Green brick film-forming moisturizing agent, ink-jet printing ink, decorative glue and preparation methods of green brick film-forming moisturizing agent and ink-jet printing ink

A humectant and film-forming technology, which is applied in the field of ceramic tiles, can solve problems such as deviation from the preset position, expensive inkjet glue, and loss of dry particle bonding, so as to prevent smoke from blowing away and reduce shrinkage. Glaze defect, effect of improving suspension performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

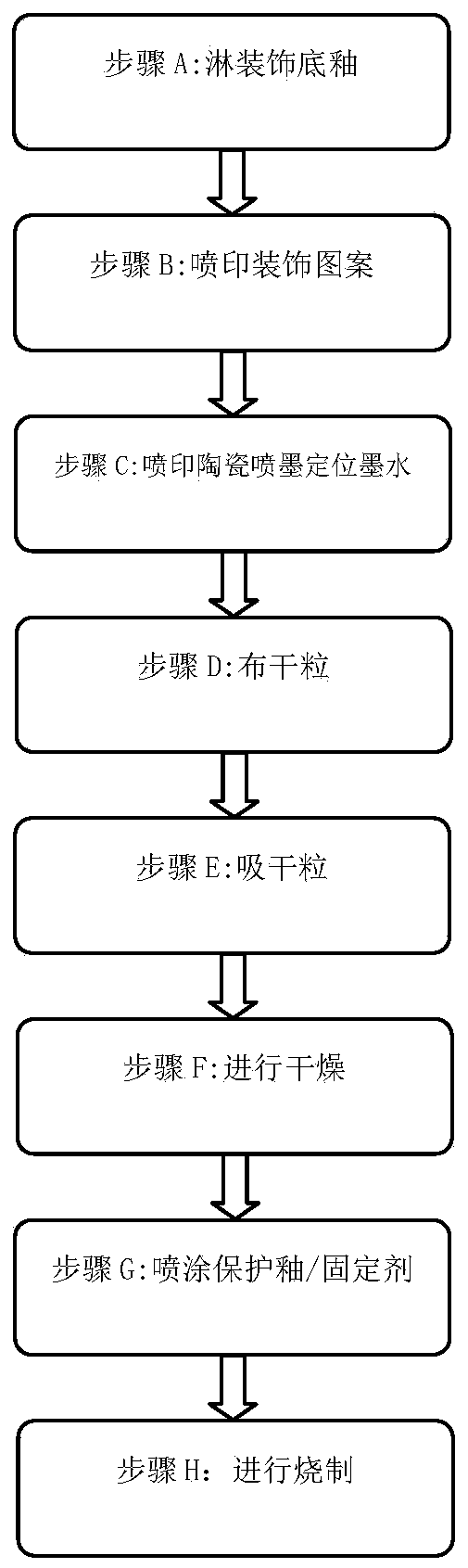

[0032] see figure 1 As shown, in the case of short glaze line and limited production conditions, ceramic inkjet positioning ink combined with dry granulation equipment is used for dry granule positioning decoration. The specific implementation plan is as follows:

[0033] Production process: Step A: Sprinkle decorative bottom glaze → Step B: Print decorative patterns → Step C: Print ceramic inkjet positioning ink → Step D: Cloth dry granules → Step E: Blot dry granules → Step F: Dry → Step G: Spray protective glaze / fixative → Step H: Perform firing

[0034] In step A, the brick body is poured with a decorative bottom glaze through a disc bell jar, the amount of decorative bottom glaze: 610-620g / ㎡, the specific gravity of the decorative bottom glaze: 1.78-1.80, and the flow rate: 25-30s.

[0035] In step B, before the adobe is spray-printed with a decorative pattern, the temperature of the adobe is 40-60° C., and the adobe is spray-printed with an eight-channel inkjet machine....

Embodiment example 2

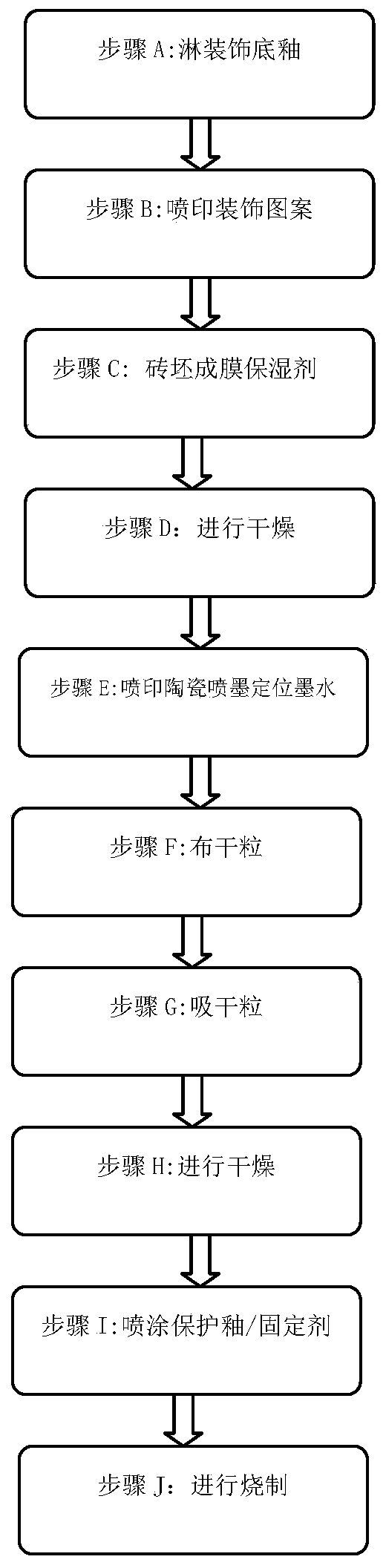

[0043] see figure 2 As shown, in the production process of Case 1, the amount of ceramic inkjet positioning ink is very large, which greatly increases the production cost and the burden on the nozzle of the inkjet machine. If the printing time is too long, ink shortage is prone to occur, and the nozzle needs to be washed frequently. It is not conducive to the continuity of the production process, and it will cause a certain loss to the production. This implementation case is to use the brick film-forming moisturizer combined with ceramic inkjet positioning ink and dry granulation equipment when the production conditions permit and the glaze line is long. The production method, this process method can greatly reduce the production cost (it can reduce the consumption of ceramic inkjet positioning ink by 60-80 parts), and the specific implementation plan is as follows:

[0044]Production process: Step A: Sprinkle decorative bottom glaze → Step B: Print decorative patterns → Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com