Experimental device for solid-state fluidized mining crushing of natural gas hydrate, and experimental method thereof

An experimental device, solid-state fluidization technology, applied in cyclone devices, chemical instruments and methods, measuring devices, etc., can solve the problems of high cost, complex structure, secondary crushing and separation of hydrate particles, and achieve simplified design, The effect of convenient parameter collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

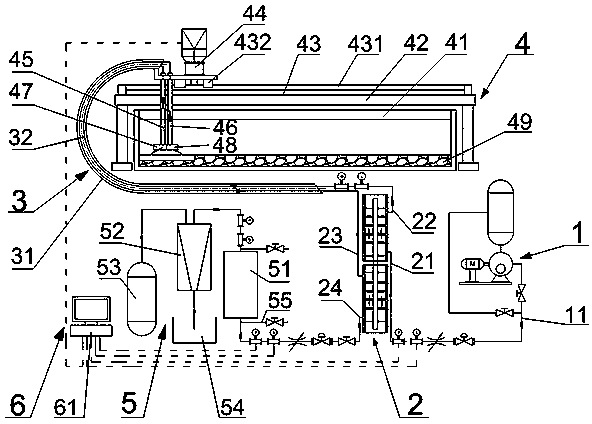

[0037] Such as figure 1 and figure 2 As shown, the present invention provides a natural gas hydrate solid fluidization mining crushing experimental device, the experimental device includes: power fluid supply module 1, hydrate suction module 2, pipeline delivery module 3, hydrate fluidization crushing module 4 , secondary processing module 5 and experimental data information collection and processing module 6.

[0038] Among them, the power fluid supply module 1, which generates power fluid to provide power for the hydrate suction module 2 and the hydrate fluidization crushing module 4; Hydrate; the pipeline transport module 3, which includes an input pipeline 31 and an output pipeline 32, the input pipeline 31 transports the power fluid to the hydrate fluidization crushing module 4, and the output pipeline 32 transports the crushed hydrate to the hydrate suction module 2; The materialized crushing module 4 comprises an experimental tank 41, a support frame 42 placed above ...

specific Embodiment 2

[0045] Such as figure 1 As shown, according to the first embodiment, it can be further improved that the power fluid outlet 11 of the power fluid supply module 1 and or the fluid output port 24 of the hydrate suction module 2 are equipped with a flow and or pressure regulating device.

[0046] The experimental method of the improved experimental device is the same as the experimental method of the specific embodiment 1. The improvement of this embodiment is to change the pressure and flow of multiple points, including the pressure and flow of the power fluid outlet 11 and or the fluid output port 24, To find the best pressure and flow parameters of the experimental device.

specific Embodiment 3

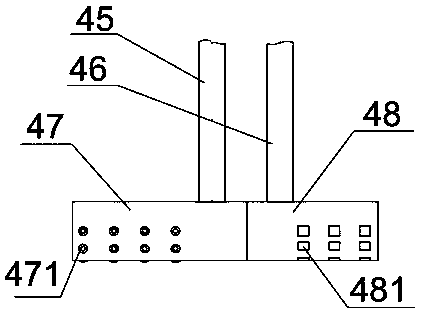

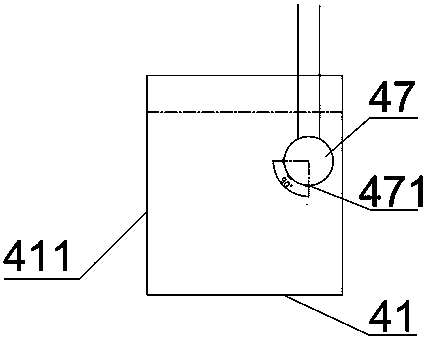

[0047] Such as figure 1 , figure 2 and Figure 4 As shown, according to the first embodiment, the further improvement is that the vertical heights of the high pressure jumper pipe 45 and the suction jumper pipe 46 can be adjusted through the clamp 433 fixed on the moving slider 432 . The jet nozzle 471 is fixed on the spray head 47 through threads, and the spray head 47 is fixed on the high pressure jumper pipe 45 through threads; the recovery head 48 is fixed on the suction jumper pipe 46 through threads.

[0048] The experimental method of the improved experimental device is the same as the experimental method of the specific embodiment one. The improvement of this embodiment is that the high-pressure jumper 45, the suction jumper 46, the spray nozzle 47, the jet nozzle 471 and the recovery head are detachable to realize Multiple parameters can be adjusted, including adjusting the distance between the jet nozzle 471 and the sample 49, and replacing the jet nozzle 471 and / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com