Patents

Literature

964results about "Vortex flow apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

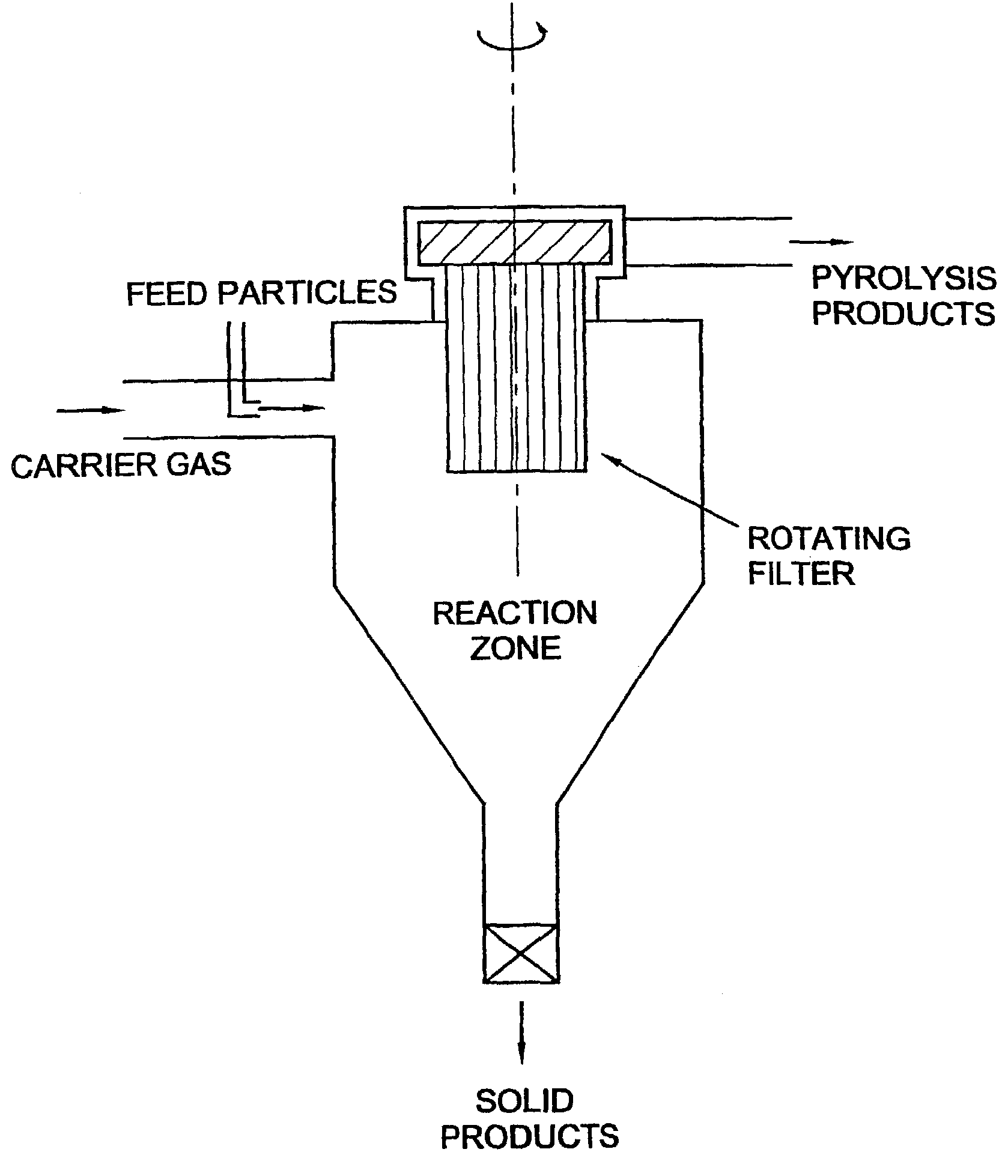

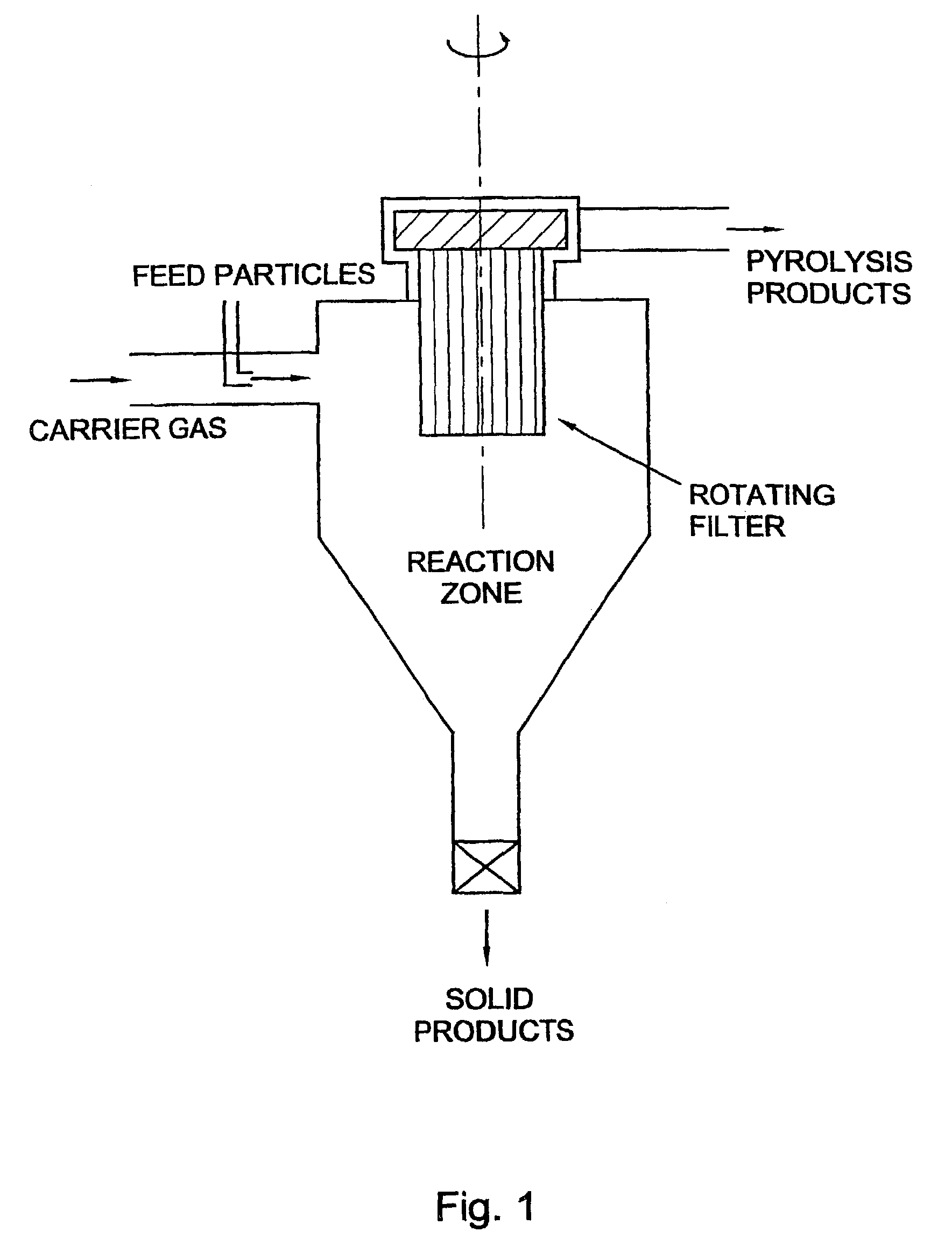

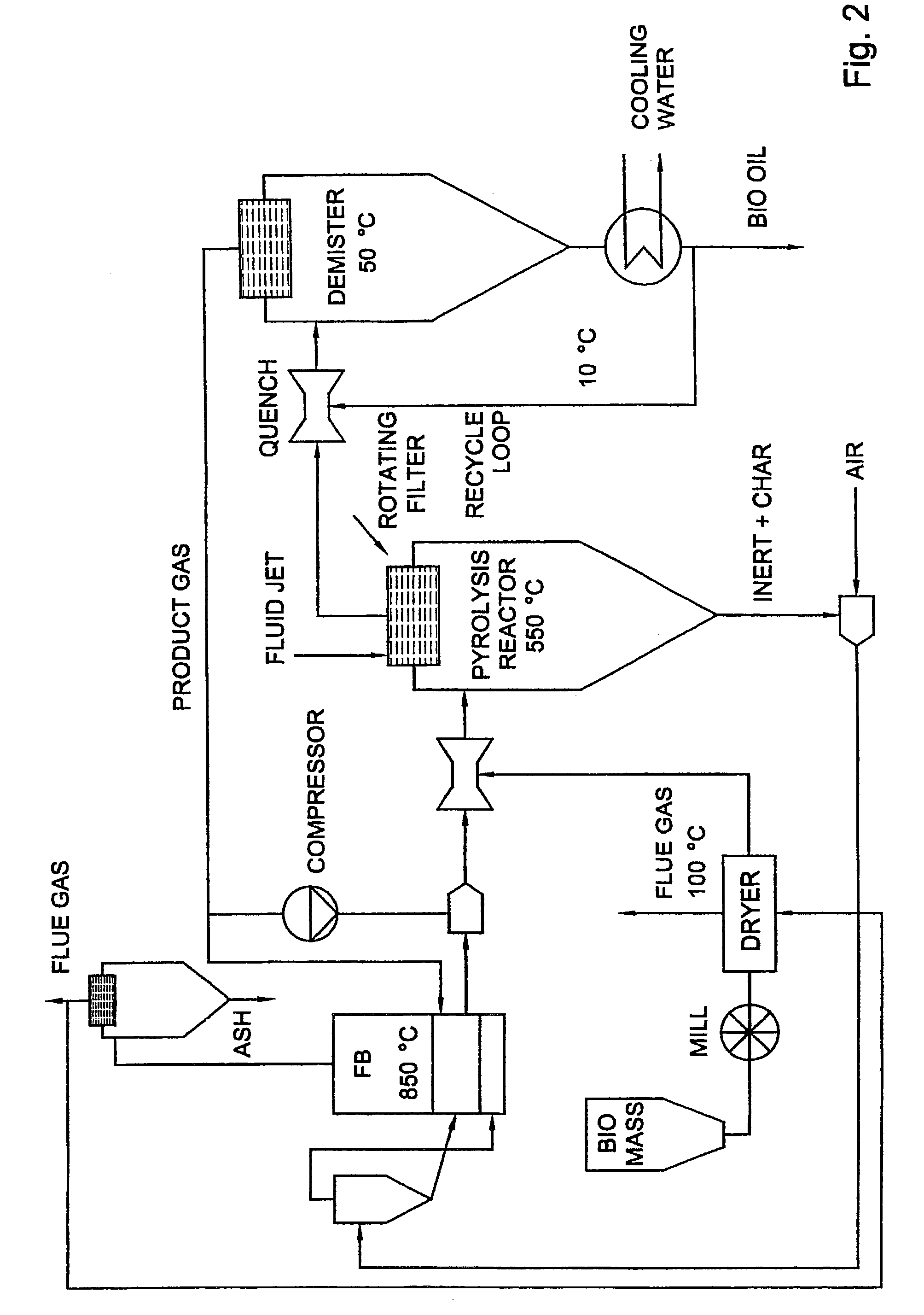

Flash-pyrolysis in a cyclone

InactiveUS7202389B1Excessive crackingCombination devicesDispersed particle filtrationParticulatesCyclone

A process for the pyrolysis of carbonaceous material is carried out in a cyclone reactor which is fitted with enhanced filtering equipment. In addition the invention relates to the use of a cyclone fitted with a rotating filter as a pyrolysis reactor. By using a cyclone of the rotating separator type as a pyrolysis reactor, carbonaceous material, such as biomass, can effectively be converted in a product having excellent chemical properties and which product is free from particulate matter.

Owner:UNIVERSITY OF TWENTE

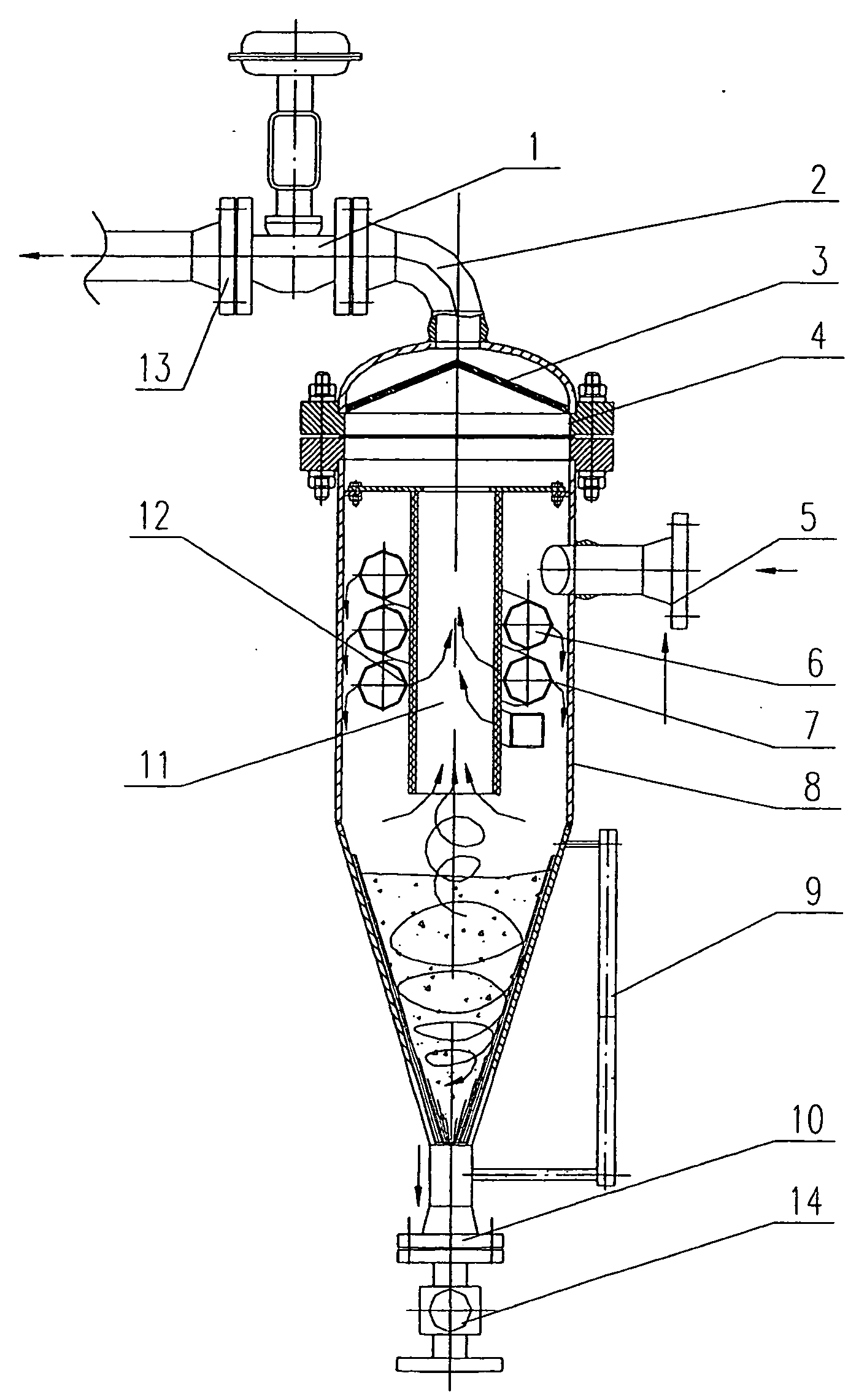

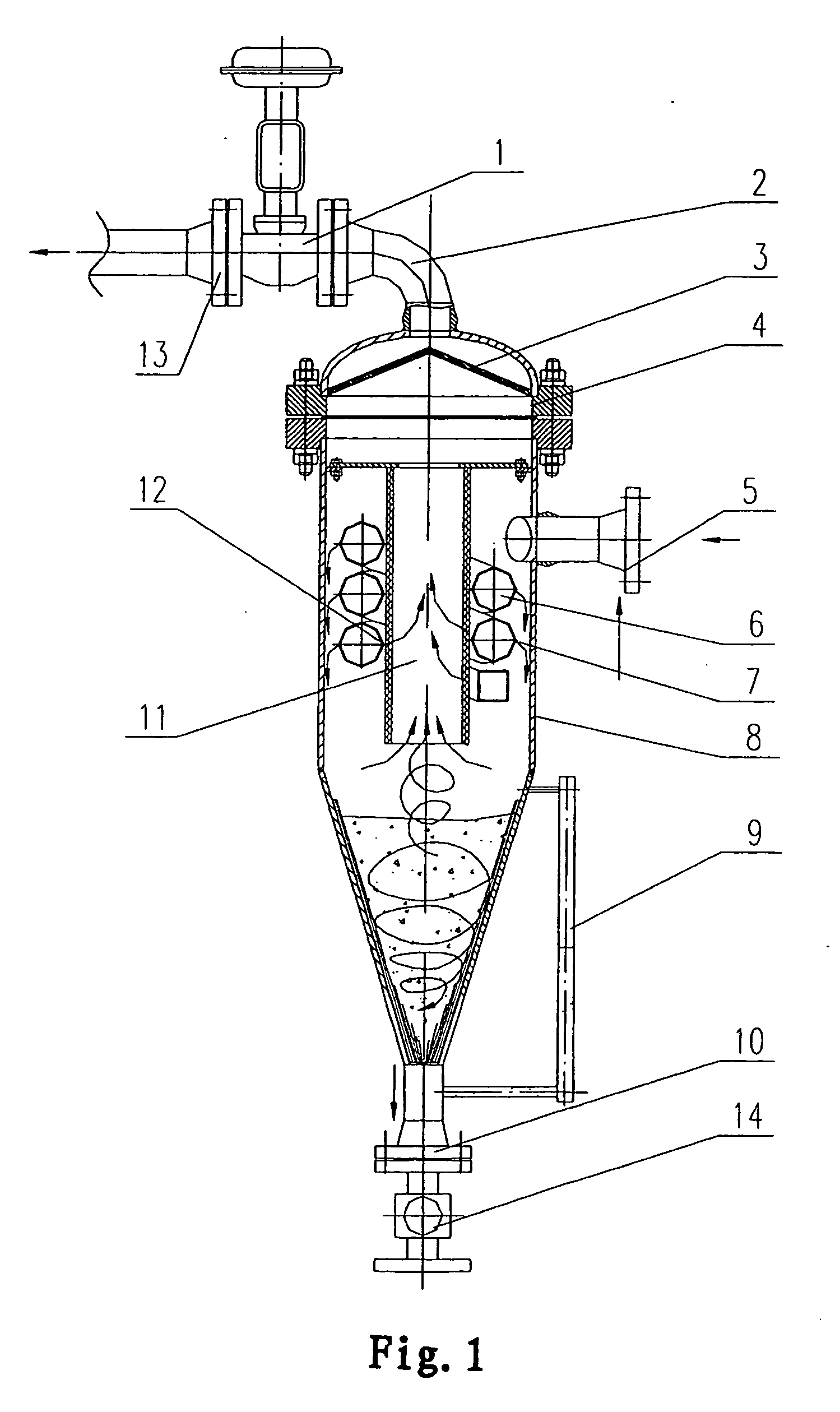

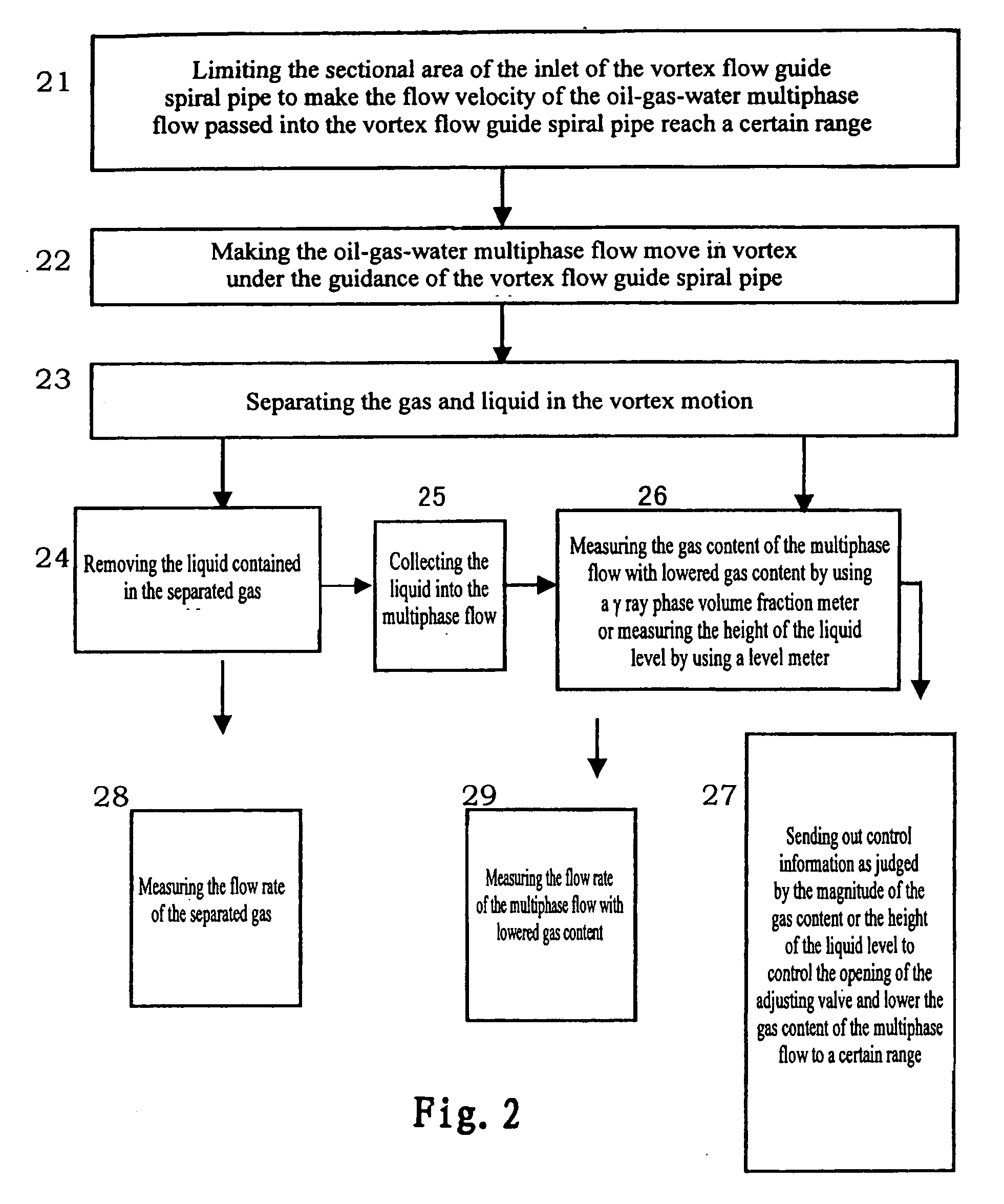

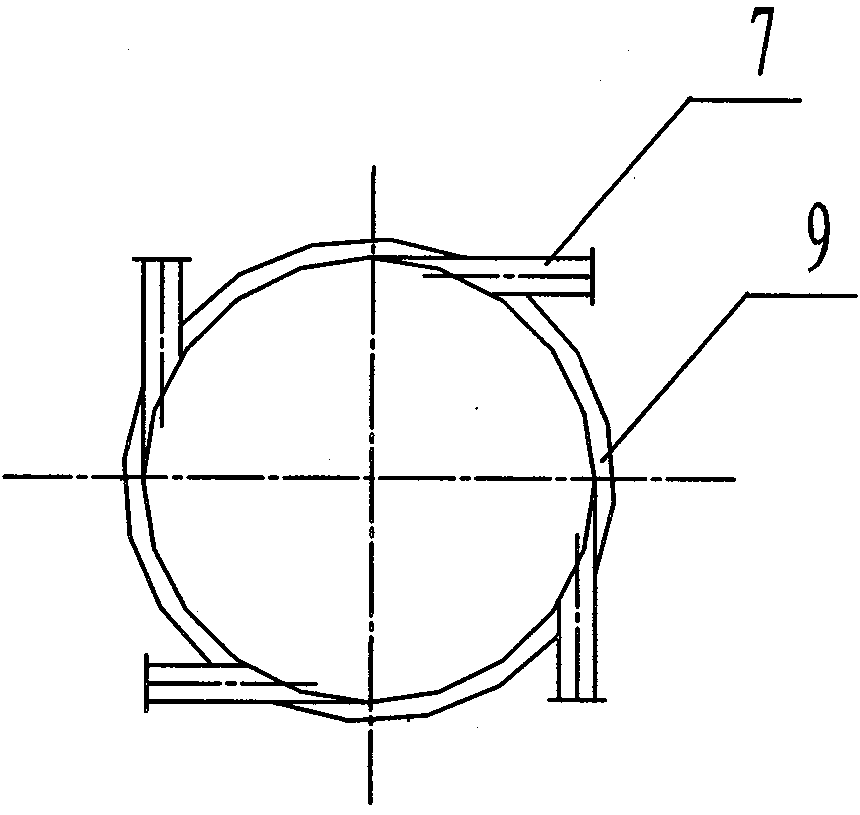

Adjustable gas-liquid centrifugal separator and separating method

ActiveUS20070084340A1Reduce gas contentSmall volumeCombination devicesLiquid degasificationEngineeringPhase volume

An adjustable type guide vortex gas-liquid separating apparatus is provided, it comprises a case, a vortex flow guide spiral pipe, a mist eliminator, an adjusting valve and a γ ray phase volume fraction meter. Its separating method is to make the oil-gas-water multiphase flow move in vortex, and thus to realize the gas-liquid separation, then to measure the gas content of the separated liquid phase by using the γ ray phase volume fraction meter and to send out control information as judged by the magnitude of the gas content in the liquid phase, so as to control the opening of the adjusting valve of the gas circuit, thus to achieve adjustment of the gas-liquid separation effects, and to control the gas content of the liquid phase to a certain range.

Owner:HAIMO TECH INC

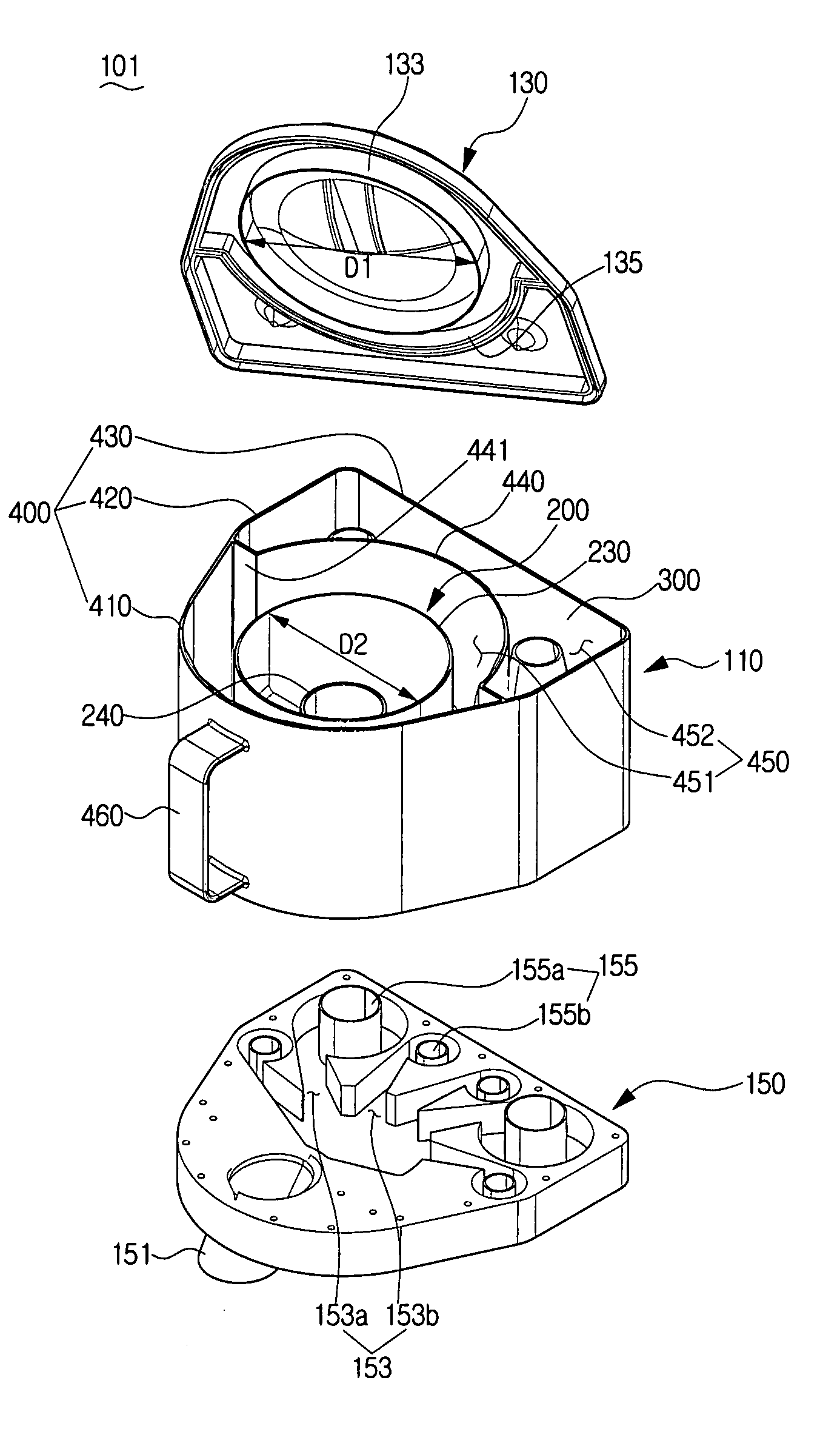

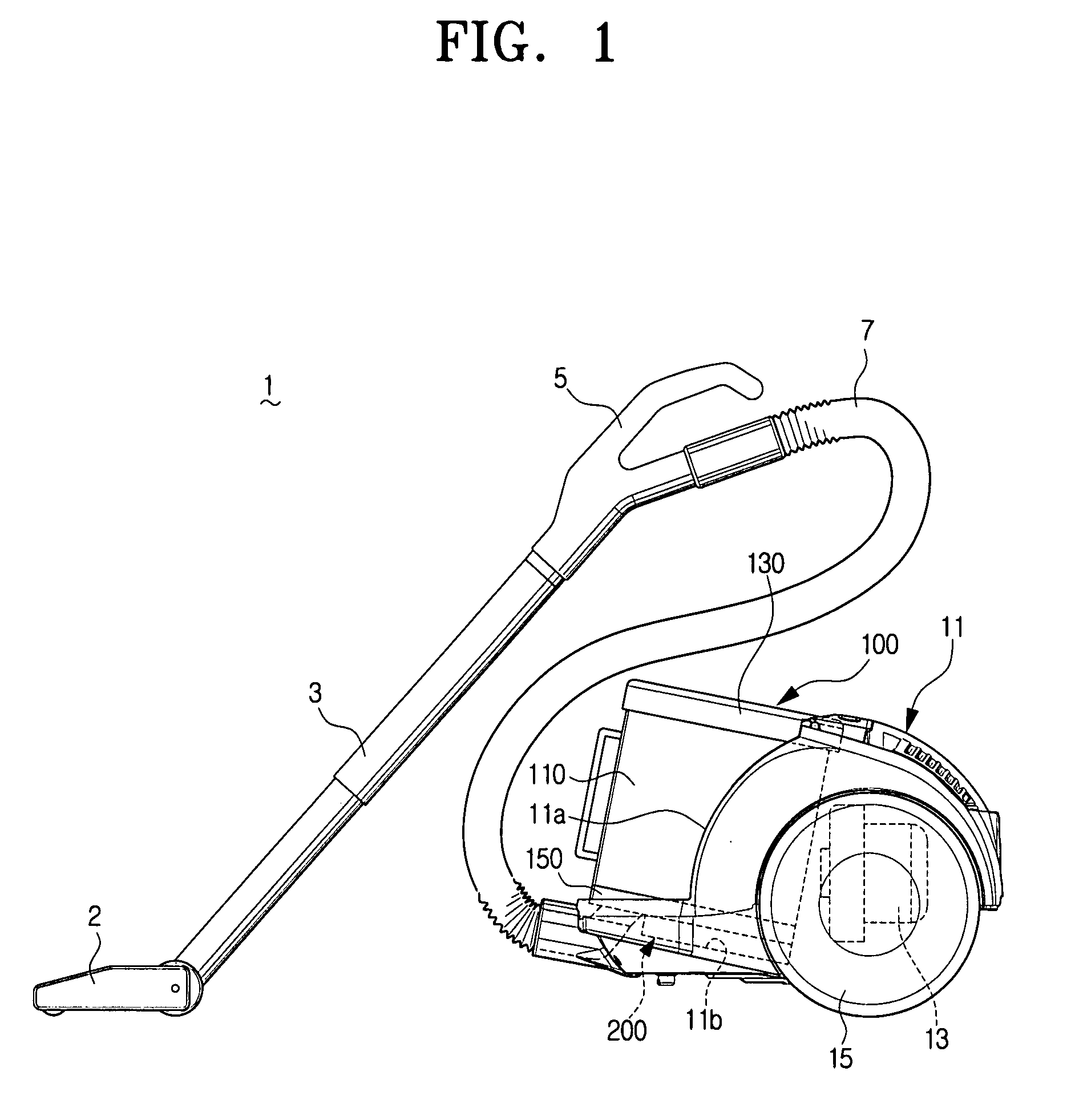

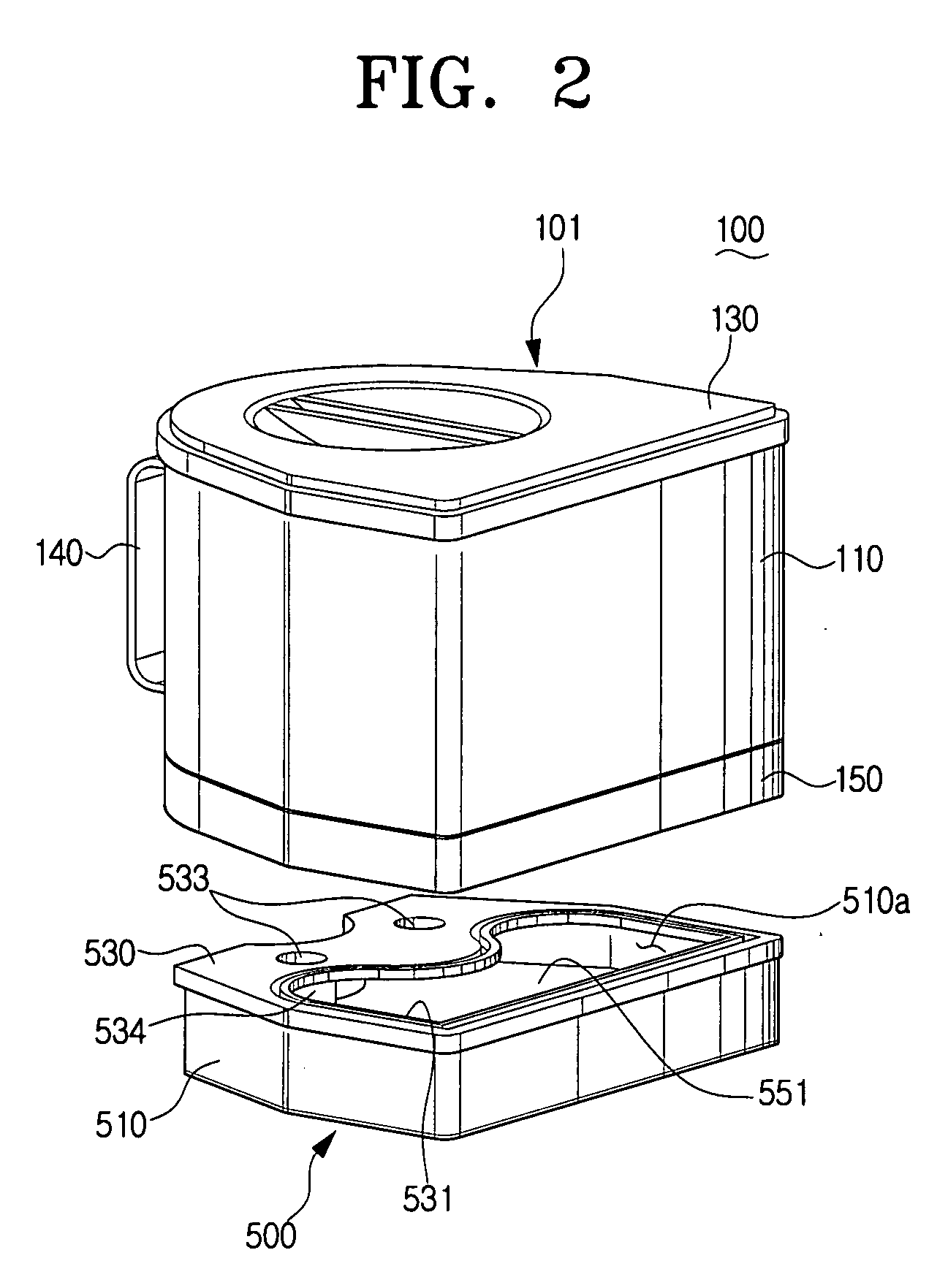

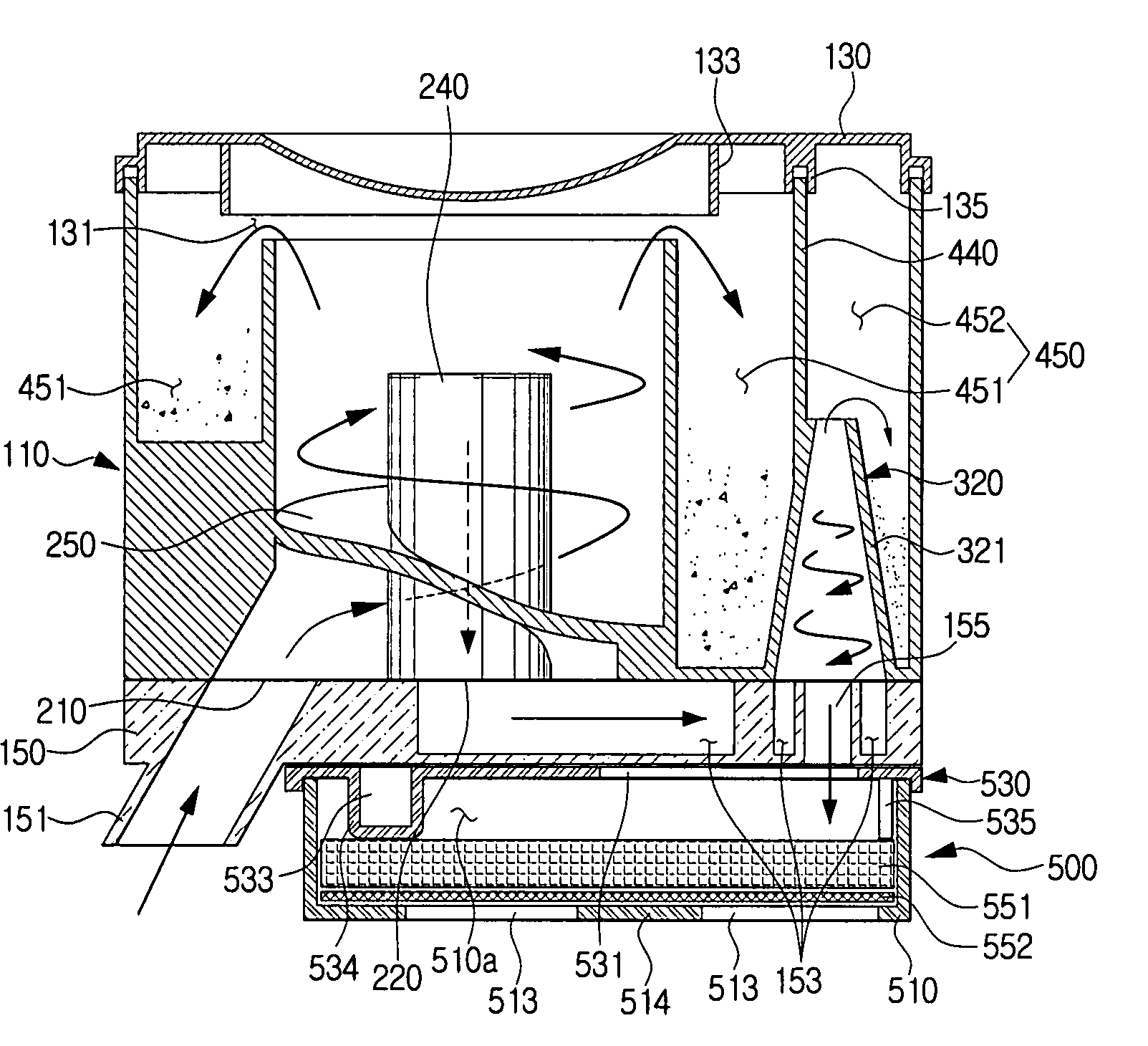

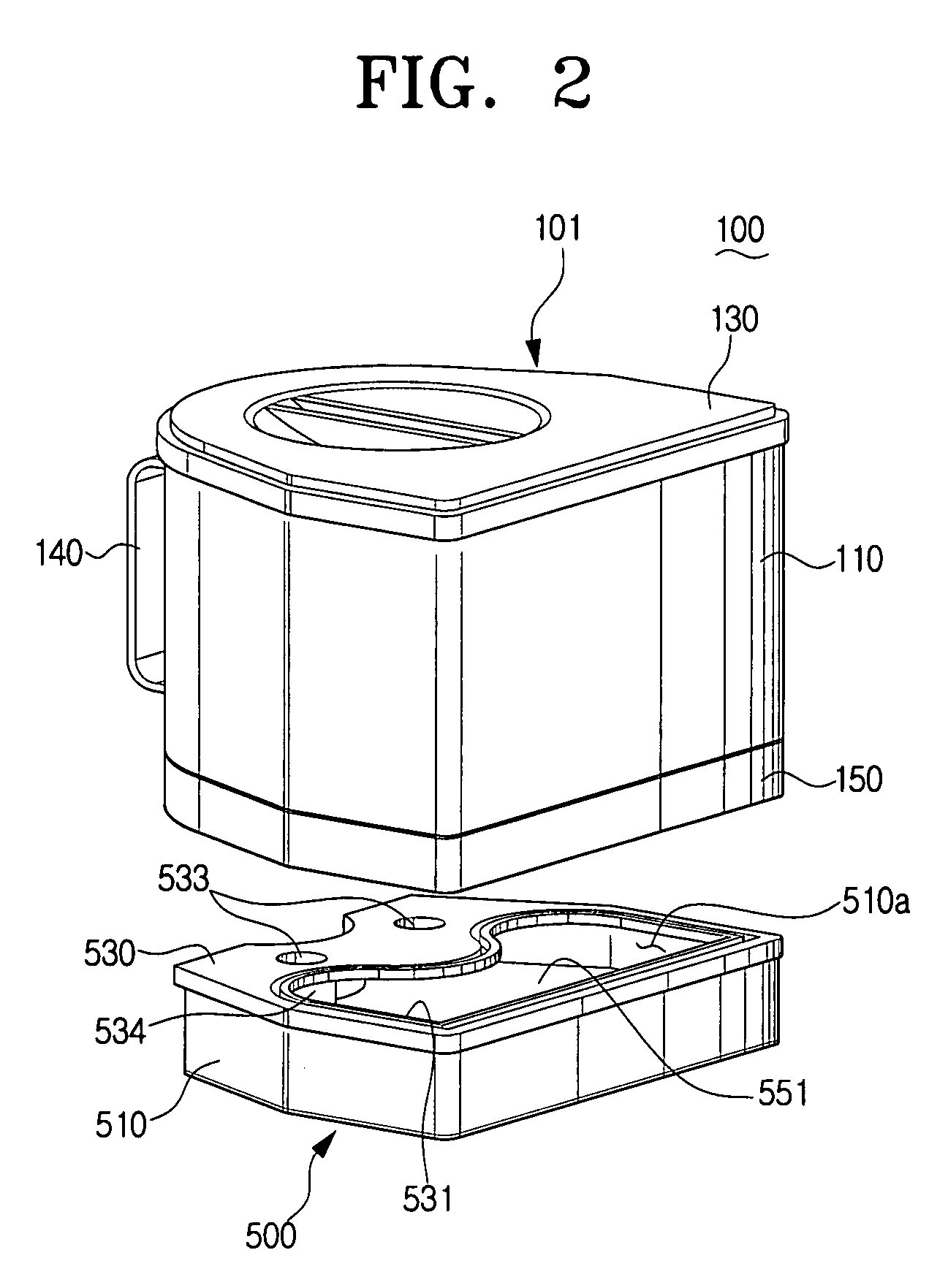

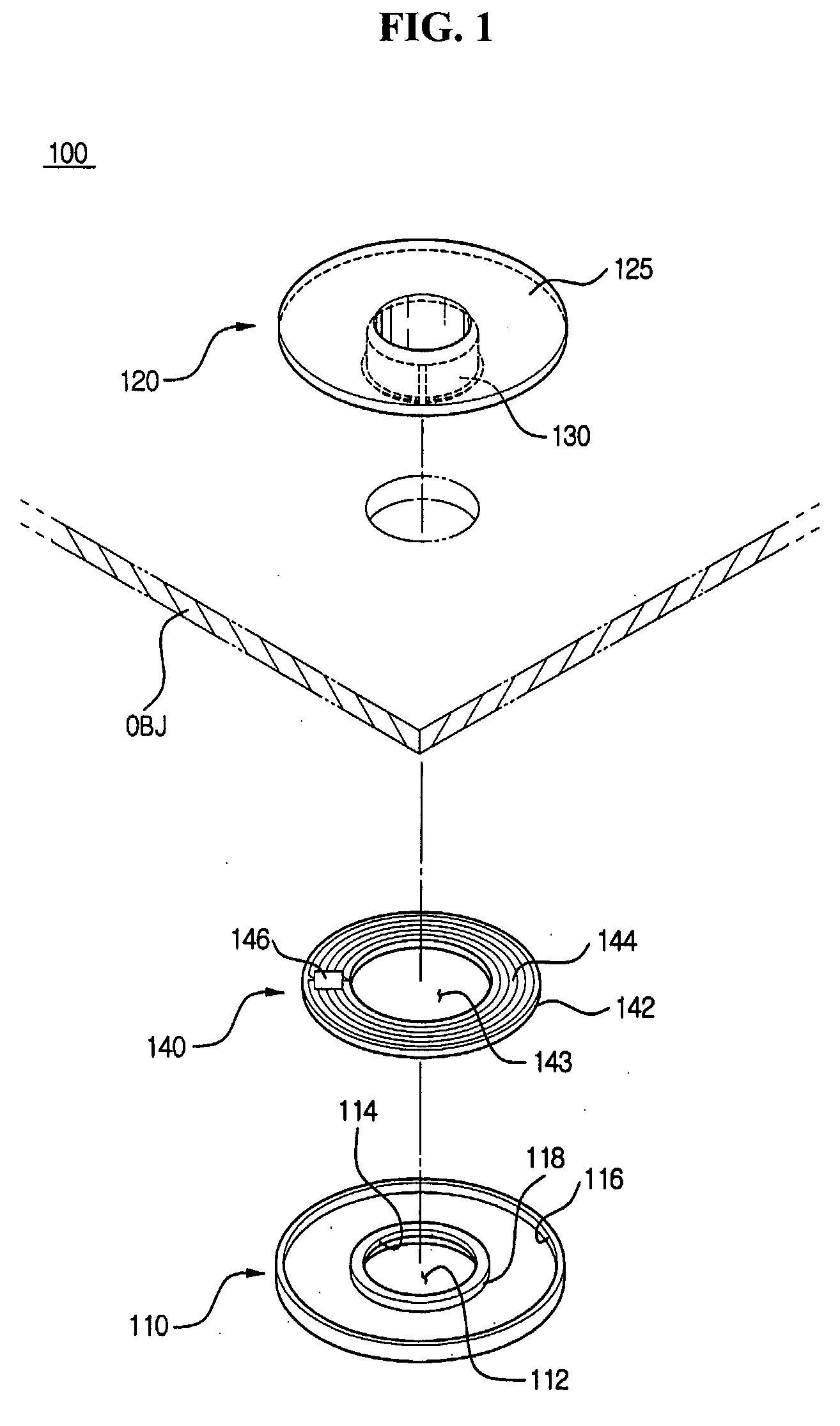

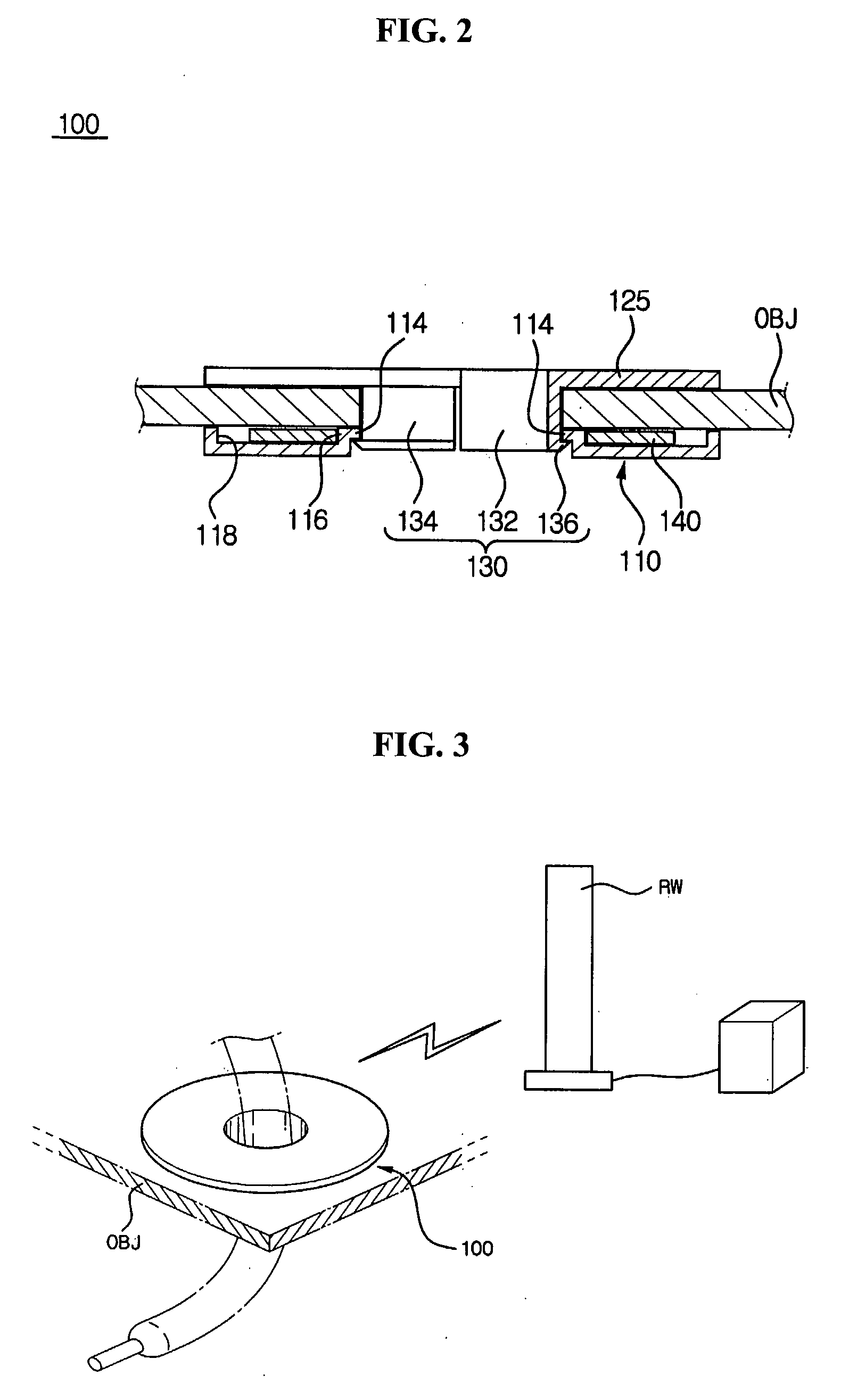

Multi-cyclone dust separating apparatus having a filter assembly

A multi-cyclone dust separating apparatus includes a cyclone unit and a separable filter assembly adapted to be disposed at least partially in a discharge path of the cyclone unit. The cyclone unit includes a main cyclone, a secondary cyclone adapted to be disposed at substantially a same plane as the main cyclone, and a dust collecting casing adapted to substantially surround the main cyclone and the secondary cyclone. The dust collecting casing includes a dust chamber to collect dust separated at the main cyclone and the secondary cyclone.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

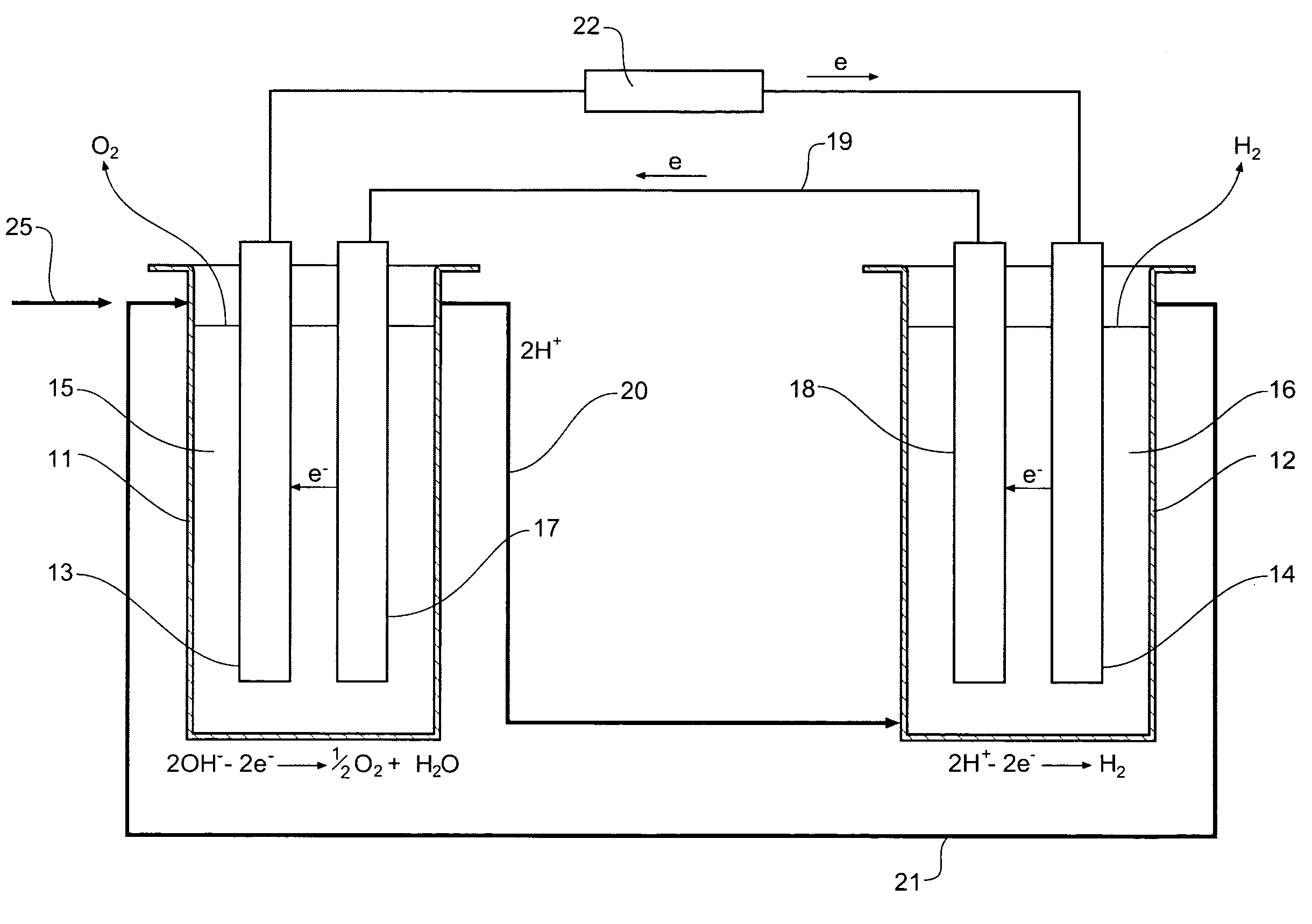

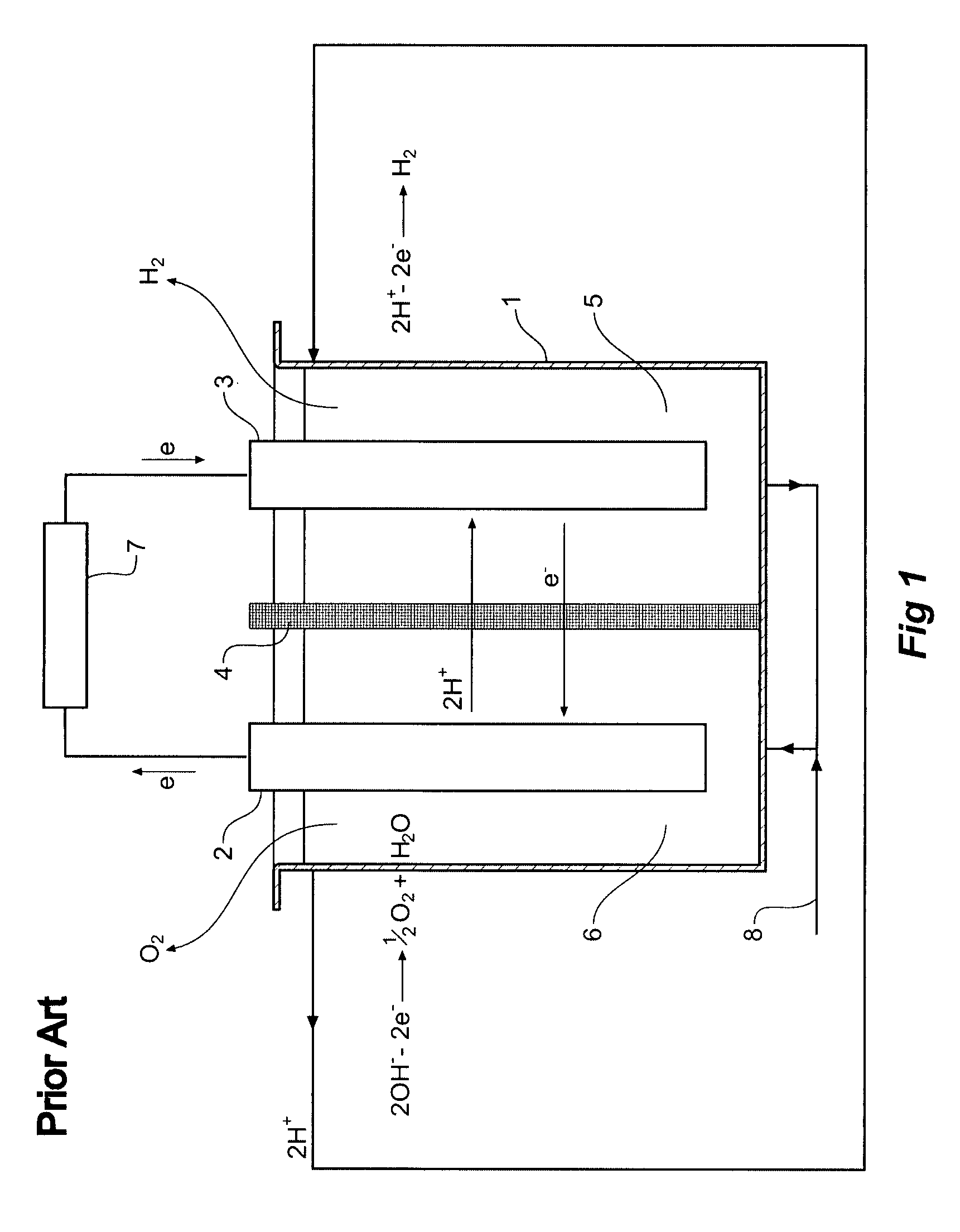

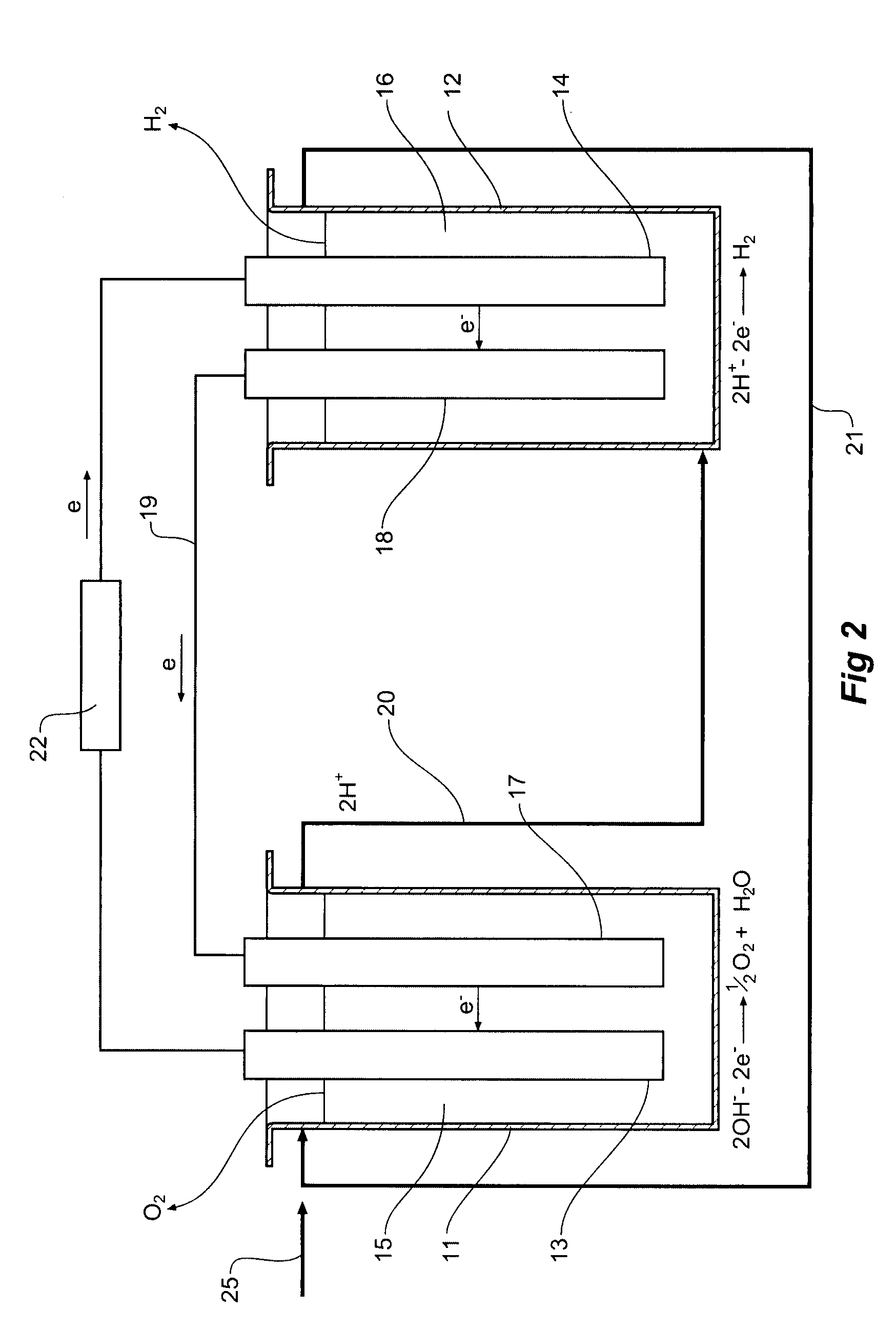

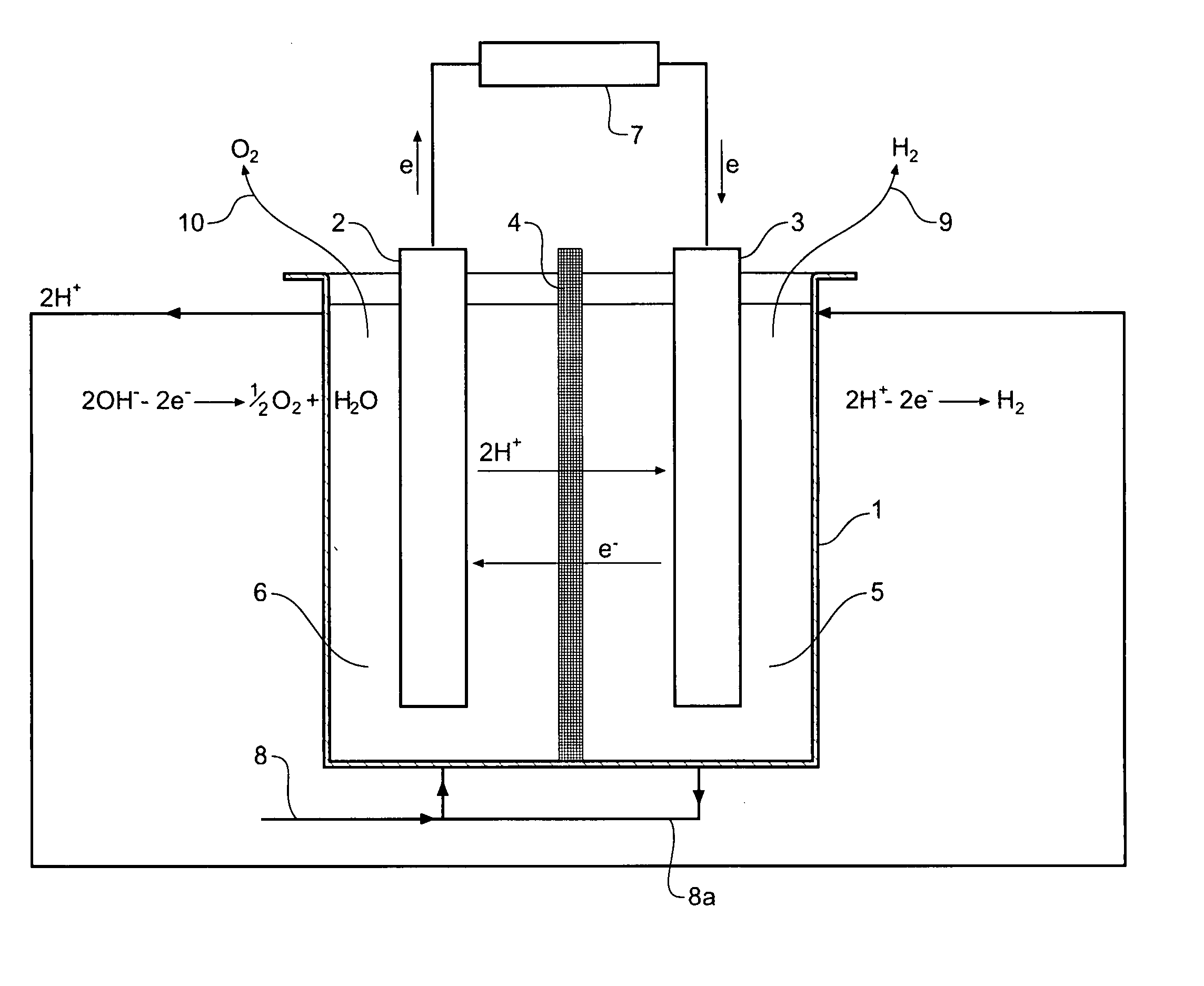

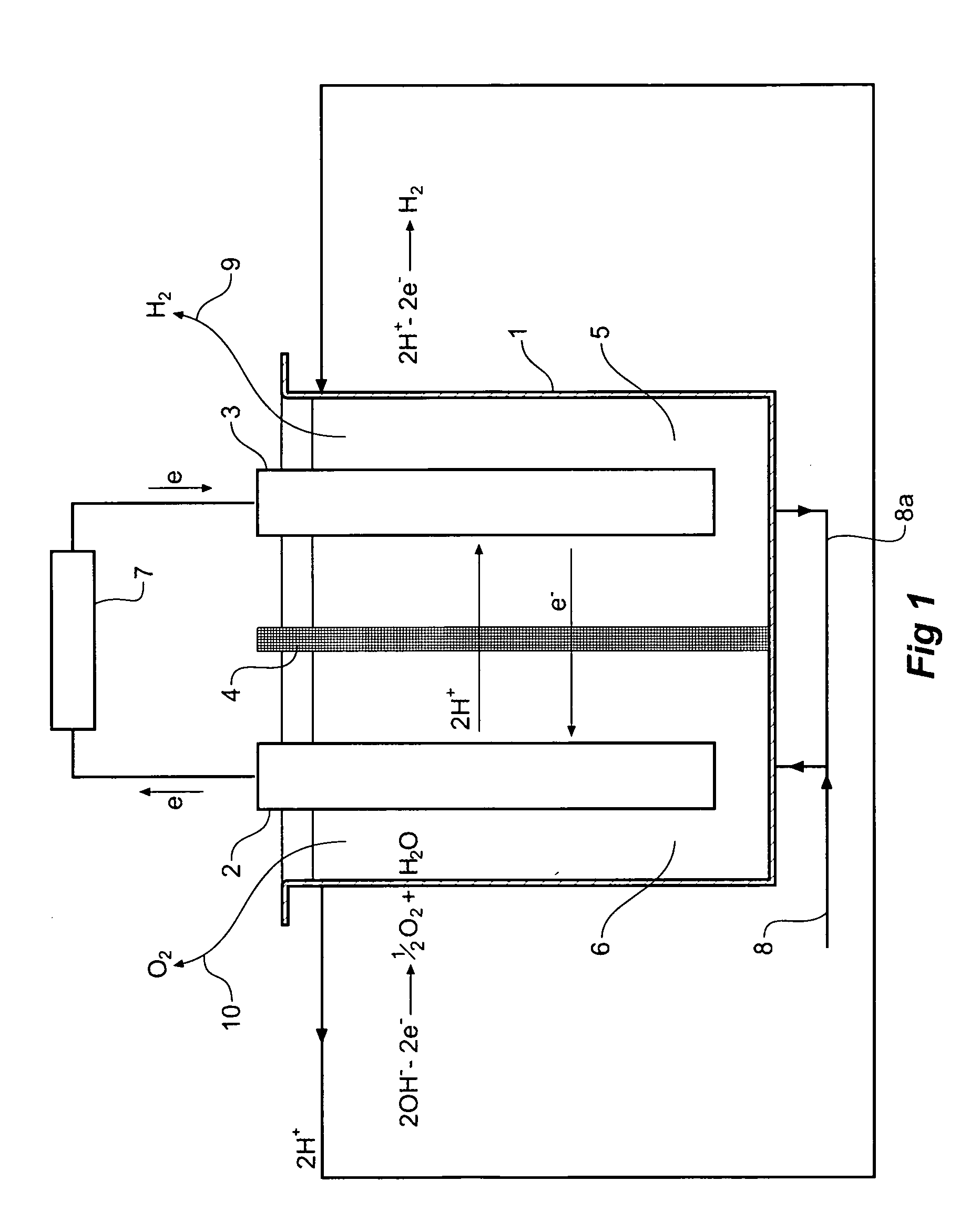

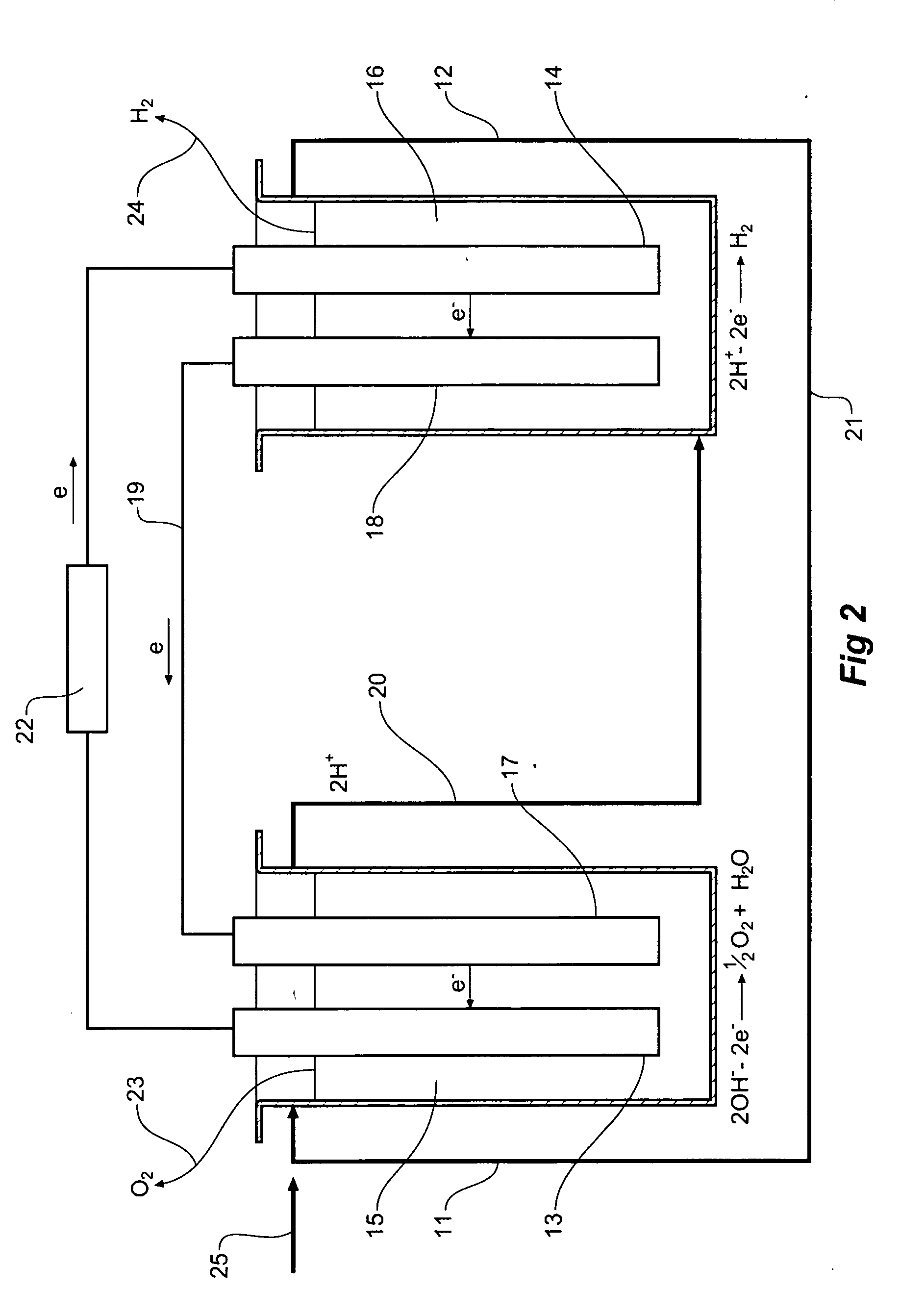

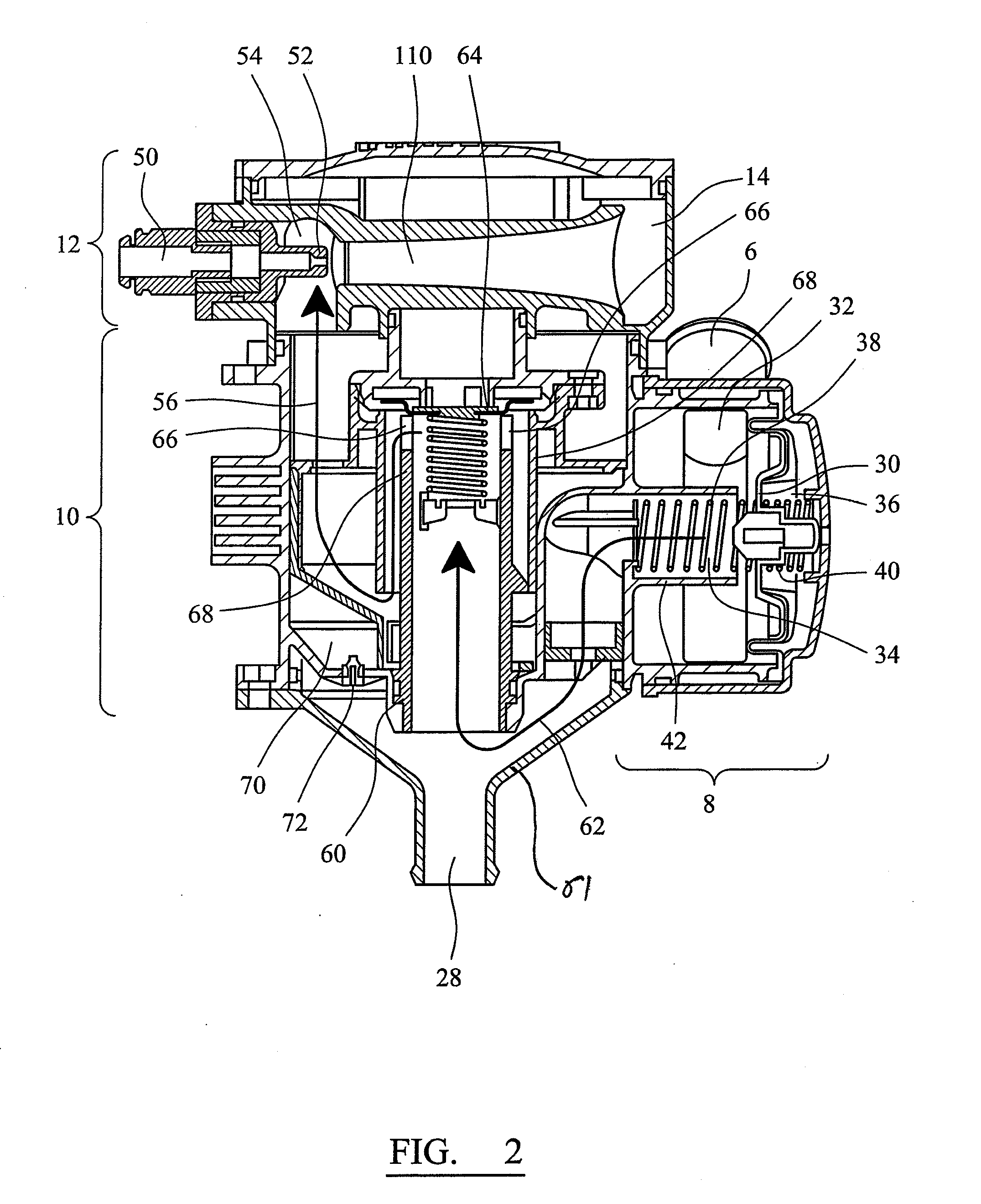

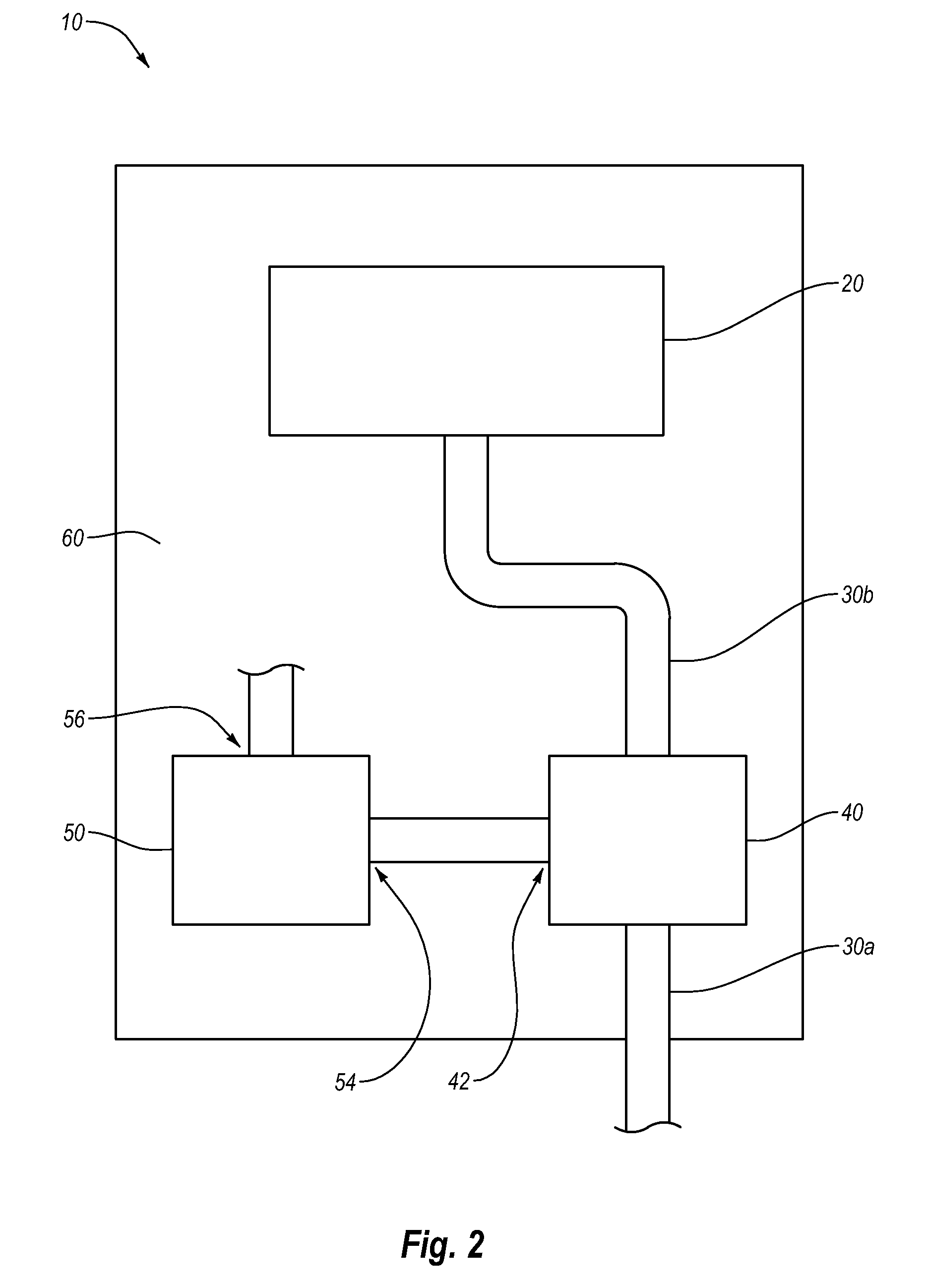

Commercial production of hydrogen from water

InactiveUS7326329B2Minimizing energyReduce voltageCellsPhotography auxillary processesWater useElectrical conductor

Large quantities of low cost hydrogen free of carbon oxides are required as fuel for the hydrogen economy. Commercial quantities of hydrogen can be produced from the electrolysis of water using a diaphragm-less electrolytic cell. The electrolytic cell has an anode cell (31) and a cathode cell (32) connected by a DC power source (53) and an external conductor (52). An alternate apparatus method to produce hydrogen is to electrolyze water using unipolar activation. Unipolar activation uses separate anode and cathode circuits and can use secondary cathode (132) and anode (139) cells to recover energy and produce further hydrogen.

Owner:RODOLFO ANTONIO M GOMEZ

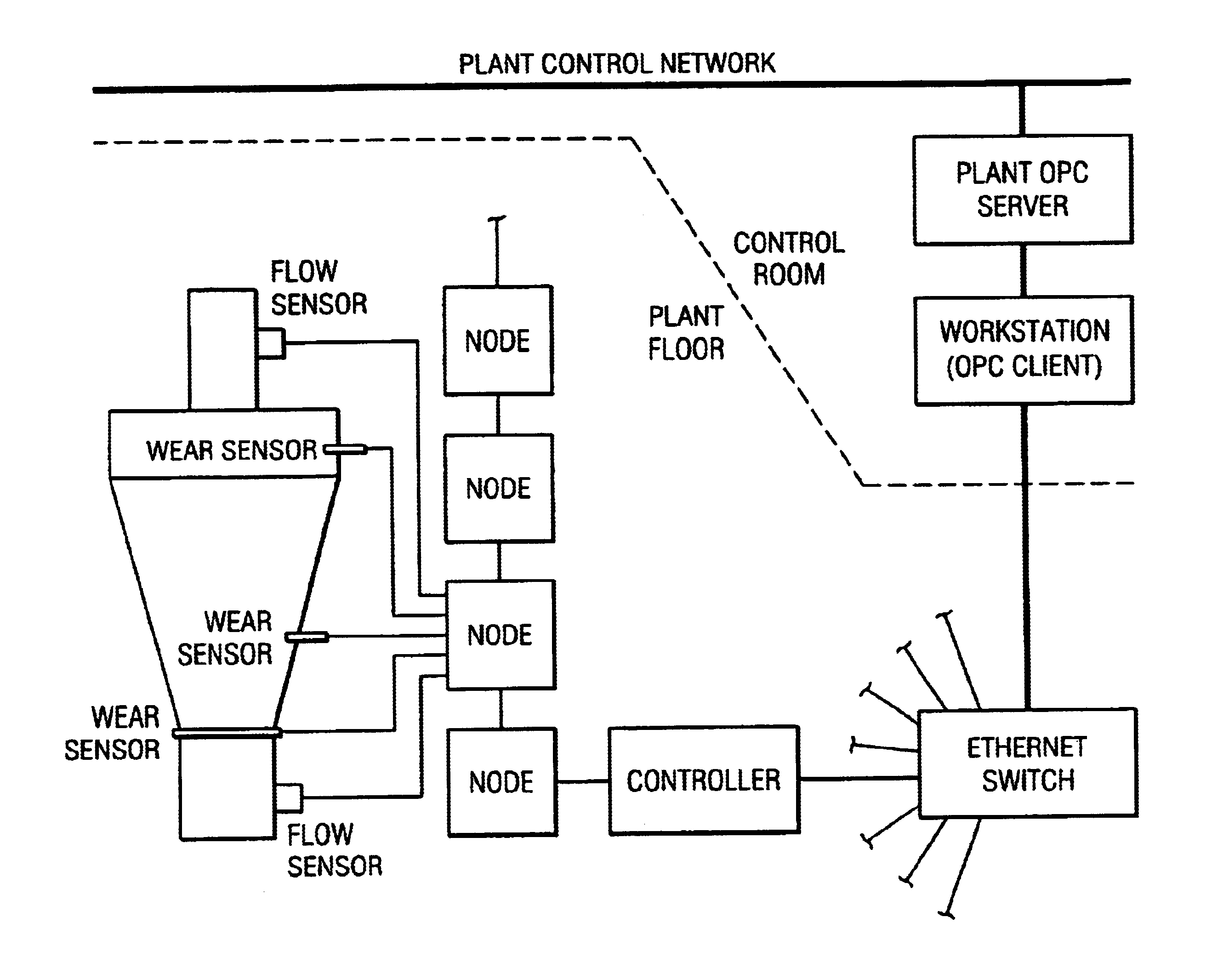

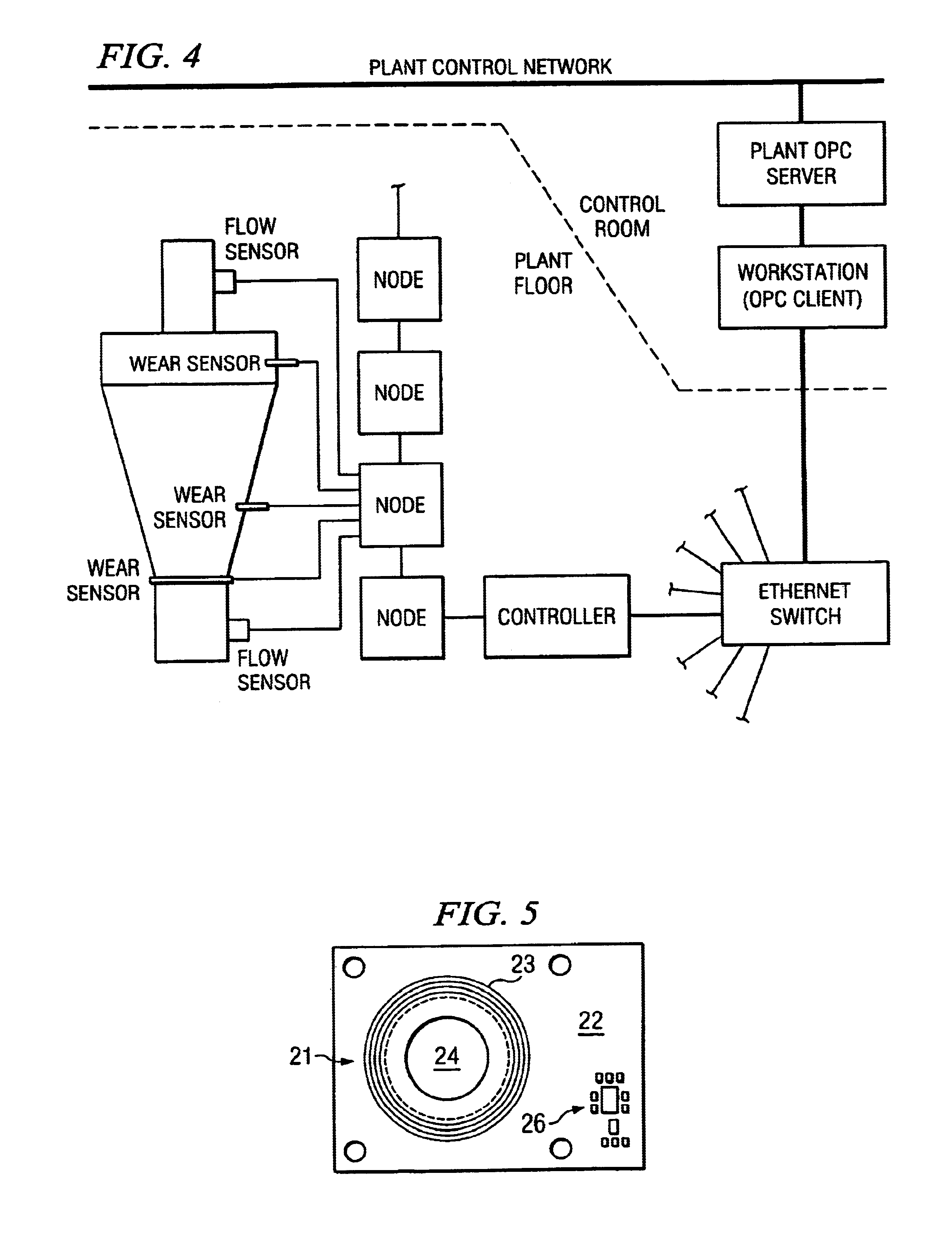

Hydrocyclone wear-detection sensor

Wear-detection sensor has a body of electrically insulating material with an opening through which a flowable substance can pass, and one or more electrical conductors surrounding the opening and adapted to undergo a discernable change in conductivity as the insulating material is worn away by the flowable substance.

Owner:KREBS ENGINEERS CORP +1

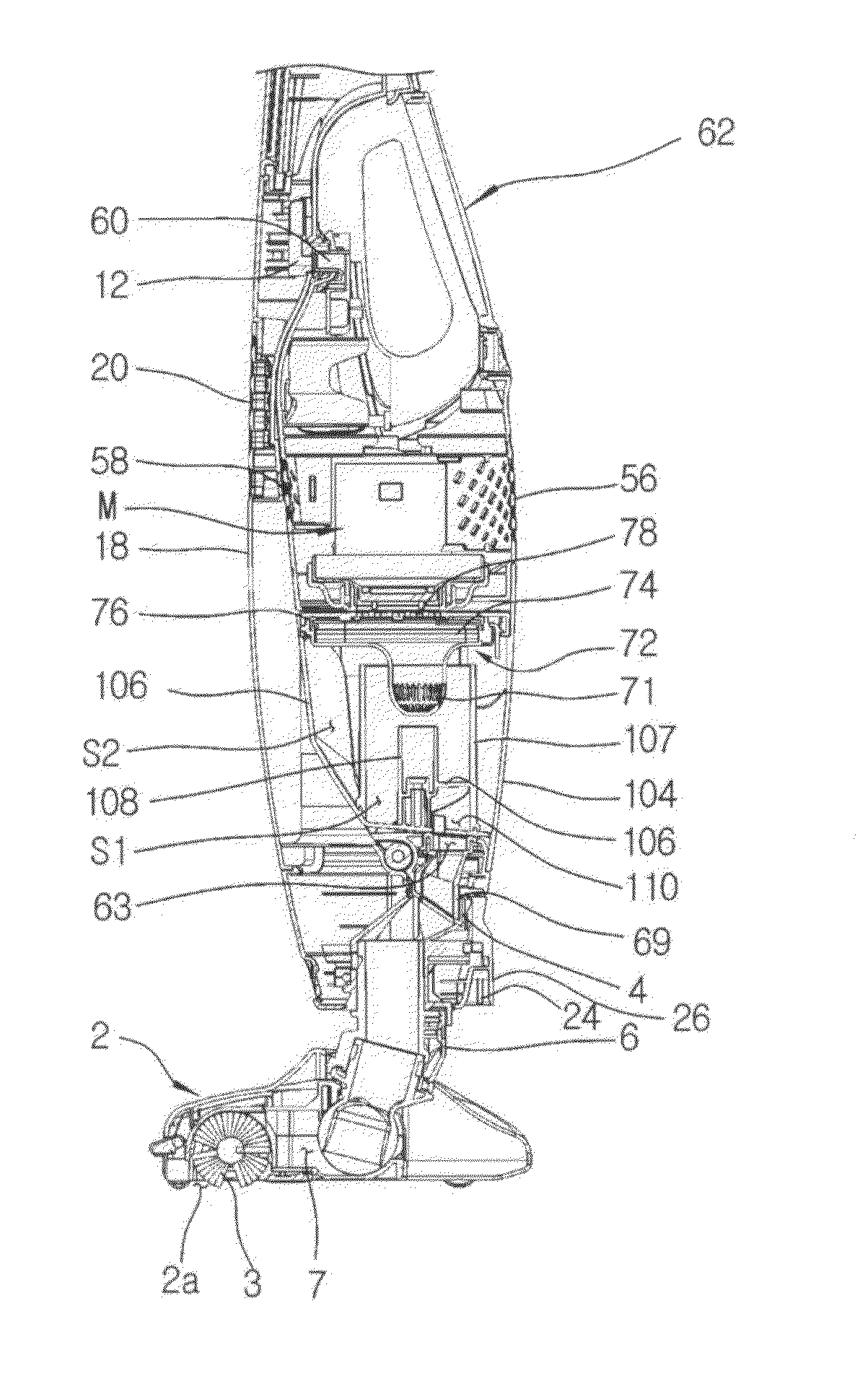

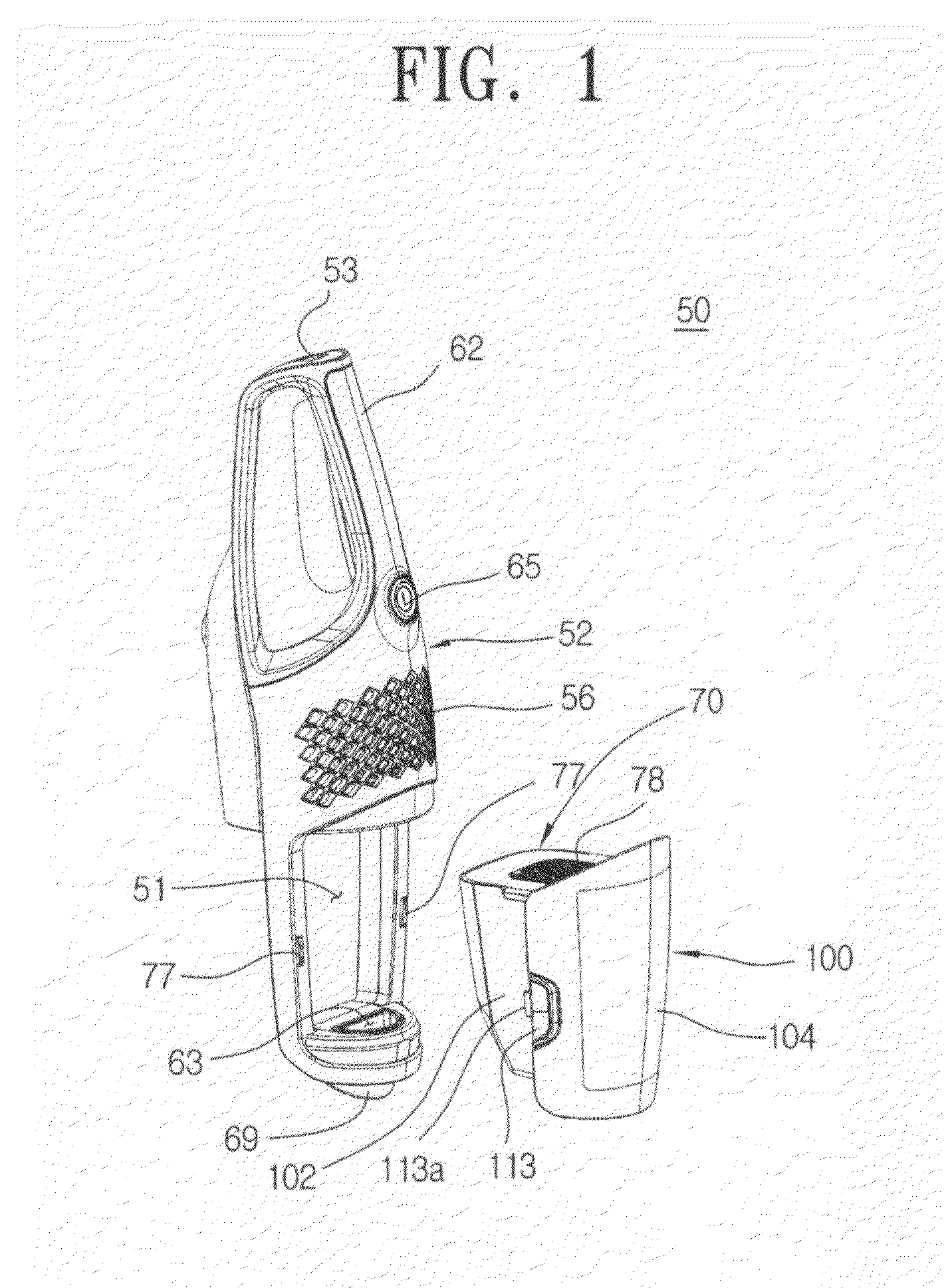

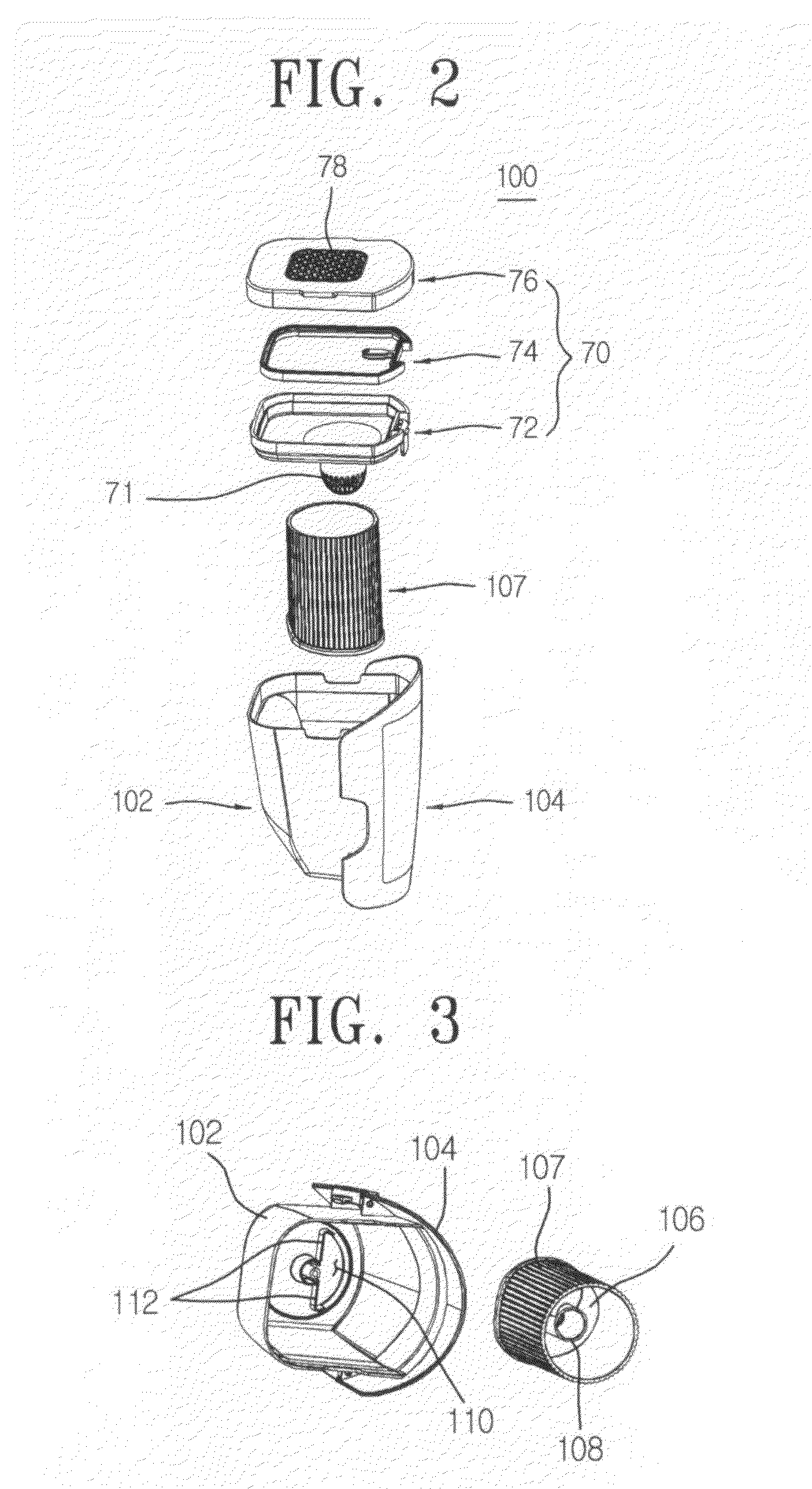

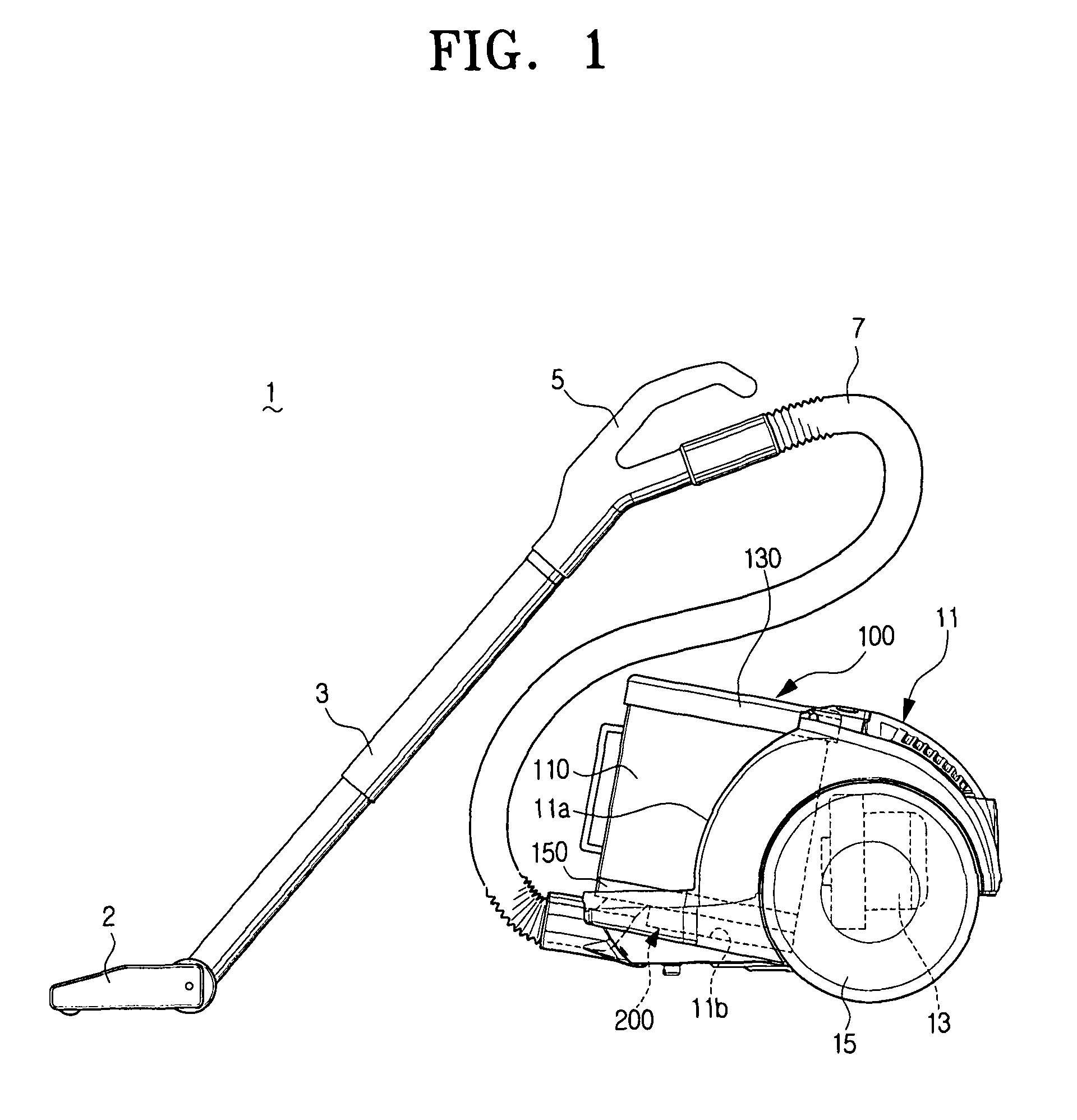

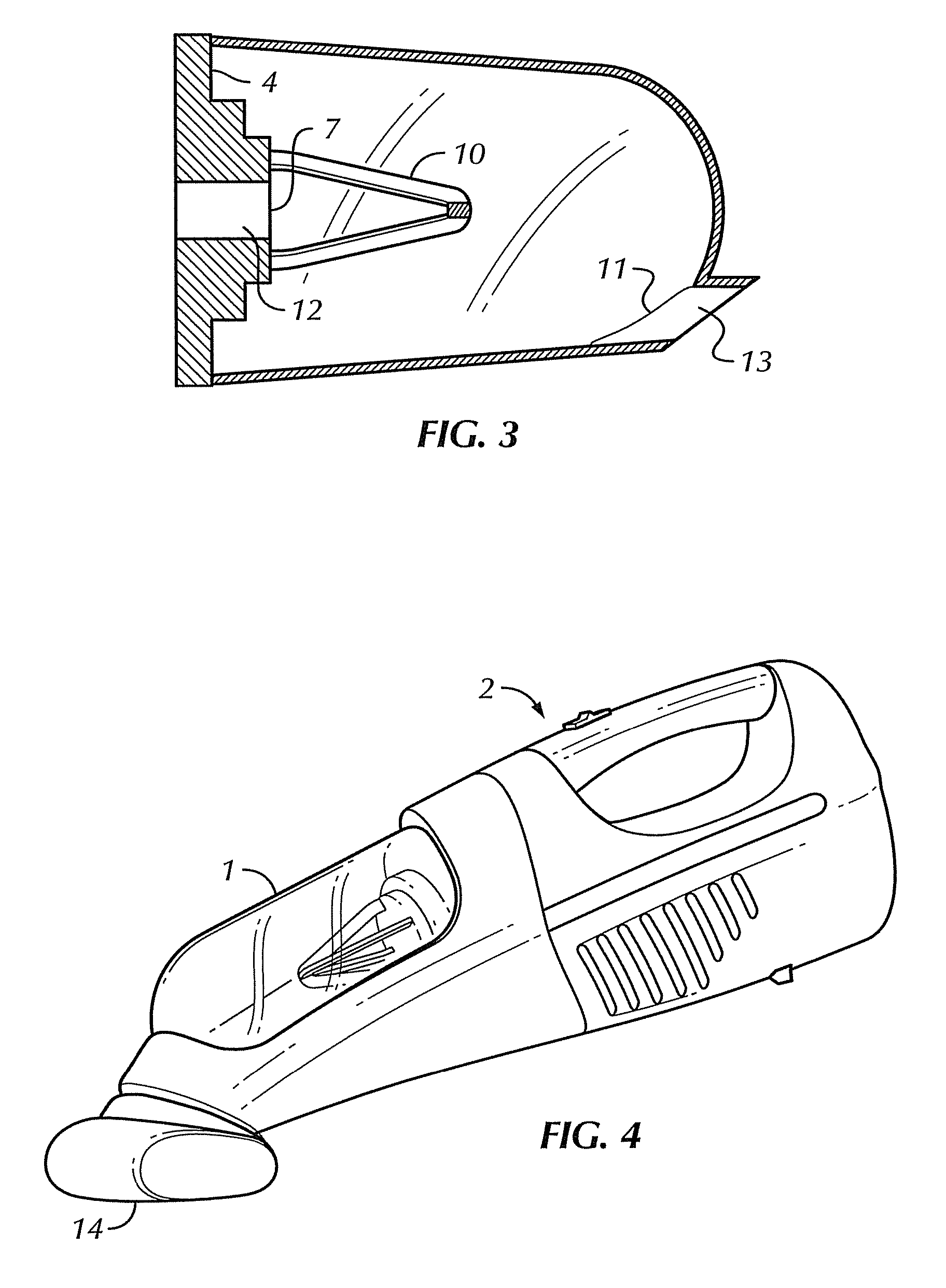

Cyclone dust collecting apparatus and hand-held cleaner having the same

ActiveUS20110289720A1Reduce total pressure lossImprove efficiencyCombination devicesVortex flow apparatusCycloneSpiral flow

The hand-held cleaner includes a body, and a cyclone dust collecting apparatus detachably mounted in the body. The cyclone dust collecting apparatus includes a pre-motor filter unit having a filter grill and a filter member, a dust collecting bin having one end to which the pre-motor filter unit is coupled and the other end opposite to the one end in which an cyclone inlet is formed, and a cyclone bin disposed in the dust collecting bin and having a spiral flow path-guide member integrally formed therein. A moving path of air drawn into the cyclone inlet is maintained in the same direction until the air is discharged through the pre-motor filter unit via the cyclone bin.

Owner:SAMSUNG ELECTRONICS CO LTD

Commercial production of hydrogen from water

InactiveUS20050126924A1Minimizing energyReduce voltageCellsPhotography auxillary processesWater useElectrical conductor

Large quantities of low cost hydrogen free of carbon oxides are required as fuel for the hydrogen economy. Commercial quantities of hydrogen can be produced from the electrolysis of water using a diaphragm-less electrolytic cell. The electrolytic cell has an anode cell (31) and a cathode cell (32) connected by a DC power source (53) and an external conductor (52). An alternate apparatus method to produce hydrogen is to electrolyze water using unipolar activation. Unipolar activation uses separate anode and cathode circuits and can use secondary cathode (132) and anode (139) cells to recover energy and produce further hydrogen.

Owner:RODOLFO ANTONIO M GOMEZ

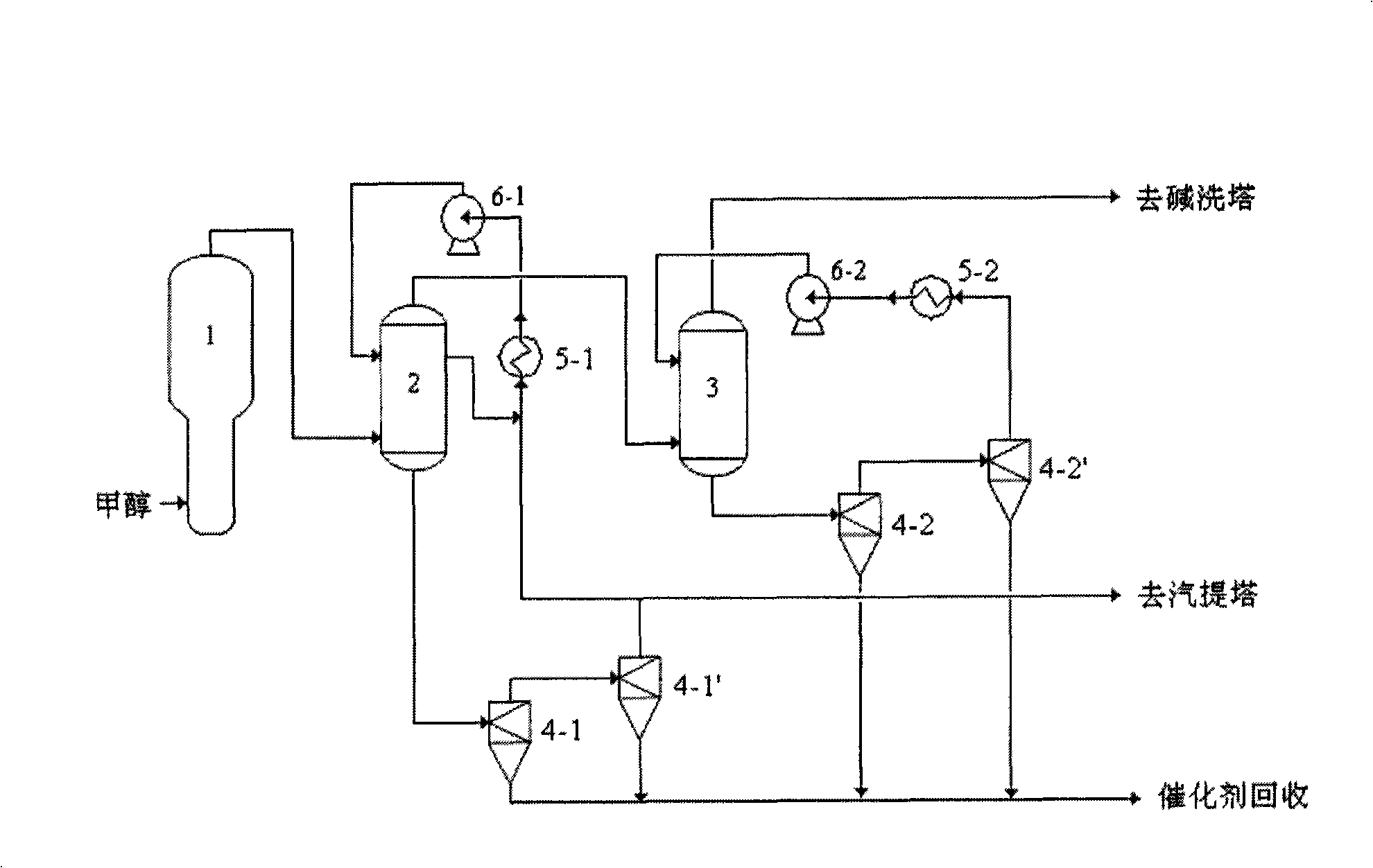

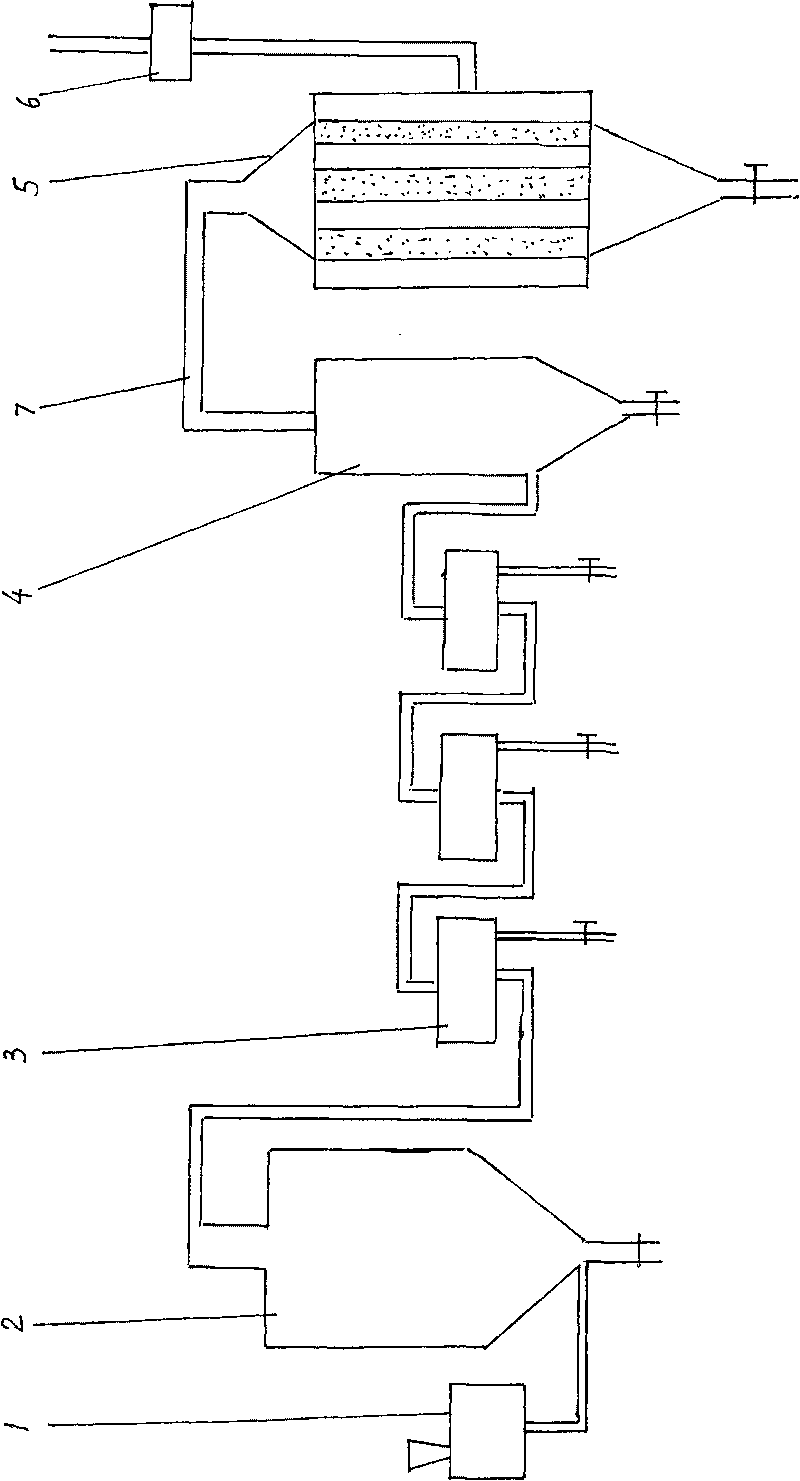

Method and apparatus for micro hydrocyclone separation of MTO quench water and water of water-washing factory, and for concentration of fine catalyst in the same

InactiveCN101352620AVortex flow apparatusCentrifugal force sediment separationEnrichment methodsQuenching

The invention provides a micro-vortex flow concentration method used for fine catalyst in MTO quenching water and washing water, comprising the steps as follows: micro-vortex flow separation of MTO quenching water is carried out so as to carry out the concentration processing on the contained catalyst and micro-vortex flow separation of MTO washing water is carried out so as to carry out the concentration processing of the contained catalyst. The invention also provides a micro-vortex flow concentration device used for the fine catalyst in the MTO quenching water and washing water.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

Separator

ActiveUS20140165977A1Improve efficiencyReduce sealCombination devicesAuxillary pretreatmentFilter mediaEngineering

A separator has a first inlet arranged to receive a fluid stream, and first and second separation stages coupled together in series; A pump coupled to the second separation stage generates an area of reduced pressure to draw the fluid stream through the first and second separation stages. One of the stages includes a variable impactor separator comprising a first chamber arranged to receive the fluid stream, and a second chamber coupled to the first chamber through an aperture to accelerate the first fluid stream. The stream is incident upon an impaction surface to separate contaminants from the fluid stream. An actuator adjusts the open area of the aperture according to a pressure differential between fluid pressure in the first chamber and a reference fluid pressure in a third chamber. The other of the separation stages is a second variable impactor separator or a filter media.

Owner:PARKER HANNIFIN MFG LTD

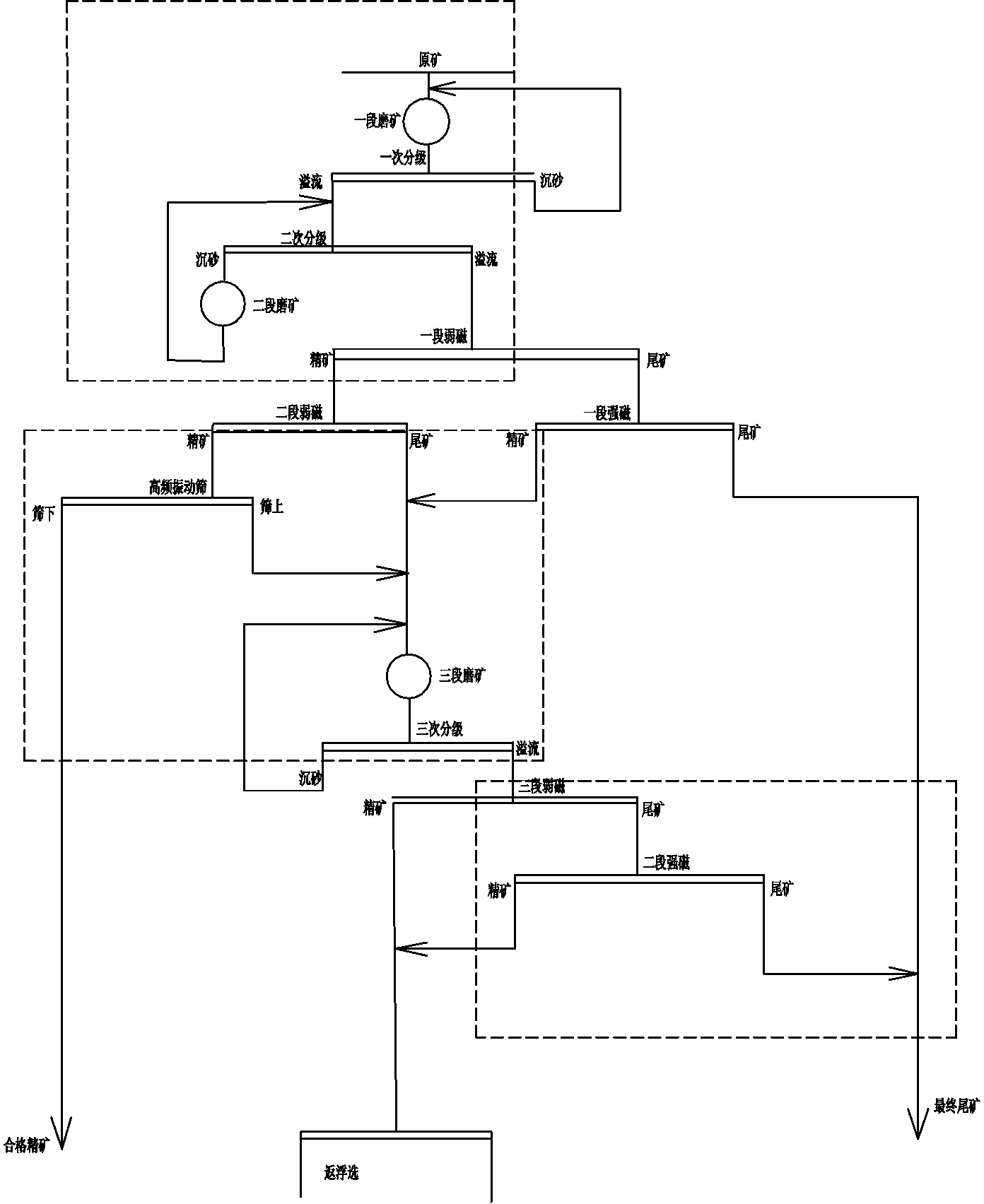

Mineral processing process for processing mixed ore of magnetic iron ore and hematite-limonite ore

The invention relates to a mineral processing process for processing mixed ore of magnetic iron ore and hematite-limonite ore. The mineral processing process comprises steps as follows: raw ore containing the mixed ore of the magnetic iron ore and the hematite-limonite ore is smashed and then subjected to two-stage continuous ore grinding; overflowing ore of a secondary classifying cyclone is subjected to two-stage low-intensity magnetic separation and one-stage fine screening and separation in combination of a single magnetic separation, fine screening and regrinding process for processing magnetic ore; under the condition of rougher ground ore particles, a part of undersize qualified magnetite concentrate products are firstly obtained, the other part of oversize products are combined with one-stage high-intensity magnetic separator concentrate and two-stage low-intensity magnetic separator tailings to serve as middlings, and the middlings are subjected to three-stage ore grinding classification operation for regrinding and separation; and overflowing ore of a tertiary classifying cyclone is subjected to three-stage low-intensity magnetic separation and high-intensity magnetic separation, fine-grain qualified tailings are thrown again, three-stage low-intensity magnetic concentrate and two-stage high-intensity magnetic concentrate are combined to obtain mixed magnetic concentrate, the mixed magnetic concentrate is subjected to a reverse flotation process for separation, and a qualified flotation concentrate product is obtained. According to the mineral processing process, the mixed ore of the magnetic iron ore and the hematite-limonite ore with different dissemination particle sizes is reasonably processed, the qualified iron ore concentrate product is obtained, and the mineral processing process is economical, energy-saving and environment-friendly.

Owner:ANSTEEL GRP MINING CO LTD

Multi-cyclone dust separating apparatus having a filter assembly

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

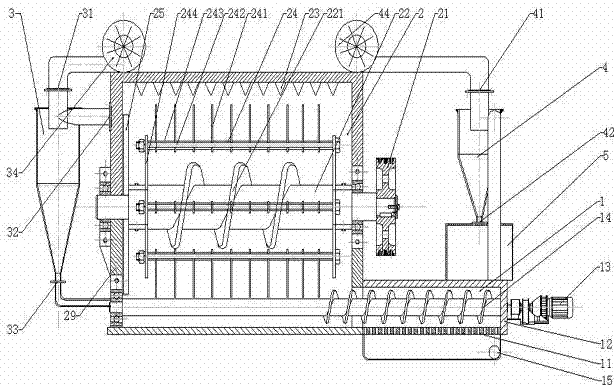

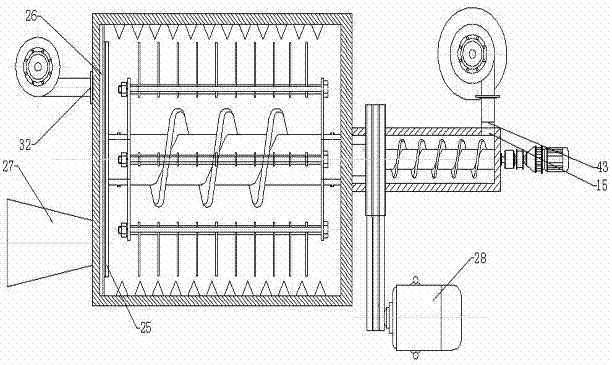

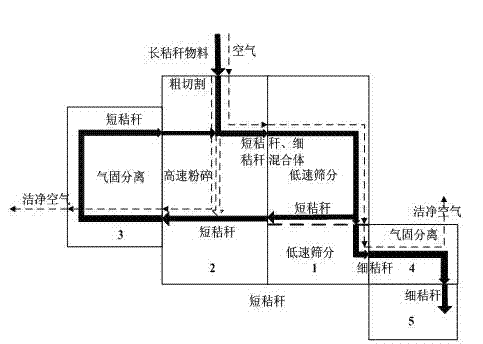

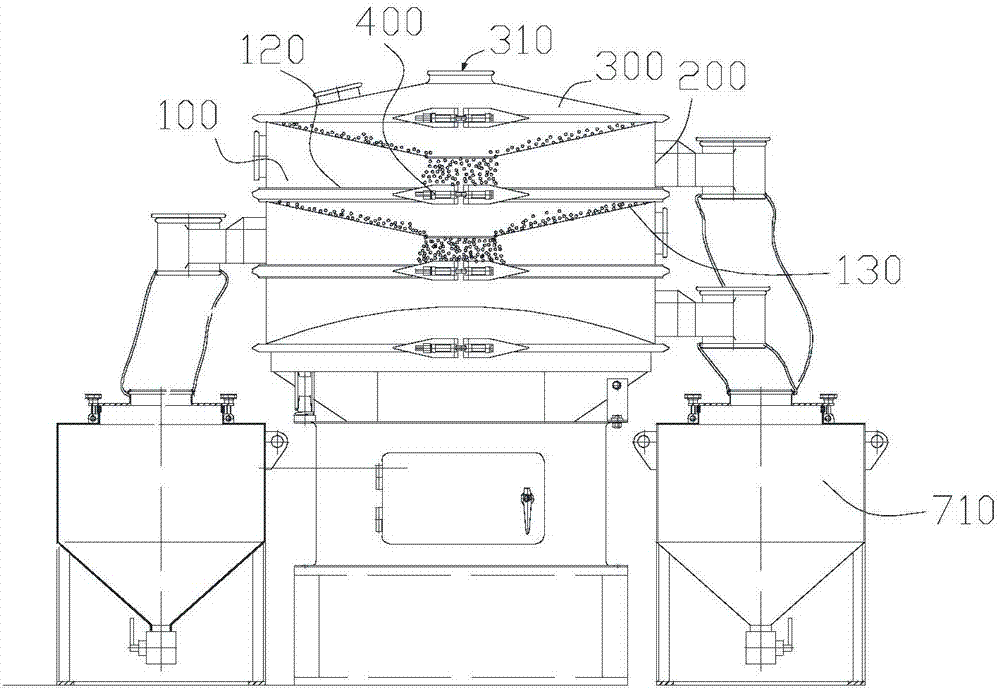

Straw cutting, crashing and sieving integrated device and method

ActiveCN103084286AIncrease production capacityPromote sustainable developmentVortex flow apparatusCuttersCycloneAgricultural engineering

The invention discloses a straw cutting, crashing and sieving integrated device and a method and belongs to the technical field of agricultural machines. The straw cutting, crashing and sieving integrated device comprises a sieving chamber, a cutting and crashing chamber, a first cyclone separator, a second cyclone separator and a storage bin. According to the straw cutting, crashing and sieving integrated device provided by the invention, low-speed sieving is distinguished from high-speed cutting and crashing, and the sieving capacity of a material is enhanced due to the agitation effect of sieving blades, so that a thin material can be sufficiently sieved, and a coarse and short material can be returned back to the cutting and crashing chamber again for secondary crashing; and meanwhile, the crashing efficiency is improved. The straw cutting, crashing and sieving integrated device provided by the invention has the advantages of compact structure and small occupied area due to the integrated design of the sieving chamber and the cutting and crashing chamber. The straw cutting, crashing and sieving integrated device provided by the invention is applicable to straw resourceful treatment of small-size facility horticulture planting enterprises and individual farmers; the machining environment is improved; the labor intensity is reduced; the machining efficiency is improved; the production cost is reduced; and the high-efficiency production and the sustainable development of facility horticulture cleaning can be promoted.

Owner:万华禾香板业(公安县)有限责任公司

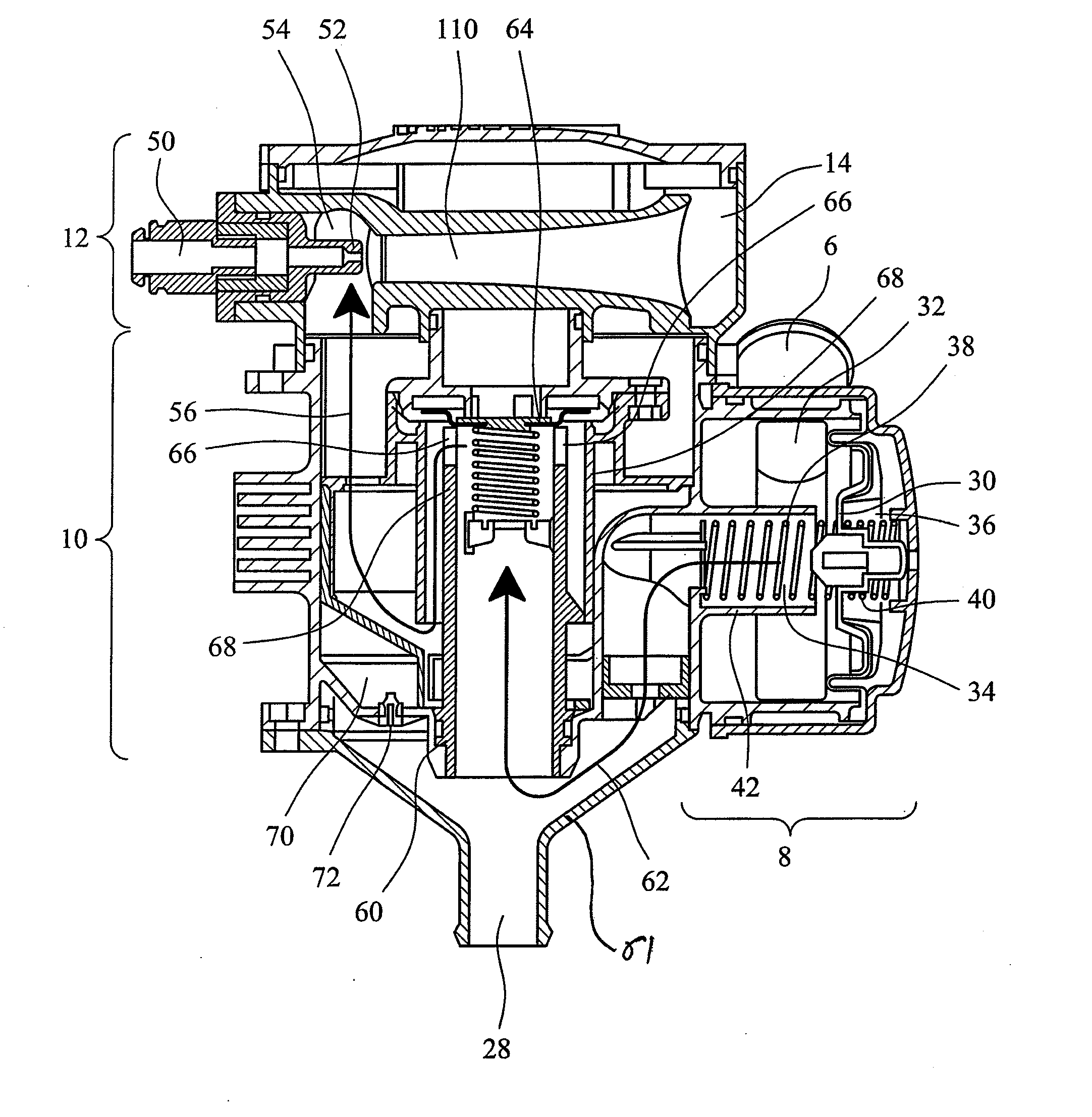

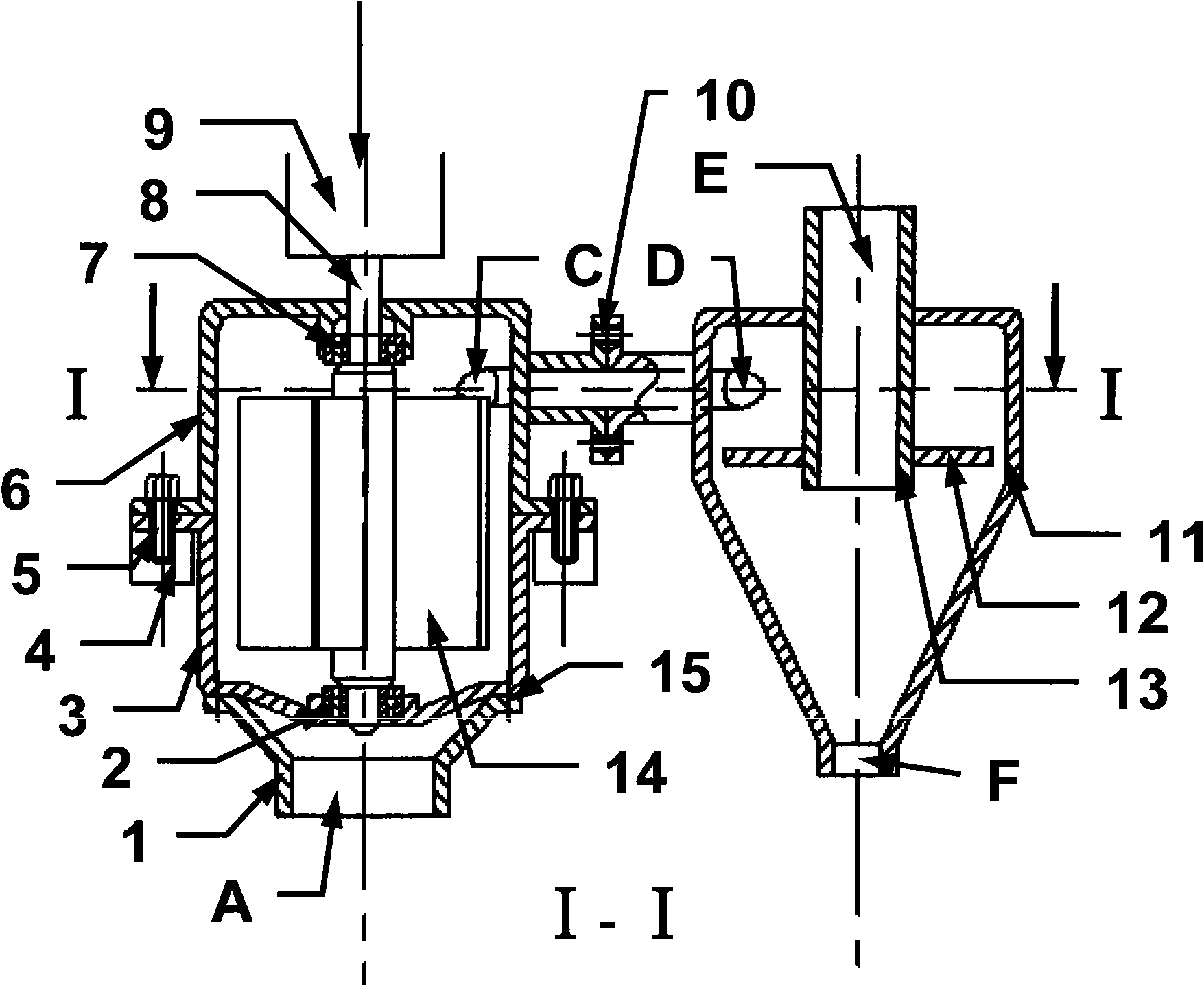

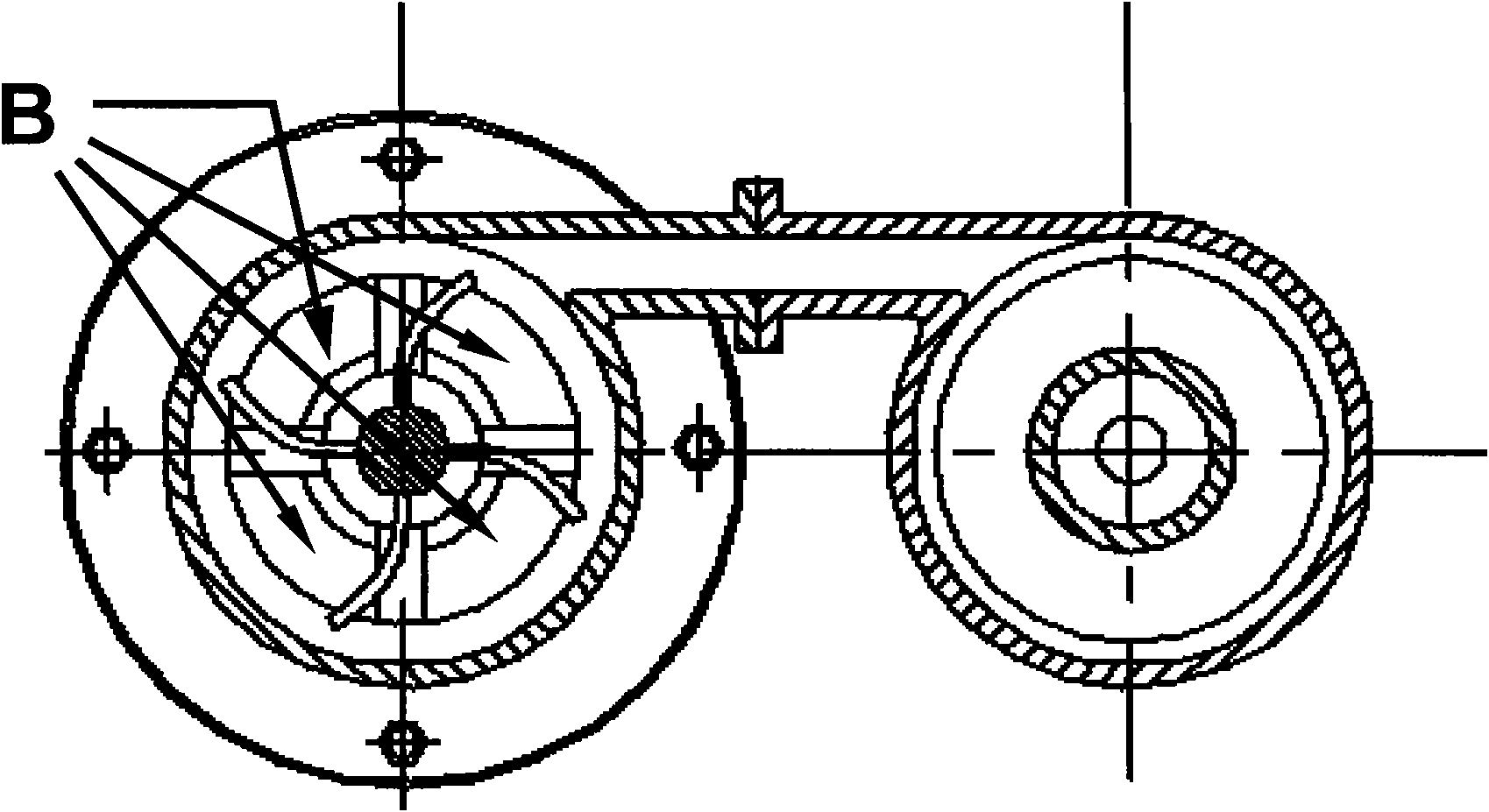

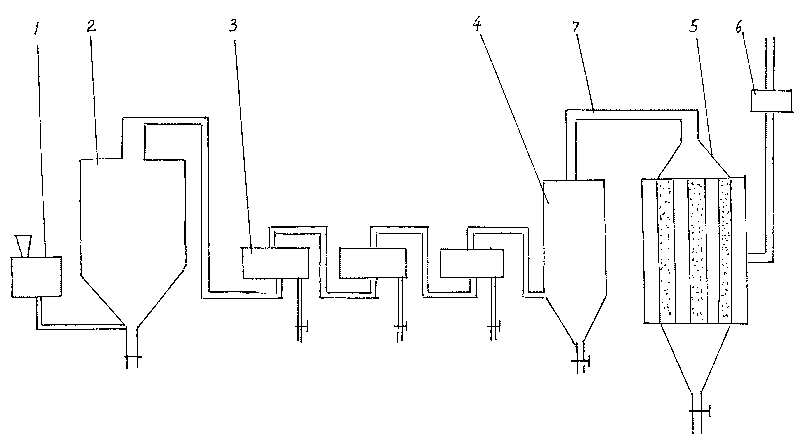

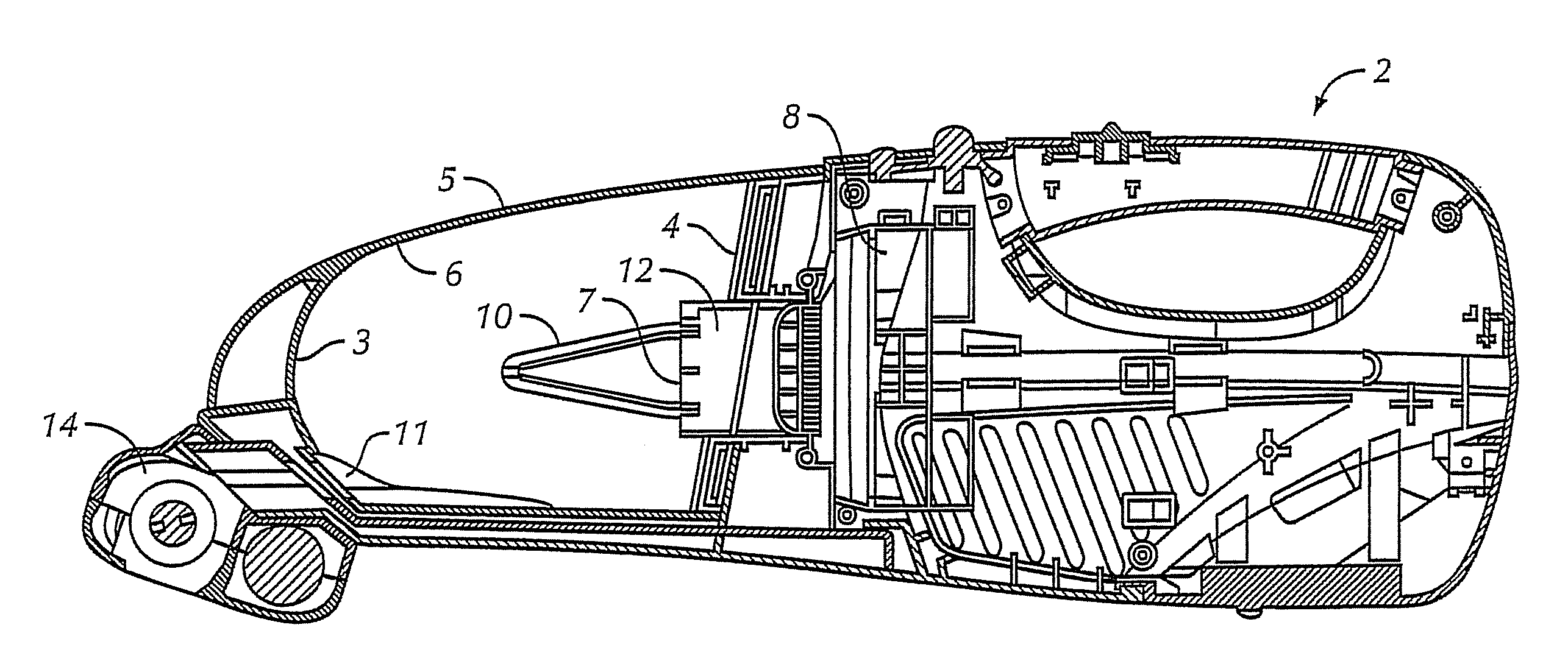

Composite oil gas separation method and composite oil gas separator

InactiveCN101549331AImprove separation efficiencySimplify the shapeVortex flow apparatusMachines/enginesCycloneSolid particle

The present invention relates to a method and a device for separating liquid or solid particles in air flow, especially to a composite oil gas separation method applied to the crankcase blow-by of internal combustion engine and a composite oil gas separator. The method adopts a mode of combining an active centrifugal type separation and a passive cyclone type separation for separating. The device is mainly composed of an active centrifugal type separator and a passive cyclone type separator. The active centrifugal type separator adopts a one-stage separation. The passive cyclone type separator adopts a two-stage separation. The air outlet (C) of active centrifugal type separator is communicated with the gas tangential inlet (D) of passive cyclone type separator. The center of separation chamber of passive cyclone type separator is installed with an exhaust insertion tube (13) for forming a gas outlet (E) of passive cyclone type separator. The lower end of separation chamber of passive cyclone type separator is installed with an engine oil outlet (F) communicated with the crankcase. The method and the device of the invention have the characteristics of high separation efficiency and suitability for the changing of blow-by along with the work condition.

Owner:JILIN UNIV

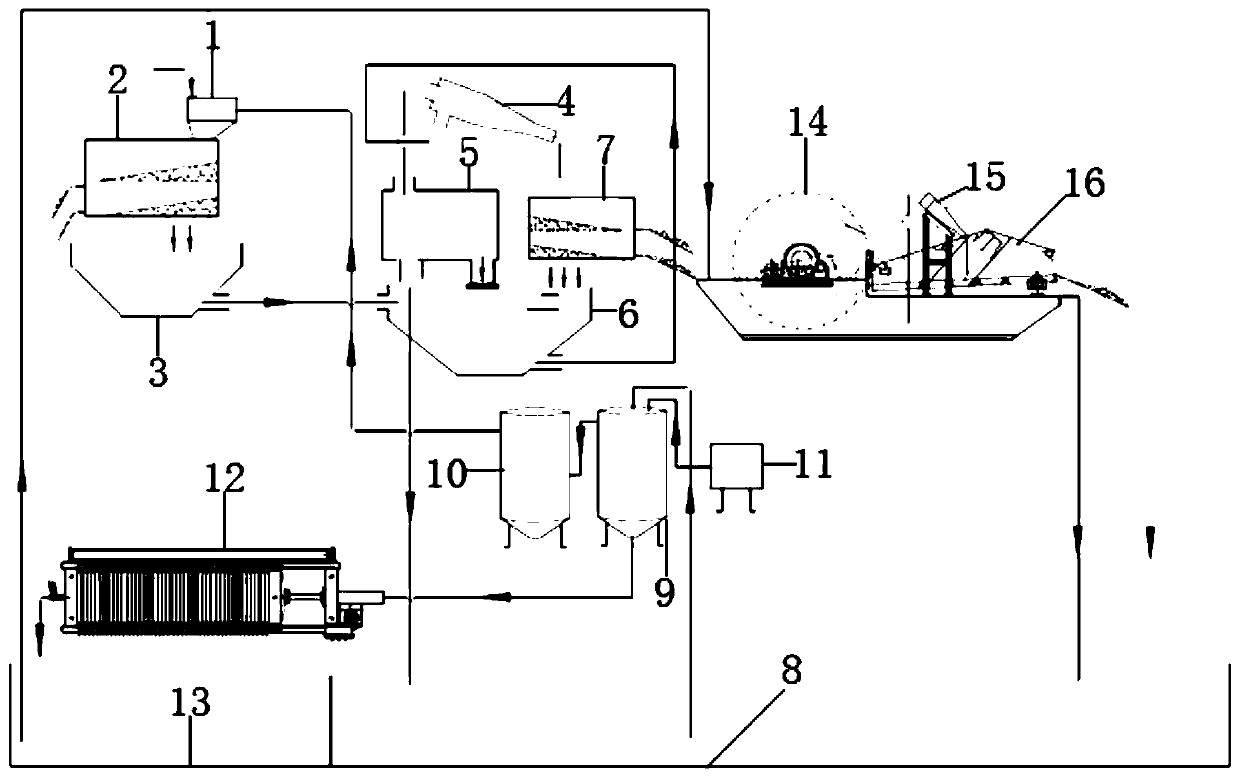

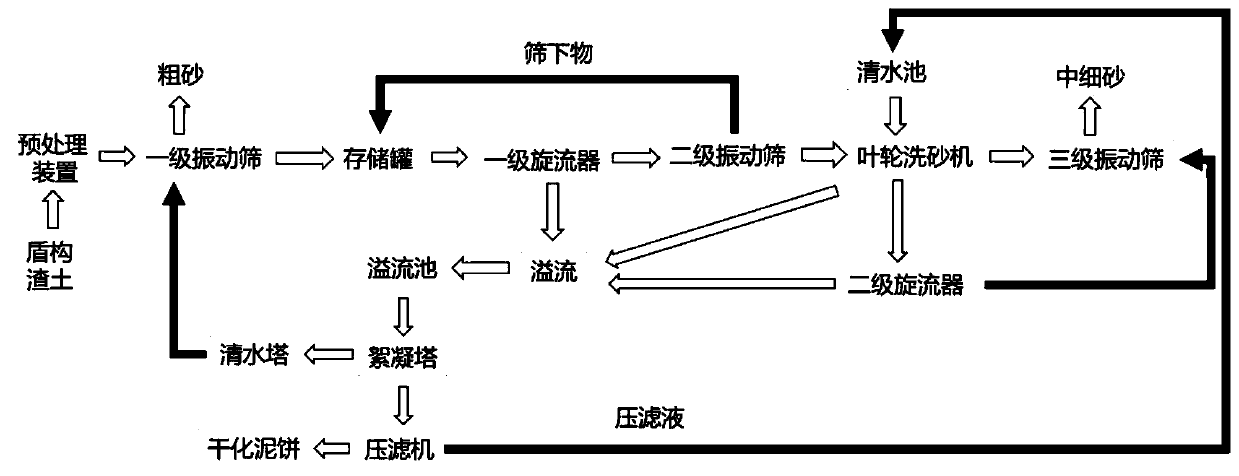

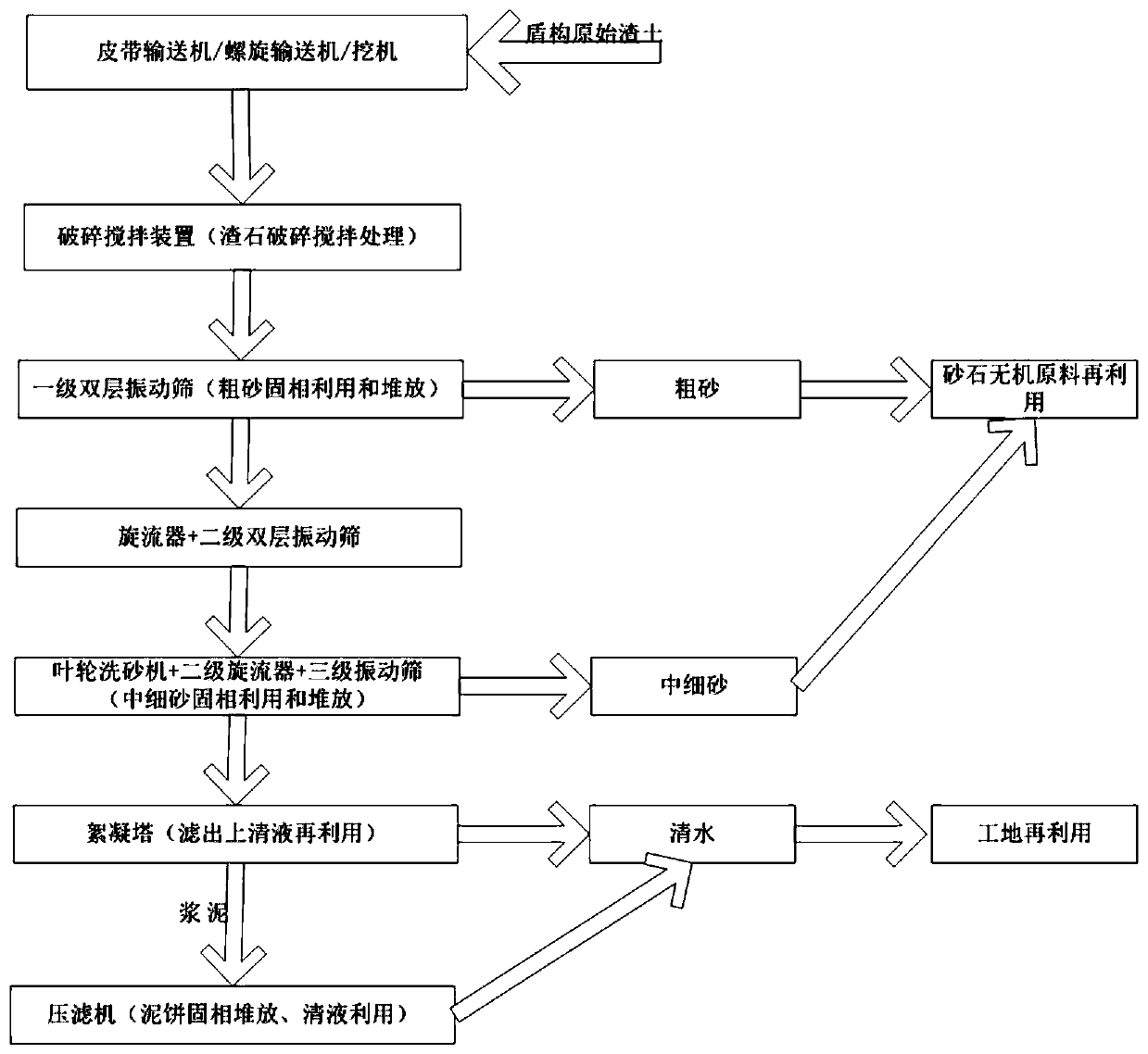

Shield construction muck treatment system and method

ActiveCN110303033AAchieve graded solid-liquid separationReduce transport volumeSievingConstruction waste recoveryEngineeringSlurry

The invention relates to the technical field of shield construction muck treatment, in particular to a shield construction muck treatment system and method. The muck generated by shield construction is crushed and stirred by a crushing and stirring device and then enters a primary-stage double-layer vibrating screen, oversize products are discharged out of the system, undersize products enter a sieve cone tank, the sieve cone tank is connected with a swirler through a pump, an intermediate tank is connected to an overflow port of the swirler, a discharge port of the intermediate tank is connected to an overflow tank through a pipeline, the slurry in the overflow tank is pumped to a flocculation tower through a pump, the flocculation tower is connected with an automatic dosing device, a flocculation medicament is pumped into the flocculation tower, the slurry in the flocculation tower is pumped to a filter press through a pump, drying mud cake treatment is carried out through the filterpress, the treated clear water flows into a clear water tank for reutilization, the dried mud cake is discharged out of the system, so that classified solid-liquid separation of different particle size components and water in the shield muck is realized, reutilization of inorganic raw materials and water resources of the shield muck is formed, and huge economic benefits are generated while the social resources are saved.

Owner:CHINA RAILWEY ENG SERVICE CO LTD

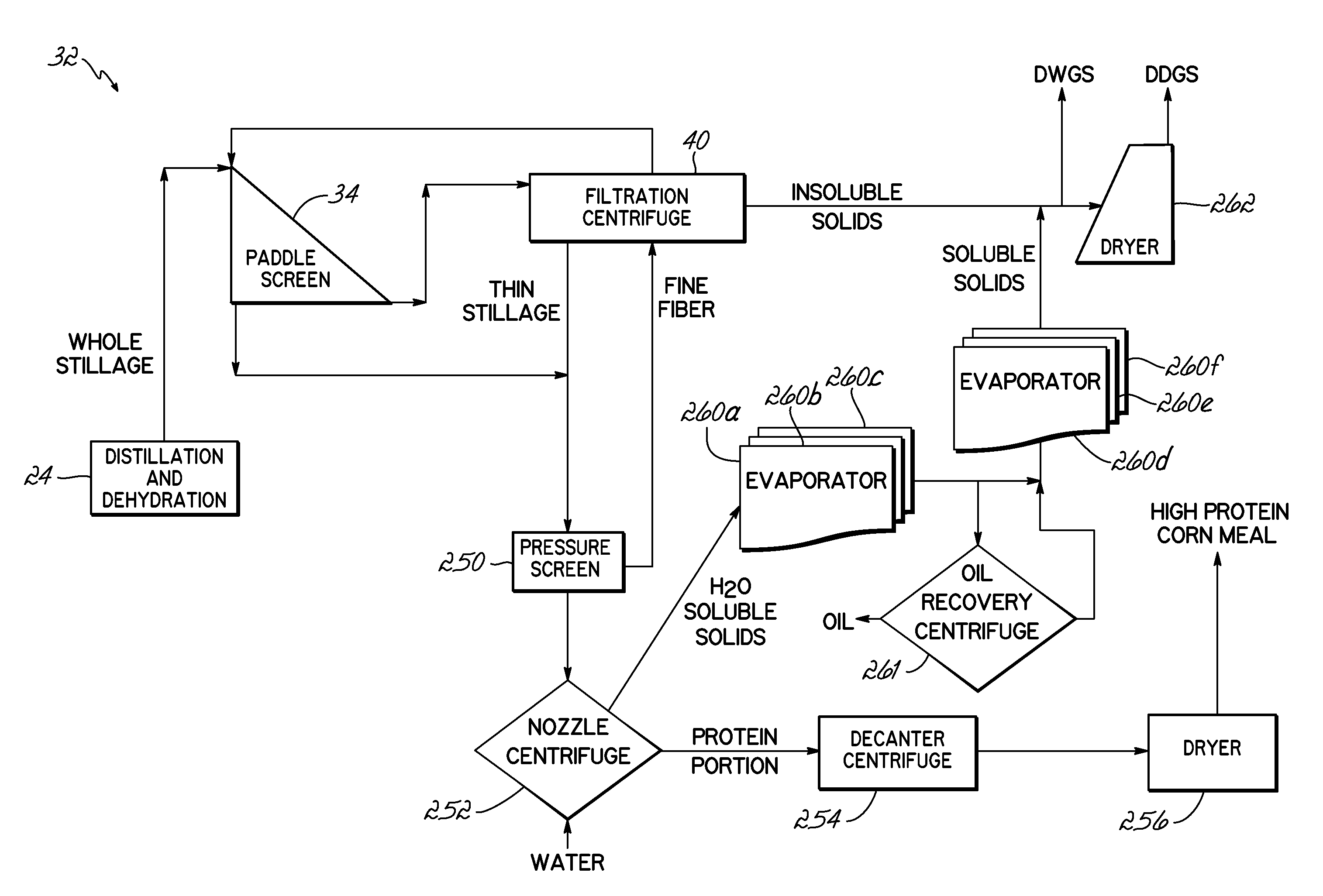

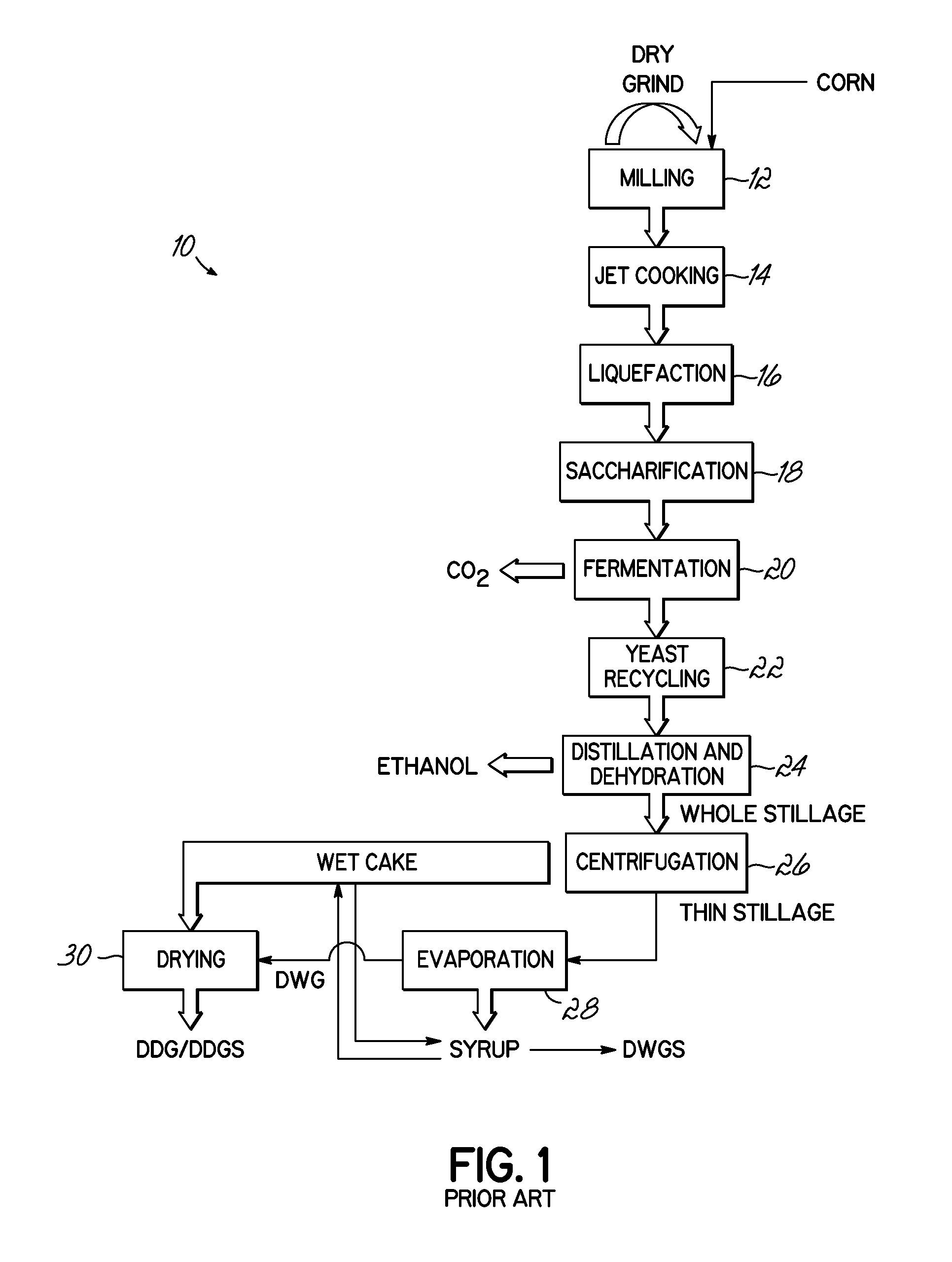

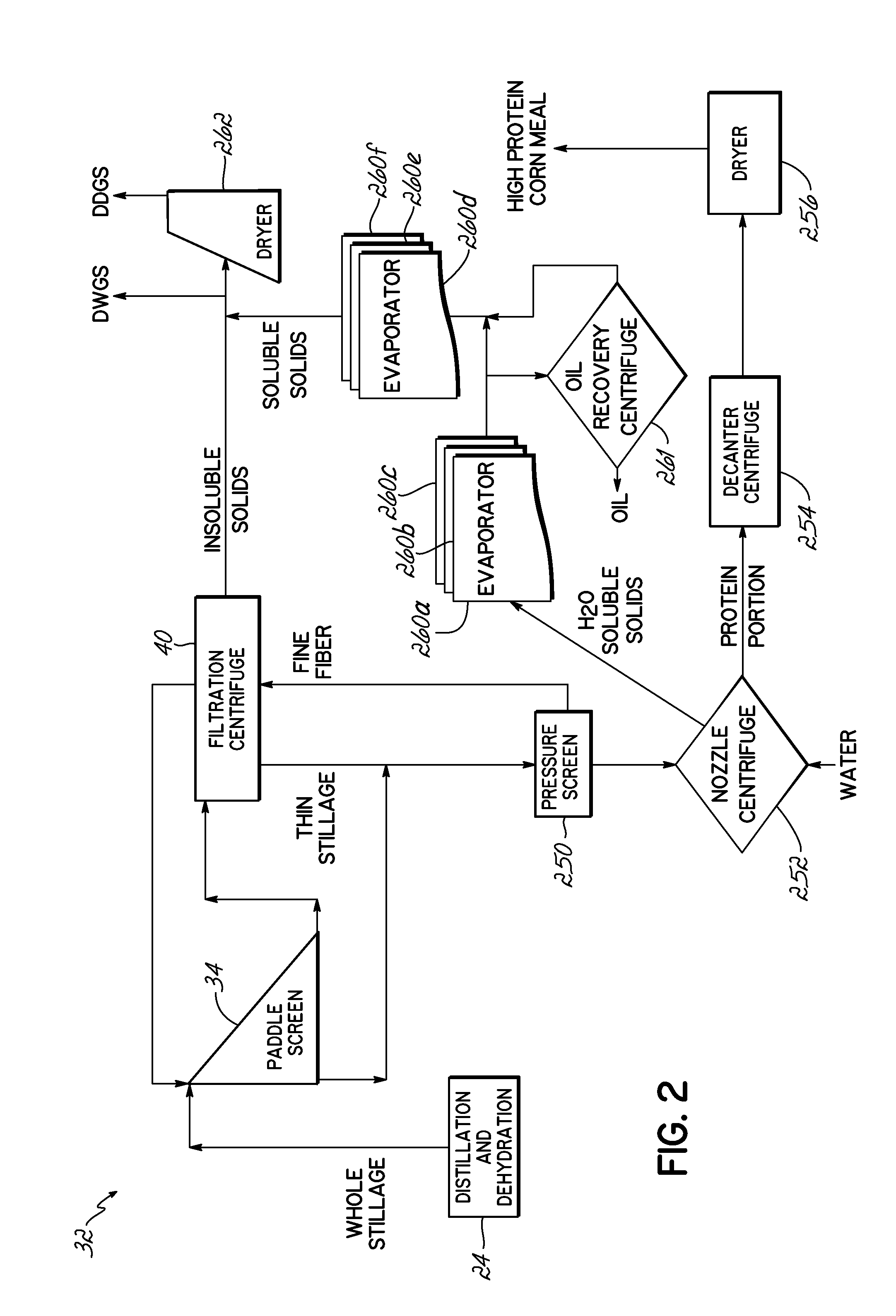

Methods for producing a high protein corn meal from a whole stillage byproduct and system therefore

ActiveUS20120064213A1High in proteinFatty oils/acids recovery from wasteBy-product recoveryWater solubleCorn meal

The present invention relates generally to corn dry-milling, and more specifically, to methods for producing a high protein corn meal from a whole stillage byproduct produced in a corn dry-milling process for making ethanol and a system therefore. In one embodiment, a method for producing a high protein corn meal from a whole stillage byproduct includes, in a corn dry-milling process for making ethanol, separating the whole stillage byproduct into an insoluble solids portion and a thin stillage portion. The thin stillage portion is separated into a protein portion and a water soluble solids portion. Next, the protein portion is dewatered then dried to define a high protein corn meal that includes at least 40 wt % protein on a dry basis.

Owner:FLUID QUIP TECH LLC

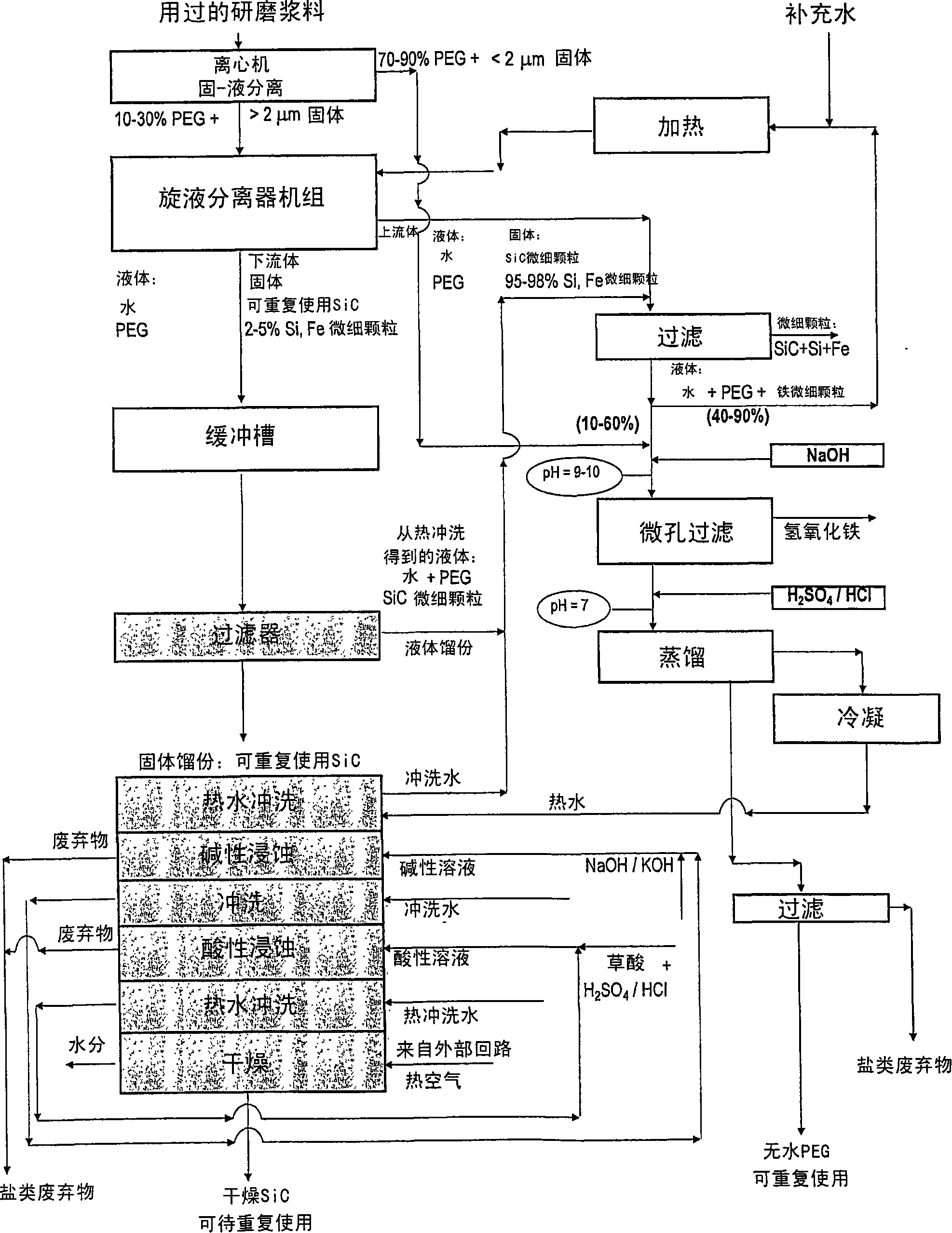

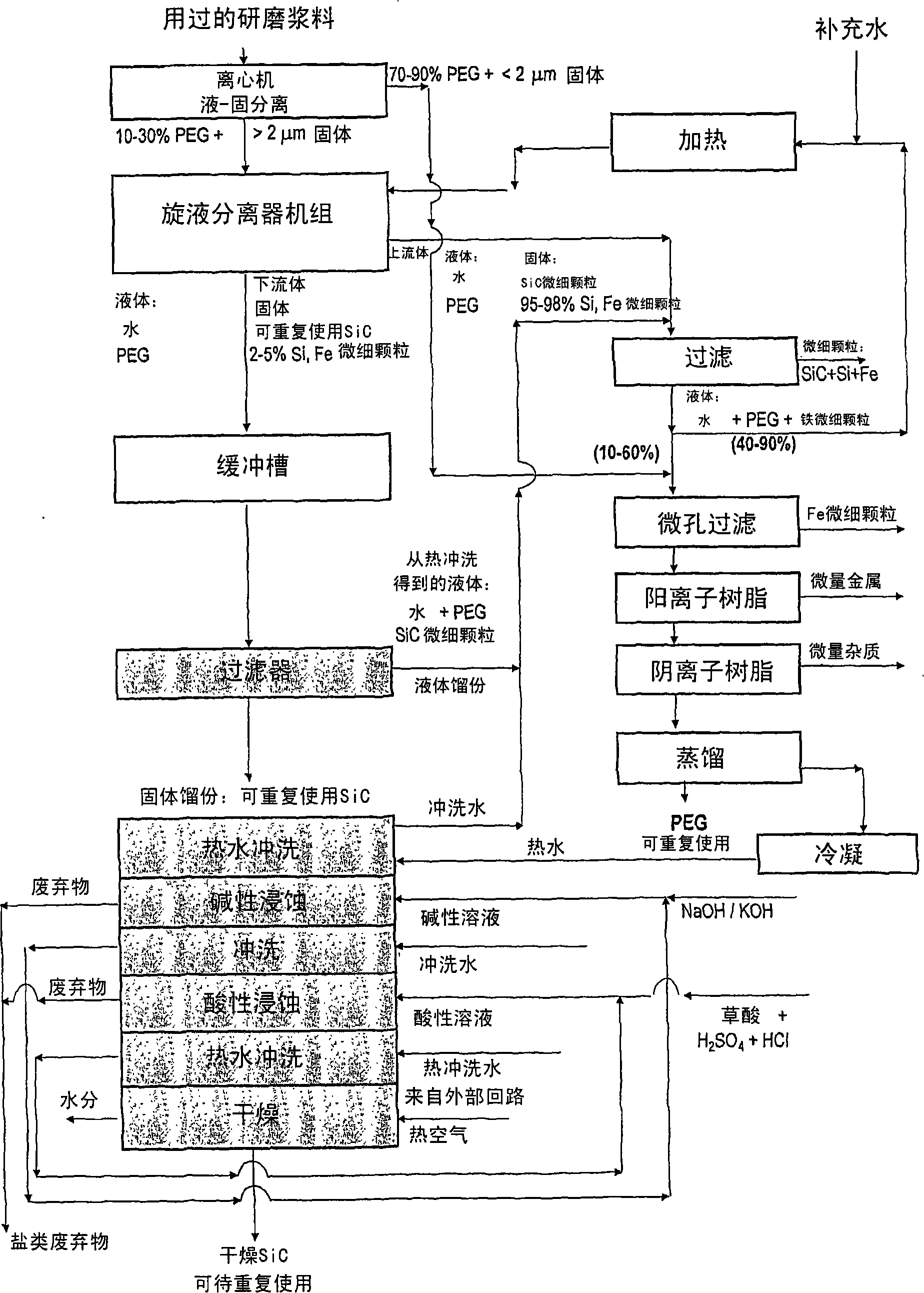

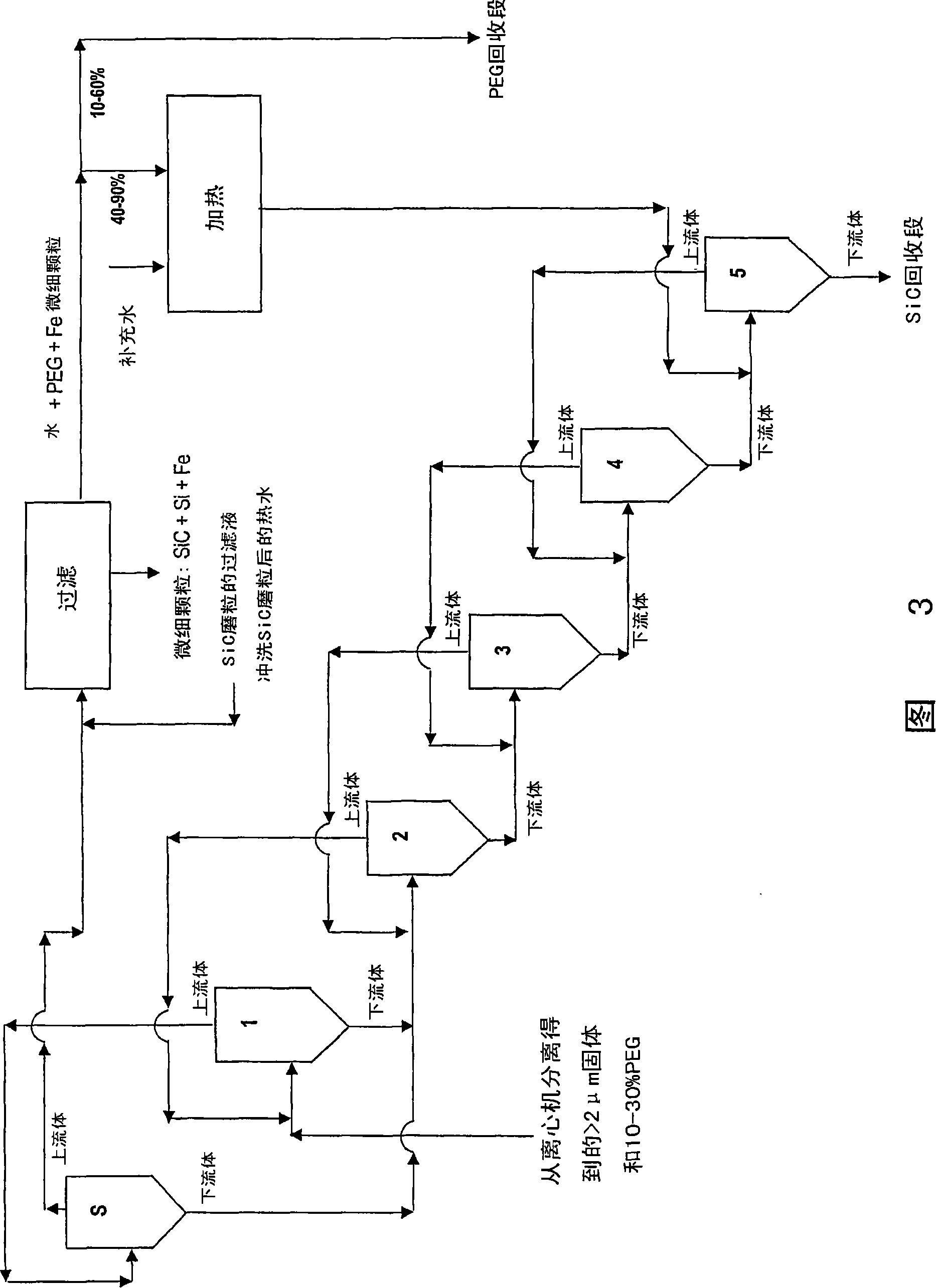

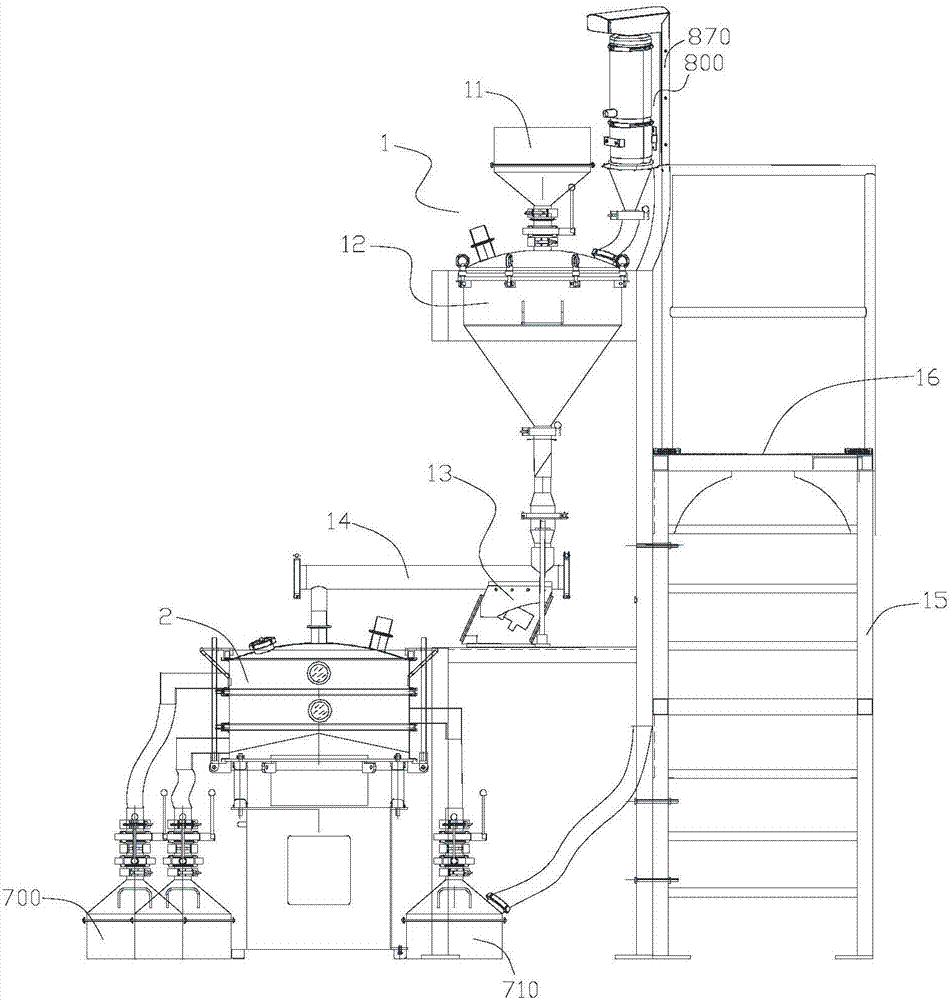

Process and apparatus for treating exhausted abrasive slurries for the recovery of their reusable components

InactiveCN101218068AReduce in quantityOrganic anion exchangersVortex flow apparatusCrystalline materialsSlurry

Process for completely recovering the reusable components of an abrasive slurry used in slicing crystalline materials of silicon, quartz or ceramics when it becomes exhausted and enriched with undesired waste matter. The process consists of an initial centrifuge separation of the exhausted slurry as such and of a wet size-sorting treatment of the fraction containing the abrasive grains obtained from the centrifuge, carried out in a battery of hydrocyclones or centrifuges connected in series. The section for the recovery and purification of the abrasive grains comprises a multifunctional apparatus that performs all the required operations within a single pressure vessel. The process enables the complete recovery of the reusable abrasive grains contained in the exhausted slurry as well as of the suspending or cutting liquid of the abrasive slurry, in order to reuse both components in the manufacturing process. The invention also concerns an apparatus for carrying out the treatment of exhausted abrasive slurries according to the process described.

Owner:SIC PROCESSING

Air precleaner arrangement for an internal combustion engine comprising two cyclone filters

ActiveUS7682413B2Easy to cleanCombination devicesAuxillary pretreatmentCycloneExternal combustion engine

Owner:DEERE & CO

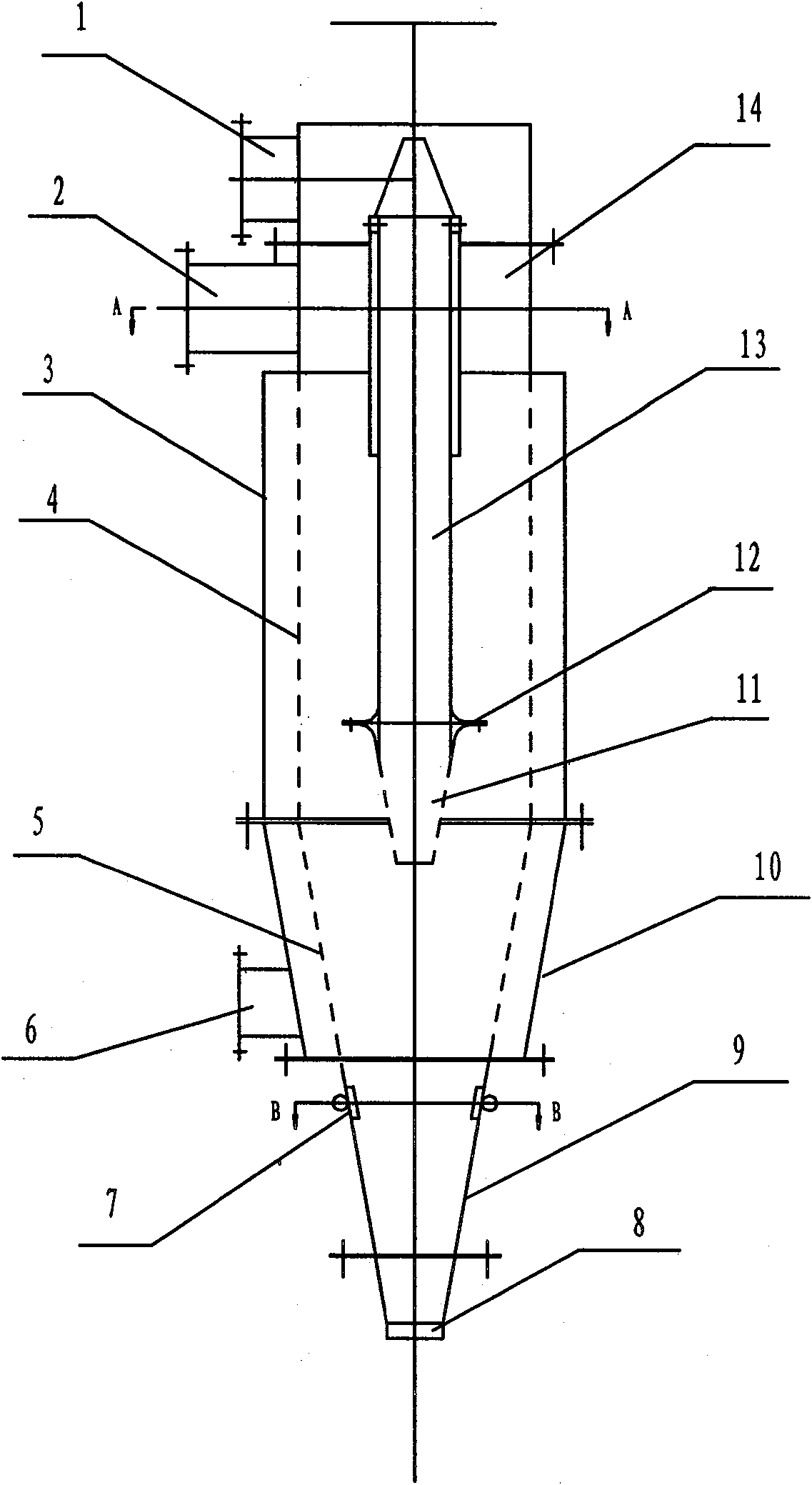

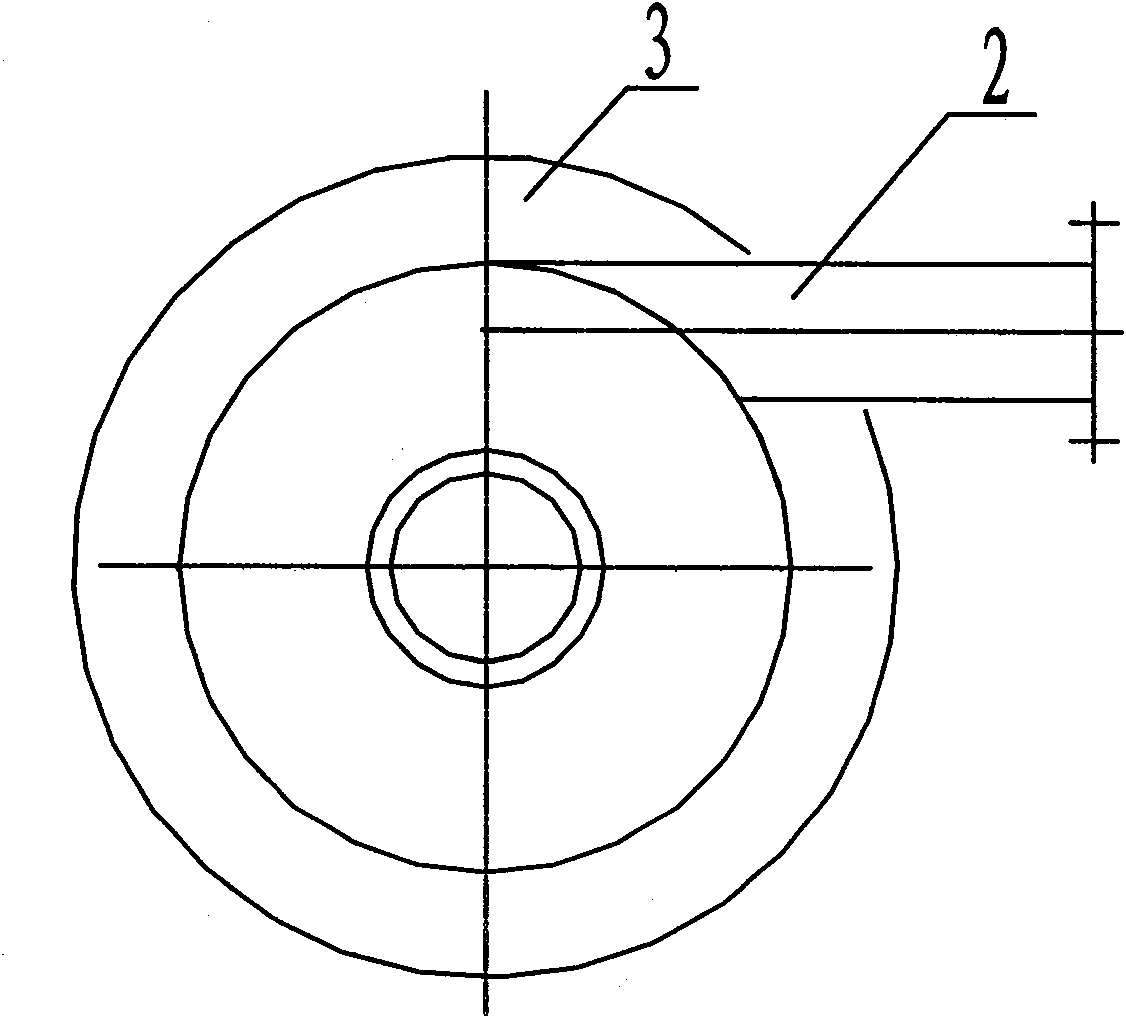

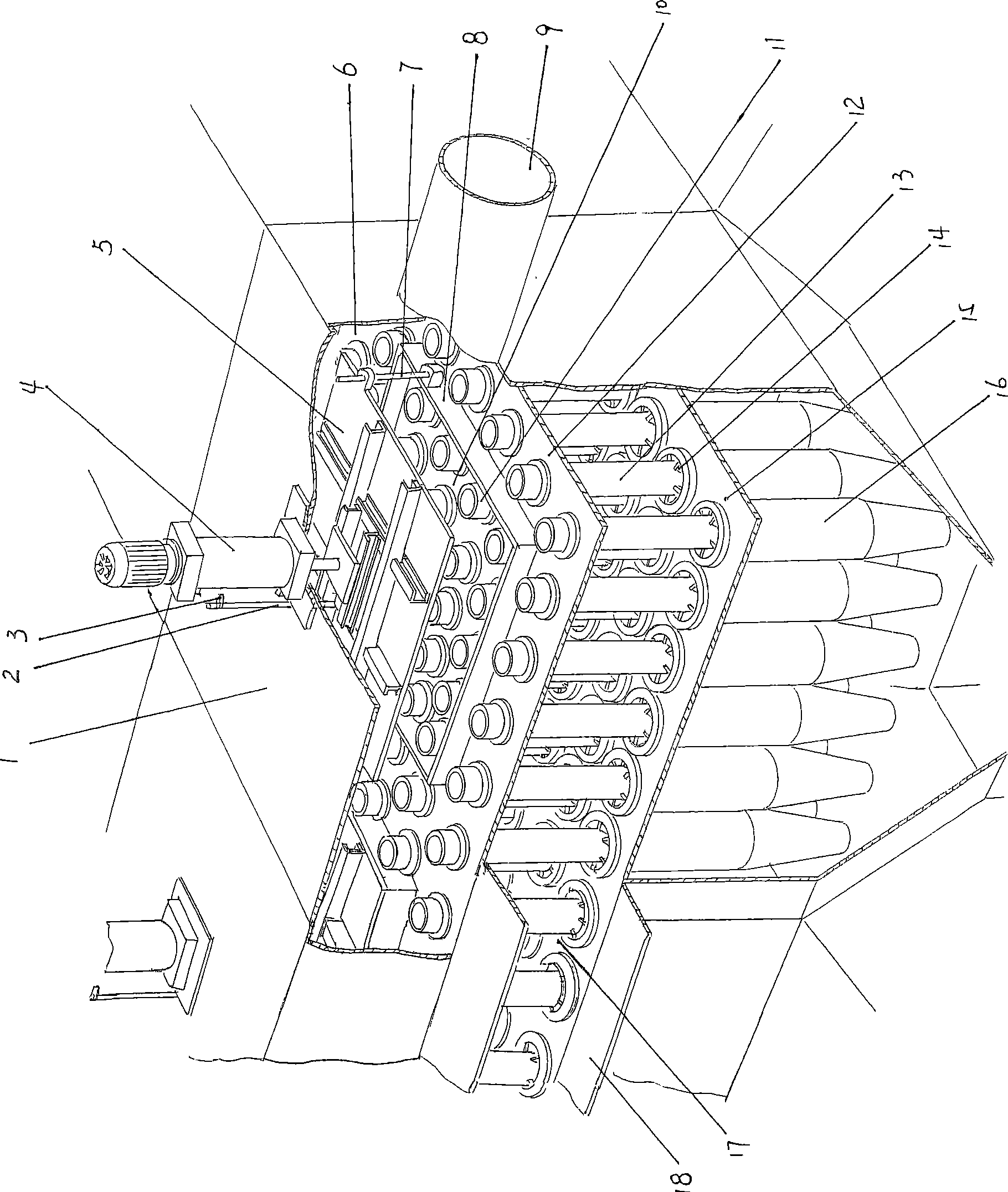

Three-product cyclone classifying screen

ActiveCN101844115APrevents overflow from mixingAvoid enteringVortex flow apparatusCycloneEngineering

The invention relates to a three-product cyclone classifying screen. The three-product cyclone classifying screen comprises a cylindrical draft tube, a cyclone cylinder and a cyclone cone, wherein a central tube which passes through the cylindrical draft tube is arranged in the cyclone cylinder; a lower port of the cylindrical draft tube is connected with a cylinder screen; the bottom of the cylinder screen is connected with a cone screen; the cyclone cylinder is sleeved outside the cylinder screen; the lower part of the cyclone cylinder is connected with a cyclone upper cone which is sleeved outside the cone screen; the lower port of the cone screen is connected with a cyclone lower cone; a hole for discharging sieved products is formed on the cyclone upper cone; a water supply nozzle is arranged on a cyclone lower cone; the lower port of the central tube is provided with a central cone screen; and a guide flow disc is arranged between the central tube and the cone screen. The three-product cyclone classifying screen screens fine particles through the screen by using the pressure difference of outer rotational flows of a side wall under a powerful centrifuge field, eliminates coarse circulatory flows around the side wall of the cyclone and a top cover, effectively controls oversize fractions in overflows and undersize fractions in underflows are, and improves the classification efficiency and the treating capacity of the cyclone.

Owner:CHINA UNIV OF MINING & TECH

Method for producing green silicon carbide FEPA F P

InactiveCN101705076AImproves breakage resistanceStable water pressureOther chemical processesVortex flow apparatusMicro cracksSilicon carbide

The invention provides a method for producing green silicon carbide FEPA F P, comprising the following steps in turn: sifting raw materials, grinding, classifying by air flow, cleaning by water, classifying by water conservancy and coating surface, filtering by pressure, drying, calcining, sieving, packaging and warehousing. The invention uses a Raymond grinder for grinding and an air flow classification device for multiple classification, and classifies into products in different levels by water conservatory classification; in water conservatory classification, cladding materials are used asdispersant; in classification, water pressure is stable, multi-level precision is improved by siphon overflow classification, impurities in the crack of the micro powder grains are fully evaporated by calcination and tempering in the later period of production, and the cracks can be healed by high-temperature calcination. The production method in the invention greatly enhances product purity, increases crushing resistance of the grains in grinding and polishing, the grain fineness distribution is even with no large grain and with excellent shape and good affinity to grinding liquid. The invention can produce various green silicon carbide FEPA F P with grain size being less than 100mm.

Owner:HUNAN JINCHENG NEW MATERIAL TECH

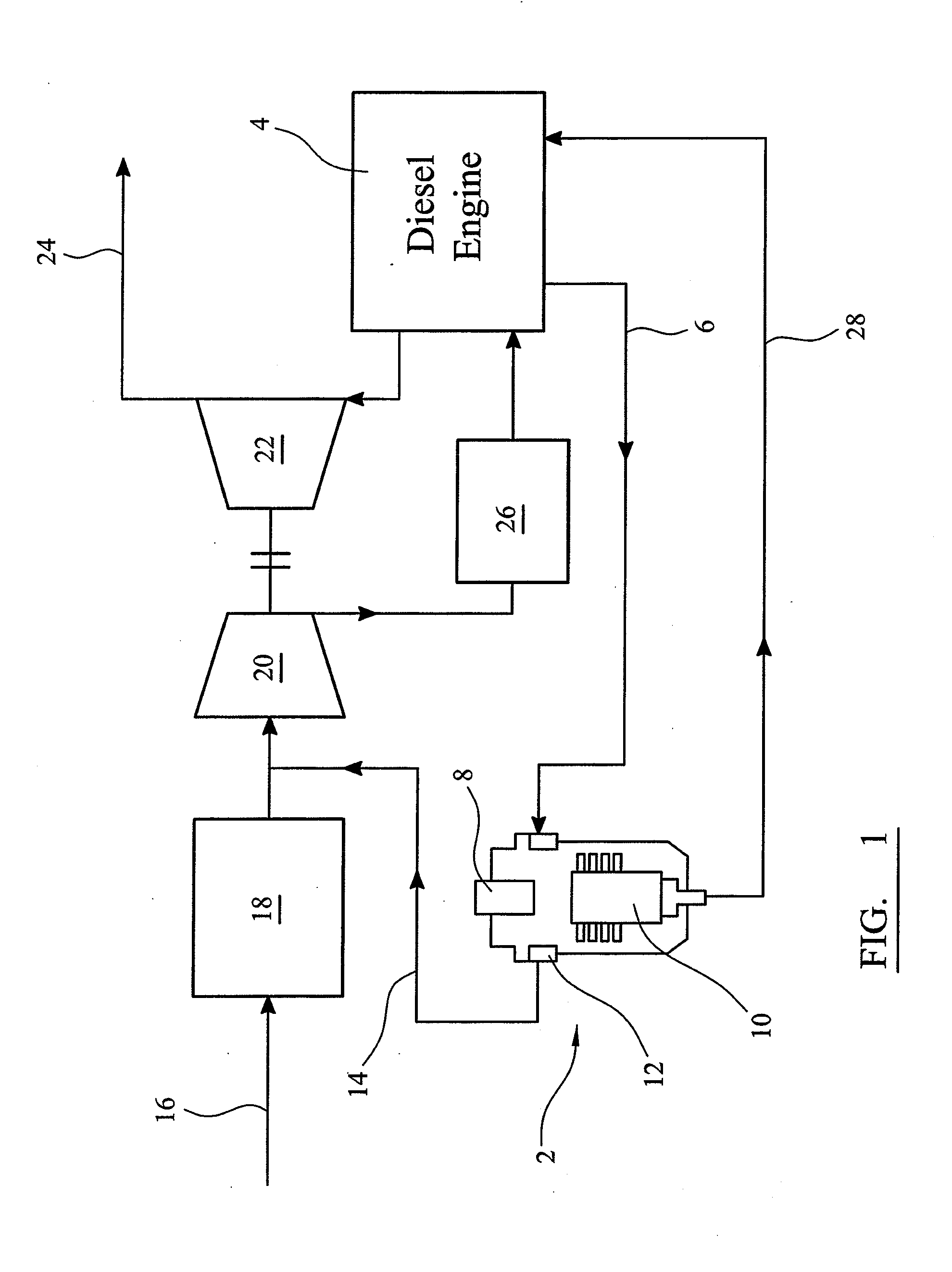

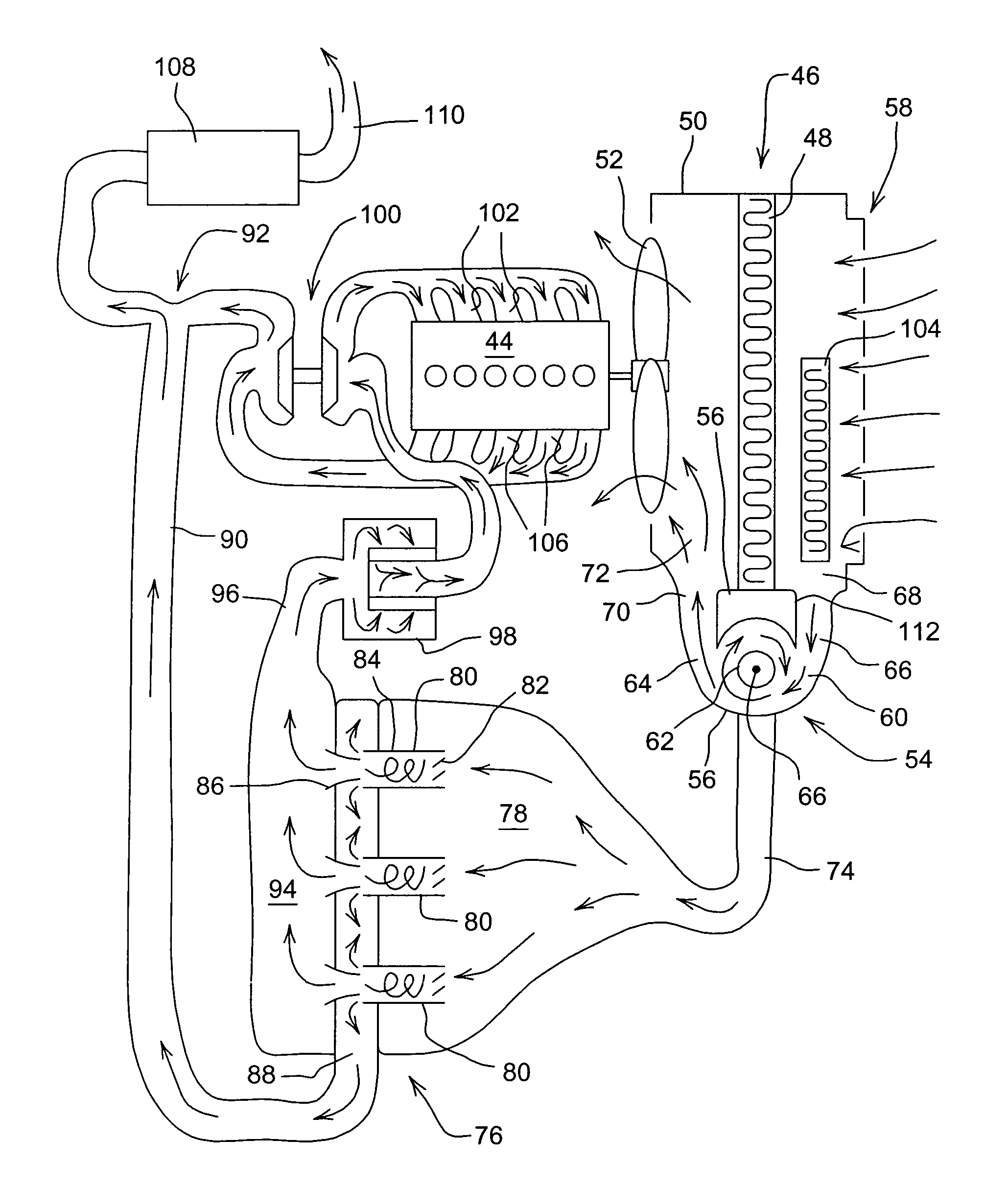

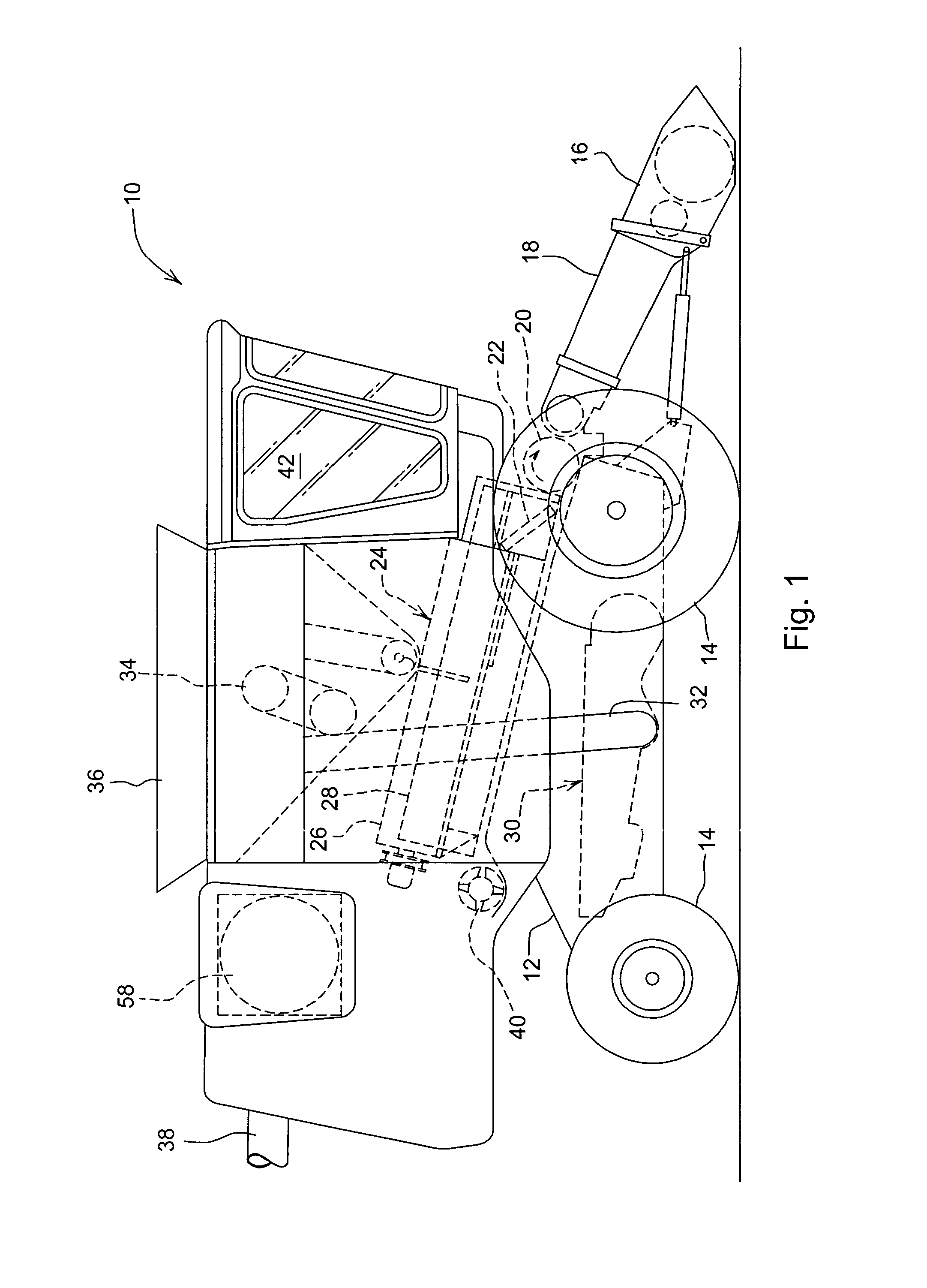

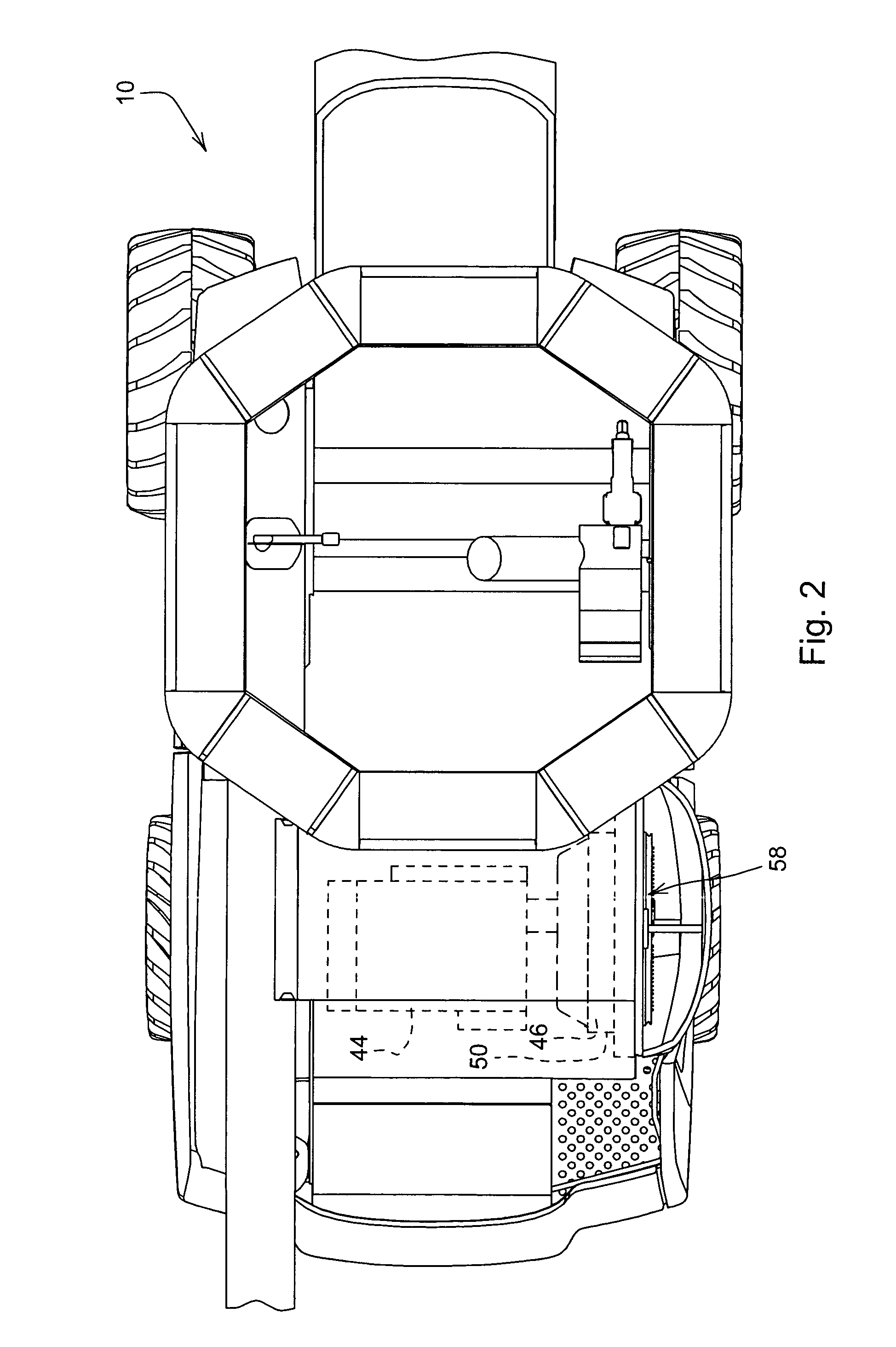

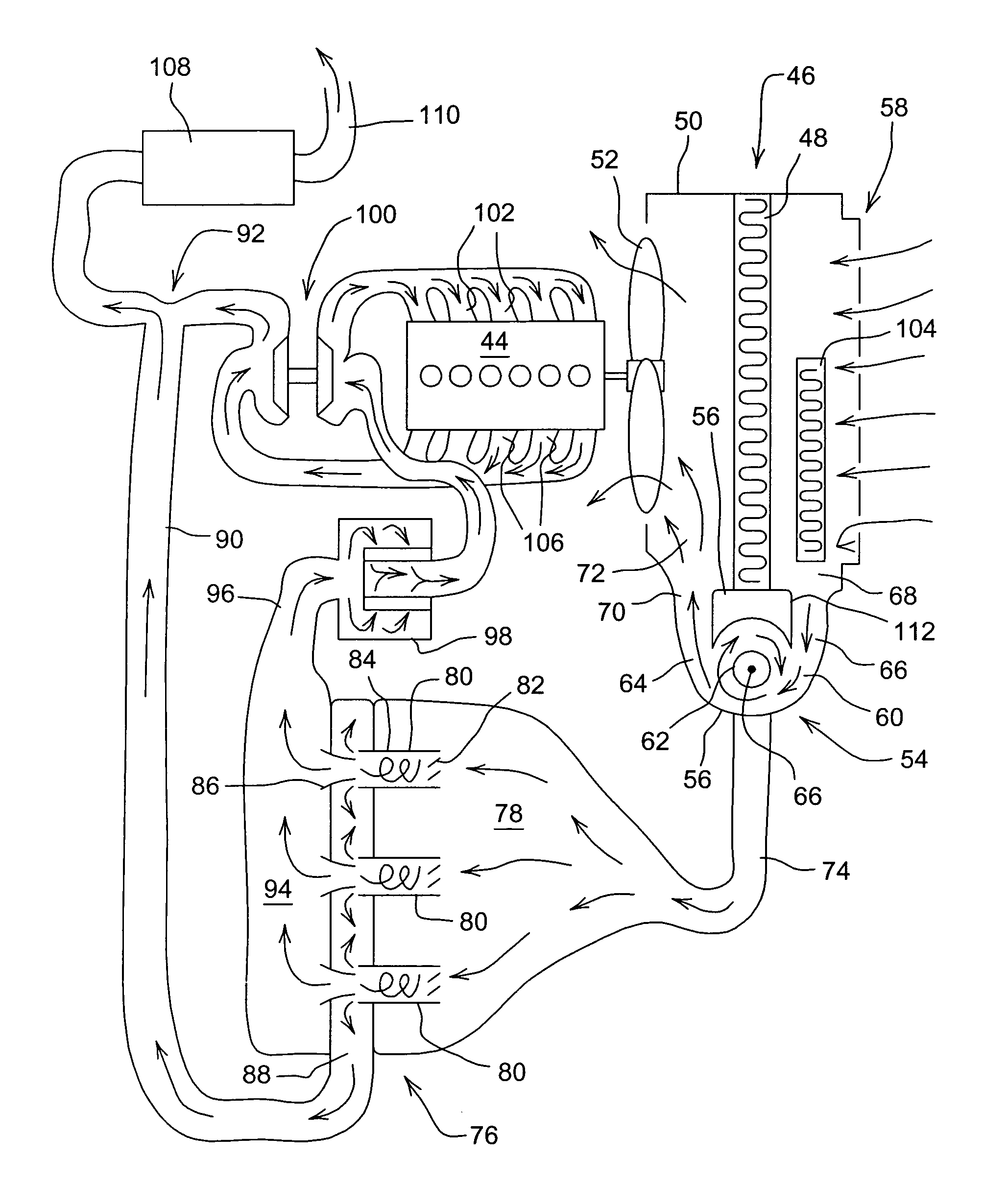

Air precleaner arrangement for an internal combustion engine comprising two cyclone filters

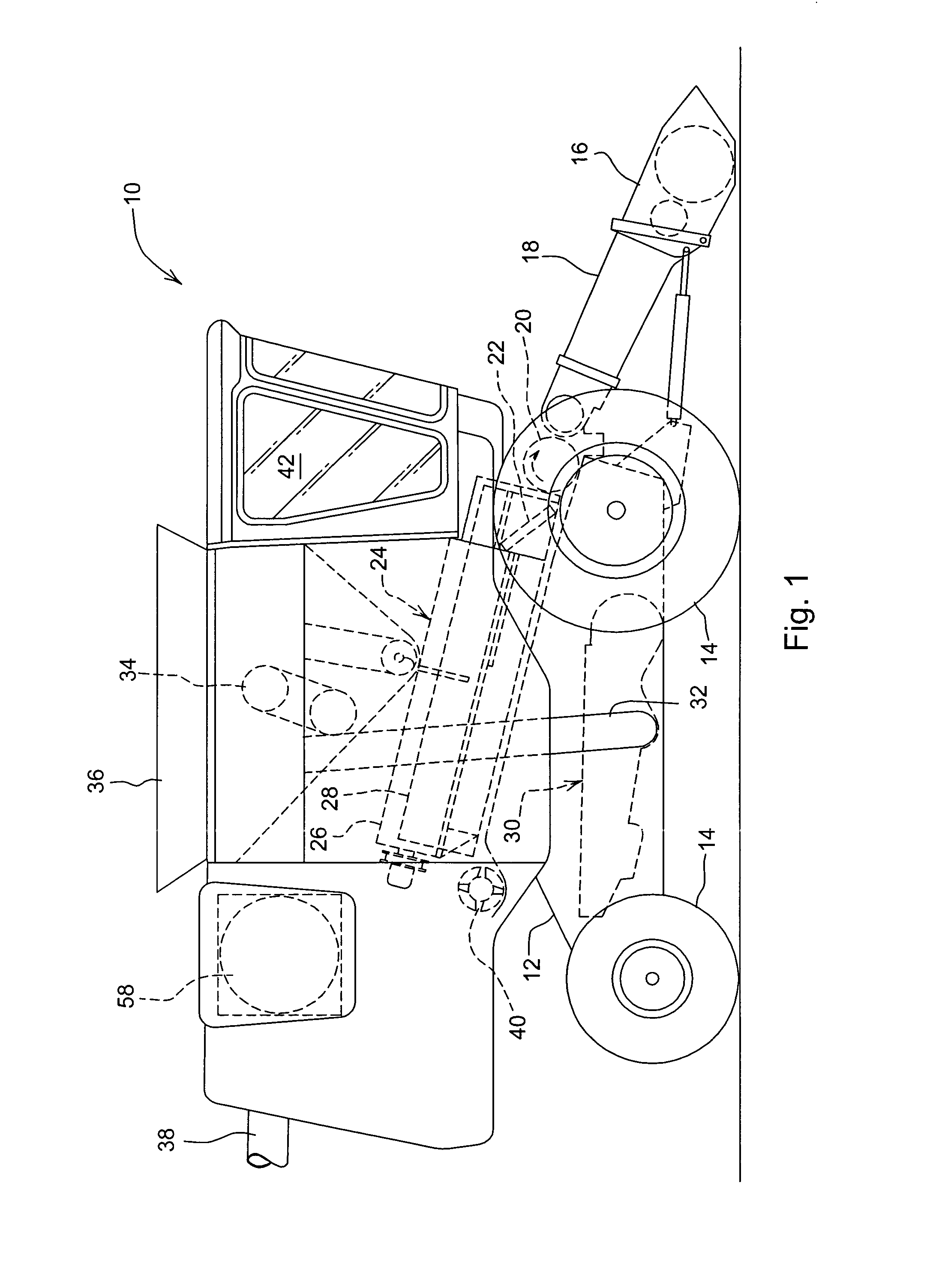

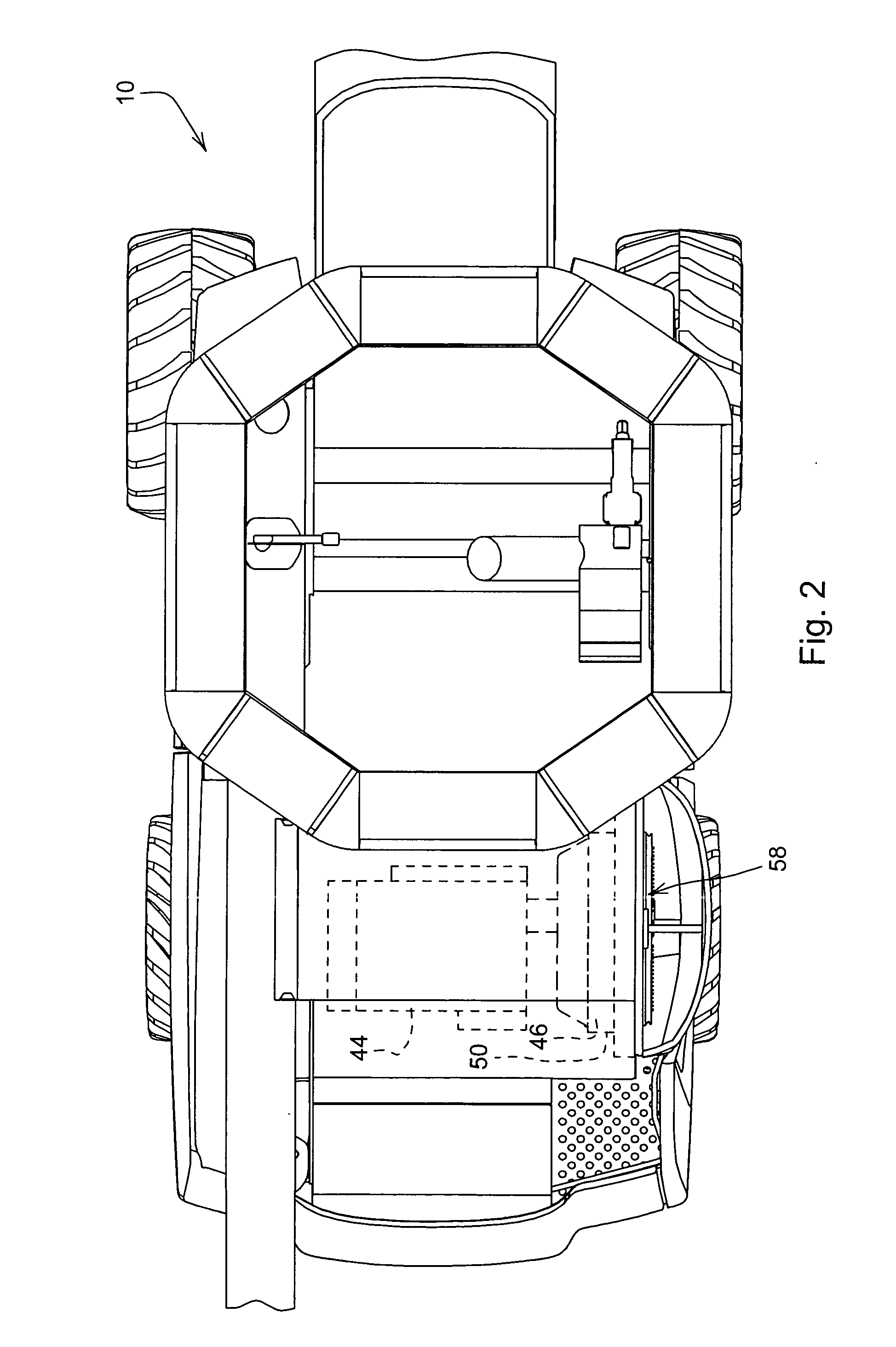

ActiveUS20080086989A1Easy to cleanCombination devicesAuxillary pretreatmentCycloneExternal combustion engine

An air precleaner arrangement for an internal combustion engine comprises a screen, a shroud, a fan, a first cyclone filter and a second cyclone filter. The screen has air permeable openings sized to retain debris. A fan is cooperating with the screen to provide an air stream from an upstream surface through the openings of the screen to a downstream surface. The shroud encloses the fan and the screen. The first cyclone filter has an air inlet receiving air on the downstream surface of the screen, an air outlet and a scavenge port in communication with interior of the screen and thus with the air stream of the fan. The second cyclone filter has an air inlet connected to the air outlet of the first cyclone filter, an air outlet connected to the air inlet of the internal combustion engine and a scavenge port connected to an exhaust venturi in the exhaust stream of the engine.

Owner:DEERE & CO

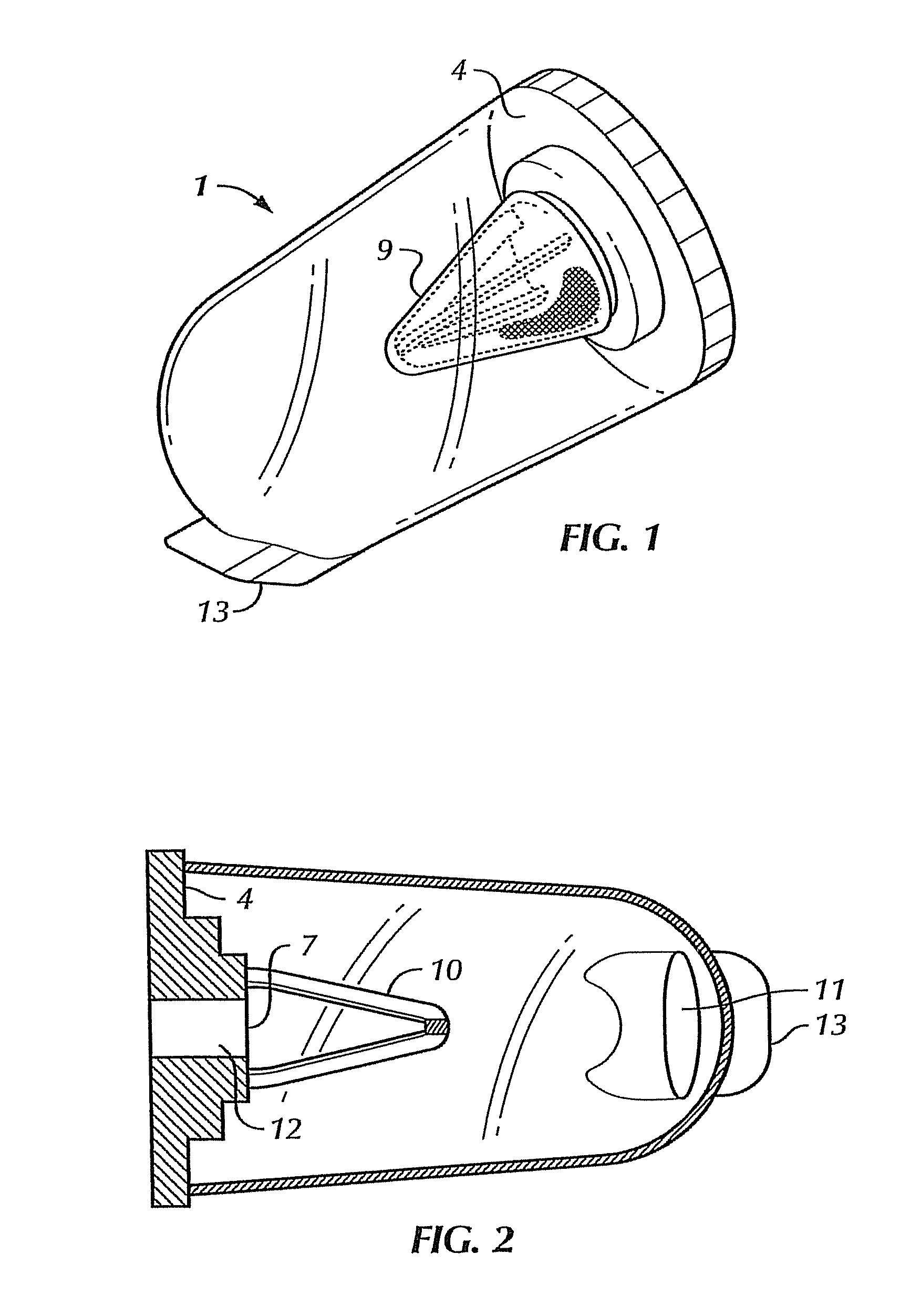

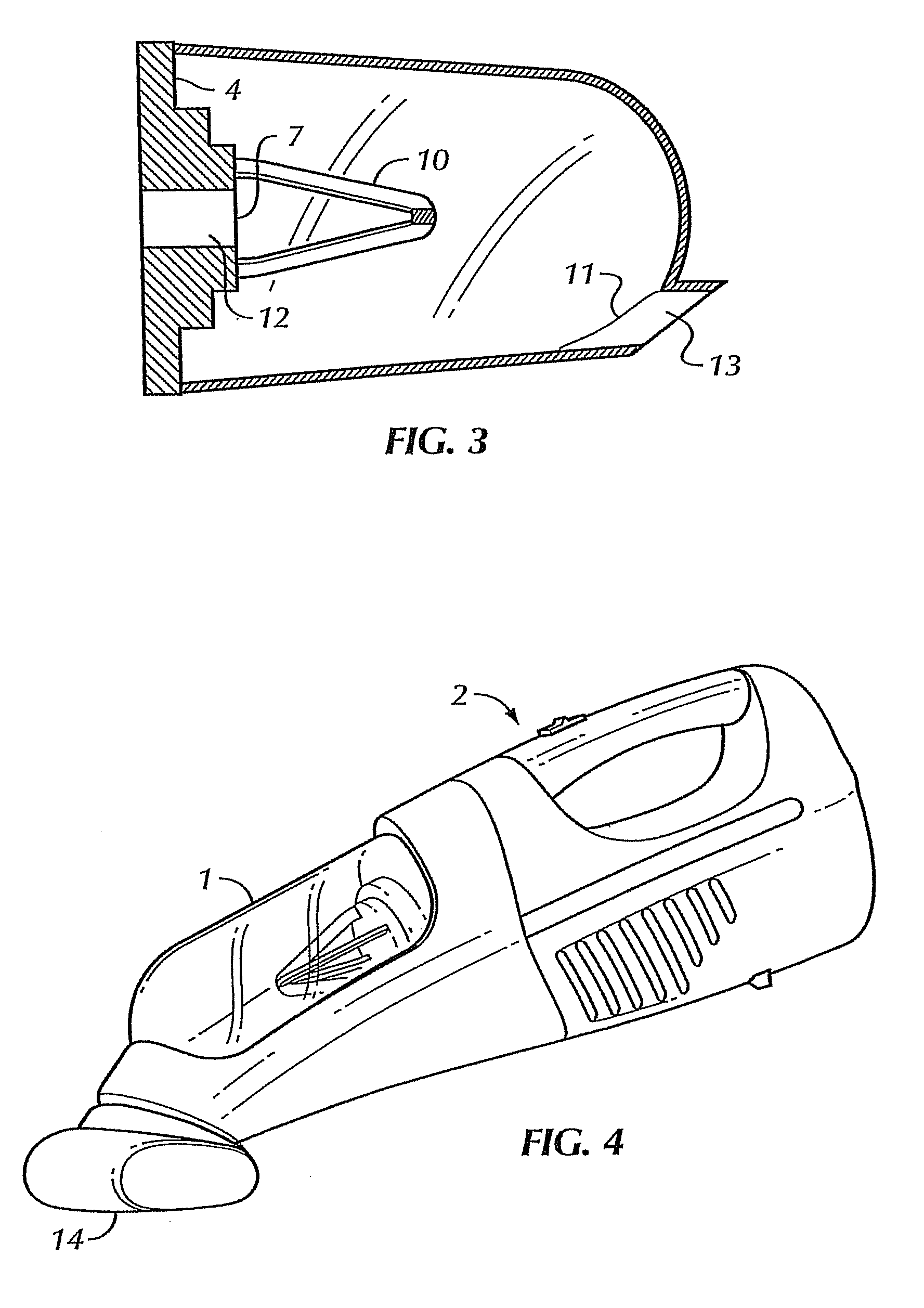

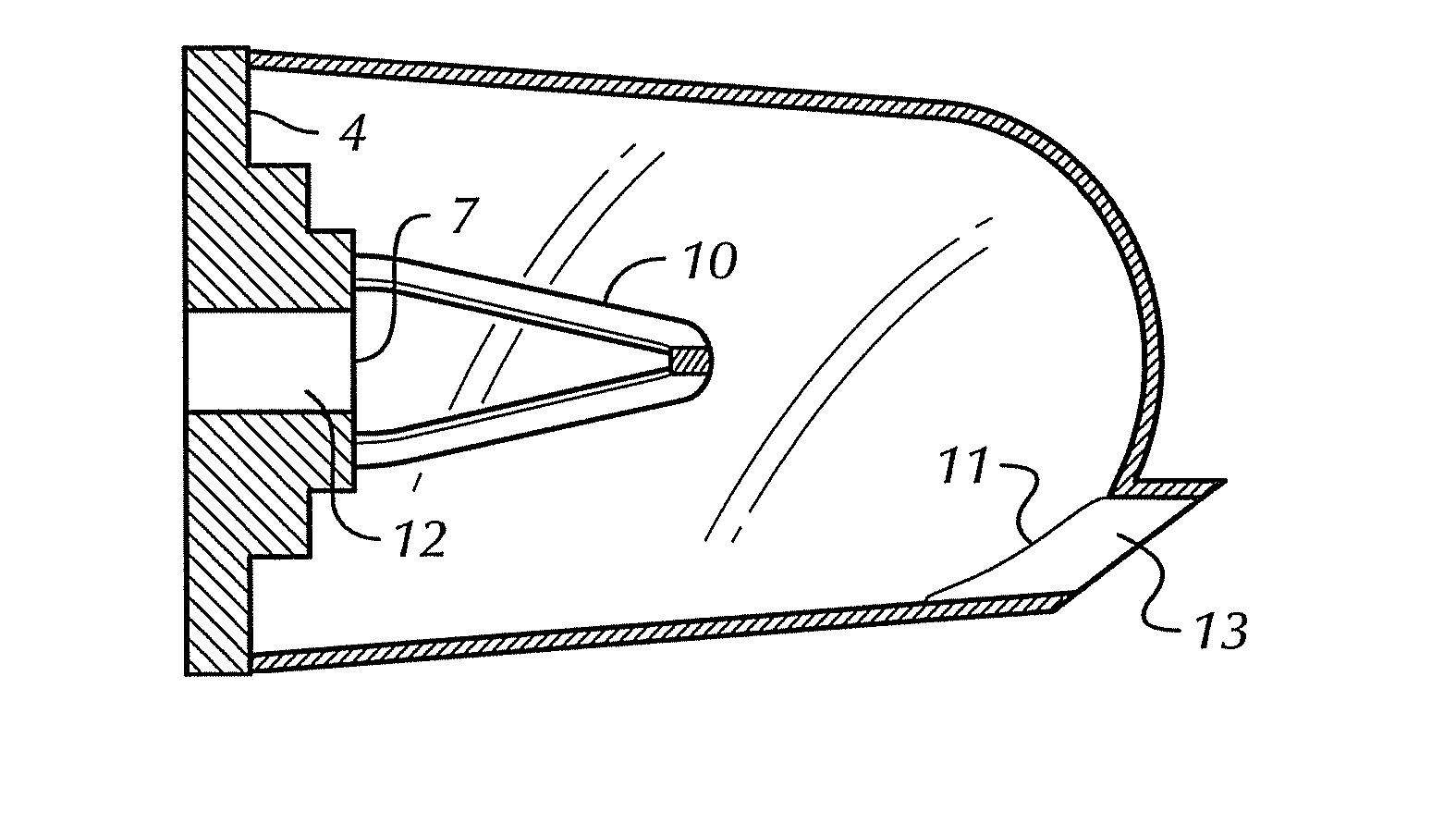

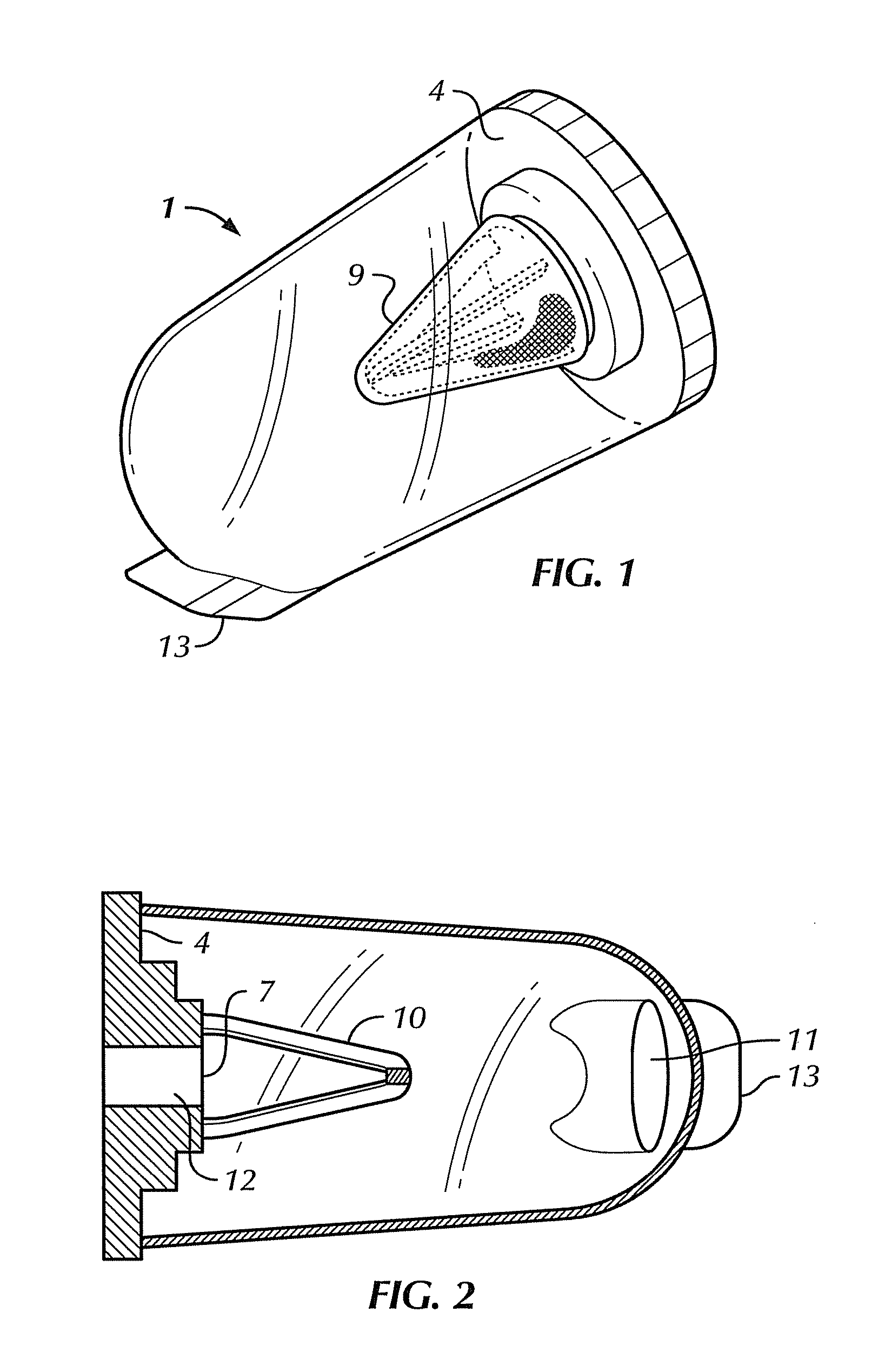

Cyclonic chamber for air filtration devices

A cyclonic chamber for use in air filtration devices. The chamber includes an apex opposite a base with sidewalls extending therebetween. The cyclonic chamber is preferably parabolic in cross-section or tubular with a hemi-spherical cap. The base contains an outflow passage and a conical filter extending therefrom. An inflow passage is provided proximate the apex. The inflow and outflow passages are parallel but not aligned. The chamber interior is smooth. The smooth interior and offset relationship of the inflow and outflow passages causes air to take a cyclonic path between the inflow passage and the filter. Debris in the airstream is pushed outward—away from the filter—by centripetal force. Eddies form proximate the base. Debris escapes the airstream there, where it either remains or, depending upon the chamber's orientation relative to gravity, falls back into the airflow where it is again directed away from the filter.

Owner:WAI LAU YING

Cyclonic chamber for air filtration devices

A cyclonic chamber for use in air filtration devices. The chamber includes an apex opposite a base with sidewalls extending therebetween. The cyclonic chamber is preferably parabolic in cross-section or tubular with a hemi-spherical cap. The base contains an outflow passage and a conical filter extending therefrom. An inflow passage is provided proximate the apex. The inflow and outflow passages are parallel but not aligned. The chamber interior is smooth. The smooth interior and offset relationship of the inflow and outflow passages causes air to take a cyclonic path between the inflow passage and the filter. Debris in the airstream is pushed outward—away from the filter—by centripetal force. Eddies form proximate the base. Debris escapes the airstream there, where it either remains or, depending upon the chamber's orientation relative to gravity, falls back into the airflow where it is again directed away from the filter.

Owner:WAI LAU YING

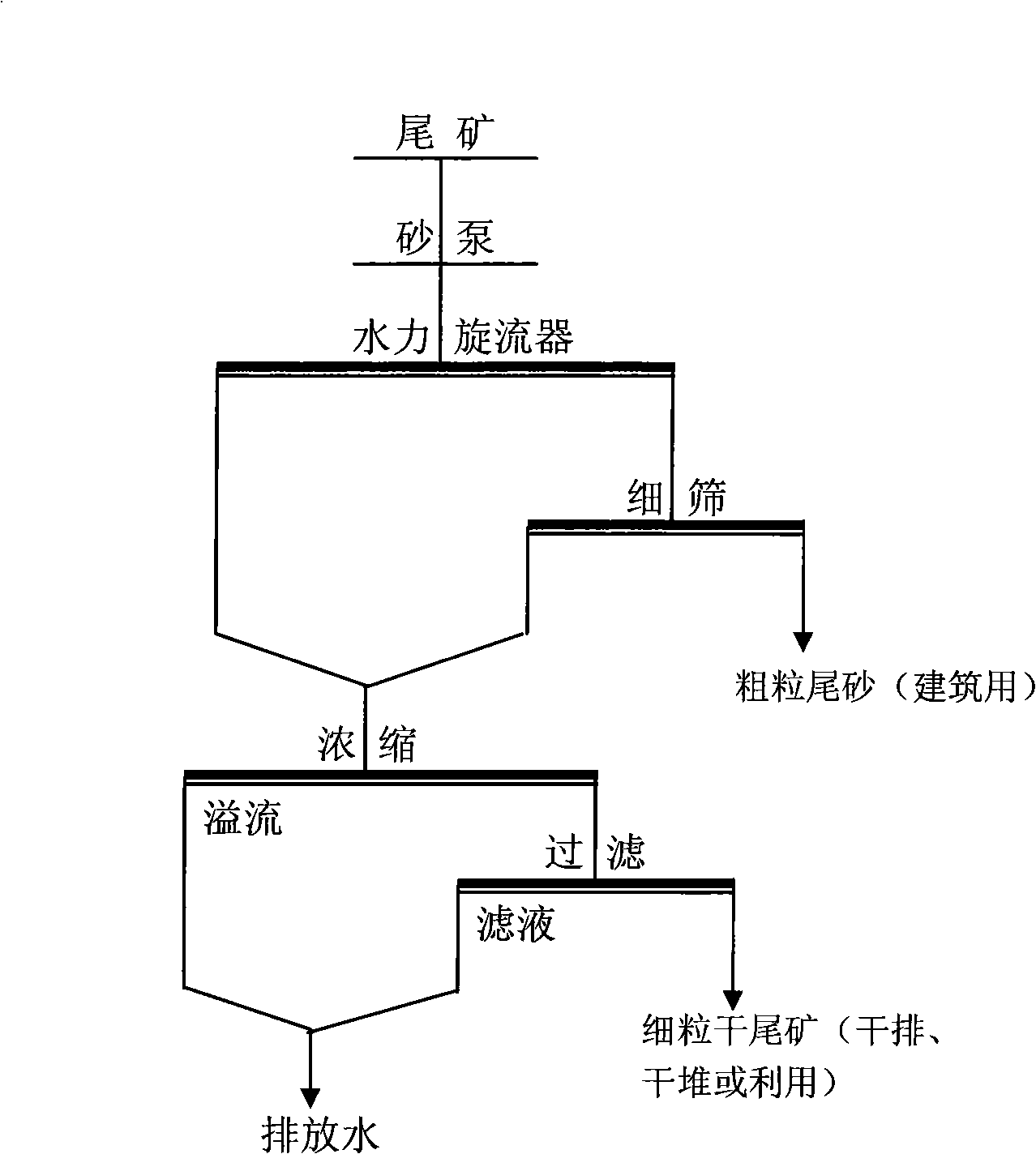

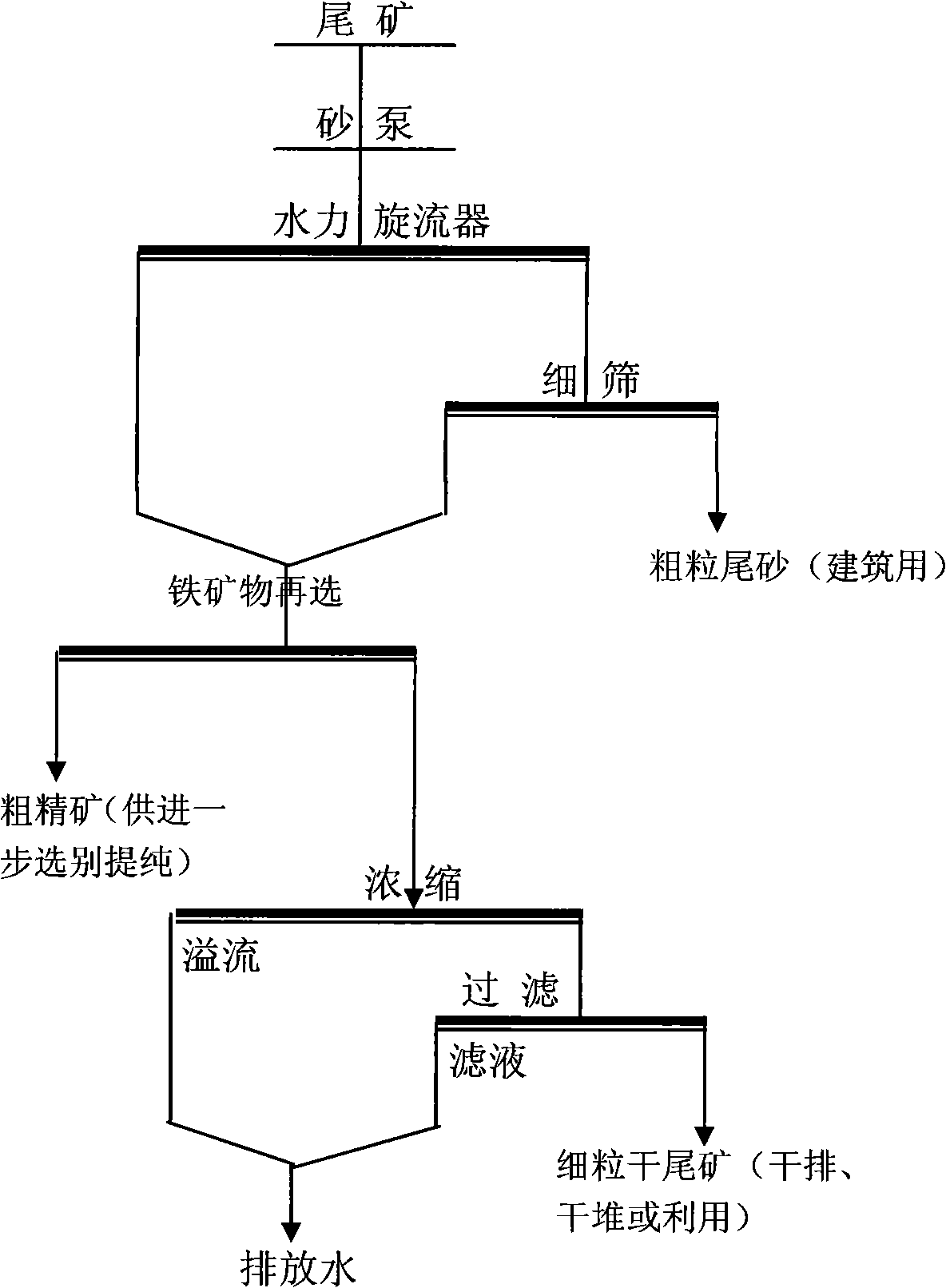

Overall utilization and treating process of iron ore mine

InactiveCN101513625ARealize the comprehensive utilization of a large amountReduce tailingsSievingScreeningYardMaterials science

The invention discloses an overall utilization and treating process of iron ore mine, which comprises the following steps: (1) according to a grading process, separating coarse grain ore mine from the iron ore mine, in which SiO2 is not less than 40%, wherein, the content of 0.16mm grade in the coarse grain ore mine is not more than 10%; (2) according to a magnetic separation method, recovering the iron mine from the fine grain ore mine separated by the grading process, thus obtaining a rough concentrate and a fine new ore mine; (3) performing the dehydration onto the fine grain ore mine or the fine new ore mine via a densifier and a filter to obtain a fine dry ore mine, wherein, the water content is not more than 20%; (4) discharging the fine dry ore mine to a dry ore mine storage yard or using the fine dry ore mine as industrial raw material. The invention has advantages that: valuable component can be overall recovered, the ore mine can be greatly utilized, meanwhile, zero ore discharge in the ore mine base can be achieved. Accordingly, the invention is widely used for overall utilization and safety treatment of magnetic iron ore and hematite ore mine.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Air volume controller for cyclone dust collectors

The invention provides an air volume controller of a cyclone dust collector, which belongs to the technical field of the environmental protection. The cyclone dust collector comprises a dedusting tank and a plurality of cyclones arranged inside the dedusting tank. Each cyclone comprises a cyclone unit, a guider arranged on the cyclone unit, and an air-guide tube inserted on the guider and extending into the cyclone unit. The cyclone dust collector is characterized in that an air volume controller is arranged above the upper supporting plate; the air volume controller comprises a valve base, an openable / closable valve cover and an electrohydraulic pusher; the valve base is mounted on the upper plane of the upper supporting plate; an opened end is formed at the upper part of the valve base; the openable / closable valve cover is positioned above the valve base and used for covering the opened end at the upper part of the valve base; the electrohydraulic pusher is mounted at the top of the dedusting tank; and the lower end of the electrohydraulic pusher extends inside the cavity of the dedusting tank and is coupled to the openable / closable valve cover. The invention has the advantage of being favorable for ensuring an extremely-high dust collection efficiency of the cyclone dust collector.

Owner:JIANGSU XINHUANENG ENVIRONMENTAL ENG CO LTD

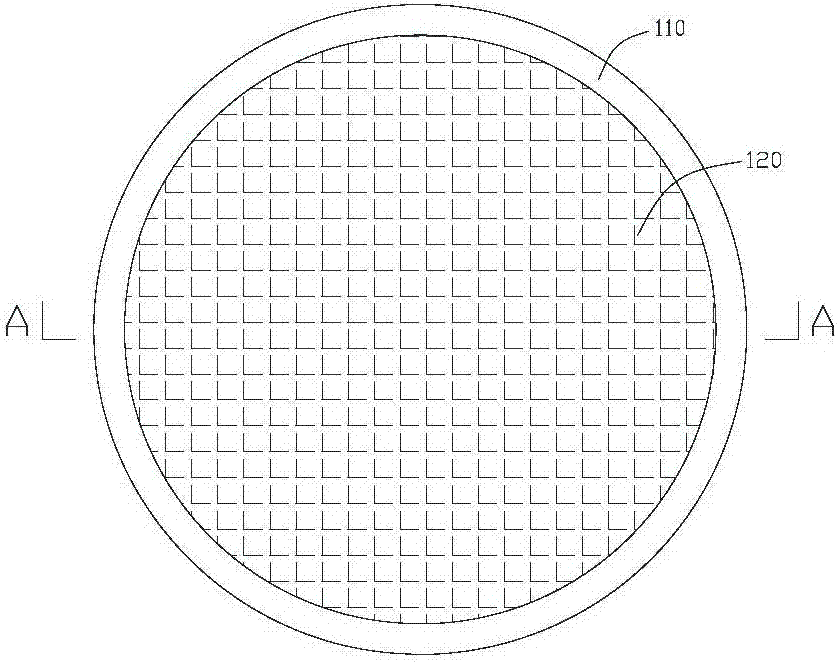

Screening device and titanium alloy powder screening system

PendingCN107159562ASimple structureEasy to processSievingAdditive manufacturing apparatusScreening effectEngineering

The invention provides a screening device and a titanium alloy powder screening system and belongs to the technical field of 3D printing powder screening and production. The screening device comprises a feeding assembly, a screening assembly and a vacuum feeding assembly. The screening assembly comprises a screen frame, a screen body and a guide piece. The guide piece is provided with a first opening, a second opening and a guide wall by which a guide channel is defined. The guide piece is mounted on the screen frame. The first opening is configured to receive materials falling off from the screen body. The guide wall is configured to receive materials falling off from the first opening and guide the materials to the second opening. The vacuum feeding assembly is configured to collect the materials screened from the screen body and put the materials to the feeding assembly. In the use process of the screening device, the screened materials falling off from the screen body can be gathered and fall into the next stage of screen to be screened; and the materials do a involute helicoid motion along with the swing of the screening machine, the screening effect is good, the screen body is not likely to be blocked, multiple times of screening can be conducted, and the yield is increased.

Owner:苏州三峰激光科技有限公司

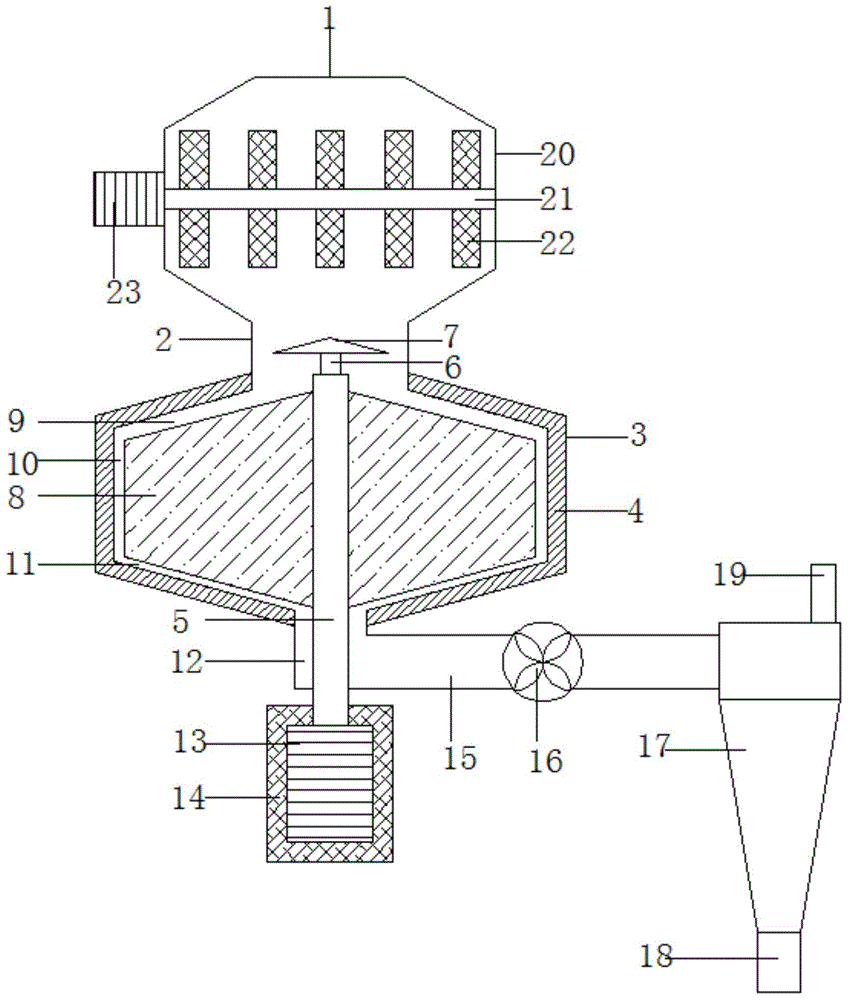

Pulverizer provided with deironing device and used for producing ceramics

InactiveCN104923334AQuality assuranceReduce noiseVortex flow apparatusMagnetic separationMaterial qualityCeramic

The invention discloses a pulverizer provided with a deironing device and used for producing ceramics. The pulverizer comprises a feeding funnel, a pulverizing cavity and a deironing cavity, wherein the deironing cavity is connected to the lower side of the feeding funnel, a rotary shaft is horizontally disposed inside the deironing cavity, electromagnets are disposed on the outer wall of the rotary shaft in an up-down symmetry manner, the left end of the rotary shaft extends out of the deironing cavity and is connected with a drive motor, and a discharging pipe is connected to the bottom end of the feeding funnel. The pulverizer has the advantages that materials are pulverized by three pulverizing gaps formed in an up-down manner, the size of the pulverizing gaps gradually decreases from top to bottom, long pulverizing time and high efficiency are achieved, pulverizing effect of the pulverizer is guaranteed, a material dispersing plate can effectively avoid material blocking during pulverizing, a cyclone separator is used to recycle the materials and achieve automatic discharging, dust pollution during discharging is avoided, raw materials are saved, the rotary electromagnets are used for deironing, good deironing effect and sufficient deironing are achieved, and material quality is guaranteed.

Owner:顾马飞

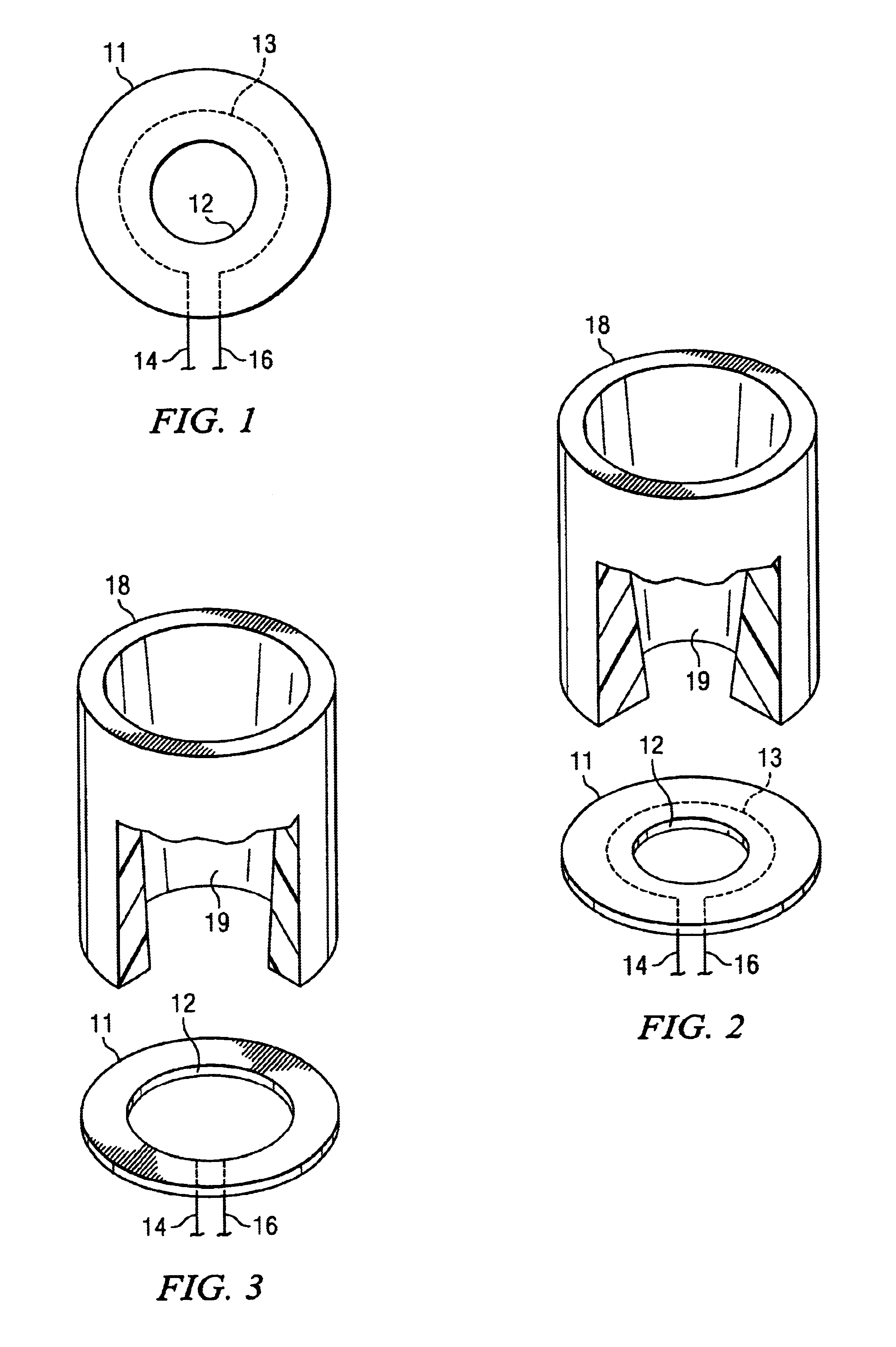

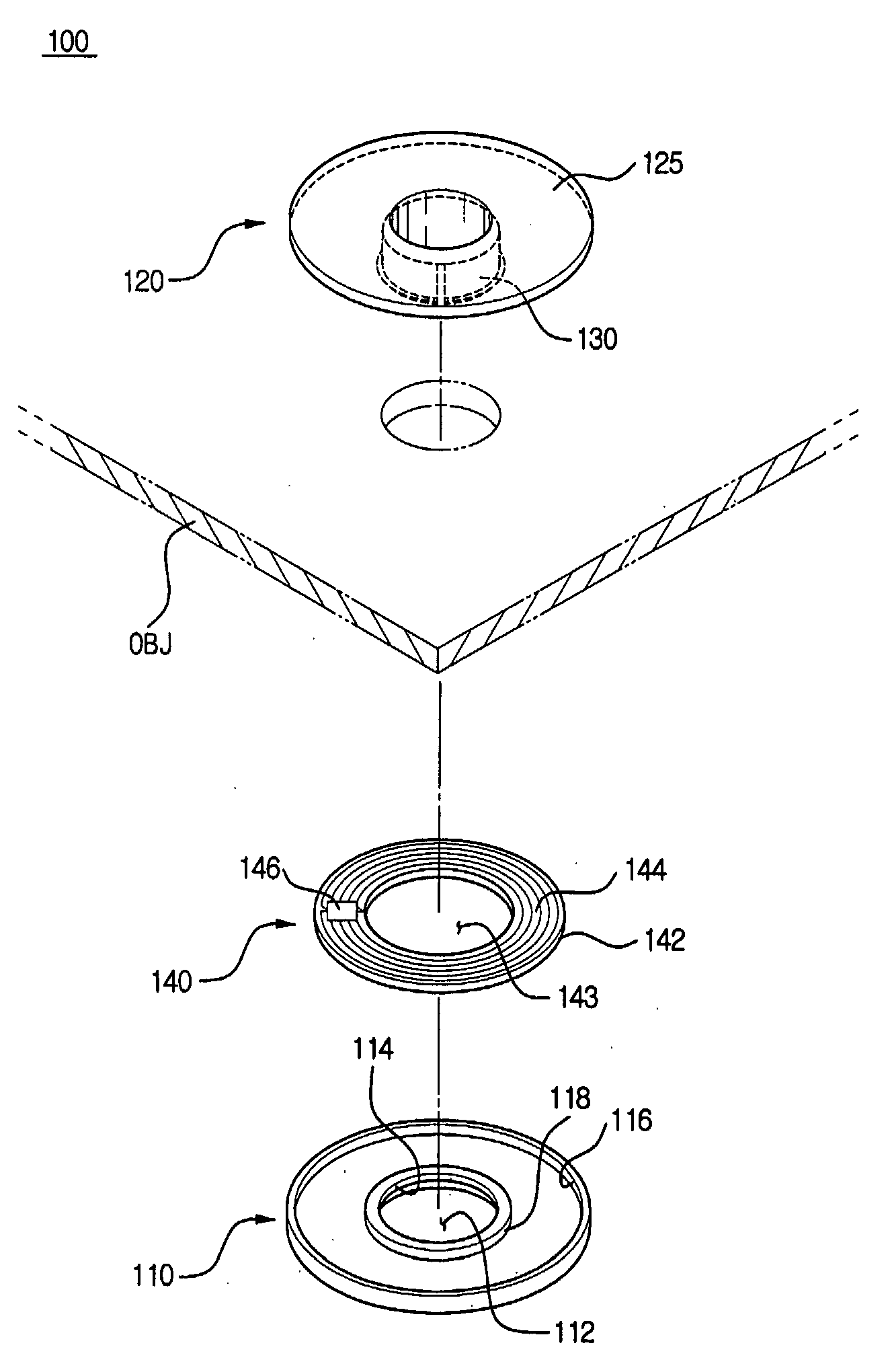

Eyelet for a radio frequency identification

InactiveUS20070171075A1Poor durabilityAvoid impactVortex flow apparatusDisinfectionConductive materialsFlange

Provided is an RED eyelet performing non-contact identification function. The RFID eyelet includes an eyelet washer and eyelet base composed of nonconductive material, and an RED module is interposed between the eyelet washer and eyelet base. The RFID eyelet contains the RFID module in nonconductive material, thereby performing smooth electromagnetic wave communication without disturbance, and the eyelet base is simply coupled. with the eyelet washer by using a slanted projection formed in the eyelet base and a locker formed in the eyelet washer. Also, the RED module can be easily installed by using an internal flange or external flange formed in the inside of the eyelet base or eyelet washer, thereby having a merit of mass production.

Owner:RFCAMP

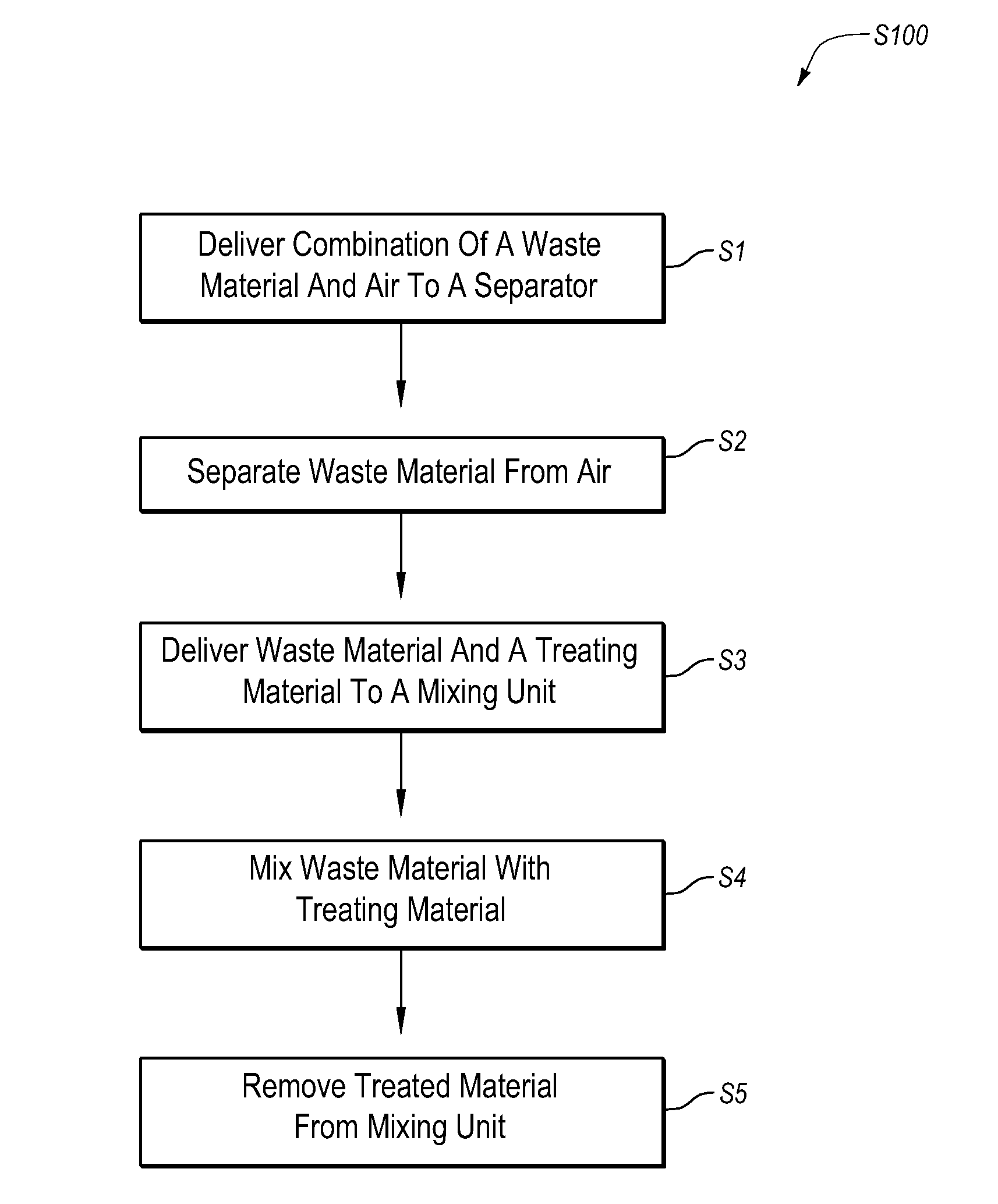

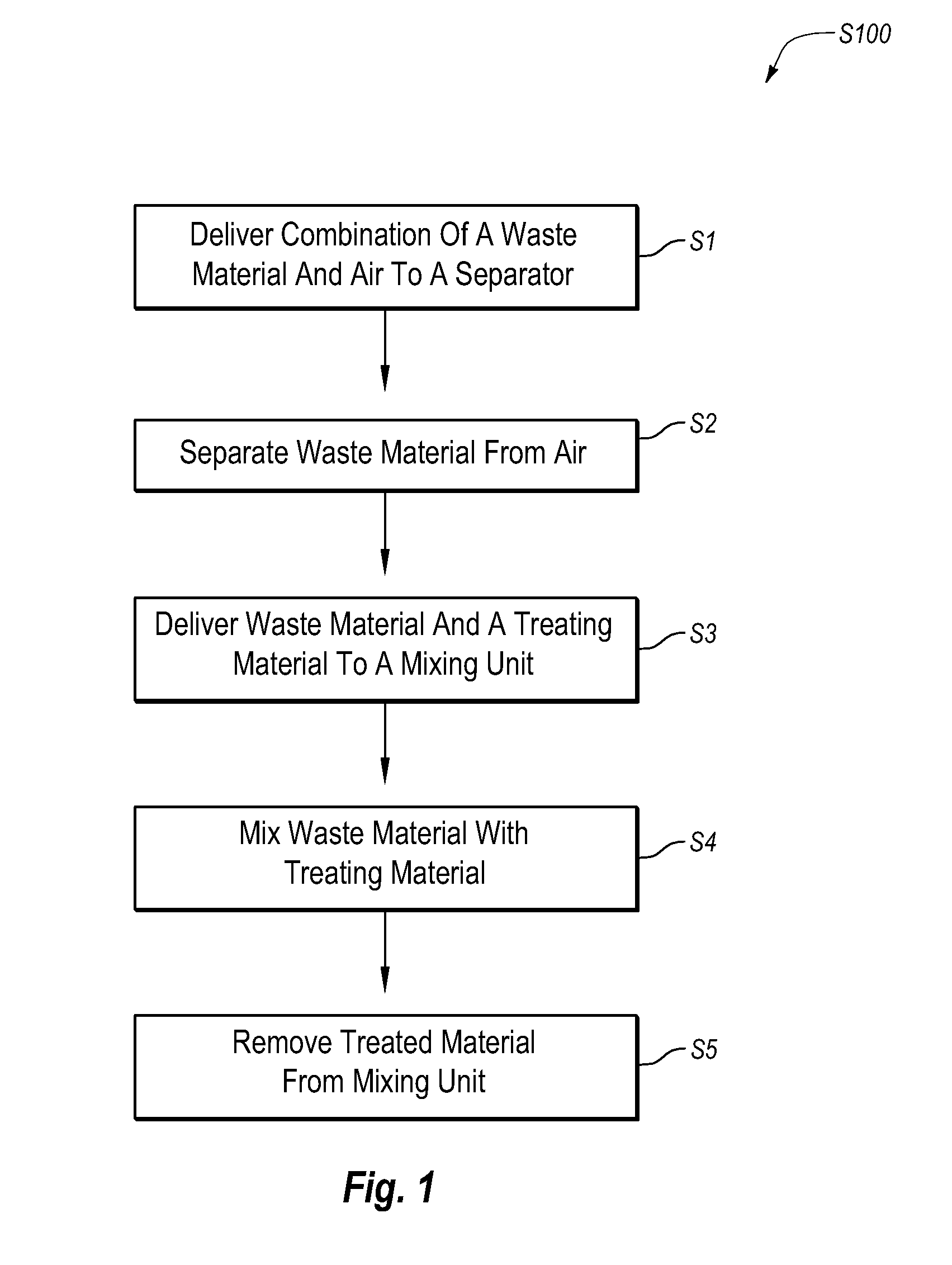

Apparatus and method for collecting and treating waste

InactiveUS20120292257A1Reduce air pressureWater/sewage treatment by centrifugal separationLiquid degasificationMotor driveMobile device

Devices and methods for collecting and treating waste materials. One implementation of the present invention includes a mobile apparatus that continuously collects a waste material and continuously treats the waste material so that it is suitable for disposal, transportation, or reuse at a desired location. Such an apparatus may include a delivery mechanism that delivers a waste material to a motor driven mixing unit at a selectable rate. This delivery mechanism may include a pump or a motor driven blower and separator. The mixing unit may be configured to receive a treating material and to mix the waste material with the treating material. Advantageously, the delivery mechanism and the mixing unit are positioned together on a portable unit (e.g., a trailer, a barge, a railroad car, etc.) so that the apparatus is mobile and portable.

Owner:HARTLEY DWIGHT

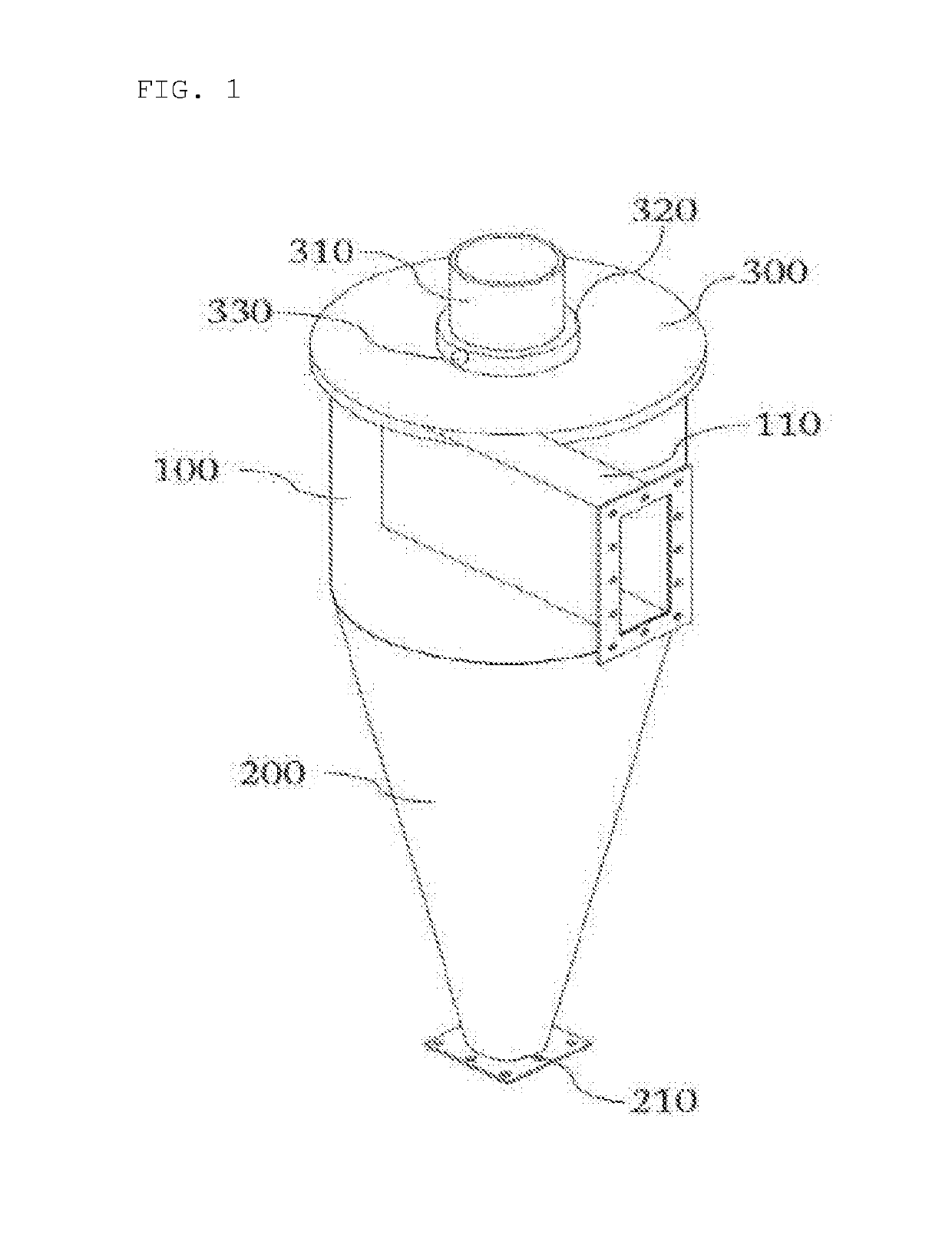

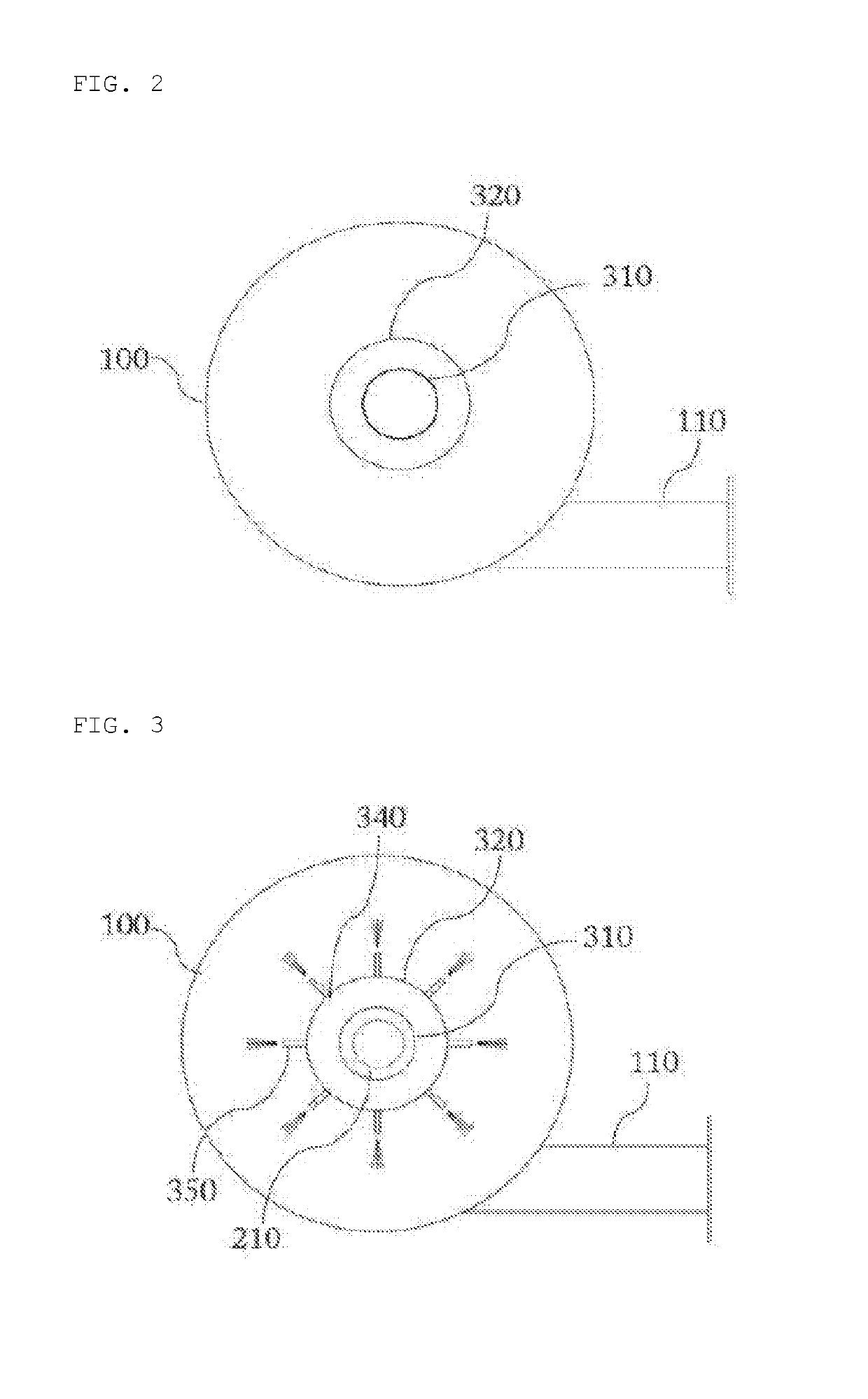

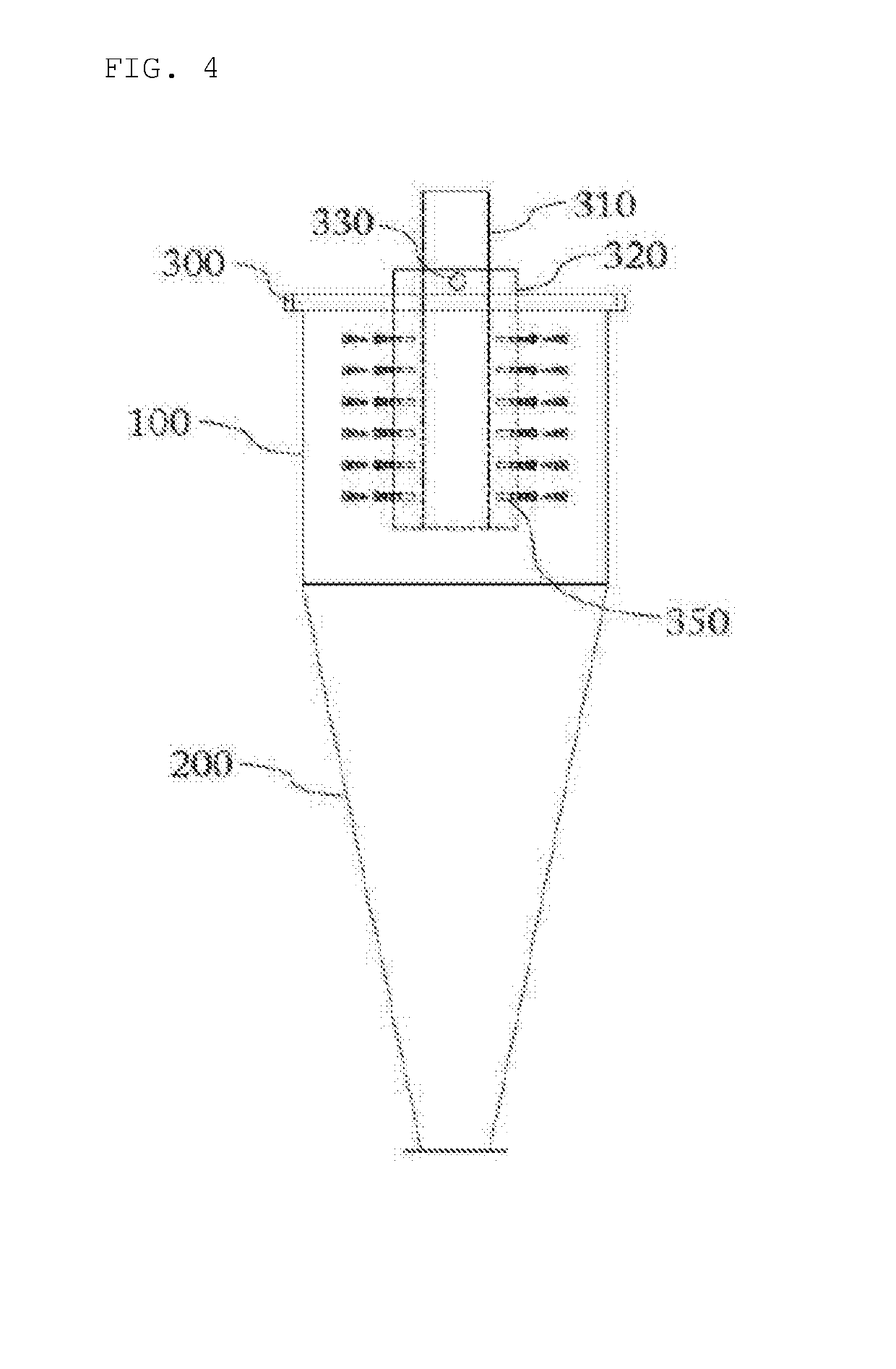

Wet type dust collector using electrospray and vortex

ActiveUS20190336904A1Efficient removalEasy to operateCombination devicesLiquid supply arrangementsElectricityGas-discharge lamp

The present invention relates to a wet type dust collector using electrospray and a vortex, the dust collector having a cyclonic structure and removing dust contained in exhaust gas by spraying fine droplets that are generated when high voltage is applied to the dust collector. More particularly, the present invention relates to a wet type dust collector using electrospray and a vortex, the dust collector including: a cylinder having an exhaust gas intake pipe for guiding exhaust gas containing granular pollutants at a predetermined position on the outer side, and forming an empty space; a hollow cone tapered downward, connected to the bottom of the cylinder at the top, and having a liquid discharge port at the bottom; a lid through which a hollow cylindrical gas discharge pipe is disposed to discharge gas with granular substances removed to the outside and, that is disposed on top of the cylinder; a positive (+) lead wire connected to the cylinder; and a negative (−) lead wire connected to the gas discharge pipe, in which a liquid container having one or more liquid spray ports is disposed on the gas discharge pipe.

Owner:KOREA INST OF ENERGY RES

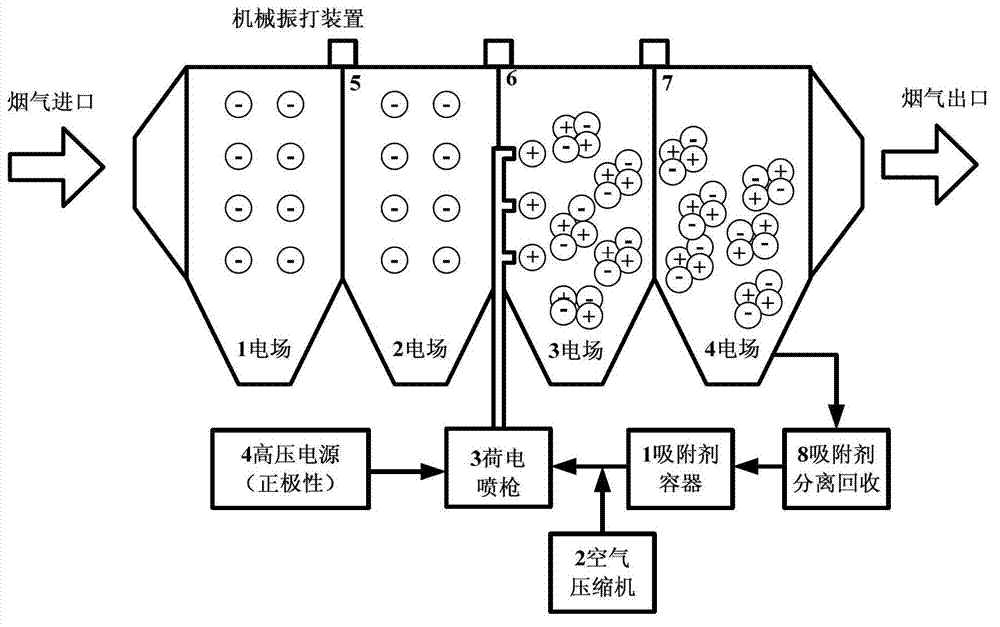

Method for removing fine particles and heavy metals in coal fume

ActiveCN102773162ALarge structure sizeLess investmentElectrostatic separationVortex flow apparatusSorbentPre-charge

The invention relates to a method for removing fine particles and heavy metals in coal fume. The method is an electric precipitator coupling charging absorbing agglomeration technology. The method comprises the steps of: pre-charging (positive charge) on an adsorbent by a charging spray gun, and spraying the adsorbent to an area between two adjacent electric fields of the electric precipitator; by a Coulomb agglomeration action between a positively charged absorbent particle and a fine particle which is negatively charged by last electric field and is not captured, and an absorption action of the charged absorbent, capturing a plurality of pollutants including fine particles, heavy metals and condensable substances, onto the absorbent to form larger particles; and efficiently capturing the larger particles by the electric field at the back of the electric precipitator, so as to achieve the purpose of synergistically removing a plurality of pollutants in smoke. Compared with prior art, the method of removing fine particles and heavy metals in coal fume has the advantages of high efficiency and low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

Popular searches

Transportation and packaging Direct heating destructive distillation Biofuels Indirect and direct heating destructive distillation Liquid hydrocarbon mixture production Indirect heating destructive distillation Pyrolysis reactions Discharging devices Hydrocarbon by hydrocarbon cracking Membrane filters

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com