Patents

Literature

52results about How to "Avoid dead volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

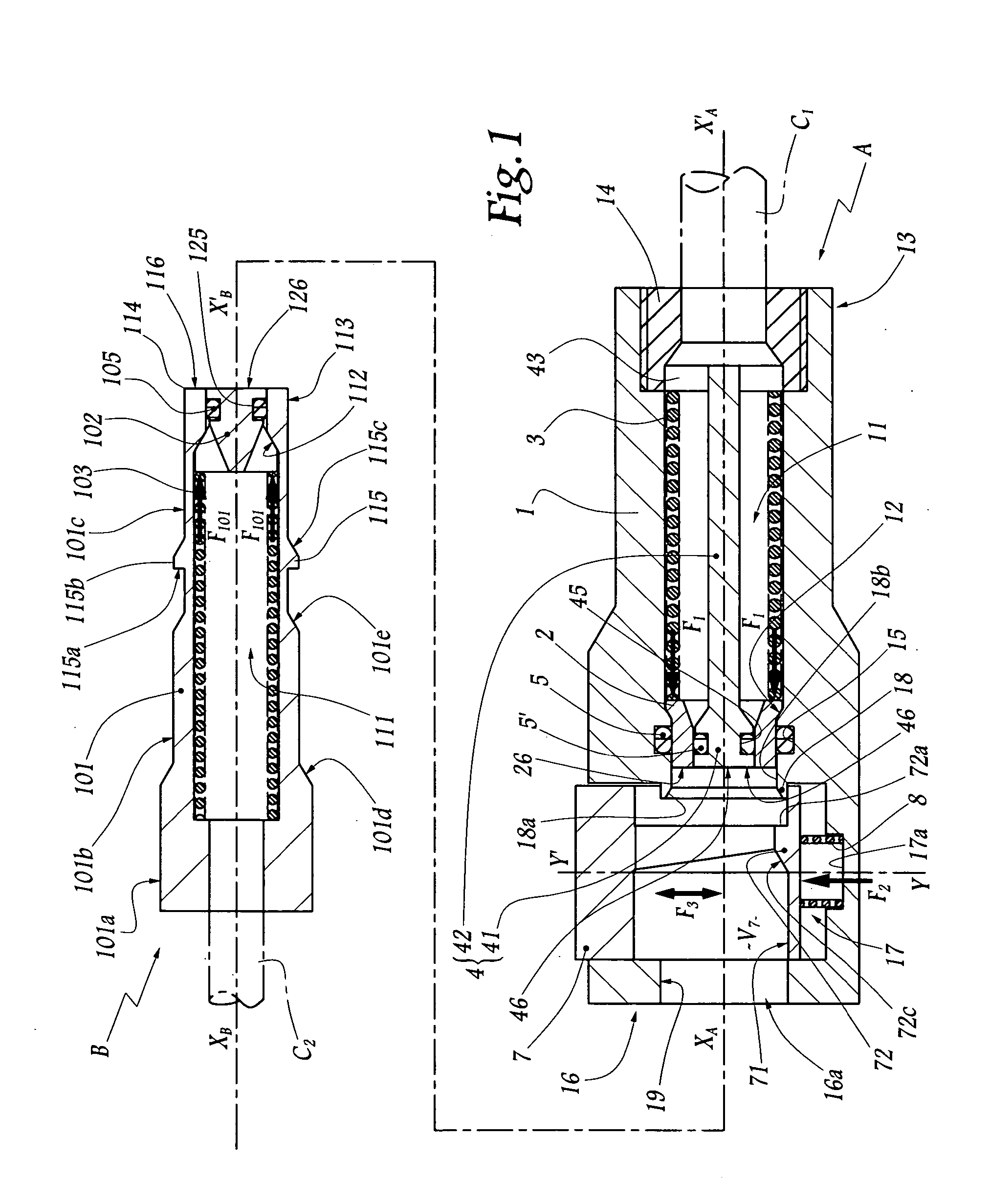

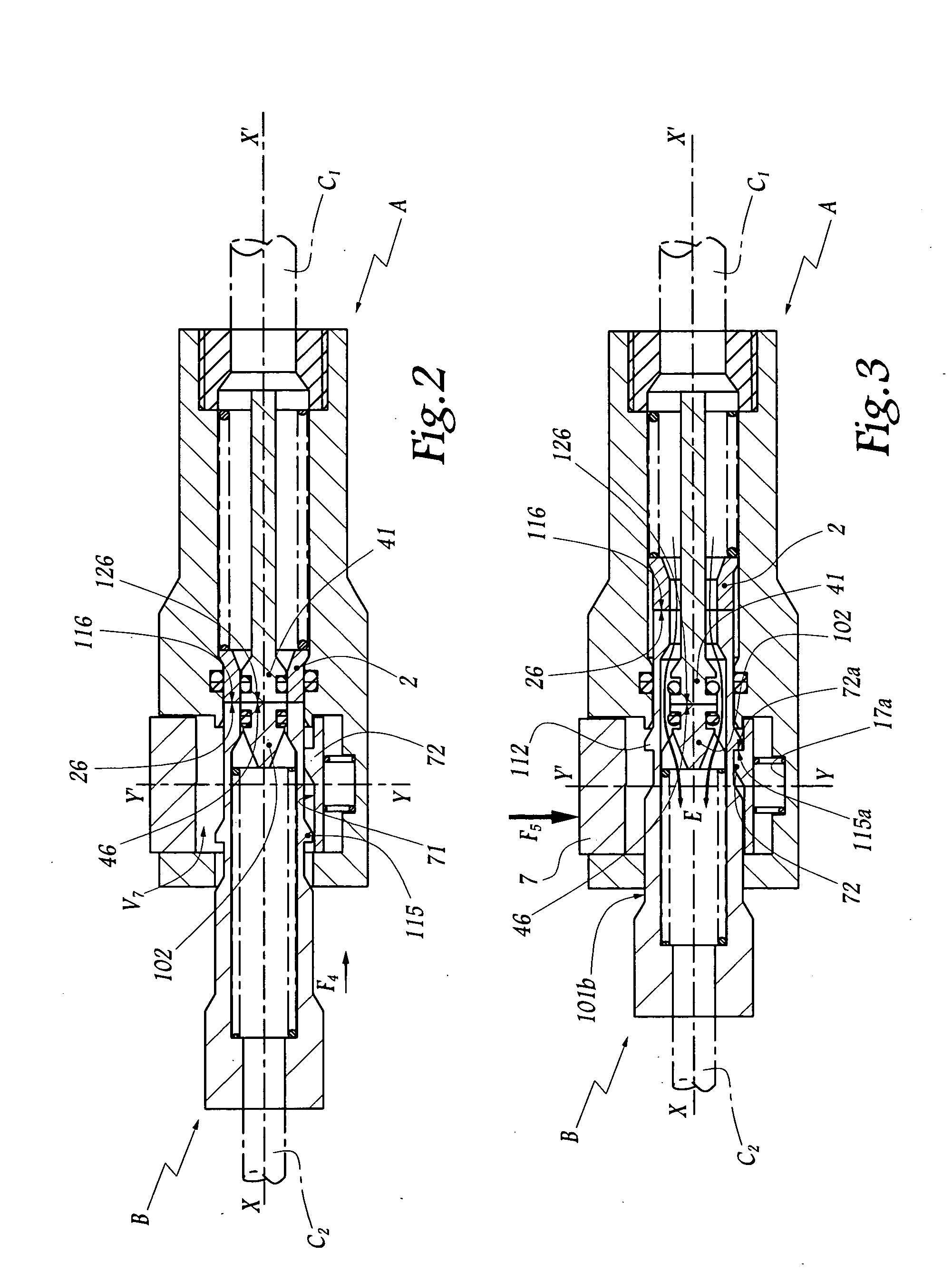

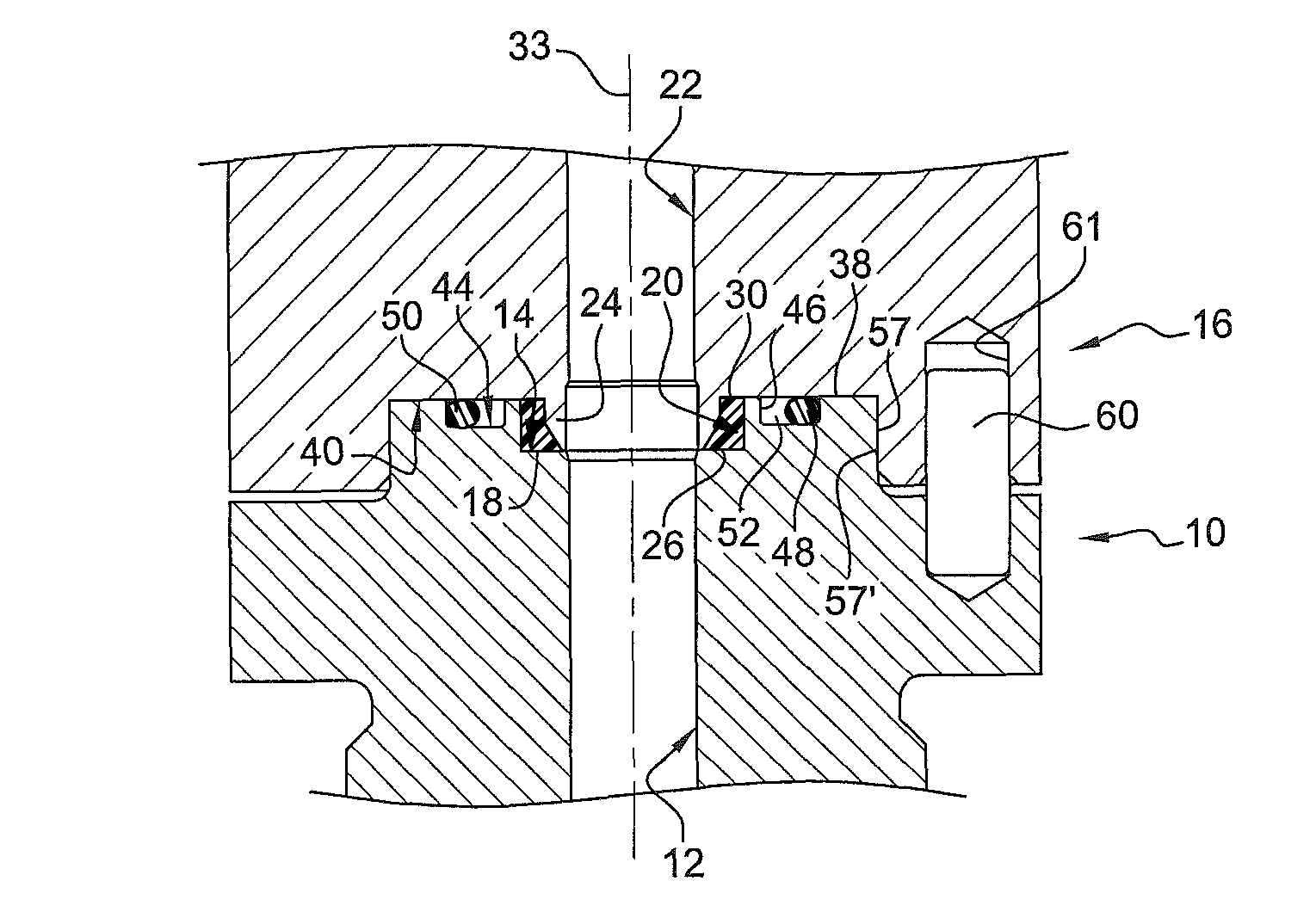

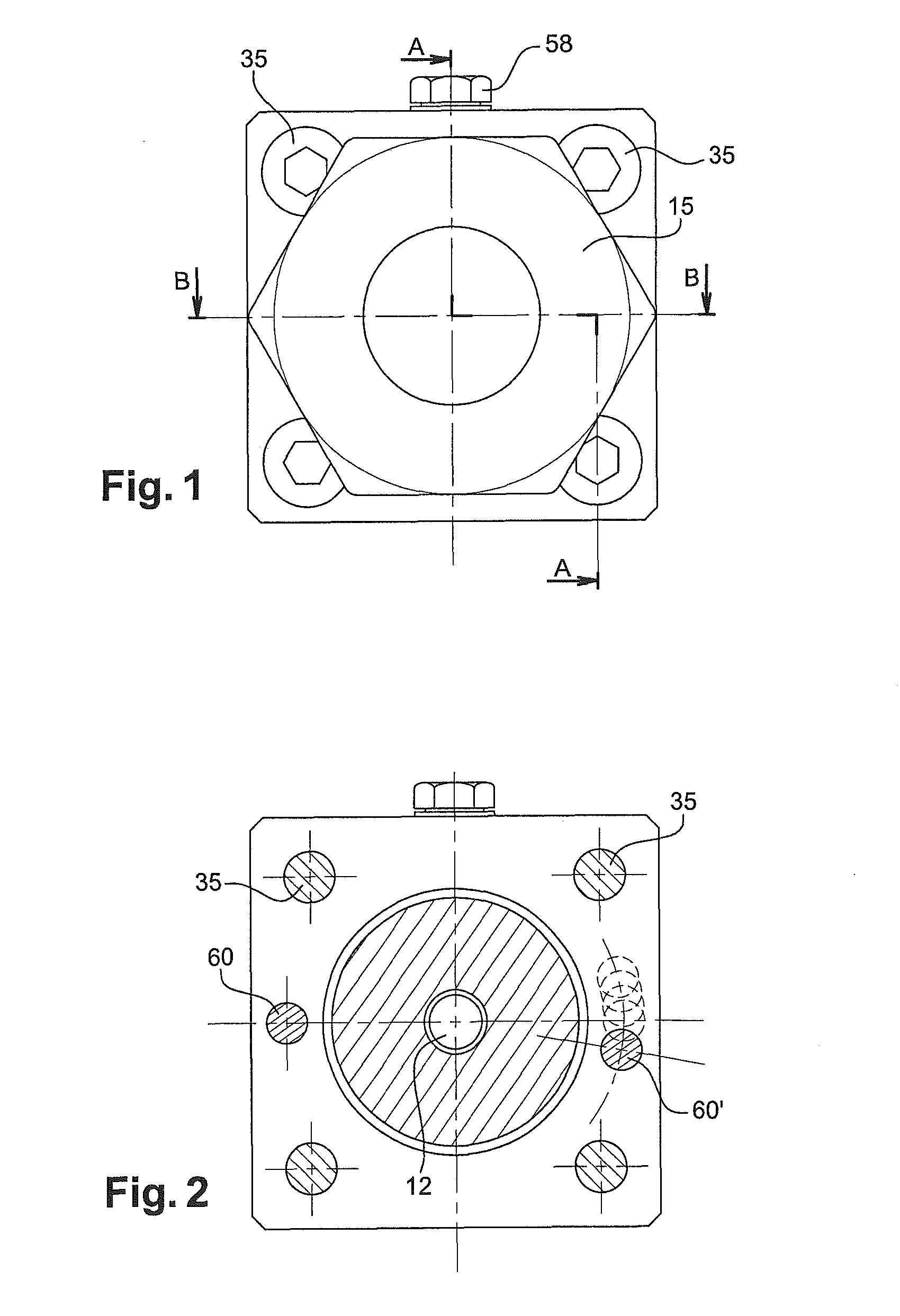

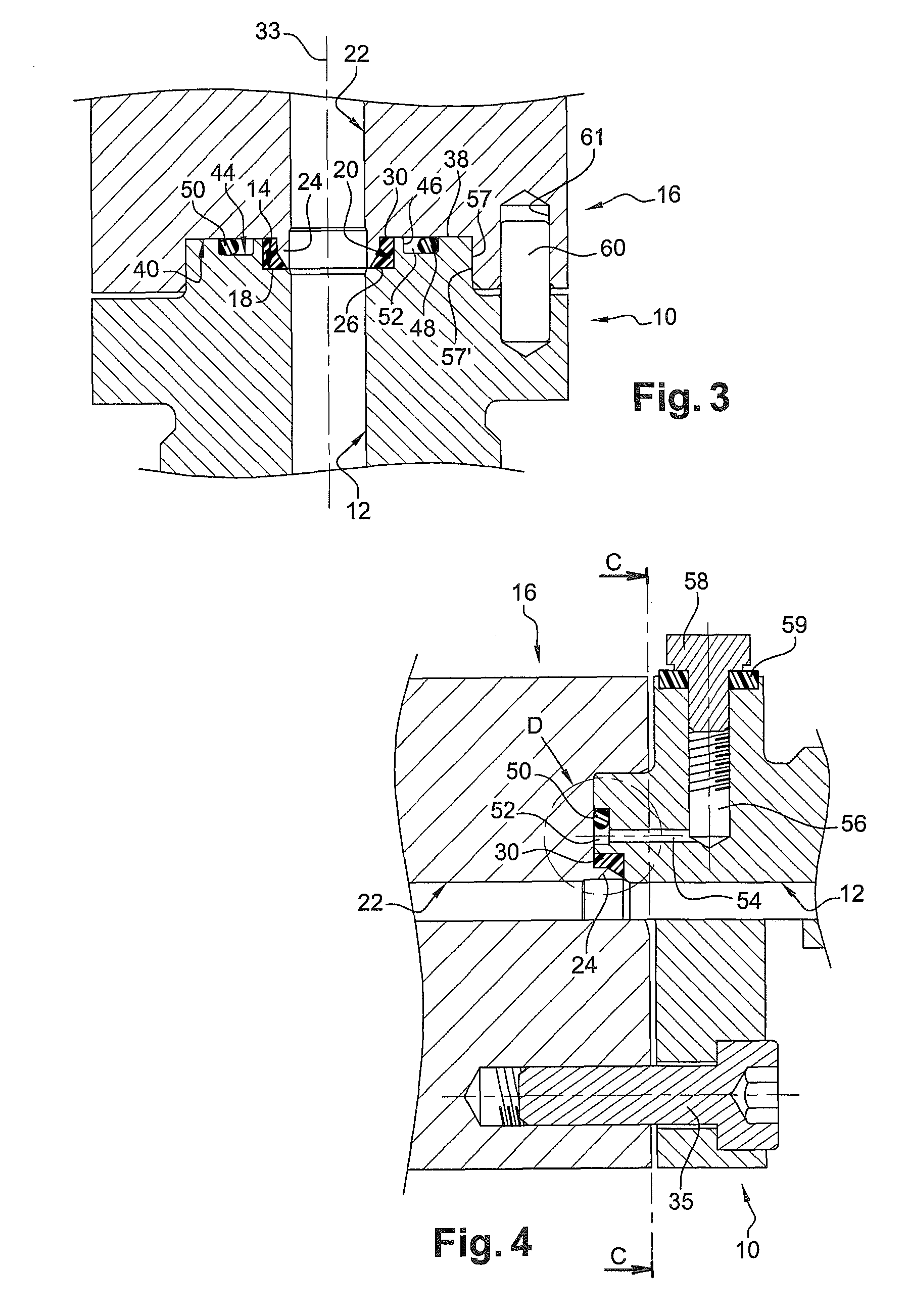

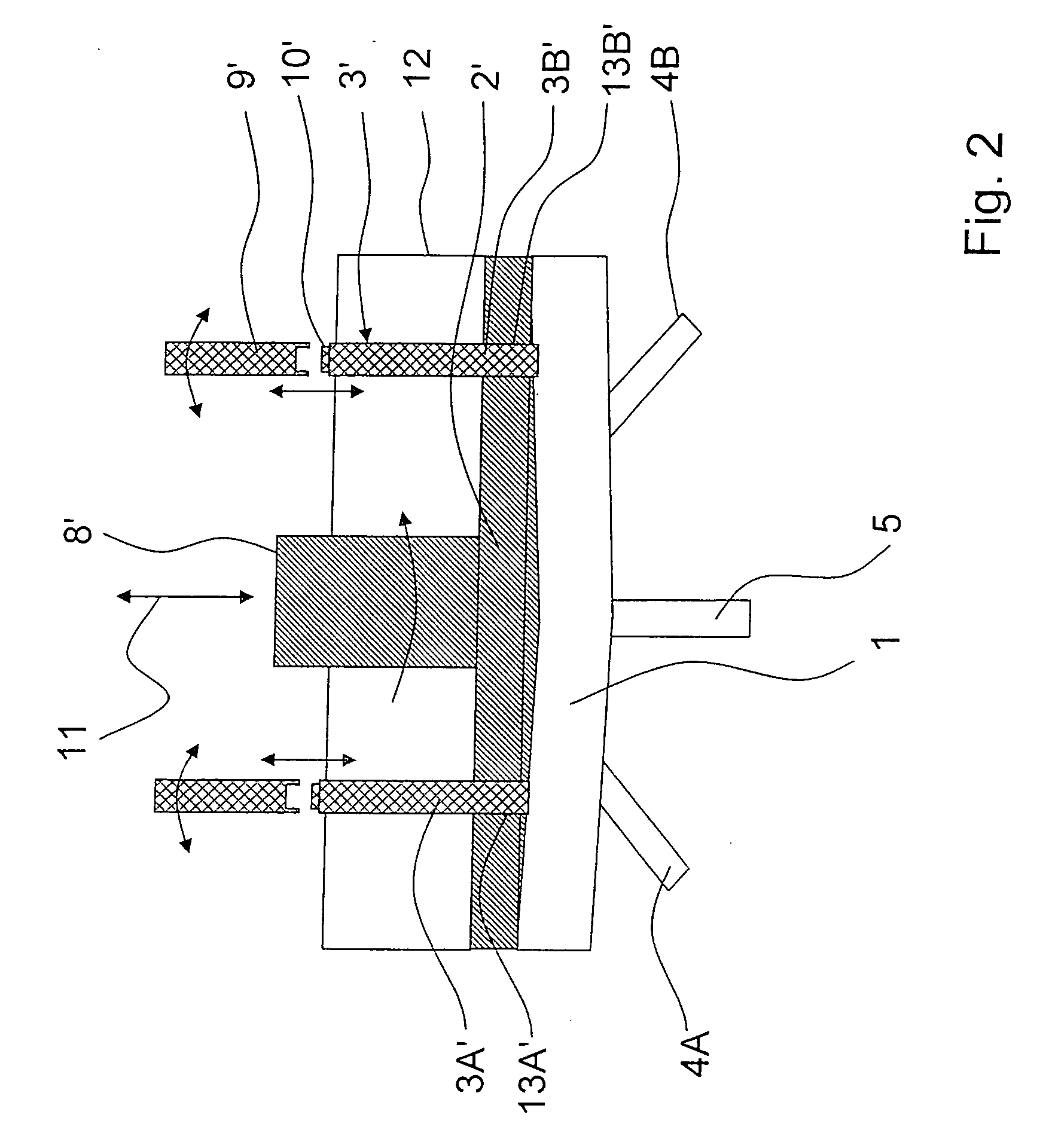

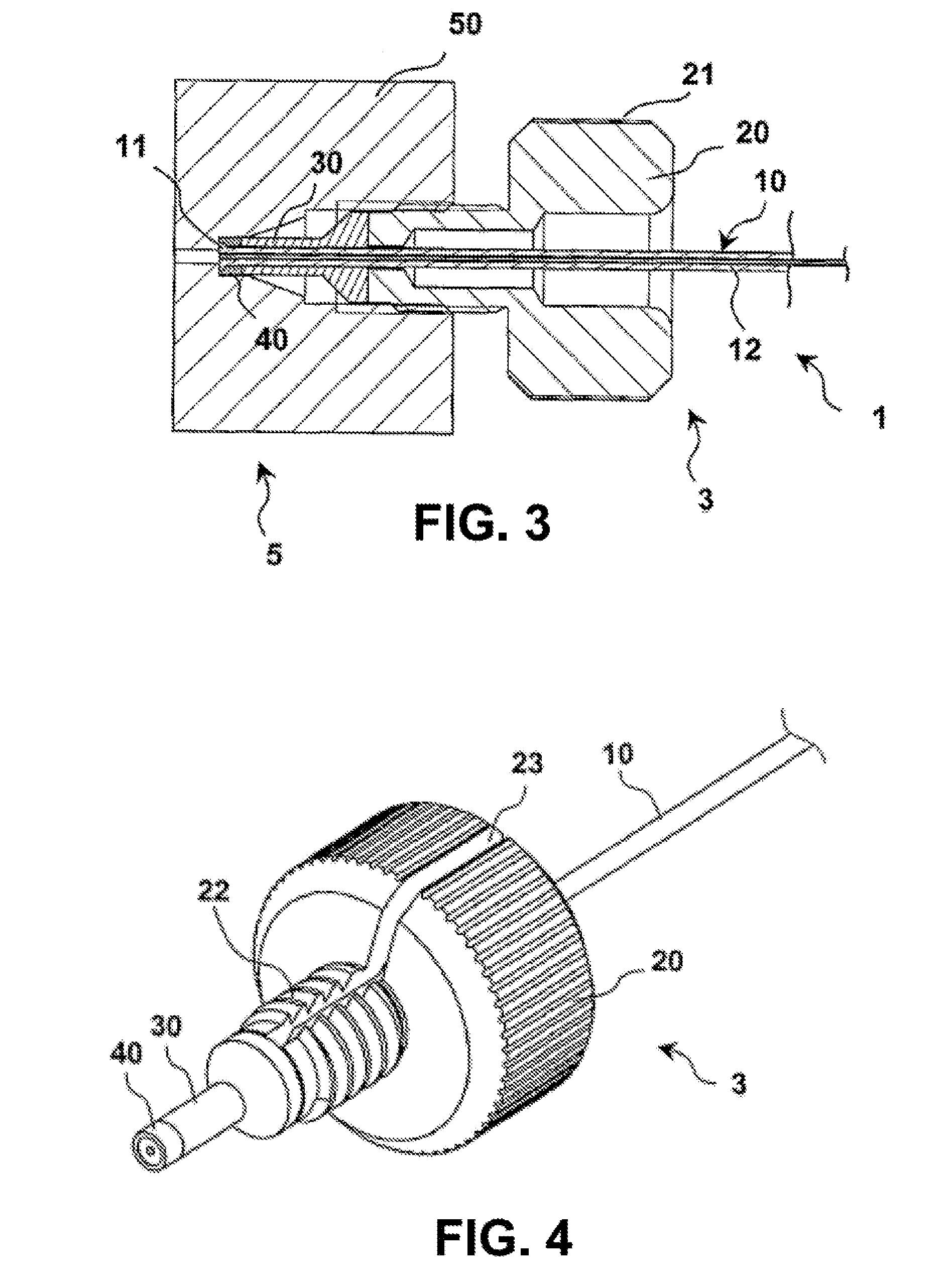

Quick connection for removably joining two pipes and use of such a connection

ActiveUS7044161B2Minimized dimensionLittle riskCouplingsThin material handlingEngineeringMechanical engineering

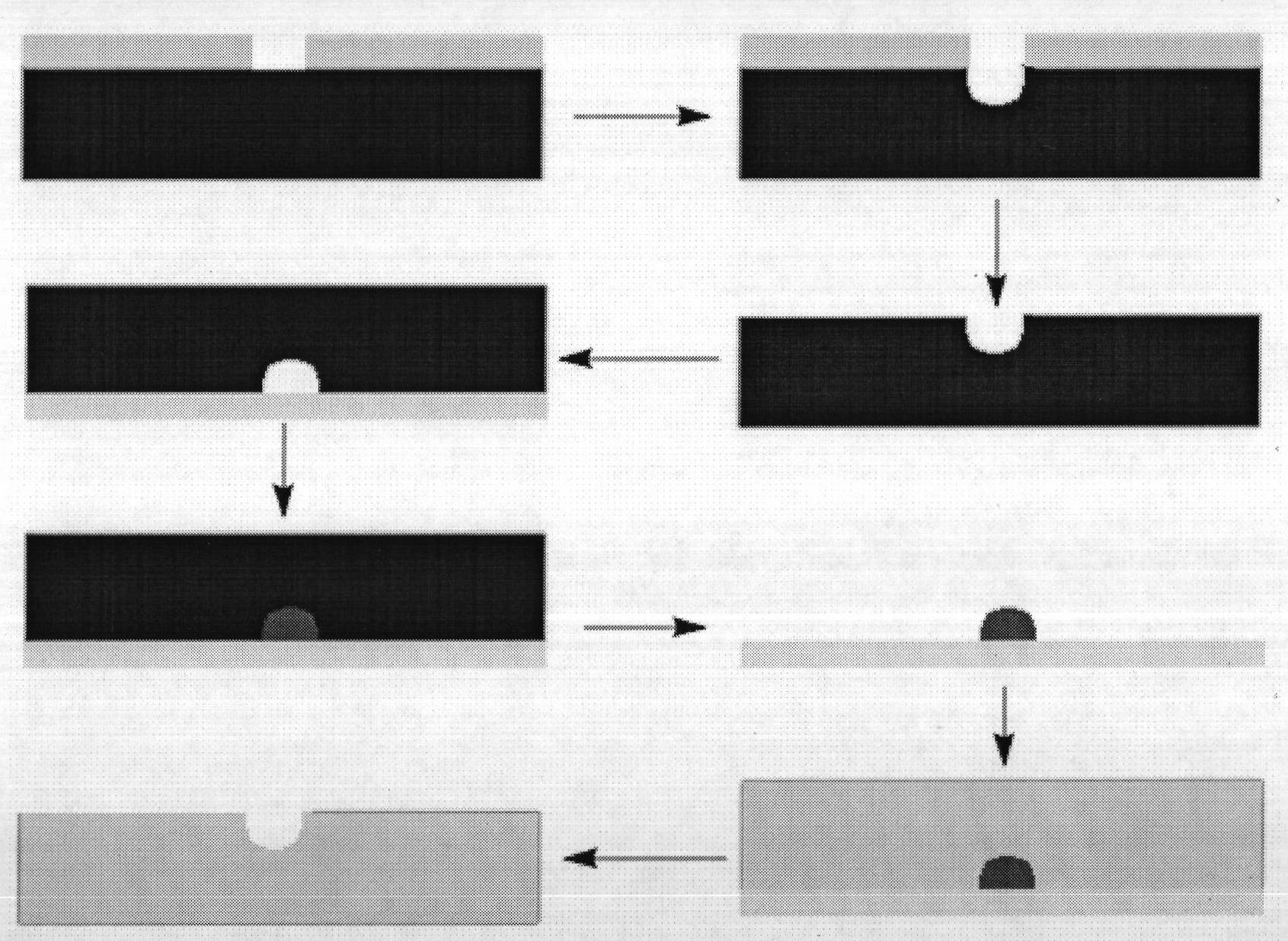

A quick connect coupling including male and female elements that are adapted to fit axially in each other and each includes a valve that is displaced to an open position by engagement by a fixed pusher part of each element when they are being fitted together. The female element is provided with a locking member in which a part of the male element is received and which is reciprocally movable in a radial direction with respect to an axis of fit of the elements between two positions in which the locking member respectively allows or opposes the separation of the male and female elements and wherein the engaging surfaces of the valves and pusher parts is such that no open volumes or voids are created therein in which a liquid may collect during assembly or disassembly of the male and female elements.

Owner:STAUBLI FAVERGES SA

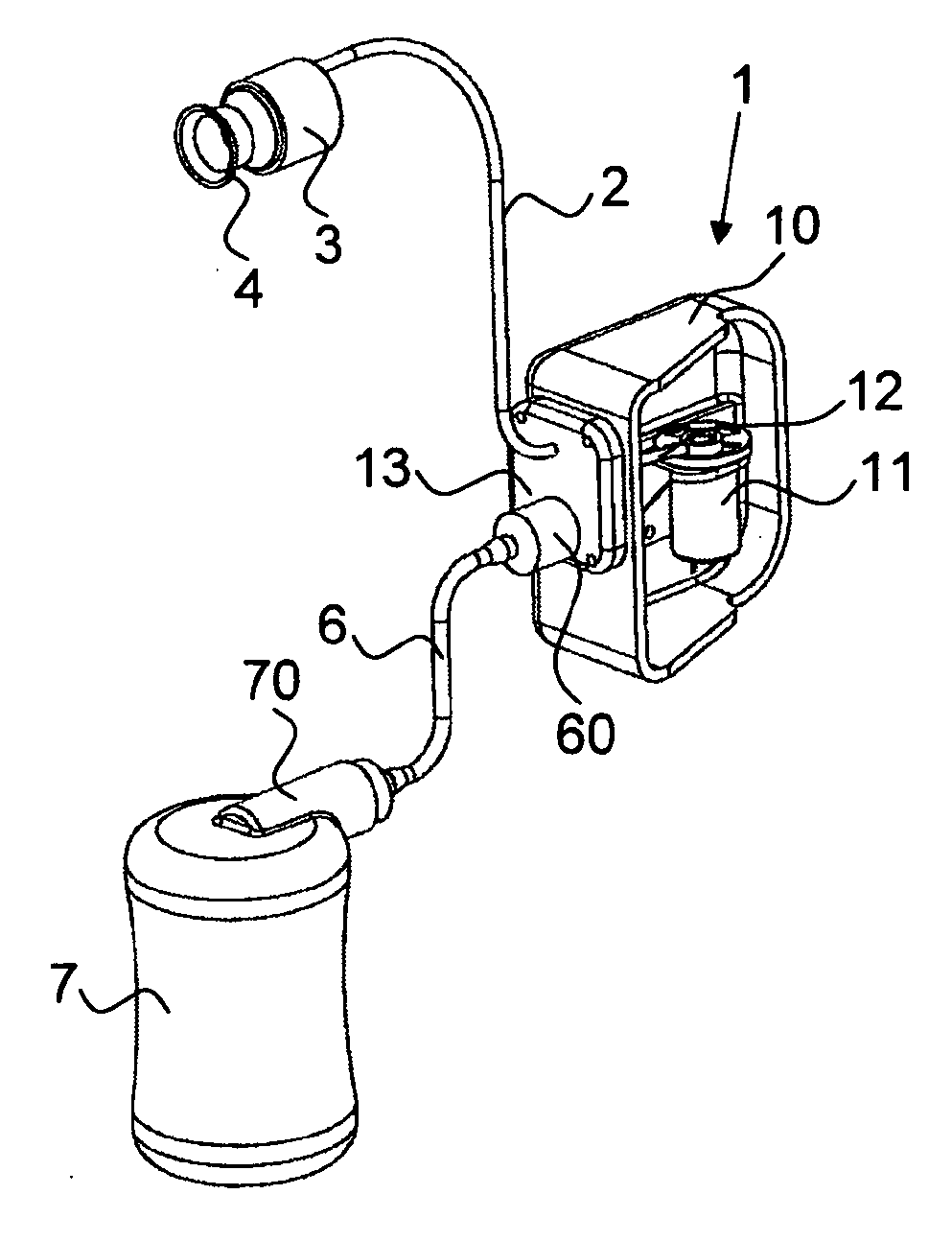

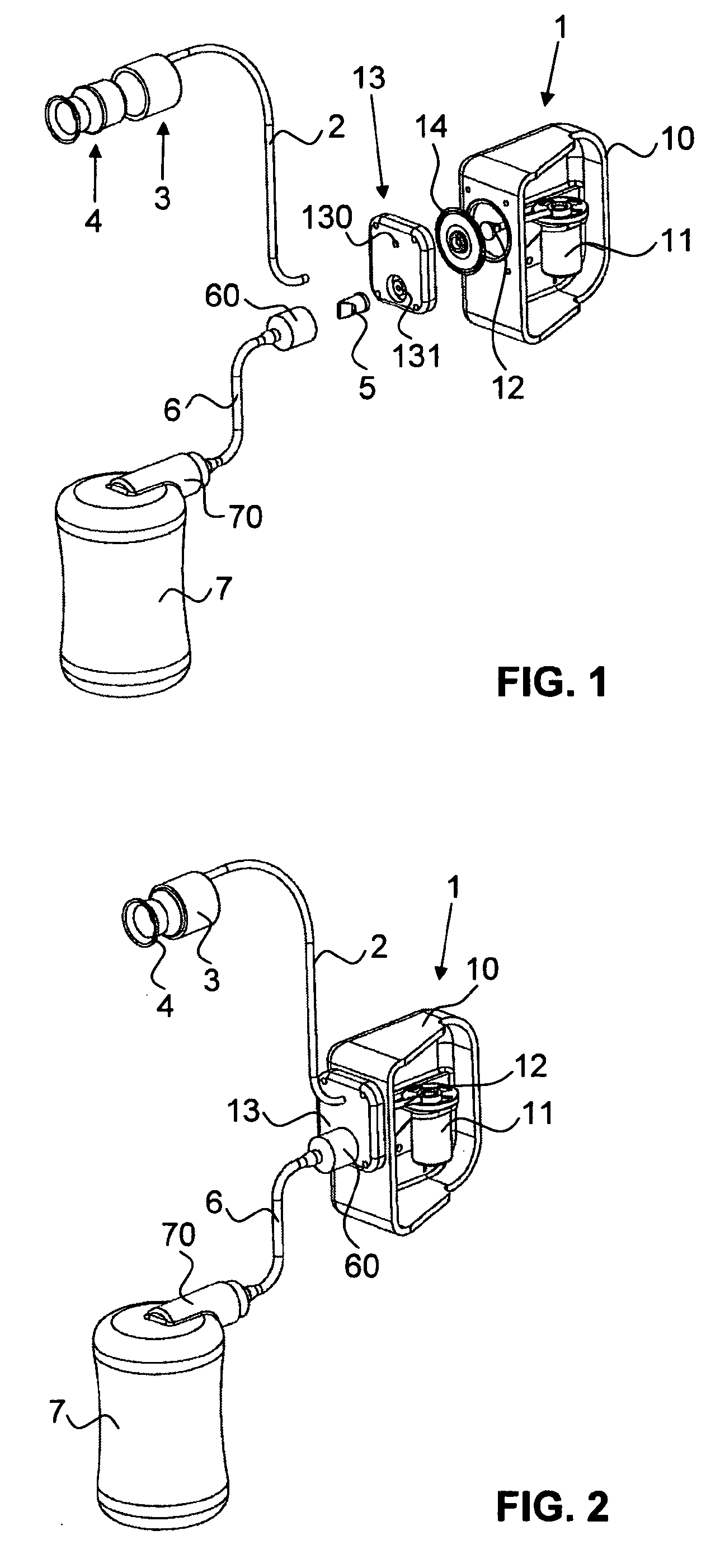

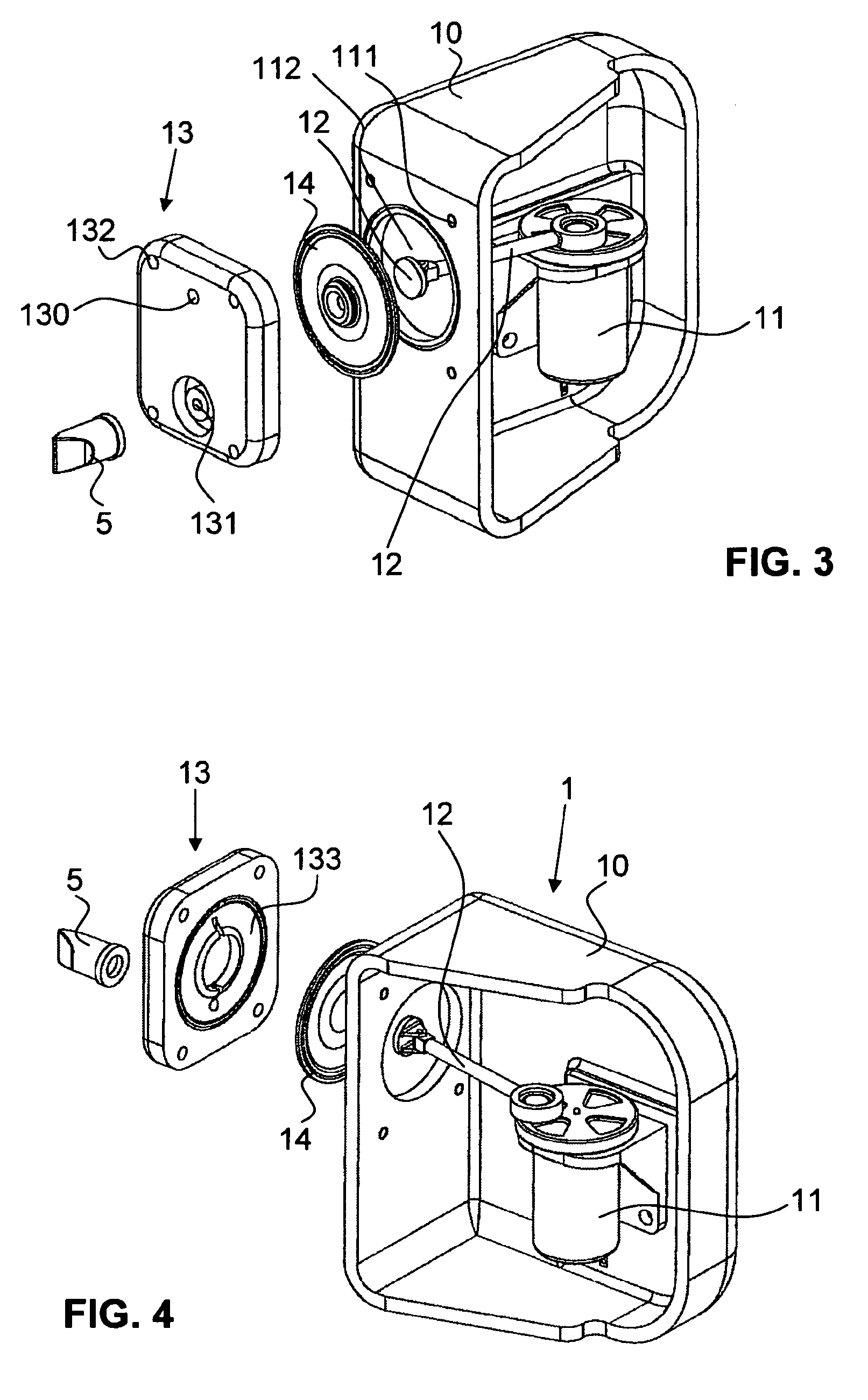

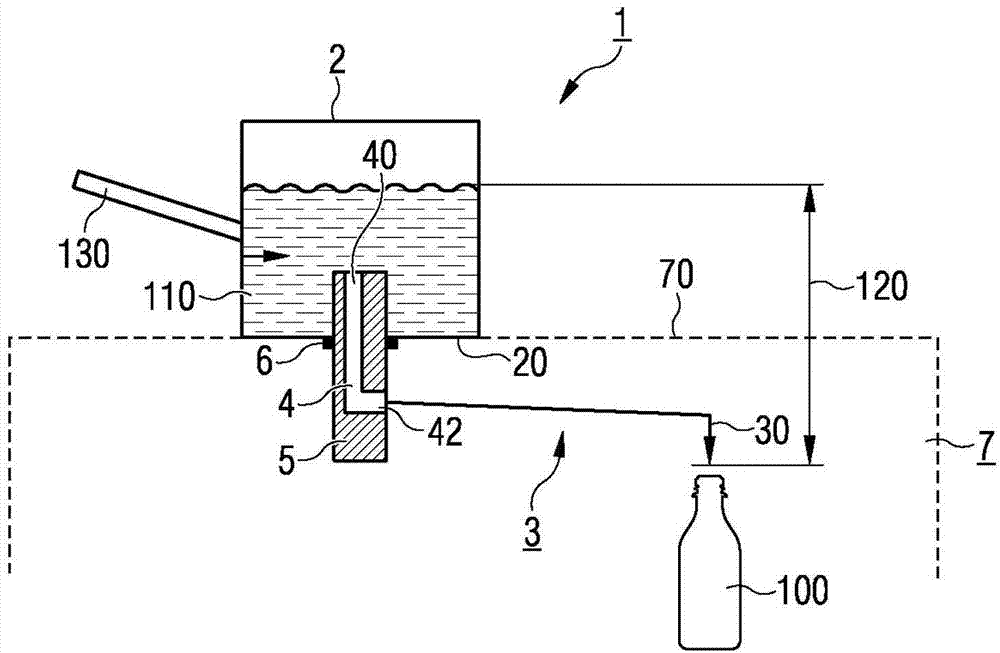

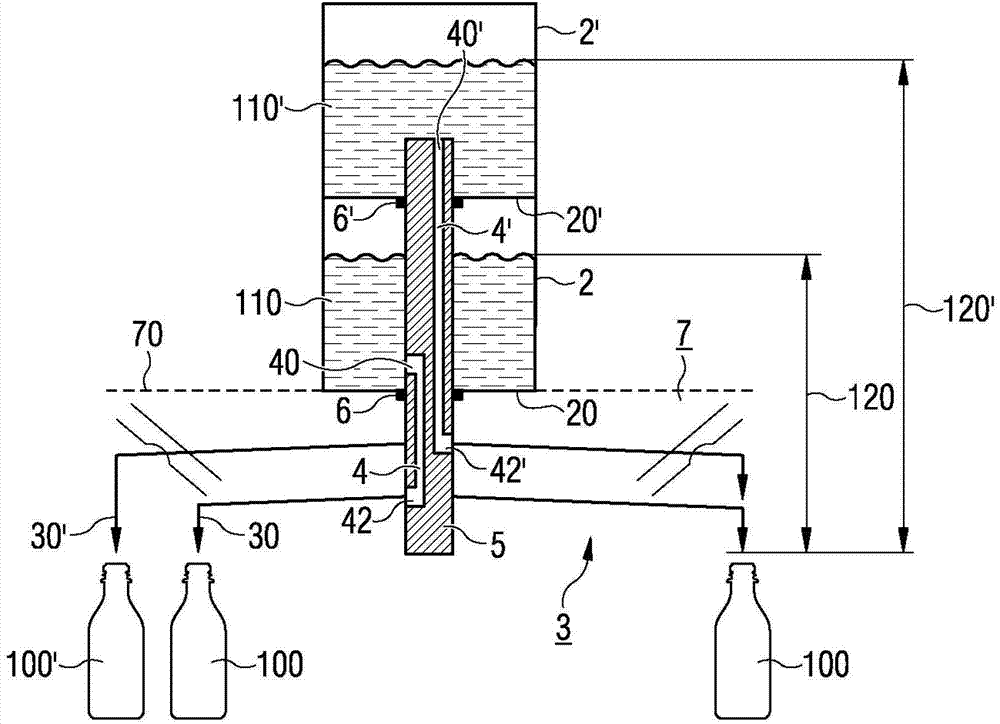

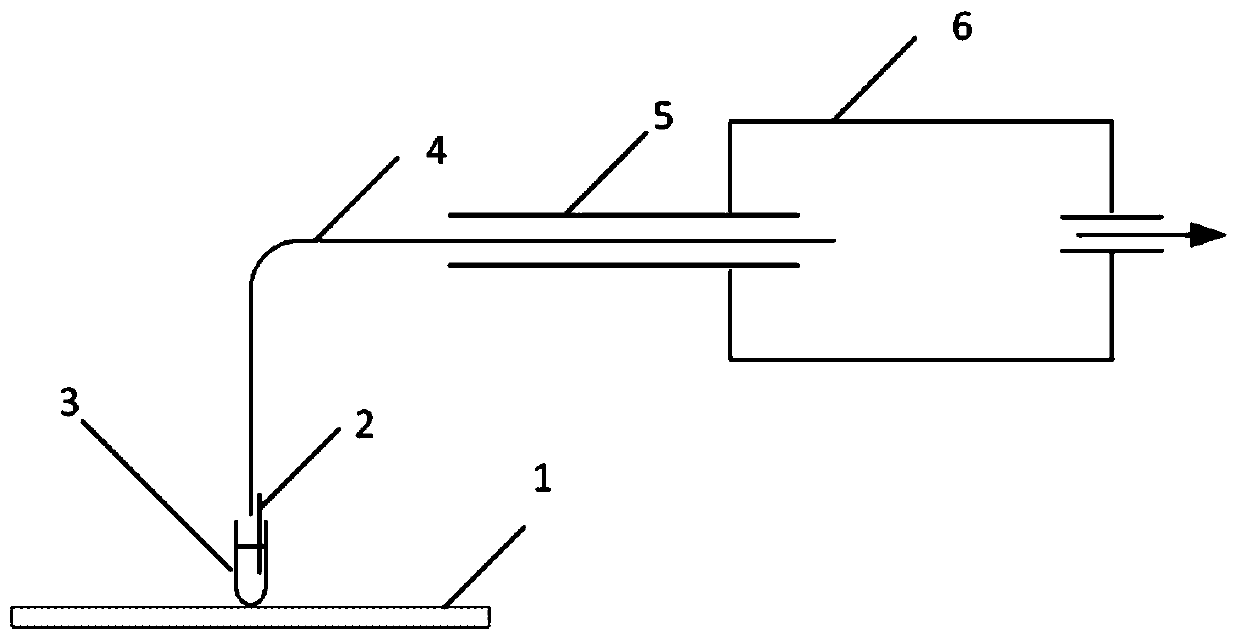

Device and method for expressing human breast milk

ActiveUS20120277728A1Less conspicuous to onlookersReduce pump powerNon-adhesive dressingsMilking pumpMammary lineLine tubing

A device for expressing human breast milk has a breast shield for bearing against a mother's breast, a vacuum pump for generating a vacuum, a line which connects the vacuum pump to the breast shield and is intended for transmitting the vacuum generated to the breast shield, and a chamber. The line ends on the pump side in a first port of the chamber. The chamber has a second port for connection to a milk collecting container. The two ports in the chamber are connected to each other in terms of fluid communication. During the expressing operation, the line forms a milk line for transporting breast milk expressed in the breast shield to the chamber and from the chamber to the milk collecting container. The pump can be designed to be quiet and small.

Owner:MEDELA HLDG AG

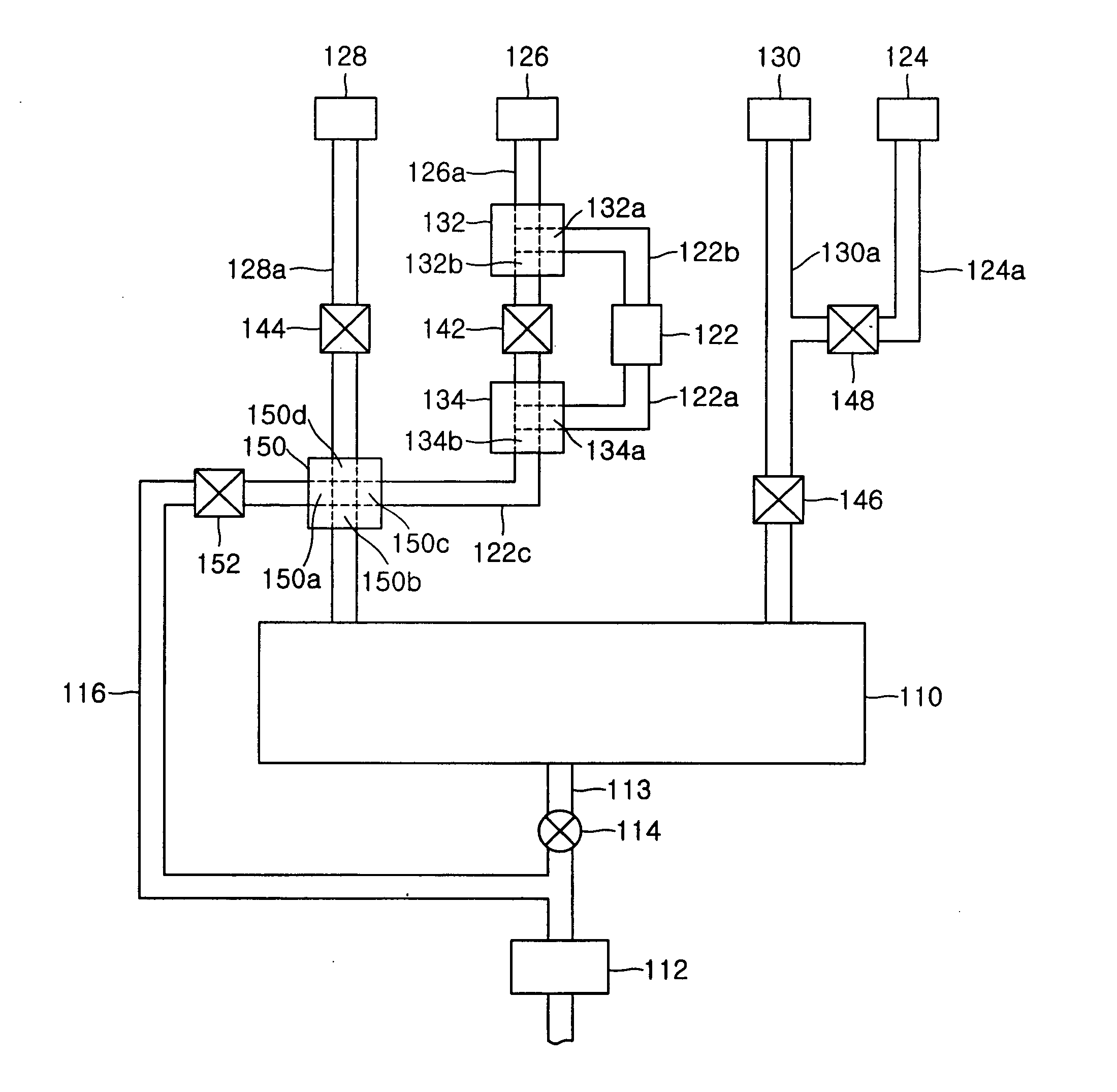

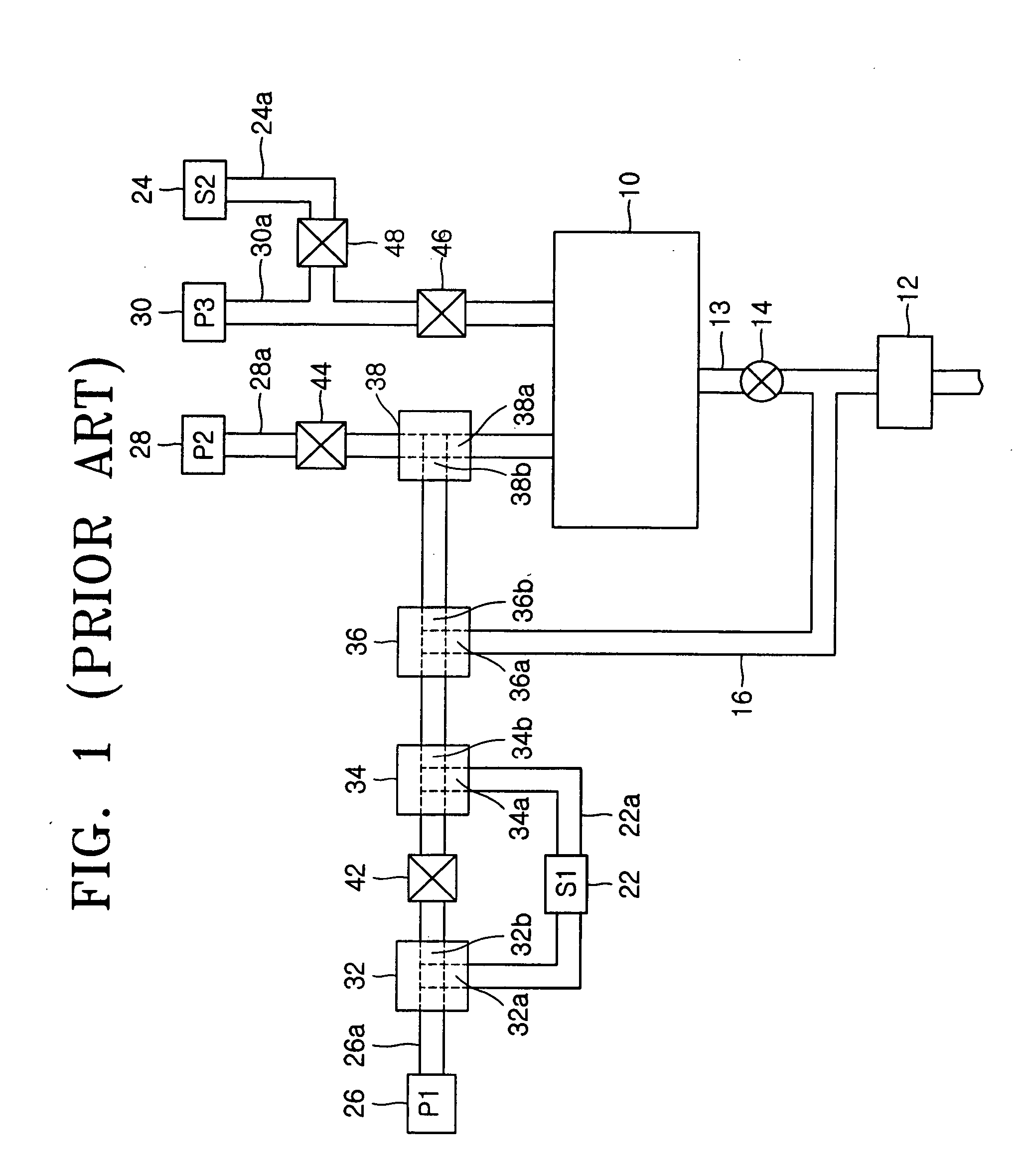

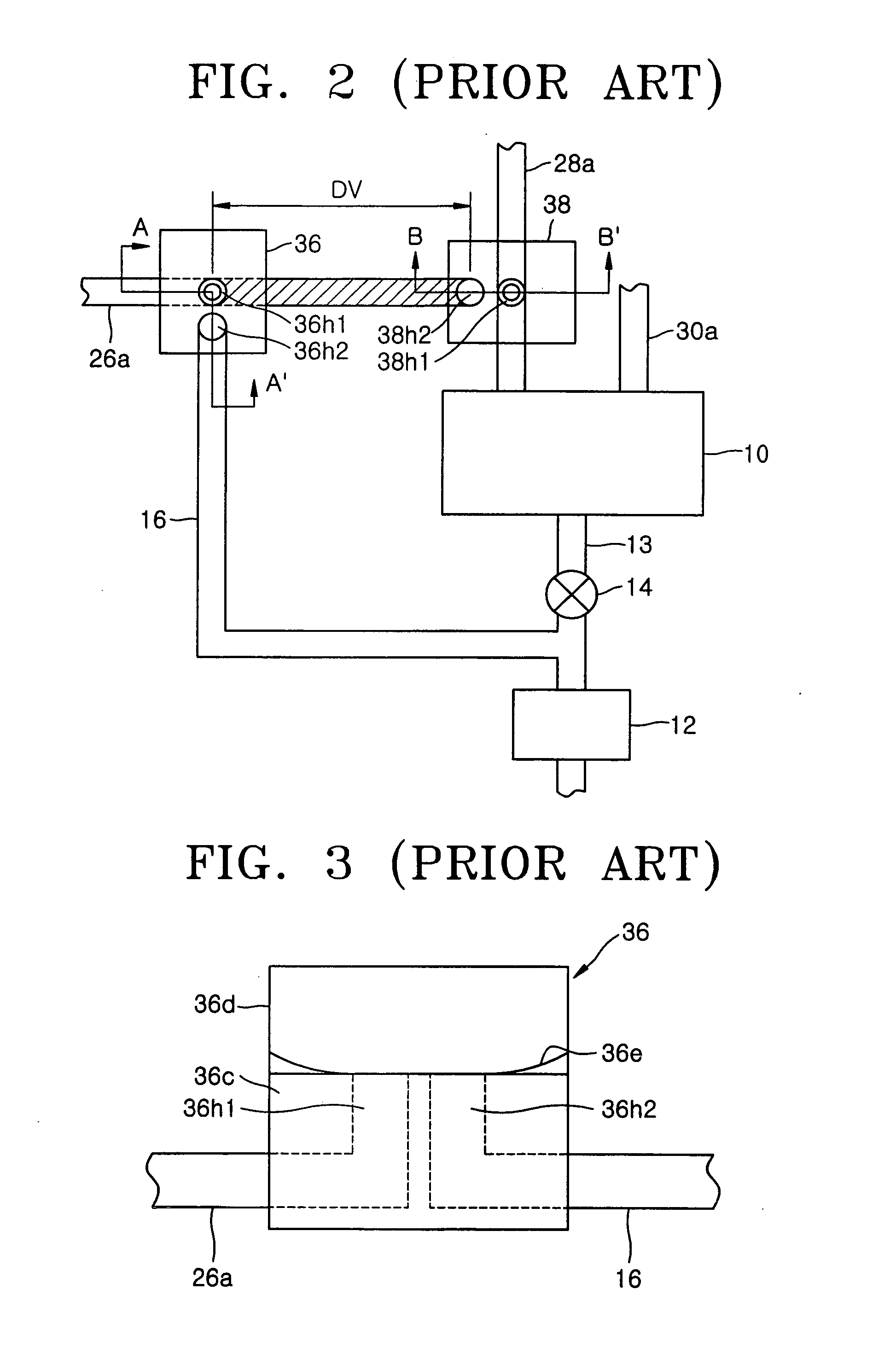

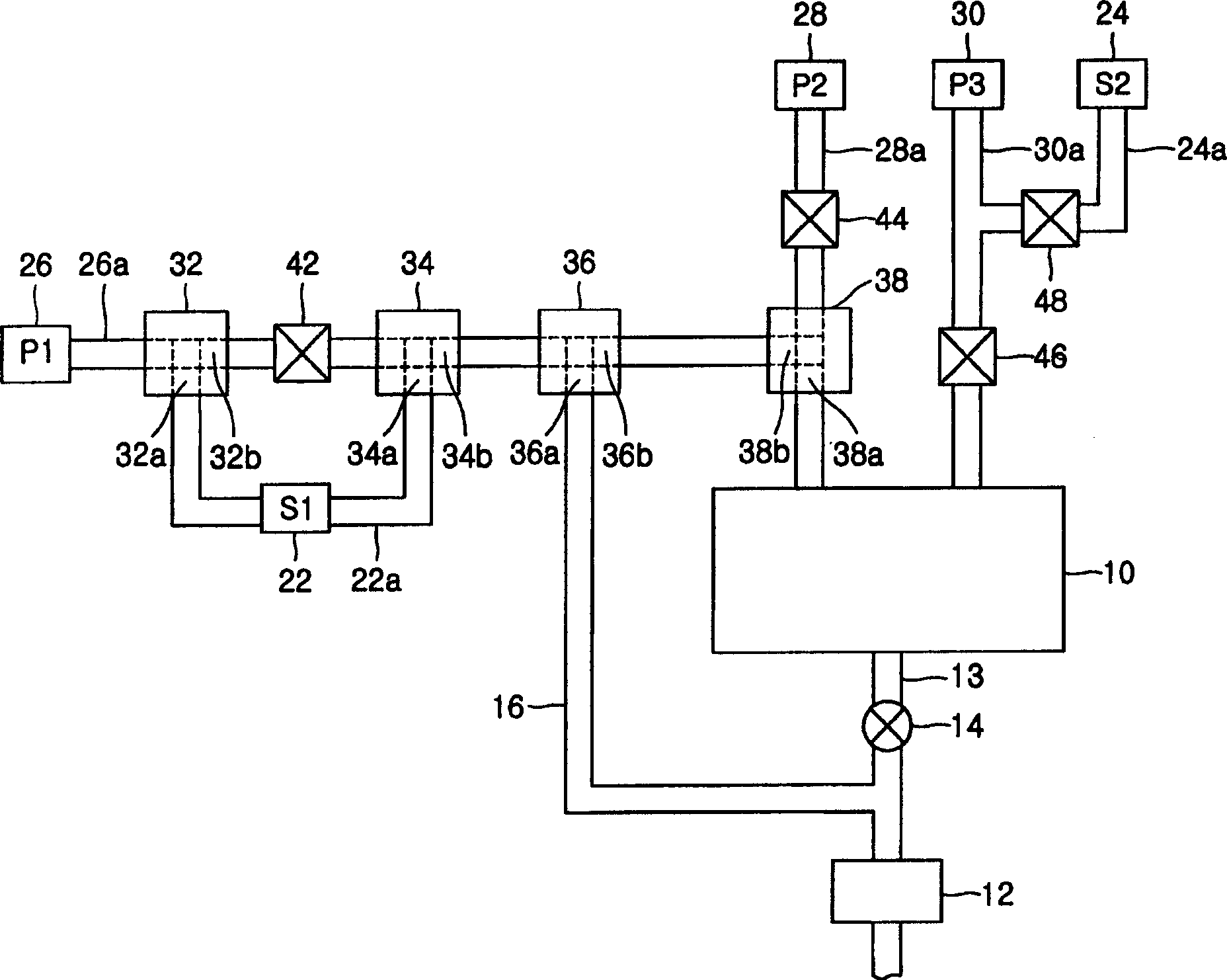

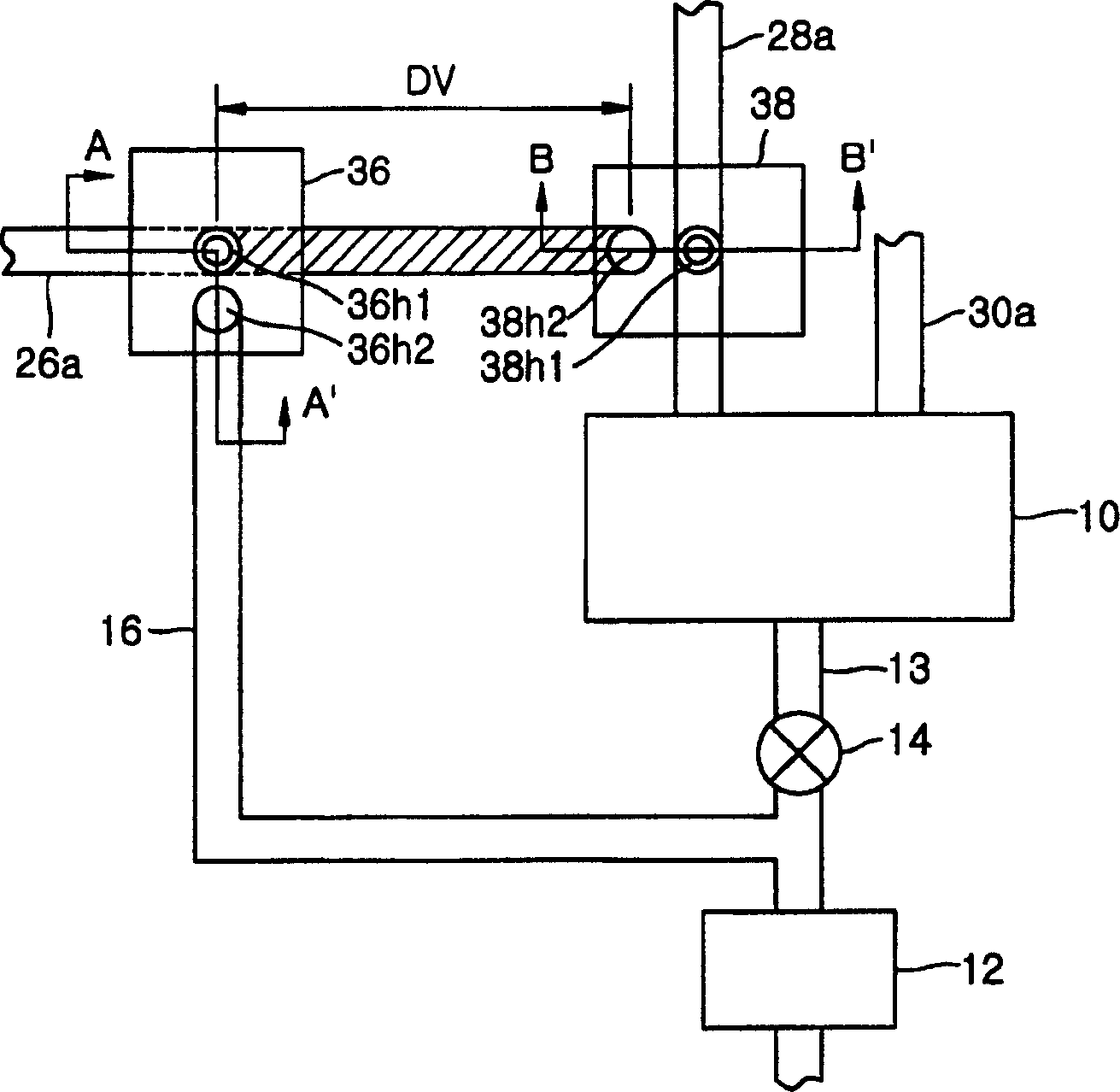

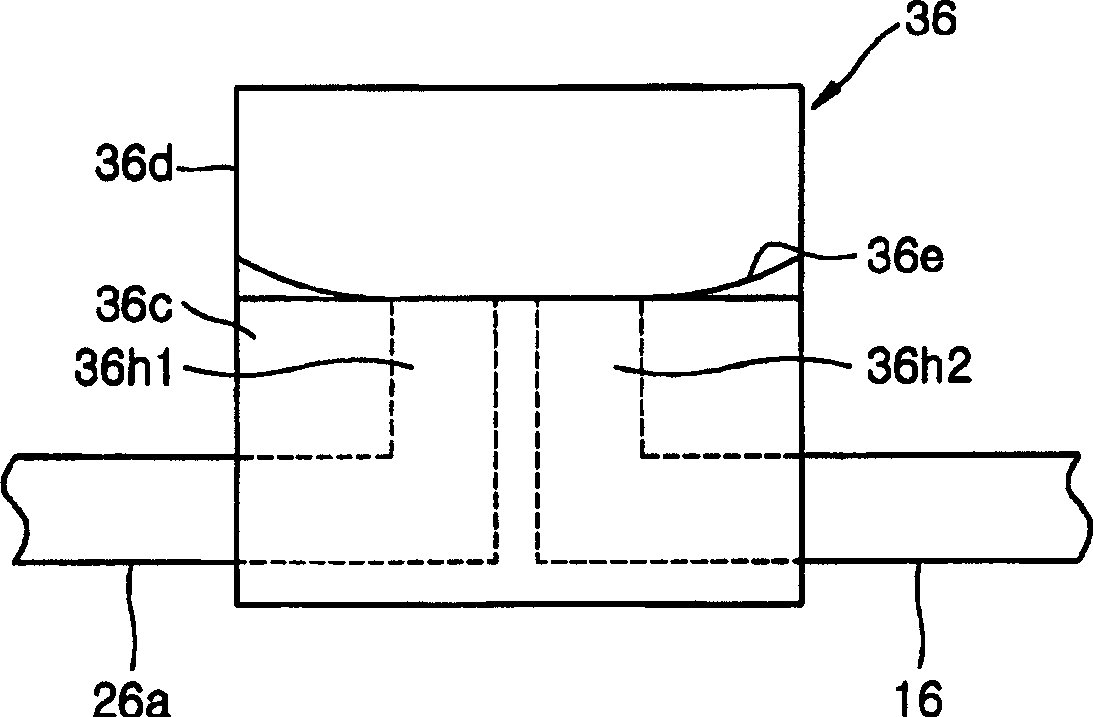

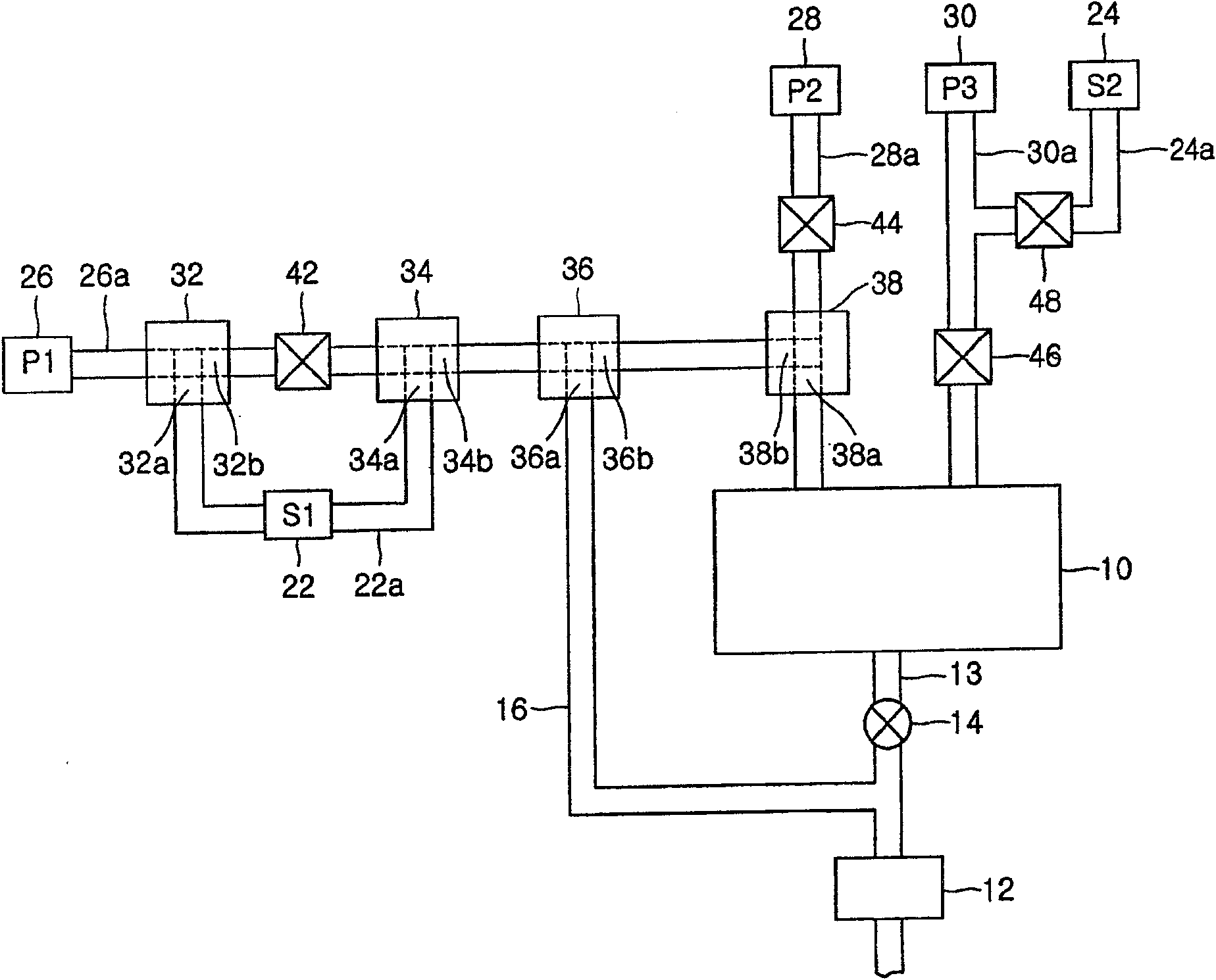

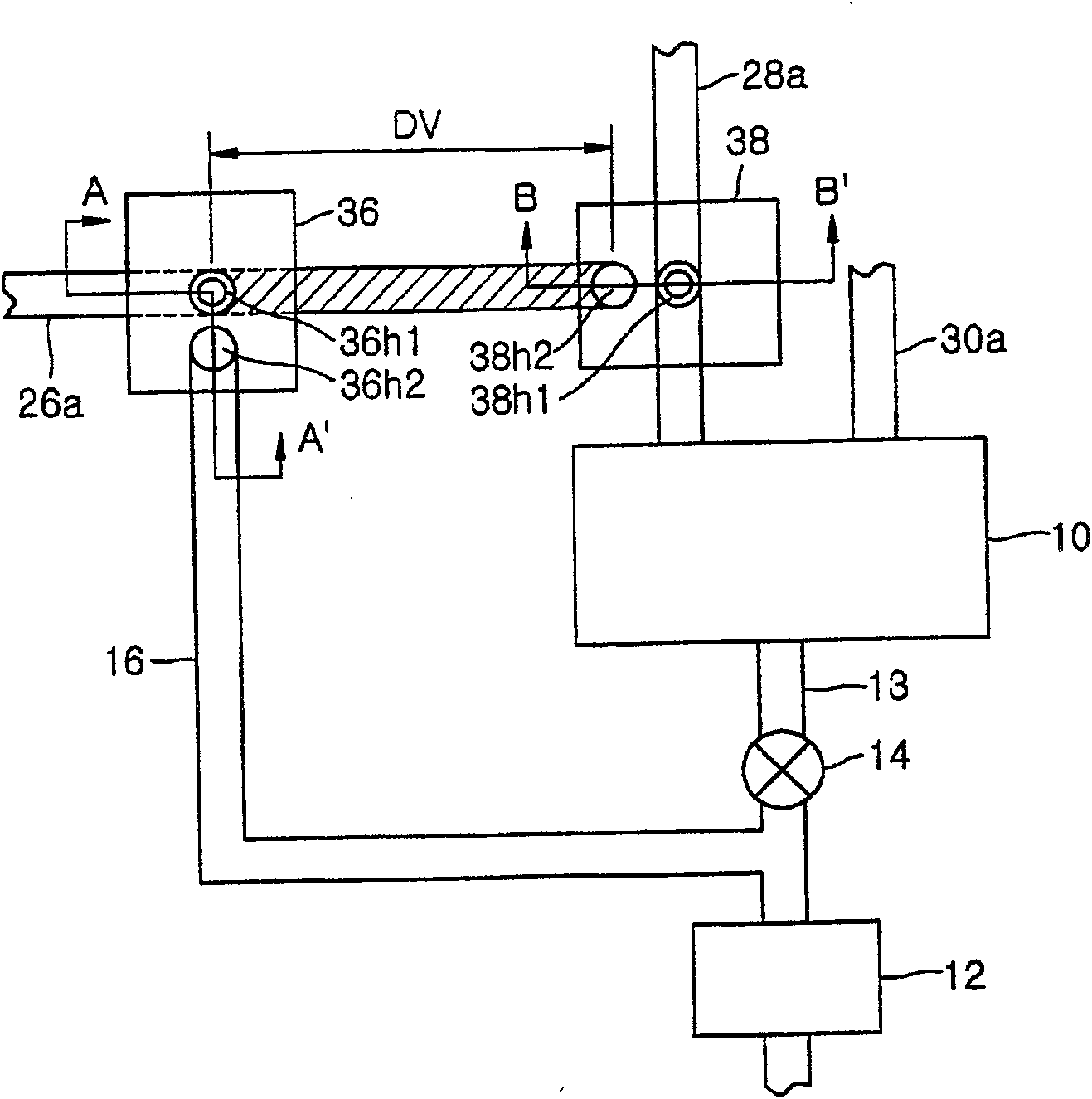

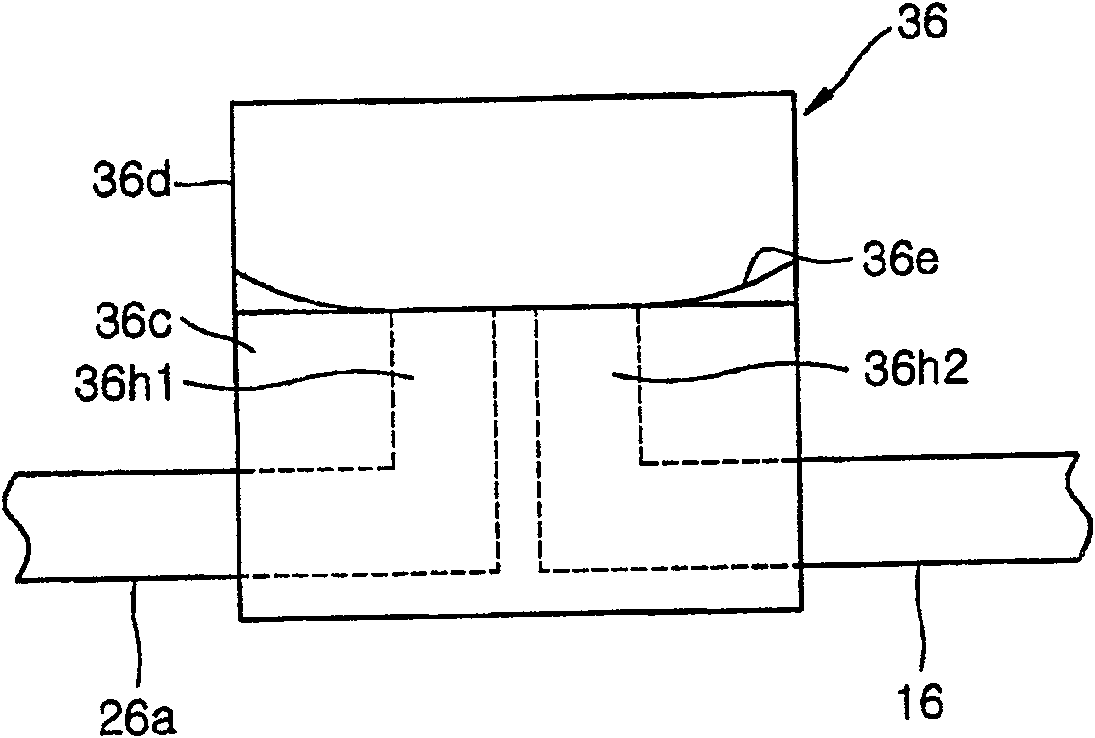

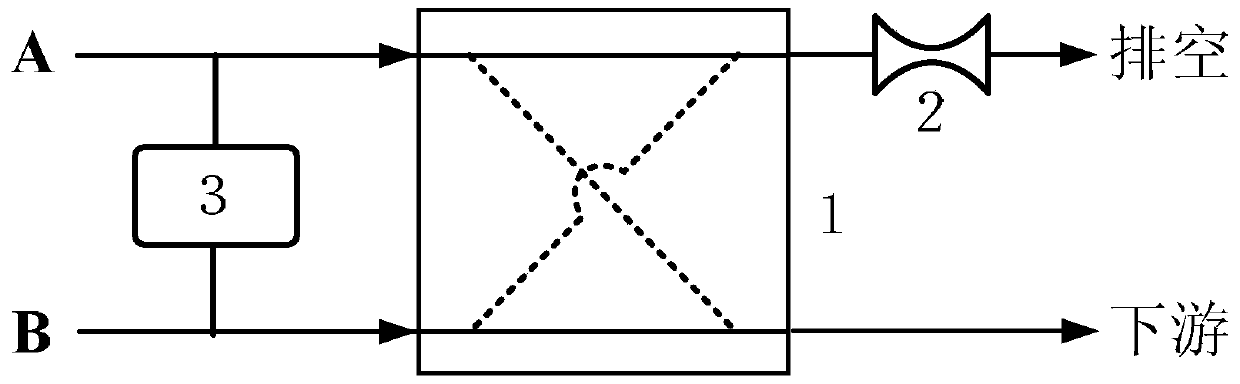

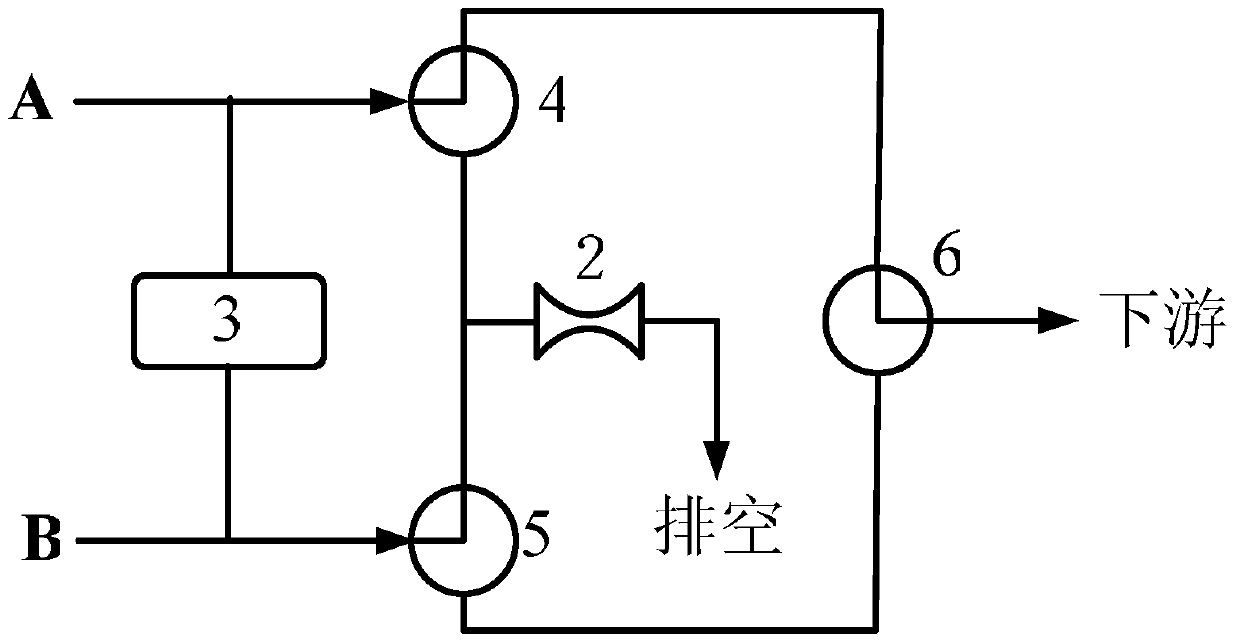

Apparatus including 4-way valve for fabricating semiconductor device, method of controlling valve, and method of fabricating semiconductor device using the apparatus

InactiveUS20060156980A1Improve purge efficiencyAvoid dead volumeDecorative surface effectsSemiconductor/solid-state device manufacturingFour-way valveDevice material

An apparatus and method for fabricating a semiconductor device using a 4-way valve with improved purge efficiency by improving a gas valve system by preventing dead volume from occurring are provided. The apparatus includes a reaction chamber in which a substrate is processed to fabricate a semiconductor device; a first processing gas supply pipe supplying a first processing gas into the reaction chamber; a 4-way valve having a first inlet, a second inlet, a first outlet, and a second outlet and installed at the first processing gas supply pipe such that the first inlet and the first outlet are connected to the first processing gas supply pipe; a second processing gas supply pipe connected to the second inlet of the 4-way valve to supply a second processing gas; a bypass connected to the second outlet of the 4-way valve; and a gate valve installed at the bypass.

Owner:SAMSUNG ELECTRONICS CO LTD +1

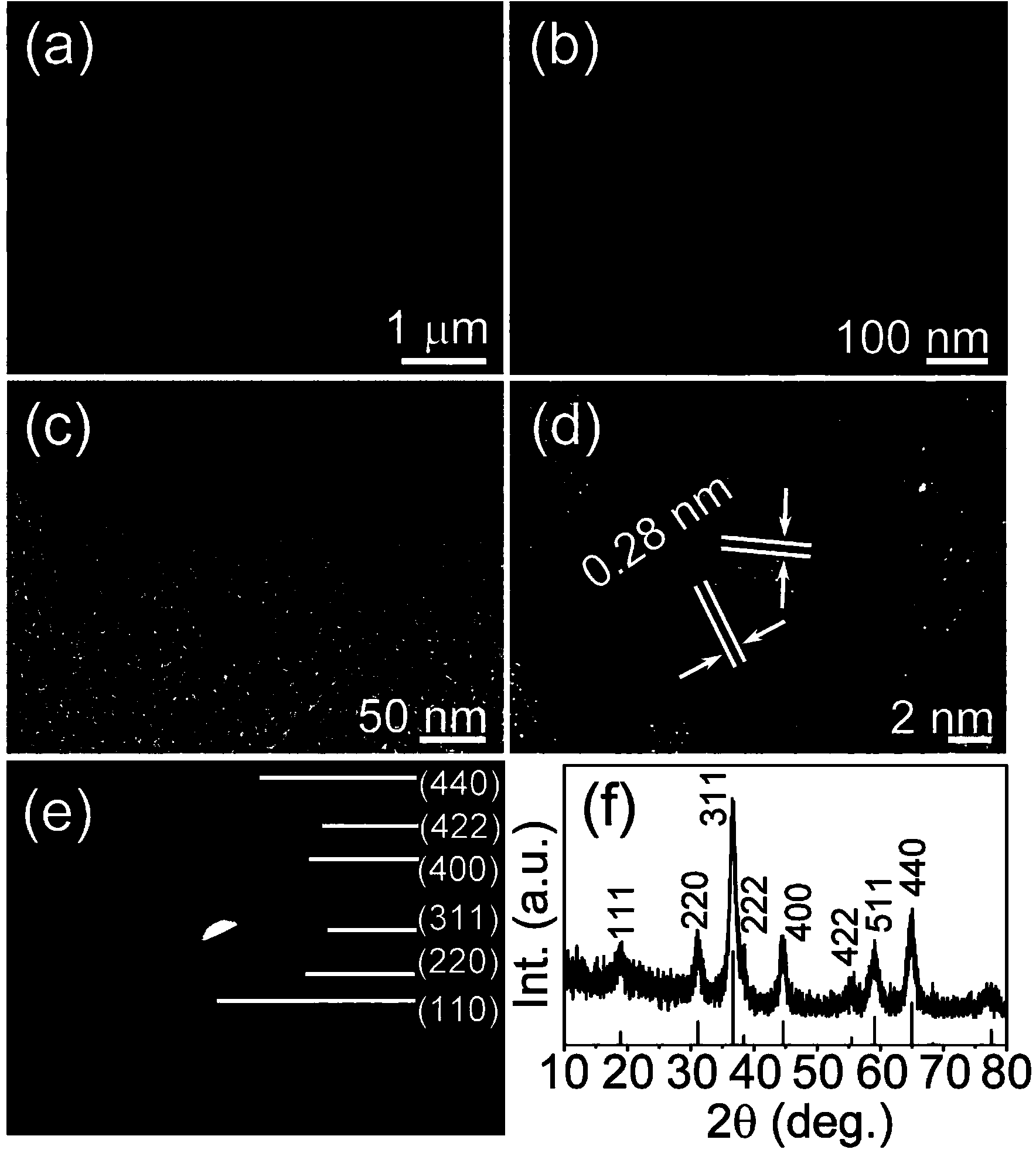

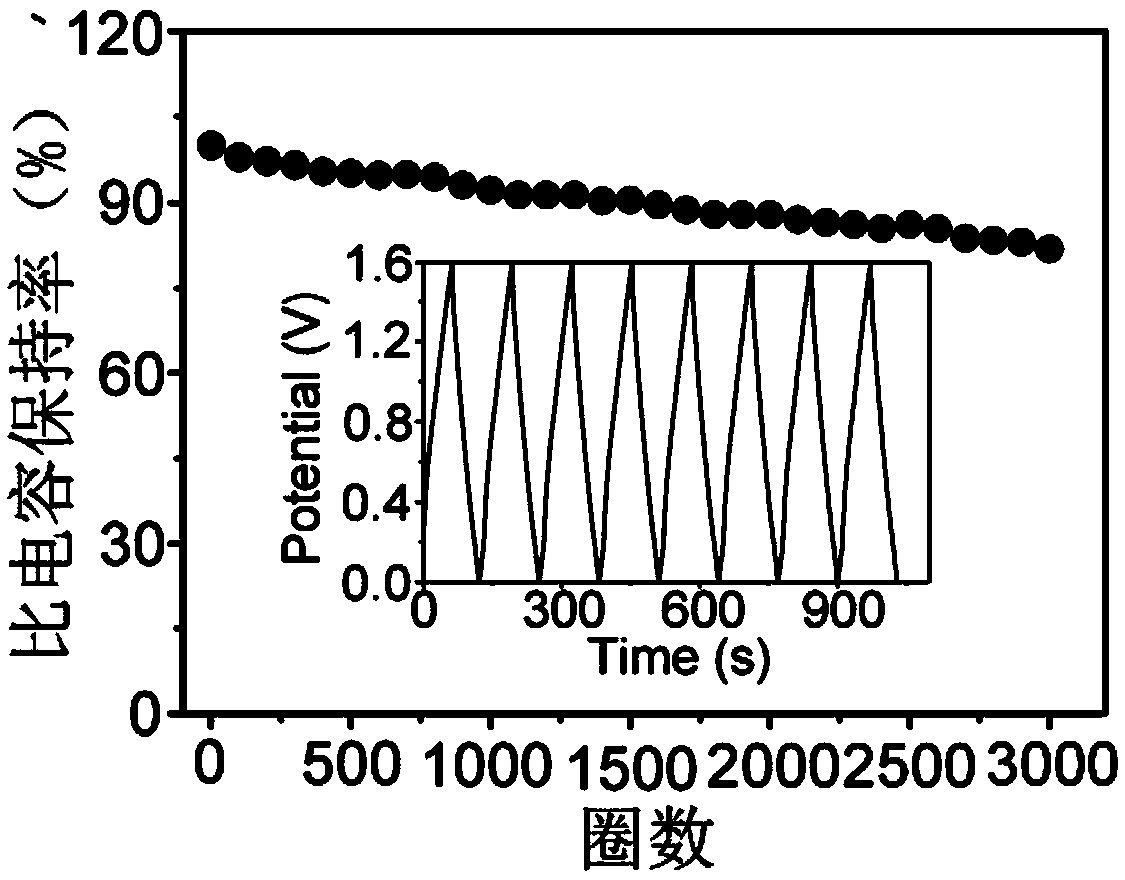

Preparation method of asymmetric supercapacitor of water system

InactiveCN103824705AHigher area than capacitanceIncrease energy densityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceCapacitor voltage

The invention relates to a preparation method of an asymmetric supercapacitor of a water system. The preparation method comprises the steps of (1) growing a NiCo2O4@CoxNi(1-x)(OH)2 core-shell nanosheet array on foamed nickel as a cathode material of a supercapacitor; (2) coating the foamed nickel with activated carbon CMK-3 as an anode material; (3) with a potassium hydroxide solution as an electrolyte solution, assembling the NiCo2O4@CoxNi(1-x)(OH)2 cathode material and the CMK-3 anode material to form the asymmetric supercapacitor. The NiCo2O4@CoxNi(1-x)(OH)2 electrode material prepared by the method has relatively high area specific capacitance up to 5.71F / cm<2>, and the obtained NiCo2O4@CoxNi(1-x)(OH)2 / / CMK-3 asymmetric supercapacitor of the water system has the voltage window of 1.6V and is high in energy density, good in stability and simple in preparation process.

Owner:DONGHUA UNIV

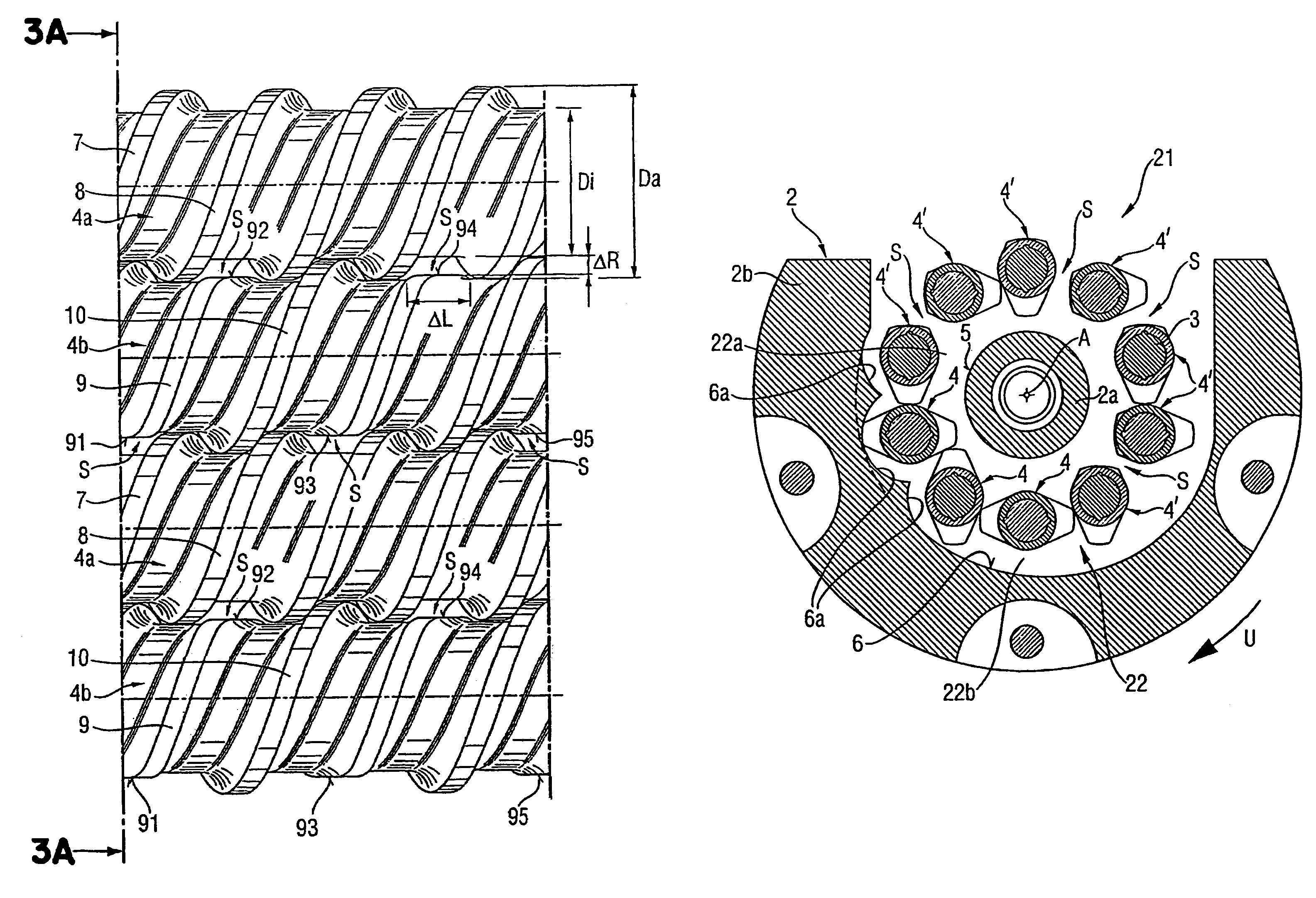

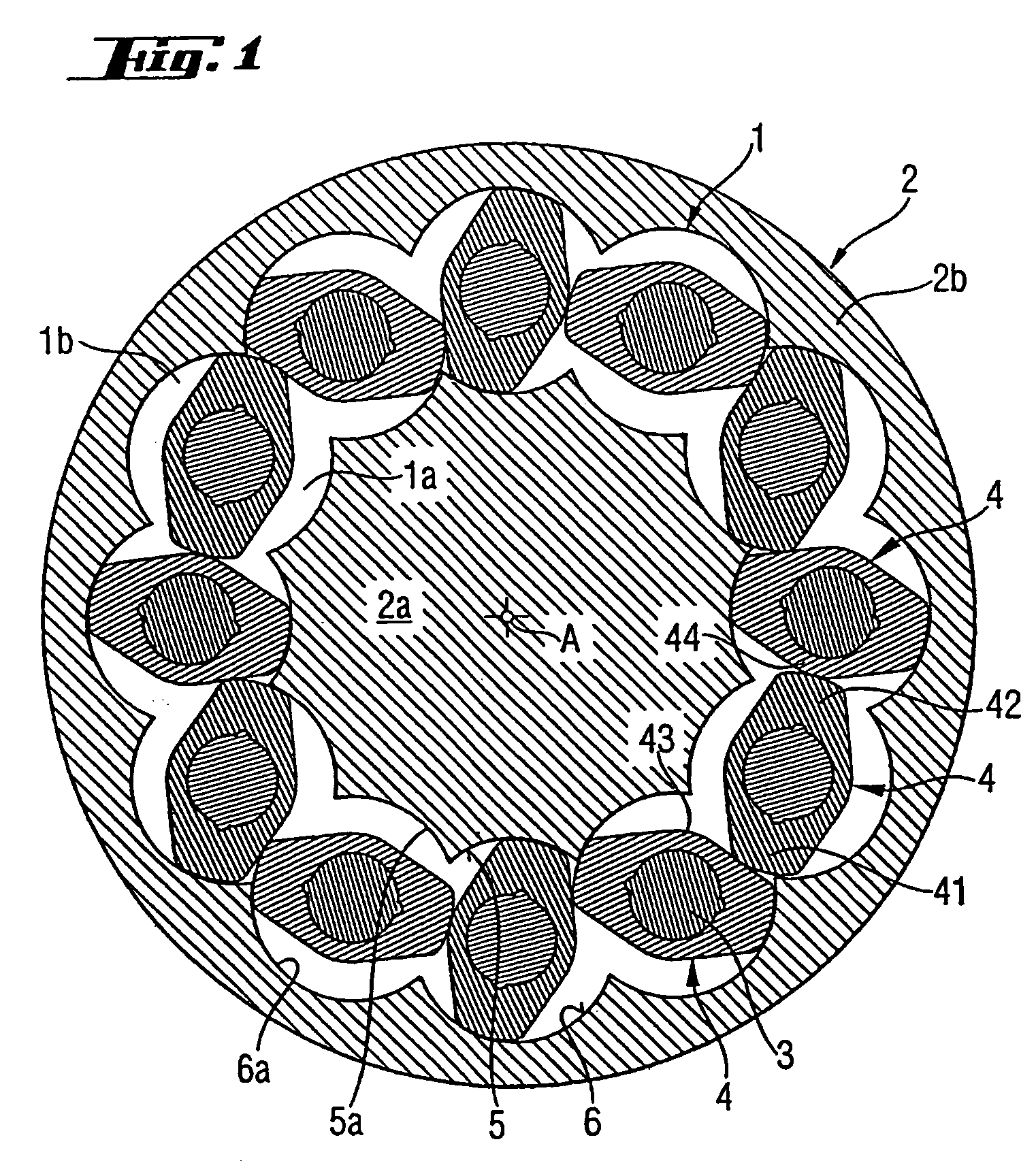

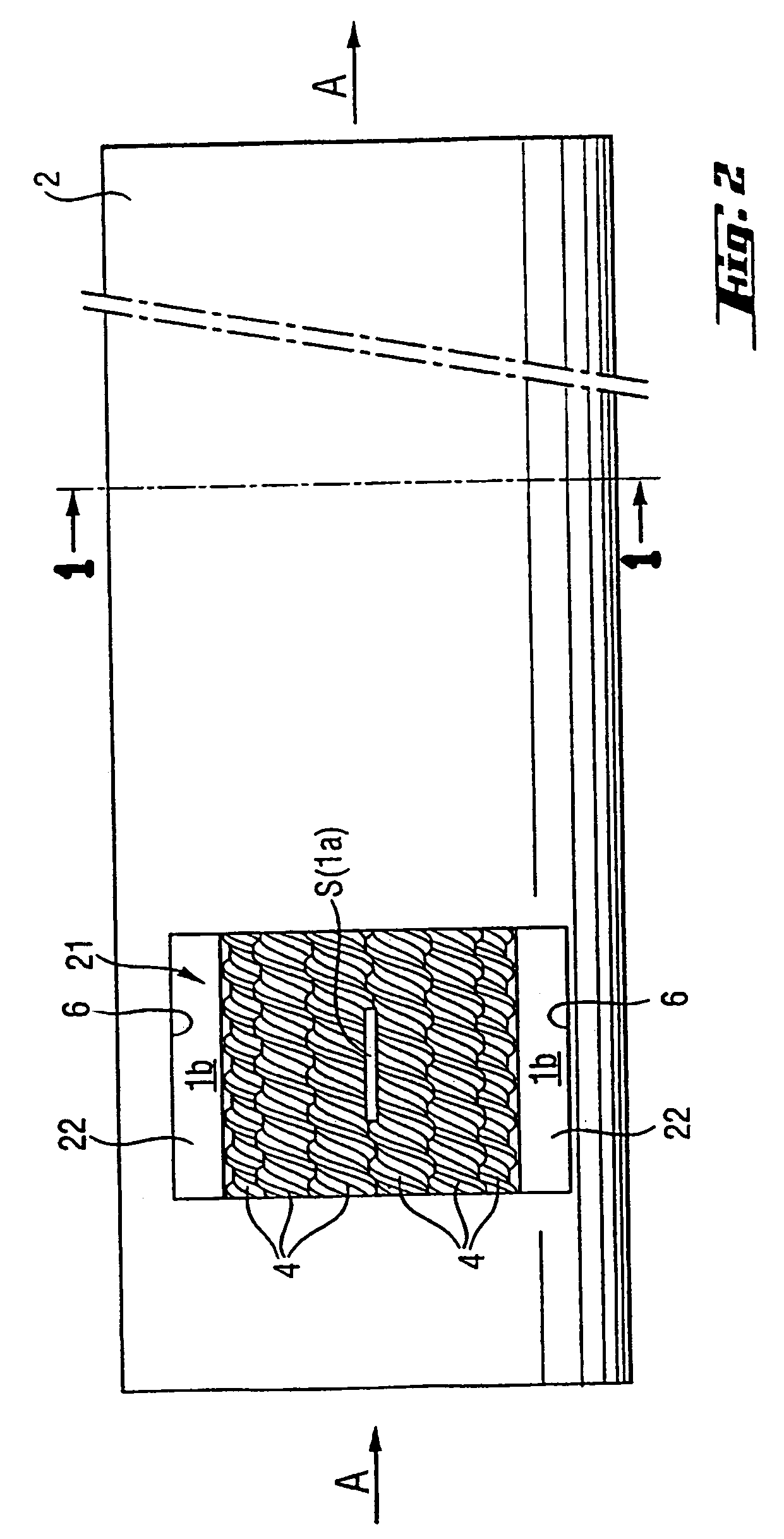

Multi-screw extruder

InactiveUS7080935B2Improve the delivery effectImprove carrying capacityRotary stirring mixersFrozen sweetsEngineeringProcessing element

The invention relates to a multi-shaft extruder for the continuous treatment and / or processing of bulk material, especially a powdery, granular or flocculent product, comprising a plurality of shafts (3) which are arranged in a crown-like manner in a cavity (1) of an extruder housing (2), said shafts extending parallel to the axial direction (A) of the extruder and forming an inner processing chamber (1a) inside the crown, and an outer processing chamber (1b) outside the crown. Each shaft carries a number of axially successive processing elements (4), at least part of the same being elements (4a; 4c; 4e) having a transporting effect, and with which adjacent shafts engage in a sealed manner at least in partial regions. At least one transporting endless screw element (4b; 4d; 4f) comprising at least one transporting screw thread (9, 10; 14, 15, 16; 19, 20) is placed in the region of the supply opening (21) in the extruder housing (2), and does not engage in a sealing manner in at least one partial region along the axial direction (A).

Owner:BUHLER THERMAL PROCESSES

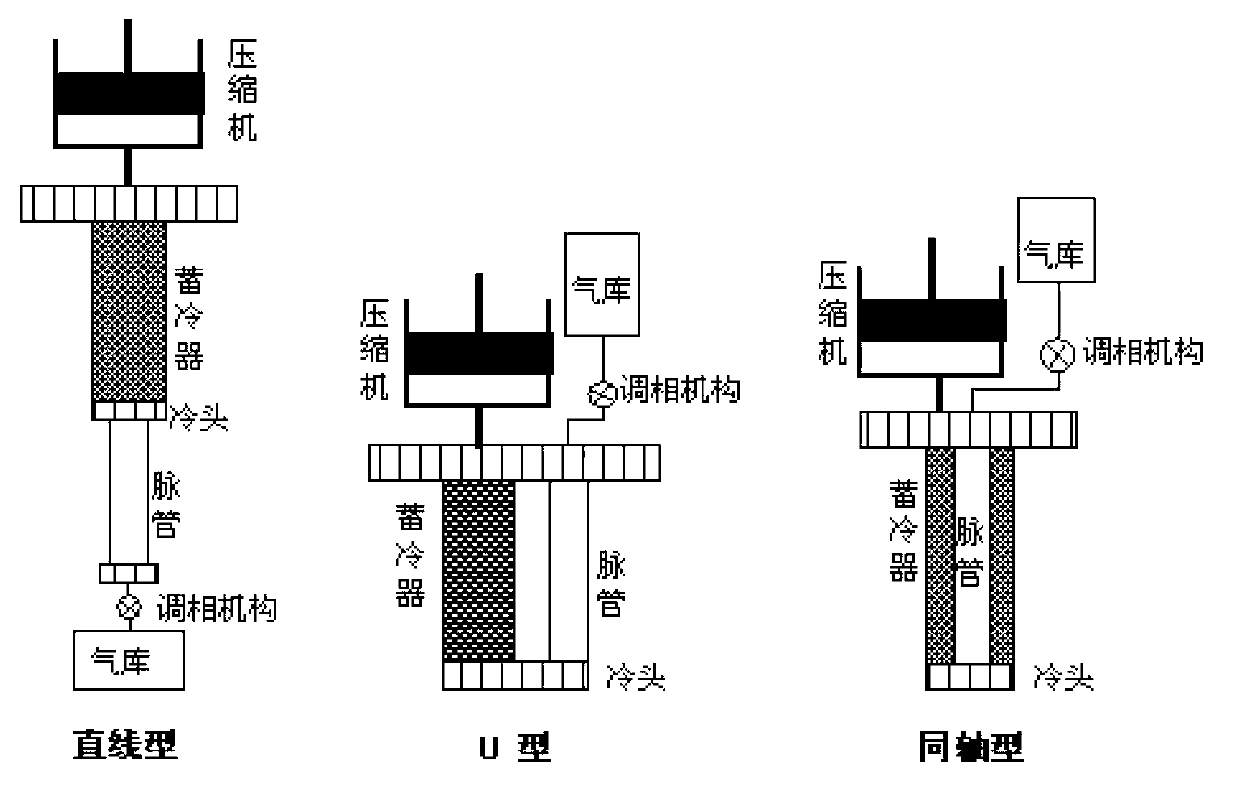

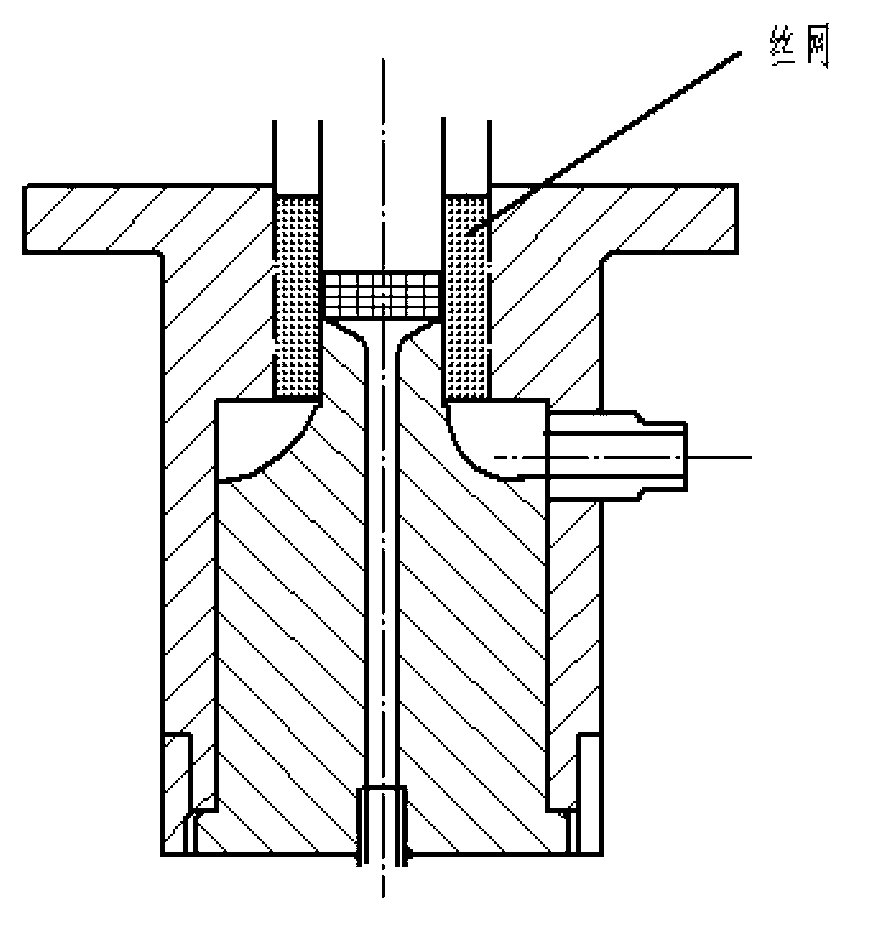

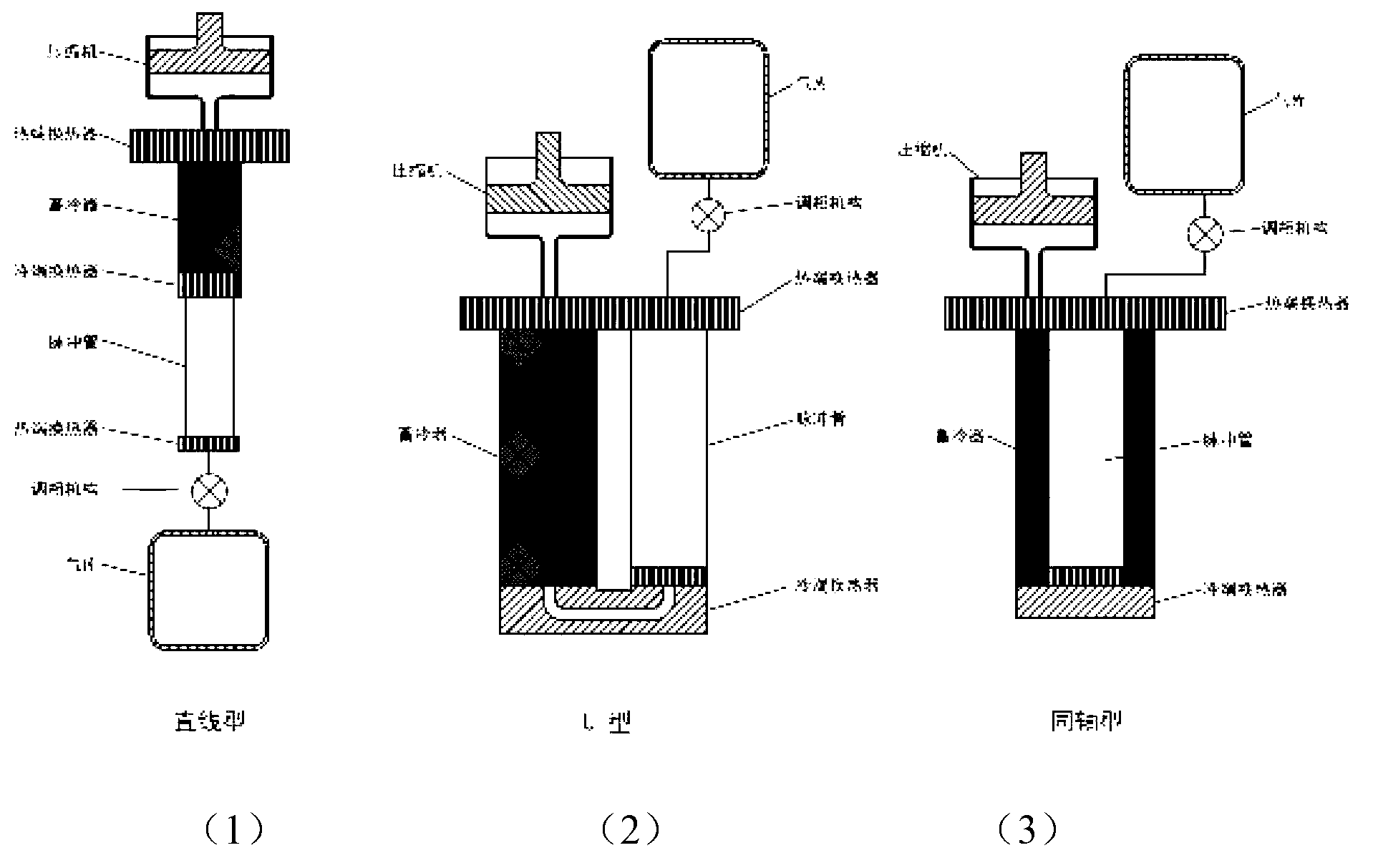

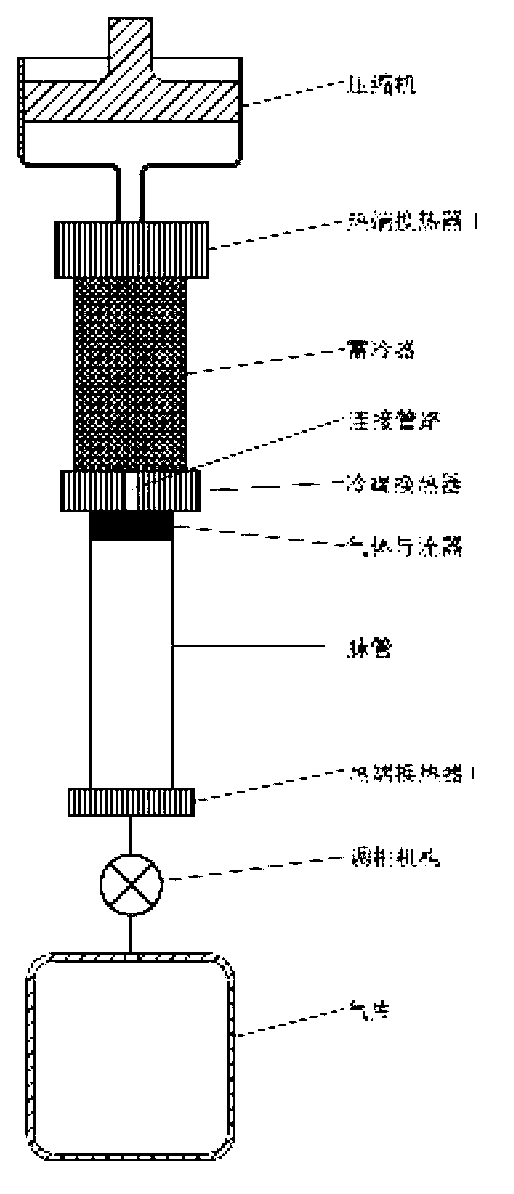

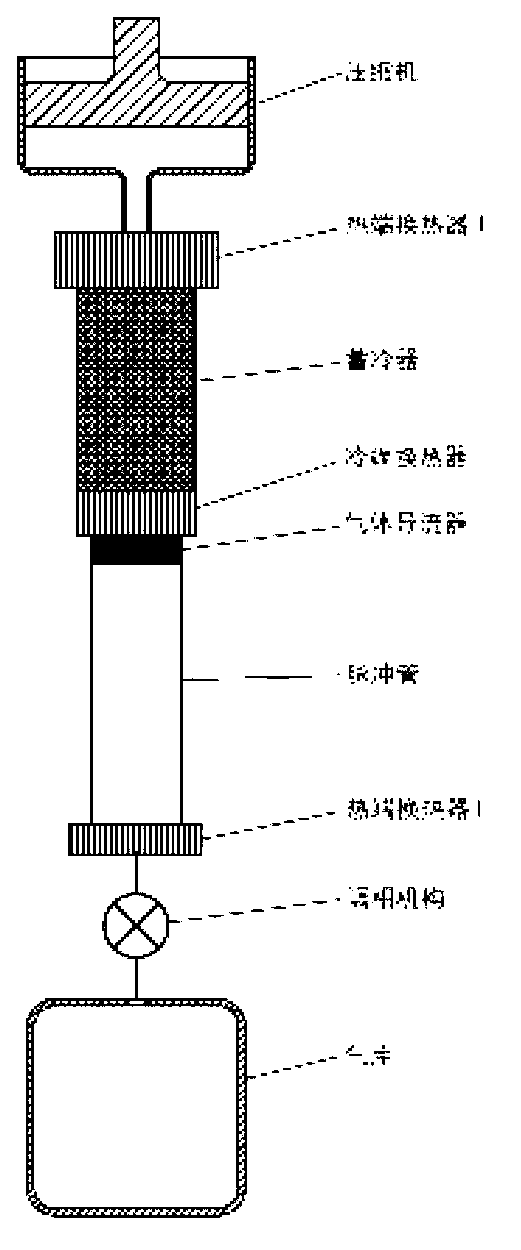

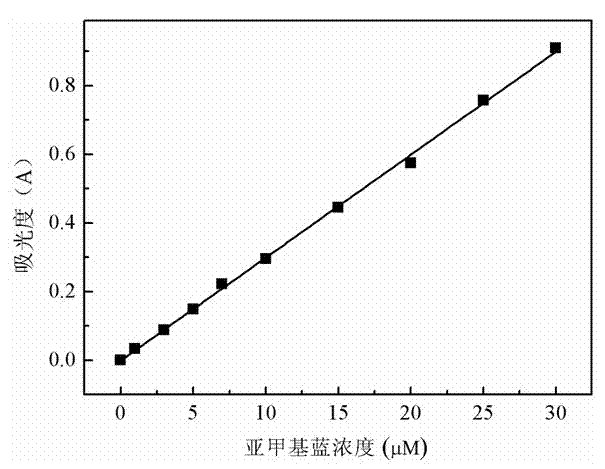

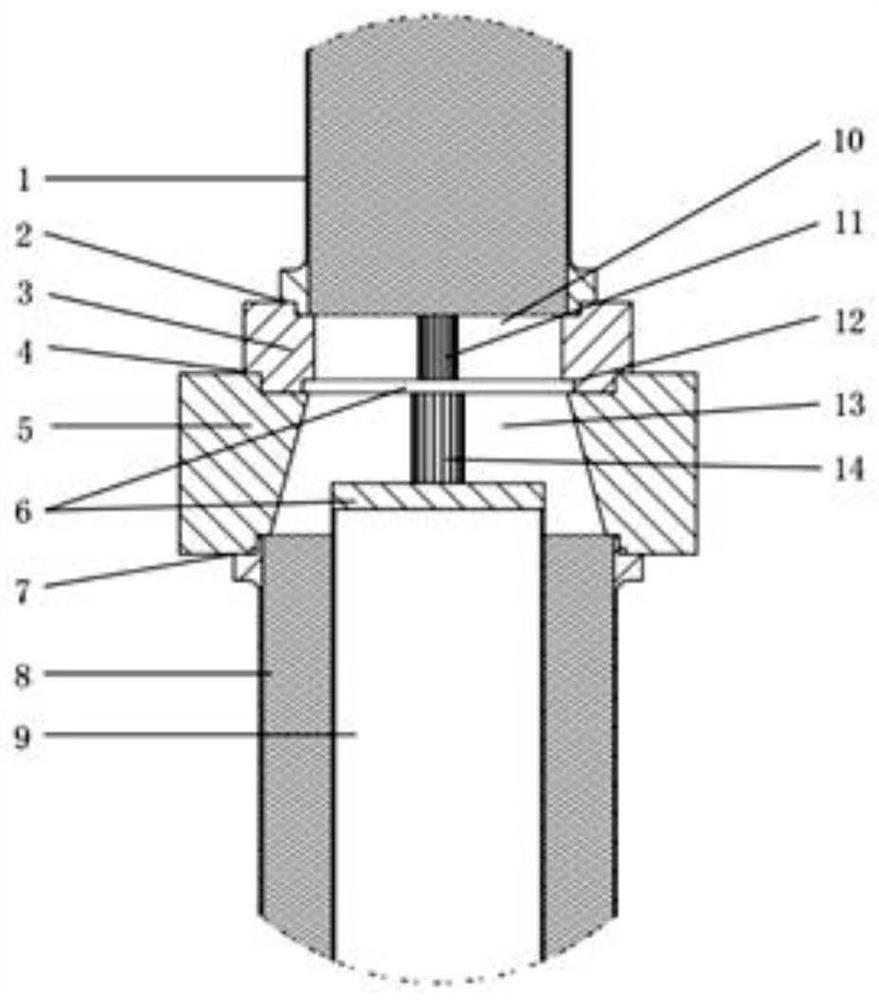

Conical slit-type hot end heat exchanger of coaxial pulse tube refrigerator and manufacturing method

ActiveCN102735088AImprove thermodynamic performanceImprove machine performanceCompression machinesSoldering apparatusPulse tube refrigeratorEngineering

The invention discloses a conical slit-type hot end heat exchanger of a coaxial pulse tube refrigerator and a manufacturing method. The heat exchanger structurally consists of a hot end flange, a conical slit and a hot end plug, wherein the conical slit is inserted into the hot end flange in a tight fit way, the radius of a circle of contact on the top of a cone frustum is equal to the radius of a cold accumulator and the radius of the bottom of the cone frustum is equal to the radius of the hot end plug. The hot end plug and the hot end flange not only can be connected through bolts to form a detachable split-type hot end heat exchanger, but also can be hermetically welded to form an integrated hot end radiator. The conical slit-type hot end heat exchanger has the advantages that the structure is simple, compact and high-efficiency, the hot end radiating capacity of the refrigerator can be exerted to the utmost extent and the hot end pressure ratio of the pulse tube refrigerator is increased at the same time. The structure can intensively realize the major functions of a high-efficiency hot end heat exchanger, a hot end gas flow guide device of the pulse tube refrigerator and a hot end gas even distributor of the cold accumulator, and can improve the performance of the entire pulse tube refrigerator to a great extent.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

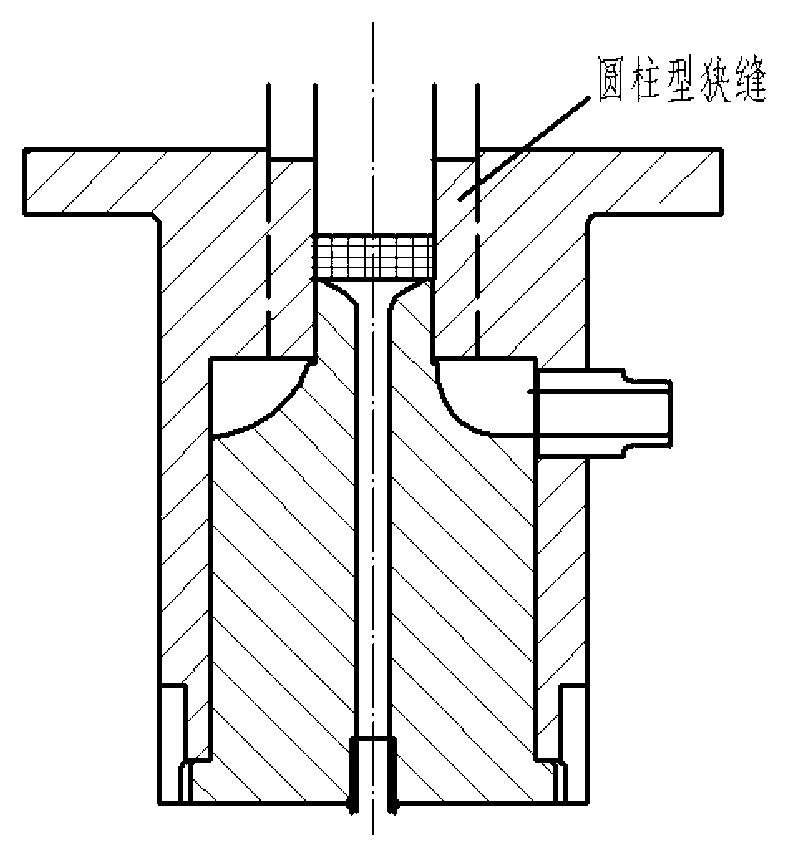

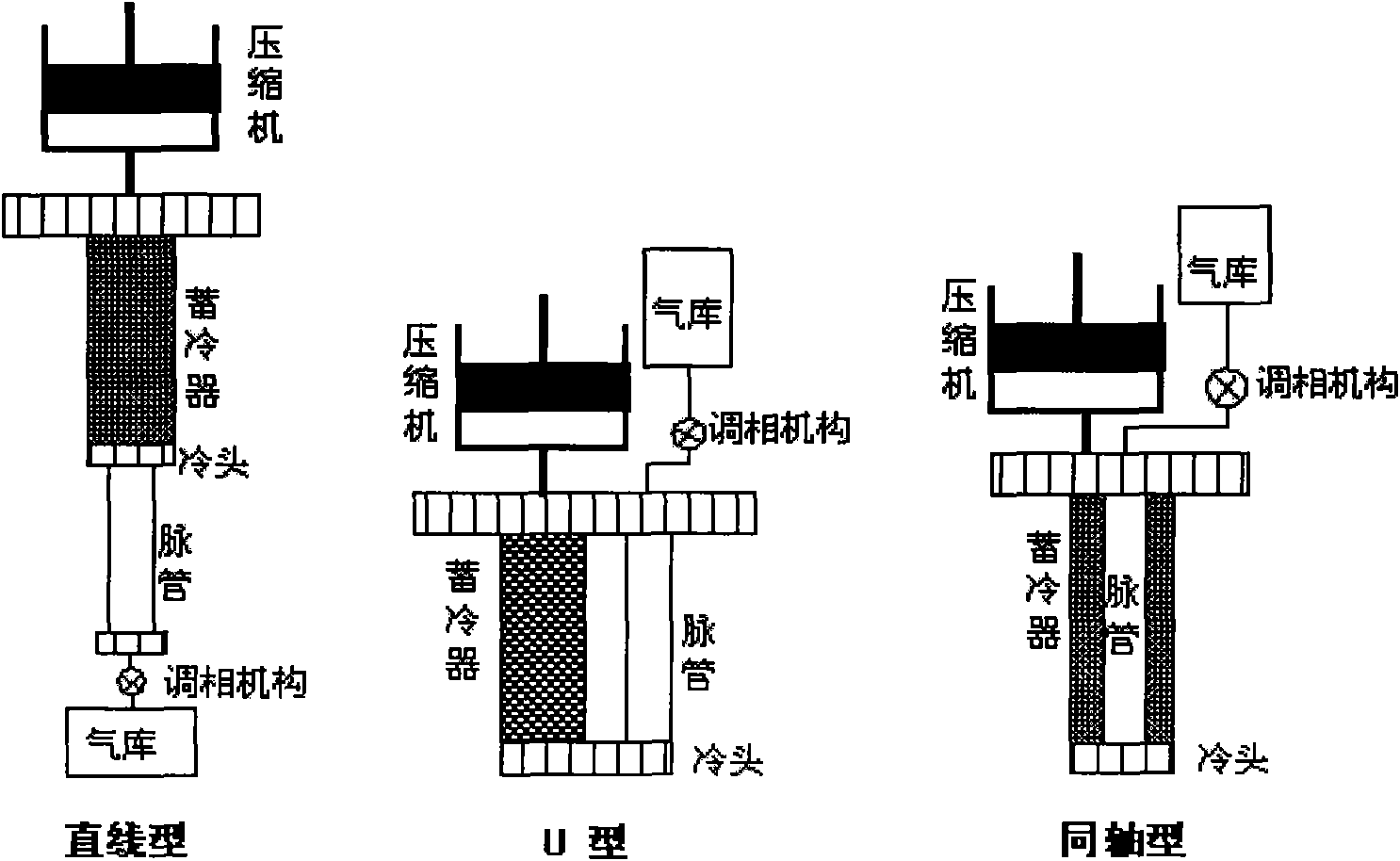

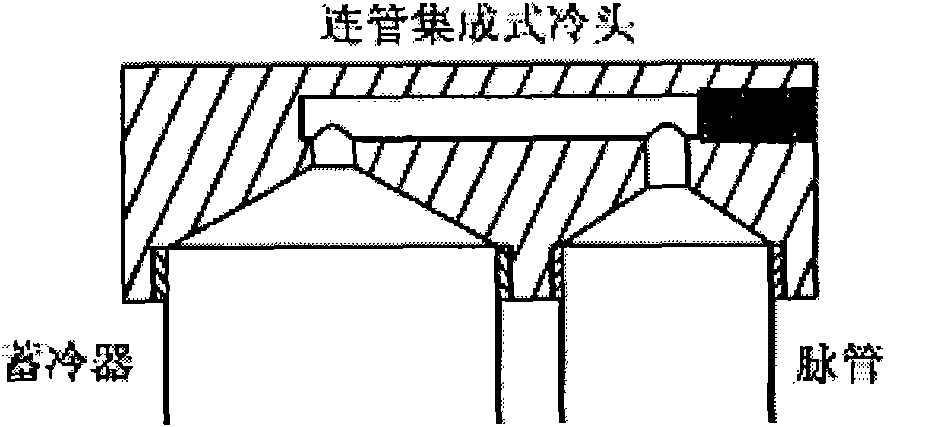

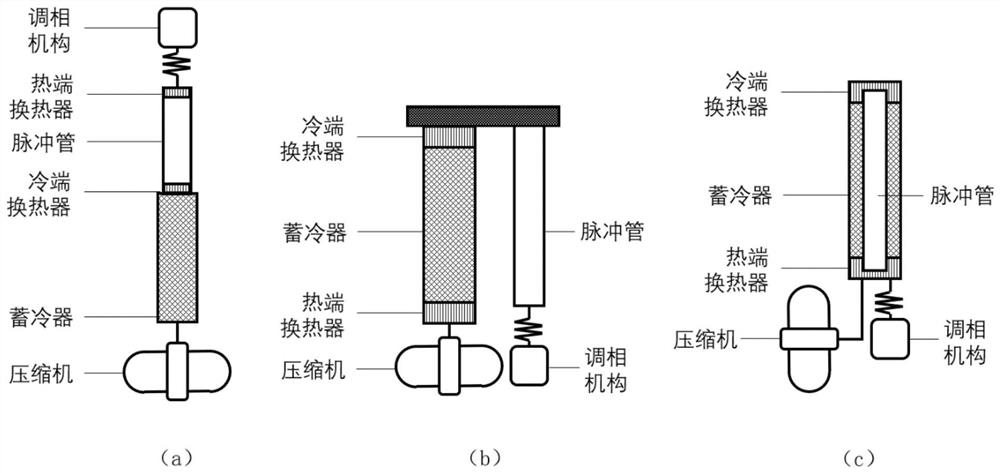

Integrated slit cold head of U-shaped pulse tube refrigerating machine and manufacturing method

InactiveCN102042711AMaintain laminar effectImprove thermodynamic performanceCompression machinesGas cycle refrigeration machinesEngineeringTop cap

The invention discloses an integrated slit cold head of a U-shaped pulse tube refrigerating machine and a manufacturing method. The cold head comprises two parts of a top cover and a lower flange, wherein two cylindrical lug bosses protrude below a big lug boss of the top cover, outer diameters of the two cylindrical lug bosses are respectively equal to inner diameters of a cold regenerator and a pulse tube; the two lug bosses integrally cut and penetrate through a slit in parallel horizontally and uniformly; through insertion holes matched with the cylindrical lug bosses of the top cover are arranged on the lower flange, a sealing groove and a location groove matched with the big lug boss of the top cover are cut on the upper surface of the lower flange, the lower flange, the cold regenerator and the pulse tube are hermetically welded to form an assembly; the top cover and the lower flange not only can be connected by bolts to form a detachable split cold head, but also can be hermetically welded to form an integrated cold head. In the invention, the main functions of three parts of an efficient cold end heat exchanger, a pulse tube cold end gas director and a cold regenerator cold end gas distributor can be intensively realized in an integrated slit cold head structure, the overall performance of the U-shaped pulse tube refrigerating machine is enhanced.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

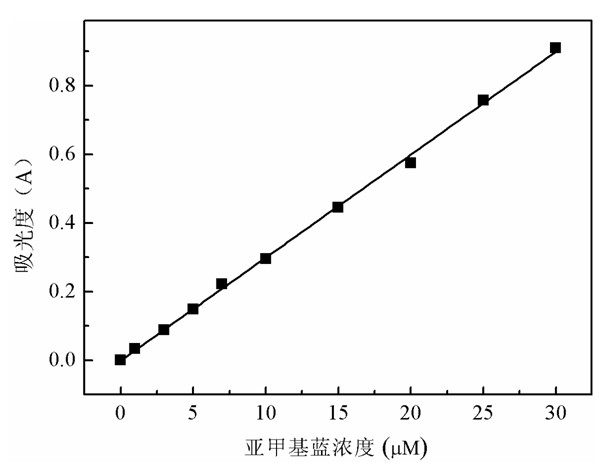

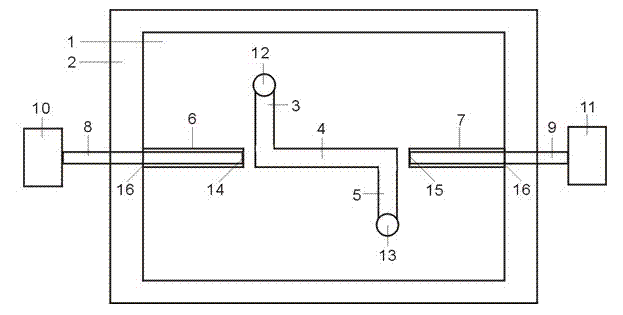

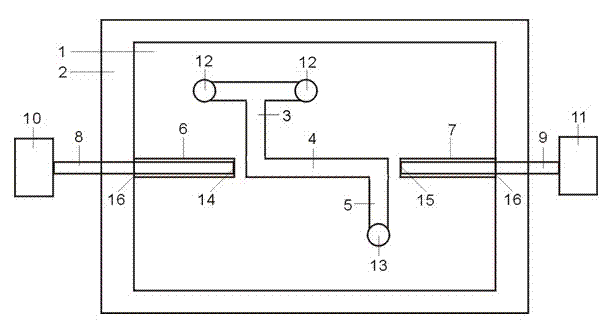

Long-path optical fiber-microfluidic chip sensor for detecting absorbance and refraction index

InactiveCN102539361AHigh sensitivitySmall numerical aperturePhase-affecting property measurementsColor/spectral properties measurementsRefractive indexFibre Channel

The invention discloses a long-path optical fiber-microfluidic chip sensor for detecting absorbance and refraction index, which comprises a microfluidic chip made of a transparent material. A detection passage, an incident optical fiber passage and an emergent optical fiber passage are arranged in the microfluidic chip. The detection passage is provided with a sample inlet, a sample outlet, a light incidence port and a light emergence port. The detection passage is arranged between the incident optical fiber passage and the emergent optical fiber passage. The detection passage, the incident optical fiber passage and the emergent optical fiber passage are mutually isolated. Emergent light from the incident optical fiber passage is absorbed by a sample in the detection passage, is reflected by the inner wall surface of a side wall and then shoots into the emergent optical fiber passage. The incident optical fiber passage and the emergent optical fiber passage are respectively matched with optical fibers which are arranged in the incident optical fiber passage and the emergent optical fiber passage. The end surface of the emergent ends of the optical fibers in the incident optical fiber passage and the end surface of the light emergence port of the incident optical fiber passage are on the same level. The end surface of the emergent ends of the optical fibers in the emergent optical fiber passage and the end surface of the light incidence port of the emergent optical fiber passage are at the same level. The long-path optical fiber-microfluidic chip sensor for detecting absorbance and refraction index can realize high-sensitivity biochemical sensing at low sample consumption.

Owner:ZHEJIANG UNIV

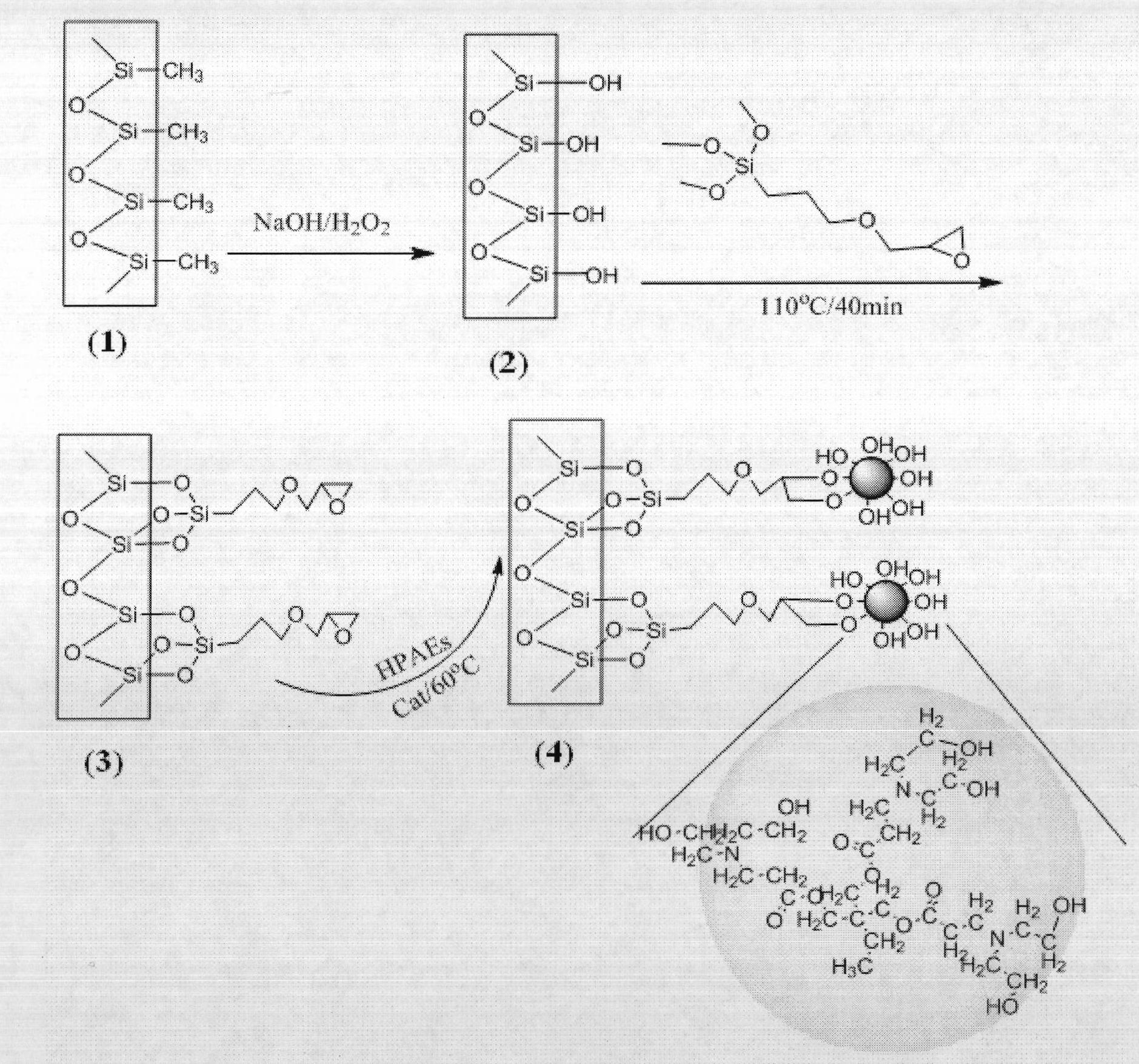

Hydroxy-terminated hyperbranched polyamine-ester polymer and application thereof in microfluidic chip

InactiveCN102060988AImprove hydrophilicityInhibition of adsorptionMaterial analysisPolymer scienceTrimethylolpropane

The invention relates to hydroxy-terminated hyperbranched polyamine-ester polymer and an application thereof in a microfluidic chip. The preparation method of the hydroxy-terminated hyperbranched polyamine-ester polymer comprises the following steps: using equimolar diethanol amine and methyl acrylate to react and obtain N,N-dihydroxyethyl-3-aminomethyl propionate; and using trimethylolpropane and N,N-dihydroxyethyl-3-aminomethyl propionate to react, wherein G2 hydroxy-terminated hyperbranched polyamine-ester polymer, G3 hydroxy-terminated hyperbranched polyamine-ester polymer and G4 hydroxy-terminated hyperbranched polyamine-ester polymer are obtained respectively when the molar ratio of trimethylolpropane to N,N-dihydroxyethyl-3-aminomethyl propionate is 1:9, 1:21 or 1:45. The hydroxy-terminated hyperbranched polyamine-ester polymer is used to prepare the hydrophilic microfluidic chip. The preparation method of the chip comprises the following steps: oxidizing a polydimethylsiloxane (PDMS) microfluidic chip substrate in oxygen atmosphere; and connecting silane coupling agent with the inside of the substrate, and connecting the polymer with silane coupling agent. By strictly controlling the reaction conditions and the molar ratio of reactants, relatively regular polymer can be prepared. The polymer in the invention is used to modify PDMS, thus the hydrophilicity can be maintained permanent, any expensive instrument is not used and the preparation is convenient and fast.

Owner:UNIV OF JINAN

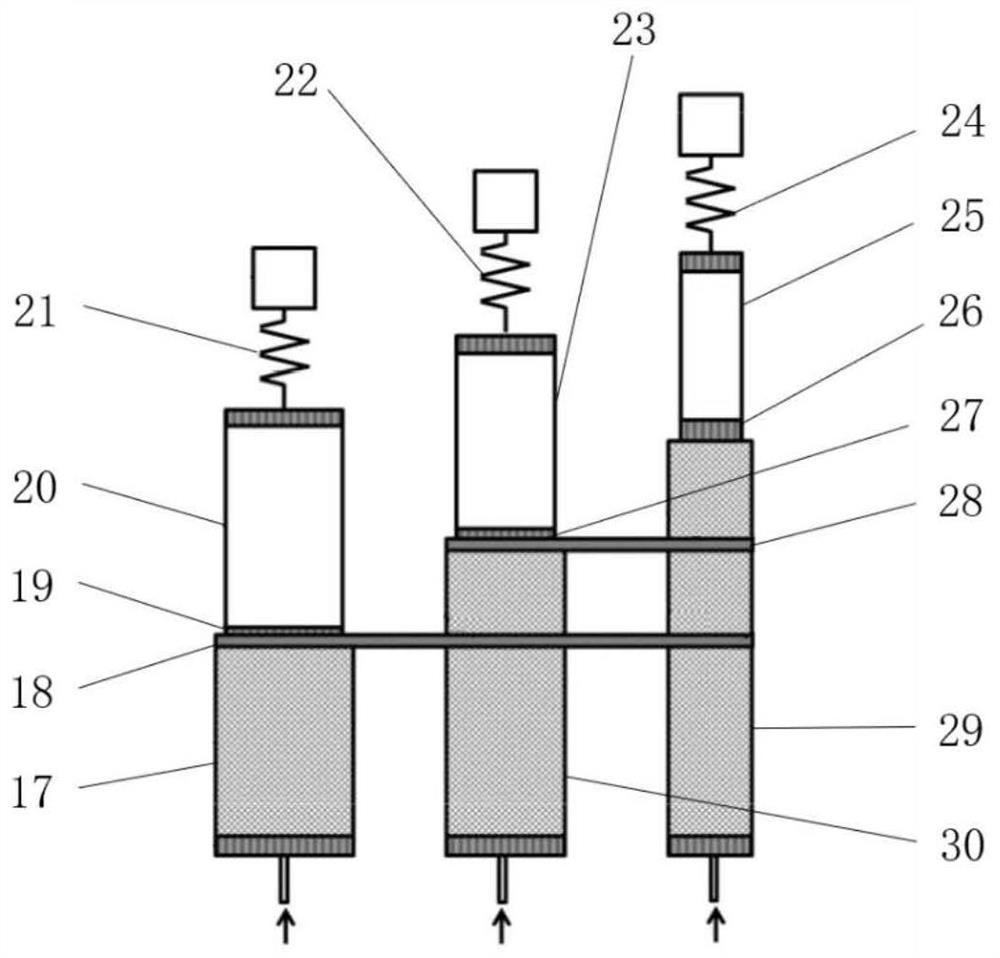

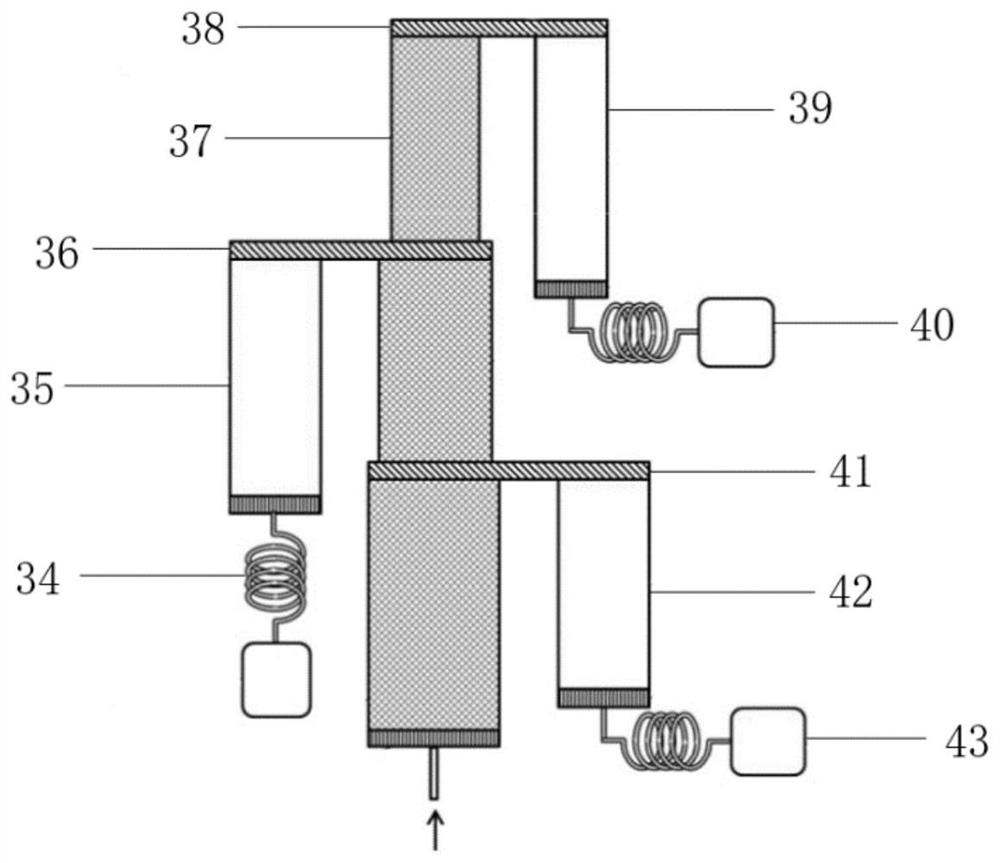

Integrated tapered slit cold-end heat exchanger of linear pulse tube refrigerator and manufacturing method

ActiveCN103017394AGuaranteed heat exchange effectAvoid dead volumeCompression machinesGas cycle refrigeration machinesLow speedWire cutting

The invention discloses an integrated tapered cold-end heat exchanger for a linear pulse tube refrigerator and a manufacturing method. The heat exchanger mainly comprises a shell, a tapered slit body and a T-shaped guide core column, wherein the shell is a main heat-dispersing surface and a coupled interface, protects the tapered slit body and the T-shaped guide core column and is connected with a regenerator and a pulse tube; the tapered slit body is cut inside the shell by a low-speed wire cutting technology; the T-shaped guide core column is arranged in the center; and a core column slit is cut on the guide core column. According to the heat exchanger, the heat exchanging area is maximized within a limited volume by uniformly cutting the tapered slit in unequal diameters; the cutting way makes a natural transition from a large diameter end to a small diameter end; the thermal resistance and flow loss are minimized; and the gas in the pulse tube is laminarized without an additional gas director. The heat exchanger greatly improves the performance of the whole linear pulse tube refrigerator and is very significant to the practicality of the linear pulse tube refrigerator, aerospace application and other aspects.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

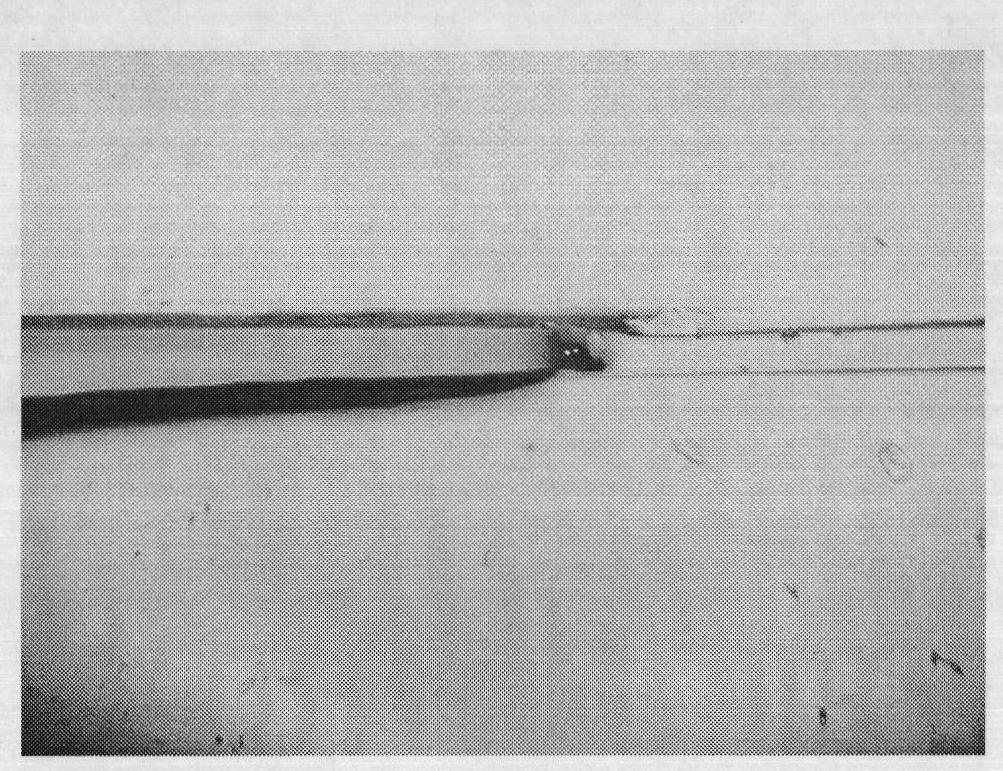

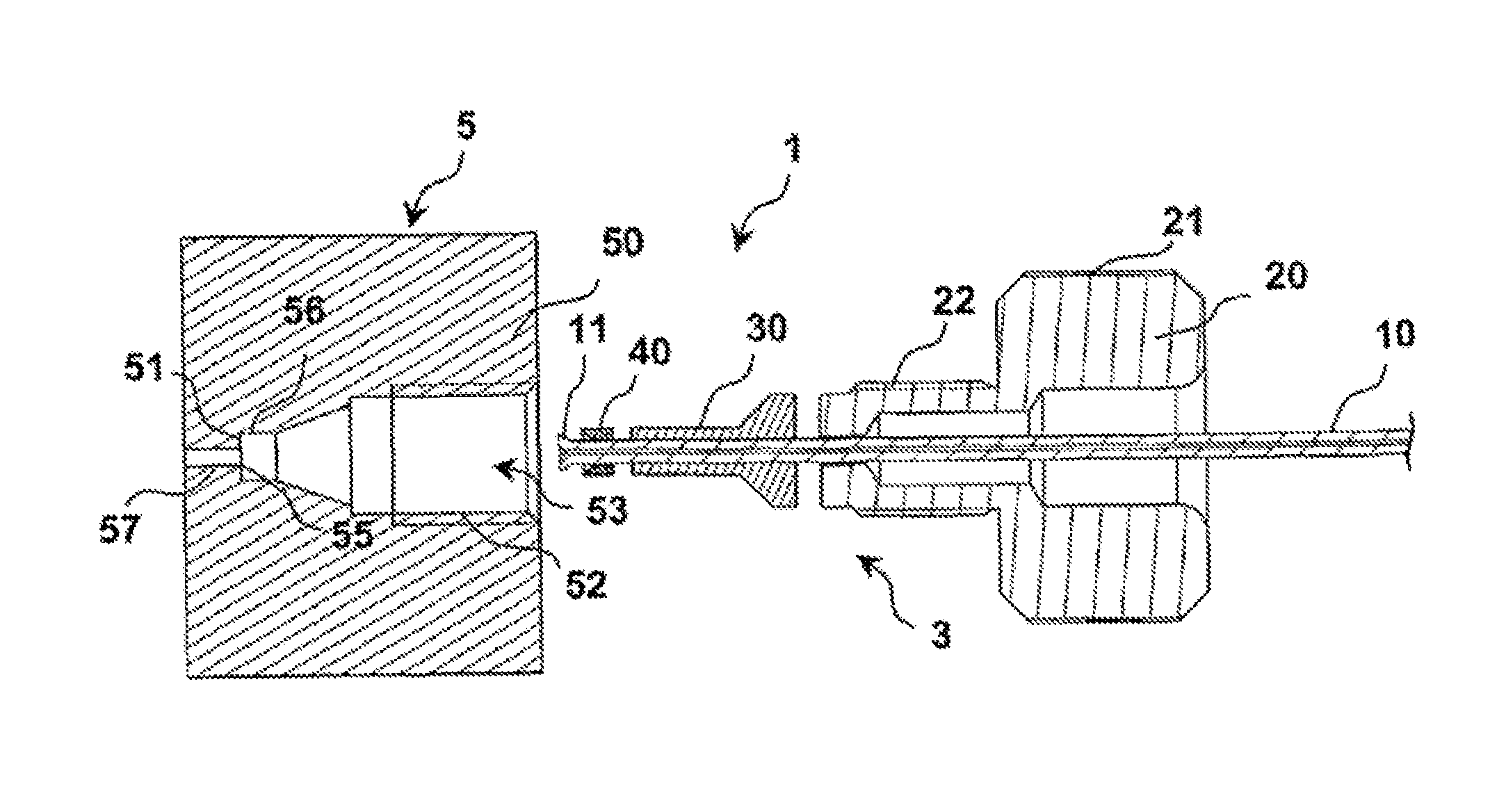

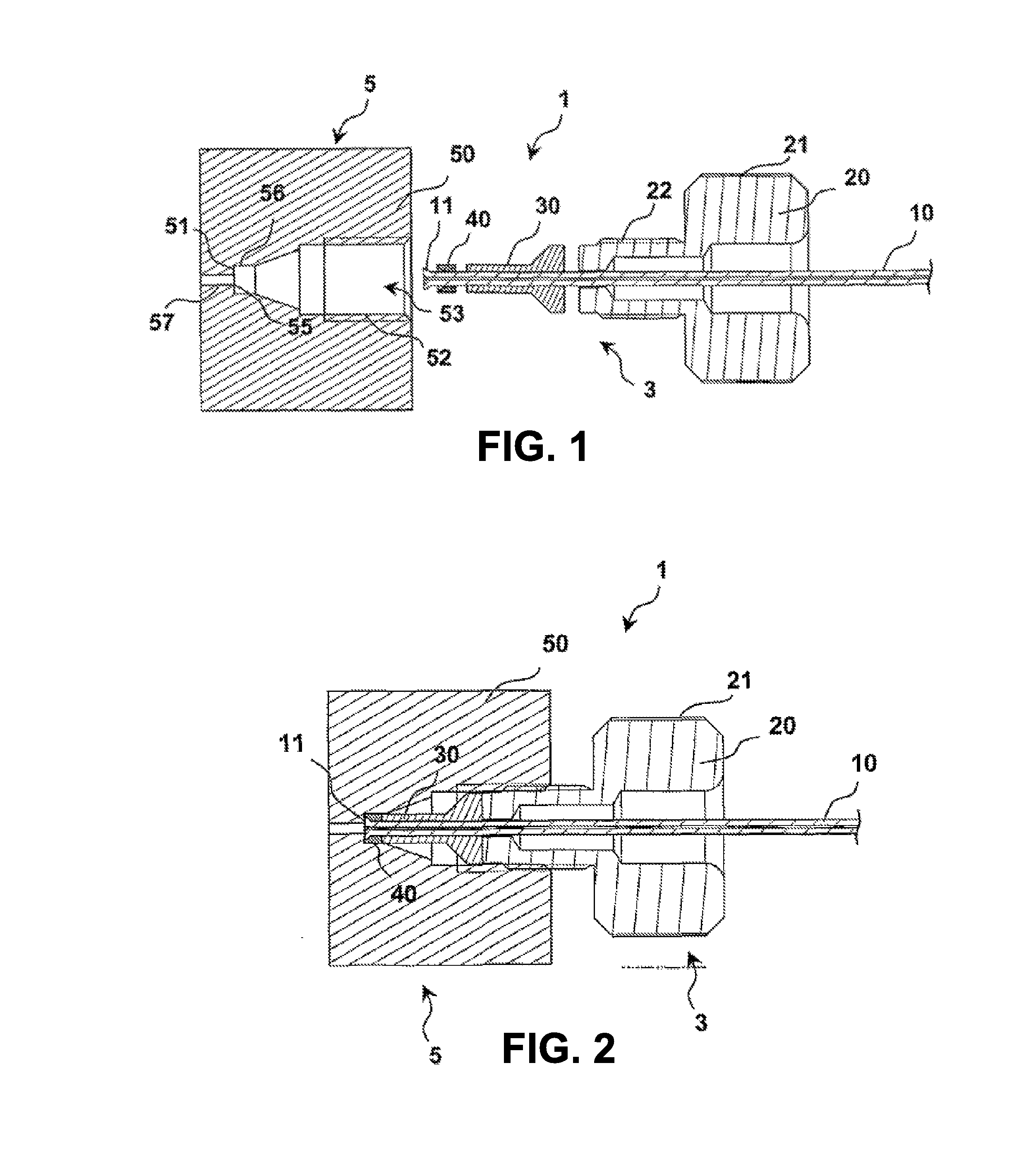

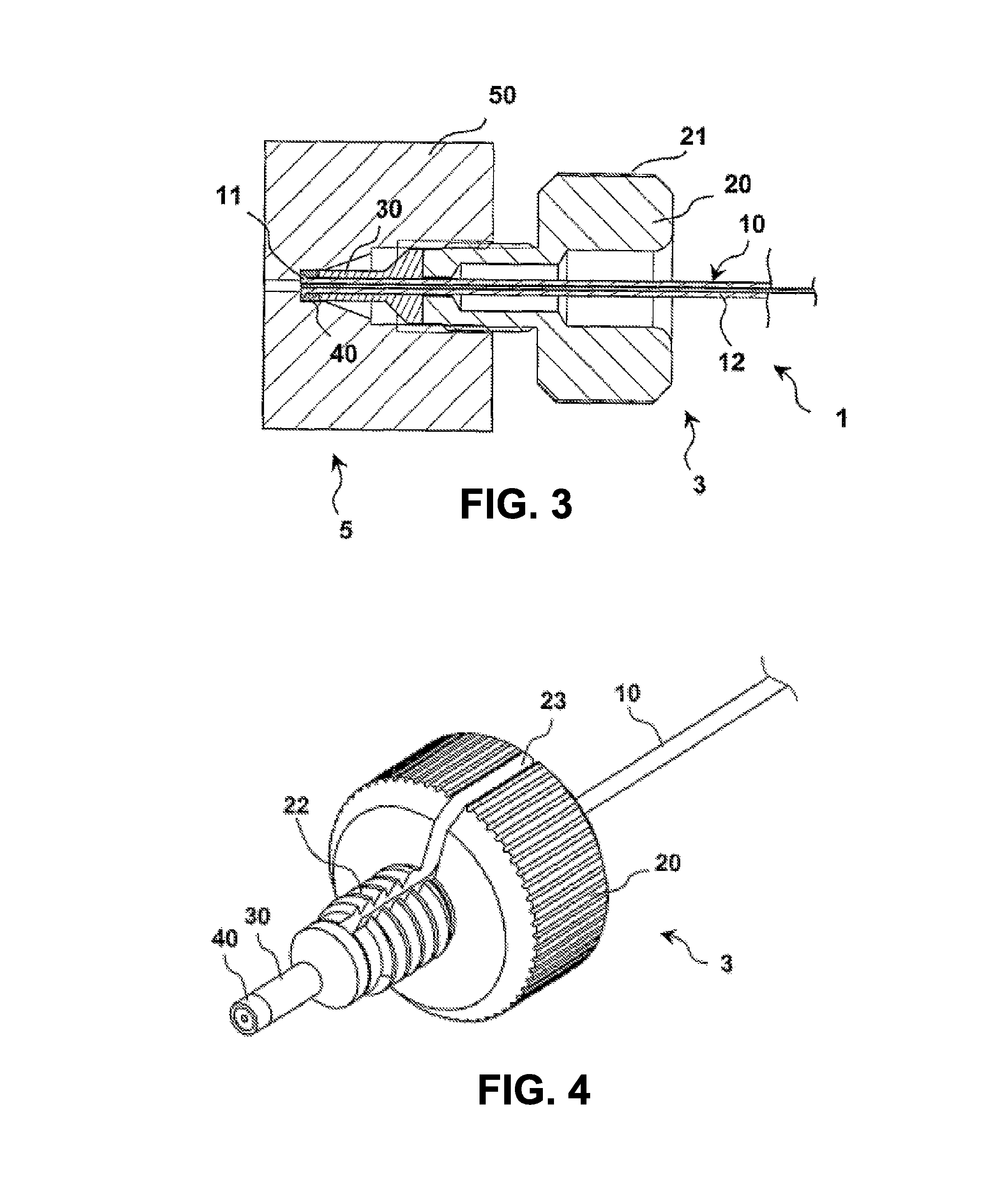

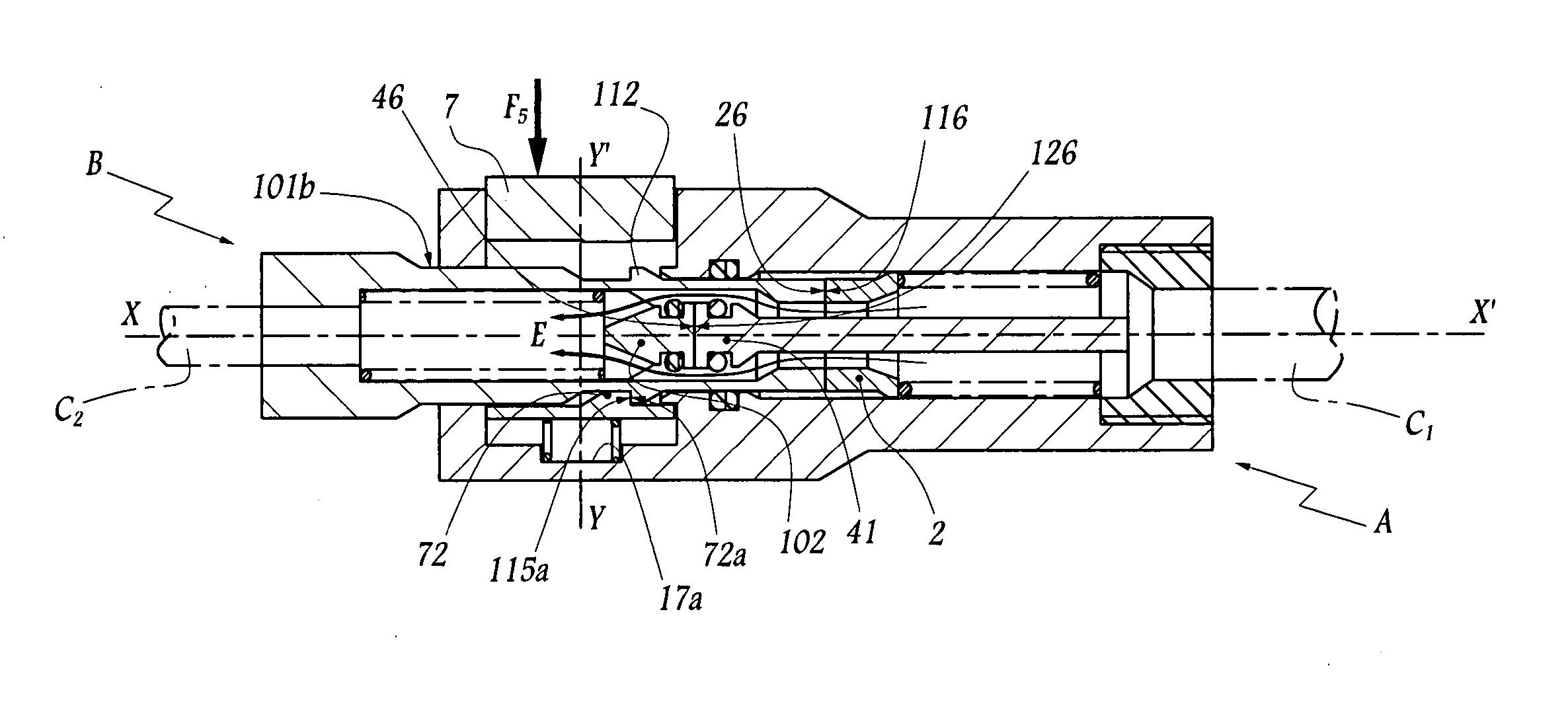

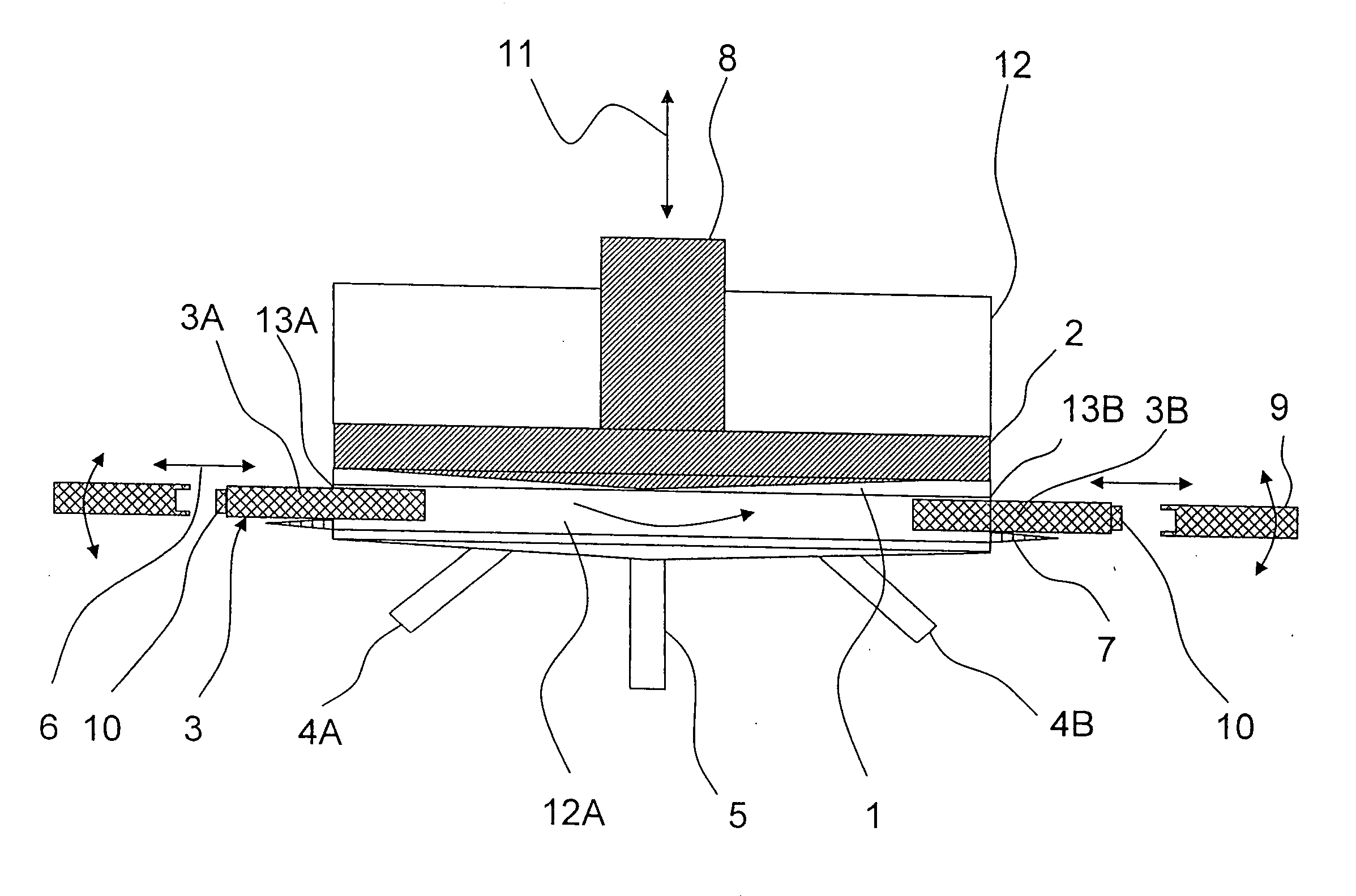

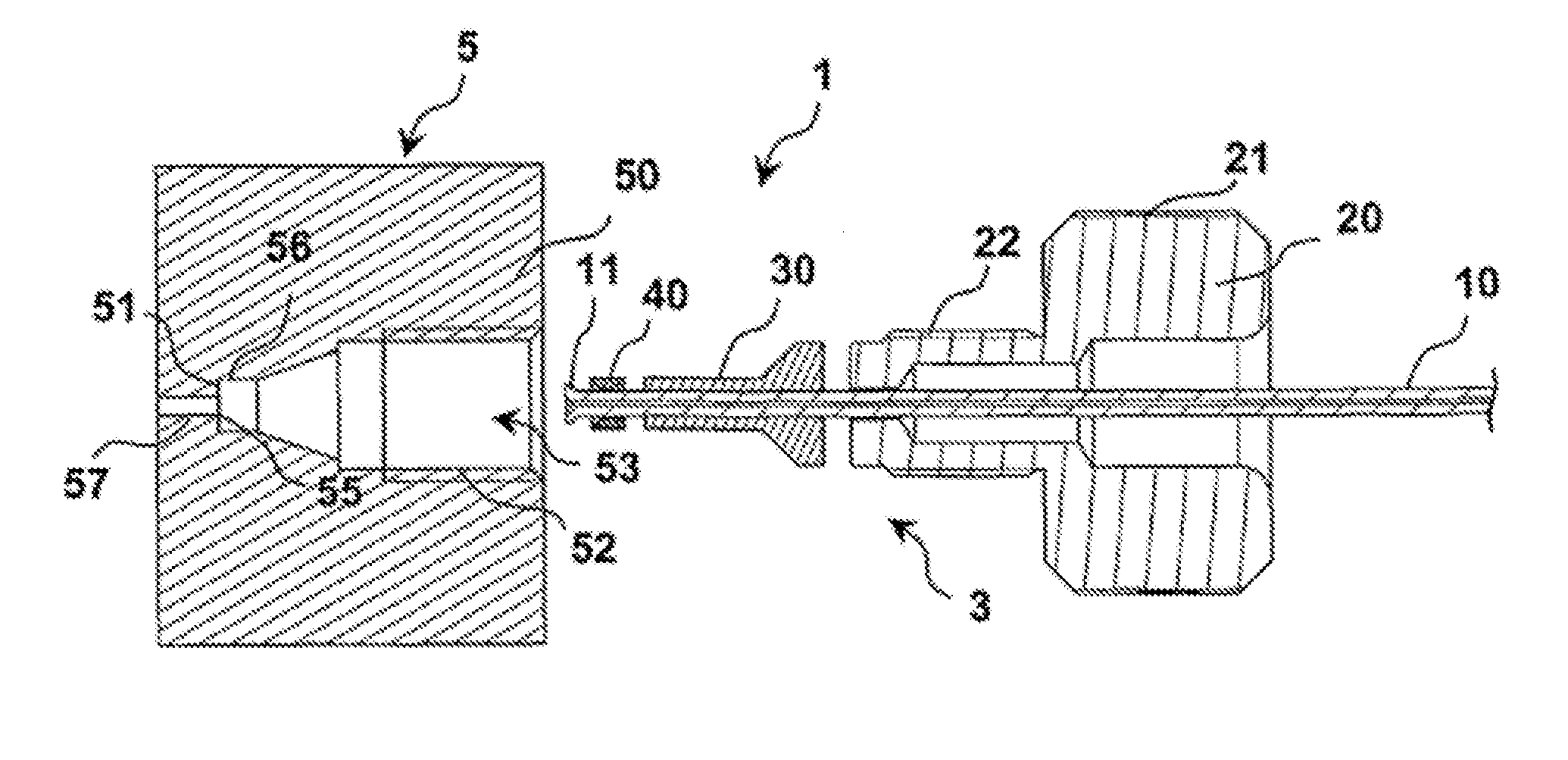

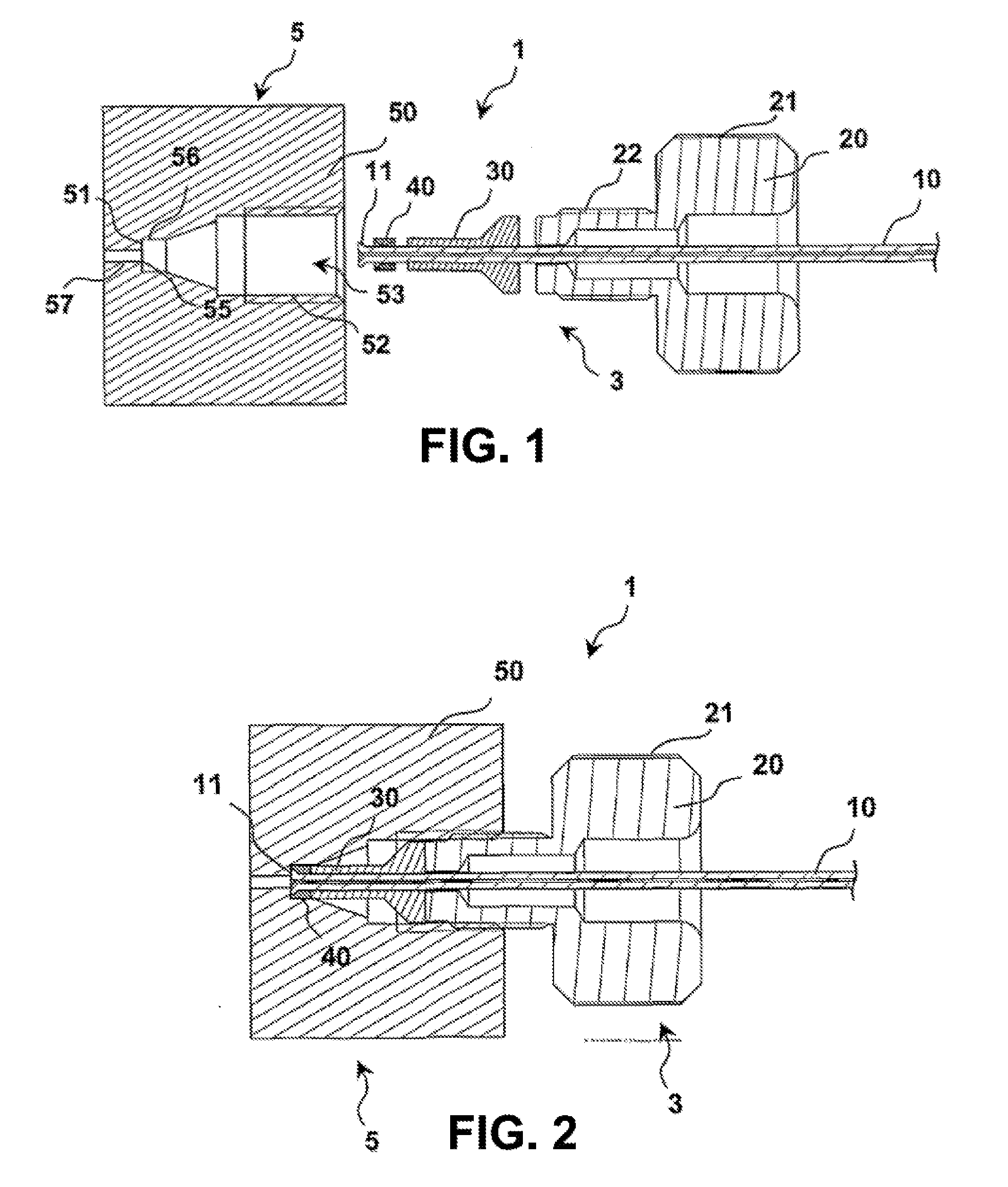

Plug unit and connection system for connecting capillary tubes, especially for high-performance liquid chromatography

ActiveUS9134283B2Avoid dead volumeGuaranteed contactSleeve/socket jointsFluid pressure sealed jointsEngineeringLiquid phase

A plug unit and system for connecting capillary tubes, especially for high-performance liquid chromatography, with a plug capillary tube projecting through a hole of a plug housing, which is detachably connectable to a bushing unit. The plug capillary tube front end projects into a capillary tube receptacle in the bushing unit with its end face essentially aligned opposite a front end of a bushing capillary tube or a bushing capillary passage opening of the bushing unit, the end face of which is butted against. The plug housing applies a force, with its end face facing the plug capillary tube end, directly or indirectly on an annular sealing element surrounding the plug capillary tube in the region of the front end of the plug capillary tube such that the front end of the plug capillary tube is sealed through deformation of the sealing element against the capillary tube receptacle opening.

Owner:DIONEX SOFTRON

Apparatus including 4-way valve for fabricating semiconductor device, method of controlling valve, and method of fabricating semiconductor device using the apparatus

ActiveCN1825537AAvoid dead volumeImprove purge efficiencyDiaphragm valvesEngine diaphragmsDead volumeProduct gas

An apparatus and method for fabricating a semiconductor device using a 4-way valve with improved purge efficiency by improving a gas valve system by preventing dead volume from occurring are provided. The apparatus includes a reaction chamber in which a substrate is processed to fabricate a semiconductor device; a first processing gas supply pipe supplying a first processing gas into the reaction chamber; a 4-way valve having a first inlet, a second inlet, a first outlet, and a second outlet and installed at the first processing gas supply pipe such that the first inlet and the first outlet are connected to the first processing gas supply pipe; a second processing gas supply pipe connected to the second inlet of the 4-way valve to supply a second processing gas; a bypass connected to the second outlet of the 4-way valve; and a gate valve installed at the bypass.

Owner:SAMSUNG ELECTRONICS CO LTD +1

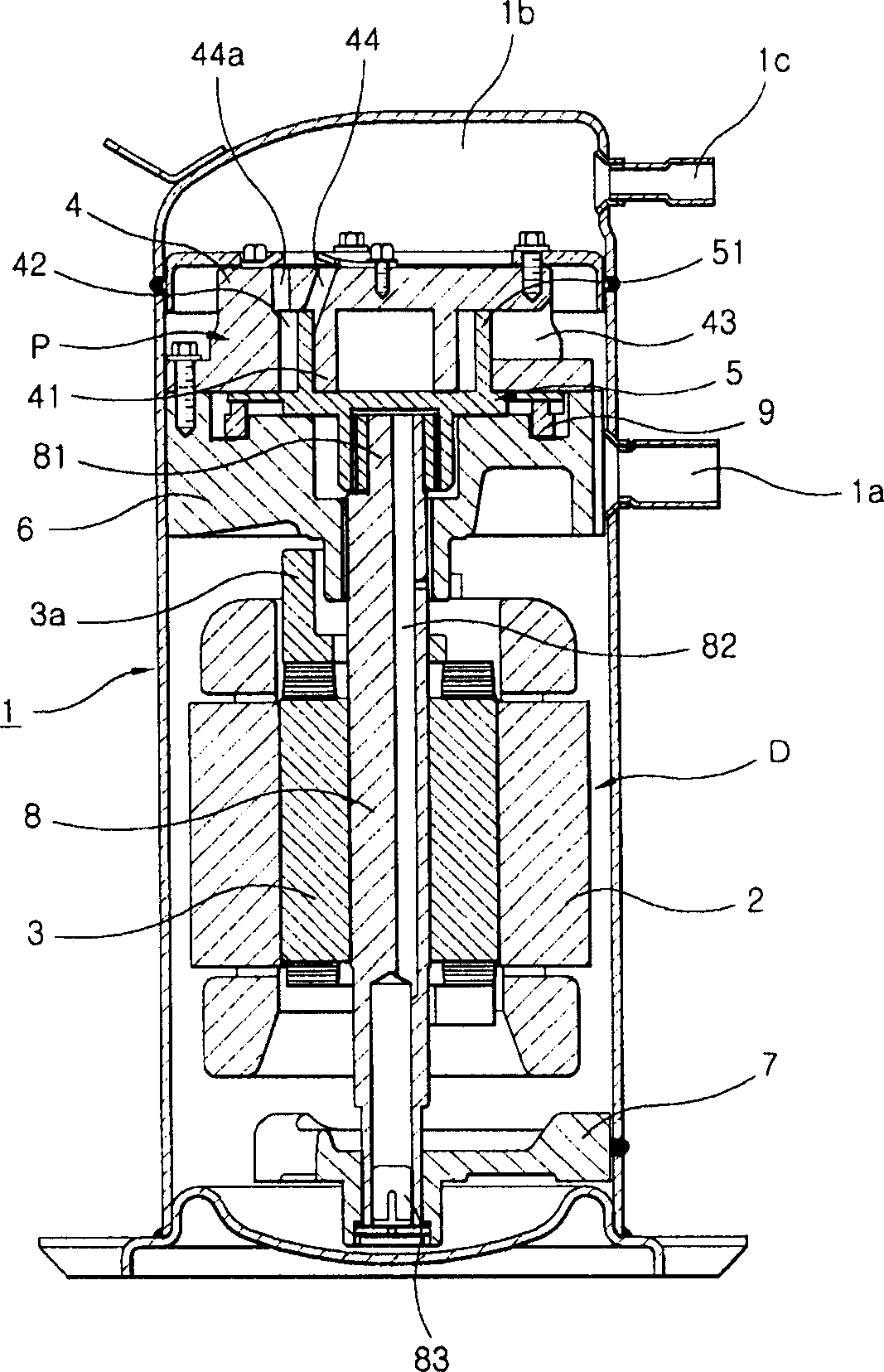

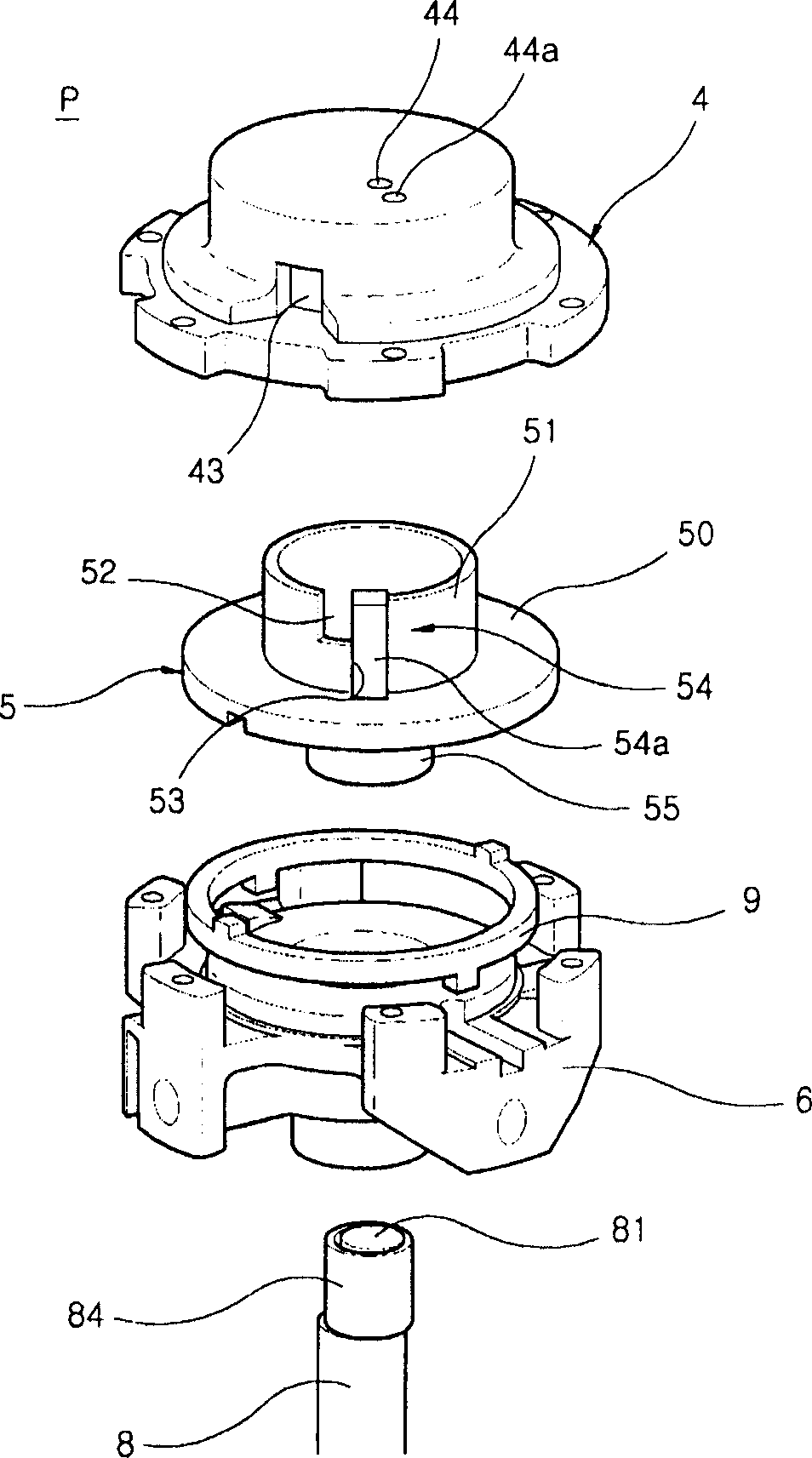

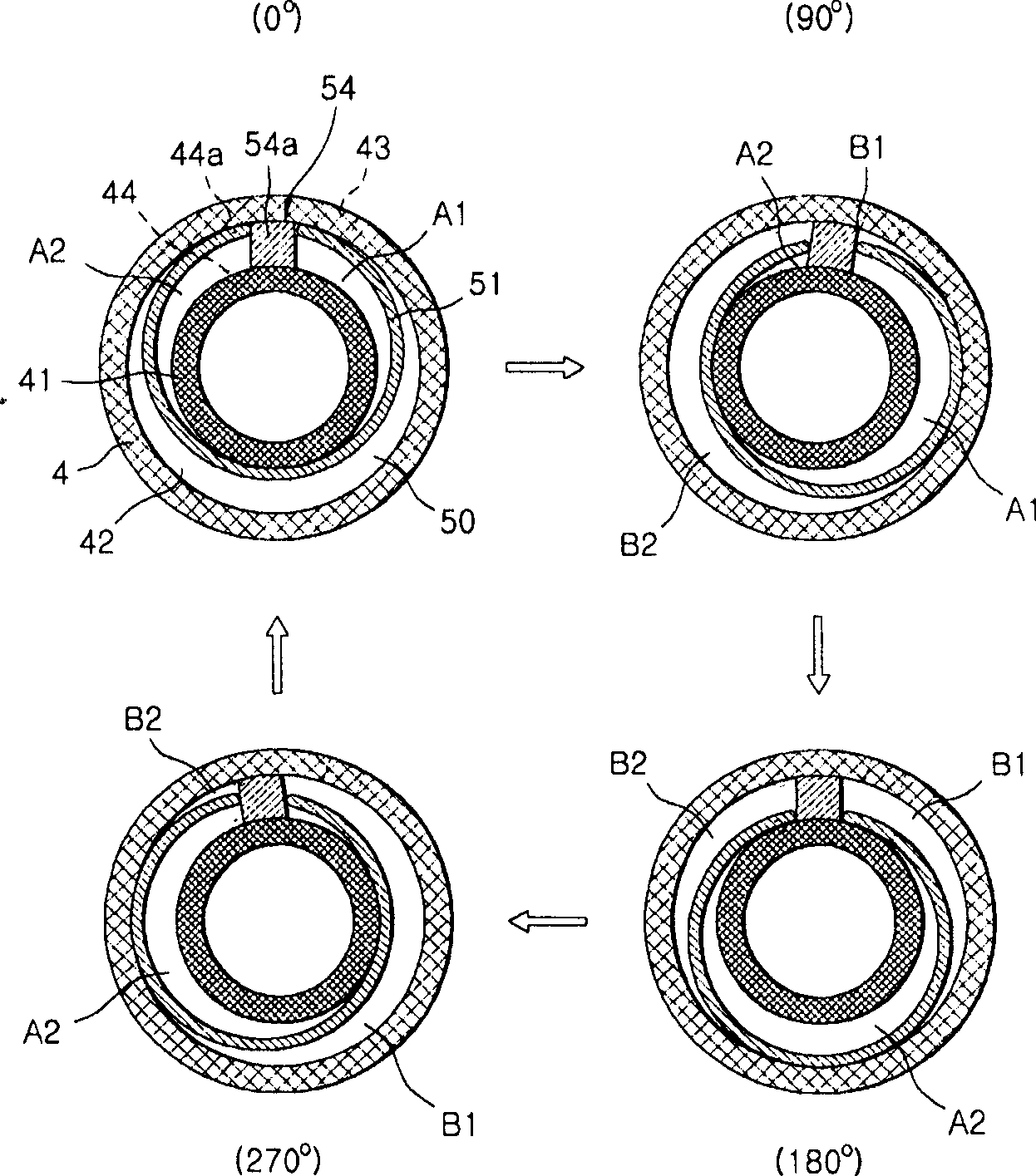

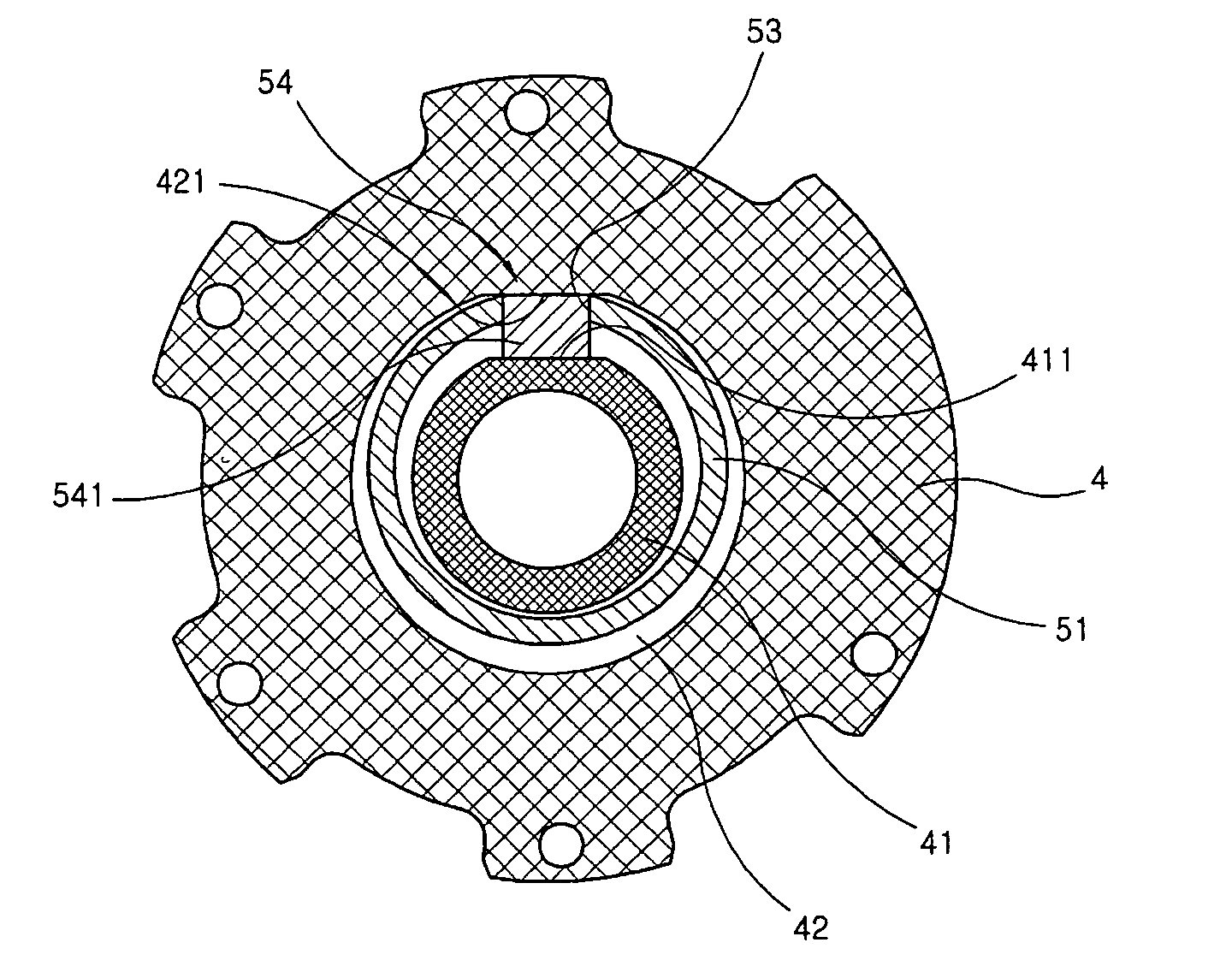

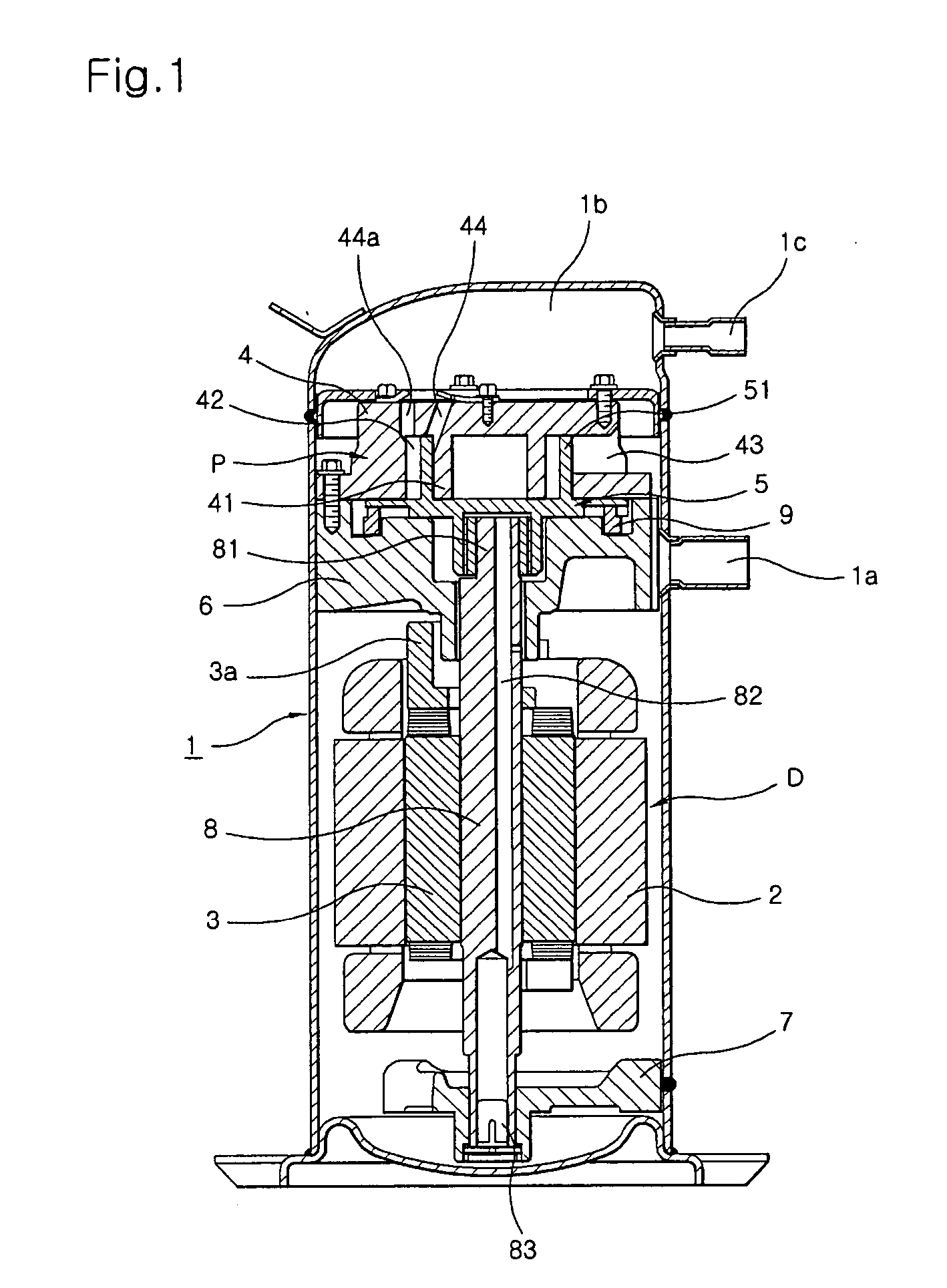

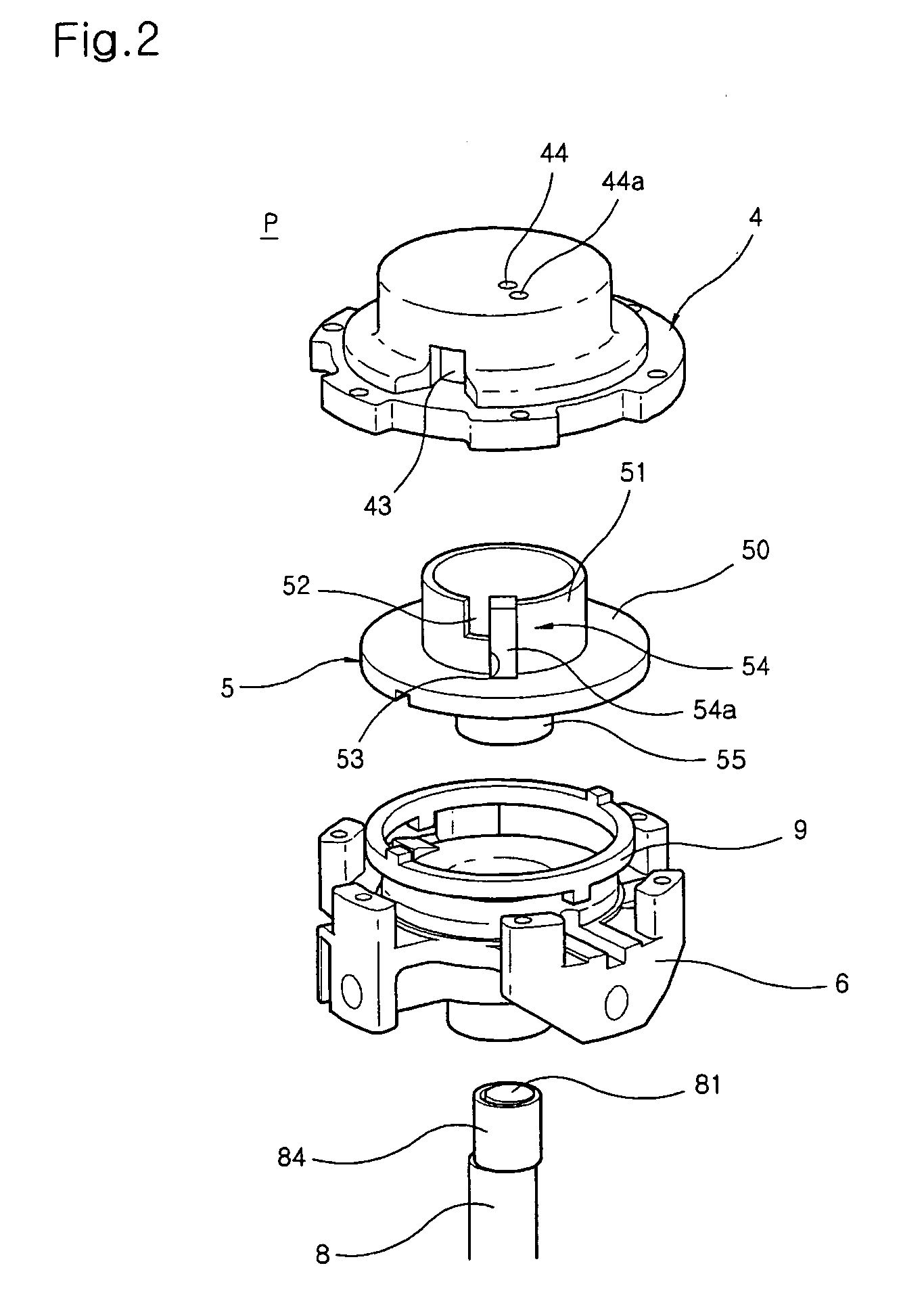

Compression unit of orbiting vane compressor

InactiveCN1757923AClose contactEasy to manufactureSealing arrangement for pumpsRotary piston pumpsReciprocating motionGas compressor

Disclosed herein is a compression unit of an orbiting vane compressor having improved tight contact between a circular vane and sealing means wherein the sealing means can be easily manufactured. The compression unit compresses refrigerant gas introduced by an orbiting movement of a circular vane in an annular space defined between the inner wall of a cylinder and an inner ring. The compression unit comprises a first horizontal contact surface formed at the outer circumferential surface of the inner ring, a second horizontal contact surface formed at the inner wall of the cylinder while being parallel with the first horizontal contact surface, and a linear slider disposed in an opening formed at the circular vane for performing a linear reciprocating movement along the first and second horizontal contact surfaces.

Owner:LG ELECTRONICS INC

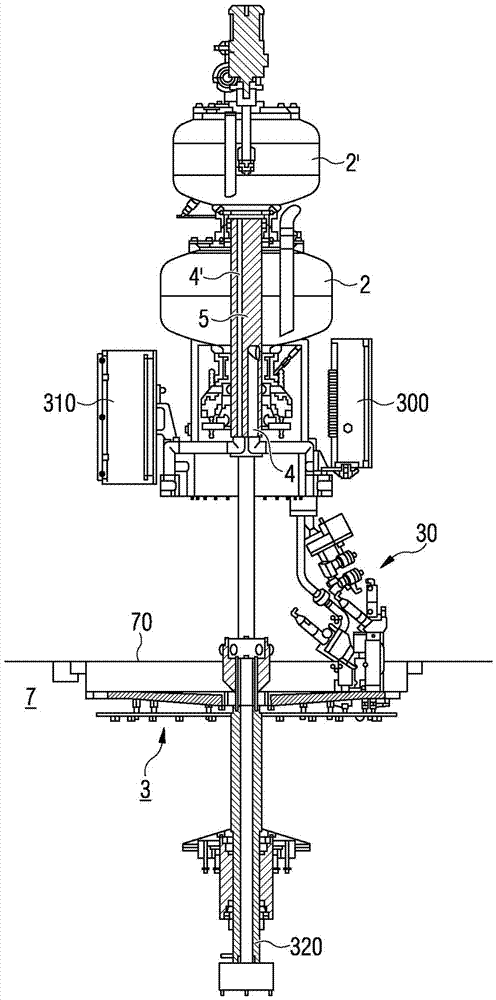

Device for filling at least one container with a filling product

ActiveCN103771315AOptimize filling speedEasy to controlLiquid fillingEngineeringMechanical engineering

Owner:KRONES AG

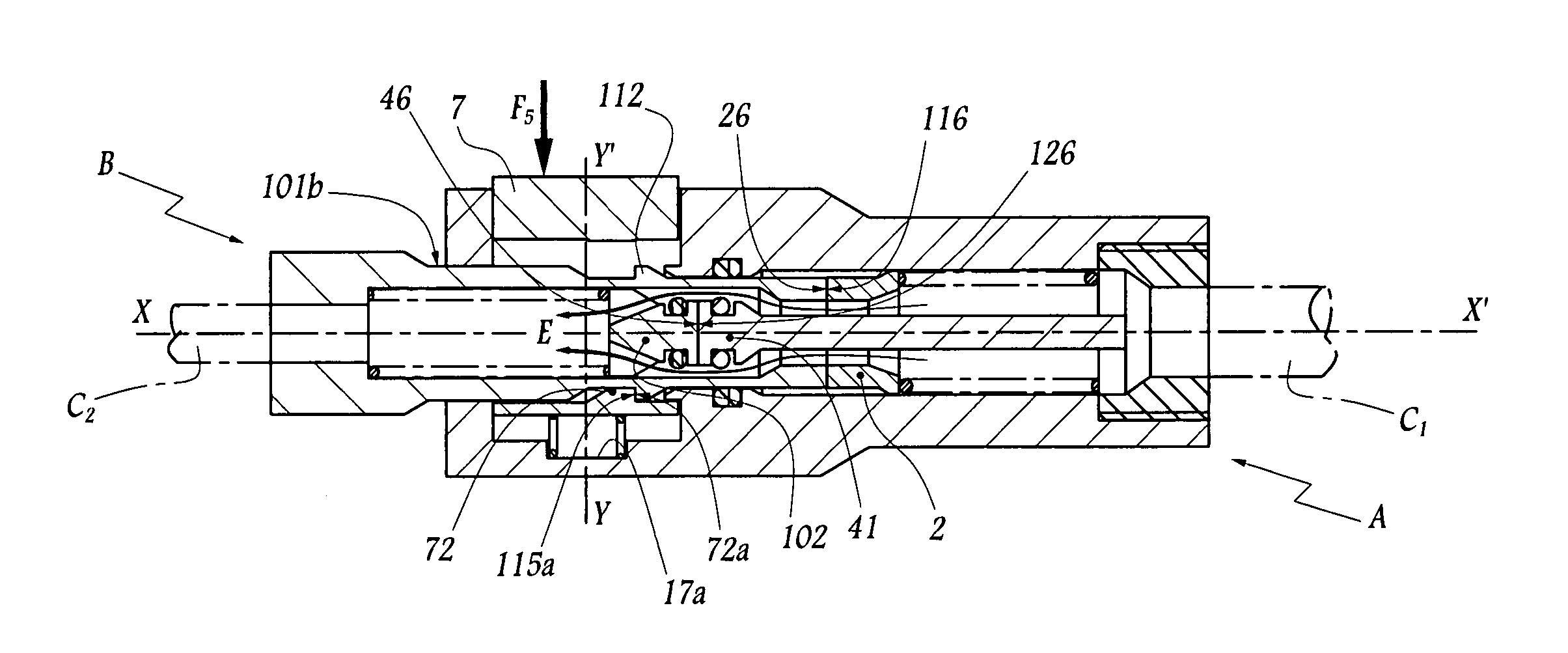

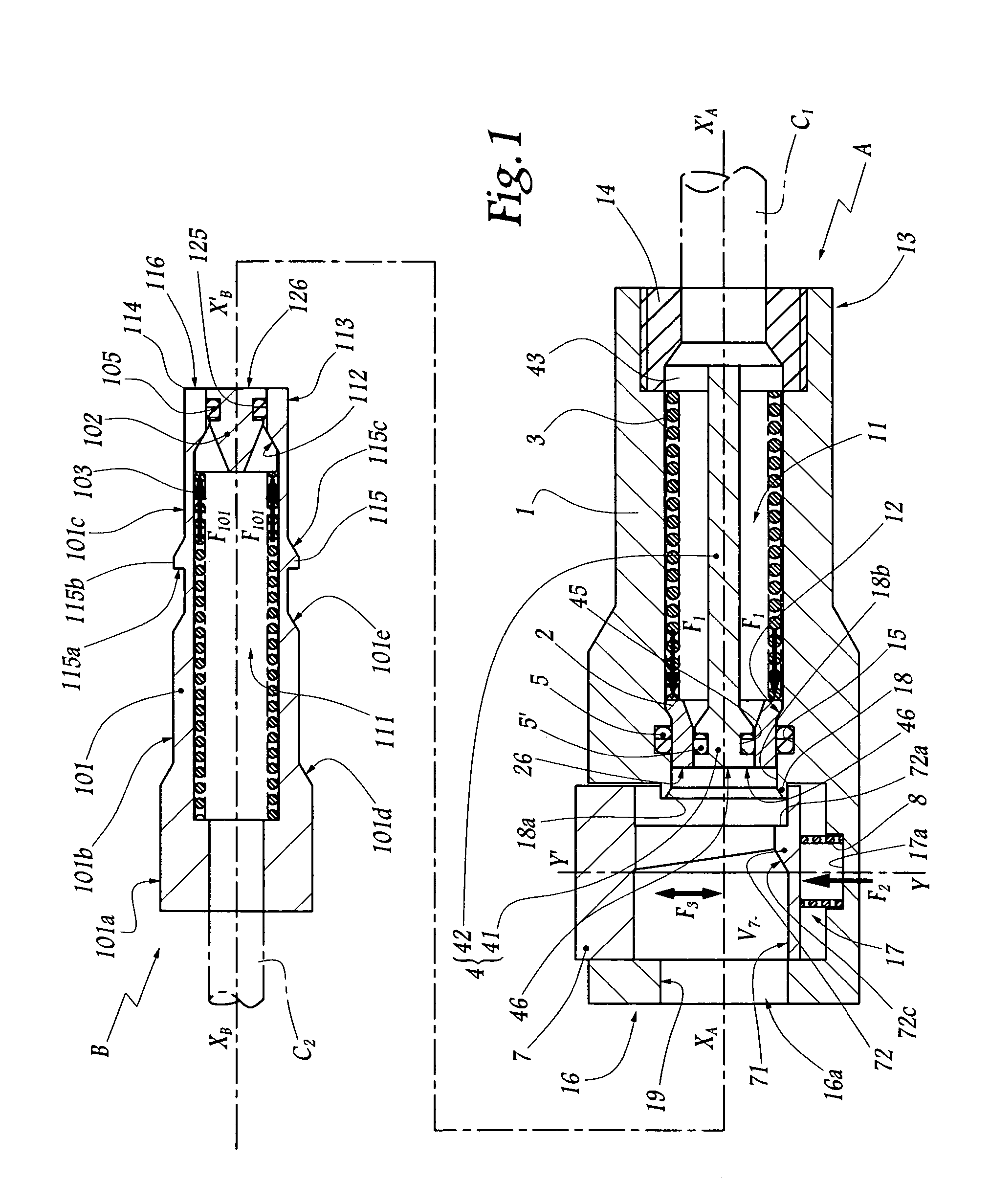

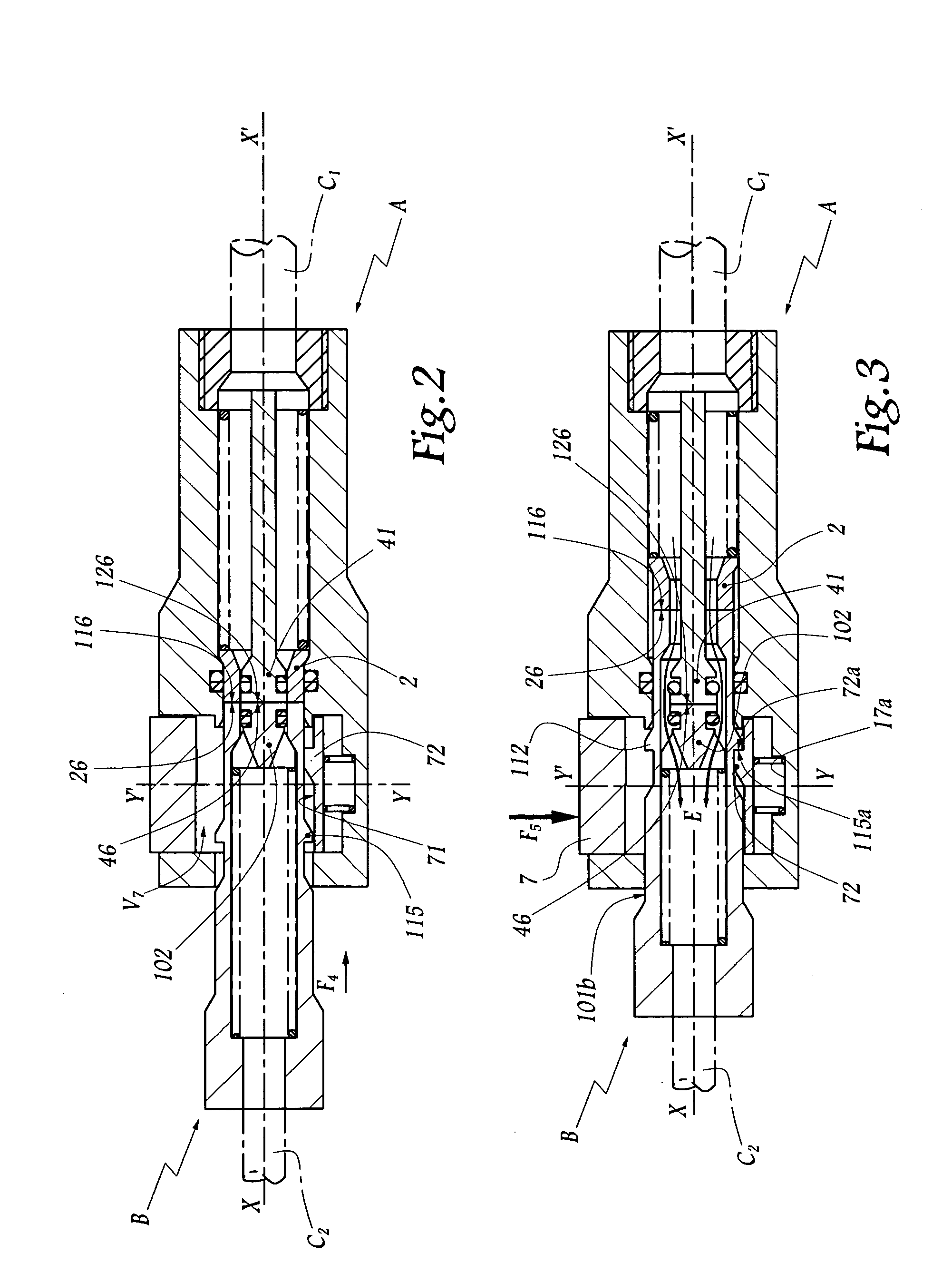

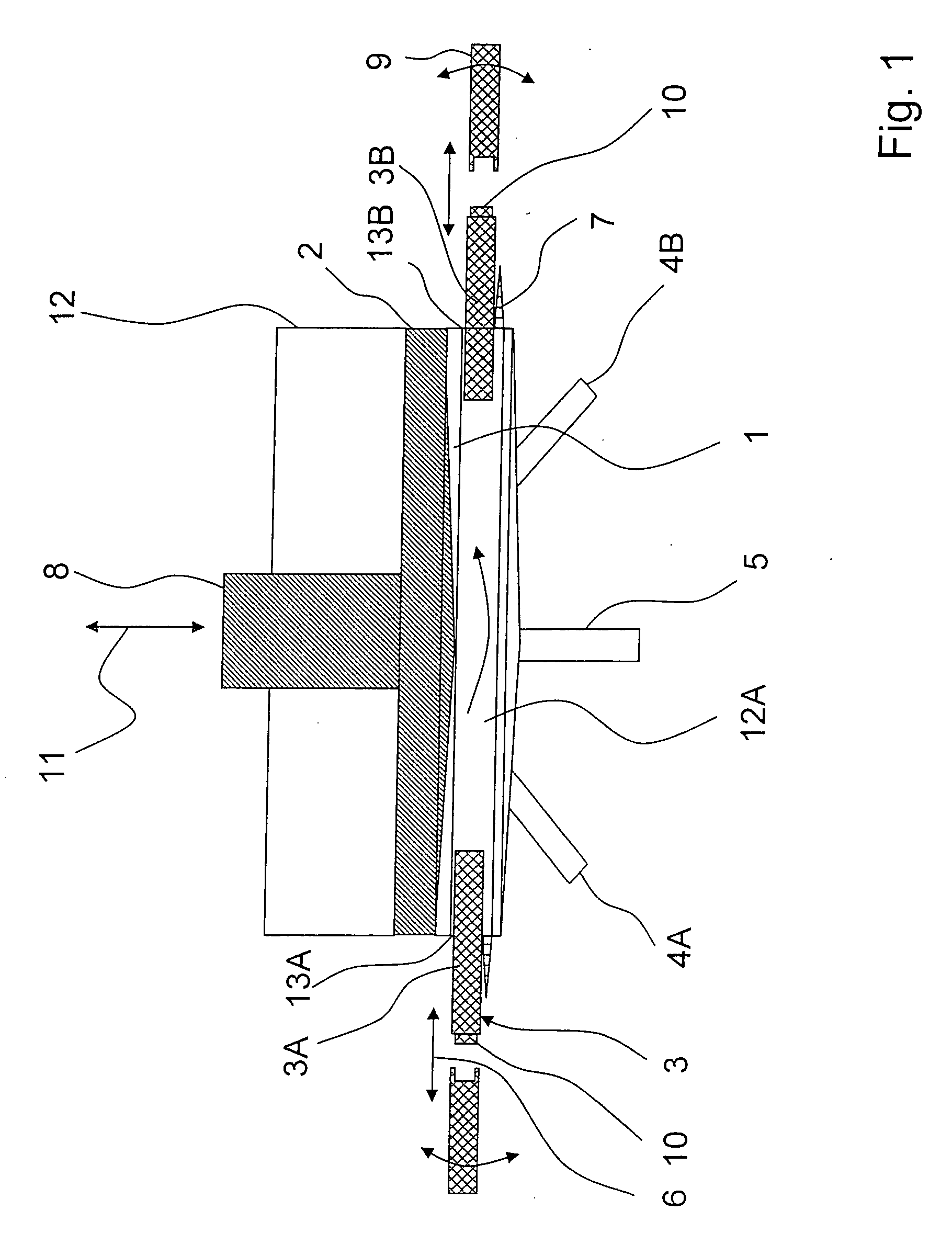

Quick connection for removably joining two pipes and use of such a connection

ActiveUS20050081929A1Minimized dimensionLittle riskCouplingsThin material handlingDead volumeEngineering

The connection according to the invention is constituted by two elements, male and female, adapted to fit axially in each other and each comprising a body, inside which a valve is mobile. A fixed part of each element is adapted to displace the mobile valve of the other element when they are being fitted. The female element is provided with a locking member in which may be introduced a part of the male element and which is mobile in translation in a radial direction with respect to the axis of fit of the elements, between two positions in which it respectively allows or opposes the separation of the male and female elements; when these elements are separated, their respective fixed part and mobile valve together define complementary volumes of which the opposite surfaces may come into surface abutment on each other, this avoiding the formation of dead volumes capable of generating drainings or leakages.

Owner:STAUBLI FAVERGES SA

Compression unit of orbiting vane compressor

InactiveUS20060073054A1Easy to manufactureEnhance tight contactRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringRefrigerant

Disclosed herein is a compression unit of an orbiting vane compressor having improved tight contact between a circular vane and sealing means wherein the sealing means can be easily manufactured. The compression unit compresses refrigerant gas introduced by an orbiting movement of a circular vane in an annular space defined between the inner wall of a cylinder and an inner ring. The compression unit comprises a first horizontal contact surface formed at the outer circumferential surface of the inner ring, a second horizontal contact surface formed at the inner wall of the cylinder while being parallel with the first horizontal contact surface, and a linear slider disposed in an opening formed at the circular vane for performing a linear reciprocating movement along the first and second horizontal contact surfaces.

Owner:LG ELECTRONICS INC

Sealed flange joint for high pressure and high purity gas channels

InactiveUS8007011B2Quality improvementAvoid dead volumeSleeve/socket jointsFlanged jointsHigh pressurePolymer

A sealed flange joint for high pressure and / or high purity fluid channels includes a first flange with a first fluid channel and a cylindrical front cavity. The front cavity is axially delimited by a ground surface and radially by a peripheral surface. The first fluid channel passes axially through the first flange to open into the ground surface. A polymer seal ring has a radial outer surface and a radial inner surface, and is fitted into the cylindrical front cavity so that its radial outer surface engages the peripheral surface of the front cavity. A second flange is removably fixed onto the first flange, and has a second fluid channel in axial continuation of the first fluid channel. The second flange has an axially protruding cylindrical front nipple with a conical head, the second fluid channel axially opening into an end surface of the conical head. The conical head engages the radial inner surface of the seal ring to radially press the latter with its radial outer surface against the peripheral surface of the front cavity.

Owner:LUXEMBOURG PATENT CO SA

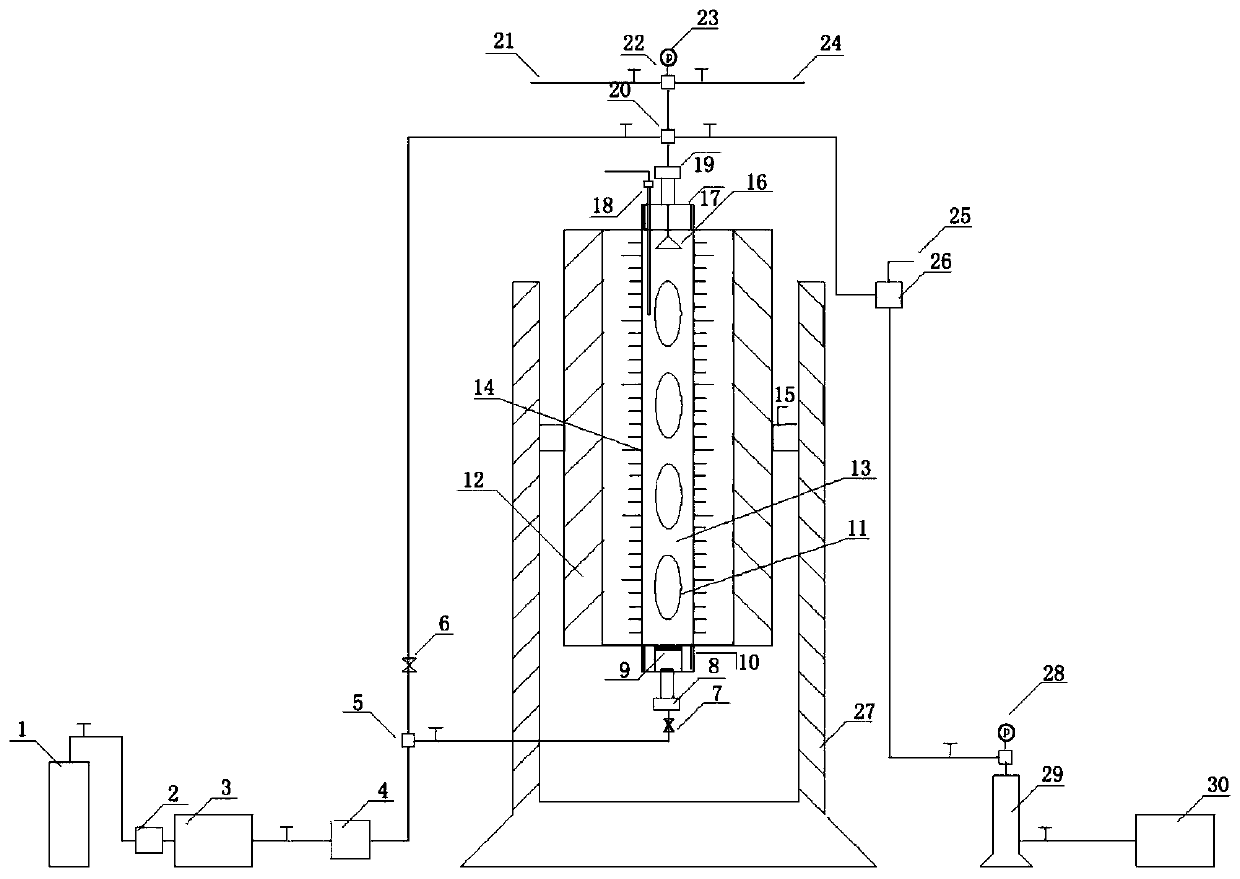

Oil-displacement foam system evaluation device and evaluation method thereof

The invention discloses an oil-displacement foam system evaluation device and an evaluation method thereof, and belongs to the field of oilfield development. According to the oil-displacement foam system evaluation device, a transparent window and a graduated scale are arranged on a cavity wall; a temperature control device is arranged on the periphery of the cavity wall; a temperature sensor is arranged in a cavity; a cavity top cover is arranged on the top of the cavity; a second rapid connection head is arranged on the cavity top cover; a foam generator and a cavity bottom cover are arranged at the bottom of the cavity; a first rapid connection head is arranged on the cavity bottom cover; a gas source is respectively connected with a first four-way valve and the first rapid connection head through a first three-way valve; pipelines among the above parts are each provided with a needle valve; another three joints of the first four-way valve are respectively connected with the secondrapid connection head, a back pressure control system and a first pipeline; the first pipeline is an escape pipe; and pipelines among the above parts are each provided with a needle valve. By means ofthe oil-displacement foam system evaluation device in the invention, dead volume of foam liquid and generation of an observation blind hole are effectively avoided; the measurement error is reduced;and furthermore, multiple gases can be evaluated.

Owner:PETROCHINA CO LTD

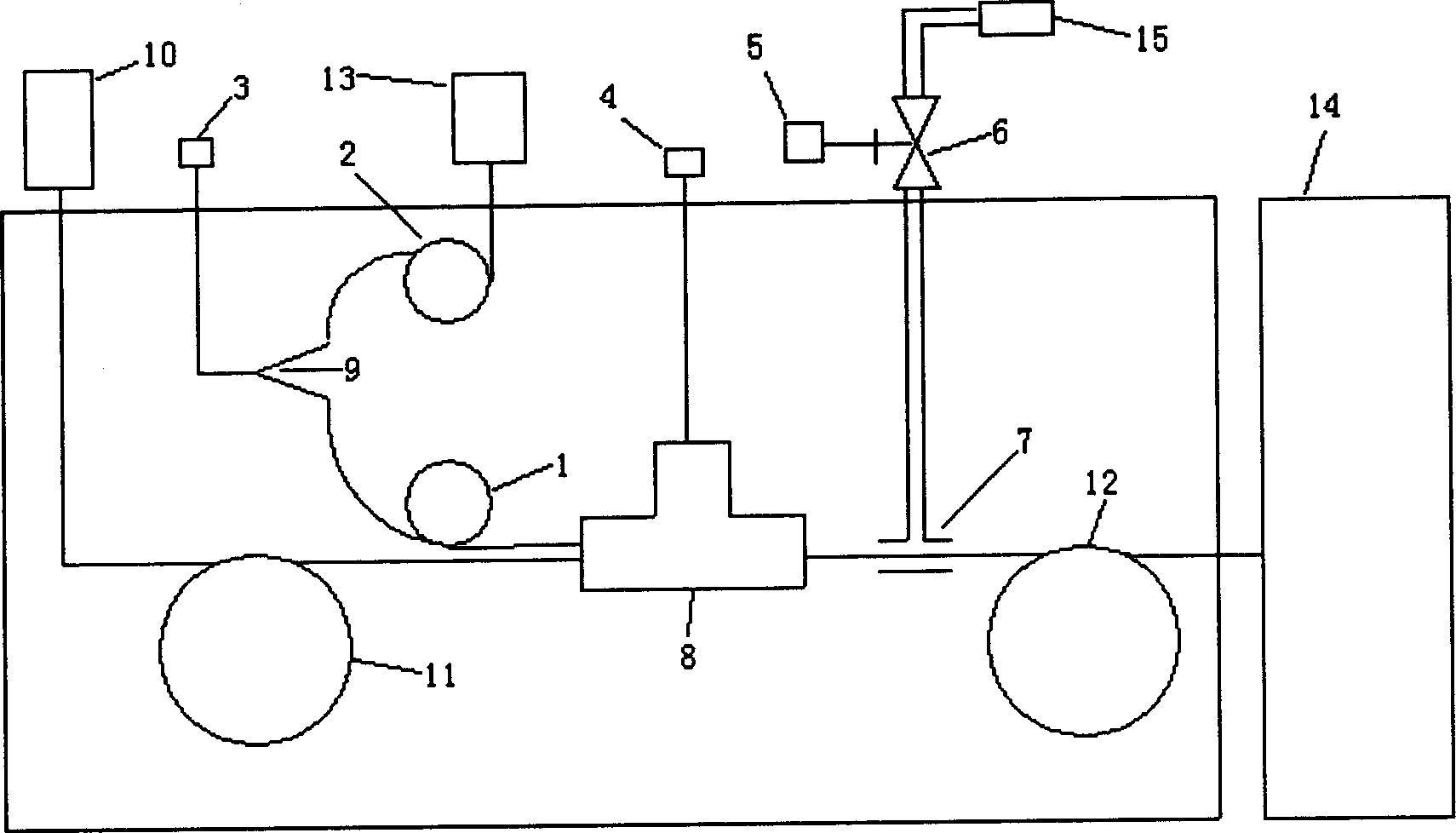

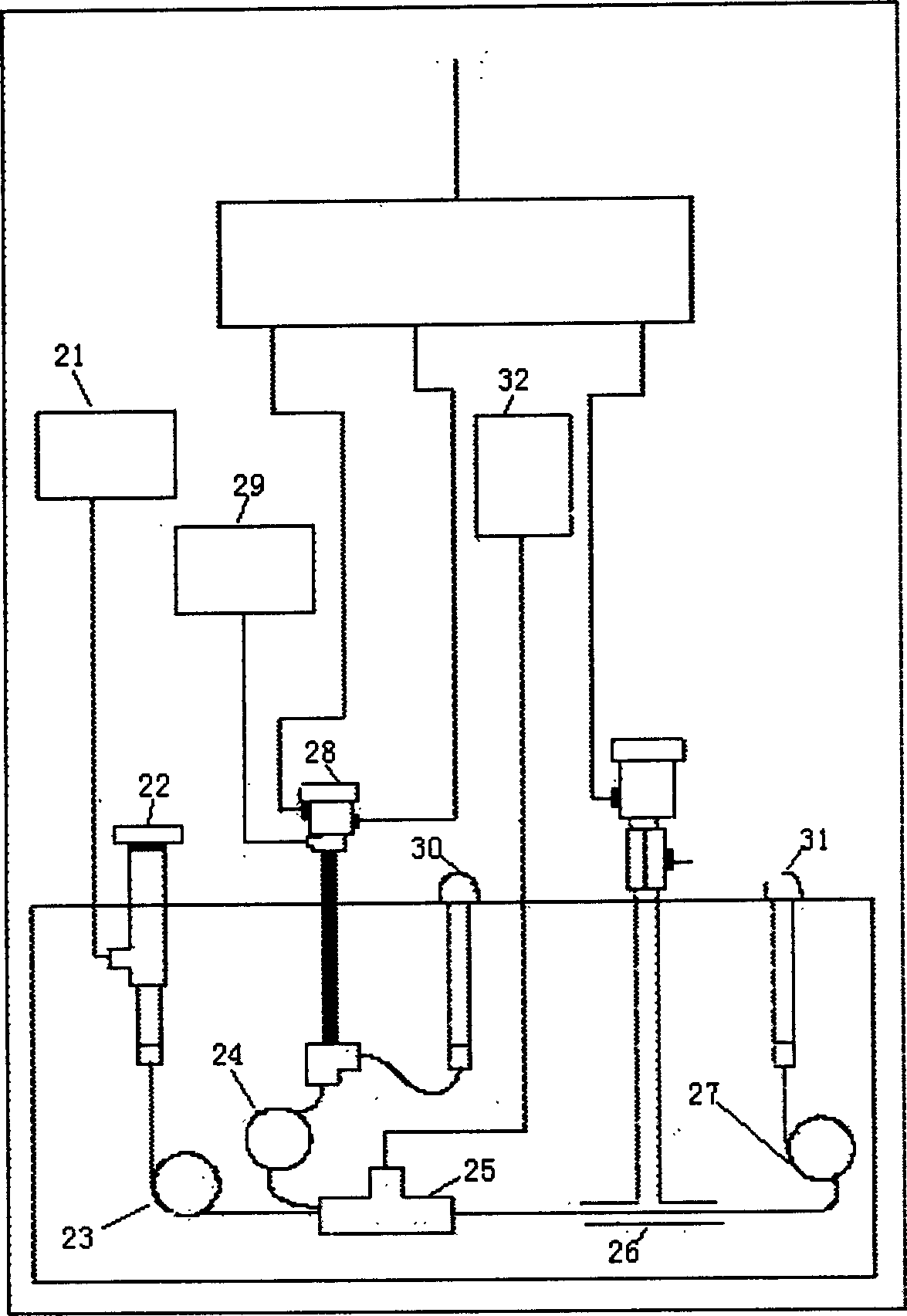

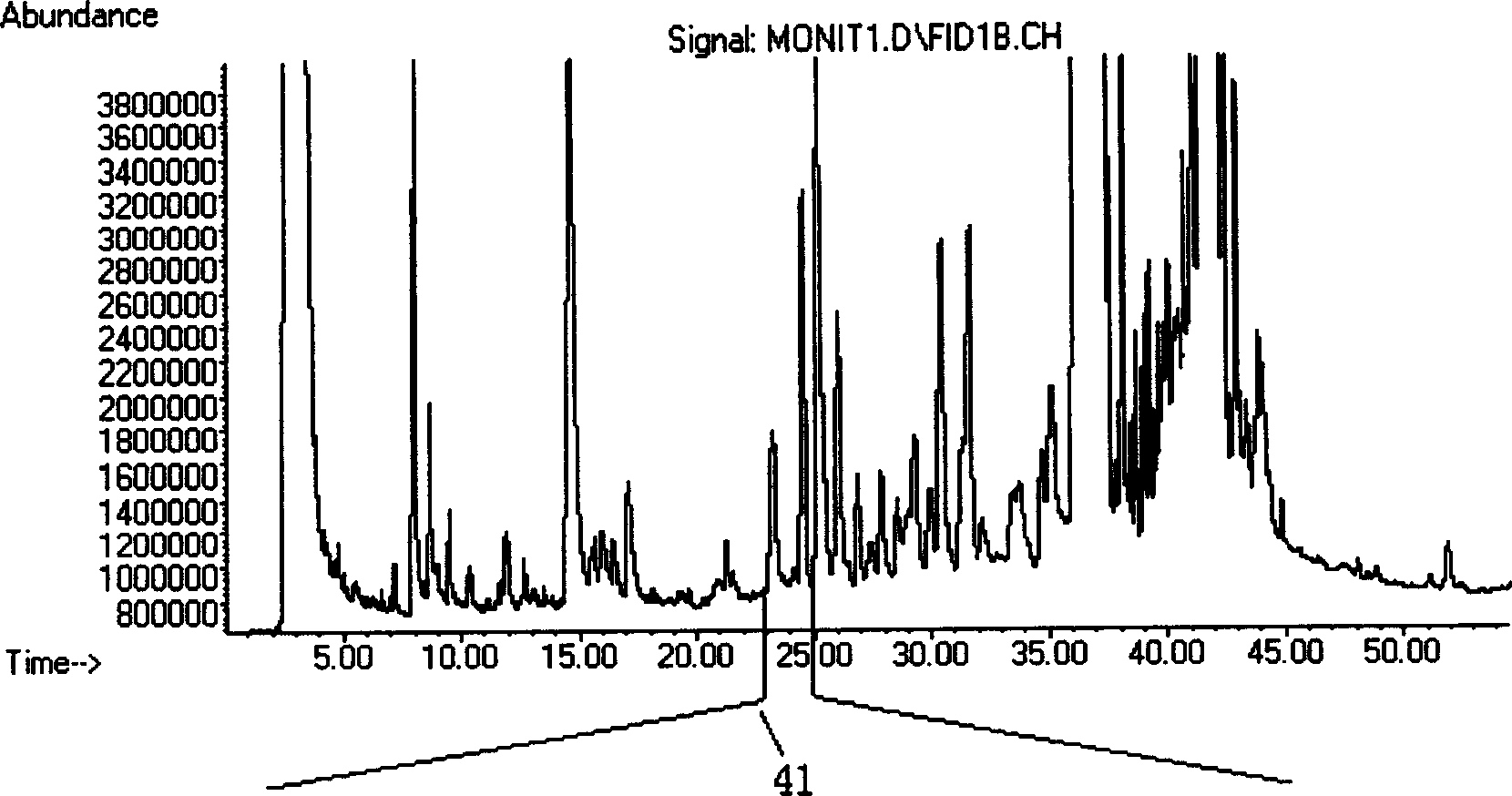

Automatic multi-dimensional gas-phase chromatographic system and use with non-valve pressure switching

ActiveCN1301406CAvoid dead volumeAvoid failure rateComponent separationSystems analysisGas liquid chromatographic

An automatic multidimensional gas phase chromatography system is featured as switching mixture sample from precolumn to analysing column by controlling pressure difference between axiliary pressures based on pressure balance principle to have overcome defect of valve leakage and block in normal system. A method utilizing the system to analyse mixture is also disclosed.

Owner:SHANGHAI TOBACCO GRP CO LTD

Device for mixing at least two media

InactiveUS20060285432A1Good intermixtureReduce wasteRotating receptacle mixersTransportation and packagingActuatorViscous medium

A device for mixing at least two media, in particular highly viscous media, having at least one mixing chamber, its volume in a mixer housing being variable by a movable plunger, and having at least one mixing tool. With the aid of an actuator, the mixing tool is insertable into the mixing chamber for mixing the media and is retractable from the mixing chamber following the mixing.

Owner:ROBERT BOSCH GMBH

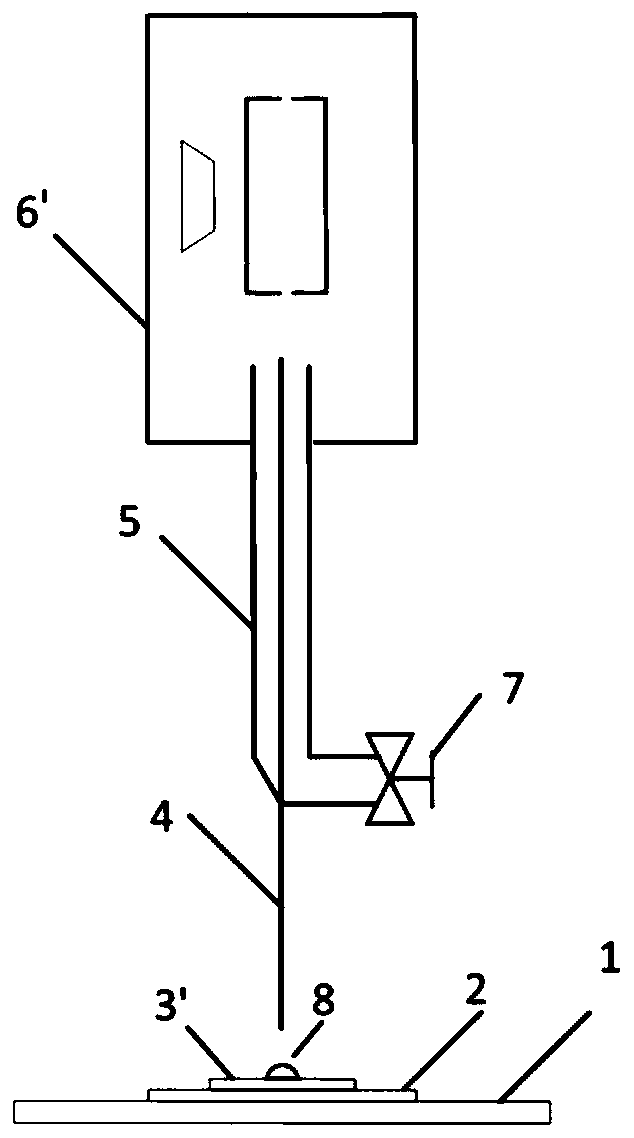

Pulse electrospray ion source, pulse sample injection method and mass spectrum detection system

InactiveCN111243936AIncrease profitReduce consumptionIon sources/gunsMass spectrometersCapillary TubingElectrospray

The invention discloses a pulse electrospray ion source, a pulse sample injection method and a mass spectrum detection system. The ion source comprises a sample supply appliance, a sample injection capillary tube and an electrode, and a sample solution provided by the sample supply appliance enters from the sample injection end of the sample injection capillary tube and is output from the output end of the sample injection capillary; the electrode electrifies the sample solution so as to provide voltage required for forming electrospray; the ion source also comprises a moving device coupled tothe sample supply appliance or the sample introduction capillary, during sample injection, the sample supply device and the sample injection capillary tube intermittently move relative to each otheraccording to a set pulse time sequence, so that a sample in the sample supply device is intermittently contacted with the sample injection end of the sample injection capillary tube, and pulse type electrospray sample injection is realized. According to the invention, pulse sample injection and ionization are synchronously carried out, and the sample utilization rate is improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

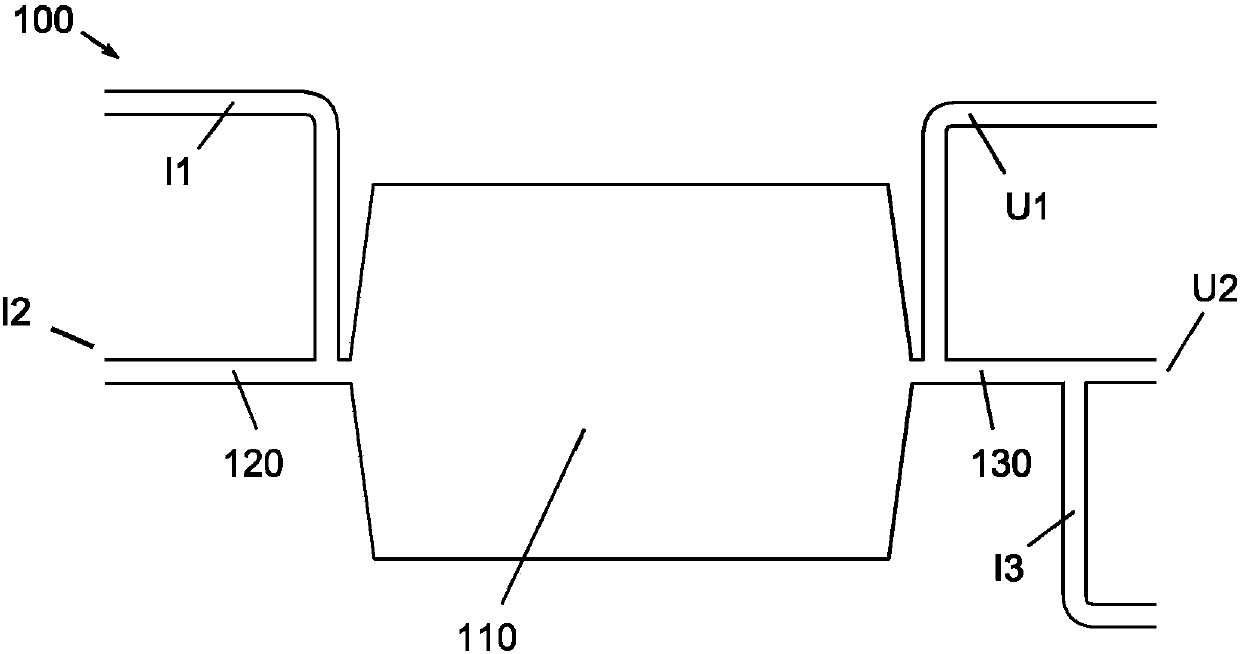

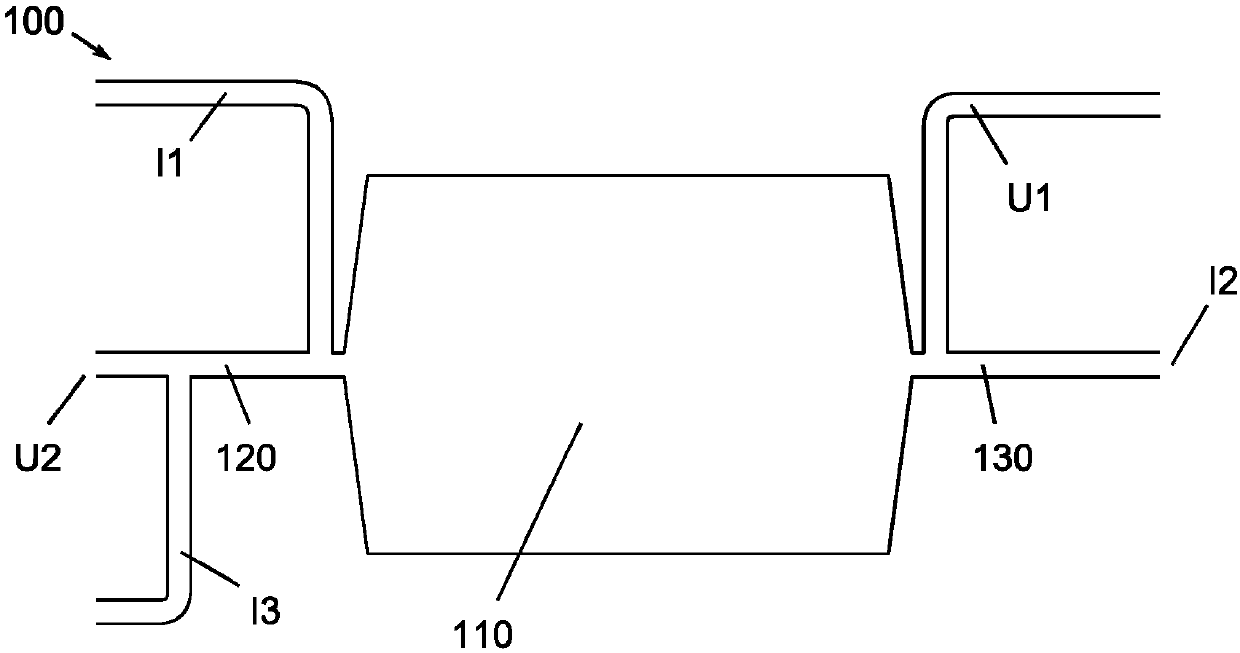

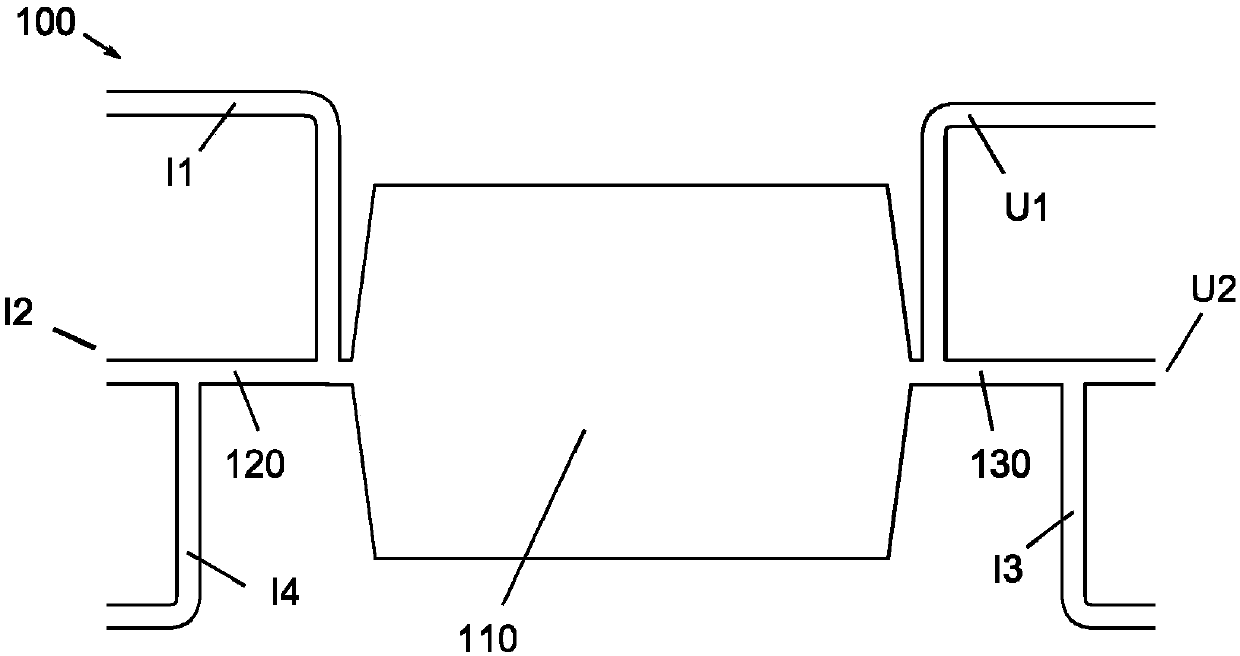

Microfluidic device

ActiveCN107850582AControllable fluid flowAvoid blockingSamplingComponent separationTrappingEngineering

A microfluidic device (100) for separating a phase in a specimen has been described. This is based on a microfluidic trapping area (110), channels (120,130) connected to it and integrated inputs (I1,I2) and outputs (U1,U2) connected onto the channels (120,130). An additional integrated input (I3) is provided which allows the flow in the device to be controlled and which may prevent leaking of thespecimen and the phase.

Owner:PHARMAFLUIDICS NV

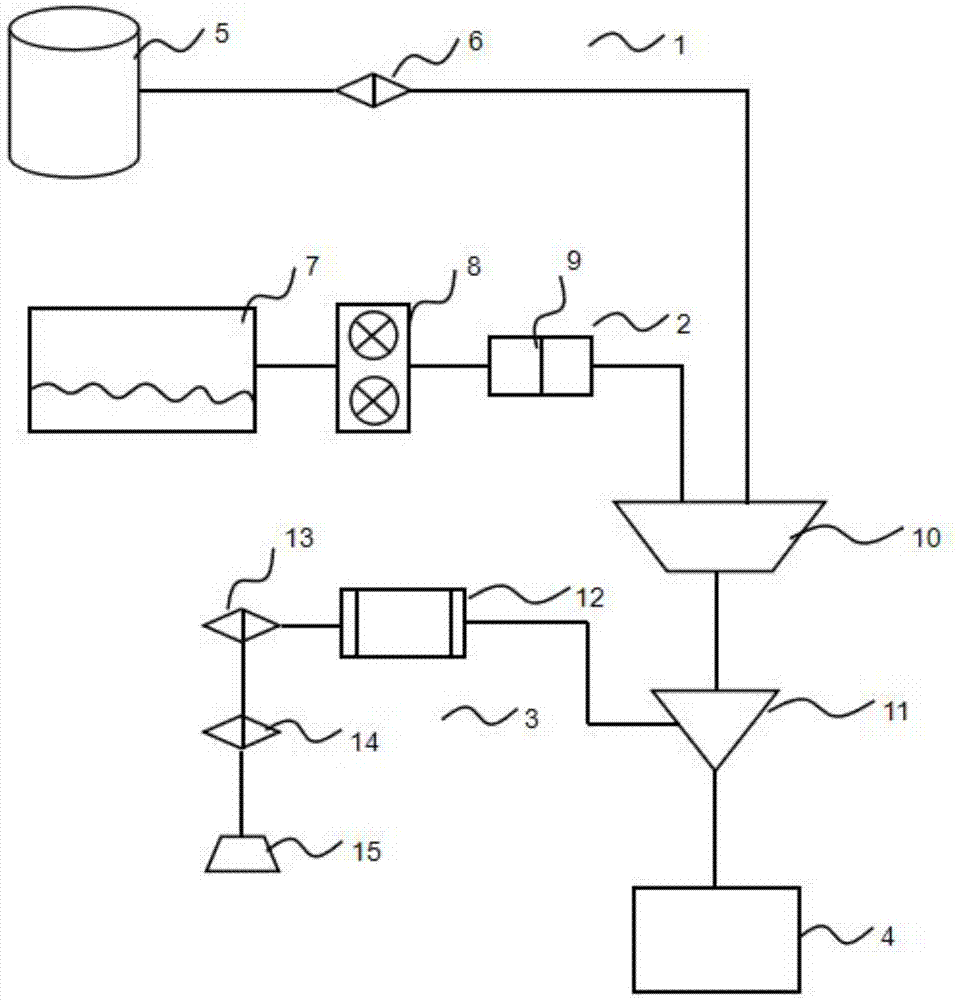

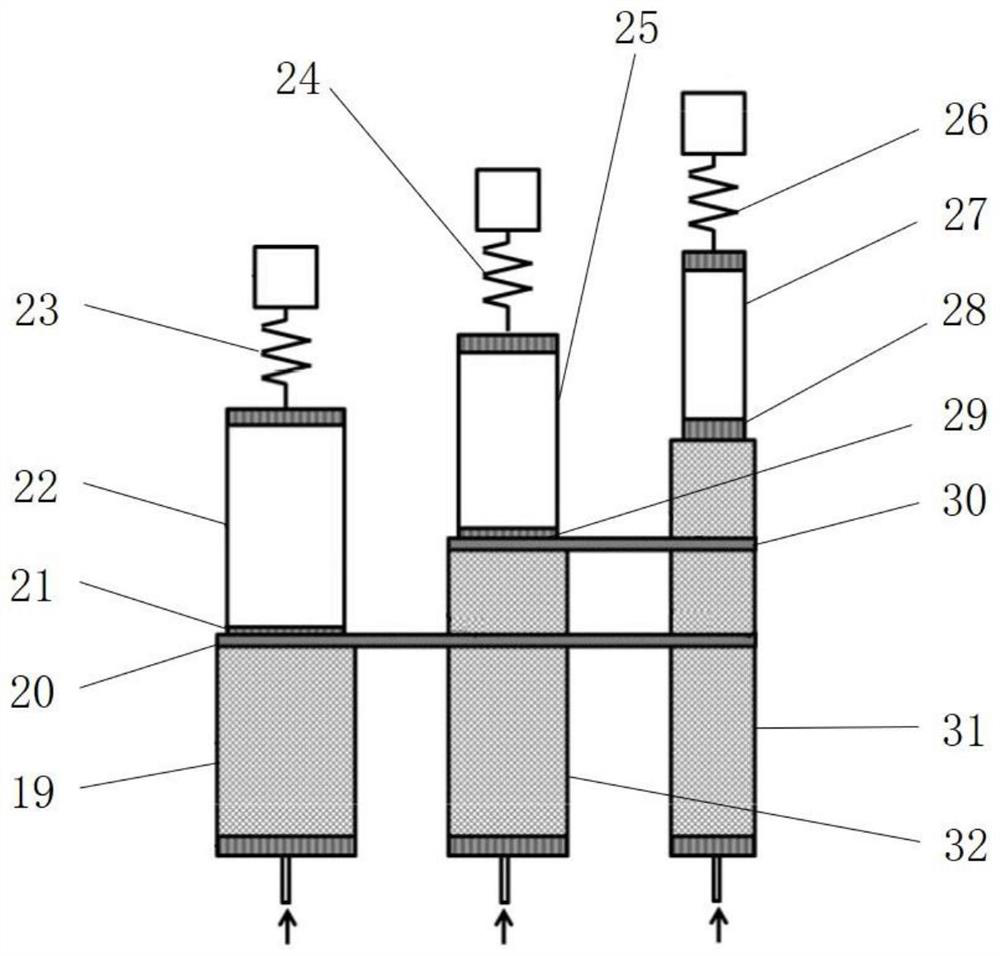

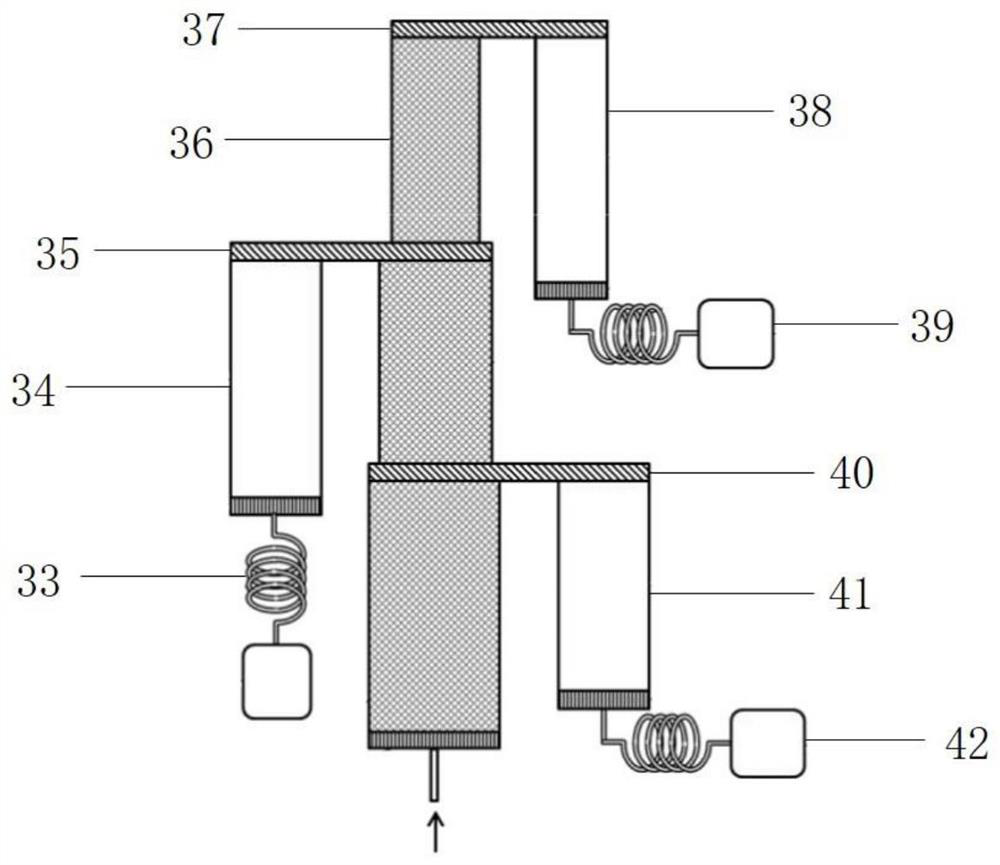

Catalyst testing system

InactiveCN106896183AAddressing the Effects of Impact TrialsThe test effect is goodMaterial analysisLiquid stateDead volume

The invention belongs to the technical field of chemical testing, and particularly relates to a catalyst testing system, which includes a gas supply device, a sample feeding device, a separation reaction device, and a liquid sample detector. Before entering the detector, it is easy to cause the problem of gas-liquid mixing affecting the test effect. It has the beneficial technical effects of good test effect, prevention of condensation, avoiding dead volume, precise control of water content in the gas, and less water content of the sample after separation.

Owner:天津神能科技有限公司

Long-path optical fiber-microfluidic chip sensor for detecting absorbance and refraction index

InactiveCN102539361BHigh sensitivityIncrease absorbancePhase-affecting property measurementsColor/spectral properties measurementsRefractive indexFibre Channel

Owner:ZHEJIANG UNIV

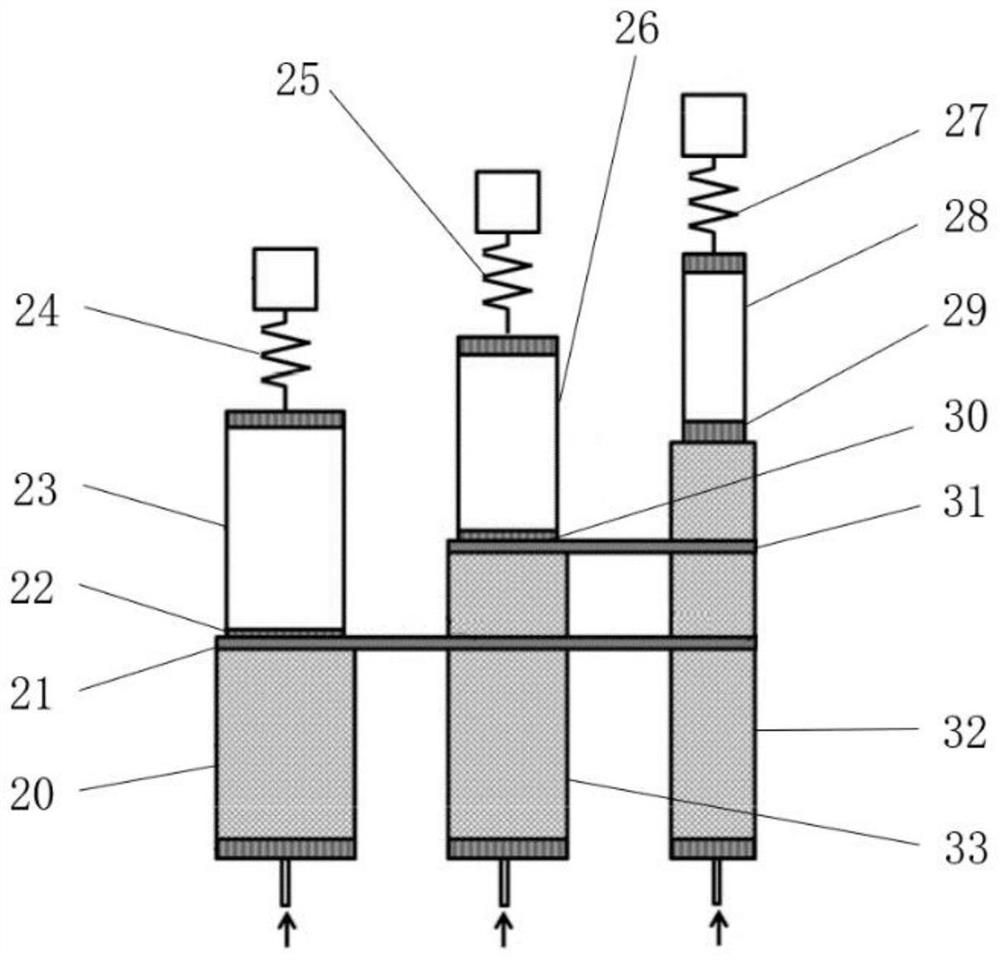

Channel type cold end heat exchanger of gas coupling pulse tube refrigerator and implementation method

ActiveCN113154714AGuaranteed uniformityMiniaturizationDomestic cooling apparatusEvaporators/condensersMixed flowPulse tube refrigerator

The invention discloses an implementation method for a channel type cold end heat exchanger of a gas coupling pulse tube refrigerator. The channel type cold end heat exchanger comprises a first heat exchanger outer shell, a second heat exchanger outer shell, a first conical slit body, a second conical slit body, a first through hole, a second through hole, a first laminar flow element, a second laminar flow element, a third laminar flow element, a first channel, a second channel and a plug, conical slits are cut in the left heat exchanger outer shell and the right heat exchanger outer shell respectively, and channels are formed in the heat exchangers, so that connection among a first-stage regenerator, a second-stage regenerator and a first-stage pulse tube is achieved. The channel type cold end heat exchanger of the gas coupling pulse tube refrigerator and the implementation method realize efficient matching of front-and-rear-stage cold fingers of the pulse tube refrigerator while maintaining the high-efficiency heat exchange advantage of a traditional heat exchanger, inhibit the backflow, mixed flow and turbulence disturbance of the gas working medium in the heat exchange channel, and ensure the uniformity of gas flow. According to the channel type cold end heat exchanger of the gas coupling pulse tube refrigerator and the implementation method, the heat exchange efficiency and the overall performance of the refrigerating machine are remarkably improved, and the channel type cold end heat exchanger has very positive significance in the aspect of achieving compactness and practicability of the multi-stage pulse tube refrigerating machine.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Plug unit and connection system for connecting capillary tubes

ActiveUS20150338000A1Avoid dead volumeGuaranteed contactSleeve/socket jointsComponent separationEngineeringLiquid phase

A plug unit and system for connecting capillary tubes, especially for high-performance liquid chromatography, with a plug capillary tube projecting through a hole of a plug housing, which is detachably connectable to a bushing unit. The plug capillary tube front end projects into a capillary tube receptacle in the bushing unit with its end face essentially aligned opposite a front end of a bushing capillary tube or a bushing capillary tube opening of the bushing unit, the end face of which is butted against. The plug housing applies a force, with its end face facing the plug capillary tube end, directly or indirectly on an annular sealing element surrounding the plug capillary tube in the region of the front end of the plug capillary tube such that the front end of the plug capillary tube is sealed through deformation of the sealing element against the capillary tube receptacle opening.

Owner:DIONEX SOFTRON

Apparatus for fabricating semiconductor device, control method, and method of fabricating semiconductor device

ActiveCN100573813CAvoid dead volumeImprove purge efficiencyDiaphragm valvesEngine diaphragmsDead volumeProcess engineering

Owner:SAMSUNG ELECTRONICS CO LTD +1

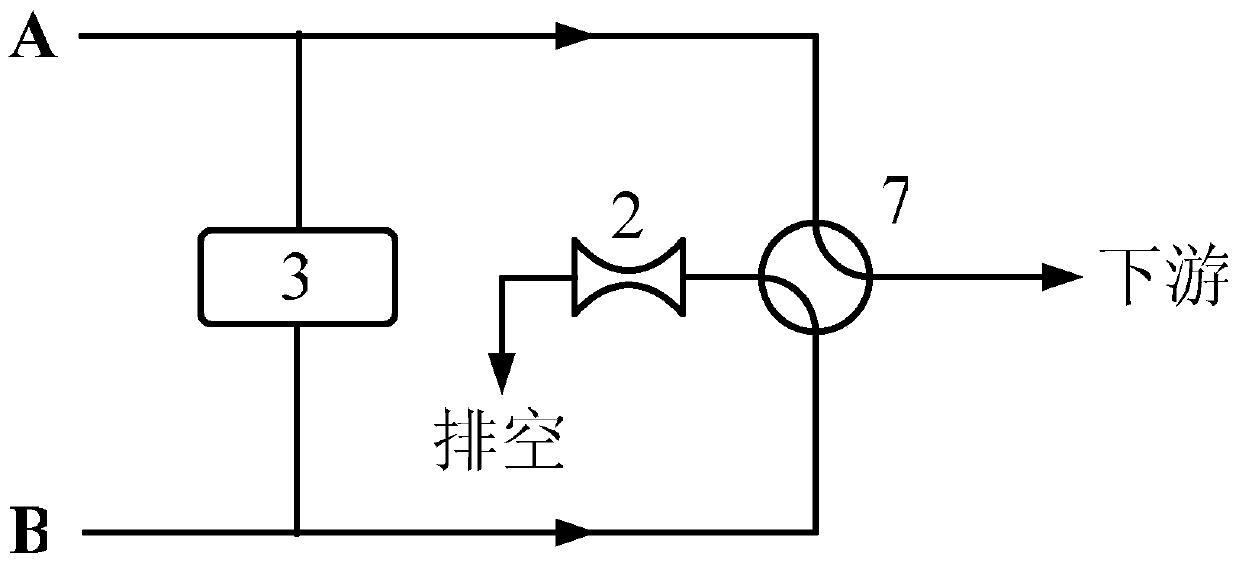

A Method and System for Steady and Rapid Atmosphere Switching and Their Application

ActiveCN105259801BSolve the problem of smooth and fast switchingAvoid problemsChemical/physical/physico-chemical microreactorsMaterial analysis by electric/magnetic meansDifferential pressureInlet pressure

A method and system for switching atmosphere smoothly and quickly and its application, which can solve the problem that the existing reversing valve system cannot replace the atmosphere in the microreactor smoothly and quickly, thereby affecting the reliability, repeatability and accuracy of the analysis process . The airflow reversing unit of the present invention quickly switches the intake airflow flowing to the downstream; the inlet pressure controller and the pressure transmitter jointly control the pressure difference between the intake airflows to be close to zero, so that the switching process is smooth and fast. The invention can realize the smooth and rapid switching of the component concentration of the downstream airflow in a manner close to the ideal rectangular wave. The invention can be applied to analyze the multi-stage in-situ reaction process of solid particles based on atmosphere switching; and quantitatively characterize the diffusion and back-mixing of the gas flow in the microreactor.

Owner:HARBIN INST OF TECH

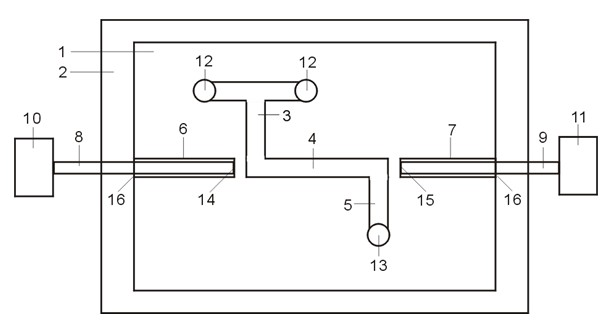

A gas-coupled pulse tube refrigerator split-type cold-end heat exchanger and design method

ActiveCN112212536BRealize natural diversionGuaranteed uniformityCompression machinesGas cycle refrigeration machinesThermodynamicsPulse tube refrigerator

The invention discloses a design method for a split-flow cold end heat exchanger of a gas-coupled pulse tube refrigerator, which comprises an upper heat exchanger shell, a lower heat exchanger shell, a rectangular slit body, a through hole, a laminar flow element, a conical Slit body, T-shaped through hole. Laminar flow elements are tightly filled in the cylindrical gap between the upper heat exchanger shell and the lower heat exchanger shell, and the upper and lower heat exchanger shells are connected by welding to realize the first stage cold storage, the first stage pulse tube and the second stage Connection of secondary cold storage. While maintaining the high-efficiency heat exchange advantages of the traditional heat exchanger, the invention realizes the natural diversion of the gas working medium, suppresses the turbulent disturbance of the gas in the heat exchange channel, and ensures the uniformity of the gas flow. The invention will significantly improve the overall performance of the refrigerator, and has very positive significance for realizing the compactness and practicality of the pulse tube refrigerator.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

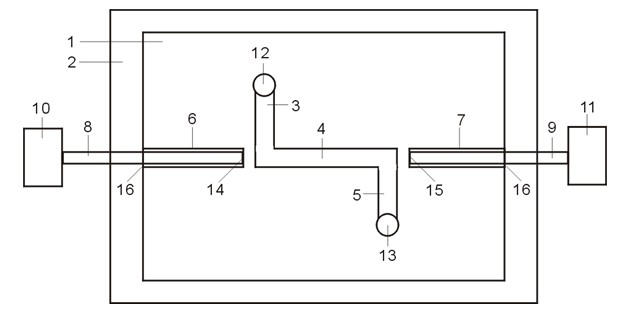

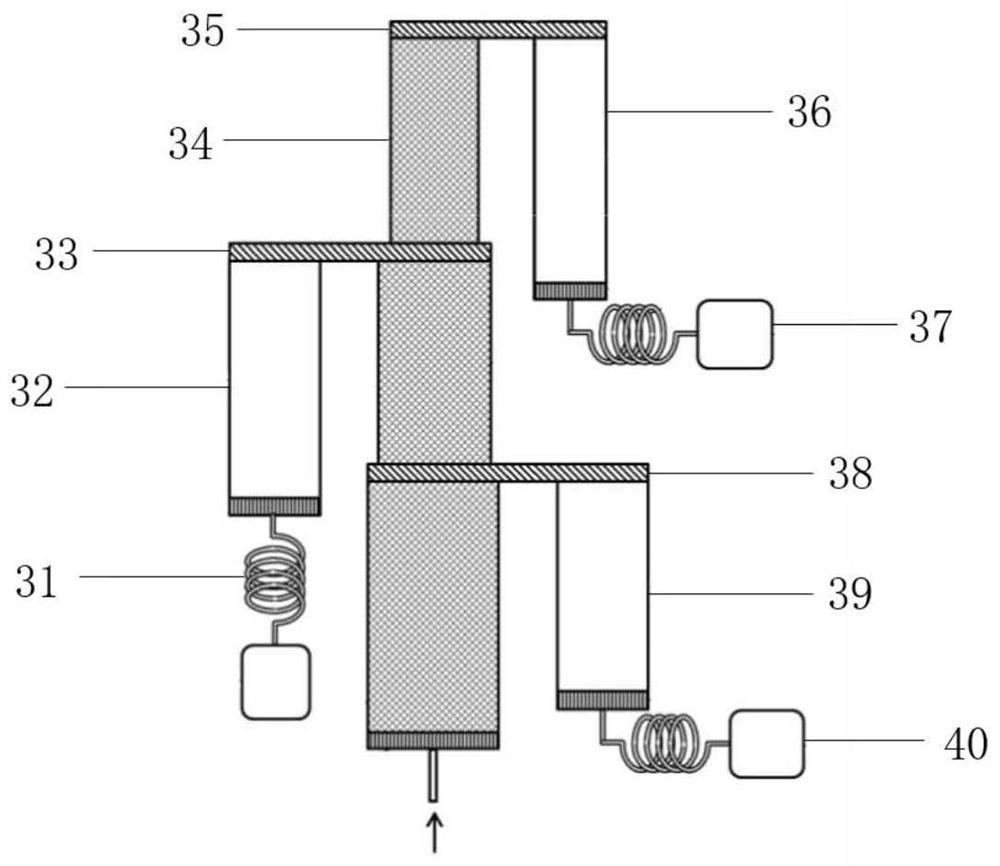

Multi-stage U-shaped gas-coupled pulse tube refrigerator connected-tube heat exchanger and its realization method

ActiveCN112880225BAvoid mixed flowPrevent backflowDomestic cooling apparatusEvaporators/condensersMixed flowPulse tube refrigerator

The invention discloses a tube-connected heat exchanger for a multi-stage U-shaped gas-coupling pulse tube refrigerator and a method for realizing the same. The cold-end heat exchanger comprises a heat exchanger shell, a connecting tube, a conical slit body, a The first through hole, the laminar flow element, the second conical slit body, and the second through hole. Conical slits are cut on the left and right sides of the heat exchanger shell respectively, and the two parts are connected by welding connecting pipes, and the connection of the first-stage regenerator, the second-stage regenerator and the first-stage pulse tube is realized at the same time. The invention maintains the advantages of high-efficiency heat exchange of traditional heat exchangers, and realizes high-efficiency matching between the front and rear stage cooling fingers of the pulse tube refrigerator, suppresses the backflow, mixed flow and turbulent disturbance of the gas working medium in the heat exchange channel, and ensures the uniformity of gas flow. sex. The invention will significantly improve the heat exchange efficiency and overall performance of the pulse tube refrigerator, and has very positive significance in realizing the compactness and practicality of the multi-stage pulse tube refrigerator and obtaining extremely low temperature.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com