Patents

Literature

1683 results about "Phosphorite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphorite, phosphate rock or rock phosphate is a non-detrital sedimentary rock which contains high amounts of phosphate minerals. The phosphate content of phosphorite (or grade of phosphate rock) varies greatly, from 4% to 20% phosphorus pentoxide (P₂O₅). Marketed phosphate rock is enriched ("beneficiated") to at least 28%, often more than 30% P₂O₅. This occurs through washing, screening, de-liming, magnetic separation or flotation. By comparison, the average phosphorus content of sedimentary rocks is less than 0.2%. The phosphate is present as fluorapatite Ca₅(PO₄)₃F typically in cryptocrystalline masses (grain sizes < 1 μm) referred to as collophane-sedimentary apatite deposits of uncertain origin. It is also present as hydroxyapatite Ca₅(PO₄)₃OH or Ca₁₀(PO₄)₆(OH)₂, which is often dissolved from vertebrate bones and teeth, whereas fluorapatite can originate from hydrothermal veins. Other sources also include chemically dissolved phosphate minerals from igneous and metamorphic rocks. Phosphorite deposits often occur in extensive layers, which cumulatively cover tens of thousands of square kilometres of the Earth's crust.

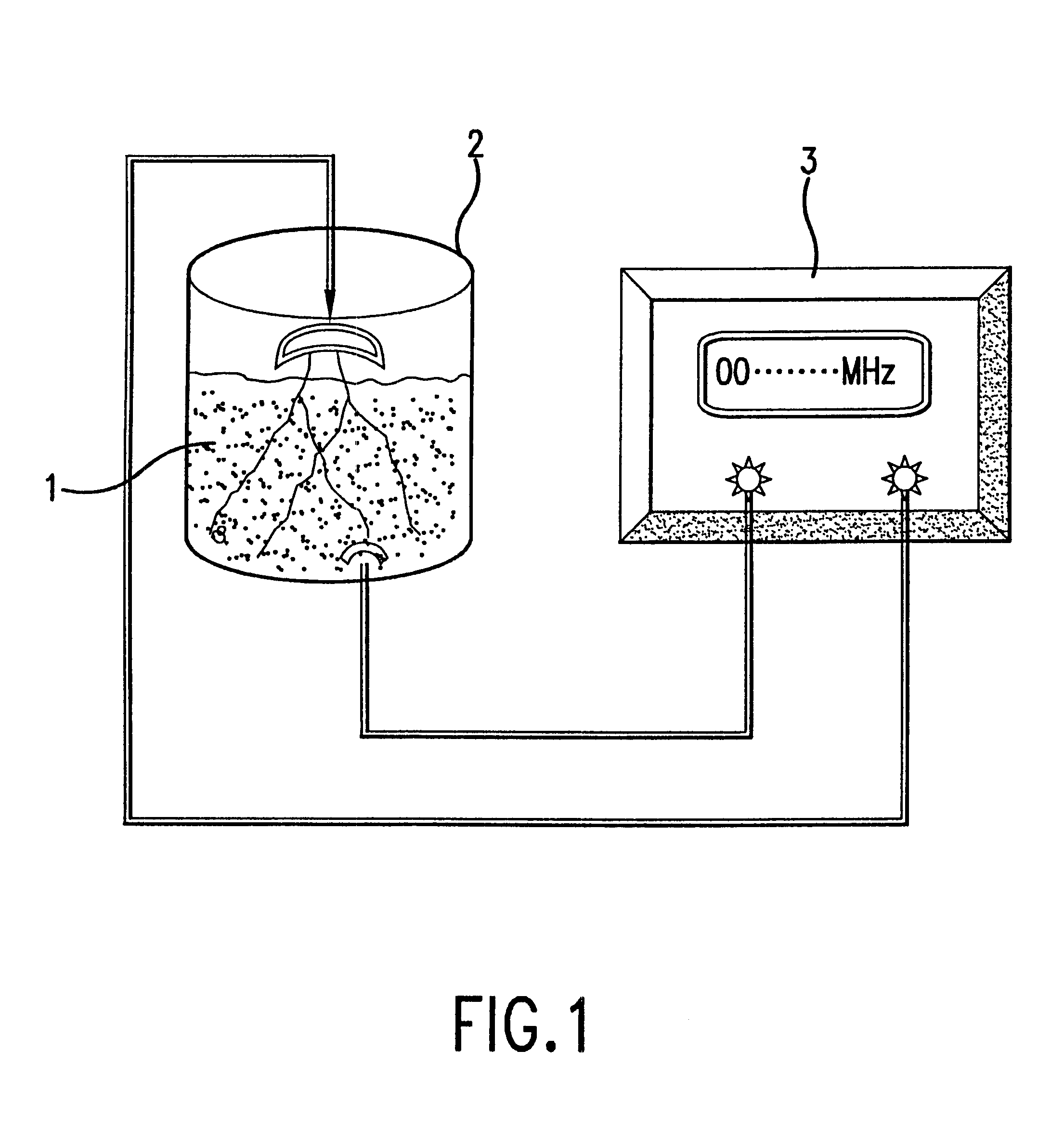

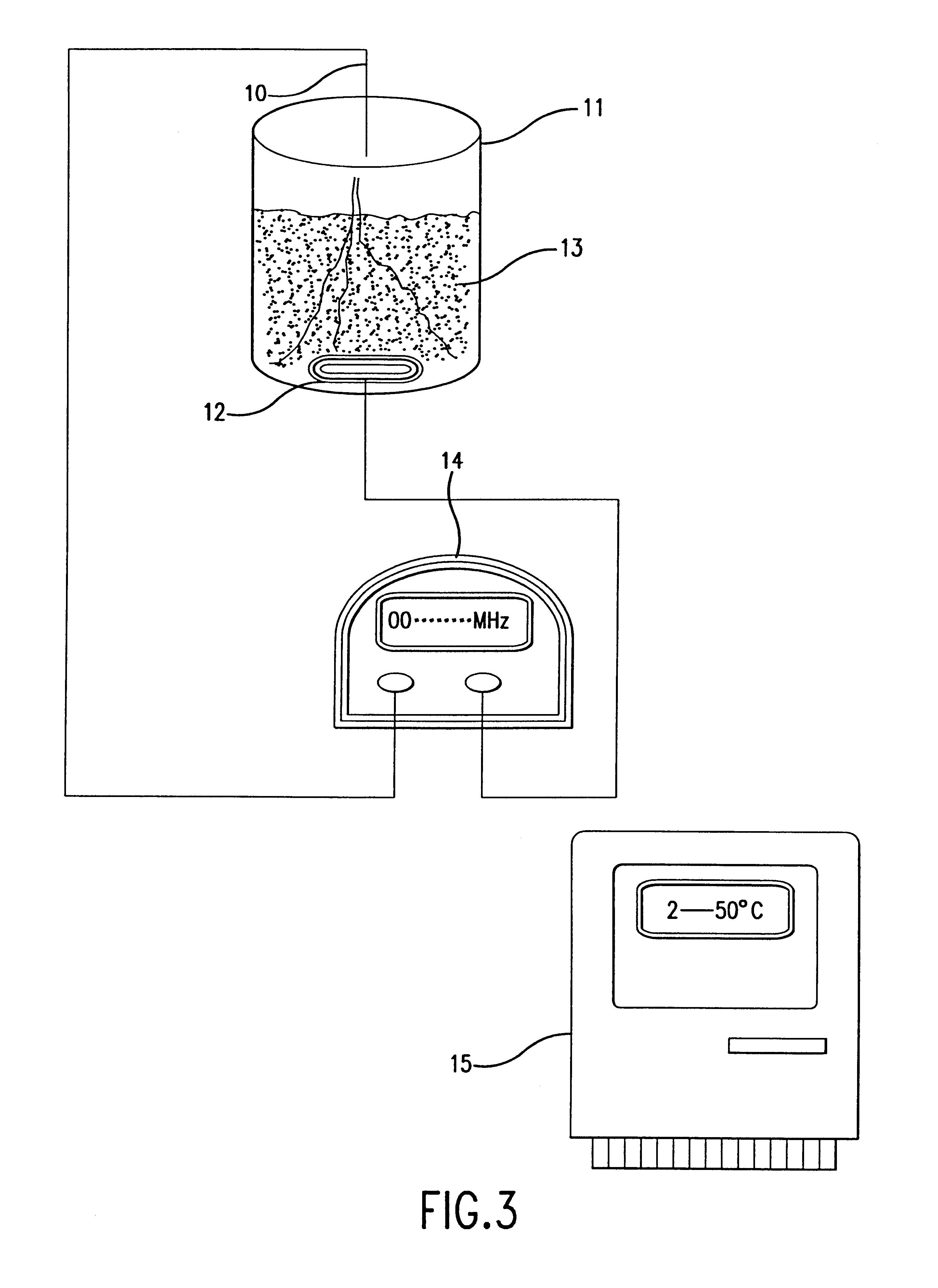

Biological fertilizer based on yeasts

The present invention provides biological fertilizer compositions that comprise yeast cells that have an enhanced ability to fix atmospheric nitrogen, decompose phosphorus minerals and compounds, decompose potassium minerals and compounds, decompose complex carbon compounds, over produce growth factors, and over produce ATP. The biological fertilizer composition of the invention can replace mineral fertilizers in supplying nitrogen, phosphorus, and potassium to crop plants. Methods of manufacturing the biological fertilizer compositions and methods of uses are also encompassed.

Owner:ULTRA BIOTECH

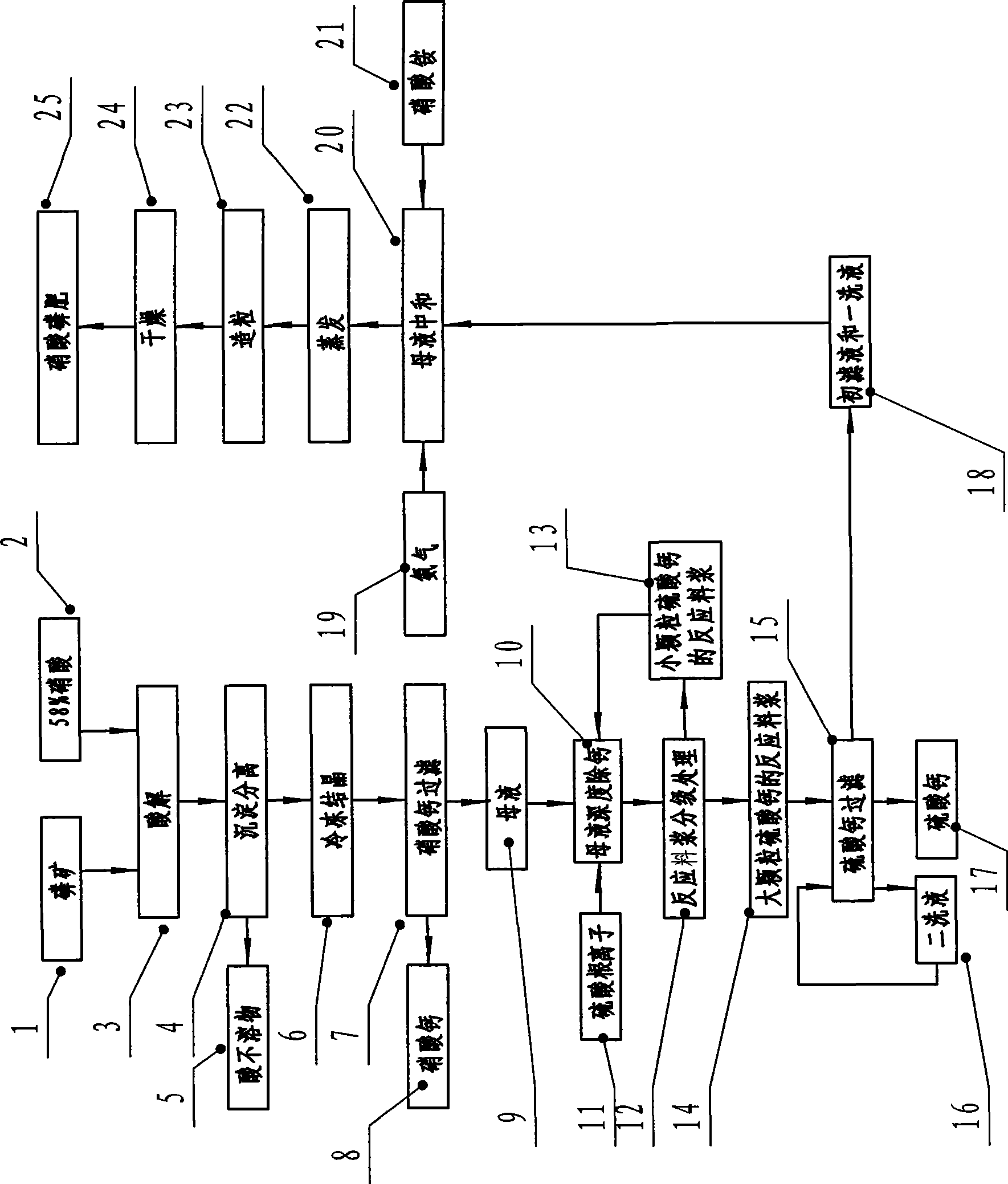

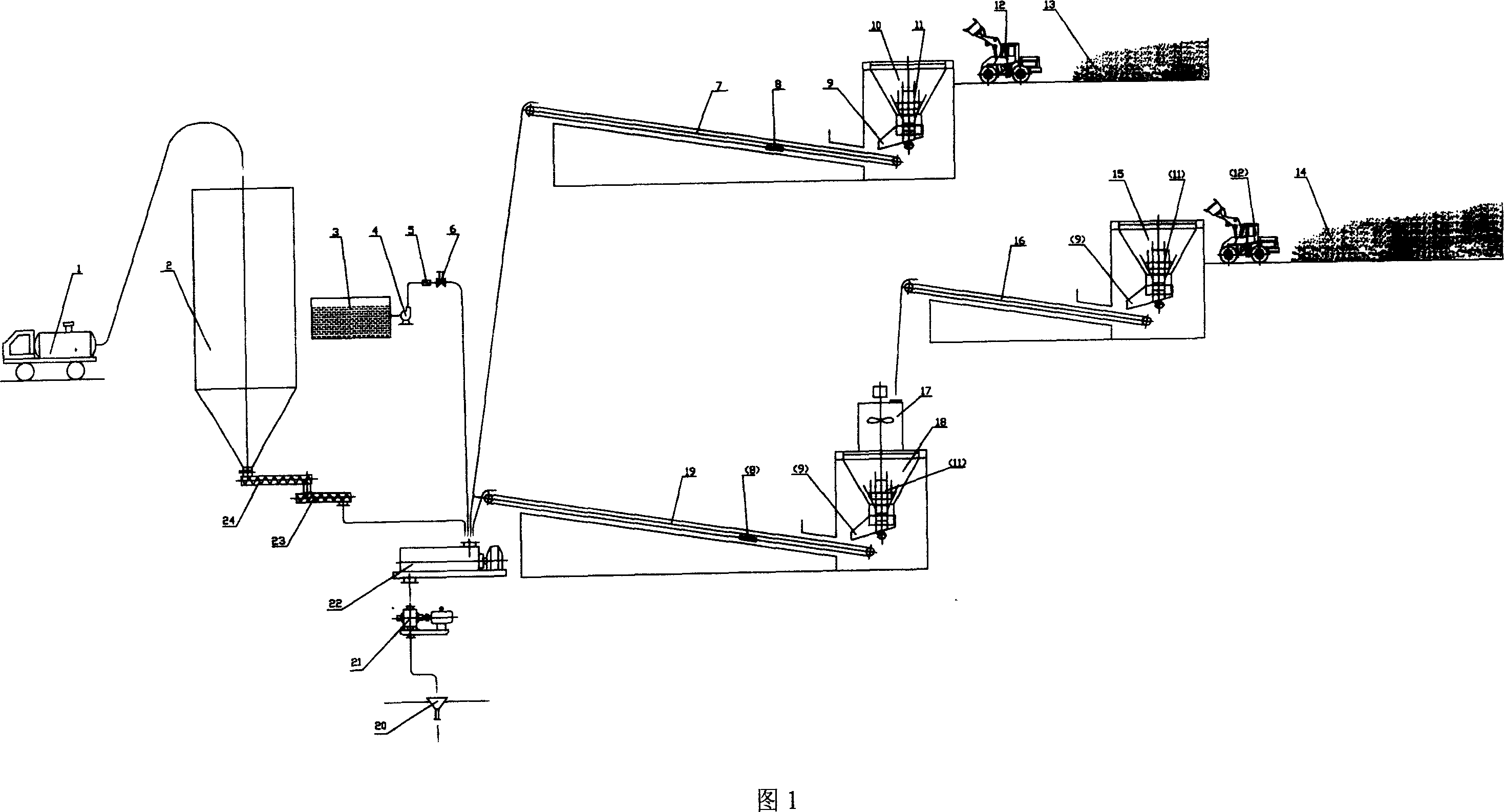

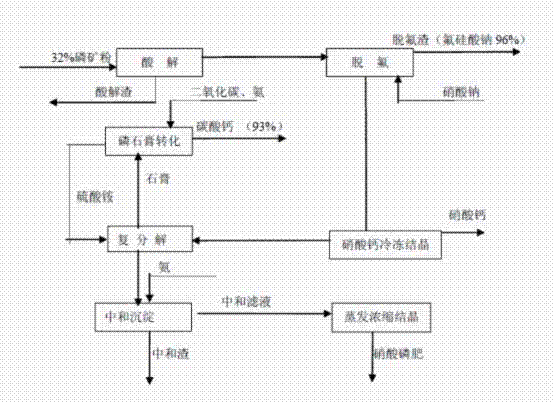

Technological process for producing high concentration nitric-phosphate fertilizer

The invention discloses a technique method for producing high-concentration nitric phosphate, which comprises the following steps of: adding nitric acid into phosphorus ore for acidolysis, depositing and separating acid non-soluble substance, freezing and crystallizing calcium nitrate, filtering the calcium nitrate, neutralizing the mother liquid, vaporization, pelleting and drying. The invention is characterized in that: a step of thoroughly removing the calcium of the mother liquid is arranged between the steps of filtering the calcium nitrate, and neutralizing the mother liquid. The steps comprise the following steps of: I) thoroughly removing the calcium of the mother liquid and adding sulfuric acid or ammonium sulfate; the calcium ions and the sulfate ions in the mother liquid generate dihydrate calcium sulfate crystal; II) the grading processing of reaction slurry: employing a grading device to carry out grading processing to the reaction slurry; returning the reaction slurry provided with small grain calcium sulfate to the mother liquid for thoroughly removing the calcium, and feeding the reaction slurry provided with large grain calcium sulfate to the calcium sulfate for filtering; and III) filtering and washing the filtering reaction slurry of calcium sulfate by a filter, feeding the primary filtrate and the primary lavage fluid into the working procedure of neutralizing, and returning the secondary lavage fluid to the filter. The invention has the advantage of using middle-low quality phosphorite to prepare the high-concentration nitric phosphate.

Owner:TIANJI COAL CHEM IND GROUP +1

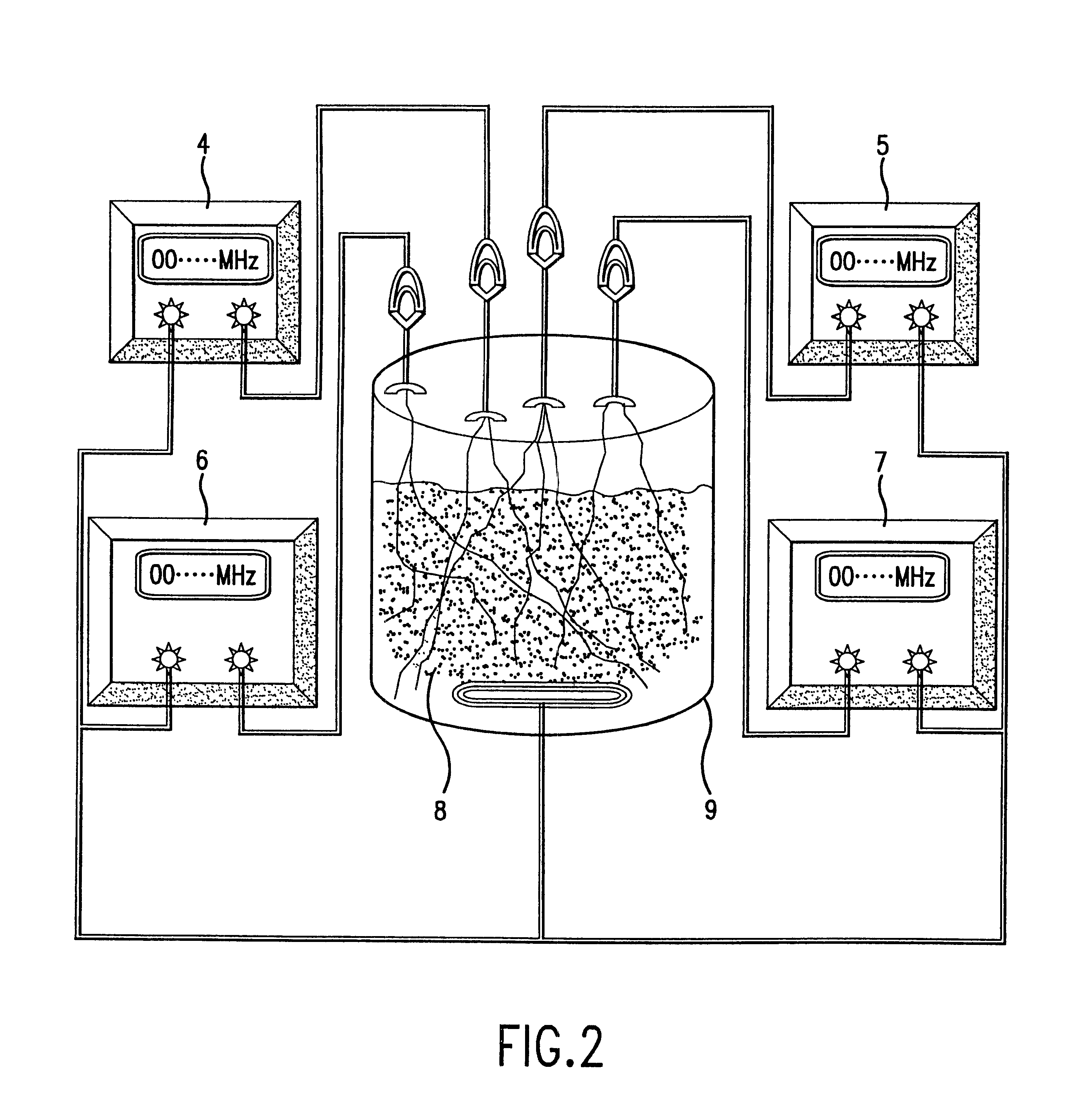

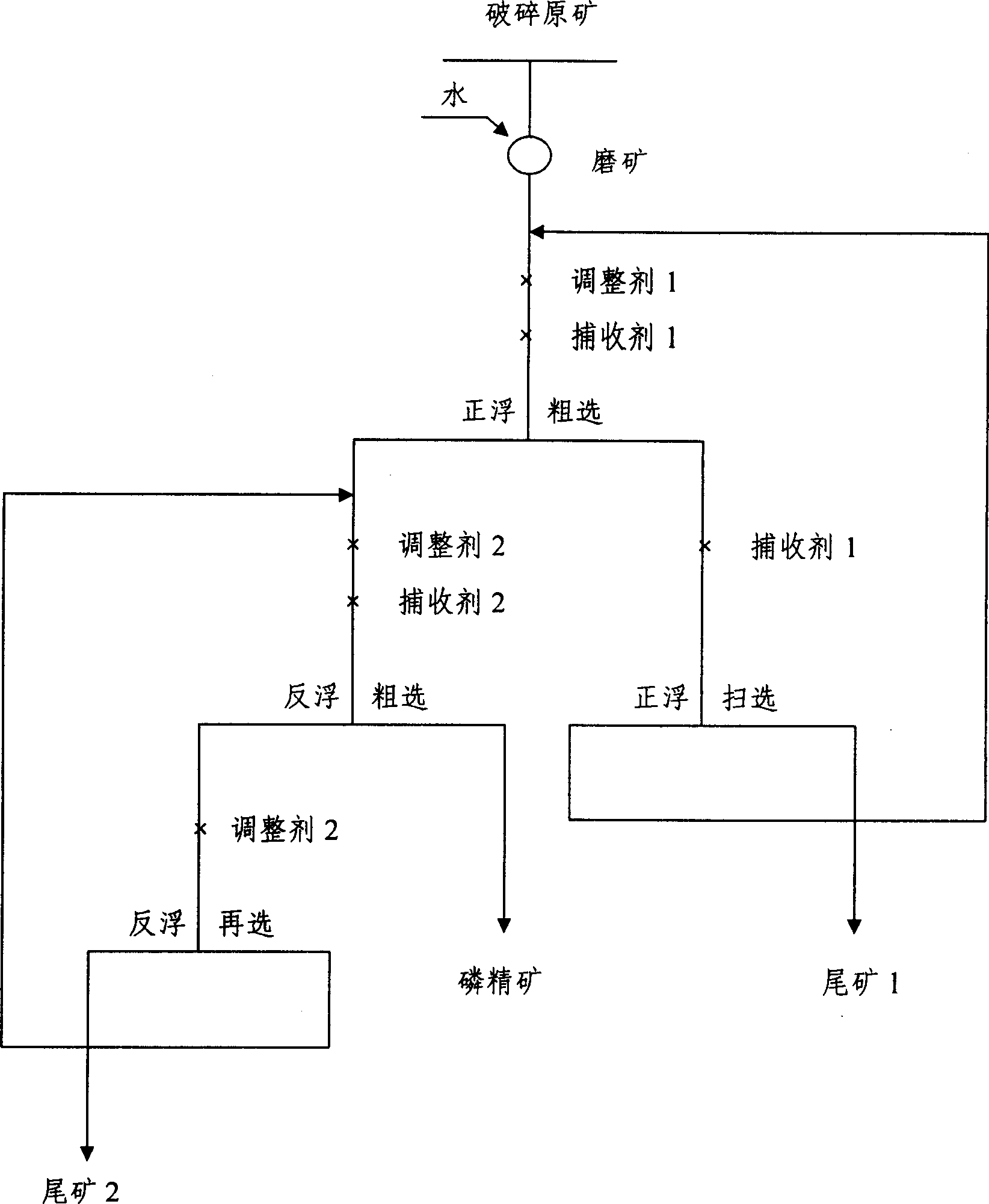

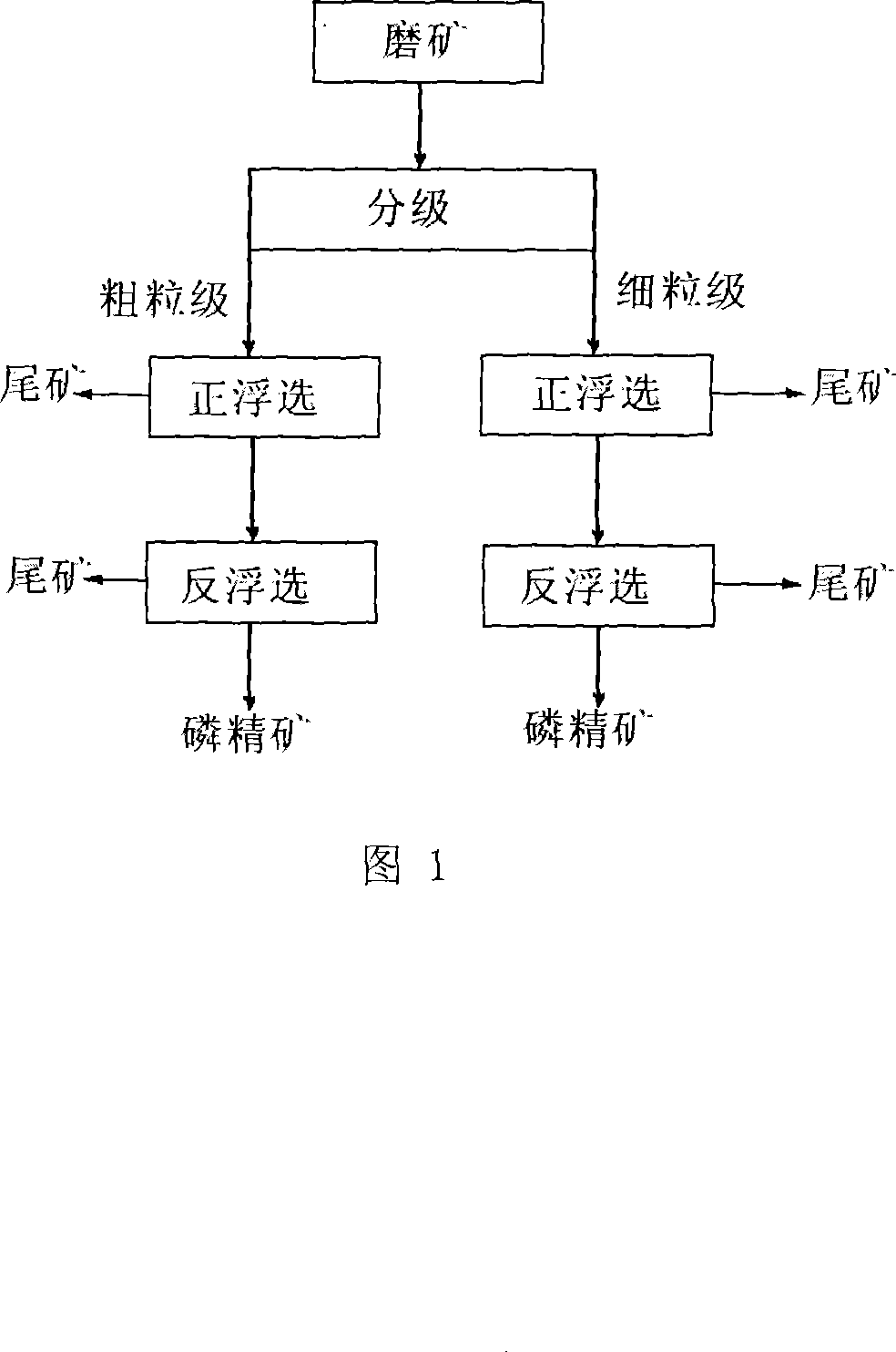

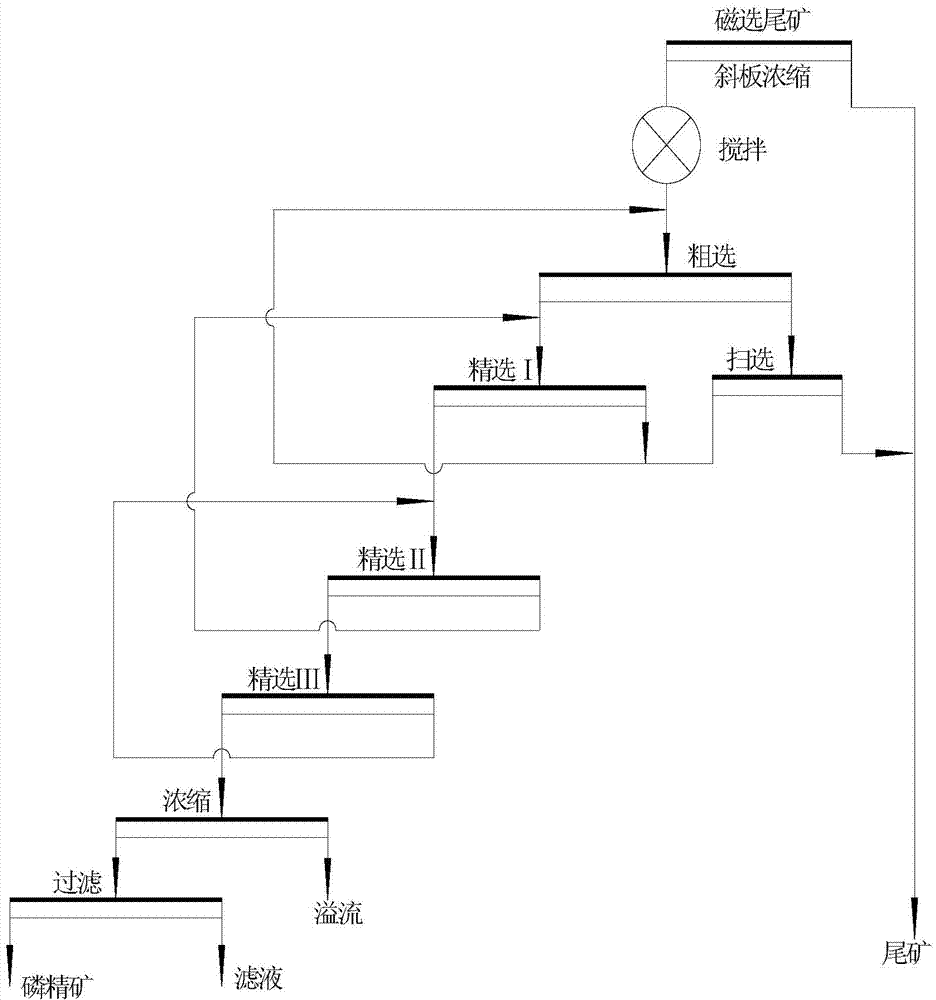

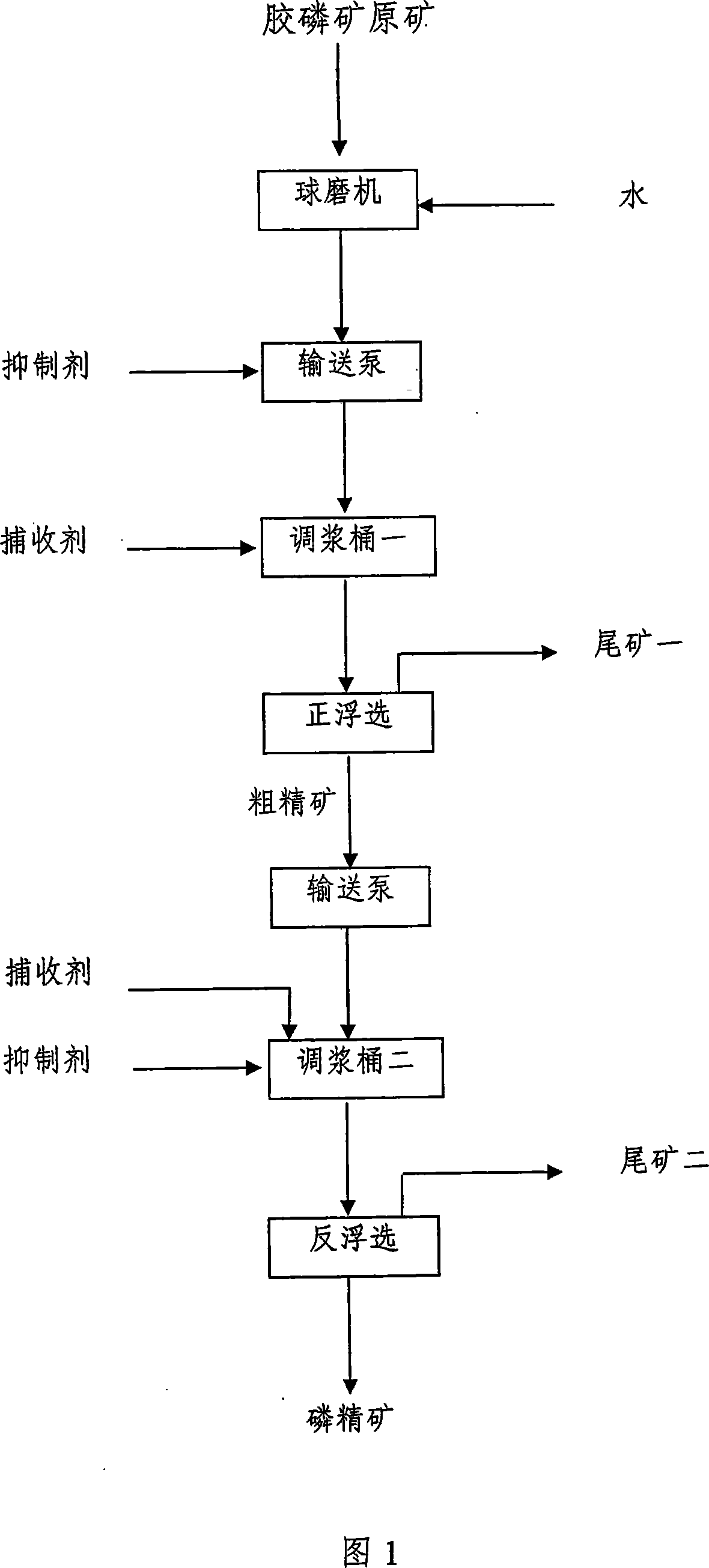

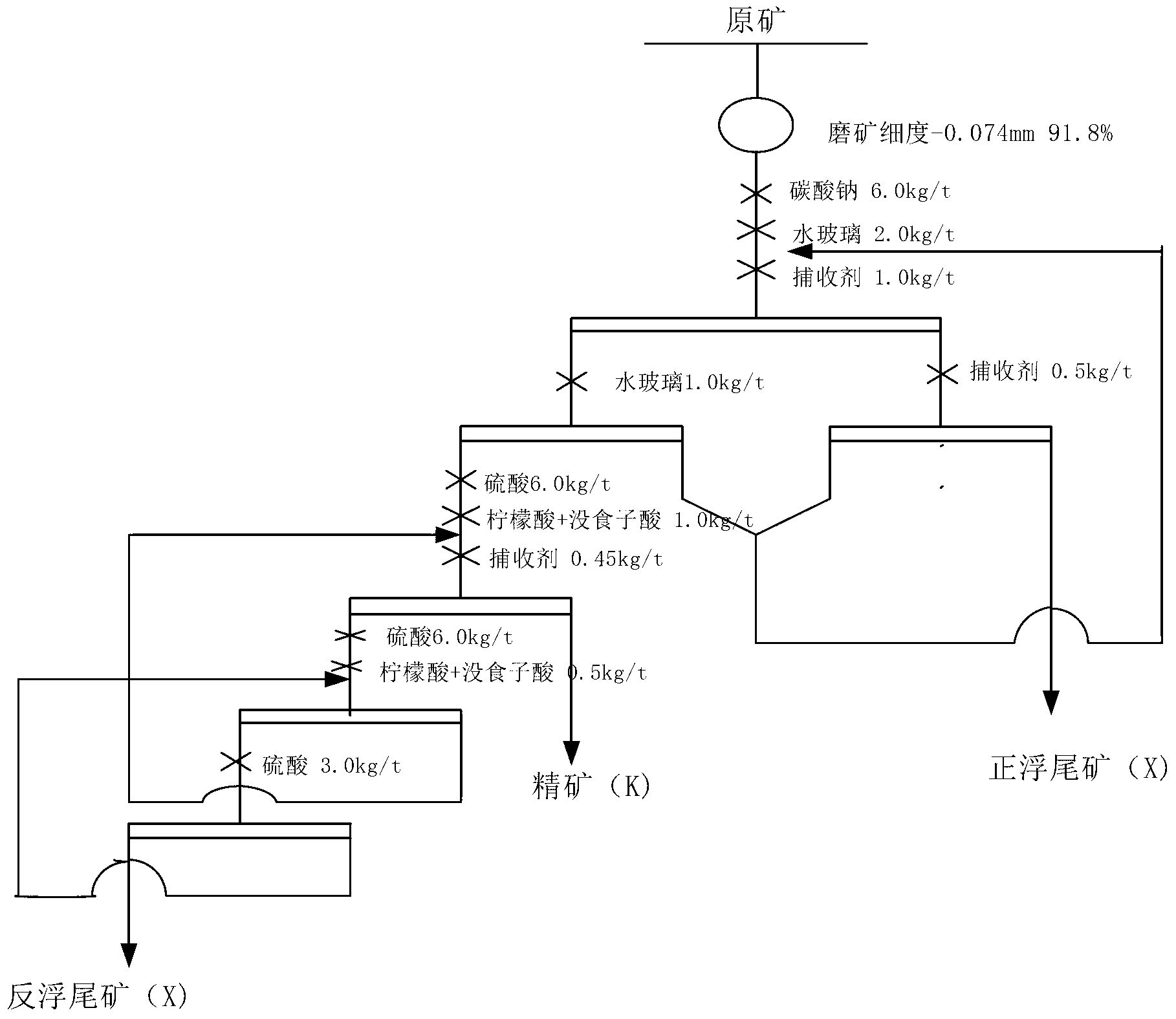

Collophanite direct flotation and reverse flotation technique

The invention relates to a positive-negative floatation technology for cellophane, which comprises the following steps: subjecting siliceous-calcareous collophane ore to breaking and grinding process to dissociate ore monomer; adding water to it get ore pulp with concentration of 20 -50%; Leading the mixture to agitated tank; adding modifying agent sodium silicate and positive collector agent to ore pulp; processing the mixture in positive floating system to get foamed product; adding negative floatation agent inorganic acid and collector agent to the foamed product in negative flotation agitated tank; processing the mixture in negative floating system with carbonate vein mineral negative flotation to get foamed product as negative flotation debris and product in tank as clean ore. The invention can simplify process, deduce cost and recycle the water.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Biological fertilizer compositions comprising swine manure

Owner:ULTRA BIOTECH

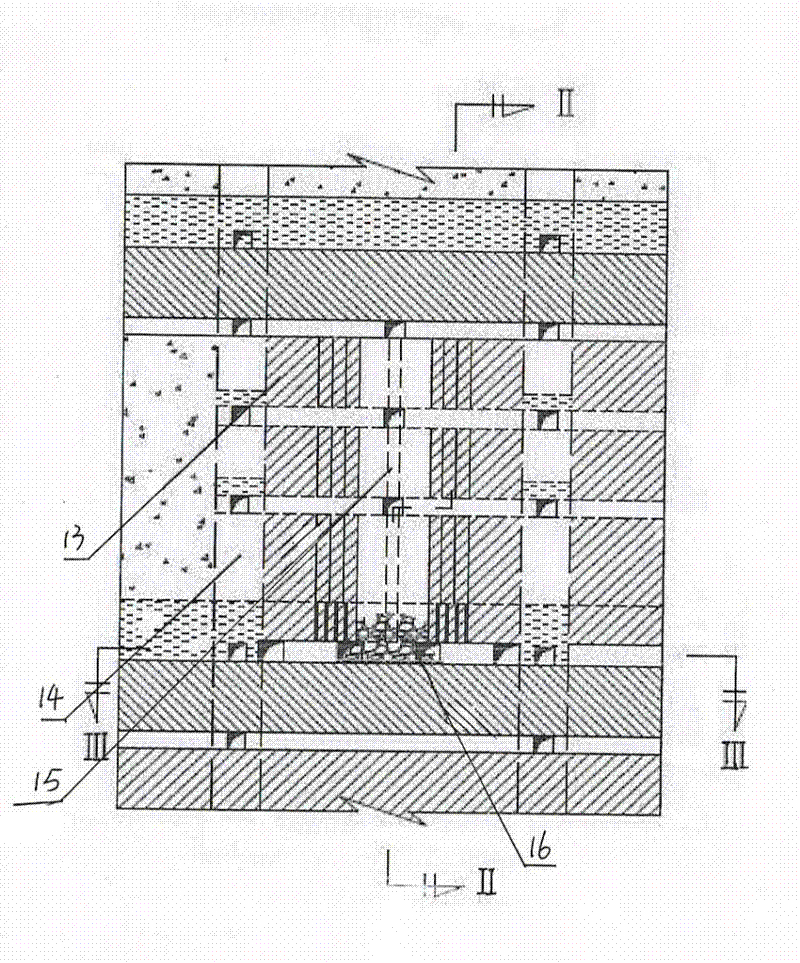

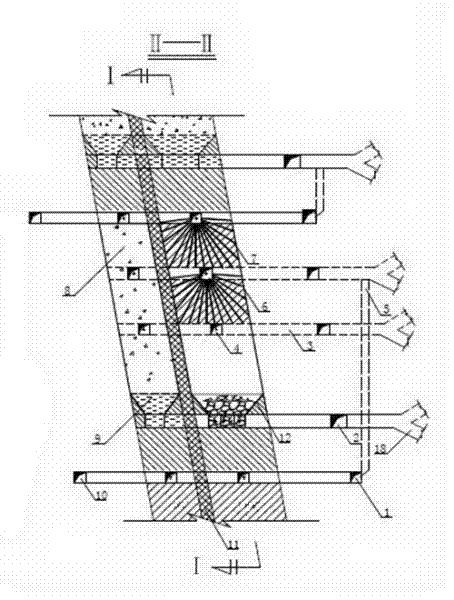

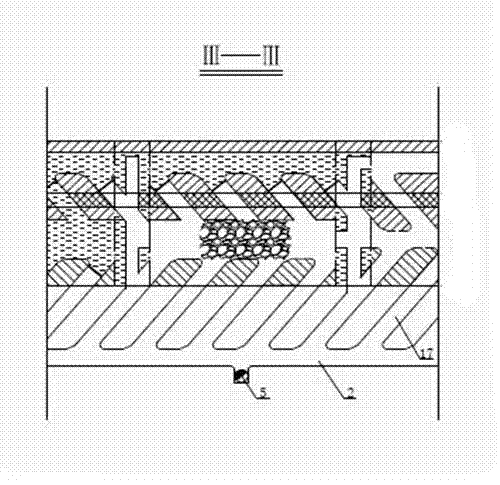

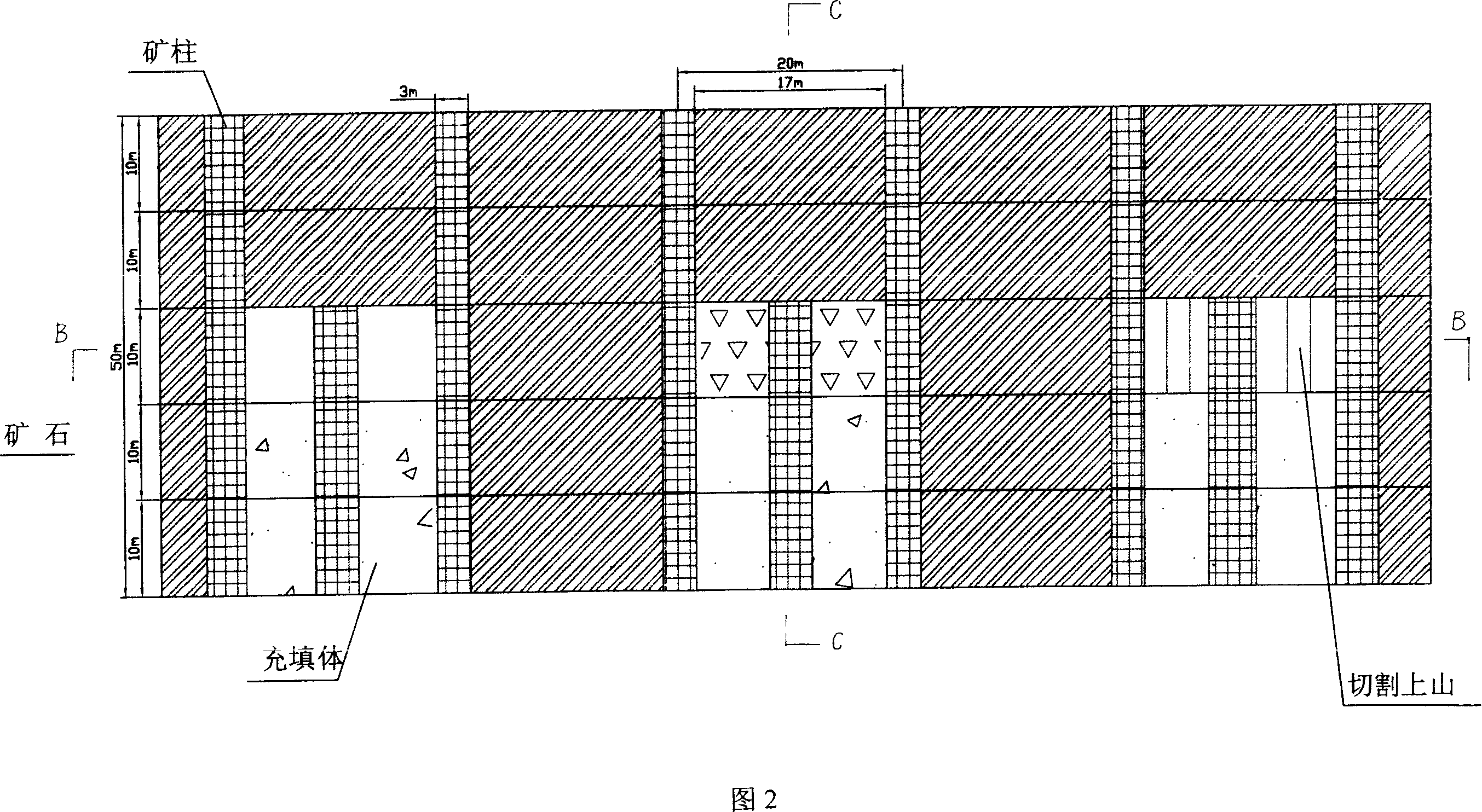

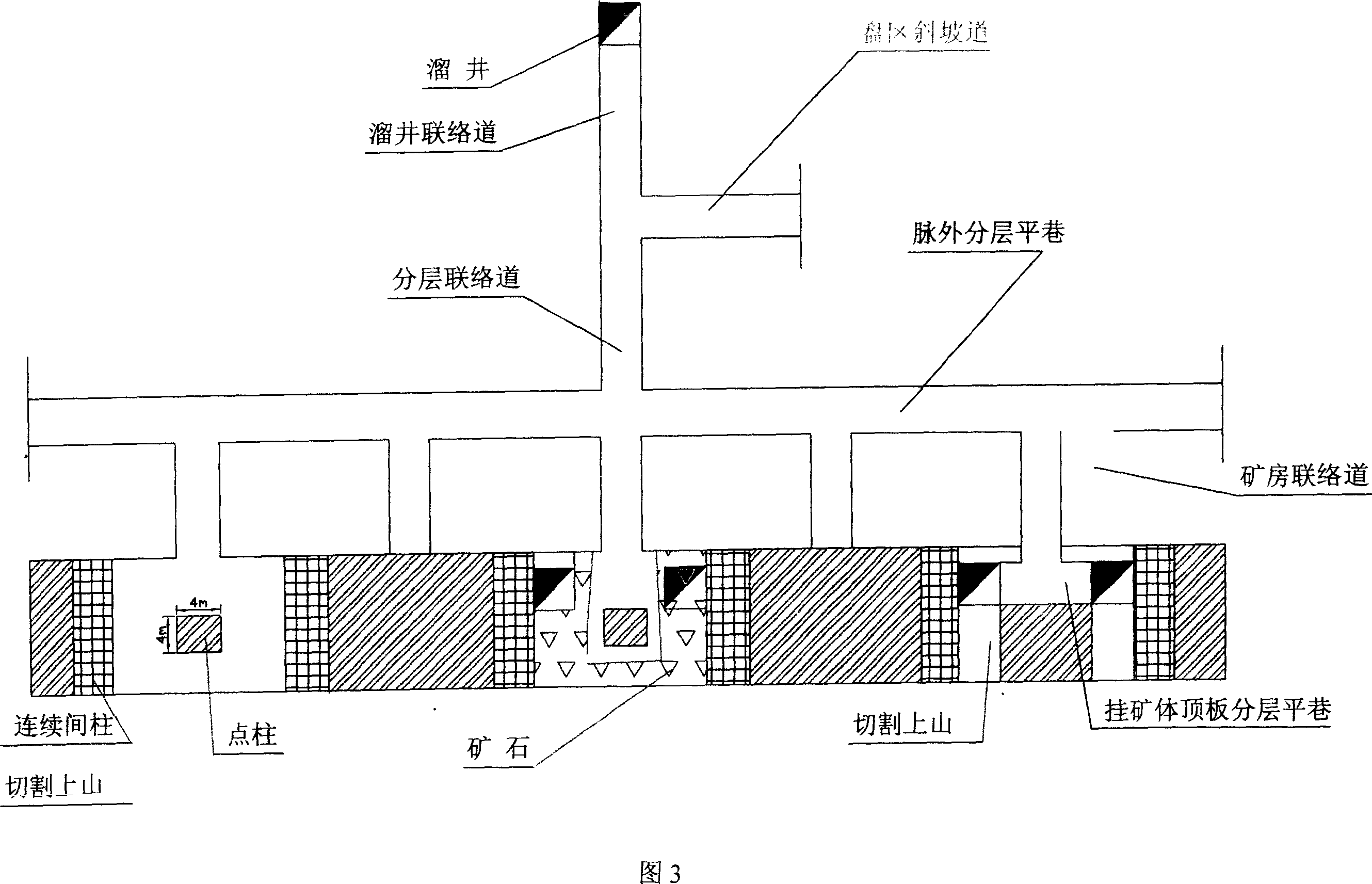

High-sublevel subdivision mining method of moderately thick heavy-pitch waste-rock-containing interlayer phosphate orebody along strike

InactiveCN102418526AAvoid damageIncrease productivityUnderground miningSurface miningMining engineeringSlag

The invention discloses a high-sublevel subdivision mining method of a moderately thick heavy-pitch waste-rock-containing interlayer phosphate orebody along a strike. The high-sublevel subdivision mining method comprises four steps of exploiting, mining preparation, cutting and recovery, wherein a footwall intermediate-section main roadway is respectively arranged on a high sublevel along a top plate and a bottom plate of the orebody, and the intermediate-section main roadways of the top plate and the bottom plate are connected through a communication channel at intervals of 100m, therefore reduced roadway cutting construction, small development rate and simple process are achieved; after overall blasting of a stope is finished, a large amount of concentrated ore drawing is carried out, and the production efficiency is high; tail sand is adhered and filled after space pillars are mined first, then rooms are evacuated, and the rooms are filled with waste rocks or tail sand in a non-adhering way, thus recovery rate is high; and the high-sublevel subdivision mining method has little damage to the environment and capabilities of changing oredressing tail sand and waste rocks generated in open-air production into valuables and reducing geological disaster from happening. Due to the adoption of the high-sublevel subdivision mining method disclosed by the invention, ore recovery rate can be increased, ore dilution rate and emission of mine wastes are reduced, capacity of slag disposal pit is relatively increased, expropriation of land is decreased, and mineral land harmony is promoted.

Owner:WENGFU (GRP) CO LTD

Biological fertilizer compositions comprising poultry manure

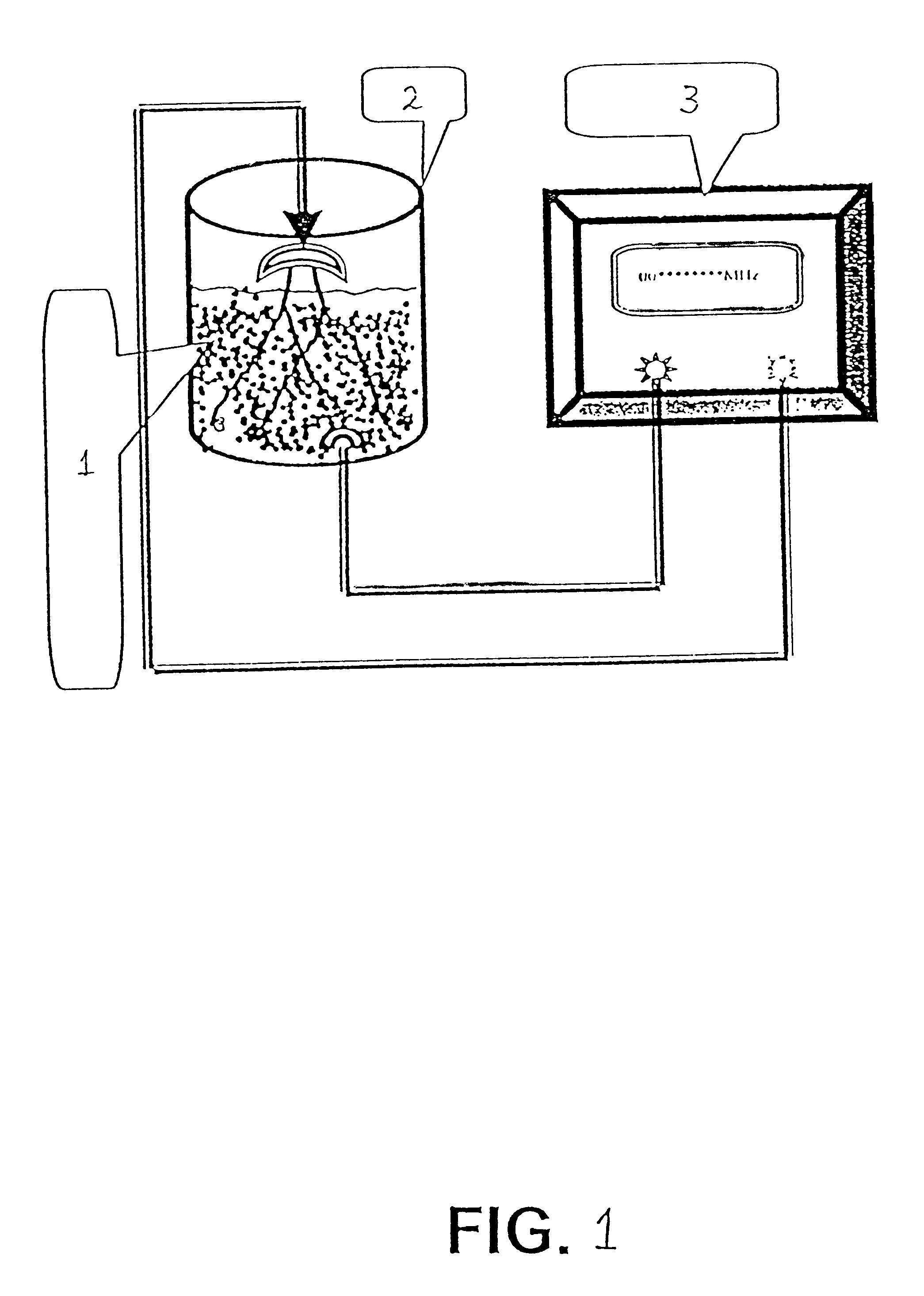

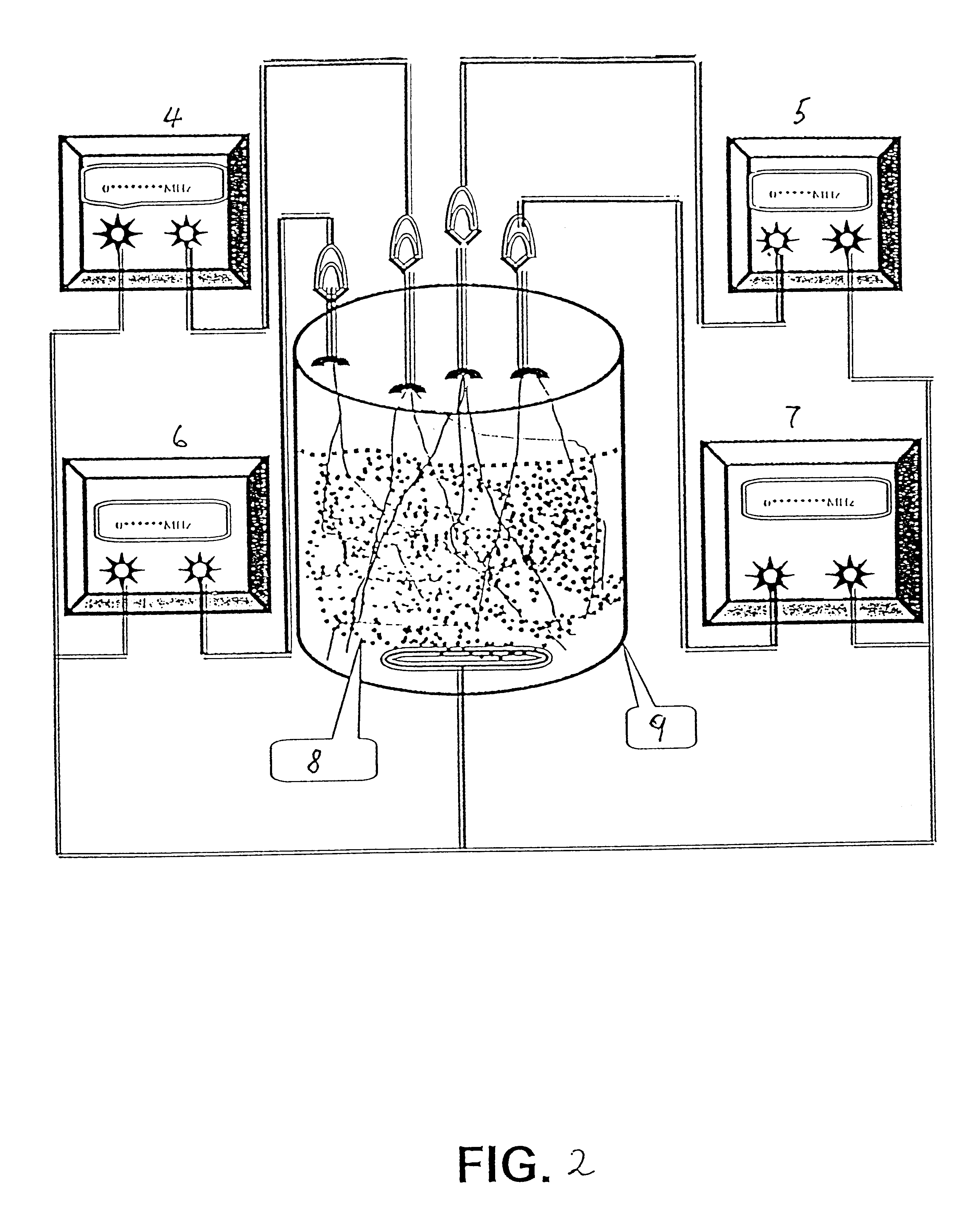

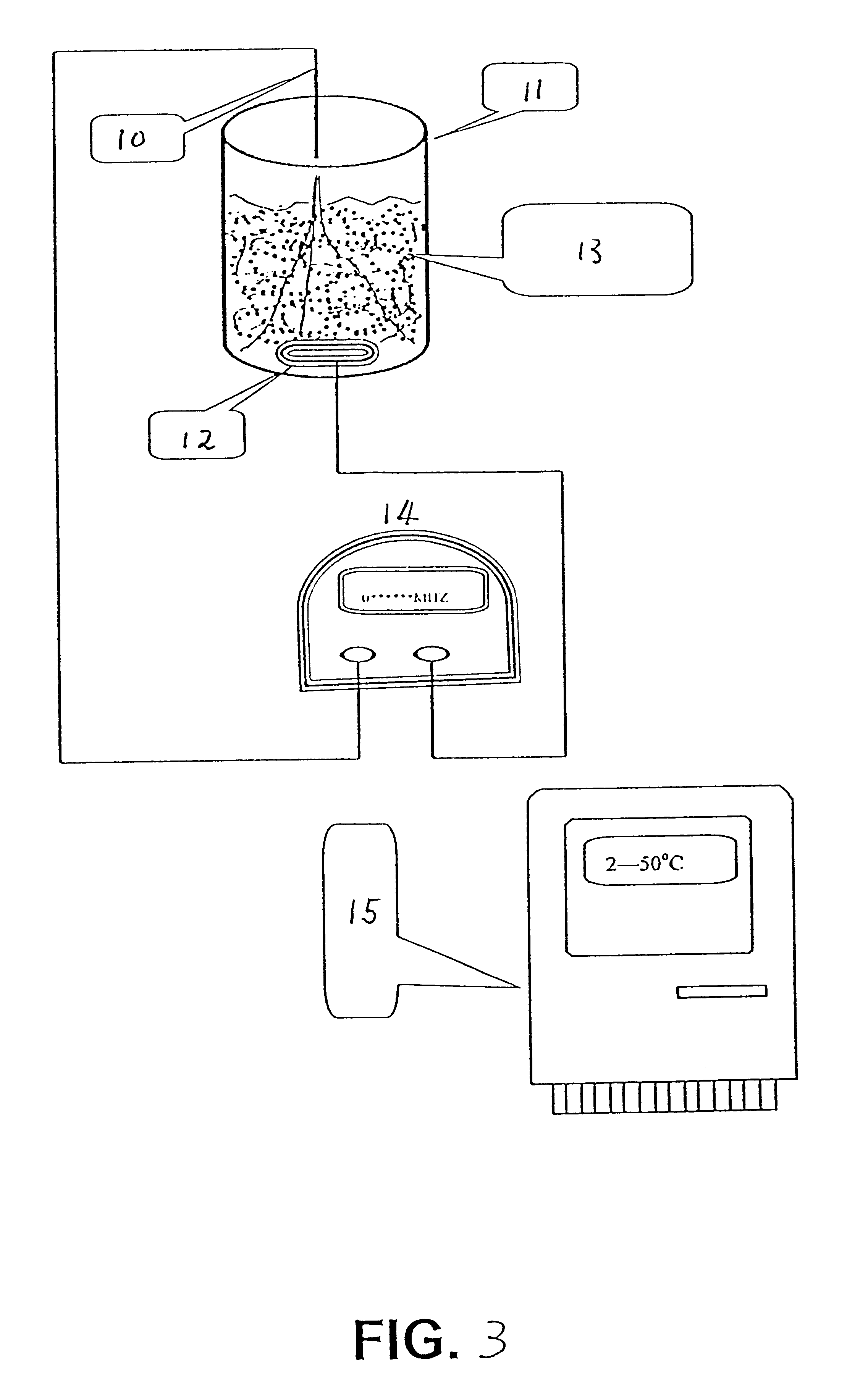

InactiveUS6596272B2Reduce odorEasy to solveBiocideBioreactor/fermenter combinationsPotassiumPoultry manure

The present invention provides biological fertilizer compositions that comprise yeast cells and poultry manure. The yeast cells of the invention have an enhanced ability to fix atmospheric nitrogen, decompose phosphorus minerals and compounds, decompose potassium minerals and compounds, decompose complex carbon compounds, overproduce growth factors, overproduce ATP, decompose undesirable chemicals, suppress growth of pathogenic microorganisms, or reduce undesirable odor. The biological fertilizer composition of the invention can replace mineral fertilizers in supplying nitrogen, phosphorus, and potassium to crop plants. Methods of manufacturing biological fertilizer compositions, and methods of uses are also encompassed.

Owner:ULTRA BIOTECH

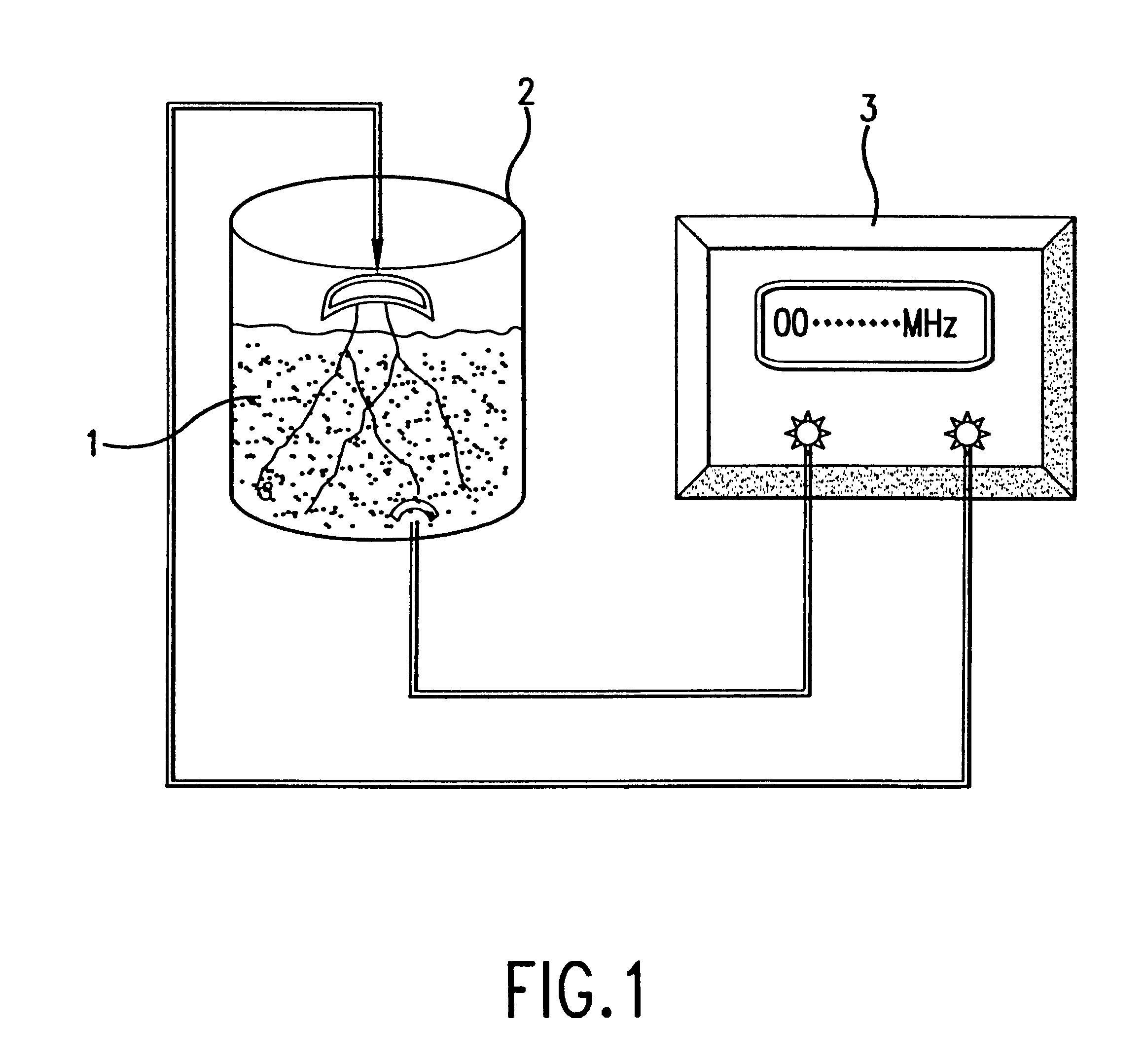

Phosphate rock floating process

InactiveCN101020159AAvoid mutual interferenceReduce consumptionFlotationHigh concentrationPhosphorite

The phosphate rock floating process is one phosphate rock grading forward-backward floating process, in which the raw ore pulp is first separated into two parts of different fineness and then forward-backward floated in two separated branches. The coarse ore pulp is made to separated in high concentration so as to save floating chemical; while the fine ore pulp is floated through adding dispersant to raise the floating efficiency. The grading floating process can avoid the mutual interference between coarse and fine grains, and thus has raised separating efficiency, raised floated concentrate quality, lowered floating chemical consumption and raised technological and economic indexes.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Biological fertilizer compositions comprising cattle manure

The present invention provides biological fertilizer compositions that comprise yeast cells and cattle manure. The yeast cells of the invention have an enhanced ability to fix atmospheric nitrogen, decompose phosphorus minerals and compounds, decompose potassium minerals and compounds, decompose complex carbon compounds, overproduce growth factors, overproduce ATP, decompose undesirable chemicals, suppress growth of pathogenic microorganisms, or reduce undesirable odor. The biological fertilizer composition of the invention can replace mineral fertilizers in supplying nitrogen, phosphorus, and potassium to crop plants. Methods of manufacturing biological fertilizer compositions, and methods of uses are also encompassed.

Owner:ULTRA BIOTECH

Phosphogypsum cementing and post-filling mining method and pulping technology thereof

ActiveCN101008316ASolve problems that are difficult to handle in large blocksIncrease profitMaterial fill-upAdhesivePhosphorite

The invention discloses a stuff mining method when the ardealite adhesive is solidified and relative pulp production. The stuff mining method comprises that preparing mine house, stuffing preparation, preparing pulp, and stuffing. The pulp preparation comprises that using ardealite, coal powder / dolostone and cement as the stuff material to be added into water and mixed into stuff pulp; the stuff pulp via the stuff drill hole or the pump station is input to the upper outer flat channel of the mining field via the stuff tube, to be fed into the mining field. The inventive stuff mining method can confirm the yield and stability of mine, to improve the recycle rate of mineral and protect the environment.

Owner:贵州开磷设计研究院有限责任公司

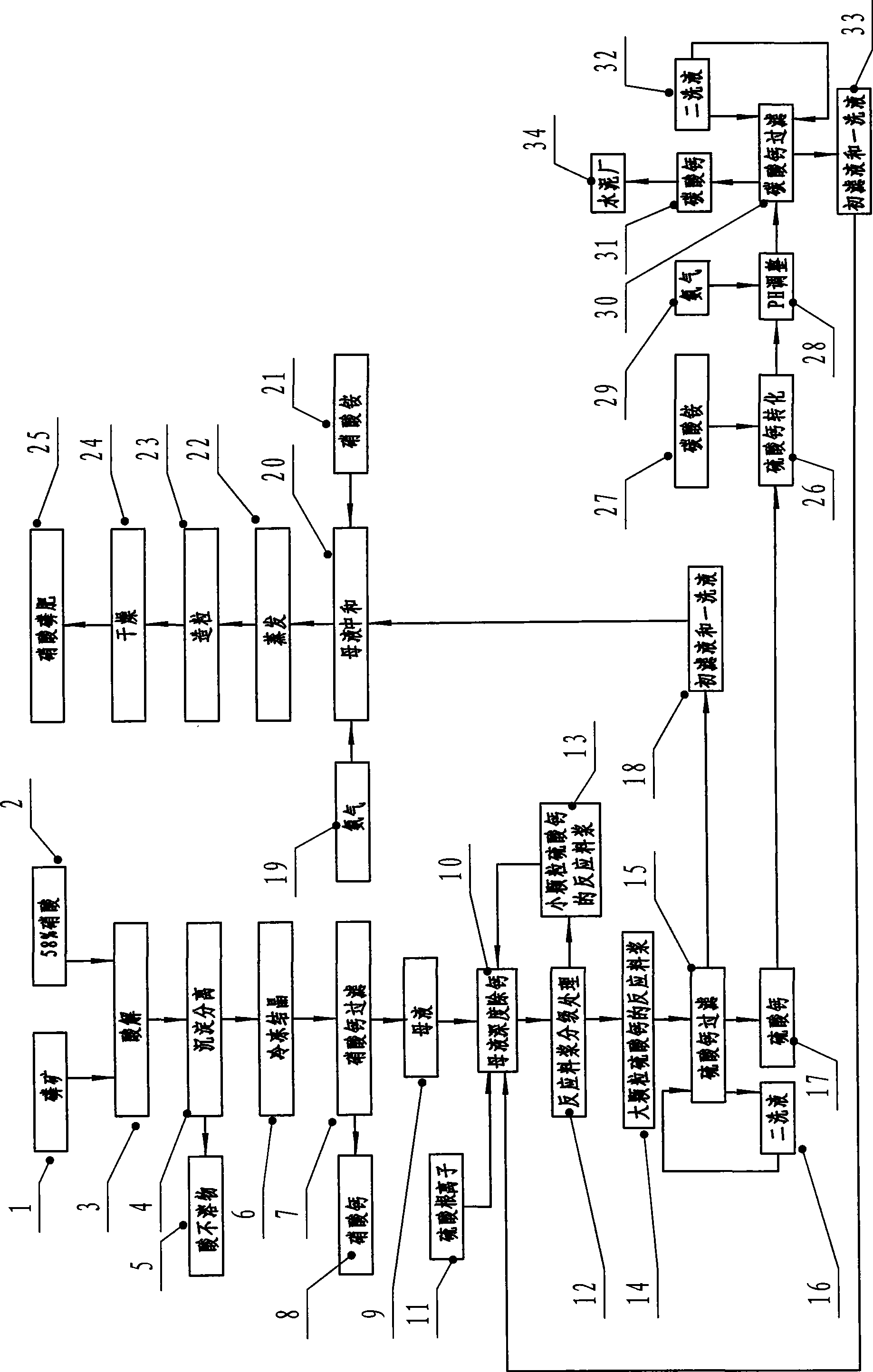

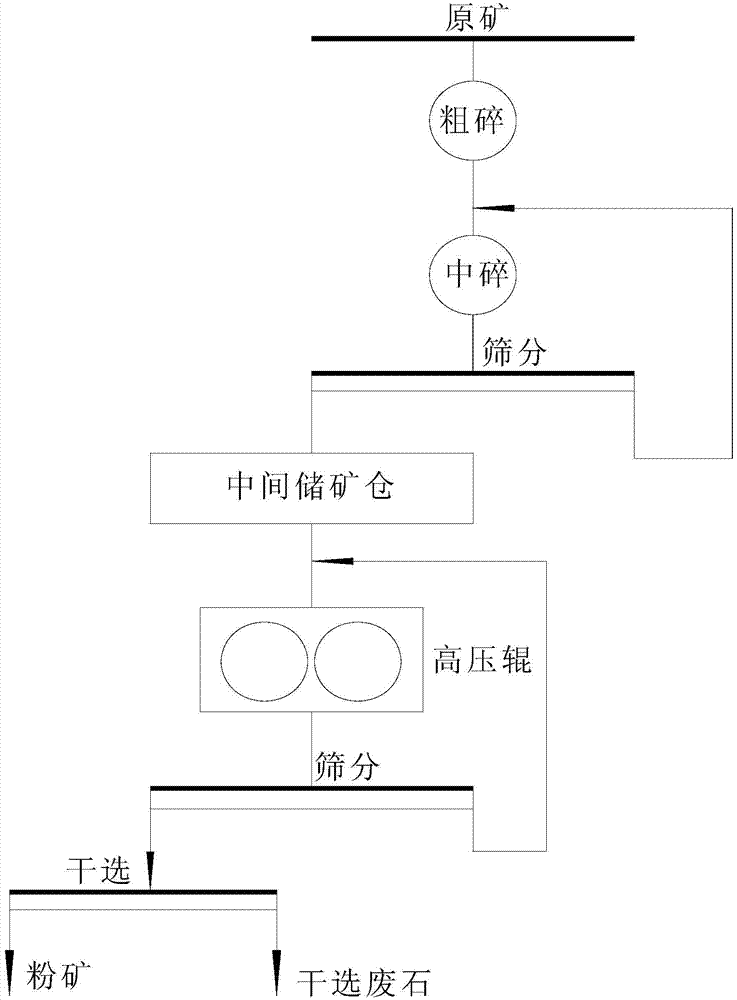

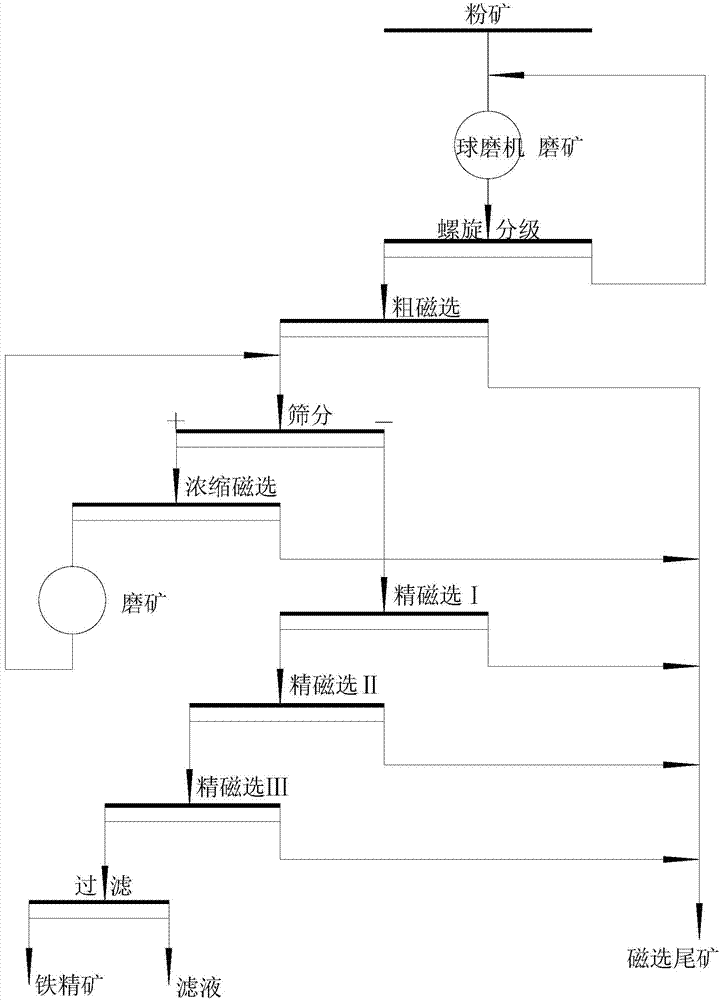

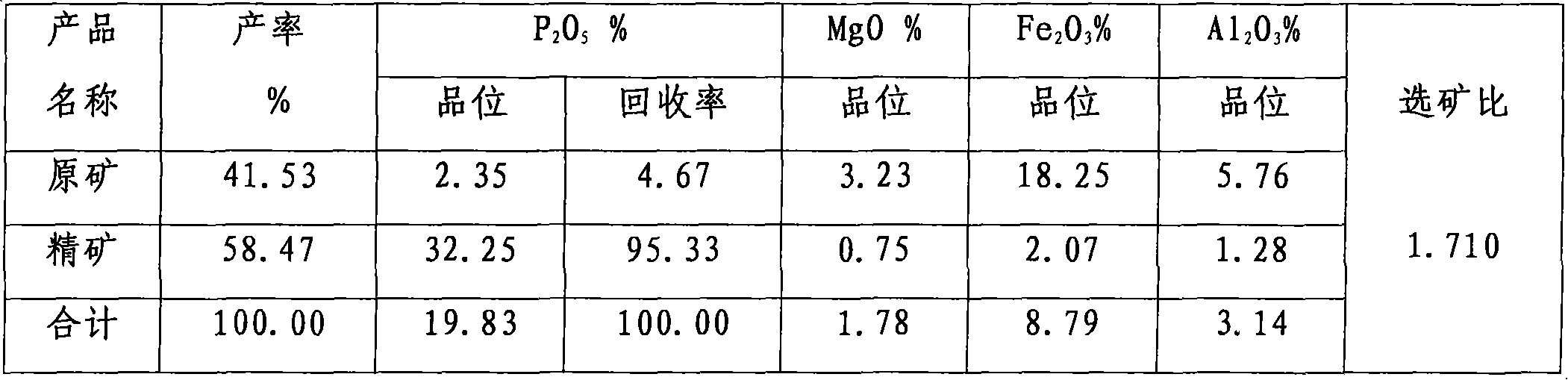

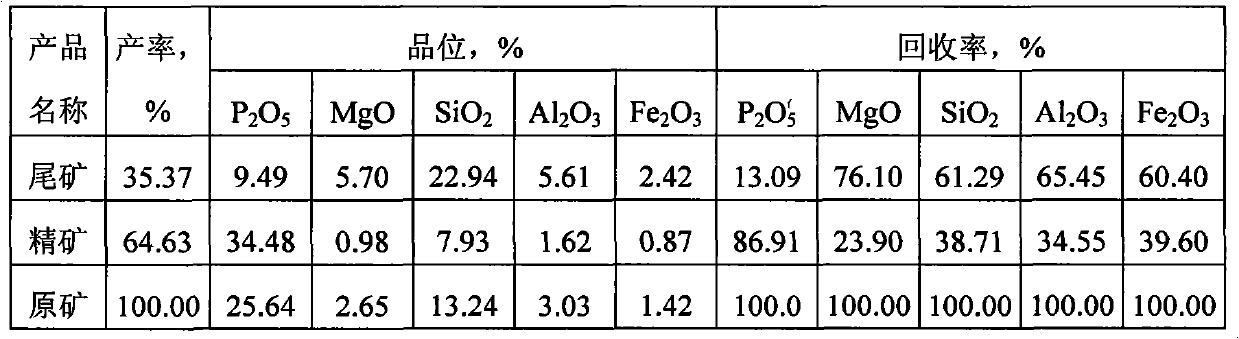

Combined beneficiation method and combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals

The invention belongs to the technical field of efficient development of ultralow-grade ore resources and comprehensive utilization of associated minerals, and in particular relates to a combined beneficiation method and a combined beneficiation system for comprehensive recovery of associated iron-phosphate minerals. The combined beneficiation method for the comprehensive recovery of the associated iron-phosphate minerals comprises the following steps: sequentially performing three-section and two-closed-loop crushing and screening flow on raw ores, and performing dry separation to obtain fine ores; performing two-section closed-loop ore-grinding flow on the fine ores, performing fine magnetic separation for three times, and concentrating by using a wash mill to separate iron ore concentrate and discharge tailings; performing one-time roughing, one-time scavenging and three-time concentrating on the tailings at the temperature of 10-15 DEG C to obtain phosphate ore concentrate by floatation. Compared with the prior art, the invention provides a comprehensive recovery scheme for magnetic iron ore resources and phosphate ore resources in ultralow-grade associated iron-phosphate minerals. According to the scheme, the separation cost is low, the efficiency is high, energy is saved, the space occupation is low, and the comprehensive recovery of the magnetic iron ores and the phosphate ores can be realized.

Owner:中冶沈勘工程技术有限公司

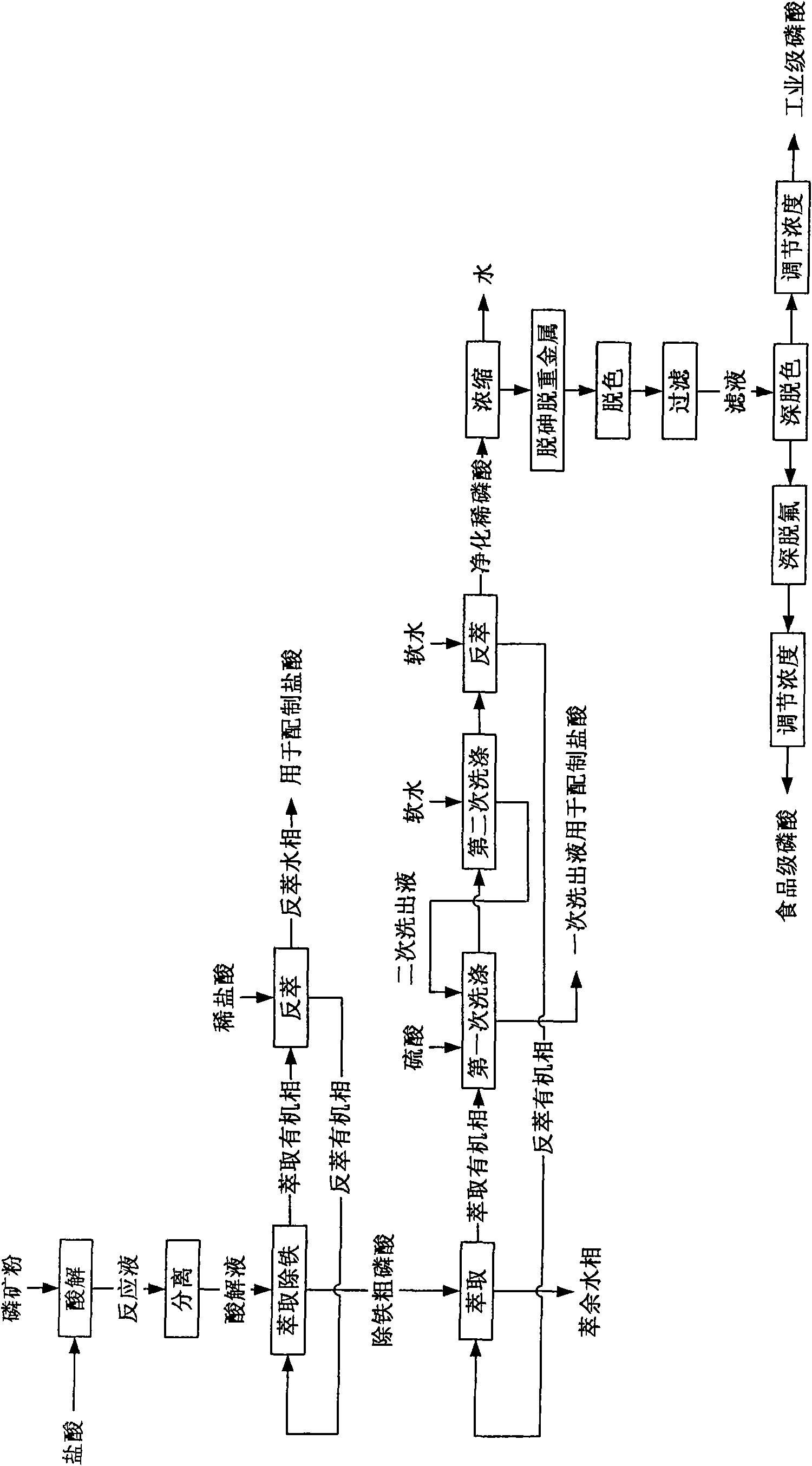

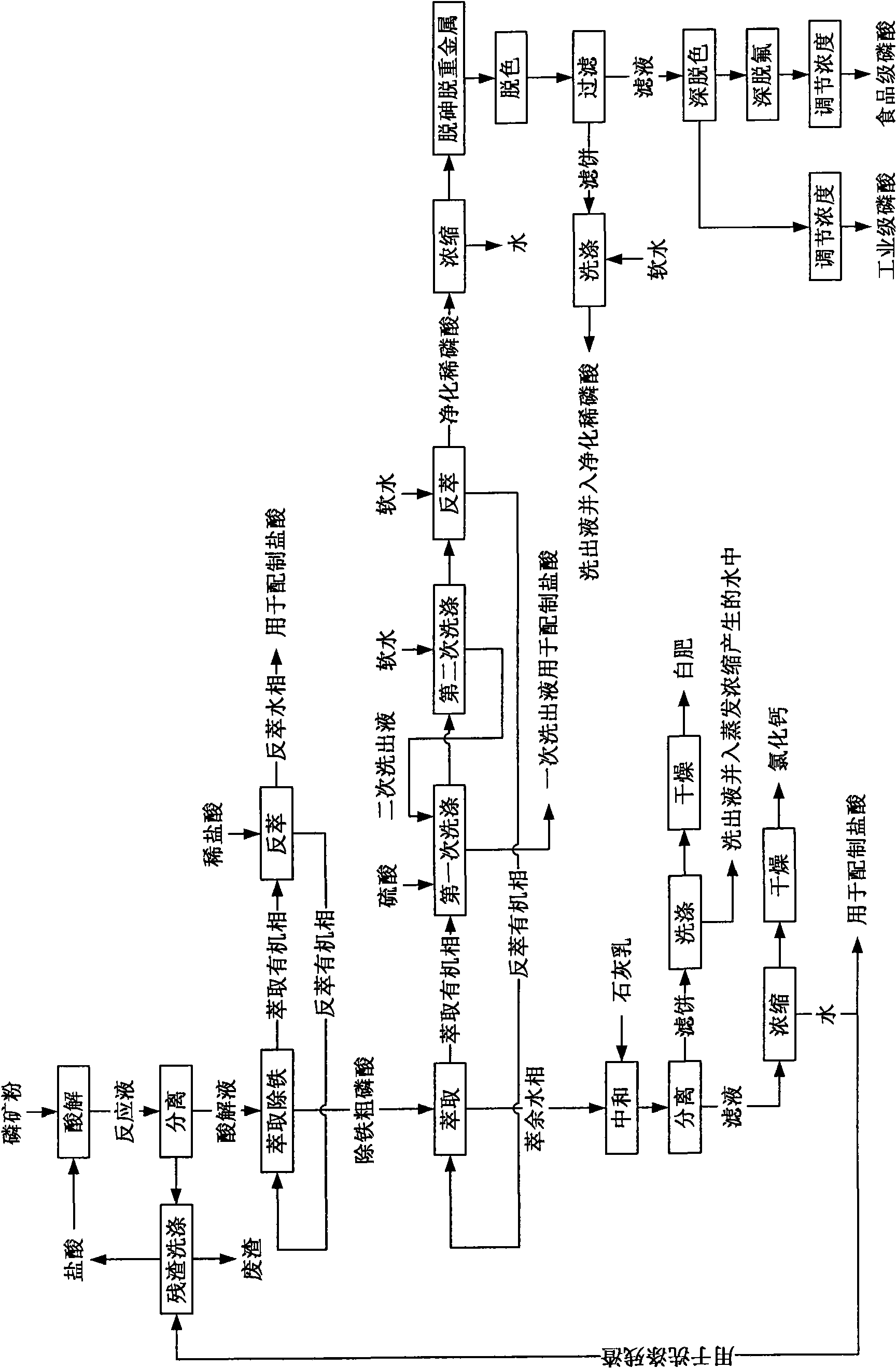

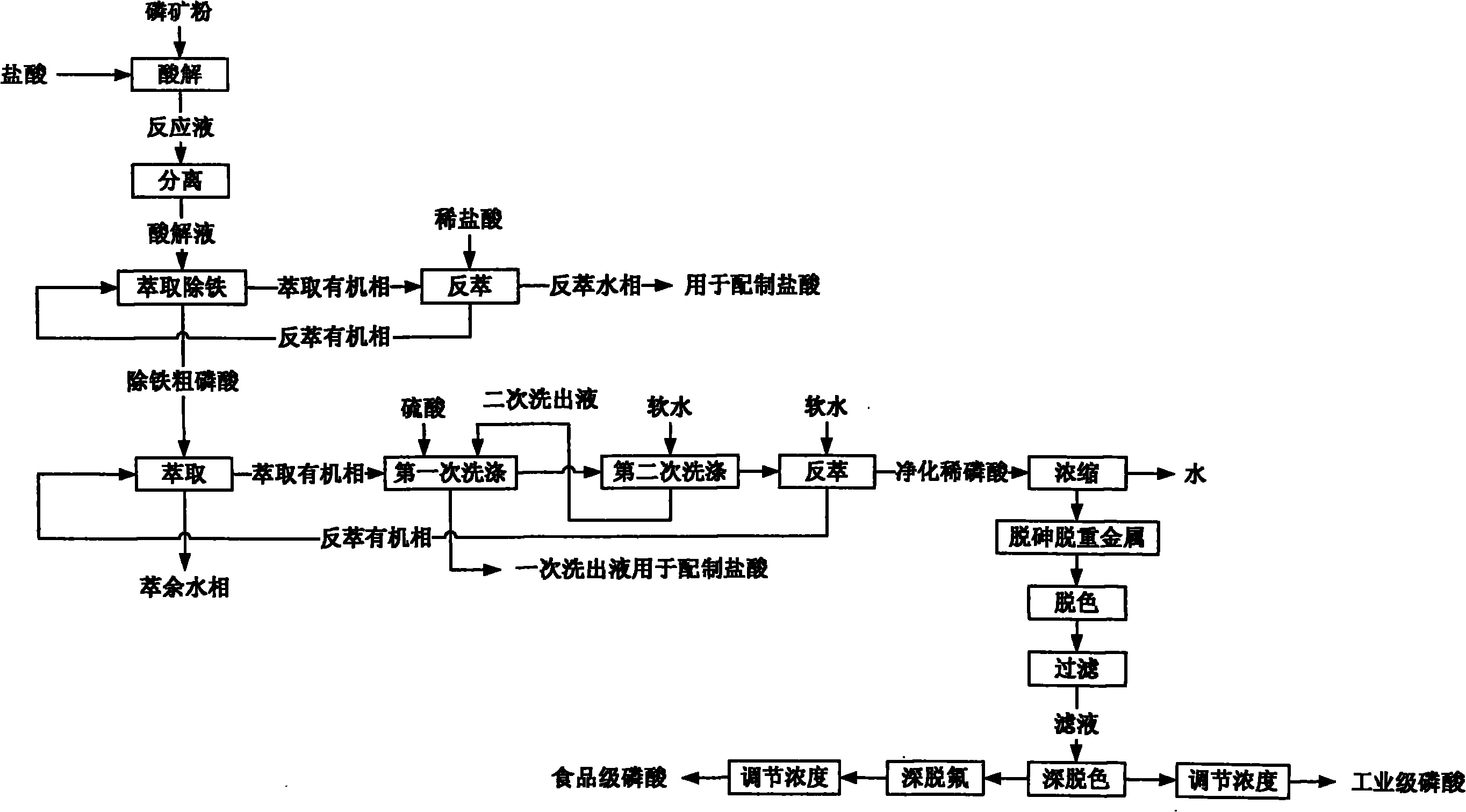

Method for preparing industrial grade and food grade phosphoric acid by decomposing low grade phosphate rocks with hydrochloric acid

The invention relates to a method for preparing industrial grade and food grade phosphoric acid by decomposing low grade phosphate rocks with hydrochloric acid. The method comprises the following processing steps: (1) decomposing phosphate rock powder with hydrochloric acid; (2) extracting to remove iron; (3) preparing dilute phosphoric acid; (4) preparing industrial grade phosphoric acid; and (5) preparing food grade phosphoric acid. Food grade phosphoric acid can be prepared only by adding deep defluorination process on the basis of the preparation steps of industrial grade phosphoric acid. The deep defluorination process adopts vacuum steam stripping process and the processing conditions are as follows: the vacuum degree is 0.075-0.090MPa, and the temperature is 95-110 DEG C. Industrial grade phosphoric acid prepared by the method of the invention meets the super grade or first-class product standards of GB / T 2091-2008; and food grade phosphoric acid meets the standards of GB 3149-2004.

Owner:SICHUAN UNIV

Compound fertilizer

The invention discloses a compound fertilizer comprising straw, weathered coal, peat soil, phosphorite powder, wheat middling, EDTA (Ethylene Diamine Tetraacetic Acid), potassium fulvate, rice hull powder, sweet potato powder, mixed strain powder and urea. The compound fertilizer is capable of increasing yield and improving soil for a long term and inhibiting soil-borne diseases and is low in cost, simple in process and free of residue and pollution, so that the compound fertilizer has a good popularization and application prospect.

Owner:河北百斗嘉肥料有限公司

Method for preparing phosphoric acid and byproduct building brick by using phosphatic ore tailings after phosphate ore dressing

InactiveCN1837129AReduce consumptionReduce energy consumptionSolid waste managementPhosphoric acidBrickPhosphoric acid

The invention discloses a preparing phosphoric acid and by-product building brick method by debris with phosphor after phosphorus ore dressing ore, which comprises the following steps: adding in dinas rock powder, coking carbon powder (coal gangue powder), caoline to mix up; adding in water; ageing the mixture; modeling by vacuum extrusion machine or brick press; dipping after drying; putting mixture in kiln vehicle and entering tunnel oven; getting phosphor vapour and carbon monoxide after preheating and heating-up; getting concentrated phosphoric acid through hydrated tower; getting carrying brick production through heat transferring and cooling. The invention uses the mine and ore dressing fag-end to prepar acid and brick. We can use the ore when the P2O5 is not smaller than 6%.

Owner:HUBEI SANXIN PHOSPHORIC ACID

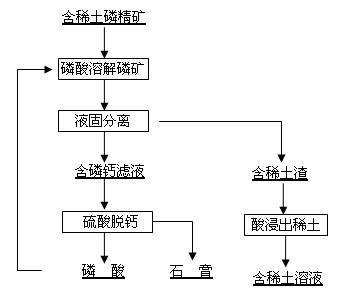

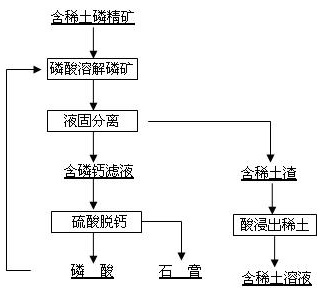

Method for separating tombarthite from phosphorus ore

The invention discloses a method for separating tombarthite from phosphorus ore and relates to the method for separating the tombarthite from the phosphorus ore containing the tombarthite. The method is characterized in that the process steps are as follows: (1) mixing phosphate concentrate containing the tombarthite with a phosphoric acid solution for performing reaction; (2) filtering for getting a reaction solution and slag containing the tombarthite; (3) adding acid into the slag containing the tombarthite for leaching for getting leachate containing the tombarthite, and further recycling the tombarthite through one or more of an extraction method, an ion exchange adsorption method, a precipitation method and a crystallization method; and (4) performing decalcification on the reaction solution obtained by filtration and then returning to the step (1). By adopting the method, the precipitation rate of the tombarthite in the phosphorus ore is greater than 85%, the slag rate is small, the grade of the tombarthite in the slag is high, the leaching rate of the tombarthite in the slag is high, no additives are added during the process and the product quality of the phosphoric acid is not affected; and furthermore, the phosphoric acid used during the process can be self-produced and can also be circulating dilute phosphoric acid, dilute phosphoric acid and the like generated during the production process of the phosphoric acid, thereby being tightly linked with the production process of the phosphoric acid through the sulfuric acid method.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

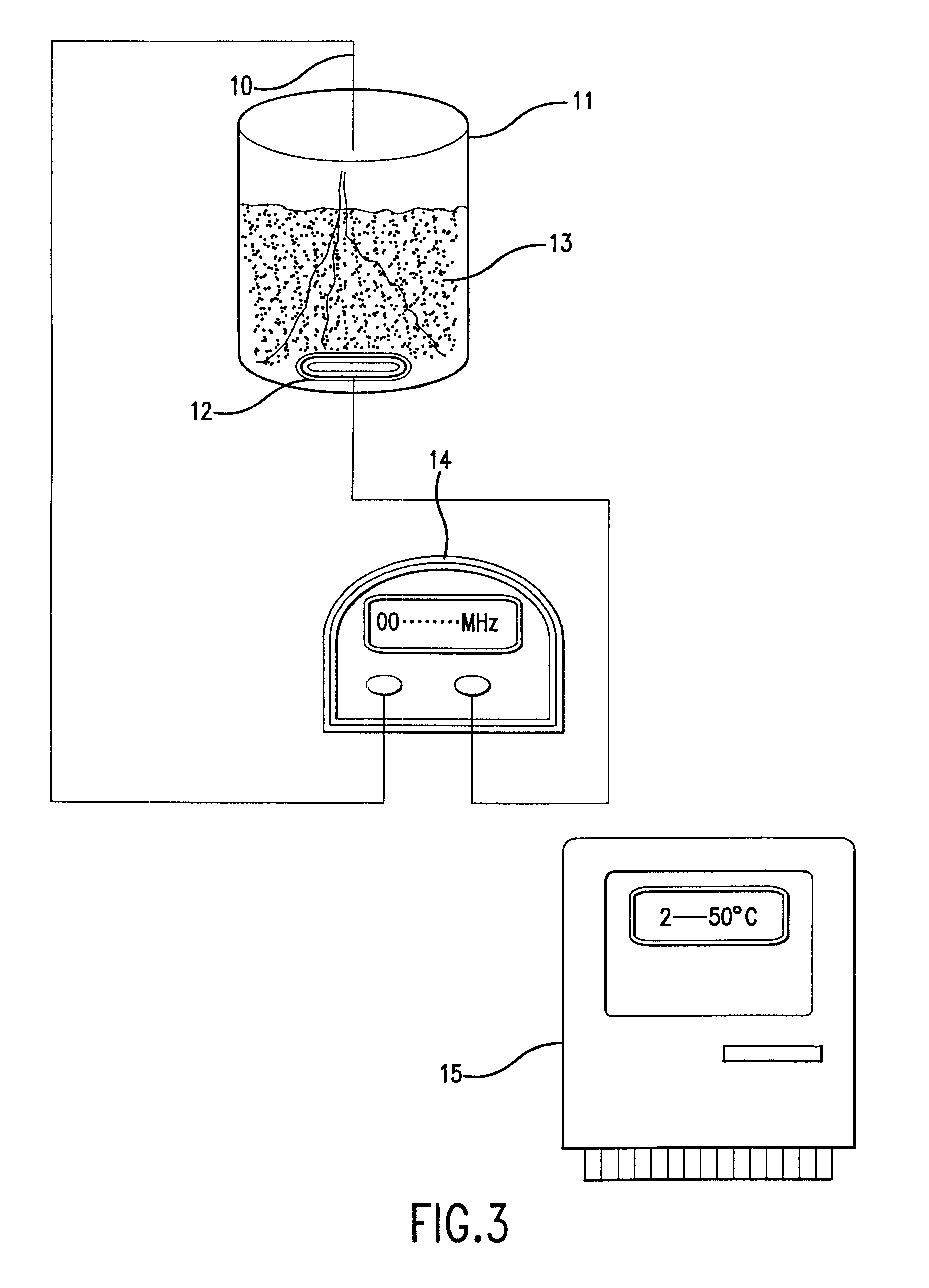

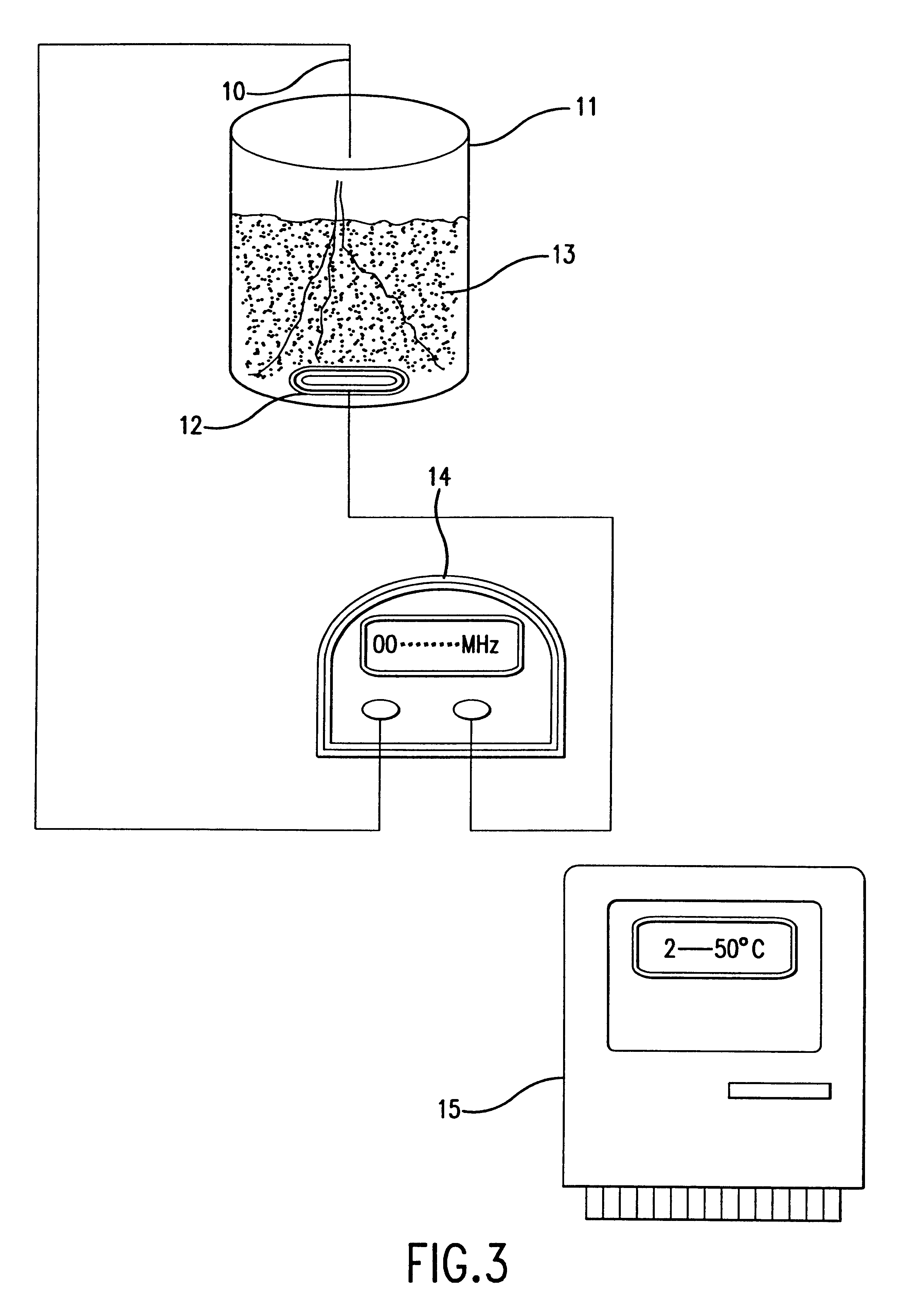

Low-temperature-resistant collophanite reverse-flotation collecting agent and method for preparing low-temperature-resistant collophanite reverse-flotation collecting agent

ActiveCN104107762ARealization of Magnesium Removal by Low Temperature Reverse FlotationWide range of raw materialsFlotationFoaming agentPhosphorite

The invention relates to a low-temperature-resistant collophanite reverse-flotation collecting agent. The low-temperature-resistant collophanite reverse-flotation collecting agent is composed of a basic active flotation material, an auxiliary component and water, wherein the basic active flotation material is composed of, by weights, 10 parts to 30 parts of unsaturated sulfonated aliphatic acid and 50 parts to 80 parts of higher aliphatic acid, the auxiliary component is composed of, by mass, 5 parts to 10 parts of surface active agents, 5 parts to 15 parts of foaming agents and 10 parts to 20 parts of inorganic base, and the ratio of the sum of the mass of the basic active flotation material and the mass of the auxiliary component to the mass of the water ranges from 1:1 to 1:10. When the low-temperature-resistant collophanite reverse-flotation collecting agent is used for collophanite flotation, phosphorus concentrate with the low MgO content (1.60%) can be obtained, and the high P2O5 recovery rate (90.03%) can be achieved. The low-temperature-resistant collophanite reverse-flotation collecting agent has the advantages that the range of sources of raw materials is wide, the preparing technology is simple and easy to execute, the stability is high, the environmental friendliness is achieved, and the market promotion value is high.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Collophanite floatation method

The present invention discloses one kind of cellophane floating process, which has floatation columns applied for eliminate impurity and includes direct floatation to eliminate silicon and reverse floatation to eliminate magnesium. The cellophane floating process includes crushing crude cellophane, milling and grading to form 20-40 wt% concentration pulp; mixing the pulp with direct floatation reagent, and floatation in direct floatation columns to obtain foamed rough concentrate in the top and direct floated tailings in the bottom; mixing the foamed rough concentrate with reverse floatation reagent in one other mineralizing tank, and floatation in reverse floatation columns to obtain cellophane concentrate in the bottom and foamed reverse floated tailings. The process is simple and stable, and has easy control, high depurating effect, high concentrate quality, less phosphate loss and other advantages.

Owner:YUNNAN CHEM RES INST +1

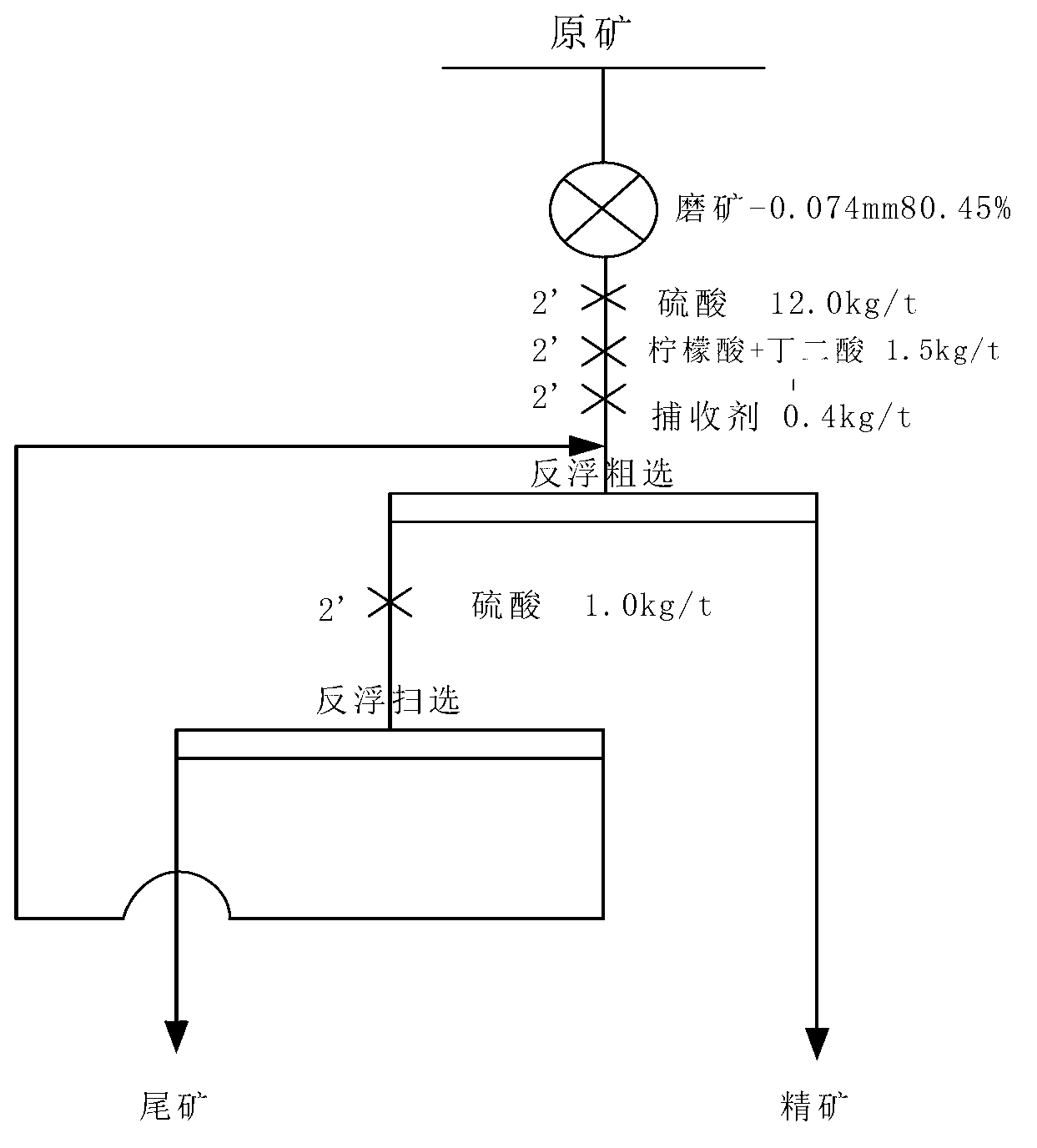

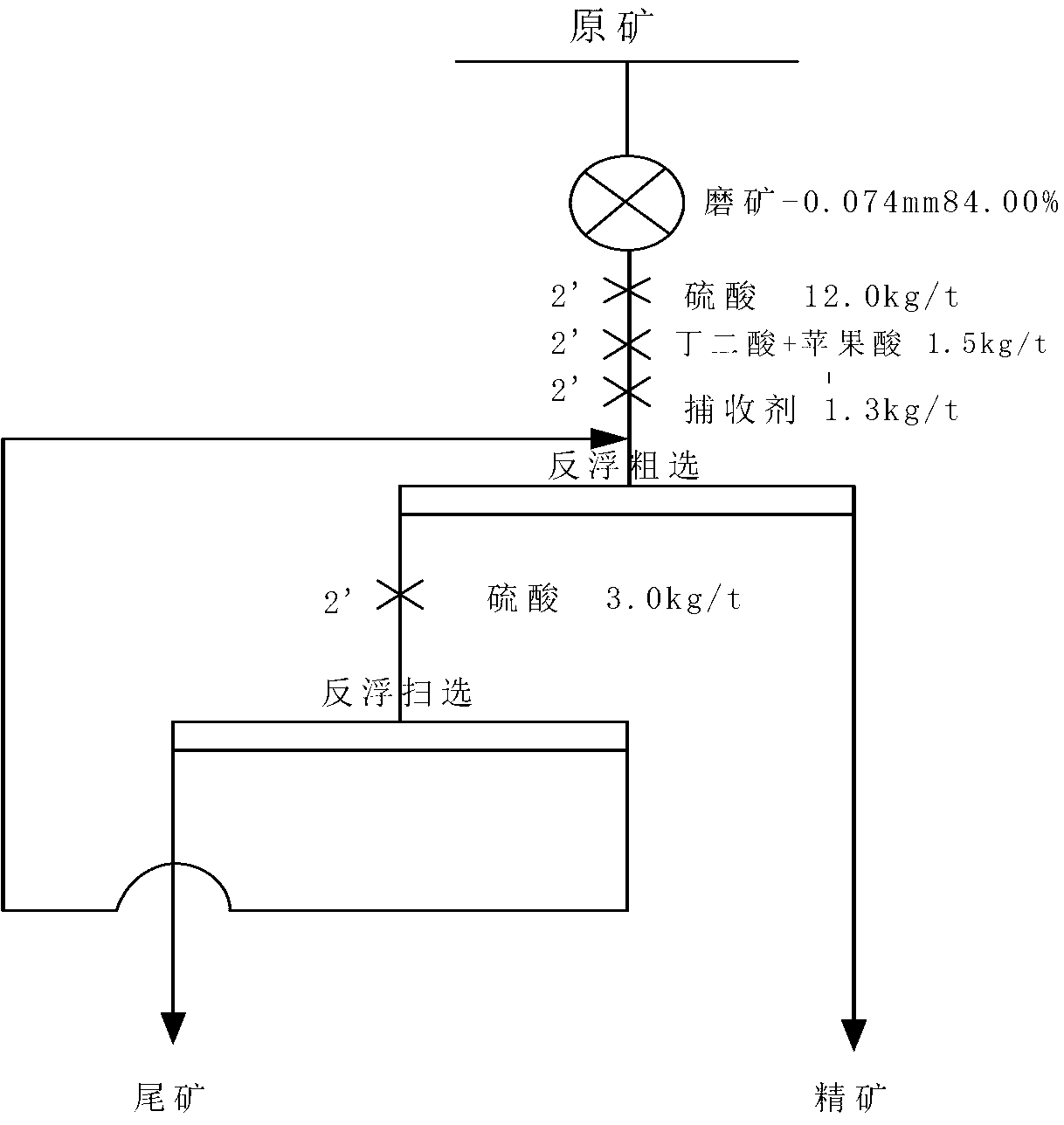

Phosphorite reverse flotation process

ActiveCN103212484ANo pollution in the processEfficient separationFlotationOrganic acidPhosphoric acid

The invention relates to a phosphorite reverse flotation process which comprises the following steps: after carrying out ore crushing, ore grinding and size mixing on phosphorite, enabling the obtained product to enter the reverse flotation process, wherein ore pulp obtained after size mixing is added with sulfuric acid or phosphoric acid to form a regulator and an inhibitor and then is added with micromolecule organic acid to form a combined inhibitor for inhibiting phosphate minerals; carrying out reverse flotation to separate out carbonate minerals by using fatty acids or fatty acid soaps as a collecting agent so as to obtain high-grade low-magnesium phosphate concentrates. The phosphorite reverse flotation process has the following advantage that the micromolecule organic acid inhibitor is adopted to implement effective separation of collophanite and dolomite, so that the grade of the phosphate concentrates is improved, the grade of tailings is reduced and the recovery rate can be improved. Meanwhile, application of phosphoric acid and derivatives thereof to phosphorite reverse flotation is replaced, so that phosphorus resources are saved, service time of phosphate rock resources is prolonged and the defects in the prior art are overcome.

Owner:远安县燎原矿业有限责任公司

Slope artificial soil conditioner with water retention role

InactiveCN101391930ALow costStrong targetingClimate change adaptationExcrement fertilisersRevegetationSodium Bentonite

The invention provides a conditioner for artificial soil on a slope with the function of water retention, which is prepared by the following raw materials according to weight percentage by compounding and mixing: 10 to 25 percent of livestock manure, 25 to 50 percent of super absorbent resin, 5 to 15 percent of ground phosphorite, 1 to 5 percent of anhydrite powder, 20 to 35 percent of humic acid, 5 to 10 percent of zeolite powder, 1 to 10 percent of chitosan, 0 to 10 pecent of bentonite, 0 to 5 percent of phosphate ester and 0 to 5 percent of citrate acid. The conditioner has obvious effects of enhancing the water retention of soil, reducing the water loss and soil erosion, improving the physical and chemical properties of soil and promoting the revegetation.

Owner:SICHUAN UNIV

Process for extracting rare-earth from sulfuric acid treating phosphorite process

ActiveCN101824536AEasy extractionHigh yield of rare earth extractionProcess efficiency improvementRare-earth elementPhosphorite

The invention provides a process for extracting rare earth from a sulfuric acid treating phosphorite process. In the process, a sulfuric acid refining process and a rare earth extracting process are combined, and the rare earth is reclaimed from low-concentrate sulfuric acid raffinate generated in a crude phosphoric acid extracting and refining process so as to realize reclamation of a rare-earth element. The process comprises the following steps of: (1) extracting the rare-earth element from the raffinate by adopting acidic or neutral extractant to obtain rare earth loaded organic phase and secondary raffinate; (2) washing the rare earth loaded organic phase and performing back extracting on the rare earth-loading organic phase by using acid to obtain rare earth strip liquor and blank organic phase; and (3) precipitating the rare earth strip liquor to obtain solid rare earth salt after pH value of the obtained rare earth strip liquor is adjusted, and calcining the strip liquor to obtain rare earth oxide. The process has the advantages of realizing reclamation of the rare-earth element, relatively easily extracting the rare earth, along with high rare earth extraction yield.

Owner:GRIREM ADVANCED MATERIALS CO LTD

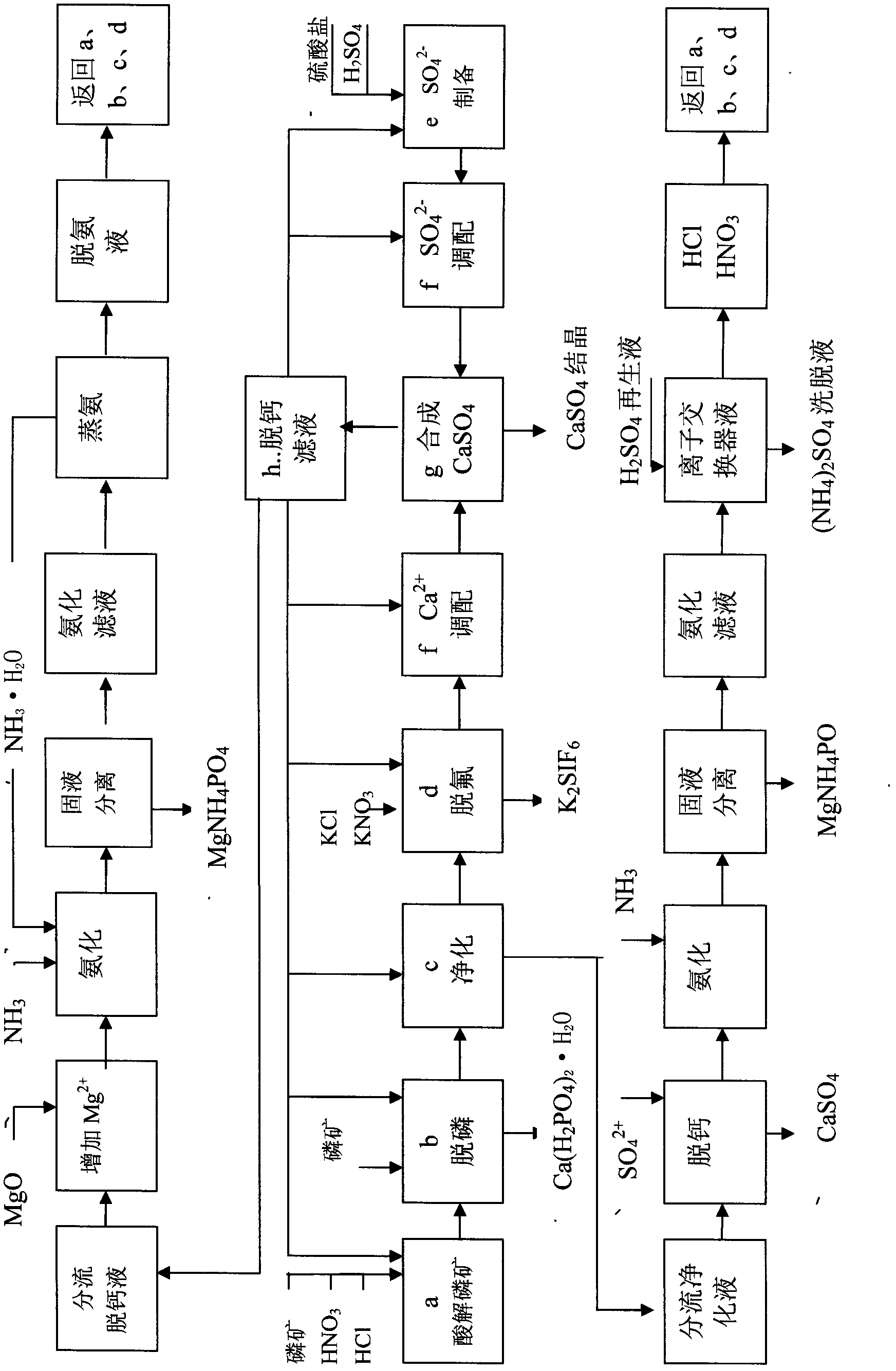

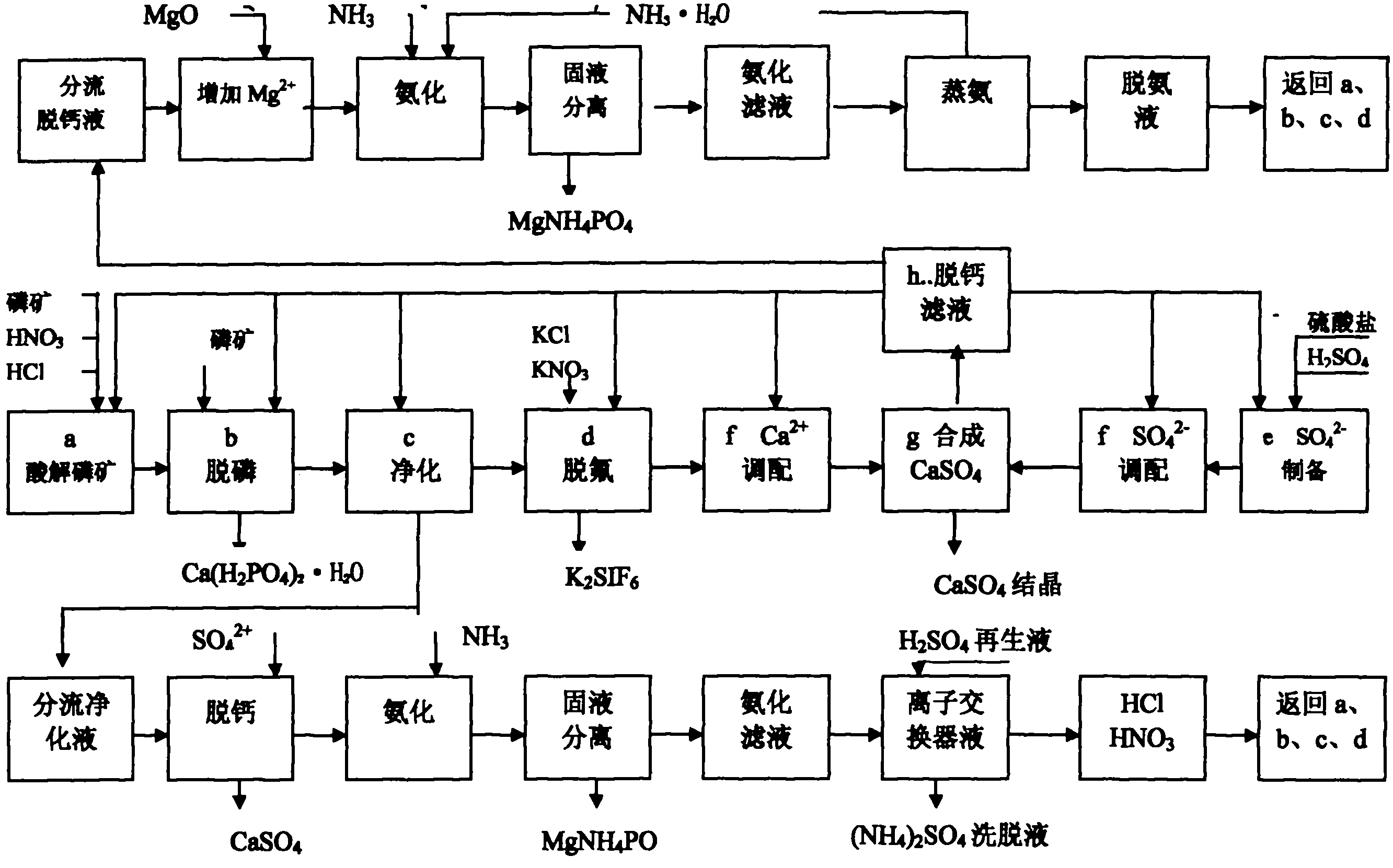

Method for producing high-water solubility nitrophosphate fertilizer by phosphorite nitrolysis and calcium nitrate freezing

InactiveCN102351590APromote absorptionImprove qualityCalcium/strontium/barium carbonatesFertilizer mixturesSolubilityChemical industry

The invention discloses a method for producing high-water solubility nitrophosphate fertilizer by phosphorite nitrolysis and calcium nitrate freezing. The high-water solubility nitrophosphate fertilizer is prepared from the processes of phosphorite nitrolysis, fluorine removal, calcium nitrate freezing separation, further removal of calcium in ammonium sulfate, ammonia liquor neutralization and deposition removal of impurities, and evaporation concentration and crystallization. Specially, the method for producing high-water solubility nitrophosphate fertilizer by phosphorite nitrolysis and calcium nitrate freezing comprises the following steps of 1, acidolysis, 2, fluorine removal, 3, calcium nitrate freezing crystallization, 4, double decomposition removal of calcium in ammonium sulfate,5, neutralization and deposition removal of impurities, 6, evaporation concentration and crystallization, and 7, phosphogypsum transformation. The high-water solubility nitrophosphate fertilizer prepared by the method has a dissolution rate great than or equal to 99.9% in water, wherein nitrate nitrogen is easy for be absorbed by drops, satisfies requirements of a few commercial crops, has a highutilization rate, and improves a crop yield by 8 to 25% and crop quality. The method reduces waste discharge, is environmentally friendly, can be utilized for structure adjustment and product upgradeand update of the traditional phosphorus chemical industry, and has good economic and environmental benefits.

Owner:GUIZHOU RES INST OF CHEM IND

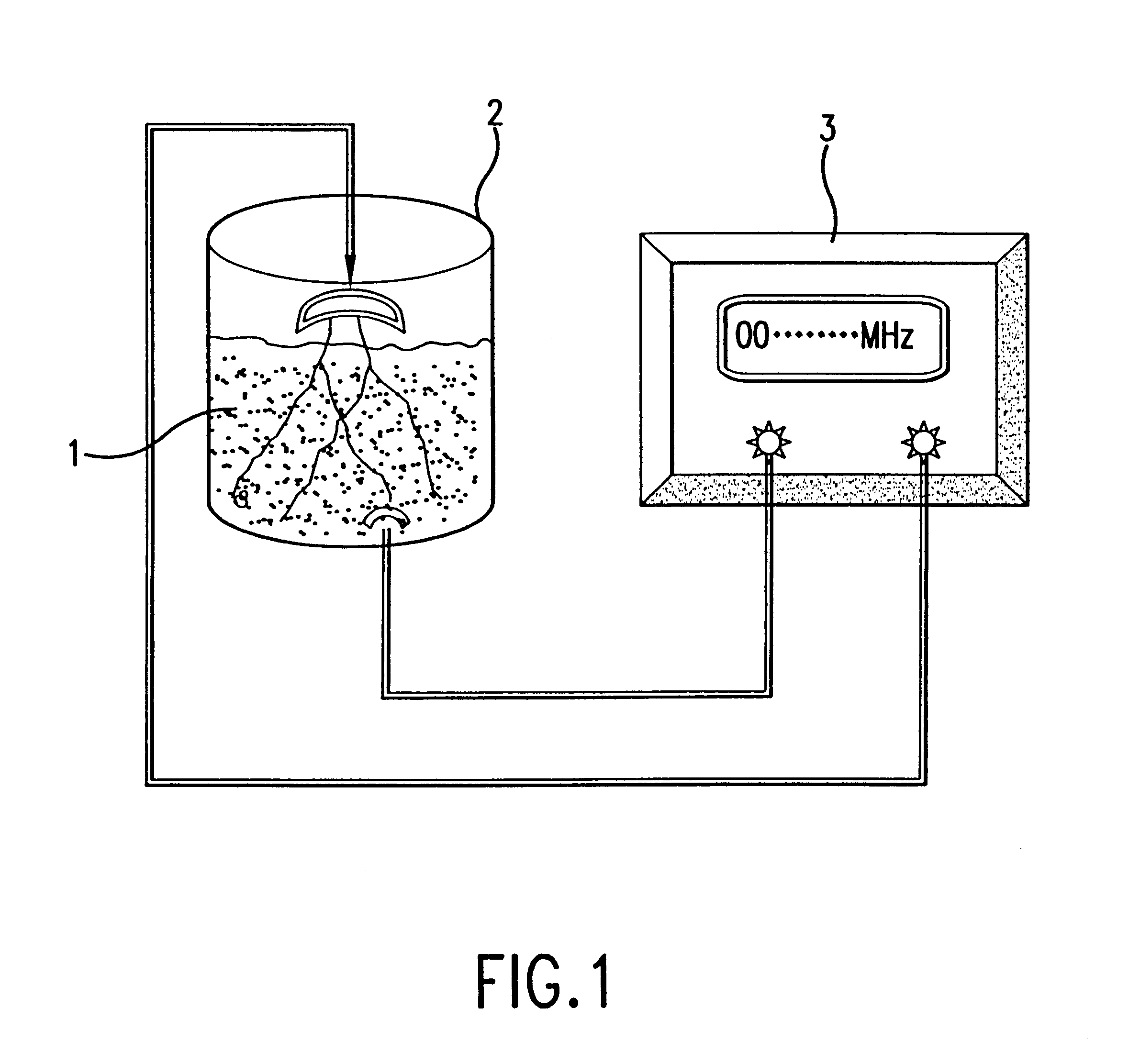

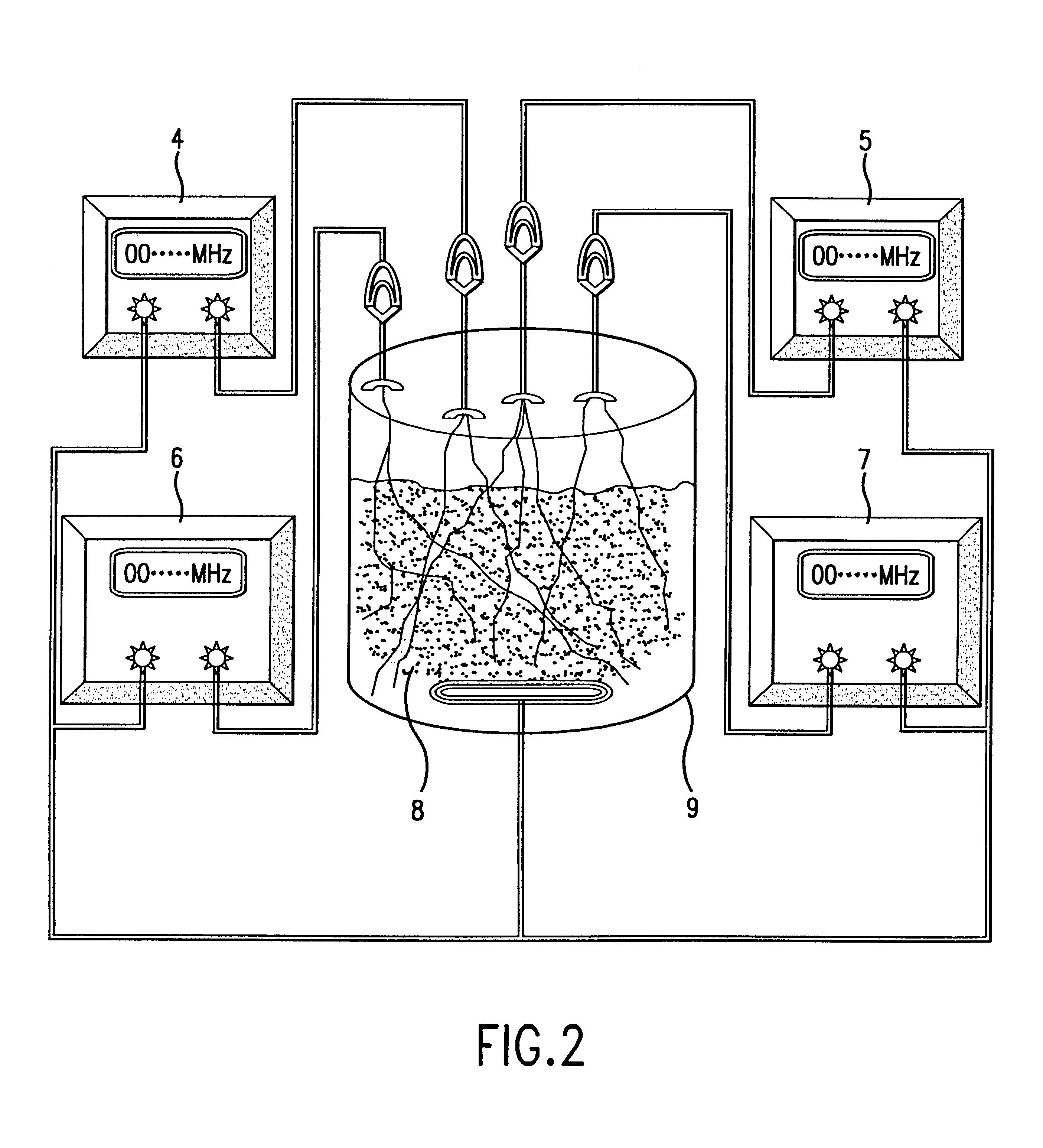

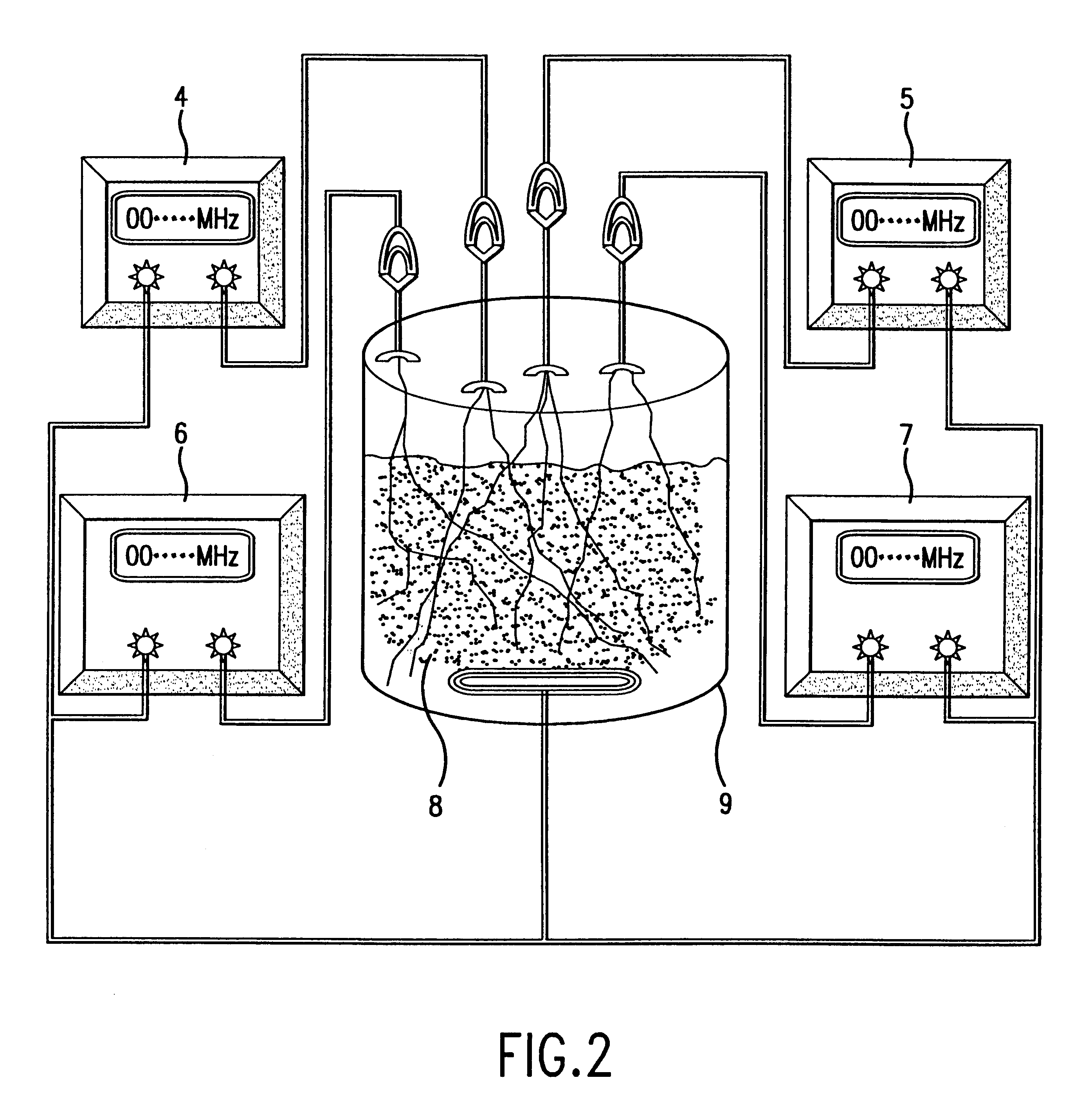

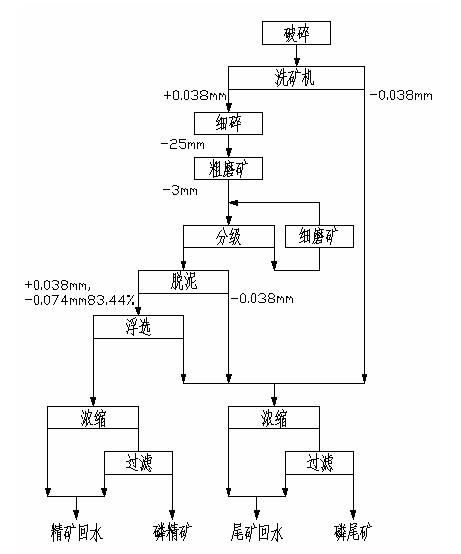

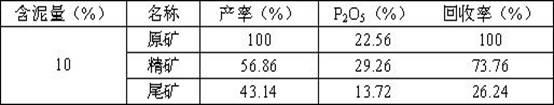

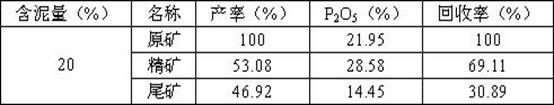

Direct and reverse flotation desliming process of collophanite

The invention discloses a flotation desliming process of collophanite. The flotation desliming process of collophanite comprises the following steps of: scrubbing collophanite crude ore; dividing the crude ore into a coarse fraction part and a fine fraction part according to different particle diameters of particles; feeding the coarse fraction part into a grinding and classification flow after getting the coarse fraction part through an ore washer; feeding into a hydraulic cyclone to deslime for the first time; feeding a settled sand part into a direct and reverse flotation flow after getting the settled sand part through the hydraulic cyclone to obtain flotation concentrate and flotation tailing; removing fine silt from the fine fraction part after getting the fine fraction part throughthe hydraulic cyclone; concentrating and filtering the flotation concentration to obtain finished products phosphate concentrate and concentrate backwater; concentrating and filtering desliming tailing of the ore washer, desliming tailing of the hydraulic cyclone and flotation tailing to obtain phosphorus tailing and tailing backwater; recycling the concentrate backwater and tailing backwater; and returning to each backwater utilization site in the ore washer or a flotation plant. According to the flotation desliming process, the flotation recovery rate and the concentrate grade can be improved, the agent consumption is reduced, and the utilization efficiency of flotation equipment is increased.

Owner:云南三明鑫疆磷业股份有限公司

Collophanite flotation collector and method for preparing same

ActiveCN101797536AStable chemical propertiesGood water solubilityFatty acids production/refiningFlotationSolubilityFatty acid

The invention relates to a collophanite normal-temperature flotation collector, in particular to collophanite flotation collector prepared from natural rubber seed oil fatty acid, belonging to the collector. The invention also relates to a method for preparing the collophanite flotation collector. The collophanite flotation collector comprises natural rubber seed oil fatty acid, tall oil, tributyl phosphate, tween 80, dodecyl benzene sulfonic acid, inorganic base and water. The collophanite flotation collector has stable chemical performance, good water solubility, high flotation speed, suitable viscosity and strong selectivity and collection performance, is easy to diffuse in collophanite pulp, can be used for obverse floatation and reverse flotation and can generate uniform bubbles, obviously shorten the floatation time, improve the concentrate grade and reduce the content of impurities in the concentrate product.

Owner:YUNNAN CHEM RES INST

Reverse/direct flotation technology of collophanite

The invention discloses a reverse / direct flotation technology of collophanite. The technology comprises the following steps of: performing ore reduction, ore grinding and size mixing on the silicon calcium type collophanite; adding a carbonate gangue mineral flotation regulator and fatty-acid soap respectively to perform size mixing; performing reverse flotation on the material after the size mixing, wherein the product in the tank is reverse flotation concentrate; dehydrating the reverse flotation concentrate and adding sodium carbonate so as to adjust the pH value to 8-10; performing closed-loop ore grinding and grading on the base flow; enabling the grading overflow to enter a direct flotation stirring tank, and adding water glass and fatty acid soap into the tank respectively to perform size mixing; performing direct flotation on the material subjected to the size mixing, wherein the direct flotation foam product is direct flotation concentrate; and performing concentration, filtration and drying to obtain the finished product of phosphate concentrate. After dehydration (reagent removal), the technology disclosed by the invention can be used for remarkably reducing the amount of sodium carbonate for neutralizing acid water; the sodium carbonate has a dispersion and grinding aid function, and the over-grinding of the material of direct flotation can be reduced; and the fresh surface and proper size composition generated by the ore grinding are favorable for improving the sorted behavior of the direct flotation and improving the sorting efficiency.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

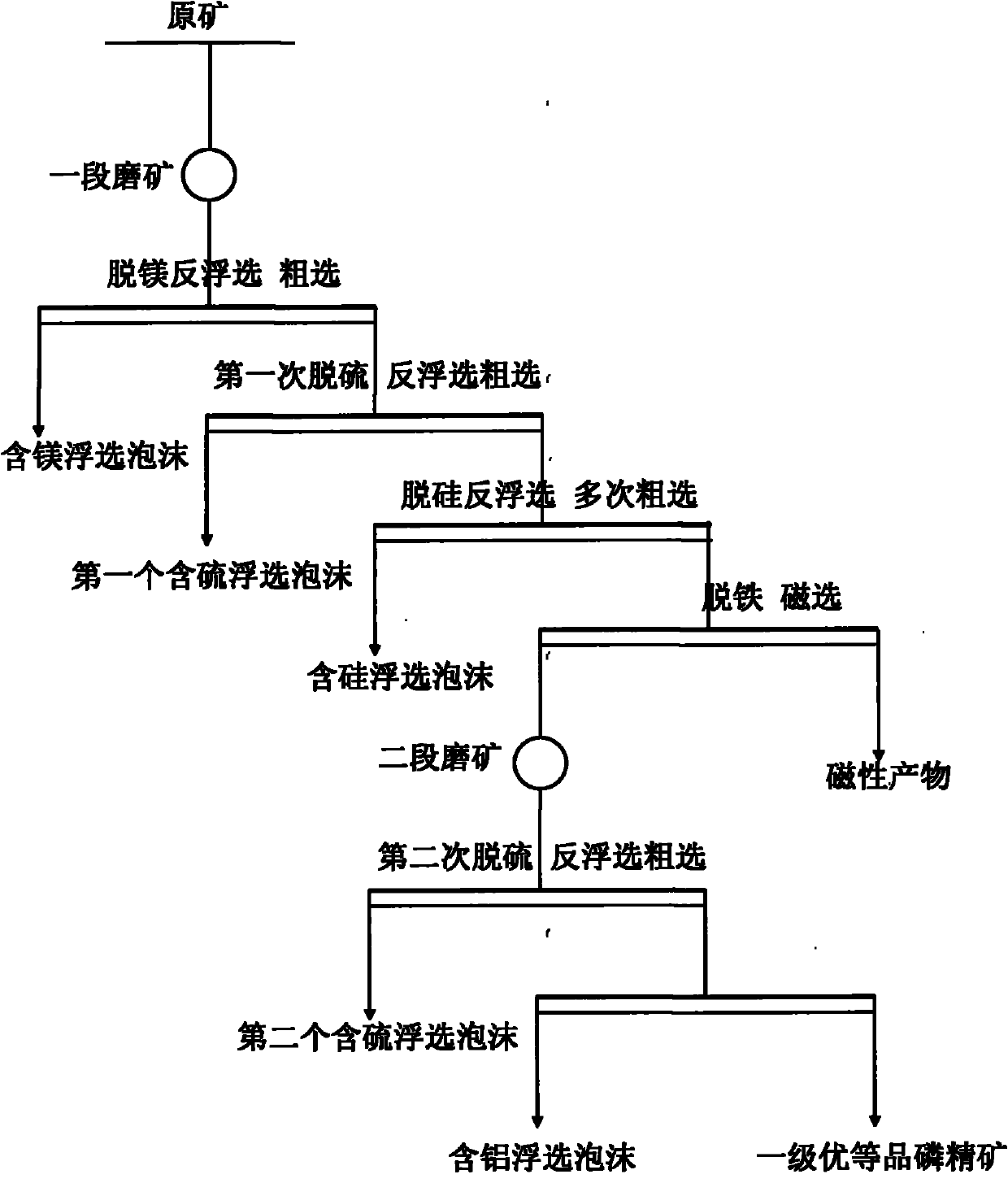

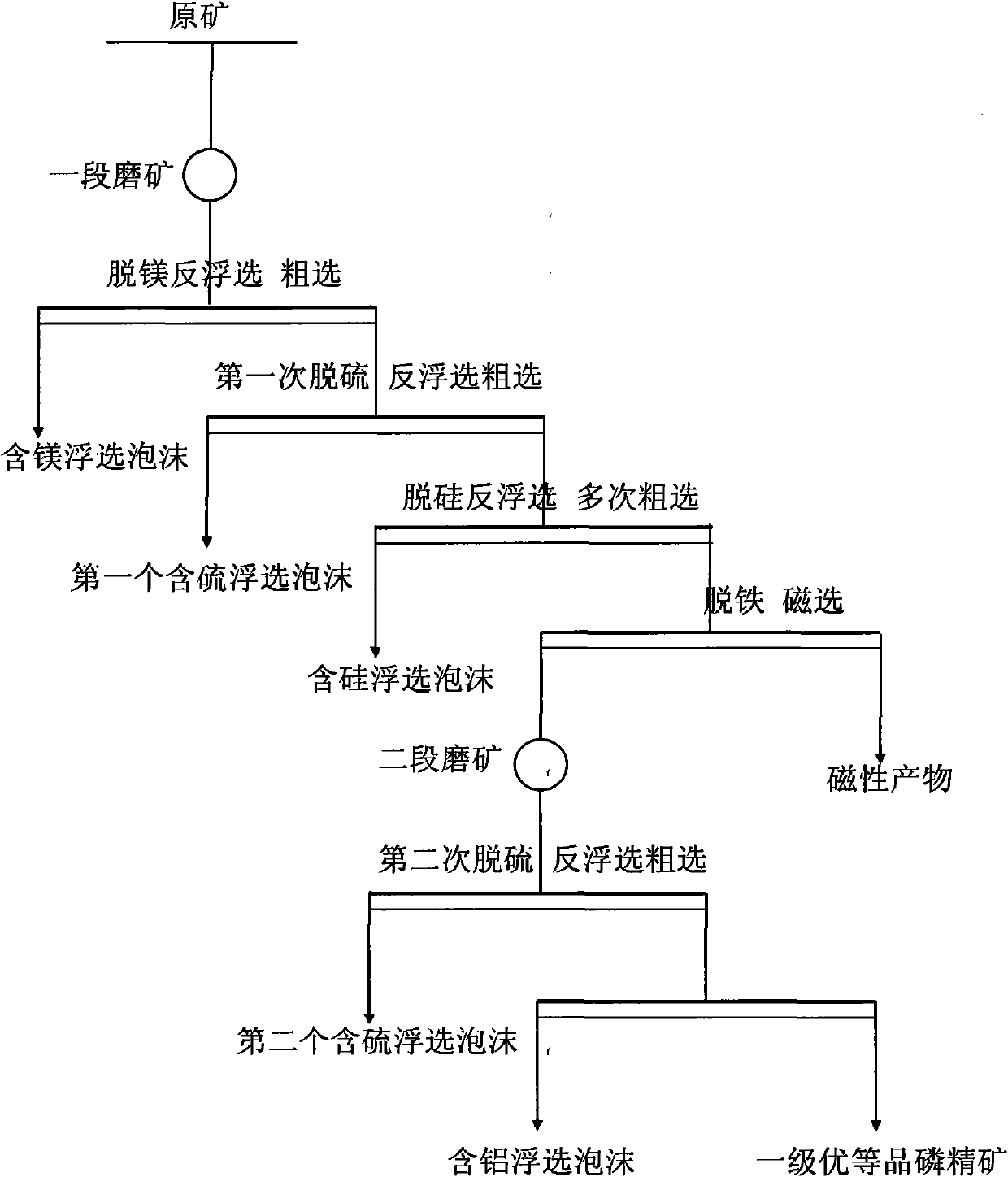

Method for separating collophanite

The invention relates to a method for separating collophanite, which is characterized by comprising the following steps of: (1) coarsely grinding raw collophanite; (2) performing reverse floatation on the grinding product to remove magnesium; (3) reacting floatation base flow of the step (2) with a desulfurization floatation medicament for reverse floatation to remove sulfur; (4) reacting the floatation base flow in the step (3) with a desilicification floatation medicament for reverse floatation to remove silicon; (5) performing intensity magnetic separation on the floatation base flow in the step (4) to remove iron; (6) regrinding a non-magnetic product in the step (5); (7) reacting the grinding product in the step (6) with a desulfurization floatation medicament for reverse floatation to remove sulfur; and (8) reacting the floatation base flow in the step (7) with a dealumnization floatation medicament for reverse floatation to remove aluminum to obtain aluminum-containing floatation foam and the floatation base flow, wherein the floatation base flow is the final phosphorus concentrate. The method can perform floatation at normal temperature and even low temperature to obtain phosphorus concentrate, and has the advantages of high separation property, low energy consumption and effective improvement of the P2O5 recovery rate.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Biological fertilizer compositions comprising garbage

The present invention provides biological fertilizer compositions that comprise yeast cells and garbage. The yeast cells of the invention have an enhanced ability to fix atmospheric nitrogen, decompose phosphorus minerals and compounds, decompose potassium minerals and compounds, decompose complex carbon compounds, overproduce growth factors, overproduce ATP, decompose undesirable chemicals, suppress growth of pathogenic microorganisms, or reduce undesirable odor. The biological fertilizer composition of the invention can replace mineral fertilizers in supplying nitrogen, phosphorus, and potassium to crop plants. Methods of manufacturing biological fertilizer compositions, and methods of uses are also encompassed.

Owner:ULTRA BIOTECH

Phosphate beneficiation process using methyl or ethyl esters as float oils

ActiveUS20050269248A1Fatty/oily/floating substances removal devicesSewerage structuresPhosphoriteEthyl ester

A process for use in a phosphate ore beneficiation process to minimize the long-term environmental impact of the use of petroleum based hydrocarbon materials mixed with fatty acid based primary floatation reagents for froth flotation in the flotation of phosphate ores, wherein the process comprises substituting the petroleum based hydrocarbon materials with methyl and / or ethyl esters of fatty acids.

Owner:ARRMAZ PROD INC

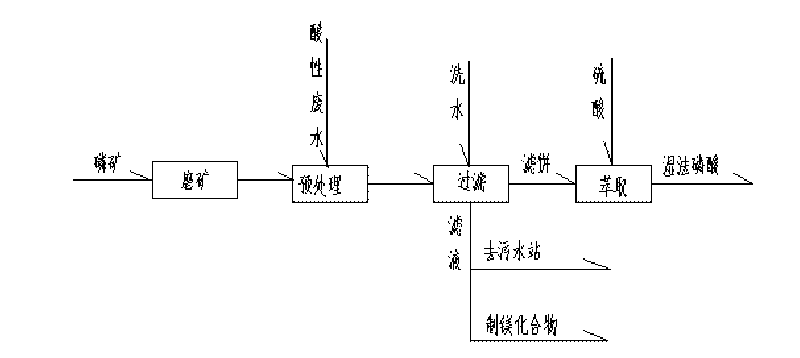

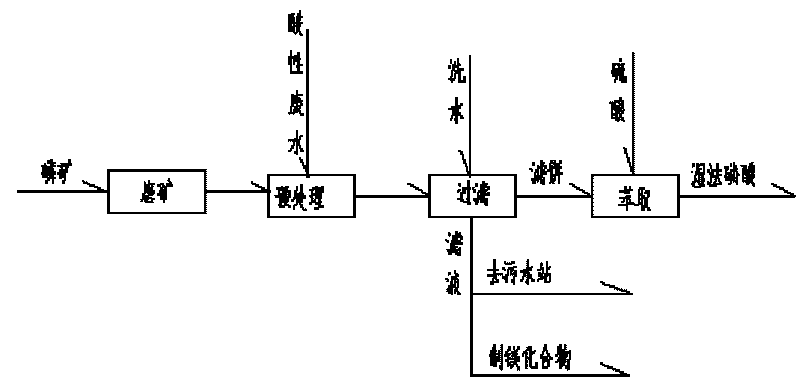

Method for pre-treating phosphorite by using acidic waste water in the production process of titanium pigment

ActiveCN101759166AReduce processing costsControl the strength of sulfuric acidPhosphoric acidPhosphoric acidSlurry

The invention discloses a method for pre-treating phosphorite of wet process phosphoric acid by using acidic waste water in the production process of titanium pigment, which comprises the following steps: (1), collecting the acidic waste water into an acidic waste water storage groove, controlling the acid degree to be 2 to 5 percent and the total iron concentration to be 0.3 to 0.5 percent; (2), adding the acidic waste water and the milled phosphorite in a solid-to-liquid ratio of 2-5:1 into a reaction groove for reaction; and (3), performing solid-liquid separation on the slurry which is obtained in the step (2) to obtain a solid phase, namely the required phosphorite. The content of magnesium in the phosphorite which is treated by the method is reduced by over 70 percent, the loss ratio of the phosphorus is controlled to be within 1 percent; when the phosphorite which is treated by the process is used for producing the phosphoric acid by a wet method, the consumption of the sulfuric acid for mine per ton is reduced by about 10 percent; and the acidic waste water pretreats phosphorite and then is delivered to a sewage station for treatment, the consumption of lime or other alkaline substance is reduced by 60 percent compared with the mode of directly delivering the waste water to the sewage station, so the economical efficiency of the process is high.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Passivator for controlling pollutions of heavy metals copper, lead and cadmium on soil and applications thereof

InactiveCN102559198ADoes not destroy physical and chemical propertiesPassivation is effectiveContaminated soil reclamationOrganic fertilisersSoil heavy metalsMaterials science

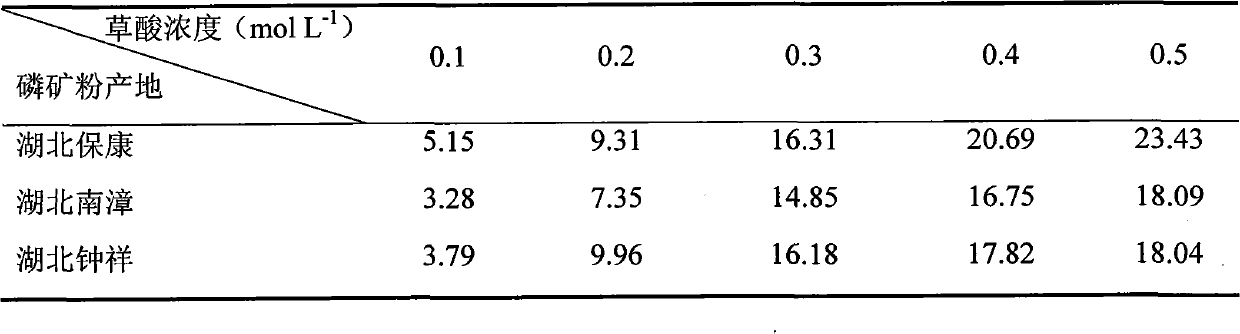

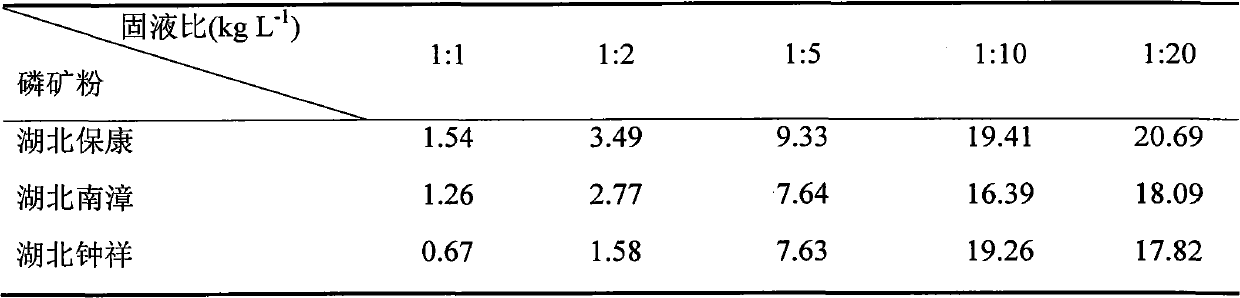

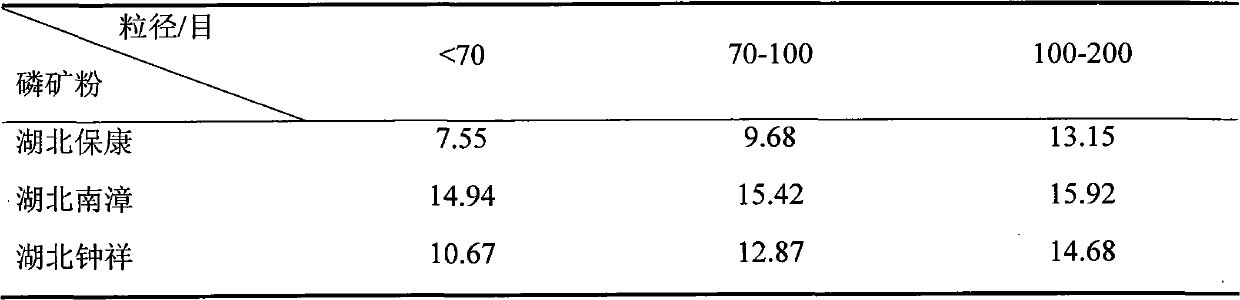

The invention belongs to the technical field of soil heavy metal pollution control and particularly relates to a passivator which is suitable for the in-situ control of the pollutions of heavy metals copper, lead and cadmium on soil and applications thereof. The passivator uses middle-grade and low-grade phosphate ore powder as the main raw material and the heavy metal passivator is prepared to passivate heavy metals in soil. The preparation method of the passivator comprises the following steps: smashing the middle-grade and low-grade phosphate ore of which P2O5 content is 20-30%, sieving with a 100 meshes of screen to obtain phosphate ore powder, mixing the phosphate ore powder with 0.1-0.7mol / L of oxalic acid according to the solid-to-liquid ratio of 1:1-1:20, activating at 28 DEG C for 6 days, and then drying at 50 DEG C for 20-24h to obtain the passivator. 3.97g of the prepared passivator is applied in 1kg of soil which is polluted by heavy metals; and the lettuce which grows for 120 days is harvested, and sampling is performed to measure the content of various forms of heavy metals in soil and the plant absorption amount. The passivator fully utilizes the middle-grade and low-grade phosphate ore resource which is difficult in use in China; and the passivator has the characteristics that the investment is low, the engineering quantity is low, the physicochemical properties of soil can not be damaged and secondary pollution can not be caused.

Owner:HUAZHONG AGRI UNIV

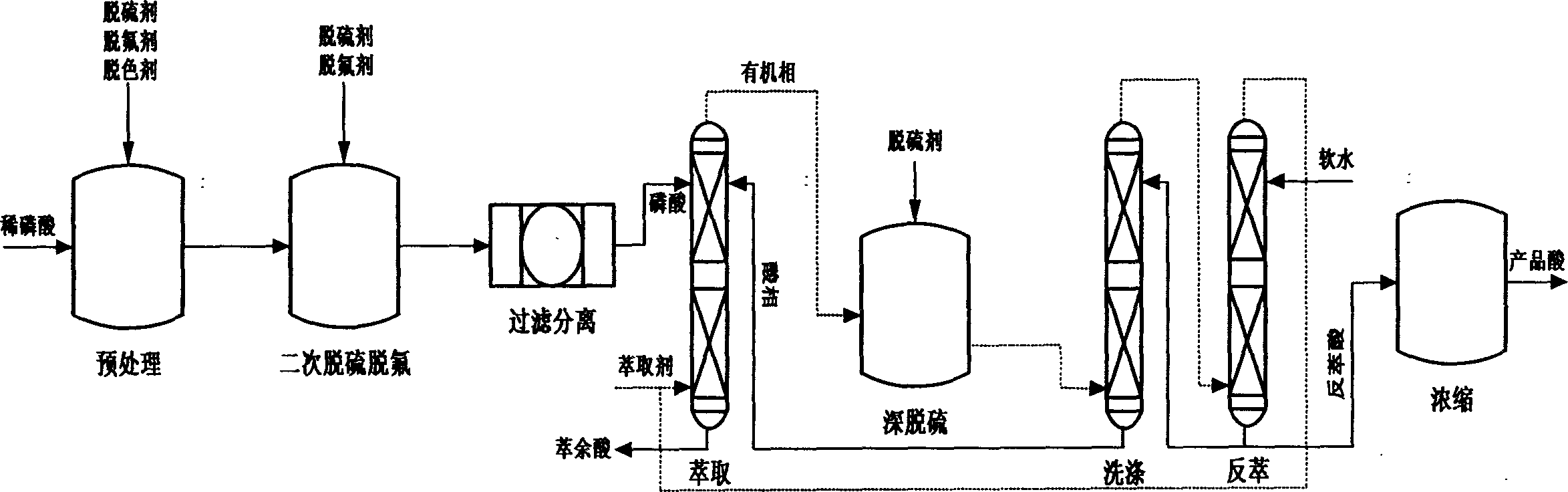

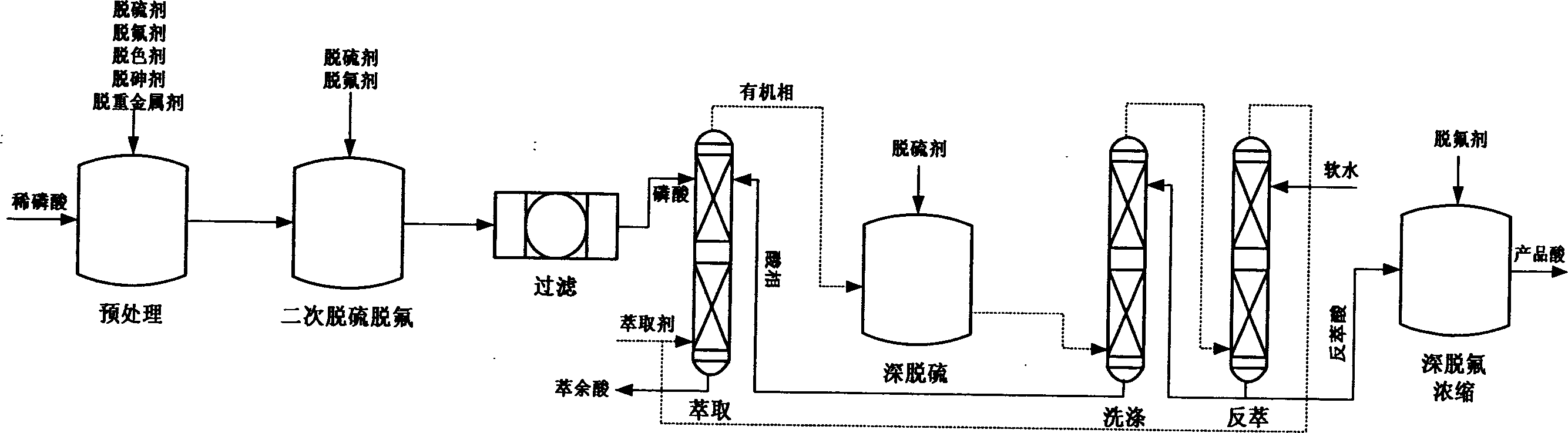

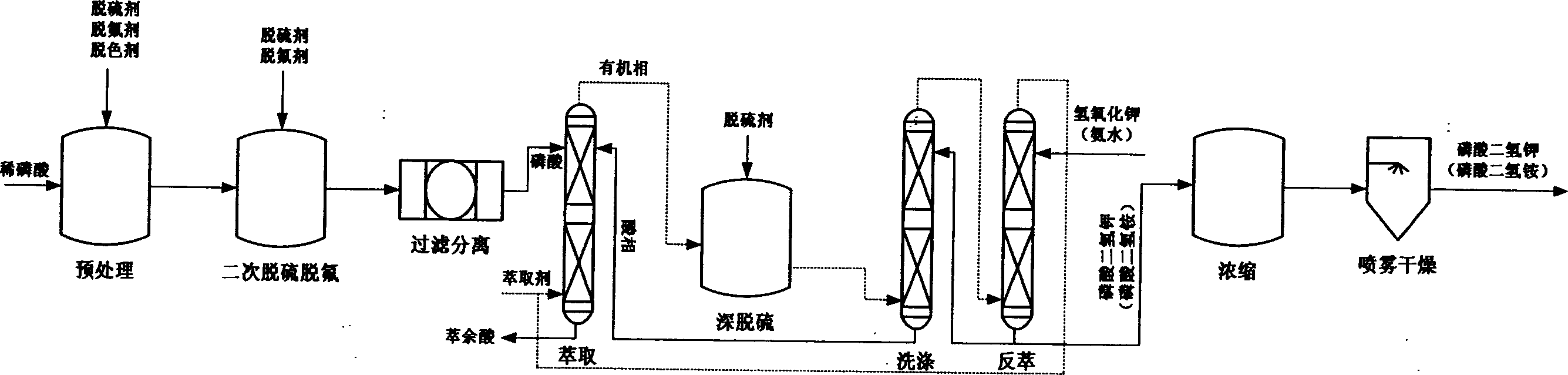

Method for preparing technical grade phosphoric acid, foodstuff grade phosphoric acid and phosphate using wet method and thin phosphoric acid

The invention discloses a method for preparation of technical grade phosphoric acid with wet- process diluted phosphoric acid, which sequentially contains pretreation, secondary desulfurizion and defluorination, filteration and separation, extraction, deeply desulfurization, washing, retrograde extraction and concentration. Different from method for preparation of food-grade phosphoric acid with wet-process diluted phosphoric acid, the pretreating contains not only desulfurization, defluorination, decoloring, but also de-arsenic, de-heavy metal, and defluorination and deep concentration proceeds parallelly after retrograde extraction. The process of preparation of technical grade phosphoric acid with wet- process diluted phosphoric acid sequentially contains pretreation, secondary desulfurization and defluorination, filteration and separation, extraction, deeply desulfurization, washing, retrograde extraction, concentration, spray drying or shotcrete granulation, the extractant using in the process of retrograde extraction being KOH saturated solution or NH4OH saturated solution. With said process, it can decrease the energy consumption and the production cost; and it can produce and purify phosphoric acid, and also directly produce plural of phosphonate with the same device.

Owner:SICHUAN JINGCUI CHEM TECH

Acidolysis method of magnesium-containing phosphate rock

ActiveCN102417169AAchieving Theoretical UtilizationEasy to processCalcium/strontium/barium sulfatesAmmonium sulfatesHigh magnesiumPhosphor

The invention discloses an acidolysis method of magnesium-containing phosphate rock. The method provided by the invention is characterized by comprising the following steps of: carrying out acidolysis on the magnesium-containing phosphate rock to obtain a water-soluble calcium, magnesium and phosphoric acid containing acidolysis solution, carrying out acidolysis on the phosphate rock by using the generated phosphoric acid to generate Ca(H2PO4)2.H2O solid, performing a reaction between H2SO4 and water-soluble calcium to generate high-pureness calcium sulfate whisker, and performing a reaction between water-soluble magnesium and phosphor in the acidolysis solution and NH3 to generate character separation magnesium ions of a MgNH4PO4 solid so as to realize complete high-efficiency comprehensive utilization of the acidolyzed magnesium-containing phosphate rock. The focus of the invention is to change magnesium ions into controllable parameters which are beneficial to circulation of the acidolysis solution. The magnesium-containing phosphate rock can be efficiently utilized, and also the compound magnesium ammonium phosphate can be used to realize the separation of phosphor magnesium from a circulation medium HCl or HNO3 or CaCL, Ca(NO3)2, thus realizing the combination and combined production with a present ammonium phosphate and phosphor product processing technology. The method provided by the invention has advantages of concise technology, less investment, low energy consumption, low cost, high benefit and no discharge of ''three wastes (waste gas, wastewater and industrial residue)'', and fully presents great business value and great resource value of the high magnesium-containing phosphate rock.

Owner:武善东 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com