Patents

Literature

122 results about "Dibutyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dibutyl ether is a chemical compound belonging to the ether family with the molecular formula of C₈H₁₈O. It is colorless, volatile, and flammable liquid and has peculiar ethereal smell. Liquid dibutyl ether is lighter than water. On the other hand, the vapor is heavier than air. It is not soluble in water, but it is soluble in acetone and many other organic solvents. Due to this property, dibutyl ether is used as solvent in various chemical reactions and processes. For example, phenyllithium is commercially available as a ca. 1.8 M solution in dibutyl ether.

Solvent for treating polysilazane and method of treating polysilazane with the solvent

InactiveUS7344603B2Improve abilitiesAvoid adversely affecting the properties of a groundSemiconductor/solid-state device manufacturingDetergent compounding agentsAlkaneNonane

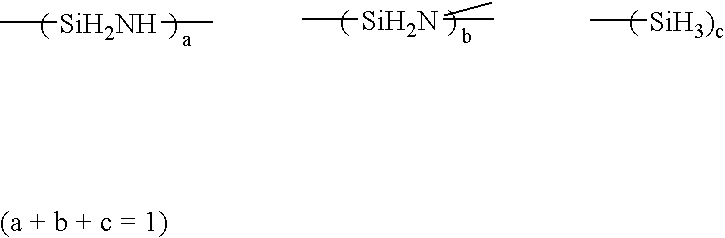

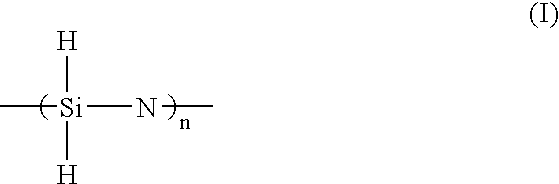

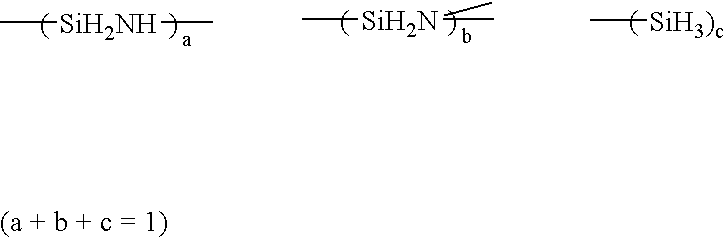

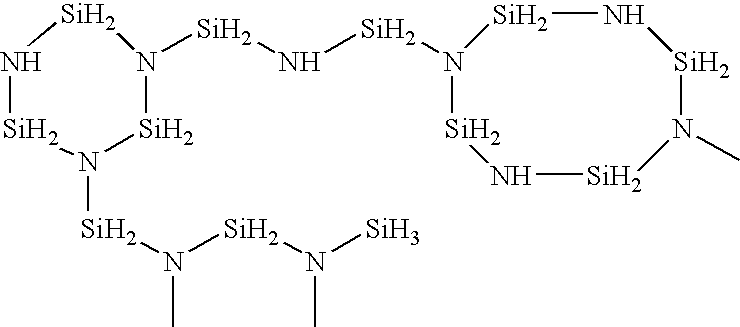

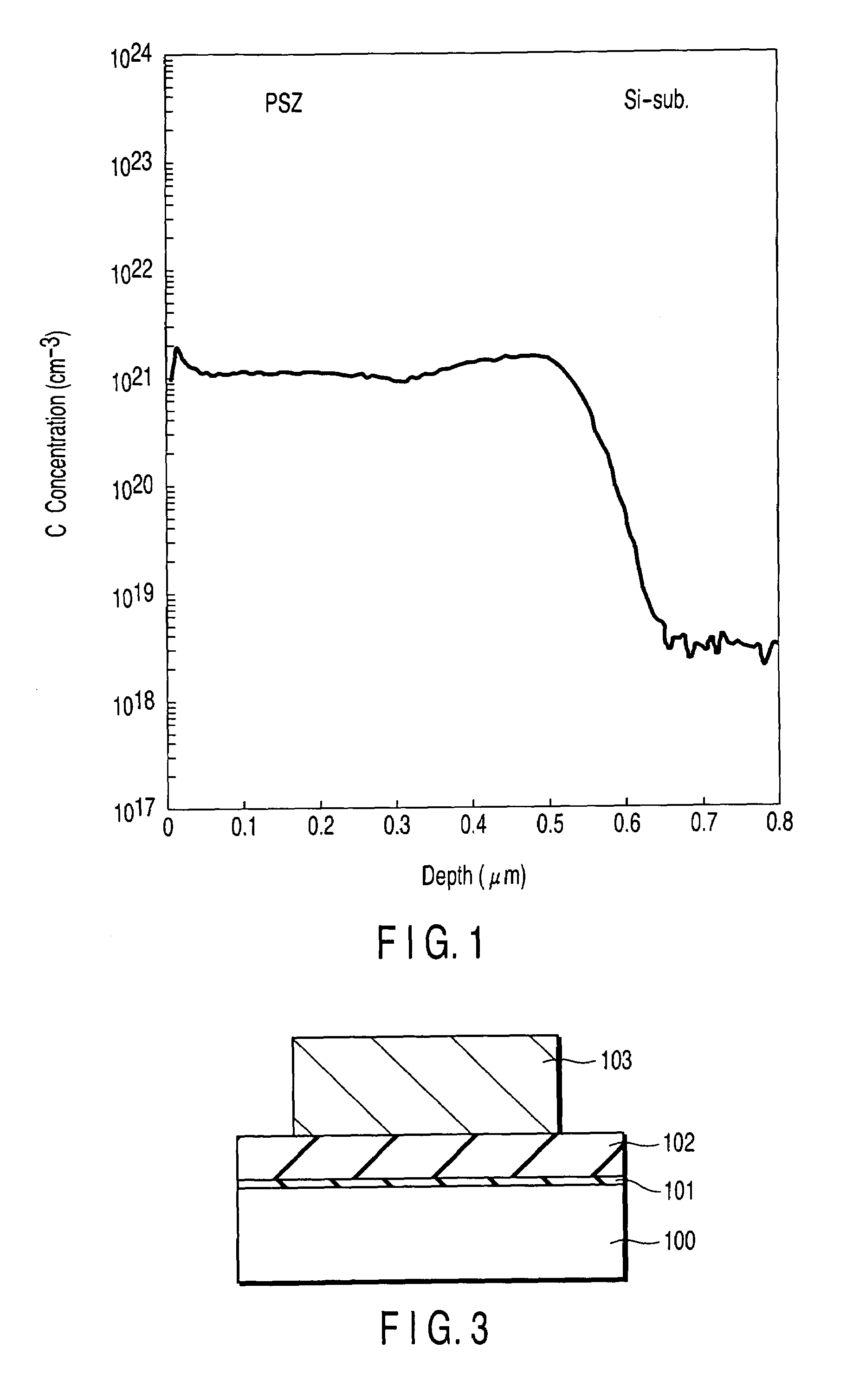

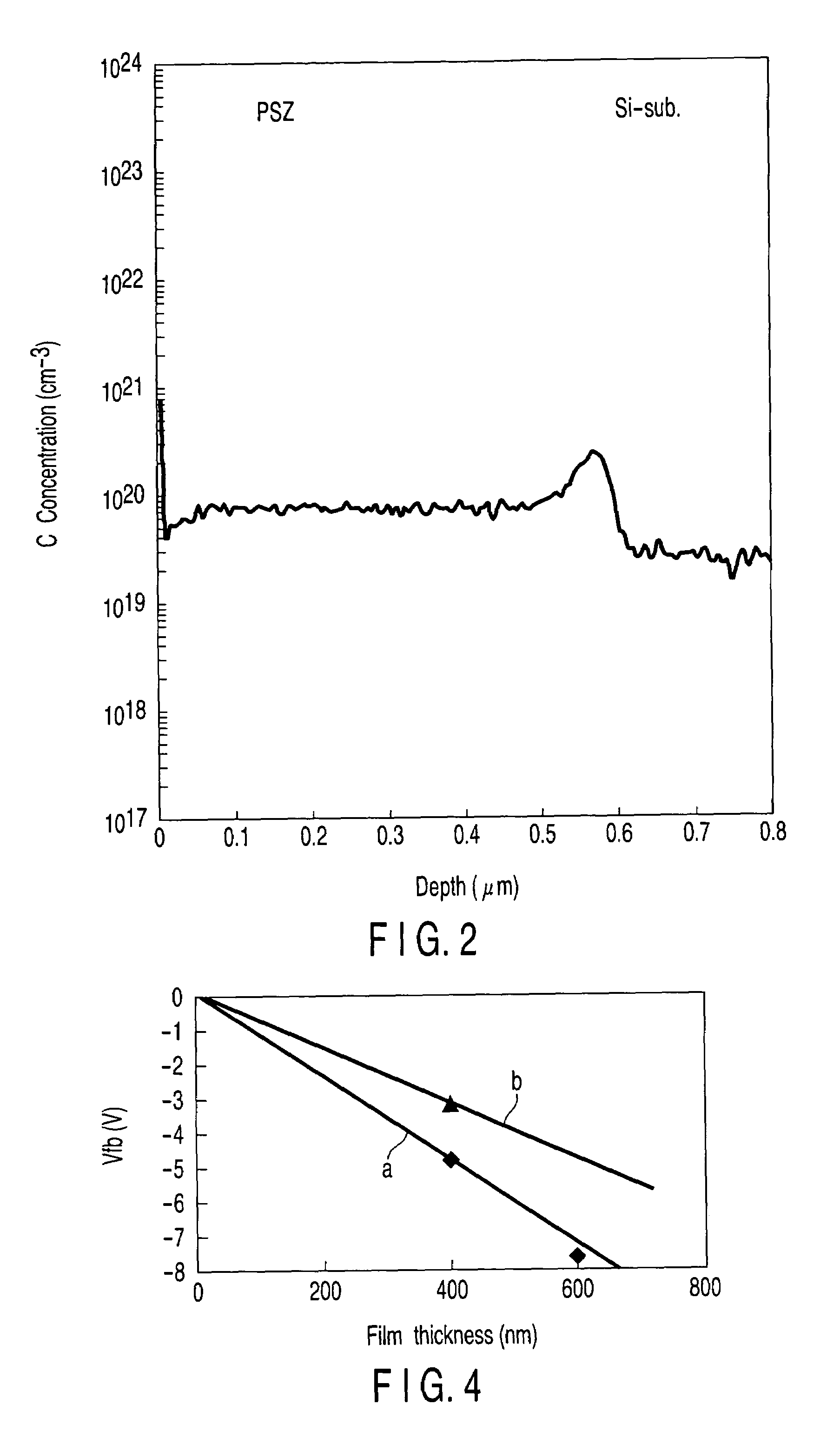

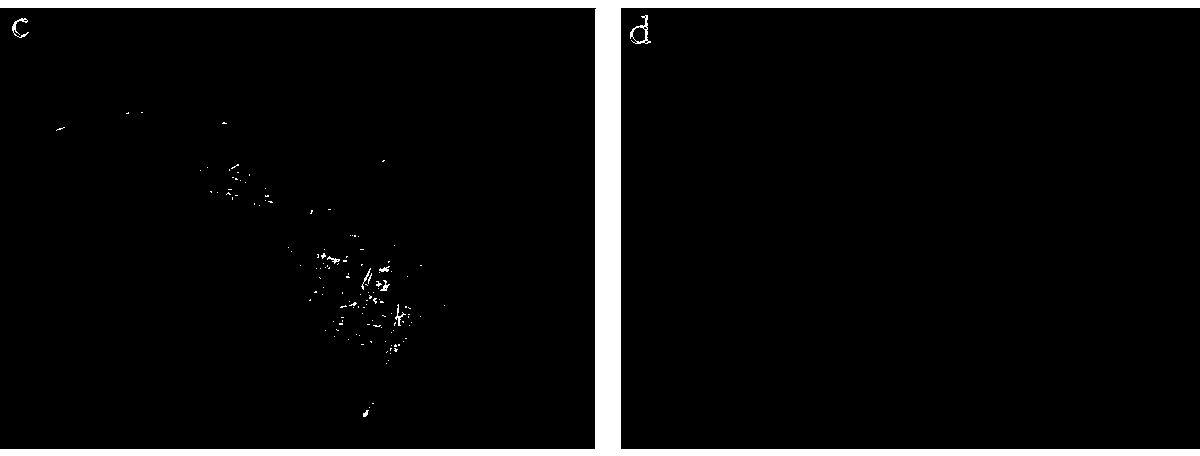

Polysilazane is treated with a single or mixed solvent comprising one or more members selected from the group consisting of xylene, anisole, decalin, cyclohexane, cyclohexene, methylcyclohexane, ethylcyclohexane, limonene, hexane, octane, nonane, decane, a C8-C11 alkane mixture, a C8-C11 aromatic hydrocarbon mixture, an aliphatic / alicyclic hydrocarbon mixture containing 5 to 25% by weight of C8 or more aromatic hydrocarbons, and dibutyl ether, wherein the number of 0.5 micron or more fine particles contained in 1 ml of the solvent is 50 or less. As the treatment of polysilazane, there are illustrated, for example, edge-rinsing and back rinsing of a polysilazane film formed by spin coating polysilazane on a semiconductor substrate. The water content of the solvent is preferably 100 ppm or less.

Owner:MERCK PATENT GMBH

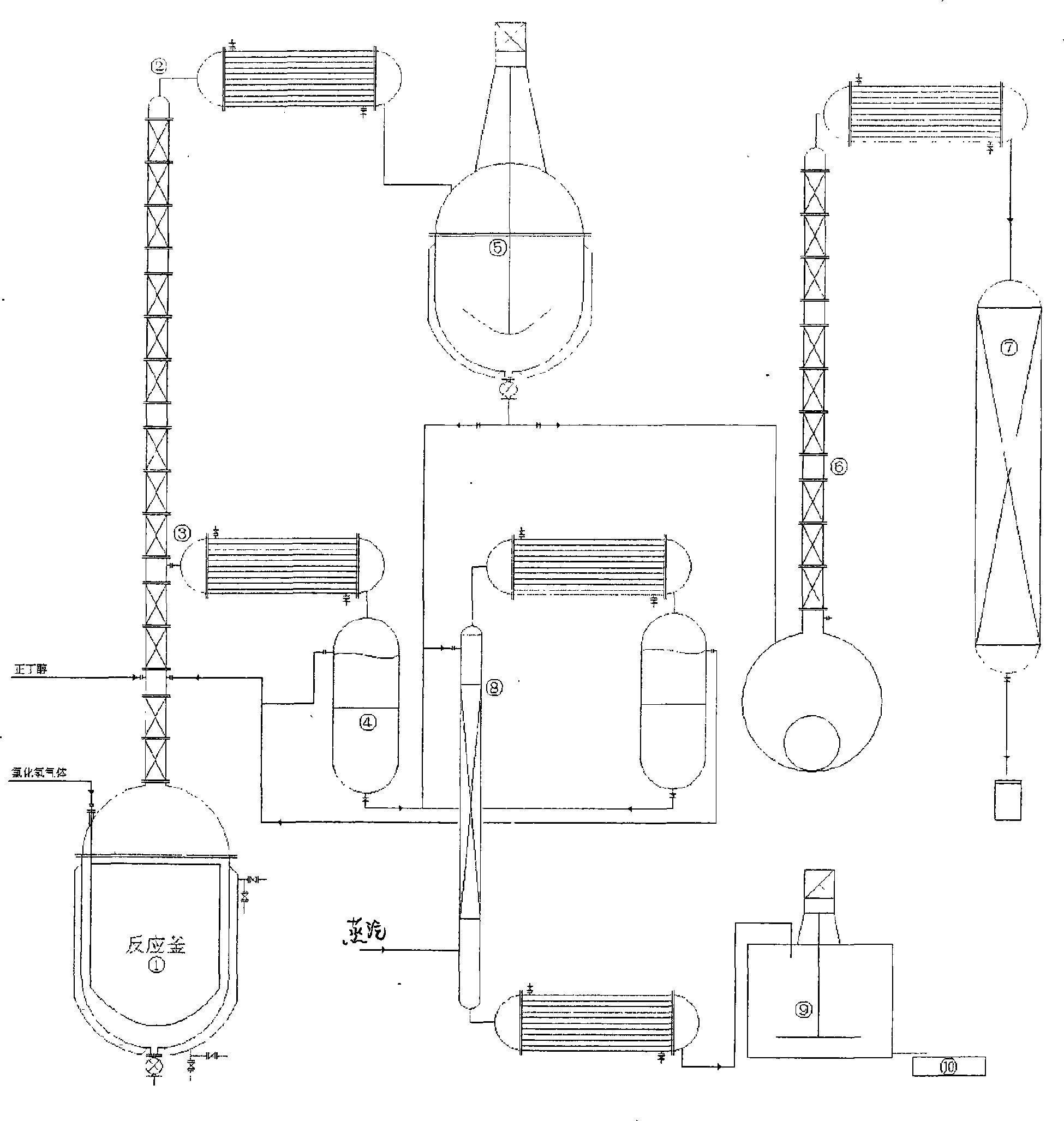

Method for continuous production of n-butyl chloride

ActiveCN101475440AReduce wasteReduce lossChemical industryHalogenated hydrocarbon preparationIsobutanolOrganic synthesis

The invention provides a method for continuously producing n-chlorobutane, which belongs to an organic synthesis process. The process consists of reactive distillation stage, an isobutanol recovery stage and a washing distillation stage. The process substitutes hydrogen chloride gas for 30 percent of hydrochloric acid, integrates a reaction stage with a separation stage, adopts an azeotropic water-shift technique, controls the unit consumption needed for producing one ton of 99.5 percent n-chlorobutane to be less than 0.86 ton of isobutanol, 1.8 tons of hydrogen chloride gas, 1.8 tons of steam, 60 kwh or electrical power and less than 0.001 ton of formed COD, reduces 80 percent of sewage discharged during the whole process, and reduces 80 percent of energy consumption. A product obtained by the method contains more than 99.5 percent (weight) of n-chlorobutane, less than 0.02 percent (weight) of isobutanol and less than 0.01 percent (weight) of dibutyl ether.

Owner:JIANGSU CHANGJILI NEW ENERGY TECH CO LTD

Solvent for treating polysilazane and method of treating polysilazane with the solvent

InactiveUS20050027089A1Excellent propertyImprove trimming effectSemiconductor/solid-state device manufacturingDetergent compounding agentsAlkaneNonane

Polysilazane is treated with a single or mixed solvent comprising one or more members selected from the group consisting of xylene, anisole, decalin, cyclohexane, cyclohexene, methylcyclohexane, ethylcyclohexane, limonene, hexane, octane, nonane, decane, a C8-C11 alkane mixture, a C8-C11 aromatic hydrocarbon mixture, an aliphatic / alicyclic hydrocarbon mixture containing 5 to 25% by weight of C8 or more aromatic hydrocarbons, and dibutyl ether, wherein the number of 0.5 micron or more fine particles contained in 1 ml of the solvent is 50 or less. As the treatment of polysilazane, there are illustrated, for example, edge-rinsing and back rinsing of a polysilazane film formed by spin coating polysilazane on a semiconductor substrate. The water content of the solvent is preferably 100 ppm or less.

Owner:MERCK PATENT GMBH

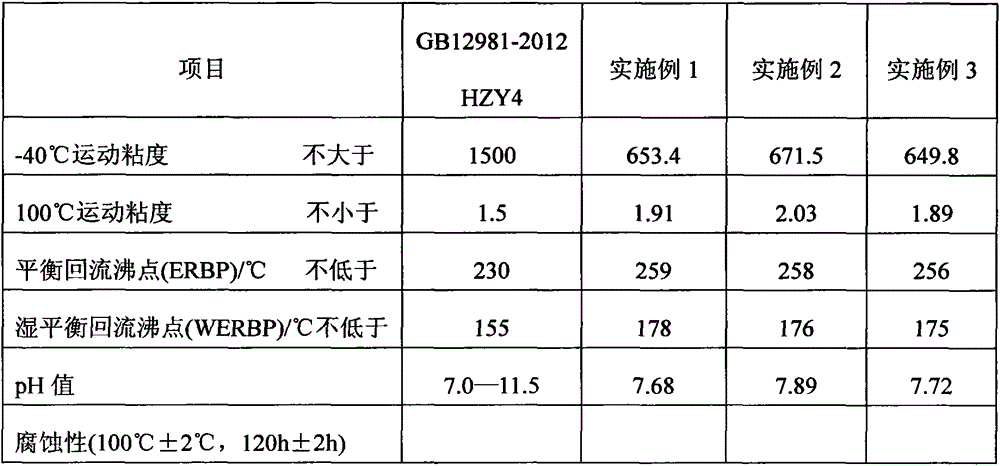

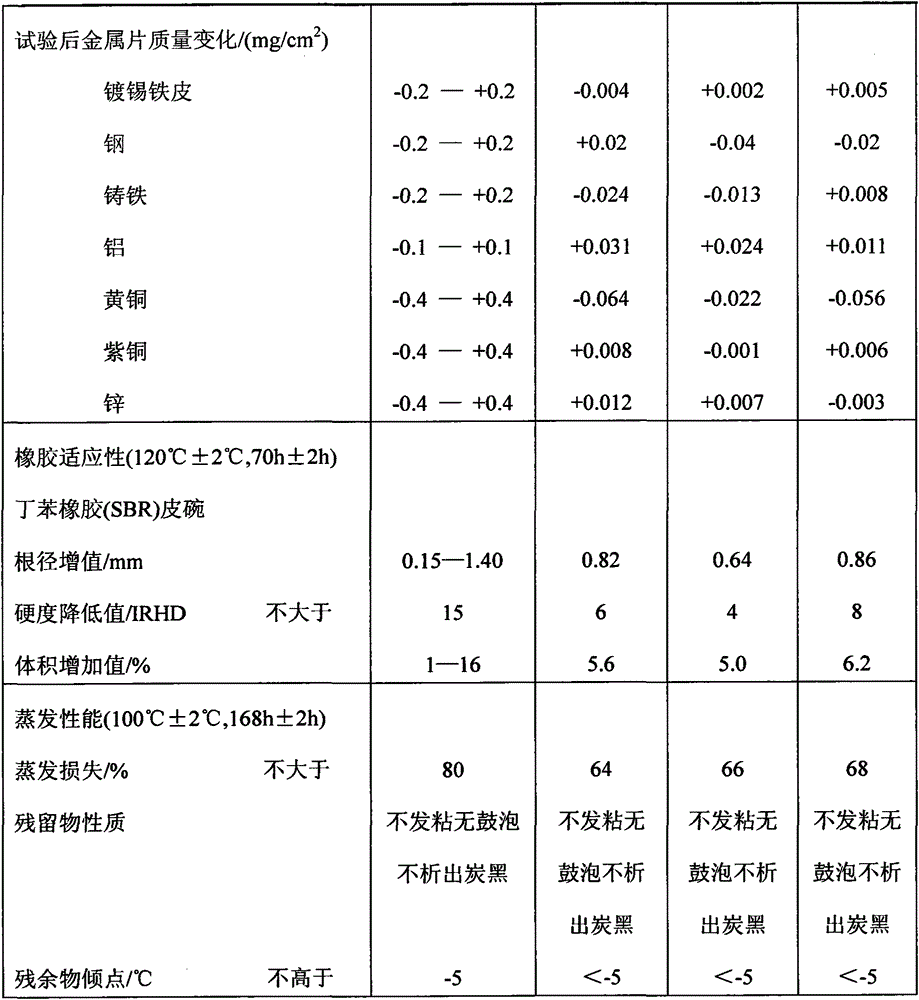

Advanced locomotive brake fluid composition

The invention discloses an advanced locomotive brake fluid composition, and relates to a car brake fluid composition, and the advanced locomotive brake fluid composition is invented fro solving the problems of poor compatibility, poor corrosion resistance and poor low-temperature performance of an existing car brake fluid. The advanced locomotive brake fluid composition is prepared from the following raw materials in percentage by weight: 60-74% of triethylene glycol monomethyl ether borate, 10-21% of di-ethylene glycol di-butyl ether, 14-20% of a polyalcohol rubber expansion restraint, 0.1-1.0% of an antioxidant, 0.1-1.0% of a preservative and 0.5-1.0% of a pH regulator. A preparation method for advanced locomotive brake fluid composition comprises the following steps: preparing triethylene glycol monomethyl ether borate from triethylene glycol monomethyl ether and borate at a weight ratio of 10 to 1; then, adding raw materials into a reaction kettle, stirring for 60 minutes at a normal temperature under normal pressure, and keeping the stirring speed at 50r / min; and after sufficiently mixing and dissolving various raw materials, sampling, detecting, filtering and guiding the raw materials into a finished product tank. The advanced locomotive brake fluid composition has the advantages of good compatibility, good corrosion resistance and good low-temperature performance.

Owner:LIAONING RUNDI AUTOMOTVE ENVIRONMENTAL PROTECTIONTECH

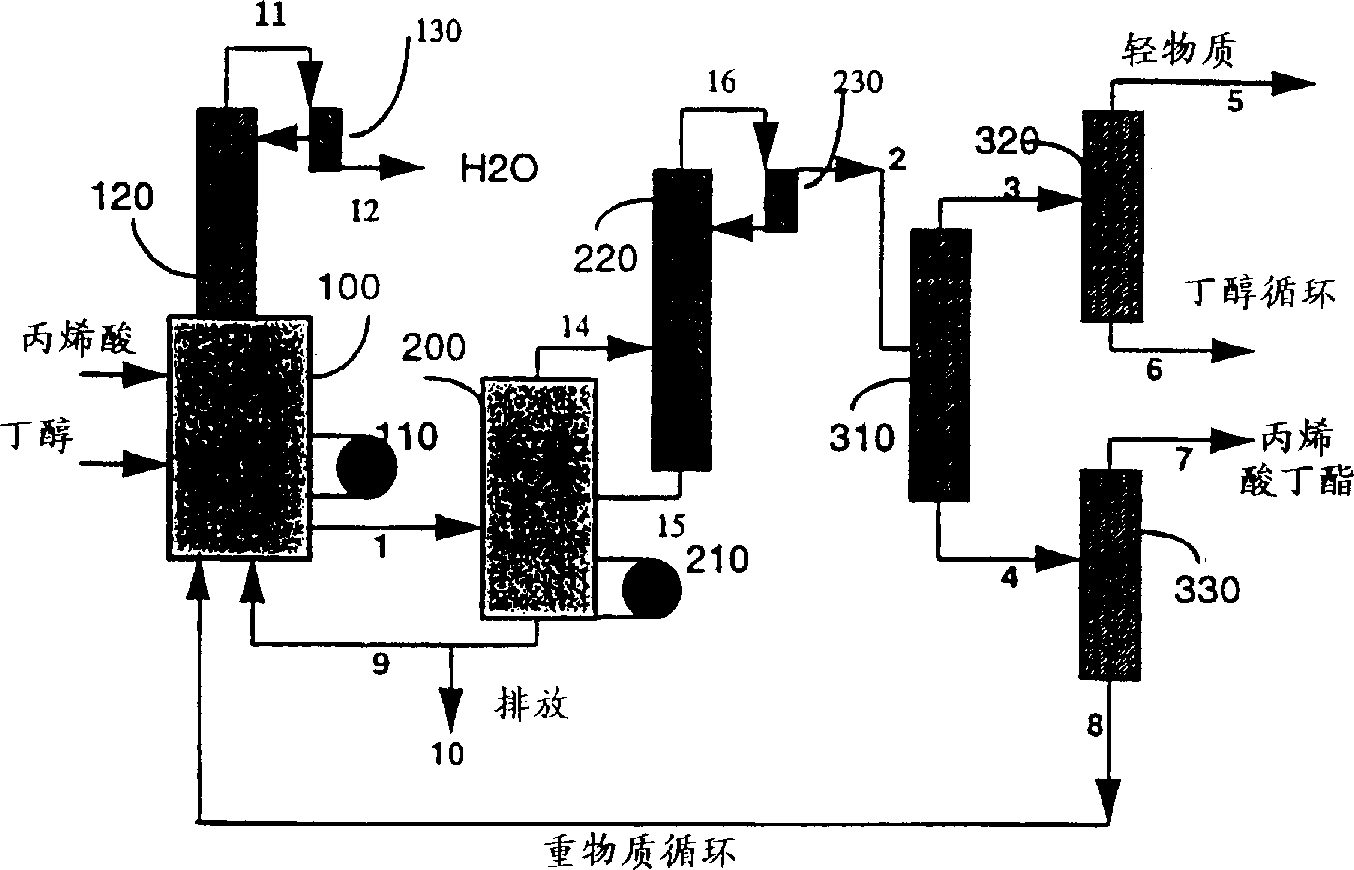

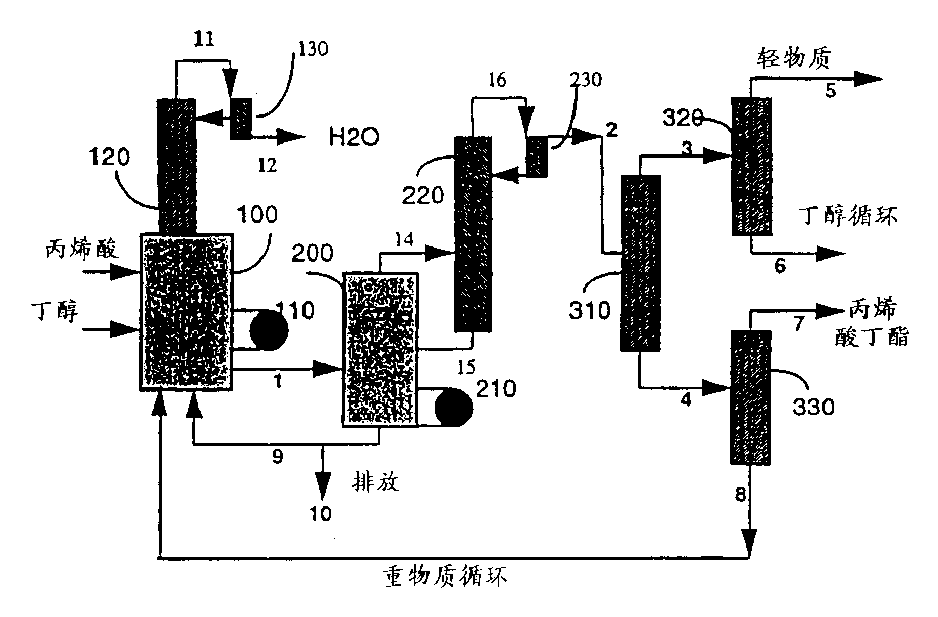

Process for refining butylacrylate

InactiveCN1254331AOrganic compound preparationCarboxylic acid esters preparationPolymer scienceEthylic acid

Crude butyl acrylate streams, e.g., from the reaction of butanol and acrylic acid, are refined using a splitter distillation column to yield a butyl acrylate- and heavies-containing bottoms fraction and an overhead fraction containing dibutyl ether, butyl acetate, butanol and butyl acrylate. The bottoms fraction is then subjected to separation, e.g., by distillation, to separate heavies from the bottoms fractions and to recover butyl acrylate. A process for the production of butyl acrylate is also disclosed, which process comprises not only the above-mentioned refining steps but also includes the steps of withdrawing from the splitter distillation column the overhead fraction and distilling the overhead fraction to recover a bottoms stream containing butanol and butyl acrylate, at least a portion of which could be recycled for reaction with acrylic acid to make butyl acrylate, and recovering the separated heavies, at least a portion of which could be recycled to a reaction zone for the production of butyl acrylate. At least 10,000 lb(avoir) quantities of a butyl acrylate product comprising at least 99.8% by weight of butyl acrylate and containing not more than about 200 ppm butyl ether and not more than about 200 ppm butyl acetate are producible.

Owner:DOW GLOBAL TECH LLC

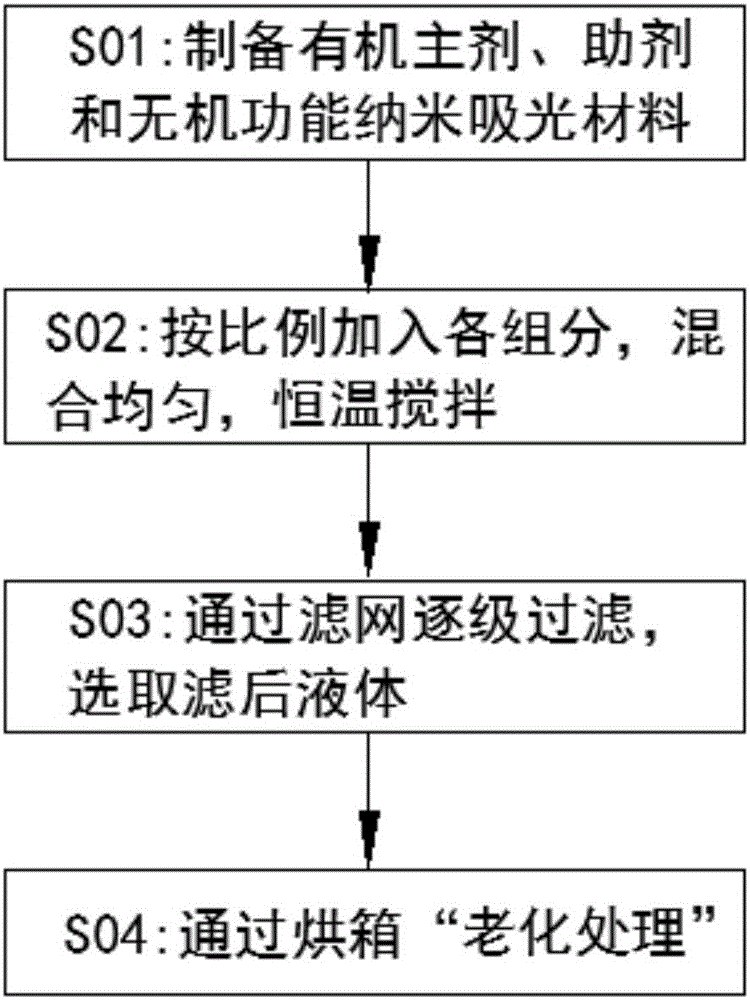

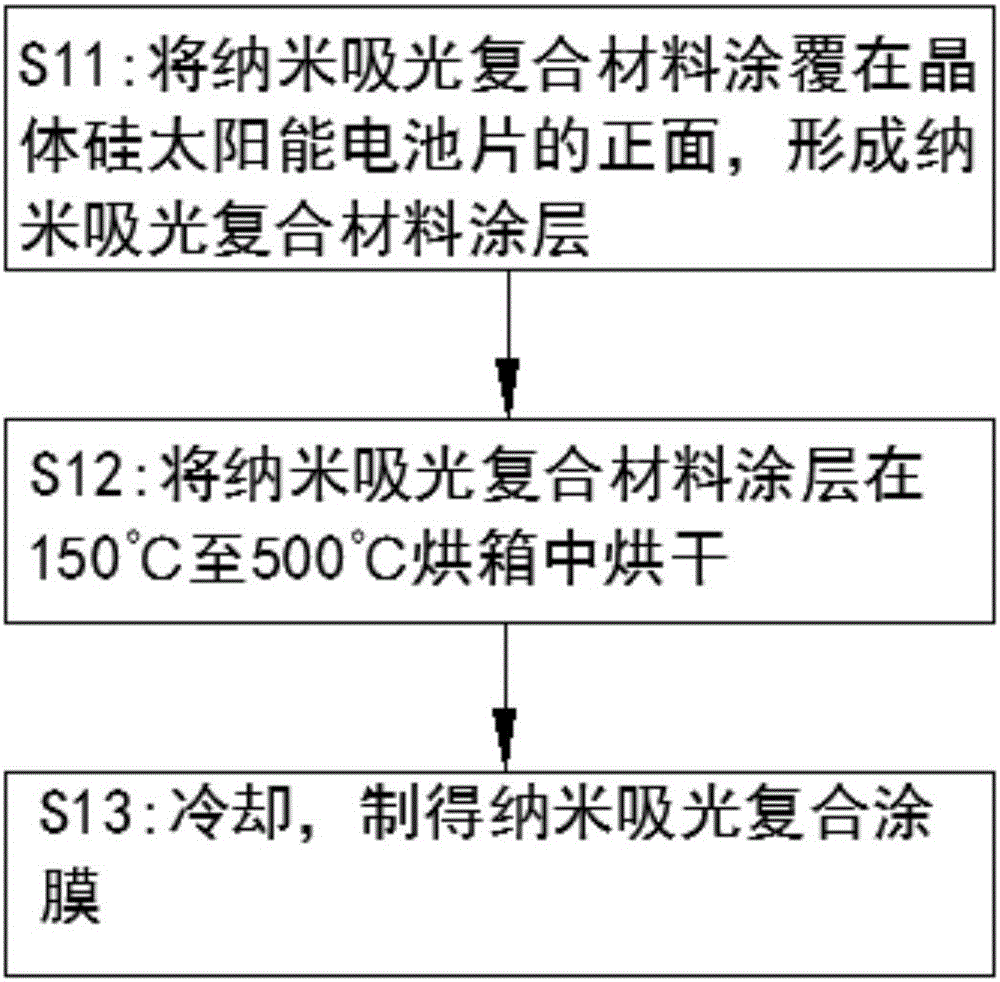

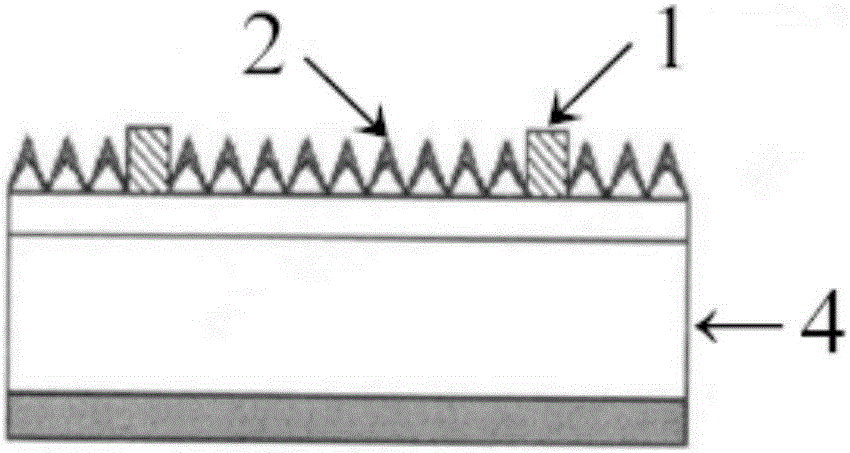

Nano light absorption composite material and preparation method thereof, and coated film preparation method

InactiveCN106653875AAdd refraction pathIncrease the absorption areaPhotovoltaic energy generationSemiconductor devicesDiethylene glycol monobutyl etherIndium

The invention discloses a nano light absorption composite material and a preparation method thereof, and a coated film preparation method. The nano light absorption composite material comprises an organic main agent, an auxiliary agent and an inorganic functional nano material, wherein the organic main agent is selected from at least one of ethylene glycol, diethylene glycol monobutyl ether, diethylene glycol dibutyl ether, ethylene glycol monoethyl ether acetate, n-butyl acetate, terpilenol, n-butanol and methyl isobutyl ketone; the auxiliary agent includes at least one of dispersant, thickener, flatting agent and defoaming agent; and the inorganic functional nano material is selected from at least one of zinc oxide, zinc sulfide, indium oxide, titanium dioxide, MxO, gallium compounds, cadmium telluride, calcium titanate, perovskite, graphene and nano precious metal. According to the nano light absorption composite material disclosed by the invention, a multilayer efficient antireflection branched structure is constructed on a surface of a textured antireflection layer of a crystalline silicon solar cell piece, so that a solar cell has excellent overall properties such as high incident light absorption, improved short circuit current, good electrical property and the like.

Owner:ENVIRONMENTAL NATURAL CHEM JIANGSU

Safe sole material and preparation method thereof

The invention provides a safe sole material and a preparation method thereof. The safe sole material comprises, by weight, 100 parts of TPE, 150 parts of PS, 111 parts of PE, 70 parts of rice bran, 22 parts of dibutyl ether, 36 parts of ethyl acetate, 27 parts of thiosulfate, 18 parts of olive oil, 19 parts of acetone and 10 parts of aniline. The preparation method for the safe sole material comprises the following steps: mixing above-mentioned components in proportion and placing obtained mixture in an internal mixer for banburying; granulating the mixture after banburying with a granulator so as to obtain particles; cooling the particles in a water tank and drying the particles at room temperature. Soles prepared from the safe sole material provided in the invention are antistatic and oil resistant, have a good heat insulating and cold-proof effect, and are applicable to a variety of work environments.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

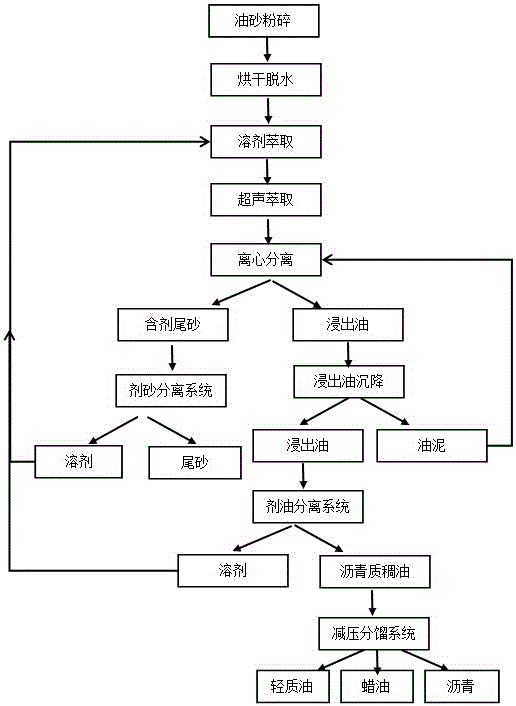

Compound solvent for extracting asphalt from oil sand and extracting process

ActiveCN105733642AHigh recovery rateReduce contentLiquid hydrocarbon mixture productionButyl acetateColloid

The invention discloses a compound solvent for extracting asphalt from oil sand and an extracting process.The compound solvent comprises a basic solvent and auxiliaries, the basic solvent is 200# solvent oil, and the auxiliaries are butyl acetate, dimethylbenzene, petroleum ether and dibutyl ether.Solvent extraction technology and ultrasonic extraction technology are combined creatively, so that extraction rate is high; the compound solvent can be recycled, normal-temperature technology is adopted for separation process treatment, so that influence on colloid and asphaltene in asphaltic heavy oil is small, and the compound solvent is high in practicability.

Owner:SHANDONG TONGRUN ENERGY CO LTD

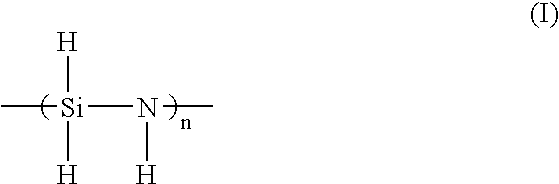

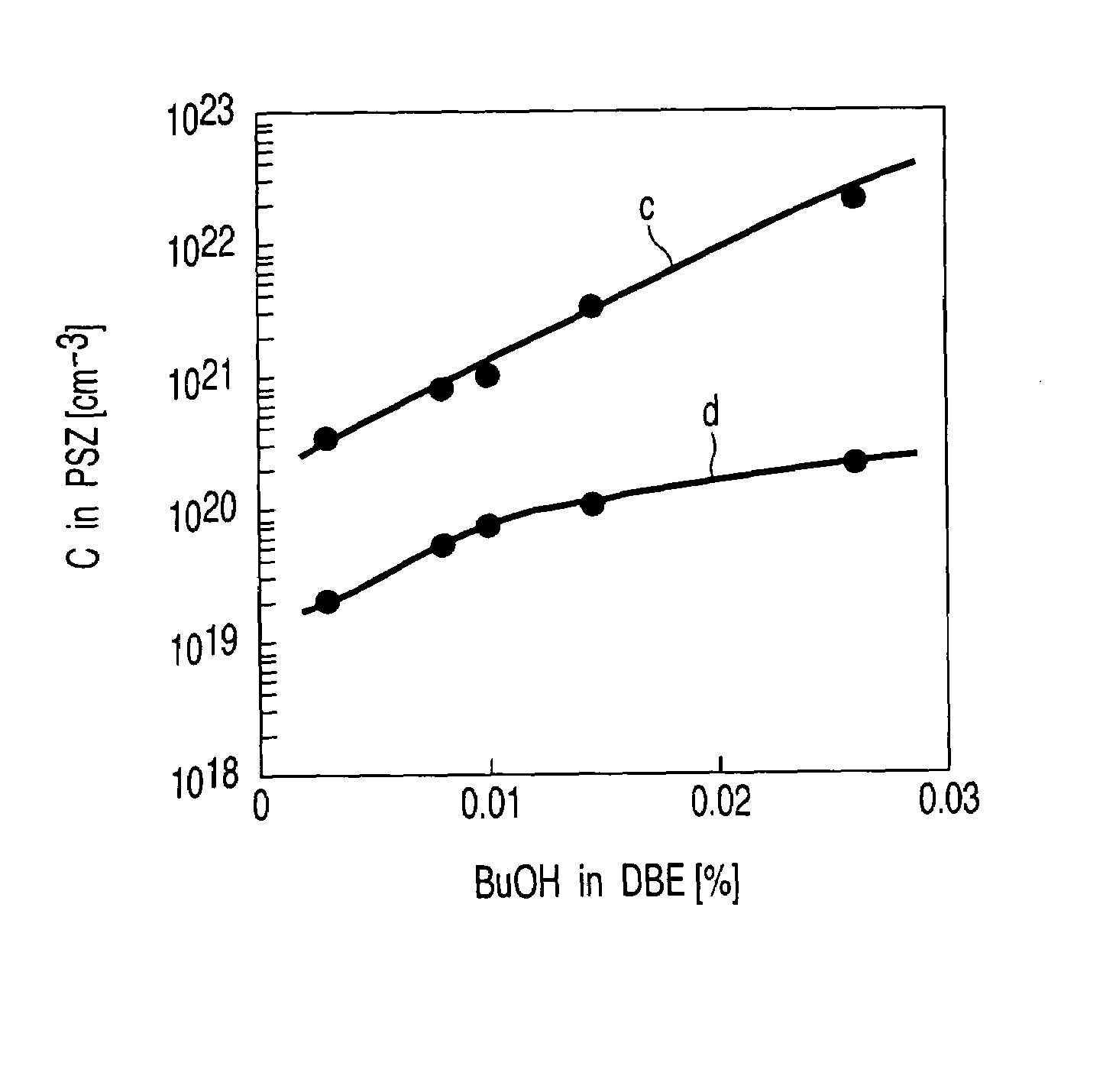

Polysilazane perhydride solution and method of manufacturing a semiconductor device using the same

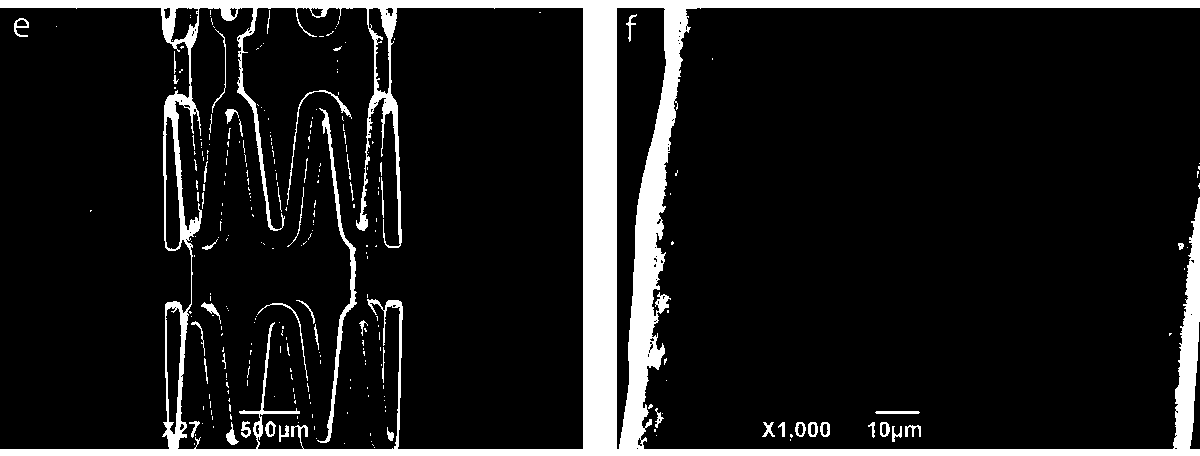

Disclosed is a method of manufacturing a semiconductor device comprising forming an element isolation trench in a semiconductor substrate, coating a polysilazane perhydride solution on the semiconductor substrate having the element isolation trench formed thereon to form a polysilazane perhydride film, the polysilazane perhydride solution comprising dibutyl ether having a butanol concentration of 30 ppm or less, and polysilazane perhydride dissolved in the dibutyl ether, subjecting the polysilazane perhydride film to oxidation in an atmosphere containing water vapor to form a silicon dioxide film, and selectively removing the silicon dioxide film to leave the silicon dioxide film in the element isolation trench to form an element isolating insulation film.

Owner:KIOXIA CORP

Preparation of hyperthermia drying wafer capacitance electrode silver plasm

InactiveCN101206958AAvoid scratchesDisadvantages of preventing sheddingFixed capacitor electrodesElectrolytic capacitorsCapacitanceAdhesive

The invention relates to a preparation method of low temperature baking disc capacitance electrode silver paste, which comprises the steps that: firstly, 200 model ethyl cellulose, 40 model ethyl cellulose, polyvinyl butyral, diethylene glycol dibutyl ether acetate are mixed to prepare an adhesive; secondly, super fine silver powder, frit and bismuth oxide are mixed to prepare a powder material; thirdly, terpilenol and diethylene butyl alcohol ethylether are mixed to prepare a thinning agent; fourthly, the adhesive and the power material are mixed, the fineness is adjusted through a trio mill, the thinning agent is added, and then the silver paste is prepared. The preparation process is simple, the prepared silver paste can prevent the defects that the silver layer is scratched and deciduous under the low temperature and baking conditions, ensure that the volatilization of the solvent during the low temperature and baking process is uniform, the air bubble is not existent, and the invention is suitable for the electrode solver paste under the high temperature (higher than 300 DEG C) and baking conditions.

Owner:宁波元太导电材料科技有限公司

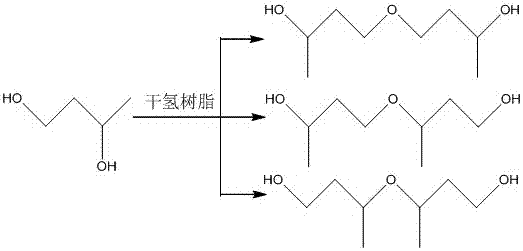

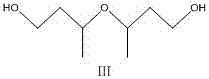

Green preparation method of dihydroxy dibutyl ether

ActiveCN103319316AEasy to handleEasy to separateEther preparation by compound dehydrationCholagoguesCholagogue

The invention relates to the field of preparation of chemical raw materials, and discloses a high-efficiency simple method for preparing dihydroxy dibutyl ether which satisfies the medicinal standard. The method comprises the following steps: condensing 1,3-butanediol at 70-190 DEG C by using 1.0-80 wt% cation exchange resin catalyst as a cation exchange resin catalyst to prepare dihydroxy dibutyl ether; and after the reaction finishes, cooling the reaction solution, filtering, and distilling under reduced pressure to obtain the dihydroxy dibutyl ether of which the content is at least 97%. The product is suitable for producing an active pharmaceutical ingredient of cholagogue Baodanjiansu. The method has the advantages of environmental protection, high efficiency and low cost, and is simple to operate and suitable for industrial large-scale production.

Owner:DALIAN UNIV OF TECH

Electrochemical polishing solution for zinc alloy devices and polishing method thereof

The invention relates to an electrochemical polishing solution for zinc alloy devices and a polishing method thereof, particularly an electrochemical polishing solution for zinc alloy products and a polishing method thereof, belonging to the field of zinc alloy material surface treatment. The electrochemical polishing solution for zinc alloy devices is composed of the following substances in percentage by volume: 10-40% of phosphoric acid, 20-85% of ethylene glycol butyl ether and 5-50% of acetic acid. The polishing solution has the characteristics of low toxicity, high component stability and the like, and can be used for electrochemical polishing of zinc alloy products. The polished zinc alloy product has the advantages of high brightness and smooth surface. The electrochemical polishing solution is free of environmentally harmful components and biologically toxic components, can not introduce toxic substances onto the zinc alloy surface, and is especially suitable for electrochemical polishing of medical zinc alloy instruments. The electrochemical polishing solution has low component volatilization rate, and thus, is beneficial to shortening the polishing solution replacement period.

Owner:XIAN ADVANCED MEDICAL TECH

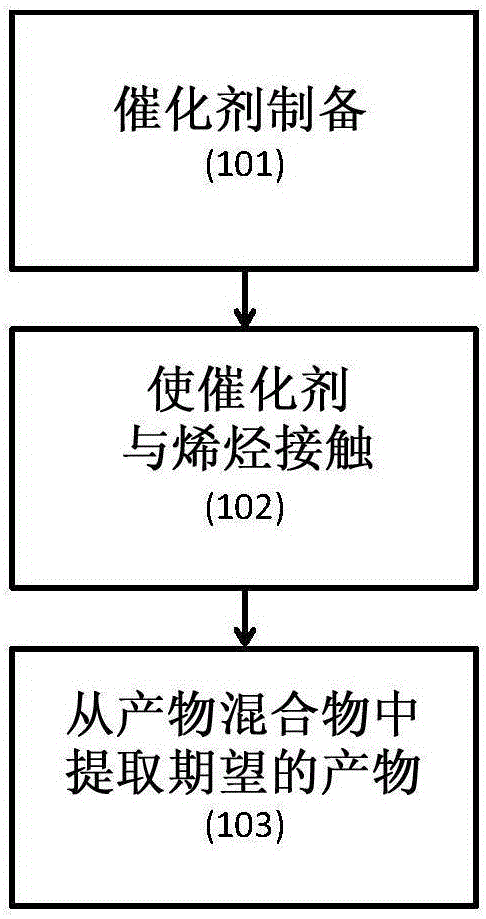

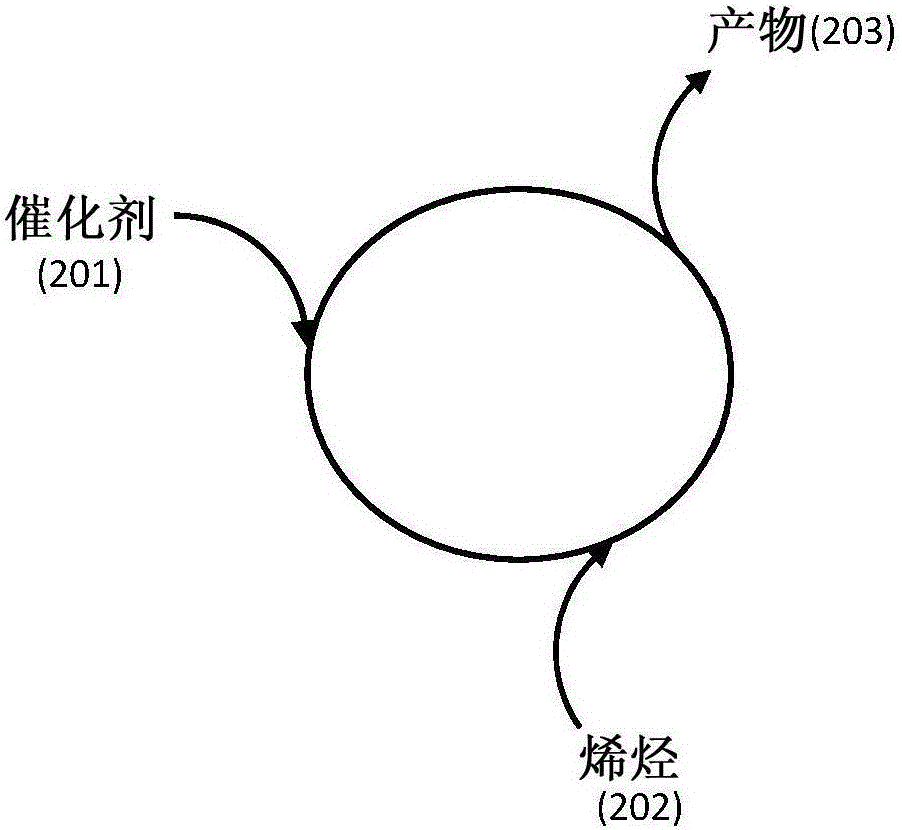

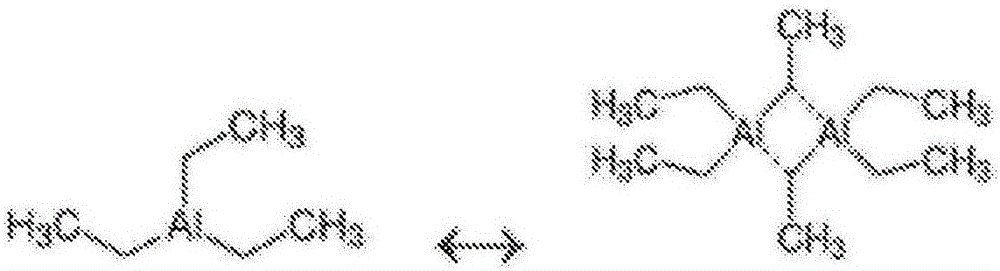

Catalyst compositions for selective dimerization of ethylene

InactiveCN105828941AOrganic-compounds/hydrides/coordination-complexes catalystsHeterogenous catalyst chemical elementsSilazaneFluorocarbon

A catalyst composition, including a titanate of the formula Ti(OR)4 wherein each R is the same or different, and is a hydrocarbon residue; a catalyst additive, wherein the catalyst additive is a dibutyl ether a silicate, a silazane, an aromatic ether, a fluorocarbon, or a combination comprising at least one of the foregoing; and an organic aluminium compound.

Owner:SAUDI BASIC IND CORP SA

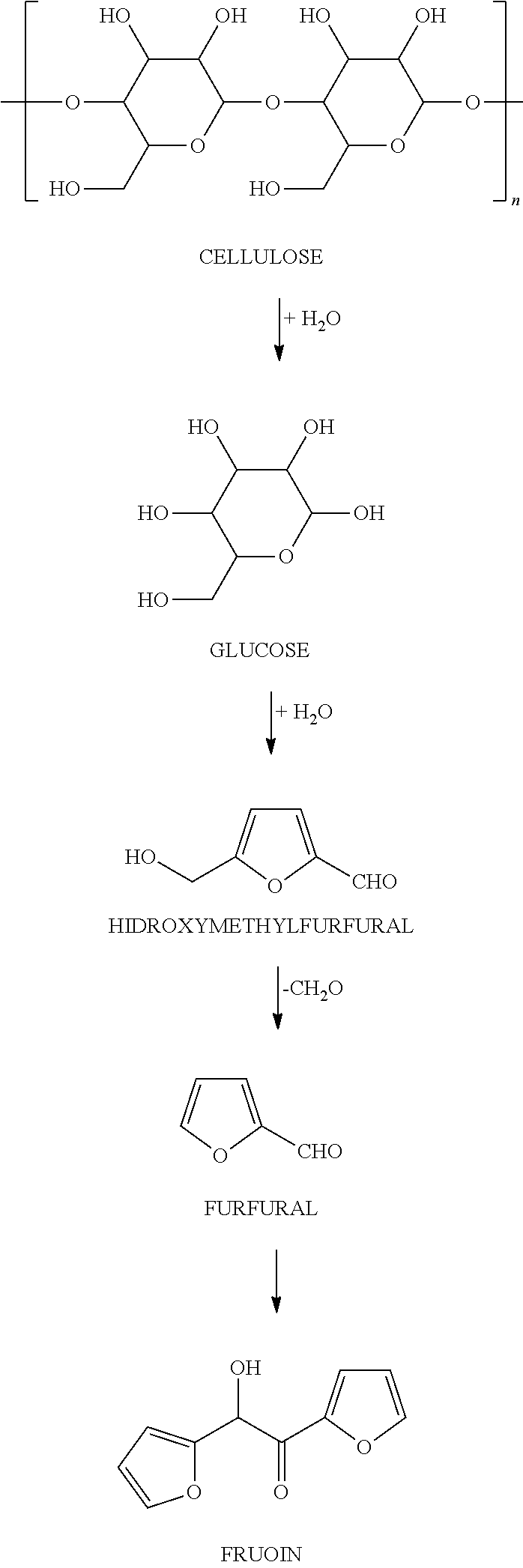

Production process of furfural from cellulose using as a solvent and catalyst an imidazolium sulphate or chloride in a reaction with simultaneous extraction with dibutyl ether

Furfural is a known component of both gasoline or diesel fuels as well as a chemical raw material.We disclose a new production process from cellulose, using as a solvent and catalyst an alkyl imidazole sulphate or chloride or a mixture of both in a reaction with simultaneous extraction, using as a solvent dibuthyl ether.Furfural and dibuthyl ether are later separated by distillation.

Owner:CORREIA PEDRO BRITO

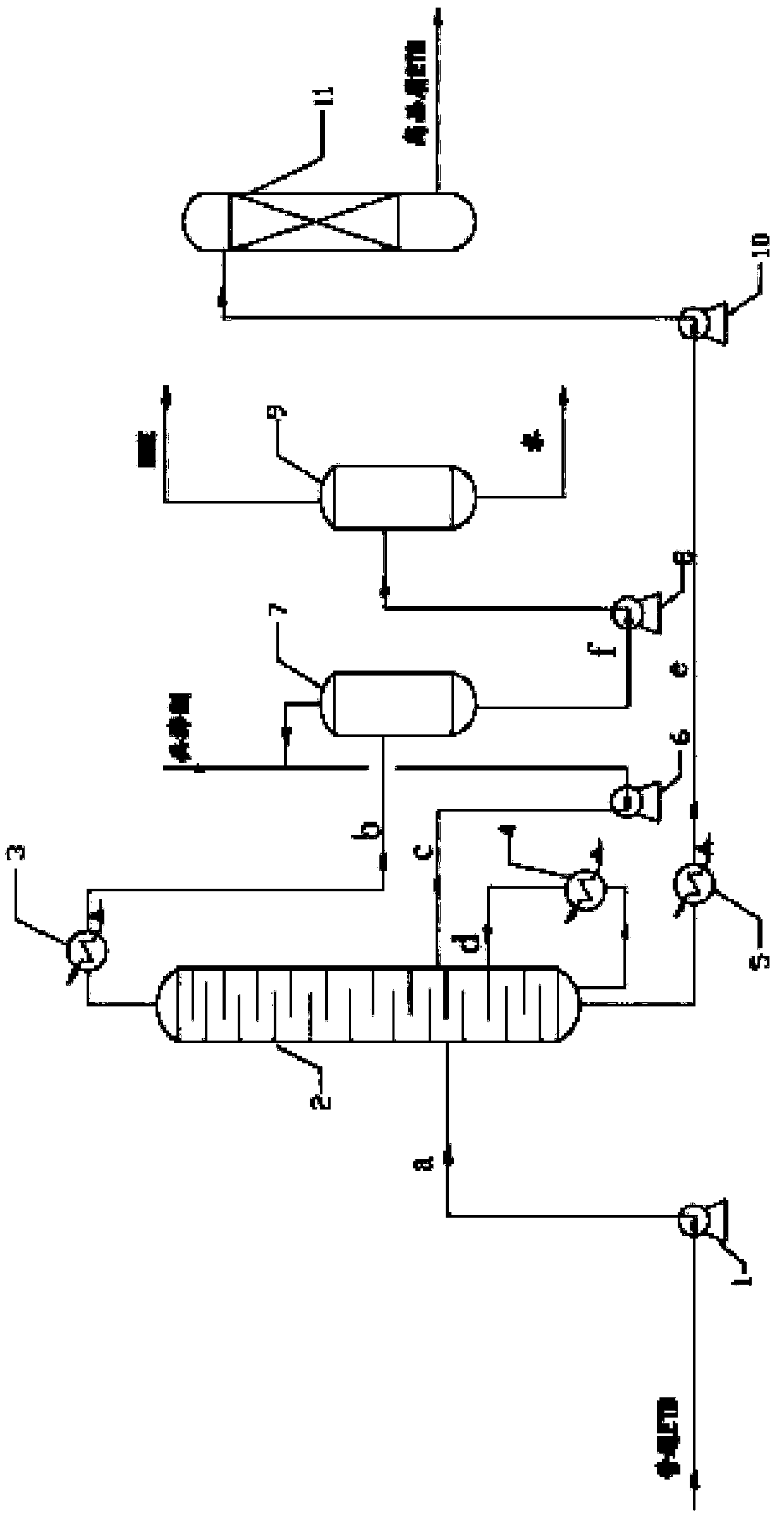

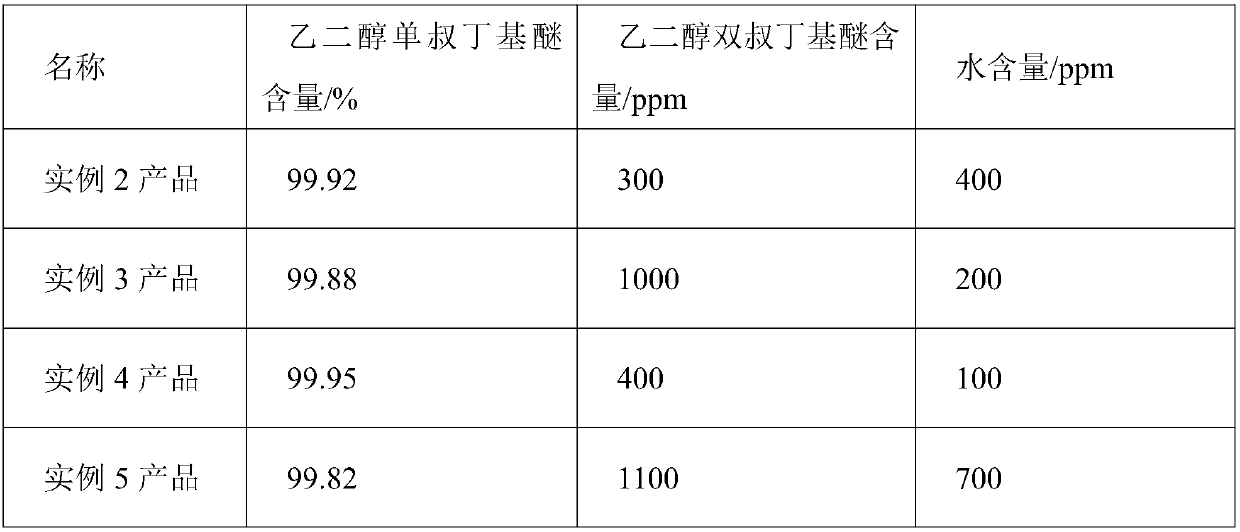

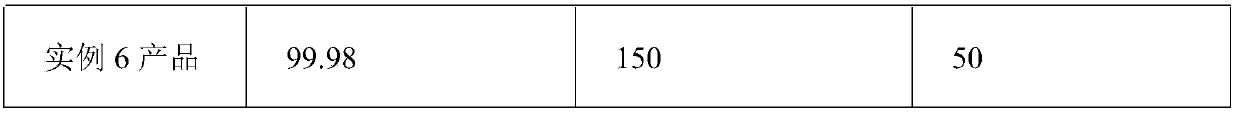

Process method for producing ethylene glycol mono-tert-butyl ether

ActiveCN107556172AIncrease contentHigh market valueEther separation/purificationChemical productsCleansing Agents

The invention discloses a process method for producing ethylene glycol mono-tert-butyl ether and belongs to the field of process production of chemical products. The production process comprises the following steps: taking common ethylene glycol mono-tert-butyl ether as a raw material, adding a certain proportion of a special entrainer, carrying out azeotropic distillation under certain conditions, and rectifying out impurities, namely ethylene glycol tert-dibutyl ether and water in the ethylene glycol mono-tert-butyl ether, so that the content of the product ethylene glycol mono-tert-butyl ether is greater than or equal to 99.9 percent, the content of the ethylene glycol tert-dibutyl ether is smaller than 500 ppm and the water content is smaller than 100 ppm; the process method can be used for the fields of pharmaceutical intermediates, high-end coatings, high-end electronic cleaning agents and the like. The process has the advantages of simplicity, low energy consumption, high purityof products, environment friendliness and the like; the entrainer is simple in separation and can be recycled; in addition, the process is an advanced production process of the ethylene glycol mono-tert-butyl ether with high quality.

Owner:CHAMBROAD CHEM IND RES INST CO LTD +1

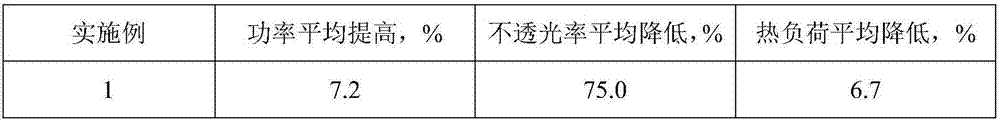

Polymethoxy dialkyl ether-type oxygen-containing diesel for plateau section

InactiveCN107446633ARelieve incomplete combustionImprove powerLiquid carbonaceous fuelsDiethyl etherOxygen

The invention discloses polymethoxy dialkyl ether-type oxygen-containing diesel for a plateau section. The polymethoxy dialkyl ether-type oxygen-containing diesel is characterized by consisting of the following components in percentage by volume: 30%-100% of polymethoxydialkyl ether and 0-70% of diesel, wherein the polymethoxydialkyl ether consists of one or more of polymethoxy dimethyl ether, polymethoxy diethyl ether, polymethoxy dipropyl ether, polymethoxy dibutyl ether, polymethoxy diamyl ether, polymethoxy dihexyl ether, polymethoxy diheptyl ether, polymethoxy dioctyl ether, polymethoxy dinonyl ether, and polymethoxy didecyl ether. According to the polymethoxy dialkyl ether-type oxygen-containing diesel for a plateau section disclosed by the invention, incomplete combustion of the diesel caused by anoxia on the plateau can be effectively relieved, the dynamic performance of a diesel engine can be improved, the emission of exhaust fumes can be greatly reduced, heat load can be reduced, the service life of the engine can be prolonged, the failure rate can be reduced, equipment maintenance costs can be reduced, social and economic benefits are high and practicality is high.

Owner:军事科学院系统工程研究院军事新能源技术研究所

Preparation of low temperature drying wafer capacitance electrode silver plasm

InactiveCN101206957AAvoid scratchesDisadvantages of preventing sheddingFixed capacitor electrodesElectrolytic capacitorsCapacitanceAdhesive

The invention relates to a preparation method of low temperature baking disc capacitance electrode silver paste, which comprises the steps that: firstly, 200 model ethyl cellulose, 40 model ethyl cellulose, polyvinyl butyral, diethylene glycol dibutyl ether acetate are mixed to prepare an adhesive; secondly, super fine silver powder, frit and bismuth oxide are mixed to prepare a powder material; thirdly, terpilenol, butyl glycol ether and cellosolve are mixed to prepare a thinning agent; fourthly, the adhesive and the power material are mixed, the fineness is adjusted through a trio mill, the thinning agent is added, and then the silver paste is prepared. The preparation process is simple, the prepared silver paste can prevent the defects that the silver layer is scratched and deciduous under the low temperature and baking conditions, ensure that the volatilization of the solvent during the low temperature and baking process is uniform, the air bubble is not existent, and the invention is suitable for the electrode solver paste under the low temperature (lower than 250 DEG C) and baking conditions.

Owner:宁波元太导电材料科技有限公司

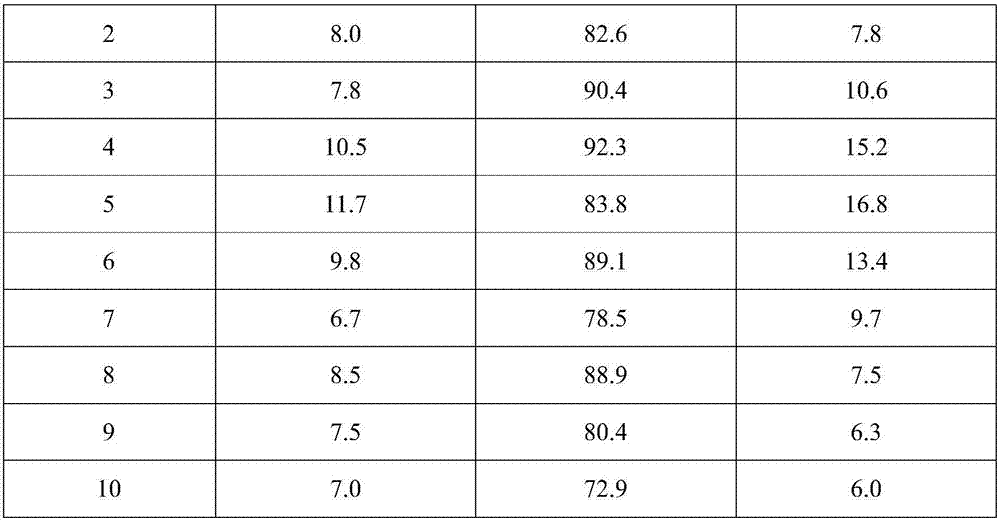

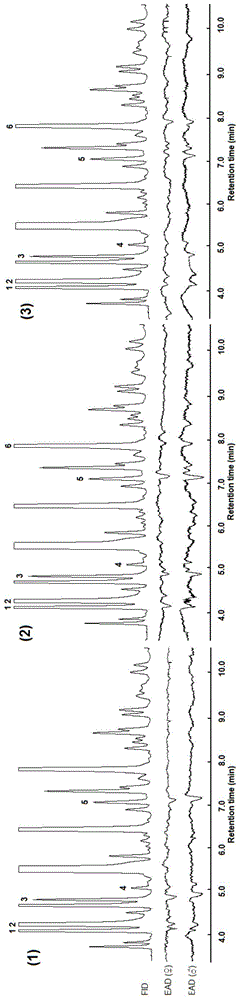

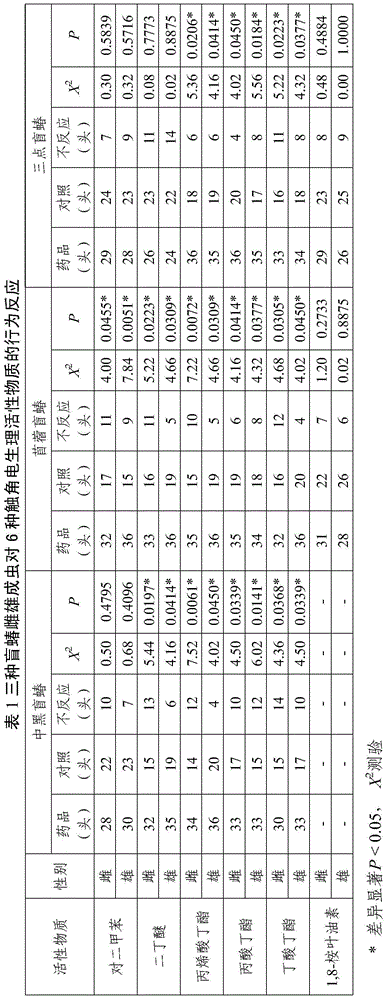

Botanical attractant of three kinds of fleahoppers as adelphocoris lineolatus

The invention relates to a botanical attractant of three kinds of fleahoppers as adelphocoris lineolatus, which is respectively paraxylene, dibutyl ether, butyl acrylate, butyl propionate and butyl butyrate, wherein the butyl acrylate, the butyl propionate or the butyl butyrate has obvious sucking actions on adult insects of the three kinds of fleahoppers, and can be used as a common botanical attractant of the three kinds of the fleahoppers as the potential adelphocoris lineolatus.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI

Method for preparing hexafluoropropylene oxide

InactiveCN104650010AThermally stableHigh selectivityOrganic chemistryHexafluoropropyleneReaction speed

The invention discloses a method for preparing hexafluoropropylene oxide through molecular oxygen liquid-phase oxidation. A reaction solvent adopted for reaction is perfluorinated dibutyl ether or perfluorinated diamyl ether, and because the reaction solvent has excellent dissolving property on hexafluoropropylene and oxygen and has good chemical stability and heat stability, the method disclosed by the invention has the characteristics of high reaction speed, high transformation rate and selectivity, environmental friendliness and the like and is suitable for industrialized production.

Owner:SHANXI FUNUOOU NEW MATERIAL TECH CO LTD

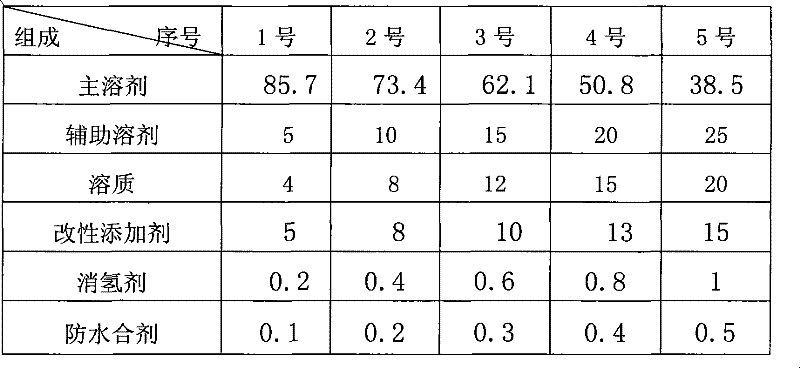

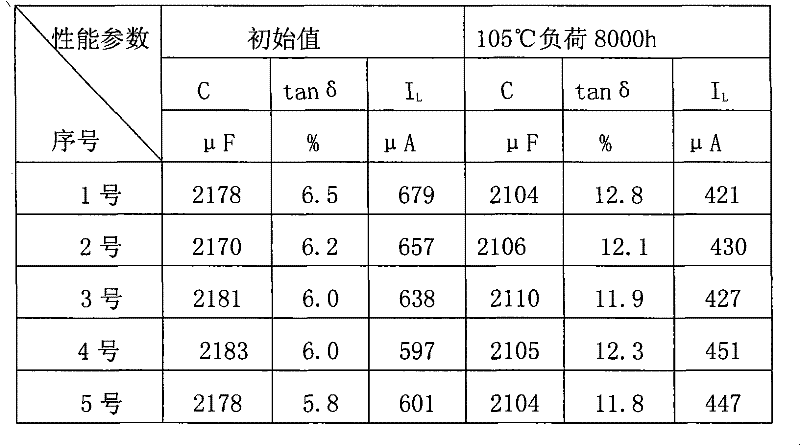

Electrolysis solution and preparation method thereof as well as preparation method for obtained aluminum capacitor

ActiveCN101556867BImprove corrosion resistanceHigh temperature stabilityLiquid electrolytic capacitorsElectrolysisPhosphate

The invention relates to electrolysis solution and a preparation method thereof as well as a preparation method for an obtained aluminum capacitor. The electrolysis solution is composed by the components according to the following weight by parts: 38.5-85.7 wt % of primary solvent, 5-25 wt % of auxiliary solvent, 4-20 wt % of solute, 5-15 wt % of modified additive, 0.2-1 wt % of hydrogen eliminating agent and 0.1-0.5 wt % of waterproof combination agent. The primary solvent is glycol; the auxiliary solvent is one or more of tributyl phosphate, mono butyl ester phosphate, diglycol dibutyl ether; the solute is one or more of ammonium sebacate, 1.6-dodecyl ammonium bisgallic acid, 1.10-dodecyl ammonium bisgallic acid organic carboxylate. In the preparation method for the aluminum capacitor using the electrolysis solution, positive pressure and vacuum-pumping is required to be applied in an impregnation tank in an alternate recycle way with the recycle impregnation interval period being 20-60min.The electrolysis solution has the characteristics of high temperature resistance, high sparking pressure and strong corrosion resistance. The screw large capacitor has a service life of 8,000 hours at 105 DEG C or 2,000 hours at 125 DEG C.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Hogwash oil micro-emulsion type cutting fluid and preparation method thereof

The invention relates to a hogwash oil micro-emulsion type cutting fluid, which is prepared from the following raw materials by weight: 2-3 parts of diethanolamine, 6-8 parts of polyvinyl alcohol, 1-2 parts of sodium hydrogen carbonate, 1-2 parts of lauryl alcohol polyoxyethylene ether sodium sulfate, 1-2 parts of sodium hydroxide, 20-23 parts of hogwash oil, 4-5 parts of diethylene glycol dibutyl ether, 12-14 parts of tetrabutyl titanate, 6-8 parts of an auxiliary agent, and 200 parts of water. According to the hogwash oil micro-emulsion type cutting fluid, the tetrabutyl titanate is adopted, such that the viscosity is stable, and no precipitation is generated; the hogwash oil is adopted, such that characteristics of good lubricity and environmental protection are provided; and the hogwash oil micro-emulsion type cutting fluid is the water base cutting fluid, and further has characteristics of rapid cooling, good cleaning performance and good economic benefits.

Owner:王亚军

Method for preparing mycophenolate mofetil

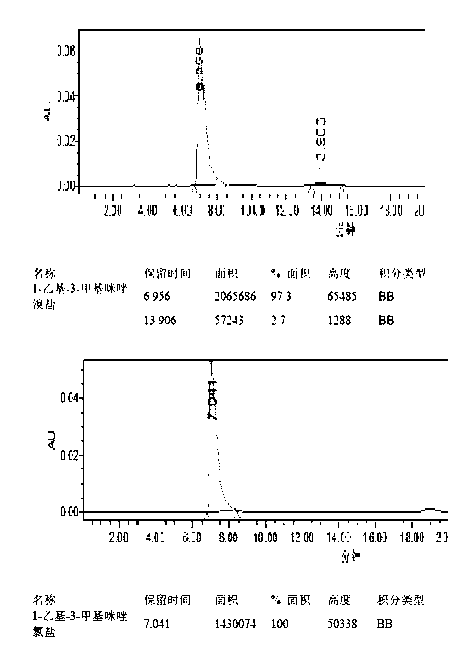

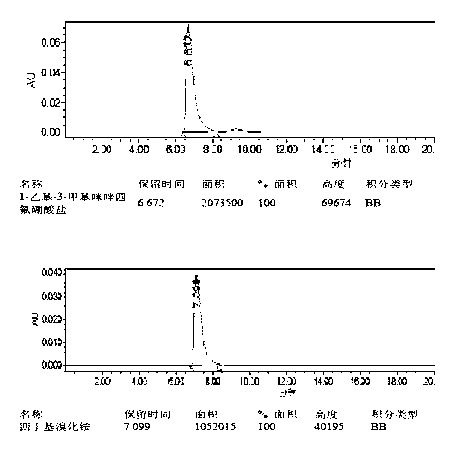

The invention discloses a method for preparing mycophenolate mofetil, which comprises the following steps of: using dibutyl ether as a solvent, performing complete reaction between MPA and 2-hydroxyethyl morpholine under inert gas protection and constant boiling water conditions so as to obtain a crude product of the mycophenolate mofetil; and using an ionic liquid as a chelating agent to decolor and purify, seeding the mycophenolate mofetil, and crystallizing a mixed solvent to obtain high-purity mycophenolate mofetil. The method has the advantages of short reaction time, high MPM purity, high reaction yield, low generation cost and the like, and has a wide industrial application prospect, and the problem of the color of a final product is solved.

Owner:CHONGQING UNIV OF TECH

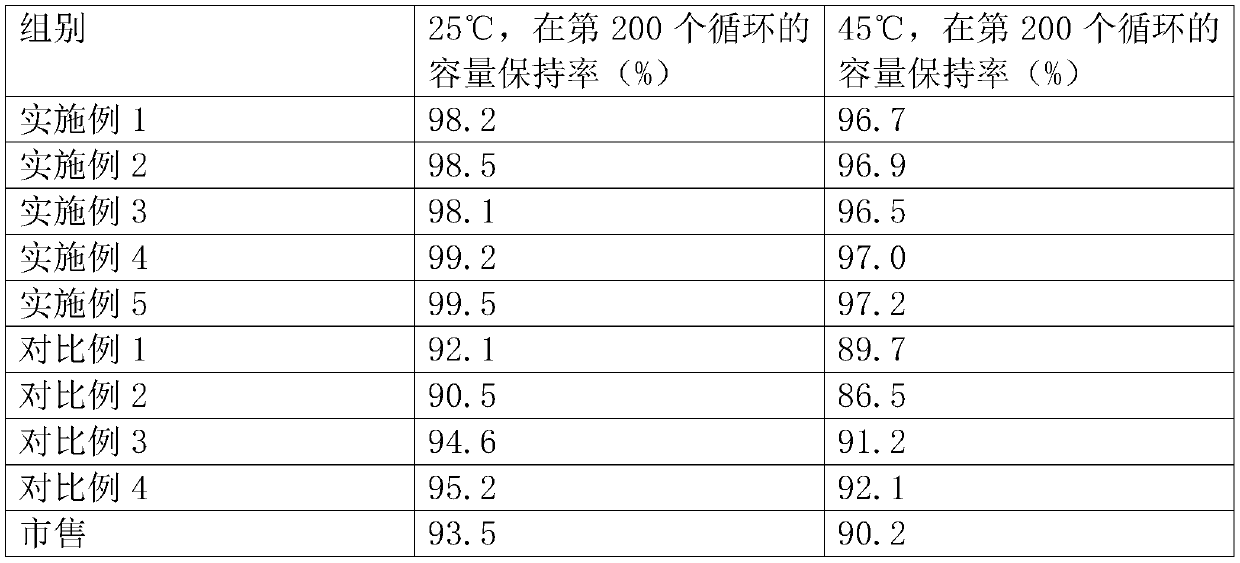

Lithium battery electrolyte as well as preparation method and application thereof

PendingCN111600072ALow costReduced thermal stabilitySecondary cells servicing/maintenanceOrganic electrolytesElectrolytic agentOrganosolv

The invention provides a lithium battery electrolyte, which is characterized by comprising a lithium salt, ethylene glycol dibutyl ether, a fluorine-containing organic solvent, a high and low temperature resistant additive and imidazolyl ionic liquid. The lithium battery electrolyte prepared by the invention can form a relatively stable passivation film, and the layer of passivation film is inhibited along with the prolonging of the storage time, so that the storage performance of the lithium battery is remarkably improved, and the storage life of the lithium battery is remarkably prolonged. Meanwhile, the electrolyte has a relatively low freezing point and high-temperature incombustibility, the electrolyte is endowed with very strong flame resistance at the same time, the quick charging performance of the battery can also be enhanced, and the electrolyte can be widely applied to quick-charging lithium batteries.

Owner:犀望新能源科技(昆山)有限公司

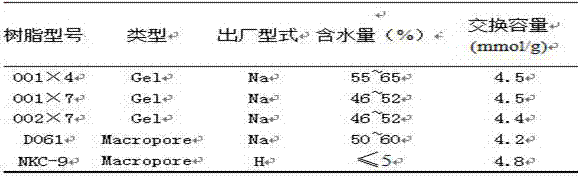

Dihydroxy dibutyl ether synthesized through catalysis with dry hydrogen resin and preparation method of dihydroxy dibutyl ether

ActiveCN107266293AOvercoming the need for regenerationOvercoming activityOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound dehydrationHydrogenButanediol

The invention discloses a novel preparation method for synthesizing dihydroxy dibutyl ether through catalysis of 1,3 butanediol with dry hydrogen resin. The dry hydrogen resin is selected from H type cation exchange resin with the water content lower than or equal to 5%, the resin can be used without regeneration, is simple to treat, has higher catalytic efficiency as compared with wet gel resin in the prior art, has high reuse rate, avoids corrosion caused by sulfuric acid to equipment and is an efficient and environment-friendly catalyst. The process synthesis route is simple, has the mild condition and is an environment-friendly synthesis route prone to industrialization.

Owner:河北凯盛医药科技有限公司

Rust inhibiting coating for steel and preparation method of rust inhibiting coating

InactiveCN106010025AThe appearance of the coating film is smooth and brightWidely producedAnti-corrosive paintsCyclohexanonePhosphoric acid

The invention discloses a rust inhibiting coating for steel and a preparation method of the rust inhibiting coating. An acrylate emulsion, tannic acid, a phosphorizing liquid, iron oxide red, water, sodium nitrite, aluminum stearate, barium chromate, aluminum triphosphate, butanol, cyclohexanone-oxime, ethylene glycol dibutyl ether, diethanolamine and chlorinated paraffin are weighed, stirred and ground. The coating is flat, bright and light red in appearance, the surface dry time is 30-50 min, and the hard dry time is 1-5 h; the flexibility is 120-140 mm, and the adhesion reaches level 1-2; for the water resistance, the coating does not blister or fall off after soaked in water at 25-35 DEG C for 6-10 d, the impact strength is 550-750 N / cm, and the pencil hardness reaches H.

Owner:WUXI EPIC TECH

Elastic puncture-proof sole material

The invention discloses an elastic puncture-proof sole material, which is made from the following raw materials by weight: 40-45 parts of fluorinated silicone rubber, 80-88 parts of butadiene rubber, 12-20 parts of diethylene glycol, 12-20 parts of dimethylformamide, 5-8 parts of dibutyl ether, 12-16 parts of carbon black, 8-10 parts of a calcium zinc salt, and 10-18 parts of petroleum wax. A sole made from the sole material disclosed in the invention has good elasticity and puncture-proofness, so the sole material is suitable for industrialized production.

Owner:WUJIANG XINXU PLASTIC SHOES COMPLETE

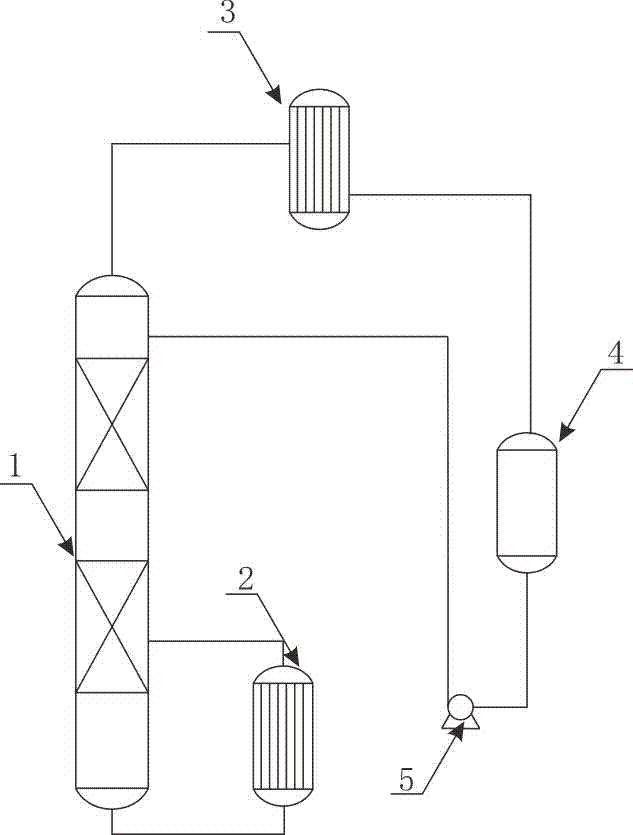

Anti-blocking device of system for rectifying poly-methoxy dibutyl ether and method for refining same

ActiveCN106966875ASolve the blockageReduce energy consumptionOrganic chemistryOrganic compound preparationReboilerEngineering

The invention discloses an anti-blocking device of a system for rectifying poly-methoxy dibutyl ether and a method for refining the same. The system comprises a rectifying tower, a reboiler, a condensation cooler, a reflux tank and a reflux pump which are sequentially communicated with one another. The reflux pump is communicated with the rectifying tower. The method includes (1), delivering to-be-separated mixtures into the rectifying tower from the middle of the rectifying tower, separating the to-be-separated mixtures under the conditions of the pressures ranging from -0.01 MPa to 1.0 MPa, the tower top temperatures ranging from 90 DEG C to 160 DEG C and the tower bottom temperatures ranging from 120 DEG C to 180 DEG C, extracting poly-methoxy dibutyl ether solution from a tower bottom and extracting mixture steam from a tower top; (2), allowing the mixture steam to flow into the condensation cooler from a material steam inlet, cooling the mixture steam at the temperatures ranging from 80 DEG C to 120 DEG C to obtain condensed liquid, then allowing the condensed liquid to flow into the reflux tank from a material liquid outlet, allowing a part of the condensed liquid to flow back into the rectifying tower to continue to be rectified and extracting portions which do not flow back to the rectifying tower from the system. The anti-blocking device and the method have the advantages that the problem of easiness in blocking equipment can be effectively solved, and the separation purity of the poly-methoxy dibutyl ether can be enhanced.

Owner:SICHUAN DAXING ENERGY +2

Multi-effect coating and preparation method therefor

ActiveCN104987794AImprove securityImprove comfortFireproof paintsPolyurea/polyurethane coatingsMelamineMulti effect

The invention provides a multi-effect coating and a preparation method therefor, and is characterized in that: the multi-effect coating comprises crosslinkable polyacrylate, polyurethane, melamine, red phosphorus, ammonium dihydrogen phosphate, propanetriol, ethylene glycol, ethylene glycol dibutyl ether, Na2O.nSiO2, TiO2 and water; 100 parts by weight of the crosslinkable polyacrylate correspond to 3-5 parts of polyurethane, 10-15 parts of melamine, 5-10 parts of red phosphorus, 5-15 parts of ammonium dihydrogen phosphate, 5-12 parts of propanetriol, 3-5 parts of ethylene glycol, 5-10 parts of ethylene glycol dibutyl ether, 5-10 parts of Na2O.nSiO2, 10-20 parts of TiO2 and 150-180 parts of water; the raw materials are added according to the ratio into deionized water with a proper temperature; and after thorough agitating, and a coating product of the invention is obtained. The multi-effect coating provided by the invention has sufficient frame-retardancy and sufficient flexibility and uniformity to ensure the overall performance such as safety, comfort and aesthetics of the coating surface.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

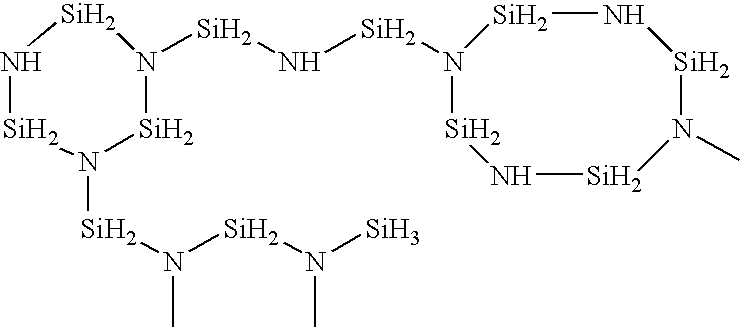

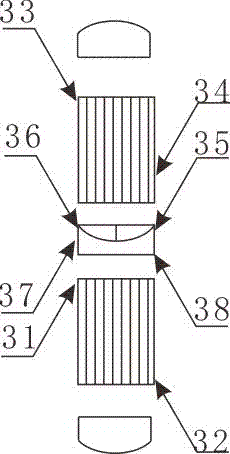

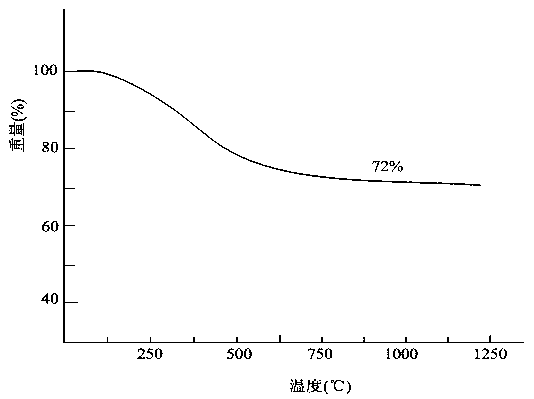

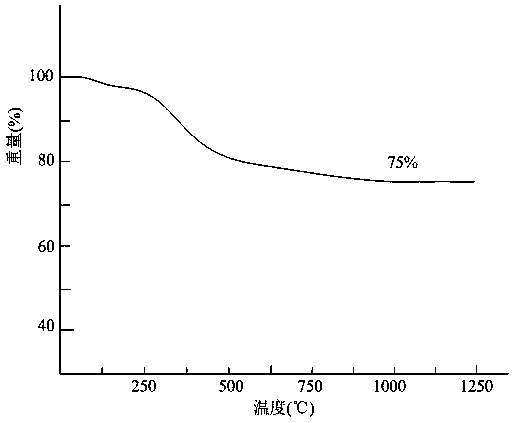

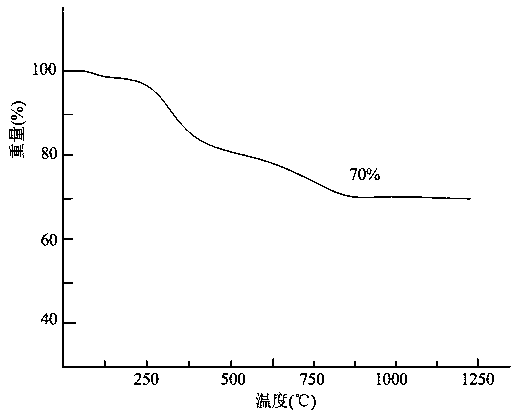

Preparation method of modified polymethylsilane

The invention discloses a preparation method of modified polymethylsilane. The invention relates to the technical field of modification of polymethylsilane. According to the preparation method, dibutyl ether is used as a solvent, various chlorosilanes and metal sodium are subjected to sodium condensation reaction firstly, then allyl magnesium chloride alkylation is used for end capping, and thereby a product with uniform molecular weight distribution and stable properties is obtained. The modified polymethylsilane has the advantages of being liquid at normal temperature, low in viscosity and high in ceramic yield.

Owner:内蒙古三友化学有限公司

Antistatic ceramic material and preparation method thereof

InactiveCN106747427AImprove performanceImprove anti-static performanceChemical compositionCopper oxide

The invention discloses an antistatic ceramic material which comprises the following substances in parts by weight: 40-60 parts of zirconium oxide, 2-5 parts of alumina, 3-6 parts of copper oxide, 2-6 parts of quartz sand, 10-25 parts of polypropylene, 4-8 parts of polyethyleneimine, 1-4 parts of 5-carboxyl pyrrolidone, 12-15 parts of dibutyl ether, 4-7 parts of probenazole and 10-20 parts of diethyl phthalate. By adding the multiple chemical components in the ceramic technical process, the prepared ceramic material has the advantages of high wear resistance, high bending strength and favorable antistatic property. The preparation technique has the advantages of simple steps and energy saving.

Owner:苏州耐思特塑胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com