Circular microchannel wave surface plate heat exchange core body, manufacturing method and heat exchanger

A micro-channel and heat exchanger technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of inability to guarantee the heat exchange area and heat exchange, and the reduction of the heat exchange air side area. , to achieve the effect of favorable long-term high-efficiency heat exchange, sufficient heat exchange, and not easy to accumulate dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

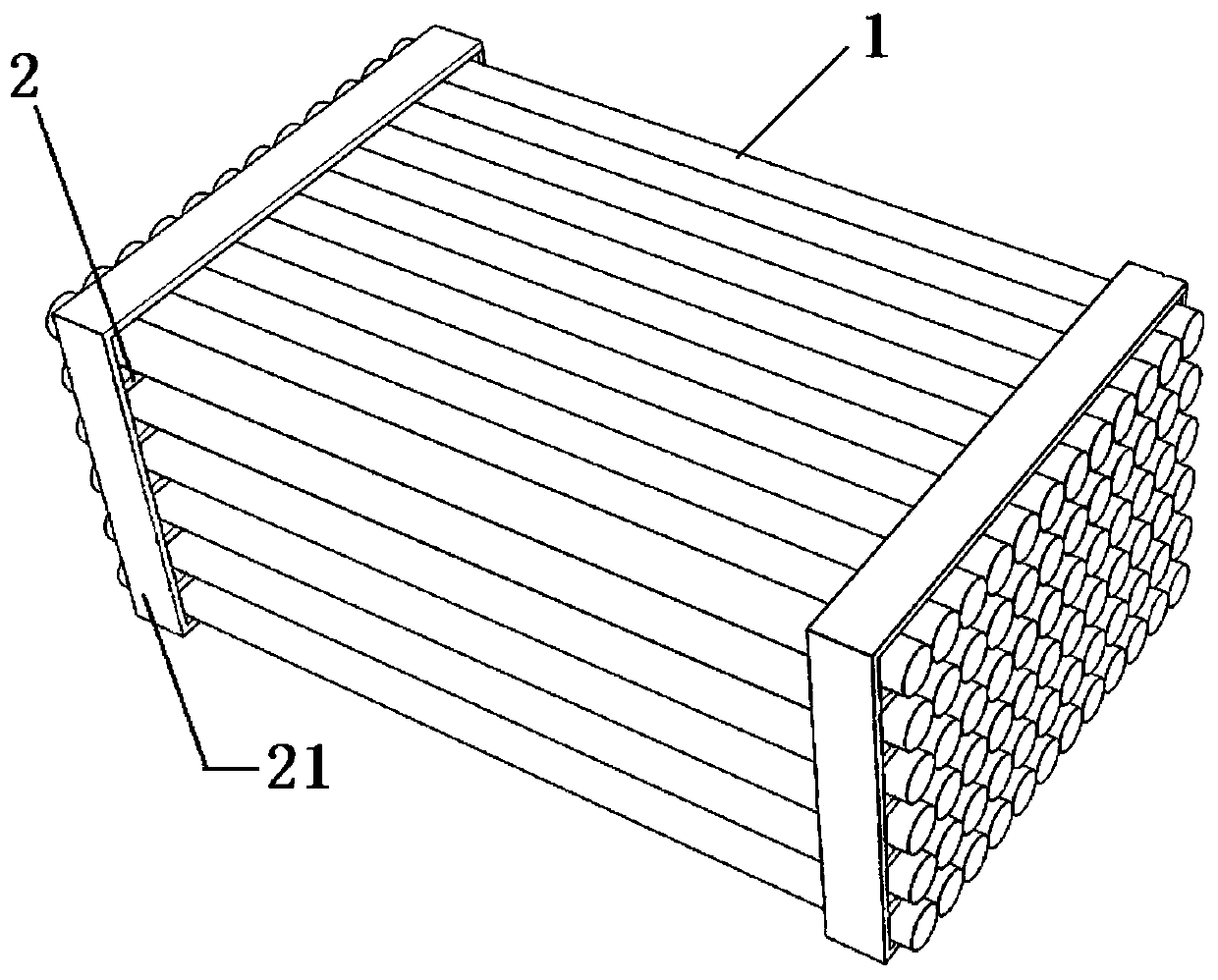

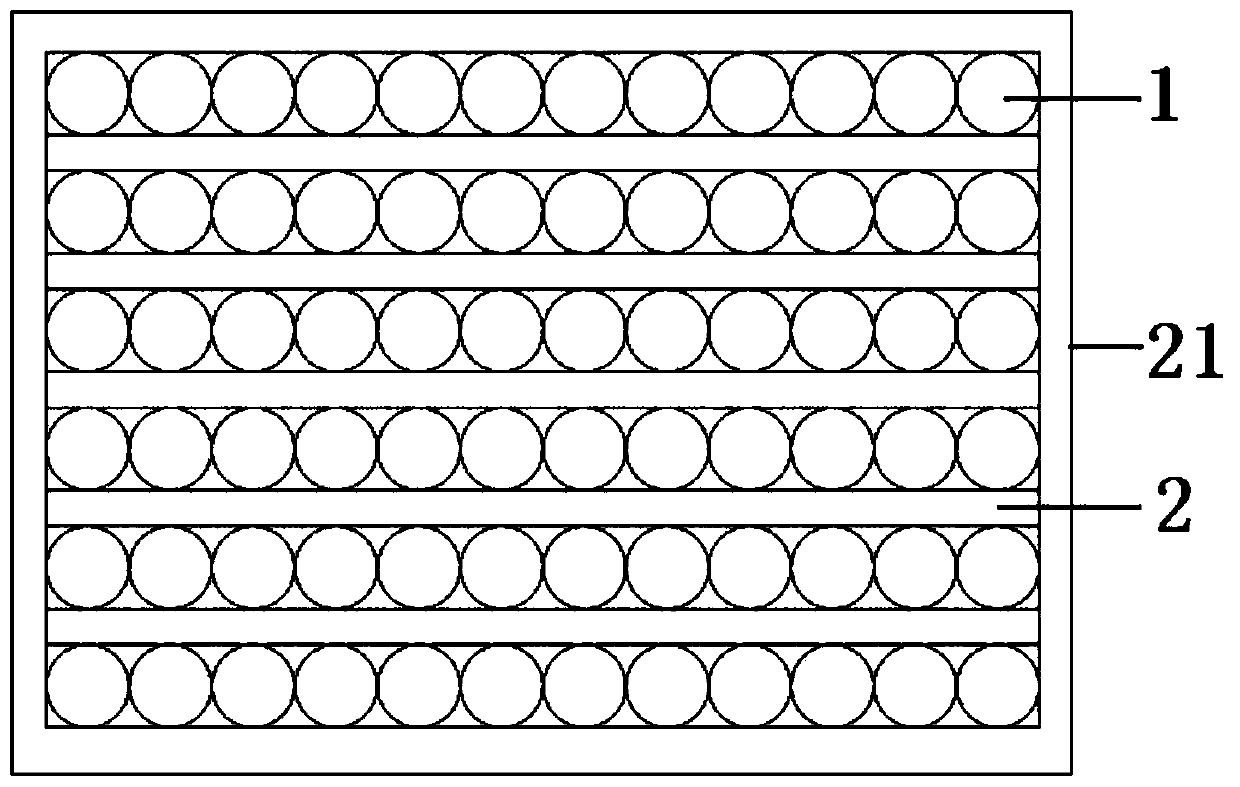

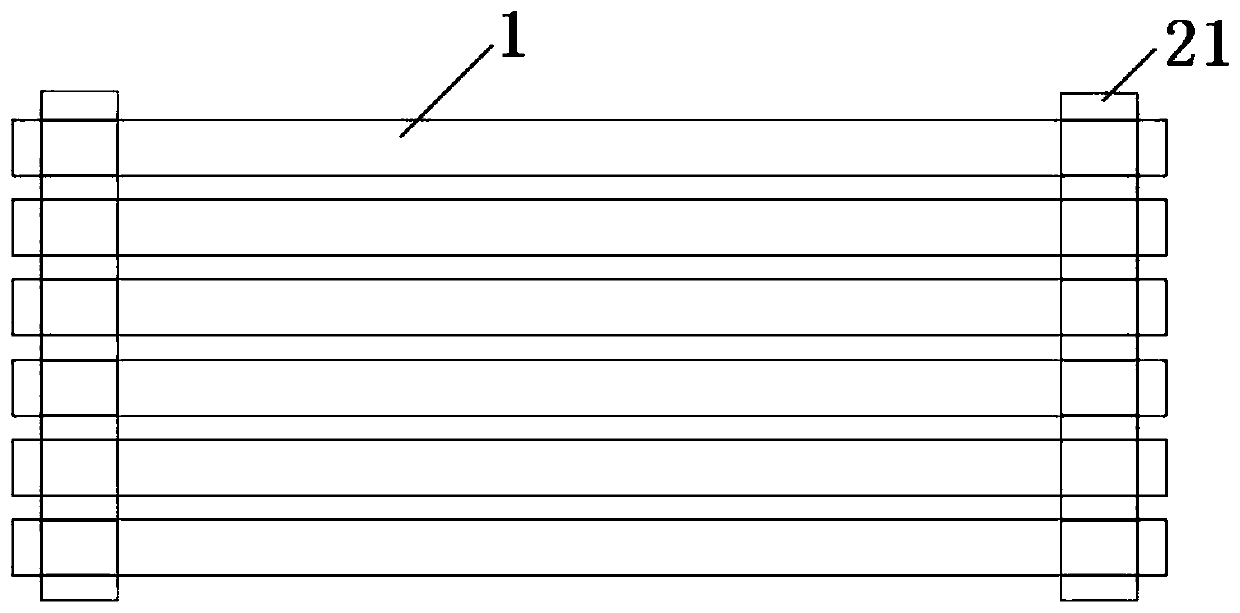

[0059] Such as Figure 1 to Figure 3 As shown, a circular microchannel wave panel heat exchanger core is composed of several circular microchannel wave surface heat exchange plates alternately stacked and fixed in two heat exchanger core frames 21 through tube slats 2 . For the structure of each circular microchannel wave surface heat exchange plate, see Figure 4 , Including several circular microchannels 1, the circular microchannels 1 are arranged closely to each other, and the two ends are respectively clamped and fixed by two tube slats 2, and there are also protrusions 3 between the tube slats 2 for Maintain the close fit between the circular microchannels 1.

[0060] The wavy surface heat exchange plates of the circular microchannels are laminated and fixed to each other by the tube strips 2 at both ends of the circular microchannel 1, and the two ends of the circular microchannel 1 extend out of the tube strip 2 for a certain length, and the extension parts are flush. ....

Embodiment 2

[0078] This embodiment is a heat exchanger using the core of the circular microchannel wave panel heat exchanger in embodiment 1. Such as Figure 8 As shown, a circular microchannel wave panel heat exchanger. The two ends of the core of the circular microchannel wave panel heat exchanger are respectively connected to the liquid collecting pipe 4, and the liquid collecting pipes 4 on both sides are provided with The flow baffle 5 where the tube strips 2 of the core of the microchannel round tube heat exchanger are fixed. The flow baffle 5 divides the inside of the liquid collecting pipe 4 into several flows, and the liquid collecting pipe is provided with a fluid inlet and a fluid outlet.

[0079] In order to make the liquid distribution between different heat exchange plates and between different circular microchannels 1 more uniform, in the liquid collecting pipe 4, a number of liquid uniform hoods are provided at the circular microchannel liquid inlet of each process 6. The li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com