Compound solvent for extracting asphalt from oil sand and extracting process

A composite solvent and oil sand technology, applied in the chemical industry, can solve the problems of poor oil sand extraction effect, increased economic loss, low recovery rate, etc., and achieve the effect of reducing operating cost input, reducing waste, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

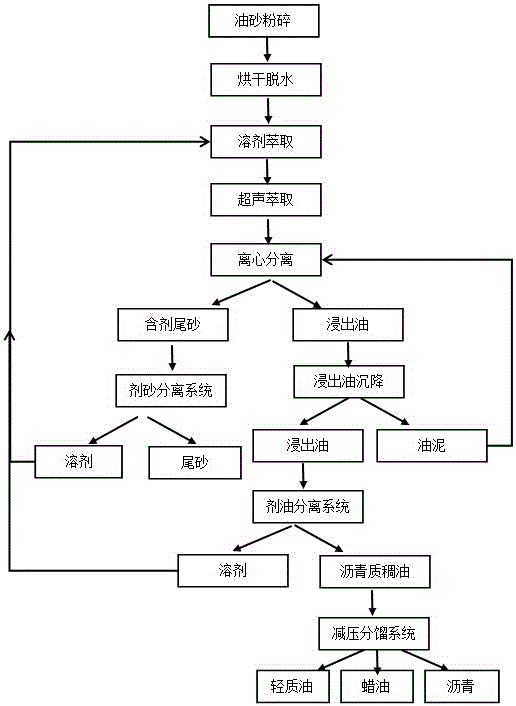

Image

Examples

Embodiment 1

[0036] Embodiment one, a kind of asphalt process method with composite solvent extraction, process method is as follows:

[0037] Step 1: Oil sand crushing, using a crusher to crush the oil sand to less than 3cm;

[0038] Step 2: Drying and dehydration, using a drying kiln to reduce the moisture content of the oil sand in step 1 to below 5%;

[0039] Step 3: Solvent extraction, sending the compound solvent and the oil sand obtained in step 2 into the stirring extraction kettle, the ratio of the compound solvent to the oil sand is 1.5:1, and the extraction time is 3 hours;

[0040] The percentage by weight that each material accounts for in the composite solvent is as follows:

[0041] 200# solvent oil 55% butyl acetate 20% petroleum ether (distillation range 90-120 degrees) 15%

[0042] Xylene 5% Dibutyl ether 5%

[0043] Step 4: Ultrasonic extraction, the oil sand obtained in Step 3 is sent to an ultrasonic extraction machine, and the extraction rate of asphaltene heavy oi...

Embodiment 2

[0050] Embodiment two, a kind of asphalt process method with this composite solvent extraction, process method is as follows:

[0051] Step 1: Oil sand crushing, using a crusher to crush the oil sand to less than 3cm;

[0052] Step 2: Drying and dehydration, using a drying kiln to reduce the moisture content of the oil sand in step 1 to below 5%;

[0053] Step 3: Solvent extraction, sending the composite solvent and the oil sand obtained in step 2 into the stirring extraction kettle, the ratio of composite solvent to oil sand is 2:1, and the extraction time is 2 hours;

[0054] The percentage by weight that each material accounts for in the composite solvent is as follows:

[0055] 200# solvent oil 60%

[0056] Butyl acetate 20%

[0057] Petroleum ether (distillation range 90-120 degrees) 13%

[0058] Xylene 3%

[0059] Dibutyl ether 4%

[0060] Step 4: Ultrasonic extraction, the oil sand obtained in Step 3 is sent to an ultrasonic extraction machine, and the extraction ...

Embodiment 3

[0067] Embodiment three, a kind of asphalt process method with this composite solvent extraction, process method is as follows:

[0068] Step 1: Oil sand crushing, using a crusher to crush the oil sand to less than 3cm;

[0069] Step 2: Drying and dehydration, using a drying kiln to reduce the moisture content of the oil sand in step 1 to below 5%;

[0070] Step 3: Solvent extraction, sending the composite solvent and the oil sand obtained in step 2 into the stirring extraction kettle, the ratio of composite solvent to oil sand is 3:1, and the extraction time is 2 hours;

[0071] The percentage by weight that each material accounts for in the composite solvent is as follows:

[0072] 200# solvent oil 65%

[0073] Butyl acetate 22%

[0074] Petroleum ether (distillation range 90-120 degrees) 5%

[0075] Xylene 5%

[0076] Dibutyl ether 3%

[0077] Step 4: Ultrasonic extraction, the oil sand obtained in Step 3 is sent to an ultrasonic extraction machine, and the extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com