Patents

Literature

255results about How to "Change traffic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

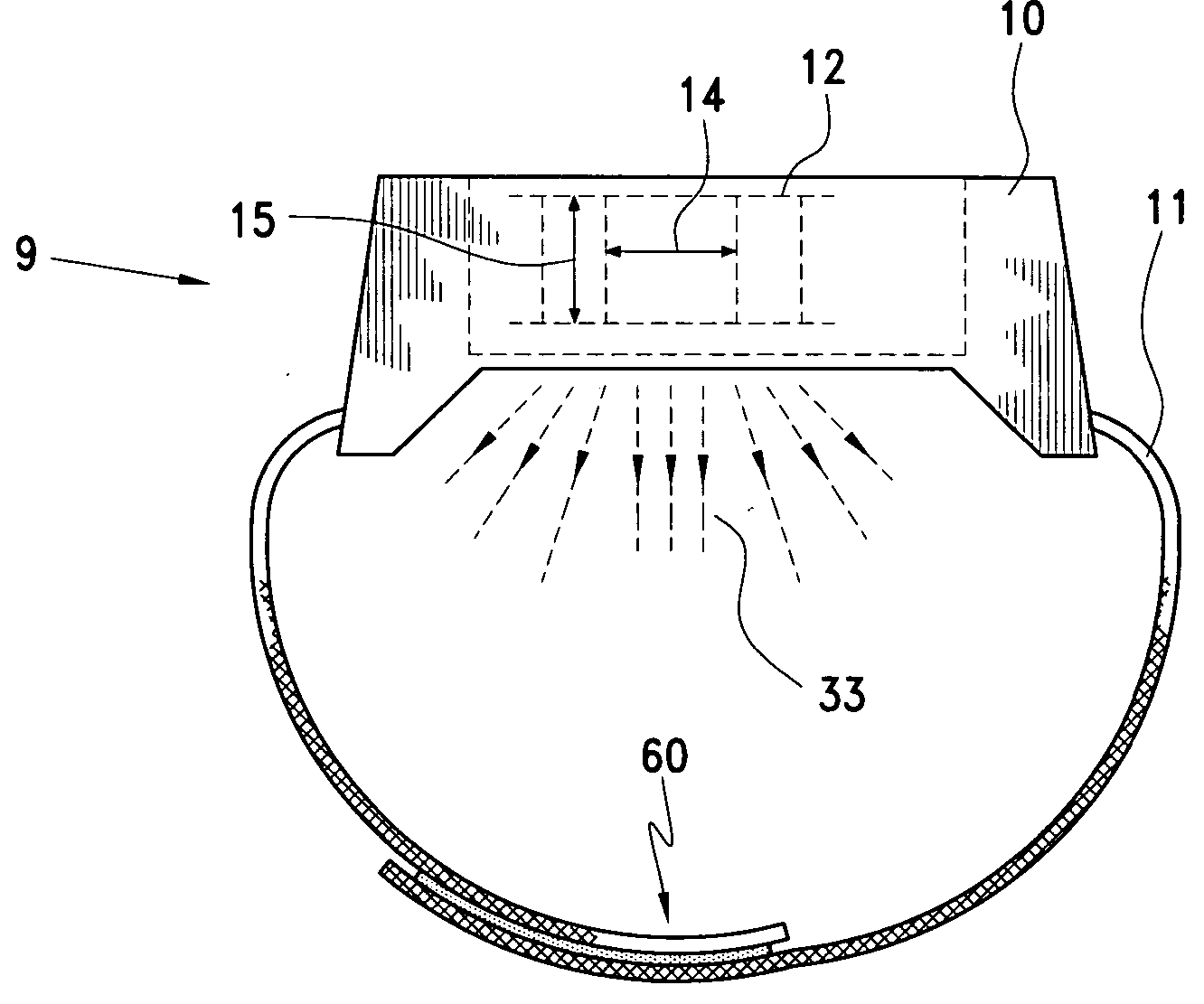

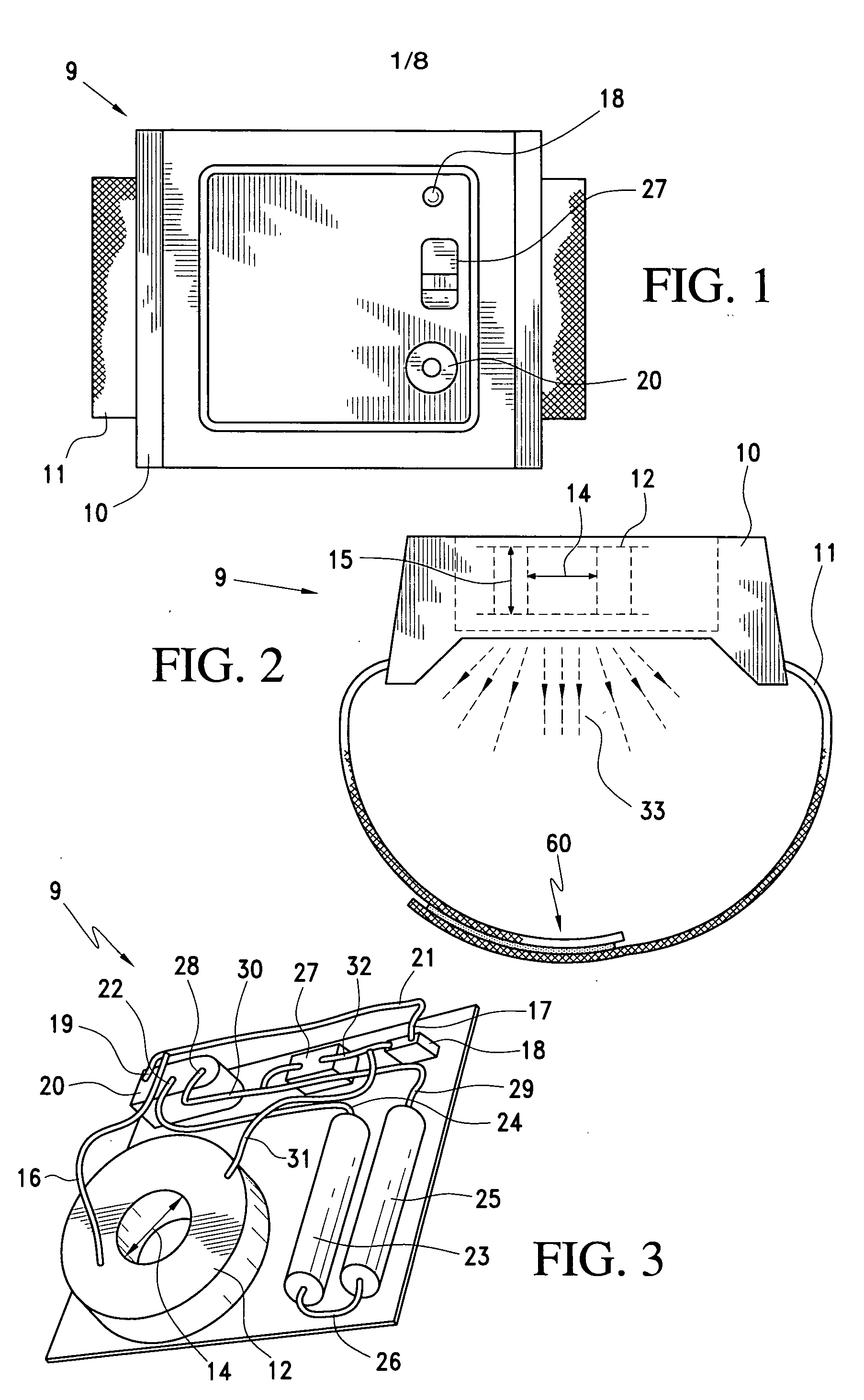

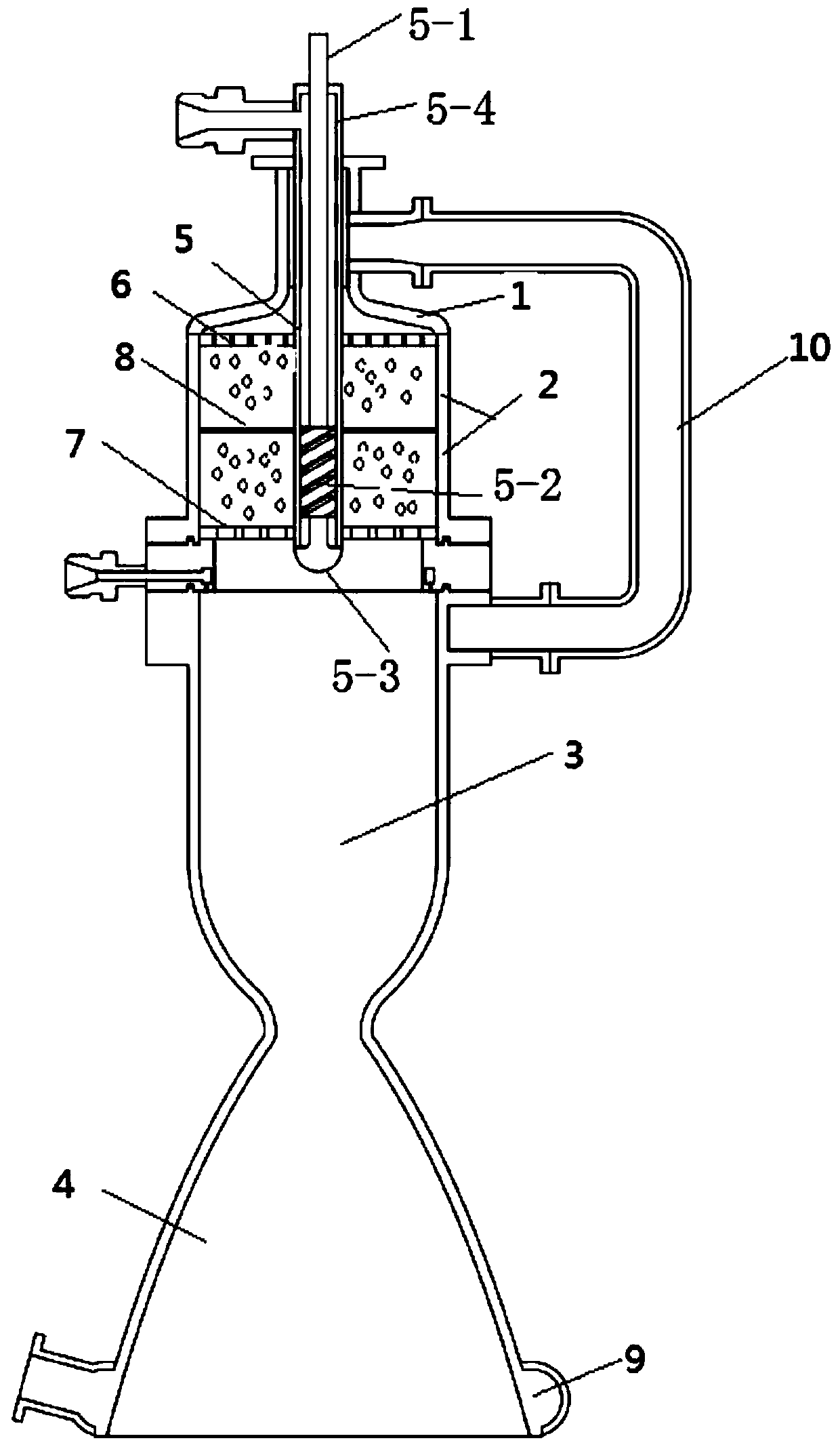

Respiratory devices

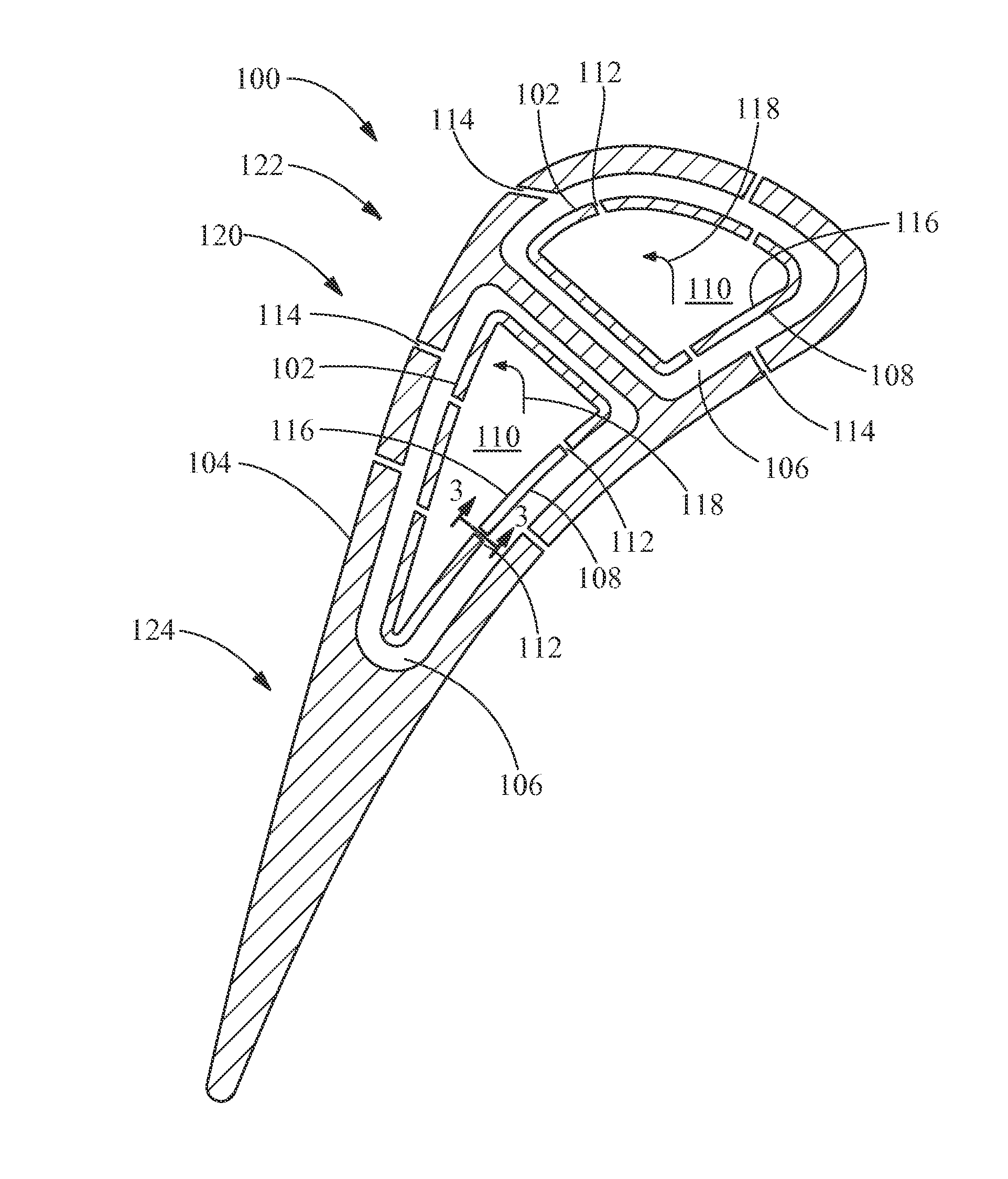

InactiveUS20060144398A1Avoid inhalationAvoid expirationOperating means/releasing devices for valvesBreathing filtersNostrilMedical disorder

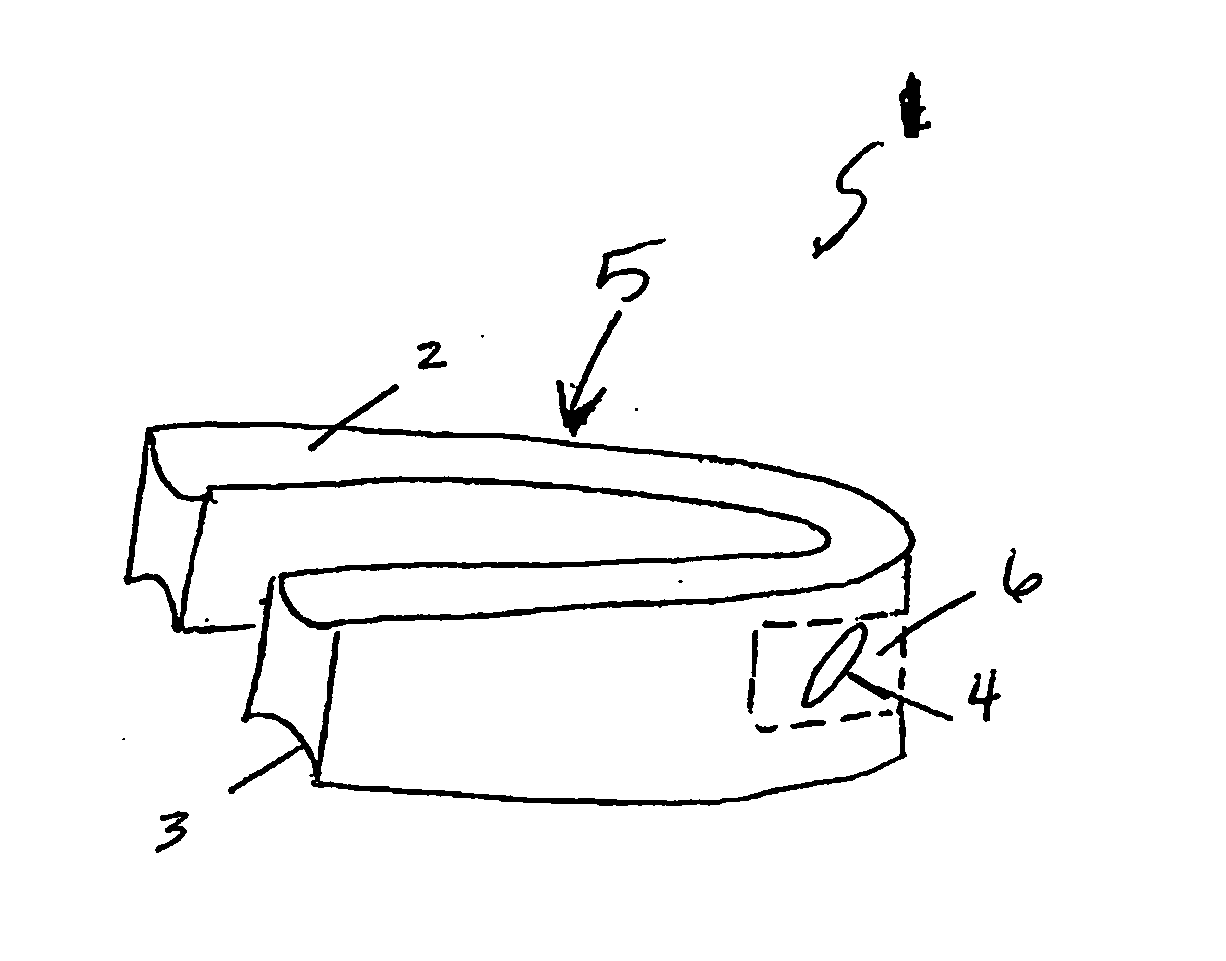

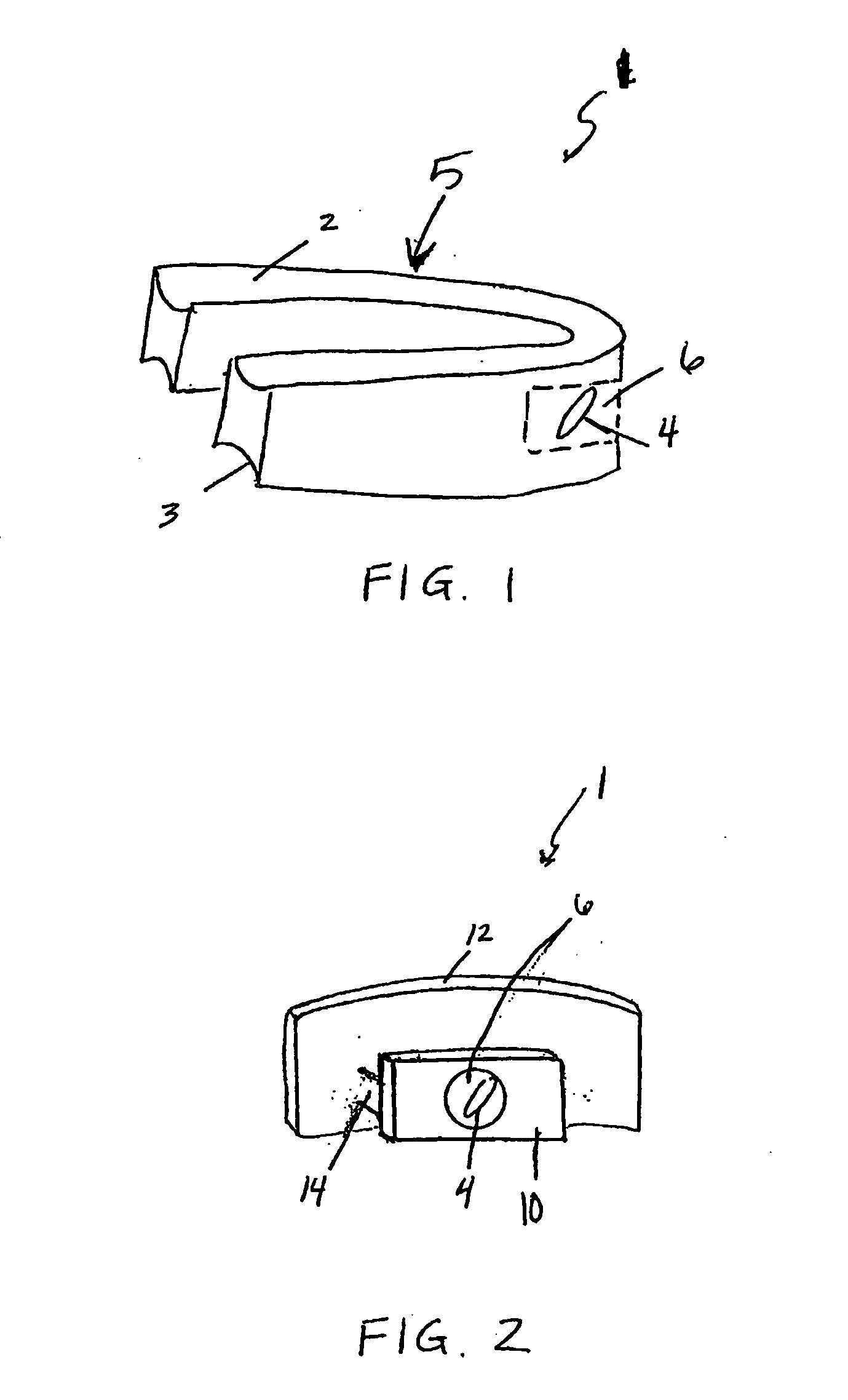

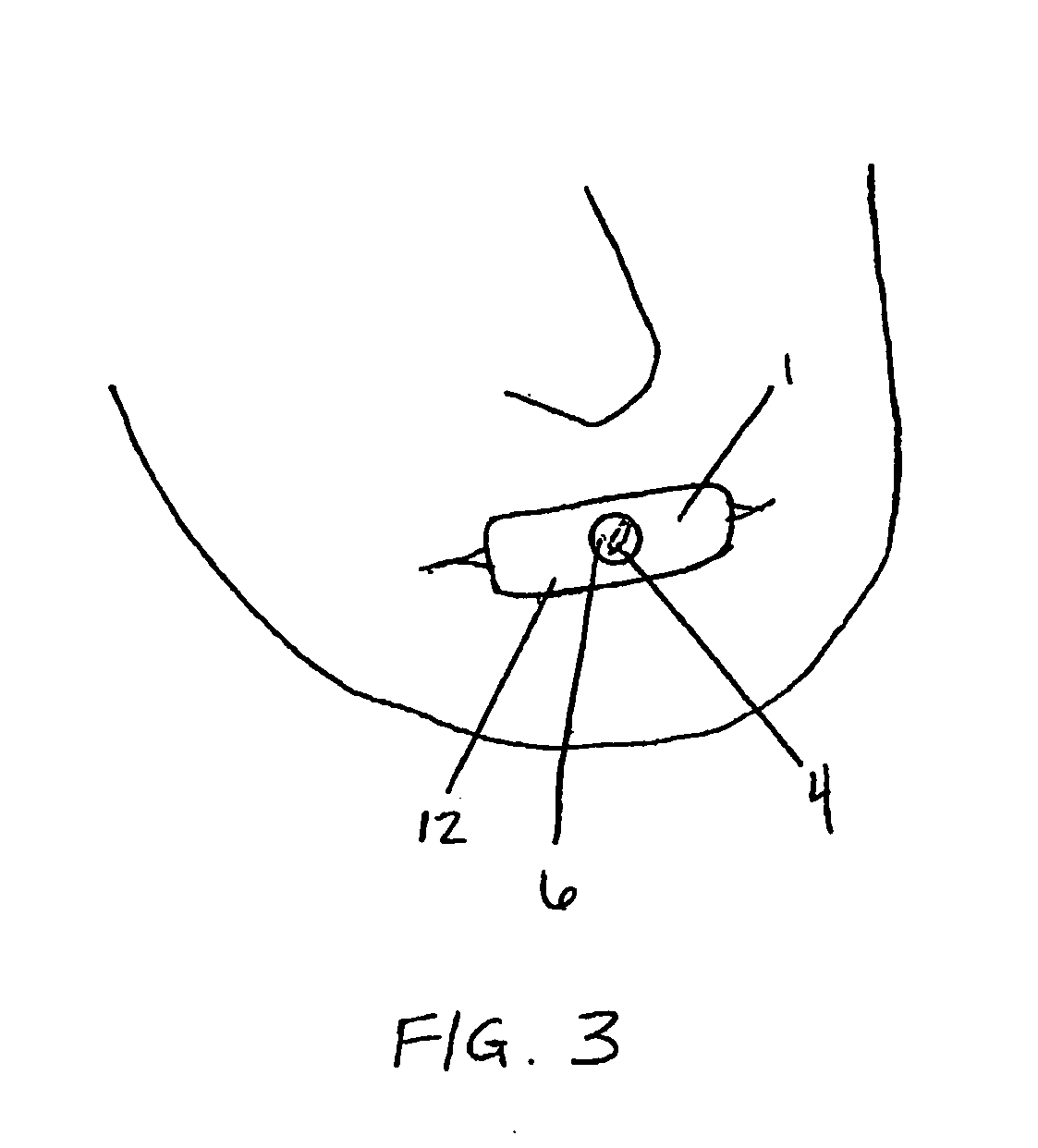

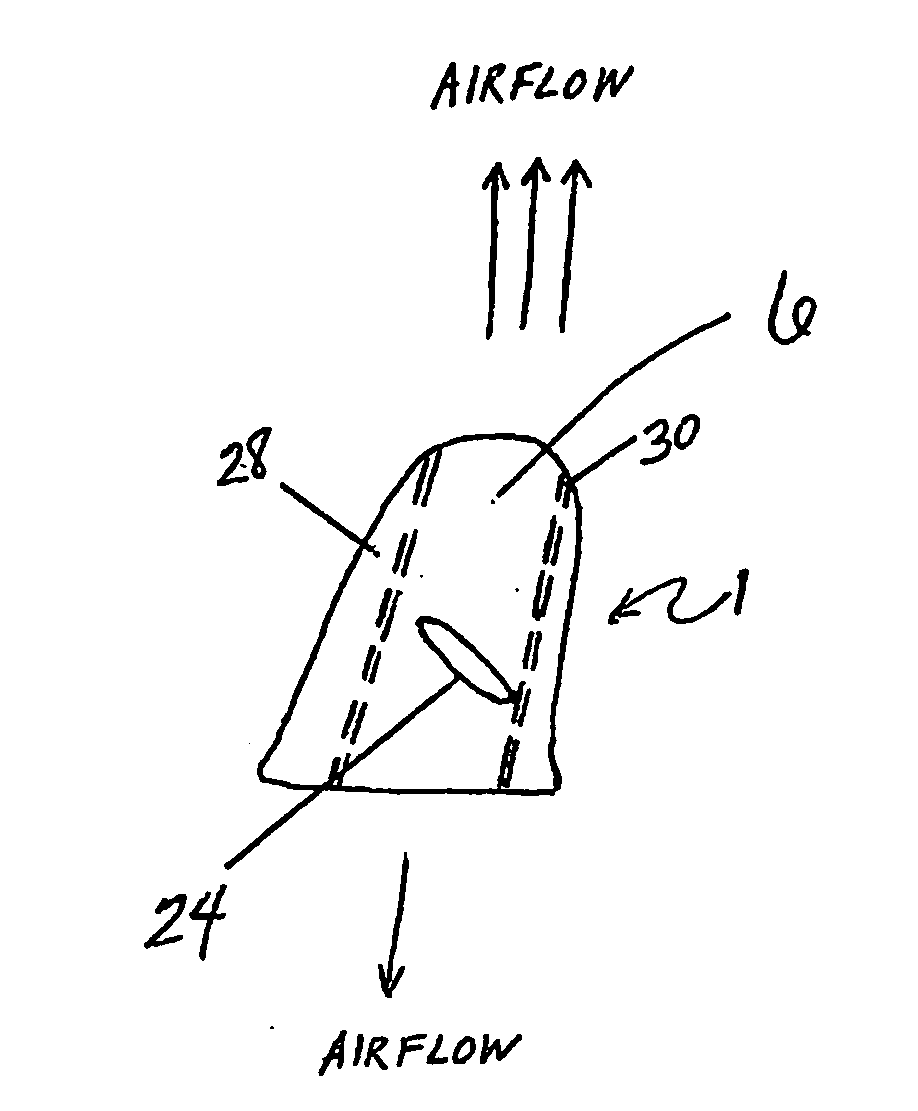

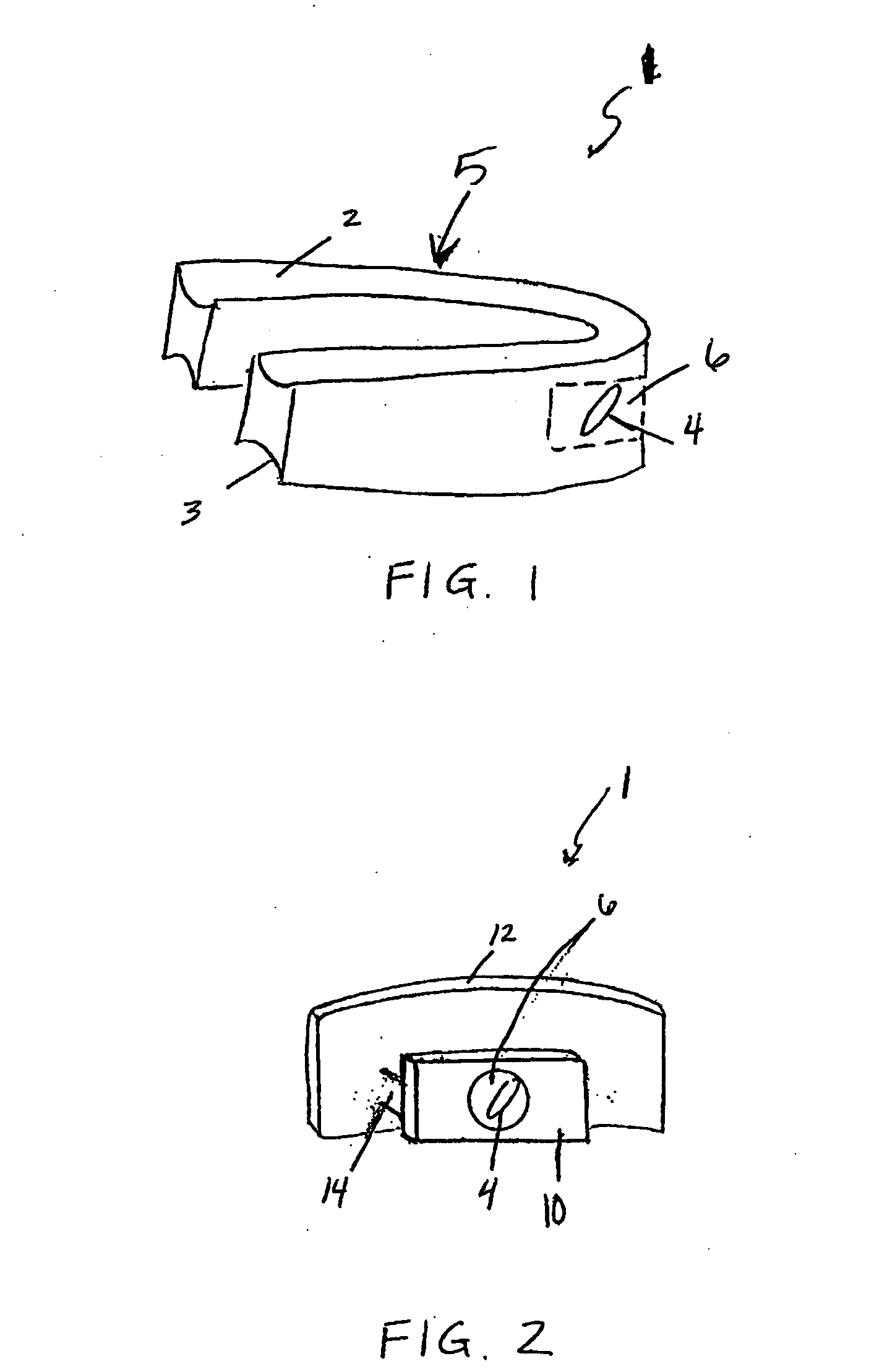

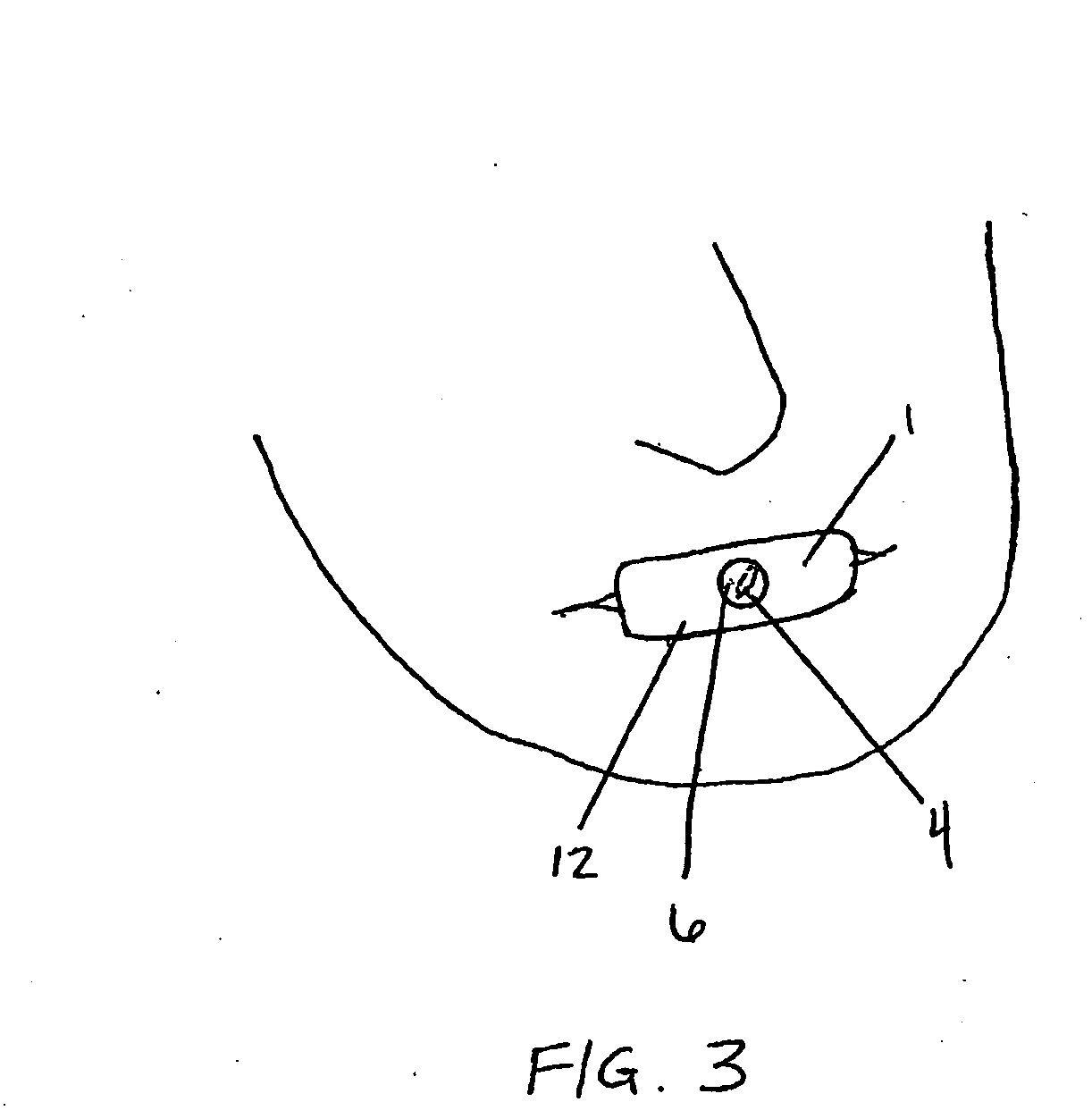

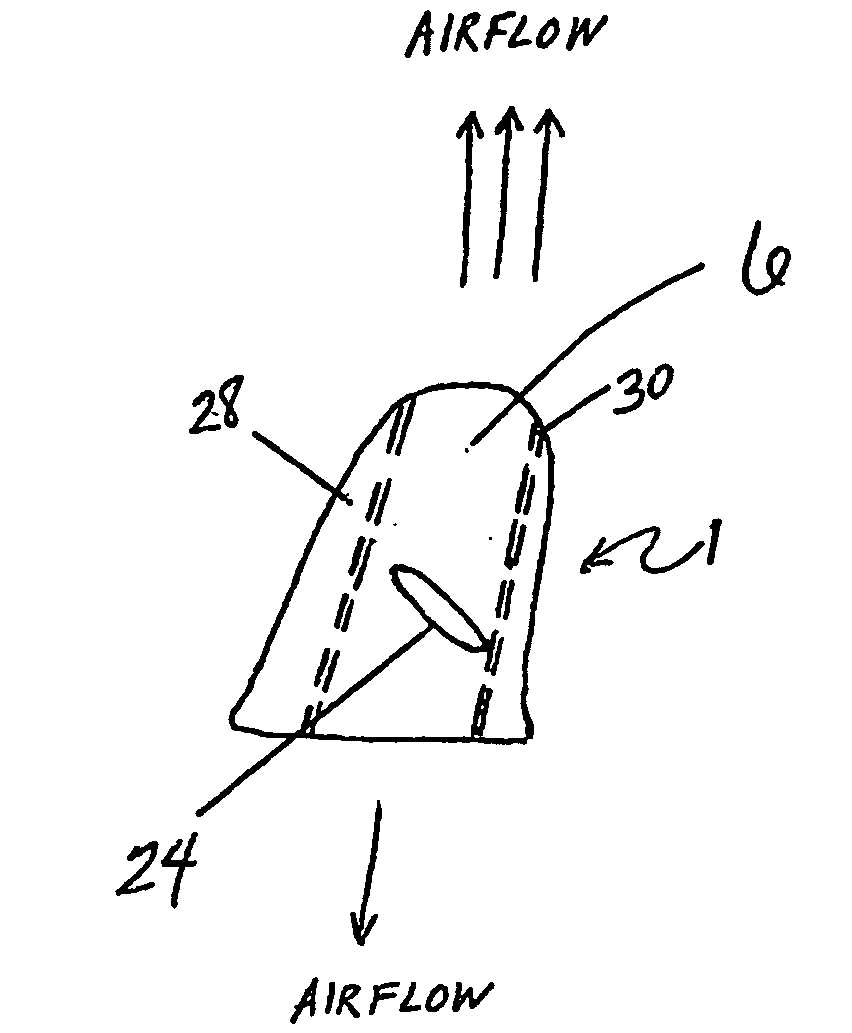

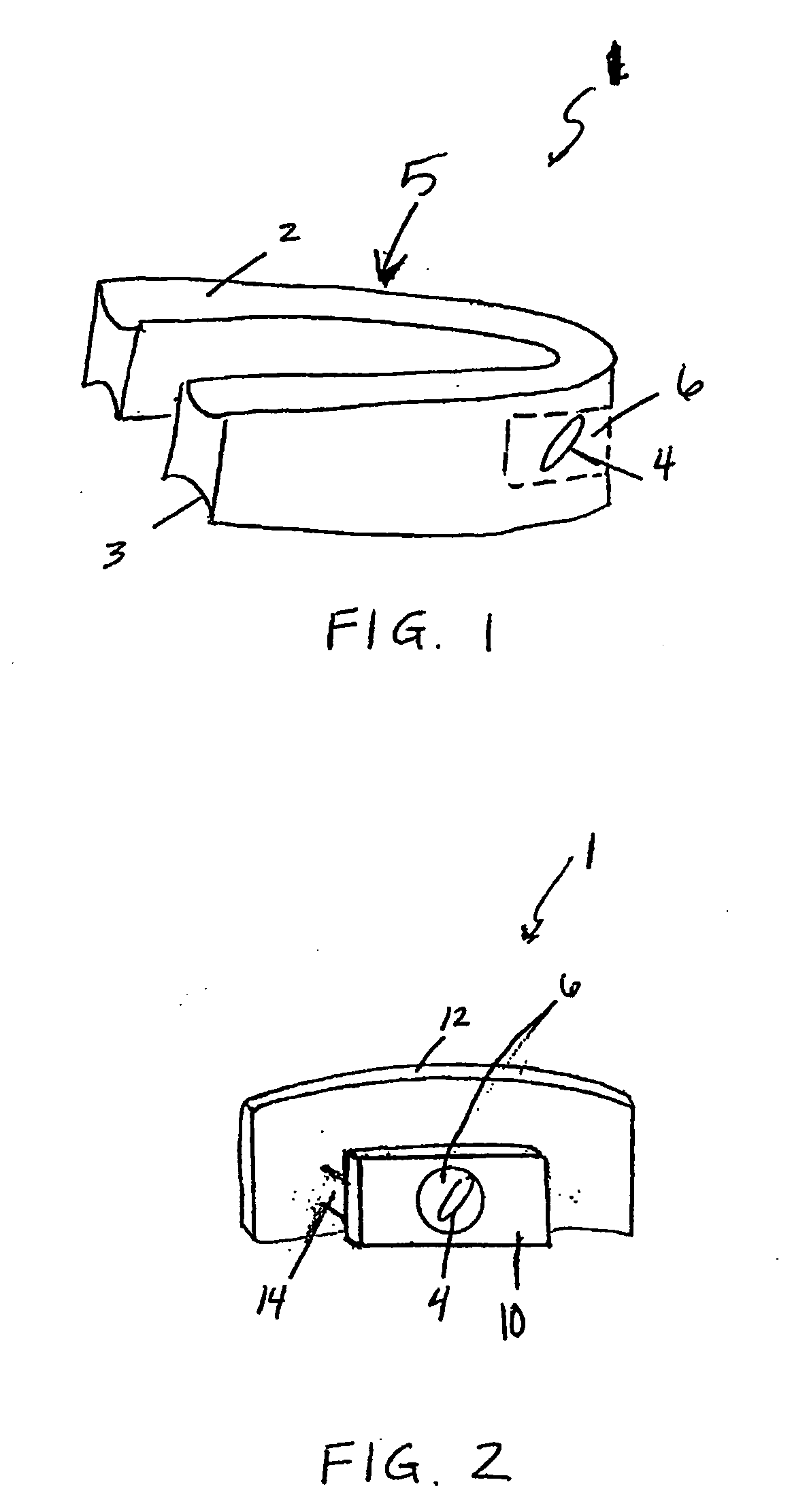

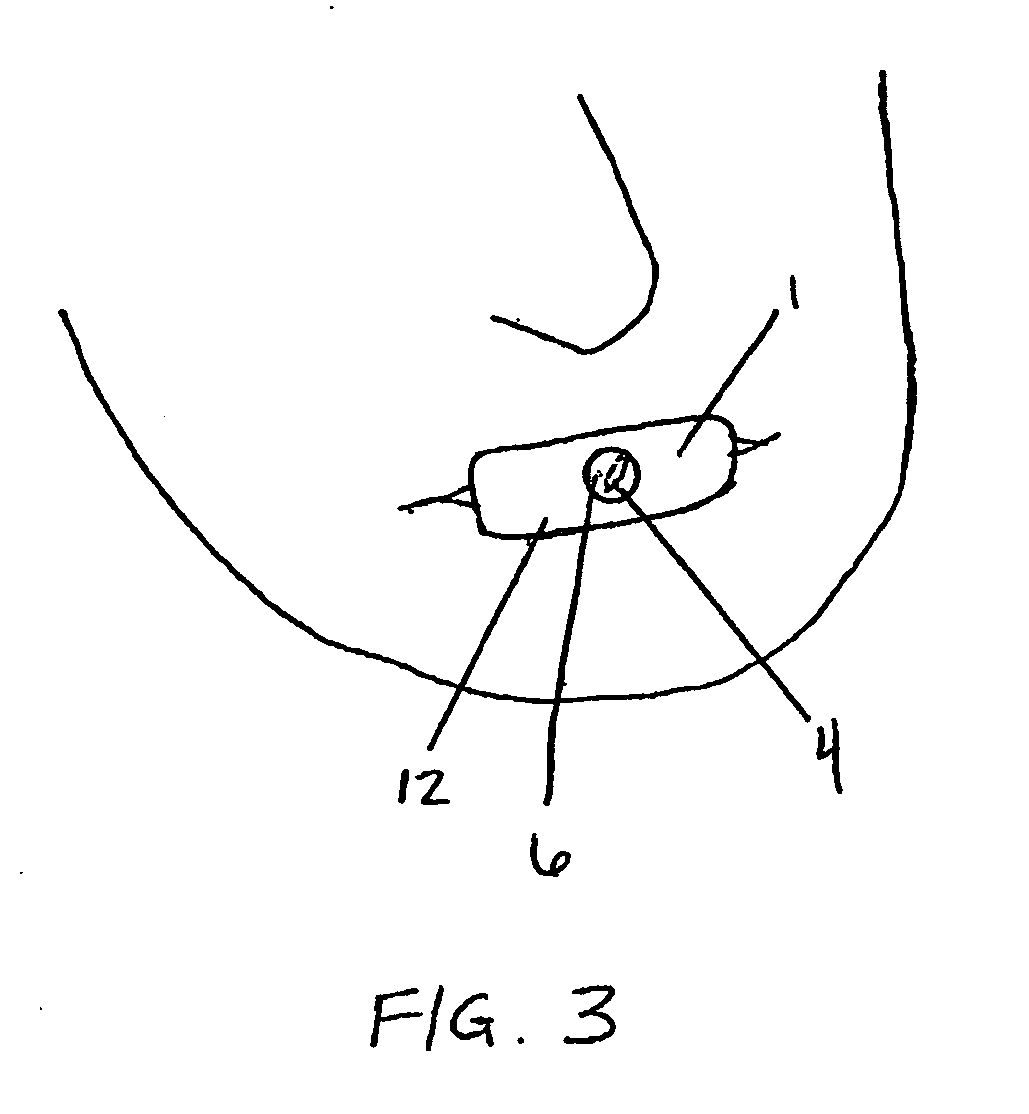

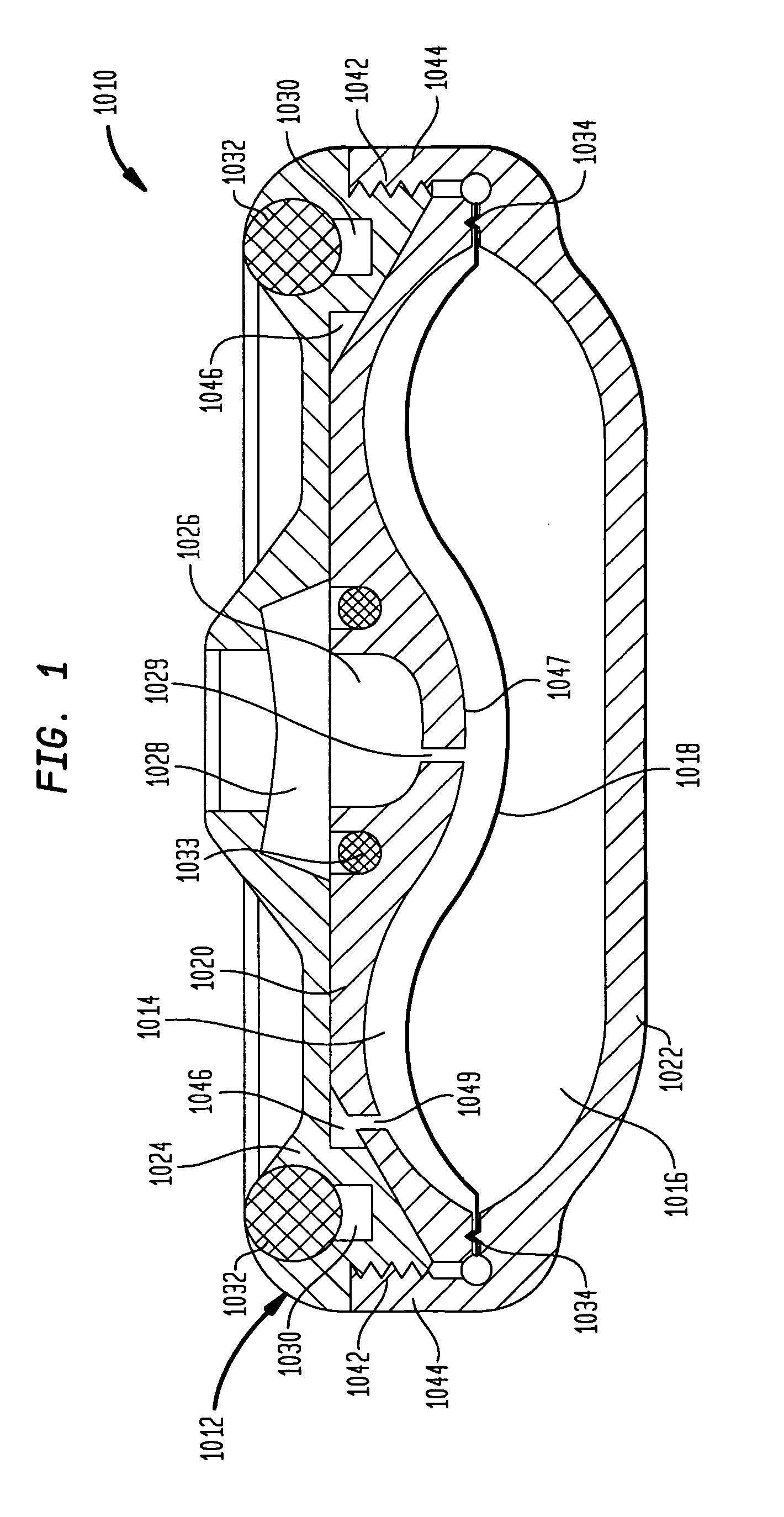

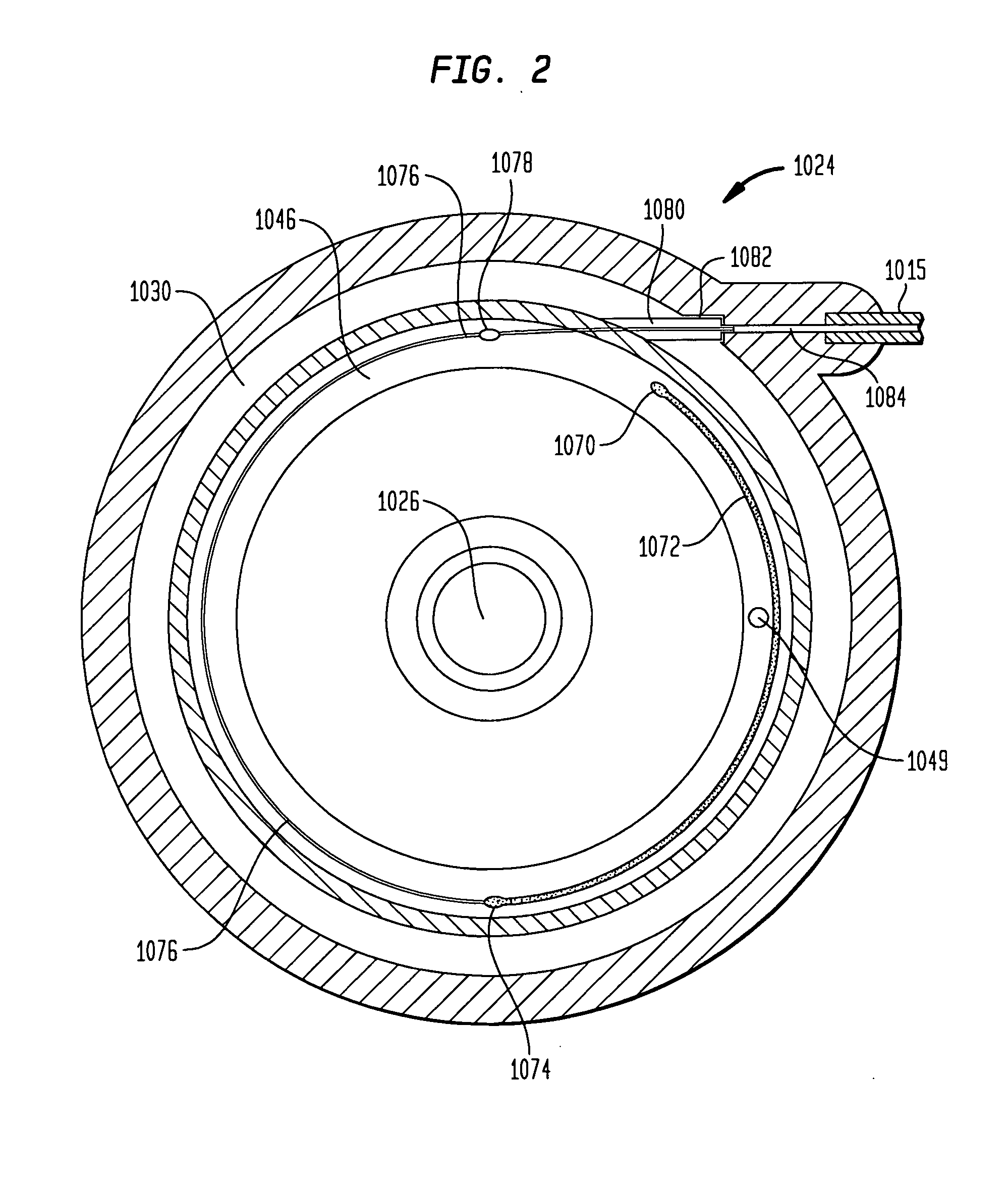

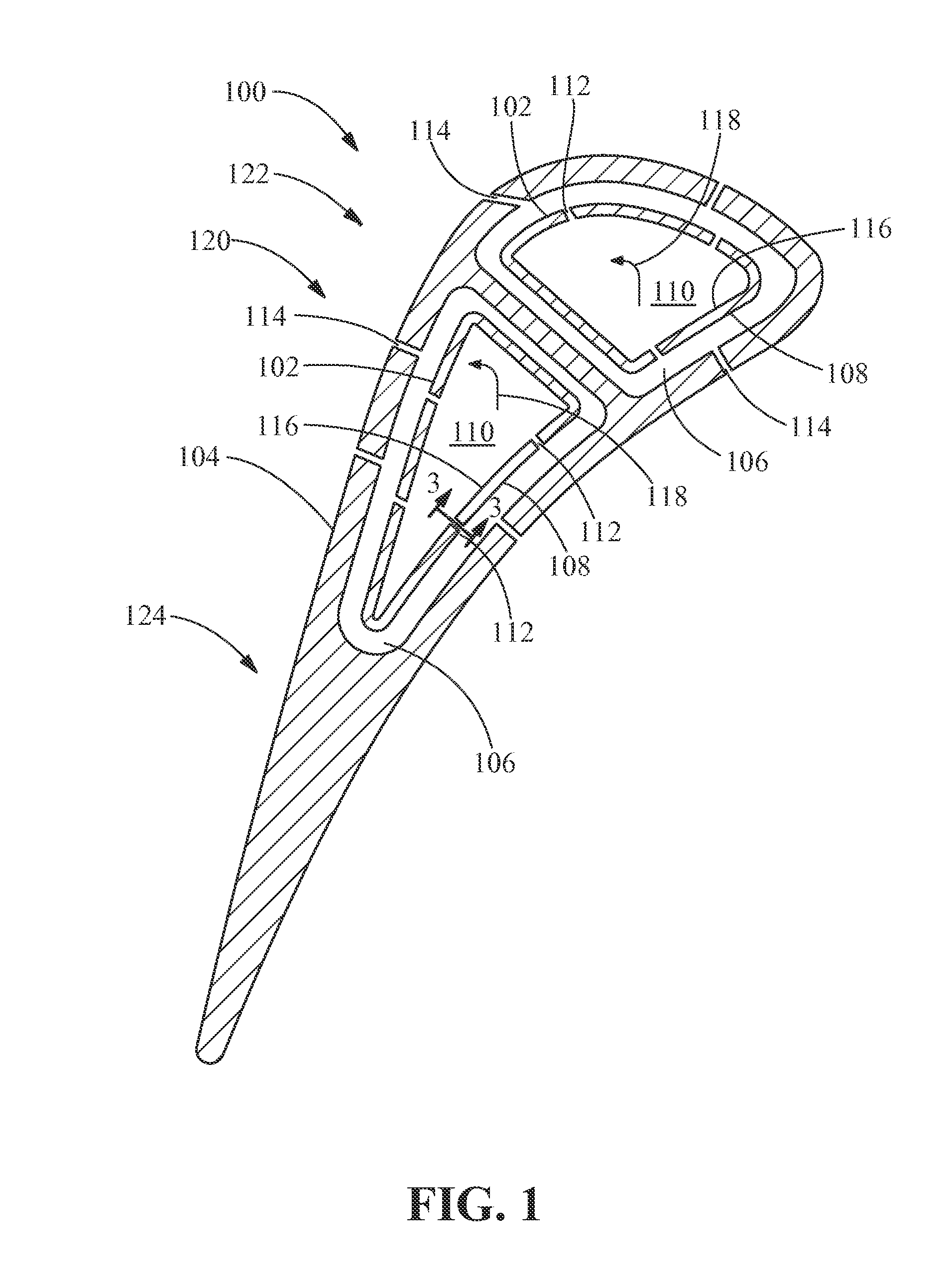

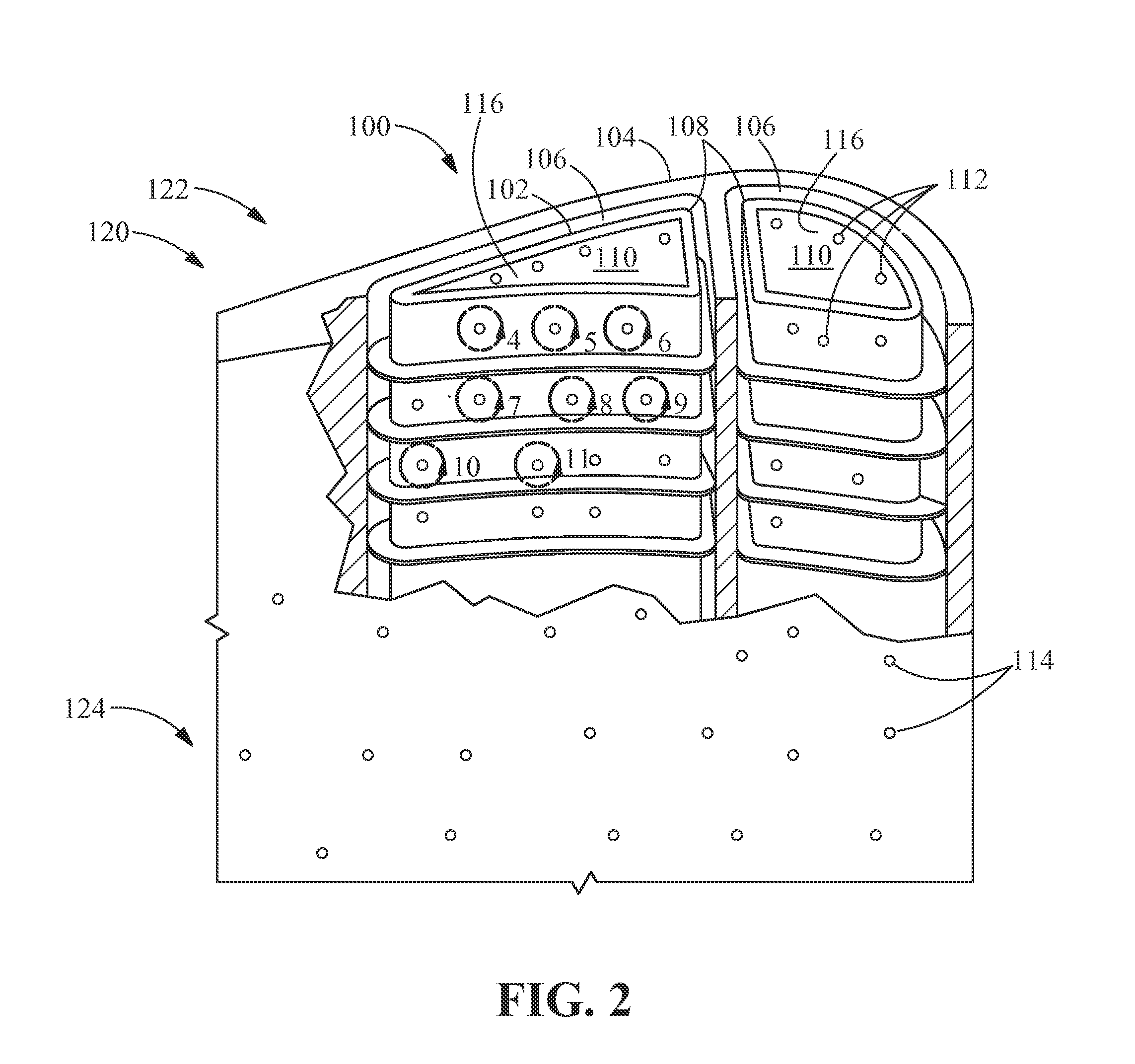

Described here are devices for altering the flow of air in a respiratory cavity such as the mouth and nostrils of the nose. These methods and devices may be useful for affecting a physiologic benefit in patients suffering from a variety of medical diseases, particularly those that may benefit from “pursed-lip” breathing and non-invasive ventilation, such as COPD, heart failure, sleep apnea, and other medical disorders. The devices are typically removable devices that may be placed over or in a respiratory cavity to increase resistance to airflow within the respiratory cavity. Resistance to expiration may be selectively increased relative to inspiration. Removable oral and removable nasal devices are described. Oral and nasal devices that filter inhaled airflow of debris and allergens are also provided. A nasal device that increases patency of the nares is also provided.

Owner:THERAVENT

Methods of treating respiratory disorders

InactiveUS20060150978A1Improve the immunityChange trafficBreathing filtersRespiratory masksMedical disorderNostril

Owner:THERAVENT

Nasal respiratory devices

InactiveUS20060150979A1Improve the immunityChange trafficBreathing filtersRespiratory masksMedical disorderNostril

Described here are methods, devices, and kits for altering the flow of air in a respiratory cavity such as the nostrils of the nose. These methods and devices may be useful for affecting a physiologic benefit in patients suffering from a variety of medical diseases, particularly those that may benefit from “pursed-lip” breathing and non-invasive ventilation, such as COPD, heart failure, sleep apnea, and other medical disorders. The devices are typically removable devices that may be placed over or in a respiratory cavity to increase resistance to airflow within the respiratory cavity. Resistance to expiration may be selectively increased relative to inspiration. Removable nasal devices are described.

Owner:THERAVENT

Variable flow infusion pump system

InactiveUS20070112328A1Increase and decrease flow rateAlter shapeInfusion devicesPharmaceutical delivery mechanismEngineeringElectronics

Owner:AQULINX MEDICAL

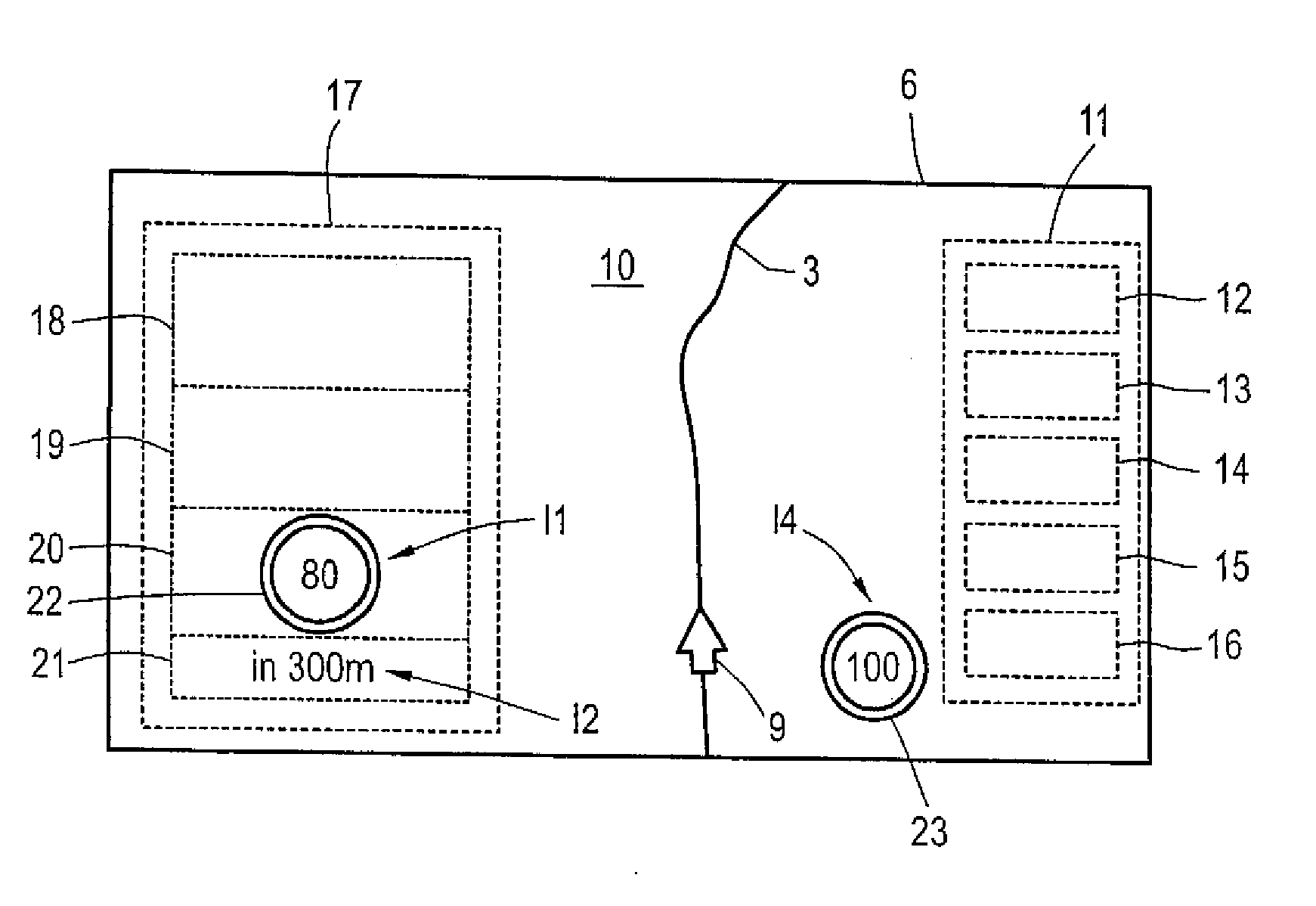

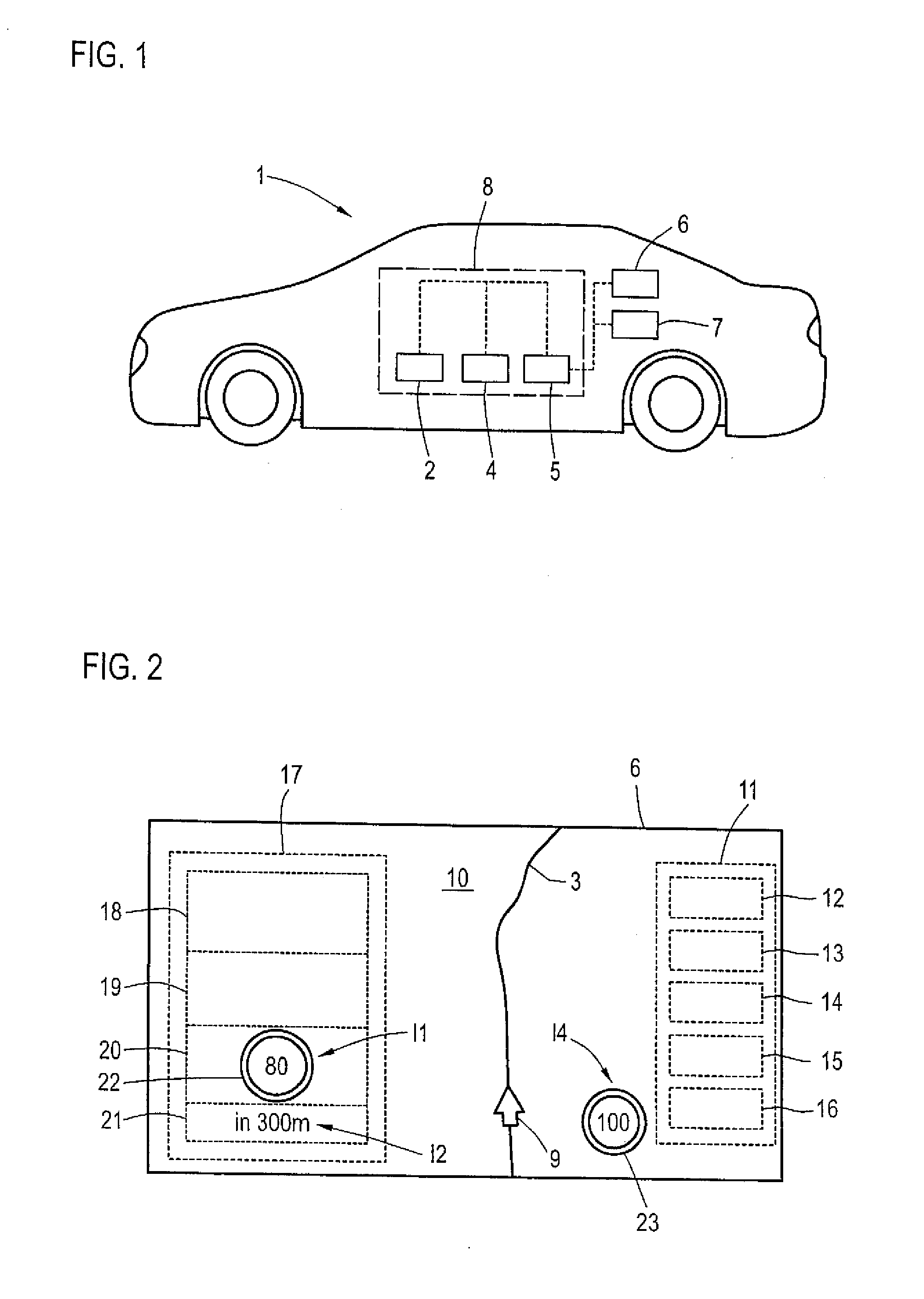

Motor vehicle

InactiveUS20120223845A1Respond quicklyReduce motor speedRoad vehicles traffic controlInstrument arrangements/adaptationsMobile vehicleTraffic signal

A motor vehicle includes a detection device for detecting a route actually traveled by the motor vehicle and the actual position of the motor vehicle on the route, a storage device with route-specific traffic sign information, and a control device with a display for outputting route-specific traffic sign information. The route-specific traffic sign information includes first information relating to at least one traffic sign ahead of the actual position of the motor vehicle on the route and second information representing a measure for the distance between the traffic signal ahead and the actual position of the motor vehicle.

Owner:AUDI AG

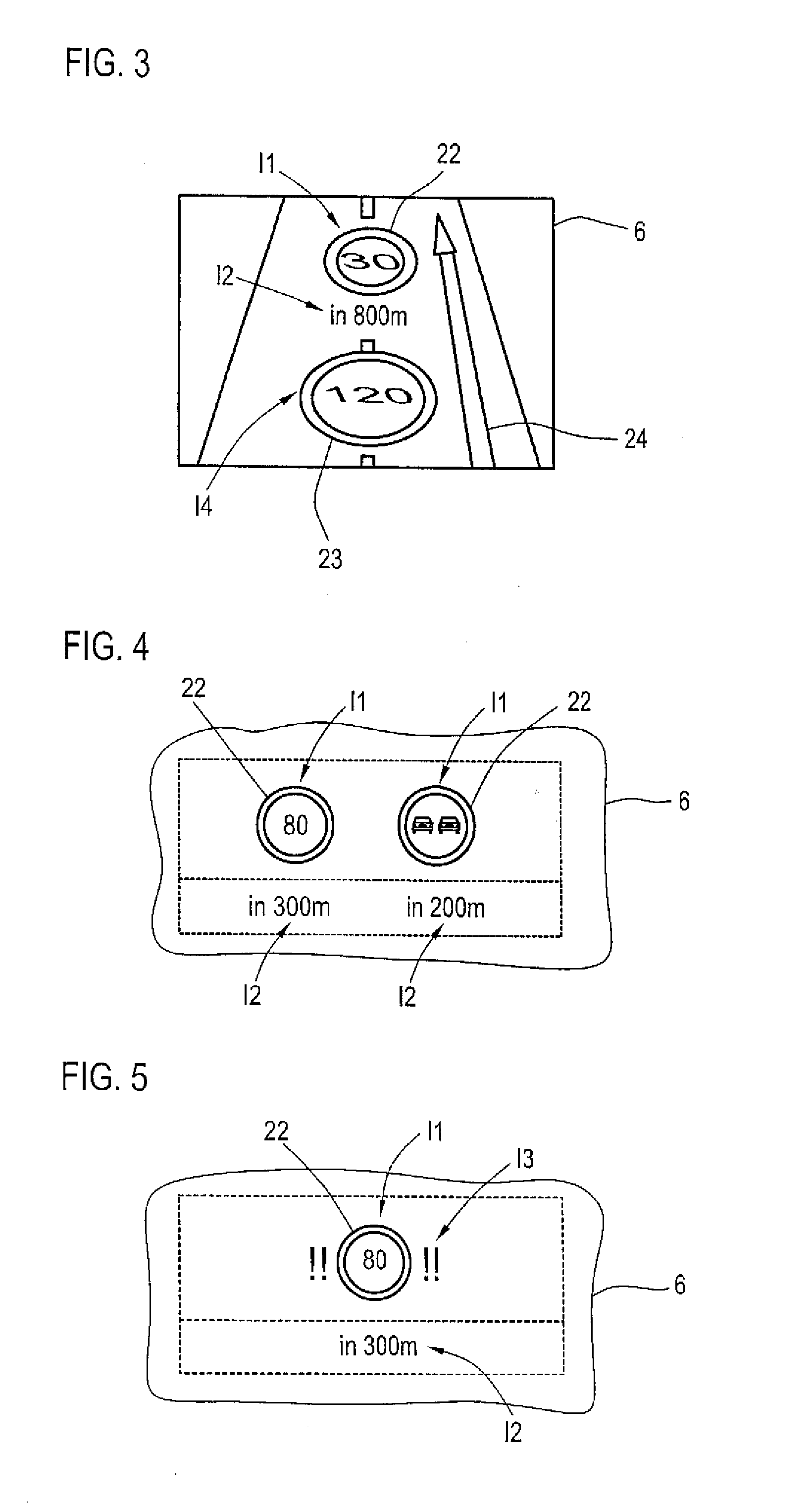

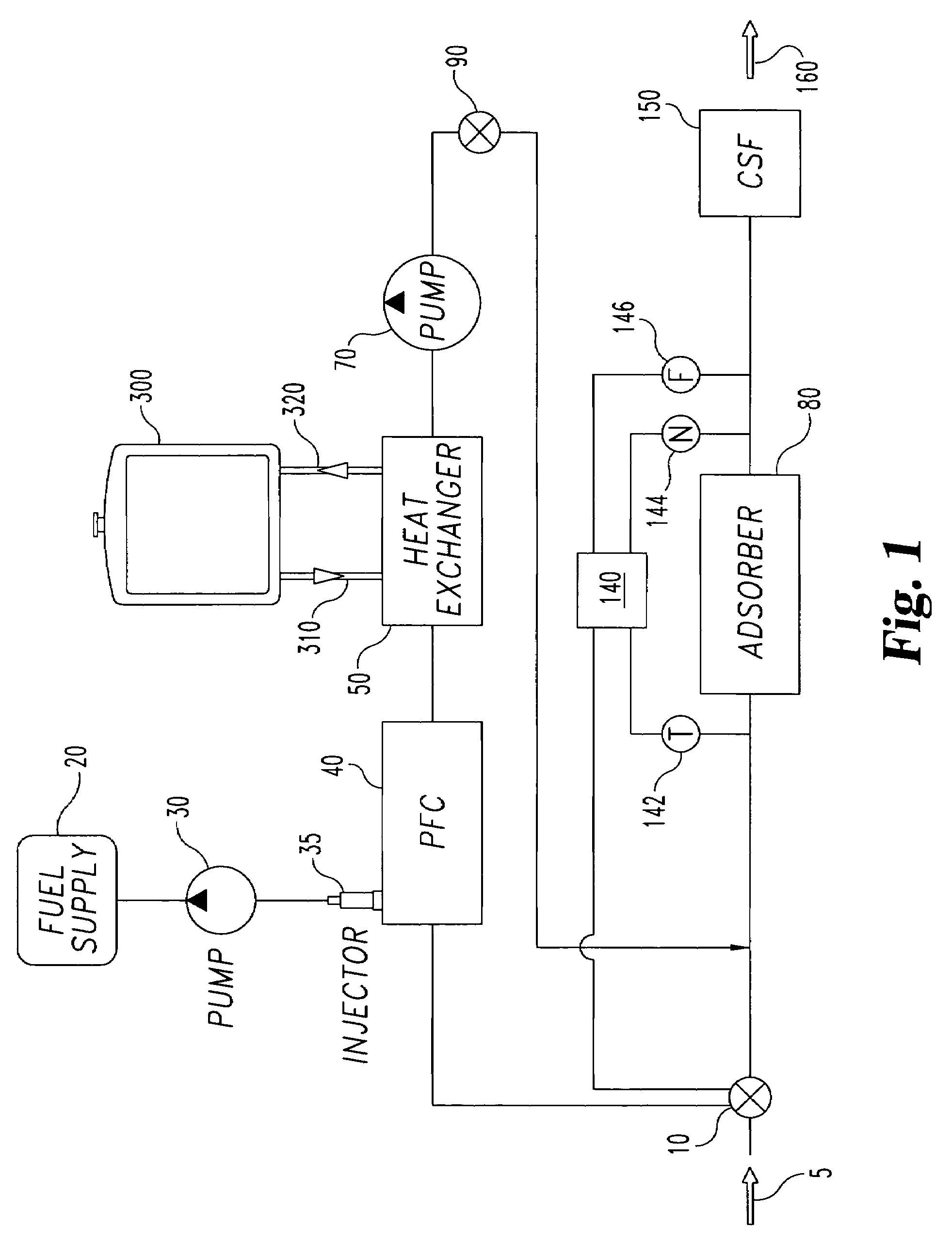

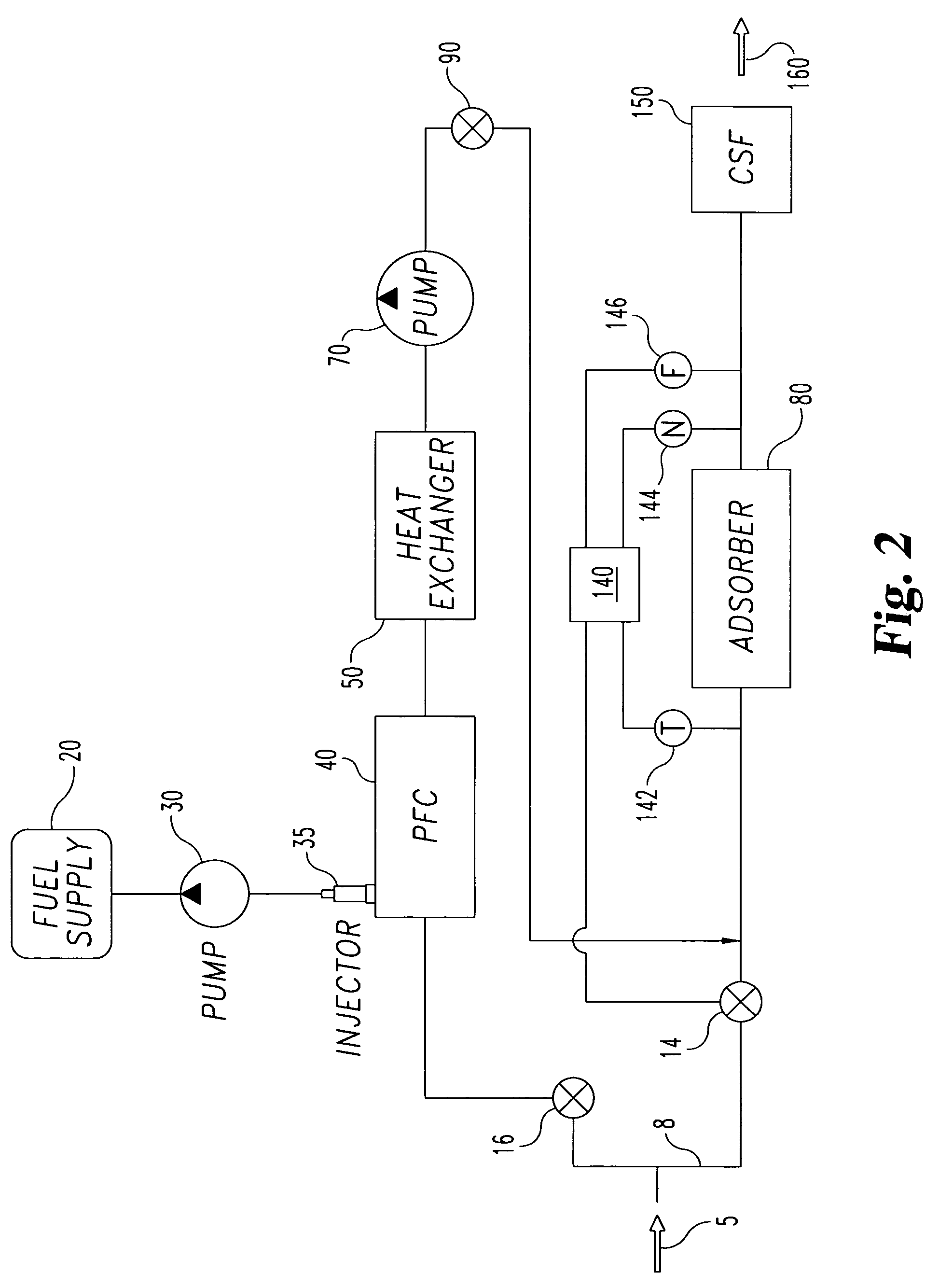

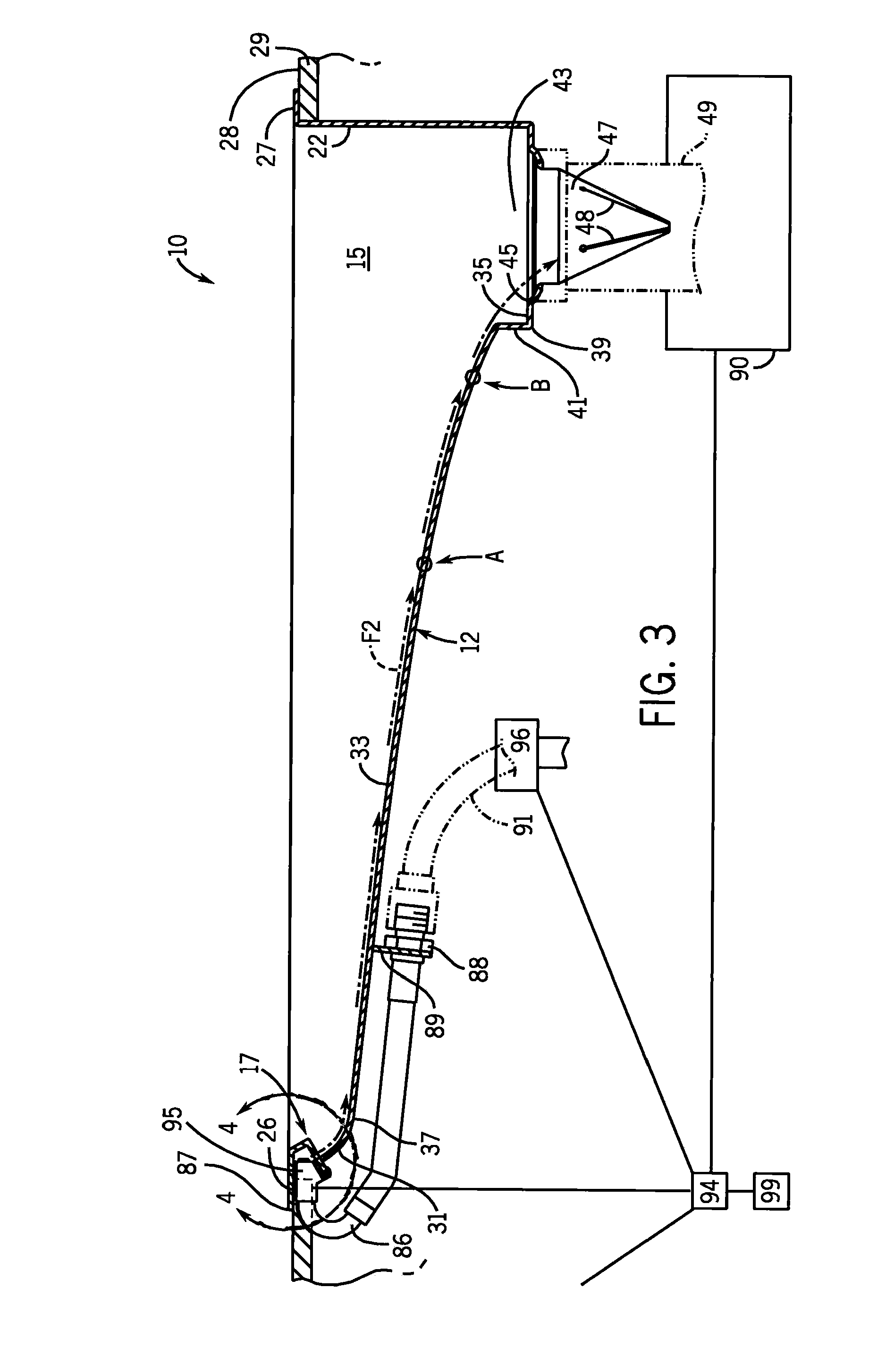

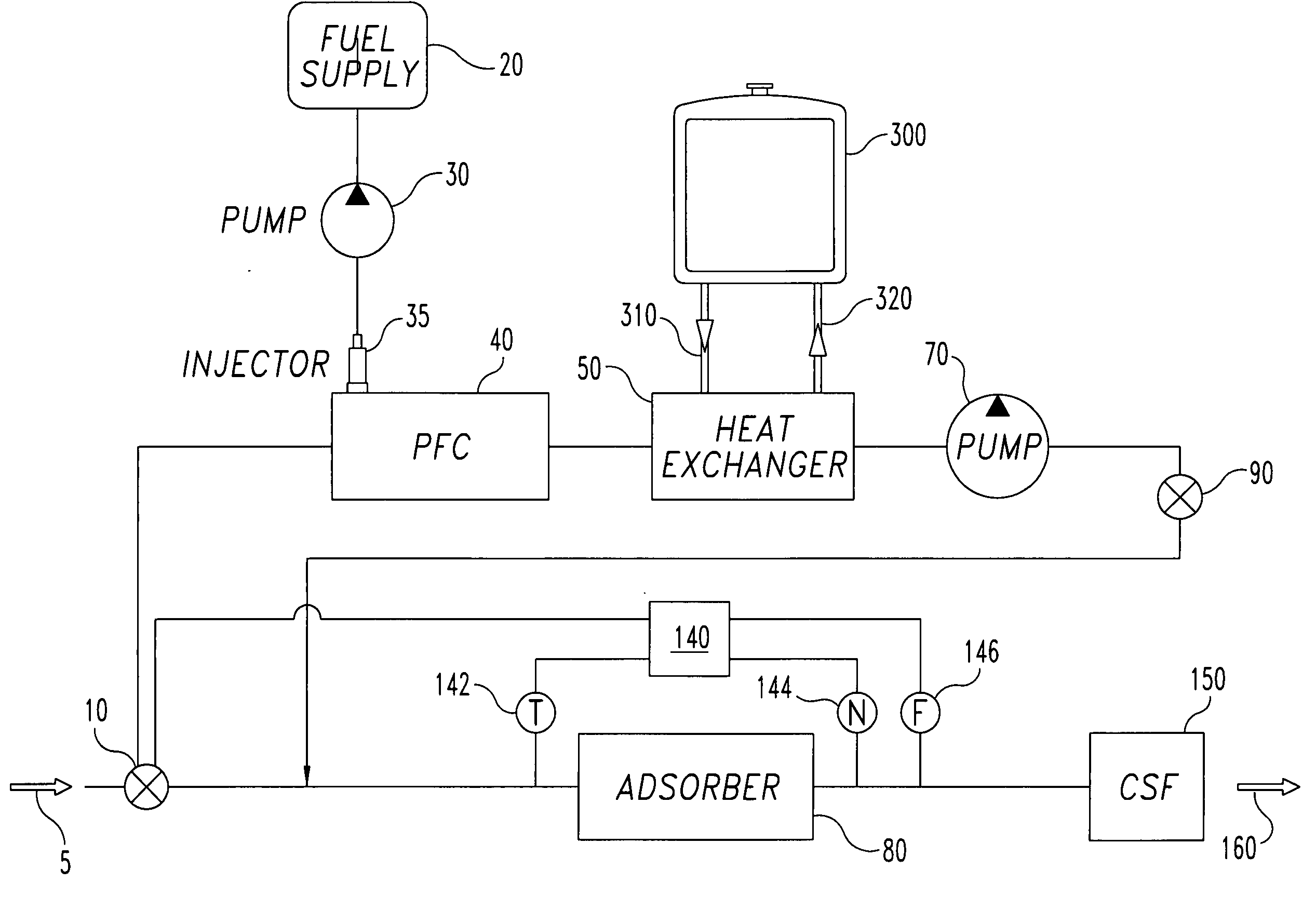

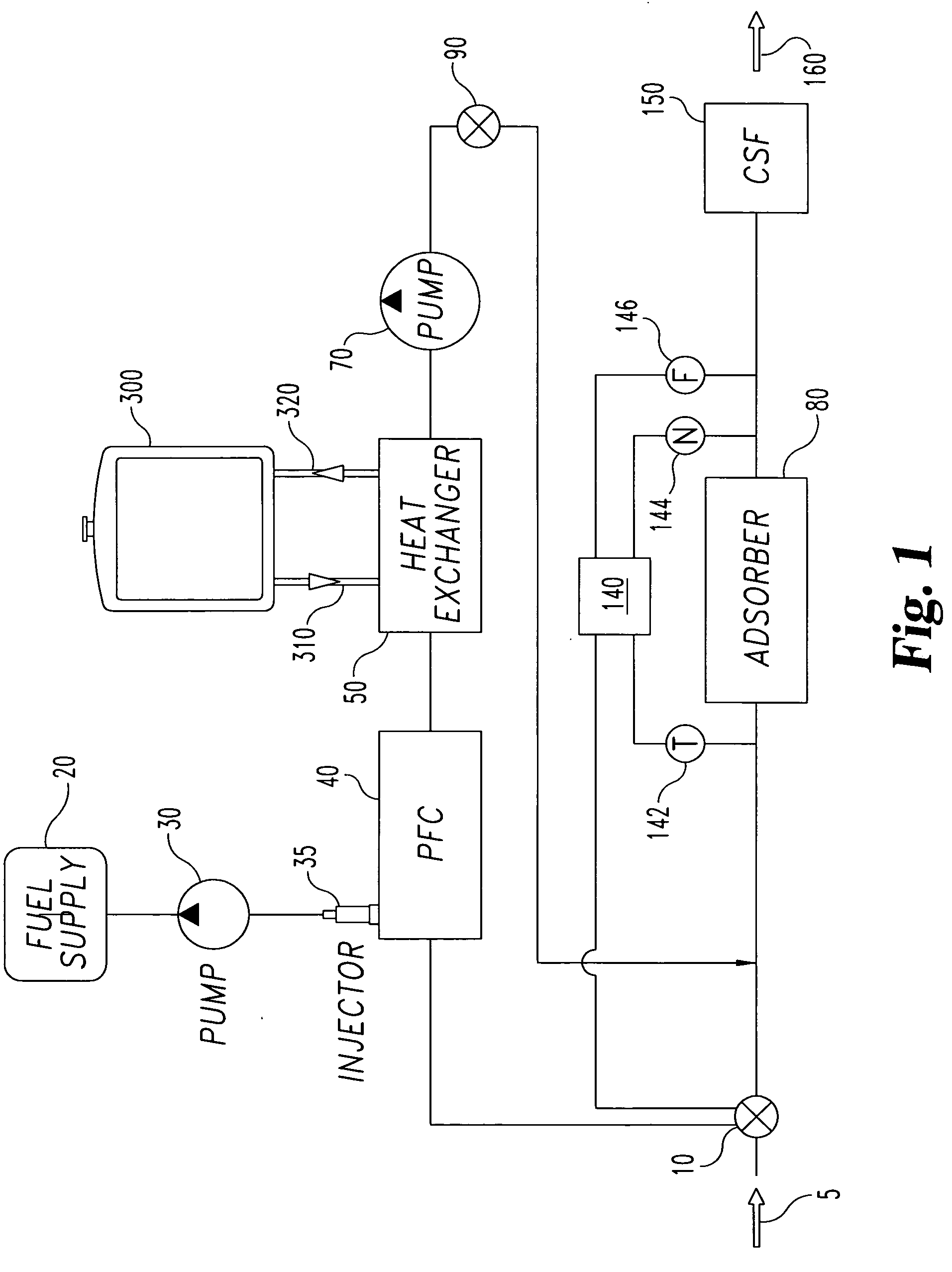

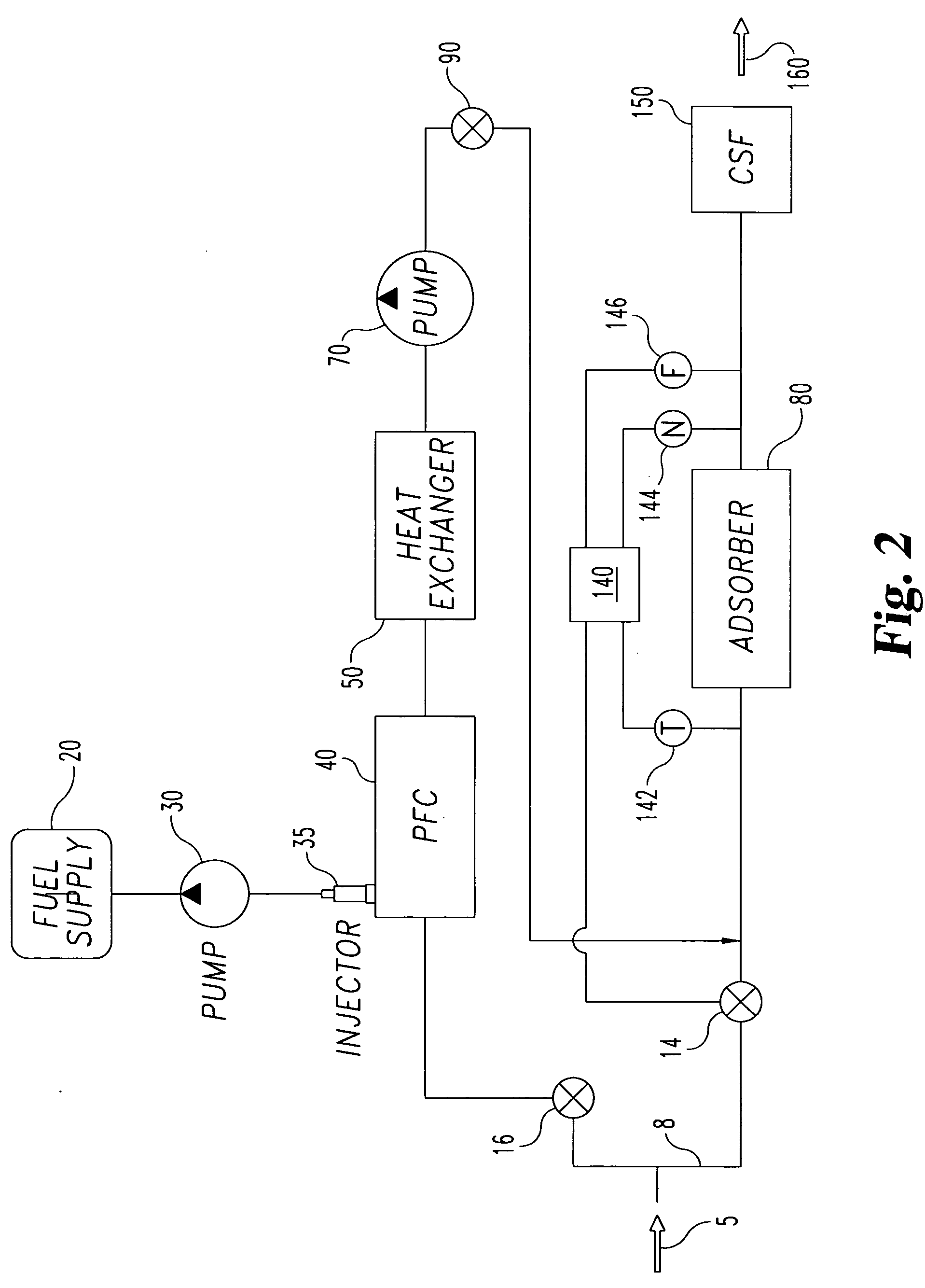

Plasma fuel converter NOx adsorber system for exhaust aftertreatment

InactiveUS7377101B2Increase production and deliveryChange trafficExhaust apparatusSilencing apparatusControl systemExhaust fumes

The invention provides a NOx adsorber aftertreatment system for internal combustion engines which utilizes a plasma fuel converter operatively coupled to at least one NOx adsorber to aid in the regeneration of the NOx adsorber. Fuel and engine exhaust is injected into a plasma fuel converter upstream of a NOx absorber producing reductant such as H2, and CO, which are inlet into the NOx absorber. Reductants such as H2 and CO acting along and together help to efficiently regenerate the NOx Adsorber which in turn releases exhausts products such as CO2 and N2. Using the reductants generated by the plasma fuel converter NOx adsorbers, catalytic soot filter, and the like can be regenerated at exhaust temperatures less than 250° C. The plasma fuel converter, NOx adsorber regenerating aftertreatment system of the present invention may be used with any suitable control system.

Owner:CUMMINS FILTRATION INC

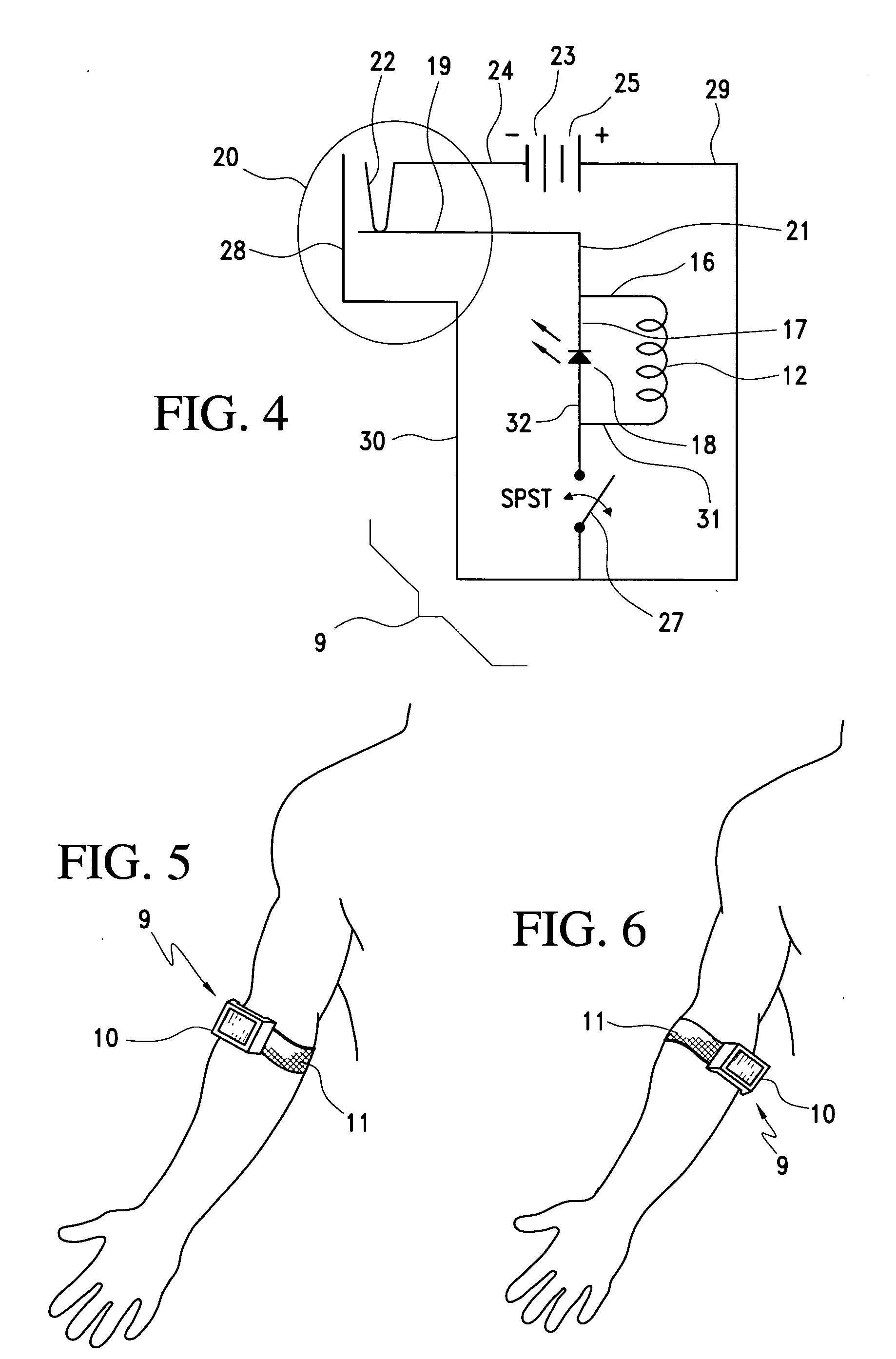

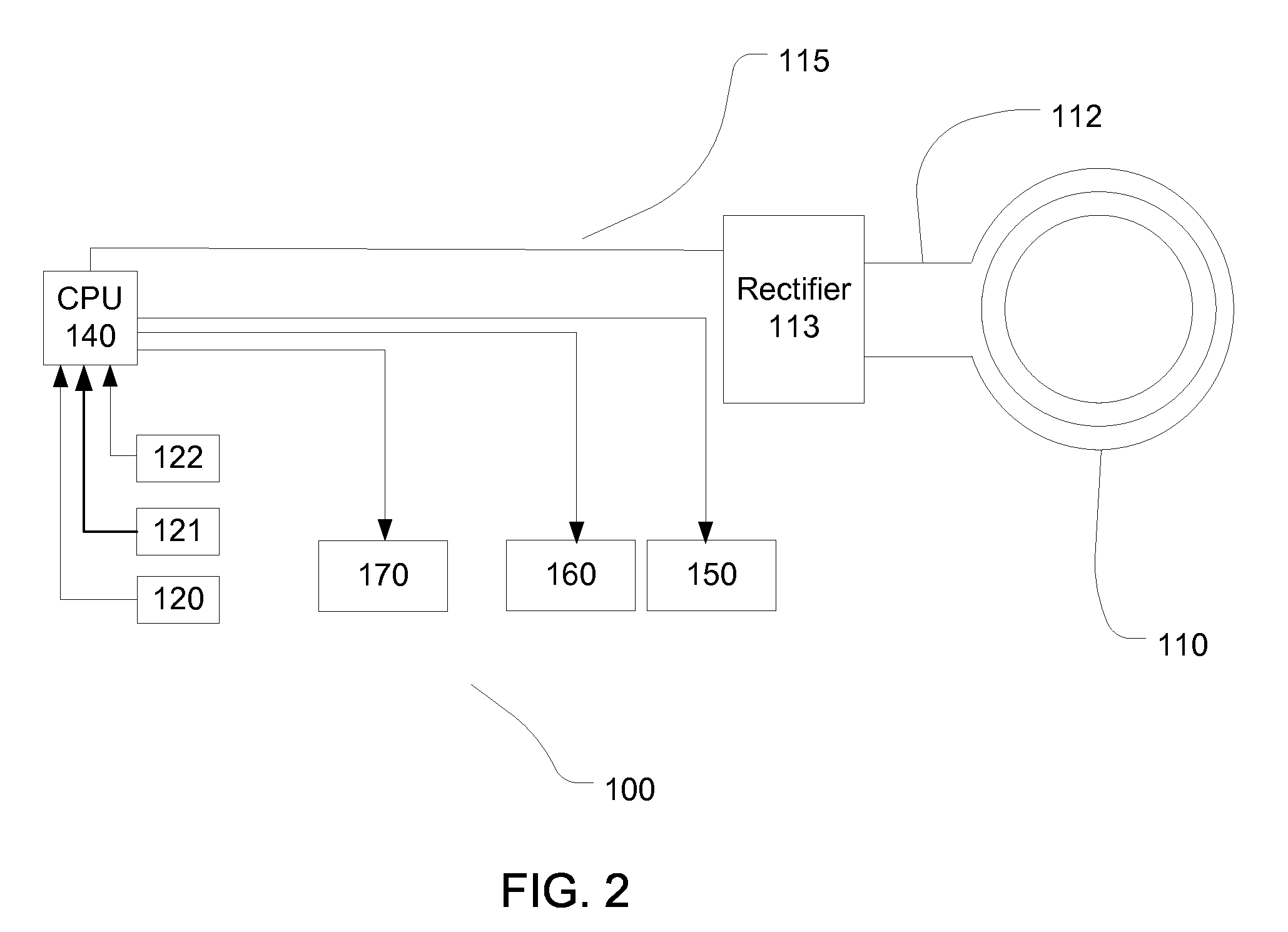

Method and apparatus for therapeutic treatment of inflammation and pain with low flux density, static electro-magnetic fields

InactiveUS20060129022A1Safe and effectiveReduce inflammationElectrotherapyMagnetotherapy using coils/electromagnetsHuman bodyCell membrane

A portable Static Electro Magnetic Field (SEMF) generating device and method for the therapeutic treatment of inflammatory and painful disorders of the human limbs including fingers, hands, wrists, forearms, elbows, toes, feet and ankles preferably includes a wearable, portable battery powered solenoid or coil. The coil is configured to focus a substantially time invariant magnetic flux field onto a selected part of the body. The SEMF generating device's coil, when energized, works by slightly changing the charges associated with voltage-dependant ion channels in the cell membranes of the human body, thereby stabilizing abnormal fluid transport into the cells through aquaporin channels and the sodium ions relating to them, treating inflammation and altering the flow of calcium, chloride and potassium ions through their respective neuronal ion channels and treating pain.

Owner:PAIN MEDICATION TECH

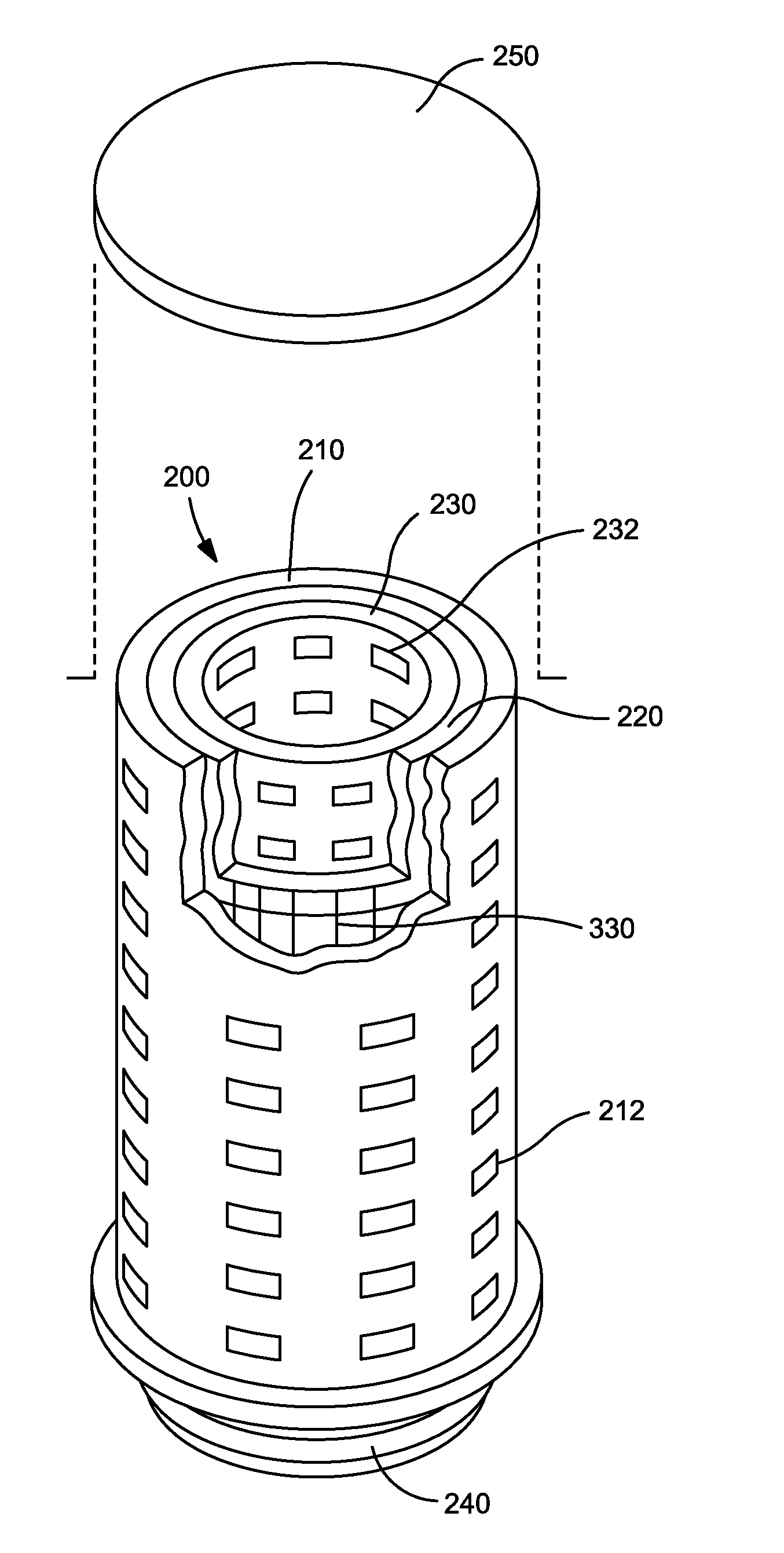

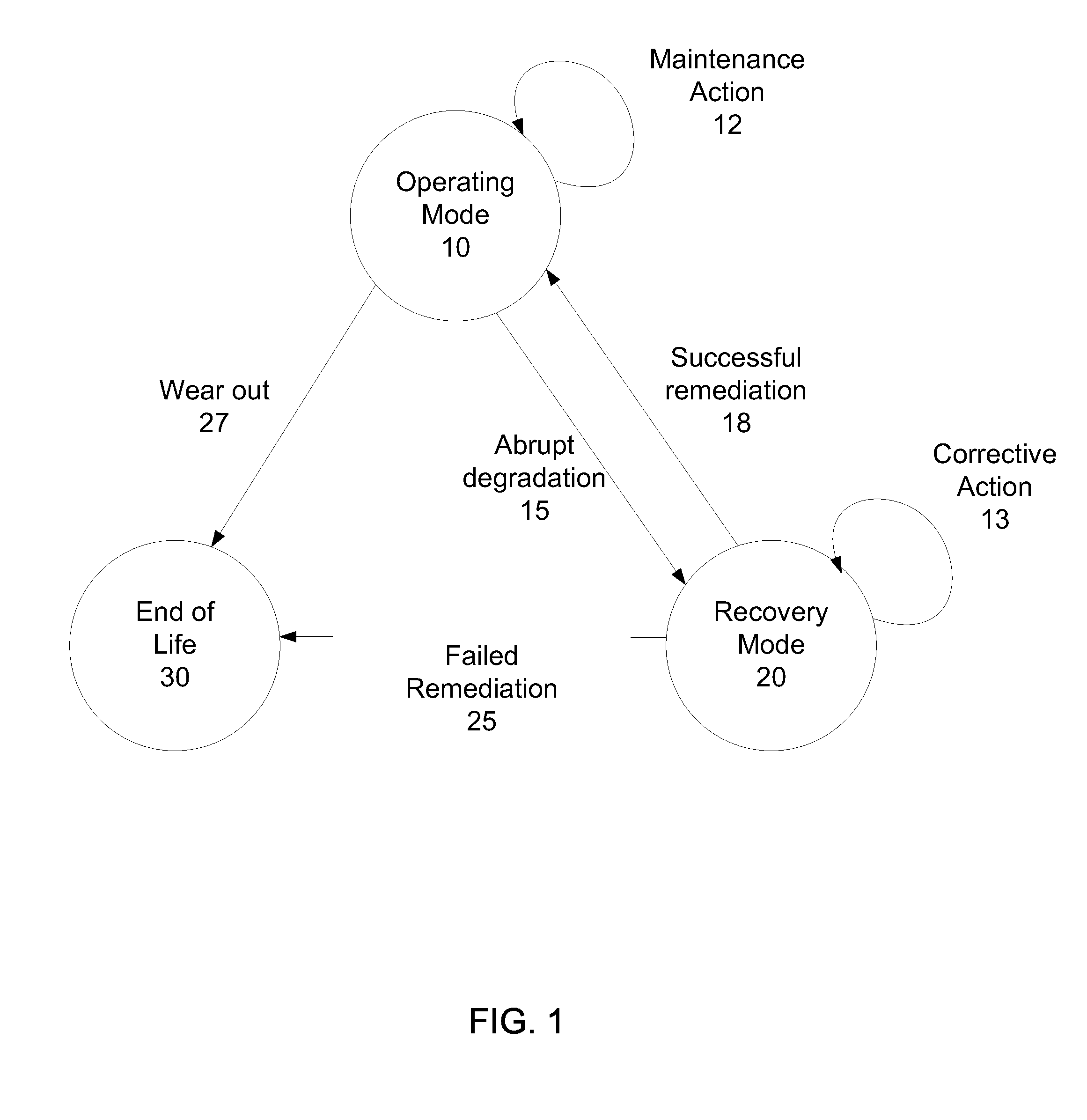

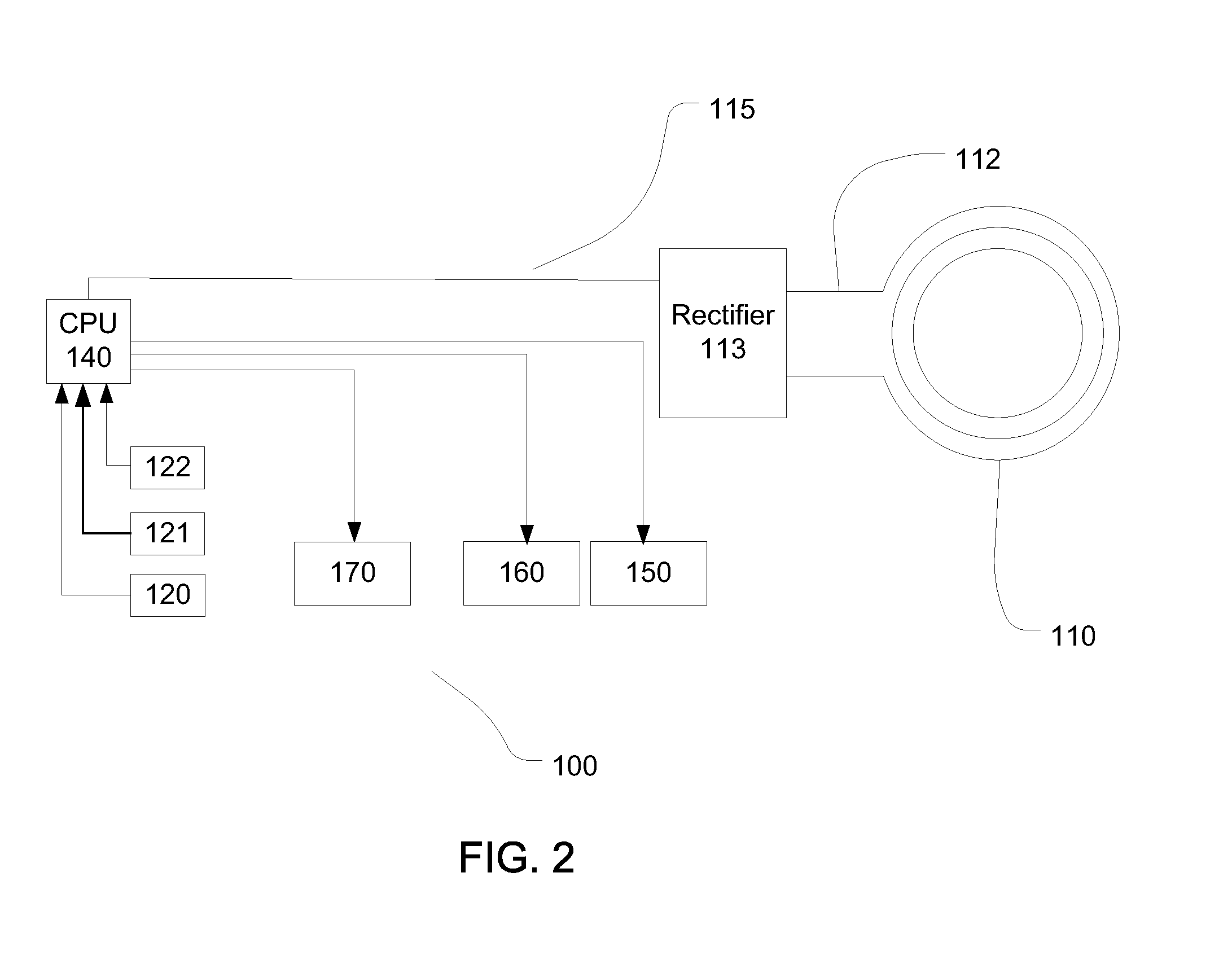

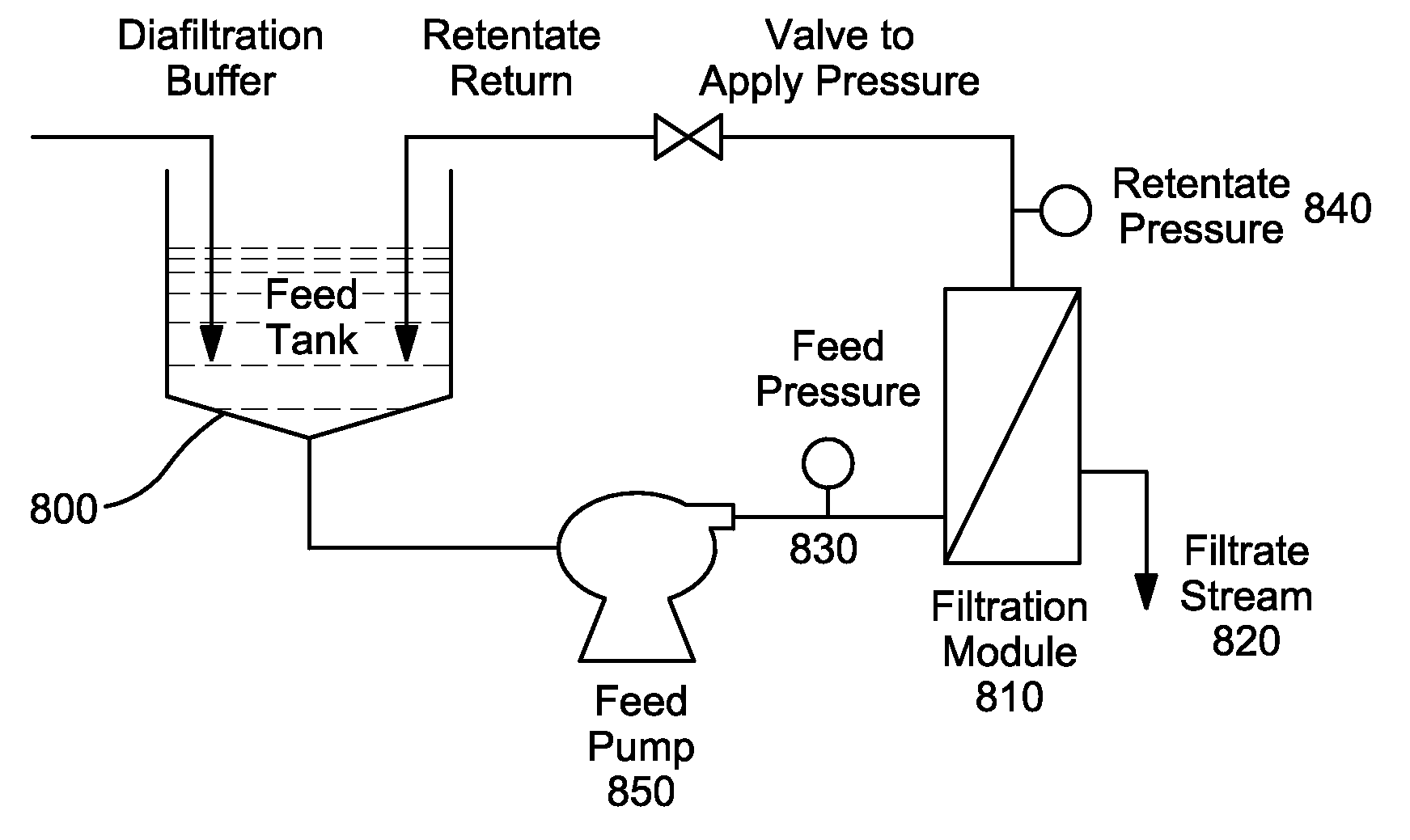

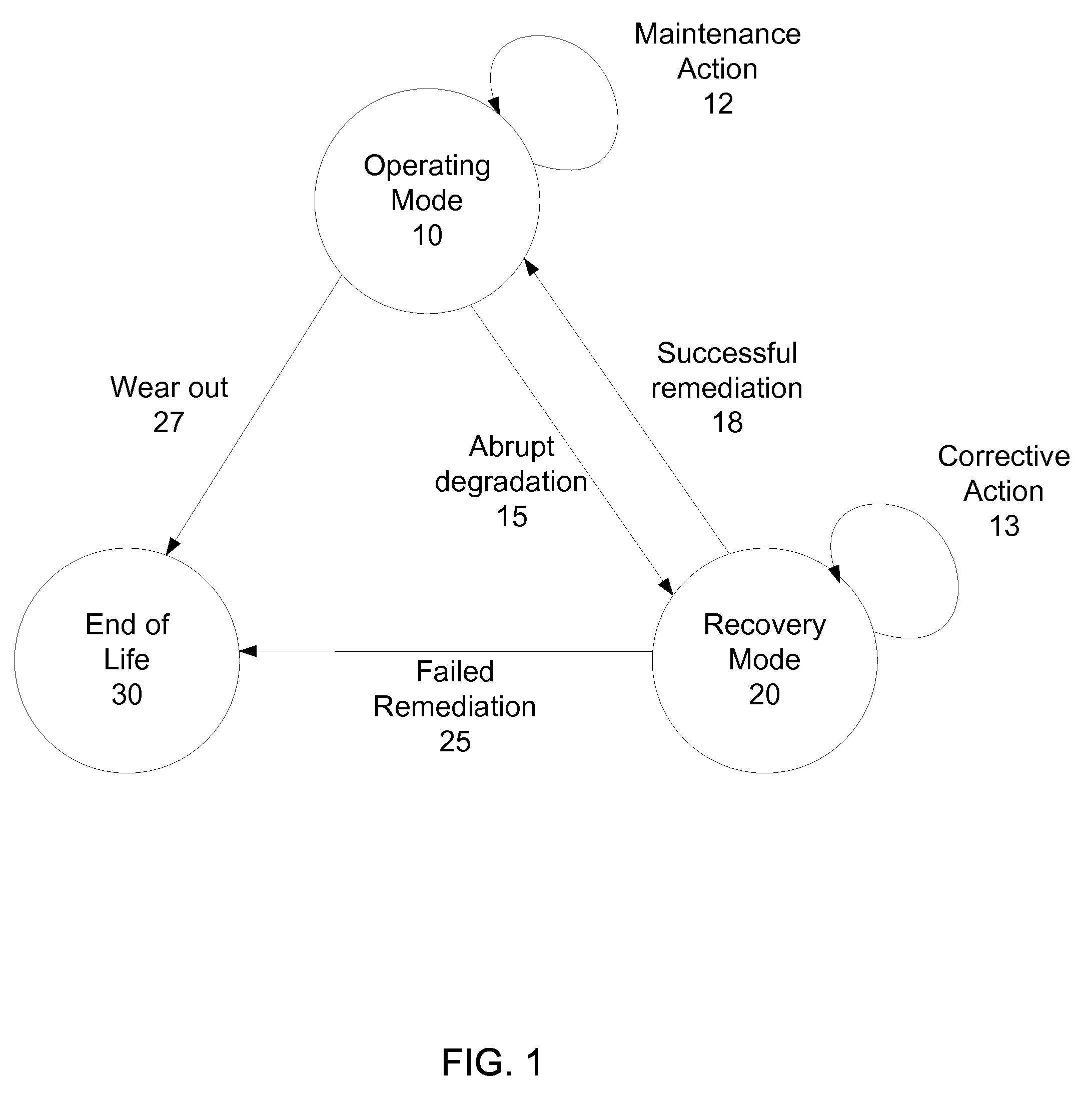

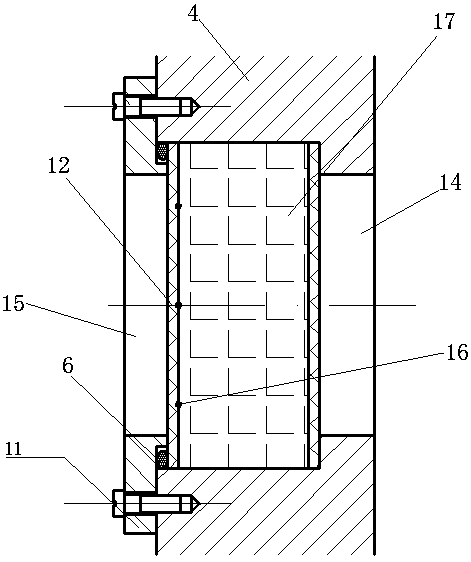

Autonomous Filter Element

InactiveUS20130008838A1Reduce flow rateChange trafficMembranesVolume/mass flow measurementEngineeringControl logic

An autonomous filter device and a method for improving the filter life and performance is disclosed. The filter element is equipped with one or more sensors, adapted to measure one or more characteristics. In response to the measured characteristic, the control logic within the filter element is able to determine an appropriate response. For example, the control logic may determine that a sudden, but temporary, blockage has occurred in the filter membrane. In response, the control logic may initiate a specific response designed to alleviate the blockage. The control logic will then determine the success of the response, based monitoring any change in the fluid characteristics. Based thereon, the control logic may alert the operator that the filter element must be replaced. Alternatively, if the response was successful in correcting the blockage, the control logic need not notify the operator, as the filter element is back to normal operating operation.

Owner:EMD MILLIPORE CORP

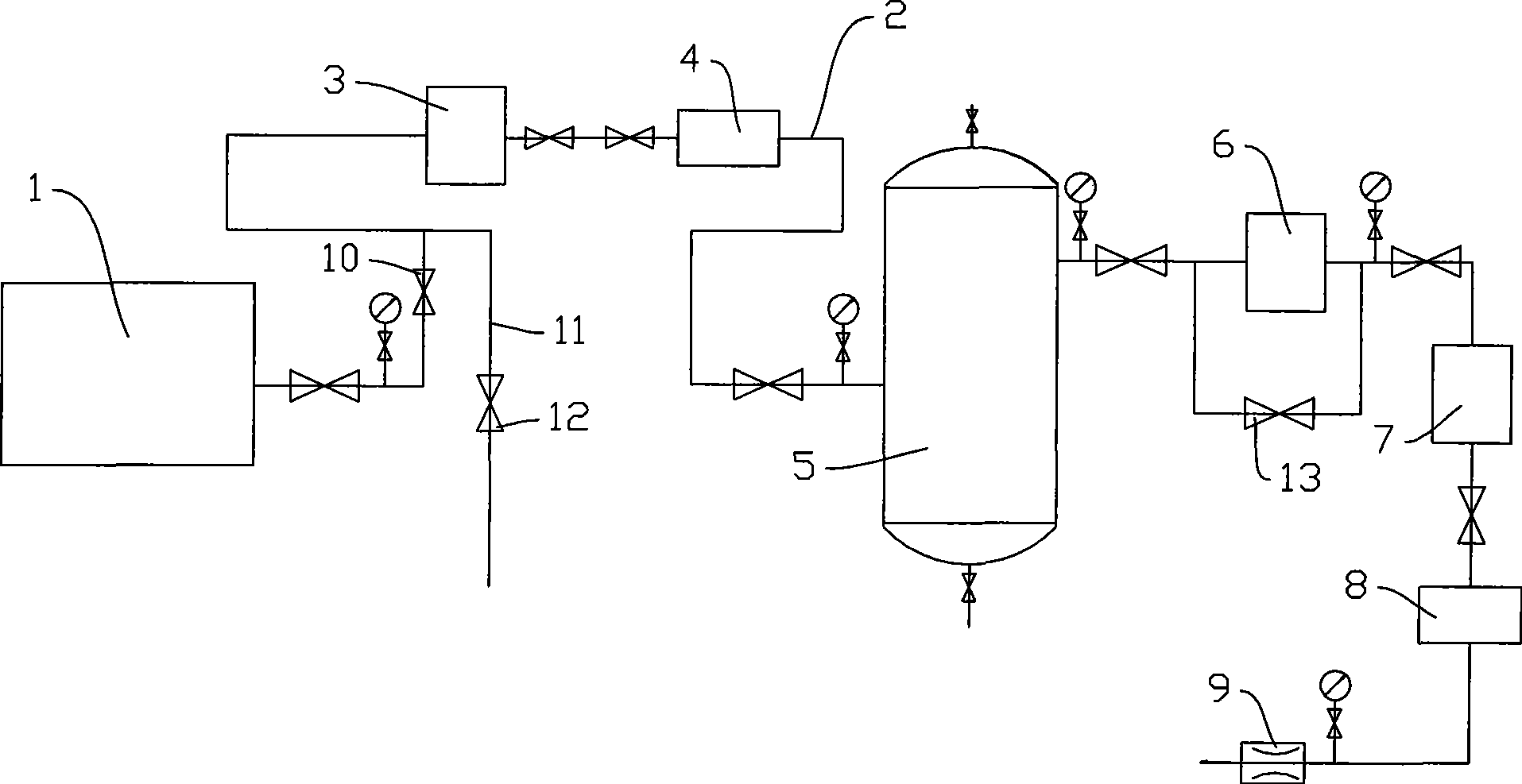

Nitrogen purging device of hydraulic line and method for cleaning hydraulic line

InactiveCN101480653AReduce adhesionEasy to useHollow article cleaningProcess engineeringNitrogen source

The invention provides a device and a method for cleaning hydraulic pipelines, in particular to a nitrogen purging device (cleaning device) for hydraulic pipelines, which has good cleaning effect, high efficiency and not pollution. The nitrogen purging device for hydraulic pipelines adopts the structure that a gas drier used for the drying treatment of nitrogen, a gas filter used for the filtering treatment of nitrogen and a flow control valve used for regulating the output flow of nitrogen are connected in series on an output pipeline which is connected with a nitrogen source. In addition, the cleaning method for hydraulic pipelines adopts nitrogen after being dried and filtered to purge the hydraulic pipelines.

Owner:CHINA 19TH METALLURGICAL CORP

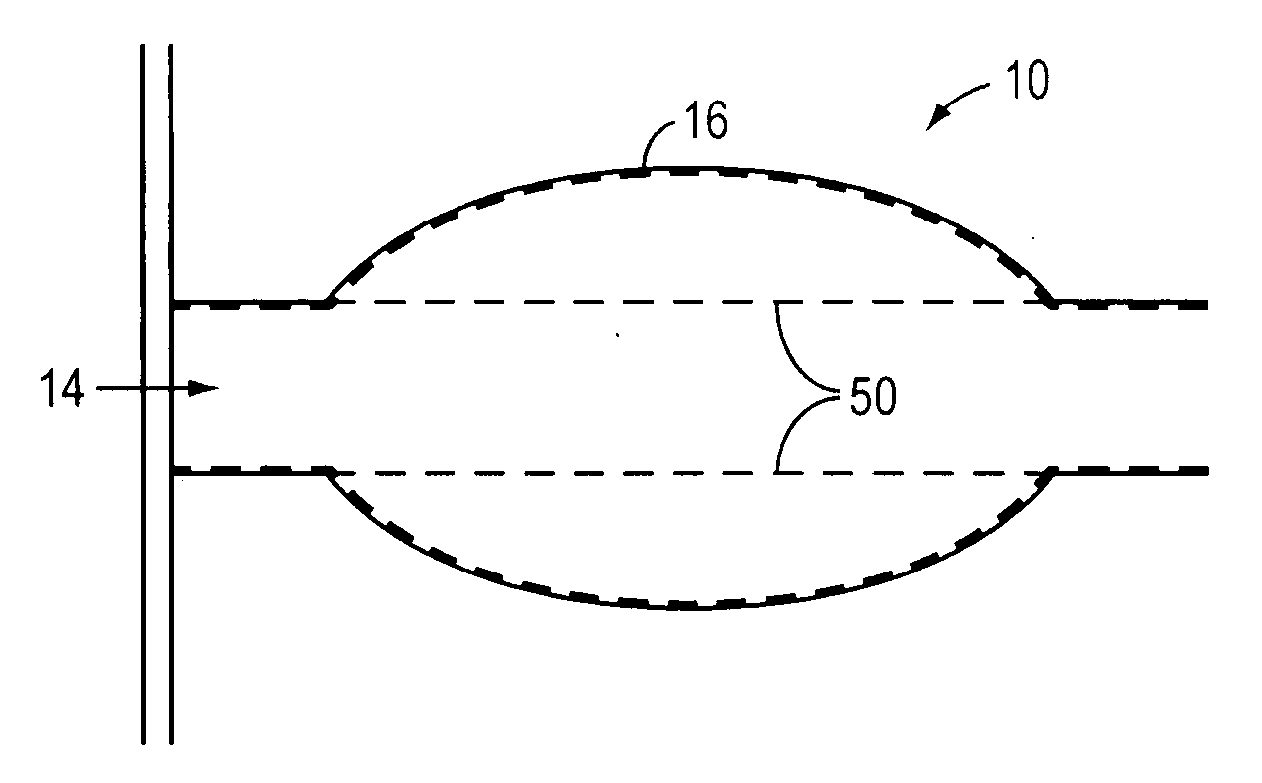

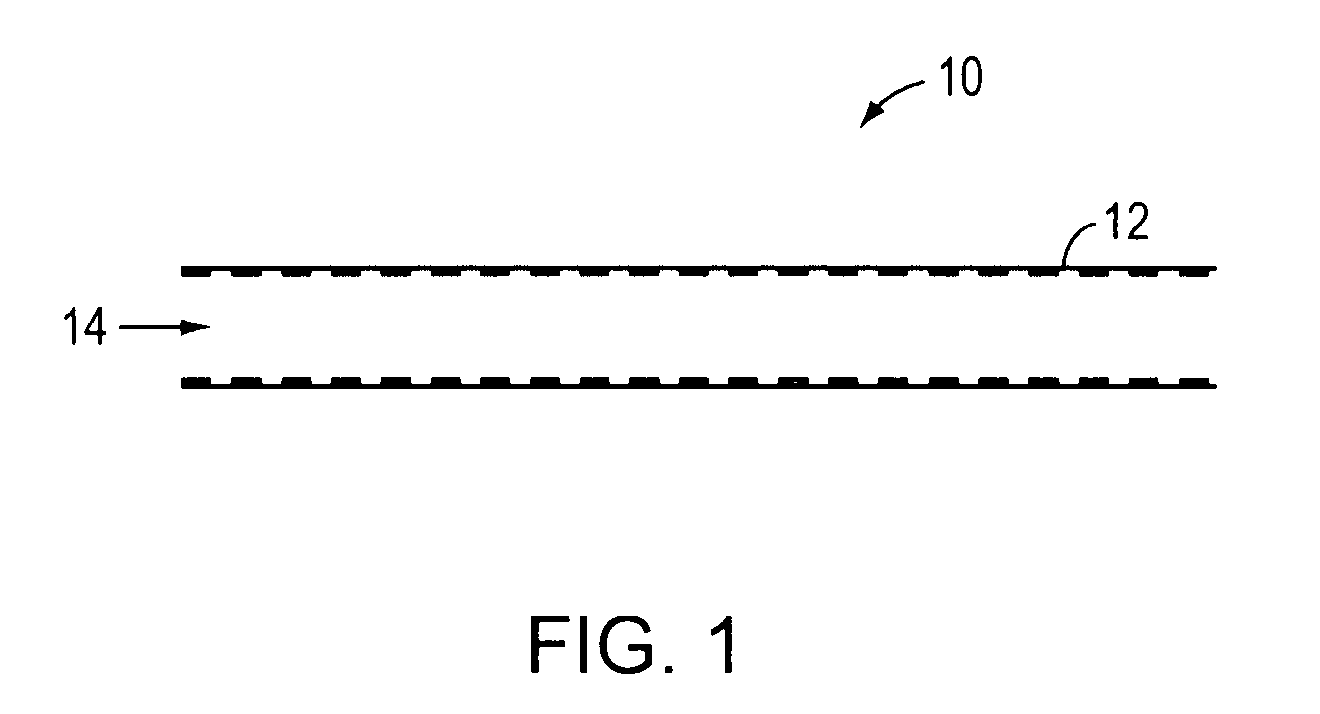

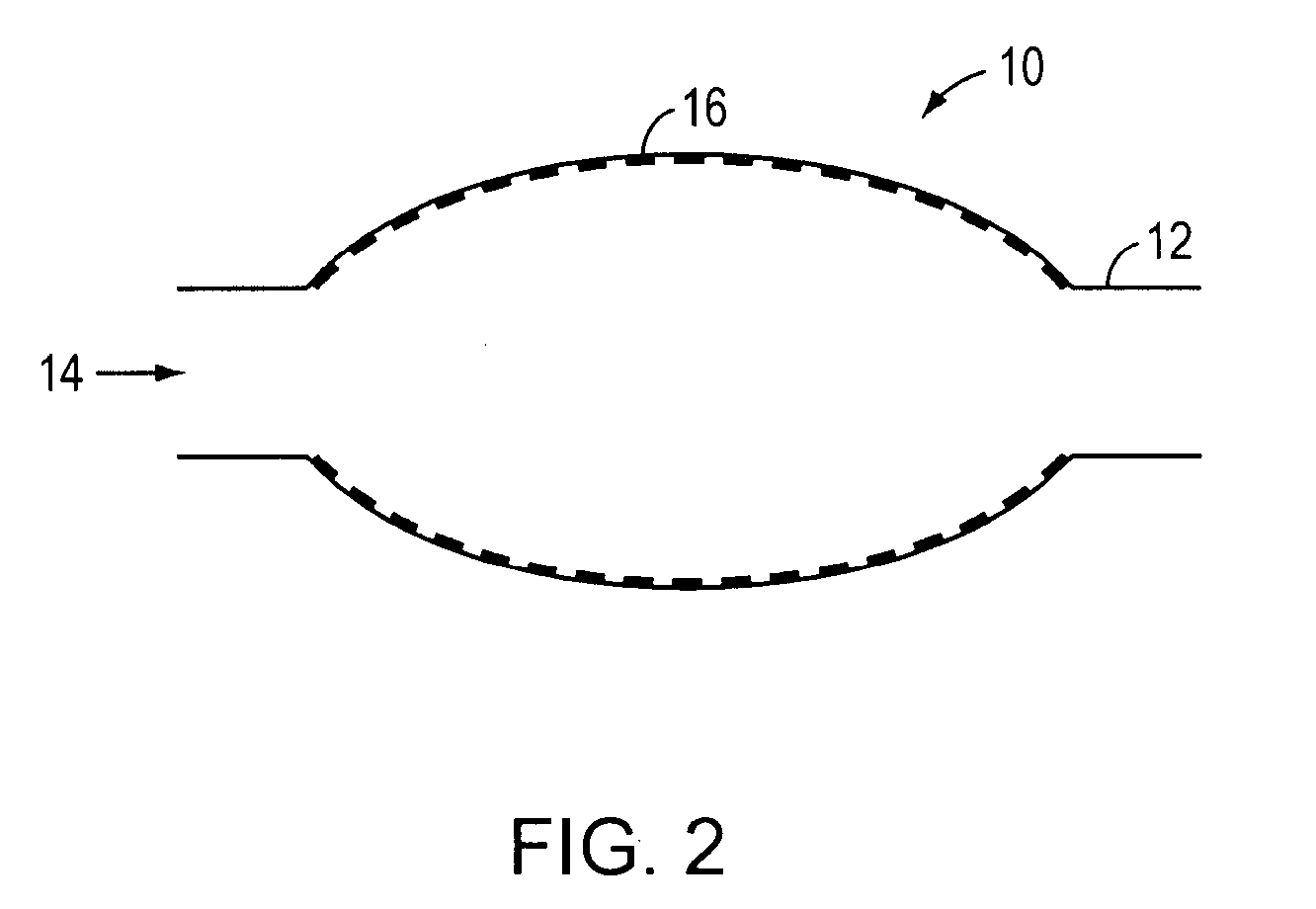

Endovascular devices with axial perturbations

Endovascular devices are provided. The endovascular devices include a conformable scaffold with one or more outpocketings. The outpocketing in the endovascular device creates a corresponding outpocketing of a vessel wall, thereby altering local fluid dynamics.

Owner:MASSACHUSETTS INST OF TECH

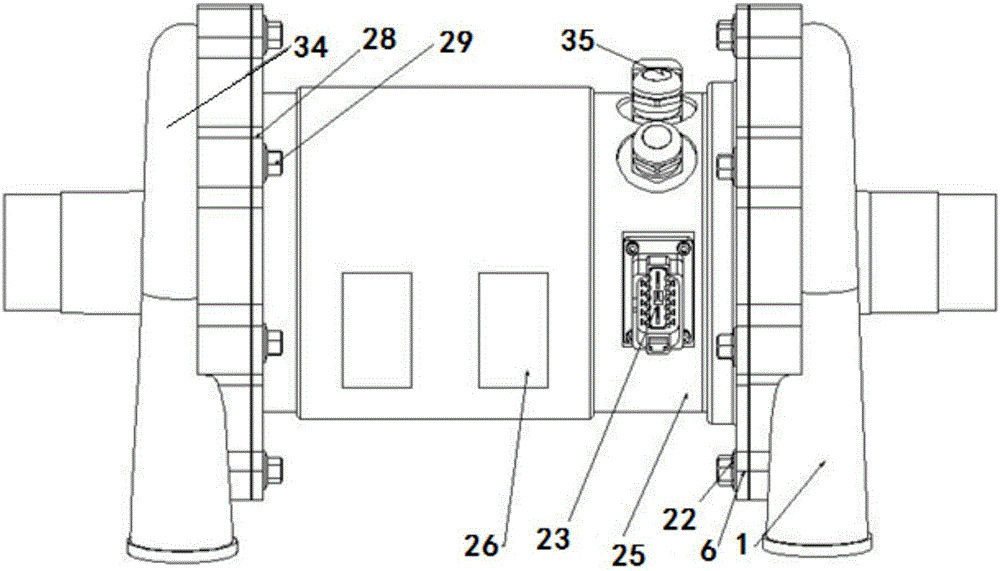

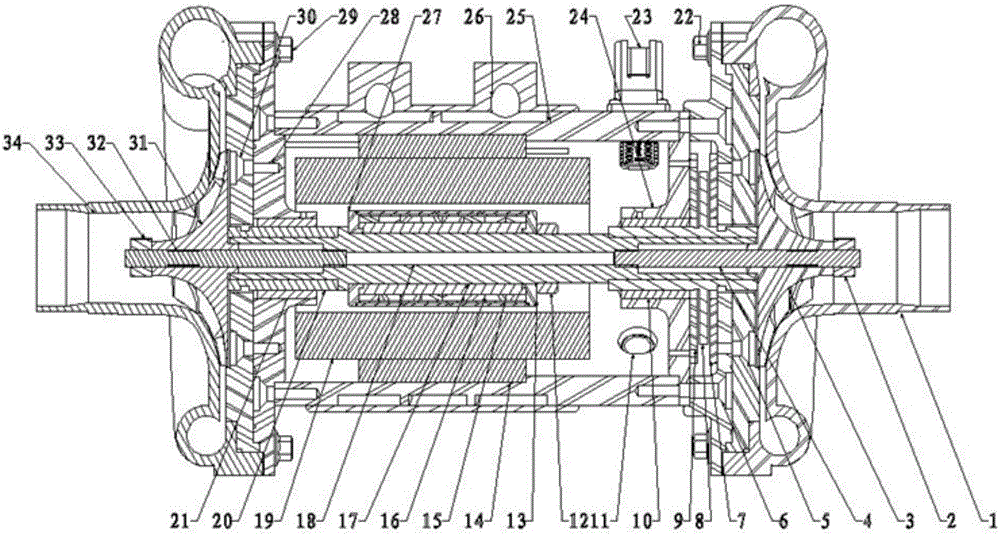

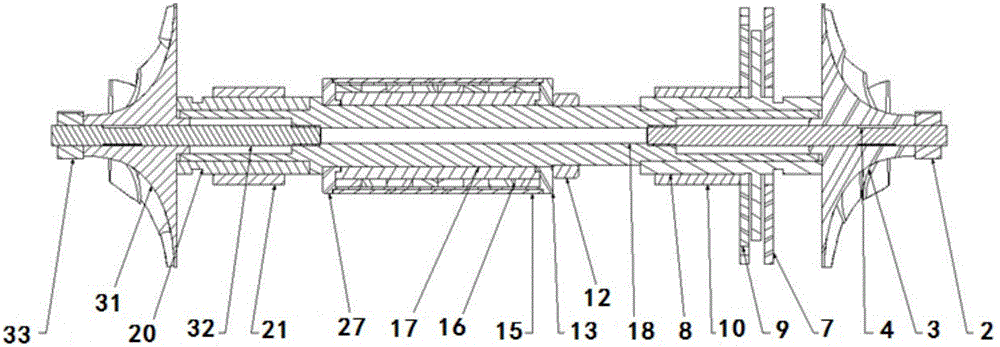

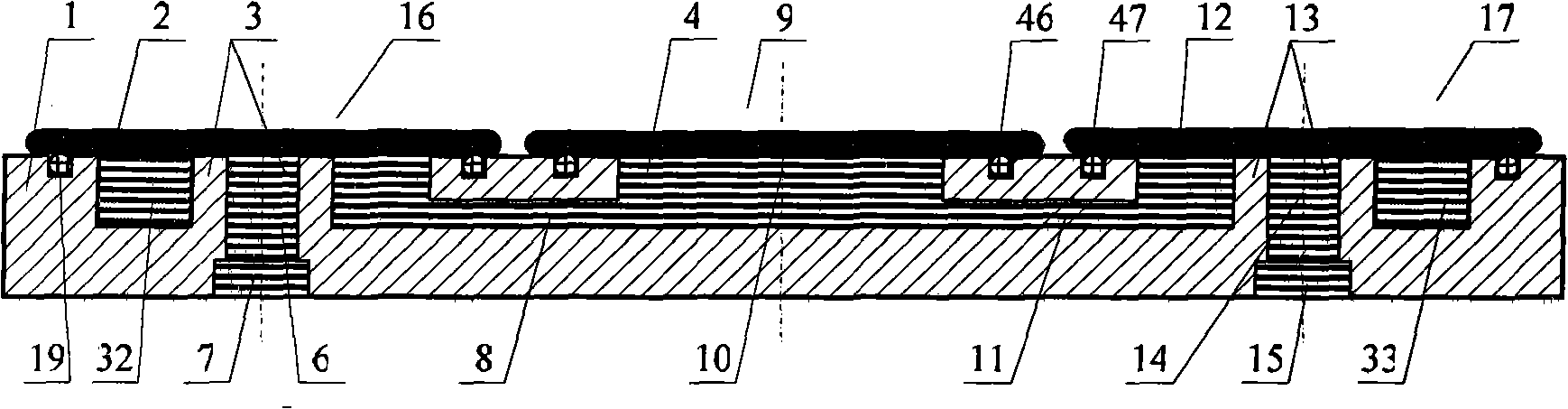

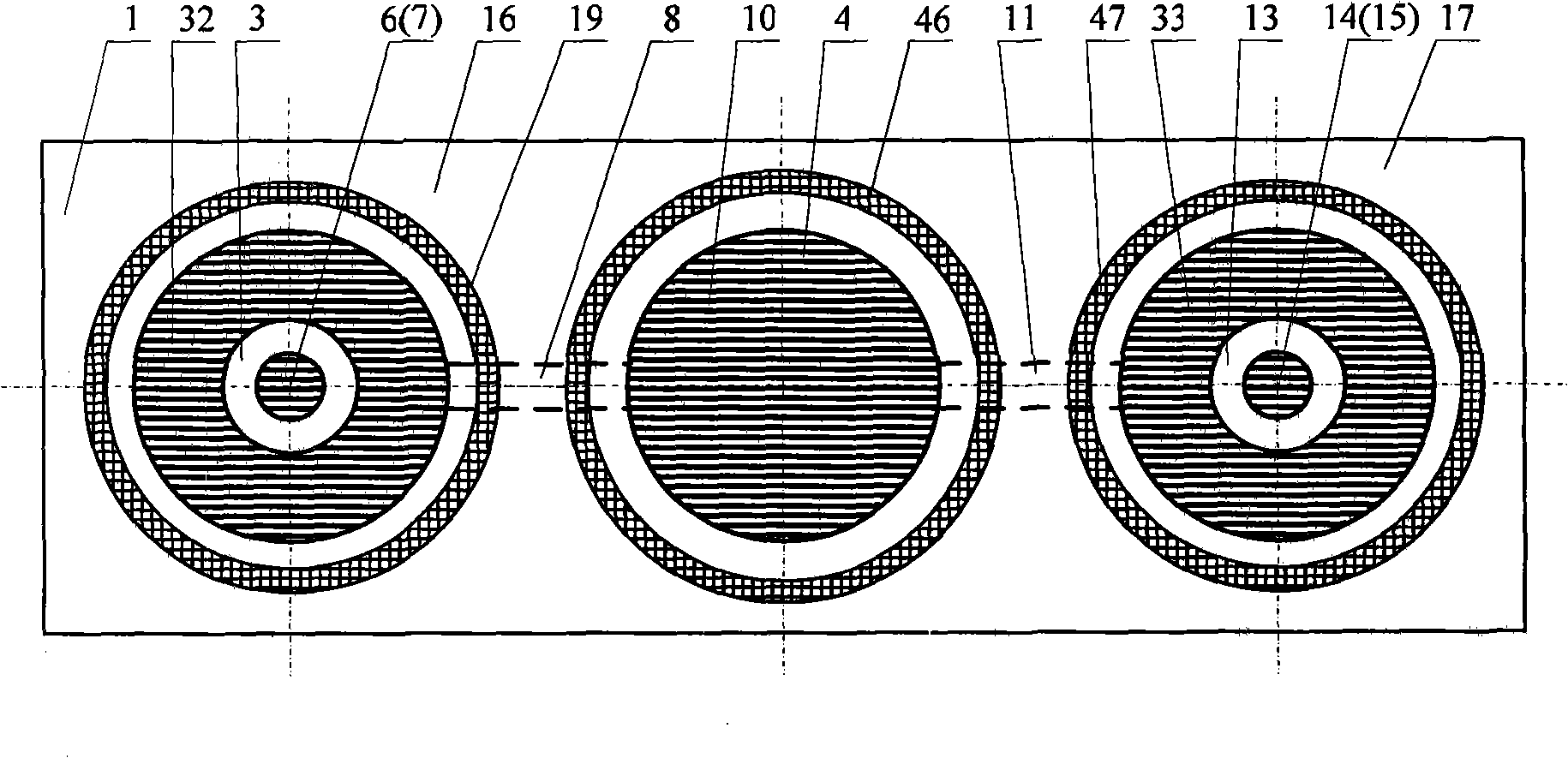

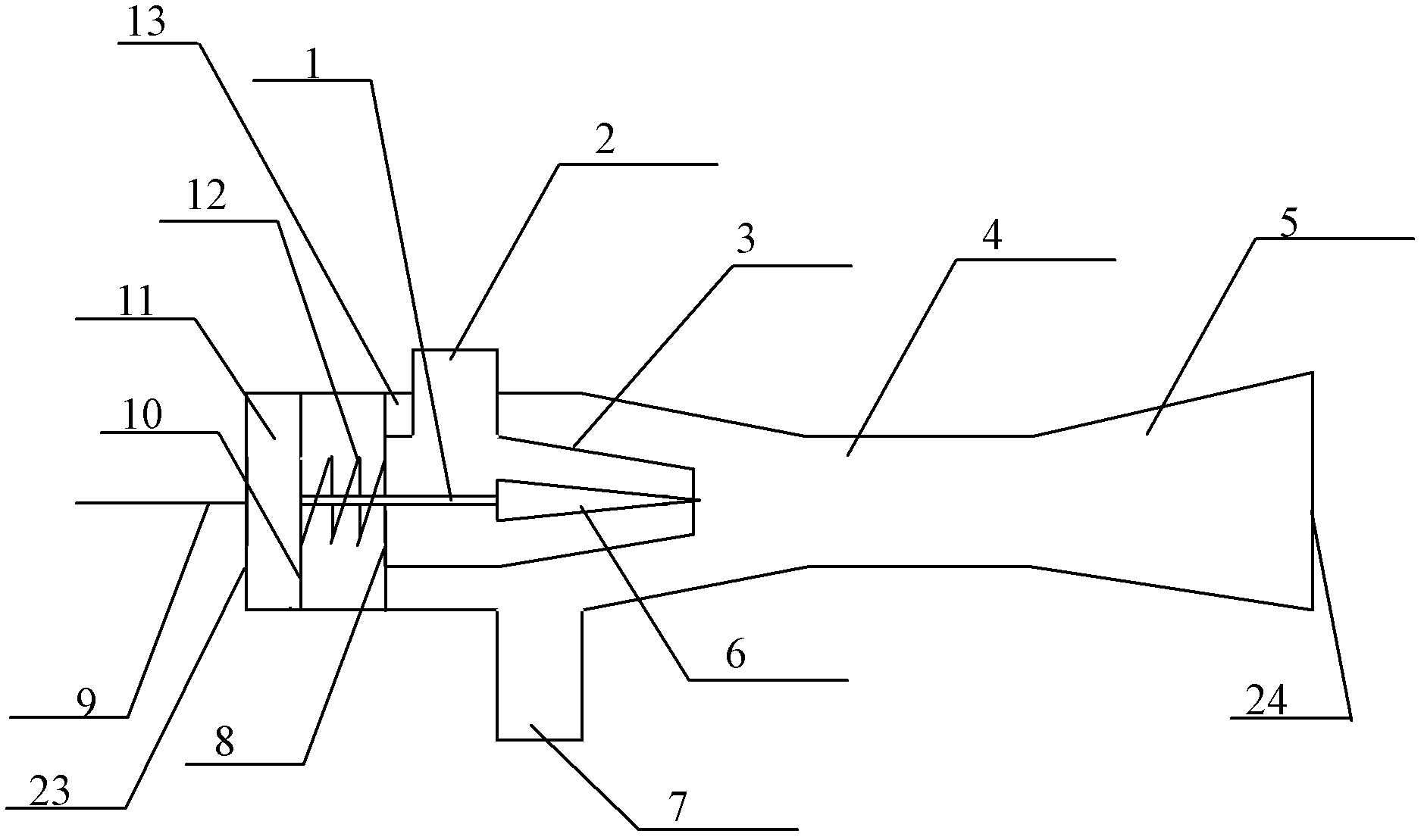

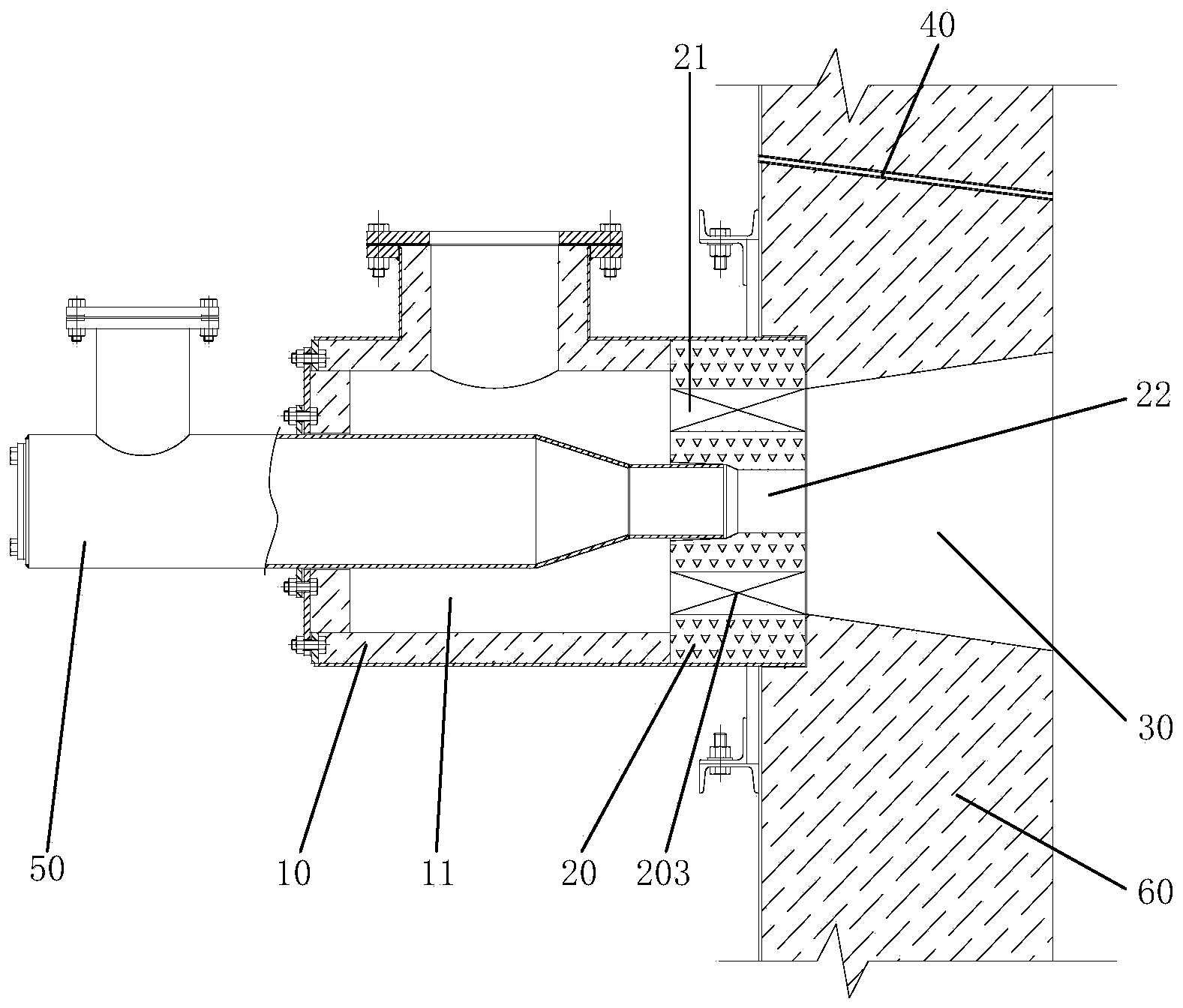

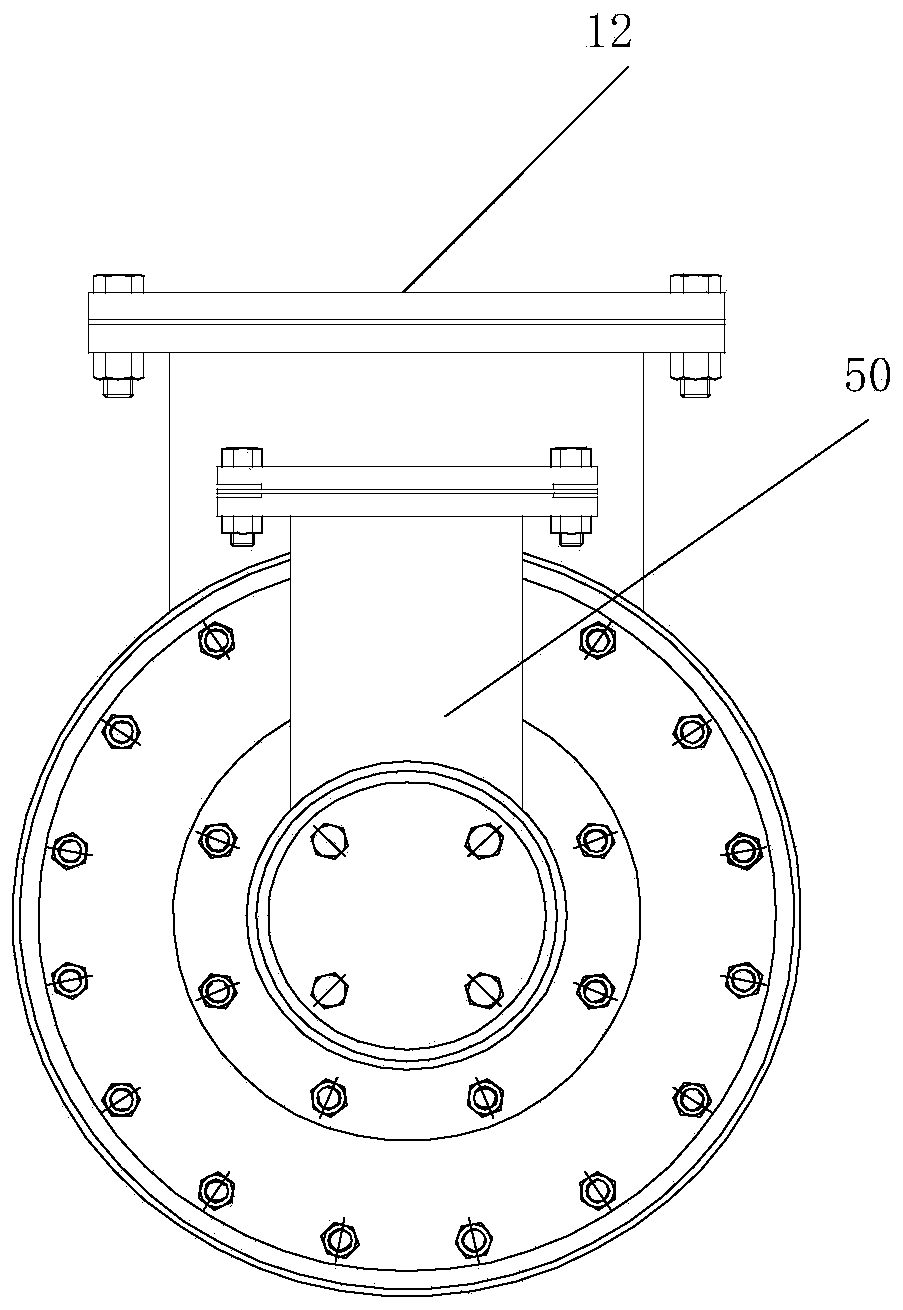

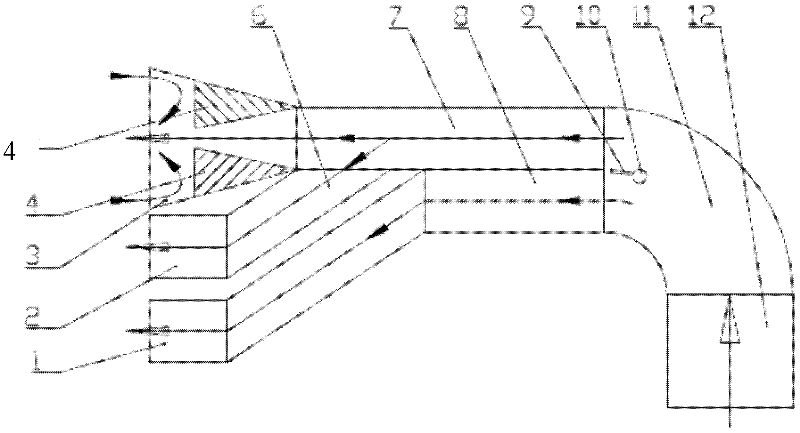

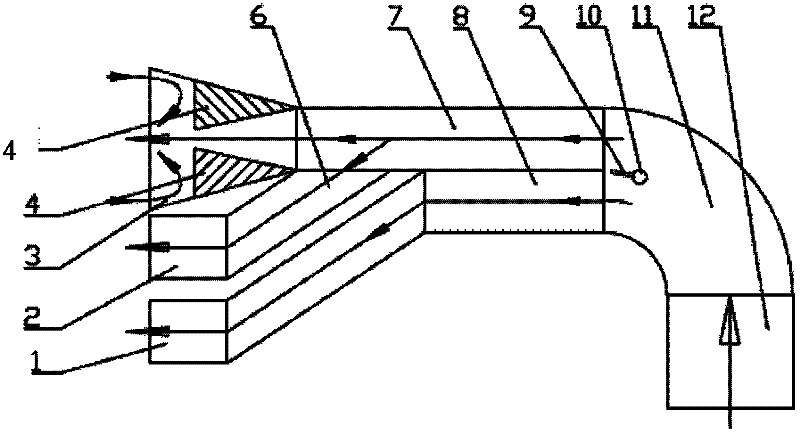

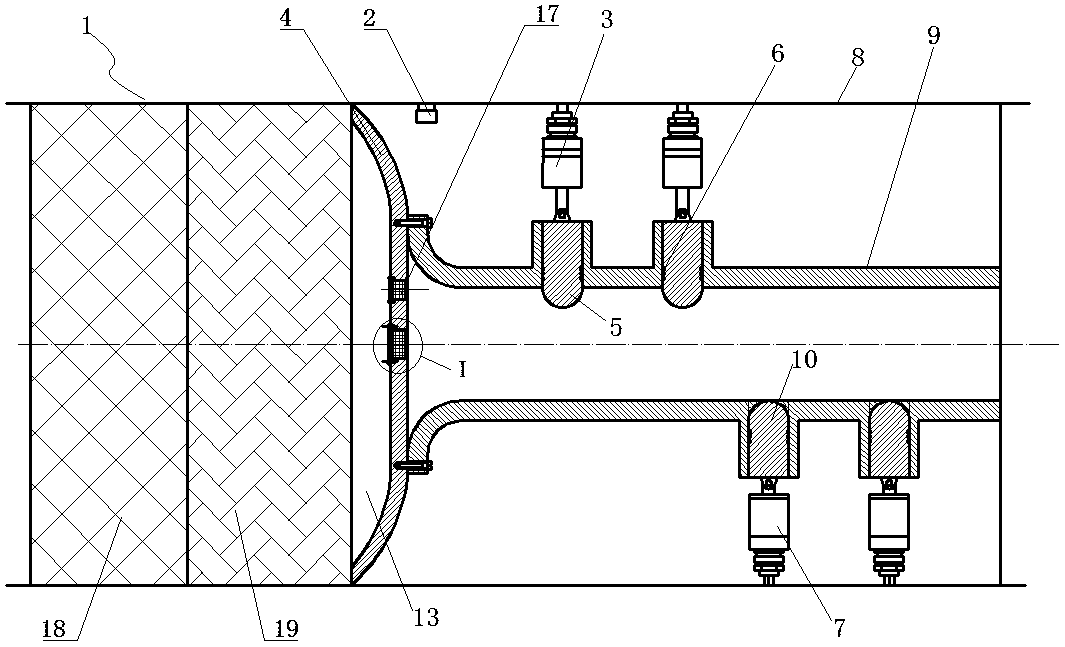

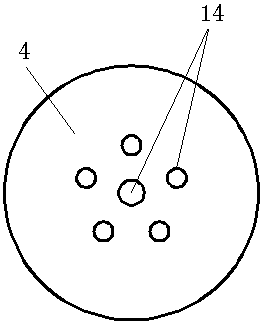

Two-stage series pressurization direct-driven centrifugal air compressor of fuel cell engine

ActiveCN105889096AImprove reliabilityReduce volumeMagnetic circuit rotating partsPump componentsImpellerStator

The invention relates to a two-stage series pressurization direct-driven centrifugal air compressor of a fuel cell engine. The two-stage series pressurization direct-driven centrifugal air compressor comprises end covers, a spindle, volutes, impellers, a rotor, a stator and a driver. The spindle is supported by a left-end radial supporting air foil bearing, a left-end radial supporting air foil bearing bush, an air foil axial thrust bearing and a right-end radial supporting air foil bearing, wherein the left-end radial supporting air foil bearing and the left-end radial supporting air foil bearing bush are arranged on the left side, and the air foil axial thrust bearing and the right-end radial supporting air foil bearing are arranged on the right side of the spindle. The left-end radial supporting air foil bearing bush is arranged on the outer side of the spindle in a surrounding manner. The left-end radial supporting air foil bearing is fixed to the outer side of the left-end radial supporting air foil bearing bush. The air foil axial thrust bearing is fixed to the outer side of the spindle in a bush form. The right-end radial supporting air foil bearing is fixed to the outer side of the air foil axial thrust bearing. Compared with the prior art, the two-stage series pressurization direct-driven centrifugal air compressor is more suitable for the air inlet pressurization scene of the fuel cell engine with the high oilless air inlet requirement, and the durability and reliability of the air compressor of the fuel cell engine can be improved.

Owner:TONGJI UNIV

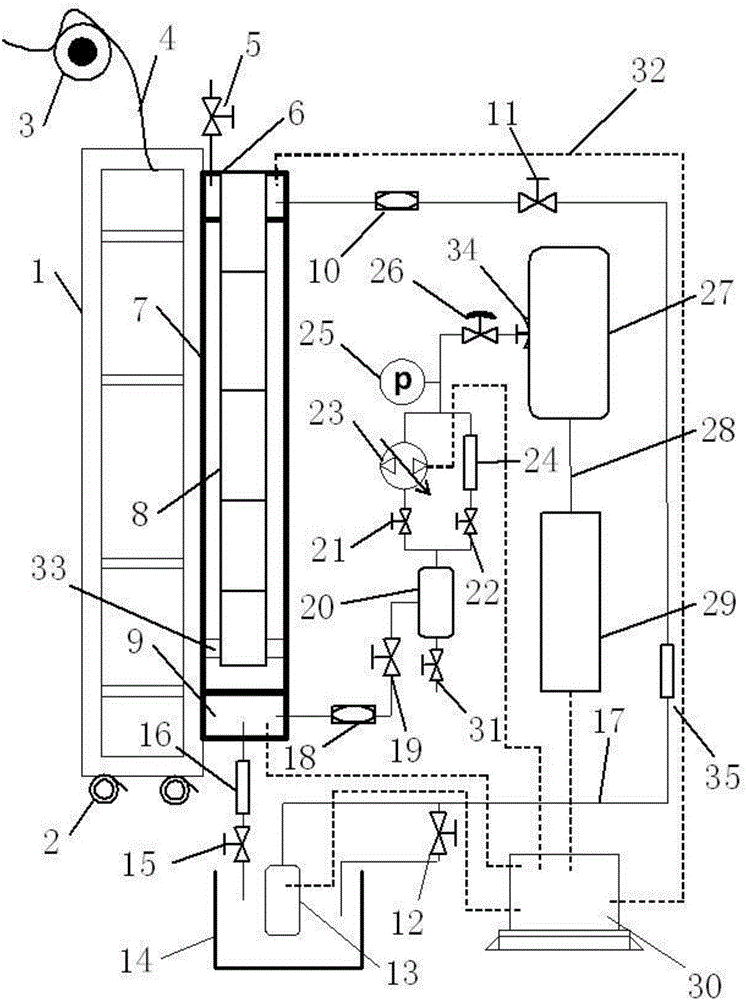

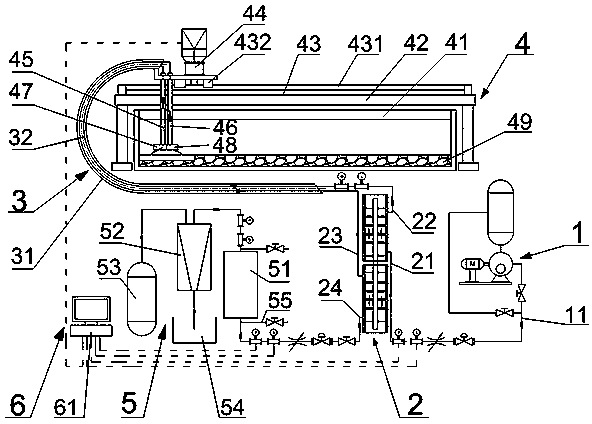

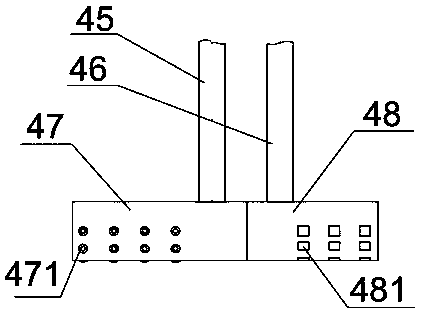

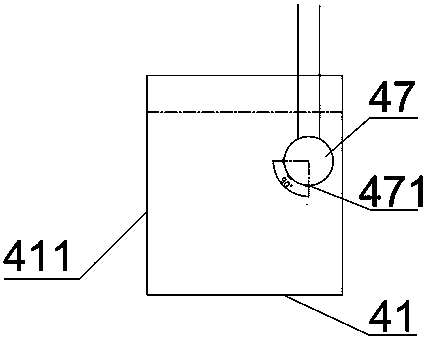

Coal-bed gas well shaft drainage gas recovery visual simulation experiment device and simulation method

The invention discloses a coal-bed gas well shaft drainage gas recovery visual simulation experiment device which comprises a shaft simulation device and a moveable bracket, wherein an upper connector and a lower connector with release valves are respectively arranged at two ends of the shaft simulation device; the upper connector is connected with a first one-way valve, a liquid injection valve, a liquid injection flowmeter and a water pump in sequence; the lower connector is connected with a fluid meter and a draining valve in sequence; the lower connector is connected with a second one-way valve, a main gas injection valve, a gas-liquid separator, a large flow valve, a vortex shedding flowmeter, a pressure gauge, a pressure adjusting valve , a gas storage tank valve, a gas storage tank and an air compressor in sequence; the gas-liquid separator is in secondary connection with the pressure gauge through a parallel connected pipeline; a rotor flowmeter and a small flow valve are arranged in sequence on the parallel connected pipeline; the shaft simulation device comprises a transparent pressure-resistant glass tube and a multi-section type central tube. The invention further provides a coal-bed gas well shaft drainage gas recovery visual simulation method. By adopting the coal-bed gas well shaft drainage gas recovery visual simulation experiment device and the coal-bed gas well shaft drainage gas recovery visual simulation method, the flowing state of multi-phase flow inside a coal-bed gas well in any shaft deflection and deflection stabilizing section can be simulated.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

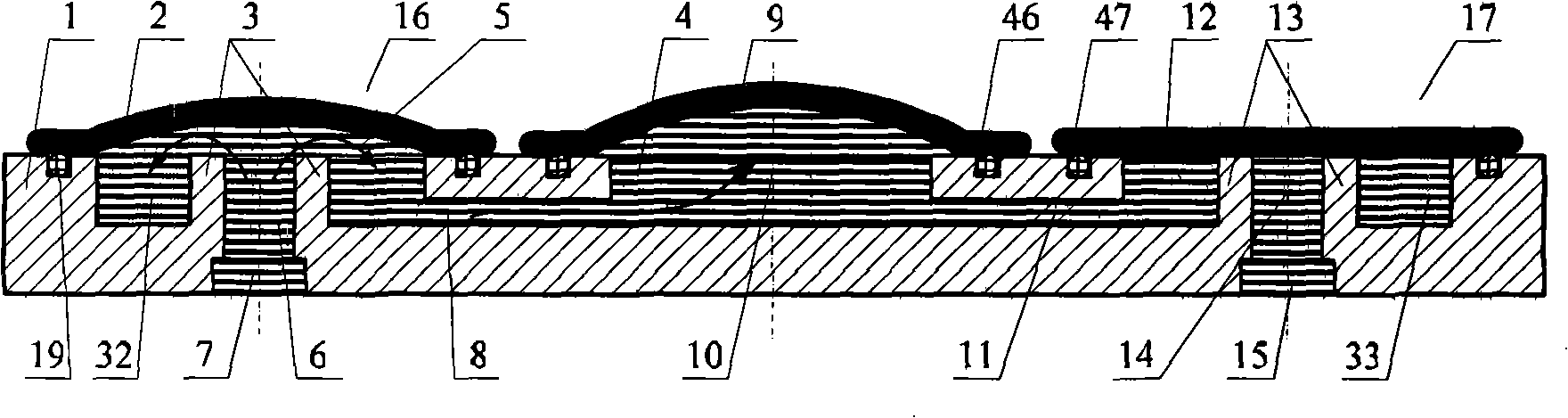

Micro-fluid pump with active control capability

InactiveCN101354030AReduce trafficHigh control precisionPositive displacement pump componentsFlexible member pumpsElectricityControl signal

The invention discloses a micro-pump provided with active control capability. A microfluid active control valve with toroidal boundary is adopted to compose a liquid inlet valve and a liquid outlet valve; an electrically controllable film actuating element is adopted to cover an open face of a cylindrical counterbore of a pump body so as to compose a pump cavity which is connected with a cylindrical (cylindrical center hole) liquid cavity of the microfluid valve; the cylindrical center hole (toroidal) liquid cavity of the microfluid valve is respectively connected with a liquid inlet and a liquid outlet. The frequency, amplitude value and phase relation of a controlling signal (a periodic signal and a positive signal) acting on the microfluid valve and the film actuating element of the pump are changed to control the flow, pulse and outputting pressure of the micro-pump. When a driving signal does not exist, the film actuating element and toroidal boundary of the microfluid valve have precompressing force, thus being in commonly closed state. The micro-pump with active and precise controlling capacity of the invention is a bilaterally controllable micro-pump with active and precise control capacity.

Owner:CHONGQING UNIV

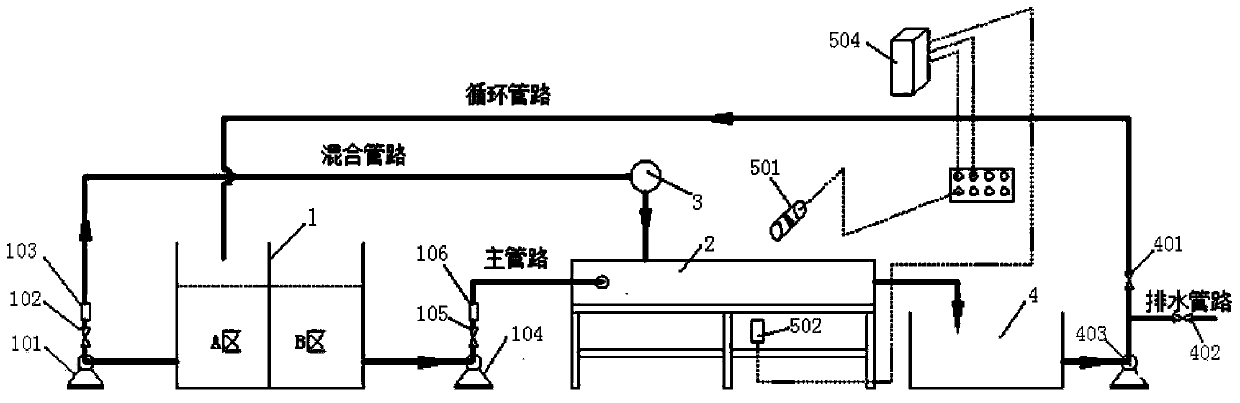

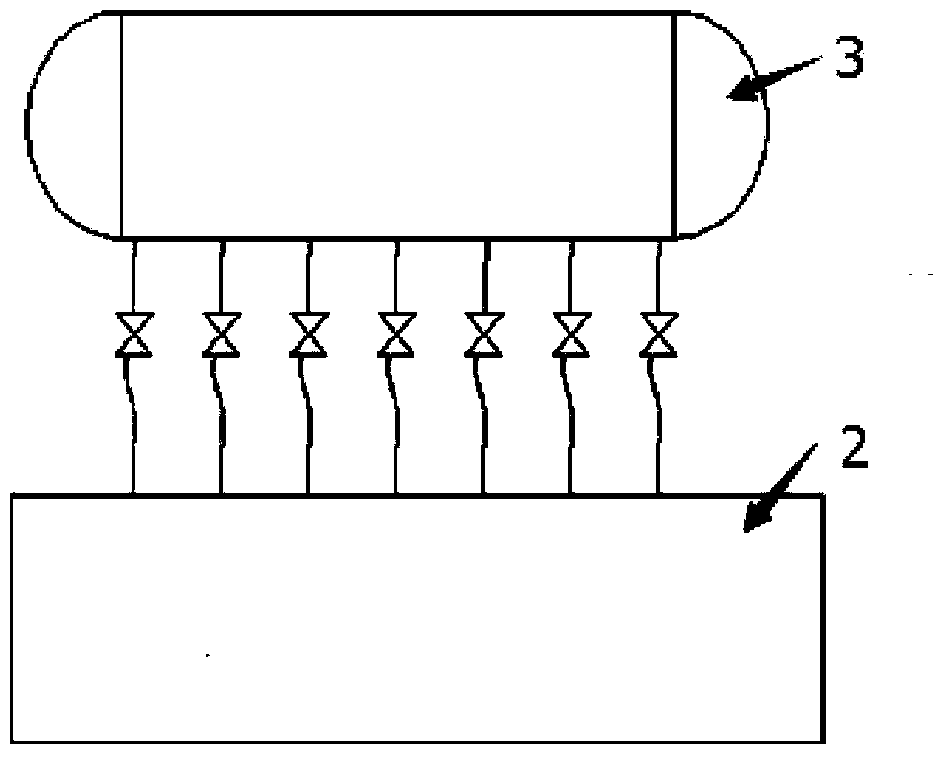

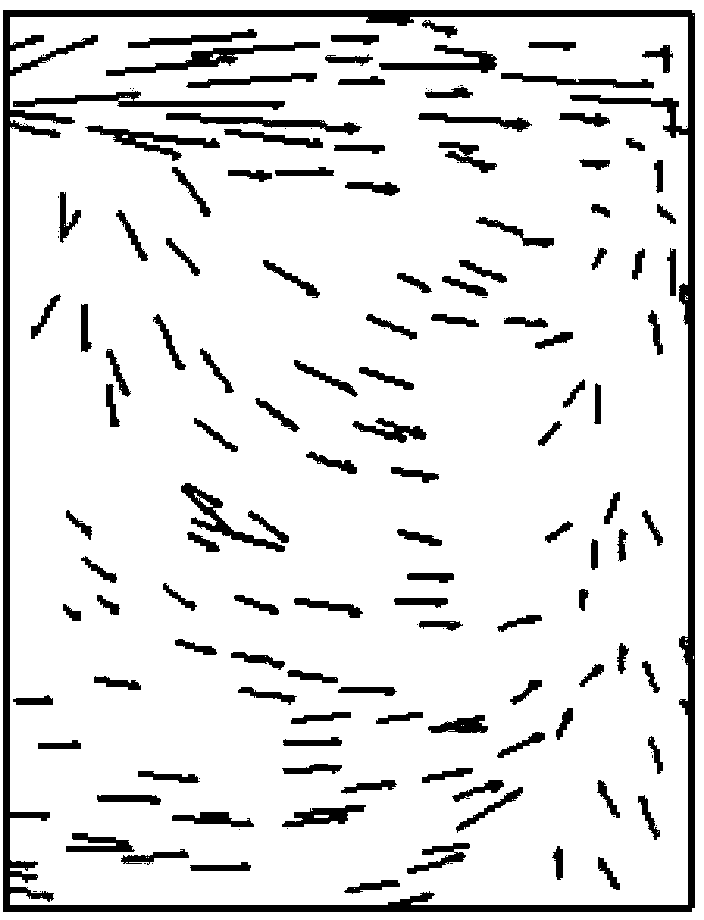

PIV (Particle Image Velocimetry)-based mixed liquid flow field and concentration measuring device and measuring method

InactiveCN104316291AFunctionalFlexibleHydrodynamic testingFluorescence/phosphorescenceWater storageSoil science

The invention belongs to the technical field of fluid measurement, and discloses a PIV (Particle Image Velocimetry)-based mixed liquid flow field and concentration measuring device, and a method of using the device for measuring the flow field or the concentration. The measuring device comprises a main water box, an experimental box body, a buffer tank, a water storage box and a PIV system, wherein the main water box is divided into an A-region box body and a B-region box body for providing liquid of a mixed pipeline and liquid of a main pipeline respectively, the liquid is mixed in the experimental box body, and measurement on the flow filed or the concentration is carried out via the PIV system. Tracer particles are sprayed in water in the main water box and the buffer tank, and the flow field of the mixed liquid is measured via the PIV system; fluorescent particles are added to the two box bodies of the main water box respectively for preparing different concentrations, and the concentration of the mixed liquid can be measured via the PIV system in combination with a LIF (Laser Induce Fluorescence) system; measurement on the mixed flow field and the mixed concentration can be carried out in the same device, water and tracer particles can be saved, and the flow field and the concentration can be detected in real time.

Owner:SOUTH CHINA UNIV OF TECH

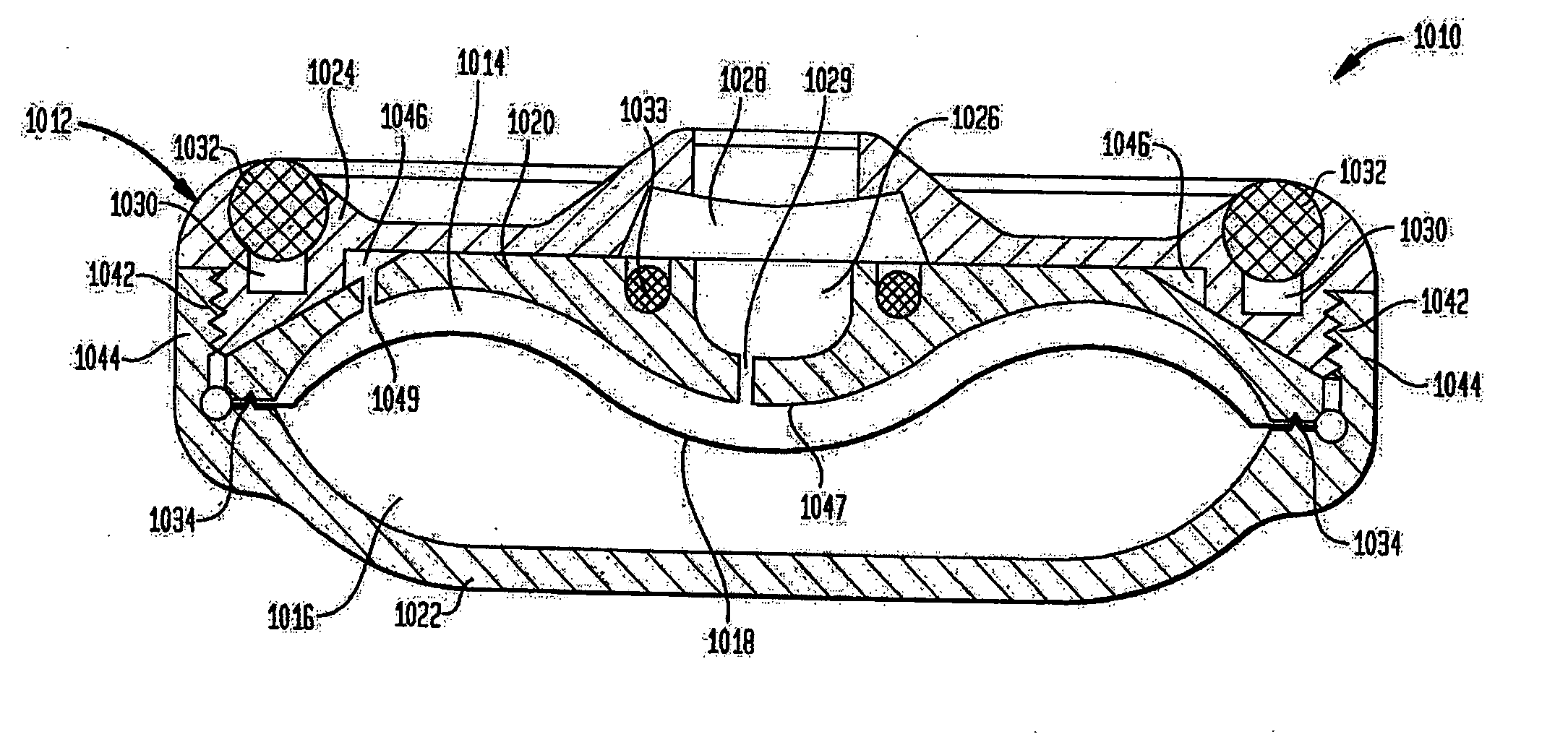

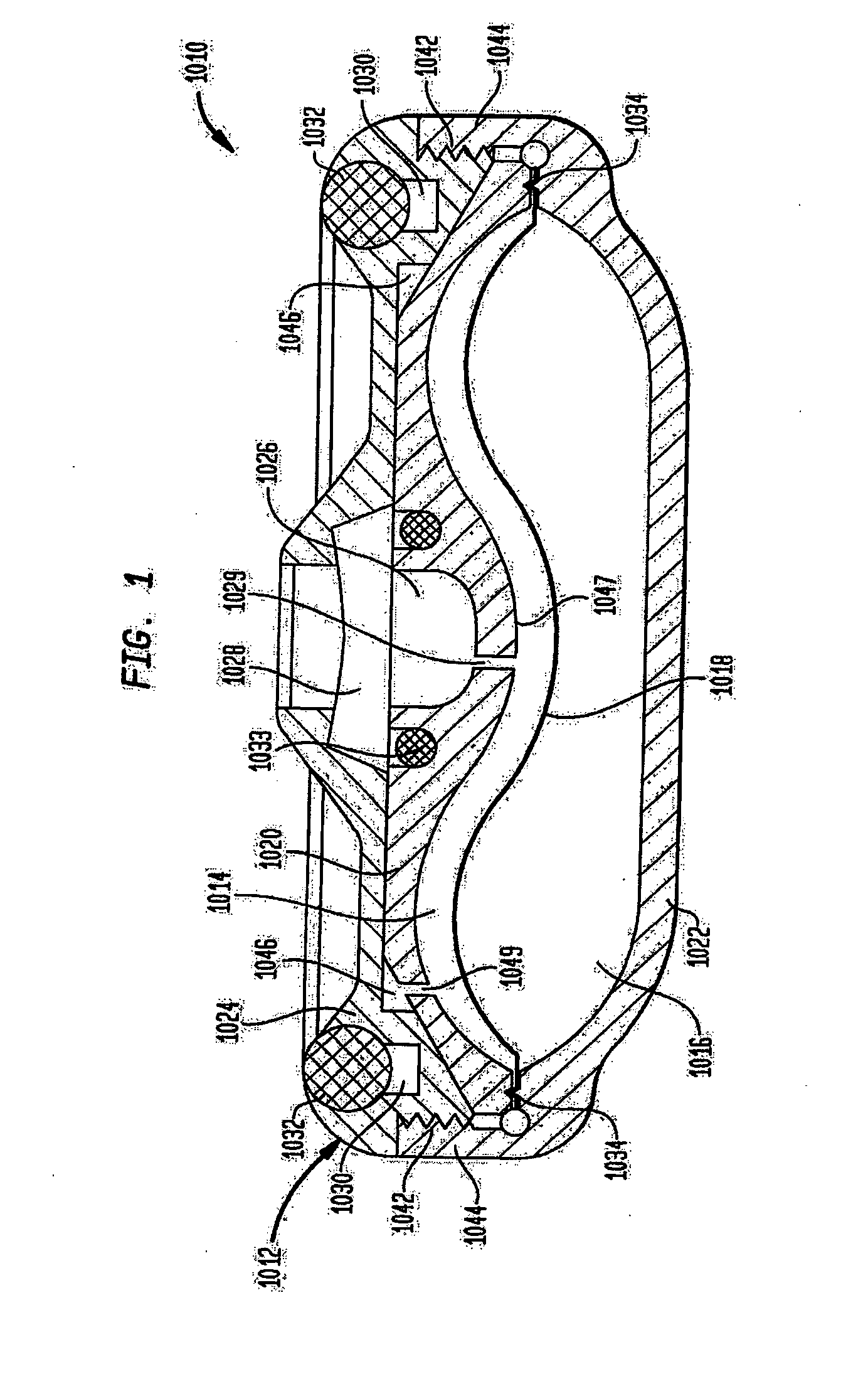

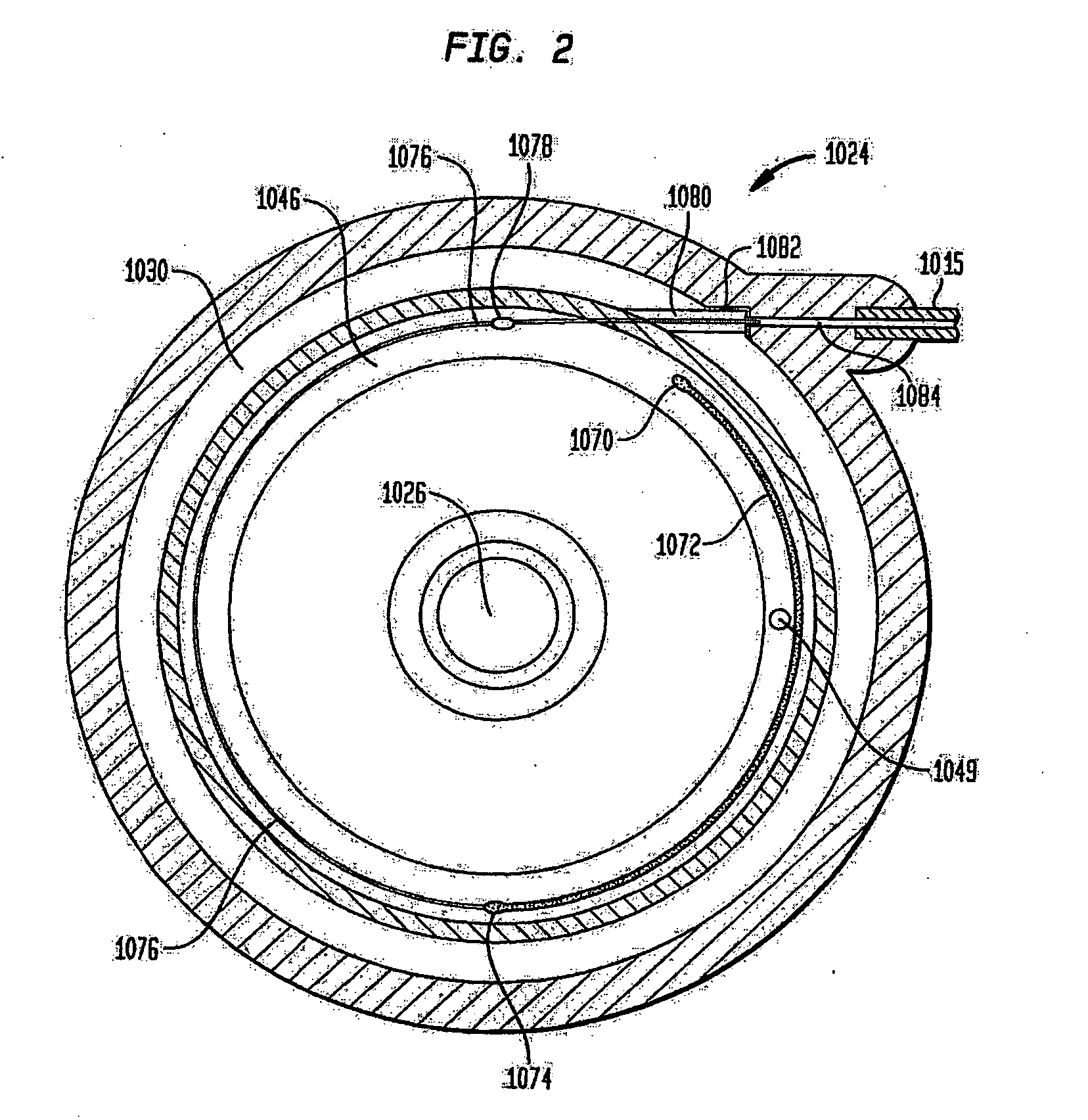

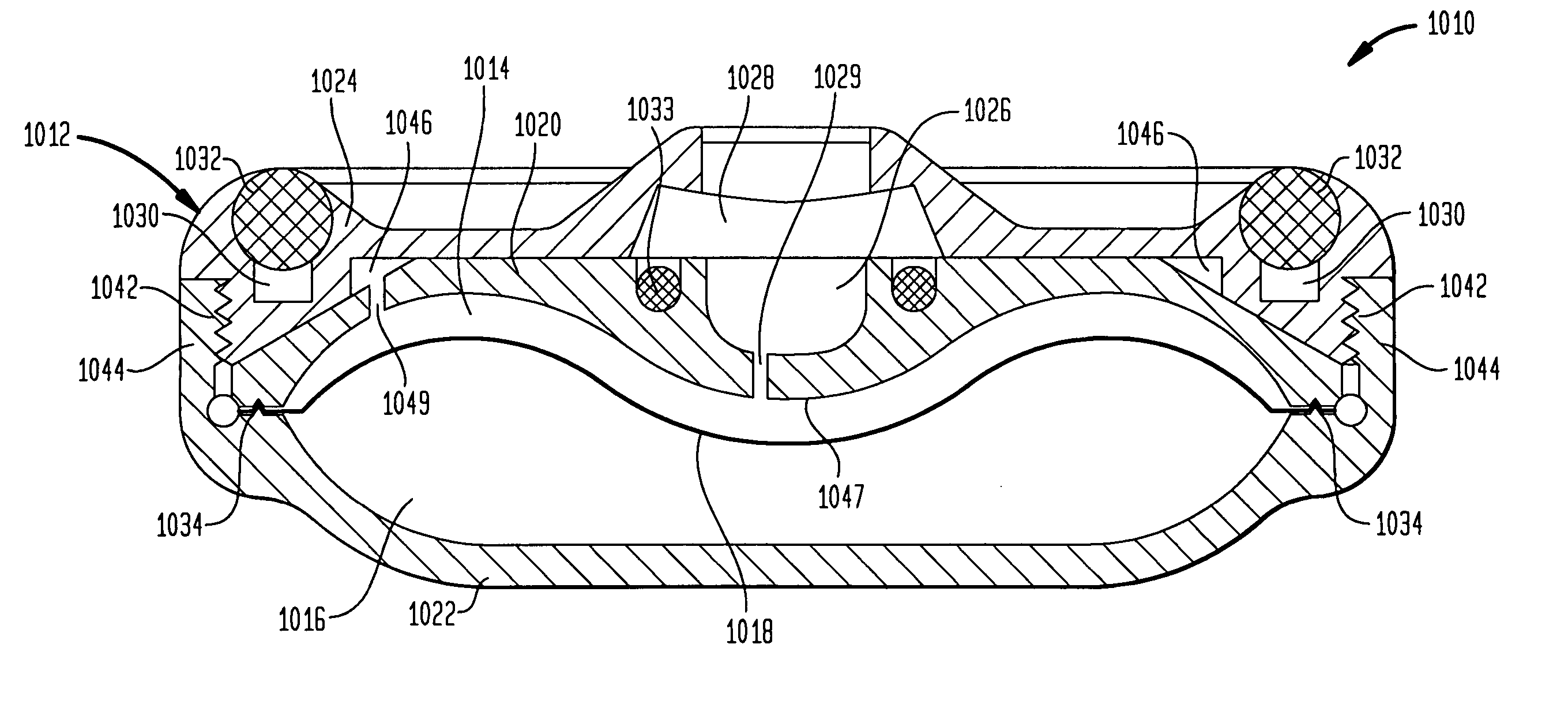

Reduced size implantable pump

InactiveUS20060259016A1Increase and decrease flow rateAlter shapeInfusion devicesMedical devicesReduced sizeMembrane configuration

A variable hydraulic resistor for use with implantable pumps is disclosed. The variable hydraulic resistor according to the present invention is particularly useful in varying the flow rate of a medication fluid from an otherwise constant flow implantable pump. An implantable pump is also disclosed, which does not require a complicated clinching system or the like, and which may include an undulating membrane and chamber design to reduce the height of the pump.

Owner:AQULINX MEDICAL

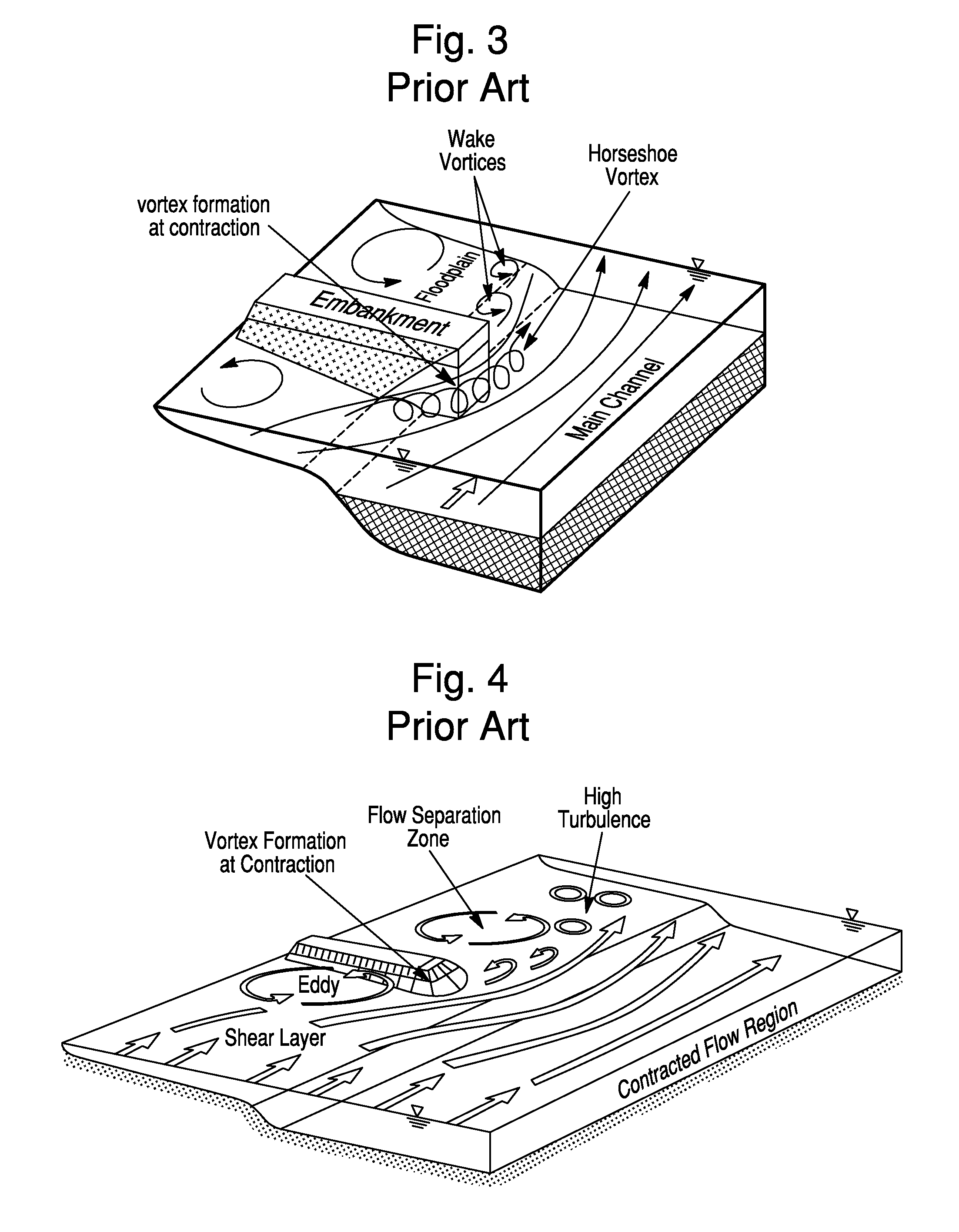

Bridge pier and abutment scour preventing apparatus with vortex generators

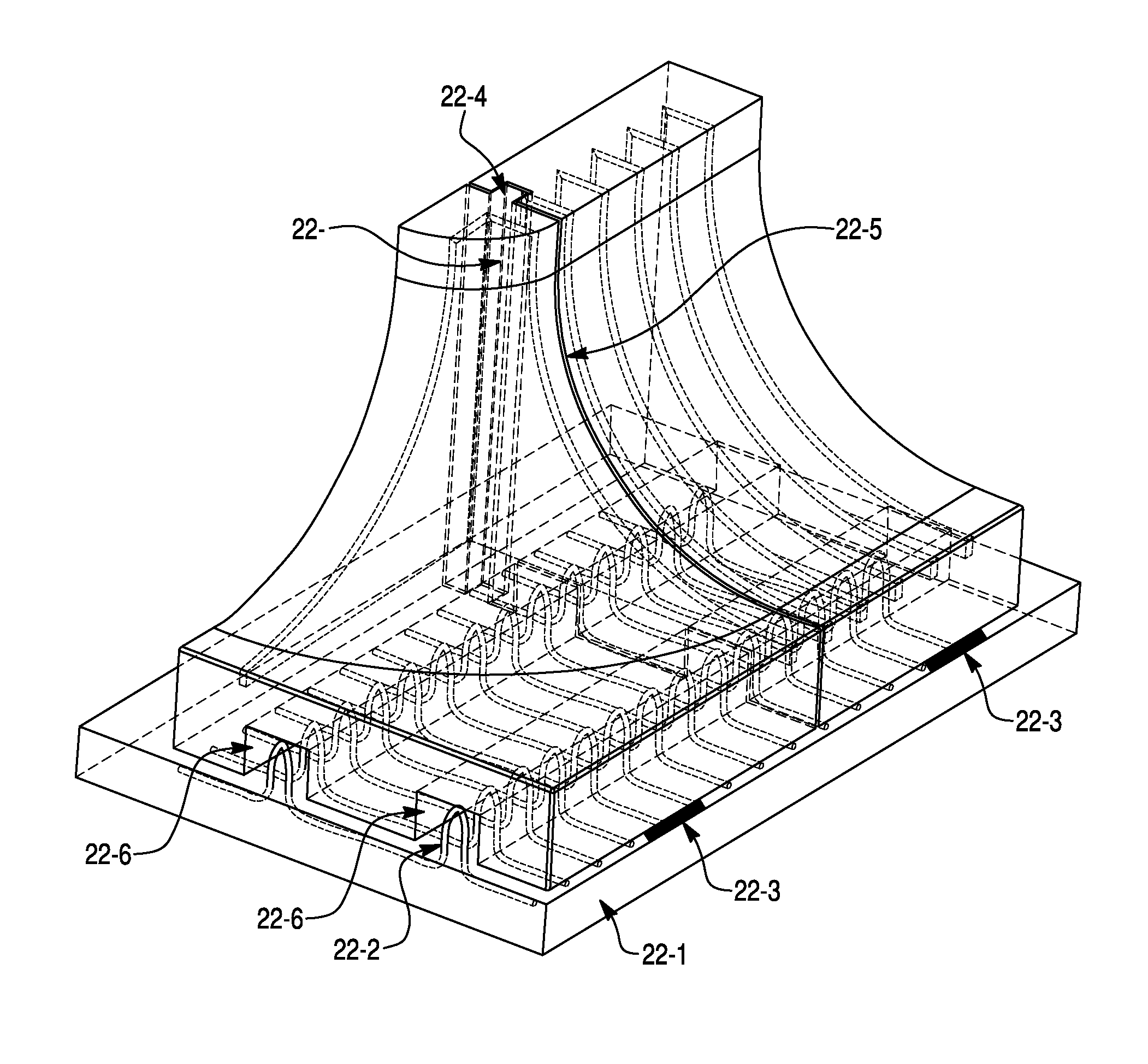

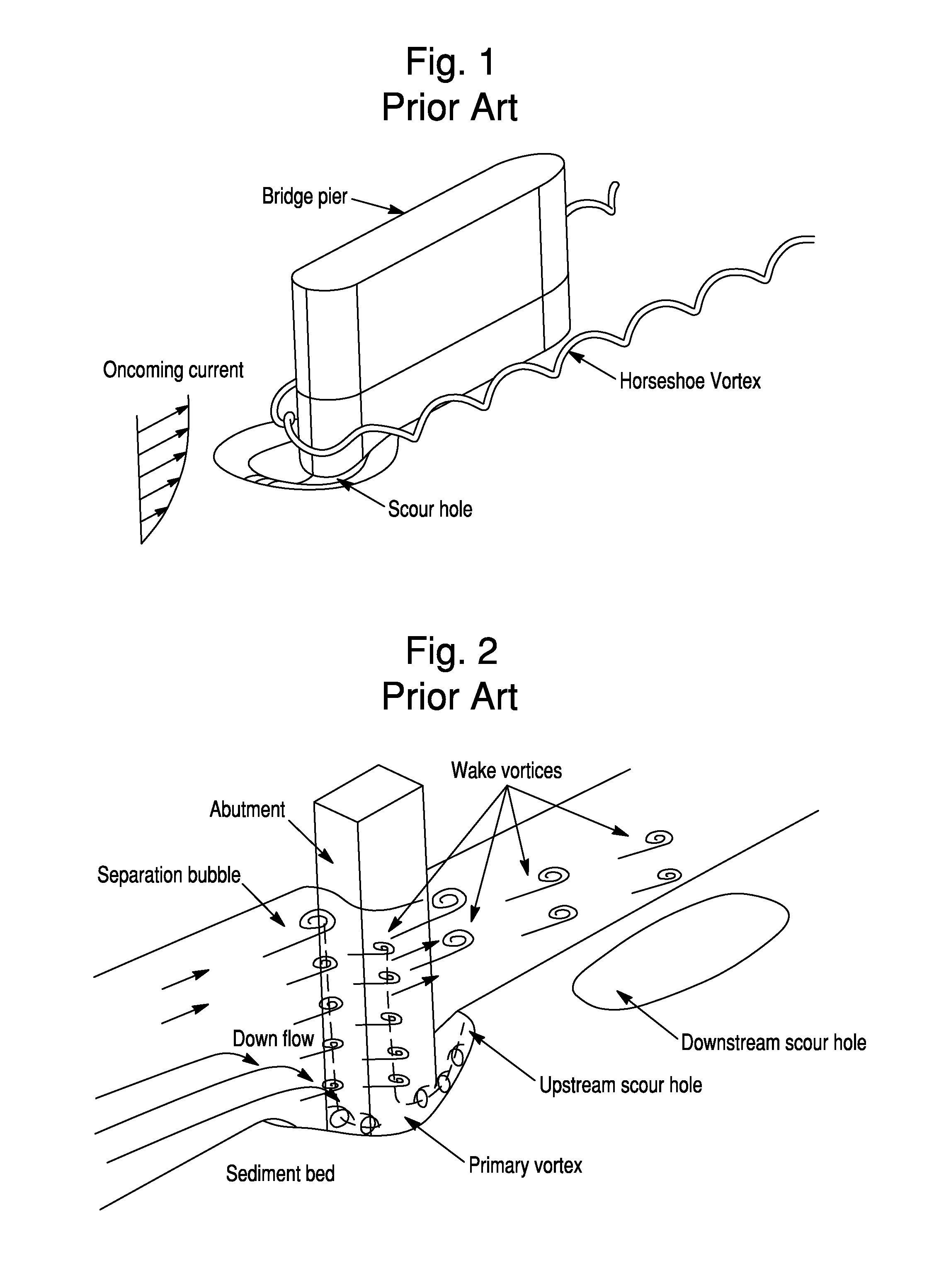

ActiveUS20120134753A1Avoid scourAvoid separationBarrages/weirsProtective foundationHydraulic structureEngineering

Disclosed is a manufactured three-dimensional convex-concave fairing with attached vortex generators, for hydraulic structures such as bridge piers and abutments, whose shape prevents the local scour problem around such hydraulic structures. The device is a conventionally made concrete or fiber-reinforced composite, or combination of both, vortex generator equipped hydrodynamic fairing that is fit or cast over an existing or new hydraulic structure around the base of the structure and above the footing. The vortex generators are positioned so as to energize decelerating near wall flow with higher-momentum outer layer flow. The result is a more steady, compact separation and wake and substantially mitigated scour inducing vortical flow.

Owner:APPLIED UNIV RES

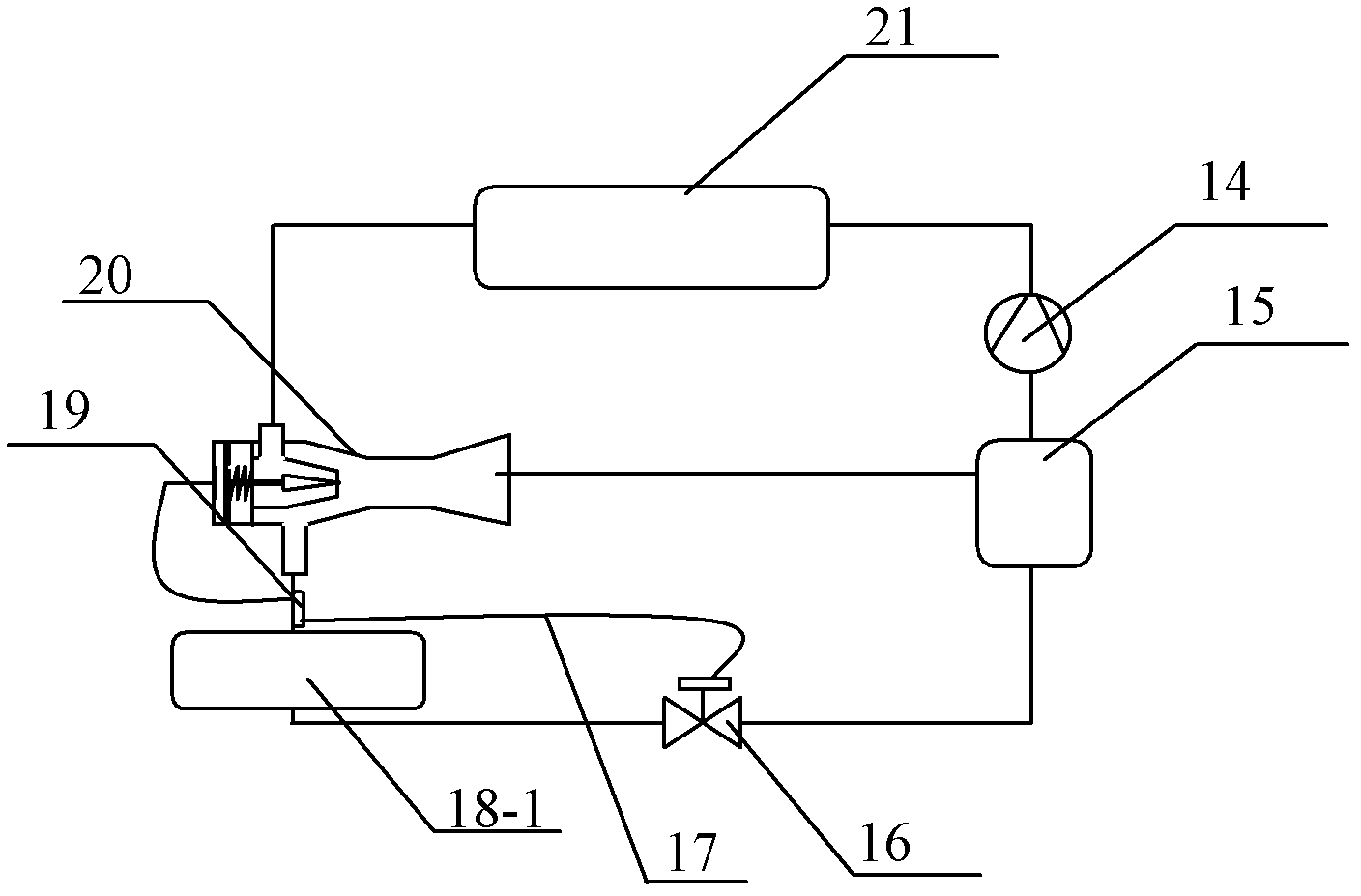

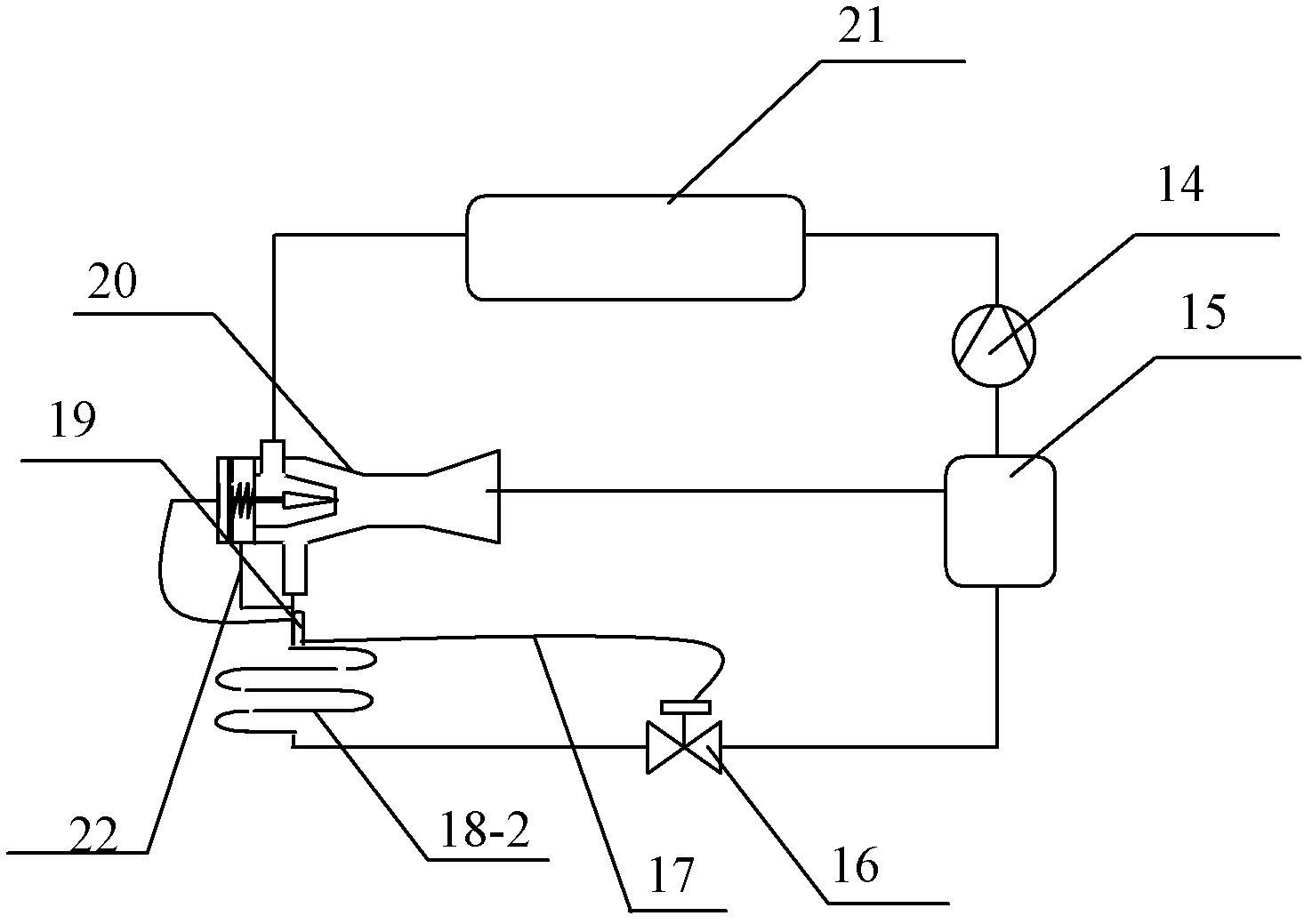

Ejector with automatic adjustment of ejecting flow and refrigerating system comprising same

The invention discloses an ejector with automatic adjustment of ejecting flow and a refrigerating system comprising the same. The invention is characterized in that with the change of the refrigerating load of the refrigerating system, the flow of the ejecting fluid can be adjusted to offset the influence of the load change on the working performance of the ejector and further guarantee the operating performance of the refrigerating system in a wider range. The side surface of an ejector nozzle is connected with a main fluid inlet connecting pipe; the rear part of the nozzle is connected with a baffle; one end of a main body receiving chamber of the ejector is provided with an end cover; a diaphragm is arranged between the end cover and the baffle; the diaphragm and the baffle are respectively welded with the inner side of an ejector main body along the circumferential edge; a first pressure cavity is formed between the diaphragm and the end cover; a second pressure cavity is formed between the diaphragm and the baffle; the nozzle is internally provided with a valve needle and a push rod; the front end of the valve needle corresponds to the end surface of a nozzle outlet, and the rear end of the valve needle is fixedly connected with the push rod which is fixedly connected with the diaphragm; a spring is sheathed at the outer part of the push rod in the second pressure cavity; and the end cover is provided with a first connecting pipe.

Owner:TIANJIN UNIV OF COMMERCE

Autonomous filter element

InactiveUS20100237013A1Improving filter life and performanceReduce blockingMembranesVolume/mass flow measurementMembrane configurationEngineering

An autonomous filter device and a method for improving the filter life and performance is disclosed. The filter element is equipped with one or more sensors, adapted to measure one or more characteristics or parameters of the fluid, such as temperature, pressure, or flow rate. In response to the measured characteristic or parameter, the control logic within the filter element is able to determine an appropriate response. For example, the control logic may determine that a sudden, but temporary, blockage has occurred in the filter membrane. In response to this, the control logic may initiate a specific response designed to alleviate the blockage. This response may be a temperature change, a vibration, a change in fluid flow path, or some other action. The control logic will then determine the success of the response, based monitoring any change in the fluid characteristics. Based thereon, the control logic may alert the operator that the filter element must be replaced. Alternatively, if the response was successful in correcting the blockage, the control logic need not notify the operator, as the filter element is back to normal operating operation.

Owner:MILLIPORE CORP

Hydrogen peroxide kerosene variable working condition thrust chamber adopting syringe injector

ActiveCN111022218AChange trafficSimplify ignition structureRocket engine plantsCombustion chamberFuel gas

The invention discloses a hydrogen peroxide kerosene variable working condition thrust chamber adopting a syringe injector. The hydrogen peroxide kerosene variable working condition thrust chamber adopting the syringe injector comprises an injection chamber, a catalytic chamber and a combustion chamber which are sequentially connected from top to bottom, and further comprises the injector, whereinthe injector is coaxially arranged in the injection chamber, the catalytic chamber and the combustion chamber in the axial direction, and the injection end of the injector is located in the combustion chamber; and the injection end of the injector is provided with a kerosene injection port with an adjustable opening size, and the kerosene injection port is used for injecting kerosene fuel into the combustion chamber and mixing and combusting with the decomposed hydrogen peroxide fuel. Through the characteristic that the high-temperature gas subjected to hydrogen peroxide catalysis is self-ignited after being in contact with the kerosene, the ignition structure is simplified.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

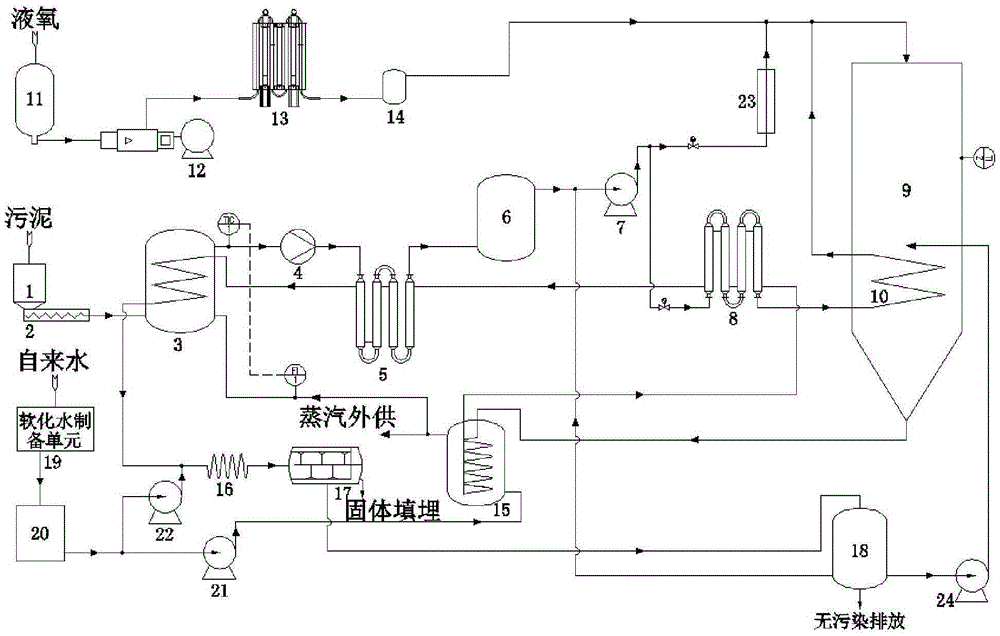

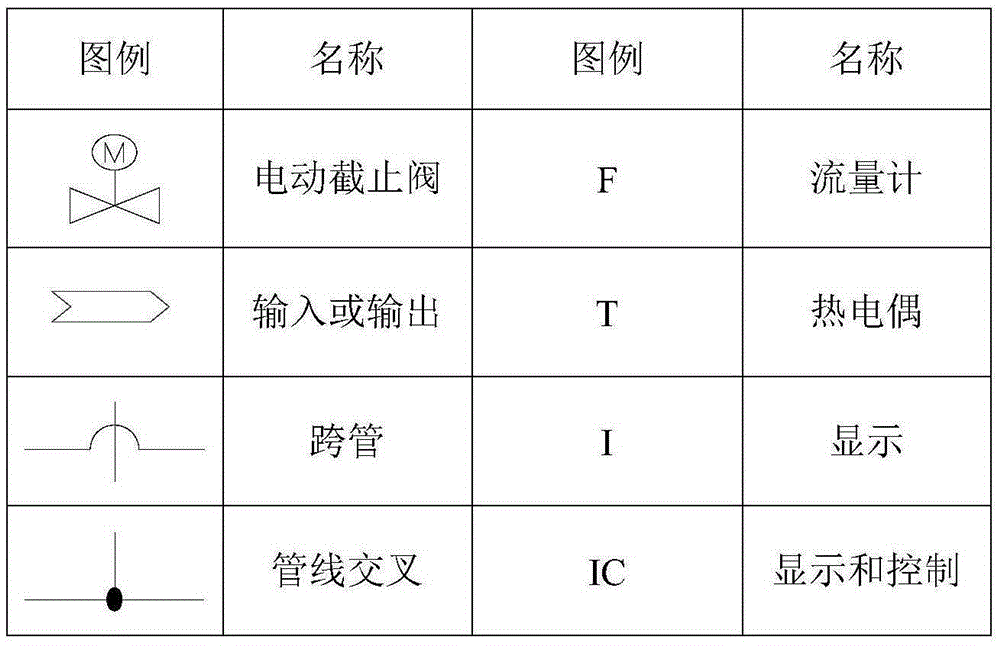

Supercritical water oxidation treatment system and supercritical water oxidation treatment system process for high-concentration dyeing sludge

InactiveCN105293856AChange trafficPrecise regulation of pressure dropSludge treatment by oxidationHigh concentrationTransformer

The invention provides a supercritical water oxidation treatment system and a supercritical water oxidation treatment system process for high-concentration dyeing sludge. After the high-concentration dyeing sludge is ground, the particle sizes of insoluble particles are reduced, and high-flow-speed suspension conveying can be realized; the sludge is further subjected to pyrohydrolysis, cell walls are broken and the viscosity is remarkably reduced; the sludge can be stably conveyed through a high-pressure diaphragm pump and enters into a heat exchanger for preheating, so that the required temperature is reached; subsequently, the sludge and oxygen jointly enter into an inlet in the upper part of a reactor, materials completely react in the up-down flowing process, organic matters are degraded and inorganic salts are separated out; the inorganic salts are secondarily dissolved by the cooling of a small amount of reacted clean fluid introduced from an inlet in the upper part of a third heat exchanger and sludge at the inner pipe side of a fourth heat exchanger; materials flow out of a cone base at the lower part of the reactor for heating soften water to generate steam and preheating the materials; cooled and reacted fluid is decompressed through coarse adjustment of a capillary step-down transformer and fine conditions of flow; decompressed fluid is separated through a pipeline filter to obtain a solid which is finally collected into a liquid collecting tank.

Owner:山川丽(苏州)环保科技有限公司

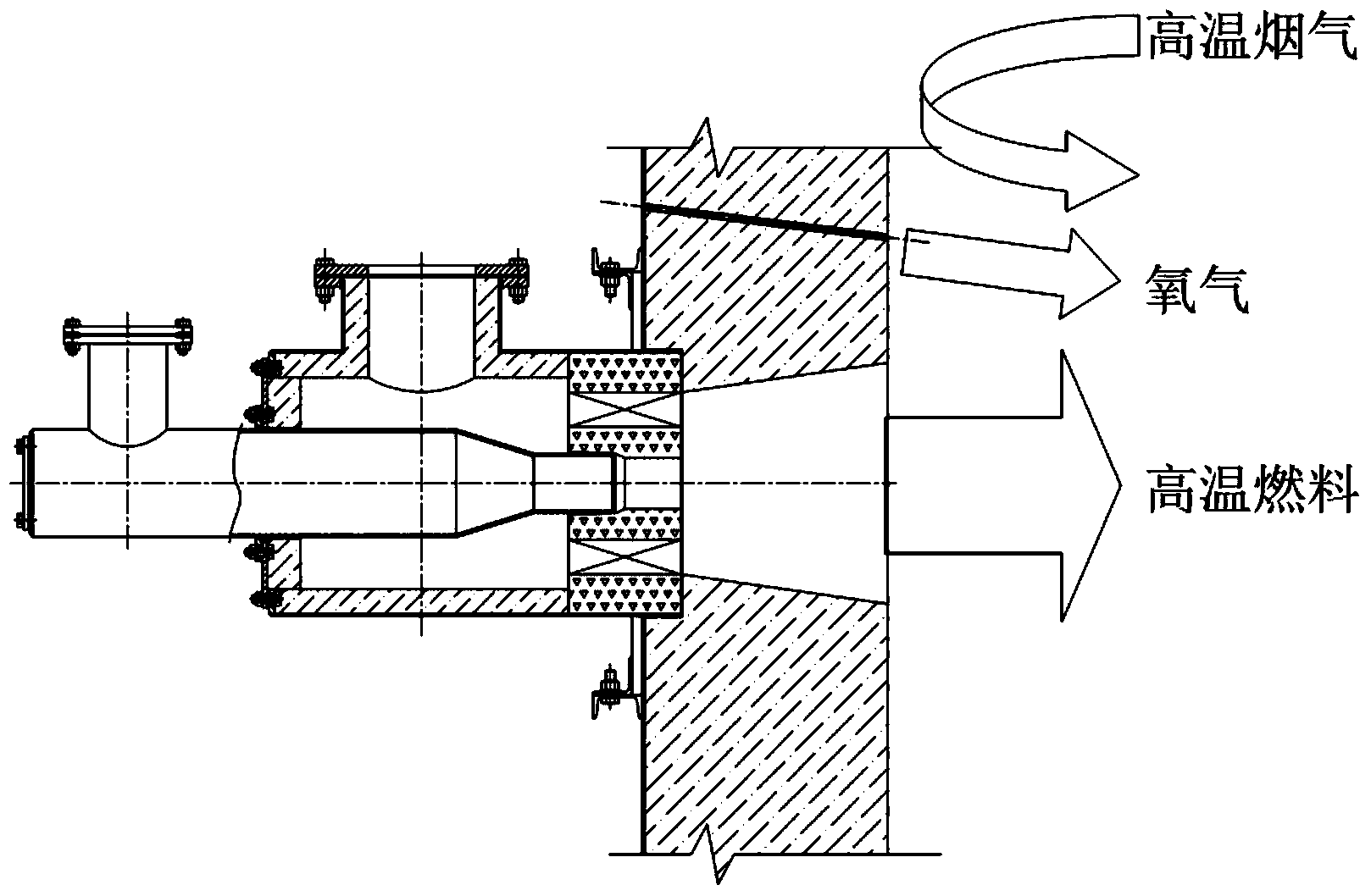

Oxygen-enriched and flameless gas burner and control method thereof

ActiveCN104266190ASimple structureEasy to implementIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringHearth

The invention discloses an oxygen-enriched and flameless gas burner which comprises a burner casing, an air distribution plate, a prechamber, an oxygen nozzle and a fuel nozzle. A channel penetrating a wall body of a furnace wall of a heating furnace is arranged on the furnace wall. The burner casing is installed on one side of the channel, and the prechamber is formed in the space in the channel. A combustion-supporting air channel is arranged on the burner casing, and the fuel nozzle penetrates through the burner casing in an inserting mode. A fuel channel is arranged on the fuel nozzle. An air inlet and a fuel inlet are arranged on the air distribution plate. The oxygen nozzle is provided with an oxygen pipe and installed on the furnace wall of the heating furnace, the oxygen channel is communicated with a hearth of the heating furnace, the oxygen nozzle is slantingly arranged on the furnace wall of the heating furnace, and a spray head end of the oxygen nozzle is close to the prechamber. The oxygen-enriched and flameless gas burner organically combines the dilution combustion technology and the oxygen-enriched combustion technolog, achieves flameless combustion in the furnace, meanwhile optimizing temperature distribution in the furnace, and reduces NOx emission.

Owner:WISDRI WUHAN WIS IND FURNACE

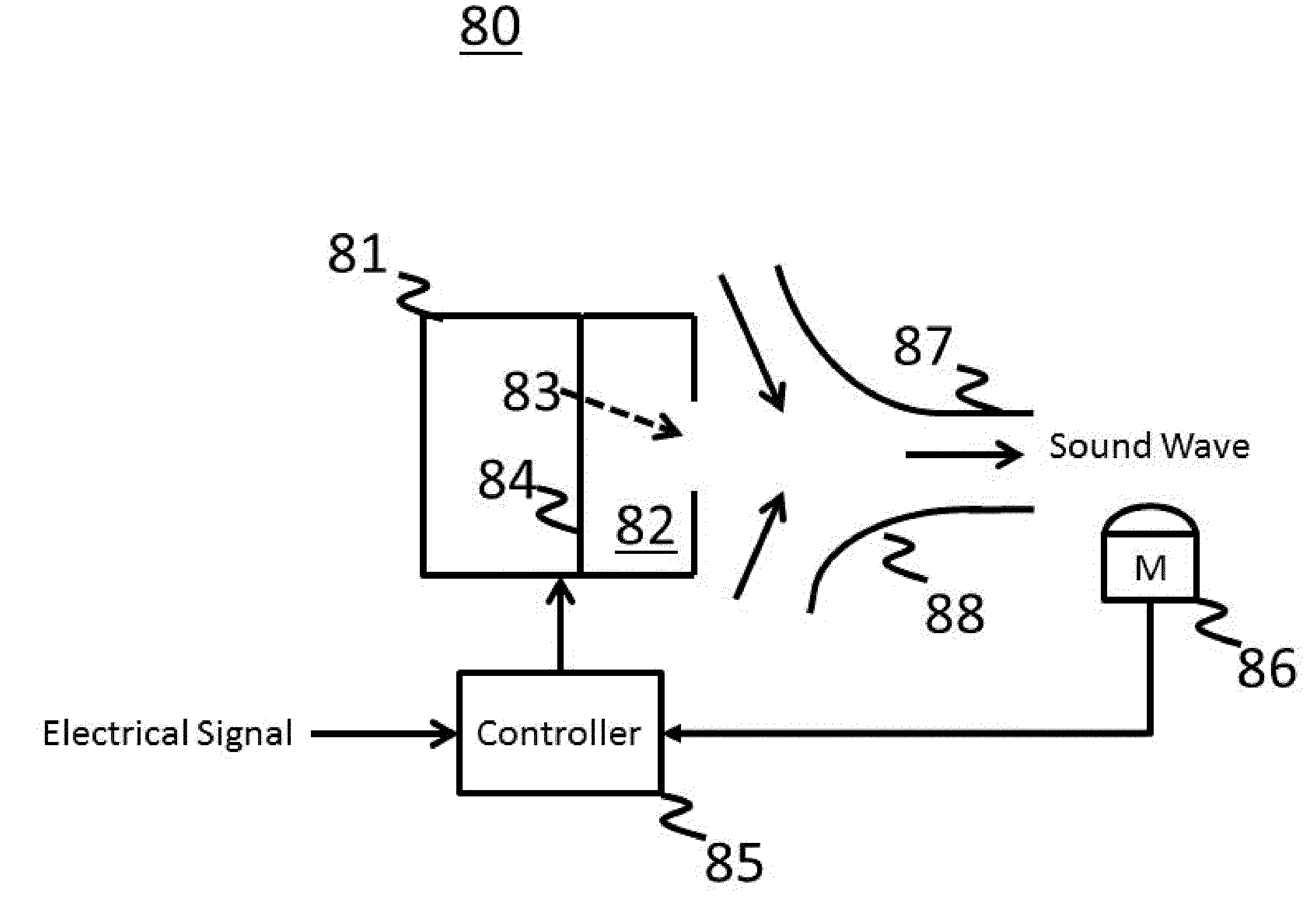

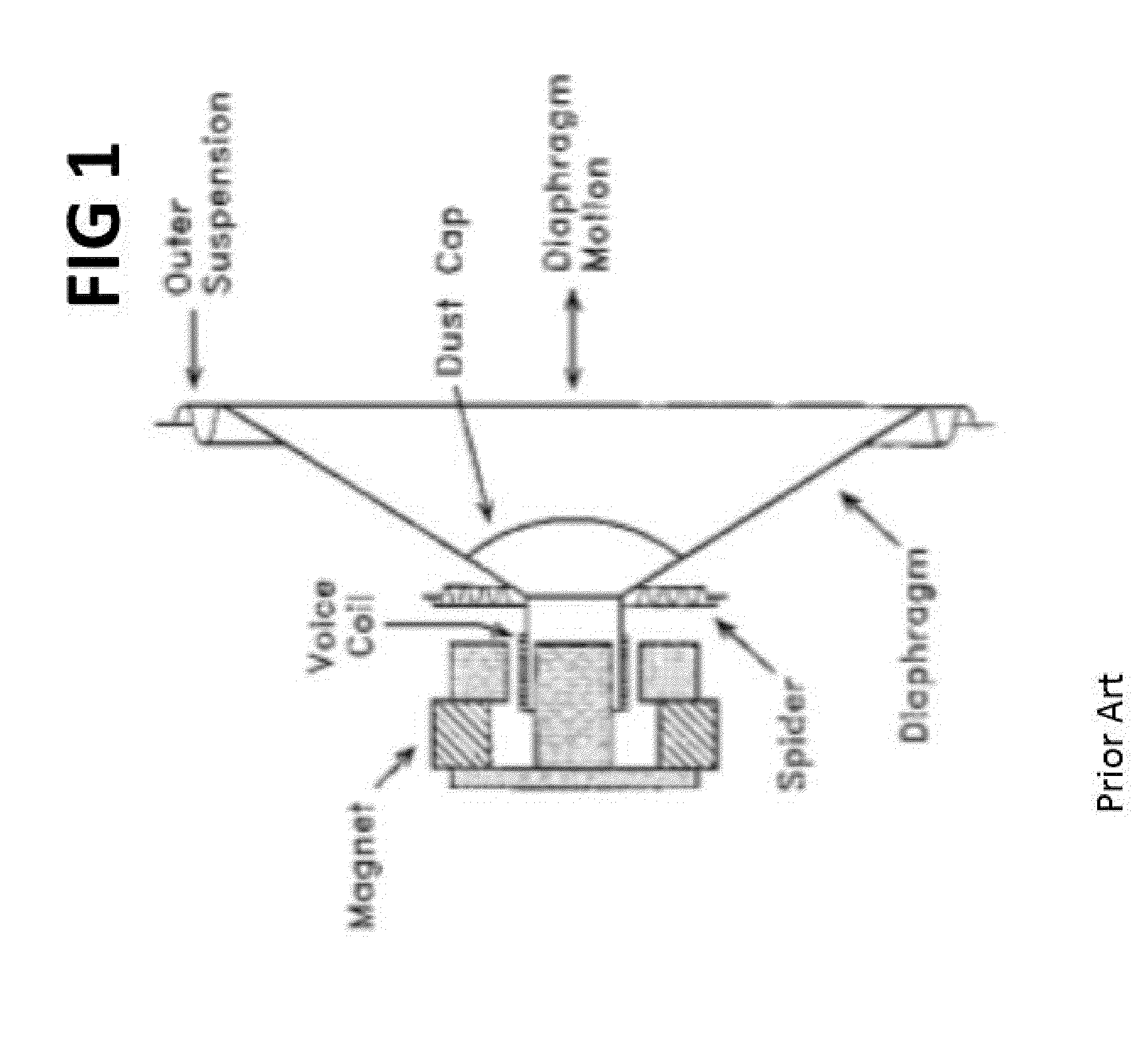

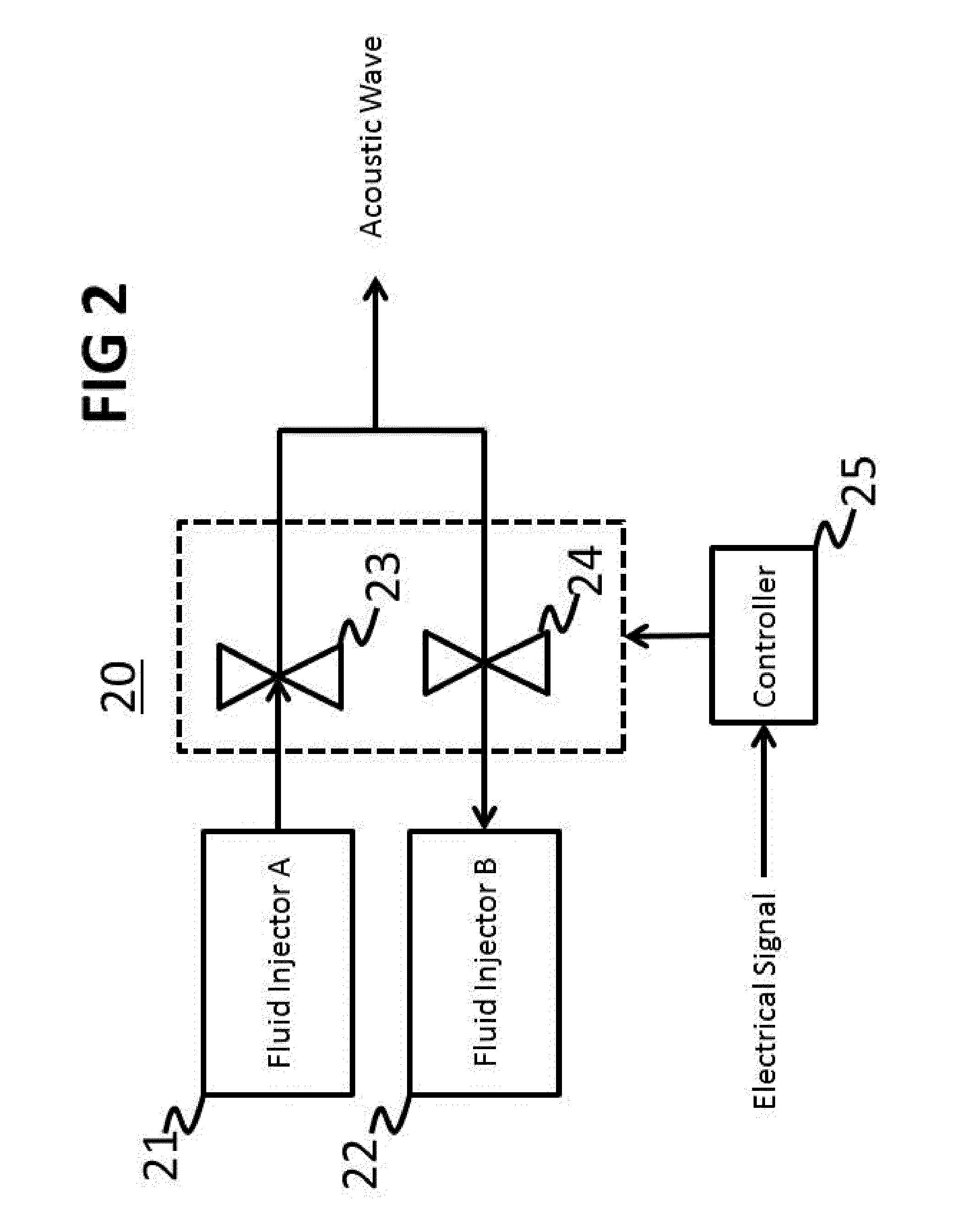

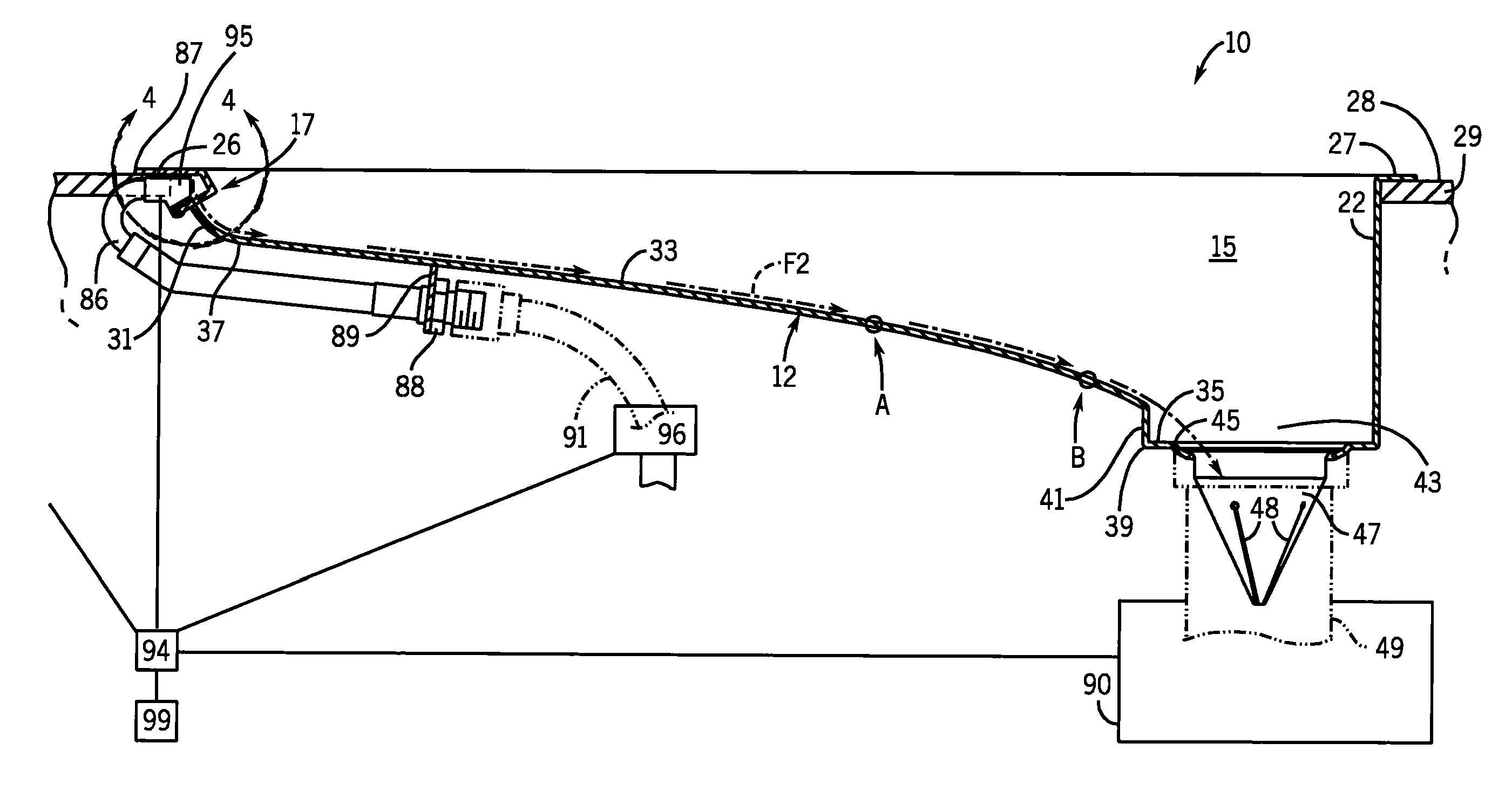

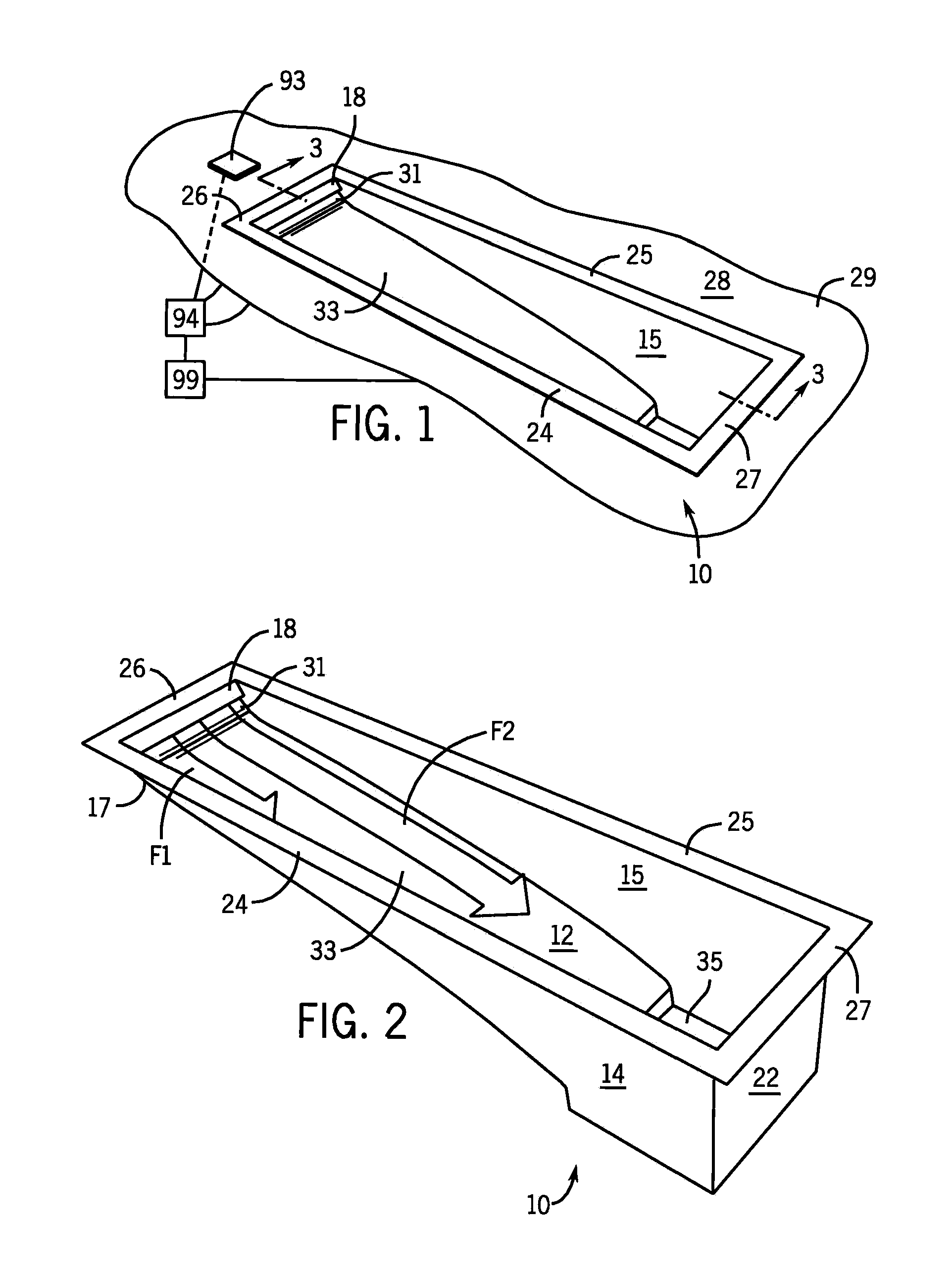

Acoustic wave generator employing fluid injector

InactiveUS20140064036A1Improve fidelitySmall sizeSirensSeismic energy generationControl signalAcoustic wave

To reproduce sound in an extremely compact size, fluid injectors are used that can generate fluid flow sufficient to create a desired acoustic pressure wave, but which fluid flow operates in a manner that is decoupled from the desired acoustic pressure wave. Fluid flow within the fluid injectors needed to generate the desired acoustic pressure wave need not be directly proportional to the frequencies of the desired acoustic pressure wave. The fluid injector has a control input capable of altering fluid flow relative to a received control signal, which is generated by a controller in response to an electrical signal. The fluid injector produces fluid flow outward and inward in response to the control signal, thereby creating an acoustic wave proportional to the electrical signal. The devices herein may employ valves or not. Synthetic jets may also be used.

Owner:TSENG HO PING

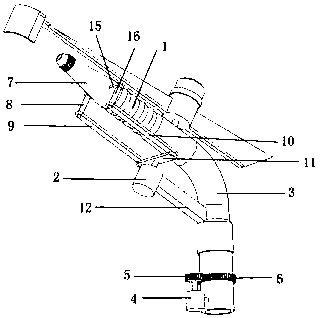

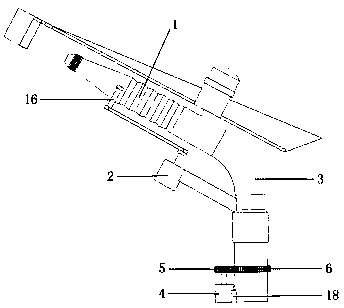

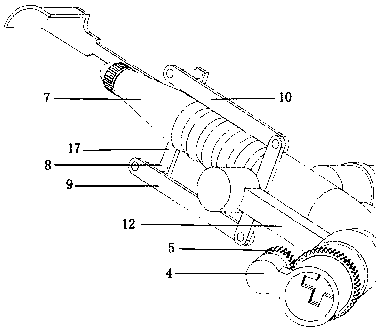

Pulverized coal decoupling combustor and decoupling combustion method thereof

InactiveCN102297425AMeet or exceed concentration efficiencyOver concentration efficiencyPulverulent fuel combustion burnersCombustorGuide tube

The invention relates to a pulverized coal decoupling combustor and a decoupling combustion method thereof. The decoupling combustor comprises a first-stage air duct (12), an inertia separator (11), air current conduits and a spout which are sequentially connected along the air current direction, wherein the air current conduits comprise a dense side air current conduit (7) and a fresh side air current conduit (8); the fresh side air current conduit (8) is communicated with a third-stage spout (1); the dense side air current conduit (7) is connected with a first-stage spout (3); a second-stage spout conduit (6) communicated with the dense side air current conduit (7) is led out of a pipeline between the dense side air current conduit (7) and the first-stage spout (3) on the dense side aircurrent conduit (7); the second-stage spout conduit (6) is communicated with a second-stage spout (2); the first-stage spout (3) is a gradually-increasing spout; a pair of pulverized coal collecting flame stabilizing devices (4) is oppositely arranged at the upper side and the lower side inside the front end of the first-stage spout (3); the cross sections of the pulverized coal collecting flame stabilizing devices (4) along the air current direction is gradually increased; and the area of the cross section of an air current channel is decreased along the air current direction, thus the coupling combustion is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Food Preparation Sink

ActiveUS20090249541A1Facilitate automatic movement of food wasteMuch of food can be wastedDomestic plumbingWater flowFood waste

Food preparation sinks are disclosed which have an integral raised work area that is rinsed by an automatic system. Food waste or the like present in that area can be washed into a sump above a drain, and the weight of the waste and water in the sump is enough to automatically drive them through a baffle to a food waste disposer, without requiring the baffle to be manually opened. An automatic controller system coordinates water flow and food waste disposer operation, and the water supply can be linked to the sink below the sink rim to save counter top space. In some forms multiple rinsing nozzles are provided which pulse in altering fashion.

Owner:KOHLER CO

Spraying head with wind resisting function

ActiveCN108144782AFully automatedReduce manual operationsClimate change adaptationSpraying apparatusWater savingAgricultural engineering

The invention relates to a spraying head with a wind resisting function and belongs to the technical field of agricultural water saving. The spraying head with the wind resisting function comprises aflow adjusting device, a steering device, an extensible and retractable pipe, a spraying pipe, a spray head and a wind speed and wind direction measuring device. According to the spraying head with the wind resisting function, the flow size and the steering direction of the spray head can be controlled according to the different wind speeds and wind directions, and so that the change of ejecting range is achieved; when wind is following wind, the flow can be adjusted to be reduced, meanwhile, the spray head is adjusted to rotate toward a windward side; and when wind is dead wind, the flow is adjusted to be increased, meanwhile, the spray head is adjusted to rotate toward a windward side, the spraying range of the spray head is not changed, and the wind resisting requirement is met. The spraying head with the wind resisting function is easy to operate, time and labor are saved, and the spraying head has the beneficial effects that integral selectivity is achieved, the cost is saved, andthe efficiency and the spraying uniformity are high. The spraying head with the wind resisting function achieves spraying automation, a motor is adjusted according to needs to adjust different waterinlet flows and nozzle angles, man-made operation is reduced, and the opening diameter adjusting precision is improved.

Owner:KUNMING UNIV OF SCI & TECH

Plasma fuel converter NOx adsorber system for exhaust aftertreatment

InactiveUS20050178107A1Increase production and deliveryChange trafficExhaust apparatusSilencing apparatusControl systemExhaust fumes

The invention provides a NOx adsorber aftertreatment system for internal combustion engines which utilizes a plasma fuel converter operatively coupled to at least one NOx adsorber to aid in the regeneration of the NOx adsorber. Fuel and engine exhaust is injected into a plasma fuel converter upstream of a NOx absorber producing reductant such as H2, and CO, which are inlet into the NOx absorber. Reductants such as H2 and CO acting along and together help to efficiently regenerate the NOx Adsorber which in turn releases exhausts products such as CO2 and N2. Using the reductants generated by the plasma fuel converter NOx adsorbers, catalytic soot filter, and the like can be regenerated at exhaust temperatures less than 250° C. The plasma fuel converter, NOx adsorber regenerating aftertreatment system of the present invention may be used with any suitable control system.

Owner:CUMMINS FILTRATION INC

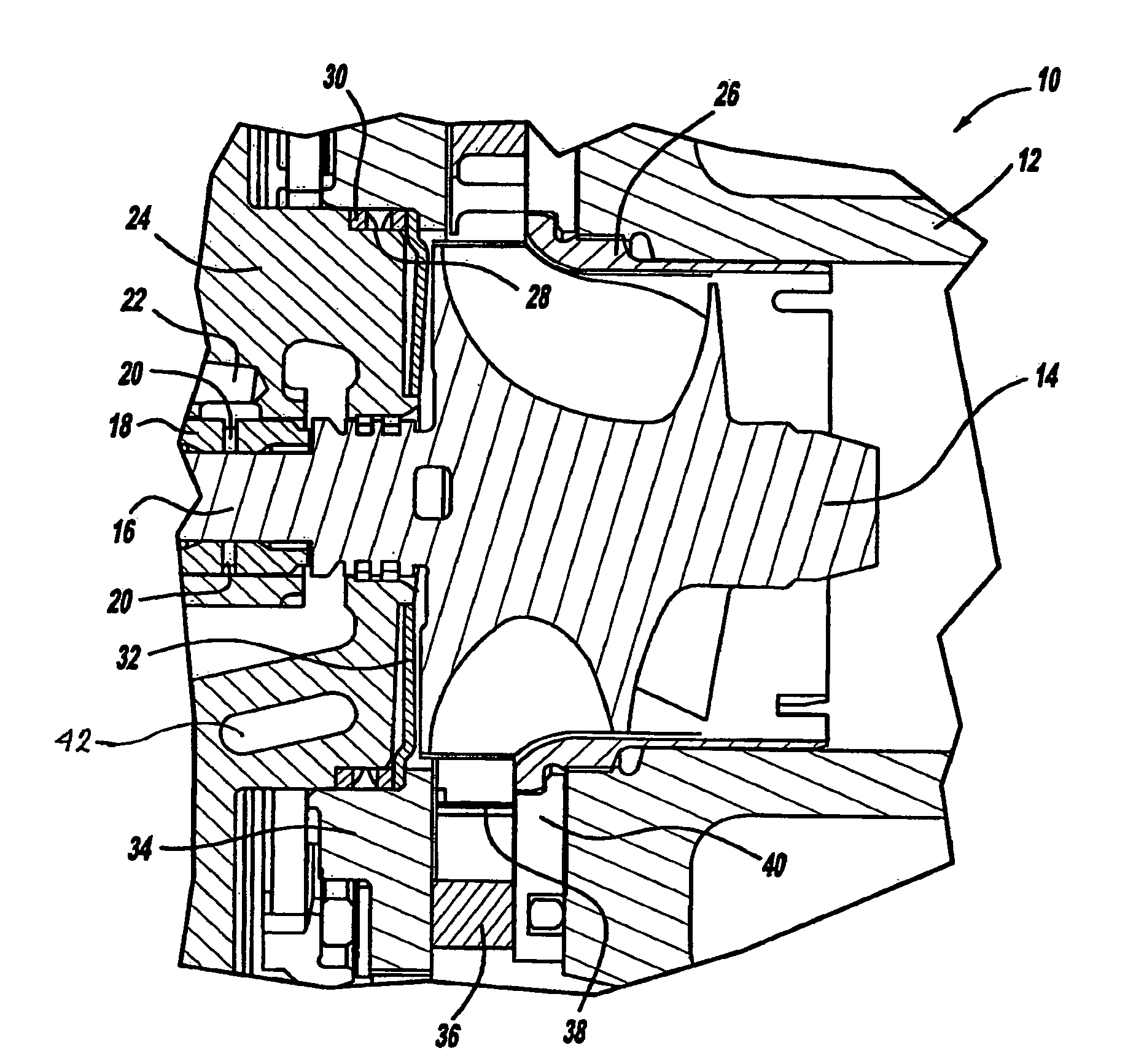

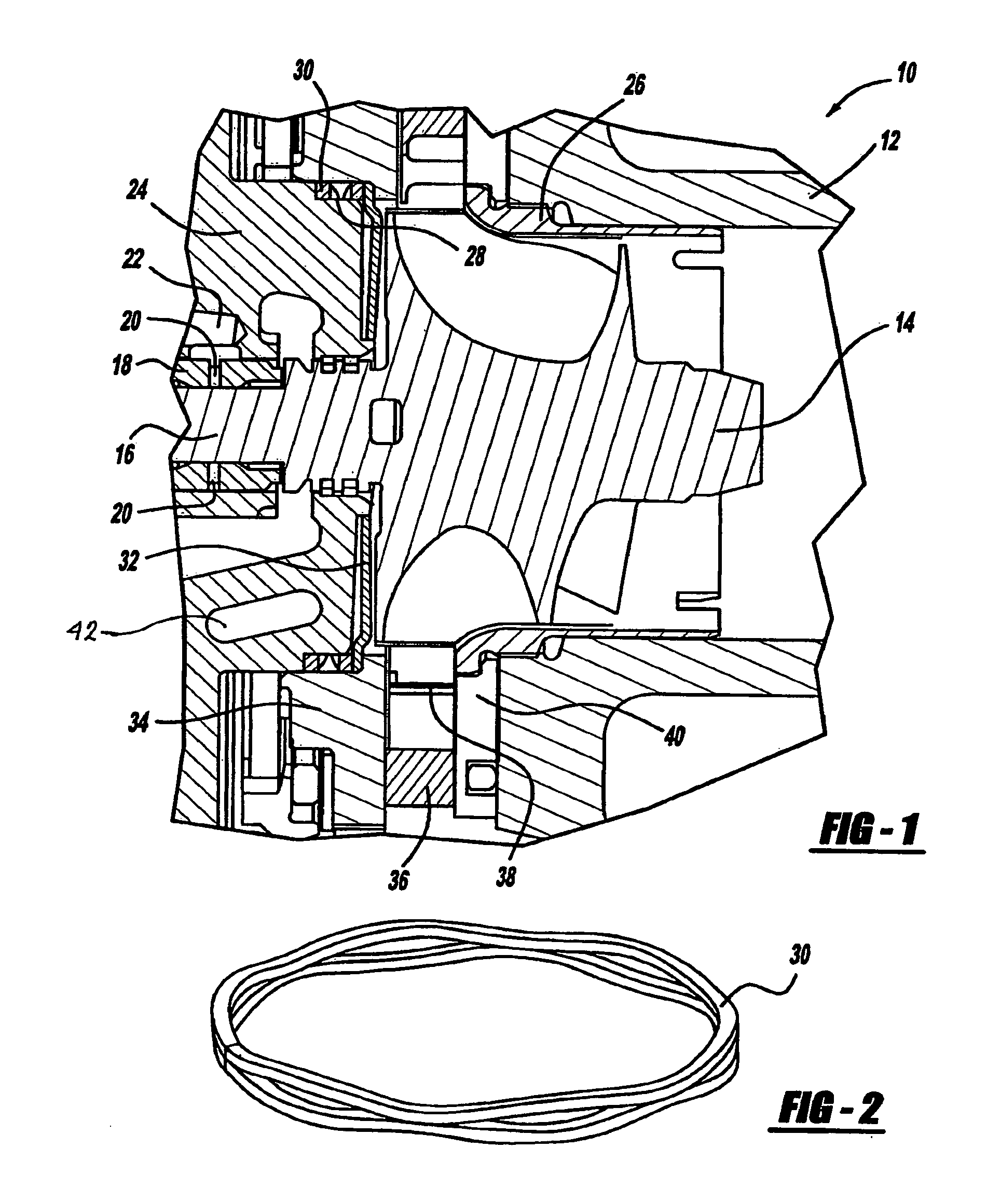

Vtg Mechanism Assembly Using Wave Spring

The present invention is a turbocharger unit (10) incorporating variable turbine geometry. The unit (10) has a turbine for receiving exhaust gases from an engine having a turbine wheel (14) located inside a turbine housing (12), and an intermediate housing (24) connected to the turbine housing (12), having a recessed portion (28). A spring member is located in the recessed portion (28), and a heat shield (32) for receives apply force from the spring member. There is also a cartridge (36) for providing variable turbine geometry located between a first disk (34) and a second disk (40) in the turbine housing (12); the second disk (40) is held in contact with the turbine housing (12) by a contoured sleeve (26). The apply force received by the heat shield (32) from the spring member transfers through the first disk (34), the cartridge (36), and the second disk (40), locating the cartridge (36) in proximate relationship to the turbine wheel (14).

Owner:BORGWARNER INC

Solid rocket ramjet engine gas flow adjusting device

PendingCN107795409ALarge flow adjustment rangeChange trafficRocket engine plantsRam jet enginesRamjetElastomer

The invention discloses a solid rocket ramjet engine gas flow adjusting device. The solid rocket ramjet engine gas flow adjusting device comprises a master controller, a projectile body, a gas generator and a spraying pipe; the spraying pipe comprises a sealing plate and a hollow pipe, an unthreaded hole is formed in the wall of the pipe in the direction vertical to the pipe axis direction, a plunger sliding valve is installed in the unthreaded hole in a sealed manner, and a driving device is arranged on the plunger sliding valve; N through air inlet holes are formed in the sealing plate, theair inlet holes are distributed within the pipe diameter scope, plugging covers capable of sealing and plugging the air inlet holes are arranged in N-1 air inlet holes, and detonation devices capableof detonating the plugging covers are arranged on the plugging covers; and a pressure sensor is installed in a cavity between the pipe outer wall and the projectile body and is electrically connectedwith the master controller, and the master controller is electrically connected with the driving device; and the pressure sensor is electrically connected with the detonation devices. By means of thesolid rocket ramjet engine gas flow adjusting device, a larger flow adjusting scope can be achieved under the non-jamming state and the jamming state of a solid rocket ramjet engine, and the beneficial effects of being low in price, accurate and reliable in work and the like are achieved.

Owner:湖南宏大日晟航天动力技术有限公司

Experimental device for solid-state fluidized mining crushing of natural gas hydrate, and experimental method thereof

The invention discloses an experimental device for solid-state fluidized mining crushing of natural gas hydrate. The experimental device comprises a power liquid supply module, a hydrate suction module, a pipeline conveying module, a hydrate fluidized crushing module, a secondary machining module and an experimental data information collecting and processing module. An experimental method of the experimental device comprises the steps that the power liquid supply module, the hydrate suction module, the pipeline conveying module, the hydrate fluidized crushing module and the secondary machiningmodule are started; and the experimental data information collecting and processing module collects pressure and flow data at multiple positions. The experimental device for solid-state fluidized mining crushing of the natural gas hydrate, and the experimental method thereof have the beneficial effects that a flow-jet solid fluidized mining process is simulated, meanwhile, a plurality of pressureand flow detecting points and crushed sample sampling openings are formed, and thus parameter collecting is conducted conveniently; the parameters of the multiple parts are flexible and variable andcomprise change of the dragging-back speed of a movable sliding block, the shape parameters of jet flow nozzles and the power liquid pressure and flow rate; and the experimental device is simplified through the design of spraying heads, and thus the dynamic process of jet flow crushing can be observed from the side face of an experimental groove.

Owner:SOUTHWEST PETROLEUM UNIV

Article and manifold for thermal adjustment of a turbine component

ActiveUS20170051612A1Change trafficGood thermal contactContinuous combustion chamberEngine manufactureEngineeringTurbine

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com