Polycarboxylic acid for electrolyte as well as preparation method and application thereof

A polycarboxylic acid and polycarboxylic acid ester technology, which is applied in the preparation of carboxylate, electrical components, electrolytic capacitors, etc., can solve the problems of insufficient large-scale production, low electrolyte conductivity, and poor low temperature resistance. Achieve the effect of high yield, simple operation and high flash voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

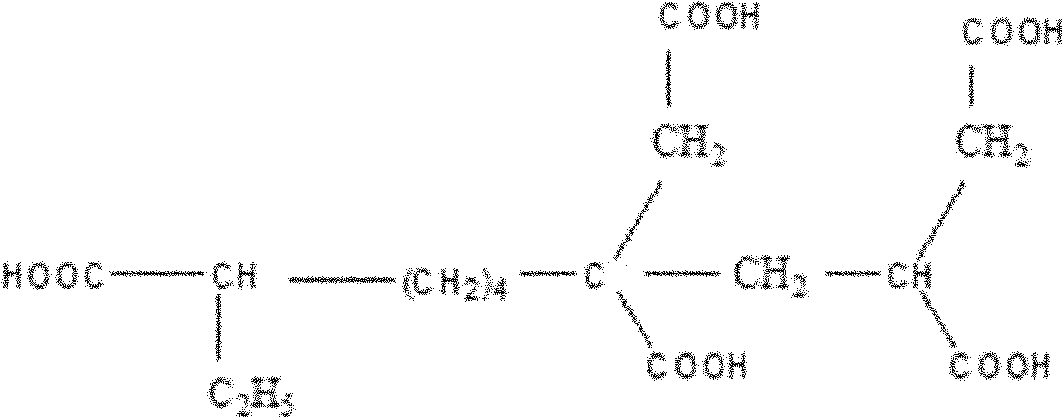

[0047] The preparation method of polyvalent carboxylic acid for electrolyte comprises the following steps:

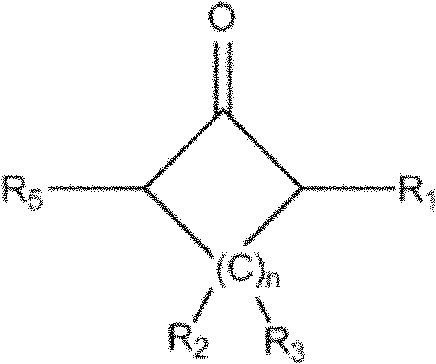

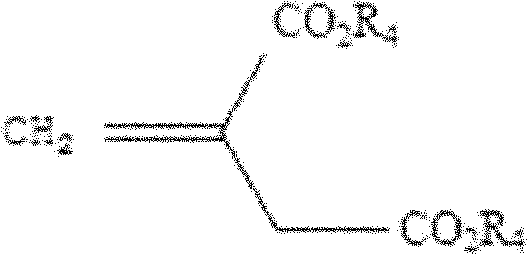

[0048] a. Add 500 ml of anhydrous methanol and 49 g (0.5 mol) of cyclohexanone into a well-dried 1 L four-neck flask equipped with stirring, dropping funnel, and thermometer, and cool down to -5°C. Then, 3.0 g of concentrated sulfuric acid was slowly added dropwise from the dropping funnel. After completion, dropwise add 30% volume concentration of H 2 o 2 The solution was 57.8g, and the temperature was kept at about 8°C. After the completion, the stirring was continued for 15 minutes.

[0049] b. Add 79 g (0.5 mol) of dimethyl itaconate dissolved in methanol solvent dropwise into the reaction solution, keeping the temperature at -10-5°C. After completion, continue stirring for 15 min. 140g of FeSO 4 ·7H 2O was slowly added to the reaction solution, keeping the temperature below 5°C. After completion, continue stirring for 30 min. Add 100g of diethyl ether for e...

Embodiment 2

[0072] The preparation method of polyvalent carboxylic acid for electrolyte comprises the following steps:

[0073] a, step a with embodiment 1;

[0074] b. Add 158 g (1 mol) of dimethyl itaconate dissolved in methanol solvent dropwise into the reaction solution, keeping the temperature at -10-5°C. After completion, continue stirring for 15 min. 140g of FeSO 4 ·7H 2 O was slowly added to the reaction solution, keeping the temperature below 5°C. After completion, continue stirring for 30 min. Add 100g of diethyl ether for extraction, wash with water, and distill off the solvent to obtain the carboxylate product.

[0075] c. Add the above carboxylate product into 800 g of 10% sodium methoxide solution by weight, raise the temperature to 120° C., and react for 4 hours to obtain the sodium carboxylate product.

[0076] d. Acidify the obtained sodium carboxylic acid product with 150 g of 50% dilute sulfuric acid to obtain a total of 243.8 g of the carboxylic acid product.

...

Embodiment 3

[0080] The preparation method of polyvalent carboxylic acid for electrolyte comprises the following steps:

[0081] a, step a with embodiment 1;

[0082] b. Add 237 g (1.5 mol) of dimethyl itaconate dissolved in methanol solvent dropwise into the reaction solution, keeping the temperature at -10-5°C. After completion, continue stirring for 15 min. 140g of FeSO 4 ·7H 2 O was slowly added to the reaction solution, keeping the temperature below 5°C. After completion, continue stirring for 30 min. Add 100g of diethyl ether for extraction, wash with water, and distill off the solvent to obtain the carboxylate product.

[0083] c, adding the above-mentioned carboxylate product to 800g weight concentration is 20% Na 2 CO 3 In the solution, the temperature was raised to 100°C, and the reaction was carried out for 10 hours to obtain the sodium salt of carboxylic acid.

[0084] d. The obtained sodium salt was acidified with 150 g of dilute sulfuric acid with a weight concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com