On-line molten steel slag modification method

A liquid steel slag and modification technology, applied in the field of iron and steel metallurgy, can solve the problems of ineffective utilization, large consumption of water resources, and high input cost, and achieve the effects of sufficient raw material sources, reduction of modification costs, and low procurement costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

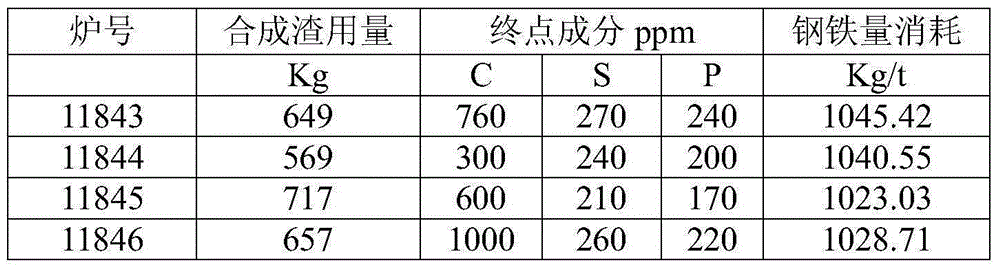

Image

Examples

Embodiment 1

[0024] A steel slag modifier of this embodiment comprises the following components in mass percentage: 25% of dolomite, 40% of limestone, 15% of magnesite and 20% of siderite. The particle sizes of the carbonate minerals dolomite, limestone, magnesite and siderite are all less than 50 mm, and setting the particle size in this embodiment to be smaller than 50 mm will facilitate internal thermal decomposition of massive carbonate minerals. In this embodiment, dolomite, limestone, and magnesite are used to adjust the alkalinity and magnesium oxide content of liquid steel slag, and siderite is used to adjust the melting point of liquid steel slag. The specific modification principle will be described below. The steel slag modifier of this embodiment has sufficient sources of raw materials and low purchase cost, which reduces the cost of steel slag modification and is convenient for popularization and application.

[0025] In this embodiment, the specific process of using the steel...

Embodiment 2

[0031] An online modification method of liquid steel slag in this embodiment is basically the same as in Embodiment 1, except that the steel slag modifier of this embodiment includes the following components in mass percentage: 5% dolomite, 85% limestone, Magnesite 5% and Siderite 5%. In this embodiment, low-phosphorus converter slag with a temperature of 1350°C (the mass percentage of phosphorus is less than 2%) and the mixed and dried steel slag modifier are poured into the slag ladle at the same time, and the balance between the steel slag modifier and the liquid steel slag is controlled. The ratio of feeding rate is equal to the mass ratio of steel slag modifier to liquid steel slag, the mass percentage of steel slag modifier to the total mixture is 15.0%, the mixture is cooled to 500°C, and the modification is completed.

Embodiment 3

[0033] A method for on-line modification of liquid steel slag in this embodiment is basically the same as in Embodiment 1, except that the steel slag modifier of this embodiment includes the following components in mass percentage: 15% of dolomite, 15% of limestone, Magnesite 40% and Siderite 30%. In this embodiment, low-phosphorus converter slag with a temperature of 1400°C (the mass percentage of phosphorus is less than 2%) and the mixed and dried steel slag modifier are poured into the slag ladle at the same time, and the balance between the steel slag modifier and the liquid steel slag is controlled. The ratio of feeding rate is equal to the mass ratio of steel slag modifier to liquid steel slag, the mass percentage of steel slag modifier to the total mixture is 40.0%, the mixture is cooled to 500°C, and the modification is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com