A method for preventing carbon black accumulated at the edge of casting rolls from falling off and pressing into the casting plate

A technology of casting rolls and carbon black, which is applied in the direction of cleaning methods using gas flow, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of greater impact on product quality, black threads, black bars, etc., and achieve the elimination of carbon black The effect of black pollution sources, avoiding pollution and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

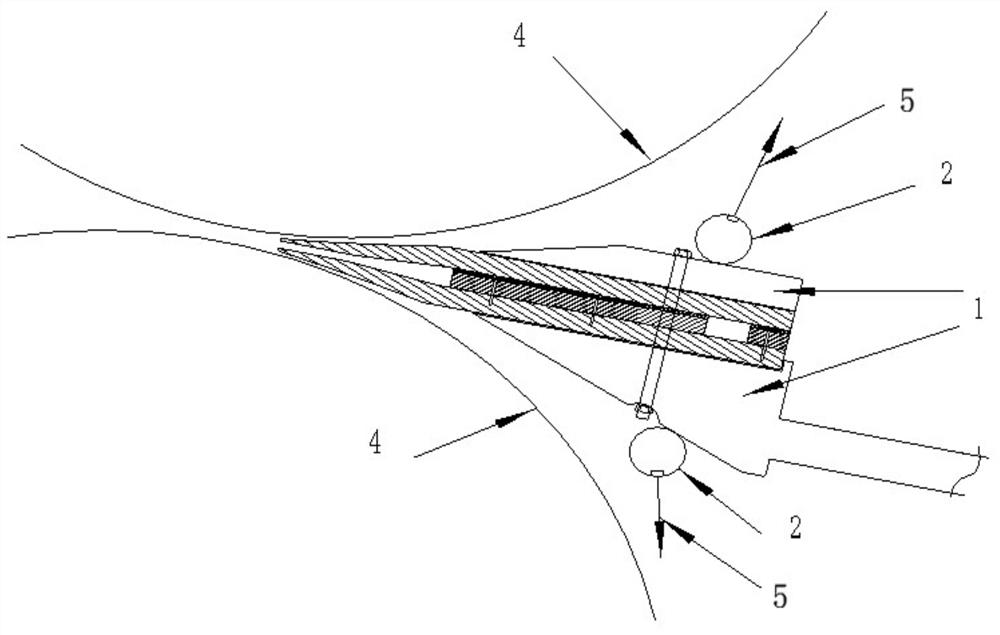

[0028] A method for avoiding the accumulation of carbon black at the edge of the casting roll from falling off and pressing into the casting plate, such as figure 1 As shown, in this method, it is necessary to use the nozzle clamp 1 arranged between the upper and lower casting rolls 4 . The upper and lower sides of the casting nozzle fixture 1 and the positions close to the lip are respectively equipped with purge pipes 2. The airflow blown by the purge pipe 2 is tangent to the roll surface of the corresponding casting roll 4, and is used to blow off and accumulate on the casting roll 4. Carbon black on both sides.

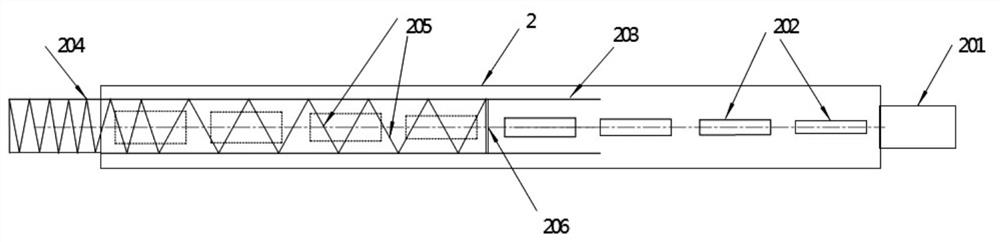

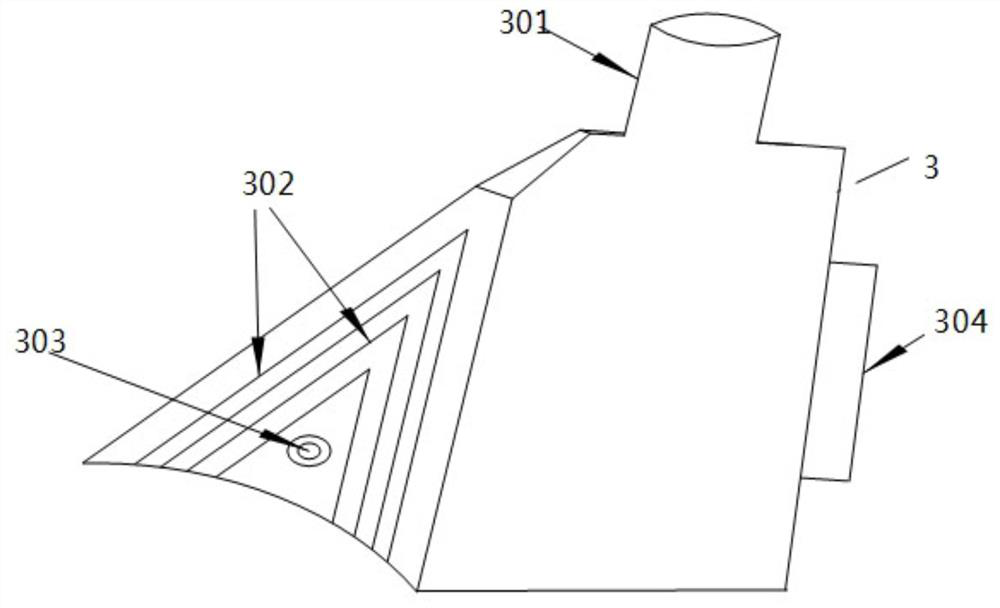

[0029] Specifically, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com