Conical slit-type hot end heat exchanger of coaxial pulse tube refrigerator and manufacturing method

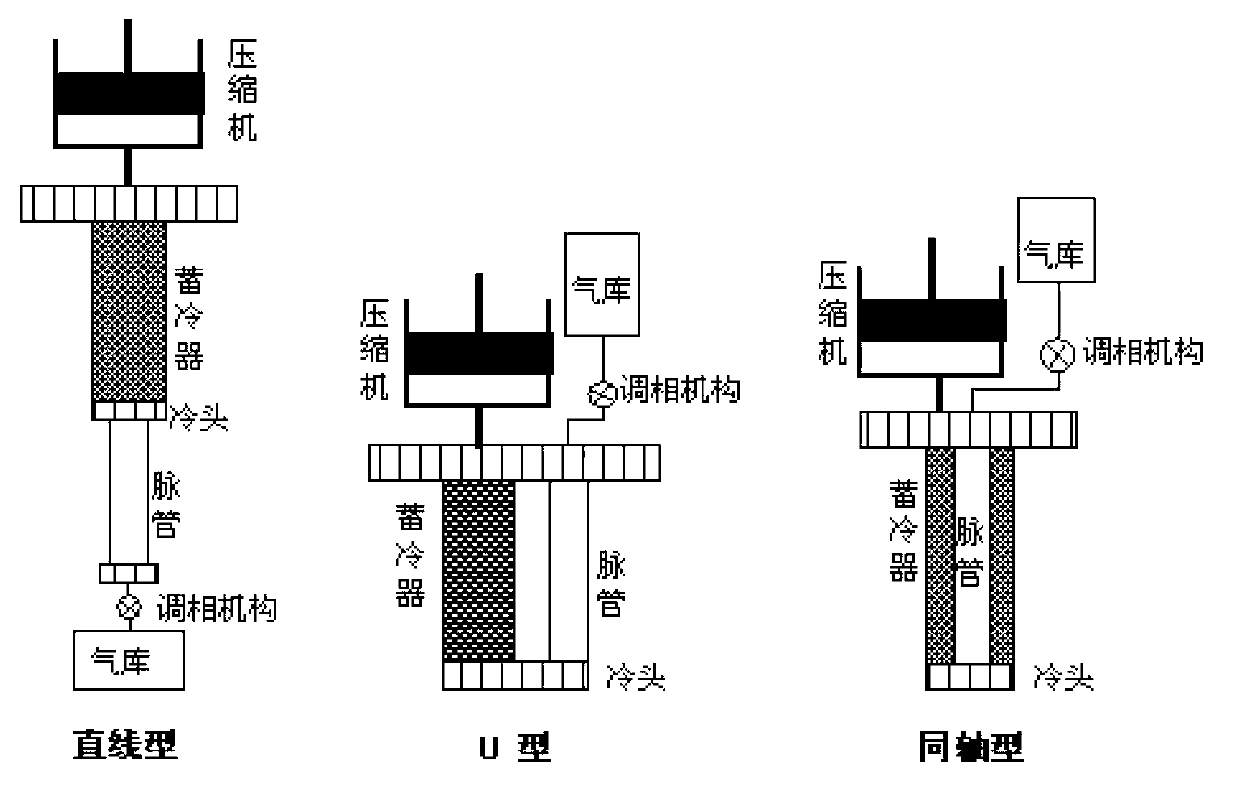

A technology of pulse tube refrigerator and coaxial type, which is applied in refrigerators, indirect heat exchangers, gas circulation refrigerators, etc., and can solve problems such as difficult process, failure to meet heat dissipation requirements, and large heat exchanger losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the specific embodiment of this patent is described in further detail:

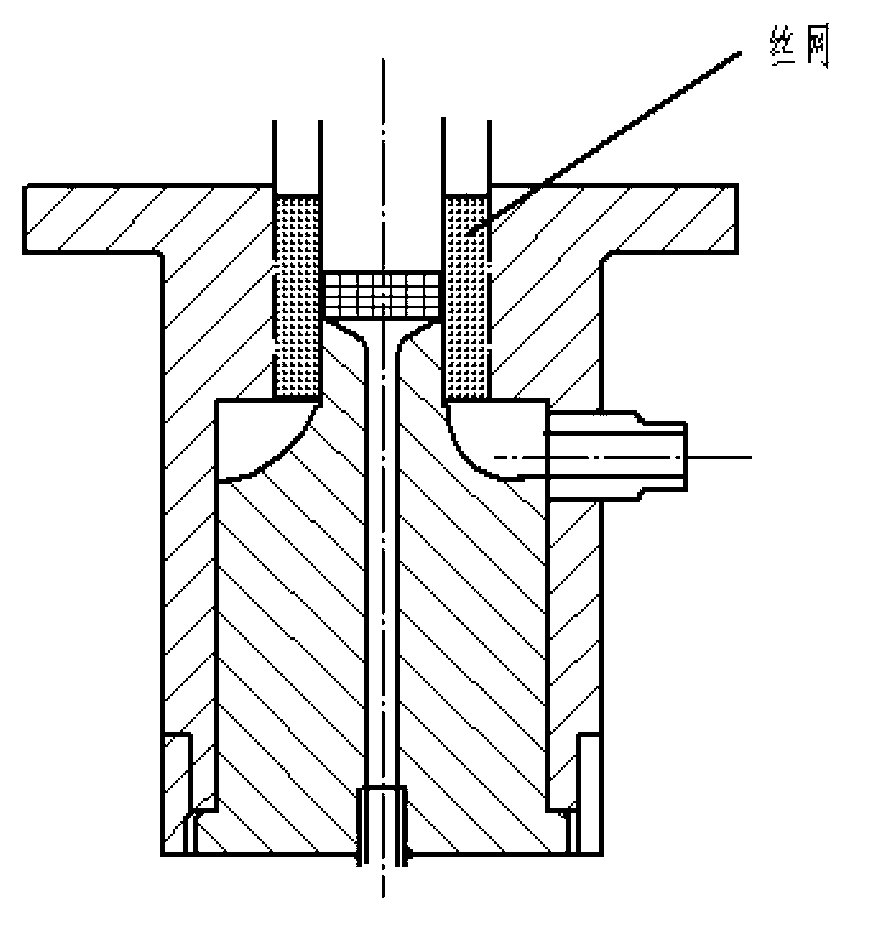

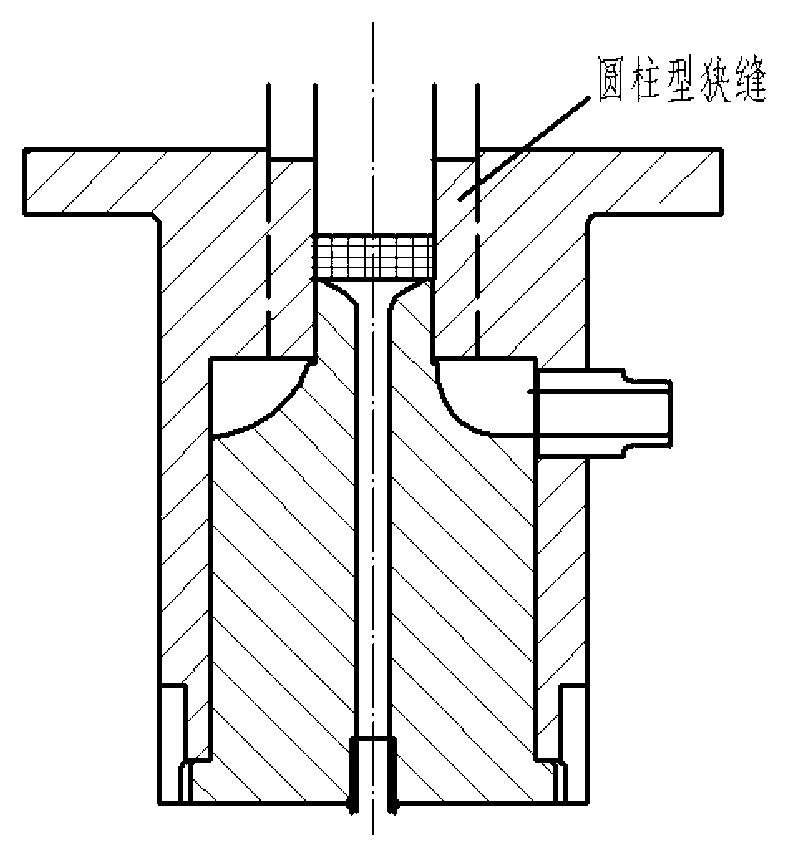

[0032] The hot-end tapered slit of the patented coaxial pulse tube refrigerator consists of three parts: the hot-end flange 7 , the tapered slit 1 and the hot-end plug 5 .

[0033] like Figure 5 As shown: the hot-end flange 7 and the hot-end air inlet 10 are connected by silver welding or brazing, and the inner wall surface 11 of the hot-end flange coincides with the outlet of the hot-end air inlet during welding. like Figure 7 As shown: the upper boss of the tapered slit heat exchanger 1 in the hot end flange 7 is smaller than the lower boss, and the radius of the tangential circle of the upper boss is equal to the outer diameter of the cold storage 2, and the tangential radius of the lower boss The radius of the circle is equal to the radius of the tangential circle of the hot end plug, and the inner diameter of the conical slit heat exchanger i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com