Patents

Literature

48results about How to "Maximize heat transfer area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light fixtures and lighting devices

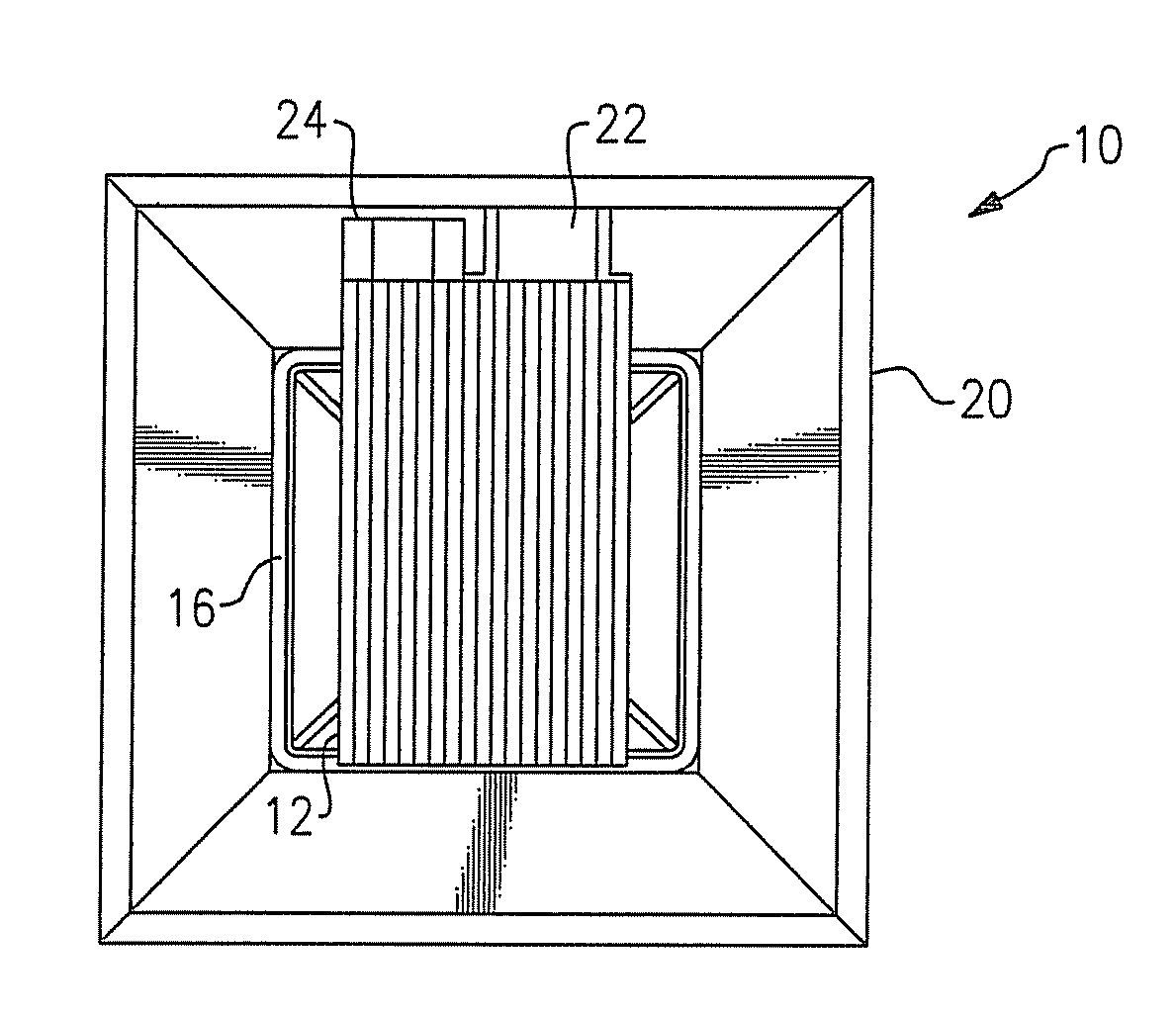

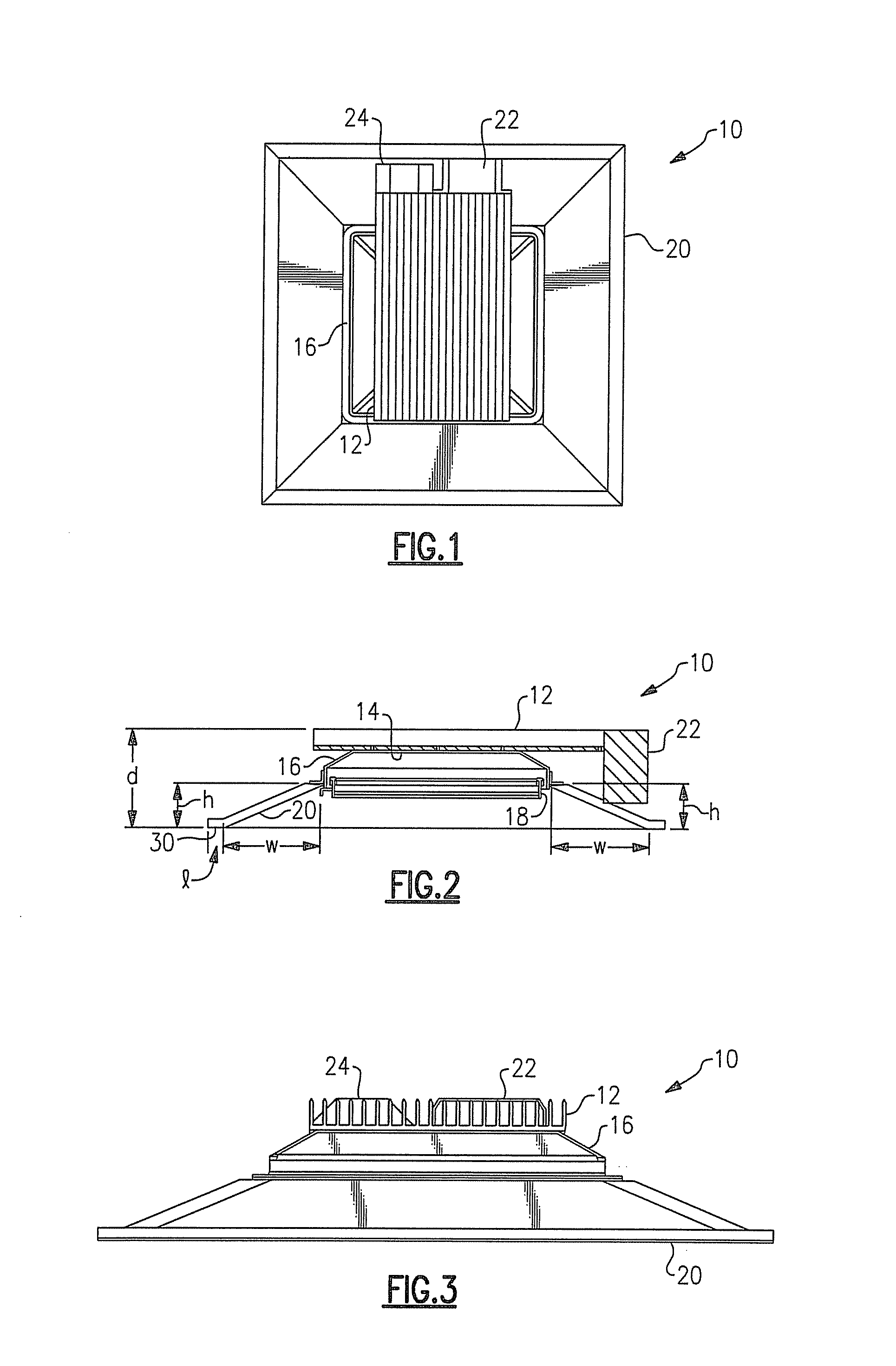

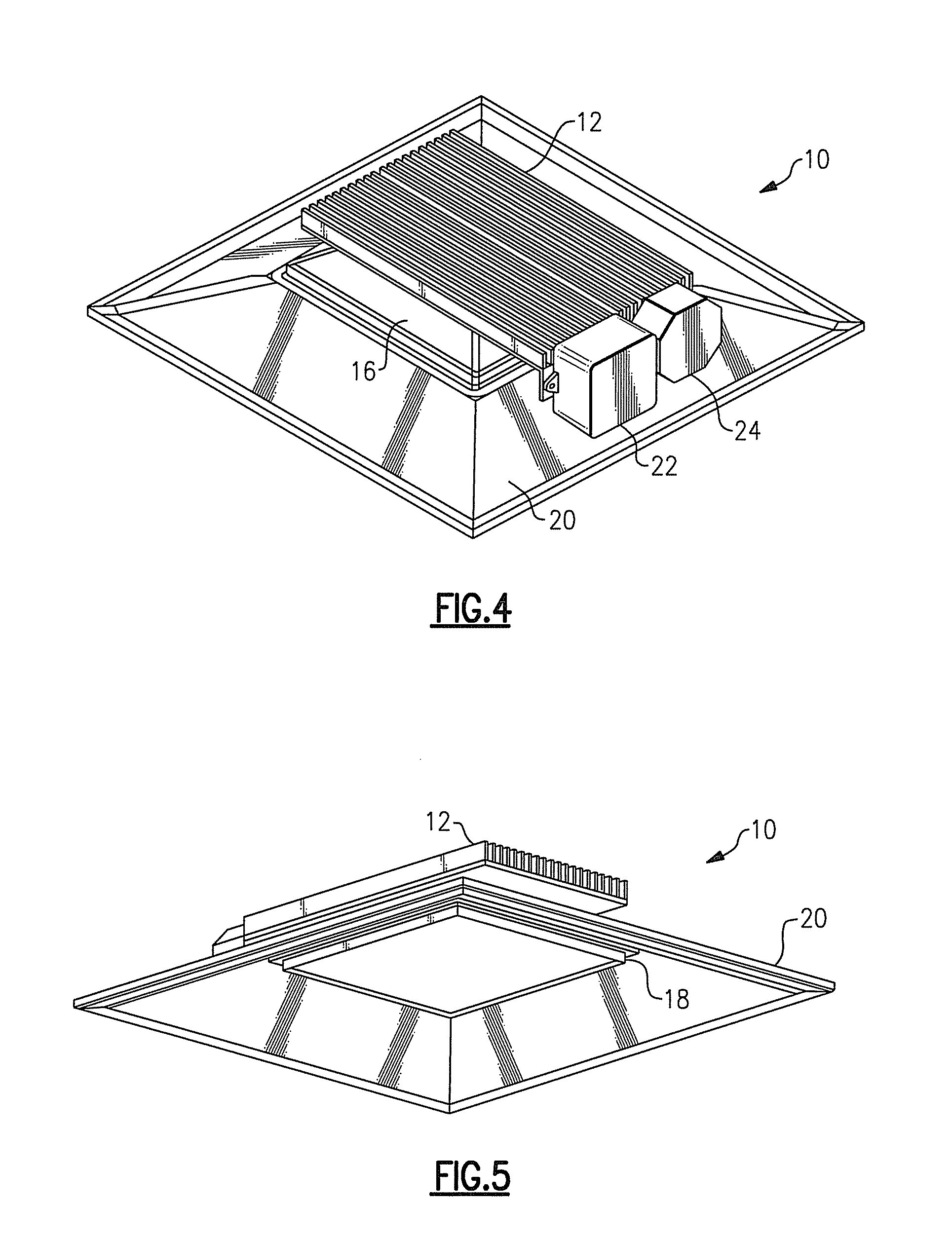

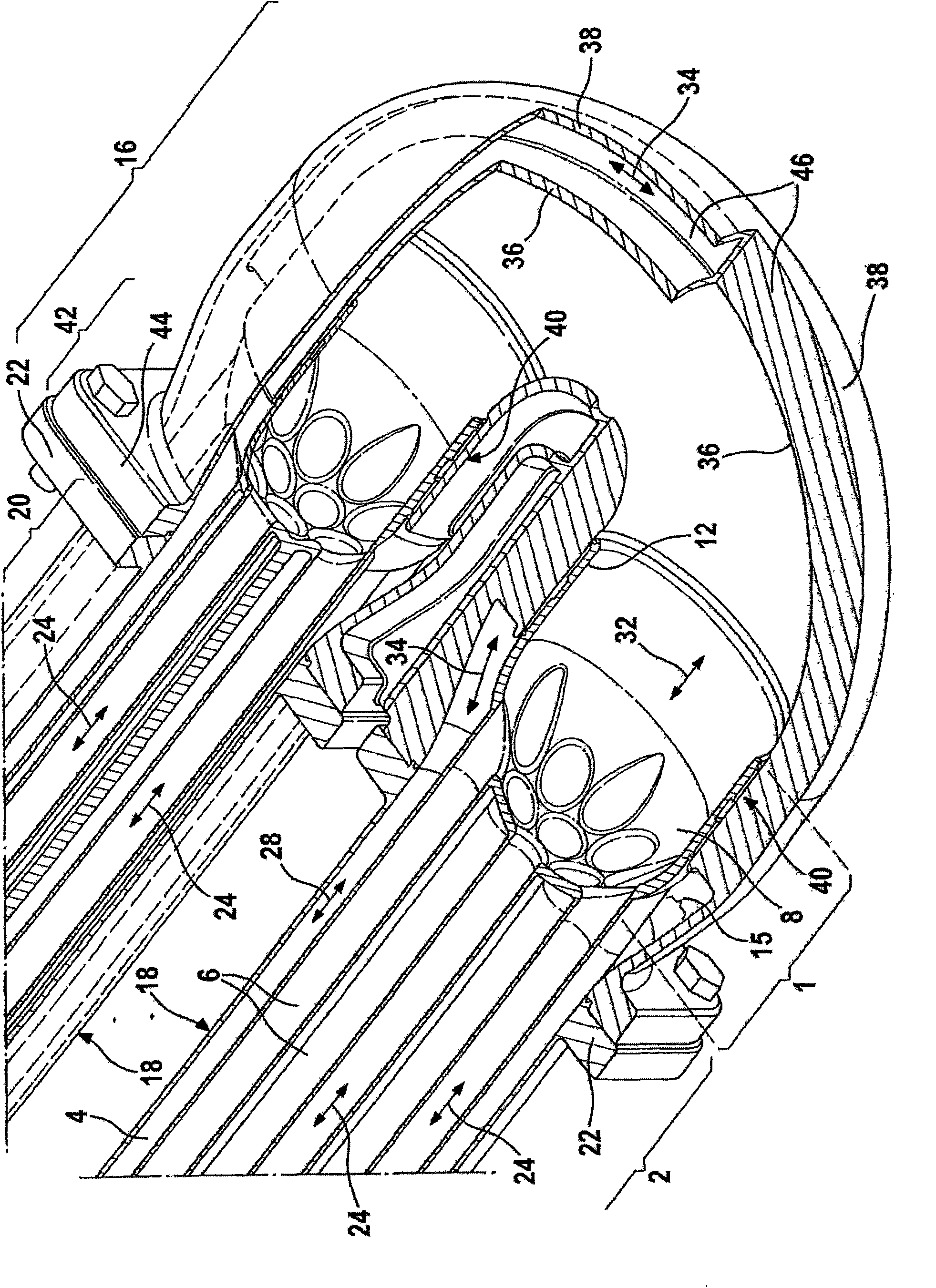

ActiveUS20080278950A1Minimize striationMinimize hot spot projected wallLighting support devicesPoint-like light sourceLight equipmentEffect light

A lighting device comprises a heat sink, a housing mounted to and / or thermally coupled to the heat sink, a basket assembly attached to the housing, a solid state light emitter thermally coupled to the heat sink, and a baffle assembly attached to the housing. Also, a lighting device comprising a basket assembly and a baffle assembly. In some embodiments, the basket assembly comprises a first member defining a first opening, a second member, a space between the first and second members, and lenses in the opening and in the space. In some embodiments, the heat sink extends farther in a first direction in a first plane than a largest dimension of the housing in any plane which is parallel to the first plane. In some embodiments, at least one additional component (e.g., a power supply module or a junction box) is in contact with the heat sink element.

Owner:IDEAL IND LIGHTING LLC

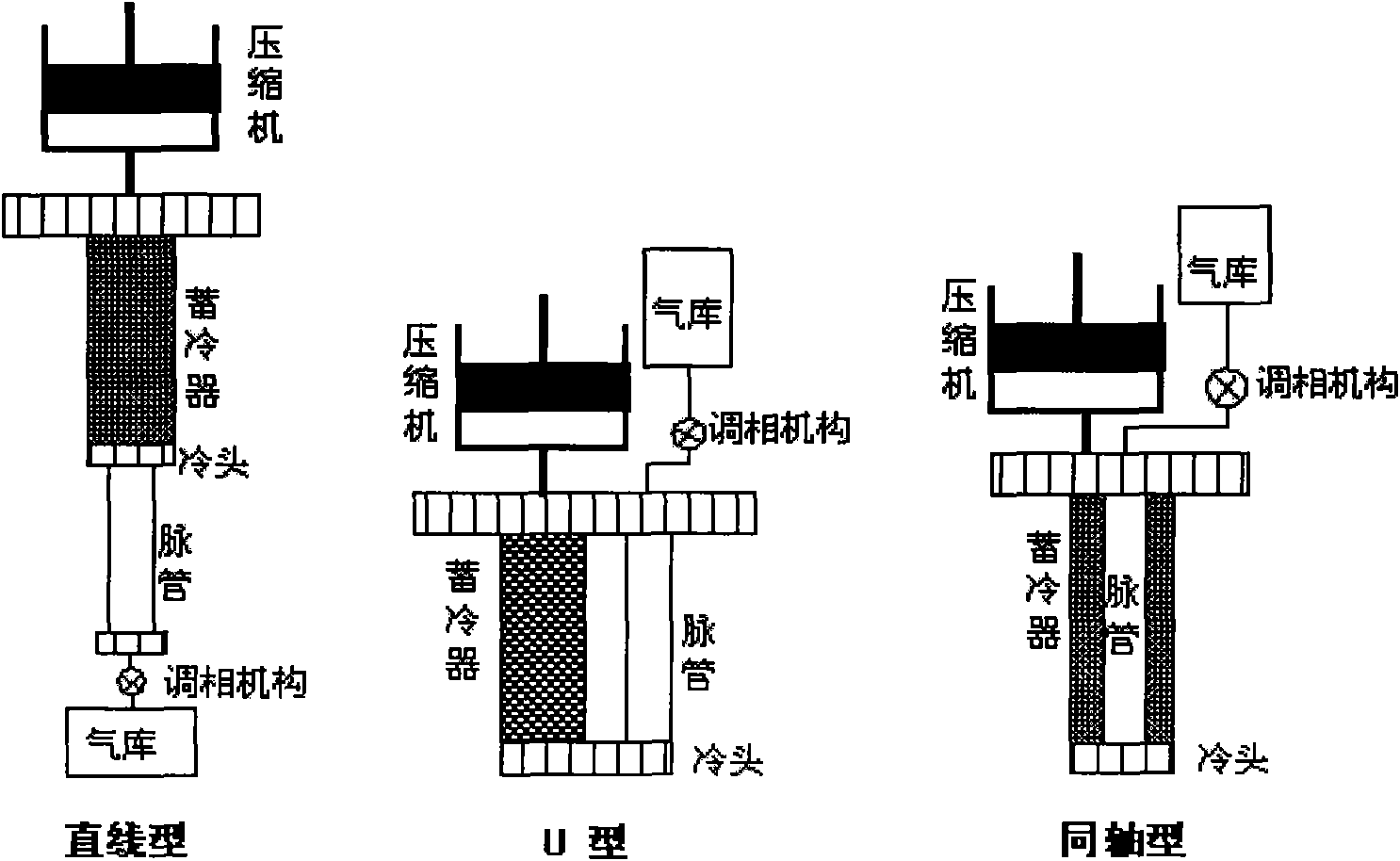

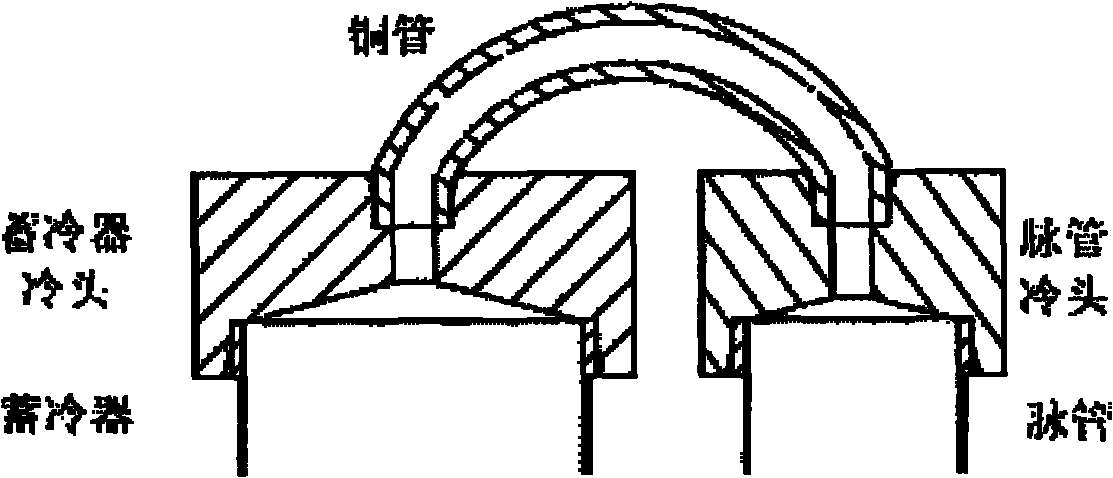

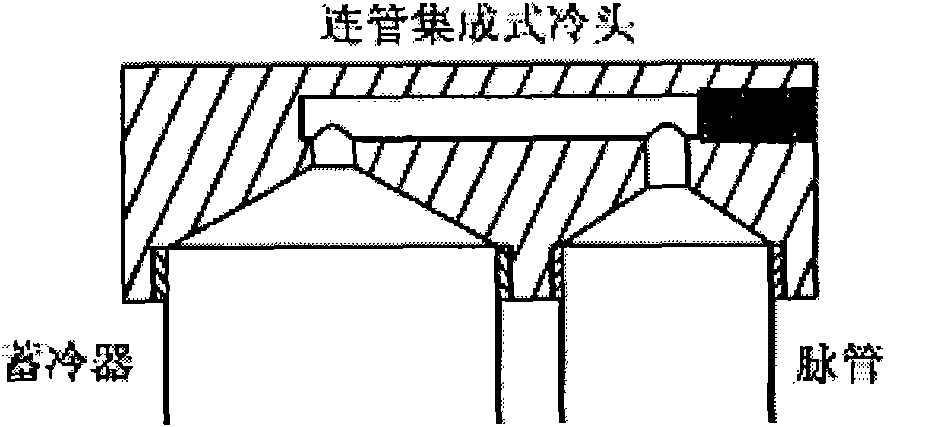

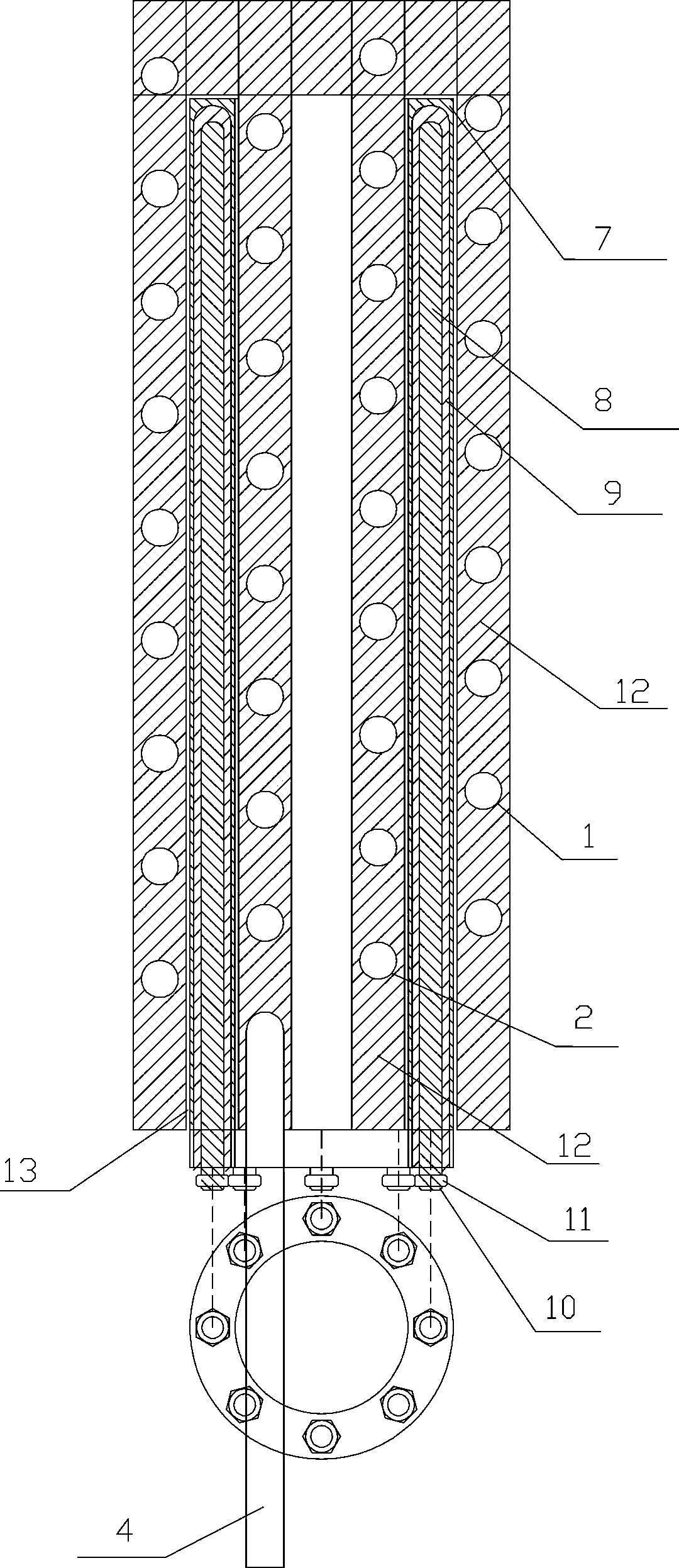

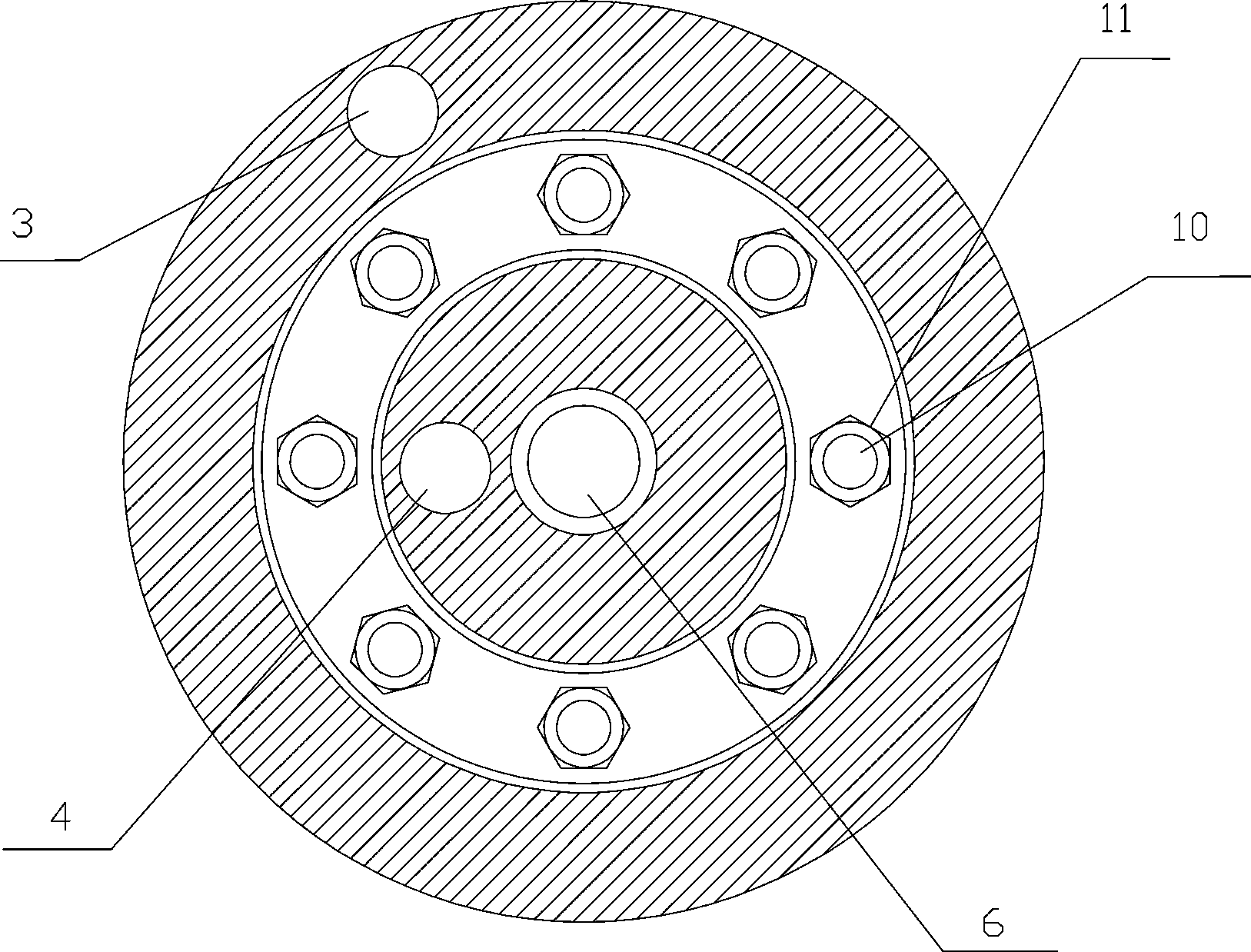

Integrated slit cold head of U-shaped pulse tube refrigerating machine and manufacturing method

InactiveCN102042711AMaintain laminar effectImprove thermodynamic performanceCompression machinesGas cycle refrigeration machinesEngineeringTop cap

The invention discloses an integrated slit cold head of a U-shaped pulse tube refrigerating machine and a manufacturing method. The cold head comprises two parts of a top cover and a lower flange, wherein two cylindrical lug bosses protrude below a big lug boss of the top cover, outer diameters of the two cylindrical lug bosses are respectively equal to inner diameters of a cold regenerator and a pulse tube; the two lug bosses integrally cut and penetrate through a slit in parallel horizontally and uniformly; through insertion holes matched with the cylindrical lug bosses of the top cover are arranged on the lower flange, a sealing groove and a location groove matched with the big lug boss of the top cover are cut on the upper surface of the lower flange, the lower flange, the cold regenerator and the pulse tube are hermetically welded to form an assembly; the top cover and the lower flange not only can be connected by bolts to form a detachable split cold head, but also can be hermetically welded to form an integrated cold head. In the invention, the main functions of three parts of an efficient cold end heat exchanger, a pulse tube cold end gas director and a cold regenerator cold end gas distributor can be intensively realized in an integrated slit cold head structure, the overall performance of the U-shaped pulse tube refrigerating machine is enhanced.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

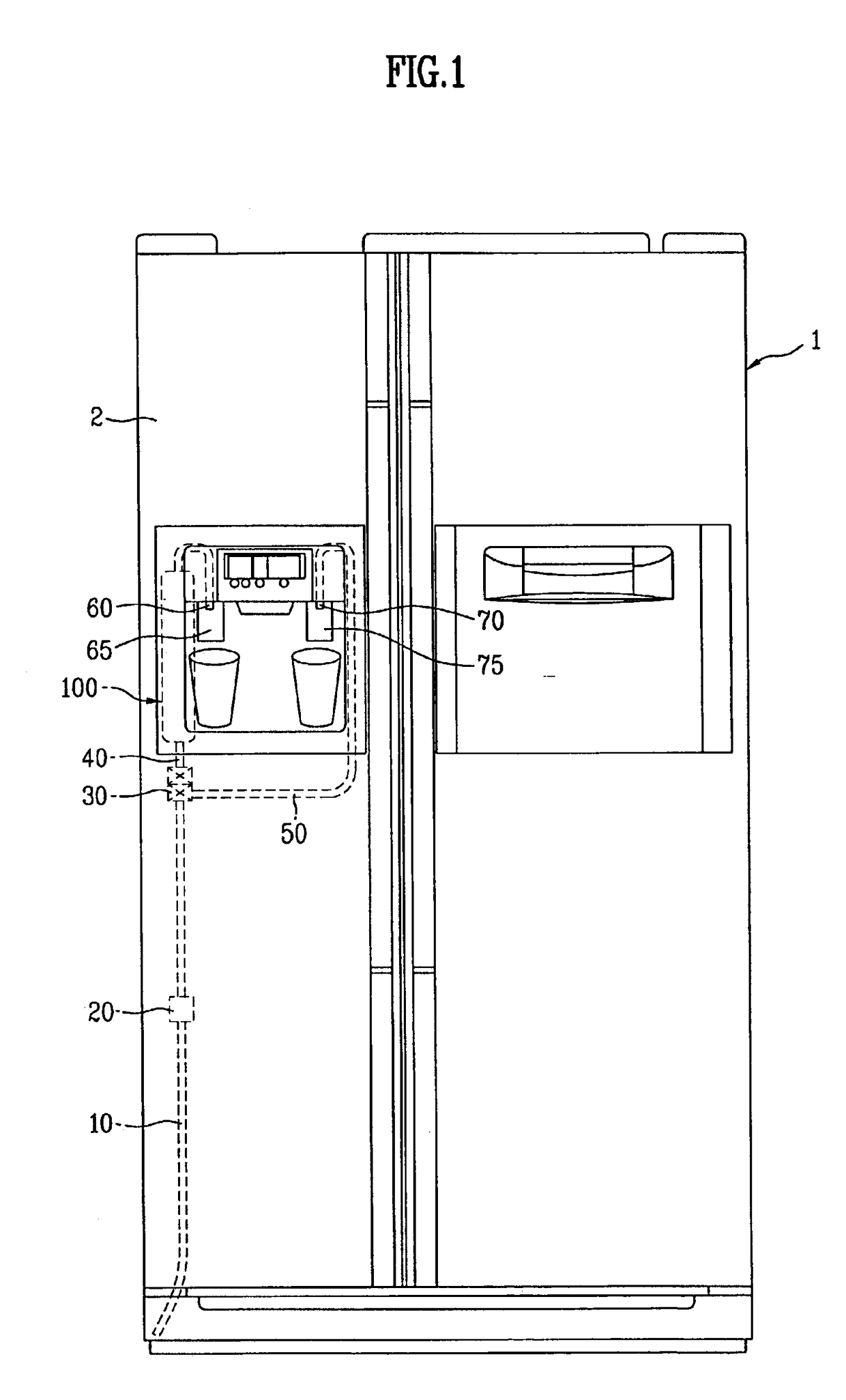

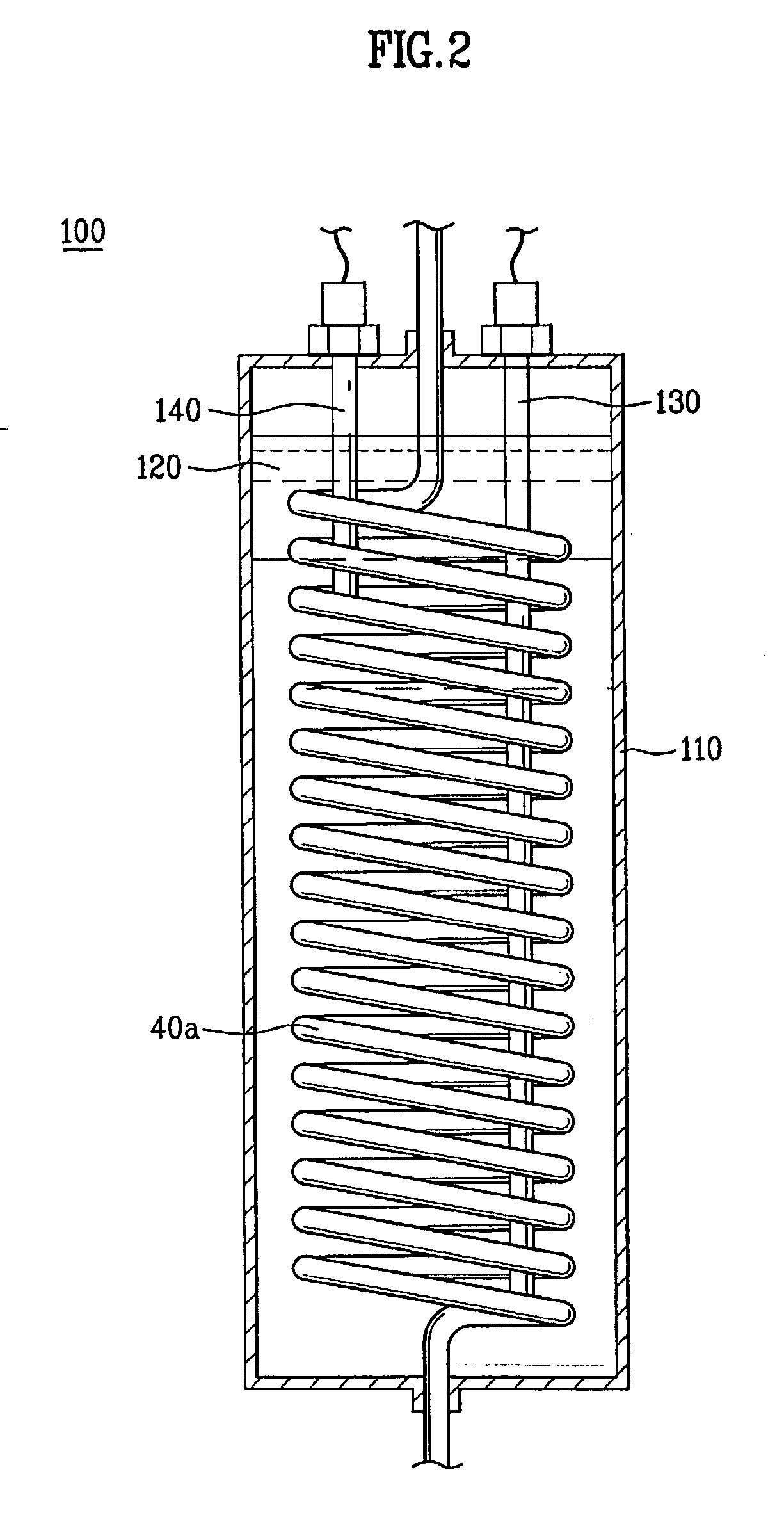

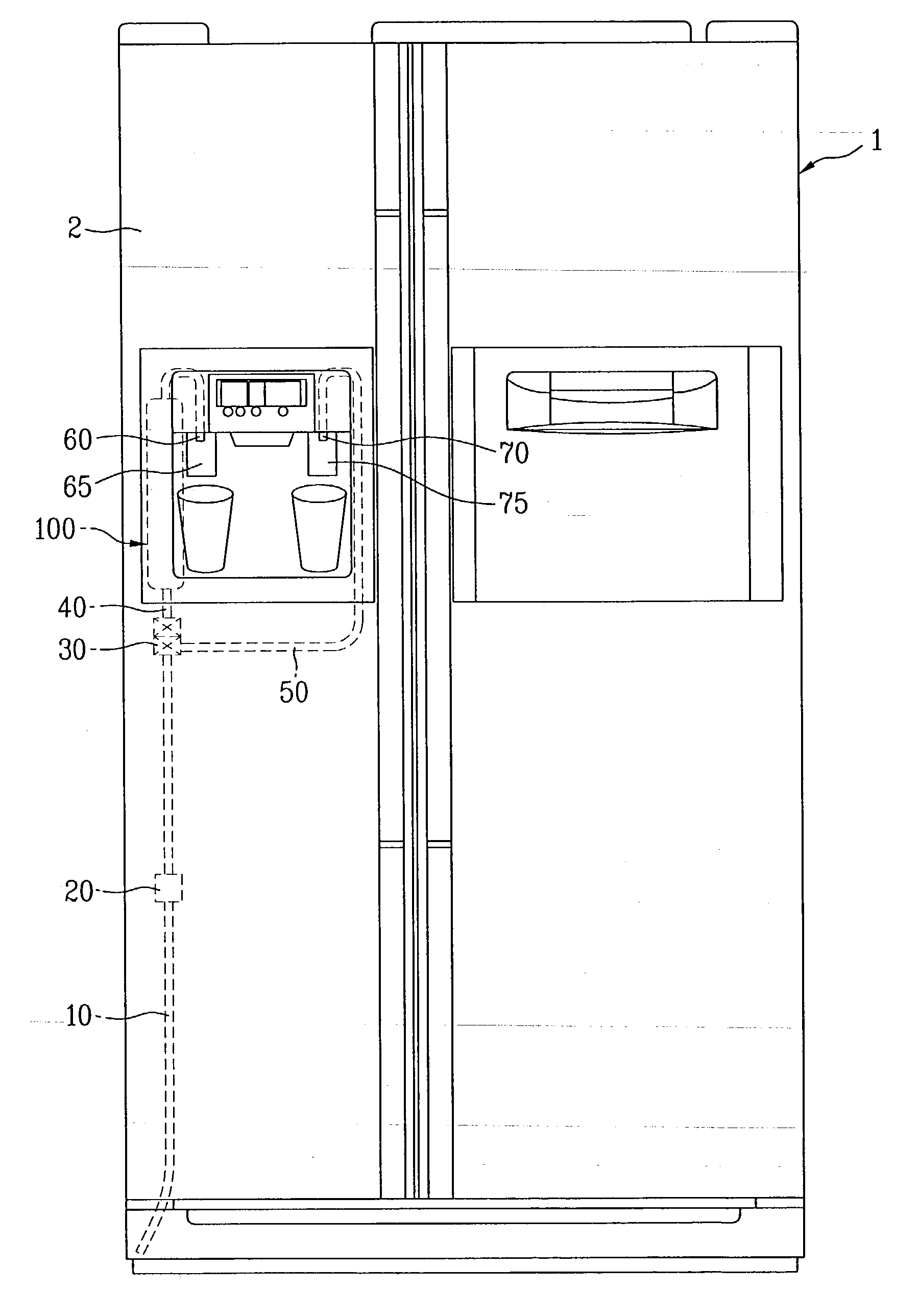

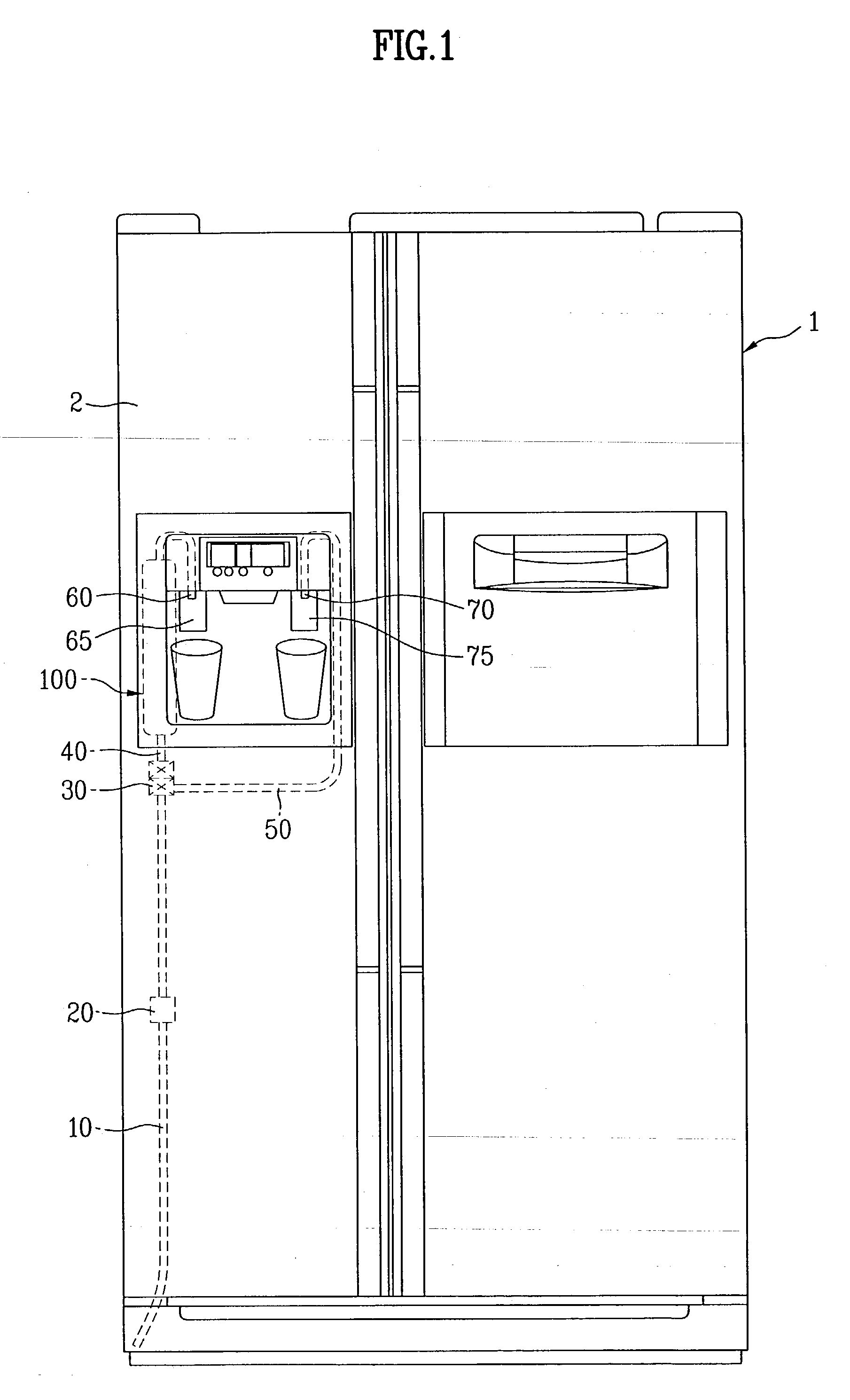

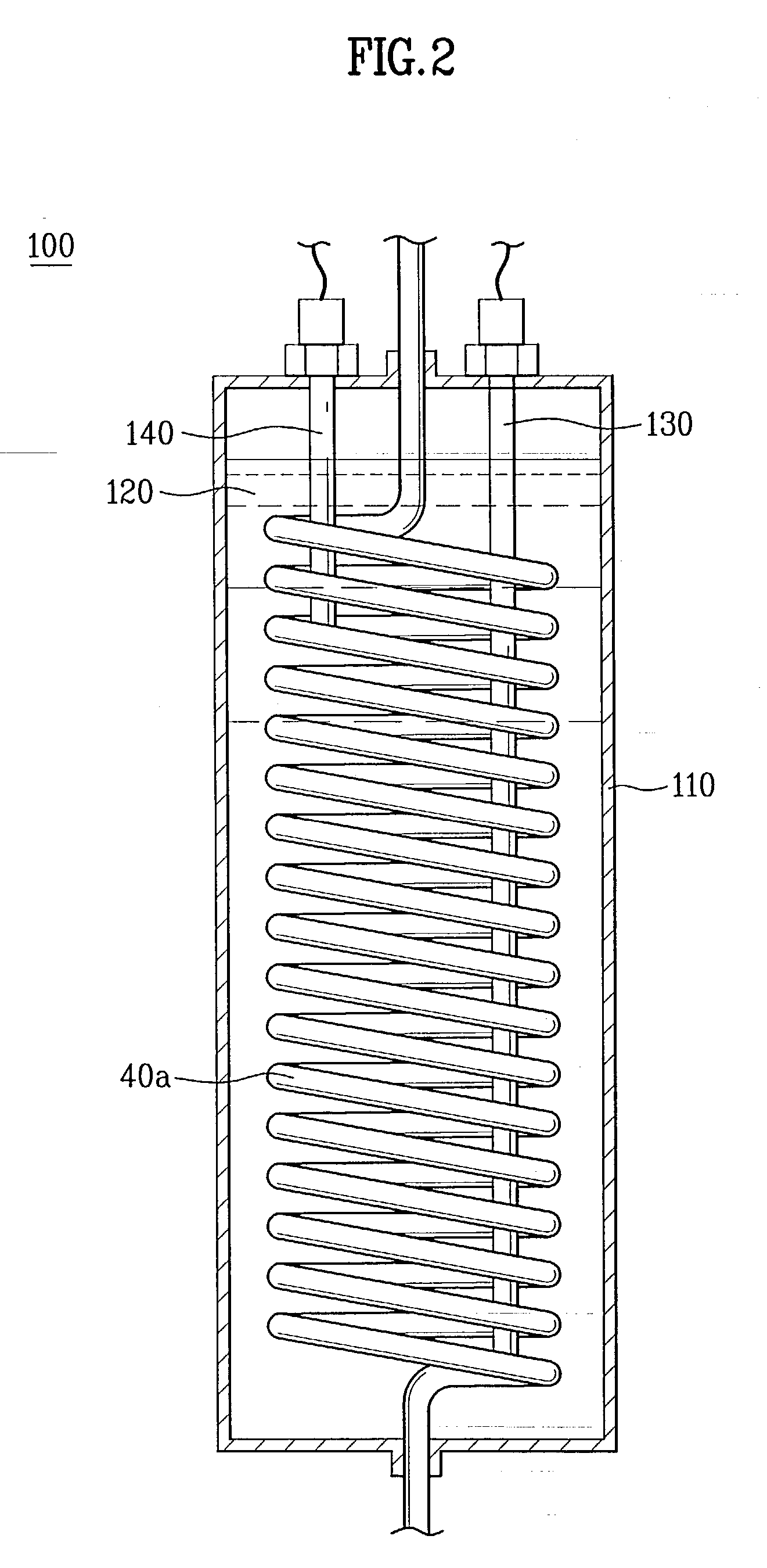

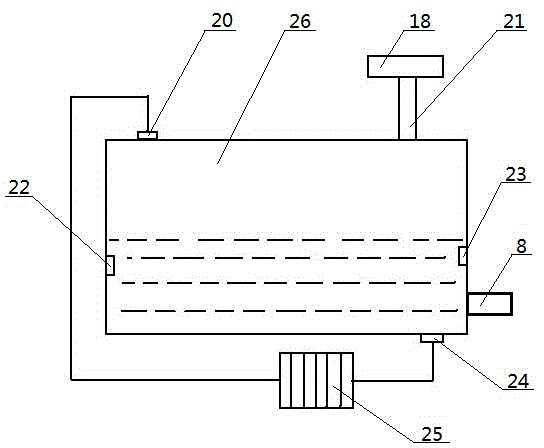

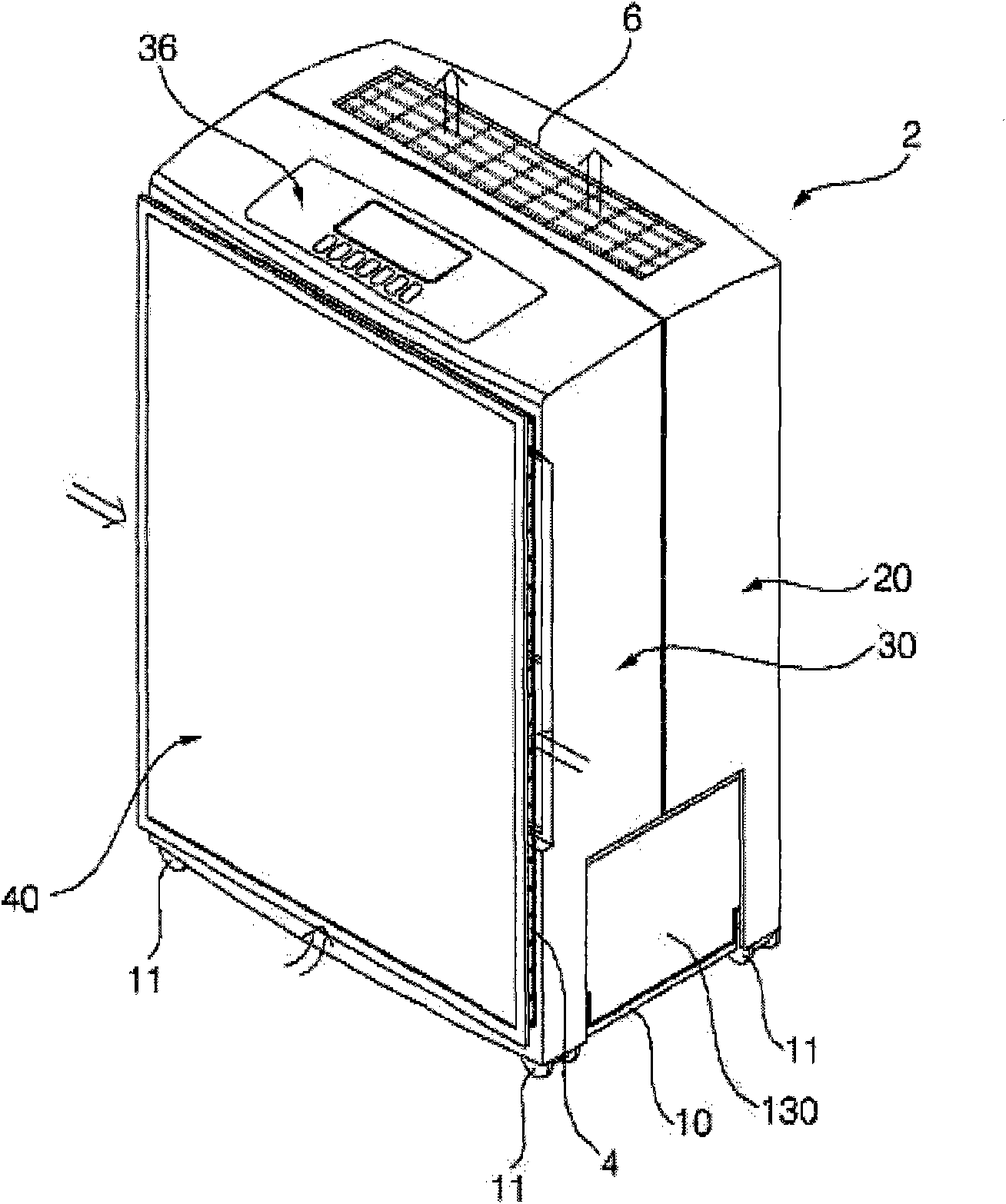

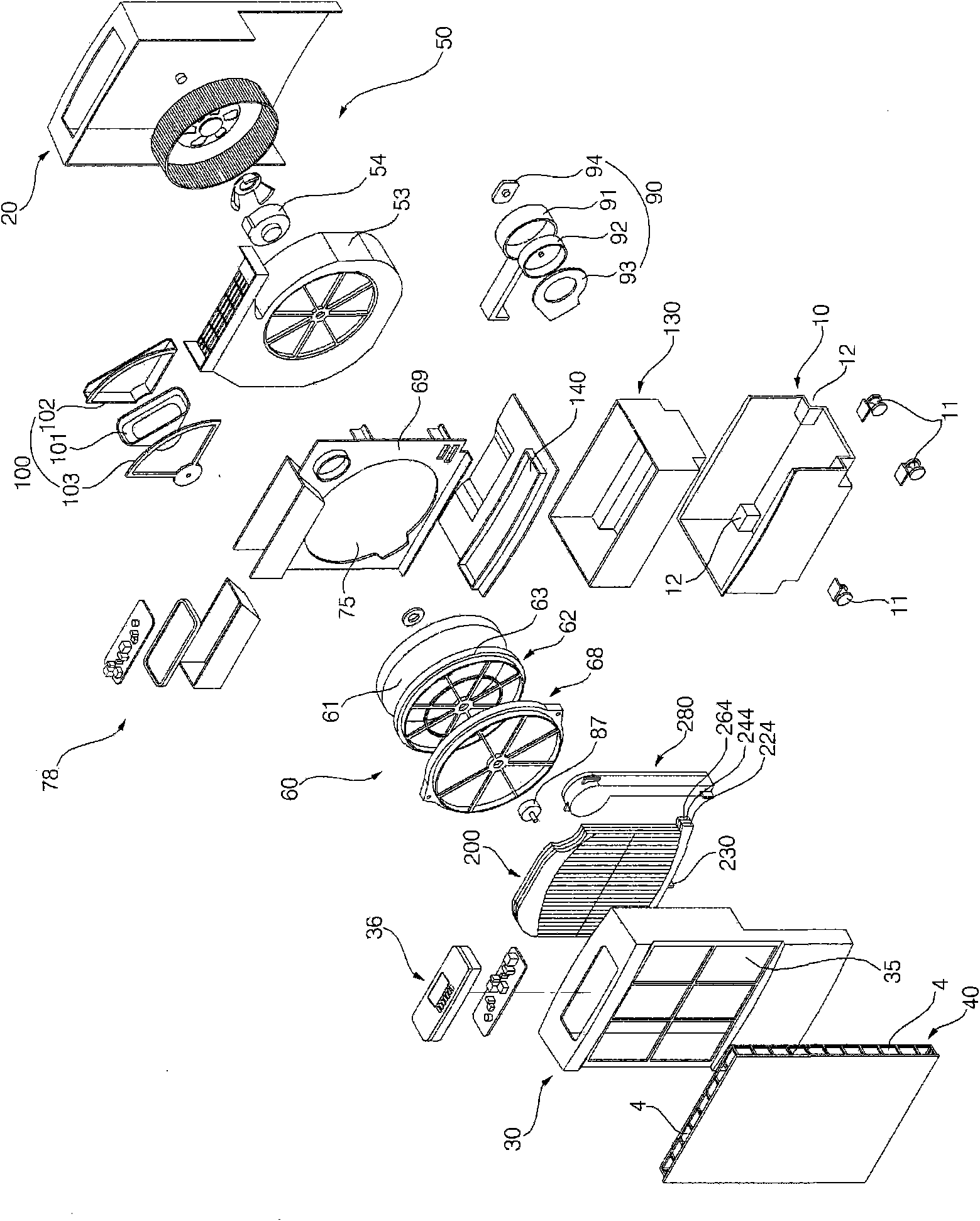

Water heating apparatus and refrigerator having the same

ActiveUS7130533B2Maximize heat transfer areaImprove sanitationDomestic refrigeratorsStorage heatersTime delaysEngineering

Owner:LG ELECTRONICS INC

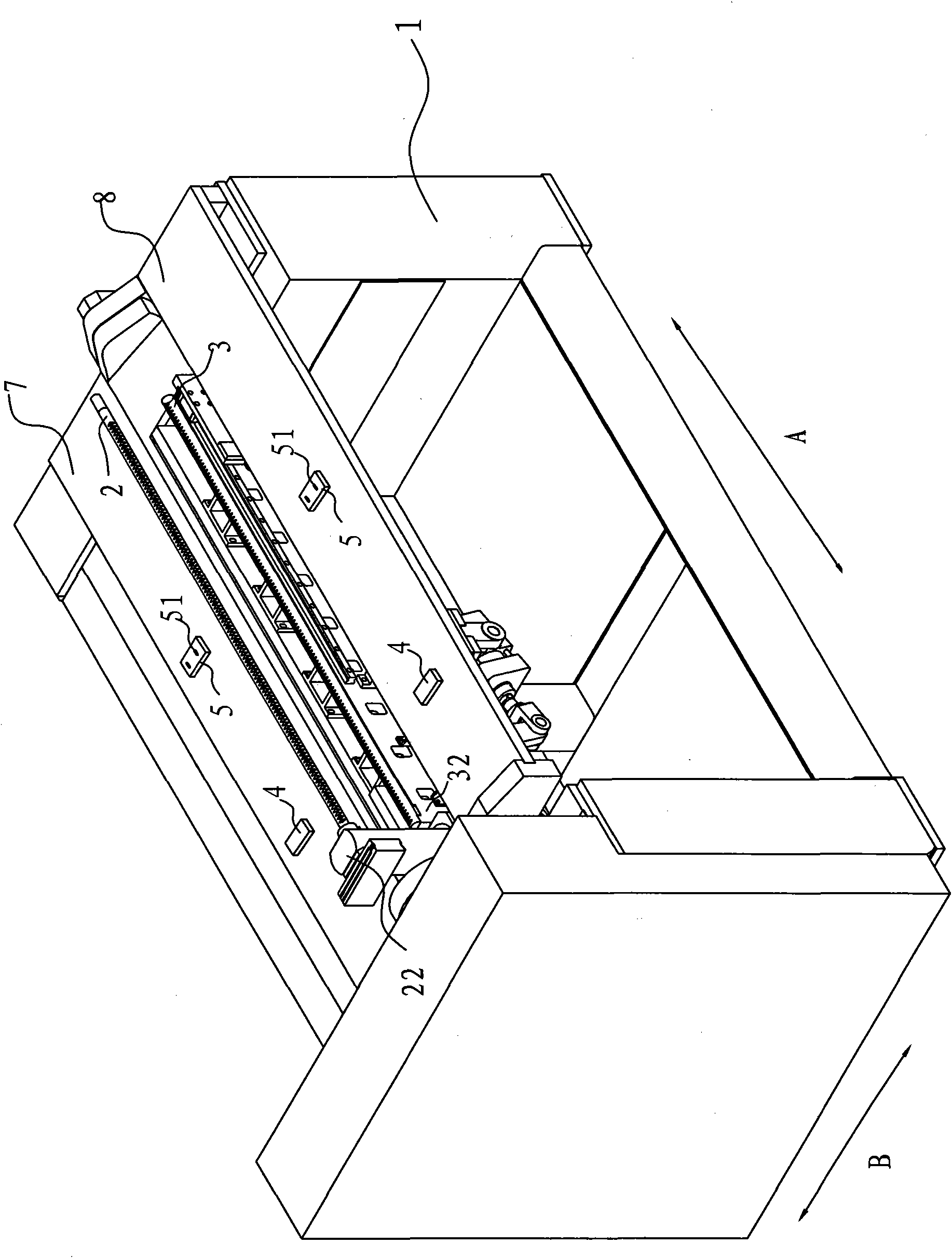

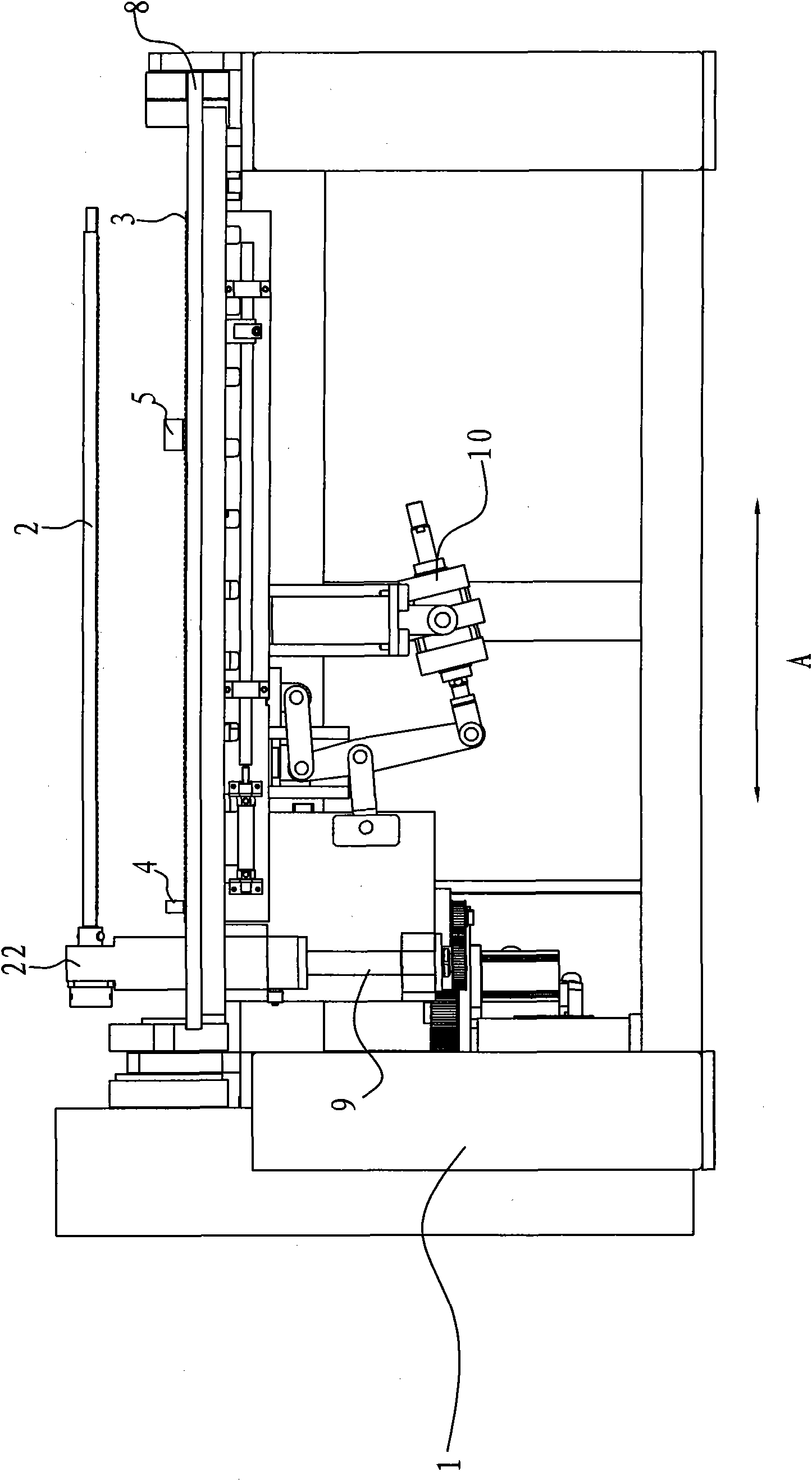

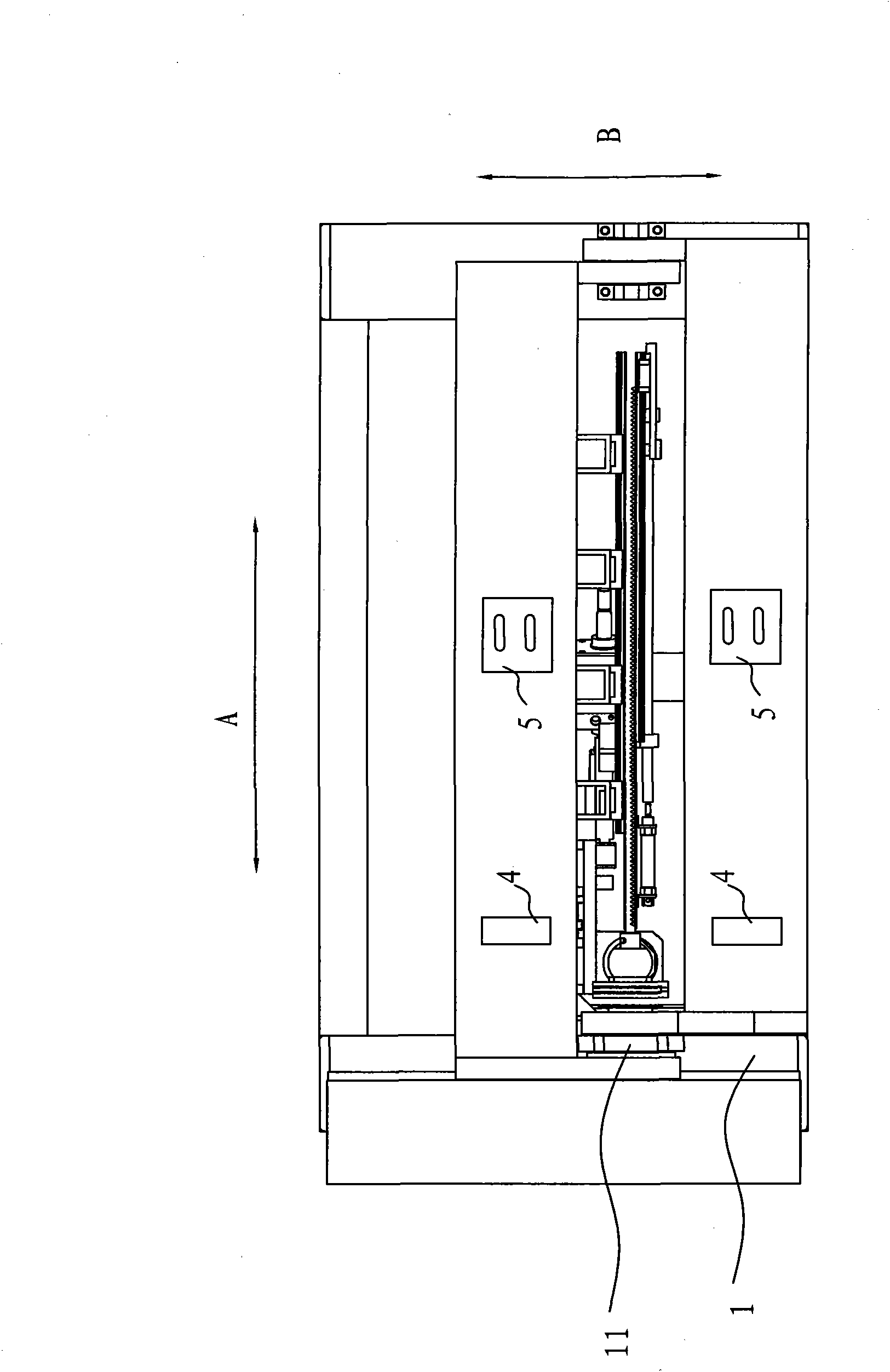

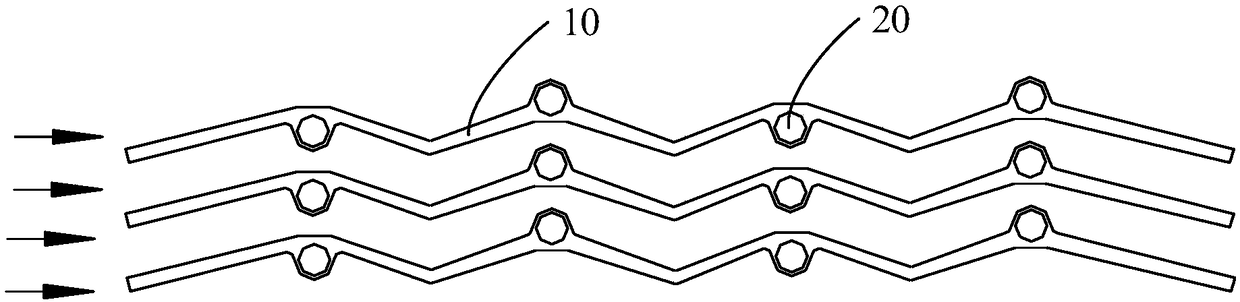

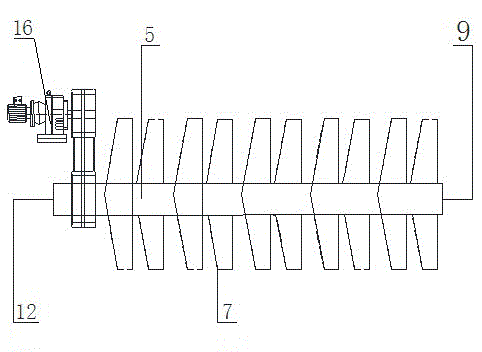

Bending equipment of heat exchanger and method for manufacturing bending heat exchanger

ActiveCN101837399AGuaranteed stabilityEnsure consistencyHeat exchange apparatusEngineeringMechanical engineering

The invention discloses bending equipment of a heat exchanger and a method for manufacturing a bending heat exchanger by utilizing the bending equipment. The bending equipment comprises a stand, an upper core shaft, a lower core shaft, a first bending plate and a second bending plate, wherein the upper core shaft is installed on the stand along the longitudinal direction of the stand, a plurality of upper grooves which are arranged along the longitudinal direction and are respectively provided with a downward opening are formed on the peripheral surface of the upper core shaft, the lower core shaft is installed on the stand along the longitudinal direction, a plurality of lower grooves which are arranged along the longitudinal direction and are respectively provided with an upward opening are formed on the peripheral surface of the lower core shaft, the plurality of lower grooves align with the plurality of upper grooves one by one in the vertical direction, the first bending plate and the second bending plate are respectively arranged at both transverse sides of the stand and can overturn, and at least one of the upper core shaft and the lower core shaft can move to twist a flat tube of the heat exchanger. Based on the bending equipment of the heat exchanger, all the flat tubes can be simultaneously twisted and bended in one step after the flat tubes, fins and collecting tubes are assembled and welded, and therefore, the consistency of the bending sizes and the stability of the whole bended heat exchanger are ensured and the production efficiency is enhanced.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

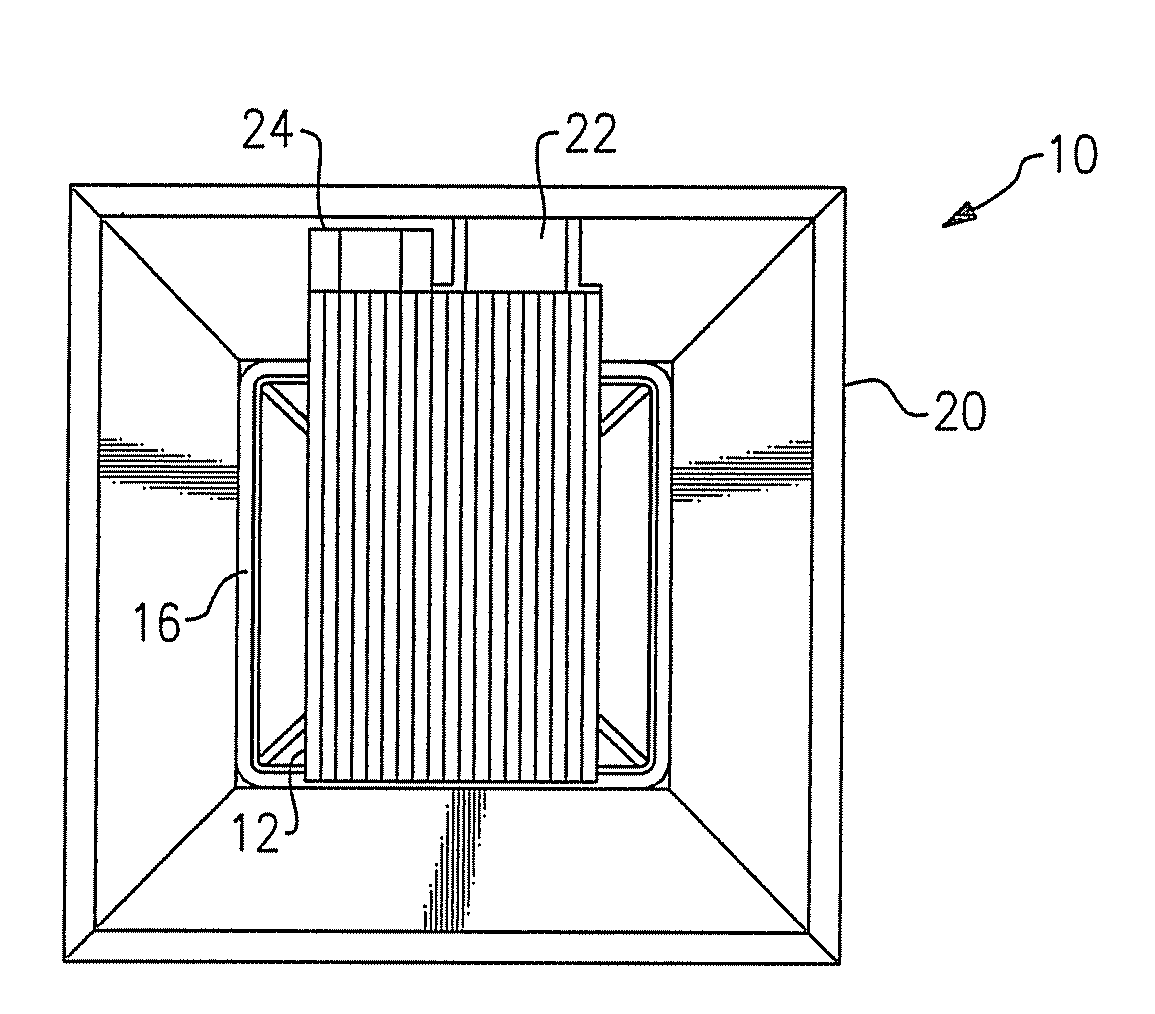

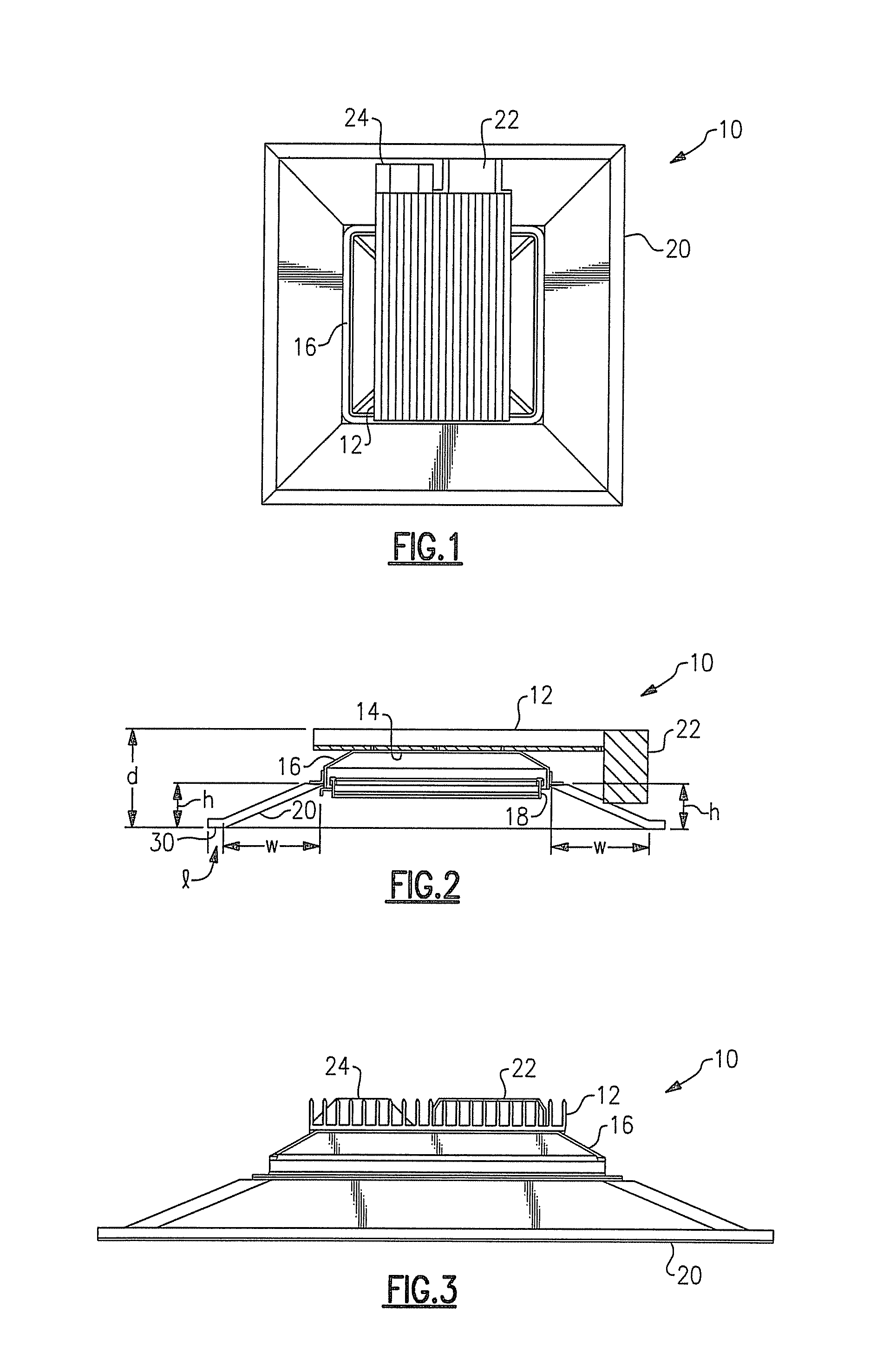

Light fixtures and lighting devices

ActiveUS8136965B2Minimize striations or hot spots projected on wallsMaximize heat transfer areaLighting support devicesPoint-like light sourceLight equipmentEffect light

A lighting device comprises a heat sink, a housing mounted to and / or thermally coupled to the heat sink, a basket assembly attached to the housing, a solid state light emitter thermally coupled to the heat sink, and a baffle assembly attached to the housing. Also, a lighting device comprising a basket assembly and a baffle assembly. In some embodiments, the basket assembly comprises a first member defining a first opening, a second member, a space between the first and second members, and lenses in the opening and in the space. In some embodiments, the heat sink extends farther in a first direction in a first plane than a largest dimension of the housing in any plane which is parallel to the first plane. In some embodiments, at least one additional component (e.g., a power supply module or a junction box) is in contact with the heat sink element.

Owner:IDEAL IND LIGHTING LLC

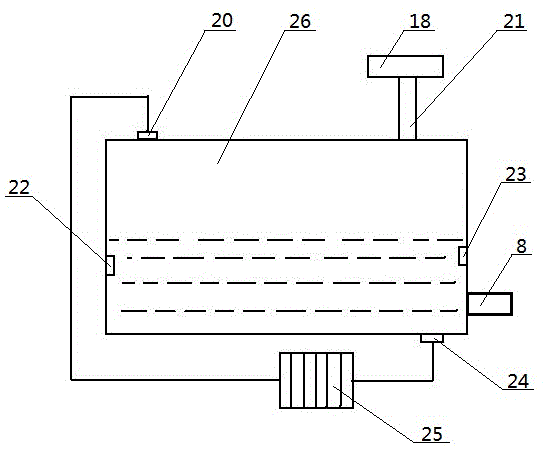

Water heating apparatus and refrigerator having the same

ActiveUS20040202457A1Improve heat resistanceAvoid corrosionDomestic refrigeratorsStorage heatersTime delaysEngineering

The present invention relates to a water heating apparatus having a heat exchanger that has a maximized heat transfer area between a hot water supply tube and a heater so that clean hot water is continuously fed without a time delay. To achieve these objects, a water heating apparatus comprises: a case defining a body; a hot water supply tube having an heat exchanger installed in the case; a heat storage liquid material received in the case; and a heater installed in the case, for heating the heat storage liquid material.

Owner:LG ELECTRONICS INC

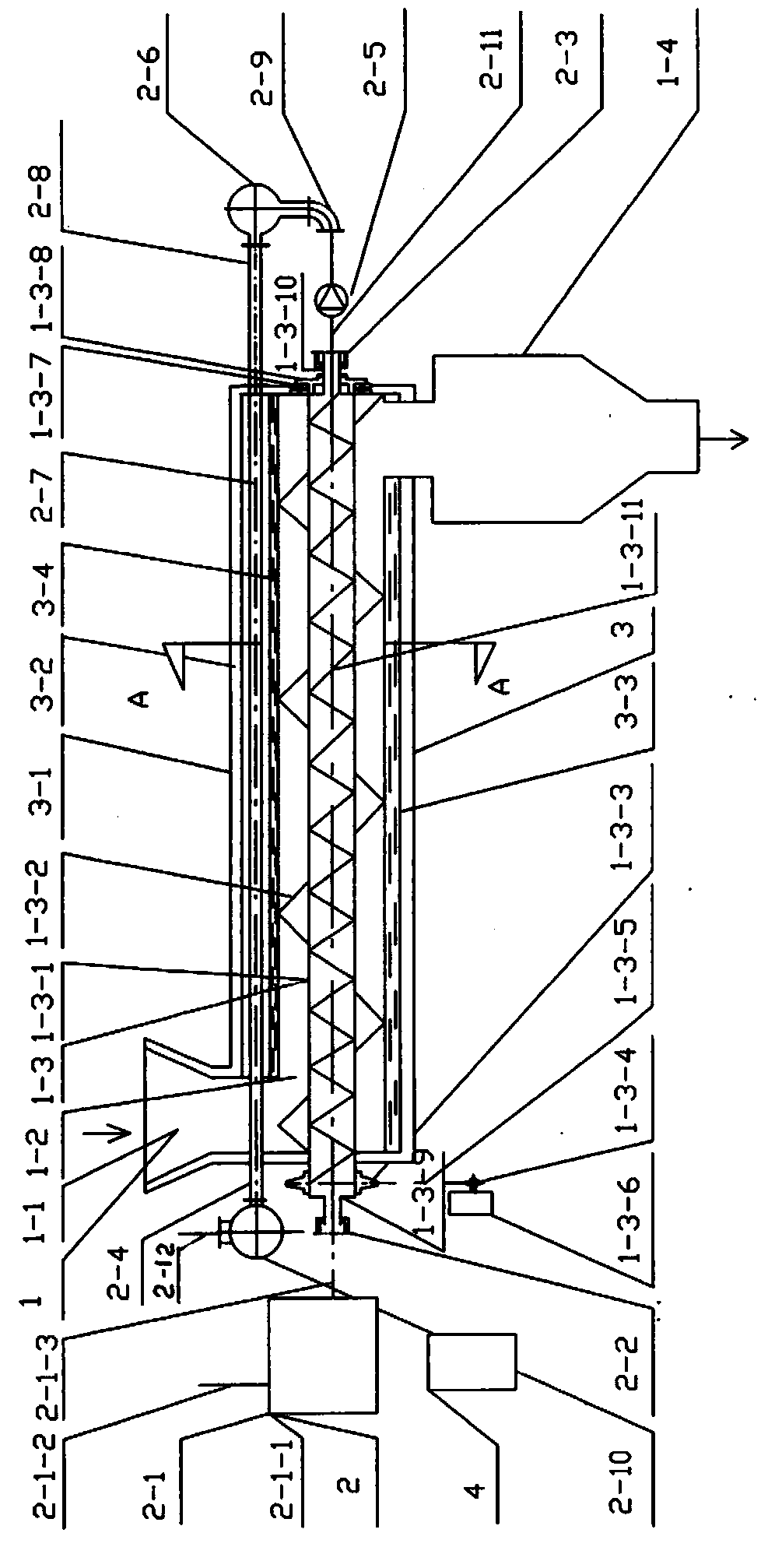

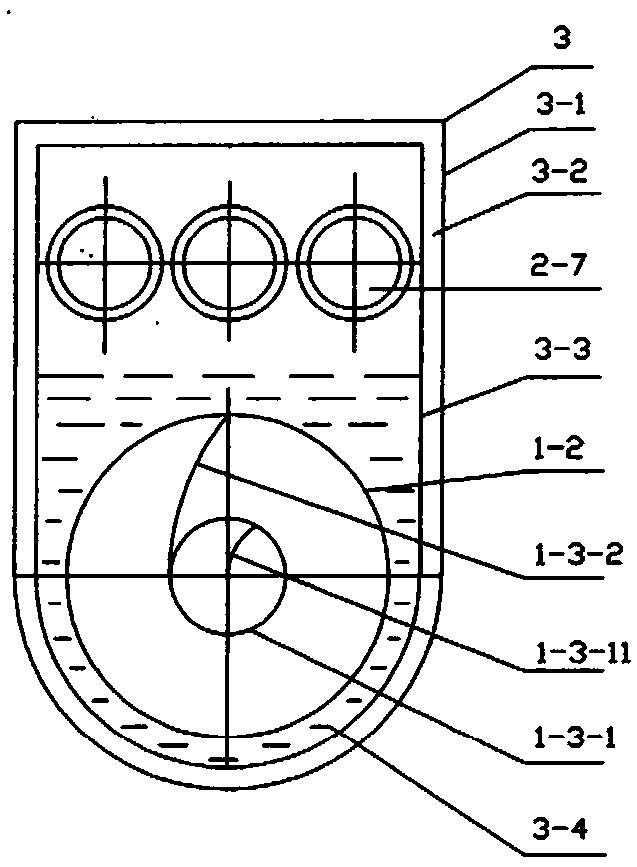

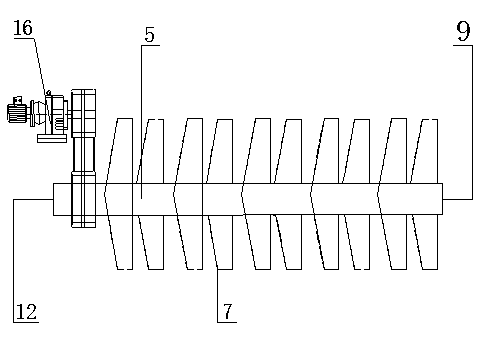

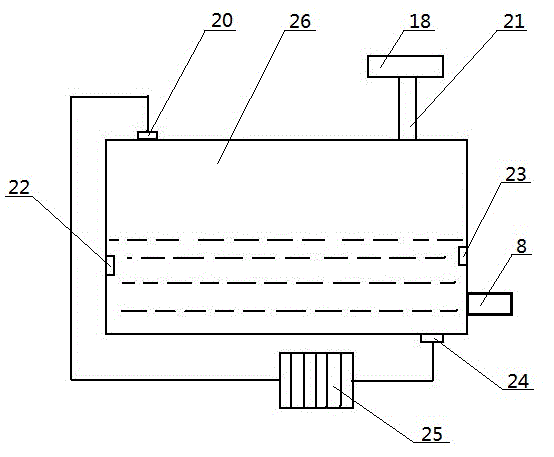

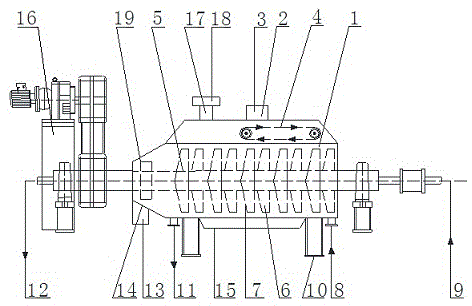

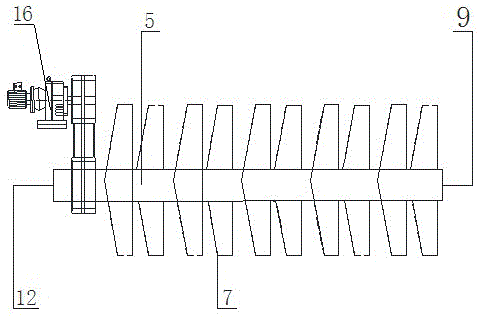

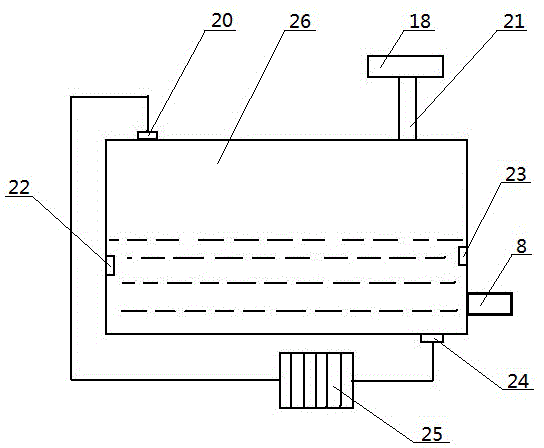

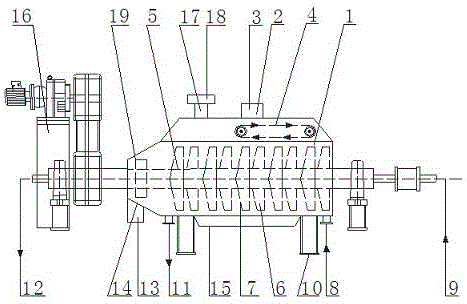

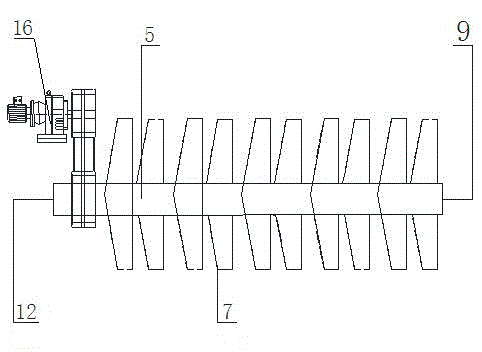

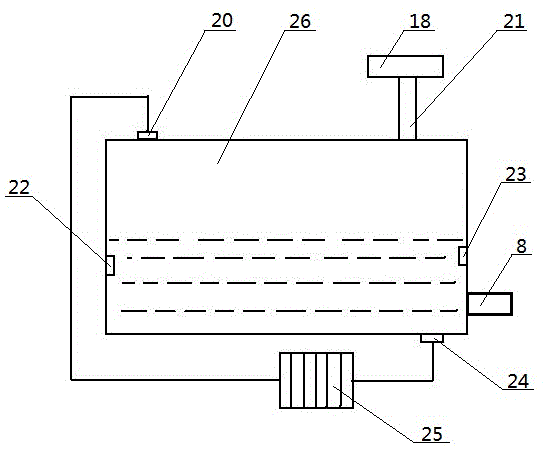

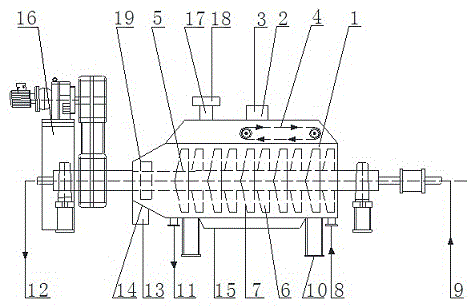

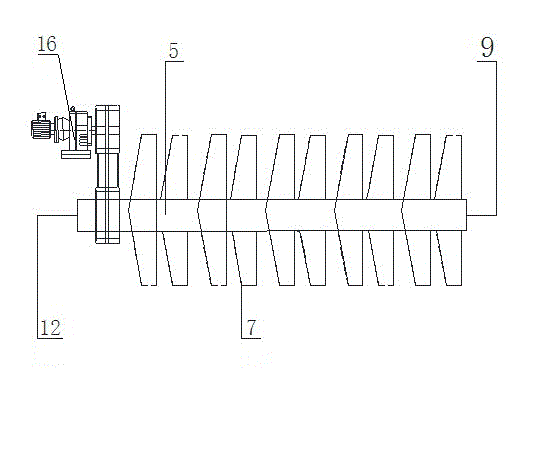

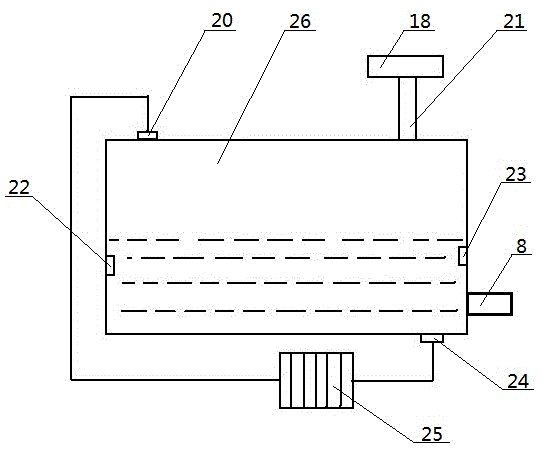

High-temperature solid bulk cargo waste heat recovery device

ActiveCN104180357AMaximize heat transfer areaMaximize the heat transfer effectSteam generation using hot heat carriersThermal energyBulk cargo

The invention discloses a high-temperature solid bulk cargo waste heat recovery device which comprises a high-temperature solid bulk cargo heat exchange system (1), a water heat exchange system (2), a high-temperature working medium heat exchange system (3) and an electric control cabinet (4). The left end and the right end of a screw propulsion cylinder (1-3-1) in the high-temperature solid bulk cargo heat exchange system (1) are connected with a water tank water outlet pipe (2-1-3) and a high-pressure water pump water inlet pipe (2-11) in the water heat exchange system (2) through a left moving seal device (2-2) and a right moving seal device (2-3) respectively, and a heat exchange bin (1-2) in the high-temperature solid bulk cargo heat exchange system (1) is welded with a high-temperature working medium box (3-3) in the high-temperature working medium heat exchange system (3). The high-temperature solid bulk cargo waste heat recovery device has the advantages that the heat exchange bin (1-2) is completely soaked in a high-temperature working medium (3-4), heat exchange effect is maximized, a screw propulsion device (1-3) is arranged in the heat exchange bin (1-2), low-temperature water flows in the screw propulsion device (1-3), so that high-temperature solid bulk cargoes exchange heat with two walls, the heating surface of a finned pipe (2-7) is large, feed hopper light pipes (2-4) are heated by the high-temperature solid bulk cargoes with the temperature of about 900 DEG C, and the output quality of heat energy is improved.

Owner:朱杰 +1

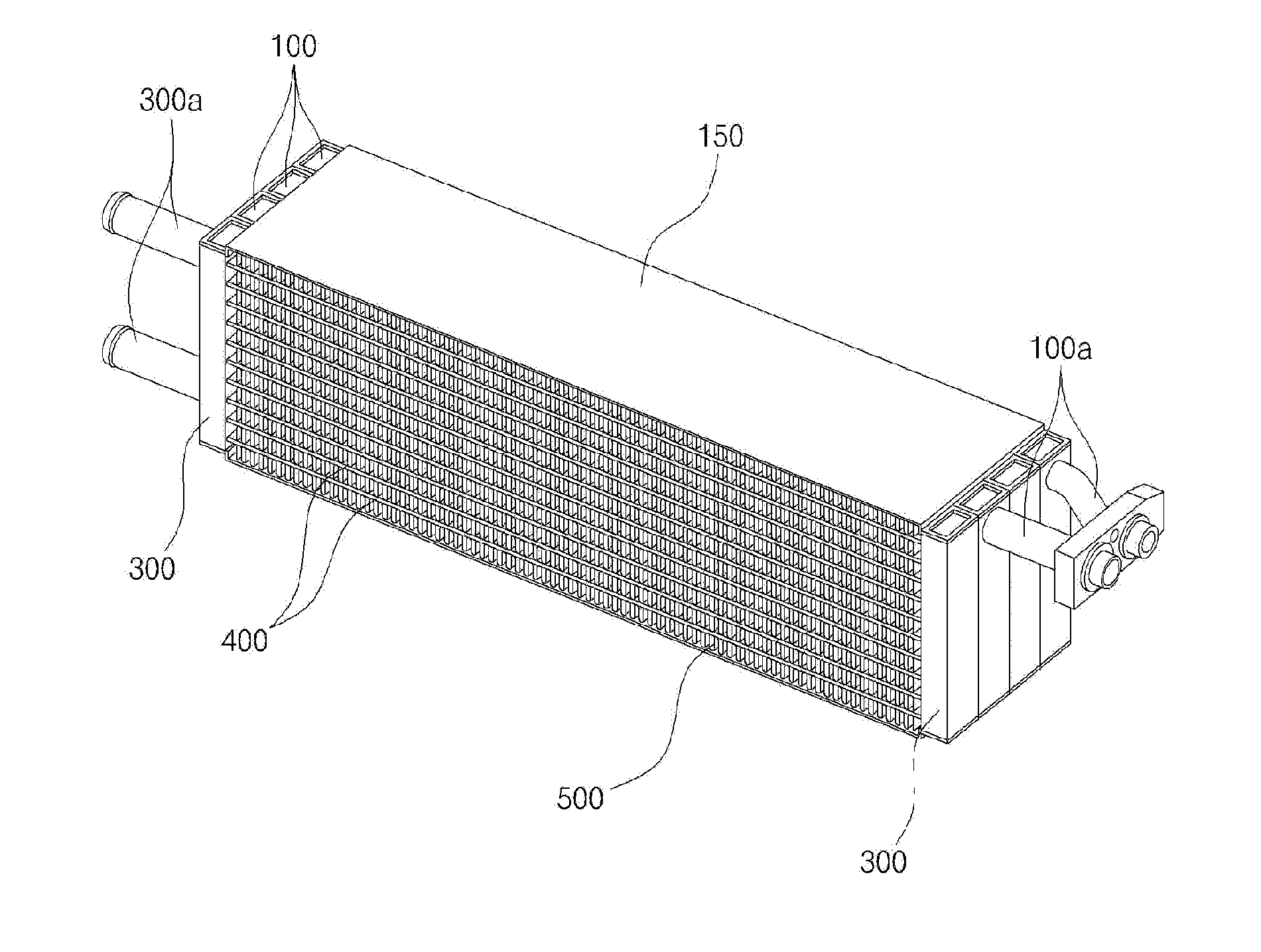

Evaporator having vertical arrangement of header pipe for vehicle air conditioner

InactiveUS20170038104A1Maximize heat transfer areaMaximum efficiency of heat exchangeEvaporators/condensersVehicle heating/cooling devicesCoolant flowVaporization

The present invention provides an evaporator having a vertical arrangement of header pipes for a vehicle air conditioner, the evaporator including: a pair of header pipes disposed to face each other with a gap therebetween, providing a circulation path for a coolant supplied in the cooling cycle, and discharging the coolant that has exchanged heat; a plurality of tubes laterally arranged between the pair of header pipes to communicate with the header pipes, connected in a longitudinal direction of the header pipes, and allowing a coolant flowing inside through inlets of the header pipes to exchange heat with air while flowing in a zigzag pattern toward outlets of the header pipes; and heat-dissipating fins disposed among the tubes and dissipating heat of vaporization from the tubes while passing the air supplied from the fan.

Owner:DONGHWAN IND CORP

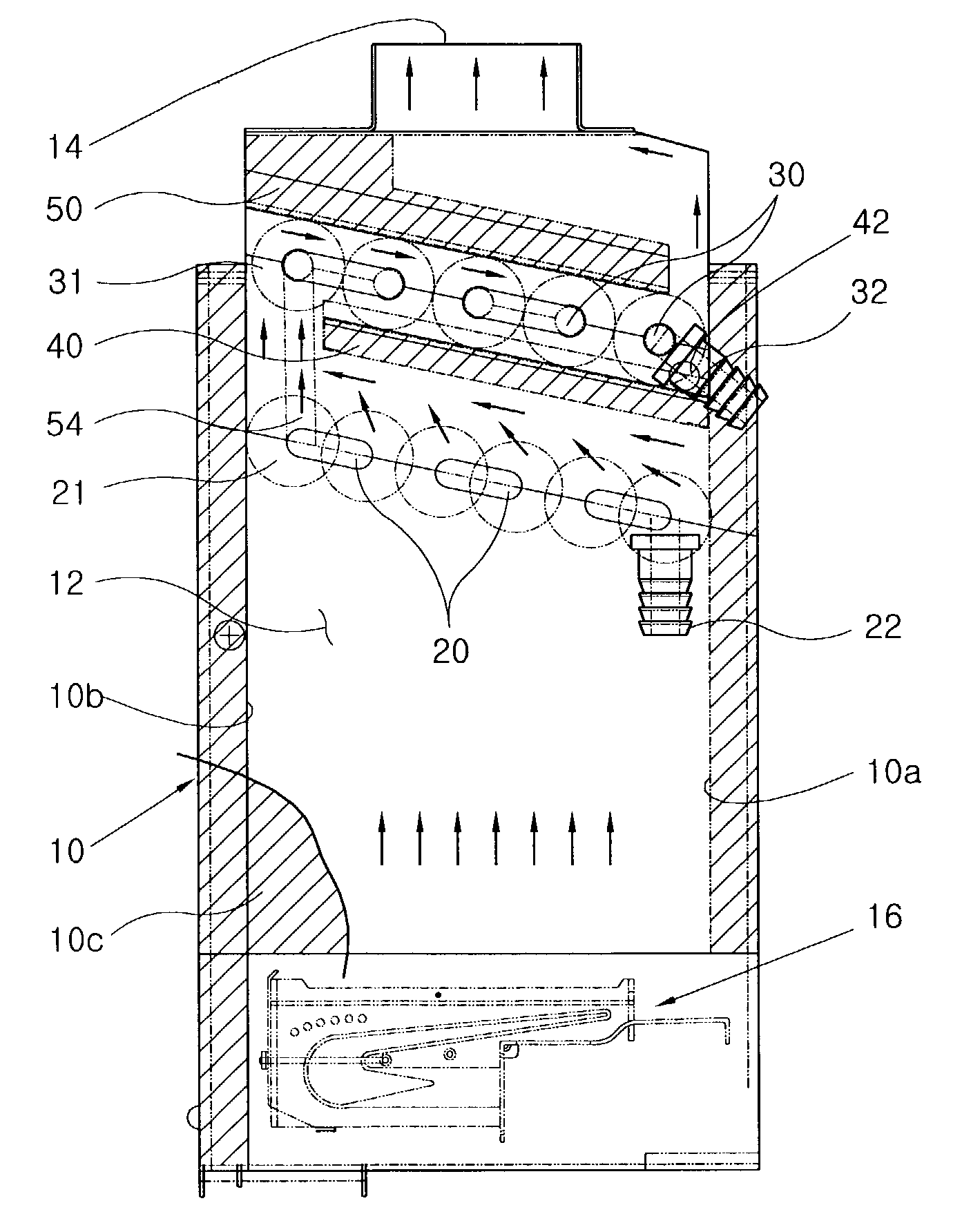

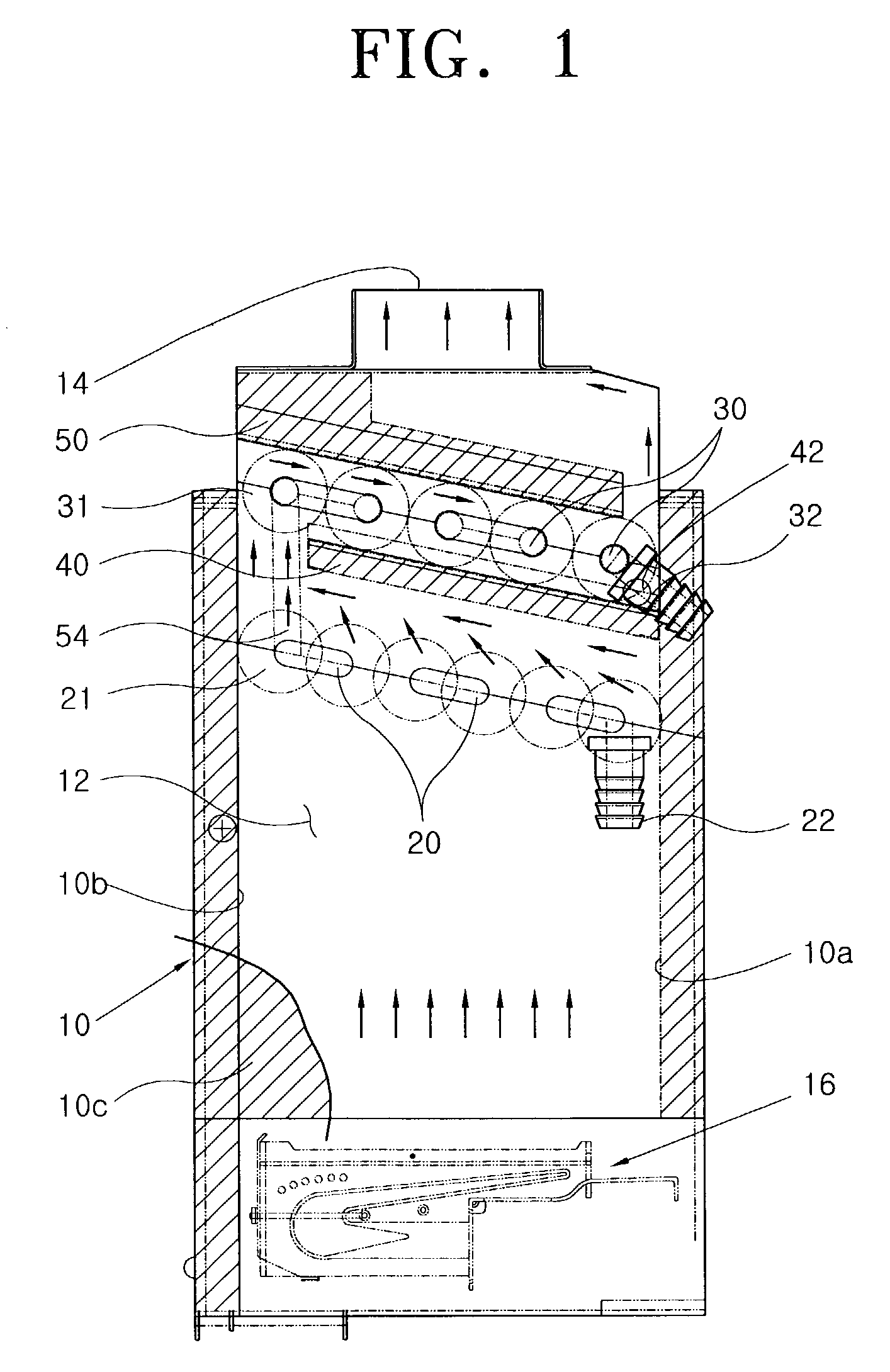

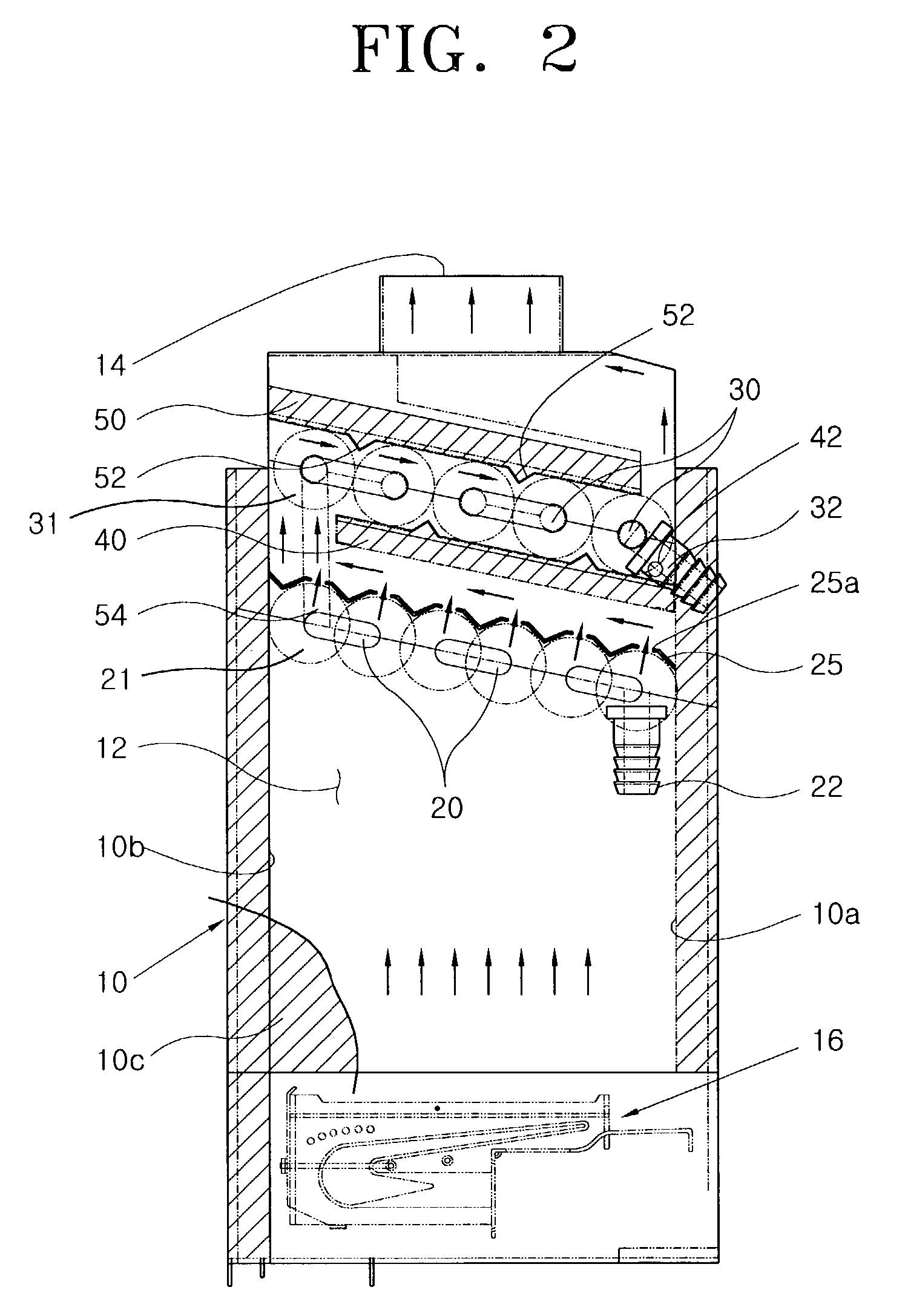

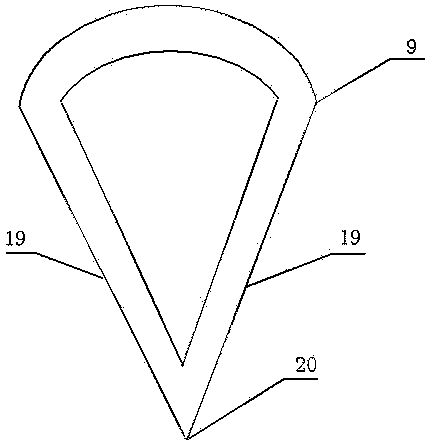

Arrangement structure of heat exchanger in condensing gas boiler

ActiveUS7353781B2Accomplish compactnessMaximize heat transfer areaBoiler water tubesAir heatersCombustion chamberHorizontal axis

An arrangement structure of heat exchangers in a condensing gas boiler is provided, which includes a casing provided with a combustion chamber therein, and a gas burner provided in the lower portion of the combustion chamber. The arrangement structure of heat exchangers in a condensing gas boiler includes: a present heat exchanger slantly arranged with a predetermined slope with respect to a horizontal axis on a transverse cross-section in the casing; a latent heat exchanger disposed in parallel with the present heat exchanger, in the same area as that of the present heat exchanger in the upper portion of the present heat exchanger; a condensed waterspout provided in parallel with between the present heat exchanger and the latent heat exchanger, whose one end contacts one of the inner wall surfaces of the casing and whose other end is disposed spaced from the other of the inner wall surfaces thereof; and an exhaust gas flowing plate provided in parallel with the outer wall of the latent heat exchanger, whose one end is spaced from one of the inner wall surfaces of the casing and whose other end contacts the other of the inner wall surfaces of the casing in order to induce condensed water and exhaust gas to flow in an identical direction. Thus, the heat transfer area is maximized, and present heat and condensing conditions are made to improve a heat exchanging efficiency, and to accomplish compactness and corrosion resistance of the boiler.

Owner:KYUNGDONG NAVIEN

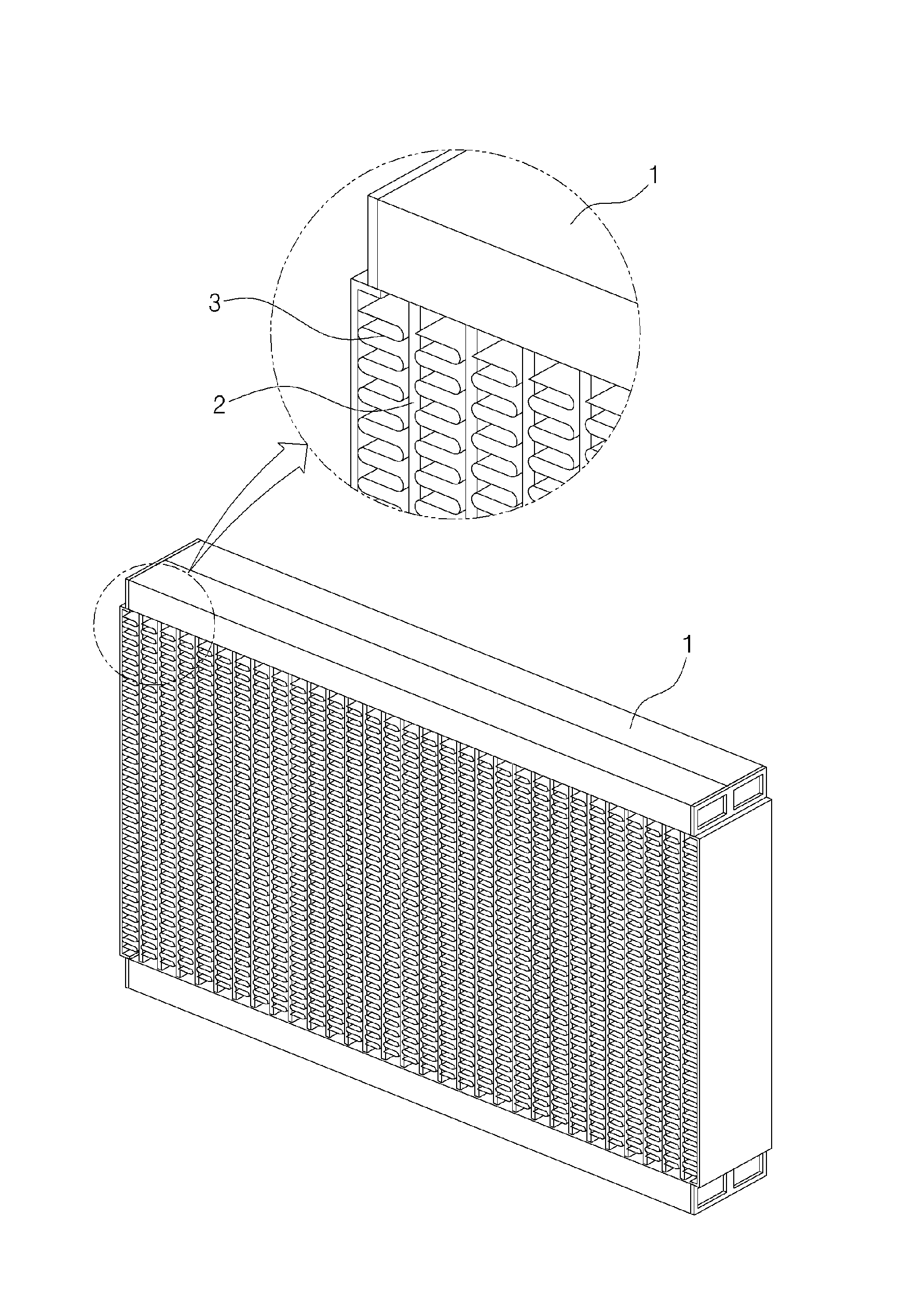

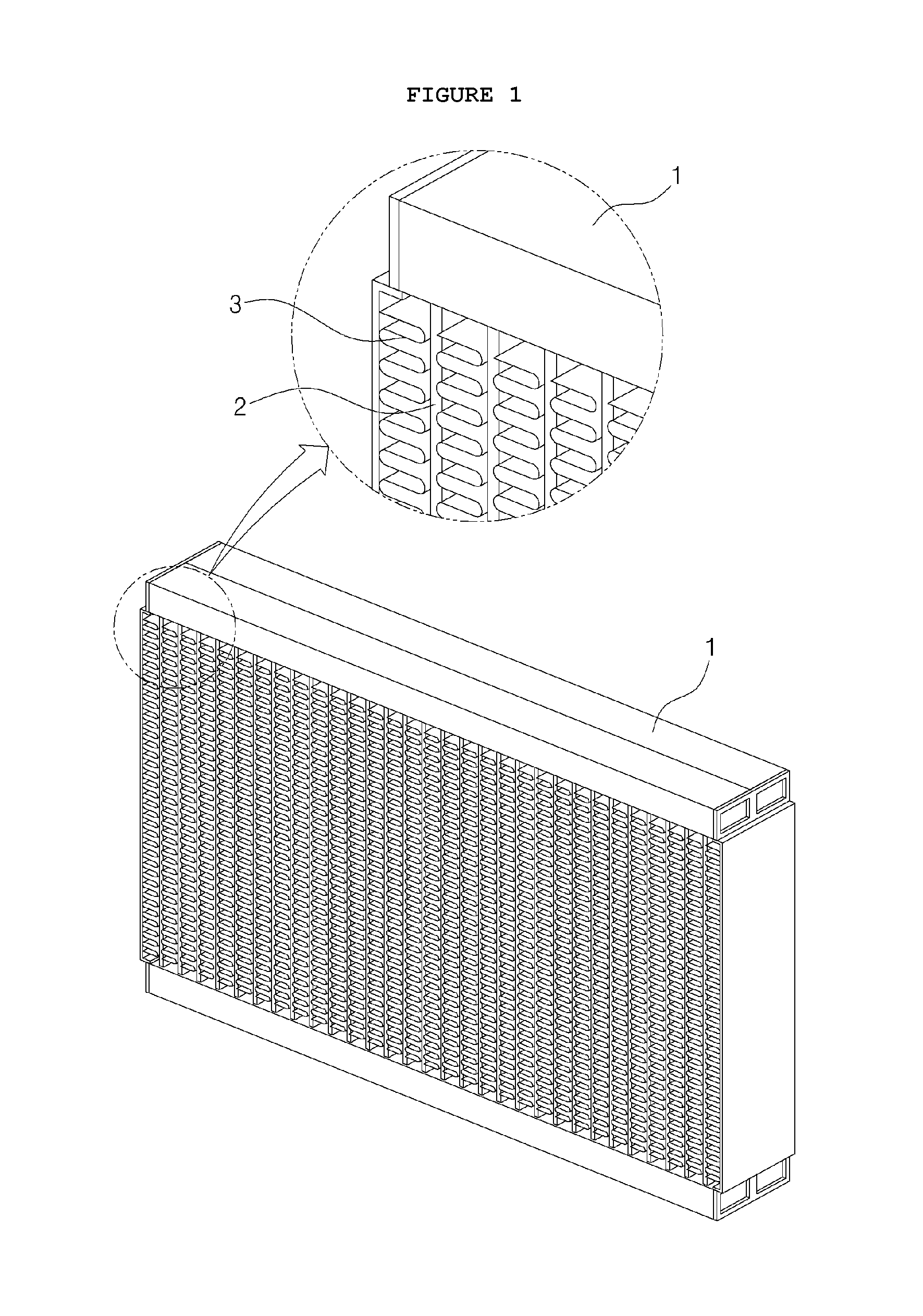

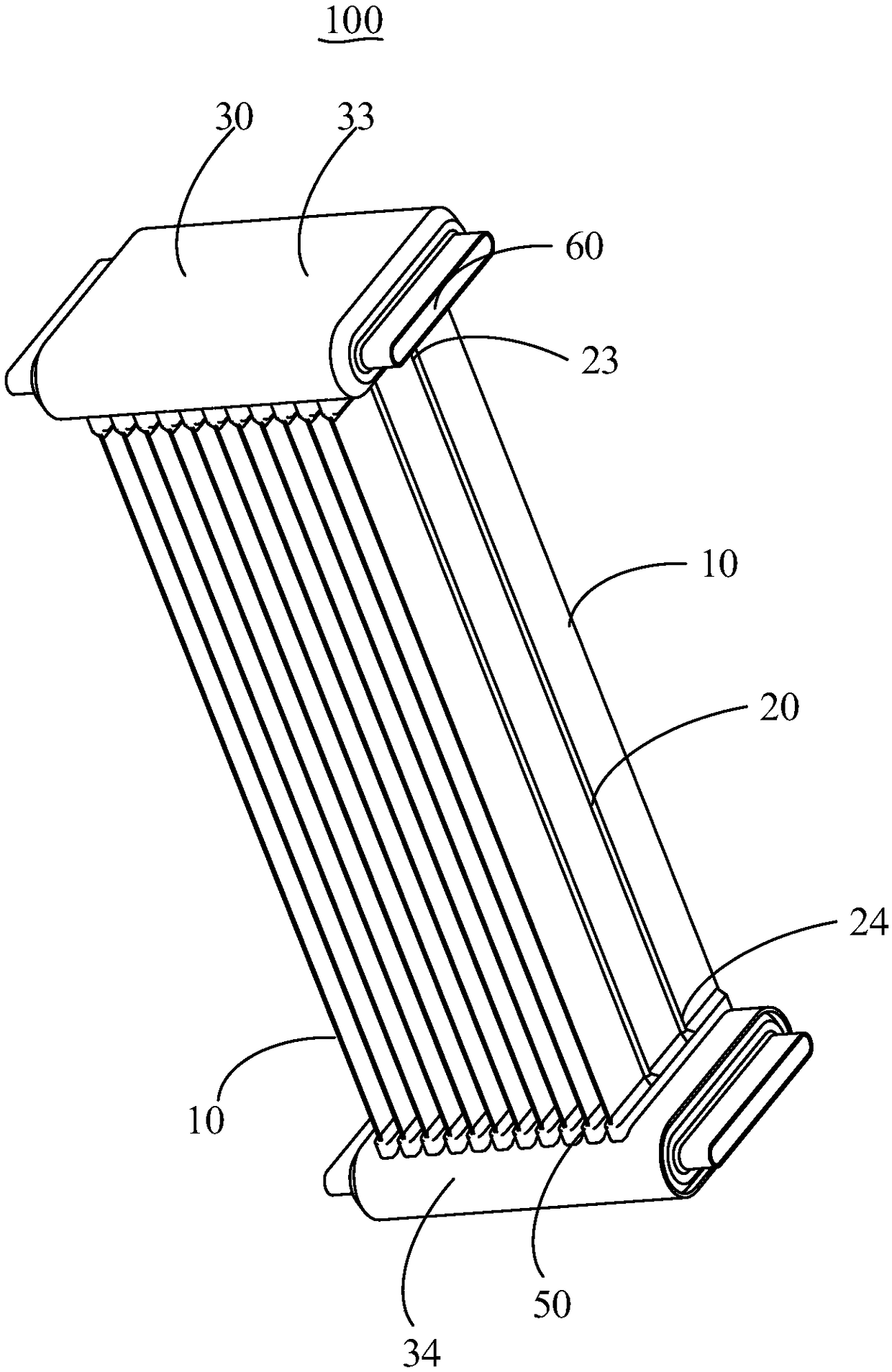

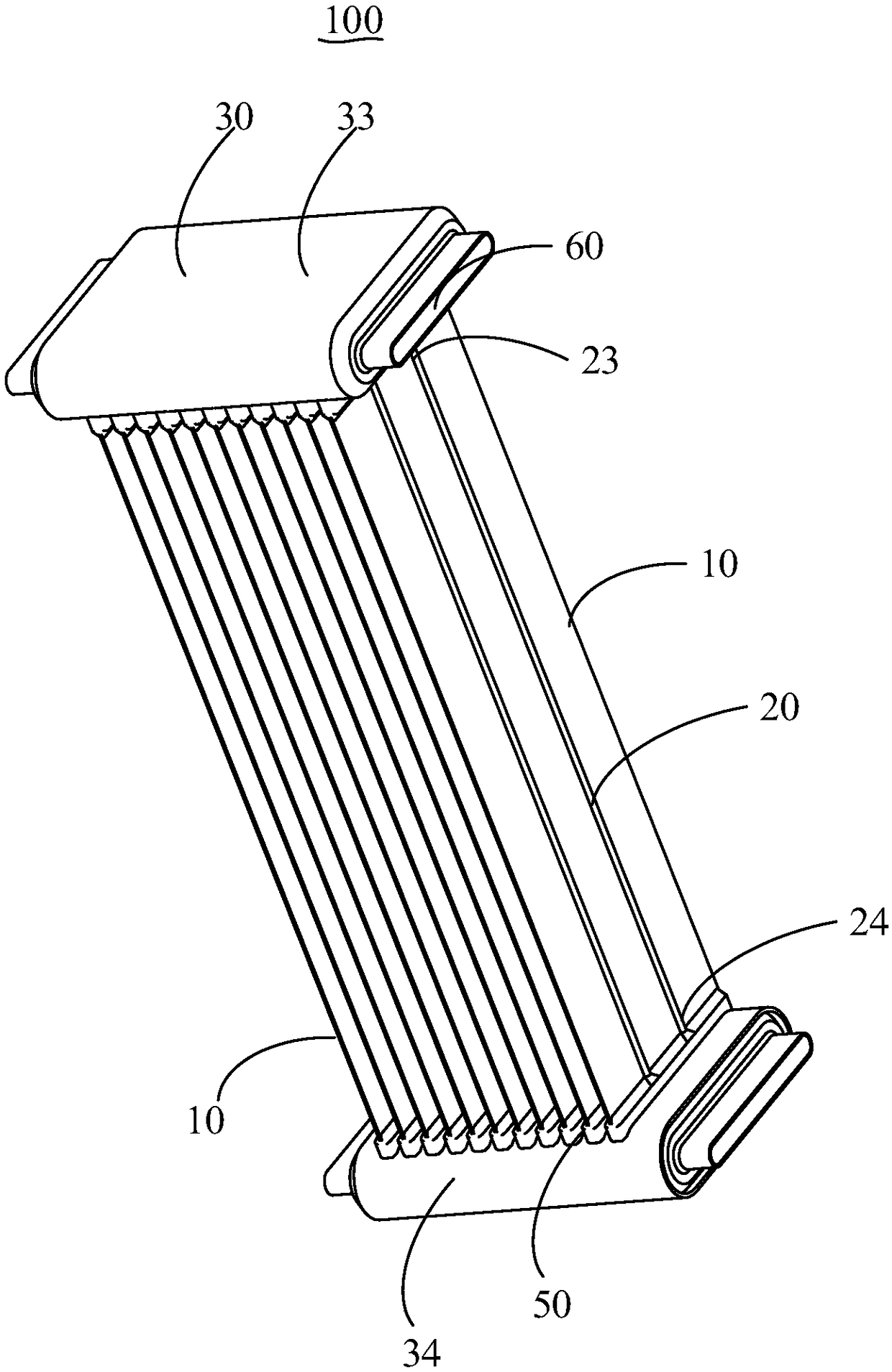

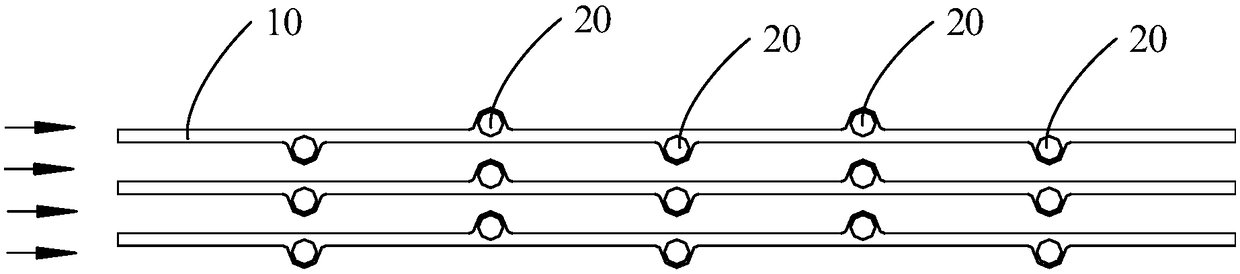

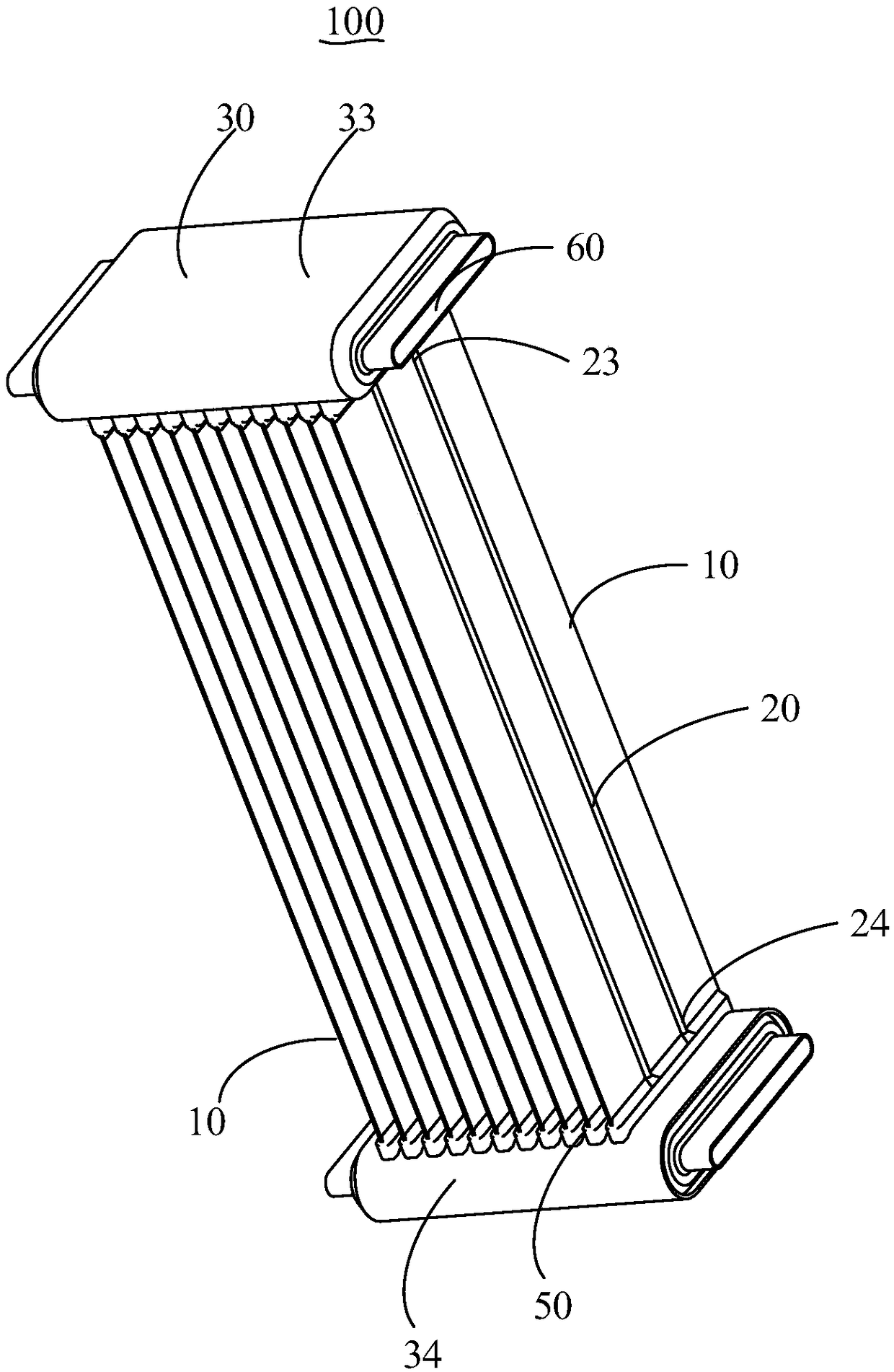

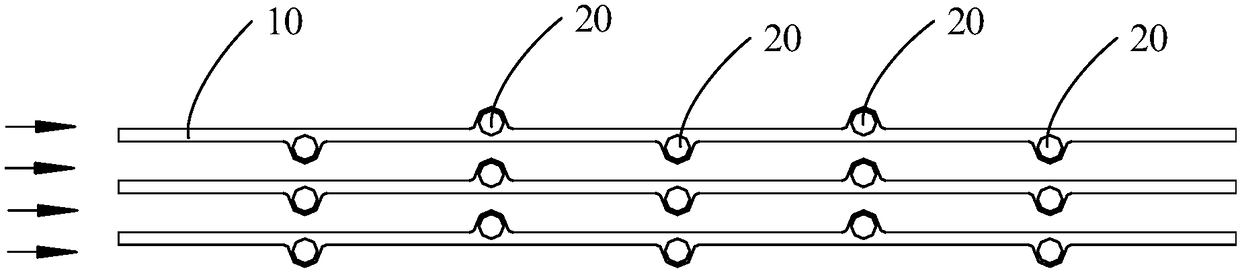

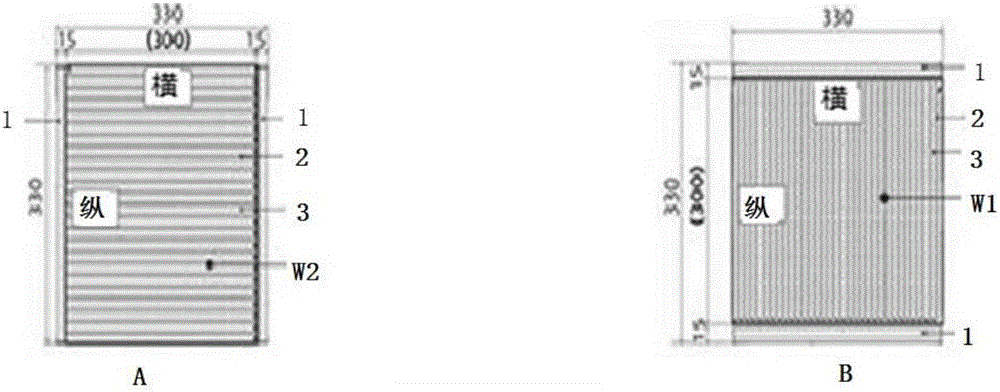

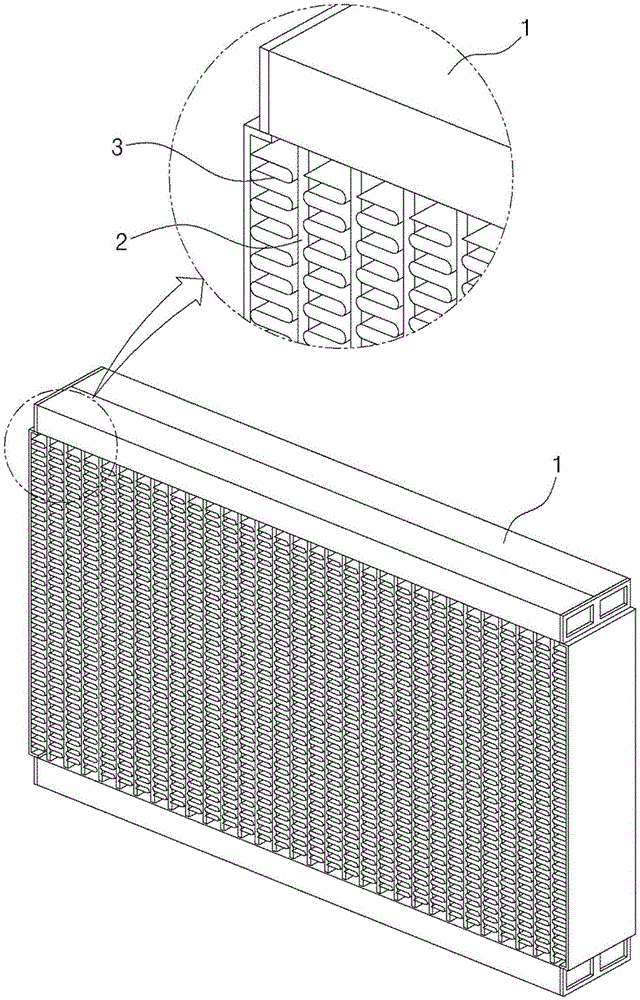

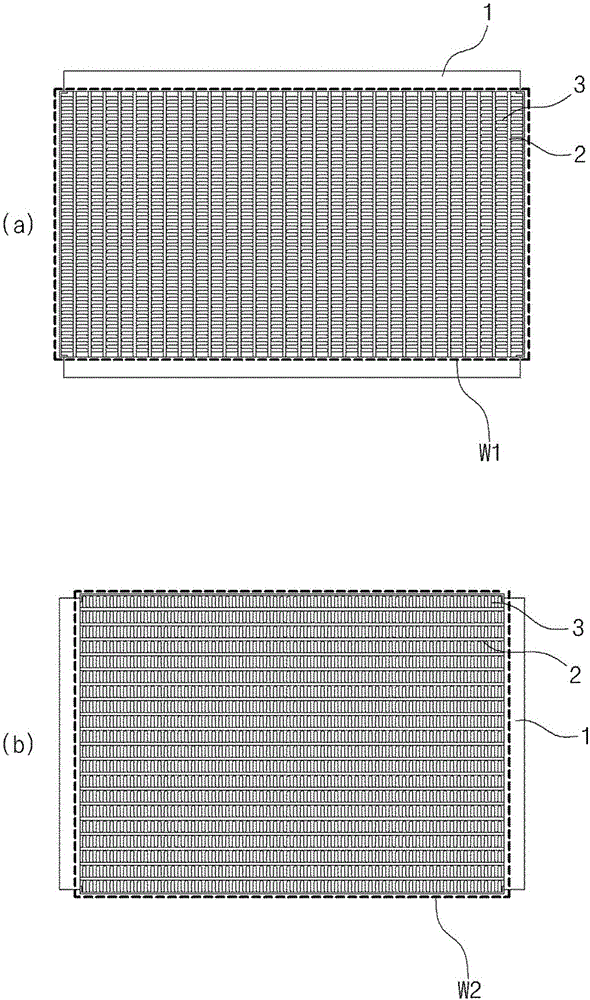

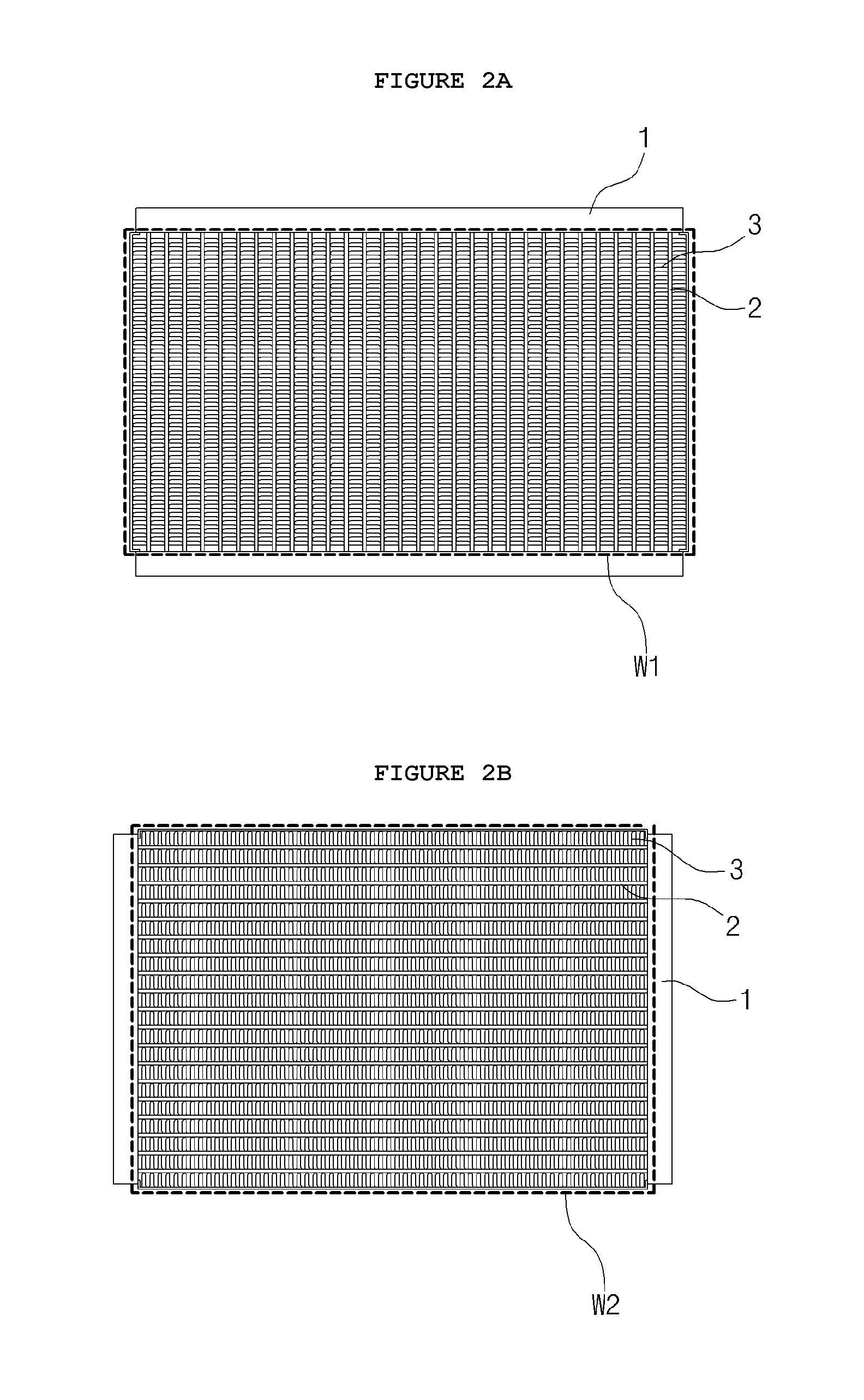

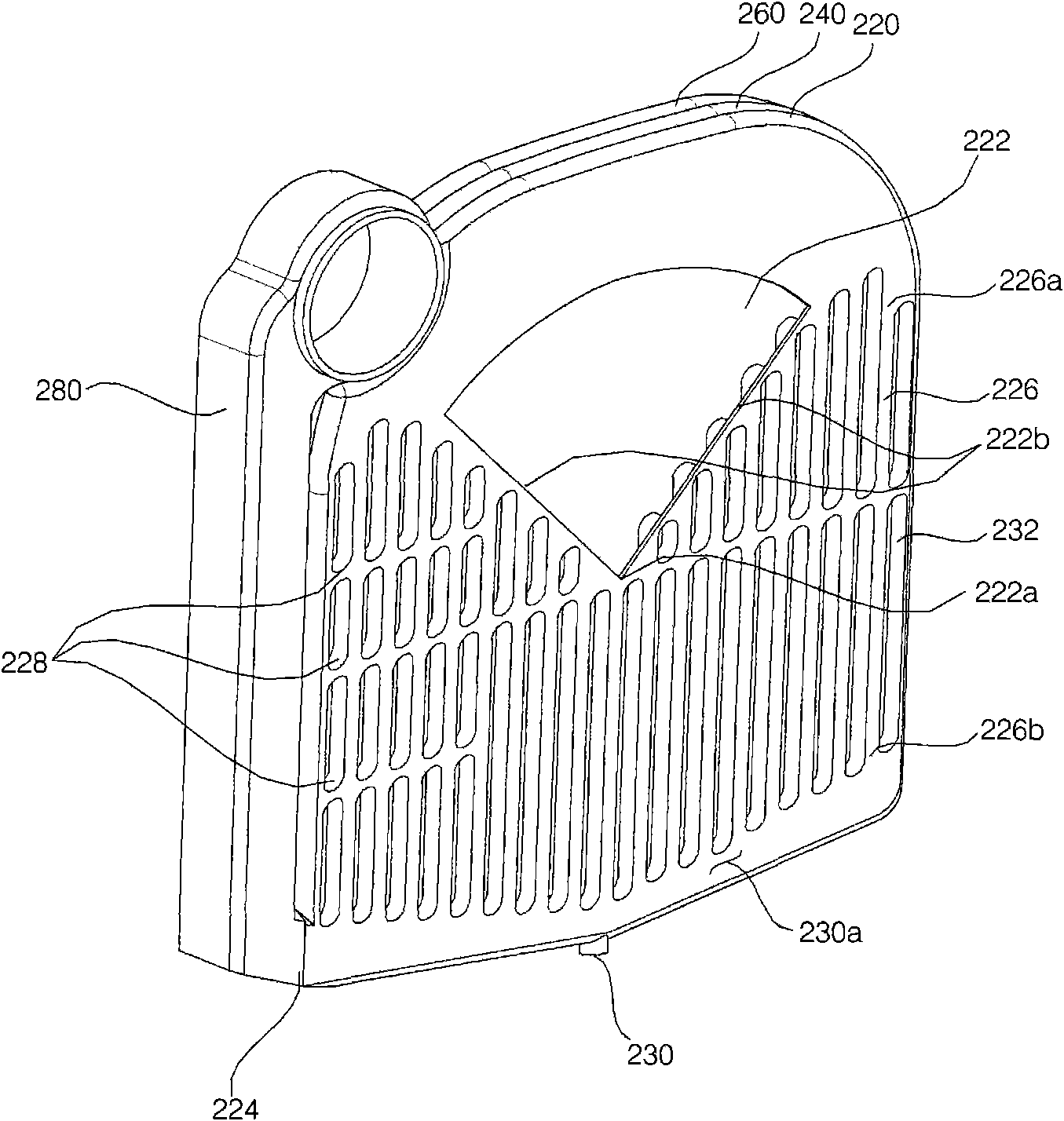

Heat exchanger and heat exchange apparatus

InactiveCN108562176AMaximize heat transfer areaMaximize the heat transfer effectHeat exhanger finsStationary conduit assembliesEngineeringMicro heat exchanger

The invention provides a heat exchanger and a heat exchange apparatus. The heat exchanger comprises: a plurality of fins that are arranged at intervals; a plurality of heat exchange pipes extended onthe surface of the fins or formed in the fins. The heat exchanger and the heat exchange apparatus have the advantage the heat exchange pipes and the fins are high in heat exchange quantity and heat exchange efficiency.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

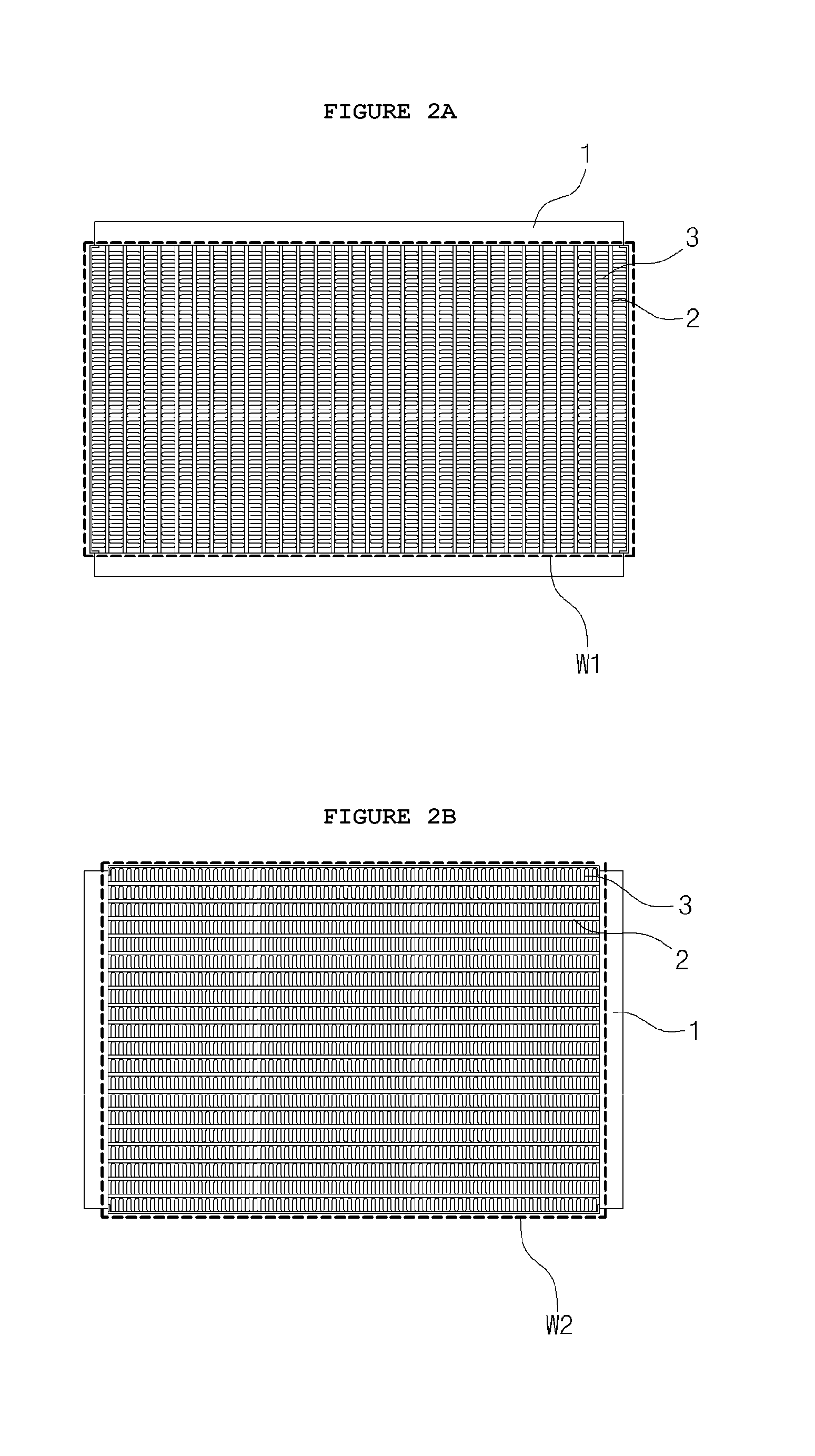

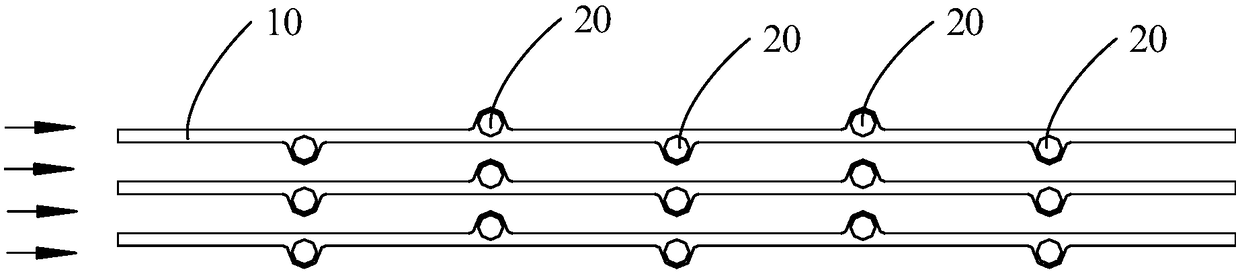

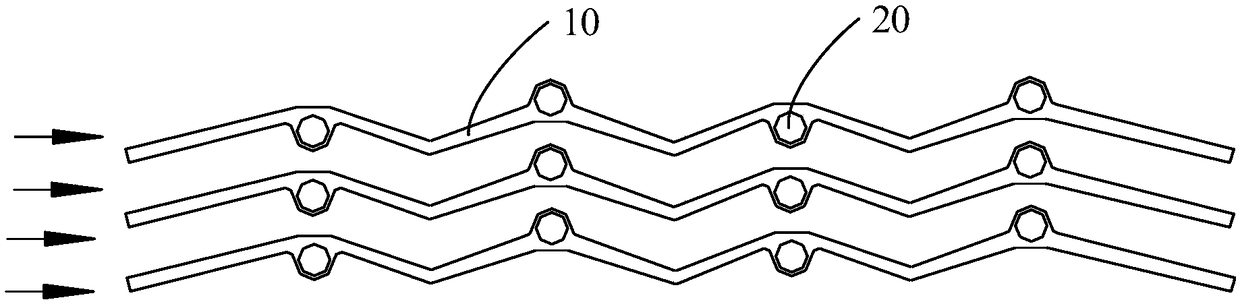

Heat exchanger and heat exchange equipment

PendingCN108592654AMaximize heat transfer areaMaximize the heat transfer effectEvaporators/condensersStationary conduit assembliesMiniaturizationEngineering

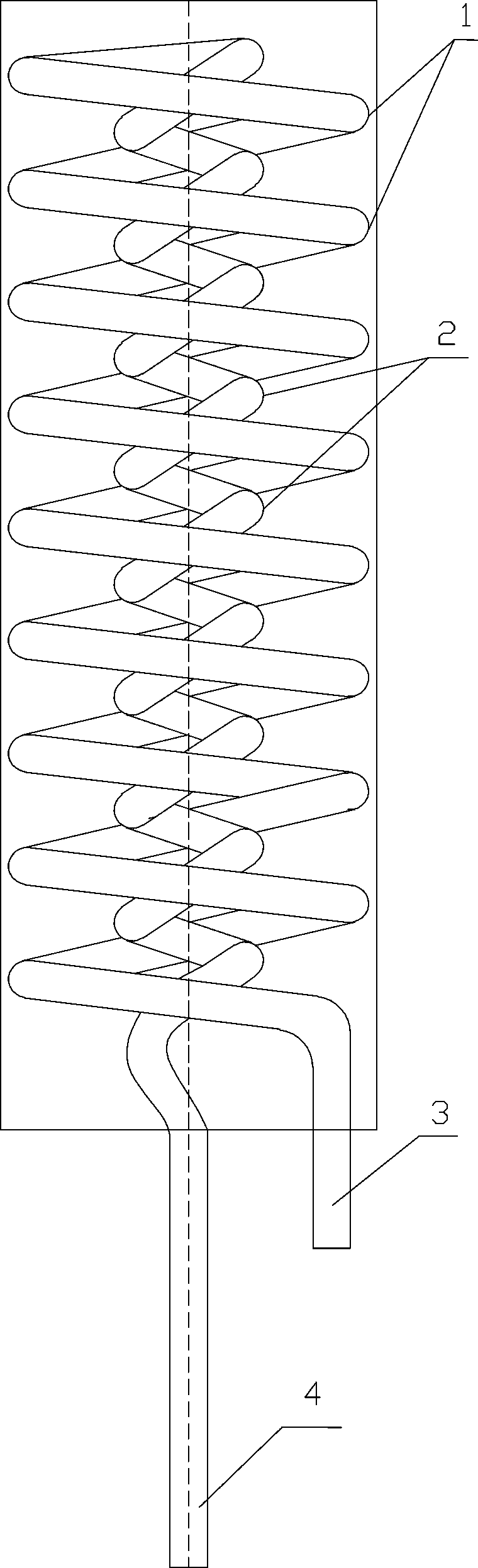

The invention provides a heat exchanger and heat exchange equipment. The heat exchanger comprises a plurality of fins, heat exchange tubes and an unilateral collecting flow tube, wherein the pluralityof fins are arranged at intervals, the heat exchange tubes extends to the surfaces of the fins or are formed in the fins, and the heat exchange tubes are arranged in a buckling and folding shape; theunilateral collecting flow tube is arranged at one end in the length directions of the fins, the unilateral collecting flow tube comprises an inflow passage and an outflow passage, wherein the inflowchannel and the outflow channel are arranged at the two ends in the width direction of the fins correspondingly; and the two ends of the heat exchange tubes correspondingly communicate with the inflow channel and the outflow channel. According to the heat exchanger and the equipment, the heat exchanger and the heat exchange equipment has the advantages of being compact in structure, high in heatexchange, high in heat exchange efficiency and capable of realizing miniaturization design of the heat exchanger.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Detachable instant type heater

ActiveCN103983009AImprove thermal conductivityUniform temperatureWater heatersElectricityInsulation layer

The invention discloses a detachable instant type heater. A double-ring coiled pipe comprises a coiled pipe outer ring and a coiled pipe inner ring; the coiled pipe inner ring is arranged in the middle of the coiled pipe outer ring; the upper end of the coiled pipe inner ring is communicated with the upper end of the coiled pipe outer ring in a sealing mode; the lower end of the coiled pipe outer ring is a coiled pipe water inlet; the lower end of the coiled pipe inner ring is a coiled pipe water outlet; heat conduction materials casted outside the double-ring coiled pipe; space between the coiled pipe outer ring and the coiled pipe inner ring is a heater groove; the upper end of the heater groove is closed and the lower end is open; an electric heater body is arranged inside the heater groove; tolerance clearance is formed between the electric heater body and the heater groove; colloidal state thermal conduction materials paint inside the tolerance clearance; a central position of the coiled pipe inner ring is provided with a temperature sensor blind pipe; the electric heater body comprises a heater outer casing; heating wires are arranged inside the heater outer casing; an insulation layer is arranged between the heating wires and the heater outer casing; the heating wires are in U shapes; positive and negative ends of the heating wires respectively penetrate the insulation layer to be fixedly connected with heating wire binding posts; the heating wire binding posts comprise a positive terminal binding post and a negative terminal binding post.

Owner:山东黄金太阳科技发展有限公司

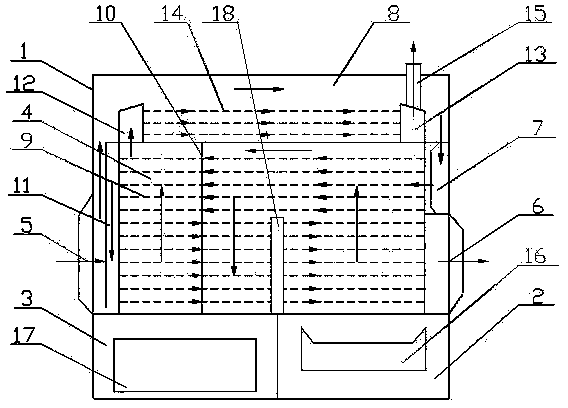

Multi-tube high-temperature hot blast stove with heart-shaped heat exchange tubes

ActiveCN104061678AMaximize heat transfer areaIncrease walking distanceAir heatersHot blastCombustion chamber

A multi-tube high-temperature hot blast stove with heart-shaped heat exchange tubes comprises a stove body, a combustion chamber, a dust chamber and a heat exchange chamber, wherein the combustion chamber, the dust chamber and the heat exchange chamber are formed in the stove body; an air inlet and an air outlet are formed in the two sides of the stove body respectively. An air inlet chamber is formed in the upper end of the air outlet. An interlayer space is formed between the stove body and the heat exchange chamber. The interlayer space is a waste heat return airway. One end of the waste heat return airway is communicated with the air inlet. The other end of the waste heat return airway is communicated with the air inlet chamber. The multiple heart-shaped heat exchange tubes which horizontally penetrate through the heat exchange chamber are arranged inside the heat exchange chamber. The tips of the heat shapes of the heart-shaped heat exchange tubes face downwards. The two inclined edges of each heat shape are heated surfaces. A plurality of baffles are vertically and axially arranged inside the heat exchange chamber. An air chamber communicated with the heat exchange tubes is formed in the side face of the heat exchange chamber. The heat exchange tubes in the upper half of the heat exchange chamber are communicated with the air inlet chamber. The heat exchange tubes in the lower half of the heat exchange chamber are communicated with the air outlet. A flue gas inlet cavity and a flue gas outlet cavity are formed above the heat exchange chamber. The flue gas inlet cavity is communicated with the air chamber. The flue gas inlet cavity is connected with the flue gas outlet cavity through a plurality of horizontally arranged hot air tubes. The flue gas outlet cavity is connected with an exhaust pipe.

Owner:泉州恒灼热力机械科技有限公司

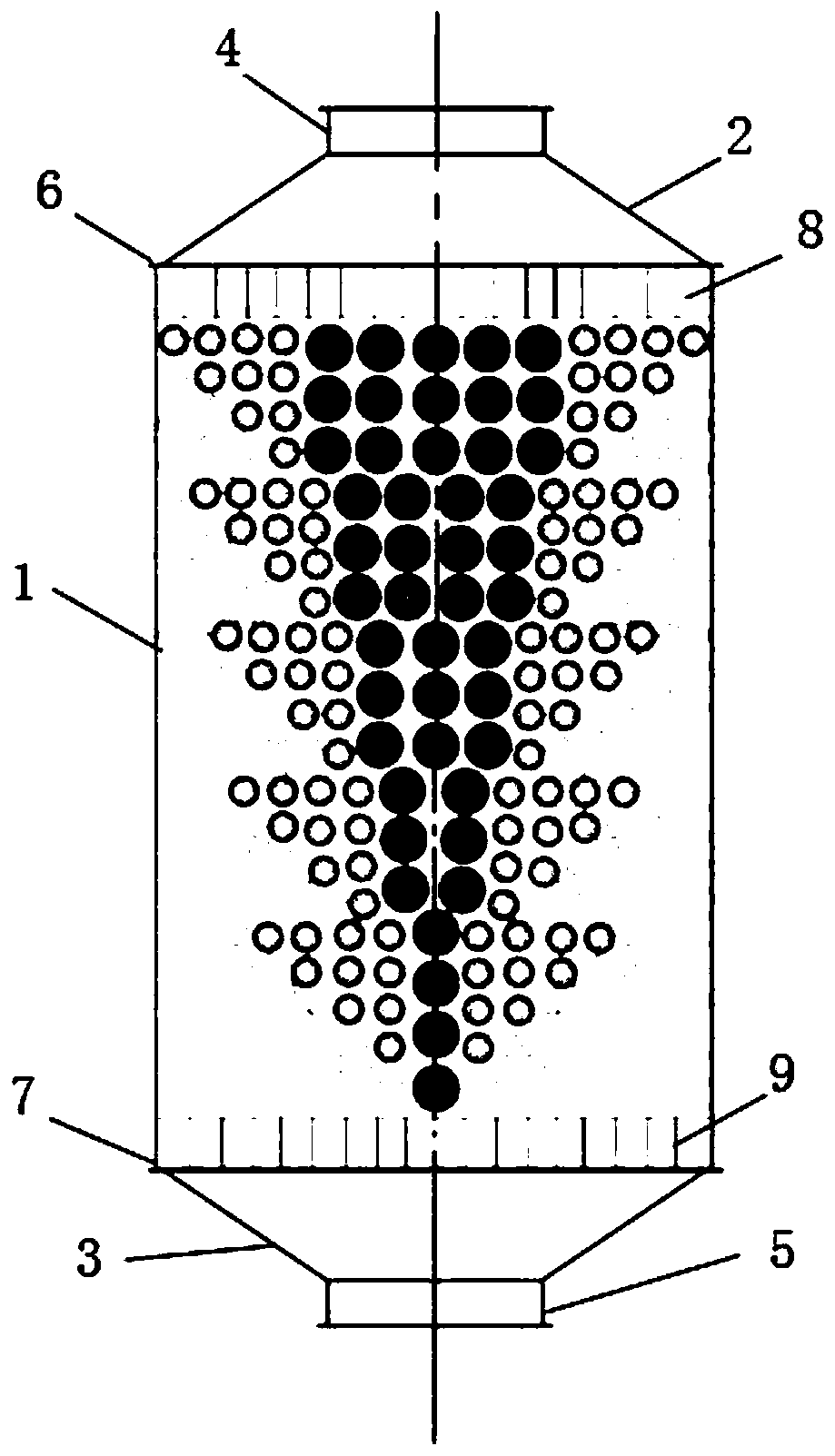

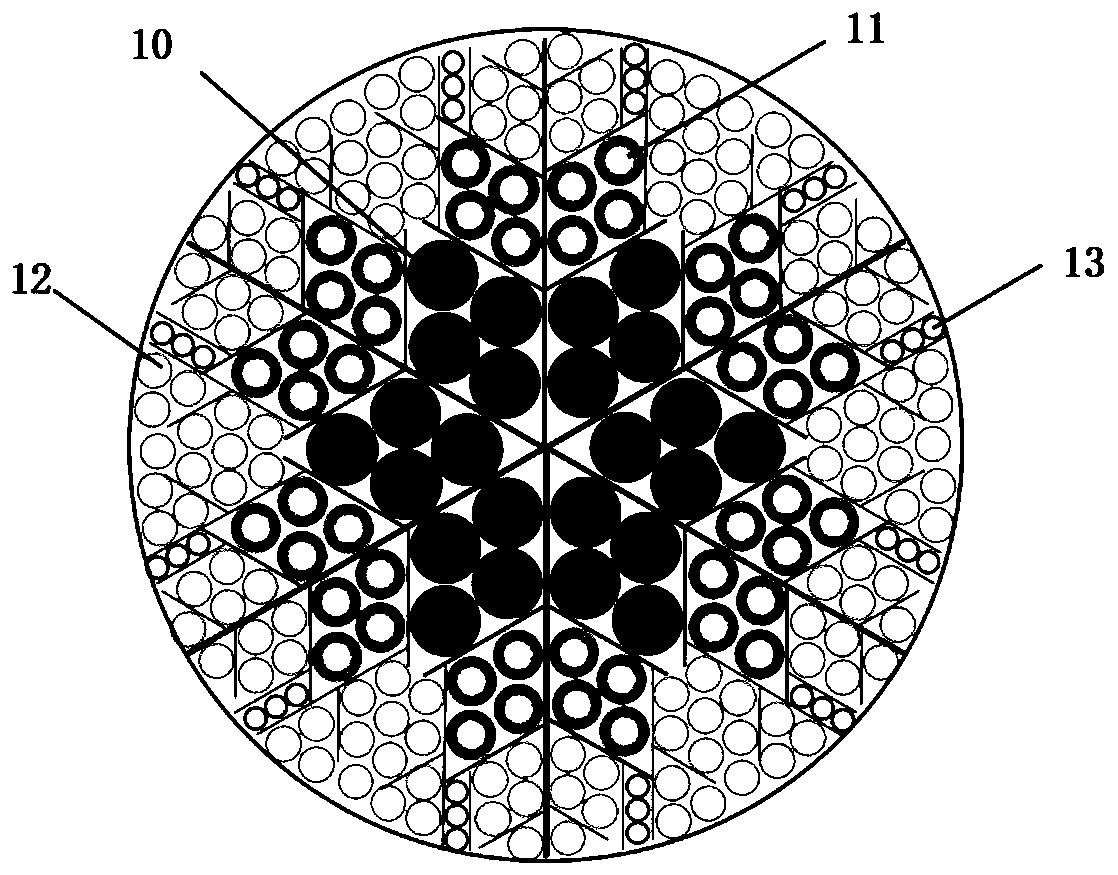

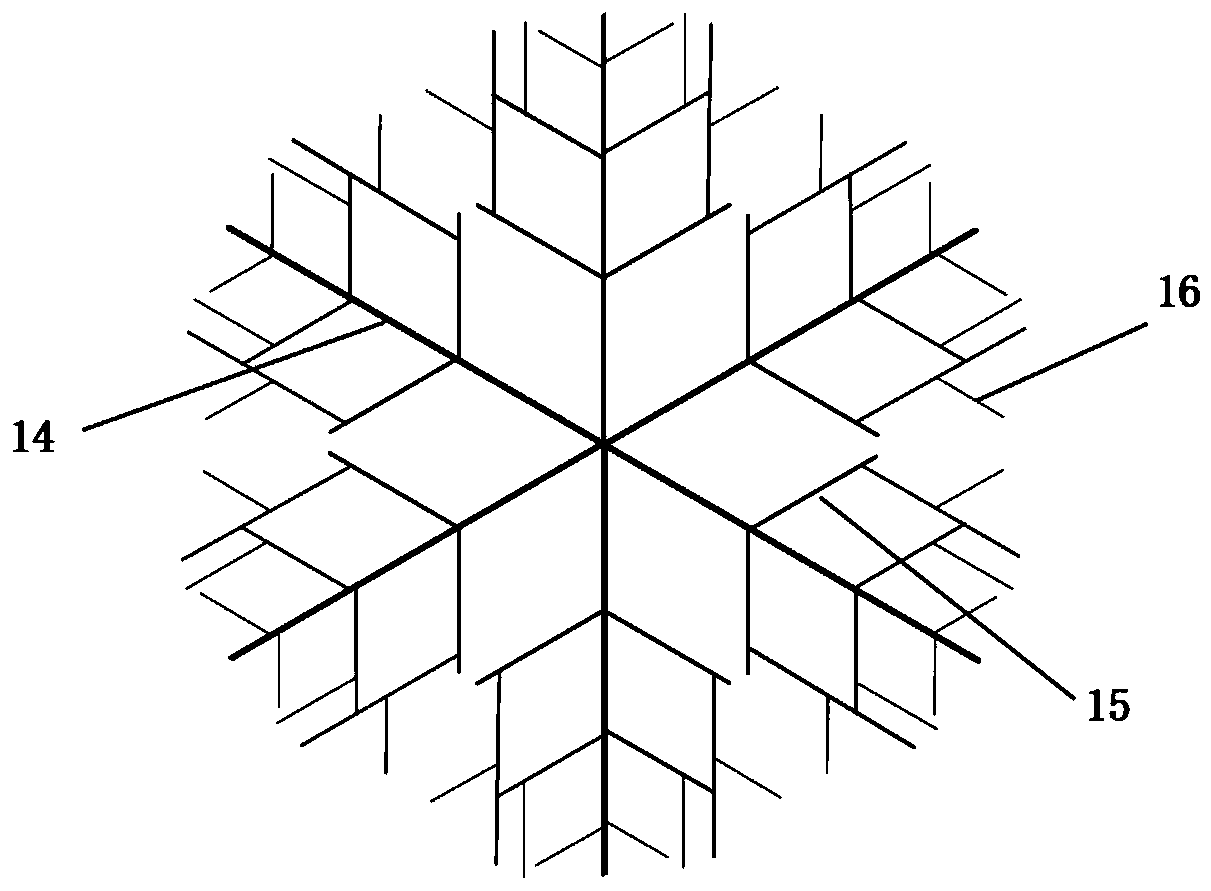

Single-tank packed bed heat storage device following generalized Murray's law and provided with bionic choroid structure and using method thereof

ActiveCN111473673AStrong theoretical background supportImprove heat transfer efficiencySolar heating energySolar heat storageThermal energy storage systemMechanical engineering

A single-tank packed bed heat storage device following the generalized Murray's law and provided with a bionic choroid structure and a using method thereof, and belongs to the field of energy storage.The problems of low heat storage density, small heat exchange area and uneven heat storage speed in a traditional packed bed heat storage system are solved. The heat storage device is characterized by comprising a storage tank, a bracket is arranged in the storage tank in the form of the bionic choroid structure, heat storage balls with different diameters following the generalized Murray's law are distributed in the storage tank, and the bracket is used for supporting the heat storage balls and preventing the heat storage balls from floating at will. The using method achieves heat storage, heat release and heat storage through the heat storage balls which follow the generalized Murray's law and are provided with the bionic choroid structure. By changing the arrangement mode and size of the heat storage balls in the storage tank, compared with the traditional system, the heat storage system achieves higher heat storage efficiency, higher heat storage density and faster thermal response capability, and the bionic choroid structure is a naturally selected efficient nutrient delivery system which has unique advantages in substance transportation and energy transfer.

Owner:HARBIN INST OF TECH AT WEIHAI

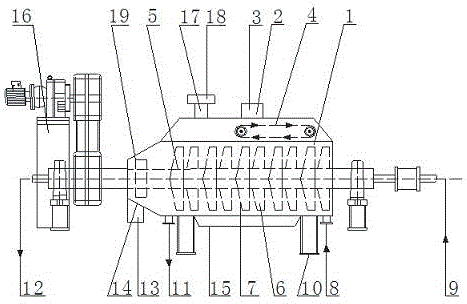

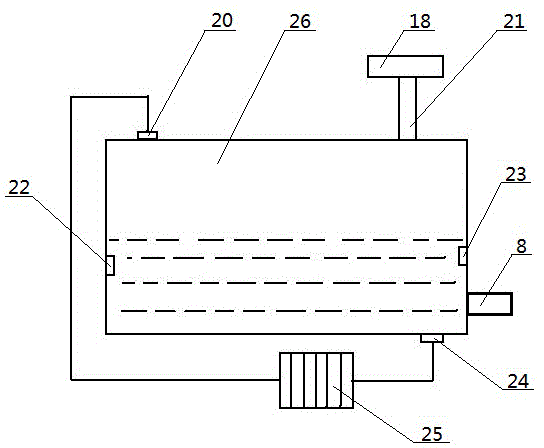

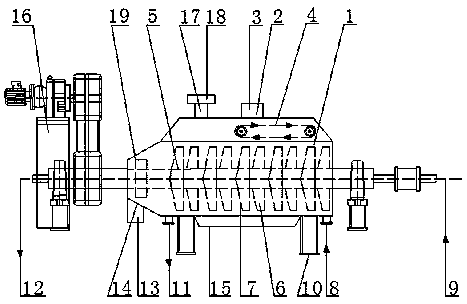

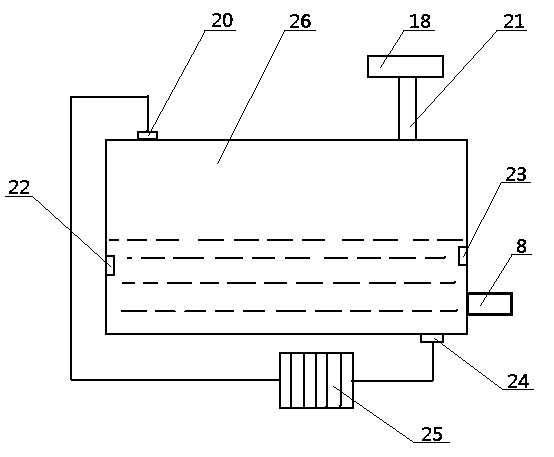

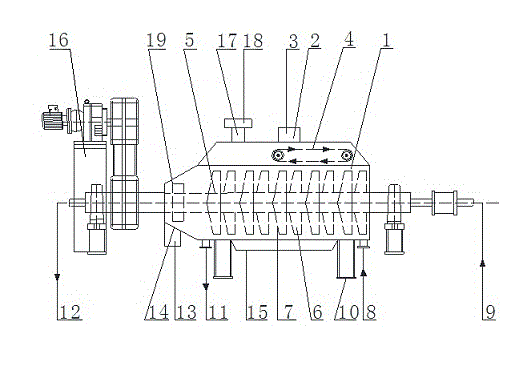

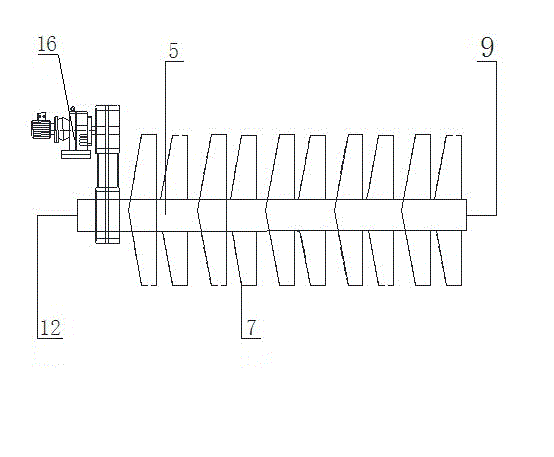

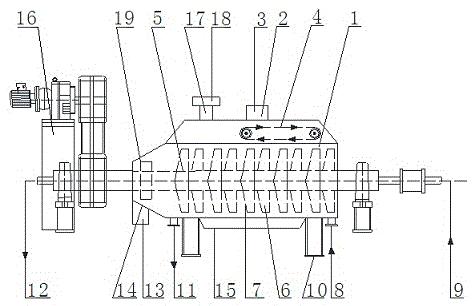

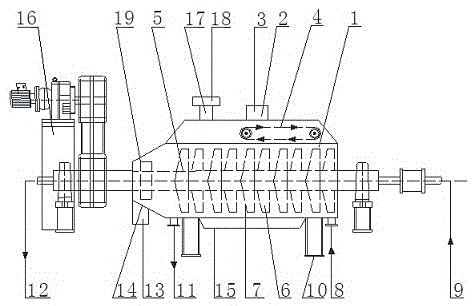

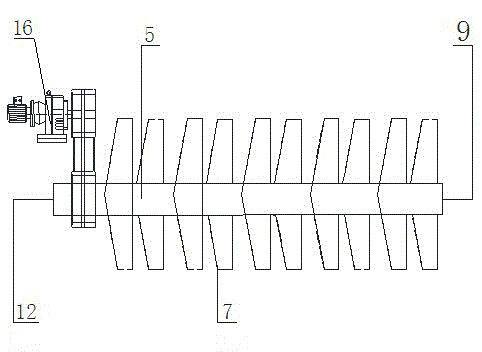

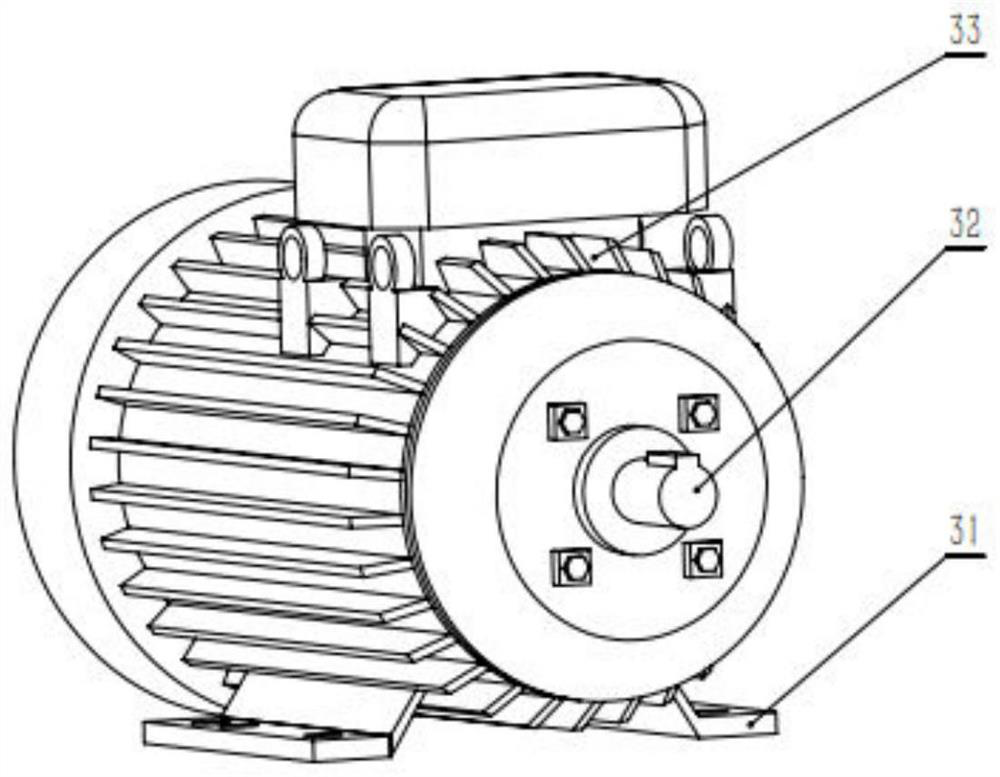

A sludge drying integrated machine

InactiveCN104649540ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningTemperature controlSludge

The invention relates to the field of environment protection equipment, and particularly relates to a sludge drying integrated machine. The sludge drying integrated machine comprises a machine body, gear type spiral push shafts, a bracket, a condensate water circulating device, a drive system, an air cleaning system and an automatic temperature control system. The air cleaning system is arranged on the machine body. The two gear type spiral push shafts parallel to each other and the automatic temperature control system are arranged in the machine body. Two ends of the machine body are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet, and two ends of the gear type spiral push shafts are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet. The machine body is horizontally arranged on the bracket. The condensate water circulating device is arranged below the bracket. The drive system is arranged at one end of the gear type spiral push shafts. The sludge drying integrated machine achieves an integrated process of sludge drying, achieves low energy consumption and high efficiencies in the operation process, and adopts a fully-automatic operation mode without the need of a specially-assigned person for watching.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

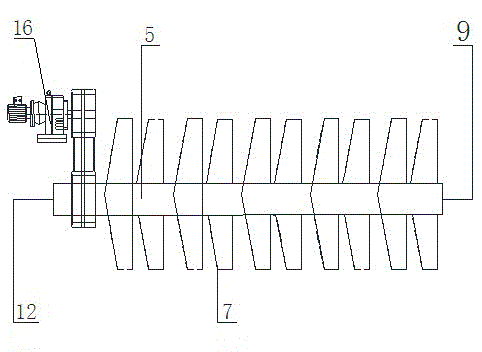

Gear type sludge dryer

InactiveCN103588376ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningTemperature controlSludge

The invention relates to the field of environmental protection equipment, in particular to a gear type sludge dryer which comprises a dryer body, gear type spiral pushing shafts, a support, a condensation water circulation device, a driving system, an air purification system and an automatic temperature control system, wherein the air purification system is arranged above the dryer body; the two gear type spiral pushing shafts placed in parallel and the automatic temperature control system are arranged in the dryer body; heat conducting medium inlets and heat conducting medium outlets are formed at the two ends of the dryer body and the gear type spiral pushing shaft; the dryer placed in parallel is arranged above the support; the condensation water circulation device is arranged below the support; and the driving system is arranged at one end of the gear type spiral pushing shaft. The dryer realizes an integrated sludge drying work process, as well as low energy consumption and high efficiency during operation, and is in a full automatic unattended operation mode.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

A rotating extrusion type sludge dewatering machine

InactiveCN104649538ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesTemperature controlGear wheel

The invention relates to the field of environment protection equipment, and particularly relates to a rotating extrusion type sludge dewatering machine. The sludge dewatering machine comprises a machine body, gear type spiral push shafts, a bracket, a condensate water circulating device, a drive system, an air cleaning system and an automatic temperature control system. The air cleaning system is arranged on the machine body. The two gear type spiral push shafts parallel to each other and the automatic temperature control system are arranged in the machine body. Two ends of the machine body are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet, and two ends of the gear type spiral push shafts are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet. The machine body is horizontally arranged on the bracket. The condensate water circulating device is arranged below the bracket. The drive system is arranged at one end of the gear type spiral push shafts. The machine achieves an integrated process of sludge drying, achieves low energy consumption and high efficiencies in the operation process, and adopts a fully-automatic operation mode without the need of a specially-assigned person for watching.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

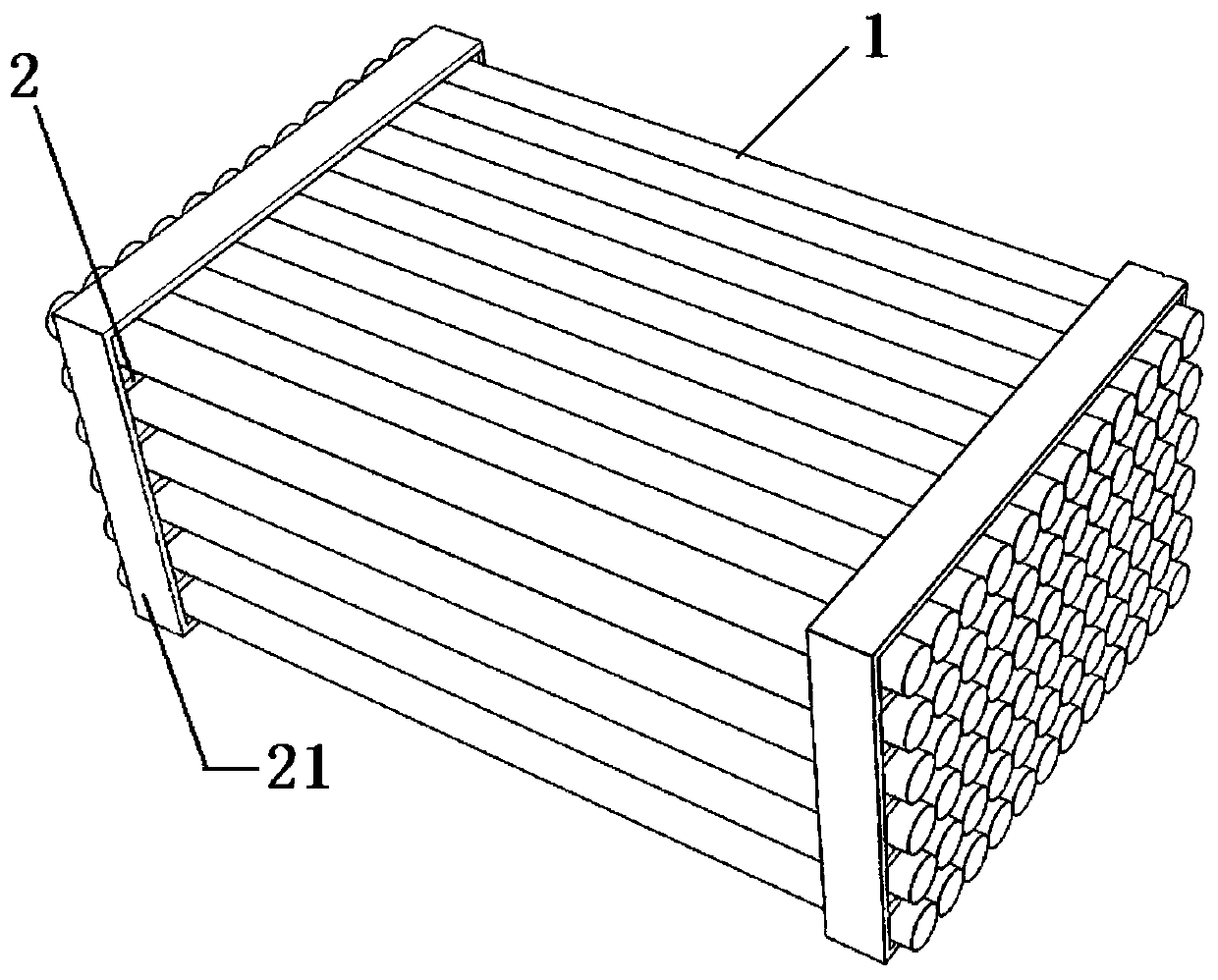

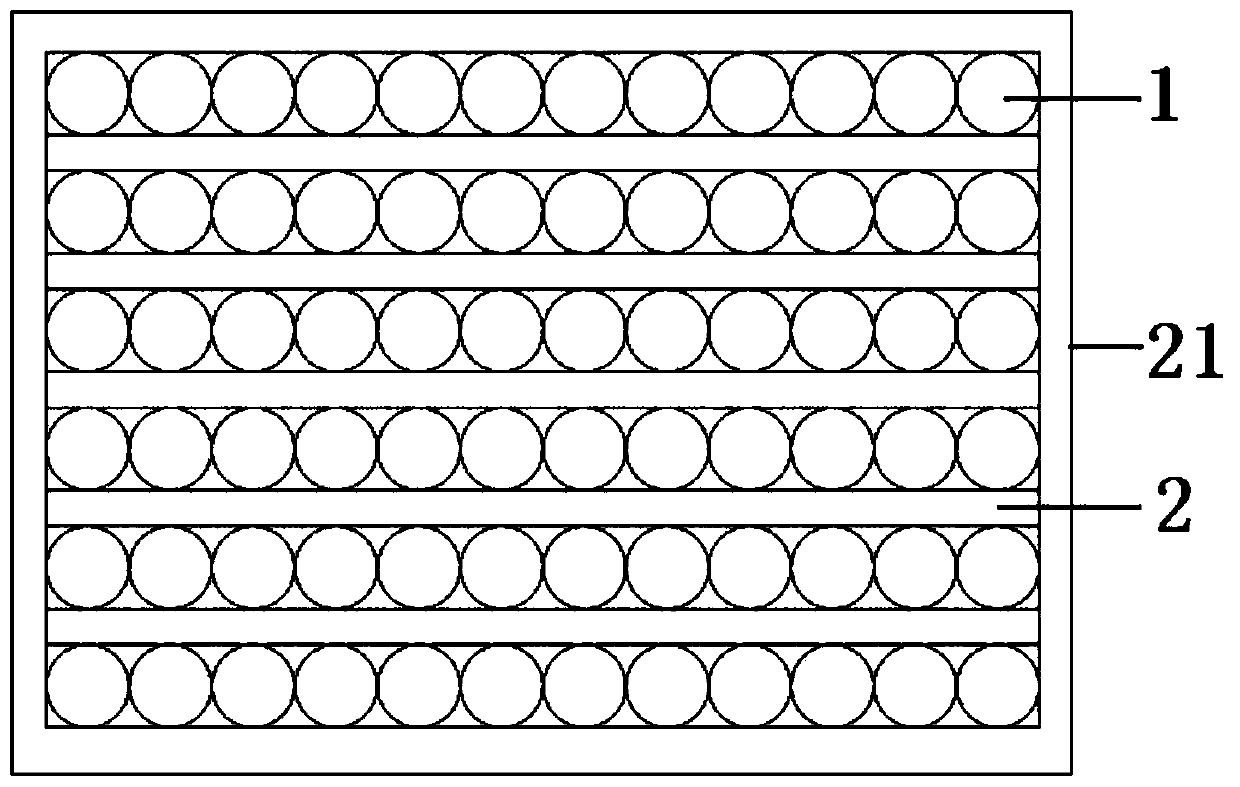

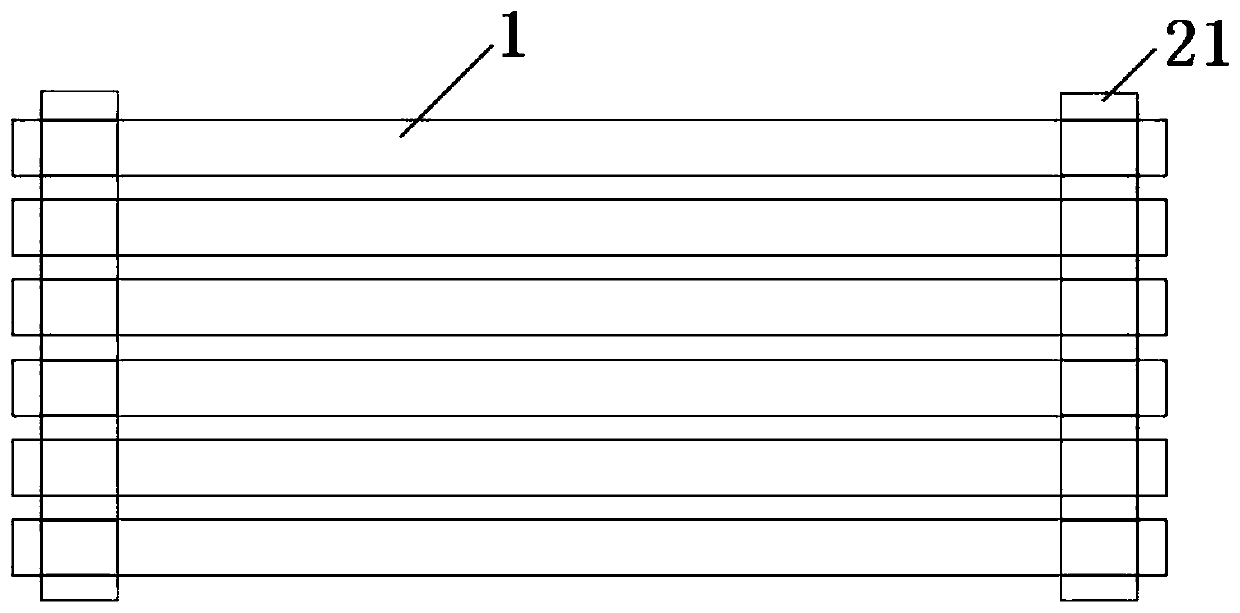

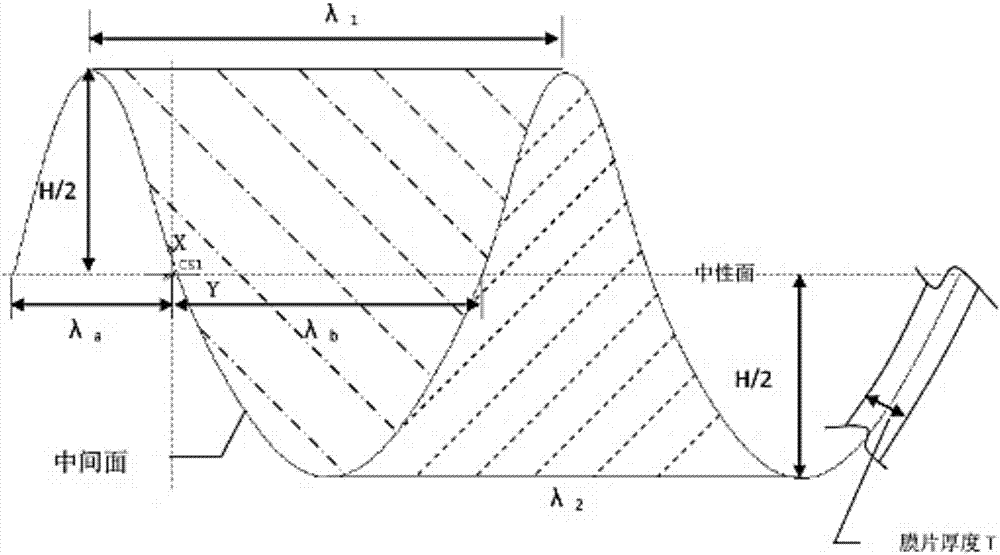

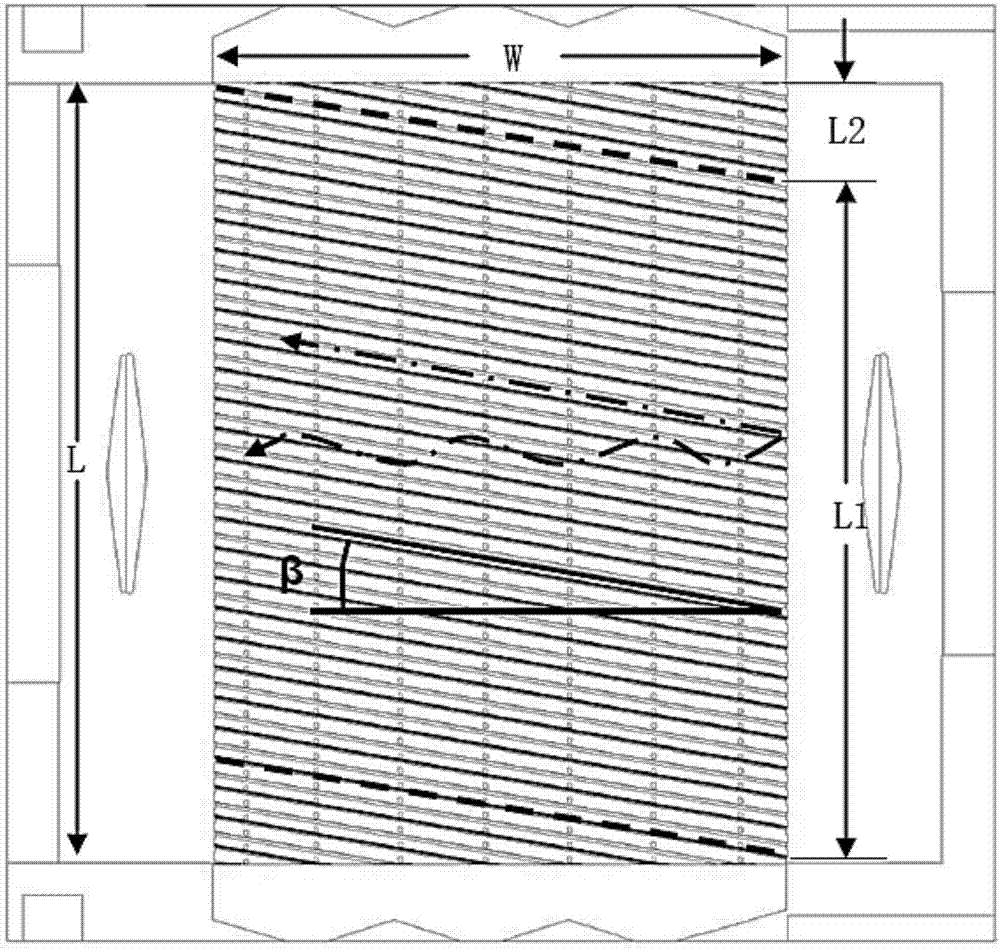

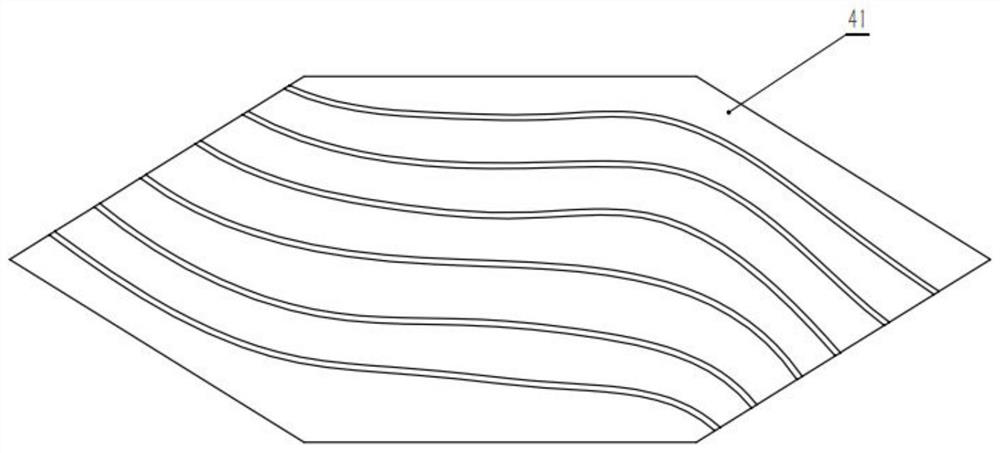

Circular microchannel wave surface plate heat exchange core body, manufacturing method and heat exchanger

InactiveCN109737780AGood heat transfer effectFull heat exchangeHeat exchanger casingsLaminated elementsSurface heatEngineering

The invention discloses a circular microchannel wave surface plate heat exchange core body, a manufacturing method and a heat exchanger. The circular microchannel wave surface plate heat exchange corebody comprises heat exchanger core body frames, multiple circular microchannel wave surface heat exchange plates and multiple pipe battens; the multiple circular microchannel wave surface heat exchange plates are alternately laminated and fixed in two heat exchanger core body frames through the pipe battens at two ends of circular microchannels; each circular microchannel wave surface heat exchange plate is formed by fixedly connecting multiple single-layer circular microchannels tightly bonded side by side; and the inner diameters of the circular microchannels in the same circular microchannel wave surface heat exchange plates are the same. The heat exchanger core body can be used for manufacturing the heat exchanger; on the one hand, the heat exchange surface area is increased; and on the other hand, through turbulent flows on the surfaces of waves, heat transfer boundary layers can be changed, so that the heat exchange is more sufficient.

Owner:徐雅岚

Full-automatic sludge drier

InactiveCN104649549ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningTemperature controlSludge

The invention belongs to the field of environmental protection equipment, and specifically relates to a full-automatic sludge drier. The full-automatic sludge drier comprises a machine body, two gear-type spiral drive shafts, a support, a condensate water circulating device, a driving system, an air cleaning system, and an automatic temperature control system; the air cleaning system is arranged above the machine body; the two gear-type spiral drive shafts are arranged in the machine body in parallel; the automatic temperature control system is arranged in the machine body; the two ends of the machine body and the two gear-type spiral drive shafts are all provided with heat-conducting medium inlets and imported medium outlets; the machine body is arranged on the upper part of the support in parallel, and the lower part of the support is provided with the condensate water circulating device; and the driving system is arranged on one ends of the gear-type spiral drive shafts. The full-automatic sludge drier is capable of realizing integration process of sludge drying; energy consumption of operation process is low; efficiency is high; and guardless automatic operation is realized.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

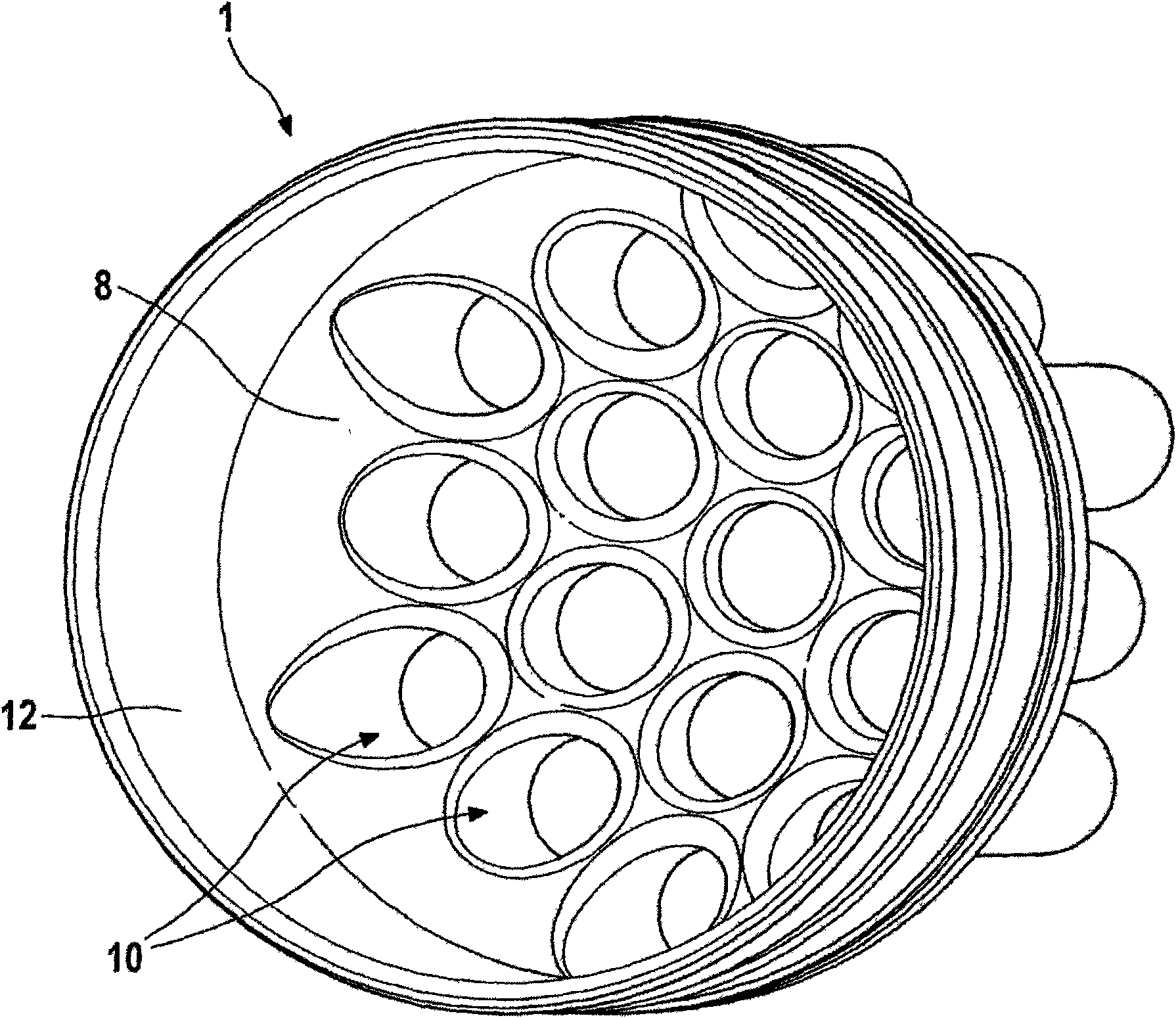

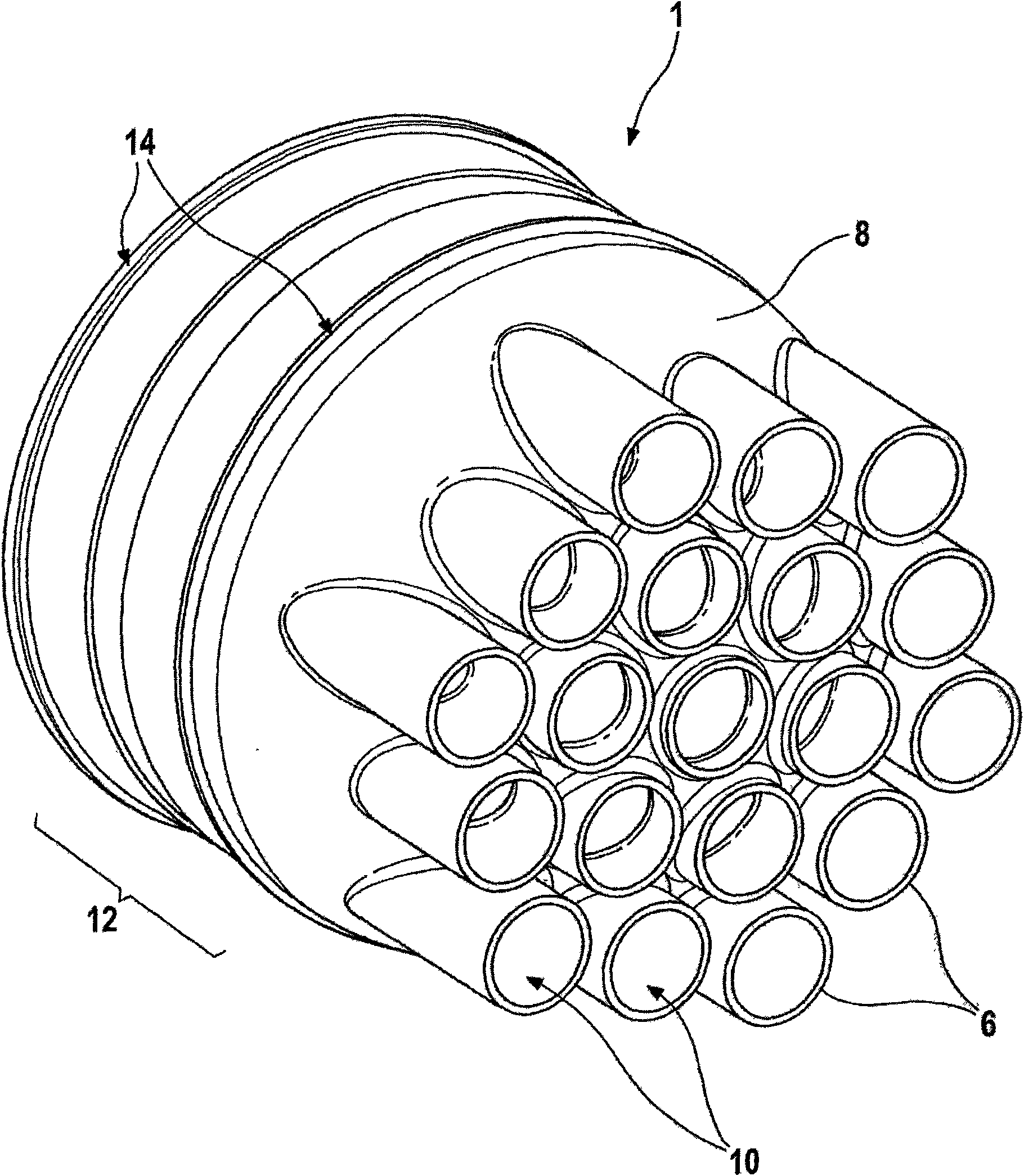

Pipe heat exchanger, dual deflection flanged bend, adapter, system and method for transferring heat

InactiveCN101676669AAvoid Flow ProcessingIncrease costMilk preservationFood preservationProcess engineeringMicro heat exchanger

The present invention relates to a pipe heat exchanger (2) for heat exchange between at least two food flows (26; 30), a dual deflection flanged bend (16) for the pipe heat exchanger, an adapter (56)and a system for the pipe heat exchanger. Furthermore, described is a method for transferring heat between at least two food flows (26, 30). The dual deflection flanged bend (16) includes two separated flow paths (32, 34), wherein a first food flow (26) may be transferred in the first flow path (32) of the dual deflection flanged bend (16); and the second food flow (30) may be transferred in the second flow path (34) of the dual deflection flanged bend (16). In addition, the heat may be transferred between the two flow paths (32, 34) of the dual deflection flanged bend (16).

Owner:KRONES AG

Automatic sludge drier

InactiveCN104649557AHigh degree of integrationThe overall structure is compactWater treatment parameter controlSludge treatment by de-watering/drying/thickeningAir cleaningWater circulation

The invention belongs to the field of environmental protection equipment, and specifically relates to an automatic sludge drier. The automatic sludge drier comprises a machine body, two gear-type spiral drive shafts, a support, a condensate water circulating device, a driving system, an air cleaning system, and an automatic temperature control system; the air cleaning system is arranged above the machine body; the two gear-type spiral drive shafts are arranged in the machine body in parallel; the automatic temperature control system is arranged in the machine body; the two ends of the machine body and the two gear-type spiral drive shafts are all provided with heat-conducting medium inlets and heat-conducting medium outlets; the machine body is arranged on the upper part of the support in parallel, and the lower part of the support is provided with the condensate water circulating device; and the driving system is arranged on one ends of the gear-type spiral drive shafts. The automatic sludge drier is capable of realizing integration process of sludge drying; energy consumption of operation process is low; efficiency is high; and a full-automatic guardless operation mode is realized.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

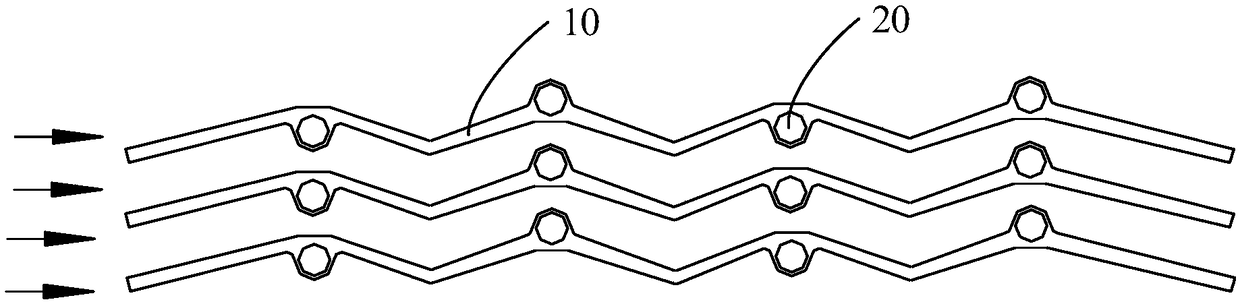

Heat exchanger and heat exchange equipment

PendingCN108592655AMaximize heat transfer areaMaximize the heat transfer effectEvaporators/condensersStationary conduit assembliesTotal thicknessEngineering

The invention provides a heat exchanger and heat exchange equipment. The heat exchanger comprises a plurality of fins and heat exchange tubes; the plurality of fins are arranged at intervals; the heatexchange tubes extend on the surfaces of the fins or are formed in the fins; when the heat exchange tubes extend on the surfaces of the fins, the ratio of the total thickness of each heat exchange tube and the corresponding fin to the thickness of the corresponding fin is larger than or equal to 1 and less than or equal to 15; and when the heat exchange tubes are formed in the fins, the ratio ofthe thickness of each heat exchange tube to the thickness of the corresponding fin is larger than or equal to 1 and less than or equal to 15. The heat exchanger and the heat exchange equipment have the advantages that the machining difficulty of the heat exchange tubes is reduced, and meanwhile, the heat exchange effect is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

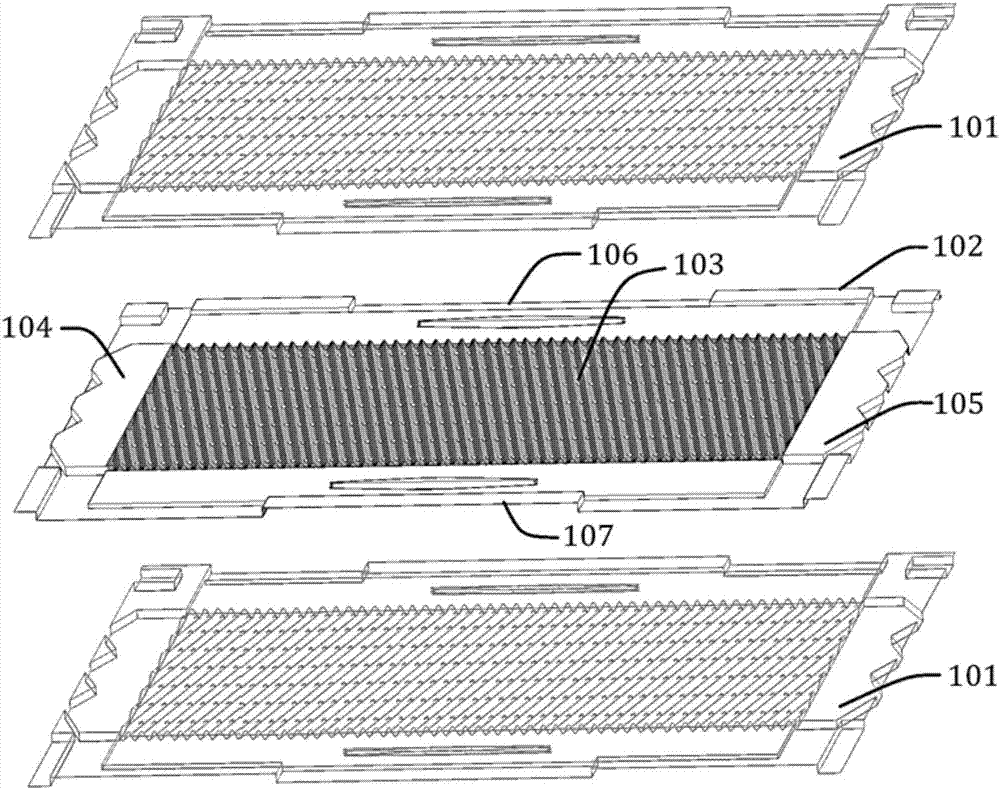

Membrane type dew point indirect evaporative cooling heat exchanger

PendingCN107543438AReduce thicknessAchieve balanceStationary plate conduit assembliesEvaporative coolerSemi open

The invention discloses a membrane type dew point evaporative cooling heat exchanger in the technical field of heat exchangers. The membrane type dew point evaporative cooling heat exchanger is internally provided with first heat exchanging membranes and second heat exchanging membranes all of which are overlapped in an alternate manner, wherein a hydrophilic face of each first heat exchanging membrane and a hydrophilic face of the corresponding second heat exchanging membrane are oppositely arranged to form a wet heat exchanging channel layer, and a hydrophobic face of each first heat exchanging membrane and a hydrophobic face of the corresponding second heat exchanging membrane are oppositely arranged to form a dry heat exchanging channel layer; and a first foldable cavity face and a second foldable cavity face are combined at the semi-opening ends of the wet heat exchanging channel layers to form a water inlet and outlet cavity and are closed at the dry heat exchanging channel layers. By means of the membrane type dew point indirect evaporative cooling heat exchanger, mixing of countercurrent and cross-flow can be achieved, meanwhile, by improving cross section structures of thedry heat exchanging channels and the wet heat exchanging channels, while the relative small heat exchanging temperature difference is guaranteed, the flowing pressure drop is reduced, and the heat exchanging efficiency is improved.

Owner:陈祖卫

A sludge drying machine with an automatic temperature control system

InactiveCN104649542ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningTemperature controlSludge

The invention relates to the field of environment protection equipment, and particularly relates to a sludge drying machine with an automatic temperature control system. The sludge drying machine comprises a machine body, gear type spiral push shafts, a bracket, a condensate water circulating device, a drive system, an air cleaning system and the automatic temperature control system. The air cleaning system is arranged on the machine body. The two gear type spiral push shafts parallel to each other and the automatic temperature control system are arranged in the machine body. Two ends of the machine body are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet, and two ends of the gear type spiral push shafts are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet. The machine body is horizontally arranged on the bracket. The condensate water circulating device is arranged below the bracket. The drive system is arranged at one end of the gear type spiral push shafts. The machine achieves an integrated process of sludge drying, achieves low energy consumption and high efficiencies in the operation process, and adopts a fully-automatic operation mode without the need of a specially-assigned person for watching.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Evaporator having vertical arrangement of header pipe for vehicle air conditioner

InactiveCN106440533AMaximize heat transfer areaImprove heat exchange efficiencyEvaporators/condensersVehicle heating/cooling devicesCold airEvaporation

The present invention relates to an air conditioning evaporator for a vehicle which is connected to a refrigeration cycle system constituting an air conditioner and which provides heat of vaporization while supplying a cold air to provide cold air by heat exchange with air supplied from the fan. The evaporator comprises a pair of header pipes disposed in opposing form for the supply of refrigerant from said refrigeration cycle system, providing a circulation path and discharging refrigerant to complete heat exchange; a plurality of tubes which are provided so as to be transparently connected in the form of passing through the pair of header pipes and provided in the longitudinal direction of the head pipes so as to move the refrigerant flowing into the inflow port of the head pipes to the discharge port of the head pipes in a zigzag shape to simultaneously carry out heat exchange with the air; and cooling fins which are disposed among the above tubes so as to cool the evaporation heat from the tubes when unchoking the air provided by the tubes. The tubes are arranged in a vertical direction and the tubes are arranged in a horizontal direction, the length of the tubes being larger than the length of the head pipes and forming a rectangle.

Owner:DONGHWAN IND CORP

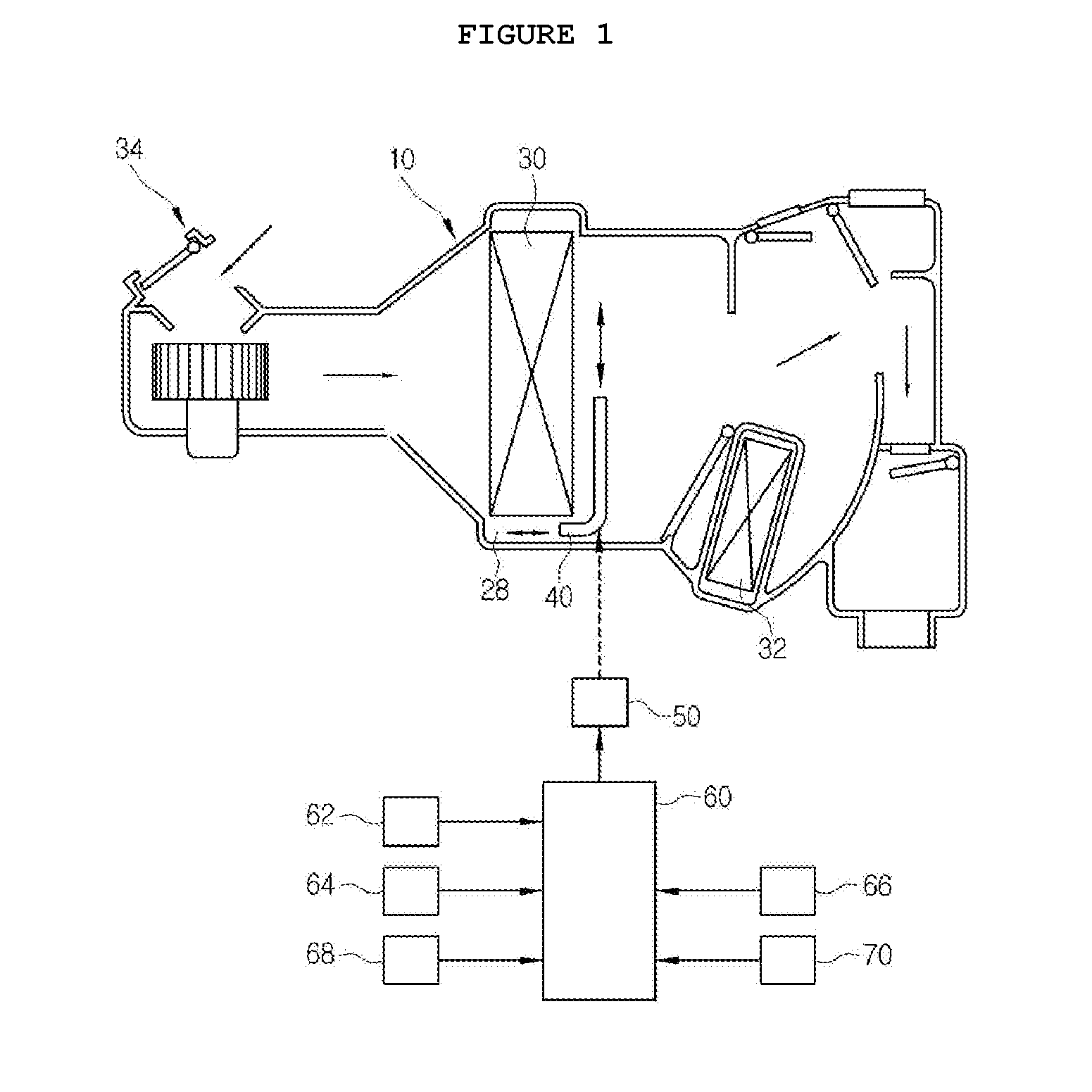

Integrated module of evaporator-core and heater-core for air conditioner

InactiveUS20170036509A1Simple processLower the volumeAir-treating devicesEvaporators/condensersCold airAutomobile air conditioning

The present invention relates to a heat exchanger that is disposed in an automotive air conditioner and provides cold air or hot air through heat exchange with air supplied by a fan and, more particularly, to an integrated module of an evaporator core and a heater core for an automotive air conditioner whereby the integrated module can simplify an automotive air conditioner by integrating an evaporator for cooling and a heater core for heating in the automotive air conditioner. According to the present invention, evaporator headers and heater headers are stacked and fixed in an integrated unit, so it is possible to simplify a facility. Accordingly, installation is easy and a volume can be reduced, as compared with the related art, whereby it is possible to reduce the weight of a vehicle.

Owner:DONGHWAN IND CORP

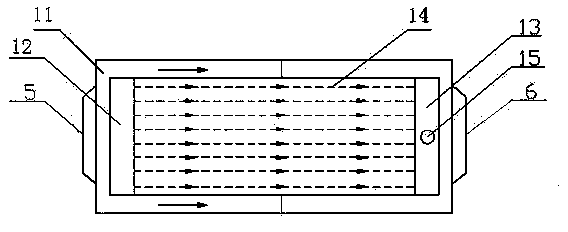

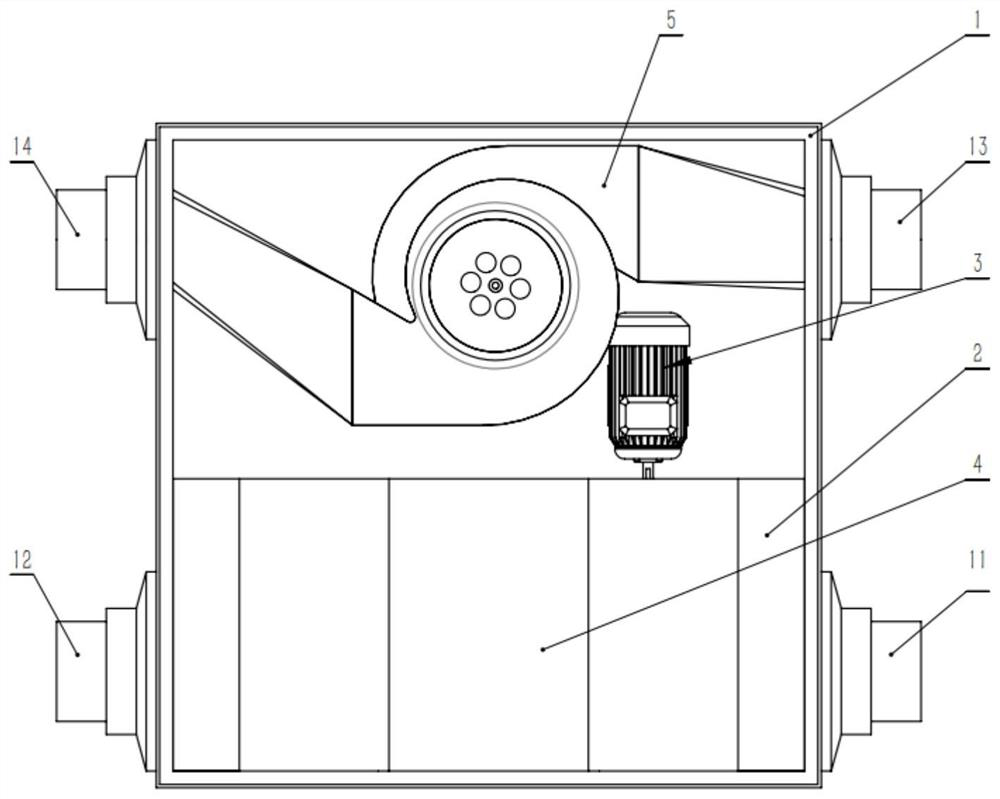

Vibration total heat exchanger for enhancing heat transfer

PendingCN113405196ALess internal supportReduce drag along the wayEnergy recovery in ventilation and heatingLighting and heating apparatusEngineeringNoise reduction

The invention discloses a vibration total heat exchanger for enhancing heat transfer. The vibration total heat exchanger comprises a noise reduction machine shell, an outdoor air inlet, an indoor air outlet, an indoor air inlet, an outdoor air outlet, a pair of filter screens, a heat exchange core and a double-layer fan, wherein the outdoor air inlet and the indoor air outlet are formed in one side of the noise reduction machine shell, the indoor air inlet and the outdoor air outlet are formed in the other side of the noise reduction machine shell, the pair of filter screens are arranged on the noise reduction machine shell, the heat exchange core is arranged between the pair of filter screens, and the double-layer fan is used for connecting the indoor air outlet and the outdoor air outlet; and a heat exchange plate is arranged in the heat exchange core and is of a special-shaped structure, and corrugations are arranged on the surface of the heat exchange plate. Through the arrangement of the heat exchange plate special-shaped structure, inner supports are reduced, on-way resistance is small, wind pressure loss is small, maximization of the heat transfer area is guaranteed, and therefore the maximum heat exchange efficiency is achieved.

Owner:ZHEJIANG SCI-TECH UNIV

Novel sludge drier

InactiveCN104649554ASolve processing problemsHigh degree of integrationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesTemperature controlSludge

The invention belongs to the field of environmental protection equipment, and specifically relates to a novel sludge drier. The novel sludge drier comprises a machine body, two gear-type spiral drive shafts, a support, a condensate water circulating device, a driving system, an air cleaning system, and an automatic temperature control system; the air cleaning system is arranged above the machine body; the two gear-type spiral drive shafts are arranged in the machine body in parallel; the automatic temperature control system is arranged in the machine body; the two ends of the machine body and the two gear-type spiral drive shafts are all provided with heat-conducting medium inlets and heat-conducting medium outlets; the machine body is arranged on the upper part of the support in parallel, and the lower part of the support is provided with the condensate water circulating device; and the driving system is arranged on one ends of the gear-type spiral drive shafts. The novel sludge drier is capable of realizing integration process of sludge drying; energy consumption of operation process is low; efficiency is high; and guardless automatic operation is realized.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Dehumidifier

InactiveCN101574610AImprove dehumidification effectSpeed up the flowDispersed particle separationStationary conduit assembliesPlate heat exchangerEngineering

The present invention provides a dehumidifier, including a main body, comprising a dehumidification passage in which indoor air is sucked in and the sucked-in indoor air is dehumidified and a reconditioning passage in which reconditioning air circulates, a dehumidification rotor, comprising a dehumidification portion configured to dehumidify the indoor air and a reconditioning portion reconditioned using the reconditioning air, and a condensing heat exchanger, comprising reconditioning air introduction units into which the reconditioning air is introduced and reconditioning air discharge units from which the reconditioning air is discharged. Each of the reconditioning air introduction units of the condensing heat exchanger has a width which, at a position opposite to the reconditioning portion, increases according to a distance from a center of the condensing heat exchanger corresponding to a center of the dehumidification rotor. The reconditioning air discharge units are formed on one side of a circumferential portion of the condensing heat exchanger. Accordingly, the dehumidification performance of the dehumidifier can be improved and noise caused when the dehumidifier is driven can be reduced.

Owner:LG ELECTRONICS INC

Novel sludge dewatering machine with steam discharging port

InactiveCN104649541AHigh degree of integrationThe overall structure is compactSludge treatment by de-watering/drying/thickeningAir cleaningWater circulation

The invention relates to the field of environment protection equipment, and particularly relates to a novel sludge dewatering machine with a steam discharging port. The sludge dewatering machine comprises a machine body, gear type spiral push shafts, a bracket, a condensate water circulating device, a drive system, an air cleaning system and an automatic temperature control system. The air cleaning system is arranged on the machine body. The two gear type spiral push shafts parallel to each other and the automatic temperature control system are arranged in the machine body. Two ends of the machine body are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet, and two ends of the gear type spiral push shafts are respectively provided with a heat conducting medium inlet and a heat conducting medium outlet. The machine body is horizontally arranged on the bracket. The condensate water circulating device is arranged below the bracket. The drive system is arranged at one end of the gear type spiral push shafts. The machine achieves an integrated process of sludge drying, achieves low energy consumption and high efficiencies in the operation process, and adopts a fully-automatic operation mode without the need of a specially-assigned person for watching.

Owner:TAIZHOU LANHAI ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com