Technological process for producing high concentration nitric-phosphate fertilizer

A technology of nitrophosphate fertilizer and process method, which is applied in the field of producing high-concentration nitrophosphate fertilizer, can solve problems such as the inability to meet the quality standards of nitrophosphate fertilizer products, and achieve the effects of improving particle size and distribution, high filtration intensity and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The quality indicator of the phosphate rock 1 of the present embodiment: P 2 o 5 27%, CaO 42%, AI 18%, MgO 2%, Fe 2 (Al 2 O) 3 A total of 3%, other impurities; the concentration of nitric acid 2 was 58%.

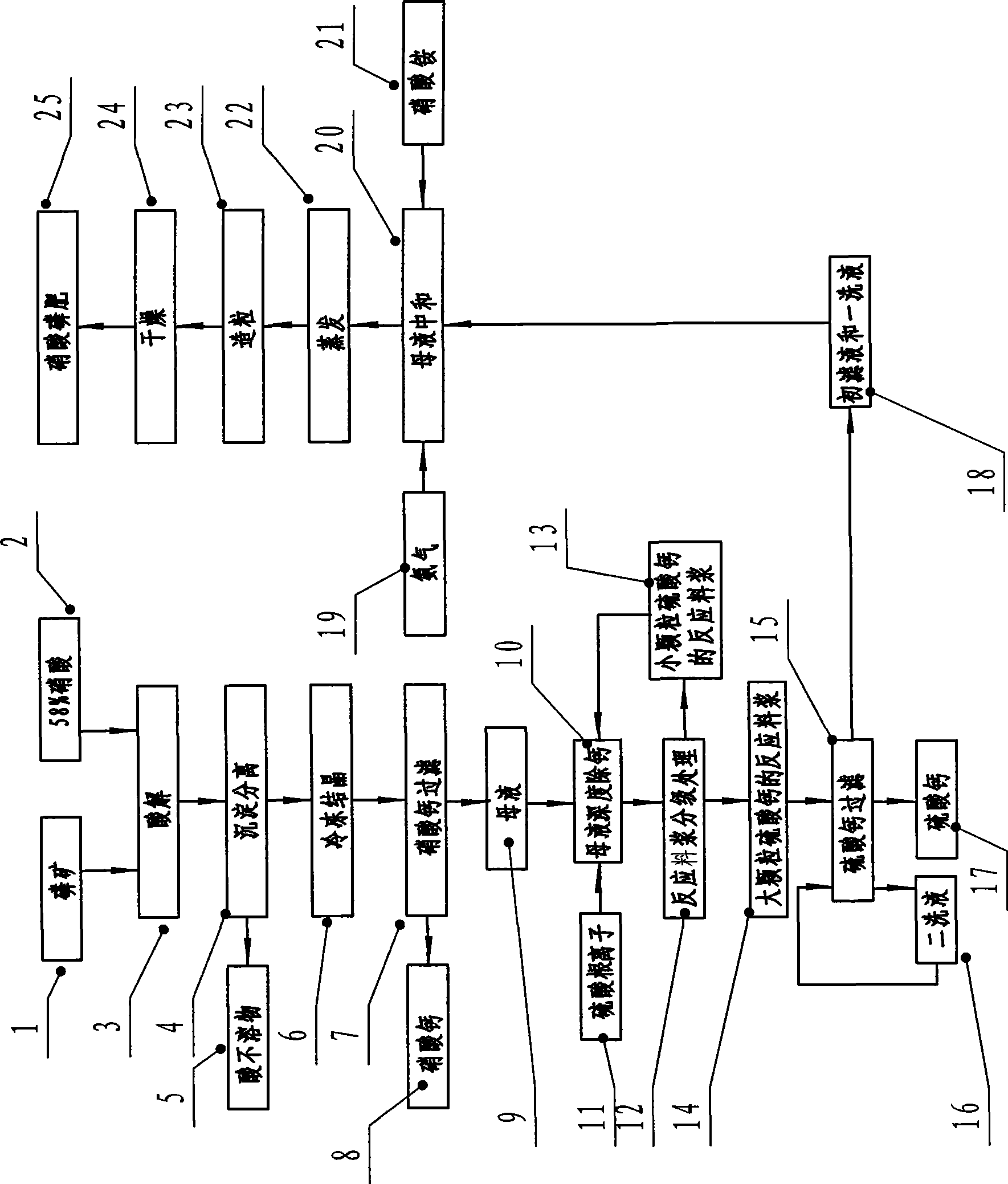

[0046] This embodiment is on the basis of the technological process of known frozen nitrophosphate fertilizer production, and between calcium nitrate filtration and mother liquor neutralization, 10 steps of mother liquor depth decalcification are added, and its technological flow is shown in figure 1 ,

[0047] Nitric acid 2 and phosphate rock 1 are added to the acid hydrolysis tank 3 according to the stoichiometric ratio of 1.1:1 for acid hydrolysis, the acid insoluble matter 5 in the acid hydrolysis solution is separated by precipitation separation 4, and then the acid insoluble matter 5 is separated The solution is sent to the frozen crystallization 6, and the calcium nitrate 8 is precipitated from the acid solution through the frozen crystallization and filt...

Embodiment 2

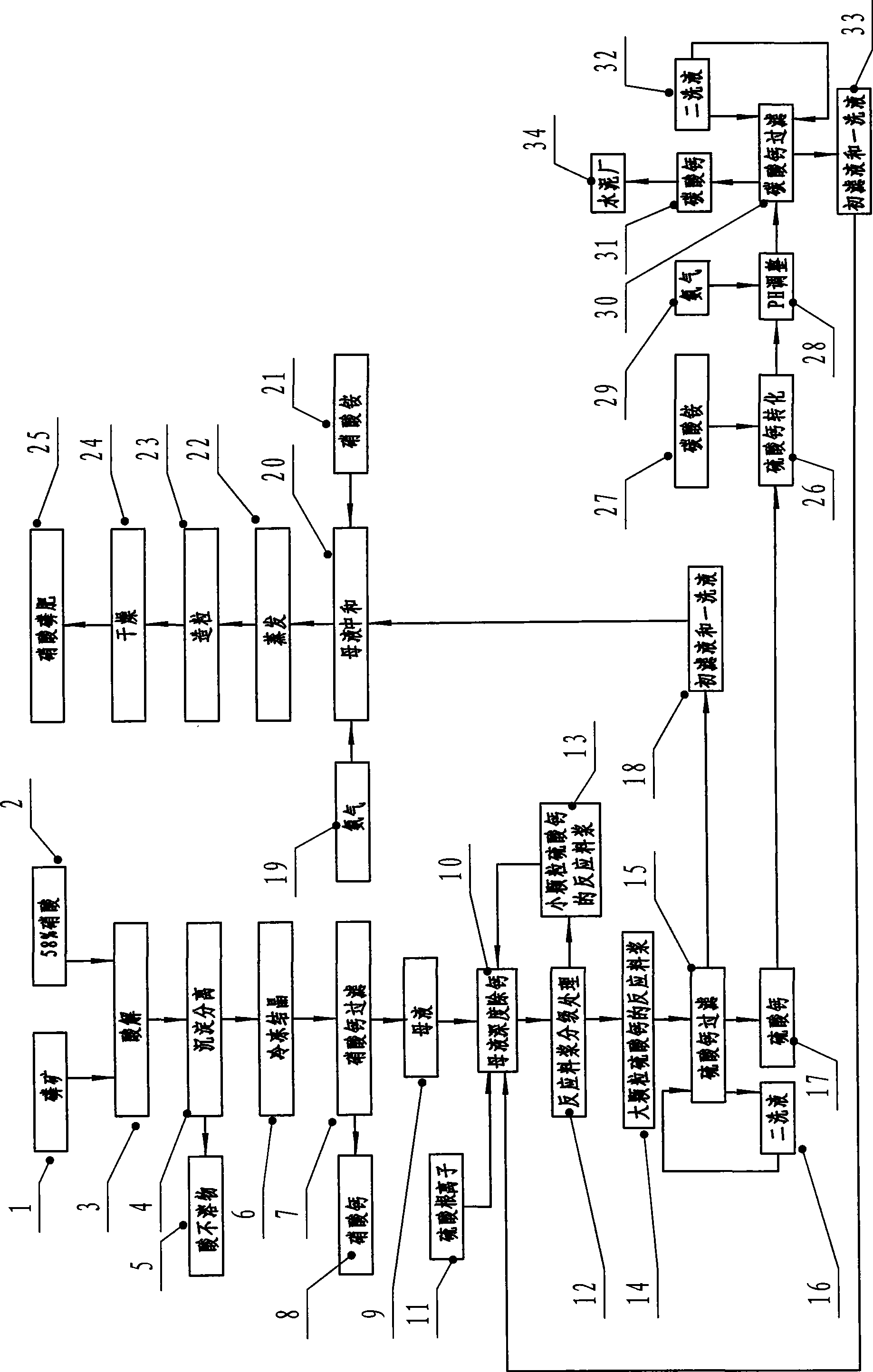

[0050] In this embodiment, in the process of producing high-concentration nitrophosphate fertilizer according to Embodiment 1, a calcium sulfate conversion process is added, and its technological process is shown in figure 2 . Here, the conversion process of calcium sulfate 17 is mainly described, which mainly includes calcium sulfate conversion 26 , pH adjustment 28 and calcium carbonate filtration 30 . The calcium sulfate 17 of embodiment one is sent to the calcium sulfate conversion equipment to carry out calcium sulfate conversion 26, add the solution that contains ammonium carbonate 27, the concentration of this solution is 60%, the calcium sulfate in the reaction slurry is converted into calcium carbonate crystallization , the process reaction conditions are reaction temperature 70° C., stirring for 2 hours, and the reaction is shown in equation (2).

[0051] Through ammonia gas 29 in the calcium sulfate transformation process, carry out pH adjustment 28, the pH of con...

Embodiment 3

[0054] The quality index of the phosphate rock 1 of the present embodiment is different from that of embodiment one, and the quality index is: P 2 o 5 22%, CaO 45%, AI 18.7%, MgO 2.0%, Fe 2 (Al 2 O) 3 Total 3.2%, other impurities; nitric acid concentration 58%. The difference between the present embodiment and embodiment one is that when the reaction slurry classification treatment 12, by mass percentage, the reaction slurry 14 with large particles of calcium sulfate accounts for 30% of the total slurry ratio and enters the filter for sulfuric acid Calcium filter 15 and wash. The reaction slurry 13 with small particles of calcium sulfate accounts for 70% of the total slurry ratio and returns to the mother liquor depth decalcification 10 process to provide crystal seeds for calcium sulfate crystals and further grow and grow into the next classification cycle. Other process is identical with embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com