Polybenzimidazole and its derivative functional graphene oxide

A technology of polybenzimidazole and its derivatives, which is applied in the field of polybenzimidazole and its derivatives functionalized graphene oxide and its preparation, can solve the problems of weak reactivity, limited content of functional groups, numerous reaction steps, etc., and achieve The effect of improving electrical conductivity, improving high temperature performance, and improving thermodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

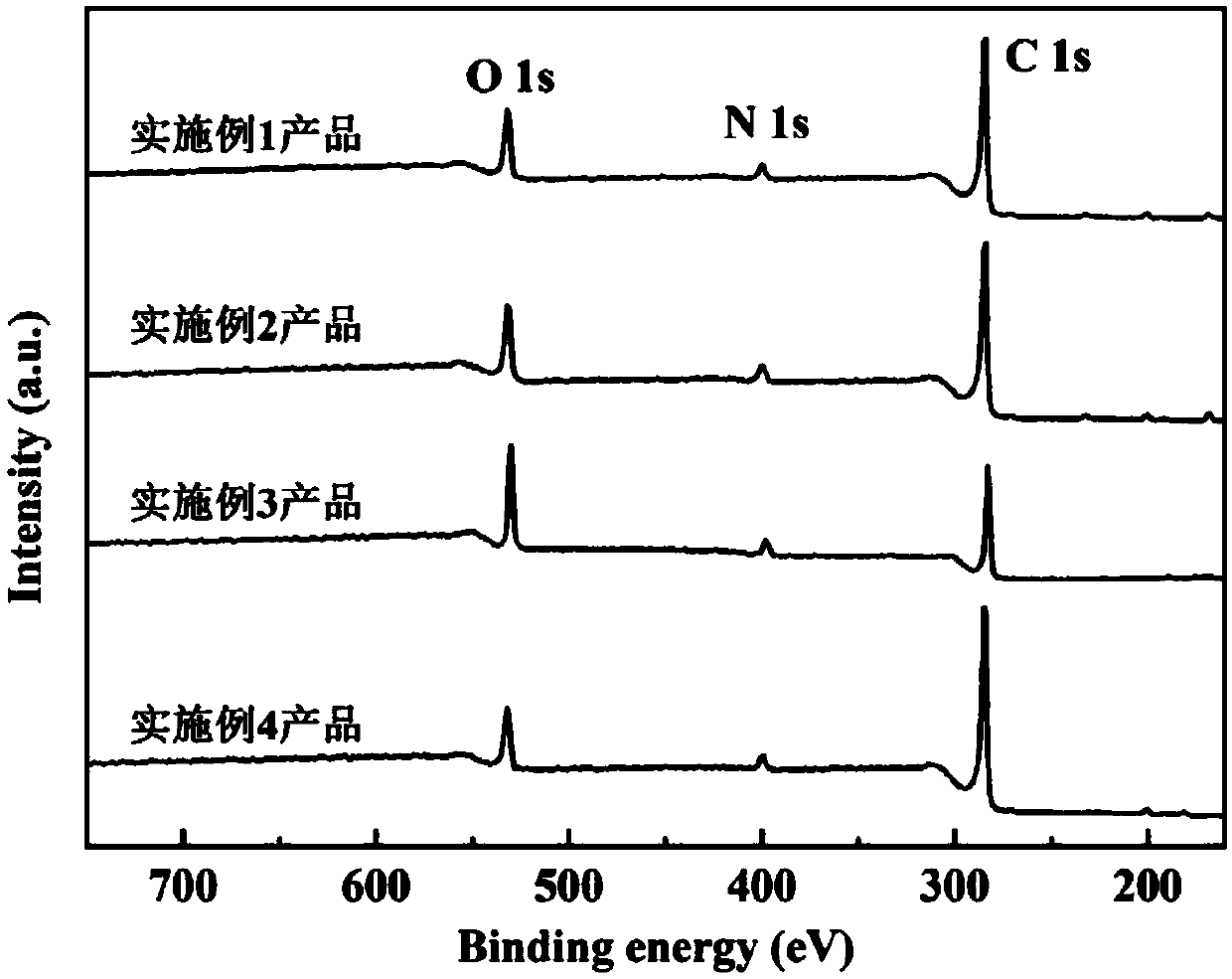

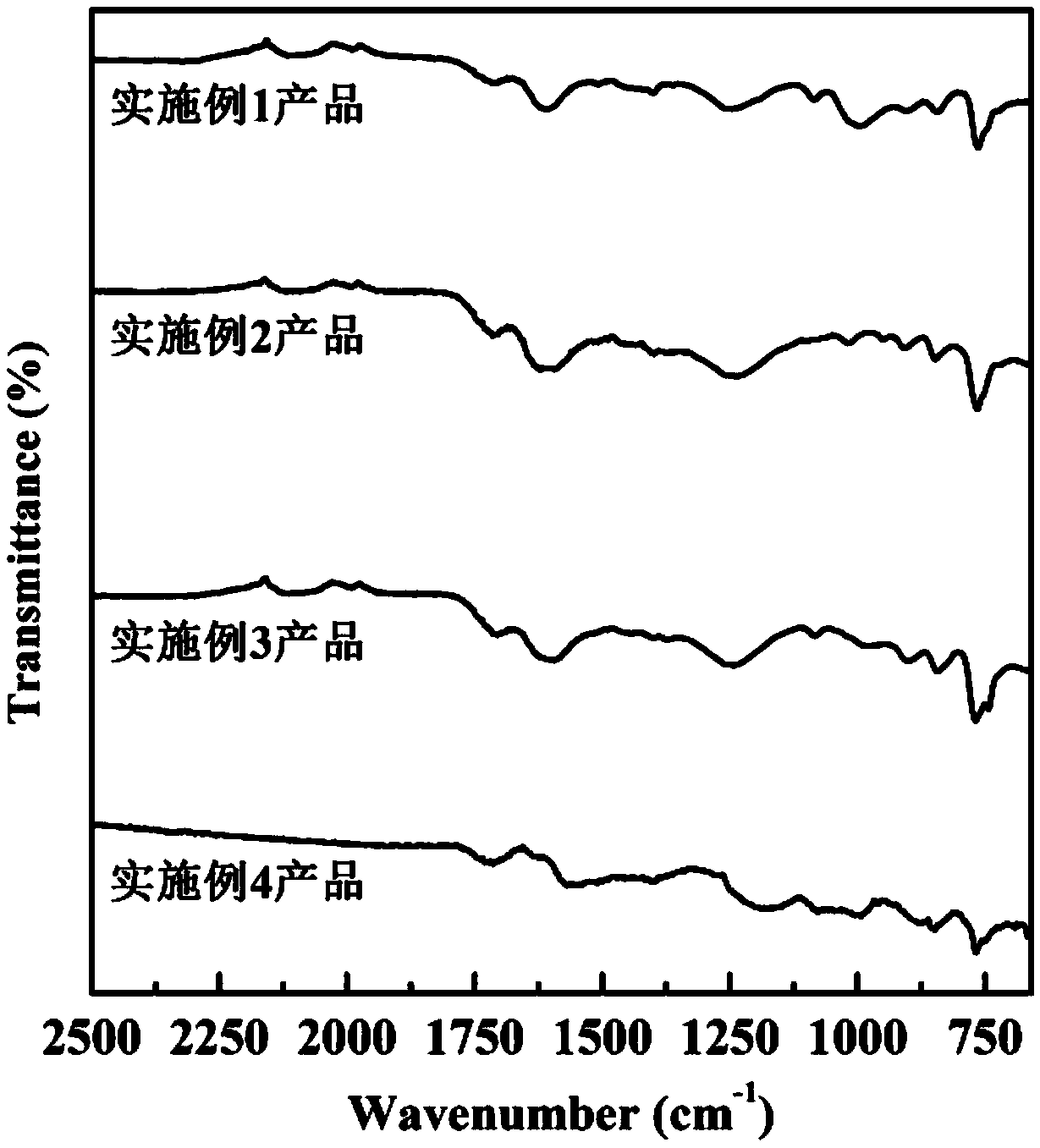

[0025] Example 1: P 1 Preparation of grafted graphene oxide

[0026] Dry graphene oxide solids (250 mg) were added to DMAc (250 mL), and ultrasonicated at room temperature for 2 hours until uniformly dispersed to form a brown suspension. Add A to the suspension 1 (0.11g) and B 1 (0.14g), magnetically stirred and dispersed evenly, poured into a three-necked flask, and added PPA (2g). Under the protection of nitrogen, the temperature was raised to 60°C and kept for 0.5 hours, and then the temperature was raised to 150°C again for 0.5 hours. After the reaction, the mixture was poured into 500mL deionized water and magnetically stirred for 0.5 hours. The product was centrifuged at 10,000rpm, washed twice with DMAc and deionized water alternately, and dried overnight at 60°C in a vacuum oven. .

Embodiment 2

[0027] Example 2: P 2 Preparation of grafted graphene oxide

[0028] Dry graphene oxide solids (250 mg) were added to DMAc (250 mL), and ultrasonicated at room temperature for 2 hours until uniformly dispersed to form a brown suspension. Add B to the suspension 2 (1g), magnetically stirred and dispersed evenly, poured into a three-necked flask, and added PPA (6g). Under the protection of nitrogen, the temperature was raised to 60°C and kept for 0.5 hours, and then the temperature was raised to 160°C again for 2 hours. After the reaction, the mixture was poured into 500mL deionized water and magnetically stirred for 0.5 hours. The product was centrifuged at 10,000rpm, washed twice with DMAc and deionized water alternately, and dried overnight at 60°C in a vacuum oven. .

Embodiment 3

[0029] Example 3: P 3 Preparation of grafted graphene oxide

[0030] Dry graphene oxide solids (250 mg) were added to DMAc (250 mL), and ultrasonicated at room temperature for 2 hours until uniformly dispersed to form a brown suspension. Add A to the suspension 1 (0.52g) and B 3 (0.73g), magnetically stirred and dispersed evenly, poured into a three-necked flask, and added PPA (10g). Under the protection of nitrogen, the temperature was raised to 60°C and kept for 0.5 hours, and then the temperature was raised to 160°C again for 3 hours. After the reaction, the mixture was poured into 500mL deionized water and magnetically stirred for 0.5 hours. The product was centrifuged at 10,000rpm, washed twice with DMAc and deionized water alternately, and dried overnight at 60°C in a vacuum oven. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com