Phosphorite reverse flotation process

A reverse flotation and process technology, applied in flotation, solid separation, etc., can solve the problems of high cost of mineral processing, low selectivity, poor inhibition, etc., and achieve the effects of high selectivity, improved recovery rate, and improved grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

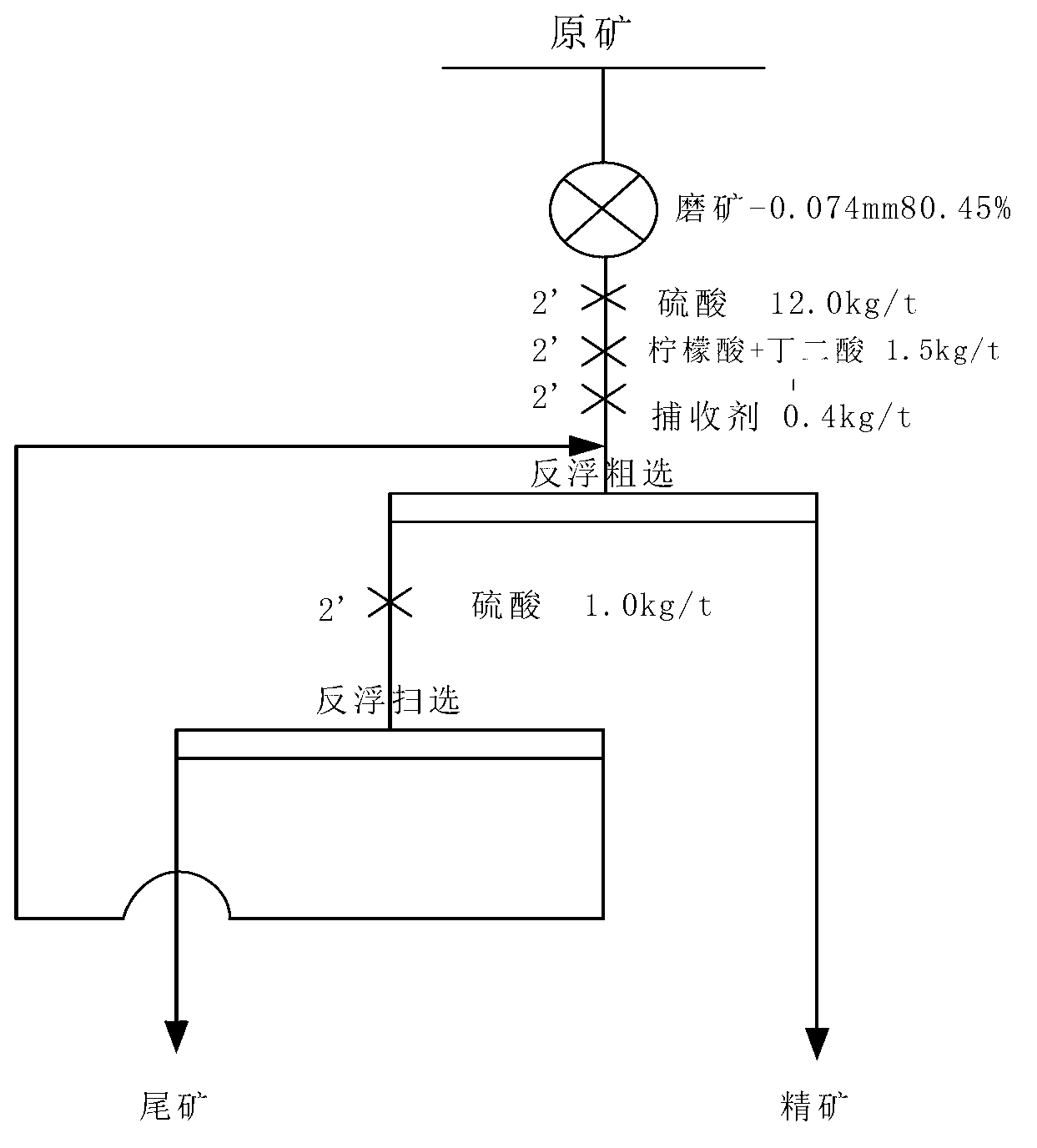

Embodiment 1

[0016] 1) Yichang high magnesium phosphate rock contains P 2 o 5 28.54%, MgO6.03%, the raw ore is crushed to -12mm by a crusher, and then ground by a grinder, the grinding fineness is -0.074mm80.45%, and the slurry is added to the concentration of 20-50%. Flotation roughing first add H 2 SO 4 The dosage is 12kg / t raw ore, adjust the pH of the pulp to 5.2-6, then add citric acid and succinic acid as joint inhibitors, the mass ratio is 2:1, the dosage is 1.5kg / t raw ore, fatty acid anion type The amount of collector TSM-2 is 0.4kg / t raw ore, and the H 2 SO 4 Under the condition of 1kg / t raw ore, reverse flotation-coarse-sweep closed-circuit process test is carried out. The flow chart of the test is shown in Figure 1, and the concentrate P 2 o 5 34.52%, yield 77.19%, P2O5 recovery rate 97.71%. Using sulfuric acid, citric acid and succinic acid as combined inhibitors, the recovery rate increased by 3.78%, the yield increased by 4.01%, and the tailings grade decreased by 3.1...

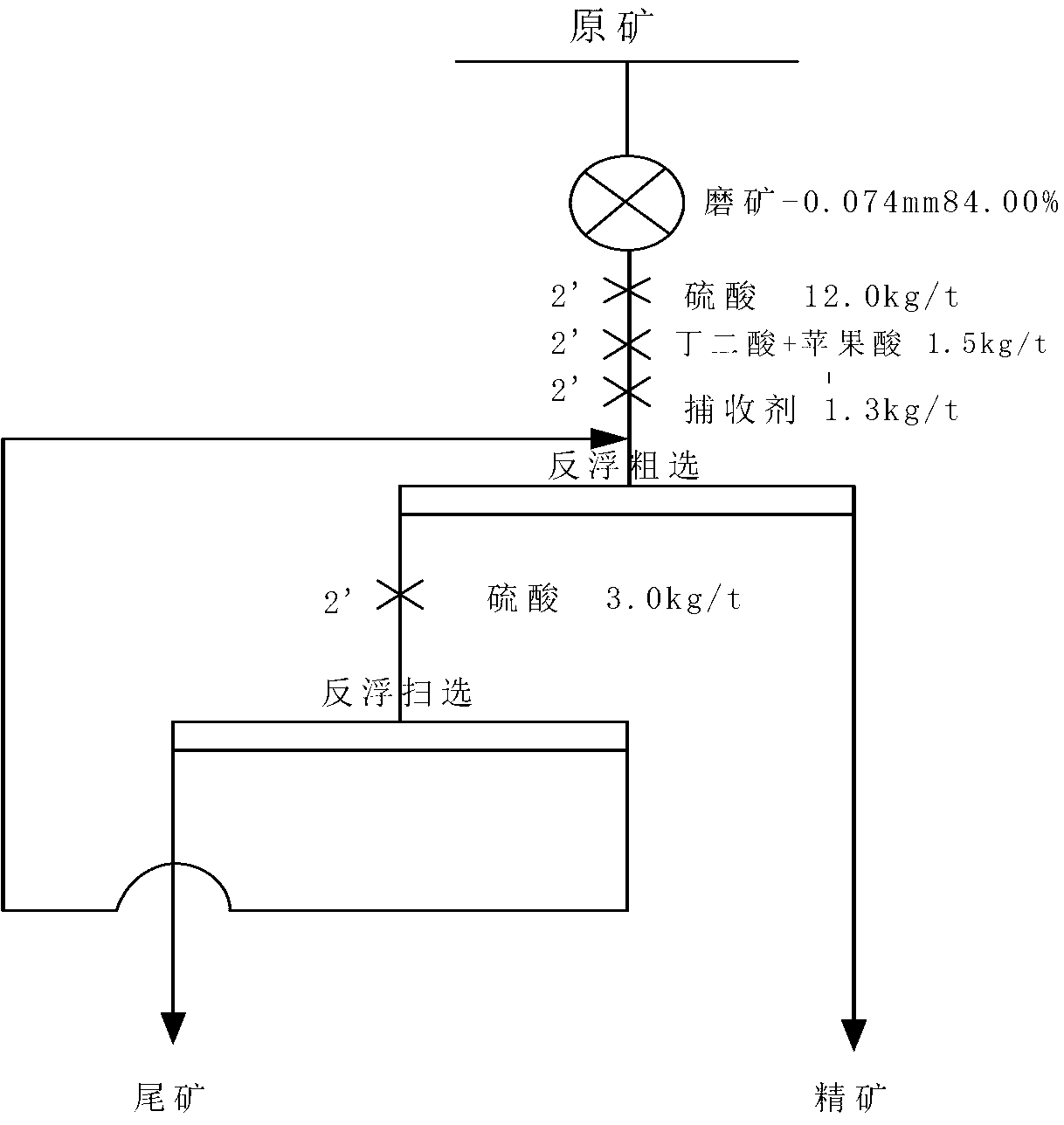

Embodiment 2

[0018] Guizhou phosphate rock contains P 2 o 5 The content of MgO is 23.45% and 3.54%. The raw ore is crushed by a crusher, and then ground by a grinding machine. The grinding fineness is -0.074mm84.00%. Add water to adjust the slurry to a concentration of 20-50%. 2 SO 4 The dosage is 12.0kg / t raw ore, then add succinic acid and malic acid as combined inhibitors, the mass ratio is 3:1, the dosage is 1.5kg / t raw ore, and then add fatty acid anionic TSM-2 to collect agent, the dosage is 1.3kg / t raw ore, sweeping H 2 SO 4 Under the condition of 3.0kg / t raw ore, the reverse flotation-roughing-sweeping closed-circuit process test is carried out. The test flow chart is as follows figure 2 , get concentrate P 2 o 5 30.25%, yield 65.67%, P 2 o 5 The recovery rate was 84.71%.

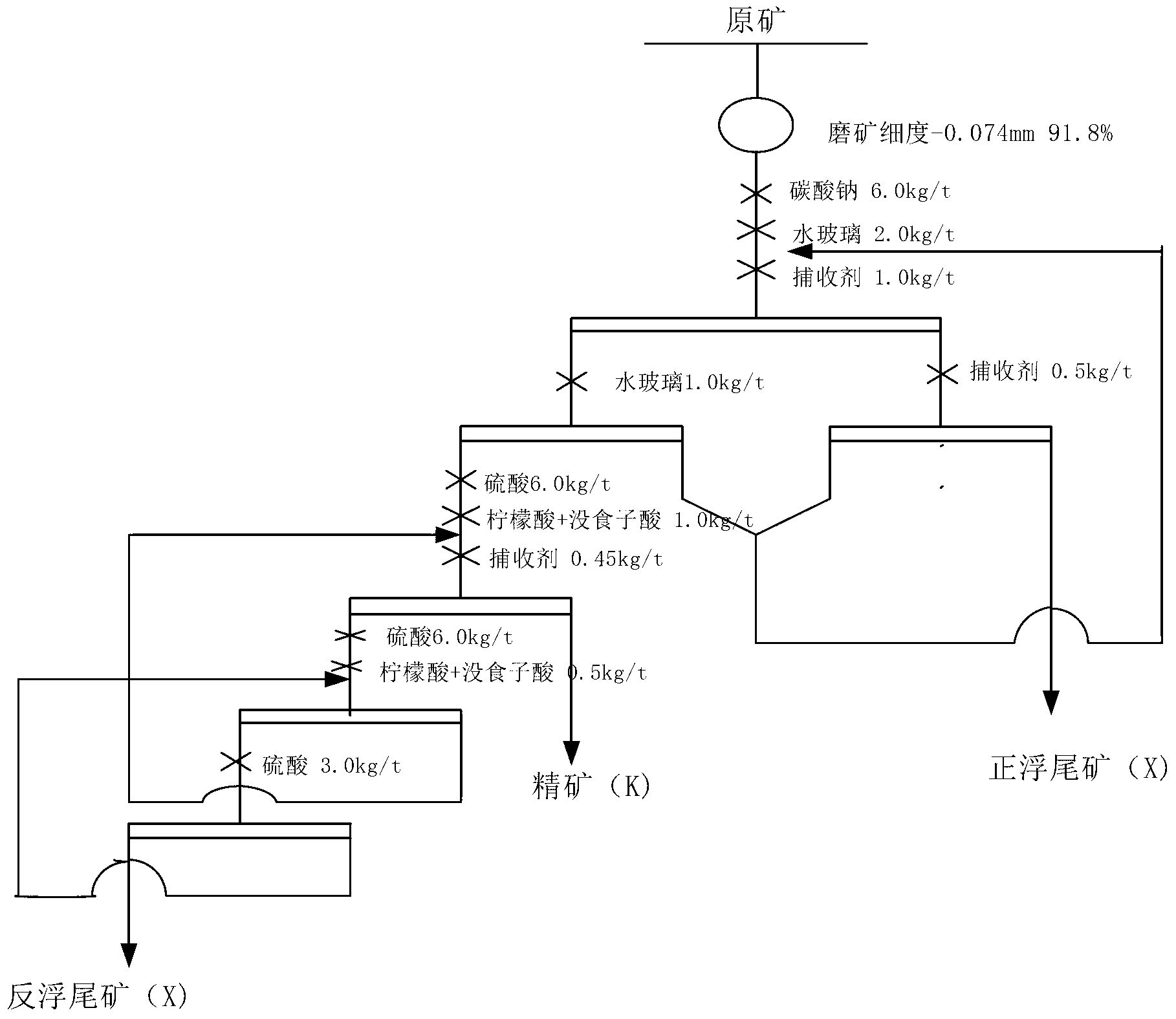

Embodiment 3

[0020] The multi-element analysis of Sichuan phosphate rock is shown in Table 1, Table 1 Chemical multi-element analysis of phosphate rock

[0021] the element

[0022] Using positive and negative flotation at normal temperature, the grade of the raw ore is 17.71%. The raw ore is crushed by a crusher, and then ground by a grinding machine. The grinding fineness is -0.074mm91.8%. Add water to adjust the slurry to a concentration of 20-50%. The positive flotation adopts one roughing, one sweeping and one beneficiation operation. The dosages of roughing sodium carbonate, water glass and fatty acid anionic collector TSM-2 are 6.0kg / t raw ore, 2.0kg / t raw ore, 1.0kg / t raw ore, the dosage of selected water glass is 1.0kg / t raw ore, and the dosage of fatty acid anionic collector TSM-2 is 0.5kg / t raw ore; Sulfuric acid 6.0kg / t raw ore for roughing, citric acid and gallic acid (the mass ratio is 4:1) as joint inhibitor dosage 1.0kg / t raw ore, fatty acid anionic collector TSM-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com