Electric heating and blowing defrosting device for optical window

A blowing defrosting and optical window technology, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as the absence of multiple needs, and achieve improved heating efficiency, improved purging and heating range, and improved Effect of purge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail below with reference to the accompanying drawings. It should be noted that the following preferred embodiments are not intended to limit the present invention.

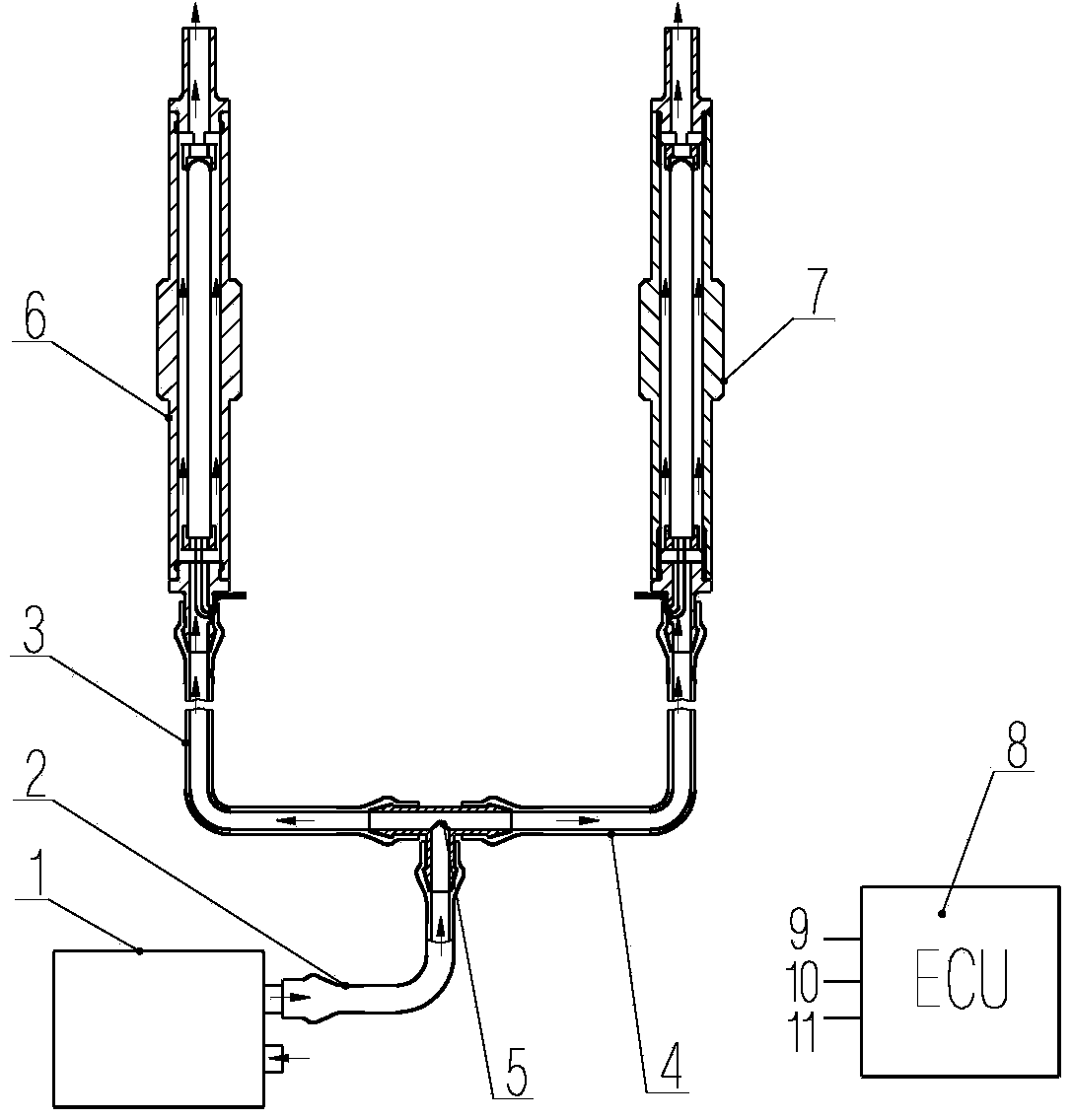

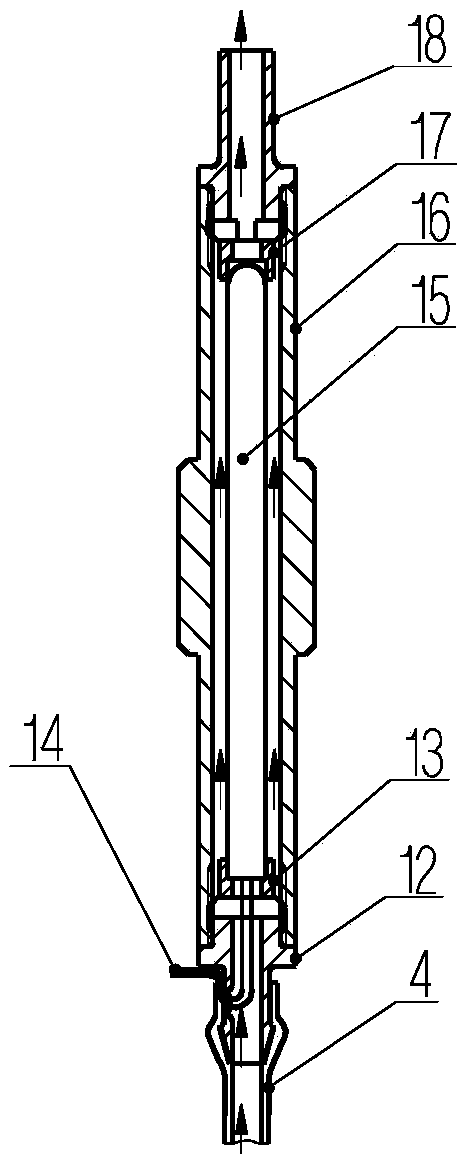

[0022] refer to figure 1 , which shows an electric heating blower defrosting device of the present invention, including a micro-vacuum pump 1, rubber hoses 2, 3, 4 of the air pipeline, a split tee 5 and two sets of heating parts 6, 7. It is characterized in that the high-pressure airflow output by the micro-vacuum pump 1 reaches the tee 5 through the rubber hose 2, and is divided into two paths. The air is blown out from the blowing nozzle after being heated by the heating part.

[0023] In this embodiment, the form of two-way blowing pipes is adopted, but the form of multi-way blowing pipes can be adopted as required. After the air flow comes out from the vacuum pump, it first enters the air distribution cavity, and after the air flow is evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com