Patents

Literature

1068 results about "Alkaline hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkaline hydrolysis, in organic chemistry, usually refers to types of nucleophilic substitution reactions in which the attacking nucleophile is a hydroxide ion.

Hydroprocessing Microalgal Oils

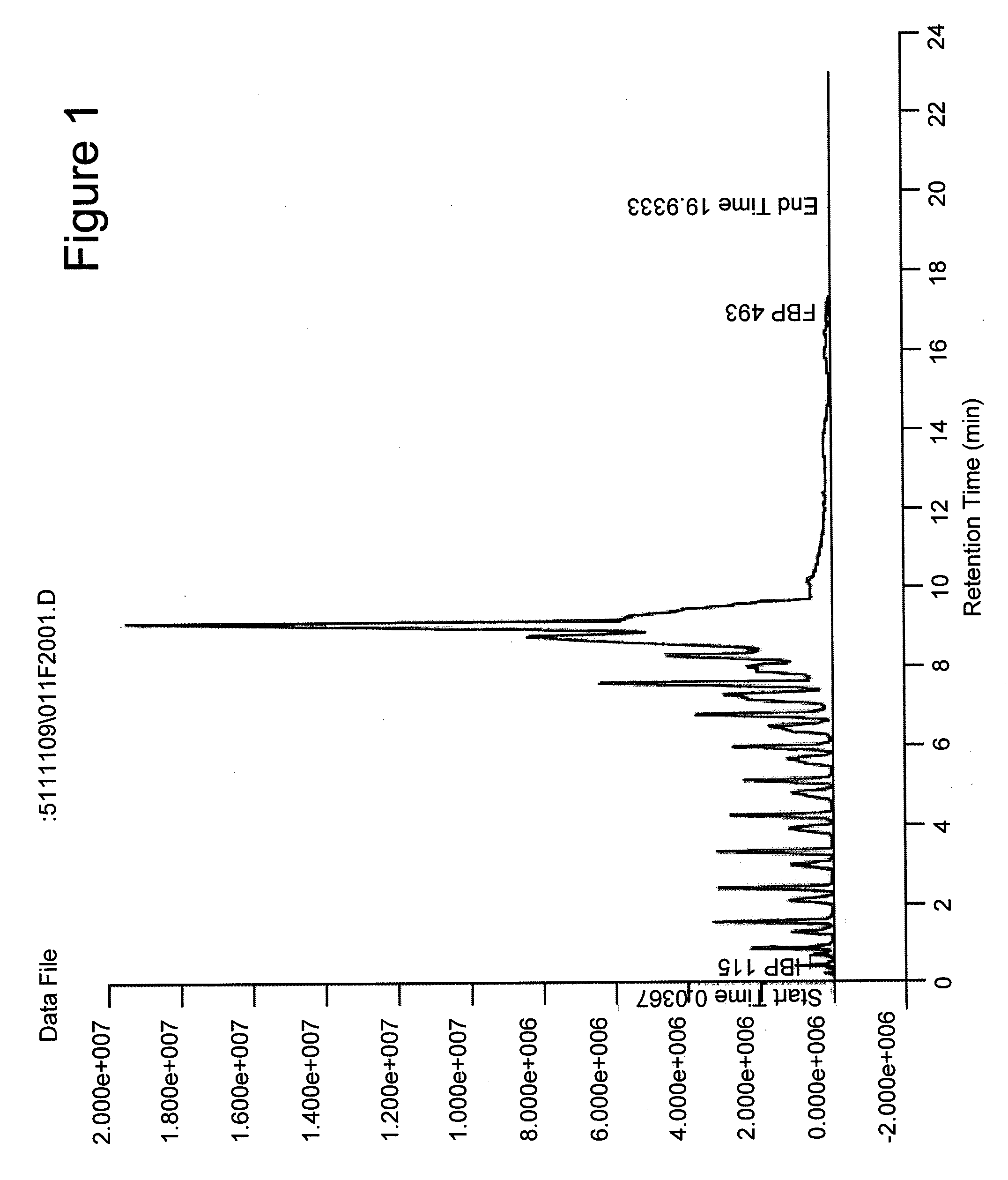

InactiveUS20100170144A1Improve efficiencyLow costHydrocarbon by isomerisationHydrocarbon purification/separationChemical treatmentAlkaline hydrolysis

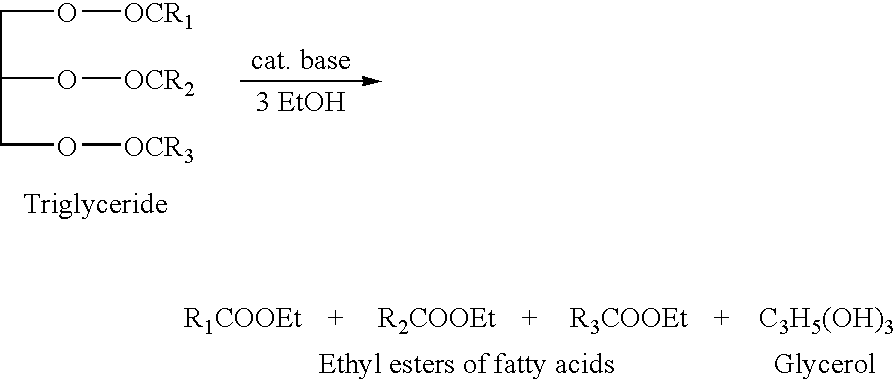

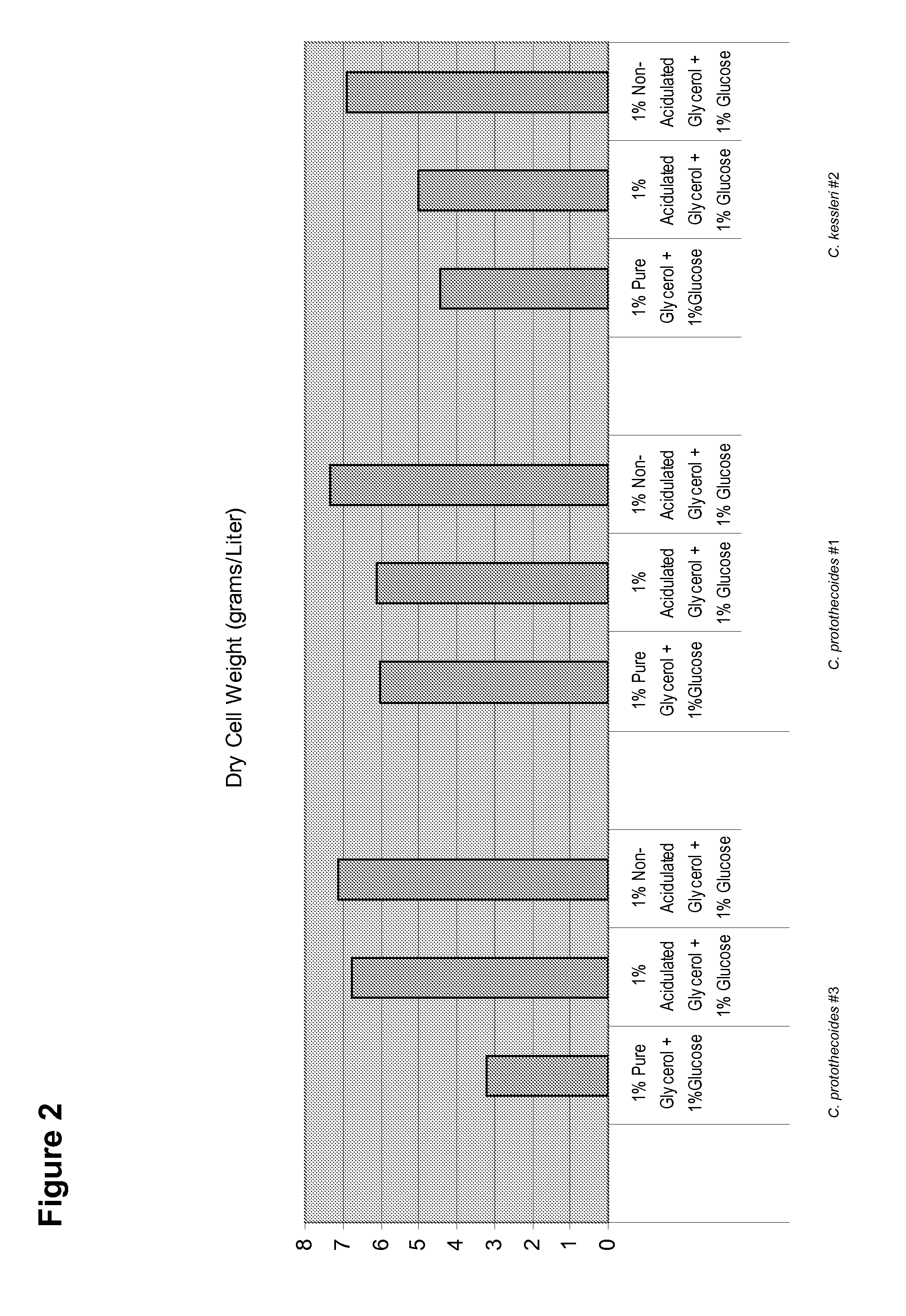

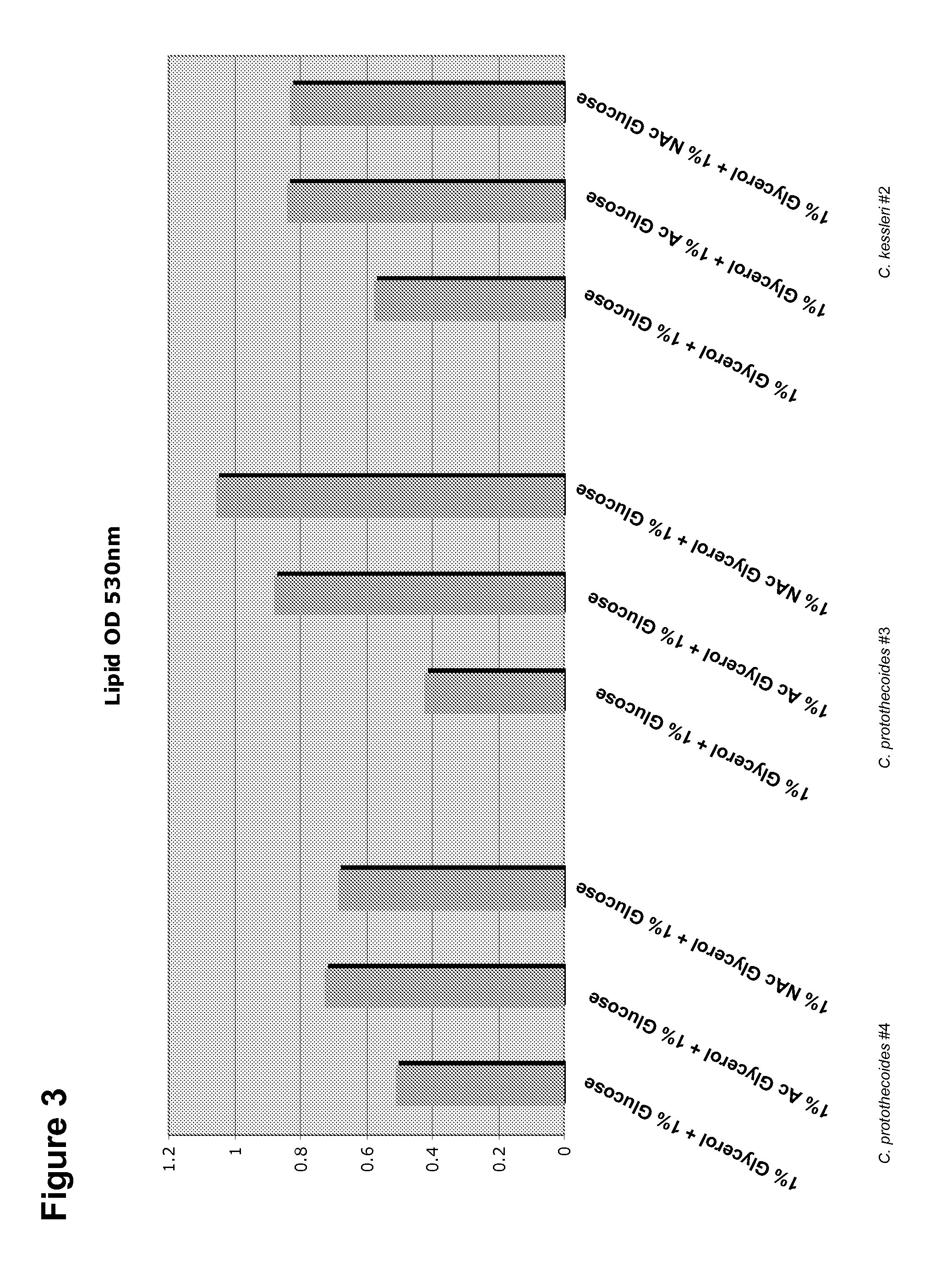

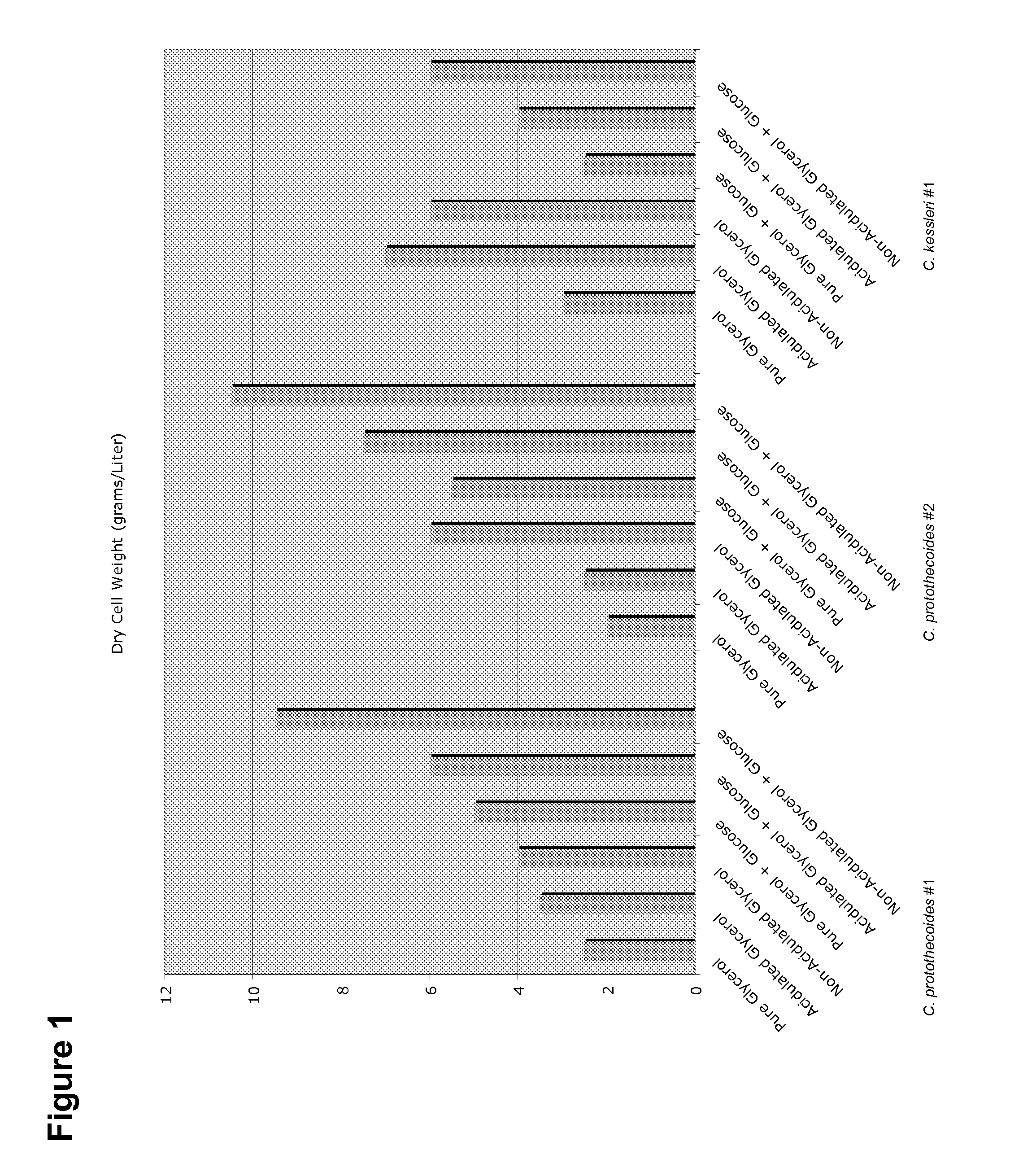

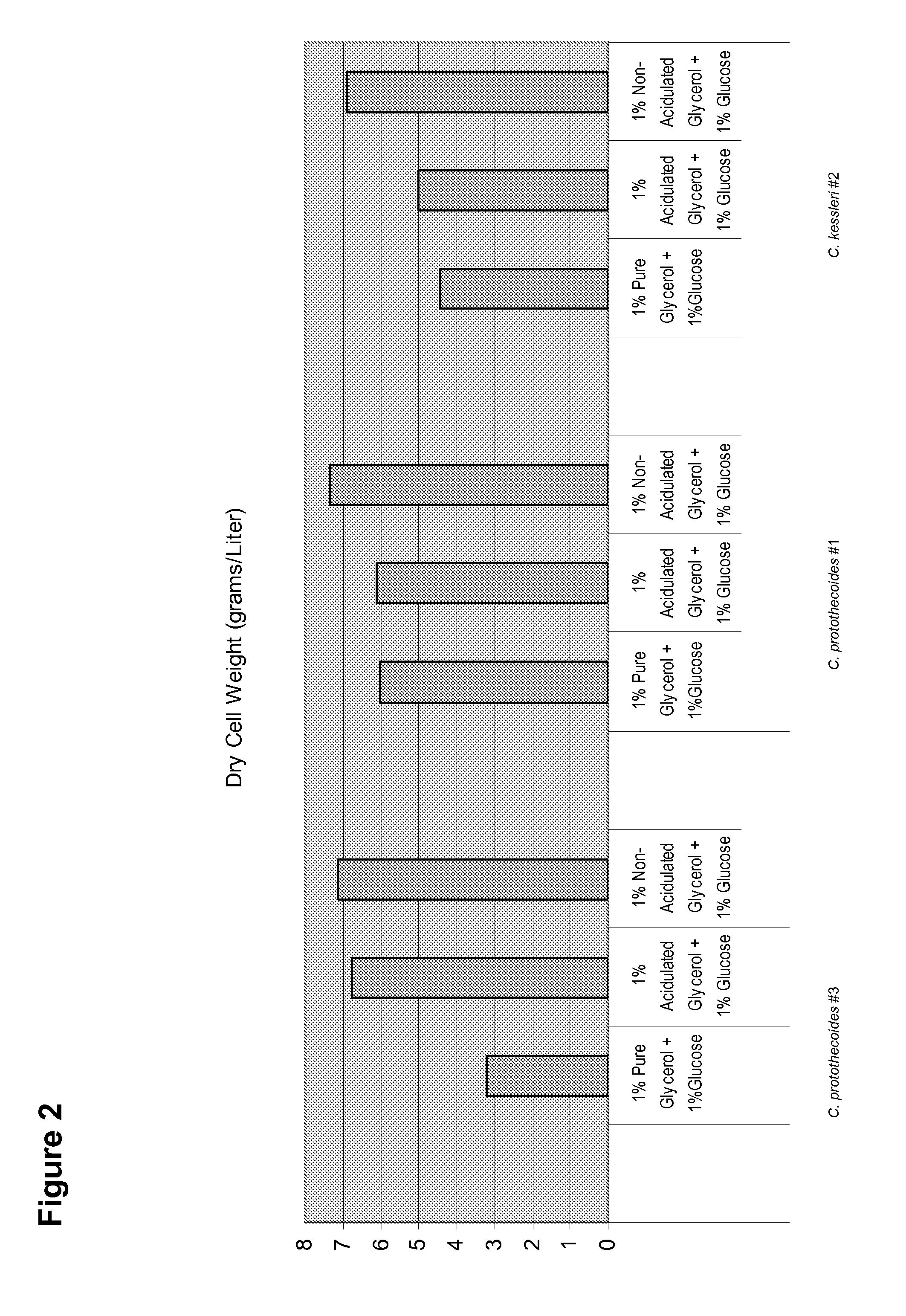

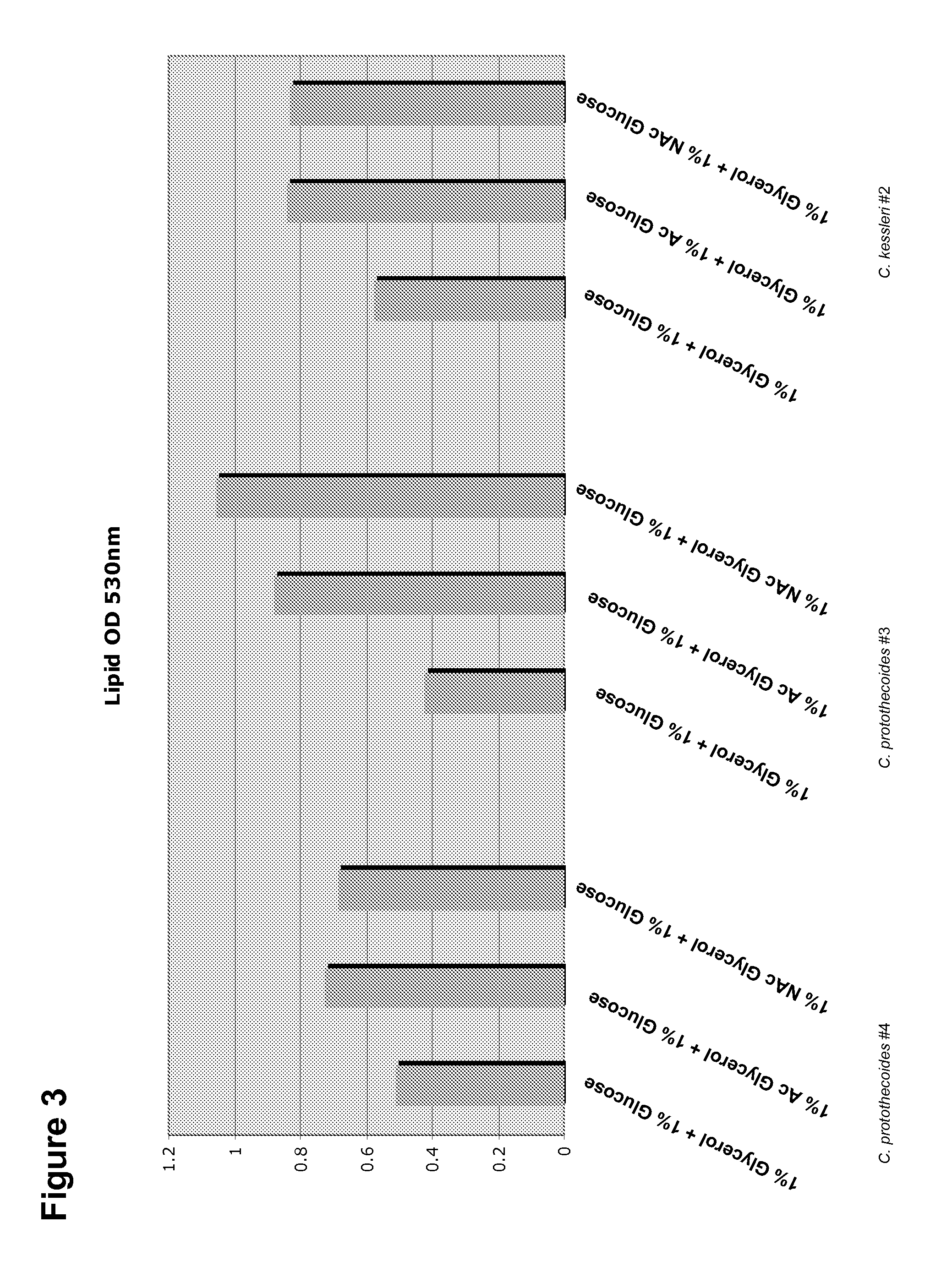

Fuels and other valuable compositions and compounds can be made from oil extracted from microbial biomass and from oil-bearing microbial biomass via hydroprocessing and / or other chemical treatments, including the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts.

Owner:TERRAVIA HLDG INC

Soaps Produced from Oil-Bearing Microbial Biomass and Oils

ActiveUS20090305942A1Improve efficiencyLow costSoap detergents with organic compounding agentsBiofuelsMicroorganismMicrobial oil

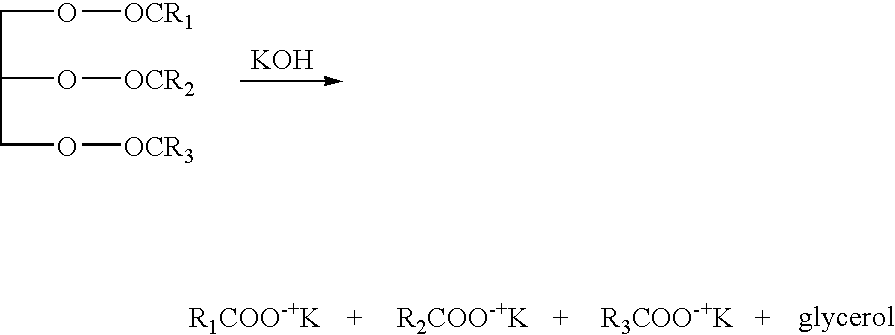

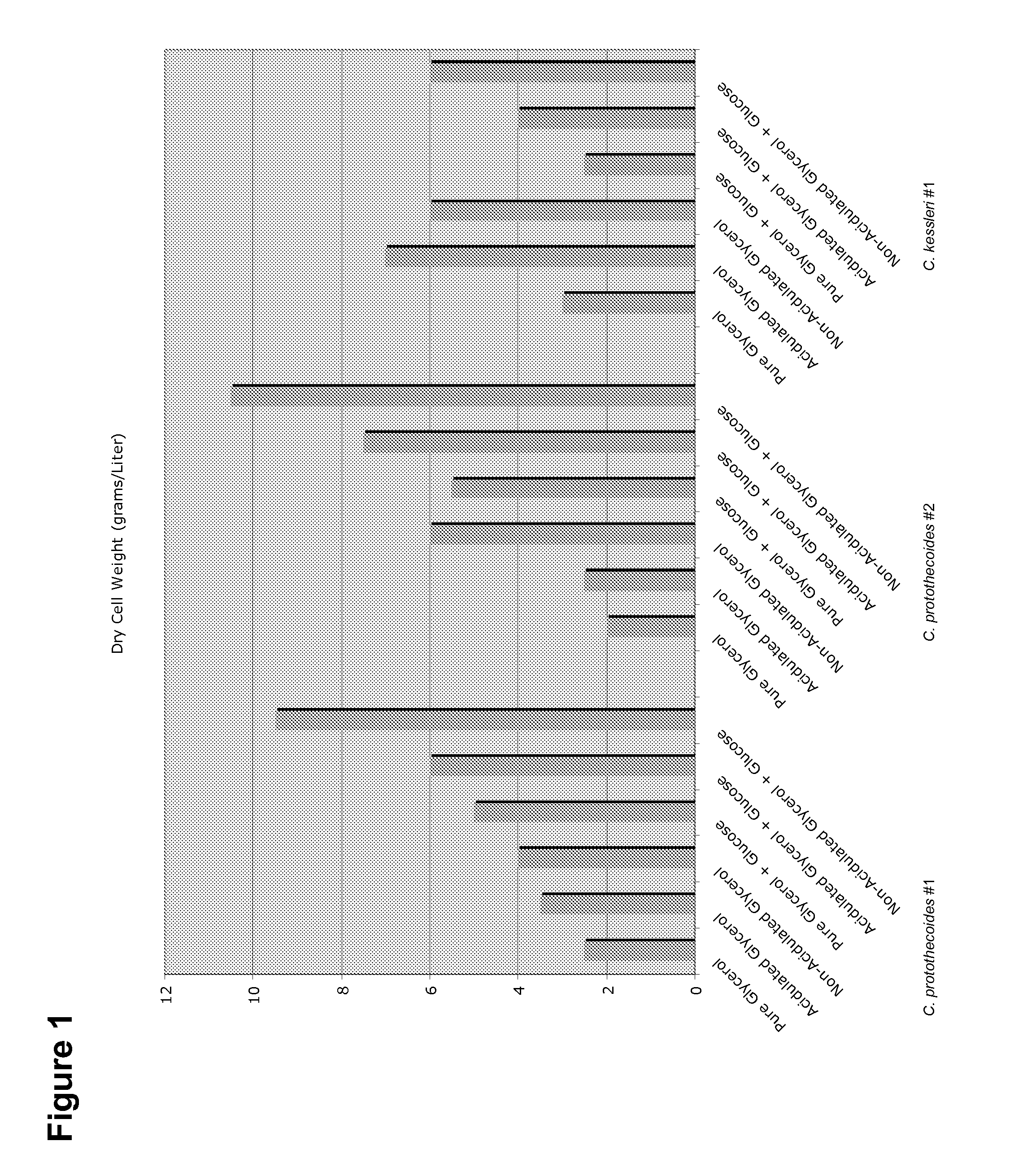

Soap and cosmetic products can be made from oil-bearing microbial biomass via the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts. The saponified microbial oils / lipids can be combined with a variety of additives to produce compositions for use as soaps and other cosmetic products, which may also contain other constituents of the biomass, including unsaponified oils, glycerol and carotenoids, among others.

Owner:CORBION BIOTECH INC

Soaps produced from oil-bearing microbial biomass and oils

ActiveUS8119583B2Low costImprove efficiencySoap detergents with organic compounding agentsCosmetic preparationsMicrobial oilGlycerol

Soap and cosmetic products can be made from oil-bearing microbial biomass via the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts. The saponified microbial oils / lipids can be combined with a variety of additives to produce compositions for use as soaps and other cosmetic products, which may also contain other constituents of the biomass, including unsaponified oils, glycerol and carotenoids, among others.

Owner:CORBION BIOTECH INC

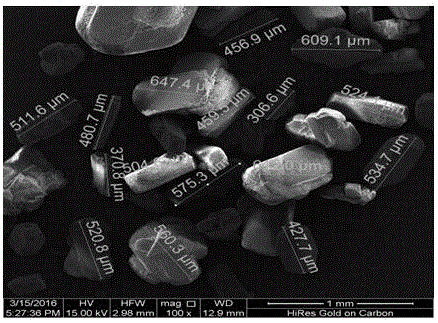

Magnetic submicron composite core-shell particles, and preparation method and application thereof

InactiveCN102360659ALarge specific surface areaGood value for moneyOther chemical processesInorganic material magnetismSewageSolvent

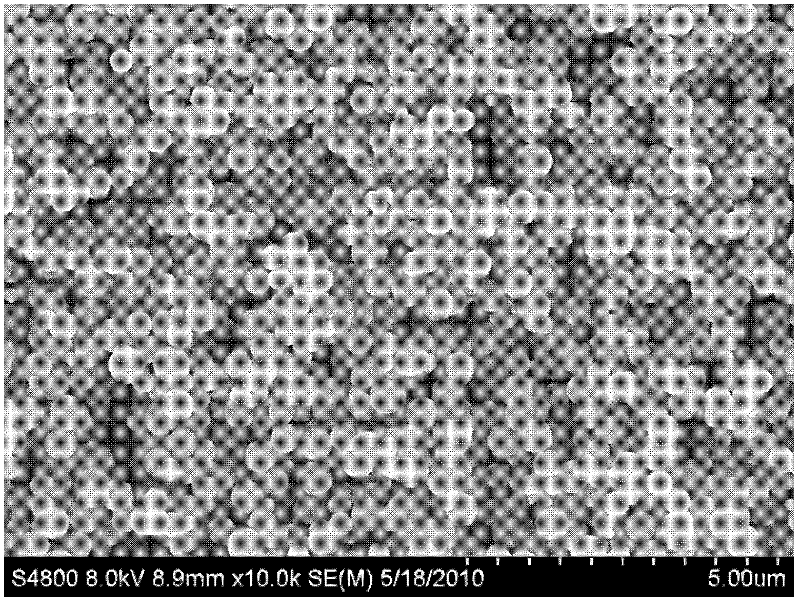

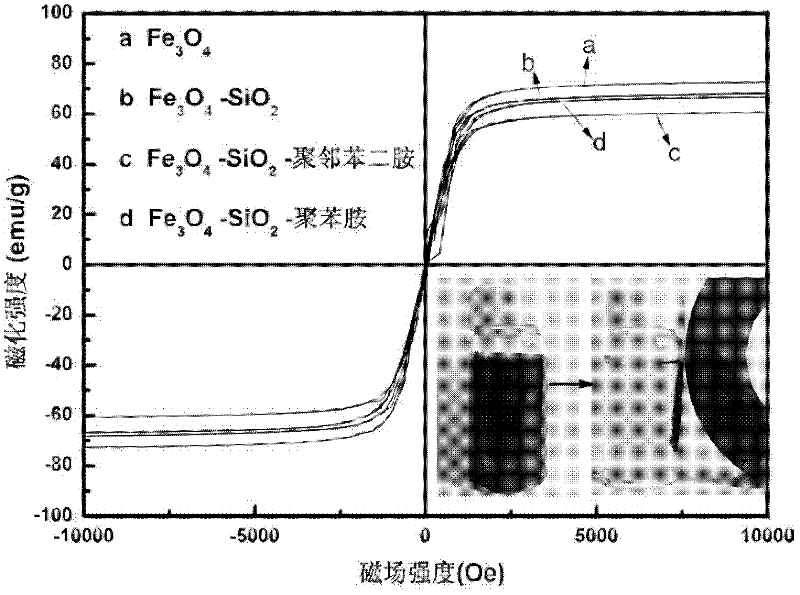

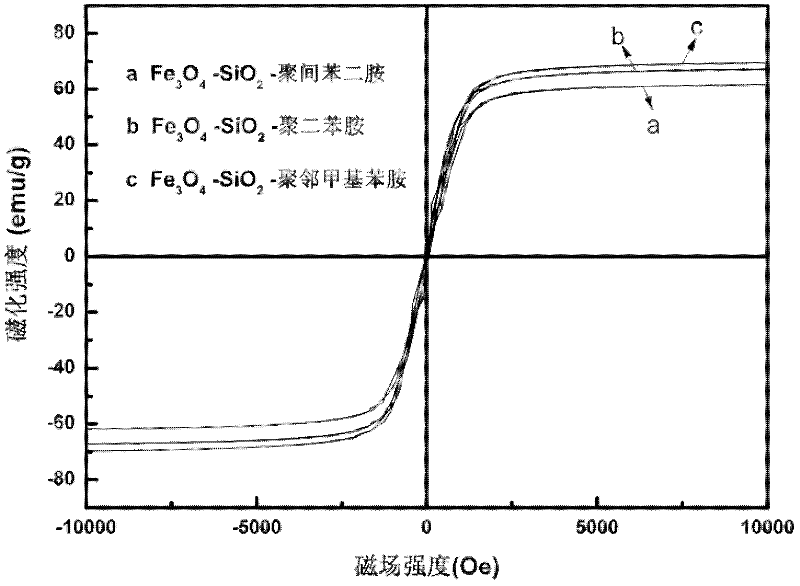

The invention discloses magnetic submicron composite core-shell particles. In the magnetic submicron composite core-shell particles, Fe3O4 particles with the particle size of between 80 and 800nm are taken as a magnetic core, amorphous SiO2 is taken as an immediate shell layer and a substance with heavy metal absorption performance is taken as an outer shell layer. The invention also discloses a preparation method for the magnetic submicron composite core-shell particles. The preparation method comprises the following steps of: preparing the Fe3O4 particles with the particle size of between 80 and 800nm by a solvothermal method and taking the Fe3O4 particles as magnetic cores, performing alkaline hydrolysis of a silicon source reagent on Fe3O4 and dehydrating and condensing hydroxy groups so as to obtain amorphous SiO2 immediate shell layers, and coating the substance with heavy metal absorption performance on obtained submicron spheres under chemical or physical action to obtain the magnetic submicron composite core-shell particles. The submicron material has high performance of absorbing heavy metal ions in the sewage; and the material has stable characteristics, can be magnetically recovered and meets environmental protection requirements, and secondary pollution is avoided.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

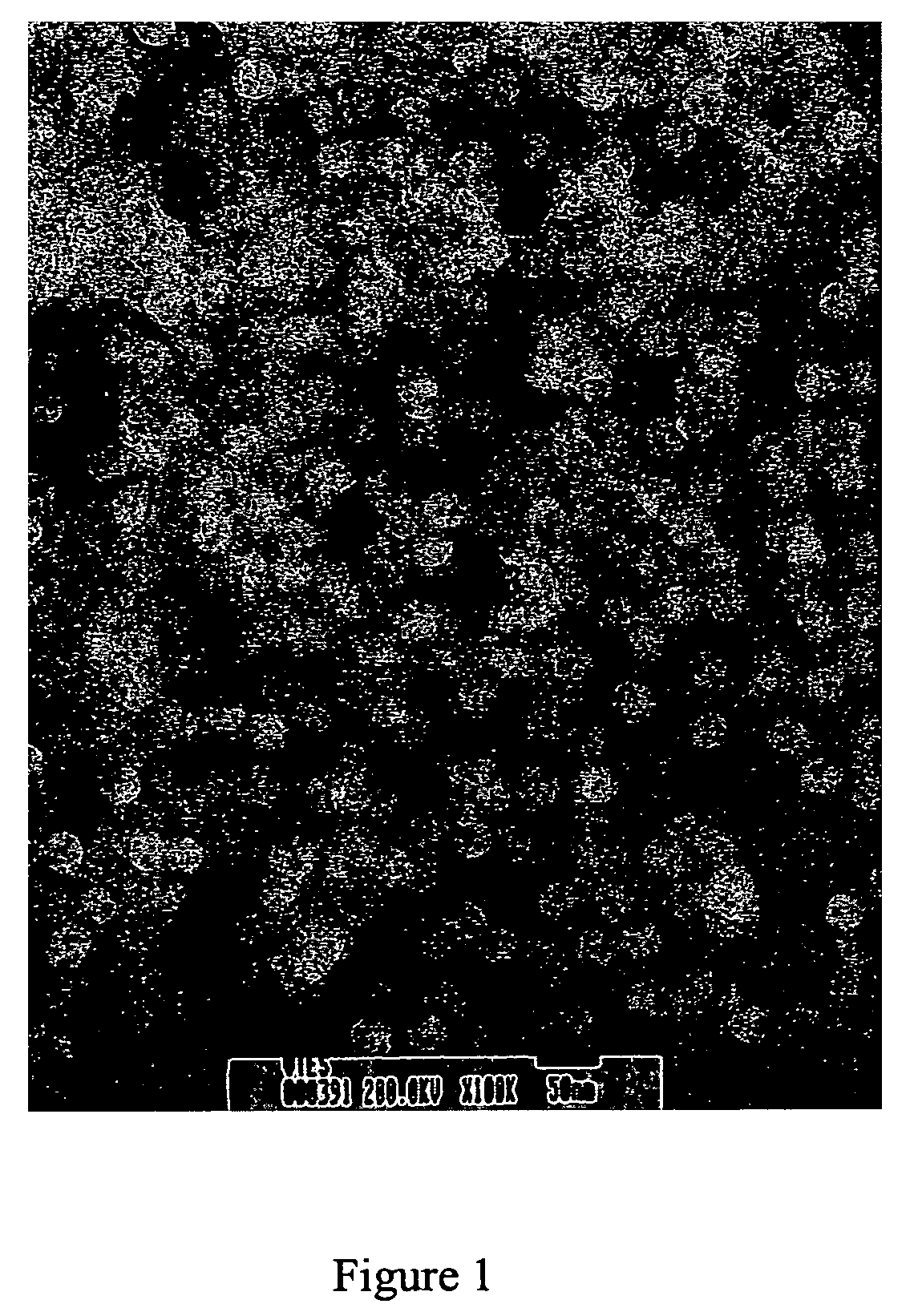

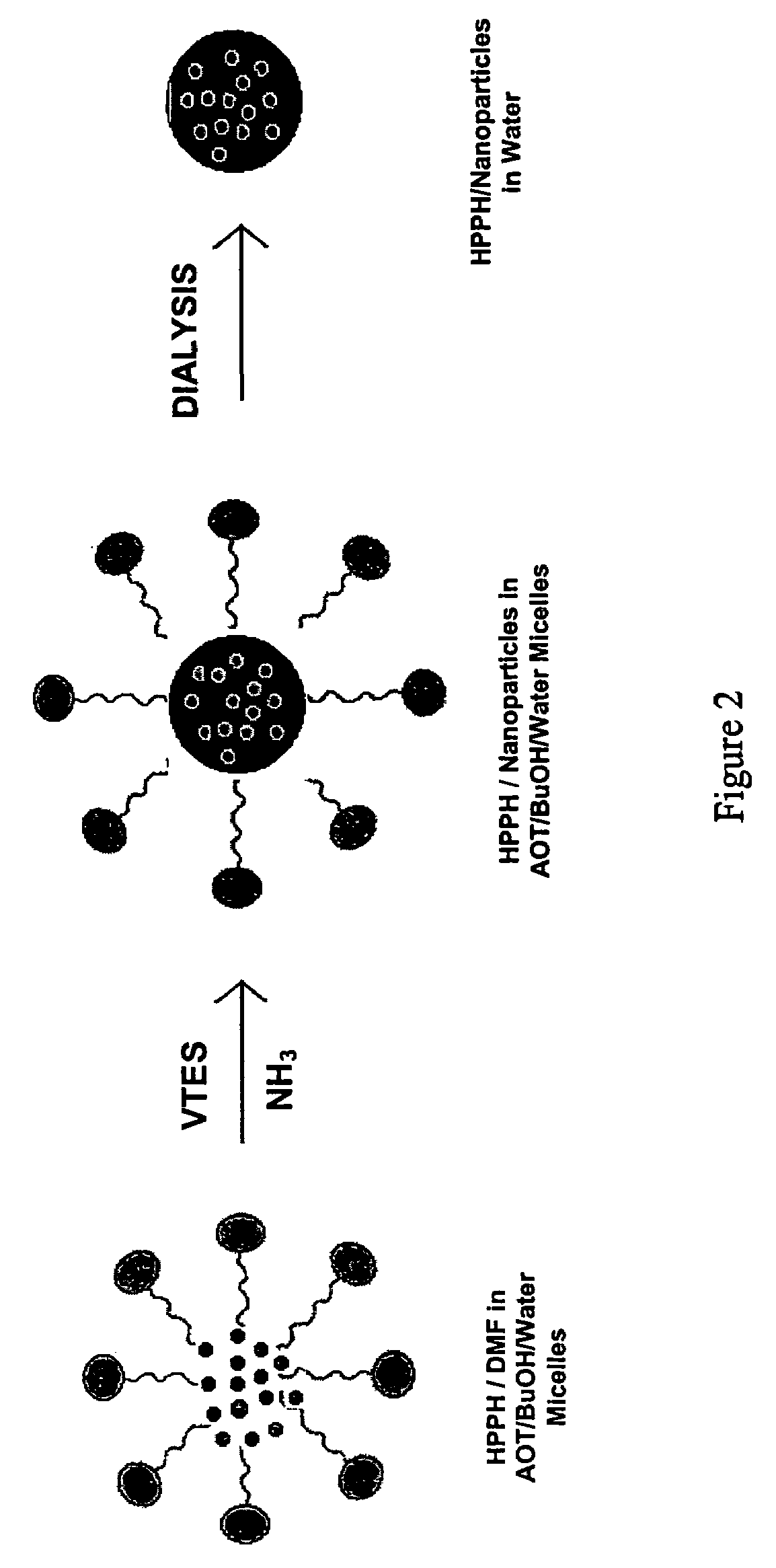

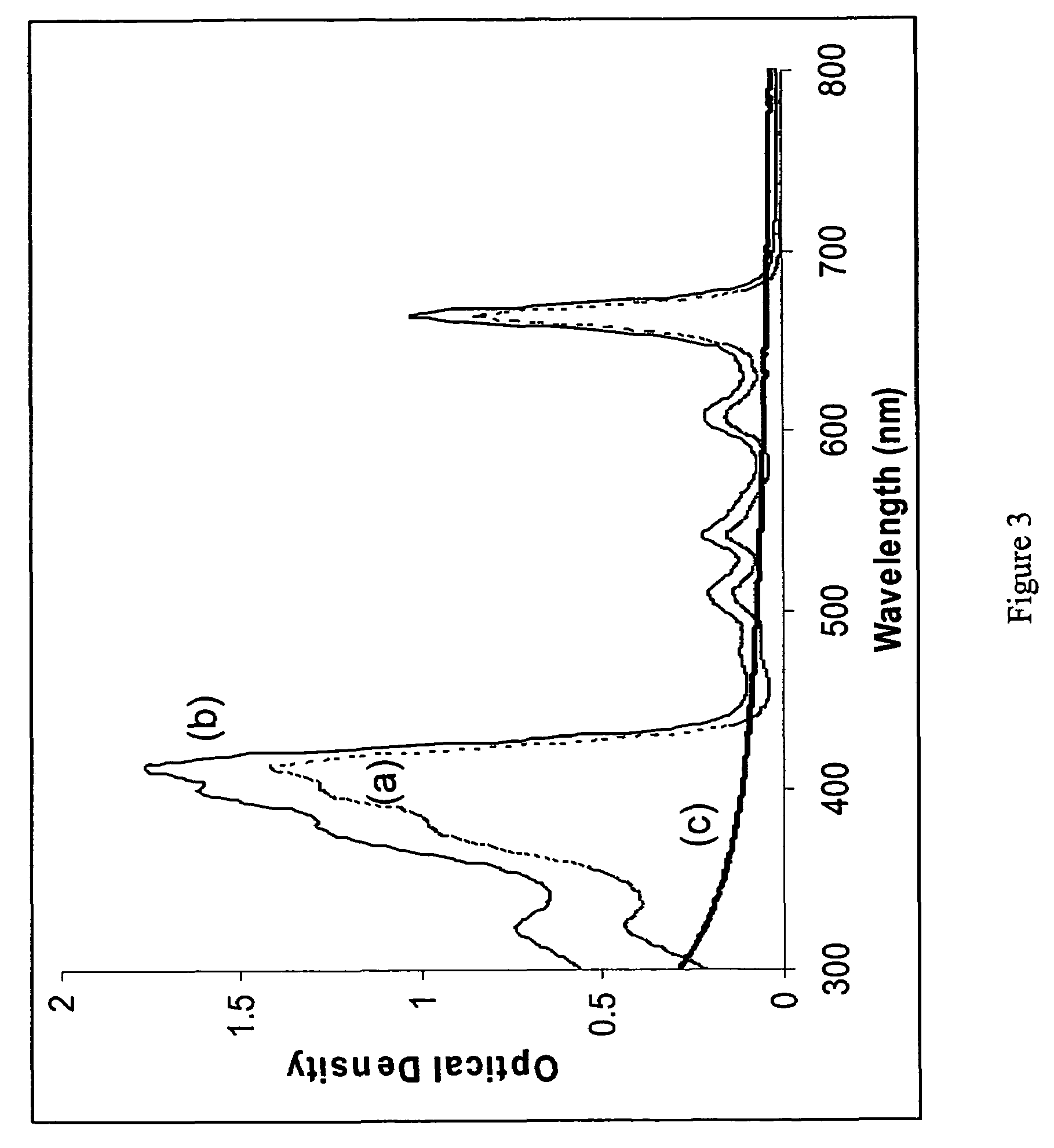

Ceramic based nanoparticles for entrapping therapeutic agents for photodynamic therapy and method of using same

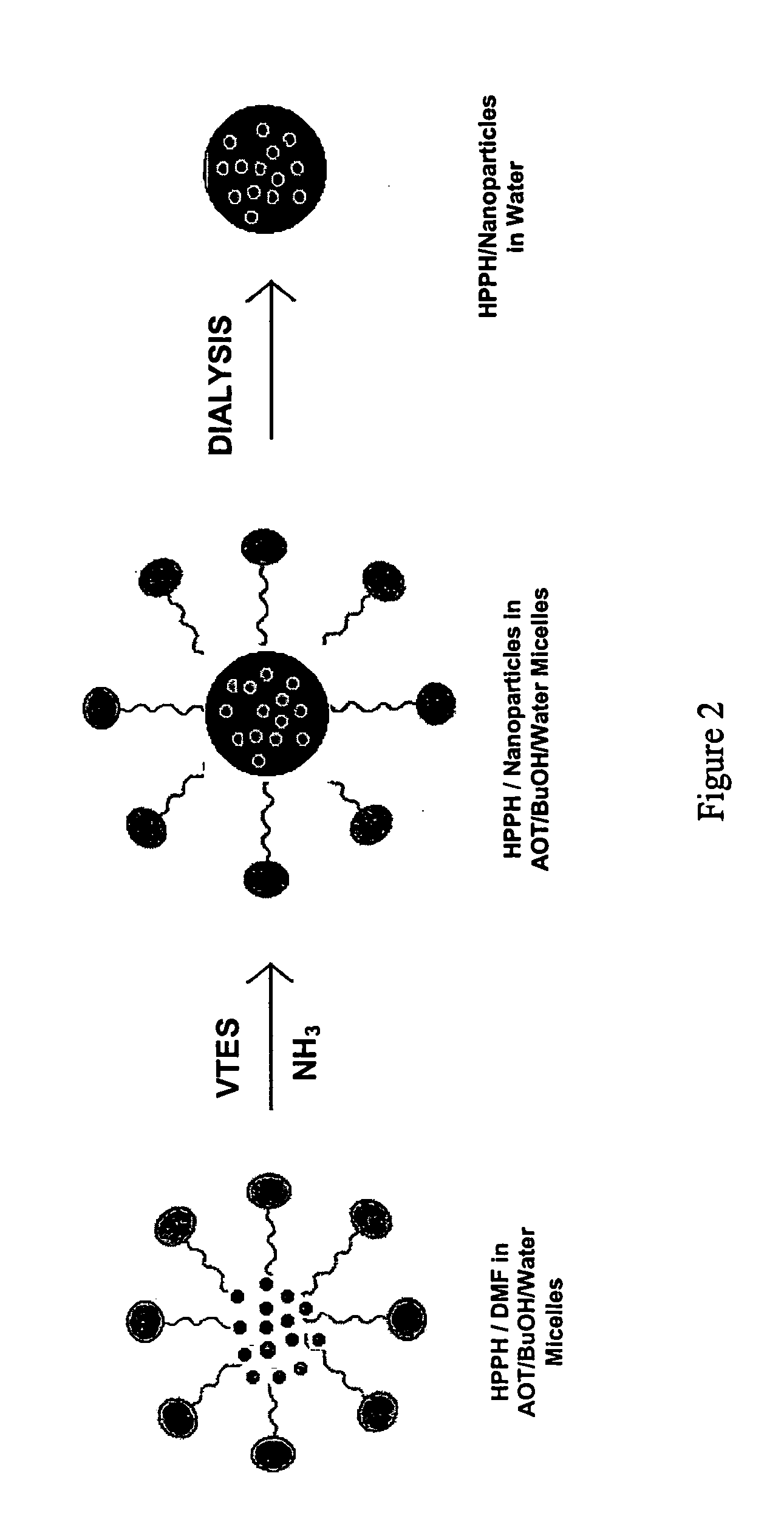

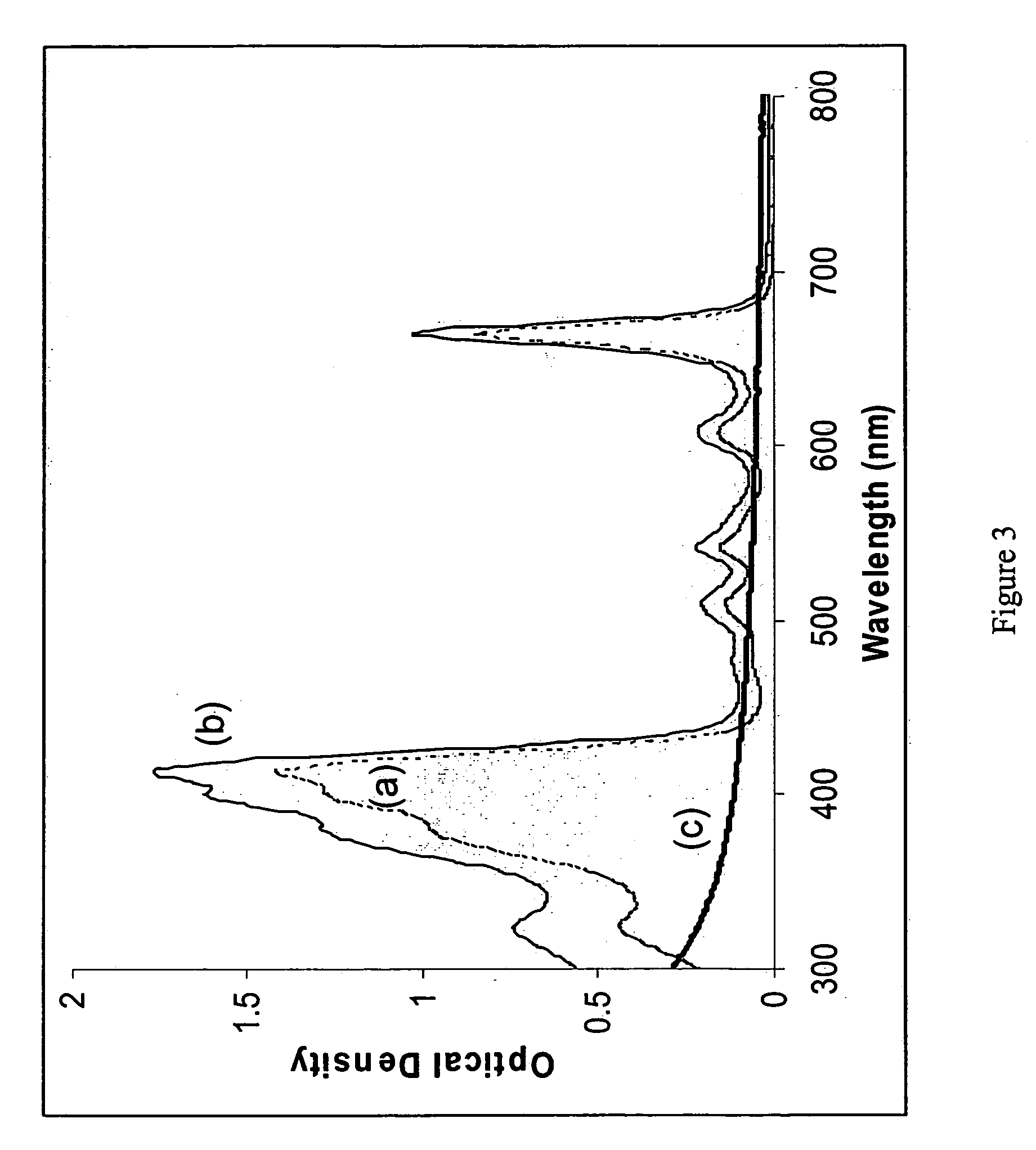

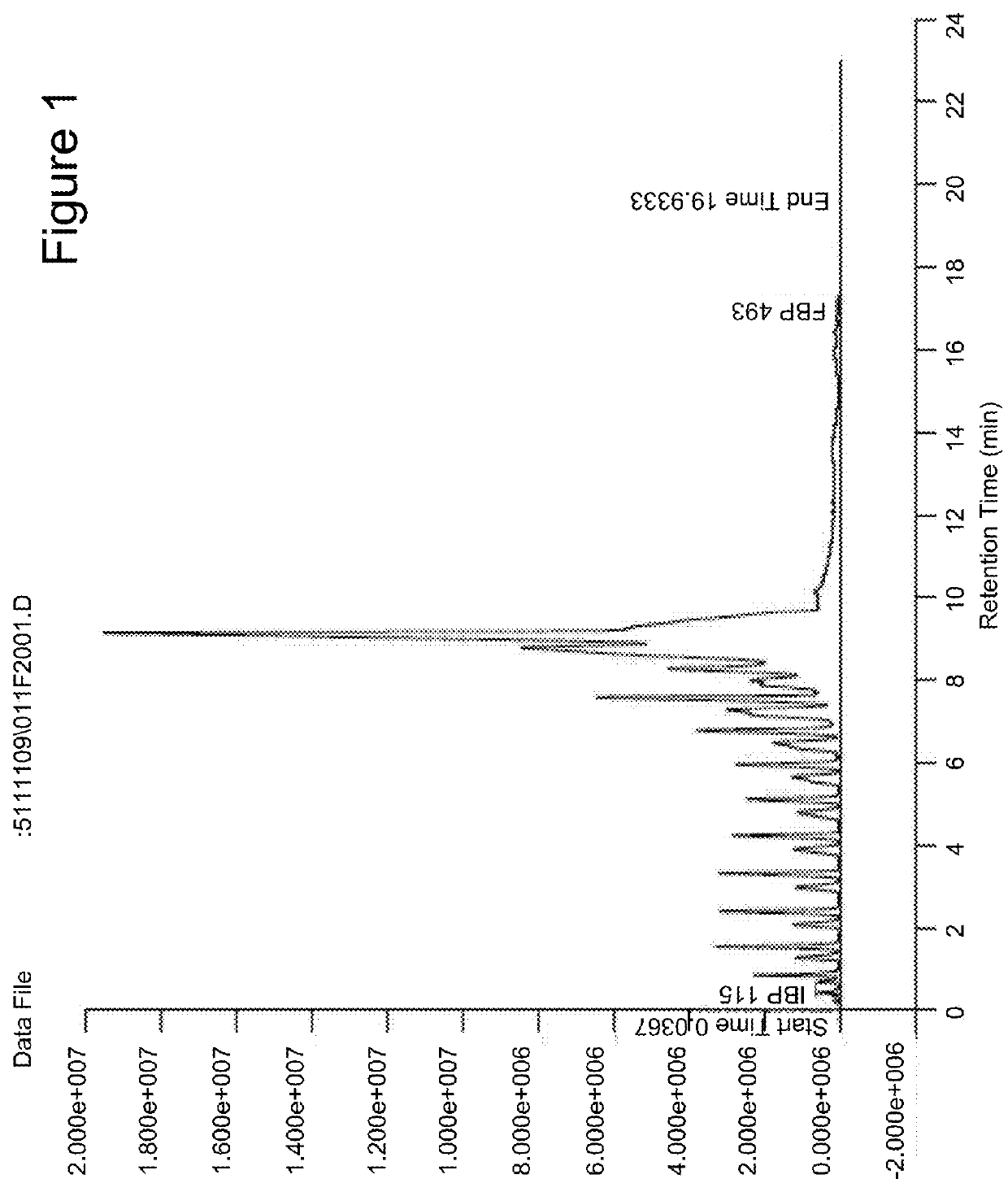

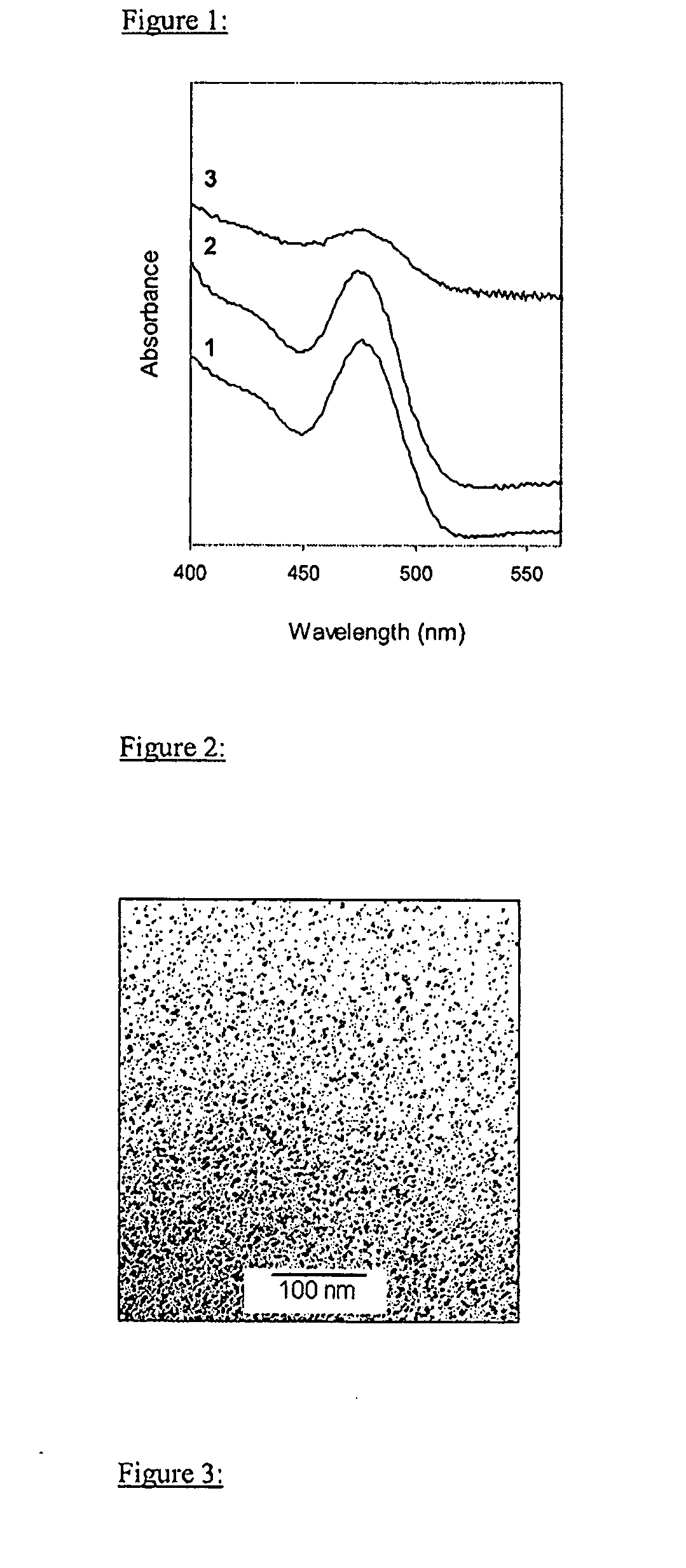

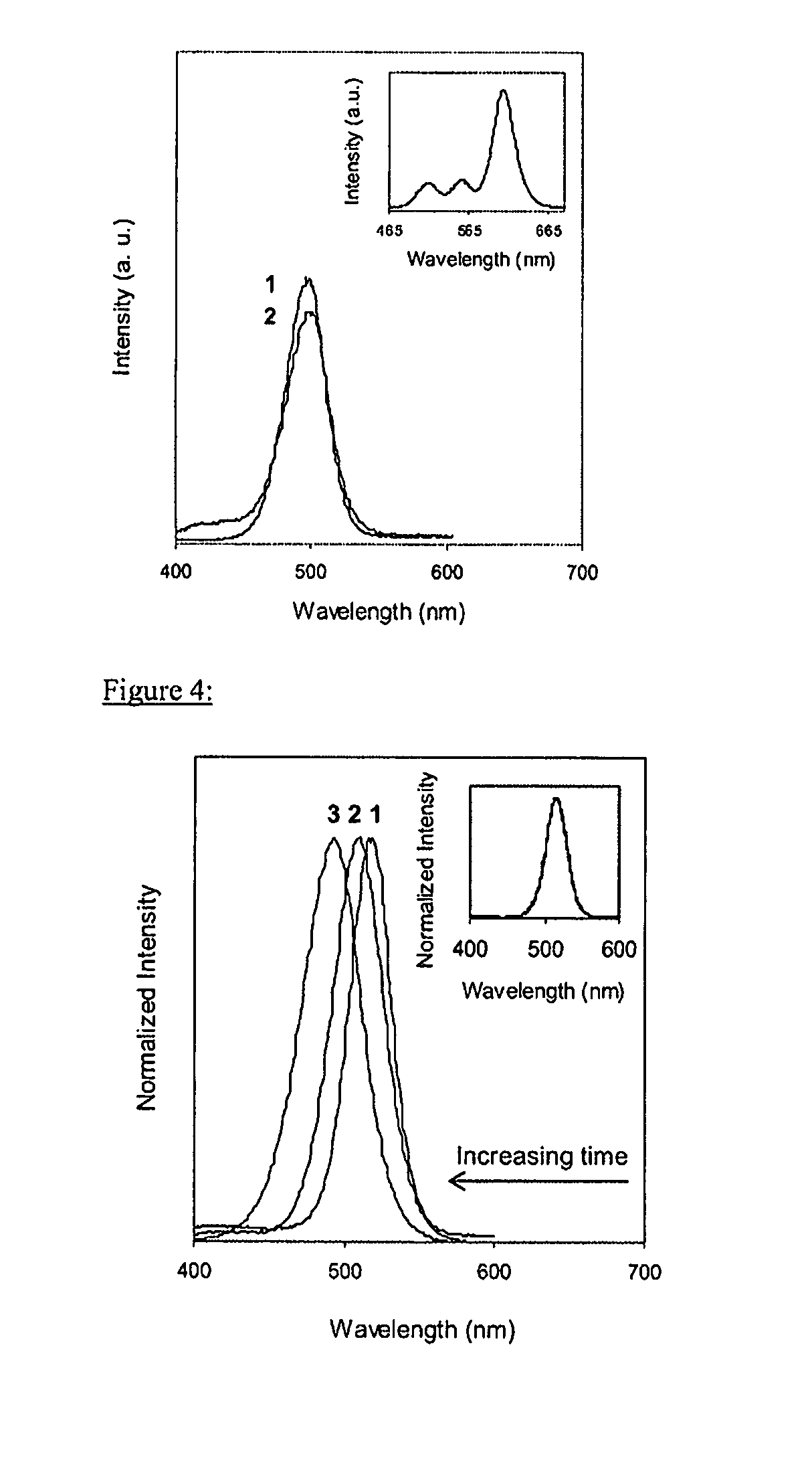

The present invention provides methods and compositions for photodynamic therapy. The composition comprises ceramic nanoparticles in which a photosensitive drug / dye is entrapped. The ceramic nanoparticles are made by formation of a micellar composition of the dye. The ceramic material is added to the micellar composition and the ceramic nanoparticles are precipitated by alkaline hydrolysis. The precipitated nanoparticles in which the photosensitive dye / drug is entrapped can be isolated by dialysis. The resulting drug doped nanoparticles are spherical, highly monodispersed, and stable in aqueous system. Irradiation with light of suitable wavelength of the photosensitizing drug entrapped inside nanoparticles resulted in generation of singlet oxygen, which was able to diffuse out through the pores of the ceramic matrix. The drug loaded ceramic nanoparticles of the present invention can be used as drug carriers for photodynamic therapy.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Hydroprocessing Microalgal Oils

InactiveUS20140305031A1Low costImprove efficiencyHydrocarbon by isomerisationHydrocarbon purification/separationChemical treatmentAlkaline hydrolysis

Owner:TERRAVIA HLDG INC

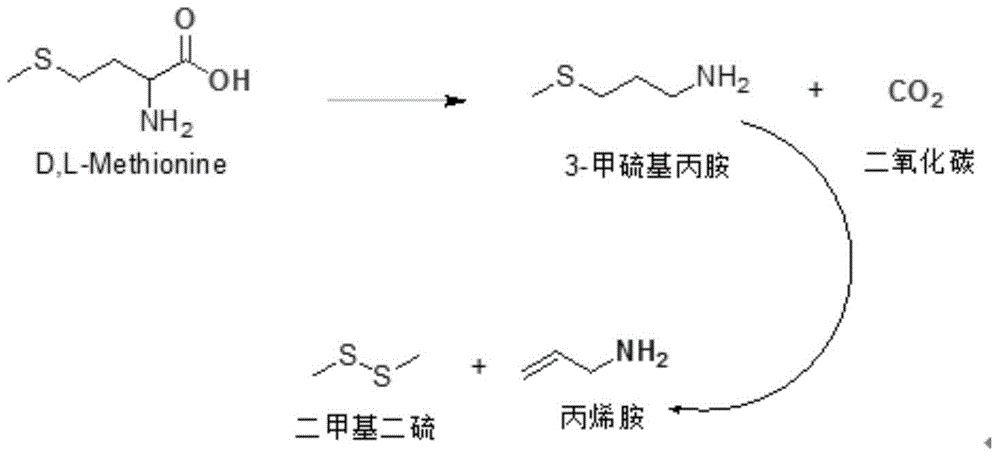

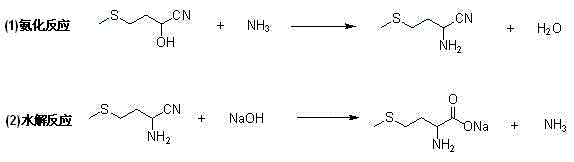

Method for preparing methionine

The invention discloses a method for preparing methionine. The method for preparing the methionine concretely comprises the steps that cyanohydrins, carbon dioxide and ammonia or sodium cyanide, 3-(Methylthio)propionaldehyde, carbon dioxide and ammonia serve as raw materials to prepare hydantoin; alkaline hydrolysis is conducted on the hydantoin and then the hydantoin is acidized to pH 3.0-6.0 to obtain a compound of the methionine and salts; crystallization is conducted under the condition of temperature ranges from 8 DEG C to 45 DEG C, then the compound is separated to obtain a methionine crystal and salt mother liquor, the methionine crystal is washed by water and dried, and washing liquor is standby; finally, the salt mother liquor is concentrated under the condition of temperature which is lower than 60 DEG C, and then the salt mother liquor passes through a chromatographic column to obtain an inorganic salt and the methionine; the preparation method can efficiently separate the methionine and the salts, the recovery rate of the methionine can reach 99%, and the method is green and protects the environment, no methionine is resolved, no large number of acid and stink wastewater is discharged, and the purity of the inorganic salt is high and can be sold as a commodity.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

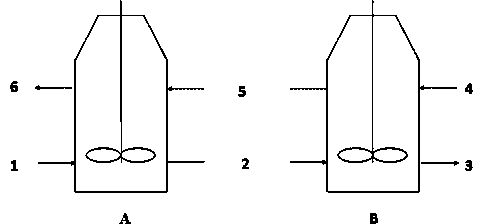

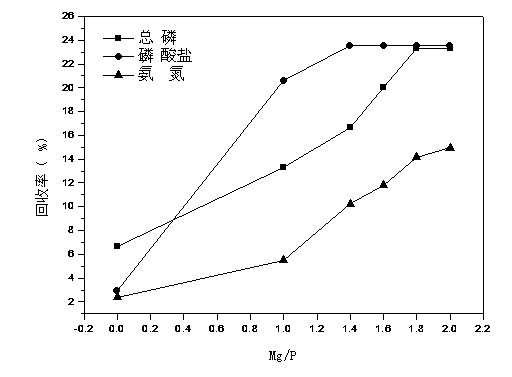

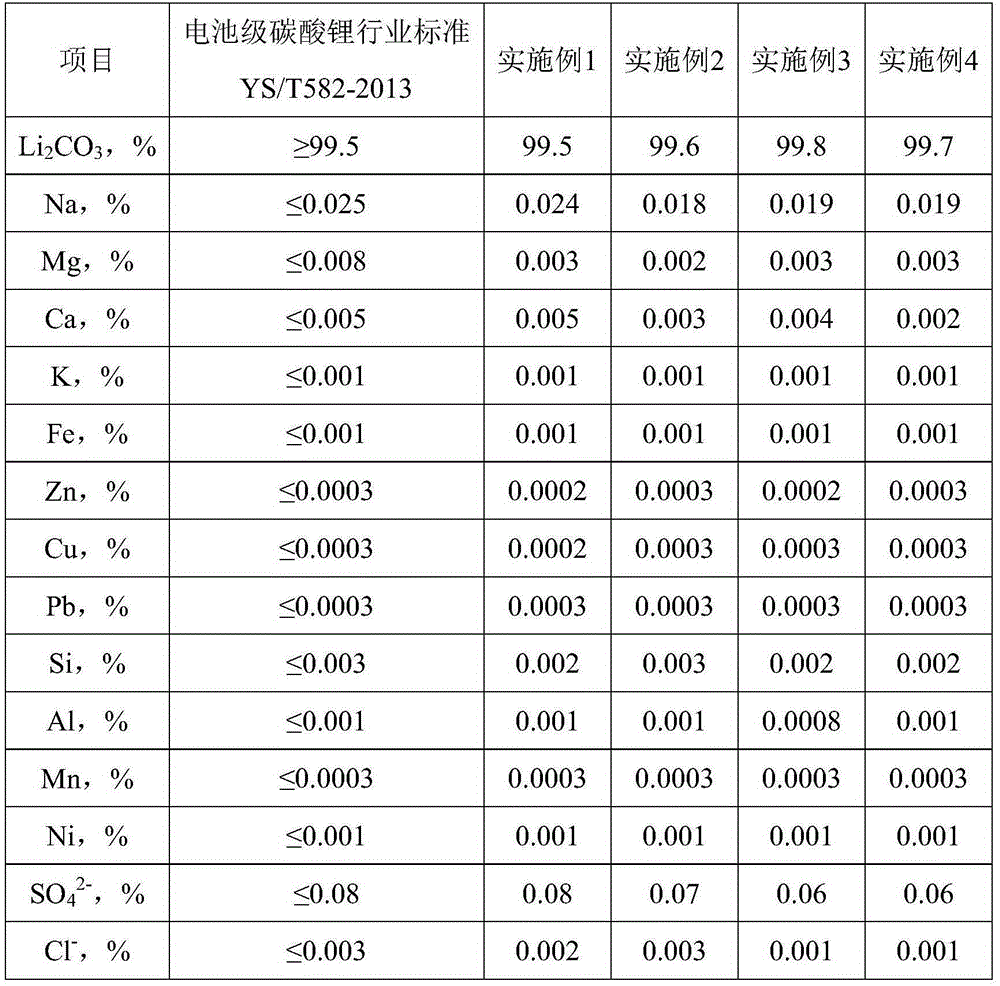

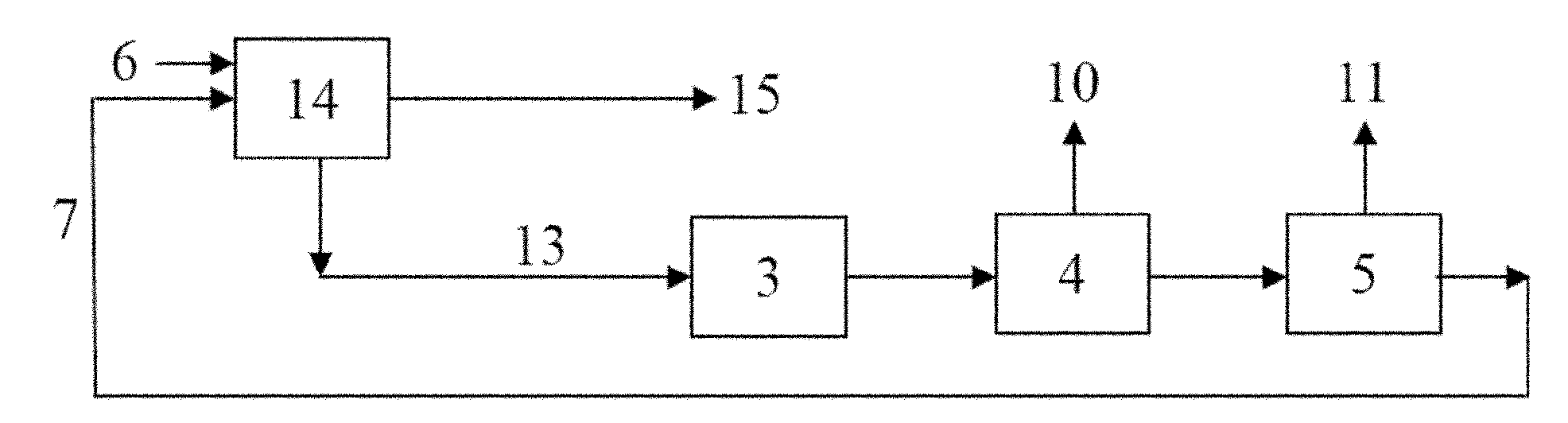

Method of economically recycling phosphor from excess sludge

ActiveCN103641283AEasy to recycleSatisfy the requirements of sedimentationSludge treatmentO-Phosphoric AcidMagnesium salt

The invention relates to a method of economically recycling phosphor from excess sludge. The method comprises the following steps: (1), pre-treating the excess sludge; (2), carrying out alkaline hydrolysis on the excess sludge, wherein the alkaline hydrolysis is carried out by a single-stage alkaline hydrolysis method or a two-stage alkaline hydrolysis method; measuring concentration of orthophosphate and ammonia nitrogen in liquid supernatant; and (3), adding magnesium salt aqueous liquor with a Mg / P molar ratio of 0.8-2, stirring and reacting for 10 minutes-120 minutes, gravitationally or centrifugally separating precipitates, naturally drying the precipitates to obtain a magnesium ammonium phosphate crude product. Organic substances remained in the liquid supernatant can be used for producing methane by anaerobic fermentation or supplementing a carbon source by a reflux wastewater treatment system, also can be used for supplementing alkalinity needed for an anaerobic unit, so that comprehensive utilization of excess sludge is facilitated. The method disclosed by the invention has the advantages that nutrient elements in the sludge are comprehensively utilized, process is simple, and phosphor can be recycled by only adding the magnesium salt; and meanwhile, ammonia nitrogen can be partly recycled without regulating pH, and the obtained magnesium ammonium phosphate crude product can be used for producing fertilizers.

Owner:SOUTH CHINA UNIV OF TECH

Ceramic based nanoparticles for entrapping therapeutic agents for photodynamic therapy and method of using same

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

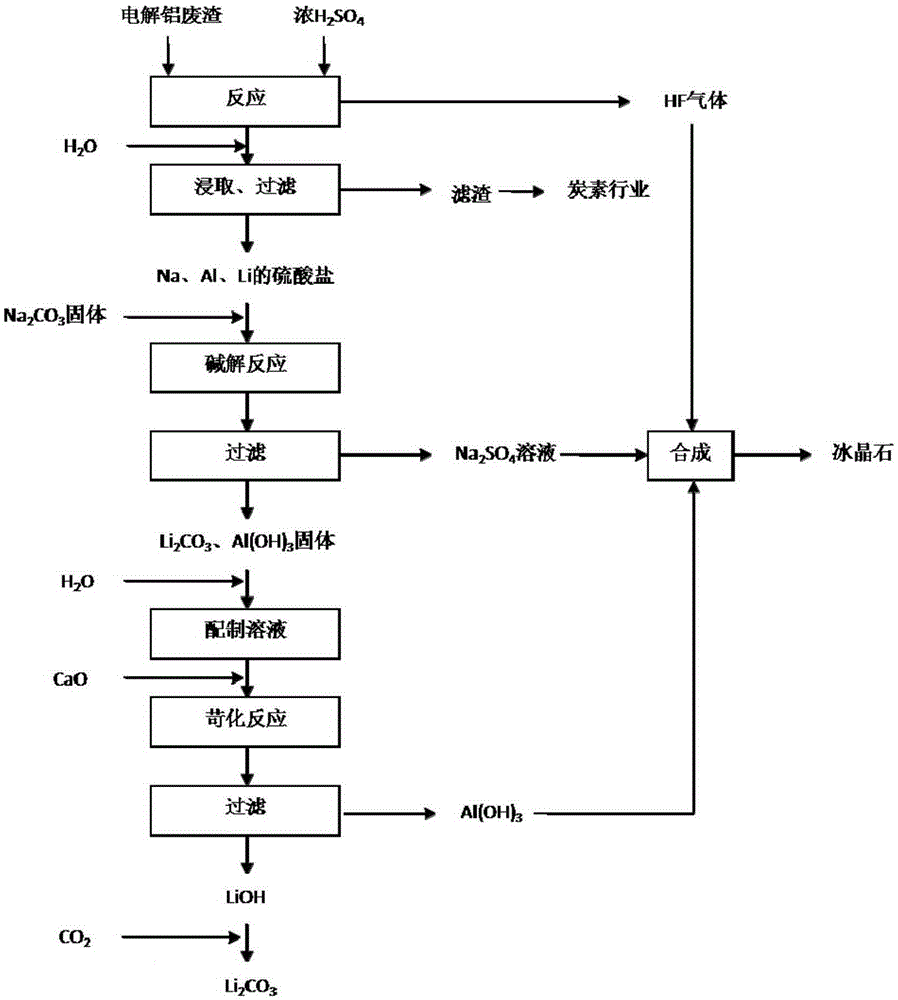

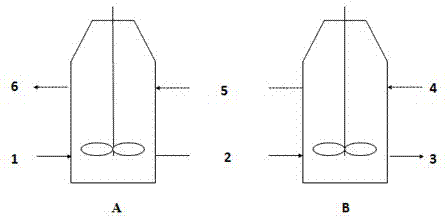

Method of extracting lithium from electrolytic aluminium waste residues

ActiveCN105293536ALow content of impurity ionsImprove product qualityProductsReagentsSocial benefitsLithium carbonate

The invention discloses a method of extracting lithium from electrolytic aluminium waste residues. The method comprises the following steps of performing a reaction on the electrolytic aluminium waste residues containing the lithium and concentrated sulfuric acid under the condition of 200 to 400 DEG C, and a mixture A is obtained; adding water into the mixture A, filtering after leaching to obtain filtrate A and a filter residue A; adding the filtrate A into sodium carbonate, and performing an alkaline hydrolysis reaction under the condition of 20 to 40 DEG C, then filtering to obtain filtrate B and a filter residue B; adding water into the filter residue B to prepare slurry, then adding lime into the slurry for a causticizing reaction, then filtering to obtain filtrate C and a filter residue C; feeding CO2 into the filtrate C in step 4) for a carbonization reaction, then filtering, washing, drying so as to obtain the lithium. The content of impurity ions in the obtained cell grade lithium carbonate is low, the quality of a product is excellent, and the problems of low yield, high production cost, weak market competitiveness when the lithium is extracted from ore to prepare the cell grade lithium carbonate at present are solved; a new process that a high value-added and high quality lithium product is produced by low-grade lithium resources is developed, the process is simple, the industrialized operation is liable to be realized, and the economic and social benefit is remarkable.

Owner:焦作多氟多实业集团有限公司

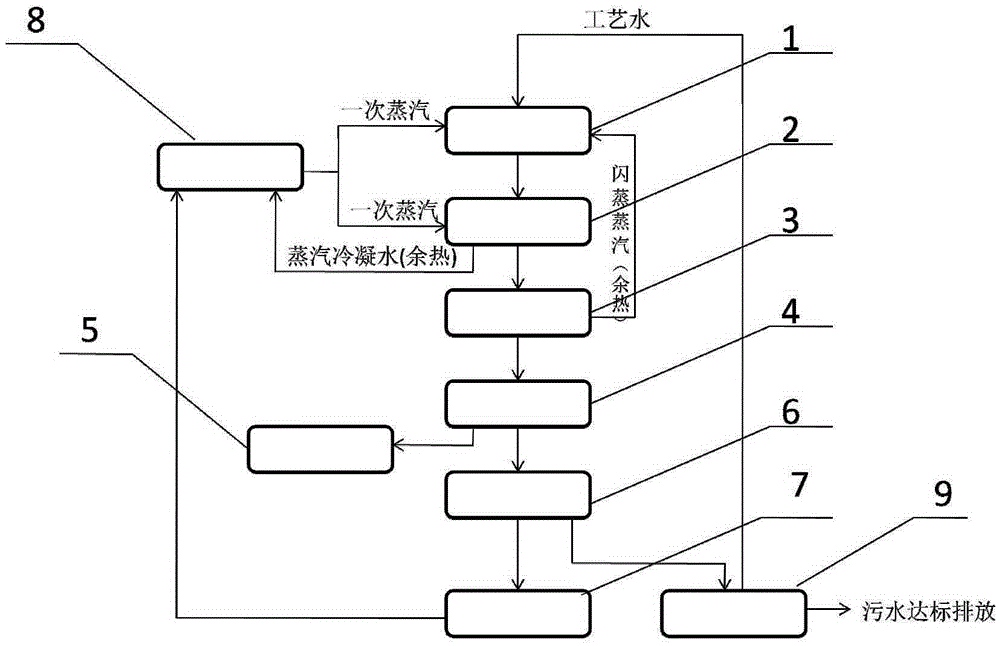

Method for processing residual sludge with integrated process of alkaline hydrolysis preprocessing, nitrogen and phosphorus recovery based on magnesium ammonium phosphate method and methane production based on anaerobic digestion

ActiveCN103693828AReduce consumptionGive full play to the role of alkaline hydrolysis pretreatmentWaste based fuelSludge processingChemical oxygen demandMagnesium salt

The invention discloses a method for processing residual sludge with an integrated process of alkaline hydrolysis preprocessing, nitrogen and phosphorus recovery based on a magnesium ammonium phosphate method and methane production based on anaerobic digestion. The method comprises the steps of: preprocessing residual sludge with a secondary alkaline hydrolysis method to obtain supernate, adding a magnesium salt solution to separate precipitates, subjecting the supernate to anaerobic processing, and drying the precipitates naturally to obtain crude magnesium ammonium phosphate; injecting the supernate into an anaerobic reactor, and inoculating with 10-60% anaerobic granular sludge, wherein the volumetric loading is controlled to be 0.30-0.75kg COD (Chemical Oxygen Demand) / (m<3>.d), and the productivity of methane reaches 200-400mL CH4 / gCOD within 72h. The method disclosed by the invention has the advantages that nutrition elements in the residual sludge are utilized comprehensively, the process is simple and is consistent in flow with low chemical consumption and electricity consumption, methane is recovered while crude magnesium ammonium phosphate is obtained, moreover, residual alkaline solids are beneficial to subsequent processing, and the reduction, stabilization and recycling of the residual sludge are realized comprehensively.

Owner:SOUTH CHINA UNIV OF TECH

Cellulose composites comprising hydrophobic particles and their use in paper products

InactiveUS20080041542A1Non-fibrous pulp additionNatural cellulose pulp/paperSolventAlkaline hydrolysis

Polymer composite films were prepared by solvent casting suspensions of quantum dots (QDs) in cellulose triacetate (CTA) solution. The films were robust and possessed the optical properties characteristic of QDs. Transmission electron microscopy (TEM) images of the films revealed that the QDs were well dispersed within the CTA film matrix. The selective alkaline hydrolysis of QD / CTA films in 0.1N NaOH over 24 hours resulted in the surface conversion of CTA to regenerated cellulose. Optical properties of the films were probed both before and after the hydrolysis reaction using fluorescence spectroscopy, and were found generally unaltered. The cellulose surfaces of the alkaline treated films allow for facile incorporation of the films into paper sheets.

Owner:ABITBOL TIFFANY +1

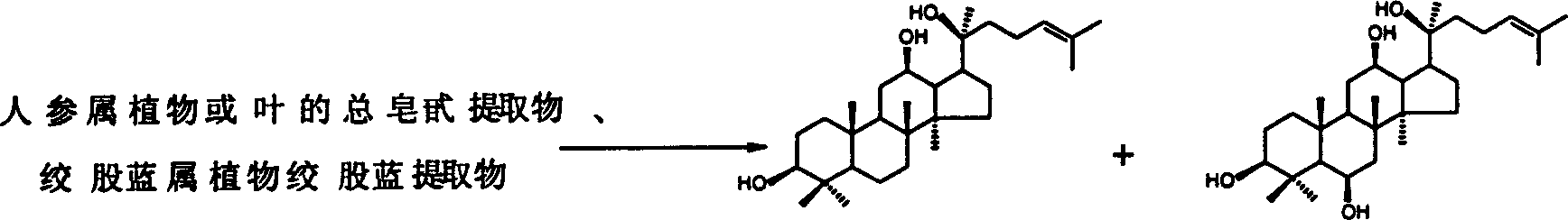

Process for preparing protopanoxadiol and protopanaxatriol

ActiveCN1569882AThere is no problem of instability, easy destruction, and easy cyclizationHigh yieldSteroidsOrganic solventProtopanaxadiol

The invention relates to the process for preparing protopanoxadiol and protopanaxatriol by using general saponin extract from panax ginseng plant leaves and gynostemma pentaphylla extractive as raw material for alkaline hydrolysis reaction in organic solvent through column chromatography and purification.

Owner:怡瑞达(上海)医药科技有限公司

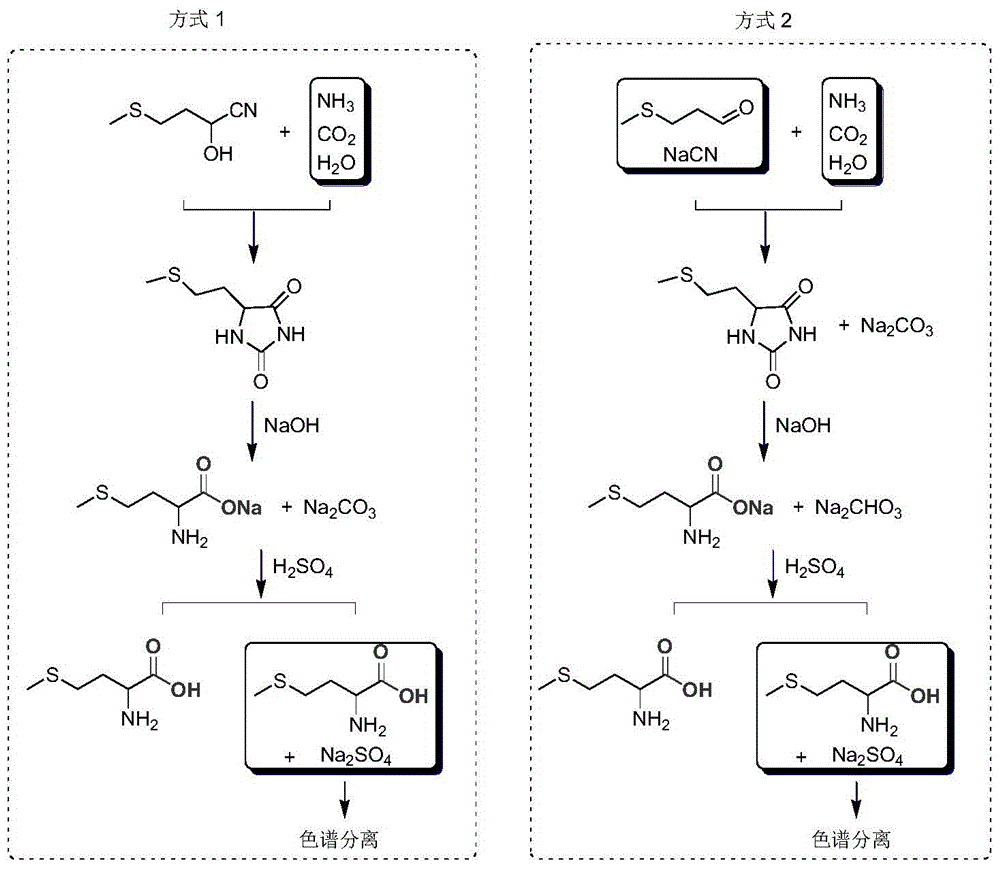

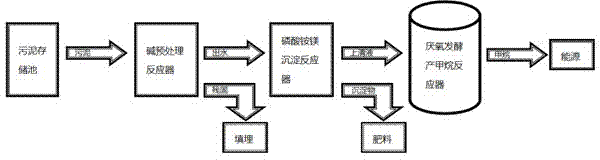

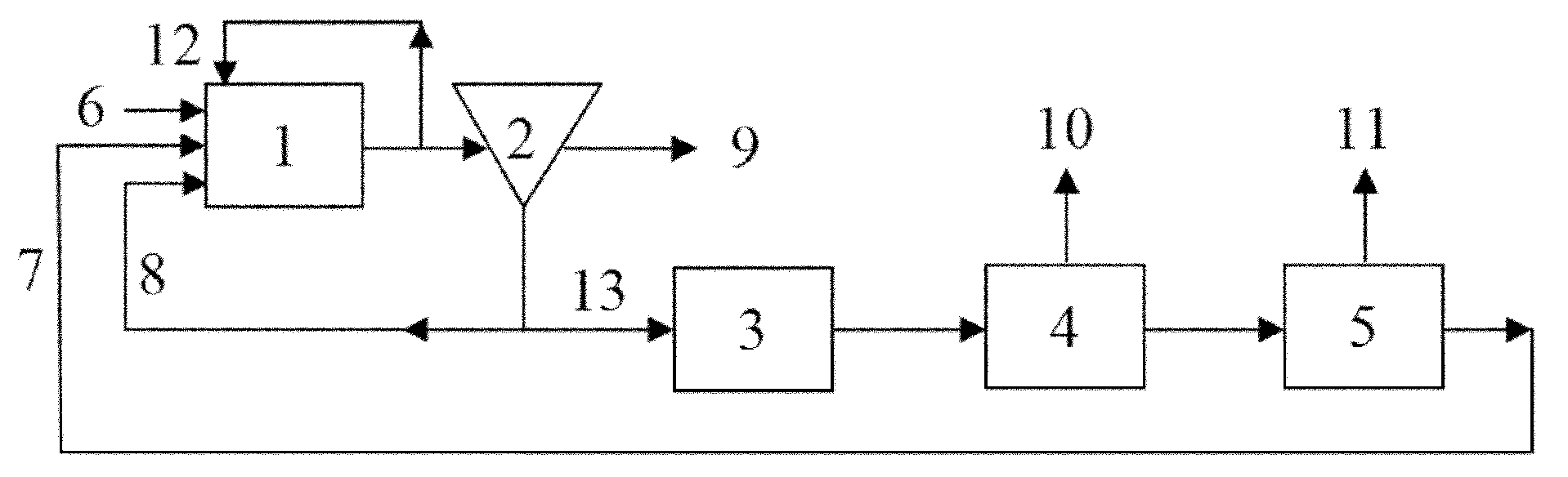

Device and method for improving biological dephosphorizing and denitriding efficiency of low carbon source sewage

InactiveCN102060412ASmall volumeReduce initial investmentSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentSolubilityHigh concentration

The invention provides a device and a method for improving the biological dephosphorizing and denitriding efficiency of low carbon source sewage, belonging to the technical fields of sewage treatment and residual sludge treatment. The method comprises the following steps of: under the microwave alkaline hydrolysis condition, hydrolyzing solid organic matters in the residual sludge into soluble organic matters; recovering and hydrolyzing nitrogen and phosphor in supernate by adopting a magnesium ammonium phosphate setting method; and adding the hydrolyzed supernate subjected to dephosphorizing and denitriding treatment in the low carbon source sewage and carrying out biological dephosphorizing and denitriding treatment on the hydrolyzed supernate so as to improve the biological dephosphorizing and denitriding efficiency of the low carbon source sewage. According to the invention, by carrying out the microwave alkaline hydrolysis treatment on the residual sludge to produce high-concentration soluble organic matters easy to biodegrade, the product can be used as a low-price carbon source subjected to biological dephosphorizing and denitriding treatment in the lower carbon source sewage, and the biological dephosphorizing and denitriding efficiency in the lower carbon source sewage can be improved; meanwhile, sludge minimization, reclamation and harmlessness can be realized. The VSS (Volatile Suspended Solids) solubility in the sludge can be improved to 82 percent, so that the effluent quality of the low carbon source sewage treated by the device and the method achieves the first-class B standard 'Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant' (GB18918-2002).

Owner:TIANJIN URBAN CONSTR COLLEGE

Method for environment-friendly clean production of D,L-methionine

InactiveCN106432018AIncrease profitAvoid accumulationOrganic compound preparationChemical recyclingChromatographic separationAlkaline hydrolysis

A method for environment-friendly clean production of D,L-methionine includes: performing alkaline hydrolysis of 5-(2-methylmercaptoethyl)-hydantoin to obtain carbonate-containing methionine alkali metal saponified solution; then feeding carbon dioxide, crystallizing, and separating to respectively obtain methionine and hydrocarbonate water solution of methionine; subjecting the hydrocarbonate water solution of methionine to chromatographic separation. The method has advantages that loss of D,L-methionine due to pyrolysis can be reduced, simplicity in operation, low cost and high utilization rate of raw materials are realized, high efficiency in acquisition of high-purity methionine crystals is achieved, the purity of the obtained methionine is up to 99.4%, the methionine recovery rate reaches 97%, and the desalinization rate reaches 98% or above. In addition, accumulation of a great quantity of impurities of methionine-containing potassium bicarbonate mother liquor and emission of the potassium bicarbonate mother liquor are avoided, discharge of saline wastewater is avoided, and accordingly environment friendliness and clean production are realized. In a whole process, potassium carbonate serving as a hydrolysis agent is recycled without loss, and replenishment of alkaline potassium compounds is avoided.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

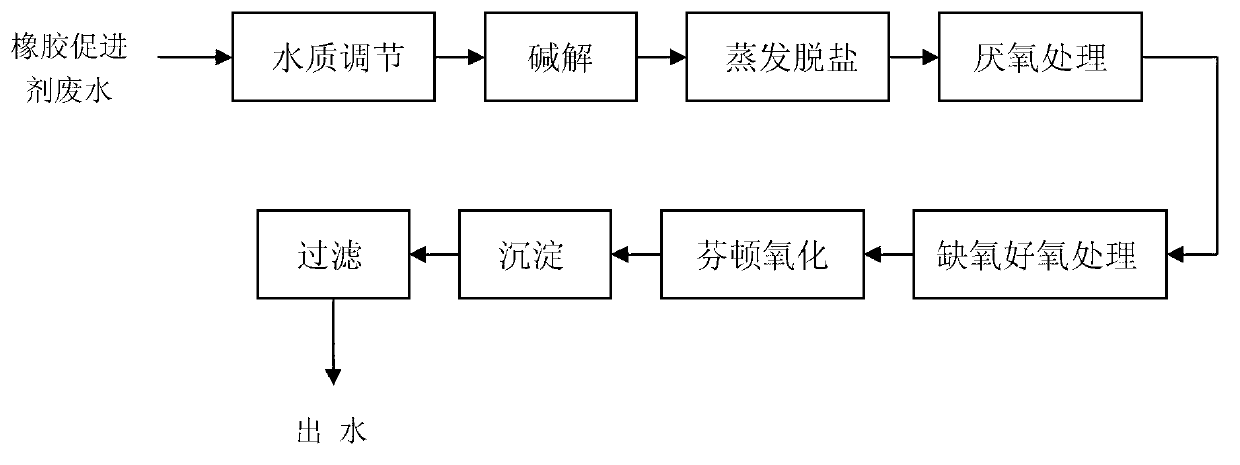

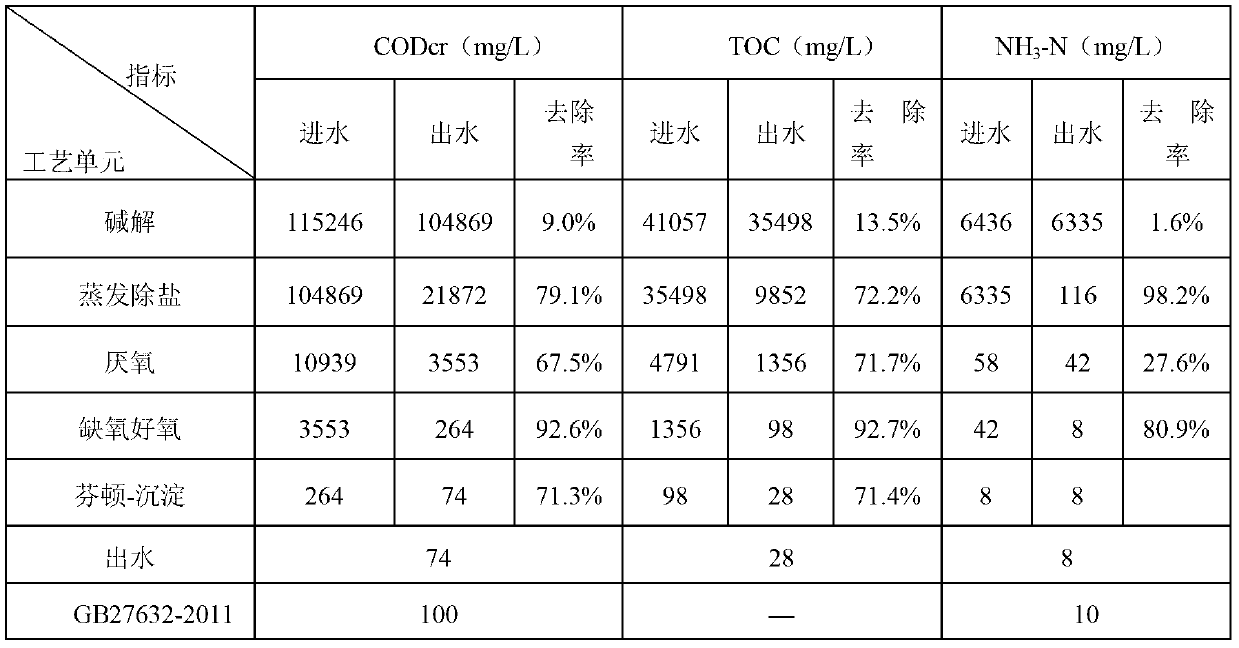

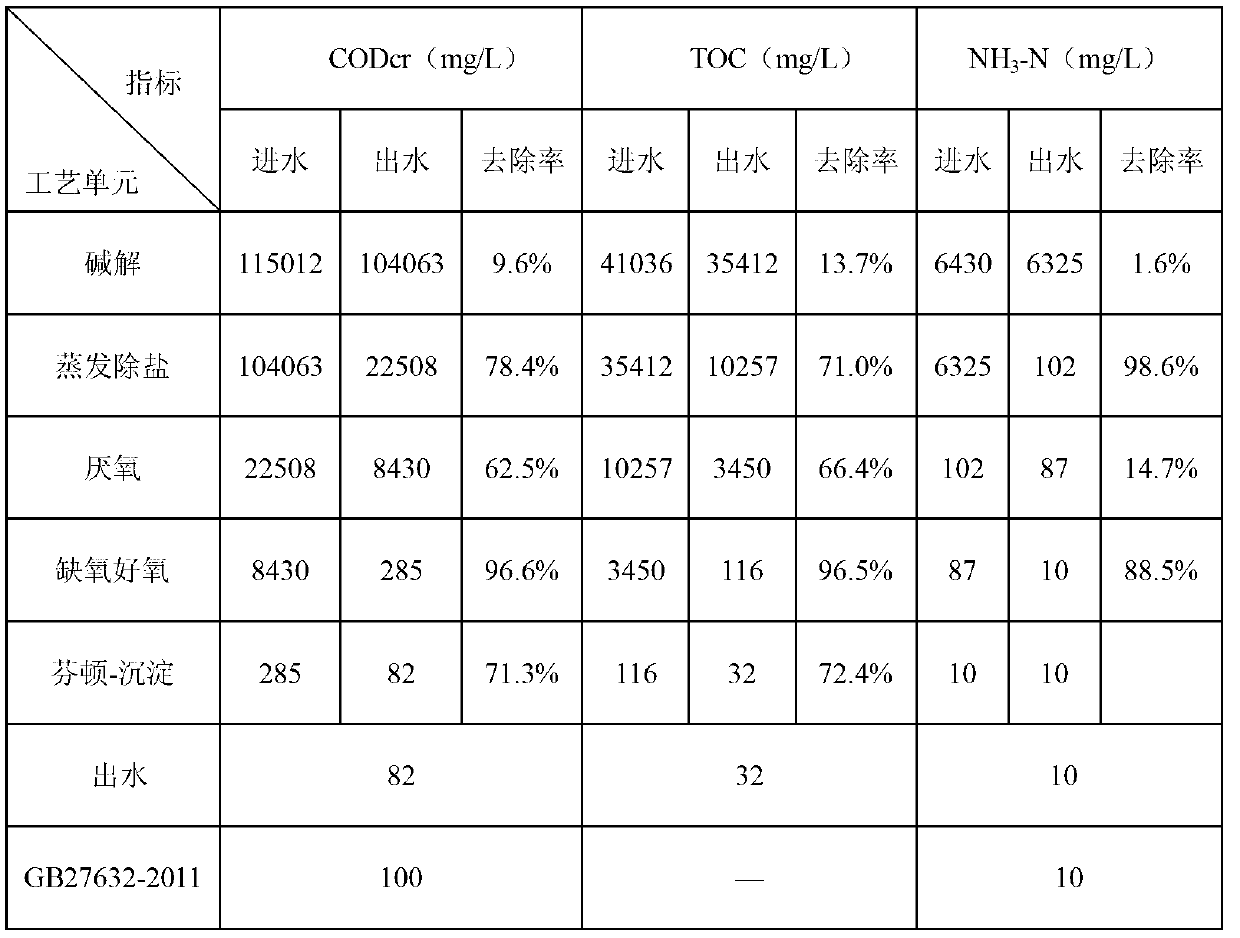

Technology for treating waste water produced by rubber accelerator production

ActiveCN103274564APH dropEfficient removalMultistage water/sewage treatmentNature of treatment waterFiltrationEvaporation

The invention relates to a technology for treating waste water produced by rubber accelerator production. The technology comprises the following steps of 1, adjusting quality and an amount of waste water produced by rubber accelerator production, adjusting pH value of the waste water to 11-13, adjusting a temperature of the waste water to 60-90 DEG C, and carrying out stirring for 2-4h for alkaline hydrolysis, 2, adjusting a pH value of the waste water to 5.0-6.0 by sulfuric acid, and carrying out evaporation desalination, 3, carrying out anaerobic treatment on the waste water subjected to evaporation desalination, 4, orderly carrying out anaerobic treatment, aerobic treatment and secondary precipitation of the anaerobic precipitation product water, wherein a mixed solution and sludge backflow process is carried out between the secondary precipitation and the anaerobic treatment, and 5, orderly carrying out Fenton catalytic oxidation, coagulating sedimentation and filtration deep treatment on the secondary precipitation product water. According to the characteristic of quality and amount of waste water produced by rubber accelerator production, the technology combines a physicochemical treatment method and a biochemical treatment method, realizes that COD and ammonia nitrogen indexes of waste water stably reach corresponding emission standards, has a compact process, is convenient for operation, has low energy consumption and strong practicality, and can be industrialized easily. The waste water treated deeply can be used as recycled water so that waste water recycle is realized.

Owner:NANJING UNIV OF TECH

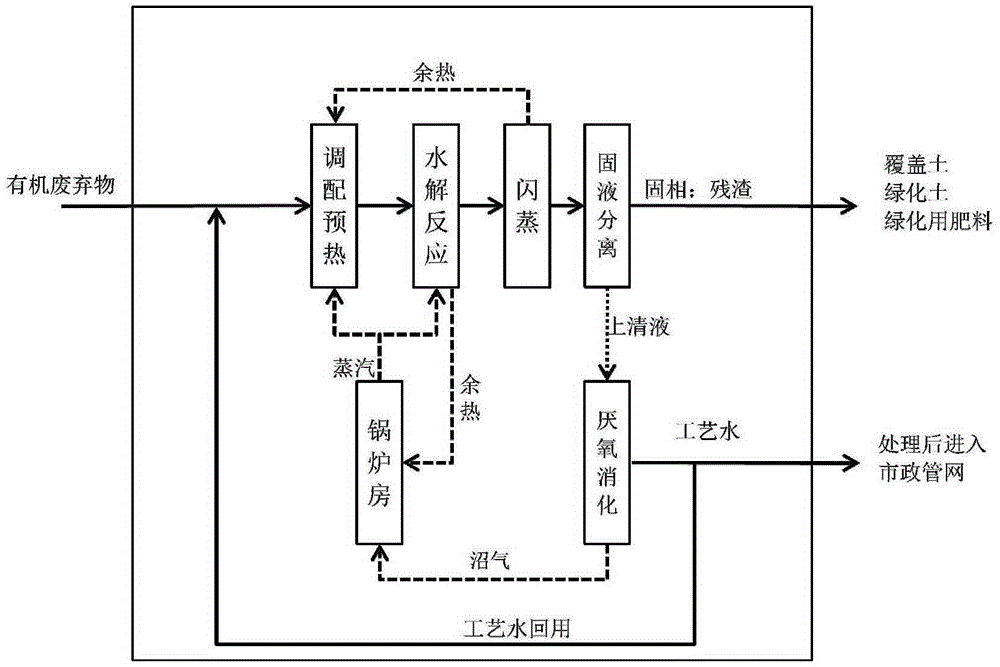

Energy regeneration method for solid organic waste alkaline thermal hydrolysis supernate

InactiveCN105396862ALow viscosityImprove liquiditySolid waste disposalWaste based fuelTemperature controlEnergy regeneration

The invention relates to an energy regeneration method for solid organic waste alkaline thermal hydrolysis supernate. Solid organic waste mainly comprises kitchen waste and sludge. The energy regeneration method for the solid organic waste alkaline thermal hydrolysis supernate comprises the following steps that (1) after the organic waste, water and alkali hydrolysis agents are proportioned and mixed in a proportioning and preheating tank, heating is conducted, so that the temperature of the materials in the tank is increased to 30-99 DEG C; (2) the materials in the proportioning and preheating tank are sent into a reaction kettle through a pump for the temperature rise reaction, and finally the temperature of the materials is controlled between 100 DEG C and 140 DEG C, and the reaction continues to be conducted for 90-120 minutes; (3) the materials after the hydrolysis reaction are conveyed into a flash evaporation tank for pressure relief and cooling, so that the temperature of the materials is decreased to 50-100 DEG C; (4) clarified liquid and solid are obtained after solid-liquid separation; and (5) the liquid obtained after solid-liquid separation is delivered into an anaerobic digestion system for anaerobic digestion treatment, and thus marsh gas is generated. By the adoption of the energy regeneration method for the solid organic waste alkaline thermal hydrolysis supernate, toxin removal, stabilization, minimization and energy regeneration of the organic waste can be achieved at a time.

Owner:天津市裕川环境科技有限公司

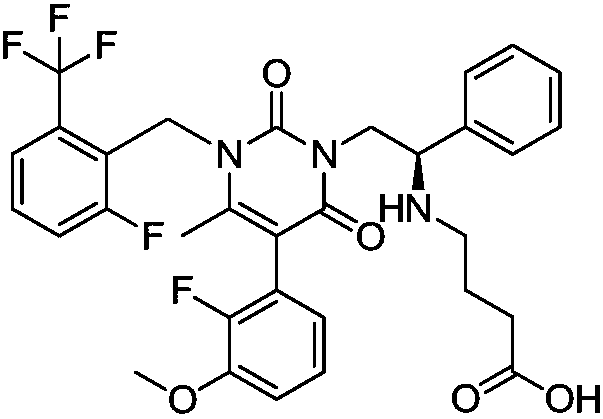

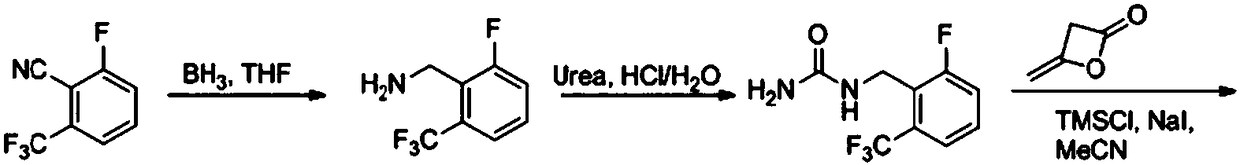

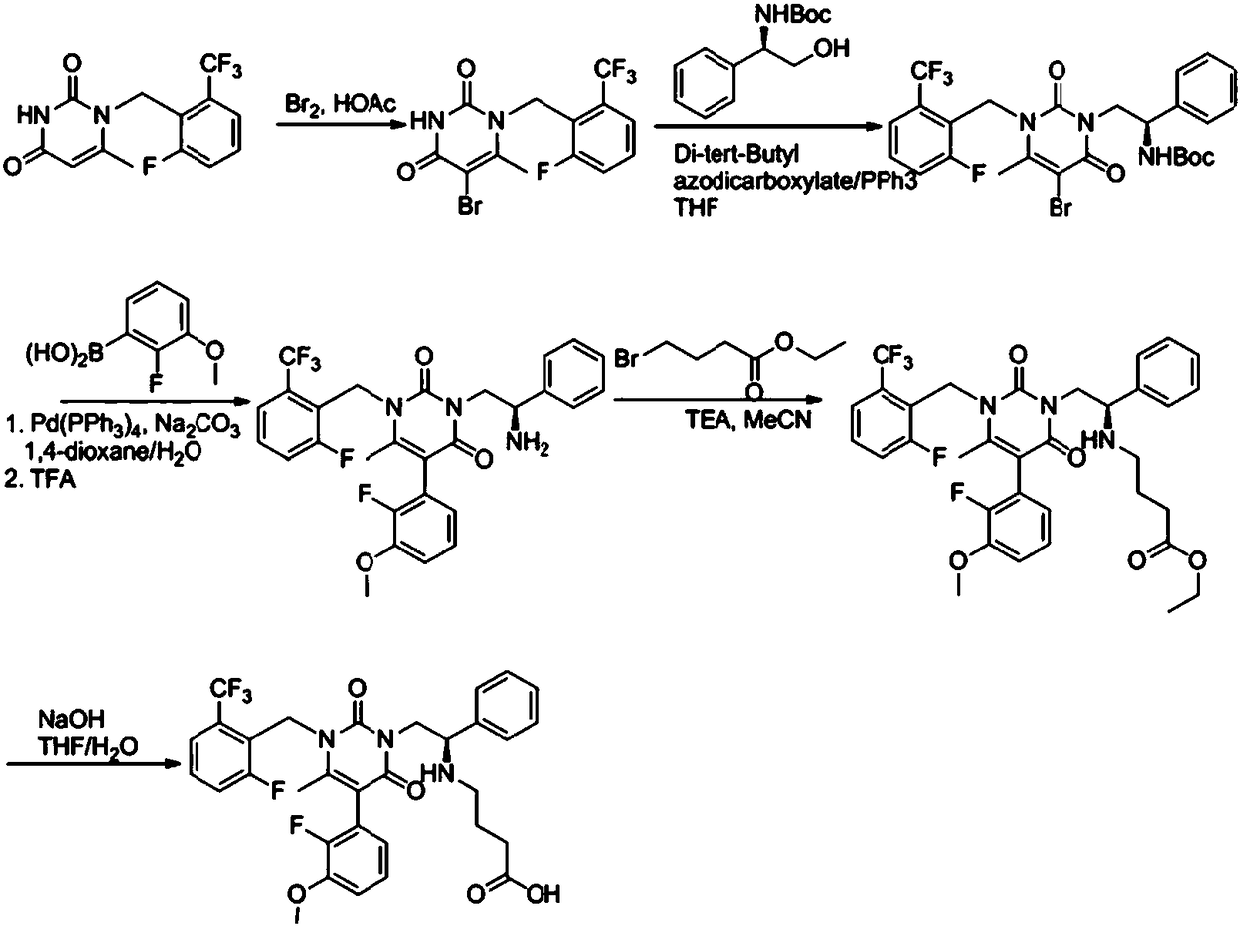

Elagolix synthesis method

The invention provides an elagolix synthesis method. The elagolix synthesis method comprises enabling a compound 5 and a compound 10 to participate in a condensation reaction to finish N-alkylation reaction to obtain a compound 11, and then implementing alkaline hydrolysis to obtain elagolix 12. The invention further discloses two synthesis methods of the compound 5: the method I comprises enabling a 5-bromine-6-methylpyrimidine-2,4(1H,3H)-diketone compound 1 and a 2-(brooethyl)-1-fluorin-3-(trifluoromethyl) benzene compound 2 to have a condensation reaction to obtain an intermediate 3, and then having a coupling reaction; the method II comprises enabling 1-halide-3-fluorin-2-anisole and acetoacetate 7 to have a coupling reaction to obtain a compound 8, and then having a condensation cyclization reaction with a compound 9; the improvements greatly shorten the route steps, the route efficiency is improved, the use of a noble metal catalyst is avoided, and the process cost is greatly lowered. The operation of the route is simple, the total yield is high, the purity of an obtained product is also relatively high, and the method is suitable for the enlarged production.

Owner:HANGZHOU CHEMINSPIRE TECH CO LTD

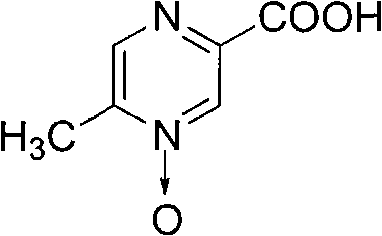

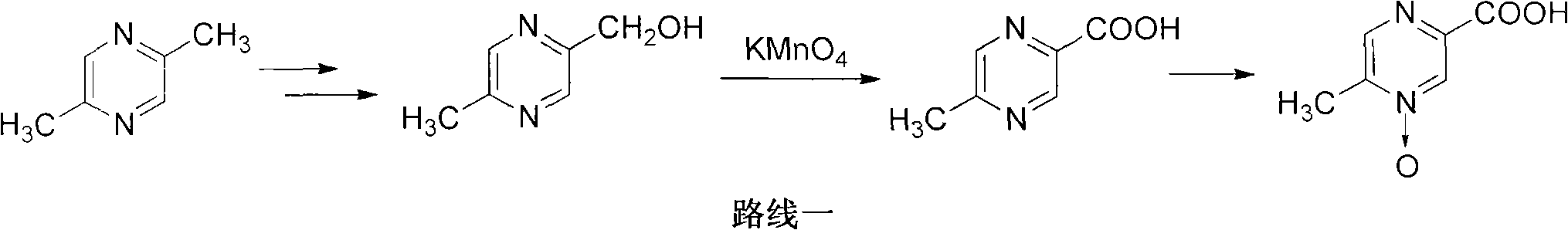

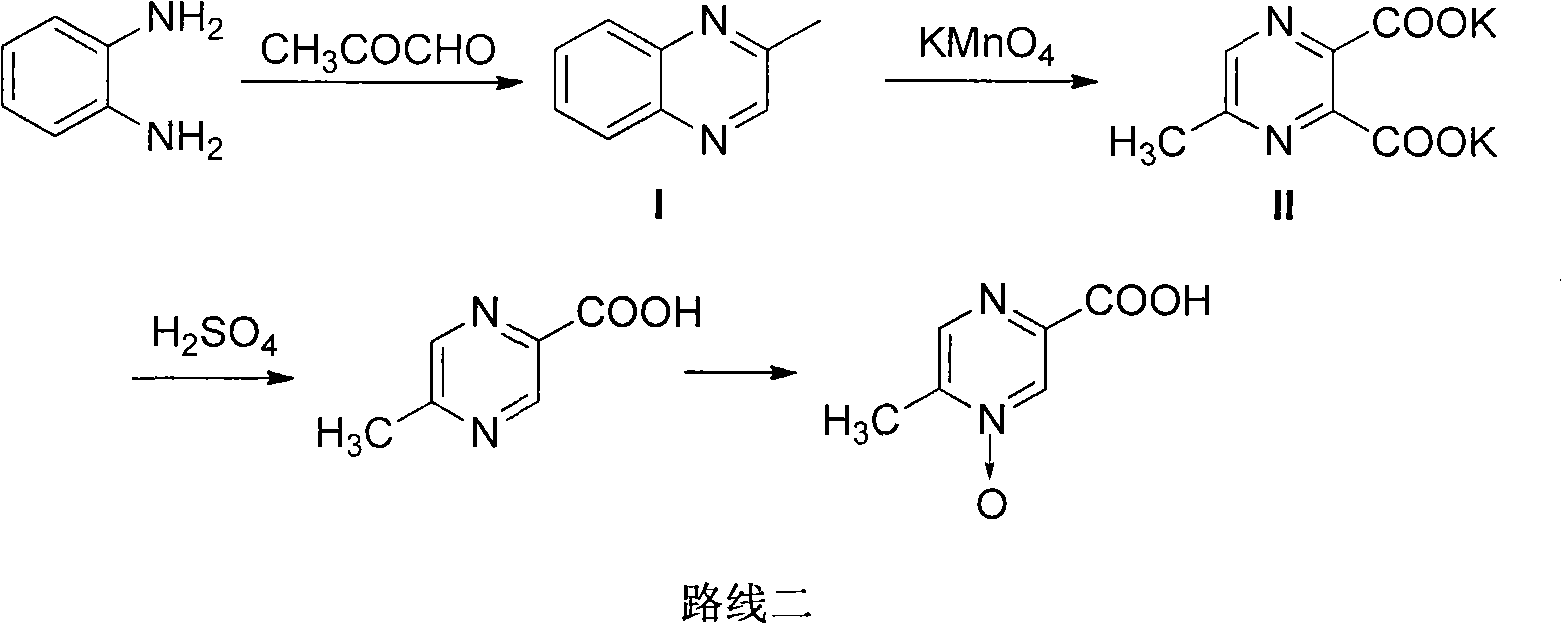

Preparation method of acipimox

InactiveCN103508963AReduce usageEasy to get materialOrganic chemistryAcetic anhydrideCarboxylic acid

The invention relates to a preparation method of acipimox for treating hyperlipidemia, belonging to the field of medicines. The invention provides an acipimox synthesis process which is simple and easy to operate. The preparation method comprises steps of with 2, 5-dimethylpyrazine as a raw material, carrying out nitrogen oxidation, reaction with acetic anhydride and alkaline hydrolysis to obtain 2-hydroxymethyl-5-methylpyrazine; directly oxidizing a post-treatment fluid by using 2,2,6,6-tetramethyl-1-piperidinyloxy / sodium hypochlorite / potassium bromide to obtain 5-methylpyrazine-2-carboxylic acid, wherein the post-treatment fluid is not needed to be dried and concentrated; oxidizing 5-methylpyrazine-2-carboxylic acid by using hydrogen peroxide / sodium tungstate to obtain acipimox.

Owner:WEIHAI WEITAI PHARMA TECH DEV

Method for degrading waste polyurethane foam to recycle polyether polyol

InactiveCN107955206AAchieve recyclingMeet recycling requirementsPlastic recyclingEnvironmental resistanceAlcohol

The invention belongs to the technical field of recycling and reutilization of waste polyurethane foam products, and in particular relates to a method for degrading waste polyurethane foam to recyclepolyether polyol. The method provided by the invention comprises the following steps: mixing and compounding low molecular alcohol and degradation auxiliary agents to form an alcoholysis solution; adding the waste polyurethane foam into the alcoholysis solution and carrying out degradation reaction; carrying out vacuum degassing treatment on degraded crude polyether to obtain recyclable crude polyether polyol. According to the method provided by the invention, the low molecular alcohol is used as an alcoholysis agent and various degradation auxiliary agents are added, so that the recycling ofthe waste polyurethane foam with different physical and mechanical properties is realized under a relatively moderate condition through reaction mechanisms of chemical alcoholysis and alkaline hydrolysis, and recycled polyether polyols with various viscosity and different hydroxyl values are obtained; the method has the advantages of low cost, simple technology, high recycling efficiency, greenness and environment protection and the like; different polyurethane foam recycling requirements are met, and the method can be stably applied to subsequent polyurethane foaming.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

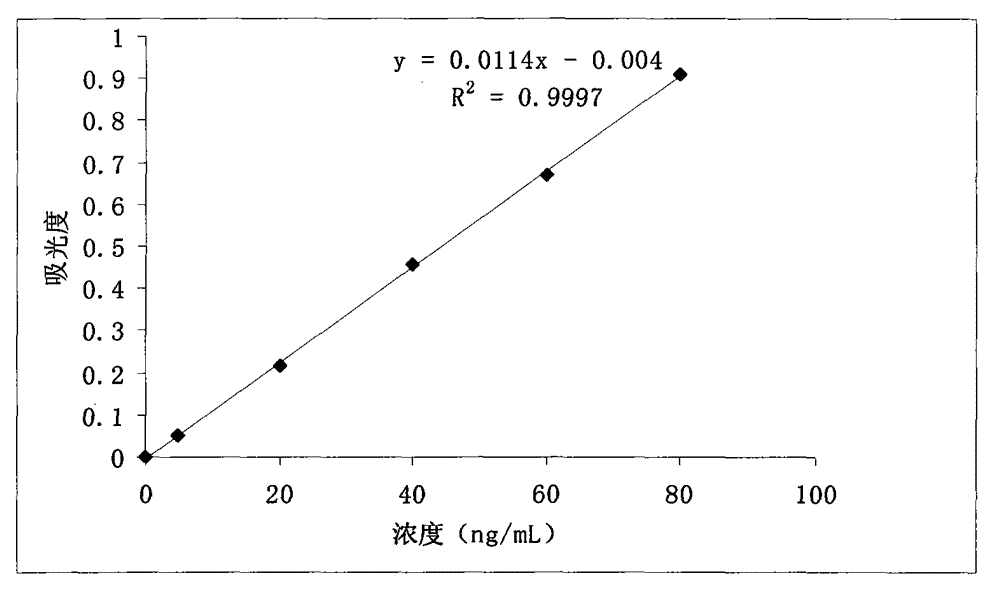

Method of detecting heavy metal lead, cadmium, arsenic and copper in TCM (Traditional Chinese Medicine) tablet

ActiveCN104697983AAvoid pollutionAvoid dangerAnalysis by thermal excitationTrace metalAlkaline hydrolysis

The invention discloses a method of detecting heavy metal lead, cadmium, arsenic and copper in a TCM (Traditional Chinese Medicine) tablet. The method comprises the following steps: after carrying out microwave alkaline hydrolysis on tablet powder with an ammonia chloride containing diluted alkali solution, quickly adding hydrogen peroxide containing dilute acid solution, and ultrasonically extracting after the pH value is adjusted to be not more than 2; carrying out constant volume on an extract after the centrifugation, condensation and microfiltration; and finally, determining by adopting an atomic absorbency method. According to the method, a sample is preprocessed by an alkaline-hydrolysis acid-extracting method, therefore, the loss of heavy metal element caused by high temperature of a dry ashing method and air pollution and potential danger caused by a resolution method can be prevented; meanwhile, the method has the advantages of being good in recovery rate, high in precision, fast in processing speed, convenient to operate, wide in range of application and the like, and is more suitable for the quantitative determination of trace metal elements.

Owner:金木集团有限公司

Method for recovering collagen and chromium salts from chromium-containing scrap leather residues

ActiveCN103014191APromote hydrolysisQuick filterConnective tissue peptidesTanning treatmentStrong acidsAlkaline hydrolysis

The invention discloses a method for recovering collagen and chromium salts from chromium-containing scrap leather residues, which comprises the following steps: carrying out alkaline hydrolysis on chromium-containing scrap leather residues with strong alkali assisted by metal oxide and surfactant, recovering collagen from the filtrate, hydrolyzing the filter residues with strong acid, and sequentially carry out redox reaction to obtain a chrome tanning solution or drying to obtain a powdery chrome tanning agent. The invention has the advantages of fewer steps, short period, high efficiency and low production cost, is simple to operate, and can implement effective separation of chromium and hydrolyzed collagen; the recovered industrial collagen has low chromium content and high added value, and thus, can be used as a raw material for producing other fine industrial chemicals; the recovered chromium salts are free of calcium salts, and thus, can be used as a tanning agent for leather tanning again; and the invention does not generate tailings or wastewater, thereby avoiding secondary pollution.

Owner:SICHUAN UNIV

Extracting method of chondroitin sulfate

The invention discloses an extraction method of chondroitin sulfate, belonging to the biological and chemical product field. The method adopts single enzymolysis technology to replace the traditional alkaline hydrolysis process and makes use of ultra-filtration membrane filtration to substitute for repeated alcohol precipitation so as to simplify the production process, ensure the integrity of chondroitin sulfate and increase the yield and purity, with the yield more than 37% and the purity more than 99.5%.

Owner:SHANDONG TOPSCI BIO TECH

Method for extracting heparin sodium by utilizing pork lungs

The invention relates to a method for extracting heparin sodium by utilizing pork lungs, which has the following steps of: grinding fresh pork lungs into pork lung paste; adding deionized water, lysis agent and preservative; reacting to obtain pork lung serous fluid; adding deionized water and sodium chloride; reacting to obtain pork lung alkaline hydrolysis liquid; slowly heating the pork lung alkaline hydrolysis liquid and adding heparin sodium protamex; after heat preservation and reaction, slowly heating and continuously carrying out heat preservation to obtain pork lung enzymolysis liquid; replenishing sodium chloride after cooling the pork lung enzymolysis liquid; reacting to obtain pork lung salt hydrolysis liquid; heating and carrying out heat preservation on the pork lung salt hydrolysis liquid; adding composite protein precipitation agent; stirring; collecting clear liquid after static placing; concentrating the clear liquid and then adding ethanol; precipitating overnight to obtain precipitate; and dehydrating and drying to obtain a crude product of the heparin sodium. According to the invention, the production cost of the heparin sodium can be reduced, the product quality and the yield can be improved, the large-scale production can be easily realized, meanwhile, the usage amount of chemical reagents is reduced, the emission of waste is reduced, and no waste gas orwaste water is discharged. The economic benefit and the social benefit are obvious.

Owner:TOPROBIO MICRO BIOTECH

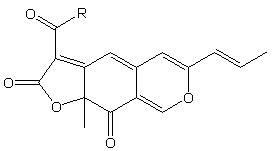

Method for extracting crocetin from gardenia

The invention relates to a preparation method of the crocetin extracted from the gardenia, which is characterized in that after the gardenia is crushed and extracted by ultrasonic enhancement in distilled water or ethanol solution, the extractant is filtered and concentrated; the glycoside substance of the gardenia is separated via the macroporous resin and the crocin eluent is concentrated and dealt with acid hydrolysis or alkaline hydrolysis (alkaline hydrolysis solution should be adjusted to pH of acidity.), centrifugal, rinse and sedimentation to get the crude product of the crocetin; after purifying the crude product of the crocetin further, the cis crocetin and the trans crocetin are separated to acquire trans crocetin of high purity which facilitates structure modification, forms a plurality of crocetin derivatives featured by different water soluble and drug efficacy, providing material for related preparation R and D and application. The preparation method of the crocetin extracted from the gardenia has the advantages of having convenient and fast method, low cost and establishing a new channel for deep processing of gardenia products.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

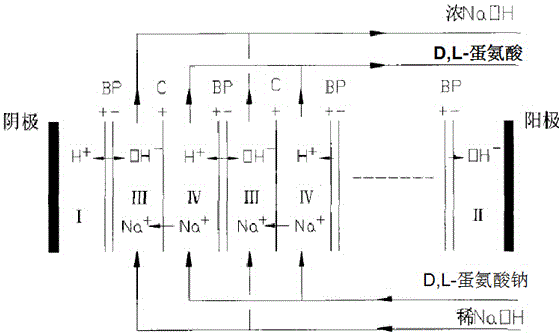

Environment-friendly clean production method of D,L-methionine

InactiveCN104130169AReduce processing costsNo three wastes pollutionOrganic compound preparationSulfide preparationAlkaline hydrolysisHydrolysis

The invention discloses an environment-friendly clean production method of D,L-methionine. The method comprises the following steps: (1) D,L-methionine salt water is adopted as a raw material, and is subjected to a bipolar membrane electrodialysis treatment in a bipolar membrane electrodialysis system, wherein the pH value in a salt chamber is controlled at 5.5-6.0, such that a D,L-methionine solution is obtained, and an alkali solution is obtained in an alkali chamber; and (2) D,L-methionine separated from the D,L-methionine solution obtained in the step (1). According to the invention, acid for neutralization is not needed, such that a by-product sulfate or hydrochloride is completely eliminated. The method causes no three-waste (waste gas, waste water, and solid waste) pollution, and helps reducing salt-containing waste water treatment cost. With the method, product quality is good, and yield is high. Also, according to the invention, the D,L-methionine salt is prepared with 2-hydroxy-4-methylthiobutyronitrile direct ammoniation, alkaline hydrolysis, and ammonia removing, such that carbonate is not produced. In the subsequent bipolar membrane electrodialysis treatment, energy consumption can be saved, and production cost can be reduced.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Easy-to-alkaline-hydrolysis poly ester and preparation method

The invention refers to a method of preparing easy-alkaline hydrolysis polyester. The main repeated unit is diglycol terephthalate, the acid containing 5-sodium sulfonate-diglycol isophthalate (SIPE), 5-10 mol% and isophthalic acid (IPA), 4-8 mol%, the polymer containing polyethylene glycol (PEG), molecular weight 1000-8000, weight %: 6-12, and compound heat stabilizing agent composed of antioxygen, cobalt acetate, phosphoric acid and phosphorous acid or its esters.

Owner:济南正昊化纤新材料有限公司

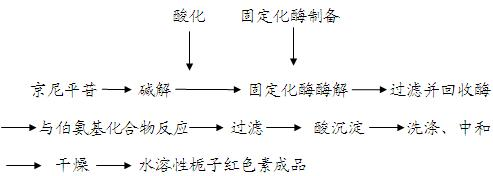

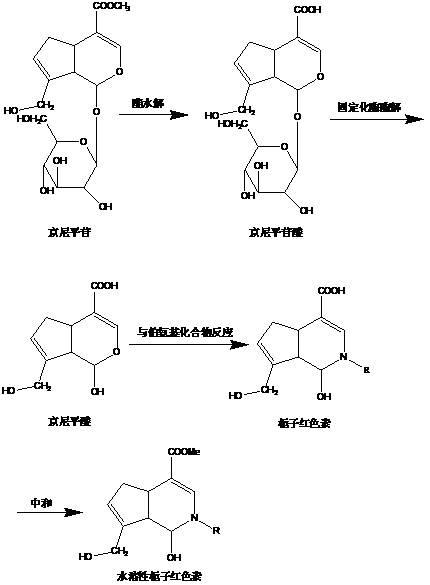

Method for preparing gardenia red pigment by using immobilized enzyme

InactiveCN101831469AEasy to separateReduce energy consumptionOn/in organic carrierFermentationSolubilityAlkaline hydrolysis

The invention provides a method for preparing a gardenia red pigment by using an immobilized enzyme, which comprises the following steps of: using geniposide as a raw material; performing alkaline hydrolysis and acidification on the raw material, and adding the immobilized enzyme into the raw material to perform enzymolysis; filtering the mixture to obtain enzymolysis solution; adding a primary amino compound into the enzymolysis into to perform a reaction; filtering the mixture to obtain solution of the gardenia red pigment; and performing acid deposition, deposition washing neutralization, dehydration and drying on the solution of the gardenia red pigment to obtain the gardenia red pigment. The method has the advantages that: an enzyme preparation can be recycled, the reaction condition is mild, an acid deposition method is adopted to perform enrichment, the process is simple, the energy consumption is low, and a product can be separated easily. The gardenia red pigment prepared by the method can obviously reduce the production cost. The product has the maximum absorption of 530 nm, has high water-solubility and high light, heat, acid, alkali and metal ion stability, and is favorable for widening the application range of the gardenia red pigment.

Owner:FUJIAN AGRI & FORESTRY UNIV

Processing method for cephalosporin dreg

ActiveCN103146761AEasy to handleDeal with economical and thoroughWaste based fuelSludge processingActivated sludgeResource utilization

The invention discloses a processing method for cephalosporin dreg. The processing method comprises the following process steps of: (A) thermal alkaline hydrolysis and separation treatment: uniformly mixing cephalosporin dreg, water and alkali, carrying out constant-temperature alkaline hydrolysis reaction, and carrying out solid-liquid separation at a certain temperature after the constant-temperature alkaline hydrolysis reaction, so as to obtain sediments to be standby; and (B) anaerobic digestion treatment: inoculating anaerobic activated sludge into an anaerobic fermentation tank, mixing the sediments obtained in the step (A) with excess sludge produced by utilizing wastewater biological treatment, injecting the mixture into the fermentation tank, carrying out constant-temperature stirring, and carrying out biogas residue discharging and feeding during fermentation. According to the processing method for the cephalosporin dreg, drug residues in the cephalosporin dreg can be completely removed, the problem that the anaerobic fermentation of single cephalosporin dreg cannot be effectively sustained is solved, and the reduction and innocent treatment to the cephalosporin dreg are realized; and biogas residues produced during the processing process can be used for preparing raw materials of organic fertilizers, the produced sewage gas can be used as clean fuels, and safe and effective disposition and resource utilization to the cephalosporin dreg are realized.

Owner:河北华药环境保护研究所有限公司

Method for preparing water-soluble monascus yellow pigment

InactiveCN101880469AEasy to separateReaction raw materials are readily availableNatural dyesAlcoholWater soluble

The invention provides a method for preparing a water-soluble monascus yellow pigment. Alcohol-soluble monascus red pigment generated by monascus metabolism is used as a raw material. The method comprises the following steps of: carrying out sulfonation reaction; and centrifuging or filtering, precipitating and washing, carrying out alkaline hydrolysis, neutralizing, drying and crushing to prepare the water-soluble monascus yellow pigment. Compared with the conventional method, the method for preparing the water-soluble yellow pigment has the advantages of readily available reaction raw materials, low price, simple process, easy separation of products, mild reaction conditions, recycling use of excess sulfuric acid and environmental protection.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com