Method for synchronously removing nitrogen and phosphorus in mixed nutritional biofilter based on pyrite

A technology of simultaneous nitrogen and phosphorus removal and biological filter, which is applied in the field of simultaneous nitrogen and phosphorus removal by mixed nutrient biological filter based on pyrite, can solve the problem that it is difficult to effectively achieve simultaneous nitrogen and phosphorus removal without sulfide. Wastewater is not suitable for use, the scope of application is narrow, etc., to achieve the effect of rational utilization, increased abundance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Step (1), preparation and filling of filler

[0038] Uniformly mix pyrite or pyrite and inorganic carbonate minerals, and fill them into the reactor;

[0039] Step (2), inoculation and hanging film

[0040] Inoculate the sludge of sulfur-containing autotrophic denitrifying bacteria to the reactor in step 1), add nutrient solution to cultivate and carry out inoculation and film formation;

[0041] Step (3), sewage treatment

[0042] Feed the sewage to be treated into the reactor, and add organic carbon sources to the sewage to be treated during the water intake process, and control the carbon-nitrogen ratio of the sewage by adding organic carbon sources to 0.5-12, and the sewage flows through the reaction in an upflow manner The reaction system is formed into a mixed nutrient biofilter, and the hydraulic retention time of the biofilter composed of coupling fillers is controlled at 0.3-1.5h. The sewage is denitrified and dephosphorized in the mixed nutrient biofilter to...

Embodiment 1

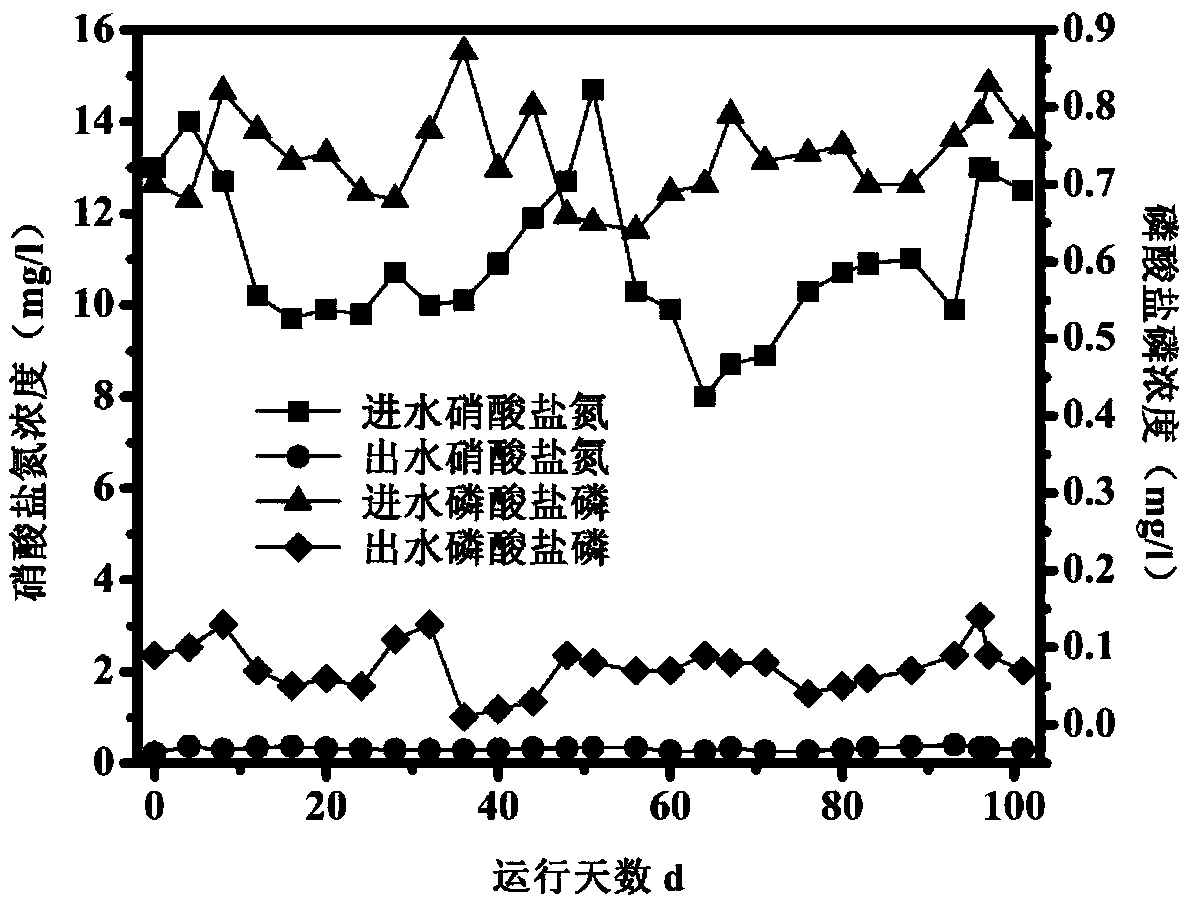

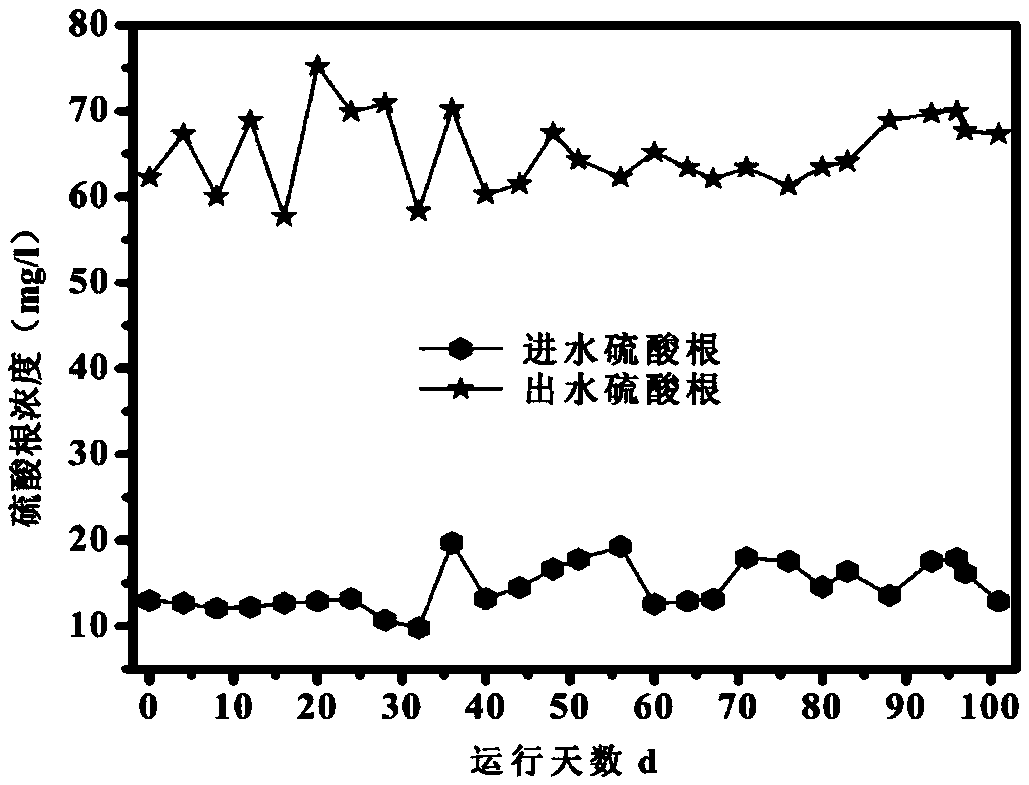

[0044] In this example, pyrrhotite was used as the sulfur source, limestone was used as the inorganic carbon source, and they were uniformly mixed at a volume ratio of 9:1 to prepare a filler with a total volume of 10 L. The average particle sizes of the two minerals were 4 mm and 3 mm, respectively. Fill the filler into the reactor, inoculate the anaerobic sludge and add the culture solution, and complete the film formation after 3 days of cultivation. Feed the influent water into the reactor, and add methanol to the influent water, so that the carbon-nitrogen ratio in the sewage is about 3, the hydraulic retention time is 1h, and the nitrogen, phosphorus and sulfate radicals in the influent and effluent water during 101 days of operation are as follows: figure 1 shown. The average influent nitrogen is 11.0mg / l, the average influent phosphorus is 0.74mg / l, the average effluent nitrogen is 0.32mg / l, the average effluent phosphorus is 0.07mg / l, and the average effluent sulfate ...

Embodiment 2

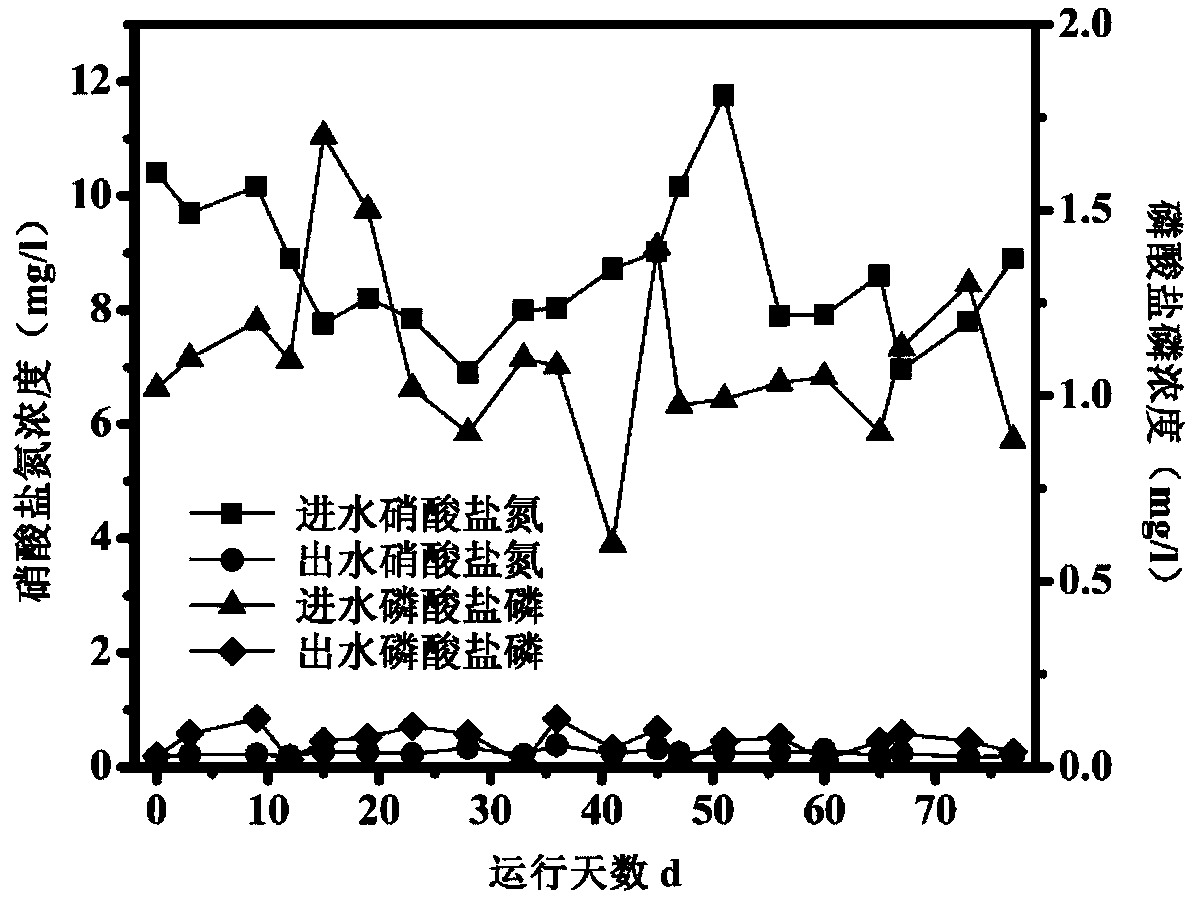

[0047] In this example, pyrite was used as the sulfur source, limestone was used as the inorganic carbon source, and they were uniformly mixed at a volume ratio of 4:1 to prepare a filler with a total volume of 2.3 L. The average particle sizes of the three minerals were 4 mm and 1 mm, respectively. Fill the filler into the reactor, inoculate the anaerobic sludge and add the culture solution, and complete the film formation after 4 days of cultivation. Influent water was passed into the reactor, and glucose was added to the influent water, so that the carbon-nitrogen ratio in the sewage was about 5, the hydraulic retention time was 0.3h, and the influent nitrogen, phosphorus and sulfate radicals were as follows figure 2 shown. The average influent nitrogen is 8.7mg / l, the average influent phosphorus is 1.1mg / l, the average effluent nitrogen is 0.24mg / l, the average effluent phosphorus is 0.07mg / l, and the average effluent sulfate is 71.7mg / l.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com