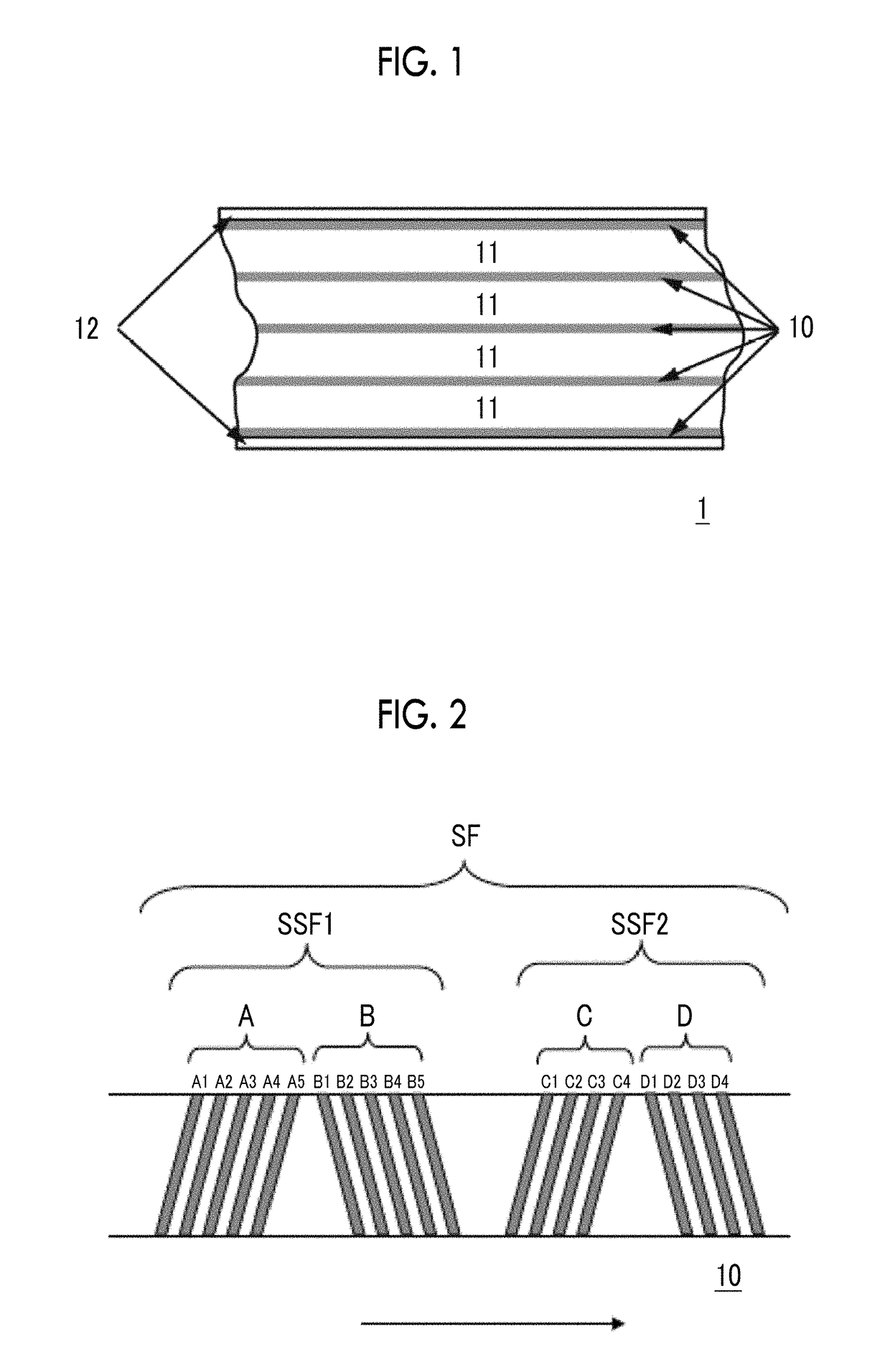

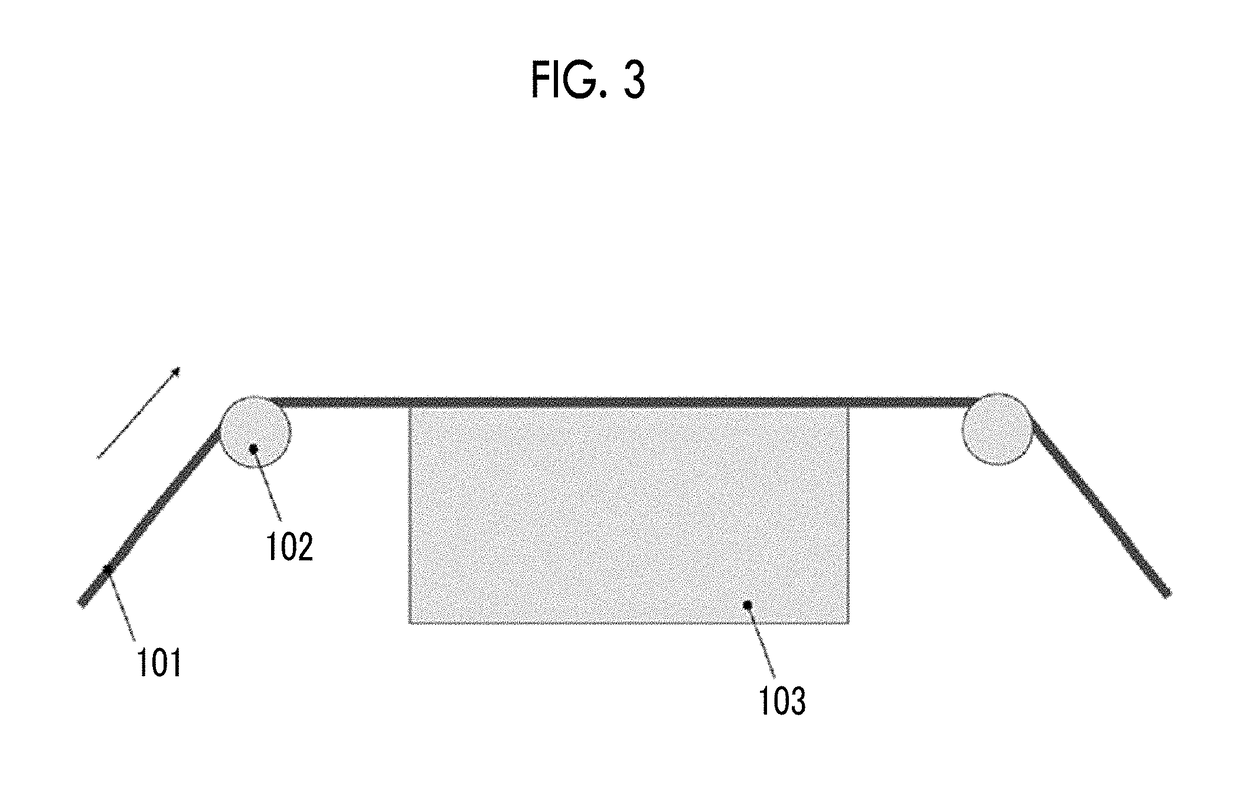

Magnetic tape device and magnetic reproducing method

ActiveUS20180286448A1Improve smoothnessImprove surface smoothnessMaterials with ironTape carriersMagnetic tapeFull width at half maximum

The magnetic tape device includes a TMR head (reproducing head); and a magnetic tape including a magnetic layer including ferromagnetic powder, a binding agent, and fatty acid ester, in which Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 7.0 nm, a difference between spacings before and after the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm, and ΔSFD (=SFD25° C.−SFD−190° C.) in a longitudinal direction of the magnetic tape is equal to or smaller than 0.50.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170372740A1Improve accuracyAccurate informationBase layers for recording layersAlignment for track following on tapesMagnetic tapeFull width at half maximum

Provided is a magnetic tape in which the total thickness is equal to or smaller than 5.30 μm, the magnetic layer includes a timing-based servo pattern, a magnetic layer surface Ra is equal to or smaller than 1.8 nm, the magnetic layer includes fatty acid ester, a full width at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before performing vacuum heating with respect to the magnetic tape is greater than 0 nm and equal to or smaller than 7.0 nm, a full width at half maximum of spacing distribution measured after performing the vacuum heating is greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured after performing the vacuum heating and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180286442A1Improve smoothnessImprove surface smoothnessMaterials with ironRecord information storageIn planeX-ray

The magnetic tape device includes a TMR head (reproducing head); and a magnetic tape including a magnetic layer including ferromagnetic hexagonal ferrite powder, a binding agent, and fatty acid ester, in which an XRD intensity ratio obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio is 0.65 to 1.00, Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between spacings before and after the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

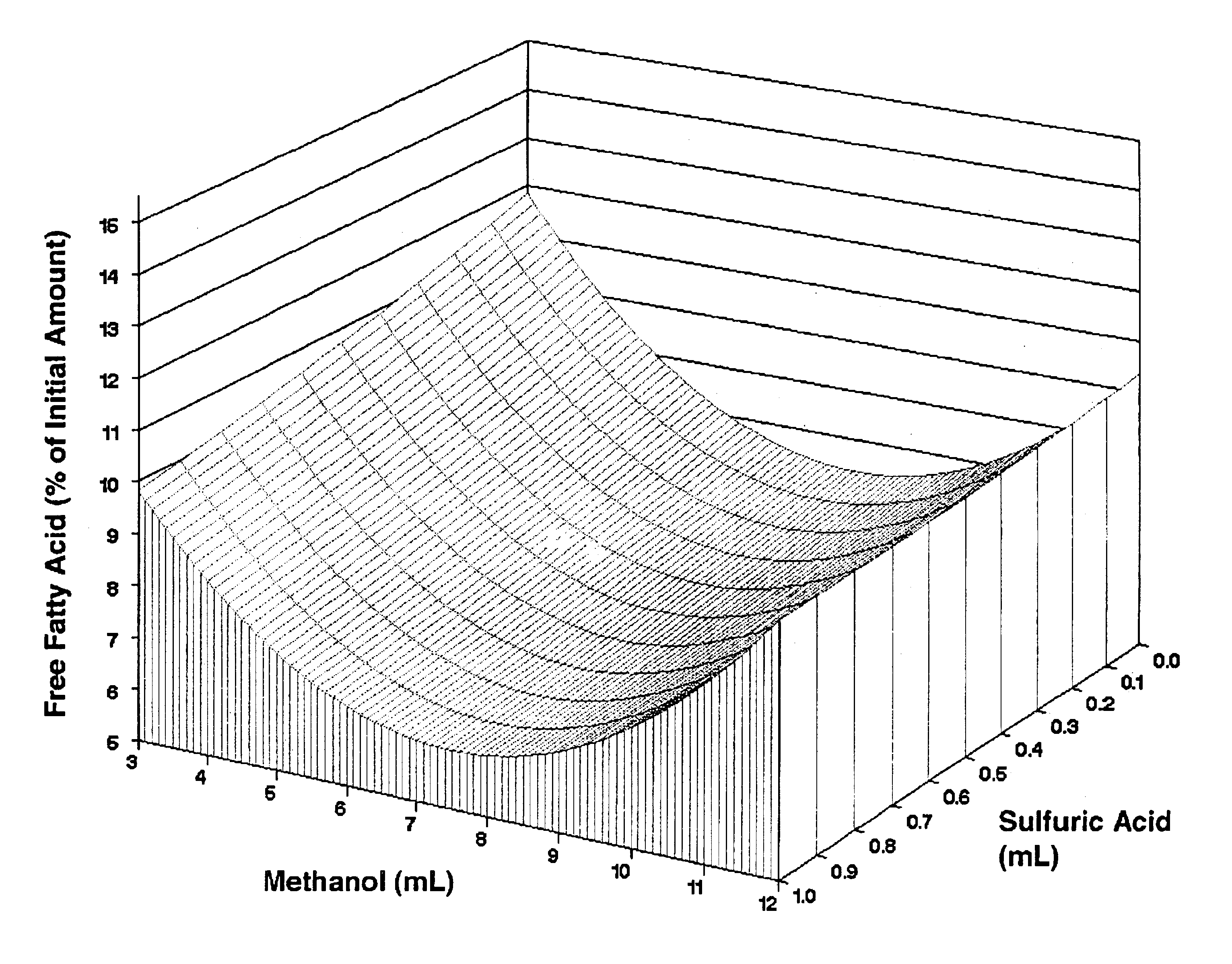

Lipid rich compositions, production of lipid rich compositions, production of fatty acid alkyl esters from heterogeneous lipid mixtures

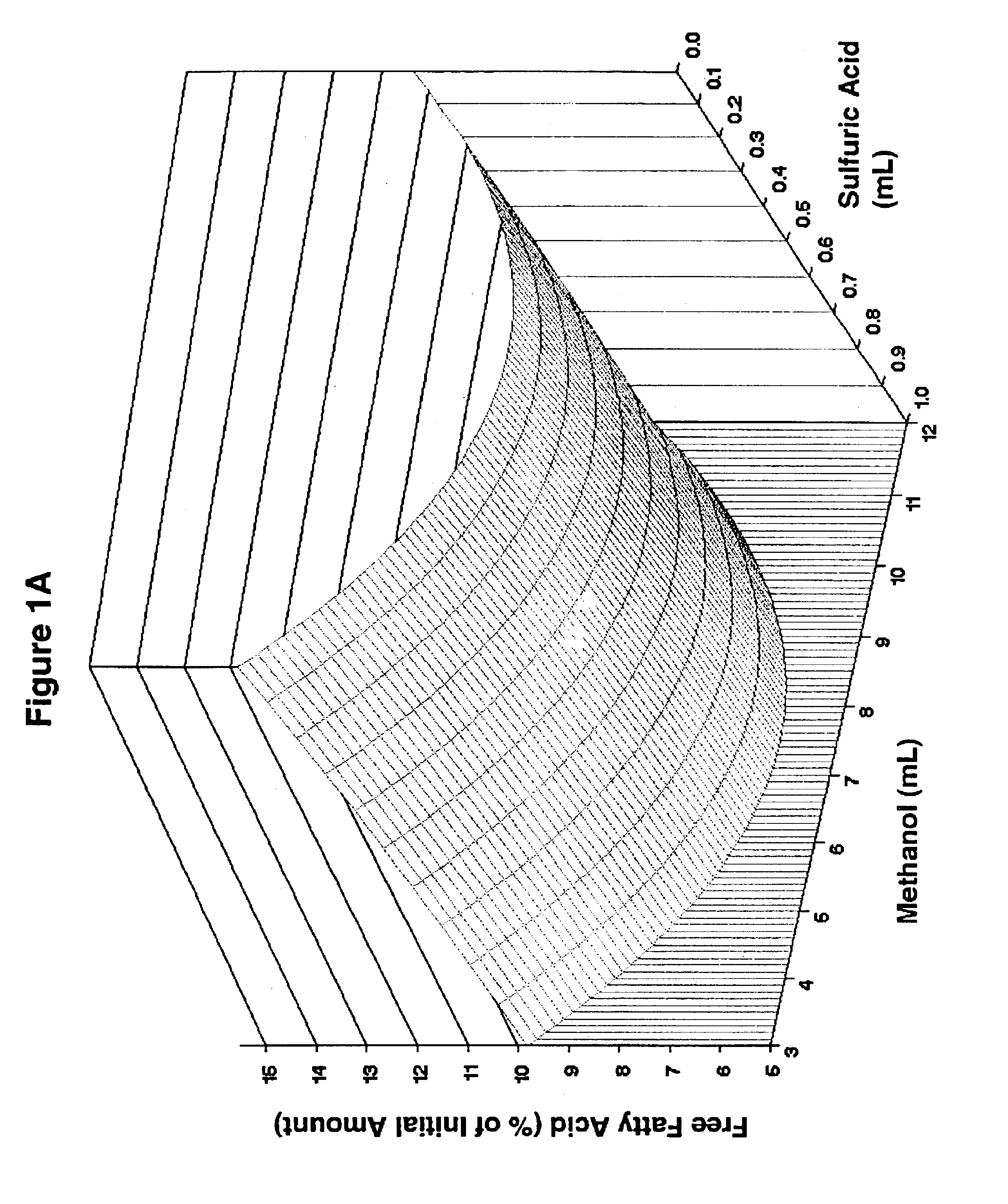

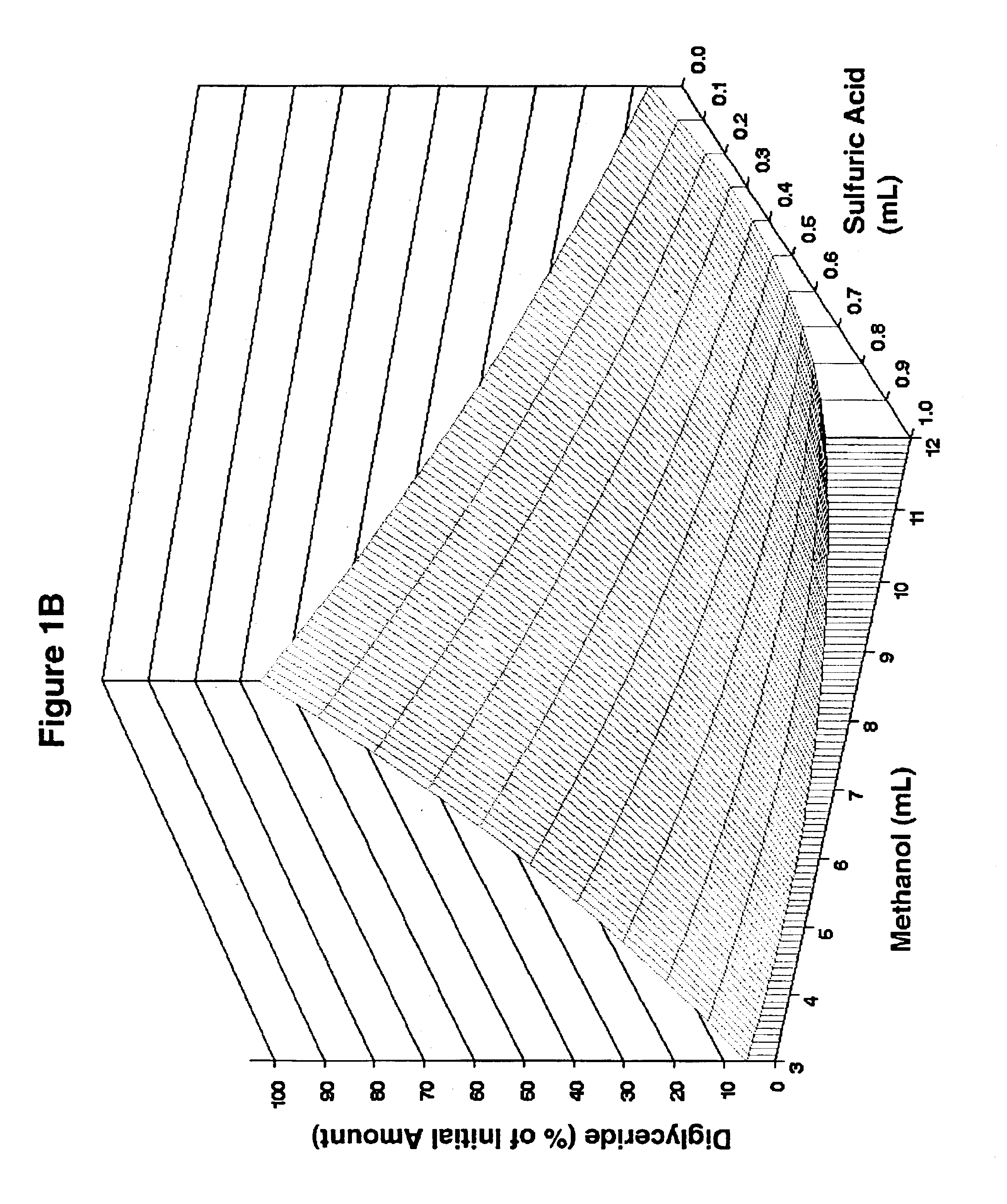

InactiveUS6855838B2Fatty oils/acids recovery from wasteFatty acid esterificationFatty acid esterSulfuric acid

The present invention relates to a method for producing fatty acid alkyl esters, involving esterifying a material containing free fatty acids (FFA) with an alcohol and an inorganic acid catalyst to form a product containing fatty acid alkyl esters, wherein (i) the material contains at least about 40% FFA and is produced by reacting a feedstock with steam and sulfuric acid at a pH of about 1-about 2 or (ii) the material contains at least about 80% FFA and is produced by reacting a feedstock with steam and alkali at a pH of about 11-about 13 and further reacting the feedstock with steam and sulfuric acid at a pH of about 1-about 2. The feedstock may be selected from the oils or soapstocks of soy, coconut, corn, cotton, flax, palm, rapeseed / canola, safflower, sunflower; animal fats; waste greases; and mixtures thereof; or other fully or partially hydrolyzed preparations of such feedstocks. The present invention also relates to a method for producing a lipid rich composition containing at least about 80% FFA, the method involving reacting a feedstock with steam and alkali at a pH of about 11-about 13 and further reacting the feedstock with steam and sulfuric acid at a pH of about 1-about 2. The feedstock may be selected from soy, coconut, corn, cotton, flax, palm, rapeseed / canola, safflower, sunflower, animal fats, waste greases, and mixtures thereof. The feedstock may be selected from the oils or soapstocks of soy, coconut, corn, cotton, flax, palm, rapeseed / canola, safflower, sunflower; animal fats; waste greases; and mixtures thereof; or other fully or partially hydrolyzed preparations of such feedstocks. Furthermore, the present invention concerns a lipid rich composition containing at least about 80% FFA.

Owner:RUNYON IND +1

Magnetic tape and magnetic tape device

ActiveUS9837116B2Increase the number ofIncrease recording capacityAlignment for track following on tapesRecord information storageMagnetic tapeSurface roughness

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20170221517A1Good electromagnetic propertiesCompromise running stabilityMagnetic materials for record carriersBase layers for recording layersMagnetic tapeOptoelectronics

The magnetic tape has a magnetic layer and a backcoat layer, wherein, each of the magnetic layer and backcoat layer contains a fatty acid ester, the Ra measured on the magnetic layer side surface is less than or equal to 2.8 nm, the difference between the spacing measured by optical interferometry on the magnetic layer side surface after and before vacuum heating is greater than 0 nm but less than or equal to 8.0 nm, the FWHMbefore on the backcoat layer side surface is greater than 0 nm but less than or equal to 10.0 nm, the FWHMafter on the backcoat layer side surface is greater than 0 nm but less than or equal to 10.0 nm; and the difference between the spacing measured on the backcoat layer side surface after and before vacuum heating is greater than 0 nm but less than or equal to 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170372744A1Restrain output decreaseImprove accuracyBase layers for recording layersAlignment for track following on tapesMagnetic tapeFull width at half maximum

Provided is a magnetic tape in which the total thickness of a non-magnetic layer and a magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes a timing-based servo pattern, the magnetic layer includes fatty acid ester, a full width at half maximum of spacing distribution measured by optical interferometry regarding the surface of the magnetic layer before performing vacuum heating with respect to the magnetic tape is greater than 0 nm and equal to or smaller than 7.0 nm, a full width at half maximum of spacing distribution measured after performing the vacuum heating is greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured after performing the vacuum heating and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape device and head tracking servo method

ActiveUS10008230B1Improve accuracyExact reproductionProtective coatings for layersFilamentary/web record carriersMagnetic tapeFull width at half maximum

The magnetic tape device includes: a magnetic tape; and a servo head, in which the servo head is a TMR head, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder, a binding agent, and fatty acid ester on the non-magnetic support, the magnetic layer includes a servo pattern, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured by optical interferometry regarding the surface of the magnetic layer after performing the vacuum heating with respect to the magnetic tape and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 9.0 nm.

Owner:FUJIFILM CORP

Soaps Produced from Oil-Bearing Microbial Biomass and Oils

ActiveUS20090305942A1Improve efficiencyLow costSoap detergents with organic compounding agentsBiofuelsMicroorganismMicrobial oil

Soap and cosmetic products can be made from oil-bearing microbial biomass via the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts. The saponified microbial oils / lipids can be combined with a variety of additives to produce compositions for use as soaps and other cosmetic products, which may also contain other constituents of the biomass, including unsaponified oils, glycerol and carotenoids, among others.

Owner:CORBION BIOTECH INC

Magnetic tape and method of manufacturing the same

ActiveUS9959894B2Solve the lack of durabilityHigh densityTape carriersRecord information storageMedicineMagnetic tape

The magnetic tape comprises a nonmagnetic layer comprising nonmagnetic powder and binder on a nonmagnetic support, and comprises a magnetic layer comprising ferromagnetic powder and binder on the nonmagnetic layer, wherein a fatty acid ester, a fatty acid amide, and a fatty acid are contained in either one or both of the magnetic layer and the nonmagnetic layer, with the magnetic layer and nonmagnetic layer each comprising at least one selected from the group consisting of a fatty acid ester, a fatty acid amide, and a fatty acid, a quantity of fatty acid ester per unit area of the magnetic layer in extraction components extracted from a surface of the magnetic layer with n-hexane falls within a range of 1.00 mg / m2 to 10.00 mg / m2, and a weight ratio of the quantity of fatty acid ester per unit area of the magnetic layer to a combined total of a quantity of fatty acid amide and a quantity of fatty acid, quantity of fatty acid ester / (quantity of fatty acid amide+quantity of fatty acid), per unit area of the magnetic layer falls within a range of 1.00 to 3.00 in the extraction components.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20180286443A1Deterioration of characteristicMaterials with ironRecord information storageMagnetic tapeFull width at half maximum

The magnetic tape has the total thickness of a non-magnetic layer and a magnetic layer of 0.60 μm or smaller, the magnetic layer including an abrasive and fatty acid ester, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer with respect to the total area of the region, obtained by plane observation performed by using an SEM of 0.02% or greater and less than 0.06%, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape of greater than 0 nm and 7.0 nm or smaller, and a difference between spacings before and after the vacuum heating of greater than 0 nm and 8.0 nm or smaller.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180286439A1Improve smoothnessImprove surface smoothnessTape carriersRecord information storageMagnetic force microscopeMagnetic tape

The magnetic tape device includes a TMR head and a magnetic tape, in which the magnetic tape includes fatty acid ester in a magnetic layer, Ra measured regarding a surface of the magnetic layer is 2.0 nm or smaller, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and 7.0 nm or smaller, a difference between spacings before and after the vacuum heating is greater than 0 nm and 8.0 nm or smaller, and a ratio of an average area Sdc of a magnetic cluster of the magnetic tape in a DC demagnetization state and an average area Sac of a magnetic cluster thereof in an AC demagnetization state measured with a magnetic force microscope is 0.80 to 1.30.

Owner:FUJIFILM CORP

Magnetic tape device and head tracking servo method

ActiveUS20190096437A1Improve accuracyExact reproductionMaterials with ironAlignment for track following on tapesMagnetic tapeFull width at half maximum

The magnetic tape device includes a TMR head (servo head); and a magnetic tape, in which a magnetic layer of the magnetic tape includes fatty acid ester, Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and equal to or smaller than 7.0 nm, a difference between spacings before and after the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm, and ΔSFD (=SFD25° C.−SFD−#° C.) in a longitudinal direction of the magnetic tape is equal to or smaller than 0.50.

Owner:FUJIFILM CORP

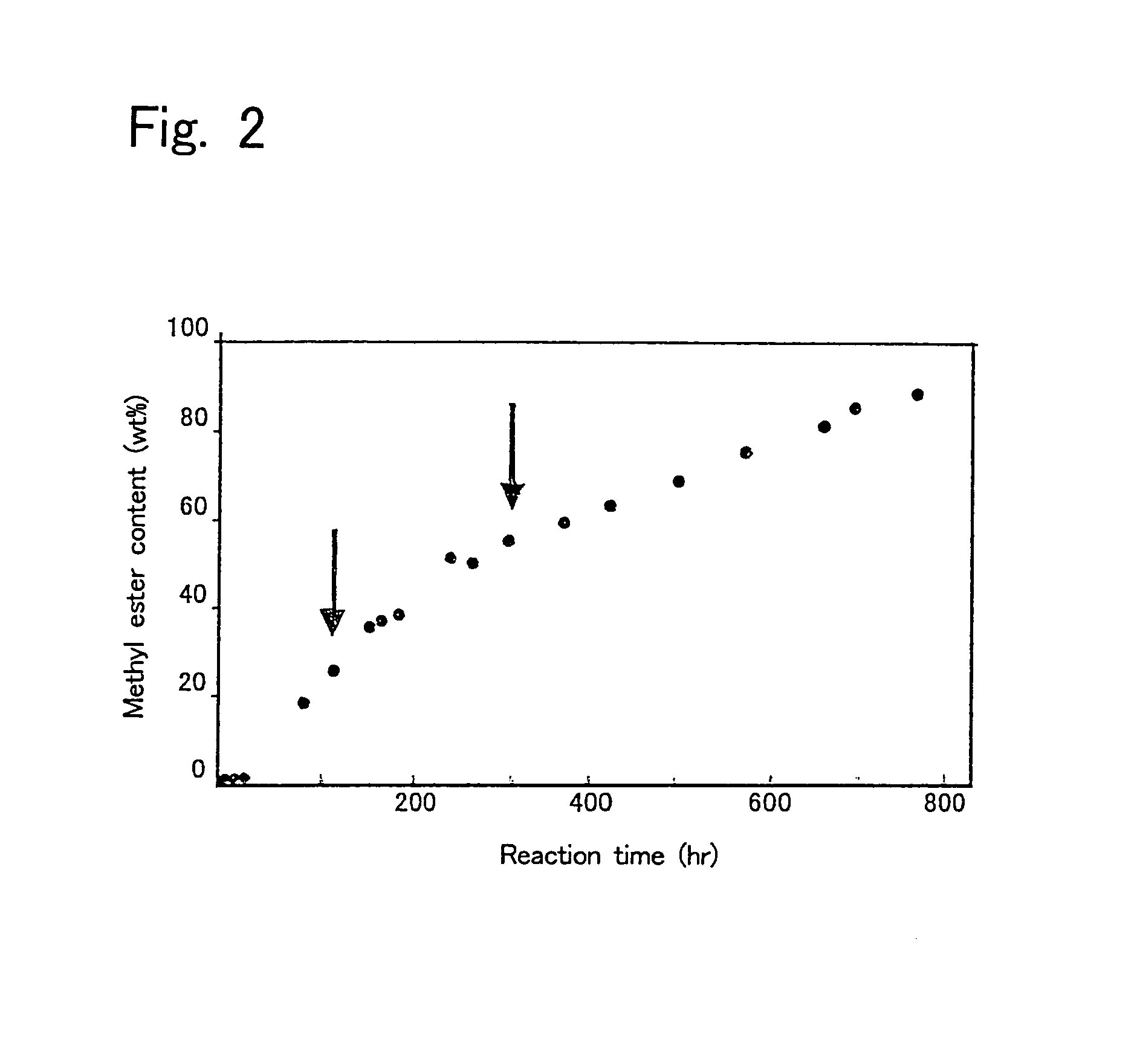

Process for producing fatty acid lower alcohol ester

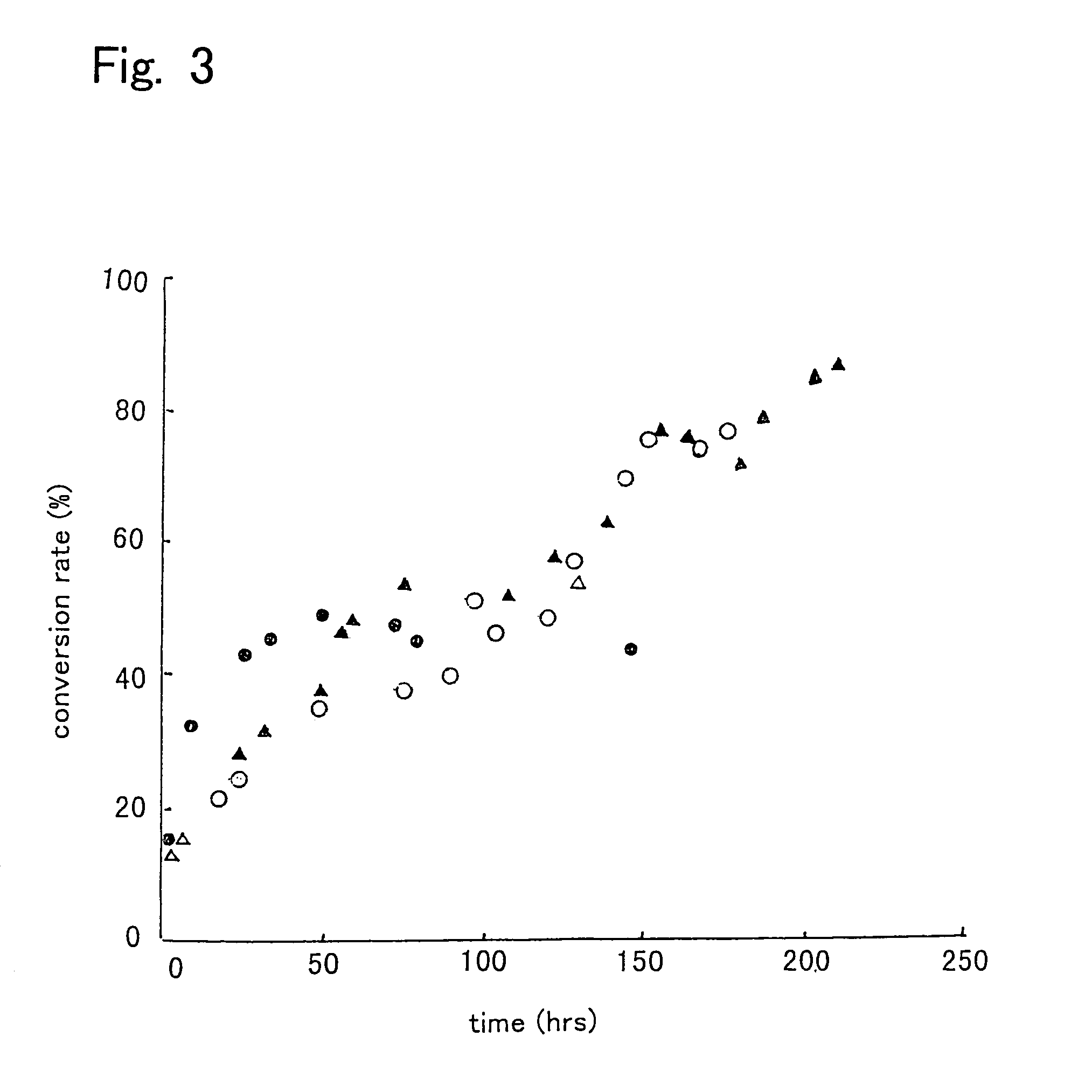

InactiveUS6982155B1Efficient productionImprove permeabilityFatty acid chemical modificationOrganic compound preparationOil and greaseMicroorganism

The present invention provides a method for producing a fatty acid ester inexpensively and efficiently by reacting a lipase or an intact mircroorganism containing a lipase, an oil and fat, and a linear lower alcohol in a system containing little or no solvent in the presence of water. The intact microorganism has not been treated with a solvent or the like, and is used as such, so that a fatty acid ester can be prepared in a simple manner. An oil and fat, a natural oil and fat such as a vegetable oil and fat, an animal oil and fat, as well as a waste oil thereof can be used. According to the method of the present invention, a reaction proceeds even in the presence of water, so that waste oils containing a large amount of water can be used as a raw material. Therefore, the waste oil to be dumped into the environment can be recycled, and a biodiesel fuel, which hardly pollutes the environment, can be provided at the same time.

Owner:KANSAI CHEM ENG CO LTD

Magnetic tape

ActiveUS20180240492A1Avoid it happening againRecord information storageTape carriersCoated surfaceMagnetic tape

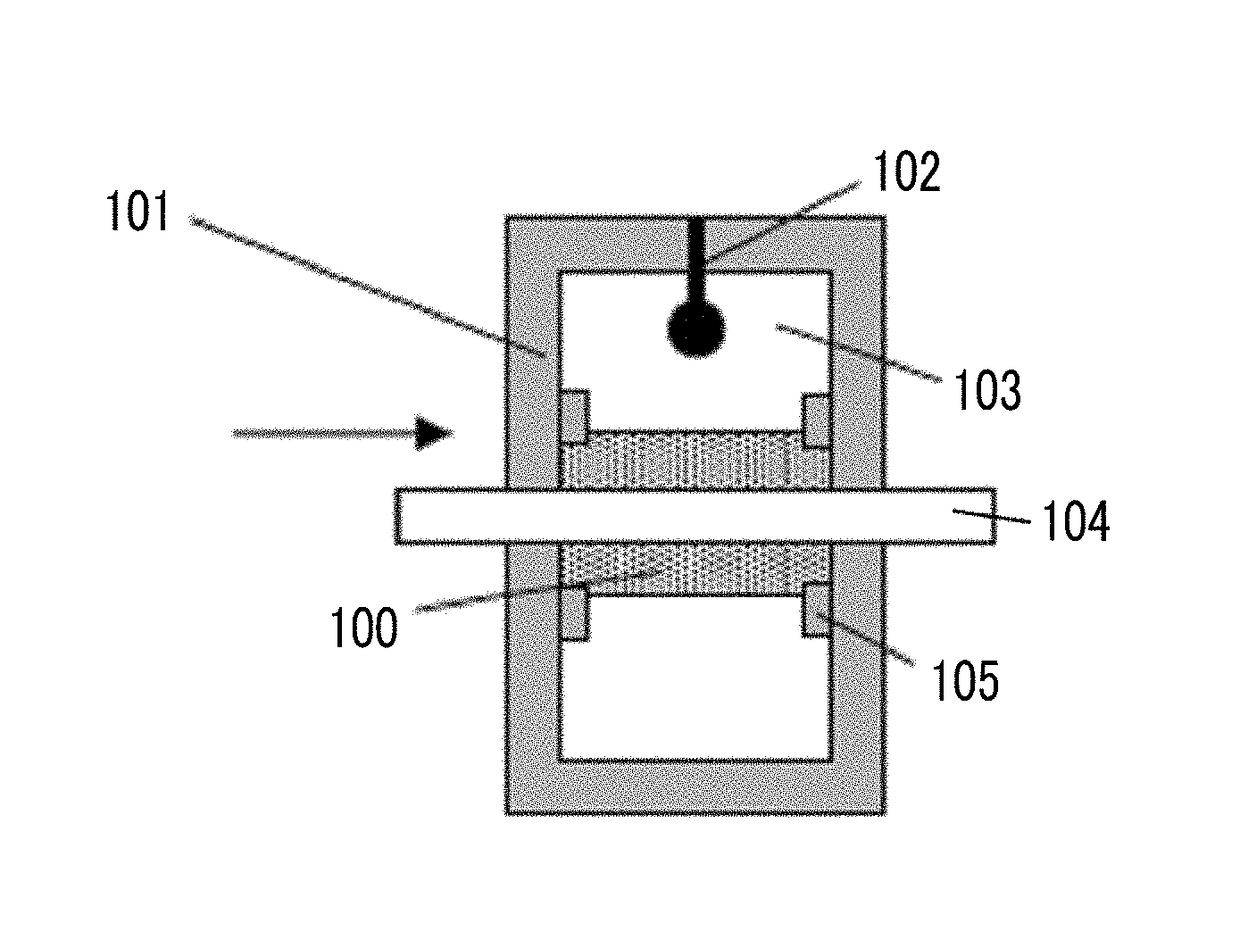

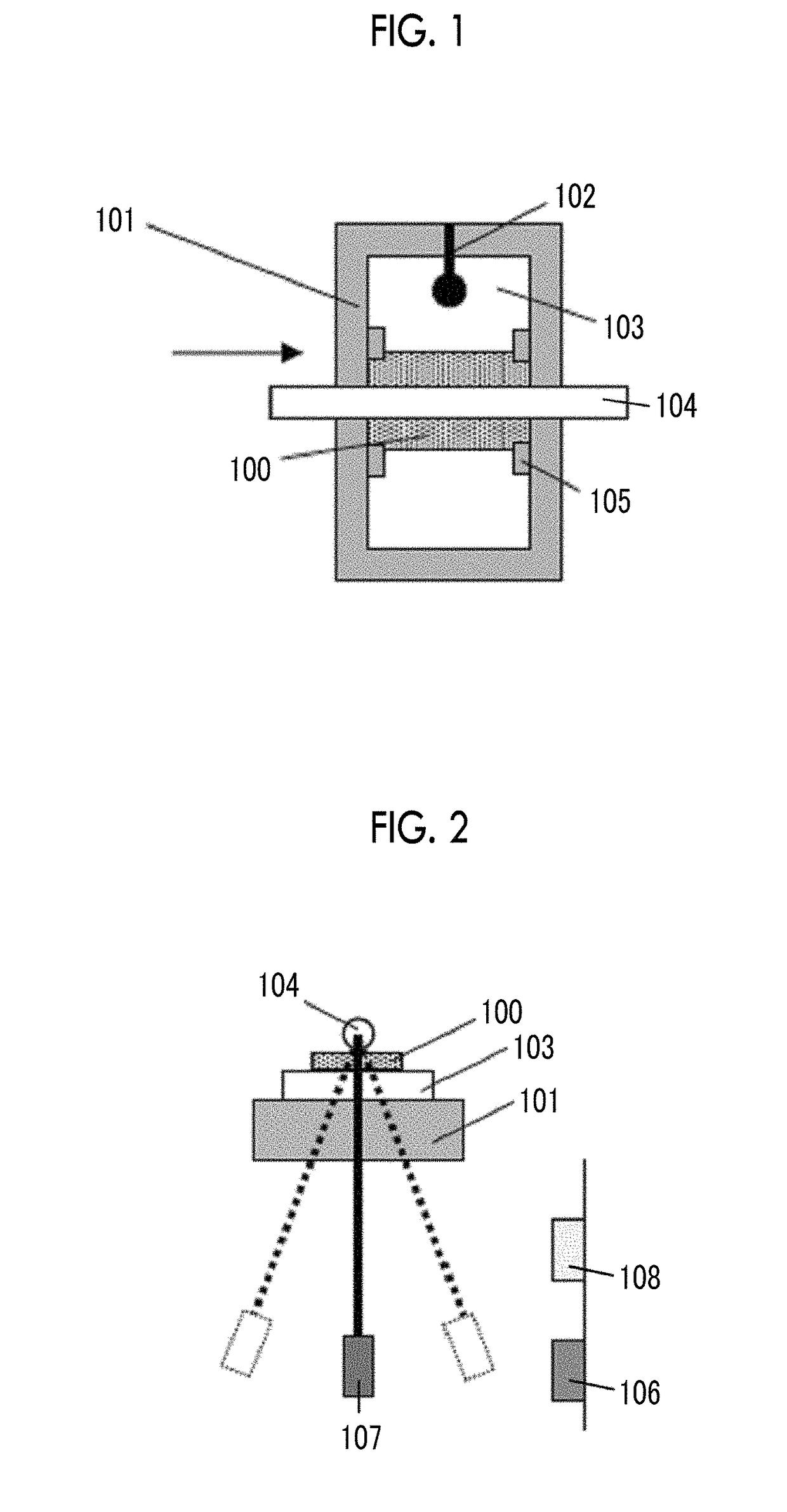

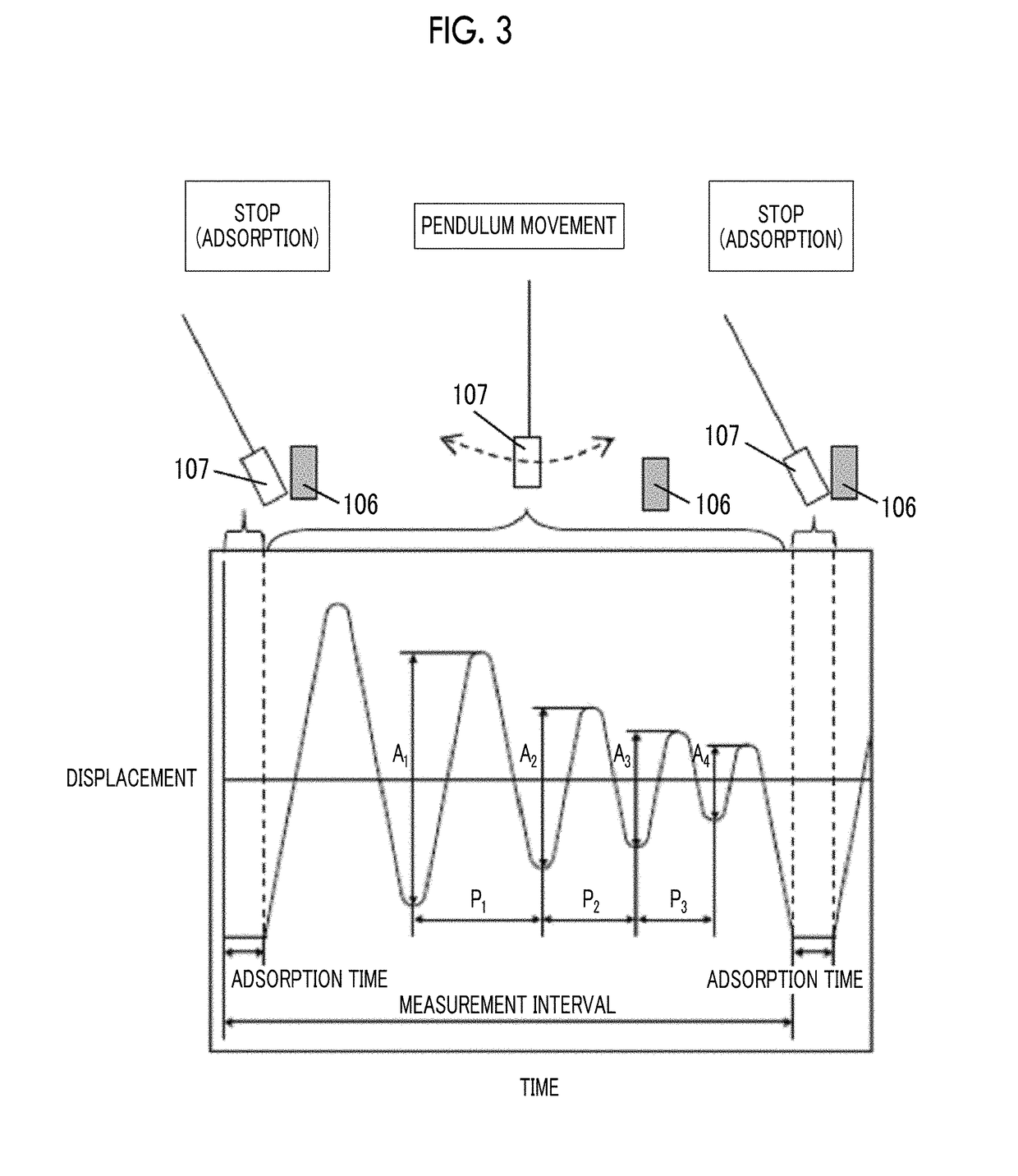

The magnetic tape includes a back coating layer having a thickness equal to or smaller than 0.30 μm and including fatty acid ester, a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding a surface of the back coating layer is equal to or smaller than 0.060, a full width at half maximum of spacing distribution measured by optical interferometry regarding the surface of the back coating layer before and after performing a vacuum heating with respect to the magnetic tape is respectively greater than 0 nm and equal to or smaller than 10.0 nm, and a difference between a spacing measured by optical interferometry regarding the surface of the back coating layer after performing the vacuum heating and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape device and head tracking servo method

ActiveUS20180286452A1Lower the resistance valueAvoid it happening againMaterials with ironAlignment for track following on tapesSurface measurementFatty acid ester

The magnetic tape device includes a TMR head and a magnetic tape, in which the magnetic tape includes fatty acid ester in a magnetic layer, Ra measured regarding a surface of the magnetic layer is 2.0 nm or smaller, full widths at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before and after performing a vacuum heating with respect to the magnetic tape are greater than 0 nm and 7.0 nm or smaller, a difference between spacings before and after the vacuum heating is greater than 0 nm and 8.0 nm or smaller, and a ratio of an average area Sdc of a magnetic cluster of the magnetic tape in a DC demagnetization state and an average area Sac of a magnetic cluster thereof in an AC demagnetization state measured with a magnetic force microscope is 0.80 to 1.30.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20170186456A1Increase frictionImprove featuresRecord information storageTape carriersMagnetic tapeMagnetization

The magnetic tape has a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support and a magnetic layer containing ferromagnetic powder and binder on the nonmagnetic layer, wherein a fatty acid ester is contained in at least the magnetic layer, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, the ferromagnetic hexagonal ferrite powder has a crystallite volume as determined by X-ray diffraction analysis ranges from 1,000 nm3 to 2,400 nm3, and a ratio of the crystallite size Dx(107) obtained from a diffraction peak of a (107) plane to a particle size in a direction of an easy axis of magnetization DTEM as determined by observation with a transmission electron microscope, Dx(107) / DTEM, is greater than or equal to 1.1, and ΔSFD in a longitudinal direction of the magnetic tape as calculated with Equation 1: ΔSFD=SFD25° C.−SFD−190° C., ranges from 0.50 to 1.60.

Owner:FUJIFILM CORP

Method of treating an oil or gas well with biodegradable low toxicity fluid system

InactiveUS7231976B2Well remediationIncrease stimulationCleaning apparatusFluid removalMETHYL SOYATEFluid system

A method of treating a well consists of introducing into the wellbore a biodegradable fluid system containing a blend of lactic acid ester, such as ethyl lactate, and a fatty acid ester, such as methyl soyate. The fluid system may be further in the form of a microemulsion that is formed by combining a blend with one or more emulsifiers, an alcohol, and water. The fluid system may be used in displacement, well remediation and stimulation as well as additional, alternative applications such as the cleaning of surface and / or downhole equipment.

Owner:BAKER HUGHES HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com