Patents

Literature

96results about How to "Improve purge efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

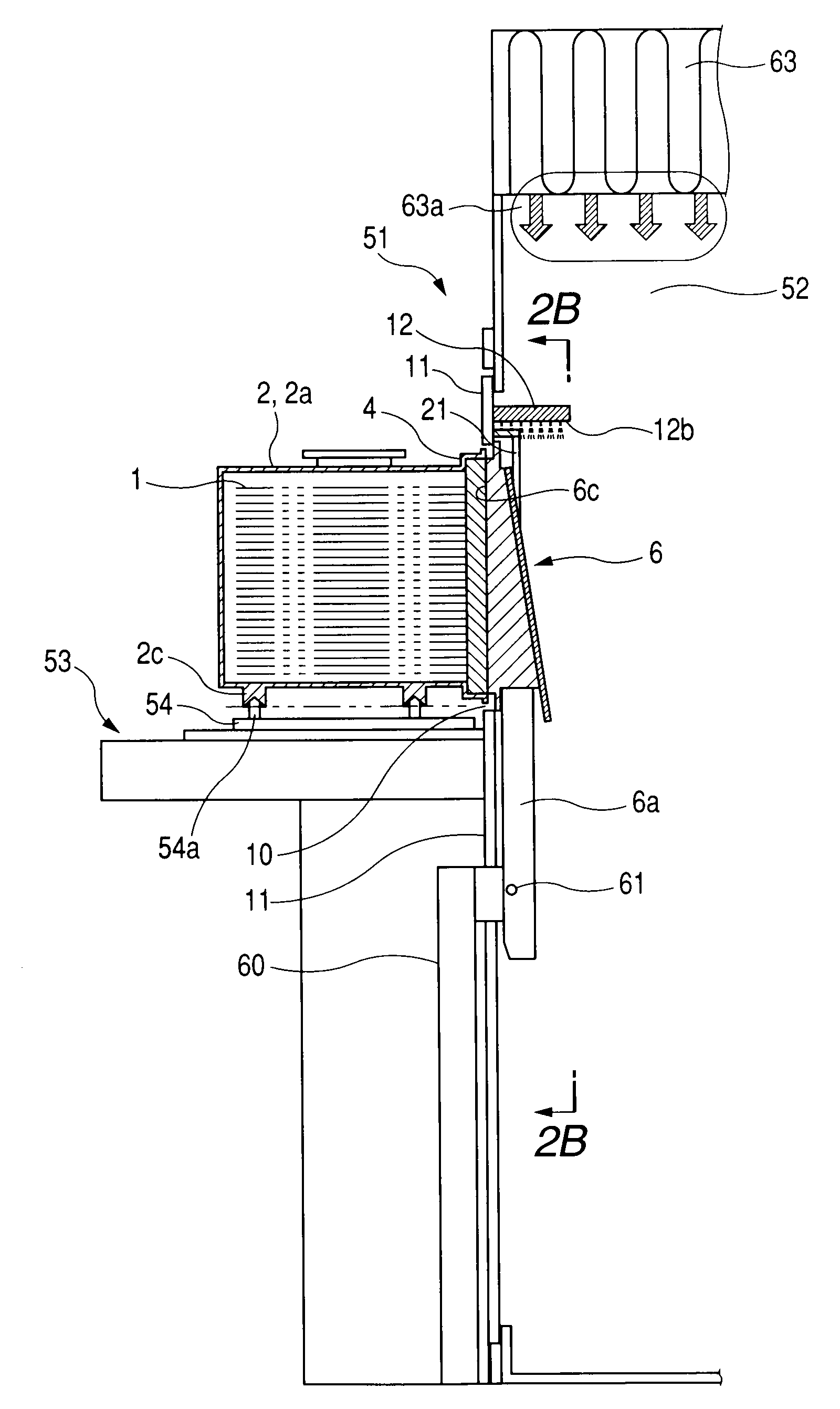

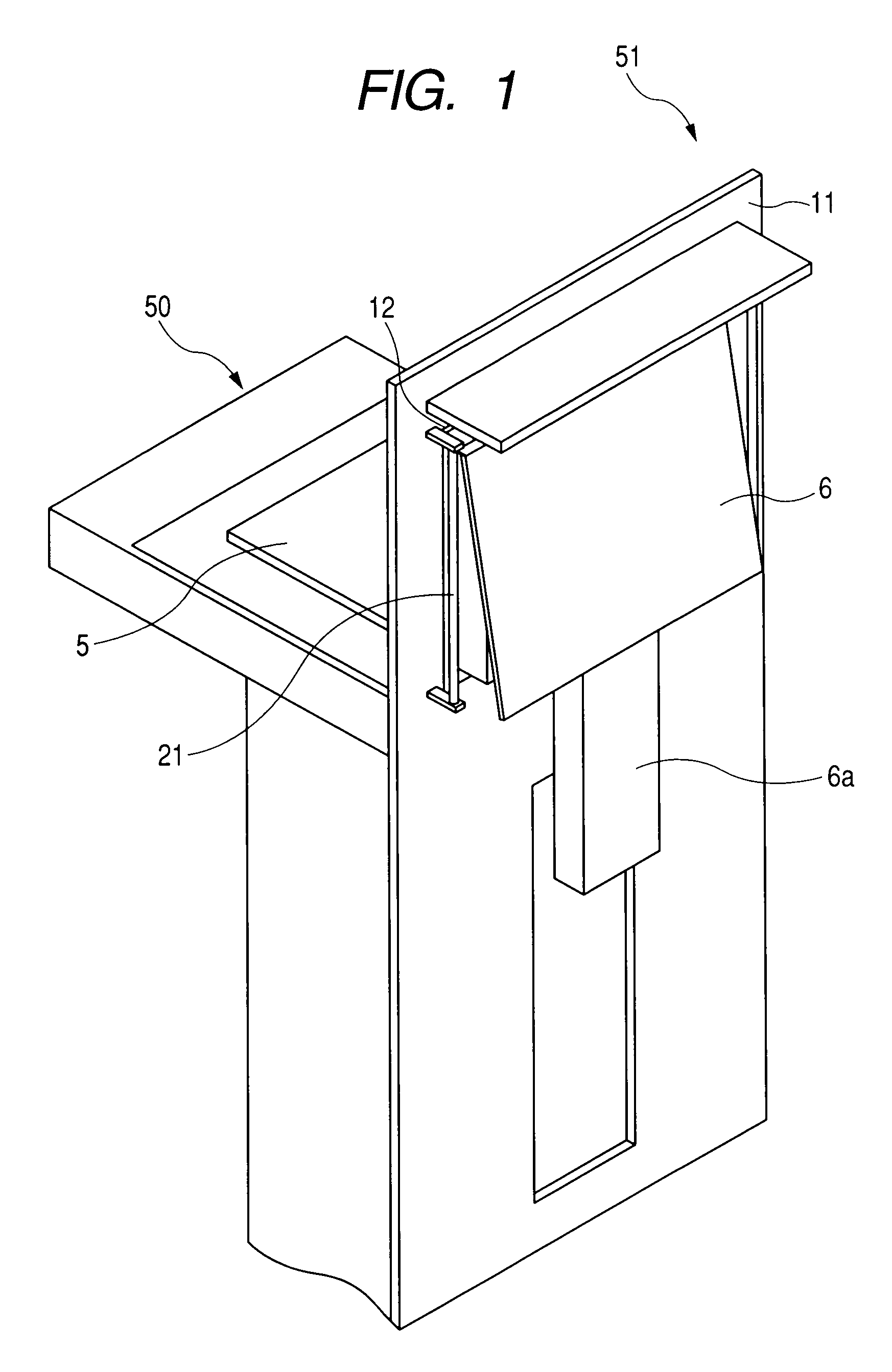

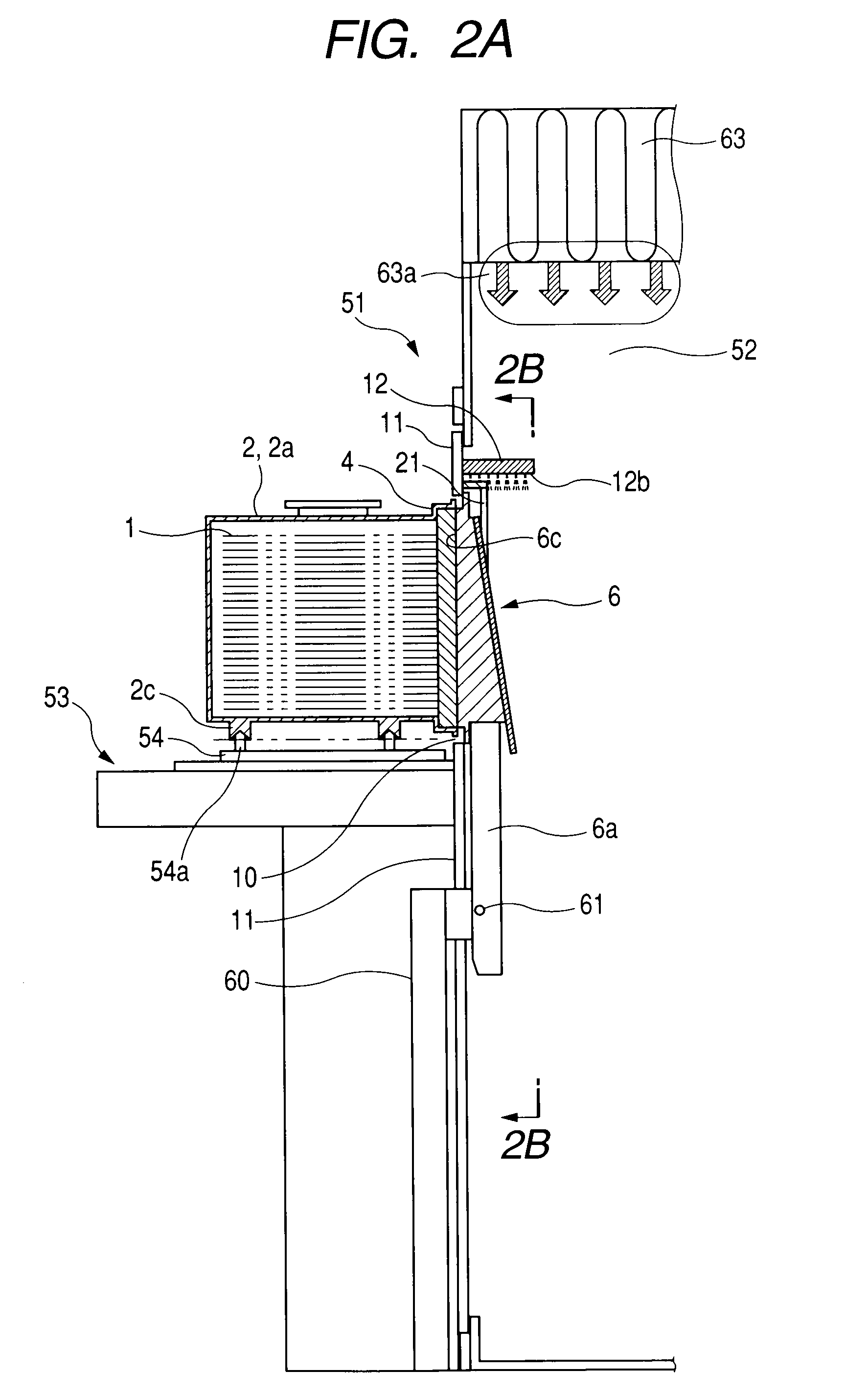

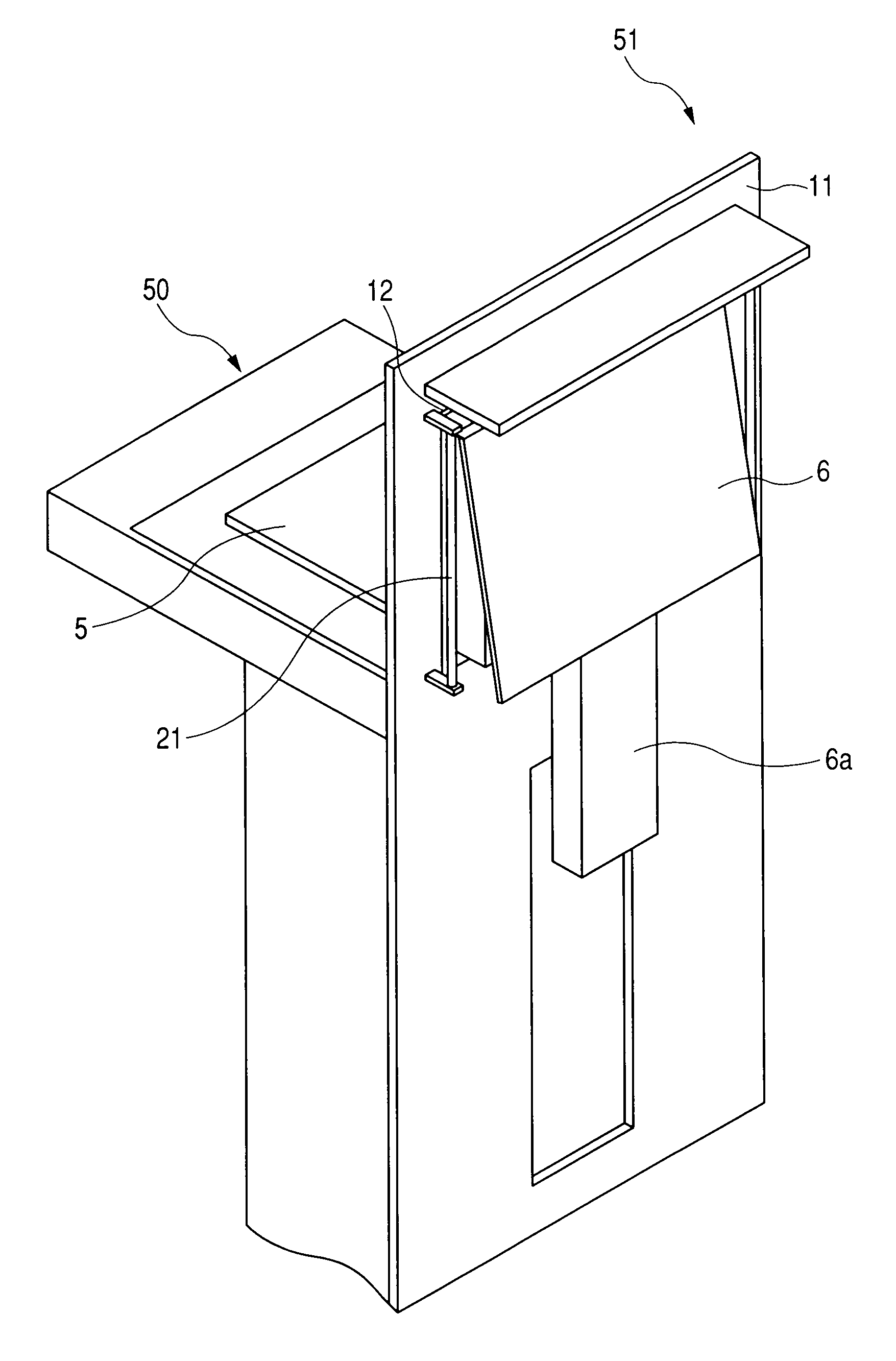

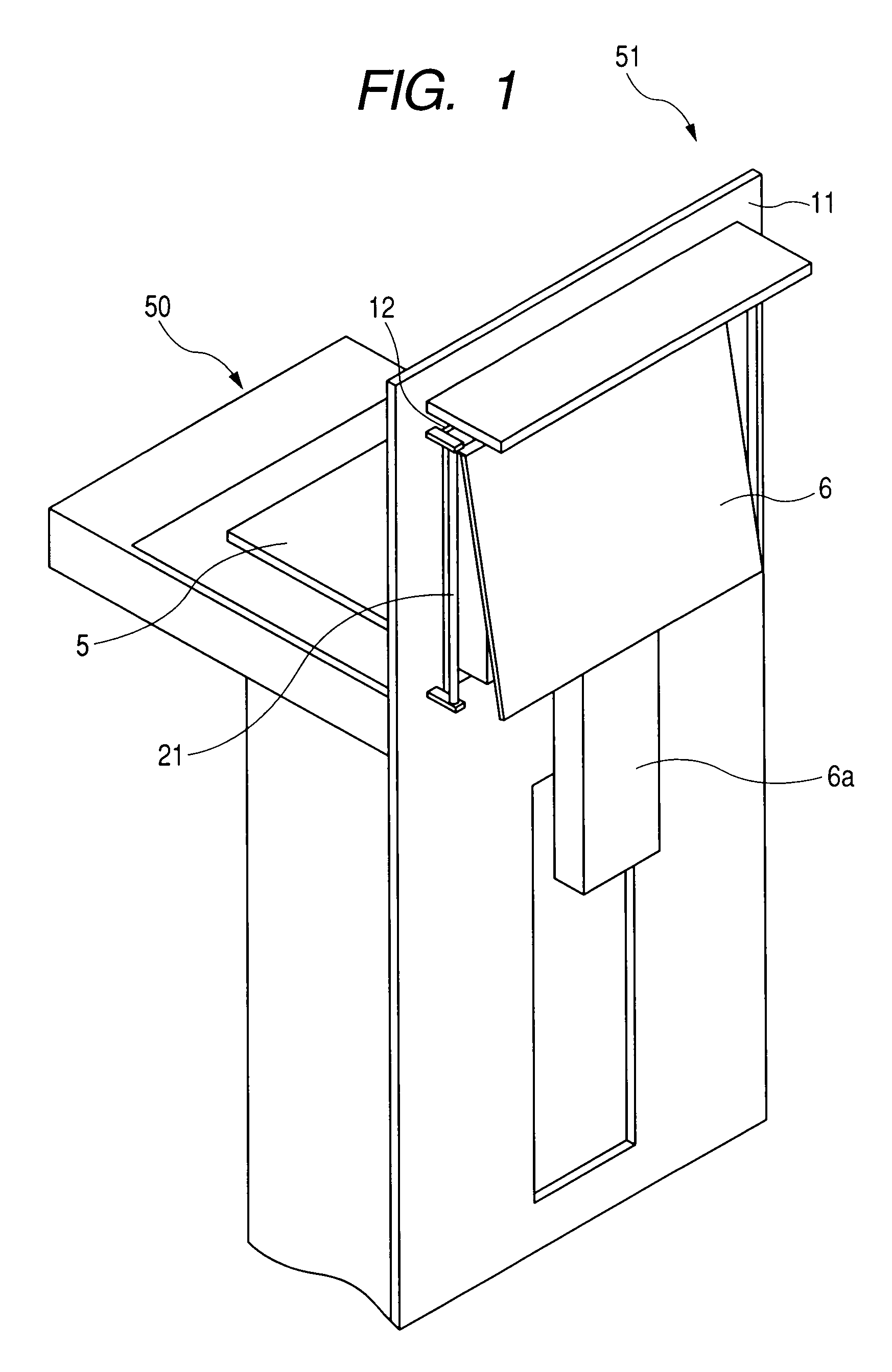

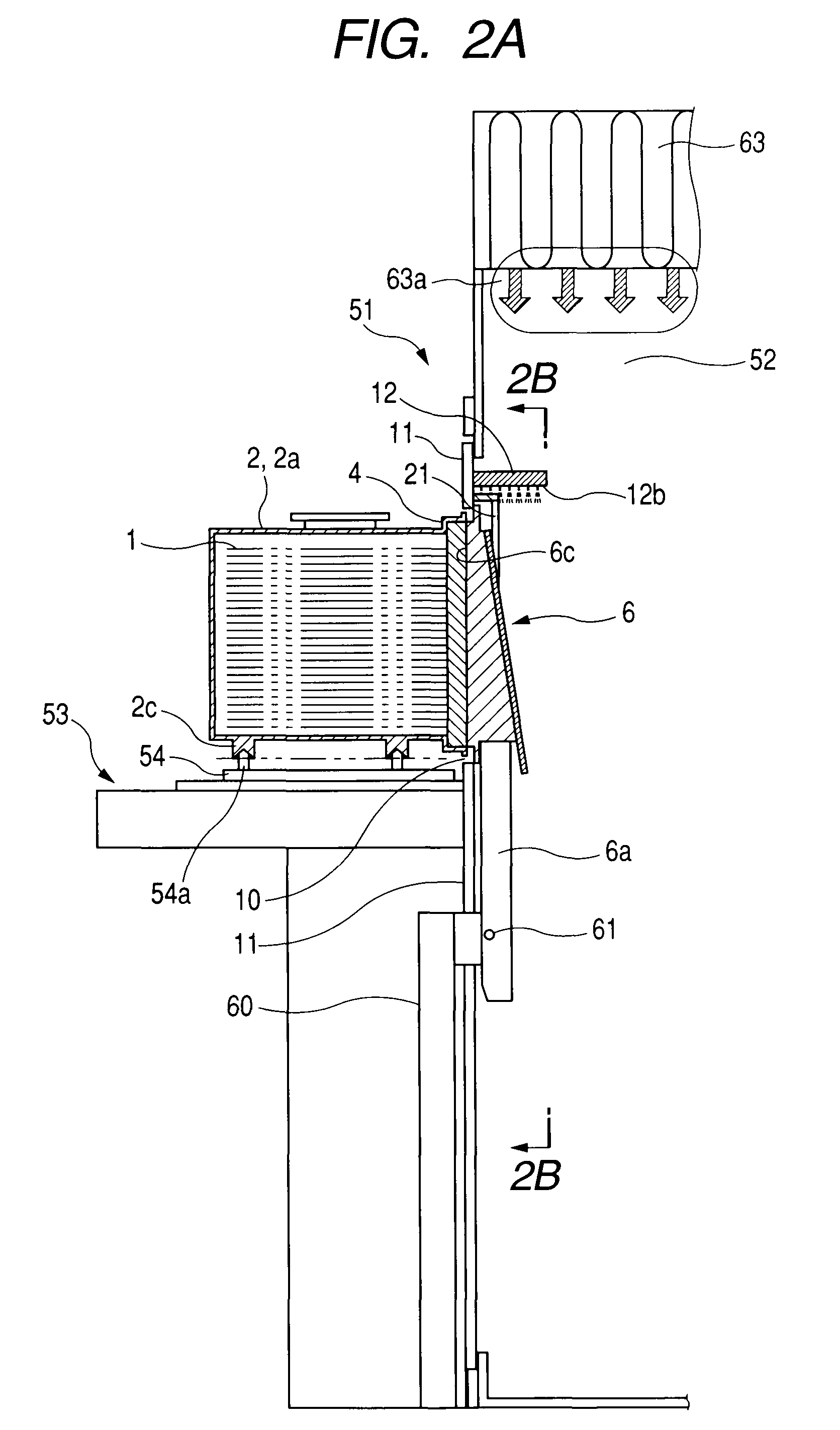

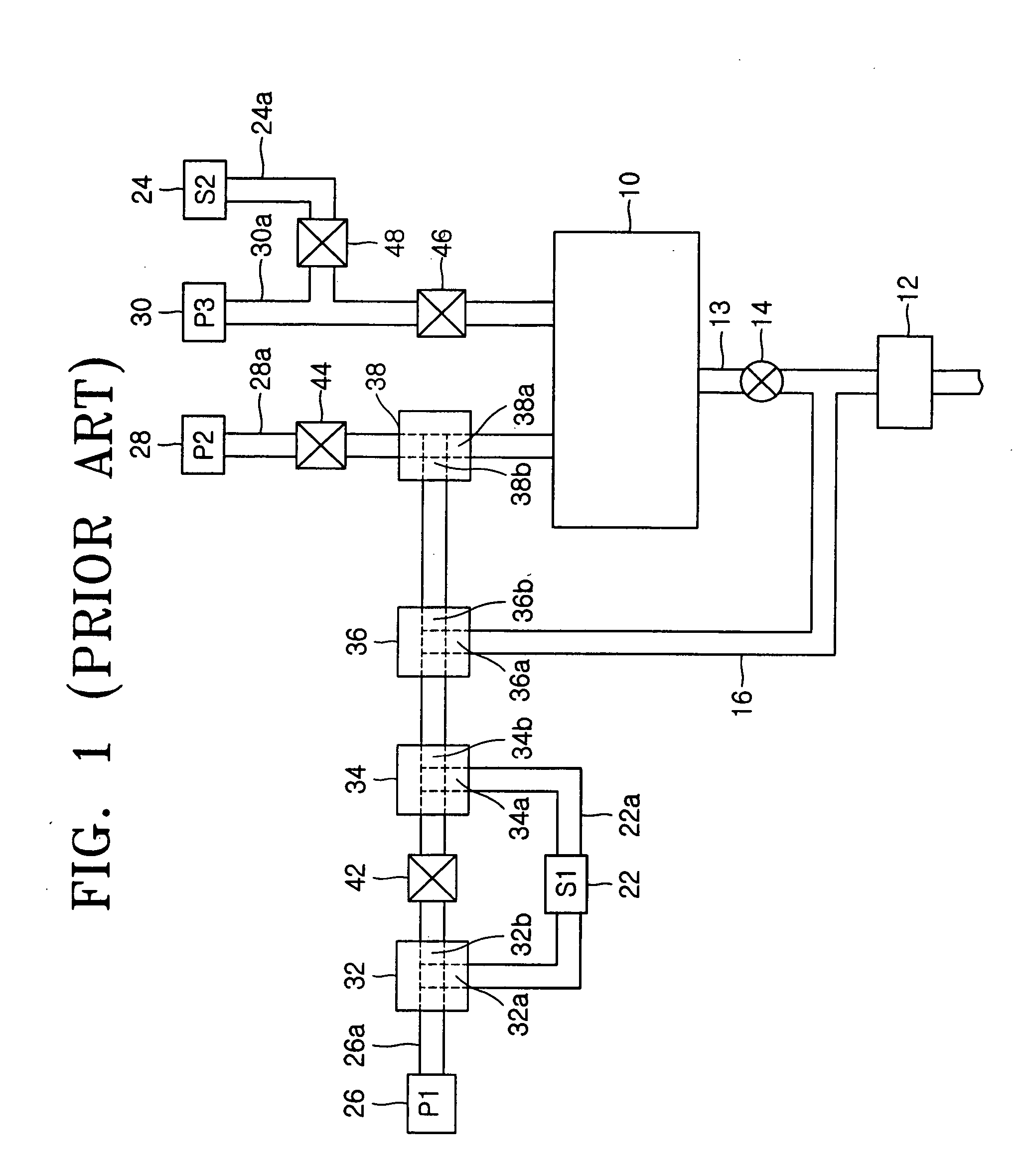

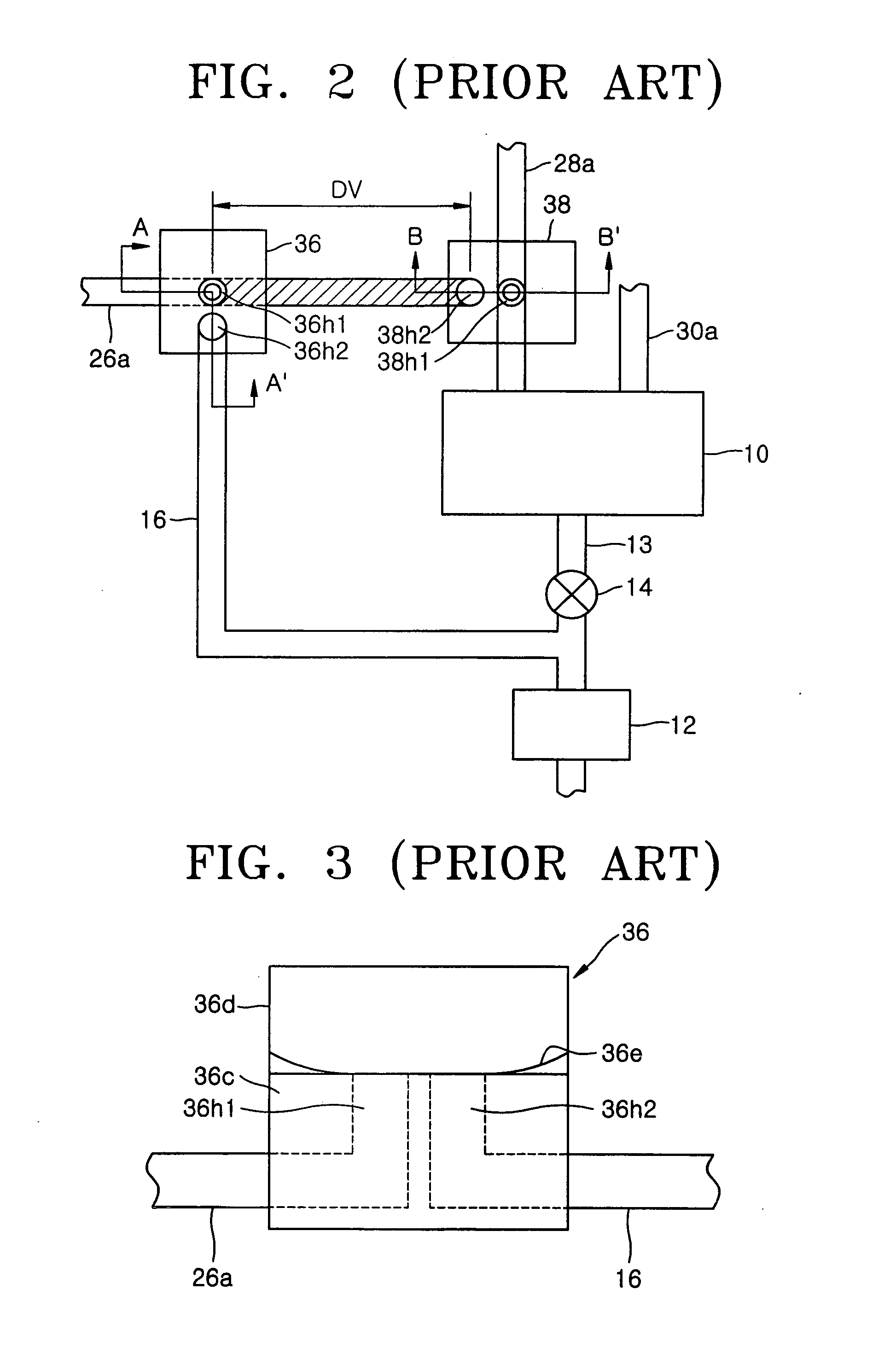

Method of processing an object in a container and lid opening/closing system used in the method

ActiveUS20090035100A1Control is possiblePurge operationLiquid fillingSemiconductor/solid-state device manufacturingGas supplyPartial pressure

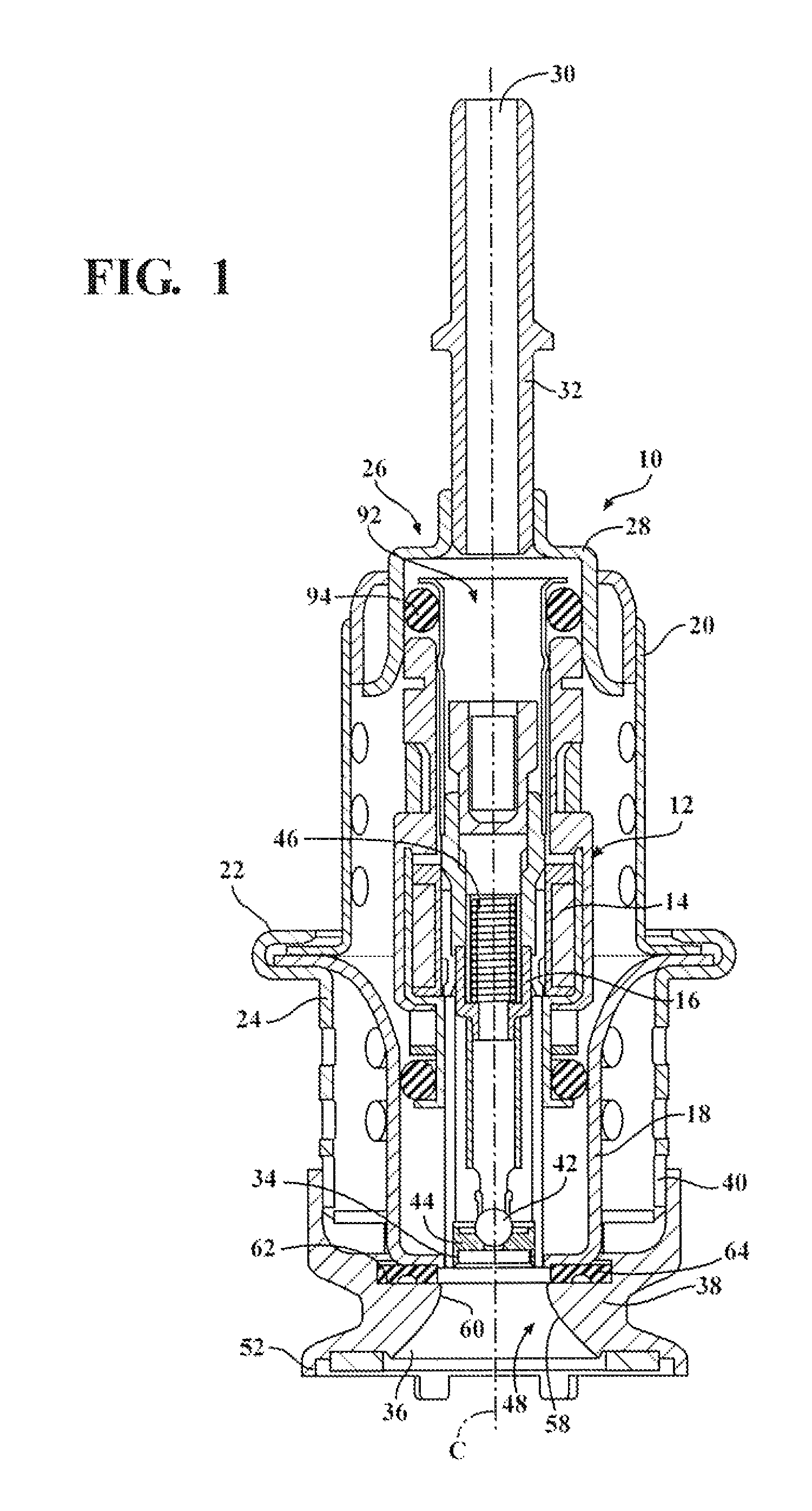

A partial pressure of oxidizing gas in an opened state FOUP fixed in a FIMS system is reduced when the FOUP is closed. Purge gas supply nozzles are placed outside of two vertical sides of an opening portion (10) within the FIMS. A curtain nozzle is additionally installed which can form a gas curtain from purge gas above the top side of the opening portion (10). When a pod (2) is closed with a lid (4), a door opening / closing mechanism keeps the lid (4) at a given angle with respect to the flowing direction of curtain gas for a given period of time, and hence purge gas supplied to the gas curtain is additionally put into use for the purging of the interior of the pod by the lid 4.

Owner:TDK CORPARATION

Method of processing an object in a container and lid opening/closing system used in the method

ActiveUS8302637B2Control is possiblePurge operationLiquid fillingSemiconductor/solid-state device manufacturingEngineeringProduct gas

A partial pressure of oxidizing gas in an opened state FOUP fixed in a FIMS system is reduced when the FOUP is closed. Purge gas supply nozzles are placed outside of two vertical sides of an opening portion (10) within the FIMS. A curtain nozzle is additionally installed which can form a gas curtain from purge gas above the top side of the opening portion (10). When a pod (2) is closed with a lid (4), a door opening / closing mechanism keeps the lid (4) at a given angle with respect to the flowing direction of curtain gas for a given period of time, and hence purge gas supplied to the gas curtain is additionally put into use for the purging of the interior of the pod by the lid 4.

Owner:TDK CORPARATION

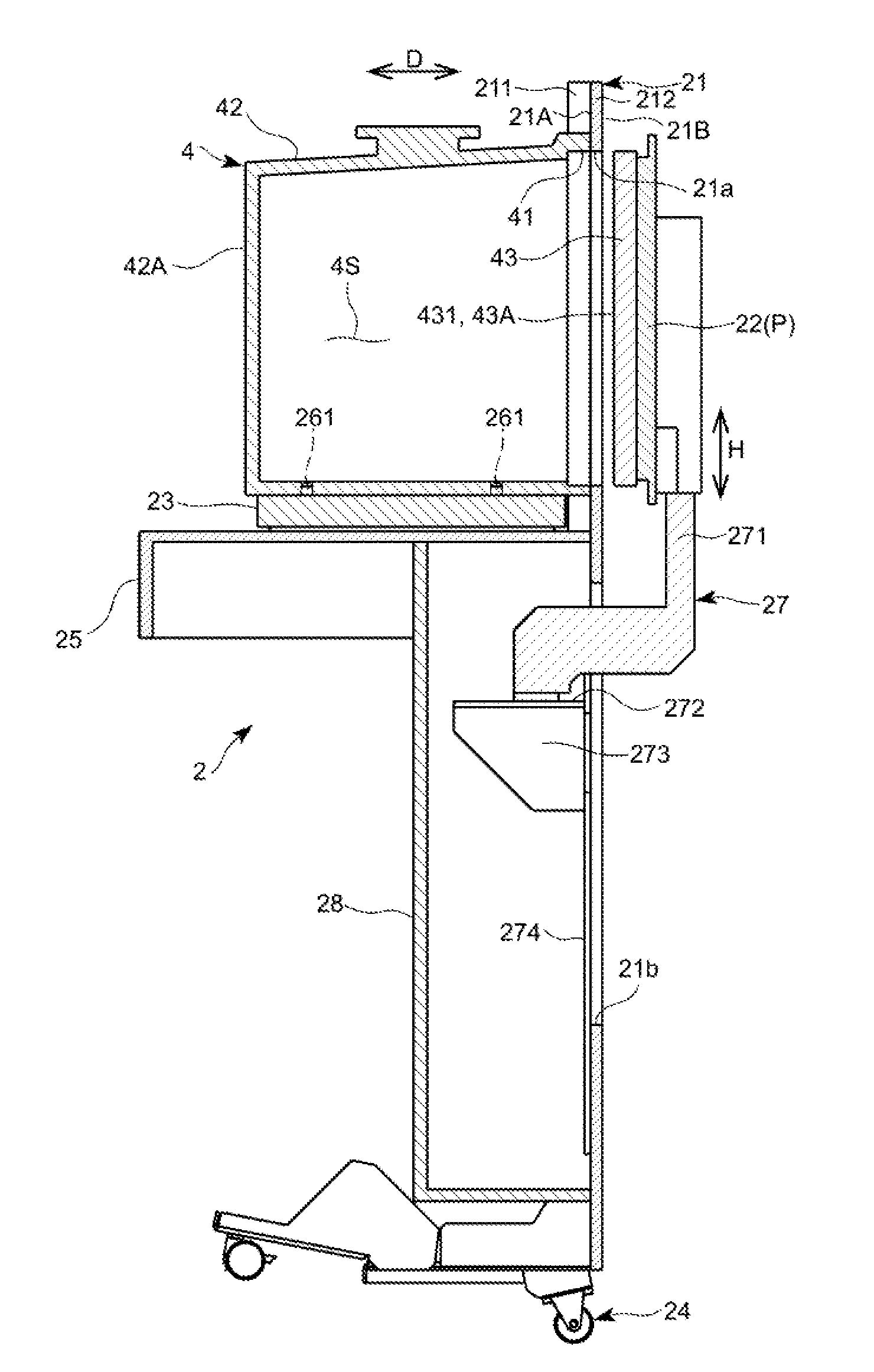

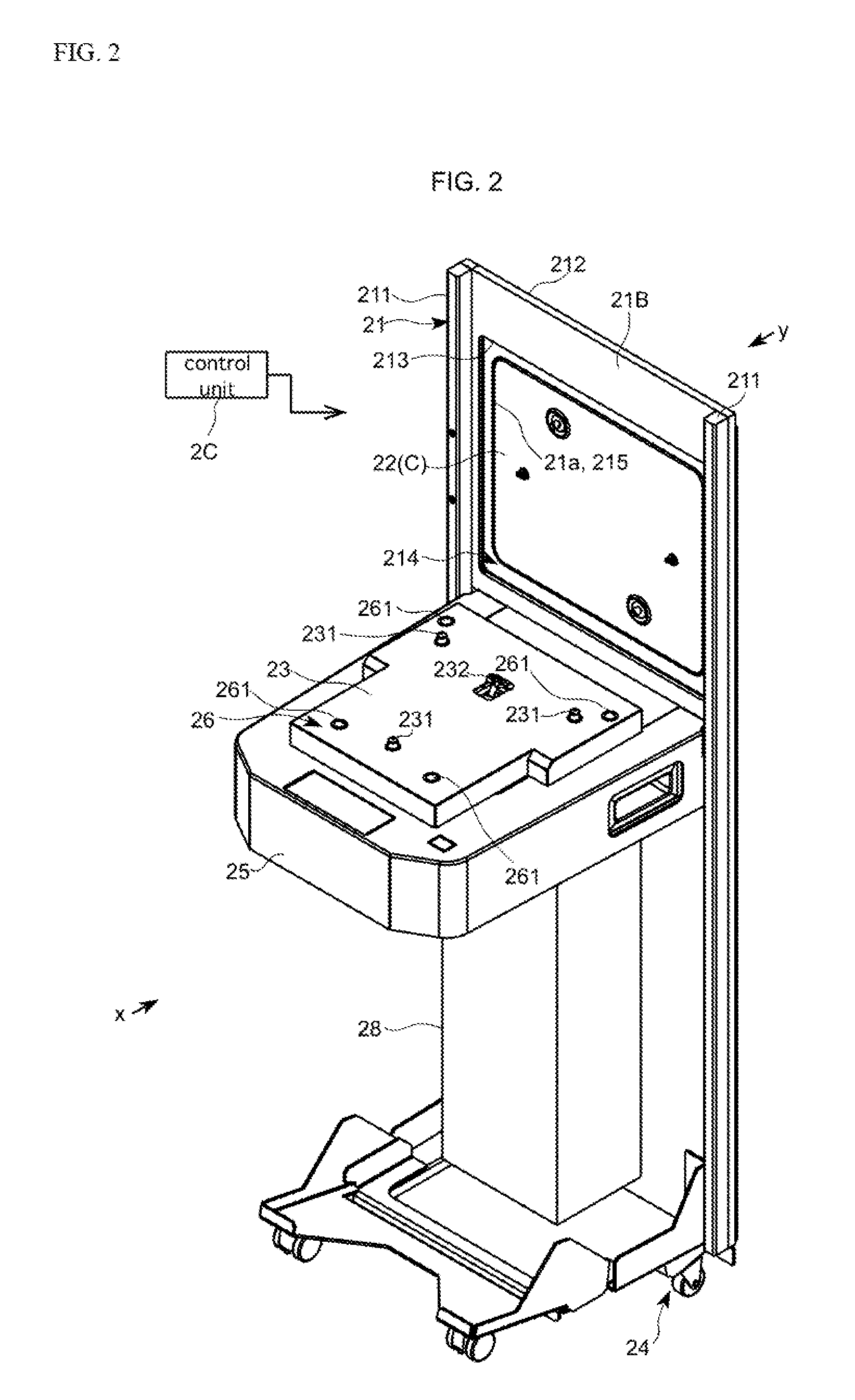

Door opening and closing apparatus

InactiveUS20160260628A1Improve purge efficiencyIncrease costSemiconductor/solid-state device manufacturingPower-operated mechanismEngineeringMechanical engineering

A door opening and closing apparatus shifts a door part holding a lid part of a storage container between a totally closed position where the inner space of the storage container body is sealed and a totally open position where the inner space of the storage container body is totally opened frontward, for putting in and taking out transfer target objects between the storage container and a transfer room. The door opening and closing apparatus puts the door part on standby at the predetermined halfway stop position every time a single access operation of a transfer robot to the storage container ends and until next access operation of the transfer robot to the storage container is performed.

Owner:SINFONIA TECHNOLOGY CO LTD

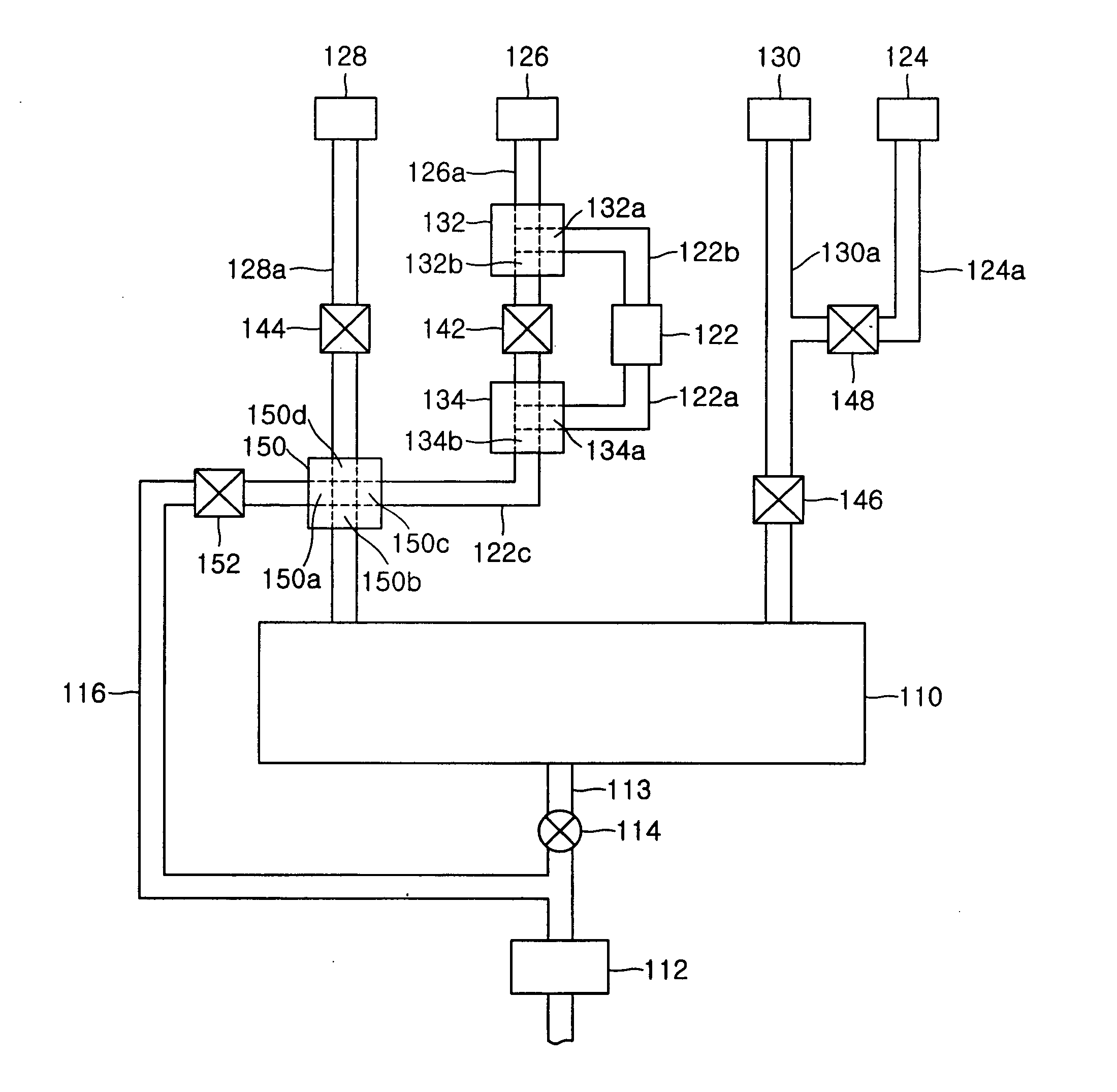

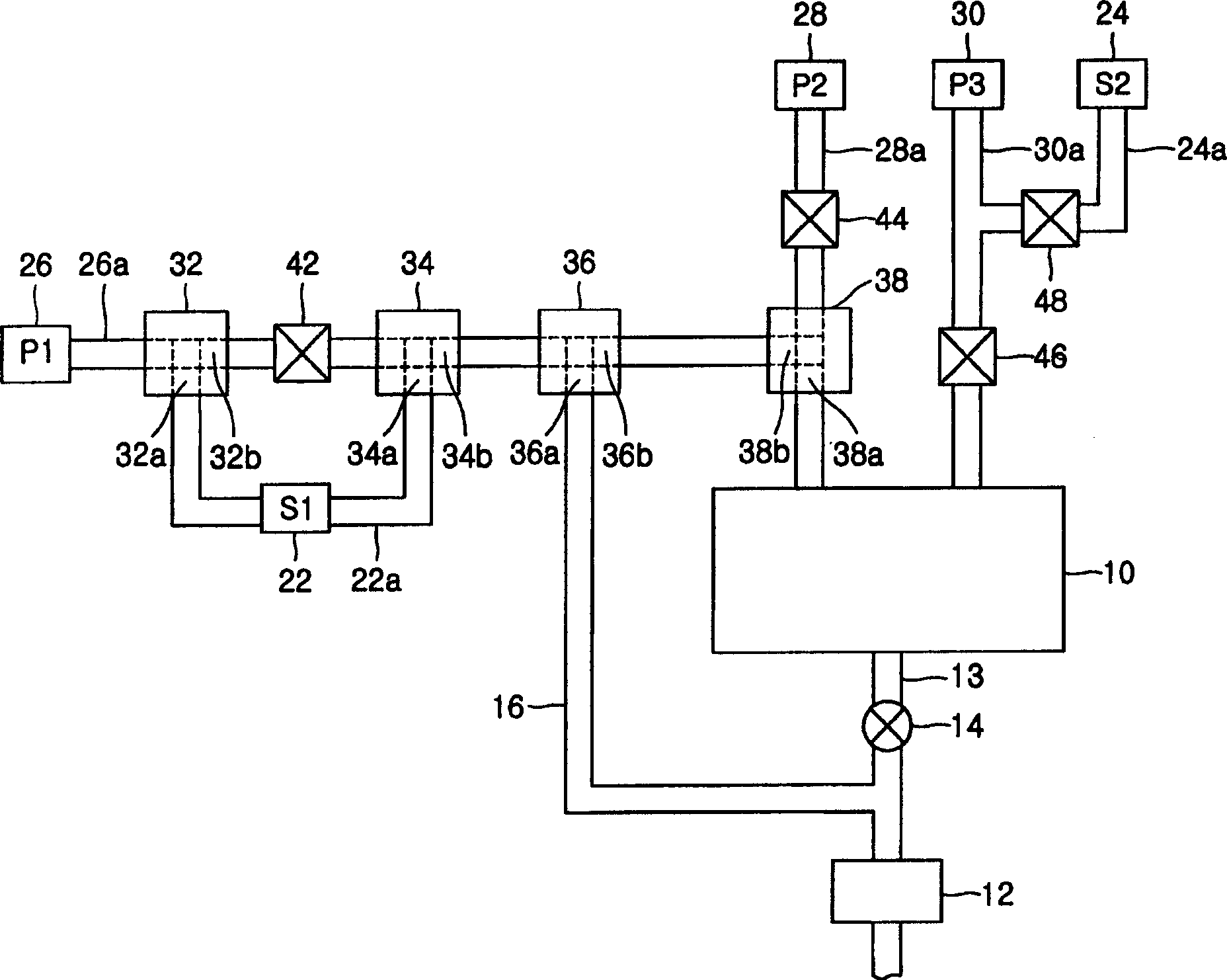

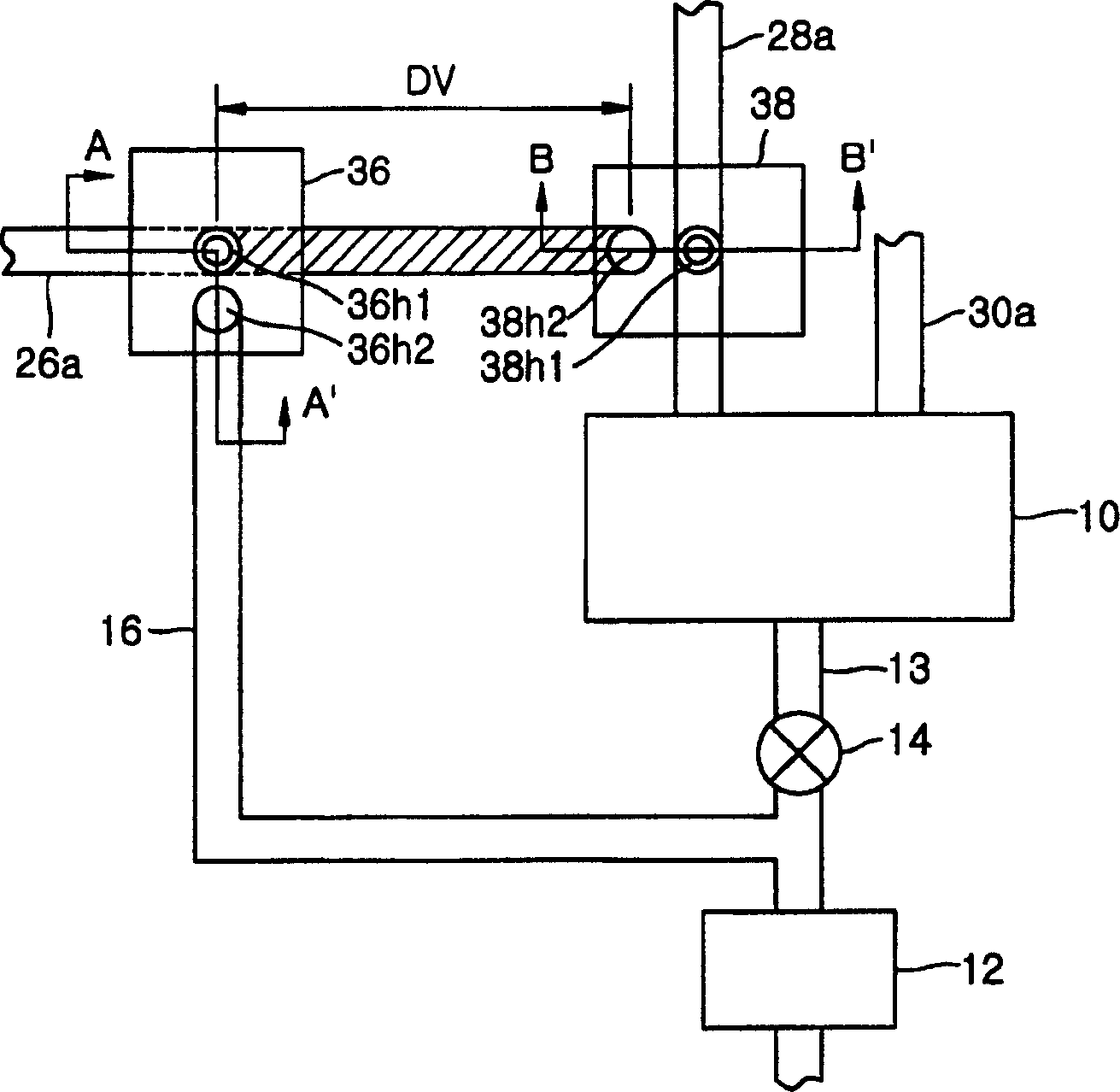

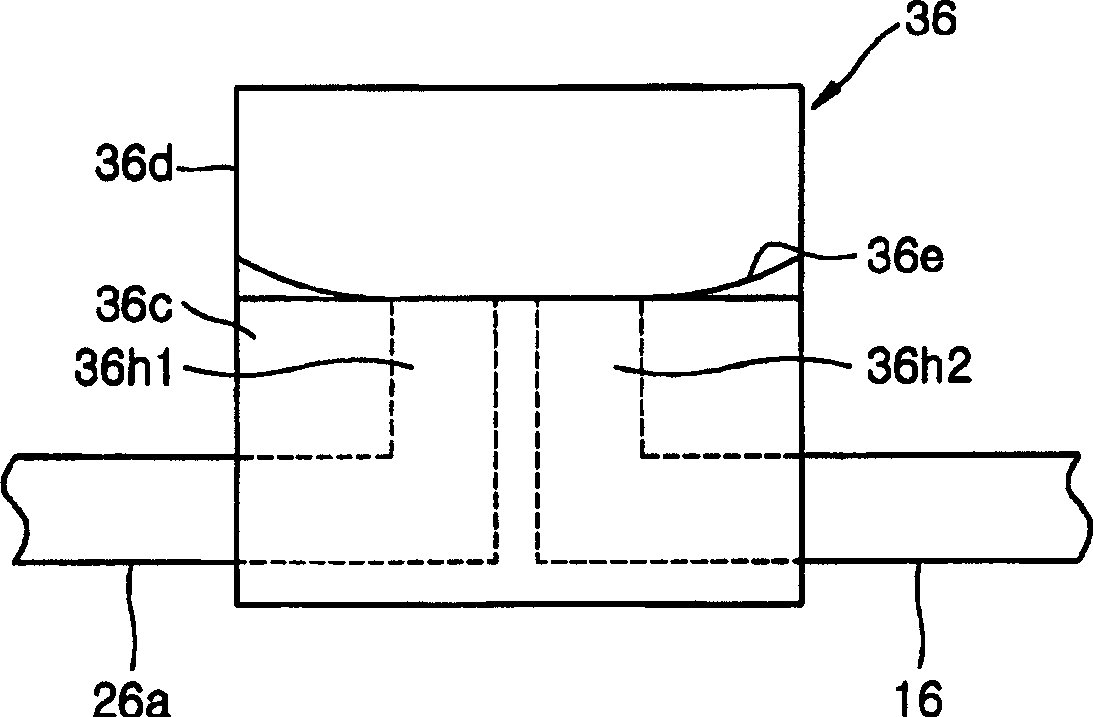

Apparatus including 4-way valve for fabricating semiconductor device, method of controlling valve, and method of fabricating semiconductor device using the apparatus

InactiveUS20060156980A1Improve purge efficiencyAvoid dead volumeDecorative surface effectsSemiconductor/solid-state device manufacturingFour-way valveDevice material

An apparatus and method for fabricating a semiconductor device using a 4-way valve with improved purge efficiency by improving a gas valve system by preventing dead volume from occurring are provided. The apparatus includes a reaction chamber in which a substrate is processed to fabricate a semiconductor device; a first processing gas supply pipe supplying a first processing gas into the reaction chamber; a 4-way valve having a first inlet, a second inlet, a first outlet, and a second outlet and installed at the first processing gas supply pipe such that the first inlet and the first outlet are connected to the first processing gas supply pipe; a second processing gas supply pipe connected to the second inlet of the 4-way valve to supply a second processing gas; a bypass connected to the second outlet of the 4-way valve; and a gate valve installed at the bypass.

Owner:SAMSUNG ELECTRONICS CO LTD +1

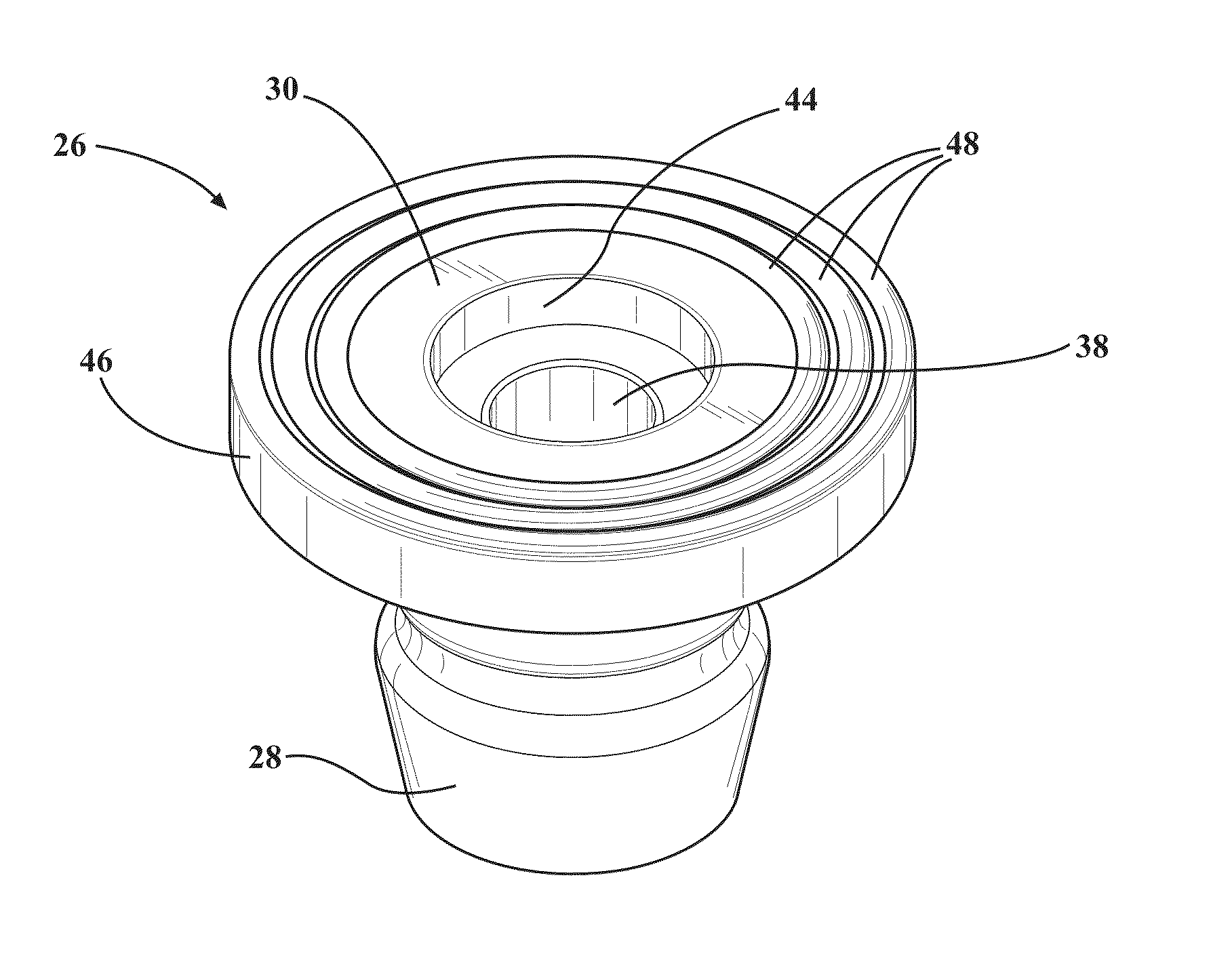

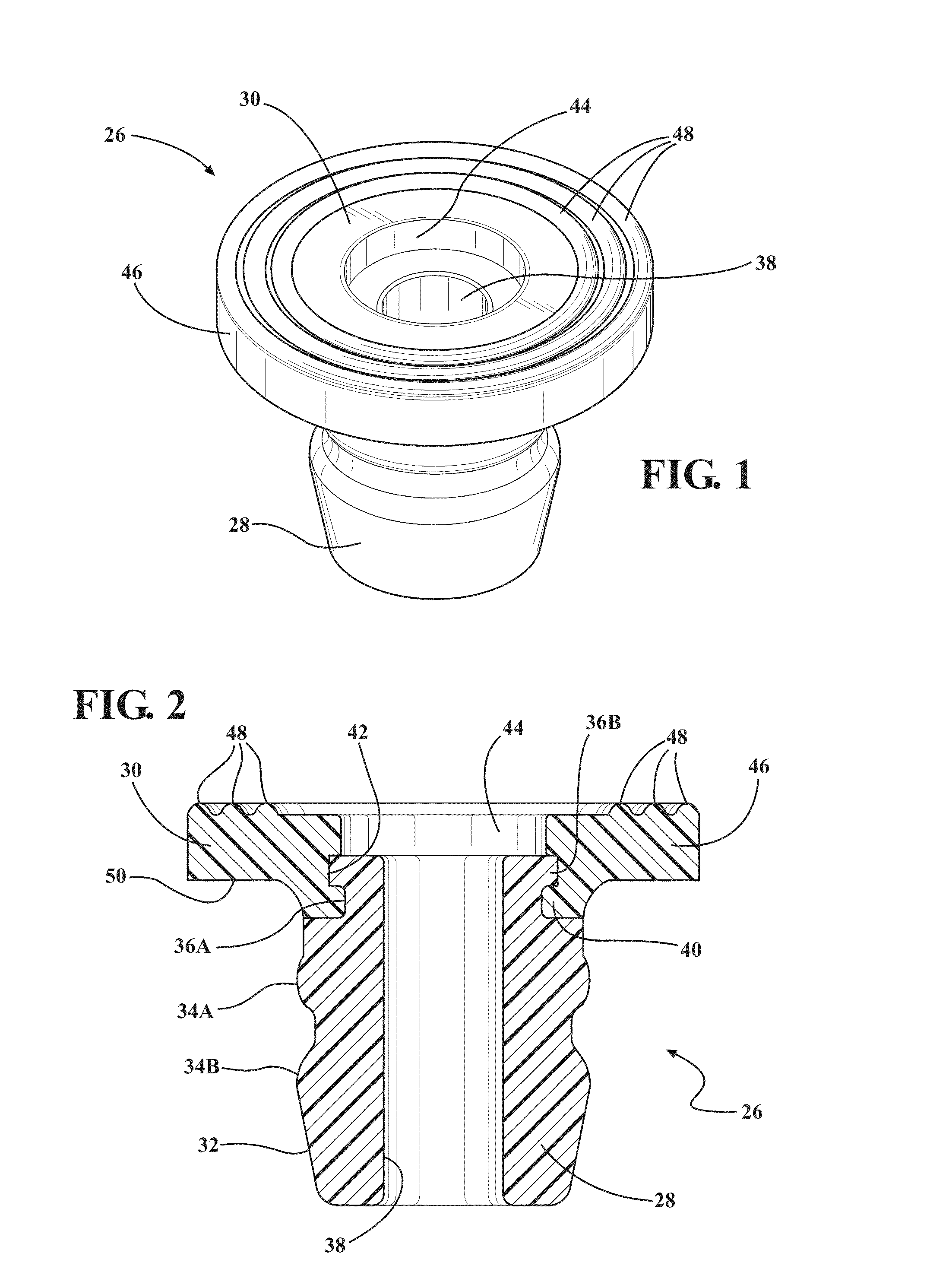

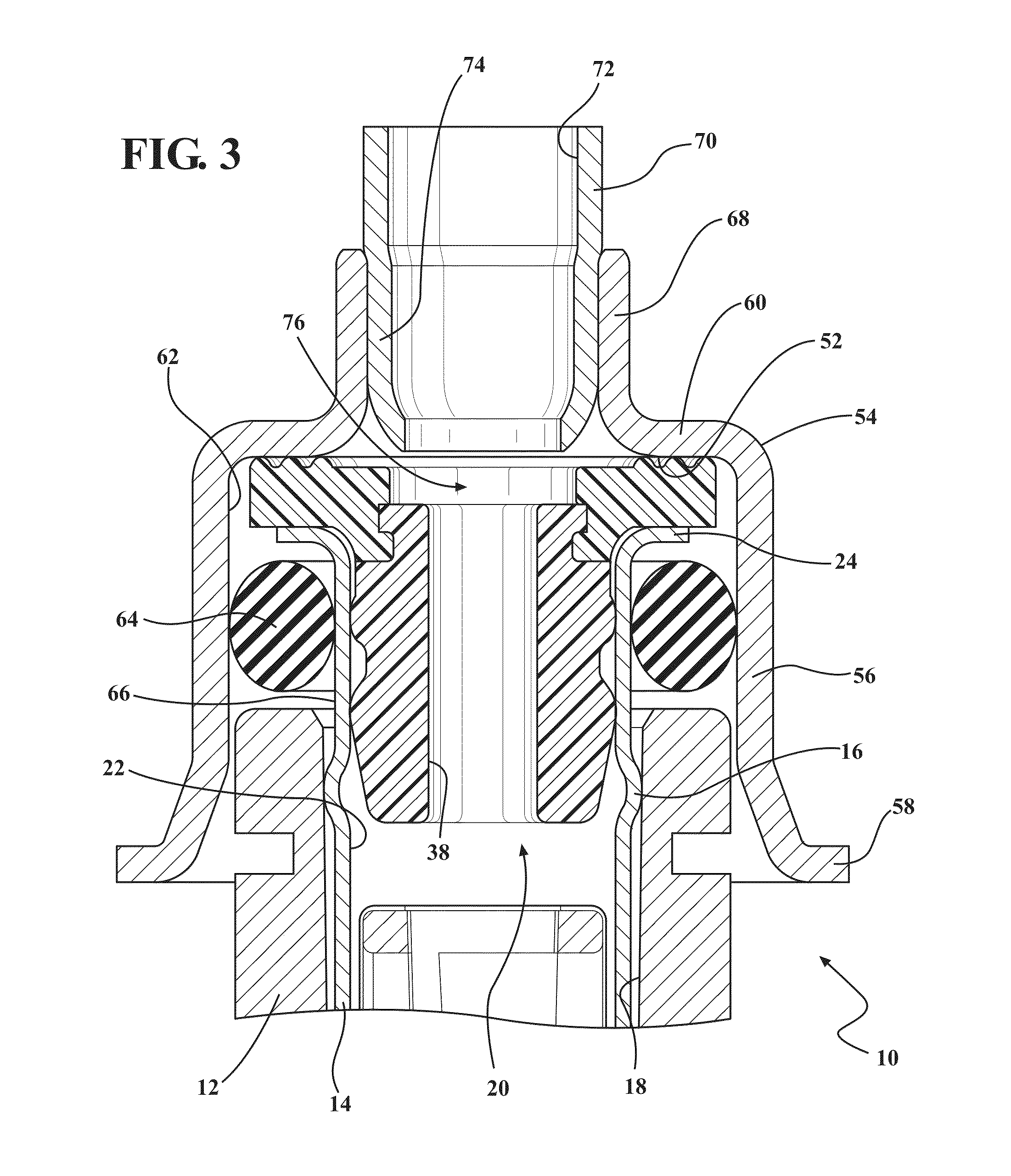

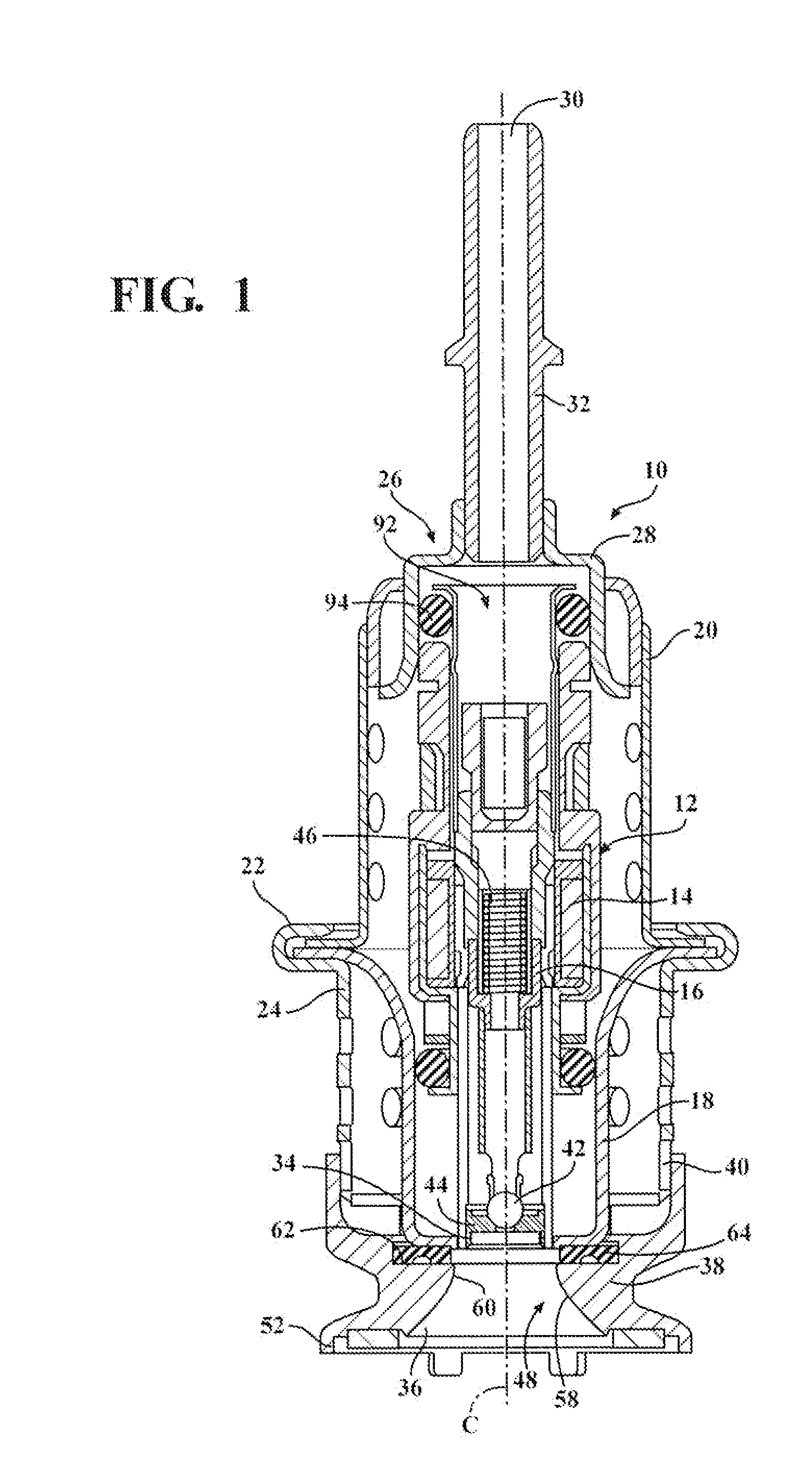

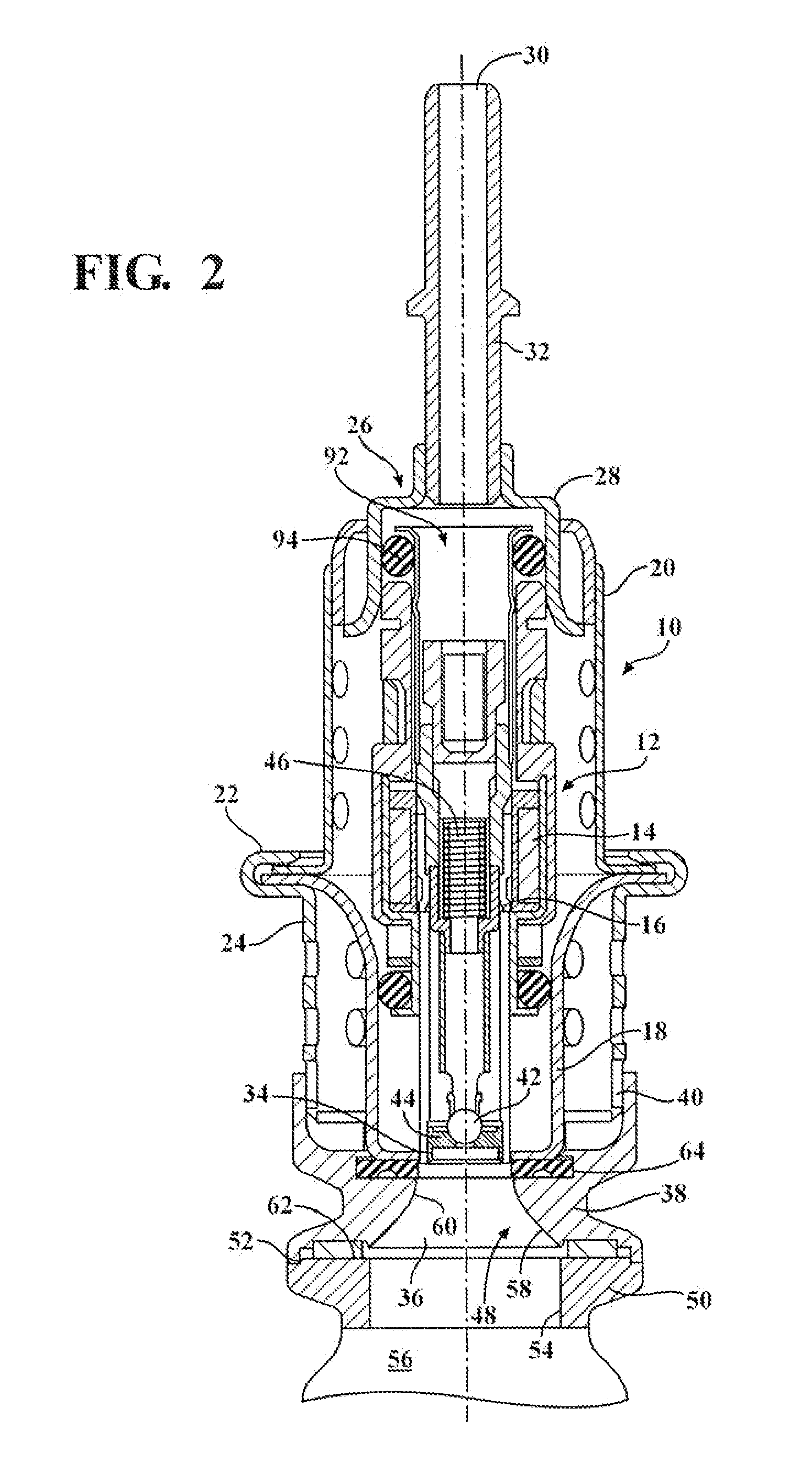

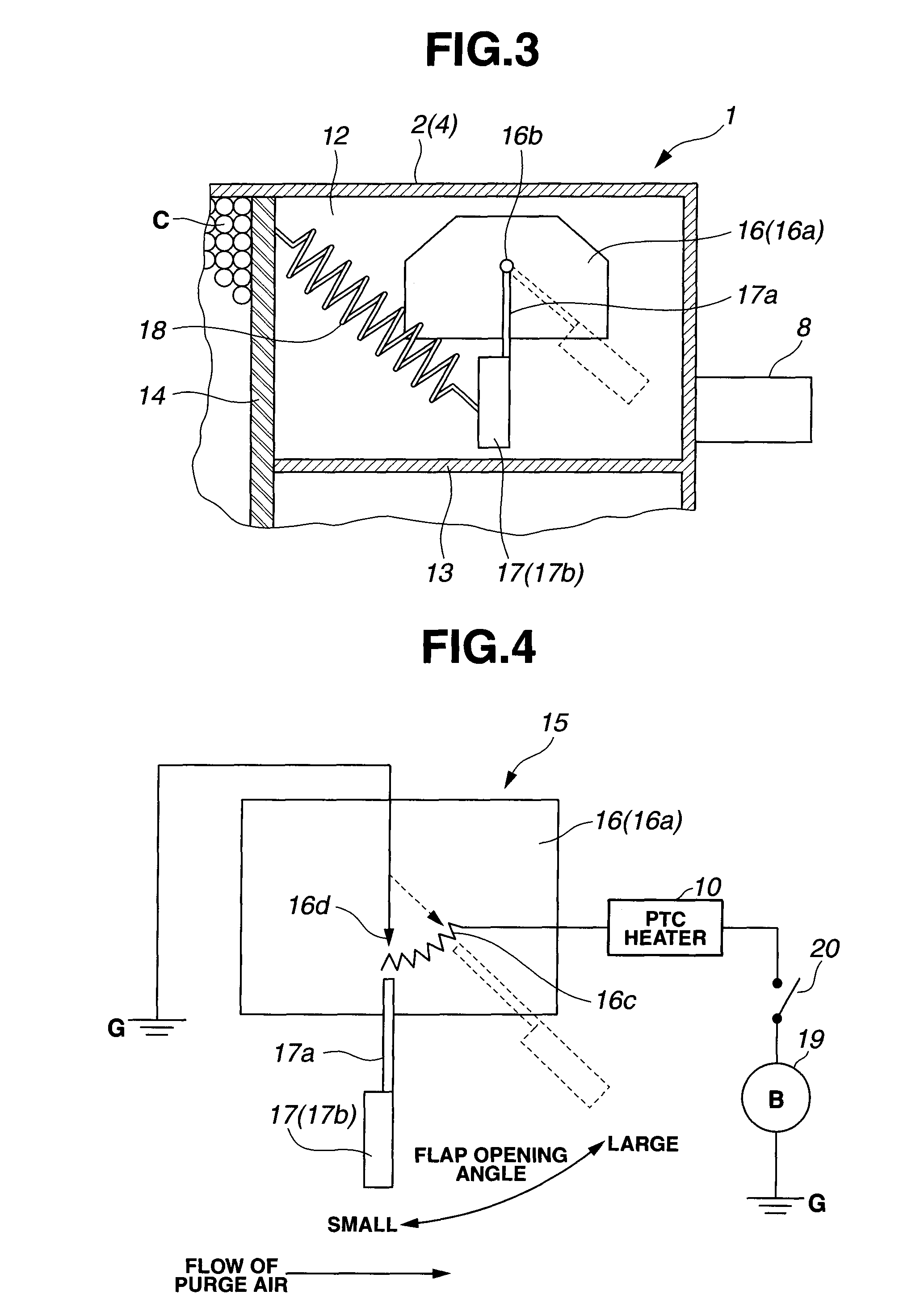

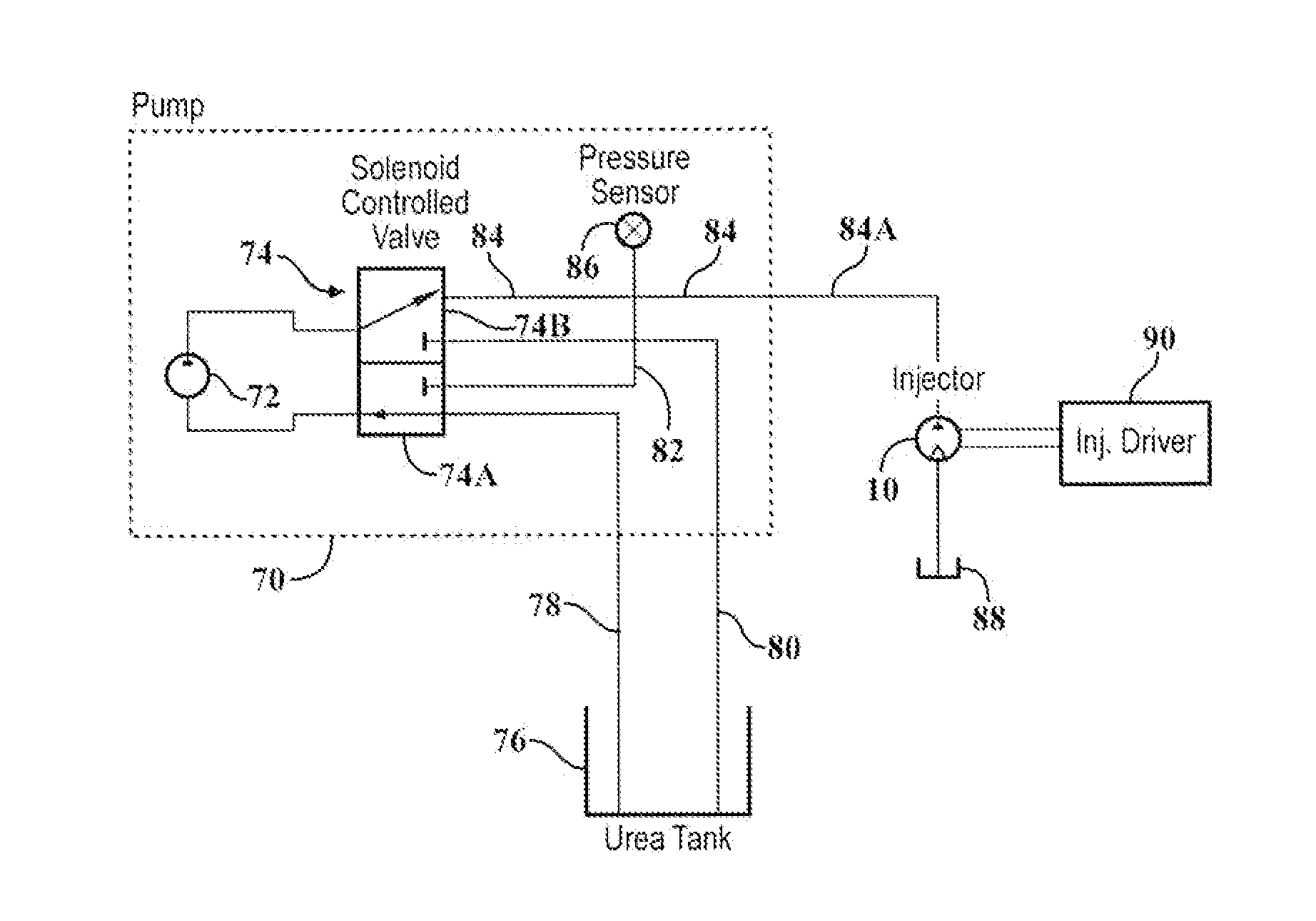

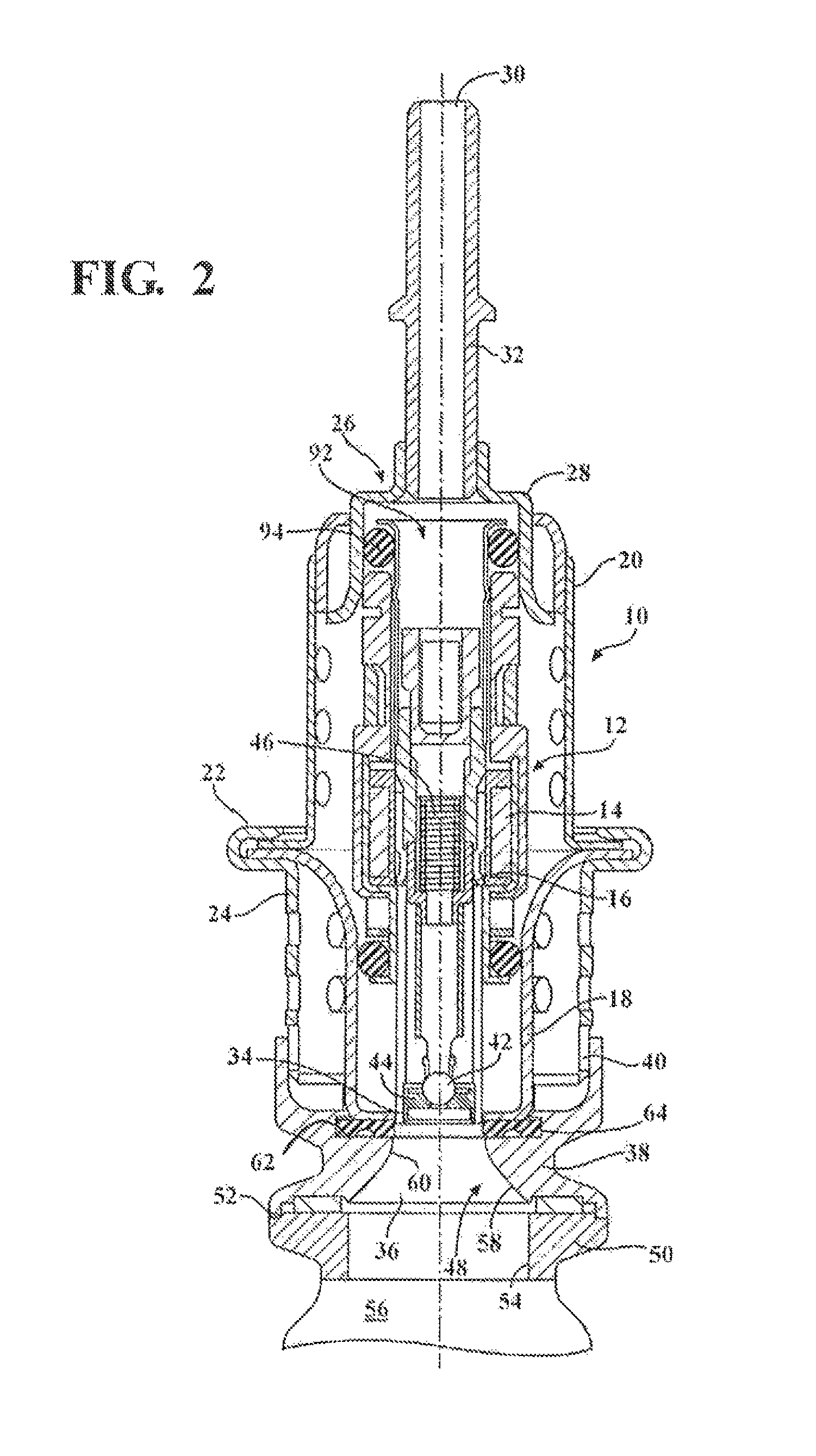

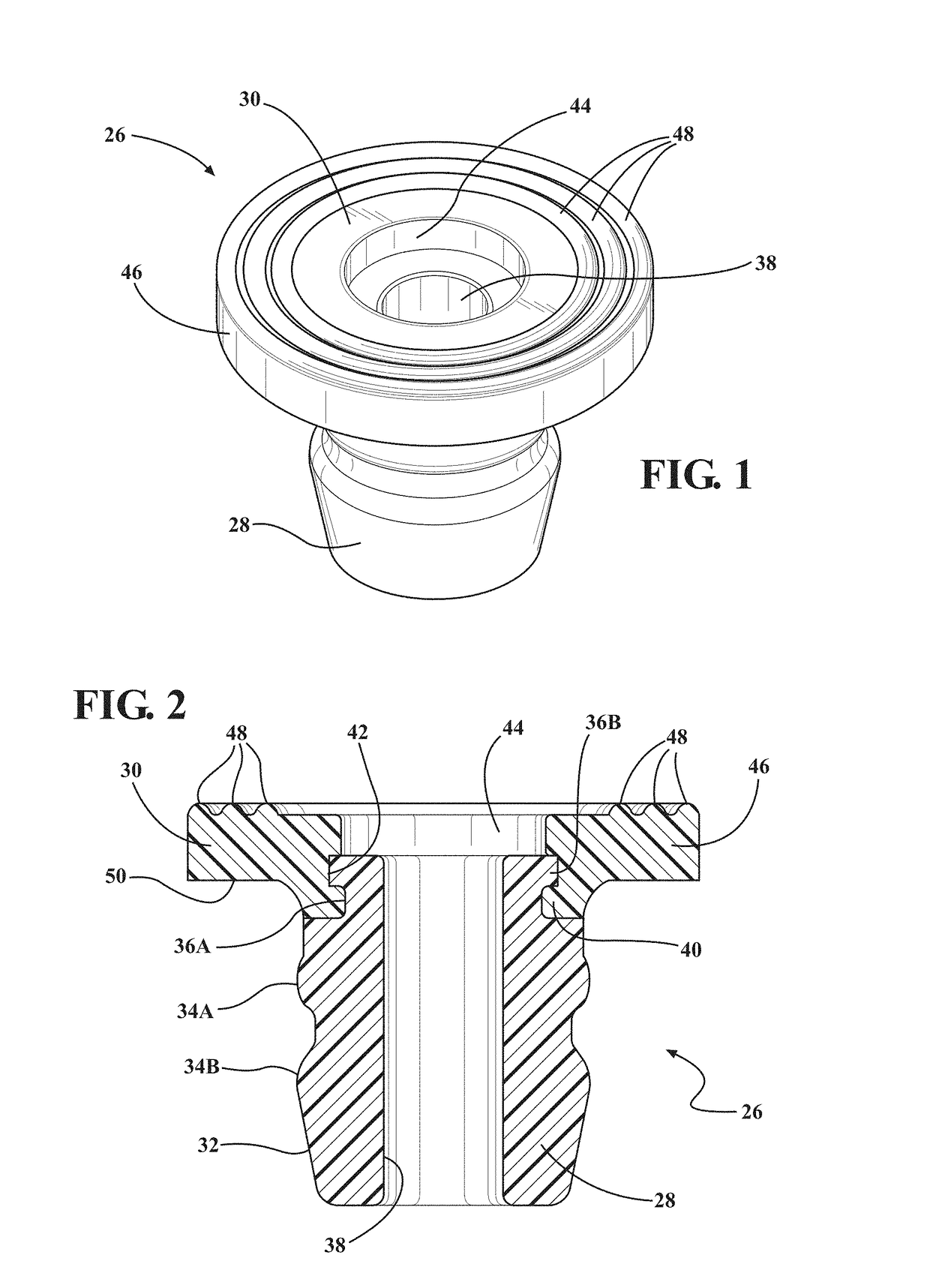

Purging and sealing - reductant delivery unit for selective catalytic reduction systems

ActiveUS20140138568A1Improve purge efficiencyImprove sealingInternal combustion piston enginesExhaust apparatusExhaust gasInjector

A sealing device which is used as part of an injector in a reductant delivery unit (RDU), where the RDU is part of a selective catalytic reduction (SCR) system for injecting diesel exhaust fluid (DEF) into an exhaust system, used for controlling exhaust emissions. This invention improves the purging efficiency of the RDU, in addition to improving the sealing performance of the unit by reducing the fluid volume to be evacuated from the injector, and provides an additional sealing barrier to reduce the sealing load of the existing sealing elements. An additional sealing device having a ring seal and a stopper element (also referred to as a “plug”) is pressed into the upper valve body of the injector, which results in a reduced fluid volume that is left behind after a purging event, due to the reduced initial volume at the beginning of the purge.

Owner:VITESCO TECH USA LLC

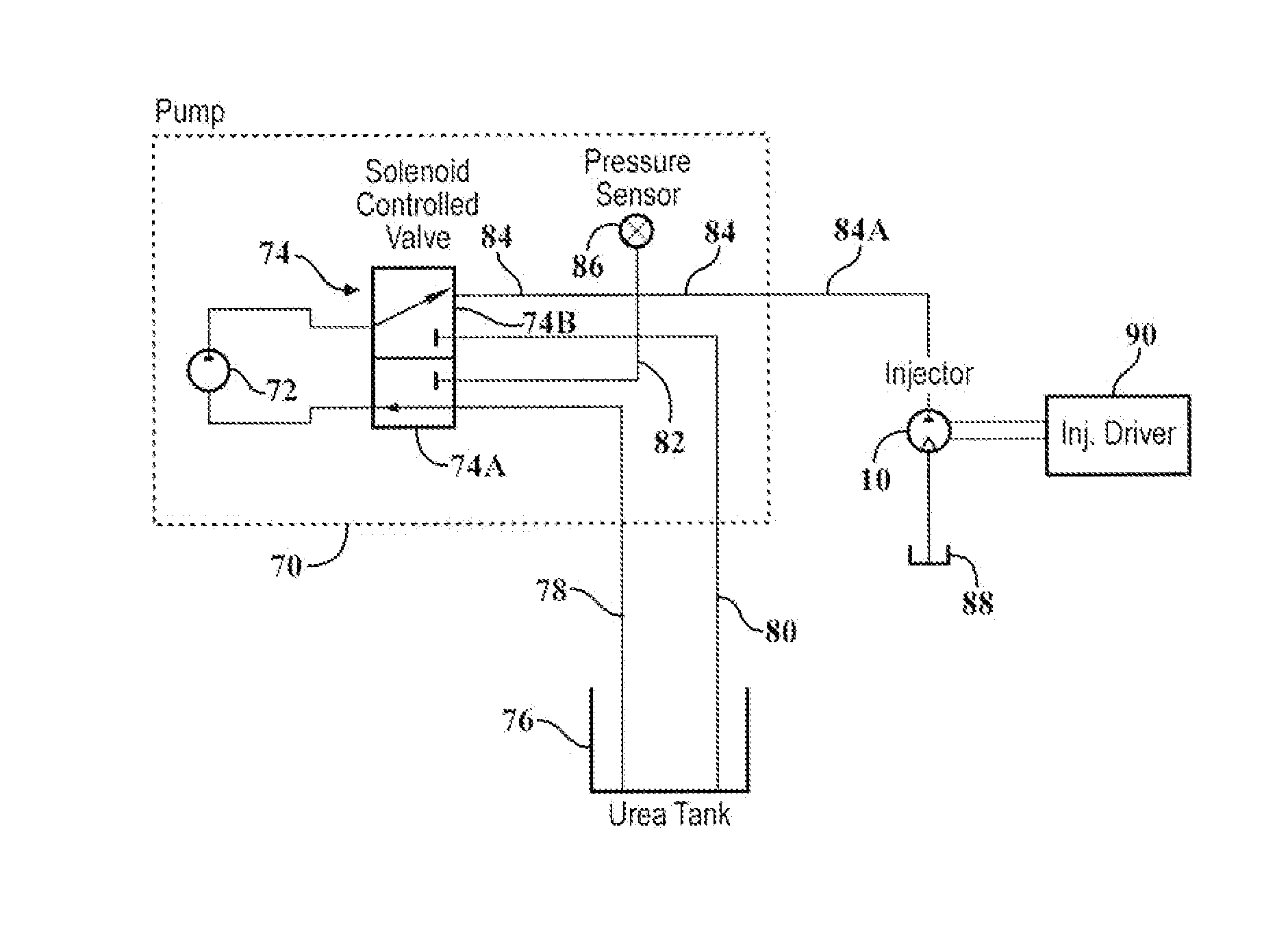

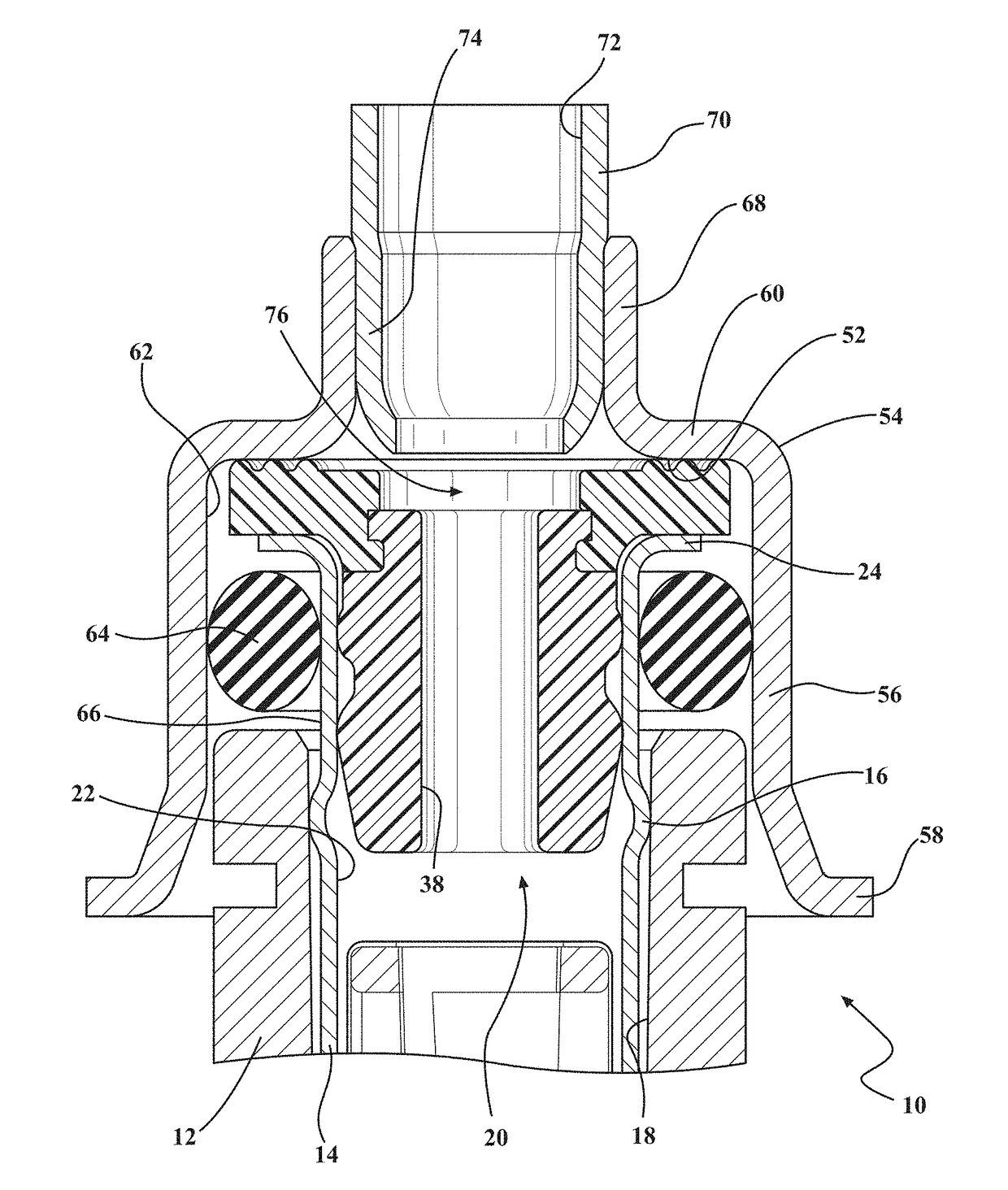

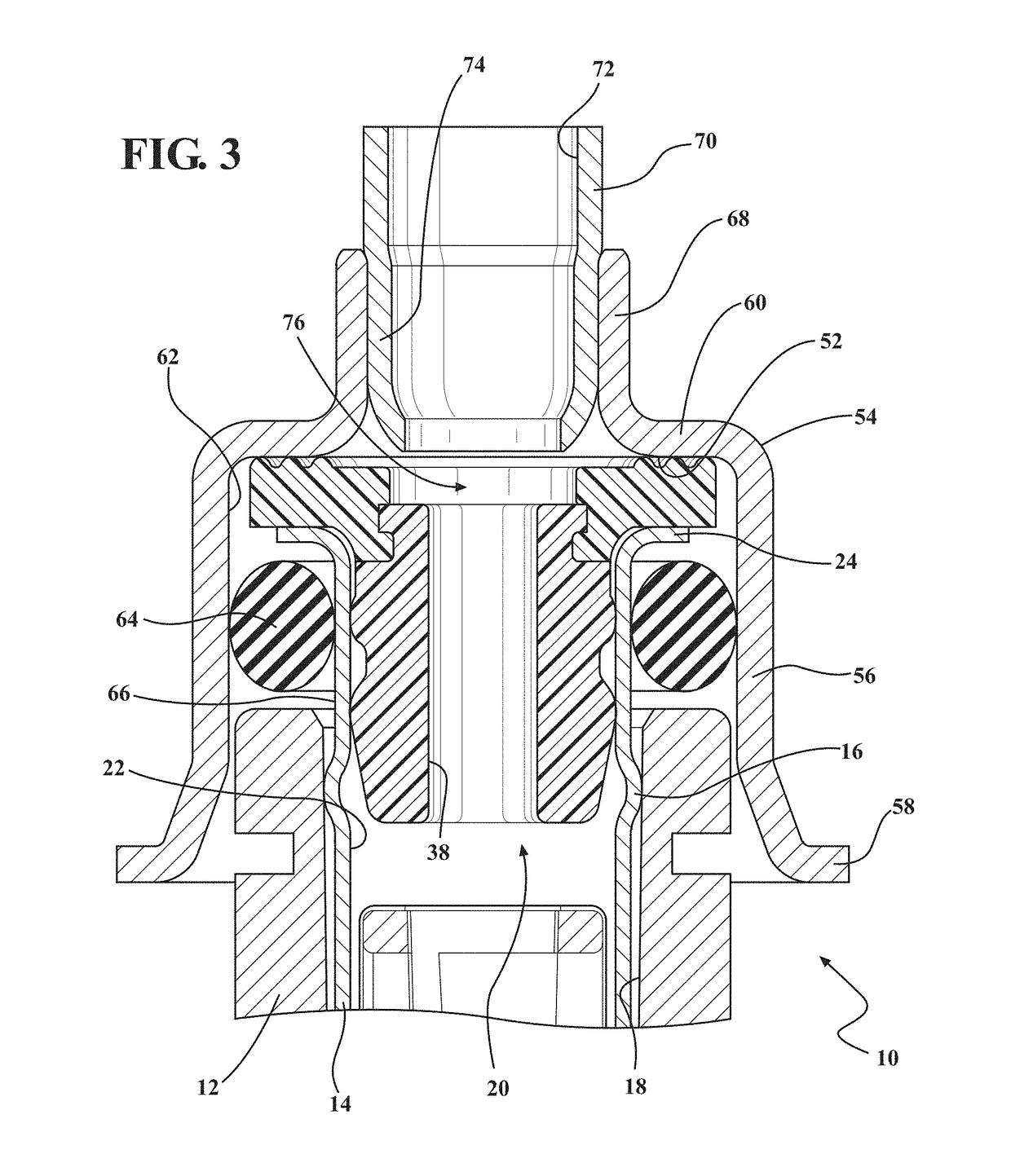

Purge system for reductant delivery unit for a selective catalytic reduction system

ActiveUS20150115051A1Maximize fluid volumeReduce sealing load of sealingInternal combustion piston enginesExhaust apparatusExhaust fumesAmbient pressure

A purge procedure which is part of an injector, that may be used as part of a reductant delivery unit (RDU), where the RDU is part of a selective catalytic reduction system for injecting diesel exhaust fluid into an exhaust system, to control exhaust emissions. The RDU delivers a reductant carrier to the engine exhaust system. The purge process includes a control strategy to improve the quality of the purge cycle (i.e., increase the amount of fluid evacuated). The sequence of the purge event is adjusted in order to generate a strong vacuum in the fluid supply line and the injector—this enhances the efficiency of the purge by increasing the initial flow rates through the injector. However, upon opening the injector, the pressure inside the fluid path increases to a level just below the ambient pressure outside the injector, therefore the gas flow rate is substantially reduced.

Owner:VITESCO TECH USA LLC

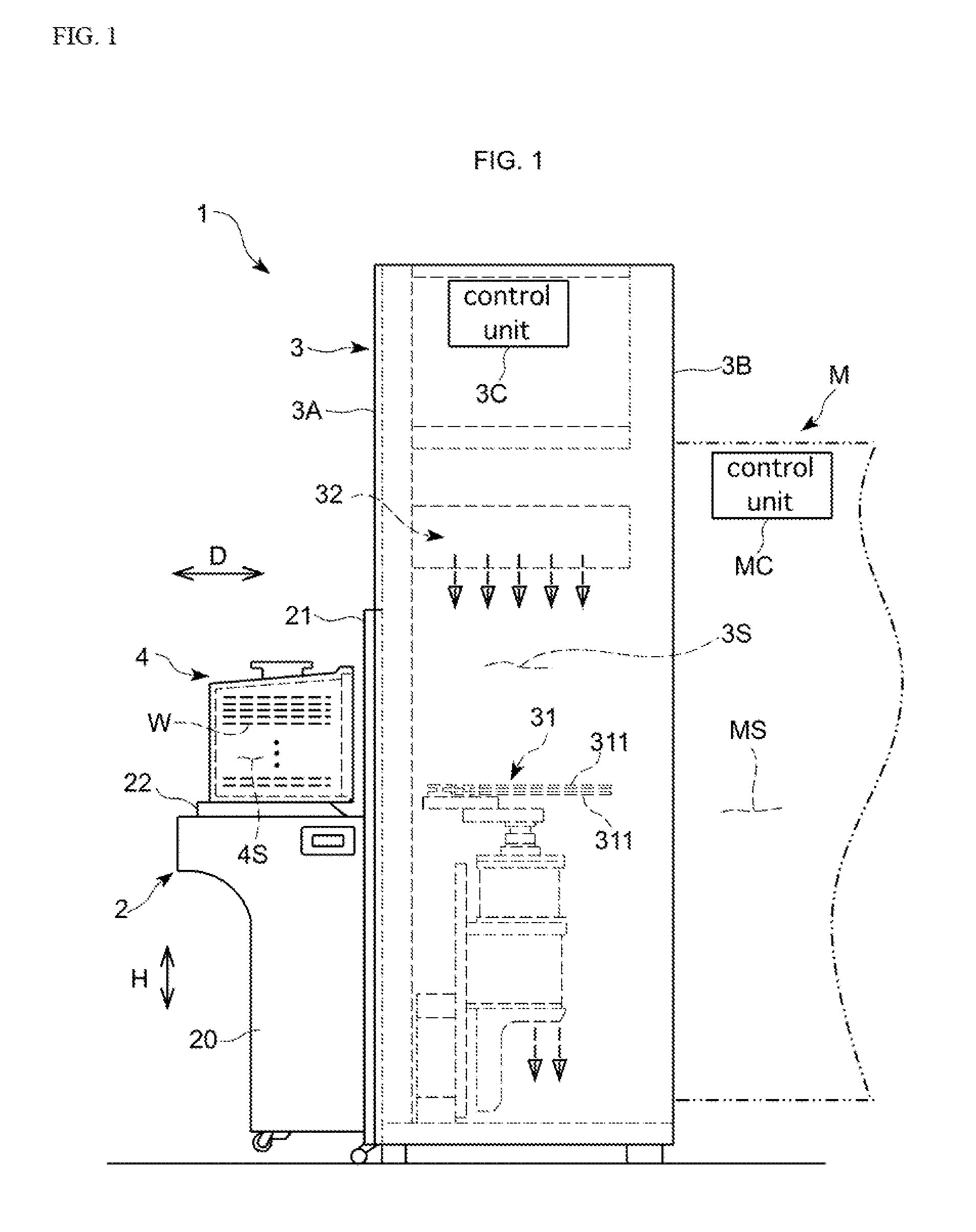

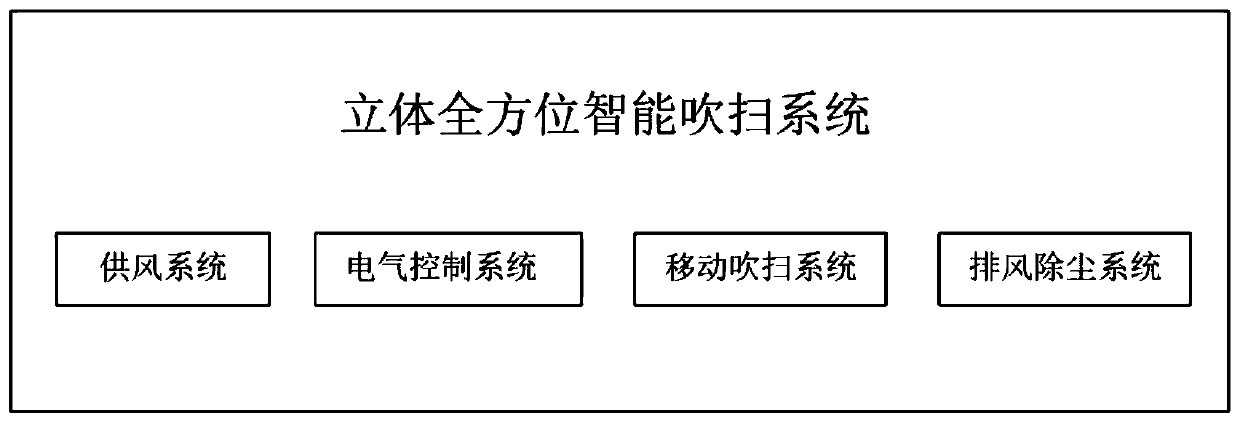

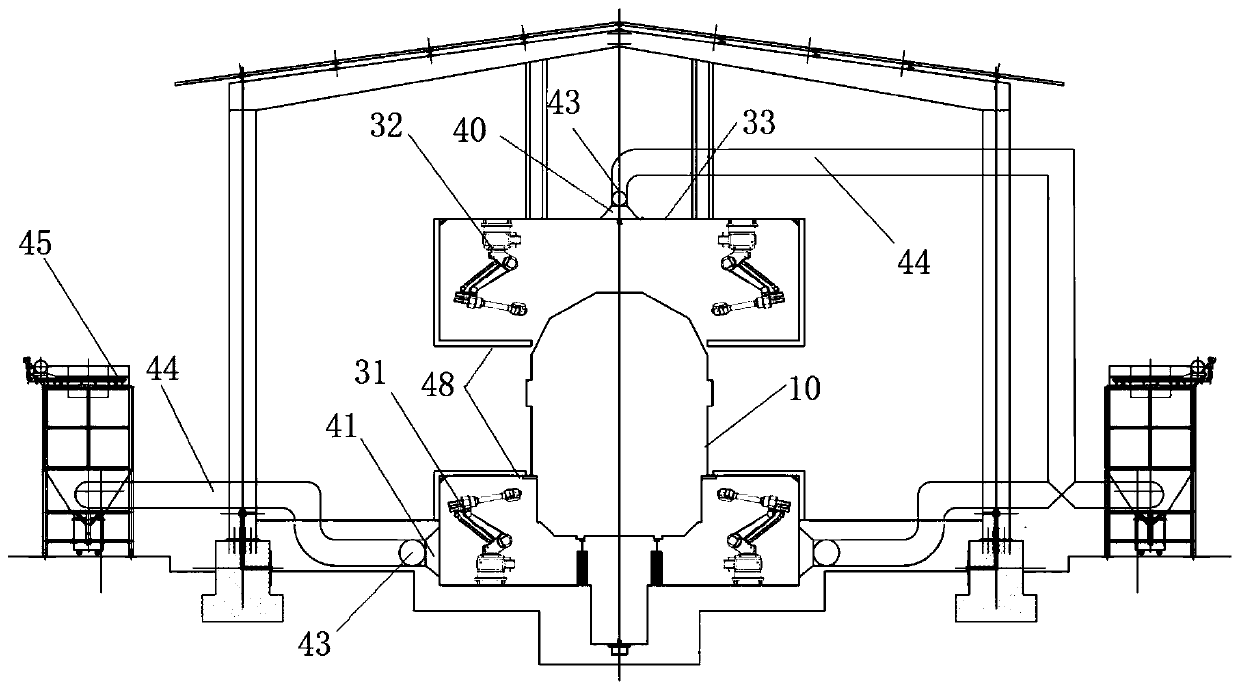

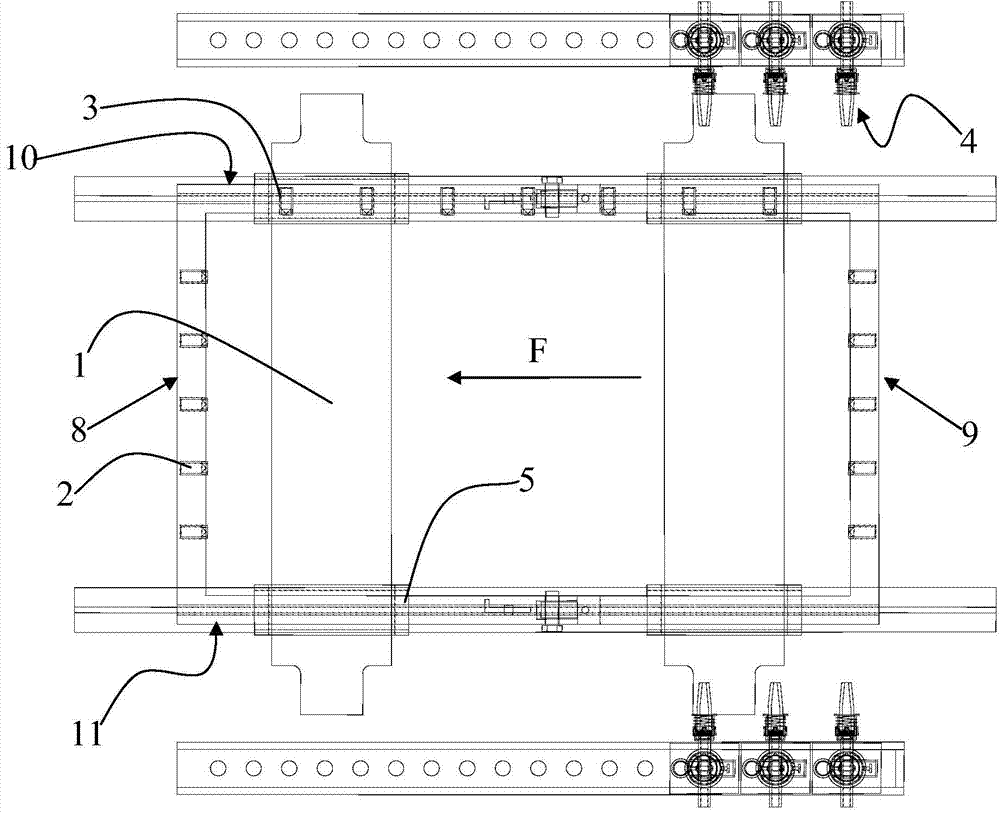

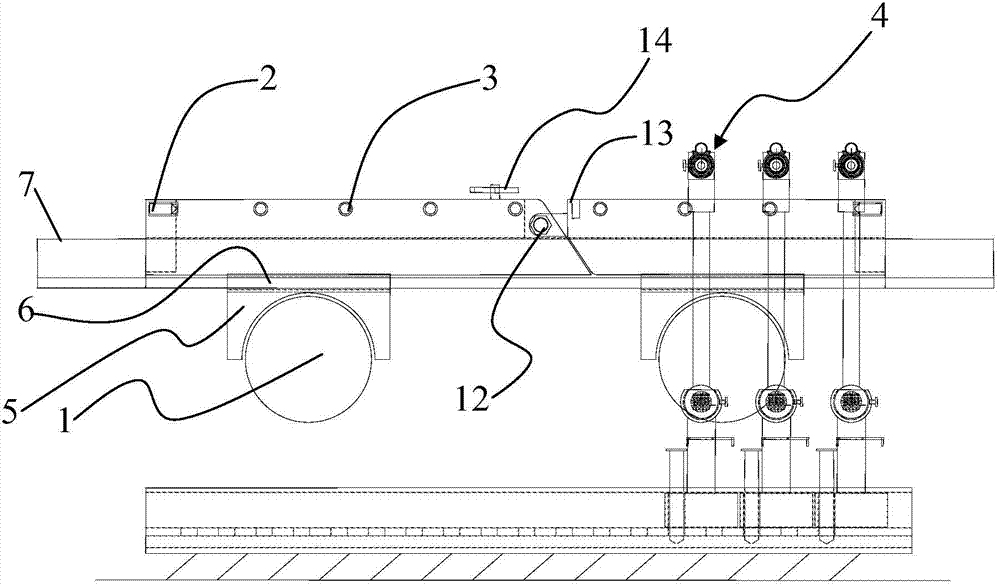

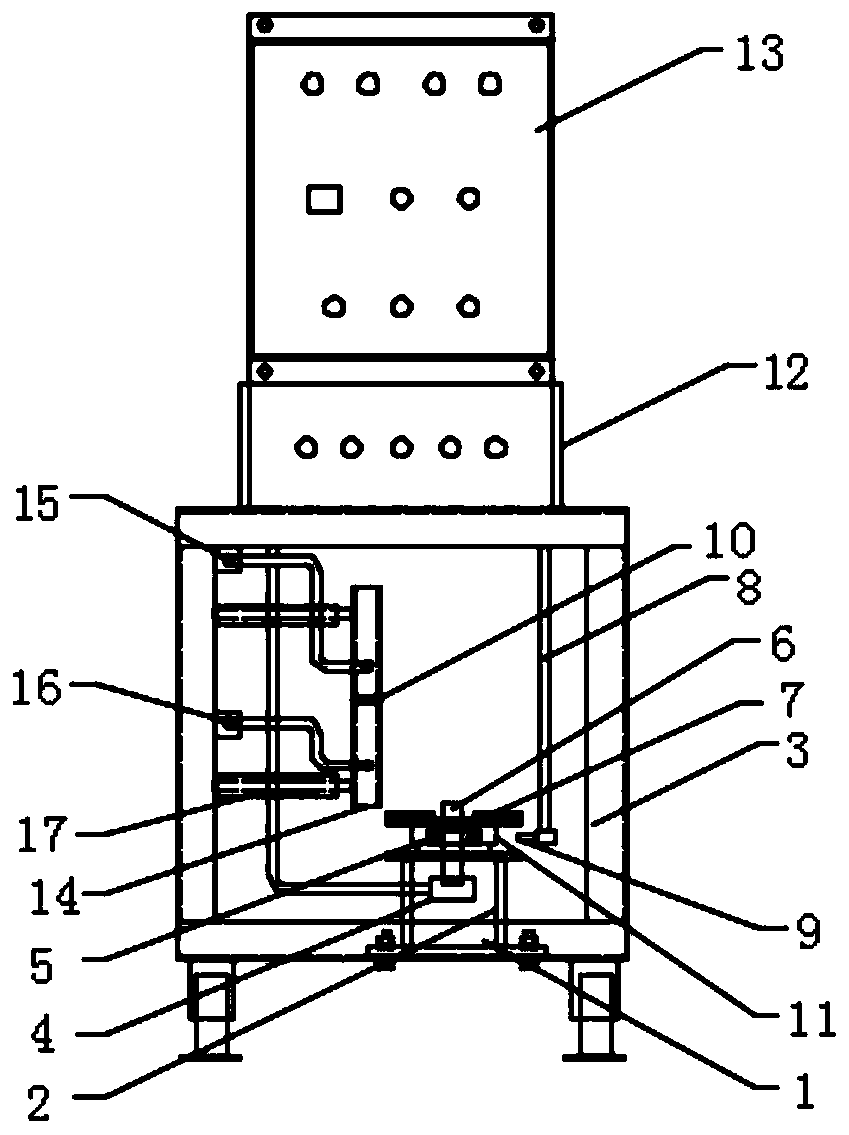

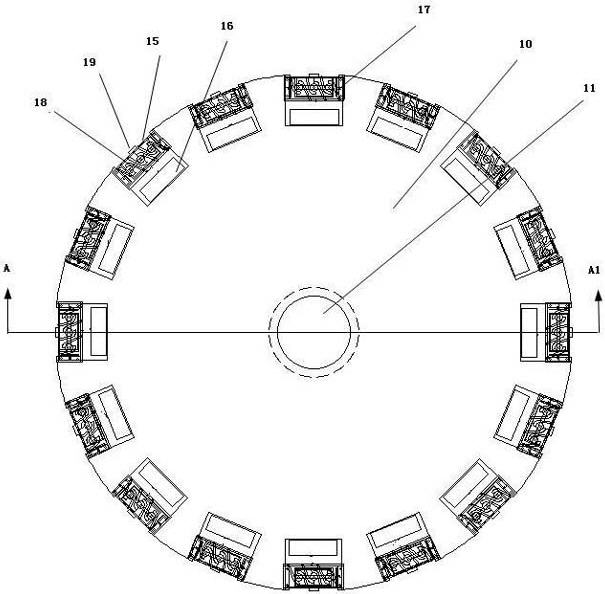

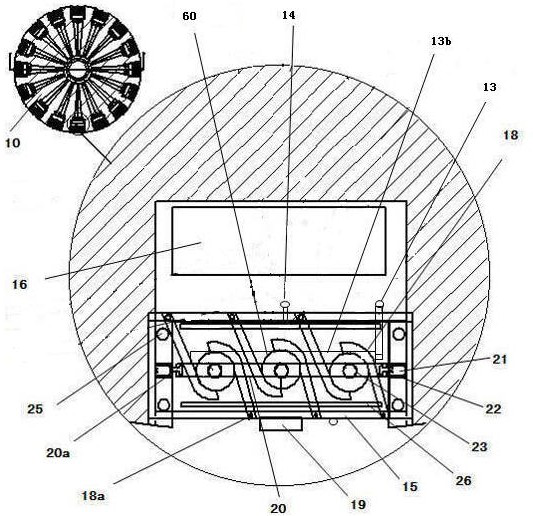

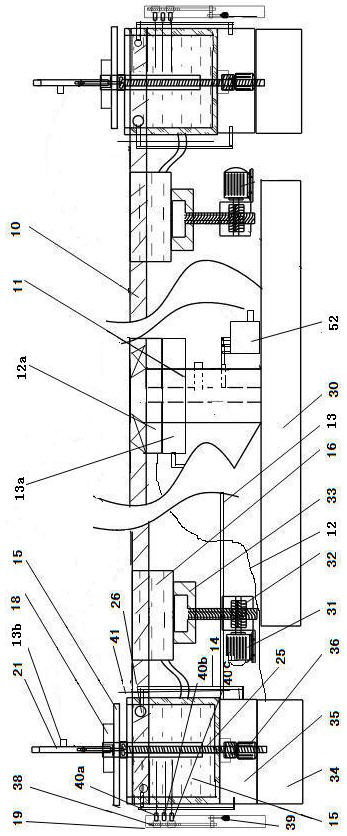

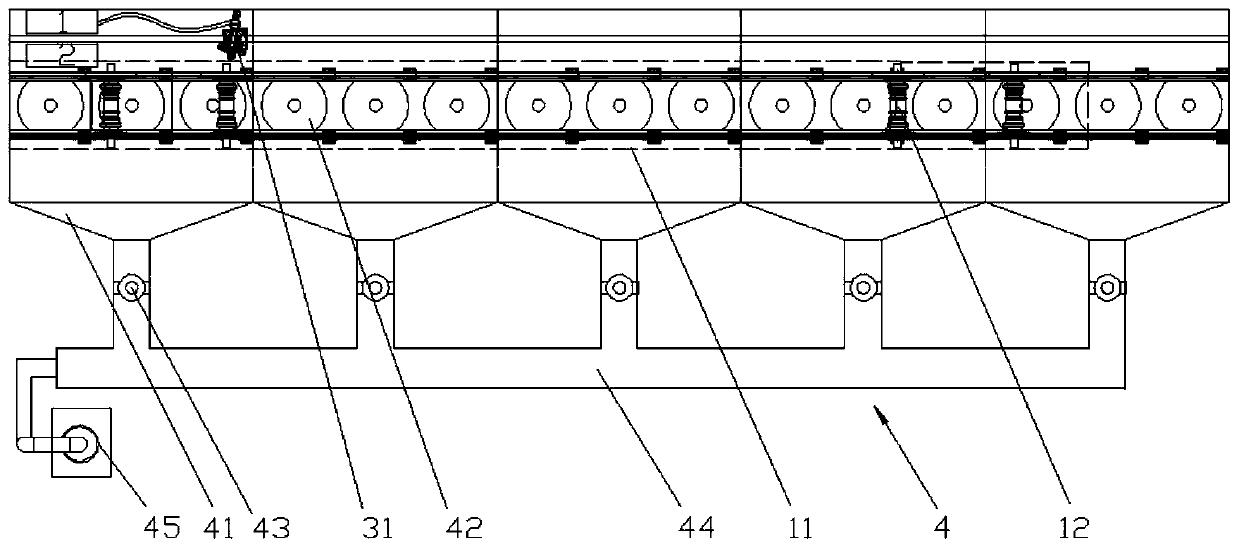

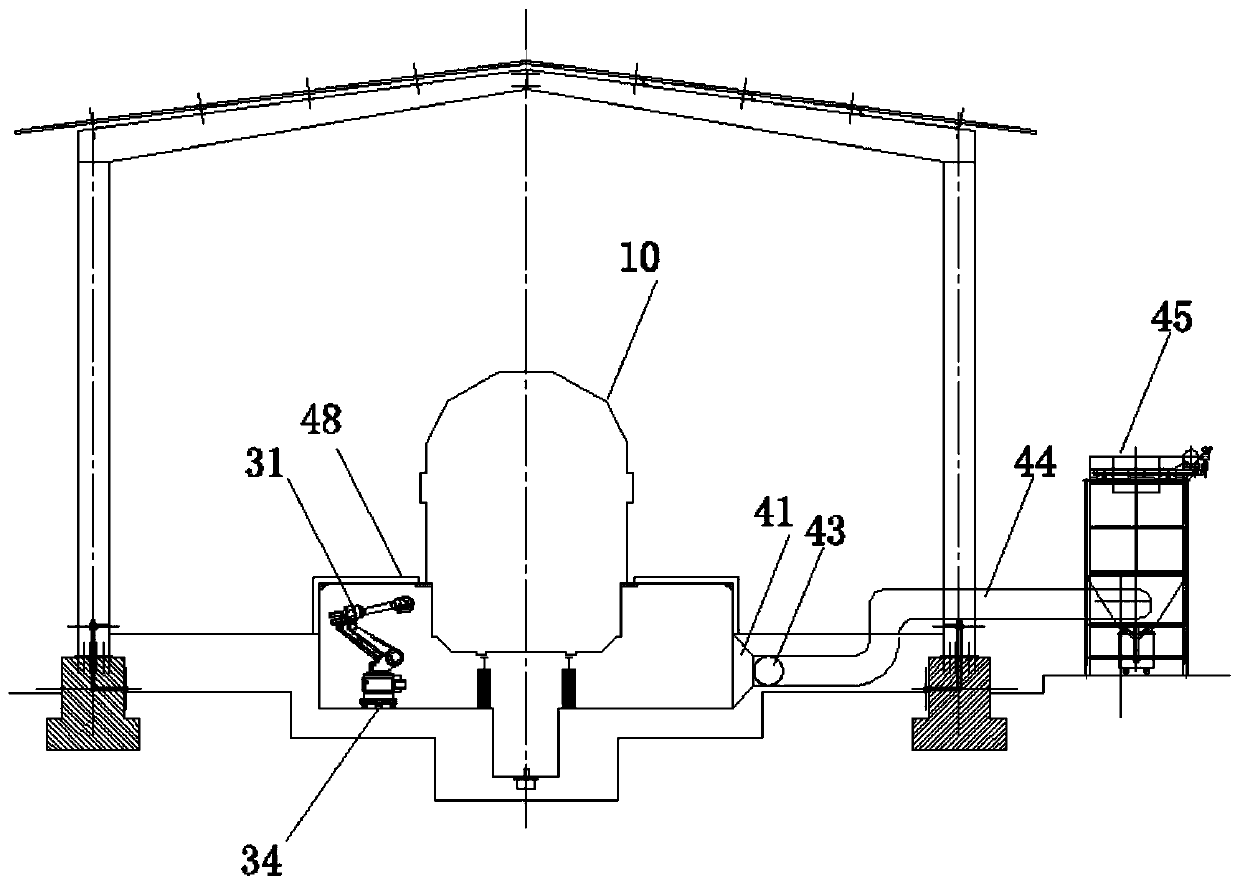

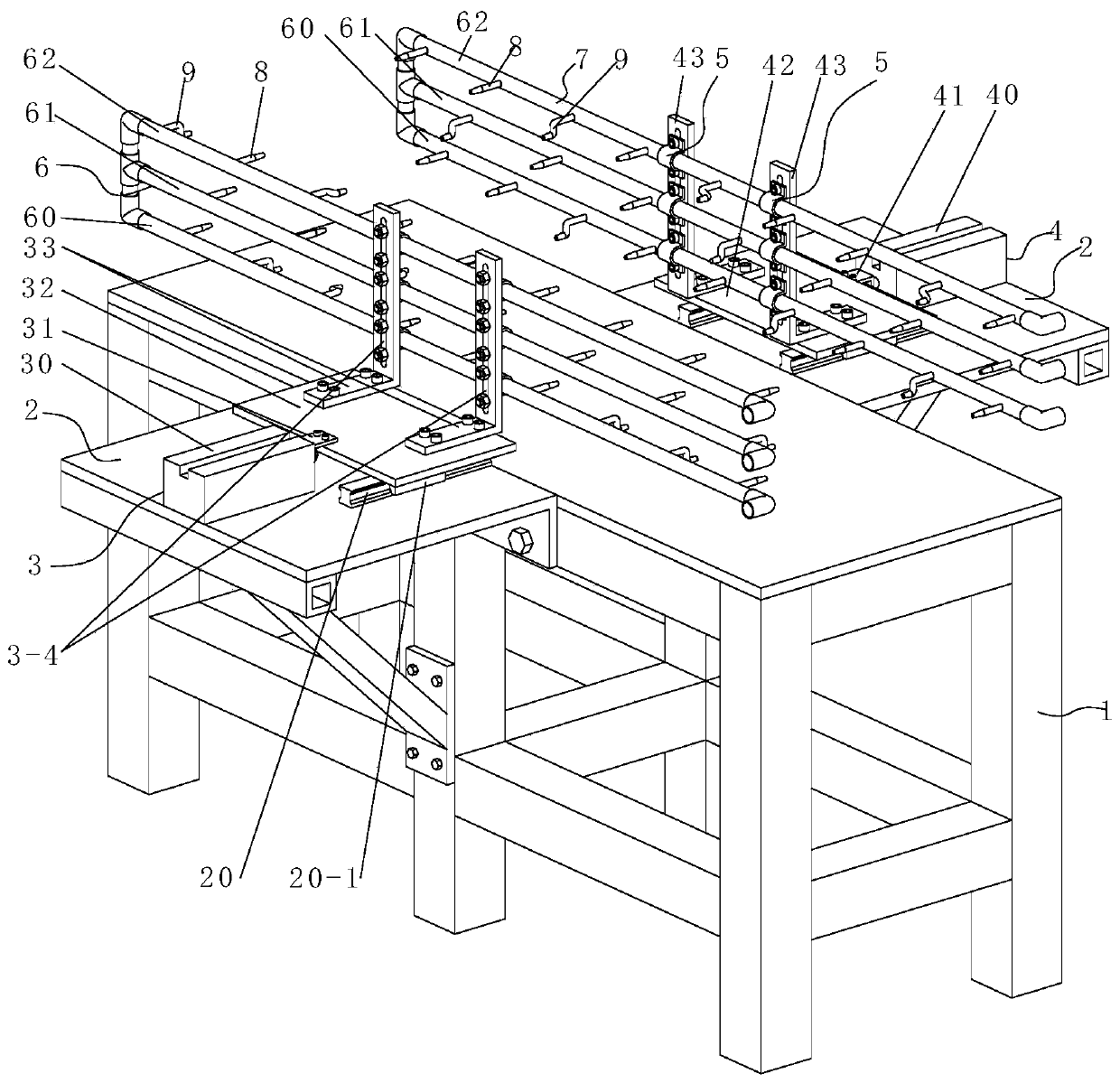

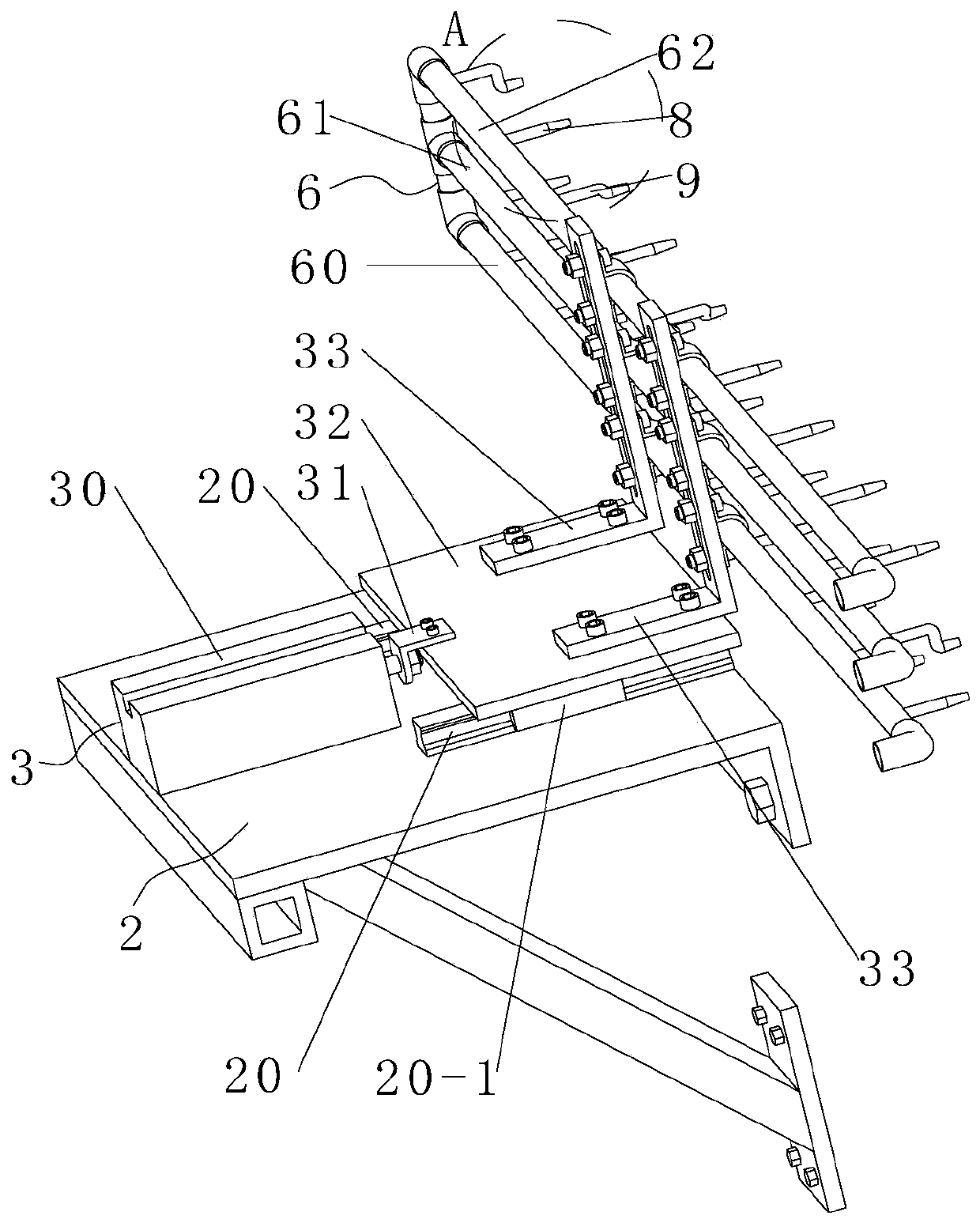

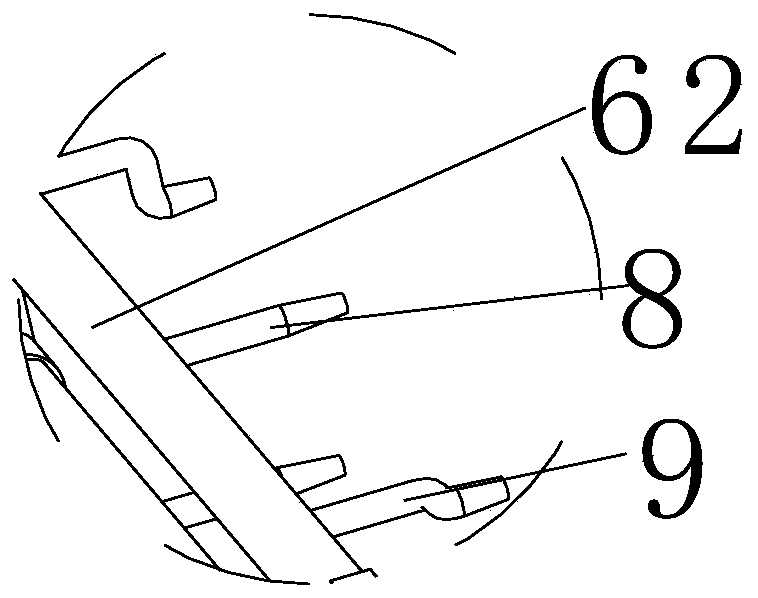

Three-dimensional omnibearing intelligent purging system and method for rail transit vehicle

PendingCN109733333AEfficient removalImprove working environmentVehicle cleaning apparatusWorking environmentElectrical control

The invention discloses a three-dimensional omnibearing intelligent purging system for a rail transit vehicle. The three-dimensional omnibearing intelligent purging system is characterized by comprising an air supply system (1), an electrical control system (2), a moving purging system (3) and an air exhaust and dust removal system (4). The moving purging system (3) comprises a bottom moving purging robot (31) and a top moving purging robot (32); the air exhaust and dust removal system (4) is respectively connected to the operation areas through pipelines; the air supply system (1) is connected with the bottom moving purging robot (31) and the top moving purging robot (32) through flexible pipelines to provide high-pressure air for the bottom moving purging robot (31) and the top moving purging robot (32); and the electric control system (2) is used for monitoring environmental parameters in a rail transit vehicle purging workshop. Dust of the vehicle can be quickly and efficiently removed, the working environment in the purging warehouse is improved, and three-dimensional omnibearing purging of the bottom, the sides and the top of the rail transit vehicle is achieved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

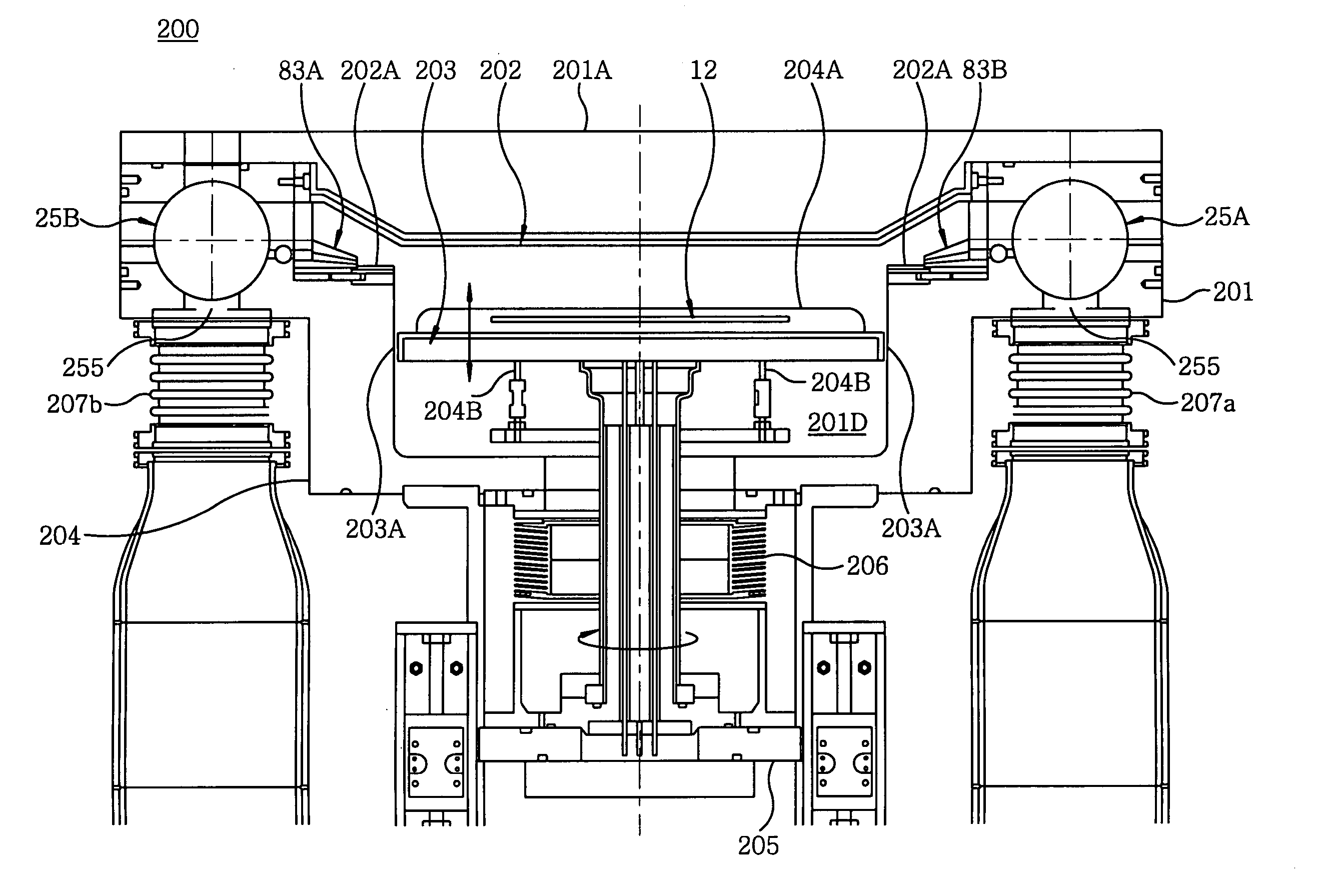

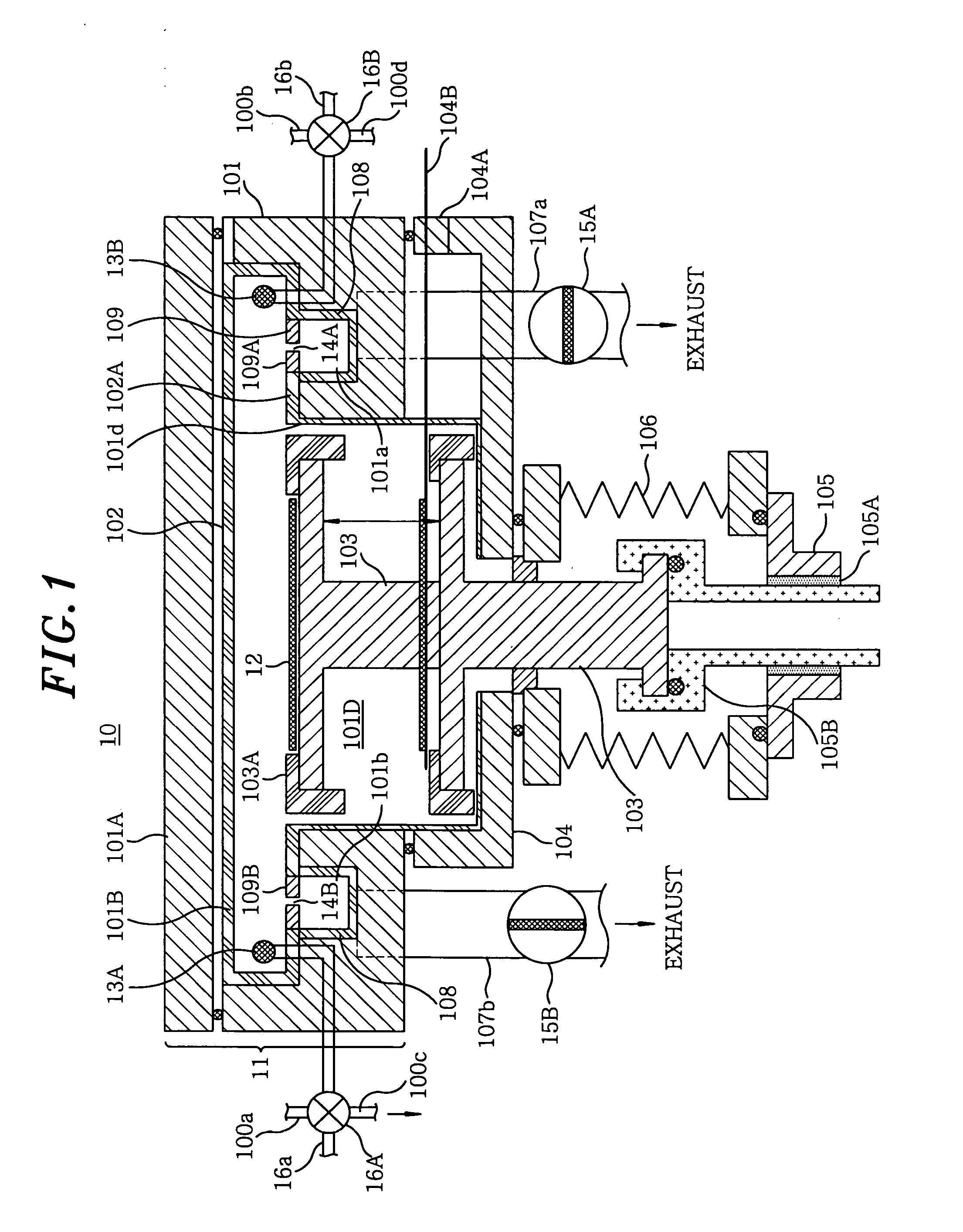

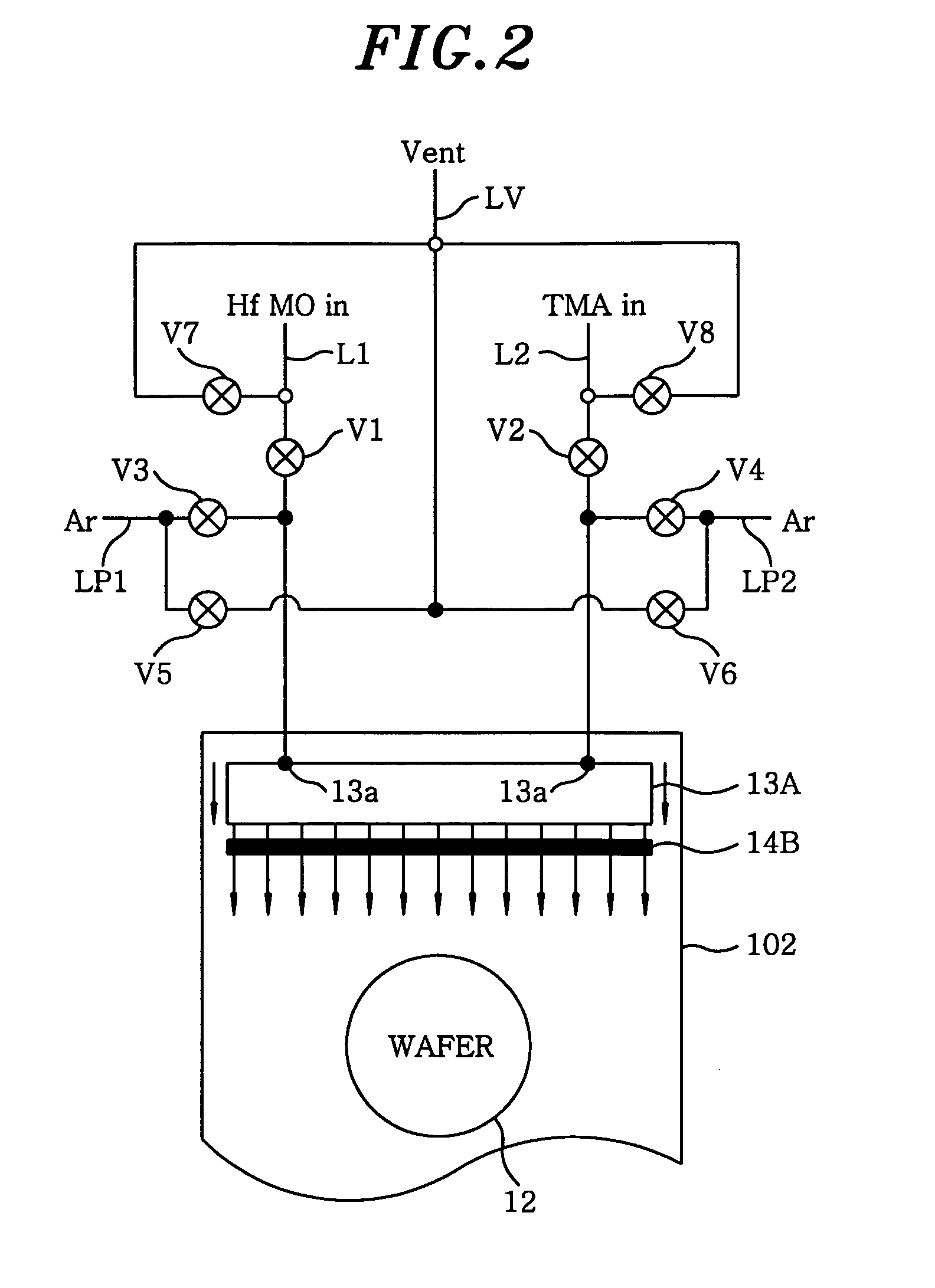

Substrate processing apparatus and method, and gas nozzle for improving purge efficiency

InactiveUS20060032445A1Efficient executionSwitching processing efficientlySemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringMulti element

A substrate processing apparatus capable of efficiently purging not only a process space but also the inside of a processing gas feed nozzle when a multi element compound film is formed on a substrate by laminating a molecular layer thereon, wherein an exhaust line is connected to one end of the processing gas feed nozzle jetting the processing gas in a laminar flow into the process space along the surface of the treated substrate, and the processing gas or purge gas is fed from the other end thereof.

Owner:TOKYO ELECTRON LTD

Apparatus including 4-way valve for fabricating semiconductor device, method of controlling valve, and method of fabricating semiconductor device using the apparatus

ActiveCN1825537AAvoid dead volumeImprove purge efficiencyDiaphragm valvesEngine diaphragmsDead volumeProduct gas

An apparatus and method for fabricating a semiconductor device using a 4-way valve with improved purge efficiency by improving a gas valve system by preventing dead volume from occurring are provided. The apparatus includes a reaction chamber in which a substrate is processed to fabricate a semiconductor device; a first processing gas supply pipe supplying a first processing gas into the reaction chamber; a 4-way valve having a first inlet, a second inlet, a first outlet, and a second outlet and installed at the first processing gas supply pipe such that the first inlet and the first outlet are connected to the first processing gas supply pipe; a second processing gas supply pipe connected to the second inlet of the 4-way valve to supply a second processing gas; a bypass connected to the second outlet of the 4-way valve; and a gate valve installed at the bypass.

Owner:SAMSUNG ELECTRONICS CO LTD +1

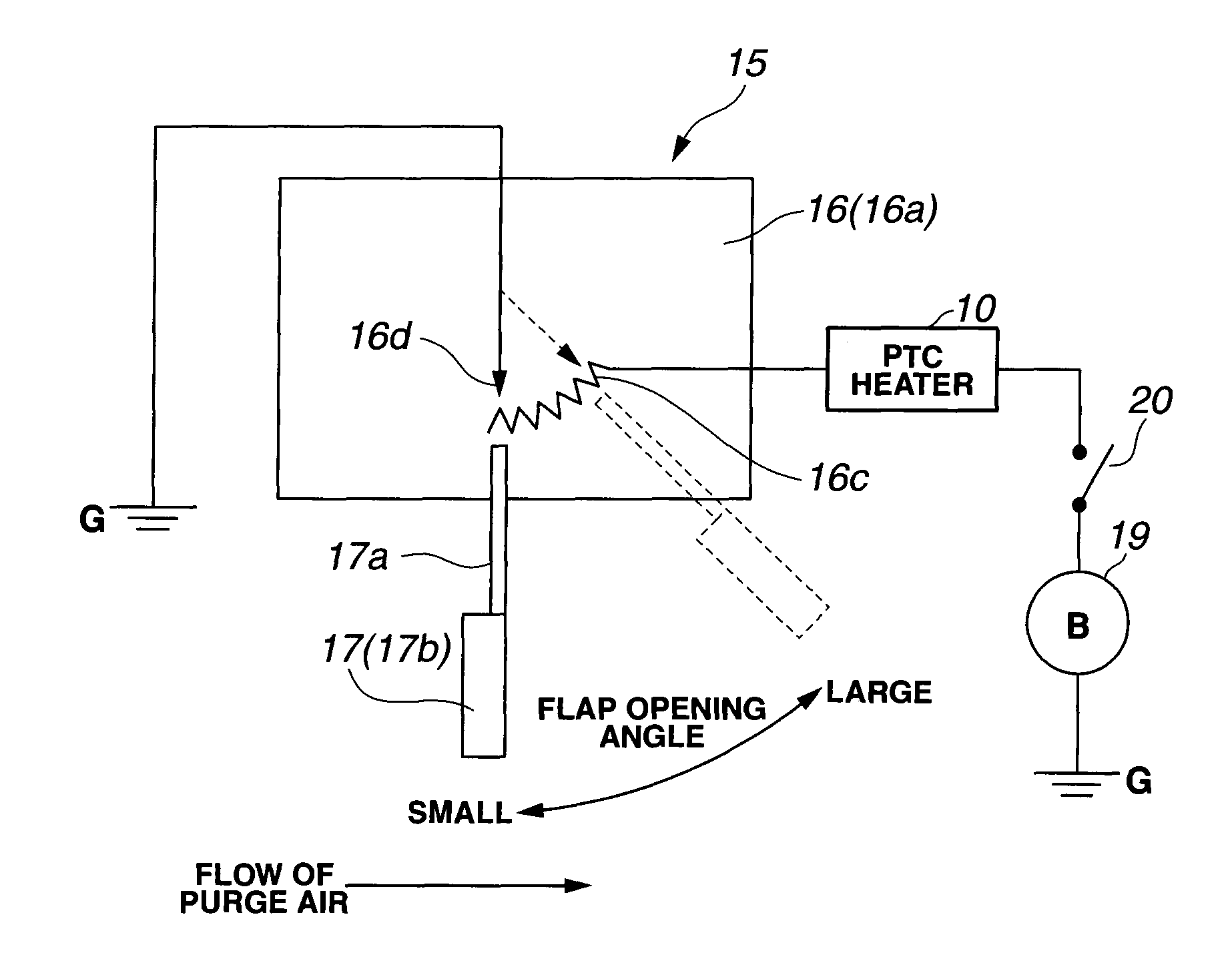

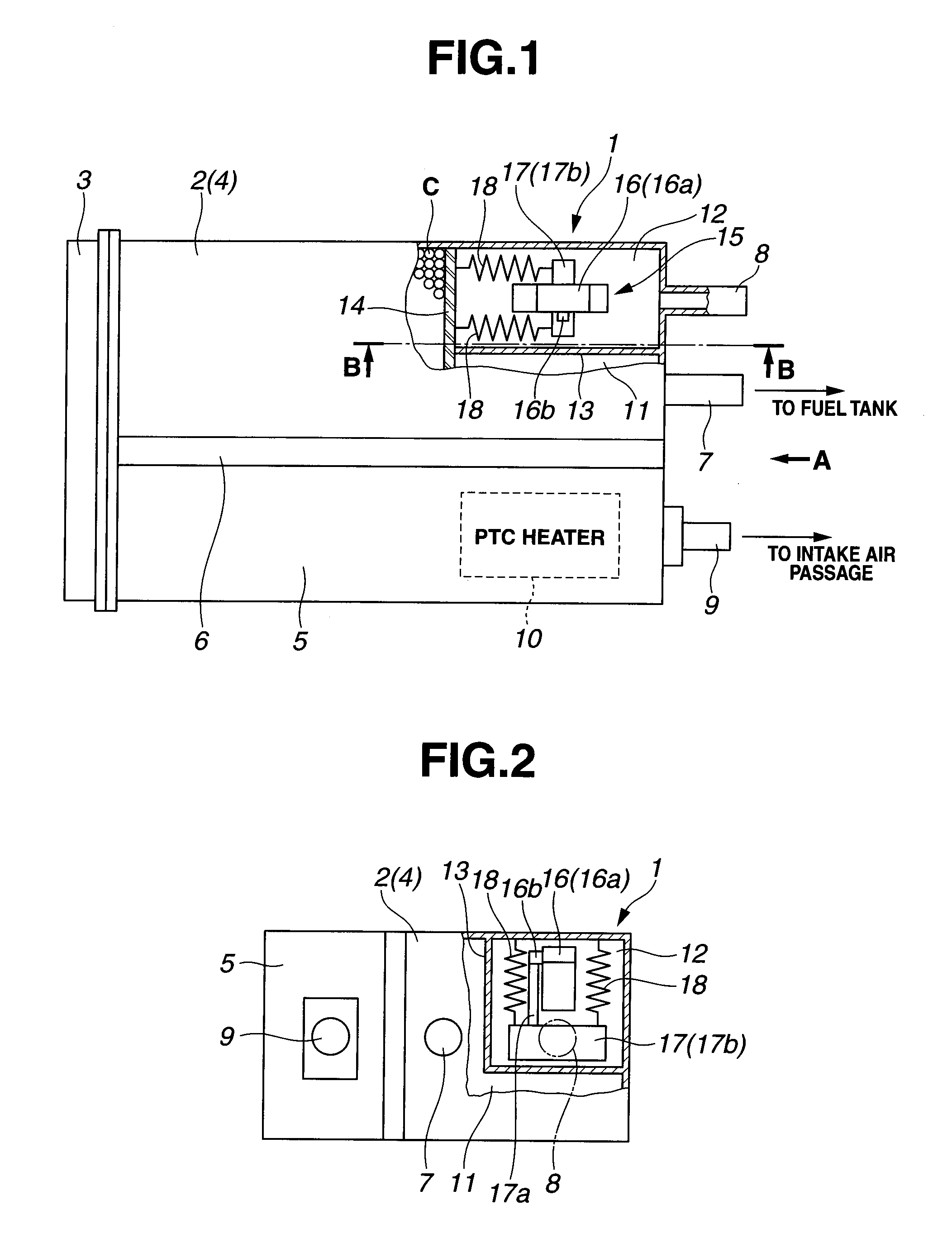

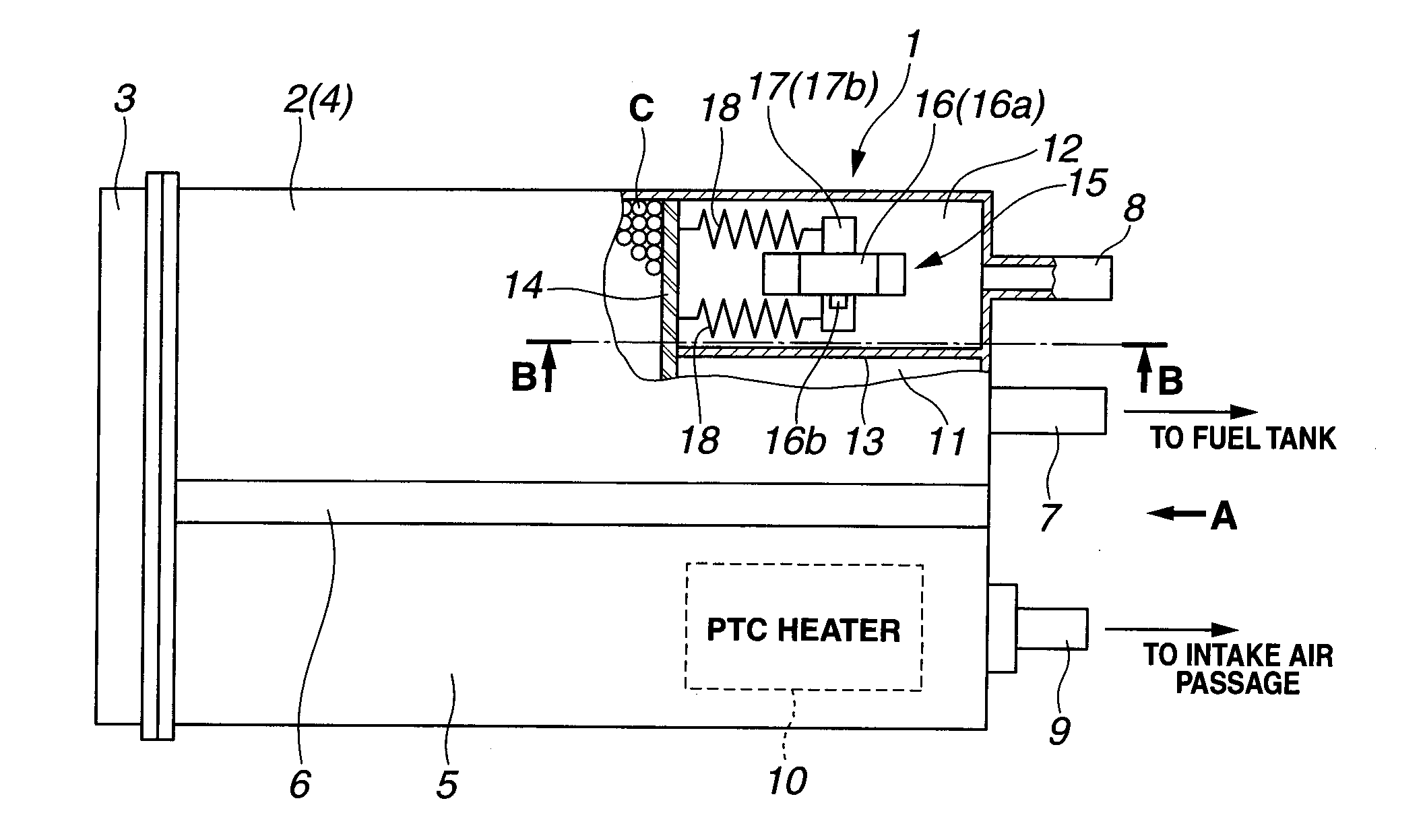

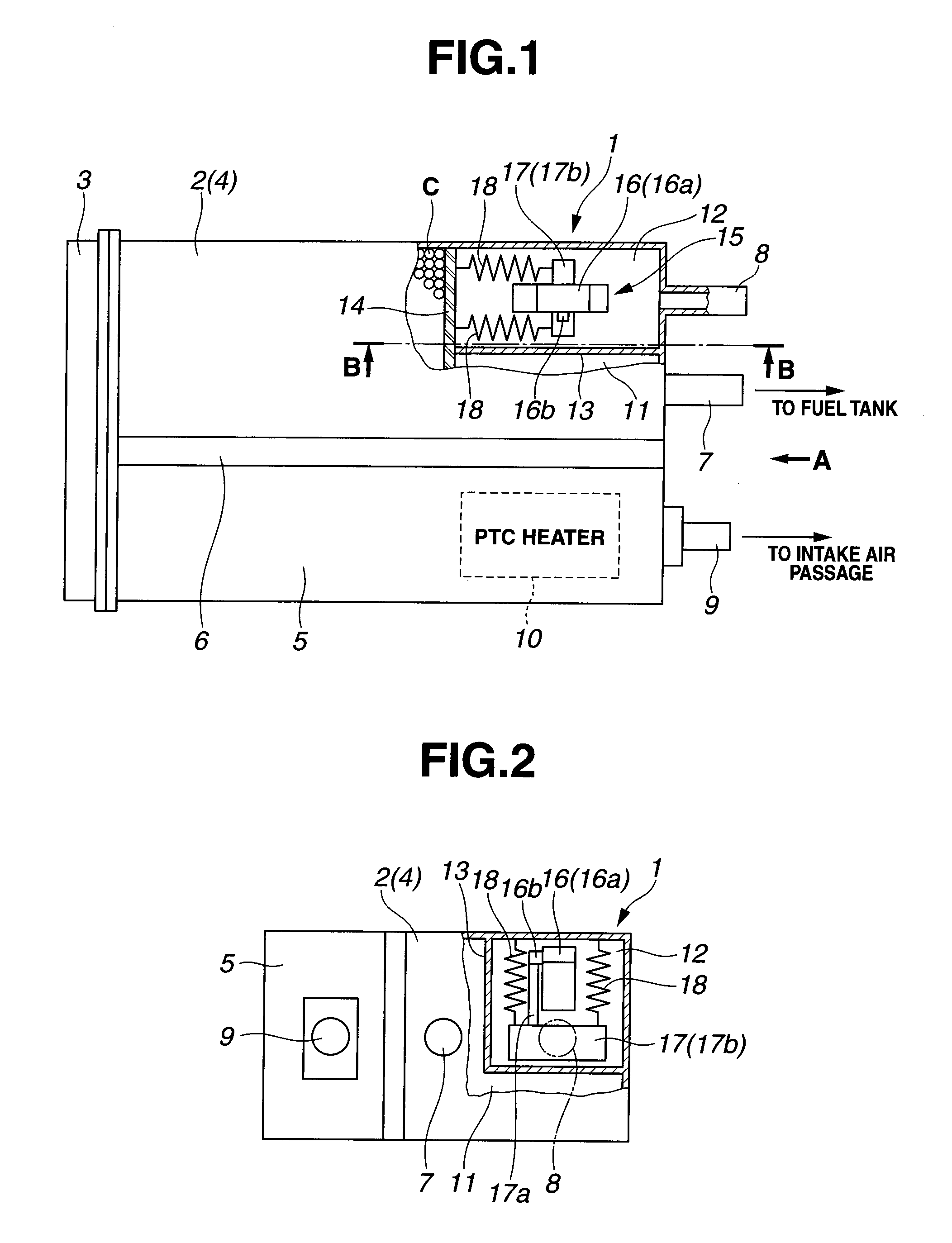

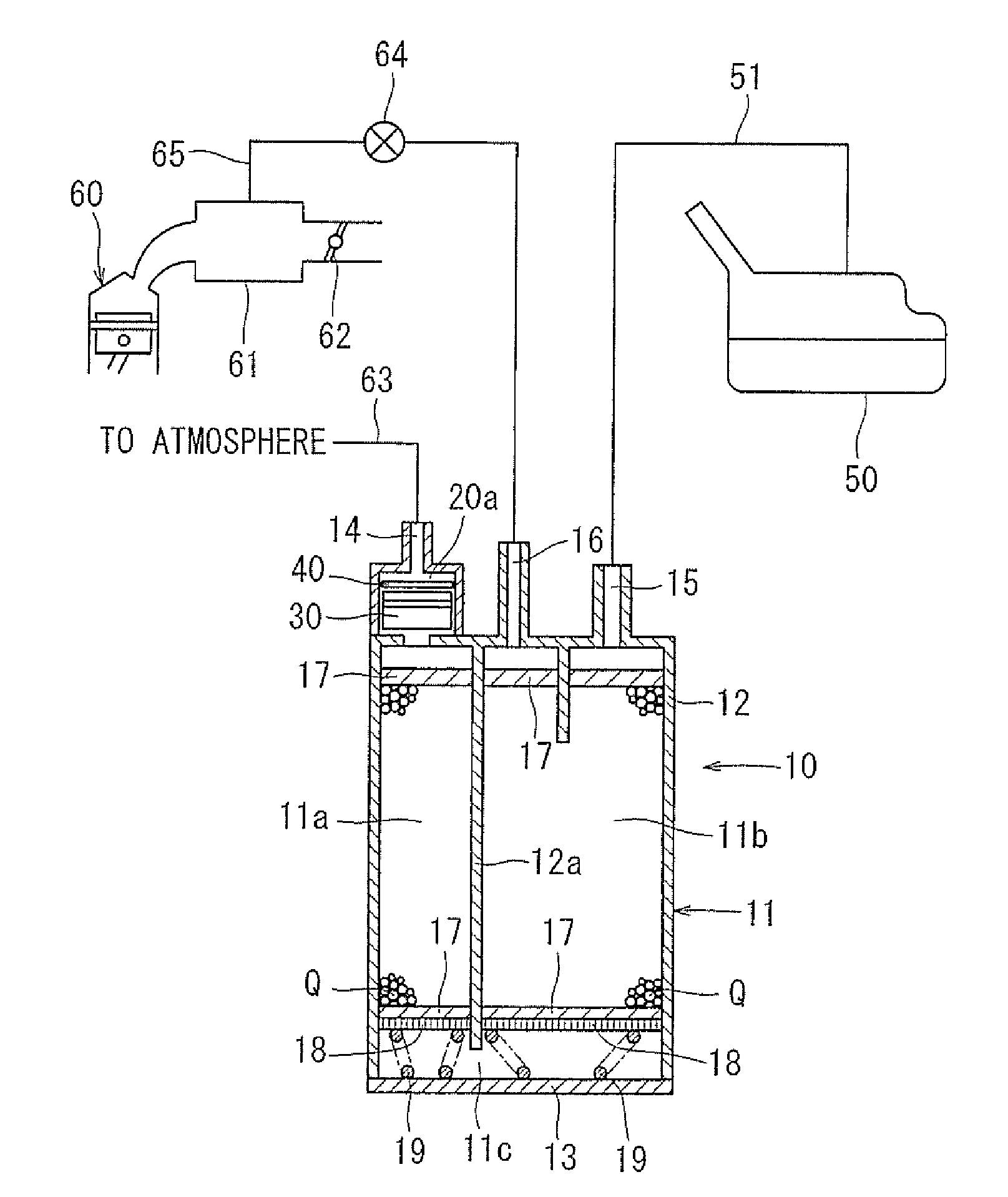

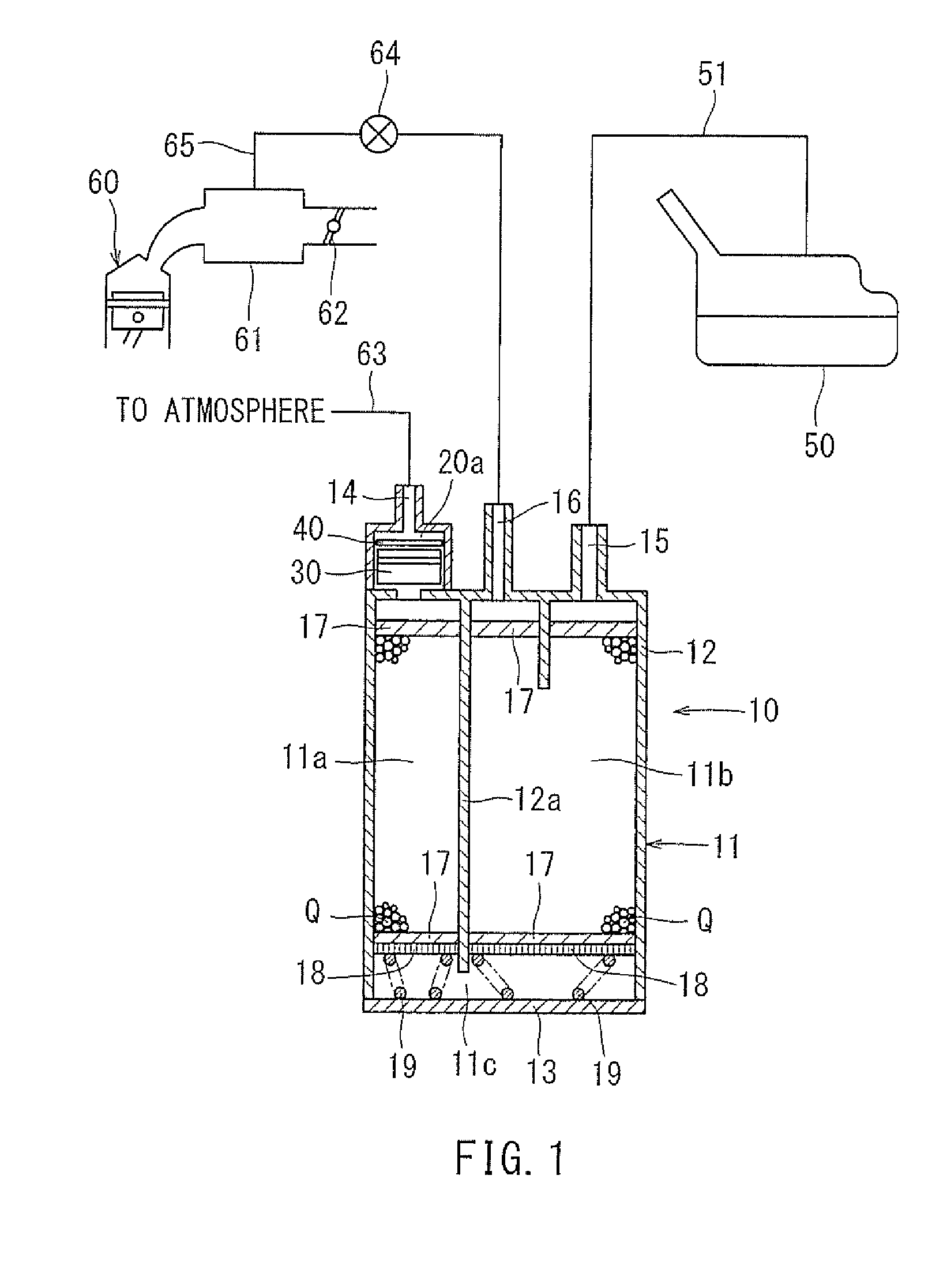

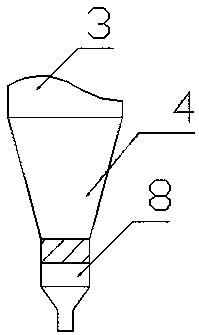

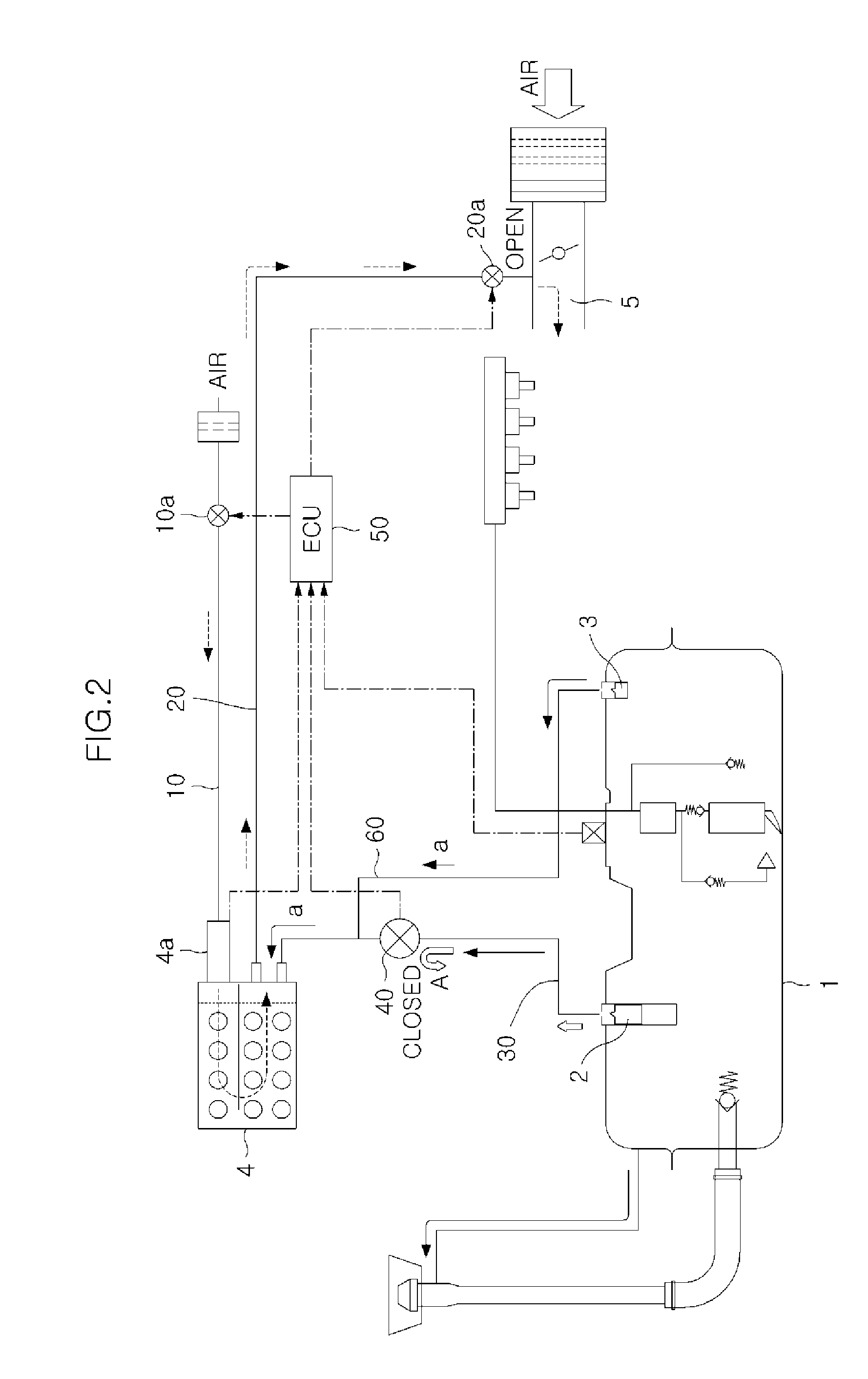

Vaporized fuel processing device and method

InactiveUS8375925B2Reduce electric powerImprove purge efficiencyElectrical controlNon-fuel substance addition to fuelFuel tankIntake pressure

In vaporized fuel processing device and method, an adsorption material provides a canister and configured to once hold the vaporized fuel generated in a fuel tank into the adsorption material within the canister, the canister into which an intake air pressure of an engine used for purge air being introduced when the engine is operated and purge air purging fuel corresponding to vaporized fuel from the adsorption material to be supplied to the engine; an electric heater configured to variably control an electric power supplied to the heater in accordance with a purge air quantity to be introduced within the canister.

Owner:MAHLE FILTER SYST JAPAN CORP

Purge system for reductant delivery unit for a selective catalytic reduction system

ActiveUS9273581B2Improve purge efficiencyPrevent component damage during freezing conditionsInternal combustion piston enginesExhaust apparatusExhaust fumesAmbient pressure

A purge procedure which is part of an injector, that may be used as part of a reductant delivery unit (RDU), where the RDU is part of a selective catalytic reduction system for injecting diesel exhaust fluid into an exhaust system, to control exhaust emissions. The RDU delivers a reductant carrier to the engine exhaust system. The purge process includes a control strategy to improve the quality of the purge cycle (i.e., increase the amount of fluid evacuated). The sequence of the purge event is adjusted in order to generate a strong vacuum in the fluid supply line and the injector—this enhances the efficiency of the purge by increasing the initial flow rates through the injector. However, upon opening the injector, the pressure inside the fluid path increases to a level just below the ambient pressure outside the injector, therefore the gas flow rate is substantially reduced.

Owner:VITESCO TECH USA LLC

Purging and sealing-reductant delivery unit for selective catalytic reduction systems

ActiveUS9777859B2Improve purge efficiencyImprove sealingInternal combustion piston enginesExhaust apparatusExhaust fumesEngineering

Owner:VITESCO TECH USA LLC

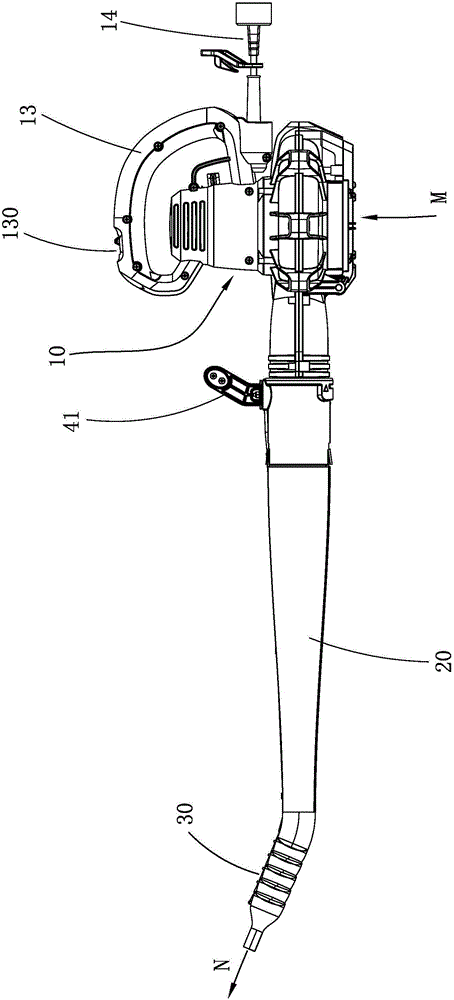

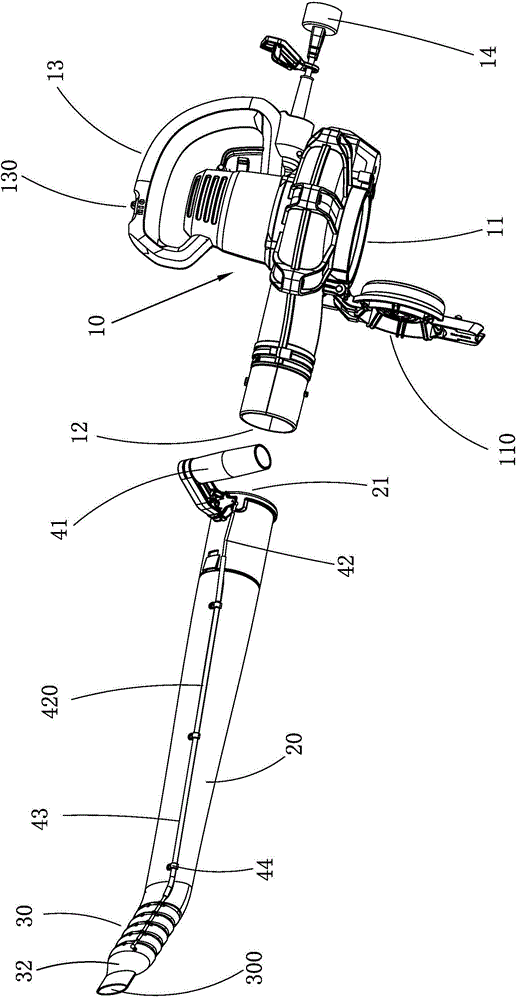

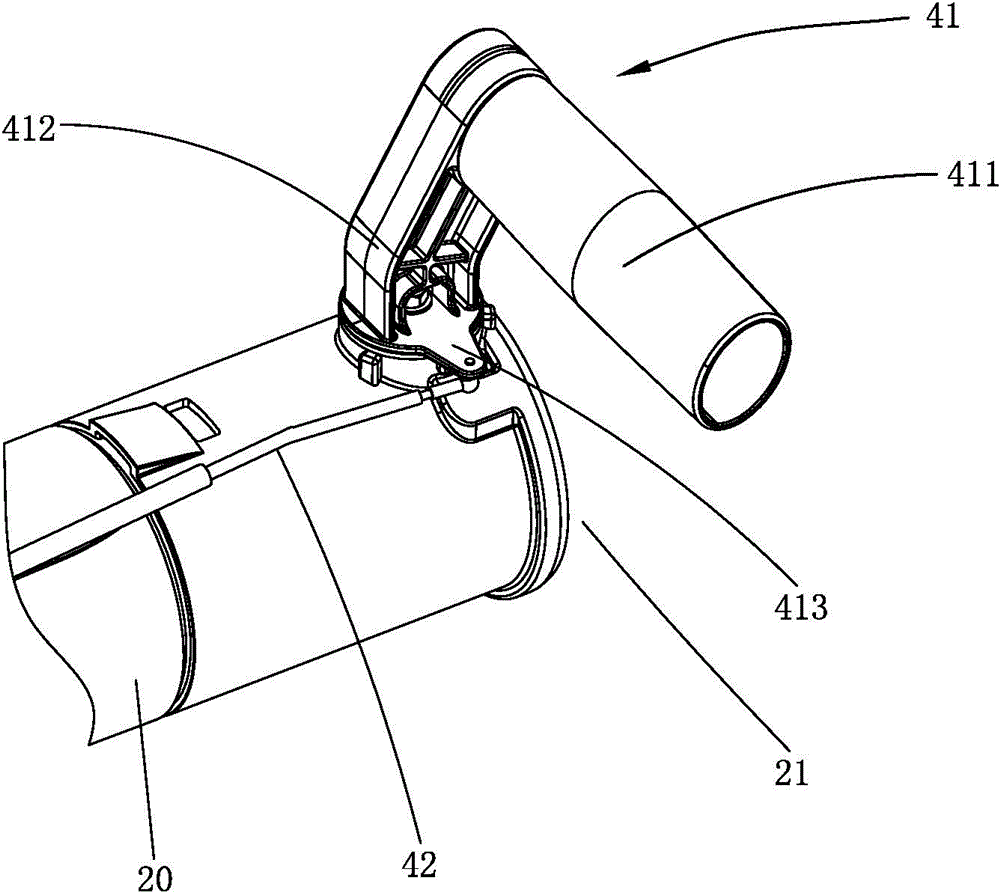

Blowing and sucking device and method for using same

The invention relates to a blowing and sucking device. The blowing and sucking device comprises a main housing, a main handle, a motor and a fan, wherein the main housing is provided with an air inlet and an air outlet; the main handle is arranged on the main housing; the motor and the fan are arranged in the main housing, and the motor drives the fan to rotate to form airflow coming in from the air inlet and going out from the air outlet. The blowing and sucking device further comprises a direction adjusting mechanism and a blowing assembly. The blowing assembly comprises an air inlet end and a blowing part, wherein the air inlet end is connected with the air outlet of the main housing, airflow is blown out from the blowing part and forms the blowing direction of the blowing and sucking device, and the direction adjustment mechanism adjusts the blowing assembly so that the blowing direction can keep in the predetermined direction. In this way, the flexibility of an air blower during use is enhanced, and blowing efficiency is improved.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Vaporized fuel processing device and method

InactiveUS20100154755A1Large powerConsumes electric powerElectrical controlNon-fuel substance addition to fuelAutomotive engineeringIntake pressure

In vaporized fuel processing device and method, an adsorption material provides a canister and configured to once hold the vaporized fuel generated in a fuel tank into the adsorption material within the canister, the canister into which an intake air pressure of an engine used for purge air being introduced when the engine is operated and purge air purging fuel corresponding to vaporized fuel from the adsorption material to be supplied to the engine; an electric heater configured to variably control an electric power supplied to the heater in accordance with a purge air quantity to be introduced within the canister.

Owner:MAHLE FILTER SYST JAPAN CORP

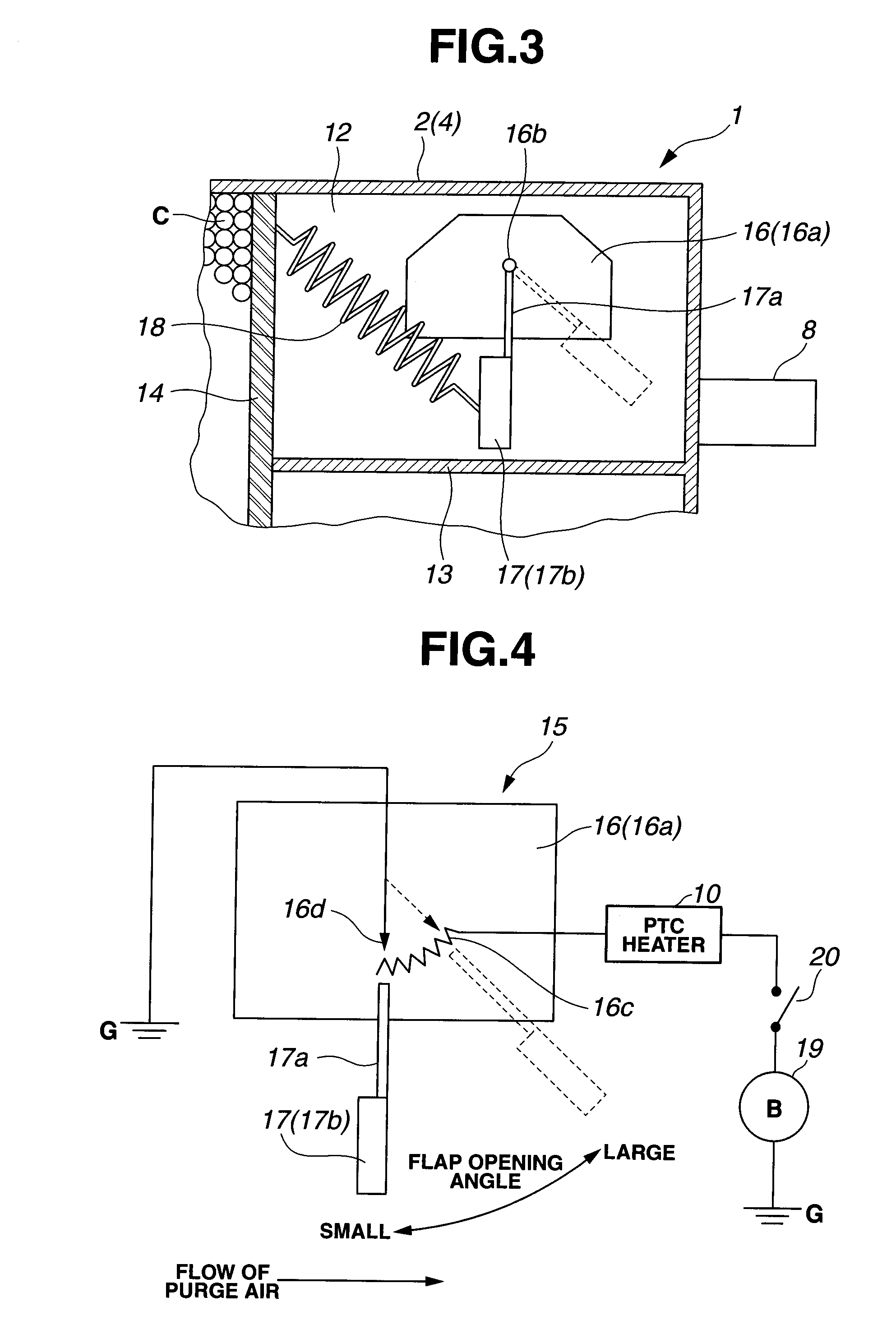

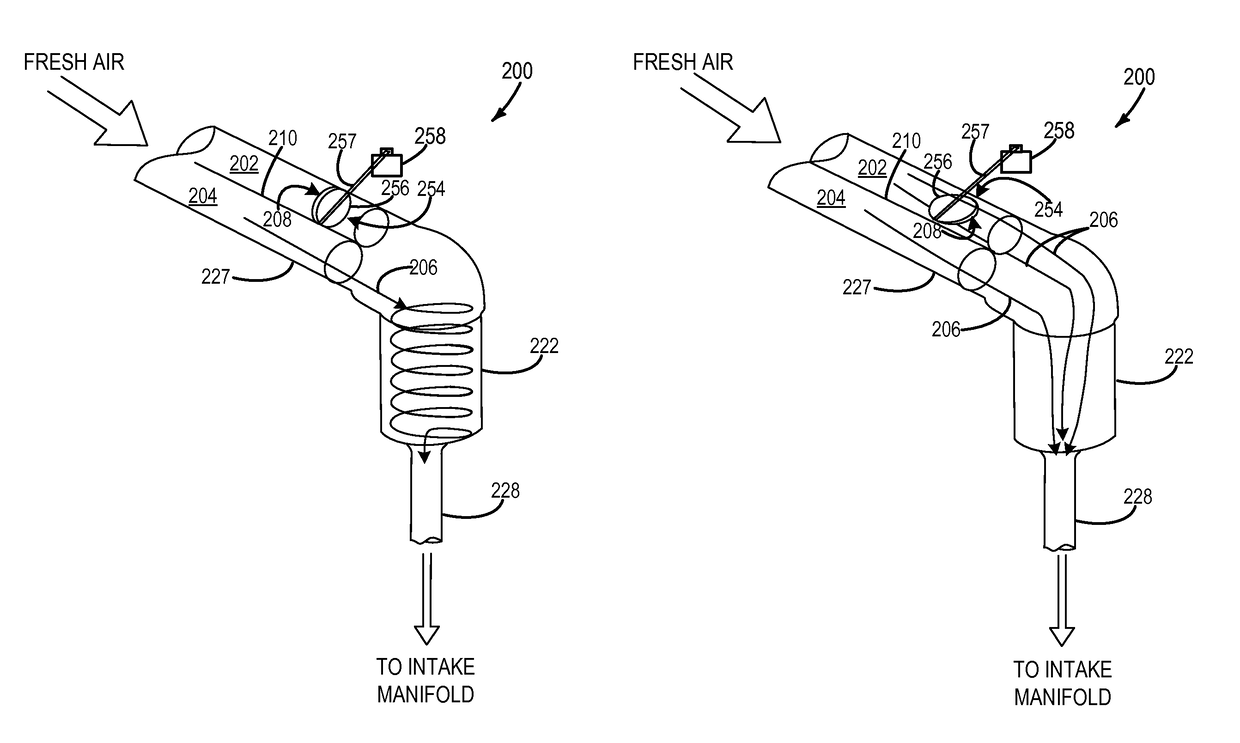

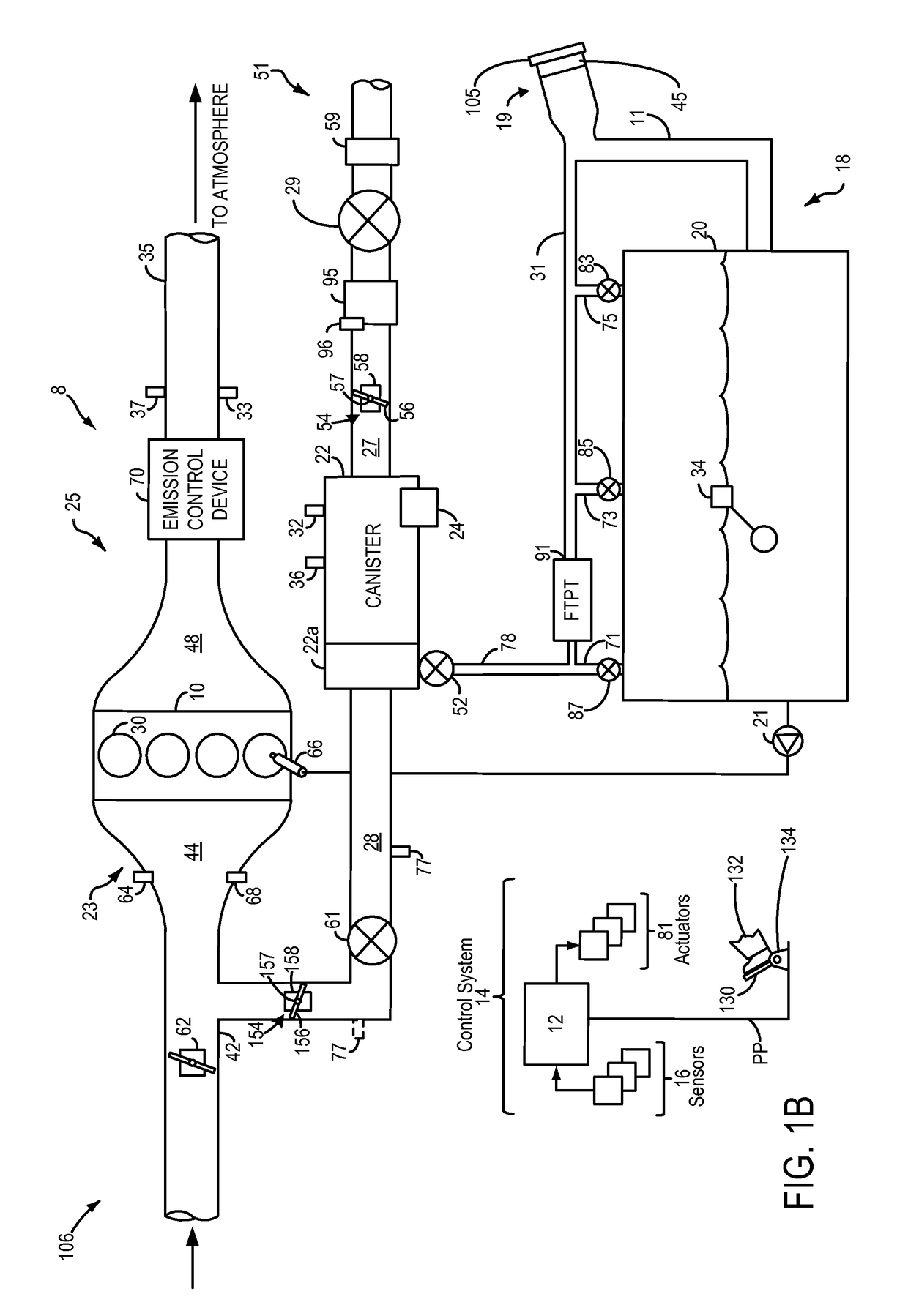

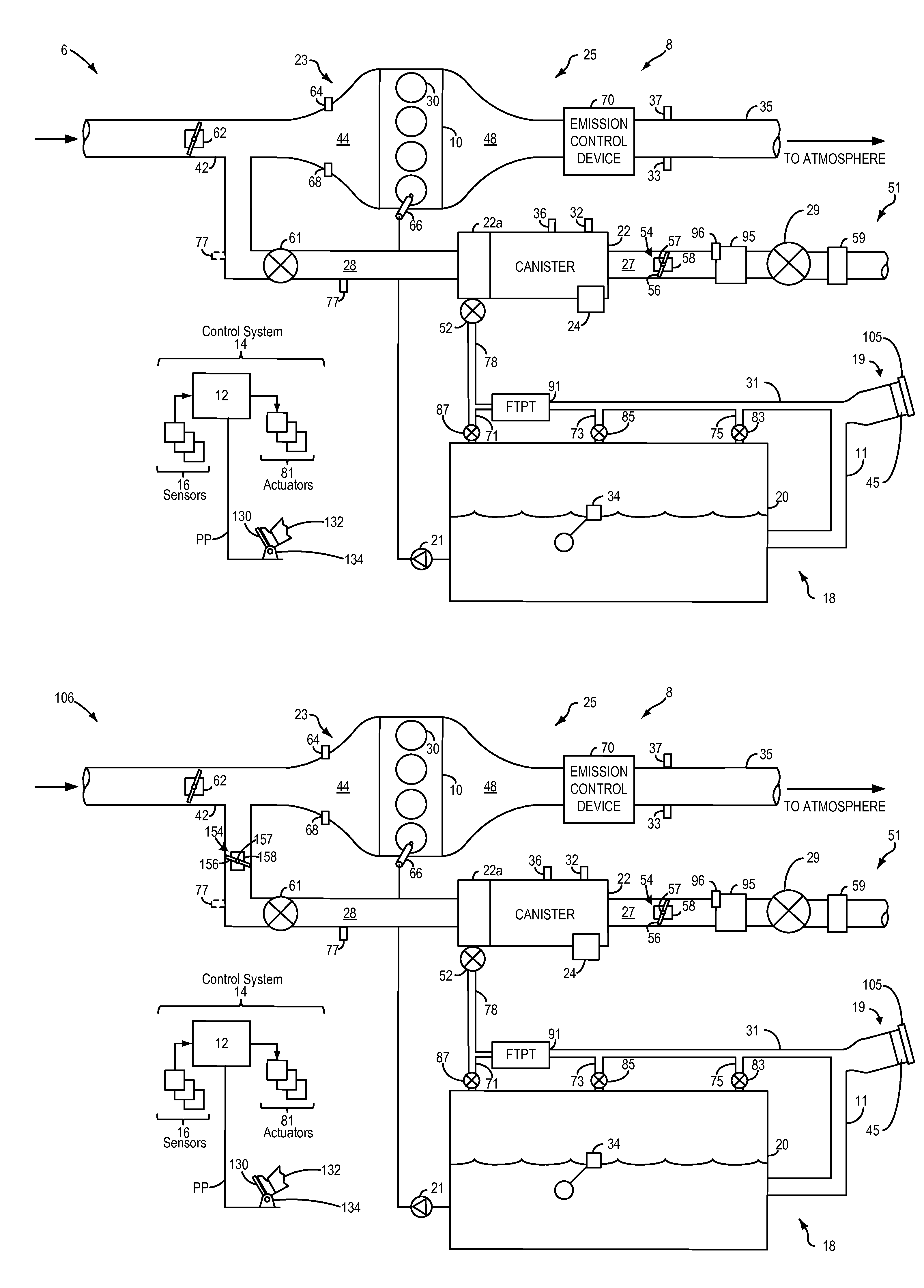

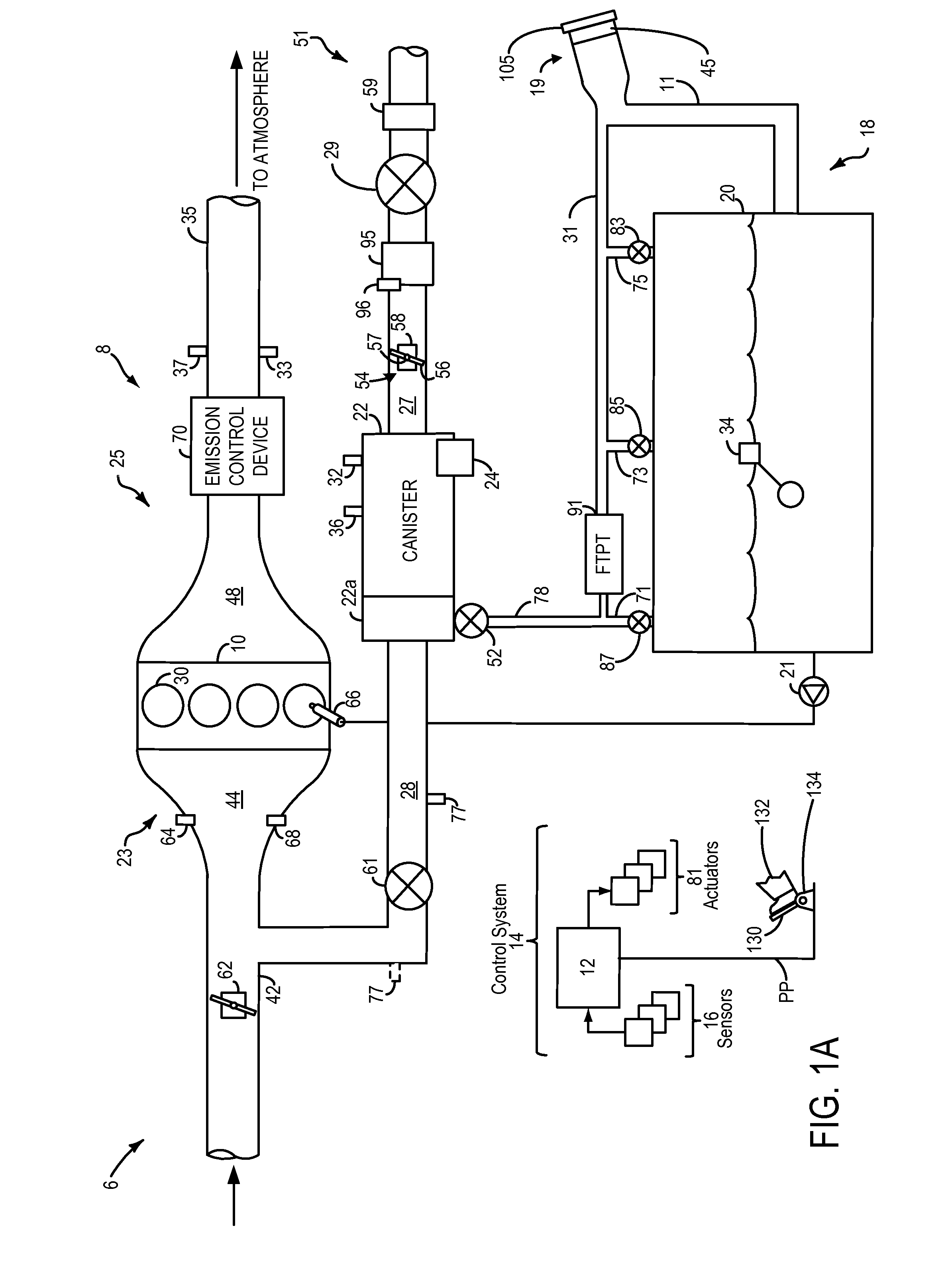

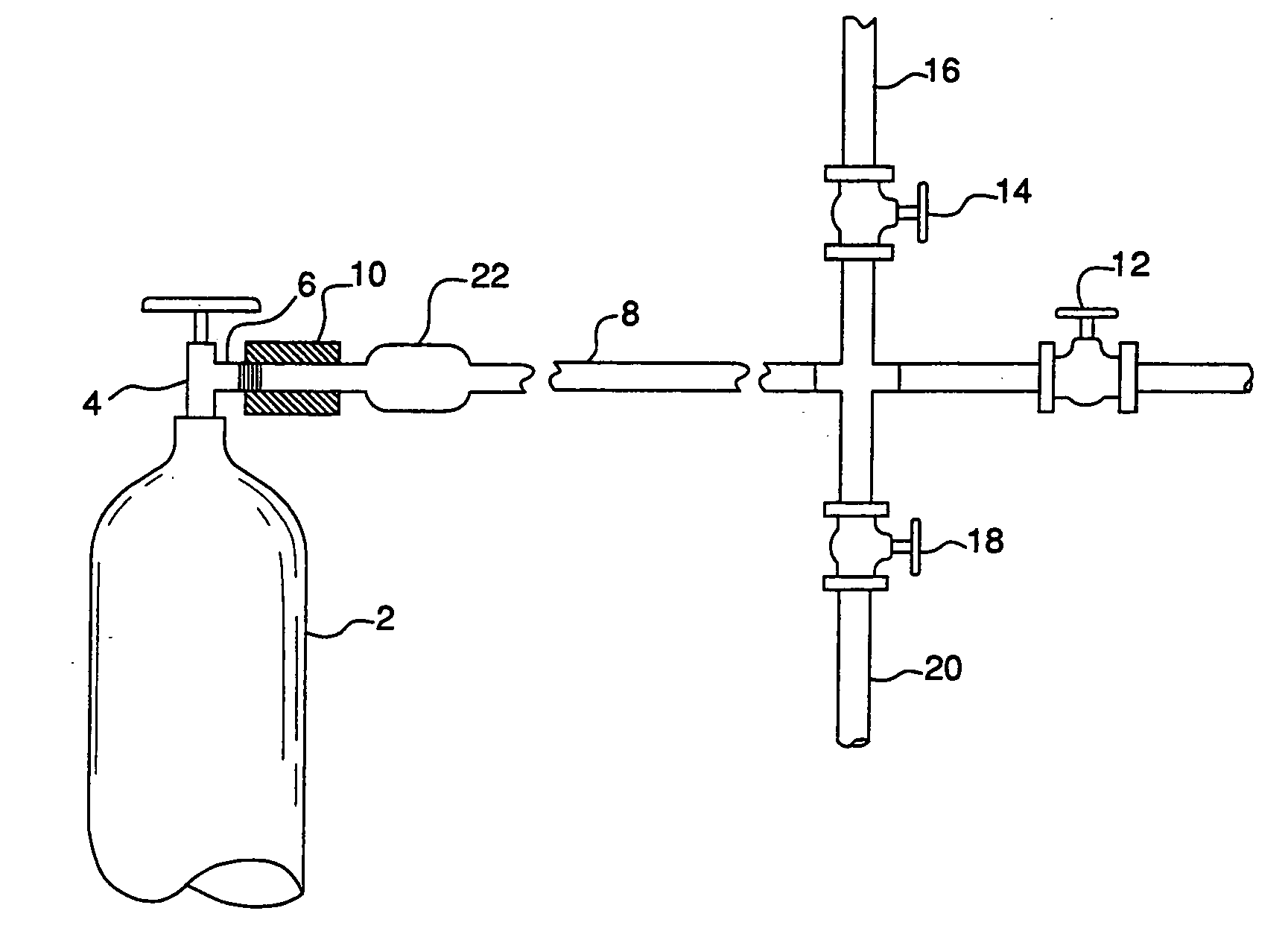

EVAP system with valve to improve canister purging

InactiveUS9845745B2Increase pressureAccelerate emissionsElectrical controlNon-fuel substance addition to fuelControl systemActuator

Systems and methods are provided for an evaporative emissions control system. In one example, a system for an engine may comprise a fuel vapor canister, a mixing valve positioned in a fresh air line upstream of the vapor canister, and an actuator physically coupled to the mixing valve for adjusting a position of the mixing valve to increase turbulence in air entering the vapor canister. The position of the mixing valve may be adjusted to increase an amount of turbulence in air entering the fuel vapor canister.

Owner:FORD GLOBAL TECH LLC

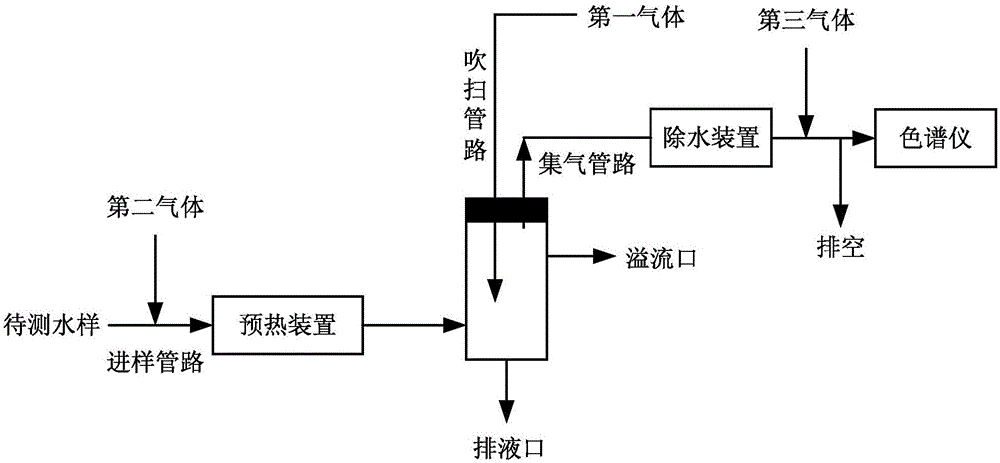

Pretreatment device and pretreatment method for online monitoring of underwater volatile organic compounds

InactiveCN106645520AStable temperatureReduce dosageComponent separationWater storagePretreatment method

The invention relates to a pretreatment device for online monitoring of underwater volatile organic compounds. The pretreatment device comprises a sweeping container, a feeding pipeline, a sweeping pipeline and a gas collecting pipeline. The feeding pipeline, the sweeping pipeline and the gas collecting pipeline are connected with the sweeping container. The pretreatment device further comprises a preheating device, a dewatering device and a cover. A to-be-detected water sample is heated by the preheating device to a preset temperature and then enters the sweeping container. The dewatering device is arranged on the gas collecting pipeline. A gas inlet of the dewatering device is lower than a gas outlet. A water storage container is arranged below the joint between the gas inlet and the gas outlet, and is communicated with the gas inlet and the gas outlet. The cover covers the sweeping container to seal the sweeping container. The sweeping pipeline and the gas collecting pipeline penetrate the cover to be respectively connected with first gas and a chromatographic instrument. The invention further provides a pretreatment method for online monitoring of the underwater volatile organic compounds. The pretreatment device has the advantages of simple structure, high sweeping efficiency, low maintenance cost, accuracy of detection results and the like.

Owner:FOCUSED PHOTONICS

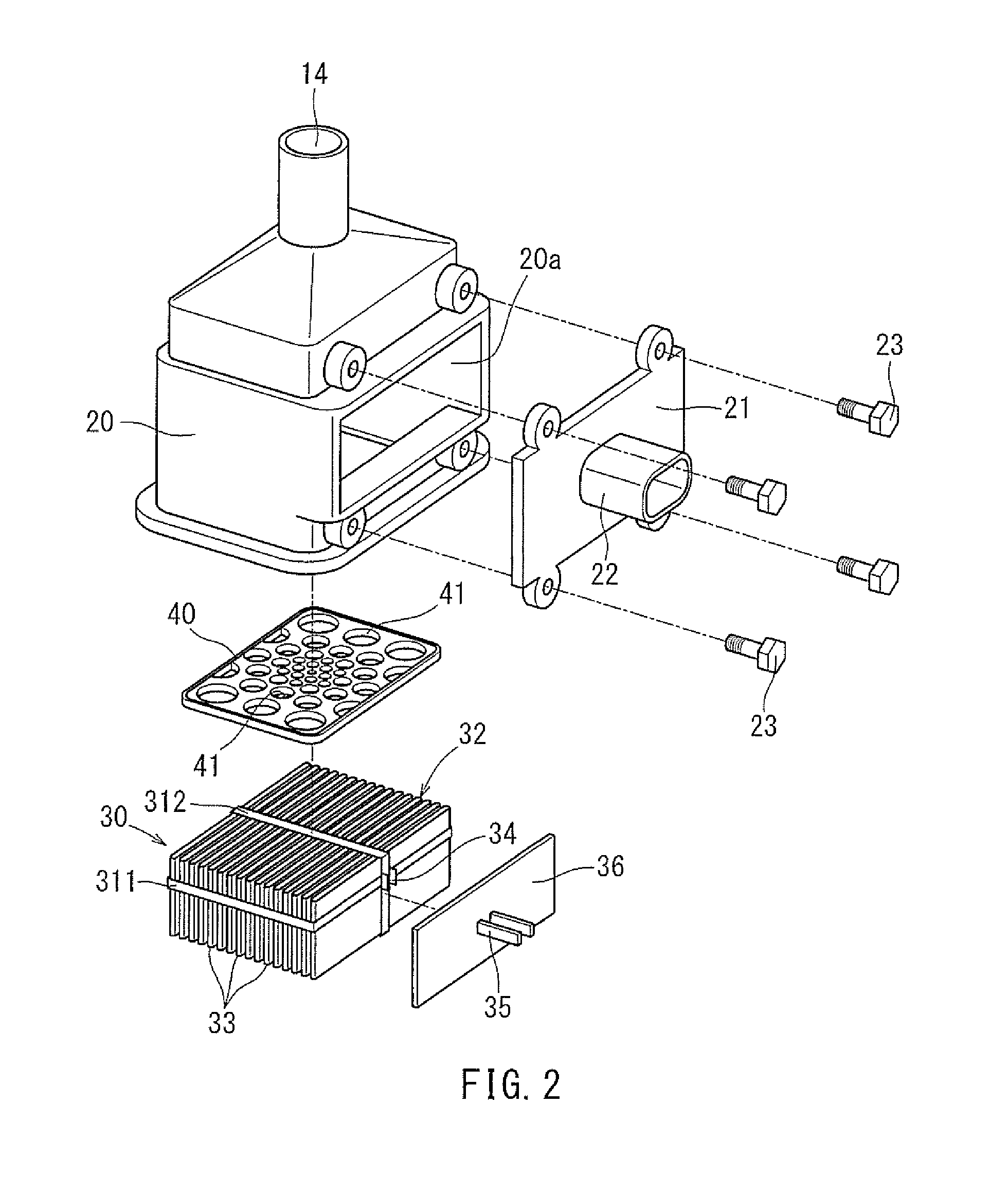

Vaporized fuel processing apparatus

InactiveUS20160076490A1Improve fuel efficiencyUniform supplyElectrical controlNon-fuel substance addition to fuelElectricityAtmospheric air

A vaporized fuel processing apparatus has a casing defining an adsorption chamber therein and having a tank port, a purge port, and an atmospheric port. The tank port is connected to a fuel tank. The purge port is connected to an internal combustion engine. The atmospheric port is open to the atmosphere. A heater is disposed between the adsorption chamber and the atmospheric port and has a fin heat exchanger and a heating element. The heating element is configured to generate heat by electricity supply. The fin heat exchanger is joined to the heating element. The surface area of the fin heat exchanger between the heating element and the adsorption chamber is larger than the surface area of the fin heat exchanger between the heating element and the atmospheric port.

Owner:AISAN IND CO LTD

Online-detection side spraying angle adjusting device and adjusting method

ActiveCN104841702AImprove purge efficiencyEasy to purgeWork treatment devicesMeasuring devicesEngineeringInverted-T shape

The invention discloses an online-detection side spraying angle adjusting device and adjusting method. The device comprises four semicircular arc-shaped plates matched with working rollers, two long T-shaped strips and four photoelectric detection blocks. Sliding grooves penetrating the upper ends of the arc-shaped plates in the longitudinal direction are formed in the upper portions of the arc-shaped blocks, and cross sections of the two long T-shaped strips are in inverted-T shapes; the long T-shaped strips are embedded in the sliding grooves of the front arc-shaped plate and the rear arc-shaped block respectively; sliding grooves are formed in the two photoelectric detection blocks which are oppositely and transversely arranged, and the photoelectric detection blocks are mounted on the T-shaped strips through the sliding grooves in a sliding manner; and a plurality of photoelectric tubes are arranged on three of the photoelectric detection blocks respectively in the longitudinal direction and the transverse direction so as to divide a blowing area into a plurality of small areas. The adjusting method comprises the steps that the blowing area is divided into the small areas through the plurality of red photoelectric tubes which are longitudinally and transversely arranged; each gas blowout part is provided with one photoelectric tube which can emit red light beams; and each gas blowout part controls one longitudinal area, and all the gas blowout parts cover the whole width range. According to the method and device, the gas blowout blowing efficiency and the blowing locating accuracy are improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Purging device and automatic filter cleaning device with purging device

PendingCN111151512AAvoid harmSolve efficiency problemsDirt cleaningCleaning using gasesWorking environmentProcess engineering

The invention is applicable to the technical field of cleaning devices, and provides a purging device and an automatic filter cleaning device with the purging device. The purging device comprises a shell, a purging mechanism, a recycling mechanism and a distributing chamber used for conveying compressed gas to the purging mechanism to perform purging on an object to be cleaned; the purging mechanism comprises a mounting base, and the mounting base is rotationally connected with a mounting seat through a rotating piece; and the distributing chamber is further used for conveying the compressed gas to a driving pipeline used for blowing the rotating piece to drive the mounting seat to rotate. According to the purging device, the compressed air is conveyed to the driving pipeline through the distributing chamber to blow the rotating piece to drive the mounting seat to rotate, and meanwhile, the compressed air is conveyed to the purging mechanism to perform purging on the object to be cleaned in cooperation with the distributing chamber, so that the purging efficiency is effectively improved; and impurities such as oil mist generated during cleaning are recycled through the recycling mechanism, so that the problems that due to the fact that most of existing filter purging operations adopt manual filter purging, the working efficiency is low, and the working environment is prone to be polluted are solved.

Owner:NANJING CHANGJIANG WATERWAY ENG BUREAU

Electric heating and blowing defrosting device for optical window

ActiveCN104034027AImprove heating efficiencyIncreased purge heat rangeAir heatersElectricityEngineering

The invention provides an electric heating and blowing defrosting device for an optical window. The electric heating and blowing defrosting device comprises a miniature vacuum pump and airflow heating portions. The miniature vacuum pump is used for pumping airflow to airflow distributing cavities, heating rods are arranged in the airflow heating portions, the airflow heating portions are used for heating the airflow, and the miniature vacuum pump, the airflow distributing cavities and the airflow heating portions are connected with one another by rubber hoses. The electric heating and blowing defrosting device has the advantages that the electric heating rods are suspended in the centers of supporting seat shells by front and rear supports, the airflow flows through uniform gaps around the heating rods, and accordingly the heating efficiency can be improved; the airflow is divided into multiple channels to be outputted, and accordingly blowing and heating ranges can be expanded; the high-pressure airflow is provided by the miniature vacuum pump, and accordingly the blowing efficiency can be improved.

Owner:BEIJING HUAHANG RADIO MEASUREMENT & RES INST

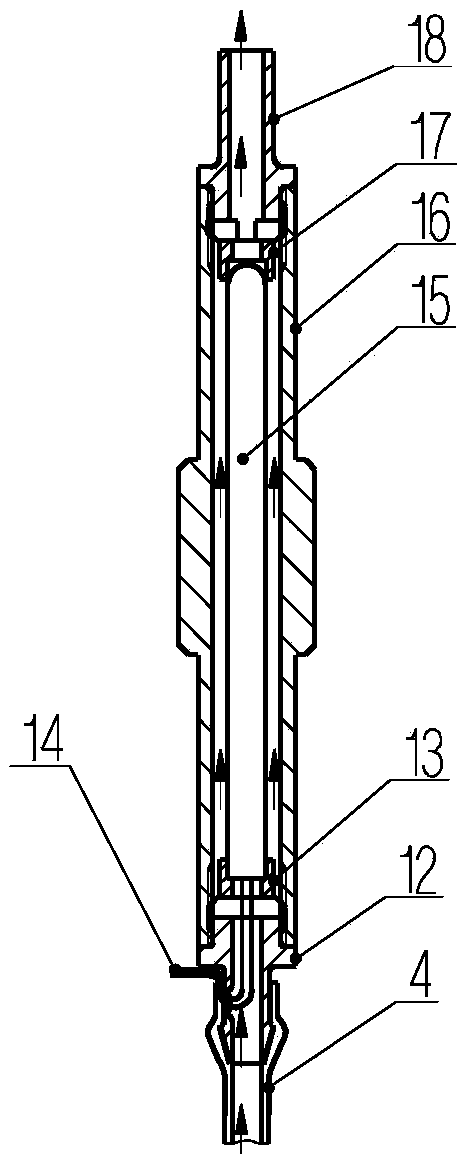

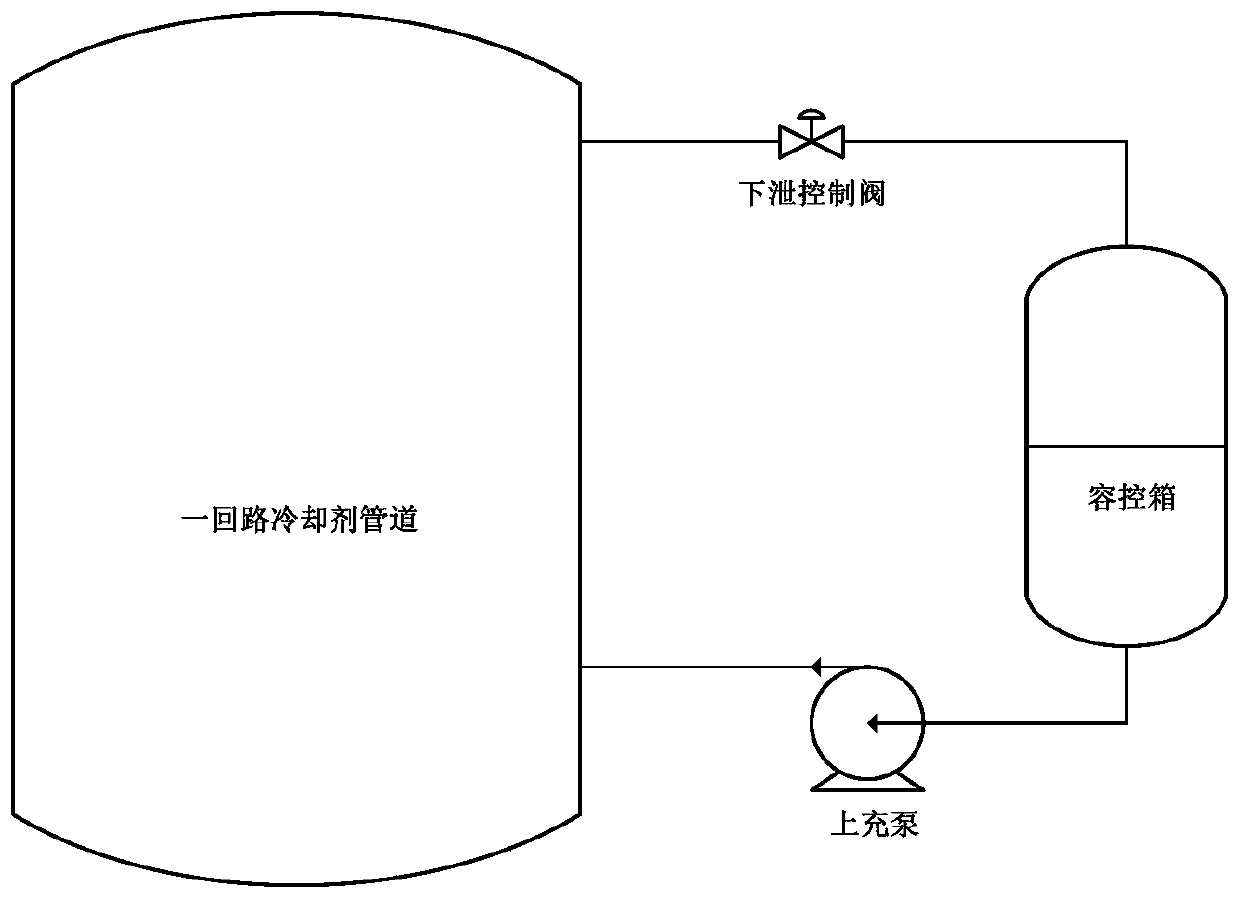

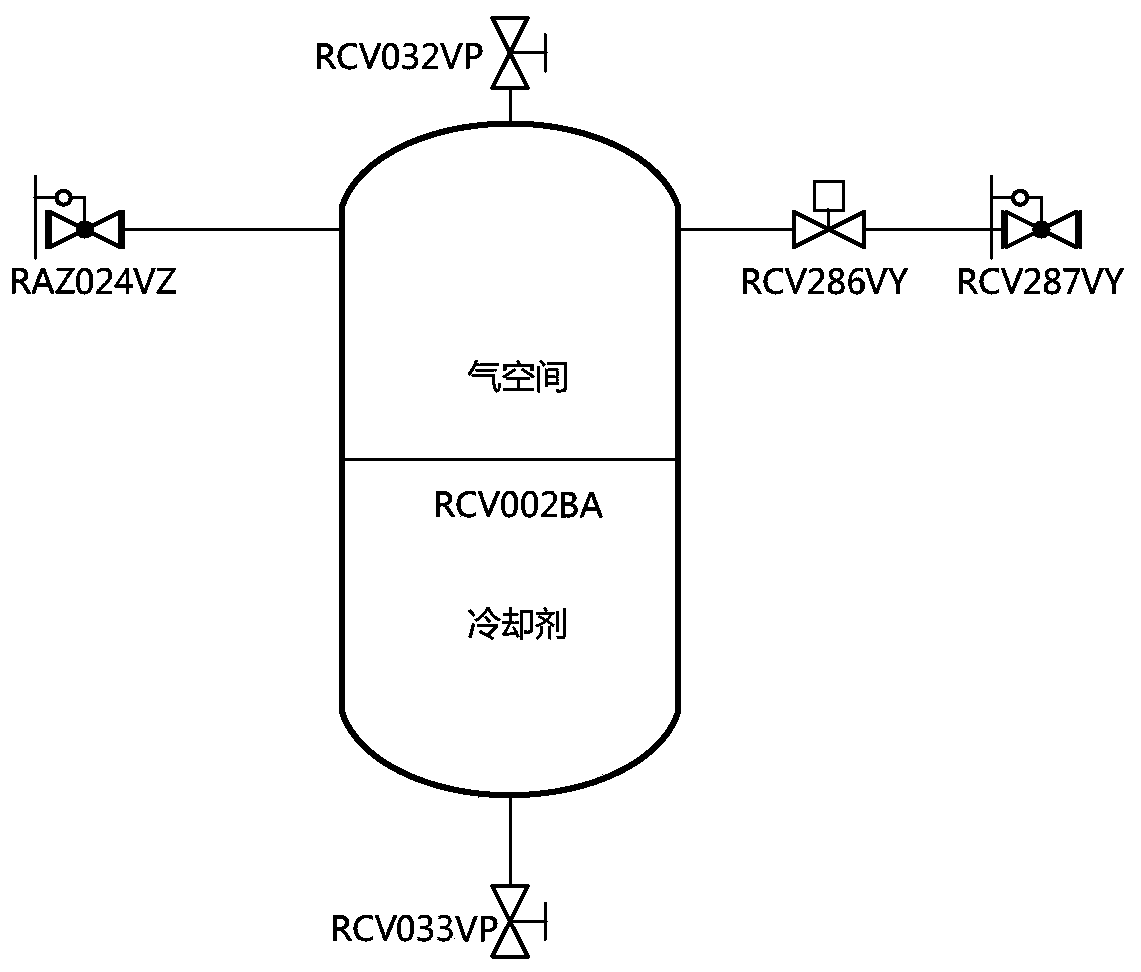

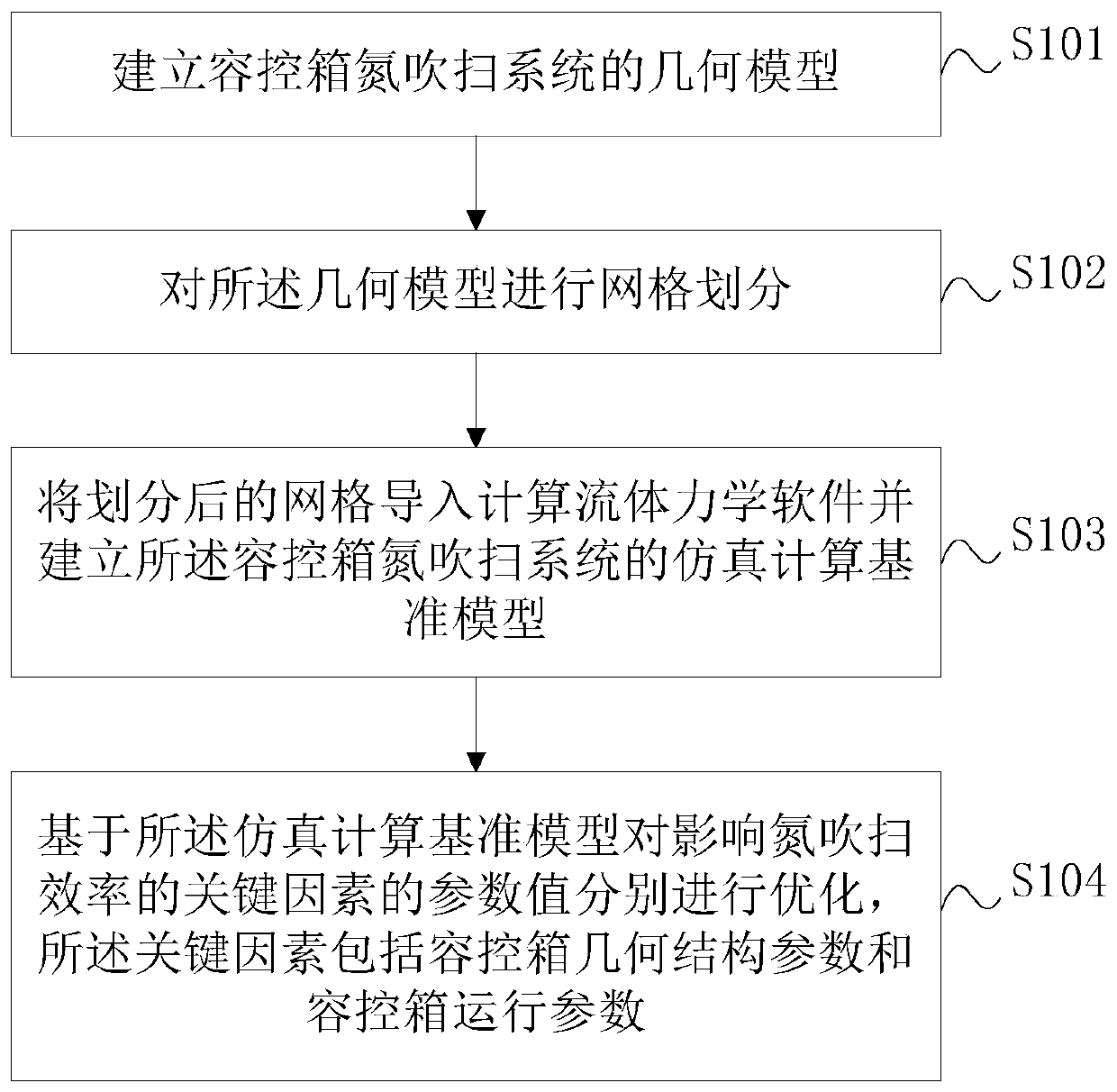

Nuclear power plant capacity control box nitrogen purging efficiency optimization method

ActiveCN109858175AOptimization of purge efficiencyImprove purge efficiencySpecial data processing applicationsReference modelNitrogen

The invention discloses a nuclear power plant capacity control box nitrogen purging efficiency optimization method. The method comprises the steps of establishing a geometric model of a capacity control box nitrogen purging system; meshing on the geometric model; importing the divided grids into computational fluid mechanics software and establishing a simulation calculation reference model of thenitrogen purging system of the capacity control box; optimizing parameter values of key factors influencing the nitrogen purging efficiency based on the simulation calculation reference model, the key factors comprise geometric structure parameters of the capacity control box and operation parameters of the capacity control box. The physical deoxygenation process of the volume control box is optimized and analyzed based on the computational fluid simulation technology, so that the nitrogen purging process can be optimized on the premise that the dynamic and static exhaust qualification standard and the nitrogen purging stage target of the volume control box are not changed; moreover, the method provided by the invention provides a theoretical scheme for improving the purging efficiency ofthe capacity control box, can greatly reduce the research cost compared with a common test bed method, can effectively improve the purging process of the capacity control box, and improves the economic benefits.

Owner:SUZHOU NUCLEAR POWER RES INST +3

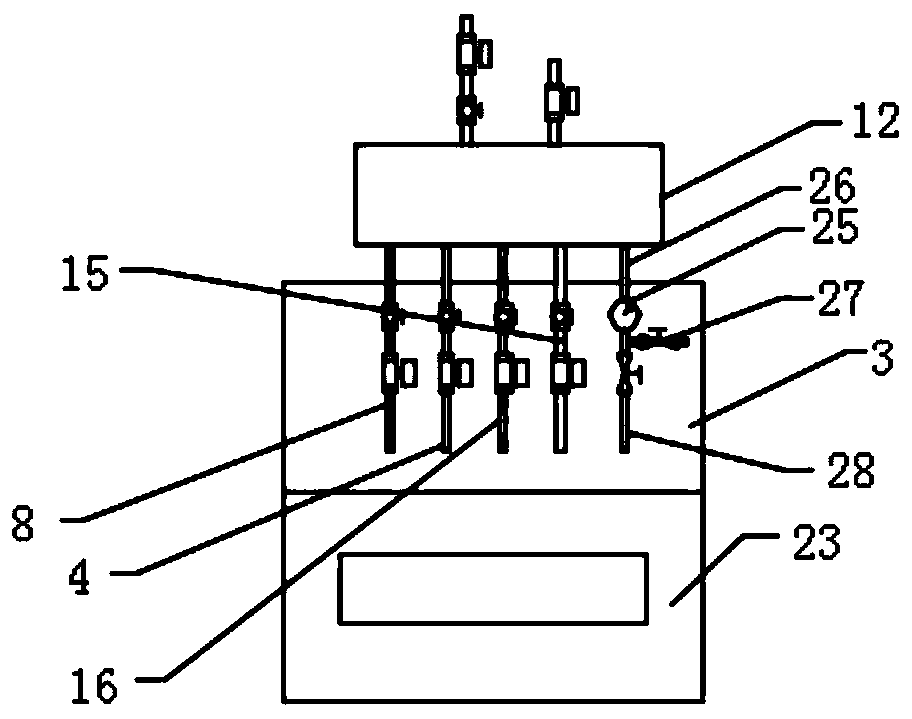

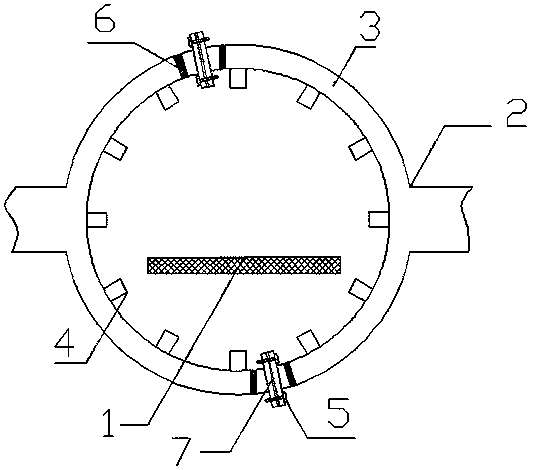

Multi-channel full-automatic termovap sample concentrator and concentrated solution detection and control method

InactiveCN111855379AConsistent purge conditionsImprove accuracyPreparing sample for investigationSimultaneous control of multiple variablesWater bathsCirculator pump

A multi-channel full-automatic termovap sample concentrator and a concentrated solution detection and control method belong to the field of laboratory instruments. A plurality of water bath tanks arearranged, the plurality of water bath tanks are uniformly arranged at the periphery of a turntable; test tube racks are arranged on the water bath tanks; purging support frames are arranged on the test tube racks; the used water and gas are heated by a heating part and are respectively conveyed to water distribution pipes and purging needles; photoelectric detection devices for detecting the liquid levels of sample solutions in test tubes are arranged beside the water bath tanks; the inner sides of the water bath tanks are communicated with auxiliary water tanks; the test tube racks and the auxiliary water tanks are respectively connected with respective lifting devices; and the lifting devices, the sample liquid level photoelectric detection devices and a cyclic pump are electrically connected with a controller. By means of the device and method, the solution evaporation speed can be increased, the purging efficiency can be improved, and therefore the experiment precision under the same condition can be obtained, errors can be reduced, and the recovery rate and the analysis precision of samples can be improved.

Owner:李明亮

EVAP system with valve to improve canister purging

InactiveUS20170009673A1Reduced steam emissionsEmission reductionElectrical controlNon-fuel substance addition to fuelEngineeringFuel vapor

Systems and methods are provided for an evaporative emissions control system. In one example, a system for an engine may comprise a fuel vapor canister, a mixing valve positioned in a fresh air line upstream of the vapor canister, and an actuator physically coupled to the mixing valve for adjusting a position of the mixing valve to increase turbulence in air entering the vapor canister. The position of the mixing valve may be adjusted to increase an amount of turbulence in air entering the fuel vapor canister.

Owner:FORD GLOBAL TECH LLC

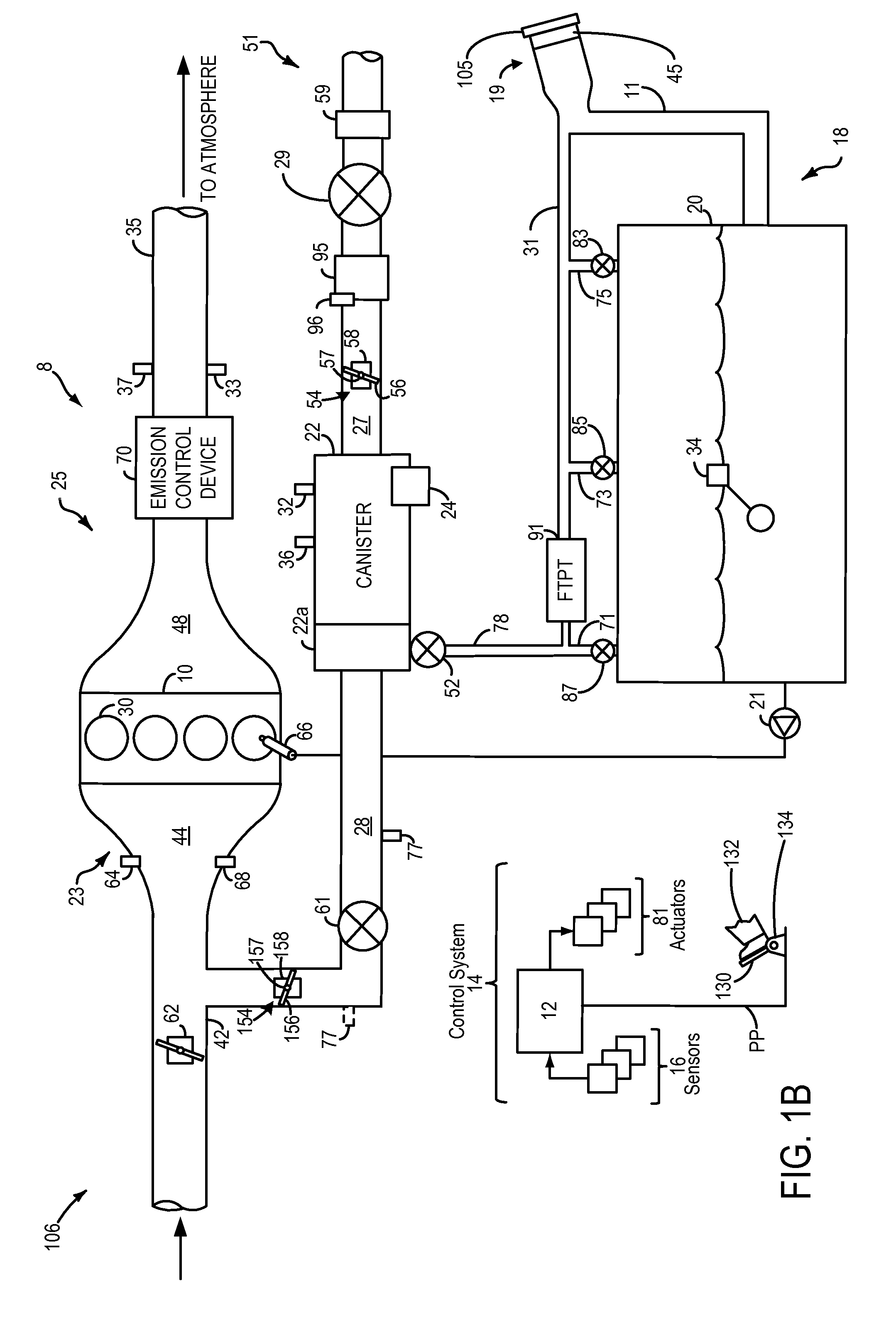

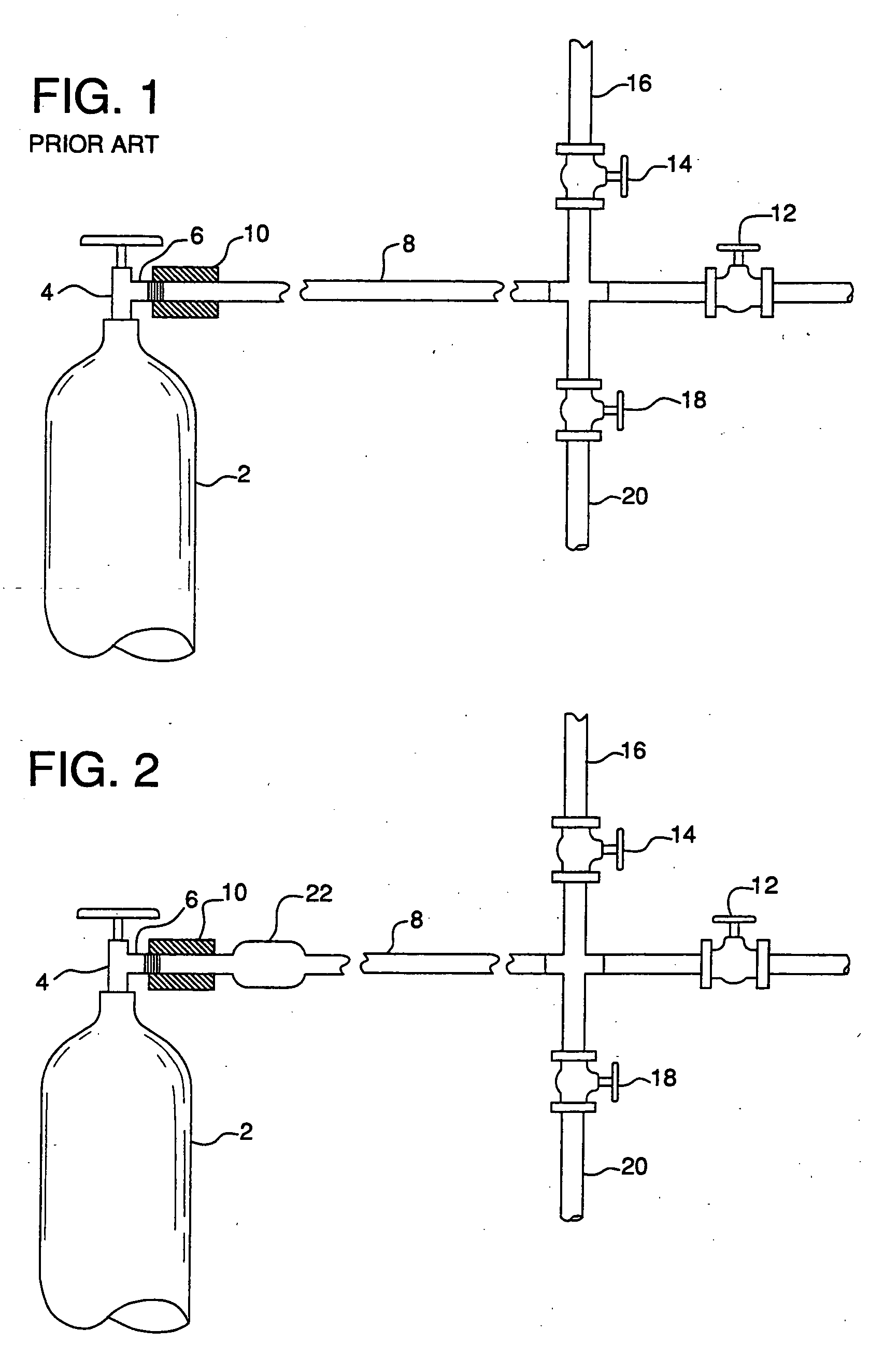

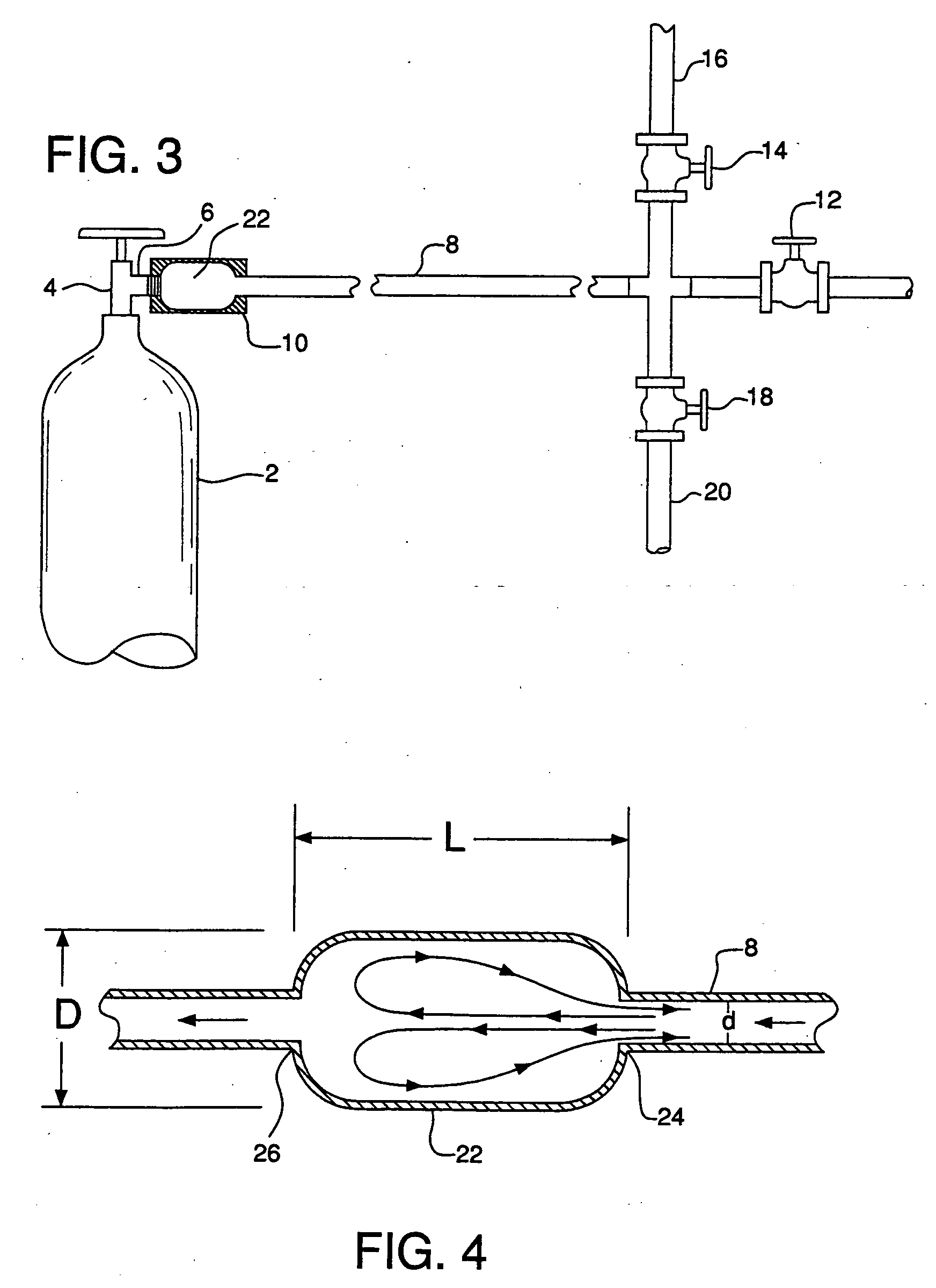

Enhanced purge effect in gas conduit

InactiveUS20060254645A1Improve purge efficiencyLow impurity contentContainer filling methodsPipeline systemsPigtailEngineering

The present invention provides an improved gas transfer apparatus designed for enhanced purging of a pigtail and a process for effecting such purging. The improvement in the apparatus resides in an integrated system of components comprising: a surge chamber having a first end, a body and a second end, said first end in communication with the pigtail conduit, said body section of said surge chamber having a cross-section larger than the cross-section of said pigtail conduit and a second end in communication with said vessel containing said gas source; and, a purge gas source for delivery of a purge gas to said pigtail conduit whereby during an alternating cycle of pressurization of said pigtail with said purge gas and depressurization, optionally with application of vacuum within said pigtail conduit, impurities can be removed from within the pigtail conduit.

Owner:VERSUM MATERIALS US LLC

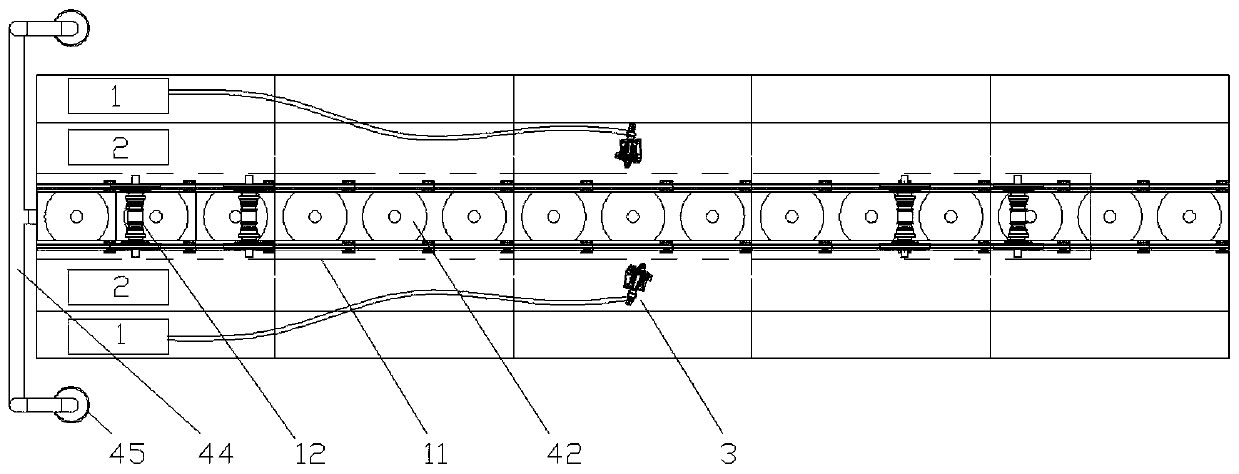

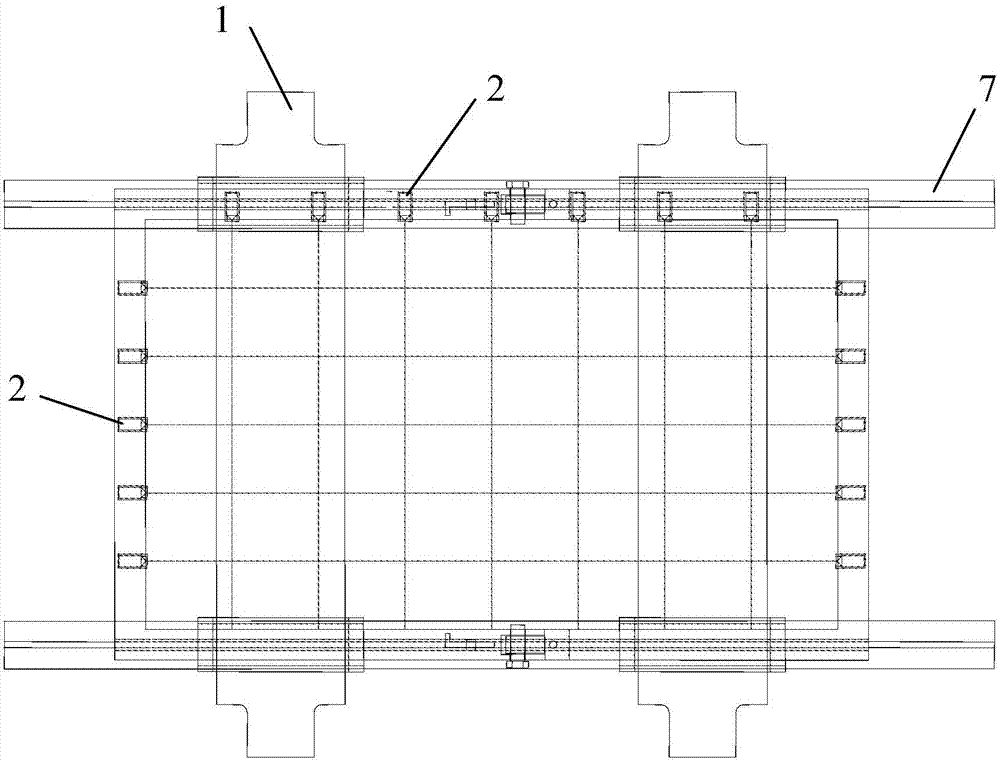

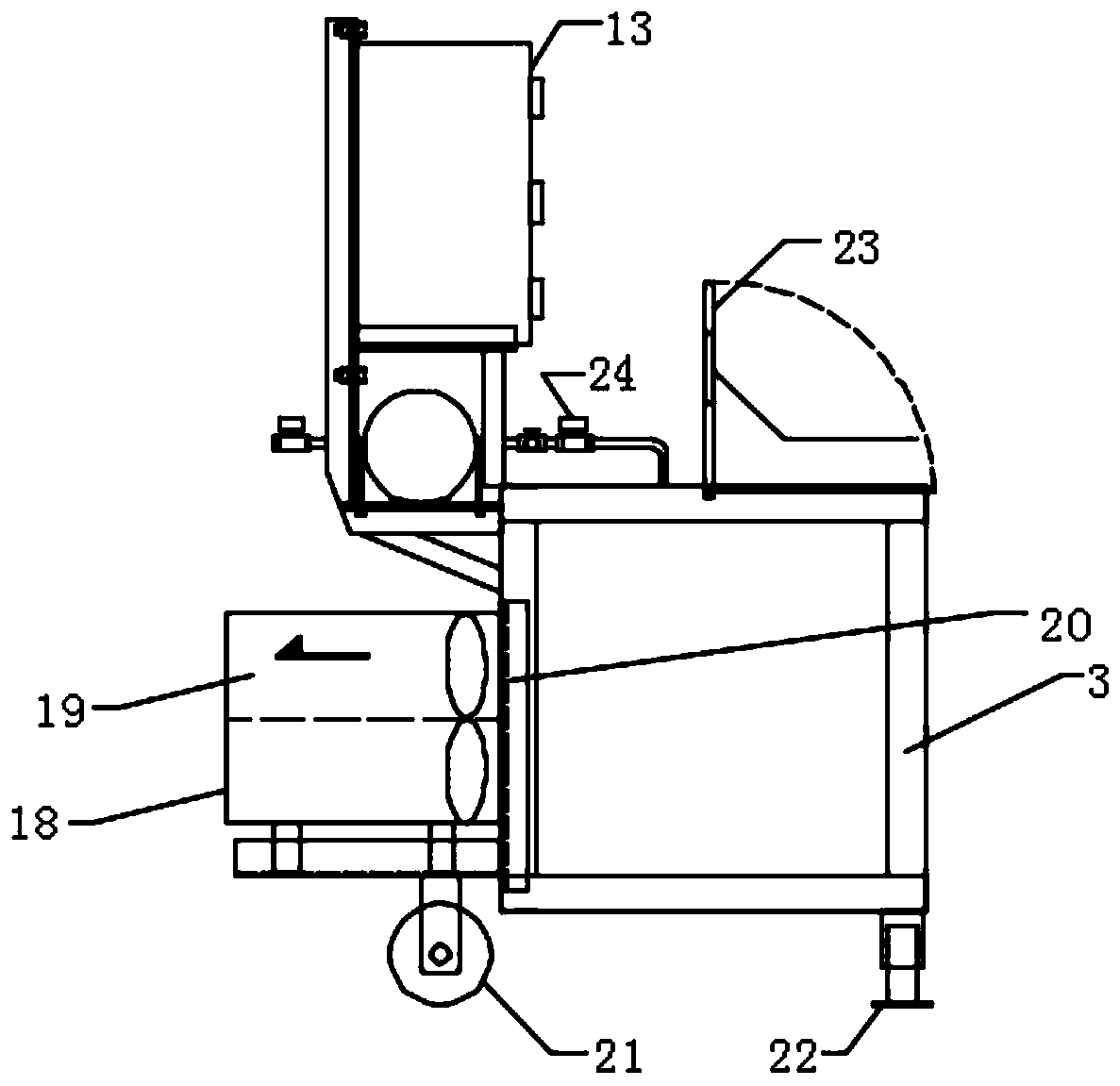

Counter-flow-type intelligent purging system and method of unilateral pathway

ActiveCN109733336AEfficient removalImprove working environmentVehicle cleaning apparatusRailway transportCounter flowPollution

The invention discloses a counter-flow-type intelligent purging system of a unilateral pathway. The counter-flow-type intelligent purging system includes a wind supply system, a movable purging systemand an exhausting and dedusting system; the movable purging system includes an electromagnetic guided AGV of a movable purging robot at the bottom and a multi-section type dedusting unit arranged atthe opposite side, the electromagnetic guided AGV drives along preset electromagnetic guided metal wire cables arranged on the two sides of a pathway of an inspection pin vehicle, and a counter-flow channel is formed. According to the counter-flow-type intelligent purging system, vehicle dust is quickly and efficiently cleaned, the operation environment in a purged garage is improved, purging of the vehicle bottom and side of a pathway transport vehicle is achieved, leading wires are hidden through a electromagnetic guided mode, pollution and damage are avoided, when the model and the marshalling length of a purged vehicle are changed, a purging road can be expanded or changed according to the requirements of vehicle purging, and the counter-flow-type intelligent purging system has the advantages that location is precise, flexibility is high, and assembling and disassembling are convenient; and counter-flow-type blowing-suction is achieved, the structure of whole composition is compact, the occupied space is small, and the purging efficiency is high.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Device for purging tapping scrap iron on engine cylinder head production line

PendingCN110102838AGuaranteed to be properly screwedImprove purge efficiencyThread cutting machinesMaintainance and safety accessoriesProduction lineCylinder head

The invention discloses a device for purging tapping scrap iron on an engine cylinder head production line. The device is located on a purging station workbench and comprises a side platform, a firstdriving system, a second driving system, half buckles, a first purging pipeline system, a second purging pipeline system, a first purging pipe and a second purging pipe, wherein the side platform is fixedly connected with the side edge of the purging station workbench; the first driving system is fixedly connected with the upper end of one side of the side platform; the second driving system is fixedly connected with the upper end of the other side of the side platform; the first purging pipeline system is fixedly connected with a first support through the half buckles; the second purging pipeline system is fixedly connected with a second support through the half buckles; and the first purging pipeline system and the second purging pipeline system respectively communicate with the first purging pipeline system and the second purging pipeline system. The device has the advantages of having no influence on the machining precision of the next process and ensuring normal screwing of boltsduring assembly; labor force is liberated; and the metal dust does not affect the health of workers, the purging is high in efficiency and not forgotten.

Owner:Y & C ENGINE

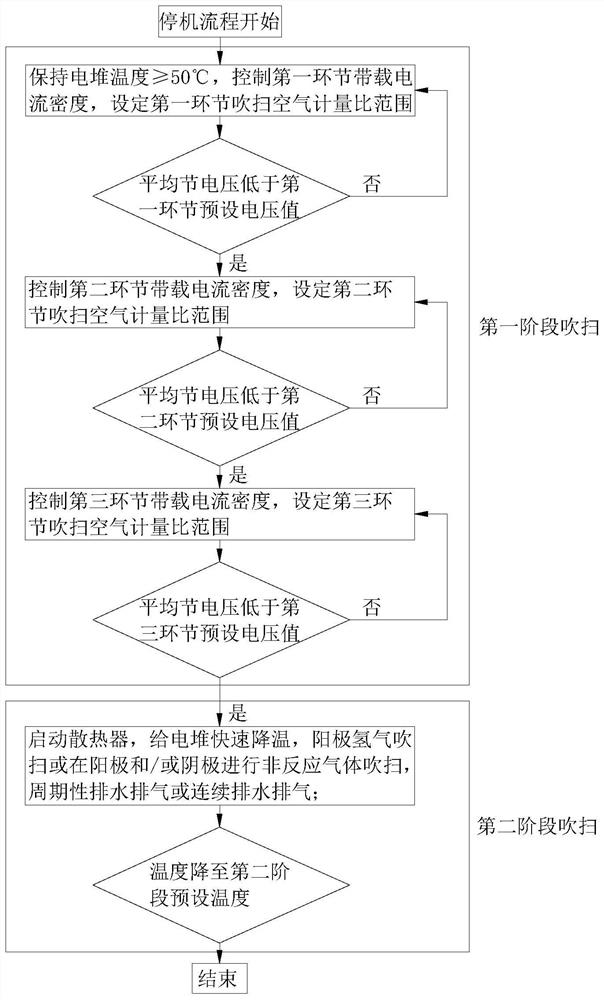

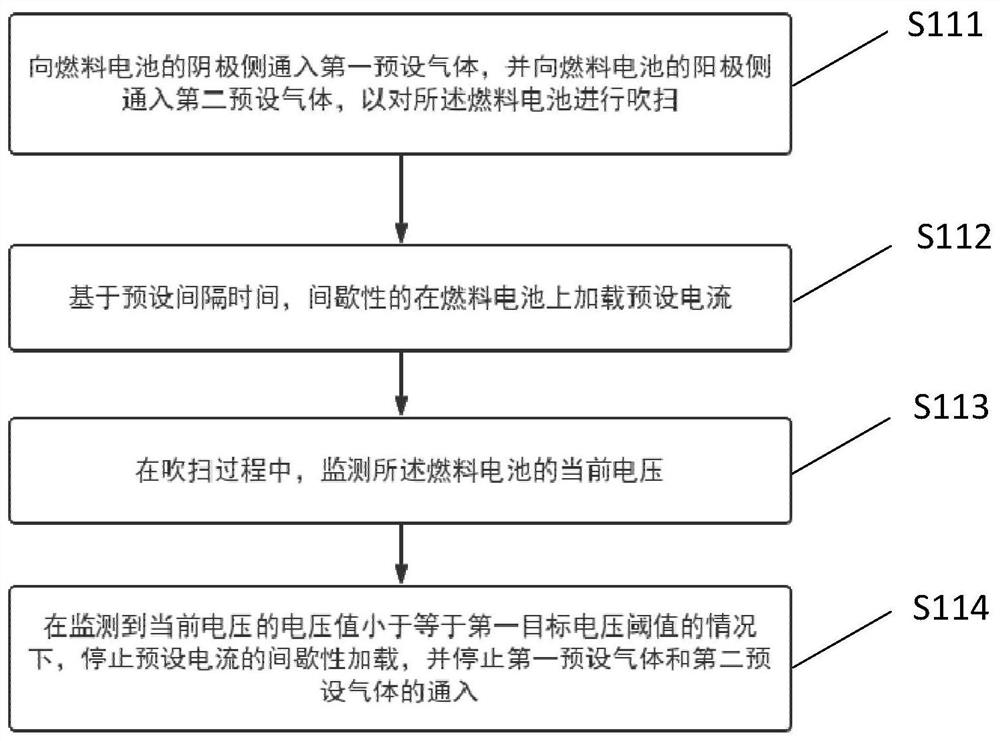

Shutdown purging method for fuel cell system

PendingCN114447375AReduce water productionReduced purge timeWater management in fuel cellsAutomotive engineeringProcess engineering

The invention belongs to the technical field of fuel cells, and particularly relates to a shutdown purging method for a fuel cell system. According to the technical scheme, the shutdown purging method for the fuel cell system comprises the following steps: first-stage purging: setting a first-stage preset temperature, and maintaining the temperature of a cooling medium at an inlet or an outlet of a fuel cell to be greater than or equal to the first-stage preset temperature; loading current, and purging the fuel cell until the monitored voltage is less than a preset voltage value; second-stage purging: forcibly cooling the galvanic pile, and introducing gas into the galvanic pile for purging; and setting a second-stage preset temperature, and stopping cooling and purging when the temperature of the fluid medium at the inlet or the outlet of the fuel cell is lower than the second-stage preset temperature, or reaches the set purging time, or reaches the set voltage mean value or minimum value. The fuel cell system shutdown purging method provided by the invention is high in purging efficiency and prevents condensate water from remaining in an electric pile.

Owner:DONGFANG ELECTRIC (CHENGDU) HYDROGEN FUEL CELL TECH CO LTD

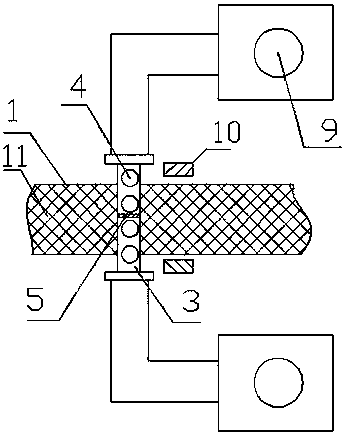

Workpiece cleaning device

InactiveCN107824552ASpeed up the purgeImprove purge efficiencyCleaning using gasesSurface coolingAnnular duct

The invention discloses a workpiece cleaning device, which includes a conveyor belt. Annular spray guns are arranged on both sides of the conveyor belt. The annular spray guns include a C-shaped air pipe and a plurality of spray heads. At least two spray heads are arranged on the C-shaped air pipe, and adjacent The gap between the nozzles is the same, the two ends of the above-mentioned C-shaped air pipe are provided with pipe plugs, and the end of the above-mentioned C-shaped air pipe is also provided with a flange plate, which solves the problem of cleaning the coolant and metal chips on the surface of the workpiece, which takes a long time and affects work efficiency. The problem.

Owner:成都龙泉马龙机械厂

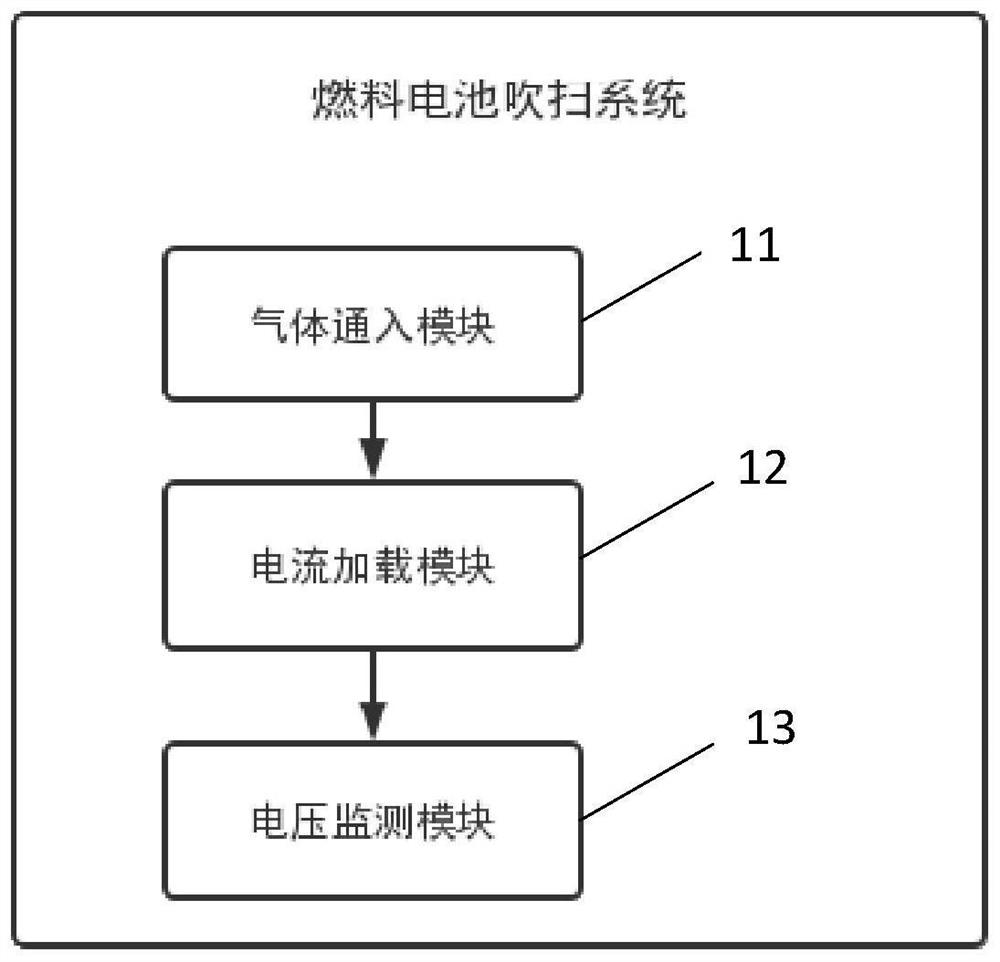

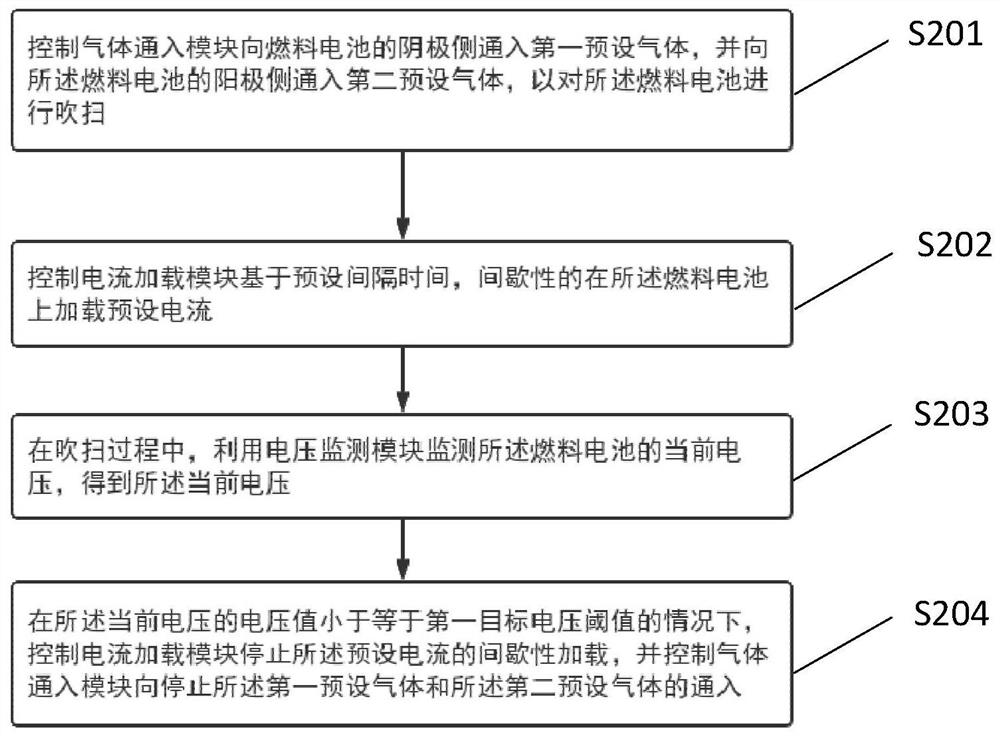

Fuel cell purging method, system, control method and control device

The invention relates to the technical field of fuel cells, and discloses a fuel cell purging method and system, a control method and a control device.The method comprises the steps that first preset gas is introduced into the cathode side of a fuel cell, and second preset gas is introduced into the anode side of the fuel cell, so that the fuel cell is purged; intermittently a preset current on the fuel cell is loaded based on the preset interval time; the voltage of the fuel cell in the purging process is monitored; and when it is monitored that the voltage value of the current voltage is smaller than or equal to the first target voltage threshold value, intermittent loading of the preset current is stopped, and introduction of the first preset gas and the second preset gas is stopped. In the purging process of the fuel agent cavity and the oxidizing agent cavity of the fuel cell, purging is carried out by monitoring the voltage of the fuel cell, loading the fuel cell for multiple times and stopping loading the current, the drying speed of water in the fuel cell can be increased, and the purging efficiency of the fuel cell is improved.

Owner:CHINA AUTOMOTIVE INNOVATION CORP

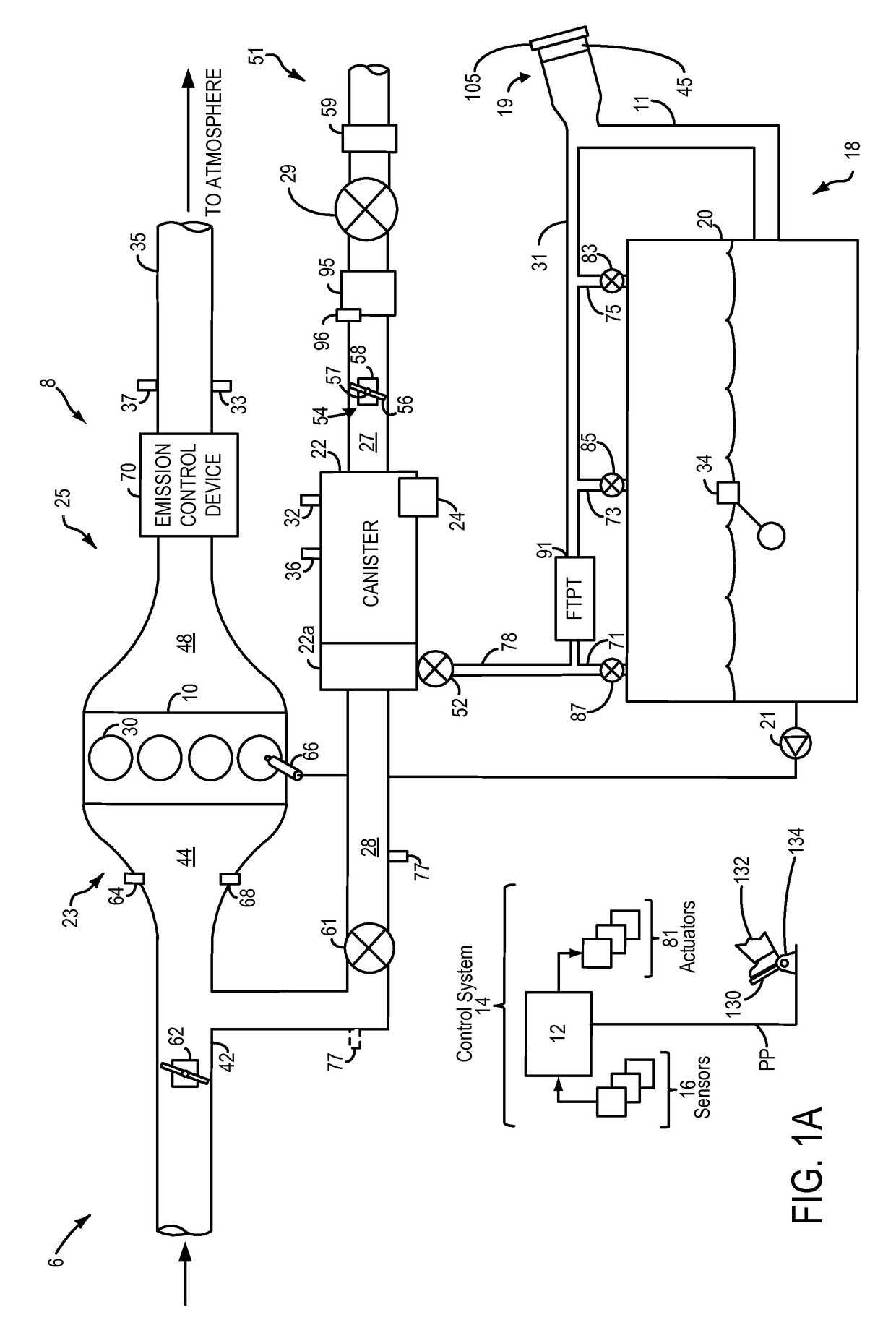

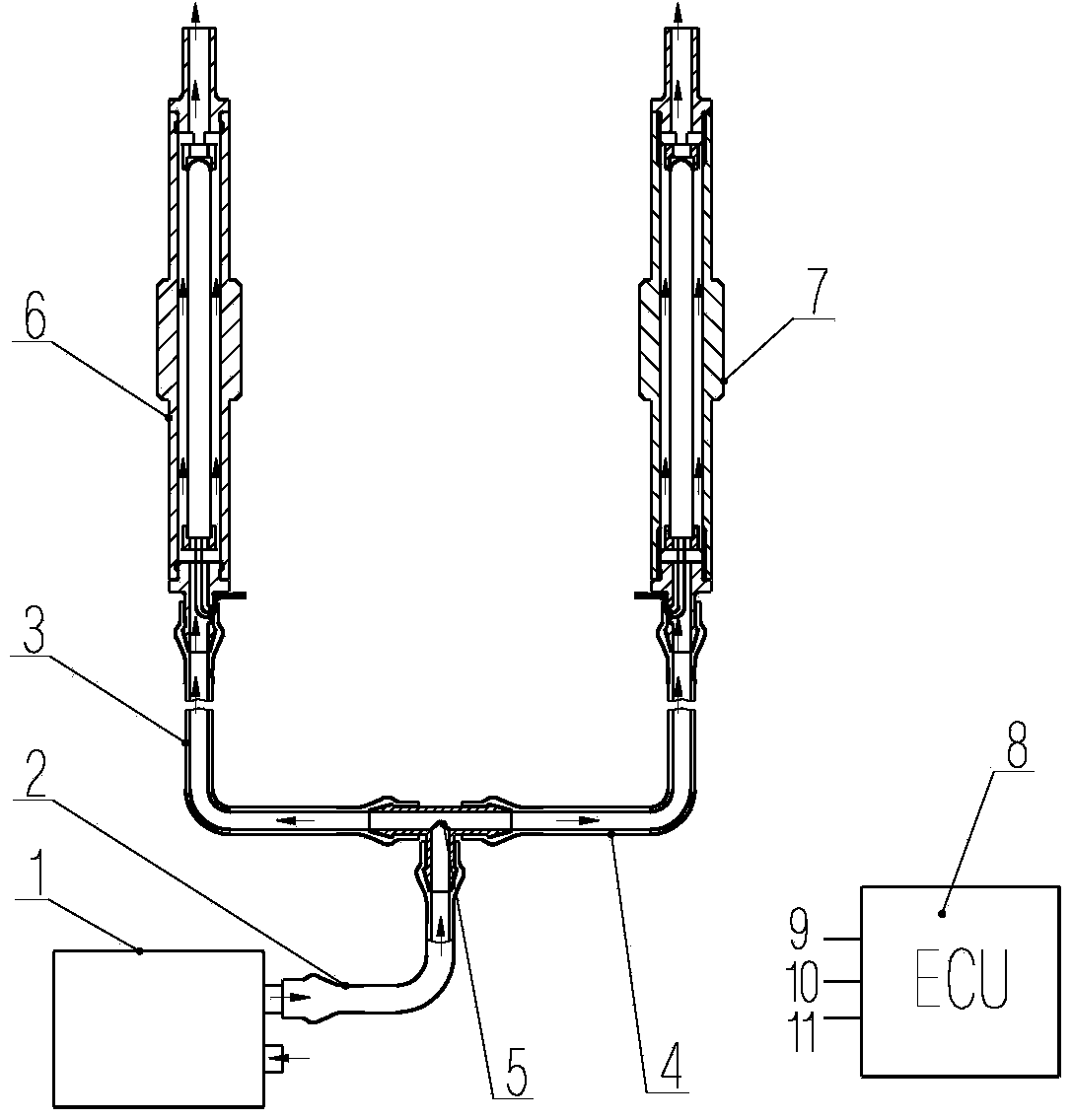

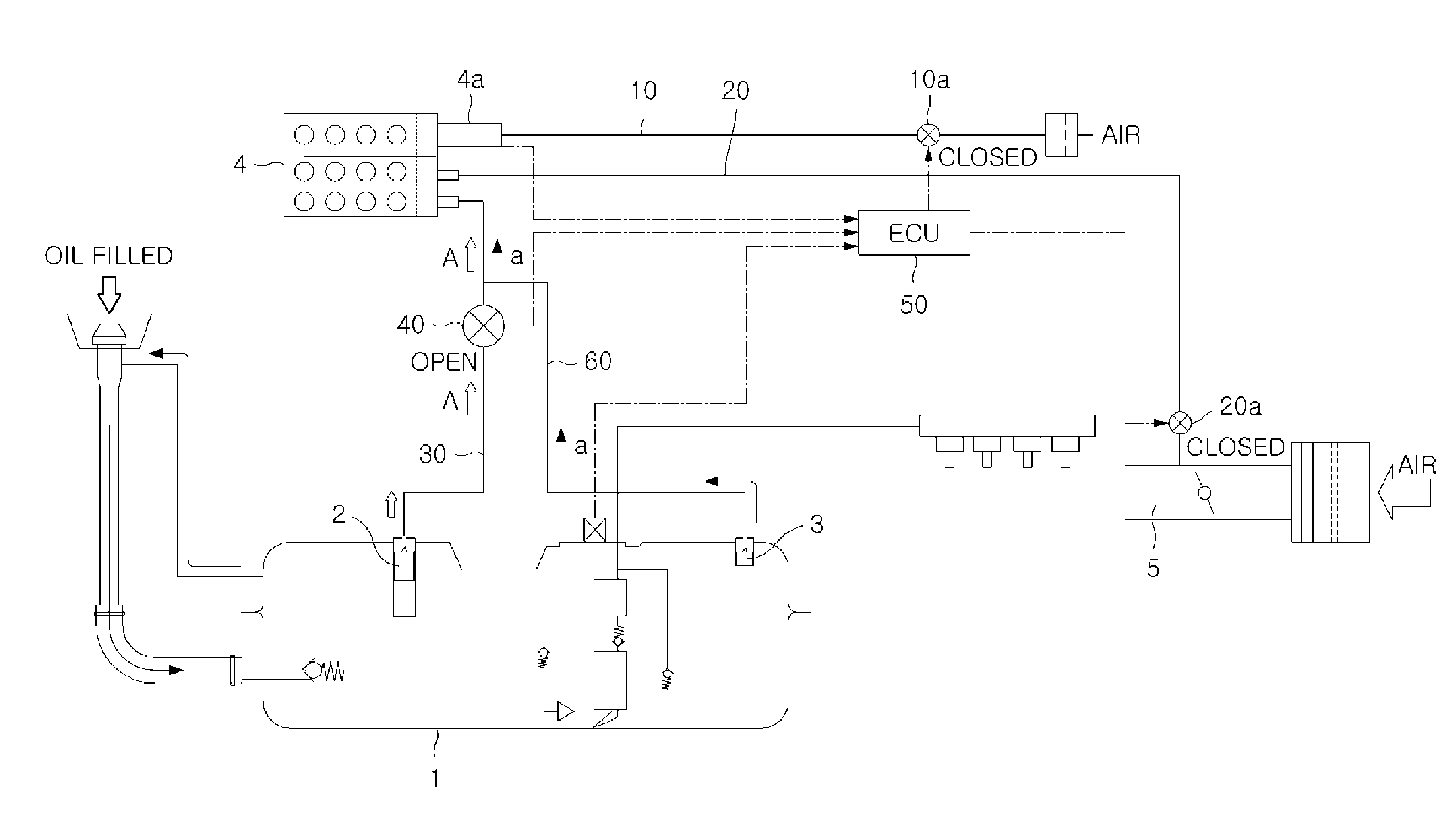

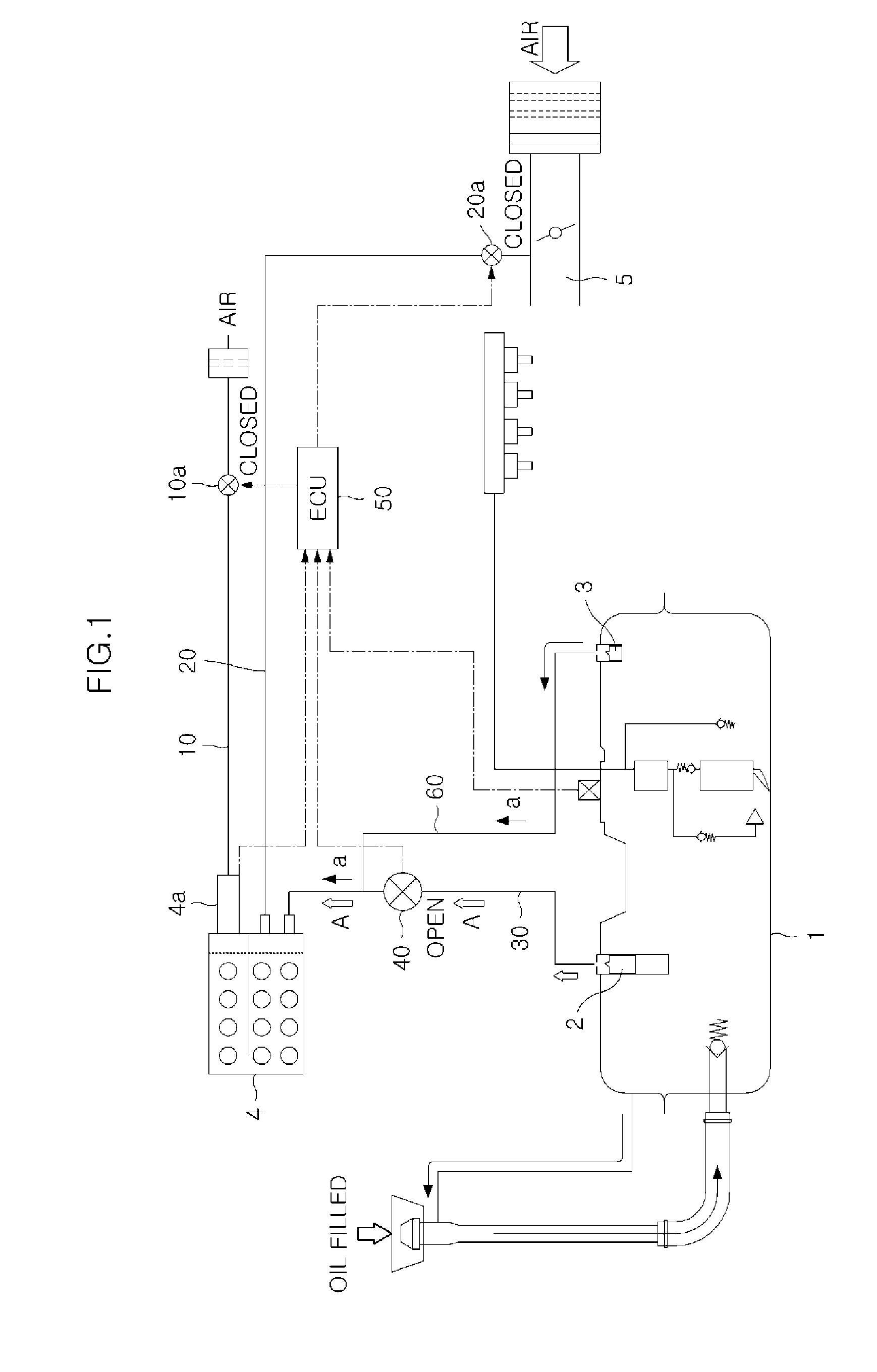

Fuel tank vaporization gas purge system

InactiveUS20120138169A1Increase capacityImprove efficiencyOperating means/releasing devices for valvesNon-fuel substance addition to fuelLine tubingHydrocotyle bowlesioides

A fuel tank vaporization gas purge system may include a fuel tank with a vent valve and a roll over valve disposed for discharging a vaporization gas, a canister for absorbing / detaching a hydrocarbon in the vaporization gas, a vent line and a sub-vent lines connected to the canister to the vent valve and the roll over valve, a vapor control valve disposed in either the vent line or the sub-vent line, and an electronic control unit (ECU) electrically connected to said vapor control valve and selectively opening / closing said vapor control valve based on a type of said vapor control valve and operating conditions of a vehicle. The vapor control valve may be of an open valve type and closed by the ECU when an engine is in purging, or of a close valve type and opened by the ECU when an engine is turned off or during refueling.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com