Membrane type dew point indirect evaporative cooling heat exchanger

A technology of dew point evaporative cooling and heat exchanger, which is applied in the direction of indirect heat exchanger, heat exchanger type, lighting and heating equipment, etc. Complex structure and other issues to achieve the effect of balance and controllability, low production cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

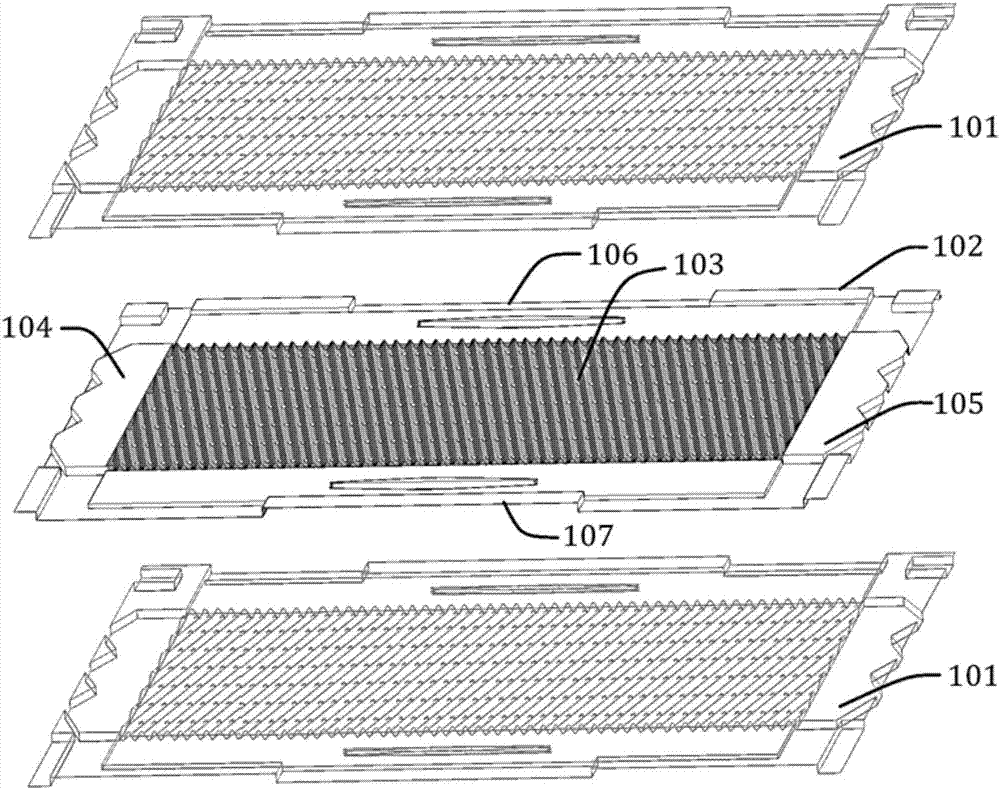

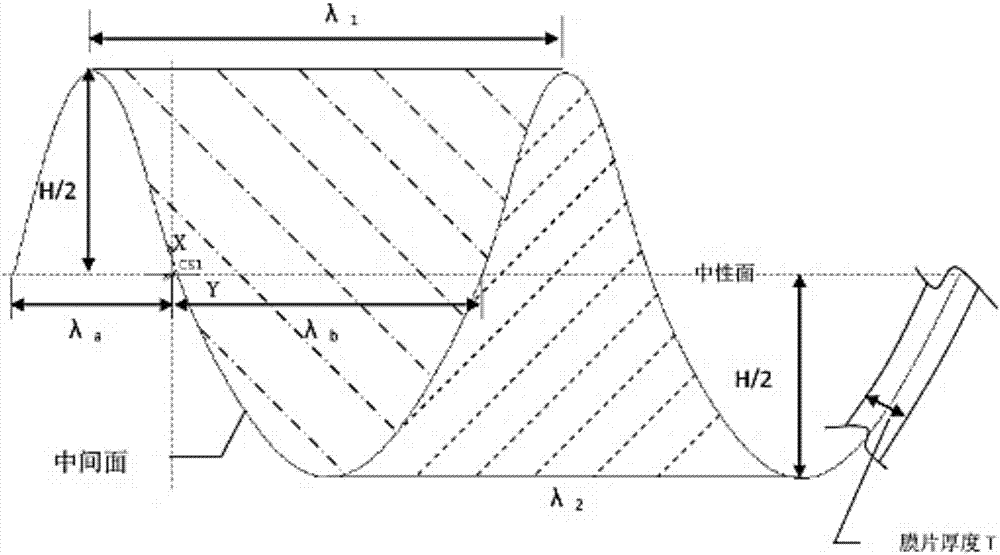

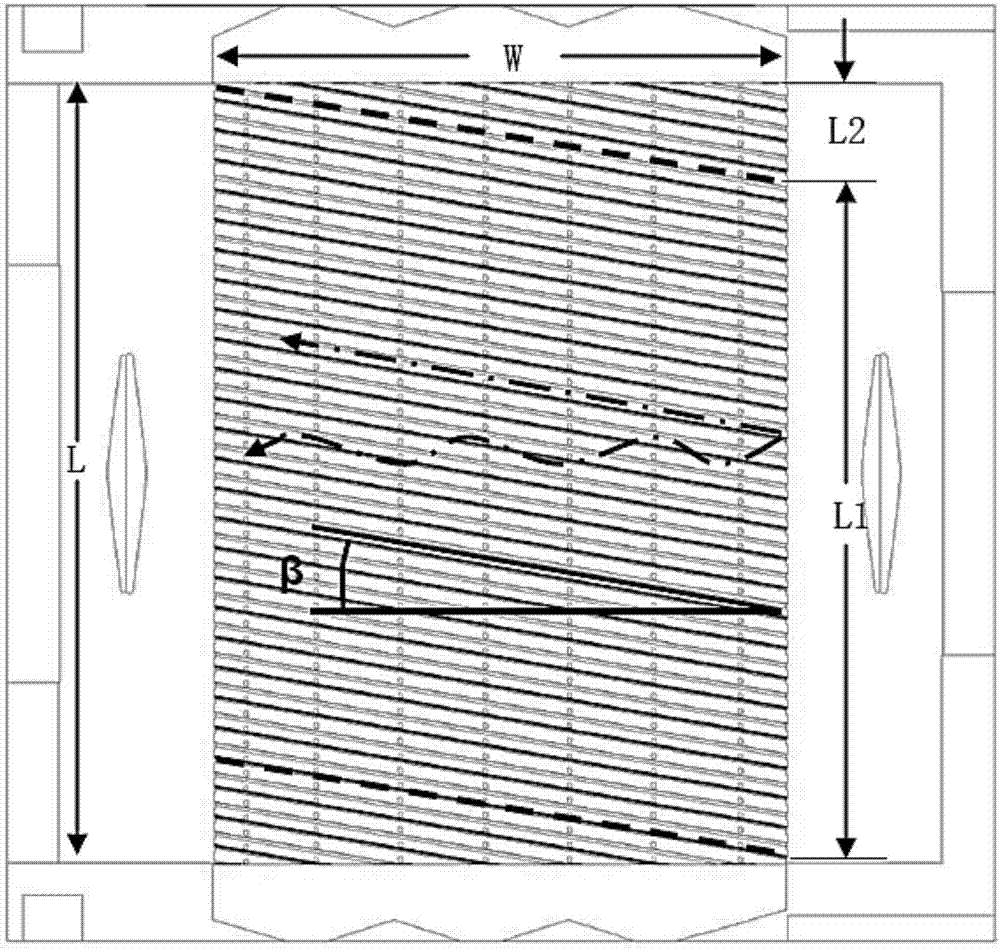

[0040] Such as figure 1 , Image 6 with Figure 7 As shown, the present embodiment is provided with alternately stacked first heat exchange membranes 101 and second heat exchange membranes 102; one side of the second heat exchange membranes 102 is a hydrophilic surface, and the other side is a hydrophobic surface , including: the central corrugated heat exchange area 103 and the first folded cavity surface 104 and the second folded cavity surface 105 arranged on both sides of the corrugated heat exchange area 103; the first heat exchange film 101 and the second heat exchange film The sheets 102 have the same structure and are centrally symmetrical, that is, the first heat exchange membrane 101 is rotated 180° by the second heat exchange membrane 102, the first folding cavity surface 104 on the first heat exchange membrane 101 and the second folding cavity Surfaces 105 respectively correspond to the second folded cavity surface 105 and the first folded cavity surface 104 on t...

Embodiment 2

[0072] Such as Figure 11 As shown, the first heat exchange membrane 101 and the second heat exchange membrane 102 constituting the heat exchanger in this embodiment are designed with no static pressure chamber and inlet and outlet flow guide structures, which can be used in heat exchangers under single cooling conditions , small size, less consumables.

[0073] Such as Figure 10 with Figure 11 As shown, this embodiment includes alternately stacked first heat exchange membranes 101 and second heat exchange membranes 102, wherein: the hydrophilic surface of the first heat exchange membrane 101 and the hydrophilic surface of the second heat exchange membrane 102 The faces are oppositely arranged to form a wet heat exchange channel layer, and the hydrophobic surface of the first heat exchange membrane 101 is arranged opposite to the hydrophobic surface of the second heat exchange membrane 102 to form a dry heat exchange channel layer; the first fold cavity surface 104 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com