Electrolysis solution and preparation method thereof as well as preparation method for obtained aluminum capacitor

An aluminum electrolytic capacitor and electrolyte technology, applied in liquid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve problems such as flash fire, breakdown, product failure, safety accidents, etc., achieve high flash fire voltage, and improve corrosion resistance. , Strong anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

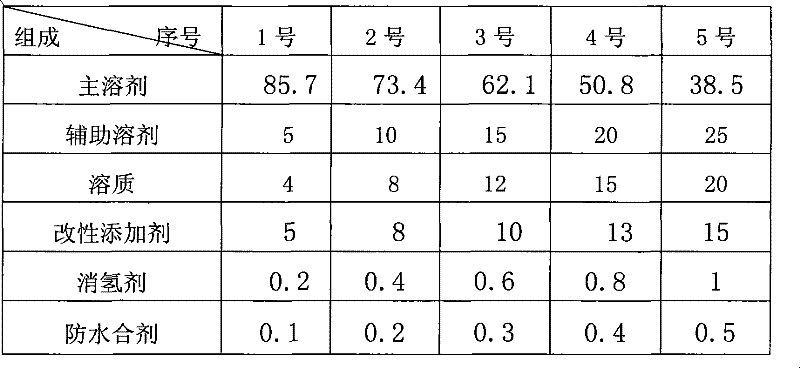

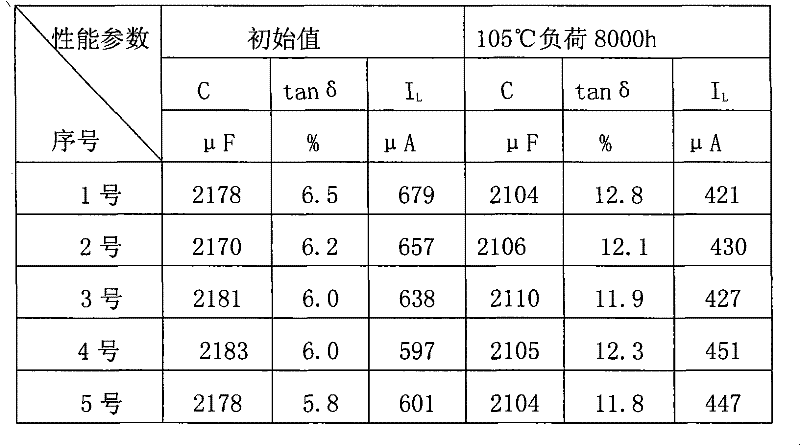

Embodiment 1

[0018] An electrolytic solution for aluminum electrolytic capacitors, its weight percent composition is No. 1 formula in Table 1, wherein: the main solvent is ethylene glycol, the auxiliary solvent is tributyl phosphate, the solute is ammonium sebacate, and the modifying additive is A mixture of pentaerythritol and polyethylene glycol, the hydrogen suppressant is p-hydroxyphenol, and the water-repelling agent is hypophosphorous acid. Heat ethylene glycol and tributyl phosphate to 70-90°C, add ammonium sebacate, heat to 110-135°C and turn off the heat, and finally add the mixture of pentaerythritol, polyethylene glycol, p-methylphenol and hypophosphite, Let it dissolve completely, and let it cool down naturally. The electrolyte was used to make 2200μF / 400 stud-type aluminum electrolytic capacitor products. The performance of the obtained products is shown in Table 2. After 8000 hours at 105°C, the performance of the product is still excellent (No. 1).

Embodiment 2

[0020] An electrolytic solution for aluminum electrolytic capacitors, its weight percent composition is No. 2 formula in Table 1, wherein: the main solvent is ethylene glycol, the auxiliary solvent is monobutyl phosphate, the solute is ammonium sebacate and 1.6-dodecyl Ammonium bis-acid, the modified additive is a mixture of phosphotungstic acid and ethyl orthosilicate, the hydrogen remover is p-hydroxyphenol, and the water-repelling agent is ammonium hypophosphite. Heat ethylene glycol and monobutyl phosphate to 70-90°C, add ammonium sebacate and 1.6-dodecanoate ammonium, heat to 110-135°C and turn off the heat, and finally add phosphotungstic acid and ethyl orthosilicate , the mixture of p-hydroxyphenol and ammonium hypophosphite, completely dissolve it, and let it cool down naturally. The electrolyte was used to make 2200μF / 400 stud-type aluminum electrolytic capacitor products. The performance of the obtained products is shown in Table 2. After 8000 hours at 105°C, the pro...

Embodiment 3

[0022] An electrolytic solution for an aluminum electrolytic capacitor, its weight percent composition is No. 3 formula in Table 1, wherein: the main solvent is ethylene glycol, the auxiliary solvent is diethylene glycol dibutyl ether, the solute is ammonium sebacate and 1.10- Ammonium dodecanoate, the modified additive is a mixture of citric acid and nano-silica, the hydrogen suppressor is p-hydroxyphenol, and the water-repelling agent is hypophosphorous acid. Heat ethylene glycol and diethylene glycol dibutyl ether to 70-90°C, add ammonium sebacate and 1.10-ammonium dodecanoate, heat to 110-135°C and turn off the heat, finally add phosphocitric acid, nanometer dioxide The mixture of silicon, p-hydroxyphenol and hypophosphorous acid is completely dissolved, and it can be cooled naturally. The electrolyte was used to make 2200μF / 400 bolt-type aluminum electrolytic capacitor products. The performance of the obtained products is shown in Table 2. After 8000 hours at 105°C, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com