Patents

Literature

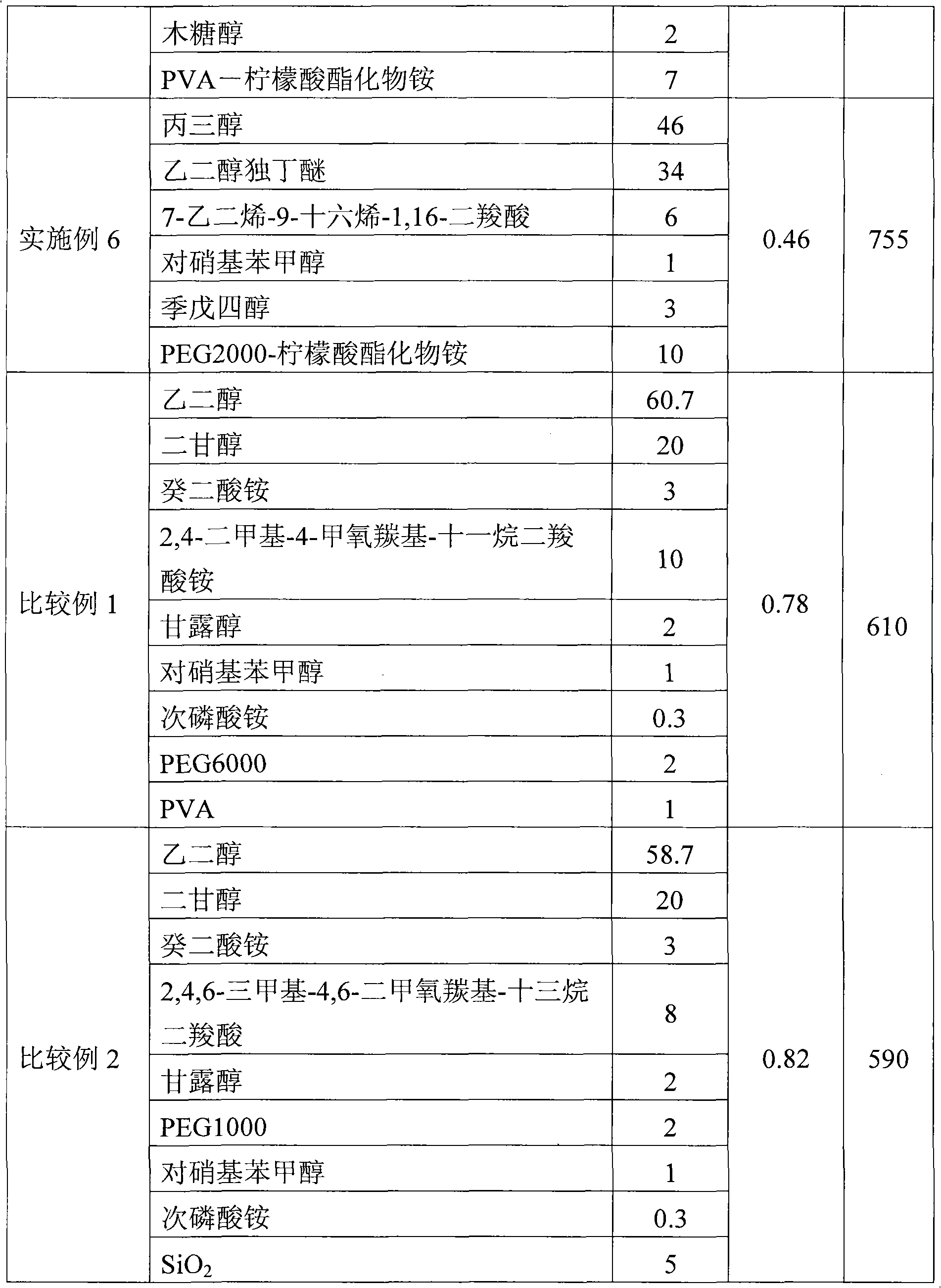

92results about How to "Increase the flash voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

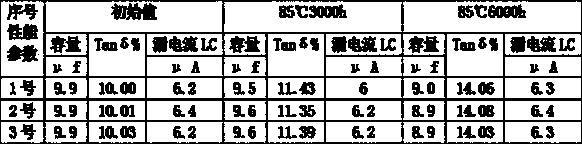

Electrolysis solution and preparation method thereof as well as preparation method for obtained aluminum capacitor

ActiveCN101556867AIncrease the flash voltageStrong corrosion resistanceLiquid electrolytic capacitorsChemistryCorrosion

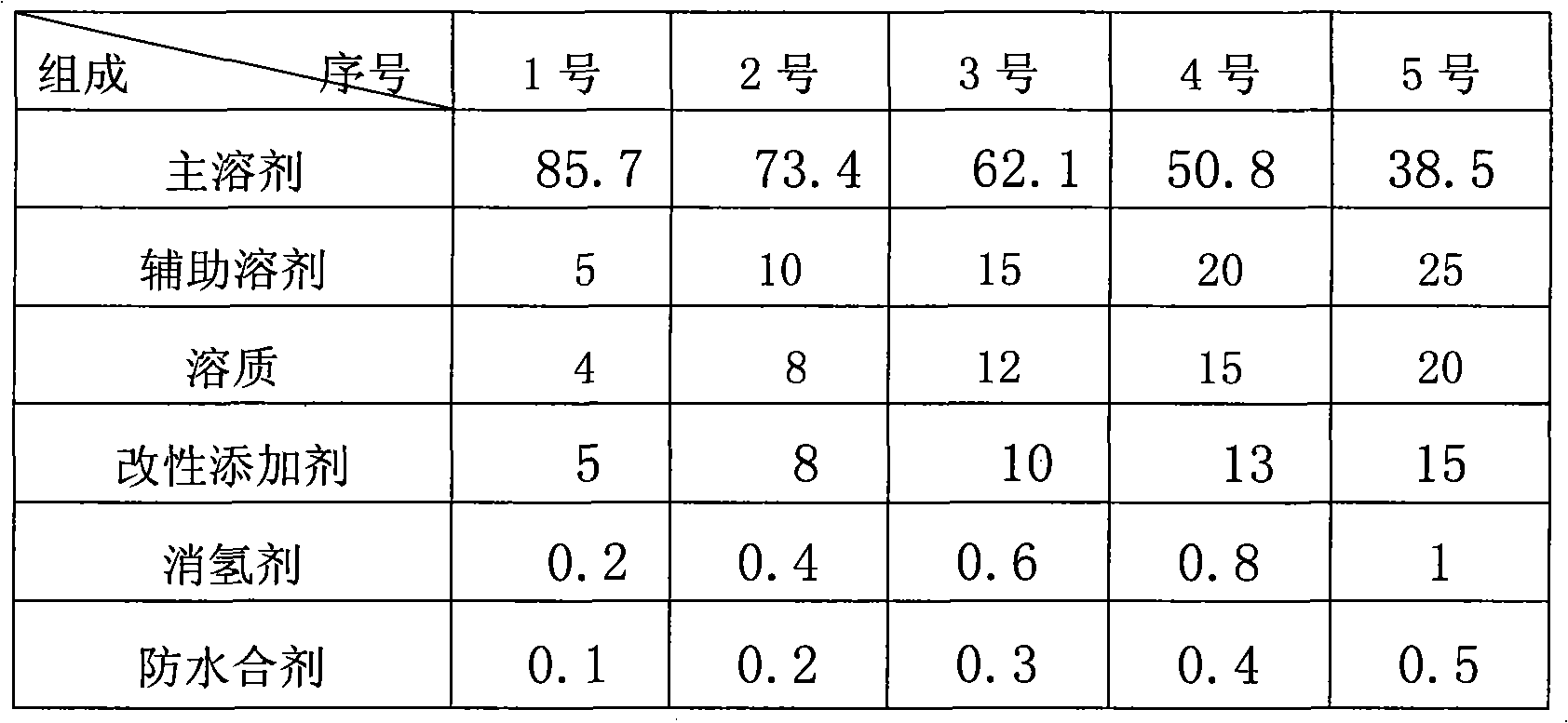

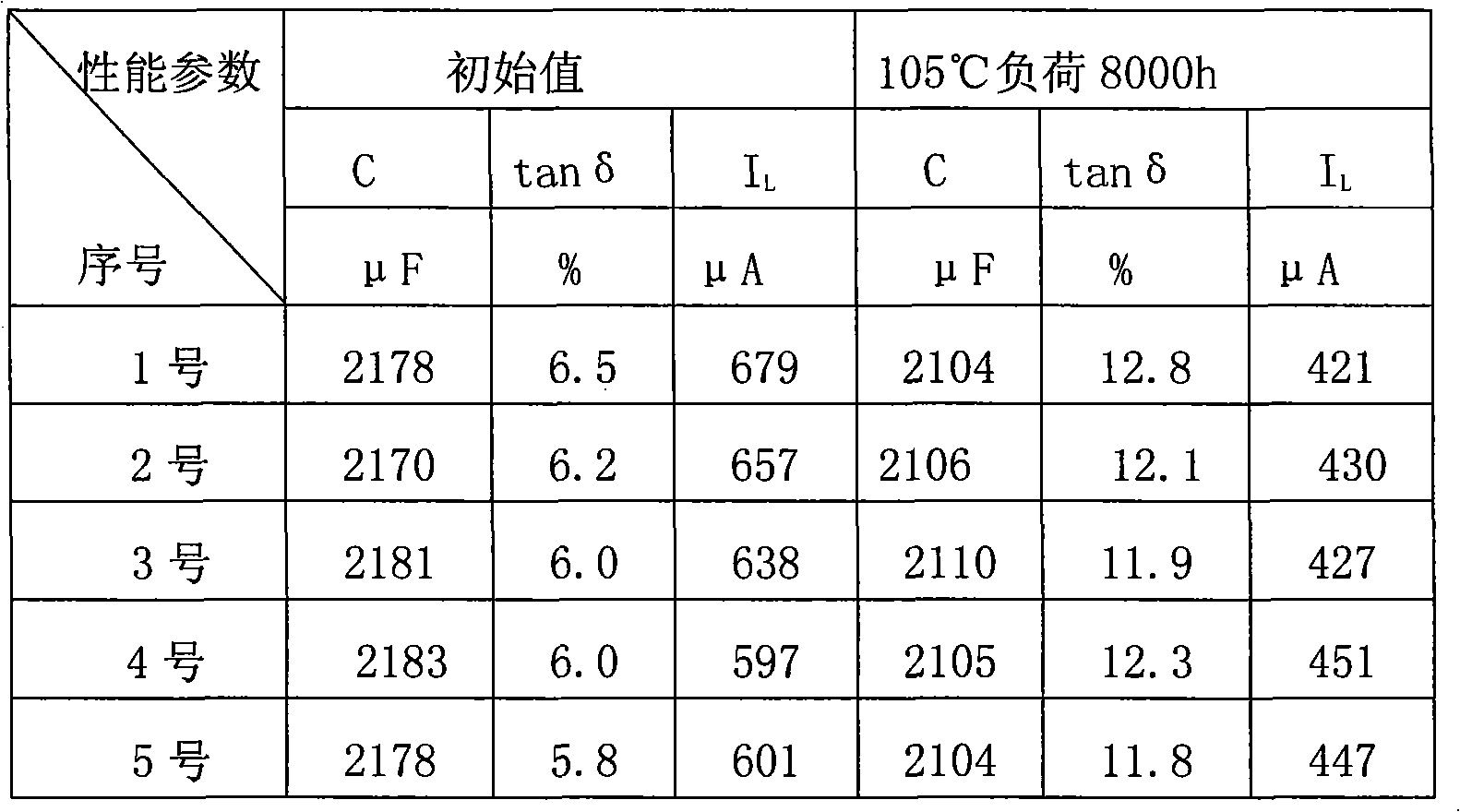

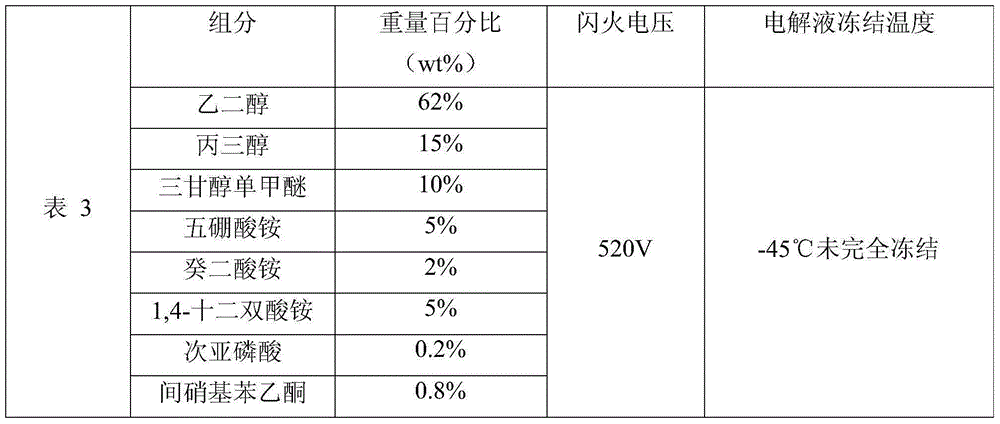

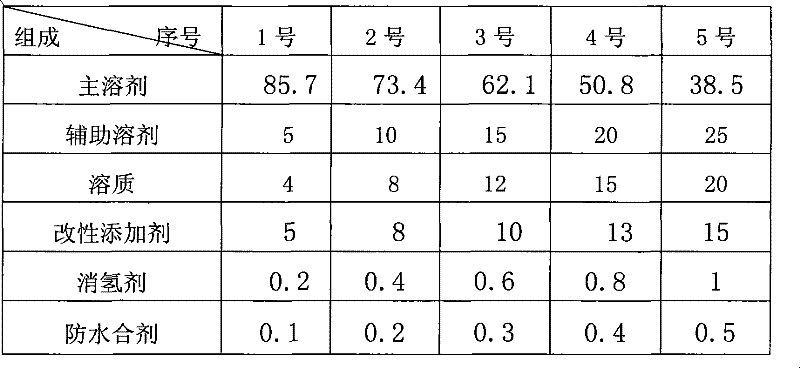

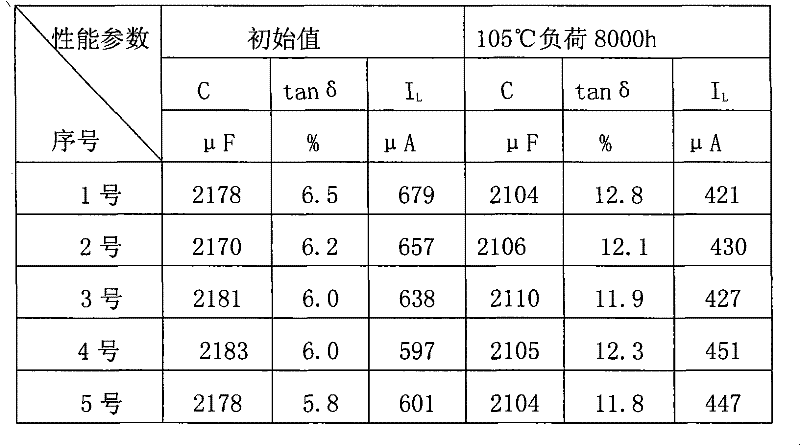

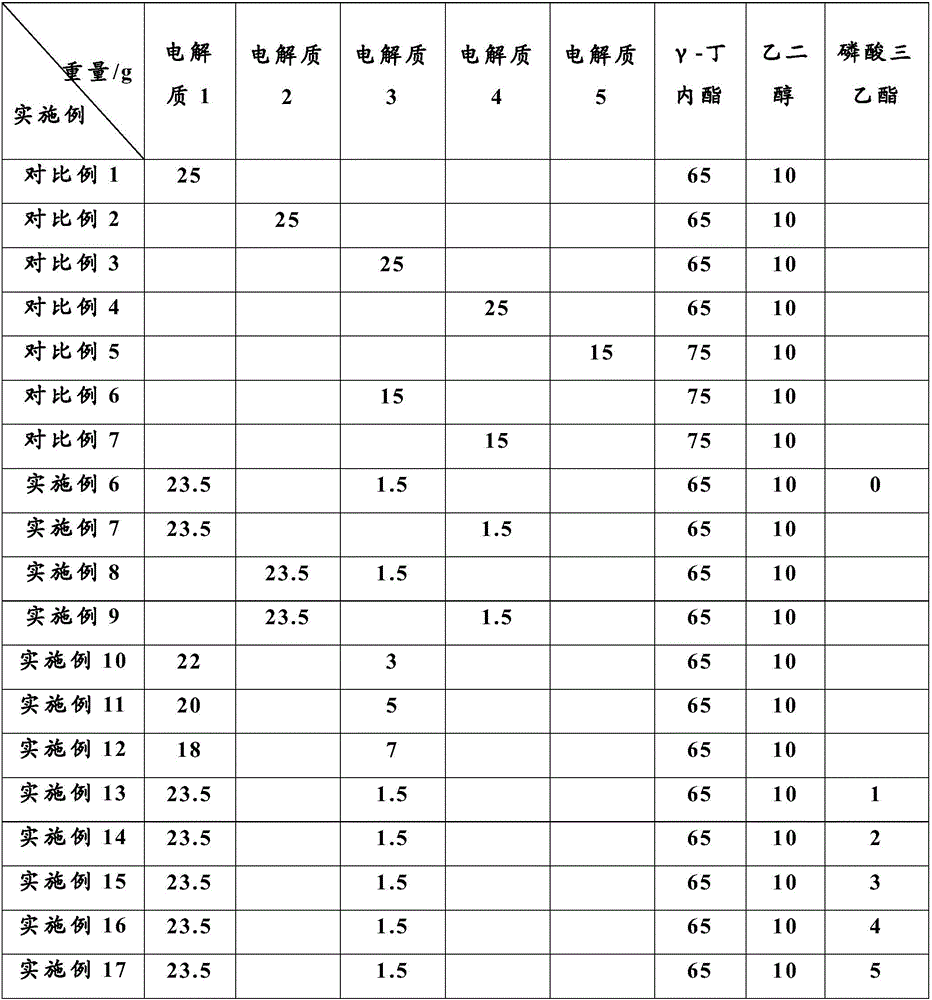

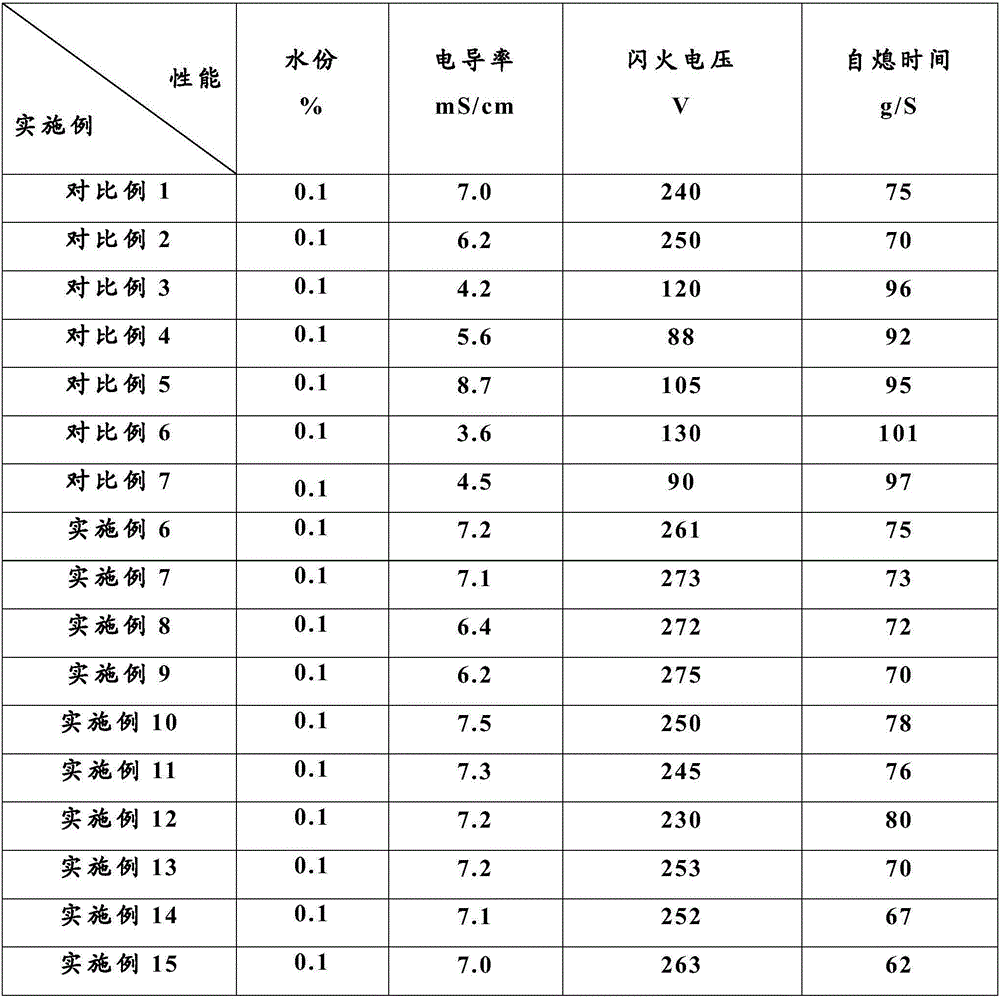

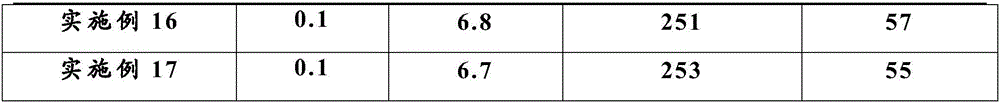

The invention relates to electrolysis solution and a preparation method thereof as well as a preparation method for an obtained aluminum capacitor. The electrolysis solution is composed by the components according to the following weight by parts: 38.5-85.7 wt % of primary solvent, 5-25 wt % of auxiliary solvent, 4-20 wt % of solute, 5-15 wt % of modified additive, 0.2-1 wt % of hydrogen eliminating agent and 0.1-0.5 wt % of waterproof combination agent. The primary solvent is glycol; the auxiliary solvent is one or more of tributyl phosphate, mono butyl ester phosphate, diglycol dibutyl ether; the solute is one or more of ammonium sebacate, 1.6-dodecyl ammonium bisgallic acid, 1.10-dodecyl ammonium bisgallic acid organic carboxylate. In the preparation method for the aluminum capacitor using the electrolysis solution, positive pressure and vacuum-pumping is required to be applied in an impregnation tank in an alternate recycle way with the recycle impregnation interval period being 20-60min.The electrolysis solution has the characteristics of high temperature resistance, high sparking pressure and strong corrosion resistance. The screw large capacitor has a service life of 8,000 hours at 105 DEG C or 2,000 hours at 125 DEG C.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Electrolyte for driving ultrahigh voltage large-sized aluminium electrolytic capacitor and solute thereof

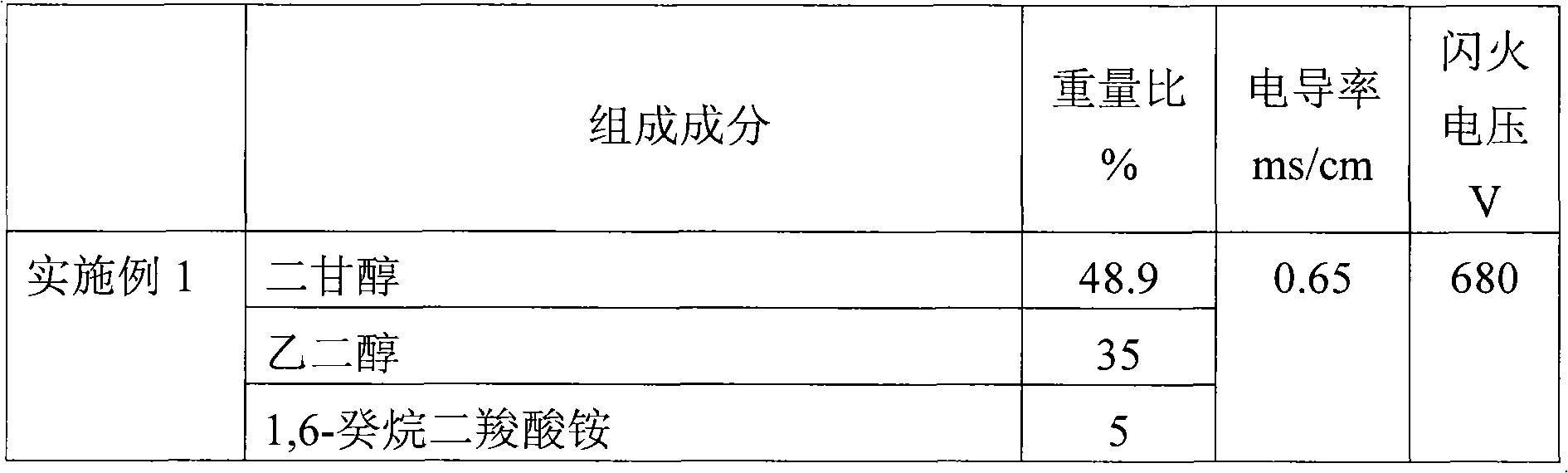

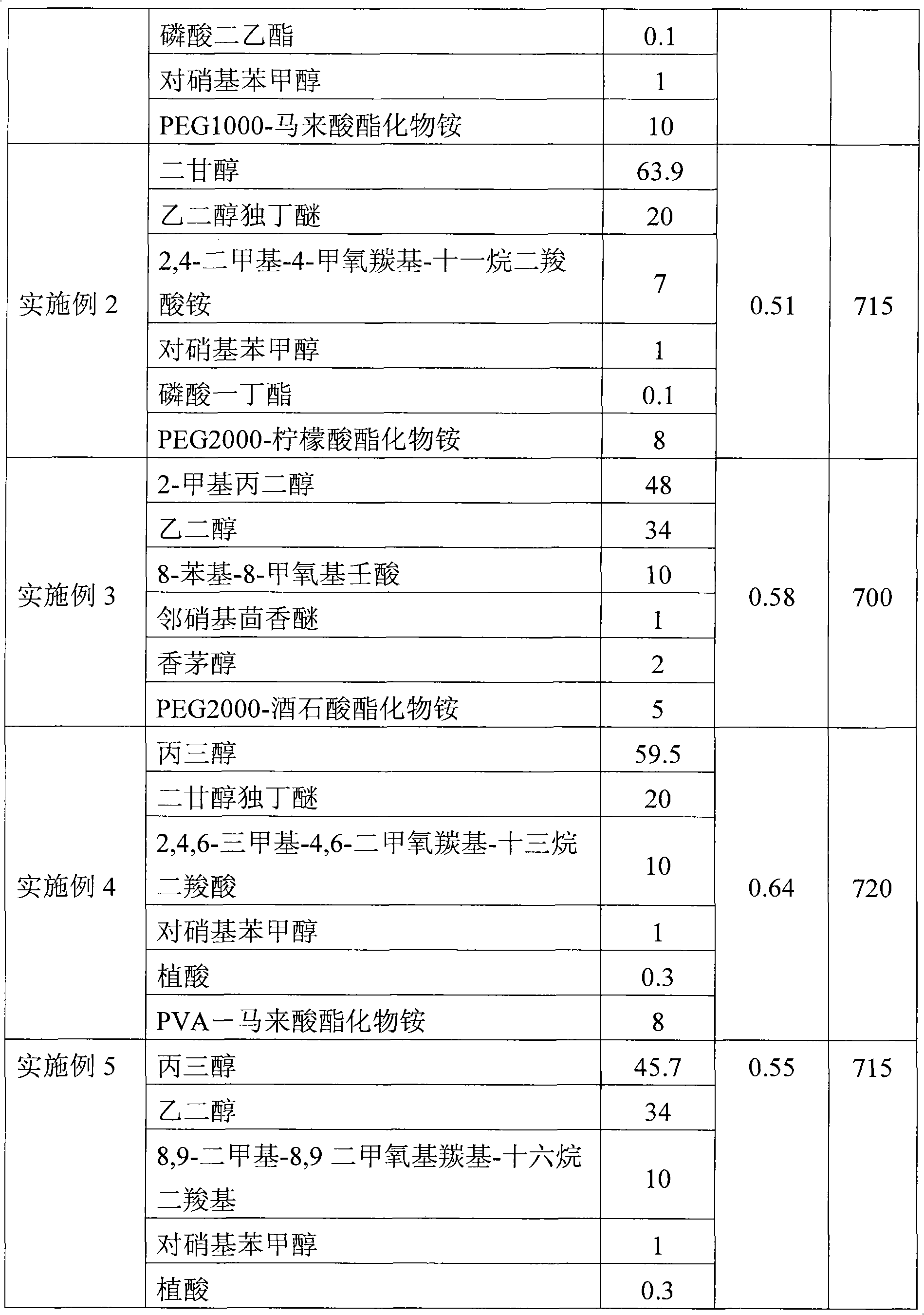

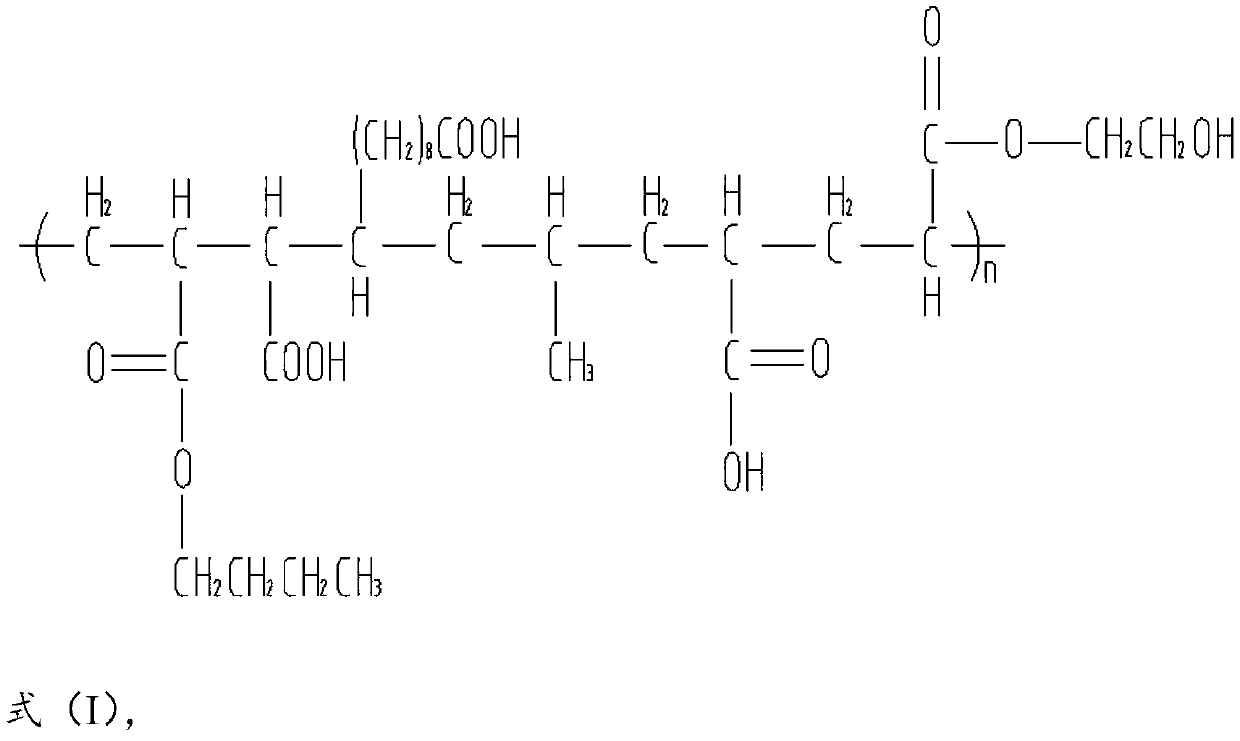

ActiveCN101866752AIncrease the flash voltageImprove conductivityElectrolytic capacitorsSolventEsterification reaction

The invention provides an electrolyte for driving an ultrahigh voltage large-sized aluminium electrolytic capacitor and a solute thereof. The solute of the electrolyte for driving the ultrahigh voltage large-sized aluminium electrolytic capacitor is a high-molecular solute, and the preparation process comprises the following steps of: uniformly mixing a polyalcohol polymer with hydroxyl at a tail end and a saturated or unsaturated binary or polybasic acid according to a certain proportion; adding a certain amount of catalyst; carrying out condensation and esterification reaction at certain temperature under the condition of decompression, cooling, and separating an ester, wherein the total number of carbon atoms positioned on a main chain of the ester is 15 or more than 15; and dissolving the ester into a solvent to prepare a solution with certain concentration, then introducing ammonia so that the pH of the solution reaches a certain range, and stopping introducing the ammonia so that the ester reacts with the ammonia to form ester ammonium salt, wherein the ester ammonium salt is the high-molecular solute used for the electrolyte. The aluminium electrolytic capacitor has very high voltage resistance, larger ripple current bearing and high reliability and finished product ratio when using the electrolyte prepared by the solute.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

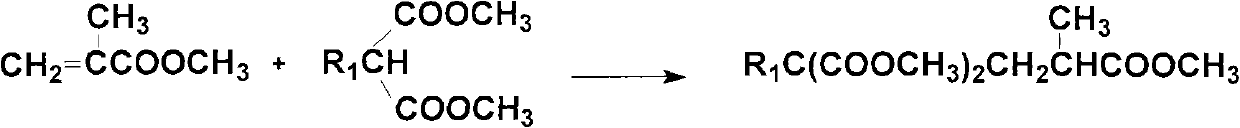

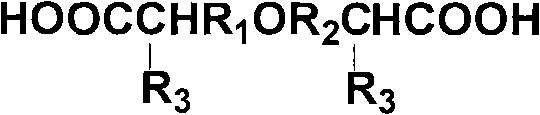

Electrolyte of medium-high voltage aluminum electrolytic capacitor and preparation method of solute thereof

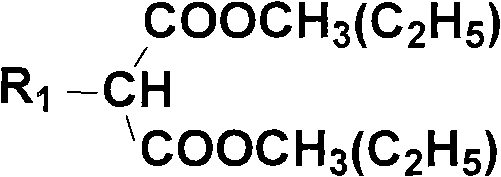

ActiveCN101572187AIncrease the flash voltageGood thermal stabilityCapacitor electrolytes/absorbentsSolventStrong acids

The invention relates to electrolyte of a medium-high voltage aluminum electrolytic capacitor and a preparation method of solute thereof. In order to solve the problems of low sparking voltage, poor thermal stability and bad solubility in the traditional electrolyte, the invention provides the electrolyte containing dicarboxylic acid having a branched chain or salt thereof as a solute and a single solvent or a mixed solvent containing more than one selected from alcohols, alcohols and ethers, amides, sulfones, sulfoxides and esters, wherein the mass percentage of the solute is 0.5-30 percent. The dicarboxylic acid having a branched chain is prepared by evenly mixing and reacting a reactant (formula is shown upper right) (A, B are electron withdrawing groups, and R1 is a branched chain) and acrylic acid derivative and catalyzer alkali, saponifying, acidizing by strong acid, decarboxylating and washing by purified water. Ammonium salt is produced if required by dicarboxylic acid containing ether group reacting with ammonia or amine. The electrolyte prepared with acid or salt thereof in the invention has better solubility and thermal stability.

Owner:HUIZHOU CAPCHEM CHEM CO LTD

High-voltage working electrolyte and preparation method thereof

The invention provides a high-voltage working electrolyte, which comprises the following raw materials by weight portion: 5.5-11 portions of solute, 80-88 portions of composite solvent, 0.1-2.5 portions of dehydrogenating agent, 0.1-1portion of waterproof combined additive, 0-2 portions of sparking voltage improving agent, 0.5-3 portions of anti-corrosion additive and 0.5-1 portion of high temperature stabilizer. The solvent is heated to 70-100 DEG C. The invention also provides a preparation method of the electrolyte, which comprises the followings steps: adding the sparking voltage improving agent, the high temperature stabilizer and the anti-corrosion additive, and uniformly mixing; heating to 120-130 DEG C, adding the solute, the dehydrogenating agent and the waterproof combined additive, holding at a temperature of 120-130 DEG C until a mixture is completely dissolved; and cooling and then obtaining the high-voltage working electrolyte. The process is simple, and the conditions are easy to control. The high-voltage working electrolyte provided by the invention has the advantages of high sparking voltage, high temperature resistance and long service life.

Owner:东莞宏强电子有限公司

Working electrolyte solution of 800 V aluminum electrolytic capacitor and preparation method of working electrolyte solution

ActiveCN104465100AIncrease working voltageExtended service lifeElectrolytic capacitorsElectrolysisSolvent

The invention discloses a working electrolyte solution of an 800 V aluminum electrolytic capacitor. The working electrolyte solution comprises, by weight, 30%-65% of main solvent, 10%-35% of auxiliary solvent, 5%-25% of solute, 5%-15% of spark voltage improver and 1.5%-3.5% of additives. The invention further discloses a preparation method of the working electrolyte solution. The working electrolyte solution makes a 700 V-750 V superhigh voltage technical breakthrough and can directly reach the 800 V superhigh voltage technical field, and the working electrolyte solution has the advantages of being high in working voltage, long in service life, stable in performance under a high temperature environment, good in pressure resistance of products, good in gas production performance and the like.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

700V high-voltage aluminum electrolytic capacitor electrolyte

InactiveCN106252079AHigh molecular weightLow mobilityLiquid electrolytic capacitorsSalicylic acidGluconic acid

Disclosed is a 700V high-voltage aluminum electrolytic capacitor electrolyte. The electrolyte comprises 50-80% of main solvent, 20-50% of auxiliary solvent, 5-20% of main solute, 2-10% of auxiliary solute, 0.1-1% of auxiliary additive and 5-15% of spark additive, wherein the main solute comprises one or more of azelaic acid, ammonium hydrogen azelate, ammonium sebacate, decane dicarboxylic acid, 7, 9-dimethyl-7, 9-dimethoxy carbonyl-1, 11-dodecane dicarboxylic acid, and 7, 8-dimethyl-7, 8-dimethoxy carbonyl-1, 14 tetradecane dicarboxylic acid; and the auxiliary solvent comprises one or more of ammonium salicylate, salicylic acid, oxalic acid, malonic acid, succinic acid, ammonium benzoate, ammonium maleate, ammonium hydrogen maleate, ammonium adipate and hexanedioic acid. The spark voltage of the electrolyte is greater than 700V; and in addition, the electrolyte is simple to prepare, stable in performance and excellent in related parameters.

Owner:HUNAN AIHUA GRP

Electrolyte for electrolytic capacitor

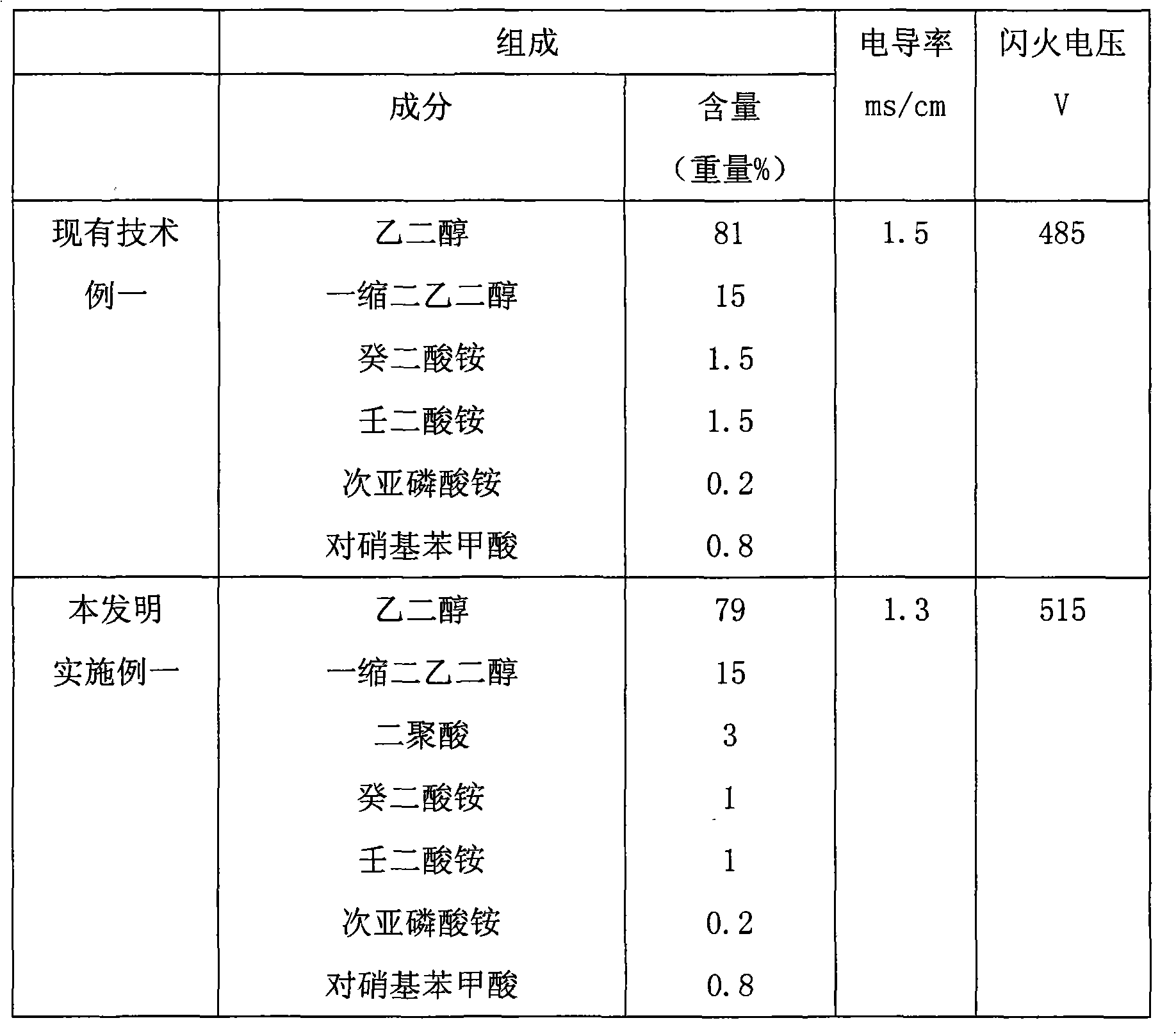

InactiveCN101404209ASolve the problems caused by insufficient withstand voltageIncrease the flash voltageElectrolytic capacitorsElectrolytic agentOctadecadienoic Acid

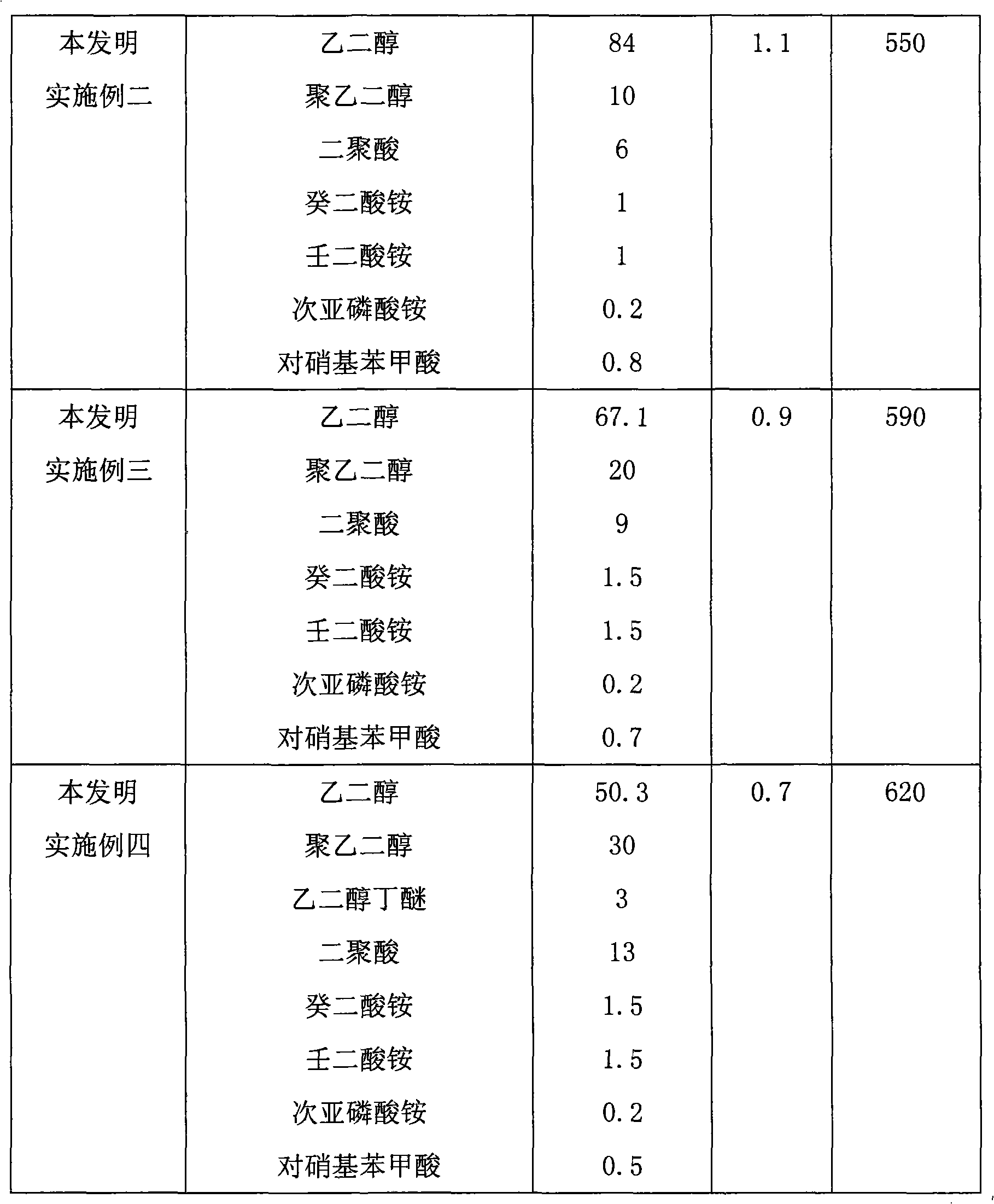

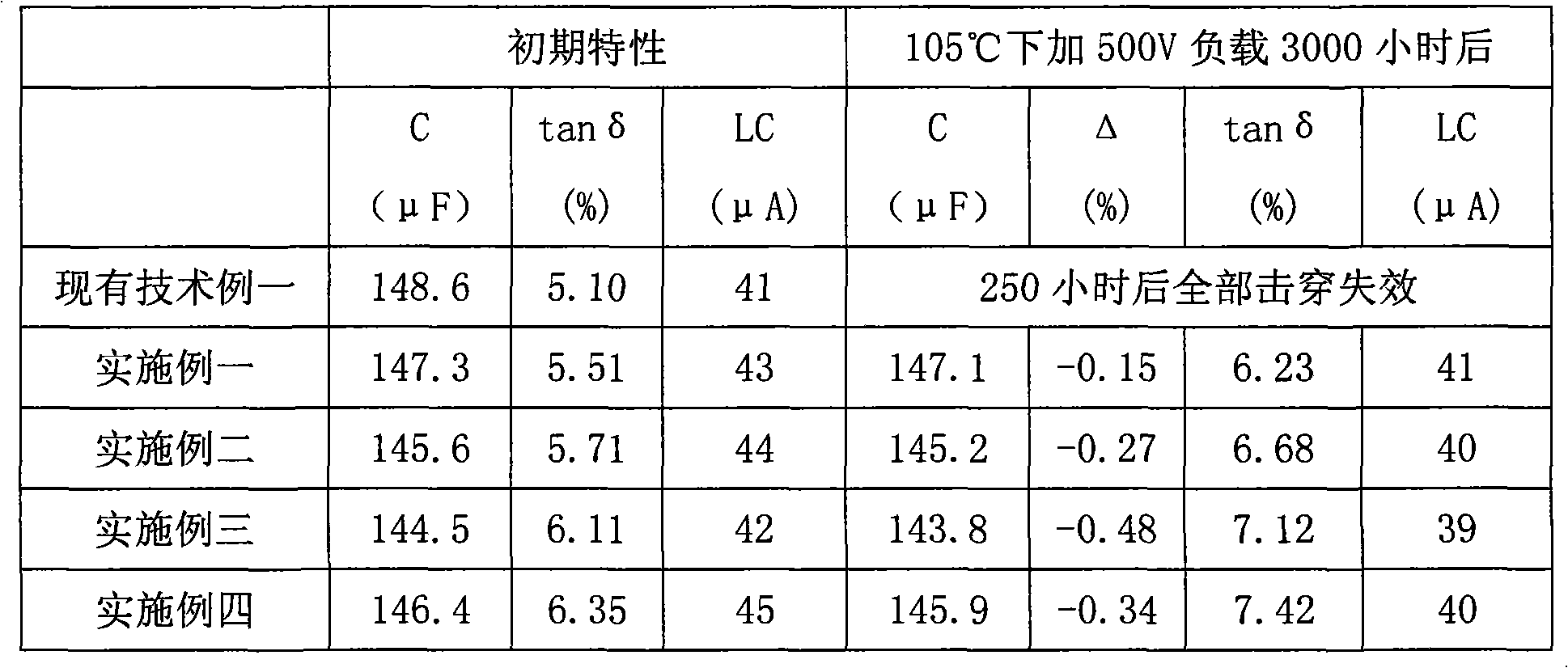

The invention relates to the field of electrolyte technique, in particular to an electrolyte used for an electrolytic capacitor. The invention adds dimer acid and salts of the dimmer acid in the original electrolyte as main solute; the dimmer acid is a compound which is formed by octadecadienoic acid in virtue of mutual polymerization of molecules and has extremely long molecule chain; as the dimer acid is used as the main solute and the long molecule chain of the dimer acid can greatly improve the flash voltage of the electrolyte used for the aluminium electrolyte capacitor, thus the electrolyte can solve the problems caused by the aluminium electrolytic container of more than 500V owning to lack of voltage withstanding.

Owner:DONGGUAN HEC CONDENSER CO LTD

Method for preventing short-circuit failure of high-voltage aluminum-electrolyzing capacitor for switching power supply

ActiveCN102324327AImprove insulation performanceOptimizing the flash voltageLiquid electrolytic capacitorsCapacitor dielectric layersOxygen ionsHigh pressure

The invention discloses a method for preventing the short-circuit failure of a high-voltage aluminum-electrolyzing capacitor for a switching power supply, which comprises an optimizing step for an aging working procedure and a step for improving the flash-fire voltage of an electrolyte, wherein the optimizing step for the aging working procedure comprises the following substeps of: in the aging process of a product, aging by adopting a segmented voltage-raising mode, prolonging the aging time step by step after entering a high-voltage stage, and raising the highest aging voltage to be 1.5 times of the working voltage of the capacitor to improve the strength of continuously restoring a dielectric film by the electrolyte; and the step for improving the flash-fire voltage of the electrolyte comprises the following substeps of: adopting a non-water-system electrolyte to decrease the concentration of hydroxyl ions and reduce the generation of oxygen-ion discharge. By optimizing an aging process, the insulating performance of the dielectric film is improved, and the pressure-resisting characteristic of the product is improved; by optimizing electrolyte components, the flash-fire voltage of the electrolyte is improved, and flash-fire breakdown is prevented from occurring when the voltage is excessive; and by optimizing electrolytic paper, the short circuit of the product due to the breakage of the electrolytic paper is prevented.

Owner:ZHAOQING BERYL ELECTRONICS TECH

Electrolyte for aluminum electrolytic capacitor and preparation method of electrolyte

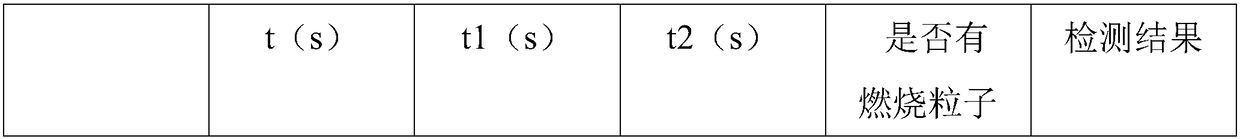

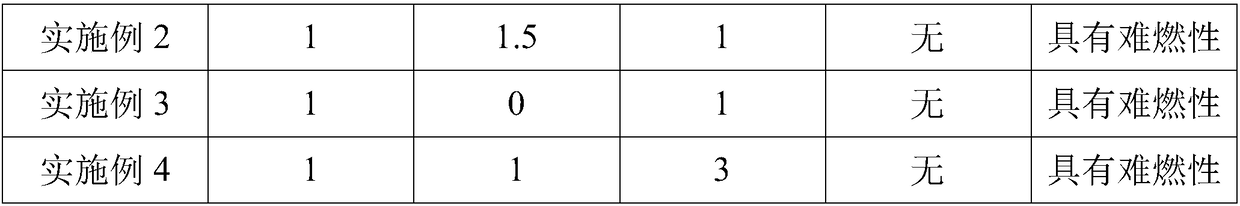

InactiveCN108538590ANon-flammableIncrease the flash voltageElectrolytic capacitorsPhysical chemistrySolvent

The invention discloses an electrolyte for an aluminum electrolytic capacitor. The electrolyte comprises the following components in percentage by weight: 15% to 20% of solute; 0.1% to 5% of oxide film stabilizer; 1% to 10% of breakdown voltage boosting agent; 0.1% to 3% of hydrogen absorption agent; 0.5% to 3% of surfactant; 5% to 10% of flame retardant; and balance, namely a solvent. After the flame retardant is added into the electrolyte, the aluminum electrolytic capacitor is less likely to burn after being ignited; and an appropriate amount of the breakdown voltage boosting agent, oxide film stabilizer and hydrogen absorption agent is added into the electrolyte, so that the breakdown voltage of the electrolyte can be increased, and the aluminum electrolytic capacitor can maintain stable and good characteristic parameters for a long time.

Owner:SUZHOU SONGCON ELECTRONICS TECH

Electrolytic capacitor

InactiveCN109326447AInhibition of dissolutionLower impedanceLiquid electrolytic capacitorsCapacitanceAluminum anode

The invention relates to the field of capacitors, and provides an electrolytic capacitor for prolonging service life of capacitors. The electrolytic capacitor comprises an aluminum foil anode, an aluminum foil cathode, a partition and electrolyte; surfaces of the aluminum foil anode and the aluminum foil cathode are covered with alumina membrane; the partition is arranged in the electrolyte between the anode and the cathode; the electrolyte comprises, by mass, 65-70 parts of ethanediol, 1-6 parts of modifiers, 8-10 parts of ammonium sebacate, 1-2 parts of ammonium dodecanedioate, 5-8 parts ofpolyethylene glycol, and 2-4 parts of additives. The anode or cathode made of the aluminum foil can suppress dissolving of aluminium effectively, reduce impedance of the capacitor, and prolong servicelife of the capacitor; combination of the aluminum anode and aluminium cathode and the electrolyte can prolong the service life of the capacitor further.

Owner:广州金立电子有限公司

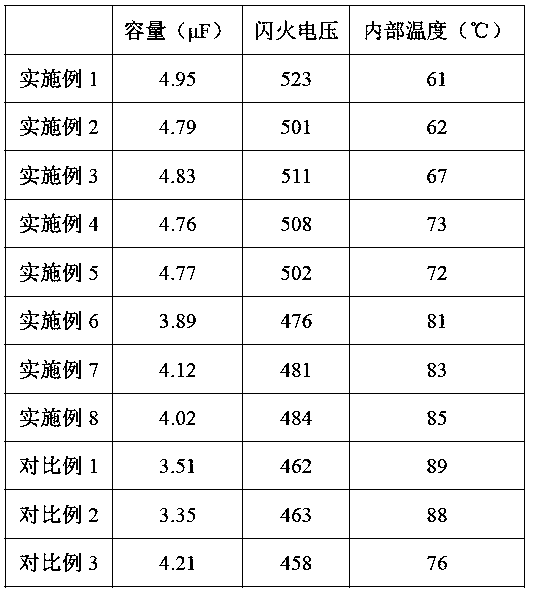

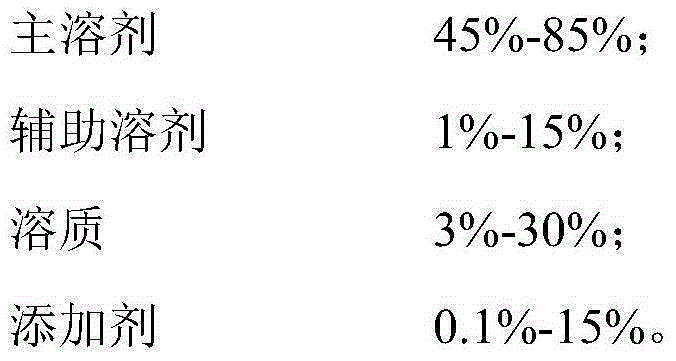

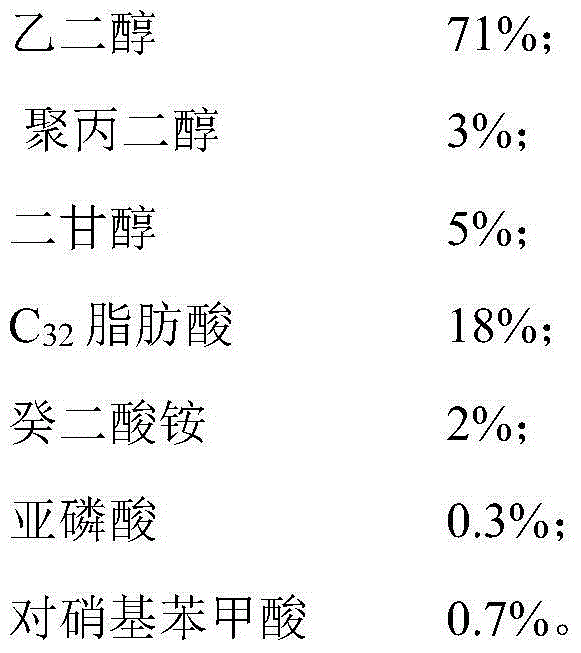

650V aluminum electrolytic capacitor working electrolyte

ActiveCN105304332AImprove conductivityIncrease the flash voltageElectrolytic capacitorsElectrolysisOctanol

The invention provides a 650V aluminum electrolytic capacitor working electrolyte, and an aluminum electrolytic capacitor made by using the electrolyte. The aluminum electrolytic capacitor working electrolyte is composed of solutes, solvents and an additive, wherein the main solute is fatty acid whose main carbon chain has 32 or 34 carbon atoms and which has a side branch chain or ammonium salt thereof; the auxiliary solute is C8 to C16 carboxylic acid; the main solvent is selected from ethylene glycol, n-butanol, diethylene glycol, n-octanol, gamma-butyrolactone, and butyl acetate; and the auxiliary solvent is selected from benzyl alcohol, 1-hydroxy-2-methoxyethane, diethylene glycol monomethylether, ethylene glycol monobutyl ether, propylene glycol or diethylene glycol. The aluminum electrolytic capacitor has advantages of high voltage resistance, large ripple current, long service life and the like, and fills blanks of the aluminum electrolytic capacitor that the national rated voltage reaches 650V.

Owner:DONGGUAN HEC CONDENSER CO LTD +1

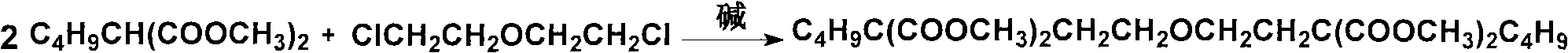

Electrolyte of aluminum electrolytic capacitor and preparation method of solute thereof

InactiveCN101572186AIncrease the flash voltageImprove thermal stabilityCapacitor electrolytes/absorbentsSolubilitySolvent

The invention relates to electrolyte of a medium-high voltage aluminum electrolytic capacitor and a preparation method of solute thereof. In order to solve the problems of low sparking voltage, poor thermal stability and bad solubility in the traditional electrolyte, the invention provides the electrolyte containing dicarboxylic acid containing ether group or salt thereof as a solute and a single solvent or a mixed solvent containing more of alcohols, alcohols and ethers, amides, sulfones, sulfoxides and esters, wherein the mass percentage of the solute is 0.1-30 percent. Additionally, the dicarboxylic acid containing ether group is prepared by reacting reactants of X1R1OR2X2(M) and (formula is shown upper right) (N) with alkali, filtering, saponifying, decarboxylating and washing. Ammonium salt is produced if required by dicarboxylic acid containing ether group reacting with ammonia or amine. The electrolyte prepared with acid or salt thereof in the invention has higher sparking voltage and better thermal stability. Furthermore, the solute in the invention has better solubility in ethylene glycol.

Owner:SHENZHEN CAPCHEM TECH

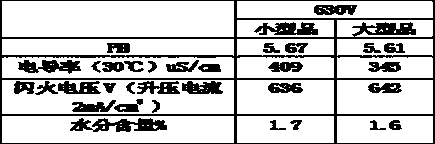

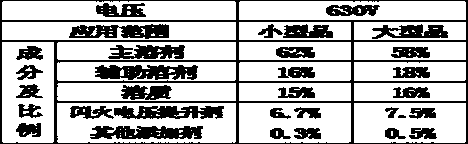

Working electrolyte of 630 V high-voltage aluminum electrolytic capacitor and manufacturing method thereof

ActiveCN103811183AIncrease working voltageSolution to short lifeElectrolytic capacitorsElectrolytic agentUltra high voltage

The invention discloses working electrolyte of a 630 V high-voltage aluminum electrolytic capacitor and a manufacturing method thereof. The working electrolyte of the 630 V high-voltage aluminum electrolytic capacitor is characterized in that the working electrolyte is composed of 38-65% of main solvent, 3-23% of secondary solvent, 8-22% of solute, 5-10% of spark voltage increasing agent and 0.2-1% of other additives by weight. The manufacturing method includes the following steps: mixing the main solvent with the secondary solvent; adding the solute under the temperature of 110 to 115 degrees centigrade, stirring and heating to 135 to 138 degrees centigrade, preserving the heat under 135 to 138 degrees centigrade, stirring and reacting for 30 to 40 minutes, and adding the spark voltage increasing agent; cooling to 70 to 90 degrees centigrade, and adding the other additives. Compared with the prior art, the working electrolyte of the 630 V high-voltage aluminum electrolytic capacitor and the manufacturing method thereof can be used under 630 V extra-high voltage, and moreover, the electrolyte performance is stable, and the batch stability is good.

Owner:上海洪微电子科技有限公司

Electrolyte 2-butyl ammonium octanedioic acid and production method thereof

InactiveCN1885458AImprove qualityIncrease added valueOrganic chemistryCapacitor electrolytes/absorbentsOperating temperature rangeAmmonia

The disclosed preparation method for 2-butyl ammonium suberate comprises: free radical polymerizing, rectifying, saponifying, adsorbing, reducing, drying and adding ammonia. This branched-chain product with 12 carbon atoms is fit to prepare the working electrolyte with 20.0+-0.5% concentration with high conductivity, high igniting voltage and other better performance, and is environmental friendly.

Owner:SHENZHEN CAPCHEM TECH

Electrolyte of medium-voltage and high-voltage aluminium electrolytic capacitors and preparation method thereof

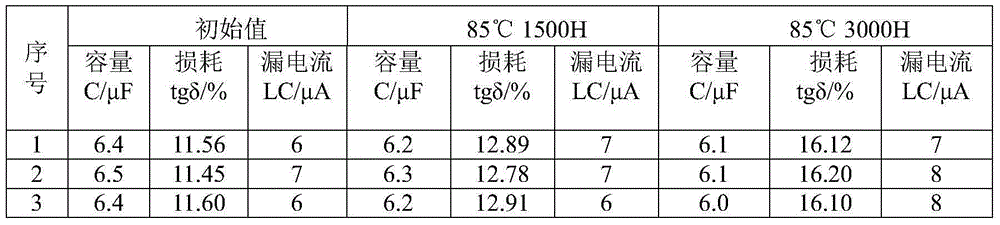

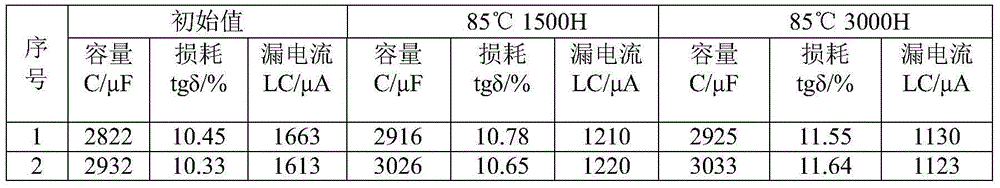

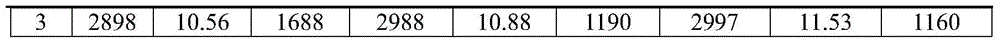

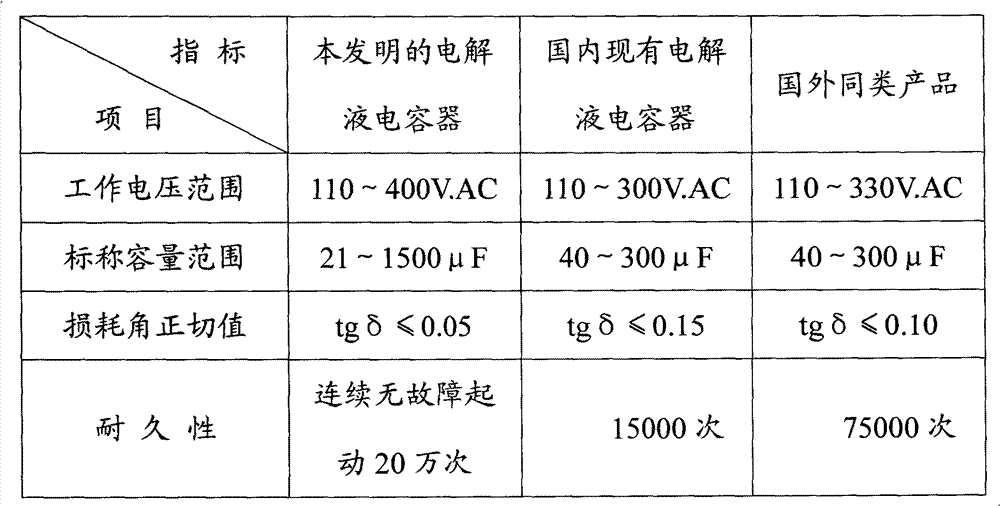

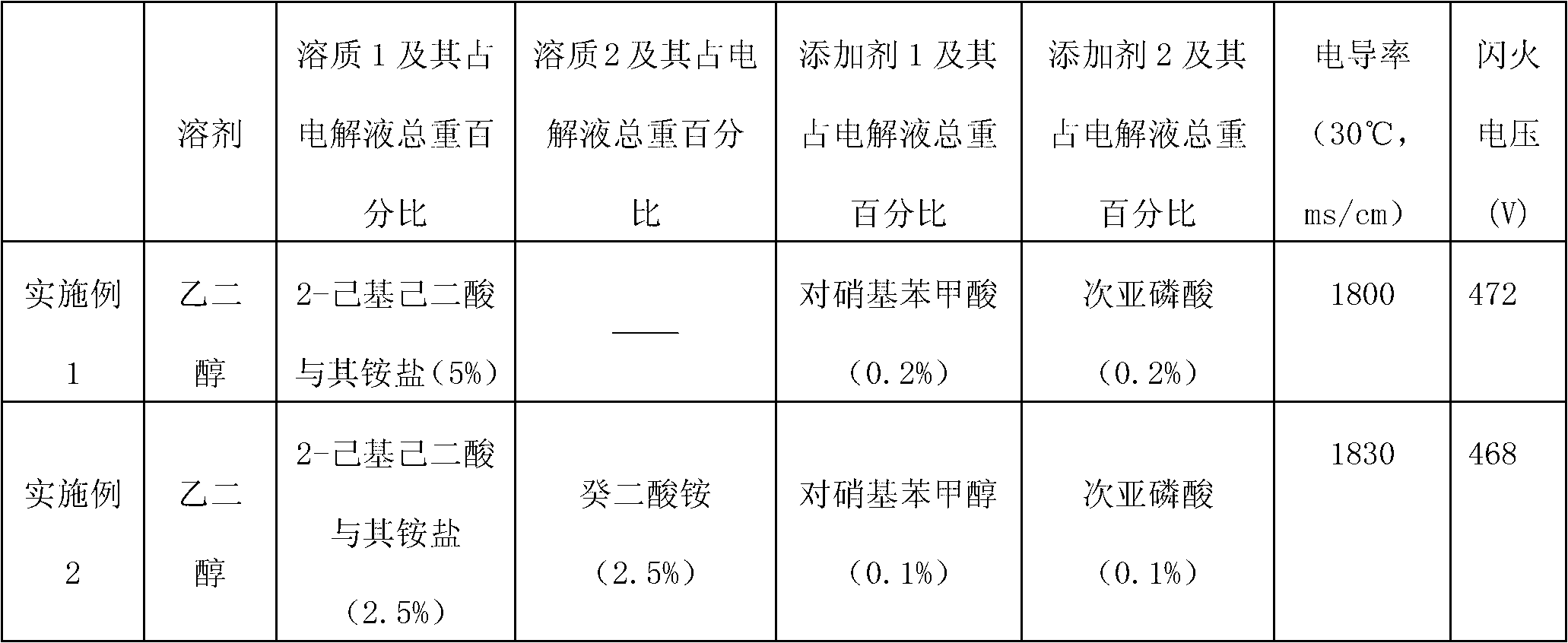

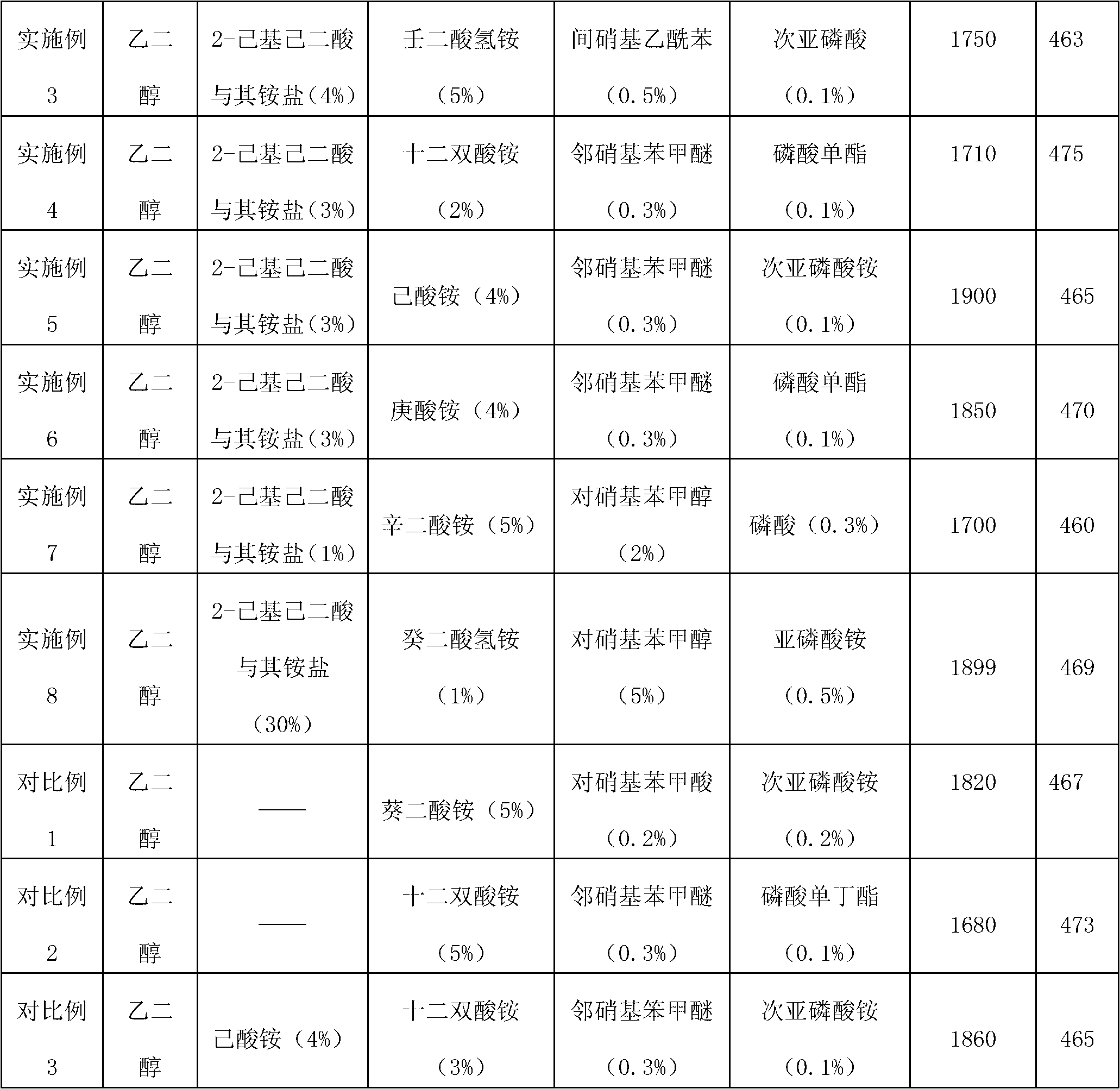

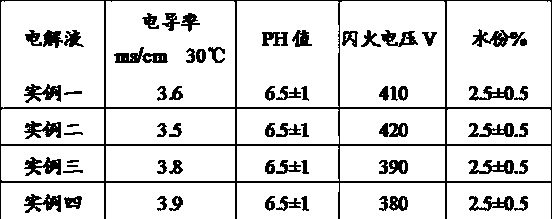

ActiveCN102760573AIncrease the flash voltageReduce hydrogen evolution and water generationElectrolytic capacitorsP-nitrobenzoic acidAmount of substance

The invention discloses an electrolyte of a medium-voltage and high-voltage aluminium electrolytic capacitors, comprising the following ingredients and percentage of the ingredients in total mass: 82% of ethylene glycol, 2% of deionized water, 10% of ammonium adipate, 5% of sebacic acid, 0.25% of p-nitrobenzoic acid, 0.25% of 2,4-dinitrophenol, and 0.5% of ammonium phosphate. By adopting the technical scheme, the management and the control requirements of European Union REACH (registration, evaluation, authorization and restriction of chemicals) laws and regulations on substances of very high concern are met; the sparking voltage and the cationic repair oxidation capacity of the electrolyte are improved, and the precipitation of hydrogen and the generation of water during a working process are reduced, so that the high-quality working electrolyte is obtained; 200000 times of the failure-free continuous starting of the electrolytic capacitors used for the starting of a compressor can be realized while new substances are used for replacing the original boric acid substances, so that the electrolytic capacitors are capable of bearing the working voltage of 400 V; and the electrolyte is short in heating time, less in preparation links, easy in control on preparation temperature, and capable of obviously improving the use performance of the aluminium electrolytic capacitors.

Owner:黄山振州电子科技股份有限公司

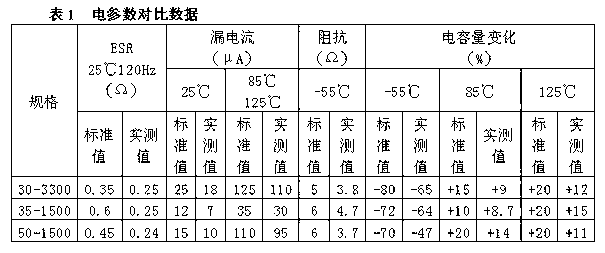

Producing method for full-tantalum-gas sealed capacitor

ActiveCN103310981AQuality improvementReduced effective resistanceElectrolytic capacitorsCapacitanceElectrolytic agent

The invention discloses a producing method for a full-tantalum-gas sealed capacitor, belongs to a capacitor manufacture method and aims to provide a manufacture method for non-solid tantalum electrolytic capacitors. The method comprises calcining a green body with the press density ranging from 5.5g / cm3 to 7.5g / cm3 into an anode tantalum block, immersing the tantalum block in an electrolyte solution to perform electrochemical treatment according to a grading boosting mode, performing vacuum heat treatment on the anode tantalum block provided with dielectric oxidation film, immersing the anode tantalum in a phosphoric acid to perform secondary electrochemical treatment, cleaning and drying the anode tantalum block which is subjected to secondary electrochemical treatment, and packaging the anode block in a tantalum casing to be prepared into a capacitor product, putting the capacitor product in an aging device to perform heating and energizing aging. The capacitor product produced through the method has the advantages of being low in equivalent series resistance and impedance, small in leakage current and capacitance change and the like.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

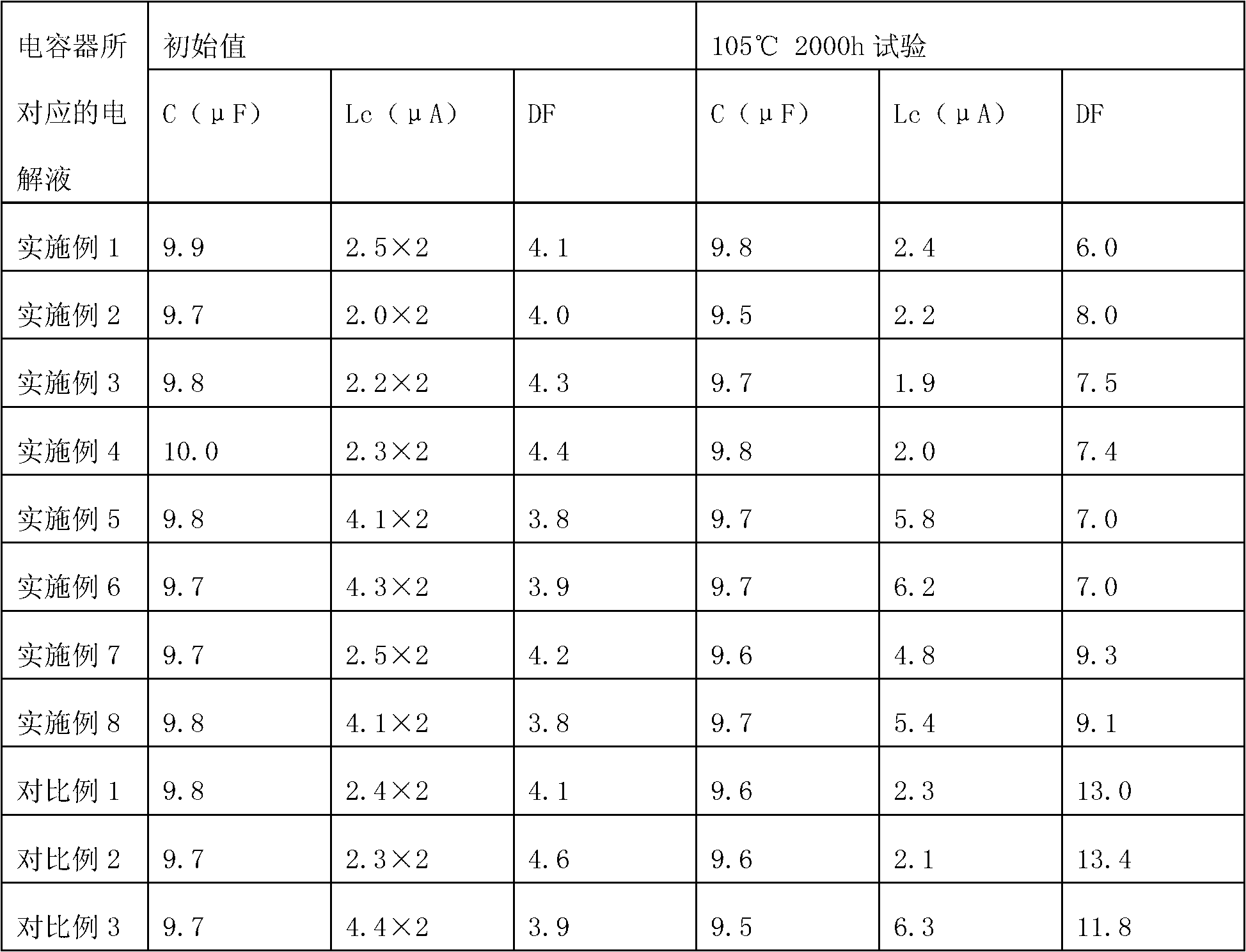

Aluminum electrolytic capacitor electrolyte and aluminum electrolytic capacitor

ActiveCN102842430AIncrease the flash voltageImprove thermal stabilityLiquid electrolytic capacitorsOrganic solventThermal stability

The invention aims at providing aluminum electrolytic capacitor electrolyte with excellent heat stability. Meanwhile the invention also provides an aluminum electrolytic capacitor prepared by the electrolyte. The electrolyte comprises following components of organic solvent and 2-hexyl ammonium adipate or combination of 2-hexyl ammonium adipate and ammonium salt of the 2-hexyl ammonium adipate. The electrolyte has better heat stability.

Owner:SHENZHEN CAPCHEM TECH

Low leakage current working electrolyte for medium-voltage aluminum electrolytic capacitor and preparation method thereof

InactiveCN110047656AImprove oxidation efficiencyReduce hydrationElectrolytic capacitorsElectrolysisLow leakage

The invention discloses a low leakage current working electrolyte for medium-voltage aluminum electrolytic capacitor and a preparation method thereof, wherein the working electrolyte comprises the following components in parts by weight: 40-80% of main solvent, 4-15% of auxiliary solvent, 7-20% of main solute, 5-15% of auxiliary solute, 0.05-2% of water-inhibiting agent, 0.5-5% of pressure-resistant promoting agent, 0.5-1.5% of oxidant, 0.5-1.5% of preservative and 0.5-1.5% of hydrogen-eliminating agent, wherein the main solvent is glycol. The invention has the advantages that sufficient voltage capacity is still ensured under the condition of high conductivity; the hydration of the aluminum foil during long-time work is reduced, the oxide film is more stable, the saturated vapor pressureof the oxide film is reduced, and the flash fire voltage is improved; the electrolyte oxidation efficiency is improved, and the corrosion probability of the anode lead of the capacitor is reduced; theleakage current is reduced, the hydrogen is eliminated, the capacitor bulge is prevented, and the service life of the product is prolonged.

Owner:益阳市开元电子有限公司

High-voltage electrolyte for hybrid super tantalum capacitor and preparation method thereof

ActiveCN103887085AReduce leakage currentSmall negative temperature capacity lossHybrid capacitor electrolytesHybrid/EDL manufactureInternal resistanceHigh pressure

The invention provides a high-voltage electrolyte for a hybrid super tantalum capacitor and a preparation method of the high-voltage electrolyte. The high-voltage electrolyte comprises, by mass, a polar organic macromolecular substance, a proton inert solvent, imidazolium salt, sulfate of transition metal, concentrated sulfuric acid and deionized water. According to the high-voltage electrolyte, the surface morphology of a ruthenium oxide electrode is effectively improved, the internal resistance of the electrode is reduced, and the adhesion strength of ruthenium oxide is enhanced; finally, the original capacity of the capacitor is increased, and the ESR is lowered.

Owner:GUIZHOU AVIC JODO TECH

Preparation method of 2-butyl ammonium sebate glycol electrolyte solution

InactiveCN106024390AImprove conductivityIncrease the flash voltageOrganic compound preparationElectrolytic capacitorsBromineN-butylmalonic acid

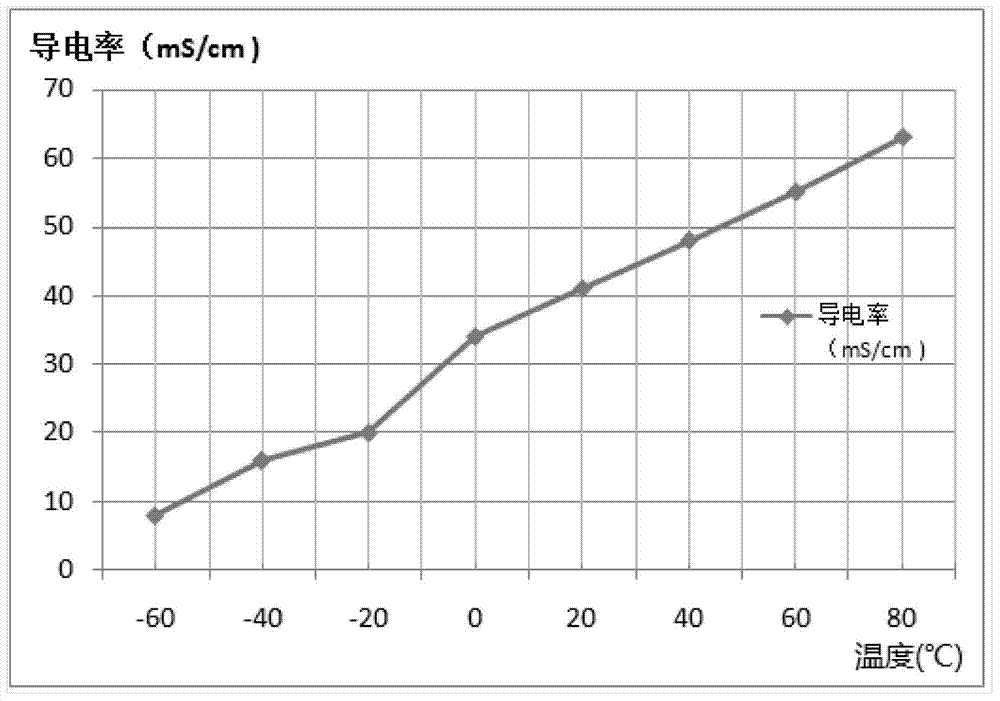

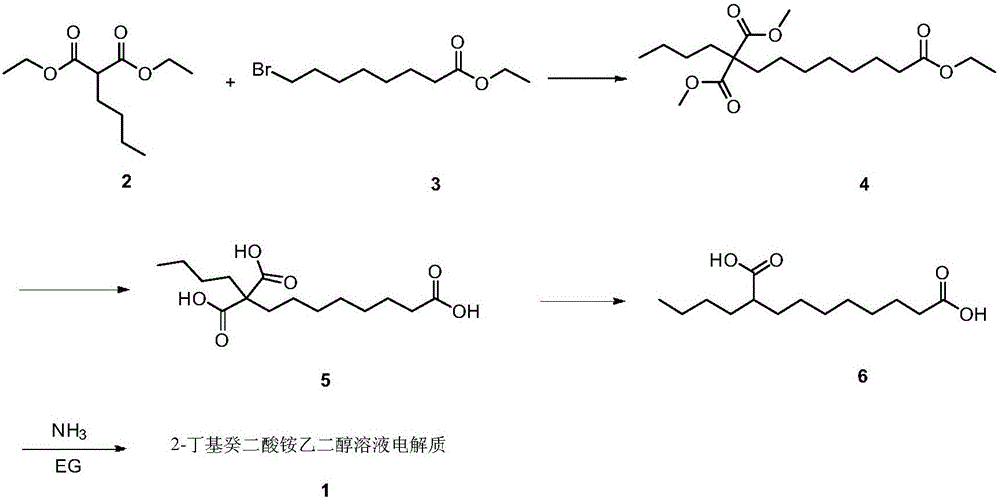

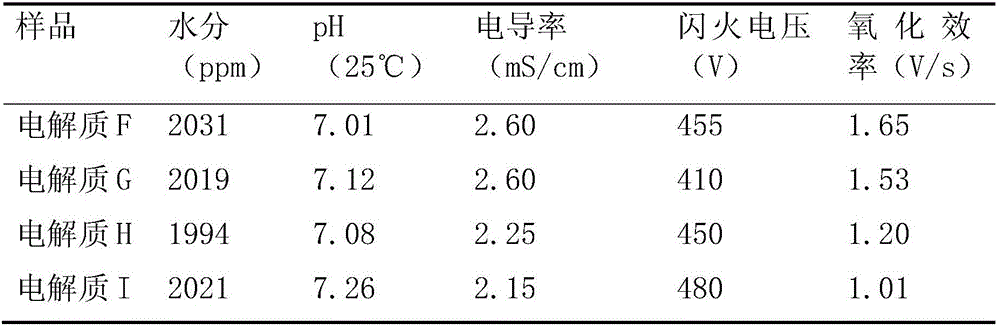

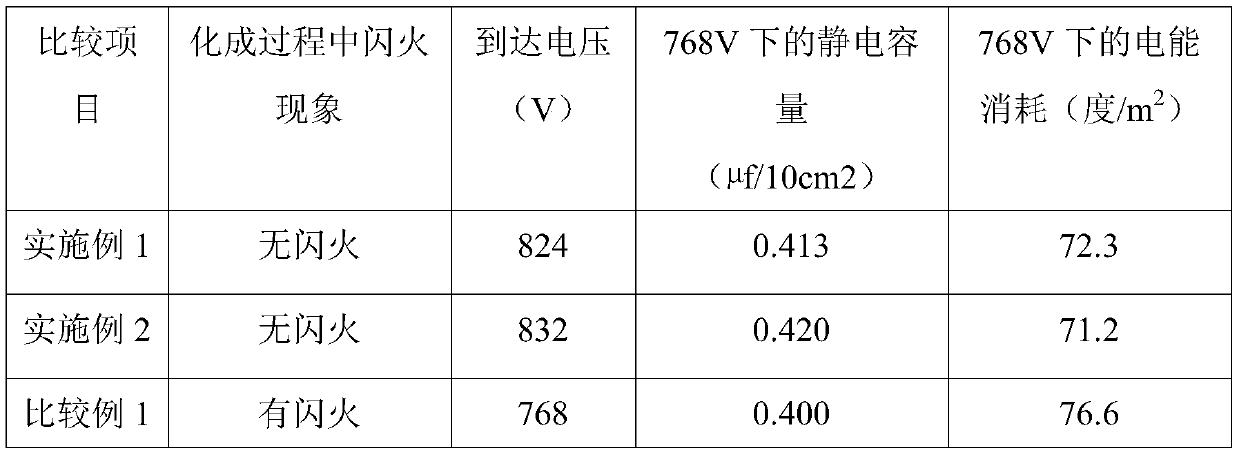

The invention relates to a preparation method of a high-performance 2-butyl ammonium sebate glycol electrolyte solution. 2-butyl sebate is prepared through the steps such as alkylating, hydrolyzing and decarboxylation by using n-butyl diethyl malonate and 8-bromine ethyl caprylate as raw materials, the yield reaches 87.8%, the compound is used for reacting with ammonia gas in glycol to prepare the electrolyte solution, the conductivity is 2.60 mS / cm (30 DEG C), the sparking voltage is 455 V (85 DEG C), the oxidation efficiency is 1.65 (2mA), the performance is superior to that of an existing market product, and the electrolyte solution has good market prospect.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

High-sparking and anti-lightning electrolyte for aluminum electrolytic capacitor and preparation method therefor

ActiveCN105469992ASimple processEasy to operate and controlElectrolytic capacitorsDiethylene glycol monobutyl etherElectrolysis

The present invention relates to the technical field of electrolytes, in particular to a high-sparking and anti-lightning electrolyte for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 1.5-2.5 parts of ammonium dodecanedioate, 0.8-1.2 parts of ammonium sebacate, 5-9 parts of sorbitol, 4-6 parts of boracic acid, 4-6 parts of diethylene glycol monobutyl ether, 1-2 parts of polyvinyl alcohol, 0.4-0.6 part of p-nitrobenzyl alcohol, 0.1-0.3 part of ammonium hypophosphite, 6-10 parts of ethylene glycol nano silica sol and 60-80 parts of glycol. The electrolyte is prepared by means of interaction among the raw materials and by strictly controlling a weight proportion of the raw materials; the sparking voltage of the prepared electrolyte can reach 590 V and the conductivity rate of the prepared electrolyte can reach 0.5 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high sparking voltage, lightning resistance and the like, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

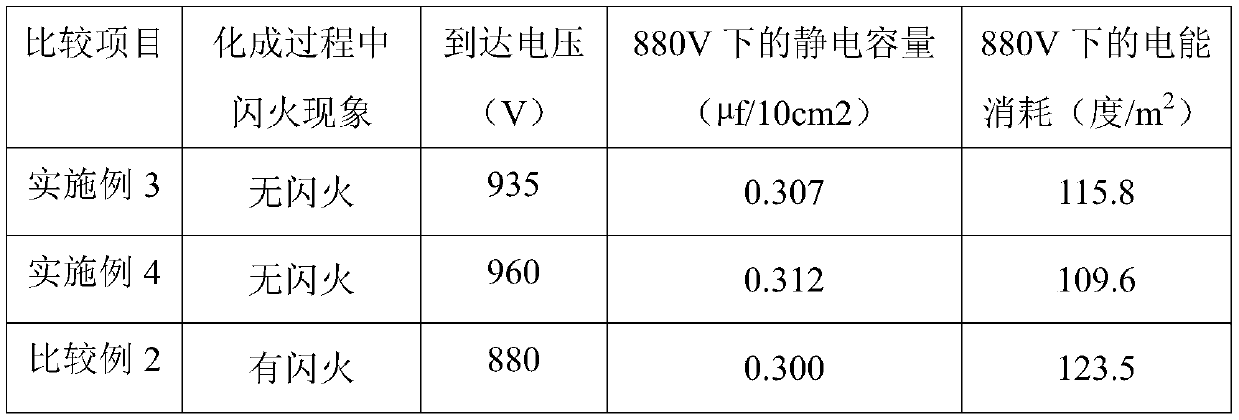

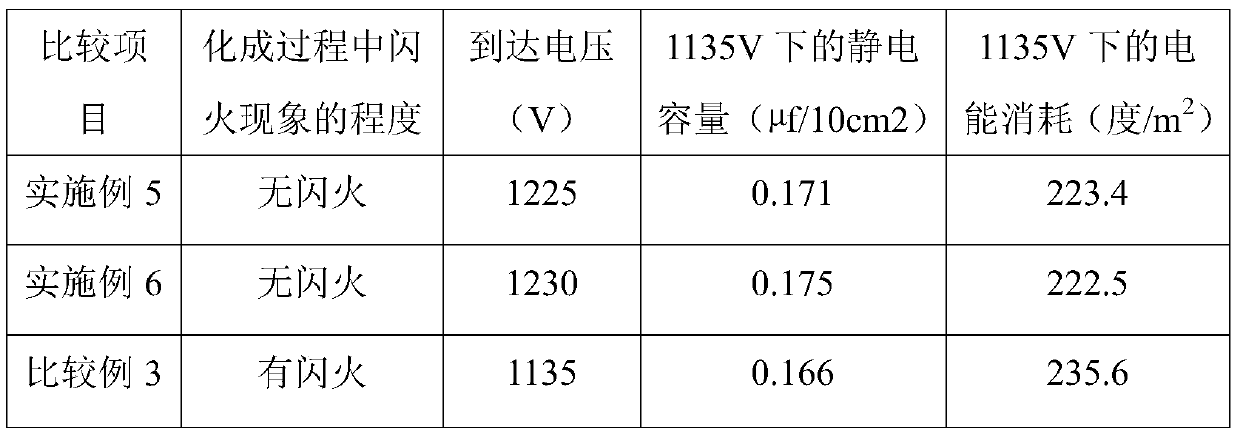

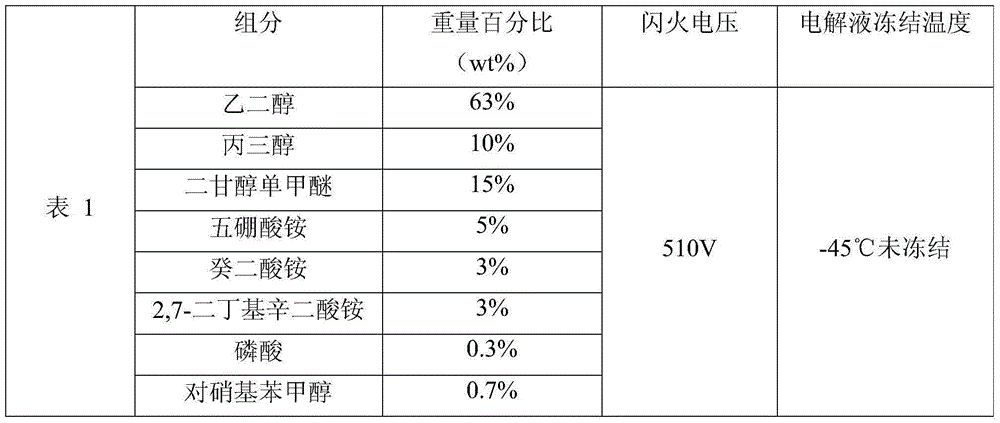

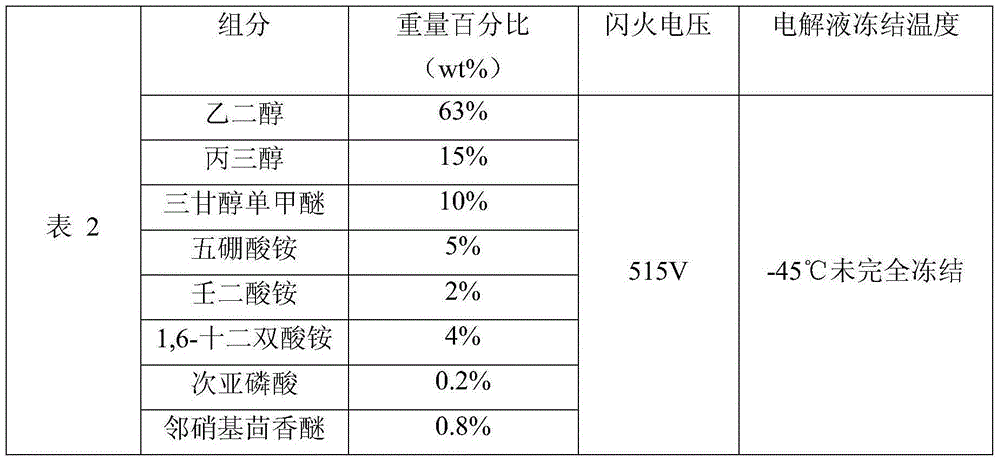

Ultrahigh-pressure formed foil forming technology for aluminum electrolytic capacitor

ActiveCN110016702AMitigation of flash fireImprove hydrophilicityAnodisationElectrolytic capacitorsHydration reactionTetramethylammonium hydroxide

The invention relates to an ultrahigh-pressure formed foil forming technology for an aluminum electrolytic capacitor. An existing boric acid forming technology is improved, high-purity aluminum foil obtained after corroding and face expanding is subjected to a hydration reaction, then four-stage formation is conducted with first-stage and second-stage electrolytic liquid being a mixed solution ofboric acid, citric acid and ammonium pentaborate and third-stage and fourth-stage electrolytic liquid being a mixed solution of boric acid, tetramethyl ammonium hydroxide and mannitol. In addition, proper phosphoric acid treatment strength is selected in aftertreatment, the voltage of the formed foil can reach 1200 V, and therefore the application field of the formed foil is further expanded.

Owner:INNER MONGOLIA ULANQAB DONGYANGGUANG FORMED FOIL CO LTD

Working electrolytic solution of aluminum electrolytic capacitor with resistance to high voltage and wide-range temperature and manufacturing method thereof

InactiveCN105140035AGood antifreeze performance at low temperatureLow costElectrolytic capacitorsElectrolytic agentFree cooling

The invention relates to a working electrolytic solution of an aluminum electrolytic capacitor with resistance to high voltage and wide-range temperature and a manufacturing method thereof, wherein the working electrolytic solution comprises, by weight percent,70 percent to 90 percent of solvent, 9 percent to 29 percent of solute, 0.1 to 1 percent of high temperature stabilizer and 0.1 to 1 percent of gas absorbent; the manufacturing method comprises: a. heating after blending the solvent by weight percent, adding solute, stirring and heating till the solute is completely dissolved; b. and adding the high temperature stabilizer and the gas absorbent into the solution that is already reacted and basically clarified in the step (a ), stirring and then naturally cooling till the electrolytic solution is acquired. According to the invention, the electrolytic solution provided herein has good low temperature freezing-resistant performance, thus the electrolytic solution has the ability to work at wide range temperature; at the same time, the electrolytic solution also has high sparking voltage and can be suitable for electrolytic capacitors with 400V to 500V high voltage; the technology of the manufacturing method is simple; and the cost is low, thus the electrolytic solution has good application prospect.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

Electrolysis solution and preparation method thereof as well as preparation method for obtained aluminum capacitor

ActiveCN101556867BImprove corrosion resistanceHigh temperature stabilityLiquid electrolytic capacitorsElectrolysisPhosphate

The invention relates to electrolysis solution and a preparation method thereof as well as a preparation method for an obtained aluminum capacitor. The electrolysis solution is composed by the components according to the following weight by parts: 38.5-85.7 wt % of primary solvent, 5-25 wt % of auxiliary solvent, 4-20 wt % of solute, 5-15 wt % of modified additive, 0.2-1 wt % of hydrogen eliminating agent and 0.1-0.5 wt % of waterproof combination agent. The primary solvent is glycol; the auxiliary solvent is one or more of tributyl phosphate, mono butyl ester phosphate, diglycol dibutyl ether; the solute is one or more of ammonium sebacate, 1.6-dodecyl ammonium bisgallic acid, 1.10-dodecyl ammonium bisgallic acid organic carboxylate. In the preparation method for the aluminum capacitor using the electrolysis solution, positive pressure and vacuum-pumping is required to be applied in an impregnation tank in an alternate recycle way with the recycle impregnation interval period being 20-60min.The electrolysis solution has the characteristics of high temperature resistance, high sparking pressure and strong corrosion resistance. The screw large capacitor has a service life of 8,000 hours at 105 DEG C or 2,000 hours at 125 DEG C.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Preparation method of porous anode aluminum foil with multi-stage mixed structure

ActiveCN111627714AReduce pollutionAvoid strong acidsAnodisationElectrolytic capacitorsElectrolytic agentMetal particle

The invention discloses a preparation method of a porous anode aluminum foil with a multi-stage mixed structure, and belongs to the field of aluminum electrolytic capacitors. Large-size aluminum metalhas a large specific surface area and high surface uniformity; small-size aluminum metal particles can play a role in supporting a three-dimensional structure during melting; high porosity of the electrode foil is maintained, meanwhile, an electron transmission channel is added, the aluminum substrate is coated with the large size aluminum and the small size aluminum particles in a mixed mode, anodic oxidation is conducted in an ammonium adipate or boric acid electrolyte, the porous electrode foil of a nano-micron multi-stage mixed structure can be obtained, and the electrode foil has high electrostatic capacity and low leakage current. The method can be used for large-scale industrial manufacturing, the specific volume of the anode aluminum foil for the aluminum electrolytic capacitor can be greatly improved, light weight and miniaturization of the aluminum electrolytic capacitor are promoted, and the comprehensive performance of the aluminum electrolytic capacitor is improved.

Owner:XI AN JIAOTONG UNIV

High-sparking and long-service-life electrolyte for aluminum electrolytic capacitor and preparation method therefor

ActiveCN105469991AGood electrochemical propertiesIncrease the flash voltageLiquid electrolytic capacitorsCapacitor manufactureElectrolysisPhosphate

The present invention relates to the technical field of electrolytes, in particular to a high-sparking and long-service-life electrolyte for an aluminum electrolytic capacitor and a preparation method therefor. The electrolyte comprises the following raw materials in parts by weight: 3-5 parts of ammonium sebate, 1-2 parts of ammonium pentaborate, 1-2 parts of sorbitol, 1.5-2.5 parts of ammonium dodecanedioate, 8-12 parts of a sparking boosting agent, 4-6 parts of branch-chain organic acid, 0.05-0.15 part of organic phosphate, 0.4-0.6 part of p-nitrobenzyl alcohol, 0.1-0.3 part of p-nitrophenol, 5-7 parts of ethylene glycol nano silica sol, 4-6 parts of Y-butyrolactone and 55-75 parts of glycol. The electrolyte is prepared by means of interaction among the raw materials; the sparking voltage of the prepared electrolyte can reach 535 V and the conductivity rate of the prepared electrolyte can reach 1.8 ms / cm; and the electrolyte has good electrochemical properties, has the advantages of high sparking voltage and long service life, and can be applied to manufacturing of the aluminum electrolytic capacitors.

Owner:DONGGUAN JIUZHI ELECTRONICS CO LTD

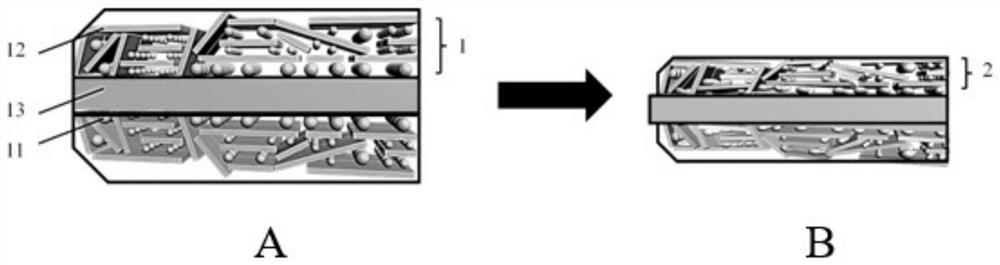

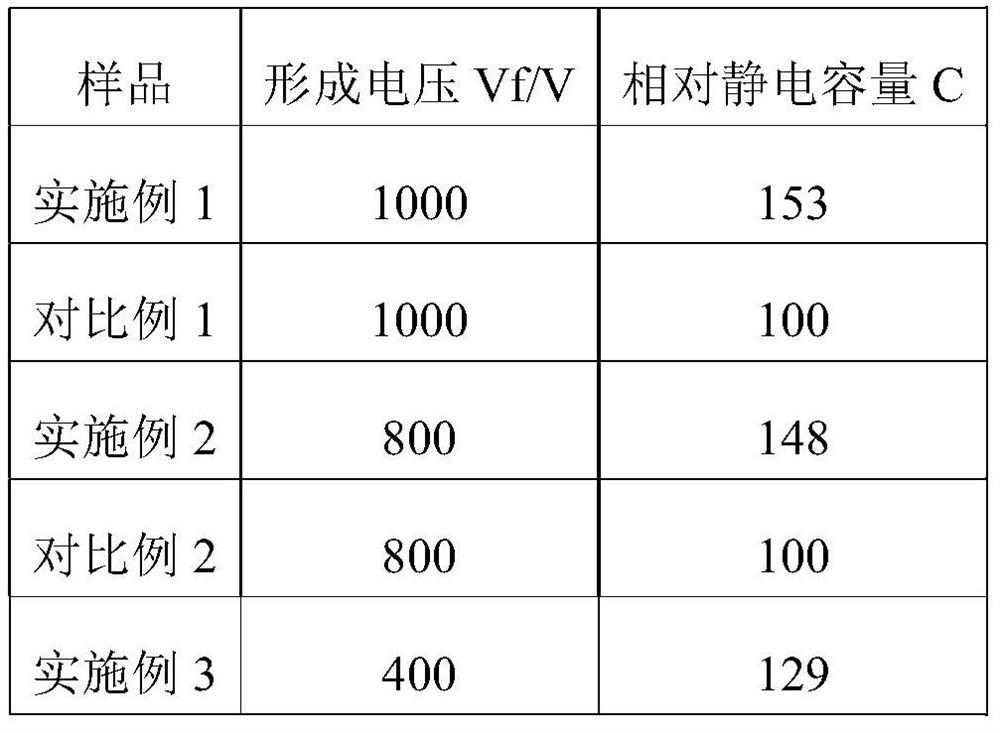

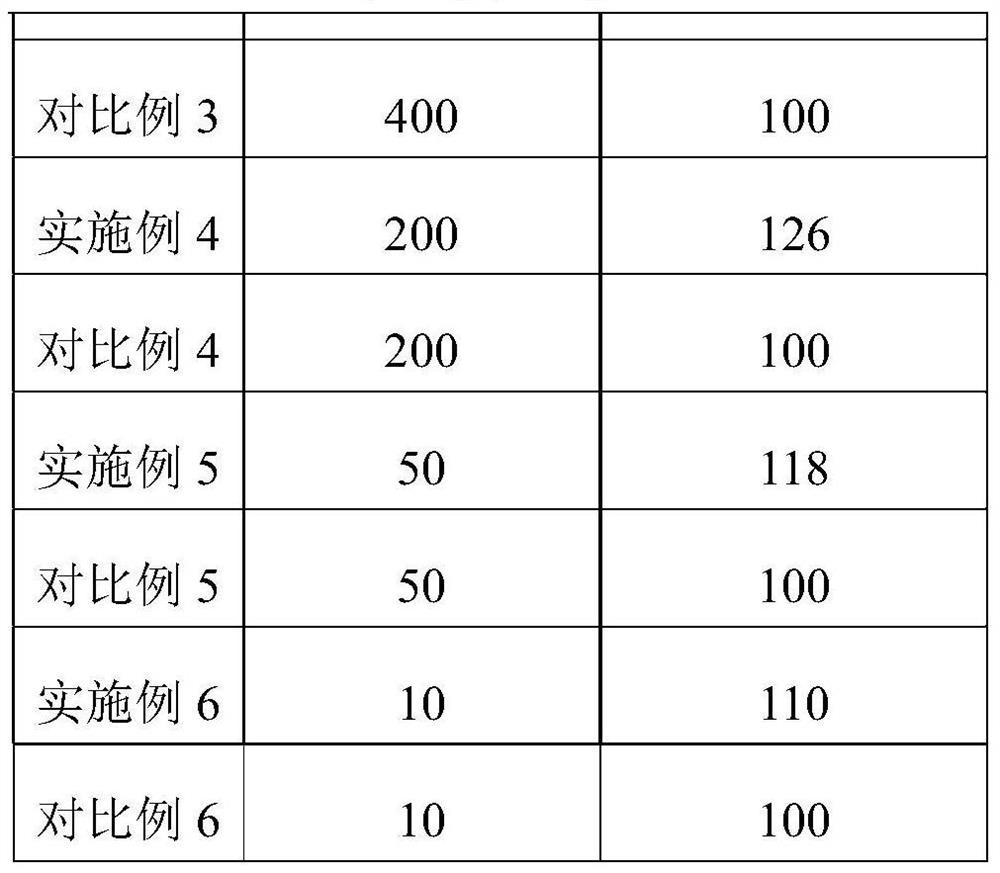

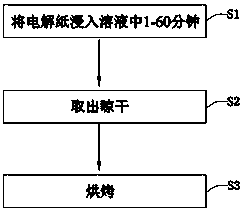

Novel electrolytic paper, manufacturing method thereof, electrolytic capacitor and manufacturing method thereof

ActiveCN108305786AHigh viscositySolve the problem of poor impregnation effectLiquid electrolytic capacitorsCapacitor dielectric layersElectrolysisBiochemical engineering

The invention provides novel electrolytic paper, a manufacturing method thereof, an electrolytic capacitor and a manufacturing method thereof. The electrolytic capacitor comprises a core package, wherein the core package comprises the novel electrolytic paper, the novel electrolytic paper has a cellular network structure, the cellular network structure is filled with a solute, and the solute can be dissolved in an electrolyte. Compared with the prior art, the novel electrolytic paper, the manufacturing method thereof, the electrolytic capacitor and the manufacturing method thereof solve a problem of poor impregnation effect through reducing the viscosity of the electrolytic and performing ultrasonic vibration impregnation. Meanwhile, a trace of solute used for adjusting the viscosity of the electrolytic and an additive are adsorbed on the electrolytic paper, the adsorbed solute is slowly released in the subsequent high-temperature aging and application after a capacitor product is assembled so as to improve the viscosity of the electrolytic and improve the sparking voltage and the safety performance.

Owner:HUNAN AIHUA GRP

Flame-retardant electrolytic solution for aluminum electrolytic capacitor

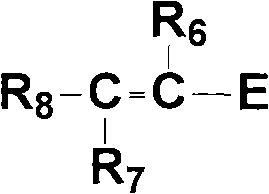

InactiveCN106449104AImprove conductivityIncrease the flash voltageLiquid electrolytic capacitorsStructural formulaSolvent

The invention provides a flame-retardant electrolytic solution for an aluminum electrolytic capacitor. The electrolytic solution comprises electrolyte salt and a solvent. The electrolyte salt comprises electrolyte salt 1 and electrolyte salt 2. The electrolyte salt 1 has a structural formula (as shown in the description) or (as shown in the description). The electrolyte salt 2 has a structural formula (as shown in the description), wherein R1, R2, R3, R4, R5, R6, R7, R8, R9 are independently selected from the alkyl group with the number of carbon atoms of 1-5. The electrolytic solution of the invention is capable of obtaining higher electrical conductivity and broken voltage, and has a good flame-retardant effect.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

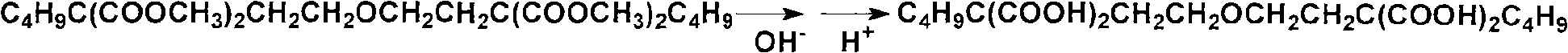

Electrolyte used for 650-700V aluminium electrolytic capacitor

ActiveCN108666138AIncrease the flash voltageImprove conductivityElectrolytic capacitorsElectrolysisSolvent

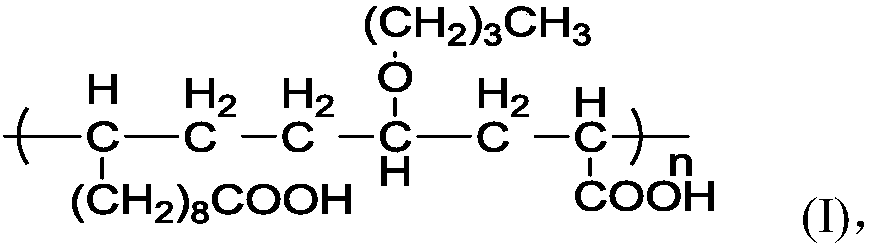

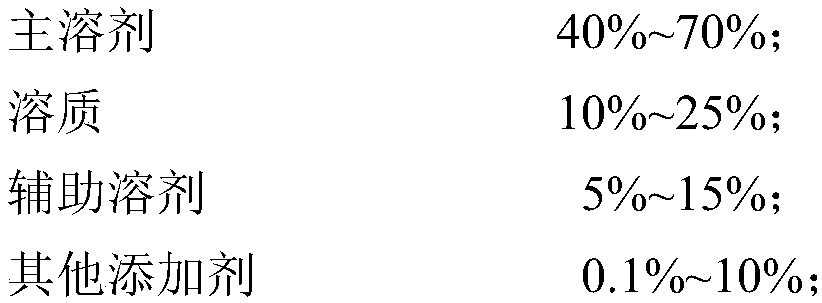

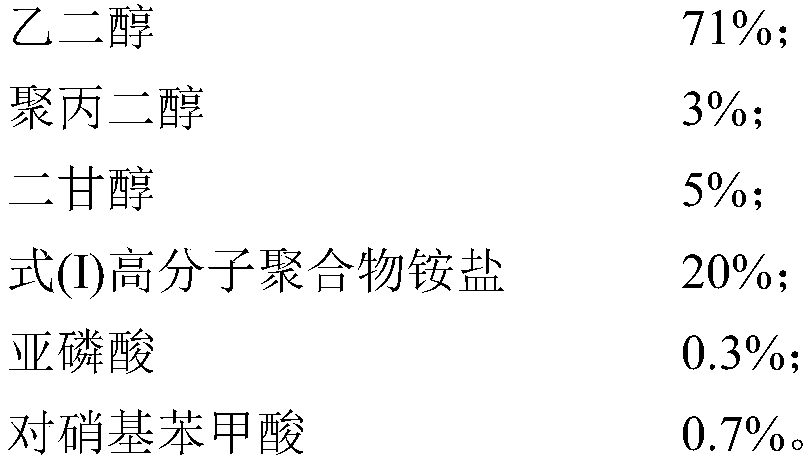

The invention provides a working electrolyte used for a 650-700V aluminium electrolytic capacitor. The electrolyte comprises a solute, a main solvent, auxiliary solvents and other additives, wherein the solute is a high-molecular polymer ammonium salt as shown in the formula (I), and has the molecular weight distribution range of 50000-100000. By virtue of the electrolyte formed by the solute which is the high-molecular polymer ammonium salt as shown in the formula (I), the spark voltage of the capacitor is obviously improved; and the obtained capacitor is relatively high in electrical conductivity, and after high-temperature long-time test, the electrical conductivity is slightly changed, higher high-temperature stability is achieved, and use requirement of the super-high-voltage aluminium electrolytic capacitor of 650V or 700V or above can be satisfied.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

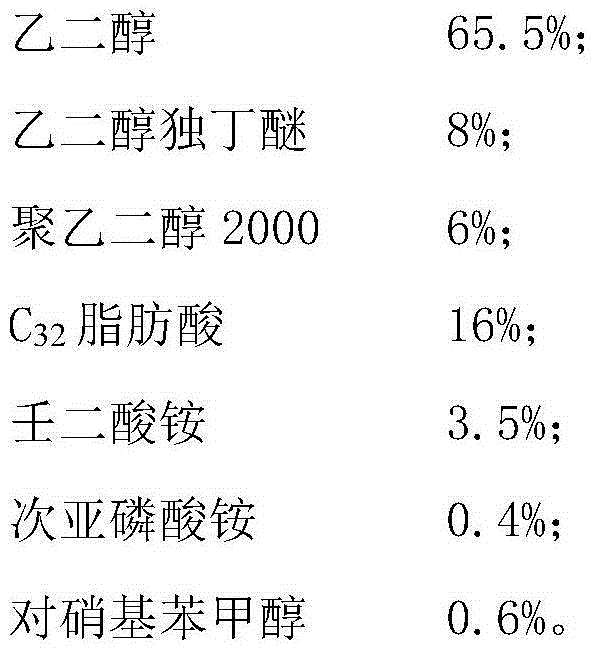

Electrolyte for high-voltage-resistant aluminum electrolytic capacitor and preparation method of electrolyte

InactiveCN110931256AIncrease the flash voltageImprove conductivityLiquid electrolytic capacitorsElectrolytic agentPhysical chemistry

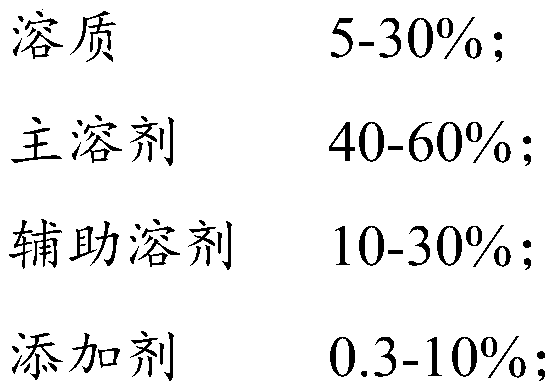

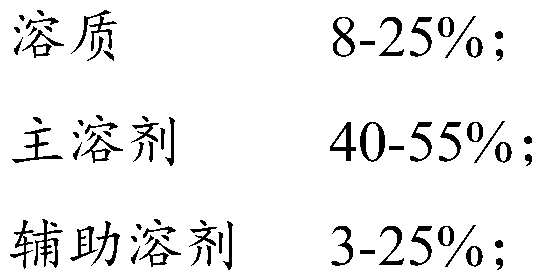

The invention provides an electrolyte for a high-voltage-resistant aluminum electrolytic capacitor and a preparation method of the electrolyte. The electrolyte for the high-voltage-resistant aluminumelectrolytic capacitor comprises solute, a main solvent, an auxiliary solvent and an additive, and the solute, the main solvent, the auxiliary solvent and the additive account for 5-30% by mass of thesolute, 40-60% of the main solvent, 10-30% of the auxiliary solvent and 0.3-10% of the additive, wherein the sum of the mass percentages of the components is equal to 100%. Provided is the electrolytic for the electrolytic capacitor, which uses an ammonium salt of a high-molecular polymer represented by formula (I) as a solute, so that the sparking voltage of the capacitor can be obviously improved. The conductivity of the obtained capacitor is better, and the capacity change rate, Tan delta, leakage current and appearance change of the prepared capacitor are less after a high-temperature long-time test, so that it is indicated that the capacitor has the better and large ripple current resistance and can meet the use requirements of the high-voltage-resistant aluminum electrolytic capacitor.

Owner:NANTONG RUIDA ELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com