Patents

Literature

99results about How to "Improve thermodynamic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Protein surface remodeling

ActiveUS20120129759A1Improve thermodynamic performanceImprove solubilityPeptide/protein ingredientsDepsipeptidesBiotin-streptavidin complexBiochemistry

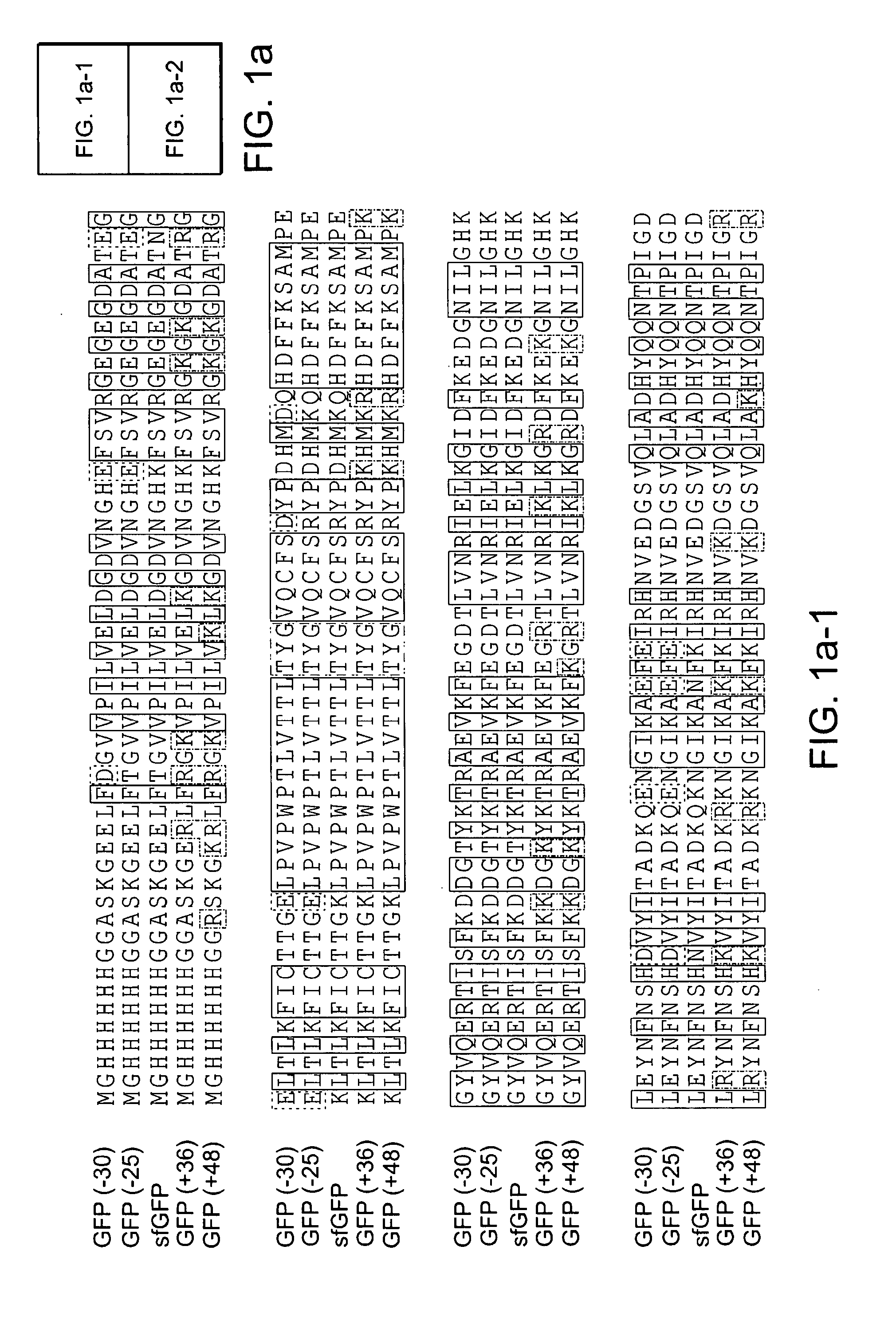

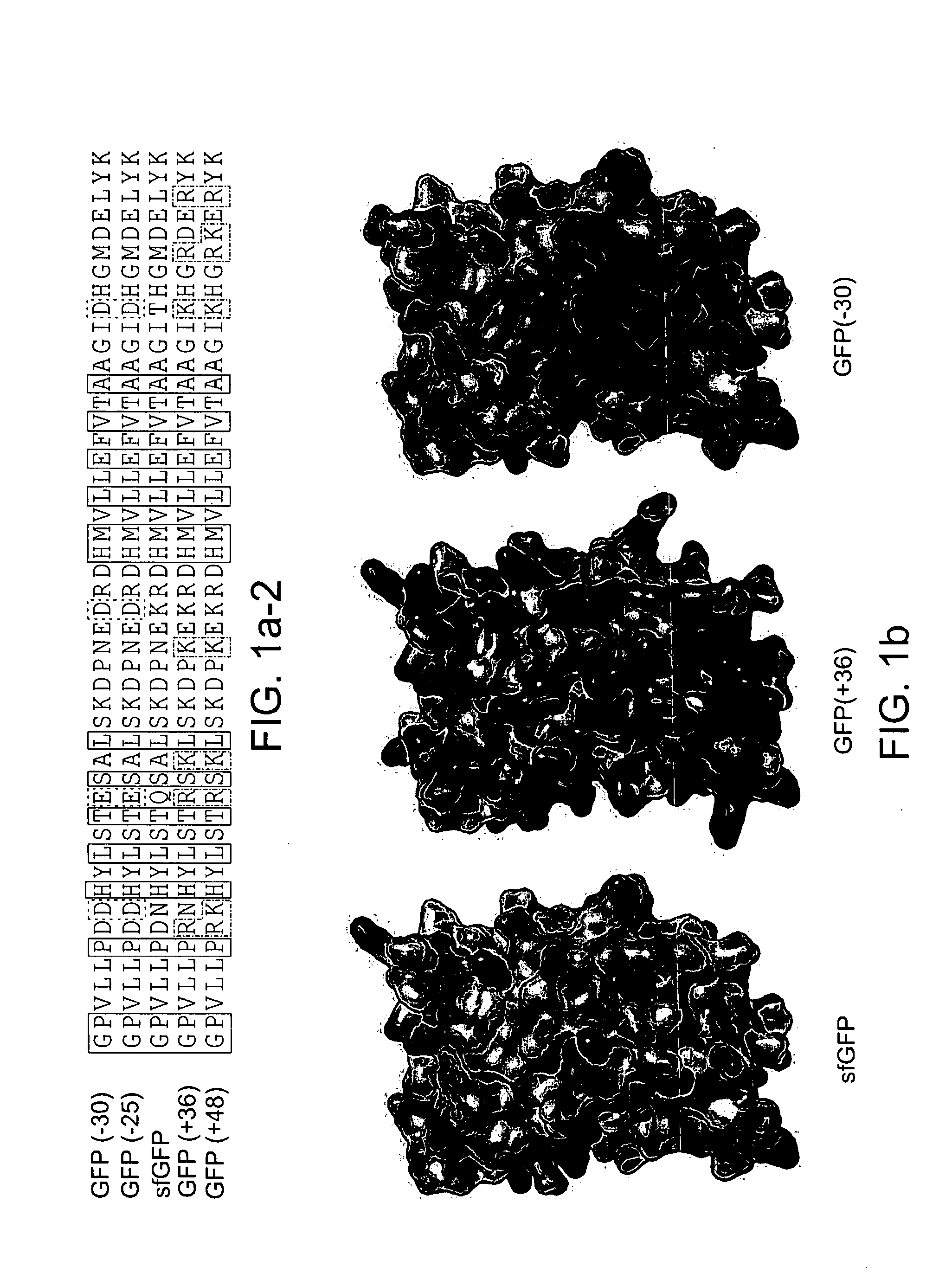

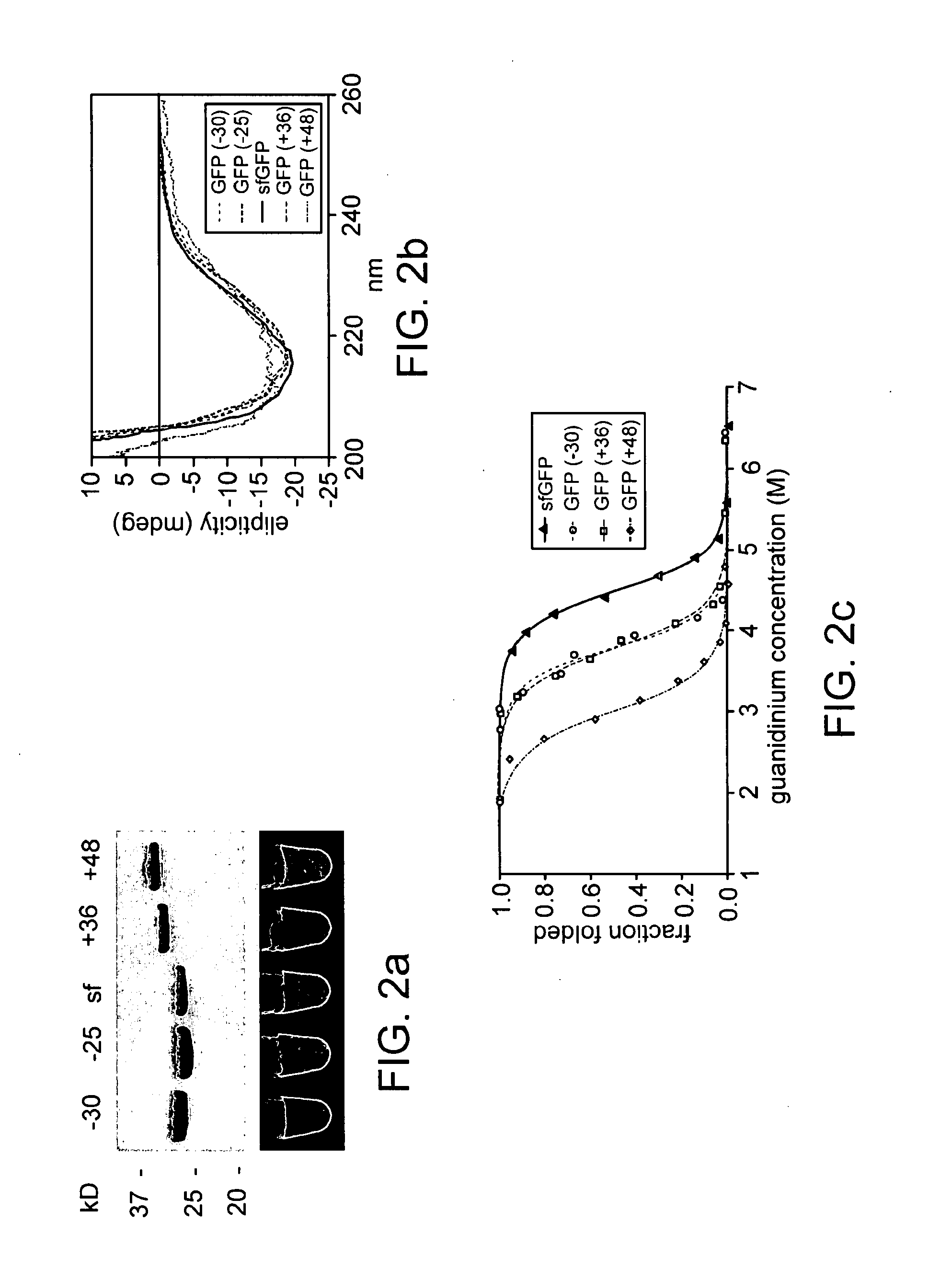

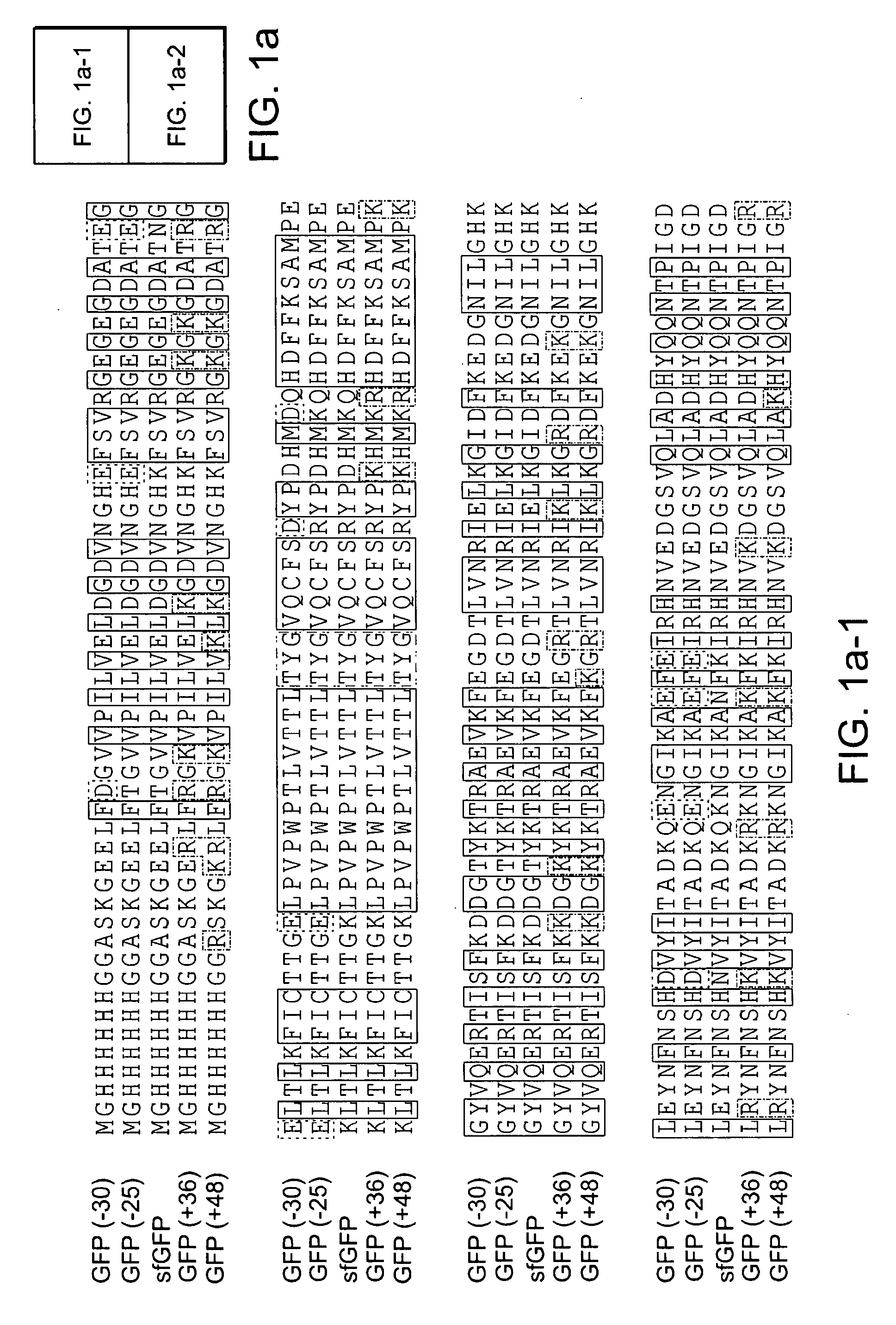

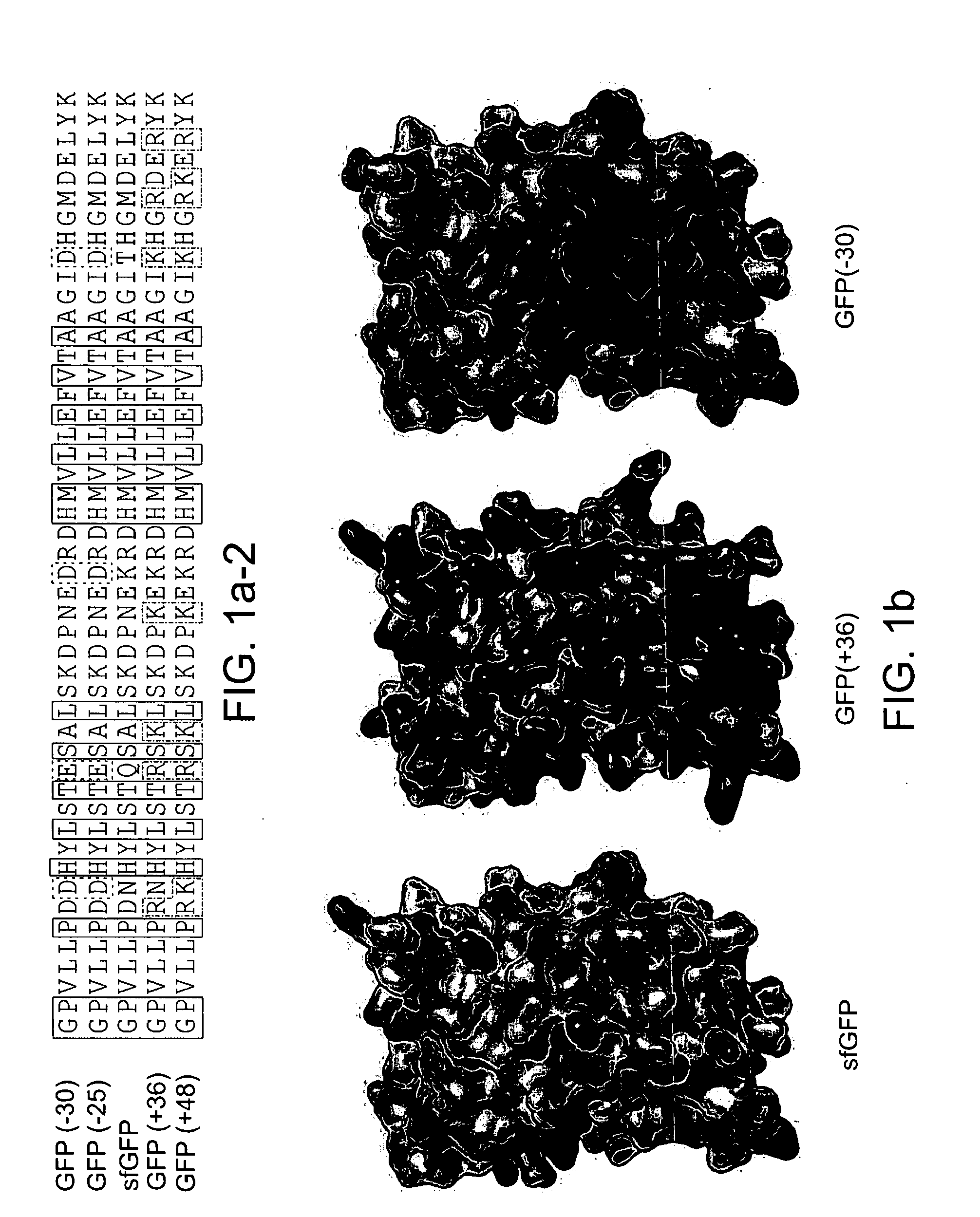

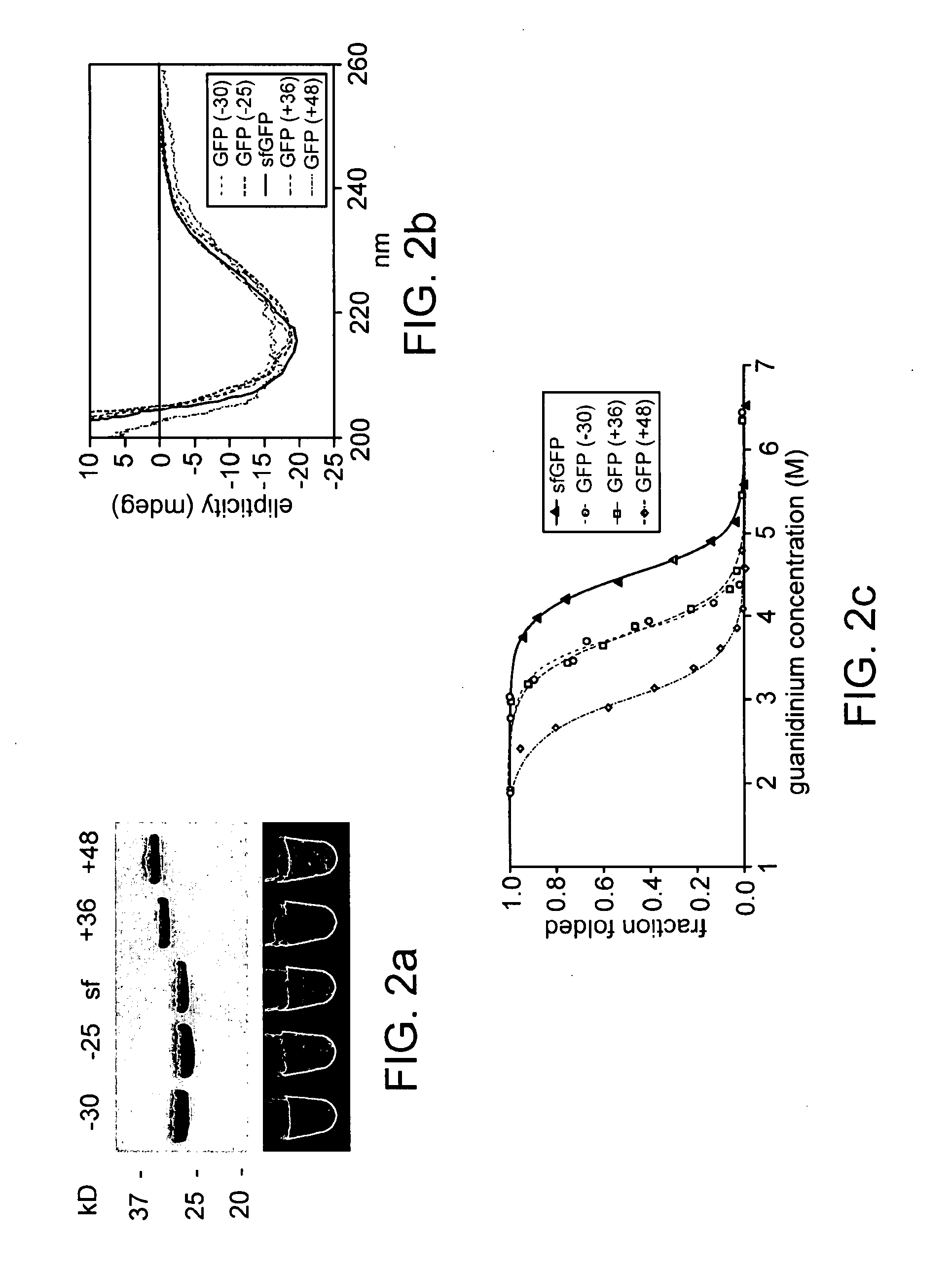

Aggregation is a major cause of the misbehavior of proteins. A system for modifying a protein to create a more stable variant is provided. The method involves identifying non-conserved hydrophobic amino acid residues on the surface of a protein, suitable for mutating to more hydrophilic residues (e.g., charged amino acids). Any number of residues on the surface may be changed to create a variant that is more soluble, resistant to aggregation, has a greater ability to re-fold, and / or is more stable under a variety of conditions. The invention also provides GFP, streptavidin, and GST variants with an increased theoretical net charge created by the inventive technology. Kits are also provided for carrying out such modifications on any protein of interest.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

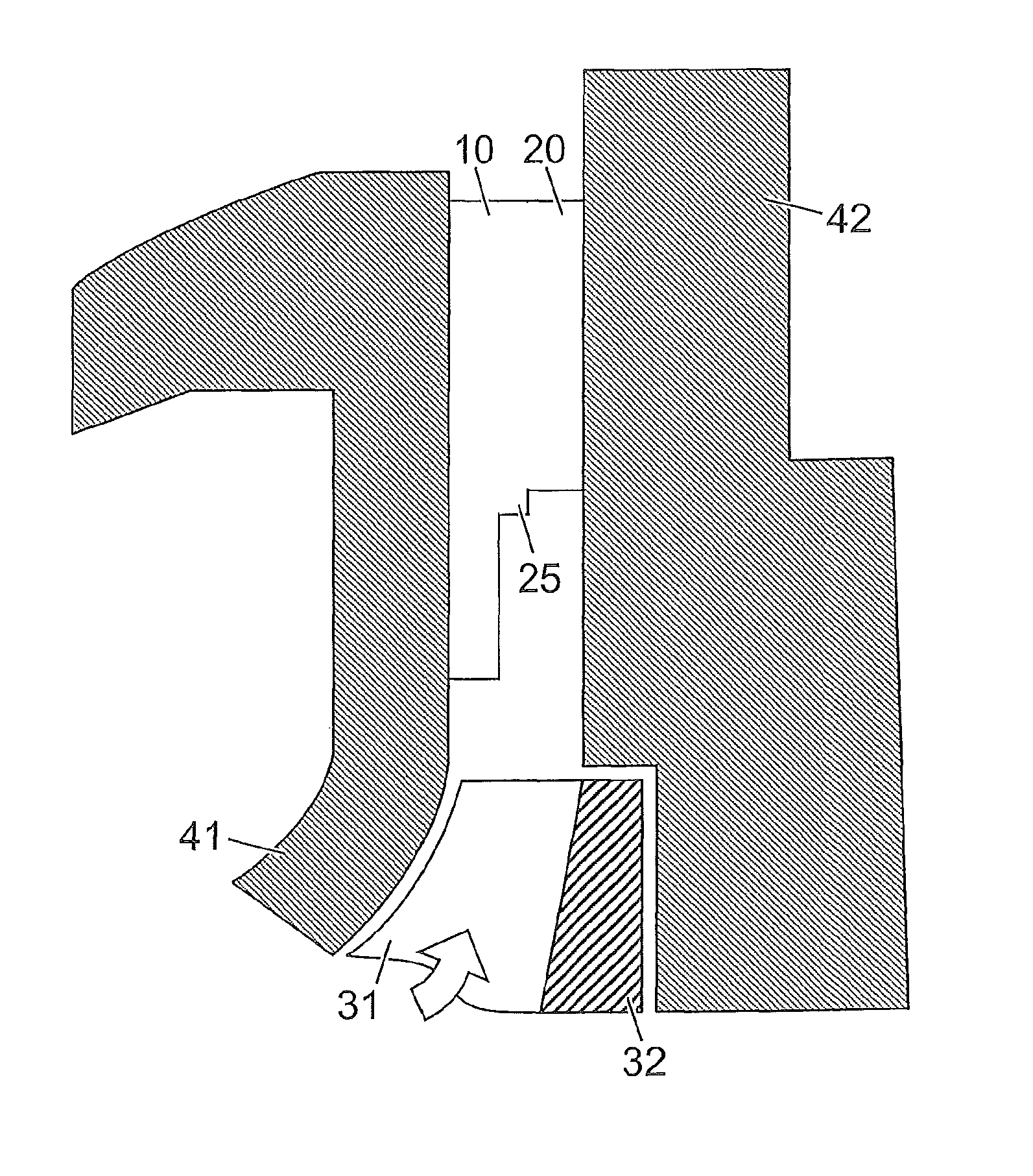

Diffusor

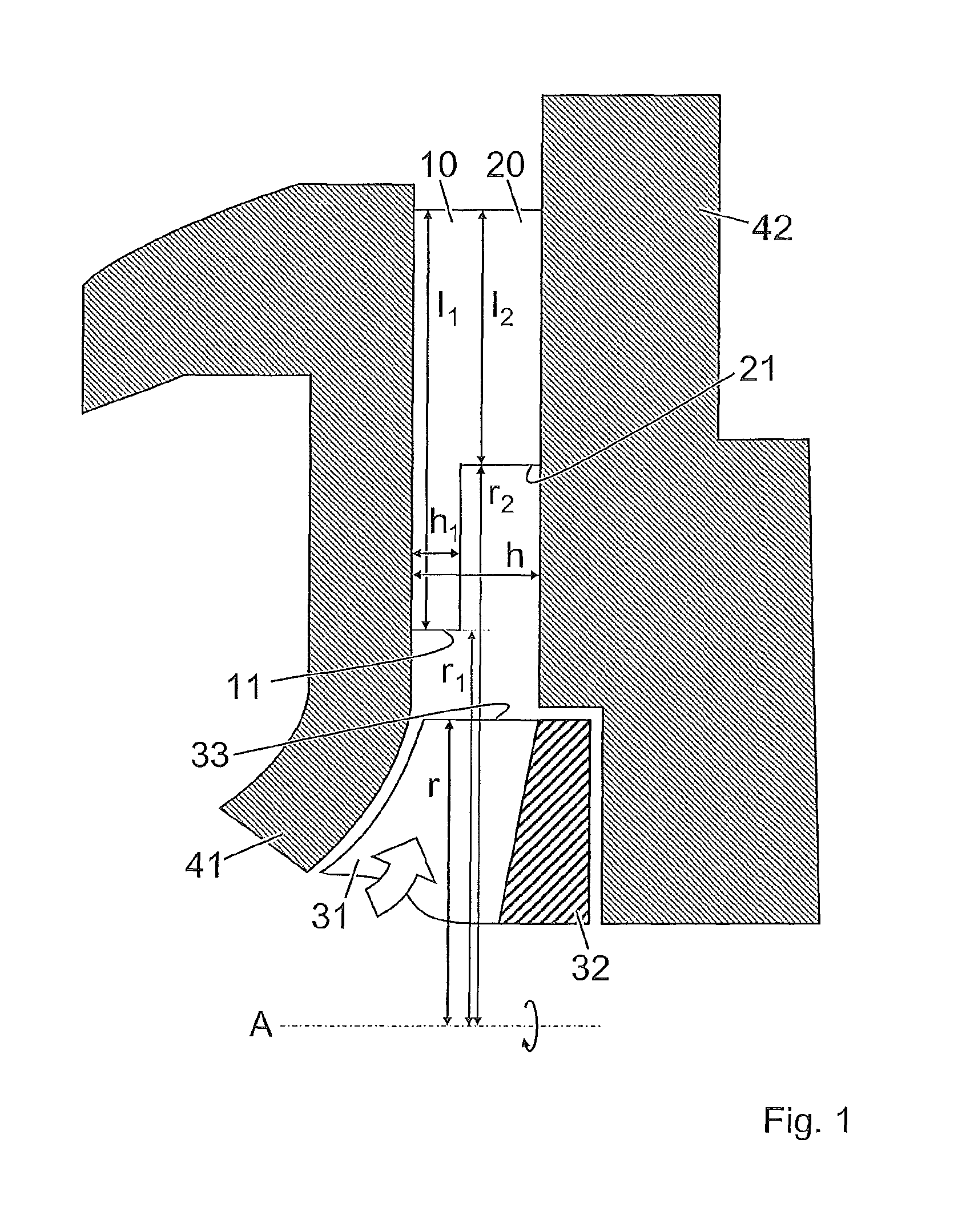

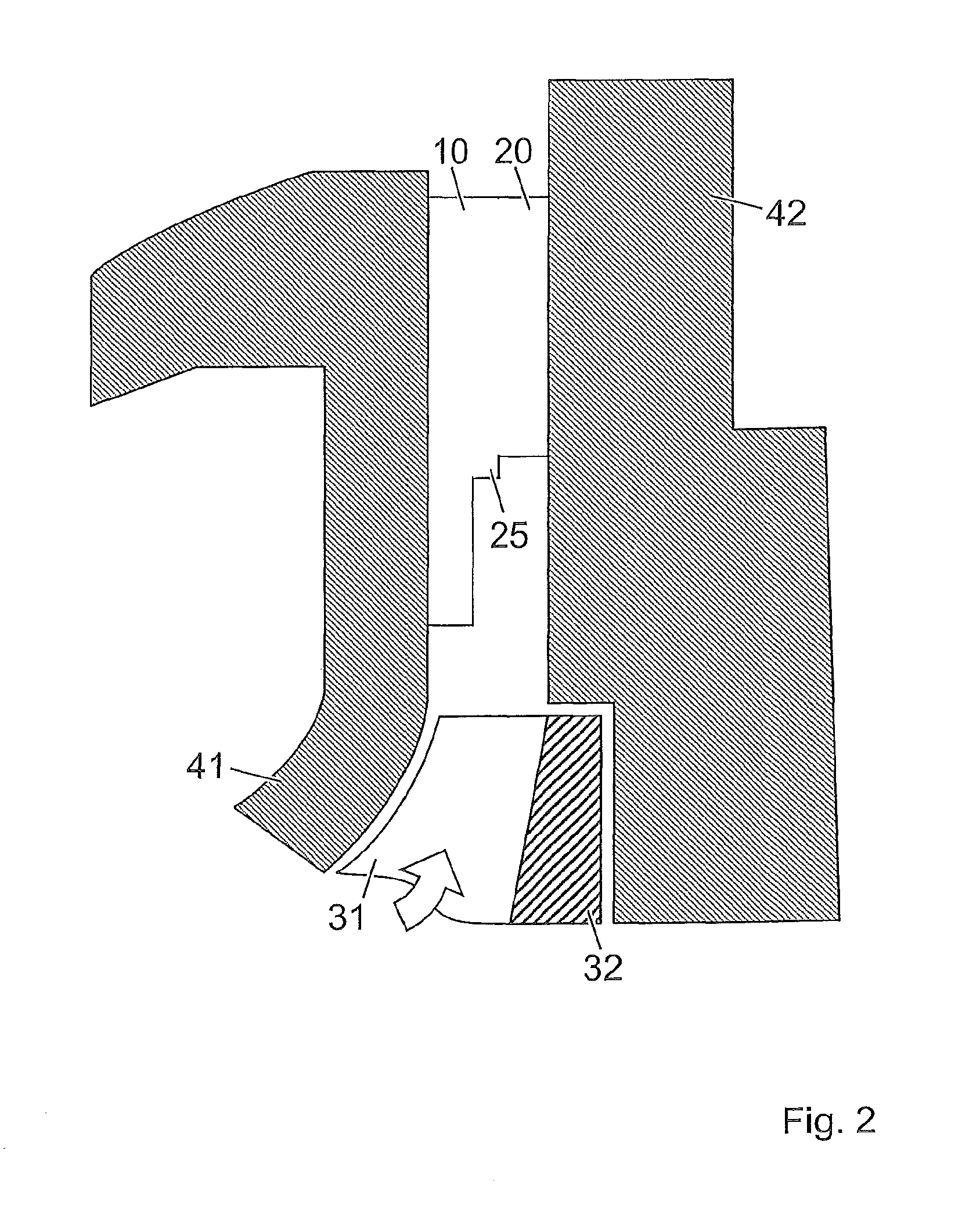

ActiveUS8162604B2Improve acoustic propertiesIncrease widthEngine manufacturePump componentsNoise fieldImpeller

The guide device for the diffusor at the compressor impeller outlet of a radial compressor has guide blades with stepped inlet edges. The step is implemented by setting back the hub-side inlet edge. This meridional stepping divides the guide blades into two component blades, of which the first component blade is made longer than the second component blade. The set-back of the inlet edge of the hub-side component blade and the associated superposition of the noise fields which are produced on the front and rear inlet edge of the diffusor leads to improvement of the acoustic properties of the compressor.

Owner:TURBO SYST SWITZERLAND LTD

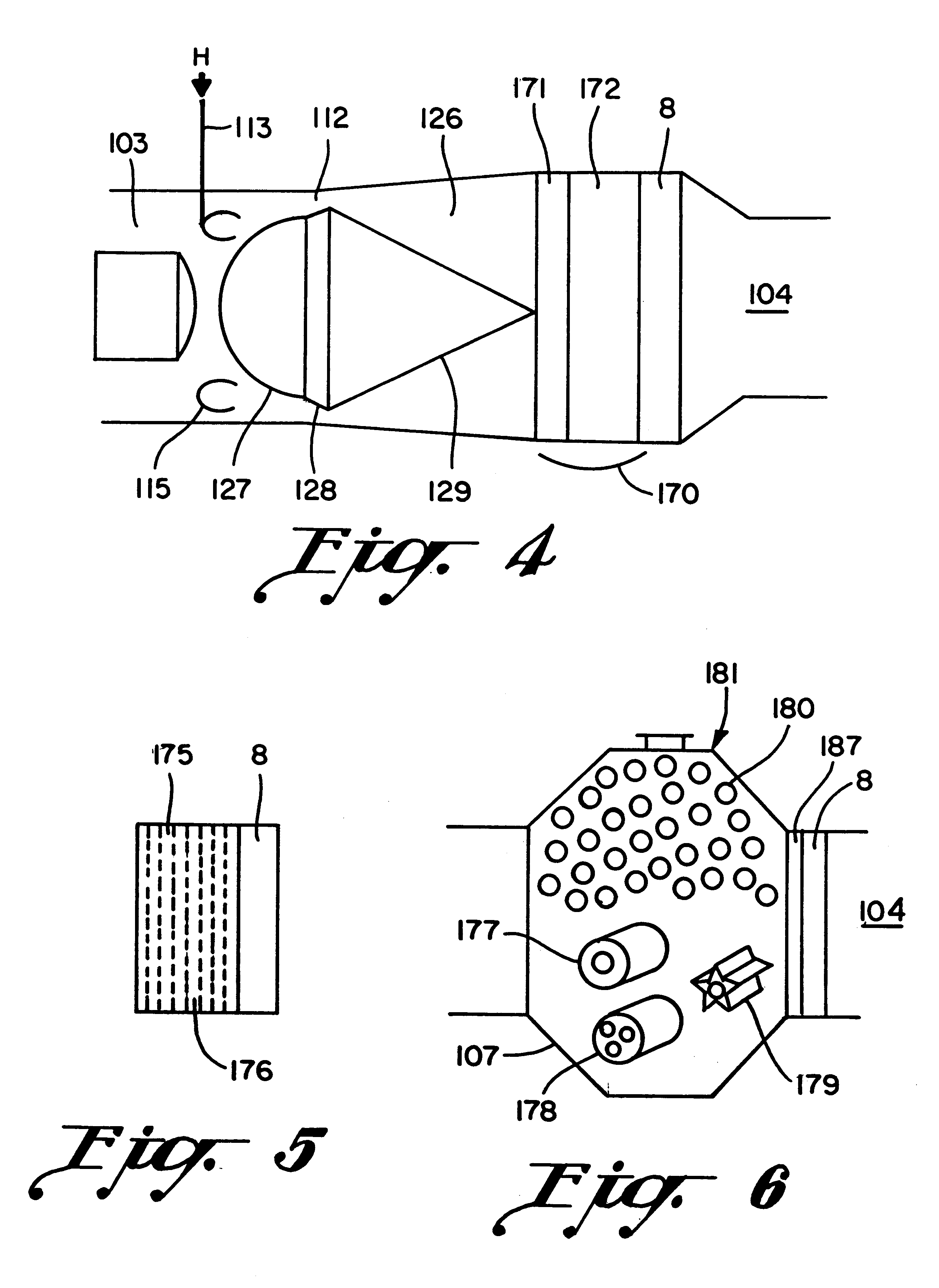

Combined gas turbine power system using catalytic partial fuel oxidation

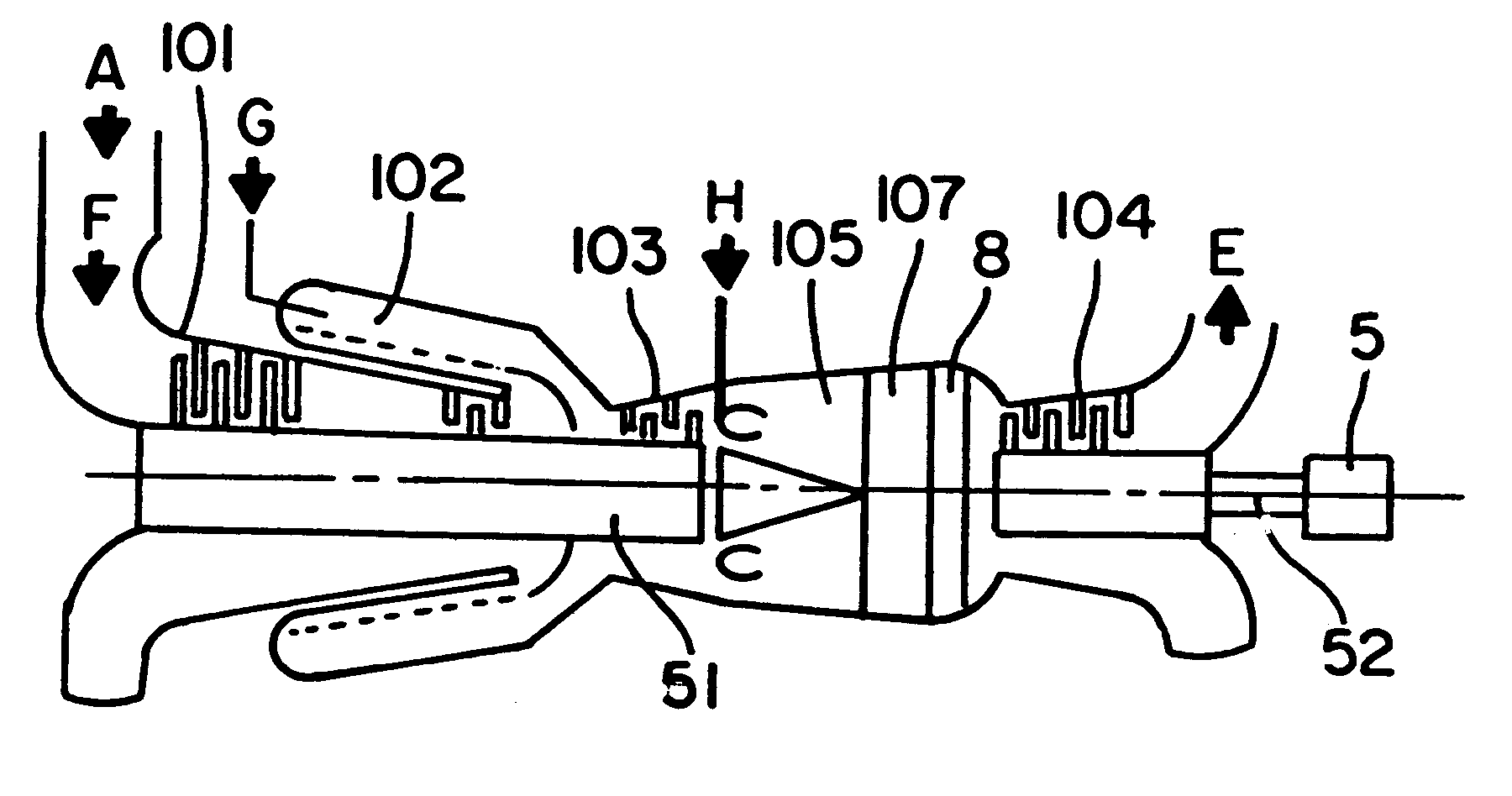

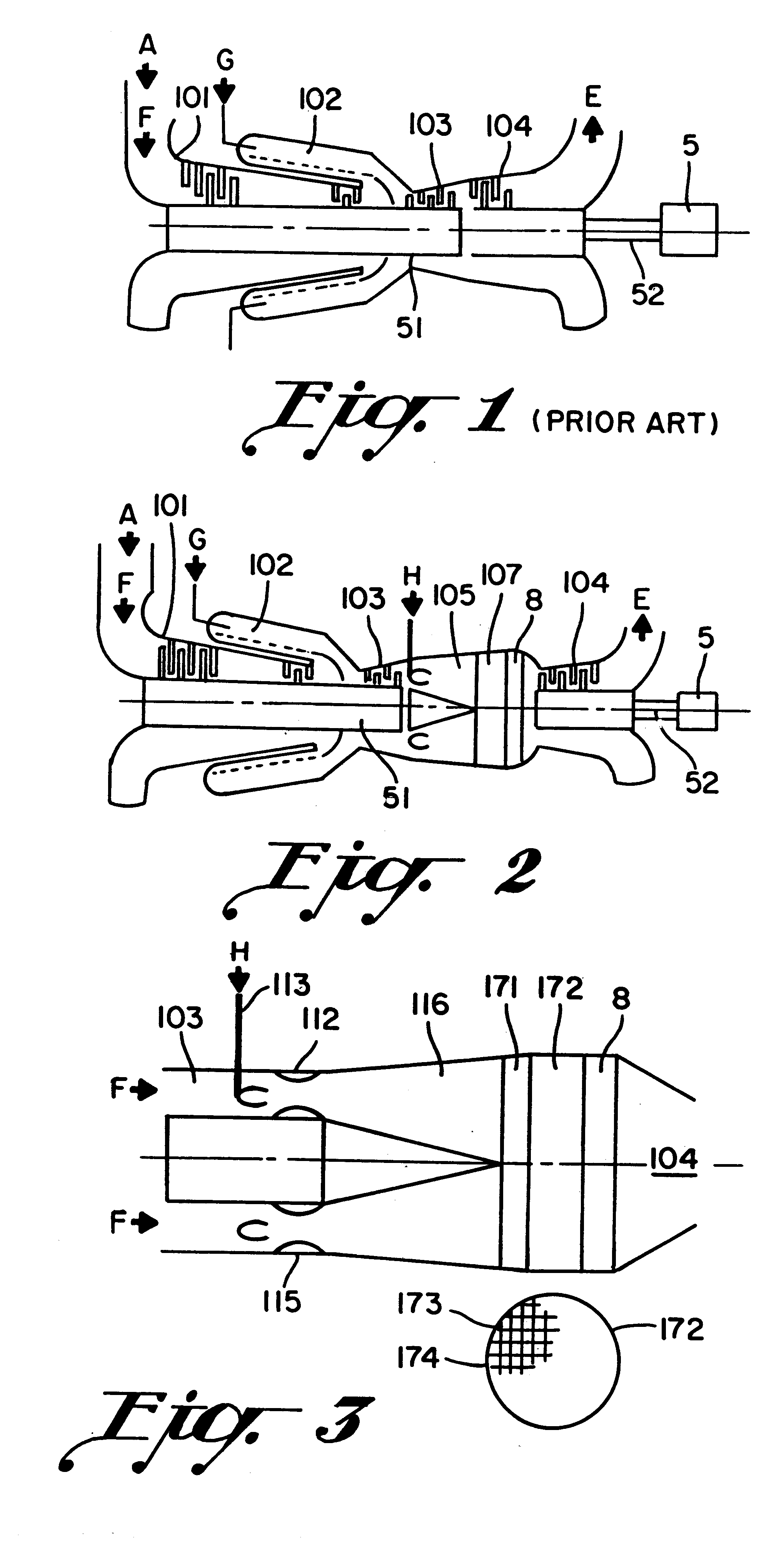

InactiveUS6189310B1Economically availableShorten the overall cycleTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionPartial oxidationCatalytic oxidation

A gas turbine power system for generating energy by means of a gas turbine cycle, wherein heat energy is more effectively used by burning the exhaust gases (109) and the partial oxidation of said exhaust gases (109) is achieved by means of a hypostoichiometric amount of air and steam fed into a catalytic reactor (107) to form a first oxidation stage followed downstream in said turbine (103) by additional oxidation occurring in a power turbine (104) or downstream therefrom, said power turbine being in turn arranged downstream from the catalytic reactor (107). Catalytic partial oxidation may be performed using a supply of an initiating agent, particularly hydrogen. The method is remarkable in that the hydrogen fed into the reactor inlet through an injector (113) is provided by recycling part of the effluent from the reactor, the power turbine or a reforming reactor for reforming part of the fuel gas with a large excess amount of steam for performing catalytic partial oxidation.

Owner:KALITVENTZEFF BORIS +1

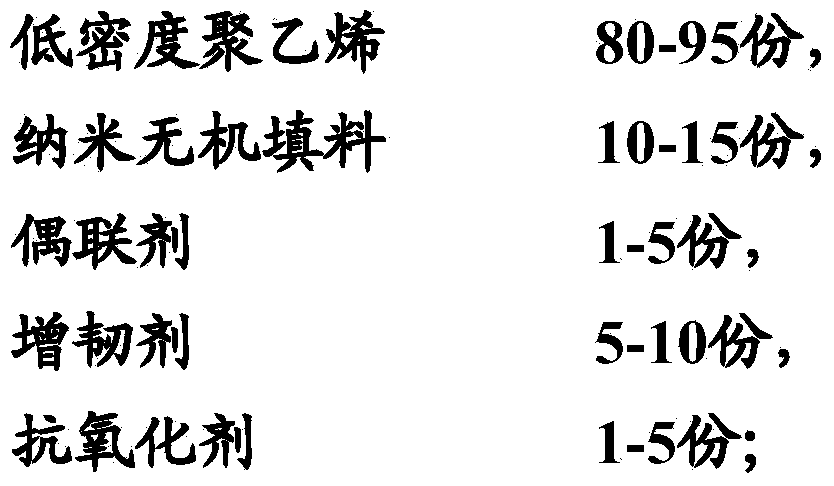

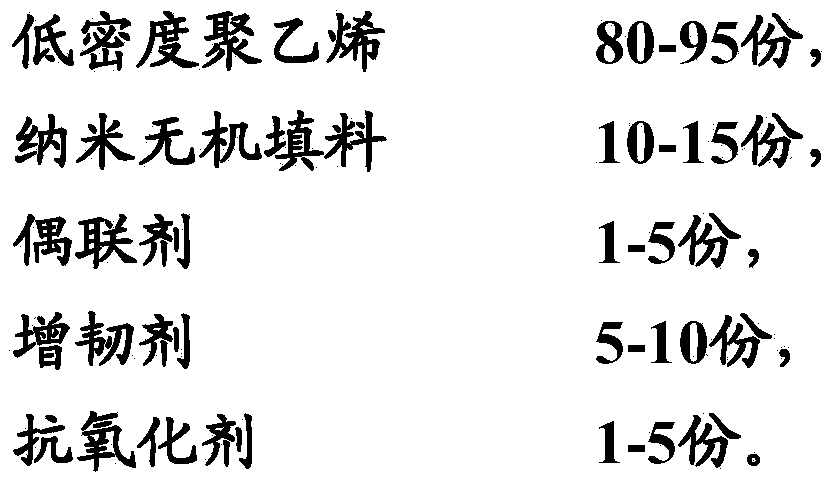

Modified low density polyethylene nanocomposite material used for 3D printing, and preparation method thereof

ActiveCN103992548AStay specialImprove thermodynamic performanceLow-density polyethyleneHeat resistance

A modified low density polyethylene material used for 3D printing comprises, by weight, 80-95 parts of low density polyethylene, 1-10 parts of an inorganic nanoparticle filler, 1-5 parts of a coupling agent, 5-10 parts of a flexibilizer, and 1-5 parts of an antioxidant. The modified low density polyethylene material has the advantages of very good fusion viscosity, very good fluidity, very good heat resistance and very good wear resistance, accords with the characteristics a 3D printing material, and has a wide application prospect in the 3D printing technology.

Owner:INST OF CHEM CHINESE ACAD OF SCI

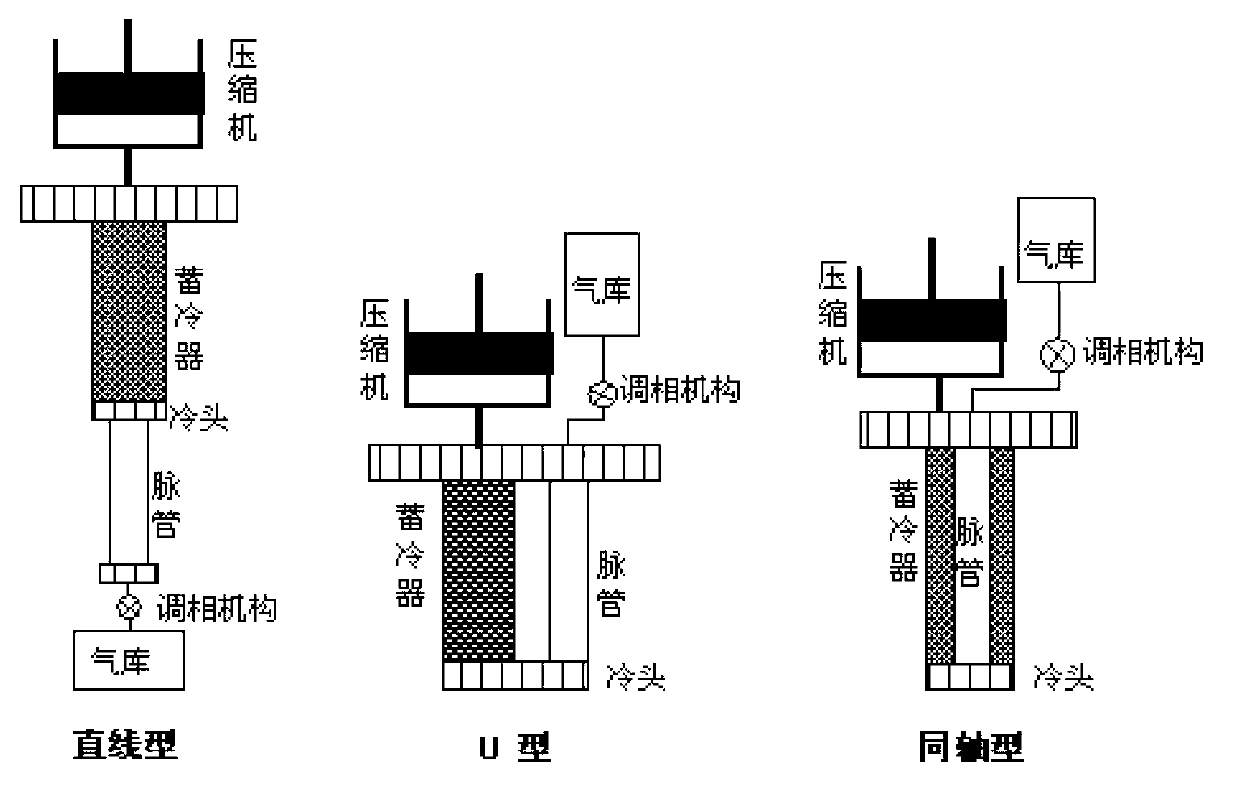

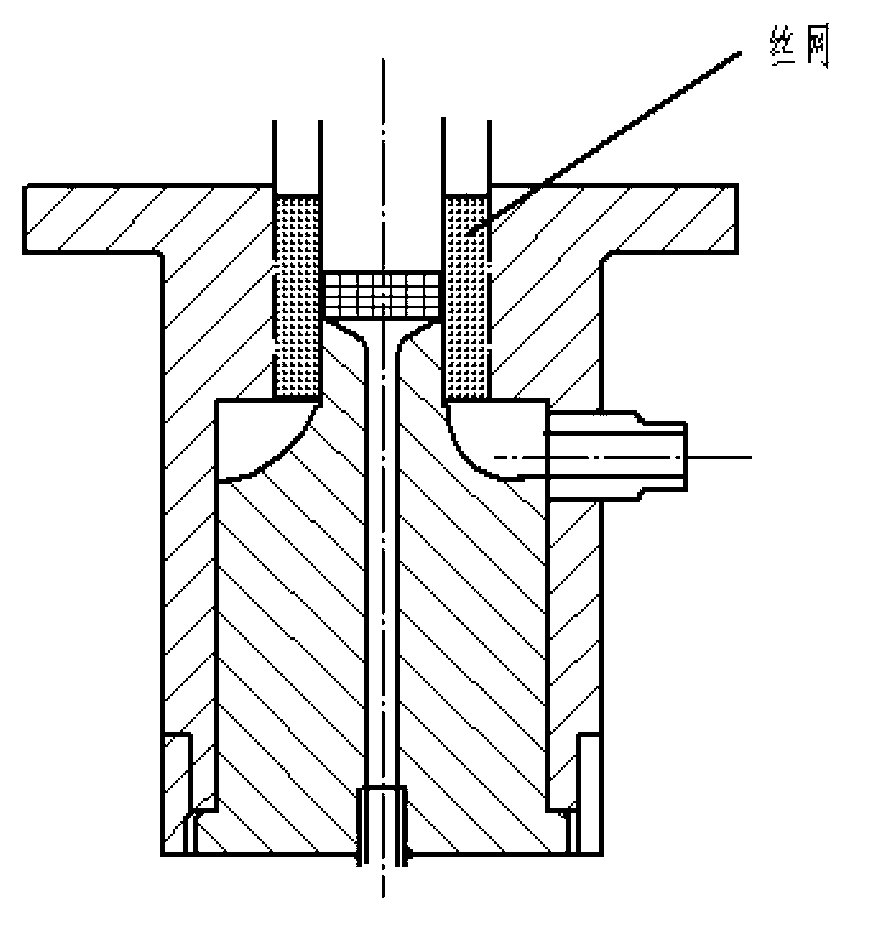

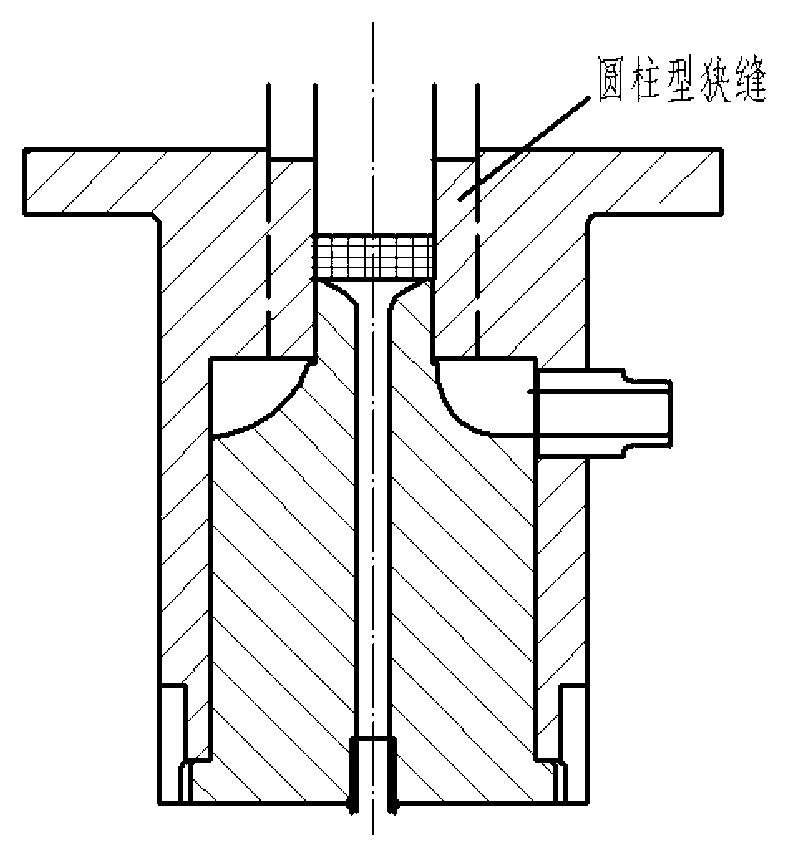

Conical slit-type hot end heat exchanger of coaxial pulse tube refrigerator and manufacturing method

ActiveCN102735088AImprove thermodynamic performanceImprove machine performanceCompression machinesSoldering apparatusPulse tube refrigeratorEngineering

The invention discloses a conical slit-type hot end heat exchanger of a coaxial pulse tube refrigerator and a manufacturing method. The heat exchanger structurally consists of a hot end flange, a conical slit and a hot end plug, wherein the conical slit is inserted into the hot end flange in a tight fit way, the radius of a circle of contact on the top of a cone frustum is equal to the radius of a cold accumulator and the radius of the bottom of the cone frustum is equal to the radius of the hot end plug. The hot end plug and the hot end flange not only can be connected through bolts to form a detachable split-type hot end heat exchanger, but also can be hermetically welded to form an integrated hot end radiator. The conical slit-type hot end heat exchanger has the advantages that the structure is simple, compact and high-efficiency, the hot end radiating capacity of the refrigerator can be exerted to the utmost extent and the hot end pressure ratio of the pulse tube refrigerator is increased at the same time. The structure can intensively realize the major functions of a high-efficiency hot end heat exchanger, a hot end gas flow guide device of the pulse tube refrigerator and a hot end gas even distributor of the cold accumulator, and can improve the performance of the entire pulse tube refrigerator to a great extent.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

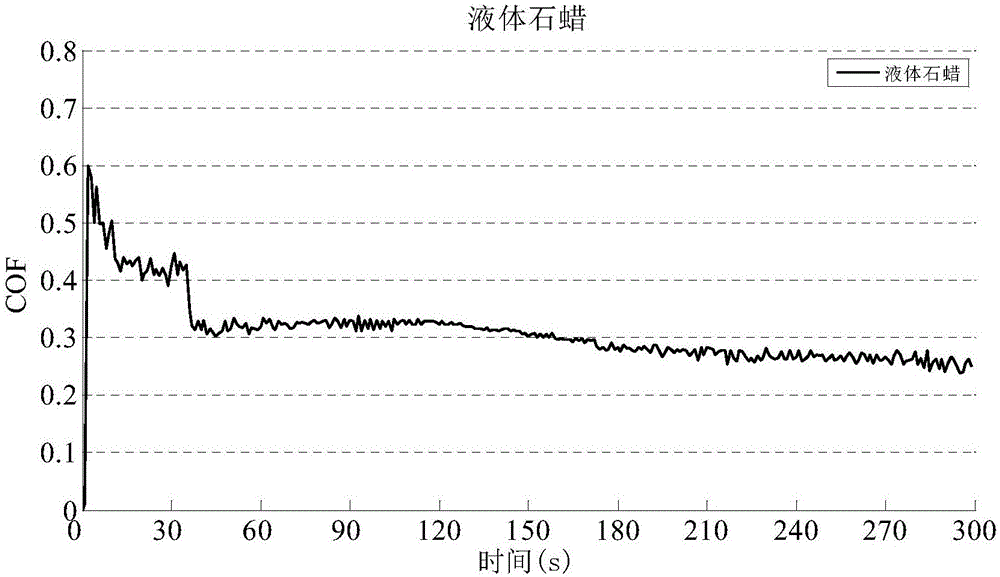

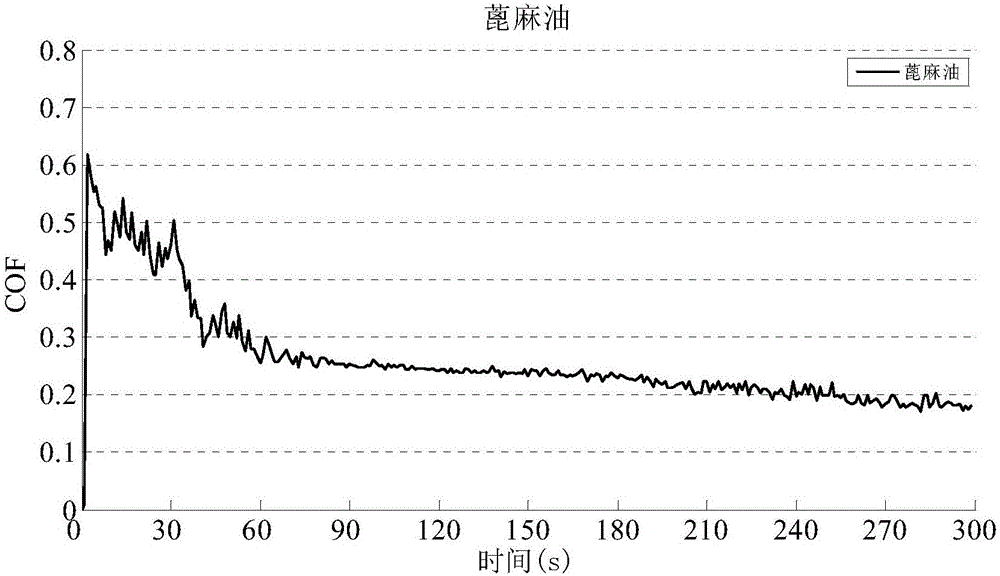

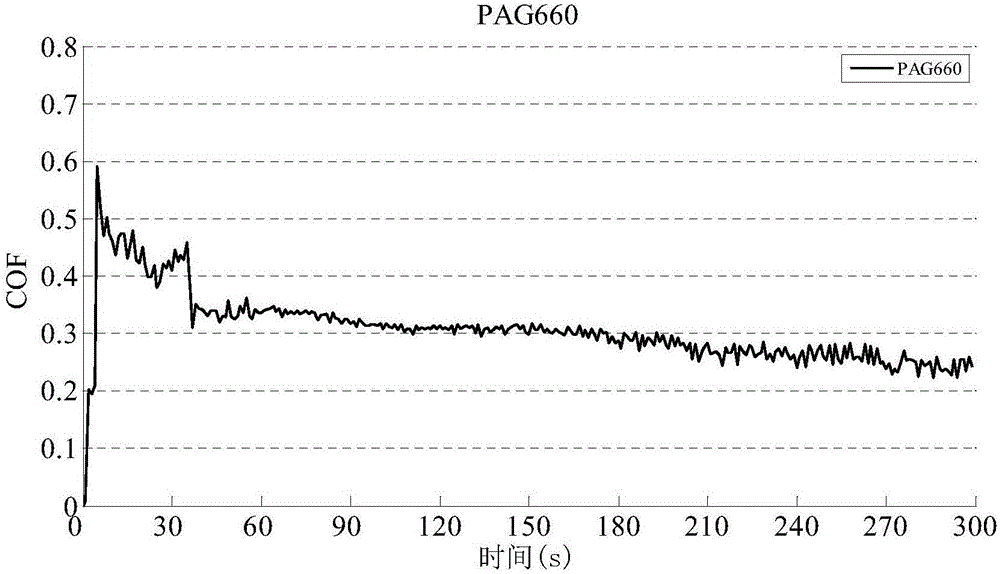

Water-based fully-synthetic titanium alloy cutting fluid

ActiveCN106479657ANot prone to corruptionExtended service lifeLubricant compositionWater basedNitrite

The invention relates to a water-based fully-synthetic titanium alloy cutting fluid. The titanium alloy cutting fluid is prepared from components in percentage by weight as follows: 1%-20% of a main lubricating agent, 1%-10% of an auxiliary lubricating agent and the balance of water. The titanium alloy cutting fluid belongs to a water-based fully-synthetic metal machining fluid, doesn't contain oily ingredients such as mineral oil, plant oil and the like, doesn't contain nitrite, secondary amine, formaldehyde, formaldehyde releasing substances, chlorine, chromium or other elements, is friendly to the environment and human bodies, doesn't easily decay and is long in service life.

Owner:超滑科技(佛山)有限责任公司

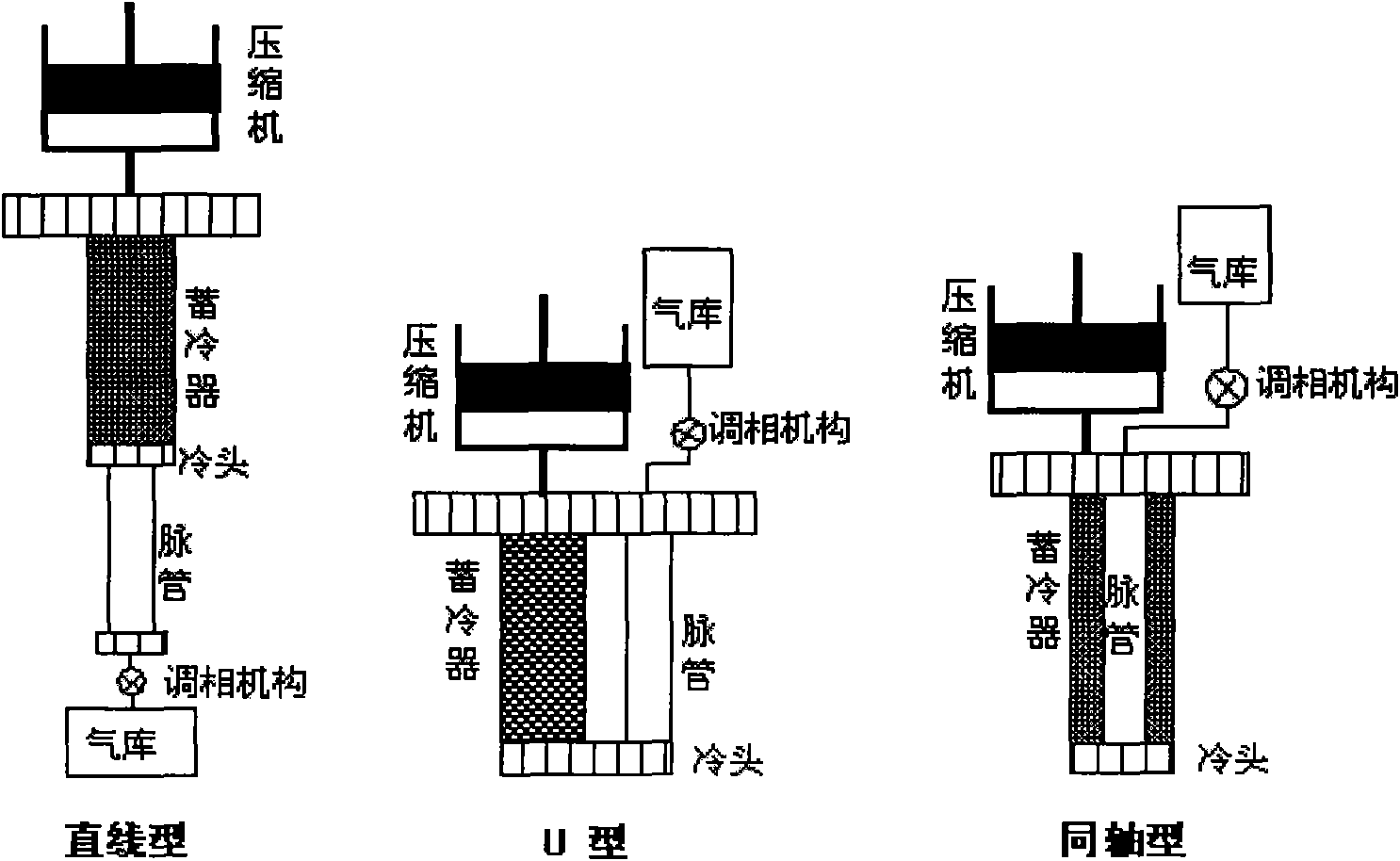

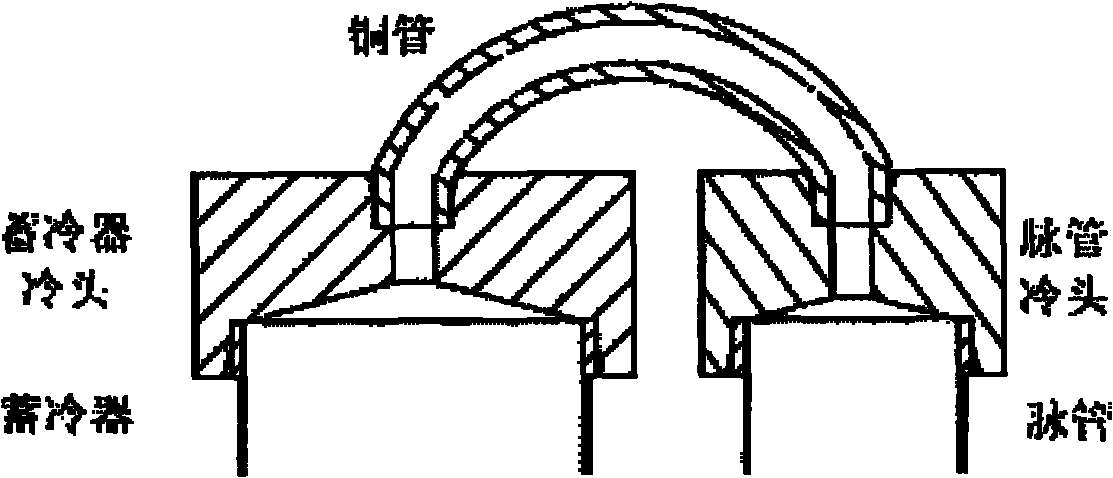

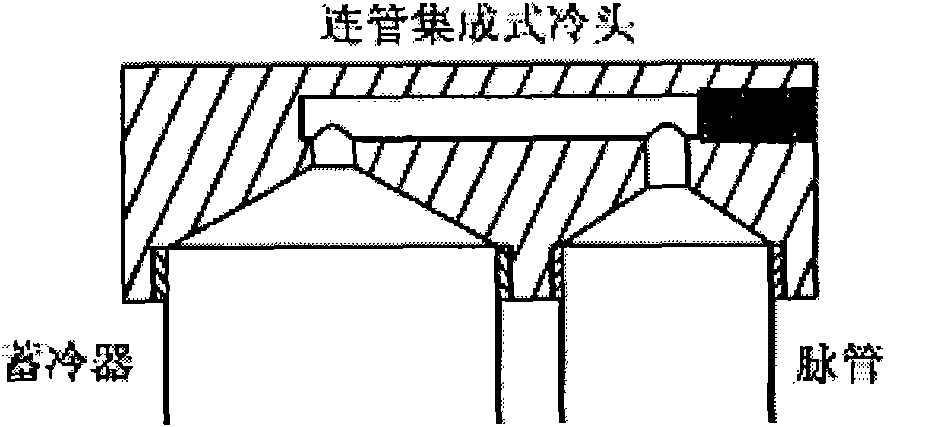

Integrated slit cold head of U-shaped pulse tube refrigerating machine and manufacturing method

InactiveCN102042711AMaintain laminar effectImprove thermodynamic performanceCompression machinesGas cycle refrigeration machinesEngineeringTop cap

The invention discloses an integrated slit cold head of a U-shaped pulse tube refrigerating machine and a manufacturing method. The cold head comprises two parts of a top cover and a lower flange, wherein two cylindrical lug bosses protrude below a big lug boss of the top cover, outer diameters of the two cylindrical lug bosses are respectively equal to inner diameters of a cold regenerator and a pulse tube; the two lug bosses integrally cut and penetrate through a slit in parallel horizontally and uniformly; through insertion holes matched with the cylindrical lug bosses of the top cover are arranged on the lower flange, a sealing groove and a location groove matched with the big lug boss of the top cover are cut on the upper surface of the lower flange, the lower flange, the cold regenerator and the pulse tube are hermetically welded to form an assembly; the top cover and the lower flange not only can be connected by bolts to form a detachable split cold head, but also can be hermetically welded to form an integrated cold head. In the invention, the main functions of three parts of an efficient cold end heat exchanger, a pulse tube cold end gas director and a cold regenerator cold end gas distributor can be intensively realized in an integrated slit cold head structure, the overall performance of the U-shaped pulse tube refrigerating machine is enhanced.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Micro-droplet preparation method applicable to micro-droplet digital PCR (Polymerase Chain Reaction)

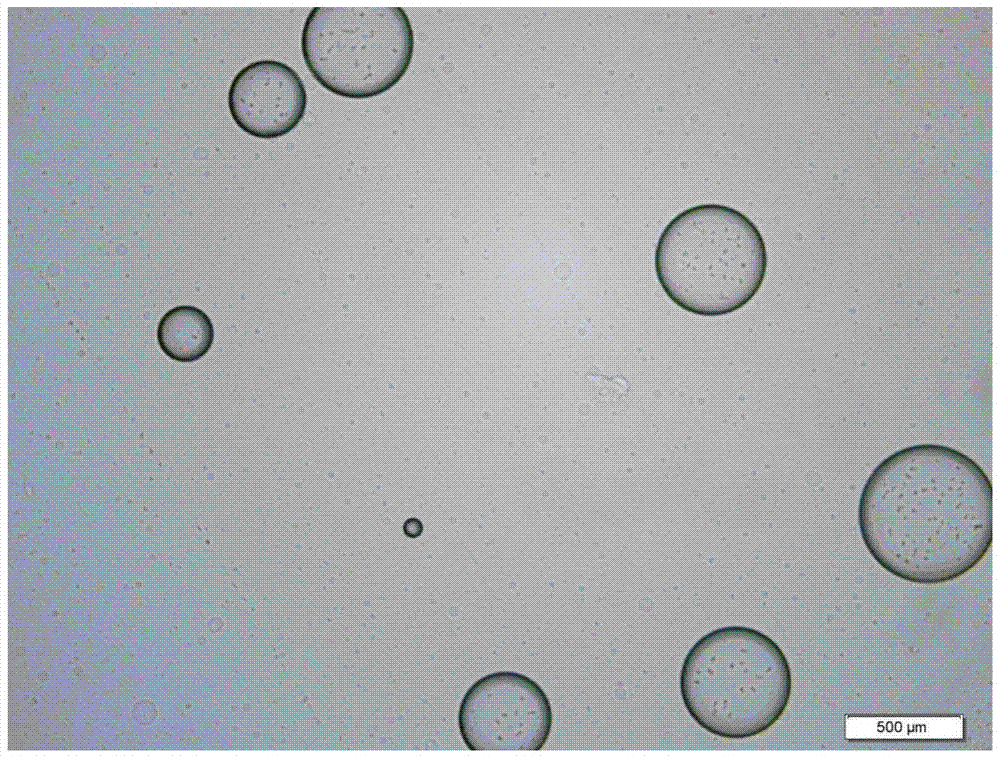

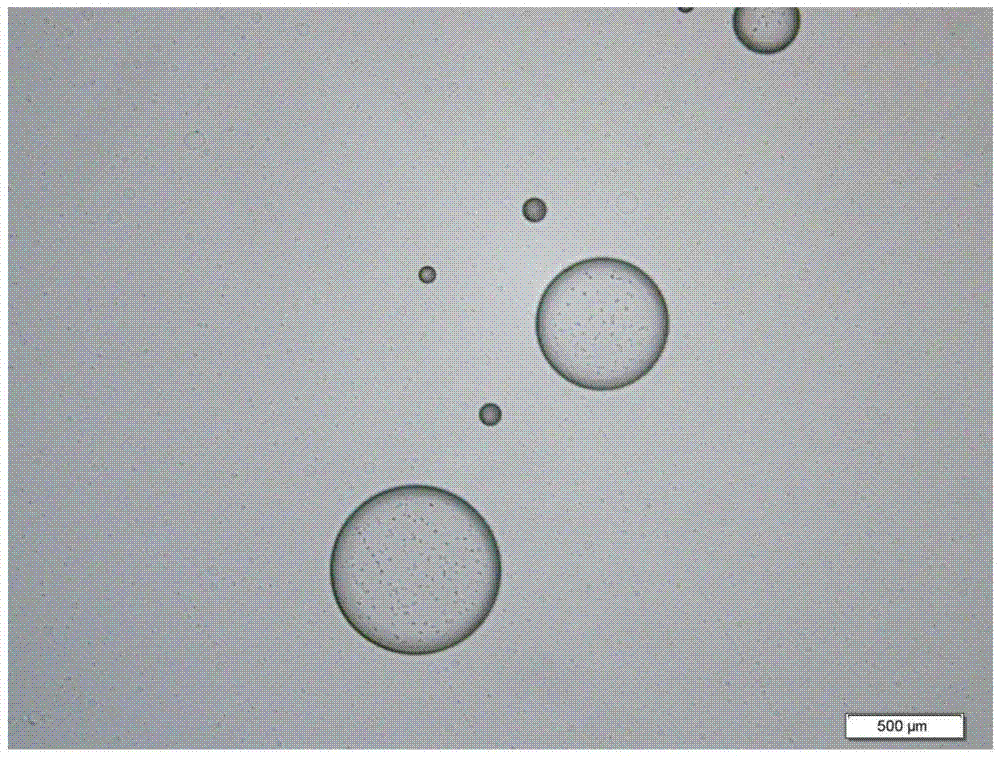

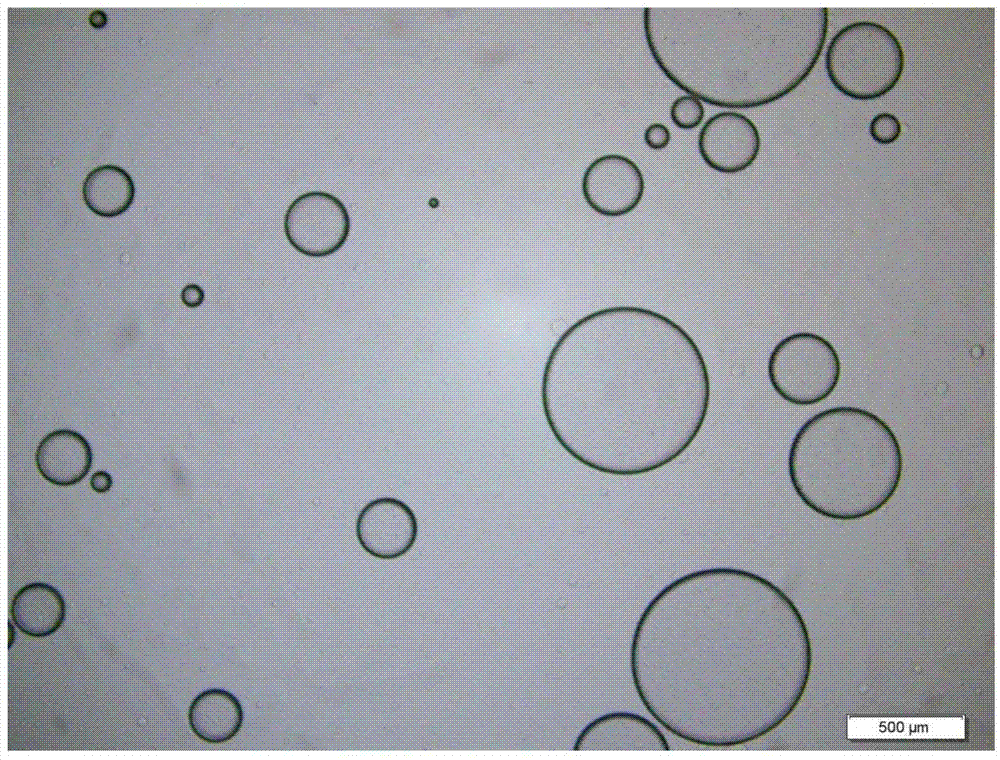

InactiveCN104846100ASimple and fast operationEasy to prepareMicrobiological testing/measurementGranularityDistilled water

The invention discloses a micro-droplet preparation method applicable to micro-droplet digital PCR (Polymerase Chain Reaction). The method comprises the following steps: preparing a PCR aqueous phase, wherein the PCR aqueous phase comprises an upstream primer, a downstream primer, a PCR template, a PCRmix and double distilled water; sequentially and uniformly mixing the medicines as a reaction aqueous phase standby; sequentially and uniformly mixing the upstream primer, the downstream primer, the PCR template and the PCRmix, dropwise adding the double distilled water, and then taking a solution system as the reaction aqueous phase standby; preparing a PCR oil phase, and sequentially and uniformly mixing glycerin, Trition X-100, Tween-80 and nonyl phenyl ether IgelCO520; adding 1vol of the PCR aqueous phase into 2vol of the PCR oil phase, and performing vortex stirring and reaction to obtain water-in-oil micro-droplets. The preparation method provided by the invention has the advantages that the water-in-oil reaction micro-droplets which are uniform in granularity and stable in thermodynamic property can be conveniently prepared, and the operation of a micro-droplet digital PCR experiment is simplified.

Owner:BEIJING UNIV OF TECH

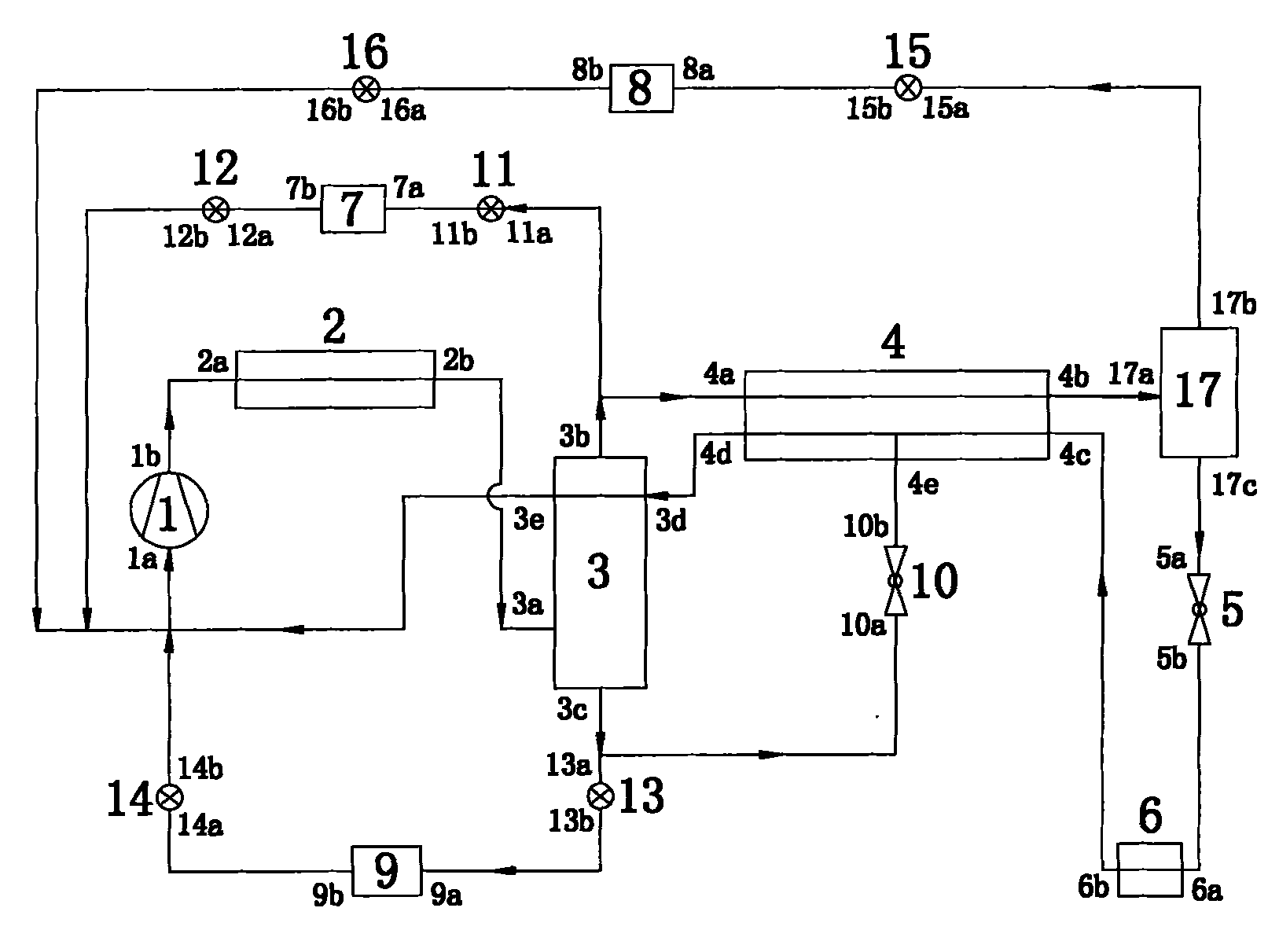

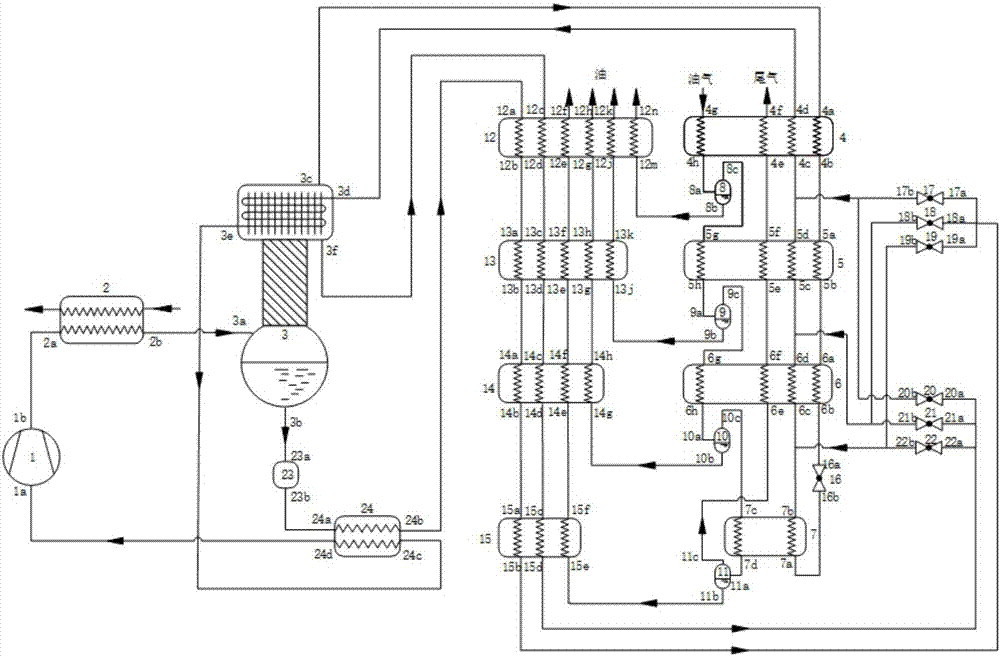

Varied concentration mixed working medium auto-cascade refrigerator

ActiveCN101776358AReduce boot pressureImproved dynamic running characteristicsFluid circulation arrangementRefrigeration safety arrangementVapor–liquid separatorLiquid storage tank

Owner:ZHEJIANG UNIV

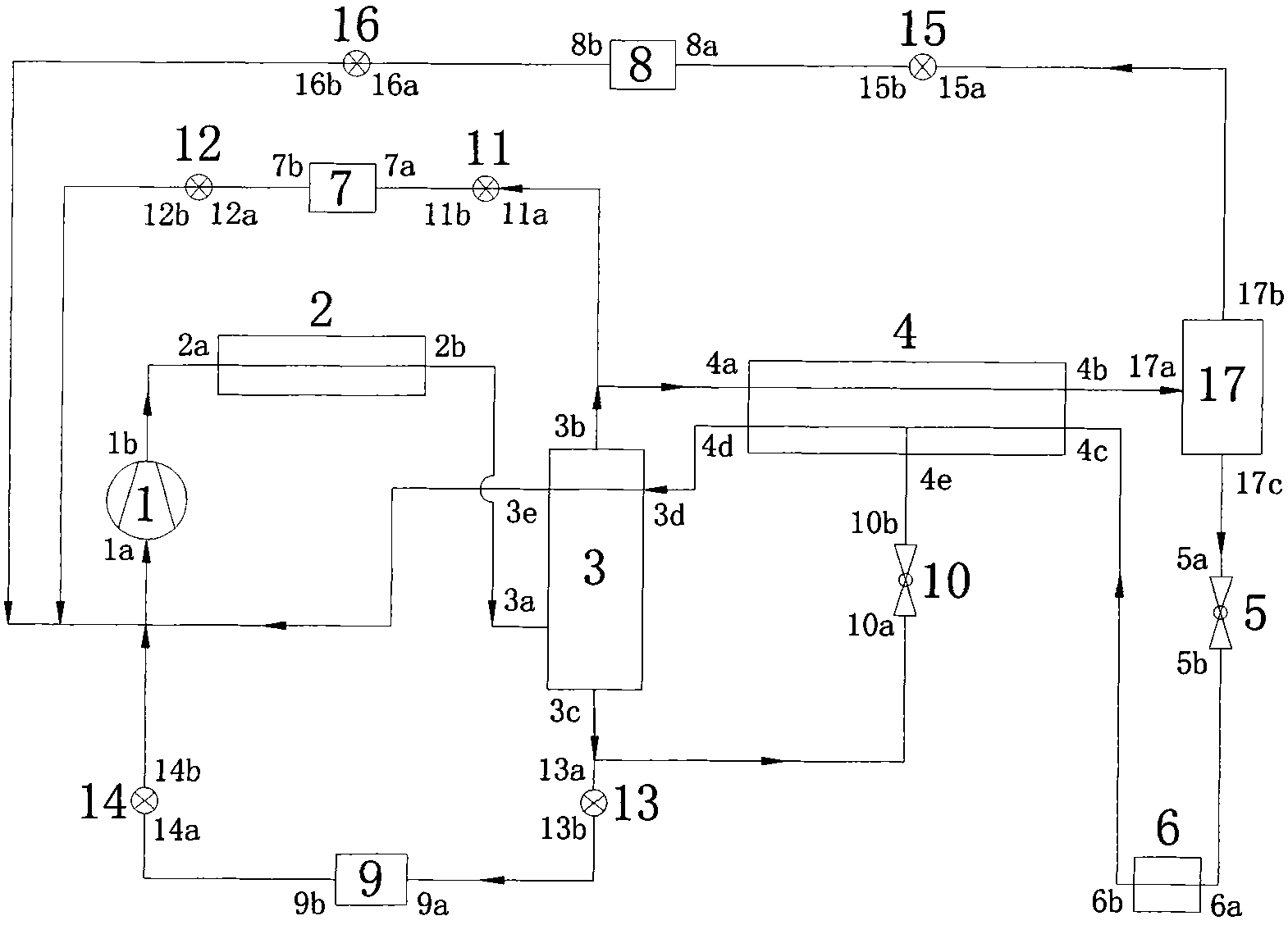

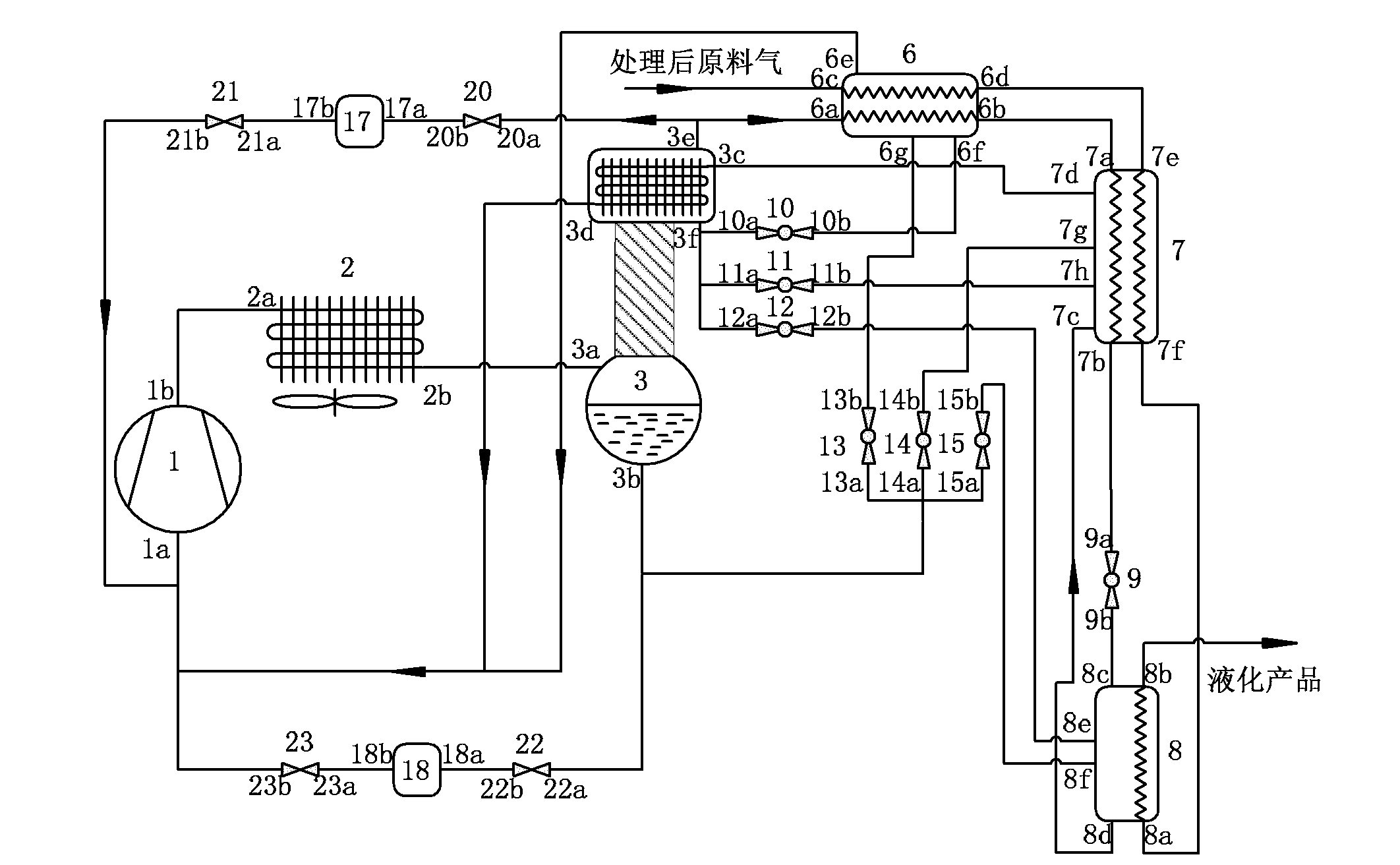

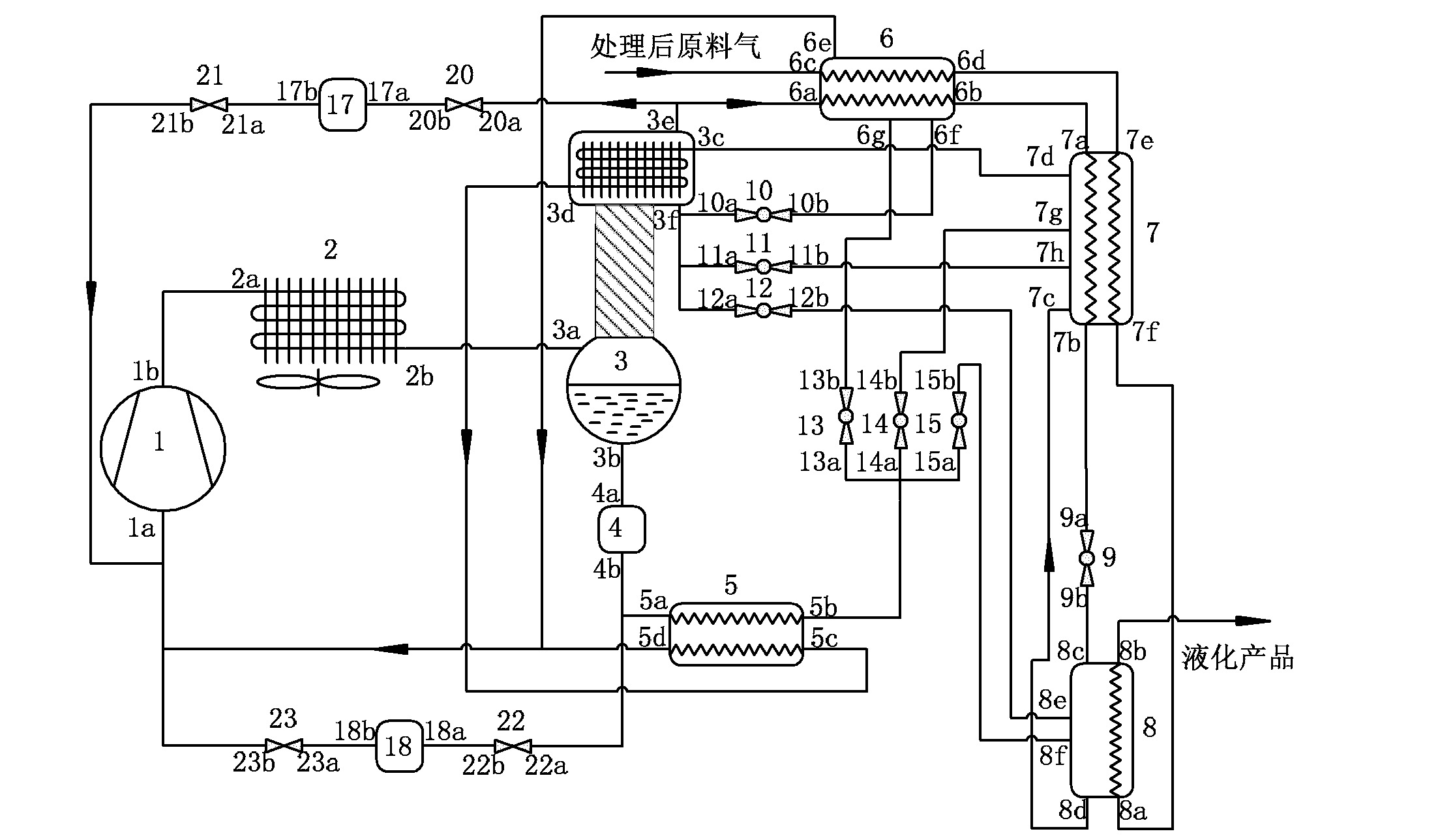

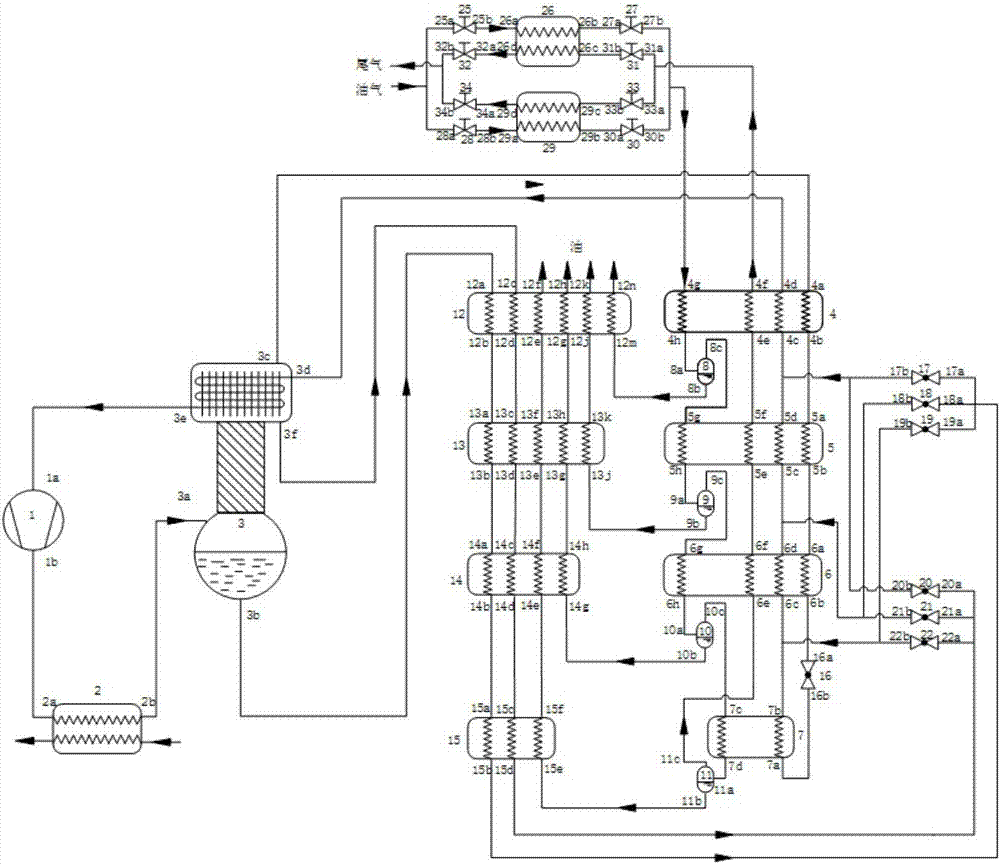

Rectifying type variation-concentration self-overlaying gas liquefaction system

ActiveCN102147162ASmall heat transfer temperature differenceReduce unit liquefaction workCompression machines with non-reversible cycleFluid circulation arrangementProcess engineeringProduct gas

The invention discloses a rectifying type variation-concentration self-overlaying gas liquefaction system which comprises a compressor, a condenser, a rectifying device and a feed gas liquefaction loop, wherein the feed gas liquefaction loop comprises a first heat exchanger group, a second heat exchanger group and a first throttle valve arranged between the first heat exchanger group and the second heat exchanger group; and two parallel arranged first variable concentration loop and second variable concentration loop are arranged between the rectifying device and an air suction hole of the compressor. The rectifying device is used for replacing a multistage separation process of the traditional mixed refrigerant gas liquefaction system, and different components of high-pressure liquids are led from the bottom and the top of the rectifying device and are respectively subjected to pressure reduction and then enter the two heat exchanger groups, water equivalent change of a feed gas cooling and liquefaction process is optimized and matched, and variable working condition regulating capacity of the liquefaction system is improved by adopting the variable concentration loops. The invention has the advantages of simple structure, operation reliability, high system liquefaction efficiency and the like, and is suitable for various small and minitype gas liquefaction systems with high performance requirements on variable working conditions.

Owner:ZHEJIANG UNIV

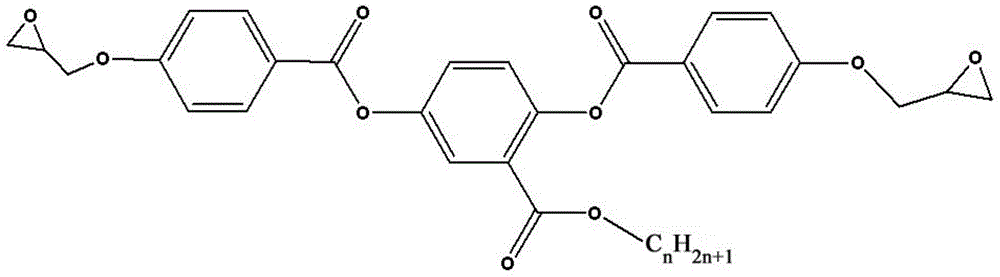

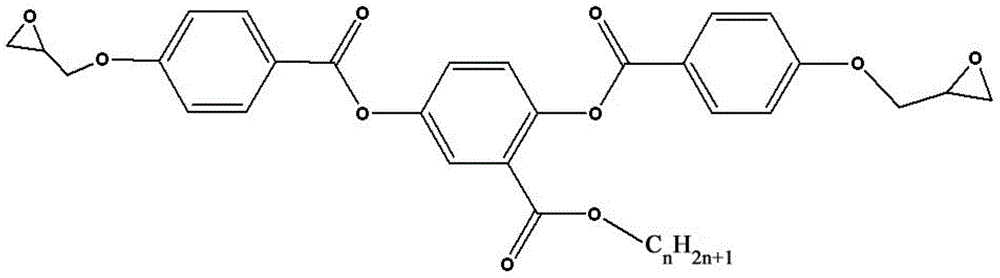

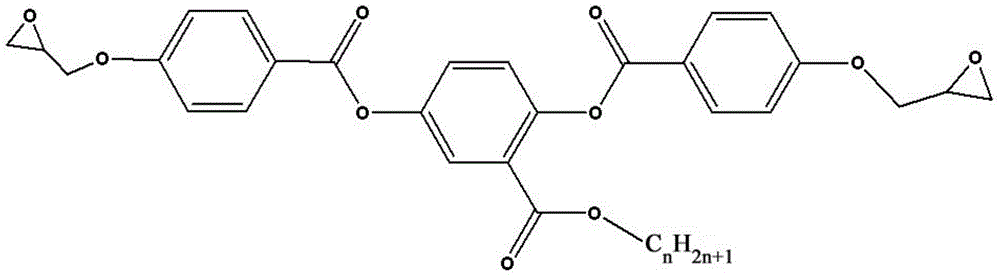

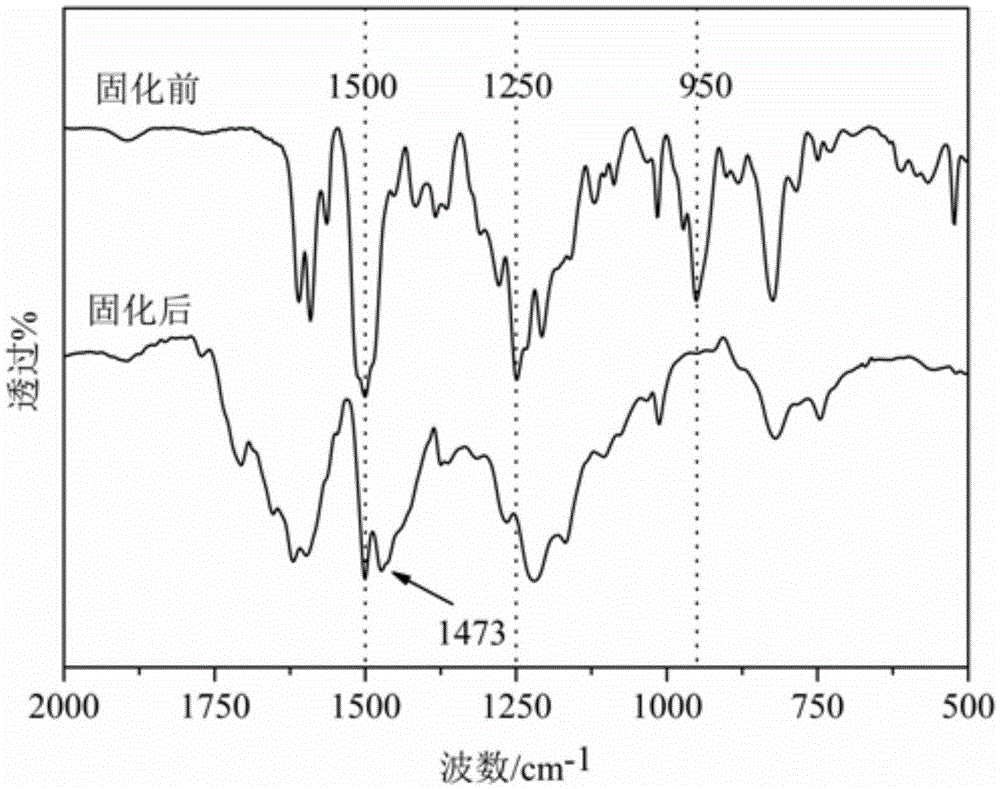

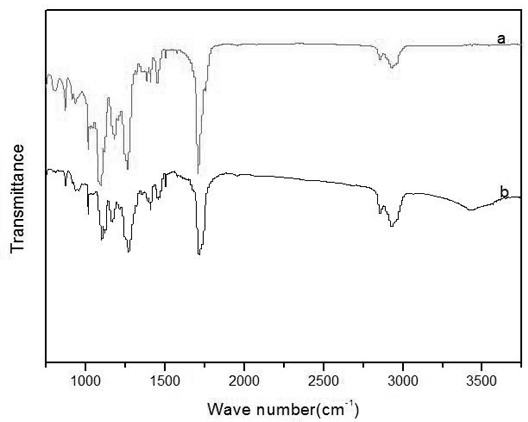

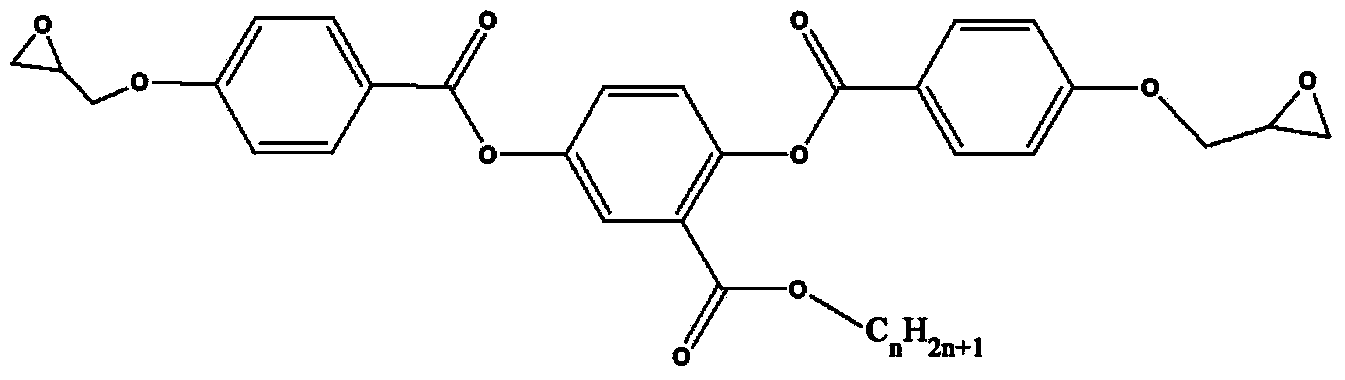

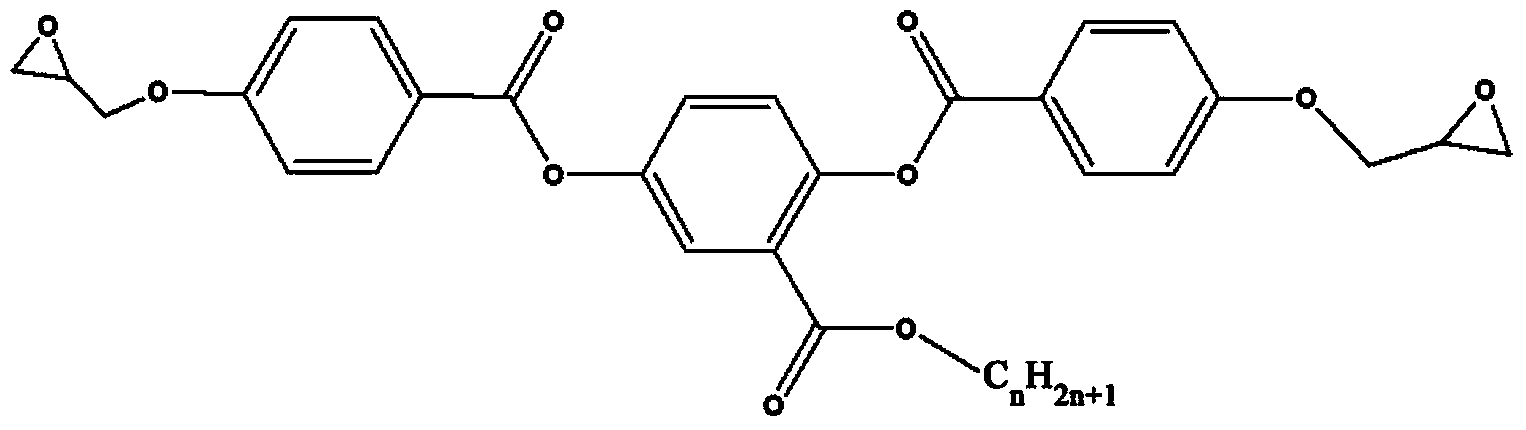

Liquid crystal epoxy resin - carbon fiber composite material and preparation method thereof

The invention belongs to the preparation field of shape memory polymers, specifically discloses a liquid crystal epoxy resin-carbon fiber composite material with shape memory properties and a preparation method thereof. The preparation method of the liquid crystal epoxy resin-carbon fiber composite material comprises three steps: (1) carbon fiber surface treatment; (2) composite material mixture preparation; and (3) curing for forming. According to the preparation method, carbon fiber is used for modifying of liquid crystal epoxy resin with branched chains, the cost can be reduced, and the thermodynamic properties of the material can be improved; and the liquid crystal epoxy resin-carbon fiber composite material prepared by the preparation method has the shape memory property, is high in response rate, is high in recovery stress, and can be applied to the technical field of biomedicine, aerospace and other sciences.

Owner:SICHUAN HUASON ELECTRONICS TECH

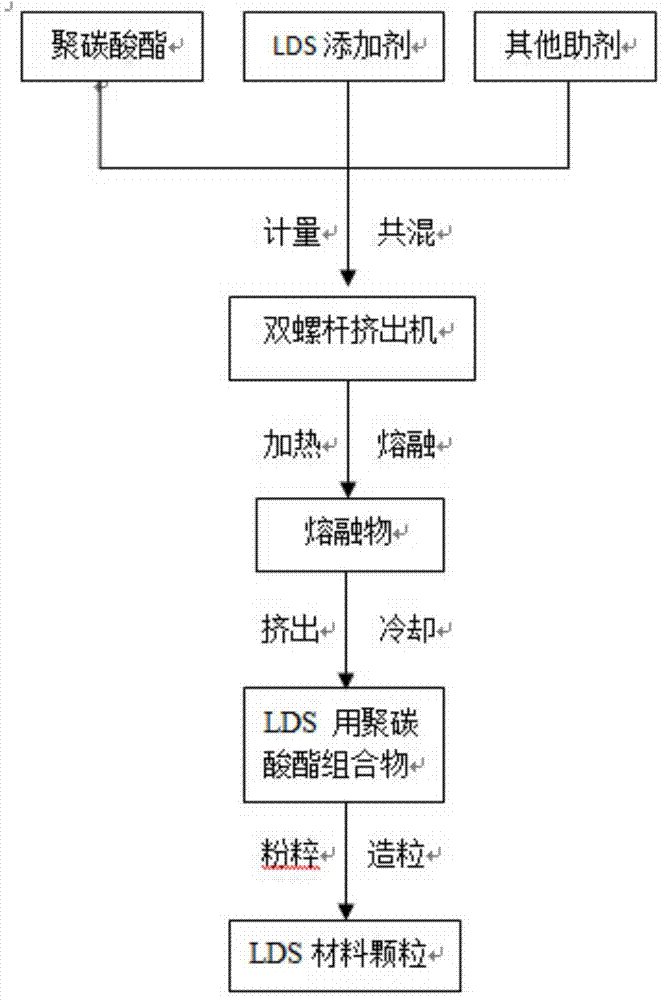

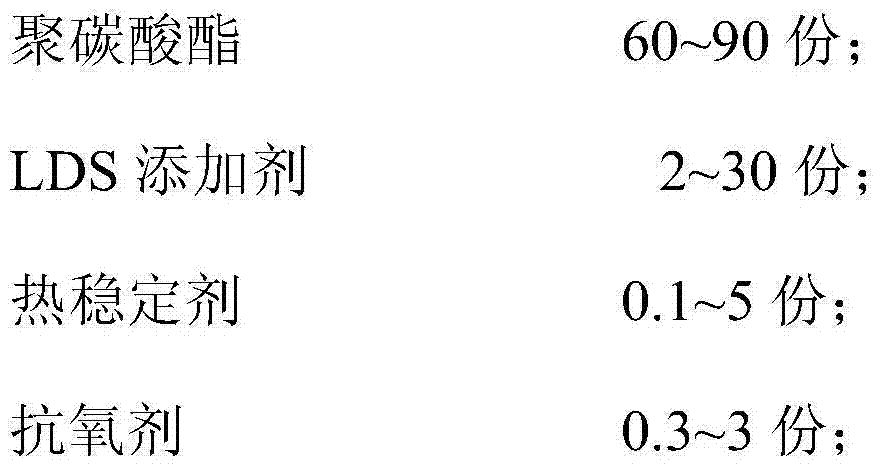

Polycarbonate composition for LDS with good thermal stability

ActiveCN104497535AInhibition of thermal degradationImprove mechanical propertiesChemical platingPhenolic antioxidant

The invention discloses a polycarbonate composition for LDS with good thermal stability. The polycarbonate composition is prepared from the following components in parts by weight: 60-90 parts of polycarbonate, 2-30 parts of an LDS additive, 0.1-5 parts of a heat stabilizer and 0.3-3 parts of an antioxidant, wherein the antioxidant is prepared from a hindered phenolic antioxidant and a phosphite antioxidant, and the heat stabilizer is prepared from a metal compound, layered double-metal hydroxide and an ultraviolet absorbent. According to the polycarbonate composition disclosed by the invention, by virtue of optimization treatment on the content of each component, particularly combination use of the metal compound, the layered double-metal hydroxide and the ultraviolet absorbent and further combination use of the hindered phenolic antioxidant, the phosphite antioxidant and the heat stabilizer, the components take synergistic effect, thermal degradation of the polycarbonate composition for the LDS is greatly inhibited, the mechanical properties and the processability of the polycarbonate composition for the LDS are improved, and meanwhile, the polycarbonate composition for the LDS is capable of resisting precipitation, solvent extraction and salinization without influencing chemical plating in the formation process.

Owner:SHENZHEN HALCYON NEW MATERIALS

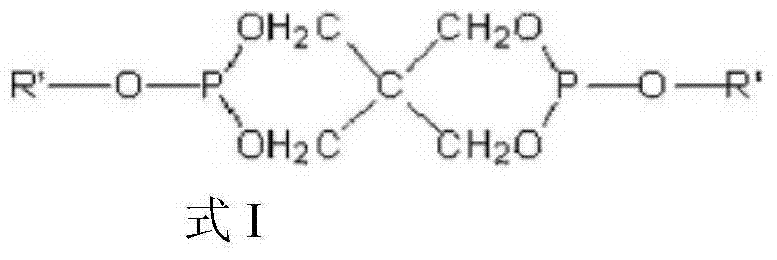

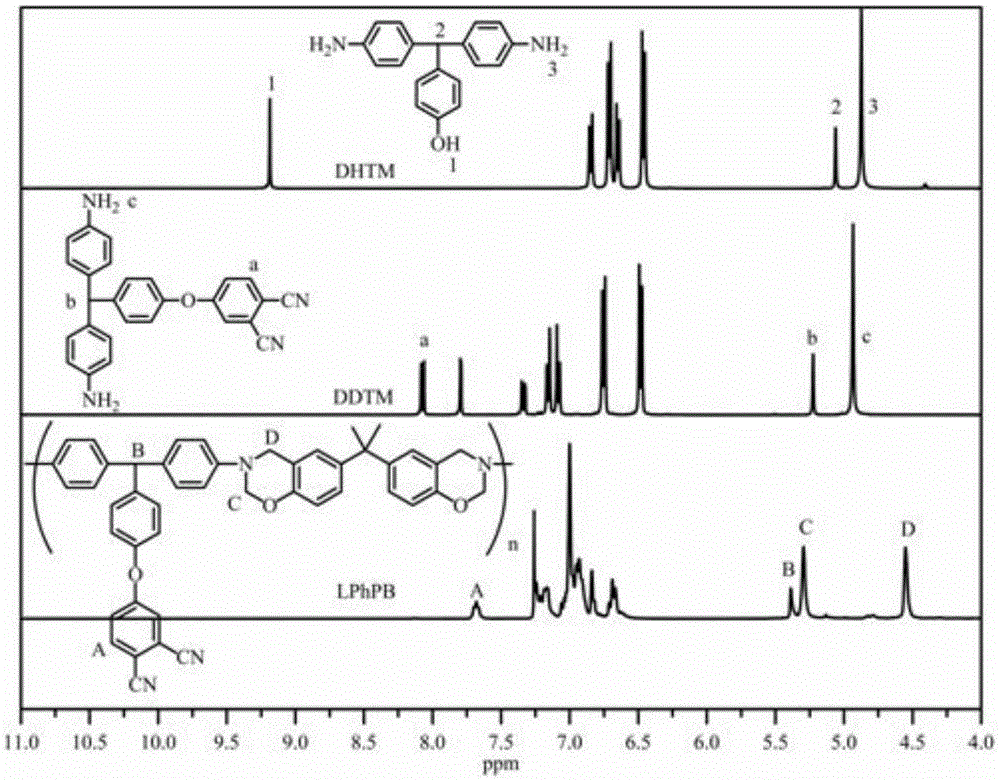

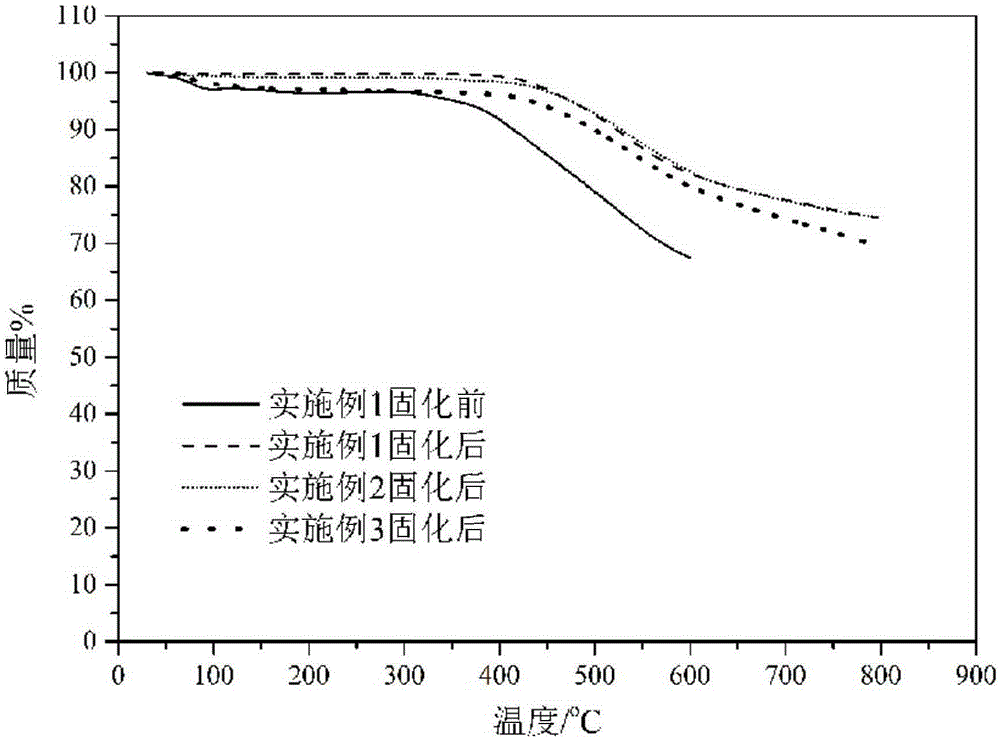

Side-chain phthalonitrile modified benzoxazine resin, preparation method and application

InactiveCN105254879AImprove thermodynamic performanceImprove flame retardant performanceChemical reactionSide chain

The invention belongs to the field of benzoxazine resin in polymer synthetic materials and discloses side-chain phthalonitrile modified benzoxazine resin, a preparation method and an application. The resin has a general structural formula shown in a formula I, wherein n is an integer larger than or equal to 1. By means of the characteristic of strong molecular structure design of a benzoxazine monomer, a polymerizable phthalonitrile group is introduced into an aromatic diamine compound through a conventional chemical reaction, then the aromatic diamine compound carrying the phthalonitrile group, paraformaldehyde and bisphenol A have condensation polymerization, and the side-chain phthalonitrile modified benzoxazine resin is prepared. Phthalonitrile which is a polymerizable group is introduced into benzoxazine, so that phthalonitrile can participate in curing, the crosslinking density of polybenzoxazine resin can be further increased, and the thermal stability of polybenzoxazine can be further improved. The preparation method is simple and convenient, a synthesis period is short, the yield is high, and raw materials are easy to obtain.

Owner:国科广化(南雄)新材料研究院有限公司 +1

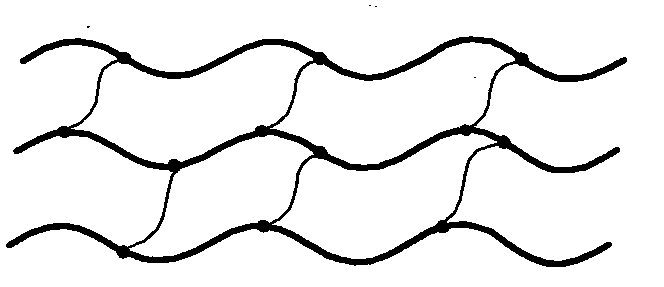

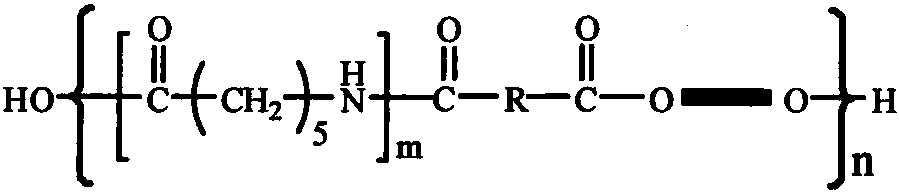

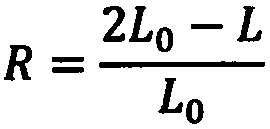

PA6-serial thermoplastic elastomer with high resilience and preparation method thereof

The invention provides a PA6-serial thermoplastic elastomer with high resilience and a preparation method thereof. The preparation method is characterized by comprising preparing a double terminated-carboxyl PA6 prepolymer through a hydrolysis ring-opening polymerization process, then adding a dibasic alcohol for esterification reaction, and finally adding polyglycol and a crosslinking agent for areaction, so as to prepare the PA6-serial thermoplastic elastomer with high resilience. With introduction of a proper amount of chemical crosslinking sites into the elastomer, the PA6-serial thermoplastic elastomer has excellent resilience while guaranteeing relatively high elongation. The PA6-serial thermoplastic elastomer disclosed by the invention is high in intrinsic viscosity, good in chainregularity, excellent in resilience (the resilience is 95% or more when the enlogation is 100%) and adjustable in Shore hardness. In addition, the caprolactam conversion rate is high and the reactionspeed is fast during elastomer synthesis, and disadvantages of the prior art are made up.

Owner:DONGHUA UNIV

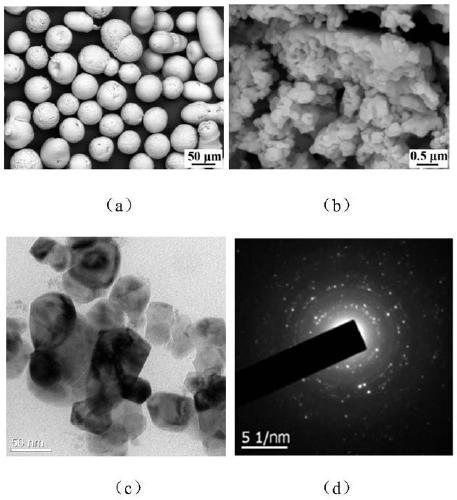

Self-reinforced multi-mode nano-structured thermal barrier coating with stable phase and preparation method thereof

The invention discloses a self-reinforced multi-mode nano-structured thermal barrier coating with a stable phase and a preparation method thereof. By adopting a supersonic plasma spraying method, alloy powder is sprayed on a substrate to form a bonding layer, and then nano-structured yttria-stabilized zirconia spherical particle aggregates are sprayed on the bonding layer to form the coating. Theprocess parameters of the supersonic plasma spraying method are that arc current is 300-550 A, arc voltage is 110-150 V, main air flow is 120-155 slpm, secondary air flow is 10-40 slpm, the spraying distance is 90-110 millimeters, and the powder feeding amount is 30-50 g / min. A nanocrystalline region (30-90 nanometers), a submicron crystalline region (110-900 nanometers), an unfused nano-region (20-60 nanometers), and a multi-mode nano-structured thermal barrier coating body composed of a semi-melted region and an amorphous region are present inside the coating. The coating has high phase stability and a self-reinforced property.

Owner:XI AN JIAOTONG UNIV

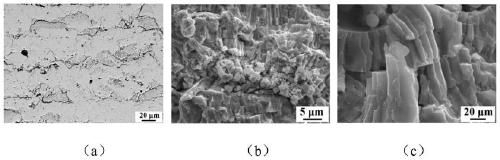

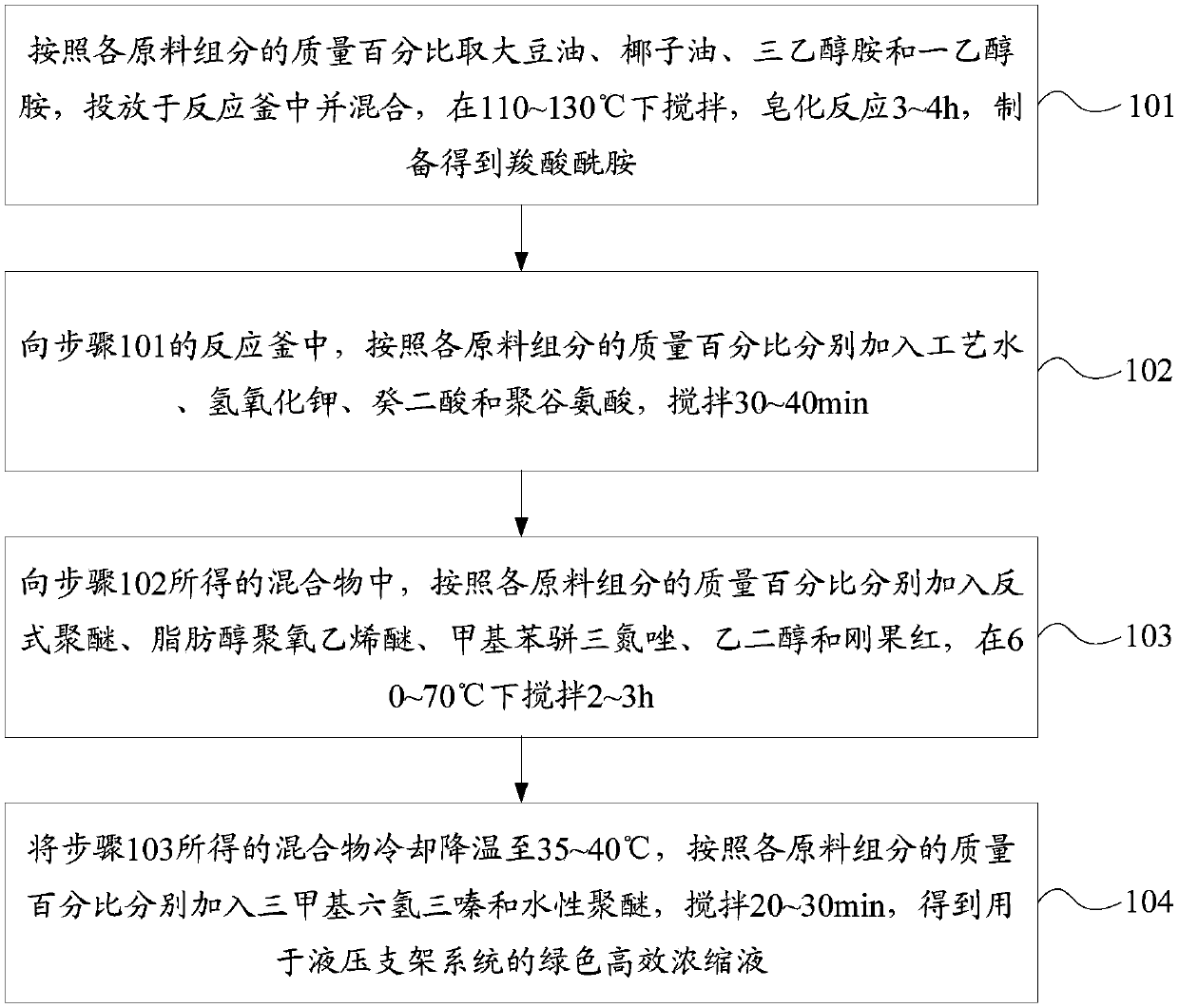

Green and efficient concentrated solution for hydraulic support system and preparation method of green and efficient concentrated solution

ActiveCN107557132AFully biodegradableGood corrosion inhibitionLubricant compositionPotassium hydroxideCarboxylic acid

The invention provides a green and efficient concentrated solution for a hydraulic support system and a preparation method of the green and efficient concentrated solution. The concentrated solution is prepared from components in percentage by mass as follows: 5%-8% of soybean oil, 3%-5% of coconut oil, 4%-6% of potassium hydroxide, 2%-3% of trans-polyether, 7%-10% of polyglutamic acid, 10%-12% ofsebacic acid, 1%-2% of fatty alcohol polyoxyethylene ether, 6%-10% of triethanolamine, 2%-4% of monoethanolamine, 10% of glycol, 0.1%-0.3% of methylbenzotriazole, 1%-2% of trimethyl hexahydrotriazine, 0.1%-0.3% aqueous polyether, 0.01%-0.02% of Congo red and the balance of reagent process water. The concentrated solution is obtained through multiple steps as follows: carboxylic acid amide is prepared from the soybean oil, the coconut oil, triethanolamine and monoethanolamine through a saponification reaction, and methylbenzotriazole, the sebacic acid and carboxylic acid amide are compounded with a metal sustained release agent.

Owner:CCTEG CHINA COAL RES INST

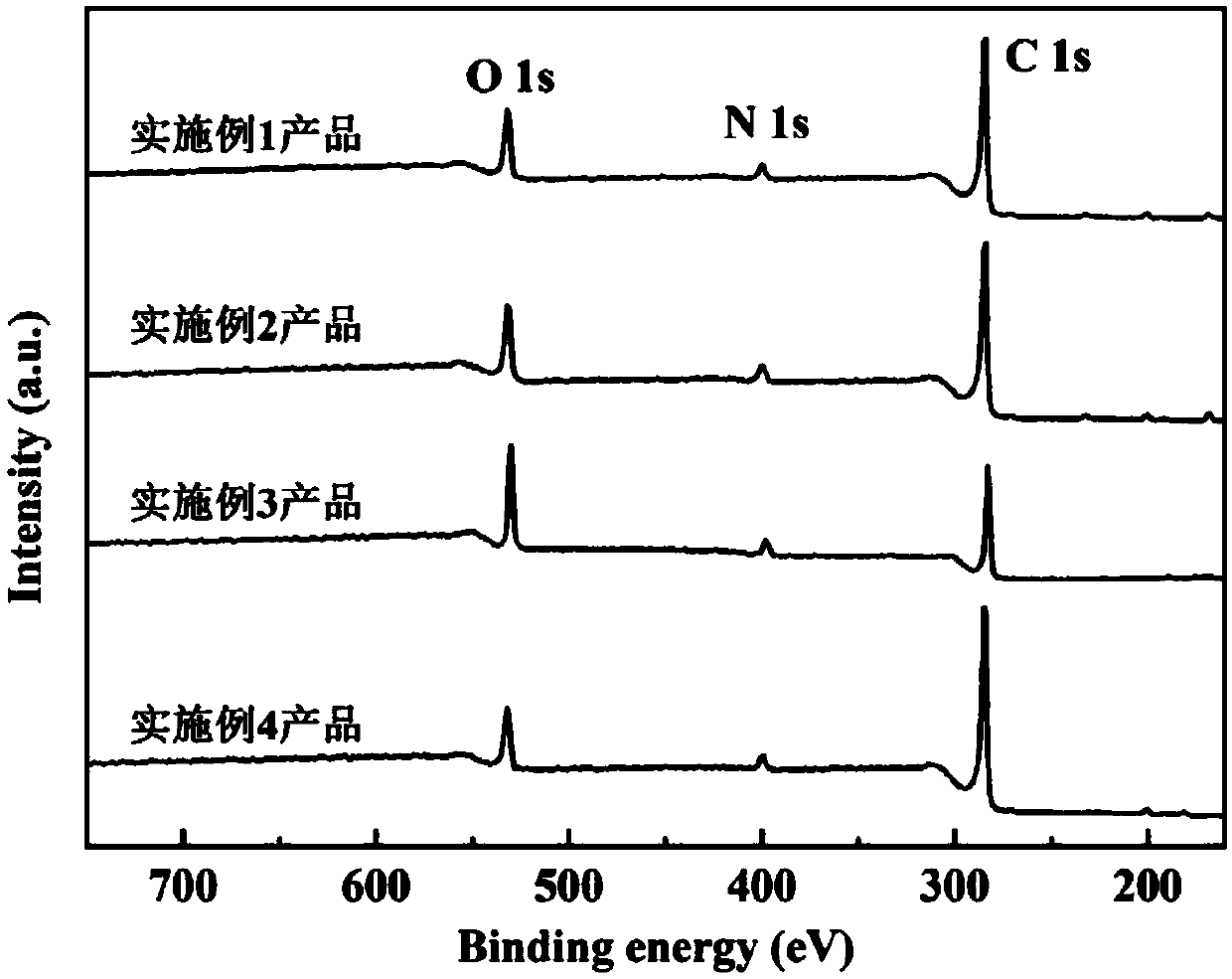

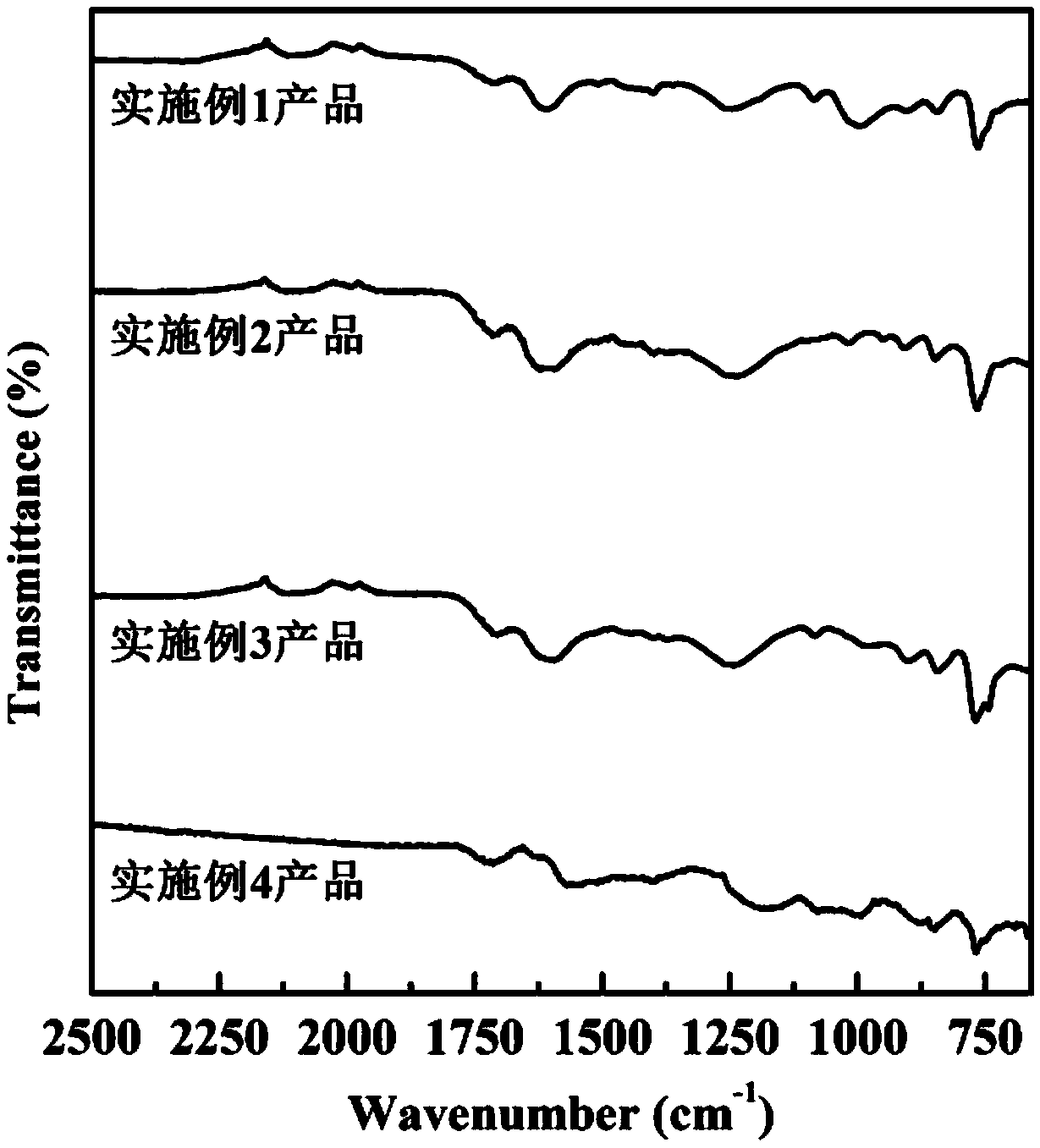

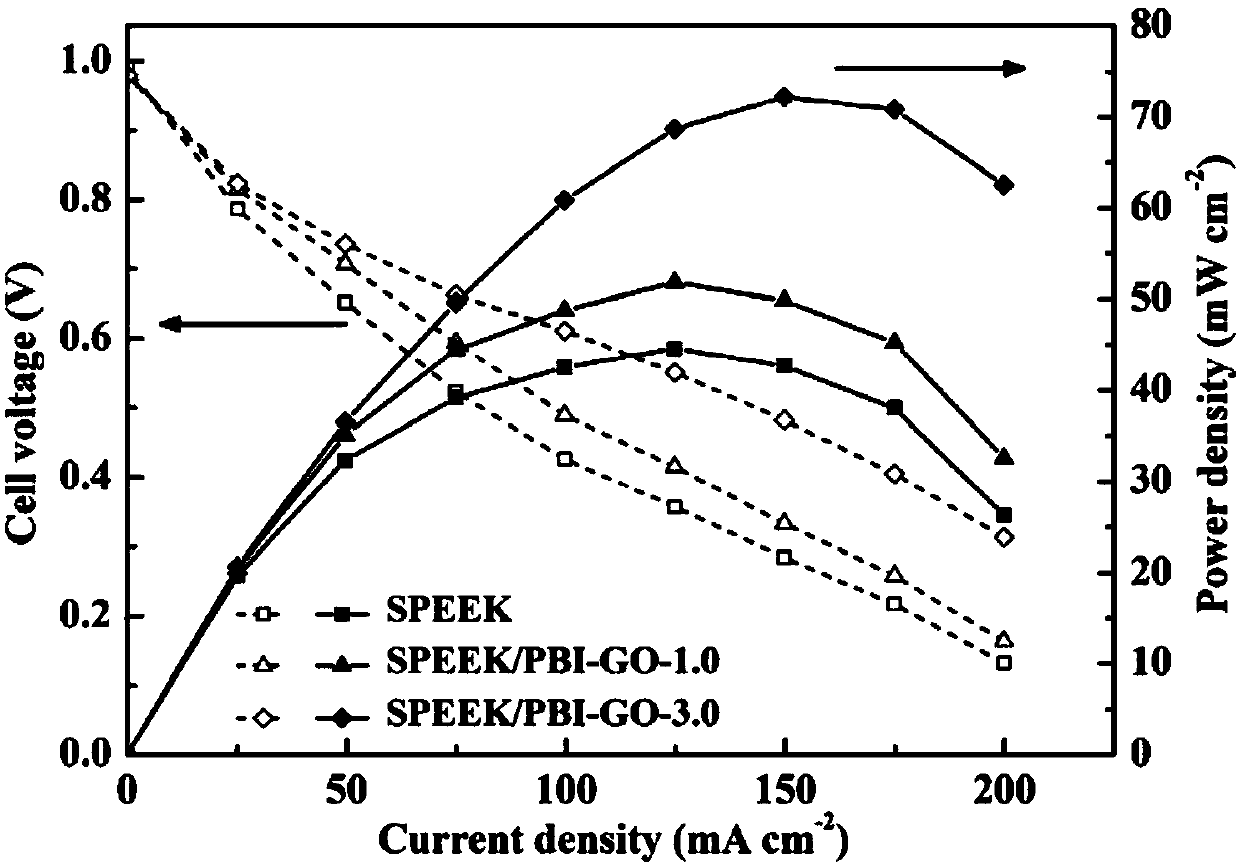

Polybenzimidazole and its derivative functional graphene oxide

InactiveCN107619046AGood chemical stabilityImprove thermodynamic performanceCarbon compoundsFuel cellsNitrogen gasMechanical property

The invention discloses a polybenzimidazole and its derivative functional graphene oxide. The derivative functional graphene oxide is prepared by grafting polybenzimidazole and its derivative to the surface of the graphene oxide; adding inorganic monomer in graphene oxide suspension liquid; stirring dispersedly and evenly; adding dehydration cyclizing agent, and reacting under 150-200 DEG C. The functional graphene oxide is high in nitrogen element content and mass in benzimidazole functional groups; the functional graphene oxide shows good dispersibility and keeps excellent compatiability with organic polymer materials. After adding the polybenzimidazole and its derivative functional graphene oxide to SPEEK as the nanofiller; effective acid-alkali interaction can be formed between the imidazole group at the graphene surface and the sulfonic acid group in SPEEK, so that the conductivity, the mechanical performance and dimension stability of a nanometer composite proton exchange membrane are improved; in the post application, the polybenzimidazole and its derivative functional graphene oxide can improve the high temperature performance of the fuel cell.

Owner:NANJING UNIV OF SCI & TECH

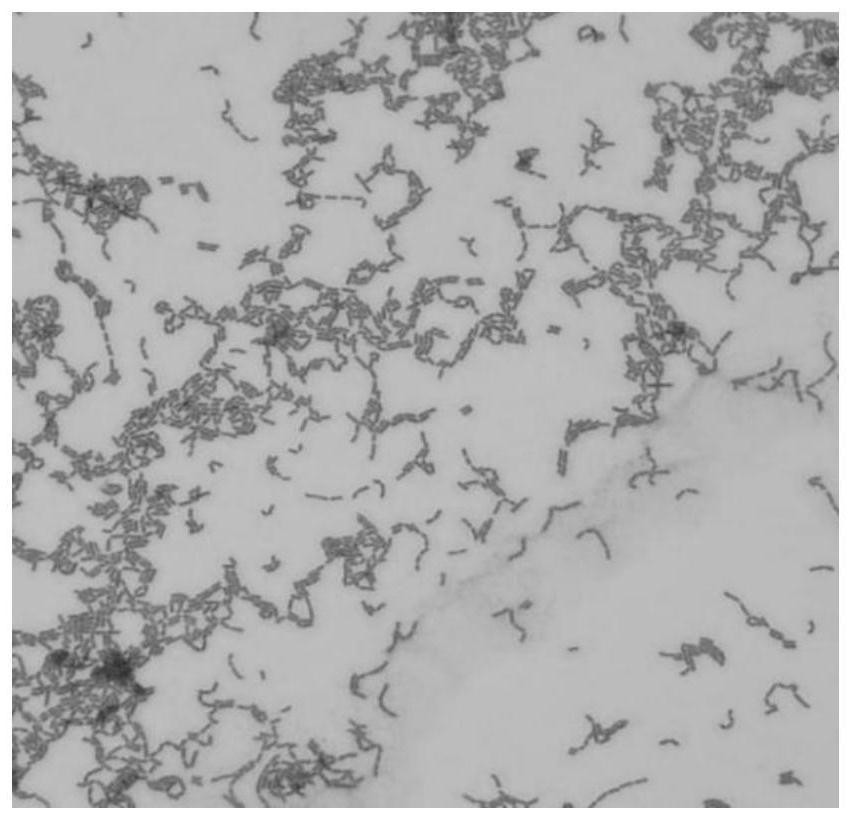

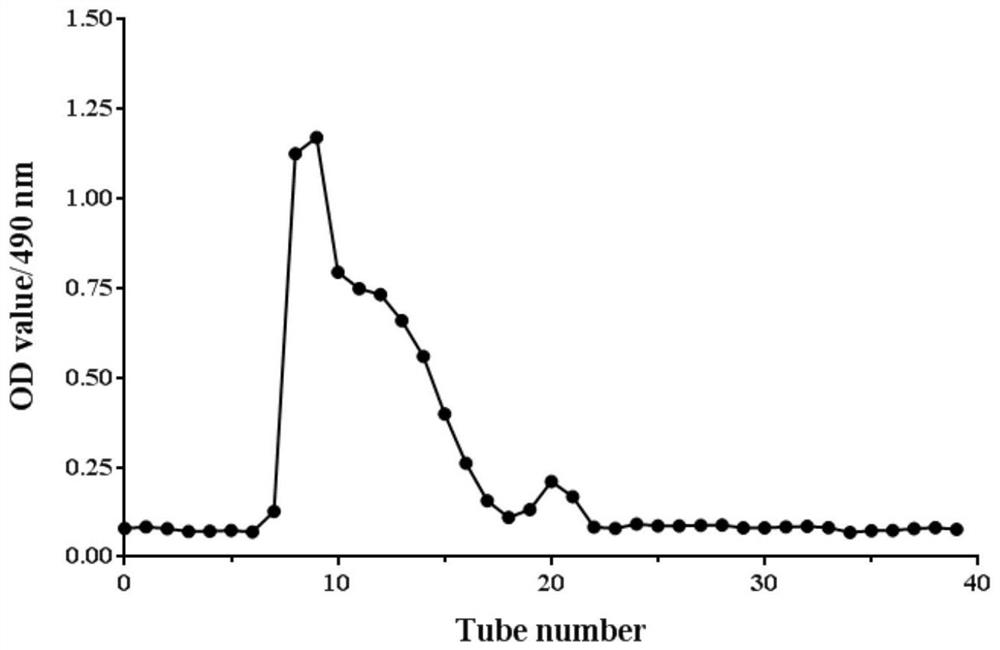

Lactobacillus rhamnosus exopolysaccharide, and preparation method and application thereof

InactiveCN112662717AGood hypoglycemic activityWide variety of sourcesOrganic active ingredientsBacteriaBiotechnologyLactobacillus rhamnosus

The invention discloses a lactobacillus rhamnosus exopolysaccharide, and a preparation method and application thereof, and belongs to the technical field of microorganisms. According to the invention, a lactobacillus rhamnosus strain separated from Xiangshuangpao yoghurt is used as an original strain to produce exopolysaccharide, the exopolysaccharide is a uniform component, and the molecular weight of the exopolysaccharide is 88650 Da; and the lactobacillus rhamnosus exopolysaccharide comprises mannose, glucuronic acid, glucose, xylose, galactose and arabinose. The exopolysaccharide has a good in-vitro hypoglycemic effect, has good in-vitro alpha-glucosidase inhibition capacity through detection, and is simple in process, wide in market prospect, stable in thermodynamic property and suitable for large-scale production. Therefore, the polysaccharide is a potential active ingredient for preventing and treating diabetes mellitus. Besides, as a fermentation product of probiotics, compared with common chemical medicines in the field of blood sugar reduction, the fermentation product has the advantages of simple and easily available active ingredients, low price, no side effect and the like, and has great application value.

Owner:SOUTH CHINA UNIV OF TECH

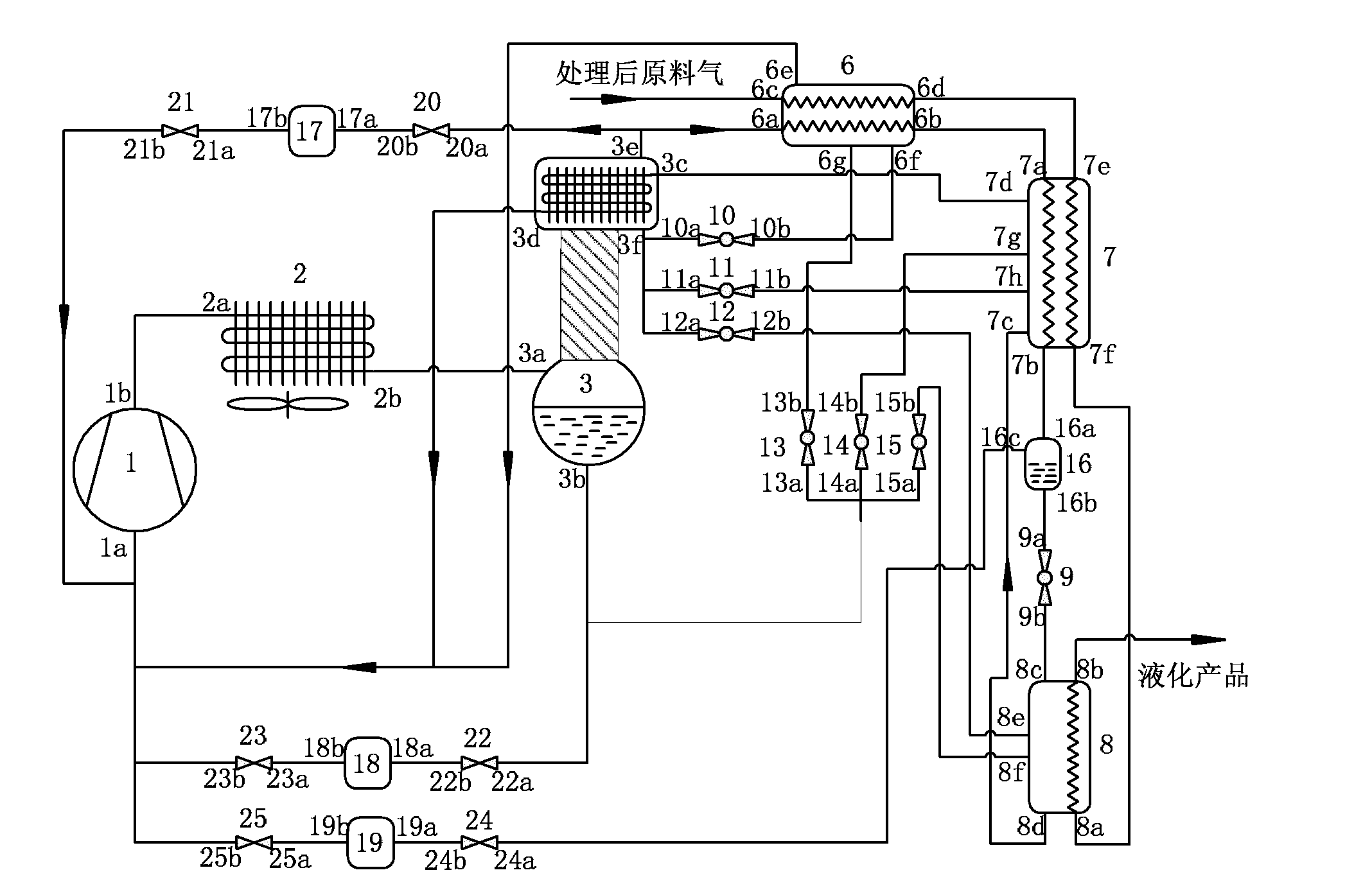

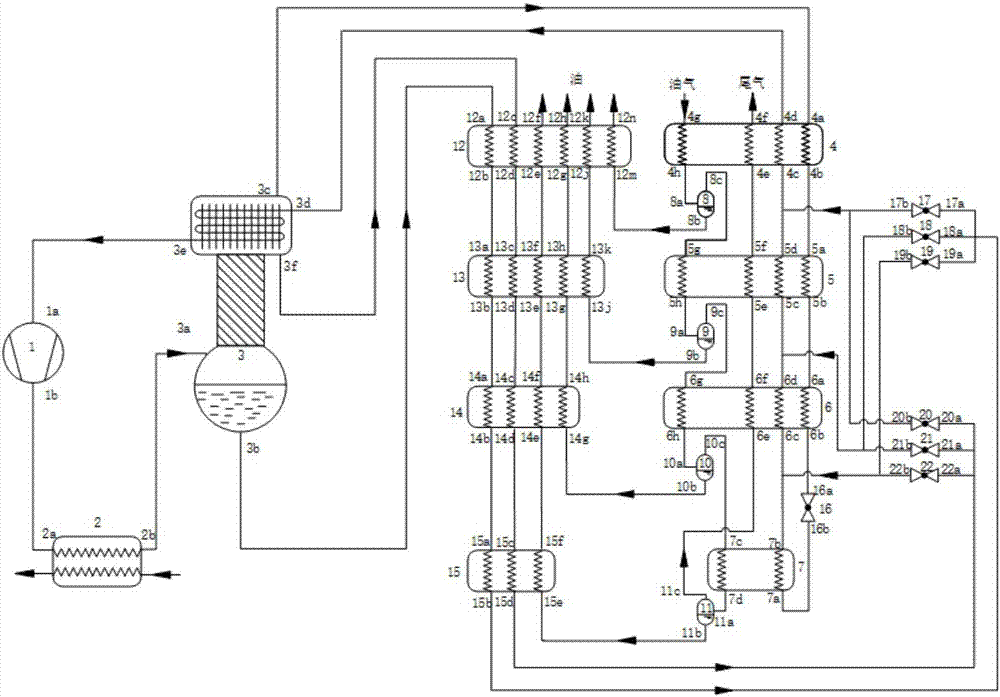

Rectification type auto-cascade low-temperature condensation oil-gas separation system with cooling capacity recovery

The invention discloses a rectification type auto-cascade low-temperature condensation oil-gas separation system with cooling capacity recovery. The system comprises a compressor, a condenser, a rectification device and an oil-gas condensation separation and cooling capacity recovery loop, wherein the oil-gas condensation separation and cooling capacity recovery loop comprises a first heat exchanger unit, a second heat exchanger unit, a third heat exchanger unit, a first restricting element and a separator unit. According to the system, the rectification device is adopted to replace multi-stage separation process of a conventional mixed working medium auto-cascade oil-gas separation system, meanwhile high-pressure liquid refrigerants of different components are respectively led out from the bottom and the top of the rectification device, condensed oil is precooled, is respectively depressurized, is fed into the first heat exchanger unit and is optimized to be matched with water equivalent weight variations of oil gases of different components in the cooling process. The system has the advantages of being simple in structure, reliable in operation, good in energy conservation and the like, and is particularly applicable to treatment on volatile oil gases in places such as oil depots, petrol stations and chemical treatment plants.

Owner:ZHEJIANG UNIV +1

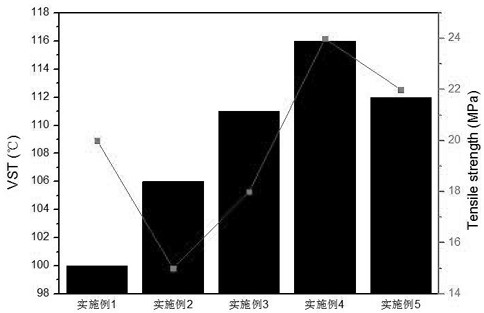

Preparation method of degradable heat-resistant copolyester

ActiveCN112280013AImprove thermodynamic performanceImprove mechanical propertiesBio-packagingPolymer sciencePtru catalyst

The invention relates to the field of high polymer material synthesis, in particular to a preparation method of degradable heat-resistant copolyester. The method comprises the following steps: addingterephthalic acid, sebacic acid, 1, 4-butanediol and an esterification catalyst into a reaction kettle for esterification reaction, entering a polycondensation stage after the reaction reaches an esterification end point, adding the polycondensation catalyst, heating while reducing the vacuum degree of a system, reacting until the torque of a motor does not rise to the polycondensation end point,stopping the vacuum of the system, and blowing nitrogen for cooling, then adding polylactic acid, melting, then starting to dropwise add a chain extender hexamethylene diisocyanate, and carrying out chain extension to the maximum value of the motor torque, thus obtaining the block degradable heat-resistant copolyester PBSeT-HDI-PLA. According to the invention, PBSeT is used as a matrix, and the heat resistance of a sample is controllably adjusted by changing the mass ratio of PBSeT to PLA and the content of a chain extender. While the biodegradability is ensured, the thermodynamic property ofthe product is improved, and the mechanical strength of the product is high. The vicat softening point is increased by 16 DEG C compared with the vicat softening point before modification, and the heat resistance is greatly improved.

Owner:ZHONGBEI UNIV

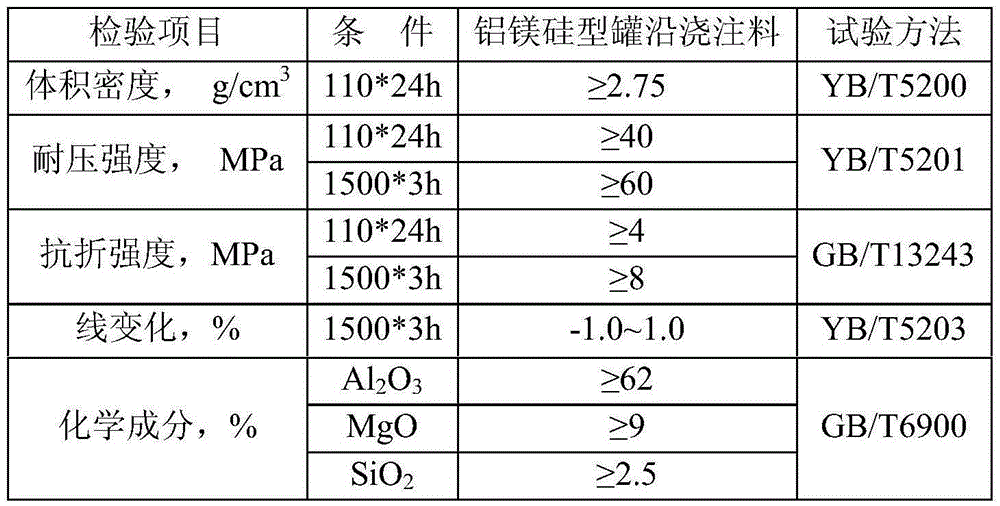

Al-Mg-Si type tank edge casting material and preparation method and application thereof

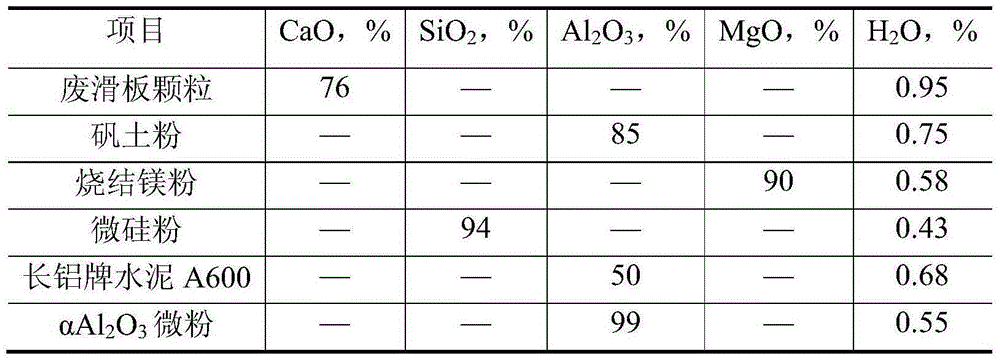

The invention belongs to the technical field of a steelmaking ladle refractory material, and in particular to an Al-Mg-Si type tank edge casting material and a preparation method and application thereof. The Al-Mg-Si type tank edge casting material is provided for a ladle tank edge and is prepared from the following raw materials in percent by weight; 20-25% of waste sliding plate particles with the grain size being 3-8mm, 45-50% of waste sliding plate particles with the grain size being 0.088-3mm, 5-8% of calcined bauxite in powder, 9-12% of sintering magnesium powder, 3-7% of cement, 3-5% of micro silicon powder, 5-7% of alpha-Al2O3 micropowder, 0.2-0.3% of sodium hexametaphosphate and 0.015-0.02% of anti-explosion fiber. The steel ladle tank edge filled with the Al-Mg-Si type tank edge casting material is tighter, high in intensity and stable in thermal performance, and the problems of poor application property, cracking, low intensity, poor thermal stability, difficulty in the processing of tank edge-adhered slags of the ladle tank edge can be effectively solved.

Owner:GANGCHENG GRP LIANGSHAN RUIHAI IND

Protein Surface Remodeling

ActiveUS20100209994A1Improve thermal stabilityMore to aggregationSugar derivativesTransferasesProtein formationProtein surface

Aggregation is a major cause of the misbehavior of proteins. A system for modifying a protein to create a more stable variant is provided. The method involves identifying non-conserved hydrophobic amino acid residues on the surface of a protein, suitable for mutating to more hydrophilic residues (e.g., charged amino acids). Any number of residues on the surface may be changed to create a variant that is more soluble, resistant to aggregation, has a greater ability to re-fold, and / or is more stable under a variety of conditions. The invention also provides GFP, streptavidin, and GST variants with an increased theoretical net charge created by the inventive technology. Kits are also provided for carrying out such modifications on any protein of interest.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

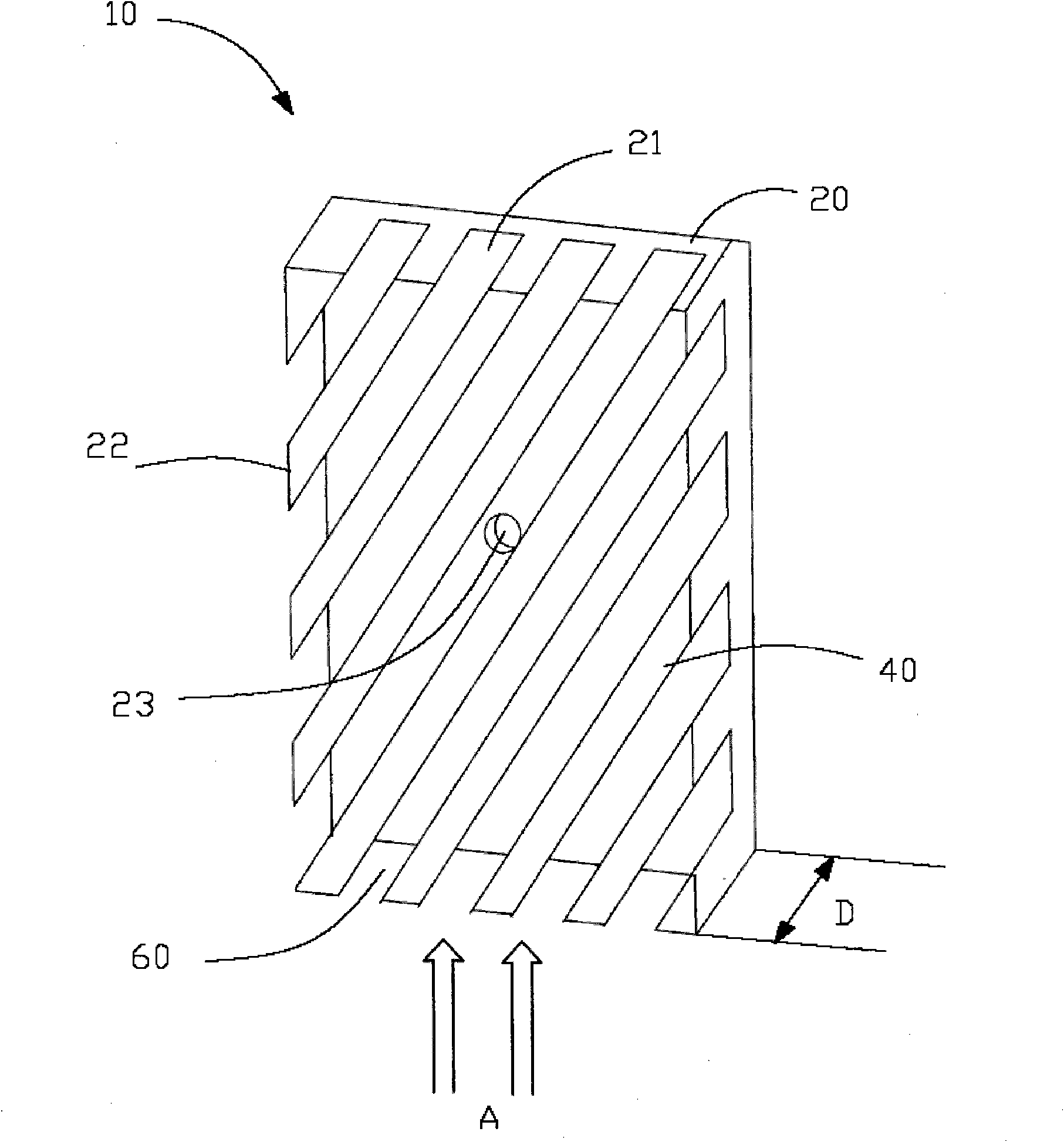

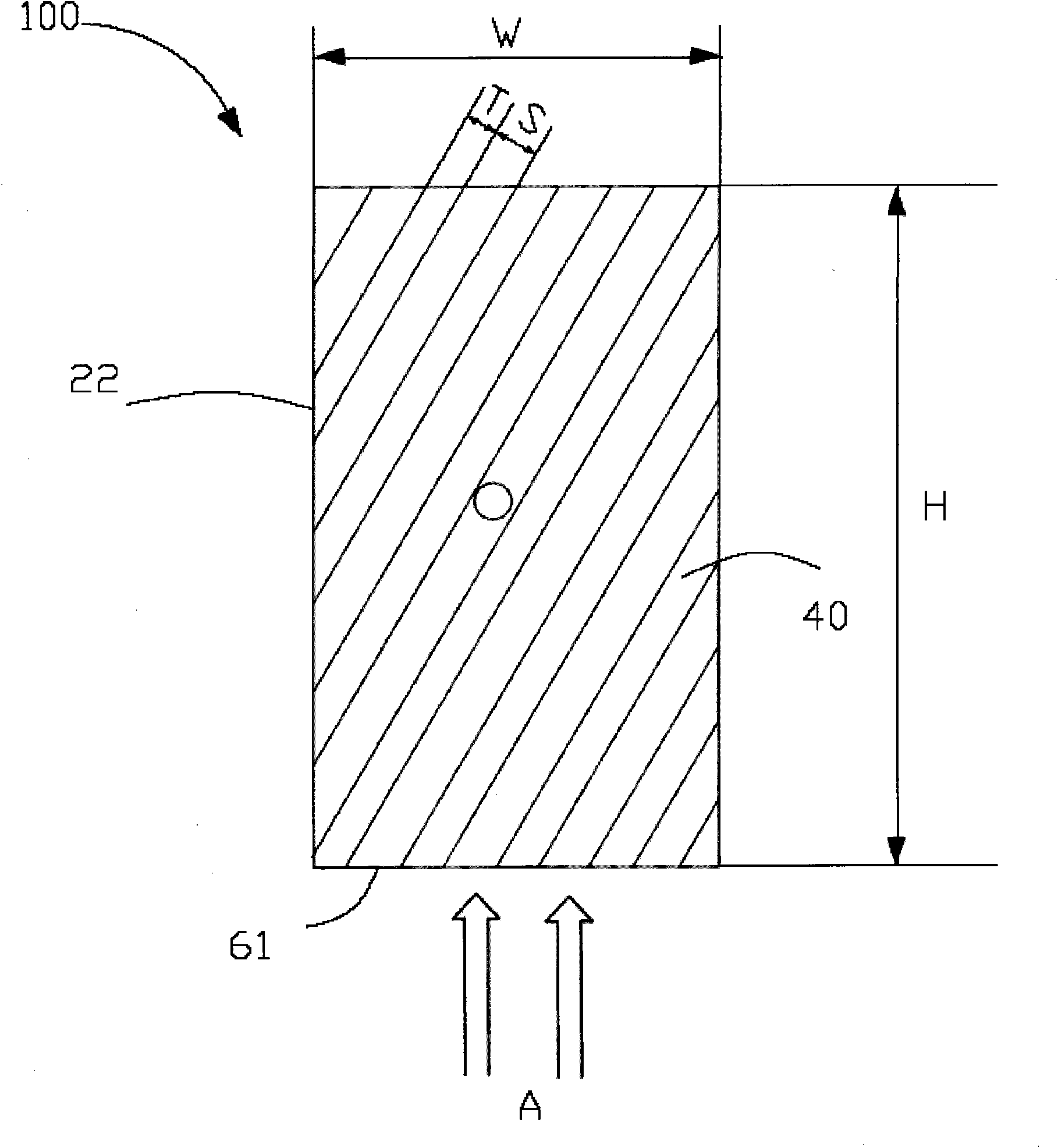

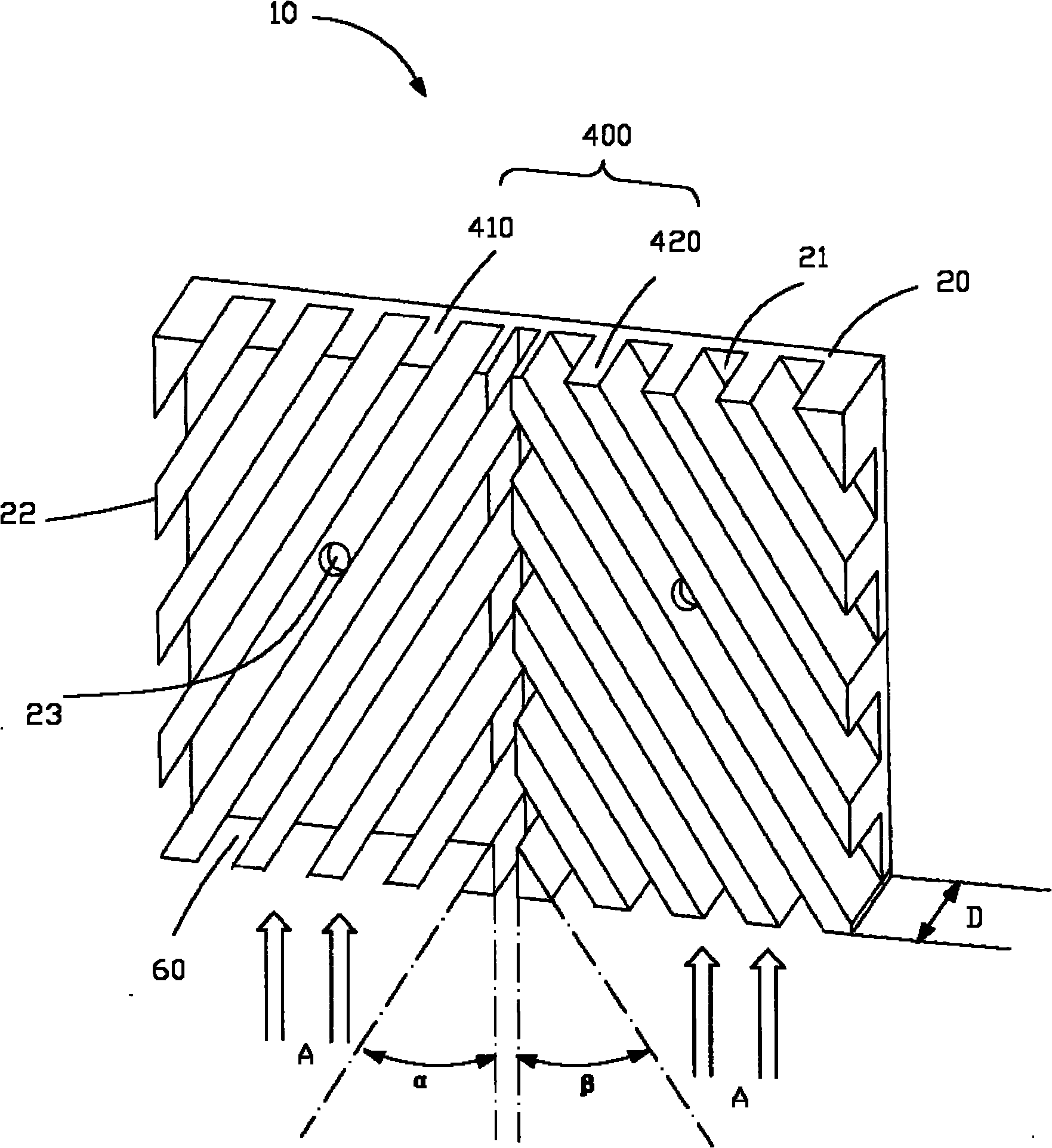

Heat sink

InactiveCN101855722AImprove cooling efficiencyImprove thermodynamic performanceDigital data processing detailsSemiconductor/solid-state device detailsHeat flowEngineering

A heat sink (10, 100) for dissipating heat from an electrical device comprises a base (20) having a generally flat top surface (21); a plurality of fins (40, 400) arranged on the top surface (21) of the base (20) such that a running direction of the fins (40, 400) is oblique to an in-flow (A) of heat flow; and a plurality of channels (60) defined between each two adjacent fins (40, 400).

Owner:ABB TECH AG

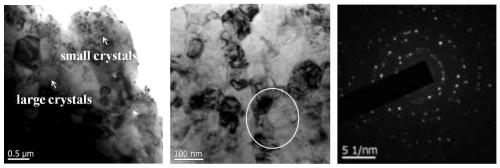

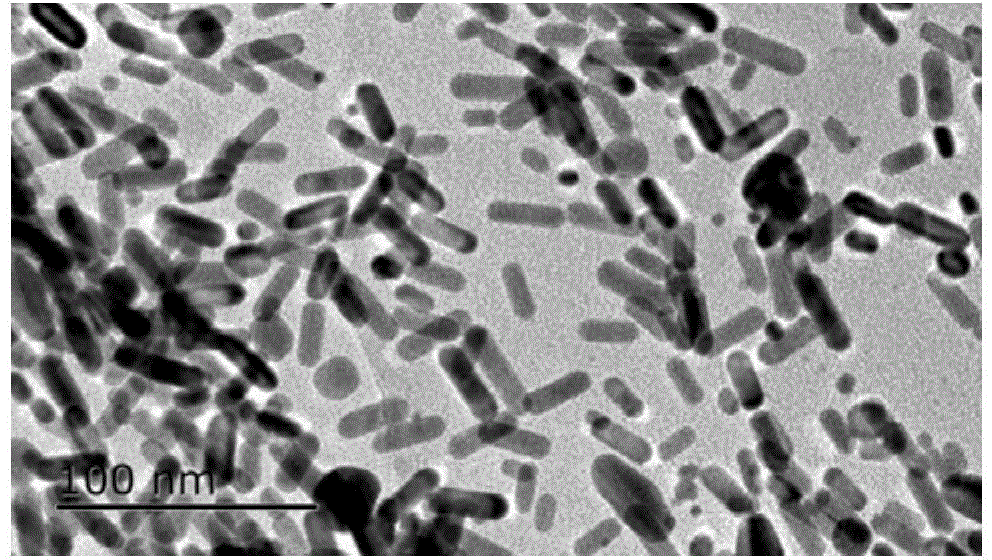

High-density and long-life data storage disk and preparation method thereof

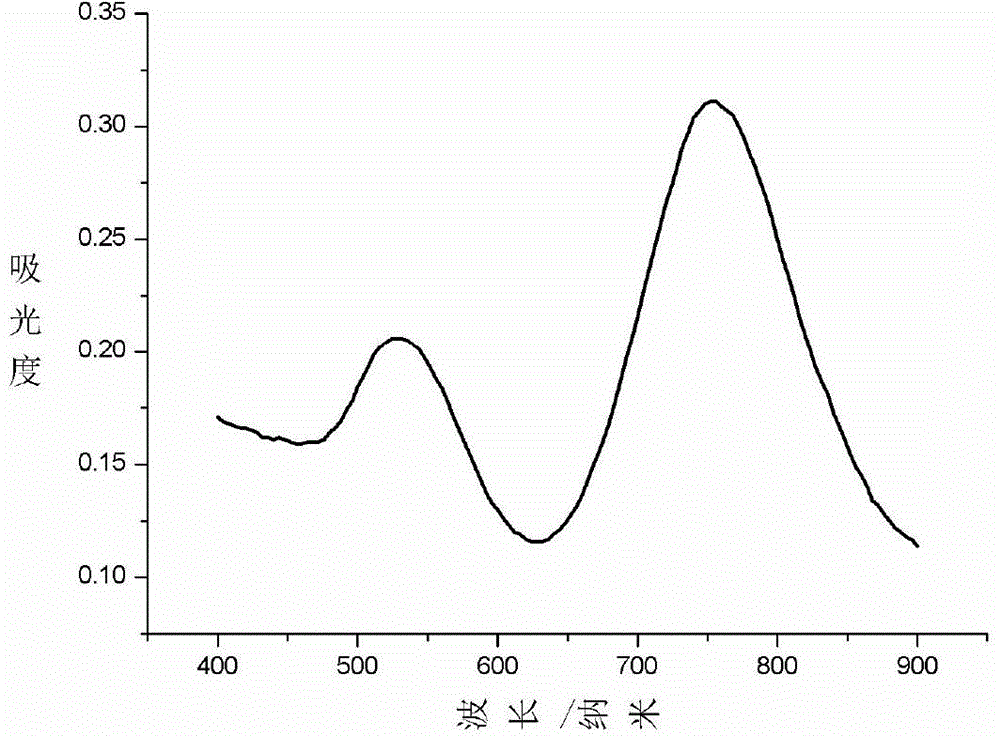

InactiveCN104700852AAddressing Chemical StabilityAchieve preservationRecord information storageOptical record carrier manufactureGold nanorodHigh density

The invention belongs to the technical field of optical information storage. A high-density and long-life data storage disk is characterized in that the surface of a glass substrate is covered with a thin film made from hybrid materials or the internal surface of a flat-bottom container is covered with a plate sample made from the hybrid materials; and high-density gold nanorods are dispersed in the hybrid materials. The data storage disk prepared by the method is stable in thermodynamic property and capable of storing recorded data for a long time.

Owner:WUHAN UNIV OF TECH

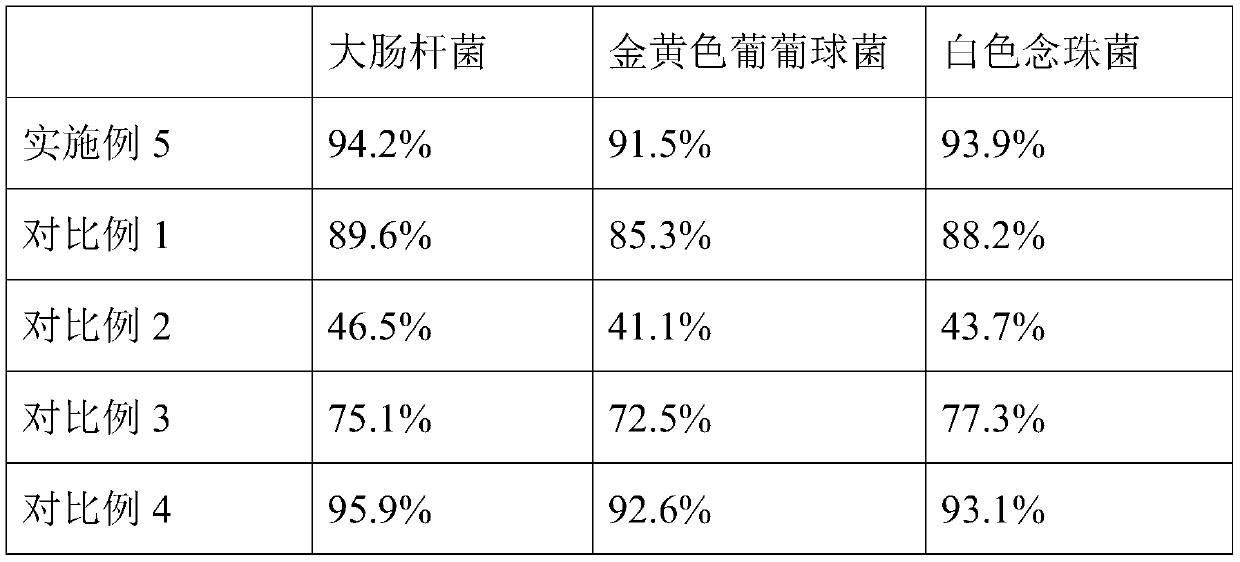

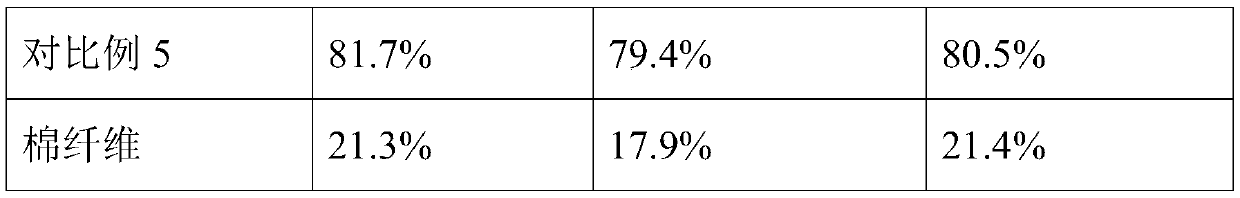

Nano-chitosan-modified cotton fiber and preparation method thereof

ActiveCN111411509AGood anti agingAvoid reunionPhysical treatmentBiochemical fibre treatmentCotton fibreCellulose

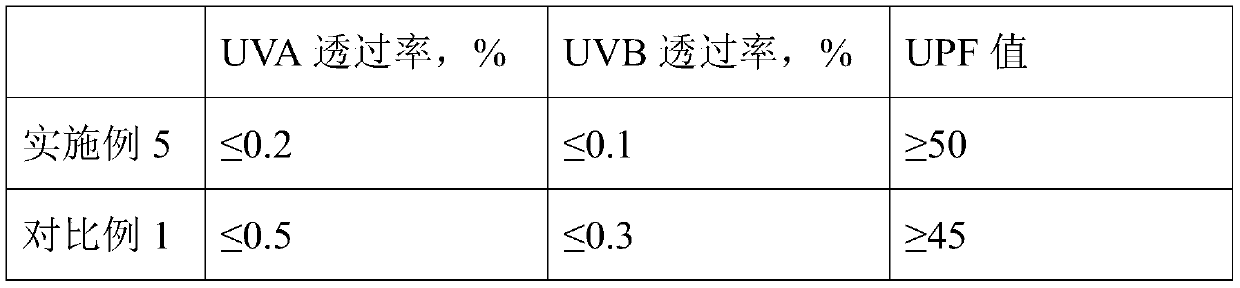

The invention discloses a nano-chitosan-modified cotton fiber and a preparation method of the nano-chitosan-modified cotton fiber. The preparation method of the nano-chitosan-modified cotton fiber comprises the steps: the cotton fiber is sent into a sodium hydroxide solution to be stirred, washed and dried, and sent into a sodium periodate solution to be stirred away from light to obtain an activated cotton fiber; nano chitosan, a cellulose dispersing agent and acetic acid are evenly mixed, isopropyl triisostearoyltitanate is added to be stirred, under the stirring state, tetraethylortho silicate is added, stirring is continued, and vacuum defoamation is conducted to obtain a pretreated nano chitosan solution; and the activated cotton fiber is steeped in the pretreated nano chitosan solution to be subjected to pulsed microwave treatment, filtered, and aired at the room temperature to obtain the nano-chitosan-modified cotton fiber. The cotton fiber is modified through the nano chitosanand thus has a good heat-insulating foundation and excellent antibacterial and anti-ultraviolet properties, the method is environmentally friendly, and the nano-chitosan-modified cotton fiber can be applied to the fields of medical health and antibacterial fabrics.

Owner:安徽省农业科学院棉花研究所

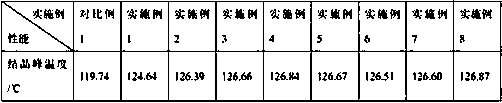

Polypropylene composition based on organic hydrazide compound nucleating agent

The invention discloses a polypropylene composition based on an organic hydrazide compound nucleating agent. The polypropylene composition comprises the following raw material components in parts by weight: 100 parts of polypropylene, 0.001-10 parts of the organic hydrazide compound nucleating agent and 0.001-5 parts of an antioxidant. According to the polypropylene composition disclosed by the invention, a modifier with excellent high temperature resistance is introduced into the polypropylene composition, so that the performance of the polypropylene material is greatly improved. By adjustingthe various raw material components and ratios thereof, the polypropylene composition has good heat resistance and low temperature resistance and excellent mechanical property and also has antioxidant property and long service life. The polypropylene composition has excellent application prospects in the field of polypropylene application and has significances for developing high-performance polypropylene materials.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

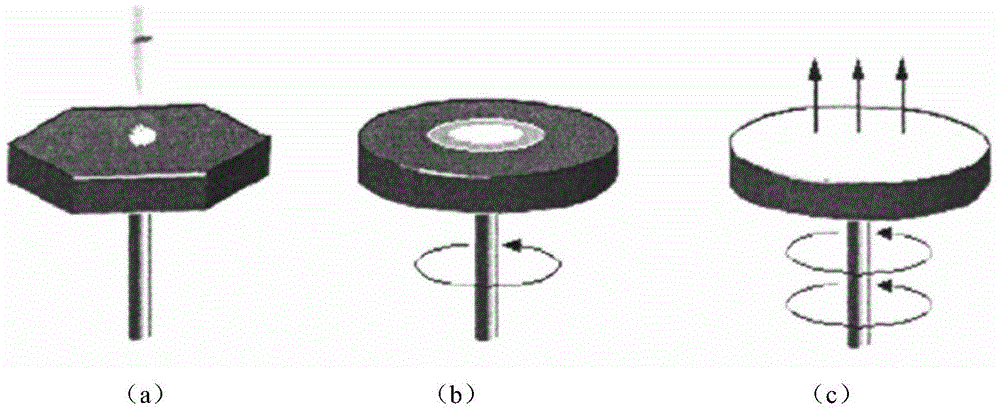

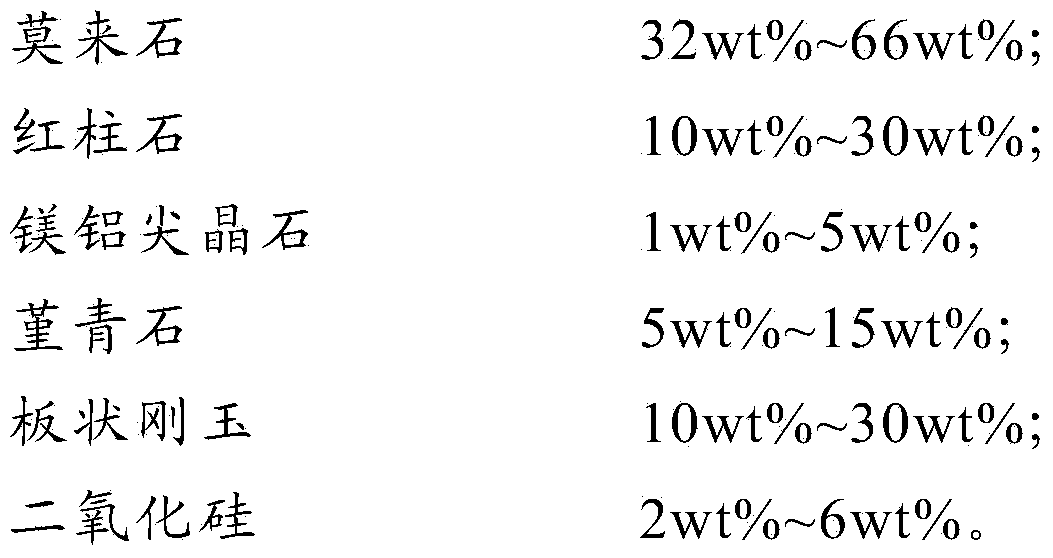

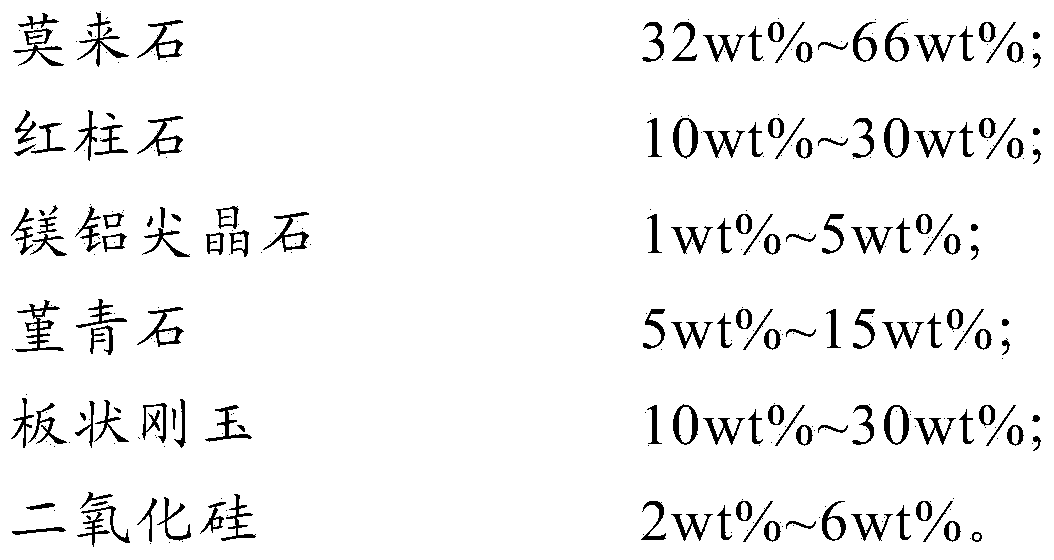

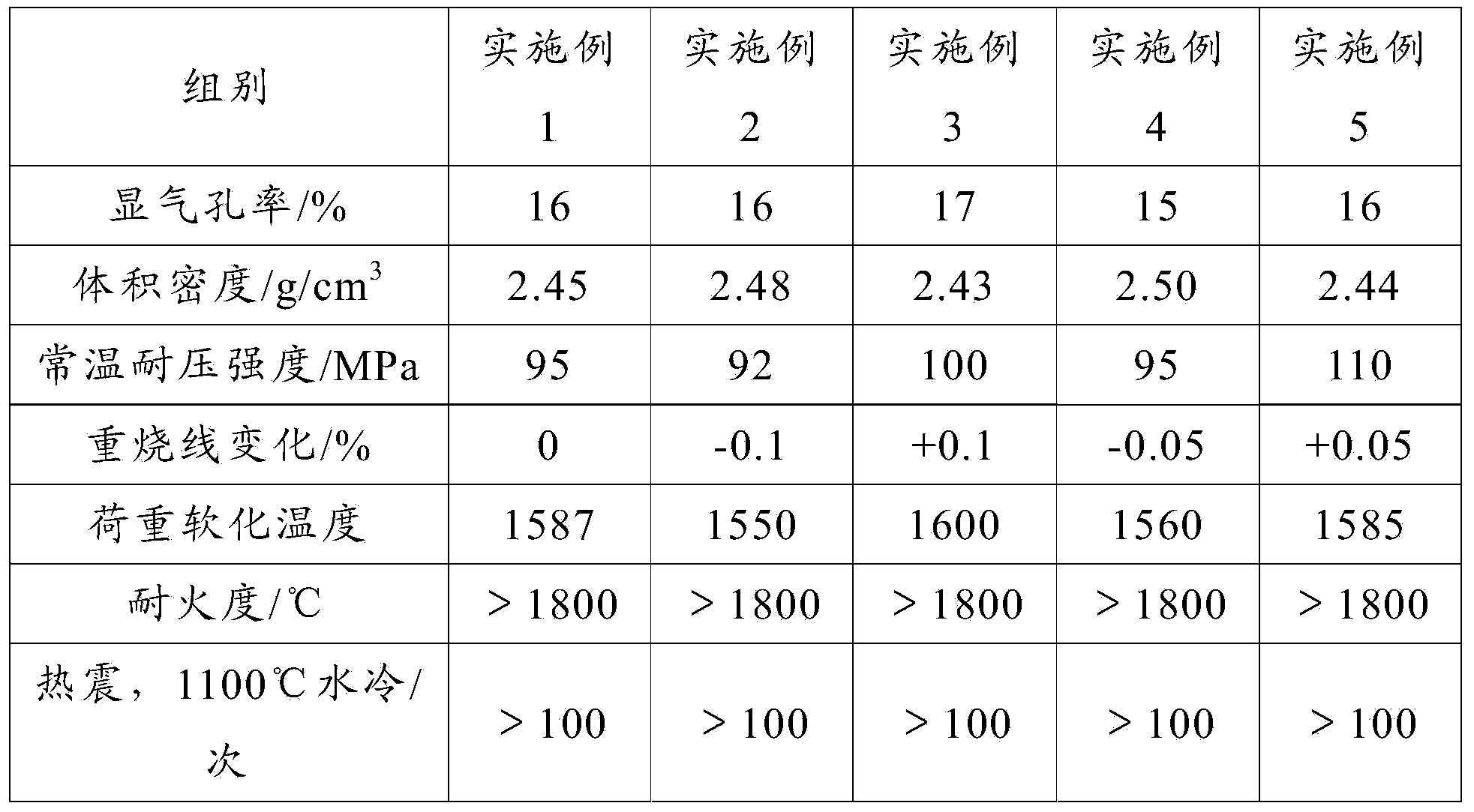

Combined brick and preparation method thereof

The invention provides a combined brick. The combined brick is prepared from a mixture through molding and firing, wherein the mixture comprises mullite, andalusite, magnesium aluminate spinel, cordierite, tabular corundum and silicon dioxide. Due to the addition of the components and control of the content of the components, the combined brick has better comprehensive thermodynamic property. The invention also provides a method for preparing the combined brick. The preparation method combines an integral molding technology with a pouring centrifugal shaping technology, so that the combined brick has better overall performance.

Owner:HUNAN XIANGGANG RUITAI TECH

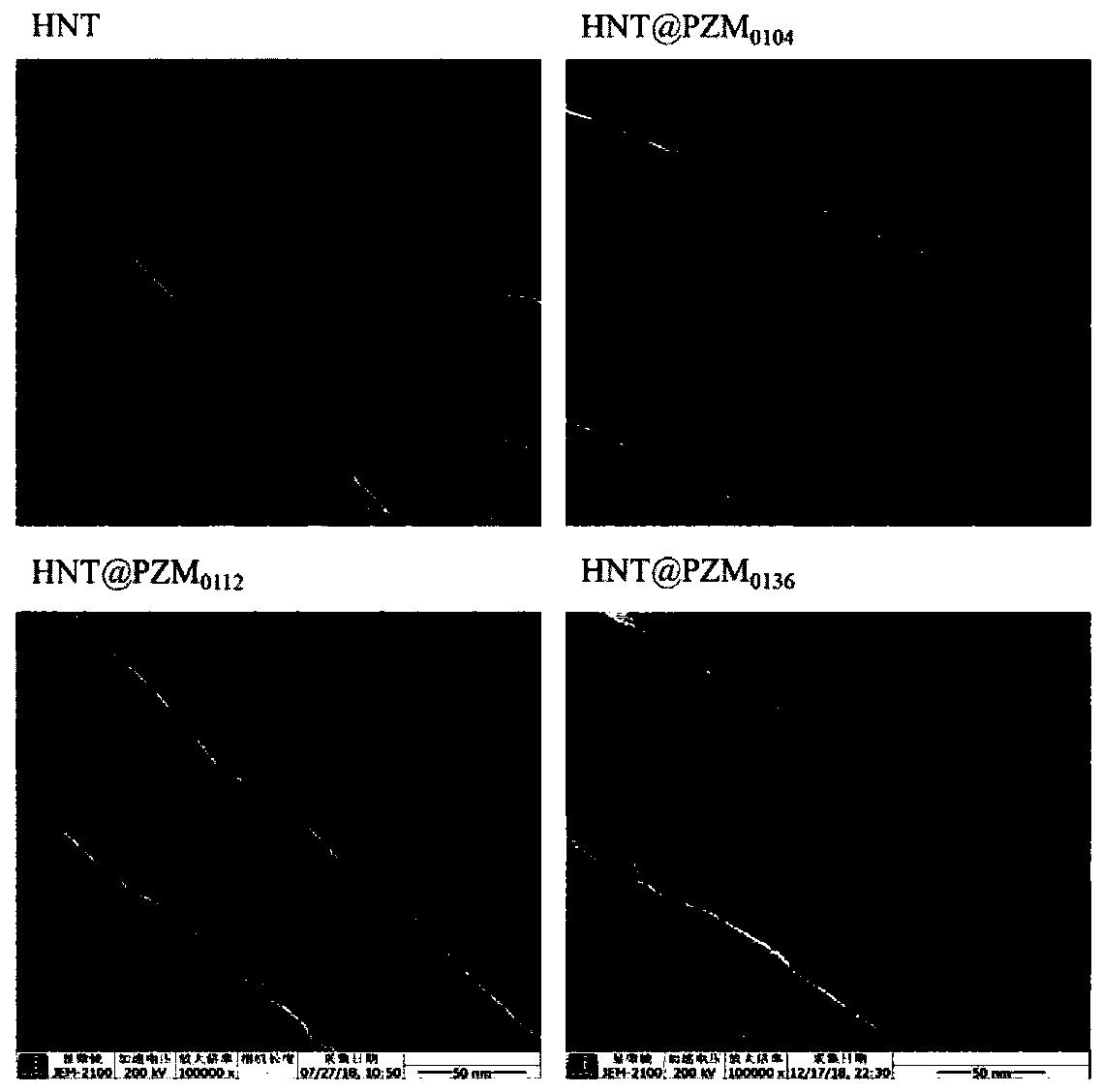

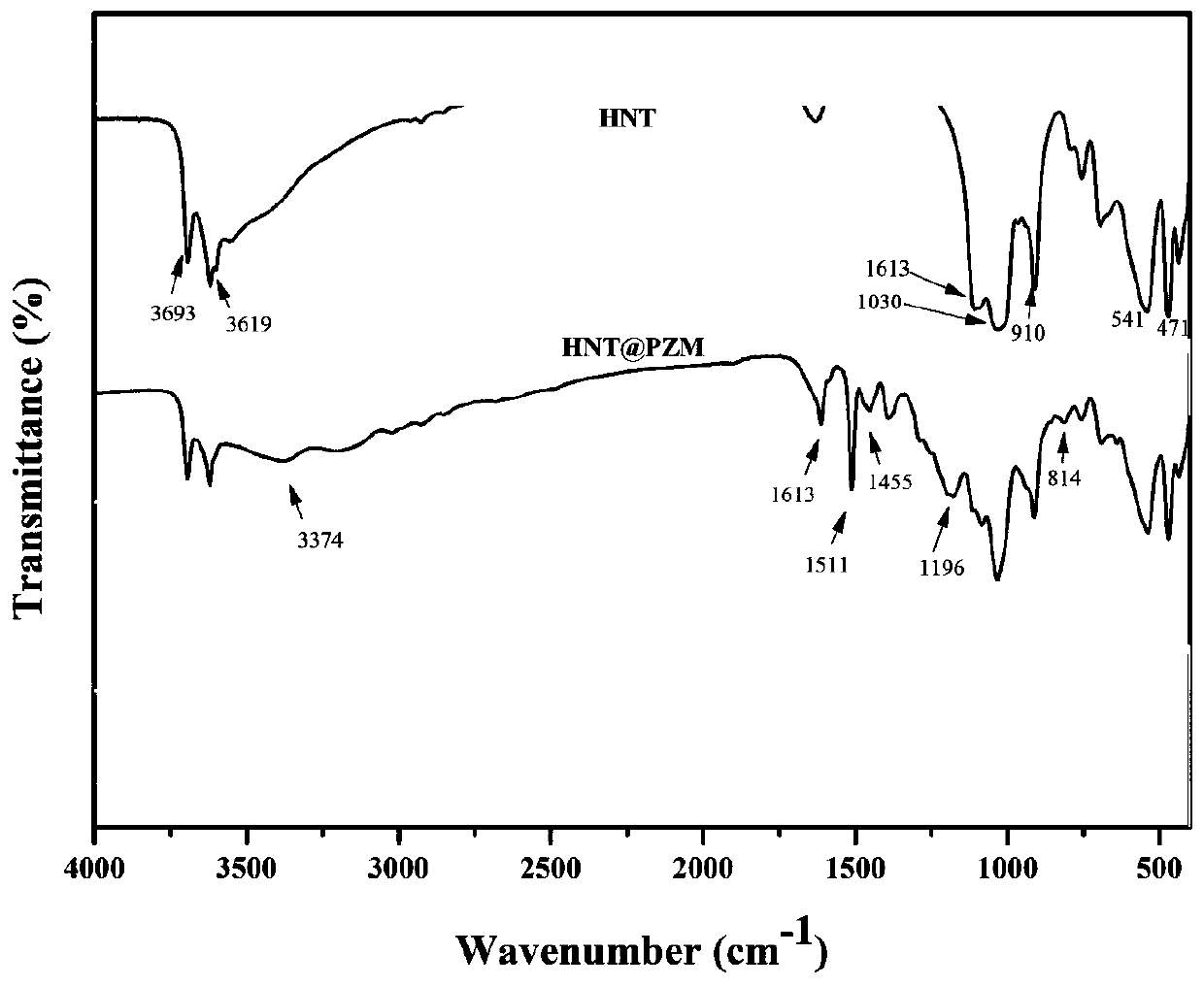

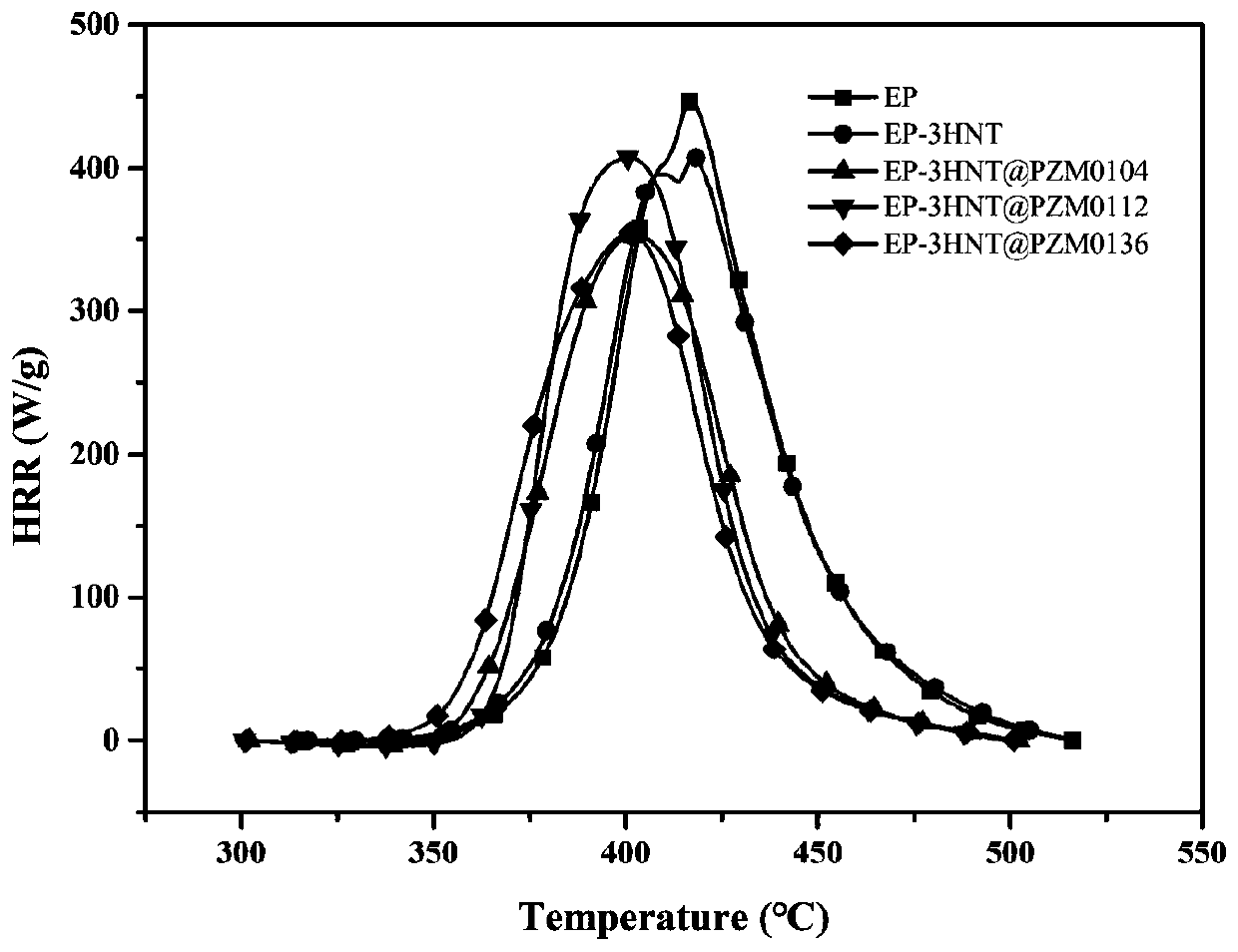

Preparation method and application of polyphosphazene polymer modified halloysite nanotube composite material with different coating thicknesses

ActiveCN110591157ARaw materials are cheap and easy to getSynthetic preparation is simpleHalloysitePolymer modified

The invention discloses a preparation method and application of a polyphosphazene polymer modified halloysite nanotube composite material with different coating thicknesses. The method includes the following steps: (1) placing an appropriate amount of halloysite nanotubes into acetonitrile, performing ultrasonic dispersion, adding a double-terminal amine substance and triethylamine in sequence, and performing stirring; (2) slowly adding an acetonitrile solution of phosphonitrilic chloride trimer with different concentrations dropwise into the material obtained in the step (1), and performing acondensation polymerization reaction under stirring at 40-80 DEG C for 6-24 h; and (3) washing the material obtained in the step (2) by using anhydrous ethanol, and performing vacuum drying at 40-80DEG C to a constant weight to obtain a pale yellow solid, so as to obtain the composite material.

Owner:XIAMEN UNIV +1

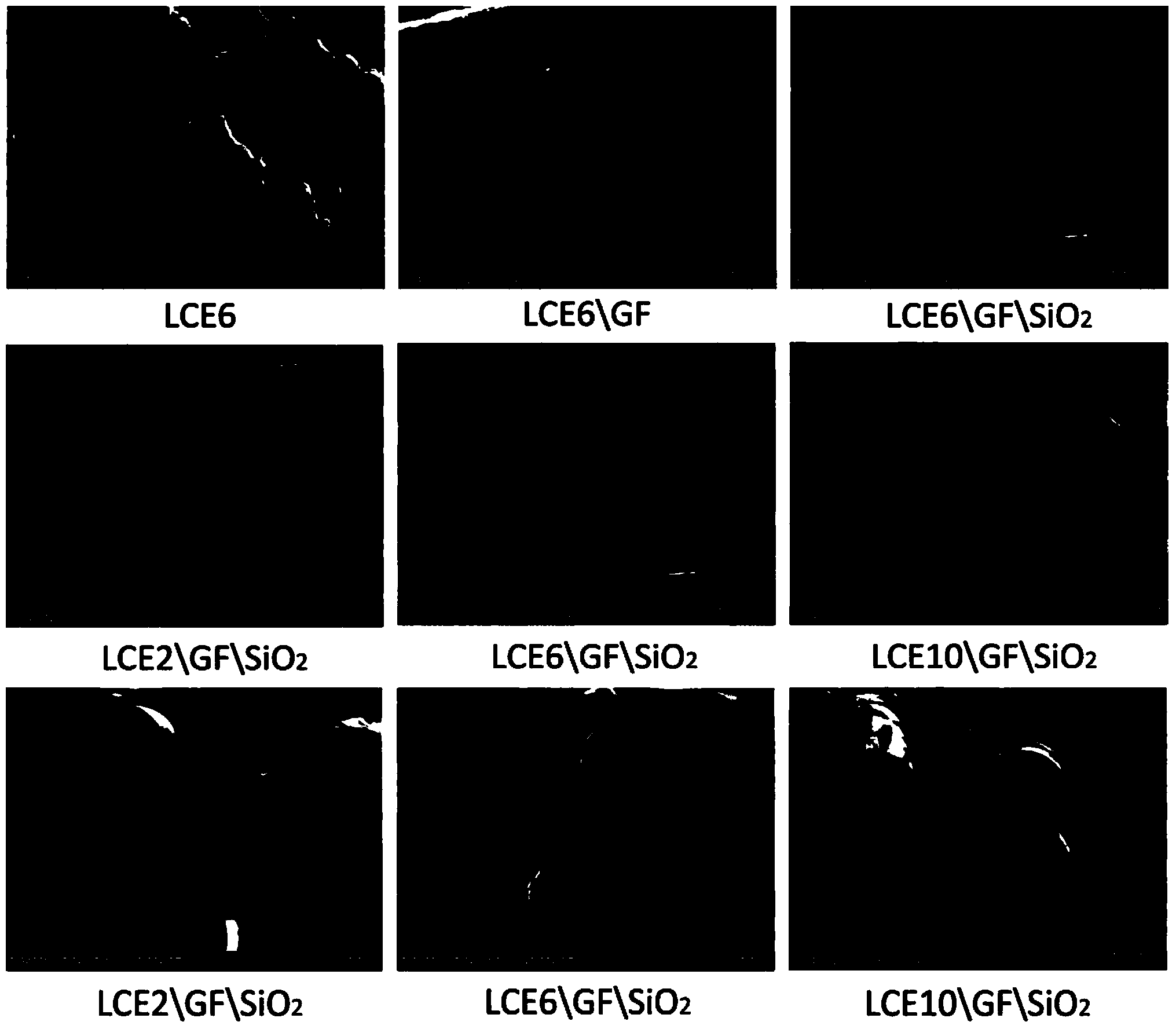

Shape memorizing liquid crystal epoxy resin-glass fiber-silicon dioxide composite and preparation method thereof

The invention belongs to composites and the field of composite preparation, and discloses a shape memorizing liquid crystal epoxy resin-glass fiber-silicon dioxide composite and a preparation method thereof. The preparation method comprises the following steps: dissolving liquid crystal epoxy resin and a curing agent into acetone, then adding silicon dioxide subjected to surface treatment by a silane coupling agent so as to obtain a composite mixed liquid, and pouring the obtained composite mixed liquid into a mould laid with glass fiber subjected to surface treatment to be reacted and cured so as to obtain the liquid crystal epoxy resin-glass fiber-silicon dioxide composite with the shape memorizing performance. The obtained material has excellent mechanical performance and shape memorizing performance, and can be applied to the fields of science and technology such as biomedicine and aerospace.

Owner:NANXIONG MATERIAL PRODION BASE OF CHINESE ACADEMY OF SCI GUANGZHOU CHEM +1

Glass fiber-reinforced PBT/ABS (Polybutylece Terephthalate/Acrylonitrile Butadiene Styrene) alloy material and preparation method thereof

InactiveCN103525038AImprove mechanical propertiesImprove thermodynamic performanceGlass fiberPolyethylene terephthalate

The invention discloses a glass fiber-reinforced PBT / ABS (Polybutylece Terephthalate / Acrylonitrile Butadiene Styrene) alloy material and a preparation method thereof. The glass fiber-reinforced PBT / ABS alloy material disclosed by the invention comprises the following components in percentage by weight: 30-70 percent of PBT, 10-30 percent of ABS, 10-30 percent of glass fiber, 5-15 percent of NBR (Nitrile-Butadiene Rubber), 2-5 percent of compatilizer, 0.2-3 percent of lubrication dispersing agent and 0.2-0.5 percent of antioxidant. The glass fiber-reinforced PBT / ABS alloy material has the characteristics of PBT and ABS; and glass fiber is used for reinforcement and modification so that the fatigue resistance, the hardness, the tensile strength, the bending strength, the bending modulus, the abrasion resistance and other aspects of the glass fiber-reinforced PBT / ABS alloy material are remarkably improved; and the glass fiber-reinforced PBT / ABS alloy material has the advantages of excellent comprehensive performance, stable size, high strength, attractive appearance, low cost and the like.

Owner:QINGDAO XINZHAN PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com