Closed gas-liquid two-phase impingement cooling system and method

A cooling system and cooling method technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as waste of heat resources and water resources, increased equipment complexity, and unused airflow, so as to save energy, Good cooling effect and less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

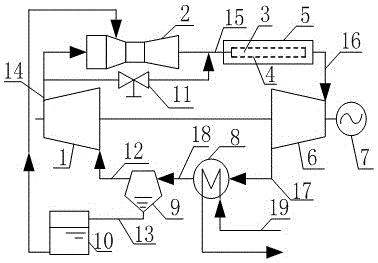

[0014] figure 1 It is a closed gas-liquid two-phase impingement cooling system proposed by the present invention, refer to below figure 1 Explain how the cooling system works.

[0015] The low-pressure gas-water mixed flow 18 on the hot side of the condenser 8 enters the gas-water separator 9 for gas-water separation: the water 13 separated by the gas-water separator 9 flows into the water tank 10; the low-pressure air 12 separated by the gas-water separator 9 is compressed by air After being compressed by machine 1, it becomes high-pressure air 14, and high-pressure air 14 is divided into two paths: one path enters ejector 2 for ejecting water 13 in water tank 10 and atomizes it; the other path passes through regulating valve 11 and exit of ejector 2 The mixed working medium is fully mixed to form a uniform high-pressure air-water mixed flow 15. The high-pressure air-water mixed flow 15 enters the impact chamber 3 and is sprayed out through the impact hole 4 to cool the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com