Method of extracting lithium from electrolytic aluminium waste residues

A technology for electrolytic aluminum waste residue and filter residue, which is used in the removal of solid waste, lithium carbonate;/acid carbonate, reagents, etc., can solve the problem of high fluorine content, achieve simple process, reduce production cost, and be environmentally friendly. Benefit and Economic Benefit Significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

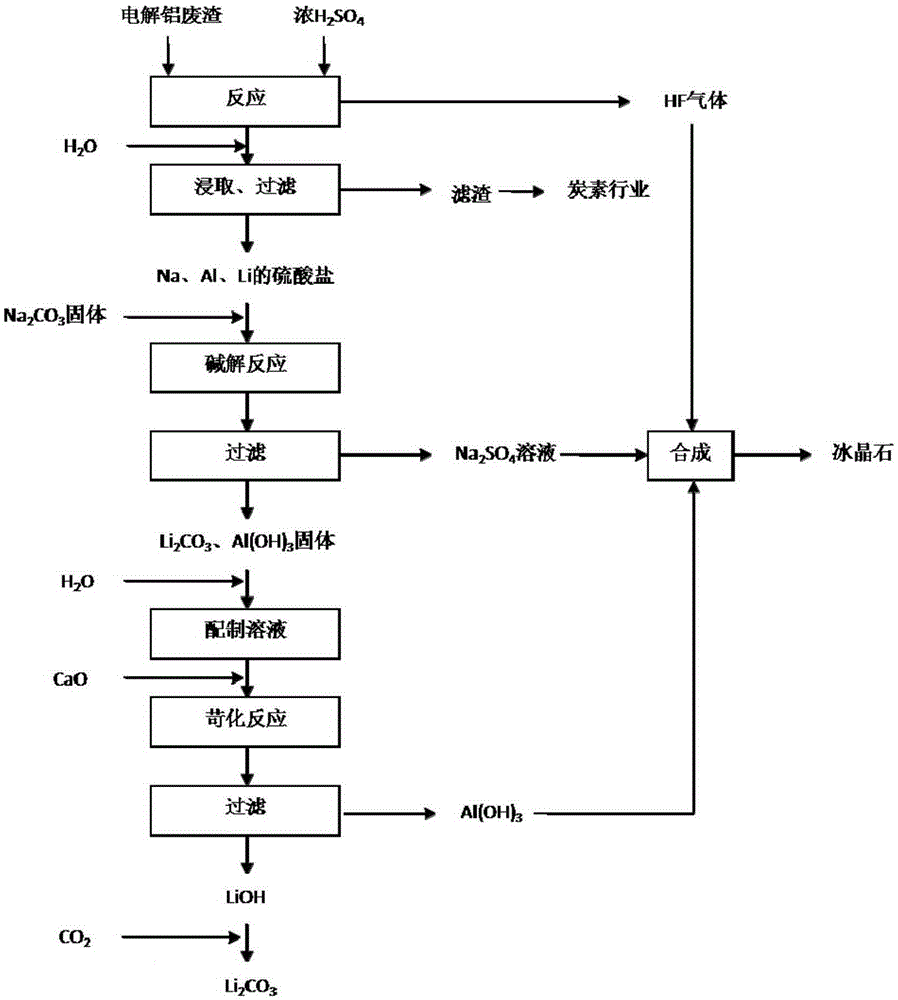

[0041] The method for extracting lithium from electrolytic aluminum waste slag of the present embodiment, such as figure 1 shown, including the following steps:

[0042] 1) Water mill the lithium-containing electrolytic aluminum waste slag to below 200 mesh, remove carbon and iron in the waste slag, and obtain a pretreated waste slag (main component content F: 45%, Al: 15%, Na: 23%, Li: 1 %);

[0043] Take 23.80 kg of pretreated waste residue, add concentrated sulfuric acid with a mass concentration of 98% according to the mass ratio of pretreated waste residue to concentrated sulfuric acid of 1:1, and react at 200° C. for 12 hours to obtain mixture A;

[0044] The HF gas generated during the reaction is condensed by a condenser, absorbed by water to a HF solution with a concentration of 40%, and used for the subsequent reaction of preparing cryolite;

[0045] 2) Take the mixture A obtained in step 1), and extract it with 47.60kg of water (the quality of adding water is twic...

Embodiment 2

[0054] The method for extracting lithium from electrolytic aluminum waste slag of the present embodiment, such as figure 1 shown, including the following steps:

[0055] 1) Dry-grind lithium-containing electrolytic aluminum waste slag to below 200 mesh, remove carbon and iron in the waste slag, and obtain pretreated waste slag (main component content F: 48%, Al: 14%, Na: 22%, Li: 2%);

[0056] Take 12.05 kg of pretreatment waste residue, add concentrated sulfuric acid with a mass concentration of 98% according to the mass ratio of pretreatment waste residue to concentrated sulfuric acid as 1:2, and react at 300°C for 10 hours to obtain mixture A;

[0057] The HF gas generated during the reaction is condensed by a condenser, absorbed by water to a HF solution with a concentration of 40%, and used for the subsequent reaction of preparing cryolite;

[0058] 2) Take the mixture A obtained in step 1), and extract it with 24.10 kg of water (the quality of adding water is twice the...

Embodiment 3

[0067] The method for extracting lithium from electrolytic aluminum waste slag of the present embodiment, such as figure 1 shown, including the following steps:

[0068] 1) Dry-grind lithium-containing electrolytic aluminum waste slag to below 200 mesh, remove carbon and iron in the waste slag, and obtain pretreated waste slag (main component content F: 40%, Al: 18%, Na: 26%, Li: 1.5%);

[0069] Take 15.62 kg of pretreated waste residue, add concentrated sulfuric acid with a mass concentration of 98% according to the mass ratio of pretreated waste residue to concentrated sulfuric acid of 1:2, and react at 400° C. for 5 hours to obtain mixture A;

[0070] The HF gas generated during the reaction is condensed by a condenser, absorbed by water to a HF solution with a concentration of 40%, and used for the subsequent reaction of preparing cryolite;

[0071] 2) Take the mixture A obtained in step 1), and extract it with 31.25kg of water (the quality of adding water is twice the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com