Patents

Literature

62results about How to "Reduce ore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

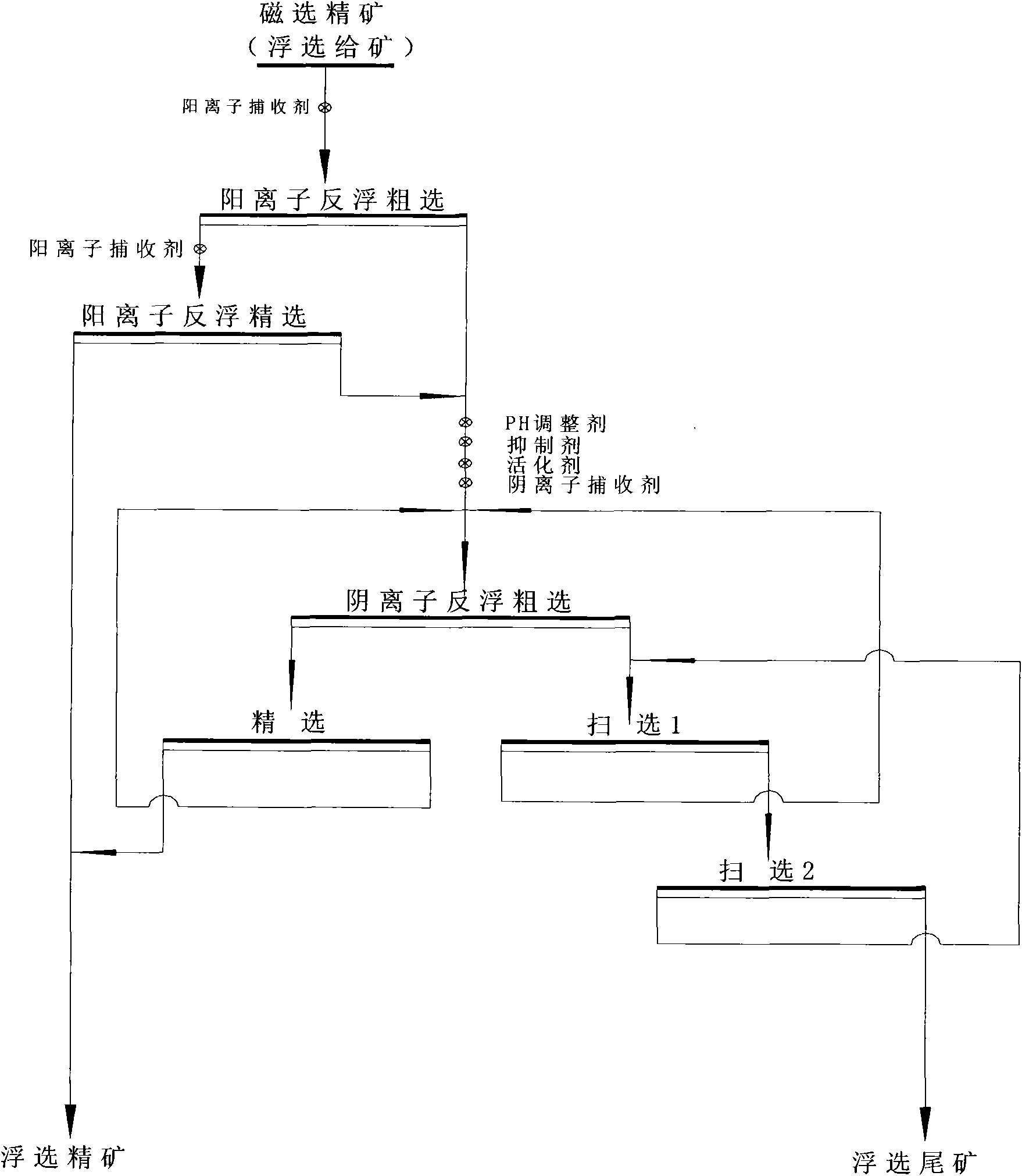

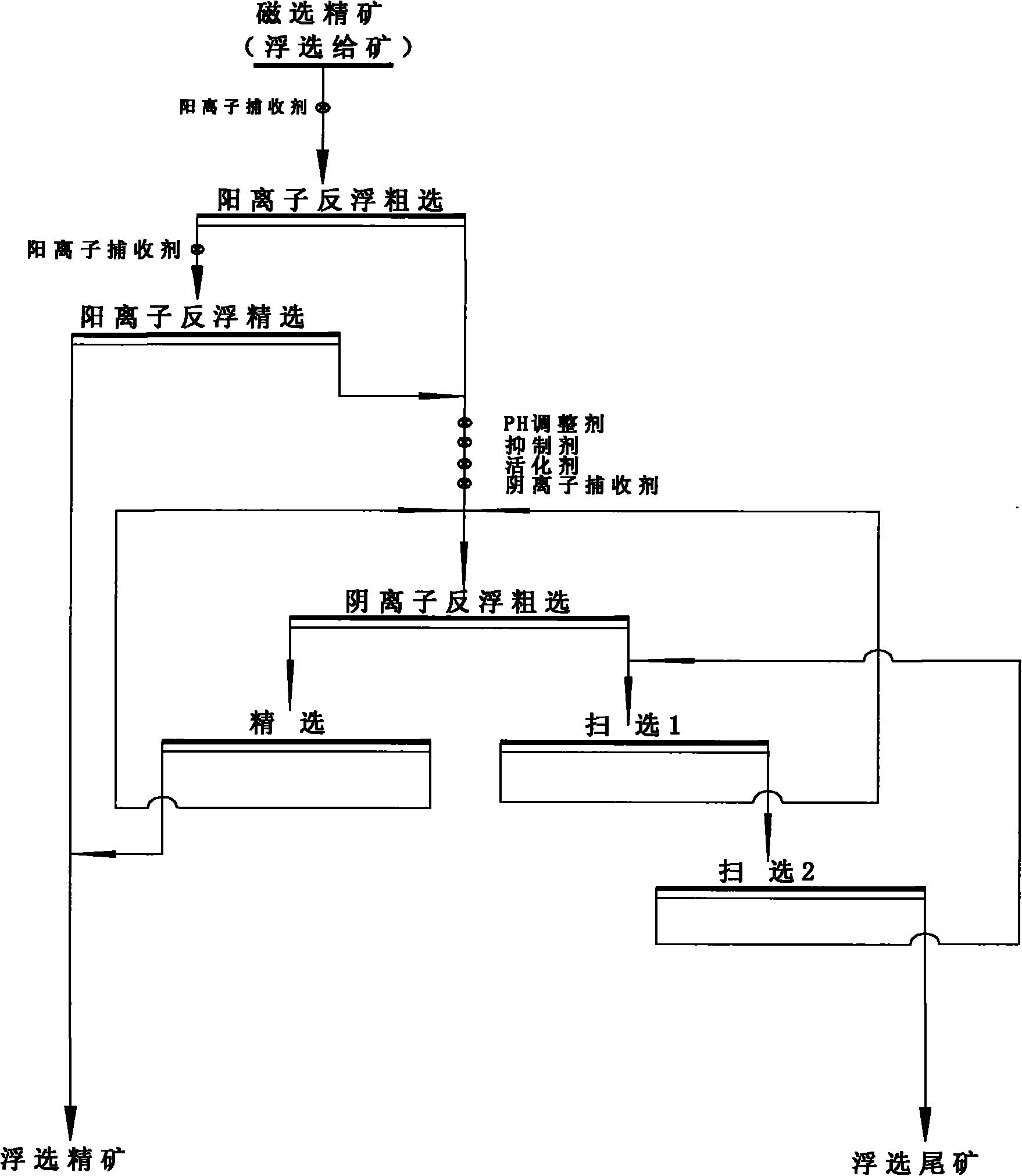

Beneficiation method for producing high-quality iron ore concentrate by low-grade magnetic iron ore

The invention discloses a beneficiation method for producing high-quality iron ore concentrate by low-grade magnetic iron ore, which comprises the following steps that a stage grinding-stage magnetic separation discarding tailing beneficiation process is adopted to produce magnetic separation ore concentrate with the iron ore concentrate grade TFe of 62-66%; a positive ion collector reverse flotation process is adopted on the magnetic separation ore concentrate to obtain positive ion collector reverse flotation iron ore concentrate and middling; a negative ion collector reverse flotation process is adopted on the middling obtained by positive ion collector reverse flotation to obtain negative ion collector reverse flotation iron ore concentrate; and the positive ion collector reverse flotation iron ore concentrate and the negative ion collector reverse flotation iron ore concentrate are combined to obtain the ultimate high-quality iron ore concentrate. The invention has the advantages of high grade of iron ore concentrate, high iron recovery rate, small loss of fine iron minerals, low beneficiation energy consumption and small consumption of medicaments, can relieve the industry difficulty of difficult filtration caused by adding starch into fine concentrate, greatly optimizes concentrate filtration operation, can be used for the sorting of magnetite ore, and can also be used for the sorting of weakly magnetic iron minerals such as hematite and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

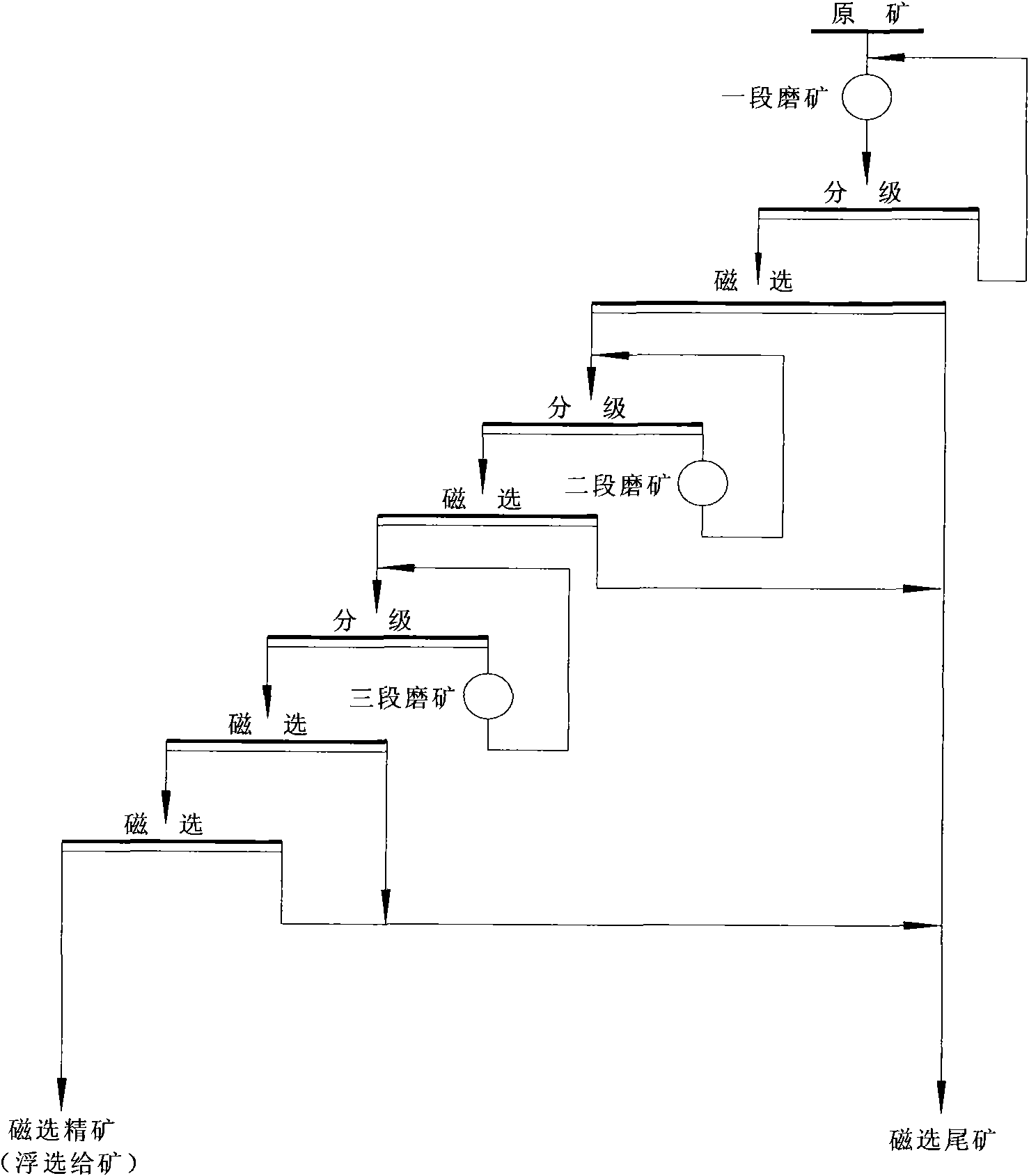

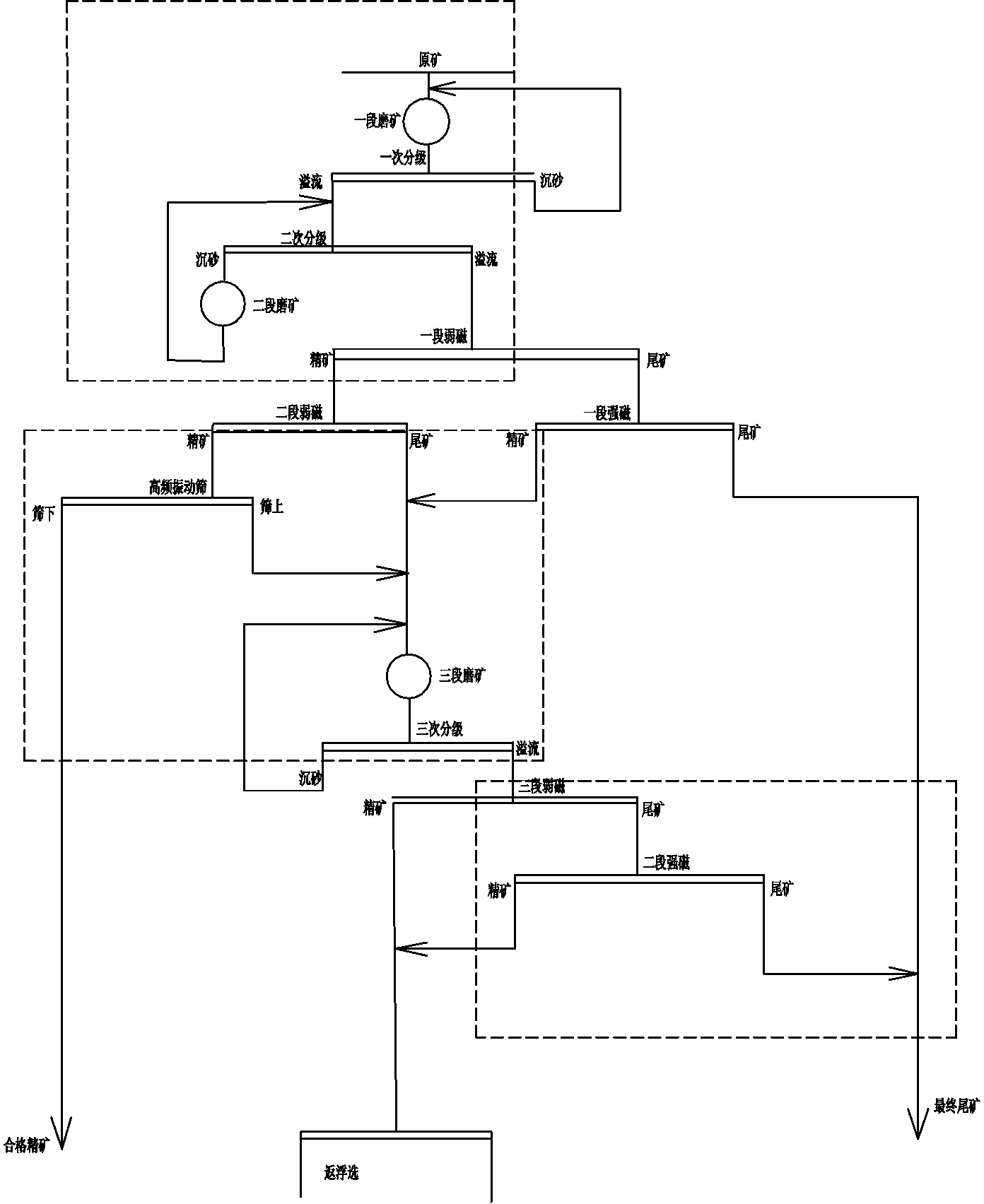

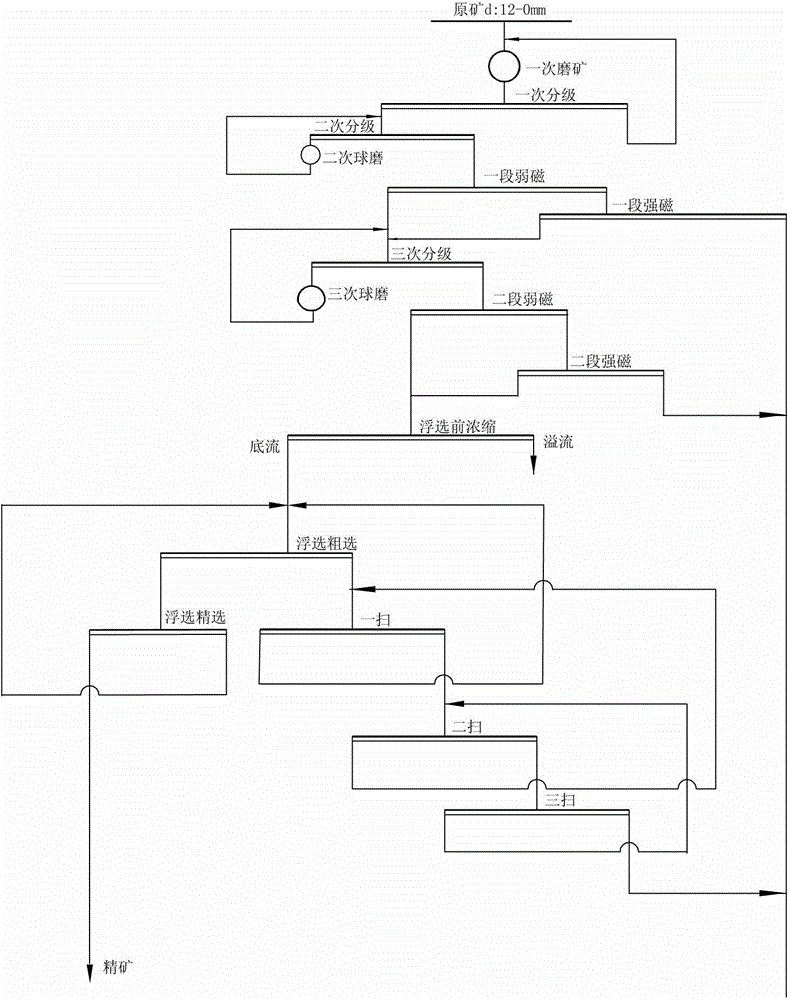

Mineral processing process for processing mixed ore of magnetic iron ore and hematite-limonite ore

The invention relates to a mineral processing process for processing mixed ore of magnetic iron ore and hematite-limonite ore. The mineral processing process comprises steps as follows: raw ore containing the mixed ore of the magnetic iron ore and the hematite-limonite ore is smashed and then subjected to two-stage continuous ore grinding; overflowing ore of a secondary classifying cyclone is subjected to two-stage low-intensity magnetic separation and one-stage fine screening and separation in combination of a single magnetic separation, fine screening and regrinding process for processing magnetic ore; under the condition of rougher ground ore particles, a part of undersize qualified magnetite concentrate products are firstly obtained, the other part of oversize products are combined with one-stage high-intensity magnetic separator concentrate and two-stage low-intensity magnetic separator tailings to serve as middlings, and the middlings are subjected to three-stage ore grinding classification operation for regrinding and separation; and overflowing ore of a tertiary classifying cyclone is subjected to three-stage low-intensity magnetic separation and high-intensity magnetic separation, fine-grain qualified tailings are thrown again, three-stage low-intensity magnetic concentrate and two-stage high-intensity magnetic concentrate are combined to obtain mixed magnetic concentrate, the mixed magnetic concentrate is subjected to a reverse flotation process for separation, and a qualified flotation concentrate product is obtained. According to the mineral processing process, the mixed ore of the magnetic iron ore and the hematite-limonite ore with different dissemination particle sizes is reasonably processed, the qualified iron ore concentrate product is obtained, and the mineral processing process is economical, energy-saving and environment-friendly.

Owner:ANSTEEL GRP MINING CO LTD

Novel beneficiation technology of high-grade ferrochrome ore

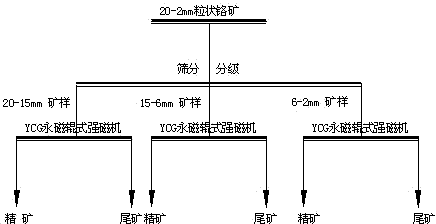

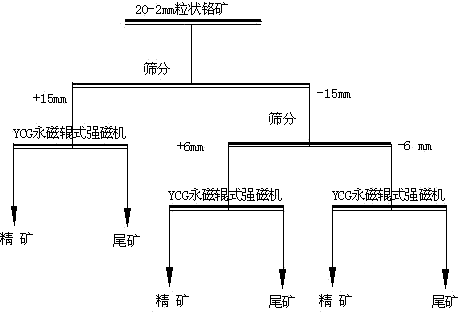

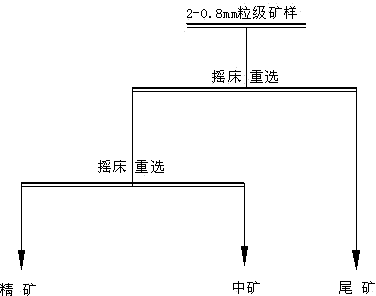

The invention discloses a novel beneficiation technology of high-grade ferrochrome ore. The novel beneficiation technology includes the following technological processes that ferrochrome ore is broken and is screened and classified into the ore of +20 mm fraction and the ore of -20 mm fraction. The ore of the +20 mm fraction receives manual back picking or hotching, large waste ore is thrown, and block concentrate is obtained. The narrow grade of the -20 mm fraction is screened and classified into four fractions, namely the 20-15 mm fraction, the 15-6 mm fraction, the 6-2 mm fraction and the 2-0 mm fraction. For the 20-15 mm fraction, the 15-6 mm fraction and the 6-2 mm fraction, a permanent magnet roller type intensity magnetic separator is used for performing dry intense magnetic separation. The 2-0 mm fraction is further screened and classified into the 2-0.8 mm fraction and the 0.8-0 mm fraction. For the 2-0.8 fraction, a shaker is selected again to obtain shaker gravity concentrate, and for the 0.8-0 mm fraction, a spiral chute and the shaker are used and a united procedure is selected again to obtain the thin-particle gravity concentrate. The novel beneficiation technology can be used for obtaining the concentrate and removing tailings in advance and has the advantage of being lower in energy consumption compared with other technologies. The technology can be used for grading chrome ore and can also be used for grading other weak magnetic iron minerals such as manganese ore, goethite, siderite and limonite.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

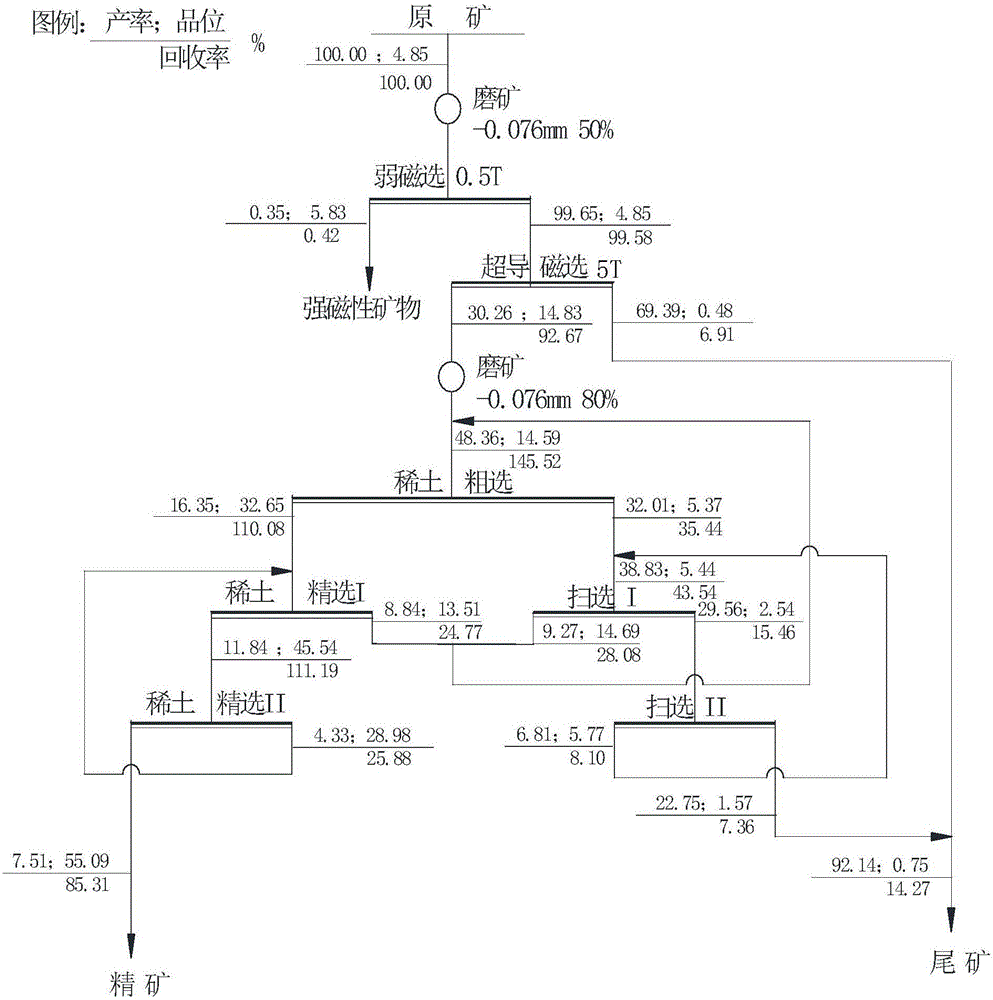

Beneficiation method of rare earth ore

ActiveCN106799300AReduce the amount requiredQuality assuranceWet separationRare earthUltimate tensile strength

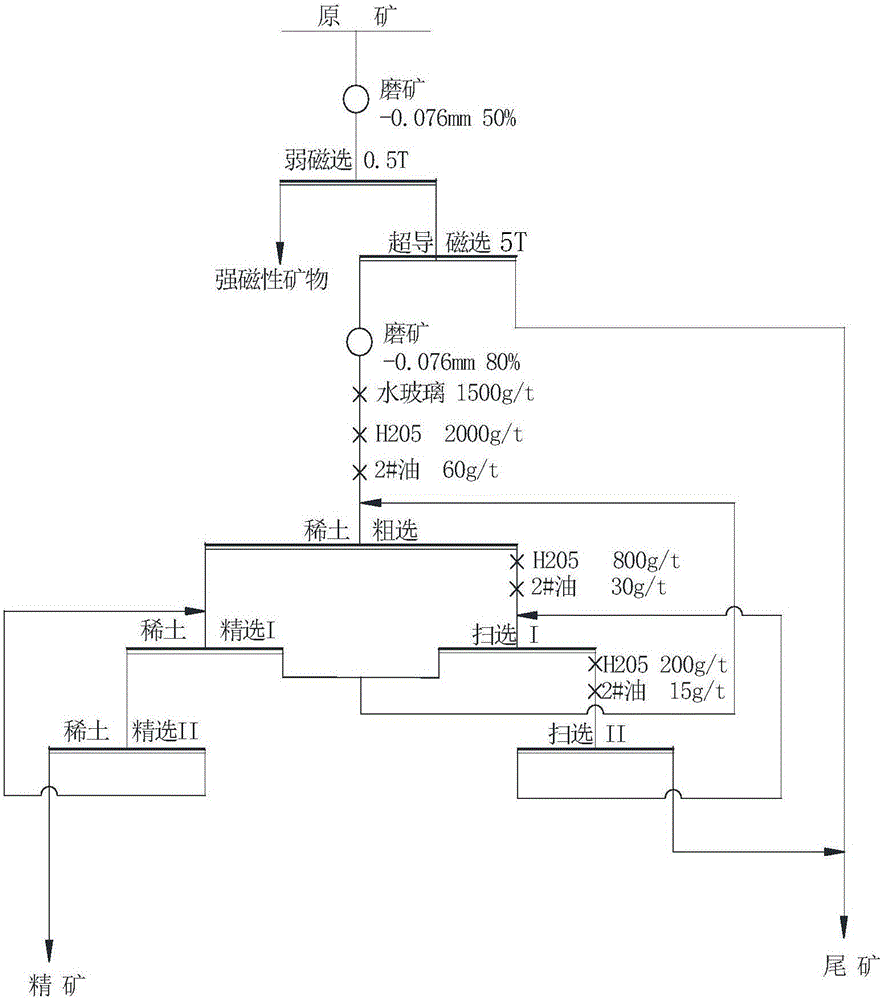

The invention discloses a beneficiation method of rare earth ore. The beneficiation method comprises the steps that crude ore is subjected to crushing and ore grinding till the crude ore with the fineness being -0.076 mm accounting for 50% or above, low intensity magnetic separation is carried out to remove strongly magnetic minerals, then superconducting magnetic separation rougher flotation is carried out to obtain rare earth rough concentrates, the rare earth rough concentrates are ground till the rare earth rough concentrates with the fineness being -0.076 mm accounting for 80% or above, conventional flotation work is carried out, and final rare earth ore concentrates are obtained; conventional flotation work includes the processes of one-section rougher flotation, two-section concentration and two-section scavenging; according to low intensity magnetic separation, the magnetic field intensity ranges from 0.1 T to 0.5 T, and the magnetic field force is (3-15)*10<5>kA<2> / m<2>; and according to superconducting magnetic separation, the magnetic field intensity is larger than 0.5 T, and the magnetic field force is larger than 3*10<7>kA<2> / m<2>. According to the method, the high-grade rare earth rough concentrates can be obtained through superconducting magnetic separation, a large quantity of tailings can be thrown out, the grading efficiency is high, the two-section ball grinding ore feeding quantity is greatly reduced, grinding and selecting energy consumption is reduced, the rare earth grade of the obtained rare earth ore concentrates is improved, and the recovery rate is high.

Owner:江苏旌凯中科超导高技术有限公司

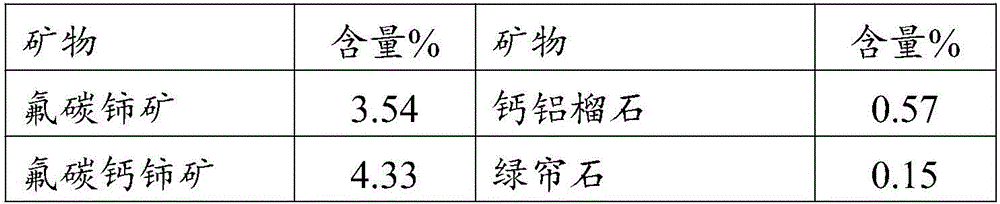

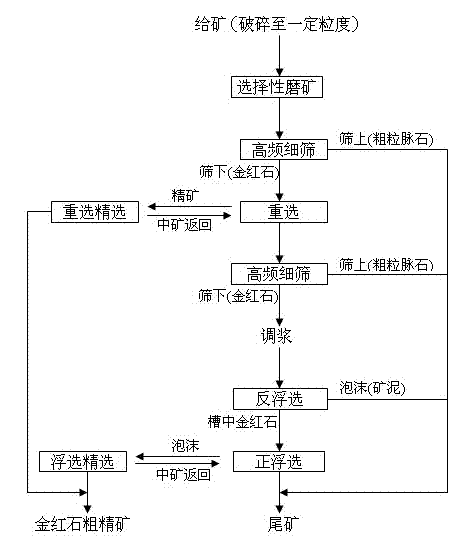

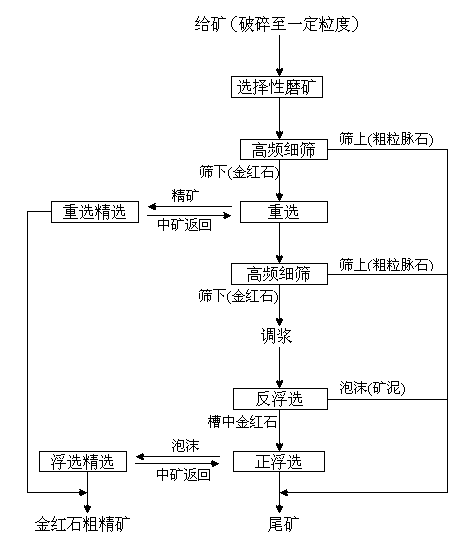

Rutile roughing technology consisting of selective ore grinding, coarse particle gravity separation and fine particle floatation

InactiveCN102500462AImprove the reselection indexEffectively discardWet separationHigh concentrationParticle composition

The invention discloses a rutile roughing technology for consisting of selective ore grinding, coarse particle gravity separation and fine particle floatation, belonging to the technical field of mineral processing engineering. According to the characteristics of complex mineral composition of rutile, containing of a large quantity of flaky rocky minerals in raw ore, small crystal size of rutile,non-uniform distribution, remarkable selective grinding phenomenon in an ore grinding process and the like, the technology comprises the following steps of: strengthening selective ore grinding by taking a steel forging as an ore grinding medium; pre-separating and discarding coarse particle tailings with a high-frequency fine sieve; narrowing the particle composition undersize minerals; recovering large-particle rutile by performing gravity separation, wherein rutile in gravity-separated tailings is distributed at a fine particle scale; sieving and discarding coarse-particle tailings; recovering small-particle rutile from minus sieve by suppressing rutile reverse flotation desliming and activating rutile positive floatation; and combining gravity-separated rough concentrate with floated rough concentrate, concentrating and purifying to obtain a high-quality rutile concentrate product. The technology has the characteristics of simple process, low ore dressing cost, high recovery rate,high concentration ratio, and the like.

Owner:KUNMING UNIV OF SCI & TECH

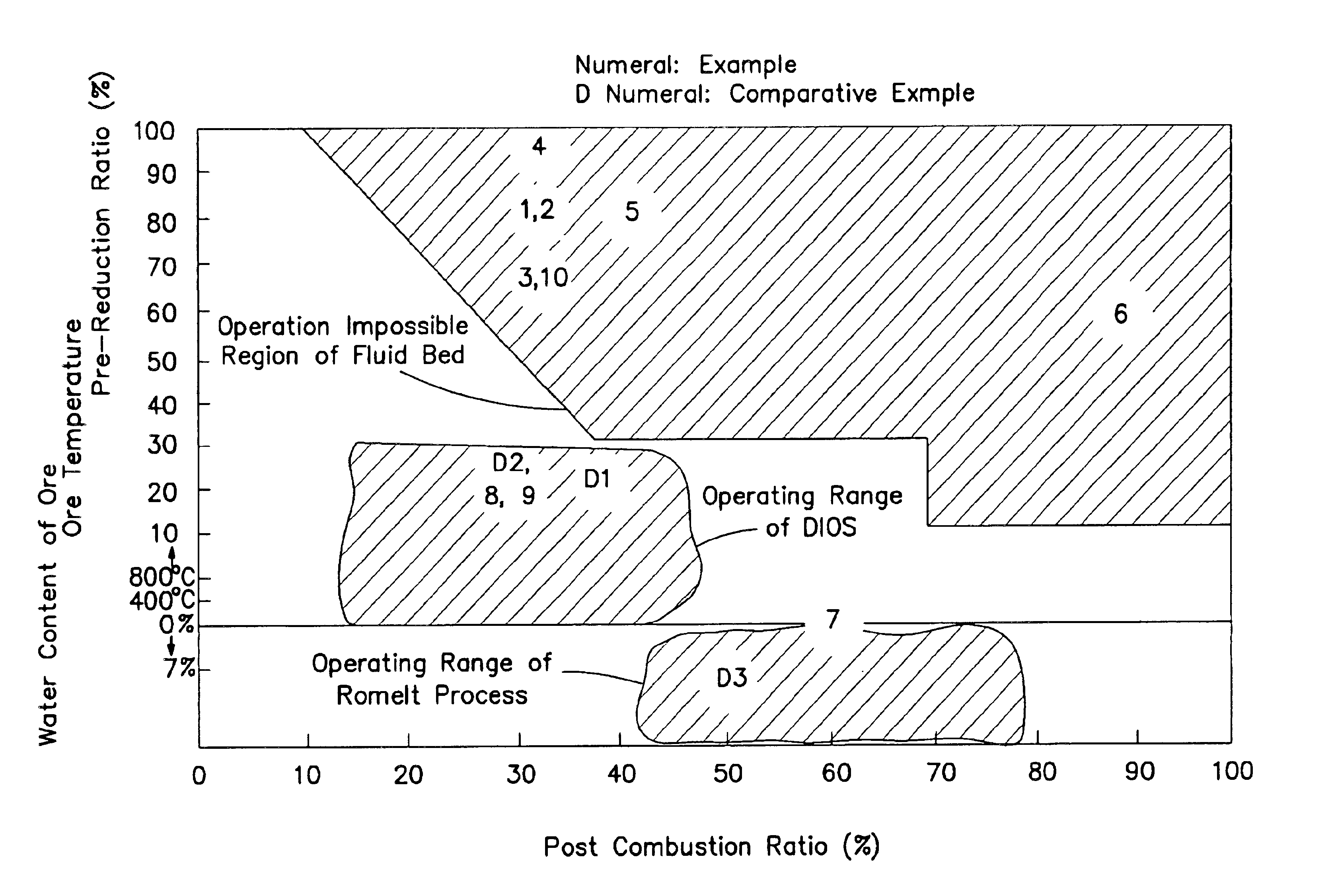

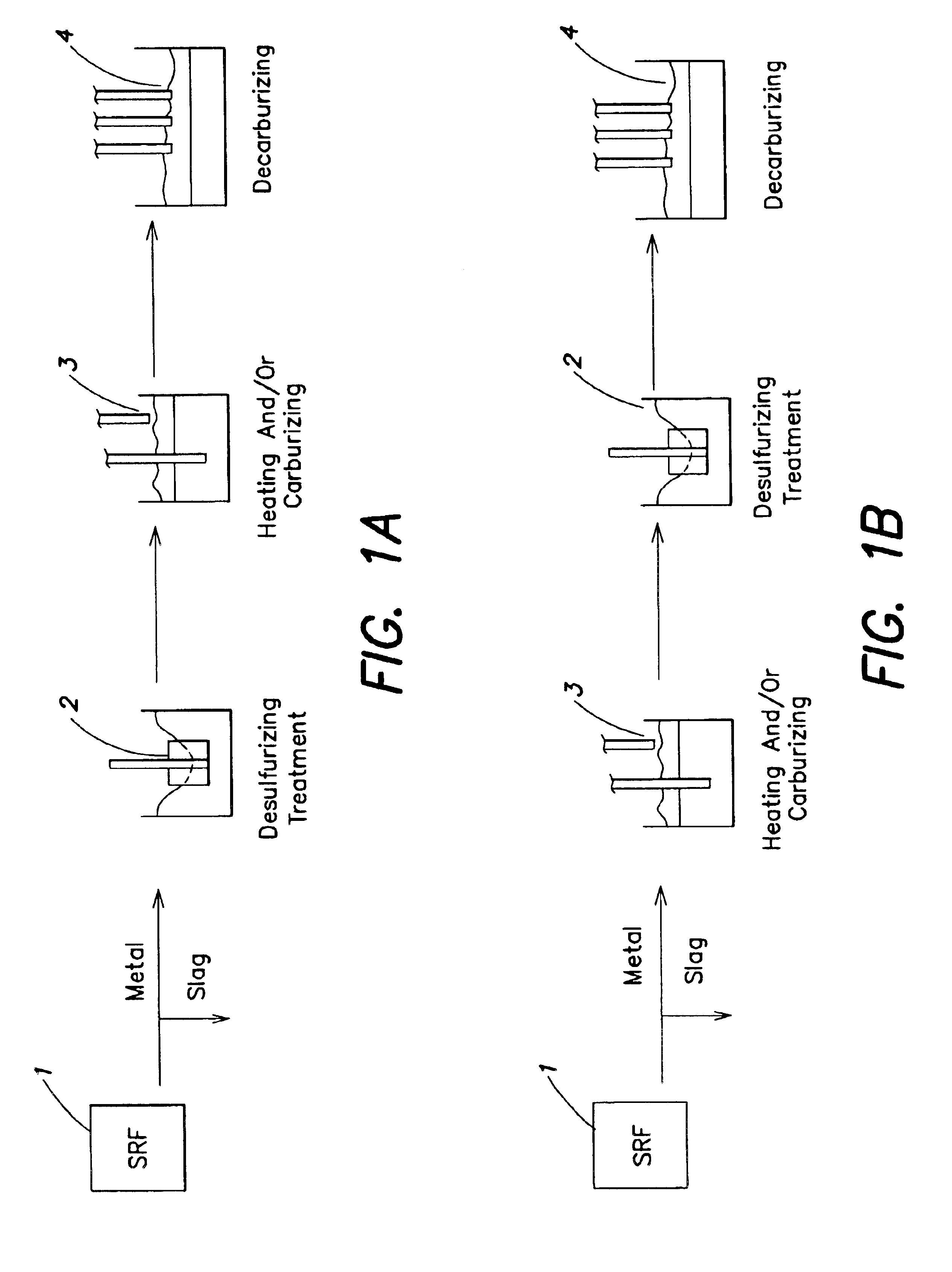

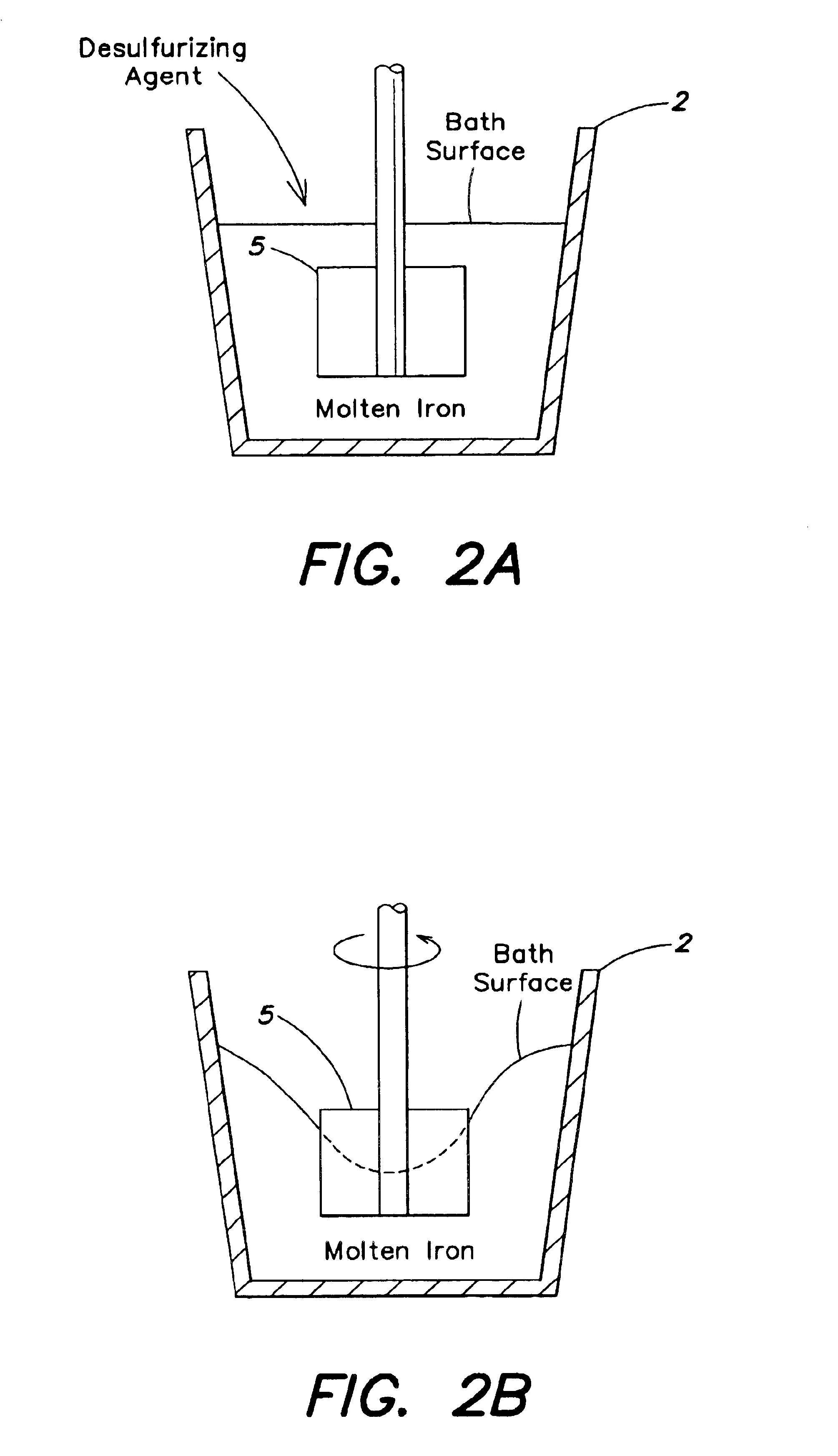

Smelting reduction method

InactiveUS6837916B2Increase carbonReduce equipment costsRotary drum furnacesManufacturing convertersOxygenMetal

A smelting reduction method comprising (a) charging a carbonaceous material and an ore into a reacting furnace to directly contact the carbonaceous material and the ore; (b) reducing the ore until at least a part of the ore is metallized, the resultant reduced ore containing at least a part of metallized metal being produced; (c) charging the carbonaceous material and the ore containing at least a part of the metallized metal from step (b) into a smelting furnace having a metal bath; and (d) blowing a gas containing 20% or more of oxygen into the metal bath in the smelting furnace to produce molten iron.

Owner:NIPPON KOKAN KK

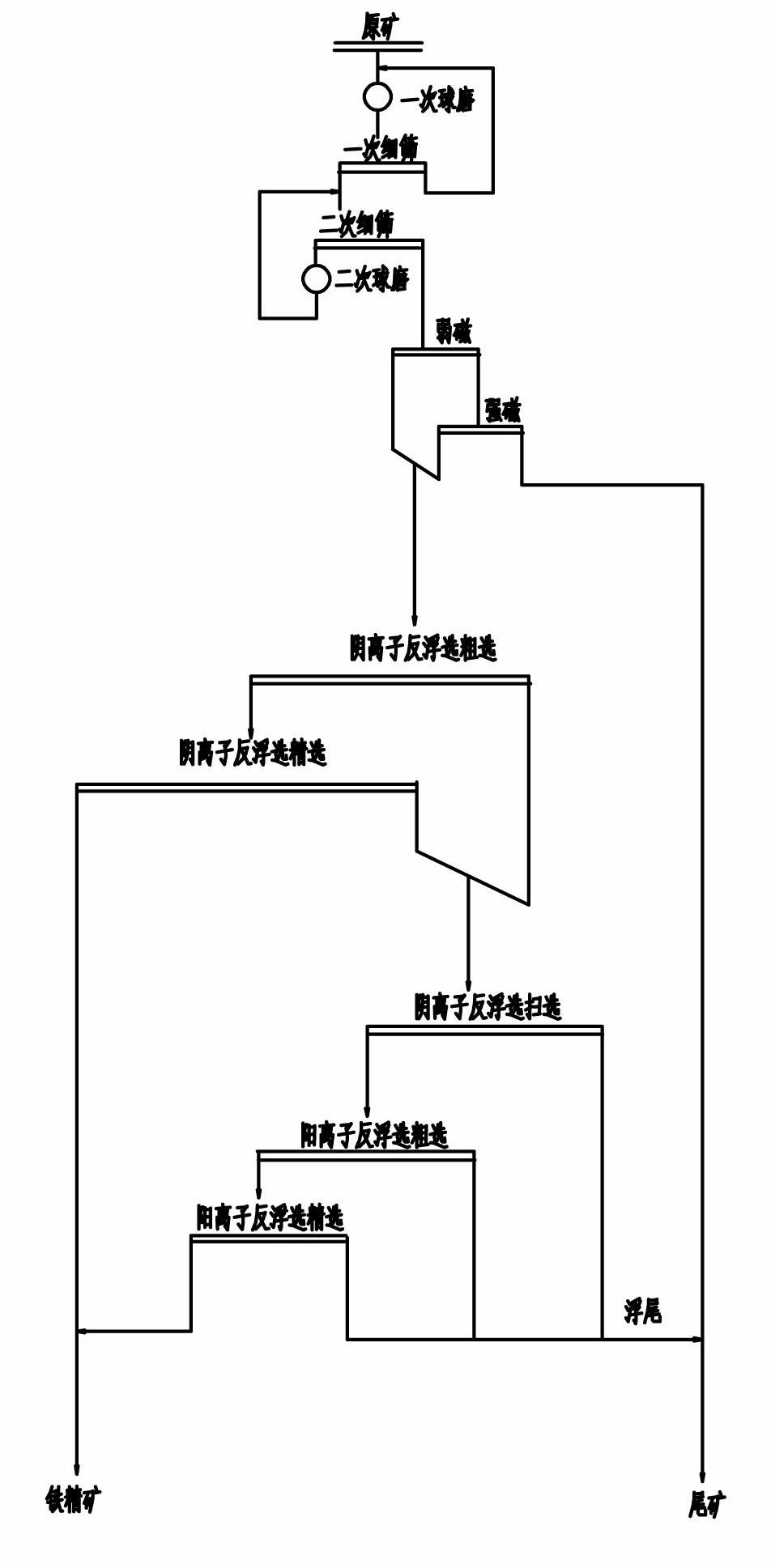

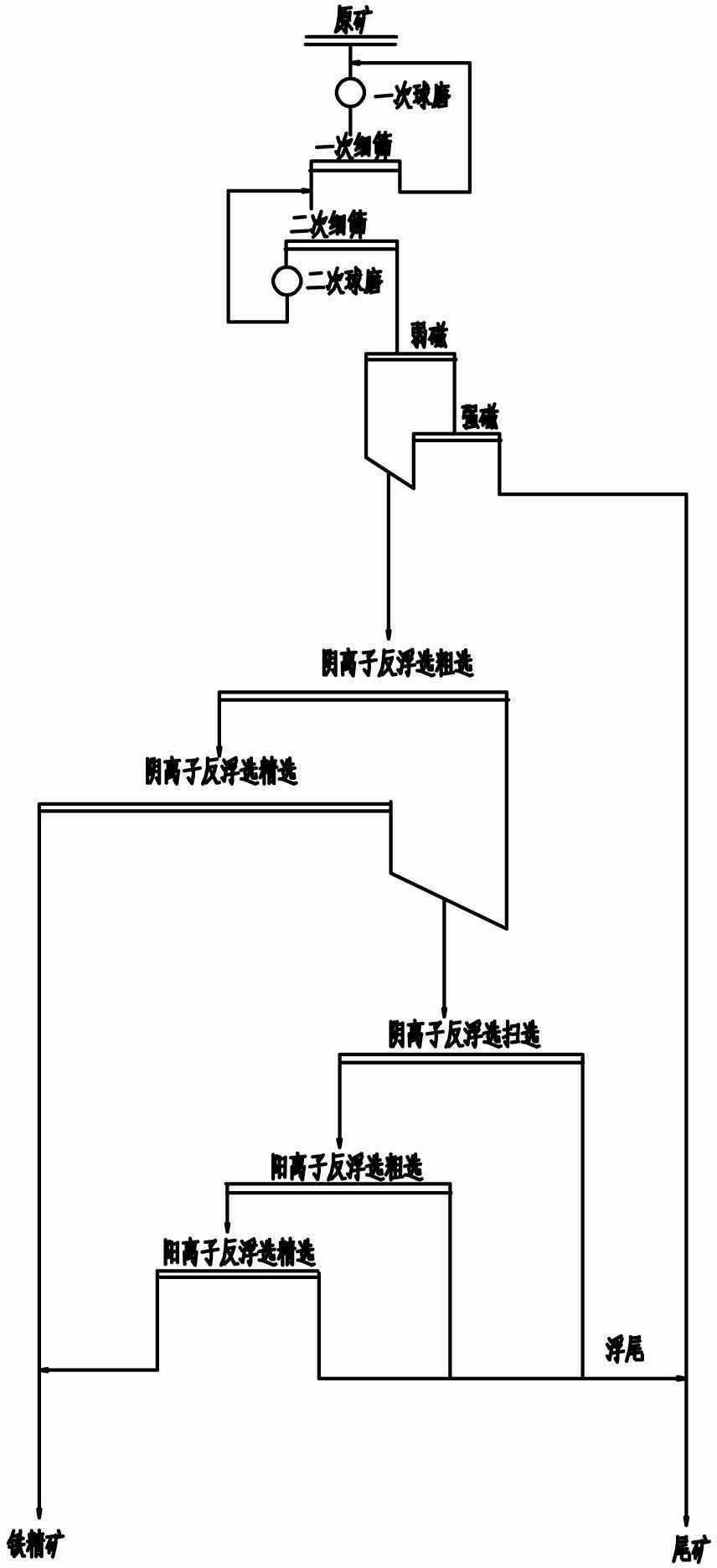

Beneficiation process for high-sulfur hematite

Provided is a beneficiation process for high-sulfur hematite, which is characterized in that two-section continuous ball-milling and screening are performed on the raw ore, magnetic separation is performed on the discharged ore, anion reverse flotation roughing is performed on magnetic-separated concentrate, anion reverse flotation agents are added, anion reverse flotation choiceness is performed on anion reverse flotation roughing concentrate, anion reverse flotation choiceness tailings are combined with anion reverse flotation roughing tailings and then are subjected to anions reverse flotation scavenging, cation reverse flotation roughing is performed on anion reverse flotation scavenging concentrate, collector dodecylamine is added, cation reverse flotation choiceness is performed on cation reverse flotation roughing concentrate, collector dodecylamine is added, cation reverse flotation choiceness concentrate and anion reverse flotation choiceness concentrate are combined into final iron ore concentrate, and anion reverse flotation scavenging tailings, cation reverse flotation roughing tailings, cation reverse flotation choiceness tailings and strong magnetic tailings are finally combined into final tailings. The beneficiation process for high-sulfur hematite improves content of iron, reduces content of silicone and sulfur and provides high-quality iron ore concentrate for steelmaking production and is suitable for beneficiation of high-sulfur magnetite.

Owner:ANSTEEL GRP MINING CO LTD

Selection method for copper sulfide copper minerals and associated elements thereof

The invention belongs to mineral processing field, relates to a beneficiation method, and particularly relates to a selection method for copper sulfide copper minerals and associated elements thereof. The method comprises rapid flotation, bulk flotation and selection period flotation. The rapid flotation step is composed of one-time rougher flotation and one-time selection. The bulk flotation step is composed of one-time copper-sulfur mixing rougher flotation and two-time scavenging. The selection period flotation step is composed of one-time rougher flotation, two-time selection, and three-time scavenging. By means of the selection method for the copper sulfide copper minerals and the associated elements thereof, rapid flotation is conducted on rough concentrate, pyrite is little in content, copper minerals are mainly monomers and rich aggregates, and selection is conducted under a weak alkali environment, so that lime is saved, and recycling of the associated elements is guaranteed at the same time. Bulk flotation is conducted on the rough concentrate, pyrite and copper-poor aggregates are high in content, regrinding high-alkali separation process is adopted, and therefore the tenor and the recovery rate of copper are enabled to be high.

Owner:JIANGXI COPPER

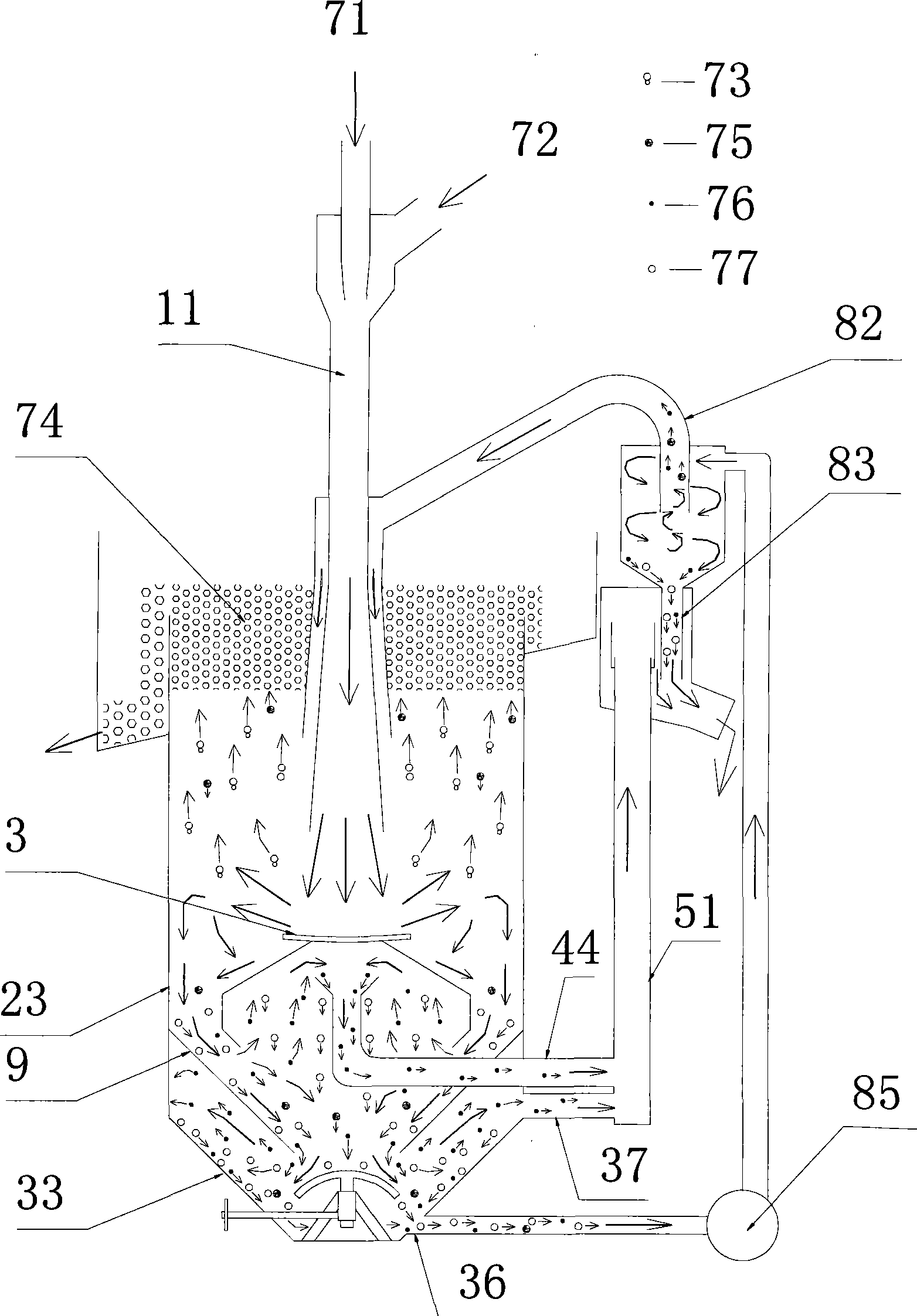

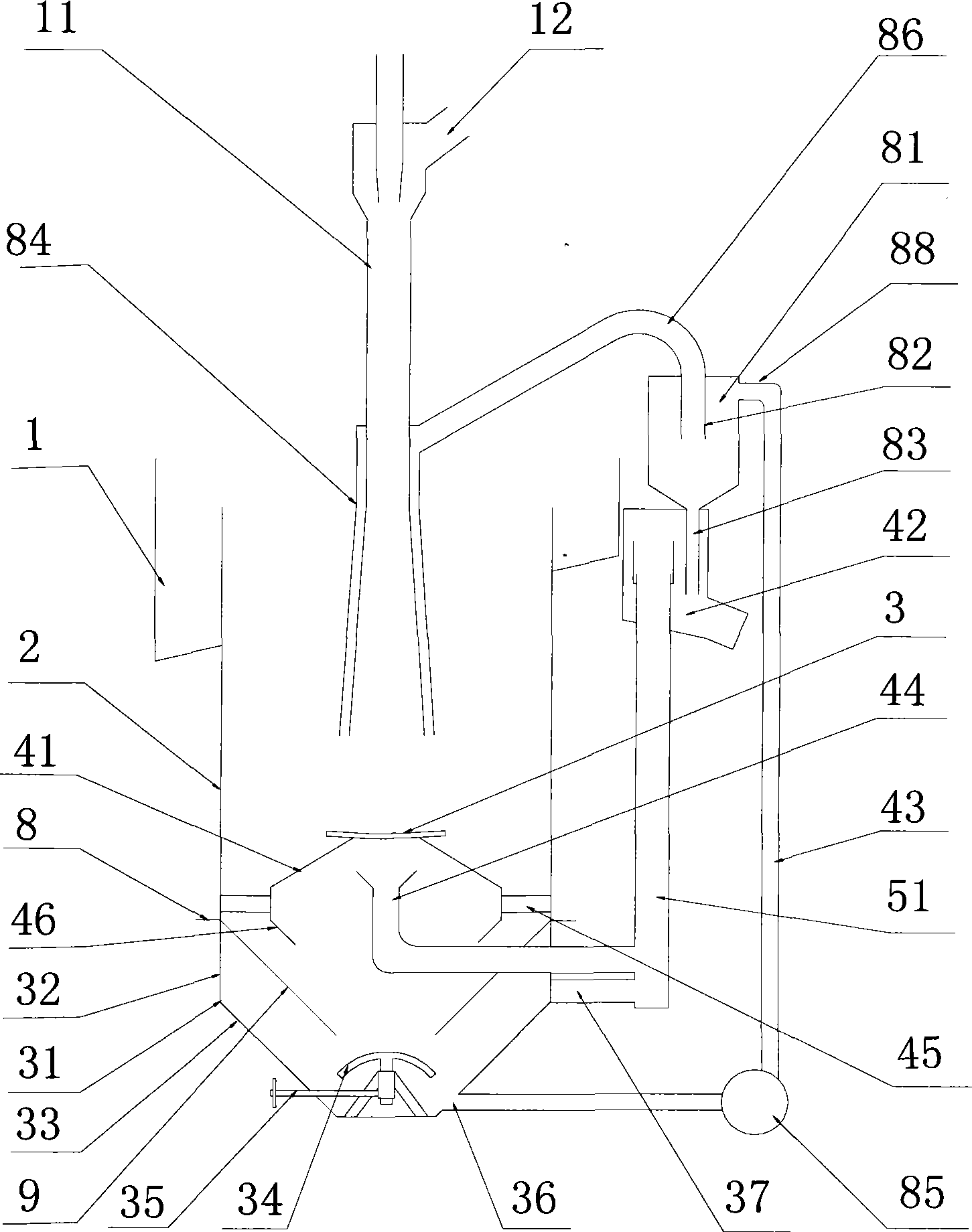

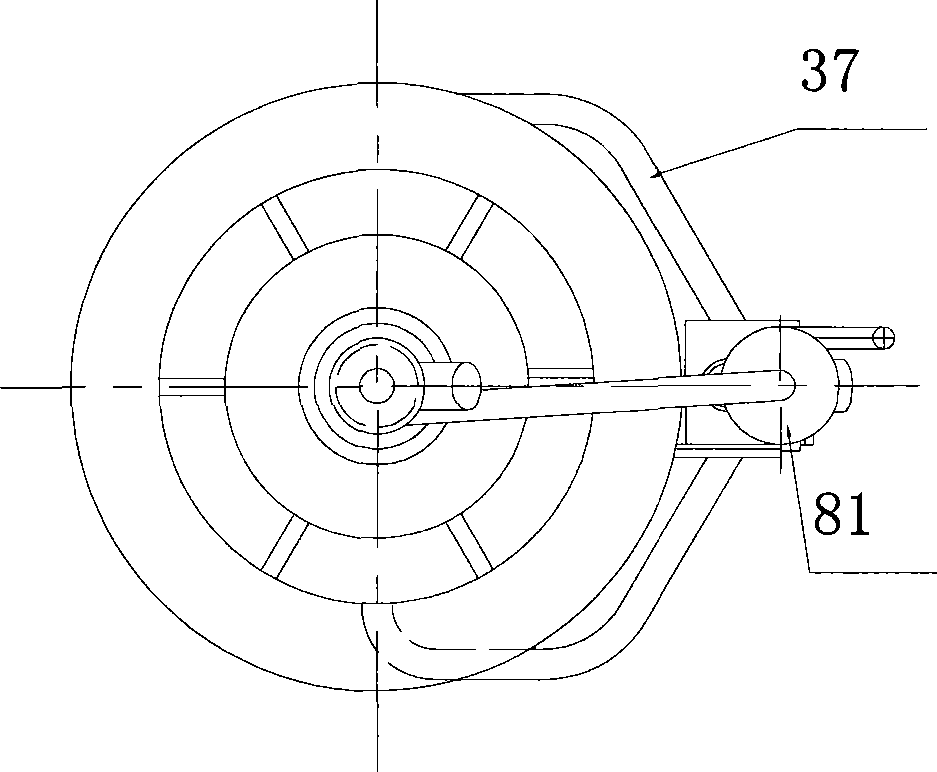

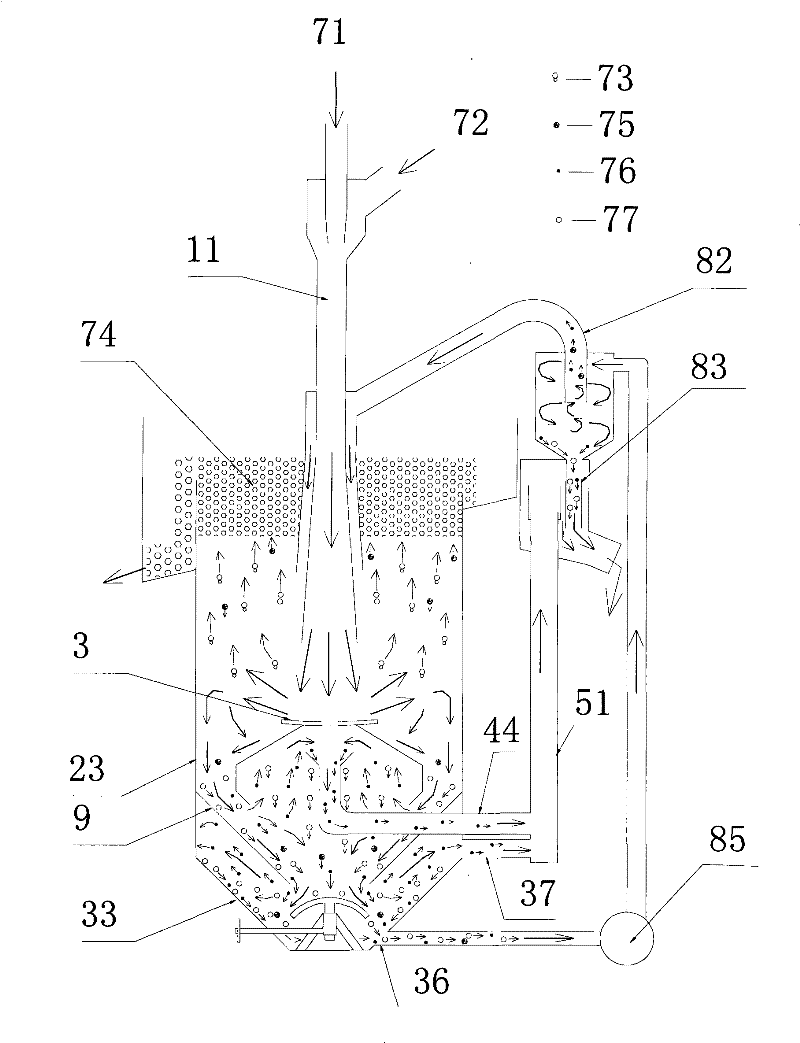

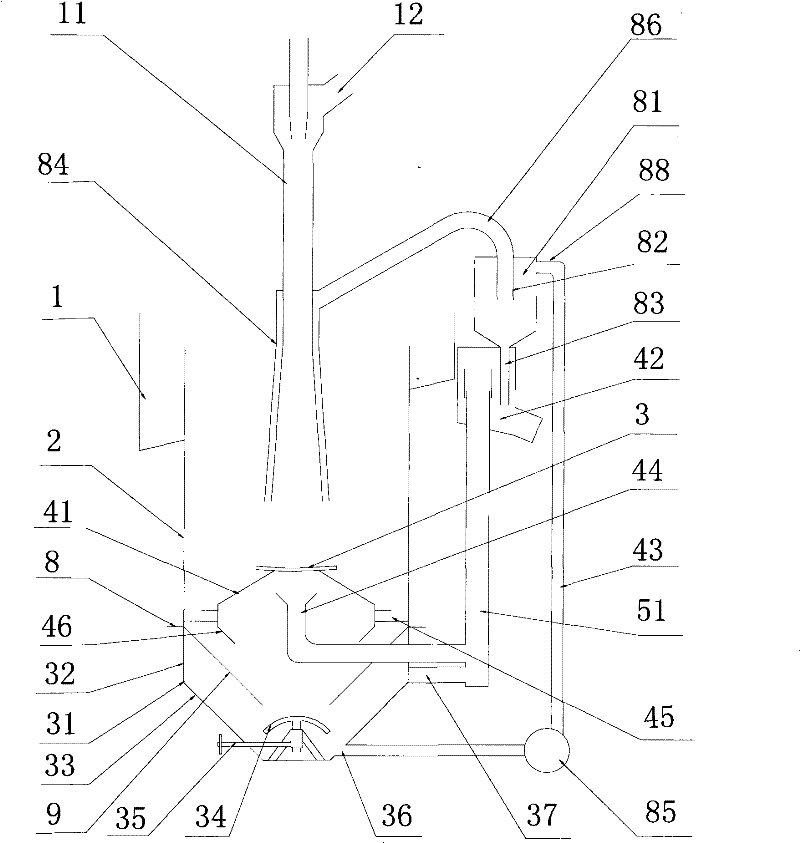

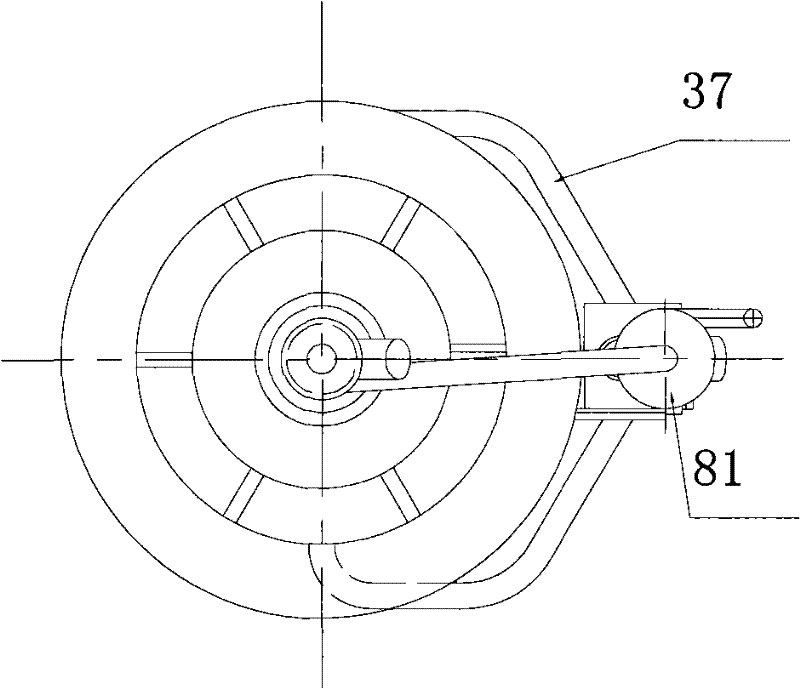

Double tail-removing gravity-flotation combined sorting method and device

The invention relates to a double-tailing discharging gravity-floating combined separation method and a device thereof, and belongs to a double-tailing discharging gravity-floating combined separation method aiming at slime and a device thereof. The aim of the invention is to solve the technical problems existing in the prior flotation machine that the separation effect of ultrafine grains is low and the upper limit of the column flotation is difficult to be effectively related with the lower limit of the heavy medium separation. The method comprises three steps of crude ore flotation and rough separation and graded tailing discharging, gravity scavenging tailing discharging and gravity separation finished ore reflotation. The double-tailing discharging gravity-floating combined separation machine comprises a jet flow flotation column, a first tailing discharging graded device and a secondary tailing discharging graded device; the first tailing discharging graded device is arranged below the jet flow flotation column, a cyclical middling underflow opening of the first tailing discharging graded device is connected with the secondary tailing discharging graded device, and a central ore feeding pipe of the secondary tailing discharging graded device is connected with the jet flow flotation column. The method and the device have multiple effects of coarse slime separation and highly selective floatation of fine coal and ultrafine coal, thereby improving the efficiency of the gravity-floating combined separation.

Owner:TAIYUAN UNIV OF TECH

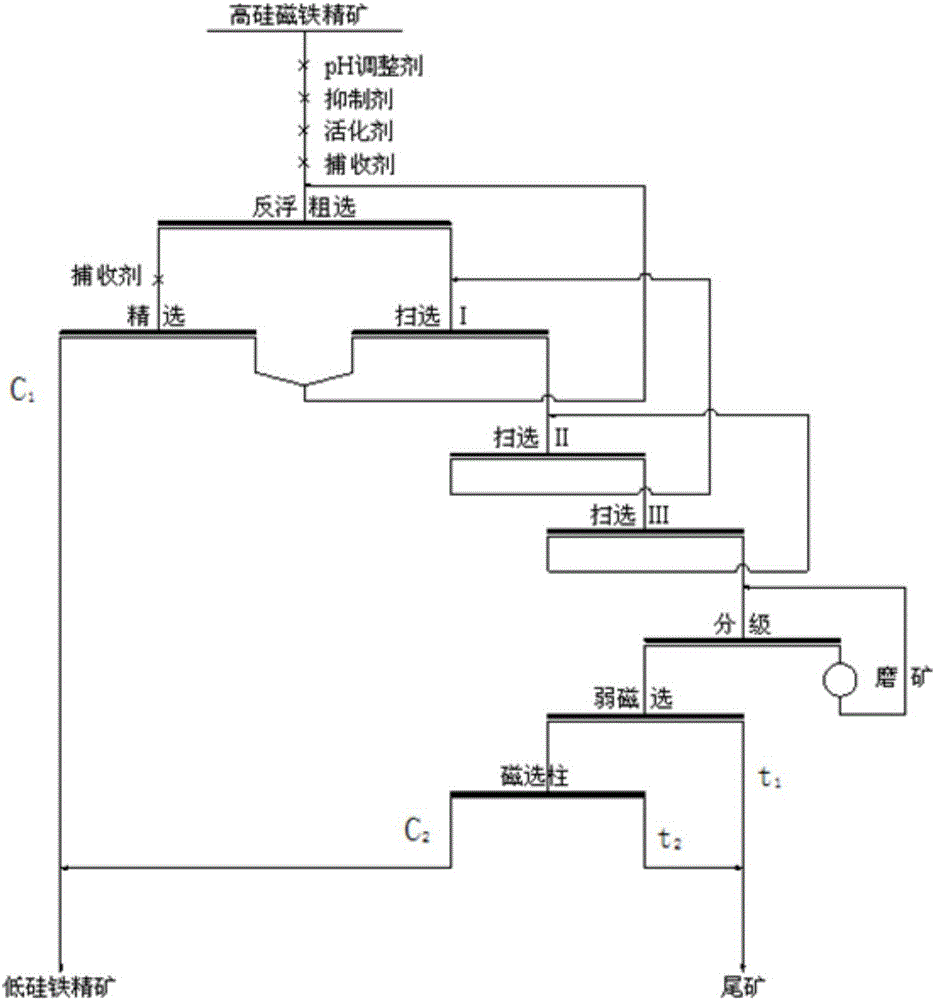

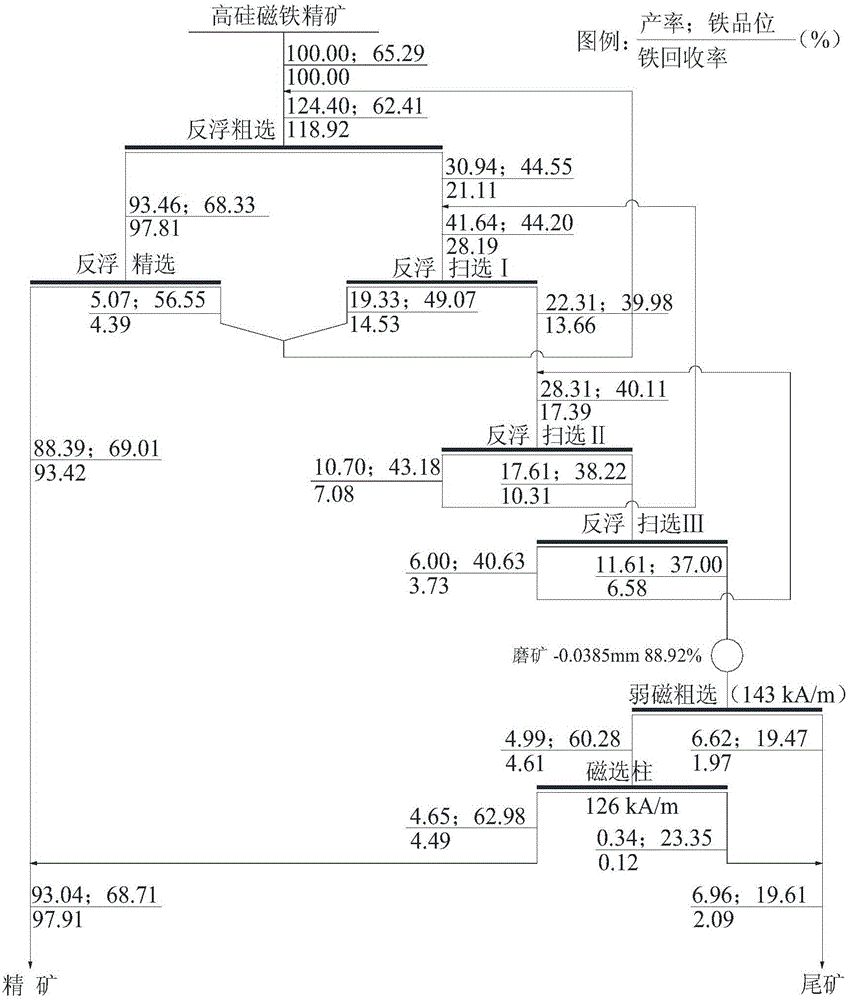

Beneficiation method for reducing content of SiO2 in magnetite concentrate

InactiveCN105728176AReduce SiO <sub>2</sub> contentSiO <sub>2</sub> Low contentDifferential sedimentationFlotationMagnetiteReverse flotation

The invention discloses a method for reducing SiO in magnetite concentrate 2 The beneficiation method adopts the following process: 1) Anion reverse flotation of high-silicon magnetite concentrate to obtain TFe≥68.75%, SiO 2 High-quality low-silicon ferrosilicon concentrate C with content <3.0% 1 , and discharge anion reverse flotation tailings; 2) anion reverse flotation tailings pre-classification-regrinding-weak magnetic separation to obtain weak magnetic separation concentrates; 3) weak magnetic separation magnetic re-separation concentrates to further obtain TFe≥ 62.5%% Magnetic Gravity Separation Iron Concentrate C 2 . The invention has the advantages of high grade iron concentrate, SiO 2 It has the advantages of low content, high iron recovery rate, small loss of fine-grained iron minerals, low energy consumption for beneficiation, stable indicators, and easy operation and management on site.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

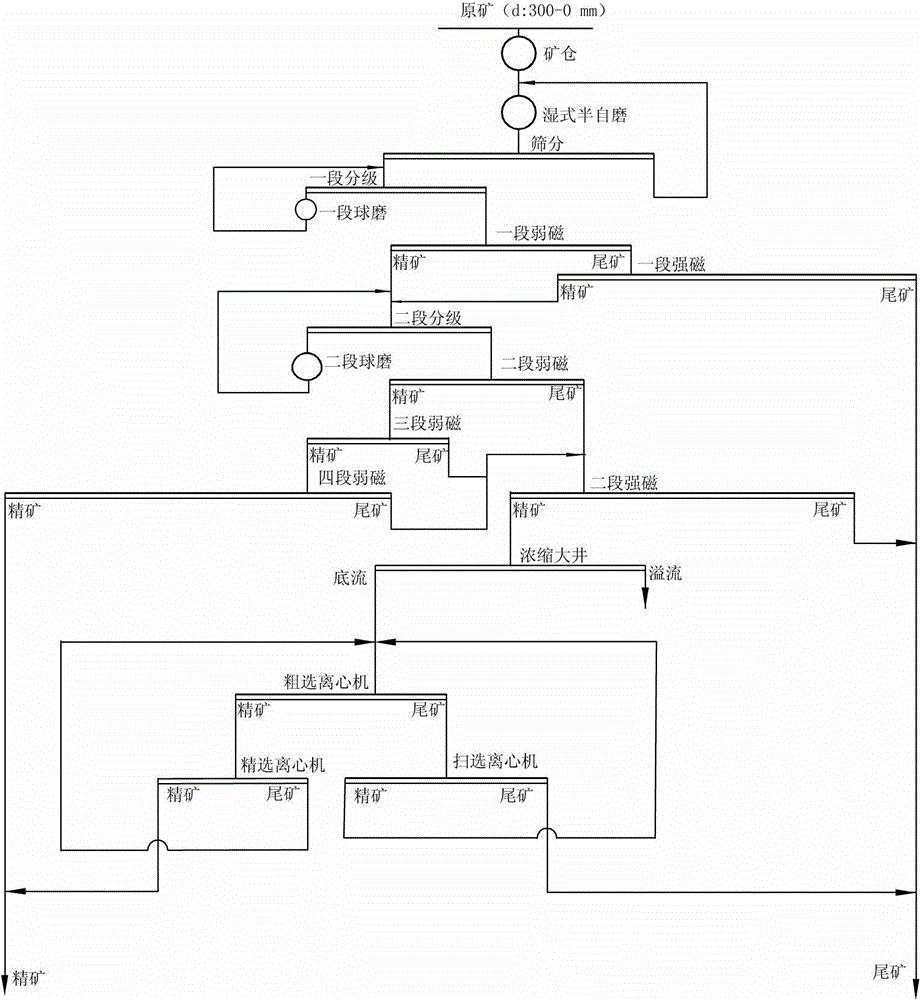

Magnetic separation-centrifuge separation technology of micro-fine particle dissemination magnet-hematite mixed ore

ActiveCN104888947AReduce oreReduce pollutionMagnetic separationSeparation technologyPhysical chemistry

The invention relates to a magnetic separation-centrifuge separation technology of micro-fine particle dissemination magnet-hematite mixed ore. The magnetic separation-centrifuge separation technology is characterized by adopting a grading operating system of wet-type semi-autogenous grinding, stage grinding, phase flux weakening-strong magnetism, and strong magnetism concentrate-centrifuge; the magnetic separation-centrifuge separation technology has the following advantages: the wet-type autogenous grinding process is adopted, so that the crushing operation is reduced; the stage grinding and stage magnetic separation method is adopted, the single magnetic separation method is adopted to recycle vignite reaching monomer separation in advance so as to throw and collect iron mineral reaching monomer separation, the effects of cost decreasing and benefit increasing are realized, and the mineral reaching monomer separation is prevented from entering next operation; the centrifuge is adopted for grading, the technological processes are short, and the equipment is simple and easy to operate, does not pollute the environment, saves energy and reduces consumption.

Owner:ANSTEEL GRP MINING CO LTD

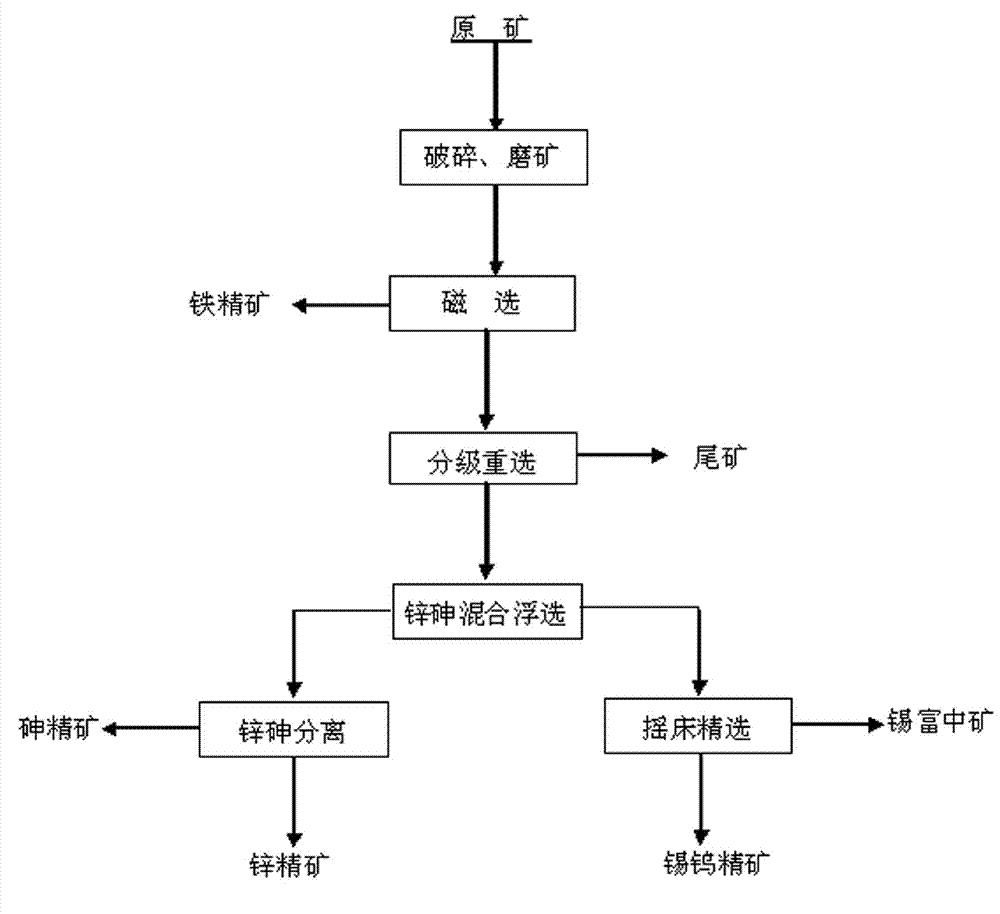

Polymetallic (iron, tin and zinc) ore comprehensive recovery beneficiation method

The invention relates to a polymetallic (iron, tin and zinc) ore comprehensive recovery combined beneficiation method, which belongs to the technical field of nonferrous metals ore beneficiation. The method comprise the steps of: smashing, grinding, magnetically separating ores to obtain iron ore concentrate; reselecting non-magnetic ore directly to obtain a tin, zinc, arsenic and tungsten heavy concentrate product; carrying out zinc and arsenic bulk flotation for the heavy concentrate product to obtain zinc and arsenic bulk concentrate; further separating the zinc and arsenic bulk concentrate to obtain zinc concentrate and arsenic concentrate, wherein floated tailings are tin and tungsten concentrates; then concentrating by a swing table to further separate high grade tin concentrate, tungsten concentrate, and tin-richened middlings. The polymetallic (iron, tin and zinc) ore comprehensive recovery combined beneficiation method provided by the invention is short in process flow, simple in method, simple to operate, energy-saving, small in occupied area, low in comprehensive cost of beneficiation, and high in recovery yield of associated metals such as iron, tin and the like.

Owner:YUNNAN TIN GROUP HLDG

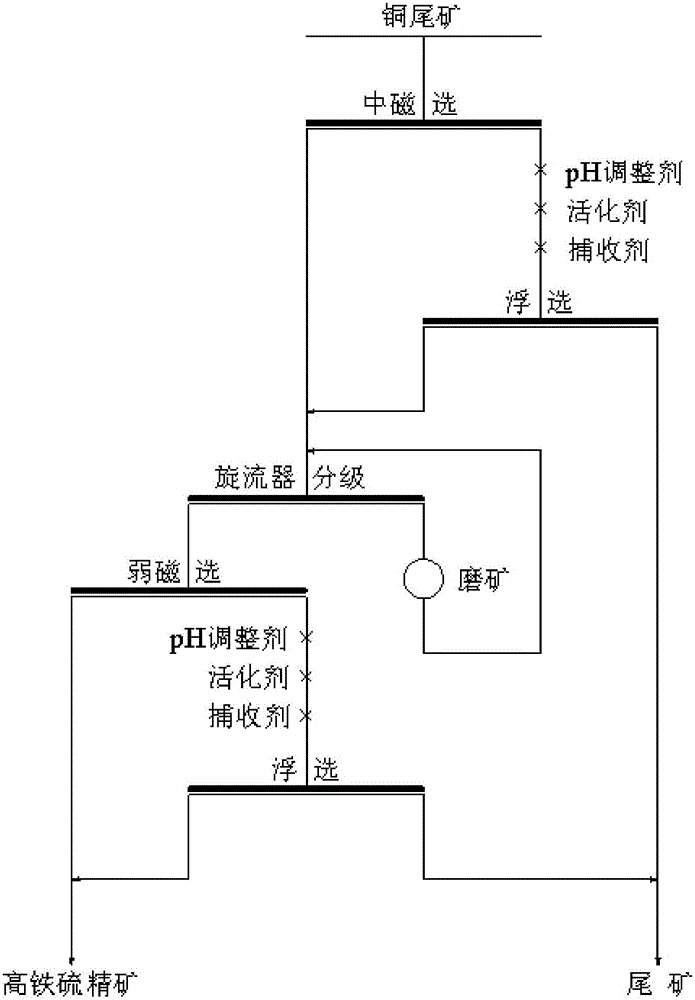

Beneficiation method for recovering high iron and high sulfur concentrate from copper tailings containing sulfur and iron

The invention discloses a beneficiation method for recovering high iron and high sulfur concentrate from copper tailings containing sulfur and iron. The method includes the technical processes that (1) preconcentrated iron pyrite is obtained by carrying out intermediate intensity magnetic separation-flotation on the copper tailings; (2) the preconcentrated iron pyrite is subjected to preliminary classification, regrinding and low-intensity magnetic separation; (3) reflotation is carried out on tailings subjected to low-intensity magnetic separation, specifically, by carrying out further flotation on the tailings subjected to low-intensity magnetic separation, the flotation high iron and high sulfur concentrate is obtained, and reflotation tailings is filtered out. The method has the advantages that the sulfur and iron resources can be recovered comprehensively, the technical process is simple, the index is stable, field operation and management are easy, the production cost is low, and the chemical dosage is low; the SS grade of the finally obtained high iron and high sulfur concentrate is higher than 25%, the TFe content is higher than 55%, the TFe content of sulfate slag after acid production is higher than 62%, and accordingly comprehensive recovery and utilization of the sulfur and iron resources are achieved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

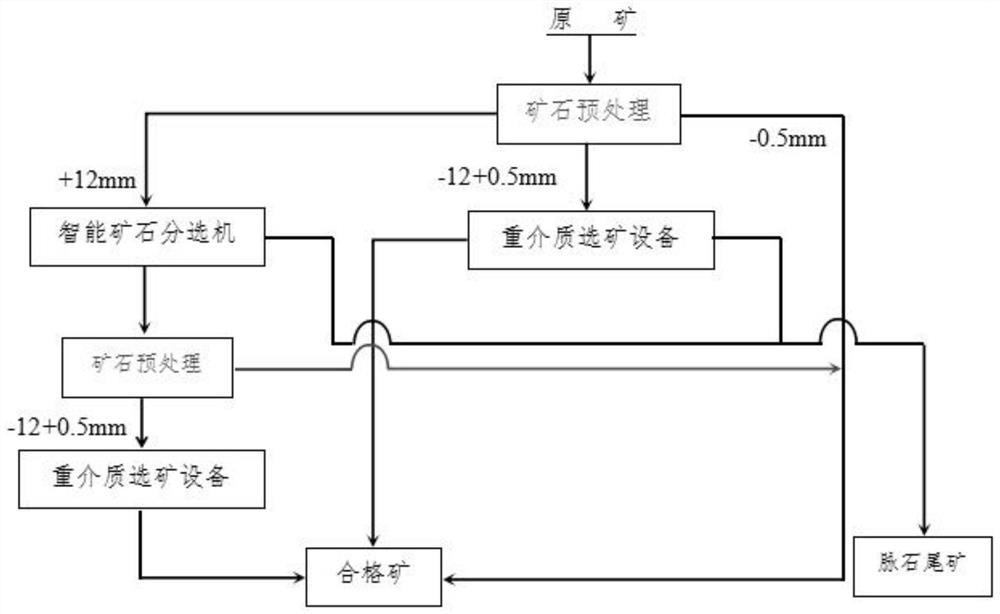

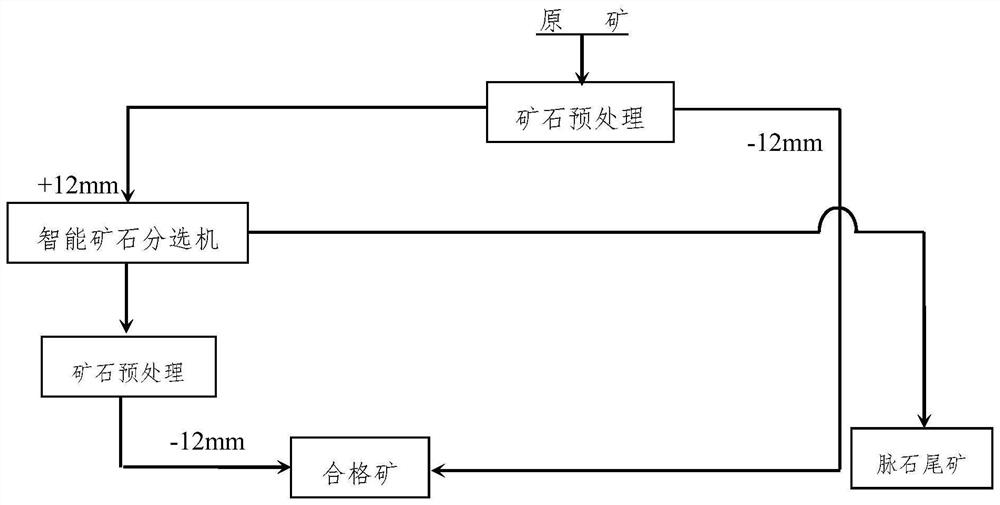

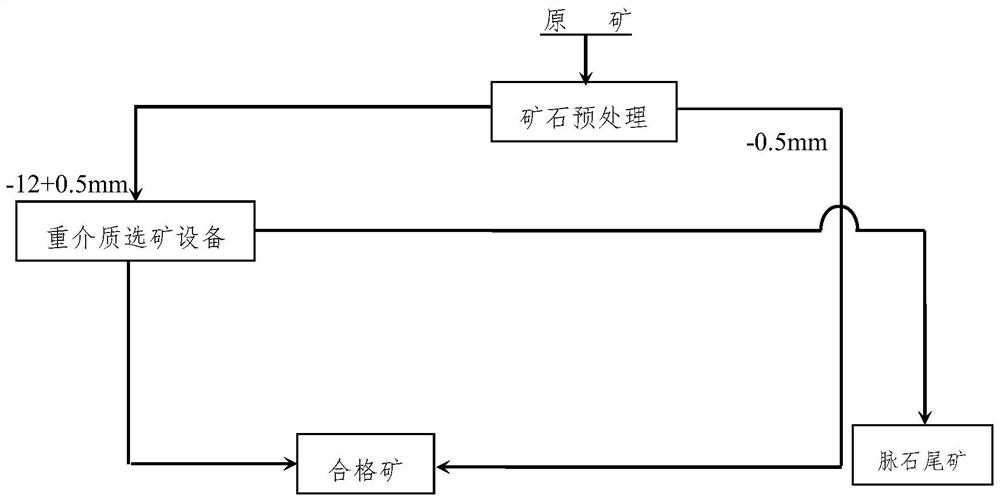

Non-ferrous metal ore pre-dressing and waste discarding method

PendingCN113634346AHigh recovery rateHigh degree of automationSolid separationGrain treatmentsMining engineeringNon-ferrous metal

The invention relates to the technical field of ore dressing, and provides a non-ferrous metal ore pre-dressing and waste discarding method. The non-ferrous metal ore pre-dressing and waste discarding method comprises the following steps: first coarse ore, first fine ore and first qualified ore are obtained through crushing and first screening and grading, the first coarse ore is subjected to pre-dressing and waste discarding through intelligent ore dressing, gangue tailings in the first coarse ore are removed, the remaining first coarse concentrate is crushed and then subjected to second screening and grading, and second fine ore and second qualified ore are obtained; and finally, the first fine ore and the second fine ore are subjected to pre-dressing and waste discarding through dense medium ore dressing, gangue tailings in the first fine ore and the second fine ore are further removed, and concentrate obtained through dense medium ore dressing is qualified ore. In addition, according to the invention, intelligent ore dressing or dense medium dressing can be independently used for pre-dressing and waste discarding, and the process steps are simpler. The method is high in automation degree, high in ore dressing accuracy, high in recovery rate for nonferrous metal ore, high in waste discarding rate, free of limitation on ore types, and wide in application range.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

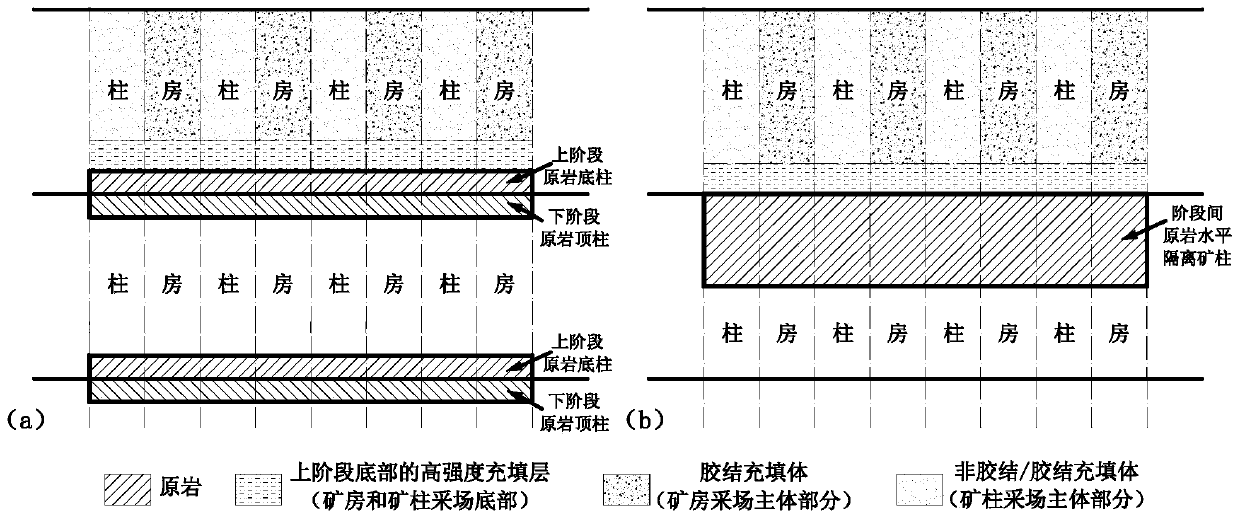

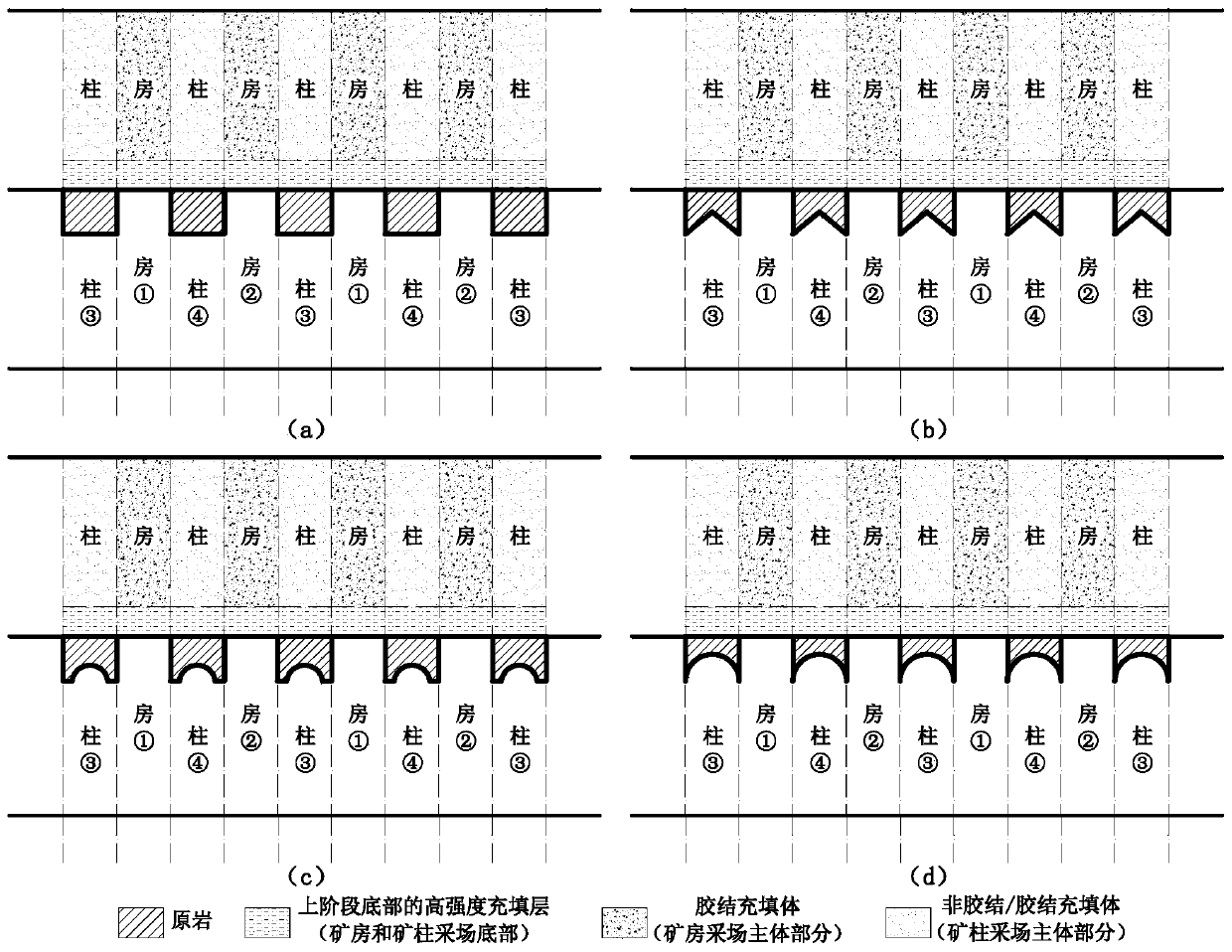

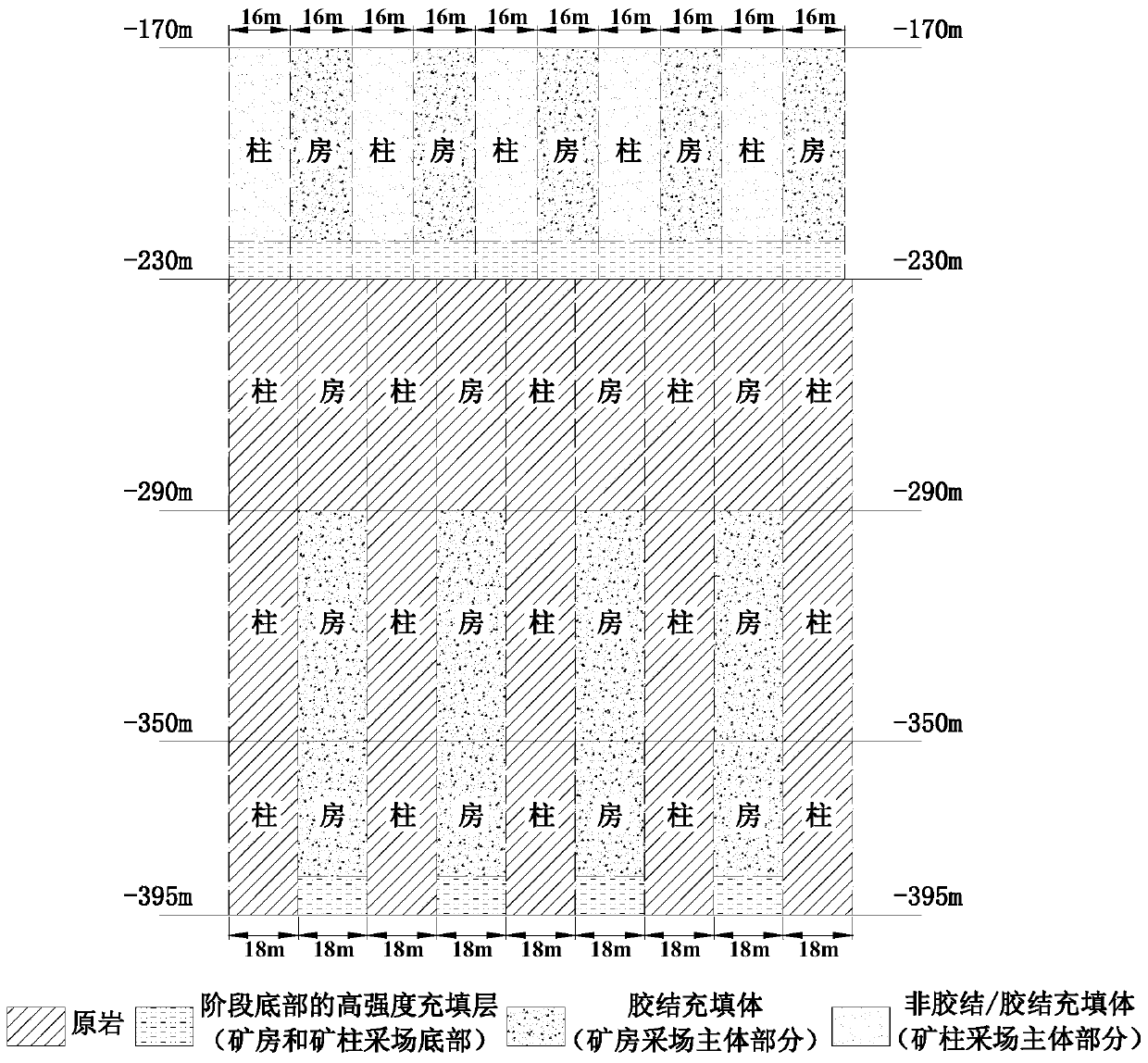

Filling body under mining method with only toothed jambs left

ActiveCN110295909AReduce oreImprove one-time high-efficiency recovery rateUnderground miningSurface miningCoalMining engineering

The invention discloses a filling body under mining method with only toothed jambs left. Mining of a one-step chamber stope and mining of a two-step jamb stope are sequentially carried out, cemented filling is adopted in the chamber stope, and non-cemented filling or cemented filling is adopted in the jamb stope. Coal extraction is carried out on the chamber stope below a filling body in one steptill coal extraction is carried out on the bottom face of the filling body, after coal extraction of the stope is finished, mine rock of the adjacent jamb stope is located on the two sides of a dead zone, the filling body is located at the top, and cemented filling is carried out after ore removal is completed; and coal extraction is carried out on the jamb stope below the filling body in two steps, the bottom face of the filling body is not exposed, and mine rock of a certain height is reserved below the filling body and is not subjected to coal extraction. After coal extraction of a stage mine body below the filling body is completed according to the above manner, no complete protolith horizontal jambs are reserved, only the toothed jambs small in mine quantity are formed, the quantity of the protolith horizontal jambs between stages is reduced, the one-time efficient coal extraction rate of resources in a normal exploitation unit is improved, and then economic benefits of exploitation of mine enterprises are increased.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

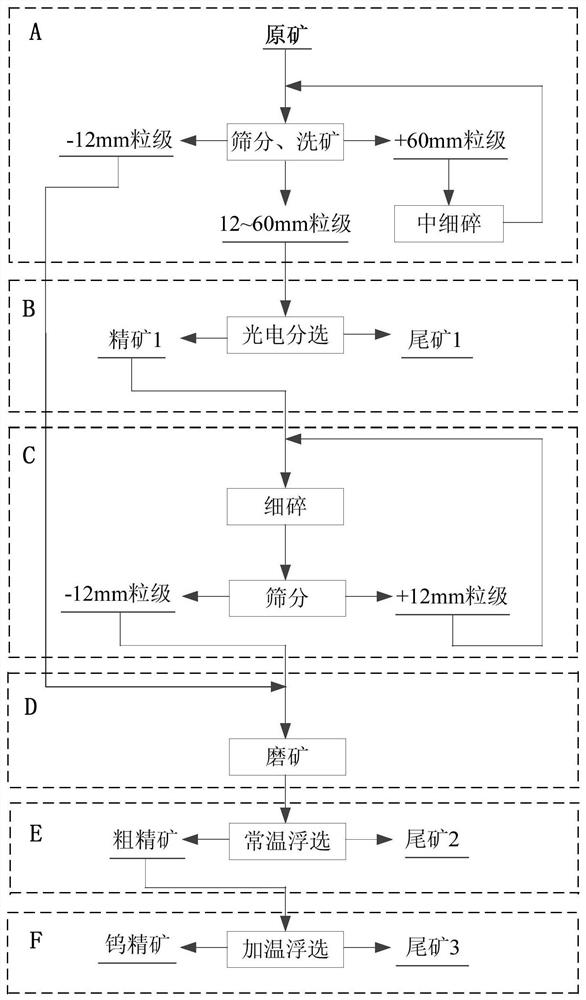

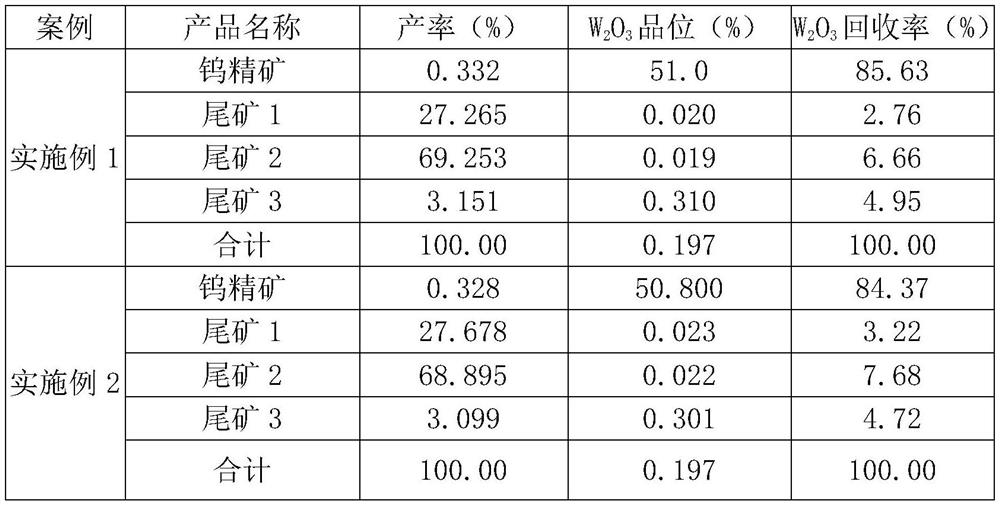

Beneficiation method of low-grade tungsten ore

InactiveCN111841871AImprove the quality of selectionEfficient use ofWet separationOre concentrateMineralogy

The invention relates to a beneficiation method of low-grade tungsten ore. A combined technology including crushing and screening, photoelectric sorting, fine screening, ore grinding and dual-temperature flotation is utilized. Qualified tungsten concentrate is obtained through three-stage tailings throwing, low-grade tungsten ore resources are utilized, tungsten can be efficiently recycled, the recovery rate of the tungsten ore W2O3 reaches 85% or above, the grading cost can also be reduced, and the comprehensive utilization rate of the resources is improved. The method has the advantages of being simple and feasible, high in operability and environmentally friendly and having important reference significance for utilization of other mineral low-grade ore, and is suitable for the mining and metallurgy industry to use.

Owner:ZIJIN MINING GROUP

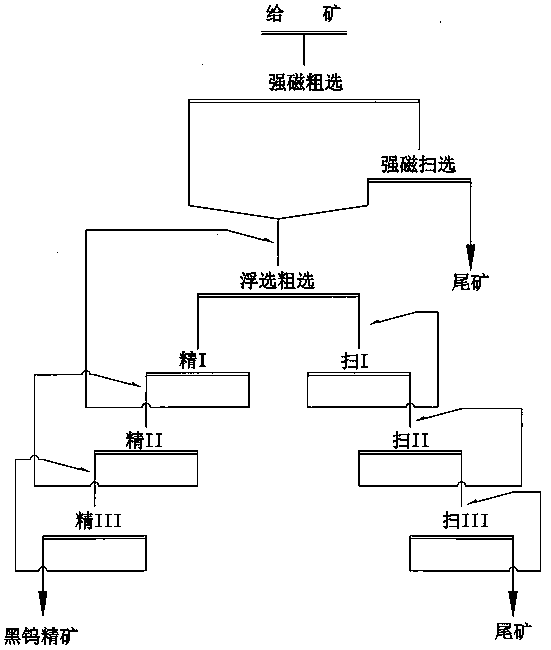

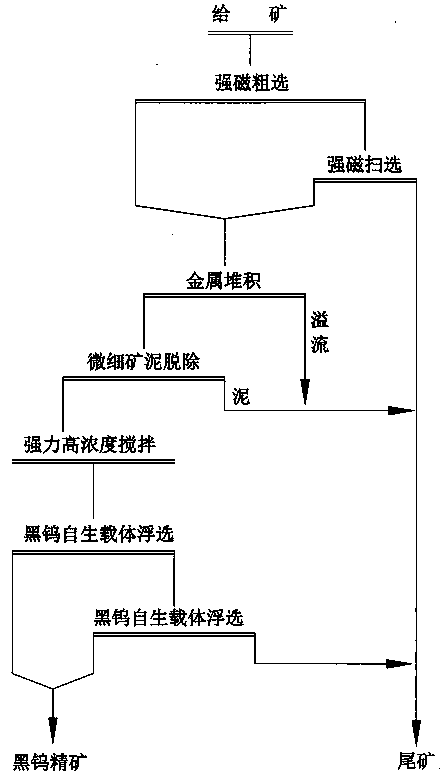

Beneficiation method combining metal accumulation with authigenic carrier flotation

The invention relates to a beneficiation method combining metal accumulation with authigenic carrier flotation. A mineral product is recycled from low-grade black tungsten nonferrous metal fine mud ore, metal accumulation and black tungsten fine mud ore authigenic carrier flotation are combined, black tungsten fine mud ore flotation needs are met, the black tungsten concentrate grade is 35%, the tungsten work recycling rate is above 91%, and the tungsten total recycling rate is above 72%.

Owner:杨和平 +1

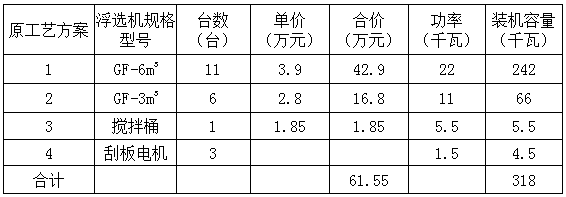

Magnetite beneficiation process capable of fully releasing mill capacity

InactiveCN110624686AReduce the effective volumeLow production costMagnetic separationGrain treatmentsMagnetiteVolumetric Mass Density

The invention relates to a magnetite beneficiation process capable of fully releasing mill capacity. The magnetite beneficiation process includes the steps that raw ore is subjected to three-section breaking and secondary dry separation and then ultrafine-ground through high-pressure roller milling, after high-pressure roller milling products are screened through screening equipment, undersize products are fed into a wet type preselection magnetic separator, wet type preselection rough concentrate is subjected to ore grinding, classifying, magnetic separating and reselecting, partially-qualified concentrate is obtained, reselecting process tailings are fed into second-section ore grinding after being subjected to concentration magnetic separation, second-section ore grinding products are subjected to magnetic separation, fine screening classification and elutriating selecting, and qualified concentrate is obtained. As the high-pressure roll milling products are subjected to wet type preselection, a large quantity of qualified tailings can be thrown out, the mill entering quantity is reduced, and the ore milling cost and the energy consumption are reduced; the partially-qualified concentrate can be recycled in advance through the magnetic and gravity combined separation process by means of the density difference between iron minerals and lean coenobium; and in the whole process,the mill capacity can be fully released, energy saving and consumption reduction are achieved, compared with current conventional processes, the effective volume of a ball mill can be reduced to be 50% or below, the investment can be greatly reduced, and the production cost is reduced.

Owner:魏建民

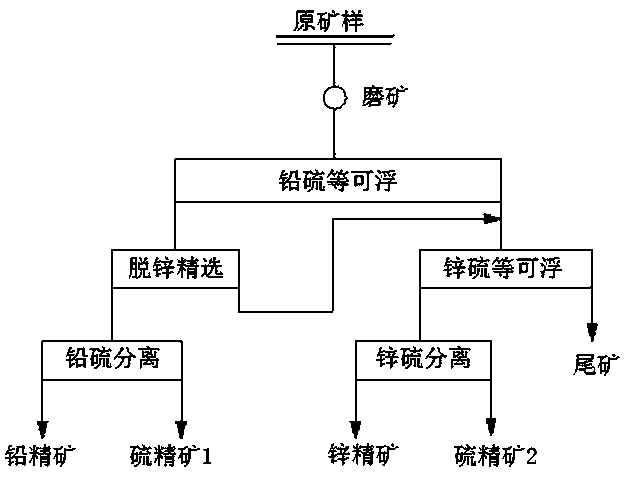

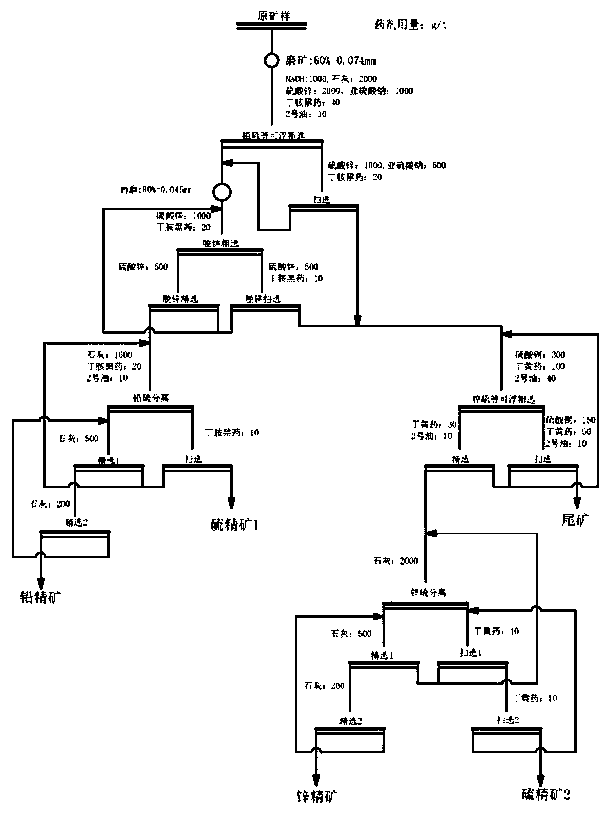

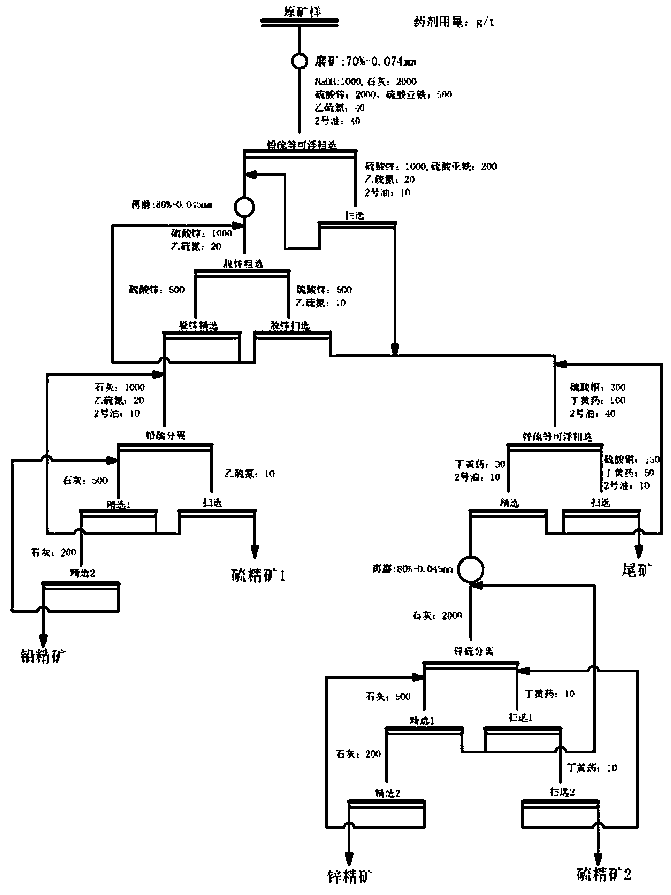

Flotation separation technology for high-sulfur and low-grade lead-zinc ore

The invention discloses a flotation separation technology for a high-sulfur low-grade lead-zinc ore. The technology is provided against the characteristics of low galena and sphalerite content and extremely high pyrite content of the high-sulfur and low-grade lead-zinc ore and serious unbalance of the proportions of the lead-zinc mineral content and the pyrite mineral content in the ore. The principle flow of floatability of sulfur and the like is adopted in the lead-zinc-sulfur flotation separation process flow design to make a part of pyrite with good floatability preferentially float upwards together with galena, lead-sulfur separation is carried out, a part of pyrite with poor floatability and sphalerite in tailings are subjected to flotation, and then zinc-sulfur separation is carriedout. The technology avoids strong pressure and strong tension of a large amount of pyrite, reduces the use amounts of medicaments and also reduces the loss of lead-zinc ore in pyrite. Compared with atraditional lead-zinc-sulfur full-priority flotation process, a lead-sulfur mixed separation-lead-sulfur separation-tailing zinc separation process, a priority lead separation-tailing zinc-sulfur mixed separation-zinc-sulfur separation process or other derived processes, the technology of the invention has the advantages of good index, stable process, low medicament consumption and the like.

Owner:KUNMING METALLURGY INST +1

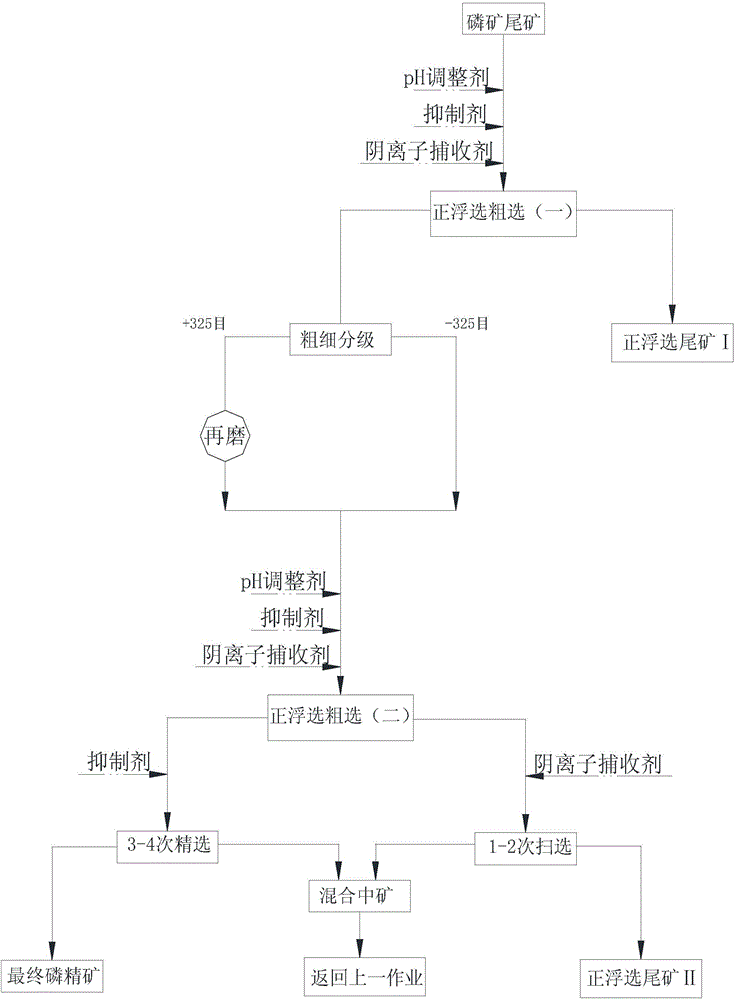

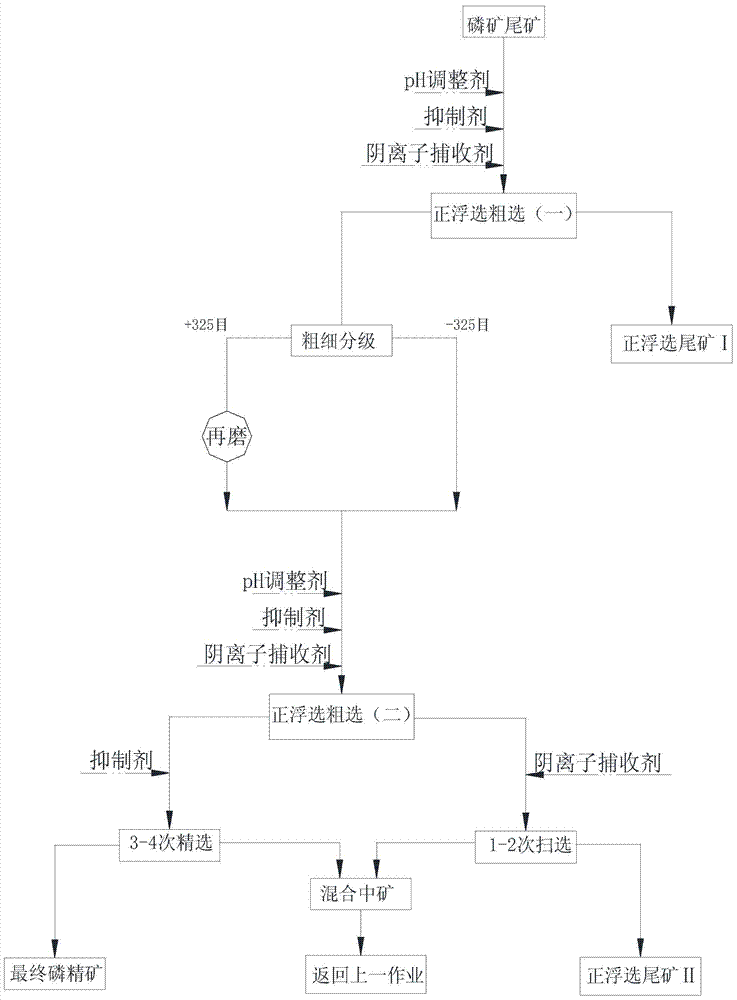

Method for processing phosphate rock tailing by adopting single direct flotation process

The invention discloses a method for processing phosphate rock tailing by adopting a single direct flotation process. The processing method comprises the following steps of directly feeding phosphate rock tailing into a roughing flotation machine, roughing by once, and properly adding a pH regulator, an inhibitor and an anionic collector during roughing; classifying a foam product during roughing according to the 325-mesh size fraction; feeding a +325-mesh product in grinding operation and grinding to the grinding fineness demanded by flotation; together combining a ground product and a -325-mesh product and then performing secondary roughing; carefully selecting the foam product during secondary roughing by 3-4 times, and scavenging the product in a slot by 1-2 times to prepare a concentrate product. The phosphate concentrate prepared by the processing method is relatively high in grade and recovery rate, and the processing method is simple in process and easy to realize industrial production. The pollution of phosphate rock tailing to environment can be greatly remitted by the method, and the processing method is very important to realize high-efficiency utilization and cyclic utilization of phosphate rock resources in our country.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

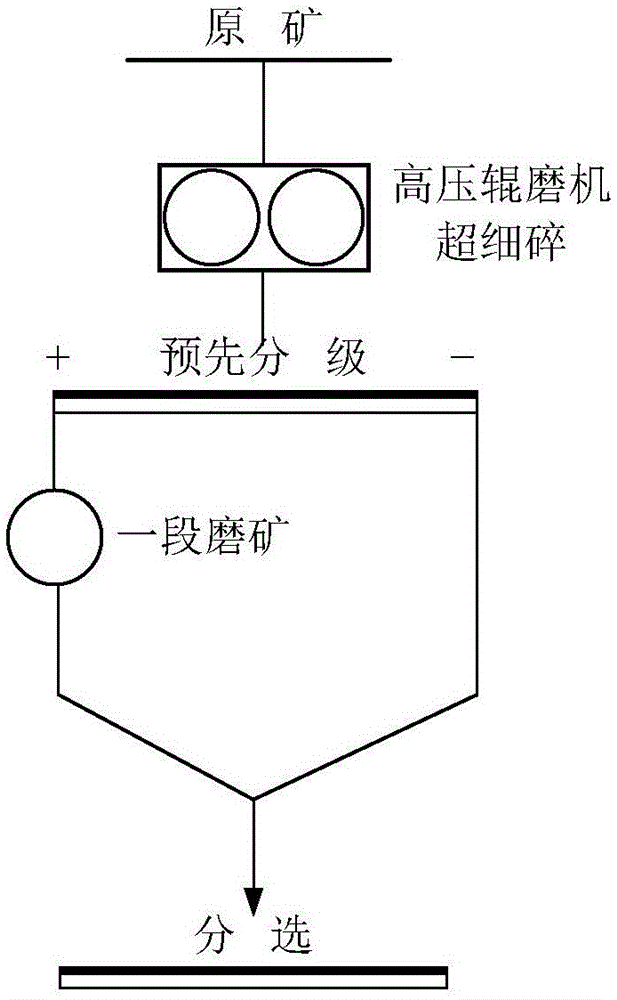

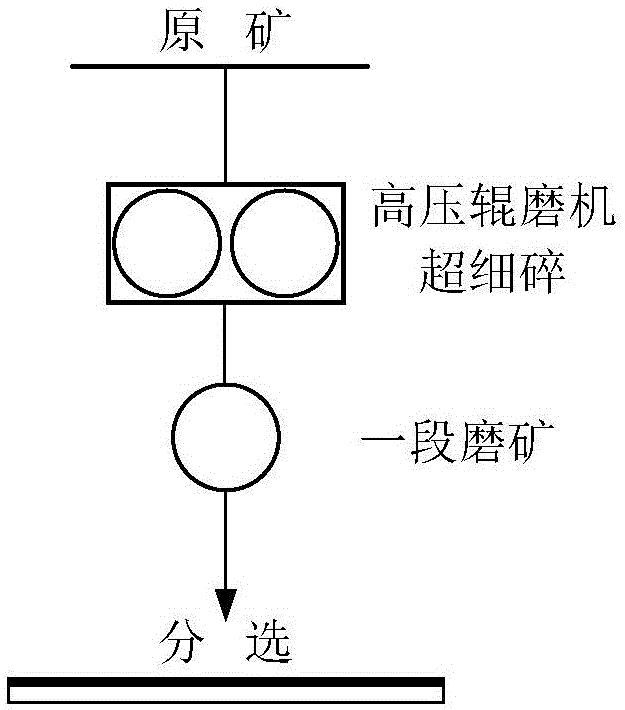

A high-efficiency and low-consumption ultra-fine crushing-grinding process

InactiveCN103934077BAvoid over crushingHigh recovery rateSaving energy measuresGrain treatmentsUltra fineHigh pressure

The invention relates to an efficient low-consumption ultrafine crushing-ore grinding process. The process is characterized in that a high-pressure grinding roller mill is utilized for carrying out ultrafine crushing, wherein the particle sizes of products subjected to the ultrafine crushing are -3.2mm; the products are pre-graded, the pre-graded fine-fraction products directly enter a sorting step without needing a primary grinding step, the pre-graded coarse-fraction products enter the sorting step after being subjected to ore grinding in the primary grinding step. According to the process, by carrying out pre-grading, the over-crushing of the dissociated fine-fraction products in the primary grinding step is avoided, the quantity of ores entering the primary grinding step is remarkably reduced, the processing capability of an ore grinding system is improved, the sorting index of ore concentrate products is improved, and meanwhile, the energy consumption is saved.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

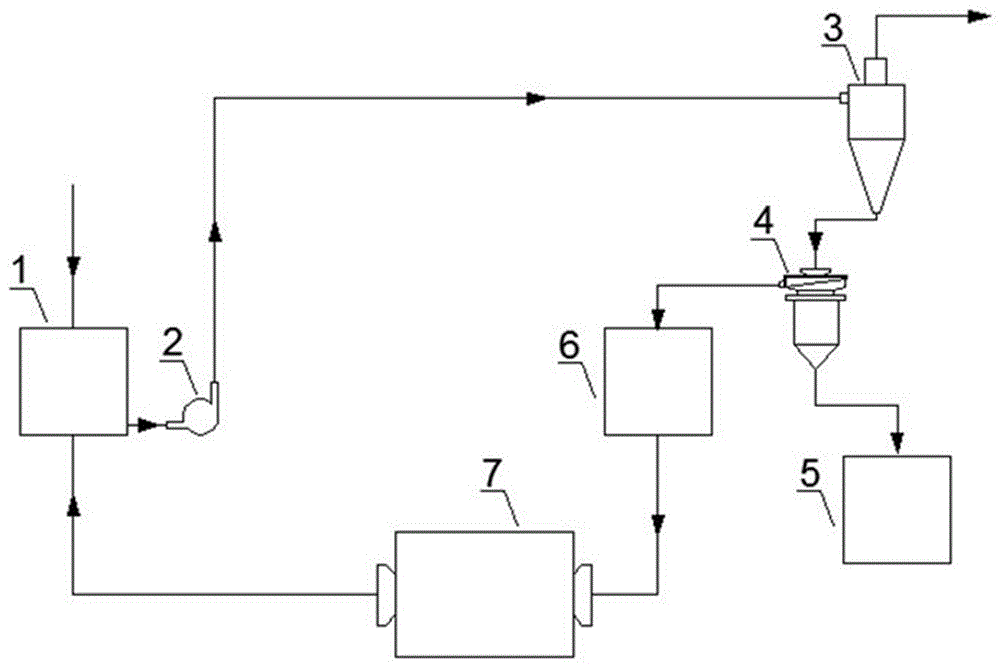

Separation technology capable of solving mineral derichment problem in grinding and classification system

InactiveCN105944812AReduce loadEasy to handleGrain treatmentsWet separationSeparation technologyEngineering

The invention discloses a separation technology capable of solving the mineral derichment problem in a grinding and classification system. The technology is characterized in that a mineral feeding box is connected with a mineral feeding pump, the mineral feeding pump is connected with a hydrocyclone, an underflow outlet of the hydrocyclone is connected with a mineral feeding opening of a separation device, the hydrocyclone flows over to enter the next technology, a product outlet of the separation device is connected with a concentrate groove, a tailing discharging part is connected with concentration equipment which is connected with a grinding machine, and the grinding machine is connected with the mineral feeding box; and the technology comprises the steps that pulp is fed into the mineral feeding box, and then is conveyed into the next-stage technology through the overflowing product of the hydrocyclone, the underflow product of the hydrocyclone is fed into the separation device, qualified products of the separation device are concentrates, tailing pulp of the separating device is fed into the concentration equipment, and the underflow pulp of the concentration equipment is fed into the grinding machine to be ground. According to the separation technology, various problems caused by derichment of target minerals in the grinding and classification system are thoroughly solved, and the aims of improving the recycling rate and grade of the target minerals, improving the grinding machine treatment amount and reducing energy consumption of the grinding machine are achieved.

Owner:莫文丛

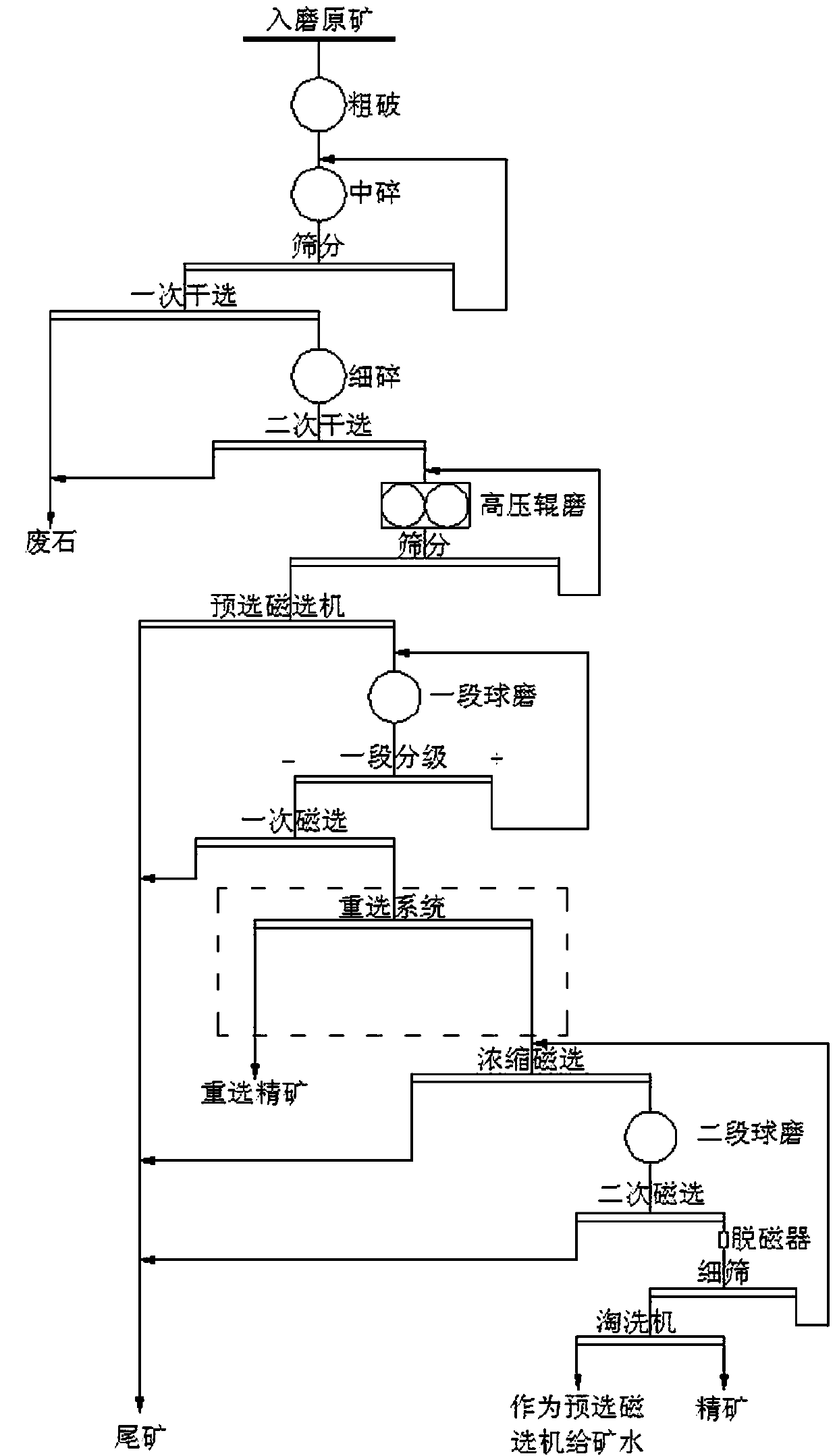

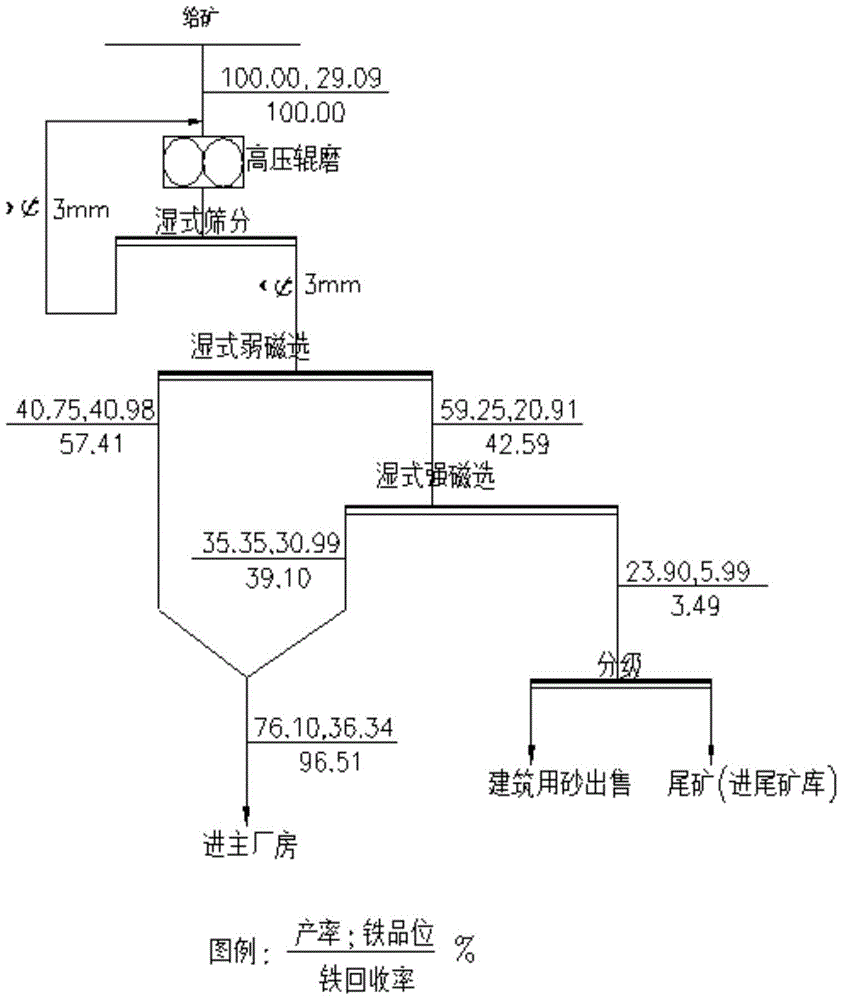

A new process and production system for composite lean iron ore pre-selection

ActiveCN104722394BImprove grindabilityIt has the effect of saving energy and reducing consumptionSievingScreeningHigh intensityAssembly line

The invention discloses a novel composite lean iron ore pre-concentration technology and a production system thereof, and belongs to the technical field of ore concentration. The novel composite lean iron ore pre-concentration technology includes the steps that composite lean iron ore is crushed; the crushed products are smashed to be phi 3 mm through a high-pressure roller milling screen fully-closed superfine crushing technology; a wet low-intensity magnetic separation and wet high-intensity magnetic separation combined technology is carried out; concentrate of a low-intensity magnetic separation machine and concentration of a high-intensity magnetic separation machine are mixed and then later ball milling grading starts; tailings of the high-intensity magnetic separation machine enters a linear vibration screen II for dehydration. The production system of the novel composite lean iron ore pre-concentration technology comprises a high-pressure roller grinding machine, a wet efficient beating machine, a linear vibration screen I, the low-intensity magnetic separation machine, the high-intensity magnetic separation machine and the linear vibration screen II which are sequentially distributed on a production assembly line according to the process sequence. By means of the technology and the system, a large amount of qualified tailings can be abandoned before the composite lean iron ore is ground, the grinding amount is lowered, and the aims that more tailing is crushed, little tailing is ground and the tailing is abandoned earlier are achieved.

Owner:ANHUI MASTEEL ENG & TECH GRP

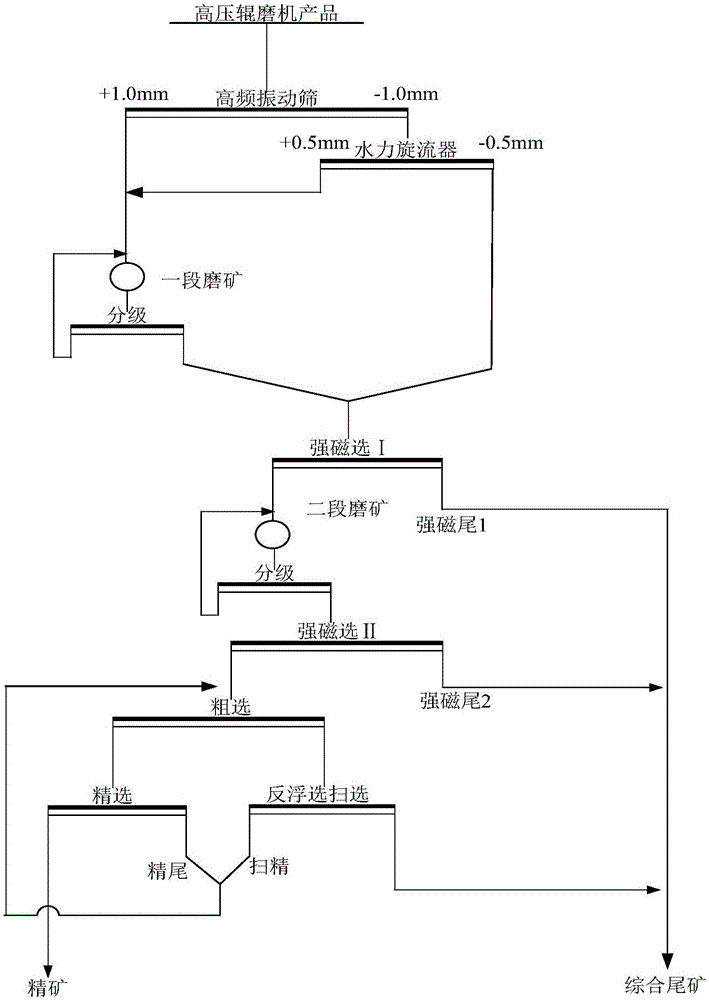

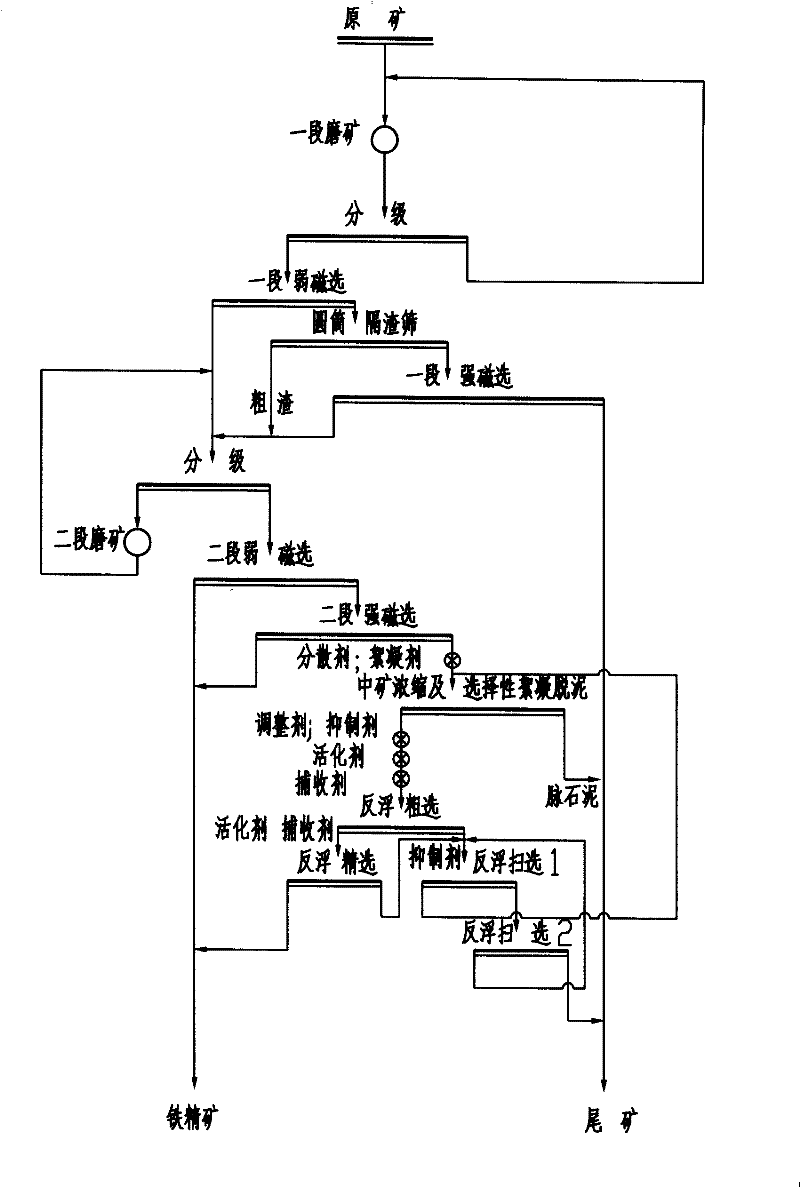

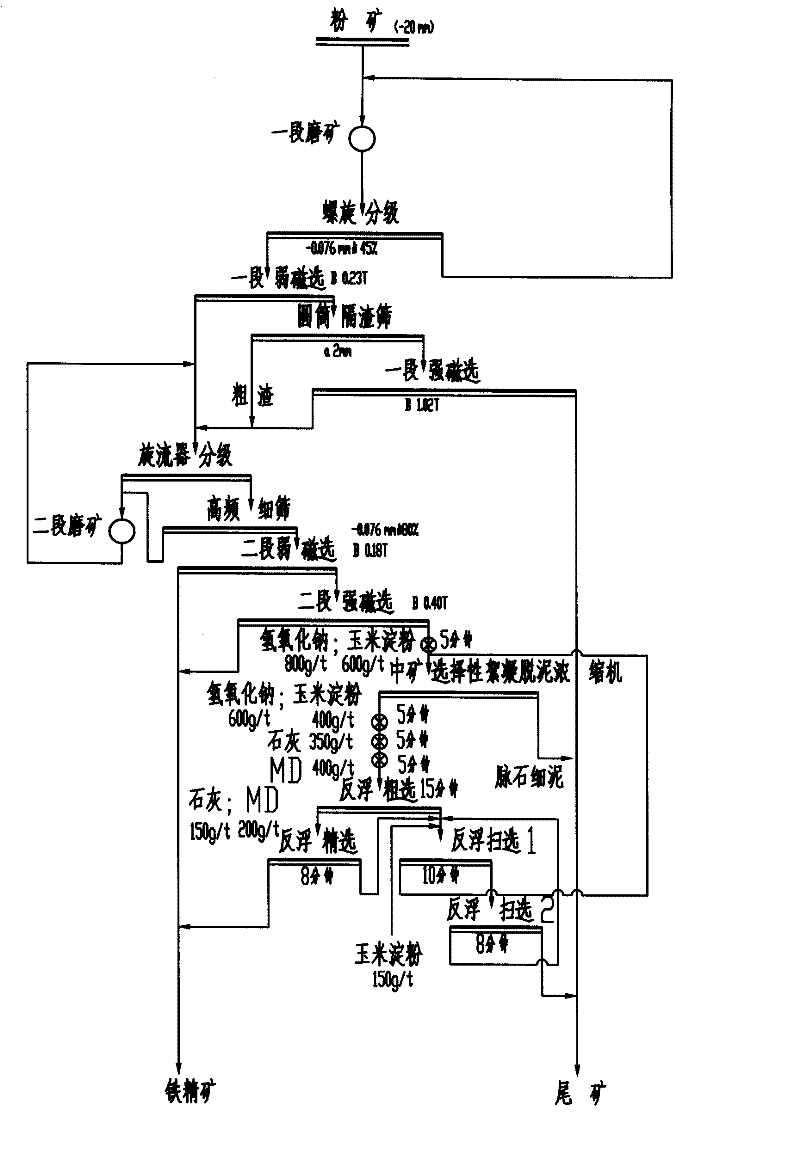

Beneficiation method for recycling specularite

InactiveCN101428248BReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

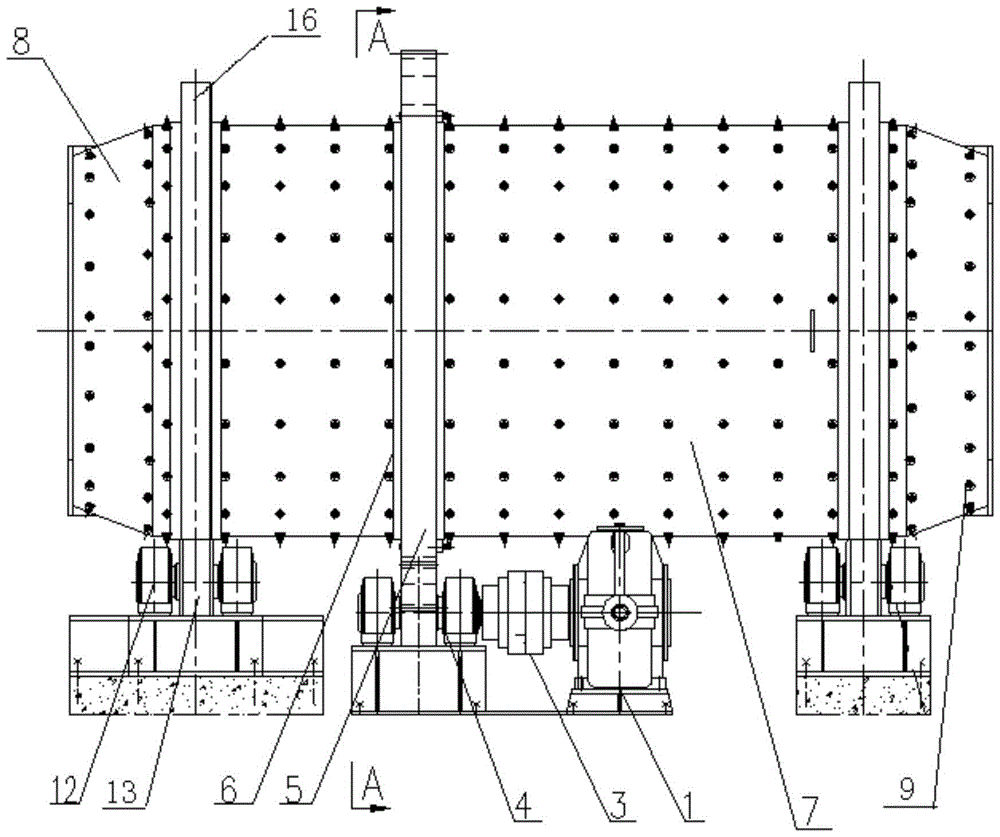

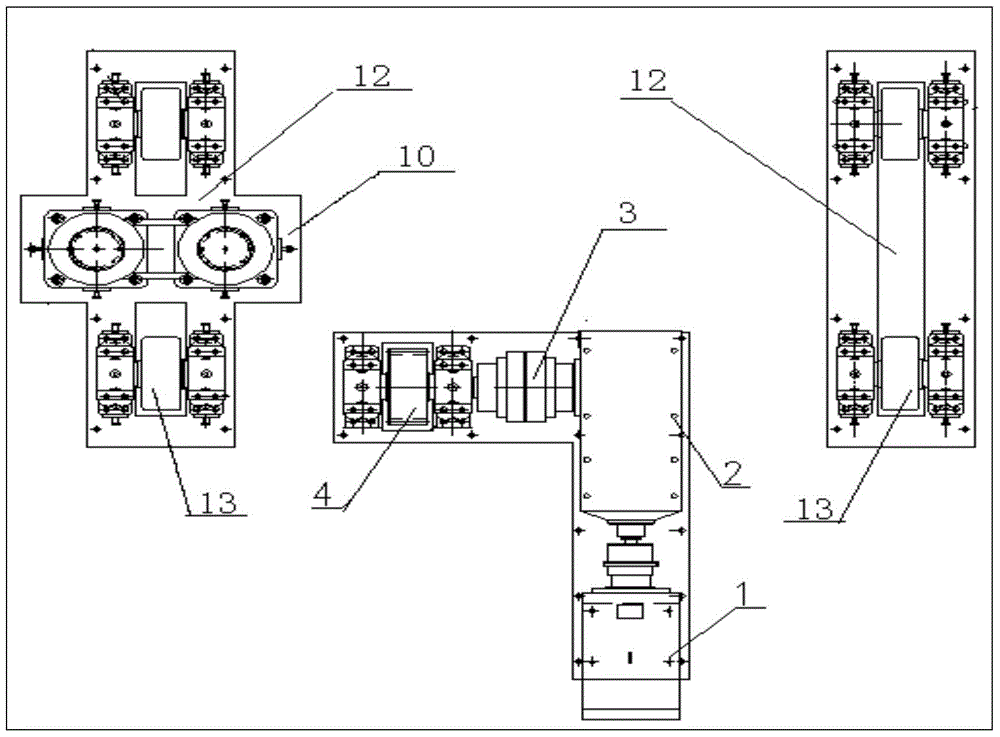

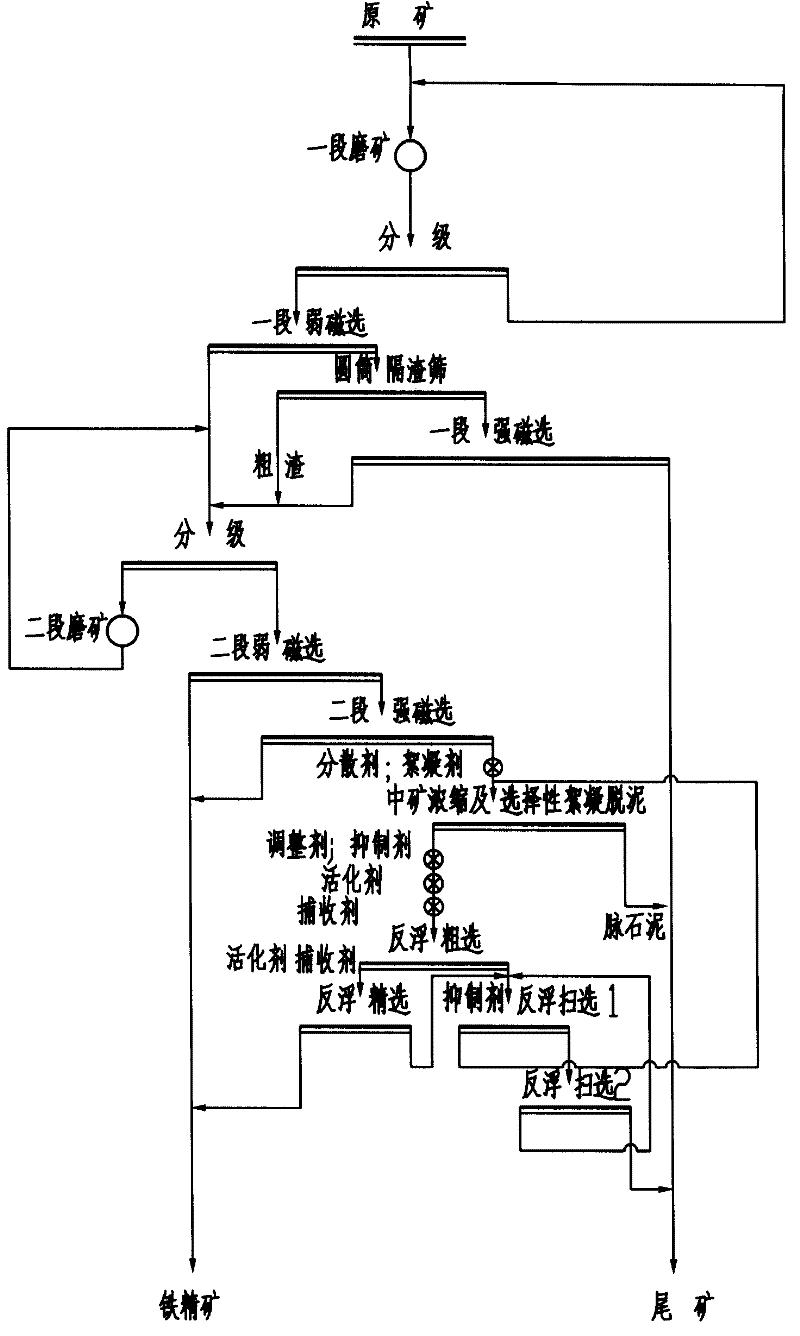

The invention discloses a benefication method for recovering specularite. The method comprises the processes of primary grinding, grading, primary low intensity magnetic separation, and tailings discarding by primary high intensity magnetic separation; rough concentrate pre-classification by the primary low intensity magnetic separation and the primary high intensity magnetic separation, secondary grinding, secondary low intensity magnetic separation to obtain concentrates, secondary high intensity magnetic separation to obtain concentrates; and selective flocculation desliming secondary conducted on high intensity magnetic separation tailings (middlings), and anionic reverse flotation. The method further comprises the step of arranging a cylindrical slag separating sieve before the primary high intensity magnetic separation. With the advantages that the iron concentrate grade and the iron recovery are high, the loss of granular iron minerals is low, the mineral process flow is short,concentrates and tailings can be obtained in advance and the energy consumption of the benefication is low, the invention can be used not only for selecting specularite ores, but also for selecting weakly magnetic iron minerals, such as hematite, goethite, siderite, limonite, and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD

Rutile roughing technology consisting of selective ore grinding, coarse particle gravity separation and fine particle floatation

InactiveCN102500462BImprove the reselection indexEffectively discardWet separationEngineeringParticle composition

The invention discloses a rutile roughing technology for consisting of selective ore grinding, coarse particle gravity separation and fine particle floatation, belonging to the technical field of mineral processing engineering. According to the characteristics of complex mineral composition of rutile, containing of a large quantity of flaky rocky minerals in raw ore, small crystal size of rutile, non-uniform distribution, remarkable selective grinding phenomenon in an ore grinding process and the like, the technology comprises the following steps of: strengthening selective ore grinding by taking a steel forging as an ore grinding medium; pre-separating and discarding coarse particle tailings with a high-frequency fine sieve; narrowing the particle composition undersize minerals; recovering large-particle rutile by performing gravity separation, wherein rutile in gravity-separated tailings is distributed at a fine particle scale; sieving and discarding coarse-particle tailings; recovering small-particle rutile from minus sieve by suppressing rutile reverse flotation desliming and activating rutile positive floatation; and combining gravity-separated rough concentrate with floated rough concentrate, concentrating and purifying to obtain a high-quality rutile concentrate product. The technology has the characteristics of simple process, low ore dressing cost, high recovery rate, high concentration ratio, and the like.

Owner:KUNMING UNIV OF SCI & TECH

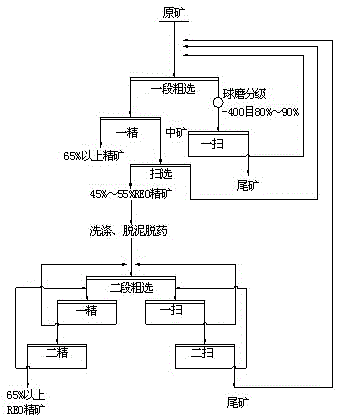

Method for selecting high-grade rare-earth concentrates step by step

The invention relates to a method for selecting high-grade rare-earth concentrates step by step, belonging to the technical field of a mineral processing technology. The select flotation comprises the following two continuous steps of (1) preferably selecting part of 65 percent of rare-earth concentrates by flotation; (2) processing middlings to select 65 percent of rare-earth concentrates by flotation, wherein during the whole technological process, stage grinding is adopted to process and fine-grind the middlings to be 80 percent to 90 percent of -400 meshes, and desliming and reagent removing are performed, thereby solving the problem that the other mineral processing technology is not easy to select subsequently caused by the phenomena that gangue mineral is packed by medicaments and the like due to medicament residuals, the generated middlings is returned to the previous stage of select flotation, and finally only the high-grade mixed rare-earth concentrates such as tailings with lower rare earth grade are produced. The method provided by the invention can be utilized to continuously and stably produce the high-grade rare-earth concentrates with the rare earth grade REO (Rare Earth Oxide) being larger than or equal to 65 percent and the recovery rate being larger than or equal to 90 percent. The method is simple and efficient in process, free of pollution, and high in rare earth recovery rate, and can effectively solve the problem that the grade of the tailings in the existing rare earth beneficiation is hard to reduce.

Owner:李梅

A method for treating phosphate rock tailings using a single positive flotation process

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Double tail-removing gravity-flotation combined sorting method and device

The invention relates to a double-tailing discharging gravity-floating combined separation method and a device thereof, and belongs to a double-tailing discharging gravity-floating combined separation method aiming at slime and a device thereof. The aim of the invention is to solve the technical problems existing in the prior flotation machine that the separation effect of ultrafine grains is lowand the upper limit of the column flotation is difficult to be effectively related with the lower limit of the heavy medium separation. The method comprises three steps of crude ore flotation and rough separation and graded tailing discharging, gravity scavenging tailing discharging and gravity separation finished ore reflotation. The double-tailing discharging gravity-floating combined separation machine comprises a jet flow flotation column, a first tailing discharging graded device and a secondary tailing discharging graded device; the first tailing discharging graded device is arranged below the jet flow flotation column, a cyclical middling underflow opening of the first tailing discharging graded device is connected with the secondary tailing discharging graded device, and a centralore feeding pipe of the secondary tailing discharging graded device is connected with the jet flow flotation column. The method and the device have multiple effects of coarse slime separation and highly selective floatation of fine coal and ultrafine coal, thereby improving the efficiency of the gravity-floating combined separation.

Owner:TAIYUAN UNIV OF TECH

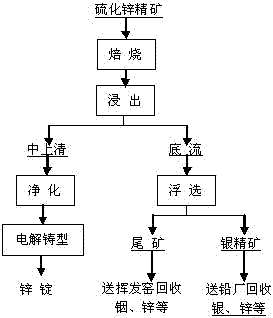

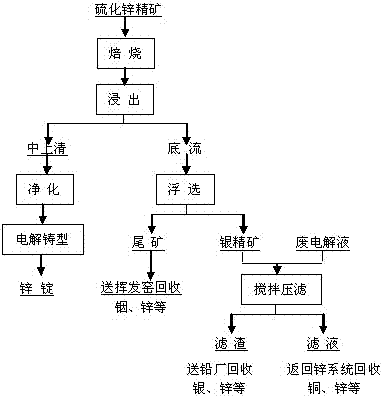

Method for reducing zinc content of flotation silver concentrates

The invention relates to a production treatment method for reducing the zinc content of flotation silver concentrates. The method comprises the following steps that (1) waste electrolyte is added into a concentrate tank for the flotation silver concentrates through a pipeline, and the proportion of the waste electrolyte and the silver concentrates is controlled to be 15-20:1; (2) the waste electrolyte and the flotation silver concentrates are subjected to stirring reaction for 10-30 min; and (3) ore pulp obtained after the reaction is subjected to filter pressing, filter residues are sent to a lead system for recovery of silver and zinc, and filtrate returns to a zinc system for recovery of zinc and copper. By means of the method, the recovery rate of zinc and copper is increased; the process is simple in operation without additional equipment and operation. The method has wide market prospects.

Owner:ZHUZHOU SMELTER GRP

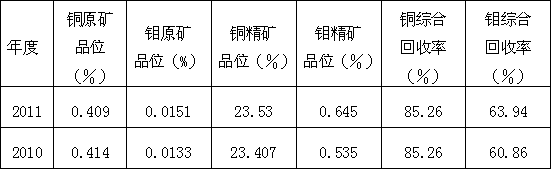

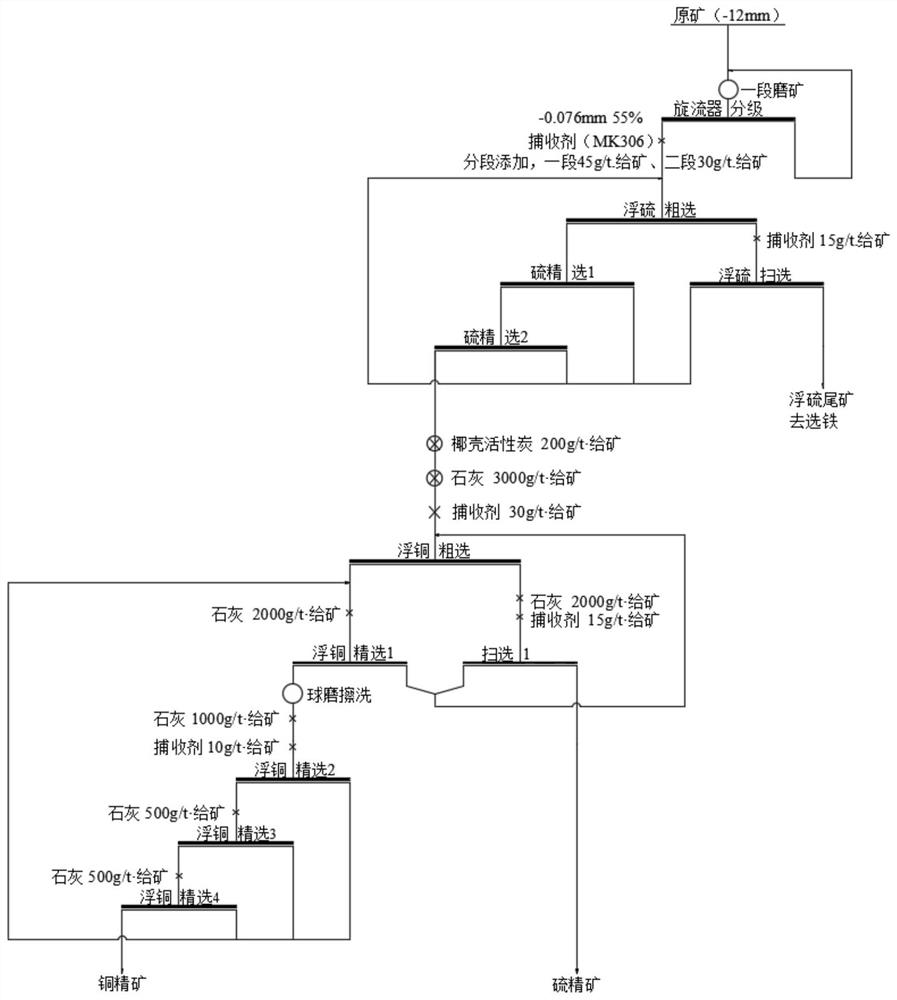

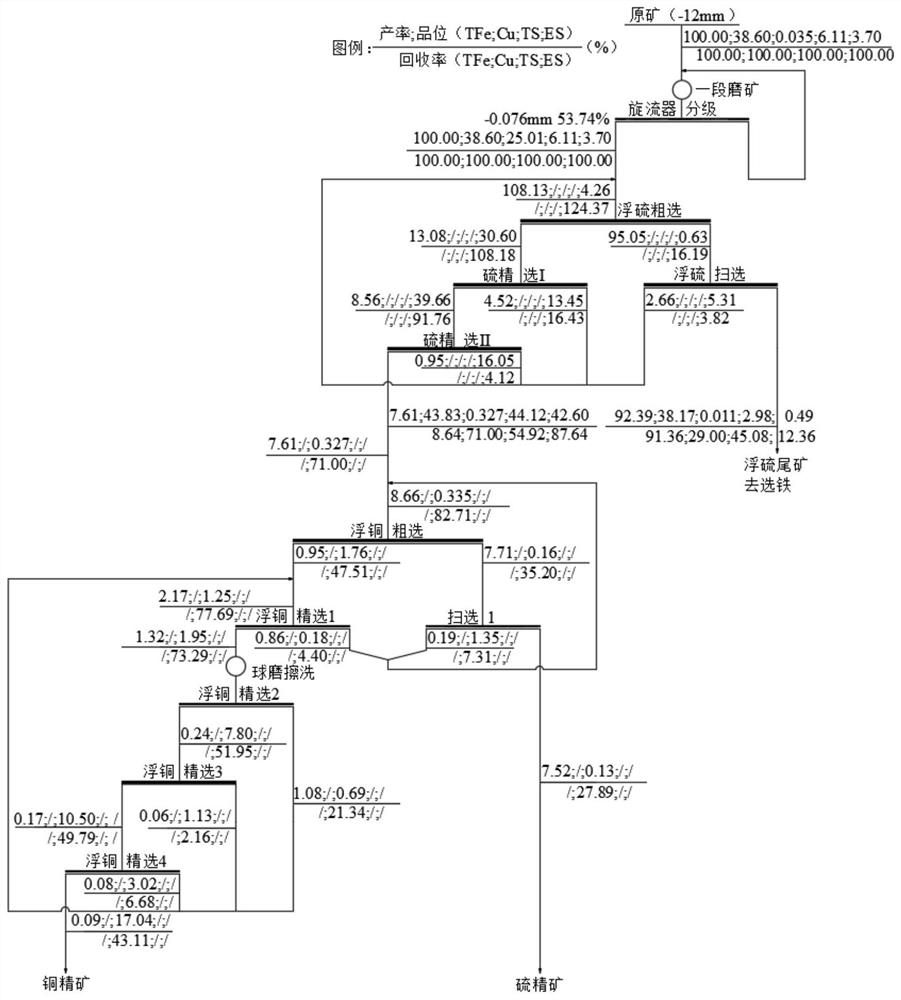

Beneficiation method for high-sulfur magnetic iron ore of low-grade copper

The invention discloses a beneficiation method for high-sulfur magnetic iron ore of low-grade copper, and belongs to the field of beneficiation. The method comprises the steps of raw ore grading, copper-sulfur bulk flotation, copper-sulfur separation-roughing-refining-sweeping and copper-sulfur separation and multiple-time concentration. According to the method, reasonable process design is conducted on bulk flotation and copper-sulfur separation of the beneficiation process, the optimal chemical adding ratio is screened out, the cost of all chemicals is effectively reduced while the beneficiation effect is guaranteed, the method is particularly suitable for copper-containing high-sulfur magnetic iron ore with the copper grade ranging from 0.02% to 0.05%, and copper concentrate with the high copper grade and the high enrichment ratio can be obtained.

Owner:安徽马钢罗河矿业有限责任公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com