Apparatus including 4-way valve for fabricating semiconductor device, method of controlling valve, and method of fabricating semiconductor device using the apparatus

a technology of apparatus and semiconductor, applied in the direction of transportation and packaging, chemical vapor deposition coating, coating, etc., can solve the problems of slow deposition of ald, dead volume (dv), and inability to purge, so as to increase the purge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

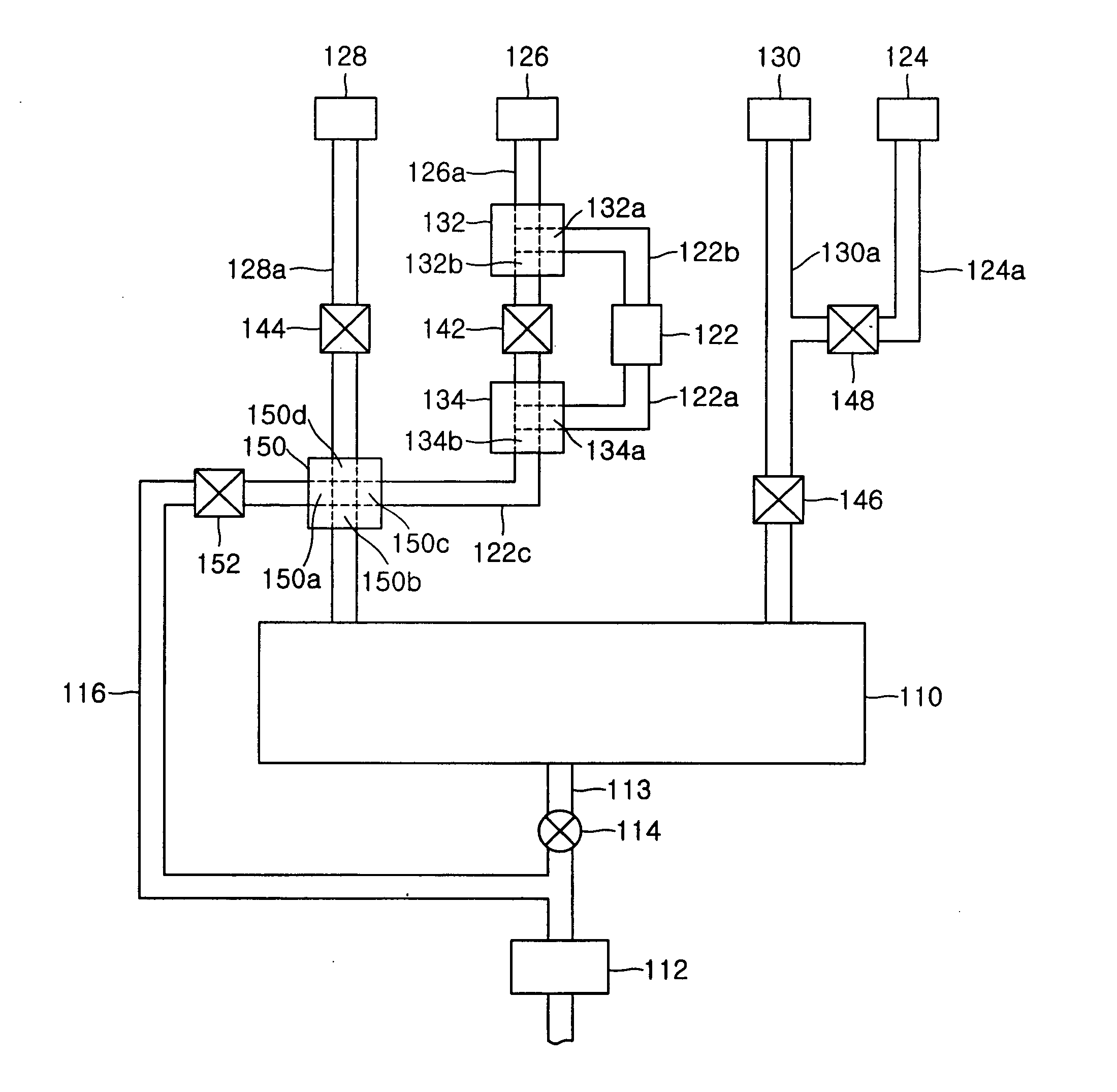

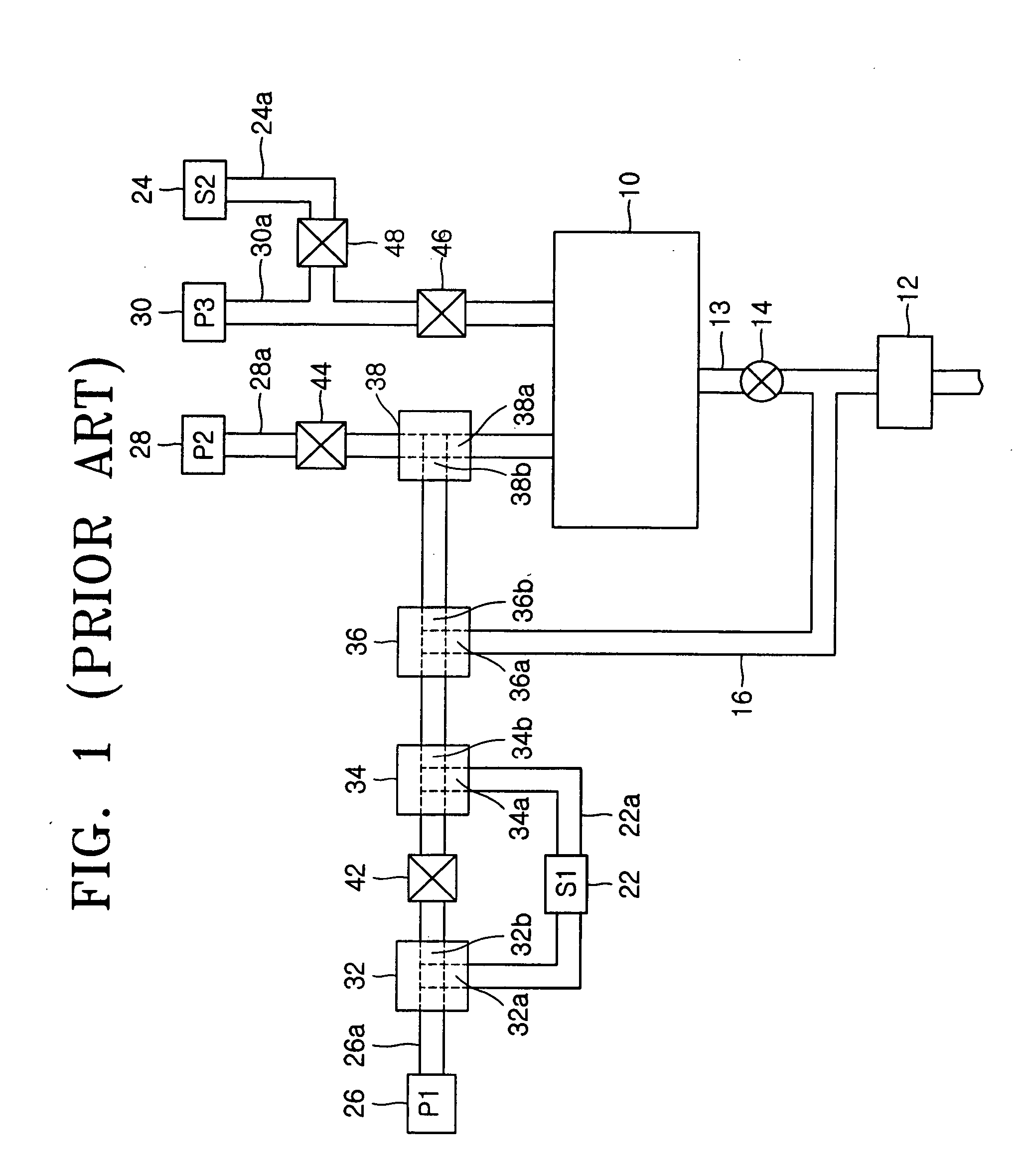

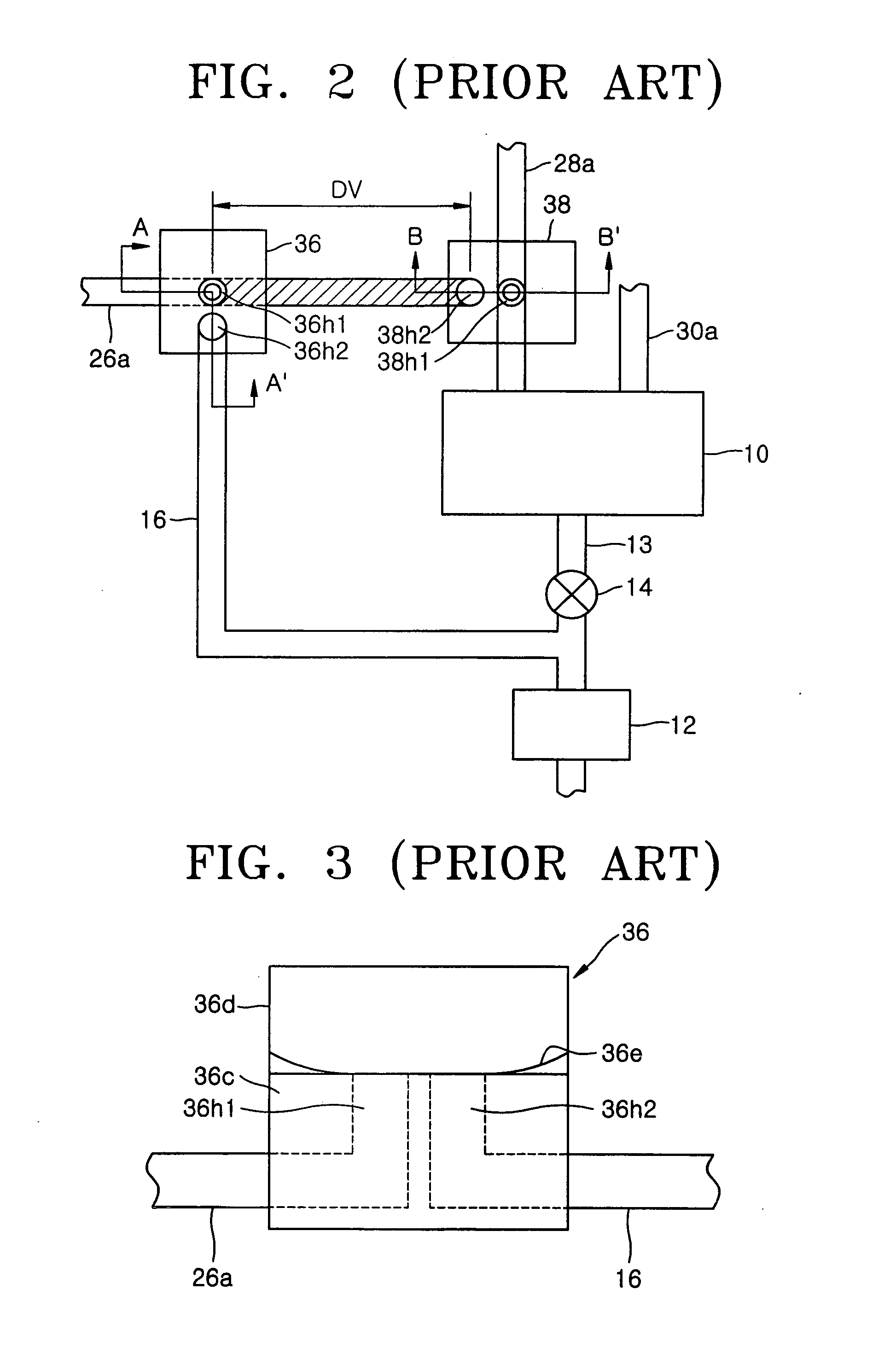

[0058]FIG. 5 is a schematic diagram illustrating an apparatus for fabricating a semiconductor device according to the present invention. FIG. 6 is an enlarged view of a part of the apparatus illustrated in FIG. 5. FIG. 7 is a cross sectional view of the part shown in FIG. 6, taken along the line CC′, in which a 2-way valve is closed. FIG. 8 is a cross sectional view of the part shown in FIG. 6, taken along the line DD′, in which a 4-way valve is closed.

[0059] The apparatus for fabricating a semiconductor device, a valve control method, and a method of fabricating a semiconductor device using the apparatus, according to the first embodiment of the present invention will be described in detail with reference to FIGS. 5 through 8.

[0060] Referring to FIG. 5, a source gas supply source 122, a reactive gas supply source 124, a purge gas supply source 128, a first carrier gas supply source 126, and a second carrier gas supply source 130 supply a source gas, a reactive gas, a purge gas, an...

third embodiment

[0087] Referring to FIG. 12, each of two source gas supply sources 122 and 222 is installed together with the first carrier gas supply line to be parallel with the source gas supply pipe 122c and the two source gas supply sources 122 and 222 are disposed symmetrically. The apparatus illustrated in FIG. 12 is designed such that one of a first source gas and a second source gas is selectively supplied using a plurality of 2-way gate valves and 3-way valves. In the third embodiment, two kinds of source gas are supplied, but more than two kinds of source gas may be selectively supplied by disposing more than two source supply lines in parallel with the source gas supply pipe 122c.

[0088] In a first source gas supply line starting from the first source gas supply source 122 supplying the first source gas, the carrier gas is supplied from the first carrier gas supply source 126 through the first carrier gas supply pipe 126a to which the first source gas supply source 122 is connected in p...

fourth embodiment

[0101] In a purge gas supply line, the purge gas is supplied from the purge gas supply source 128 to the reaction chamber 110 through the purge gas supply pipe 128a. The first 4-way valve 150 is installed at a junction of the purge gas supply pipe 128a and the first source gas supply pipe 122c. The second 4-way valve 250 is installed at a junction of the purge gas supply pipe 128a and the second source gas supply pipe 222c. The second gate valve 144 is installed between the purge gas supply source 128 and the second 4-way valve 250. In addition, gate valves 152 and 252 are installed at the bypass 116 connected with the first and second 4-way valves 150 and 250. A reactive gas supply line in the fourth embodiment is the same as those in the above-described embodiments.

[0102] The following describes in detail a process of depositing a reaction product of the source gas and the reactive gas on a surface of a substrate through ALD using the first and second source gases A1 and A2 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| right angle | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com