Patents

Literature

303 results about "Carbonate minerals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbonate minerals are those minerals containing the carbonate ion, CO₃²⁻.

Solid-chemical compositions, geochemical binder system, and improved high-shear granulation process for both conventional and slow-release fertilizer and bioremediation nutrient compositions

InactiveUS20020178772A1Less-expensive to produceWiden meansSolid/semi-solid fertilisersMatrix fertilisersSolubilityAdditive ingredient

This invention discloses advanced means for the formulation and preparation of solid-chemical compositions which provide sources of water-soluble nutrients, electron acceptors and other agents for agriculture and waste-treatment, in particular, the bioremediation of contaminated environmental media. The disclosed formulations and means of production of the slow-release solid-chemical compositions of the present invention utilize a novel and economical "biphasic" chemical-system technology which involves a combination of a first "nutrient" component (1) which comprises water-soluble nutrients and other biologically utilizable substances with a second component (2) which comprises an inorganic geochemical-binder system. The simplest embodiment of the geochemical-binder system comprises one or more salts of phosphoric acid. In the preferred embodiments of the present invention intended for the slow-release of the ingredients contained in the "nutrient" component (1), the geochemical-binder system of component (2) comprises a combination of one or more salts of phosphoric acid with a inorganic binder matrix preferably containing a mixture of low-solubility carbonates, carbonate minerals, phosphates and phosphate minerals. The different embodiments of the geochemical-binder system of this invention allows a wide variation of formulations of the nutrient component (1) to be prepared in both conventional and slow-release forms using an improved high-shear granulation process whereby the dangerous chemicals typically used in the granulation process are largely or completely replaced with water. The present invention discloses means by which such compositions can be economically prepared in large quantities so as to meet the specific needs of different sectors of the agricultural / agribusiness and phytoremediation / bioremediation markets. The disclosed solid-chemical compositions of the present invention provide improved, cost-effective means for slowing and controlling the release-rate profiles of water-soluble nutrients, such as nitrogen- and phosphorus-rich compounds, and improved means for enhanced and / or time-targeted nutrient uptake by plants and microorganisms. The present invention also provides improved means for the reduction of nutrient run-off from agricultural areas into surface waters and means of preventing or minimizing nutrient-contamination of ground-water aquifers.

Owner:HINCE ERIC CHRISTIAN MR

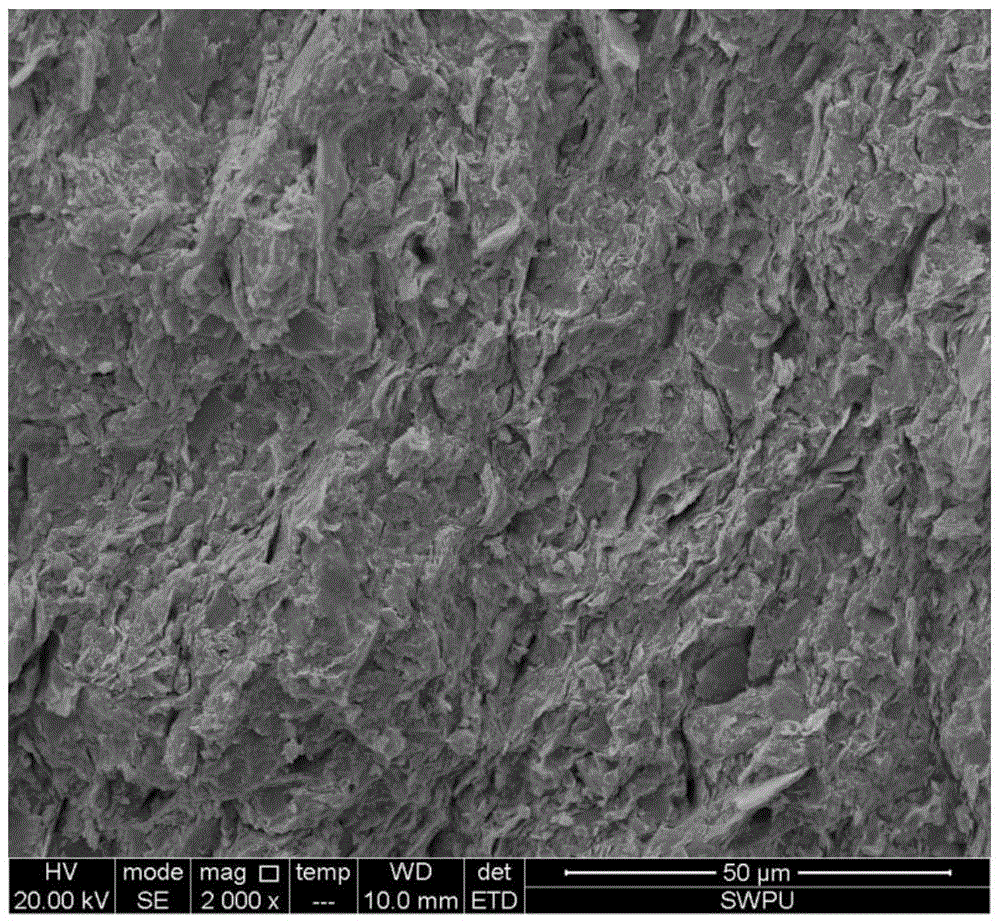

Method for improving complexity index of deep shale gas fracture

ActiveCN106567702AIncreased Fracture Complexity IndexImprove fracturing effectFluid removalEconomic benefitsFracturing fluid

The invention relates to a method for improving the complexity index of a deep shale gas fracture. The method is characterized in that when a fracturing design of the a deep shale gas well is performed, selection and an injection manner of a fracturing fluid, selection of a supporting agent, and the number of perforations are optimized and controlled, and an artificial main fracture can be opened and communicate with a natural fracture as much as possible in an extending process; extension of a single fracture is longer, expansion of the single fracture is wider, and finally the complexity of the deep shale gas fracture can be improved to the greatest extent. The method can be used for deep shale gas reservoirs having the depth of more than 3500 meters and in which the natural fractures containing carbonate minerals are distributed in a reconstruction range of the artificial main fracture, and a certain included angle is formed between the fracturing main fracture and the natural fractures. The method is reasonable in design, is simple in process, is easy to operate, is high in fracturing construction successful rate, can effectively increase the volume of deep shale gas segment fracturing fractures, can remarkably improve the fracturing construction effect, and can acquire more economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

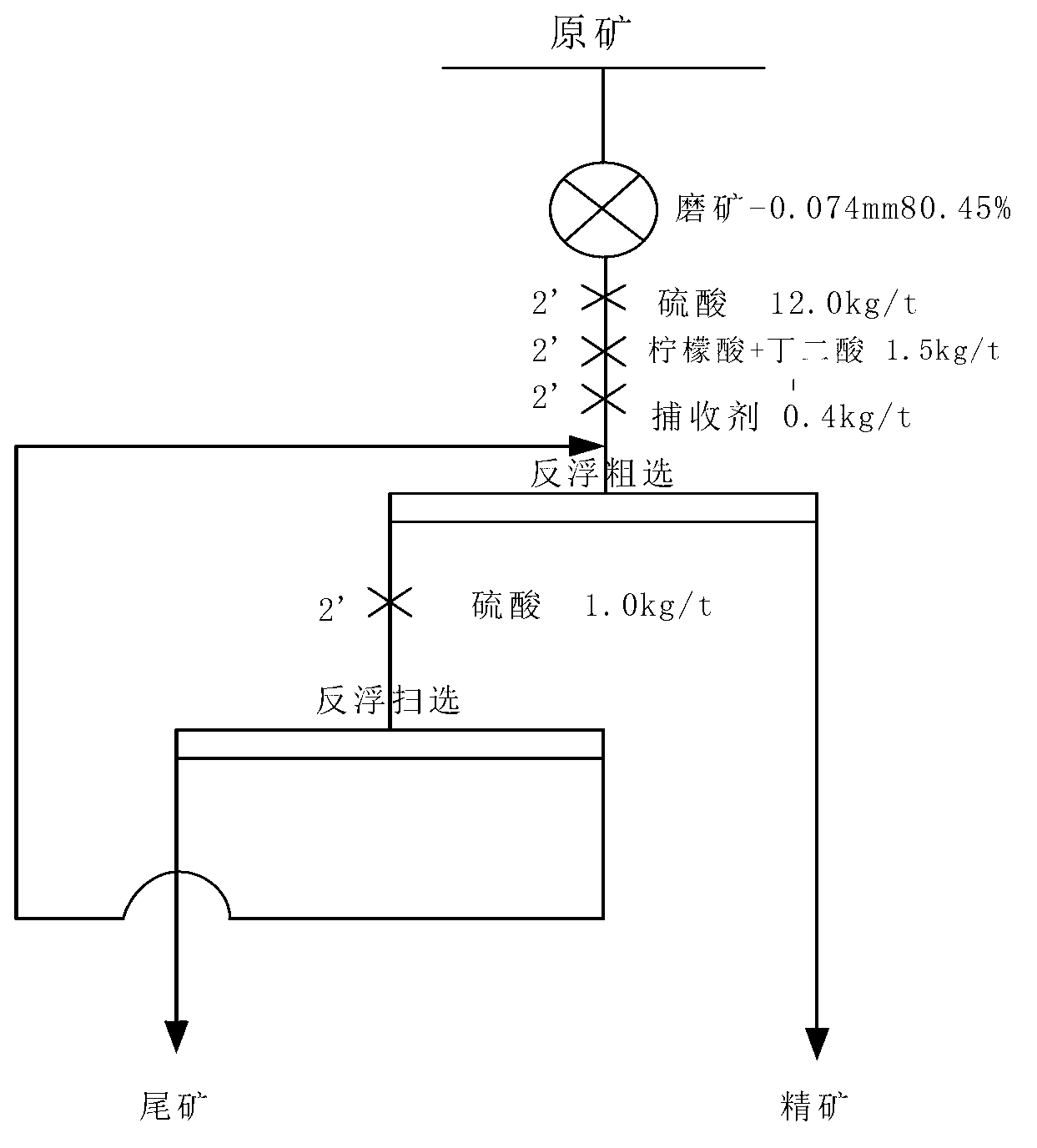

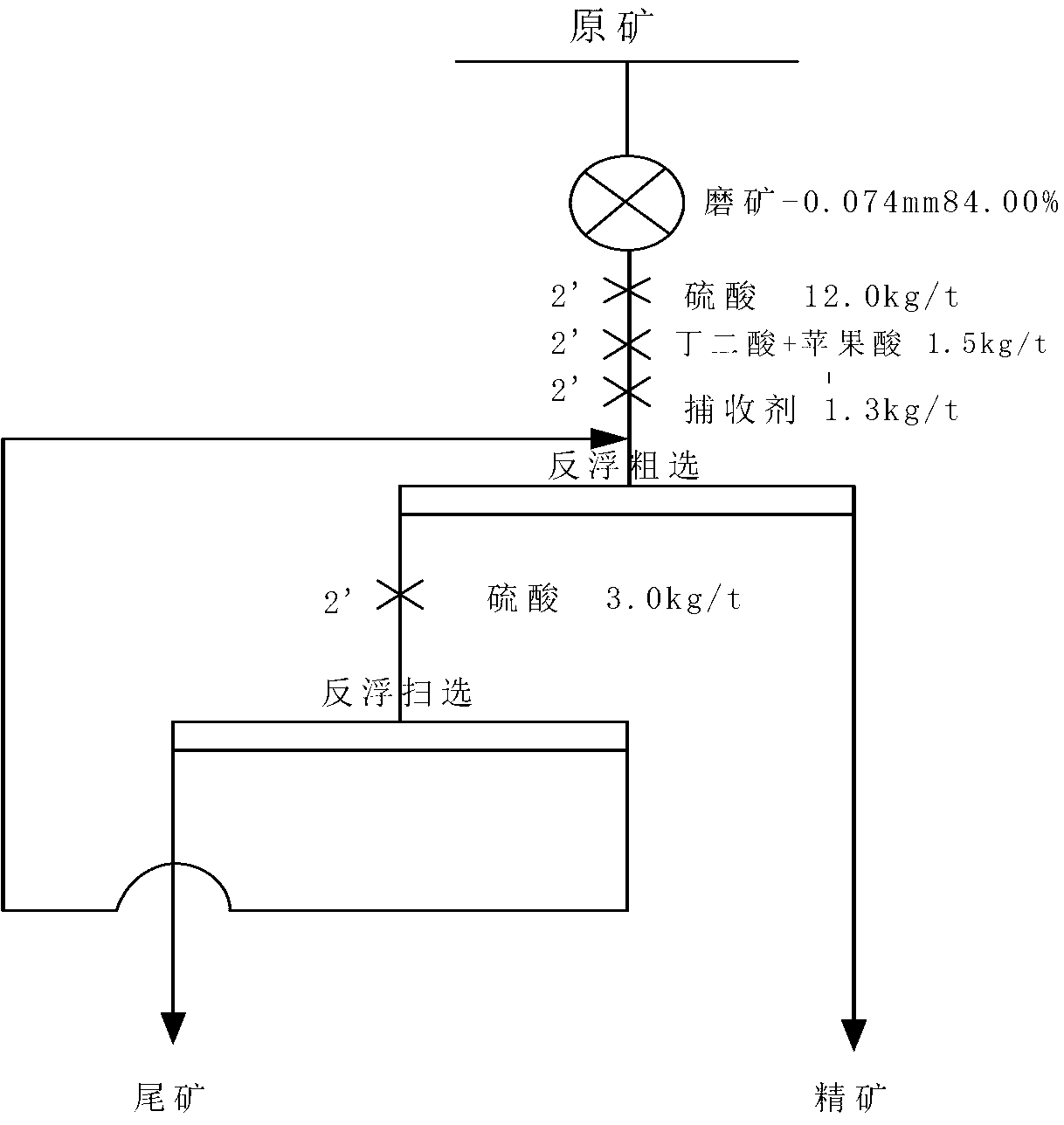

Phosphorite reverse flotation process

ActiveCN103212484ANo pollution in the processEfficient separationFlotationOrganic acidPhosphoric acid

The invention relates to a phosphorite reverse flotation process which comprises the following steps: after carrying out ore crushing, ore grinding and size mixing on phosphorite, enabling the obtained product to enter the reverse flotation process, wherein ore pulp obtained after size mixing is added with sulfuric acid or phosphoric acid to form a regulator and an inhibitor and then is added with micromolecule organic acid to form a combined inhibitor for inhibiting phosphate minerals; carrying out reverse flotation to separate out carbonate minerals by using fatty acids or fatty acid soaps as a collecting agent so as to obtain high-grade low-magnesium phosphate concentrates. The phosphorite reverse flotation process has the following advantage that the micromolecule organic acid inhibitor is adopted to implement effective separation of collophanite and dolomite, so that the grade of the phosphate concentrates is improved, the grade of tailings is reduced and the recovery rate can be improved. Meanwhile, application of phosphoric acid and derivatives thereof to phosphorite reverse flotation is replaced, so that phosphorus resources are saved, service time of phosphate rock resources is prolonged and the defects in the prior art are overcome.

Owner:远安县燎原矿业有限责任公司

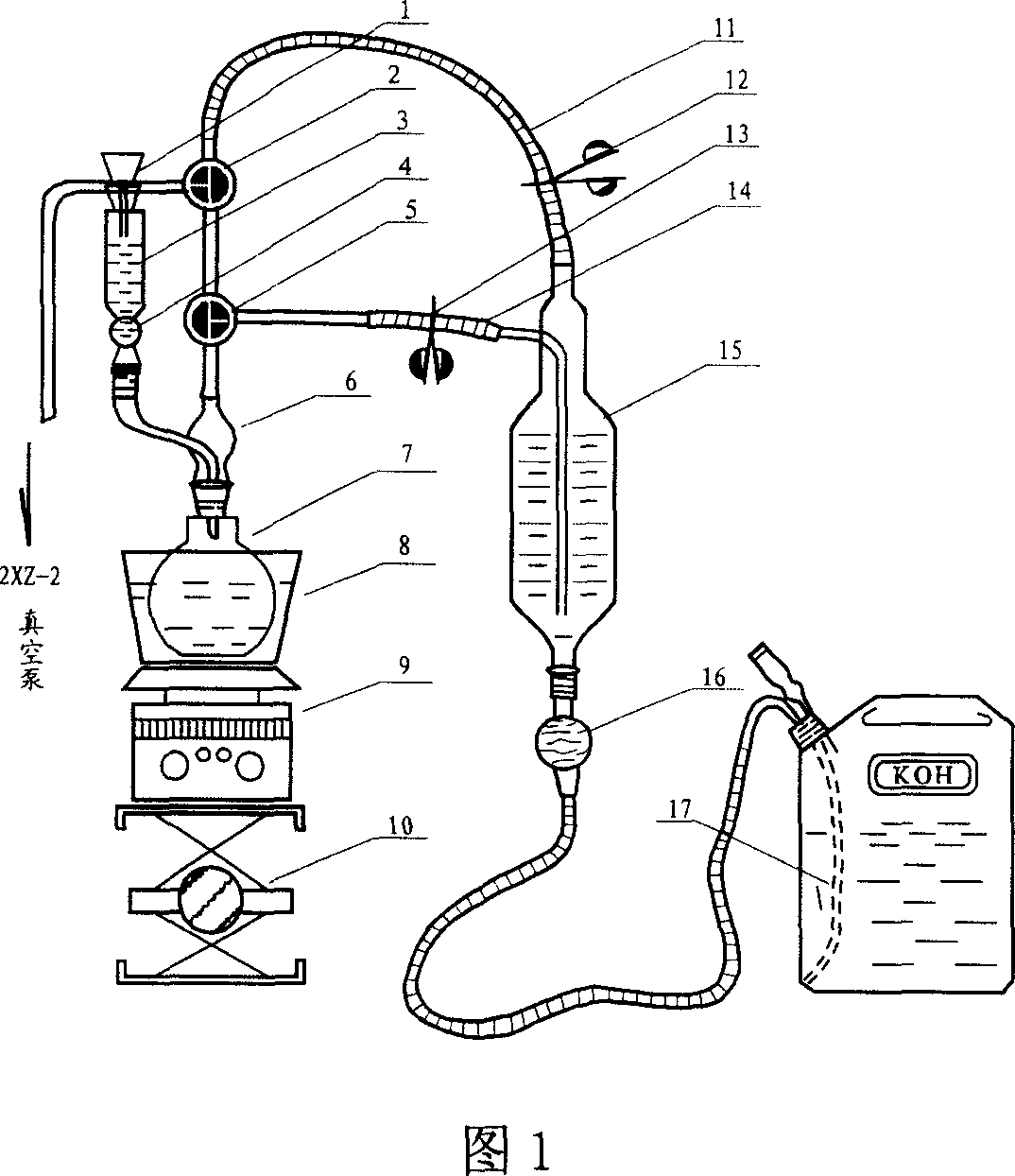

Technique of mineral carbonation CO2 fixing joint produced carbonate products

InactiveCN101134155APromote absorptionIncreased calcium conversionDispersed particle separationCarbonate/bicarbonate preparationSolid particleSolid matter

The process of carbonating mineral, fixing CO2 and co-producing carbonate product includes the following steps: crushing calcium-containing solid waste and / or silicate ore to obtain solid particle, adding acid medium, stirring at 60-80 deg.c for 30-120 min, cooling, filtering to obtain calcium ion leaching solution, adding calcium-containing alkaline matter to regulate pH value to 7-8 and filtering to obtain calcium-containing material liquid; adding organic solvent to the calcium-containing material liquid via stirring and introducing CO2 to produce carbonating reaction; filtering the resultant liquid to obtain filtrate and solid matter; washing the solid matter with deionized water and drying to obtain calcium carbonate. The present invention can utilize solid waste and greenhouse gas CO2 resource to produce light calcium carbonate in low production cost and high economic benefit.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

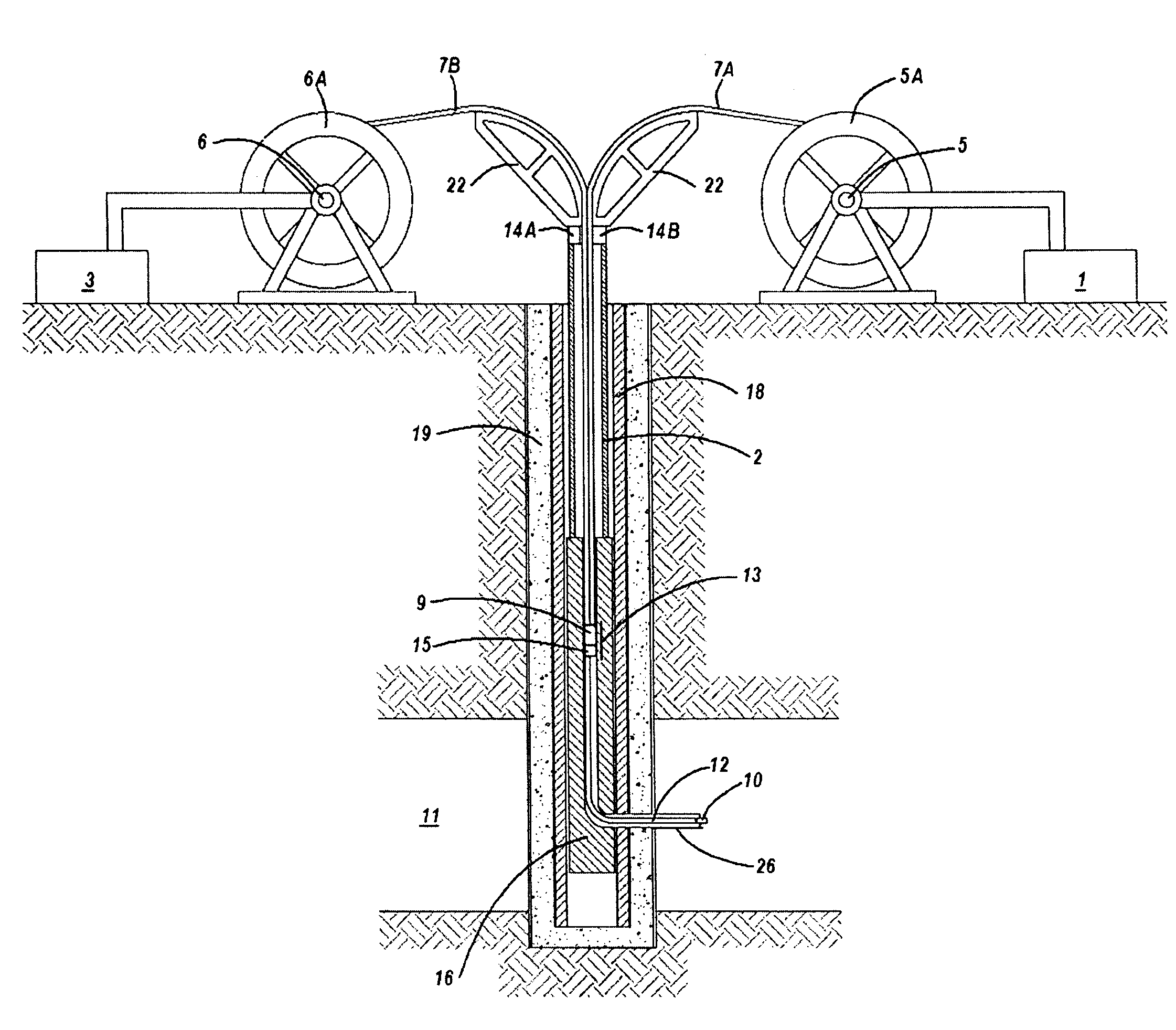

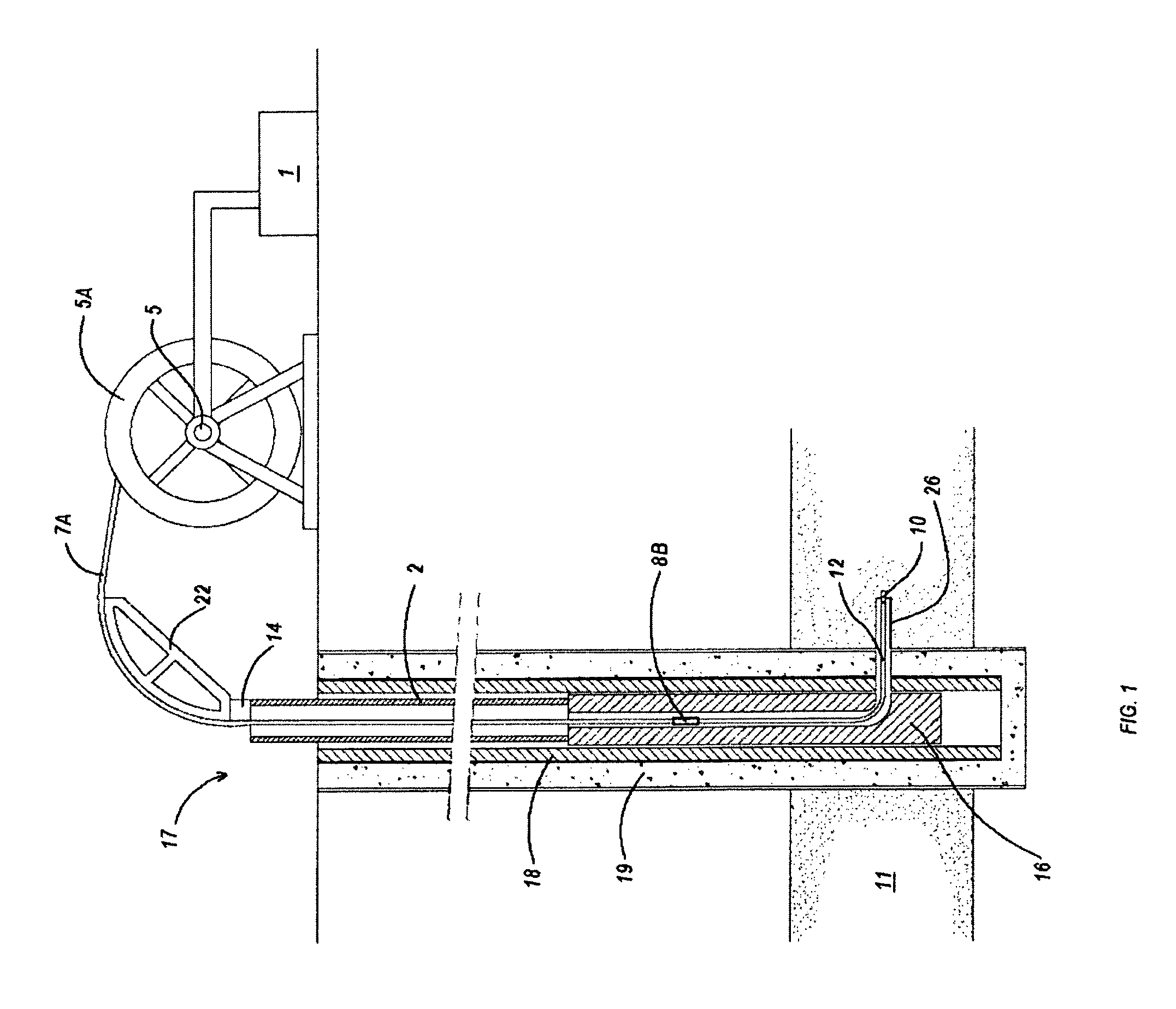

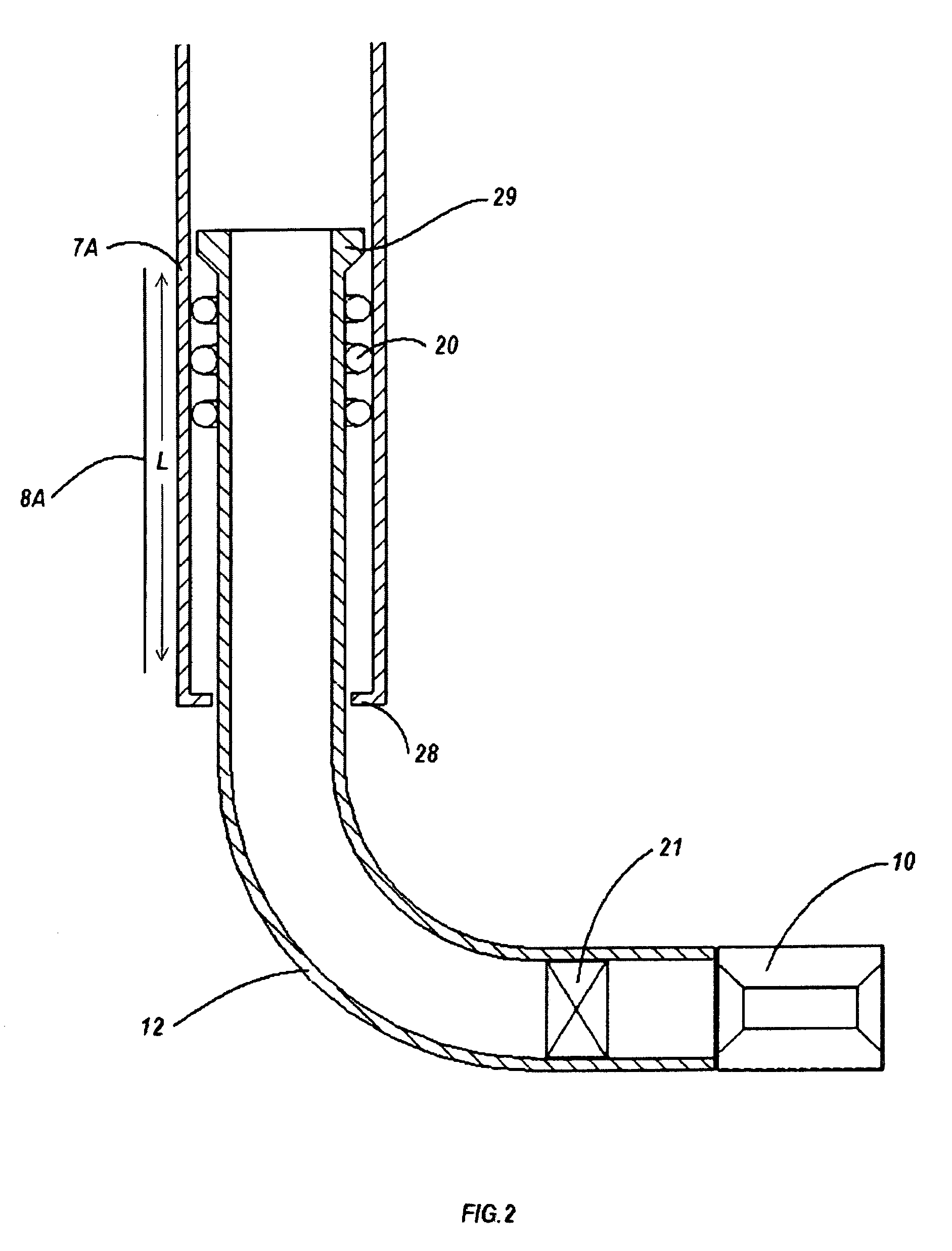

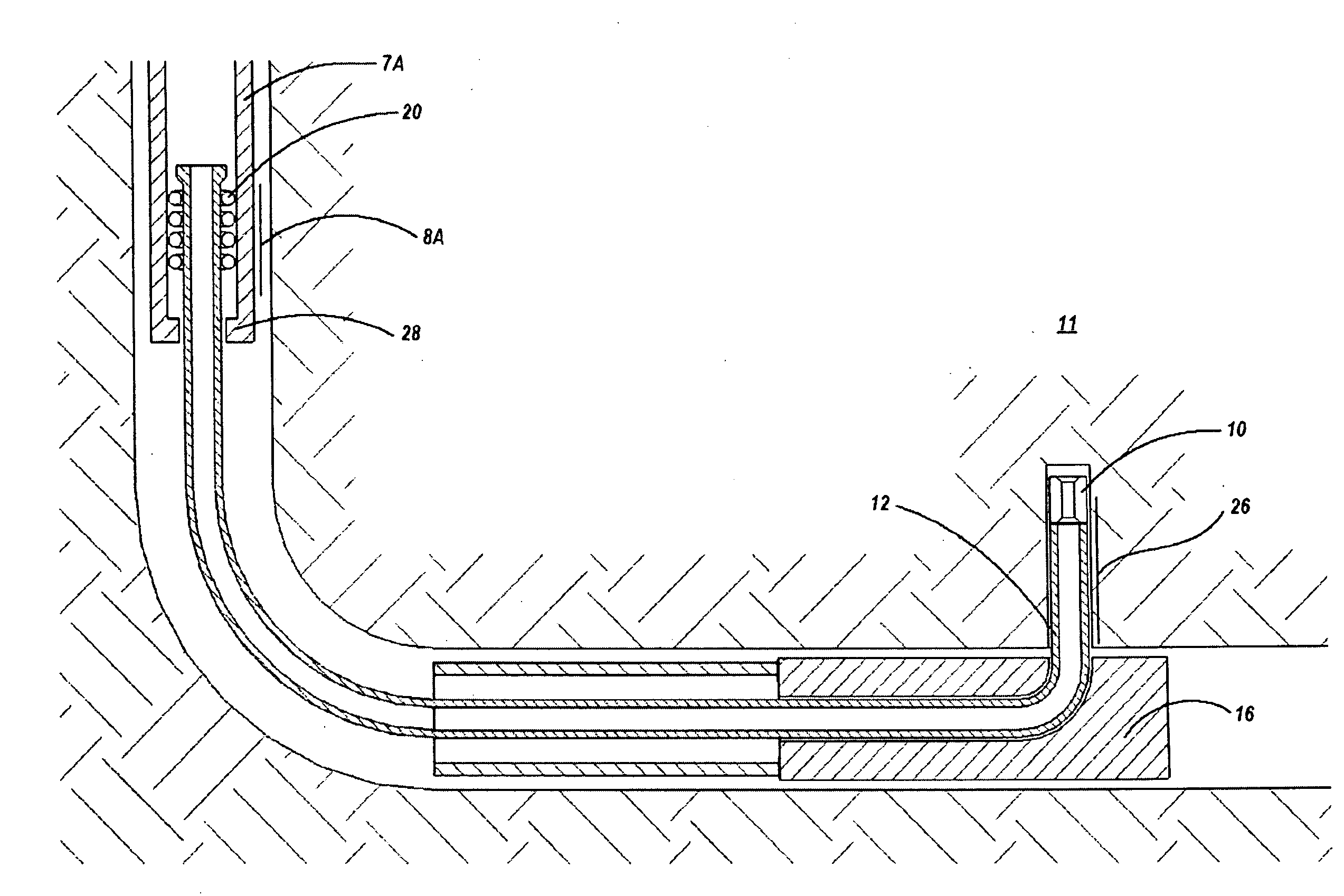

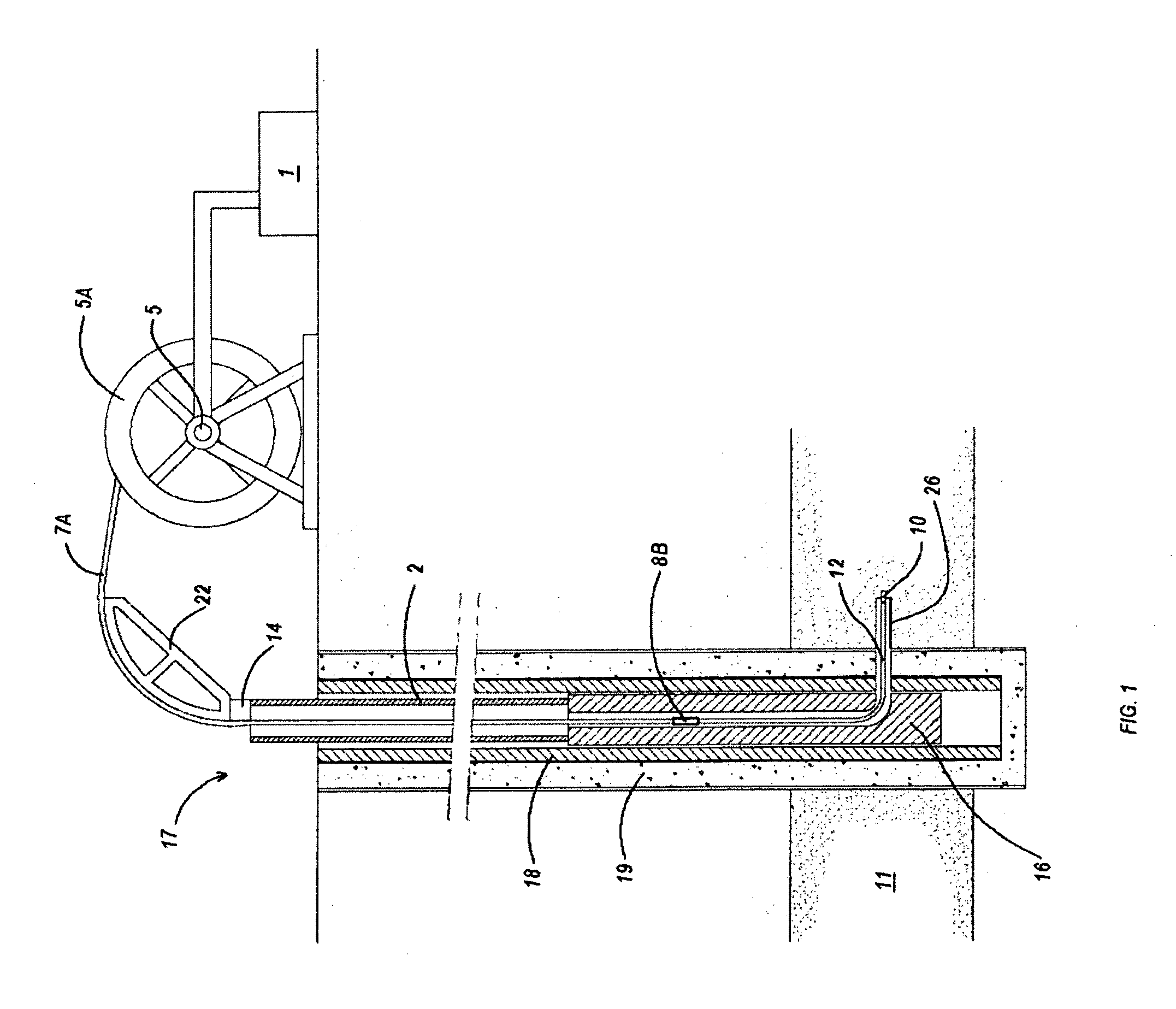

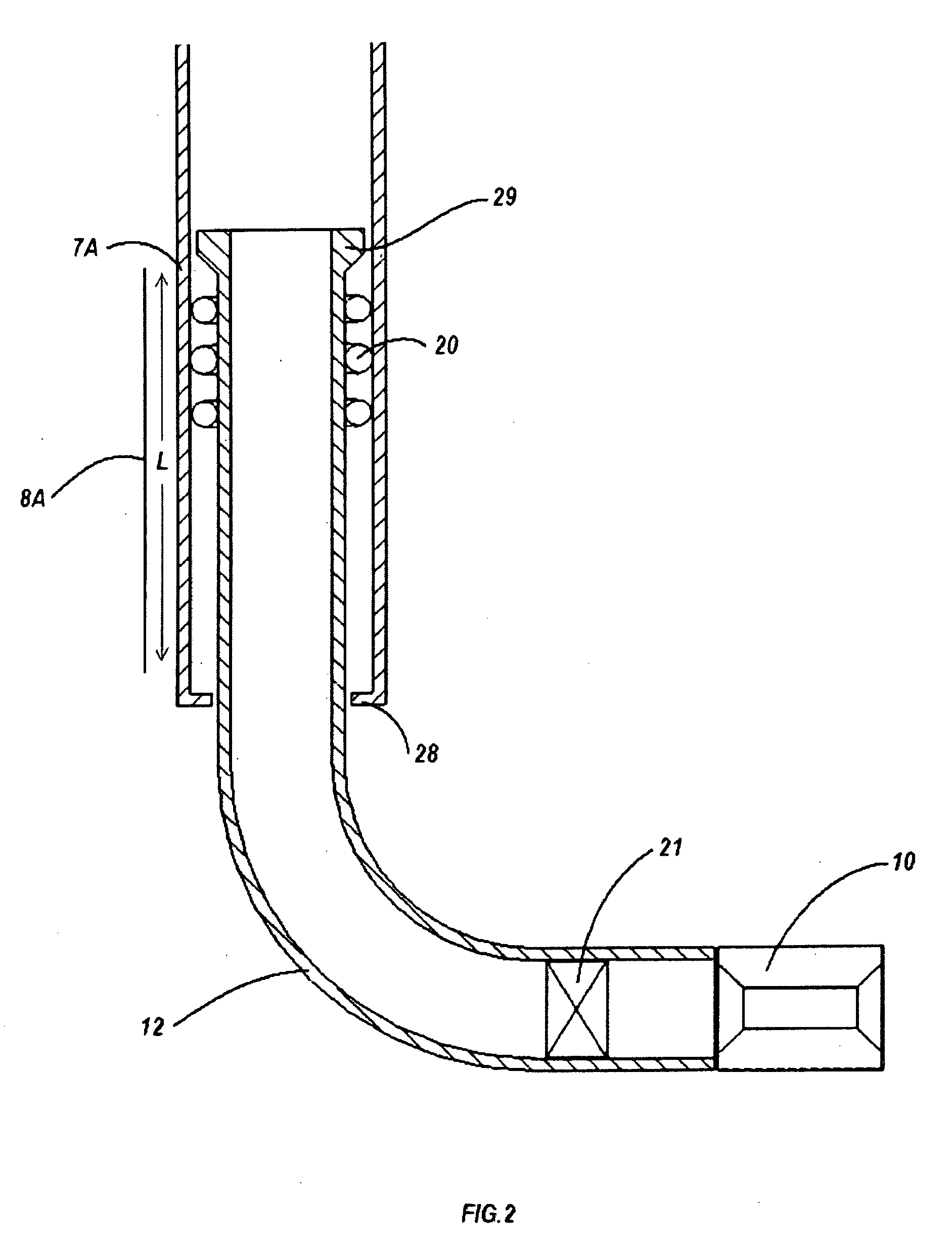

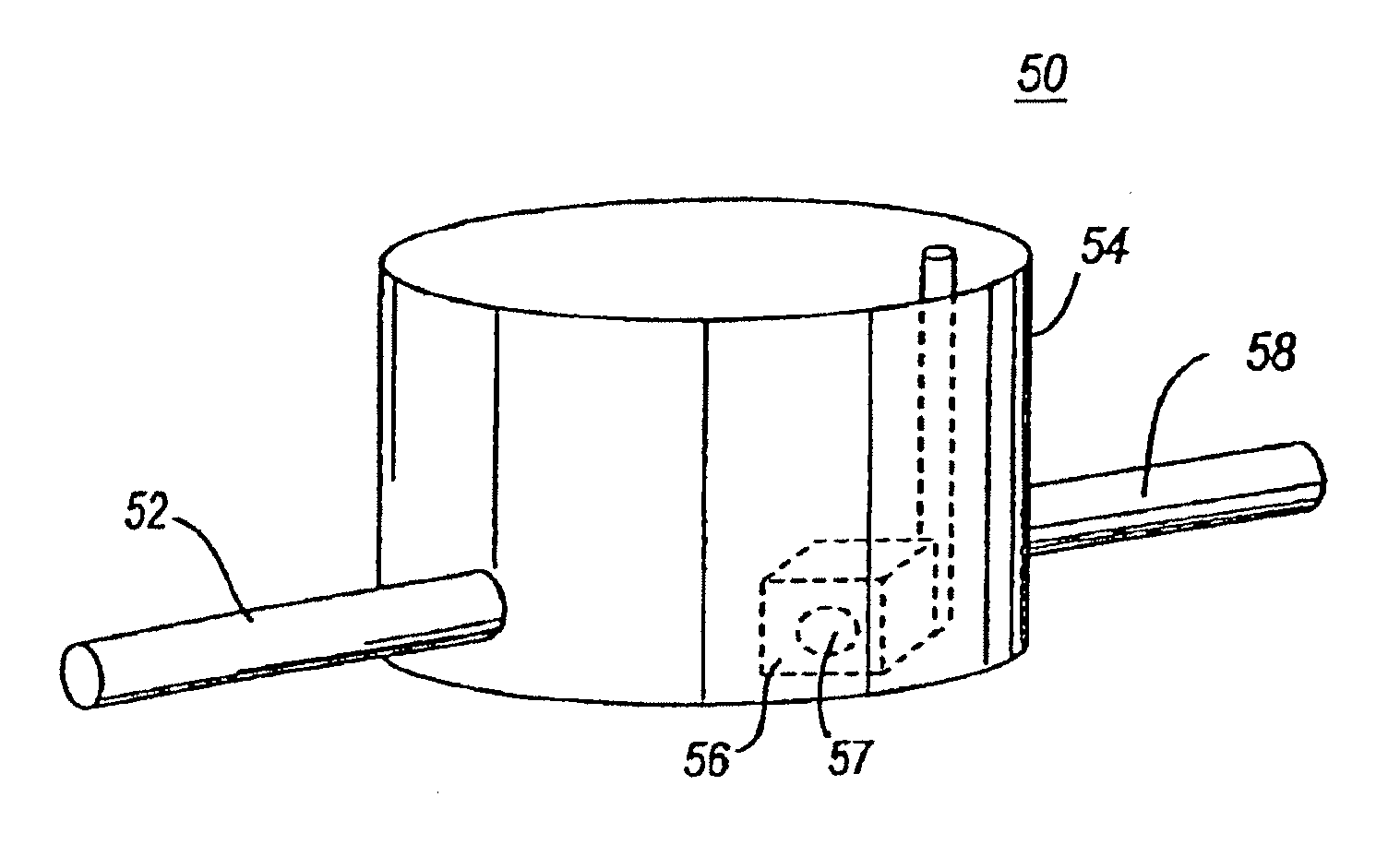

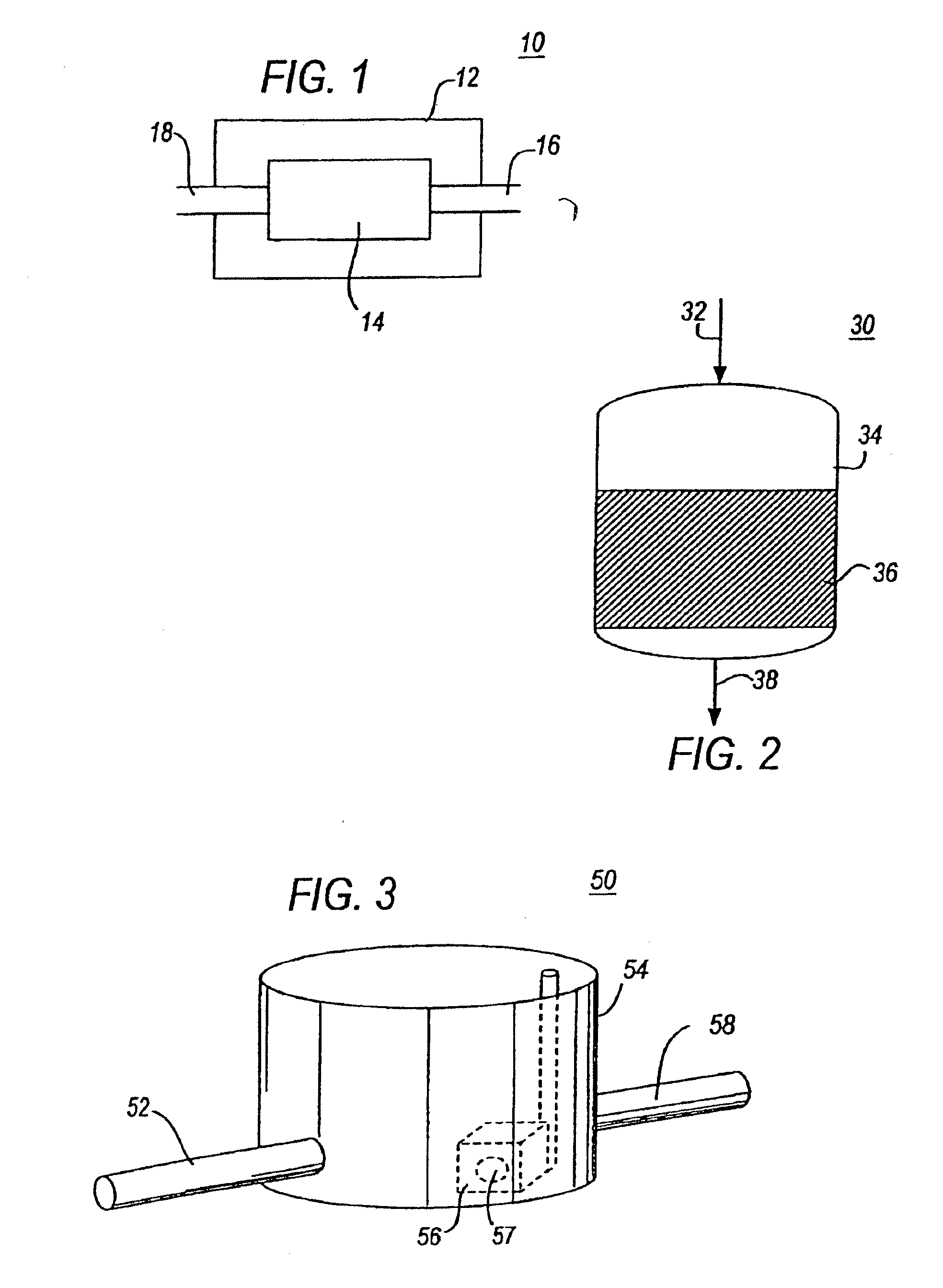

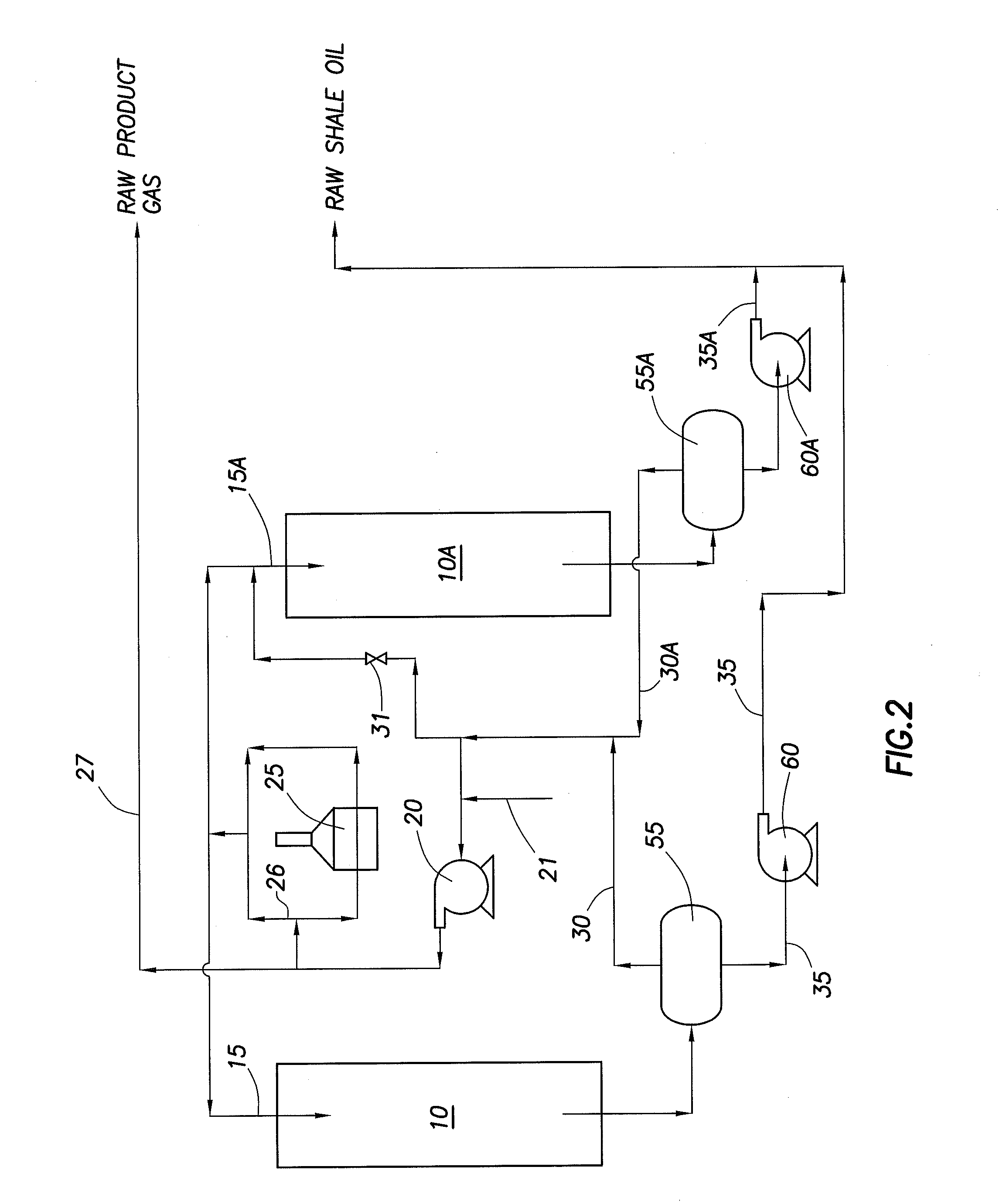

Chemically Enhanced Stimulation of oil/gas formations

ActiveUS7971658B2Increase temperatureIncrease flow resistanceDrilling rodsLiquid/gas jet drillingHigh rateWell drilling

Method is provided for drilling of formations containing carbonate minerals with flexible tubing capable of being turned in a very short radius. The very flexible tubing may be placed inside a work string in a well with coiled tubing and a micro-jet bit on the tubing be diverted to a selected direction and depth. Acidic drilling fluid pumped through the micro-jet bit allows high rates of drilling with hydrochloric acid. A slip joint between coiled tubing and the flexible tubing may be used to allow jet drilling without movement of the coiled tubing and use of a jet bit with forward-facing jets. Mixing of acid and base solutions downhole may be used to provide hotter acid solutions for drilling.

Owner:WV JET DRILLING LLC

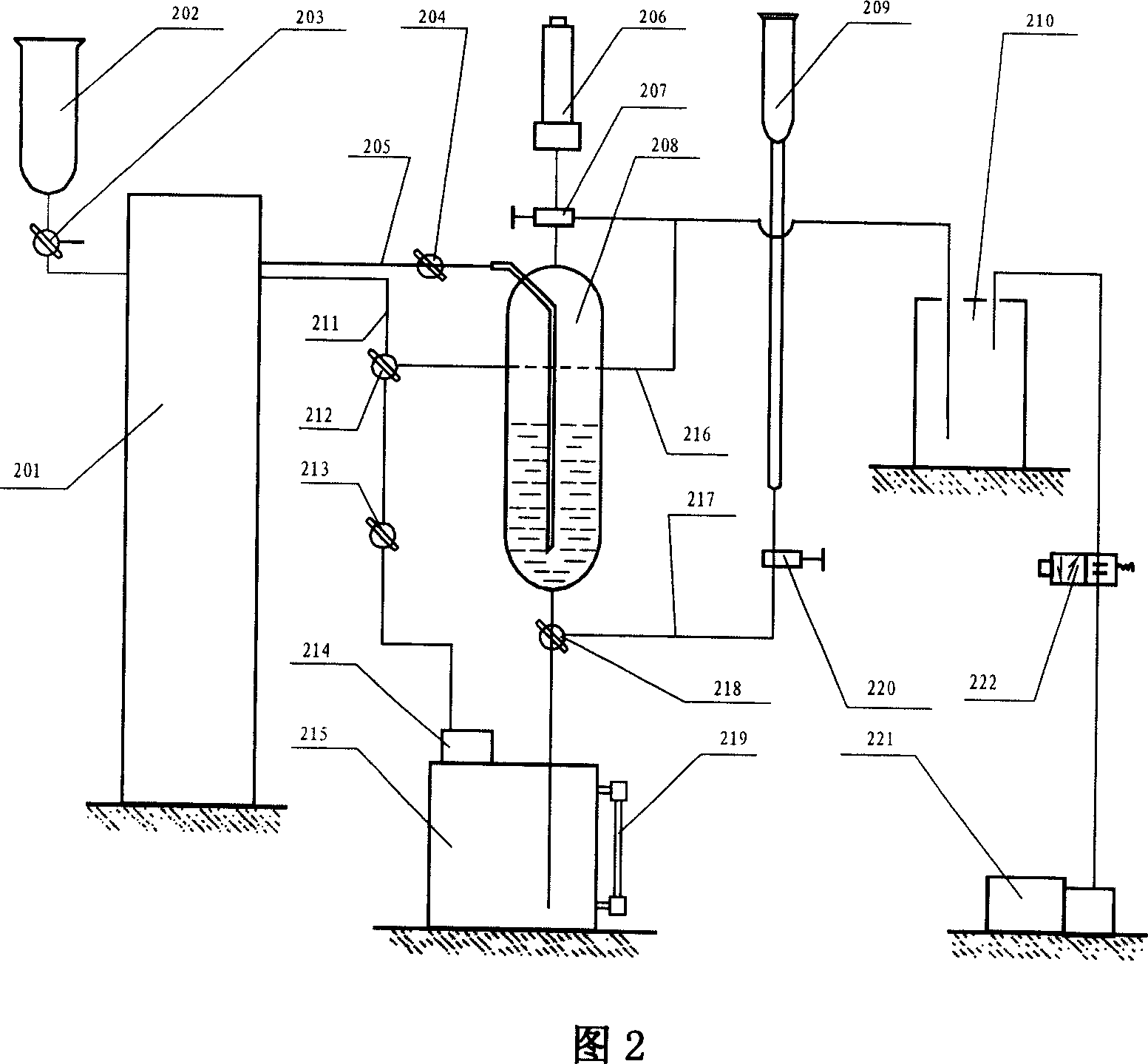

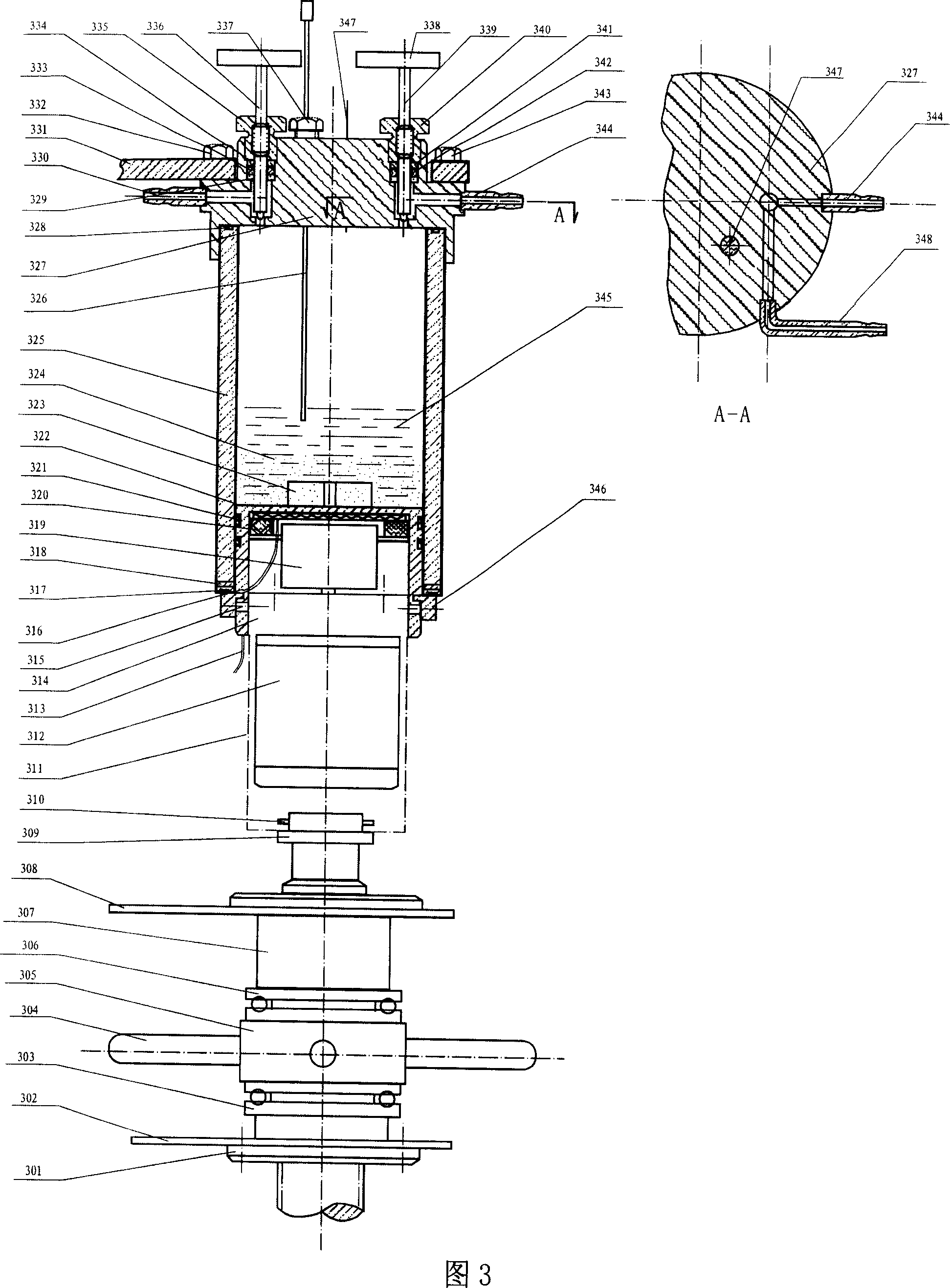

Device for preparing or collecting adsorptive gaseous hydrocarbon in rock

ActiveCN101051007AWithdrawing sample devicesPreparing sample for investigationVacuum pumpingFluid transport

A device used for preparing or collecting gas state hydrocarbon absorbed in rock consists of acidolysis and degassing integrated unit, gas collector, base liquid purification balance system, fluid transport air vent unit and vacuum-pumping unit. It is featured as using acid to decompose carbonate mineral in rock collecting and storing obtained gas state hydrocarbon for carrying out more accurate analysis on geologic sample.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for simultaneous anti-flotation of carbonate and silicate in phosphorus ore

The invention relates to a method for simultaneous anti-flotation of carbonate and silicate in phosphorus ore. The method comprises the specific steps that phosphate ore is added into a mill to be ground; the ground phosphate ore pulp is subjected to desliming to remove fine fraction; rest coarse ore pulp enters a phosphorus inhibitor agitator, and a phosphorus inhibitor is added into the agitator for pulp mixing; after pulp mixing is conducted through the phosphorus inhibitor, the ore pulp enters a collecting agent agitator, and a collecting agent is added into the agitator for pulp mixing; and after pulp mixing is conducted through the collecting agent, the ore pulp enters a flotation machine for phosphorus ore anti-flotation, floating foam is carbonate minerals and silicate minerals, and underflow in a tank is phosphorus concentrate. By the adoption of the method, the carbonate and the silicate in the phosphorus ore can be floated out simultaneously, the flotation process and the flotation reagent system are simplified, and the reagent use amount and the cost of phosphorus ore anti-flotation are reduced.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Swill-cooked dirty oil collophanite reverse flotation collecting agent and preparing method thereof

The invention relates to a swill-cooked dirty oil collophanite reverse flotation collecting agent and a preparing method thereof. The collecting agent comprises, by mass, 90-100 parts of swill-cooked dirty oil fatty acid, 10-20 parts of sodium hydroxide, 5-15 parts of OP-10 and 60-80 parts of water. The preparing method of the collecting agent includes the steps that a sodium hydroxide solution is added into the swill-cooked dirty oil fatty acid for saponification, and a mixture of fatty acid soap and incomplete reaction fatty acid is obtained; water is added to a surface active agent, and the surface active agent with the water is heated and evenly scattered to be added into the mixture of the fatty acid soap and the incomplete reaction fatty acid according to different proportions, sufficient heating is carried out for even stirring, and the reverse flotation collecting agent is obtained after emulsification is complete; the solubleness and the dispersity of the collecting agent in water are good, the selectivity is good, the collecting capacity is high, the preparing process is simple and rapid, carbonate minerals can be effectively removed at a normal temperature, the phosphorus concentrate grade is improved, and efficient normal temperature reverse flotation of collophanite is achieved.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

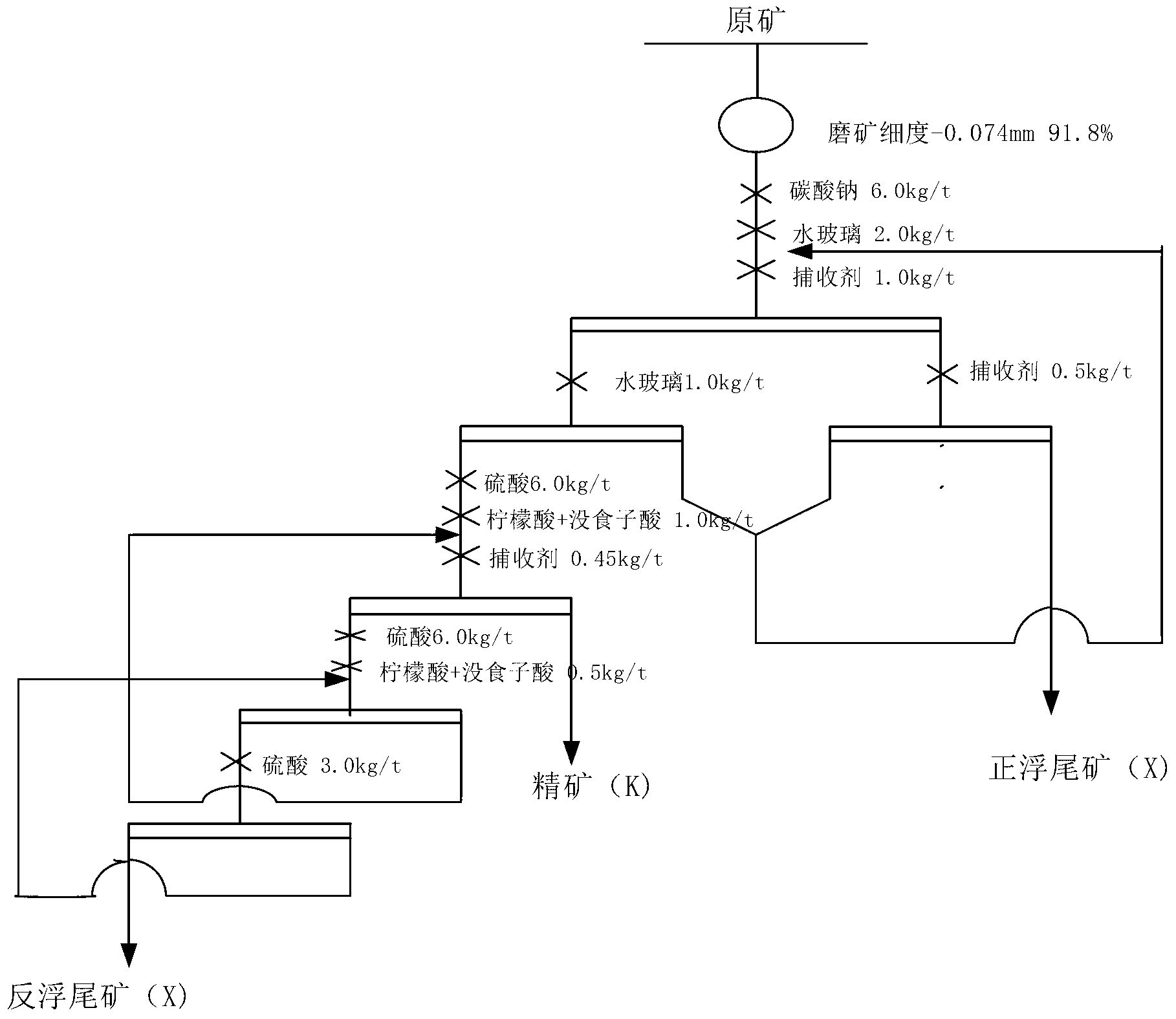

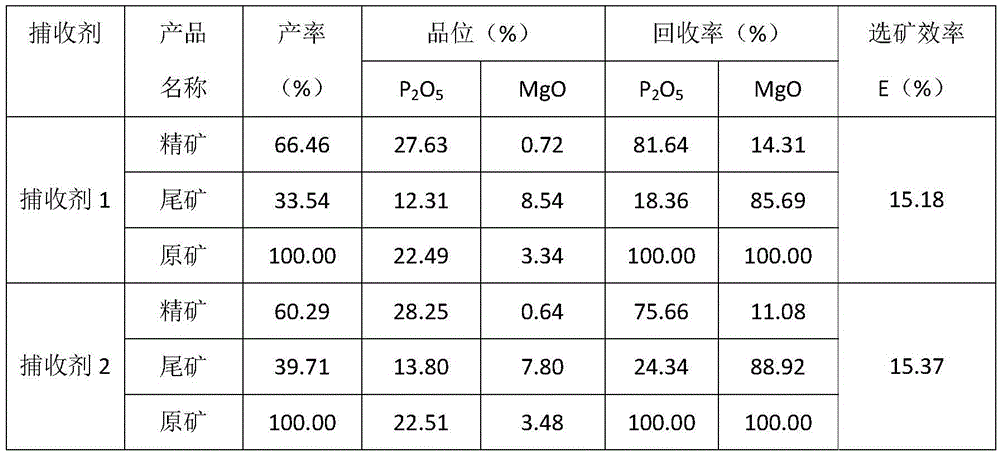

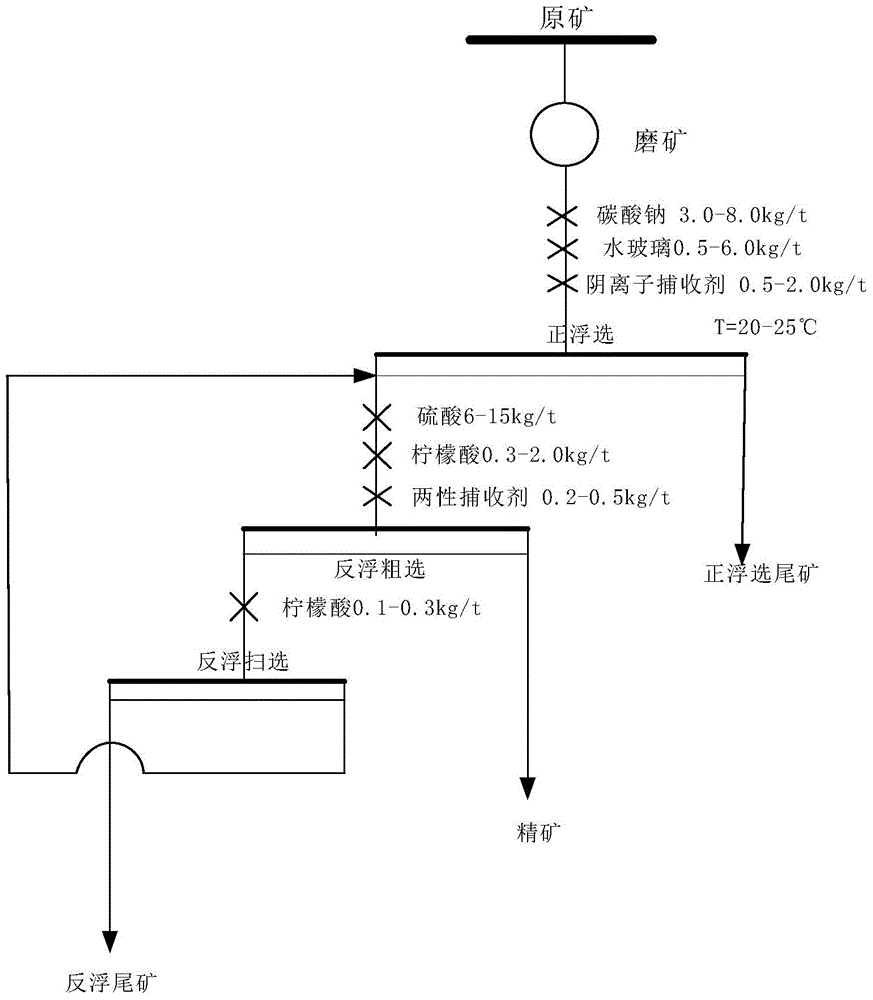

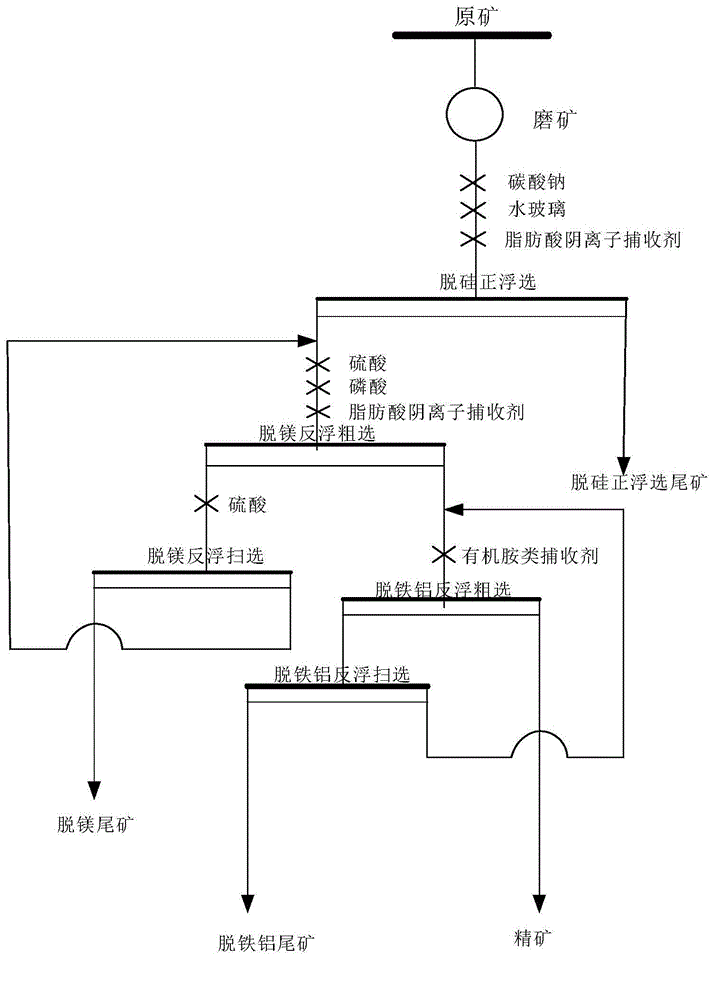

Silica-calcia low-grade collophanite positive and inverse floatation process

ActiveCN104907183AReduce contentRealize beneficiation and enrichmentFlotationCalcium in biologySesquioxide

The invention relates to a silica-calcia low-grade collophanite positive and inverse floatation process, which comprises the steps: 1 silica-calcia low-grade collophanite ores are broken up and grinded to enable phosphate minerals and gangue mineral monomers to dissociate, then are added with water to mix size, enter positive and inverse floatation, get rid of impurities in ores, and improve grade of phosphorite. Compared with the prior art, the silica-calcia low-grade collophanite positive and inverse floatation process has the advantages that the content of only one kind of gangue minerals can be reduced by adopting direct floatation and single inverse floatation, can reduce the contents of silicate minerals, carbonate minerals and iron and aluminum silicate minerals, can obtain low magnesium low power half oxide low silicon phosphate concentrate by adopting the silica-calcia low-grade collophanite positive and inverse floatation process, successfully achieves mineral processing enrichment of collophane calcium collophanite, and can improve use rate of phosphorus resource. The silica-calcia low-grade collophanite positive and inverse floatation process overcomes the defects that an existing floatation process can not be applied for mineral processing of silica-calcia collophanite which is high in content of high power half oxides.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Chemically Enhanced Stimulation of Oil/Gas Formations

ActiveUS20090107678A1Increase temperatureImprove liquidityDrilling rodsLiquid/gas jet drillingHigh ratePetroleum

Method is provided for drilling of formations containing carbonate minerals with flexible tubing capable of being turned in a very short radius. The very flexible tubing may be placed inside a work string in a well with coiled tubing and a micro-jet bit on the tubing be diverted to a selected direction and depth. Acidic drilling fluid pumped through the micro-jet bit allows high rates of drilling with hydrochloric acid. A slip joint between coiled tubing and the flexible tubing may be used to allow jet drilling without movement of the coiled tubing and use of a jet bit with forward-facing jets. Mixing of acid and base solutions downhole may be used to provide hotter acid solutions for drilling.

Owner:WV JET DRILLING LLC

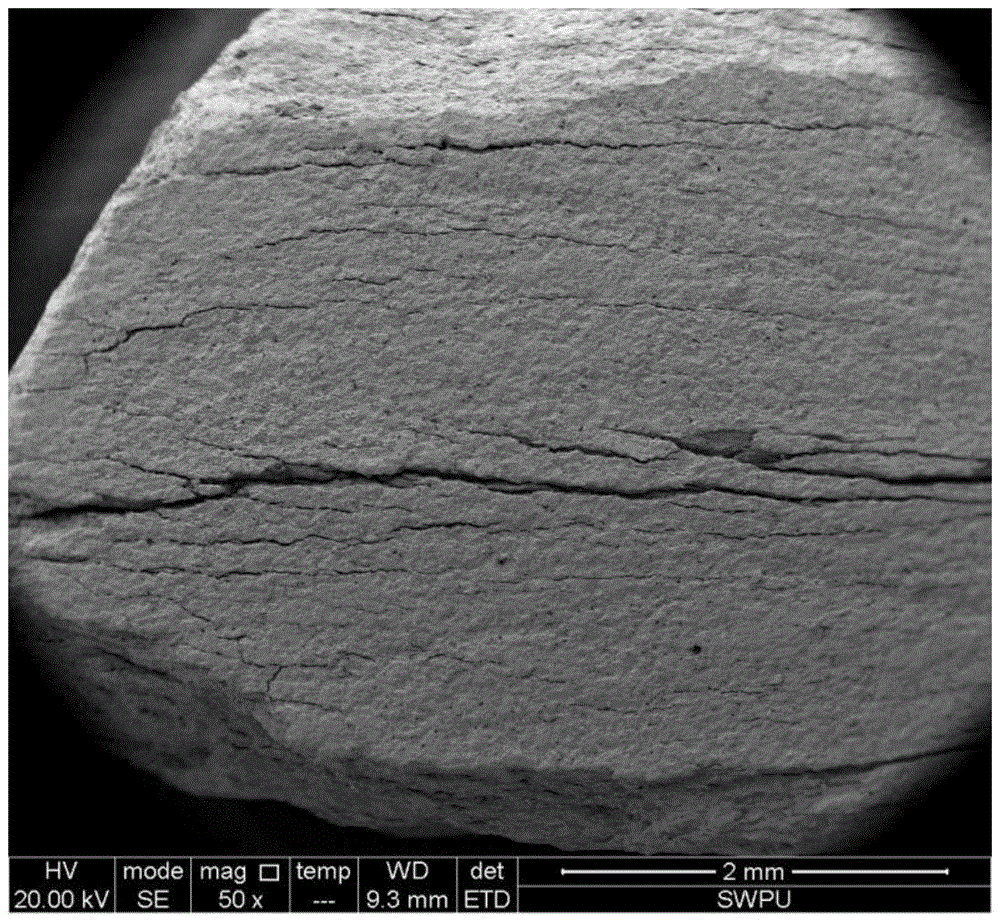

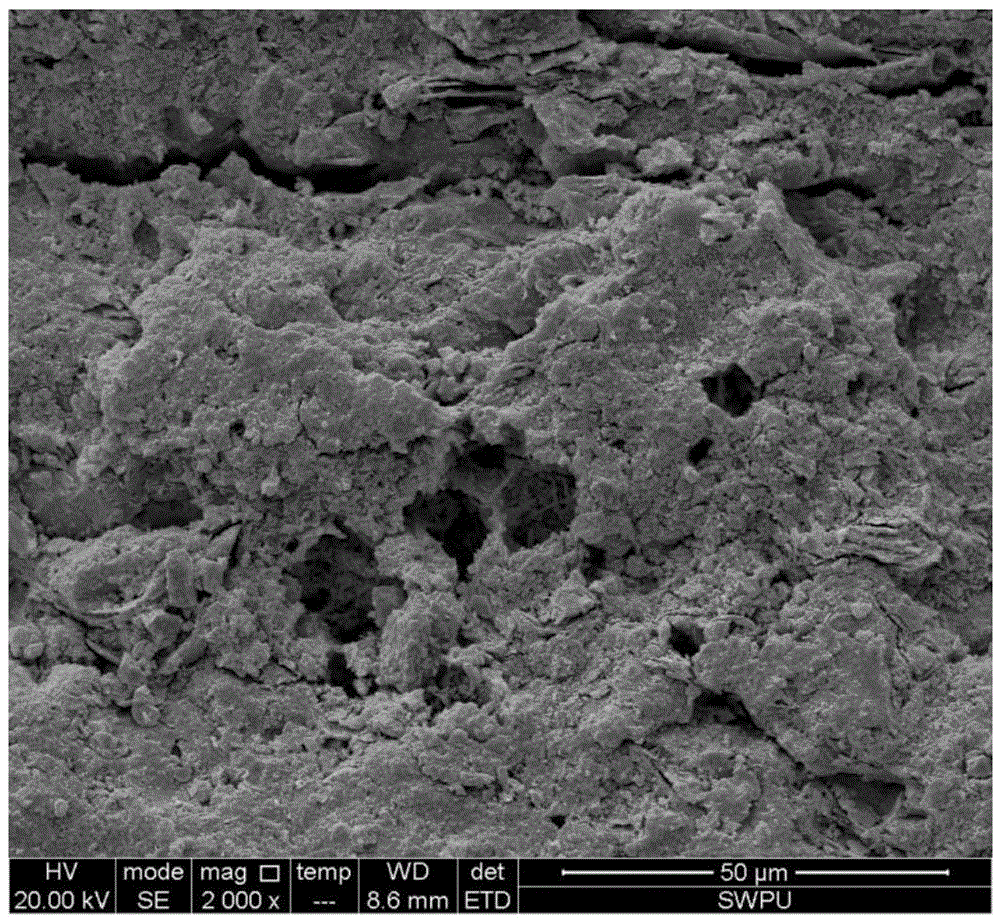

Method of increasing fracture network density for shale gas well fracturing improvement

Owner:SOUTHWEST PETROLEUM UNIV

Method and composition to reduce the amounts of heavy metal in aqueous solution

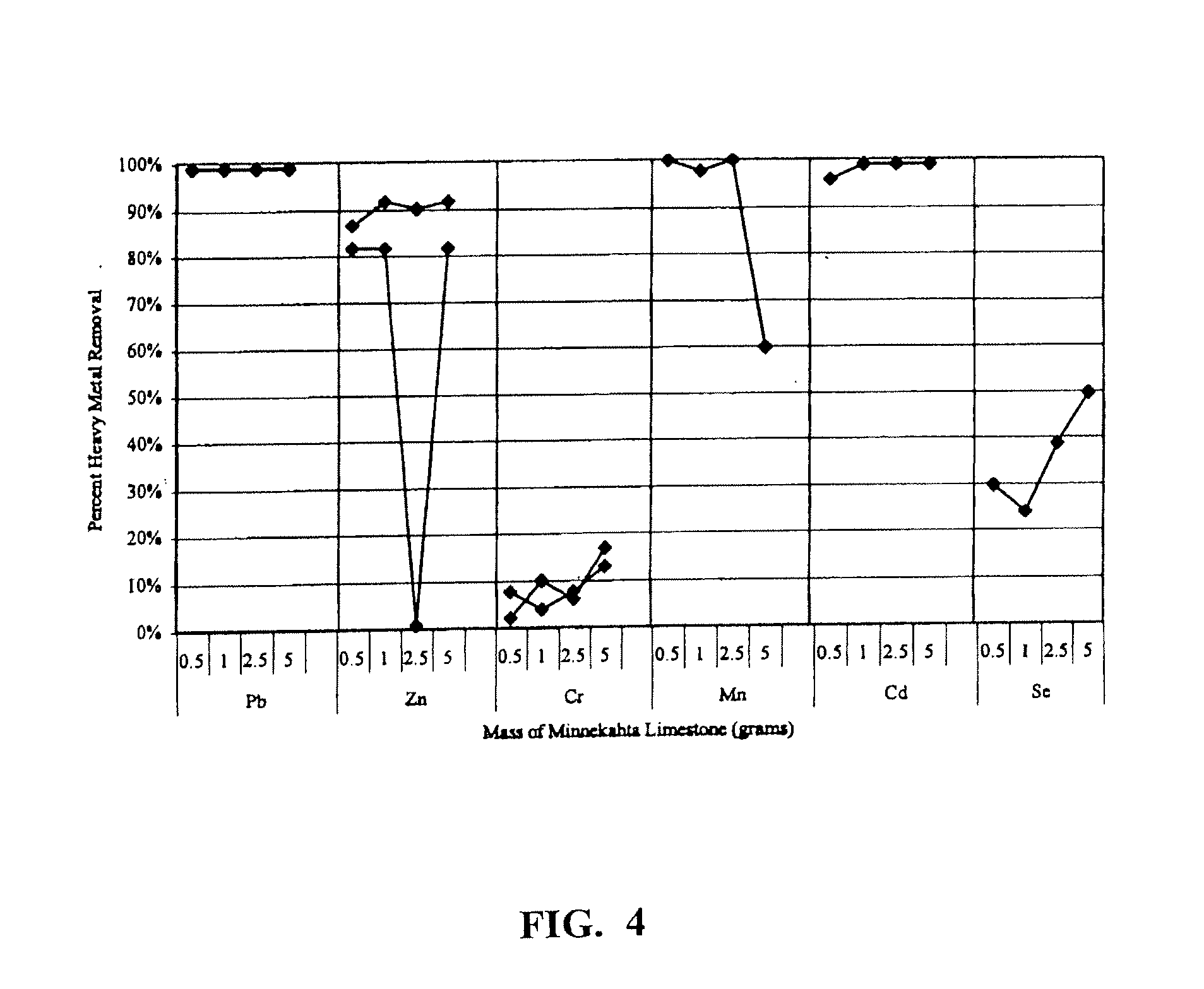

InactiveUS20120145640A1Reduce concentrationCalcium/strontium/barium carbonatesOther chemical processesAqueous solutionMaceral

The present invention relates to a method for removing heavy metals from aqueous solutions by contacting heavy metal-contaminated water with a sorption media, or in particular with carbonate minerals. The present invention also relates to methods of using modified sorption media, such as aggregates of carbonate minerals and modified carbonate minerals, for the removal of heavy metals.

Owner:SOUTH DAKOTA BOARD OF REGENTS

Process for direct flotation and double reverse flotation of low-grade collophanite

InactiveCN104858067AReduce contentRealize beneficiation and enrichmentFlotationSesquioxideAluminum silicate

The invention relates to a process for direct flotation and double reverse flotation of low-grade collophanite. The process comprises the first step of taking high sesquioxide silicon-calcium low-grade collophanite ores, performing crushing ore grinding and slurry mixing and then performing flotation; the second step of performing direct flotation desiliconization and obtaining direct flotation foam products; the third step of performing reverse flotation magnesium removal; and the fourth step of performing reverse flotation iron aluminum silicate mineral removal. Compared with the prior art, the process has the advantages that in phosphorite flotation, the content of only one gangue mineral can be reduced by the adoption of direct flotation and single reverse flotation while the content of silicate minerals, carbonate minerals and iron aluminum silicate minerals can be reduced by the direct flotation and double reverse flotation; low-magnesium low-sesquioxide low-silicon phosphate concentrate can be obtained through the process, mineral separation enrichment of silicon calcium collophanite is achieved successfully, and the utilization rate of phosphorus resources can be improved. The shortcoming that an existing flotation process cannot be applied to mineral separation of silicon-calcium collophanite too high in content of high sesquioxide is overcome.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

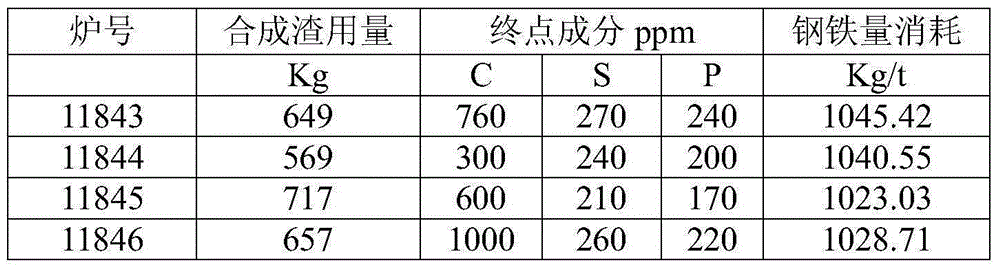

On-line molten steel slag modification method

ActiveCN104673965AIncrease alkalinityIn line with the principleManufacturing convertersElectric furnaceAlkalinitySlag

The invention discloses an on-line molten steel slag modification method, and belongs to the technical field of ferrous metallurgy. The on-line molten steel slag modification method comprises the following steps: firstly, while slag is simultaneously discharged from smelting devices such as a rotary furnace, an electric furnace and an LF furnace, uniformly mixing liquid steel slag and a steel slag modifier with certain granularity according to a certain mass ratio, and subsequently cooling. The steel slag modifier is one or more carbonate substances, and the carbonate substances are carbonate compounds or carbonate minerals. By adopting the steel slag modification technique disclosed by the invention, heat of the steel slag can be efficiently utilized to decompose the steel slag modifier into oxides, at the same time, the energy consumption of a multi-stage crushing process used in steel slag treatment can be reduced, and the modified high-alkalinity steel slag is equivalent to synthesized slag, so that the steel slag can be conveniently and repeatedly utilized.

Owner:马鞍山市华东冶金科技发展有限公司 +1

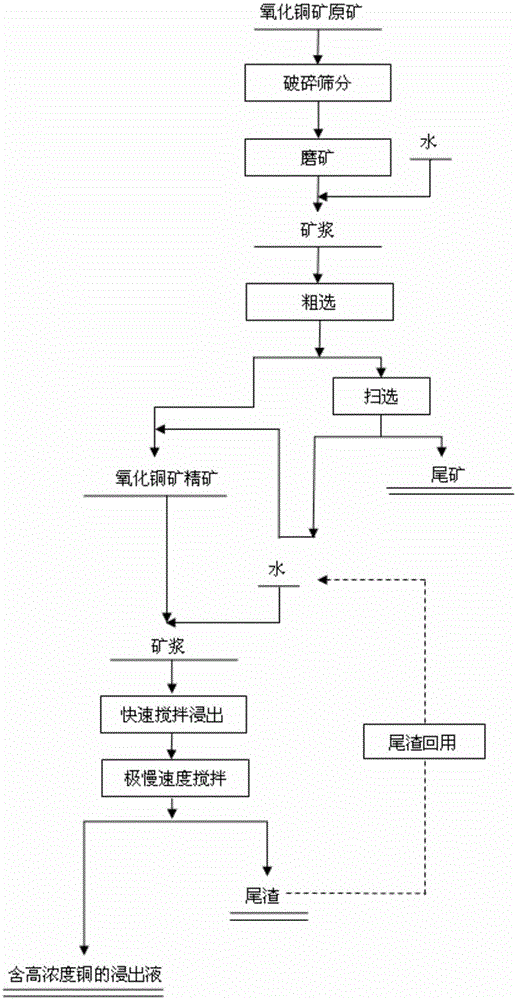

Flotation and acid leaching process for complex low-grade copper oxide ore

InactiveCN105149085AOvercoming complexityOvercome the defects of large consumption of medicineFlotationWet separationCopper oxideTalc

The invention discloses a flotation and acid leaching process for complex low-grade copper oxide ore. The flotation and acid leaching process comprises the following steps that (1) raw low-grade copper oxide ore is crushed and ground to form ore pulp; (2) flotation reagents are added to the ore pulp, and after one-time rough flotation and one-time scavenging are completed, concentrate and tailings of the copper oxide ore are obtained; and (3) after the concentrate of the copper oxide ore is prepared to form ore pulp, concentrated sulfuric acid is added with stirring for leaching, and solid and liquid separation is carried out to obtain copper-containing leach liquor and leached tailings. According to the flotation and acid leaching process, the flotation process and the acid leaching process are combined to treat the low-grade copper oxide ore, the low-grade copper oxide ore is subjected to one time of rough flotation and one time of scavenging in the existence of vulcanizing agents, and chlorite, dolomite, talc and other silicate and carbonate minerals which are high in acid consumption and copper sulphide ore in the low-grade copper oxide ore can be primarily separated; then through combination with the acid leaching process, leaching of copper can be achieved with low acid consumption. The defects that in the prior art, a copper enrichment process for the low-grade copper oxide ore is complex, high in reagent consumption, high in cost and the like are overcome.

Owner:CENT SOUTH UNIV

Production of potassium and magnesium fertilizer

InactiveCN1680217ARaise the gradeImprove stress resistanceCalcareous fertilisersMagnesium fertilisersSulfateCement kiln

Production of potassic-magnesian fertilizer is carried out by: 1) using carbonate minerals of potassium mineral, calcium, magnesium or calcium-magnesium with mass percent of burnt potash >=11% in mass ratio: 1:0.70-0.90:0.40-0.48, breaking, and mixing with powdered coal and converting agent; 2) powder milling, ball forming, putting into cement kiln at 1000-1300deg.C, sintering for 25-45 mins, and cooling; 3) powder milling, choosing two or three kinds of converting agent from (a) halide of Al3+, Mg2+, Ca2+, Na+ or NH4+, (b) sulfate and / or carbonate and (c) hydroxide, the ratio of a, b, c mass:0.8-1:0.6-1:0-0.2, converting agent mass is 2-8 wt% of furnace charge, and powdered coal mass is 8-13wt% of furnace charge. It achieves low cost and good performance.

Owner:河南省东辰钾肥工程技术研究中心

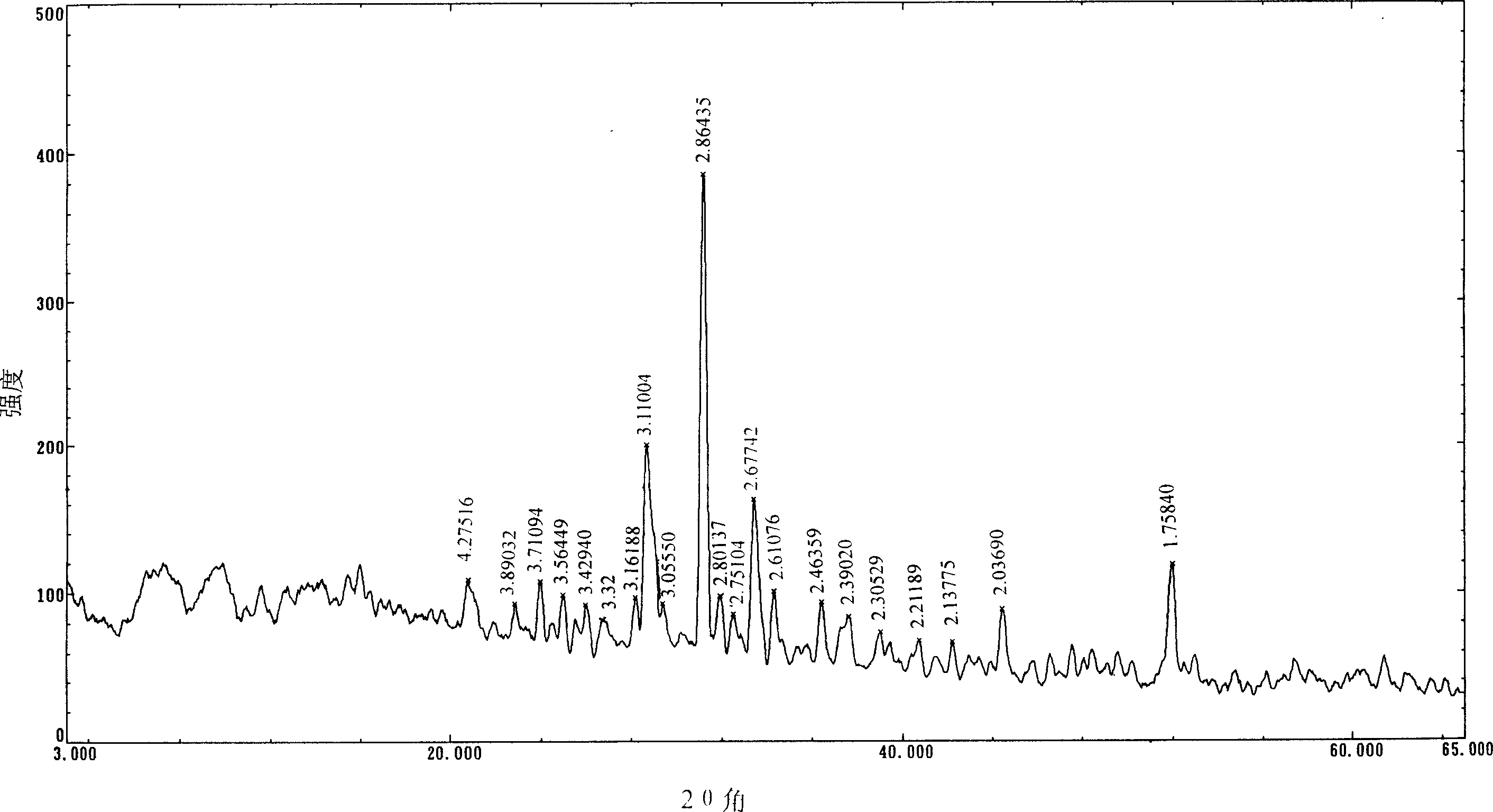

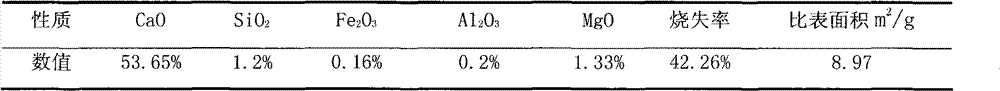

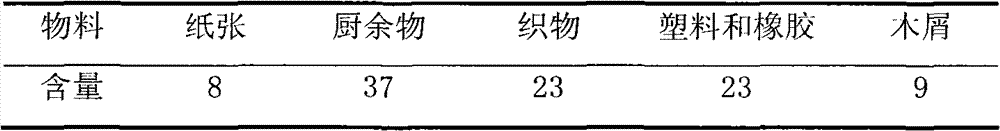

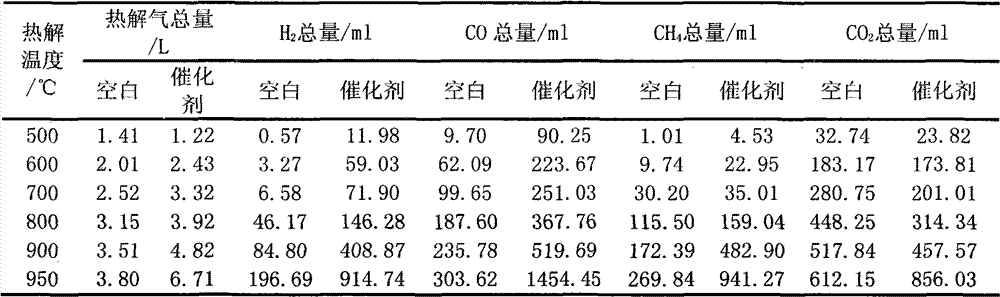

Calcium-based catalyst for regulating and controlling gas components generated in thermal decomposition and preparation method of calcium-based catalyst

InactiveCN103357411AWide variety of sourcesLow priceSpecial form destructive distillationIncinerator apparatusGeneration rateDecomposition

The invention discloses a calcium-based catalyst for regulating and controlling gas components generated in the thermal decomposition of wastes and coal mainly comprising household garbage, forestry and agricultural residues, civil sludge, slush, waste rubber, waste plastics, coal tailings and the like and a preparation method of the calcium-based catalyst. By utilizing the calcium-based catalyst, the combustible gas generation rate of the materials in the thermal decomposition process is increased; and partial carbon dioxide is converted into carbon monoxide, so that the gas components are regulated and controlled. The preparation method comprises the following steps of: crushing, screening, calcining and processing carbonate minerals (comprising tailings) taken as raw materials, thereby preparing the catalyst in different shapes and with different particle sizes. The calcium-based catalyst is mainly used for promoting a thermal cracking reaction and secondary decomposition to be carried out on the wastes and the coal as well as a reaction to be carried out on the carbon dioxide and coke, so that the content of combustible gases such as hydrogen and the carbon monoxide generated in the thermal decomposition is increased. As the calcium-based catalyst is used, the carbon dioxide in the gases generated in the thermal decomposition is reduced to a certain extent, so that the effect of carbon emission reduction is achieved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

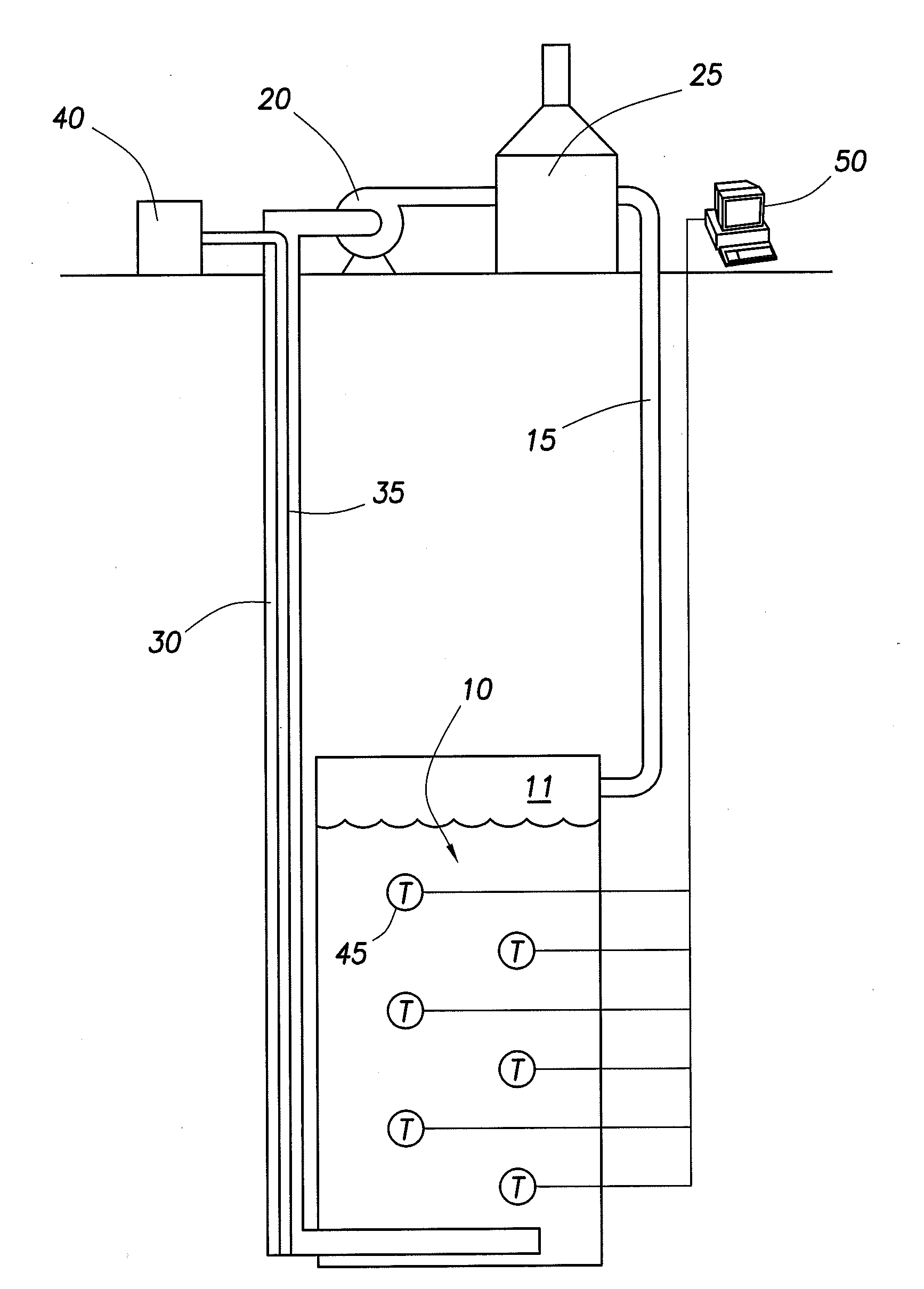

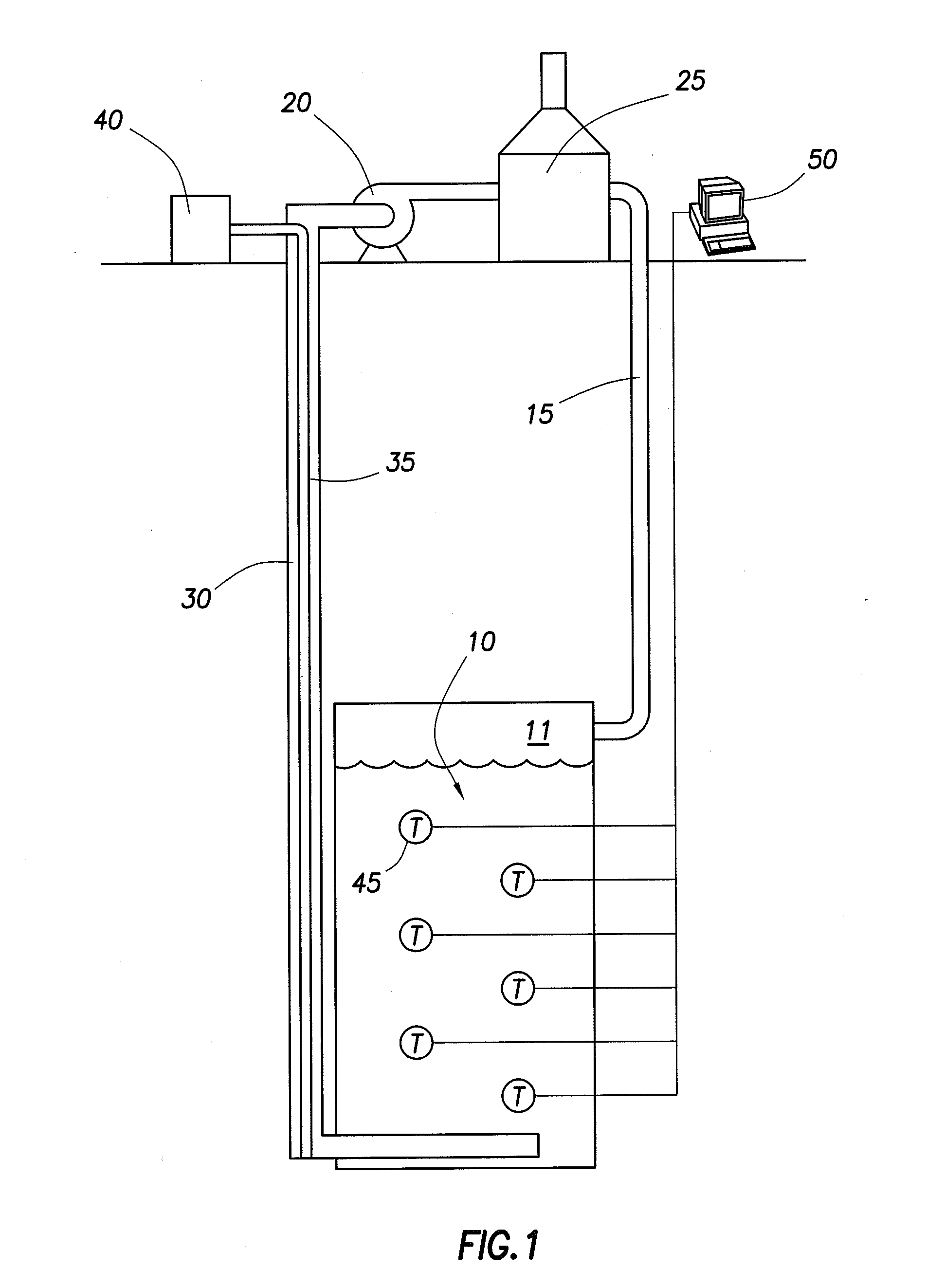

Recovery of Hydrocarbons From Oil Shale Deposits

This invention relates to recovering hydrocarbons from oil shale preferably in-situ where the temperature of the oil shale deposit is controlled to maximize recovery of hydrocarbons and minimize decomposition of carbonate minerals into carbon dioxide that might be released into the atmosphere. The process includes generating heat from hydrocarbon gases recovered from the oil shale and then later performing a controlled burn of the char that is left in the spent shale after the kerogens have been thermally cracked and the most of the recoverable hydrocarbons have been recovered. The burning of the char is also controlled based on the temperature of the oil shale in-situ, the temperature of the gases retuning to the surface from the oil shale and the carbon dioxide in the gases returning to the surface.

Owner:CONOCOPHILLIPS CO

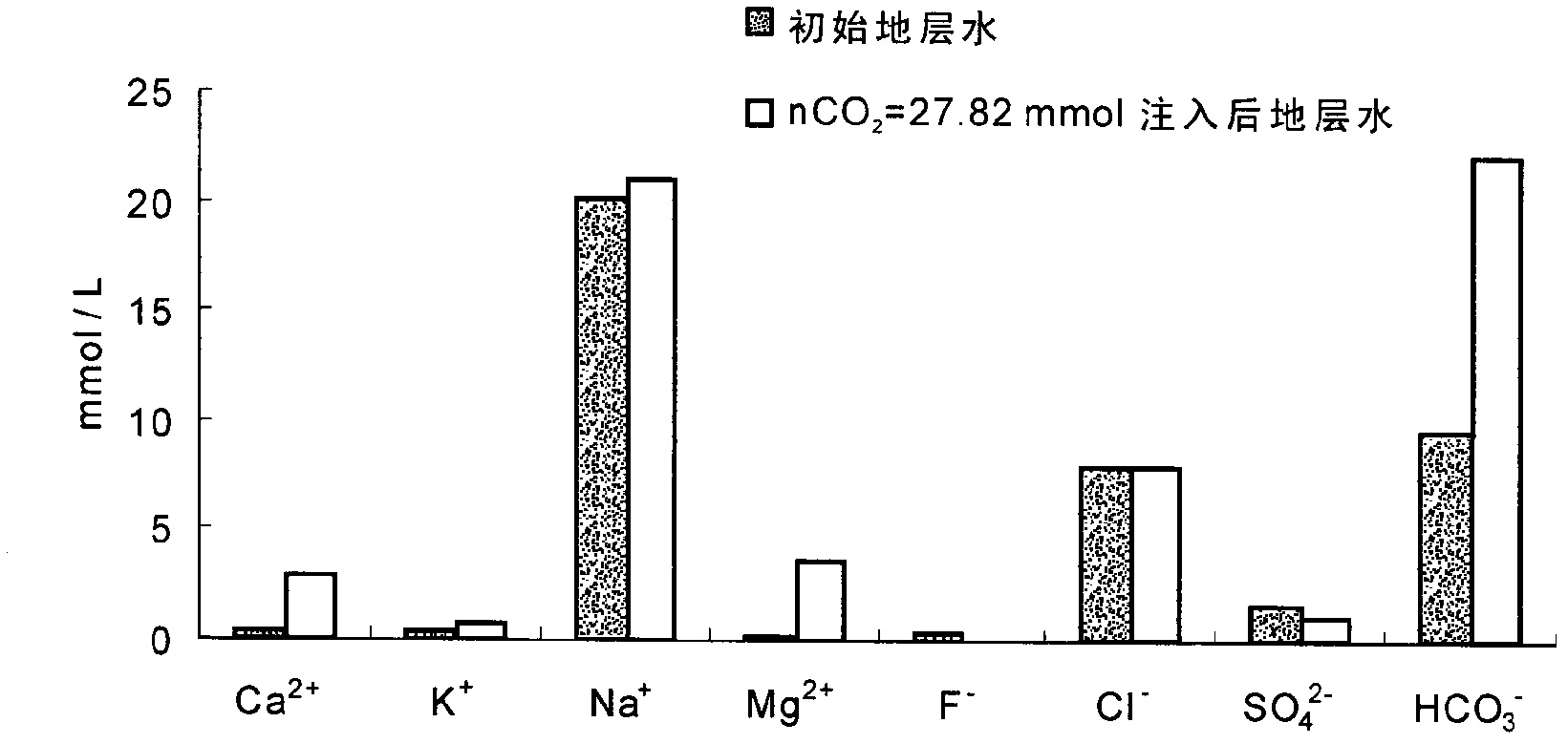

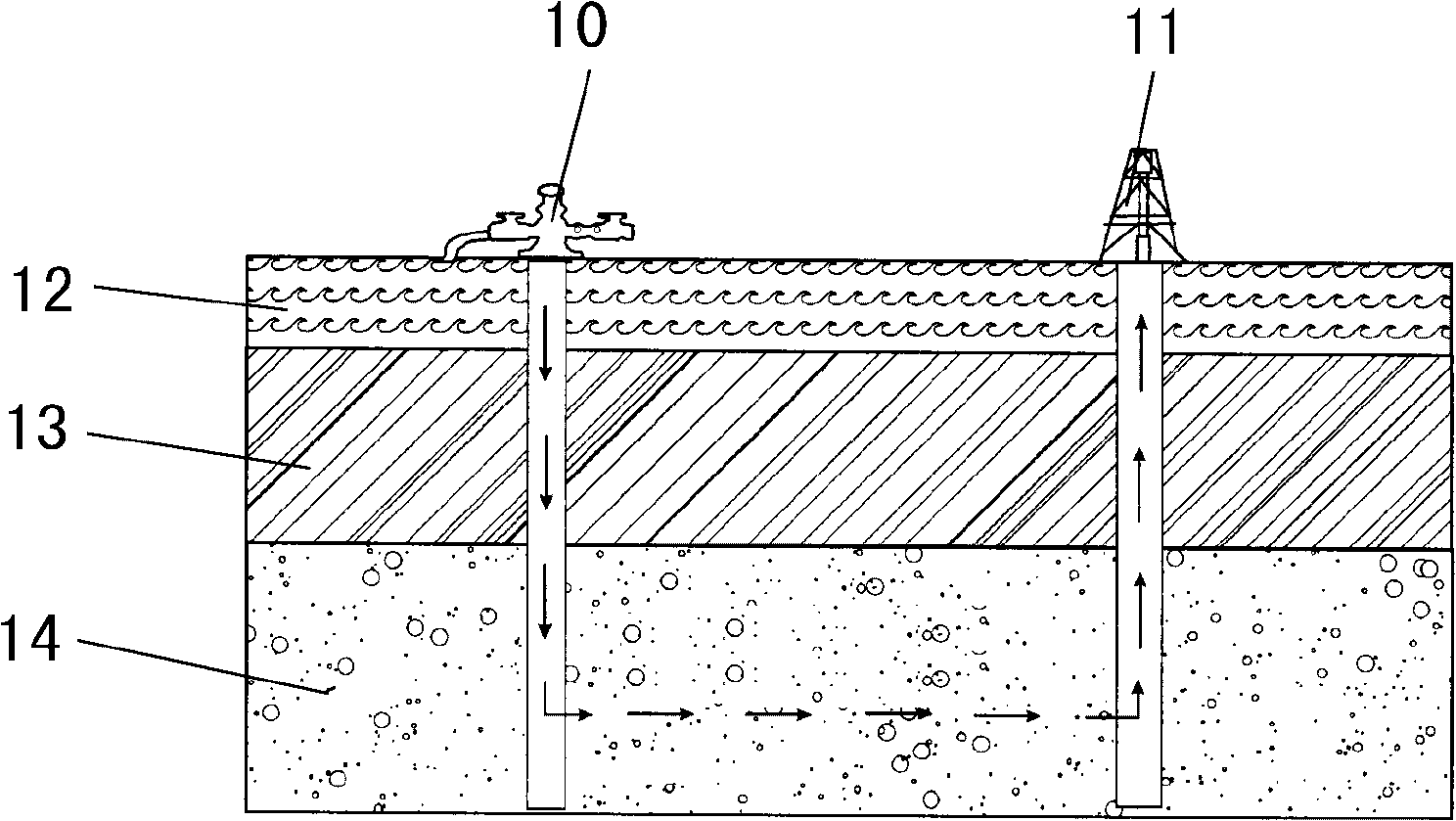

Method for integration of improvement of geothermal recharge rate and geological storage of CO2

InactiveCN102425870AAchieve energy saving and emission reductionOther heat production devicesGeothermal energy generationPorosityArenite

The invention relates to a method for integration of improvement of geothermal recharge rate and geological storage of CO2. In the method, the CO2 in the form of liquid is injected into the sandstone reservoir as a chemical exciting agent, and the penetration rate and the porosity of the sandstone reservoir are improved by reaction of the CO2 and carbonate minerals in the sandstone reservoir. In the method, the purpose of storing partial CO2 can be achieved, and the effects of energy conservation and emission reduction are realized at a certain extent.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

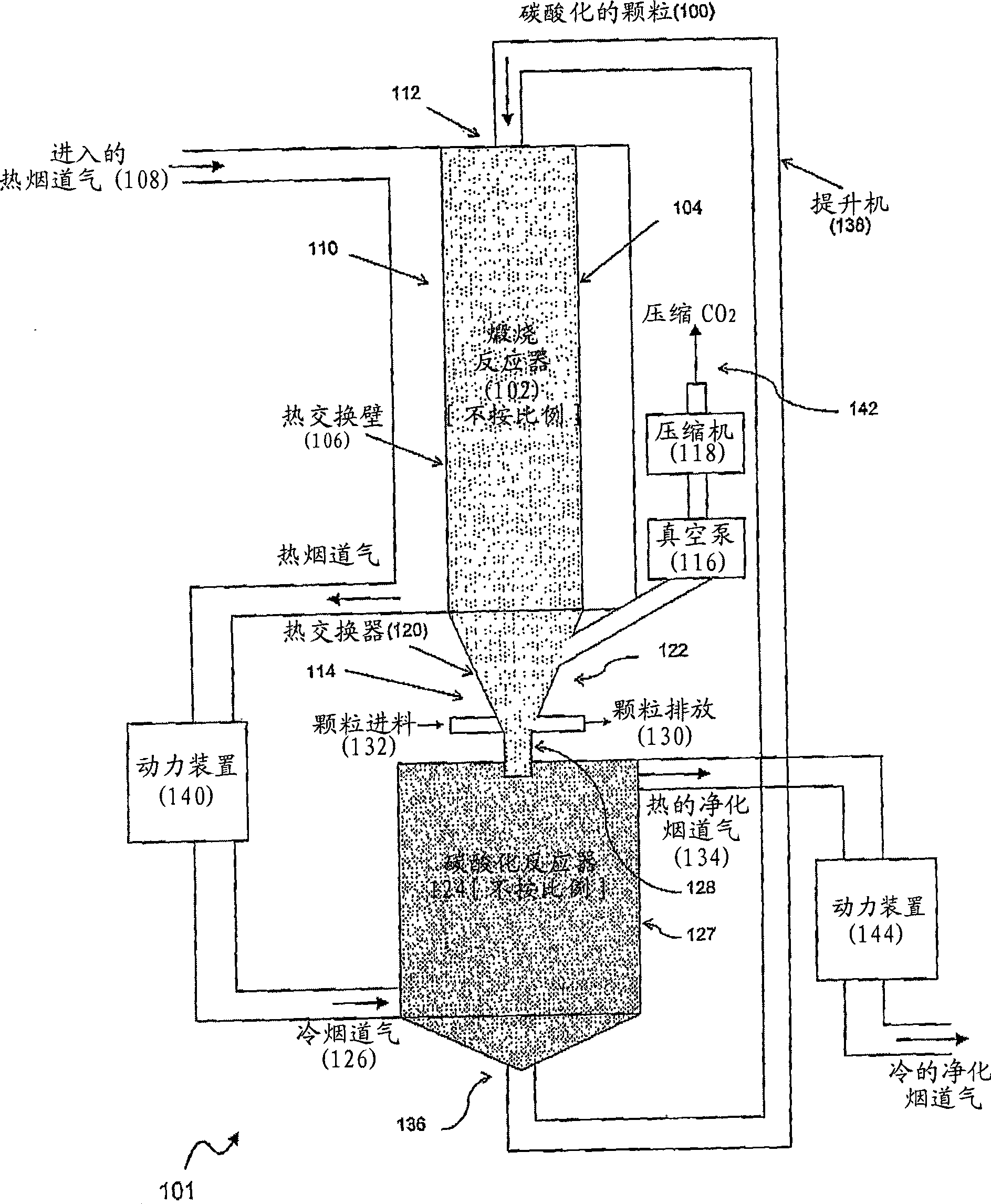

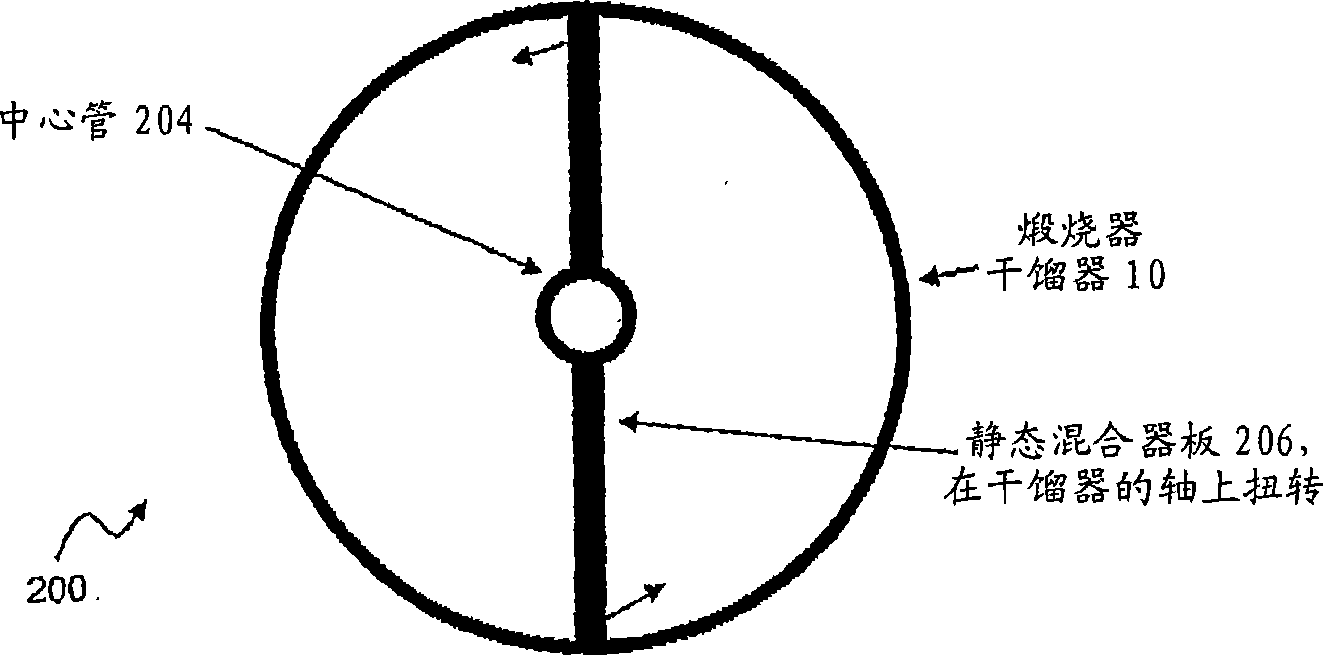

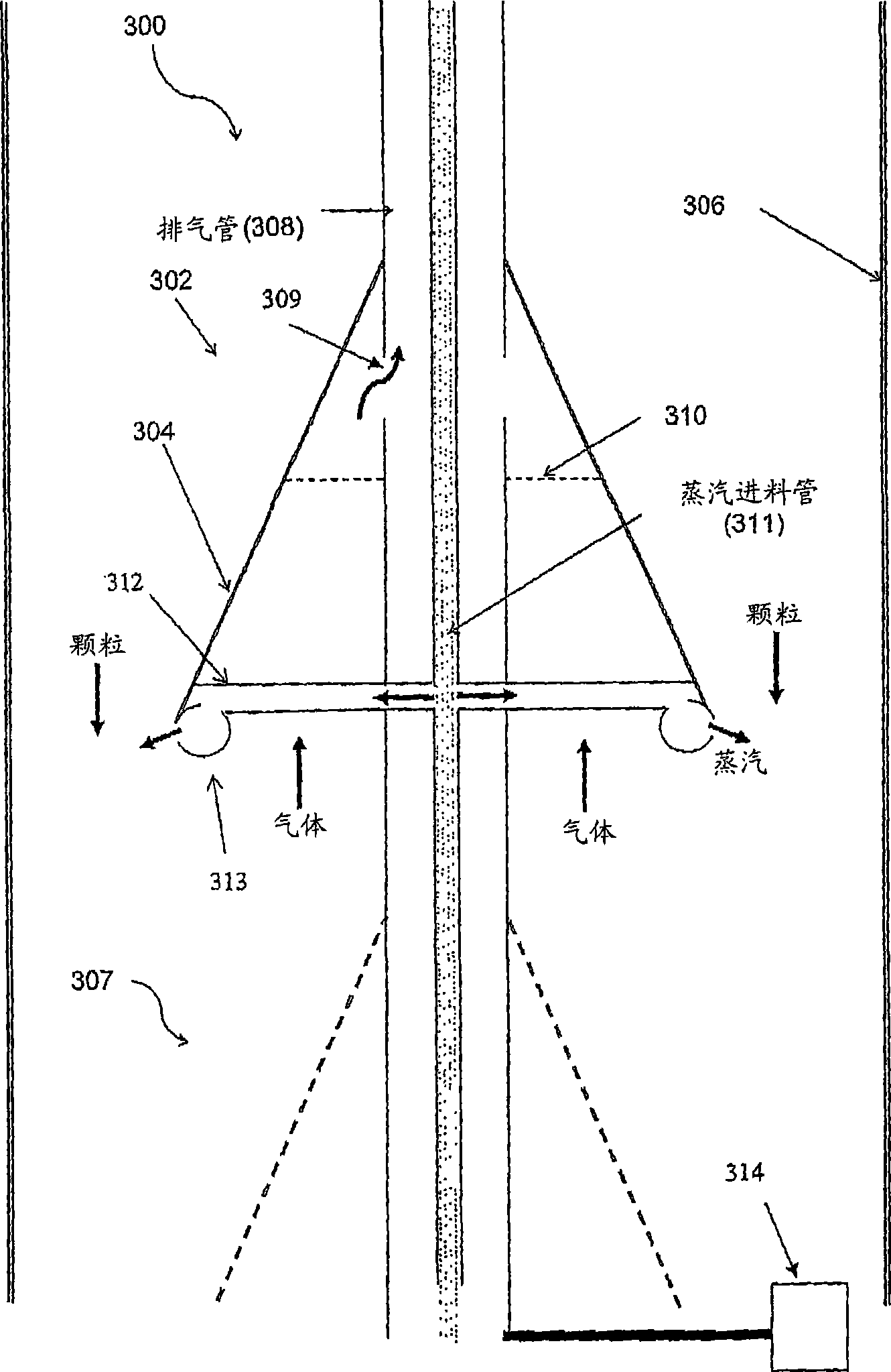

System and method for calcination/carbonation cycle processing

A system and method for calcination / carbonation cycle processing. The system comprises a calciner reactor for receiving partially carbonated mineral sorbent granules; a heat exchange structure for transferring heat through a wall of the calciner reactor to a granular flow of the sorbent granules for facilitating a calcination reaction of the sorbent granules to regenerate the sorbent granules; a gas extraction unit for removing gas products from the calciner, wherein the gas products comprise carbon dioxide from the calcination reaction; a carbonator reactor for receiving the regenerated sorbent granules from the calciner reactor and for receiving a cold flue gas, such that the regenerated sorbent granules are partially carbonised while the flue gas is scrubbed and the partially carbonated sorbent granules and the scrubbed flue gas exit the carbonator reactor as respective hot materials; and a riser unit for cycling the partially carbonated sorbent granules from the carbopator reactorto the calciner reactor.

Owner:CALIX PTY LTD

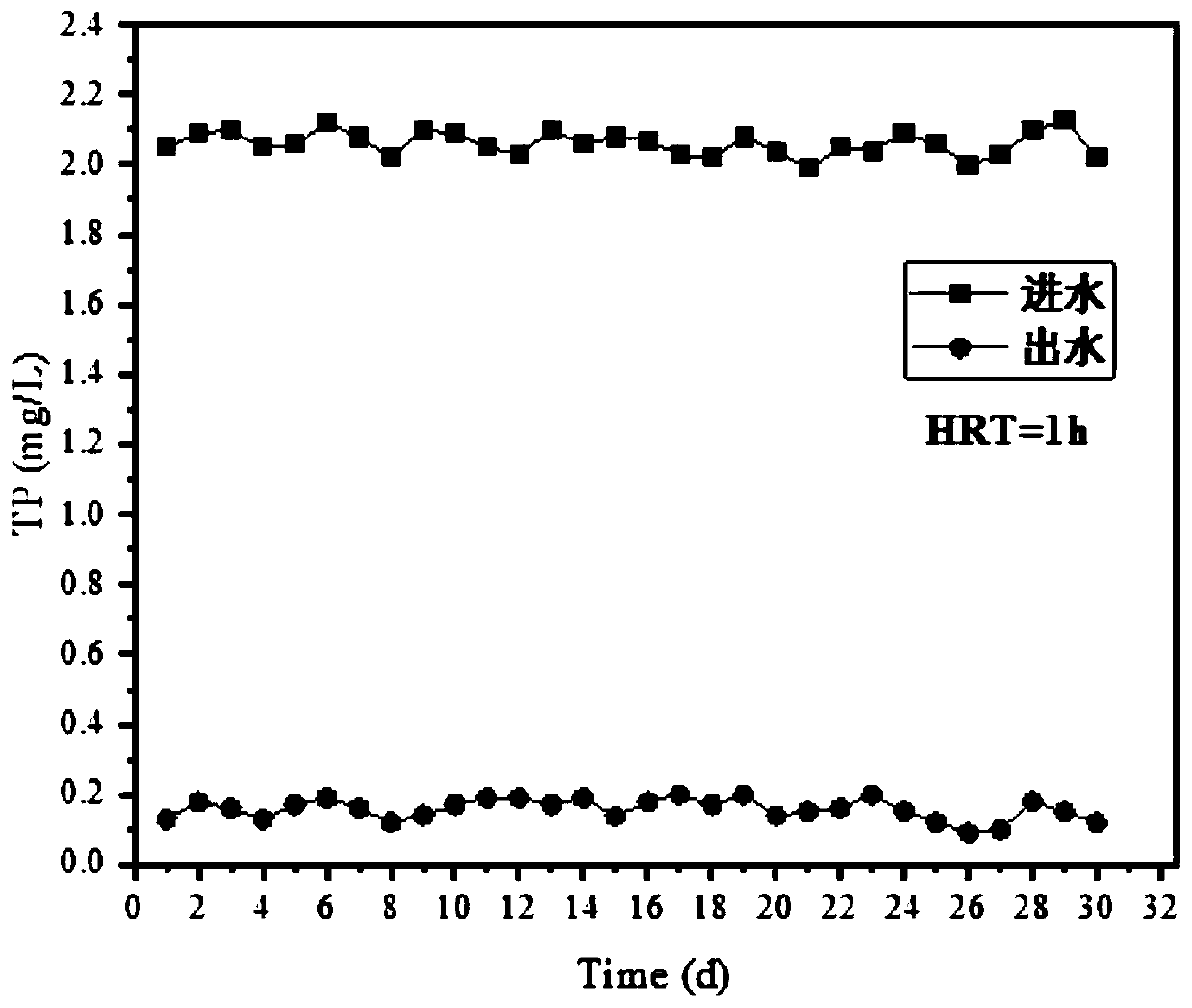

Synchronous denitrification and phosphorus removal composite filler and preparation method and application thereof

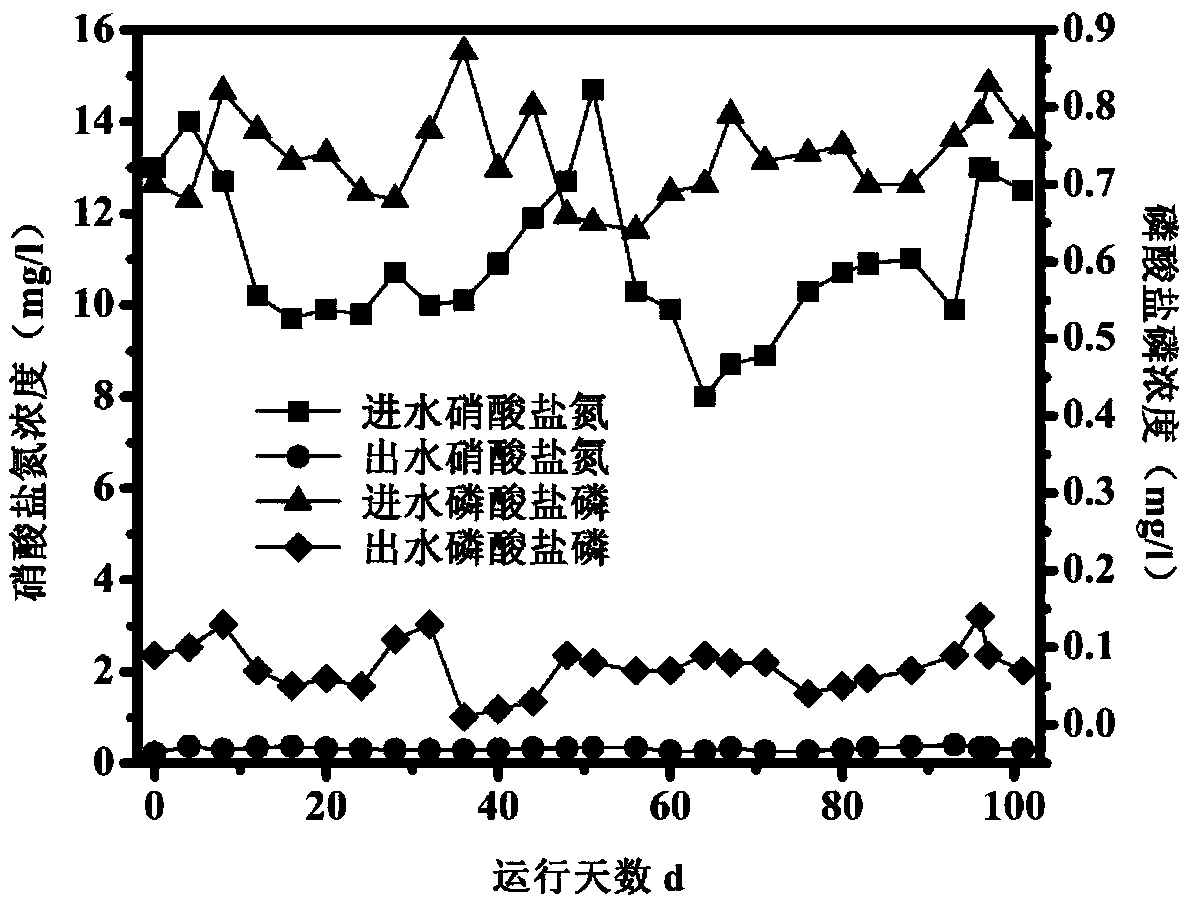

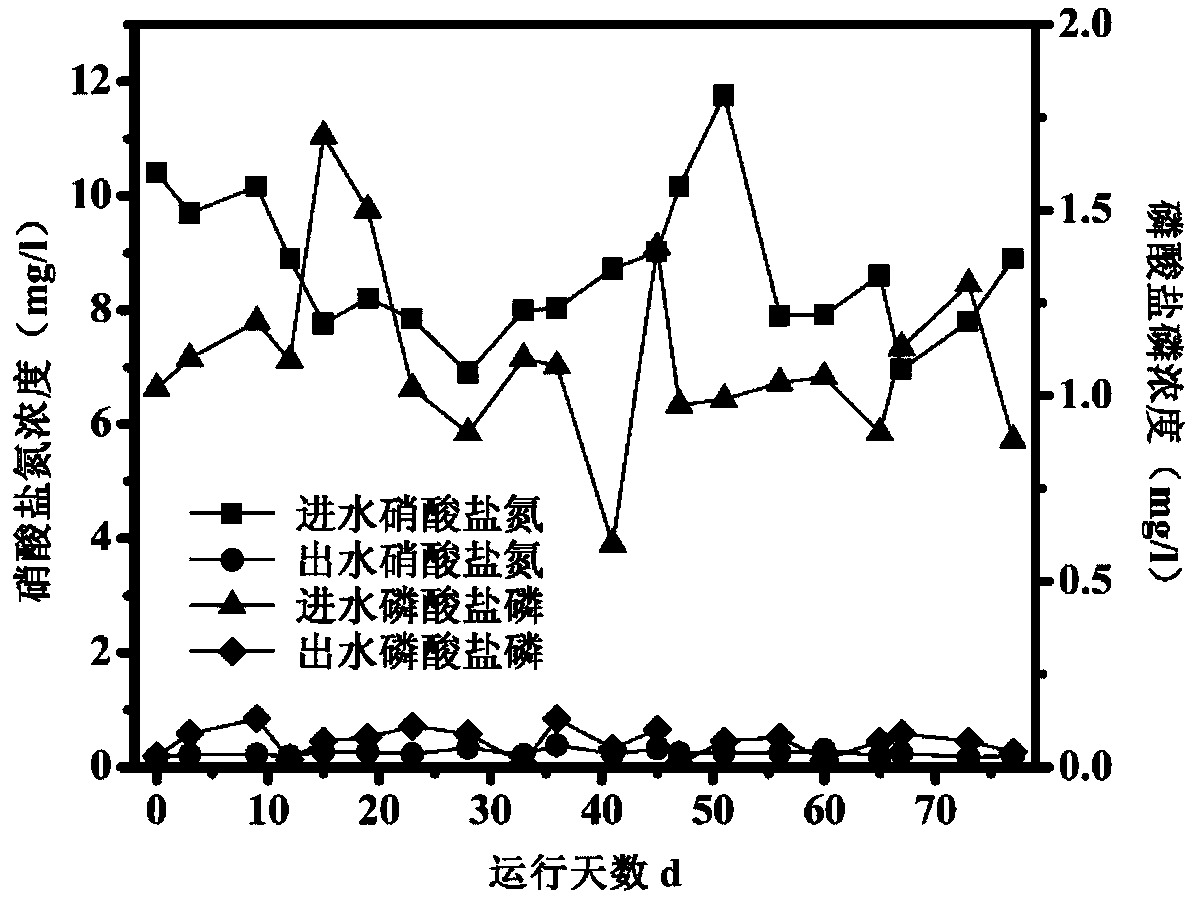

InactiveCN110683631AAchieve removalImprove stabilityTreatment with microorganism supports/carriersCarbonate mineralsSilicate Cement

The invention relates to the technical field of sewage treatment, and discloses a synchronous denitrification and phosphorus removal composite filler and a preparation method and application thereof.The composite filler comprises the following components in parts by weight: 15-20 parts of pyrite; 2-8 parts of sulfur; 0.5-1 part of carbonate minerals of calcium; 4.5-10 parts of Portland cement; 7.5-19.5 parts of water; and 0.5-3.0 parts of a foaming agent aqueous solution. Compared with a traditional sulfur autotrophic denitrification pyrite filler, the composite filler has a large specific surface area, high reactivity, light weight, and high hardness and strength, has efficient adsorption and precipitation effects on phosphorus, and has the characteristic that a large number of microorganisms can be loaded for biological denitrification, so that the composite filler is a multifunctional composite filler, and has good application prospects.

Owner:南京华创环境技术研究院有限公司

Phosphate mineral inhibitor, its application in reverse floatation of phosphorus ore and preparation method

The present invention relates to a phosphate mineral depressing agent, its application in back-flotation of phosphorus ore and its preparation method, in which the phosphate mineral depressing agent is a derivative of phosphoric acid, pyrophosphoric acid or tetraphosphoric acid. The back-flotation operation for removing carbonate mineral from raw ore containing phosphate mineral or intermediate product uses the derivative of phosphoric acid as depressing agent of phosphate mineral. The preparation method of the phosphoric acid derivative includes the following steps: in wet phosphoric acid, adding phosphorus pentoxide, its added quantity is 200-400% of wet phosphoric acid quantity, heating and stirring so as to obtain the invented phosphoric acid derivative.

Owner:WUHAN CHEM COLLEGE

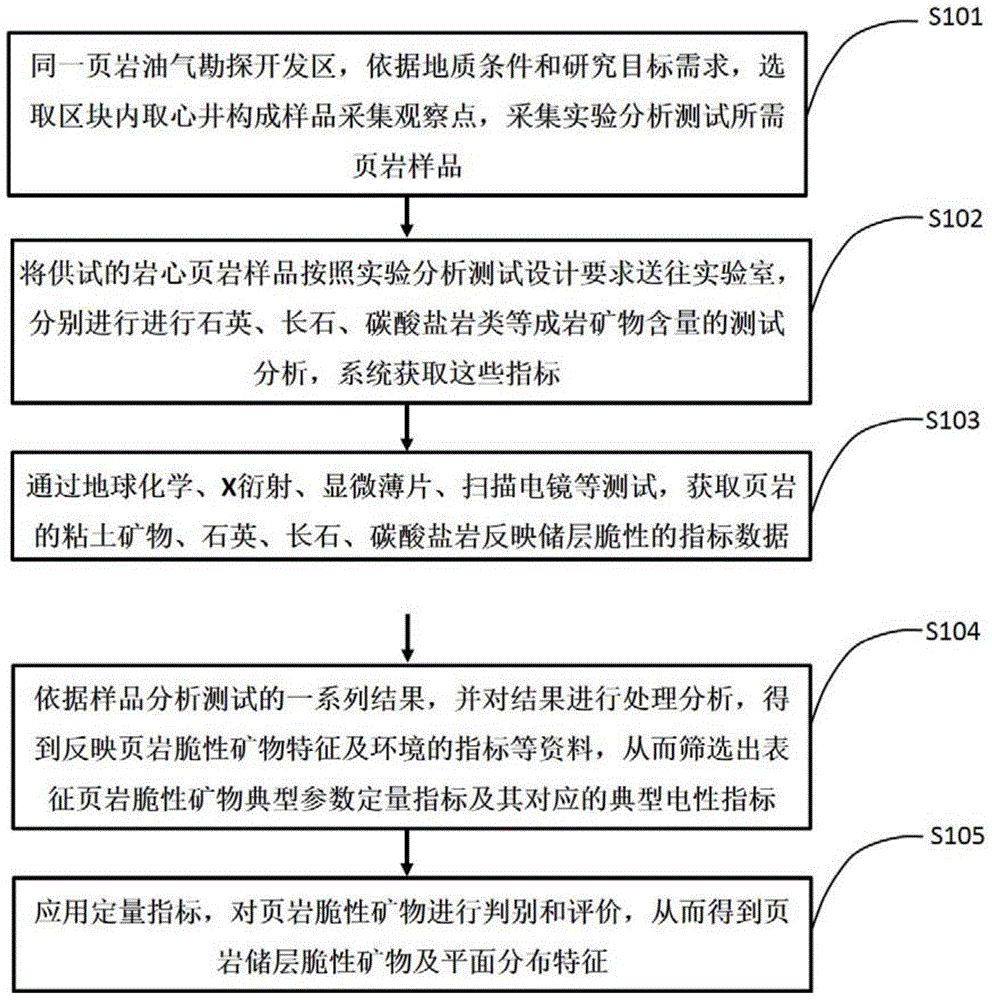

Shale reservoir brittle mineral logging quantitative characterization method

InactiveCN104569343AImprove evaluation efficiencyImprove the efficiency of exploration and development evaluationEarth material testingObservation pointTest analysis

The invention discloses a shale reservoir brittle mineral logging quantitative characterization method. The method comprises the following steps: 1, in the same shale oil and gas exploration and development area, selecting coring wells to constitute a sample collection and observation point, and collecting a shale sample; 2, testing the contents of quartz, feldspar and carbonate minerals in the sample respectively, and analyzing to acquire mineral content indexes; 3, acquiring mineral index data for reflecting shale reservoir brittleness; 4, analyzing according to a sample result to obtain index data for reflecting shale brittle mineral features and the environment, and screening typical parameter quantitative indexes of characterizing shale brittle mineral and typical electric property indexes; 5, distinguishing and evaluating shale reservoir brittleness to obtain the shale reservoir brittleness and a flat distribution feature. The method has the characteristics that predict accuracy and exploration and development success rate of a block shale brittle reservoir are improved and the exploration and development cost is low; the method can be widely applied to the fields of exploration evaluation and development design of oil and gas in shale reservoirs.

Owner:YANGTZE UNIVERSITY

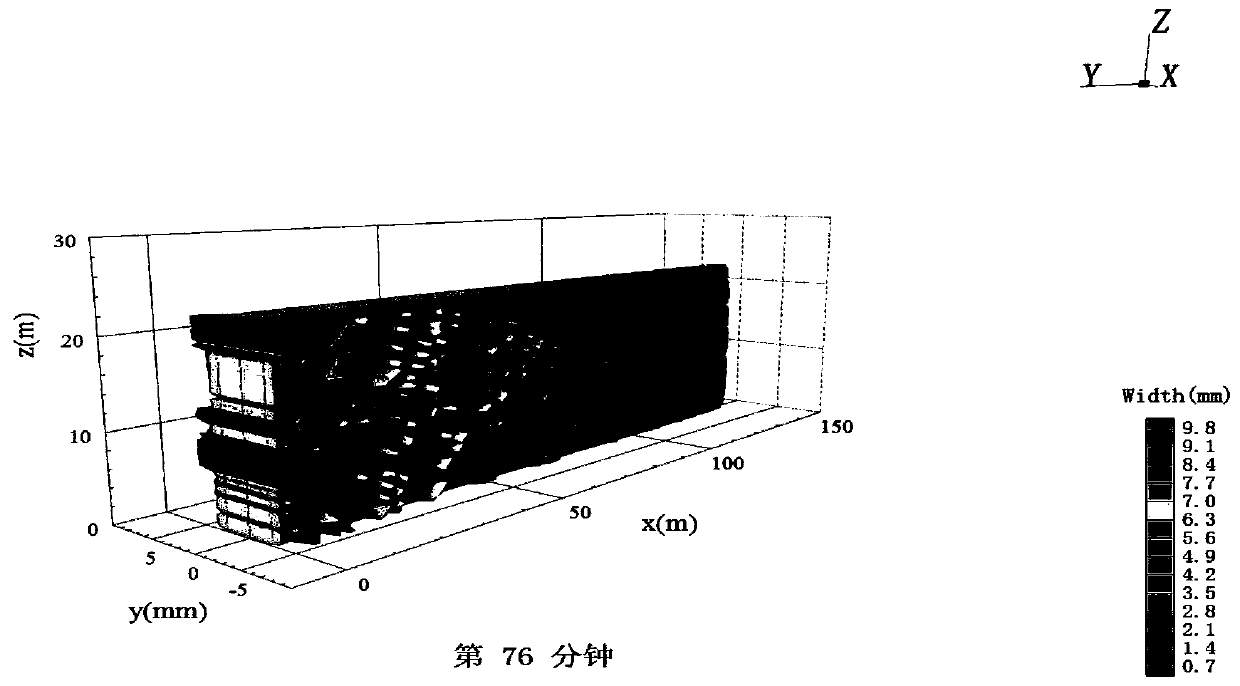

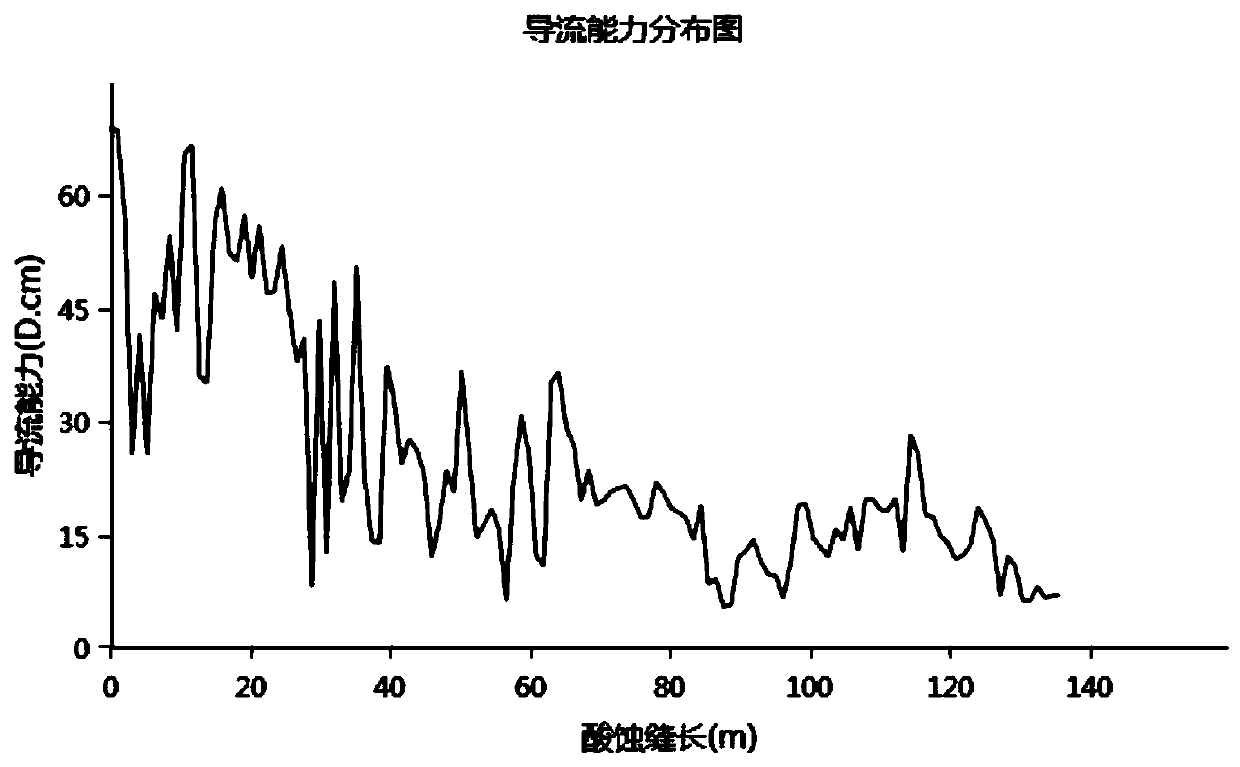

Large-discharge-capacity composite acid fracturing modification method for carbonate reservoir

ActiveCN110388199ASlow reaction rateIncrease the lengthFluid removalDrilling compositionReaction rateEffective action

The invention relates to the technical field of oil-gas field fracturing, in particular to a large-discharge-capacity composite acid fracturing modification method for a carbonate reservoir, and the method reduces the reaction rate of acid liquor and improves the length of acid-etched fractures by adopting multi-stage alternate injection of slickwater, gelled acid and variable-viscosity acid, is beneficial to communicating natural fractures and improves the acid fracturing modification volume of the reservoir; by adopting an earthworm pore acid liquid system, the acid liquid can deeply penetrate in the cracks, a longer effective action distance is formed, and the flow conductivity is improved; resistance reducing acid is adopted in the later stage, so that the acid corrosion degree of thereservoir around a shaft can be enlarged, and the flow conductivity of the reservoir in a near wellbore area is further improved; and the carbonate rock reservoir with relatively developed cracks is subjected to volume acid fracturing, natural cracks of the reservoir can be fully utilized, and the natural cracks are communicated while extended cracks and karst caves are enlarged by means of the corrosion effect of acid liquor on carbonate minerals, so that the flow conductivity of a seepage channel is increased, and the purpose of increasing the yield is achieved to the maximum extent.

Owner:PETROCHINA CO LTD

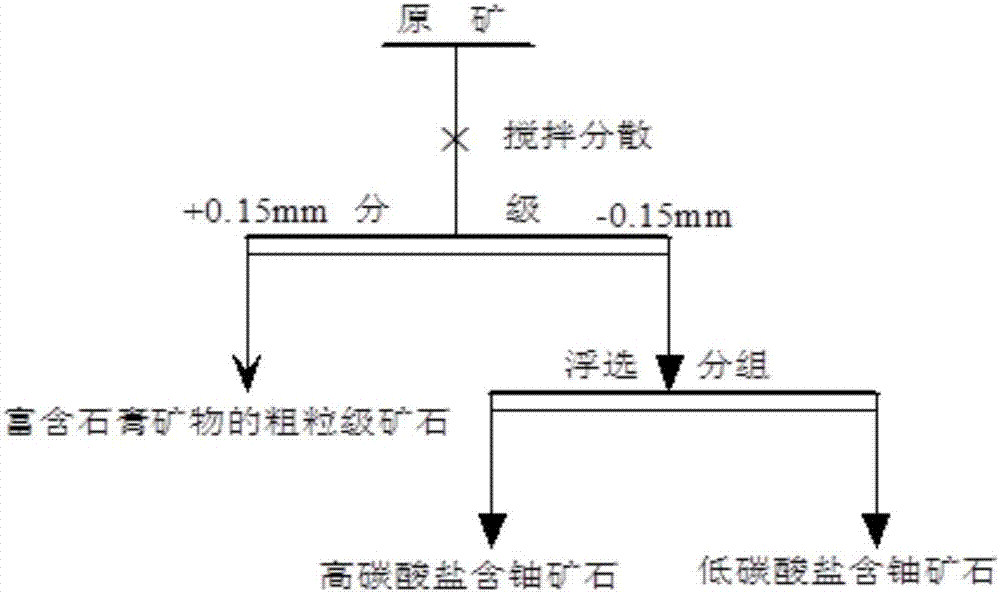

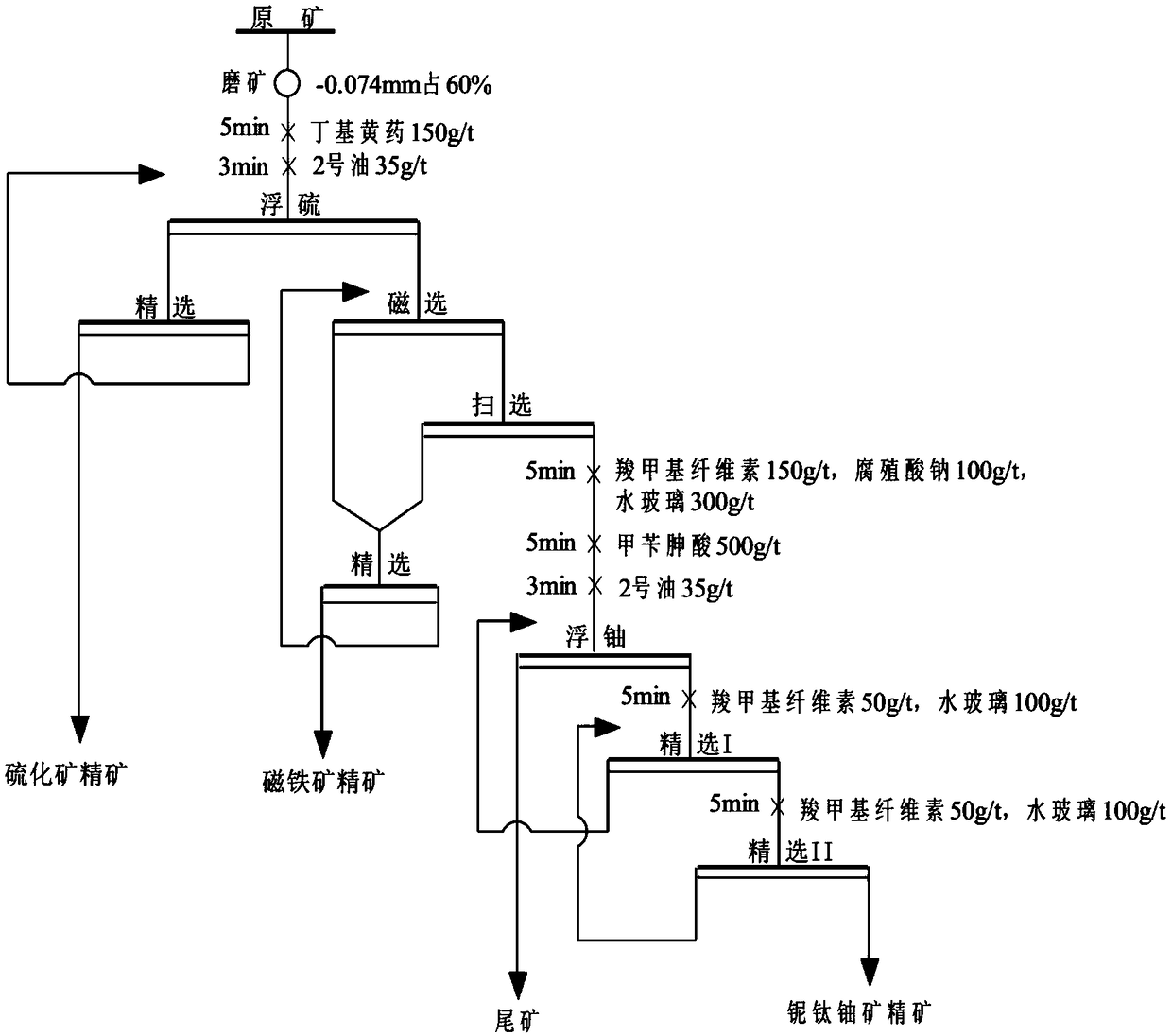

Pretreatment method for mud uranium ores

ActiveCN106944243AHigh recovery rateCost savingFlotationWet separationPretreatment methodUranium ore

The invention belongs to the technical field of uranium mining and metallurgy, and relates to a pretreatment method for mud uranium ores, in particular to a pretreatment method of mud uranium ores rich in gypsum and carbonate minerals. According to the pretreatment method for the mud uranium ores, firstly coarse-grained ores rich in the gypsum are separated, and the coarse-grained ores can recycle uranium through a dump leaching method, the ores grinding cost can be saved and the reagent consumption when fine-grained ores are leached through a alkaline process can be reduced. The fine-grained ores rich in the carbonate minerals are divided into two parts of high-carbonated uranium ores and low-carbonated uranium ores through a flotation method; the uranium can be recycled through subtractive leaching and acid leaching in the follow-up leaching, the reagent consumption can be saved, and the leaching rate is improved.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

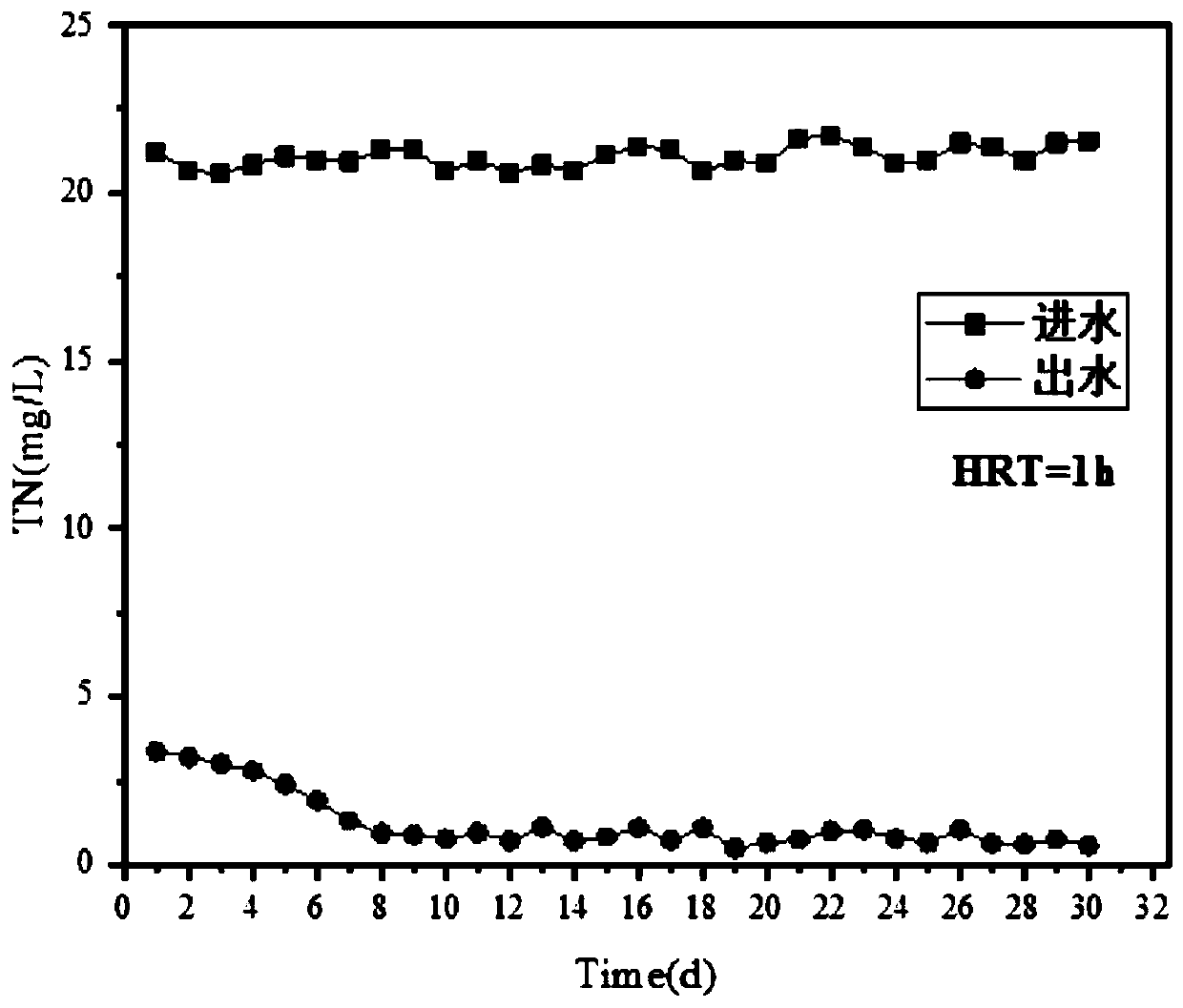

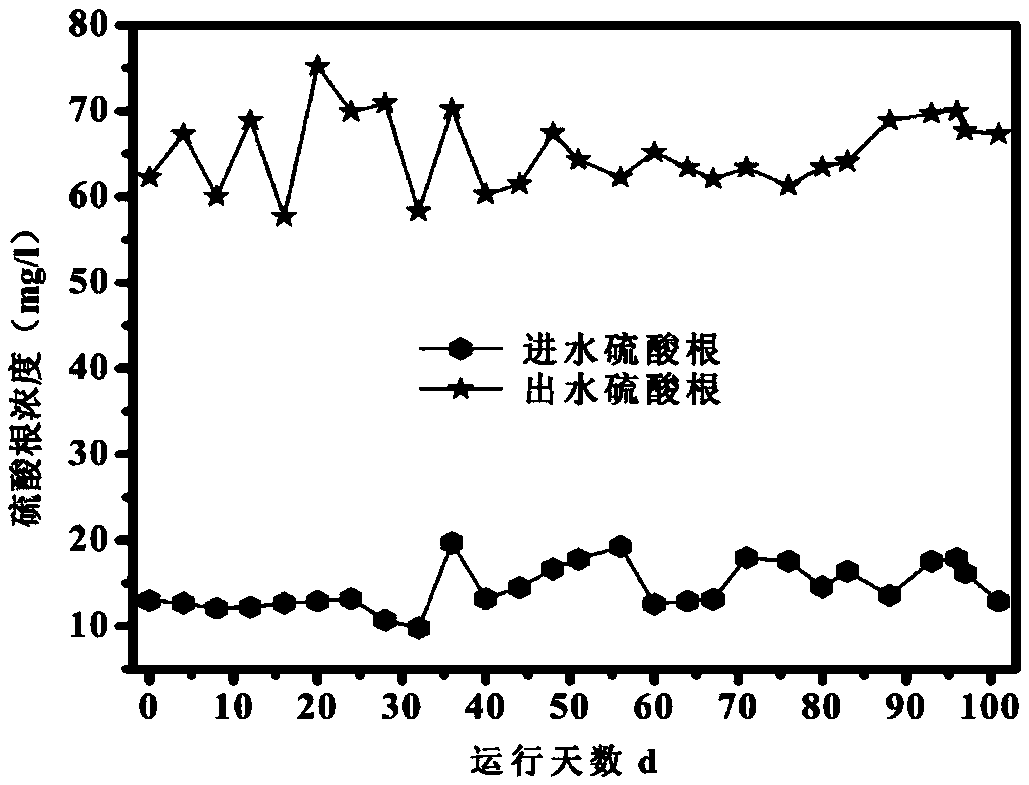

Method for synchronously removing nitrogen and phosphorus in mixed nutritional biofilter based on pyrite

InactiveCN109292972AReduce usageLow running costWater treatment compoundsWater contaminantsCarbonate mineralsDenitrification

The invention discloses a method for synchronously removing nitrogen and phosphorus in a mixed nutritional biofilter based on pyrite, and belongs to the technical field of sewage treatment. A reactoris filled with the pyrite or pyrite and inorganic carbonate minerals which are uniformly mixed, sludge containing autotrophic denitrification bacteria is inoculated into the reactor to realize biofilmformation, sewage to be treated is led into the reactor, the carbon nitrogen ratio of the sewage is controlled by adding an organic carbon source, a reaction system forms the mixed nutritional biofilter, and nitrogen and phosphorus are removed from the sewage in the mixed nutritional biofilter. The biofilter is simple and easy, and hydraulic retention time of only 0.3-1.5 hours is needed when thebiofilter is used for treating the sewage containing nitrogen and phosphorus, so that requirements can be met, nitrogen and phosphorus removing effects are excellent, and the biofilter is low in costand suitable for engineering application. Besides, compared with a traditional sulfur autotrophic denitrification biofilter, the biofilter has the advantage that the concentration of effluent sulfateradicals is greatly reduced.

Owner:NANJING UNIV

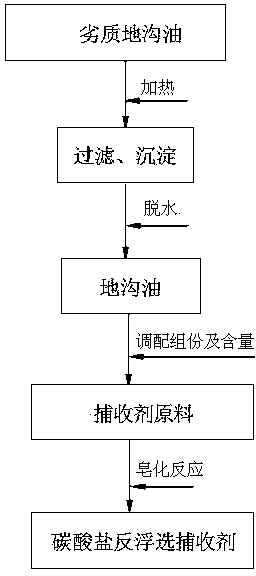

Method for preparing collophanite reverse flotation collecting agent with drainage oil

The invention relates to a method for preparing collophanite reverse flotation collecting agent with drainage oil turned into wealth from waste materials. The method comprises the steps that a. the low-quality drainage oil is heated to 40-80 DEG C, solid waste is removed by filtering and precipitating, dehydration is then carried out until water content of the drainage oil is lower than 1%; b. the component of the drainage oil is detected, blending is carried out until the content of C12-C18 in the component is larger than 60% of the whole component; c. through saponification, the pH of the drainage oil is adjusted to 11, the collophanite reverse flotation carbonate mineral collecting agent is obtained; d. 300-500g of drainage oil saponification matter is added into one ton of raw ore in industrial production of low-grade collophanite reverse flotation carbonate minerals with MgO content of 3-7%, high-quality phosphorus concentrate with MgO content lower than 1% is obtained, and removal rate of MgO is larger than 80%. According to the method, the drainage oil can be turned into wealth from waste materials for reuse, purchasing cost of flotation agent raw materials is greatly lowered, economy and environment protection are achieved, and the method is suitable for popularizing use of the drainage oil.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Method for improving permeability of shale base blocks rich in organic matters

ActiveCN105484717AImprove permeabilitySimple operation processFluid removalPyriteSoil organic matter

The invention provides a method for improving the permeability of shale base blocks rich in organic matters. An acid and an oxidizing solution are added in shale gas layer injection liquid. The liquid is injected in the shale base blocks rich in the organic matters, so that the shale organic matters and pyrites are oxidized and decomposed. Carbonate minerals are dissolved by the acid to form corrosion pores. Nanoscale pore reconstruction is realized, so that a seepage channel becomes large, the connectivity becomes good, and thus the permeability of the shale base blocks is improved. The method includes the steps of: selecting an oxidizing solution and the concentration according to the organic matter types and contents; respectively adding the oxidizing solution and hydrochloric acid into shale gas layer injection liquid; injecting the injection liquid into the shale base blocks rich in the organic matters; and flowing back the injection liquid after the injection liquid fully reacts with the shale. The method for improving the permeability of the shale base blocks rich in the organic matters can cooperate with the shale gas well hydrofracture reconstruction. The base block permeability is improved in a large range. The shale gas well output after the hydrofracture is raised. The operation technology is simple, and the economic cost is low.

Owner:SOUTHWEST PETROLEUM UNIV

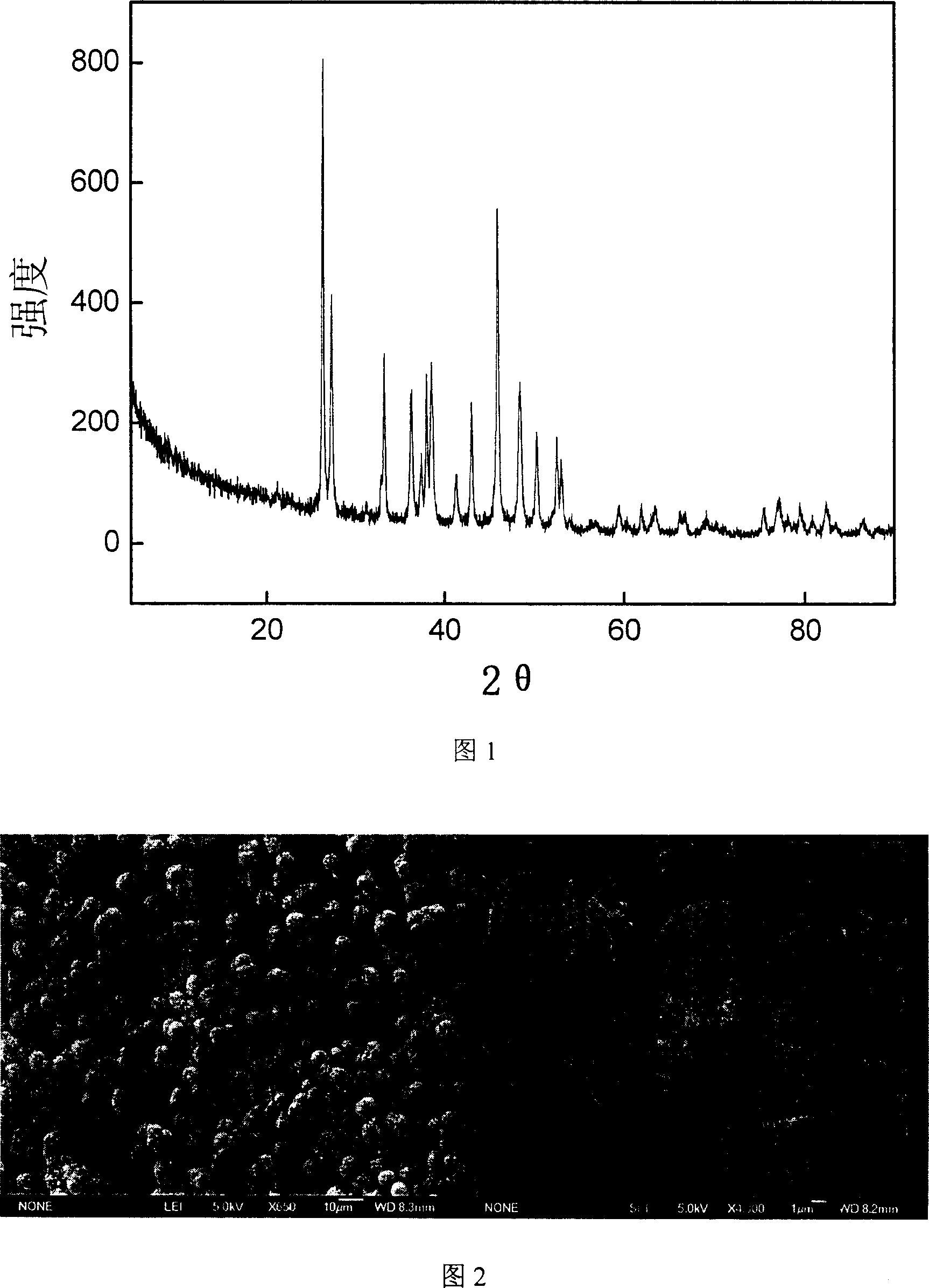

A kind of flotation method of carbonate mineral

InactiveCN102284372AImprove adsorption strengthReduce dosageFlotationFoaming agentPhysical chemistry

The invention provides a flotation method for carbonate minerals. The method comprises the following steps of: grinding, roughing, sifting and scavenging, namely after grinding, regulating the mass percentage concentration of flotation mineral slurry to 10 to 30 percent, adding acidic solution with the concentration of 0.01 to 5 mol / L until the pH value of the mineral slurry ranges from 0.1 to 5,adding a collecting agent in amount which is 0.002 to 0.05 percent of mineral solids in the mineral slurry, adding a foaming agent in amount which is 0.001 to 0.02 percent of mineral solids in the mineral slurry, stirring at a speed of between 30 and 120 revolutions / minute, and roughing, sifting and scavenging conventionally to obtain concentrates. In the flotation method, due to the addition of sulfuric acid, carbon dioxide microbubbles generated by reacting carbonates with the sulfuric acid are adsorbed to the surfaces of the minerals, so that mineral granules are adsorbed to float upwards under the bridging action of the microbubbles attached between the mineral granules and big bubbles. By the method, the using amount of the collecting agent and the foaming agent is reduced, the concentrate grades are improved by the selective adsorption of the bubbles, a process flow is simplified, and a high assorting index can be reached only by assorting once.

Owner:KUNMING UNIV OF SCI & TECH

Beneficiation method capable of reducing leaching acid consumption of samirestie concentrate

ActiveCN109482365ALess quantityHigh recovery rateFlotationMagnetic separationMagnetiteMaterials science

The invention relates to a beneficiation method capable of reducing the leaching acid consumption of samirestie concentrate. The beneficiation method capable of reducing the leaching acid consumptionof the samirestie concentrate comprises the following steps that (1) ore is grinded until the particle size of -0.074mm accounts for 40-90%, and ore pulp is obtained; (2) sulfide is subjected to flotation; (3) magnetite is removed; and (4) acid consumption gangue is restrained and samirestie is subjected to flotation. The beneficiation method capable of reducing the leaching acid consumption of the samirestie concentrate has the remarkable effects that sulphide ore with acid consumption is selected through flotation firstly before the samirestie is subjected to flotation, then the magnetite with acid consumption is recycled through weak magnetic separation, and methyl benzyl arsonic acid with good selectivity and high collecting capacity is selected as a collecting agent to operate flotation on the samirestie, inhibitors of carbonate minerals, iron minerals and aluminosilicate minerals are added at the same time, and the samirestie concentrate with high recovery ratio and high grade isobtained, and the amount of minerals with acid consumption in concentrate products is effectively reduced.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com