Patents

Literature

82results about How to "Improve flux effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

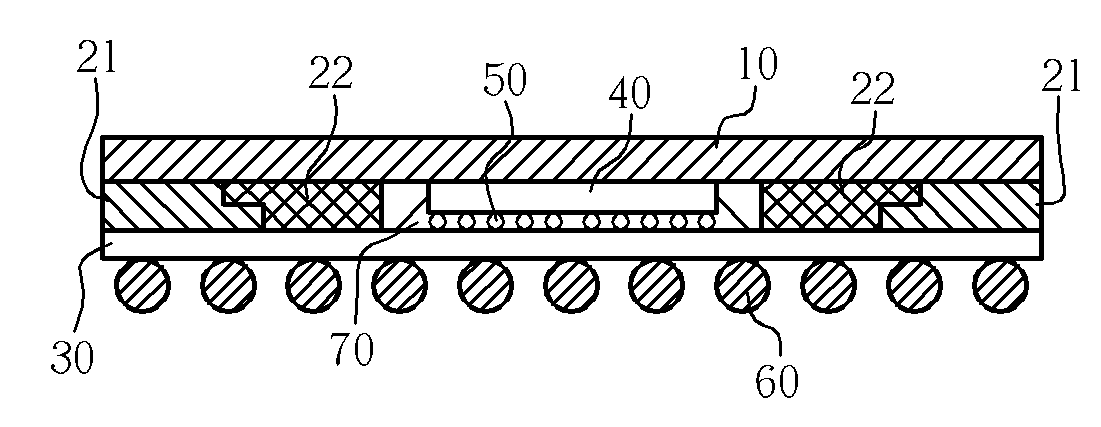

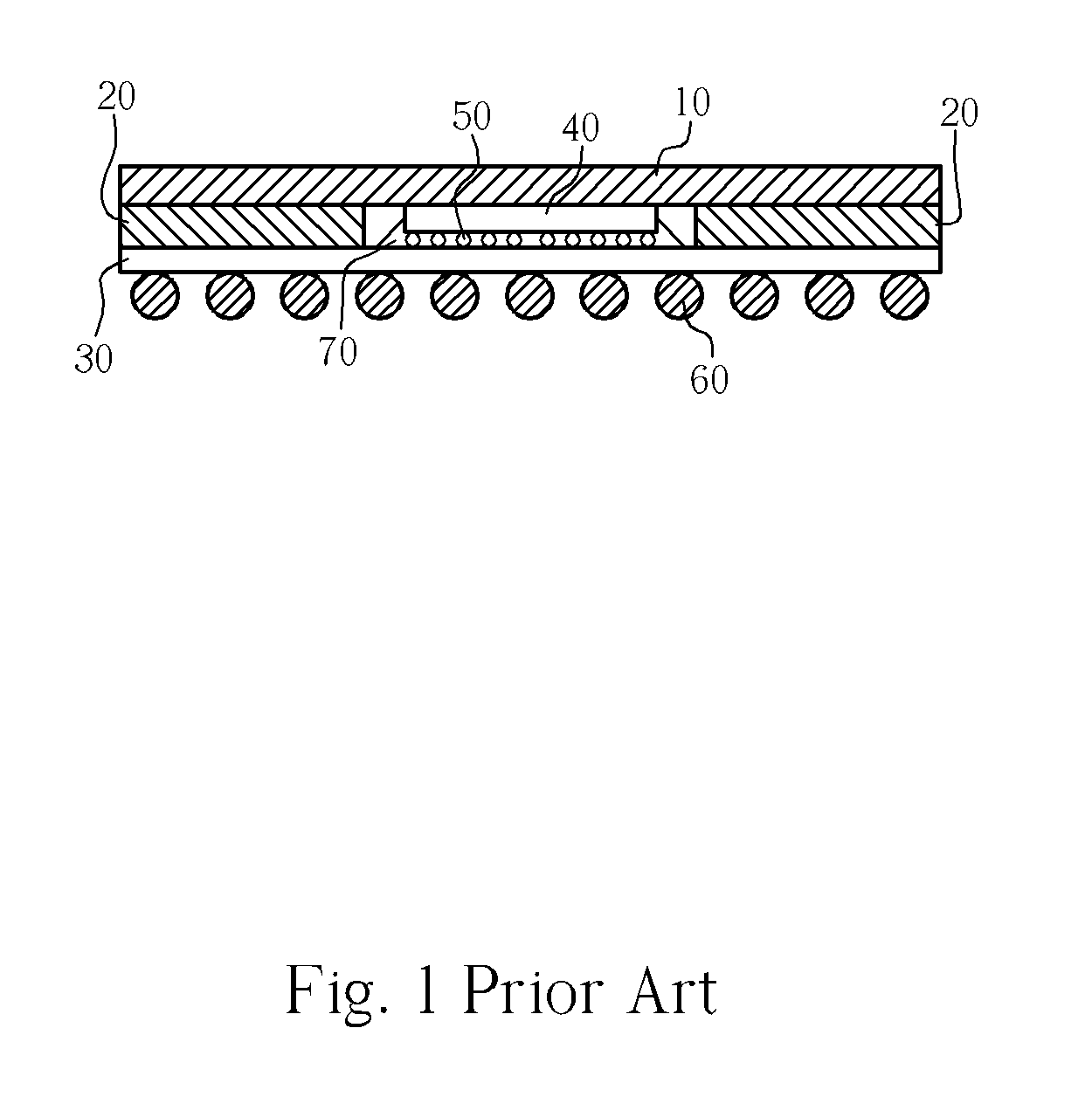

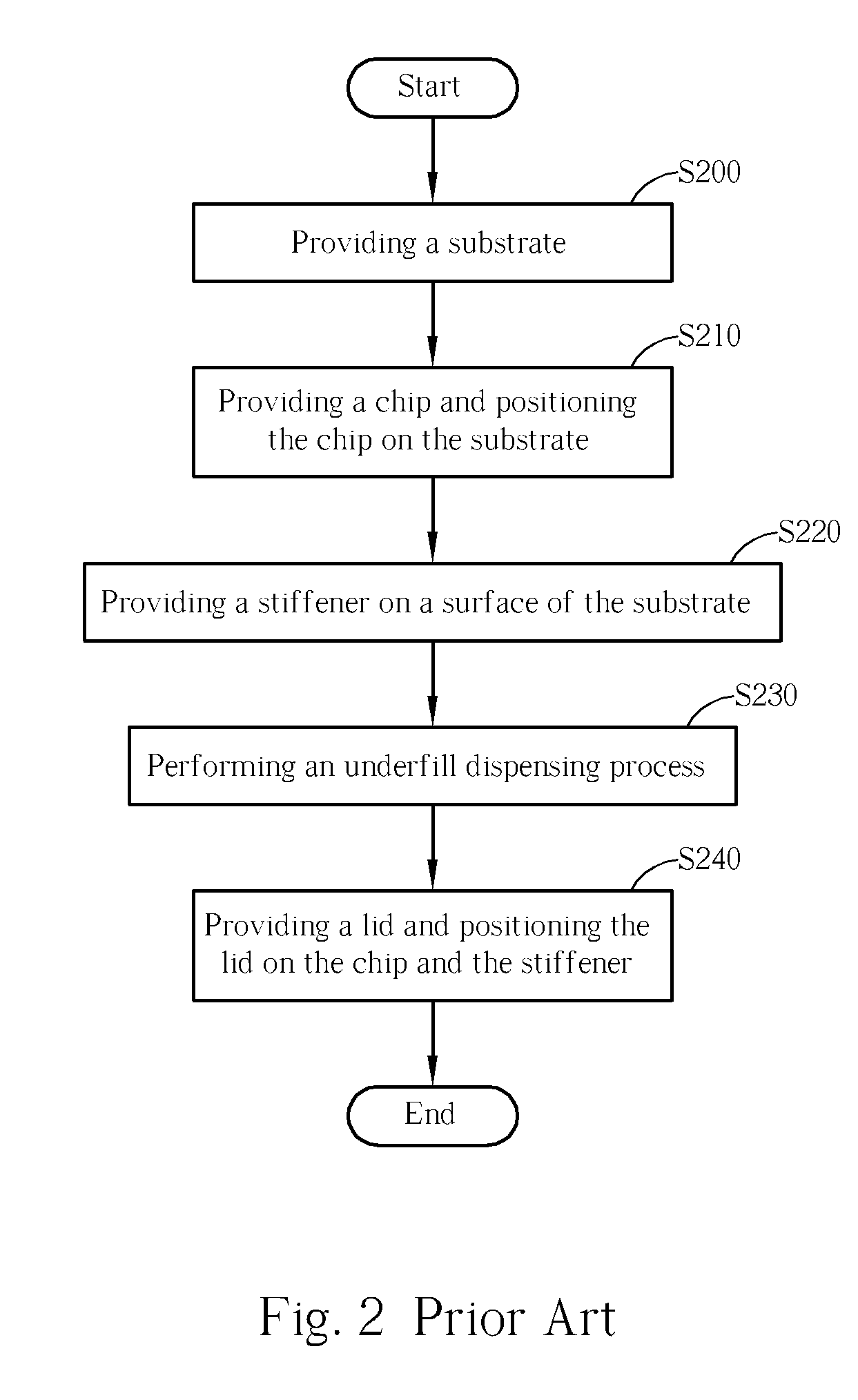

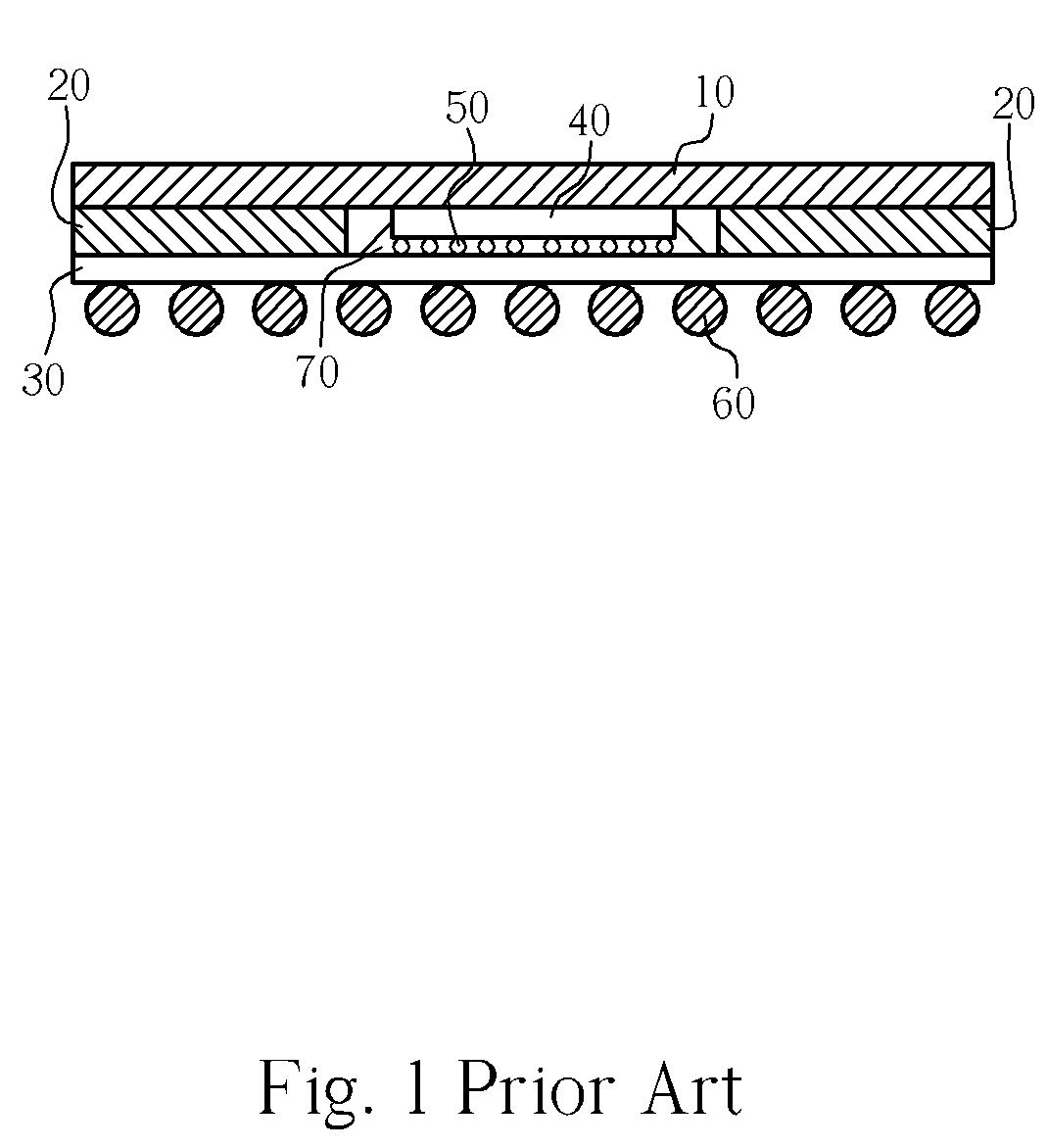

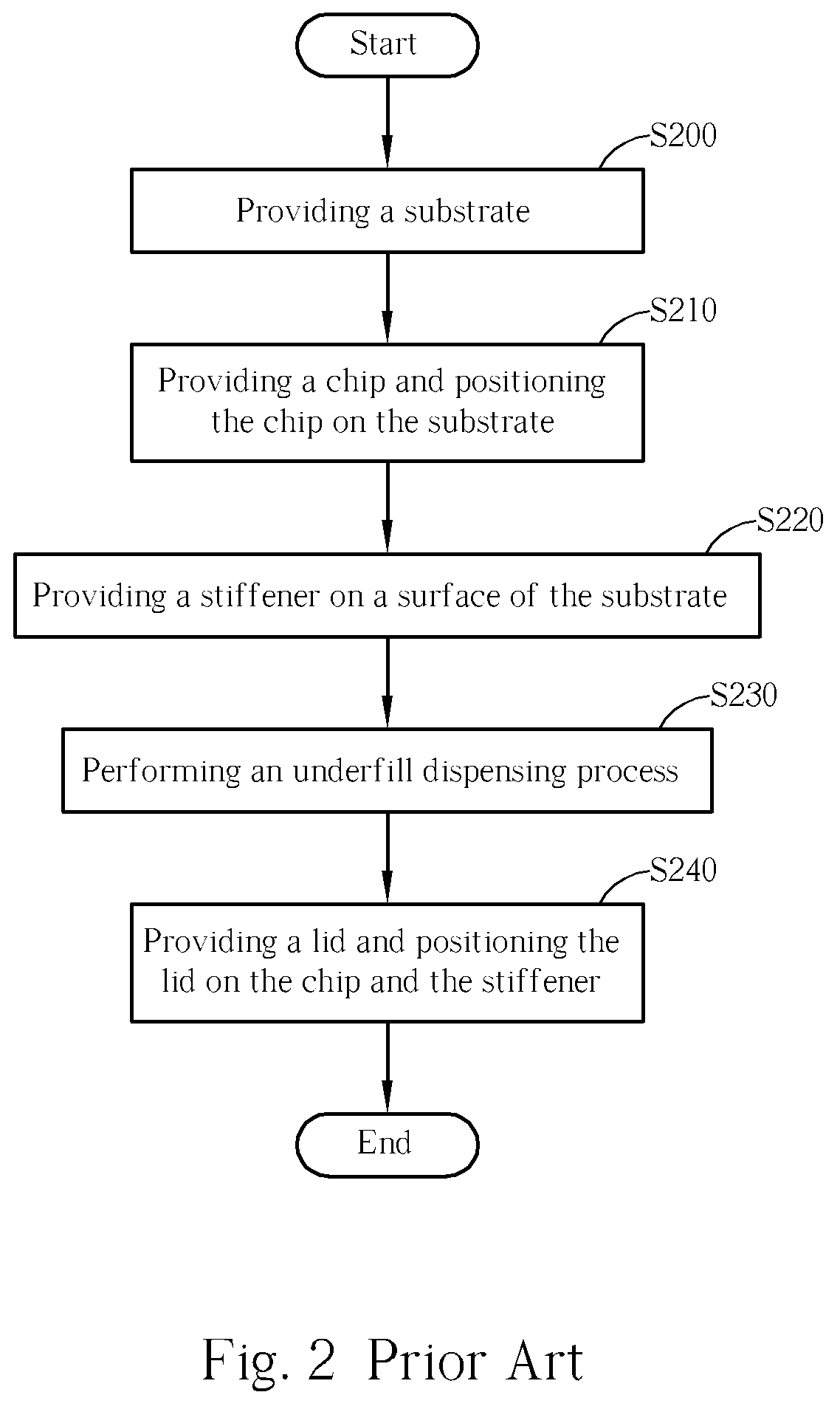

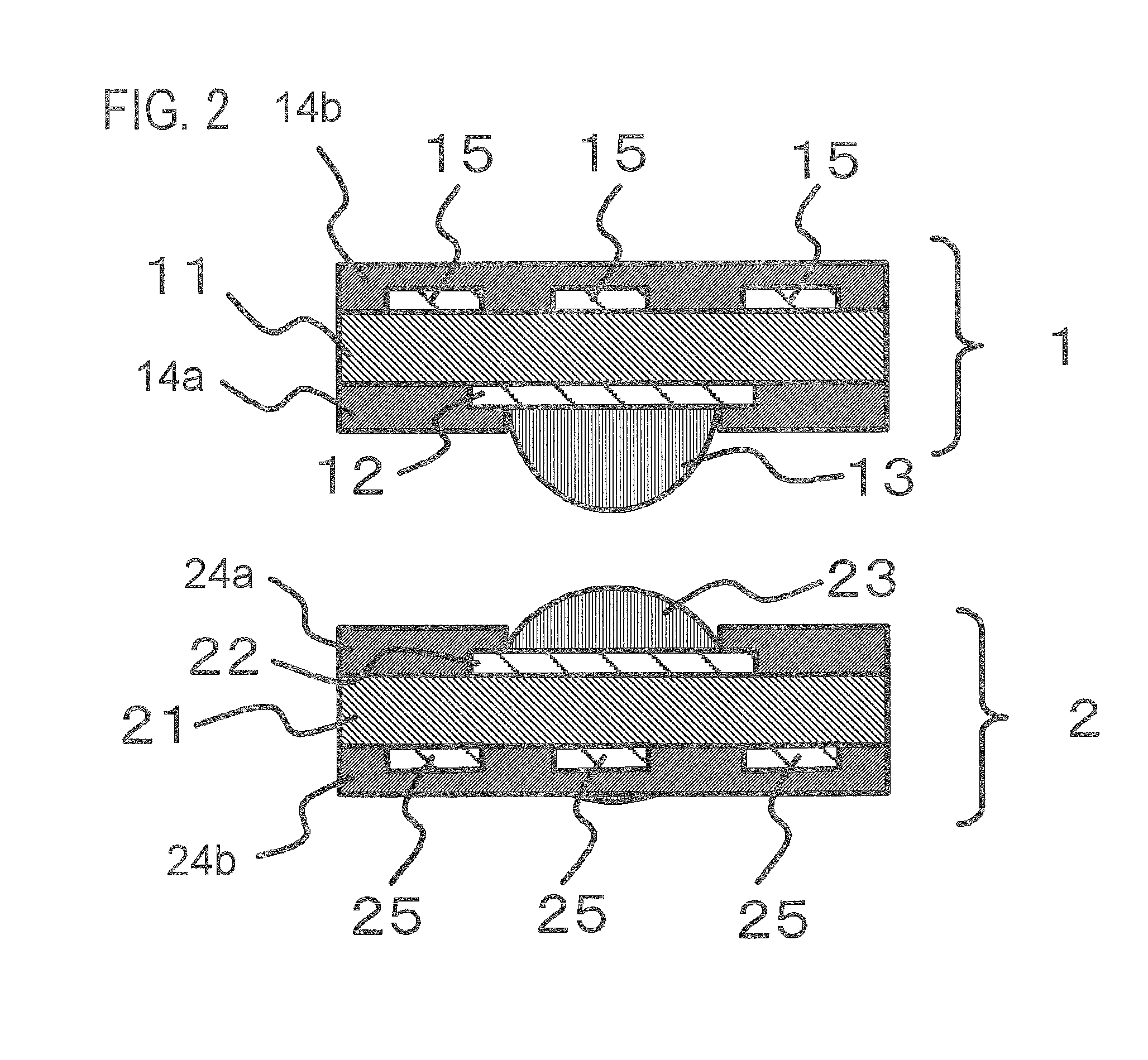

Flip-chip package structure with stiffener

ActiveUS20080001308A1Good coplanarityPackage structure is simpleSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

A flip-chip package structure with stiffener includes a substrate, a first stiffener positioned on a surface of the substrate, a chip having a plurality of bumps adopted to electrically connect the substrate and the chip, and a second stiffener positioned on the surface of the substrate and connected with the first stiffener. The first stiffener is positioned outside of the second stiffener.

Owner:ADVANCED SEMICON ENG INC

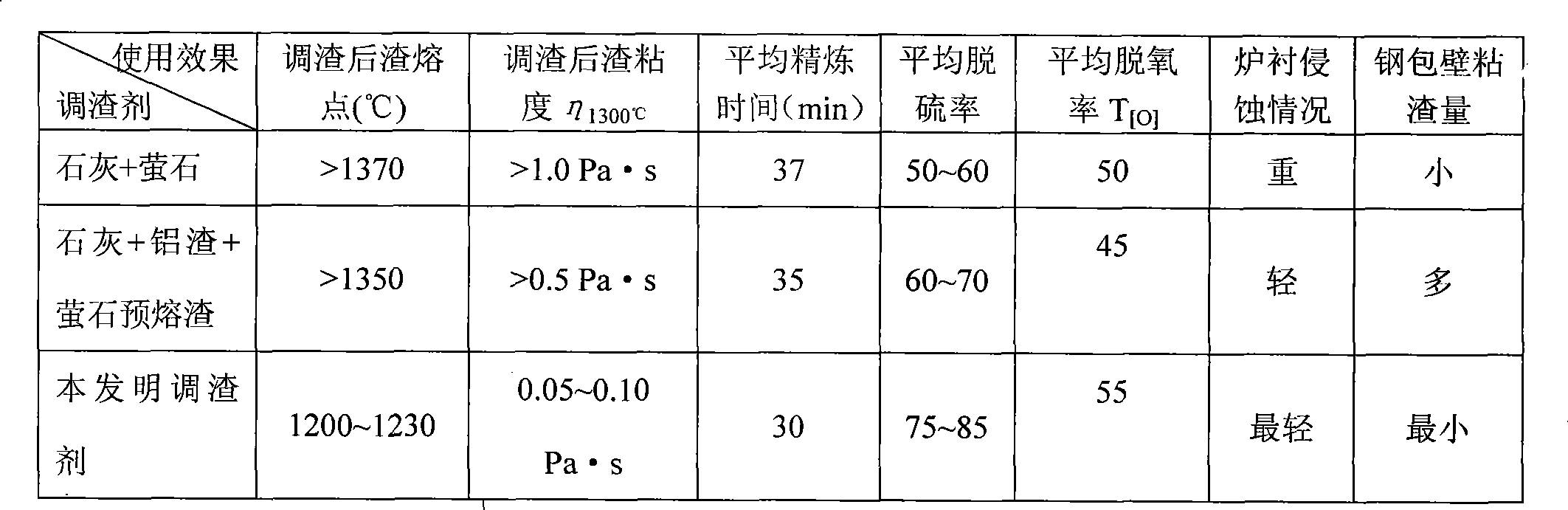

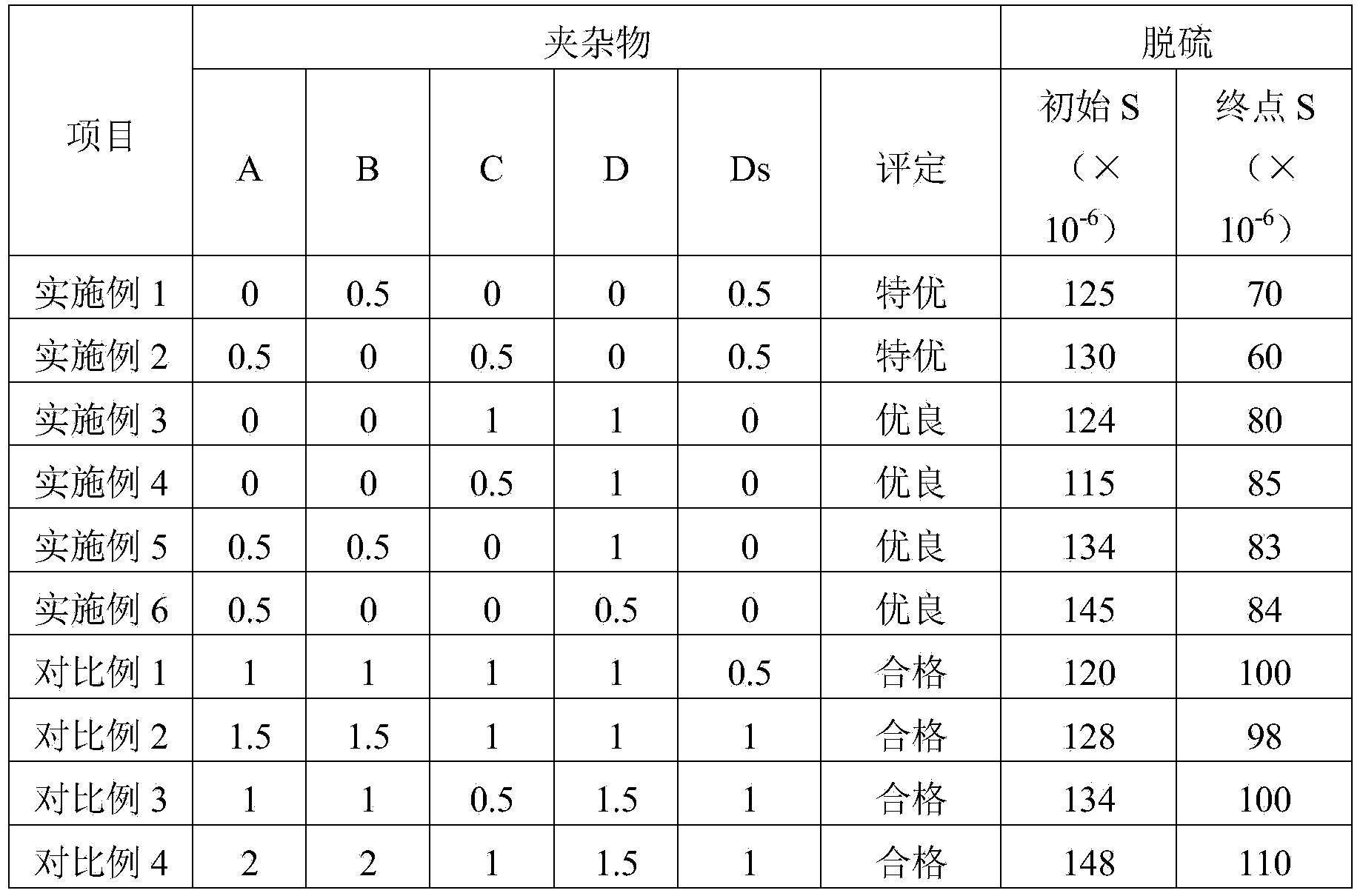

Ladle refining slag modifier, preparation method and slag modifying method

InactiveCN101519712AStrong fluxing effectImprove flux effectProcess efficiency improvementSteelmakingImpurity

The invention belongs to the technical field of steelmaking and refining, and discloses a ladle refining slag modifier, a preparation method and a slag modifying method. The slag modifier comprises the following chemical components in percentage by mass: 30 to 60 percent of CaO, 30 to 60 percent of Al2O3, 2 to 10 percent of MgO2, 2 to 10 percent of B2O3, and less than 8 percent of impurities. The slag modifying method using the slag modifier comprises that: the slag modifier is hoisted to the front of a refining furnace after a steelmaking furnace discharges steels, and then is directly fed into ladles, or the slag modifier can also be fed into the furnace along with other slags at a refining station; the components of modifying slag are determined according to the ladle residue amount and components, desulfuration amount and steel deoxidation product amount; and the modifying slag for controlling the ladle slag comprises the following components according to the adding amount: 48 to 54 percent of CaO, 26 to 32 percent of Al2O3, 6 to 8 percent of MgO, 2 to 4 percent of B2O3, and 0 to 8 percent of SiO2, wherein the modifying slag is better if the content of the SiO2 is lower. The slag modifier has the capabilities of quickly manufacturing the slag, improving desulfuration and deoxidation of the refining slag and accommodating and absorbing deoxidation products, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

Slag adhesion preventing fluorine-free slag modifier for ladle refining, preparation method and using method

InactiveCN101519713AIncrease contentIncrease surface tensionProcess efficiency improvementSteelmakingPhosphor

The invention belongs to the field of steelmaking, and particularly discloses a fluorine-free slag modifier for preventing a ladle refining device from adhering slag, a preparation method and a using method. The slag modifier consists of active lime, bauxite and boric anhydride; and the slag modifier comprises the following chemical components in percentage by mass: 75 to 85 percent of CaO, 10 to 20 percent of Al2O3, 5 to 15 percent of B2O3, 0 to 8 percent of MgO, and the balance of impurities, wherein SiO2 is less than 7.0 percent, H2O is less than 0.05 percent, and the total amount of sulfur and phosphor is less than 0.01 percent. During use, in order to prevent a ladle from adhering the slag, the slag modifier is fed into the ladle in the later period of discharging steel from a steelmaking furnace, and in order to prevent an RH dip pipe or a CAS-OB dip cover and the like from dipping into the ladle device to adhere slag, the slag modifier is fed at a refining station. The slag modifier can effectively control the refining device from slag adhesion and improve the service life of a fireproof material, is favorable for reducing the contents of the sulfur, oxygen and impurities in the steel, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

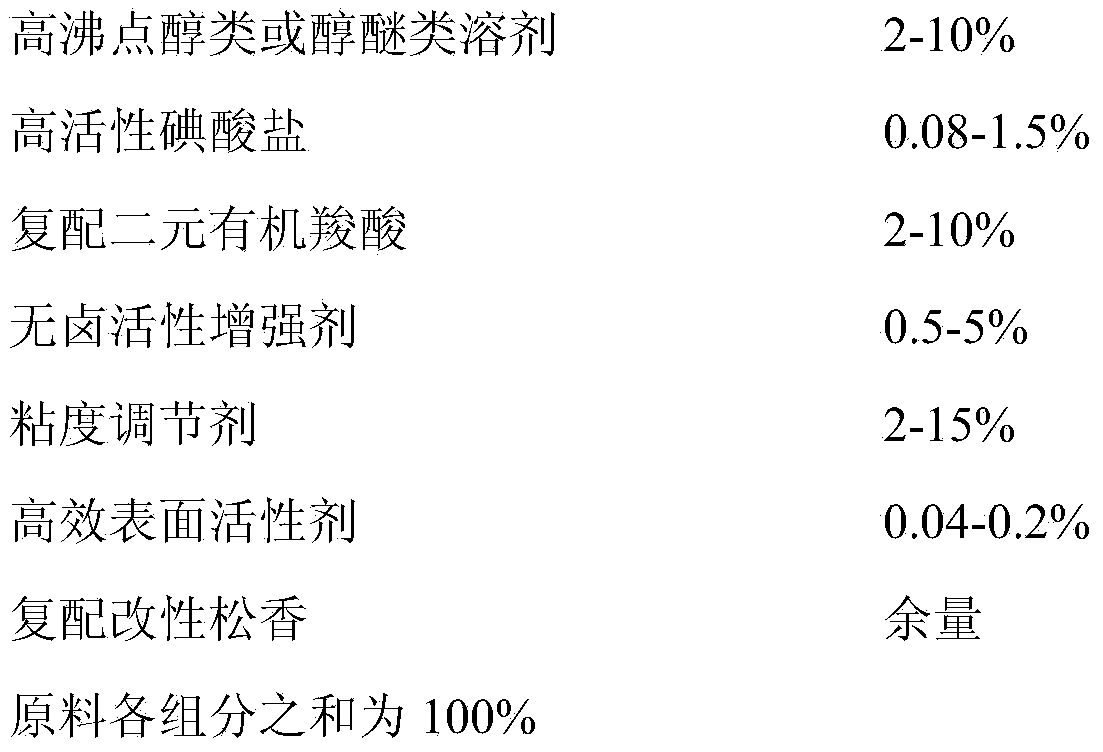

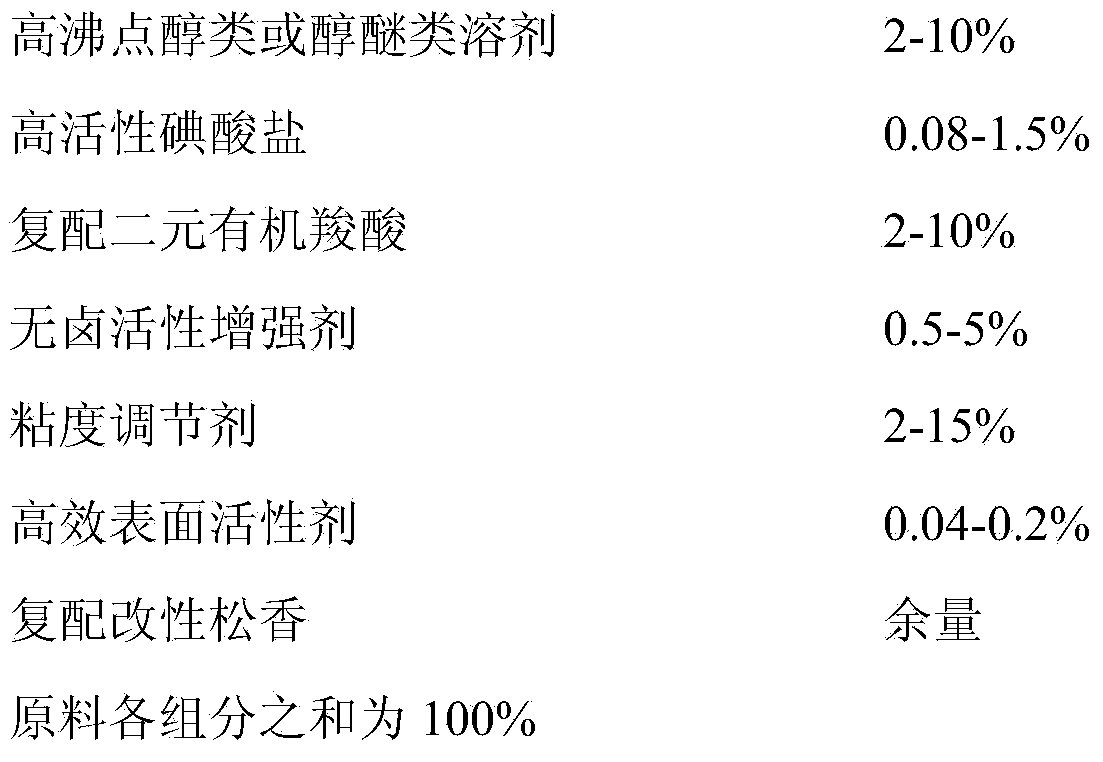

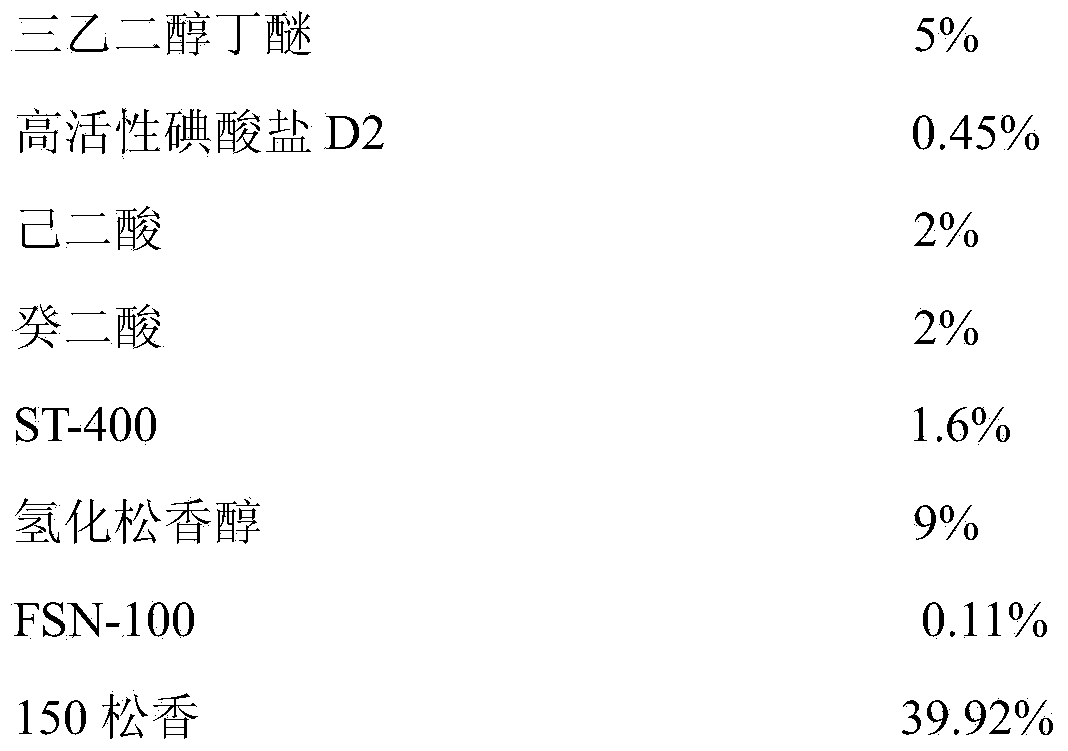

Halogen-free high-activity low-splatter solder wire soldering flux and preparing method thereof

InactiveCN104191108AHalogenatedFast tinningWelding/cutting media/materialsSoldering mediaSolventRosin

The invention discloses halogen-free high-activity low-splatter solder wire soldering flux and a preparing method thereof. The halogen-free high-activity low-splatter solder wire soldering flux comprises, by mass, 2-10 percent of alcohol or alcohol ether high-boiling-point solvent, 0.08-1.5 percent of high-activity iodate, 2-10 percent of compound binary organic acid, 0.5-5 percent of halogen-free activity enhancer, 2-15 percent of viscosity modifier, 0.04-0.2 percent of efficient surface active agent and the balance modified rosin and rosin derivatives. The preparing method includes the steps that the compound rosin and the viscosity modifier are added into a container to be heated and stirred until the compound rosin and the viscosity modifier are completely melted down, the organic acid, the novel high-activity iodate, the efficient surface active agent and the high-boiling-point solvent are added to be stirred continuously, and therefore the soldering flux is prepared. The prepared halogen-free soldering flux for solder wires is free of halogen compounds, tin is easy to apply in the soldering process, splatter is little, smells are light, soldering spots are bright and full, damage to the health and the environment is avoided, and the post-soldering reliability effect of an electronic product is ensured.

Owner:SOUTH CHINA UNIV OF TECH +1

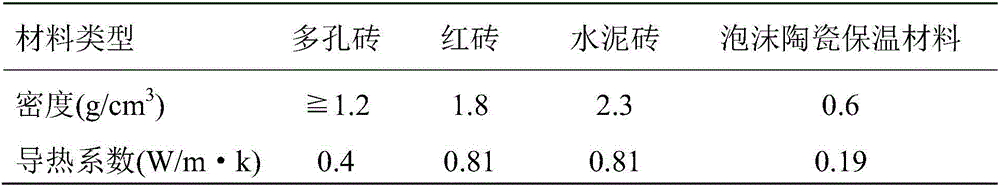

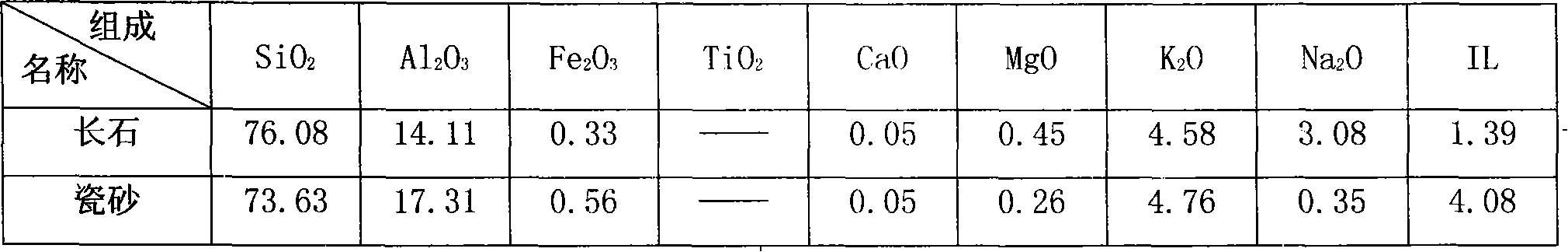

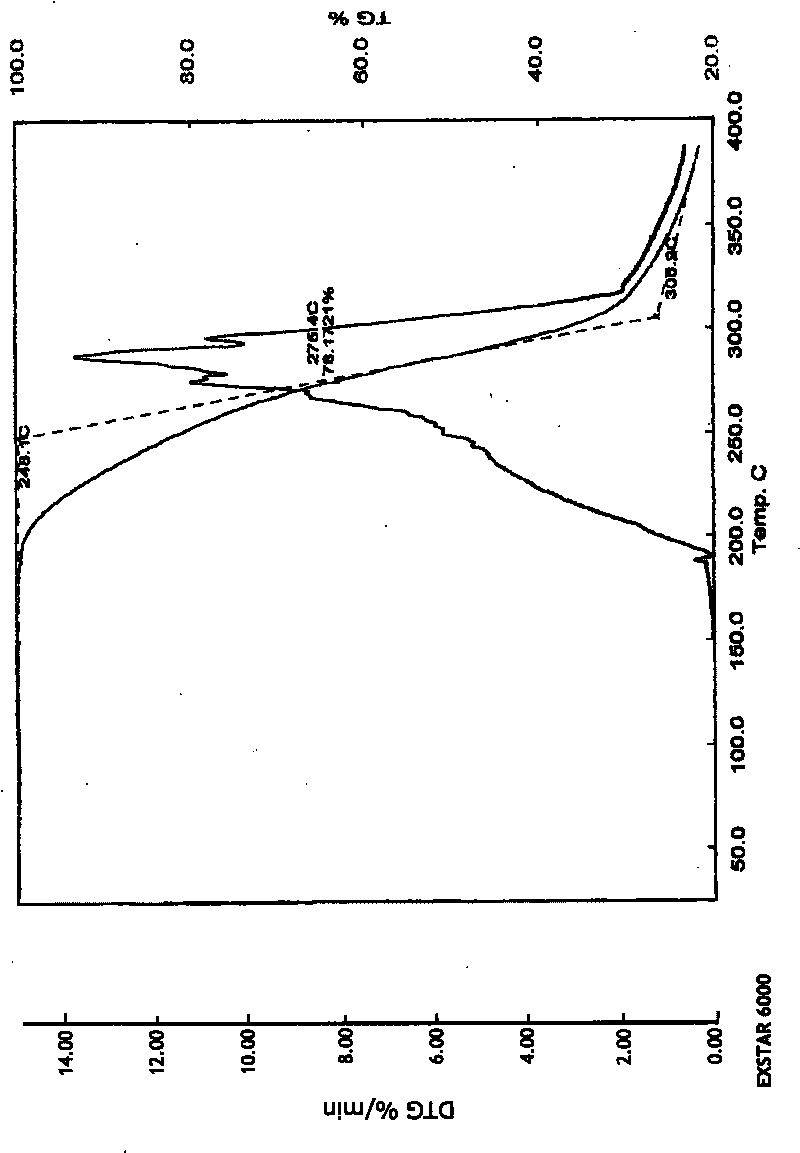

Foam ceramic insulation material and preparation method thereof

InactiveCN106082962AImprove insulation effectIncrease productivityCeramic materials productionCeramicwareLithiumFoaming agent

The invention relates to a foam ceramic insulation material and a preparation method thereof. The foam ceramic insulation material comprises the following raw materials in weight content: 30-95% of industrial waste material by mixing one or more of waste slag, waste stone flour or kaolin mine tailing, 1-18% of lithium porcelain stone, 1-20% of light-burnt magnesia, 1-30% of clay, and 0.5-20% of a foaming agent. The preparation method comprises the following steps: A) performing ball-milling on the raw materials of the foam ceramic insulation material to prepare the granular powder; B) performing burden distribution on powder and sintering the powder at the temperature of 1000-1400 DEG C, insulating for 2-5 hours to obtain the foam ceramic insulation material; and C)cutting the foam ceramic insulation material and processing the foam ceramic insulation material. According to the invention, waste slag, waste stone flour or kaolin mine tailing are used for preparing the foam ceramic insulation material, the preparation has advantage of environmental protection, the foam ceramic insulation material has the advantages of uniform distribution of inner pores, low heat conduction coefficient, high intensity and light weight, and can be used as building fireproof, insulation and energy-saving material and other insulation energy saving industries.

Owner:江西嘉陶无机材料有限公司

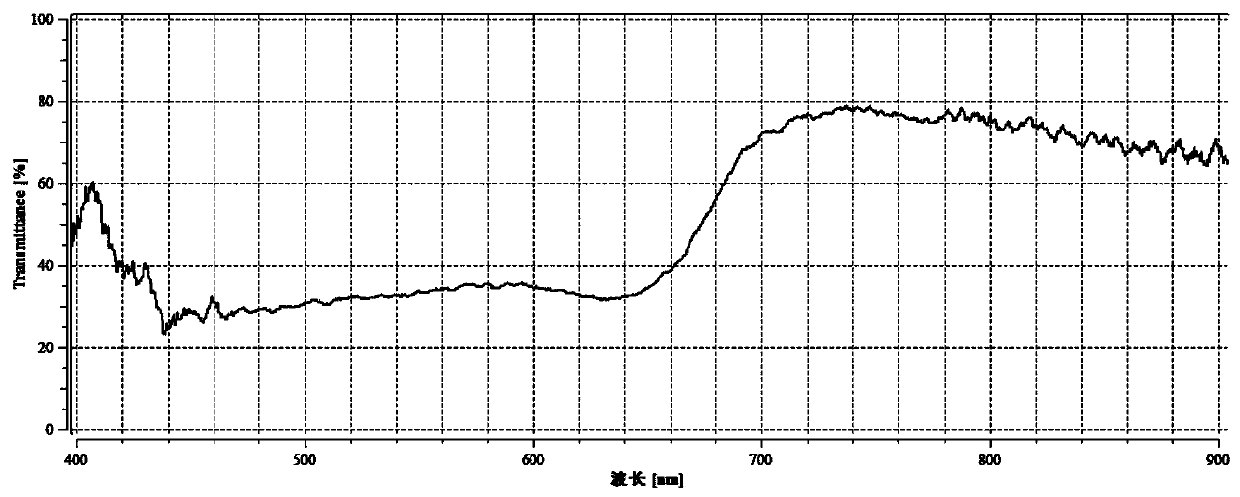

Compound fluxing agent for float glass

The invention relates to a compound fluxing agent for float glass, which is mainly used for fluxing in the process of melting the float glass. The compound fluxing agent consists of three oxides of Bi2O3, B2O3 and CeO2 and Na2O, wherein the Na2O is the inherent component of the float glass, and the three oxides of Bi2O3, B2O3 and CeO2 are added; and if the total mass of the oxides of the float glass is 100 grams, the sum range of the total mass of the three oxides of Bi2O3, B2O3 and CeO2 which are added is 0.5 to 10 grams, and the weight ratio of the Bi2O3, B2O3 to CeO2 is 80-90:8-18:2-4. Under the synergism of the four oxides, the aim of reducing the melting temperature of the float glass is fulfilled, and the melting quality of the float glass is guaranteed, so that the compound fluxing agent of the invention is particularly applied to the preparation of the float glass. Under the condition of keeping the basic properties of the float glass unchanged, the melting temperature can be reduced by 80 DEG C to the maximum extent.

Owner:WUHAN UNIV OF TECH

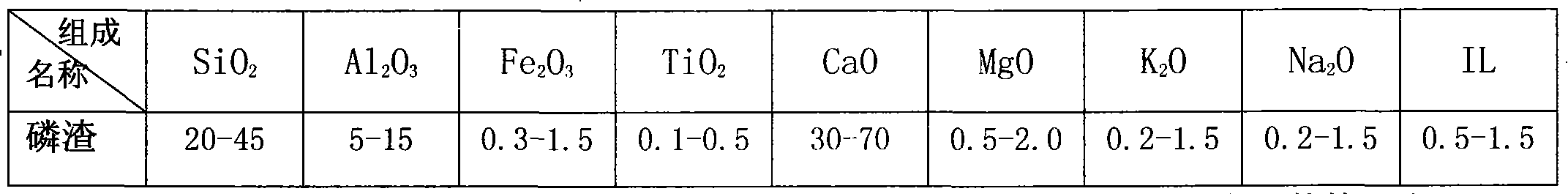

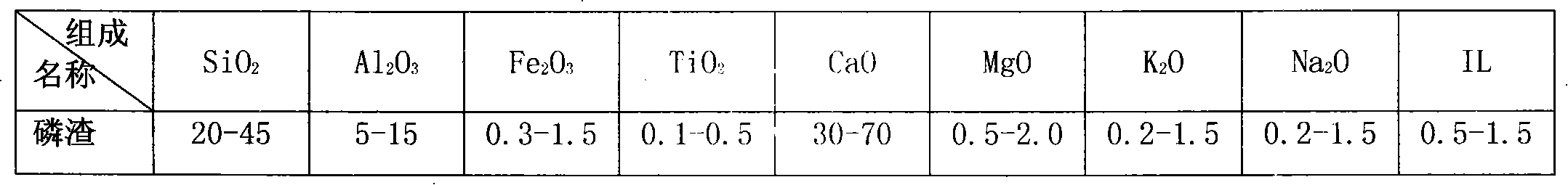

Formulation for producing ceramic tile by using phosphorus slag and producing method thereof

This invention relates to the recipe and production method for producing ceramic bricks by utilizing phosphorus slag as raw material. The industrial tailings from electro-smelting method yellow phosphorus production is used as raw material with the weight parts of 3-35 parts: the other components are: flux 20-70 parts, clay 20-80 parts; the optimum proportioning is: flux 20-70 parts, clay 20-80 parts, phosphorus slag 10-30 parts. This invention has advantages of: low raw material cost, low burning temperature, white final product, easy tinting and solving the problem of piling-up the industrial wastes.

Owner:王儒林

Lead-free and halogen-free solder paste for electronic industry

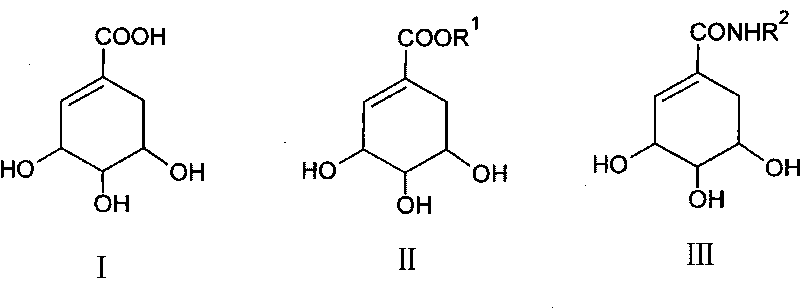

InactiveCN101733588AImprove wettabilityReduce foulingWelding/cutting media/materialsSoldering mediaSolderabilityShikimic acid

The invention relates to a chemical soldering flux in the electronic industry, in particular to a solder paste used for arranging electronic elements and the alloy welding powder is lead-free alloy. The technical scheme of the invention is as follows: the lead-free and halogen-free solder paste for electronic industry comprises 85-94wt% of alloy welding powder and 6-15wt% of flux, wherein the flux comprises 20-60wt% of resin, 10-60wt% of solvent, 1-10wt% of rheology control agent, 0.1-40wt% of activator and the balance stabilizer; and the alloy welding powder is lead-free welding powder and is characterized in that the activator contains one or more of shikimic acid with the constitutional formula shown in formula I, shikimate with the constitutional formula shown in formula II and amide of shikimic acid with the constitutional formula shown in formula III. The beneficial effect of the invention is as follows: shikimic acid or a derivative thereof is used as the activator so as to increase the wettability of the halogen-free product so as to reduce bad effects caused by the solderability in production.

Owner:SICHUAN UNIV +1

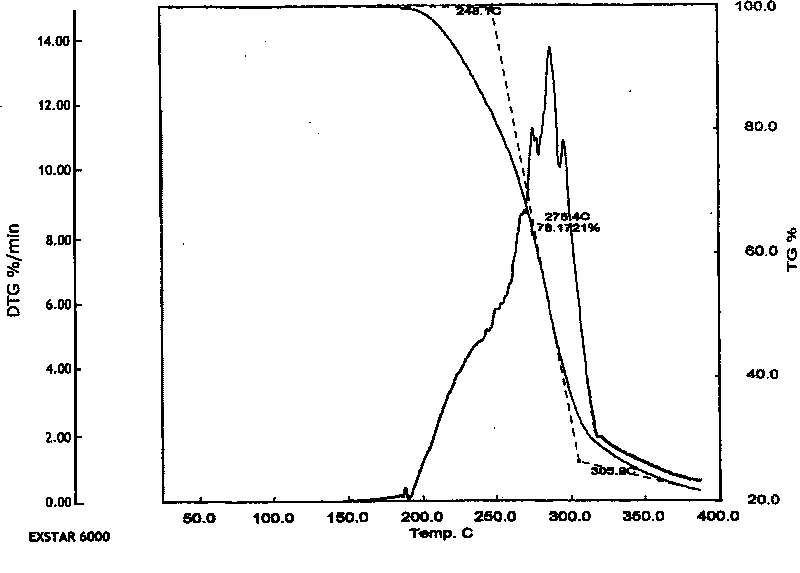

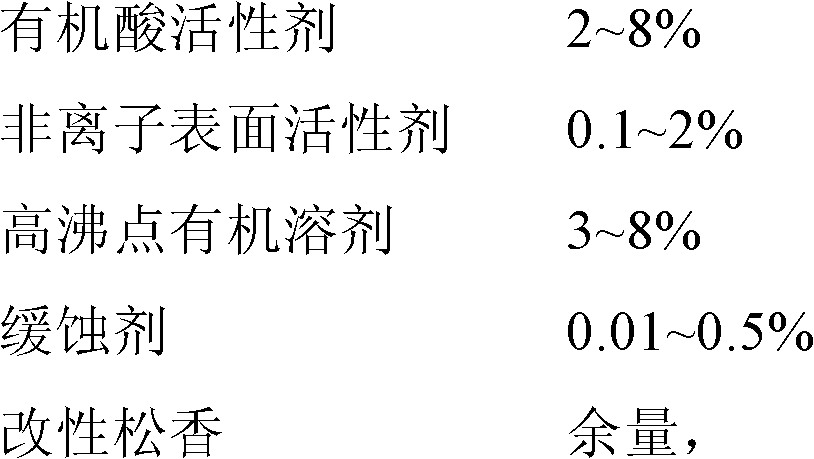

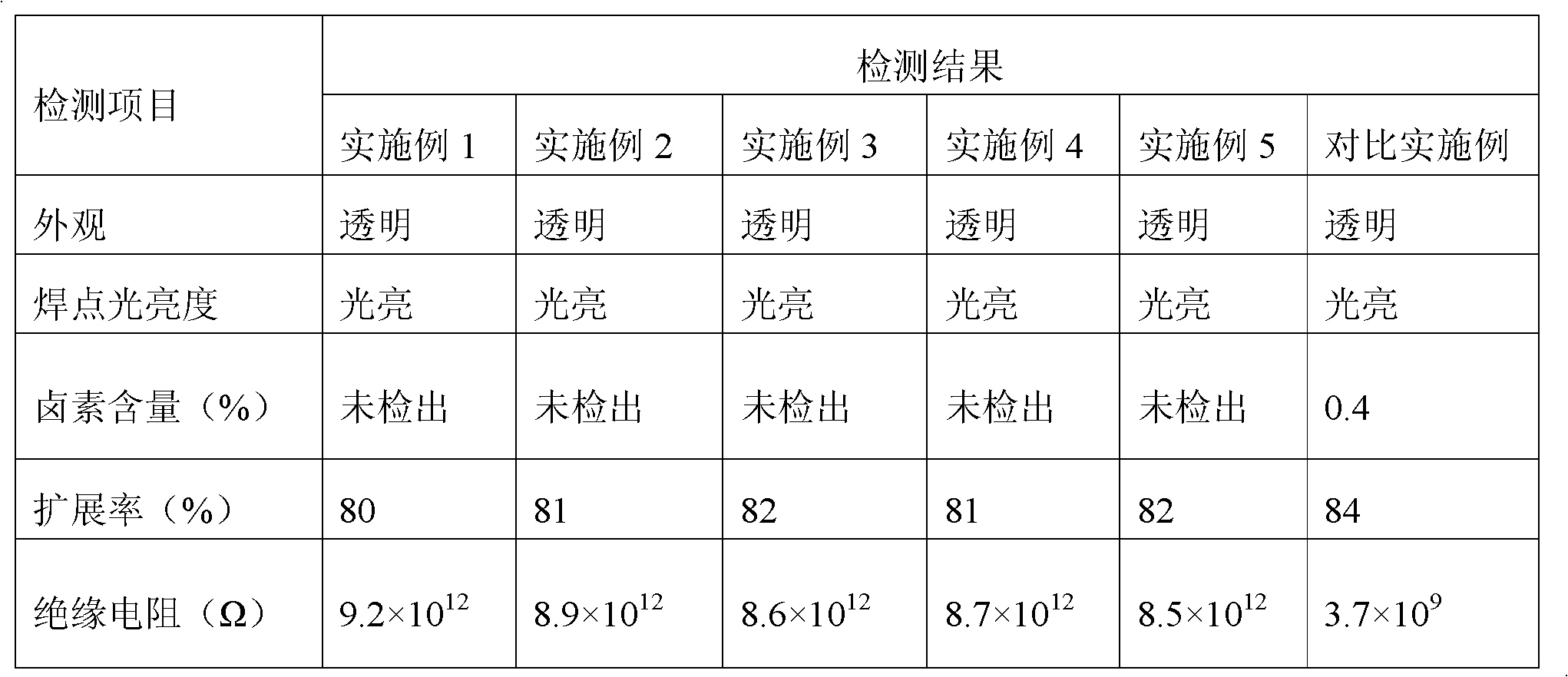

Halogen-free high-impedance soldering flux and preparation method

InactiveCN102554518AEfficient removalReduce surface tensionWelding/cutting media/materialsSoldering mediaOrganic acidOrganic solvent

The invention relates to a halogen-free high-impedance soldering flux and a preparation method. The halogen-free high-impedance soldering flux is characterized by containing the following components according to weight: 2-8% of organic acid activating agent, 0.1-2% of non-ionic surface active agent, 3-8% of organic solvent having a high boiling point, 0.01-0.5% corrosion inhibitor and the balance of modified rosin. The preparation method comprises the following steps: adding modified rosin into a container for heating and stirring until the modified rosin is completely fused; adding the organic acid activating agent, the non-ionic surface active agent, the corrosion inhibitor and the organic solvent having a high boiling point in sequence at a temperature of 130-150 DEG C, and continuing to stir for 20-30 minutes to obtain the soldering flux. The halogen-free high-impedance soldering flux has excellent welding assisting effect to lead-free solder, is halogen-free, has no harm to health and environment, causes little splashing, has less residue after welding, has high insulation resistance on the surface, and ensures the advantage and effect of reliability of electronic products after welding.

Owner:广东中实金属有限公司 +1

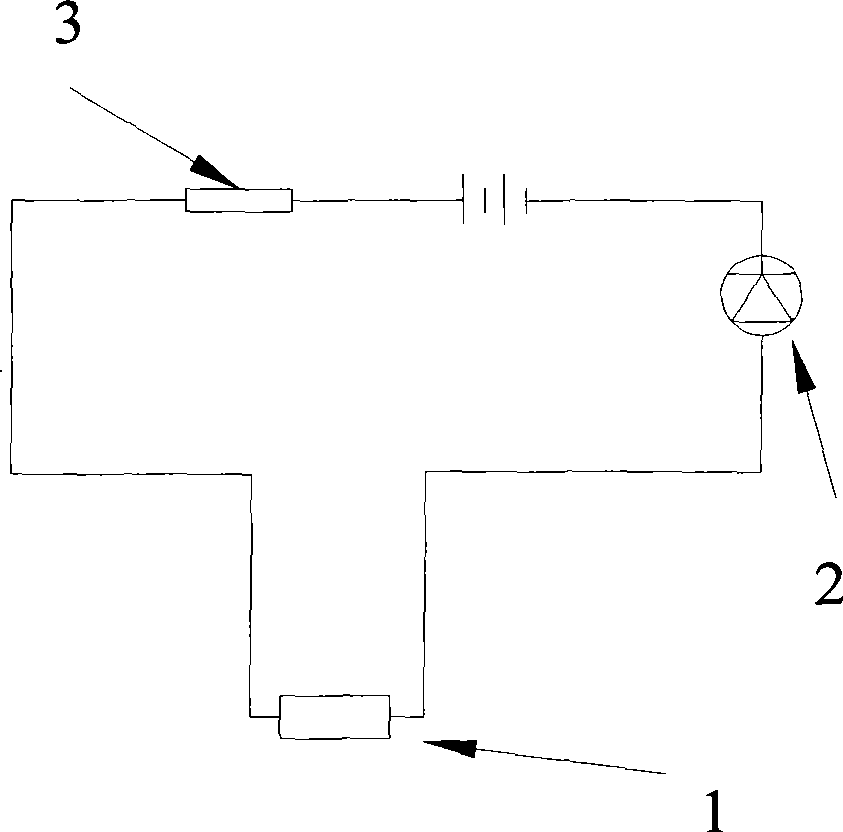

Thin type temperature fuse and fluxing medium therefore

ActiveCN101465252ALow acid valueImprove long-term durabilityEmergency protective devicesAlcoholLong term durability

The invention discloses a thin temperature fuse-related fluxing agent and a thin temperature fuse, relating to the over-temperature protection thin elements used for electronics-related products; particularly, the invention discloses a thin temperature fuse-related fluxing agent for cell phone batteries, a fluxing agent preparation method and a thin temperature fuse. The thin temperature fuse-related fluxing agent is prepared with rosin, alcohol amines, alcohols and silicone oil; based on weight percentage, the fluxing agent comprises 70-80% of rosin, 10-20% of alcohol amines, 5-8% of alcohols and 0.5-3% of silicone oil. The fluxing agent has low acid value and greatly reduces the corrosion to metals; besides, the fluxing agent has good long-term durability and obvious fluxing effect and can quickly wet the metals and enables the metals to be fused; the fluxing agent is not crystallized in high and low temperature alternation and is anti-oxidation; moreover, the fluxing agent has high flash point, small volatility and good insulation, and is an ideal fluxing agent for temperature fuses.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

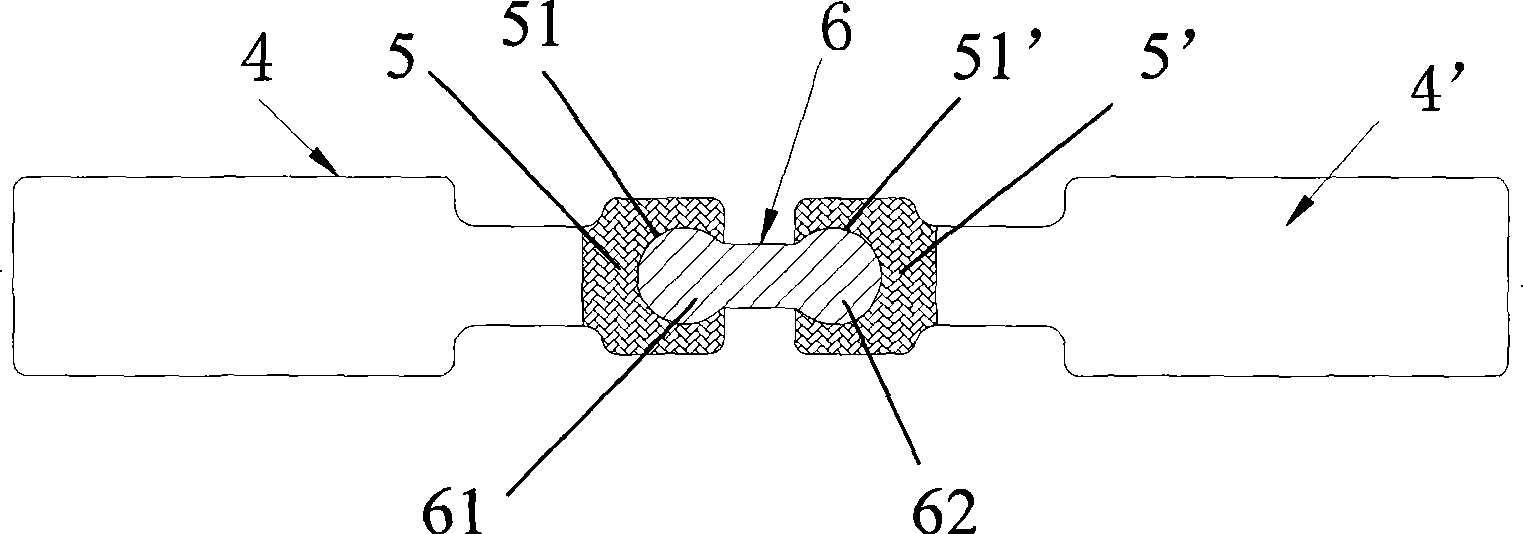

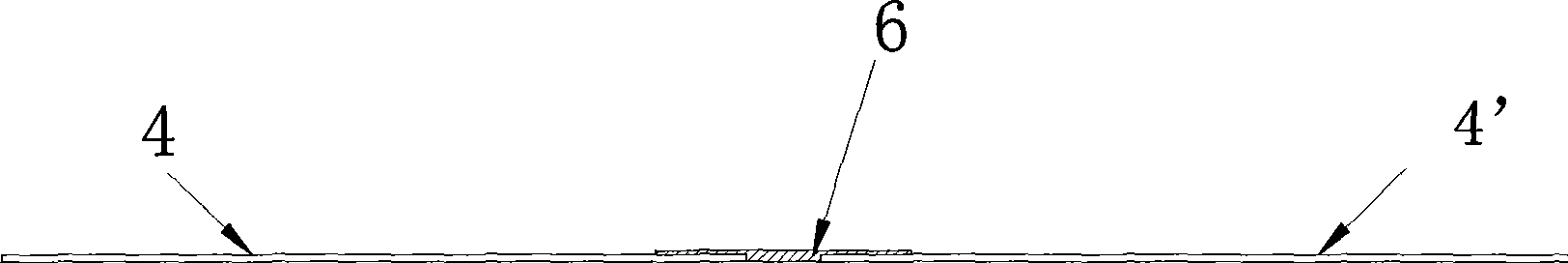

Flip-chip package structure with stiffener

ActiveUS7538421B2Good coplanarityPackage structure is simpleSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringFlip chip

A flip-chip package structure with stiffener includes a substrate, a first stiffener positioned on a surface of the substrate, a chip having a plurality of bumps adopted to electrically connect the substrate and the chip, and a second stiffener positioned on the surface of the substrate and connected with the first stiffener. The first stiffener is positioned outside of the second stiffener.

Owner:ADVANCED SEMICON ENG INC

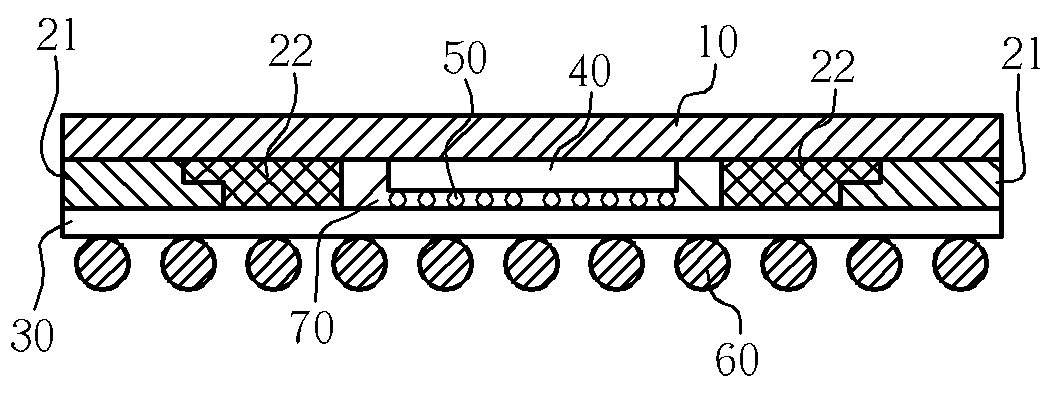

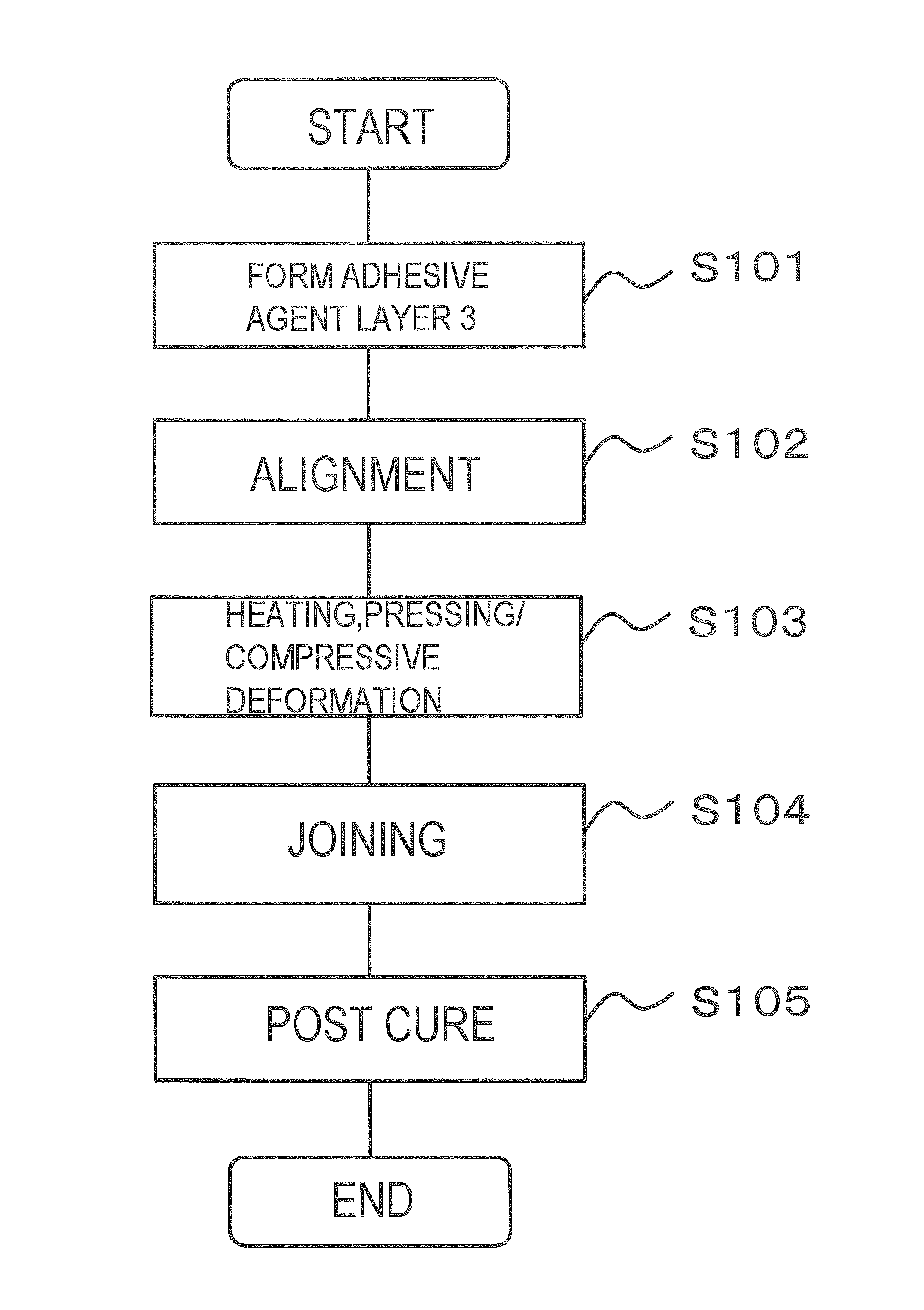

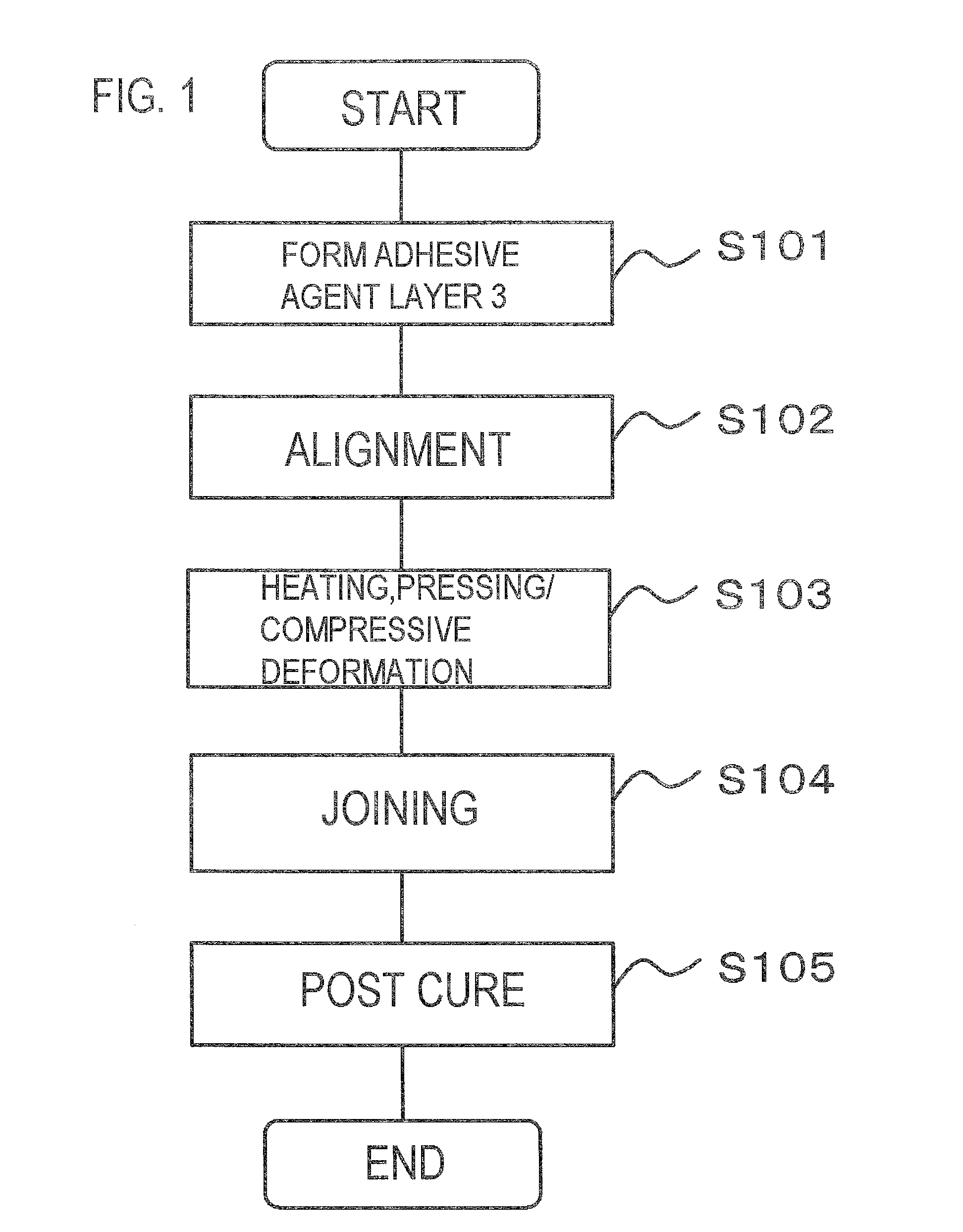

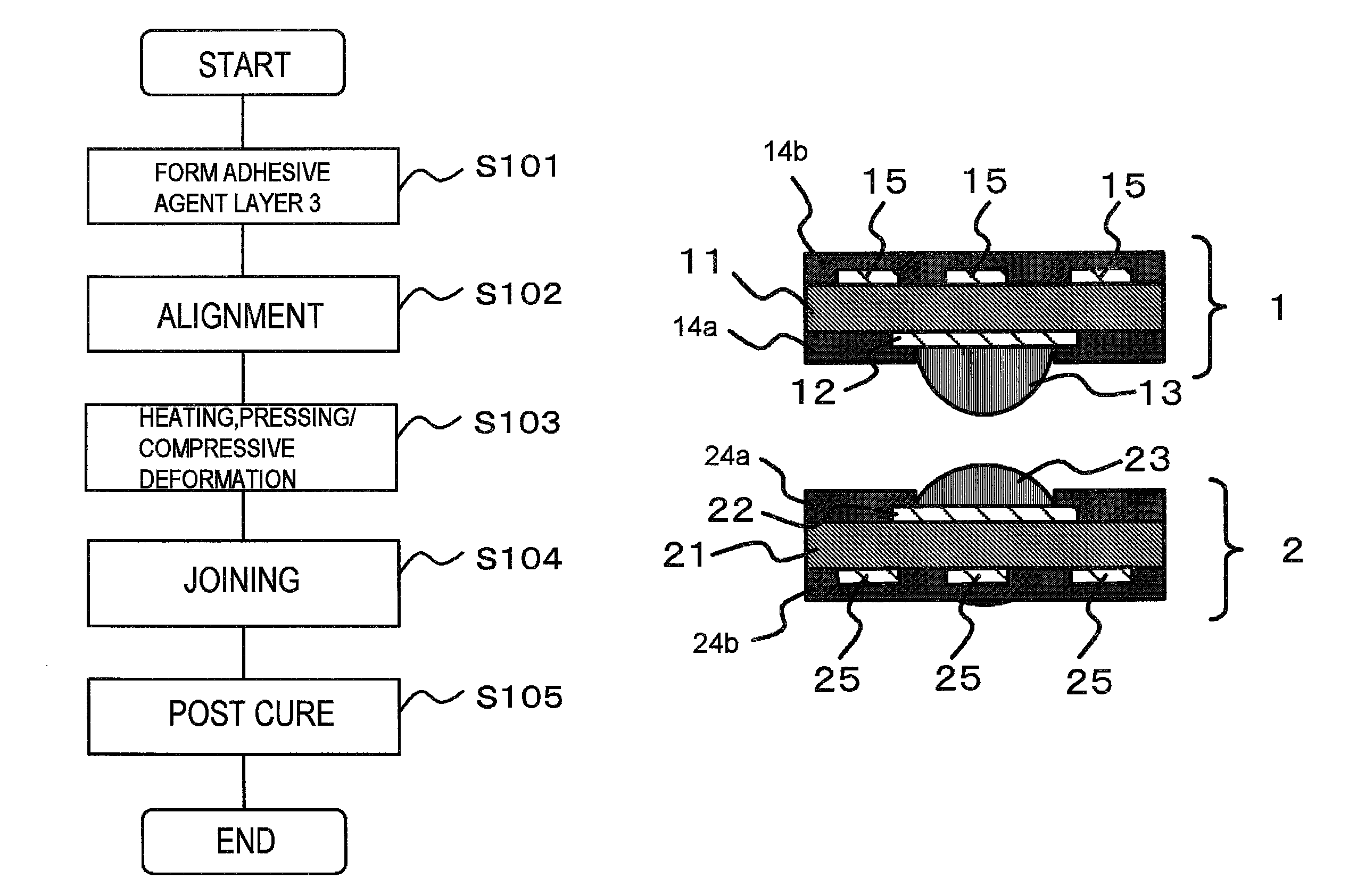

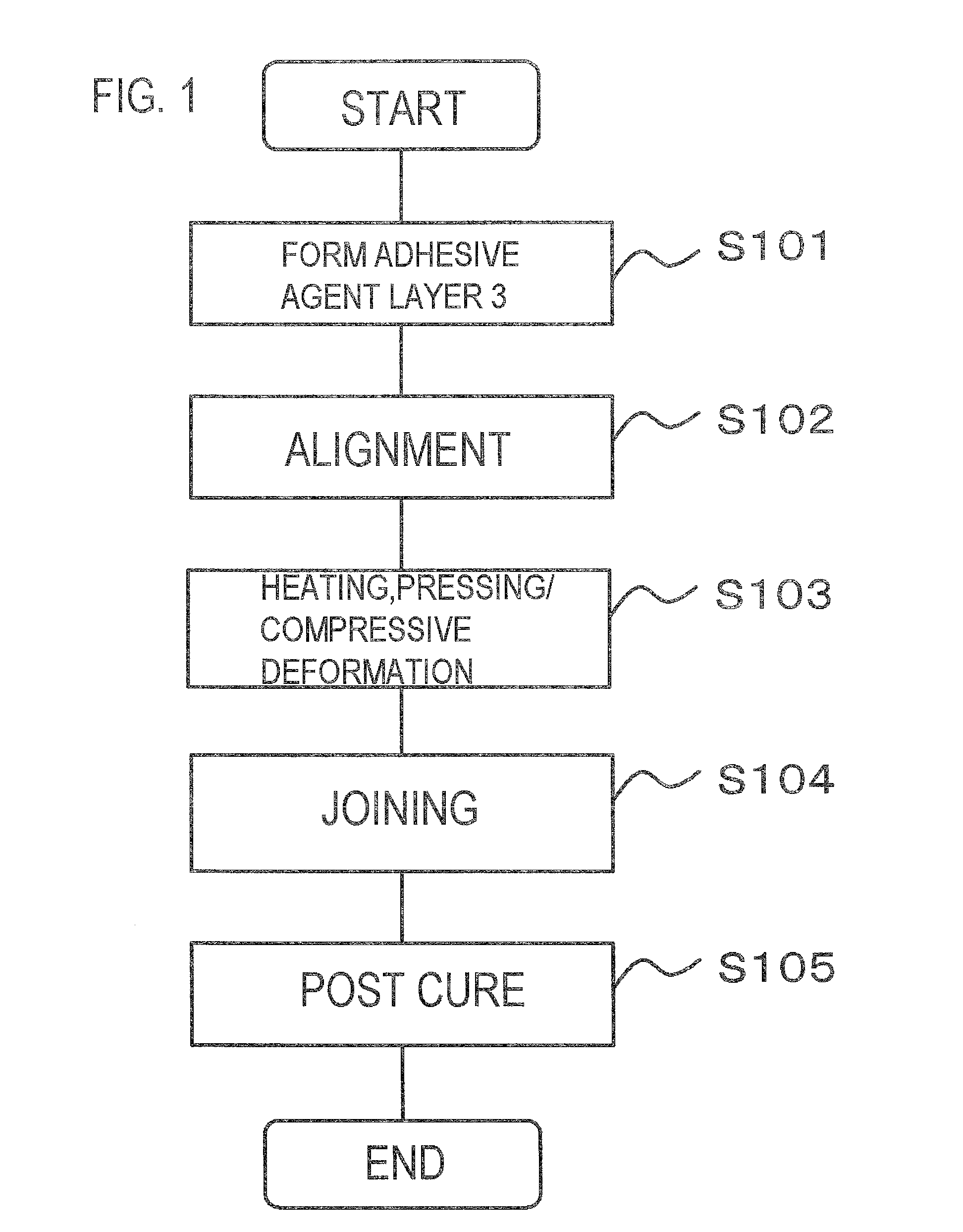

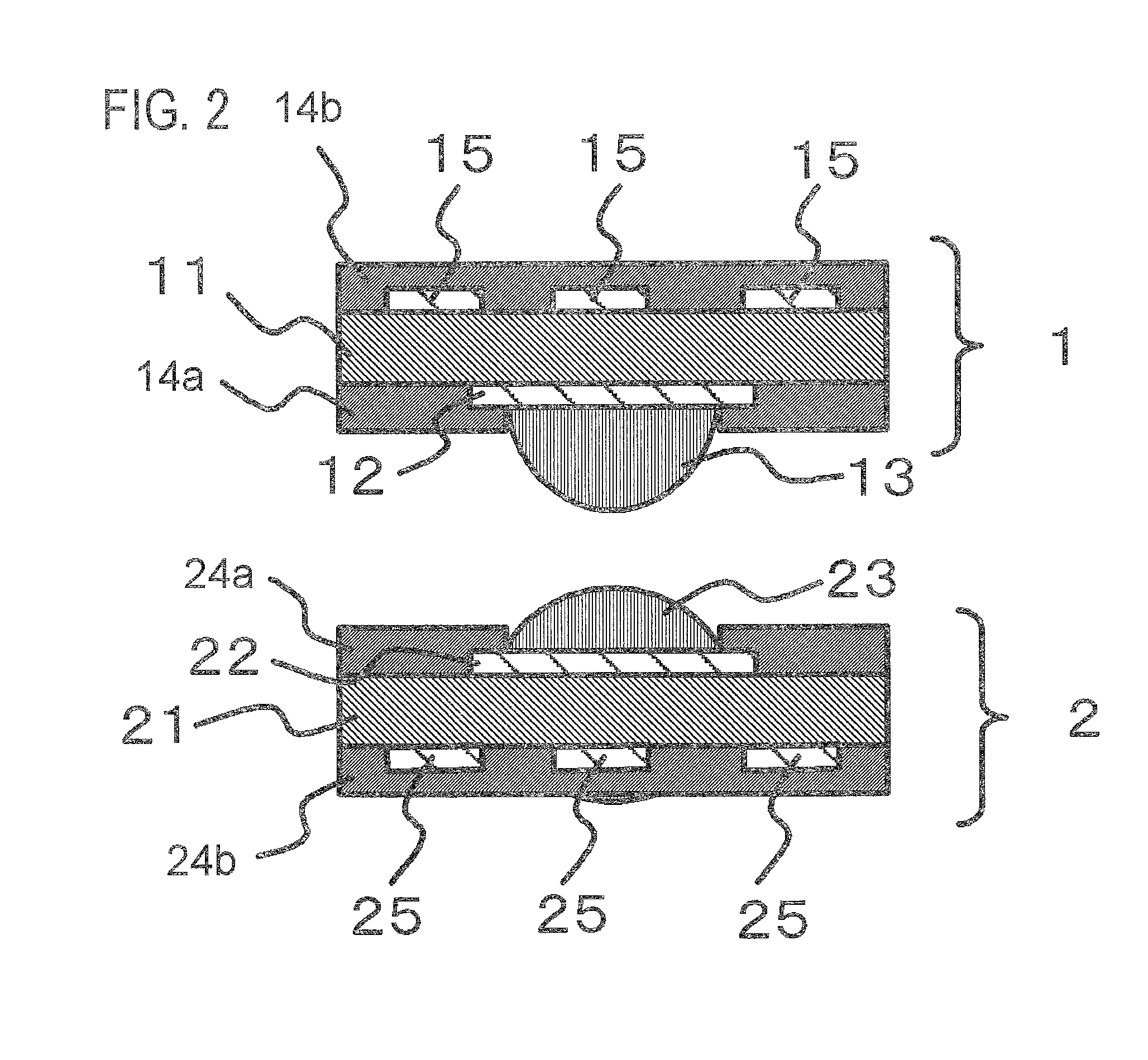

Method for providing solder connection, electronic equipment and method for manufacturing same

InactiveUS20100313416A1Improve efficiencyEnhanced couplingPrinted circuit assemblingContact member manufacturingElectrical connectionElectronic component

The method for providing the solder connection of the present invention is a method for providing a solder connection, which electrically connects a first electronic component having a solder bump to a second electronic component having a protruded electrode to provide electrical connection between the first solder bump and the protruded electrode, wherein a relation of: A+B>C is satisfied, where a height of the first solder bump from one surface of the first electronic component is presented as A [μm], a height of the protruded electrode before the compressive deformation from one surface of the second electronic component is presented as B [μm], and a thickness of the adhesive agent layer is presented as C [μm], and further comprising: disposing the adhesive agent layer in the first electronic component; and deforming the first solder bump and the protruded electrode and providing a contact of the above-described protruded electrode with the above-described first solder bump, so that the sum of the height A [μm] of the first the solder bump and the height B [μm] of the above-described protruded electrode is substantially equivalent to the thickness C [μm] of the above-described adhesive agent layer.

Owner:SUMITOMO BAKELITE CO LTD

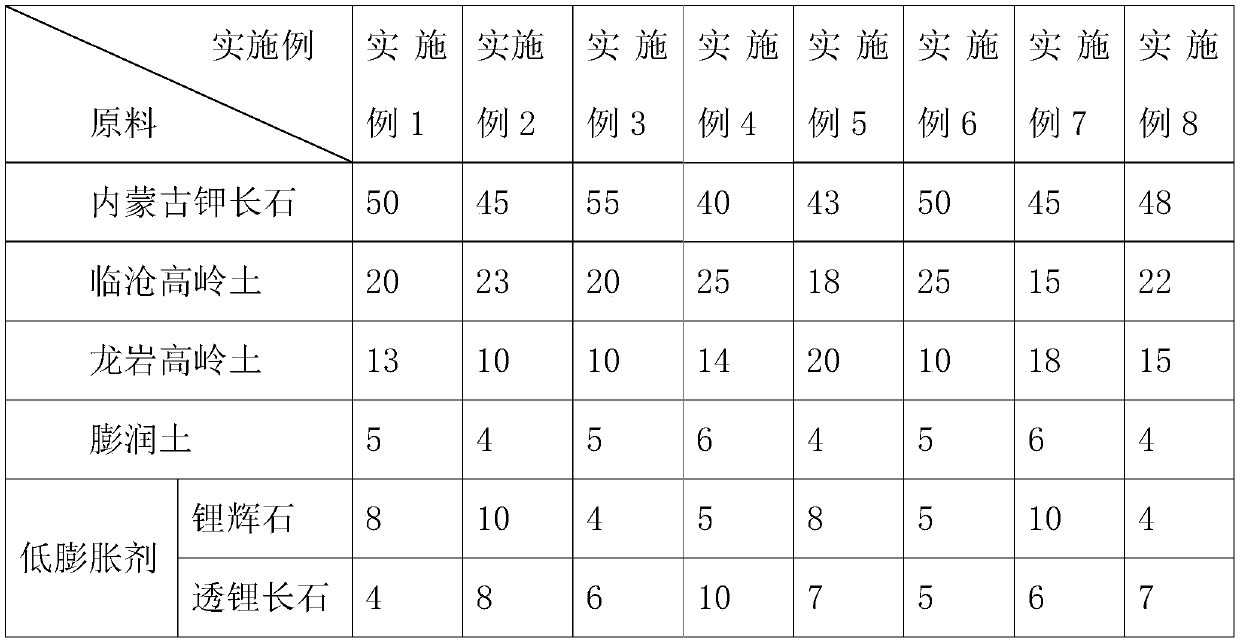

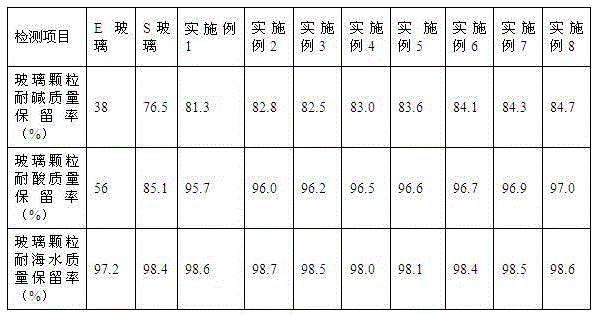

High-thermal stability and high-whiteness ceramic and preparation method thereof

The invention belongs to the technical field of daily use ceramics, and particularly relates to a high-thermal stability and high-whiteness ceramic and a preparation method thereof. The high-thermal stability and high-whiteness ceramic comprises a high-thermal stability and high-whiteness blank and a transparent glaze, and the high-thermal stability and high-whiteness blank comprises Inner Mongolia potash feldspar, Lincang kaolin, Longyan kaolin, bentonite and a low expansion agent; and the transparent glaze comprises, by weight, Jiangxi potash feldspar, quartz, Longyan kaolin, heavy calcium,calcined zinc oxide, barium sulfate, calcined talcum powder and a regulator. The prepared ceramic blank and glaze are well combined by adopting the method, so the ceramic of the invention has delicatetransparent porcelain and a smooth and bright glaze surface, has a whiteness reaching 81 or more, and achieves thermal exchange at 200-20 DEG C two times without cracking due to high thermal stability; and the preparation method has the advantages of easily availably preparation raw materials, wide firing range, simple preparation process and high product yield, and is suitable for being promotedand applied to the field of daily use ceramics.

Owner:FUJIAN QUANZHOU SHUNMEI GROUP

Conductive glass powder and its preparation method, crystalline silicon solar battery aluminum conductive paste and preparation method

InactiveCN103204632AImprove performanceImprove photoelectric conversion efficiencyNon-conductive material with dispersed conductive materialCable/conductor manufactureMetallic lithiumElectrically conductive

The invention provides a conductive glass powder and its preparation method. The glass powder comprises a glass oxide and 10-40wt% of a halogen compound of metal lithium or silver. The invention also provides a crystalline silicon solar battery aluminum conductive paste containing the conductive glass powder and a preparation method thereof. The aluminum conductive paste prepared from the conductive glass powder provided by the invention can improve the photoelectric conversion efficiency of a crystalline silicon solar battery. The formed aluminum film has small square resistance and high fill factor, the battery piece has small bending, the silicon-aluminum layer is smooth and has good adhesion, and the average photoelectric conversion efficiency of an ordinary monocrystalline silicon battery is greater than 18.20%.

Owner:BYD CO LTD

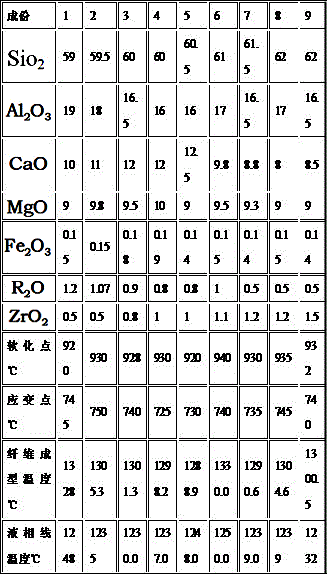

Chemical corrosion-resistance, high-strength and high-modulus glass fiber composition

The invention relates to a chemical corrosion-resistance, high-strength and high-modulus glass fiber composition. The above glass fiber has high strength, high modulus, high temperature resistance, corrosion resistance and other comprehensive performances. The composition can be widely applied in high-performance composite materials and in heat and corrosion resistant environment. The composition is characterized in that 0.5-1.5wt% of ZrO2 is added, and no Li2O, TiO2 or F2 is added, so the high strength and the high modulus of the composition are guaranteed, and the acid and alkali resistance of glass is improved. The glass fiber composition adopts a SiO2-Al2O3-CaO-MgO four-component system as a main component, and mainly comprises 59.0-62.0wt% of SiO2, 16.0-19.0wt% of Al2O3, 8.0-13.0wt% of CaO, 9.0-11.0wt% of MgO, 0.5-1.2wt% of R2O and 0.5-1.50wt% of ZrO2. The glass fiber composition can realizes tank furnace process direct production.

Owner:TAISHAN FIBERGLASS INC

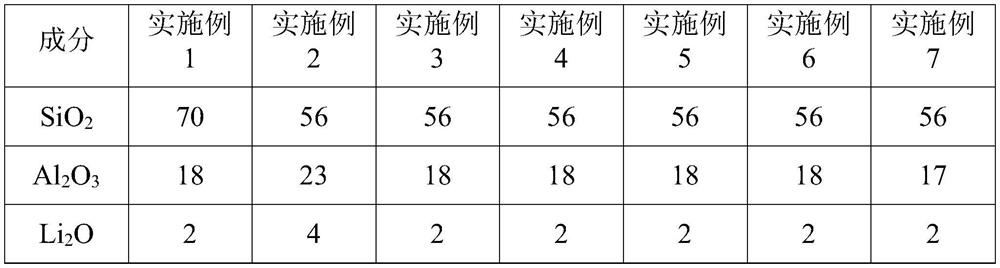

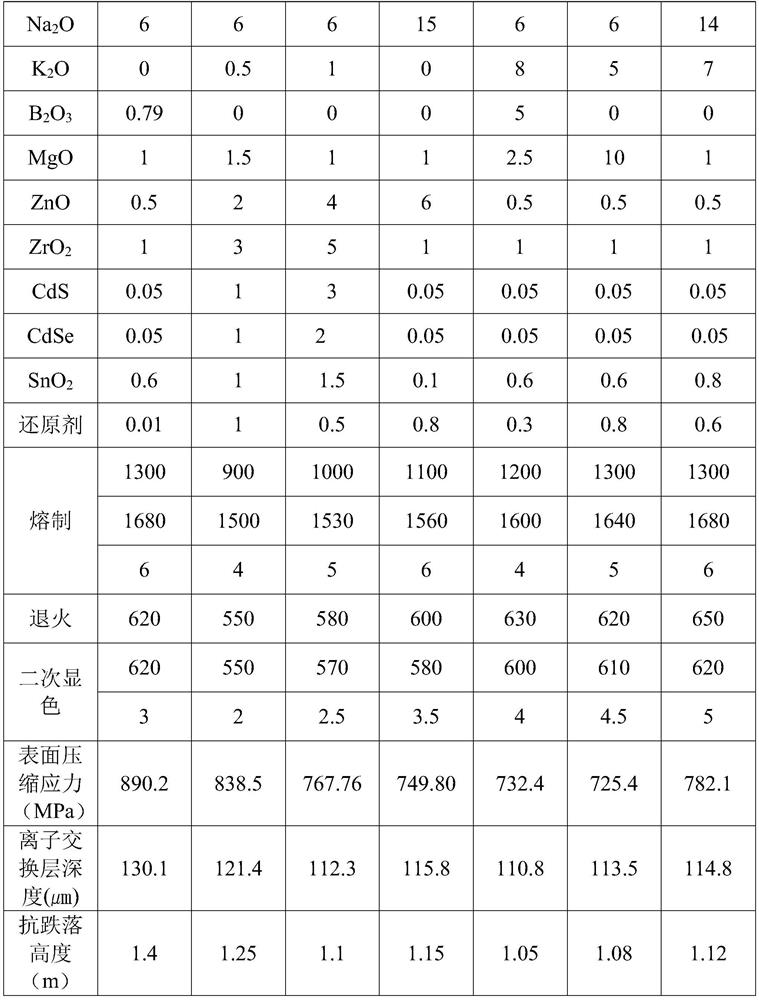

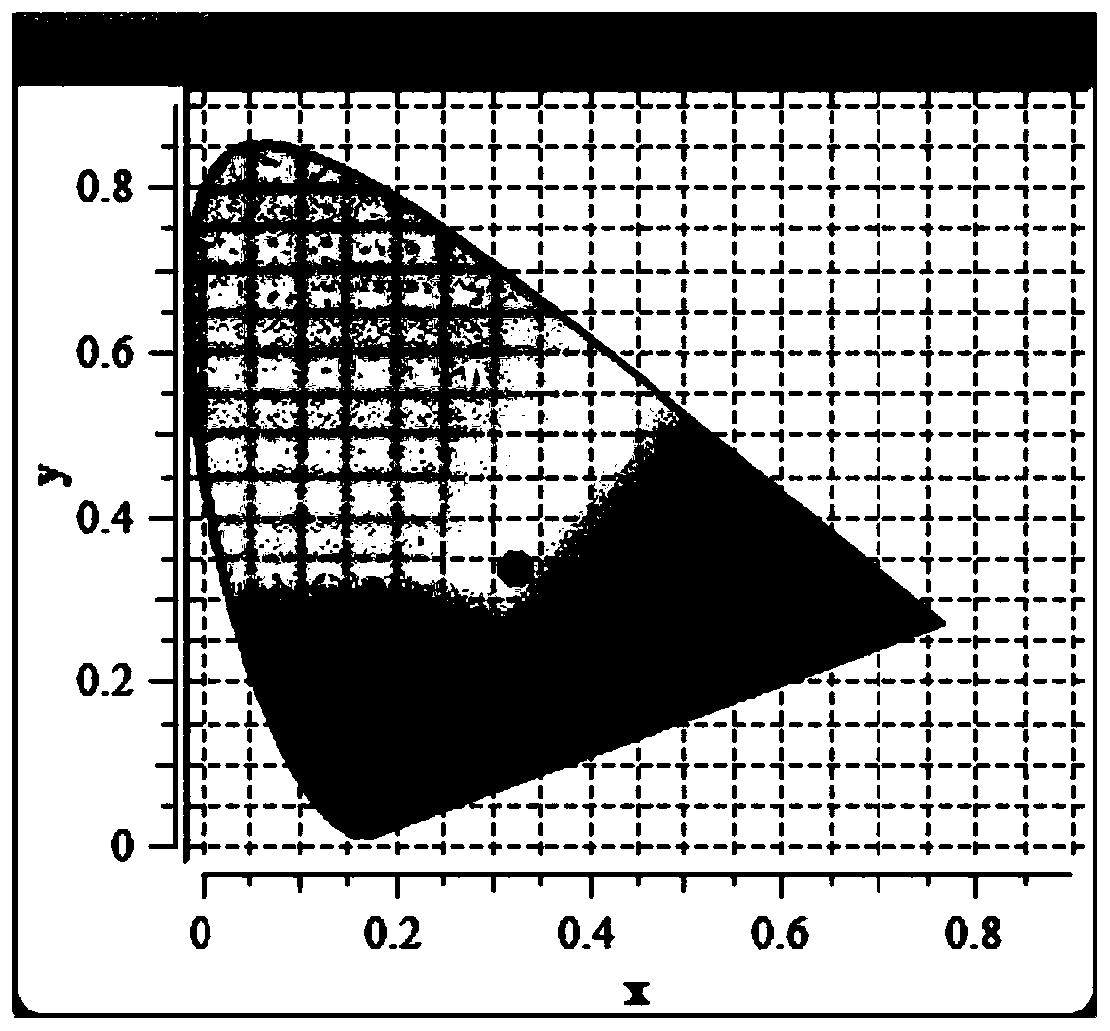

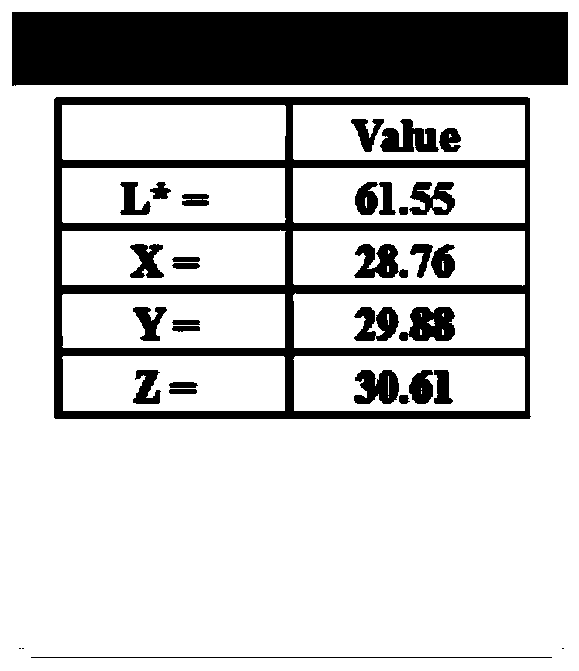

Anti-blue-light high-strength lithium-aluminum-silicon cover plate glass and preparation method and application thereof

PendingCN113121109AIncrease intrinsic strengthFacilitate ion exchangeGlass shaping apparatusGlass tempering apparatusPhysical chemistrySilicon

The invention relates to the technical field of cover plate glass, in particular to anti-blue-light high-strength lithium-aluminum-silicon cover plate glass which is prepared from the following raw materials in percentage by mass: 56%-70% of SiO2, 18%-23% of Al2O3, 2%-4% of Li2O, 6%-15% of Na2O, 1%-10% of MgO, 0.5%-6% of ZnO, 1%-5% of ZrO2, 0.05%-3% of CdS, 0.05%-2% of CdSe, 0.6%-1.5% of SnO2, 0-8% of K2O, 0-5% of B2O3 and 0.01%-1% of a reducing agent. The invention further discloses a preparation method of the anti-blue-light high-strength lithium-aluminum-silicon glass, the anti-blue-light high-strength lithium-aluminum-silicon glass is prepared through mixing, founding, annealing, secondary developing treatment and then composite chemical strengthening, and the anti-blue-light high-strength lithium-aluminum-silicon glass has an anti-blue-light effect, is suitable for being used as a screen protection material of electronic equipment such as a mobile phone and can effectively prevent the surface of a panel display product from being impacted or scratched and damaged.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

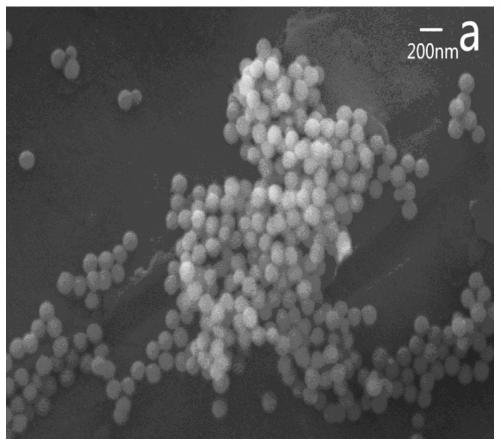

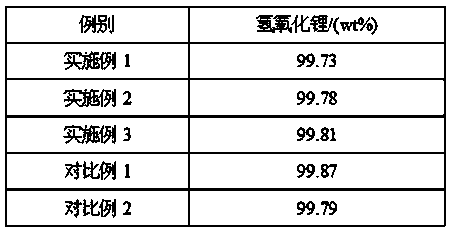

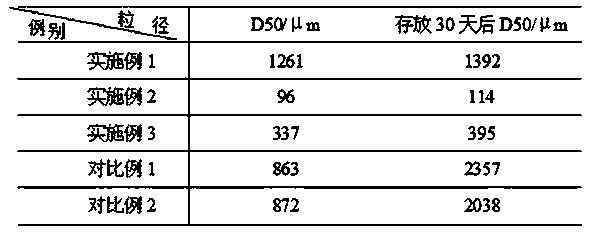

Nano spherical lithium hydroxide and preparation method thereof

ActiveCN111115663AGood dispersionPrevent compactionLithium oxides/hydroxidesMicroballoon preparationLithium oxideDispersity

The invention discloses nano spherical lithium hydroxide and a preparation method thereof. The nano spherical lithium hydroxide and the preparation method thereof are characterized in that the particle size of primary particles of the lithium hydroxide nanospheres is 10-600nm, the particle size D50 of laser particle size test is 50-2000nm, the purity of the lithium hydroxide nanospheres is greaterthan 99.7%, and the balance is 0.01-0.2% of non-polar organic matters and a proper amount of impurities. According to the nanospheres, a lithium hydroxide solution is matched with a non-polar organicsolvent and an ionic surfactant with a hydrophobic group according to a certain proportion to form stable water-in-oil, namely the structure is a structure that an organic matter wraps a water phase(W / O), the solution system is enabled to form emulsion liquid beads with nanometer and micrometer sizes, then, the lithium hydroxide of the liquid beads can be dried in the spraying process to separate out spherical nanoparticles, and in the drying process, a small amount of non-polar organic matters are remained, so that the dispersity of the lithium hydroxide nanospheres is improved, the hardening of the lithium hydroxide particles is favorably prevented, and the better physical morphology and size of the lithium hydroxide nanospheres are maintained.

Owner:苏州众鑫凯能源科技有限公司

Fluorine-free sodium-free ladle covering agent

InactiveCN102794419AImprove flux effectAvoid Pollution HazardsProcess efficiency improvementFluorine freeCarbon black

The invention relates to the technical fields of steel smelting and ladle metallurgy, particularly a fluorine-free sodium-free ladle covering agent. The invention aims to provide a fluorine-free sodium-free ladle covering agent which has the characteristics of strong basicity, strong reducibility, high absorption and inclusion capacity, favorable spreadability and excellent heat-insulating property; and the invention also aims to solve the problems of high melting point, low melting speed, low desulphurization capacity and poor use effect in the existing CaO ladle covering agent, and to overcome the defect of contamination hazard since the covering agent contains sodium oxide, calcium fluoride and the like. The invention is characterized in that the covering agent is prepared from the following components in percentage by weight: 40-80% of spodumene, 10-40% of lime, 2-15% of magnesite and 1-10% of carbon black.

Owner:JIANGSU UNIV

Fluoride-free refining slag for 20 Cr structural alloy steel and preparation method thereof

InactiveCN103849712AEliminate pollutionMeet the requirements of green metallurgyRecovering materialsGranularitySlag

The invention discloses fluoride-free refining slag for 20 Cr structural alloy steel and a preparation method thereof. The granularity of the fluoride-free refining slag is 15-35mm, and the fluoride-free refining slag comprises the following components in percentage by weight: 55-60% of CaO, 10-16% of SiO2, 15-20% of Al2O3, 4-6% of MgO, 5-10% of B2O3, less than or equal to 1% of TFe and the balance of impurities. The preparation method of the fluoride-free refining slag comprises that mineral ore raw materials containing CaO, SiO2, Al2O3, MgO and B2O3 are crushed and blended and then moulding and crushing are carried out, so that the fluoride-free refining slag finished product is obtained. The preparation method of the fluoride-free refining slag is simple, and the prepared fluoride-free refining slag has the advantages of environmental friendliness, no fluoride, high slagging speed, strong slag inclusion removal capability, less furnace lining corrosion and strong desulphurization capability.

Owner:武钢集团有限公司

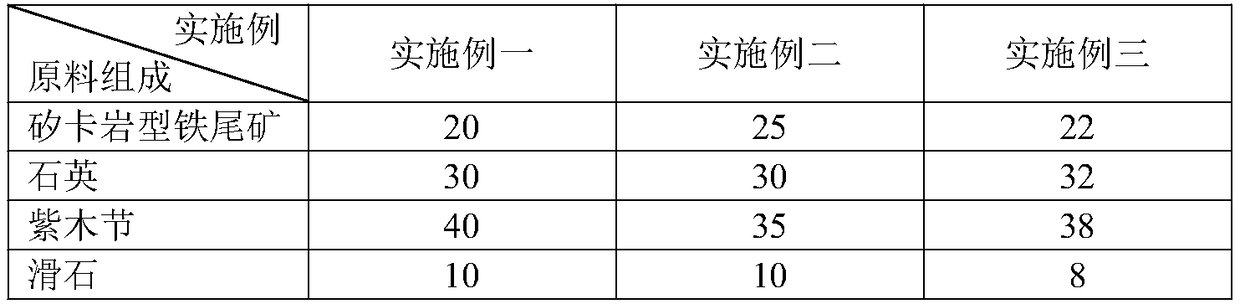

Green archaized brick prepared from iron tailings of skarn with high content of calcium and magnesium and making method thereof

ActiveCN109081677AReduce dependenceReduce manufacturing costCeramic materials productionClaywaresBrickQuartz

The invention discloses a green archaized brick prepared from iron tailings of skarn with high content of calcium and magnesium and a making method thereof. The green archaized brick is prepared from,by weight, 20-25 parts of iron tailings of skarn, 30-40 parts of quartz, 35-45 parts of knar clay, and 6-12 parts of talcum. The invention further discloses a making method of the green archaized brick prepared from iron tailings of skarn with high content of calcium and magnesium. According to the design of preparing the green archaized brick from the iron tailings of skarn with high content ofcalcium and magnesium, product quality and performance is guaranteed, dependence on high-quality raw material resources in production of green bricks is weakened, production cost of building ceramicsis lowered greatly, environmental protection and pollution treatment are both facilitated. The production of the green archaized brick is easy to control and low in cost, and thus the green archaizedbrick is easy to promote and apply and has high practical value and good application prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

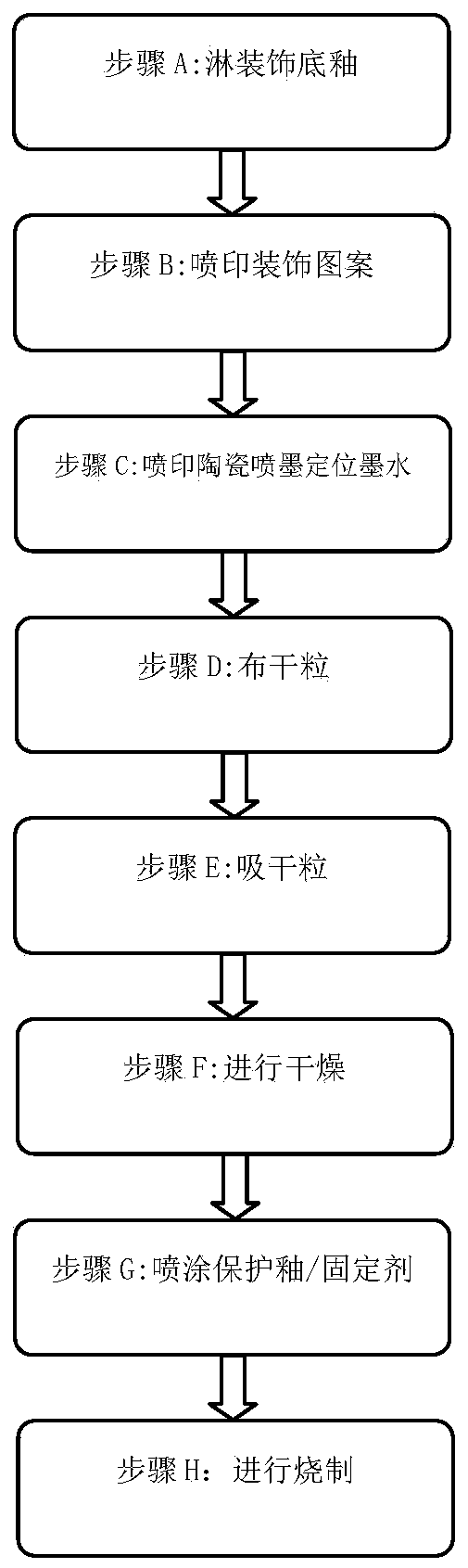

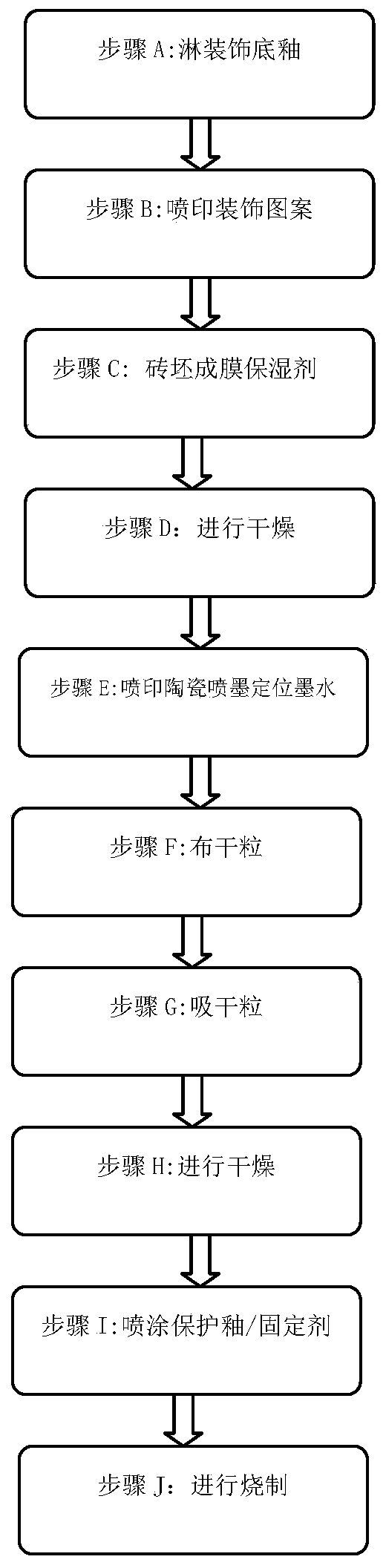

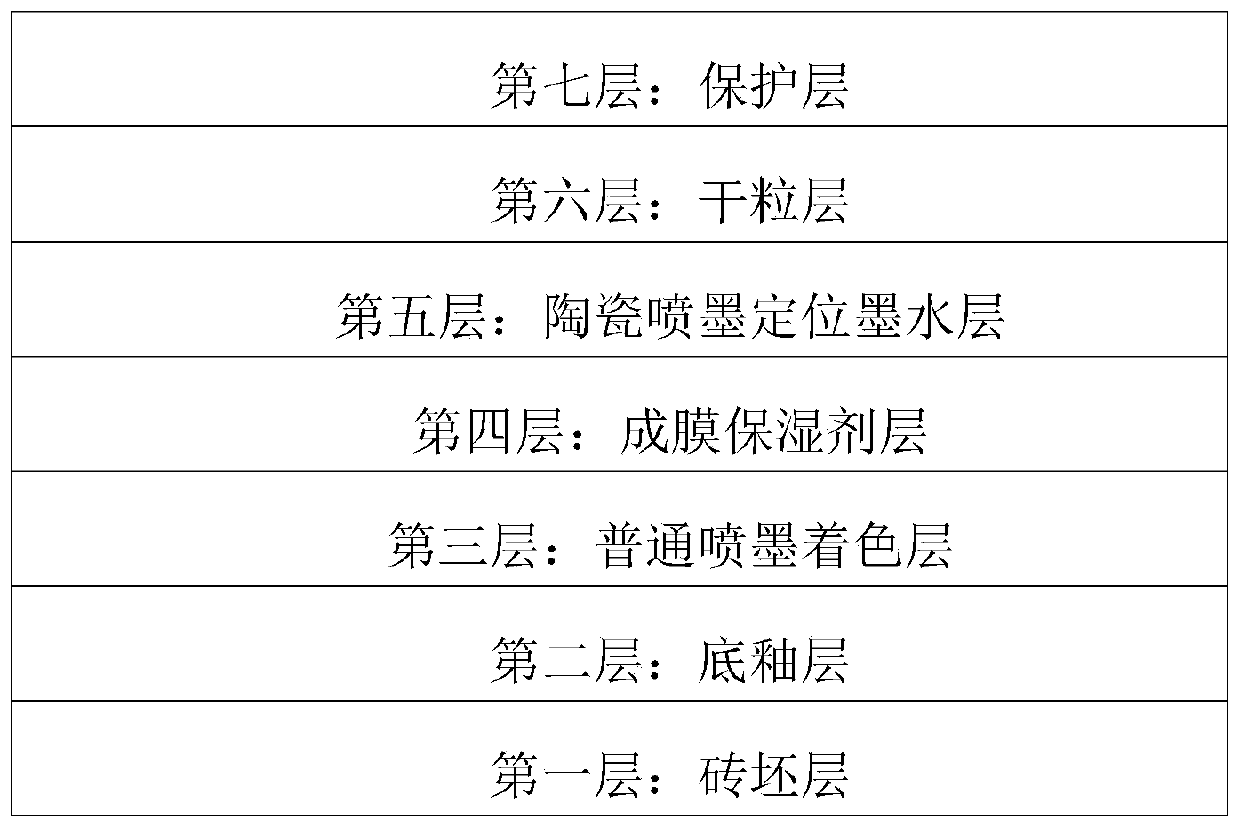

Green brick film-forming moisturizing agent, ink-jet printing ink, decorative glue and preparation methods of green brick film-forming moisturizing agent and ink-jet printing ink

InactiveCN110372212AAvoid blowing offAvoid positionAdditive manufacturing apparatusInksPolyvinyl acetateBrick

The invention relates to a green brick film-forming moisturizing agent, ink-jet printing ink, decorative glue and preparation methods of the green brick film-forming moisturizing agent and the ink-jetprinting ink. The green brick film-forming moisturizing agent is prepared from the following components in parts by weight: 50-55 parts of polyvinyl acetate, 5-10 parts of ethyl alcohol and 35-45 parts of water. The preparation method of the green brick film-forming moisturizing agent comprises the steps that (1) according to the ratio in parts by weight of the raw material components, the polyvinyl acetate, the ethyl alcohol and the water are matched according to the proportion of (40 to 60):(5 to 10):(30 to 50) and fed into a stirrer to be mixed and stirred, the stirring time is 50 min, therotating speed is 250 r / min, and thus film-forming moisturizing agent raw stock is obtained; and (2) the film-forming moisturizing agent raw stock is sieved by a 100-mesh sieve, the flow rate of theadded water is controlled to be 27-30 s, the specific gravity is 1.05-1.10 g / cm<3>, and finally, a film-forming moisturizing solution is obtained.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +3

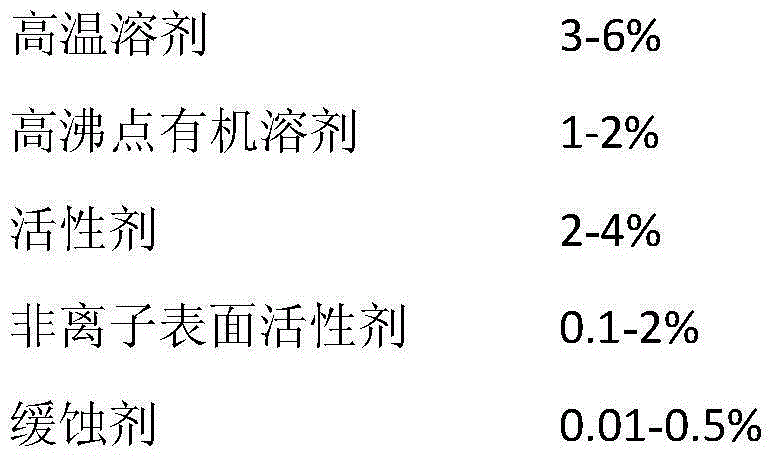

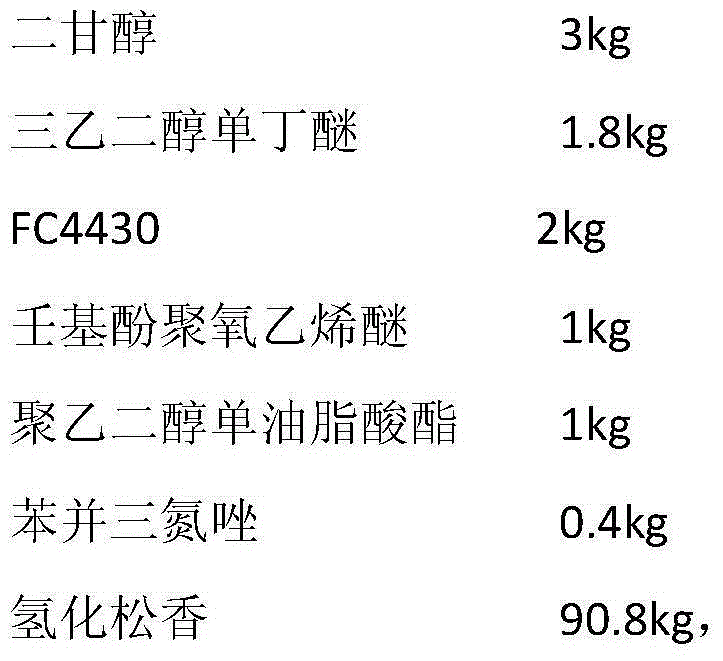

Halogen-free soldering flux in solder stick for automatic soldering robot and preparation method

InactiveCN105215579AEvenly distributedReduce corrosionWelding/cutting media/materialsSoldering mediaOrganic solventBoiling point

The invention relates to halogen-free soldering flux in a solder stick for an automatic soldering robot and a preparation method. The halogen-free soldering flux is characterized by being prepared from a high-temperature solvent, a high-boiling-point organic solvent, an activating agent, nonionic surfactant, corrosion inhibitor and modified rosin. The halogen-free soldering flux has the advantages that the excellent soldering assist effect on Sn-Cu series and Sn-Ag-Cu series lead-free solder is achieved, solder joint quality defects such as continuous tin, tip pulling, missing solder and solder beading are greatly reduced after soldering of the automatic soldering robot, oxidation films can be effectively removed, rapid soldering assist is achieved, no halogen-containing compound is added completely, and no harm is caused to health and the environment.

Owner:广东中实金属有限公司

Light heat insulation and hydrophobic glass bead used for construction and preparation method of light heat insulation and hydrophobic glass bead

ActiveCN106587640AImprove water resistanceImprove water absorptionGlass shaping apparatusAbsorption rateVolume density

The invention provides a light heat insulation and hydrophobic glass bead used for construction. The light heat insulation and hydrophobic glass bead comprises, by mass, 60%-80% of clayed perlite production tailings, 5%-25% of expanded perlite micro powder, 0.5%-2.0% of fluorite powder, 0.5%-5.0% of pure alkali, 0.3%-1% of green silicon carbide dust collection powder, 0.5%-1% of quicklime powder and 8%-12% of water glass. The invention further provides a preparation method of the light heat insulation and hydrophobic glass bead used for construction, and the light heat insulation and hydrophobic glass bead used for construction has the beneficial effects of being small in volume density, good in heat insulation performance and low in water absorption rate and is wide in application prospect.

Owner:XINYANG KEMEI NEW MATERIALS

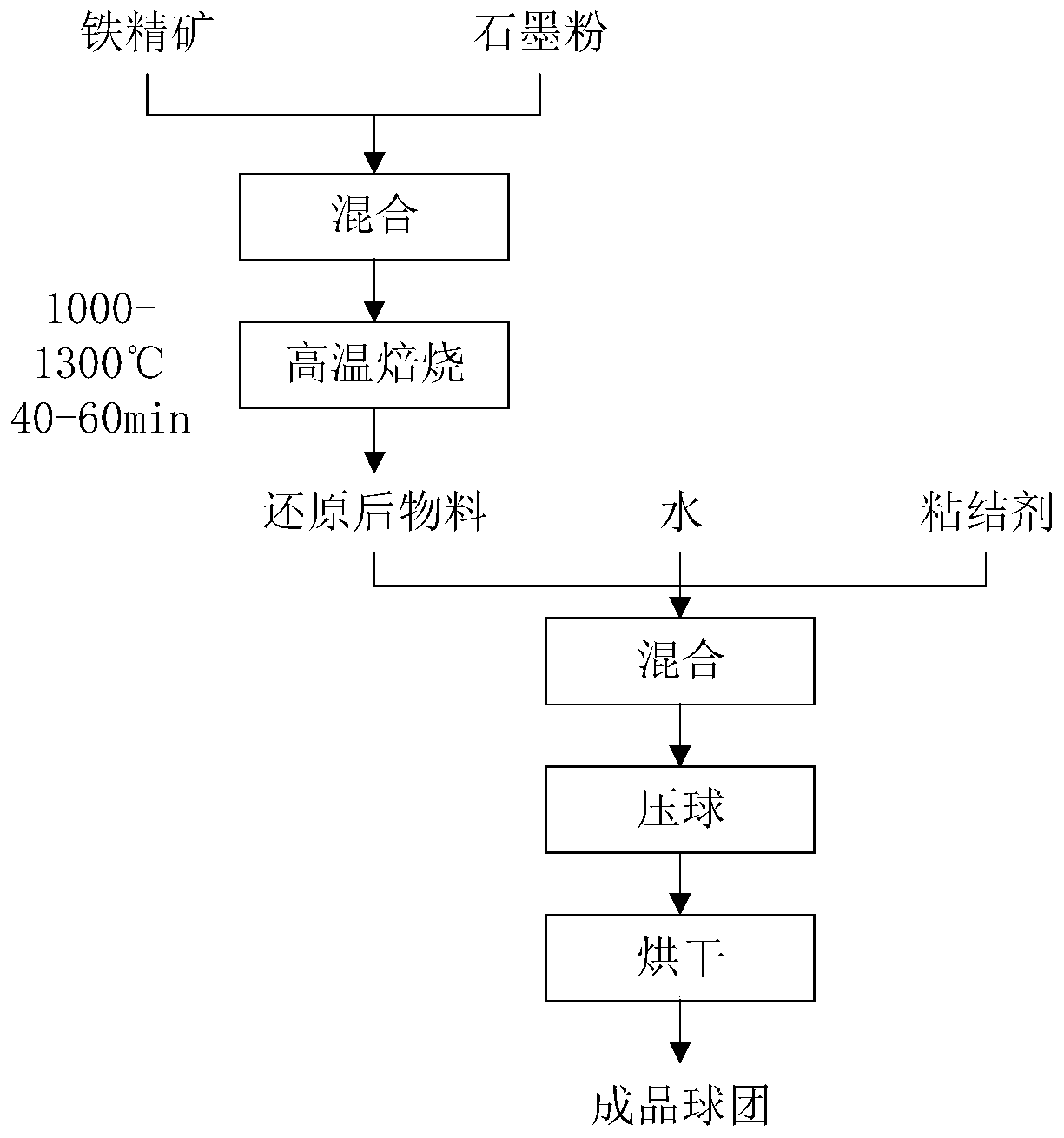

Prepraiton method of high-carbon metallized pellets for electric furnace

The invention discloses a preparation method of high-carbon metallized pellets for electric arc furnace smelting. The preparation method comprises the steps that carbon-containing powder is added intoiron concentrate for material preparation according to the mass ratio of carbon to iron of 1.5-2:1, prereduction is carried out at a reduction temperature of 1000-1300 DEG C for 40-60min, the reduction product is ground to 0.4-0.5 mm granularity, 4-6% of a binding agent and 9-12% of water are added, the mixture is mixed evenly, pressed into pellets and dried at the temperature of 120-140 DEG C for 60-90min, the high-carbon metallized pellets are obtained, and the pellets can reach the falling strength of 3-4 and reach the density of 2.6-3.3g / cm<3>. Molten steel can be stably and efficiently recarburized by the pellets below the slag-steel interface, the problems that the density of conventional carburant is insufficient, the carburant rapidly floats on the surface of furnace slag after being added, and the carburizing effect is poor are solved, meanwhile, the pellets can perform a good carbon-oxygen reaction below the slag-steel interface to remove inclusions and gas, formation of a large amount of foam slag is promoted, electric arc is stabilized, smelting time is shortened, iron loss is effectively reduced, steel material consumption is remarkably reduced, the metal yield is improved, and the smelting cost is reduced.

Owner:UNIV OF SCI & TECH BEIJING

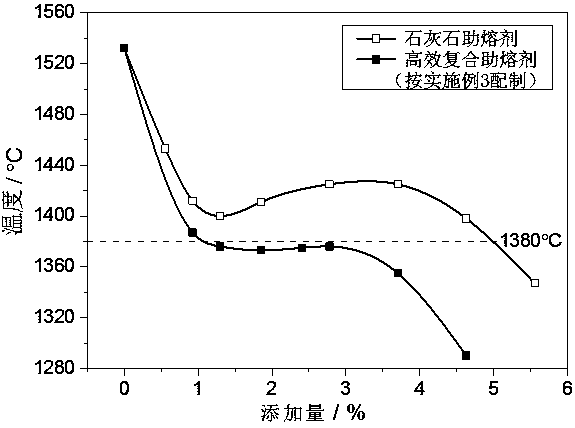

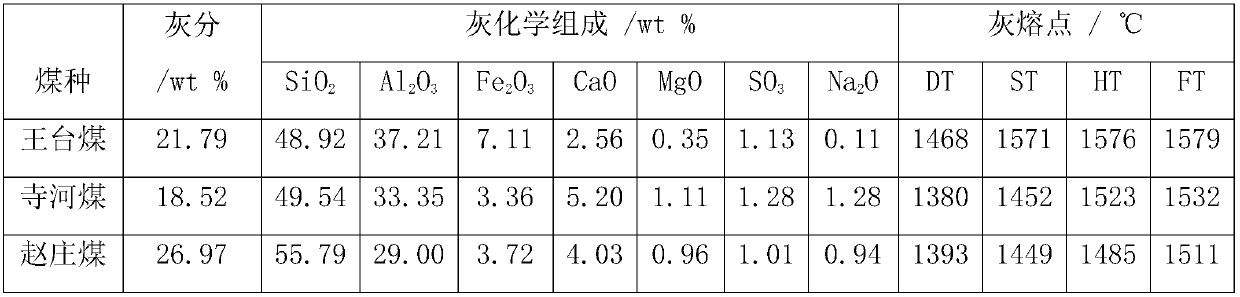

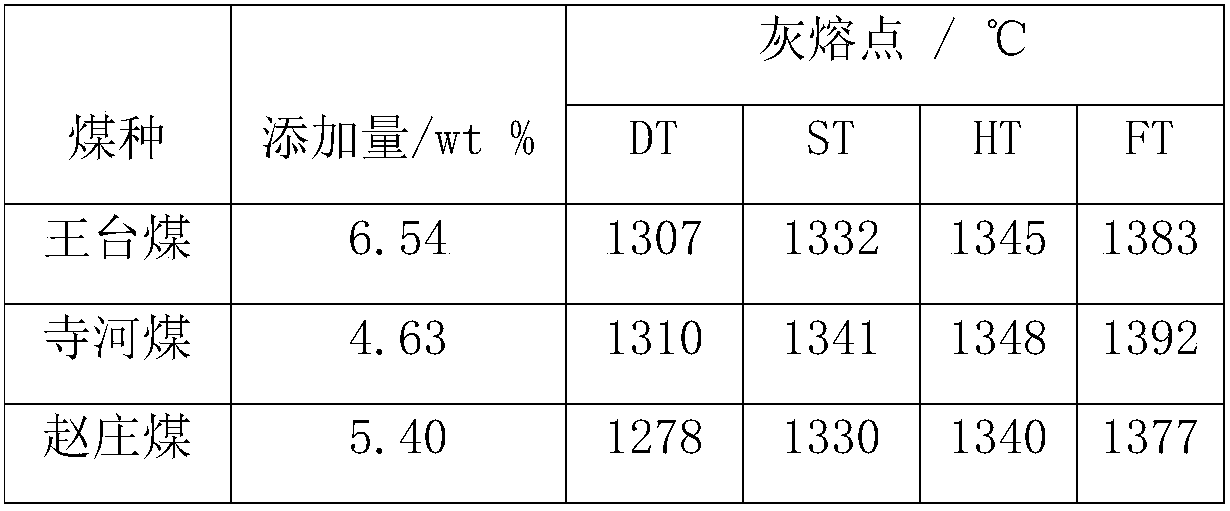

High-efficiency composite flux for lowering the melting point of coal ash and its preparation method and application

ActiveCN106520206BAdd lessImprove flux effectGasification processes detailsGranular/pulverulent flues gasificationSodium sulfateCoal

A high-efficiency composite flux for reducing the melting point of coal ash is formed by compounding calcium-containing mineral powder with sodium-containing sodium sulfate according to a ratio of 1:1 to 8:2, and mainly comprises, by mass, 48.2-79.4% of CaCO3, 19.7-49.5% of Na2SO4 and 0.2-0.7% of CaO. The high-efficiency composite flux has the advantages of small addition amount, low cost, and reduction of the melting point of the coal ash.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Electrical connection and method of manufacturing the same

InactiveUS8079141B2Improve efficiencyEnhanced couplingPrinted circuit assemblingContact member manufacturingElectrical connectionElectronic component

Owner:SUMITOMO BAKELITE CO LTD

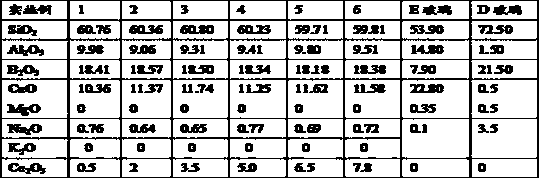

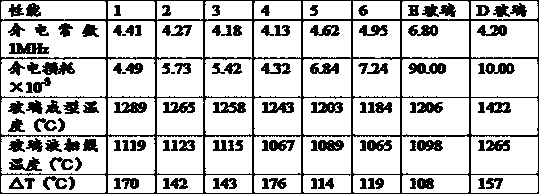

Ce2O3 containing fluorine-free low-dielectric glass fiber and preparation method thereof

InactiveCN108314330AImprove performanceExcellent dielectric propertiesGlass making apparatusGlass fiberDielectric loss

The invention provides a fluorine-free low-dielectric glass fiber, which has an excellent dielectric constant and low dielectric loss. The dielectric constant is 4.13-4.95 and the dielectric loss is 4.32*10<-3> to 7.24*10<-3> under 1 MHz. The glass fiber composition is prepared from following raw materials in percentage by mole: 56 to 66% of SiO2, 19 to 23% of B2O3, 6 to 10% of Al2O3, 0.5 to 1% ofNa2O, 8 to 15% of CaO, 0.5 to 8% of Ce2O3, and does not contain any F (fluorides) or Fe (iron oxides). The provided glass fiber can be used to prepare a reinforcing material for printed circuit boards (PCB) and can be used to strengthen radome.

Owner:UNIV OF JINAN

Lead-free solder alloy tin soldering paste

InactiveCN104162747AReduce manufacturing costGood fluxing effectWelding/cutting media/materialsSoldering mediaActive agentOrganic acid

The invention relates to lead-free solder alloy tin soldering paste and belongs to the field of tin soldering paste preparing in a chemical mode. The lead-free solder alloy tin soldering paste is characterized by being formed by lead-free solder alloy powder and scaling powder in an evenly-stirring-mixing mode according to the proportion of 11 : 89. Components of the scaling powder comprise 35% of rosin, 31% of solvents, 8% of organic acid active agents, 4.5% of thixotropic agents, 14% of viscosity modifiers and 7.5% of antioxidants. Solder alloy powder is effectively improved, so that production cost is effectively lowered, meanwhile, soldering aiding effect can be well provided, the cost performance is greatly improved, and the lead-free solder alloy tin soldering paste can be promoted and produced in a large scale under the current technology production conditions.

Owner:XIAN SANWEI SECURITY TECH

Manufacturing method of rare earth colored transparent gray crystal bead blank

InactiveCN109761502AImprove solubilityHigh refractive indexGlass pressing apparatusElectric furnaceRare earthRefractive index

The invention relates to the field of artificial crystal products, in particular to a manufacturing method of a rare earth colored transparent gray crystal bead blank. Cobalt oxide, nickel oxide and erbium oxide are mixed according to a ratio and are colored into gray; sodium carbonate, potassium carbonate, lithium carbonate and sodium fluorosilicate are used for accelerating the dissolution of glass, and also improve the product quality; due to addition of borax decahydrate, the fluxing effect is enabled to be more obvious; sodium nitrate regulates the oxidizing atmosphere during glass melting; antimony oxide plays roles of clarifying and defoaming; zinc oxide, titanium dioxide and barium carbonate are used for increasing the refractive index; aluminum oxide enhances the strength of the glass so as to enable the product structure to be stable. In addition, the method adopts an electric heating closed crucible furnace to smelt the glass, so that the color is changed conveniently; the produced transparent gray crystal bead blank has no color difference, is internally clear and transparent, is uniform in texture, and has high transmittance and the refractive index; compared with thetraditional crystal bead blank, the rare earth colored transparent gray crystal bead blank is improved by multiple grades.

Owner:广东蓝碟羽水晶饰品有限公司

Archaized brick produced through marble waste and production process of archaized brick

ActiveCN109483716AAvoid stackingImprove environmental performanceCeramic shaping plantsBrickSodium Bentonite

The invention discloses an archaized brick produced through marble waste and a production process of the archaized brick. The archaized brick is prepared from the following raw materials in parts by weight: 30-50 parts of feldspar, 10-20 parts of kaoline, 5-10 parts of high-temperature sand, 30-40 parts of low-temperature sand, 6-8 parts of black clay, 8-10 parts of bentonite, 3-6 parts of attaclay, 20-30 parts of hard clay, 10-15 parts of bauxite, 1-3 parts of white clay and the marble waste, wherein the marble waste accounts for 10-20 wt% of the total materials. According to the obtained archaized brick, the water absorption rate is 2% or below, the bending strength can reach 27 MPa or above, the excellent abrasion resistance level can be reached, and radioactivity meets the requirements; and meanwhile, by doping the marble waste to produce the archaized brick, the waste is turned into wealth, the mechanical strength of the archaized brick is guaranteed, the strength and water absorption performance of the archaized brick are not affected, good heat preservation and insulation performance can further be achieved, and environment-friendly industrial production and sustainable development are achieved.

Owner:XINLAILI CERAMIC DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com