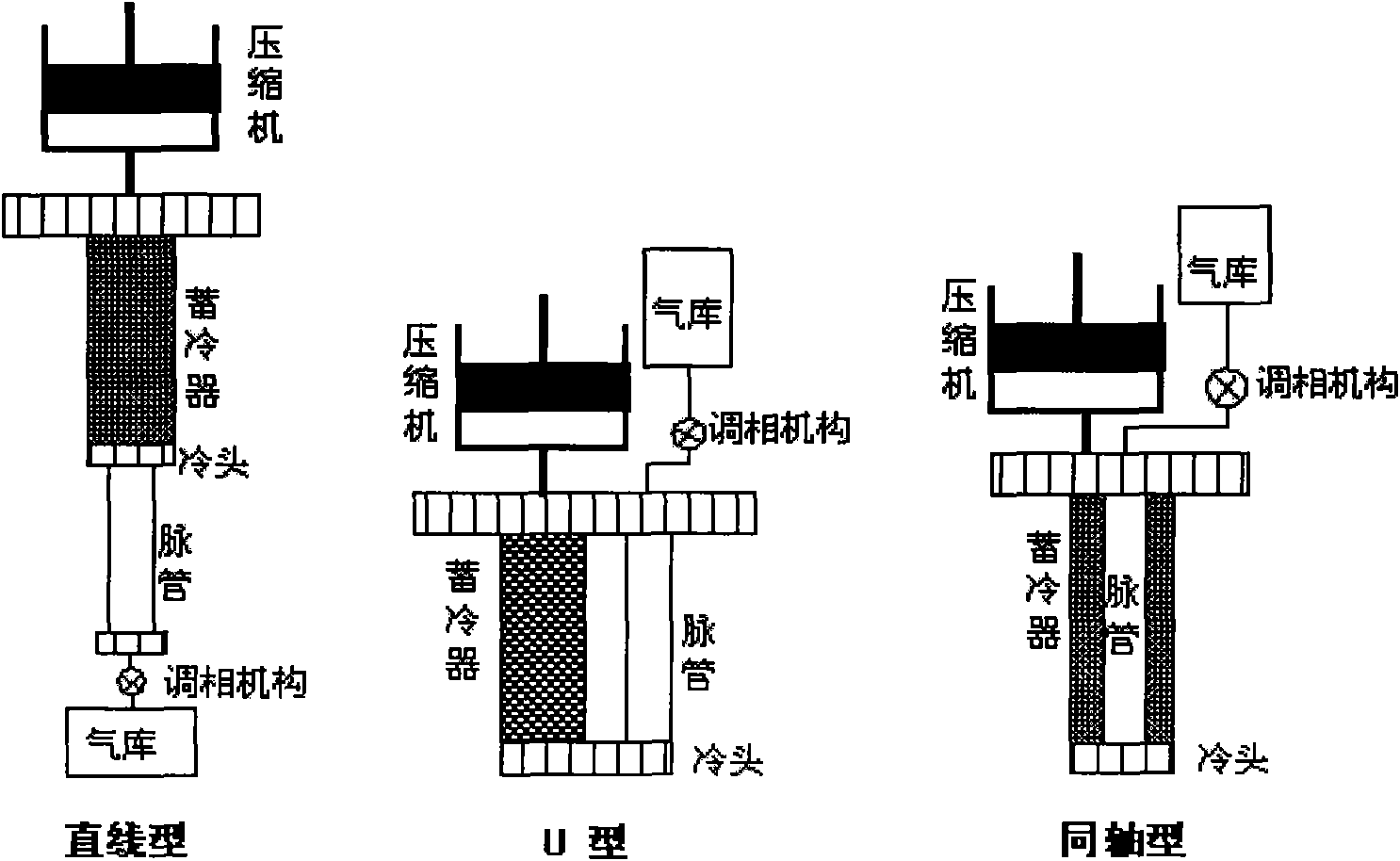

Integrated slit cold head of U-shaped pulse tube refrigerating machine and manufacturing method

A technology of pulse tube refrigerator and manufacturing method, which is applied in refrigerators, gas circulation refrigerators, refrigeration and liquefaction, etc., and can solve the problems of excessive dead volume, insufficient heat exchange area of air flow, large resistance at connecting thin tubes and Cooling loss and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

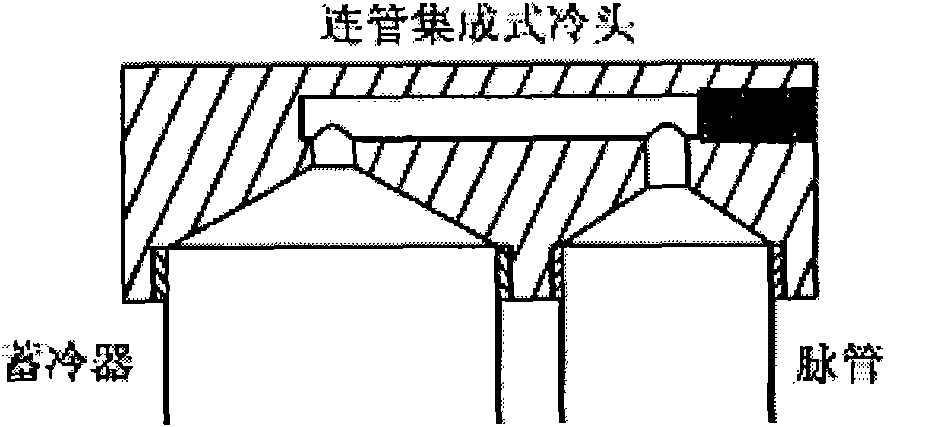

[0036] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

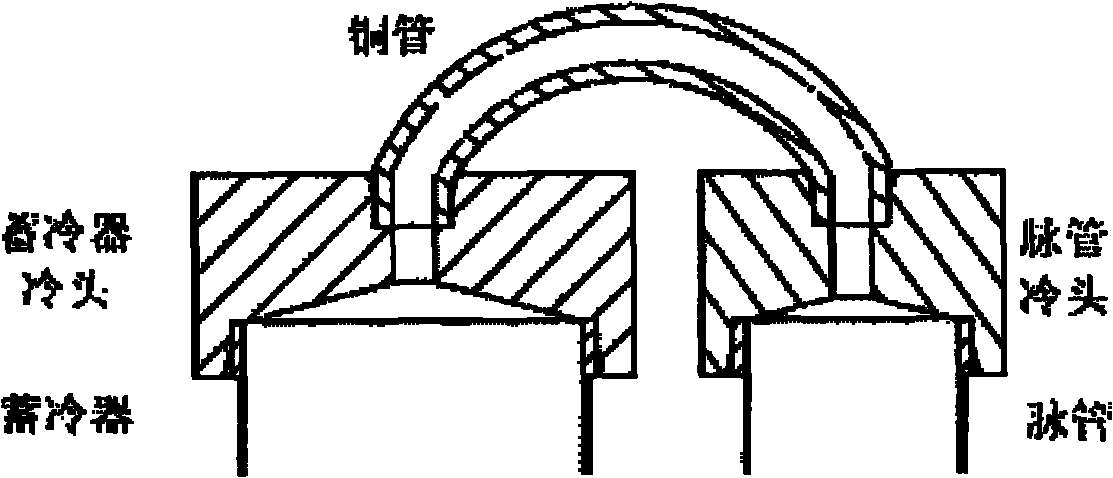

[0037] The integrated slit cold head of the U-shaped pulse tube refrigerator of the present invention consists of two parts, the top cover 0 and the lower flange 13 . In order to enhance heat transfer, both parts are made of high thermal conductivity materials.

[0038] Such as Figure 4 Shown in (a): the lower part of the upper platform 1 of the top cover 0 at first protrudes a large boss 2 with a diameter slightly smaller than the upper platform 1, and then protrudes two outside the big boss 2 above the big boss 2. The cold storage side cylinder boss 3 and the pulse tube side cylinder boss 4 with tangent edges ensure that the outer diameters of the cold storage side cylinder boss 3 and the pulse tube side cylinder boss 4 are respectively in line with the cold storage 14 and the pulse tube side. The inner diameters of the tubes 15 are equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com